Method for preparing porous metal film transparent conducting electrode based on cracking template method

A porous metal and transparent film technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problem of synergistic improvement of the optical transmittance and conductivity of nano-silver wire electrodes, difficulty in controlling the contact resistance of nano-wires, and the difficulty of contact resistance. Adhesion problems are difficult to solve and other problems, to achieve excellent light transmission, improve carrier collection efficiency, and improve electron collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

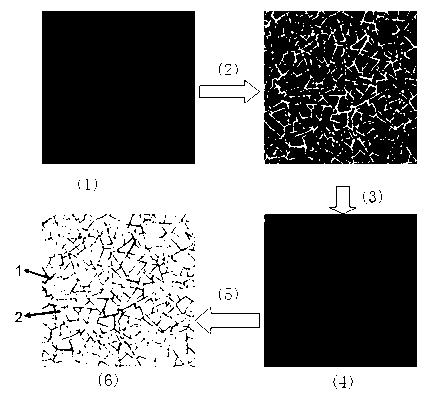

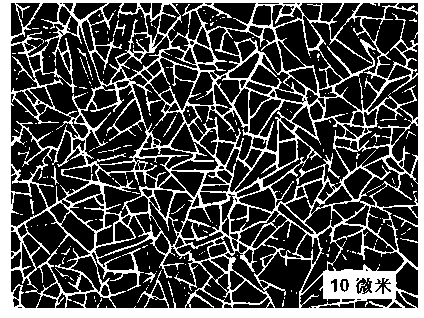

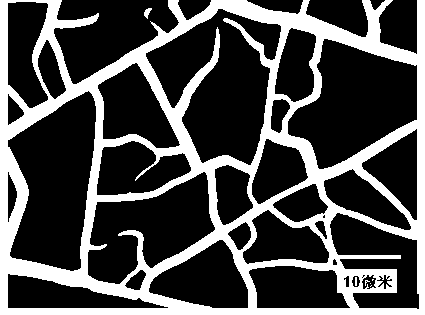

[0041] In Example 1, the method for preparing a porous metal film transparent conductive electrode based on a cracked template is as follows: figure 1 , where (1) deposition of the cracked film; (2) drying at room temperature; (3) formation of film cracks as Figure 4 (2000x magnification) and Figure 5 (12000 times magnification); (4) metal thin film deposition as Figure 6 (1000x magnification) and Figure 7 (8000 times magnification); (5) removal of cracked film; (6) formation of patterned metal nano film electrodes. It includes four main steps: one is the synthesis of the cracking liquid, the second is the deposition of the cracking liquid and cracks, the third is the deposition of metal or alloy films by magnetron sputtering, and the fourth is the removal of the cracked template and the surface of the sample Clean up to obtain porous metal film transparent conductive electrode samples such as figure 2 (50x magnification optical photo) and image 3 (Magnified 100x op...

Embodiment 2

[0059] The method for preparing a porous metal thin film transparent conductive electrode based on the crack template method provided in this embodiment includes the following steps:

[0060] (1) Synthetic cracking fluid

[0061] Using tetrabutyl titanate as raw material, first dissolve tetrabutyl titanate in absolute ethanol to form a solution a 1 , followed by mixing absolute ethanol, glacial acetic acid and deionized water to form a solution a 2 , the solution a 1 and solution a 2 Obtain solution a through magnetic stirring and mixing 3 , then in solution a 3Add absolute ethanol to the mixture, and continue to stir until the solution changes from transparent light yellow to a muddy milky white suspension to obtain the cracking liquid microcrystallized titanium dioxide sol. Wherein, in the cracking liquid configuration process, adjust the volume ratio of absolute ethanol and tetrabutyl titanate to be 6:1, 5.5:2, 5:1, 4.5:1, 4:1, 3.5:1 respectively, magnetic stirring Th...

Embodiment 3

[0068] The method for preparing a porous metal thin film transparent conductive electrode based on the crack template method provided in this embodiment includes the following steps:

[0069] (1) Preparation of cracking fluid

[0070] Using tetrabutyl titanate as raw material, first dissolve tetrabutyl titanate in absolute ethanol to form a solution a 1 , followed by mixing absolute ethanol, glacial acetic acid and deionized water to form a solution a 2 , the solution a 1 and solution a 2 Obtain solution a through magnetic stirring and mixing 3 , then in solution a 3 Add absolute ethanol to the solution and continue to stir until the solution changes from transparent light yellow to milky white suspension to obtain microcrystalline titanium dioxide sol. Ensure that the volume ratio of absolute ethanol and tetrabutyl titanate in the used cracking solution is 6:1, the rotating speed is 300r / min during magnetic stirring, and the magnetic stirring time is 3h; The diameter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com