Lithium ion battery additive, electrolyte and anode slurry

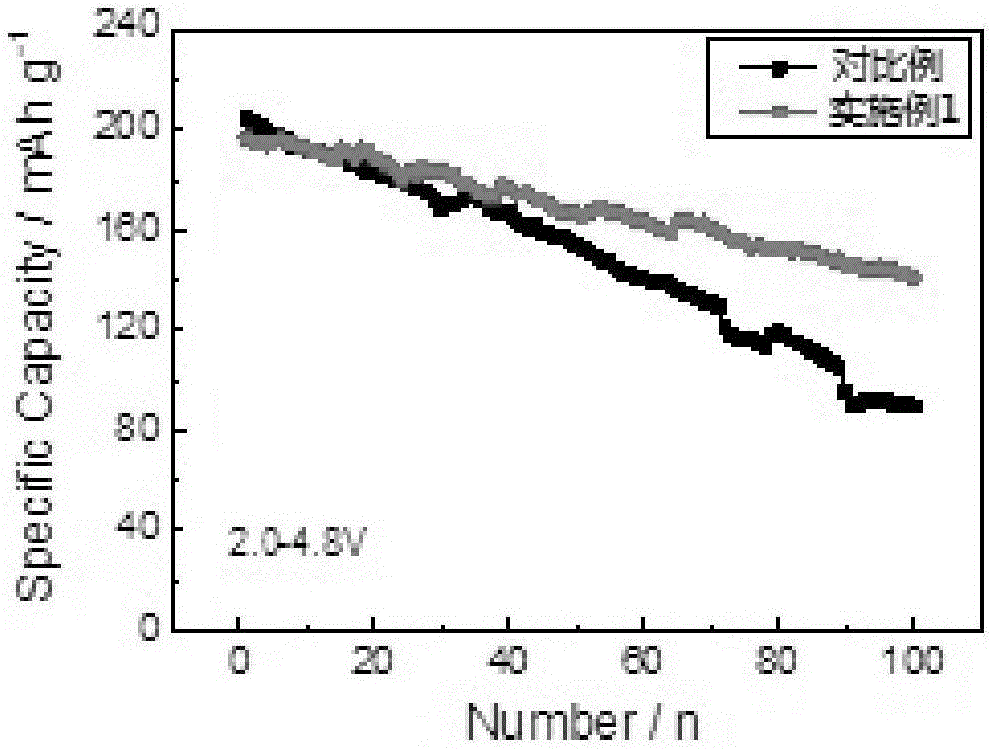

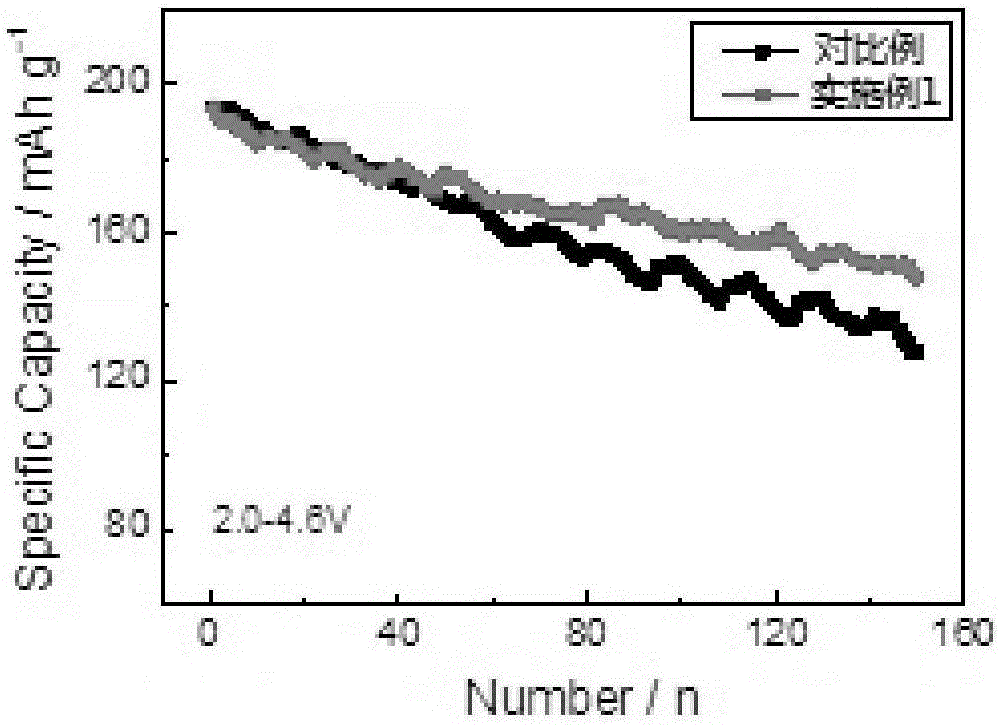

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of easy de-foil, energy density and gram capacity to be improved, and low viscosity, so as to improve dispersion uniformity, Effect of reducing exothermic side reactions and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Dissolve the N,N'-(methylene diphenyl) bismaleimide additive powder with a mass of 1% of the mass of the positive electrode active material in an appropriate amount of NMP, stir to form a uniform solution, and then add it to 90% of the Cathode active material Li 1.18 Ni 0.15 co 0.15 mn 0.52 o 2 , 4% conductive agent (the mass ratio of conductive carbon black and conductive graphite is 1:1), 6% in the mixed slurry of PVDF binding agent, stir and disperse and prepare positive electrode slurry evenly; The positive electrode slurry is coated on On the positive electrode current collector, the positive electrode sheet is obtained by drying, rolling, and cutting.

Embodiment 2

[0097] Dissolve the N,N'-(methylene diphenyl) bismaleimide additive powder with a mass of 2% of the mass of the positive electrode active material in an appropriate amount of NMP, stir to form a uniform solution, and then add it to 90% of the Cathode active material Li 1.18 Ni 0.15 co 0.15 mn 0.52 o 2 , 4% conductive agent (the mass ratio of conductive carbon black and conductive graphite is 1:1), 6% in the mixed slurry of PVDF binding agent, stir and disperse and prepare positive electrode slurry evenly; The positive electrode slurry is coated on On the positive electrode current collector, the positive electrode sheet is obtained by drying, rolling, and cutting.

Embodiment 3

[0099] Dissolve the N,N'-vinyl bismaleimide additive powder with a mass of 1% of the mass of the positive active material in an appropriate amount of NMP, stir to form a homogeneous solution, and then add it to the positive active material containing 90% Li 1.18 Ni 0.15 co0.15 mn 0.52 o 2 , 4% conductive agent (the mass ratio of conductive carbon black and conductive graphite is 1:1), in the mixed slurry of 6% PVDF binding agent, stir and disperse and prepare positive electrode slurry evenly; The positive electrode slurry is coated on On the positive electrode current collector, the positive electrode sheet is obtained by drying, rolling, and cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com