Method for preparing high-performance metallic network transparent conducting electrode through metal plating method

A technology of transparent conductive electrodes and metal electroplating, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, circuits, etc., can solve the problem of large-area mass production of metal grid electrodes, high vacuum technology photoelectric Poor performance, increased electrode application cost and other issues, to achieve excellent light transmission, improve carrier collection efficiency, and improve electron collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

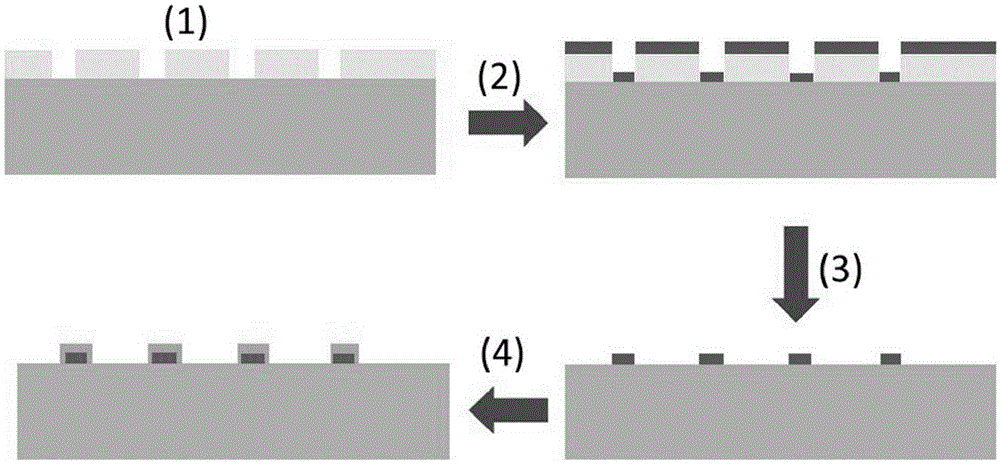

[0037] The metal electroplating method that this embodiment provides prepares the method for high-performance metal network transparent conductive electrode, such as figure 1 , where (1) represents the preparation of a cracked sacrificial layer template on the substrate; (2) represents the deposition of a metal seed layer on the cracked sacrificial layer template; (3) represents the formation of a metal seed conductive layer network; (4) It means that the metal electroplating method is used to continue to deposit metal on the metal seed conductive network, and the metal network transparent conductive electrode with excellent photoelectric performance is prepared.

[0038] The detailed process of each step is as follows:

[0039] (1) Preparation of a cracked sacrificial layer template on the substrate

[0040] For the detailed process of preparing template liquid and forming a sacrificial layer template, please refer to the part of preparing a sacrificial layer template in the...

Embodiment 2

[0050] The metal electroplating method that this embodiment provides prepares the method for high-performance metal network transparent conductive electrode, such as figure 1 , where (1) represents the preparation of a cracked sacrificial layer template on the substrate; (2) represents the deposition of a metal seed layer on the cracked sacrificial layer template; (3) represents the formation of a metal seed conductive layer network; (4) It means that the metal electroplating method is used to continue to deposit metal on the metal seed conductive network, and the metal network transparent conductive electrode with excellent photoelectric performance is prepared.

[0051] The detailed process of each step is as follows:

[0052] (1) Preparation of a cracked sacrificial layer template on the substrate

[0053] For the detailed process of preparing template liquid and forming a sacrificial layer template, please refer to the part of preparing a sacrificial layer template in the...

Embodiment 3

[0062] The metal electroplating method that this embodiment provides prepares the method for high-performance metal network transparent conductive electrode, such as figure 1 , where (1) represents the preparation of a cracked sacrificial layer template on the substrate; (2) represents the deposition of a metal seed layer on the cracked sacrificial layer template; (3) represents the formation of a metal seed conductive layer network; (4) It means that the metal electroplating method is used to continue to grow metal on the metal seed conductive network, and the metal network transparent conductive electrode with excellent photoelectric performance is prepared.

[0063] The detailed process of each step is as follows:

[0064] (1) Preparation of a cracked sacrificial layer template on the substrate

[0065] For the detailed process of preparing template liquid and sacrificial layer template film formation, please refer to the part of preparing cracked templates in the inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com