Carbon nano-tube enhanced composite type metallic oxide electrode material and preparation thereof

A technology of electrode materials and carbon nanotubes, which is applied in the direction of electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low anode power generation, reduced adhesion between materials and substrates, wear resistance, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

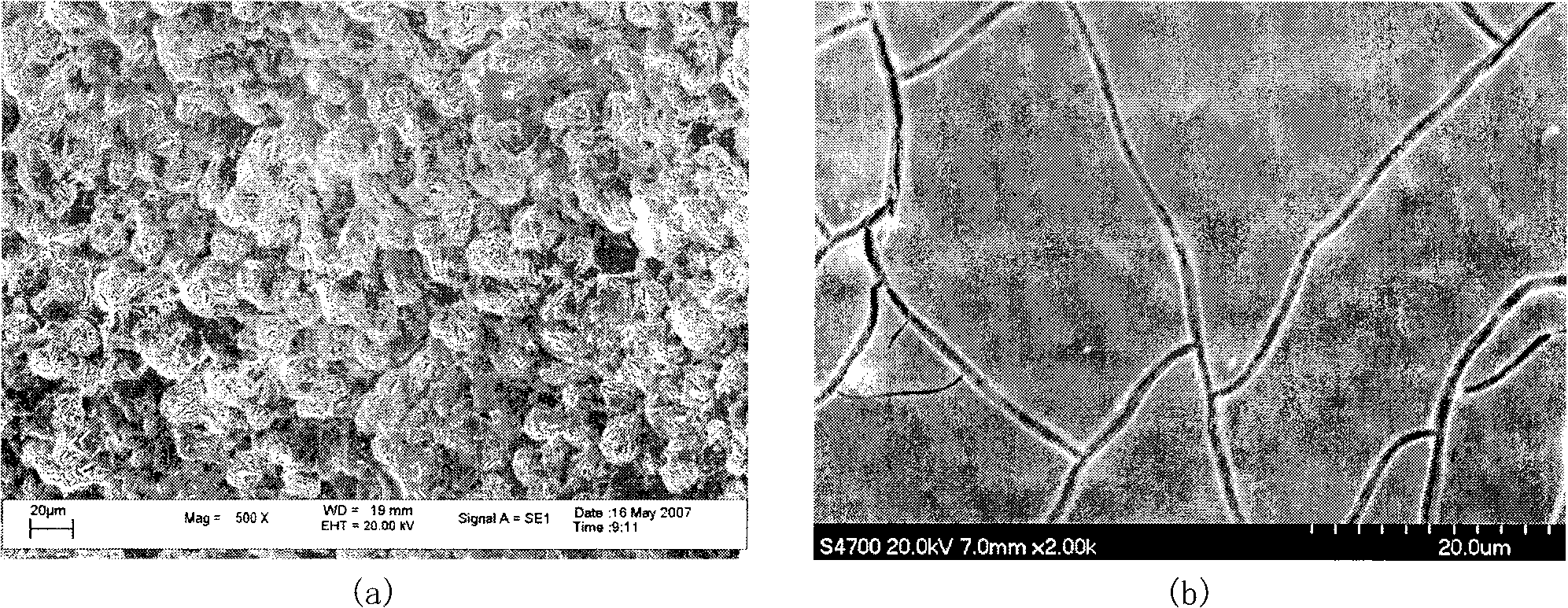

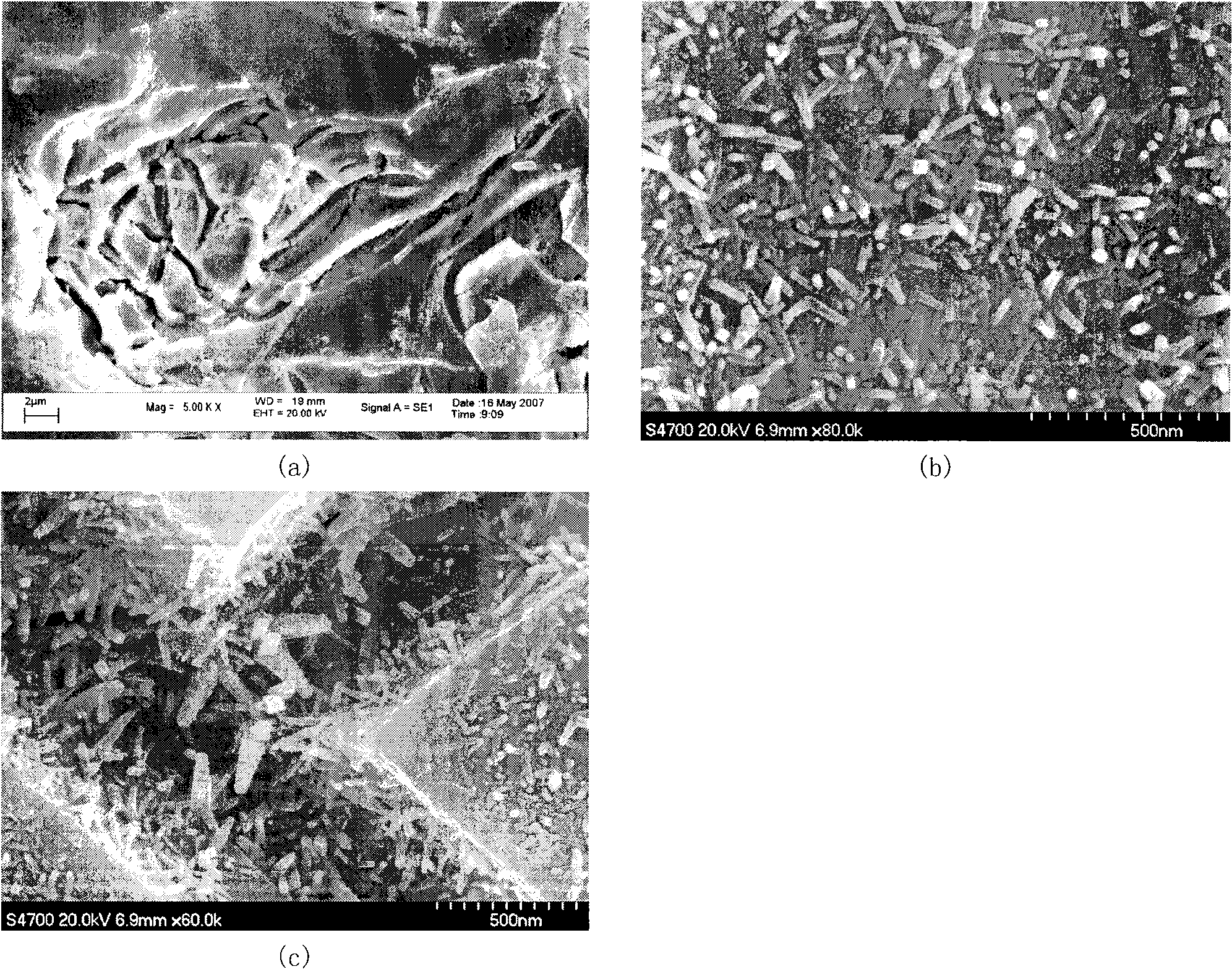

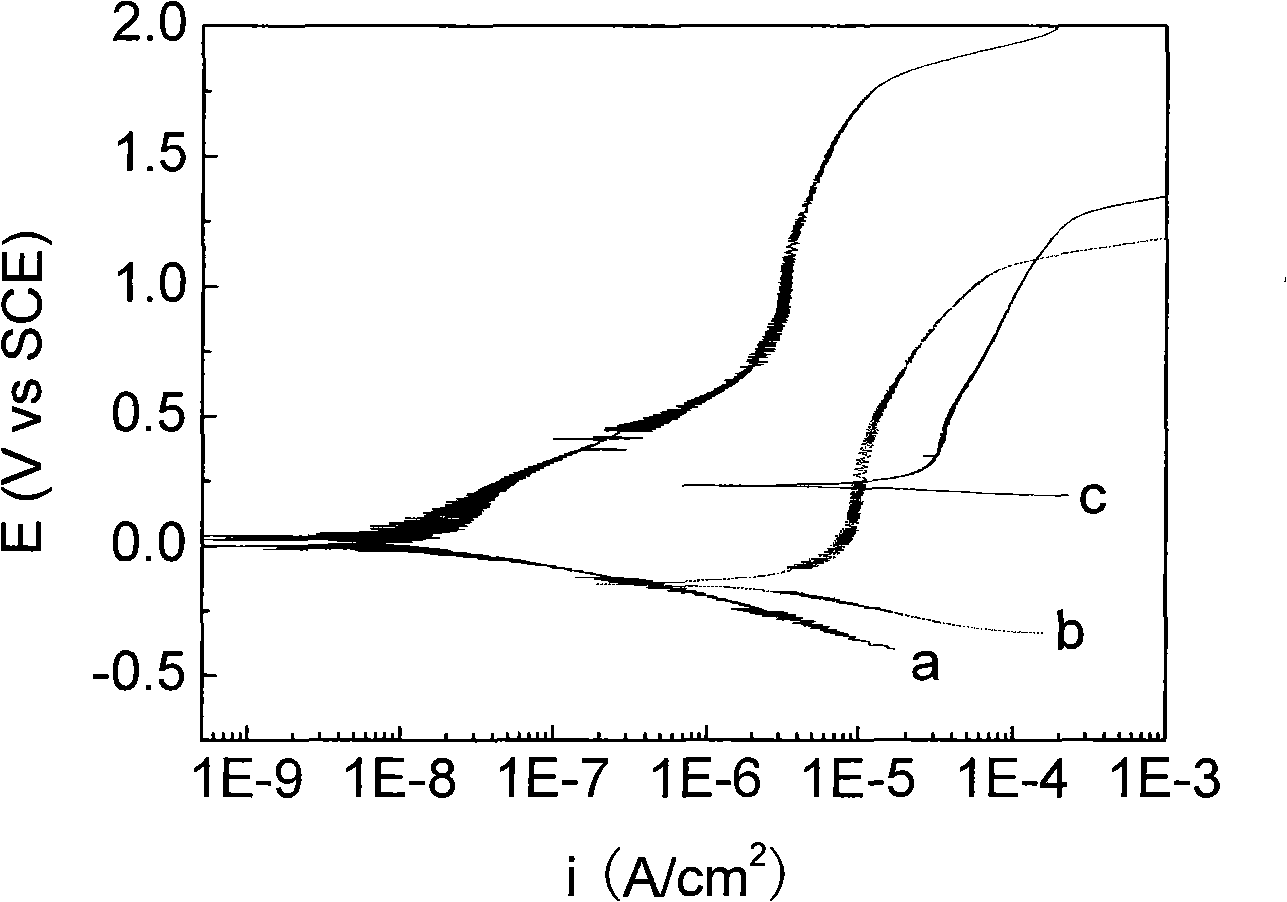

[0028] [Example 1] Preparation method of titanium-based carbon nanotube reinforced iridium and tantalum mixed metal oxide electrode material

[0029] 1. Roughen the titanium sheet (TA1) by soaking it in 10% oxalic acid solution at 95°C for 1 hour, clean it with deionized water, and then scrub it with alcohol or acetone or dry it with a hair dryer.

[0030] 2. Firstly, the carbon nanotubes were shortened by ball milling for 2 hours, then refluxed in concentrated nitric acid and concentrated sulfuric acid for 10 hours for activation and purification, washed with deionized water and dried for later use.

[0031] 3. Coating oxide precursor solution is H 2 IrCl 6 ·xH 2 O (dissolved in hydrochloric acid) solution + TaCl 5 (dissolved in n-butanol) solution, the solution was diluted with concentrated hydrochloric acid to a solution of 0.2mol / L metal ions.

[0032] 4. Calculate and weigh the required carbon nanotubes in an amount of 0.1 g / L, add them into the coating solution, and ...

Embodiment 2

[0035] [Example 2] Preparation method of titanium-based carbon nanotube reinforced iridium and tantalum mixed metal oxide electrode material

[0036] 1. Roughen the pure copper sheet with 300# sandpaper, clean it with deionized water, then scrub it with alcohol or acetone or dry it with a hair dryer.

[0037] 2. Firstly, the carbon nanotubes were shortened by ball milling for 2 hours, then refluxed in concentrated nitric acid and concentrated sulfuric acid for 10 hours for activation and purification, washed with deionized water and dried for later use.

[0038] 3. Coating oxide precursor solution is H 2 IrCl 6 ·xH 2 O (dissolved in hydrochloric acid) solution + C 16 h 36 o 4 Ti (tetrabutyl titanate) solution, dilute the solution with concentrated hydrochloric acid to a solution with a metal ion content of 0.2 mol / L.

[0039] 4. Calculate and weigh the required carbon nanotubes according to the amount of 5g / L, add to the coating solution, and fully disperse in the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com