Process for producing nanostructured tin dioxide lithium ion battery negative pole material

A lithium-ion battery, nanostructure technology, applied in tin oxide, battery electrodes, structural parts, etc., can solve the problems of troublesome synthesis process, low product yield, damage to oxide structure, etc., and achieves simple preparation process and low equipment requirements. , the effect of complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

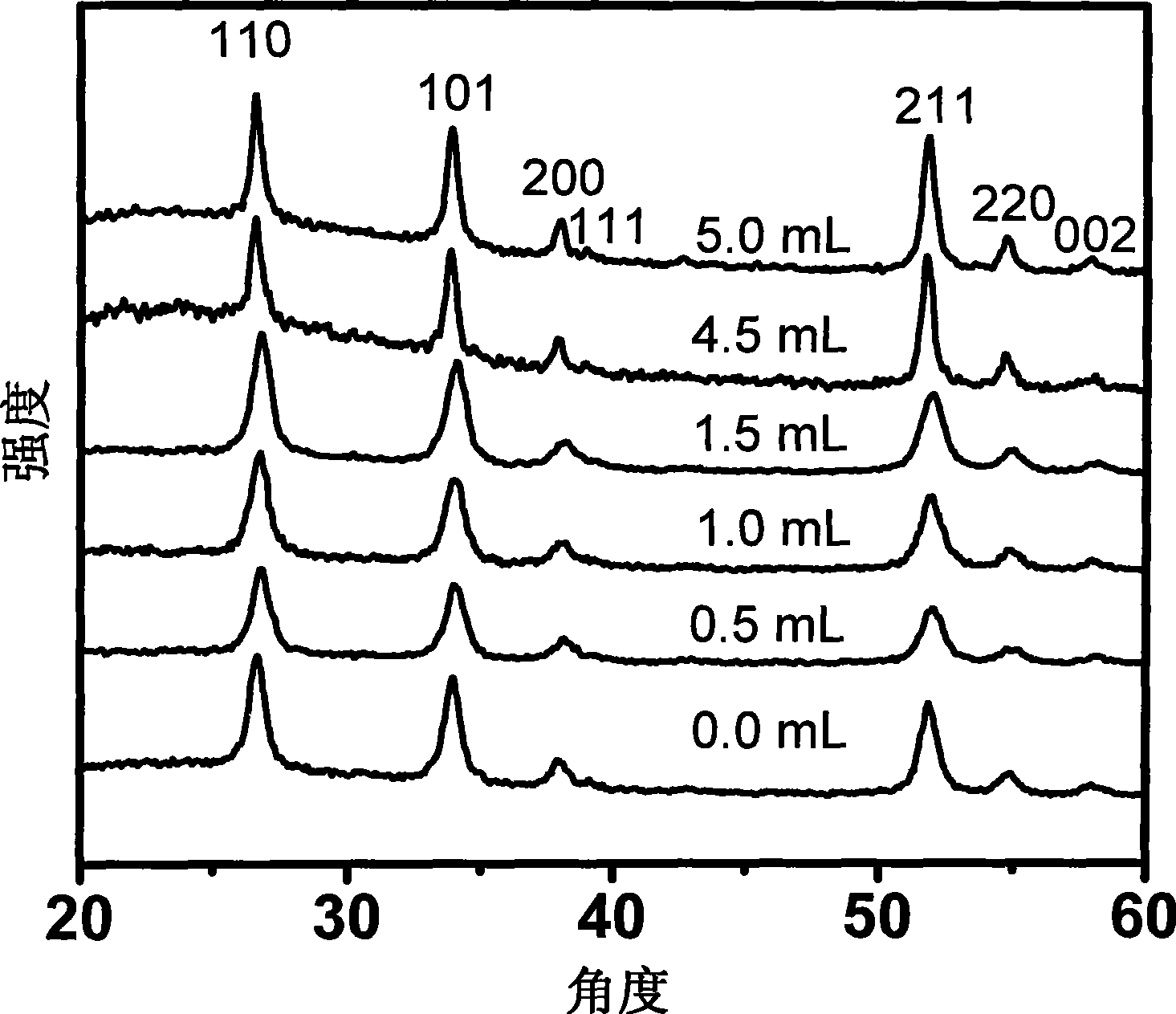

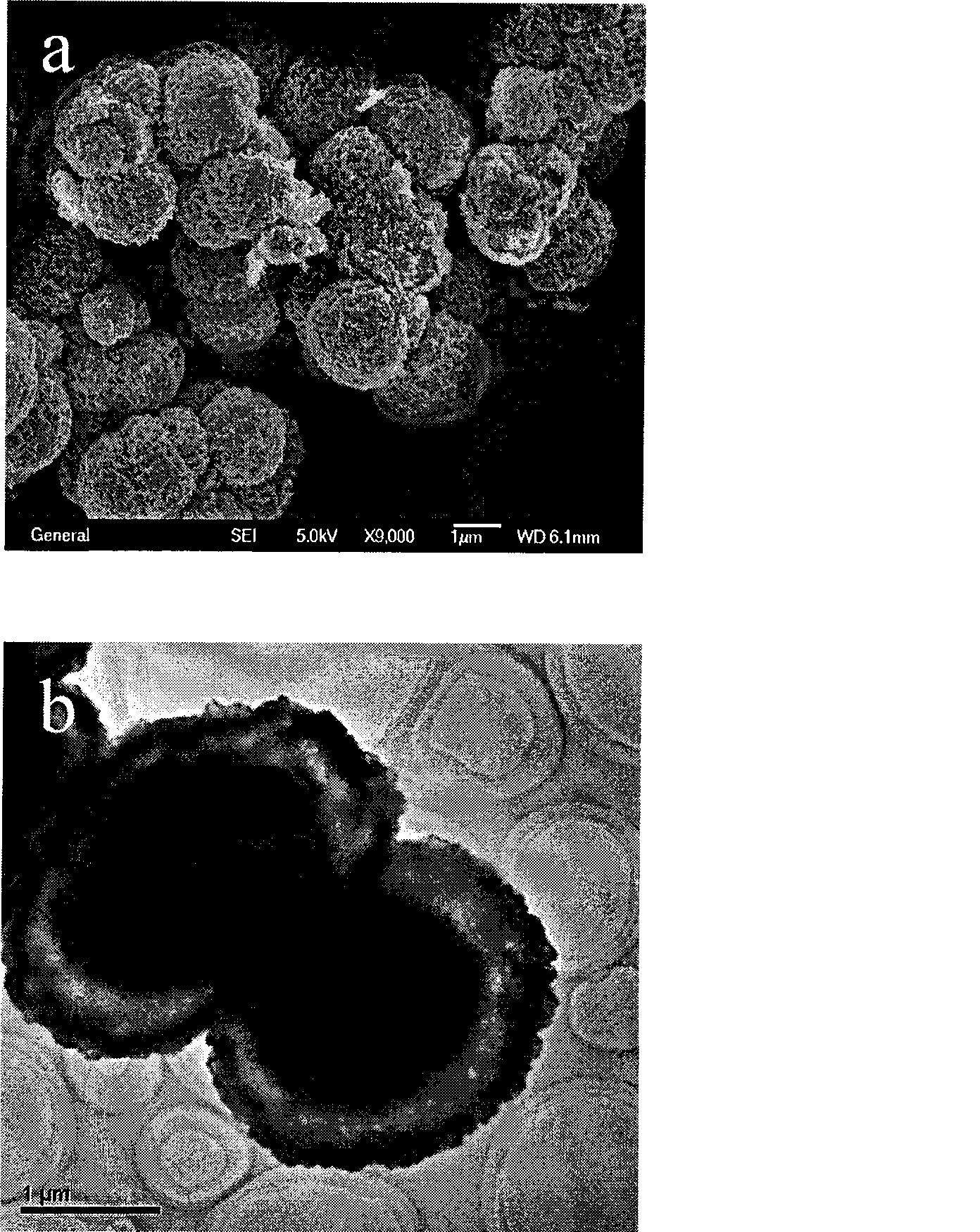

Embodiment 1

[0036] 2.25g SnCl 2 2H 2 O and 3.2 g of resorcinol were dissolved in 30 ml of deionized water, stirred evenly, then 7.0 mL of 36 wt% formaldehyde solution was added within 5 seconds, vigorously stirred for 25 seconds, and the mixed solution was transferred to a 45 mL Teflon-lined stainless steel reaction kettle, then reacted in an oven at 85°C for 48h, cooled naturally to room temperature, filtered and washed the obtained intermediate product until the pH value was 7, and then dried at 80°C. Finally, the intermediate product was placed in a tube furnace and calcined in air at 550°C for 4 hours to obtain tin dioxide microspheres with a core-shell structure. The size of the microspheres was about 2 μm, and the size of the solid core was 1.5 μm.

Embodiment 2

[0038] The experimental method was the same as in Example 1, except that 0.5 mL of hydrochloric acid with a concentration of 37 wt % was added, and tin dioxide microspheres with a core-shell structure were also obtained. The size of the microspheres was about 2 μm, and the size of the solid core was 0.8 μm.

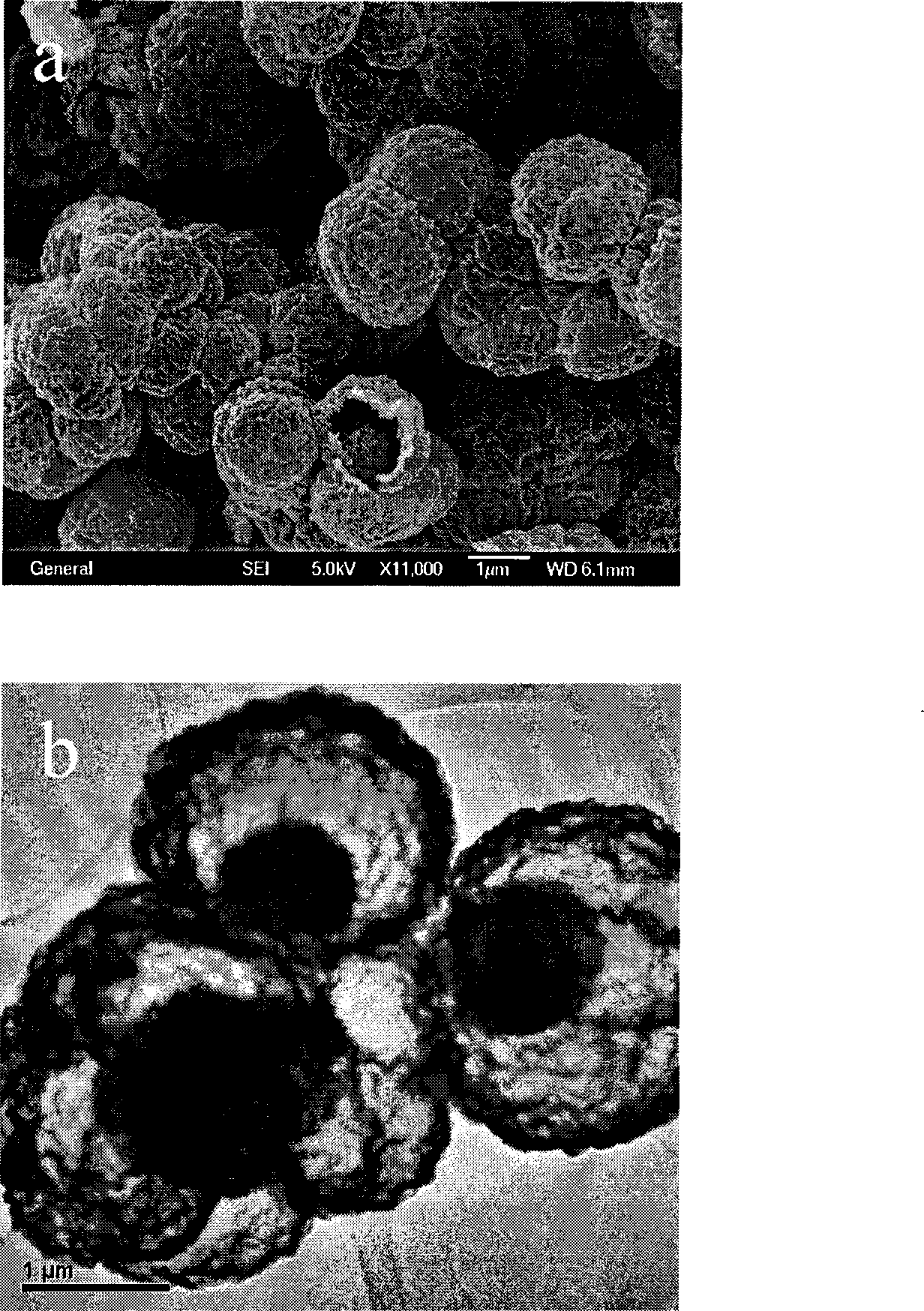

Embodiment 3

[0040] The experimental method is the same as in Example 1, except that 1.0 mL of hydrochloric acid with a concentration of 37 wt % is added to obtain tin dioxide microspheres with a hollow structure, and the size of the microspheres is about 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com