Patents

Literature

112results about How to "Meet technical needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave dielectric ceramic and preparation method thereof

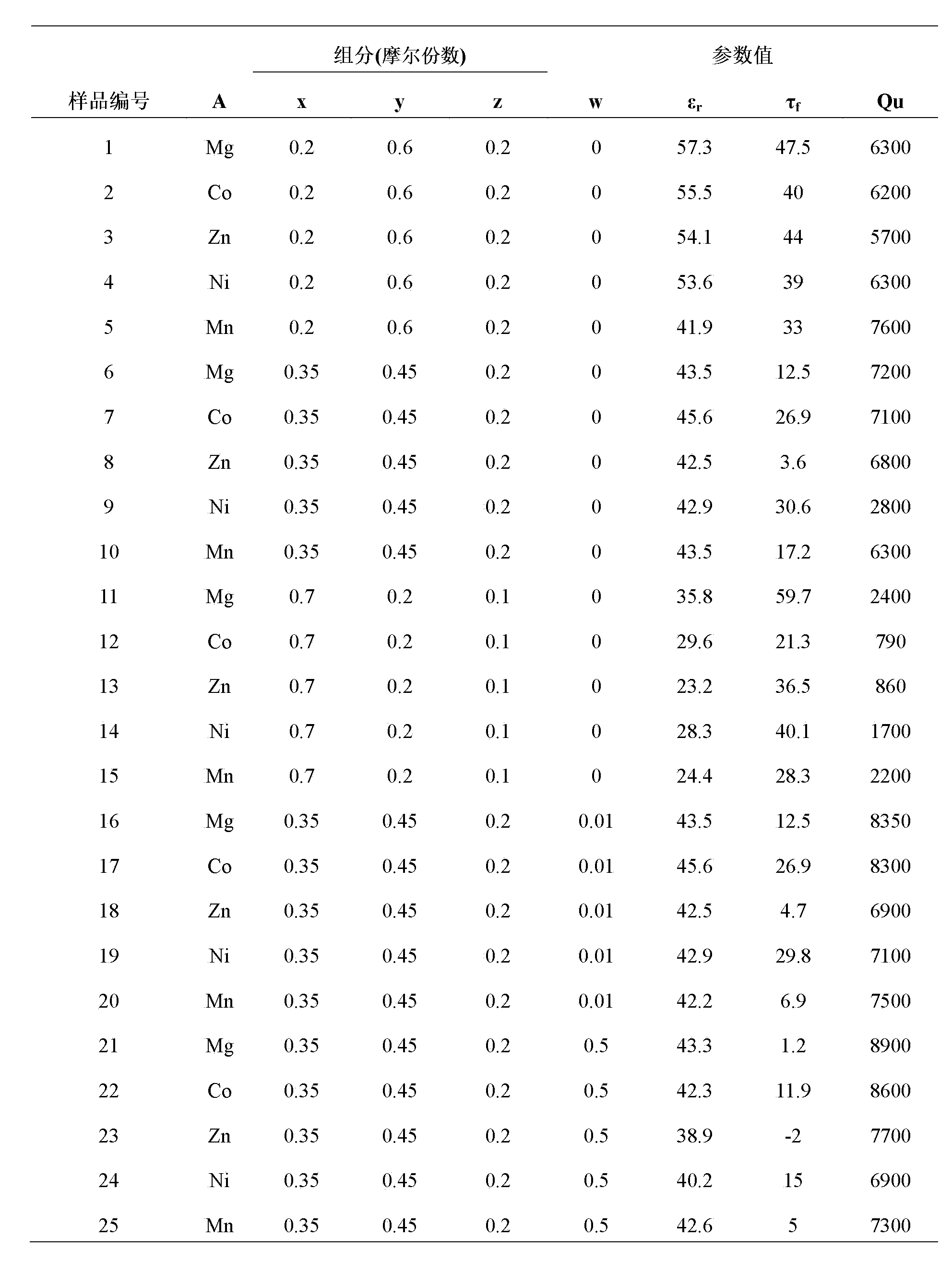

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is mainly composed of ZrO2, TiO2 and Nb2O5; the microwave dielectric property of the microwave dielectric ceramic can be improved by selectively adding MgO, CoO, ZnO, NiO and MnO2; the chemical constitution formula of the ceramic is xZrO3-YTiO2-zA(1+W) / 3Nb(2-w) / 2O3; in formula (I), A is one or more elements of Mg, Co, Zn, Ni and Mn; x, y and z are molar ratios, wherein x is between 0.2 and 0.7, y is between 0.2 and 0.6,, z is between 0.1 and 0.2, and, x plus y plus z is equal to 1; numerical range of w is l between 0 and 0.5. According to the microwave dielectric ceramic and the preparation method thereof, the ceramic has the characteristics that the dielectric constant is high, the loss is low, and the temperature coefficient is close to zero, and is liable to sinter; the preparation method has the characteristics that the price of raw materials is low, and a technology during production is simple.

Owner:HEFEI NORMAL UNIV

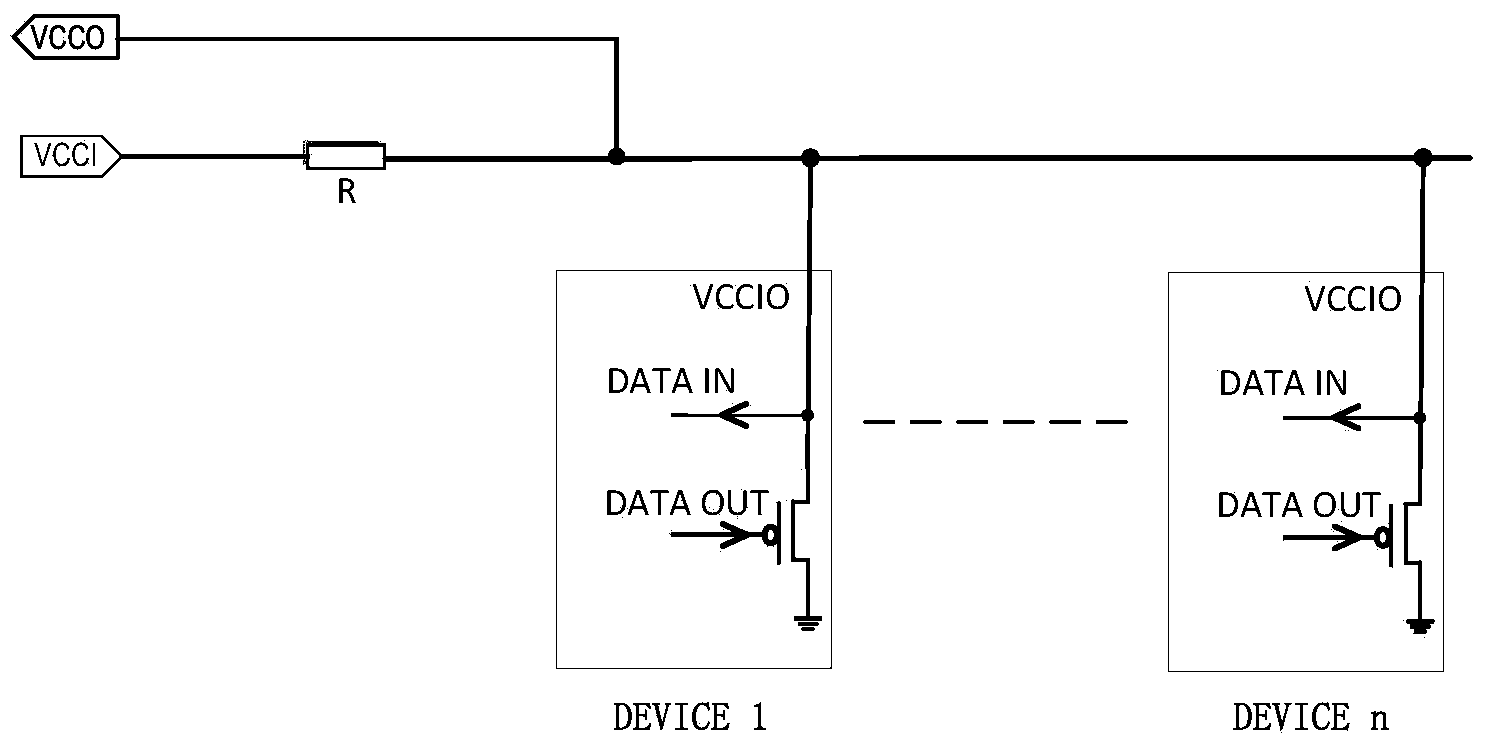

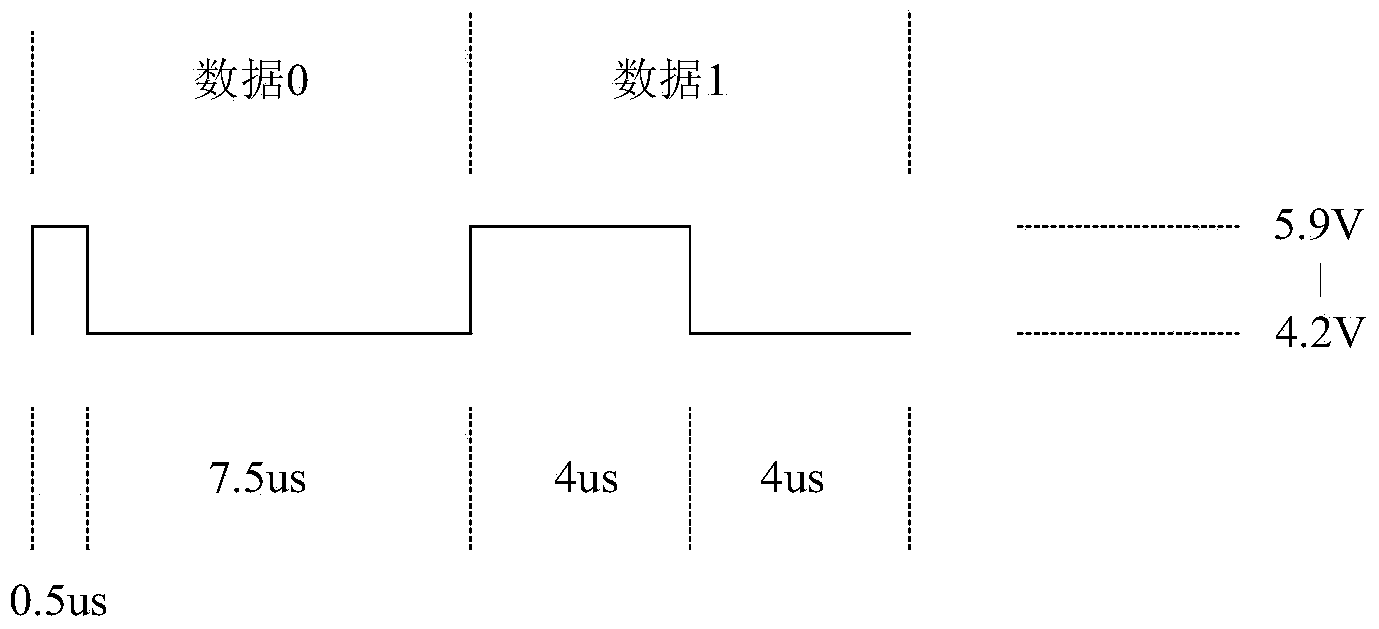

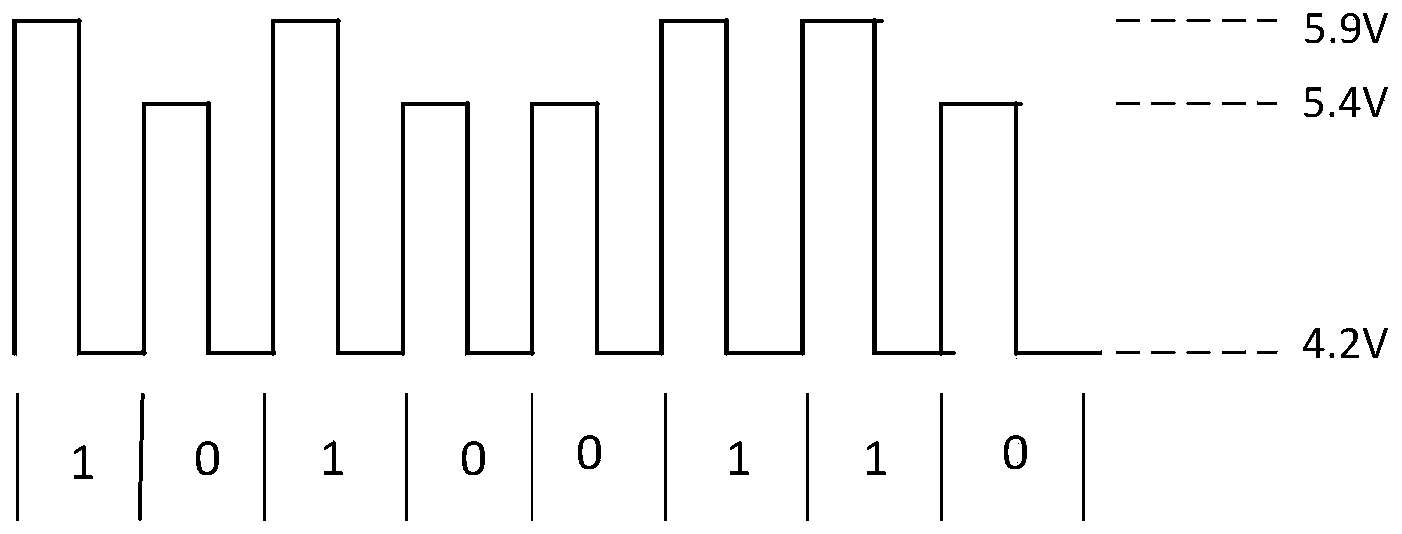

Unibus in communication with master equipment and slave equipment and communication method

InactiveCN103823776AStable jobReduce the number of I/OsElectric digital data processingEngineeringMaster controller

The invention discloses a unibus in communication with master equipment and slave equipment. The uibus is used for achieving half-duplex both-way communication and power supply transmission between a master controller and at least one slave device, and the unibus is connected with the slave equipment through a data and power supply transmission pin and a grounding pin. Meanwhile, the invention discloses a communication mode of the unibus in communication with the master equipment and the slave equipment.

Owner:SHANGHAI SINOMCU MICROELECTRONICS

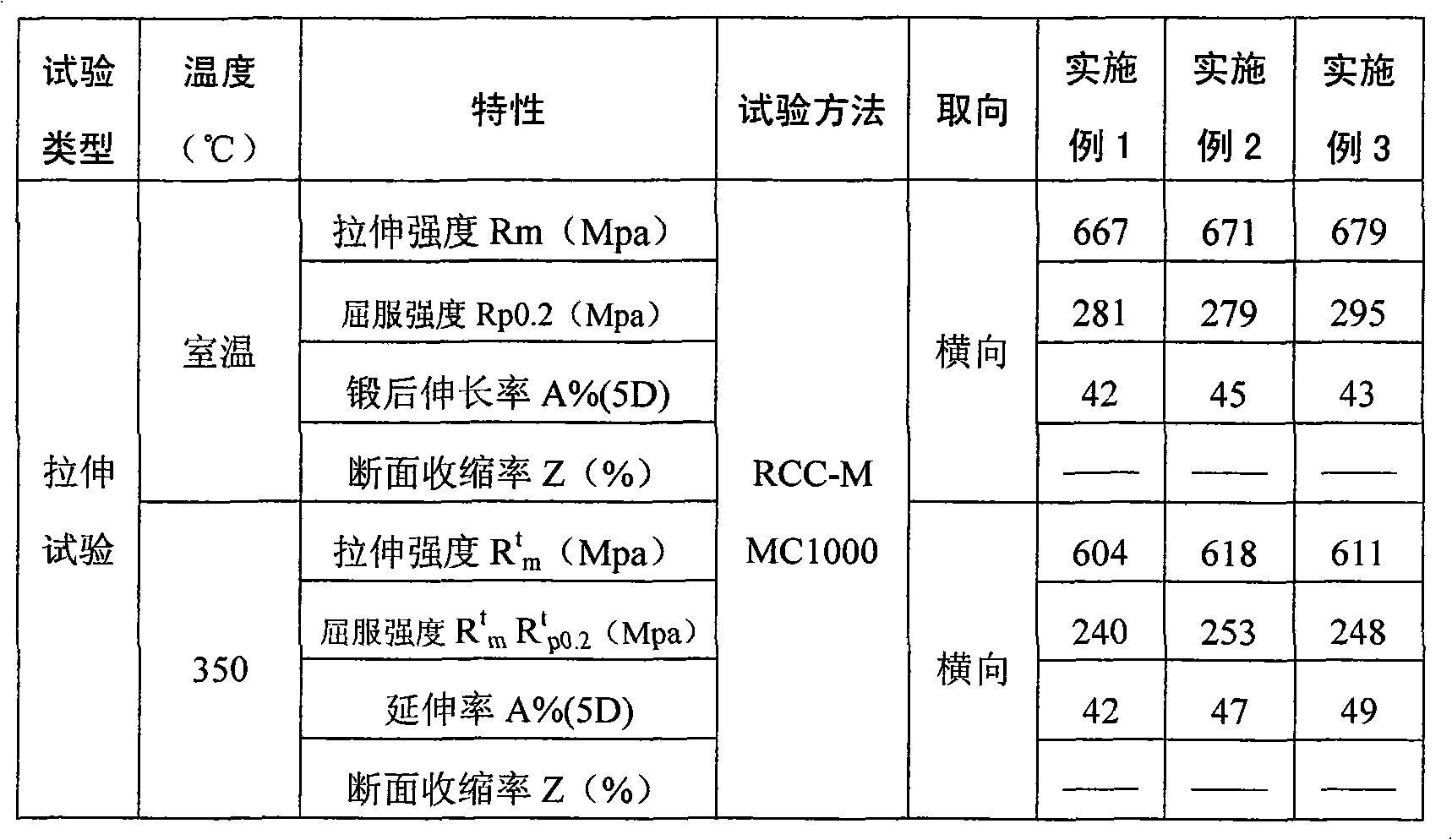

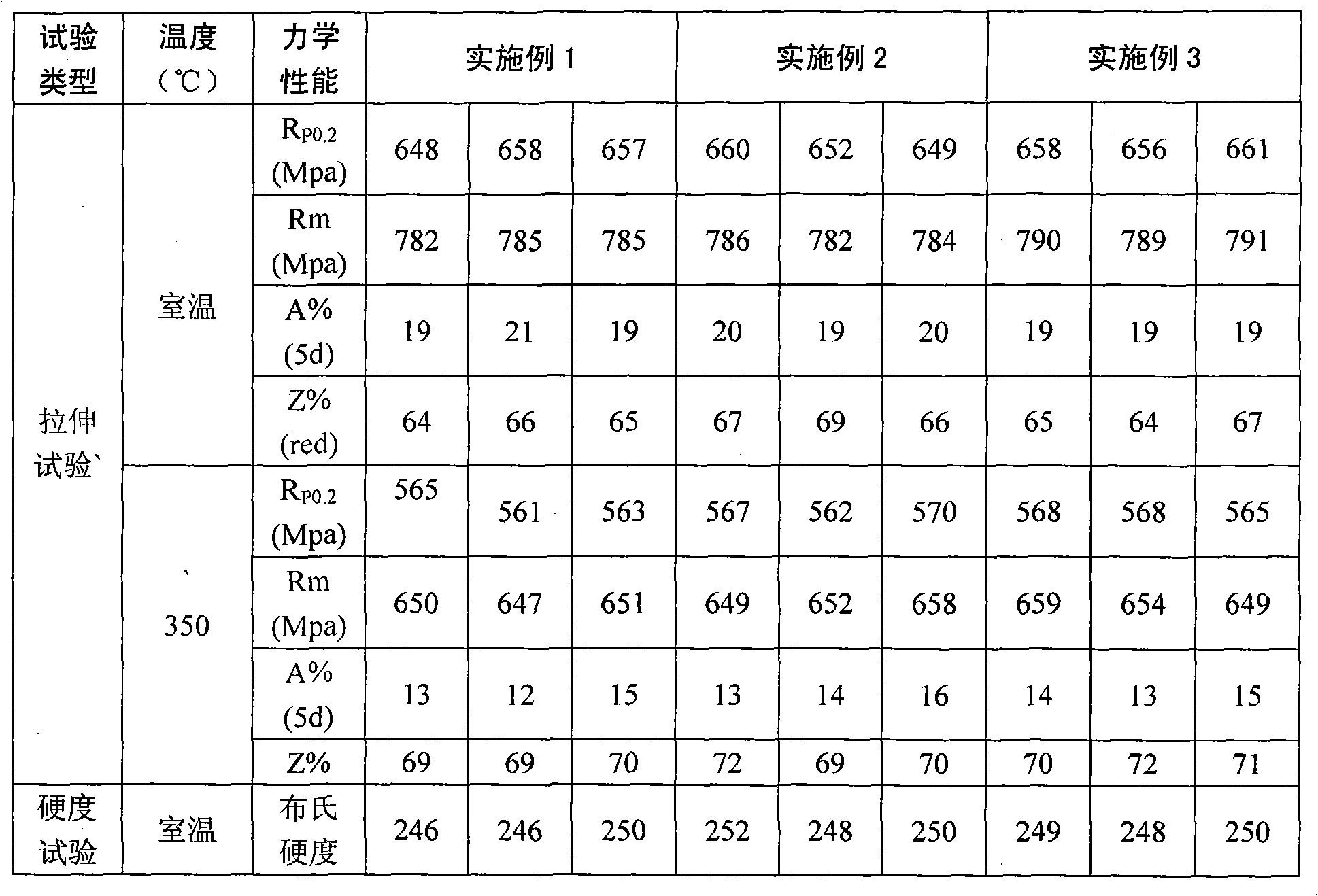

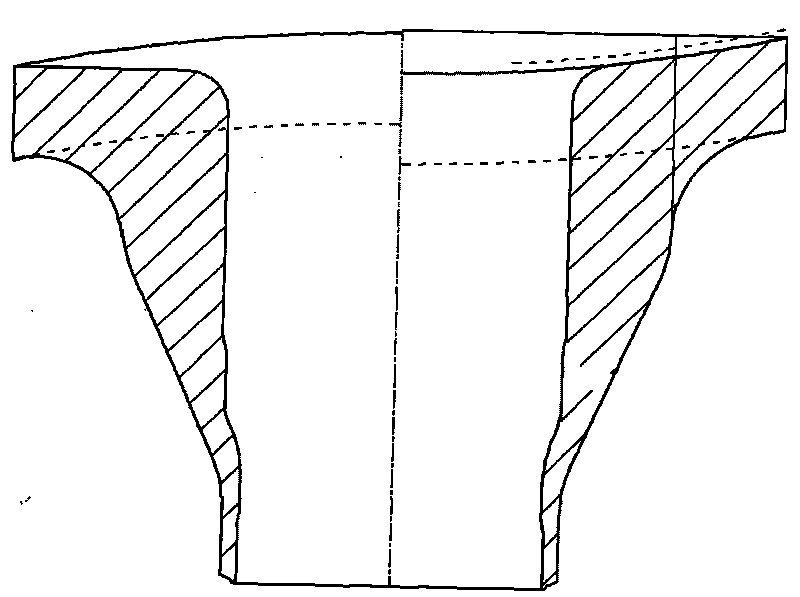

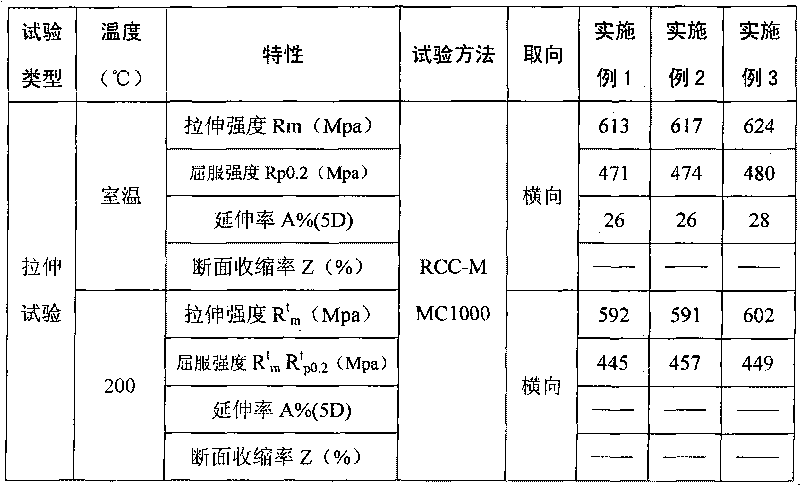

Method for manufacturing pin shaft through forging

InactiveCN101722406AMeet the use requirementsMeet technical needsEngine componentsPerformance indexIngot

The invention relates to the technical field of forging, particularly to a method for manufacturing a pin shaft through forging, which comprises the following steps of: selecting a proper steel ingot, and repeatedly upsetting and lengthening the steel ingot at the temperature of 1,180-850 DEG C to enable the forging ratio to be not less than 4; then sequentially carrying out performance heat treatment and machining to obtain the pin shaft. The method has the advantages that each performance index of the pin shaft manufactured by using the method satisfies the standard requirement of RCC-M, and ensures the use requirement of the pin shaft for a nuclear power plant, thereby greatly enhancing the security and the reliability and satisfying the technical requirement of such products.

Owner:上海新闵重型锻造有限公司

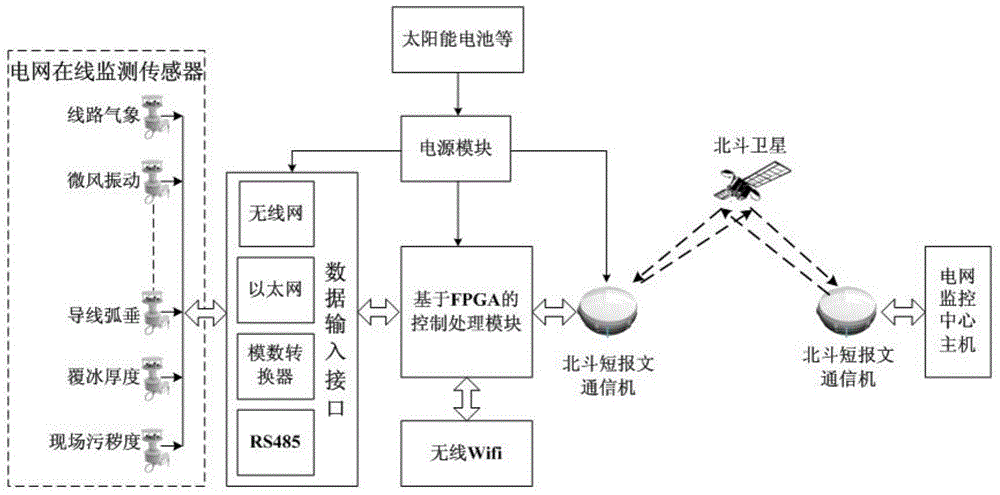

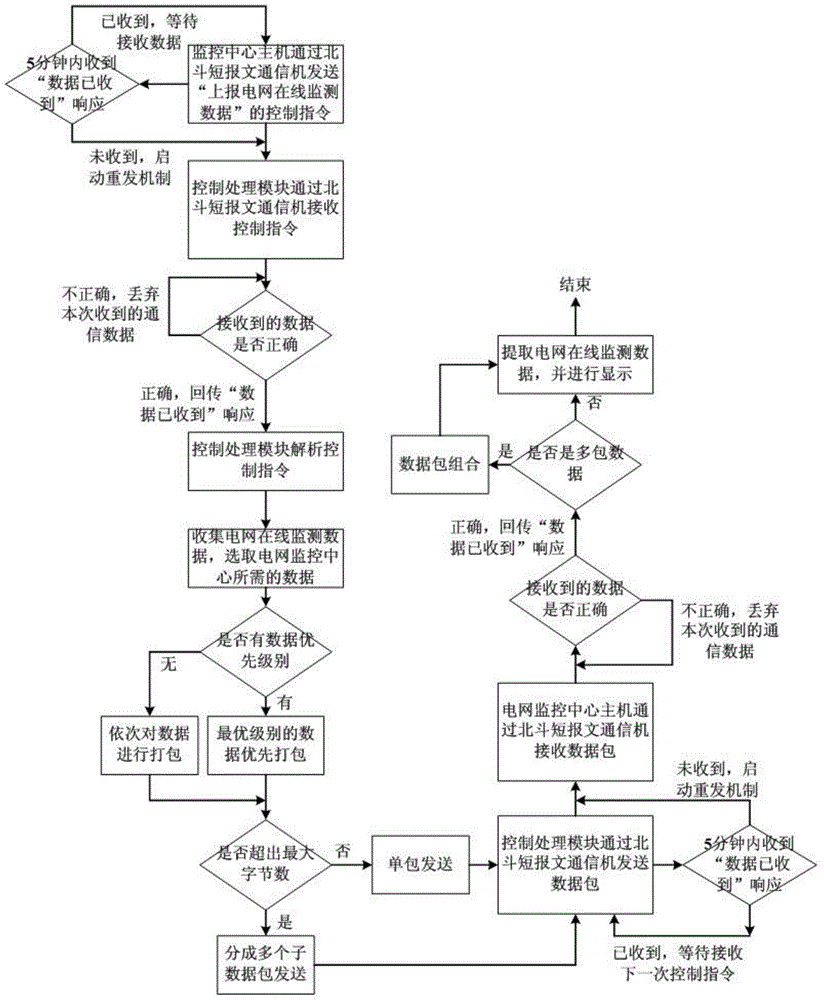

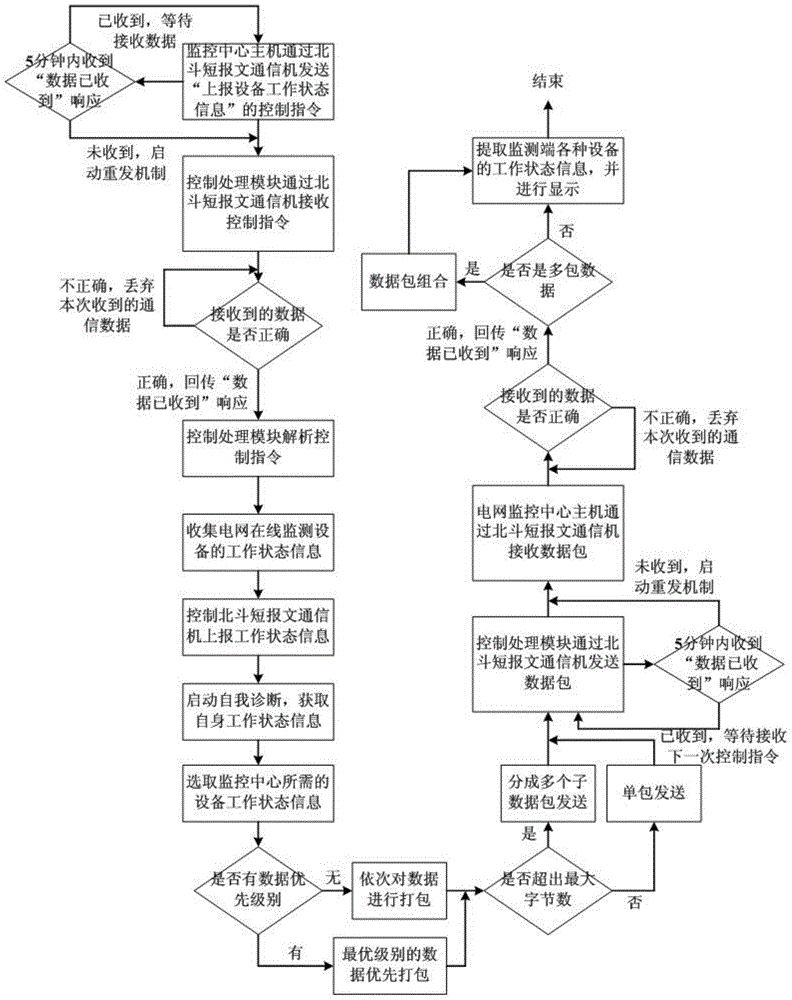

Power grid remote intelligent monitoring system based on Beidou short message communication and monitoring method

ActiveCN105098975AEasy to operateHumanized operationCircuit arrangementsMessaging/mailboxes/announcementsMonitoring systemPower grid

The invention relates to a power grid remote intelligent monitoring system based on Beidou short message communication and a monitoring method. The monitoring system comprises a power grid online monitoring sensor, a control processing module based on an FPGA, a monitoring end Beidou short message communicator, a Beidou satellite, a monitoring end Beidou short message communicator and a power grid monitoring center host. The monitoring method comprises the steps of (1) obtaining power grid online monitoring data; (2) online monitoring and controlling system monitoring the working status of an end device; and (3) a remote configuration and monitoring system monitoring parameters of the end device. The invention, without the transformation of an existing power grid online monitoring sensor and a power grid monitoring and control host, the invention makes use of the dual communication function of a Beidou short message for real-time remote monitoring of a power grid in plateau regions, mountainous areas and the like where communication is inconvenient, and the invention has the advantages of being easy to operate and user-friendly and facilitating the saving of manpower, material and financial resources.

Owner:STATE GRID CORP OF CHINA +2

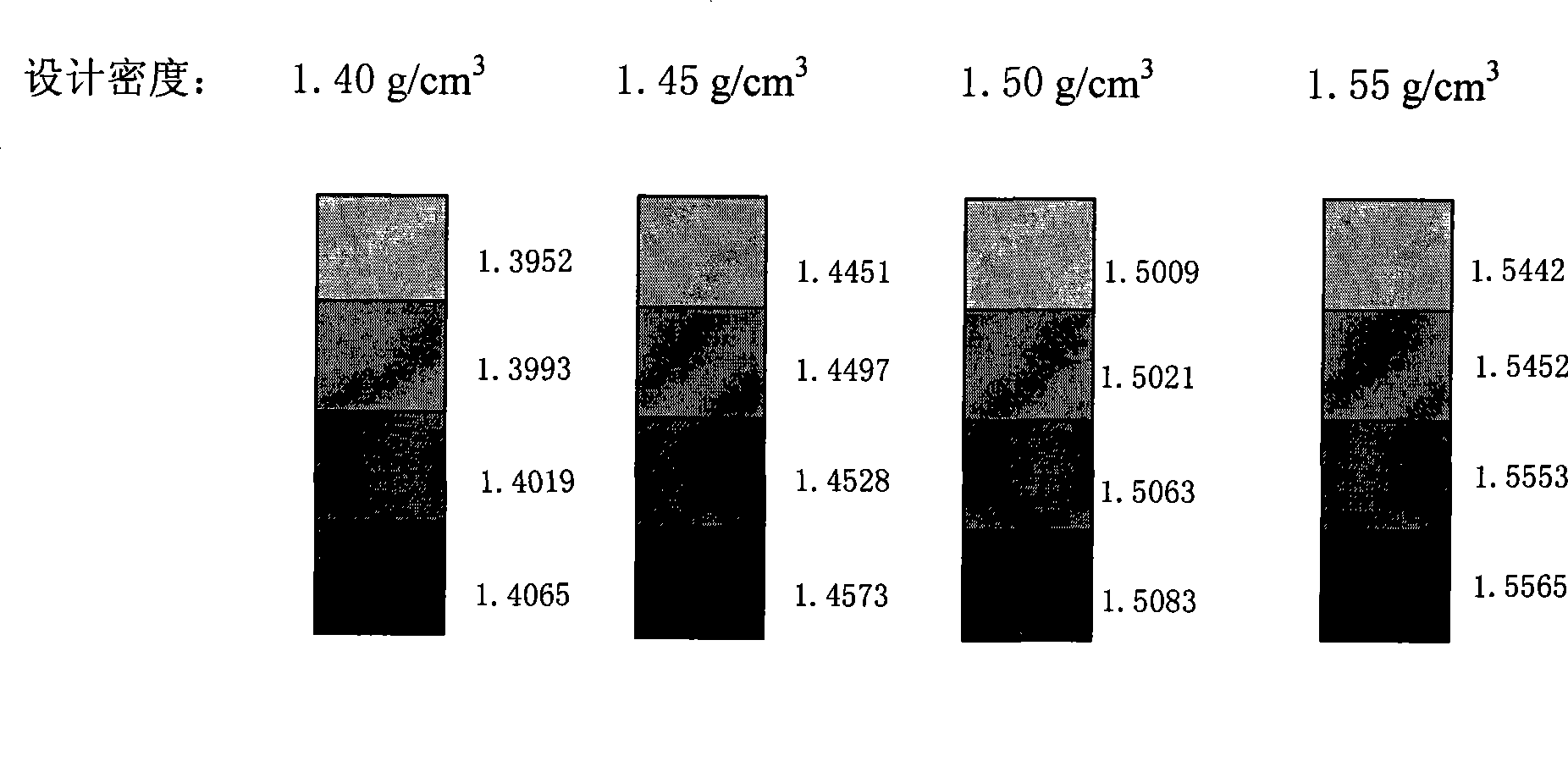

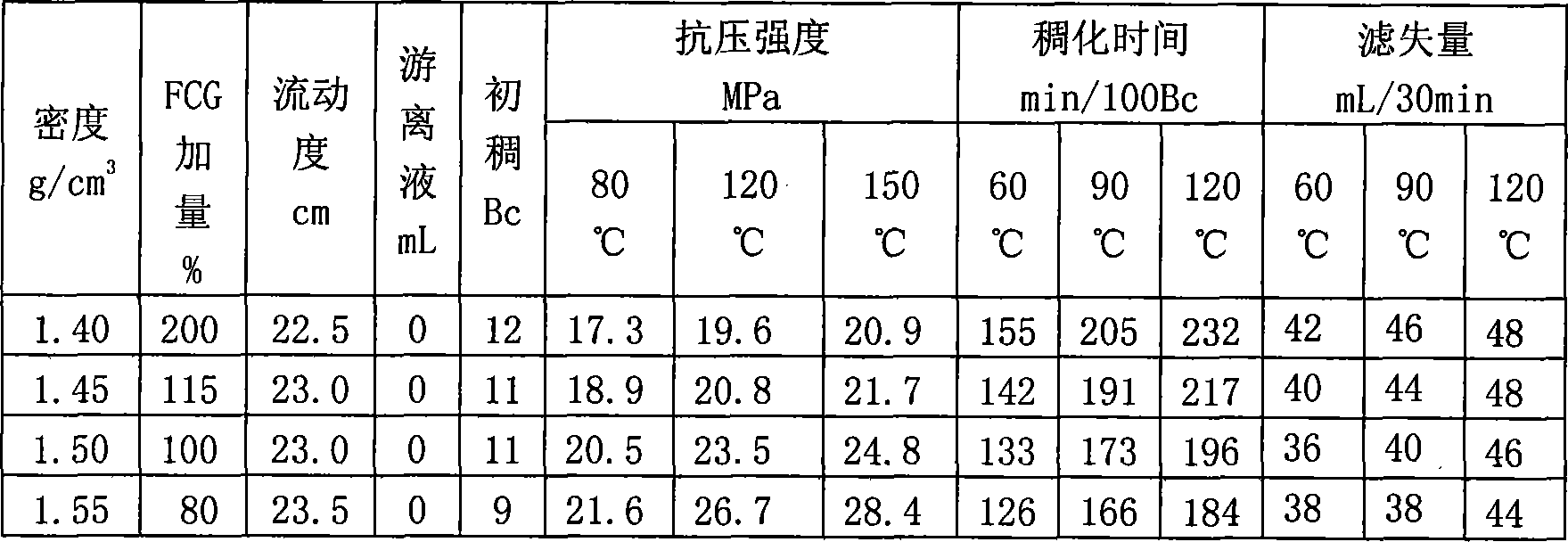

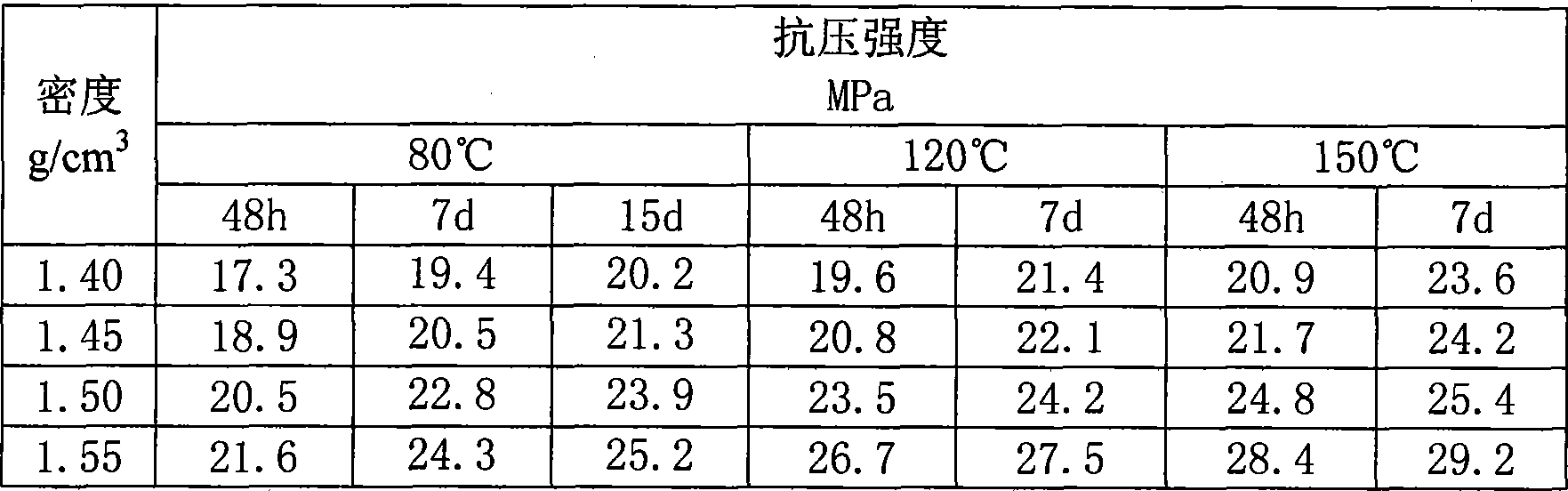

Non-floating bead low-density cement mortar

InactiveCN101475347AGood settlement stabilityMeet technical needsSolid waste managementMicrofine cementParticle density

The invention relates to a non-cenosphere light weight cement slurry, which mainly solves the problem that the cement slurry cannot keep the density thereof under a high pressure condition. The non-cenosphere light weight cement slurry is characterized by comprising the following components in portion by weight: 100 portions of cement, 116 to 321 portions of water, 52 to 136 portions of fly ash, 14 to 38 portions of silica fume, 14 to 38 portions of superfine cement, and 6 to 11 portions of early strength agent, wherein the particle diameter of the silica fume (of which the SiO2 content is more than 90 percent) is more than 0 and less than 0.5 mu m, the particle density of the silica fume and the fly ash is 2.0 grams per cubic meter, and the particle diameter of the superfine cement is more than 0 and less than 2 mu m. The light weight cement slurry forms a set of incompressible light weight cement slurry system of which the density is between 1.40 and 1.55 grams per cubic meter through preferentially selecting external additives and applying a grain composition principle, wherein the flowability and the sedimentation stability of the cement slurry are good, the set cement strength is more than 15 MPa and cannot decline at a temperature of 150 DEG C so as to satisfy the technical requirements on oil field exploration and development.

Owner:DAQING OILFIELD CO LTD +1

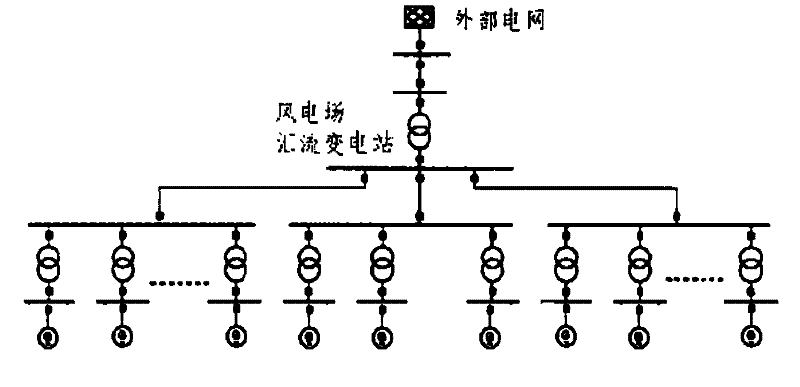

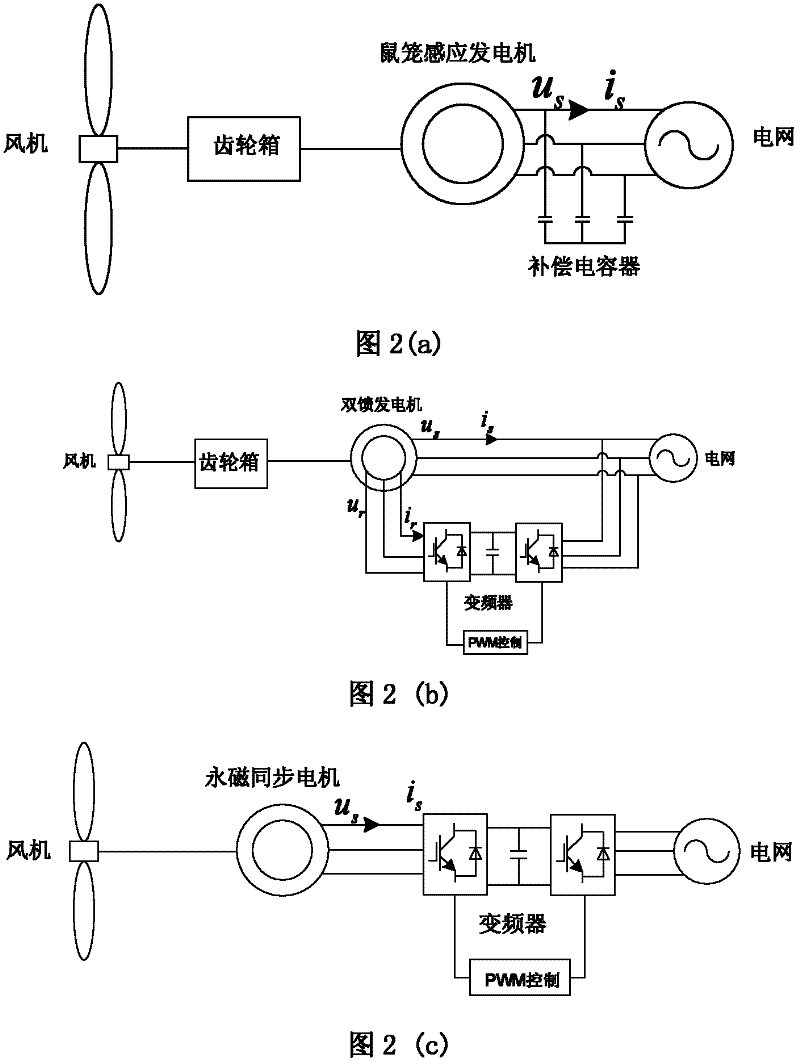

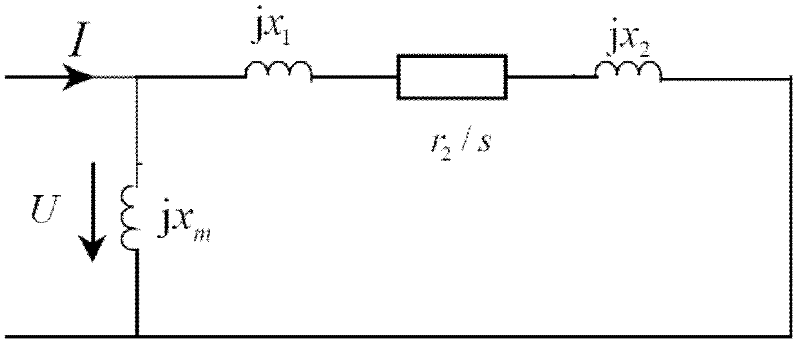

Optimal configuration and operation method for reactive compensation of wind farm

ActiveCN102377189AImprove reactive power compensation effectSatisfy economyReactive power adjustment/elimination/compensationWind energy generationSeries compensationPower grid

The invention relates to an optimal configuration and operation method for reactive compensation of a wind farm. The optimal configuration and operation method is characterized by comprising the following steps of: (1) analyzing the reactive output characteristics of the wind farm, and installing a reactive compensation device in the wind farm and configuring a volume for the reactive compensation device; and (2) detecting reactive powers of a fan outlet and an interconnection point of the wind farm, and mechanically controlling the static reactive compensation and the dynamic reactive compensation of the wind farm. The optimal configuration and operation method is designed reasonably, the combination operation of the static reactive compensation and the dynamic reactive compensation of the wind farm is realized, and the reactive powers of the wind farm and a power grid are ensured under the optimal condition of the reactive compensation device of the wind farm, therefore the effect of maintaining power grid stabilization is achieved, the reactive compensation property of the wind farm is improved, the reactive compensation equipment investment is reduced, and the reactive compensation economic and technological requirements of the wind farm are satisfied.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

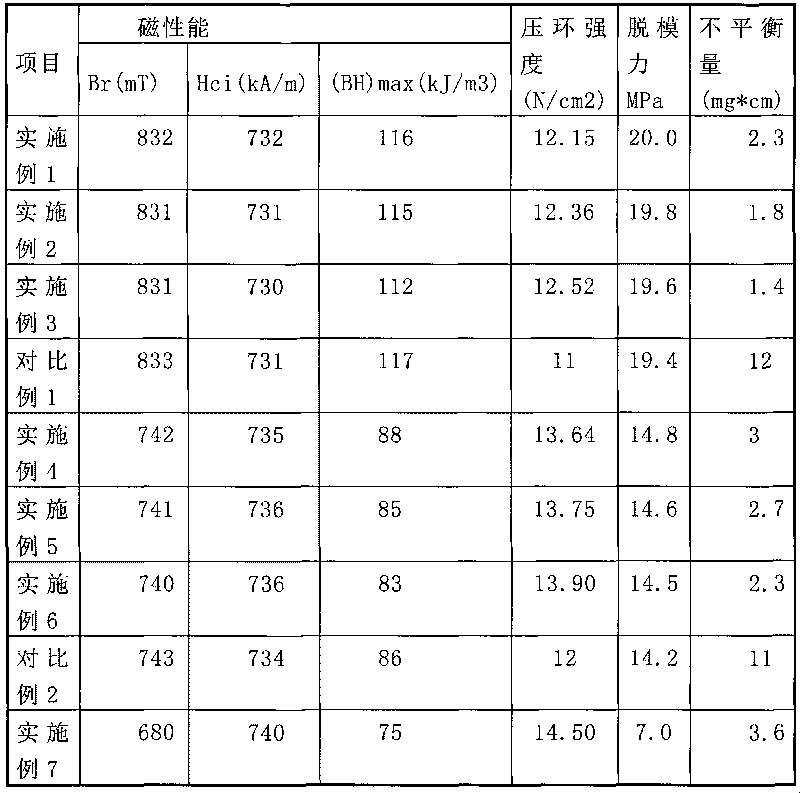

Boned neodymium iron boron permanent magnet and manufacturing method thereof

InactiveCN101710518AImprove density uniformityImprove unbalanced performanceTransportation and packagingMetal-working apparatusFirming agentNano al2o3

The invention relates to a boned neodymium iron boron permanent magnet and a manufacturing method thereof. The permanent magnet comprises NdFeB magnetic powder, thermosetting resin, a firming agent, a lubricant and a coupling agent, and also comprises nano-alumina powder of which the weight is 0.01 to 1 percent of that of the magnetic powder. The method comprises the following steps: uniformly mixing the thermosetting resin, the firming agent and acetone of which the weight is 1 to 4 times that of the resin; then performing surface treatment on the nano-alumina powder by utilizing the silane coupling agent KH-550; dispersing the nano-alumina powder by utilizing a high-power ultrasonic generator and drying the dispersed powder; mixing the thermosetting resin mixed with the nano-alumina powder after the drying with the magnetic powder uniformly by utilizing a large-scale mixer, and finally, adding the lubricant into the mixture for uniform mixing; and making the mixture into a green blank by a compression molding machine, and curing the green blank for 15 to 60 minutes at a temperature of between 150 and 220 DEG C to form a magnet. The boned neodymium iron boron permanent magnet improves the unbalanced performance of the magnet, ensures that the magnet has high stability and small vibration in a driver during high-speed rotation and better meets the technical requirements.

Owner:上海三环磁性材料有限公司 +1

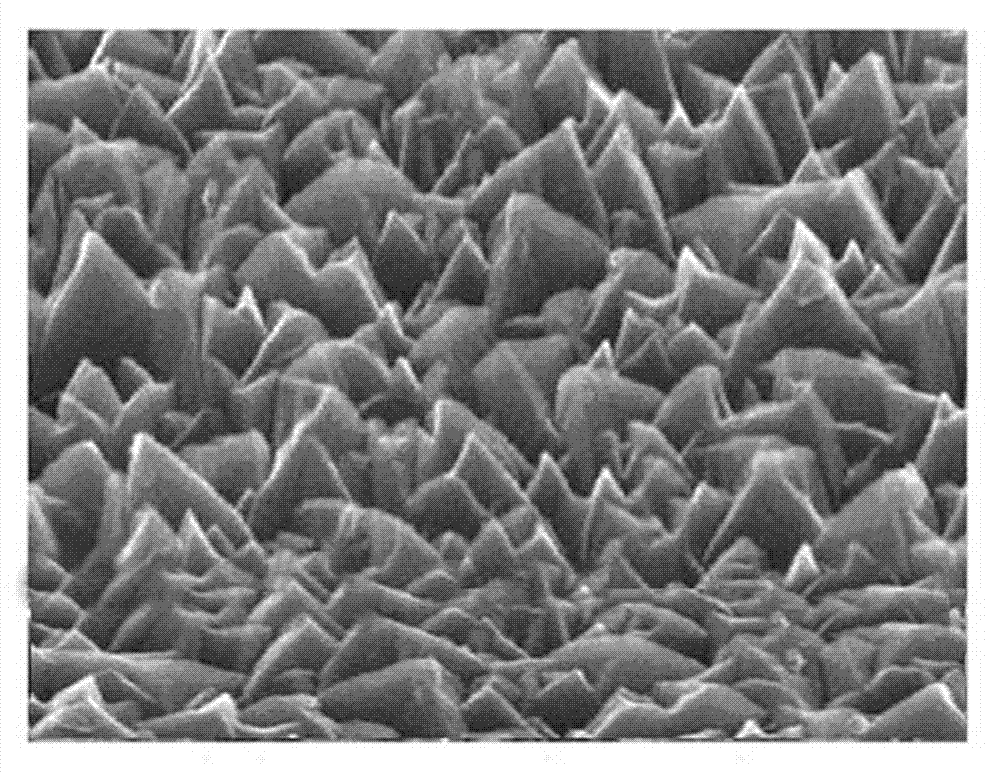

Preparation method of textured AZO (aluminum-doped zinc oxide) transparent conductive film

ActiveCN102863156AAvoid wastingReduce manufacturing costFinal product manufacturePhotovoltaic energy generationAcid etchingAluminum doped zinc oxide

The invention relates to a preparation method of a textured AZO (aluminum-doped zinc oxide) transparent conductive film. A high-alkali aluminosilicate glass substrate is subjected to texturing treatment to form a textured structure on the glass surface so as to provide foundation for the subsequent direct growth of the AZO film and the final formation of the textured surface, thereby implementing the textured structure of the directly growing AZO transparent conductive film on the glass surface, overcoming the defects of overhigh requirement for the thickness of the AZO transparent conductive film and waste of etching in the conventional technique of film formation before acid etching, and effectively lowering the production cost. The haze of the AZO transparent conductive film prepared by the method is 10-30%, the visible light transmittance is greater than or equal to 85%, and the square resistance is 8-15 ohm per square.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

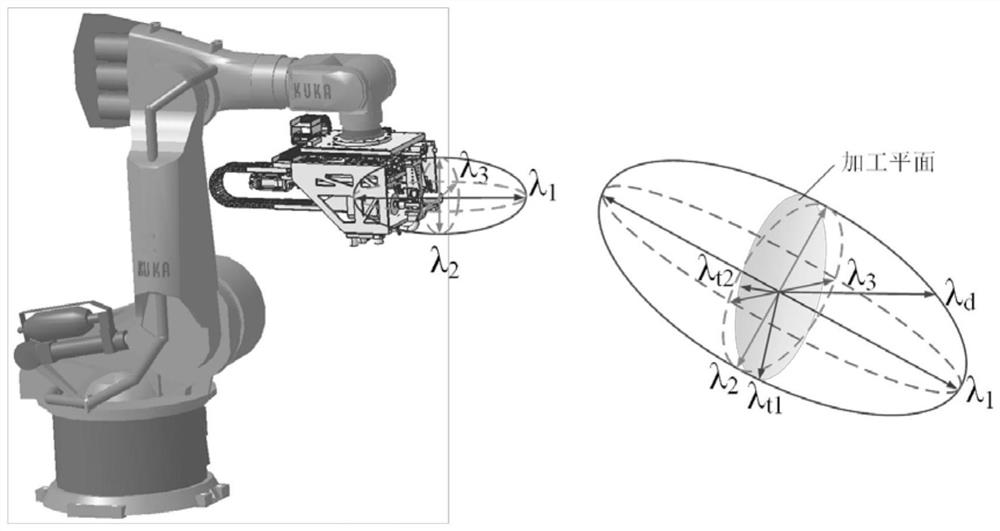

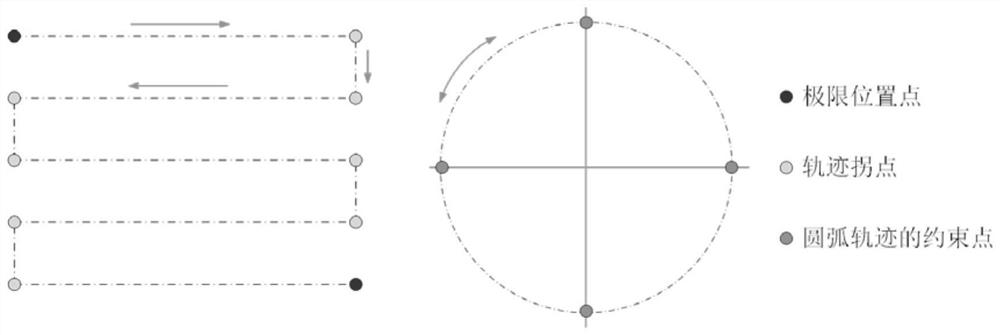

Method for optimizing working posture of industrial robot

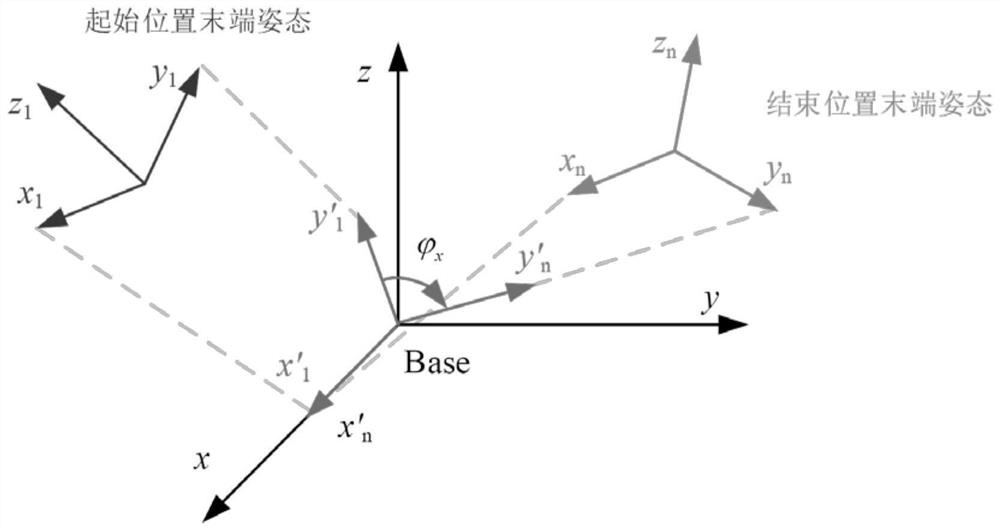

ActiveCN111702762AEasy to processMeet technical needsProgramme-controlled manipulatorWork taskControl engineering

The invention discloses a method for optimizing the working posture of an industrial robot. The method includes the following steps: establishing a rigidity model in the Cartesian space of the industrial robot; evaluating the directional rigidity of joints of the industrial robot according to the working task type; determining the characteristic points of a robot working task according to the working task type, and through the redundant degree of freedom in the axial direction of a tool of an industrial robot operating system, completing posture optimization of the characteristic points with the optimal directional rigidity performance as an optimization goal; and acquiring the optimal rigidity posture of all the characteristic points, and completing posture optimization of other target points or trajectory difference compensation positions through smoothing processing. By means of the method, selection of the optimal rigidity posture of the whole working task is achieved, rapid optimization of the robot working posture in the complex working task and improvement of the processing performance are achieved, and the technical requirements of the robot in high-precision manufacturingand processing fields such as hole making and milling are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

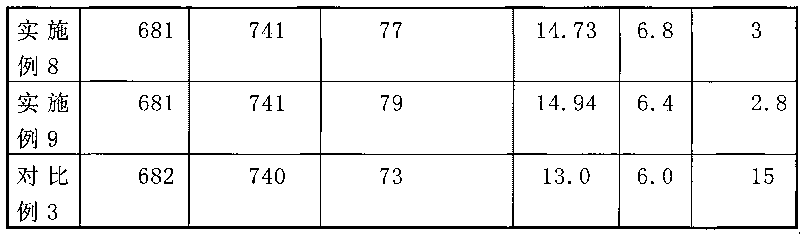

High-Q-value medium-dielectric-constant microwave dielectric ceramic and preparation method thereof

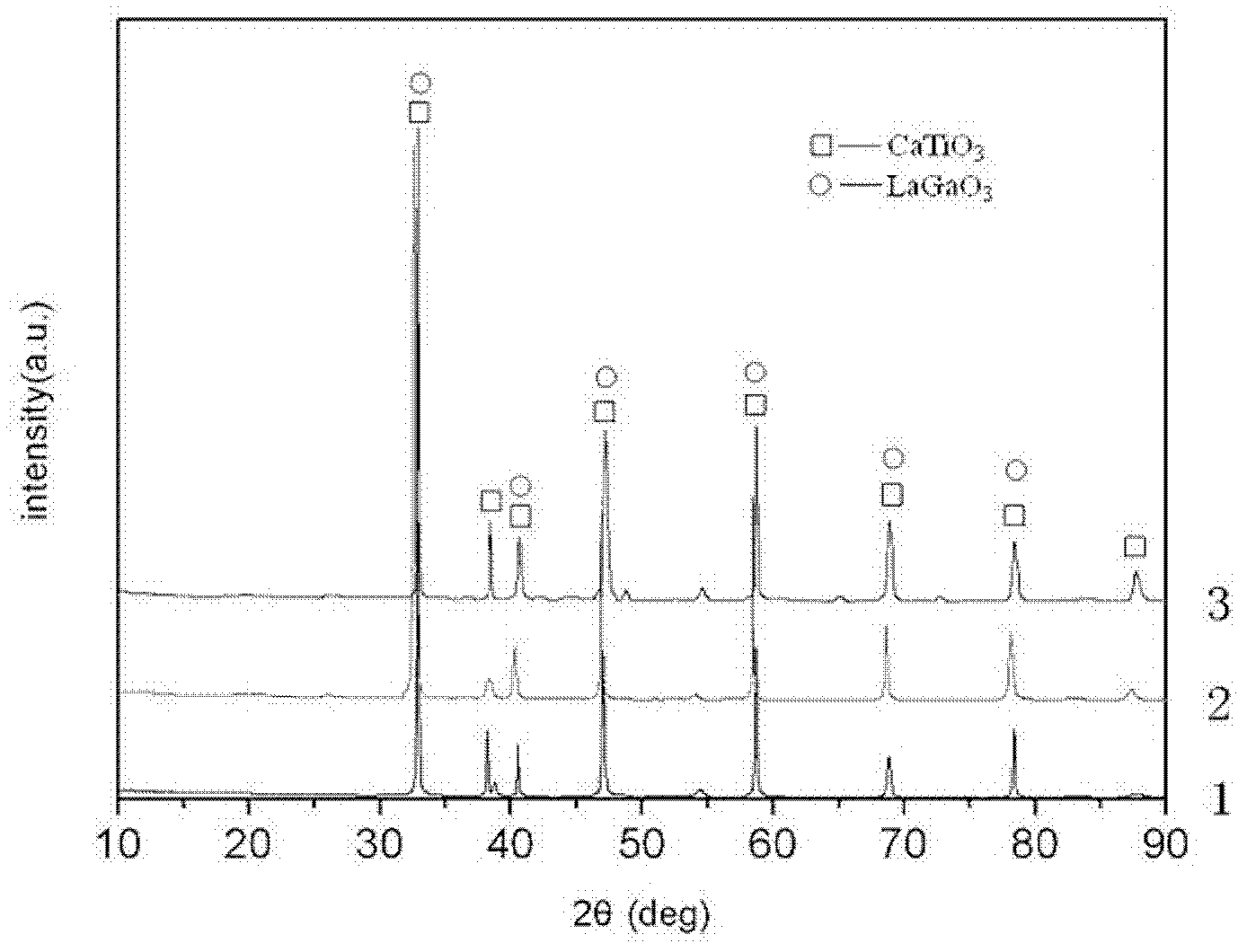

ActiveCN102531571AExcellent microwave dielectric propertiesResonant frequency temperature coefficient continuous adjustmentCompound aMicrowave dielectric properties

The invention discloses a high-Q-value medium-dielectric-constant microwave dielectric ceramic and a preparation method thereof and relates to a microwave dielectric ceramic. According to the invention, a novel material system is adopted as follows: xCaTiO3-(1-x)LaGaO3 (x is 0.66-0.62) microwave dielectric ceramic is obtained by compounding a calcium titanate (CaTiO3) phase with a lanthanum gallate (LaGaO3) phase; the microwave dielectric ceramic comprises the following components by weight percent: 25-35% of CaCO3, 15-30% of TiO2, 20-35% of La2O3 and 10-25% of Ga2O3, wherein the purities of CaCO3 and TiO2 are more than or equal to 99.0%, and the purities of La2O3 and Ga2O3 are more than or equal to 99.9%. The high-Q-value medium-dielectric-constant microwave dielectric ceramic disclosed by the invention is good in microwave dielectric property, simple in production technical process and good in repeatability, can be widely applied to preparation of good-property microwave devices such as a dielectric resonator, a filter and a duplexer and meets the technical requirements of systems such as a communication base station.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Hard disk data protection and recovery method of Linux platform

InactiveCN102495812AMeet technical needsUnauthorized memory use protectionRedundant operation error correctionRecovery methodOperational system

The invention discloses a hard disk data protection and recovery method of a Linux platform. The method implements protection and recovery for the data in a file system through a write operation redirection technology based on a hybrid file system, a protection technology based on a read-only compressed file system, an Initrd-based configuration technology for initializing a sub-system when a kernel moves later, a file system quick detection and repair technology and a root file system detection technology based on a file system identifier; and the method transparently protects the file system data of an operating system without using own file system access control of the operating system, records file modifications of the running process and recoveries the data as needed.

Owner:JIANGSU LEMOTE TECH CORP

Cultivation method for interplanting radix tetrastigmae and polygonatum cyrtonema under forest

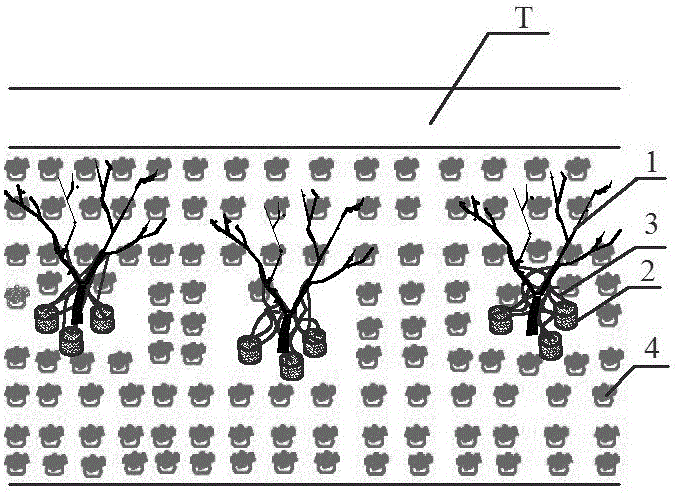

InactiveCN105830853AReduce facility costsIncrease profitPlant cultivationCultivating equipmentsHigh densityCompound management

A cultivation method for interplanting clover and Polygonatum multiflora under forests, which belongs to the technical field of agroforestry compound management and cultivation, and is characterized in that it includes 1) selection of forest stand and forest land; 2) forest stand treatment; 3) forest land treatment; 4) multi-flower Polygonatum seed stem selection; 5) Shamrock seedling selection; 6) Polygonatum multiflora cultivation; 7) Sanyeqing cultivation; 8) Post-planting management; 9) Harvesting and other steps; , using precise planting techniques such as underground bagging planting, matrix soil mixed with broken tiles, standing vine topping, and quantitative control of vine length, etc. for clover, which not only meets the technical needs of industrial transformation and upgrading, but also saves the cost of forest facilities. It has also greatly improved the comprehensive utilization rate of forest land and the output value per unit area of forest land, and the economic benefits are very significant.

Owner:LISHUI ACAD OF FORESTRY

Gold stamping glue solution and gold stamping method using same

The invention relates to the technical field of gold stamping glue solution, and specifically discloses a gold stamping glue solution and a gold stamping method using the same. The gold stamping glue solution is prepared by mixing and stirring the following raw materials by mass percent: 30%-35% of base glue, 15%-30% of a curing agent, 3%-10% of a brightener, 0.5%-1.5% of an anti-sticking agent, 0-0.1% of a wax agent and 30%-35% of diluents. Technical requirements of the transfer printing technology are satisfied, the products are shining, smooth, clearly patterned and low in cost. Technically, the original mode that the gold stamping glue is spread on a chamois leather is changed into a mode that the gold stamping glue is spread on the back of a gold stamping film paper, thus, twice silk-screen printing processes are omitted, the transfer printing technology is used, the technical effect of the transfer printing technology is as good as that of the technology of performing gold stamping after twice silk-screen printing processes, the manufacturing cost is reduced, and the manufacturing speed is accelerated.

Owner:桐乡市永盛织物整理股份有限公司

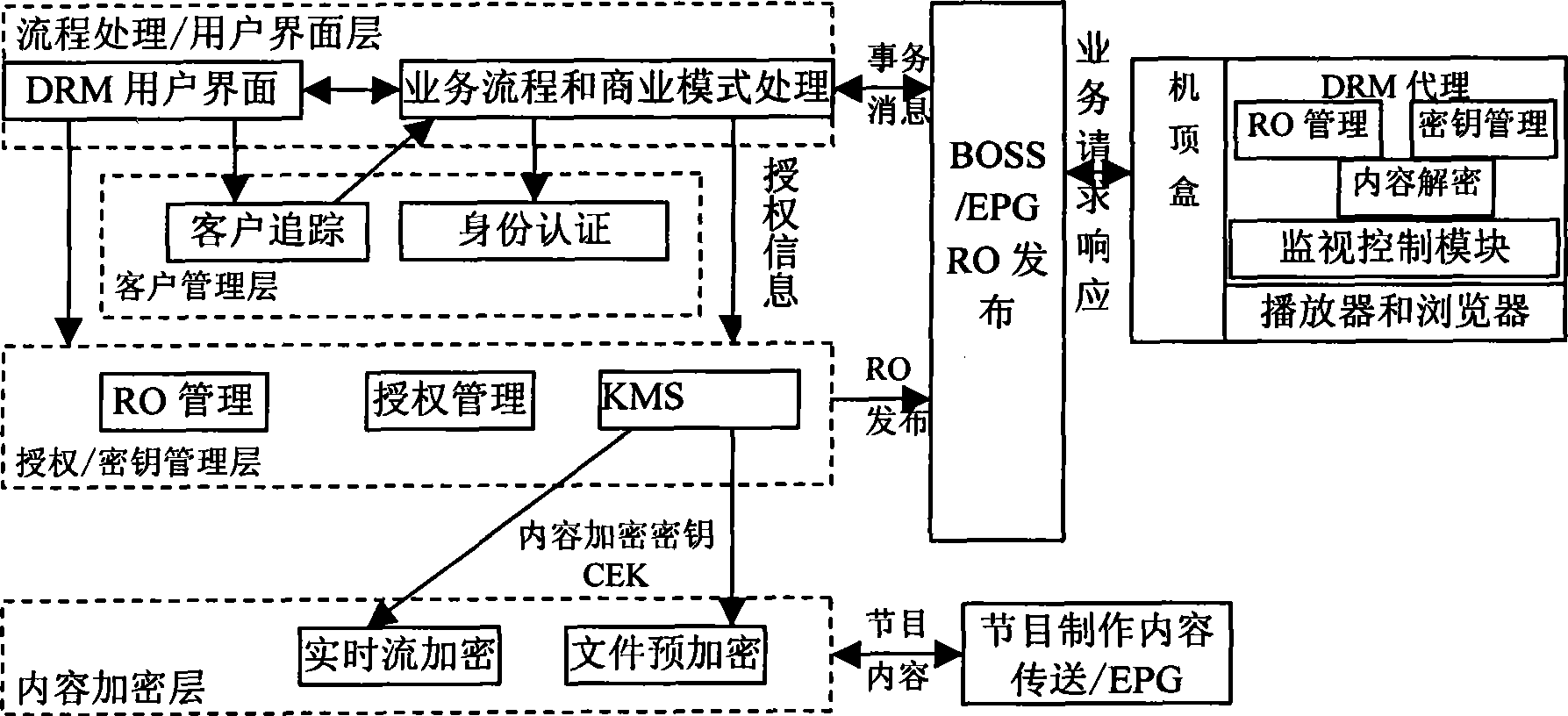

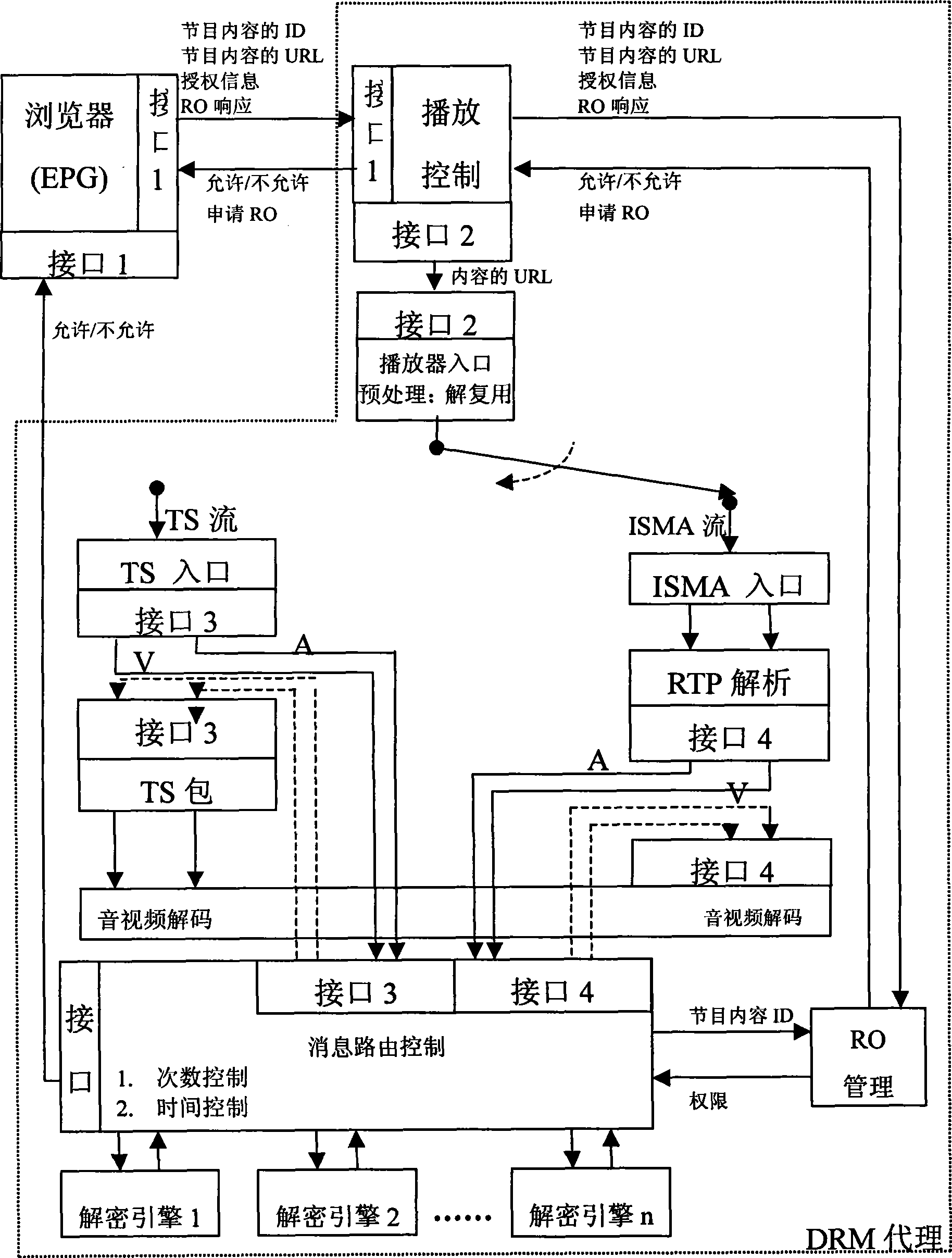

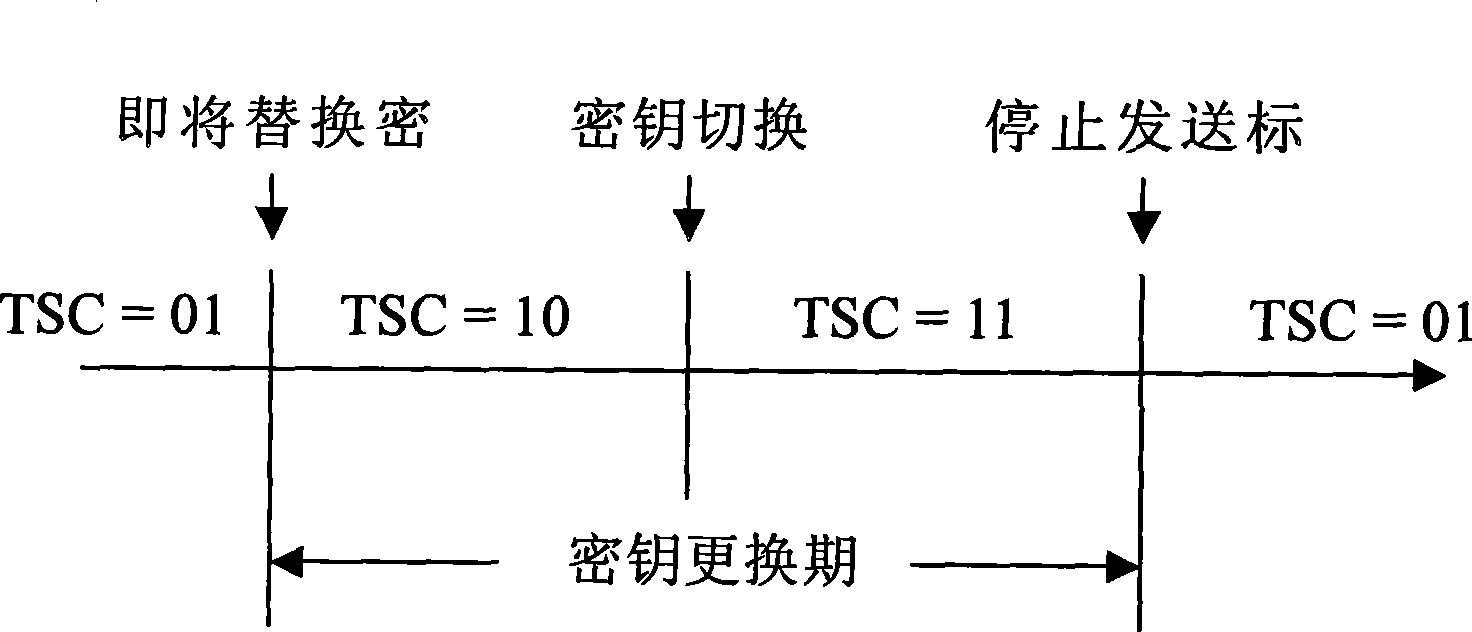

Decipher processing method for digital content format

InactiveCN101466020AMeet technical needsMake up for the limitations of not being able to handle data streamsAnalogue secracy/subscription systemsComputer security arrangementsNetwork packetDigital content

The invention discloses a decryption processing method of SDCF and relates to the technical field of digital copyright protection, aiming at solving the technical problem of SDCF decryption processing. The decryption processing method relates to the following platforms: a DRM agent of a set-top box, a DRM copyright releasing system and a middleware; wherein, the DRM agent comprises an RO management module, a key management module, a content decryption module, a monitoring control module with a playing-before control submodule, a player, a browser and the like. The decryption processing method comprises the following steps: 1) users select programs by a user interface and acquire a global unique program logo and the URL of the program contents; 2) according to the program logo, the playing-before control submodule locally searches the corresponding RO and checks the limits to rights; 3) according to the URL in a data packet for transmitting digital contents, the content decryption module acquires the corresponding RO, a decryption mode and a content key to finish the decryption. The decryption processing method has the characteristics that: the network load can be reduced; the operation is simple and convenient; and the technical requirements can be satisfied.

Owner:SHANGHAI AISINOCHIP ELECTRONICS TECH

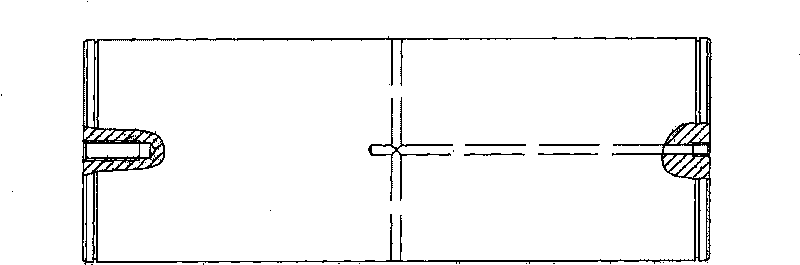

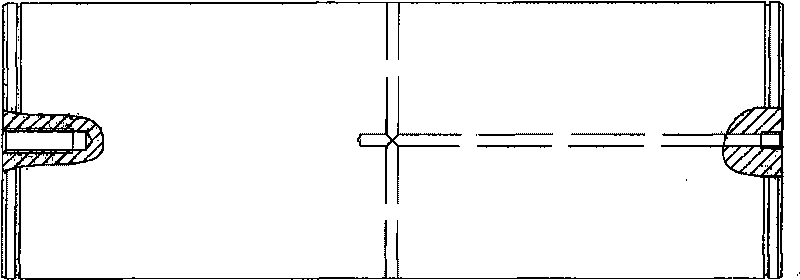

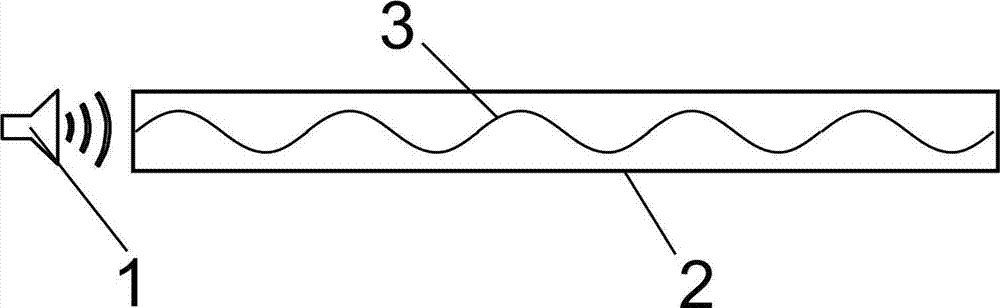

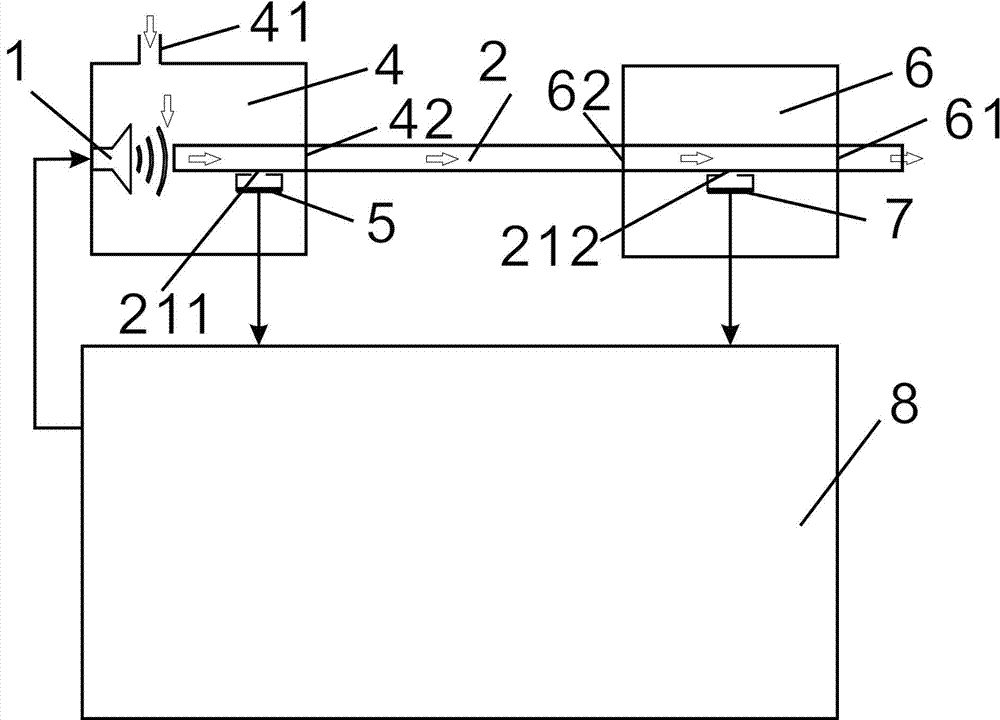

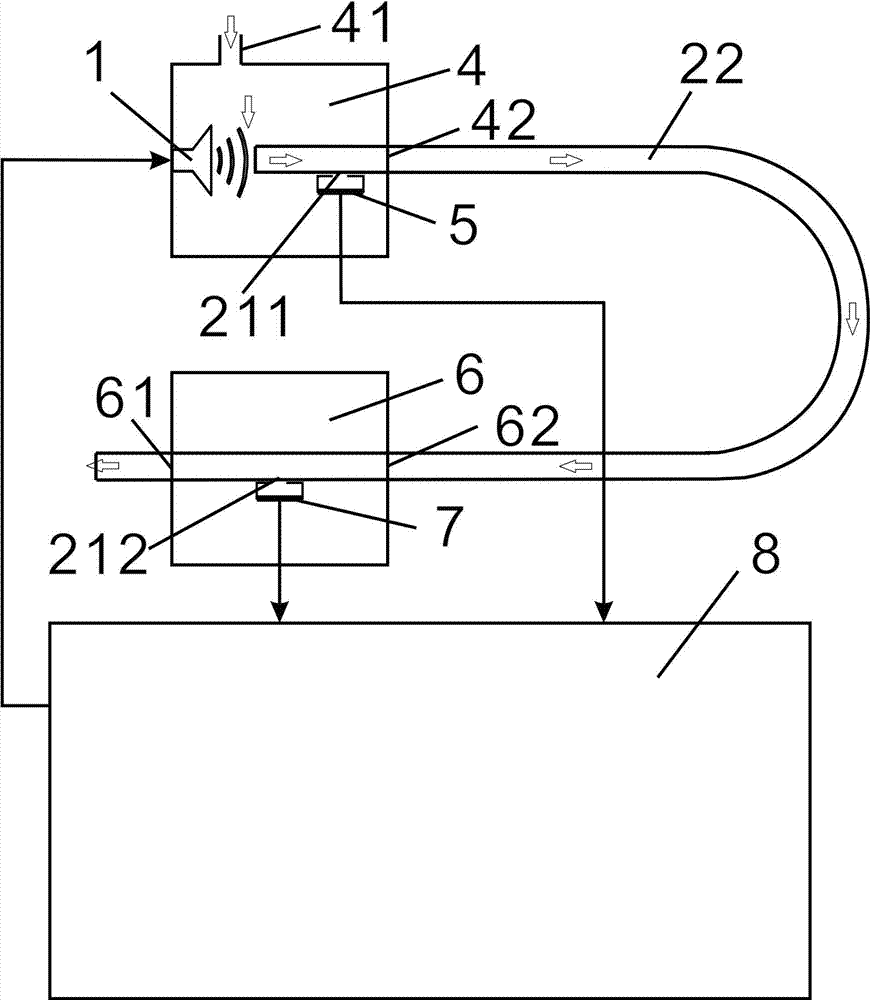

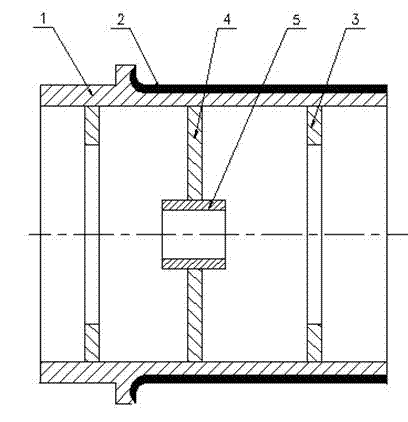

Method and device of sound velocity measurement

ActiveCN103196539AMeet technical needsRealize a high degree of automationVelocity propogationPhase differenceAcoustic wave

The invention relates to a measurement technology of sound velocity, in particular to a method and a device of sound velocity measurement. The method and the device of the sound velocity measurement are used for solving the technical problems that an existing sound velocity measurement device and an existing sound velocity measurement method are complex in operation, poor in measurement accuracy and the like. The method of the sound velocity measurement comprises the following steps of (a) inputting a sine sound wave with a frequency of fi through the front end of a sound wave guide tube, wherein the sound wave guide tube is filled with specific gas, and the length of the sound wave guide tube is 1, and recording a phase difference phi i, between the rear end and the front end of the sound wave guide tube, of the sine sound wave; (b) changing the frequency of the sine sound wave, and measuring at least one group of values from the fi to the phi i; and (c) calculating the value of 2pi l / vs using a linear fitting method according to the obtained values from the fi to the phi i, and obtaining a sound level vs. The device of the sound velocity measurement comprises a first air chamber and a second air chamber, and further comprises the sound wave guide tube. The front end of the sound wave guide tube penetrates through a first passing hole to enter the first air chamber. The rear end of the sound wave guide tube passes a third passing hole and a second passing hole, and penetrates through the second air chamber. The method and the device of the sound velocity measurement achieve high automation of measurement, and are simple in structure and low in cost.

Owner:SHANXI UNIV

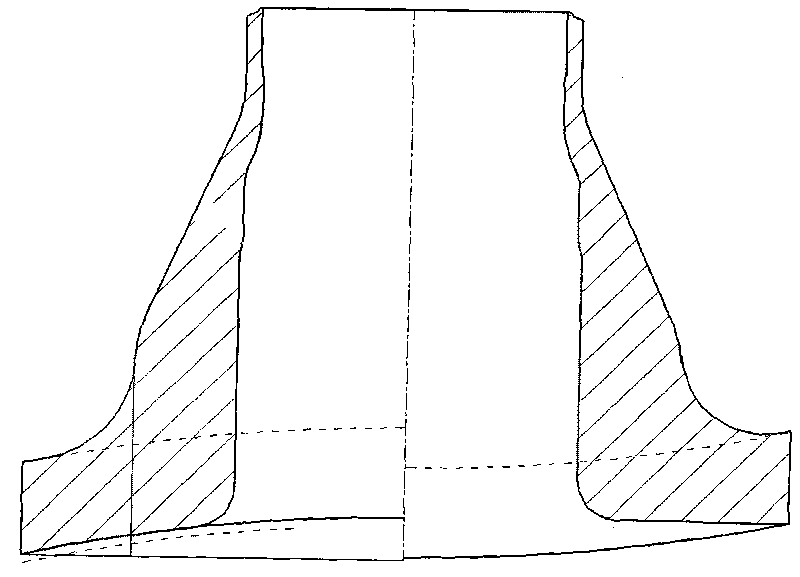

Method for forging Venturi tubes

InactiveCN101774107AMeet the use requirementsMeet technical needsFurnace typesEngine componentsNuclear powerIngot

The invention relates to the technical field of forging, in particular to a method for forging Venturi tubes for steam generators in nuclear power plants. The method specifically comprises the following steps: selecting proper steel ingots, repeatedly upsetting-drawing out the steel ingots to ensure the forging ratio to be not less than 4 in the temperature range of 1130-850 DEG C; and then carrying out rough machining, property heat treatment and machining in sequence to obtain the Venturi tubes. The invention has the following advantages: various property indexes of the Venturi tubes meet the standard requirements of RCC-M, thus ensuring the use requirements of the Venturi tubes, greatly elevating the safety and reliability of the Venturi tubes and meeting the technical requirements of the Venturi tubes.

Owner:上海新闵重型锻造有限公司

Method for forging screw and nut

ActiveCN101767179AMeet the use requirementsMeet technical needsNutsBoltsPressurized water reactorNuclear power

The invention relates to the technical field of forging, in particular to a method for forging a screw and a nut for a steam generator of a pressurized water reactor nuclear power station. The method comprises the following steps: repeatedly performing upsetting-stretching on a suitable steel ingot at the temperature of between 1,150 and 800 DEG C to ensure that the forging ratio is no less than 4; and then sequentially performing property heat treatment and machining after the heat treatment on the steel ingot to obtain the screw and the nut. The method has the advantages that: performance indexes of the screw and the nut meet the requirements of a RCC-M standard; using requirements of the screw and the nut for the steam generator of the pressurized water reactor nuclear power station are met; the safety and the reliability of the screw and the nut are greatly improved, and technical requirements of the products are met.

Owner:上海新闵重型锻造有限公司

Flame-retardant low dielectric constant polypropylene material, and preparation method and application

The invention discloses a flame-retardant low dielectric constant polypropylene material, and a preparation method and an application and relates to a polypropylene material and a preparation method of the polypropylene material. The polypropylene material aims at solving problems that dielectric properties, flame resistance, insulating properties and aging resistance of an insulating material prepared by the existing method cannot meet requirements of vehicle-mounted Ethernet wires on the insulating material. The flame-retardant low dielectric constant polypropylene material is prepared frompolypropylene resin, modified resin, composite fire retardant, low dielectric constant filling, a silane coupling agent, organic peroxide, a composite antioxidant and a composite processing aid. The method comprises the steps of: I, material weighing, II, preparation of the flame-retardant low dielectric constant functional filling, III, preparation of a functional master batch, and IV, mixing ofthe functional master batch and the polypropylene resin, and extrusion and forming to form the flame-retardant low dielectric constant polypropylene insulating material. The flame-retardant low dielectric constant polypropylene material is used for manufacturing the vehicle-mounted Ethernet wires. The flame-retardant low dielectric constant polypropylene material can be obtained.

Owner:HARBIN UNIV OF SCI & TECH +1

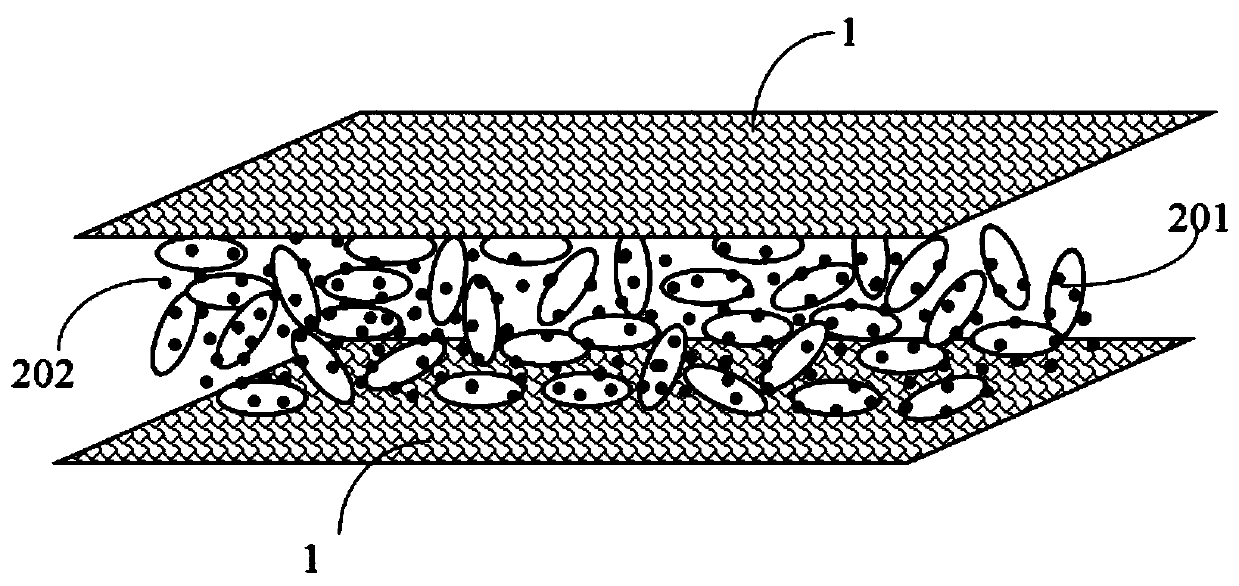

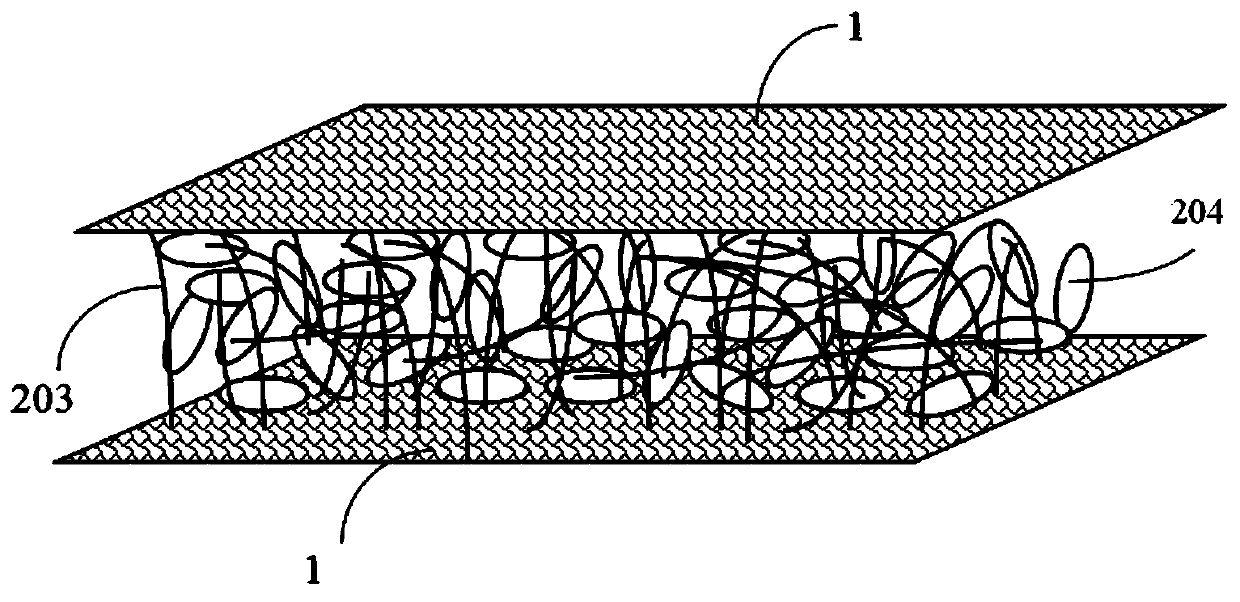

Thermal interface material and preparation method thereof

InactiveCN111572119AImprove thermal conductivityMeet technical needsMaterial nanotechnologyLaminationNanowireComposite film

The invention provides a thermal interface material and a preparation method thereof. The preparation method comprises the following steps: preparing a carbon nanotube film by adopting a floating catalysis method; preparing a nanoscale silicon dioxide powder and graphene oxide mixed dispersion solution; uniformly distributing the mixed dispersion solution on the surface of a layer of carbon nanotube film by adopting a spraying method, then covering the carbon nanotube film with a layer of carbon nanotube film, and repeatedly spraying until a set number of layers is reached, so as to form a carbon nanotube-nano silicon dioxide-graphene oxide composite film; and carrying out rapid heat treatment on the composite film in an inert protective atmosphere, reducing graphene oxide into graphene, generating silicon carbide nanowires by utilizing a carbothermal reduction reaction, and forming a three-dimensional network structure between carbon nanotubes and graphene, so as to form the carbon nanotube-graphene-silicon carbide nanowire composite film. According to the thermal interface material and the preparation method thereof, the compressibility and the heat conductivity coefficient are improved.

Owner:安徽宇航派蒙健康科技股份有限公司

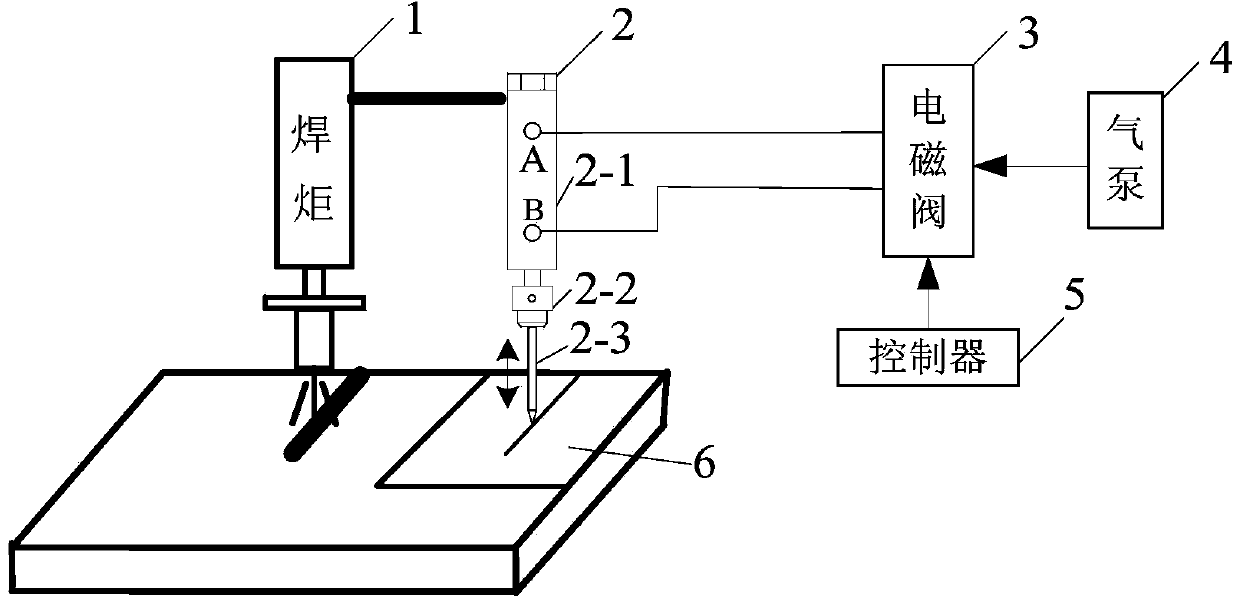

Device and method for synchronizing electric arc welding fusion depth information and welding data collection information

ActiveCN104197886AGood modelingConvenience control studiesMeasurement devicesArc welding apparatusData synchronizationFast measurement

Disclosed are a device and a method for synchronizing electric arc welding fusion depth information and welding data collection information. The device for synchronizing the electric arc welding fusion depth information and the welding data collection information is composed of a welding cabinet, a scriber, an electromagnetic valve, an air pump, a controller and a scribe board, wherein the scriber is formed by sequentially connecting an air cylinder, a scribing needle fixture and a scribing needle from top to bottom, the air cylinder is fixedly connected with the welding cabinet, and the air pump, the electromagnetic valve and the air cylinder are connected into an air circuit through air pipes. The method for synchronizing the electric arc welding fusion depth information and the welding data collection information includes steps: inputting a control signal of a controller into a control end of the electromagnetic valve so as to achieve air circuit switching, change of moving directions of the scribing needle and control of scratches on the scribe board, generated by the scribing needle; confirming data collection starting and ending positions on a work piece through marks on the scribe board after welding, cutting, polishing and eroding the work piece on a position of the maximum fusion depth along the welding direction, identifying a fusion line and performing fitting, and thereby generating the fusion depth information synchronous with the collection data. The device and the method for synchronizing the electric arc welding fusion depth information and the welding data collection information are used for rapidly measuring the welding fusion depth information offline and synchronizing the welding fusion depth information with the welding data collection information, and thereby can facilitate modeling and control studies, which are related to the fusion depth.

Owner:JIANGSU UNIV OF SCI & TECH

Surfacing treatment method of winding drum of wire drawing machine

InactiveCN103203519AAvoid crackingSmall difference in coefficient of thermal expansionArc welding apparatusHardnessEngineering

The invention discloses a surfacing treatment method of a winding drum of a wire drawing machine. The surfacing treatment method comprises the following steps of: carrying out cylindrical turning a winding drum body subjected to destressed heat treatment, carrying out sand-spraying oil-removing and water-removing pretreatment on the surface, preheating the winding drum in an electric furnace to be 350-400 DEG C, carrying out automatic surfacing with submerged arcs, stopping the surfacing when a surfacing layer reaches 5-6mm, then carrying out slow-cooling treatment, heating the winding drum in the electric furnace to be 400 DEG C, insulating for 2 hours, cooling along with the furnace, and finally forming the winding drum by turning and grinding. The surfacing treatment method has the advantages that the hardness of the winding drum reaches HRC57-60, the wear resistance is good and the service life is long.

Owner:GUIZHOU WIRE ROPE

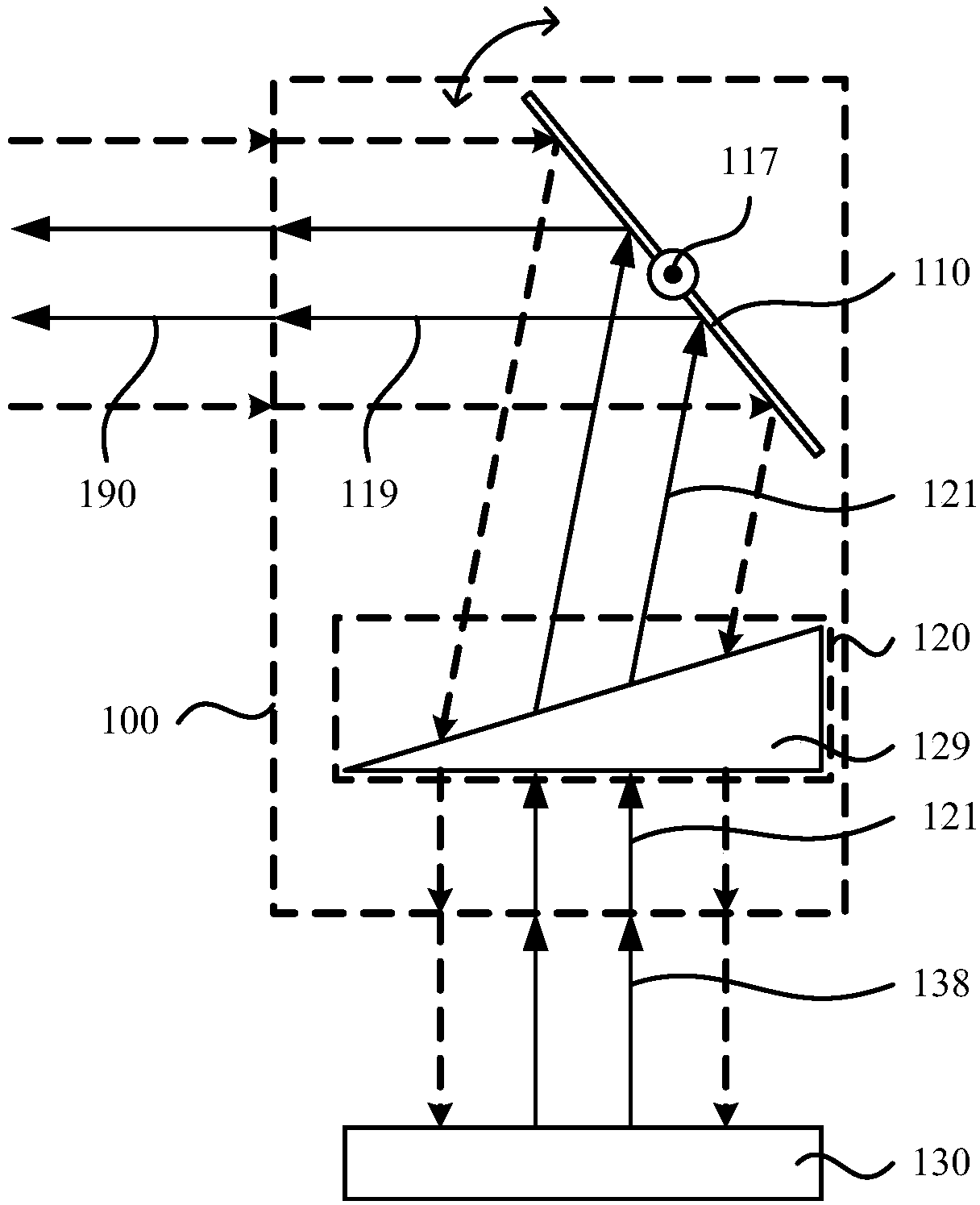

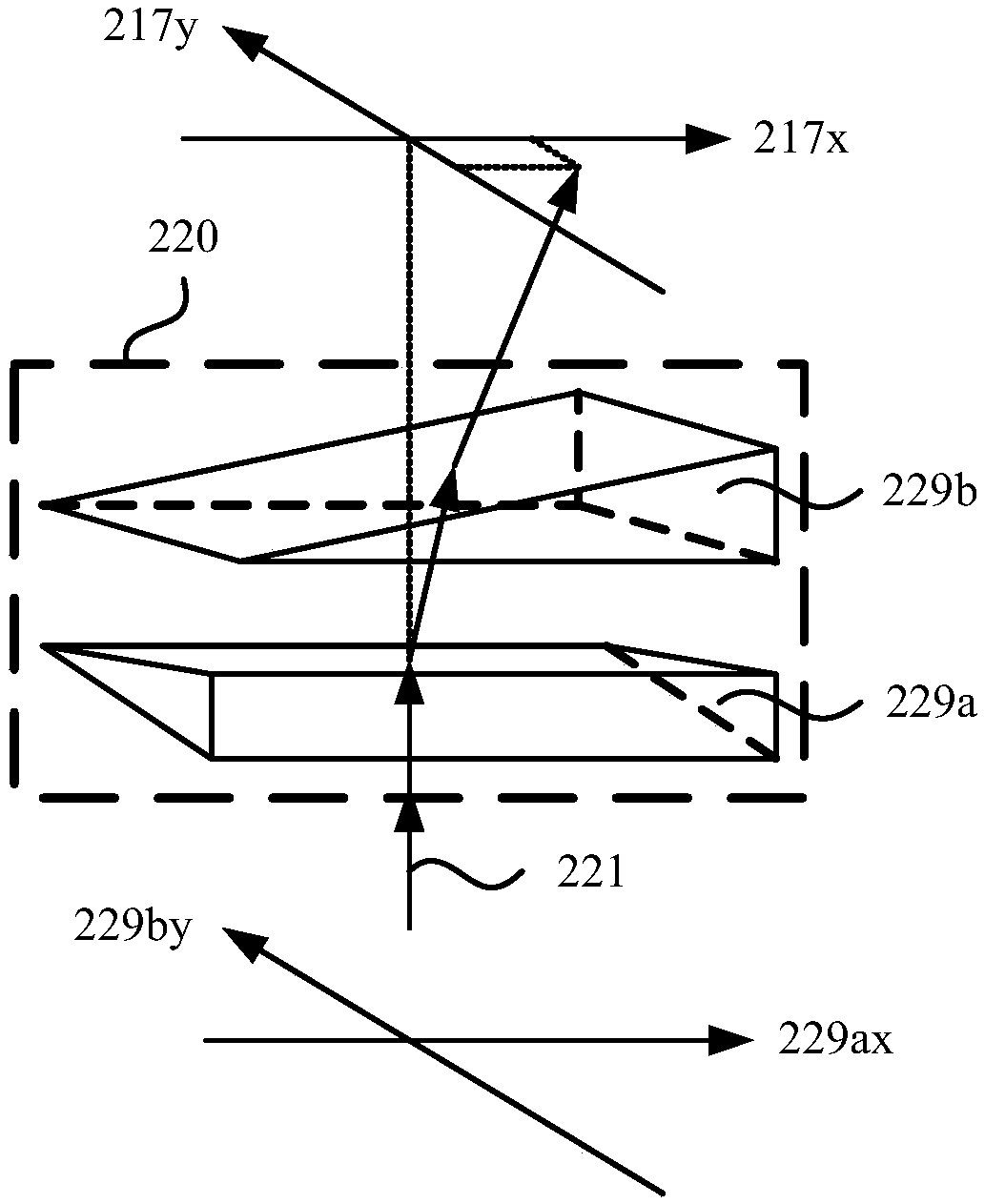

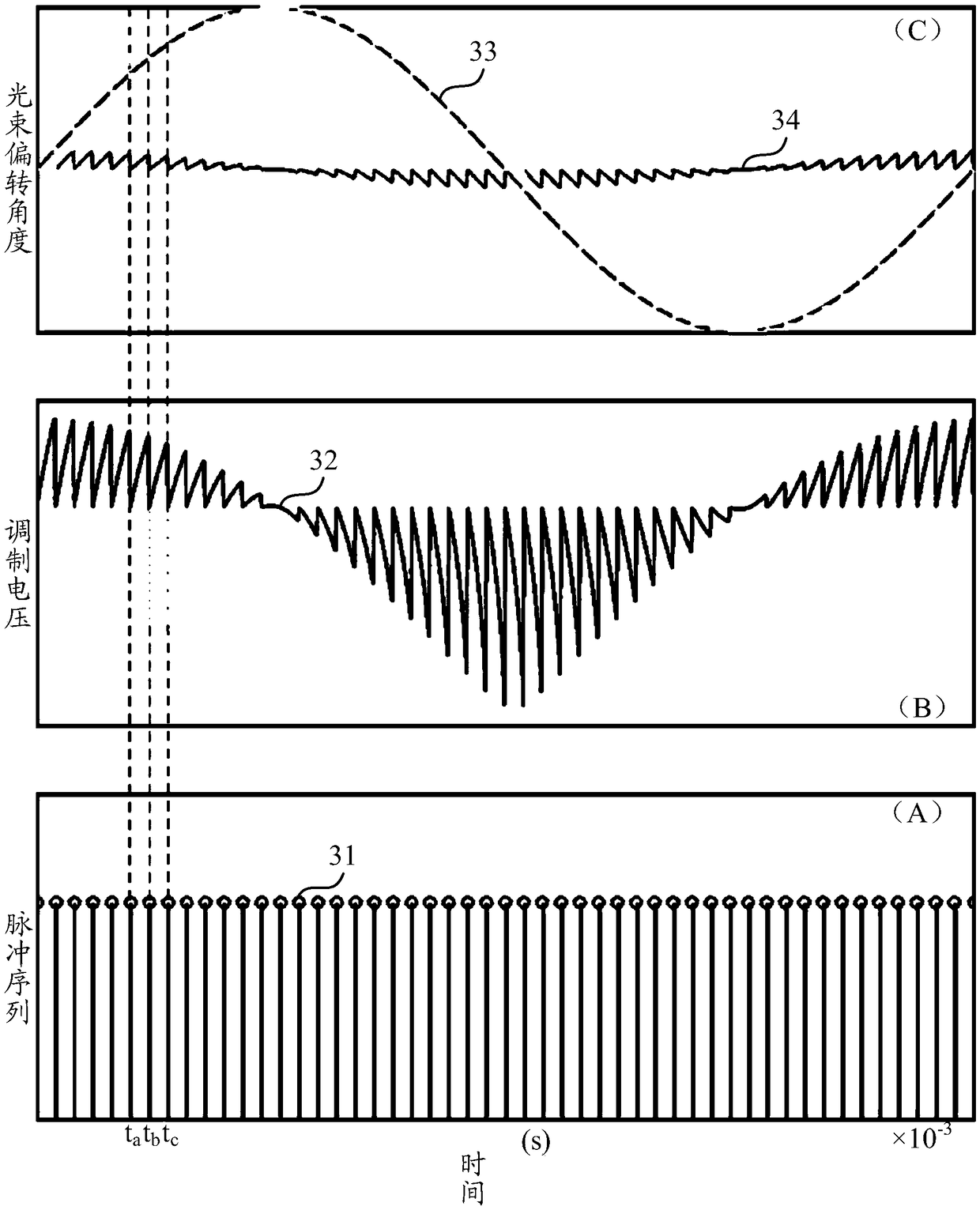

Scanning device, scanning method thereof, and laser radar

ActiveCN109444848AImprove response rateShorten the timeWave based measurement systemsRadarLight beam

The invention relates to a scanning device, a scanning method thereof, and a laser radar. The scanning device comprises a first scanning unit and a second scanning unit; the first scanning unit is suitable for making the transmission direction of an incident light beam undergo first reflection so that the incident light beam can form an outgoing light beam; the first scanning unit changes the deflection angle of the first deflection by means of rotating or swinging; the second scanning unit is located in the optical path of at least one of the incident light beam and the outgoing light beam; and when the incident light beam or the outgoing light beam is transmitted through the second scanning unit, the second scanning unit makes the propagation direction of the transmitted light beam undergo second propagation based on an electro-optical effect. The scanning device can not only realize delay angle compensation, but also effectively shorten time for single detection, effectively improvescanning frequency, and is conductive to realizing the balance between high scanning frequency and high coherence efficiency.

Owner:HESAI TECH CO LTD

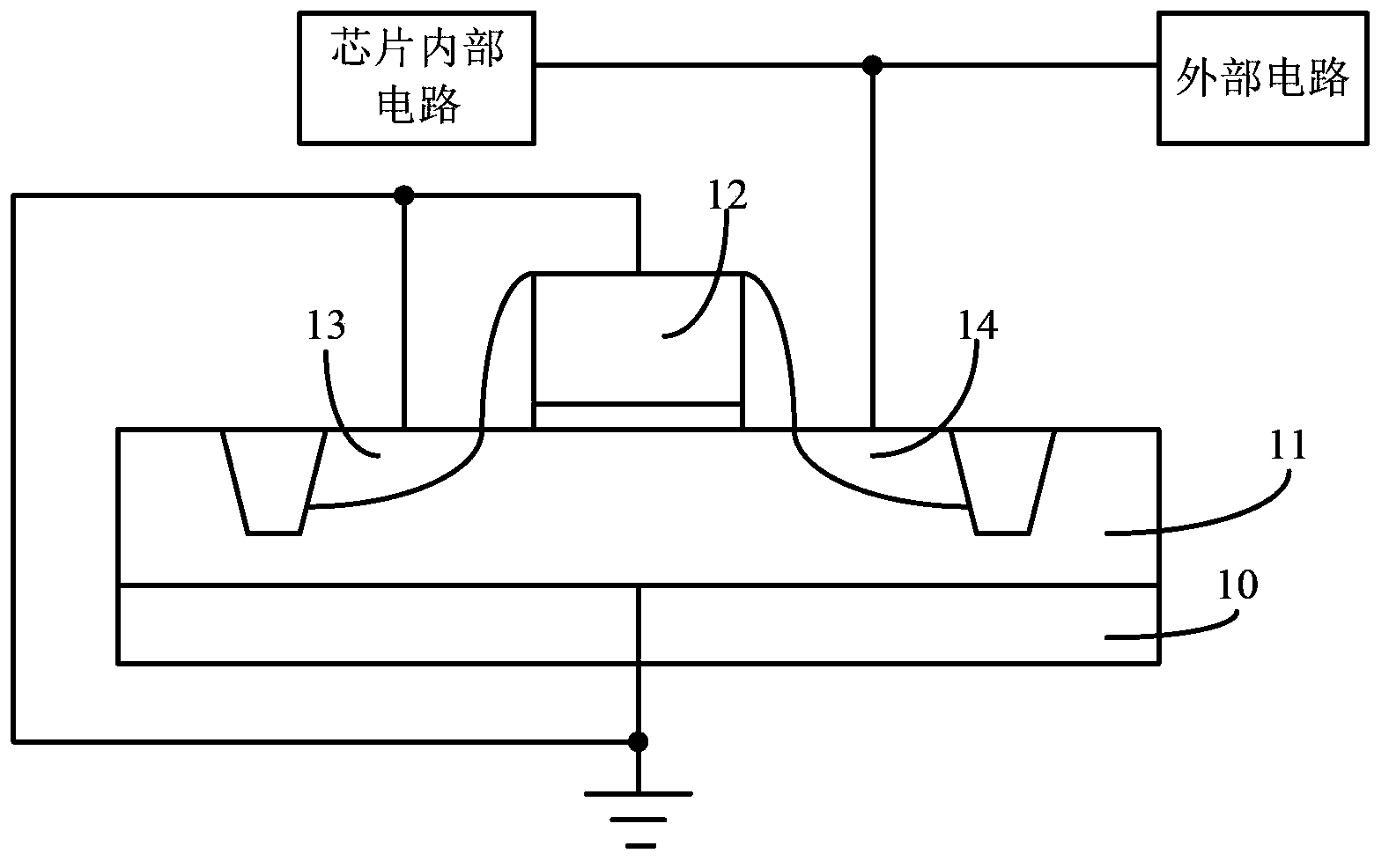

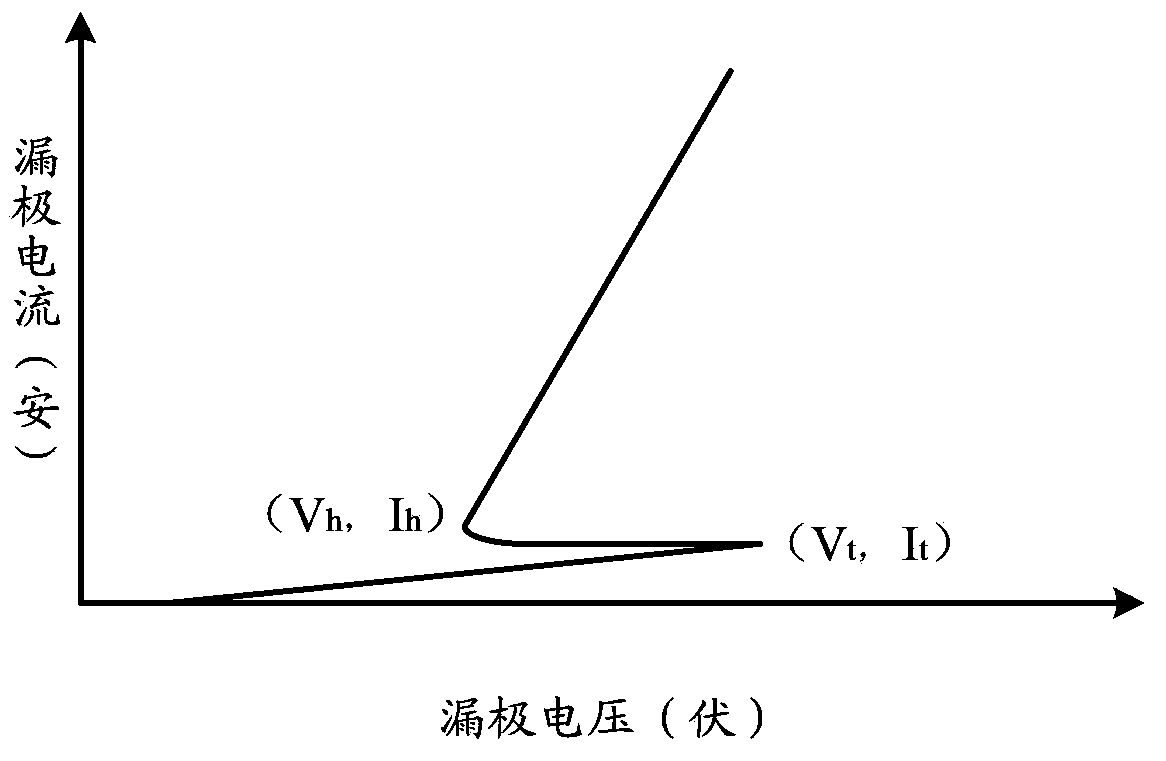

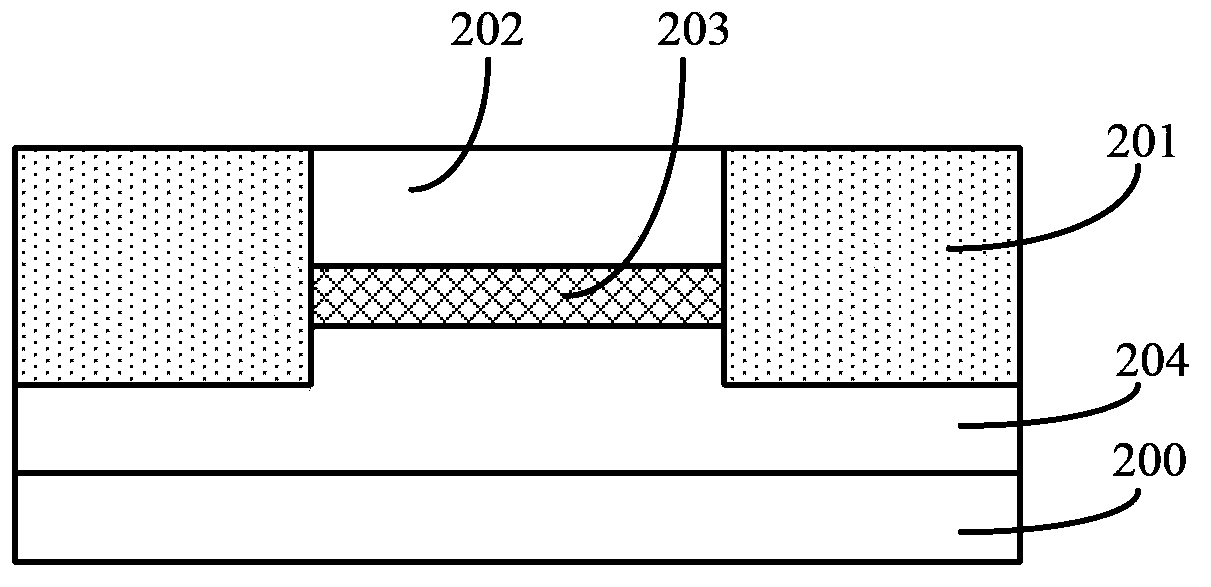

An electrostatic discharge protection structure

ActiveCN104253123AImprove cooling effectMeet technical needsSolid-state devicesSemiconductor devicesElectrostatic discharge protectionIon

The invention discloses an electrostatic discharge protection structure, which comprises a well region within a substrate, wherein the well region has doping ions of a first conductivity type therein and is electrically connected with a ground terminal; a second doped region within the substrate, wherein the second doped region is located on the surface of the well region, and has doping ions of a second conductivity type therein, wherein a doping concentration in the second doped region is higher than that in the well region; a first doped region within the substrate, wherein the first doped region is located on the surface of the second doped region, and a surface of the first doped region is flush with the substrate surface, wherein the first doped region has doping ions of a first conductivity type therein and is electrically connected with an electrostatic discharge input terminal, and wherein a doping concentration in the first doped region is higher than that in the second doped region, and the doping concentration difference between the first doped region and the second doped region is smaller than that between the second doped region and the well region. The electrostatic discharge protection structure has a low breakdown voltage so as to be improved in a protective capability.

Owner:SEMICON MFG INT (SHANGHAI) CORP

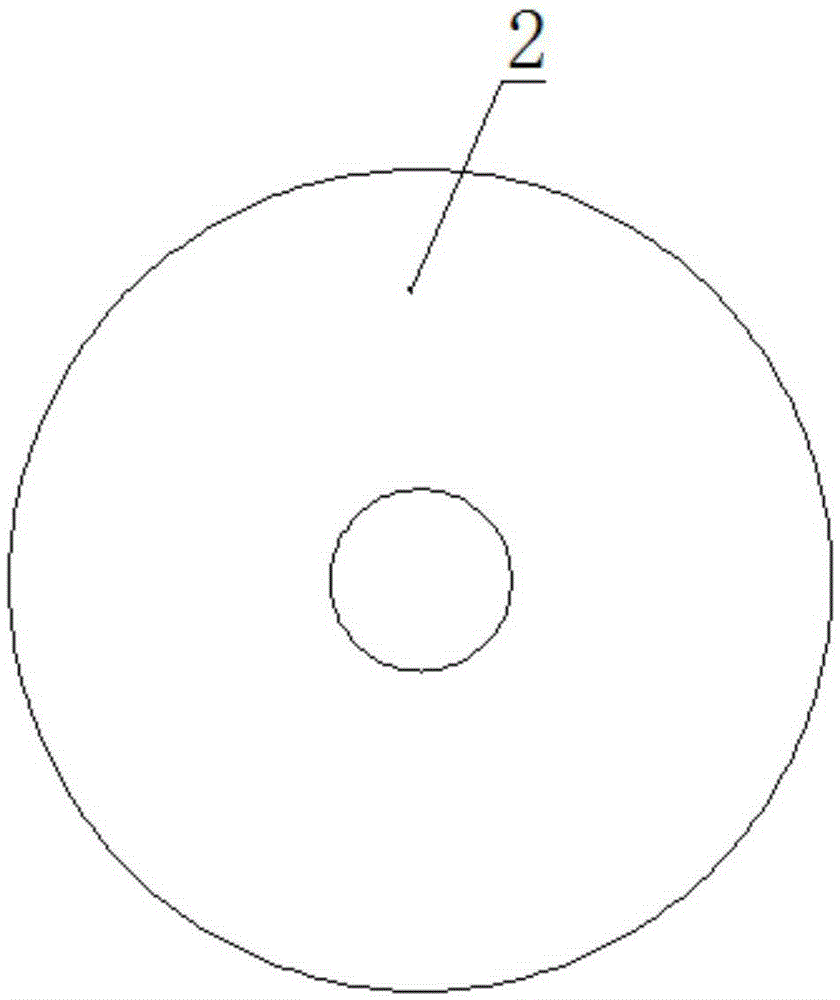

Special round UV cured and hot pressed tag for resin grinding wheel

The invention discloses a special round UV cured and hot pressed tag for a resin grinding wheel. The special round UV cured and hot pressed tag comprises a tag body with a circular structure, wherein the tag body is formed by a paper base layer as well as a bottom ink layer and an image-text ink layer which are printed on the paper base layer sequentially. In order to ensure that the hot pressed tag is clear in imprint, is not chalked or cracked and has small color change amplitude at a high temperature, modified ink used in the image-text ink layer is prepared from UV ink, epoxy acrylic resin, polyester acrylic resin, tricarboxymethylolpropane triacrylate, tripropylene glycol diacrylate, benzophenone, 1,2-diphenylethane, methyldiethanolamine, benzenediol, 502 A / B-2 adhesive, pigments and auxiliary additives in proportion. The proper paper base layer is adopted for the hot pressed tag, on the basis of the principle that hot melted chemical molecules are mutually incompatible and with adoption of a UV improved printing technology, the finished tag product is non-toxic, odorless and environment-friendly, and can be compared favorably with a screen plated tag, the cost is reduced by 30% as compared with screen printing cost, and the printing speed is 4-5 times higher than that of screen printing.

Owner:郑州市晶森彩印有限公司

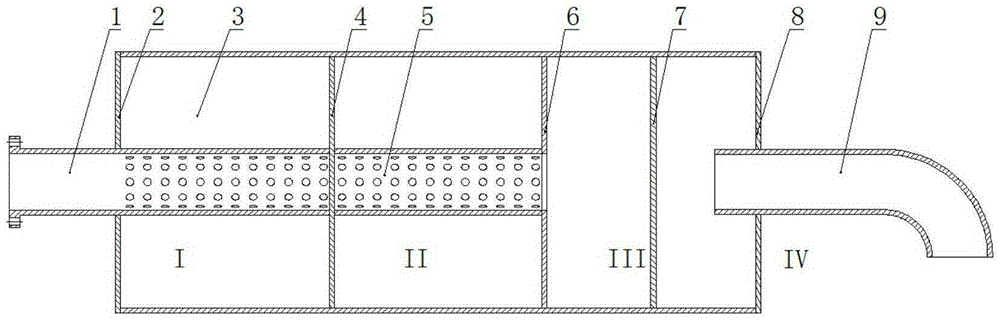

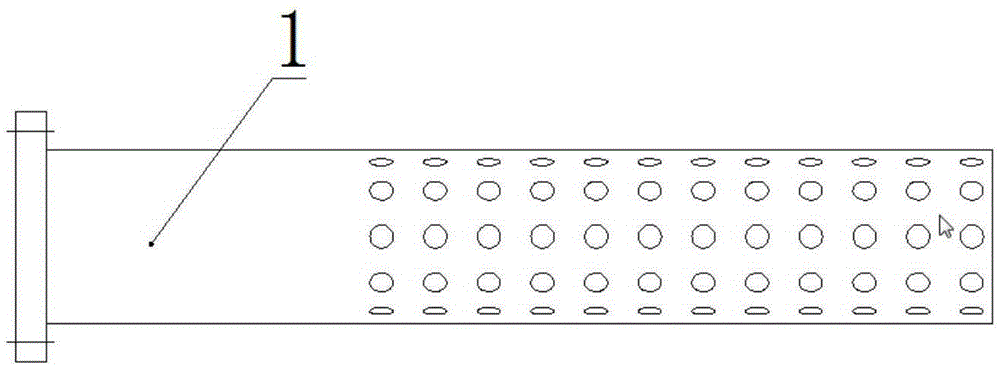

Diesel engine silencer used for high-power agricultural machinery

InactiveCN105402004AReduce volumeMeet environmental needsSilencing apparatusMachines/enginesEngineeringExpansion chamber

The invention discloses a diesel engine silencer used for high-power agricultural machinery, aiming at overcoming the problems of the prior art that the working efficiency of workers and the body health of people are affected. The silencer comprises a silencer air inlet pipe, a silencer shell, a No.1 micro-perforated panel, a micro-perforated pipe, an expansion chamber clapboard, a No.2 micro-perforated panel and a silencer exhaust pipe. The No.1 micro-perforated panel is arranged on the left side in the silencer shell and is welded with the inner wall of the silencer shell, the expansion chamber clapboard is arranged on the right side of the No.1 micro-perforated panel and is welded with the inner wall of the silencer shell, the No.2 micro-perforated panel is arranged on the right side of the expansion chamber clapboard and is welded with the inner wall of the silencer shell, the silencer air inlet pipe is arranged in a front center through hole of the silencer front end cover in the silencer shell, the right end of the silencer air inlet pipe is welded with the center part of the No.1 micro-perforated panel, two ends of the micro-perforated pipe and the No.1 micro-perforated panel are welded width the expansion chamber clapboard, and the silencer exhaust pipe is arranged and welded in a rear center through hole of the silencer rear end cover.

Owner:JILIN UNIV

Method for low-temperature sintering of porous ceramic by using waste incineration fly ash

InactiveCN108424164AReduce leaching toxicityEfficient decompositionCeramic materials productionCeramicwarePlastic wastePorous ceramics

The invention discloses a method for low-temperature sintering of porous ceramic by using waste incineration fly ash. The method comprises the following steps: with cement and the waste incineration fly ash as raw materials, adding ceramic wastes, sodium tetraborate and a glass reinforced plastic waste material for curing; and then preparing a porous ceramic material by using a low-temperature sintering method, wherein the prepared porous ceramic has the characteristics that the porosity is as high as 80 percent, apparent density is only 0.736 g / cm<-3> and compressive strength can reach 11.9 MPa. The method disclosed by the invention has the characteristics that the problem of environmental pollution caused by the waste incineration fly ash is solved; besides, the waste incineration fly ash is effectively utilized to obtain a porous ceramic body which has the characteristic of low leaching toxicity; and economic value is created while heavy metal is cured.

Owner:FUZHOU UNIV +1

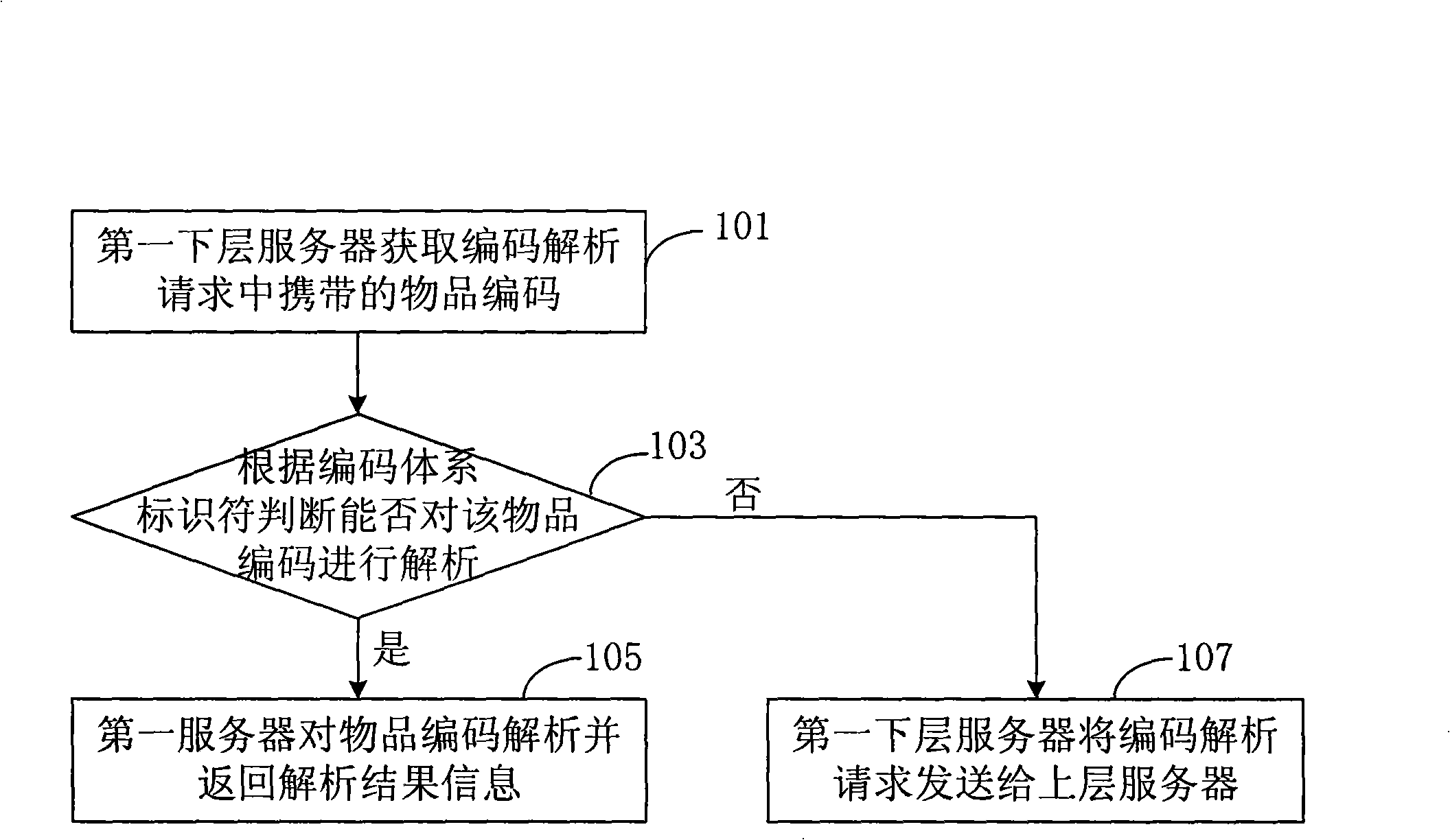

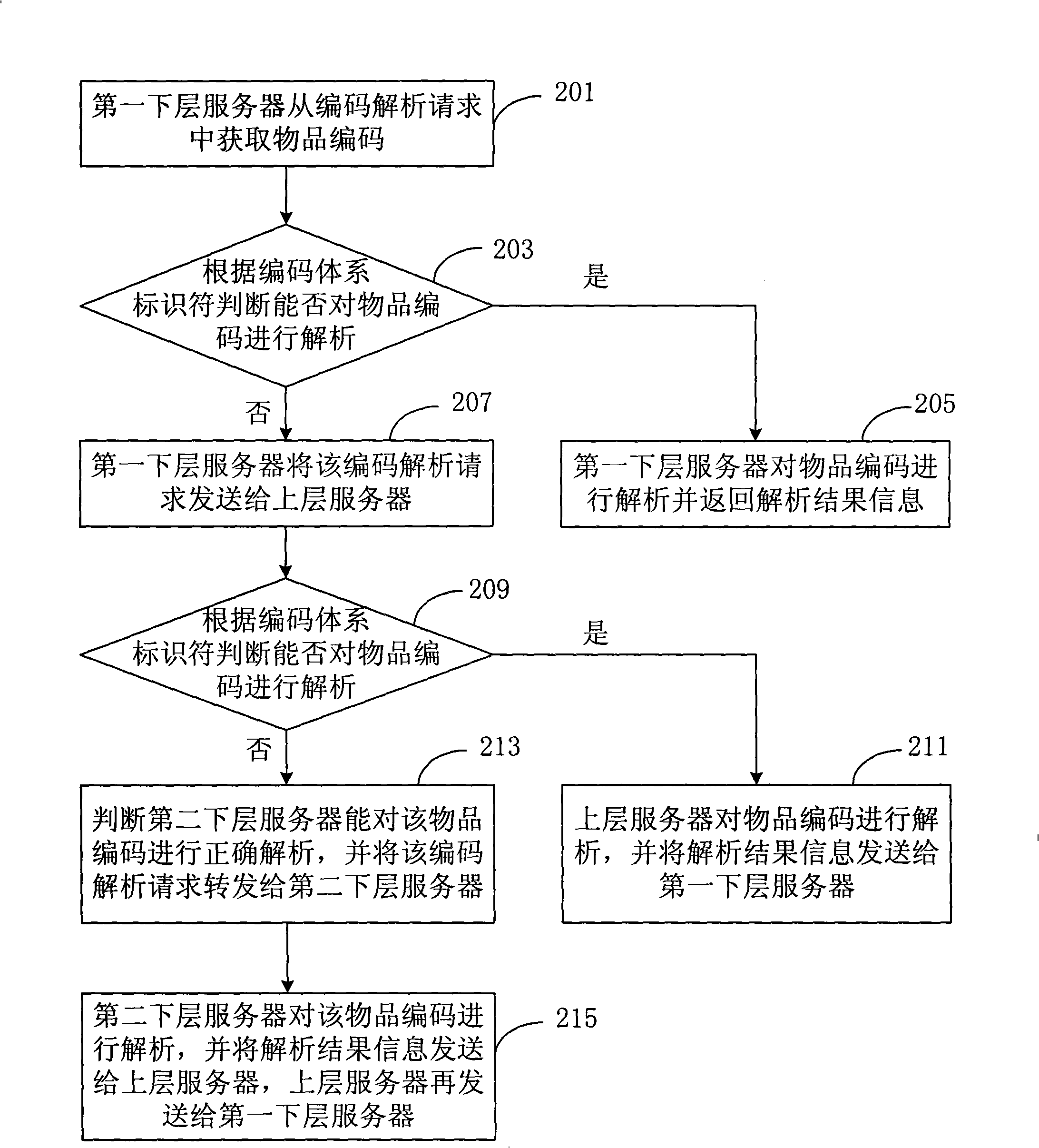

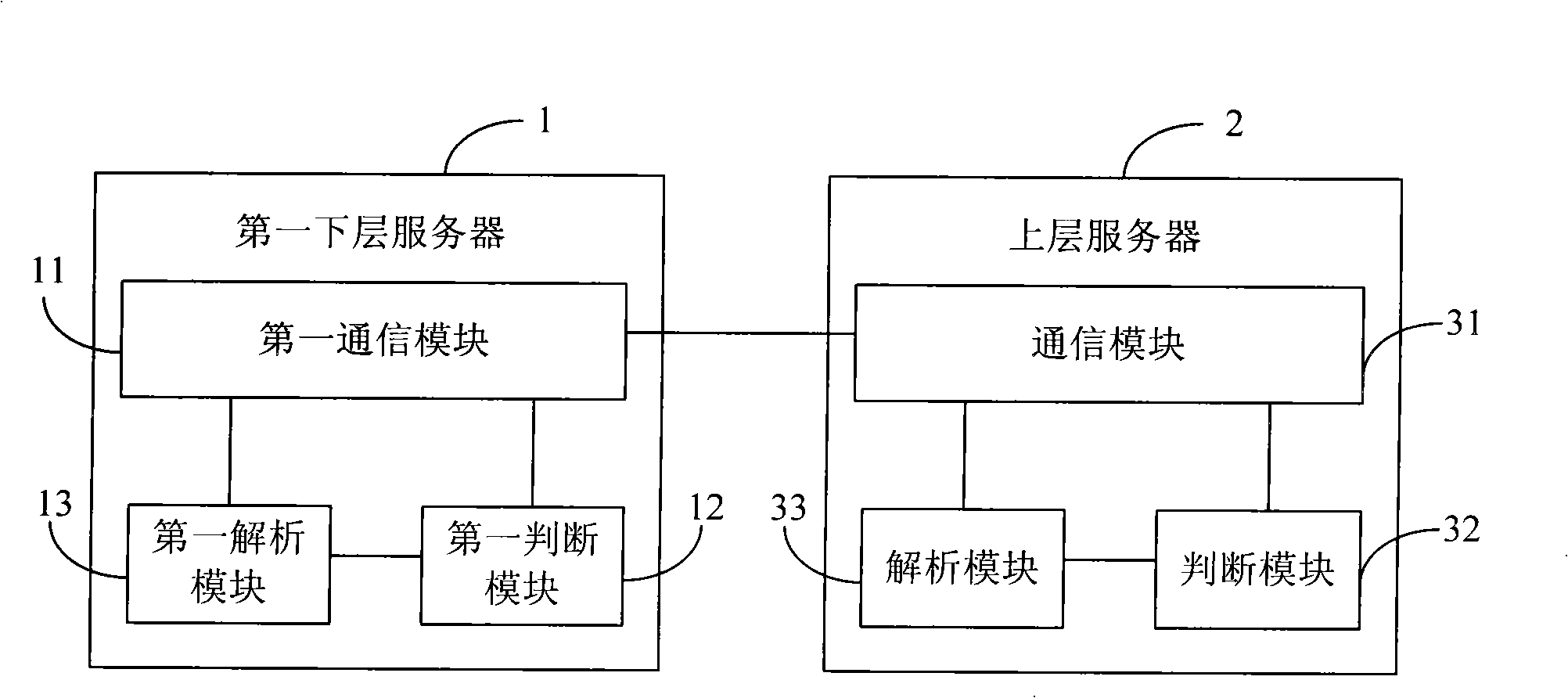

Method and system for analyzing article coding

ActiveCN101354697AMeet technical needsMeet the technical requirements of the whole network analysisSpecial data processing applicationsSystem identifierWorld Wide Web

The invention discloses an article code analytic method and an article code analytic system. The method comprises the following steps: a first layer of slave server acquires an article code carried by a code analysis request according to the received code analysis request; judgment is made whether to analyze the article code in the first slave server according to a code system identifier of the article code; and if so, the first slave server analyzes the article code and returns analysis result information, or else the first slave server transmits the code analysis request to a primary server. The system comprises the first slave server and the primary server. The first slave server and the primary server of the system can simultaneously complete the function of unified monitoring and management of article codes and can achieve the effect of sharing the article codes in the first slave server and the primary server, thereby meeting the technical demand of whole-network analysis of the article codes in different code systems.

Owner:ARTICLE NUMBERING CENT OF CHINA

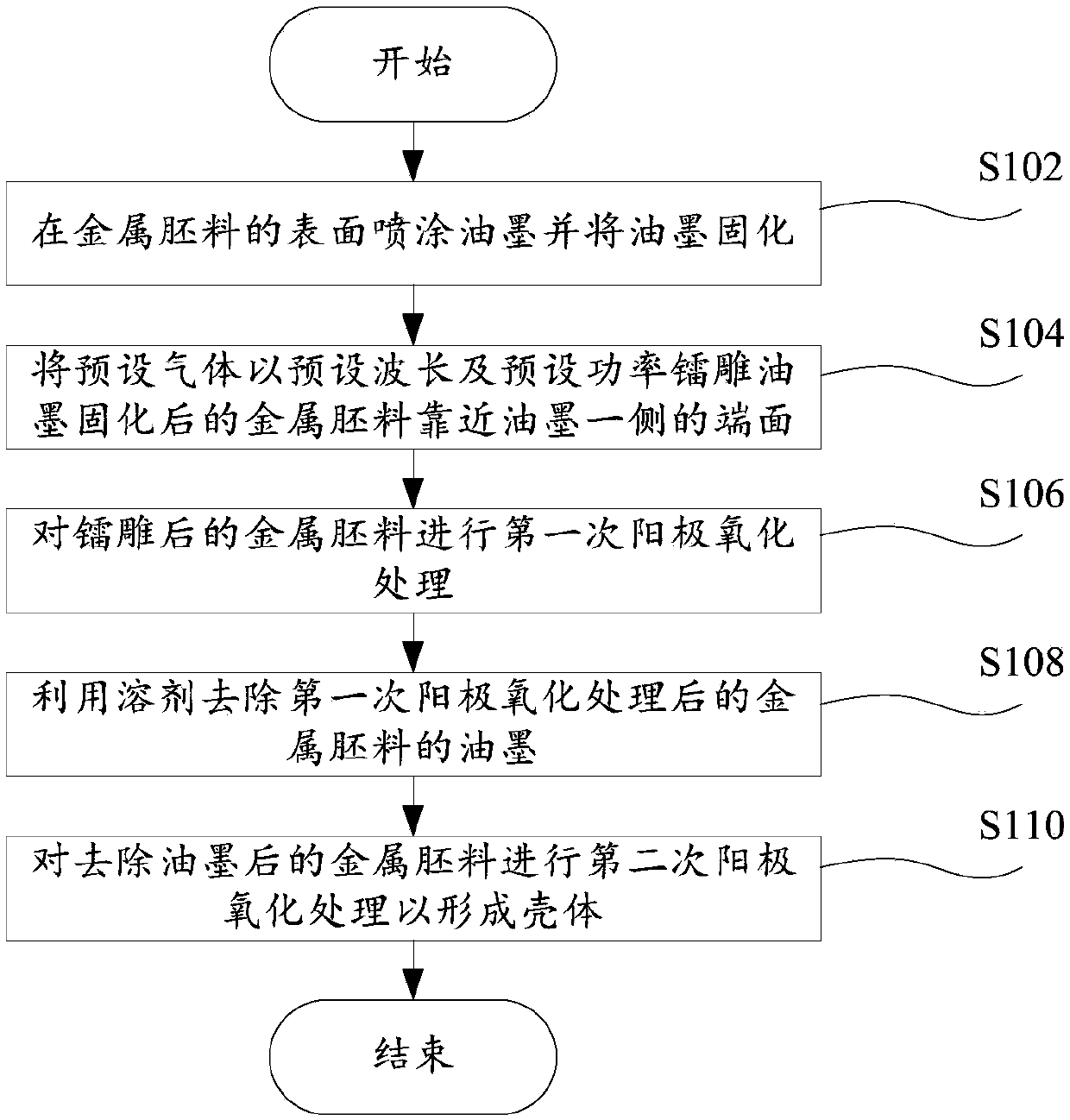

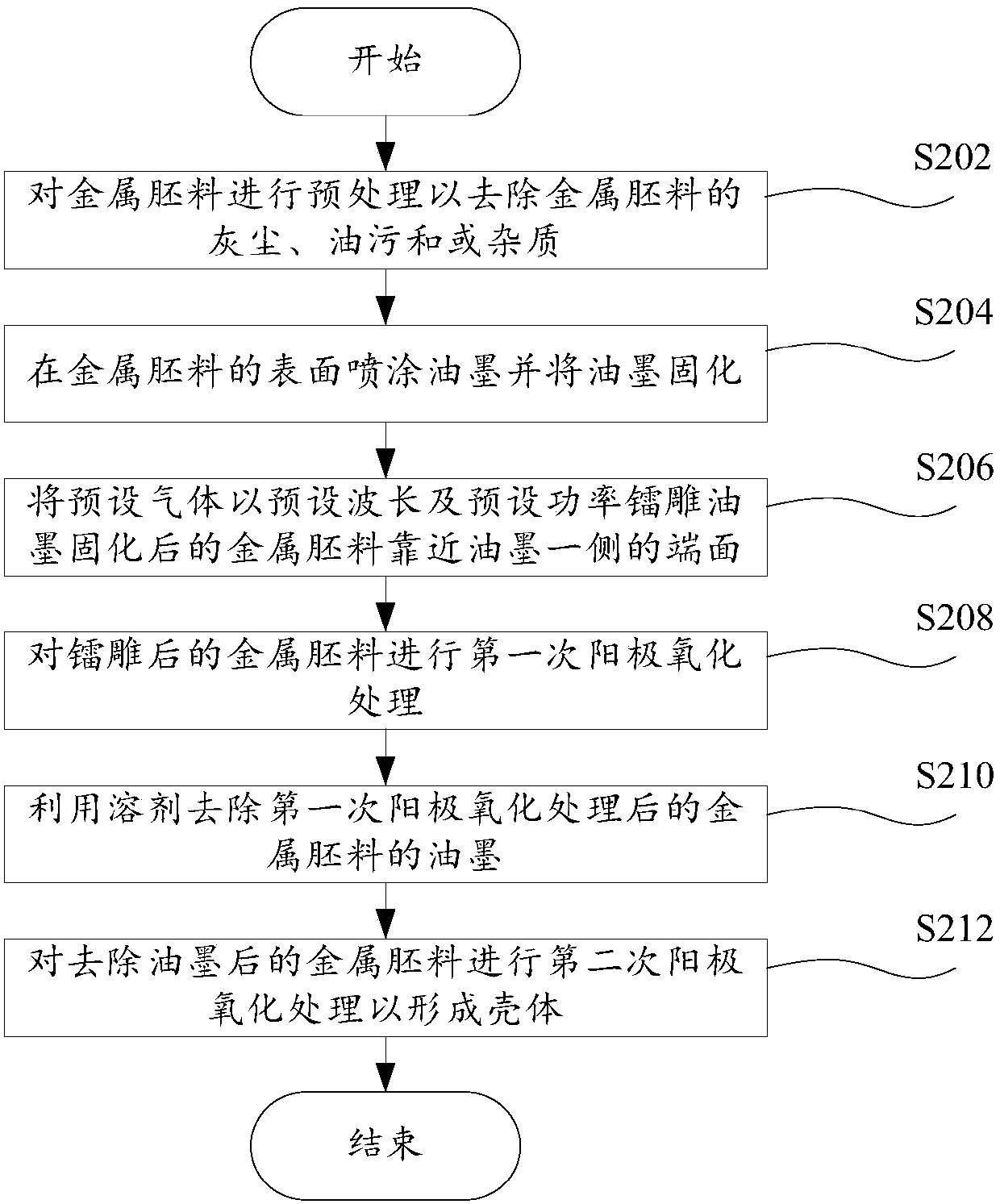

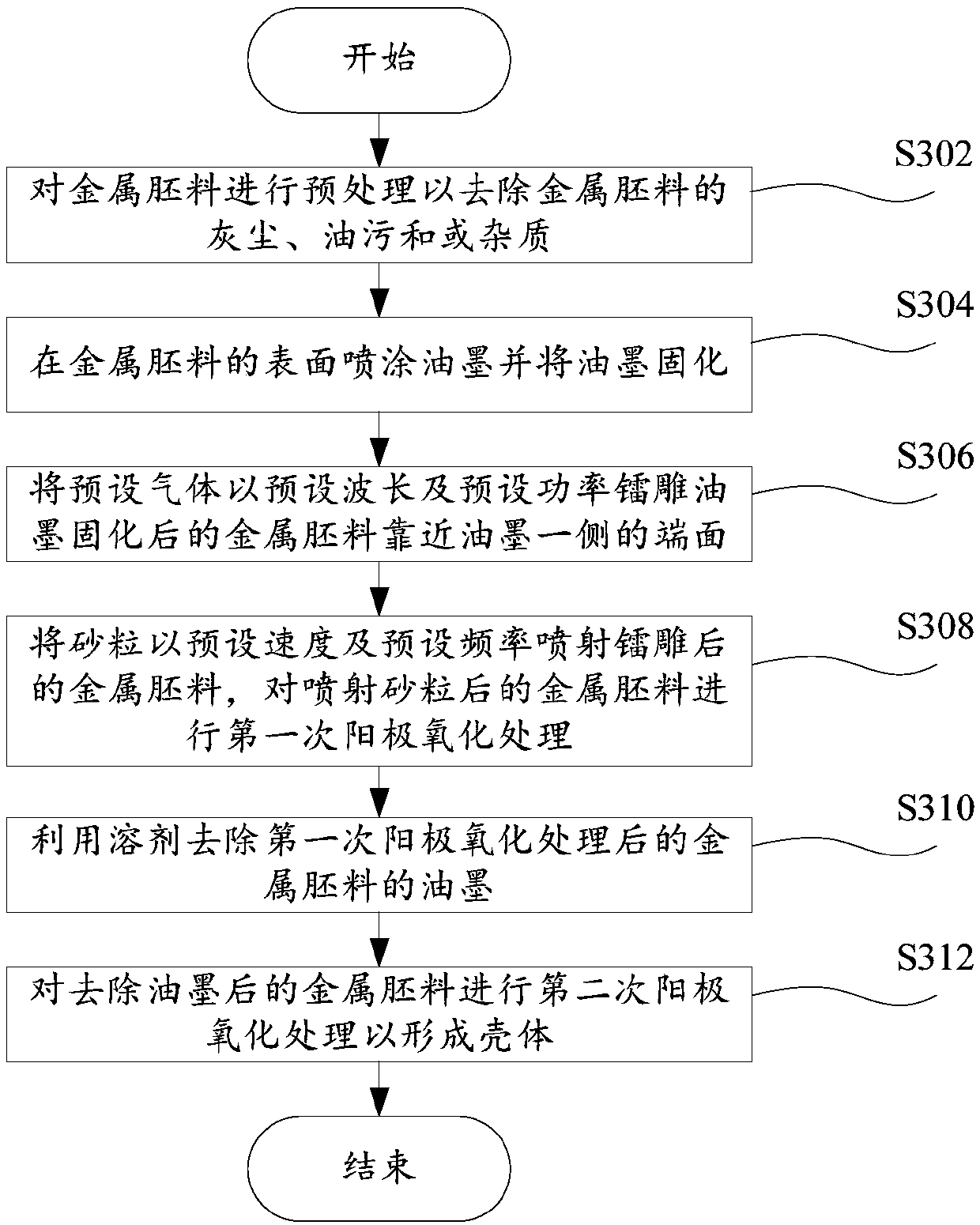

Machining method for shell and shell

ActiveCN107653476ARich use requirementsMeet technical needsAnodisationTelephone set constructionsLaser etchingMachining

The invention provides a machining method for a shell and the shell. The machining method for the shell comprises the steps that ink is sprayed to the surface of a metal blank material, and the ink iscured; preset gas is used for carrying out laser etching on the end face of the side, close to the ink, of the metal blank material with the cured ink through preset wave lengths and preset power; primary anodic oxidation treatment is carried out on the metal blank material which is subjected to laser etching; a solvent is used for removing the ink of the metal blank material which is subjected to primary anodic oxidation treatment; and secondary anodic oxidation treatment is carried out on the metal blank material with removed ink to form the shell. According to the machining method, machining of ink spraying, lather etching, primary anodic oxidation treatment, ink removing and secondary anodic oxidation treatment are sequentially carried out on the metal blank material, the shell in different colors or the shell in the same color but in different textures is formed, the preset gas is used for carrying out laser etching on the surplus ink on the metal blank material, and that is thegas is used for carrying out multi-direction, multi-angle and multi-dimension laser etching on the ink cured metal blank material.

Owner:MEIZU TECH CO LTD

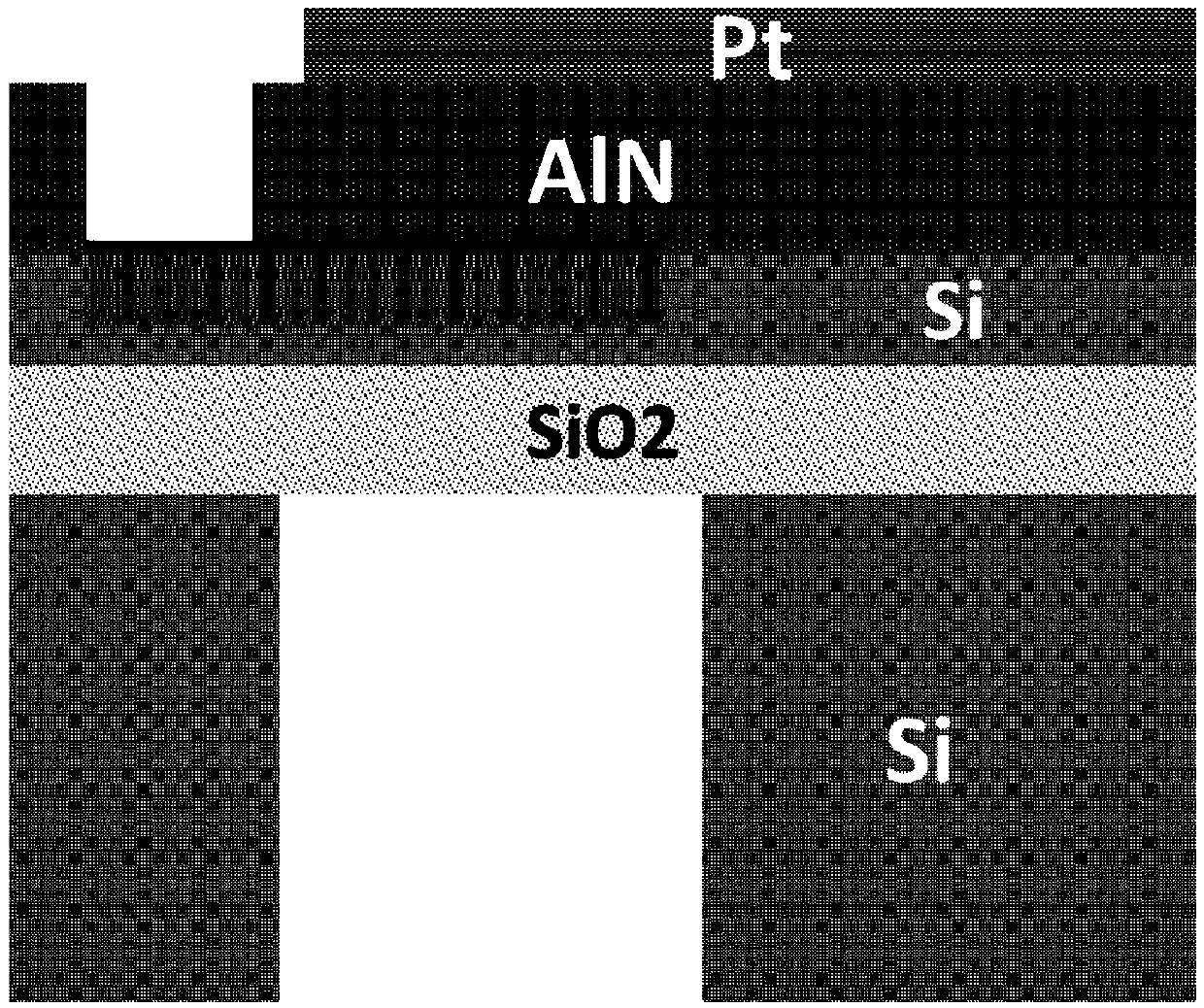

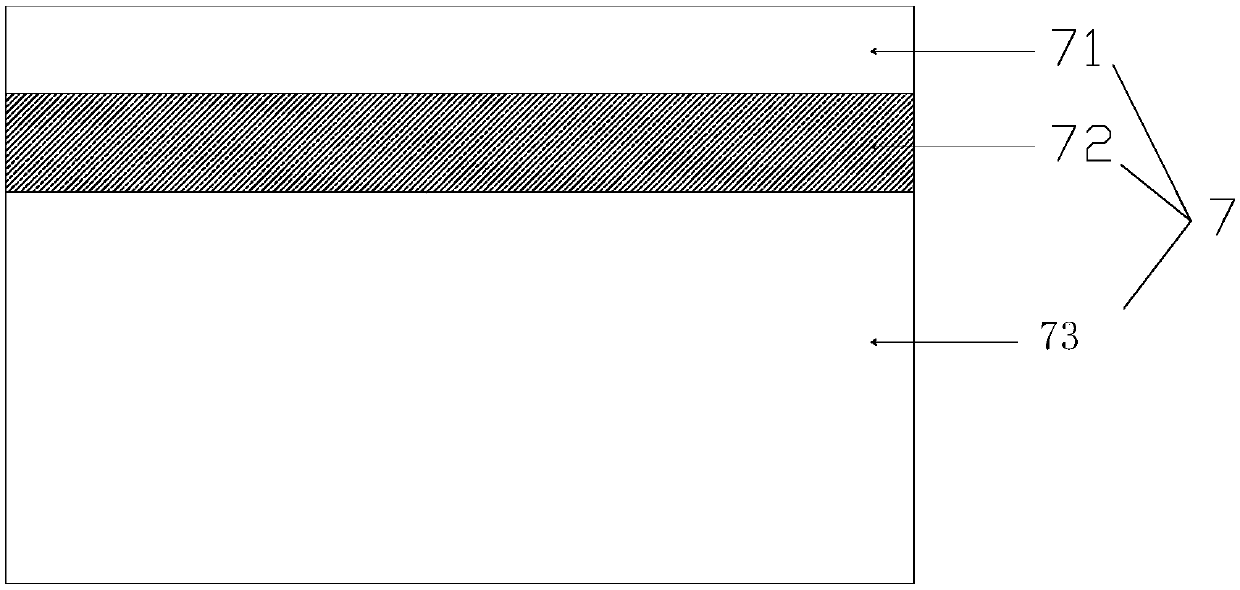

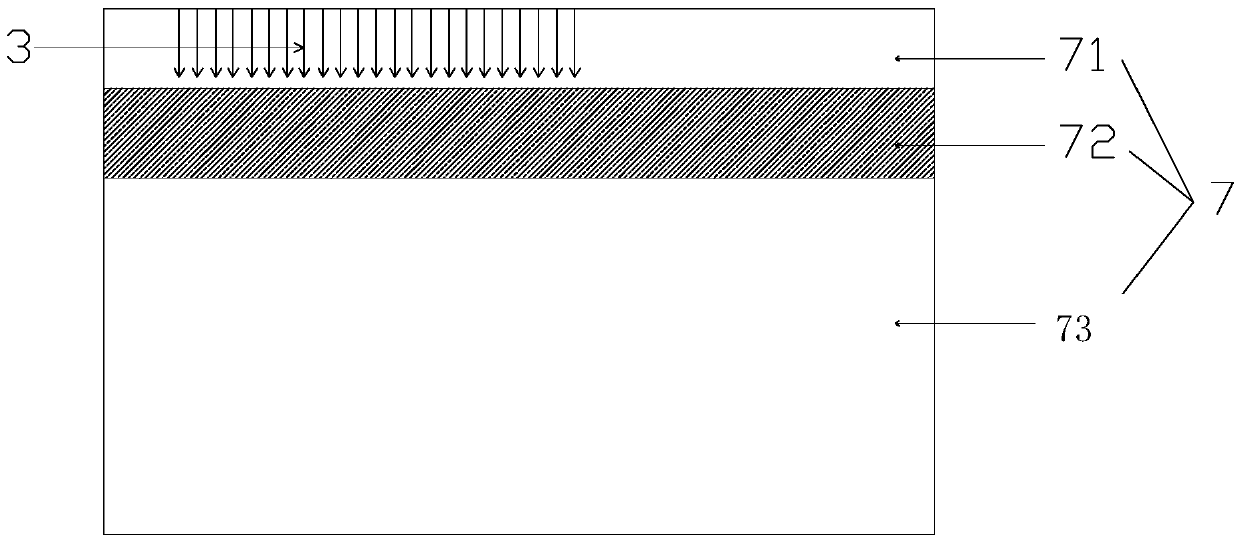

Film bulk acoustic resonator and manufacturing method thereof

PendingCN110957989ALow costReduce power consumptionImpedence networksThin-film bulk acoustic resonatorCommunications system

The invention discloses a film bulk acoustic resonator and a manufacturing method thereof. The manufacturing method comprises the steps of manufacturing a lower electrode on a first surface of an SOIsubstrate; forming a piezoelectric layer on the first surface of the SOI substrate and the lower electrode; forming a top electrode on the piezoelectric layer; and processing the second surface of theSOI substrate to form an air cavity, wherein the second surface and the first surface are arranged back to back. According to the manufacturing method provided by the invention, the preparation process of the FBAR is simplified, the AlN film crystal grown by the method is high in quality, the performance of the device is improved, and the frequency of the resonator is adjusted by controlling thethickness of top silicon through the position of silicon oxygen injection isolation; and the SOI material has the characteristics of low power consumption, high integration density, radiation resistance and the like, so that the complexity of a device preparation process is reduced, and the film bulk acoustic resonator is applicable to a radio frequency front end of a future 5G communication system.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Forging method of water supply connecting tube and secondary side manhole

ActiveCN101745786AMeet technical needsMeet the use requirementsEngine componentsSteam boilersNuclear powerPerformance index

The invention relates to the technical field of forging, in particular to a forging method of a water supply connecting tube and a secondary side manhole for an evaporator generator in a nuclear power station, which comprises the following steps: selecting a suitable steel ingot, wherein within a temperature range of 1180 DEG C-800 DEG C, the steel ingot is repeatedly upset and stretched so that the forging ratio is not less than 4; and then sequentially carrying out heat treatment after forging, rough machining before heat treatment, performance heat treatment and machining after heat treatment to obtain the water supply connecting tube and the secondary side manhole. The invention has the advantages that the actual grain size of the water supply connecting tube and the secondary side manhole manufactured by the invention is less than or equal to level 5, all performance indices meet the standard requirements of RCC-M and ASTM, the operating requirements of the water supply connecting tube and the secondary side manhole for the evaporator generator in the nuclear power station are ensured, the safety and reliability are greatly improved, and the technical requirement of the products is met.

Owner:上海新闵重型锻造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com