Microwave dielectric ceramic and preparation method thereof

A technology of microwave dielectric ceramics and expressions, which is applied in the field of microwave dielectric ceramics and its preparation, can solve the problems that the sintering performance and dielectric properties cannot meet the technical requirements of communication base stations, and achieve low loss, high dielectric constant, and production process technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

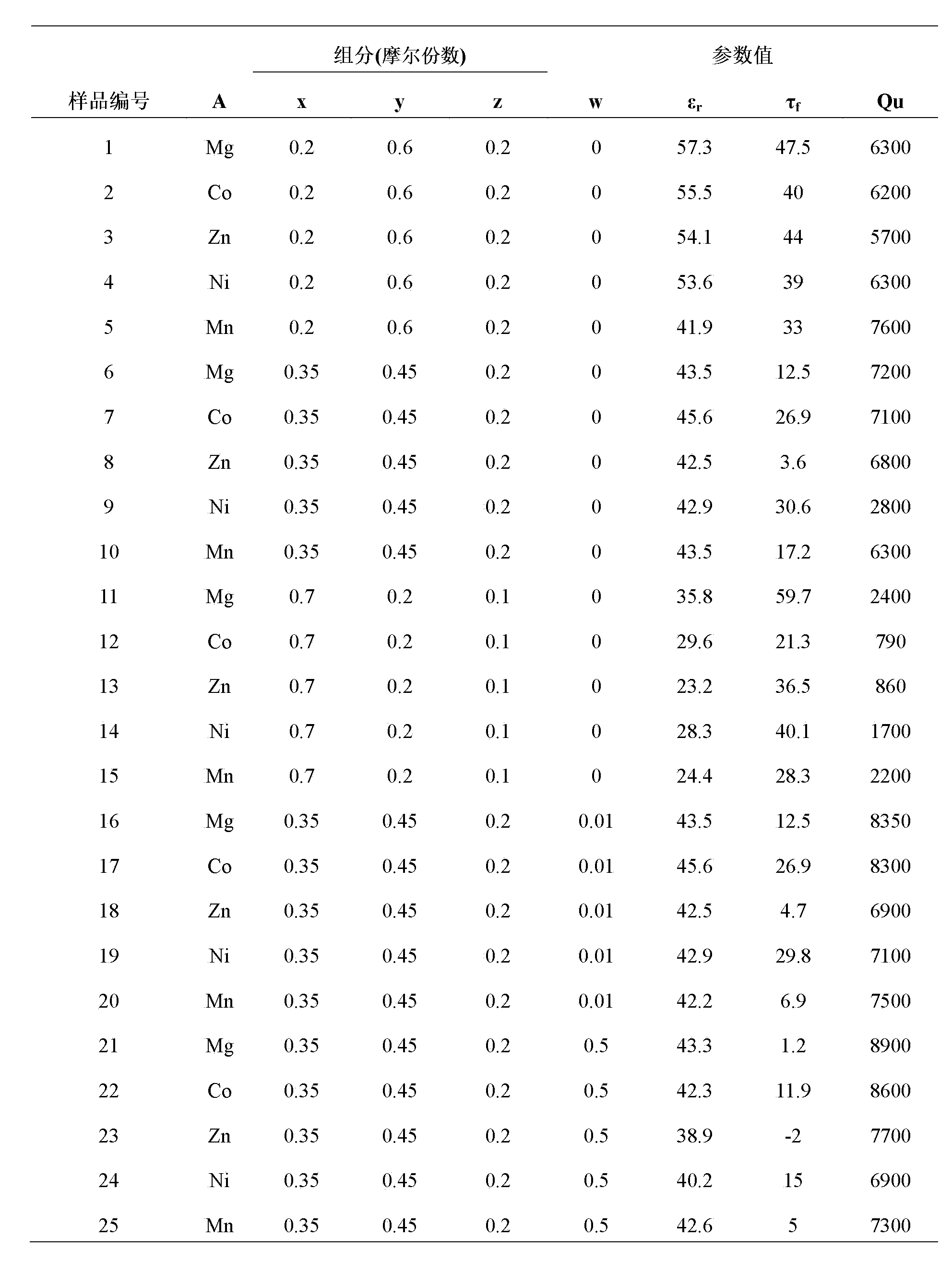

[0023] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

[0024] Microwave dielectric ceramics, the expression of its chemical composition is formula (I):

[0025] wxya 3 -yTiO 2 -zA (1+w) / 3 Nb (2-w) / 2 o 3 (I);

[0026] In the formula (I), the A represents one or several elements of Mg, Co, Zn, Ni and Mn; the x, y, and z all represent molar ratios, and 0.2≤x≤0.7, 0.2≤y≤ 0.6, 0.1≤z≤0.2, and x+y+z=1; the value range of w is: 0≤w≤0.5.

[0027] The preparation method of described microwave dielectric ceramics comprises the following steps:

[0028] Step 1: Choose pure ZrO 2 、TiO 2 , Nb 2 o 5 , MgO, CoO, ZnO, NiO and MnO 2 As a raw material, weigh the corresponding weight of the raw material according to the predetermined ratio;

[0029] Step 2: Put the weighed raw materials into the polyurethane tank for ball milling, and get the slurry after 4 hours of ball milling; add de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com