Patents

Literature

637 results about "Dielectric ceramics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

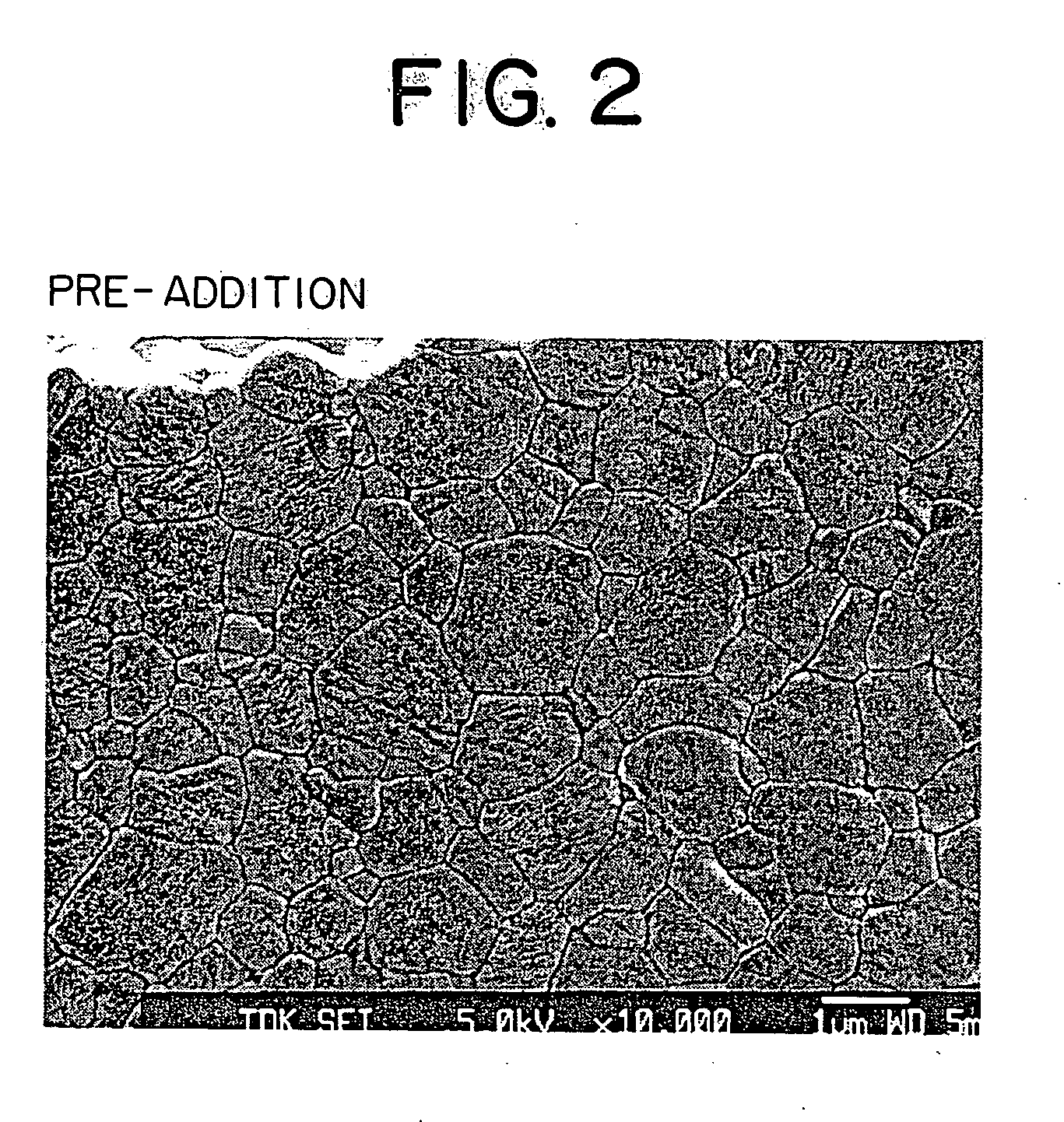

Dielectric ceramic composition and method of production and electronic device of the same

ActiveUS20050128683A1Superior low frequency dielectric characteristicImproved more accelerated lifetimeLayered productsFixed capacitor dielectricDielectricElectrical resistance and conductance

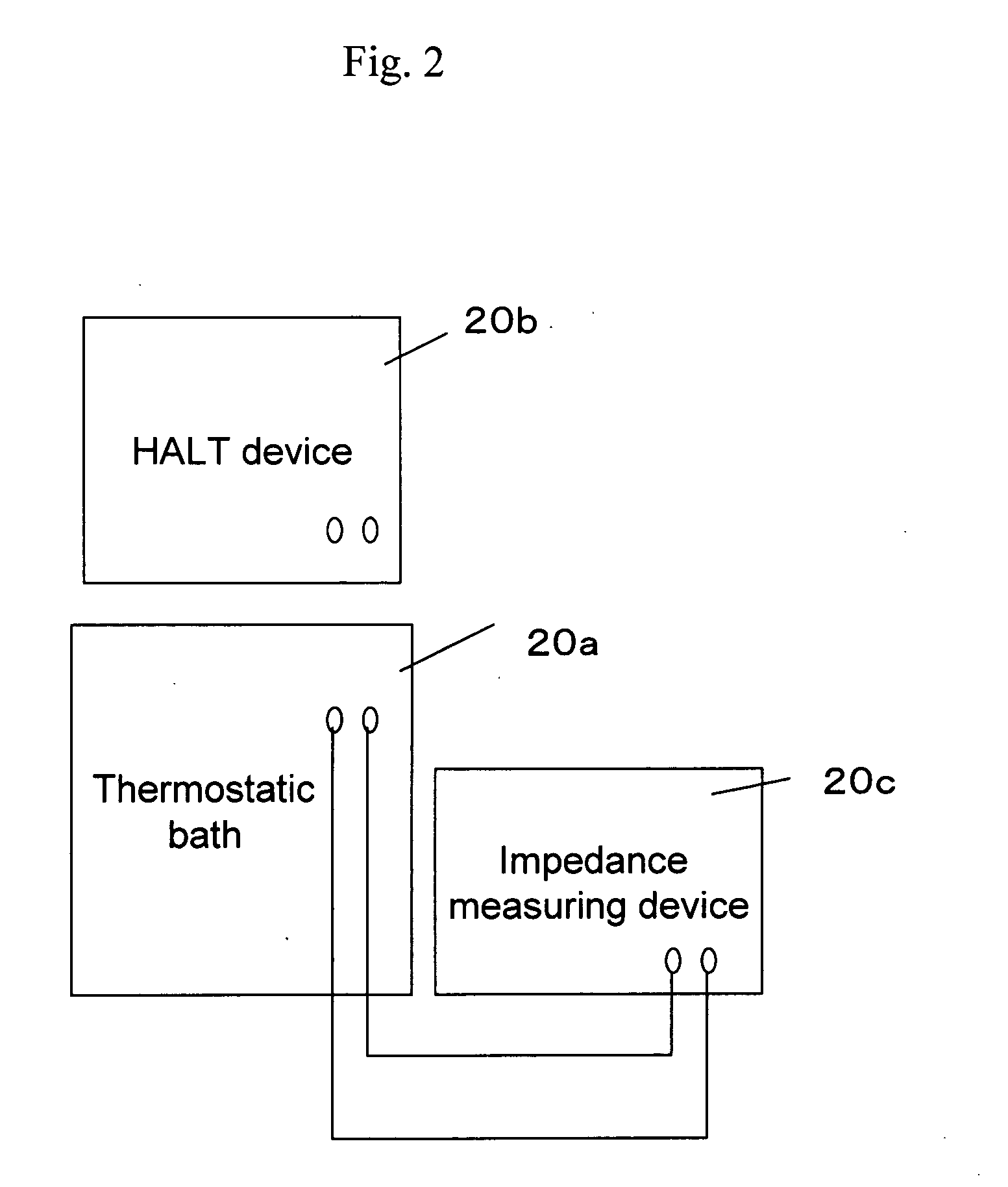

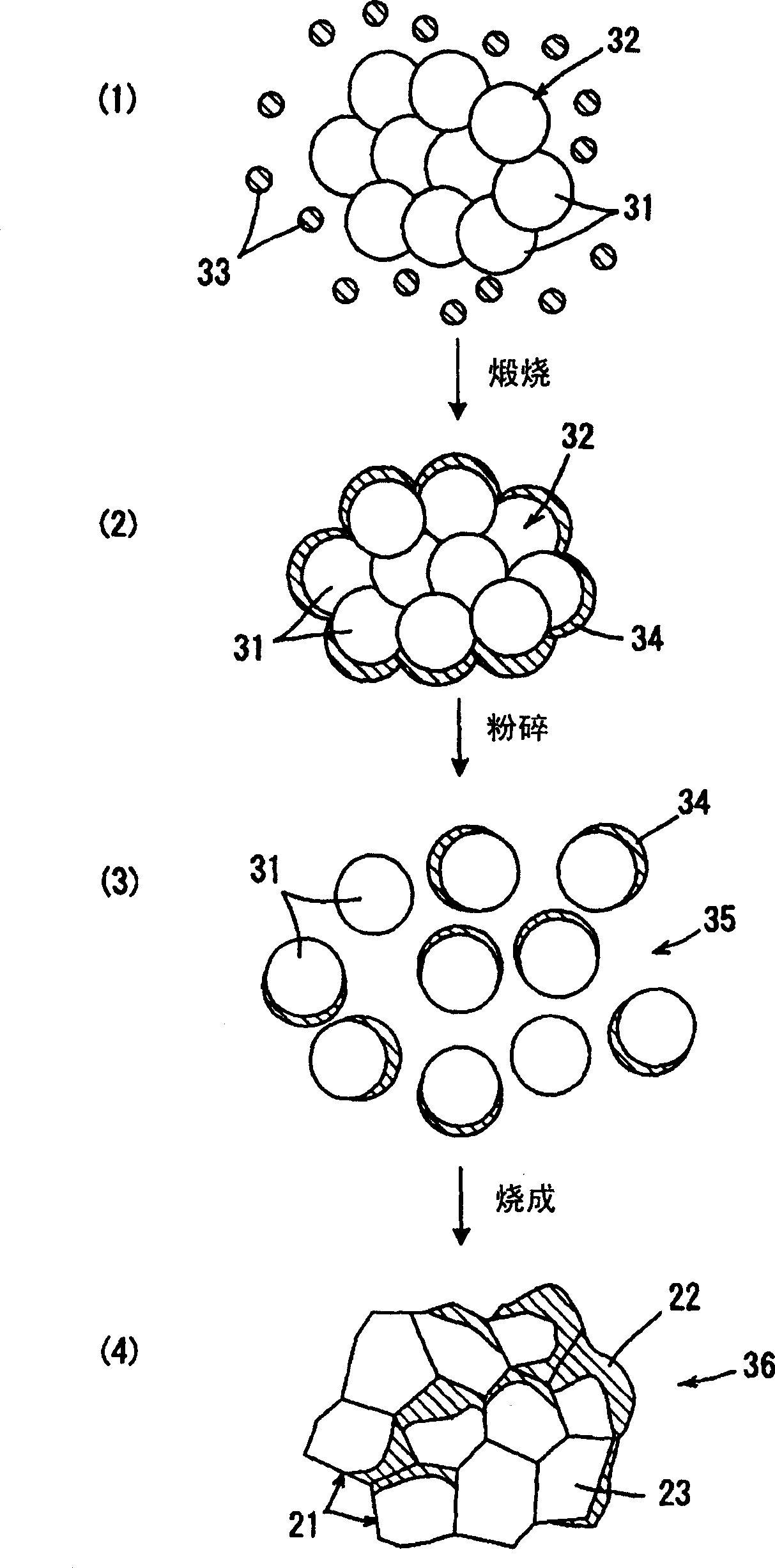

A method of production of a reduction resistant dielectric ceramic composition having a superior low frequency dielectric characteristic and further improved in accelerated lifetime of insulation resistance, specifically a method of production of a dielectric ceramic composition containing a main component including a dielectric oxide of a specific composition, a first subcomponent including a V oxide, a second subcomponent containing an Al oxide, a third subcomponent containing an Mn oxide, and a fourth subcomponent containing a specific sintering aid in a specific ratio, including a step of mixing at least part of the materials of the subcomponents excluding one or both of at least the material of the third subcomponent and material of the fourth subcomponent with the starting materials prepared for obtaining the material of the main component to prepare the pre-reaction material, a step of causing the prepared pre-reaction material to react to obtain a reacted material, and a step of mixing the materials of the subcomponents excluded when preparing the pre-reaction material with the obtained reacted material to obtain a dielectric ceramic composition.

Owner:TDK CORPARATION

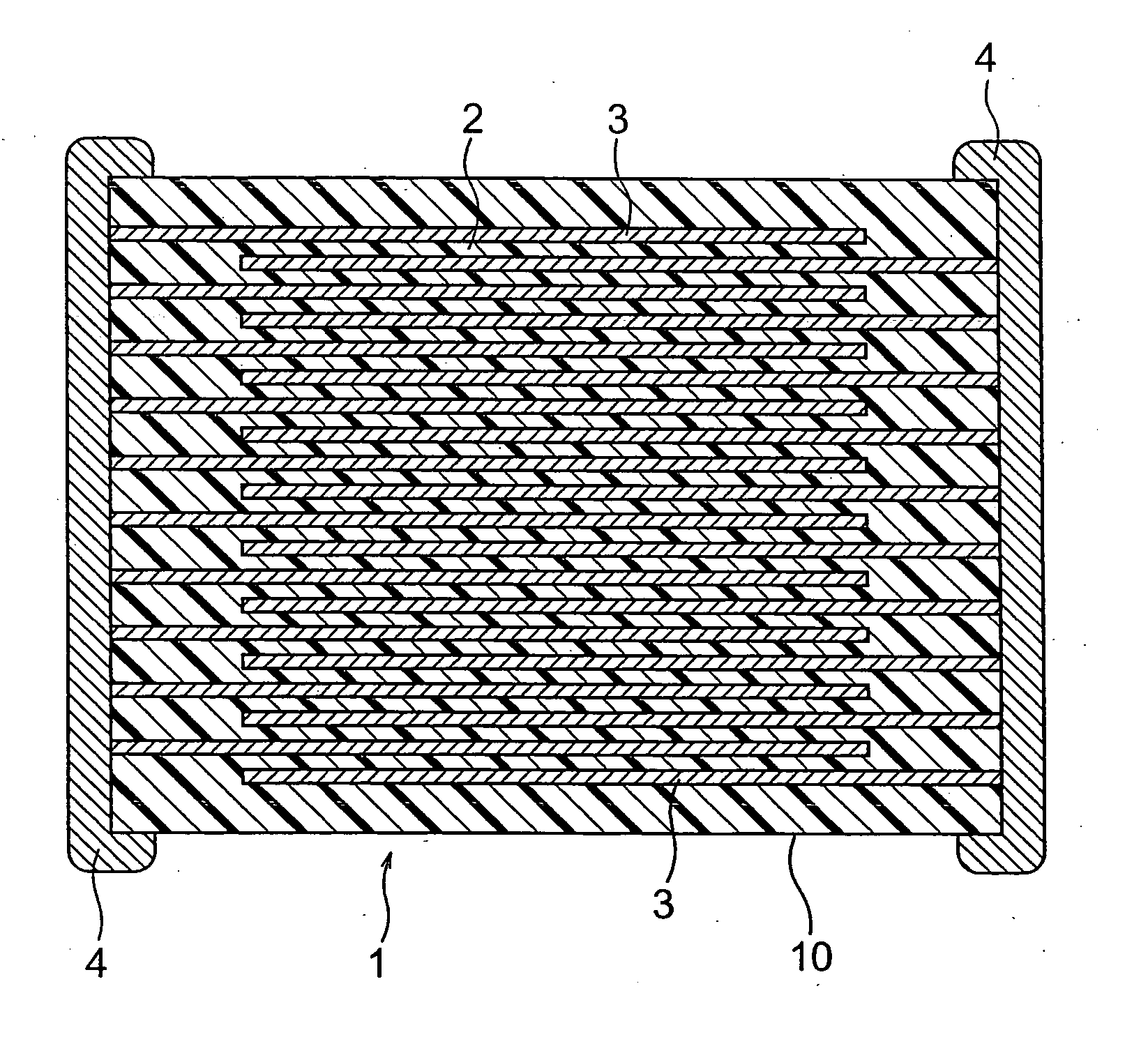

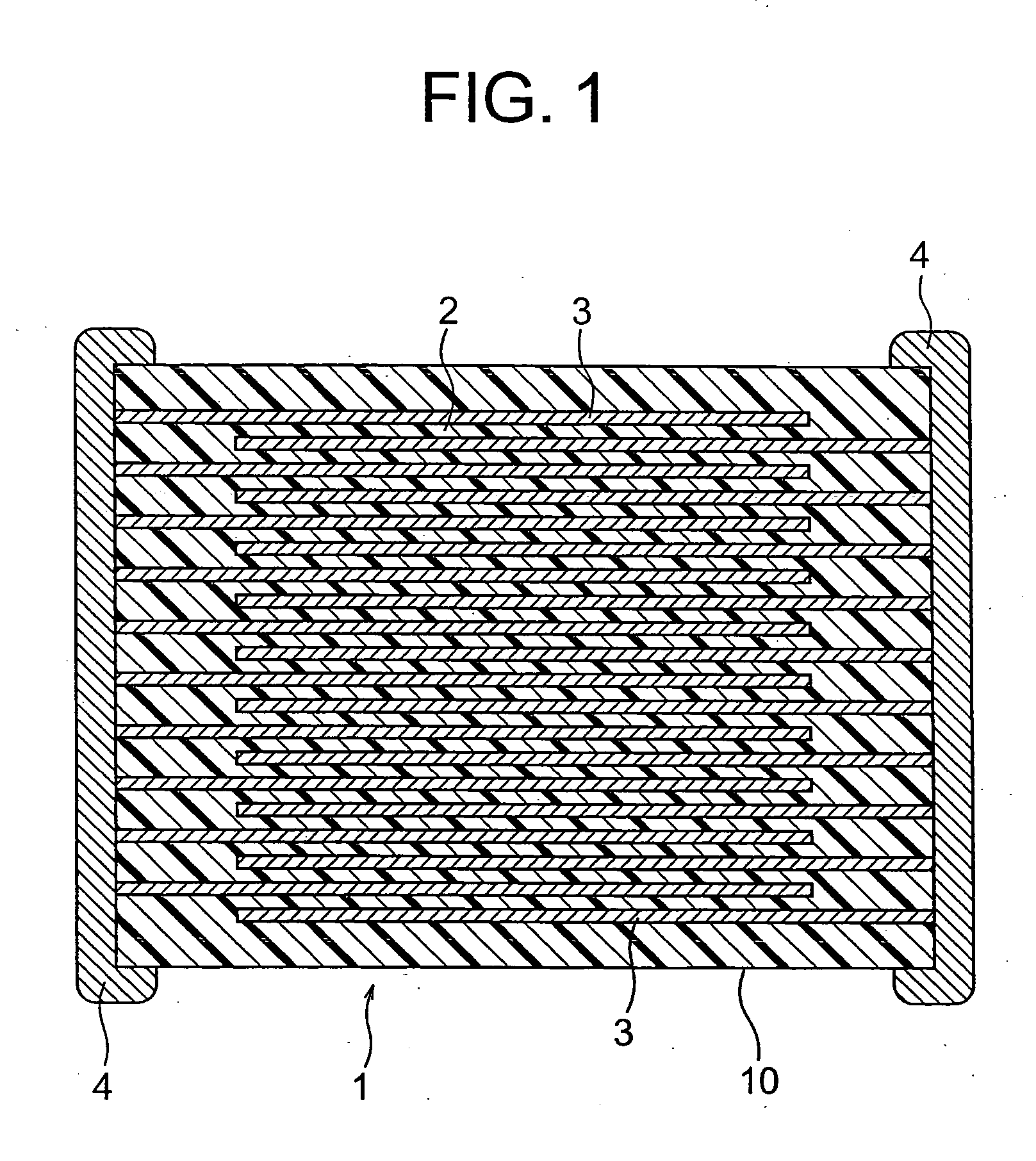

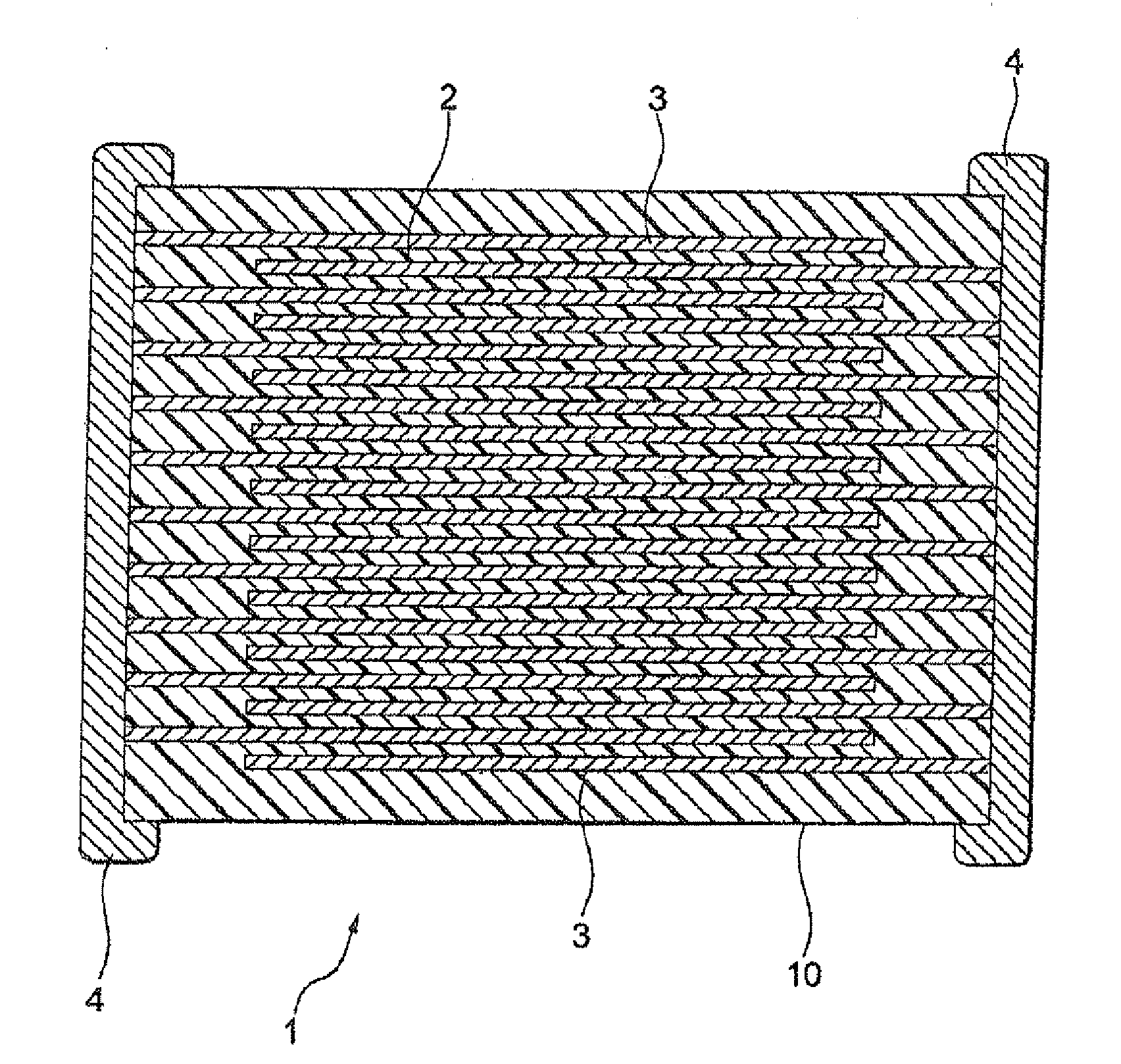

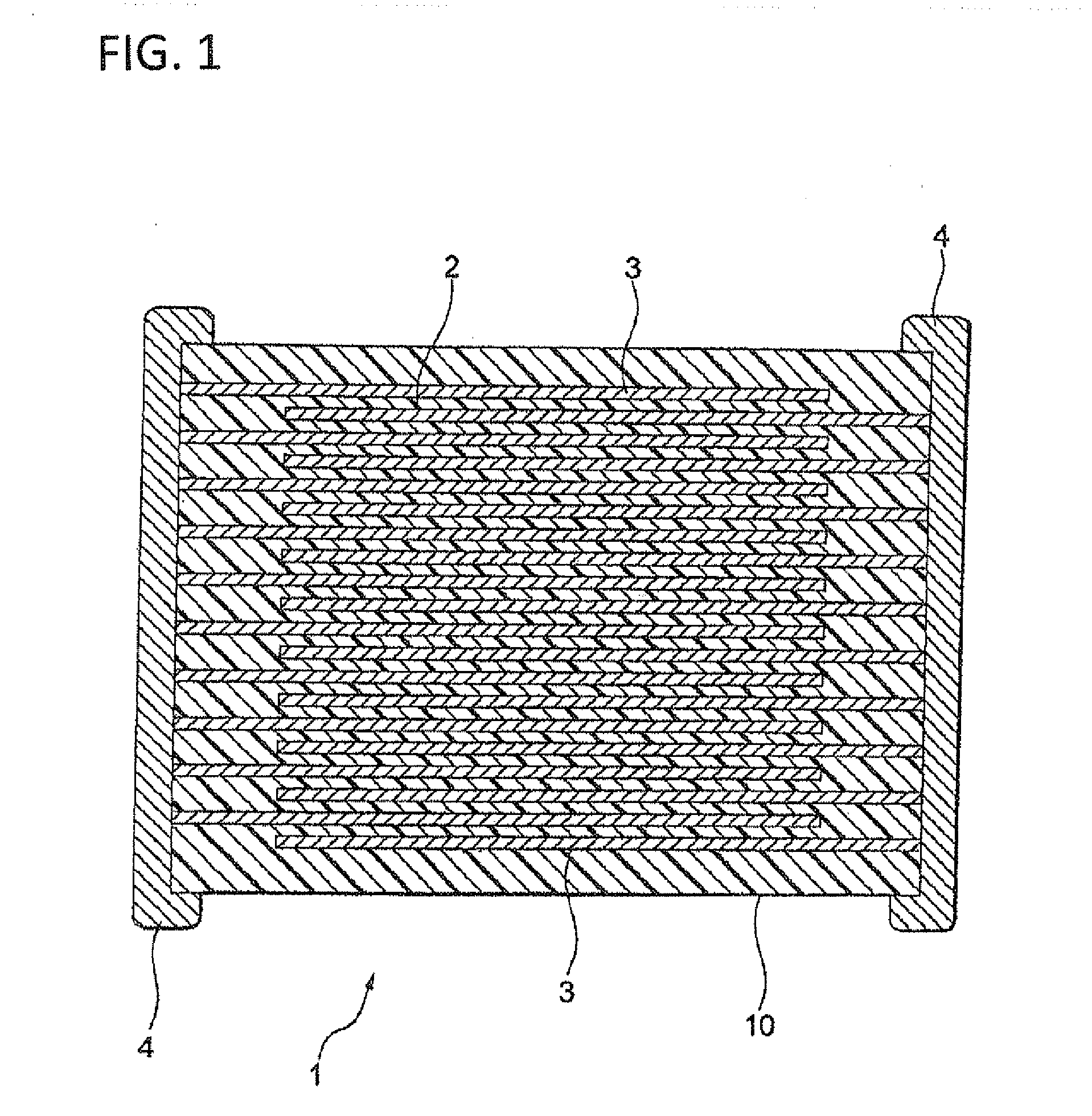

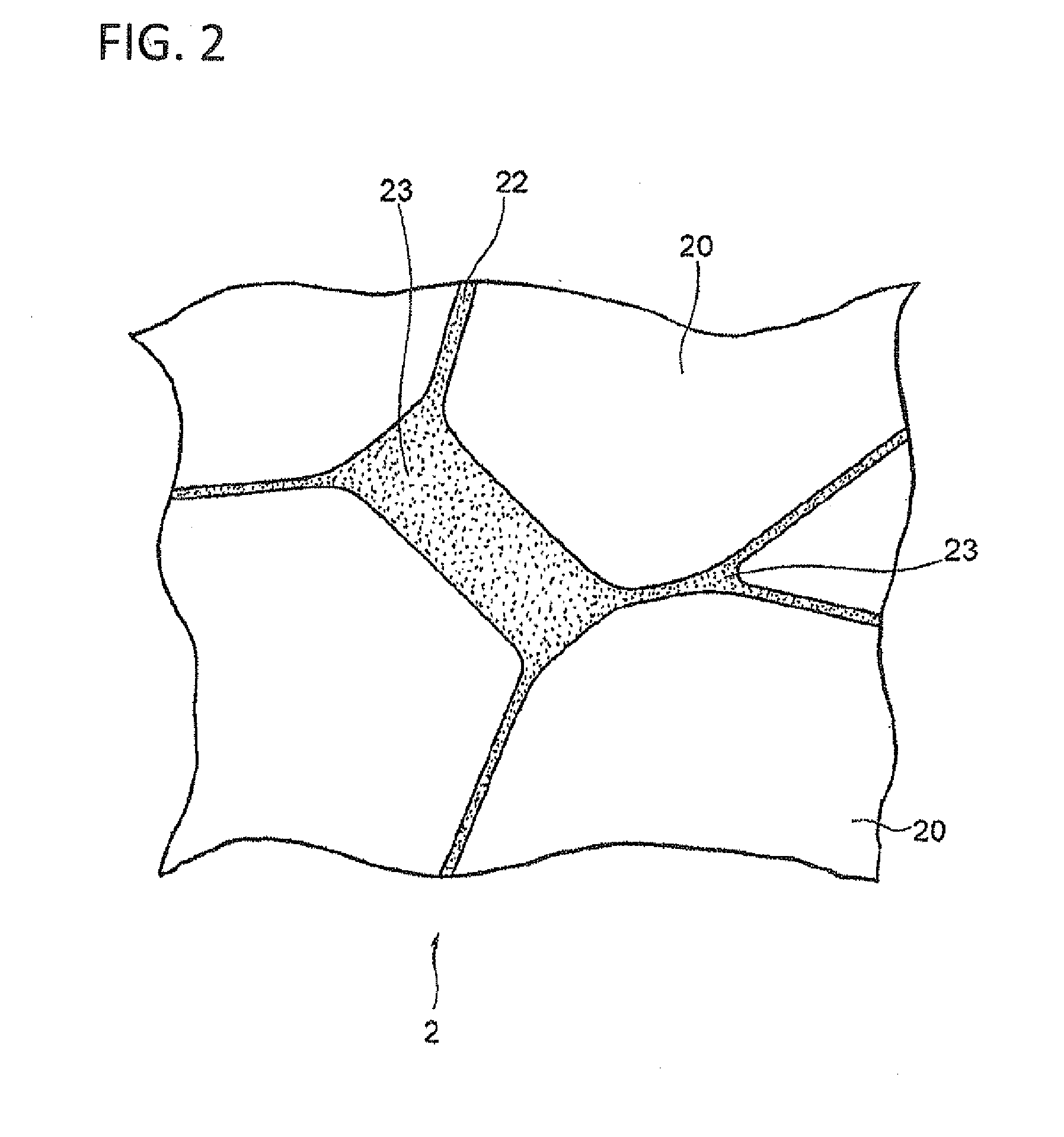

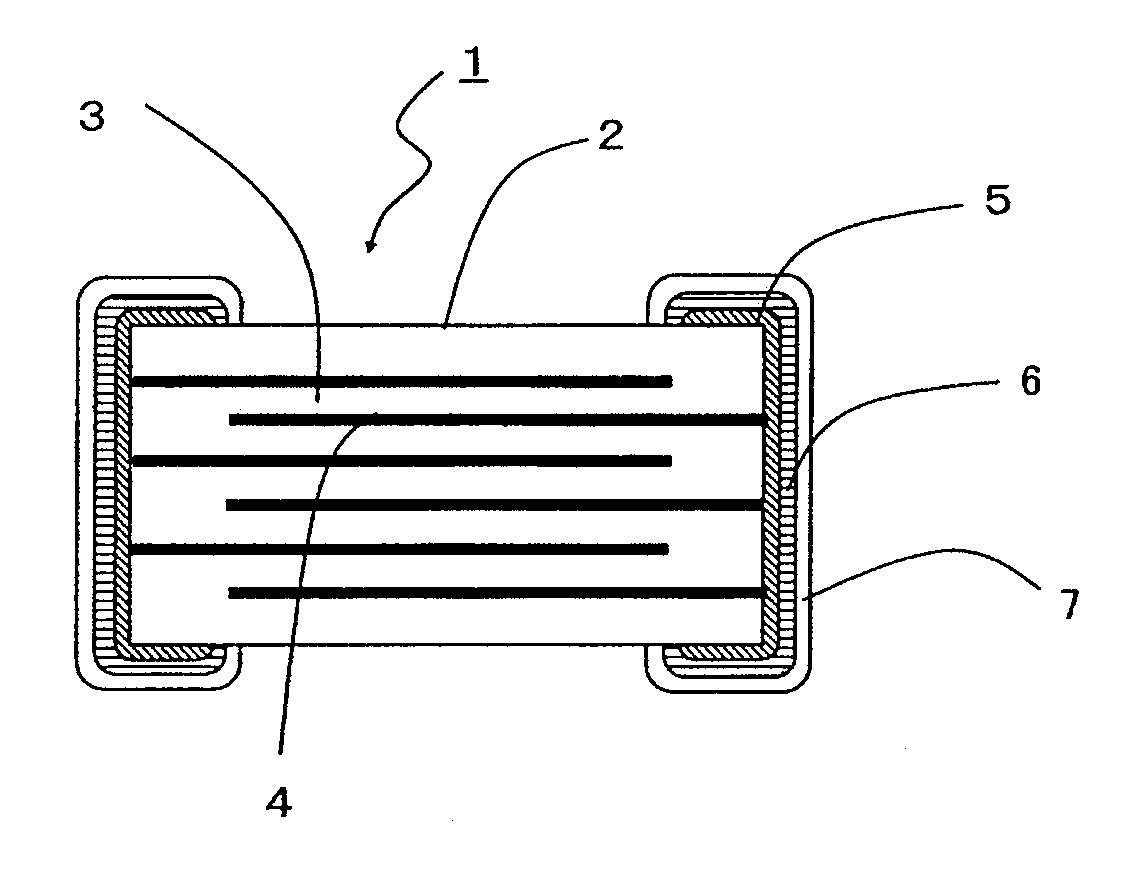

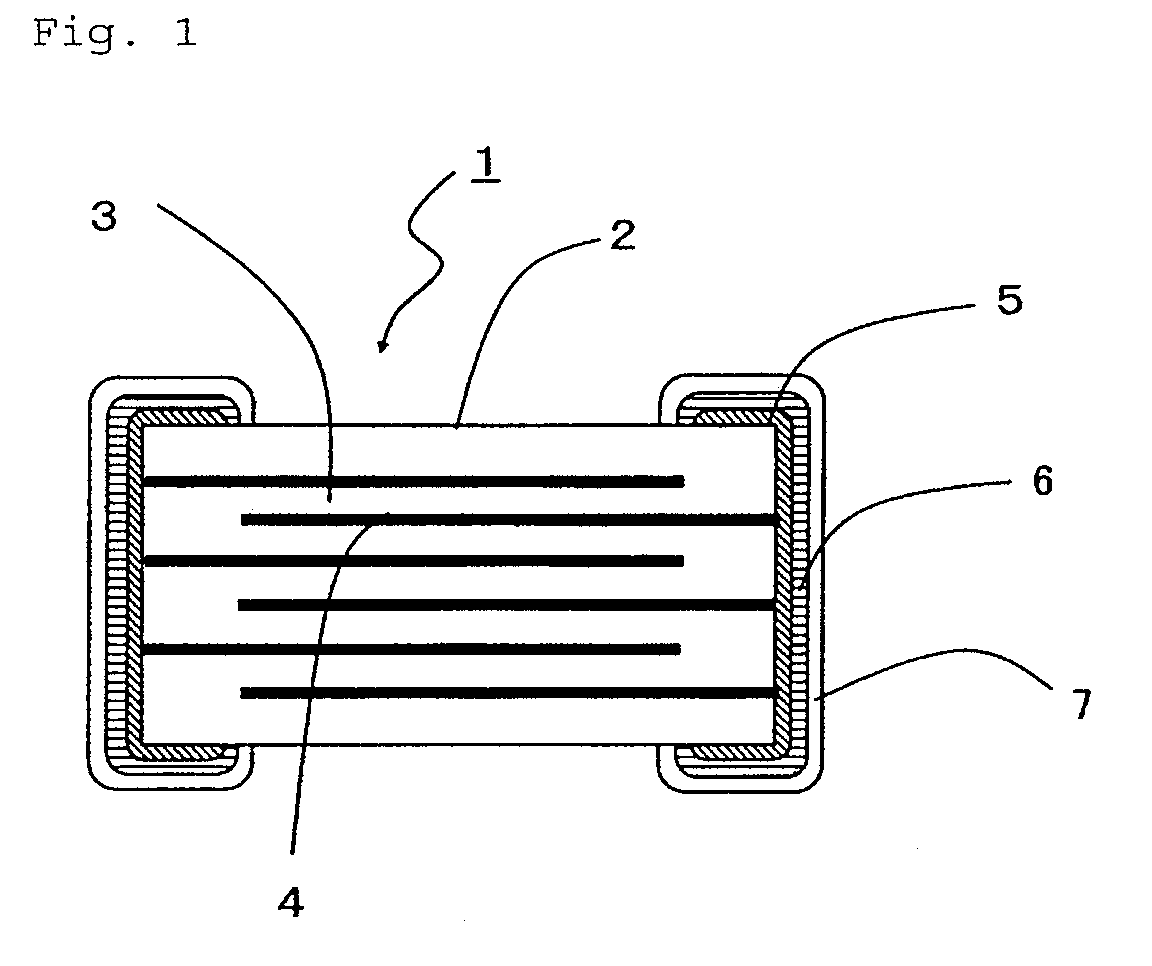

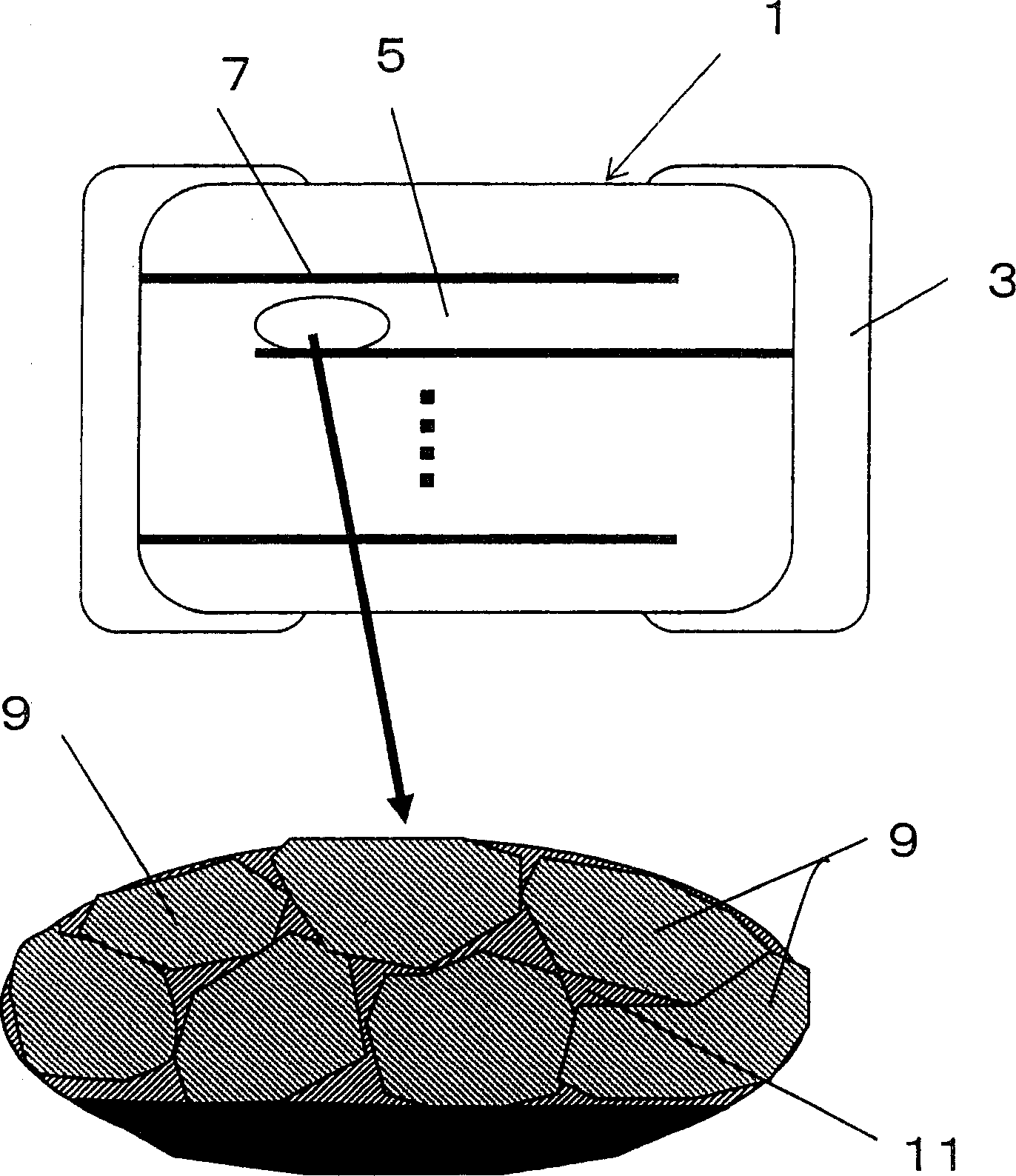

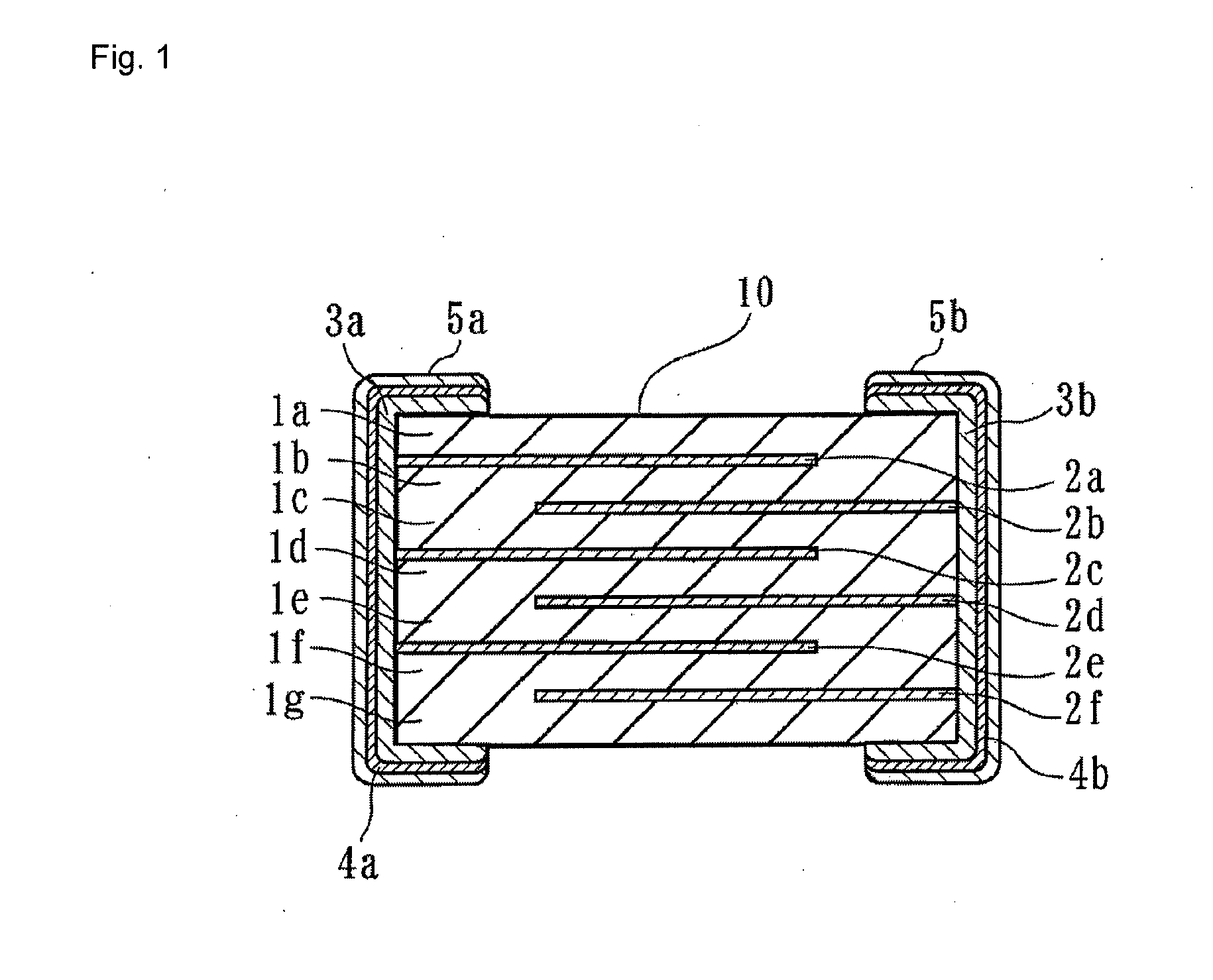

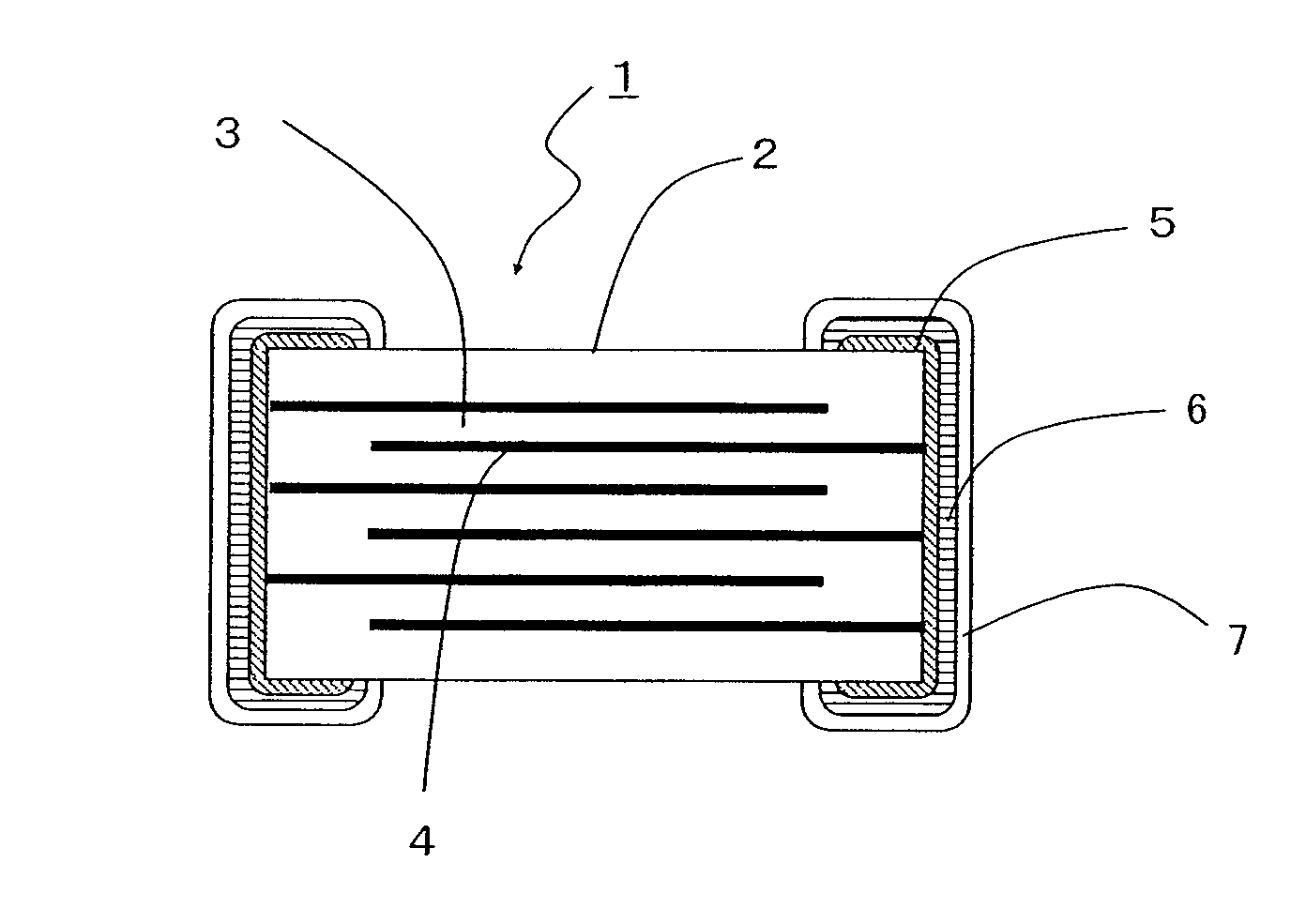

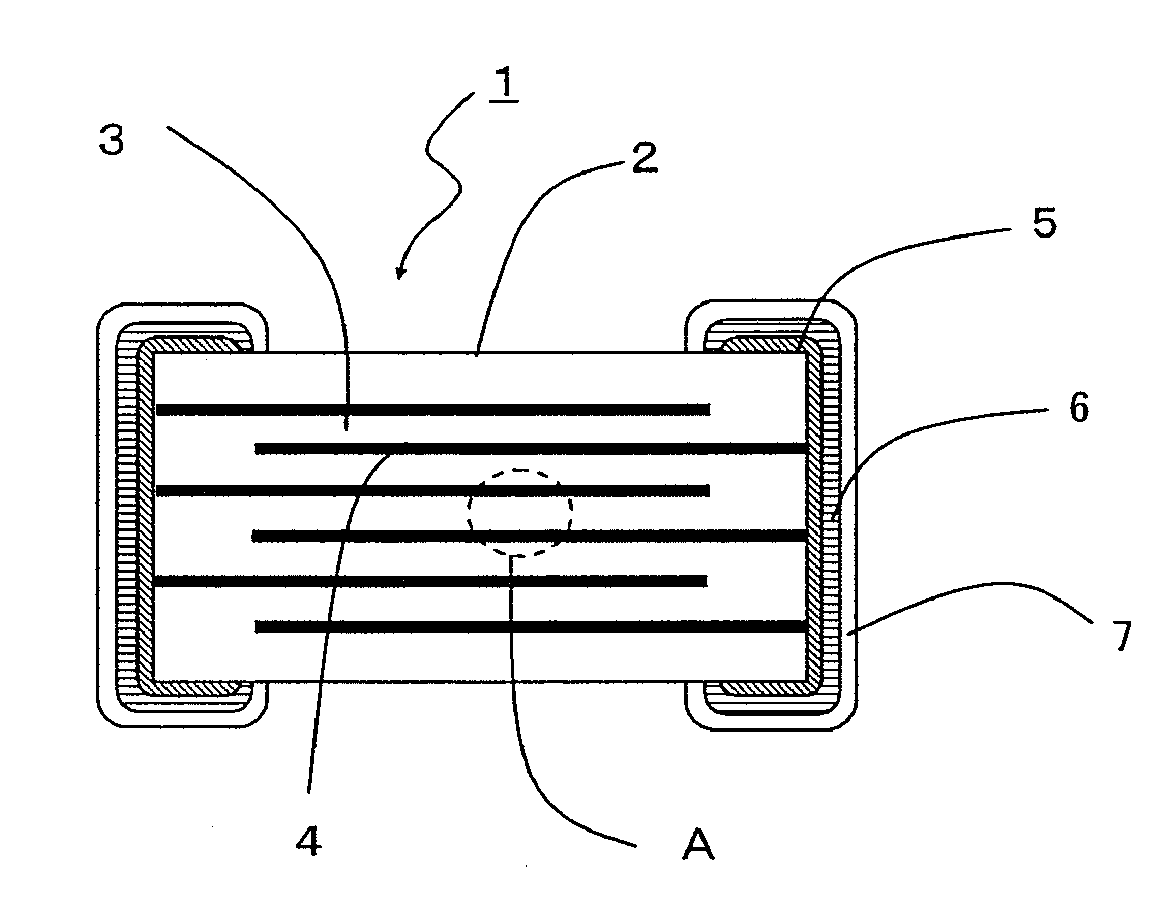

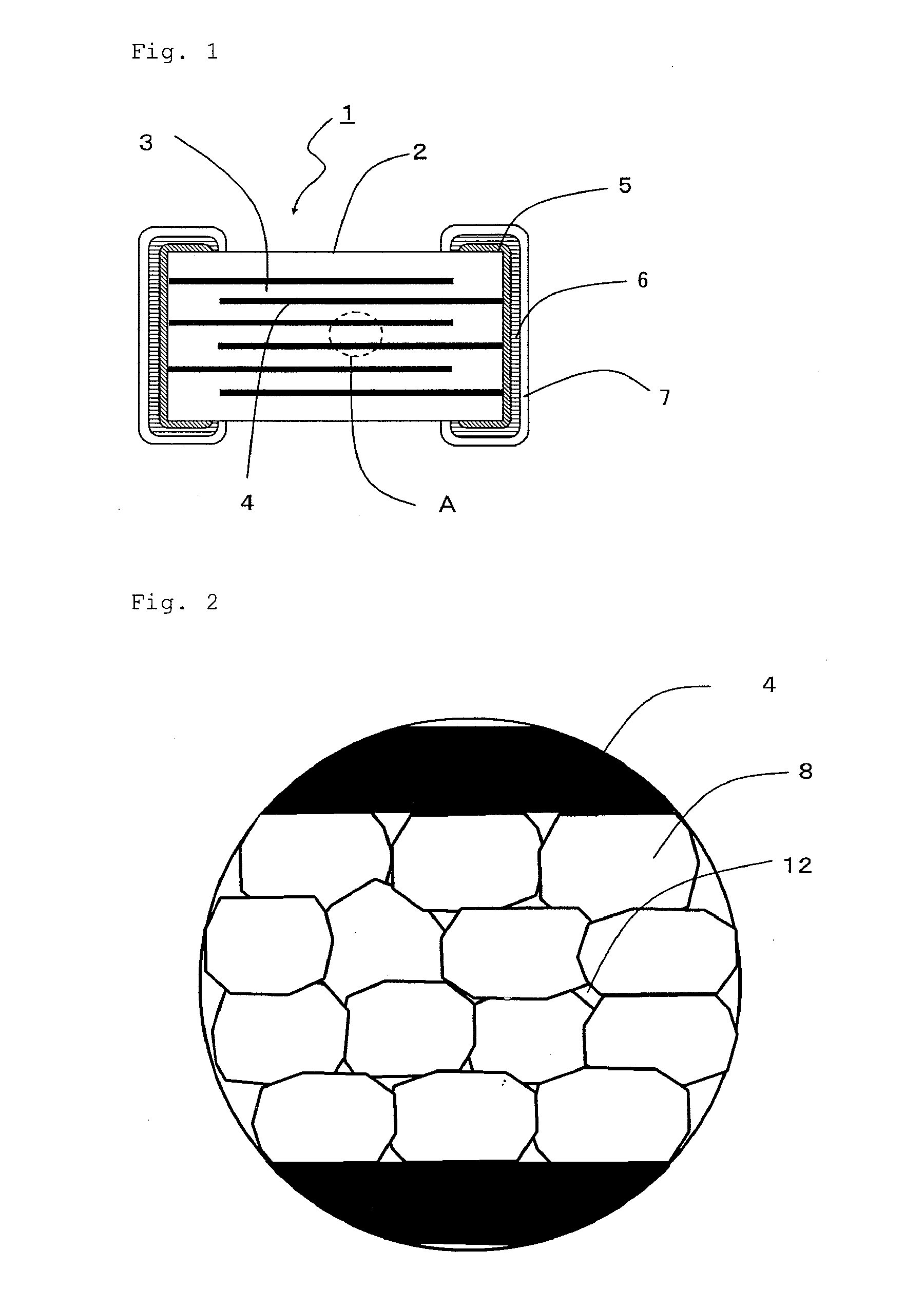

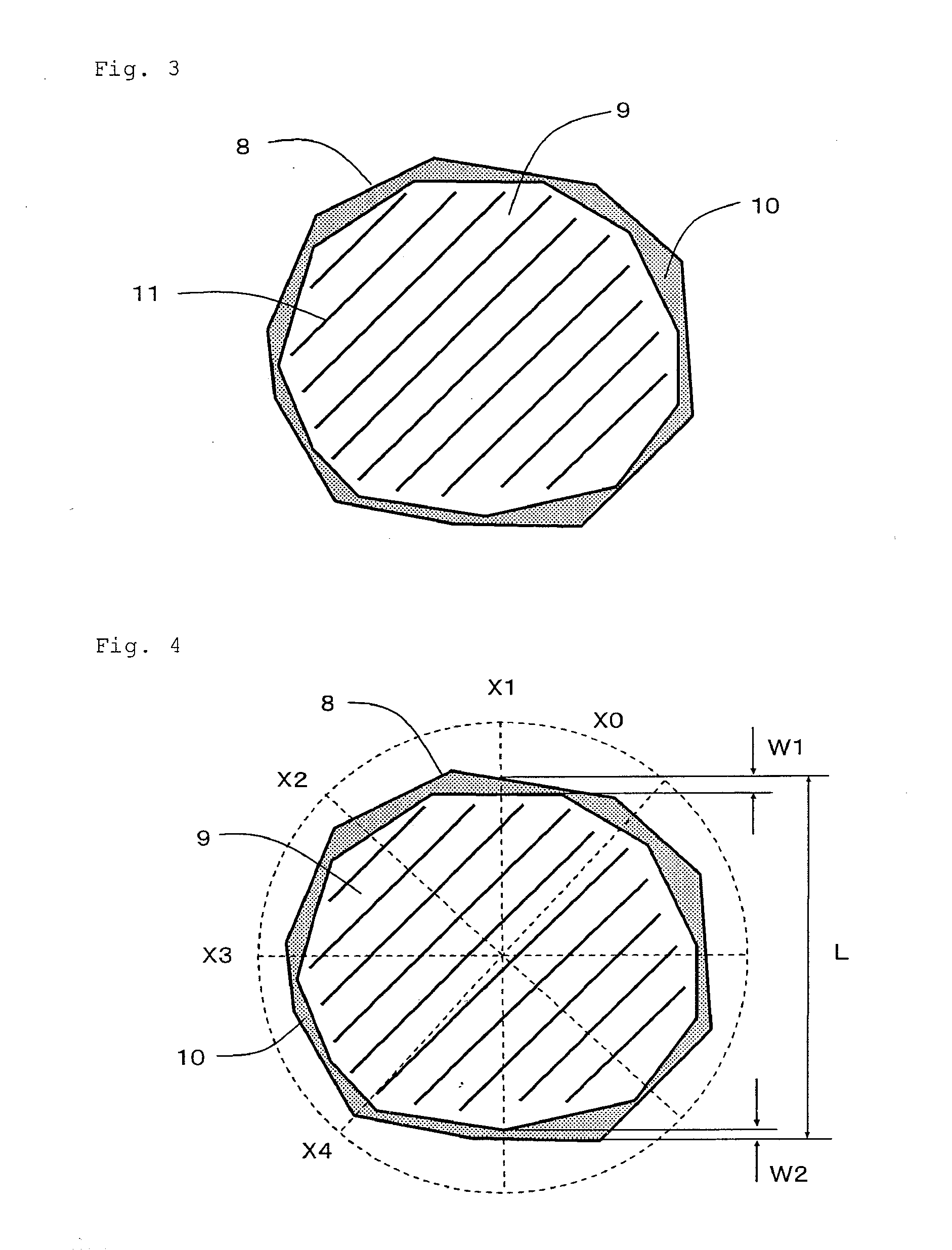

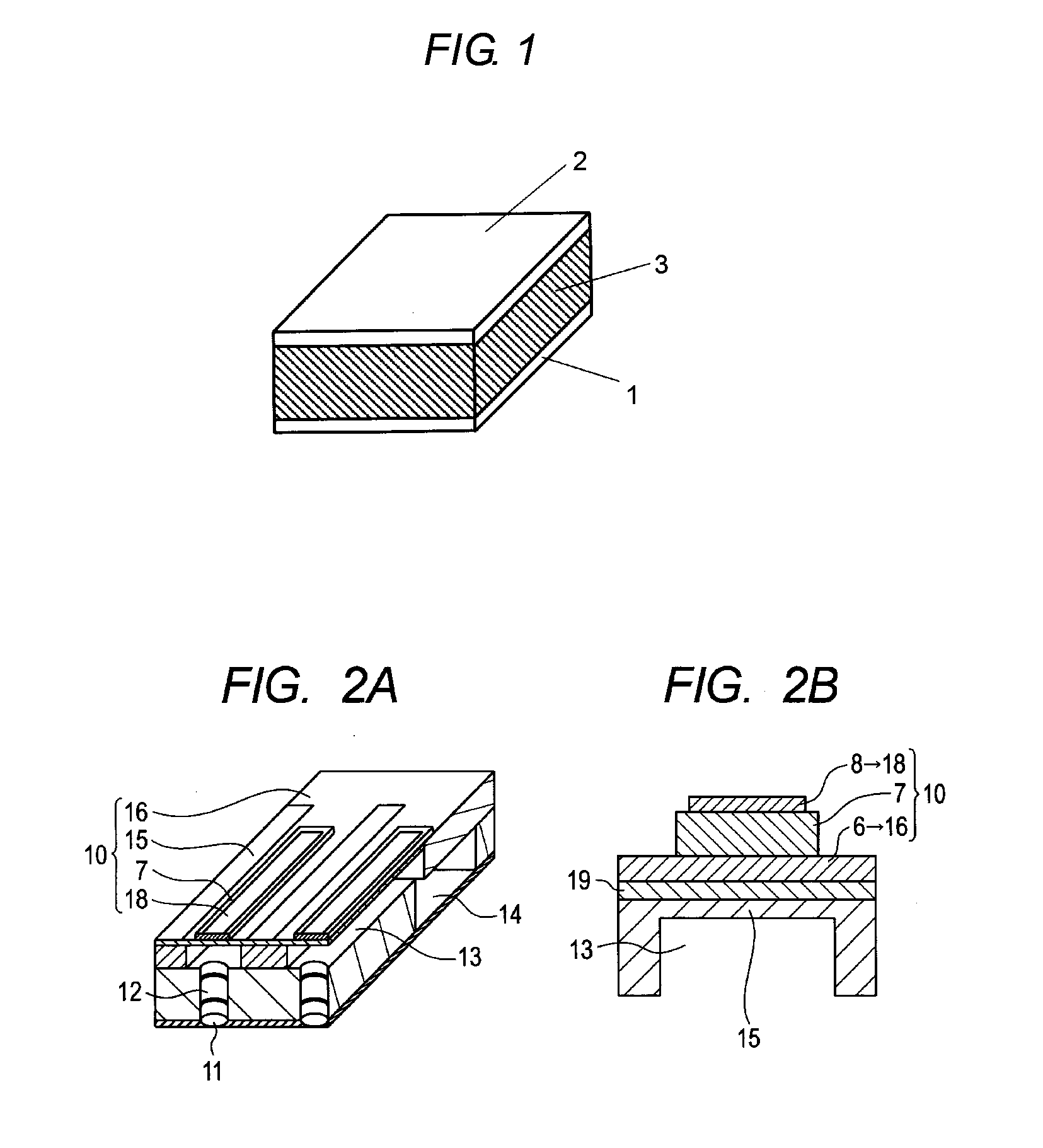

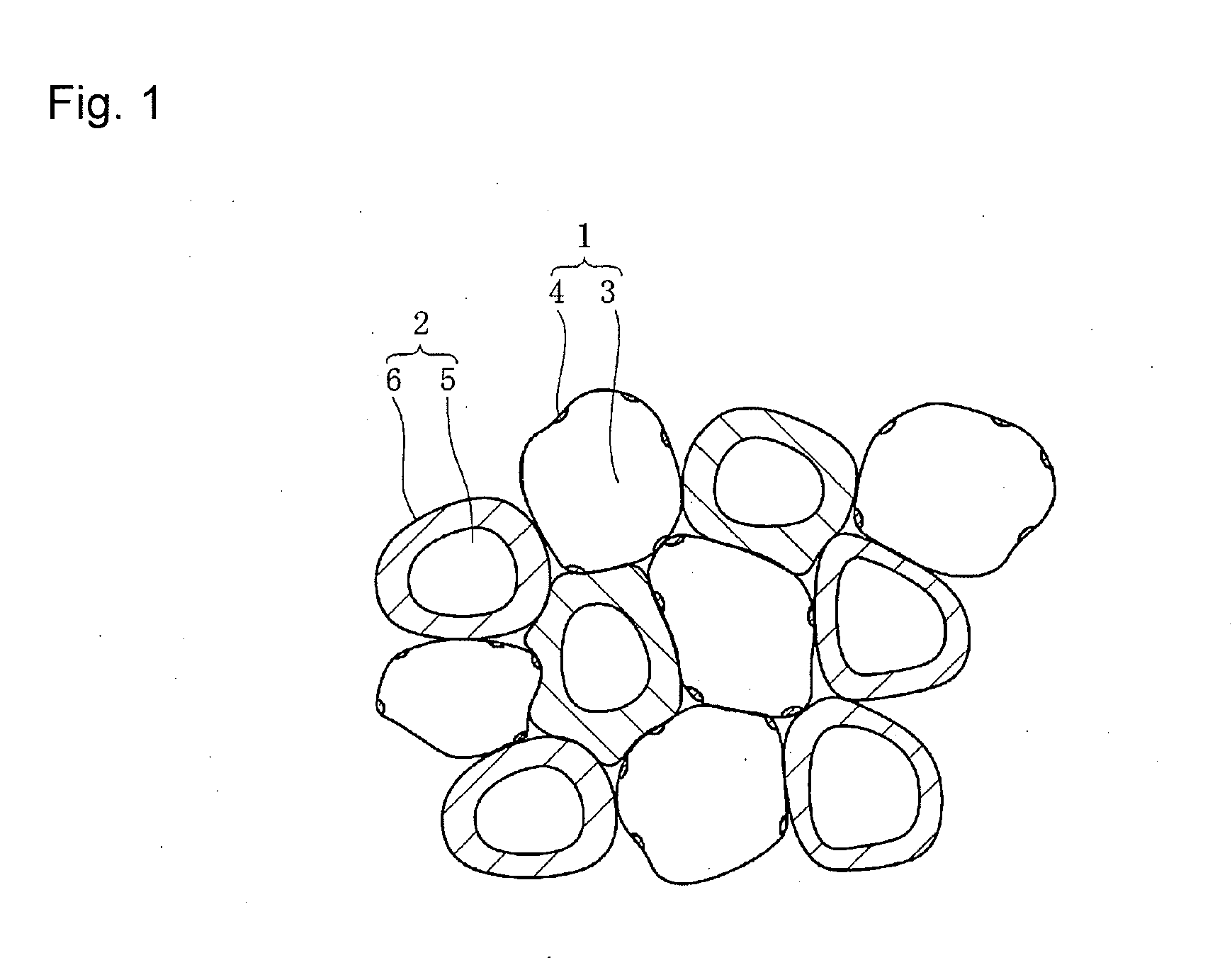

Laminated type ceramic electronic parts

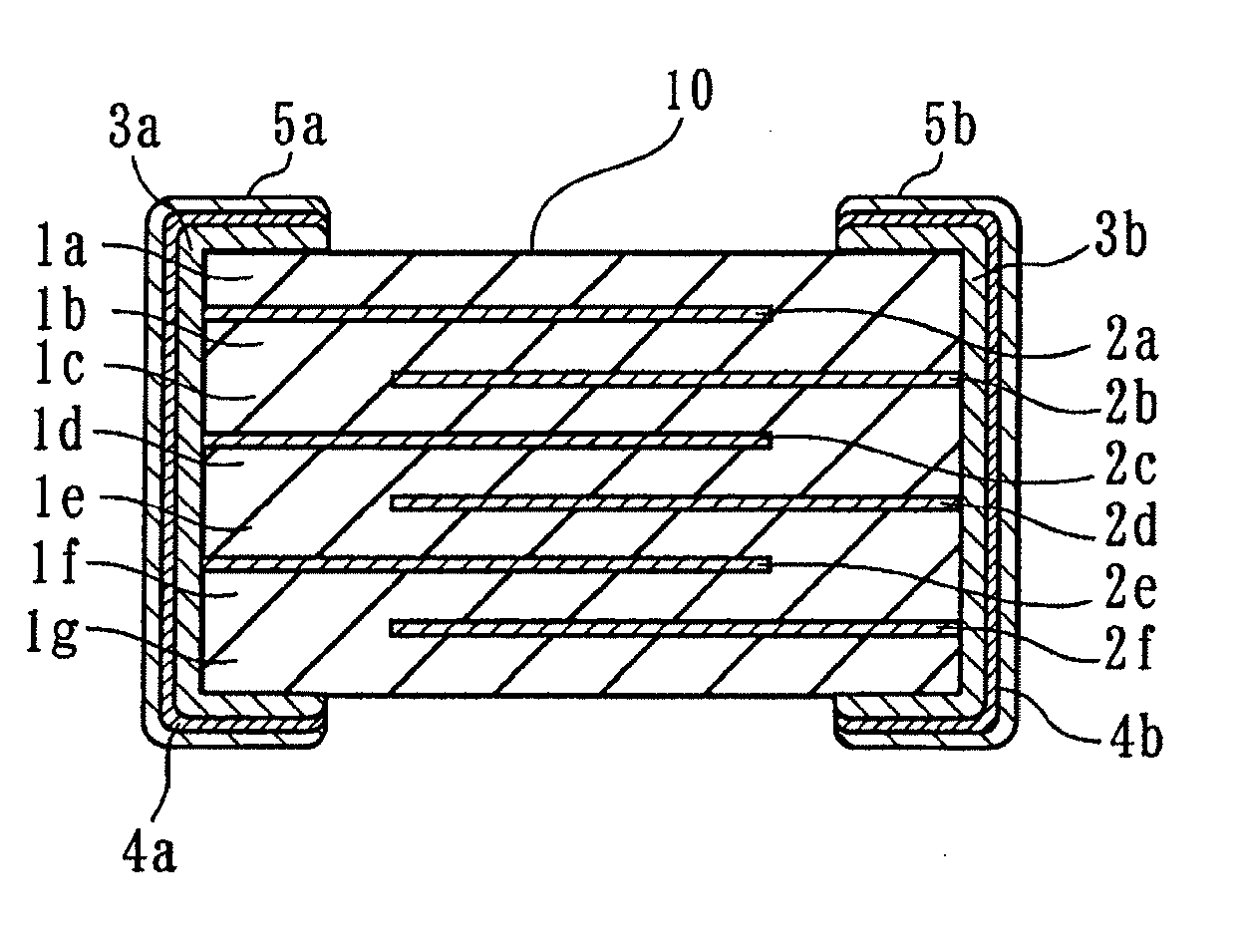

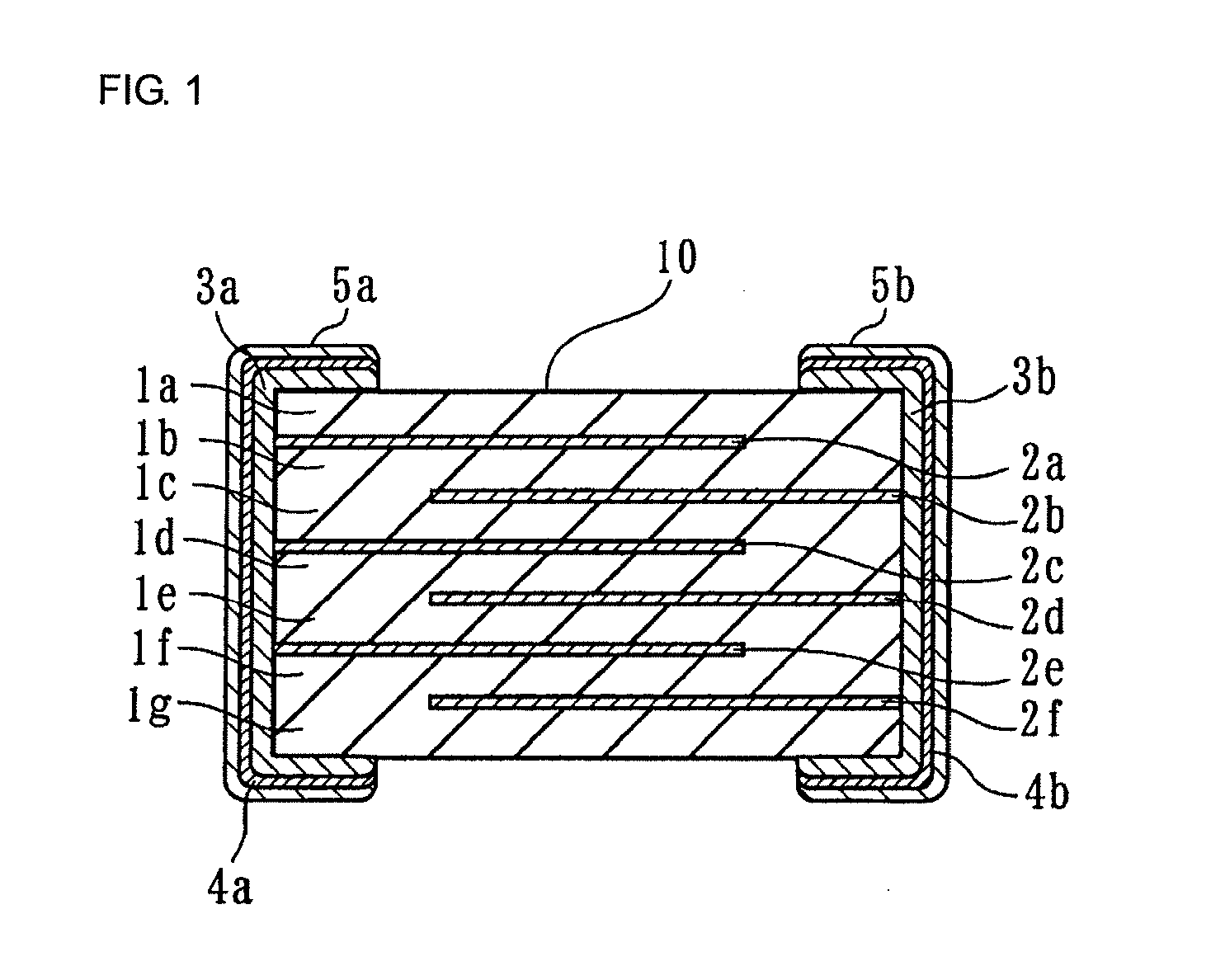

ActiveUS20120162858A1Good effectImprove featuresFixed capacitor dielectricStacked capacitorsRare-earth elementElectronic component

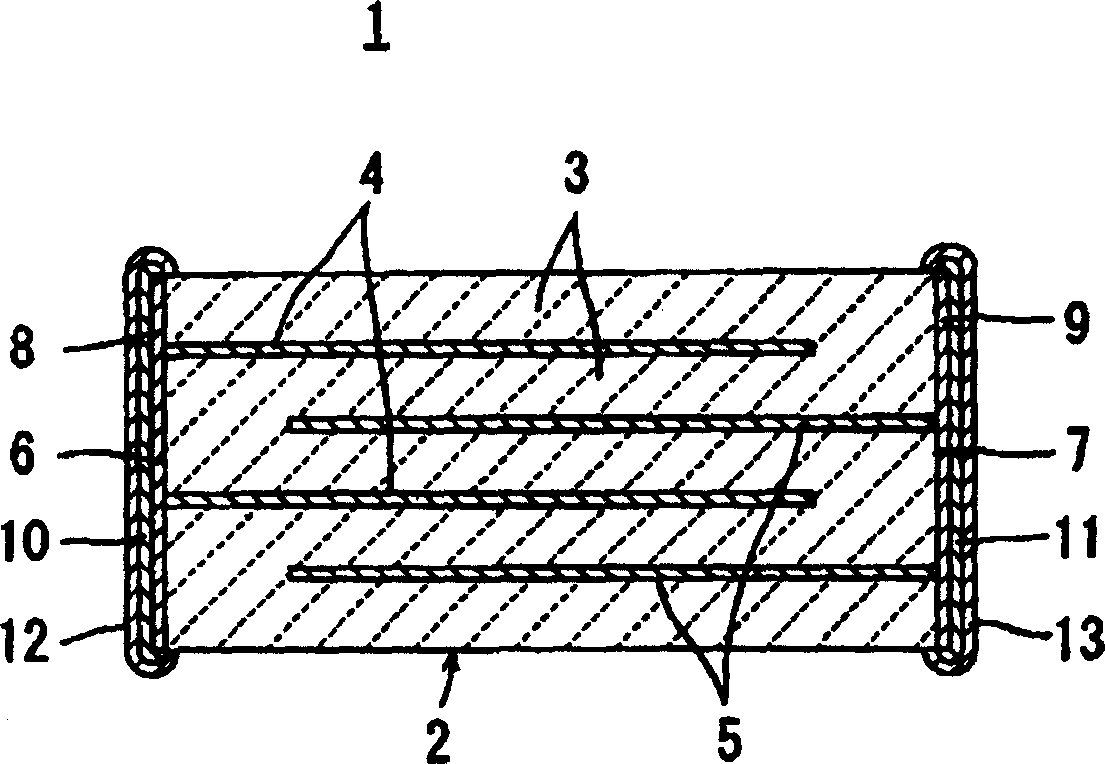

A multilayer ceramic electronic component comprising an element body in which a dielectric layer and an internal electrode layer are stacked. The dielectric layer is constituted from a dielectric ceramic composition including; a compound having a perovskite structure expressed by a formula of ABO3 (A is at least one selected from Ba, Ca, and Sr; B is at least one selected from Ti, Zr, and Hf); an oxide of Mg; an oxide of rare earth elements including Sc and Y; and an oxide including Si. The dielectric ceramic composition comprises a plurality of dielectric particles and a grain boundary present in between the dielectric particles. In the grain boundary, when content ratios of Mg and Si are set to D(Mg) and D(Si) respectively, D(Mg) is 0.2 to 1.8 wt % in terms of MgO, and D(Si) is 0.4 to 8.0 wt % in terms of SiO2.

Owner:TDK CORPARATION

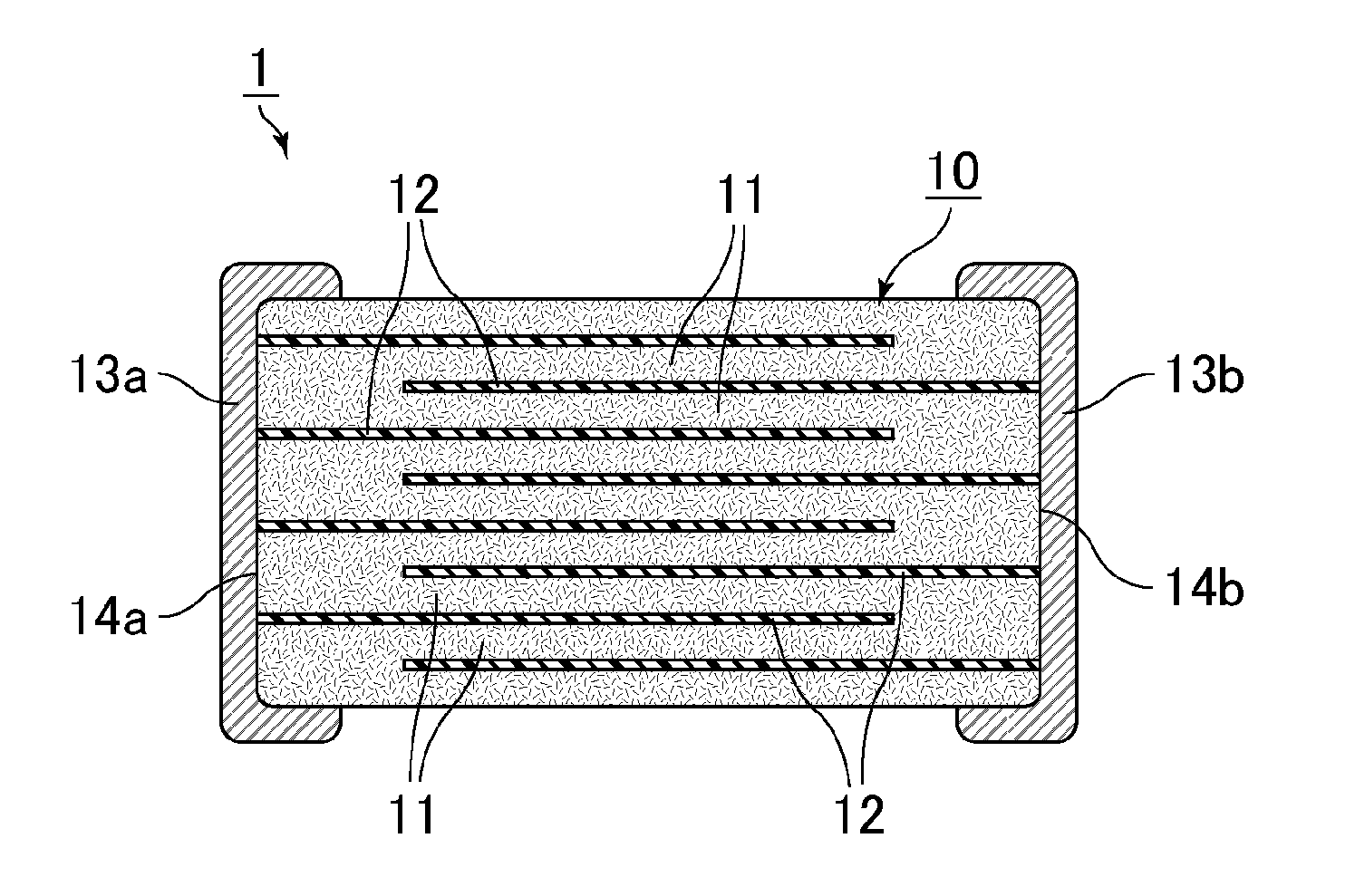

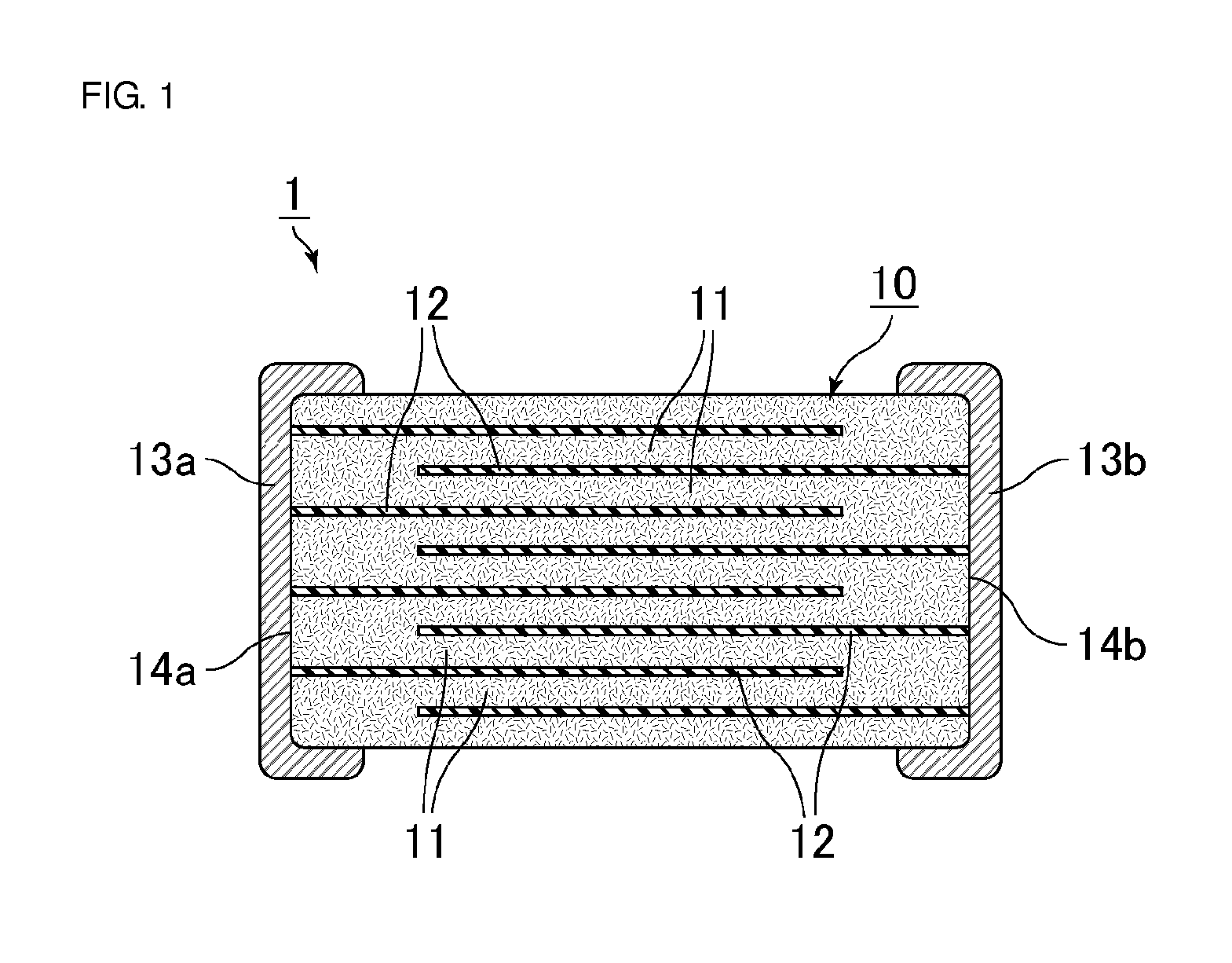

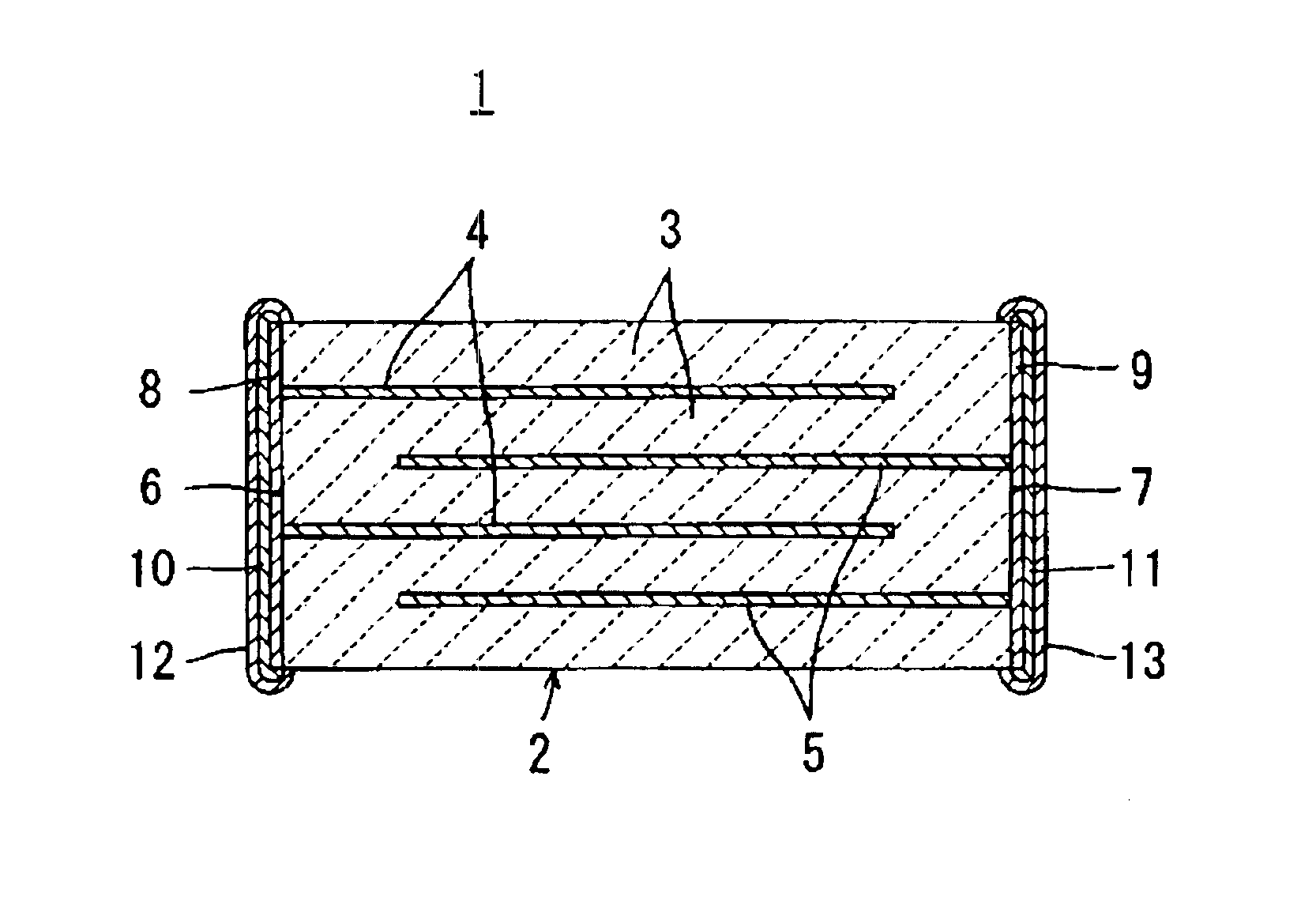

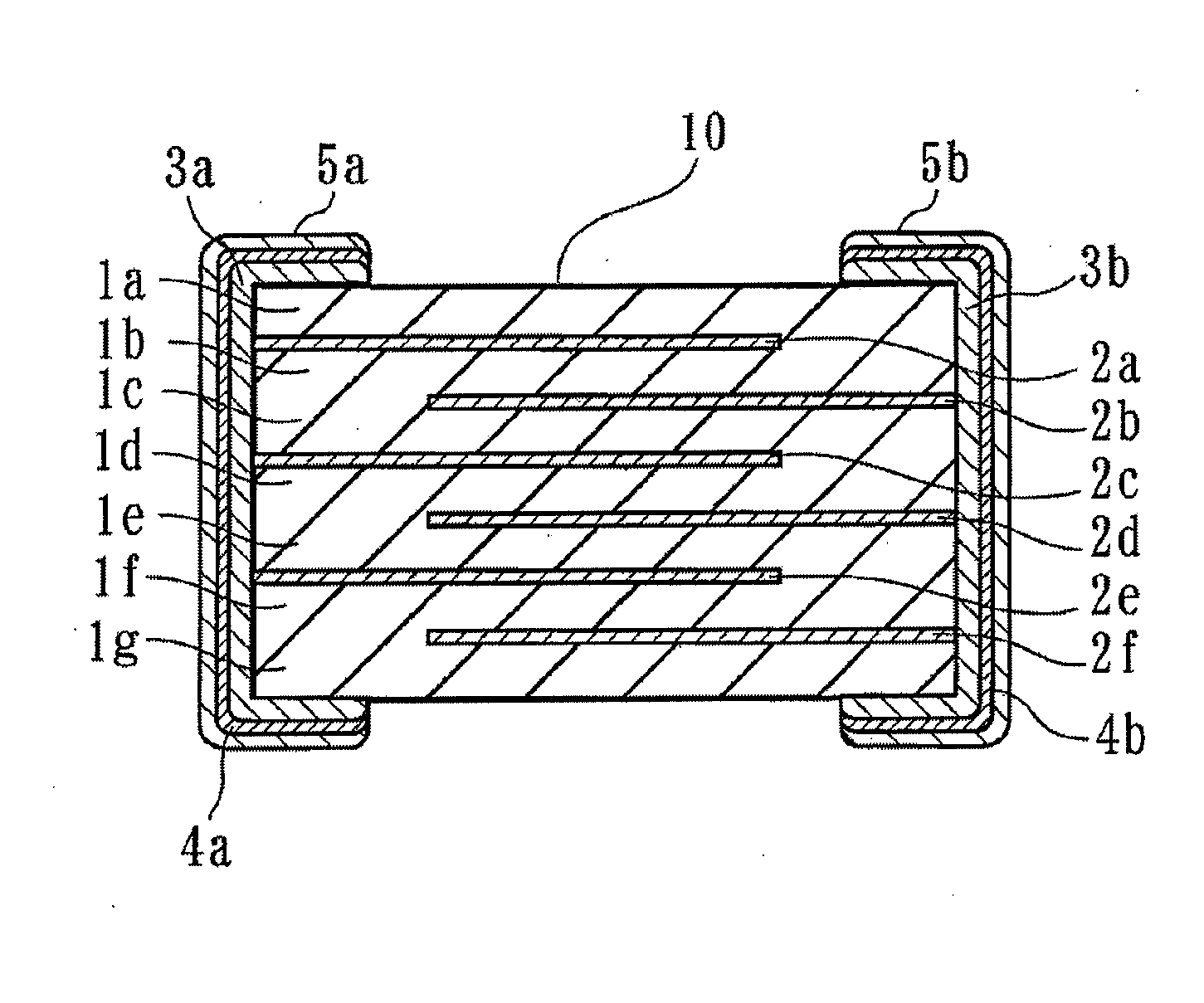

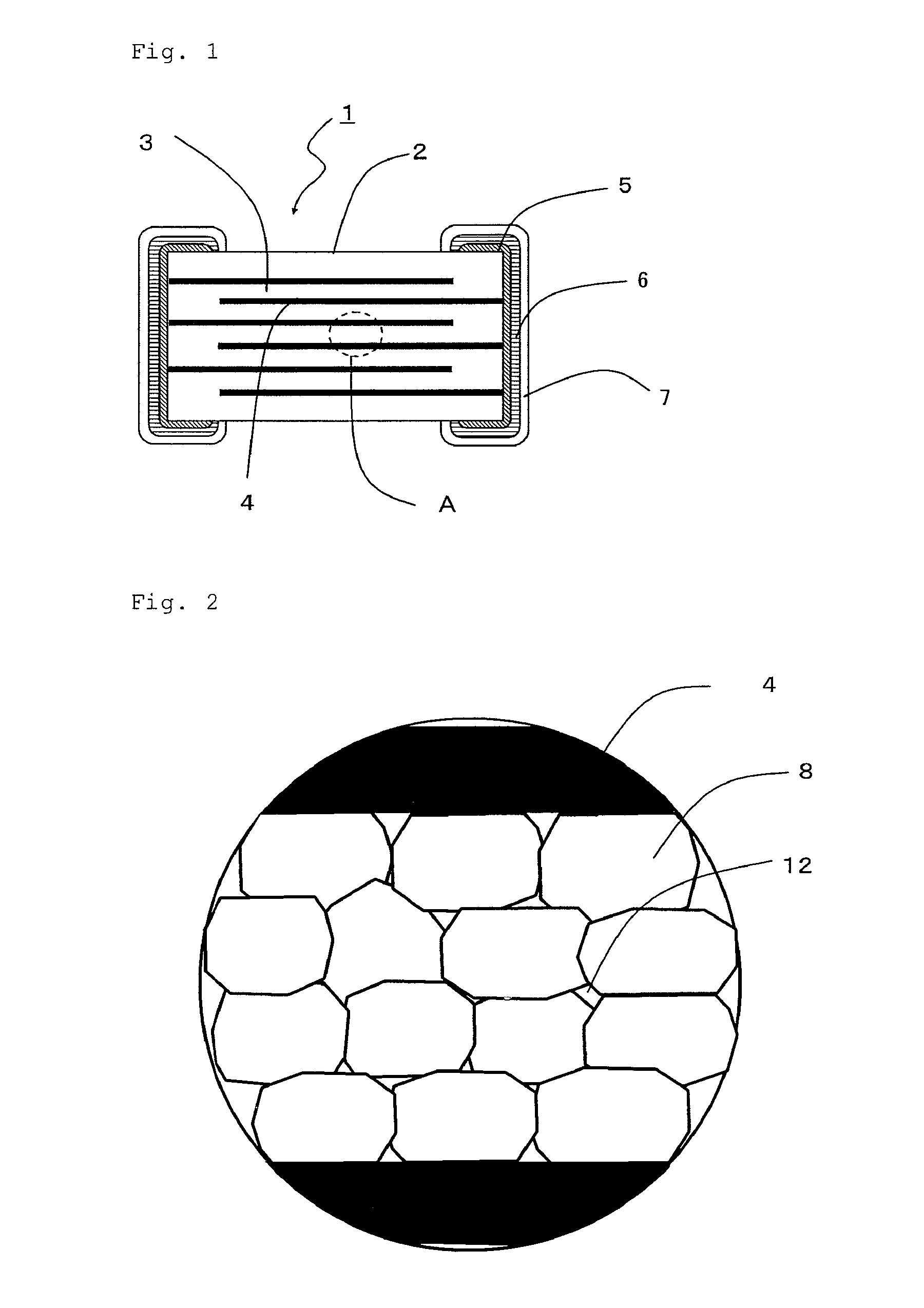

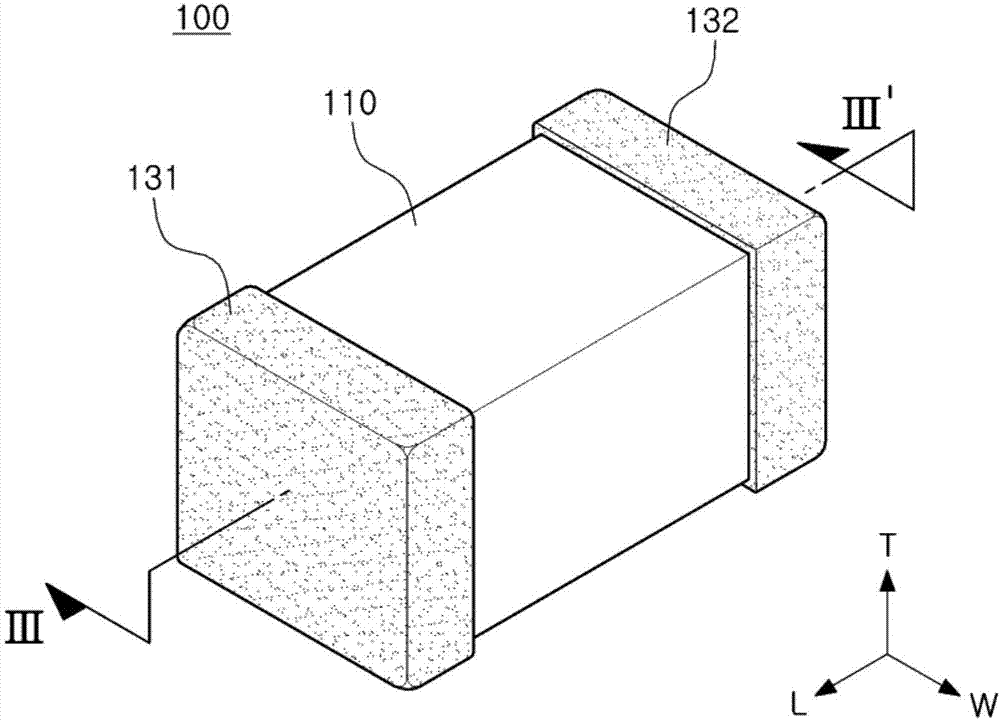

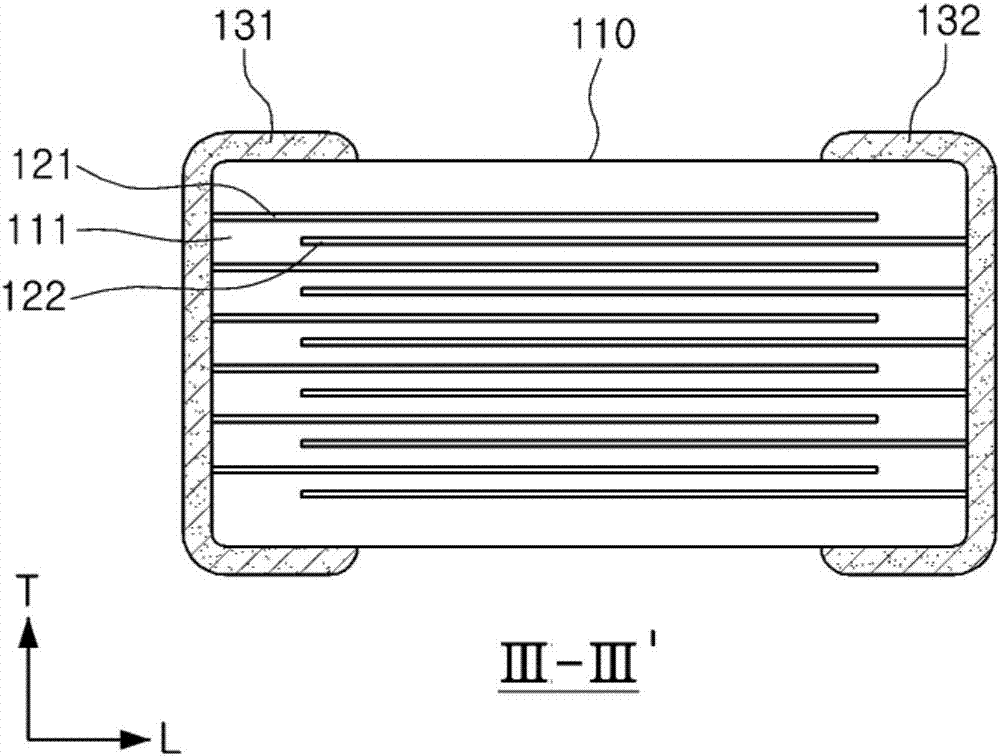

Multilayer ceramic capacitor and method for producing multilayer ceramic capacitor

ActiveUS20160155570A1Prevent movementImprove reliabilityFixed capacitor electrodesFixed capacitor dielectricDielectricCeramic capacitor

A multilayer ceramic capacitor includes a multilayer body including dielectric ceramic layers and inner electrode layers containing Ni and electrically connected to outer electrodes. The dielectric ceramic layers contain a Ba- and Ti-containing perovskite compound, Ca, Mg, R (at least one rare earth metal selected from La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y), M (at least one selected from Zr, Mn, Co, Fe, Cr, Cu, Al, V, Mo, and W), and Si. The number of parts by mole of each element relative to Ti as 100 parts is as follows:Ca, approximately 0.10 to 5.00 parts;Mg, approximately 0.0010 to 0.0098 parts;R in total, approximately 0.50 to 4.00 parts;M in total, approximately 0.10 to 2.00 parts; andSi, approximately 0.5 to 2.0 parts.

Owner:MURATA MFG CO LTD

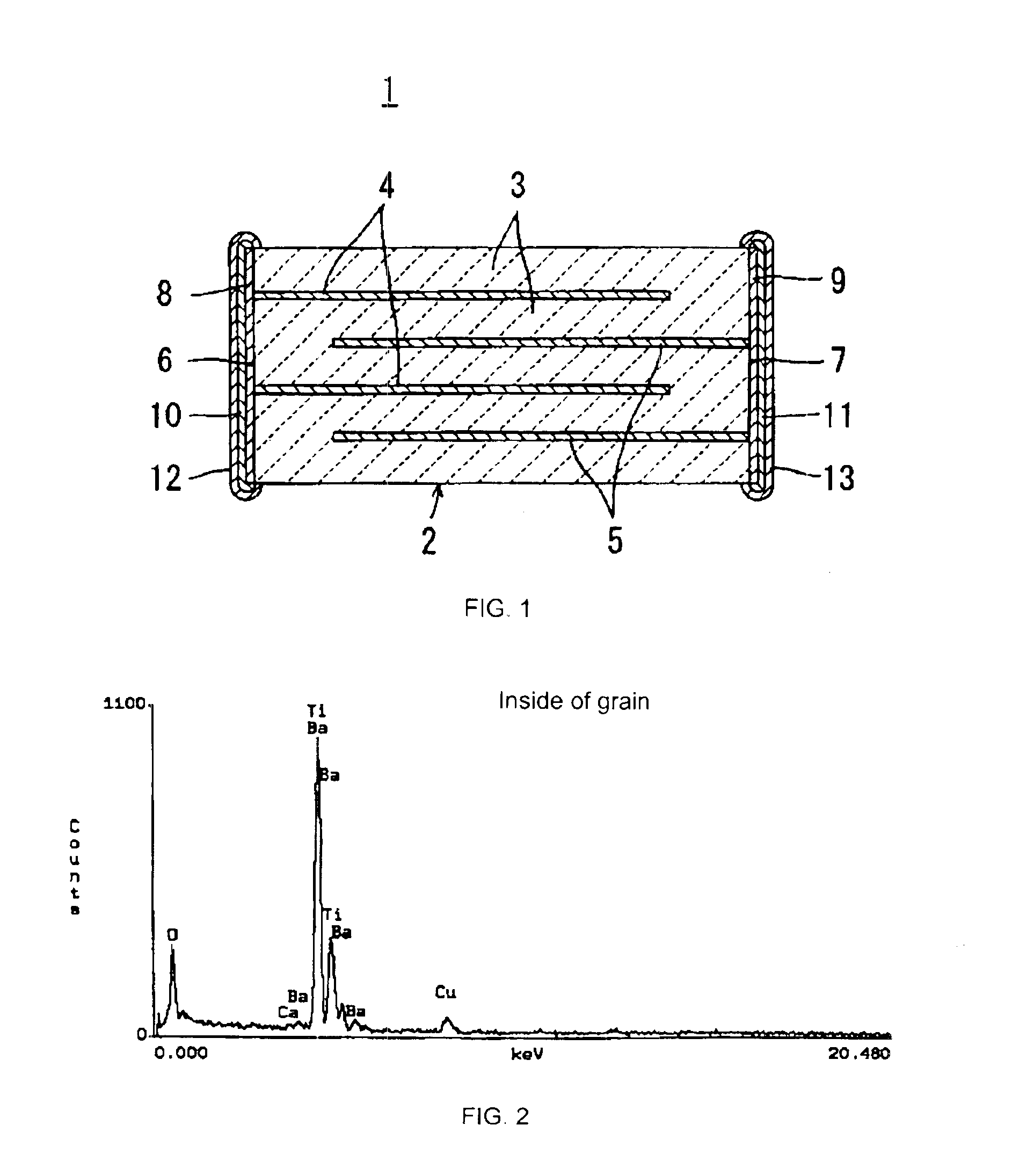

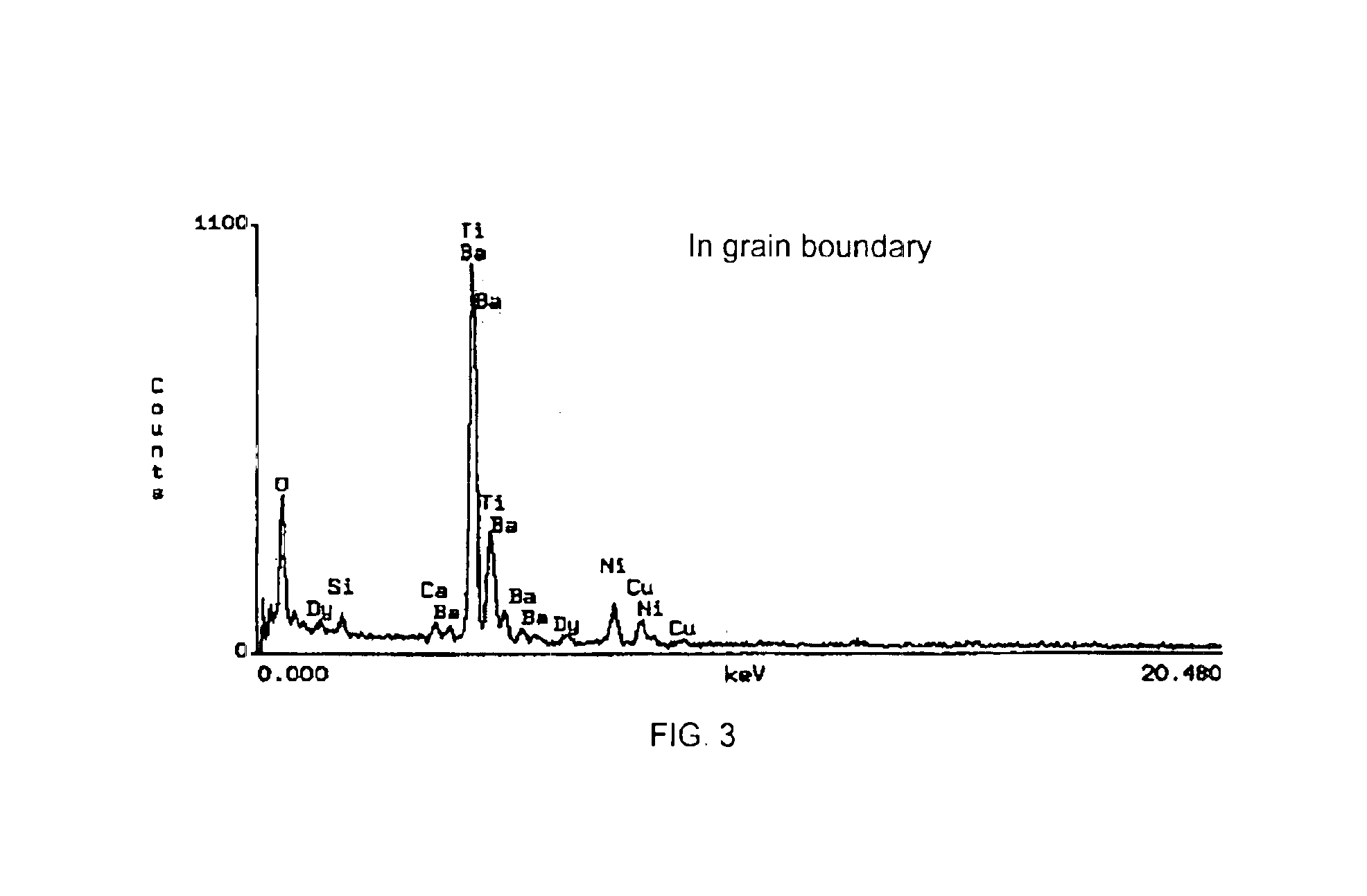

Dielectric ceramic, method of producing the same, and monolithic ceramic capacitor

ActiveUS6853536B2Improve reliabilityProduced easily and securelyFixed capacitor dielectricStacked capacitorsDielectric ceramicsCeramic capacitor

A dielectric ceramic includes, in composition, a perovskite-type compound having the general formula ABO3 containing Ba, Ca and Ti, and an additive component containing Si, R(La or the like), and M (Mn or the like), the additive component not being solid-dissolved and, moreover, the major component existing in at least 90% of the cross-section of each of the crystal grains of which the number is equal to at least 85% of that of all of the crystal grains contained in the dielectric ceramic, at least the Ba, the Ca, the Ti, the Si, the R, and the M being contained at at least 85% of the analytical points in the crystal grain boundaries of the dielectric ceramic.

Owner:MURATA MFG CO LTD

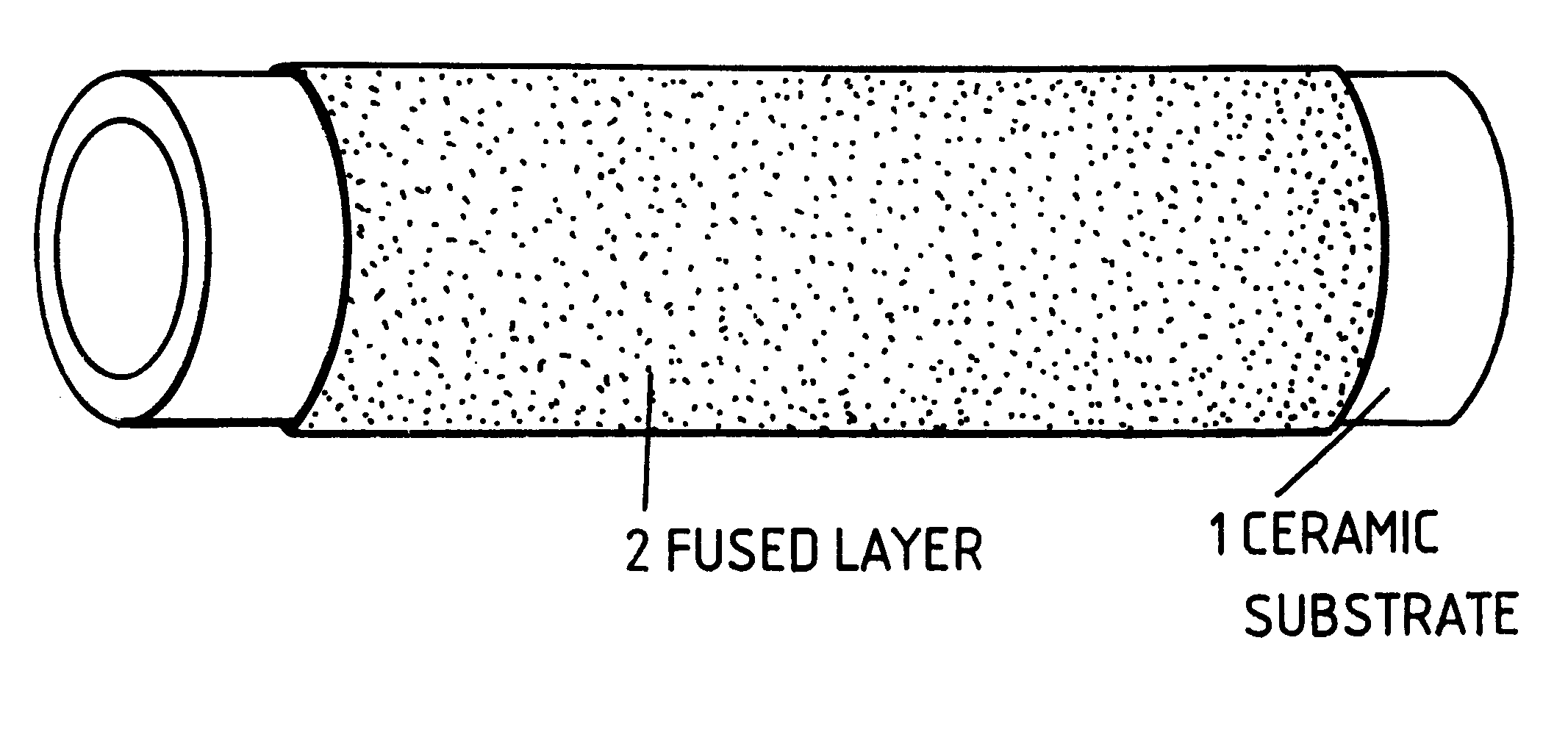

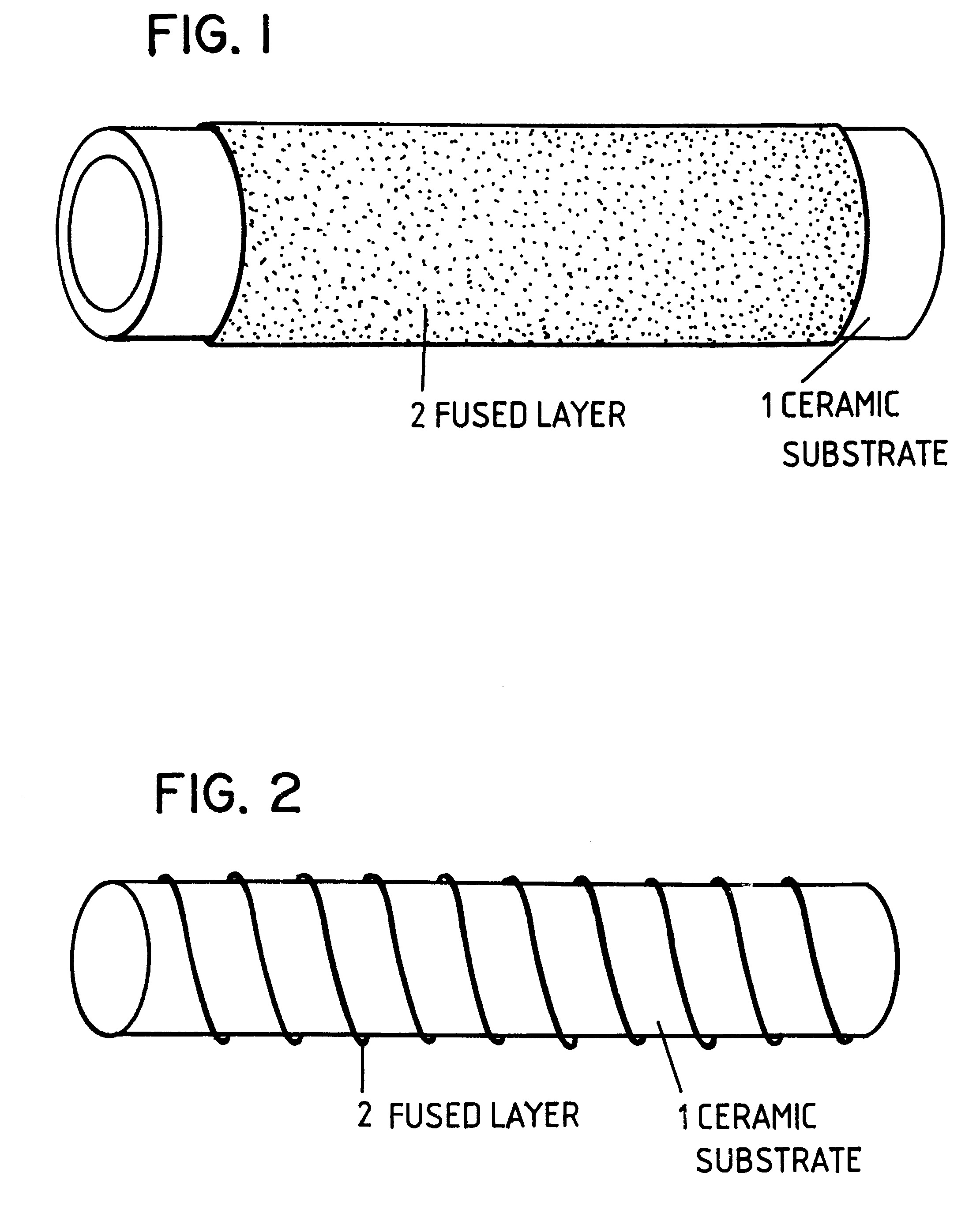

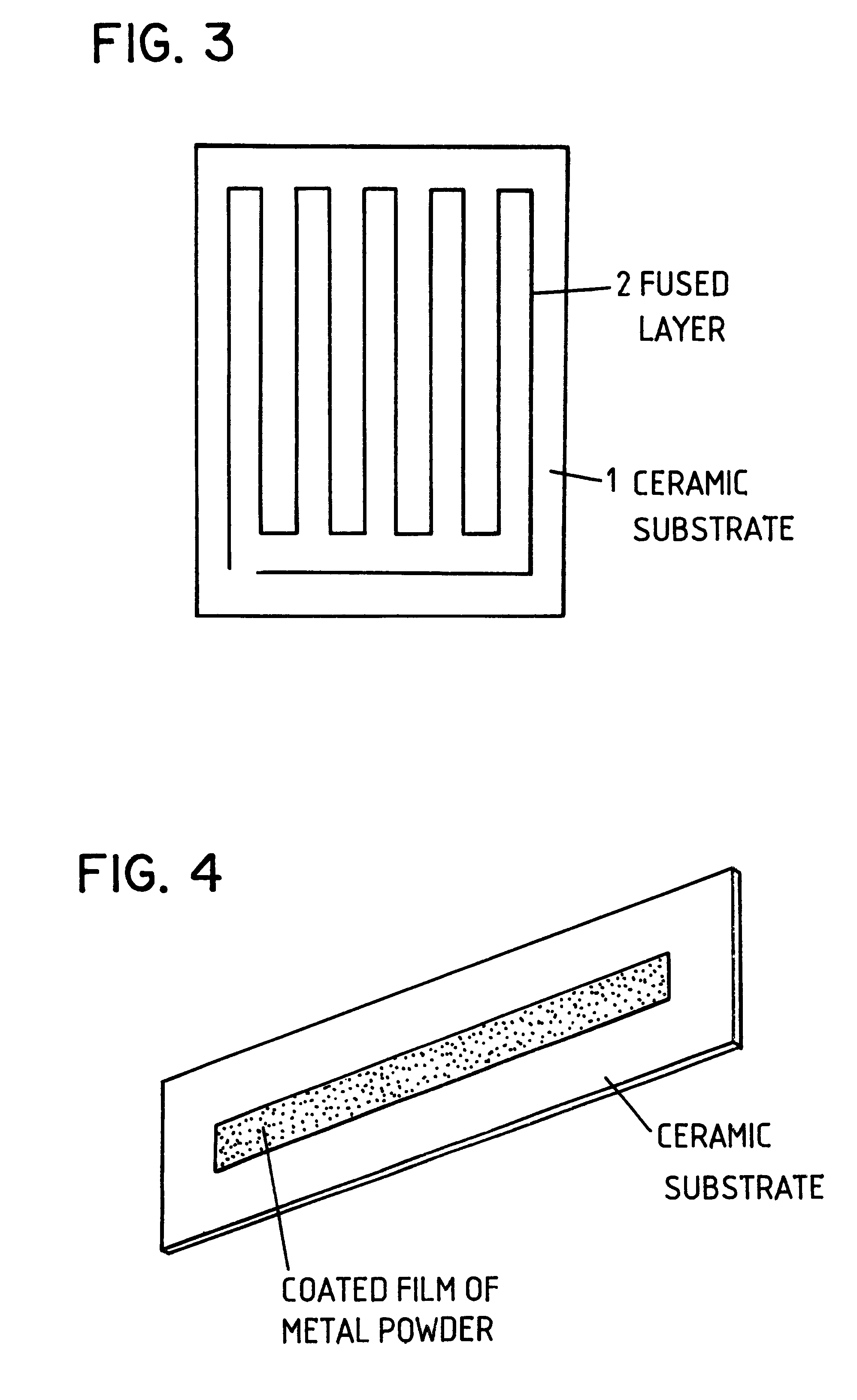

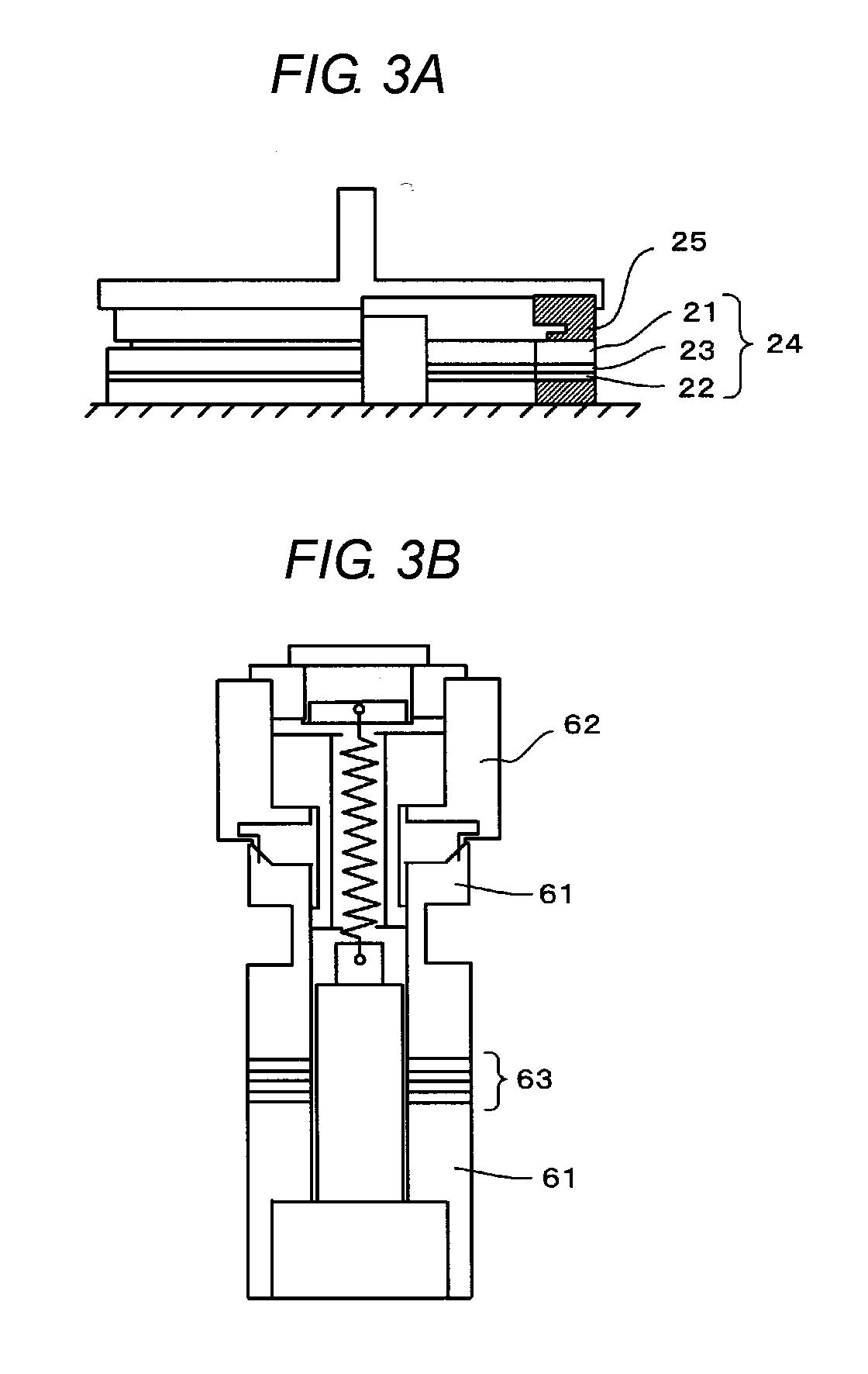

Method of manufacturing an electric heating element

InactiveUS6486447B2Hot plates heating arrangementsHeating element shapesThermal dilatationCeramic substrate

In order to eliminate the drawback of an electric heating element formed on an insulating ceramic substrate so that the element is brittle and becomes soft at a high temperature, an electrically heat-generating material film having a microstructure composed of a silicide alone, a mixture of silicide and Si, or Si alone is fused to the surface of a nitride or carbide ceramic insulating substrate.In order to provide an electrostatic chuck by which the temperature of an electrostatically chucked object to be treated, such as a semiconductor substrate, is quickly and precisely controlled, a heating mechanism is coupled with the bottom face of an electrostatically chucking mechanism provided with a dielectric ceramic and electrodes formed on the bottom face of the ceramic, and a cooling mechanism is coupled with the bottom face of the heating mechanism. The heating mechanism has a fusable electric-heating material film between two ceramic insulating substrates having the same or nearly the same coefficients of thermal expansion. The films is fused to the substrates.

Owner:TATEHO CHEM IND CO

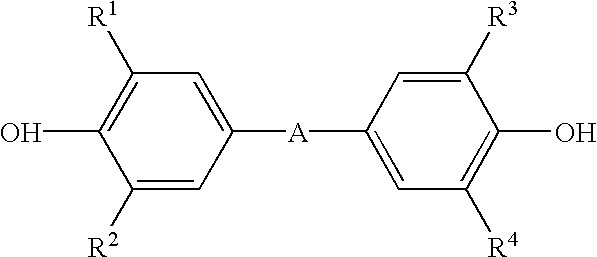

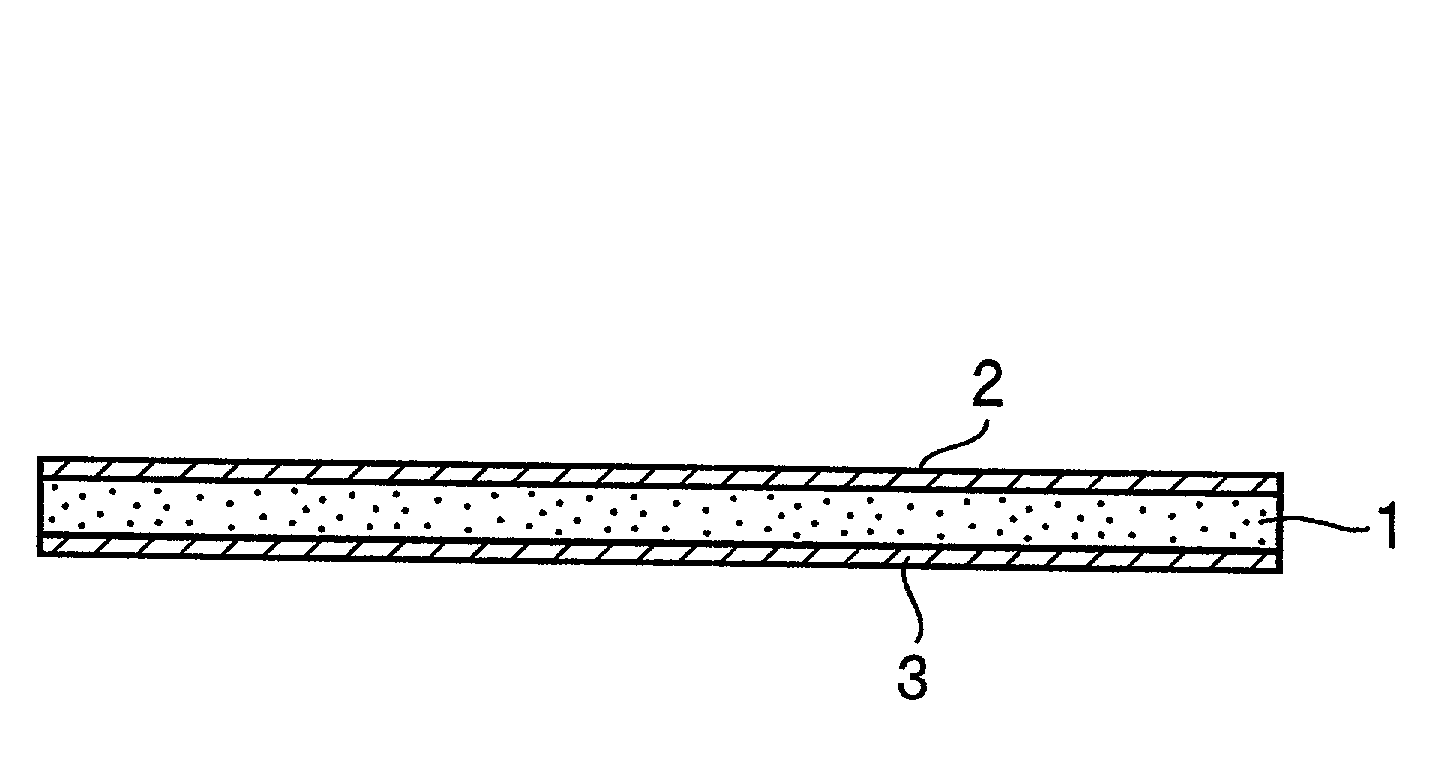

Thermosetting composite dielectric film and method of manufacturing same

InactiveUS20030017351A1Large capacityEasy to handlePlastic/resin/waxes insulatorsFixed capacitor dielectricEpoxyDielectric ceramics

A thermosetting composite dielectric film characterized in that the film has flexibility and is made of a thermosetting resin such as an epoxy resin having an epoxy equivalent of 150 to 2500 and containing dielectric ceramics having a high dielectric constant and in that the film has a dielectric constant of 25 or more.

Owner:NIPPON PAINT CO LTD

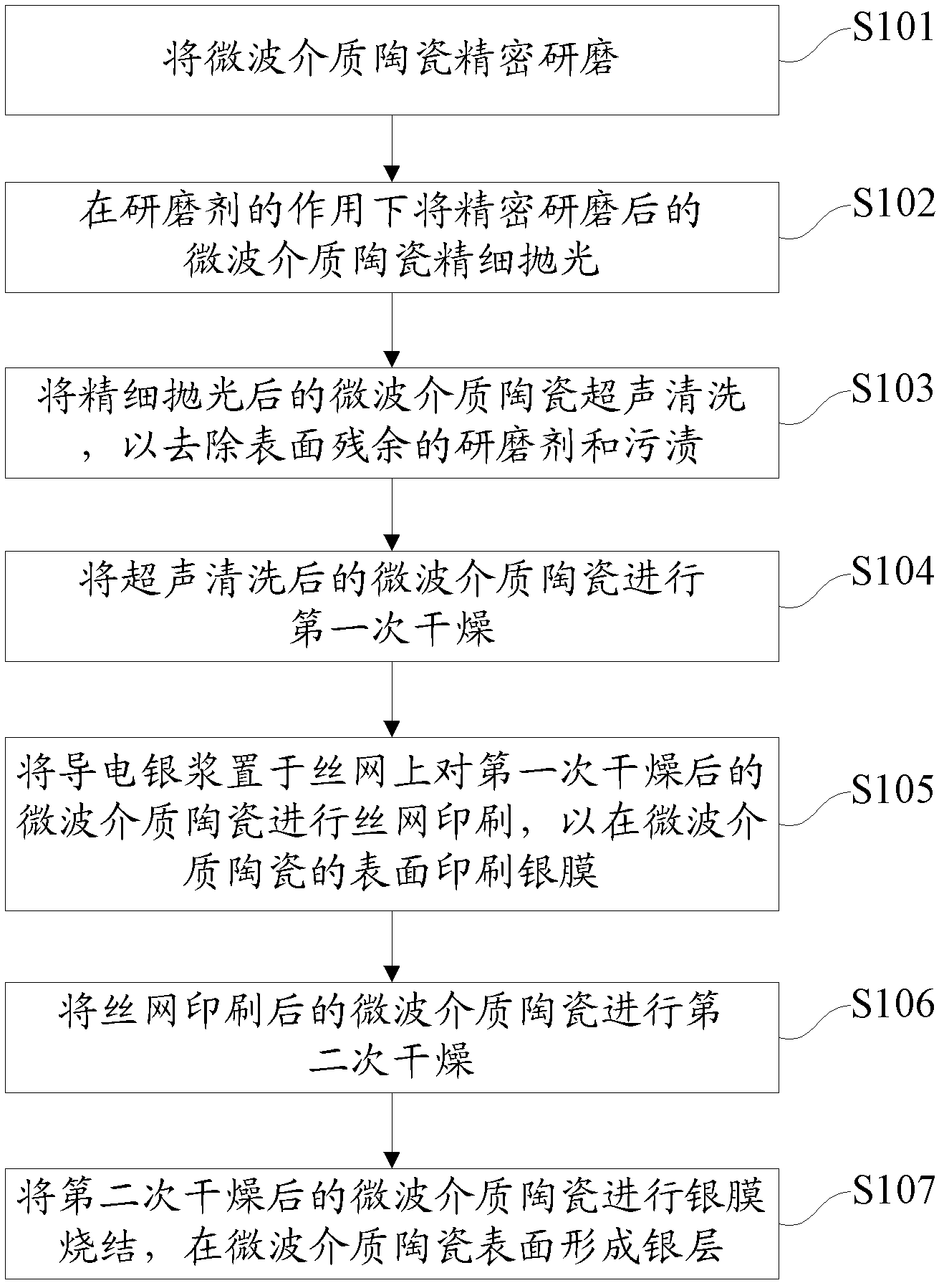

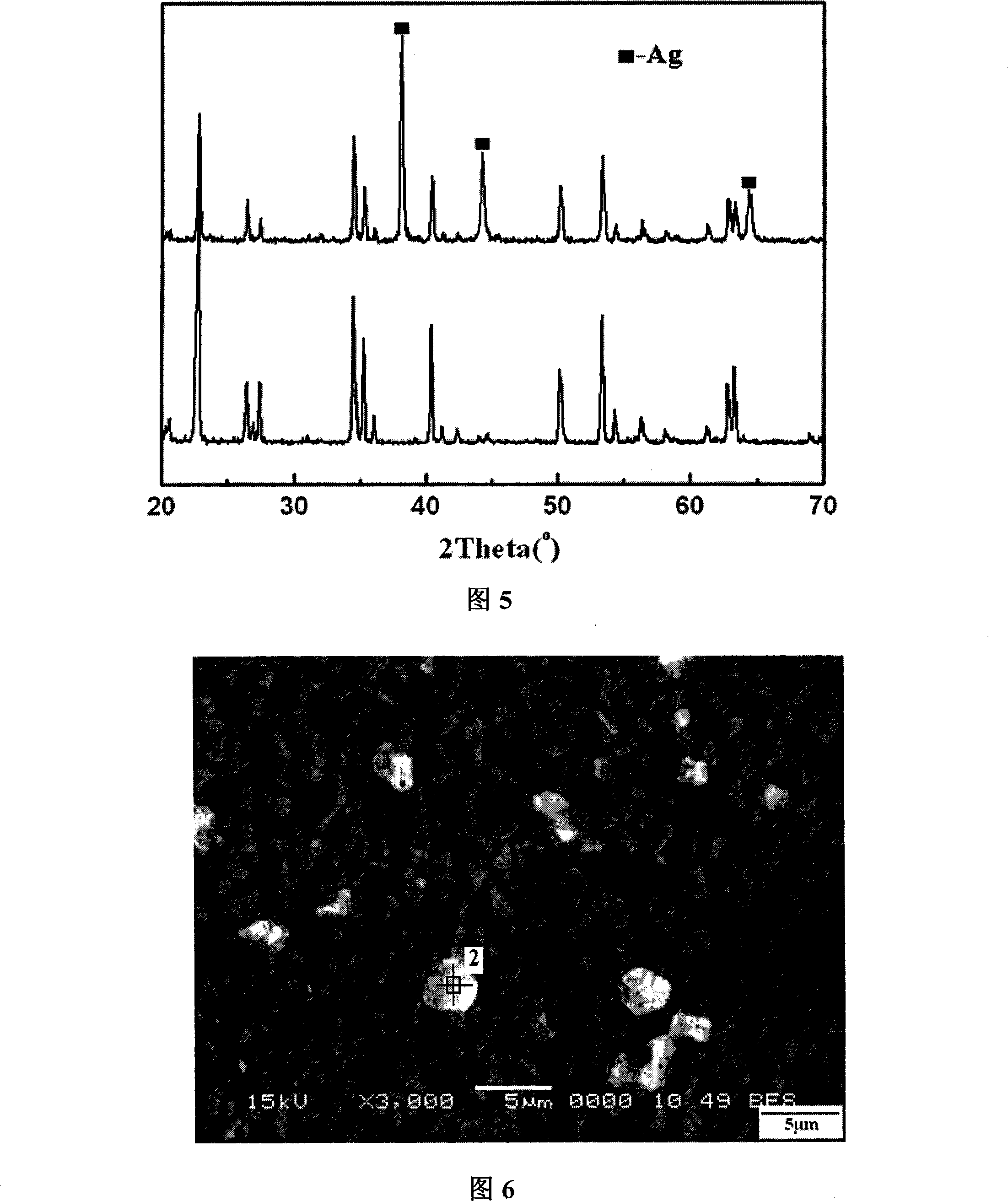

Conductive silver paste, method for preparing same and surface metallization method for microwave dielectric ceramics

ActiveCN102664055AImprove surface adhesionImprove efficiencyNon-conductive material with dispersed conductive materialCable/conductor manufactureScreen printingSilver paste

The invention discloses conductive silver paste and a method for preparing the same. The conductive silver paste comprises components including, by mass percent, from 70 to 80% of conductive silver powder, from 3 to 9% of glass powder and from 15 to 27% of an organic carrier. The invention further discloses a surface metallization method for microwave dielectric ceramics. The surface metallization method includes precisely grinding, precisely polishing, ultrasonically cleaning and primarily drying the microwave dielectric ceramics; carrying out screen printing by the aid of the conductive silver paste; carrying out secondary drying; sintering a silver skin and the like. The preparation of the conductive silver paste is optimized, the microwave dielectric ceramics are precisely ground and precisely polished before the conductive silver skin is printed, then the conductive silver skin is sintered to form a silver layer by means of controlling a sintering process, surface adhesion of the metallized silver layer on the surface of the microwave dielectric ceramics can be improved, and physiochemical property and production efficiency of a metallized electrode made of the microwave dielectric ceramics are enhanced.

Owner:ANHUI TATFOOK M&E TECH

Dielectric ceramic composition, multi-layer ceramic capacitor and manufacturing method thereof

ActiveUS7821770B2Increase resistanceFixed capacitor dielectricStacked capacitorsMischmetalRare earth

A multi-layer ceramic capacitor has a temperature characteristic satisfying an X8R property and has a high specific resistance under a high temperature circumstance, in which the dielectric ceramic composition forming the dielectric ceramics is expressed by a formula: BaTiO3+aMgO +bMOx+cReO3 / 2+dSiO2, wherein MgO represents MgO conversion, MOx represents oxide conversion for 1 atom in 1 molecule of at least one metal selected from V, Cr, and Mn, ReO3 / 2 represents oxide conversion for 1 atom in 1 molecule of at least one rare earth metal selected from Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Y, and SiO2 represents SiO2 conversion, and wherein 0.4≦a≦3.0 mol, 0.05≦b≦0.4 mol, 6.0≦c≦16.5 mol, 3.0≦d≦5.0 mol, 2.0≦c / d≦3.3, based on 100 mol of BaTiO3.

Owner:TAIYO YUDEN KK

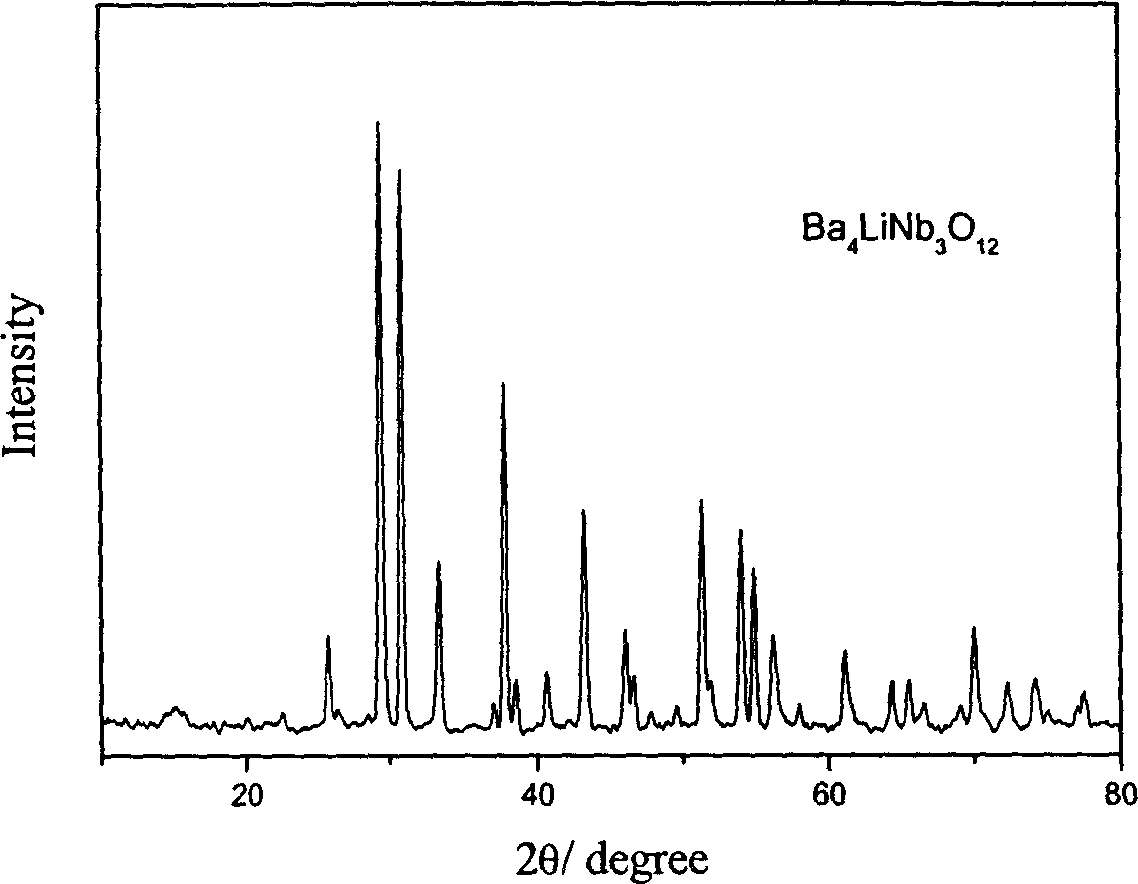

Low temp. sintering niobate microwave dielectric ceramic and preparation process thereof

The invention discloses a low temperature sintering niobate high frequency dielectric ceramic used in microwave component and ceramic capacitor or temperature compensating capacitor. The main phase of the ceramic is (Ba1-xSr x)4LiNb3-yTayO12, of which 0.00<=x<=1, 0.00<=y<=2. It is well sintering, low consumption, and high frequency dielectric constant could reach to 40-90.

Owner:WUHAN UNIV OF TECH

Dielectric ceramics, multilayer ceramic capacitor and method for manufacturing the same

The present invention provides a multilayer ceramic capacitor and a manufacturing method thereof. The average particle size of the crystal grains mainly composed of barium titanate is 0.2 μm or less, and the product of the lattice constants (a, b, c) obtained from the X-ray diffraction pattern of the crystal grains is expressed. If the volume V of each unit cell is set below 0.0643nm3, a dielectric ceramic with a high dielectric constant can be obtained. A multilayer ceramic capacitor includes a capacitor body formed by alternately laminating dielectric layers made of the dielectric ceramic and internal electrode layers, and external electrodes formed at both ends of the capacitor body.

Owner:KYOCERA CORP

Dielectric ceramic and monolithic ceramic capacitor

ActiveUS20090310279A1Good AC voltage characteristicStable capacitanceFixed capacitor dielectricStacked capacitorsDielectricRare-earth element

A dielectric ceramic represented by a general formula: 100BamTiO3+aROn+bMOv+cXOw (where R represents a rare earth element, M represents a predetermined metal element, and n, v, and w represent independently a positive number determined in accordance with the valences of the elements R and M and a sintering aid component X, respectively), and the solid solution regions of the secondary components in the main phase grains are 10% or less (including 0%) on average in terms of a cross-sectional area ratio. The sintering aid component X contains at least Si, and m, a, b, and c satisfy 0.995≦m≦1.030, 0.1≦a≦2.0, 0.1≦b≦3.0, and 0.1≦c≦5.0. In a monolithic ceramic capacitor, dielectric layers are formed from the above-described dielectric ceramic. Consequently, a dielectric ceramic having a good AC voltage characteristic, maintaining a desired large dielectric constant and a good temperature characteristic, exhibiting a small dielectric loss, and being capable of ensuring the reliability and a monolithic ceramic capacitor including the dielectric ceramic are realized.

Owner:MURATA MFG CO LTD

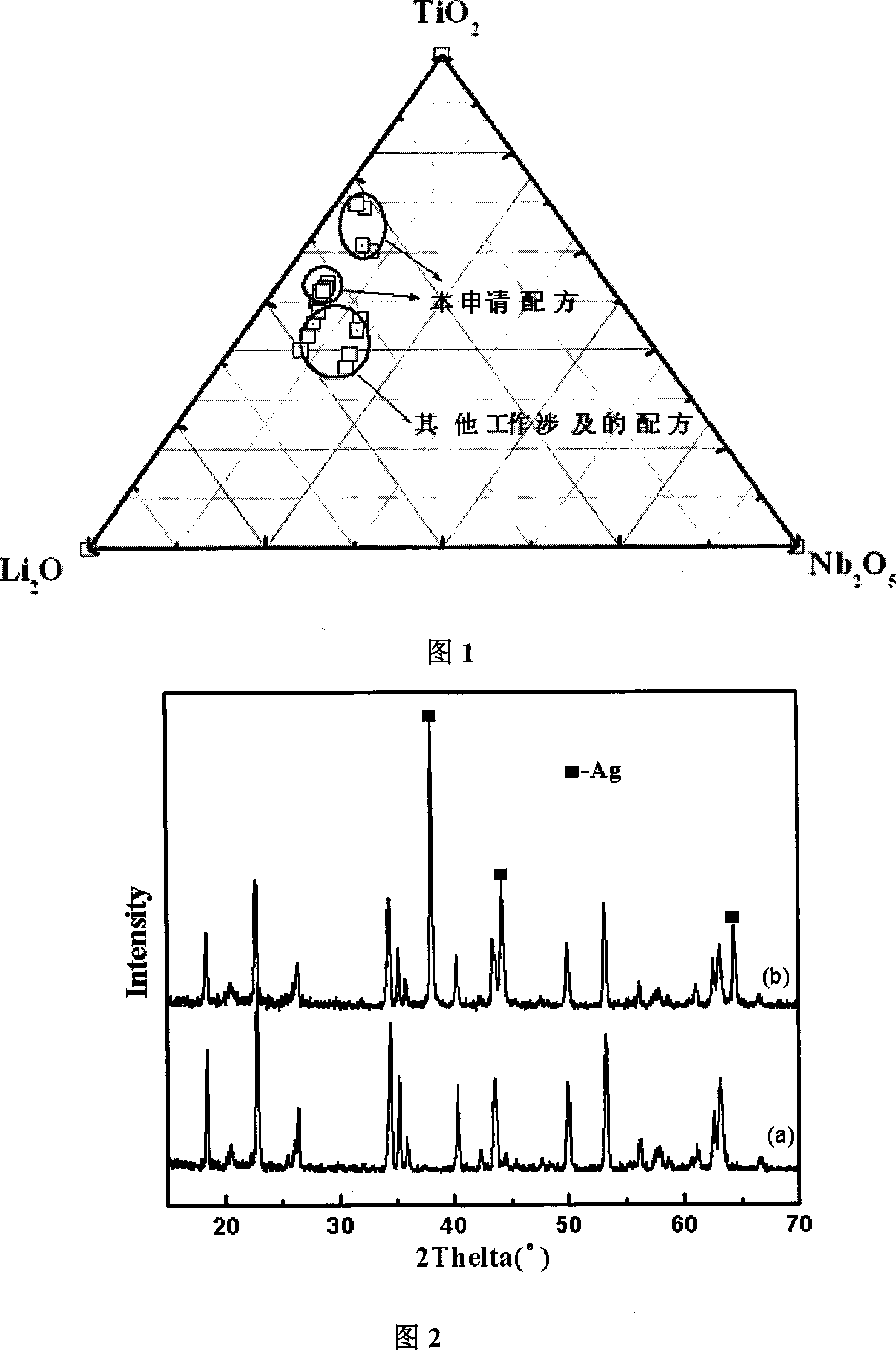

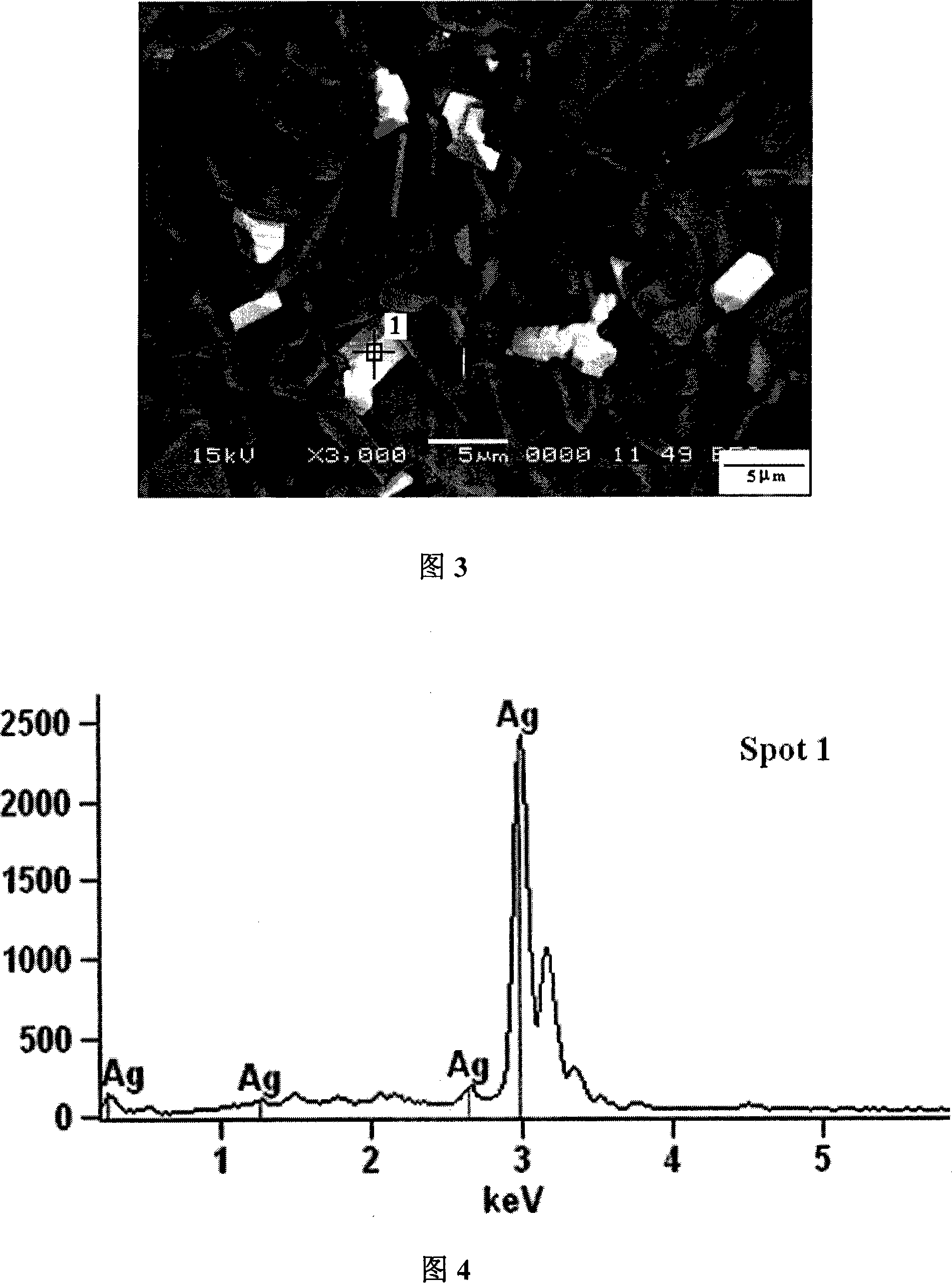

Low-temperature sintered LTCC microwave dielectric ceramics material and preparation method thereof

InactiveCN101224977AImprove performanceInherently low sintering temperatureDielectric ceramicsCo-fired ceramic

The invention discloses a low temperature co-fired ceramic LTCC microwave dielectric ceramic MWCD material, which is prepared by Li2CO3, Nb2O5 and TiO2 by the moral ratio that Li2CO5:Nb2O5:TiO2 = x:1:y, wherein, x is more than 5.5 and less than or equal to 6, y is more than 7 and is less than or equal to 7.5; the expression of structure for the made up modular is Li1+m-nNb1-m-3nTim+4nO3, wherein m is more than or equal to 0.1 and is less than or equal to 0.15, n is more than or equal to 0.2 and less than or equal to 0.25. The LTCC MWCD prepared by the invention has low sintering temperature (approx. 1,100 DEG C) and excellent microwave performance: the dielectric constant (Epsilon r) is that x is more than 32 and less than or equal to 52, Q multiplied by f value is high and Tf is small; the sintering temperature can be decreased to 900 DEG C and the microwave dielectric property can be maintained for excellence without any reaction to a Ag by adding a plurality of low melting point oxides. The pure silver can be taken as a electrode for sintering which can greatly reduce manufacturing cost for the components and applied in manufacturing of the microwave components such as a low temperature co-fired ceramic LTCC system, a multi-layer media resonator, a microwave antenna and a wave filter etc.

Owner:XI AN JIAOTONG UNIV

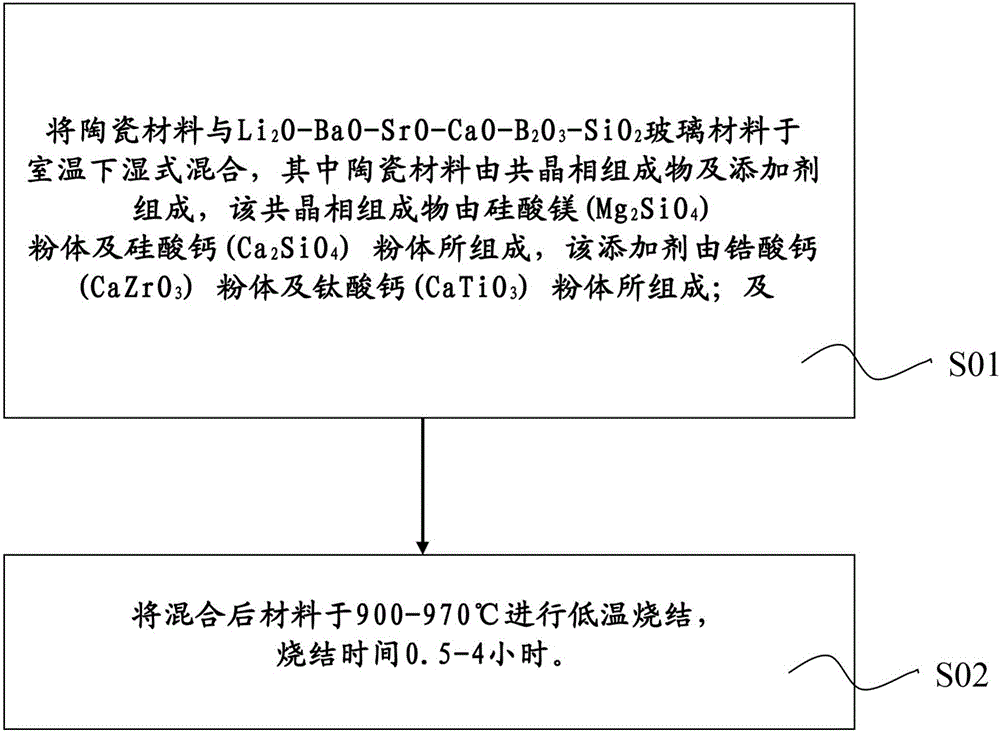

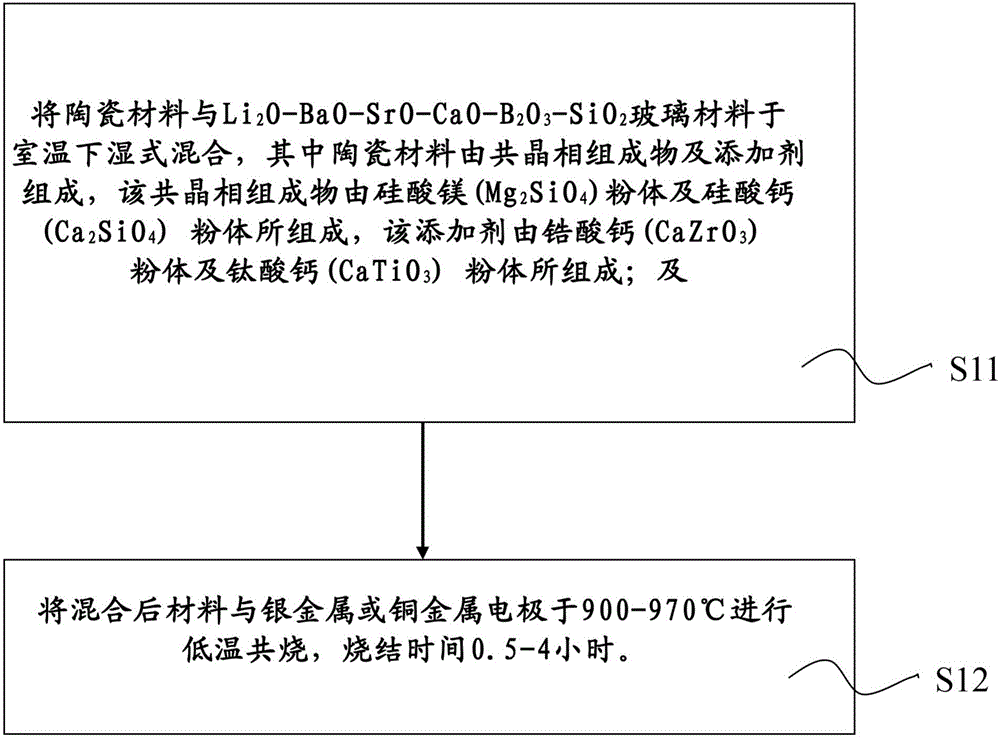

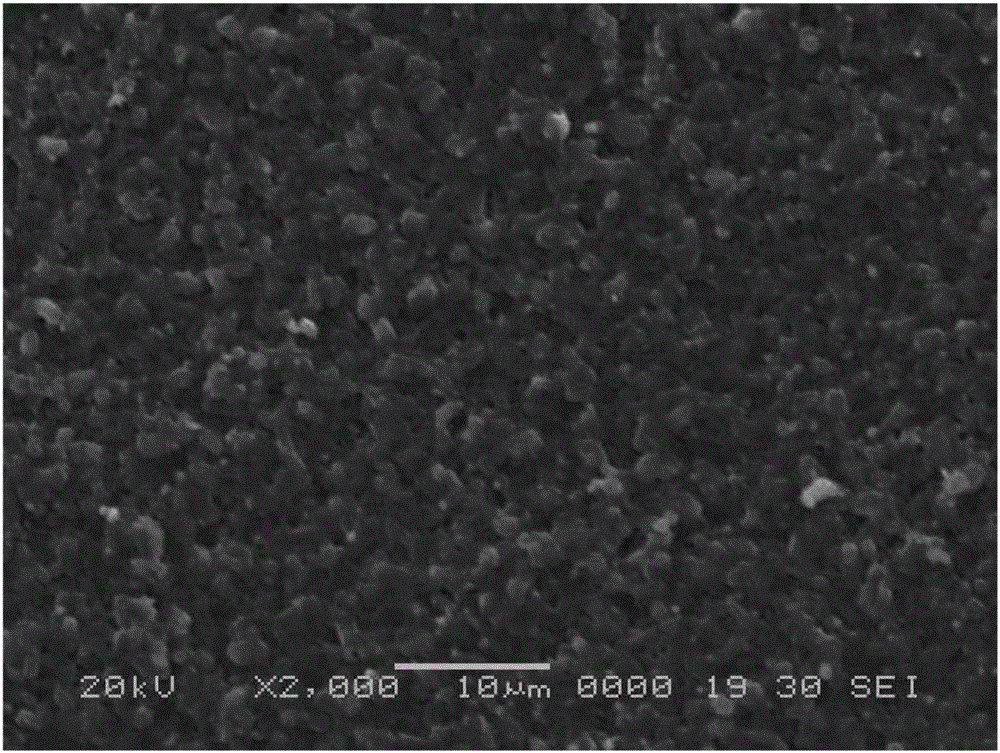

Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material which can be cofired with a silver or copper electrode at a low temperature and a preparation method thereof. The microwave dielectric ceramic material is prepared from a microwave dielectric ceramic material 1-y-z[(1-x)Mg2SiO4-xCa2SiO4]-yCaTiO3-zCaZrO3, and mixed with a multicomponent glass material Li2O-BaO-SrO-CaO-B2O3-SiO2, wherein x is more than or equal to 0.2 and is less than or equal to 0.7, y is more than or equal to 0.05 and is less than or equal to 0.3, and z is more than or equal to 0.02 and is less than or equal to 0.15. The low-temperature co-fired microwave dielectric ceramic material can be co-fired with silver or copper and other conductive metals at 900-970 DEG C at an atmosphere and inert gas environment. The material has excellent characteristics of low dielectric consumption, high quality factor, low temperature capacitance and the like, and is applicable to multilayer ceramic component manufacture procedure and processing after being fired.

Owner:WALSIN TECHNOLOGY CORPORATION

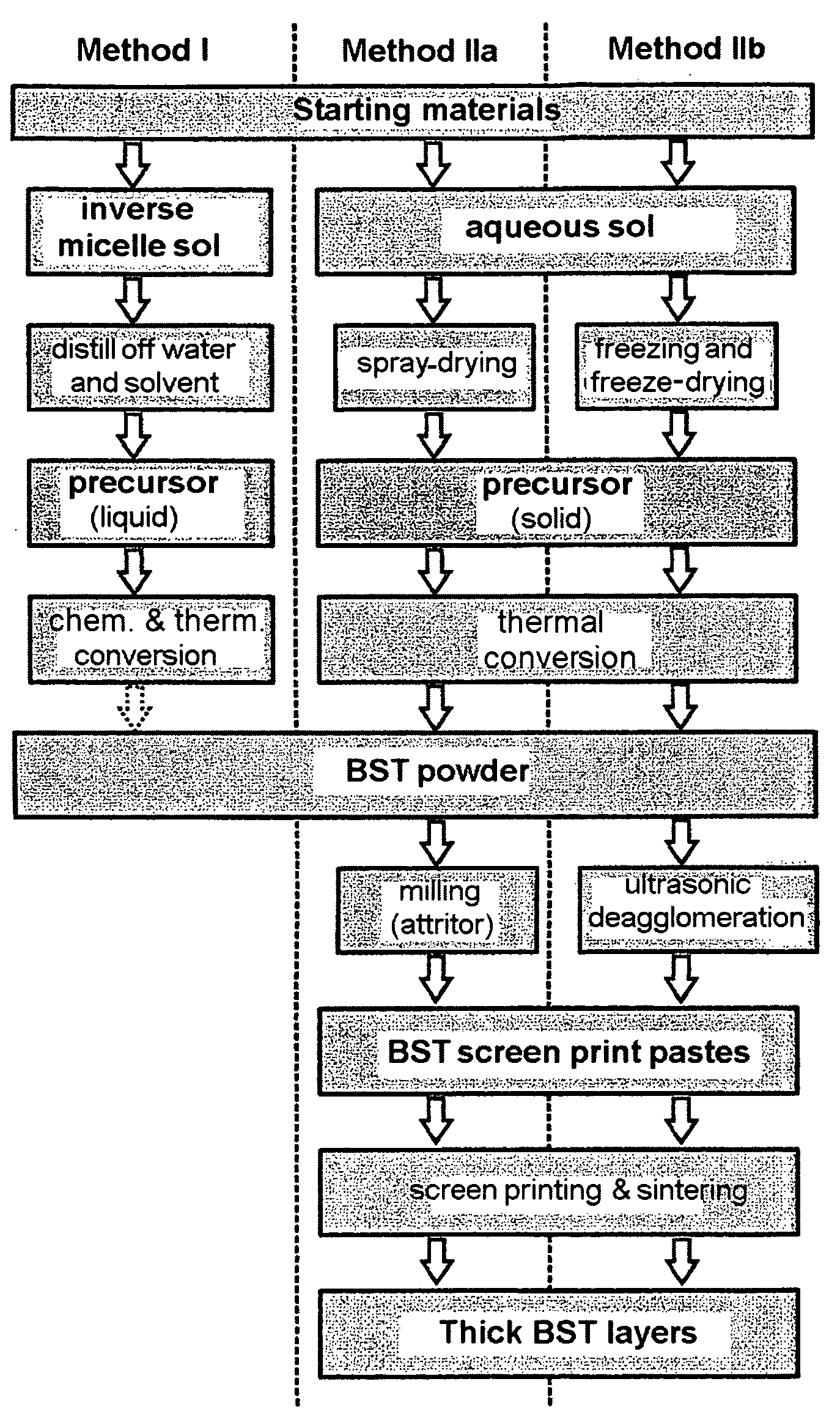

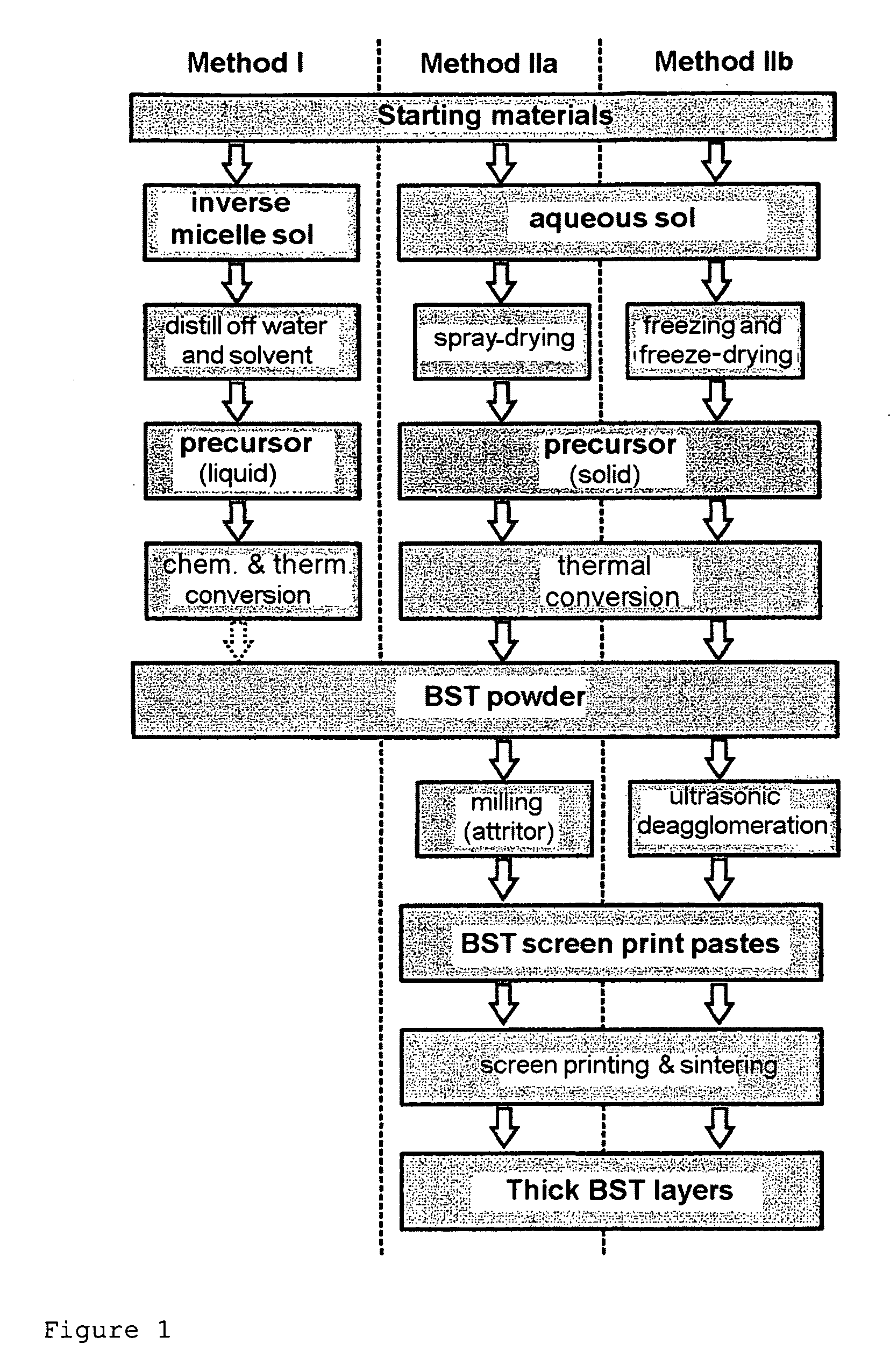

Ceramic dielectric or thin and/or thick layers containing at least one ceramic dielectric method for production and use thereof

InactiveUS20090297804A1Improve efficiencyAlkaline earth titanatesVacuum evaporation coatingDielectric ceramics

The present invention relates to dielectric ceramics, thin and / or thick layers produced therefrom and a method for the production thereof and the use of the dielectrics and of the thin and / or thick layers.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

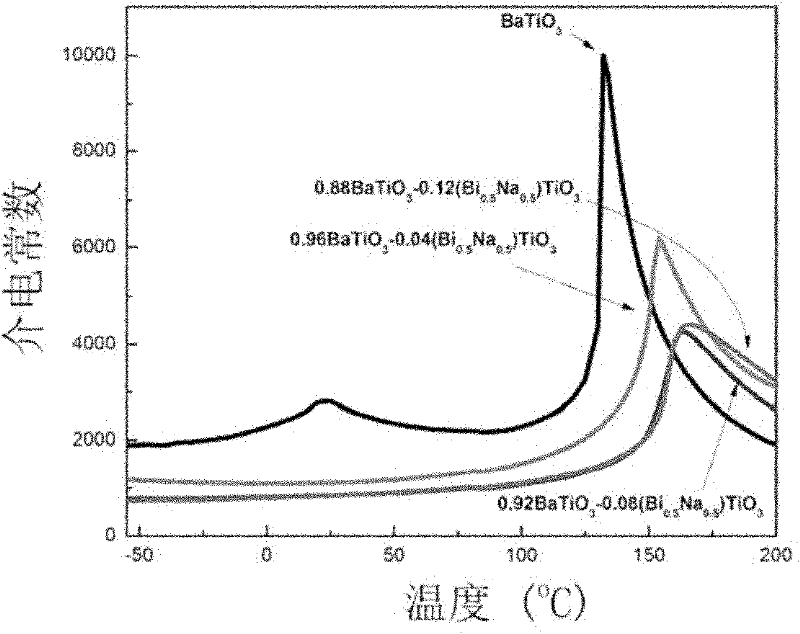

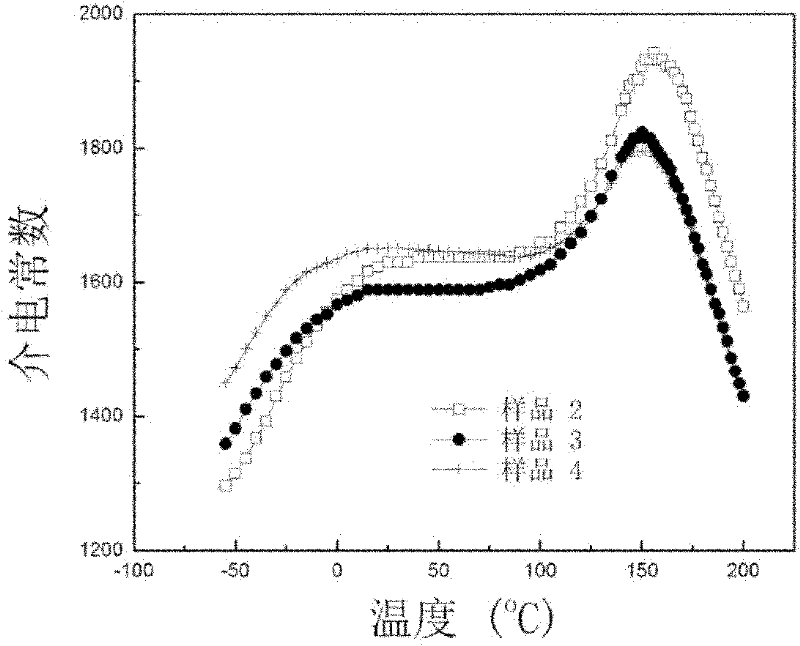

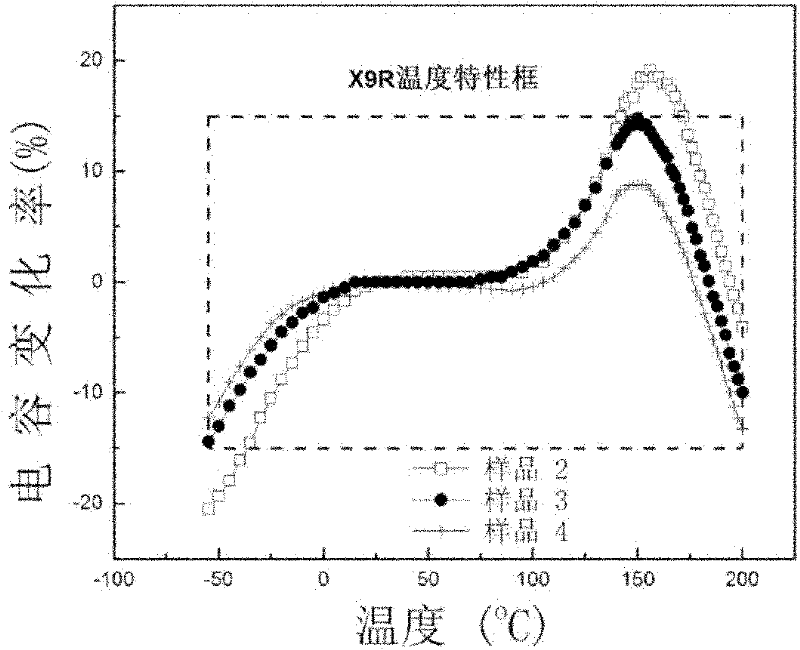

X9R ceramic capacitor dielectric material and preparation method thereof

ActiveCN102199035AImprove temperature stabilityRaise the Curie transition temperatureBarium titanatePotassium

The invention discloses an X9R ceramic capacitor dielectric material and a preparation method thereof. The material comprises 95 to 98 molar percent of barium titanate-sodium bismuth titanate complex or barium titanate-potassium bismuth titanate complex serving as a main component, and 2 to 5 molar percent of secondary additive consisting of at least one of Nb2O5, CaZrO3 and SrZrO3. According to the preparation method of the invention, the dielectric ceramic material with high property can be obtained, meeting the electronic industries association (EIA) X9R standard; the process is simple, and intermediate temperature sintering can be performed; and the material has the room temperature dielectric constant of 1,500 to 1,700, the room temperature loss of about 2 percent, the room temperature resistivity of more than or equal to 1,013omega.cm, the breakdown voltage of more than or equal to 5kV / mm, and a good industrial prospect.

Owner:TSINGHUA UNIV

Dielectric ceramics, and laminated ceramic capacitor

ActiveUS20100165541A1Improve voltage characteristicsImproved AC voltage characteristicFixed capacitor electrodesFixed capacitor dielectricRare-earth elementCeramic capacitor

A dielectric ceramic contains a BaTiO3-based compound as a main ingredient, and can be represented by the general formula: 100AmBO3+aNiO+bROn+cMOv+dMgO+eXOw where R represents a rare earth element such as Dy, M represents a metal element such as Mn, and X represents a sintering aid component containing Si. Ni is uniformly solid-solved in crystal grains, and the solid-solution region of the rare earth element in the crystal grains is an average 10% or less in terms of a cross section ratio. 0.96≦m≦1.030, 0.05≦a≦3, 0.1≦b≦1.5, 0.1≦c≦1.0, 0.1≦d≦1.5, and 0.05≦e≦3.5 are satisfied. A laminated ceramic capacitor has dielectric layers formed of the dielectric ceramic. As a result, a dielectric ceramic, and a laminated ceramic capacitor having excellent AC voltage characteristics, capable of keeping desired dielectric characteristics and excellent temperature characteristics, and having excellent withstand voltage and capable of ensuring reliability can be realized.

Owner:MURATA MFG CO LTD

Dielectric ceramics, multilayer ceramic capacitor and method for manufacturing the same

ActiveUS20060087796A1High dielectric constantStable temperature characteristicsFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

Crystal grains mainly composed of barium titanate have a mean grain size of not more than 0.2 μm. The volume per unit cell V that is represented by a product of lattice constant (a, b, c) figured out from the X-ray diffraction pattern of the crystal grains is not more than 0.0643 nm3. Thereby, a dielectric ceramics having high relative dielectric constant can be obtained. A multilayer ceramic capacitor comprises a capacitor body and an external electrode that is formed at both ends of the capacitor body. The capacitor body comprises dielectric layers composed of the dielectric ceramics, and internal electrode layers. The dielectric layers and the internal electrode layers are alternately laminated.

Owner:KYOCERA CORP

Dielectric ceramic, method for making the same, and monolithic ceramic capacitor

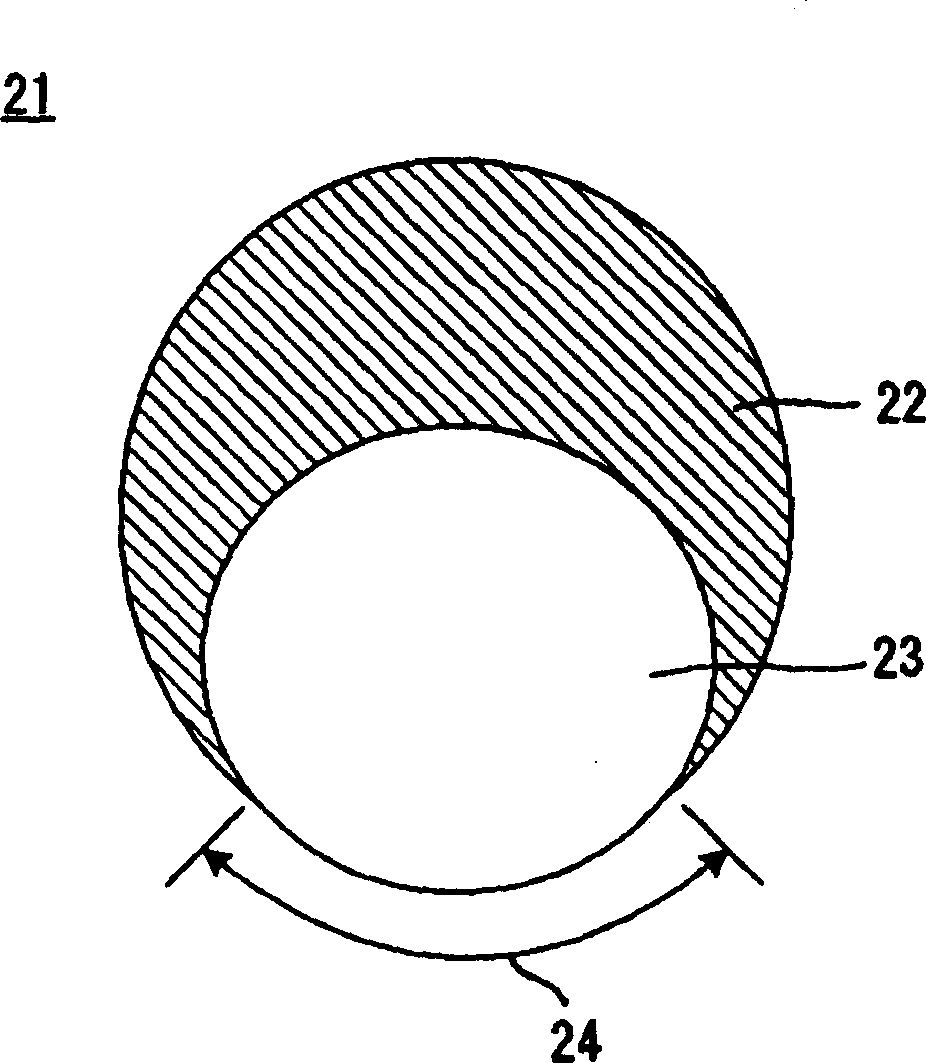

The purpose of the present invention is to provide a dielectric ceramics, which is suitable for forming the dielectric ceramics of the dielectric ceramic layer in the laminated ceramic capacitor obtained after it is sintered in the reduction ambient. In addition, even the dielectric ceramic layer is thinned; temperature dependence of dielectric constant is not worsened and the reliability is excellent for the thinned layer. The invented dielectric ceramics is mainly composed of ABO3 (A is Ba and so on; and B is Ti and so on) and contains rare earth elements. In the aspect of the chip 21 where the ceramics composition is more than 70%, when viewing its cross-section, 5 to 70% cross-section area is occupied by the solid-melting region made of rare earth elements; and 10 to 80% periphery of the cross-section is occupied by the non-solid-melting region made of rare earth elements.

Owner:MURATA MFG CO LTD

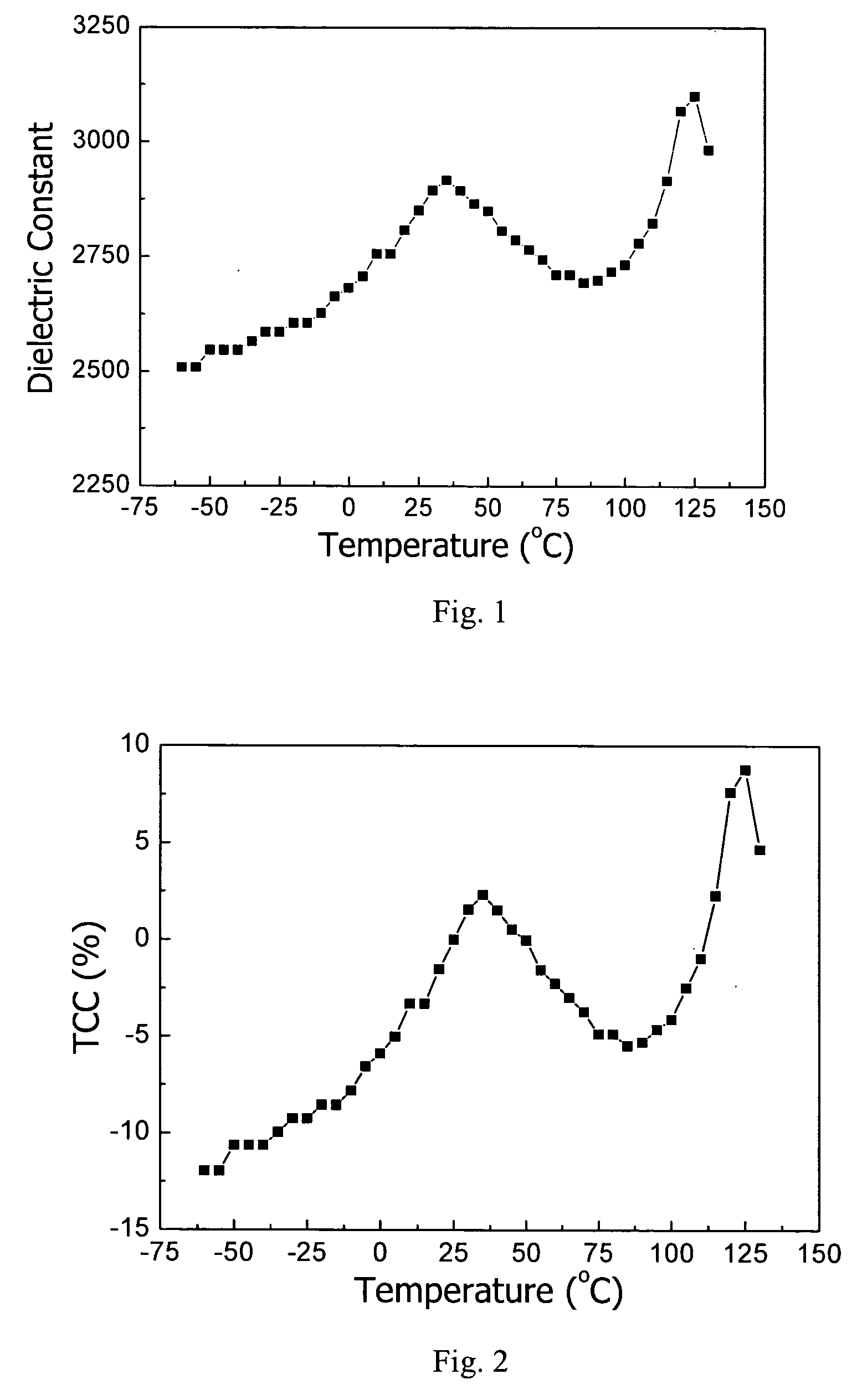

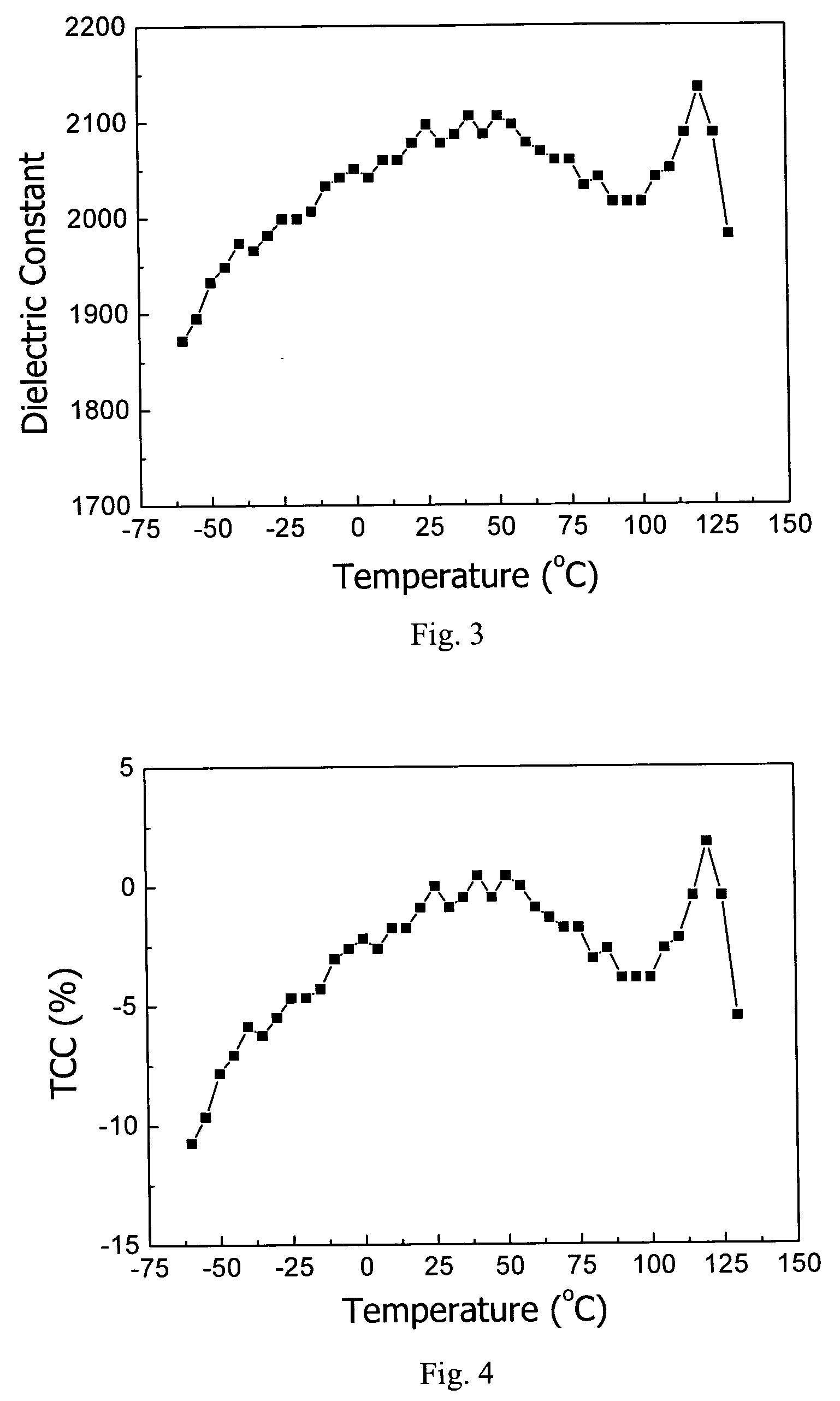

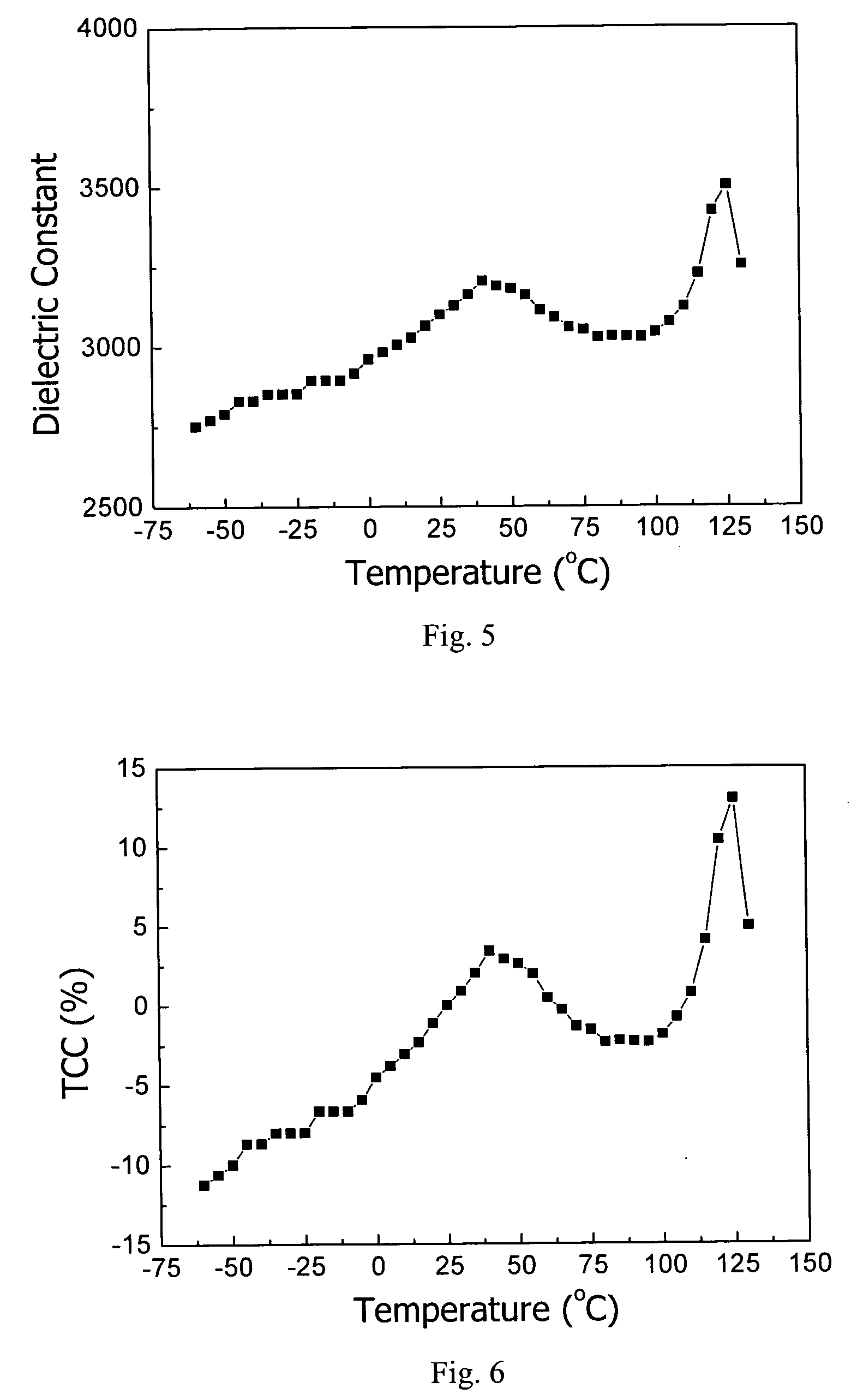

Temperature-stable dielectric ceramic composition for multilayer ceramic capacitors with base-metal electrodes

ActiveUS20040138050A1High insulation resistanceFixed capacitor dielectricCeramicsCapacitanceBarium titanate

The present invention relates to a temperature-stable dielectric ceramic composition for multilayer ceramic capacitors. The said dielectric composition comprises barium titanate and additives, wherein the barium titanate ranges from 94 to 99 mol % of the said composition, and the additives range from 1 to 6 mol % of the said composition. The additives comprise oxides of Mg, Ca, Ba, Si and Mn, and oxides of one or more elements selected from the group consisting of Co, Sr, Ti and Fe, and an oxide of Re, or carbonates, hydroxide, oxalates, acetates or nitrates of the above elements. Re represents one or more elements selected from Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu. After being sintered at 1200° C. to 1350° C. under reducing atmosphere, the room-temperature dielectric constant of the composition is 2000 to 3500 and its temperature coefficient of capacitance satisfies X7R characteristic (EIA standards). The composition is useful as material for multilayer ceramic capacitor with ultra-thin dielectric layer (thickness less than 10 mum).

Owner:TSINGHUA UNIV

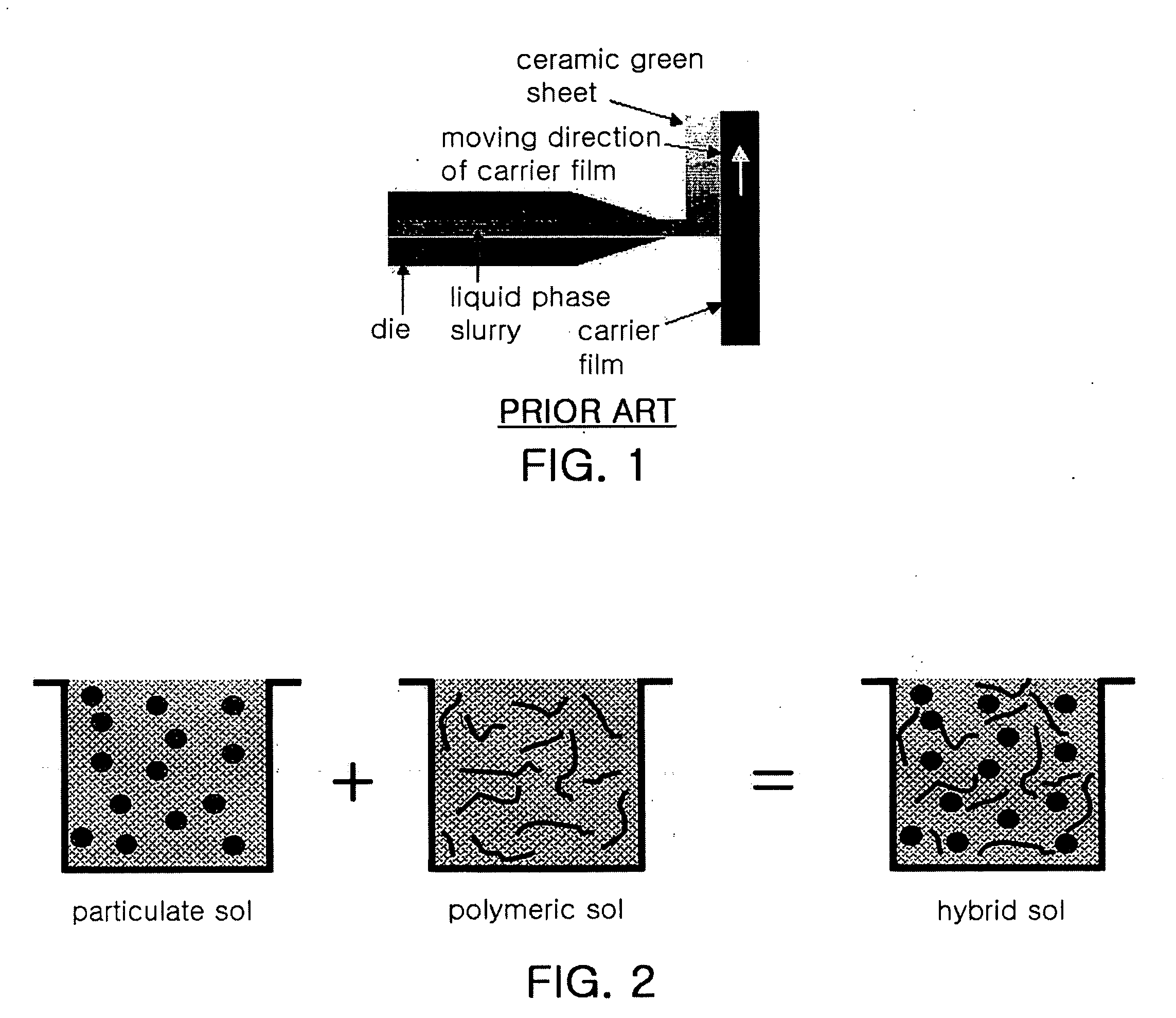

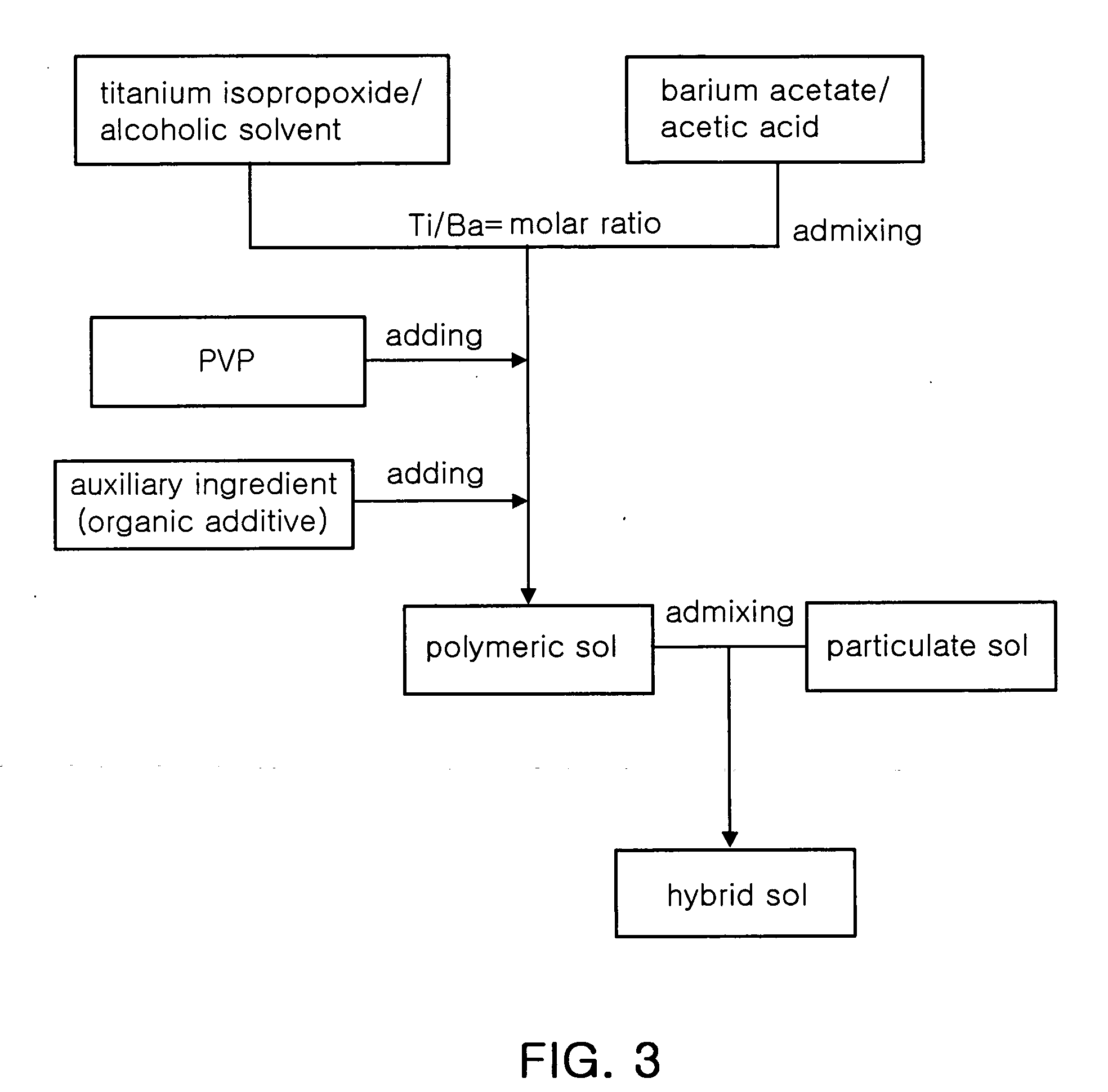

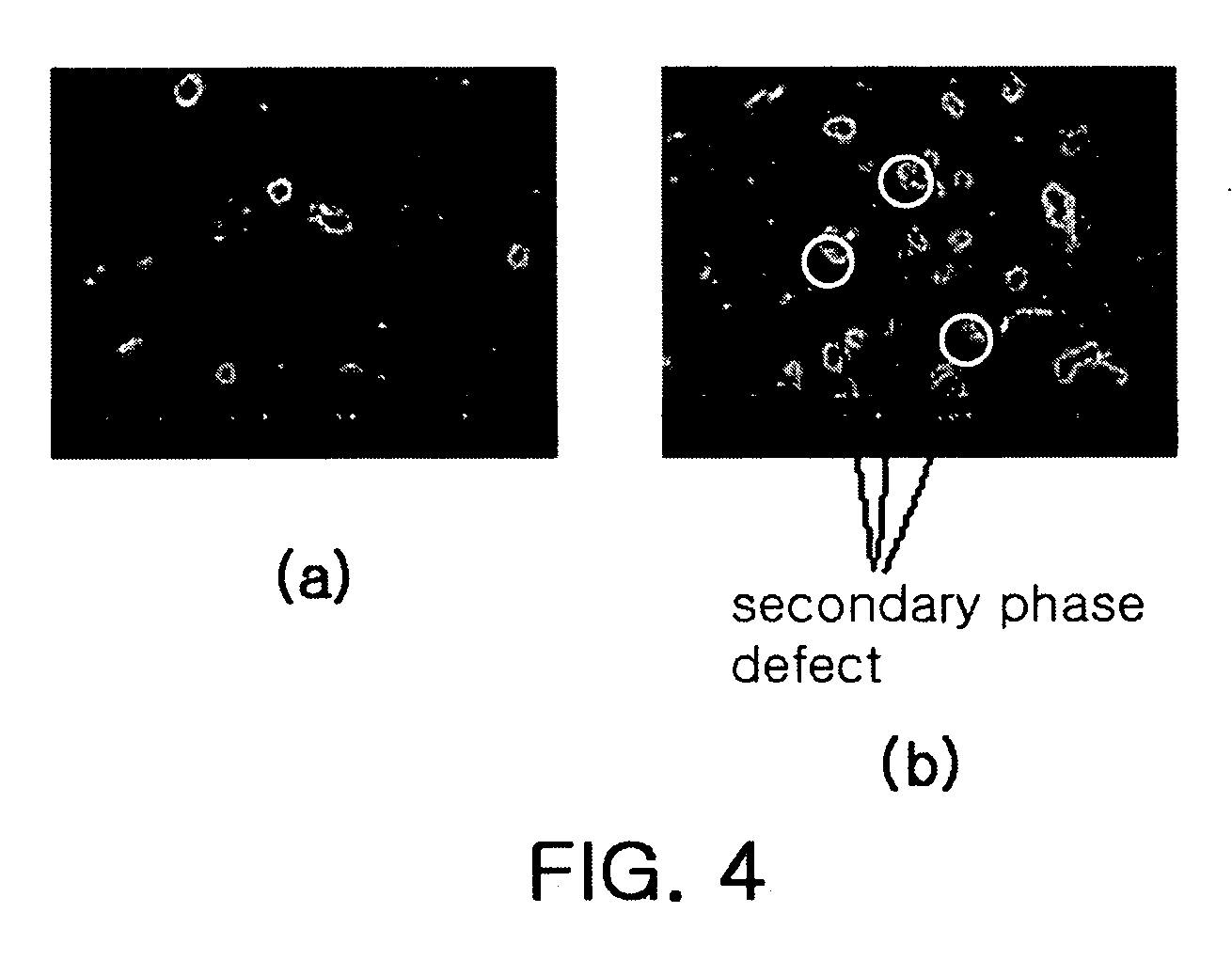

Sol composition for dielectric ceramic, and dielectric ceramic and multilayered ceramic capacitor using the same

InactiveUS20060121258A1Simple technologyCeramicsCeramic layered productsOrganic solventAdditive ingredient

Disclosed herein is a sol composition for ultrathin dielectric ceramic films, and dielectric ceramic and a multilayered ceramic capacitor manufactured using the same. The sol composition, composed of BaTiO3 as a main ingredient and an auxiliary ingredient, includes a polymeric sol having a metal precursor solution of BaTiO3 and an organic solvent, and an organic additive dissolved in the organic solvent to act as the auxiliary ingredient, in which the amount of the organic additive corresponds to the required amount of the auxiliary ingredient of the dielectric ceramic. Further, the ultrathin dielectric ceramic film, which is manufactured by a sol-gel process, includes the auxiliary ingredient, and hence, is advantageous in making low temperature sintering possible, and having a high dielectric constant, a high sintered density, and TCC characteristic meeting the X5R of EIA standard.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

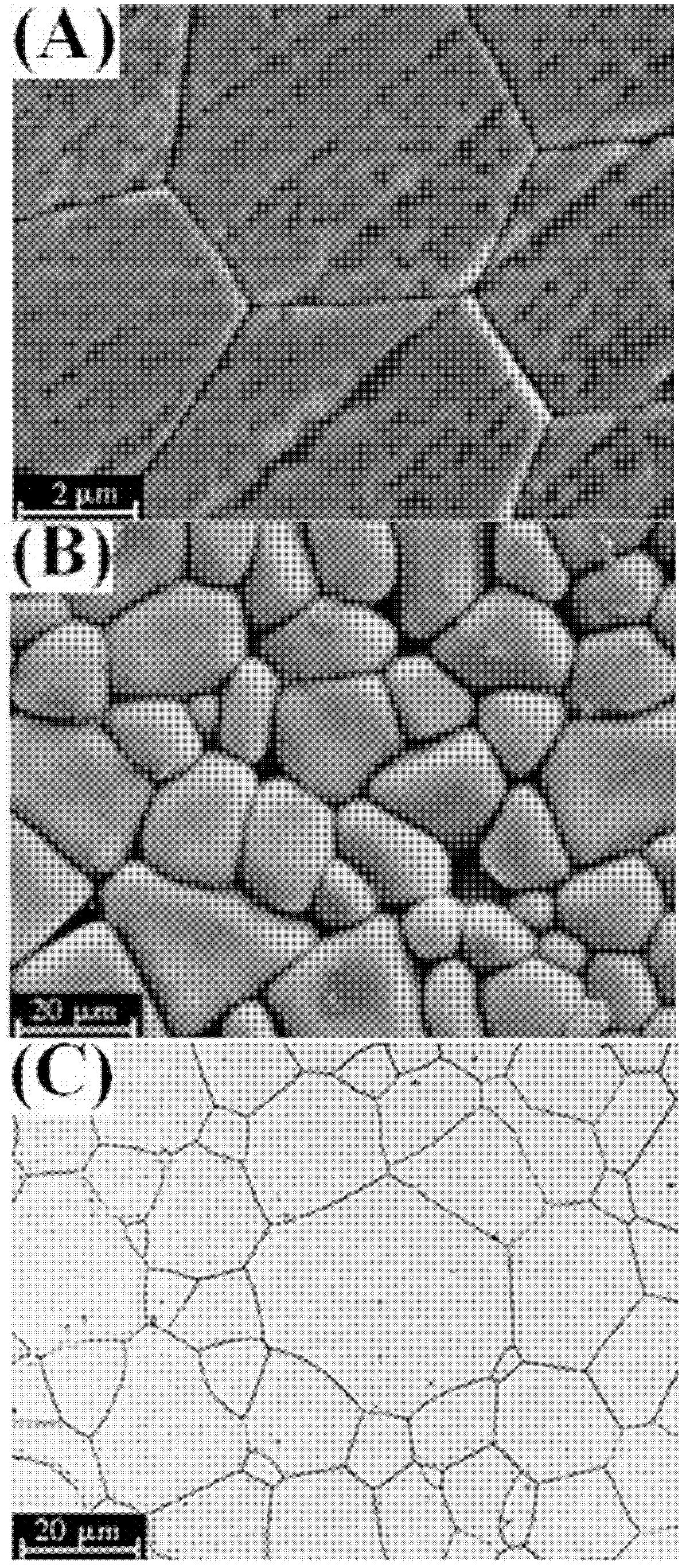

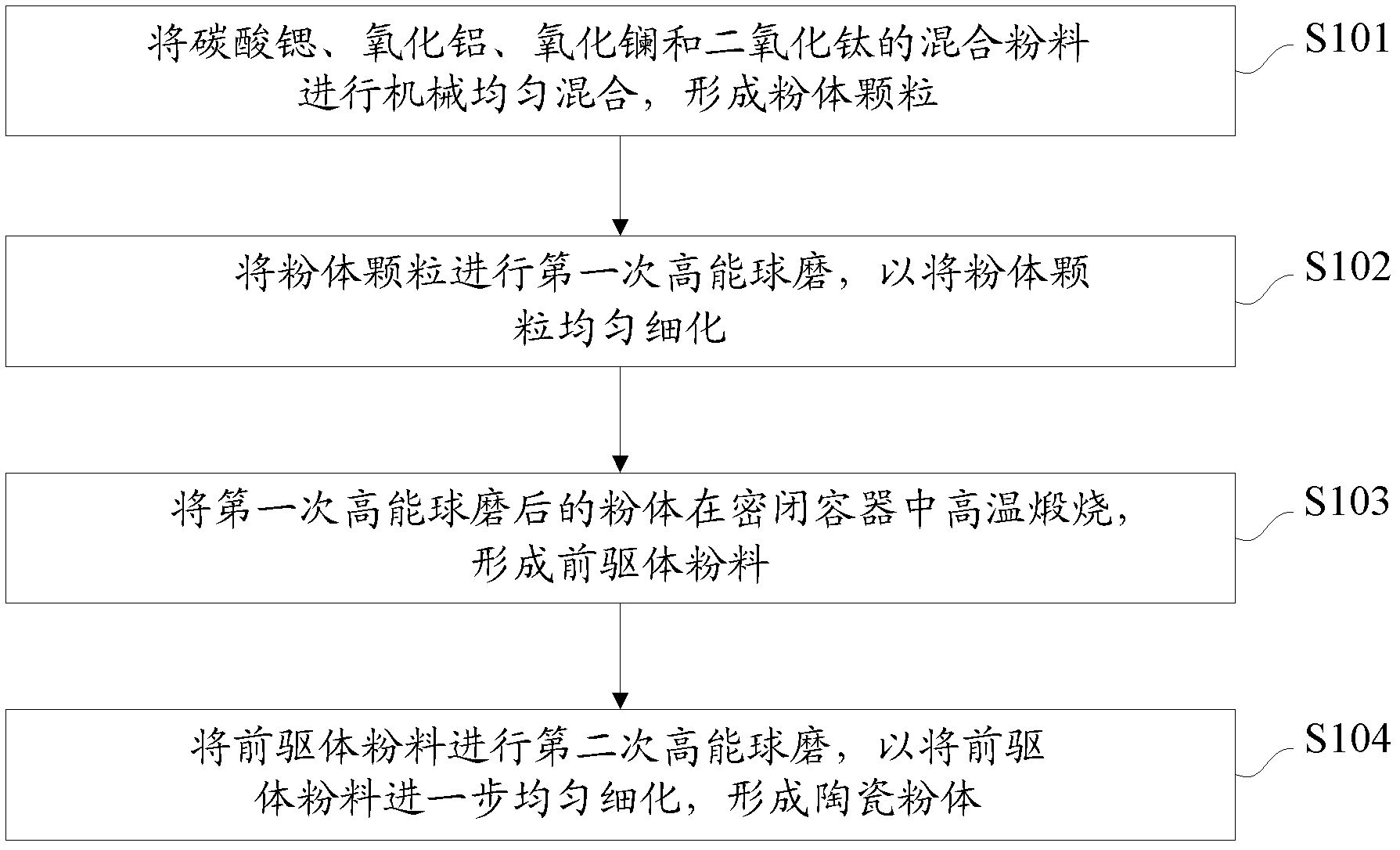

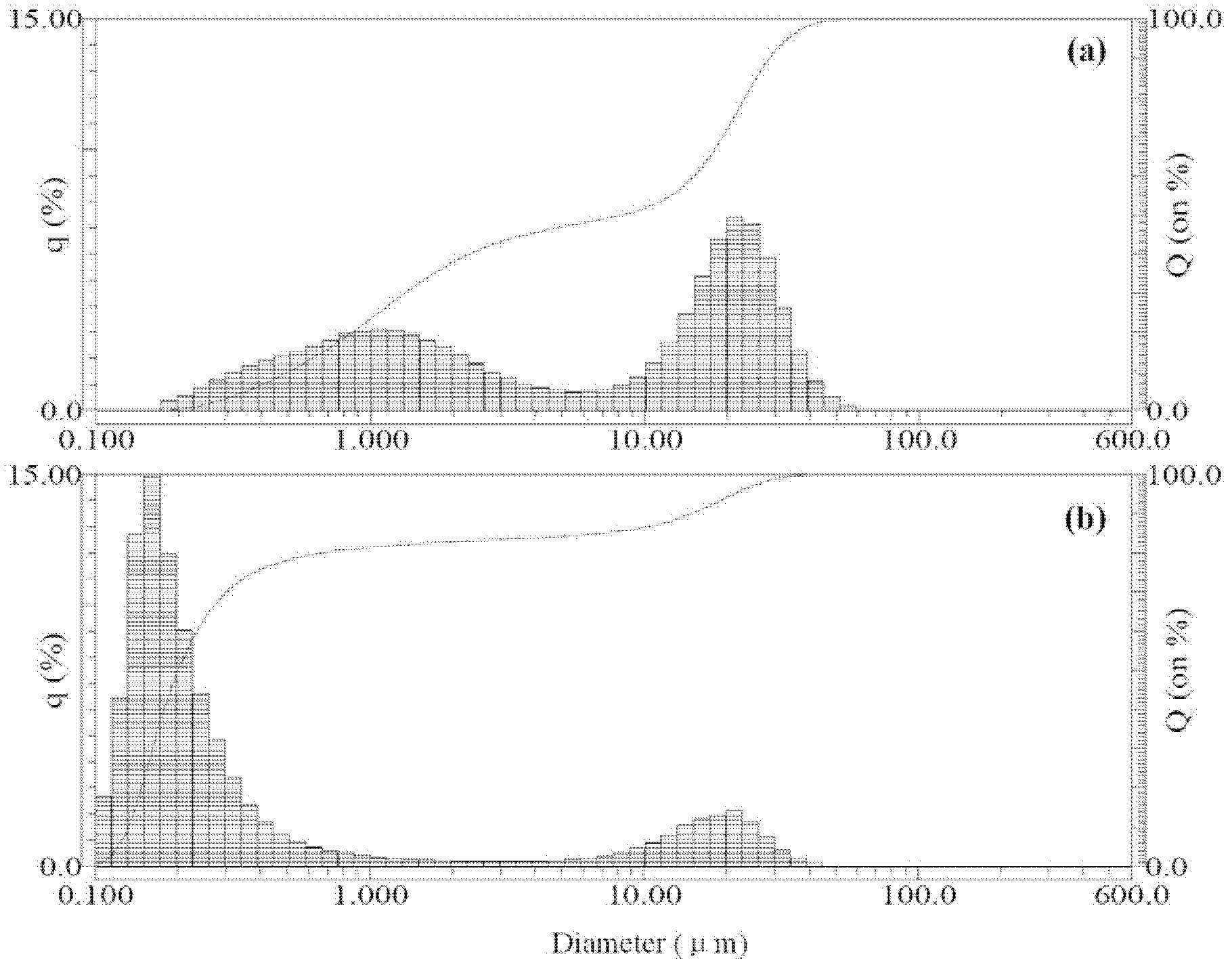

Preparation method of microwave dielectric ceramics materials

ActiveCN103130499ALower sintering temperatureReduce manufacturing costCeramicsStrontium carbonateHigh energy

The invention discloses a preparation method of microwave dielectric ceramics materials. The preparation method of the microwave dielectric ceramics materials comprises that the mixed powder of strontium carbonate, alumina, lanthanum oxide and titanium oxide are mechanically and evenly mixed in a spherical tank to form powder particles; and first time high energy ball milling is carried out on the powder particles to mill the powder particles evenly. The powder after the first time high energy ball milling is high-temperature calcined in a closed container to form precursor powder; and a second time high energy ball milling is carried out on the precursor powder to further mill the precursor powder evenly so as to form ceramic powder. The preparation method of the microwave dielectric ceramics materials sinters microwave dielectric ceramics materials with high densified mediation electric constant and a high quality factor by adopting low temperature, sintering temperature can be greatly lowered, sintering time can be greatly shortened, high densification is achieved, and therefore production cost and technical difficulty are reduced.

Owner:ANHUI TATFOOK TECH CO LTD

Components and preparing process of VHF plate sensor material

InactiveCN1397961AReduce performanceLower firing temperatureInorganic material magnetismCombustionSolid reaction

This invention relates to a formula of a VHF inductive chip material and its preparation method. There is not high performance low temp sintered ferrite materials at present so we have to use low dielectric ceramics as the medium instead to produce low inductance multi-chip inductors. The basis of the said material is a plane hexagon soft magnet ferrite matched with low temp combustion adjuvant processed by the solid phase reactance synthesis and the combustion adjuvant is applied with two times of doping VHF inductive material of excellent performance is got after ballmill, baking, preroast, ballmill, baking, granulation, formation sintering, realizing low temp sintering with temp below 900 deg.c.

Owner:TSINGHUA TONGFANG CO LTD +1

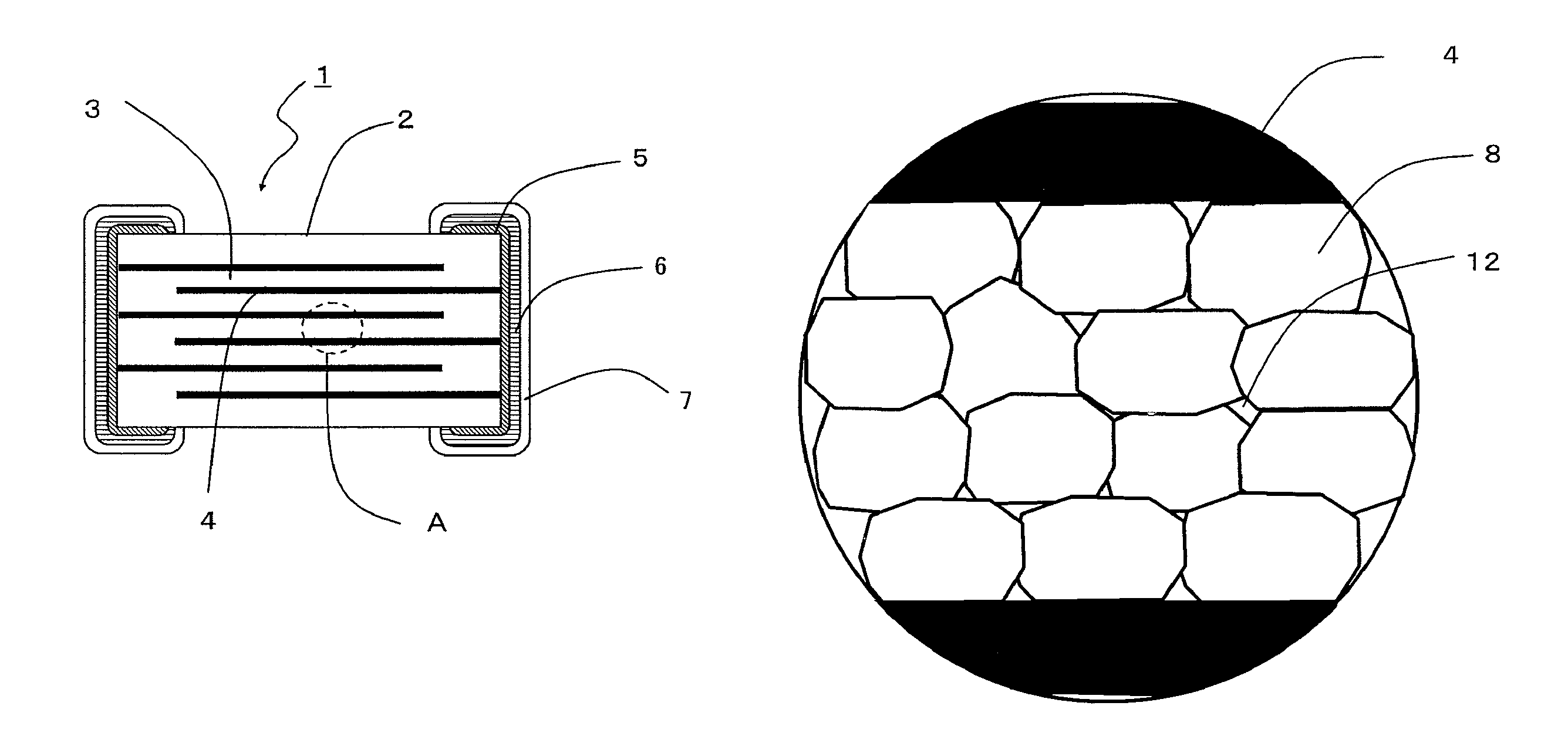

Dielectric ceramics and multi-layer ceramic capacitor

InactiveUS20070254799A1Lifetime properties of device be enhancedImprove reliabilityFixed capacitor dielectricStacked capacitorsBarium titanateCeramic capacitor

Dielectric ceramics include a sintered body comprising a principal ingredient, when represented by:ABO3+aRe+bM+Zr oxidewhere ABO3 is a barium titanate-based solid solution having a perovskite structure, Re is at least one oxide of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu and / or Y, M is at least one oxide of Mg, Al, Cr, Mn, Fe, Ni, Cu, and / or Zn, a and b each represents a mol number of the oxides per 1 mol of ABO3 within a range of: 1.100≦Ba / Ti≦1.700, 0.05≦a≦0.25, 0.05≦b≦0.25, Ti:Zr=95:5 to 60:40.

Owner:TAIYO YUDEN KK

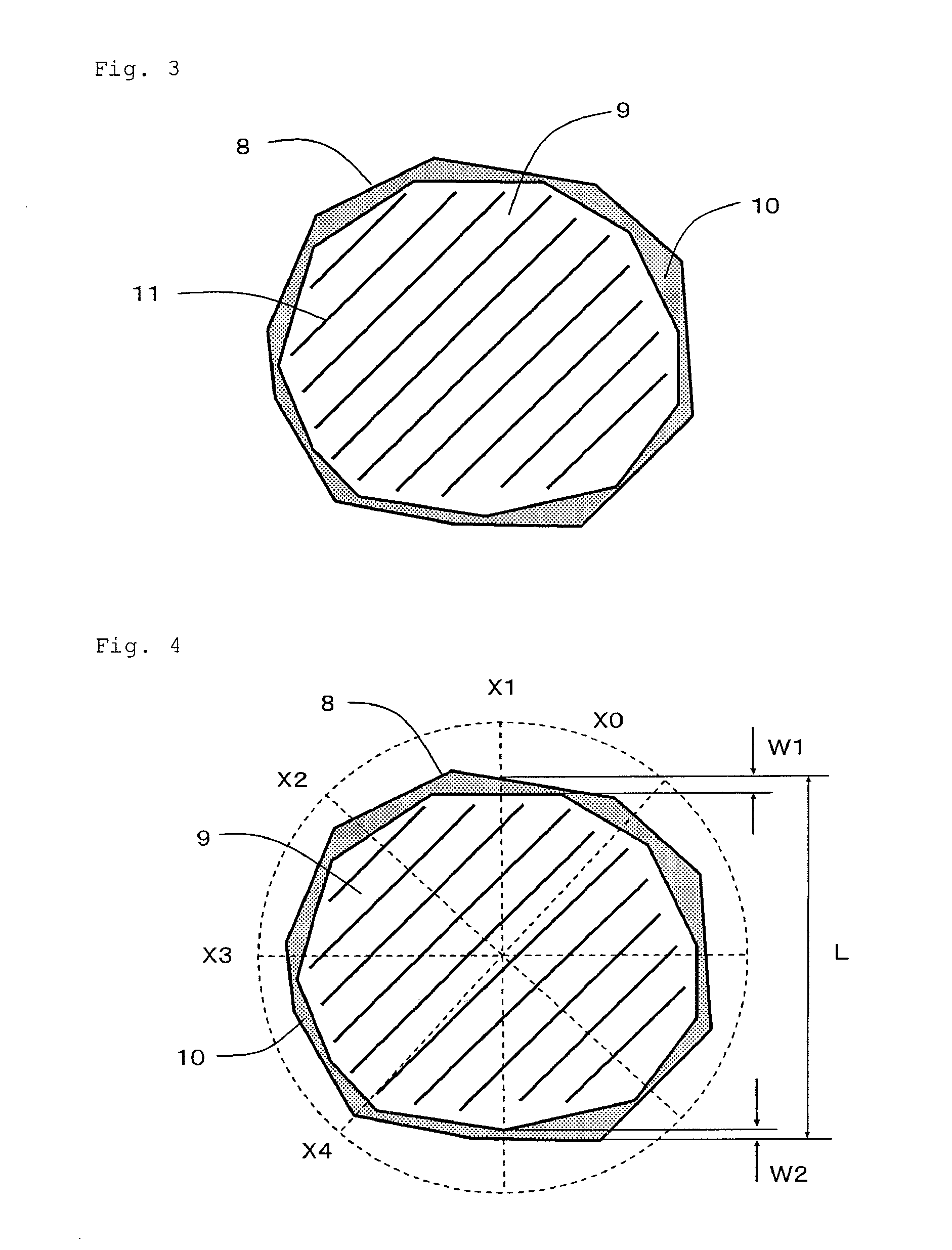

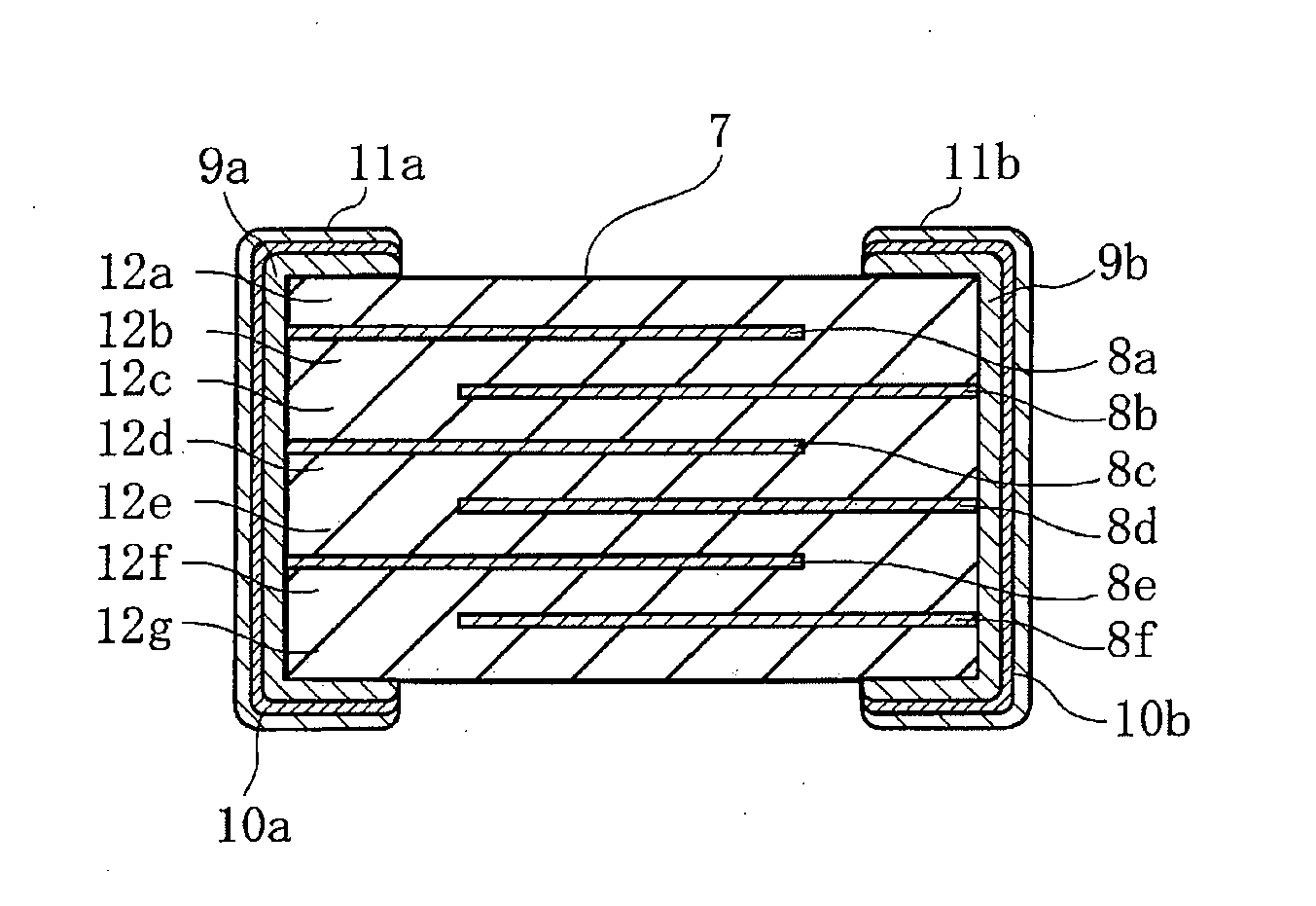

Multi-layer ceramic capacitor

ActiveUS20080068777A1Fixed capacitor dielectricStacked capacitorsCeramic capacitorDielectric ceramics

A multi-layer ceramic capacitor capable of being sintered at 1,080° C. or lower in a reducing atmosphere, having a permittivity of 2,000 or more, a temperature characteristic of X7R characteristic or X8R characteristic, and favorable life time property, in which the internal electrodes are formed of Cu or a Cu alloy, the dielectric ceramics are constituted with grains each of an average value for the diameter of 400 nm or less as viewed on the cross section and grain boundaries, the grain comprises a dielectric substance having a domain pattern and shells formed on the surface of the dielectric substance and with t / D from 2% to 10% where D represents an average value for the diameter of the grains as viewed on the cross section and t represents the average value for the thickness of the shells.

Owner:TAIYO YUDEN KK

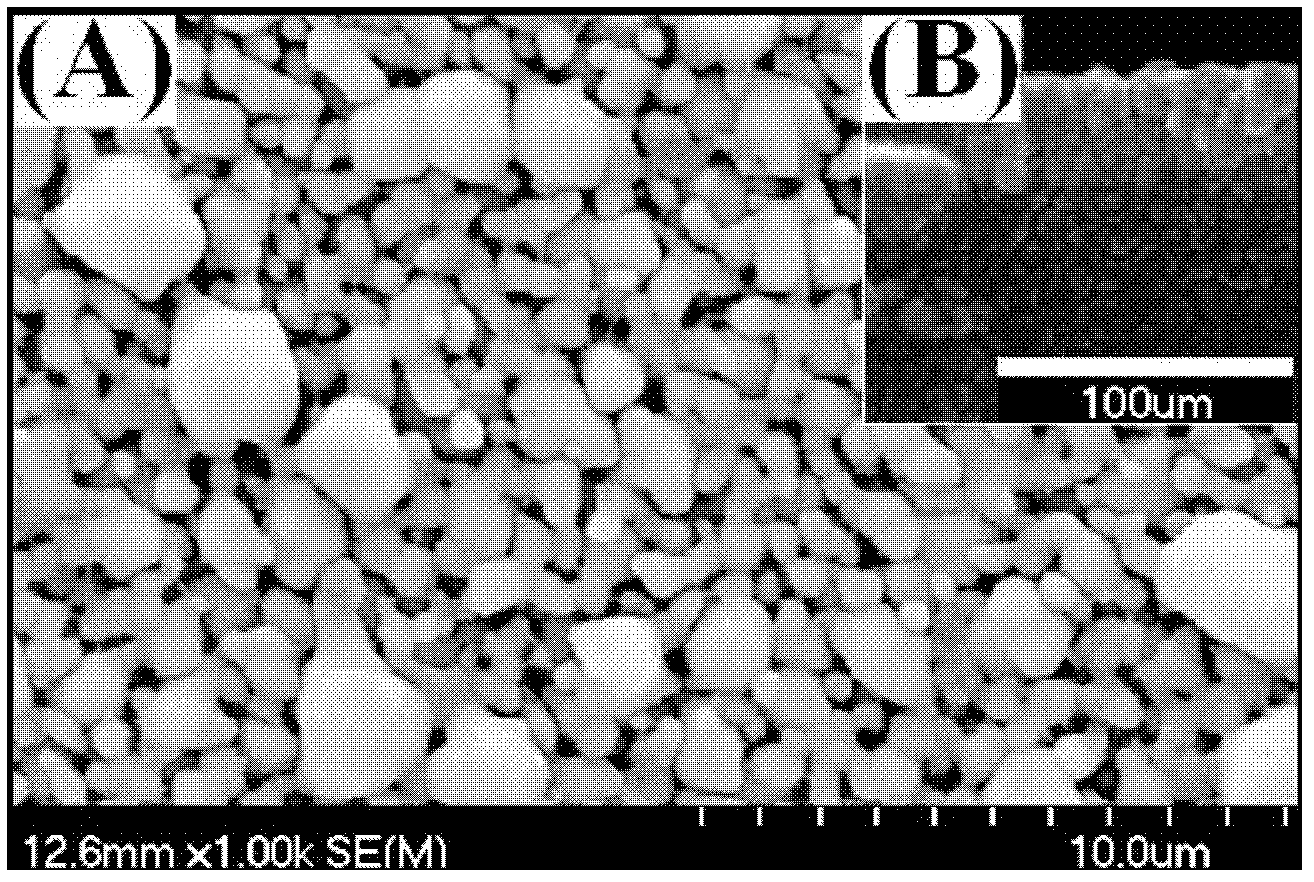

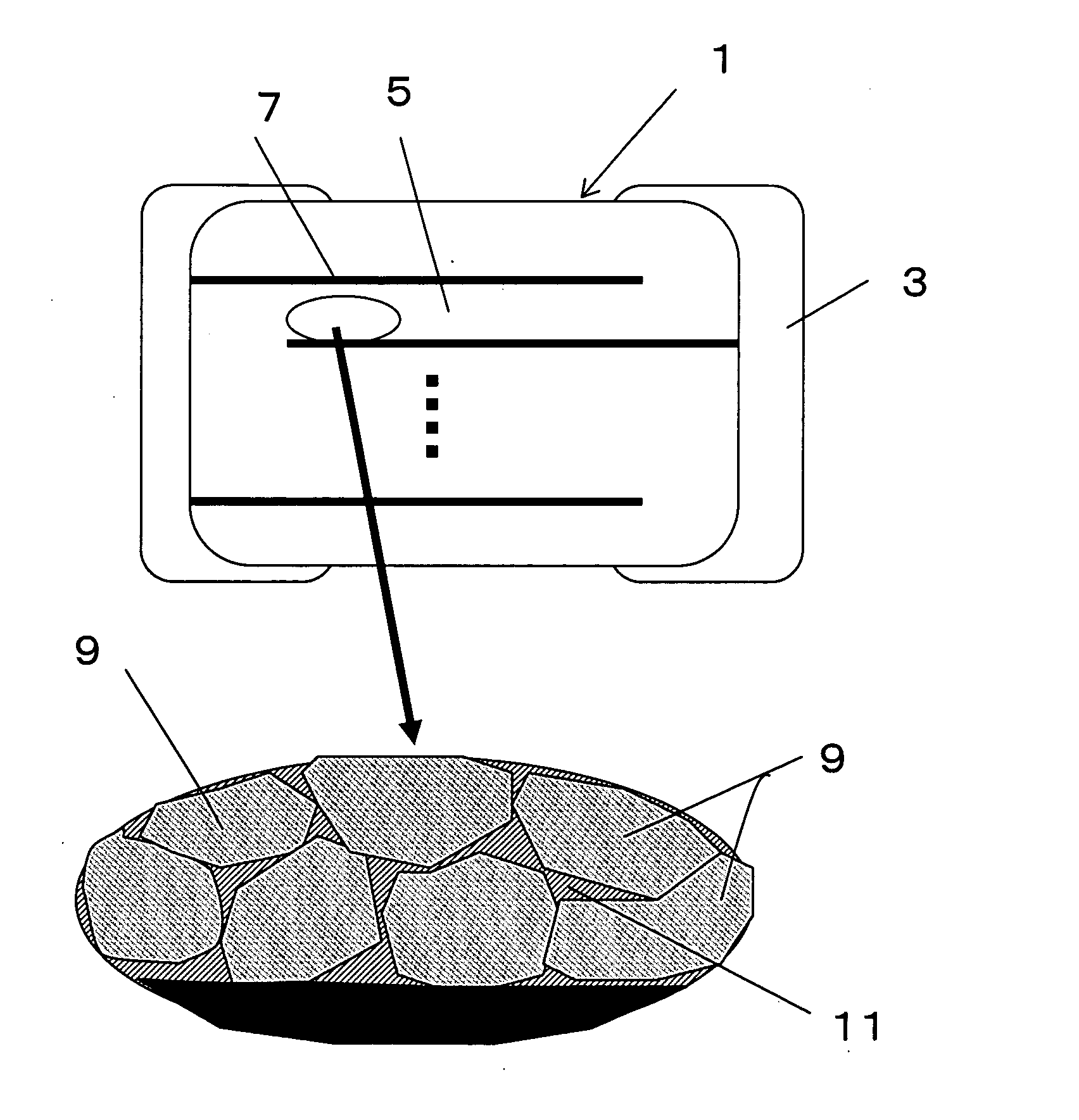

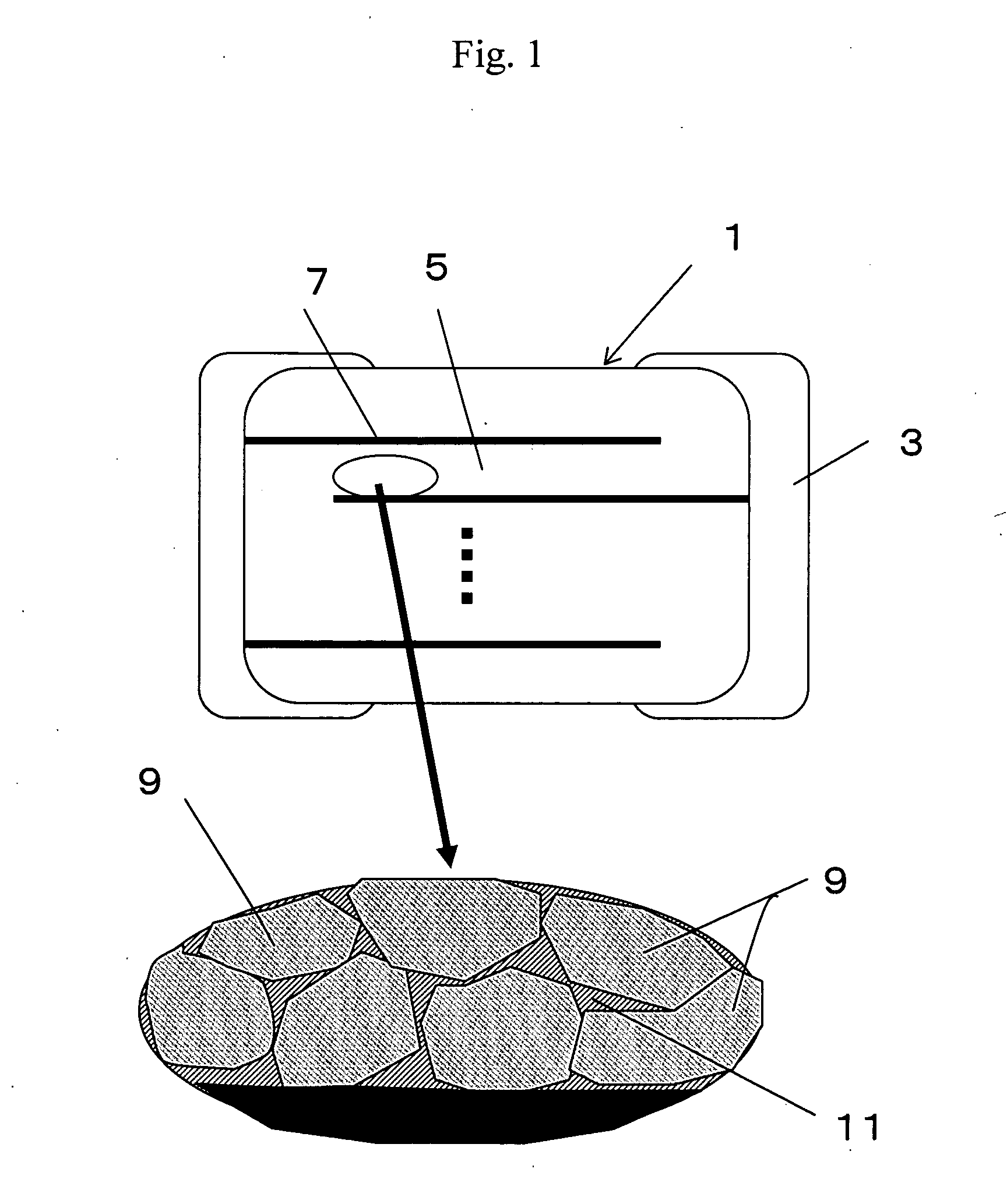

Bismuth iron oxide powder, manufacturing method for the bismuth iron oxide powder, dielectric ceramics, piezoelectric element, liquid discharge head, and ultrasonic motor

ActiveUS20110221302A1Low leakage current valueMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyLow leakageGrain boundary

Provided is a lead-free dielectric ceramics having a low leakage current value, and a bismuth iron oxide powder as a raw material thereof. The bismuth iron oxide powder includes at least: (A) grains including a bismuth iron oxide having a perovskite-type crystal structure; (B) grains including a bismuth iron oxide having a crystal structure classified to a space group Pbam; and (C) grains including a bismuth iron oxide or a bismuth oxide having a crystal structure that is classified to a space group I23. The dielectric ceramics are made of bismuth iron oxide in which the bismuth iron oxide crystals having the crystal structure classified to the space group Pbam are distributed at a grain boundary of crystal grains of the bismuth iron oxide crystals having the perovskite-type crystal structure.

Owner:CANON KK +1

Multi-layer ceramic capacitor

A multi-layer ceramic capacitor capable of being sintered at 1,080° C. or lower in a reducing atmosphere, having a permittivity of 2,000 or more, a temperature characteristic of X7R characteristic or X8R characteristic, and favorable life time property, in which the internal electrodes are formed of Cu or a Cu alloy, the dielectric ceramics are constituted with grains each of an average value for the diameter of 400 nm or less as viewed on the cross section and grain boundaries, the grain comprises a dielectric substance having a domain pattern and shells formed on the surface of the dielectric substance and with t / D from 2% to 10% where D represents an average value for the diameter of the grains as viewed on the cross section and t represents the average value for the thickness of the shells.

Owner:TAIYO YUDEN KK

Dielectric ceramic and laminated ceramic capacitor

ActiveUS20110222205A1Long lastingImprove reliabilityAlkaline earth titanatesFixed capacitor dielectricRare-earth elementCapacitance

A dielectric ceramic (and capacitor containing it) balancing high temperature load characteristics and temperature characteristics of capacitance even when layer thickness is less than 1 μmhas a mixture of different crystal grains containing a barium titanate compound as the main constituent. The first crystal grains can contain rare earth element solid solution region lat the surface layer section. The second crystal grains have a core-shell structure including a shell section having a rare earth element solid solution present. The first and second crystal grains are 12% to 84% f and 16% to 88%, respectively, of the total number of crystal grains.

Owner:MURATA MFG CO LTD

Method for Producing a Subminiature "Micro-Chip" Oxygen Sensor for Control of Internal Combustion Engines or Other Combustion Processes, Oxygen Sensor and an Exhaust Safety Switch

ActiveUS20110186446A1Reduce resistanceTemperature effect is minimizedElectrical controlWeather/light/corrosion resistanceContact padMultiple sensor

A method of making a sub-miniature “micro-chip” oxygen sensor is provided where multiple sensor elements are applied to a dielectric ceramic substrate consisting of a heater pattern, followed by a dielectric layer. Intermeshing electrodes are then applied either over the heater pattern / dielectric layers or on the opposite side of the substrate. The space between the intermeshing electrodes is filled with an n-type or p-type high temperature semiconductor which is covered by a porous protection layer. After singulation (dicing), the sensor element is assembled having conductors applied to the contact pads on the element and is packaged in an assembly for introduction to the exhaust stream of a combustion process. A large step-wise change in the resistance of the element takes place as a result of changes in oxygen content in the exhaust whereby one can determine if the exhaust is rich or lean for use in an engine management or combustion management systems for emissions control. A circuit is proposed to convert the change in resistance to a voltage signal to be used for control algorithms in engine or combustion control. Utilizing multiple units of the device for individual cylinder control of multi-cylinder engines is described. A method of using one embodiment of the invention for use as a safety switch is also revealed.

Owner:KERDEA TECH

Dielectric ceramic composition, multilayer ceramic capacitor, and method for manufacturing multilayer ceramic capacitor

The invention provides a dielectric ceramic composition, a multilayer ceramic capacitor and a method for manufacturing the multilayer ceramic capacitor. The dielectric ceramic composition contains a first main ingredient of BaTiO3 and a second main ingredient of BaTi2O5, and a base material powder containing the first and second main ingredients is represented by (1-x)BaTiO3-xBaTi2O5 and x satisfies 0.1<=x<=0.8. The dielectric ceramic composition may include additional accessory ingredients, and may be used to form ceramic sheets having internal electrodes of a multilayer ceramic capacitor disposed thereon.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

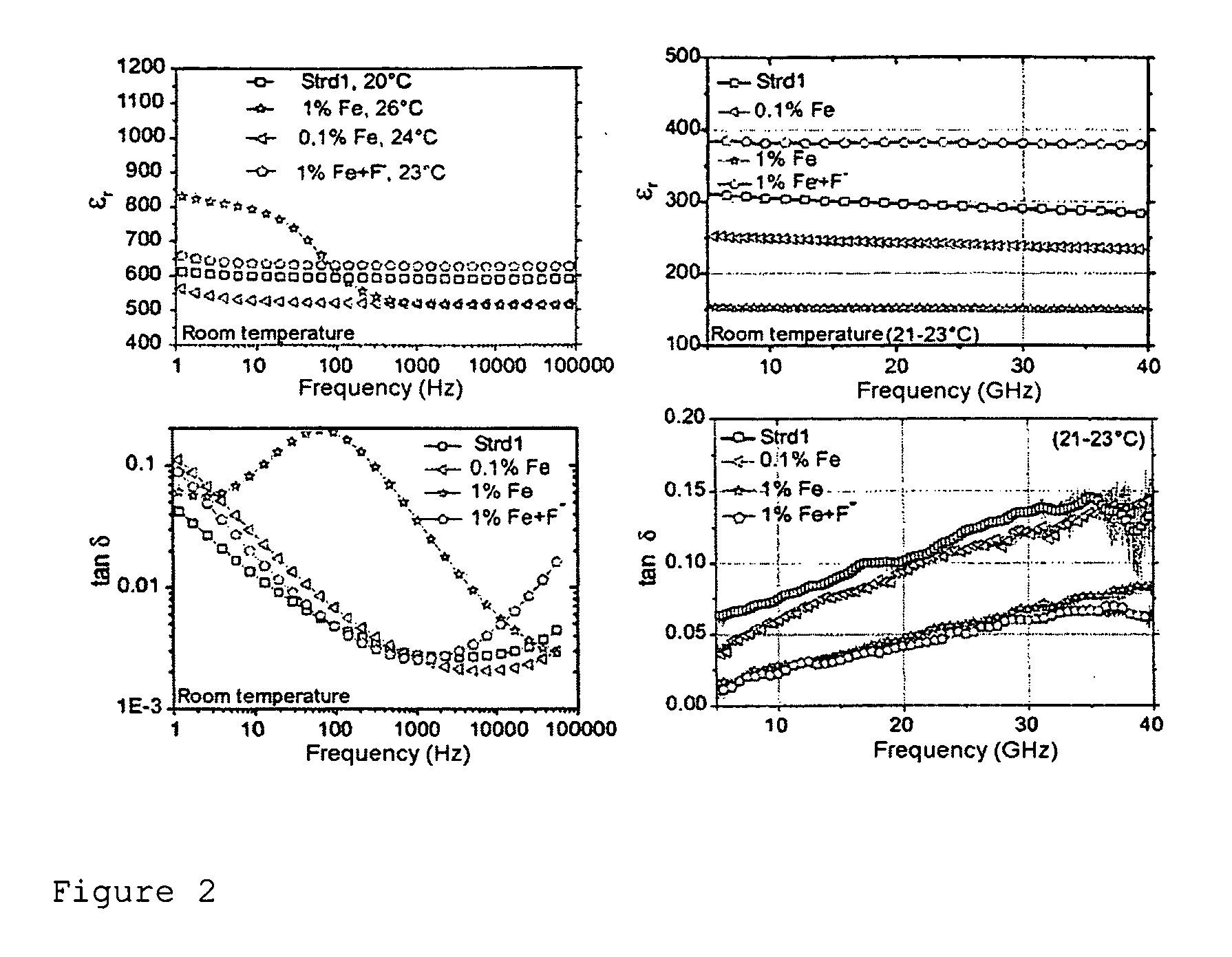

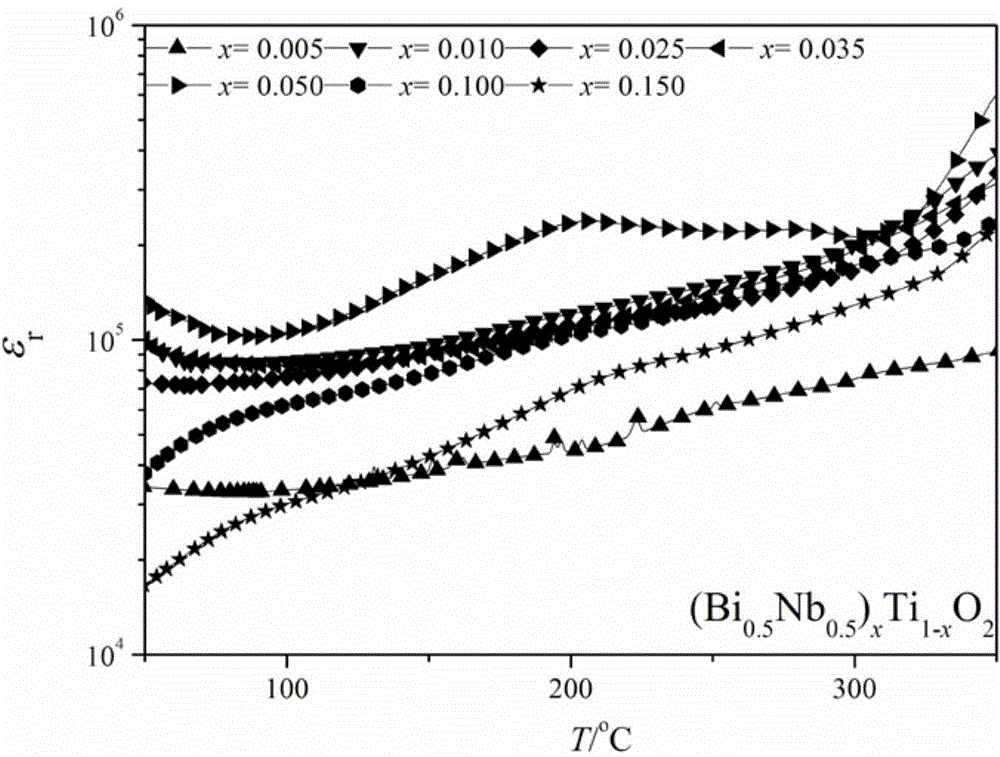

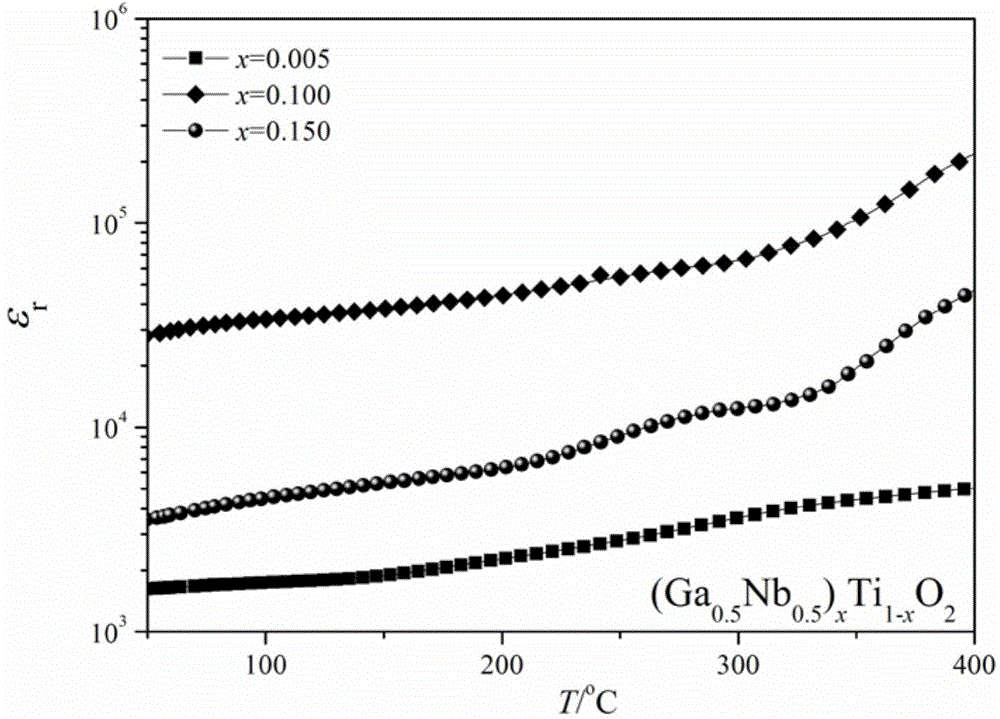

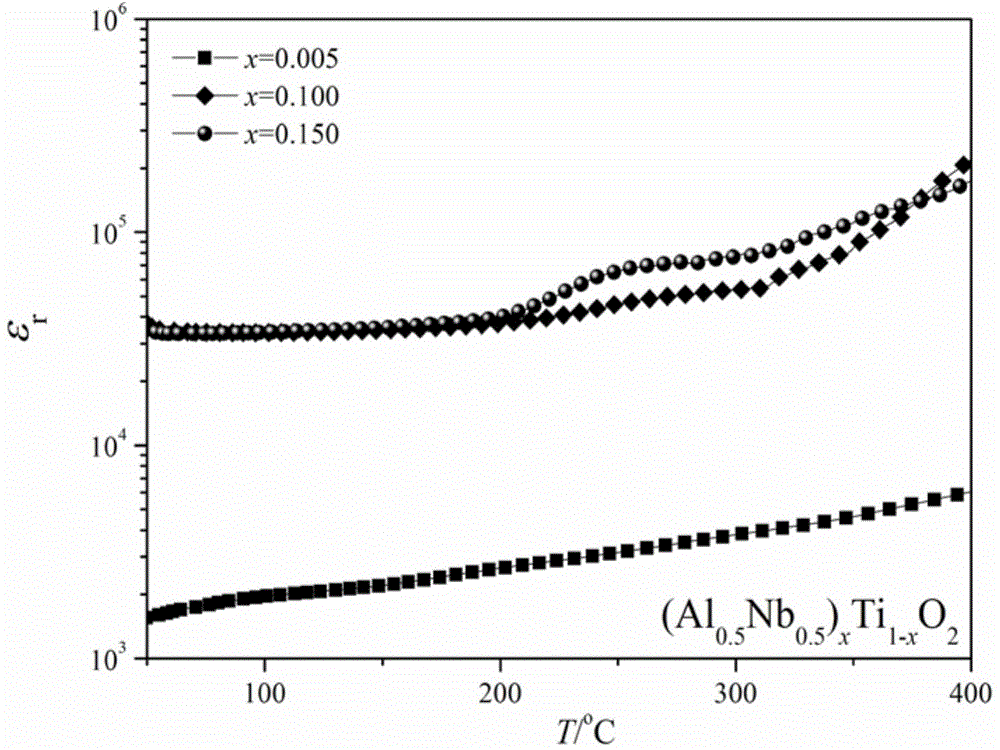

Ion modified titanium dioxide ceramic material with high dielectric constant and preparation method thereof

The invention relates to an ion modified titanium dioxide ceramic material with a high dielectric constant and a preparation method thereof, and belongs to the field of environment-friendly dielectric ceramics. The ceramic material disclosed by the invention is as shown in a general formula as follows: (A0.5Nb0.5)xTi(1-x)O2, wherein A is Bi, Al, Ga, Y, Sc, Yb, Dy, Sm, Gd and Pr, and x is not smaller than 0.005 mol content and not larger than 0.150 mol content. The ceramic material is prepared by adopting a traditional solid phase sintering process; the raw materials in the general formula are added with different trivalent A elements and the same pentavalent Nb element; the obtained ceramic material is as high as 10<6> in dielectric constant and as low as 6% in dielectric loss. The ceramic prepared by the method disclosed by the invention has a relatively large practical value in the present age when electronic elements are miniaturized and lightened, and especially the elements prepared from the ceramic have practical application values in various electronic elements such as capacitors and dynamic storage.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com