Low temp. sintering niobate microwave dielectric ceramic and preparation process thereof

A microwave dielectric ceramic and low-temperature sintering technology, applied in the field of dielectric ceramic materials, can solve the problems of small Q f value, poor comprehensive performance, difficult to meet high frequency, high reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

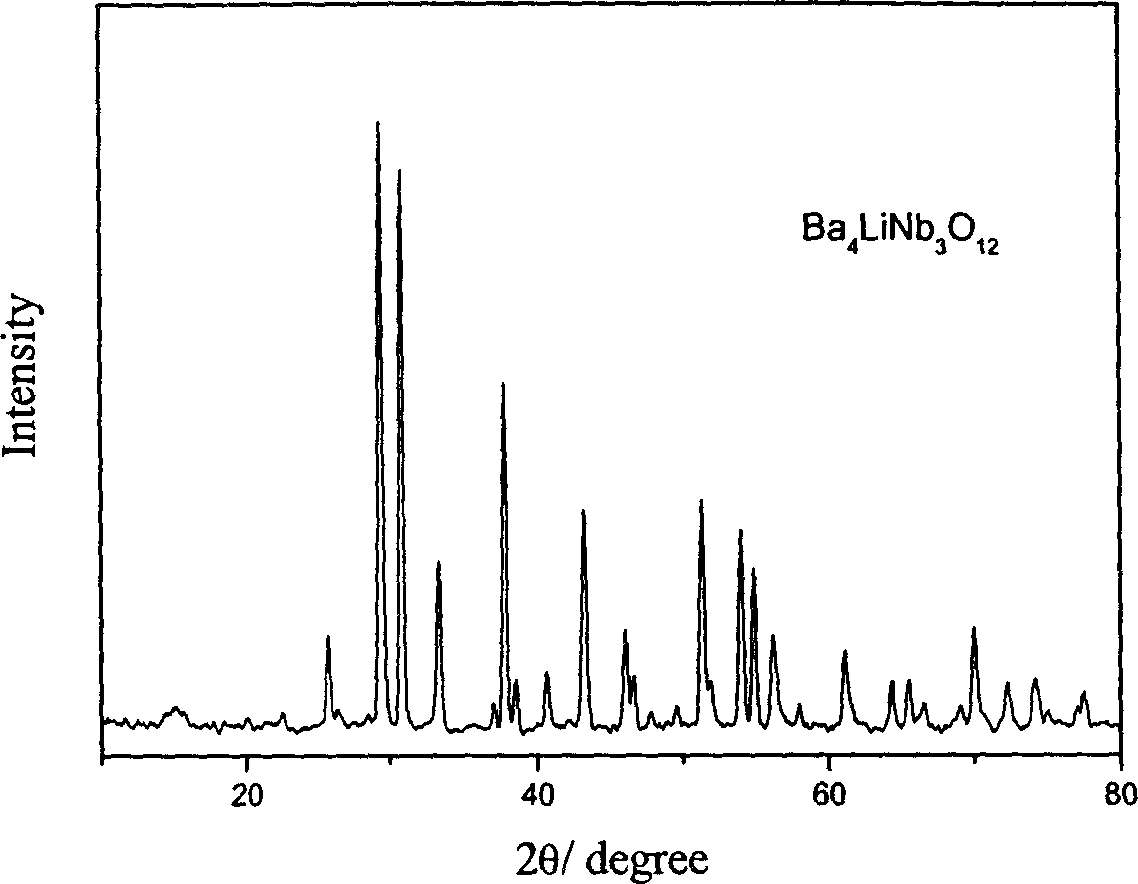

[0019] Table 1 shows several specific examples of the content of each component constituting the present invention and their microwave dielectric properties. Its preparation method is as described above, and the phase analysis of the ceramic sample after sintering is carried out by powder X-ray diffraction method, figure 1 For the X-ray diffraction pattern of Example 1, the evaluation of the microwave dielectric properties was carried out by the cylindrical dielectric resonator method.

[0020] The ceramics can be widely used in the manufacture of various dielectric resonators, filters and other microwave devices, and can meet the technical needs of mobile communication, satellite communication and other systems.

[0021] Elements such as Ca, Pb, etc., which have similar structures and chemical properties to Ba and Sr, and elements such as Ti, Sn, and Zr, which have similar structures and chemical properties to Nb, can also make dielectric ceramics similar to the crystal struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com