Preparation method of microwave dielectric ceramics materials

A technology of microwave dielectric ceramics and ceramic powders, applied in ceramics, inorganic insulators and other directions, can solve the problems of long sintering time, damage to the dielectric properties of the finished product, and high sintering temperature, so as to shorten the sintering time, reduce the production cost and technical difficulty, The effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

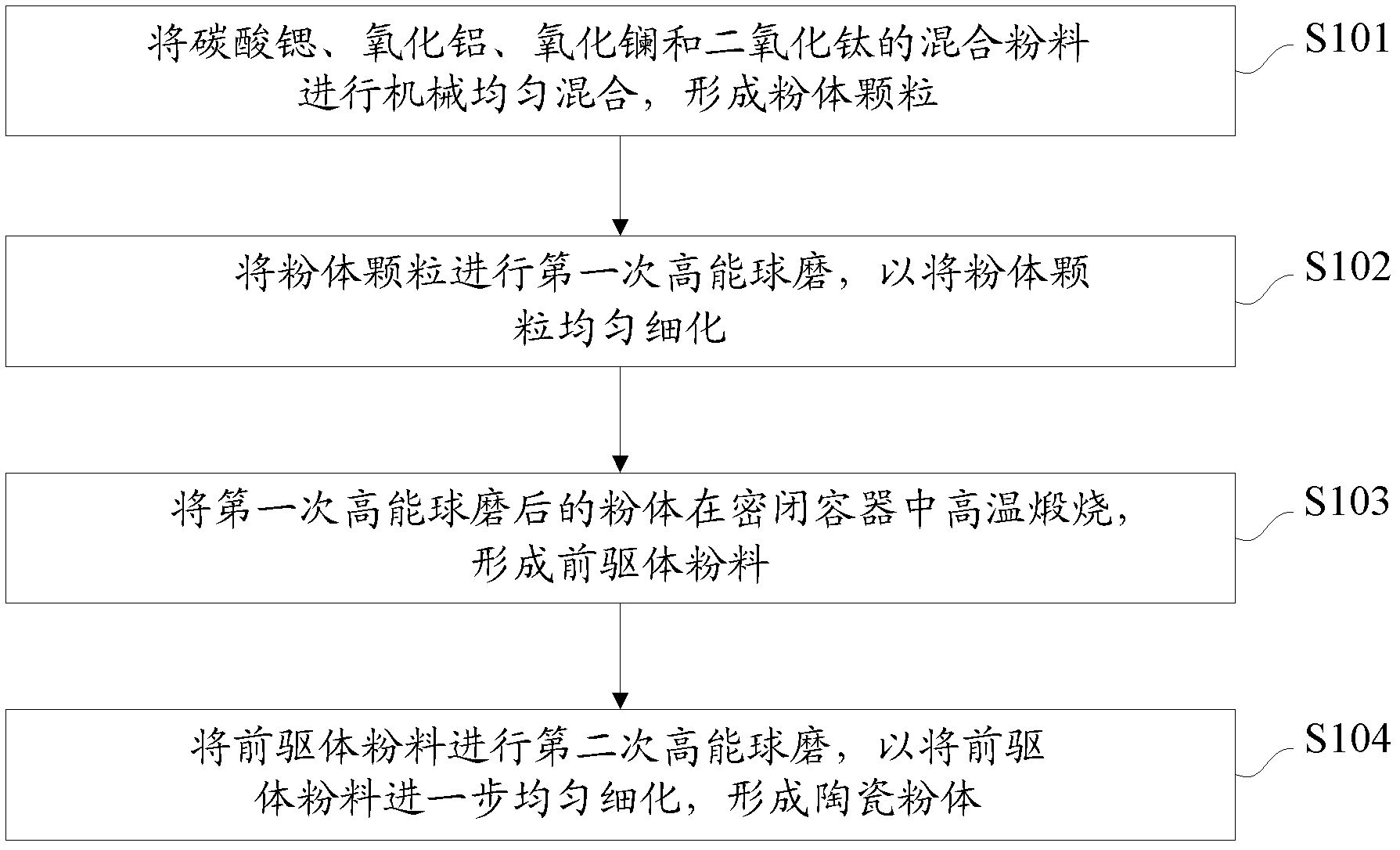

[0030] A kind of preparation method of microwave dielectric ceramic material, its schematic flow chart is as figure 1 shown, including:

[0031] Step S101, mechanically and uniformly mixing the mixed powder of strontium carbonate, aluminum oxide, lanthanum oxide and titanium dioxide to form powder particles.

[0032] In this example, the mixed powder of strontium carbonate, aluminum oxide, lanthanum oxide and titanium dioxide was weighed according to the required mole percentage formula, then placed in a spherical tank for mechanical uniform mixing, and zirconia grinding balls were added as grinding media , adding absolute ethanol or deionized water as an organic solvent, and after forming powder particles, remove the organic solvent for drying treatment, the weight ratio of the mixed powder, grinding media, and organic solvent is 1:3:3 and occupies a ball 60% to 80% of the tank volume, and the mixing time is 6 to 10 hours. Wherein, the mole percentage of strontium carbonate...

Embodiment 2

[0048] A method for preparing a microwave dielectric ceramic material, comprising:

[0049] Step 1. Pre-burn the original lanthanum oxide powder at 800 degrees Celsius for 2 hours before batching, and pre-fire the original titanium dioxide powder at 1280 degrees Celsius for 3 hours to dry; according to the chemical formula 0.68SrTiO 3 -0.32LaAlO 3 Put the mixed powder of strontium carbonate, alumina, lanthanum oxide and titanium dioxide in a spherical tank for mechanical uniform mixing; add zirconia grinding balls as grinding media, add absolute ethanol or deionized water as organic solvent, and form powder After the bulk particles, remove the organic solvent and carry out drying treatment. The ratio of mixed powder, grinding balls and solvent (weight) is 1:3:3 and it accounts for 80% of the volume of the spherical tank. The raw material mixing time is 10 hours.

[0050] In this embodiment, the stoichiometric ratios of strontium carbonate and titanium dioxide are both 0.72 mo...

Embodiment 3

[0059] A method for preparing a microwave dielectric ceramic material, comprising:

[0060] Step 1. Before batching, pre-burn the raw lanthanum oxide powder at 800 degrees Celsius for 2 hours, and pre-fire the raw titanium dioxide powder at 1280 degrees Celsius for 3 hours to dry; according to the chemical formula 0.52SrTiO 3 -0.48LaAlO 3 Put the mixed powder of strontium carbonate, aluminum oxide, lanthanum oxide, and titanium dioxide in a spherical tank for mechanical uniform mixing; add zirconia grinding balls as the grinding medium, add absolute ethanol or deionized water as the organic solvent, and mix the powder, The ratio of the ball to the solvent (by weight) is 1:3:3 and it accounts for 60% of the volume of the spherical tank, and the mixing time of the raw materials is 8 hours.

[0061] In this embodiment, the stoichiometric ratios of strontium carbonate and titanium dioxide are both 0.62 mol%, and the stoichiometric ratios of aluminum oxide and lanthanum oxide are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com