Low-temperature co-fired microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature co-firing technology is applied in the field of microwave dielectric materials and their manufacturing methods, and can solve problems such as affecting the characteristics of original materials, inability to use multilayer capacitor components, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

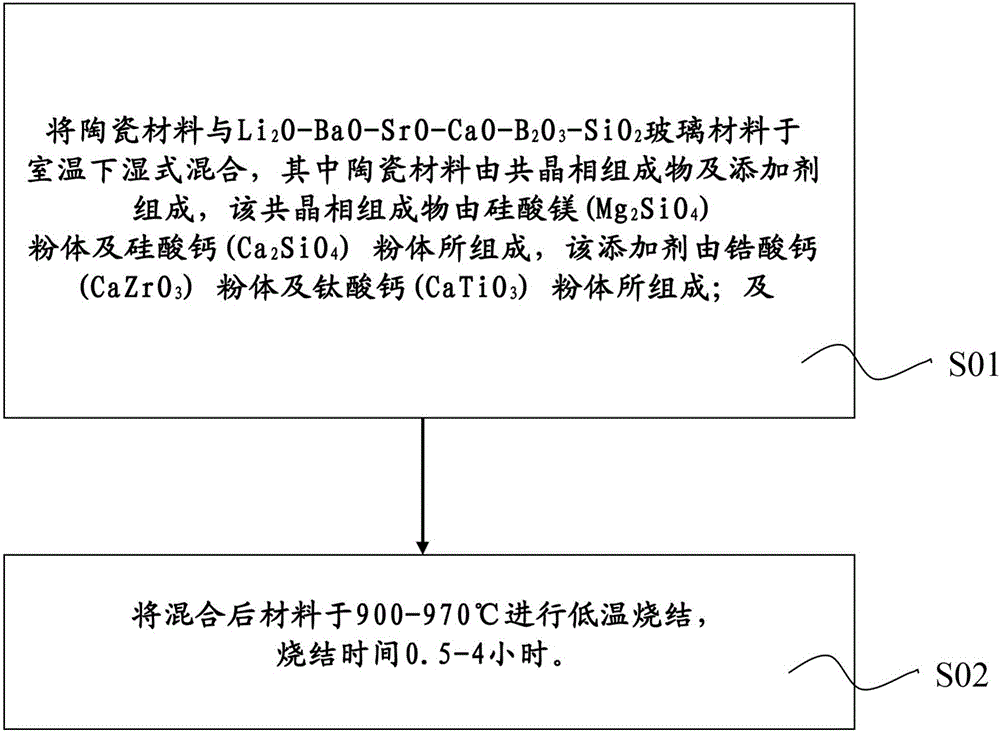

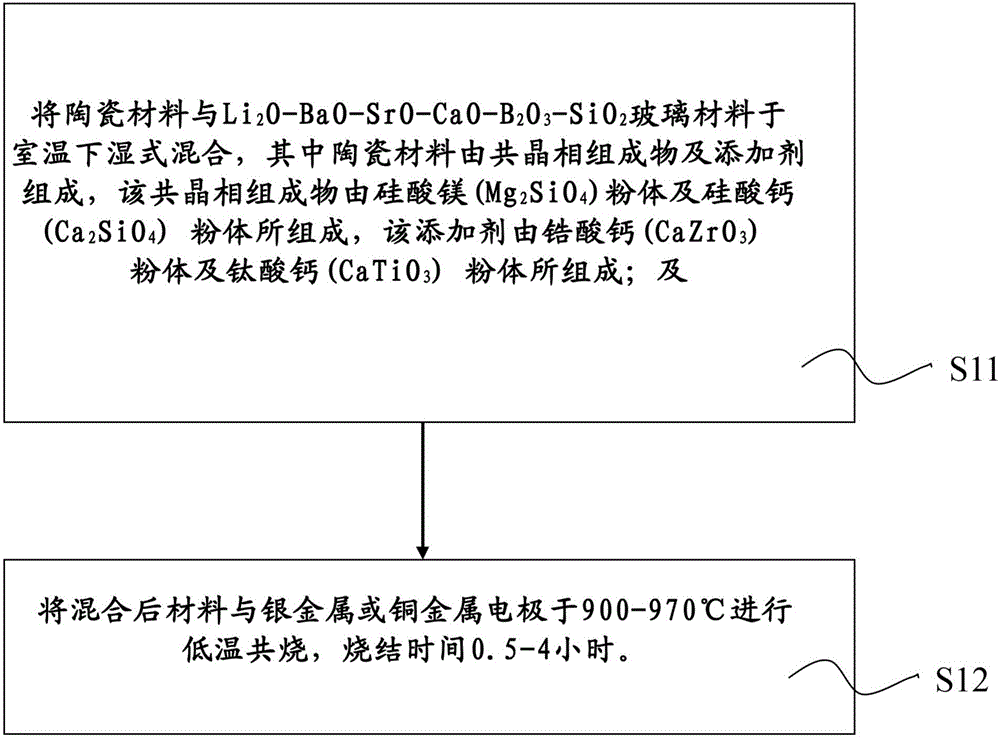

Method used

Image

Examples

Embodiment Construction

[0030] Specific examples will be described below to illustrate the implementation of the present invention, but they are not intended to limit the protection scope of the present invention.

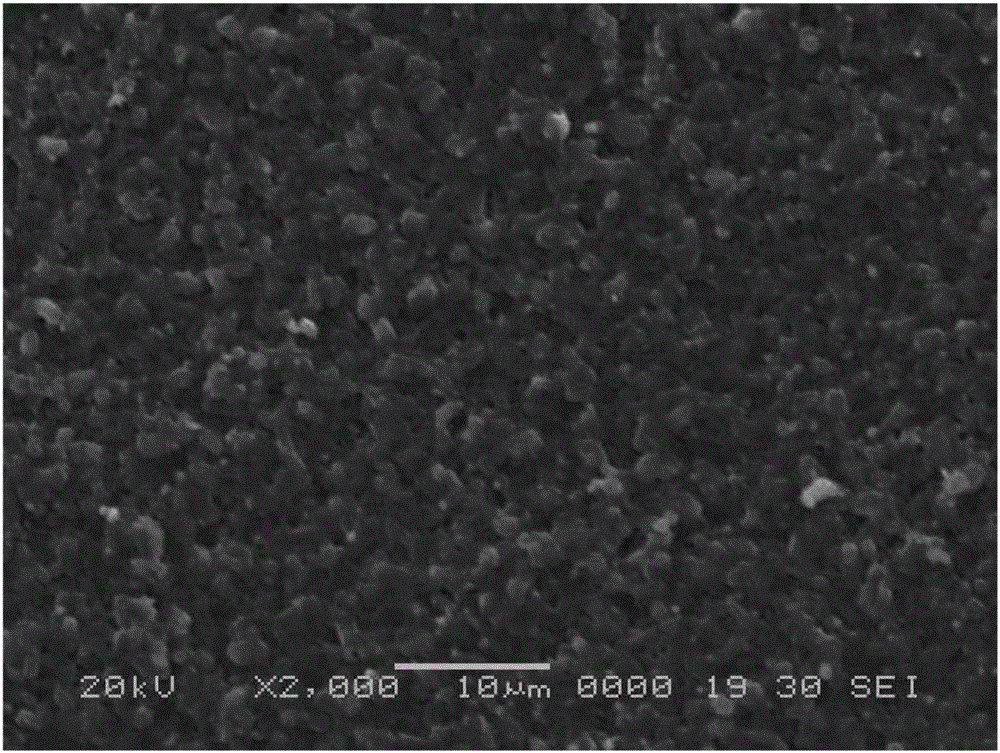

[0031] The first embodiment of the present invention provides a low temperature co-fired microwave dielectric ceramic material, which includes: 85wt% to 99wt% ceramic material and 1wt% to 15wt% glass material. The dielectric constant of the above-mentioned microwave dielectric ceramic material ranges from 8 to 15, which belongs to the range of low dielectric constant, and microwave dielectric materials with high quality factor and temperature frequency coefficient close to zero at the same time, and its sintered density distribution is 3.17 to 3.52g / cm 3 , quality factor distribution is 2900~6500, insulation resistance characteristics≧3.5×10 12 Ω.

[0032] The ceramic material is 1-y-z[(1-x)Mg 2 SiO 4 -xCa 2 SiO 4 ]-yCaTiO 3 -zCaZrO 3 . According to research, (1-x)Mg 2 SiO 4 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sintered density | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

| Temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com