Ion modified titanium dioxide ceramic material with high dielectric constant and preparation method thereof

A technology of high dielectric constant and ceramic materials, applied in the field of ceramic materials, high dielectric constant ion-modified titanium dioxide ceramic materials and their preparation, can solve problems such as high dielectric loss, achieve a wide range of operating temperature, increase the possibility of performance and performance optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

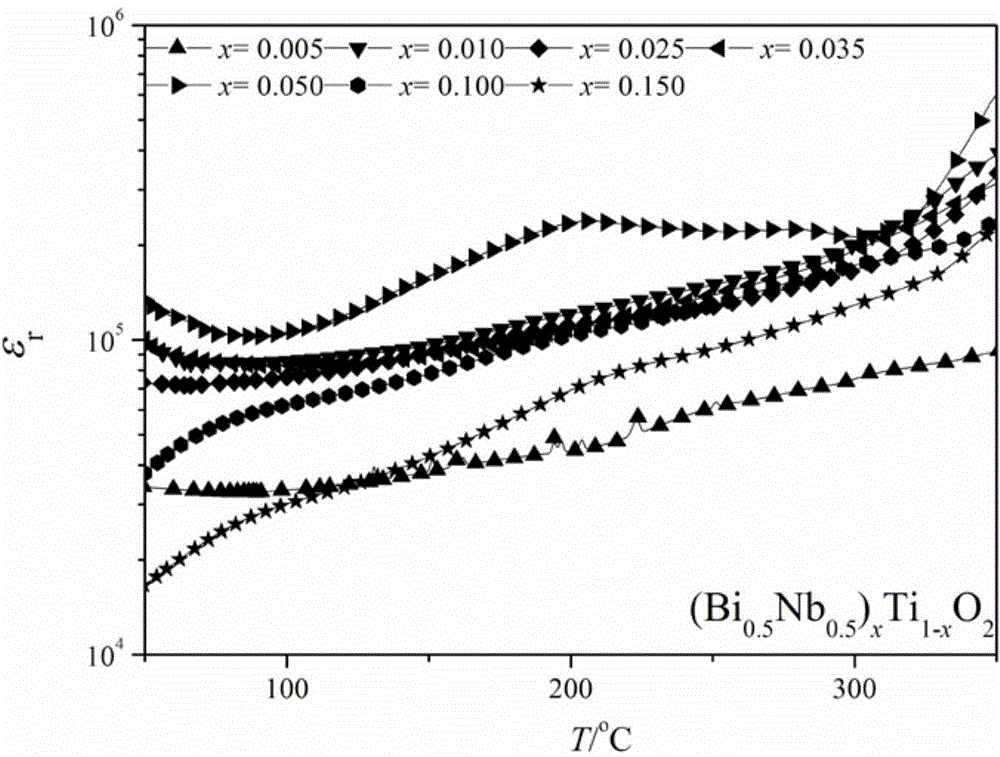

Embodiment 1

[0036] According to the general formula (A 0.5 Nb 0.5 ) x Ti 1-x o 2 The indicated ion-modified titanium dioxide ceramic component content is used for batching;

[0037] When x=0.005, A=Bi,

[0038] Its formula one is: (Bi 0.5 Nb 0.5 ) 0.005 Ti 0.995 o 2 ,

[0039] When x=0.010, A=Bi,

[0040] Its formula two is: (Bi 0.5 Nb 0.5 ) 0.01 Ti 0.99 o 2 ,

[0041] When x=0.025, A=Bi,

[0042] Its formula three is: (Bi 0.5 Nb 0.5 ) 0.025 Ti 0.975 o 2 ,

[0043] When x=0.035, A=Bi,

[0044] Its formula four is: (Bi 0.5 Nb 0.5 ) 0.035 Ti 0.965 o 2 ,

[0045] When x=0.050, A=Bi,

[0046] Its formula five is: (Bi 0.5 Nb 0.5 ) 0.05 Ti 0.95 o 2 ,

[0047] When x=0.100, A=Bi,

[0048] Its formula six is: (Bi 0.5 Nb 0.5 ) 0.1 Ti 0.9 o 2 ,

[0049] When x=0.150, A=Bi,

[0050] Its formula seven is: (Bi 0.5 Nb 0.5 ) 0.15 Ti 0.85 o 2 .

[0051] Preparation of formula 1: with analytically pure Bi 2 o 3 , Nb 2 o 5 and TiO 2 As raw materials, ...

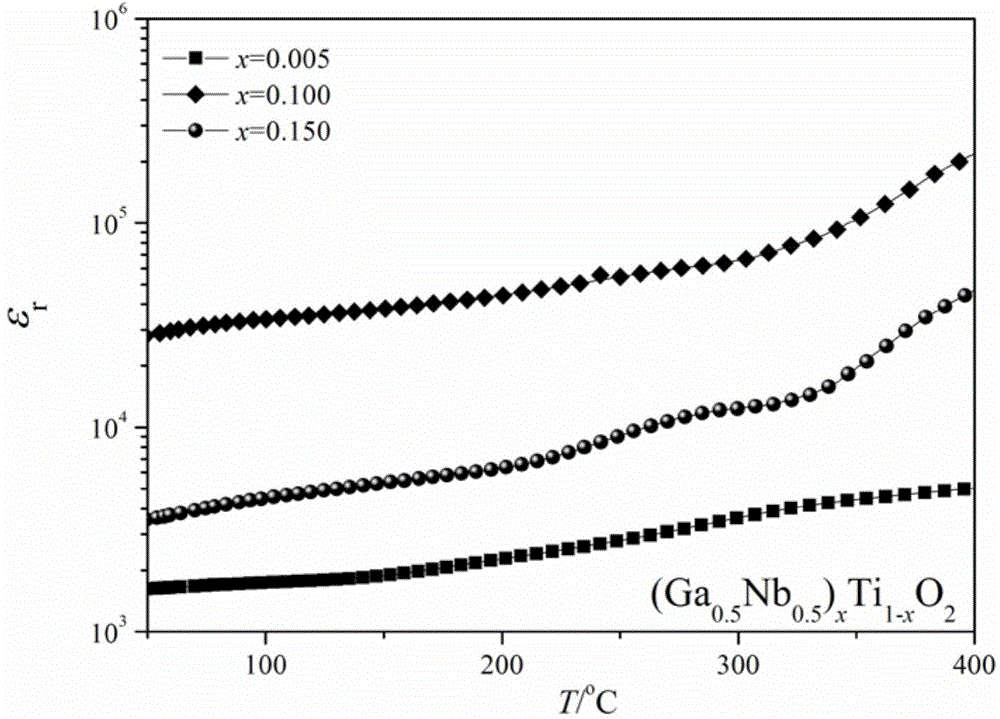

Embodiment 2

[0059] According to the general formula (A 0.5 Nb 0.5 ) x Ti 1-x o 2 The indicated ion-modified titanium dioxide ceramic component content is used for batching;

[0060] When x=0.005, A=Ga,

[0061] Its formula one is: (Ga 0.5 Nb 0.5 ) 0.005 Ti 0.995 o 2 ,

[0062] When x=0.100, A=Ga,

[0063] Its formula two is: (Ga 0.5 Nb 0.5 ) 0.1 Ti 0.9 o 2 ,

[0064] When x=0.150, A=Ga,

[0065] Its formula three is: (Ga 0.5 Nb 0.5 ) 0.15 Ti 0.85 o 2 .

[0066] Preparation of formula 1: with analytically pure Ga 2 o 3 , Nb 2 o 5 and TiO 2As raw materials, each raw material is accurately weighed according to the stoichiometric ratio, and the weighed raw materials are ball milled with absolute ethanol as a ball milling medium, and dried after ball milling for 24 hours to obtain a mixed dry powder; the obtained dry powder is pre-calcined at 1100 ° C for 4 hours, Then add the polyvinyl alcohol aqueous solution granulation that concentration is 8wt% in the pre-fire...

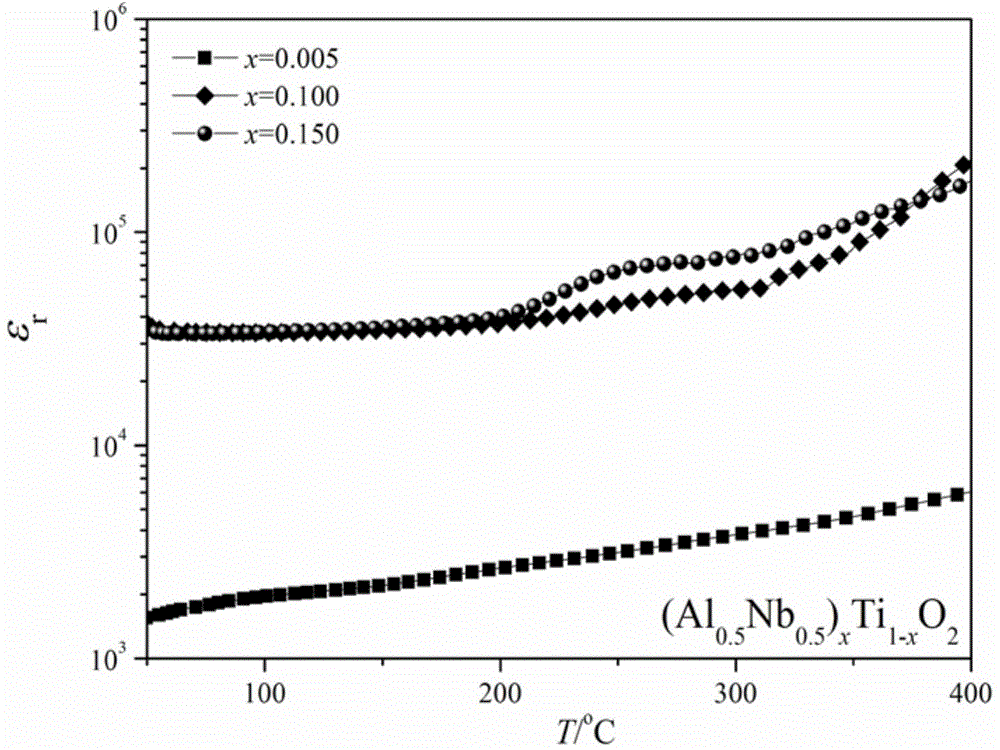

Embodiment 3

[0073] According to the general formula (A 0.5 Nb 0.5 ) x Ti 1-x o 2 The indicated ion-modified titanium dioxide ceramic component content is used for batching;

[0074] When x=0.005, A=Al,

[0075] Its formula one is: (Al 0.5 Nb 0.5 ) 0.005 Ti 0.995 o 2 ,

[0076] When x=0.100, A=Al,

[0077] Its formula two is: (Al 0.5 Nb 0.5 ) 0.1 Ti 0.9 o 2 ,

[0078] When x=0.150, A=Al,

[0079] Its formula three is: (Al 0.5 Nb 0.5 ) 0.15 Ti 0.85 o 2 .

[0080] Preparation of formula 1: with analytically pure Al 2 o 3 , Nb 2 o 5 and TiO 2 As raw materials, each raw material is accurately weighed according to the stoichiometric ratio, and the weighed raw materials are ball milled with absolute ethanol as a ball milling medium, and dried after ball milling for 24 hours to obtain a mixed dry powder; the obtained dry powder is pre-calcined at 1100 ° C for 4 hours, Then add the polyvinyl alcohol aqueous solution granulation that concentration is 8wt% in the pre-fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com