X9R ceramic capacitor dielectric material and preparation method thereof

A technology of ceramic capacitors and dielectric materials, applied in the field of ceramic materials, can solve the problems of inability to meet the capacitance change rate ≤±15%, expensive, environmentally harmful, etc., and achieve good industrialization prospects, good temperature stability, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

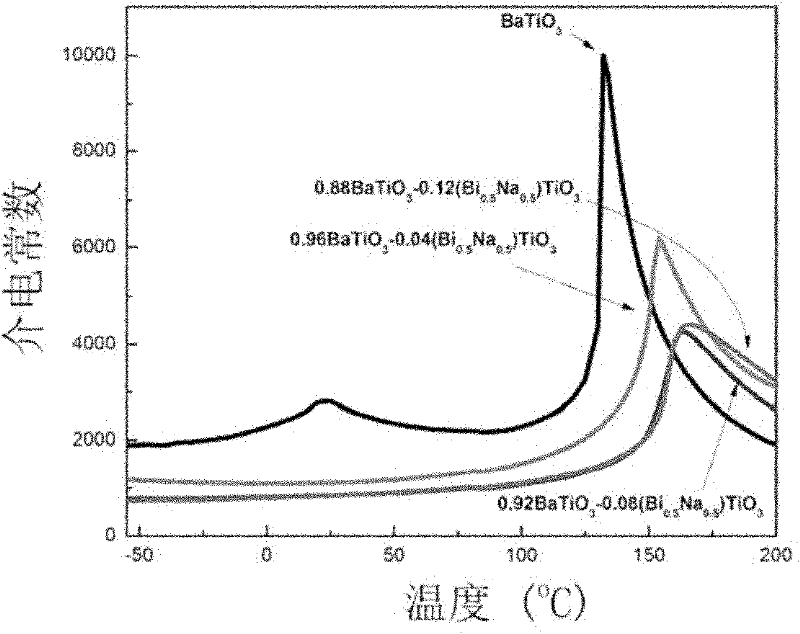

[0029] Embodiment 1, preparation (1-x) BaTiO 3 -xBi 0.5 Na 0.5 TiO 3 (x=0.04, 0.08, 0.12) barium titanate-sodium bismuth titanate complex

[0030] 1) Preparation of (1-x) BaTiO 3 -xBi 0.5 Na 0.5 TiO 3 (x=0.04, 0.08, 0.12) the barium titanate-sodium bismuth titanate composite and characterize its dielectric-temperature properties:

[0031] Chemically pure Bi 2 o 3 、Na 2 CO 3 and TiO 2 Mix according to the molar ratio of 1:1:4, ball mill with ethanol as the medium for 24 hours, dry in a drying oven at 65°C for 12 hours, pass through a 120-mesh sieve, place in a crucible, and pre-fire at 900°C for 2 hours , to obtain pure sodium bismuth titanate powder;

[0032] 2) Mix the barium titanate with an average grain size of 300nm and the obtained sodium bismuth titanate powder according to the molar ratios of 4:96, 8:92 and 12:88 respectively, ball mill with deionized water for 48 hours, pour out, and place in After drying in an oven at 105°C for 8 hours, pre-fired at 110...

Embodiment 2

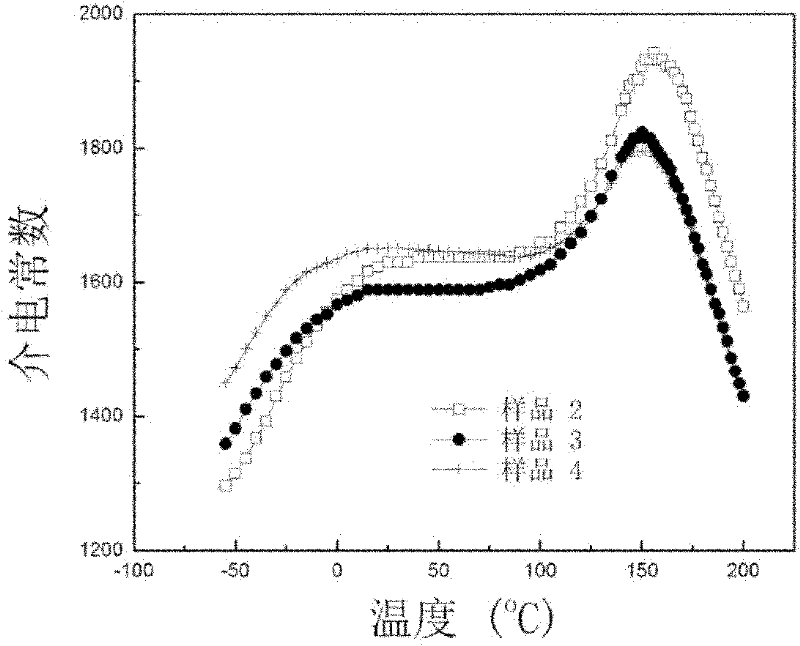

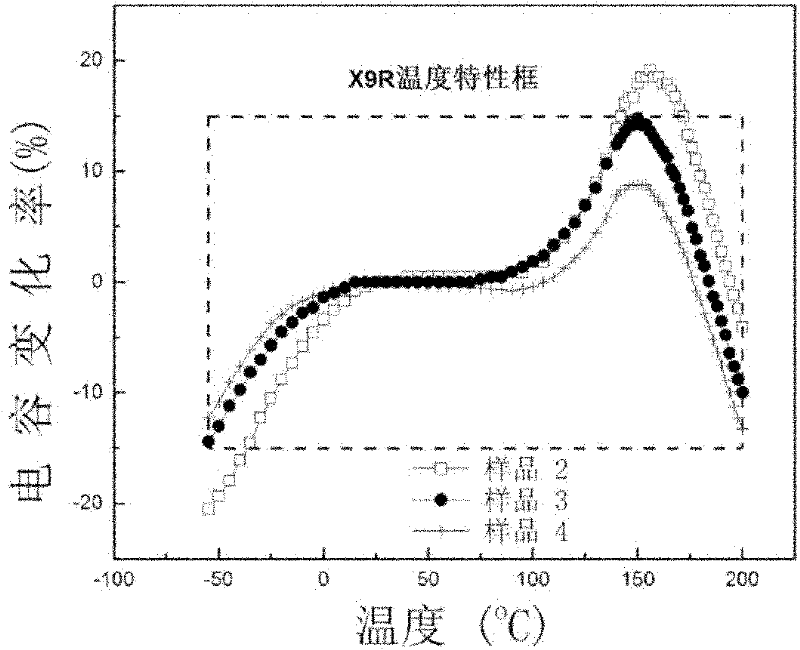

[0035] Prepared with 0.9BaTiO 3 -0.1Bi 0.5 Na 0.5 TiO 3 X9R ceramic capacitor dielectric material as the main component, and the influence of different contents of secondary dopants on its dielectric and electrical properties

[0036] Prepare 0.9BaTiO according to the same steps as in Example 1 3 -0.1Bi 0.5 Na 0.5 TiO 3 The barium titanate-sodium bismuth titanate composite powder shown is only replaced as follows: x=0.1. The obtained composite powder is mixed with a secondary dopant. The secondary dopant consists of Nb 2 o 5 and CaZrO 3 Composition, where Nb 2 o 5 and CaZrO 3 with 0.9BaTiO 3 -0.1Bi 0.5 Na 0.5 TiO 3 The molar ratios are 1.5:2:96.5, 2:2:96, 2.5:2:95.5, 3:2:95, 2.5:1:96.5, 2:1:97; 0.9BaTiO 3 -0.1Bi 0.5 Na 0.5 TiO 3 with Nb 2 o 5 and CaZrO 3 Mix according to the above molar ratio, ball mill with deionized water for 16 hours, dry at 105°C for 8 hours, pass through a 120 mesh sieve, use 5% polyethanol aqueous solution (PVA) as an organic bind...

Embodiment 3

[0044] The purpose of this example is to prepare dielectric ceramics with different component ratios of barium titanate-bismuth sodium titanate composites and barium titanate-bismuth potassium titanate composites as the main components, and to test their dielectric and electrical properties

[0045] Carry out the main component (1-x) BaTiO of preparation X9R type ceramic capacitor dielectric material according to exactly the same step as embodiment 1 3 -xBi 0.5 Na 0.5 TiO 3 The shown barium titanate-sodium bismuth titanate composite is only replaced as follows, and the values of x are respectively 0.06, 0.08 and 0.12, which are listed in Table 3: CaZrO used in Example 2 3 Replace with SrZrO as shown in Table 3 3 , to obtain samples 7-11, where Nb 2 o 5 and SrZrO 3 with (1-x)BaTiO 3 -xBi 0.5 Na 0.5 TiO 3 The molar ratios are 2:2:96; the (1-x)BaTiO 3 -xBi 0.5 Na 0.5 TiO 3 with Nb 2 o 5 and SrZrO 3 Mix according to the above molar ratio, ball mill with deionize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com