Patents

Literature

64results about How to "Avoid rough surfaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

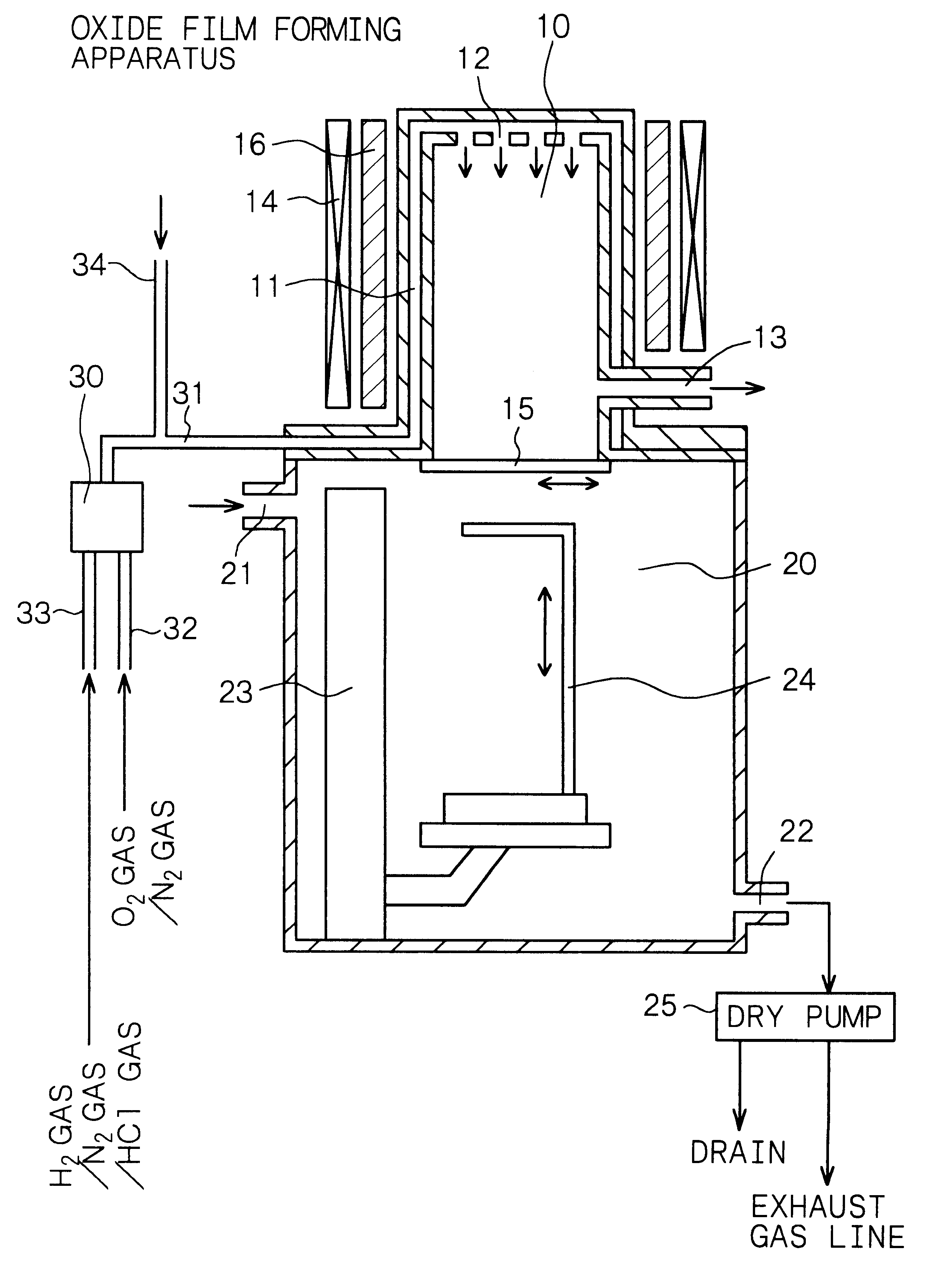

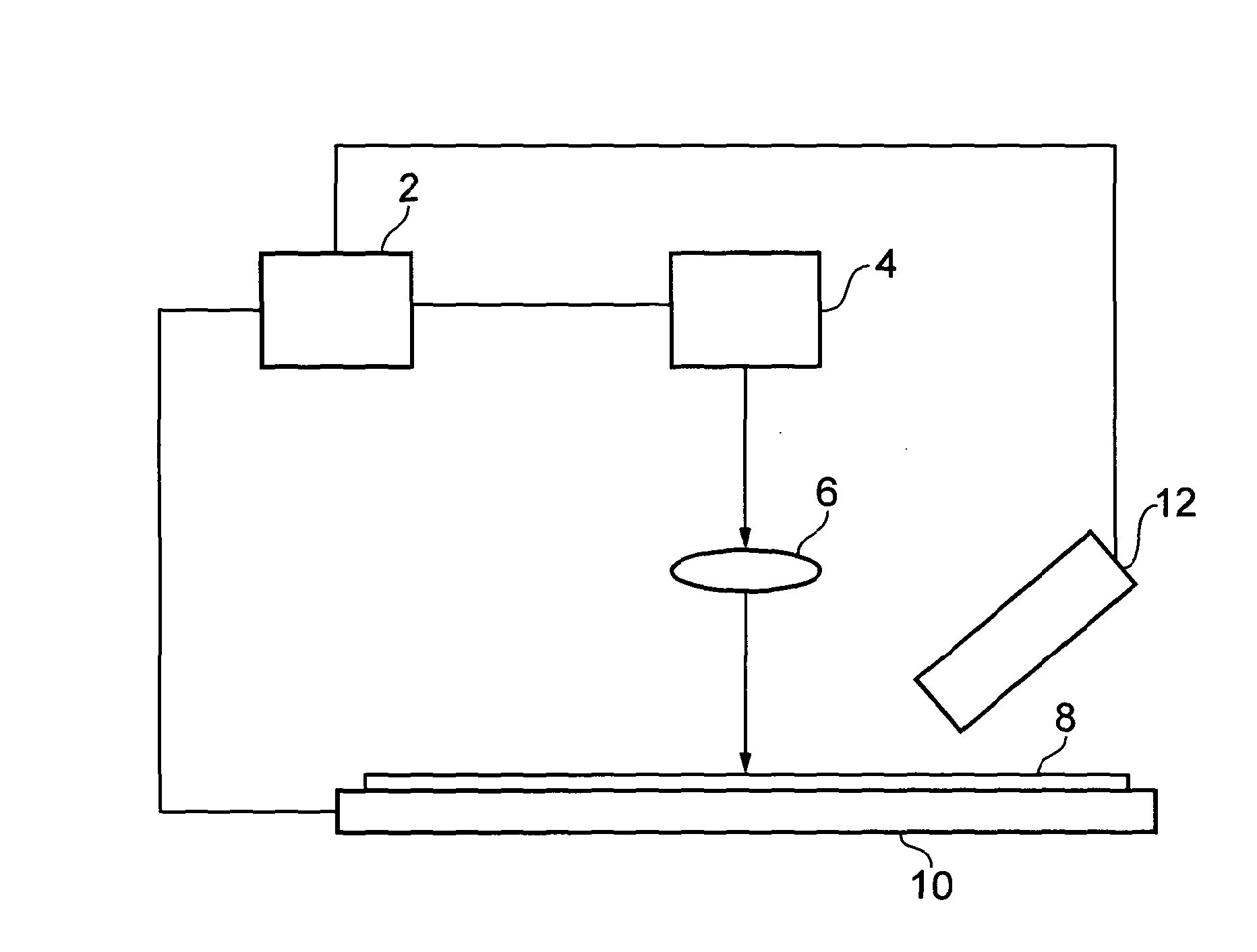

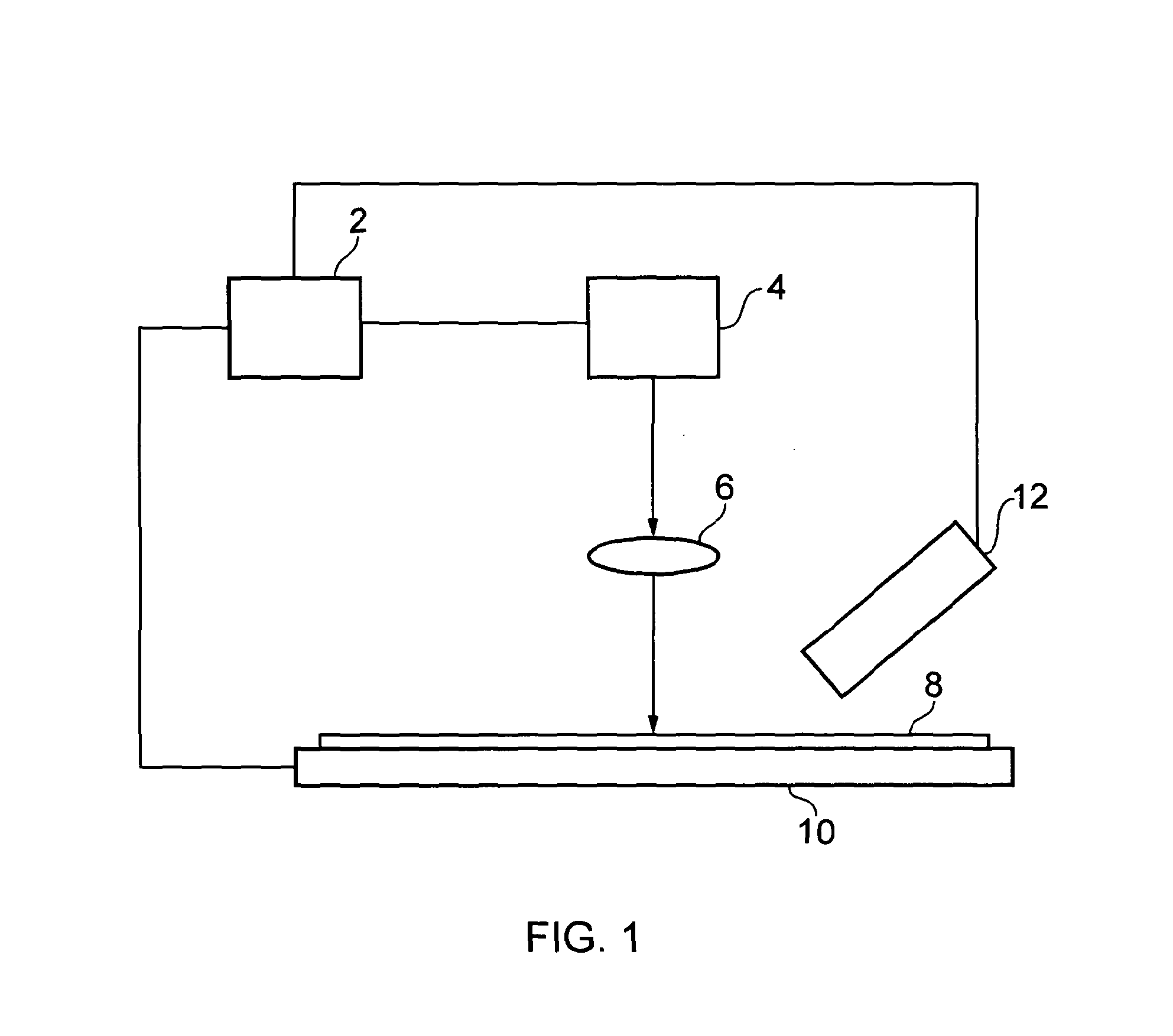

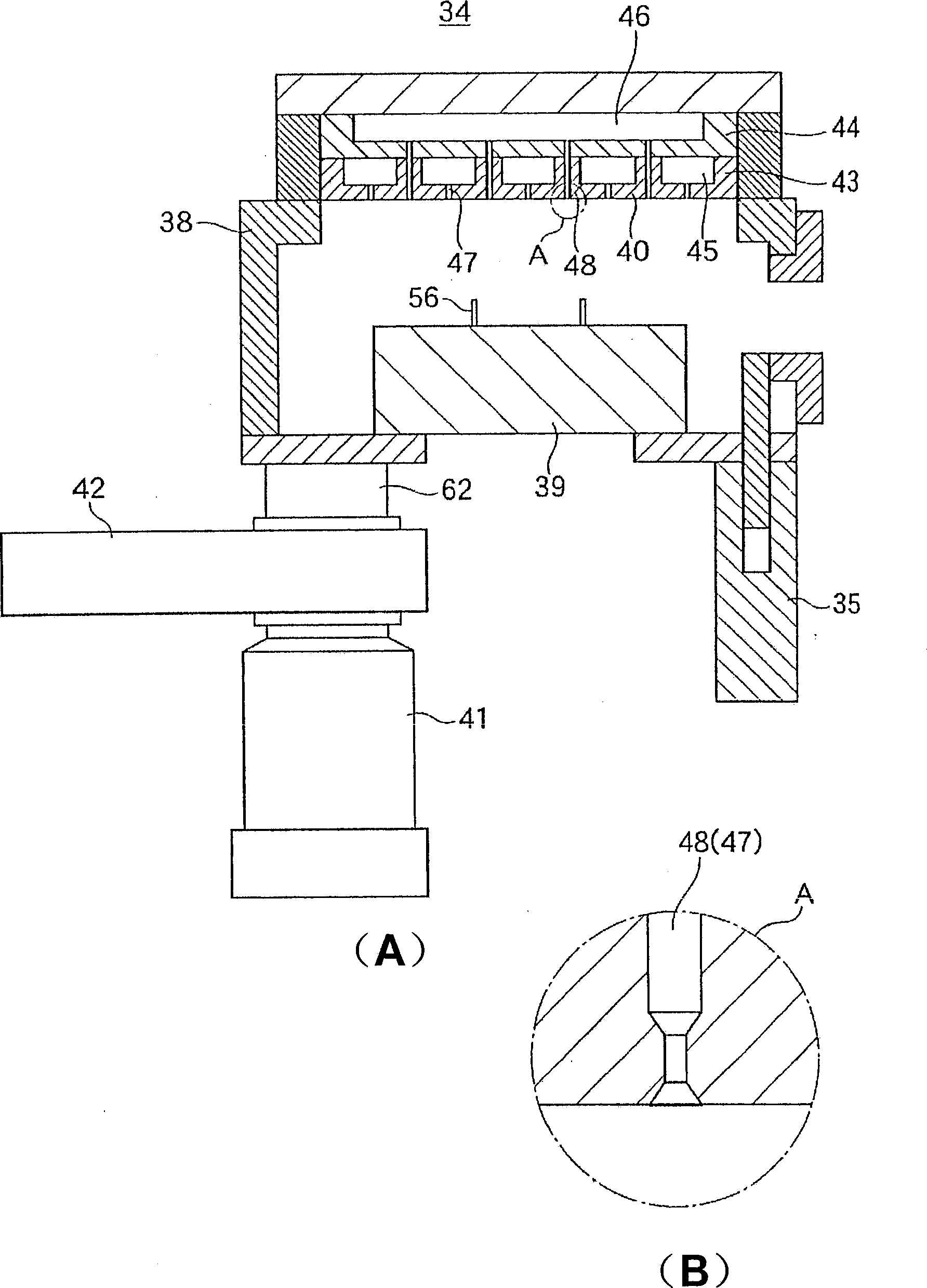

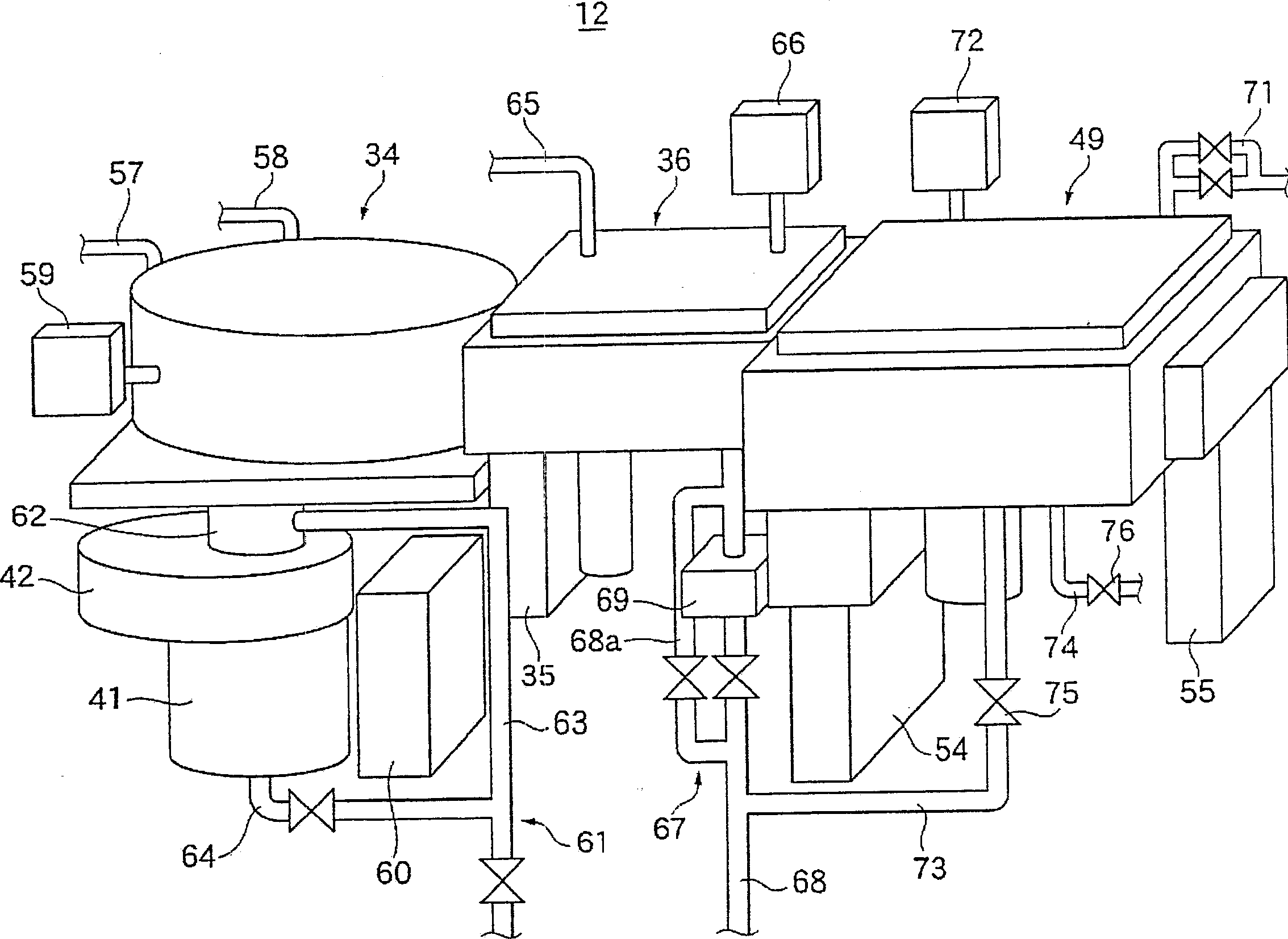

Method of forming oxide film

InactiveUS6297172B1Avoid rough surfacesMaintain good propertiesSemiconductor/solid-state device manufacturingWater vaporEngineering

A method of forming an oxide film comprising the steps of; (A) generating a water vapor atmosphere in a process chamber in a state where partitioning means is closed, and transferring a substrate into a substrate transfer portion, (B) opening the partitioning means after the transfer of the substrate into the substrate transfer portion is completed, and transferring the substrate into the process chamber having the water vapor atmosphere, (C) thermally oxidizing a semiconductor layer on the surface of the substrate in the process chamber having the water vapor atmosphere, to form an oxide film having a predetermined thickness on the surface of the semiconductor layer, and (D) changing the atmosphere in the process chamber into an inert gas atmosphere, then transferring the substrate out of the process chamber, closing the partitioning means and transferring the substrate out of the substrate transfer portion.

Owner:SONY CORP

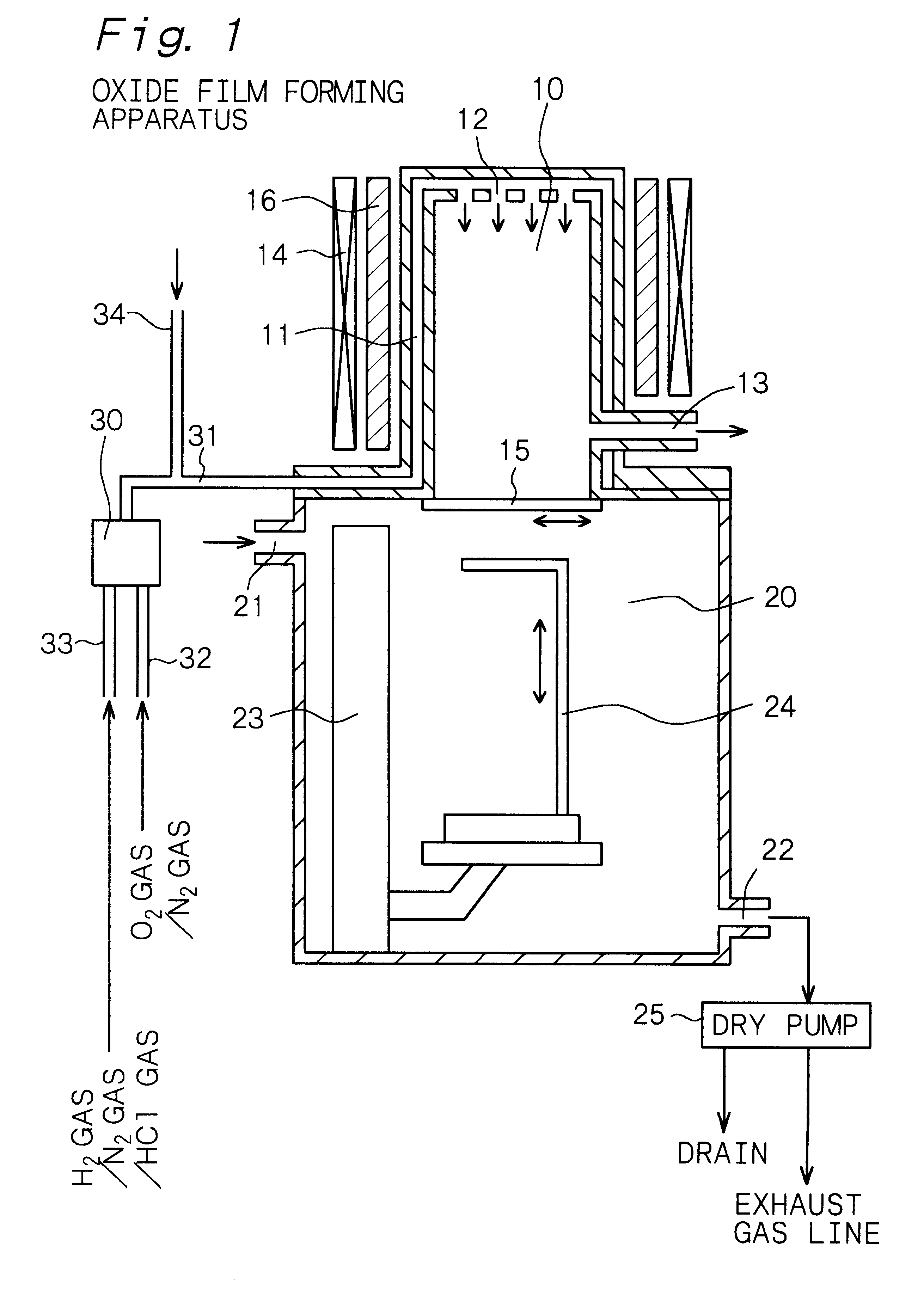

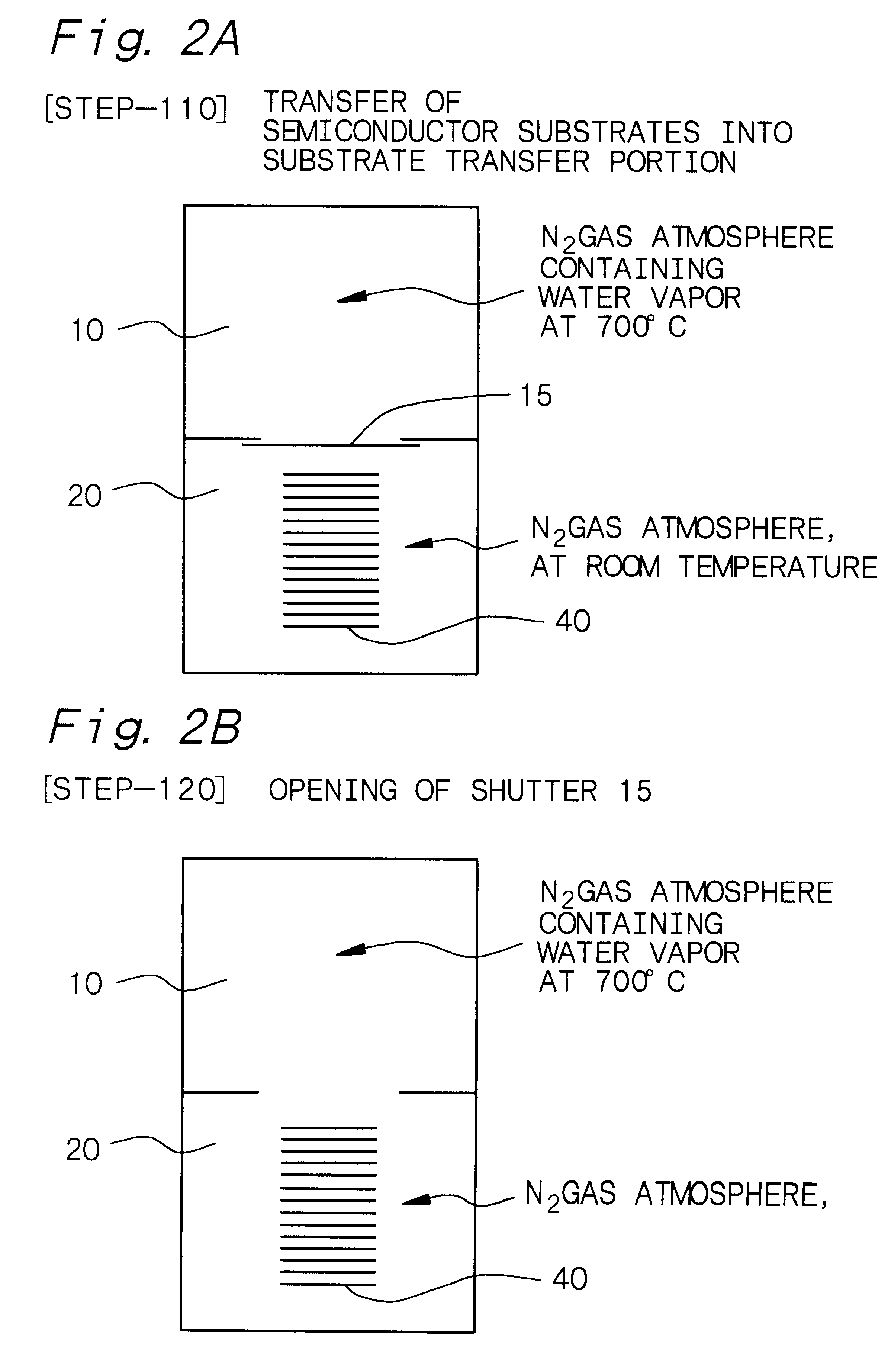

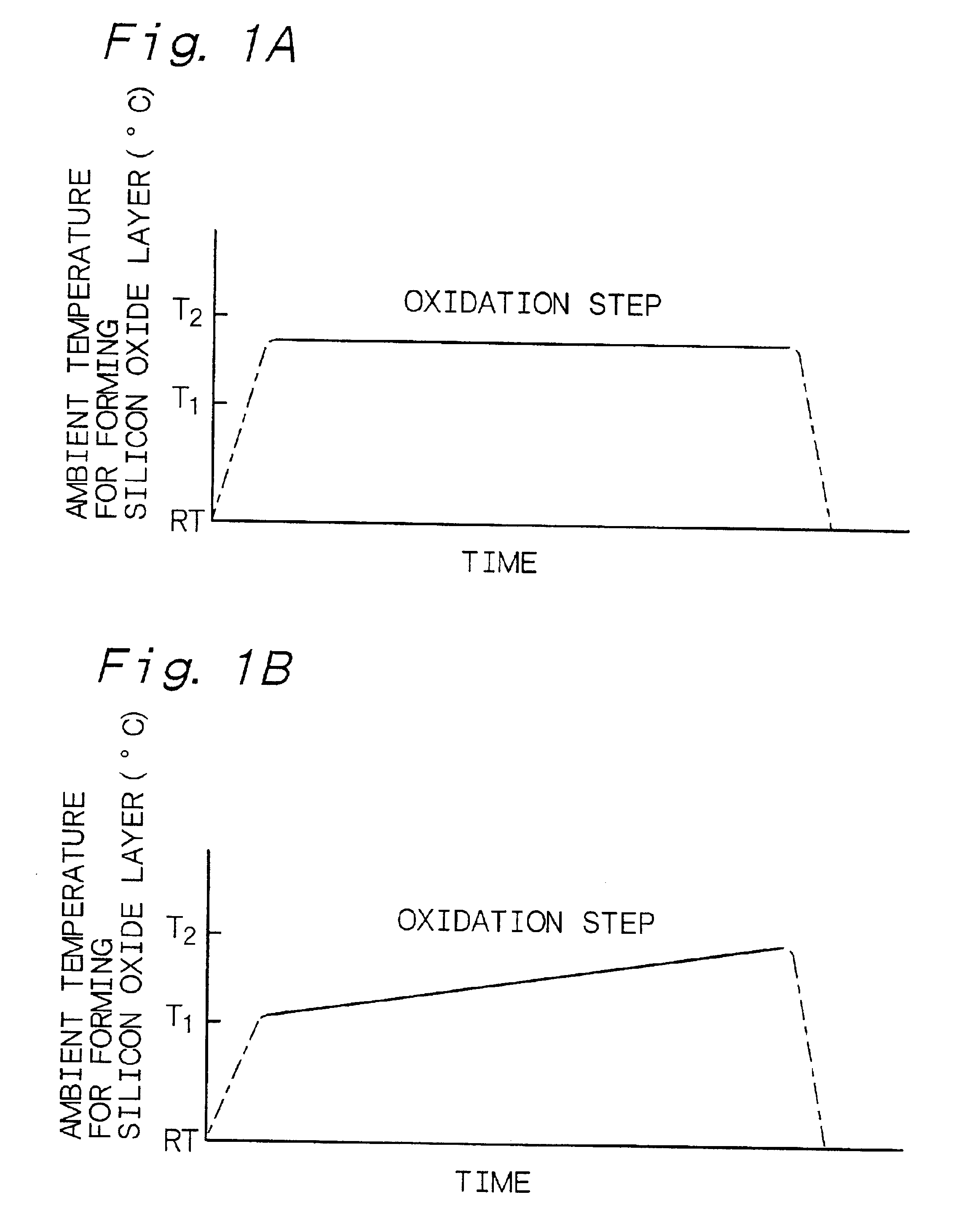

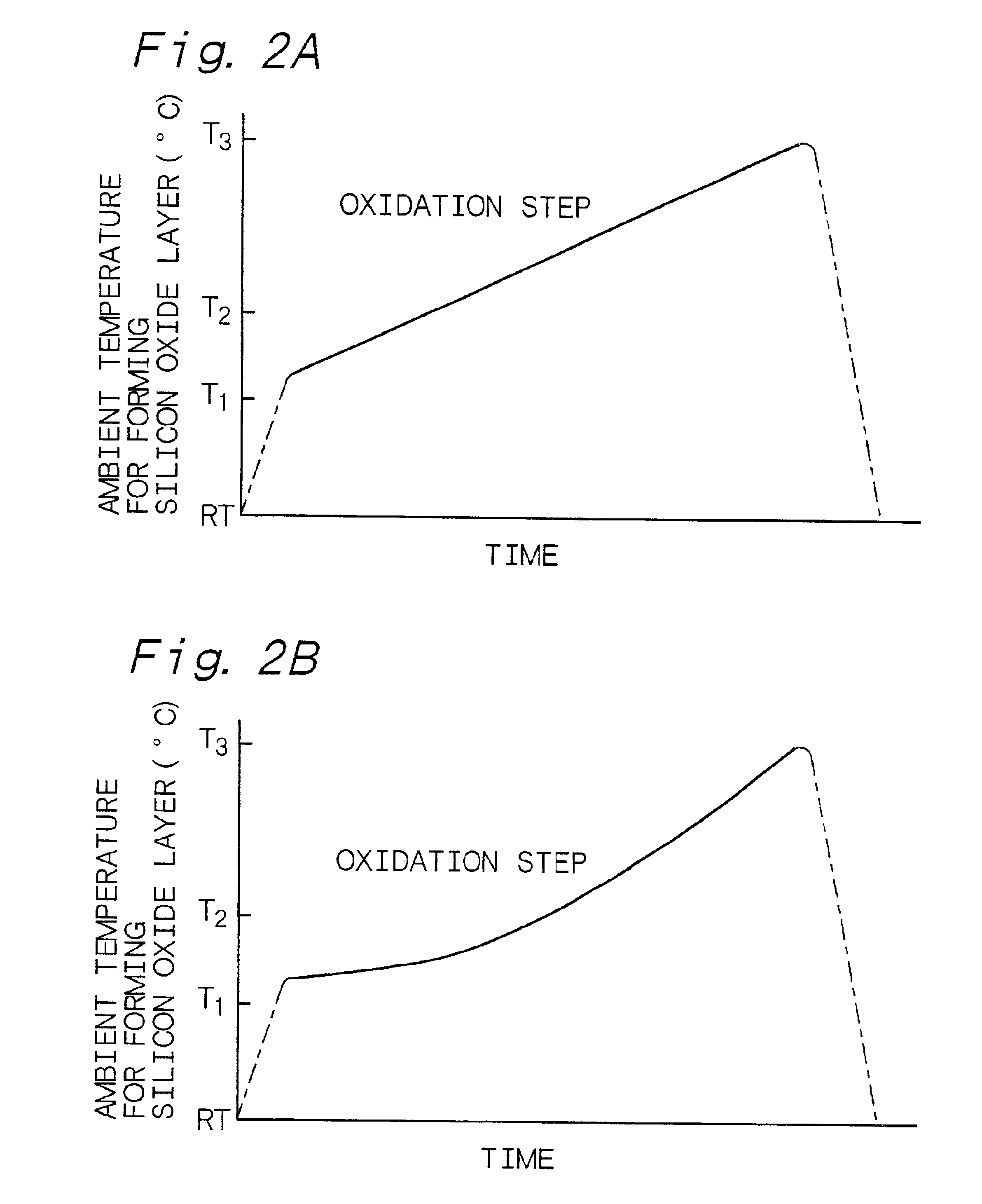

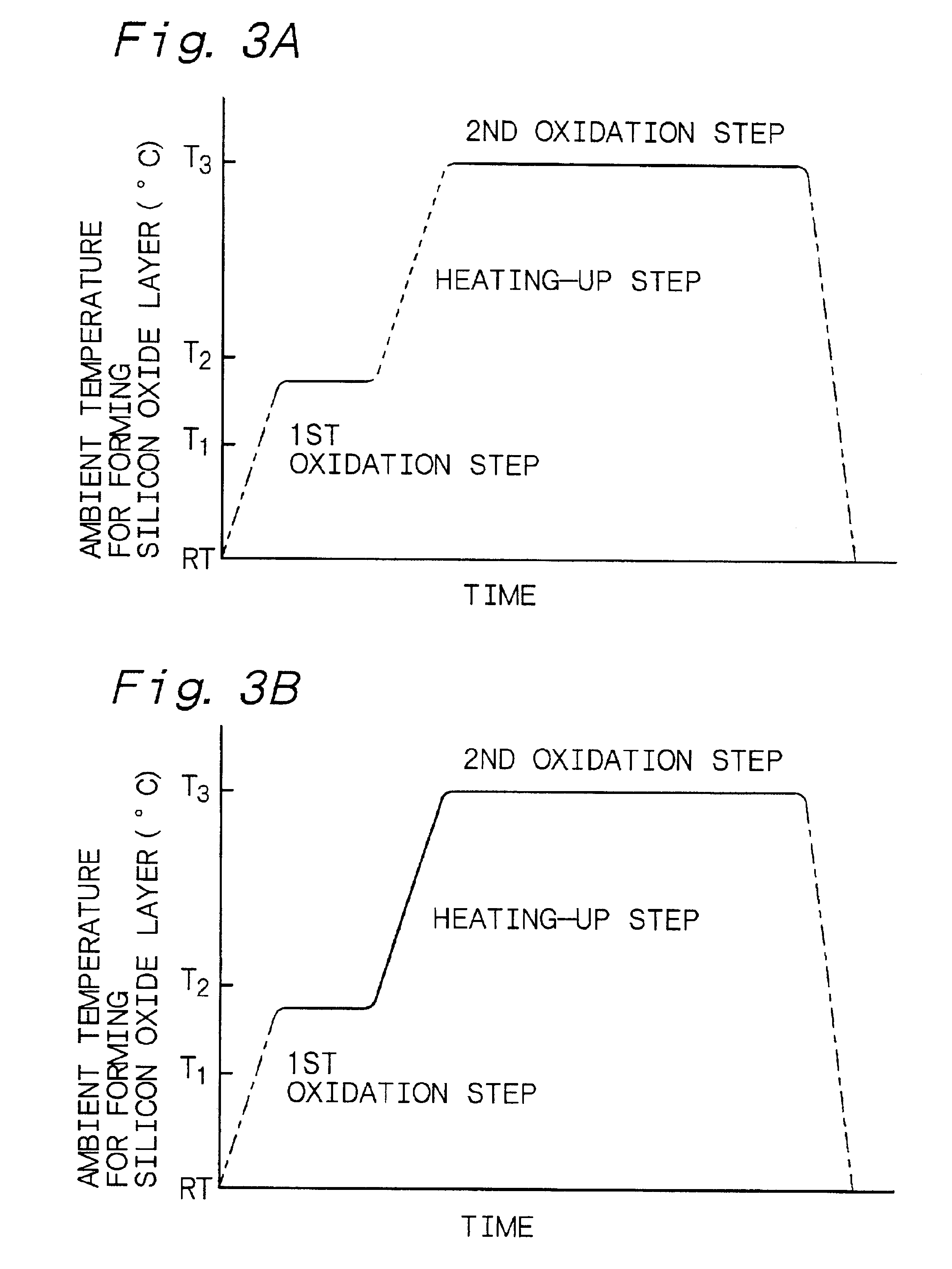

Method of forming silicon oxide layer

InactiveUS6797323B1Maintain good propertiesAvoid rough surfacesPretreated surfacesSemiconductor/solid-state device manufacturingSilicon oxideOptoelectronics

A method of forming a silicon oxide layer comprising initiating formation of a silicon oxide layer on a surface of a silicon layer by an oxidation method using wet gas at an ambient temperature at which no silicon atom is eliminated from the surface of the silicon layer, and then, forming the silicon oxide layer up to a predetermined thickness by an oxidation method using wet gas.

Owner:SONY CORP

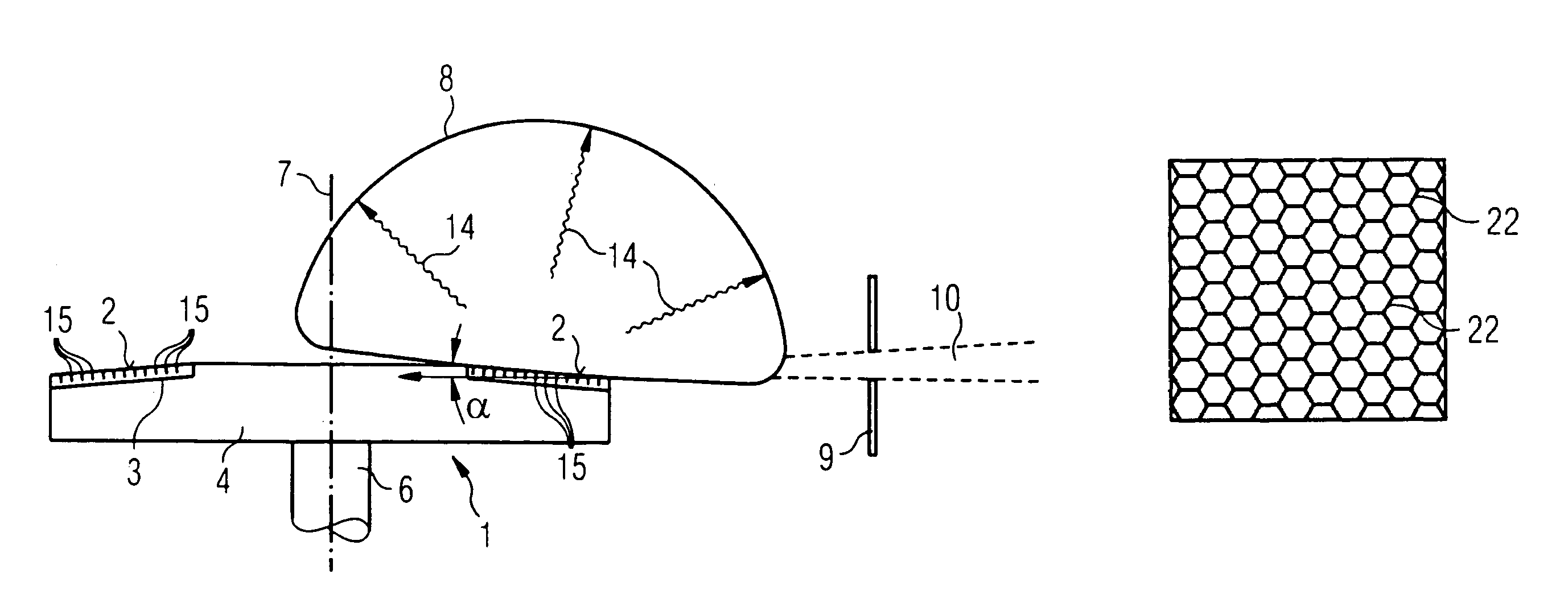

Method of forming an optical device

InactiveUS20130180959A1Reduce transferPreserving and improving reflectivity of surfaceArc welding apparatusWelding/cutting media/materialsSurface tension gradientProviding material

A method of forming an optical device comprises applying a laser beam to a target area of the surface so as to selectively heat material of the surface thereby to provide transfer of material due to a surface tension gradient, wherein the surface is such that, when liquid, parts of the surface at higher temperatures have a higher surface tension than adjacent parts of the surface at lower temperatures.

Owner:RENISHAW PLC

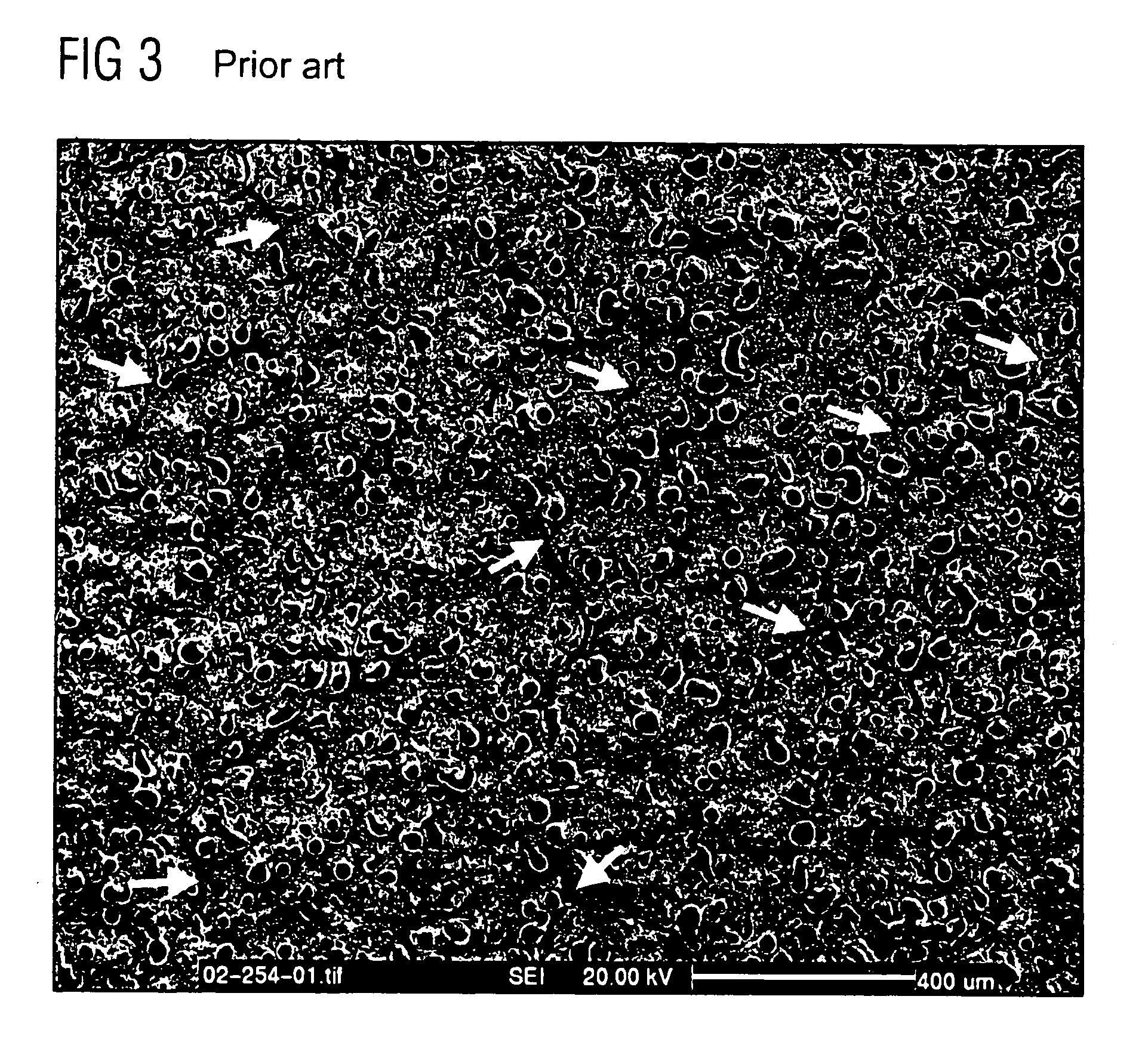

X-ray anode having an electron incident surface scored by microslits

InactiveUS7079625B2Surface rougheningHigh surfaceX-ray tube electrodesElectrical-based machining electrodesX-rayElectron

Owner:SIEMENS HEALTHCARE GMBH

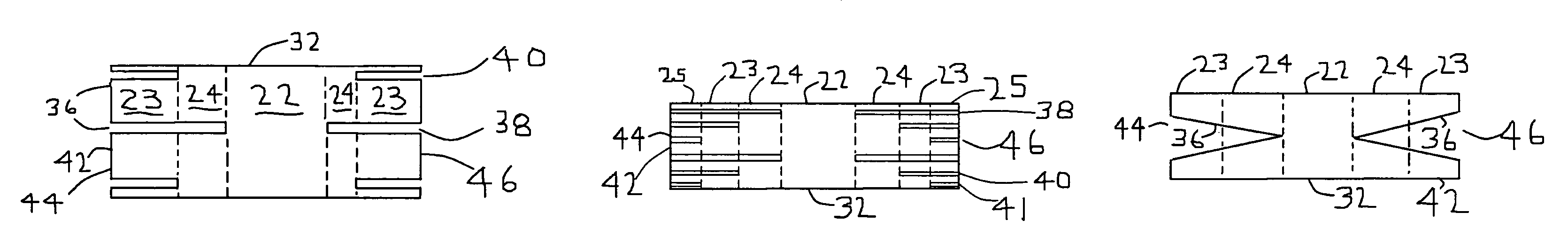

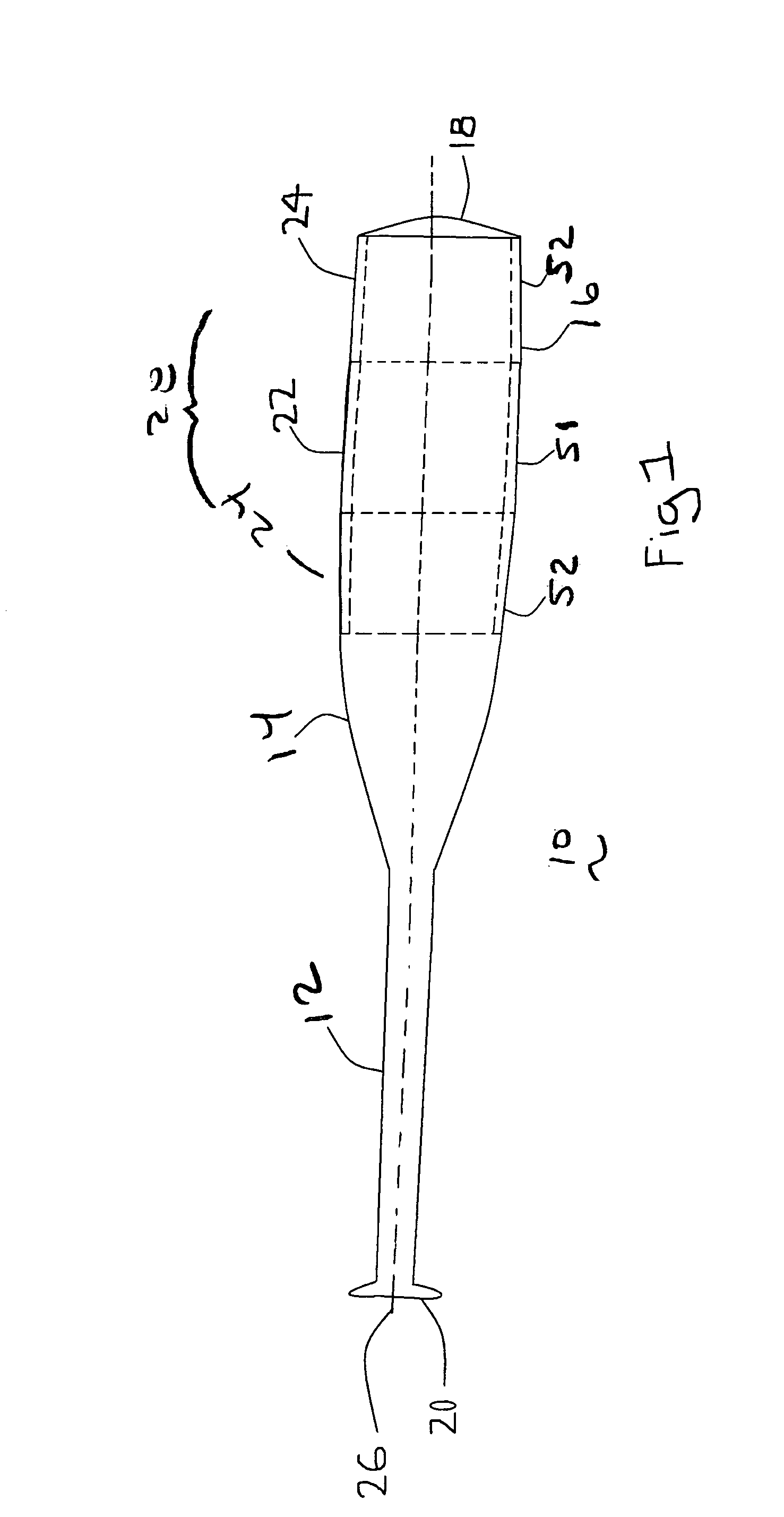

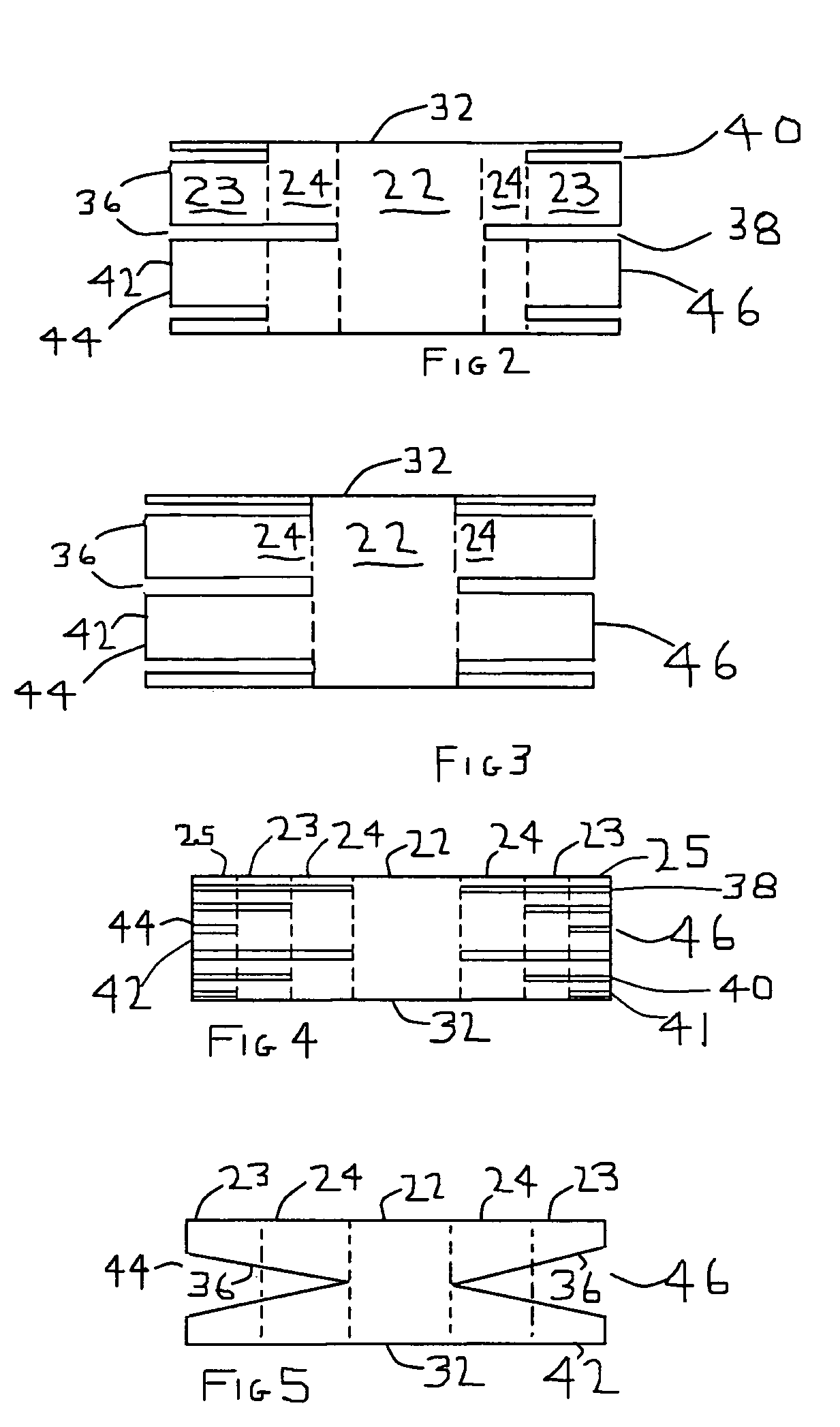

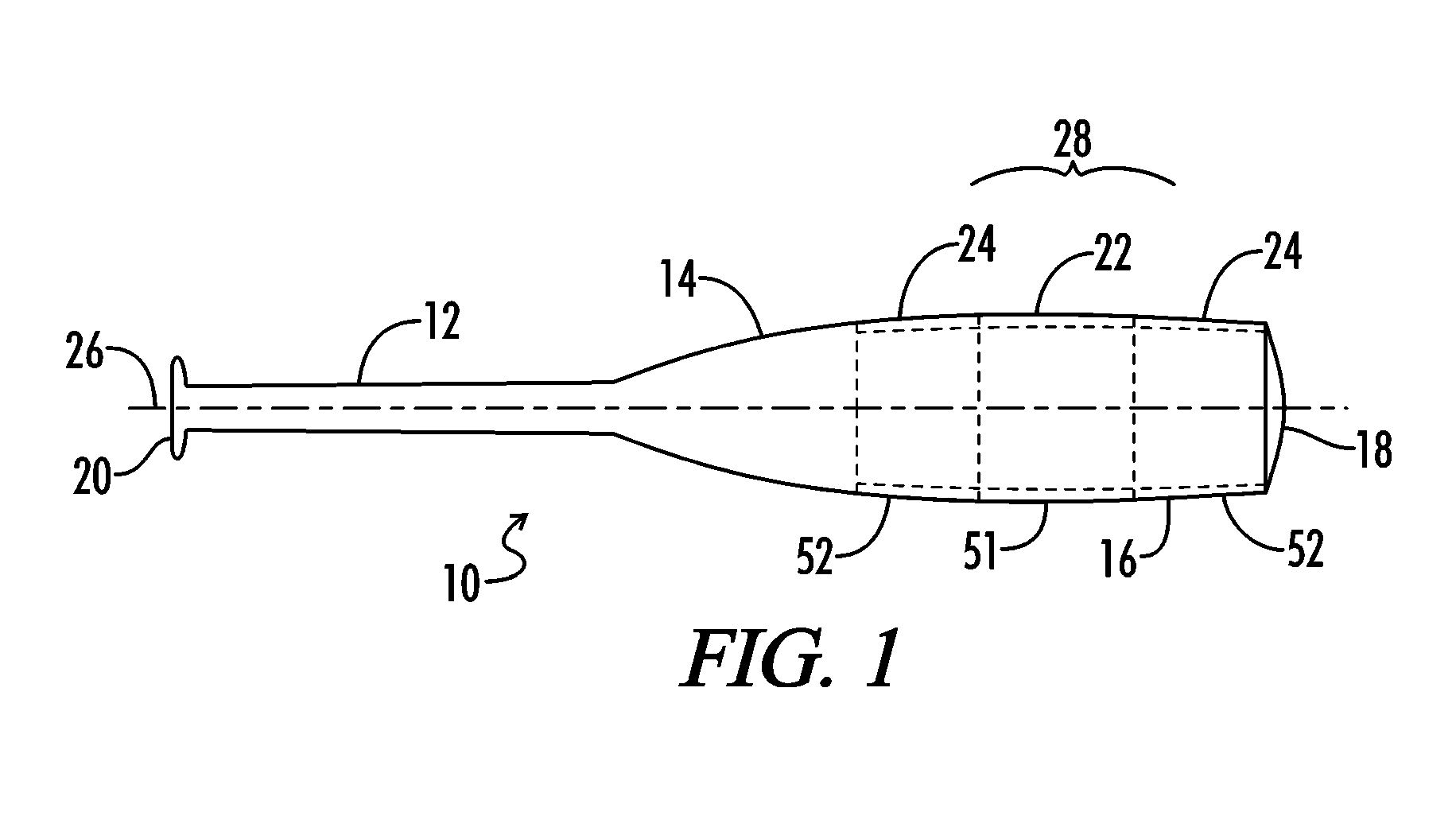

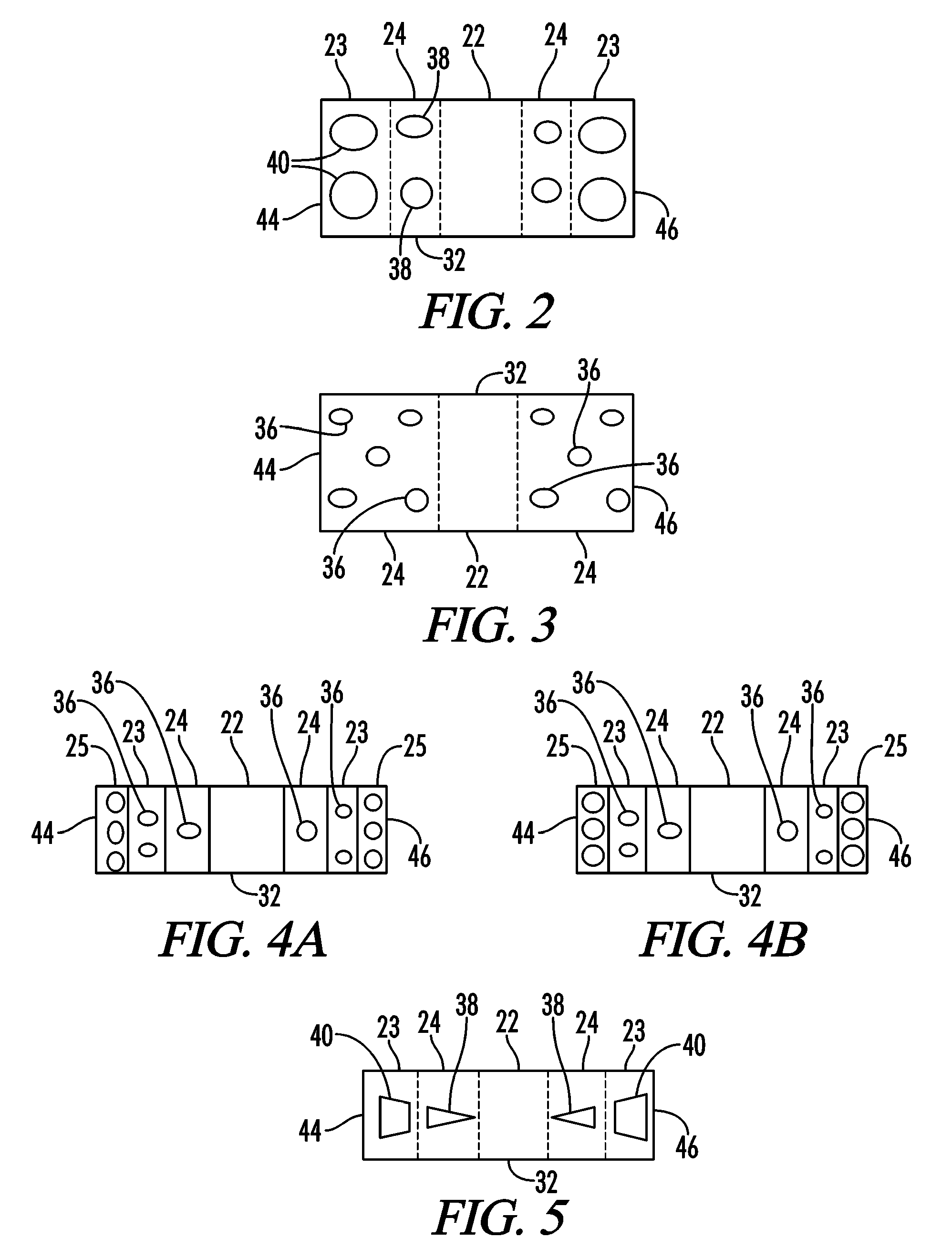

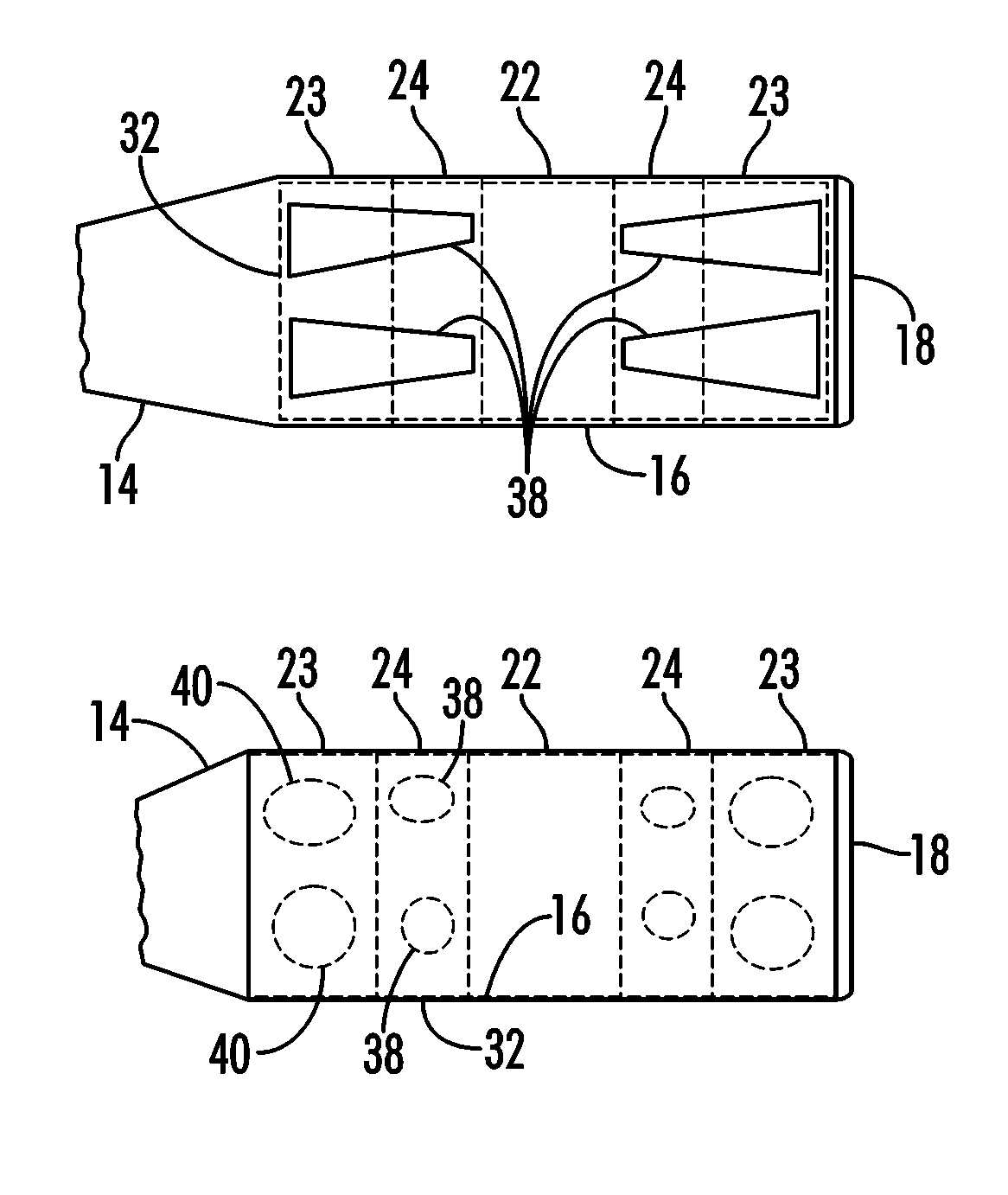

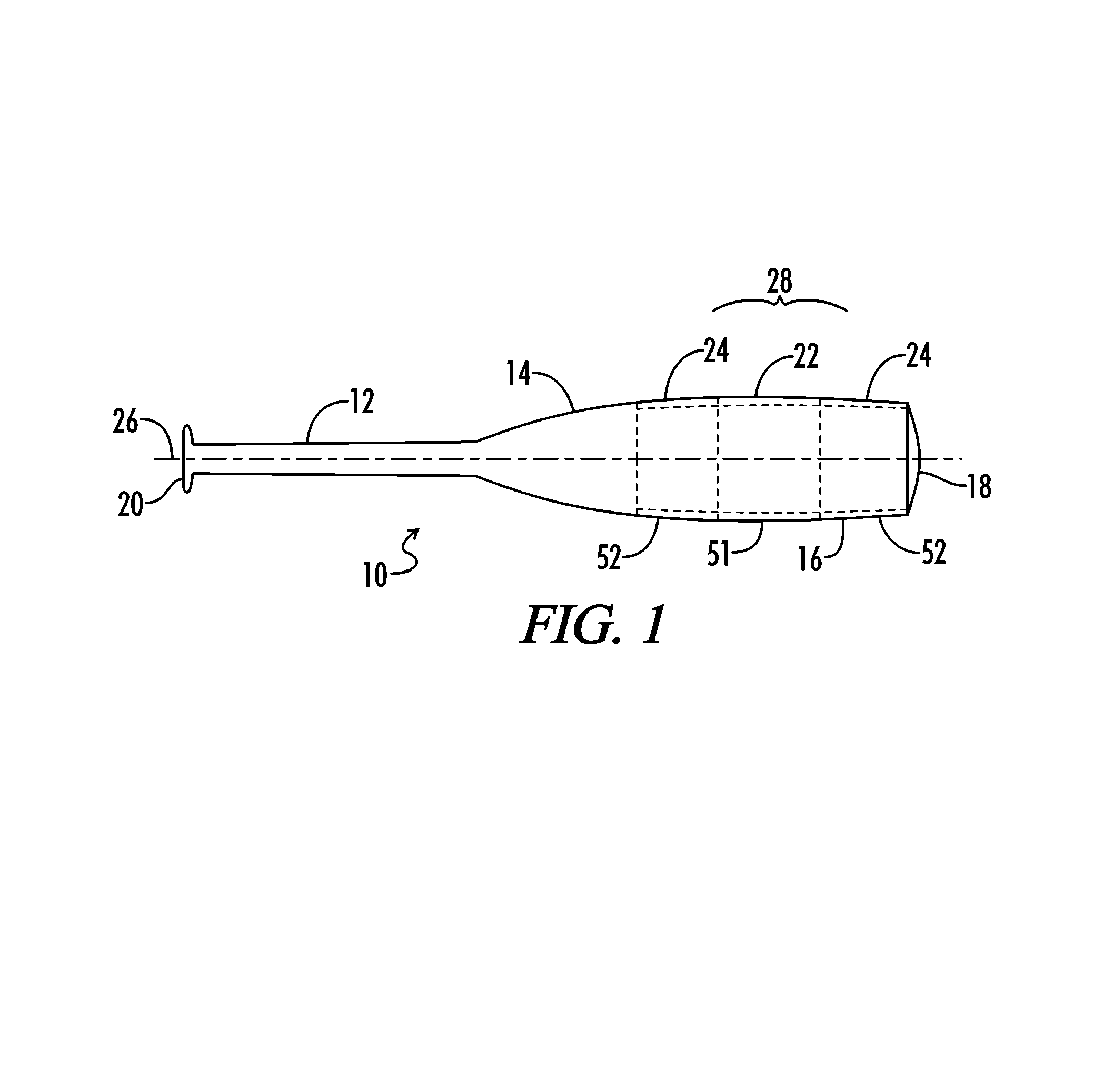

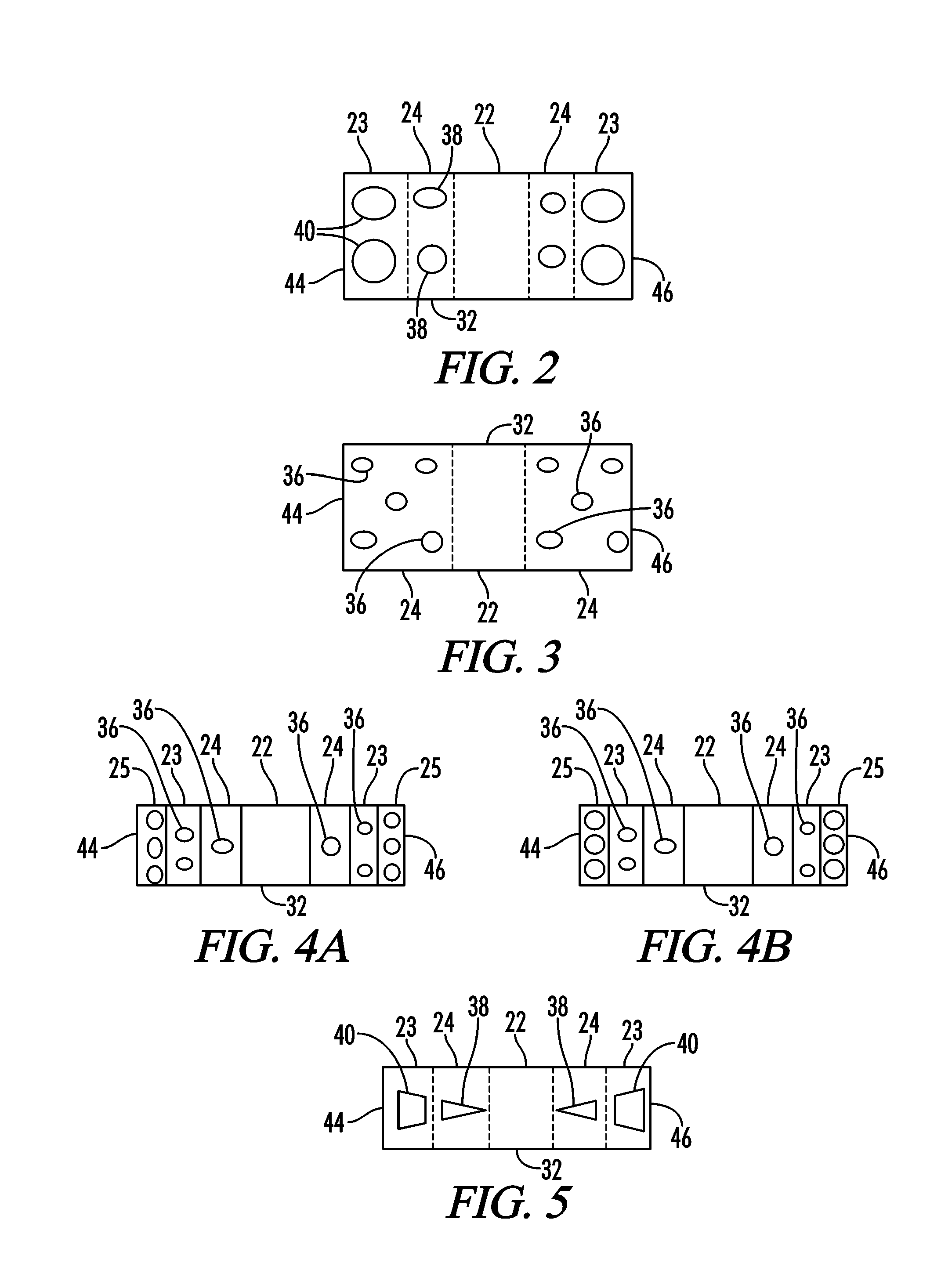

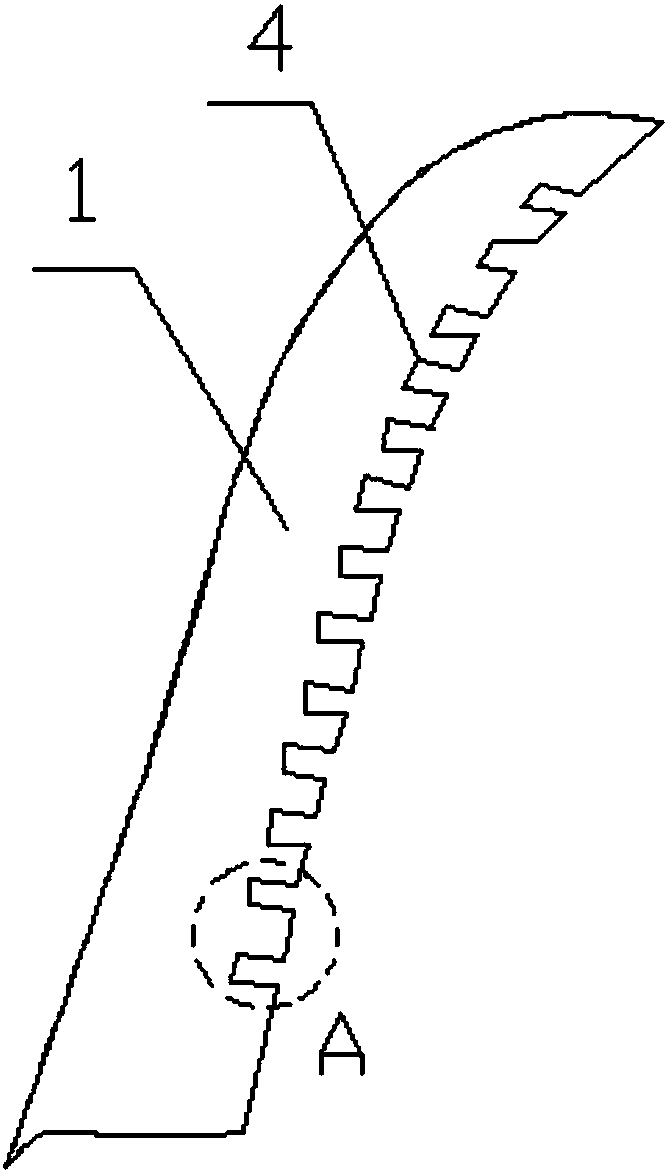

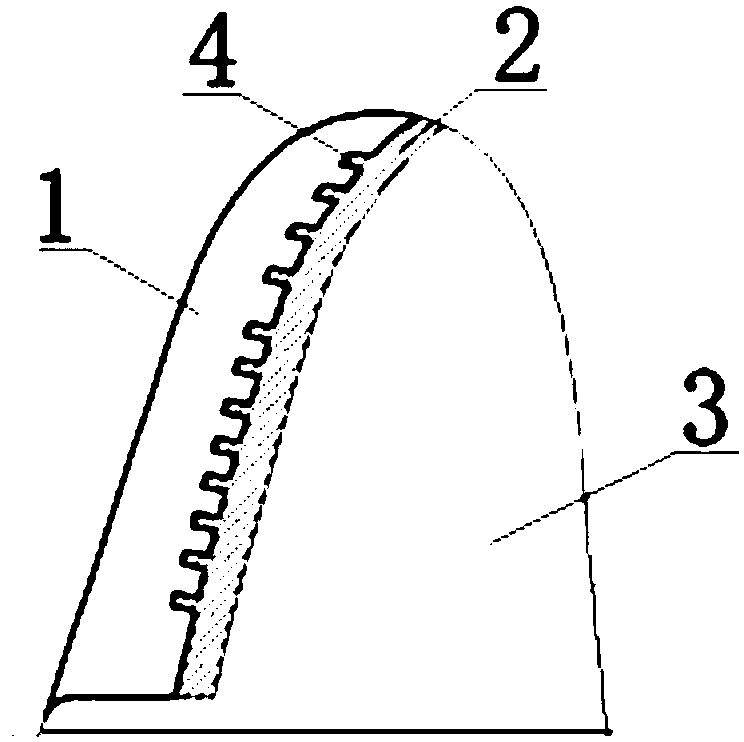

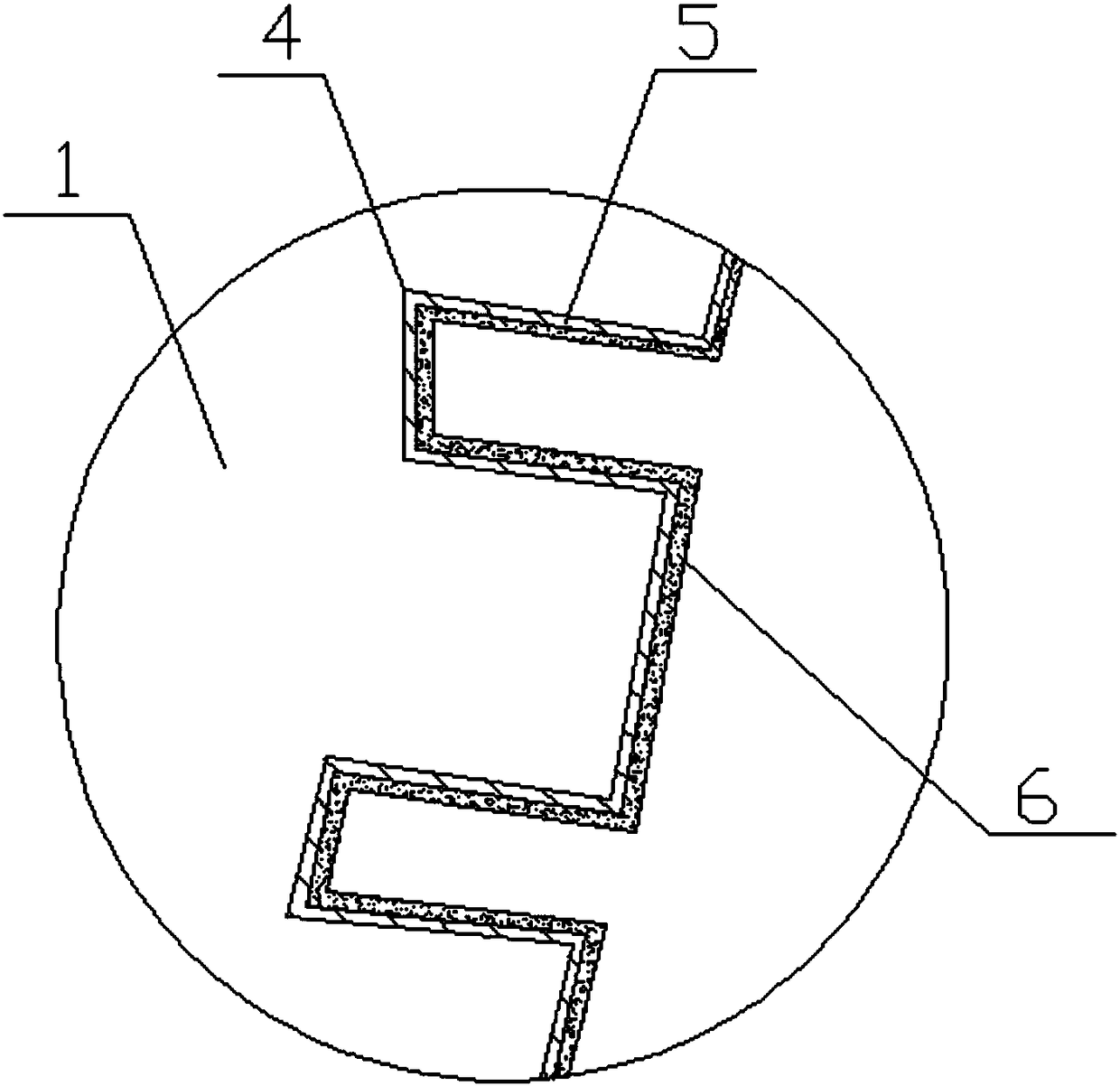

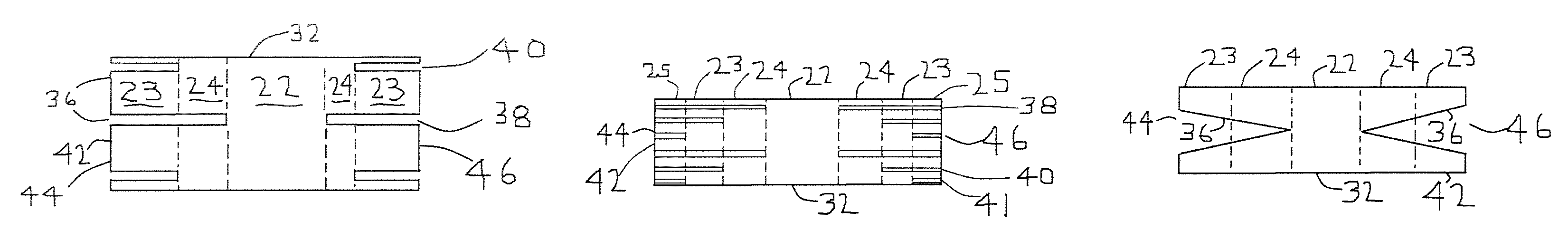

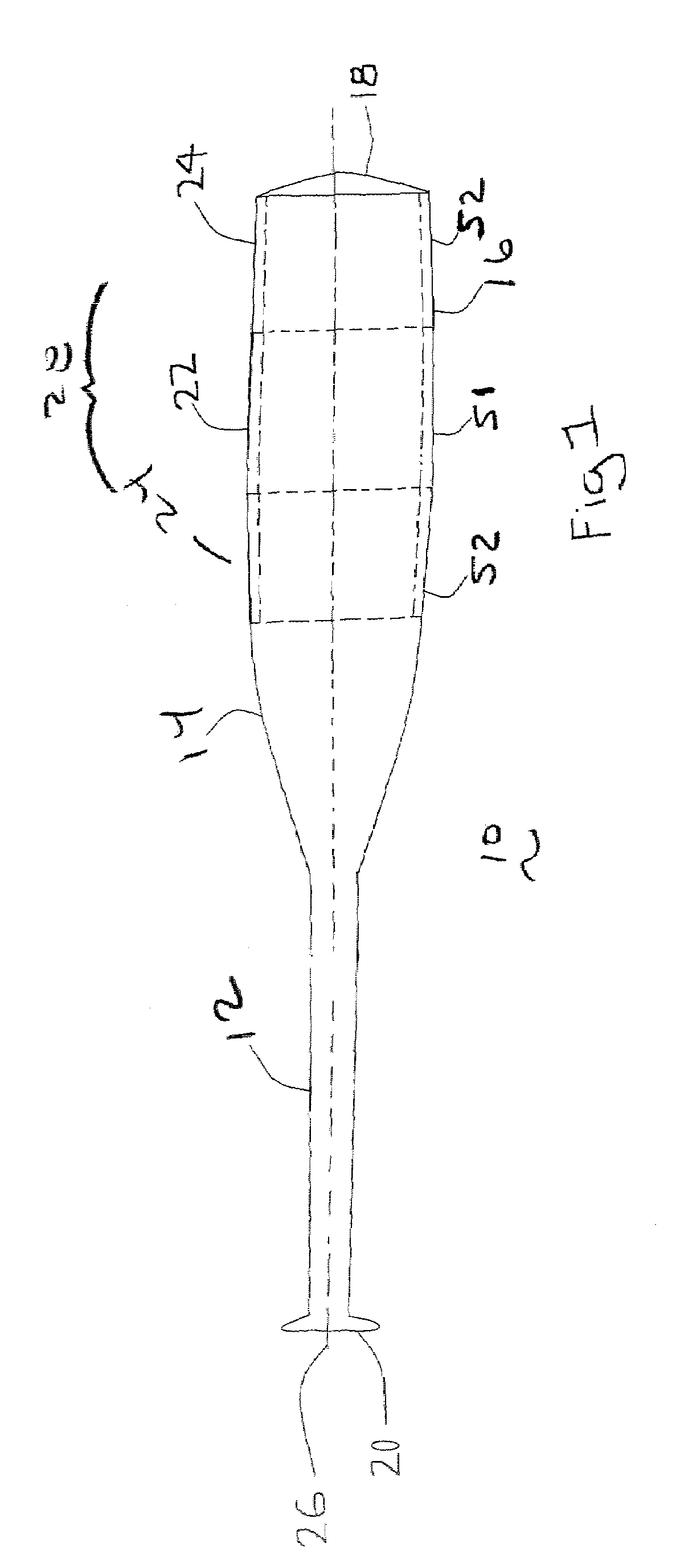

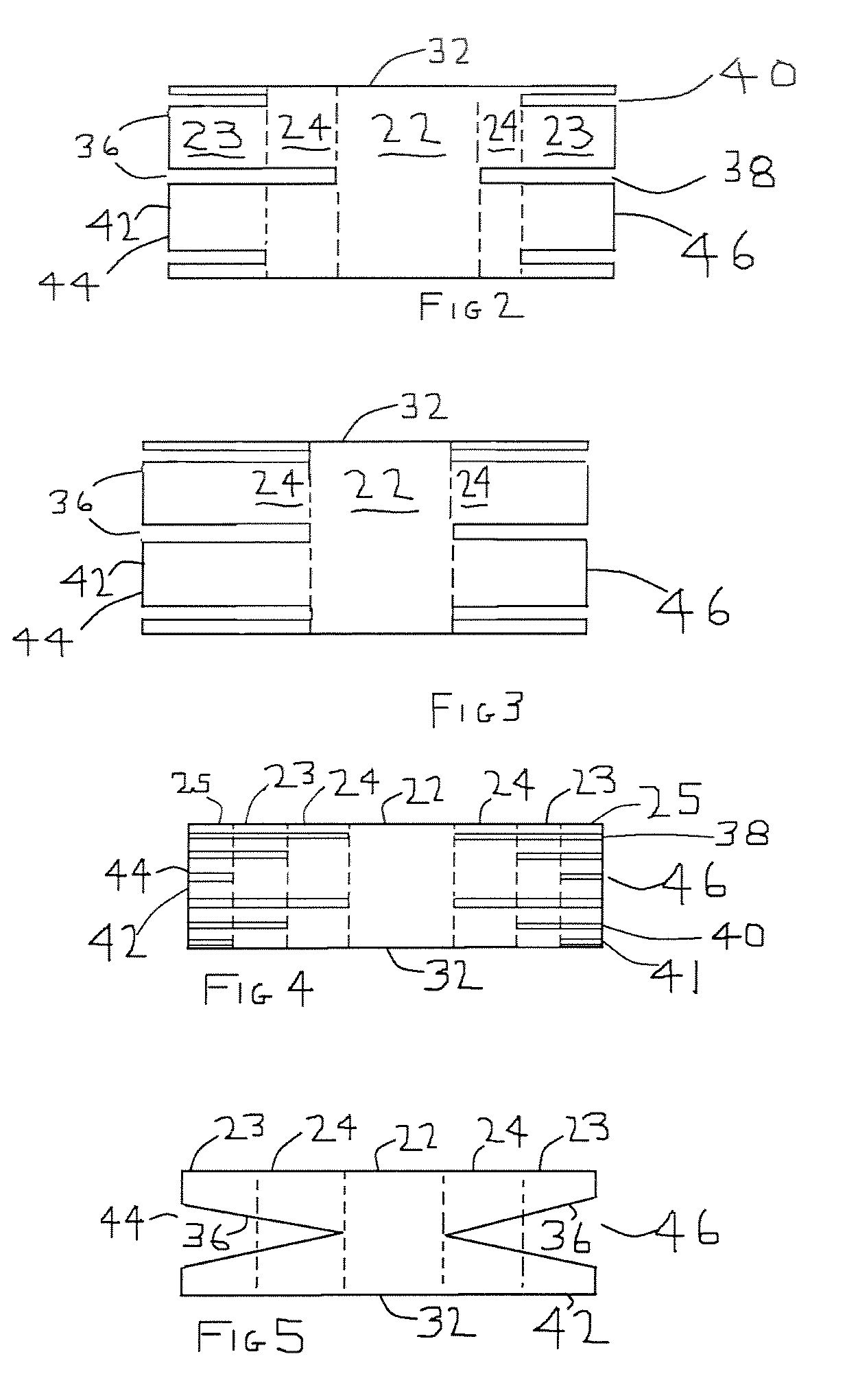

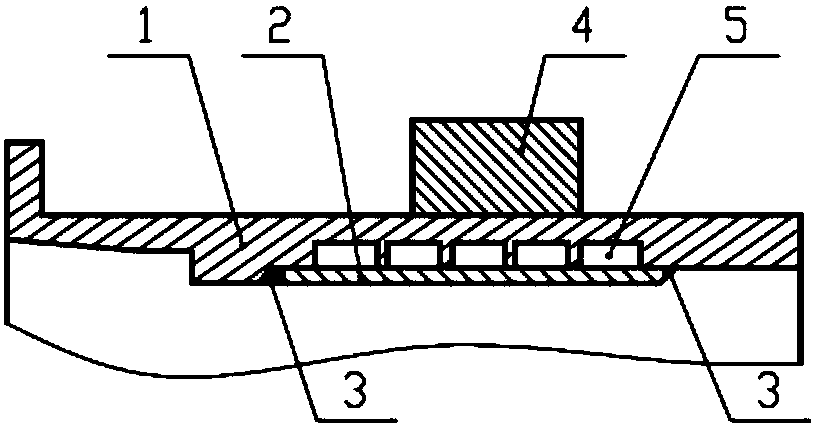

Bat having a sleeve with slots

Disclosed herein is a bat comprising a handle portion, a transition portion attached to the handle portion, and a barrel portion attached to the transition portion. The barrel portion includes one or more first cross-sections having a first stiffness and a plurality of second cross-sections having a second stiffness. Each first cross-section is beside one second cross-section or between two of the second cross-sections and the first stiffness is greater than the second stiffness. The variance in stiffness between the first cross-sections and the second cross-sections is created by varying the amount of material in the cross-section or by, more accurately, removing material in the second cross sections to make the second cross-sections more flexible by creating slots. Likewise, a bat may be provided with third cross sections on the sides of the second cross-sections distal from the first cross-section whereby the third cross-sections are less stiff that the second cross-sections because more material is removed.

Owner:RAWLINGS SPORTING GOODS

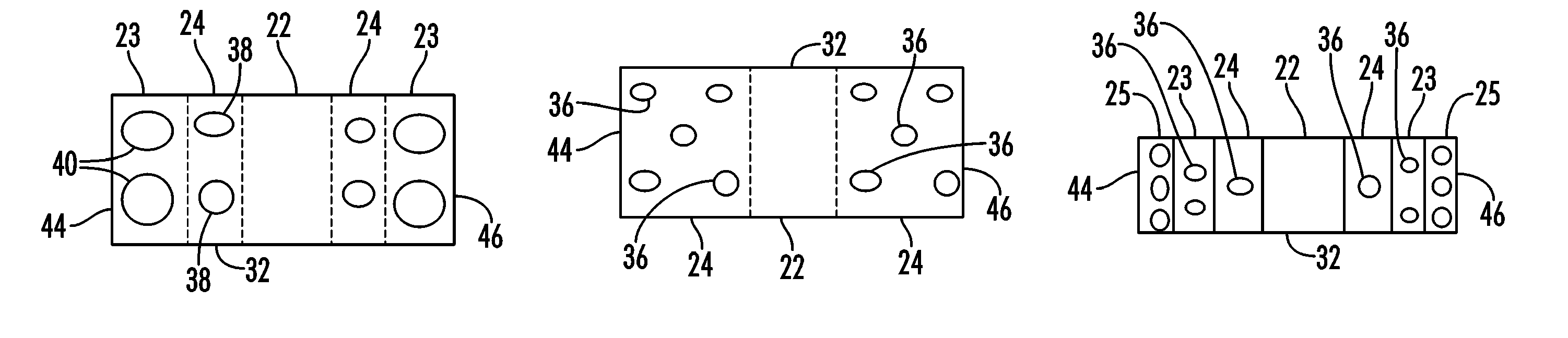

Bat having a sleeve with holes

Disclosed herein is a bat comprising a handle portion, a transition portion attached to the handle portion, and a barrel portion attached to the transition portion. The barrel portion includes one or more first cross-sections having a first stiffness and a plurality of second cross-sections having a second stiffness. Each first cross-section is beside one second cross-section or between two of the second cross-sections and the first stiffness is greater than the second stiffness. The variance in stiffness between the first cross-sections and the second cross-sections is created by varying the amount of material in the cross-section or by, more accurately, removing material in the second cross sections to make the second cross-sections more flexible by creating holes.

Owner:MIKEN SPORTS

Bat having a sleeve with holes

Disclosed herein is a bat comprising a handle portion, a transition portion attached to the handle portion, and a barrel portion attached to the transition portion. The barrel portion includes one or more first cross-sections having a first stiffness and a plurality of second cross-sections having a second stiffness. Each first cross-section is beside one second cross-section or between two of the second cross-sections and the first stiffness is greater than the second stiffness. The variance in stiffness between the first cross-sections and the second cross-sections is created by varying the amount of material in the cross-section or by, more accurately, removing material in the second cross sections to make the second cross-sections more flexible by creating holes.

Owner:MIKEN SPORTS

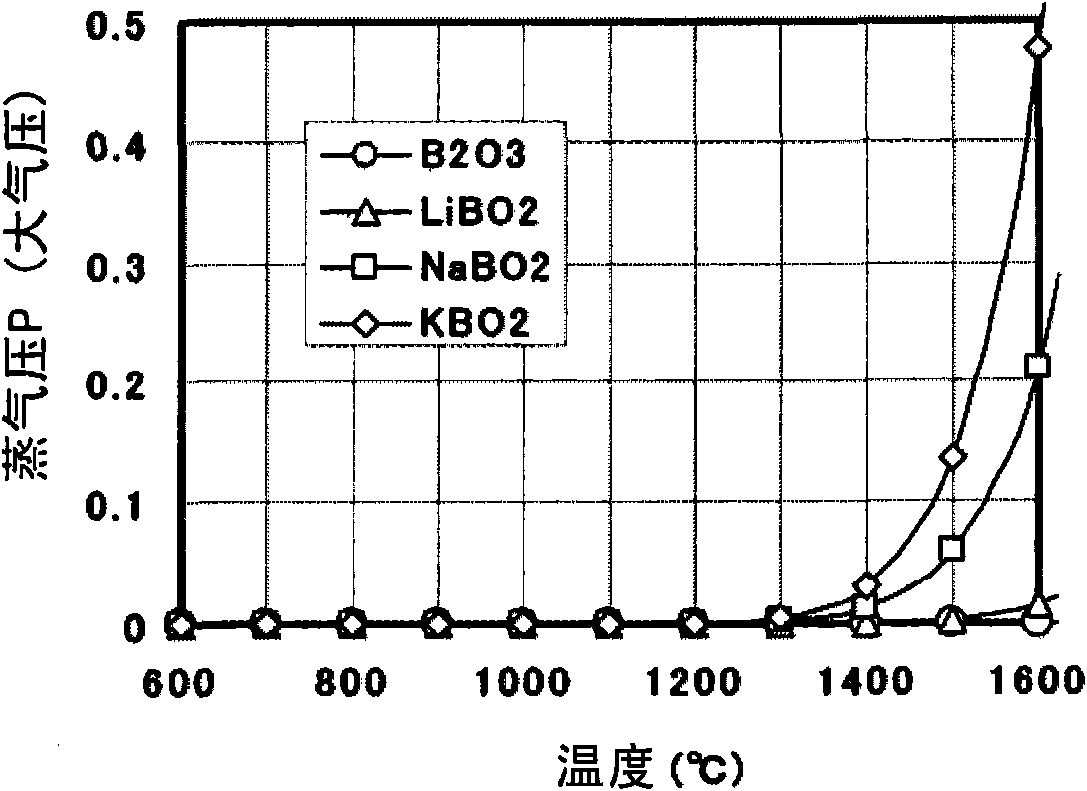

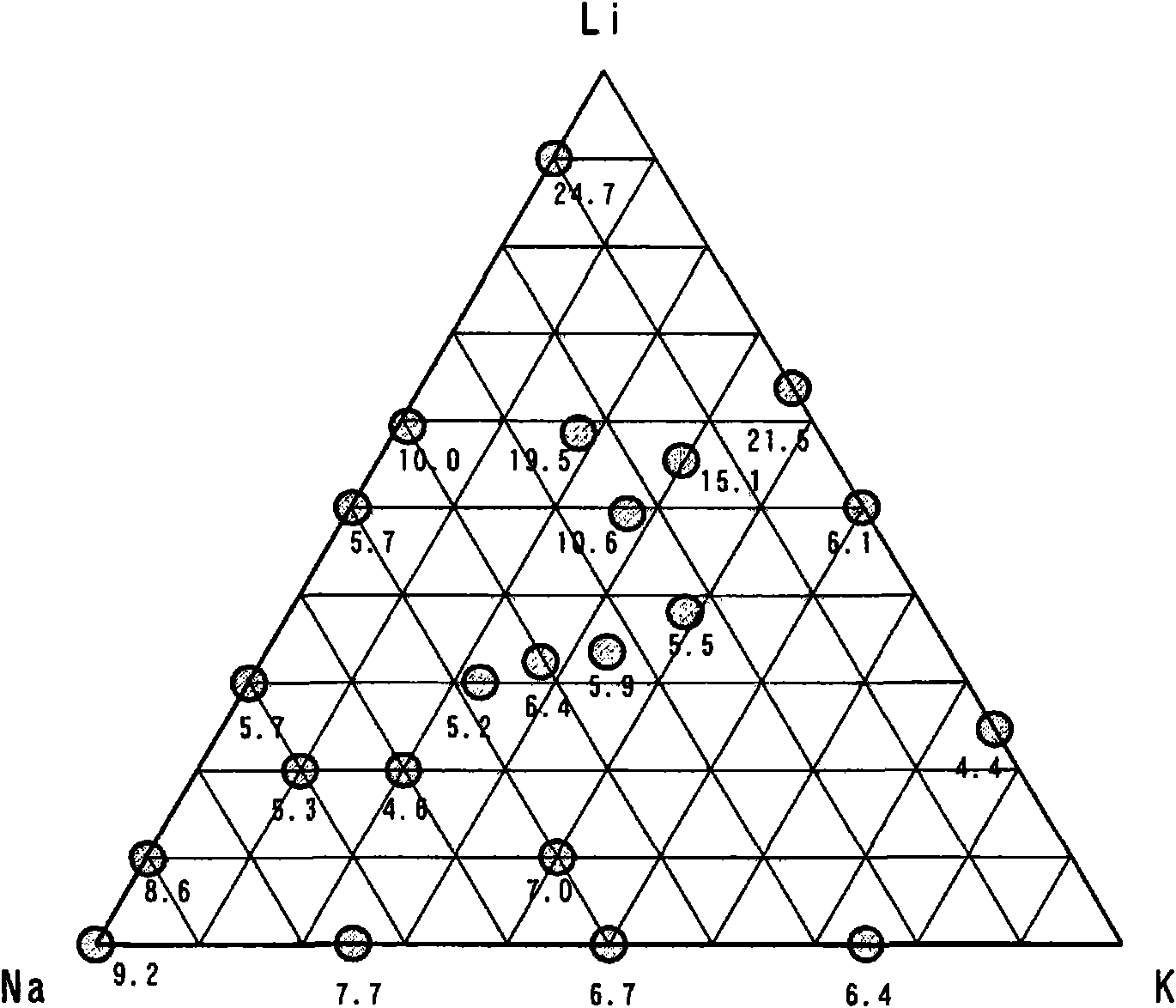

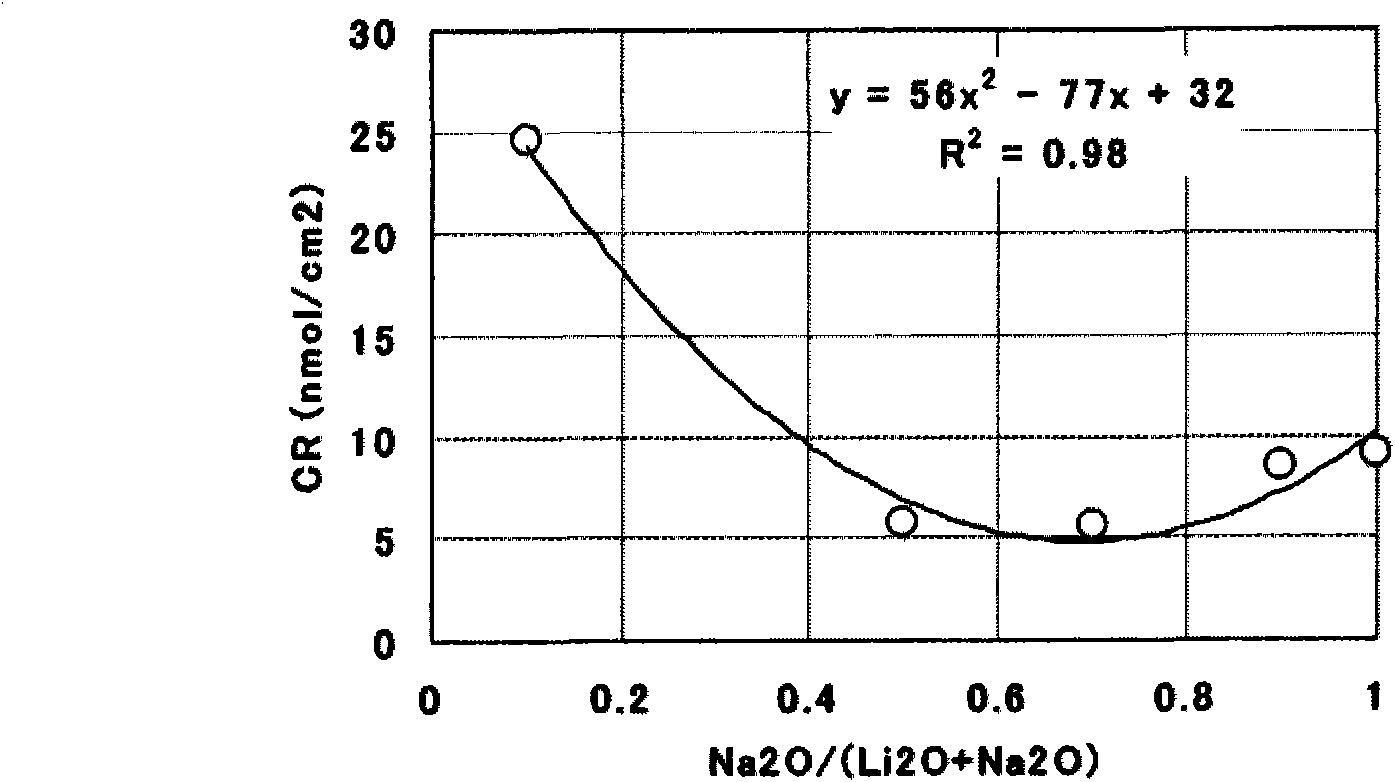

Glass for information recording medium substrate, glass substrate for information recording medium and magnetic disk

InactiveCN101857359AImprove acid resistanceAvoid rough surfacesRecord information storageMagnetic recordingWeather resistancePhotochemistry

To provide glass for an information recording medium substrate, which is excellent in the acid resistance and weather resistance. Glass for an information recording medium substrate, which comprises, as represented by mol % based on the following oxides, from 61 to 72% of SiO2, from 3 to 12% of Al2O3, from 0 to 14.3 of Li2O, from 0 to 22% of Na2O, from 0 to 22% of K2O, from 4 to 13% of MgO, from 0 to 6% of TiO2 and from 0 to 5% of ZrO2, provided that the total content of Li2O, Na2O and K2O (R2O) is from 8 to 22%, the ratio of the content of Li2O to R2O (Li2O / R2O) is at most 0.52, the ratio of the content of Na2O to R2O (Na2O / R2O) is at least 0.35, or the ratio of the content of K2O to R2O (K2O / R2O) is at least 0.45.

Owner:ASAHI GLASS CO LTD

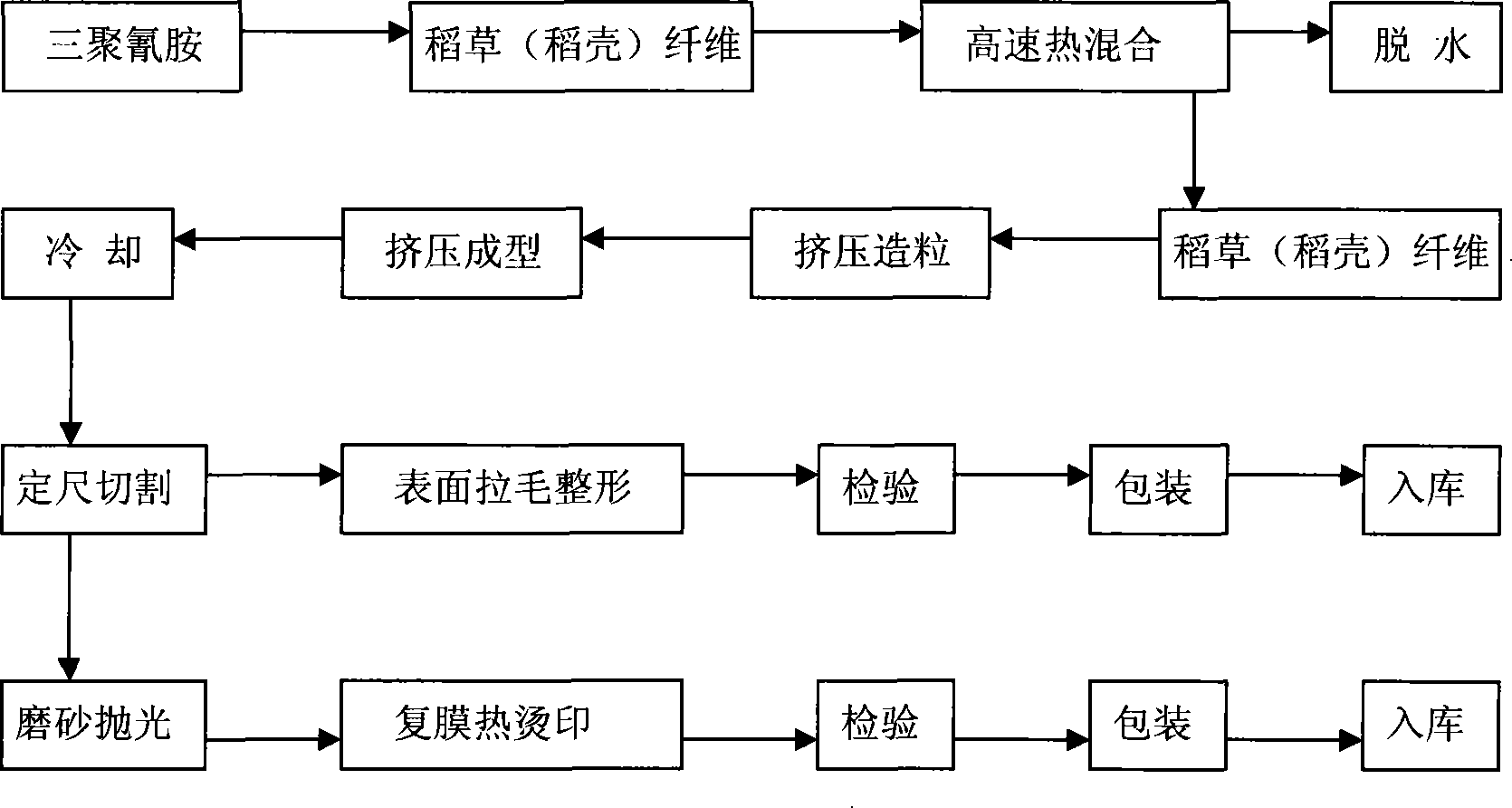

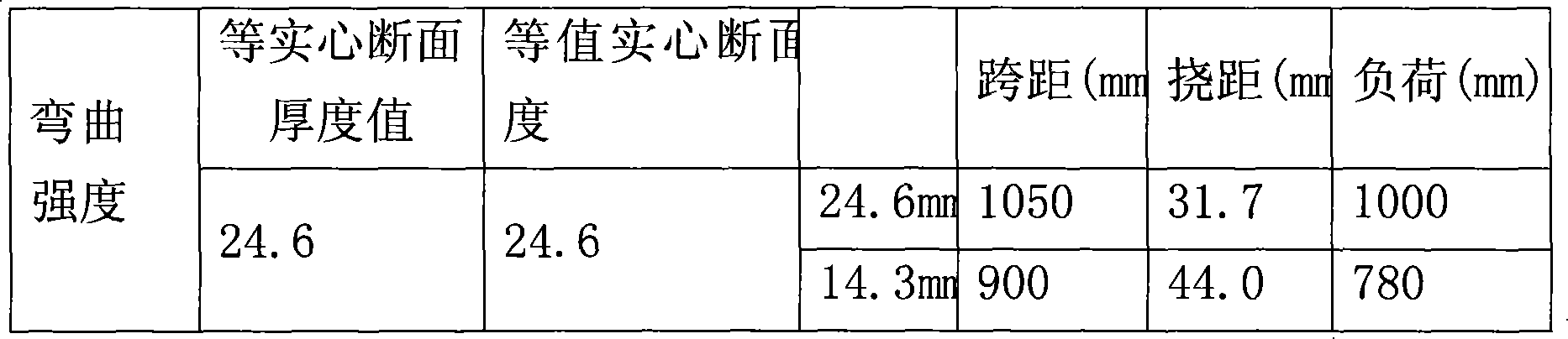

Straw, rice hull fibre base wood-plastic composite material and manufacture method thereof

InactiveCN101245189AAvoid rough surfacesImprove physical and mechanical propertiesRice strawMelamine resin

The invention relates to a wood plastic composite material and a preparation method thereof, in particular to a straw, a rice husk fiber base wood plastic composite material and a preparation thereof. The straw and the rice husk fiber base wood plastic composite material comprise the following components according to weight percentage: melamine resin: 3.5 percent; the straw and the rice husk fiber or the mixture of the straw and the rice husk: 60 percent; polyethylene with low density: 32 percent; solubilizer: 2 percent and lubricant: 2.5 percent. The wood plastic composite type building material of the invention adopts high technology, and utilizes waste plastics and a large amount of straw (rice straw, rice husk) powder to mix and extrude various formed hollow sectional materials of wood plastic at high temperature by fiber strengthening, and the wood plastic composite material is a typical environmental-friendly material. The wood plastic composite material is characterized by sun block, waterproof, anti-moth, anti-freezing and anticorrosion, and the wood plastic composite material without formaldehyde is strong in wood sense, high in surface hardness, strong in wear resistance, good in antiaging, long in service life, easy in processing, is suitable for the preferable material of decoration indoors and outdoors, and is similar to wood in shape but better than wood in property.

Owner:SHAOXING YINYING TEXTILE

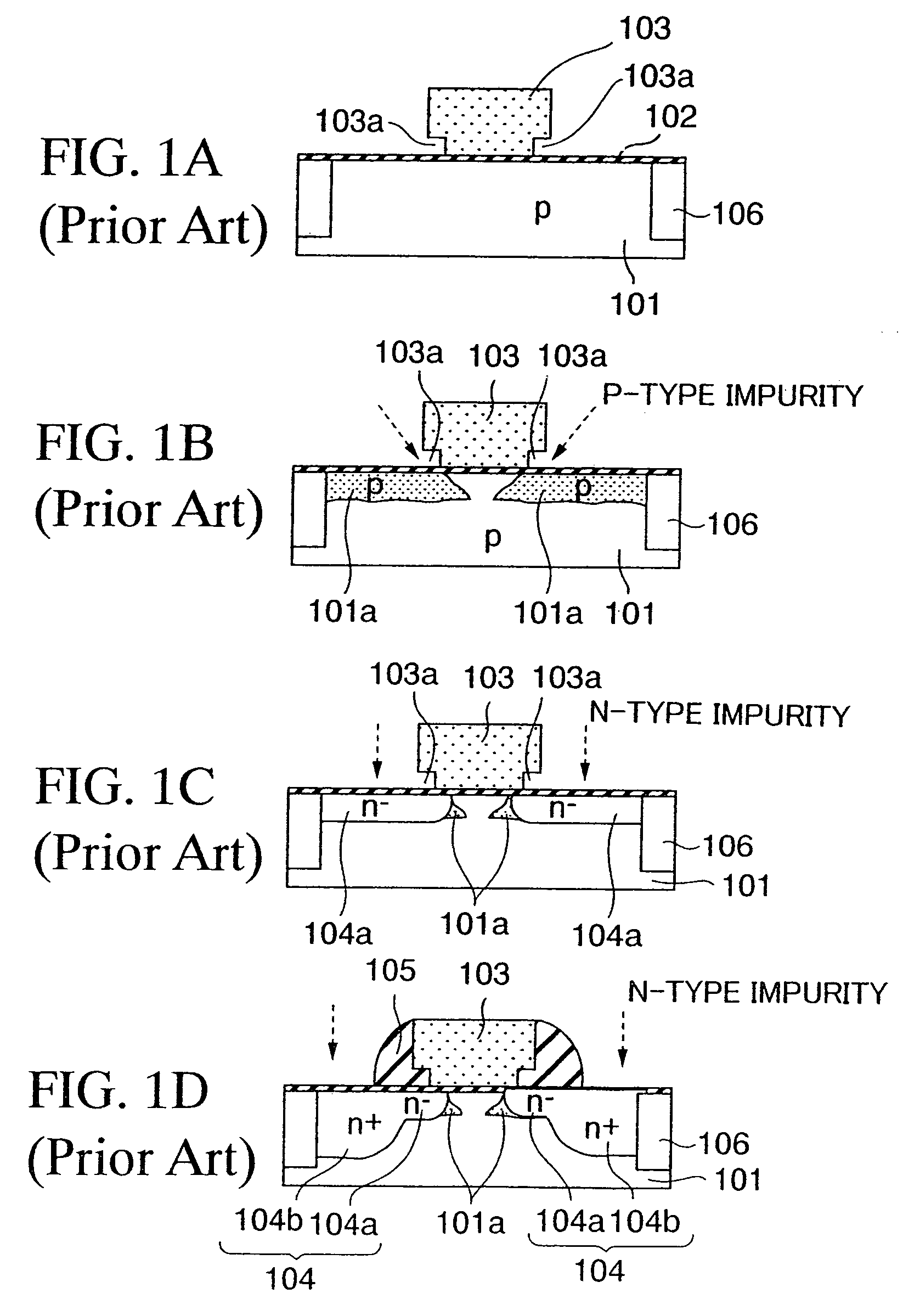

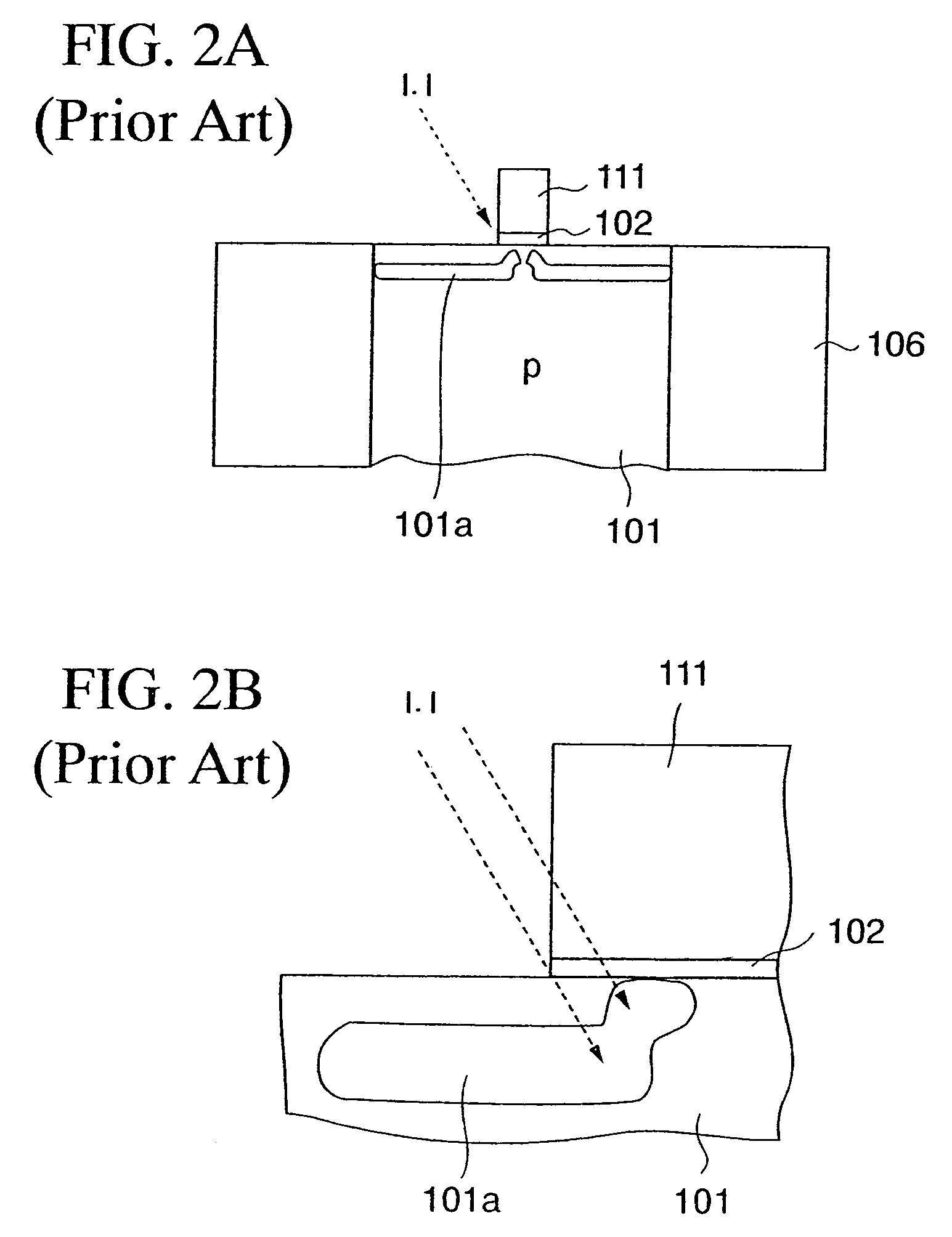

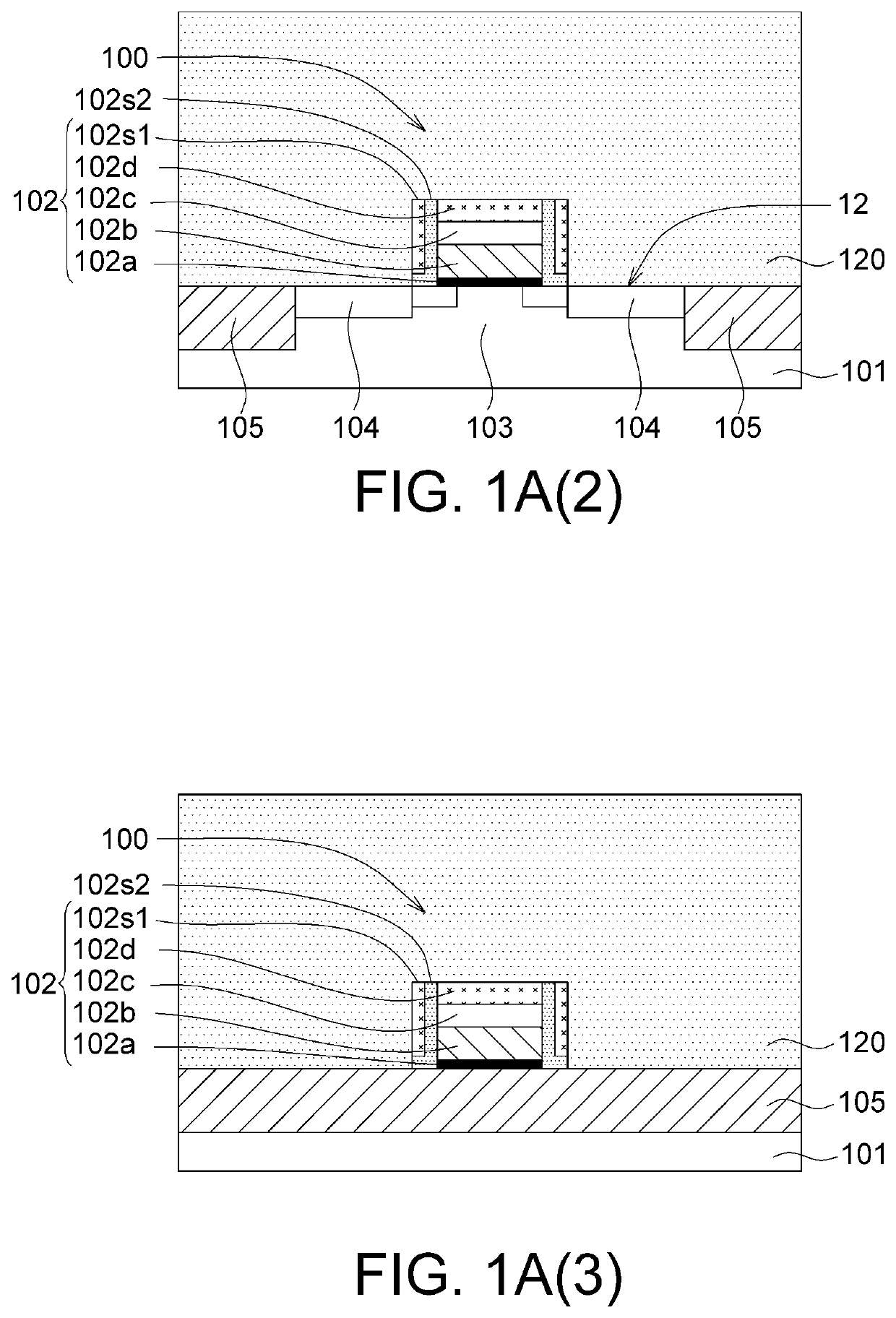

Semiconductor device and method of manufacturing the same

InactiveUS7109128B2Avoid rough surfacesShape stableTransistorSolid-state devicesPhysicsImpurity diffusion

There are provided a gate electrode formed on a semiconductor substrate of one conductivity type via a gate insulating film, ion-implantation controlling films formed on both side surfaces of the gate electrode and having a space between the gate electrode and an upper surface of the semiconductor substrate, first and second impurity diffusion regions of opposite conductivity type formed in the semiconductor substrate on both sides of the gate electrode and serving as source / drain, a channel region of one conductivity type formed below the gate electrode between the first and second impurity diffusion regions of opposite conductivity type, and pocket regions of one conductivity type connected to end portions of the impurity diffusion regions of opposite conductivity type in the semiconductor substrate below the gate electrode and having an impurity concentration of one conductivity type higher than the channel region.

Owner:FUJITSU SEMICON LTD

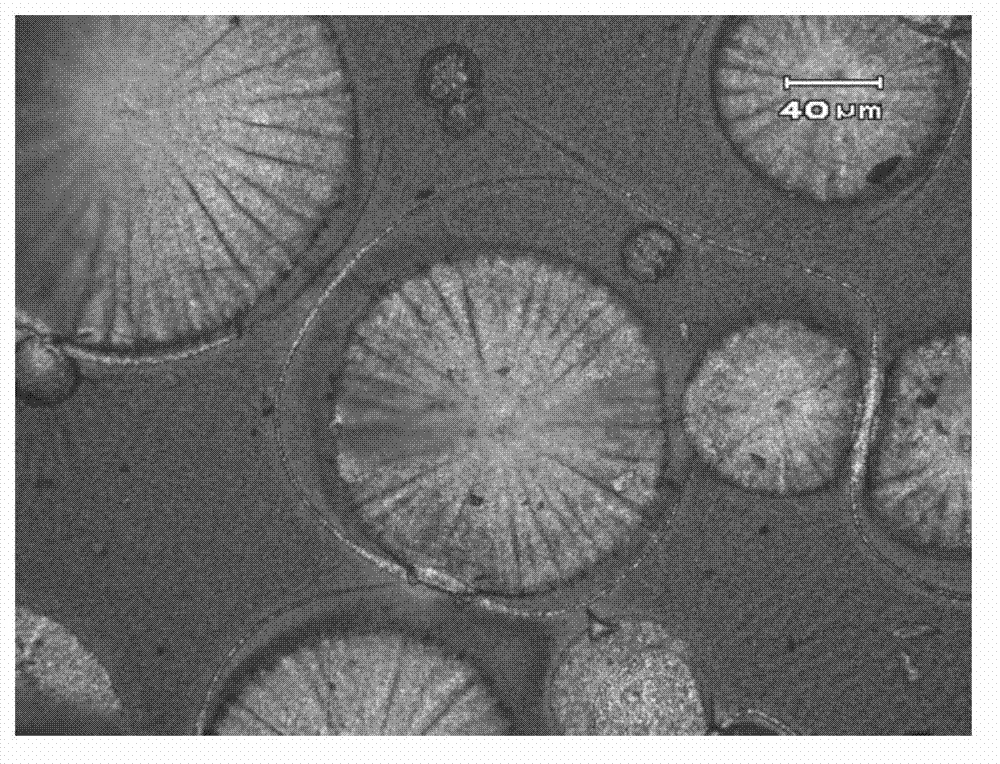

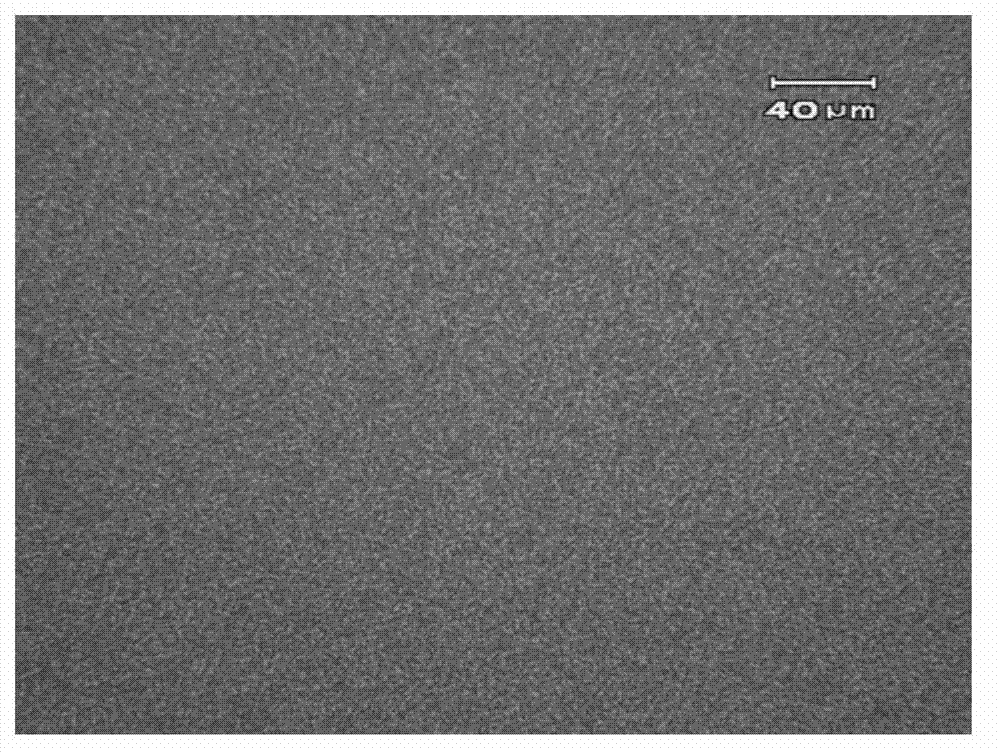

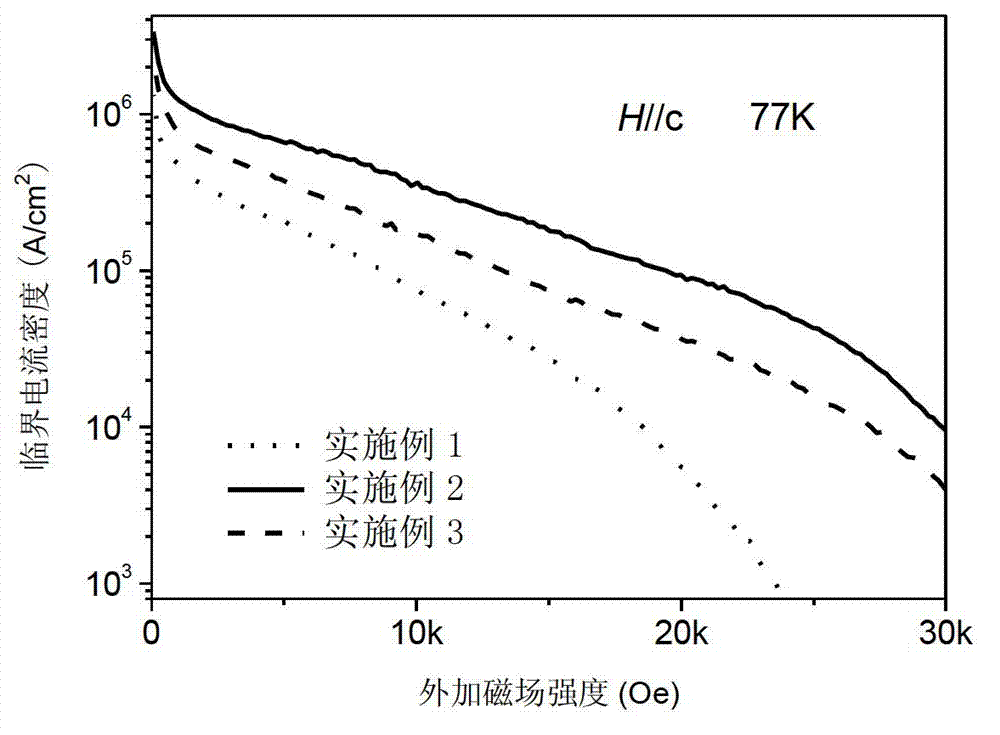

Preparation method of yttrium-barium-copper-oxidize superconducting film

The invention discloses a preparation method of a yttrium-barium-copper-oxidize superconducting film. The method comprises the following steps: preparing a yttrium-barium-copper-oxidize sol without fluorine into a yttrium-barium-copper-oxidize gel film on a monocrystal lanthanum aluminate substrate; after drying the obtained gel film, sequentially carrying out overheating treatment, crystallization treatment and oxygen permeating treatment on the gel film; and cooling the gel film, thereby obtaining the yttrium-barium-copper-oxidize superconducting film. According to the method, carbon dioxide is led into a low-temperature heat treatment process to control the conversion of a barium-contained phase, so that a reversible reaction, namely (Ba(OH)2+CO2=BaCO3+H2O is always performed in the direction at which barium carbonate is generated, so that the problem of rough surface of the yttrium-barium-copper-oxidize superconducting film due to the fact that barium hydroxide is molten at a high temperature is solved. In addition, water vapor is led into a high-temperature heat treatment process, so that the reversible reaction is performed in the direction at which the barium hydroxide is generated, so that the barium carbonate is completely converted into the barium hydroxide; and the barium hydroxide can further react with yttrium oxide and copper oxide to generate a yttrium-barium-copper-oxidize phase, and therefore, the yttrium-barium-copper-oxidize film with the good surface quality and the excellent superconducting performance is obtained.

Owner:XIAN UNIV OF TECH

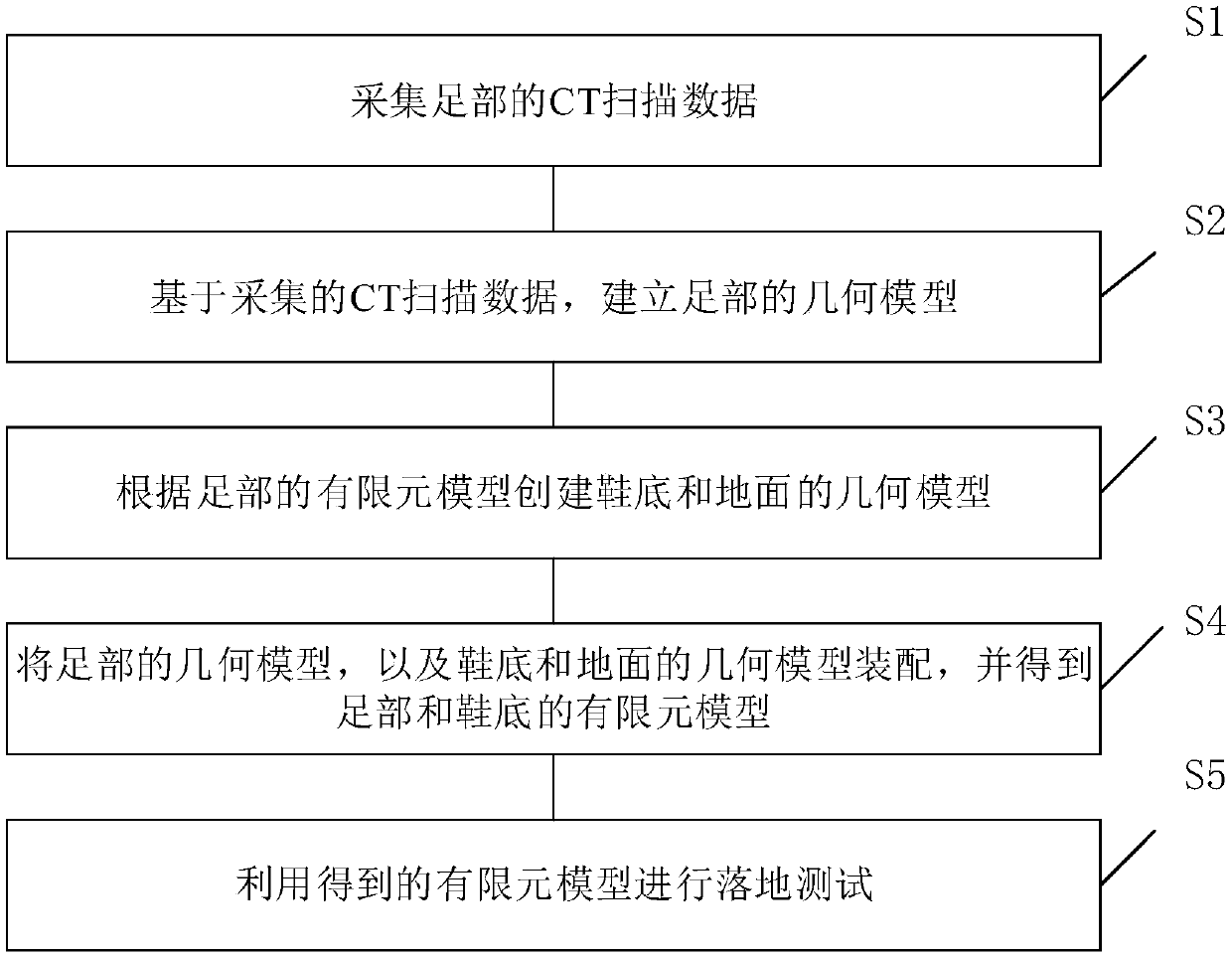

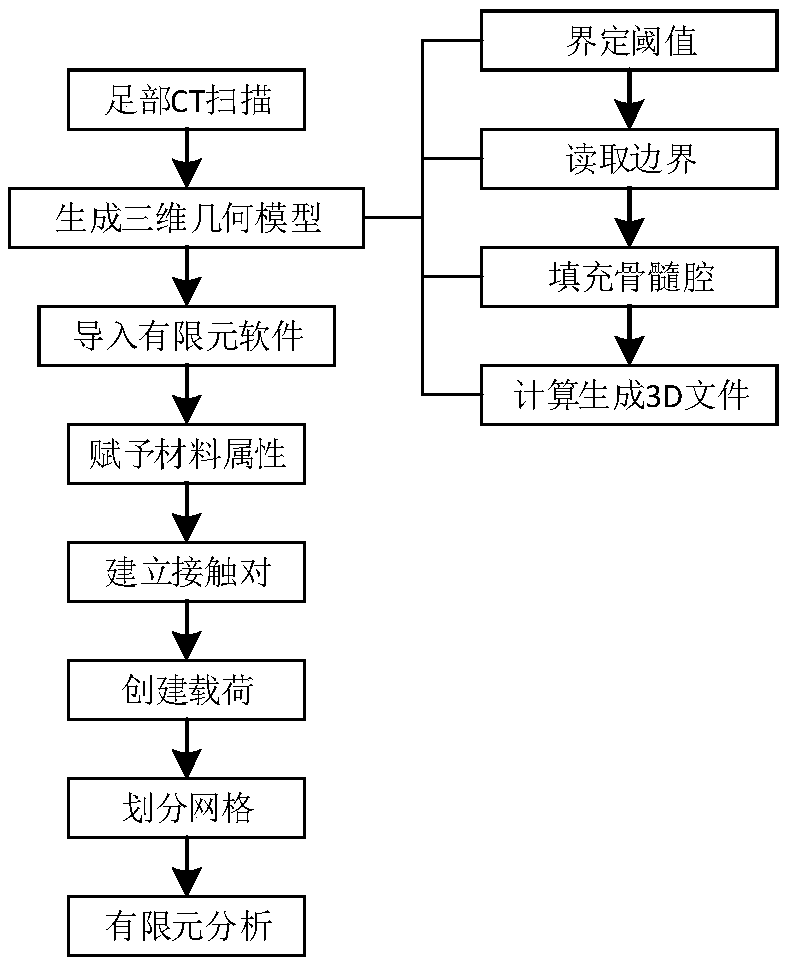

Testing method based on landing movement foot area and shoe sole finite element modeling

InactiveCN109662392AChange material arbitrarilyChange the structure arbitrarilyFoot measurement devicesElement modelComputed tomography

The invention relates to a testing method based on landing movement foot area and shoe sole finite element modeling. The method comprises the steps that S1, CT scanning data of a foot area is collected; S2, a foot area geometric model is established based on the collected CT scanning data; S3, geometric models of a shoe sole and ground are established according to a foot area finite element model;S4, the foot area geometric model, the shoe sole geometric model and the ground geometric model are assembled to obtain foot area and shoe sole finite element models; S5, landing testing is conductedon the obtained finite element models. Compared with the prior art, the shock-absorbing performance of the shoe sole in the model can be conducted, shoe sole materials and structures can be changed at will, shoe sole and foot area force bearing situations are predicted to guide the designing and production of sneakers, and a large amount of cost is reduced compared with a traditional manner in which a real object is made and then tested after being put on a body.

Owner:SHANGHAI UNIV OF ENG SCI

Method of processing and cleaning substrate, and method of and program for manufacturing electronic device

InactiveCN1822327AInhibit deteriorationAvoid destructionSemiconductor/solid-state device manufacturingLow-k dielectricCompound (substance)

A method of processing a substrate which enables a surface damaged layer and polishing remnants on the surface of an insulating film to be removed, and enable the amount removed of the surface damaged layer and polishing remnants to be controlled easily. An insulating film on a substrate, which has been revealed by chemical mechanical polishing, is exposed to an atmosphere of a mixed gas containing ammonia and hydrogen fluoride under a predetermined pressure. The insulating film which has been exposed to the atmosphere of the mixed gas is heated to a predetermined temperature.

Owner:TOKYO ELECTRON LTD

Color-masking zirconia veneer

ActiveCN108373328AEasy to processReduce vibrationImpression capsMedical preparationsNatural toothMicron scale

The invention discloses a color-masking zirconia veneer. The color-masking zirconia veneer is prepared by the steps of carrying out color masking after micro-sculptures of a zirconia veneer are processed, and finally carrying out sand blasting or processing a flake zirconia film. According to the color-masking zirconia veneer, micron-scale sculptures are prepared on the surface without mechanically damaging the material, and a porous flake surface from a nano scale to a micron scale is obtained by virtue of repeated film plating techniques before and after sintering, so that a mechanical interlocking structure between the specific surface area of the zirconia veneer and an adhesive, the adhesion bonding between the zirconia veneer and a natural tooth is enhanced, and the zirconia veneer can meet the clinical requirements on the adhesive property. The color-masking zirconia veneer has the beneficial effects that a color-masking function is considered, meanwhile, the strength of the zirconia veneer is guaranteed, and a very good aesthetic repairing effect is achieved.

Owner:HANGZHOU ERRAN TECH

Bat having a sleeve with slots

Disclosed herein is a bat comprising a handle portion, a transition portion attached to the handle portion, and a barrel portion attached to the transition portion. The barrel portion includes one or more first cross-sections having a first stiffness and a plurality of second cross-sections having a second stiffness. Each first cross-section is beside one second cross-section or between two of the second cross-sections and the first stiffness is greater than the second stiffness. The variance in stiffness between the first cross-sections and the second cross-sections is created by varying the amount of material in the cross-section or by, more accurately, removing material in the second cross sections to make the second cross-sections more flexible by creating slots. Likewise, a bat may be provided with third cross sections on the sides of the second cross-sections distal from the first cross-section whereby the third cross-sections are less stiff that the second cross-sections because more material is removed.

Owner:RAWLINGS SPORTING GOODS

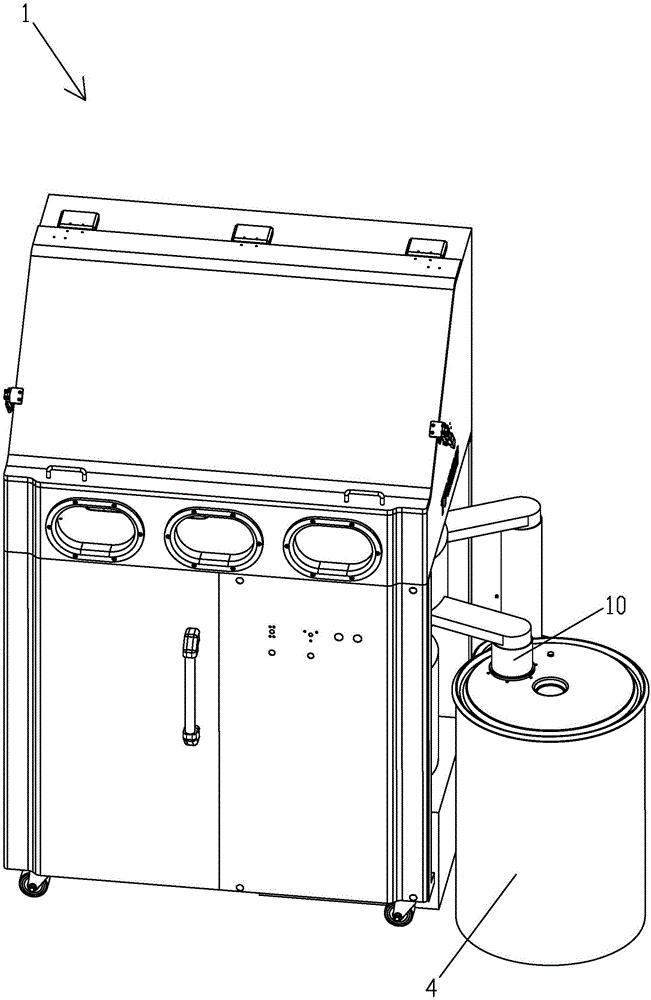

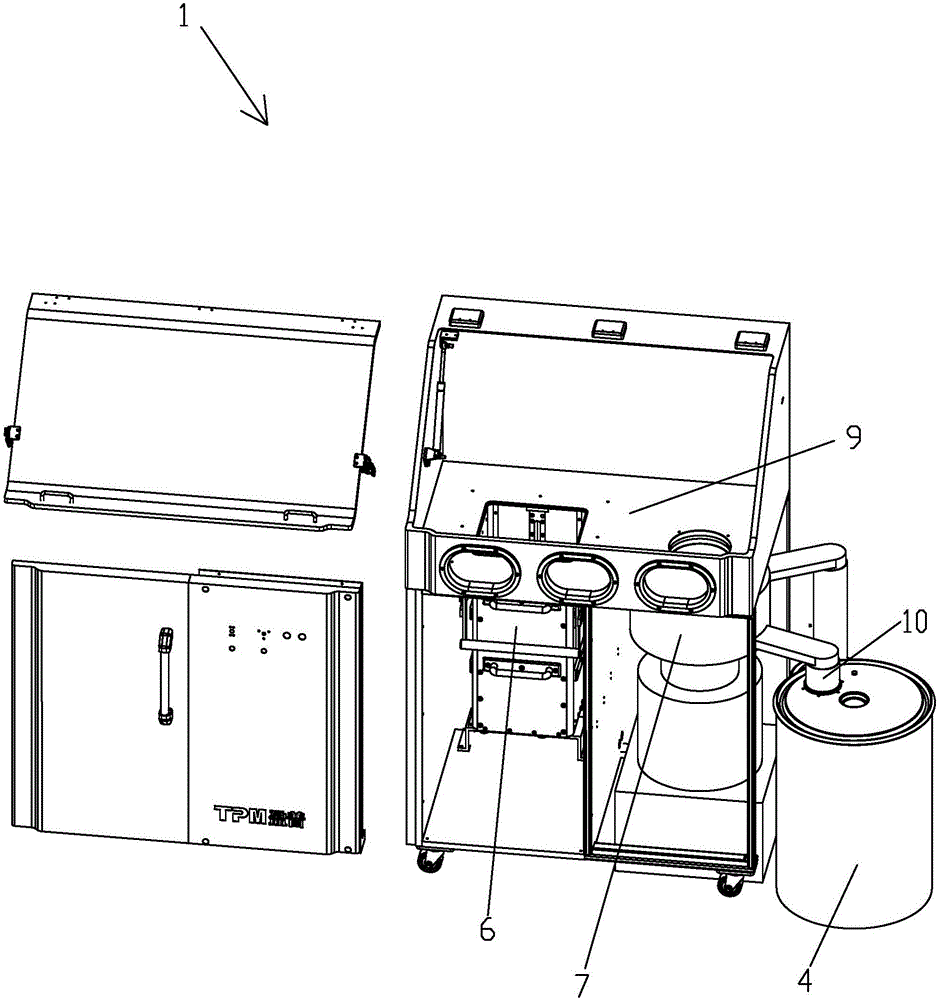

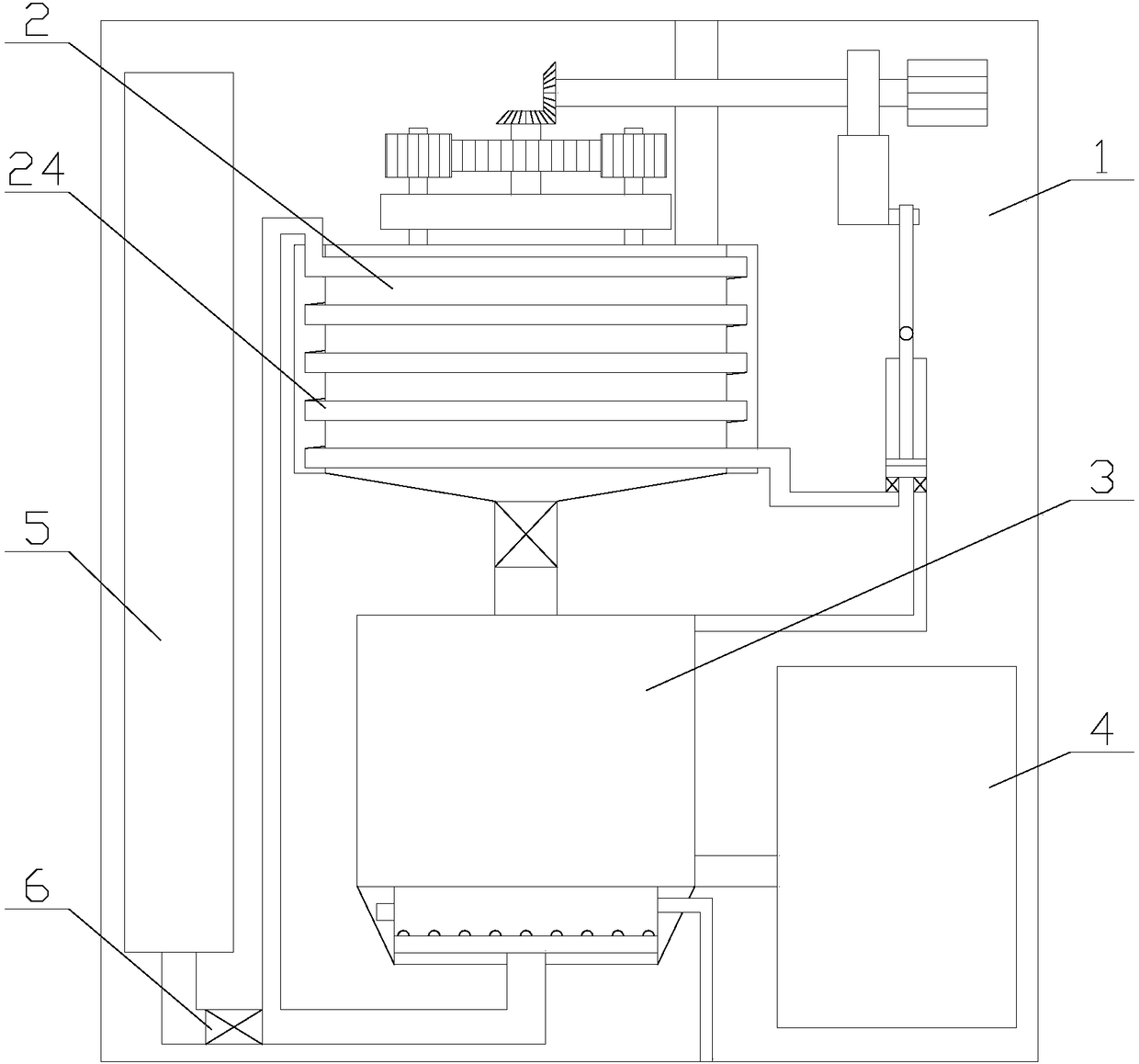

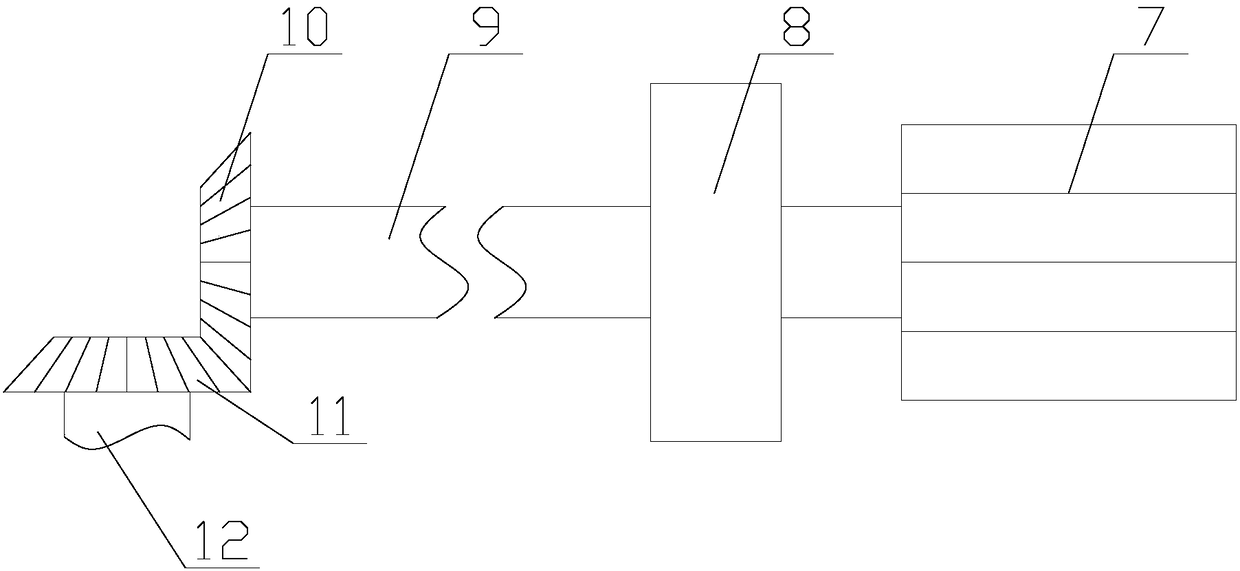

System and method for recycling and reusing laser forming old powder

The invention discloses a system and method for recycling and reusing laser forming old powder. According to the technical scheme, the system is characterized by comprising a powder screening machine, a transfer powder bucket, a powder mixer and a powder feeder, wherein the powder screening machine is used for screening qualified old powder out of old powder left after laser forming of the last time, the transfer powder bucket is used for collecting the screened-out qualified powder, the powder mixer is used for three-dimensionally rotating the transfer powder bucket so that the old powder and new powder can be fully mixed, and the powder feeder is used for feeding the mixed powder in the transfer powder bucket to a forming main machine to be reused. The method for recycling and reusing the laser forming old powder comprises the steps of powder screening, powder mixing and powder feeding. According to the system and method, powder waste and the harm to the health of human bodies can be basically avoided, and meanwhile the situations that the strength of formed parts becomes poor, and the surfaces of the formed parts are rough are avoided.

Owner:TPM MACHINERYSHANGHAI CO LTD

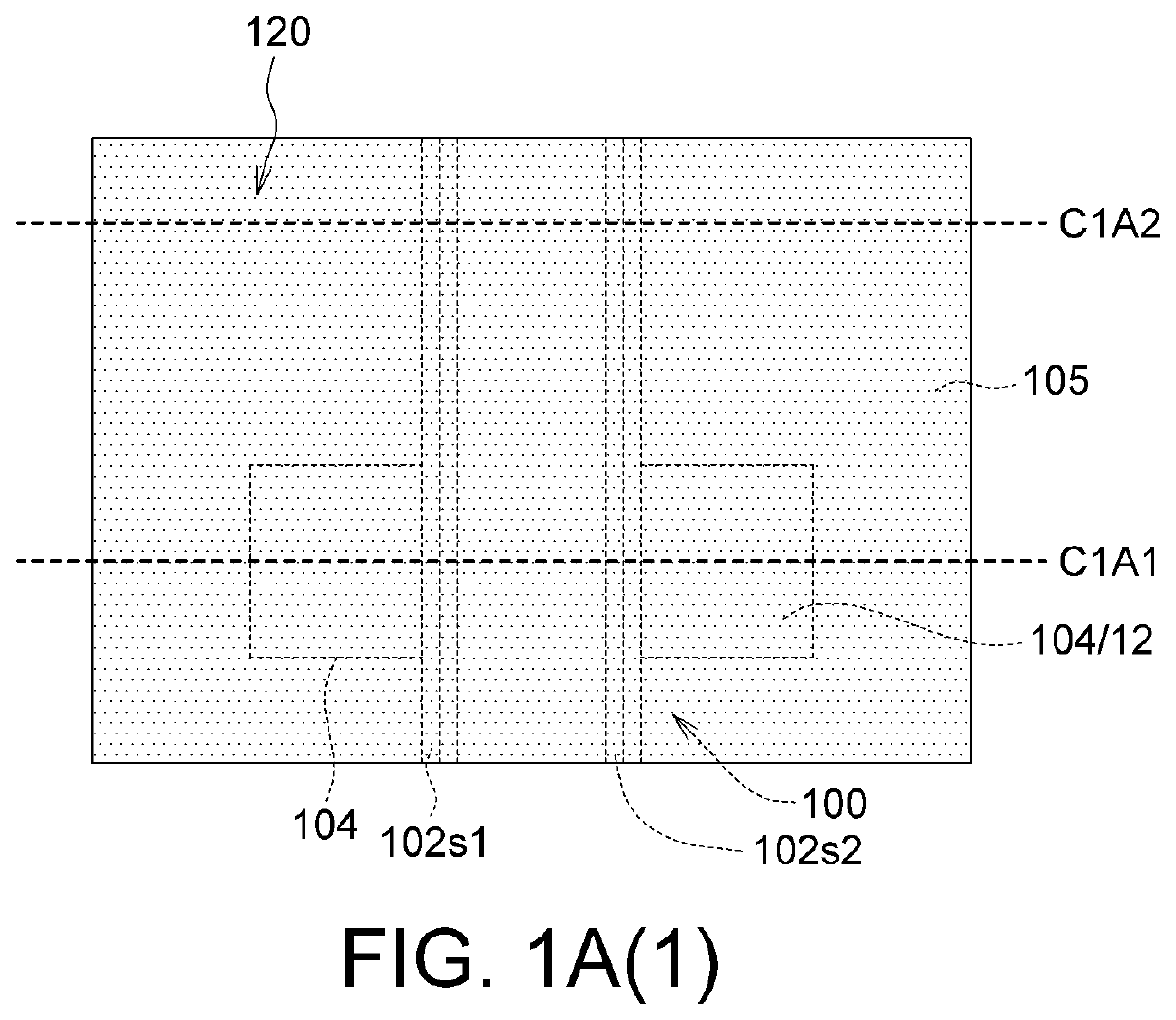

Interconnection structure and manufacture method thereof

PendingUS20220293518A1Strengthen the connection structureHigh aspect ratioSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorEngineering

An interconnection structure includes a first dielectric layer, a first conduction layer, a conductor pillar, an upper dielectric layer and an upper conduction layer. The first dielectric layer is disposed over a first terminal of a device. The first conduction layer is disposed over the first dielectric layer. The conductor pillar is connected to the first terminal. The upper dielectric layer is disposed over the first conduction layer. The upper conduction layer is disposed over the upper dielectric layer. The conductor pillar connects to the upper conduction layer but disconnects from the first conduction layer.

Owner:INVENTION & COLLABORATION LAB PTE LTD

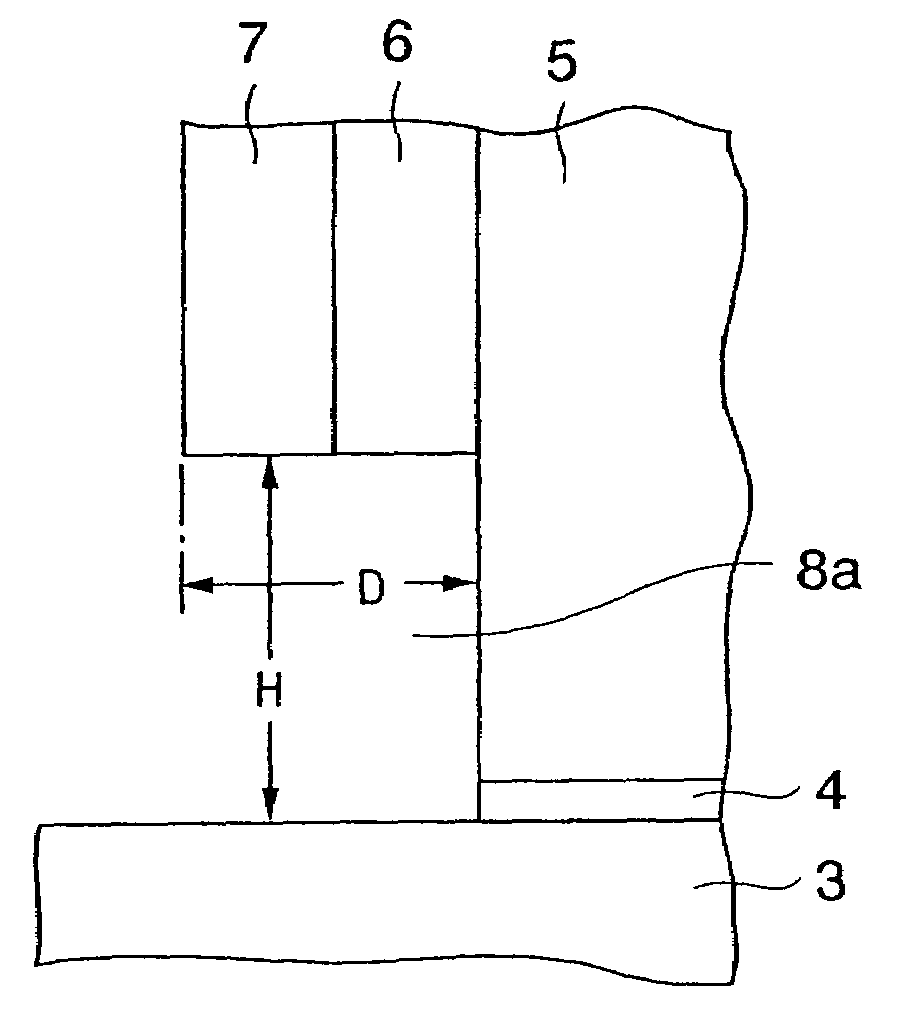

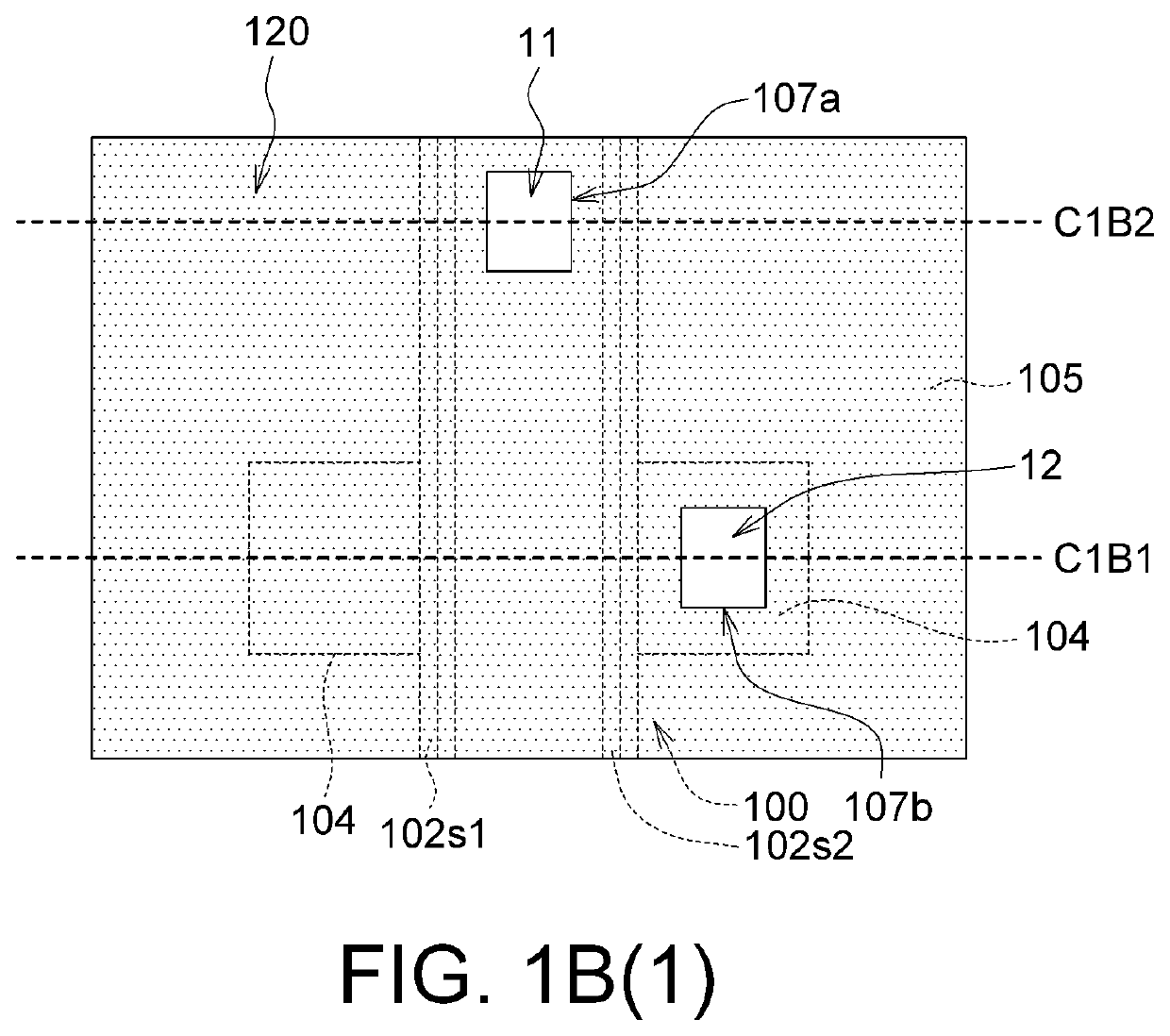

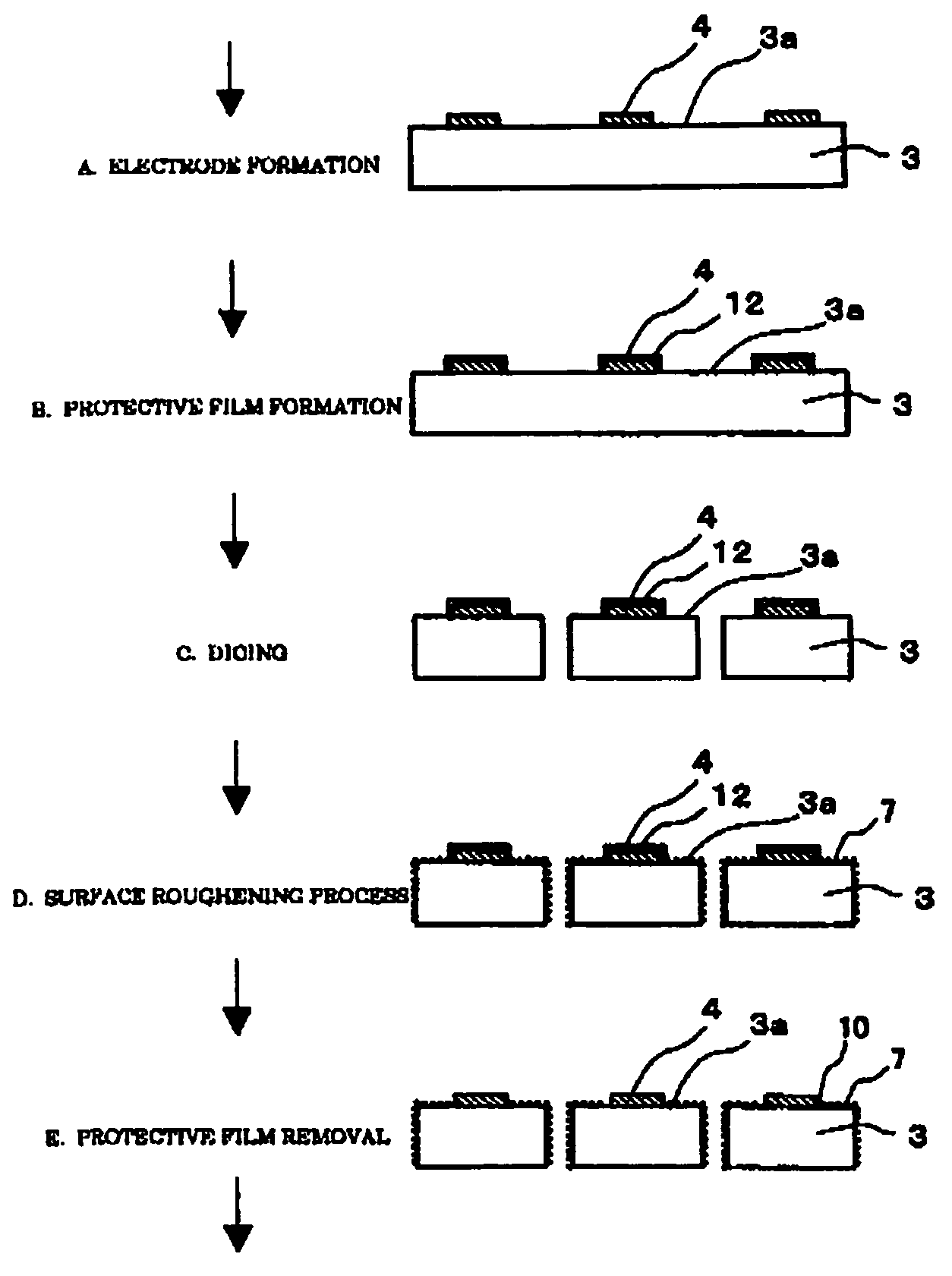

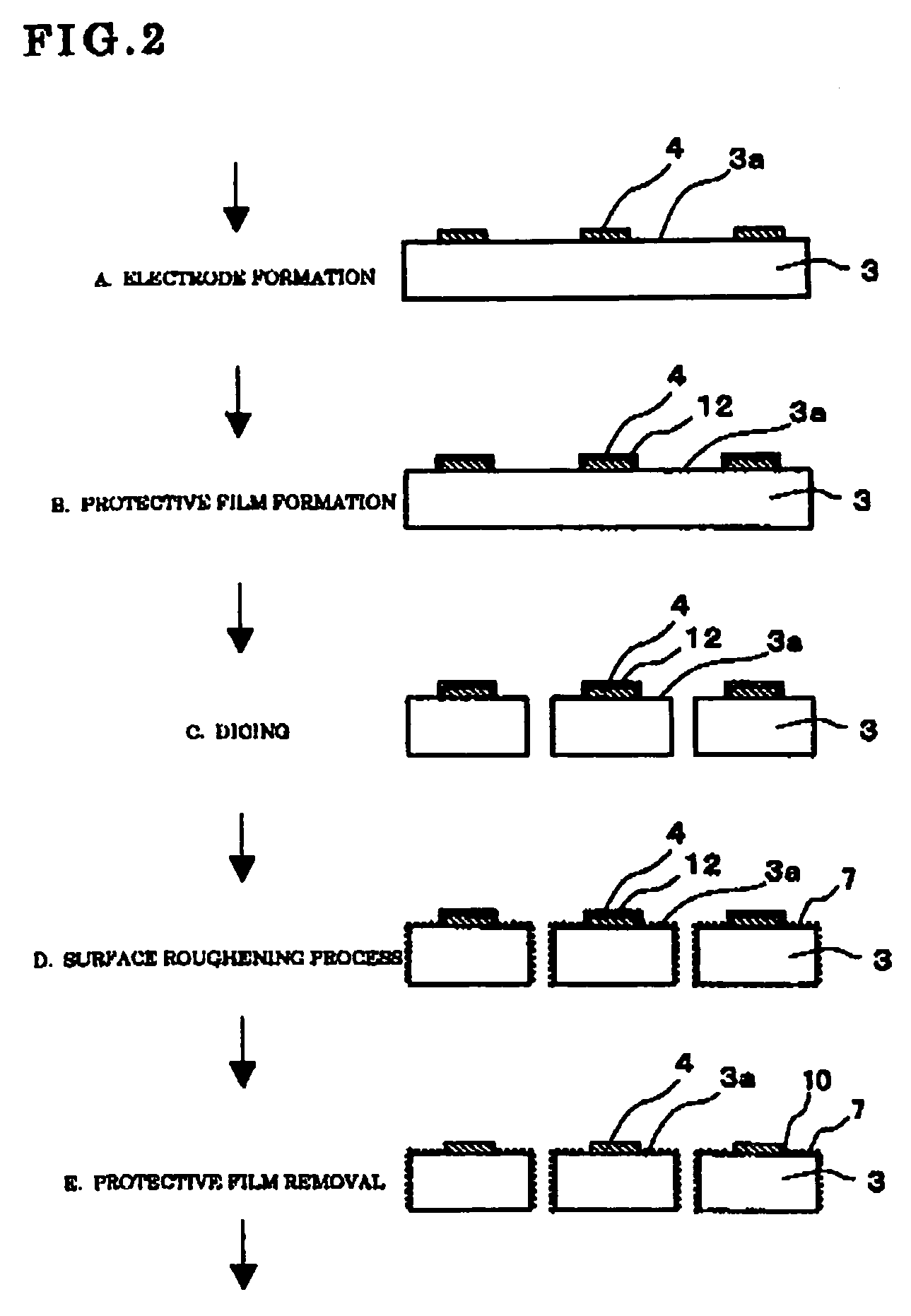

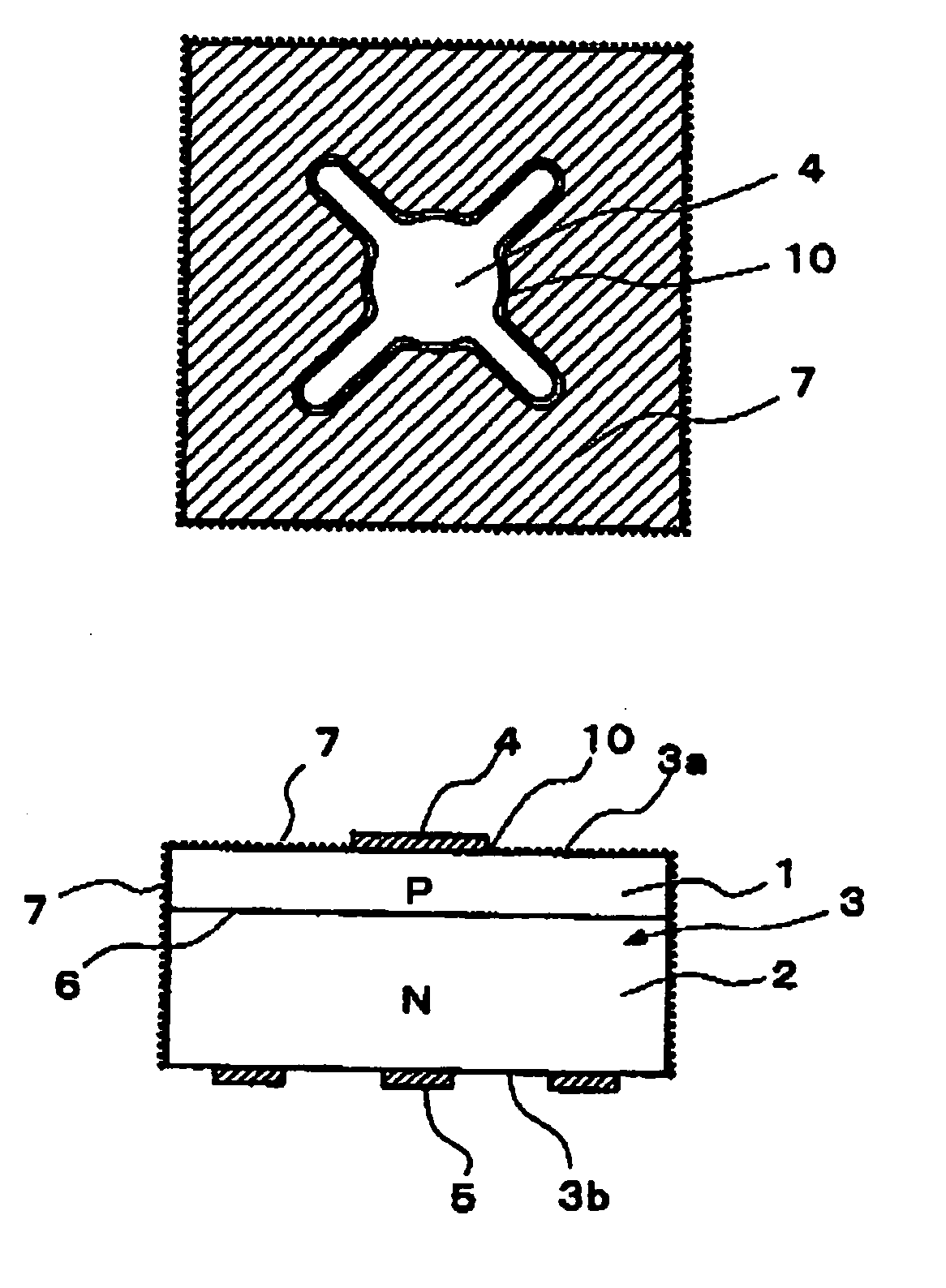

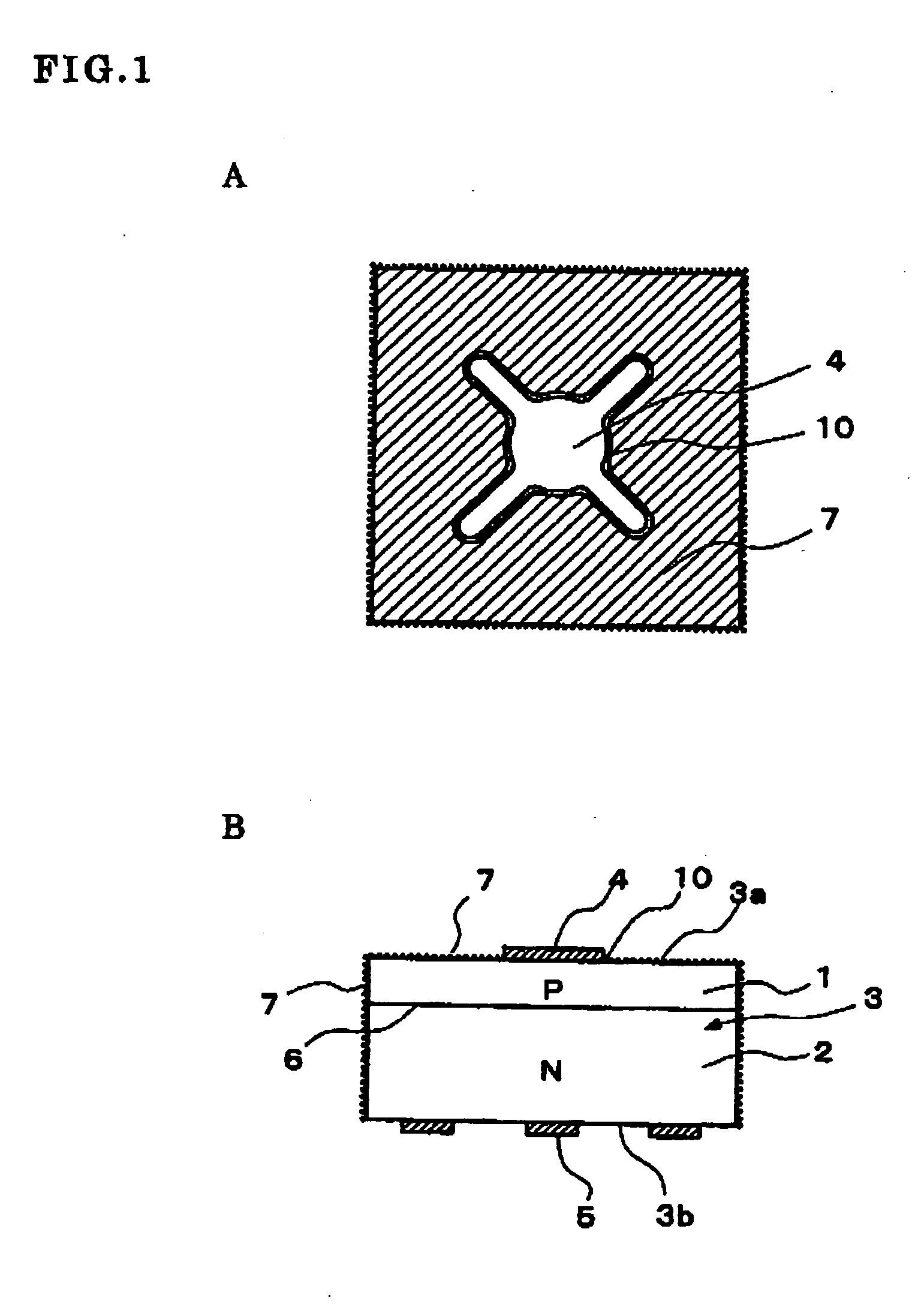

Semiconductor light-emitting element and manufacturing method thereof

ActiveUS7211834B2Improve reliabilityAvoid overetchingSemiconductor devicesChemical treatmentEngineering

An improvement in electrode reliability is realized by preventing over-etching on a peripheral lower portion of an electrode while maintaining the flow of steps of roughening a surface after forming the electrode on a semiconductor substrate. After a P-side electrode 4 is formed on a main surface 3a of a semiconductor substrate 3, a surface of the P-side electrode 4 is selectively covered with a protective film 12, after the semiconductor substrate 3 is cut into chips, the surface is roughened from above the protective film 12, the main surface 3a around the P-side electrode 4 and a side surface are roughened with a non-chemical treatment region 10 which is a non-roughened surface region being left in a peripheral portion of the P-side electrode 4 covered with the protective film 12, and thereafter the protective film 12 is removed.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

Semiconductor light-emitting element and manufacturing method thereof

ActiveUS20060011934A1Improve reliabilityAvoid overetchingSemiconductor devicesChemical treatmentEngineering

An improvement in electrode reliability is realized by preventing over-etching on a peripheral lower portion of an electrode while maintaining the flow of steps of roughening a surface after forming the electrode on a semiconductor substrate. After a P-side electrode 4 is formed on a main surface 3a of a semiconductor substrate 3, a surface of the P-side electrode 4 is selectively covered with a protective film 12, after the semiconductor substrate 3 is cut into chips, the surface is roughened from above the protective film 12, the main surface 3a around the P-side electrode 4 and a side surface are roughened with a non-chemical treatment region 10 which is a non-roughened surface region being left in a peripheral portion of the P-side electrode 4 covered with the protective film 12, and thereafter the protective film 12 is removed.

Owner:DOWA ELECTRONICS MATERIALS CO LTD

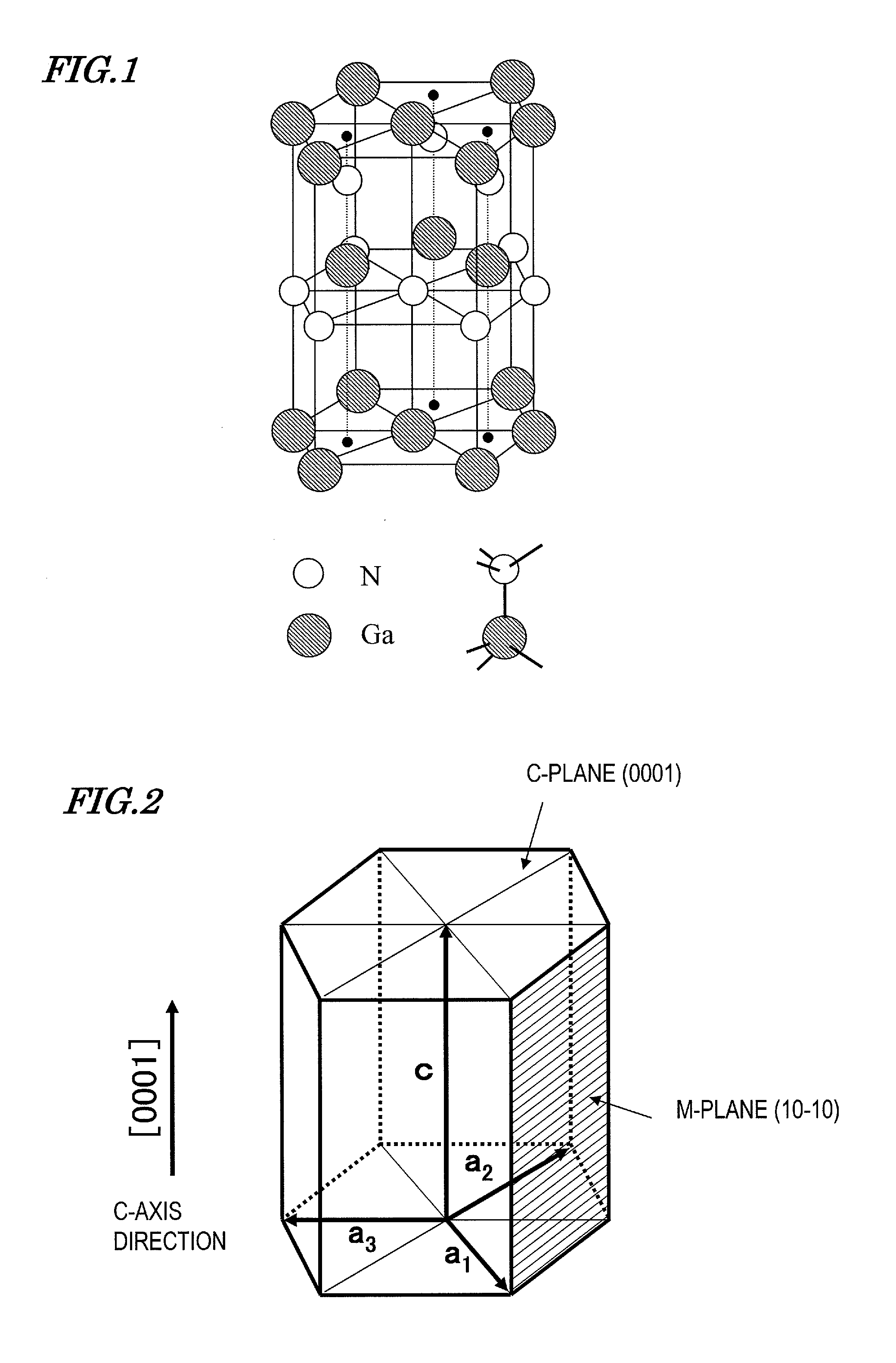

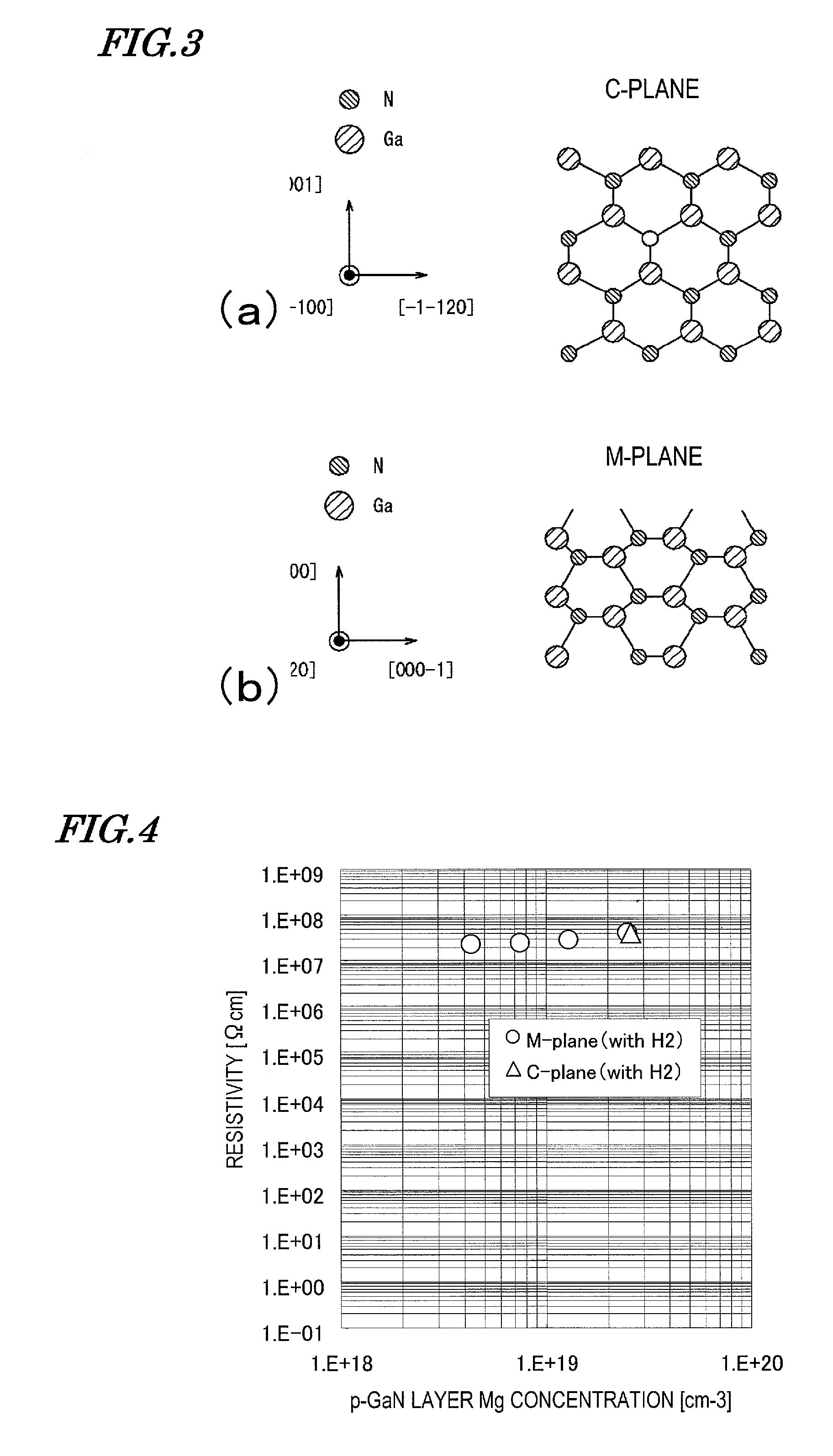

Semiconductor device manufacturing method

InactiveUS8268706B2Reduce complexityLow resistivitySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialGas phase

A method for fabricating a semiconductor device according to the present invention includes the steps of: growing a p-type gallium nitride-based compound semiconductor layer by performing a metalorganic chemical vapor deposition process in a heated atmosphere so that the crystal-growing plane of the semiconductor layer is an m plane (Step S13); and cooling the p-type gallium nitride-based compound semiconductor layer (Step S14) after the step of growing has been carried out. The step of growing includes supplying hydrogen gas to a reaction chamber in which the p-type gallium nitride-based compound semiconductor layer is grown. The step of cooling includes cooling the p-type gallium nitride-based compound semiconductor layer with the supply of the hydrogen gas to the reaction chamber cut off.

Owner:PANASONIC CORP

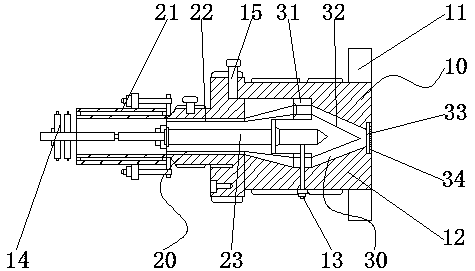

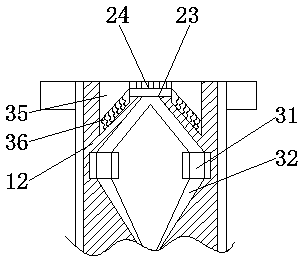

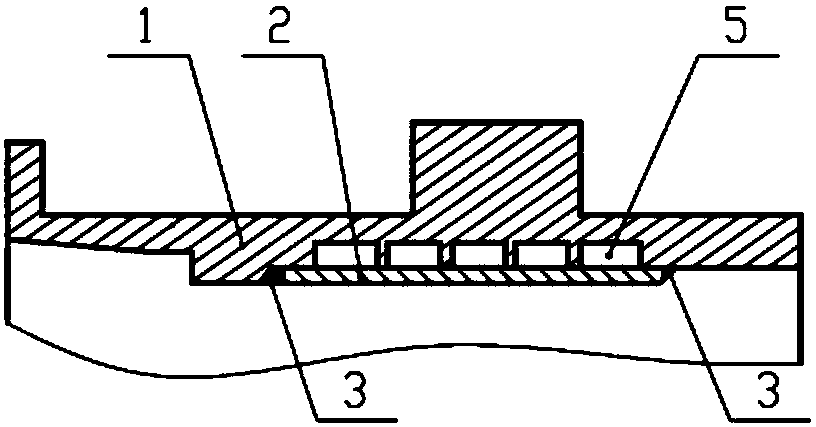

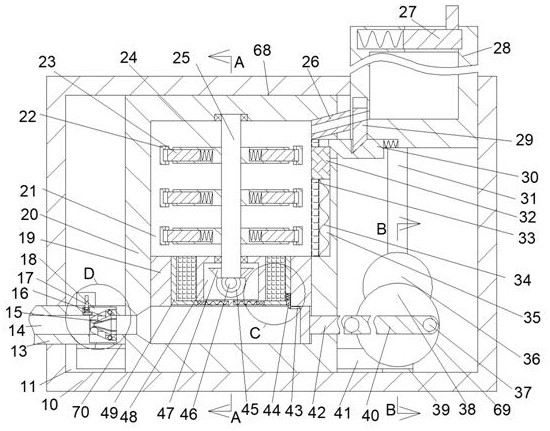

Extrusion mold used for shaping of plastic pipe

InactiveCN108032505AAvoid uneven thicknessAvoid rough surfacesTubular articlesRough surfaceEngineering

The invention discloses an extrusion mold used for shaping of a plastic pipe. The extrusion mold includes a mold body assembly, a shaping assembly and a divider assembly, wherein the mold body assembly includes a mold body, a machine head body and a rubber plug. The rubber plug is fixedly installed on the left end of the mold body. The machine head body is arranged on the right end of the mold body and is fixedly connected to the mold body. The shaping assembly includes a shaping sleeve, a bush die, and a core rod, wherein the shaping sleeve is arranged at the right side of the rubber plug andis fixedly connected to the mold body. An annular groove hole is arranged in one side, which is closed to the divider, of the right end of the machine head body. An electric heating wire is attachedto the inner surface of the annular groove hole and heats the interior of the machine head body, so that internal temperature of the divider is increased, and when molten plastic flows through the divider, the melt is further heated and plasticized so that the melt is distributed uniformly. The extrusion mold can avoid the problems of non-uniform thickness or rough surface of a plastic product dueto insufficient temperature during flowing of the melt.

Owner:青岛吉泰塑料机械有限公司

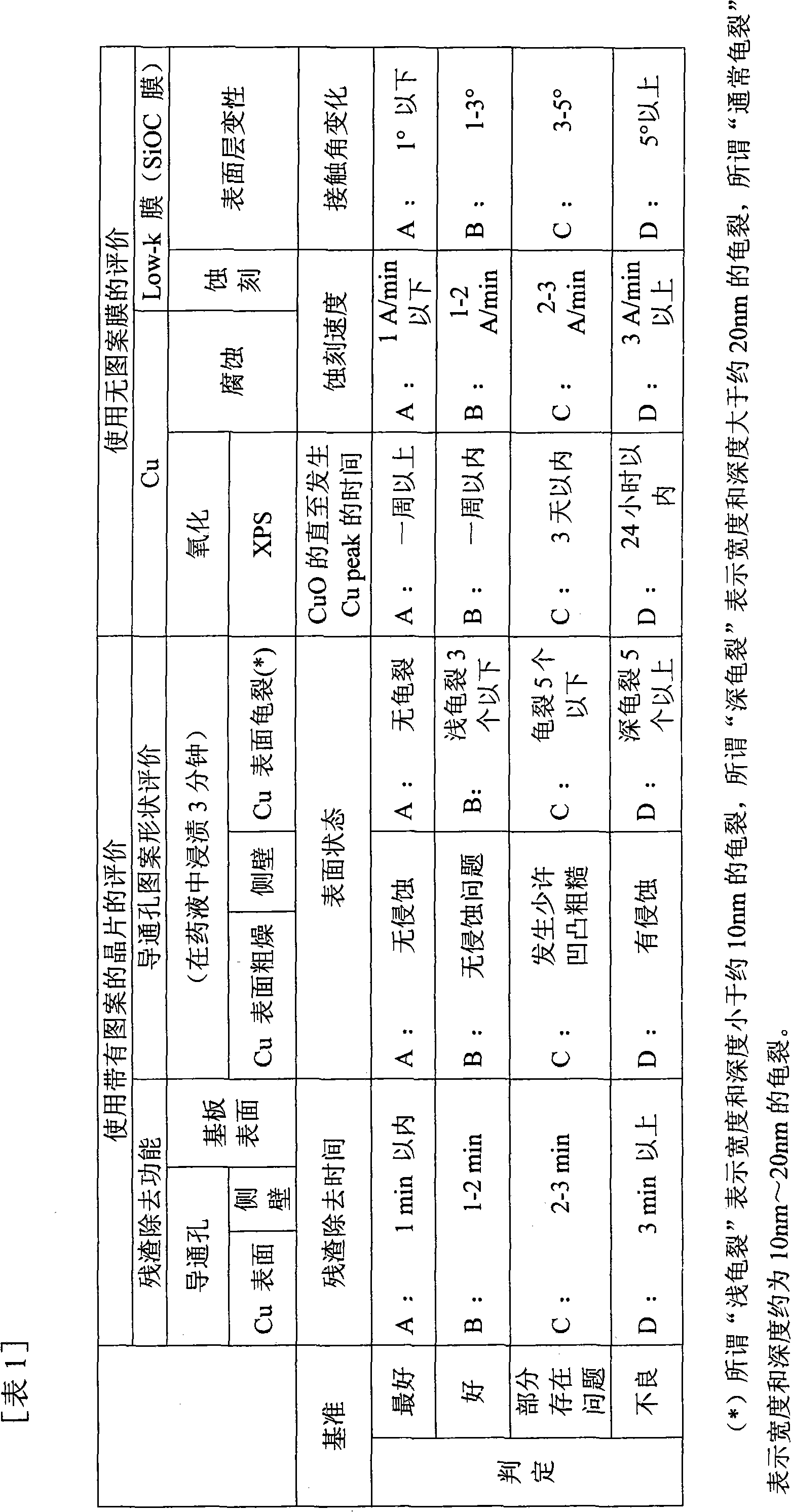

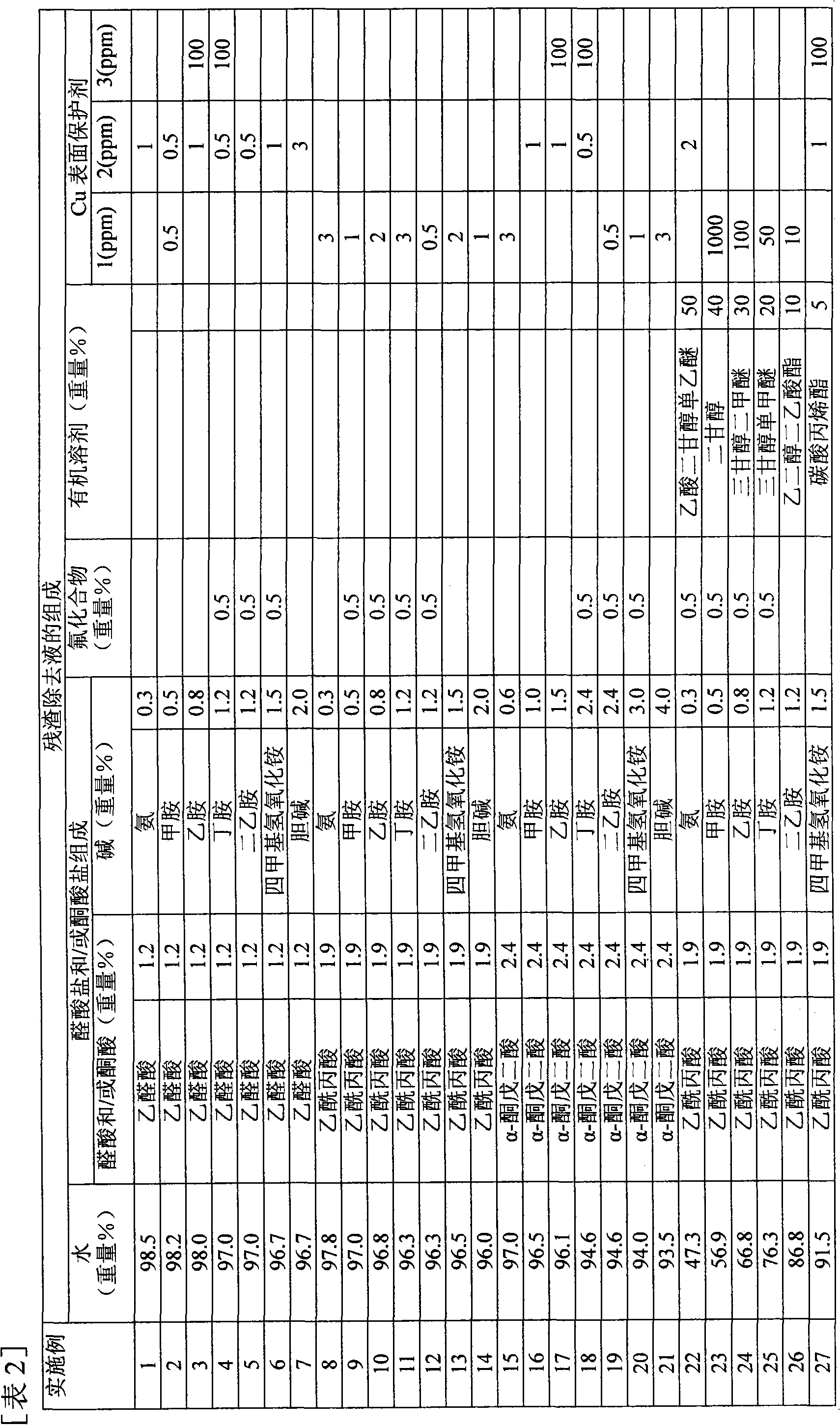

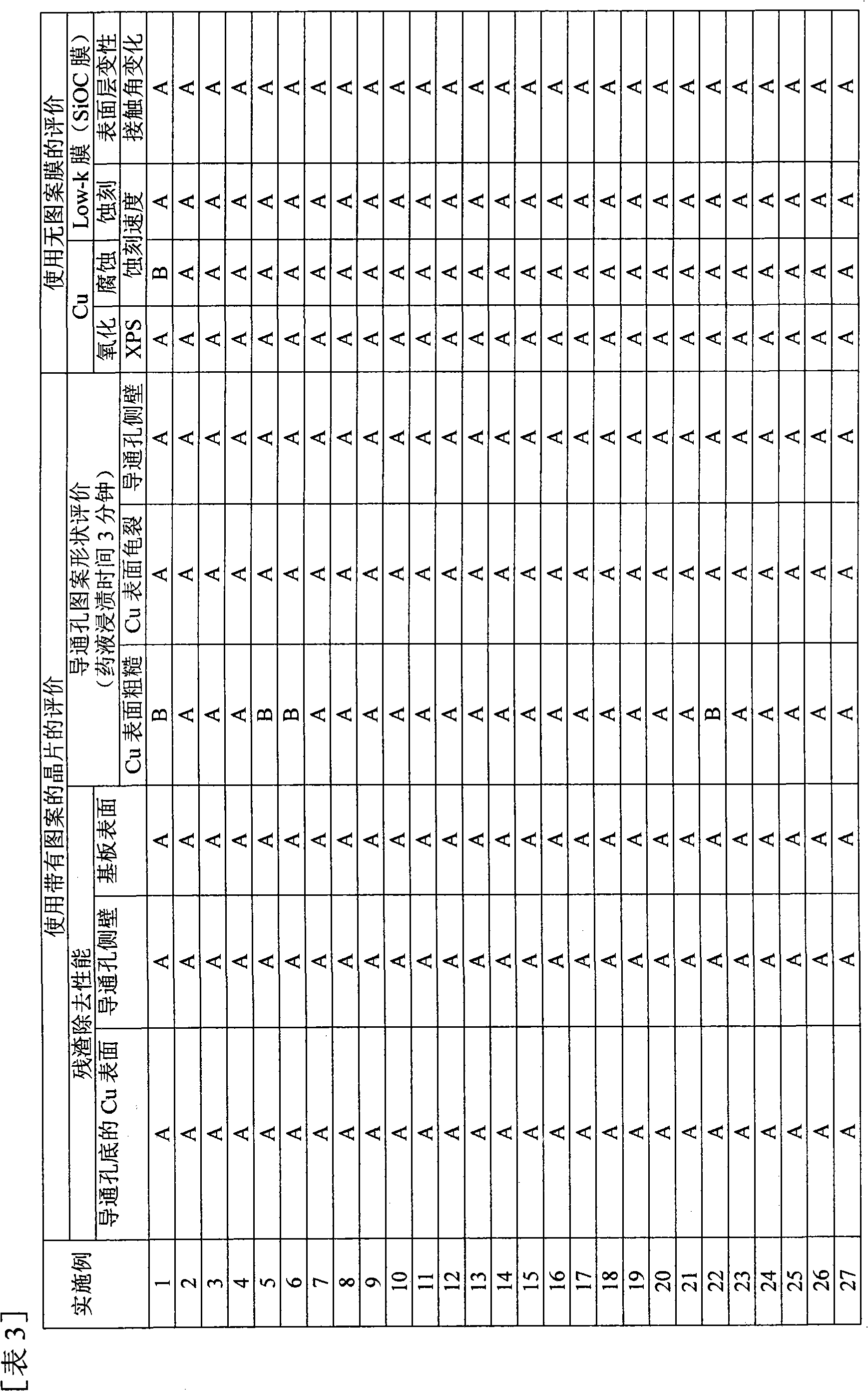

Solution for removal of residue after semiconductor dry processing, and residue removal method using the same

InactiveCN101785087AAvoid crackingAvoid rough surfacesNon-surface-active detergent compositionsDetergent mixture composition preparationNitrogenCopper

Disclosed is a solution for removing a residue after a dry processing, which can prevent the cracking or roughening of a Cu surface which cannot be overcome by a conventional liquid polymer stripper, which can prevent the oxidation of a Cu surface, and which contains a surface-protecting agent. Also disclosed is a method for producing a semiconductor device by using the solution. Specifically disclosed is a solution for removing a residue remaining on a semiconductor substrate after dry etching and / or ashing, which comprises: a Cu surface-protecting agent comprising at least one compound selected from the group consisting of (1) a compound which has, as a basic skeleton, a 5-membered heterocyclic aromatic compound having a structure represented by the formula: =N-NH- (provided that one having three contiguous N atoms is excluded) and which shows a pH value of 7 or less in the form of an aqueous solution (10 ppm, 23 DEG C); (2) a compound which has, as a basic skeleton, a 5-membered heterocyclic compound having a structure represented by the formula: -N=C(SH)-X- [wherein X represents NH, O or S] and which shows a pH value of 7 or less in the form of an aqueous solution (10 ppm, 23 DEG C) and (3) a compound which has, as a basic skeleton, a 6-membered heterocyclic aromatic compound having at least one nitrogen atom (N) and which shows a pH value of 7 or more in the form of an aqueous solution (10 ppm, 23 DEG C); a compound capable of forming a complex or chelate in coordination with Cu (copper); and water. The solution has a pH value ranging from 4 to 9.

Owner:DAIKIN IND LTD

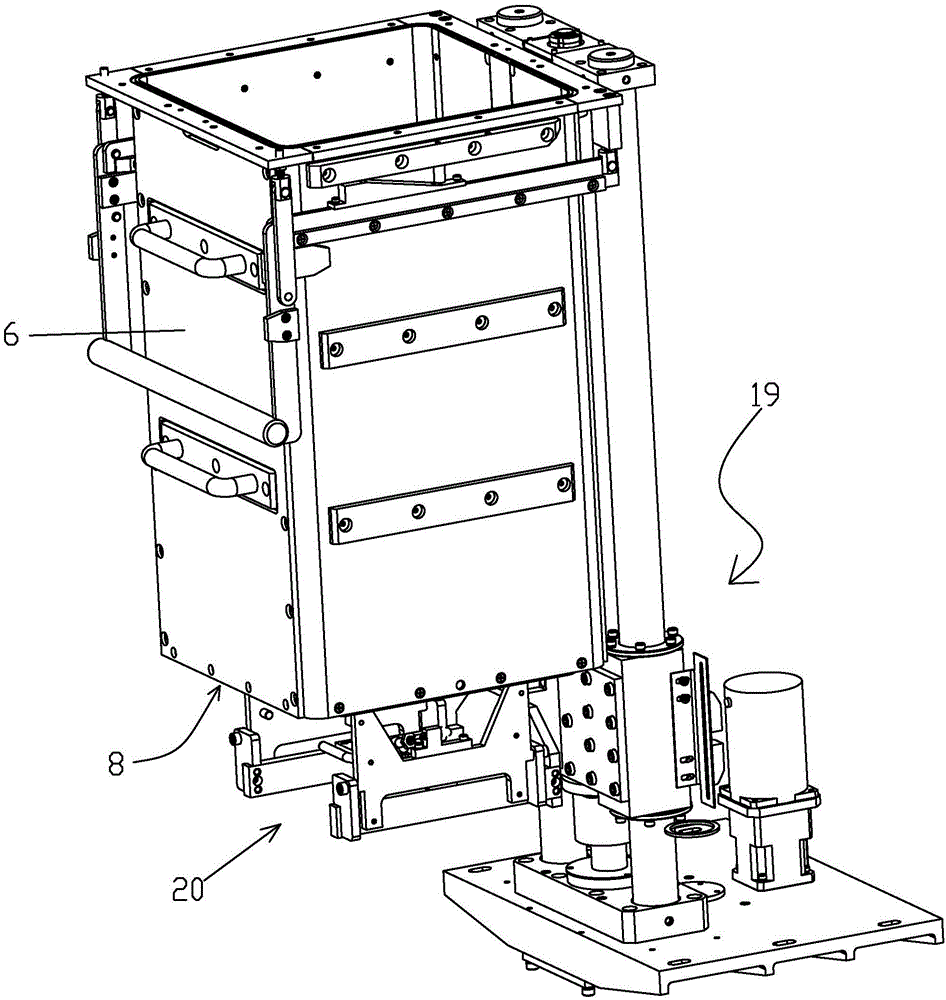

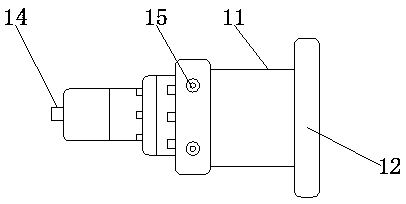

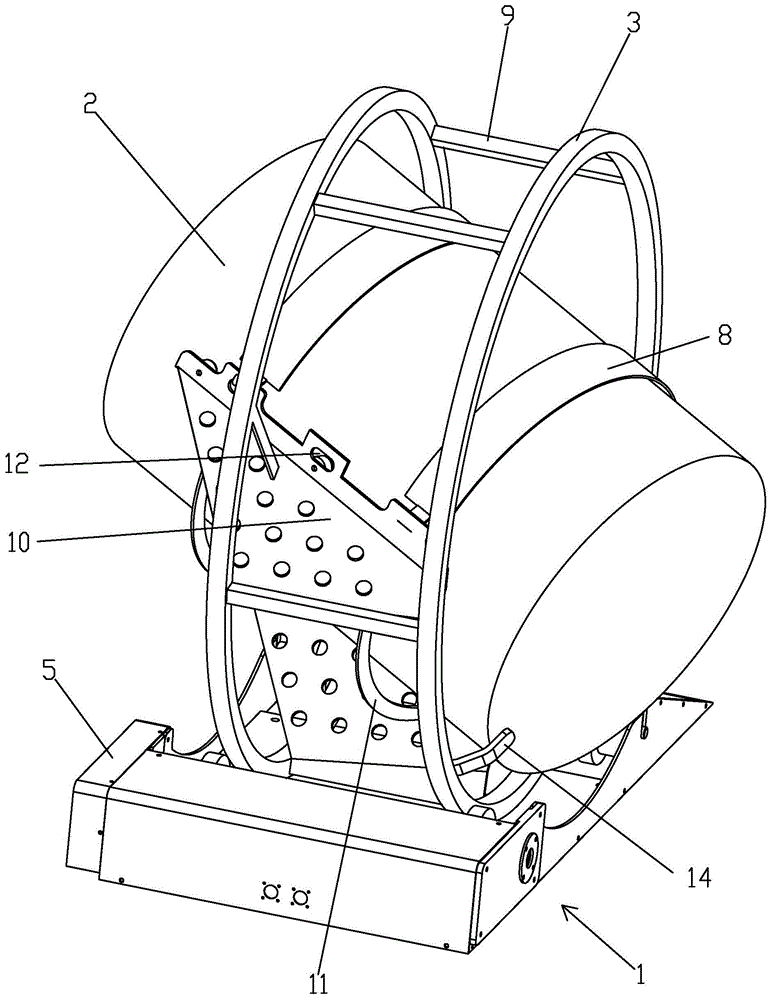

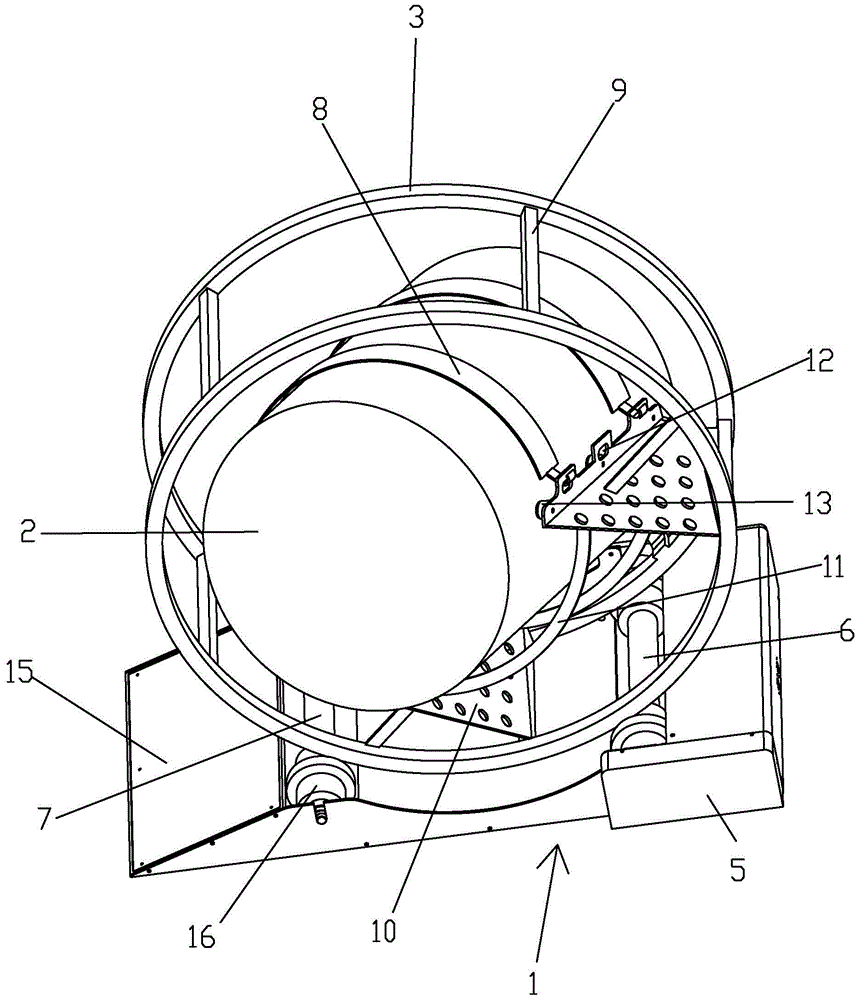

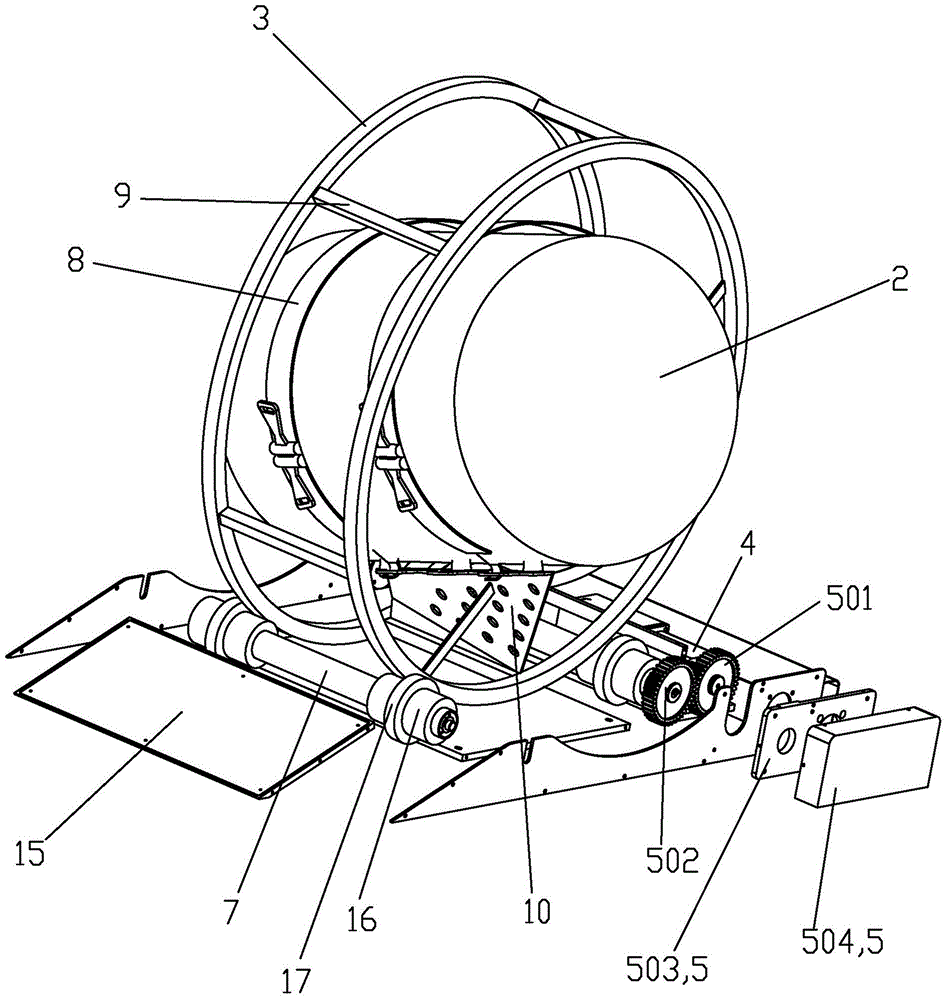

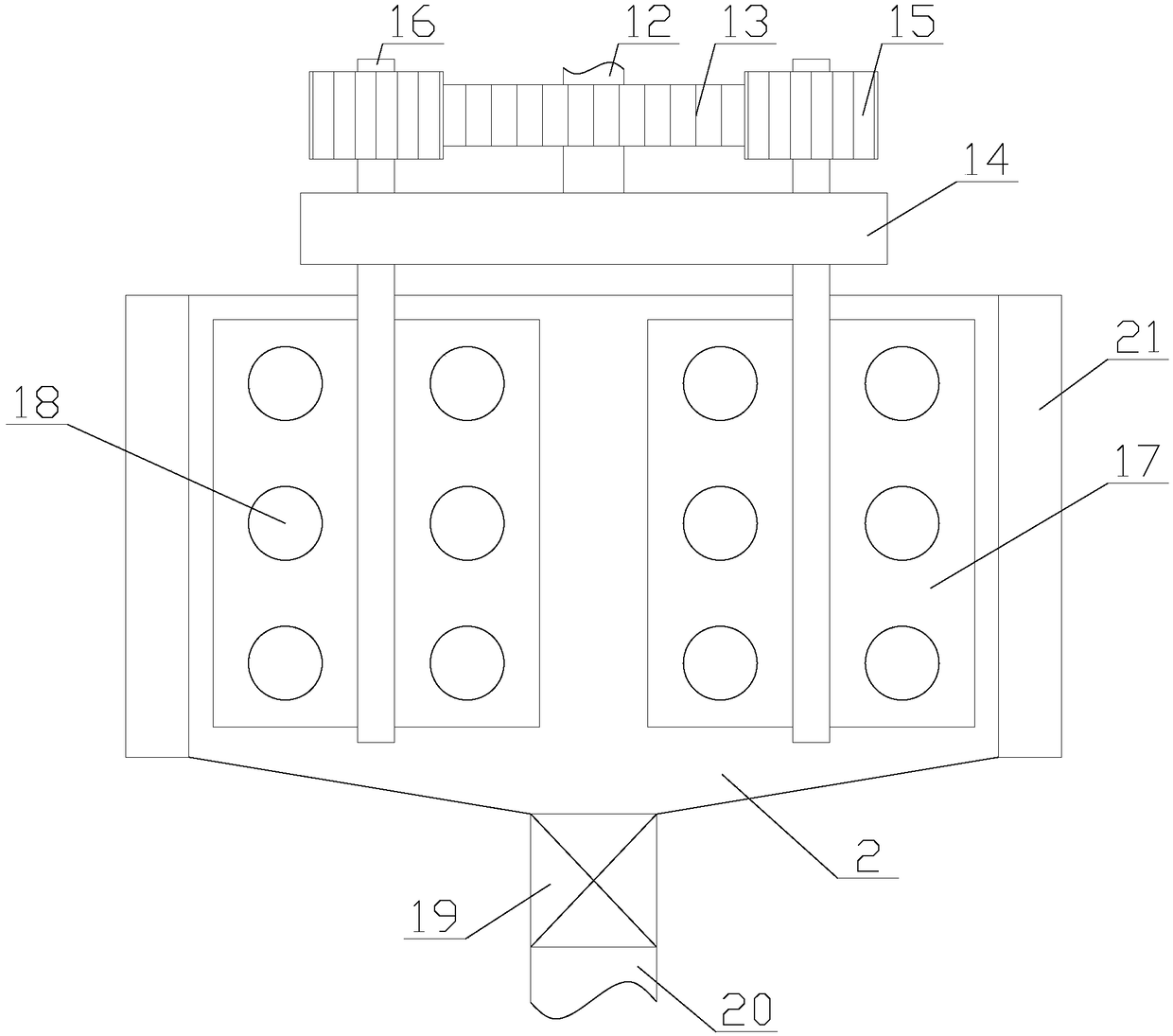

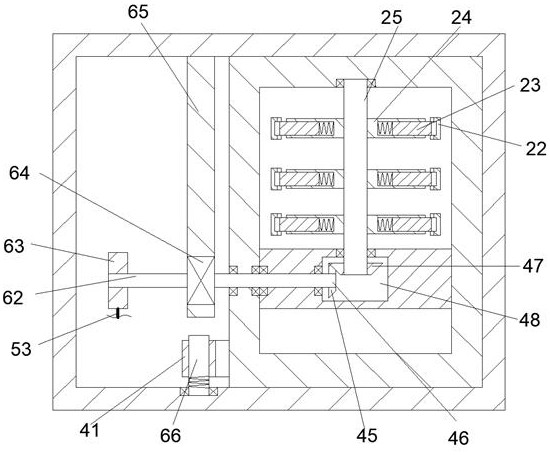

Meal mixer capable of rotating meal barrel in three-dimensional way

InactiveCN105032253AAvoid intensityAvoid rough surfacesRotating receptacle mixersAdditive manufacturing apparatusDrive motorEngineering

The invention discloses a meal mixer capable of rotating a meal barrel in a three-dimensional way. According to the key point of the technical scheme, the meal mixer comprises a base and a rolling frame which can obliquely fix a sealed meal barrel so as to rotate the meal barrel in a three-dimensional way; the base is respectively provided with a driving motor, a gear box connected with the driving motor and a first rotating shaft connected with the gear box; a second rotating shaft is arranged at the other end of the base, and the rolling frame is rotatably arranged on the first rotating shaft and the second rotating shaft. By virtue of the three-dimensional rotating meal barrel of the meal mixer, new and old powder in a stainless steel meal barrel can be fully mixed without dead angles, so as to prevent the phenomena that the strength of formed parts is poor and the surface is rough, and avoid powder flying.

Owner:TPM MACHINERYSHANGHAI CO LTD

Plastic-wood composite material and preparation method thereof

The invention discloses a plastic-wood composite material which comprises the following components in parts by weight: 2-5 parts of melamine resin, 50-70 parts of straw and rice hull fiber or combination of the two, 28-36 parts of low-concentration polyethylene, 1-5 parts of solubilizer, 1-5 parts of lubricant and 0.5-2 parts of soluble silicate. In the plastic-wood composite material disclosed by the invention, wood vinegar in the straw and rice hull fiber is quickly removed by use of the neutralization and evaporation effects generated by the melamine resin in a curing process, thus the bubble formation is avoided, and the rough surface of the plastic-wood composite material is prevented; by adding the soluble silicate into the components, the grip strength among the particles of the plastic-wood composite material is enhanced, and the nail-holding ability of a plate is improved.

Owner:贵州普林鑫泰塑木科技有限公司

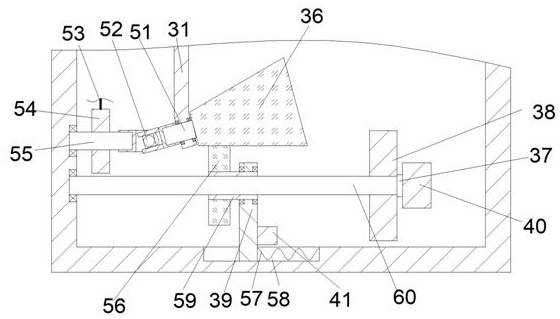

Plastic product production equipment with toxic gas eliminating and drying functions

The invention relates to plastic product production equipment with toxic gas eliminating and drying functions. The plastic product production equipment comprises a main body, wherein a drying box, a driving mechanism, a drying mechanism, a treating mechanism, a melting box and a production box are arranged in the main body, wherein the driving mechanism comprises a motor, a first gear, a transmission shaft, a second gear, a third gear and a rotary shaft; the drying mechanism comprises a fourth gear, a cross beam, a communicating pipe and two mixing units; and the treating mechanism comprises aheating unit, an extraction unit, an air supplying unit and a combustion unit. The plastic product production equipment with toxic gas eliminating and drying functions can dry raw materials through the drying mechanism to prevent surface coarseness of a product as a result of water in the raw materials or air bubbles in a plastic melt. Therefore, the plastic product production equipment can extract harmful gas generated by melting a plastic through the treating mechanism and heat the melting box by combusting the harmful gas, so that the energy sources are saved.

Owner:晋江万智进出口贸易有限公司

Double-cylinder liquid cooling device

InactiveCN108063516AInhibit sheddingAvoid rough surfacesCooling/ventillation arrangementSupports/enclosures/casingsRough surfaceWater leakage

The invention discloses a double-cylinder liquid cooling device, and the device comprises a base of a double-cylinder structure. The base is disposed at a position close to a heat source, and the interior of the base is provided with a water channel. Cooling liquid flows in the water channel in a circulating manner. The base is also provided with a locking structure, and the locking structure enables the flowing of the cooling liquid to be limited in the water channel, thereby preventing the leakage of the cooling liquid. According to the technical scheme of the invention, the cooling liquid flows in the water channel of the base in the circulating manner and the base is also provided with the locking structure, thereby preventing the leakage of the cooling liquid, avoiding the water leakage of a weld joint during grinding, preventing the falling of paint, avoiding a rough surface, and forming a flat surface of the base.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

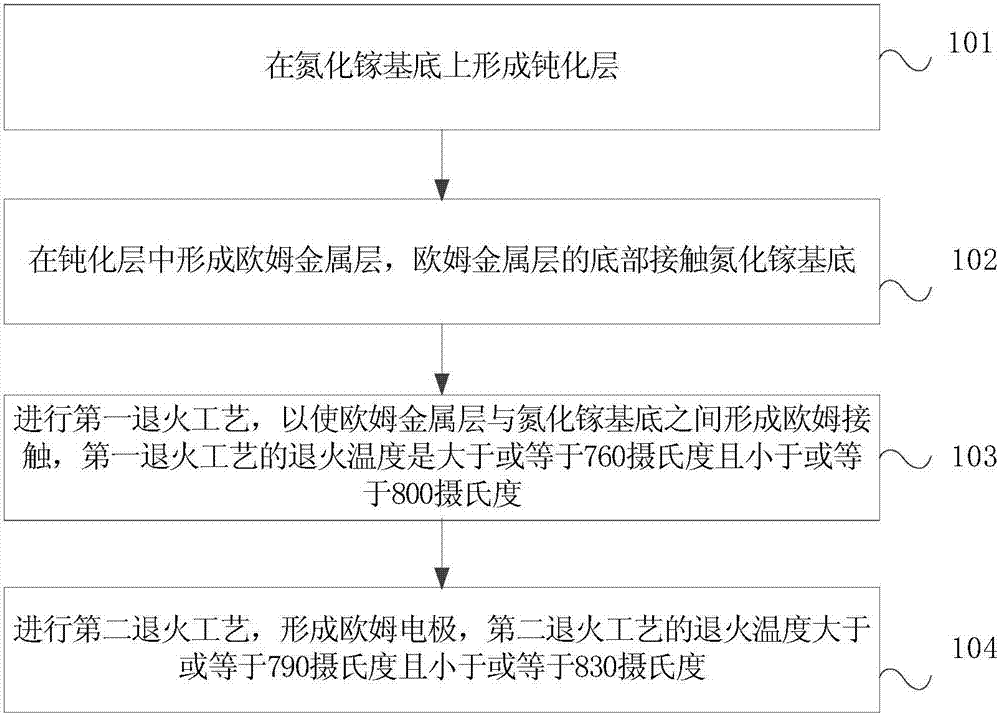

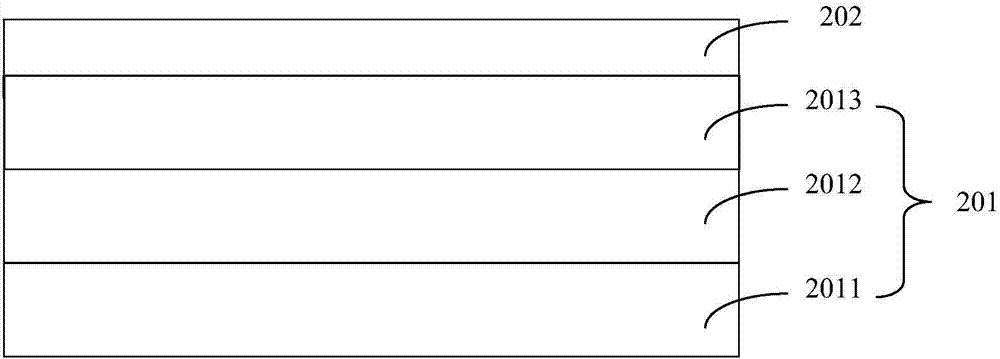

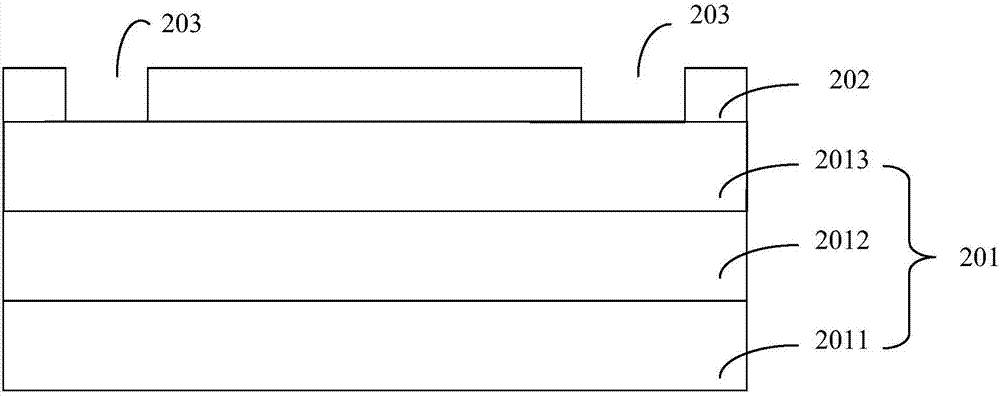

Manufacturing method of GaN field effect transistor

InactiveCN107230706AImprove uniformityImprove reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactField-effect transistor

The invention provides a manufacturing method of a GaN field effect transistor. The method comprises the following steps: forming a passivation layer on a GaN substrate; forming an ohmic metal layer in the passivation layer, wherein the bottom of the ohmic metal layer is contacted with the GaN substrate; performing the first annealing process so as to form the ohmic contact between the ohmic metal layer and the GaN substrate, wherein the annealing temperature of the first annealing process is greater than or equal to 760 DEG C and less than and equal to 800 DEG C; performing the second annealing process to form an ohmic electrode, wherein the annealing temperature of the second annealing process is greater than or equal to the 790 DEG C and less than or equal to 830 DEG C. By using the manufacturing method of the GaN field effect transistor provided by the embodiment, the good ohmic contact and good edge morphology can be formed, the voltage withstand uniformity of the GaN field effect transistor is good, and the reliability is high.

Owner:PEKING UNIV +2

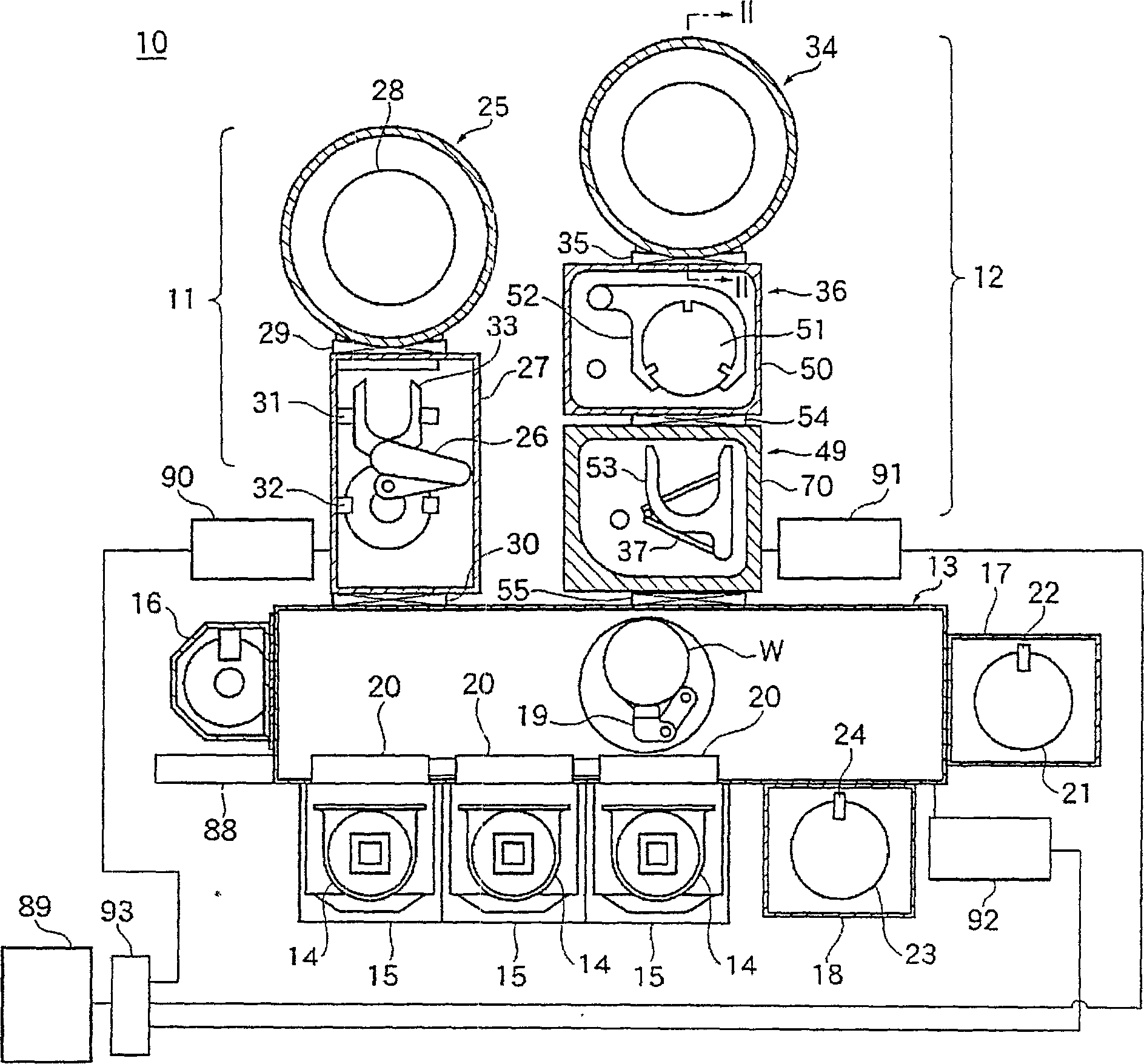

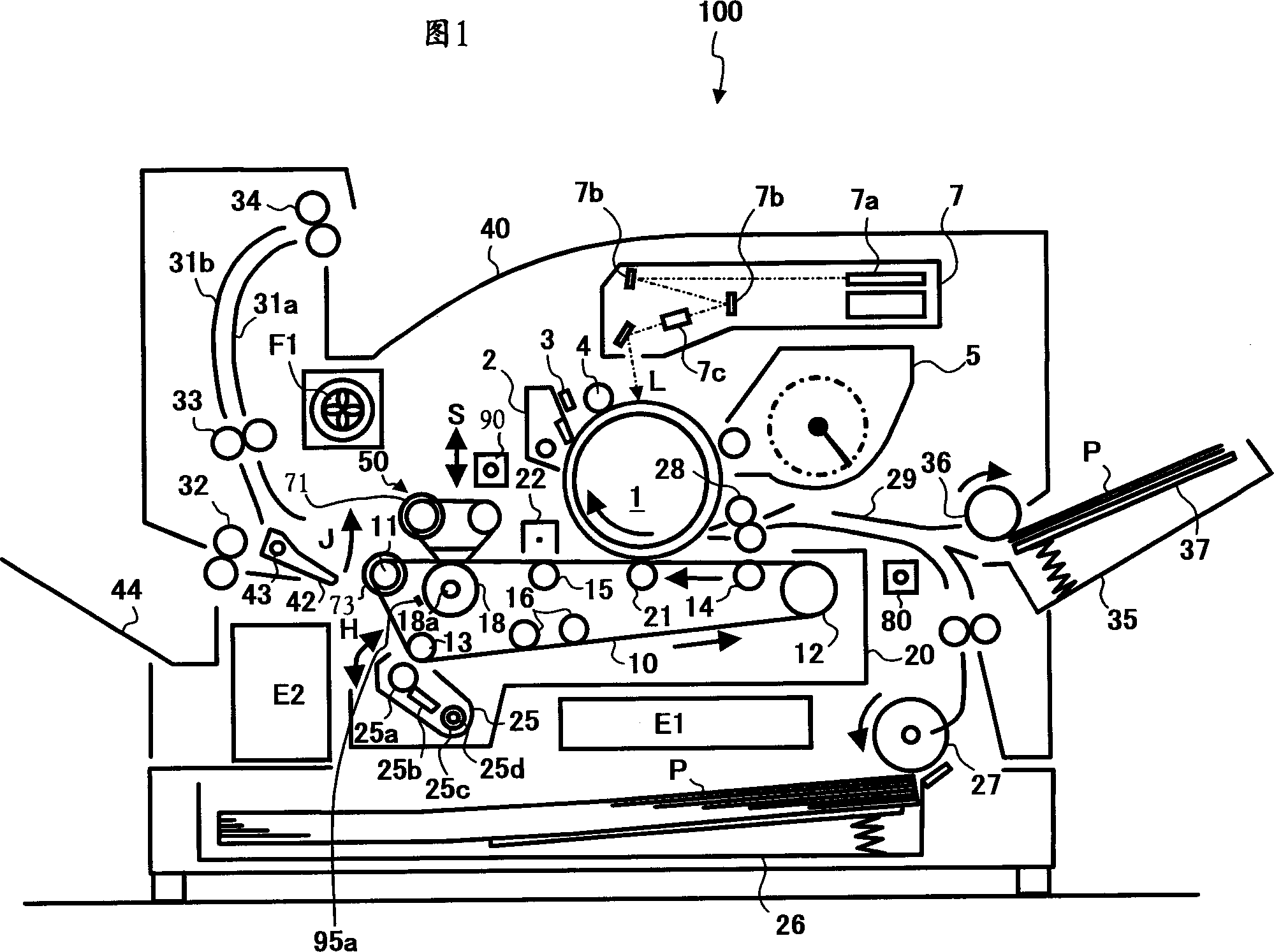

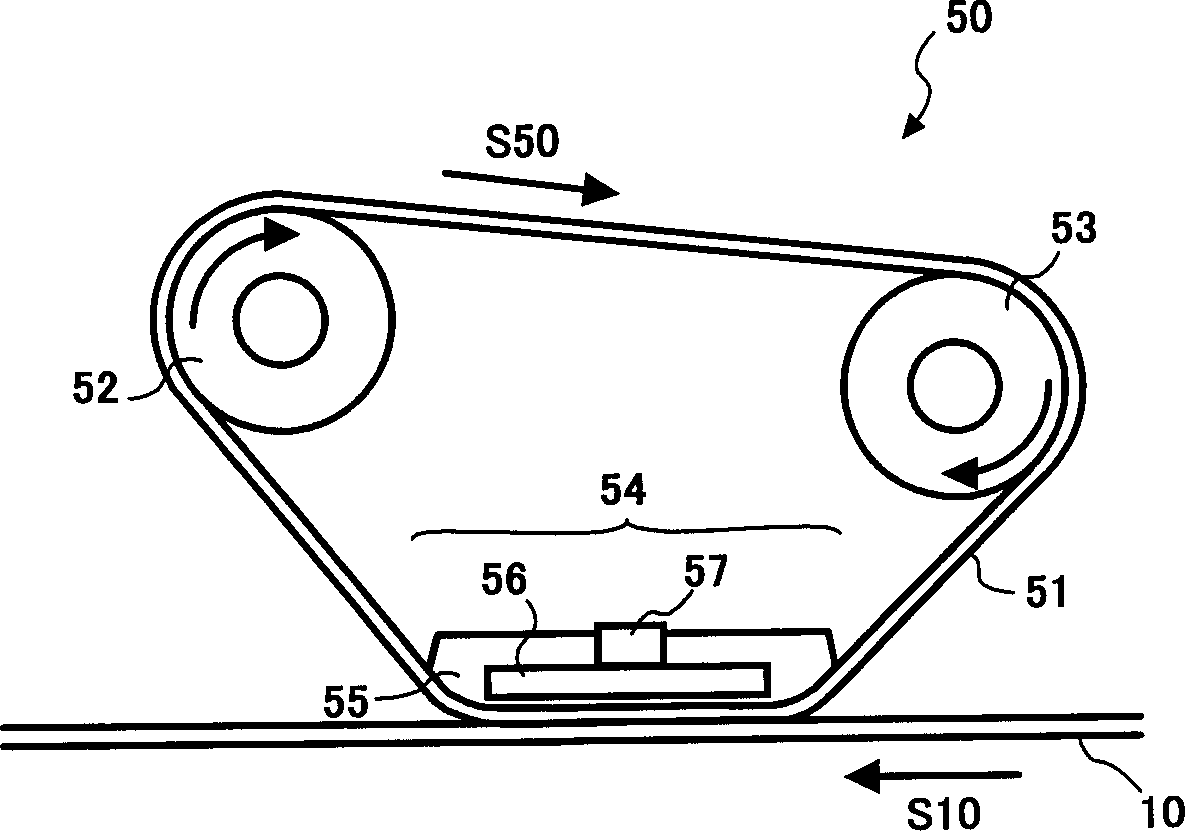

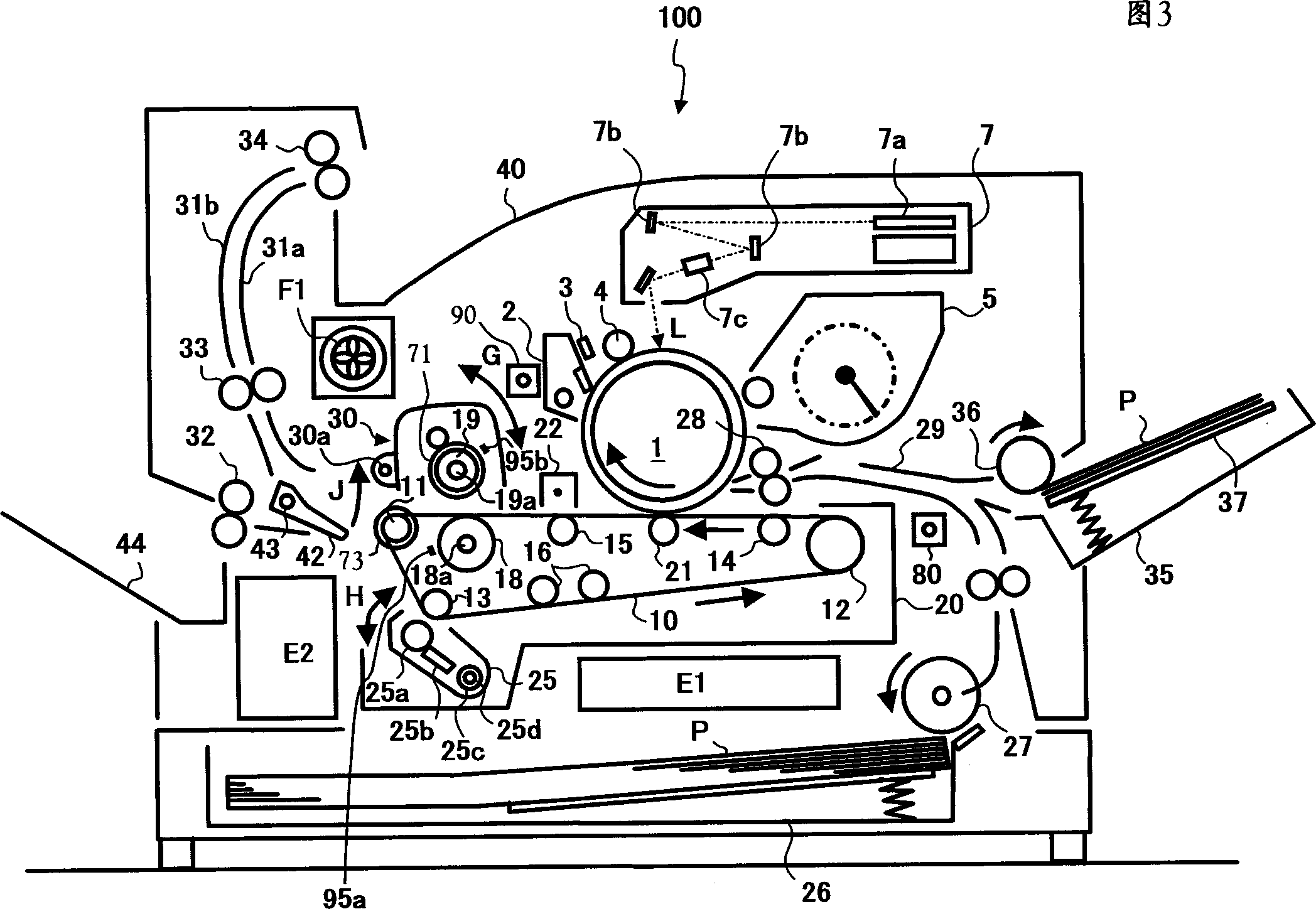

Image forming method and device

InactiveCN1347018ASame surface propertiesSame image qualityElectrographic process apparatusImage formationImage quality

Owner:RICOH KK

Adjusting extrusion device for 3D printing PLA material

InactiveCN112248441AAvoid molding effectsRealize heating, melting and stirringAdditive manufacturing apparatus3D object support structuresManufactured materialEngineering

The invention discloses an adjusting extrusion device for a 3D printing PLA material. The adjusting extrusion device comprises a mounting box, wherein a mounting cavity is formed in the mounting box,a placing mechanism is arranged in the mounting cavity, an extruding mechanism comprises a treatment box fixedly mounted on the upper end wall and the lower end wall of the mounting cavity, a treatment cavity is formed in the treatment box, check blocks are fixedly mounted on the left end wall and the right end wall of the treatment cavity, check grooves are formed in the check blocks, and a treatment groove is formed in the right end wall of the treatment cavity. When the PLA raw material at the stirring position is too little due to outflow molding of the PLA material, the PLA raw material is added, the situation that molding of the PLA material is affected due to the fact that the extruded PLA raw material is too little is avoided, the extrusion force can be adjusted in real time according to the extrusion amount, and the phenomena that the extruded material is not uniform and the surface is not smooth due to the too large extrusion amount are avoided.

Owner:天津备东科技有限公司

Manufacturing method of reinforced floorboard with high surface brightness

InactiveCN106368408AImprove flatnessGuaranteed flatnessLiquid surface applicatorsLamination ancillary operationsSurface brightnessHigh surface

The invention discloses a manufacturing method of a reinforced floorboard with the high surface brightness. The manufacturing method comprises the following steps that a steel plate is treated, specifically, the surface of the steel plate is polished to obtain a chrome-plated steel plate; an abrasion-resisting layer is treated, specifically, abrasion-resisting paper is dipped into abrasion-resisting paper dipping glue, taken out and made 10-40% dried; composite aluminum oxide powder is uniformly poured and sprayed on the surface of the dipped abrasion-resisting paper, and an abrasion-resisting layer is obtained; patterned paper and balance paper are dipped with composite melamine resin; the dipped patterned paper and the abrasion-resisting layer are sequentially laid on a fiberboard; and the dipped balance paper is laid under the fiberboard, hot pressing is conducted through the chrome-plated steel plate, and the reinforced floorboard with the high surface brightness is obtained. The surface brightness of the floorboard manufactured through the manufacturing method can reach up to 100+ / -10 degree, and the floorboard is obviously superior to ordinary floorboards. The floorboard is firm, high in corrosion resistance and long in service life, and the brightness is not prone to weakening in the use process.

Owner:普洱绿洲木业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com