Preparation method of yttrium-barium-copper-oxidize superconducting film

A technology of yttrium-barium-copper-oxygen superconducting thin film, which is applied in the field of preparation of yttrium-barium-copper-oxygen superconducting thin film, can solve problems such as surface roughness of the yttrium-barium-copper-oxygen superconducting thin film, and achieve simple and easy preparation method and high preparation efficiency , the effect of excellent superconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

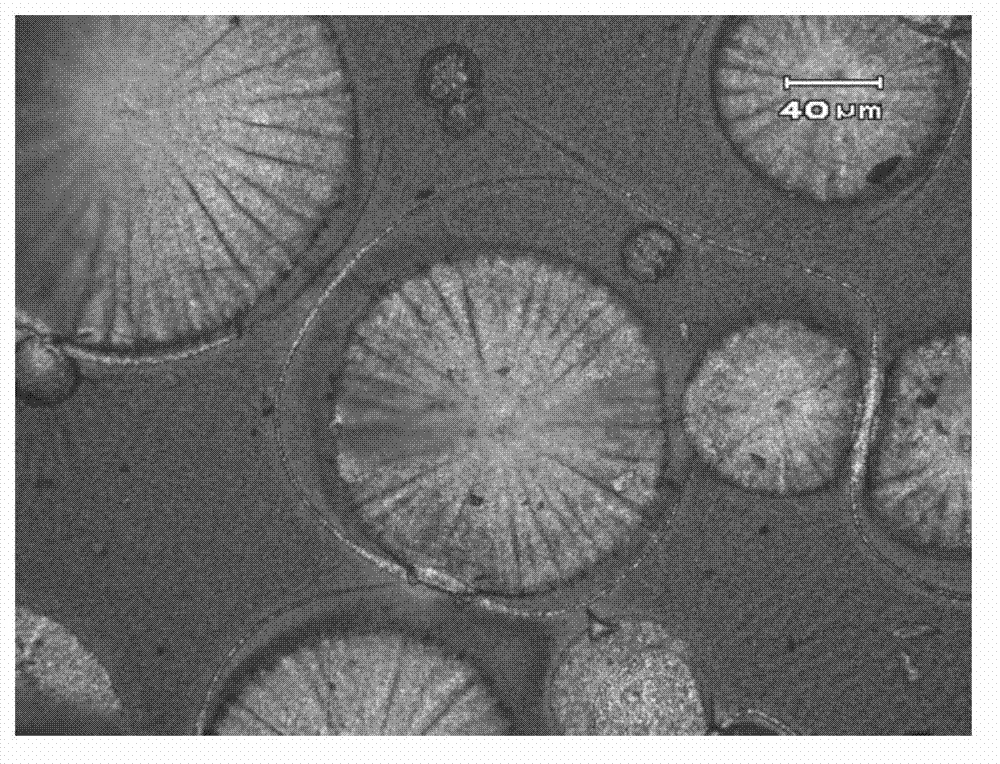

[0019] The preparation method of the yttrium-barium-copper-oxygen superconducting thin film of the present invention is as follows: firstly, a fluorine-free yttrium-barium-copper-oxysol sol is prepared on a single crystal lanthanum aluminate substrate to obtain a yttrium-barium-copper-oxygen gel film, and the yttrium-barium-copper-oxygen gel film is dried after drying. The yttrium-barium-copper-oxygen superconducting thin film is obtained by successively undergoing heat treatment, crystallization and oxygen infiltration treatment.

[0020] Specific steps are as follows:

[0021] Step 1, dissolving yttrium acetate, barium acetate and copper acetate in methanol with diethylenediamine, lactic acid and acrylic acid respectively to form three solutions, then mixing and stirring the above three solutions to obtain fluorine-free yttrium barium copper oxygen sol, acetic acid The molar ratio of yttrium, barium and copper in yttrium, barium acetate and copper acetate is 1~1.5:2:3~4;

...

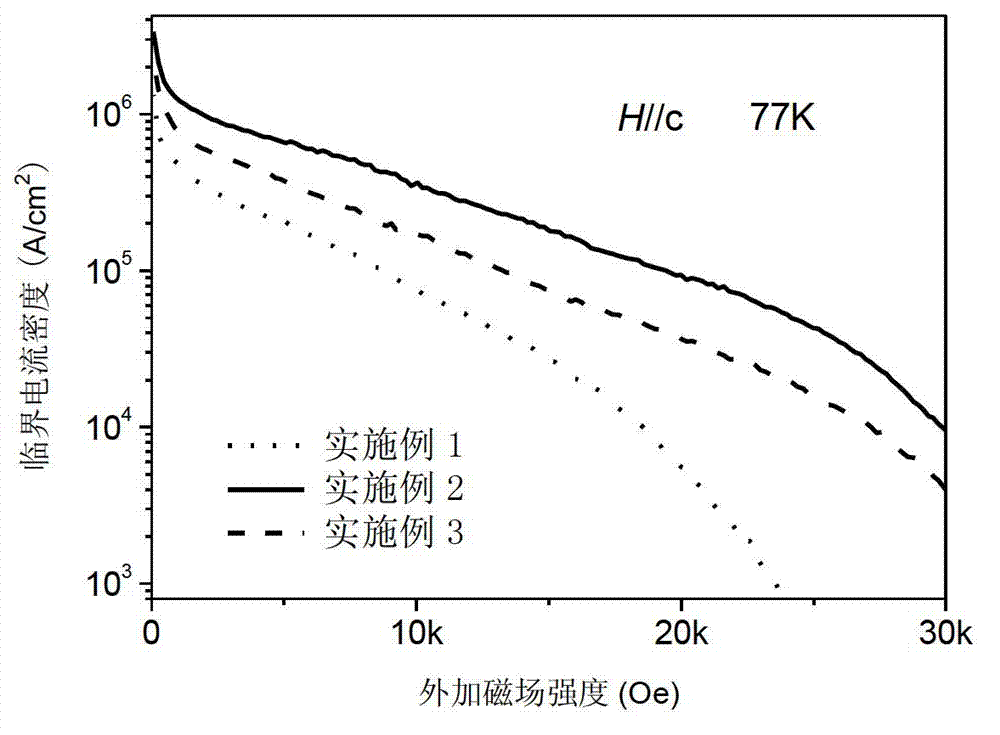

Embodiment 1

[0029] Step 1, dissolving yttrium acetate, barium acetate and copper acetate in methanol with diethylenediamine, lactic acid and acrylic acid respectively to form three solutions, and then mixing and stirring the above three solutions to obtain a fluorine-free yttrium barium copper oxygen sol, wherein The molar ratio of yttrium, barium and copper in yttrium acetate, barium acetate and copper acetate is 1:2:3;

[0030] Step 2, using the fluorine-free yttrium-barium-copper-oxysol sol obtained in step 1 to prepare a yttrium-barium-copper-oxygen gel film on a single crystal lanthanum aluminate substrate, and then drying in air at 80° C. for 30 minutes to obtain fluorine-free yttrium-barium-copper Oxygen gel film;

[0031] In step 3, the fluorine-free yttrium barium copper oxide gel film obtained in step 2 is moved to a horizontal quartz tubular atmosphere sintering furnace with a preset temperature of 100 ° C for heat treatment. The temperature was raised to 350 °C in a mixed atm...

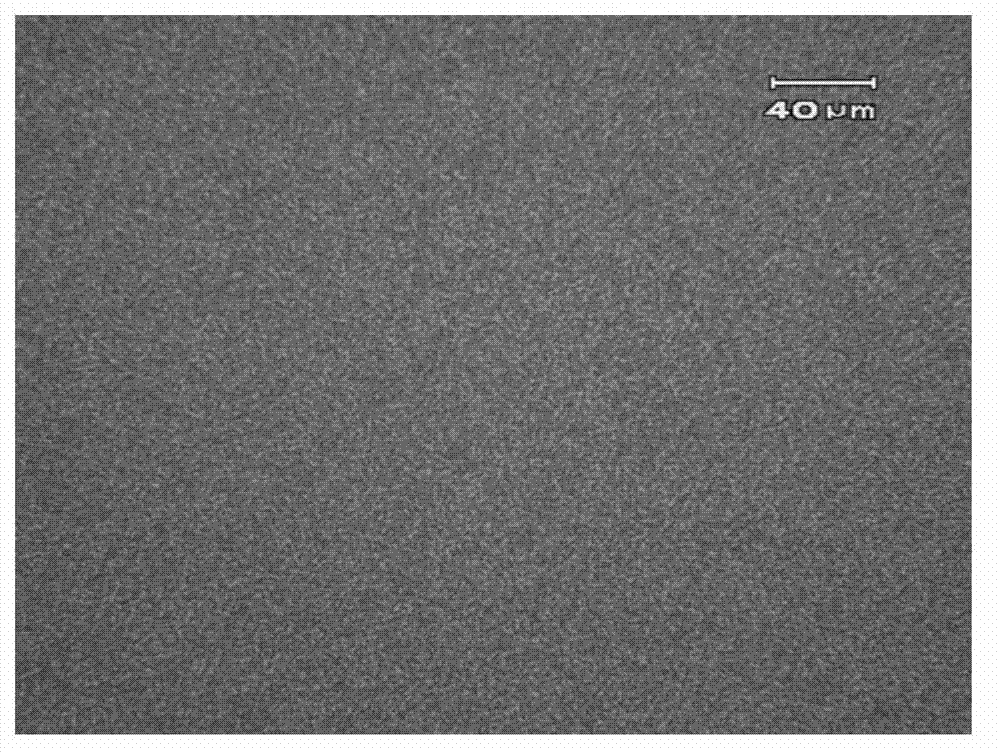

Embodiment 2

[0034] Step 1, dissolving yttrium acetate, barium acetate and copper acetate in methanol with diethylenediamine, lactic acid and acrylic acid respectively to form three solutions, and then mixing and stirring the above three solutions to obtain a fluorine-free yttrium barium copper oxygen sol, wherein The molar ratio of yttrium, barium and copper in yttrium acetate, barium acetate and copper acetate is 1.15:2:3.2;

[0035] Step 2, using the fluorine-free yttrium-barium-copper-oxysol sol obtained in step 1 to prepare a yttrium-barium-copper-oxygen gel film on a single crystal lanthanum aluminate substrate, and then drying in high-purity argon at 90° C. for 20 minutes to obtain a fluorine-free Yttrium barium copper oxide gel film;

[0036]Step 3, move the fluorine-free yttrium barium copper oxide gel film obtained in step 2 to a horizontal quartz tubular atmosphere sintering furnace with a preset temperature of 100°C for heat treatment. The specific steps of heat treatment are: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com