Patents

Literature

240results about How to "Improve superconductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for forming biaxially textured articles by powder metallurgy

InactiveUS6447714B1Improve superconductivityPolycrystalline material growthFrom solid stateRare earthAlloy

A method of preparing a biaxially textured alloy article comprises the steps of preparing a mixture comprising Ni powder and at least one powder selected from the group consisting of Cr, W, V, Mo, Cu, Al, Ce, YSZ, Y, Rare Earths, (RE), MgO, CeO2, and Y2O3; compacting the mixture, followed by heat treating and rapidly recrystallizing to produce a biaxial texture on the article. In some embodiments the alloy article further comprises electromagnetic or electro-optical devices and possesses superconducting properties.

Owner:UT BATTELLE LLC

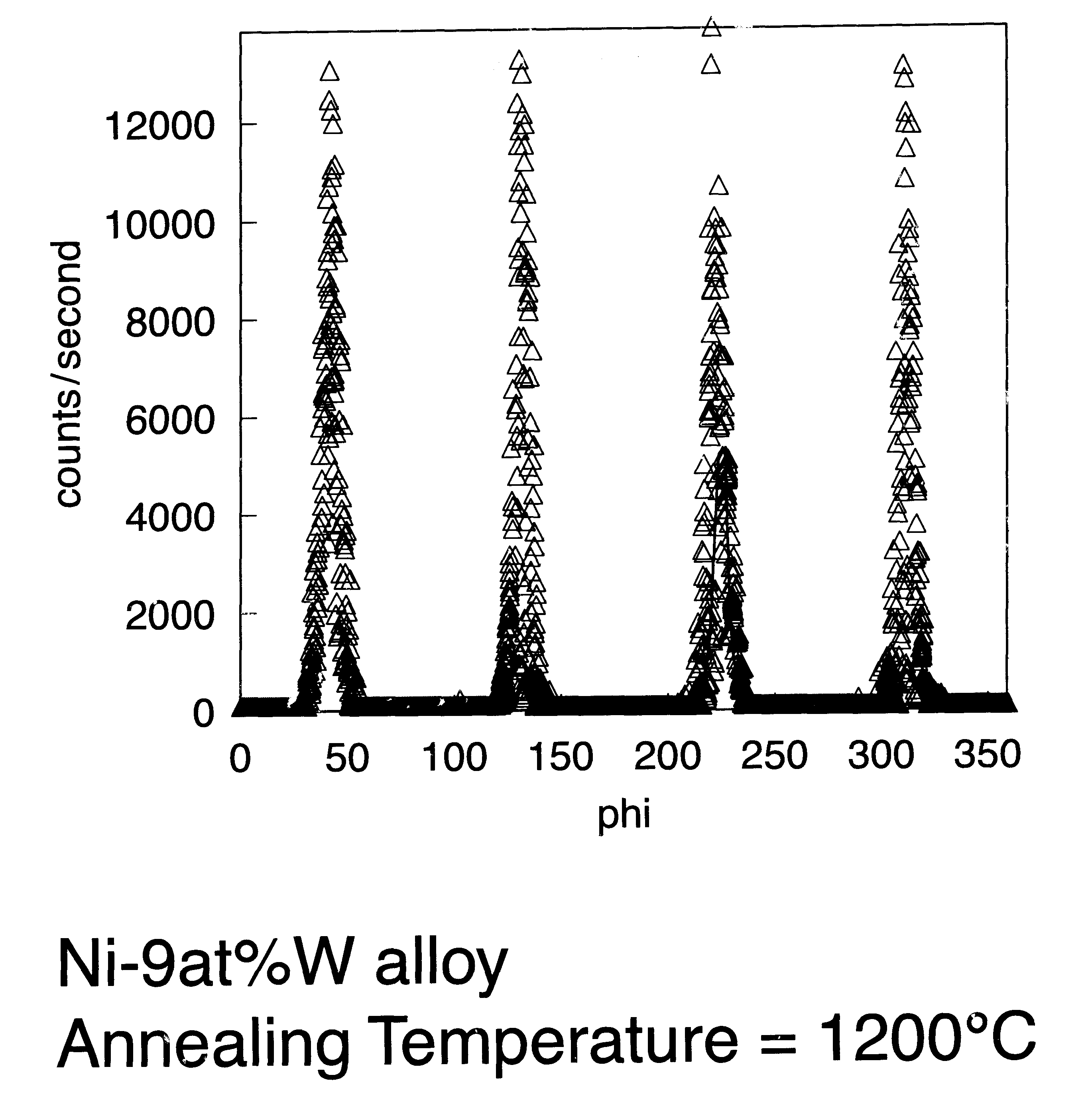

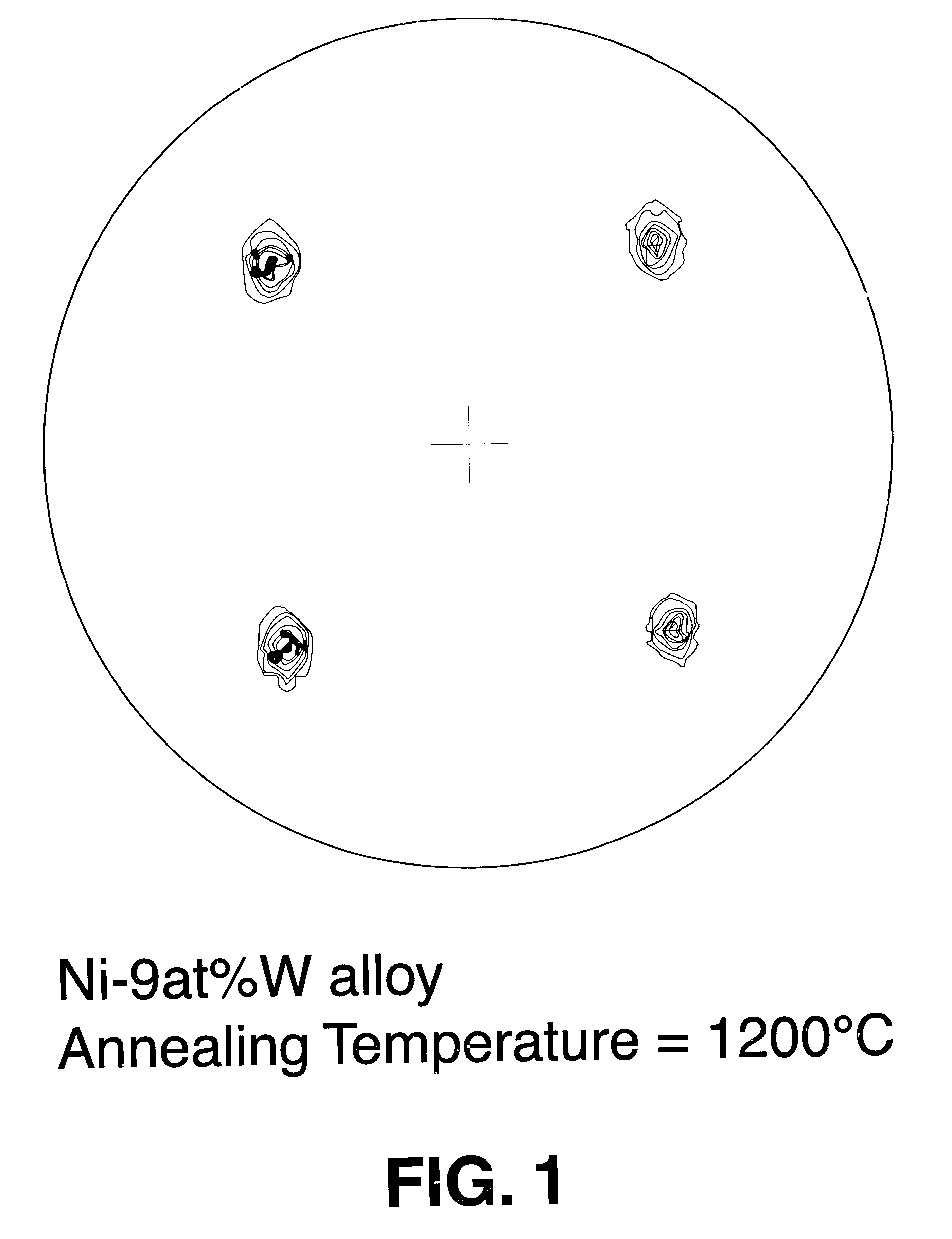

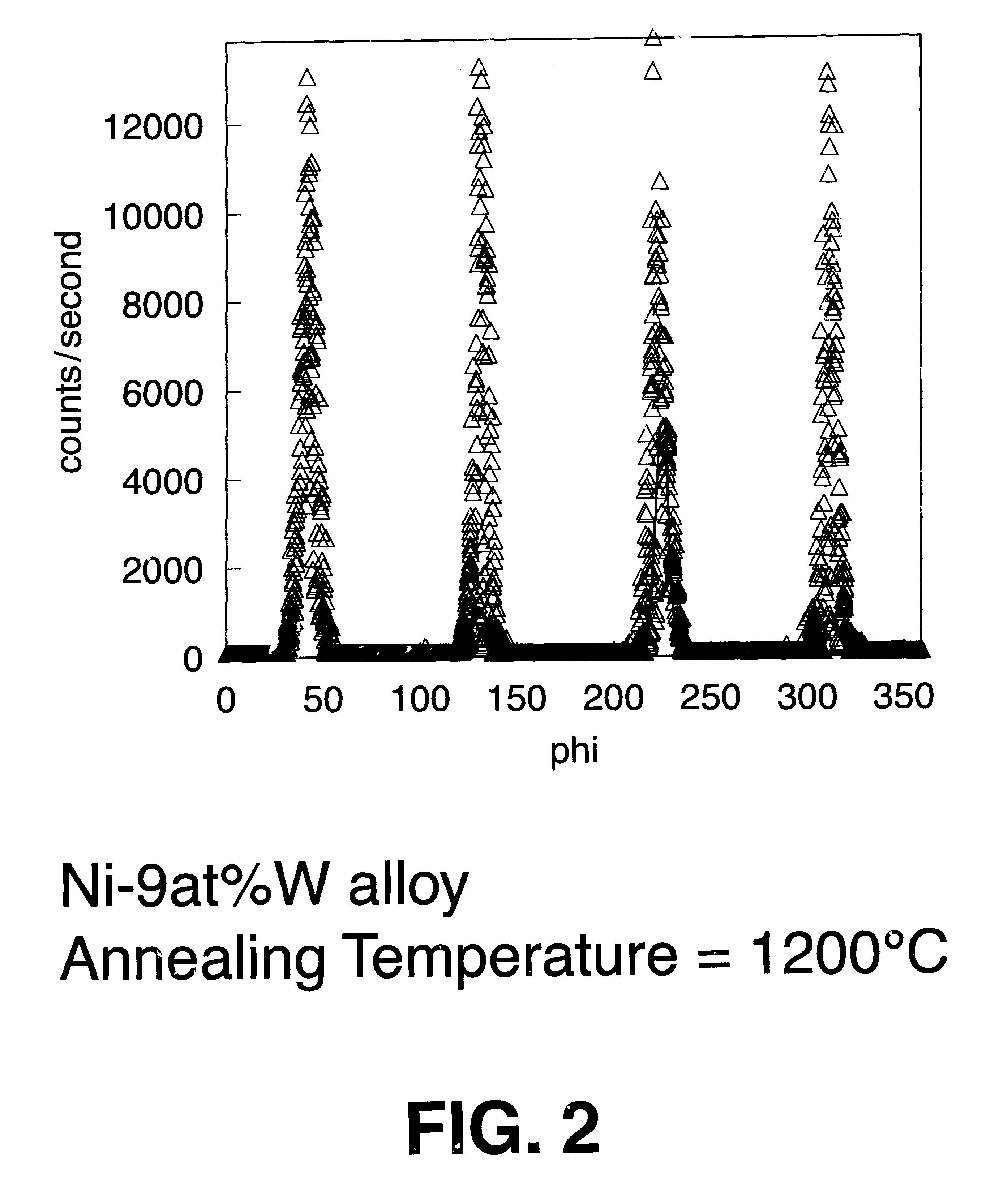

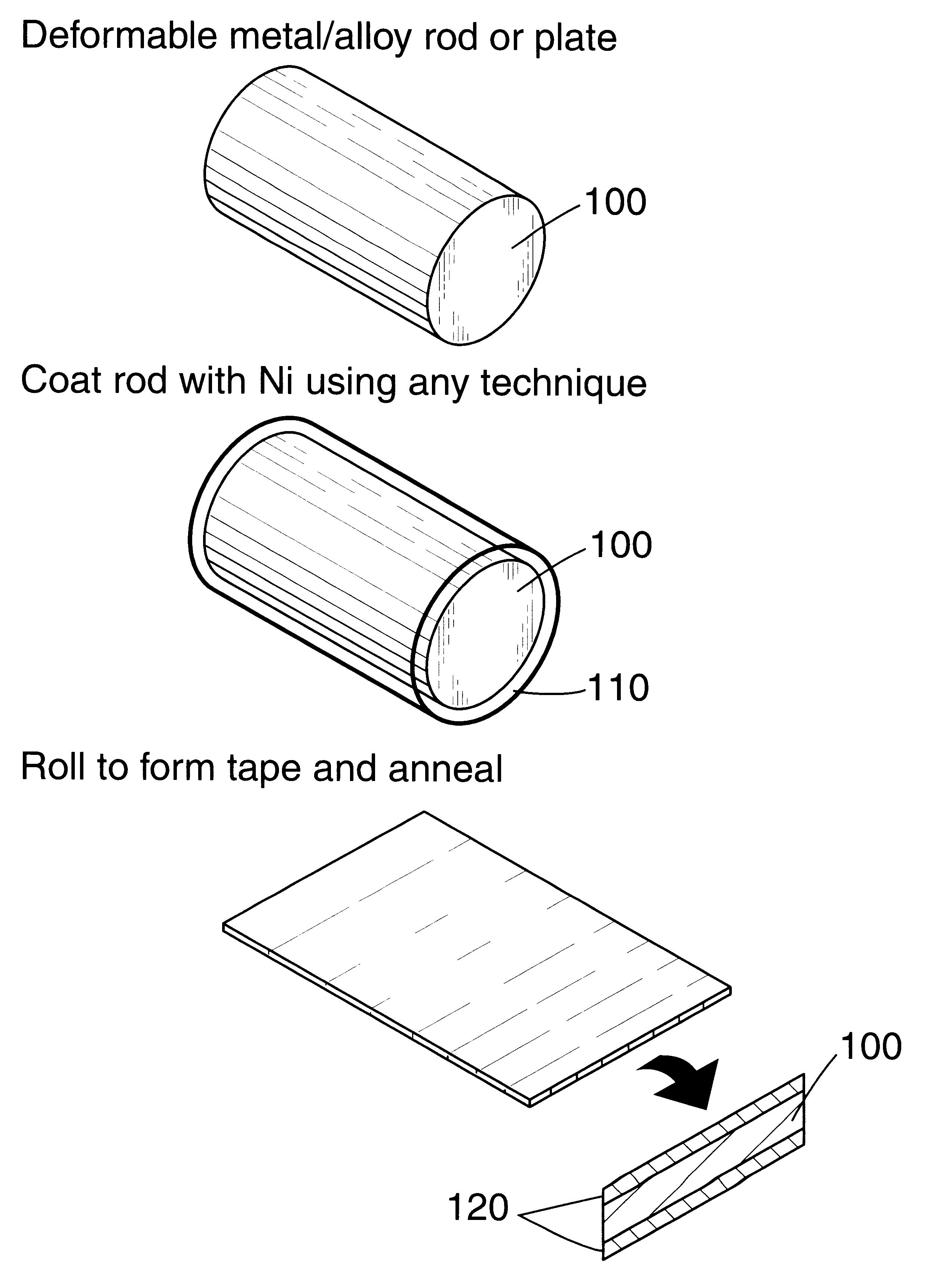

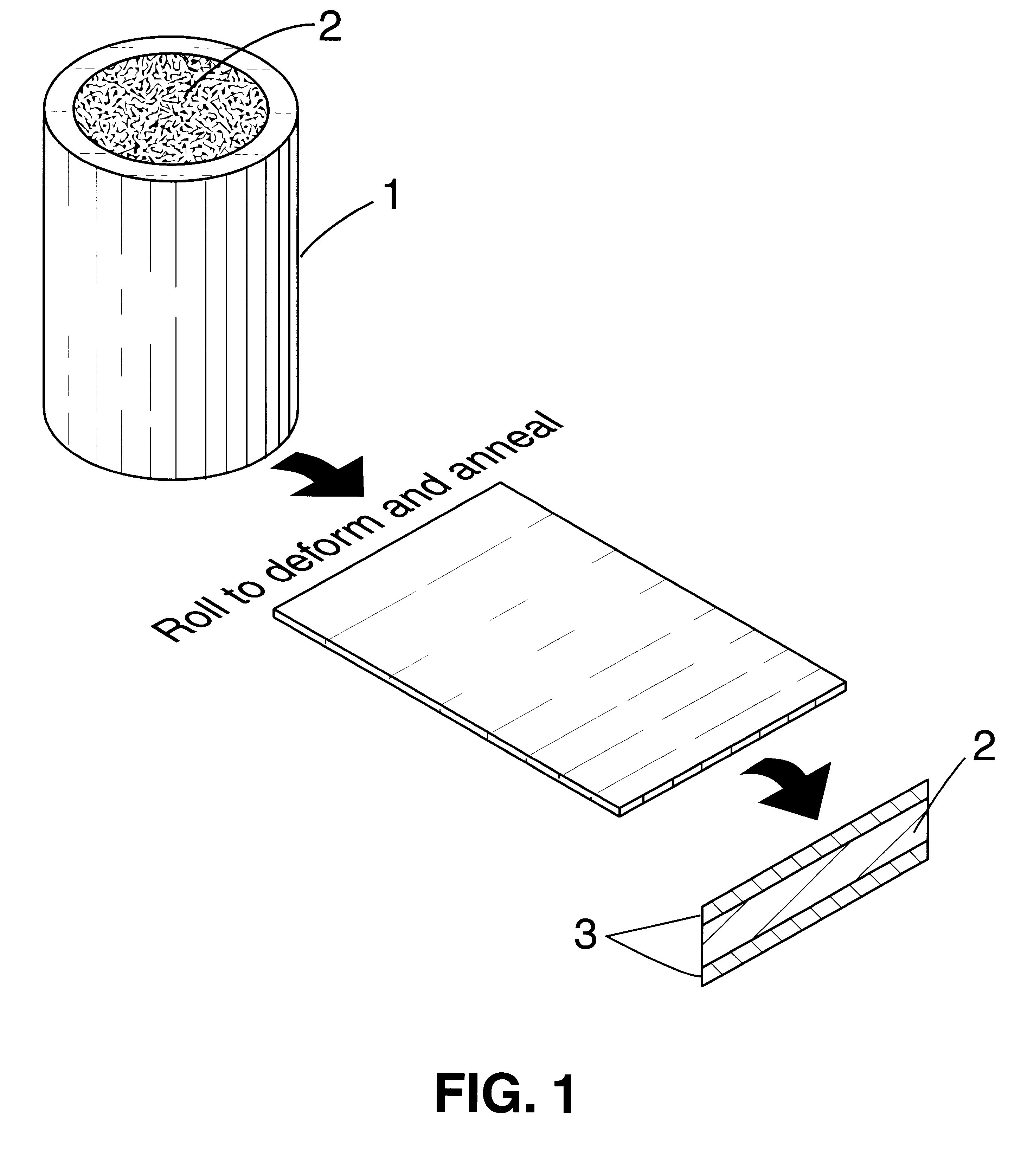

Biaxially textured articles formed by plastic deformation

InactiveUS6180570B1Improve superconductivityPolycrystalline material growthSuperconductors/hyperconductorsMetalMaterials science

A method of preparing a biaxially textured article comprises the steps of providing a metal preform, coating or laminating the preform with a metal layer, deforming the layer to a sufficient degree, and rapidly recrystallizing the layer to produce a biaxial texture. A superconducting epitaxial layer may then be deposited on the biaxial texture. In some embodiments the article further comprises buffer layers, electromagnetic devices or electro-optical devices.

Owner:LOCKHEED MARTIN ENERGY SYST INC

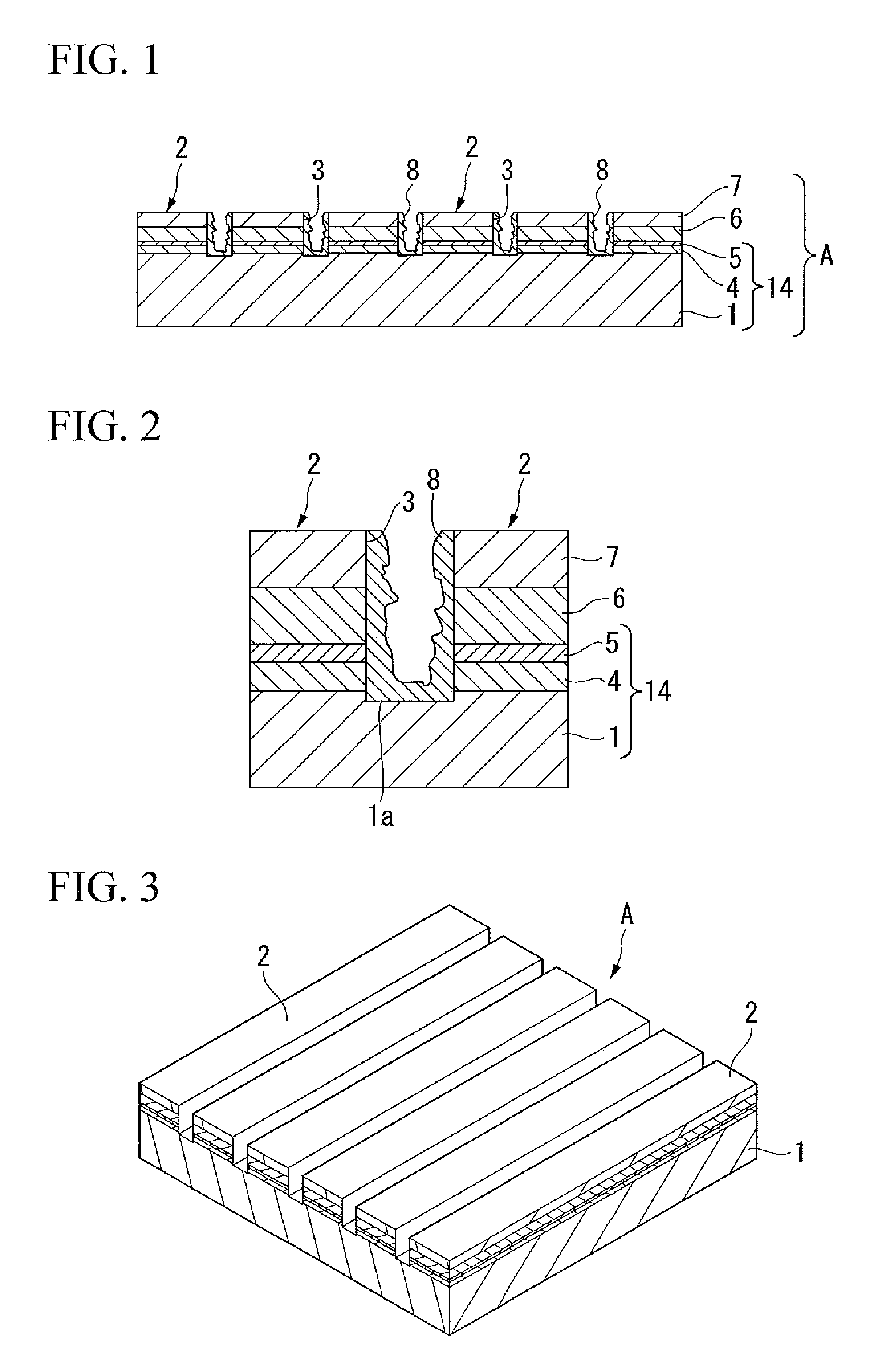

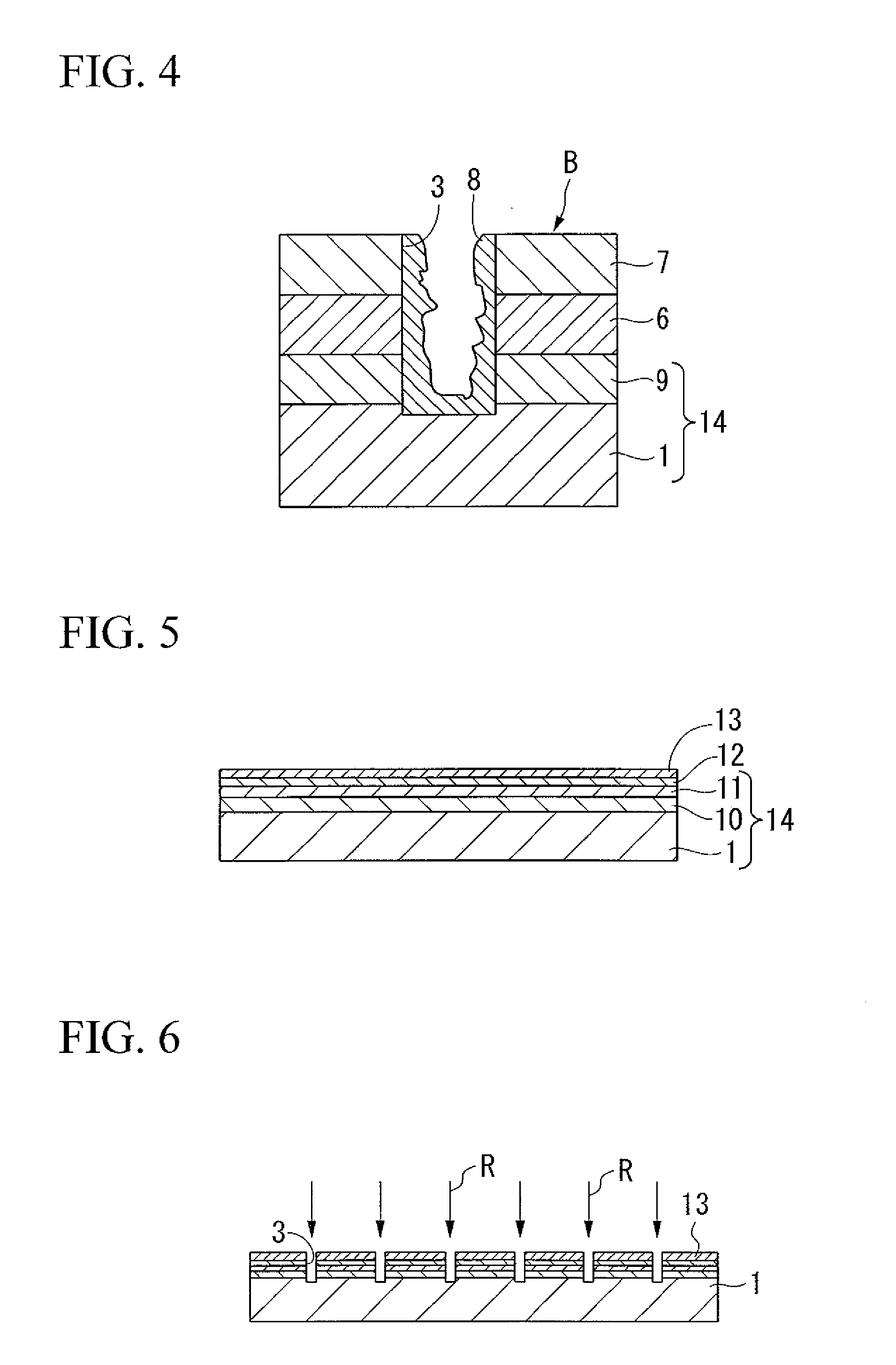

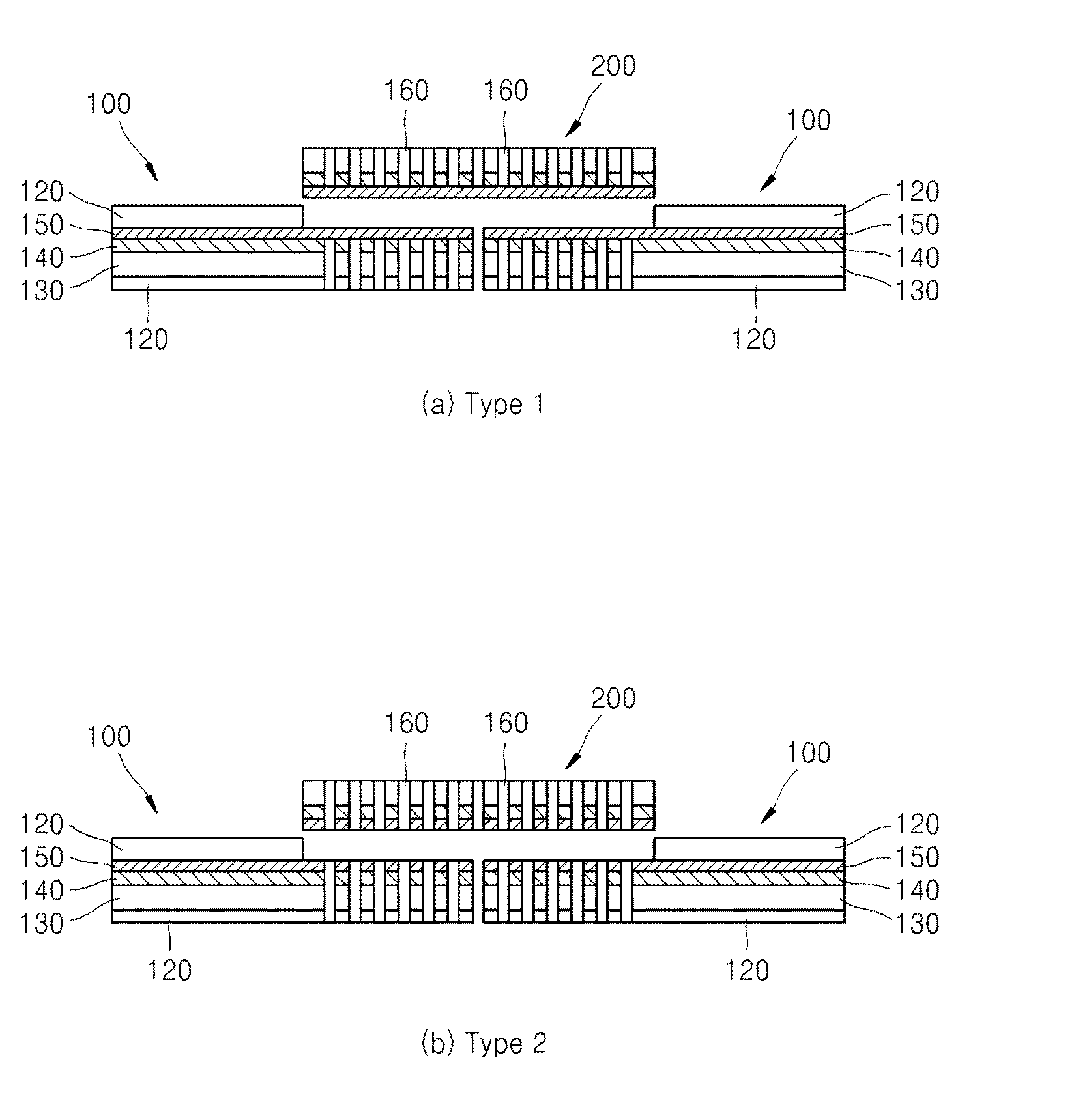

Low Alternating-Current Loss Oxide Superconductor and Fabricating Method Thereof

InactiveUS20070145100A1Reduce widthReduce lost timeCooking-vessel materialsSuperconductors/hyperconductorsHigh resistanceElectrical resistance and conductance

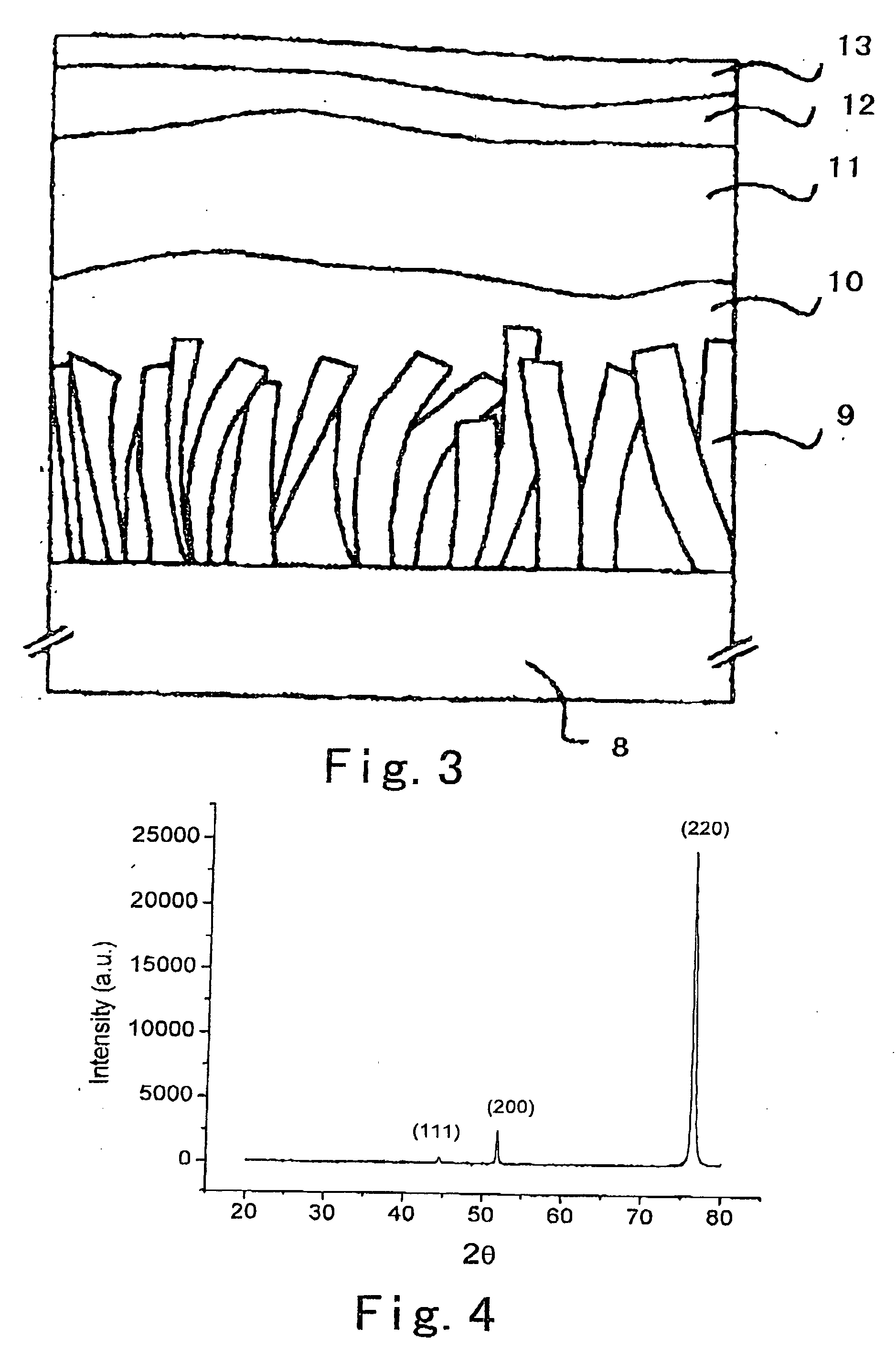

The present invention is configured such that, in a low AC loss oxide superconductor constituted by providing an oxide superconducting layer 6 on a substrate 1, said oxide superconducting layer 6 is separated into a plurality of filament conductors 2 in parallel to the lengthwise direction of said substrate 1 by dividing grooves 3 plurally formed in the widthwise direction of said substrate, and a high-resistance oxide 8 is formed in said dividing grooves 3. Because of the invention, it is possible to increase the insulation properties of individually divided mated filament conductors, and to obtain an oxide superconductor that has low AC loss.

Owner:RAILWAY TECH RES INST +2

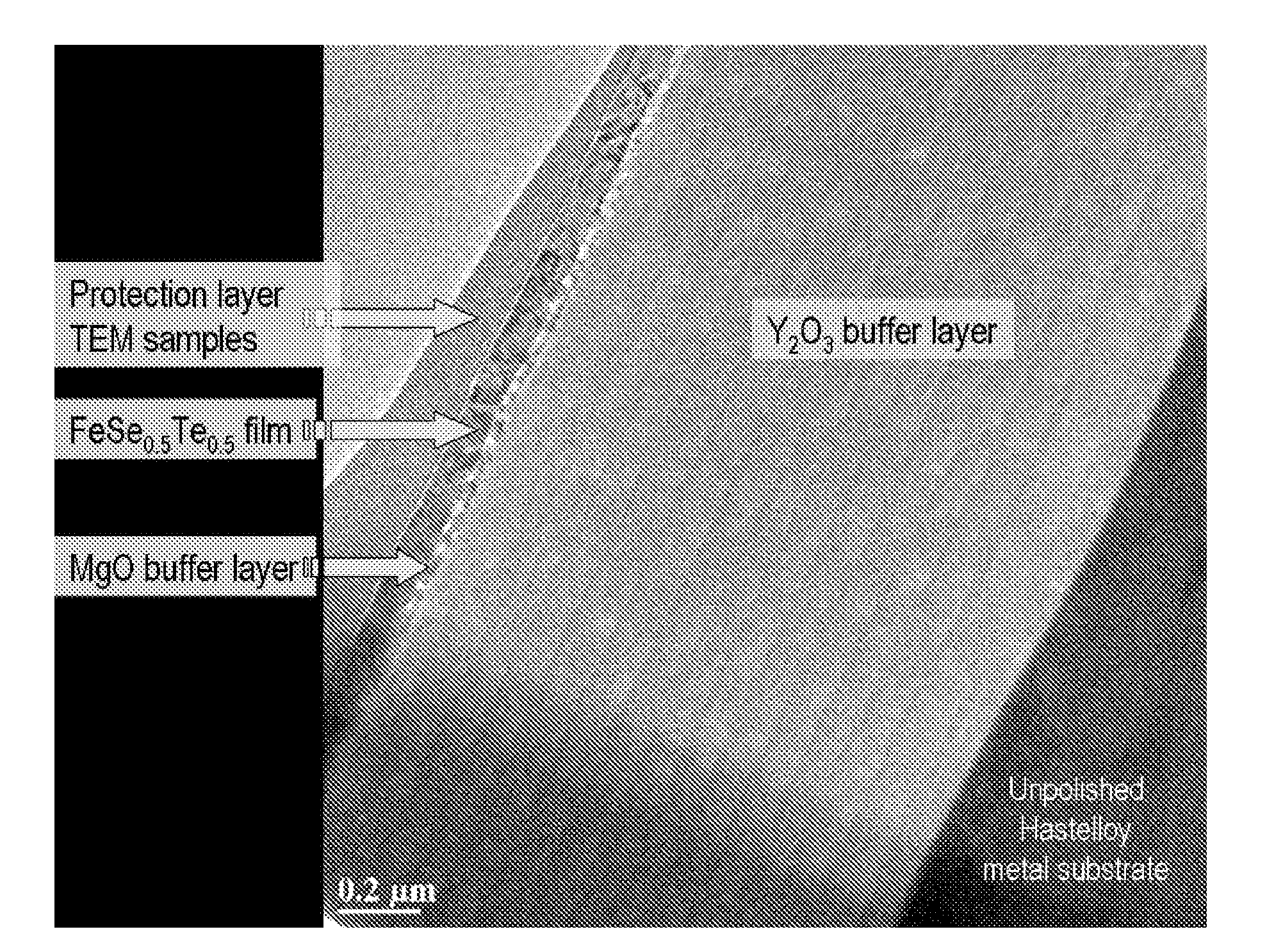

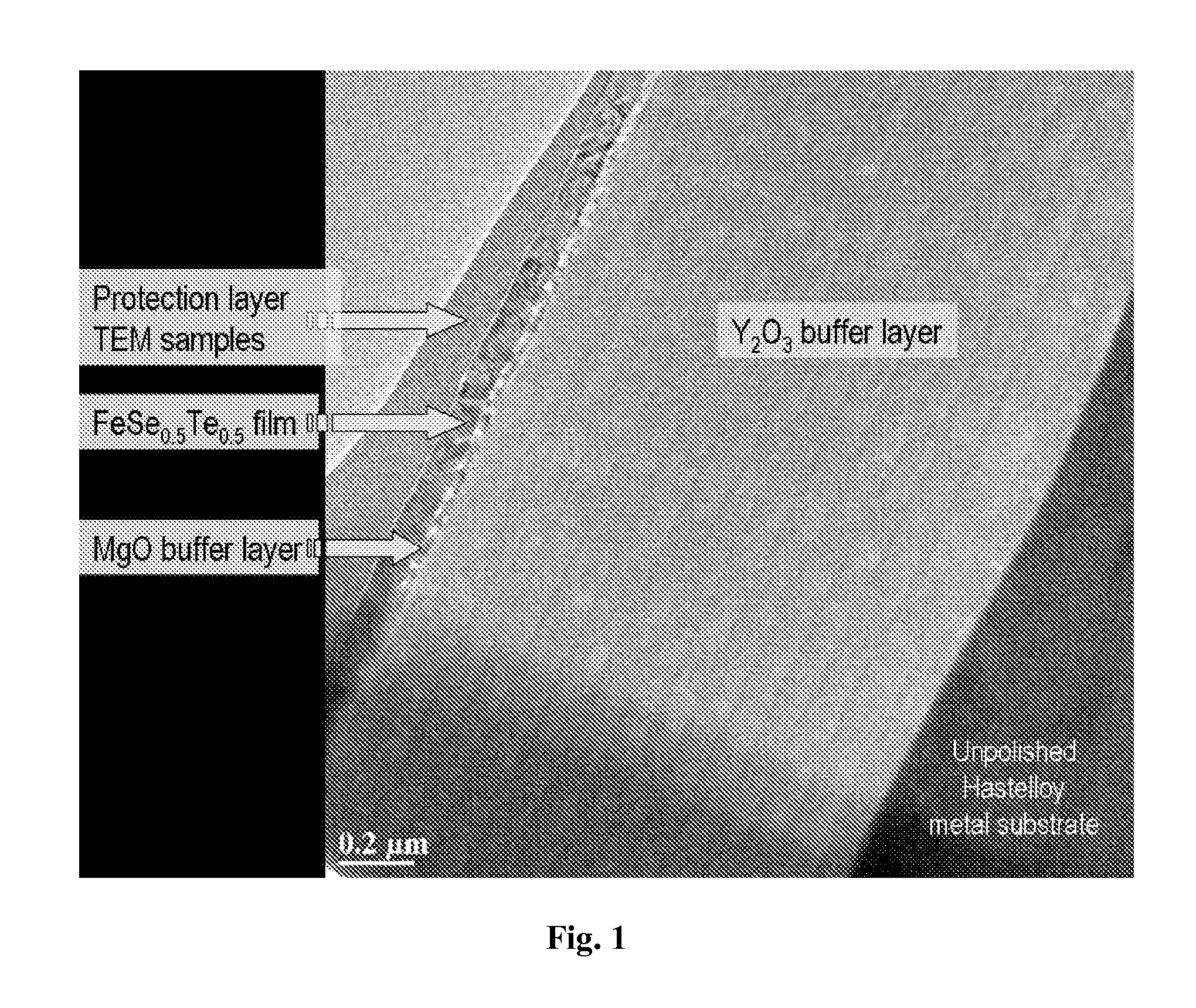

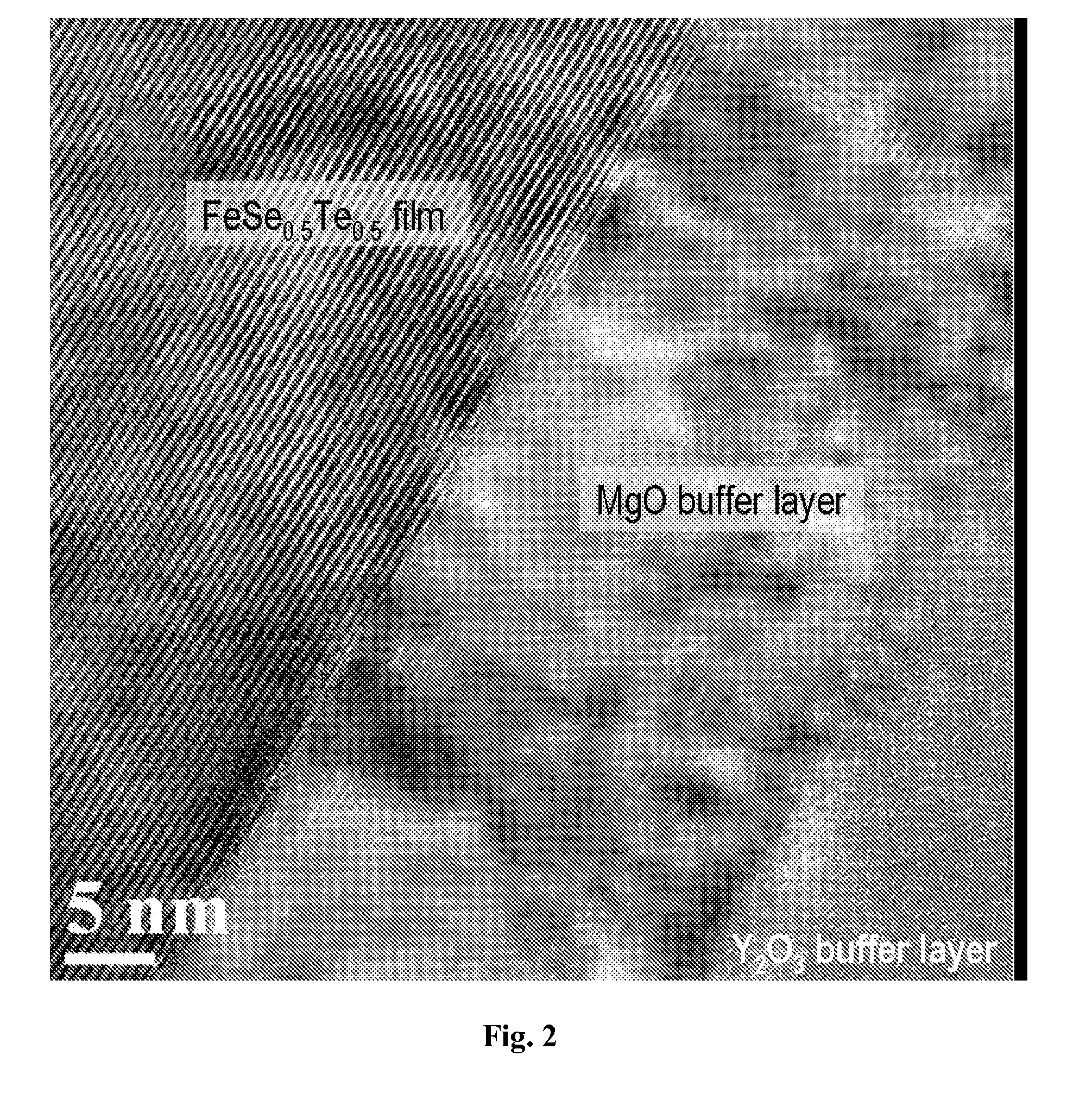

Iron based superconducting structures and methods for making the same

InactiveUS20130196856A1Improve textureImprove superconductivitySemiconductor/solid-state device detailsSolid-state devicesThin membraneLattice constant

In some embodiments of the invention, superconducting structures are described. In certain embodiments the superconducting structures described are thin films of iron-based superconductors on textured substrates; in some aspects a method for producing thin films of iron-based superconductors on textured substrates is disclosed. In some embodiments applications of thin films of iron-based superconductors on textured substrates are described. Also contemplated is the formation of a film of iron-based superconductor having a thickness and an in-plane lattice constant formed on a textured substrate having a thickness and an in-plane lattice constant similar to the in-plane lattice constant of the iron-based superconductor.

Owner:BROOKHAVEN SCI ASSOCS

Method for preparing iron-based superconductor

InactiveCN101814344ASignificant magnetic anisotropyFirmly connectedSuperconductors/hyperconductorsSuperconductor devicesSolventCrystallite

The invention relates to a method for preparing an iron-based superconductor. The method comprises the following steps: correspondingly processing iron-based superconductor precursor powder to obtain a lumpish or strip sample; putting the lumpish or strip sample into an Ar atmosphere protected or vacuum intense magnetic field heat treatment furnace; preserving the heat under a magnetic field intensity of between 0.1 and 30 Tesla and at the temperature of between 500 and 1,500 DEG C for 0.1 to 100 hours; and cooling the sample to room temperature together with the heat treatment furnace to obtain an iron-based superconductor sample; or the method comprises the following steps: dispersing sintered iron-based superconductor powder in a solvent; ultrasonically mixing the powder and the solvent; keeping the mixture in a magnetic field with a magnetic field intensity of between 0.1 and 30 Tesla for 0.1 to 2 hours; evaporating the solvent; putting the iron-based superconductor powder which is treated in the magnetic field into an Ar atmosphere or vacuum heat treatment furnace; and preserving the heat at the temperature of between 500 and 1,500 DEG C for 0.1 to 100 hours to obtain the iron-based superconductor sample. The method can effectively improve the connectivity of crystalline grains, greatly enhances the critical current density, upper critical field and irreversible field of the iron-based superconductor and makes the practicability of the iron-based superconductor become possible.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

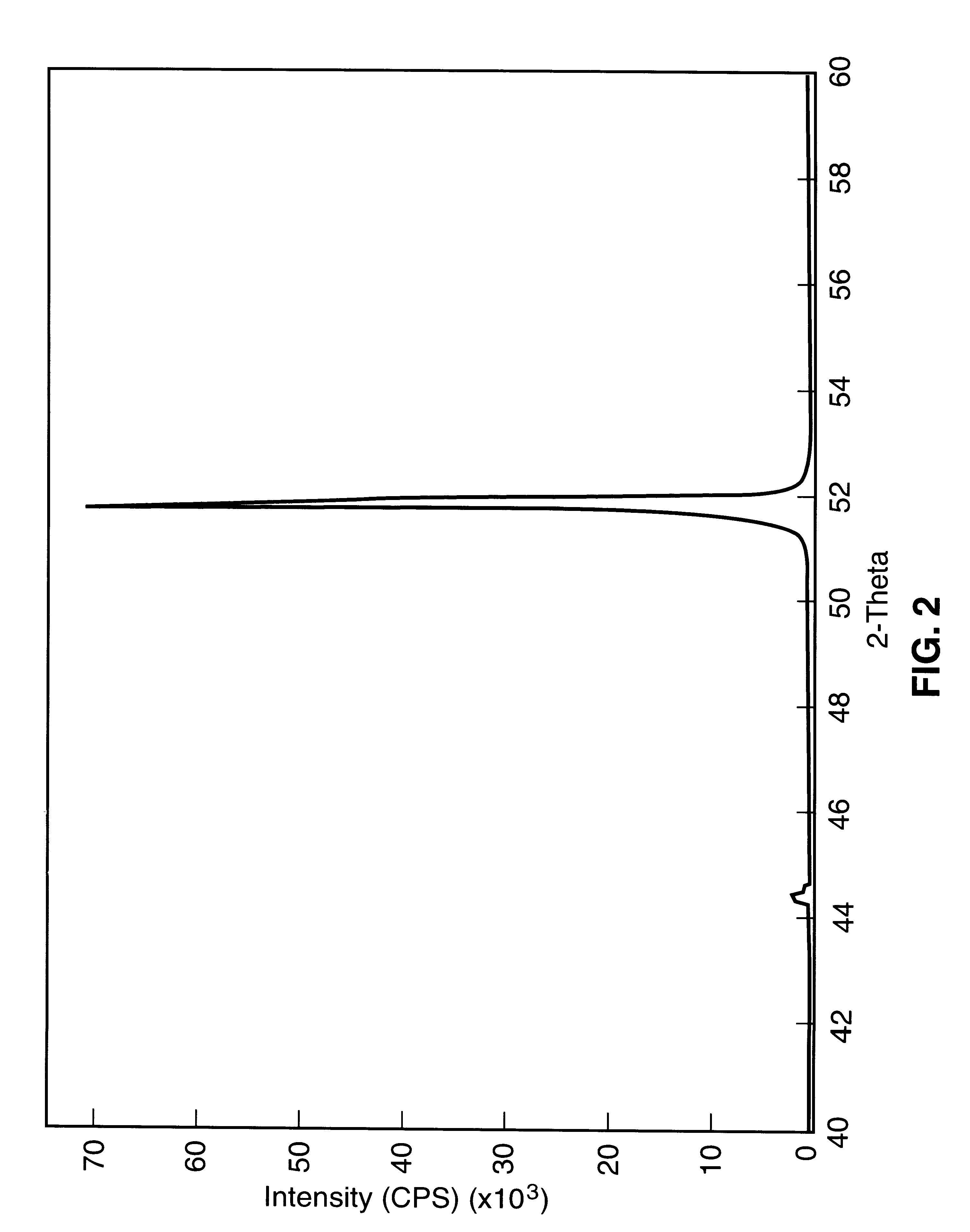

Method for manufacturing single crystal grain niobium material for radio frequency superconducting cavity

InactiveCN102400216AImprove superconductivityImprove performancePolycrystalline material growthAcceleratorsNiobiumSingle crystal

The invention discloses a method for manufacturing a single crystal grain niobium material for a radio frequency superconducting cavity. The method comprises the following steps of: refining and purifying high-melting metallic niobium serving as a raw material to prepare niobium ingots, the crystal grain size of which is over phi 100 millimeters and the residual resistance ratio (RRR) value of which is over 300; and cutting single crystal grains, rolling in a rolling compaction manner, and preparing single crystal niobium plates or sheets by thermal treatment, wherein refining and purifying are performed on the high-melting metallic niobium for many times by adopting vacuum electron beams to produce the ingots with the crystal grain size of over phi 250 millimeters, the diameter of the biggest crystal grains is 100 to 140 millimeters, and the RRR value of the ingots is over 300.

Owner:NINGXIA ORIENT TANTALUM IND

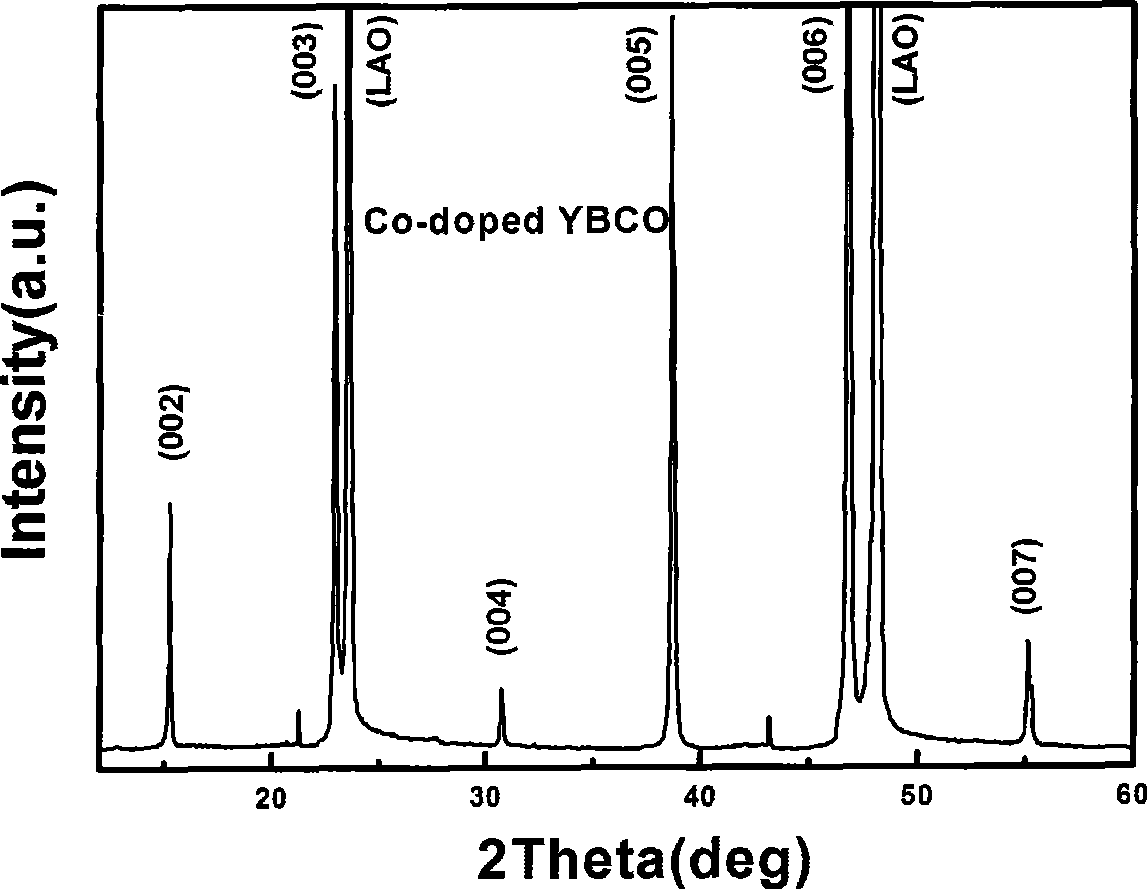

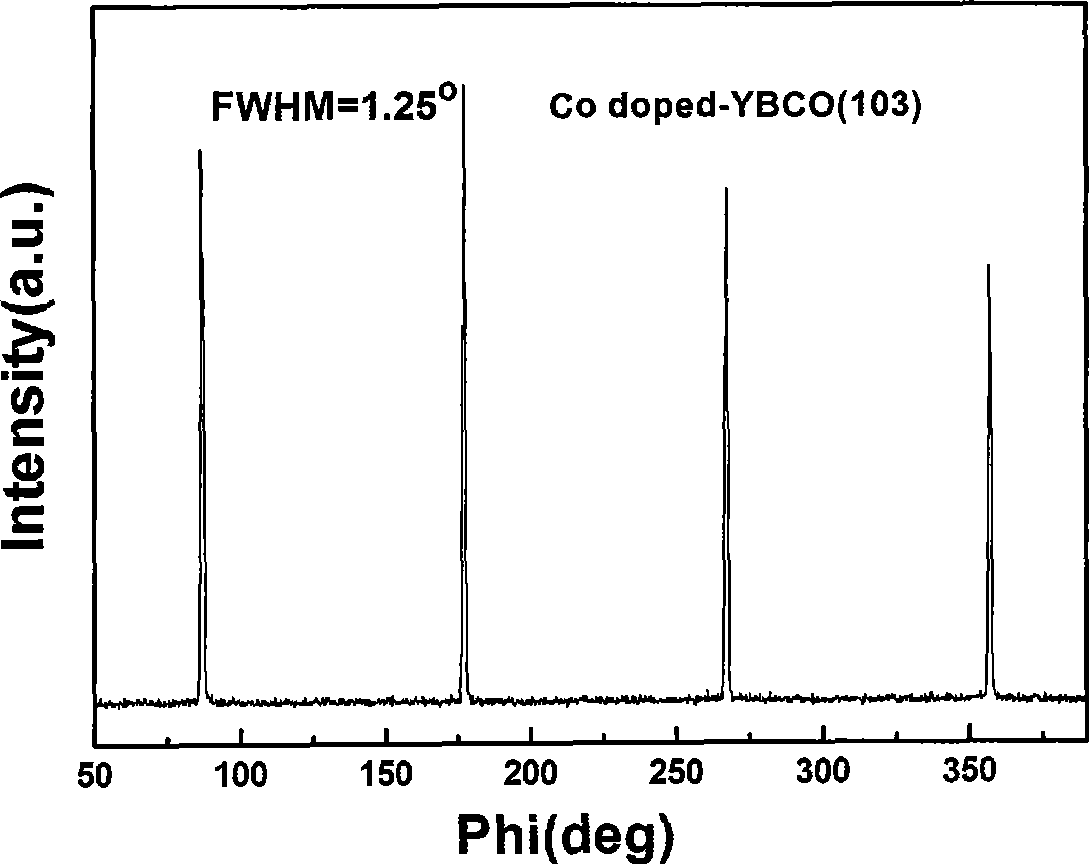

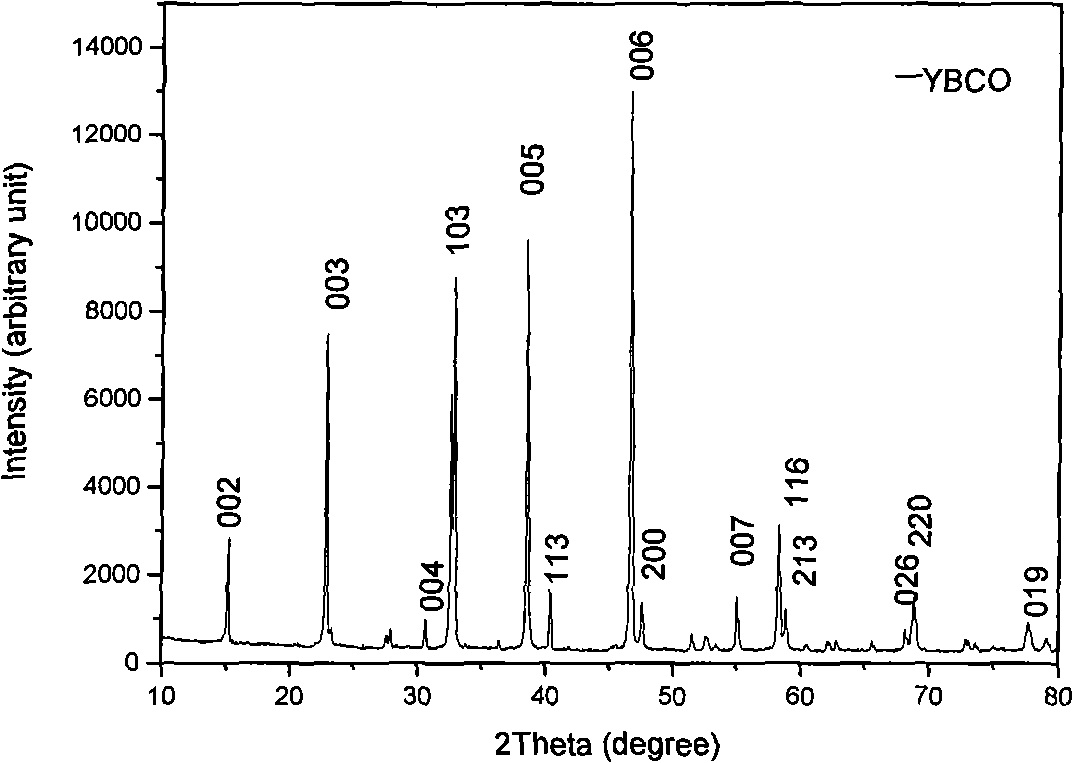

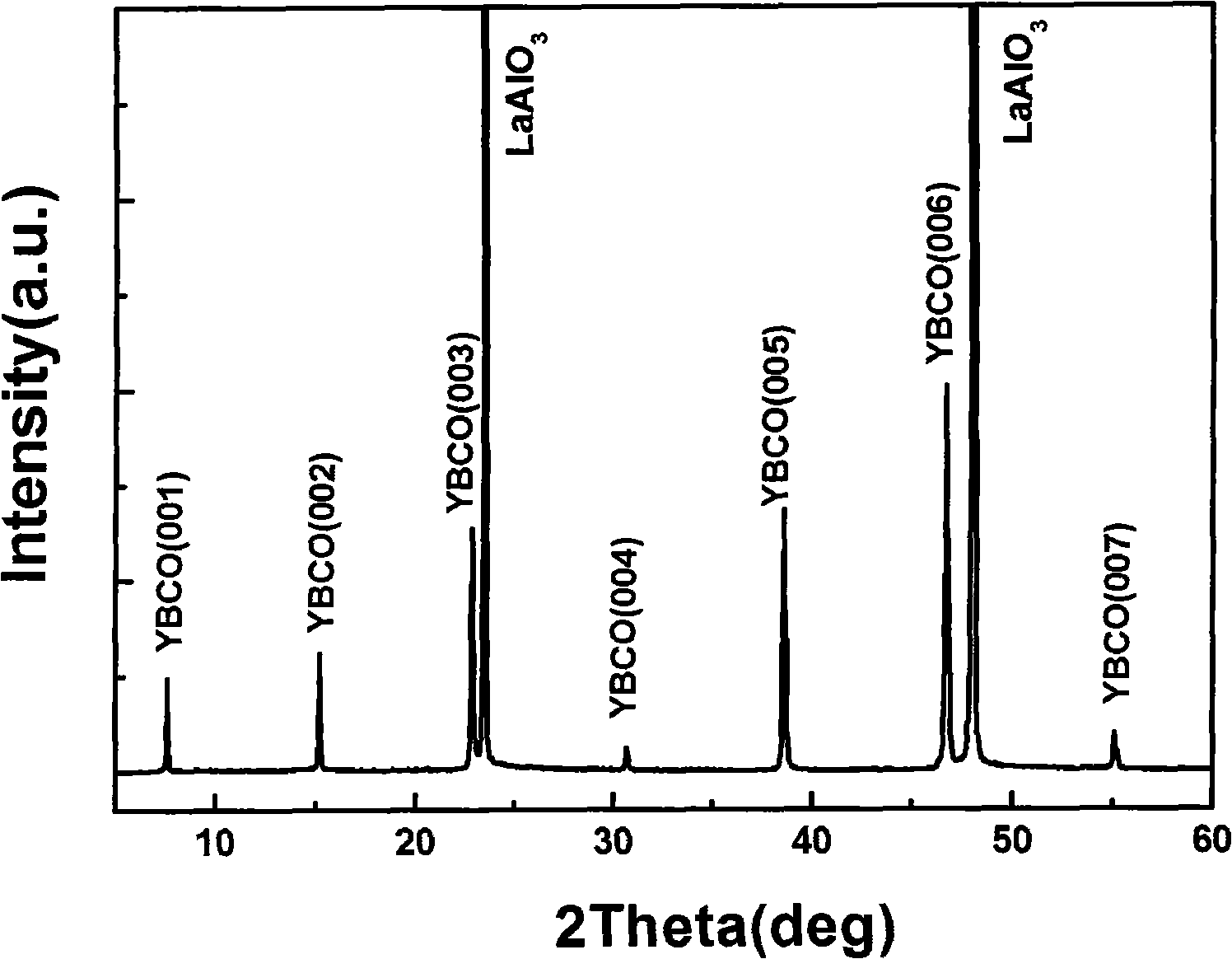

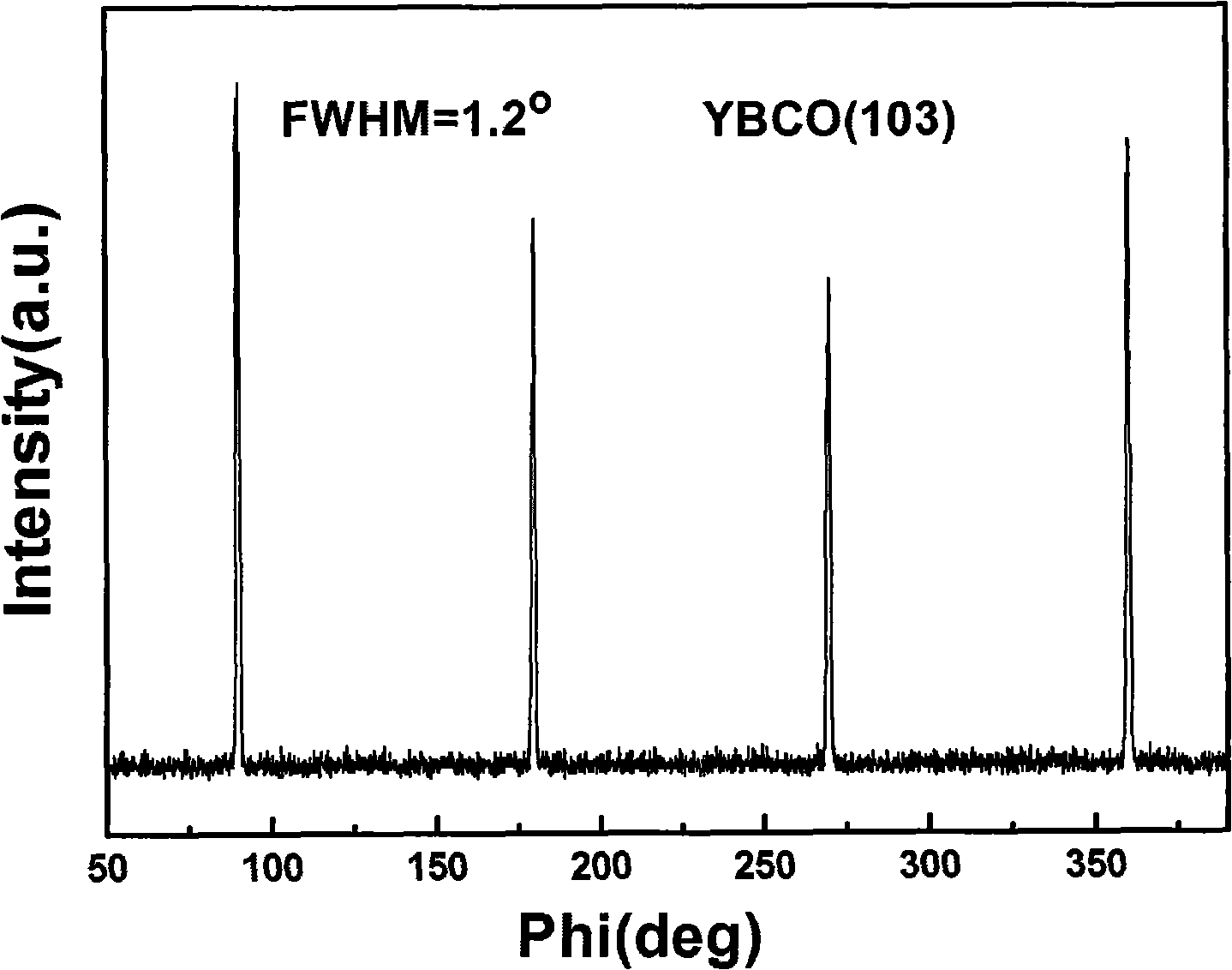

Method for preparing high critical current density yttrium barium copper oxide superconducting film

InactiveCN101456726ASimple processShorten the timeSuperconductors/hyperconductorsSuperconductor devicesPolyvinyl butyralPropanoic acid

The invention discloses a method for preparing a yttrium barium copper oxide superconducting film with high critical current density, which comprises the following concrete steps: a, preparing a precursor solution, which is to dissolve yttrium acetate, barium acetate, copper acetate and acetate of an impurity element into propionic acid according to the proportion that the stoichiometric ratio of yttrium: barium: copper: impurity element is 1: 2: 3-X: X (the X is more than or equal to 0.0002 and less than or equal to 0.008) to obtain the precursor solution, and the impurity element is one of Co, Fe, Zn, Ni, and Li; b, adding a polymer material polyvinyl butyral (PVB) into the precursor solution obtained in a step to obtain a coating colloid; c, coating and drying the coating colloid on a substrate to form a film; and d, performing thermal decomposition treatment on the substrate with the film prepared in c step and then imaging thermal treatment to obtain the YBCO superconducting film. The yttrium barium copper oxide superconducting film prepared by the method has high biaxial texture, smooth and compact surface, high critical current density under a magnetic field, low cost, and simple process, and is suitable for mass industrial production.

Owner:SOUTHWEST JIAOTONG UNIV

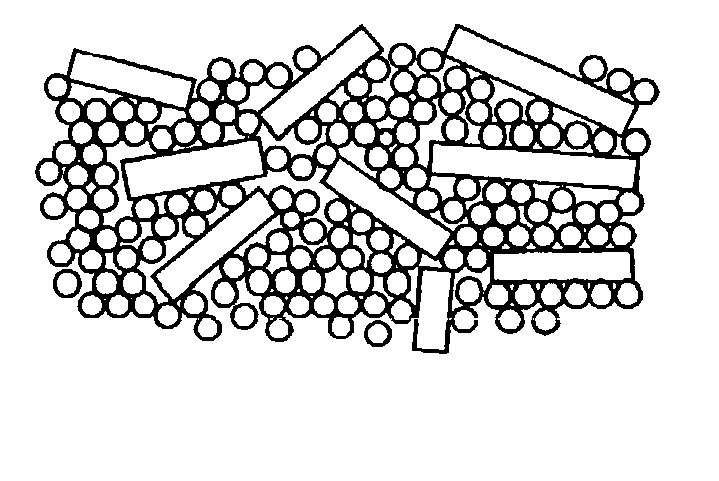

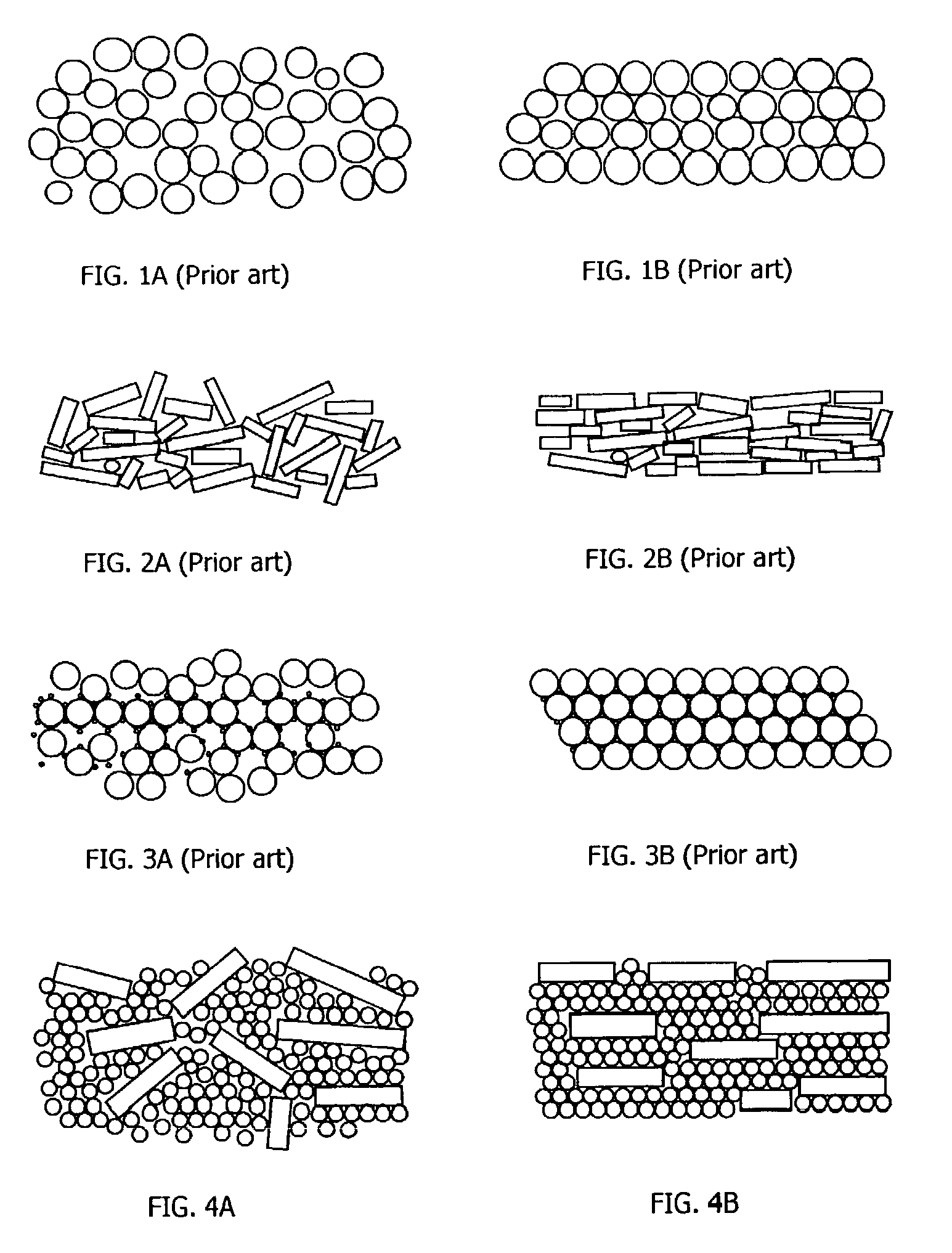

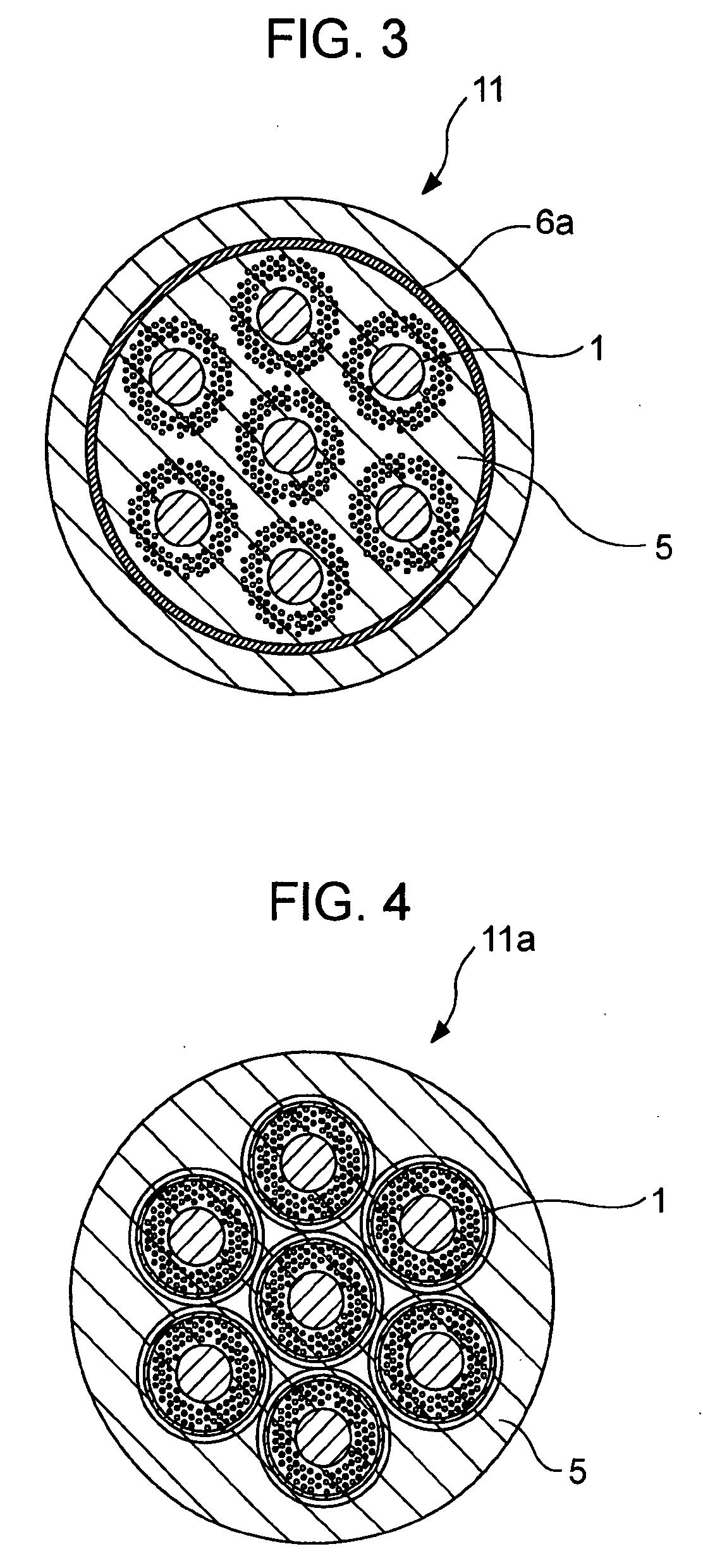

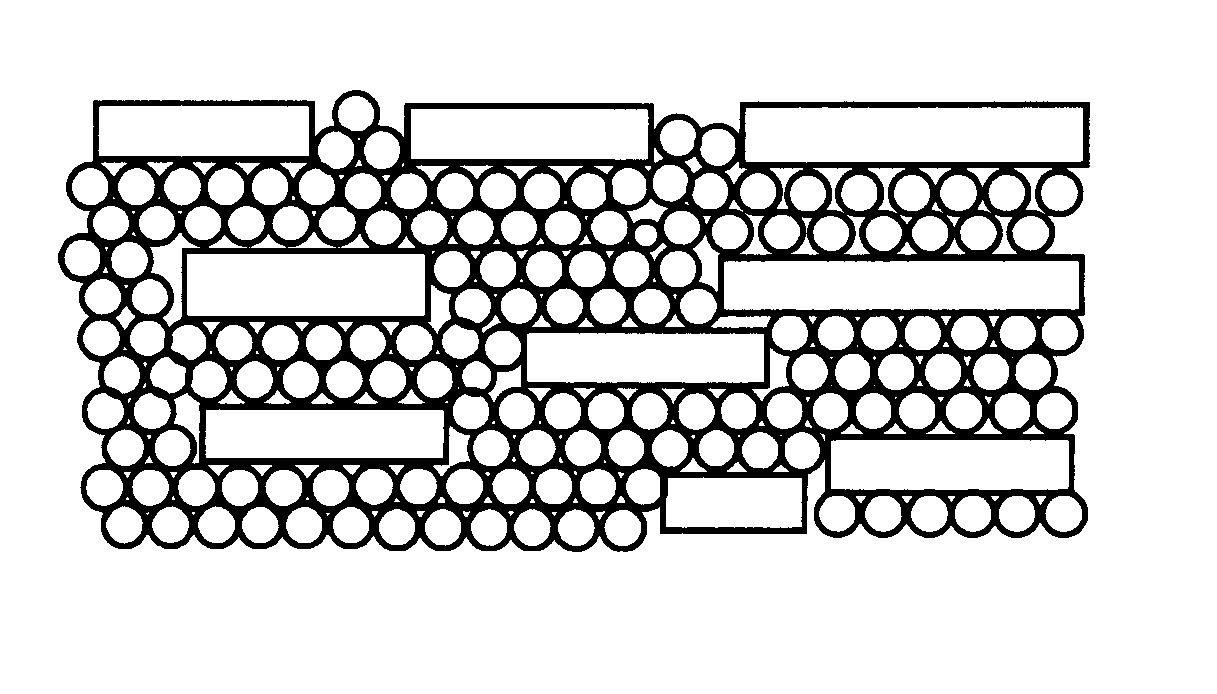

Method of preparing metal matrix composite with textured compound

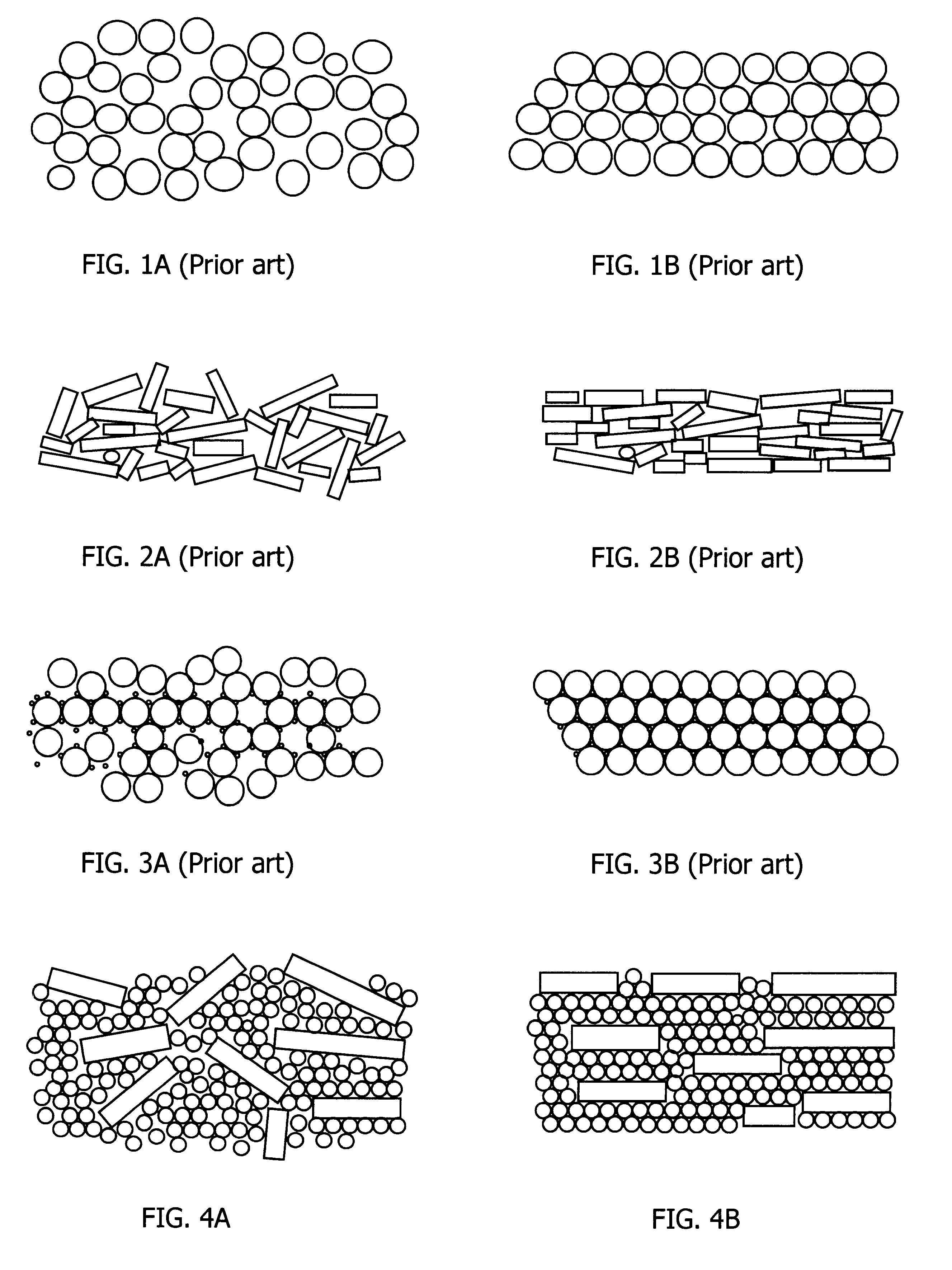

InactiveUS20020198109A1Simple process conditionsHigh critical current densityNon-insulated conductorsSuperconductors/hyperconductorsPower flowVolumetric Mass Density

The present invention provides a generic method of preparing a metal matrix composite with a textured compound. A "roller-skate" structure starting powder with a mixture of plate-like particles and smaller particles provides better flow compatibility, higher packing density, better densification and texture formation in preparing a metal matrix composite with a textured compound. In particular, the invention provides a method of preparing a textured superconducting composite wire with an improved critical current density.

Owner:WU HENGNING

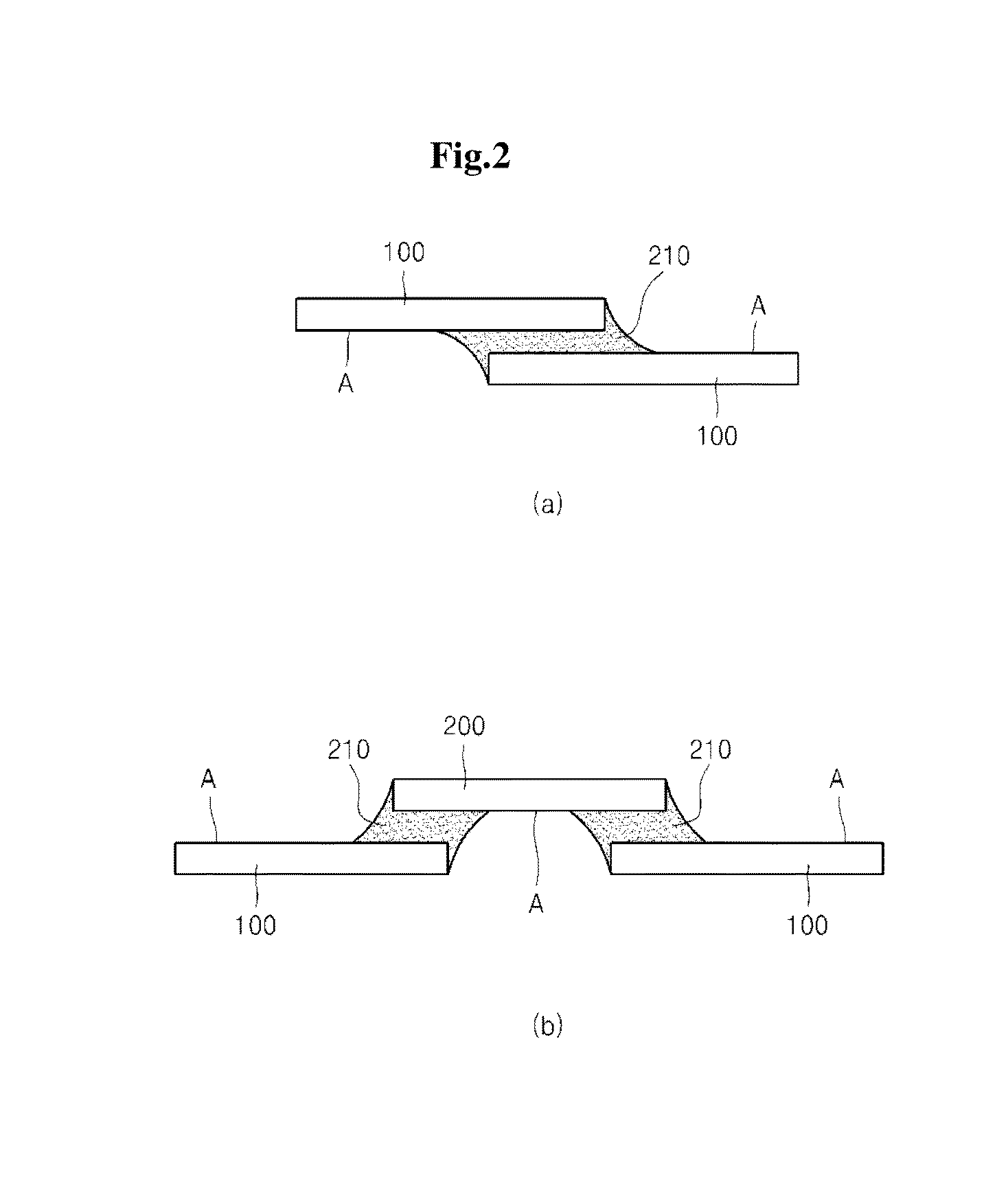

METHOD OF PERSISTENT CURRENT MODE SPLICING OF 2G ReBCO HIGH TEMPERATURE SUPERCONDUCTORS USING SOLID STATE PRESSURIZED ATOMS DIFFUSION BY DIRECT FACE-TO-FACE CONTACT OF HIGH TEMPERATURE SUPERCONDUCTING LAYERS AND RECOVERING SUPERCONDUCTIVITY BY OXYGENATION ANNEALING

InactiveUS20150357089A1Shorten the annealing timeImprove superconductivityContact member manufacturingSuperconductors/hyperconductorsElectrical conductorReaction temperature

Disclosed is a method of splicing ReBCO high temperature superconductors (HTSs), which ensures excellent superconductivity after splicing. The method of splicing 2G ReBCO HTSs allows a superconductors-spliced assembly to exhibit excellent superconductivity by direct contact of high temperature superconducting layers of two strands of 2G ReBCO HTSs and solid state atoms diffusion pressurized splicing there between at a ReBCO below peritectic reaction temperature in a vacuum, and enables loss of superconductivity caused by loss of oxygen due to transport and out-diffusion of oxygen to atoms during splicing to be recovered through oxygenation annealing.

Owner:K JOINS

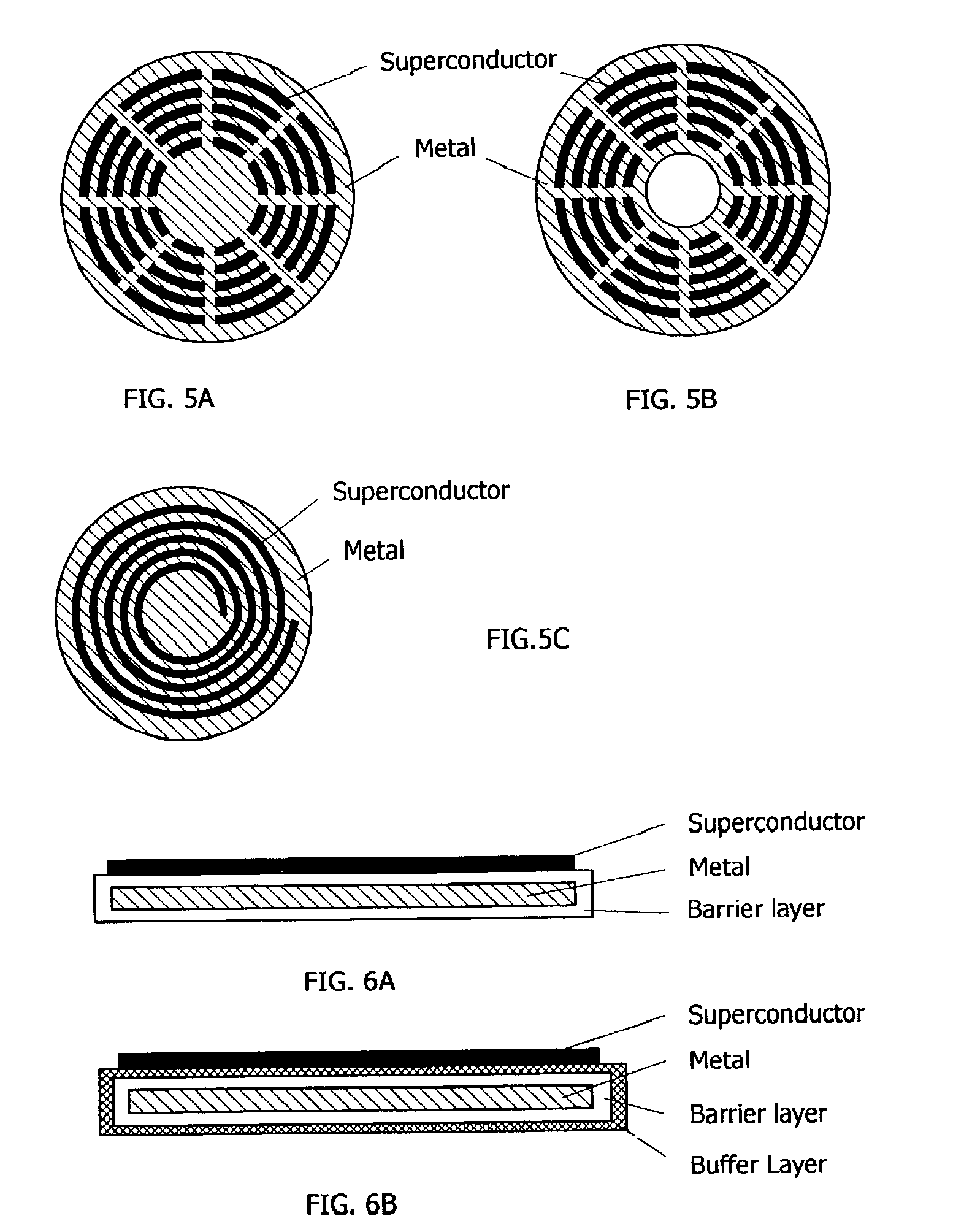

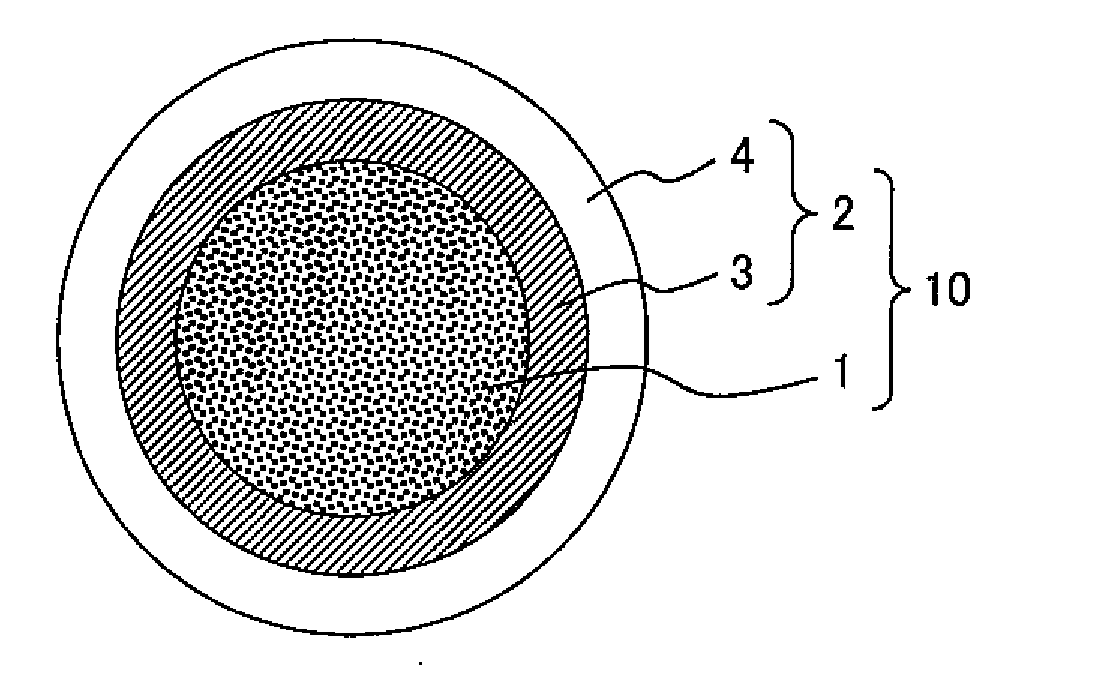

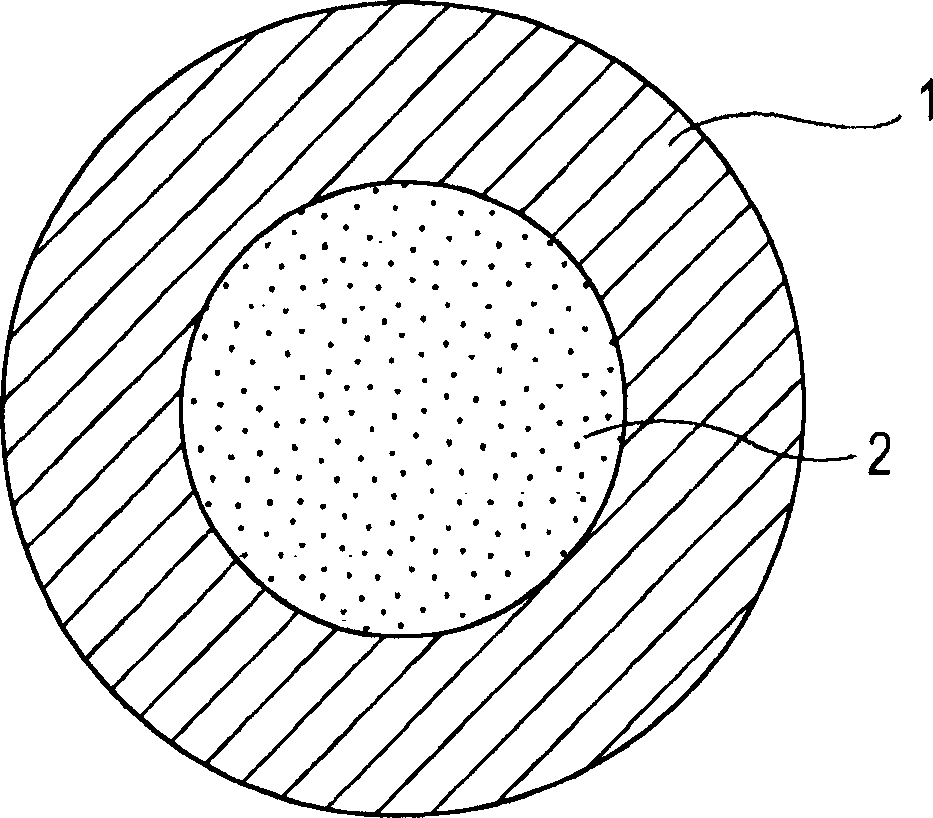

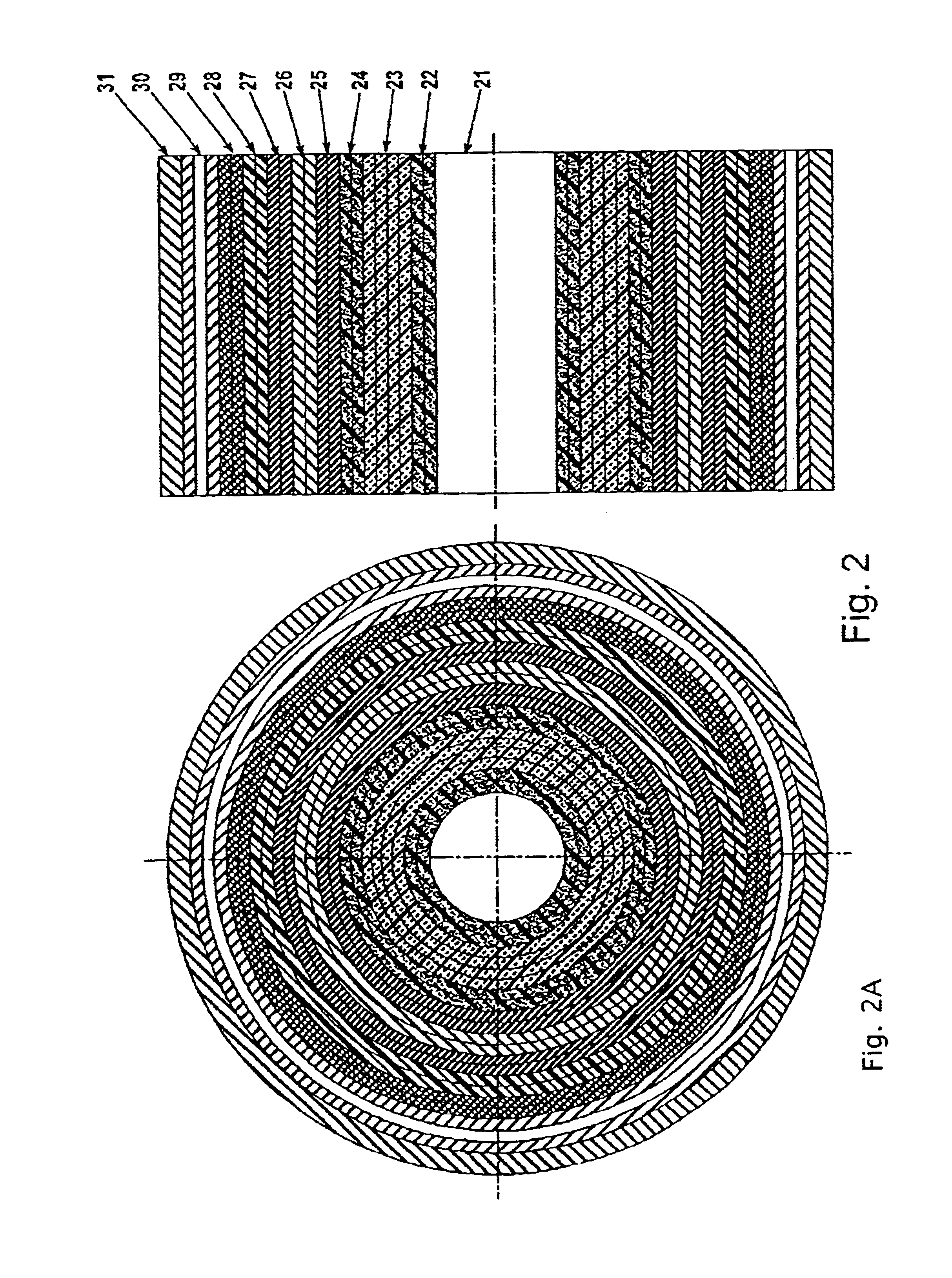

Precursor for manufacturing Nb3Sn superconducting wire and Nb3Sn superconducting wire

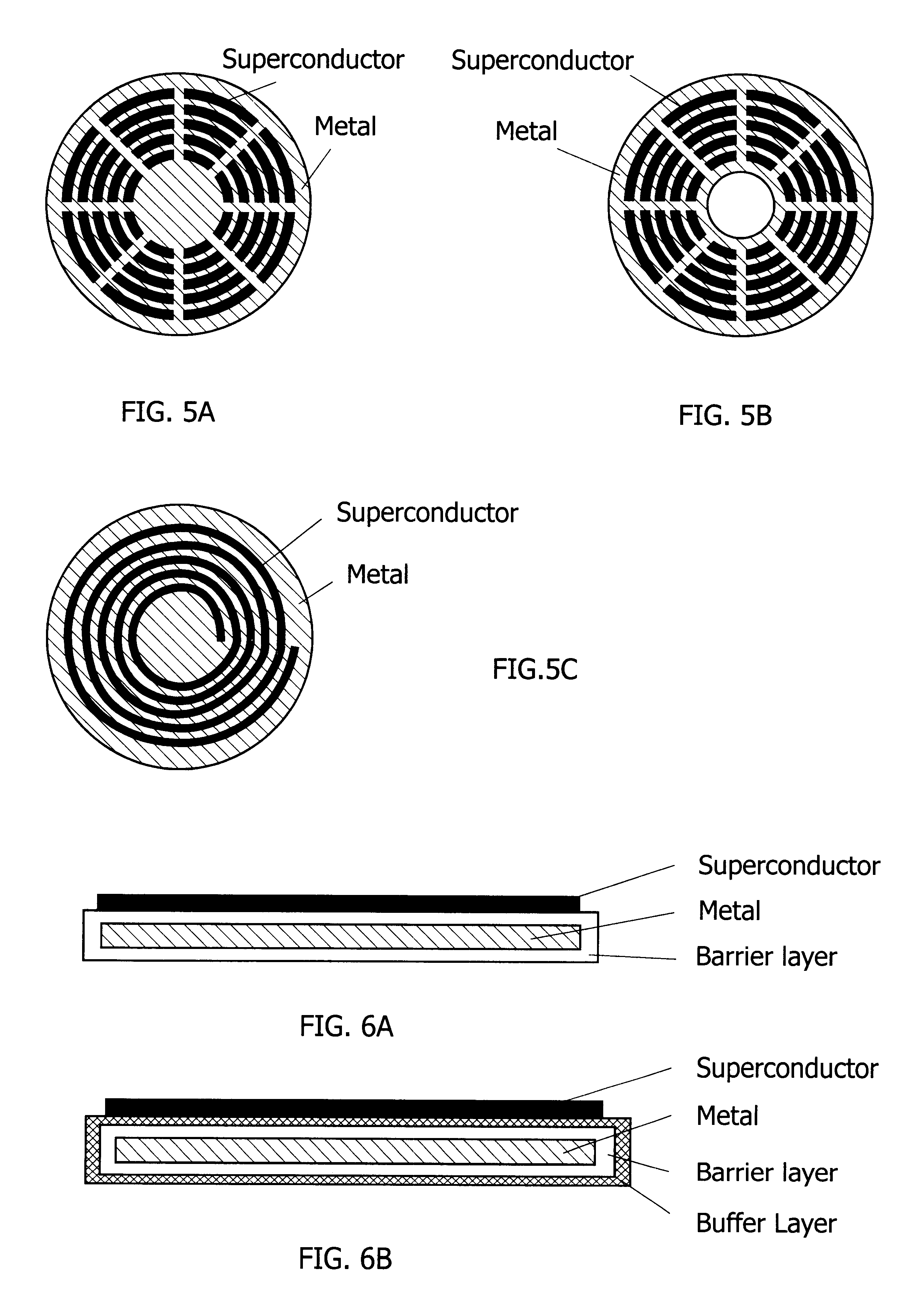

InactiveUS20070186998A1Increase the diameterSuperconducting property (or uniformity of electrical current) is excellentSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentAlloyCopper

A precursor for manufacturing a Nb3Sn superconducting wire according to the present invention includes a mono-element wire including a Sn or Sn-based alloy core disposed at the, a Cu or Cu-based alloy matrix and a plurality of Nb or Nb-based alloy filaments surrounding the Sn or Sn-based alloy core, and a diffusion barrier layer and a stabilizing copper layer surrounding the Cu or Cu-based alloy matrix. In a final shape after a reduction process, the average diameter of the Nb or Nb-based alloy filaments is set to 5 μm to 30 μm, and the average distance between the Sn or Sn-based alloy core and the Nb or Nb-based alloy filaments nearest the Sn or Sn-based alloy core is set to 100 μm or less.

Owner:KOBE STEEL LTD

Process for producing YBCO superconducting thin film target material

InactiveCN101492291AQuality improvementGuaranteed compactnessSuperconductors/hyperconductorsVacuum evaporation coatingHigh densityHigh volume manufacturing

The invention provides a method for preparing YBCO superconducting film target materials. The method comprises the following: A, a step of preparing YBCO superconducting-phase powder; B, a step of preforming, which is to put the powder prepared in a step A in a die, compress the powder by use of the pressure of between 20 and 30 MPa on a press so as to manufacture a sheet, put the sheet obtained through compression in a rubber sleeve, perform cold isostatic pressing under the pressure of between 150 and 200 MPa and obtain a superconducting sheet; C, a step of sintering the sheet, which is to sinter the superconducting sheet obtained in a step B in a box-type furnace for 20 to 30 hours at a sintering temperature of between 850 and 960 DEG C; and D, a step of performing oxygen permeation, which is to put the superconducting sheet sintered in a step C in a tubular furnace, perform oxygen permeation treatment for 2 to 3 hours at a temperature of between 450 and 500 DEG C and obtain the target material. The target material prepared by the method has the advantages of uniformity, good shape, high density and good superconducting performance. In addition, the method is low in cost and suitable for the mass production of the target material.

Owner:SOUTHWEST JIAOTONG UNIV

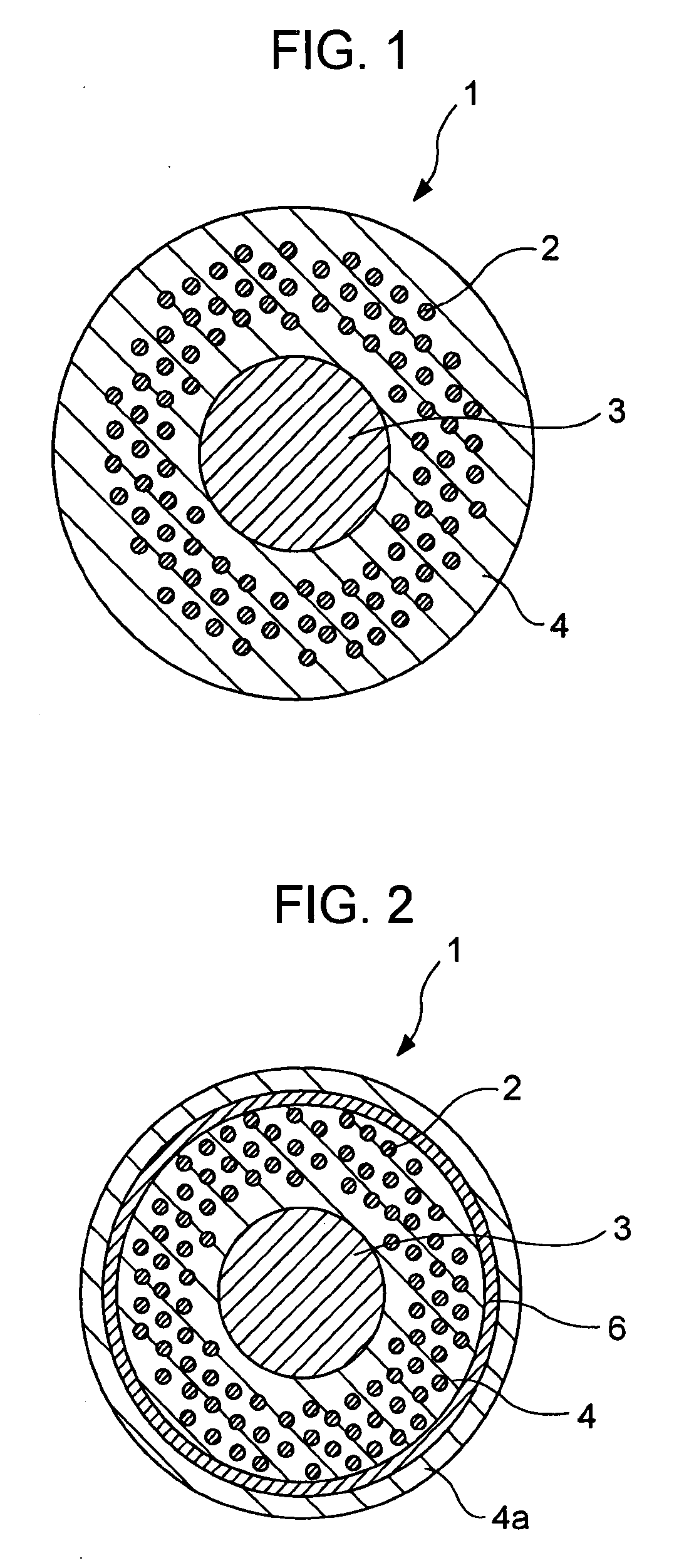

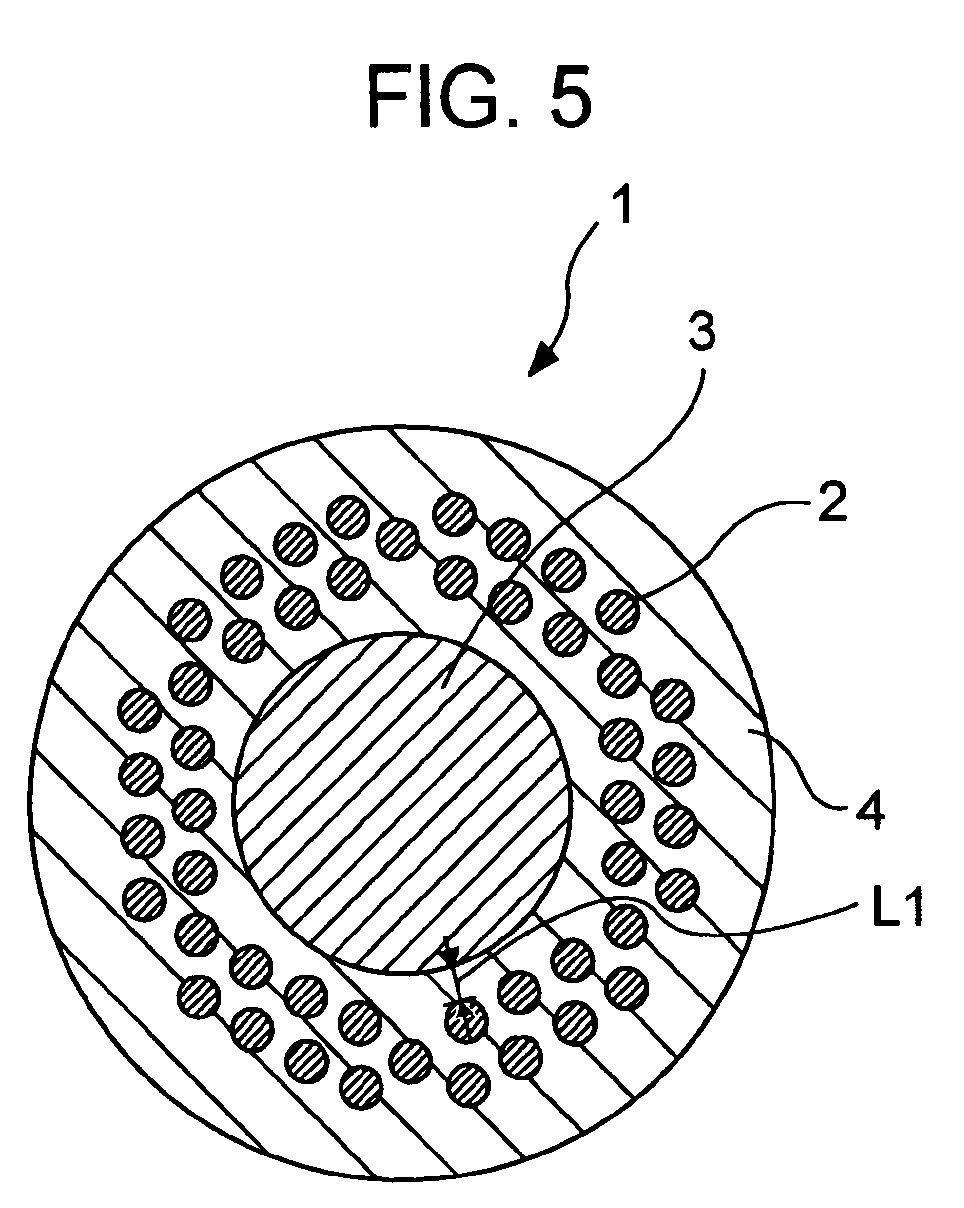

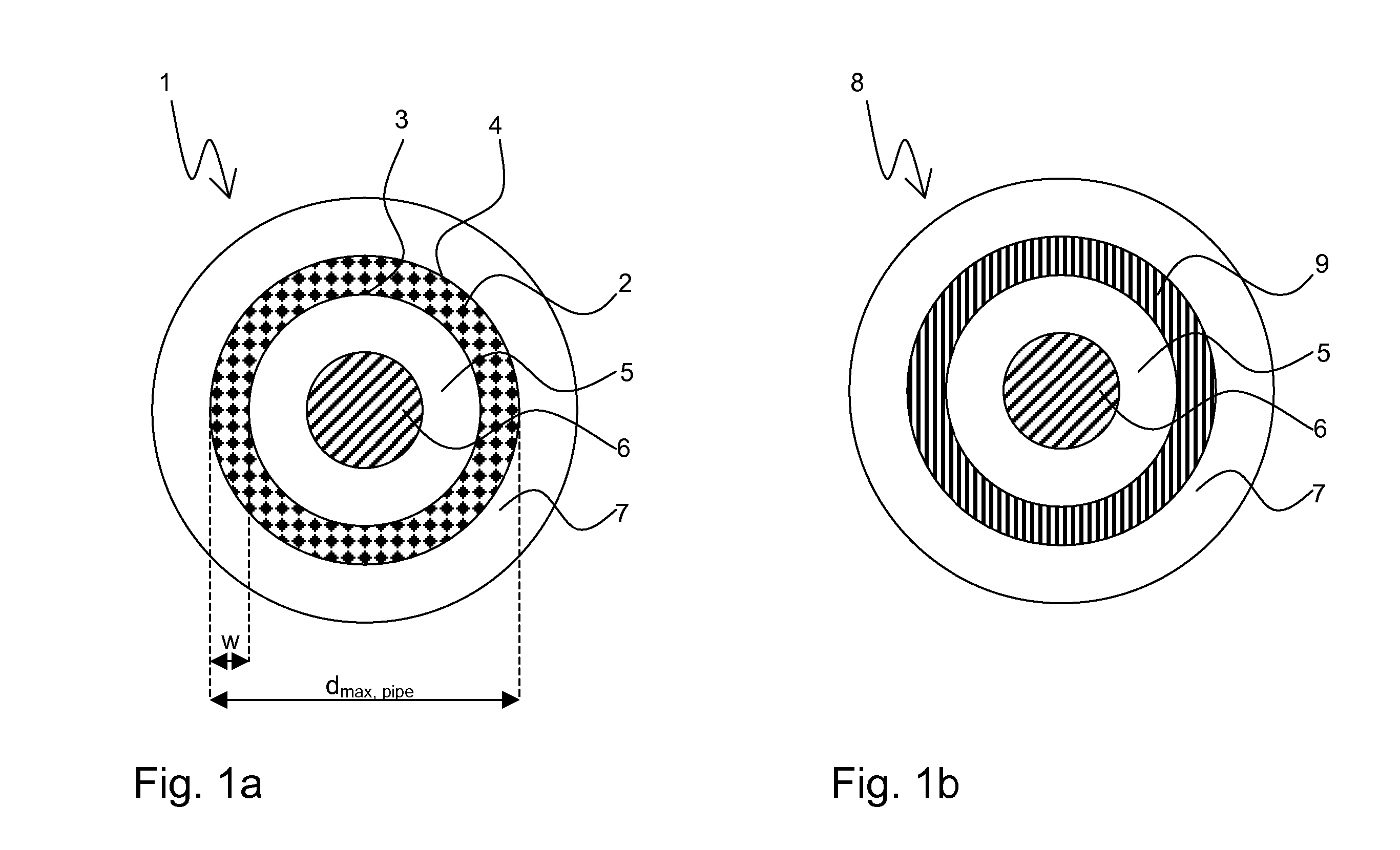

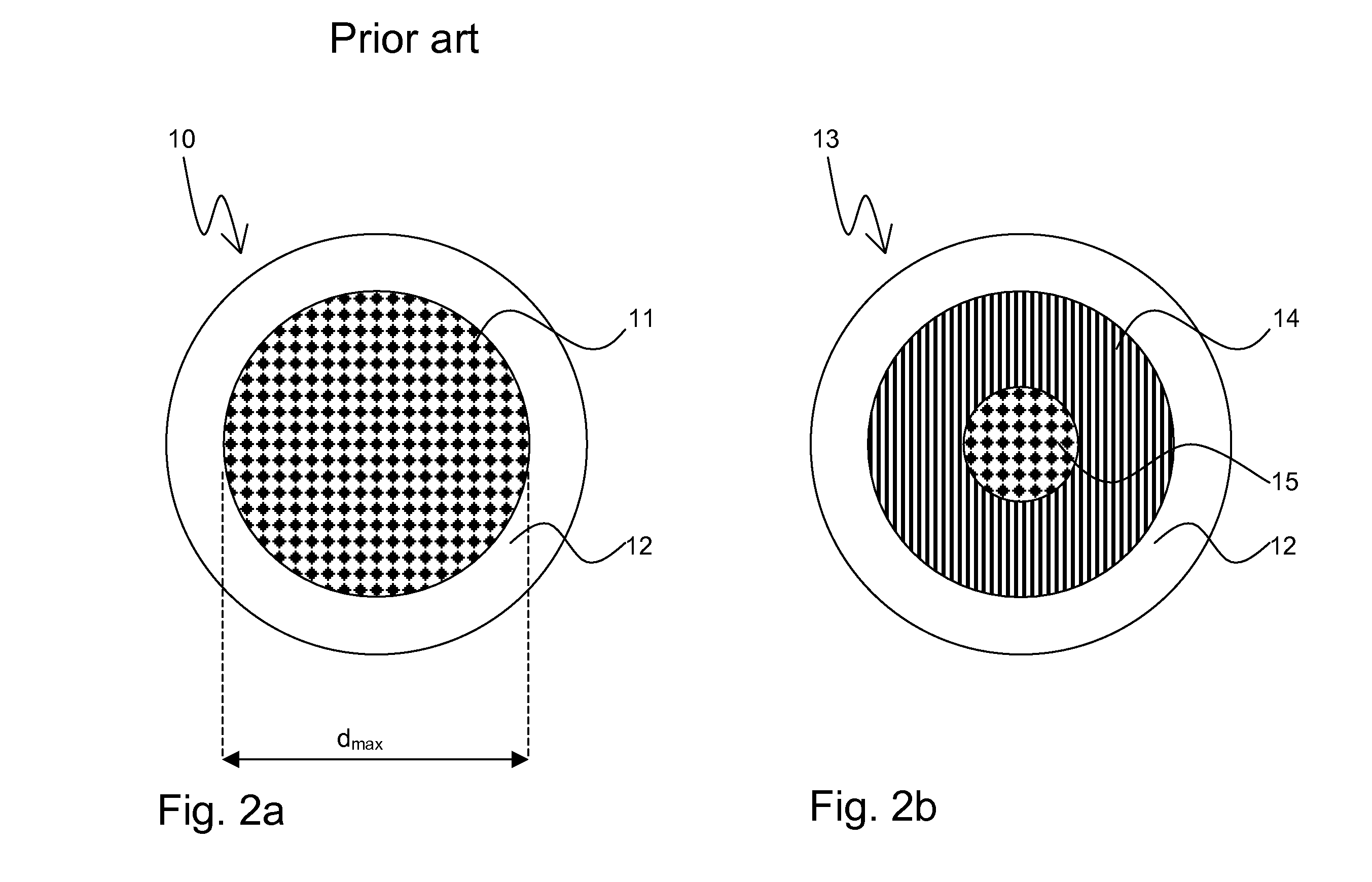

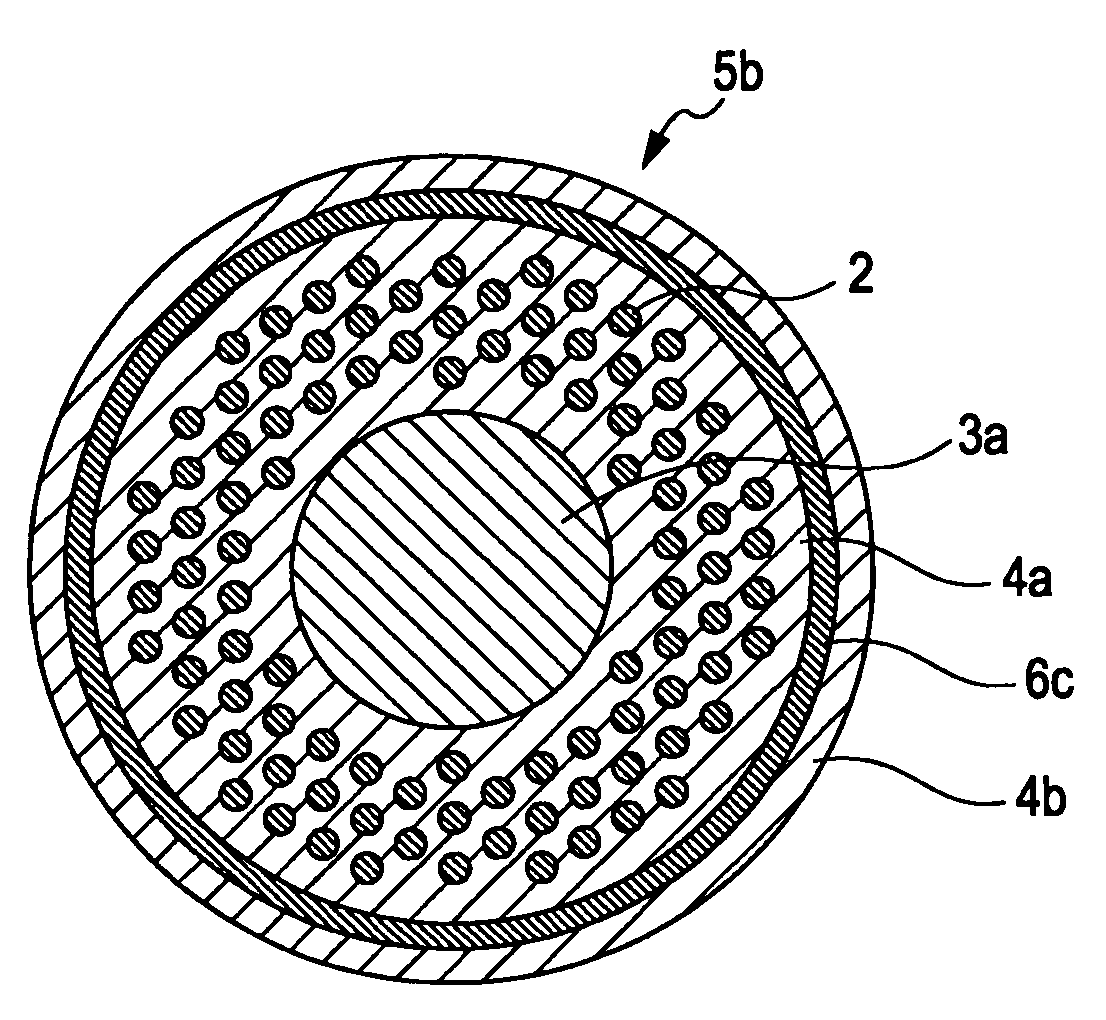

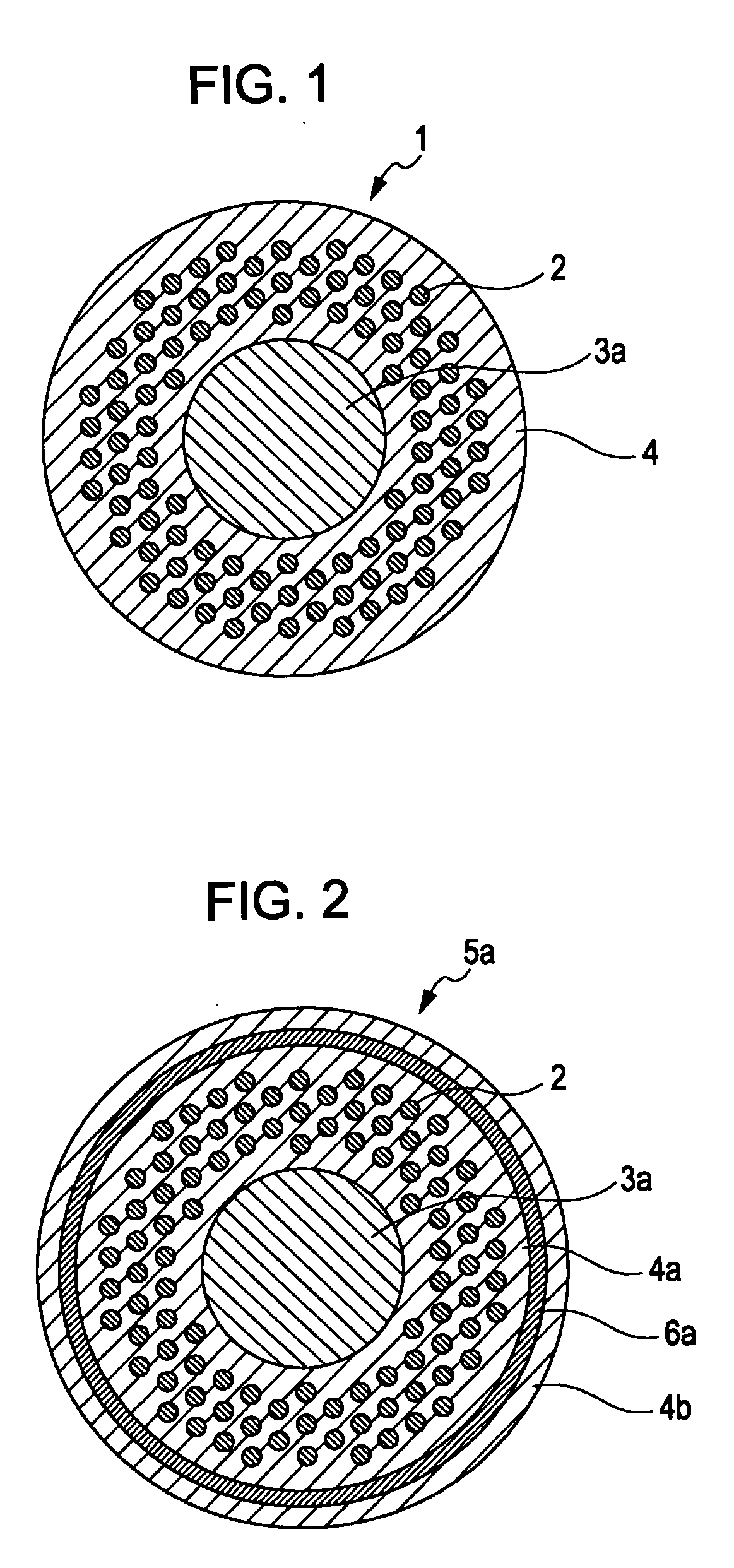

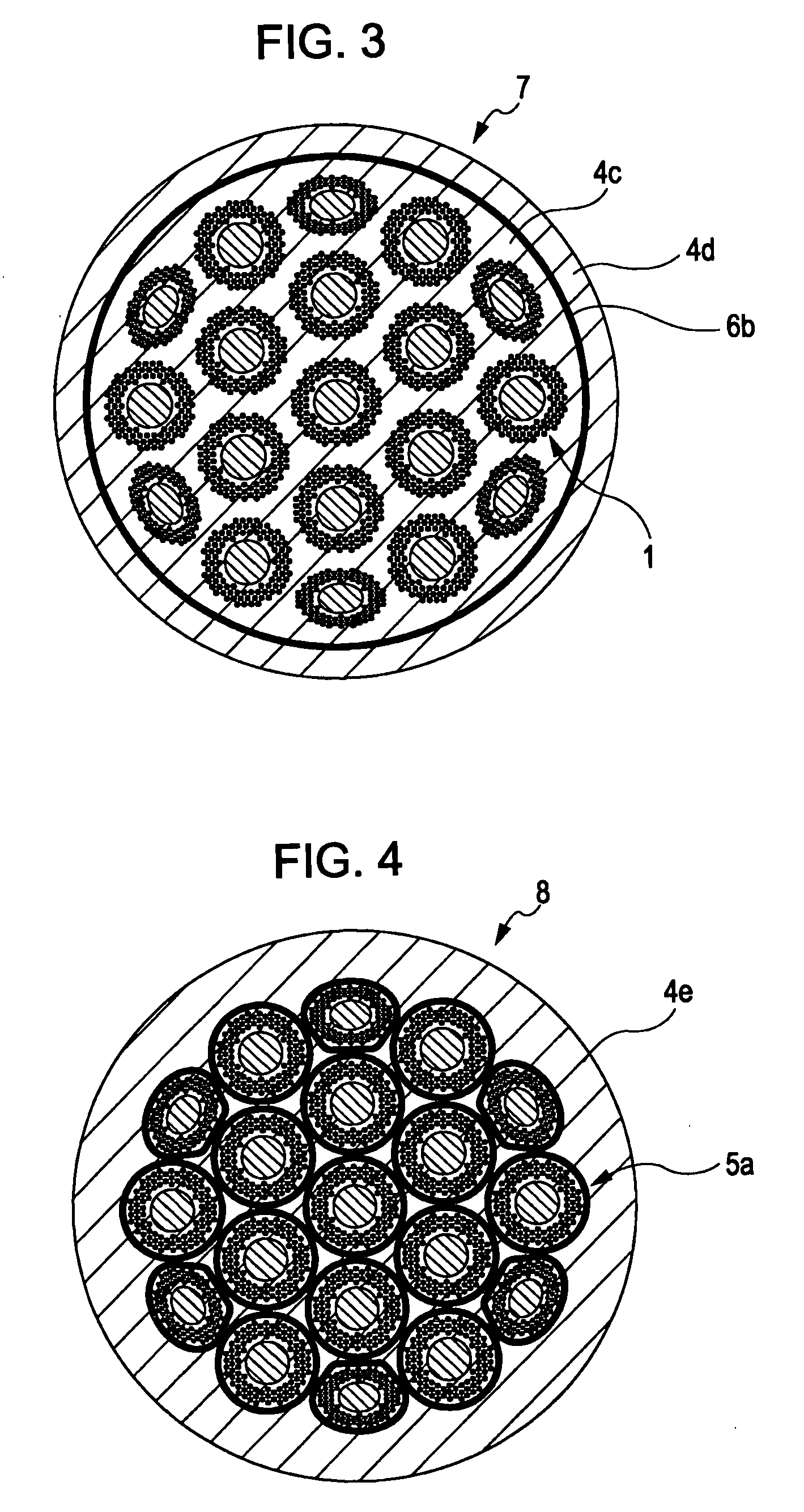

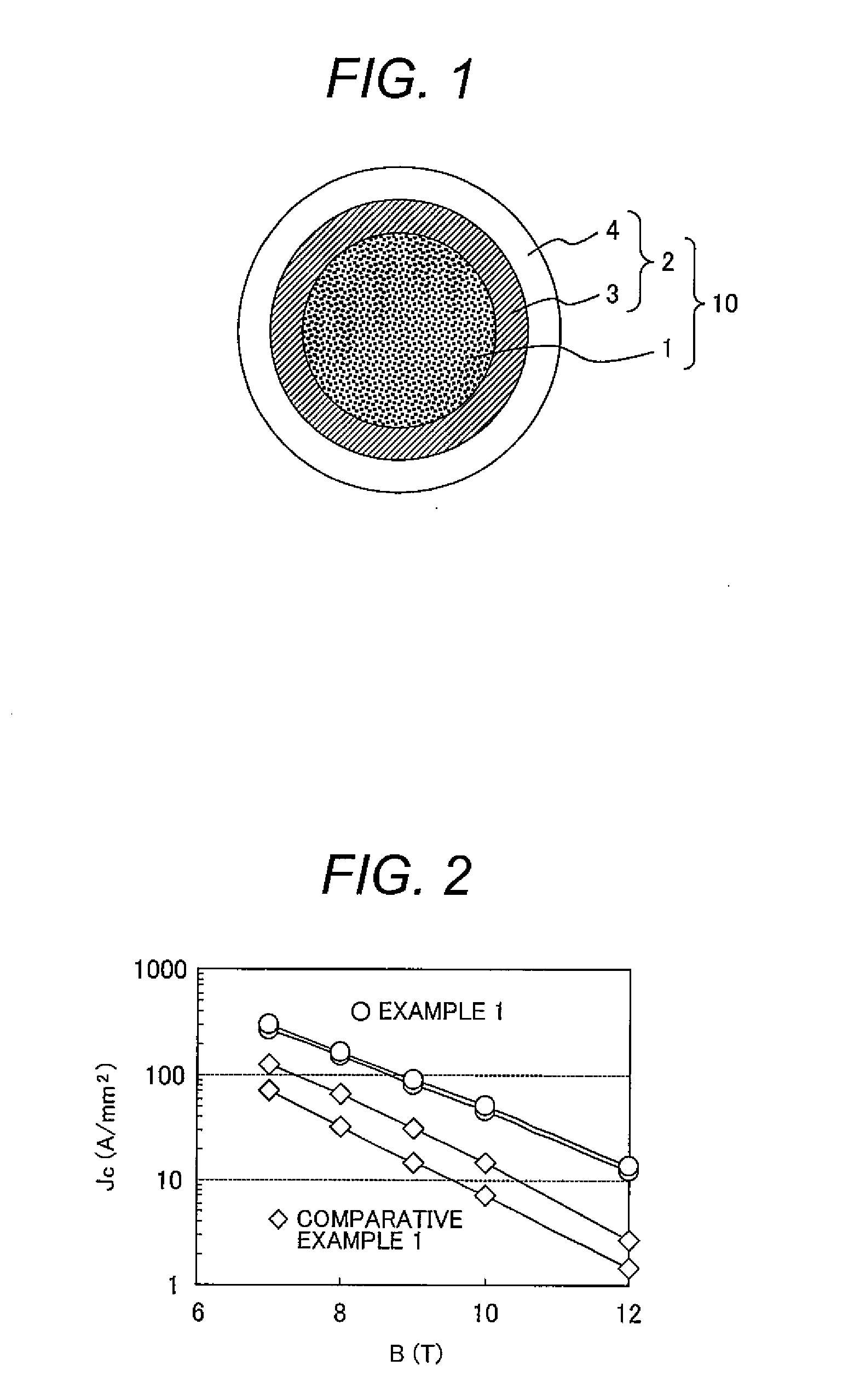

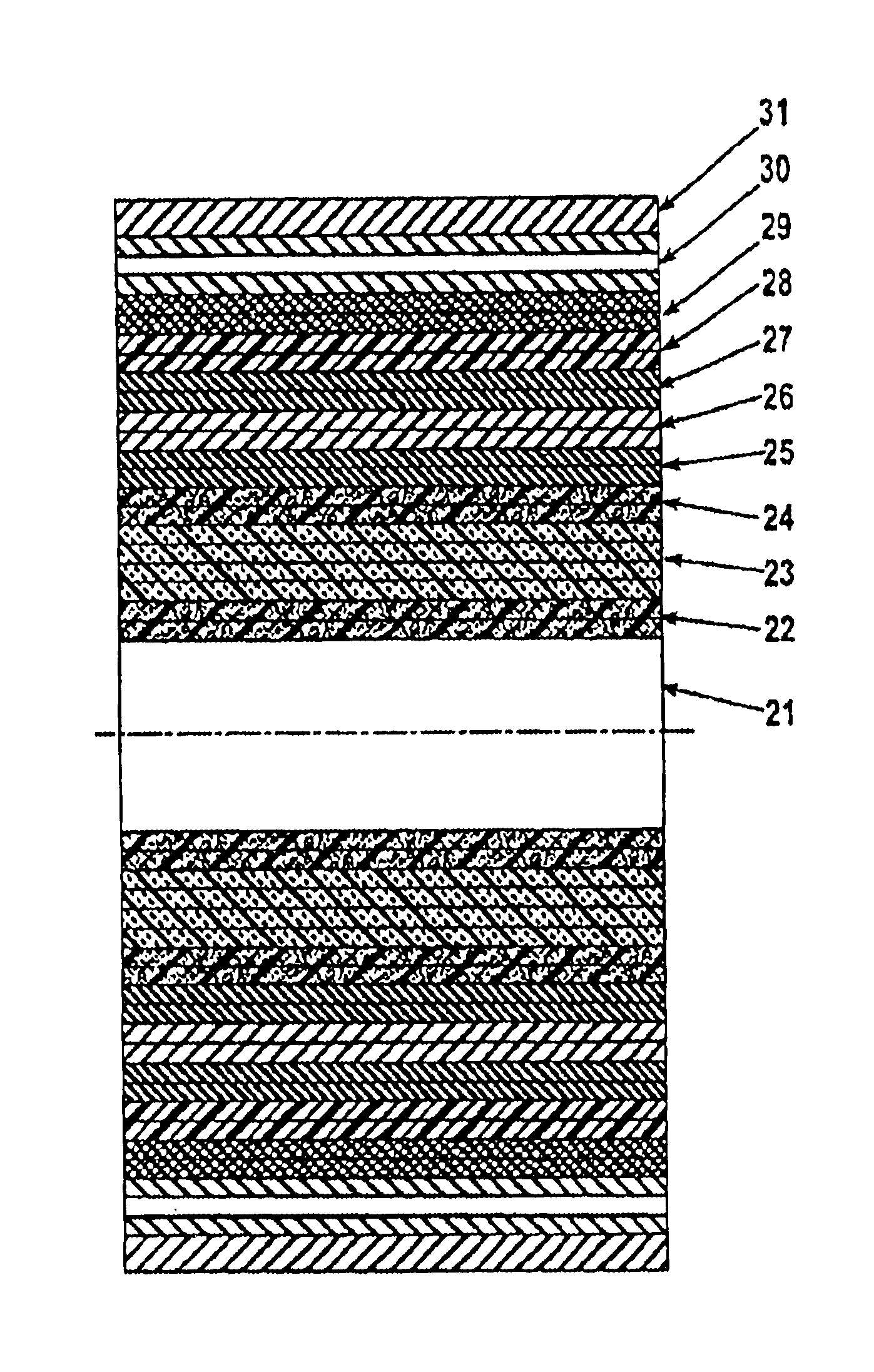

SUPERCONDUCTIVE ELEMENT CONTAINING Nb3Sn

InactiveUS20070238620A1Improve superconductivityHigh critical temperatureSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentHigh critical temperatureMetallic materials

A superconductive element containing Nb3Sn, in particular a multifilament wire, comprising at least one superconductive filament (8) which is obtained by a solid state diffusion reaction from a preliminary filament structure (1), said preliminary filament structure (1) containing an elongated hollow pipe (2) having an inner surface (3) and an outer surface (4), wherein said hollow pipe (2) consists of Nb or an Nb alloy, in particular NbTa, wherein the outer surface (4) is in close contact with a surrounding bronze matrix (5) containing Cu and Sn, and wherein the inner surface (3) is in close contact with an inner bronze matrix (5) also containing Cu and Sn, is characterized in that the inner bronze matrix (5) of the preliminary filament structure (1) encloses in its central region an elongated core (6) consisting of a metallic material, said metallic material having at room temperature (=RT) a thermal expansion coefficient αcore<17*10−6K−1, preferably αcore≦8*10−6 K−1, said metallic material having at RT a yield strength Rp0.2>300 MPa, said metallic material having at RT an elongation at rupture A>20%, and wherein the metallic material of the core (6) is chemically inert with respect to the material of the inner bronze matrix (5) up to a reaction temperature T of the solid state diffusion reaction. This element has improved superconductive properties in a large volume fraction of its superconductive filaments, in particular a high critical temperature Tc and a high critical magnetic filed strength Bc2, and is mechanically stable enough for commercial applications such as magnet coils.

Owner:BRUKER SWITZERLAND AG

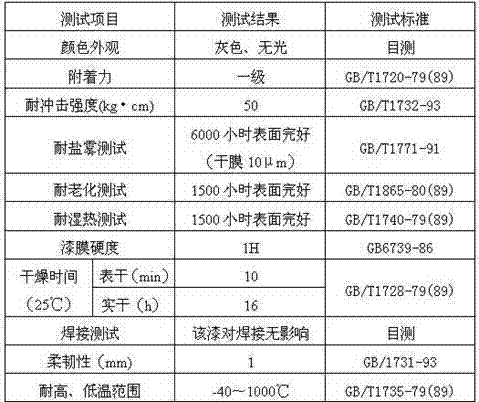

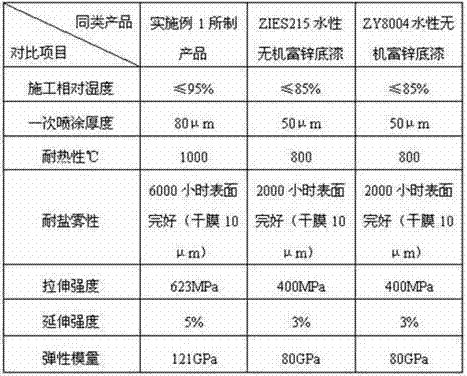

Aqueous inorganic zinc rich paint

ActiveCN102898913AOvercome the disadvantage of easily forming voids in the paint filmOvercome the disadvantage of easy void formationAnti-corrosive paintsAcrylic resinSilicic acid

The invention provides an aqueous inorganic zinc rich paint, which is prepared by mixing a component A with a component B according to a weight ratio of 4:1, wherein the component A comprises 30-32% of 500-mesh spherical / flaky zinc powder, 30-32% of 800-mesh spherical / flaky zinc powder, 30-32% of 1250-mesh spherical / flaky zinc powder, 6-8% of nanometer cerium dioxide and 2-4% of 800-mesh talcum powder; and the component B comprises 38-50% of potassium silicate, 10-20% of lithium silicate, 8-10% of potassium titanate whiskers, 5-12% of aqueous self-drying organic silicon modified acrylic resin, 0.2-0.5% of defoaming agent, 0.5-1% of wetting agent and 12-20% of water. The aqueous inorganic zinc rich paint provided by the invention has the characteristics of excellent corrosion resistance, physical and mechanical properties, wet resistance, high temperature resistance and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

Method for preparing REBa2Cu3Ox (REBCO) high-temperature superconducting block material

InactiveCN102584250AControl supersaturationControl growth rateSpontaneous nucleationHigh temperature superconducting

The invention relates to a method for preparing a REBa2Cu3Ox (REBCO) high-temperature superconducting block material, in particular to a melt texture growth (MTG) method for the REBCO high-temperature superconducting block material. The MTG method for the REBCO high-temperature superconducting block material comprises the following steps of: a) mixing raw materials; b) grinding and calcining to obtain a superconducting material rough blank; c) tabletting; d) firing; and e) cooling to obtain the REBCO high-temperature superconducting block material, namely e1) cooling to buffer temperature, and preserving heat, e2) cooling to growth temperature, and preserving heat, and e3) quenching. By the method, the technical problem that the REBCO high-temperature superconducting block material fails to grow because spontaneous nucleation is generated when temperature is reduced from the maximum temperature to the growth temperature in the conventional MTG method is solved.

Owner:SHANGHAI JIAO TONG UNIV

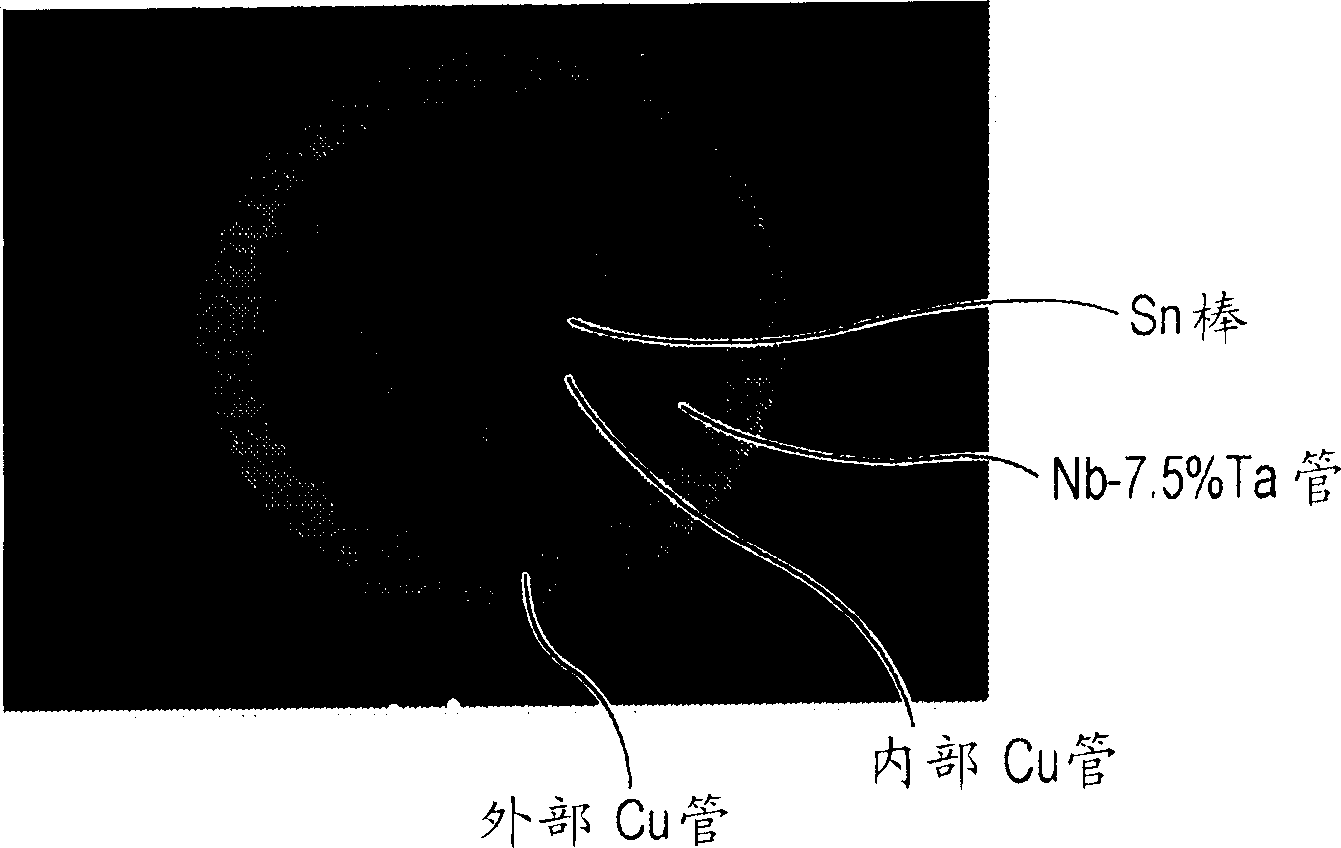

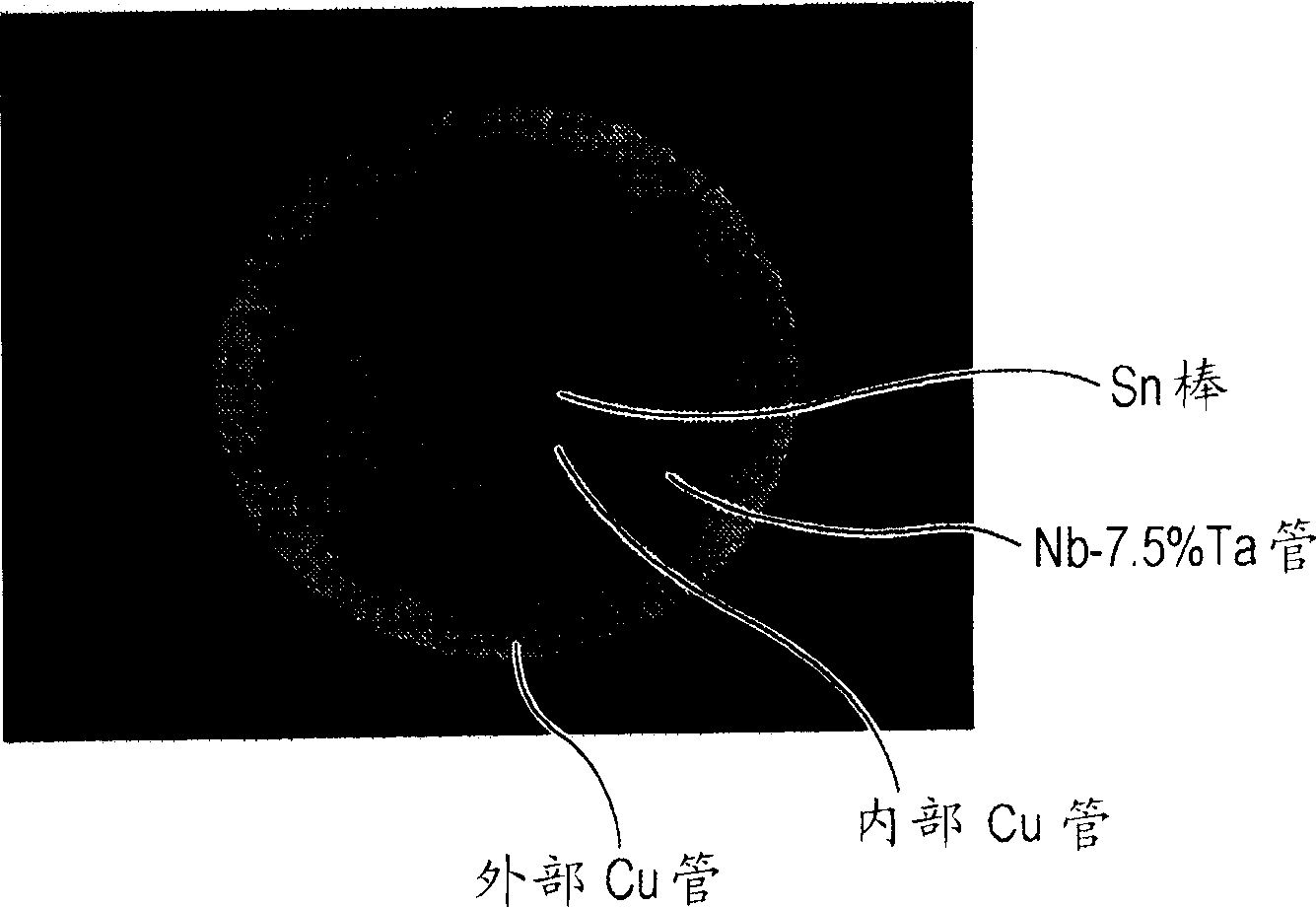

Nb3Sn superconducting wire, precursor or same, and method for producing precursor

InactiveUS20080287303A1Minimal resistanceMaintain good propertiesSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentSingle elementAlloy

A precursor for producing a Nb3Sn superconducting wire includes a bundle of single-element wires each including a Cu or Cu-based alloy matrix, Nb or Nb-based alloy filaments, at least one Sn or Sn-based alloy core, the Nb or Nb-based alloy filaments and at least one Sn or Sn-based alloy core being arranged in the Cu or Cu-based alloy matrix, an diffusion barrier layer around the periphery of the Cu or Cu-based alloy matrix, the inner diffusion barrier layer being composed of Nb or a Nb-based alloy, and a Cu or Cu-based alloy layer around the periphery of the diffusion barrier layer; an outer diffusion barrier layer around the periphery of the bundle of the single-element wires, the outer diffusion barrier layer being composed of Nb, a Nb-based alloy, Ta, a Ta-based alloy, or a combination thereof; and a stabilizing copper layer around the periphery of the outer diffusion barrier layer.

Owner:KOBE STEEL LTD

Preparation method for europium iron arsenic super conductor wire and strip material

InactiveCN101383204AHigh melting pointHigh densitySuperconductors/hyperconductorsSuperconductor devicesRoom temperatureHeating furnace

The invention relates to a Eu-Fe-As superconductor and a wire and tape preparing method. The wire and tape preparing method comprises the following steps: (1) after raw material powder which is prepared according to a chemical formula: Eu1-xAxM2Pn2 is evenly mixed, the raw material powder is put into a metal pipe and is sufficiently tamped, then both ends of the metal pipe are sealed; (2) the metal pipe is rotatablely forged, drawn and rolled according to 5 to 20 percent of pass deformation to obtain a rod, a wire or a tape; (3) the rod, the wire or the tape which is processed by the step (2) is put into a high-temperature heating furnace and vacuumized to 10<-2>-10<-5> Pa at room temperature, then argon is inflated into the high-temperature heating furnace, and then the temperature of the high-temperature heating furnace is kept for 5 to 60 hours at the temperature of 600 to 1000 DEG C, and finally, the high-temperature heating furnace is cooled to the room temperature to obtain the Eu-Fe-As novel superconductor. Compared with the common stepping preparing method, the wire and tape preparing method is safe and reliable, a sintering process can be completed once, the technology is simple, the production efficiency is high, the density of the prepared Eu-Fe-As compound superconductor is higher, and the Eu-Fe-As superconductor has good superconduction performance.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method of preparing metal matrix composite with textured compound

InactiveUS6569360B2Simple process conditionsImprove superconductivityNon-insulated conductorsSuperconductors/hyperconductorsVolumetric Mass DensityMetal matrix composite

The present invention provides a generic method of preparing a metal matrix composite with a textured compound. A "roller-skate" structure starting powder with a mixture of plate-like particles and smaller particles provides better flow compatibility, higher packing density, better densification and texture formation in preparing a metal matrix composite with a textured compound. In particular, the invention provides a method of preparing a textured superconducting composite wire with an improved critical current density.

Owner:WU HENGNING

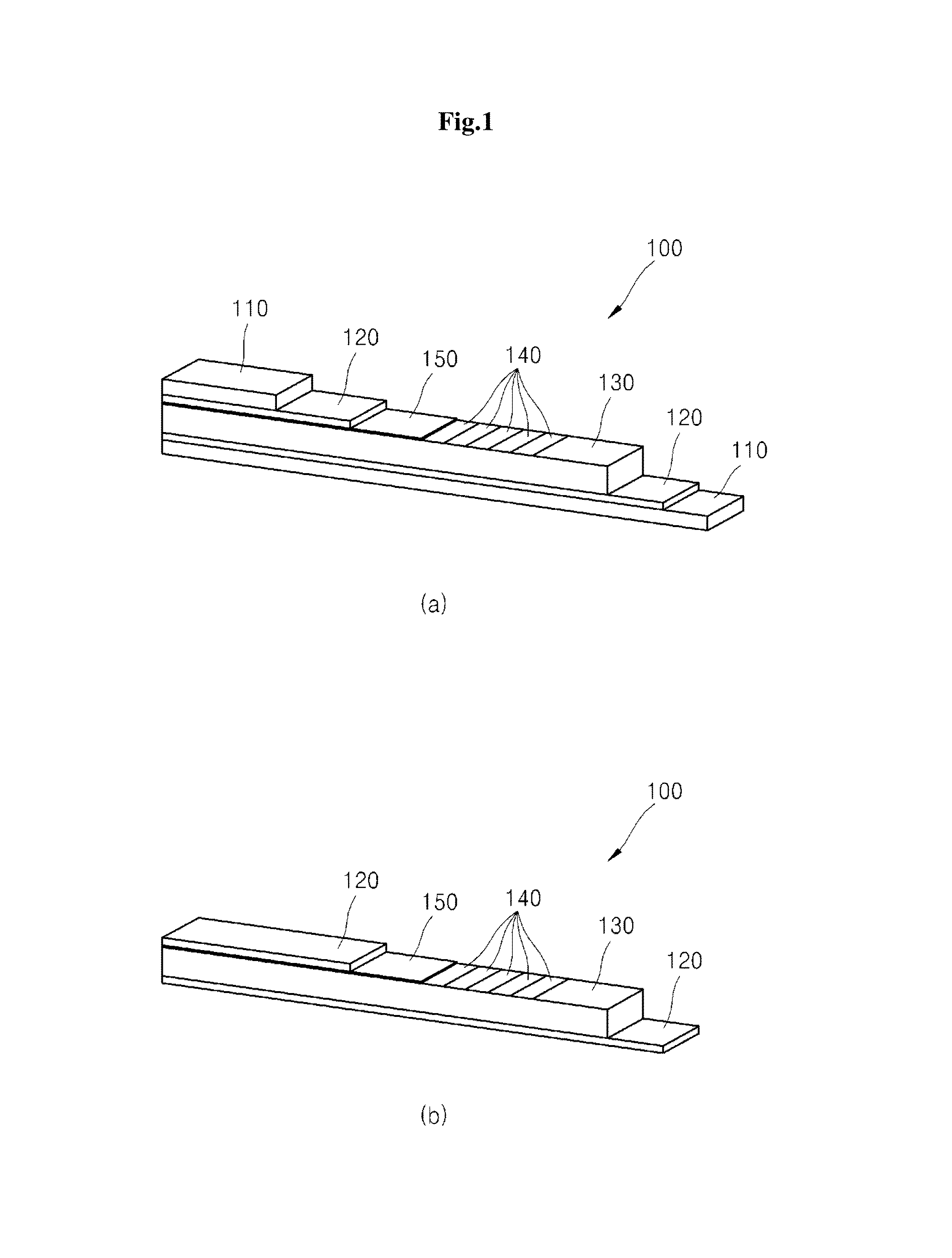

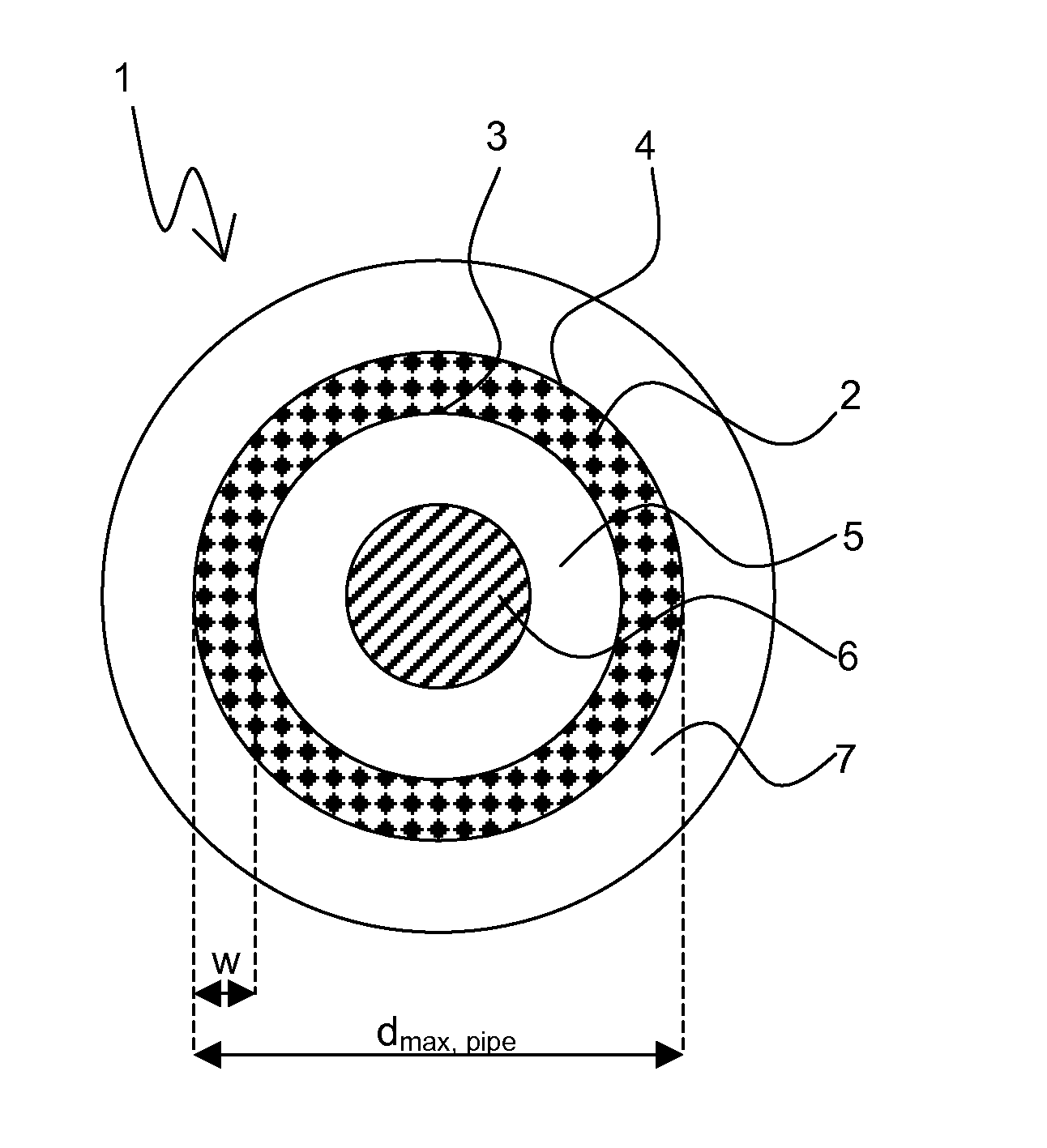

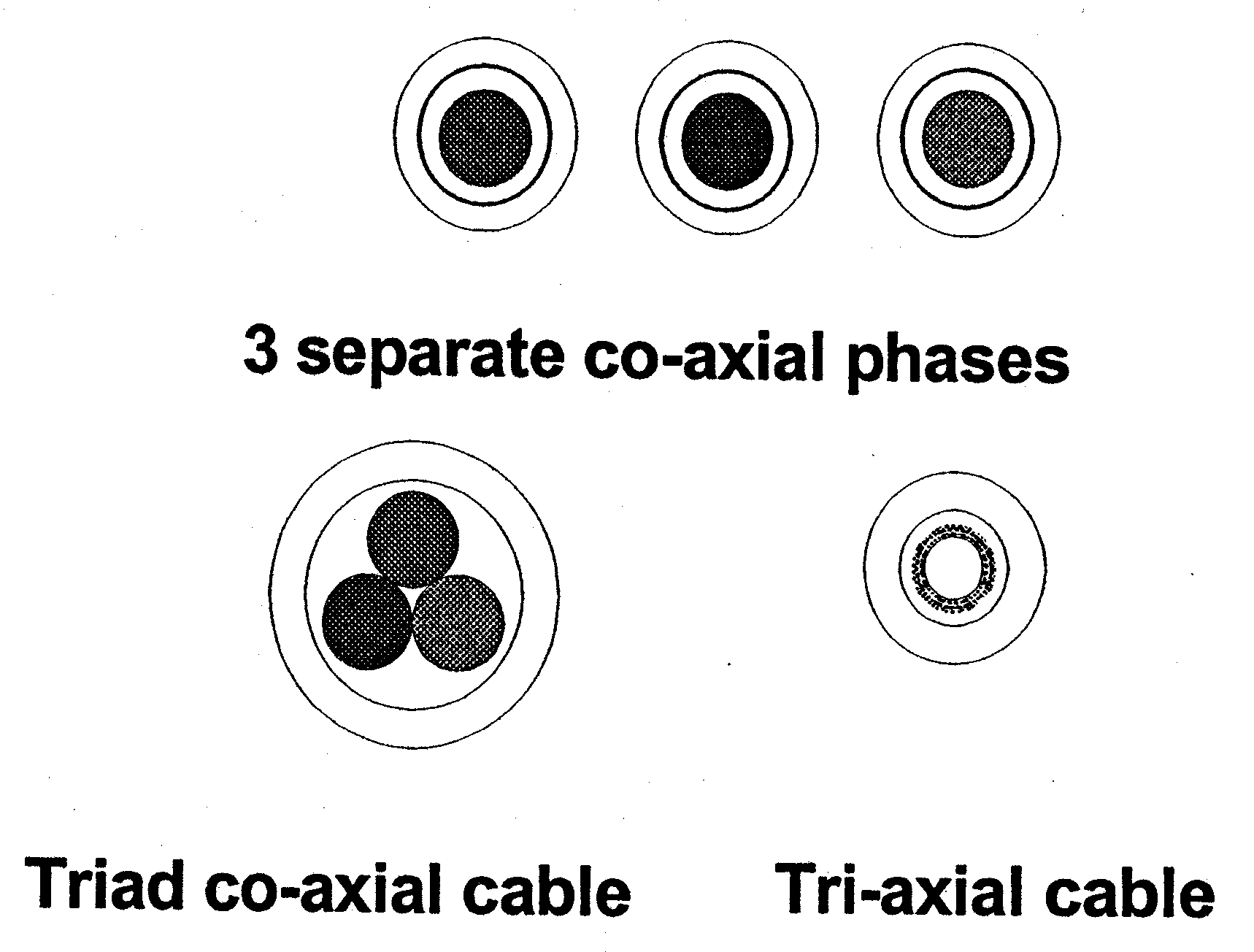

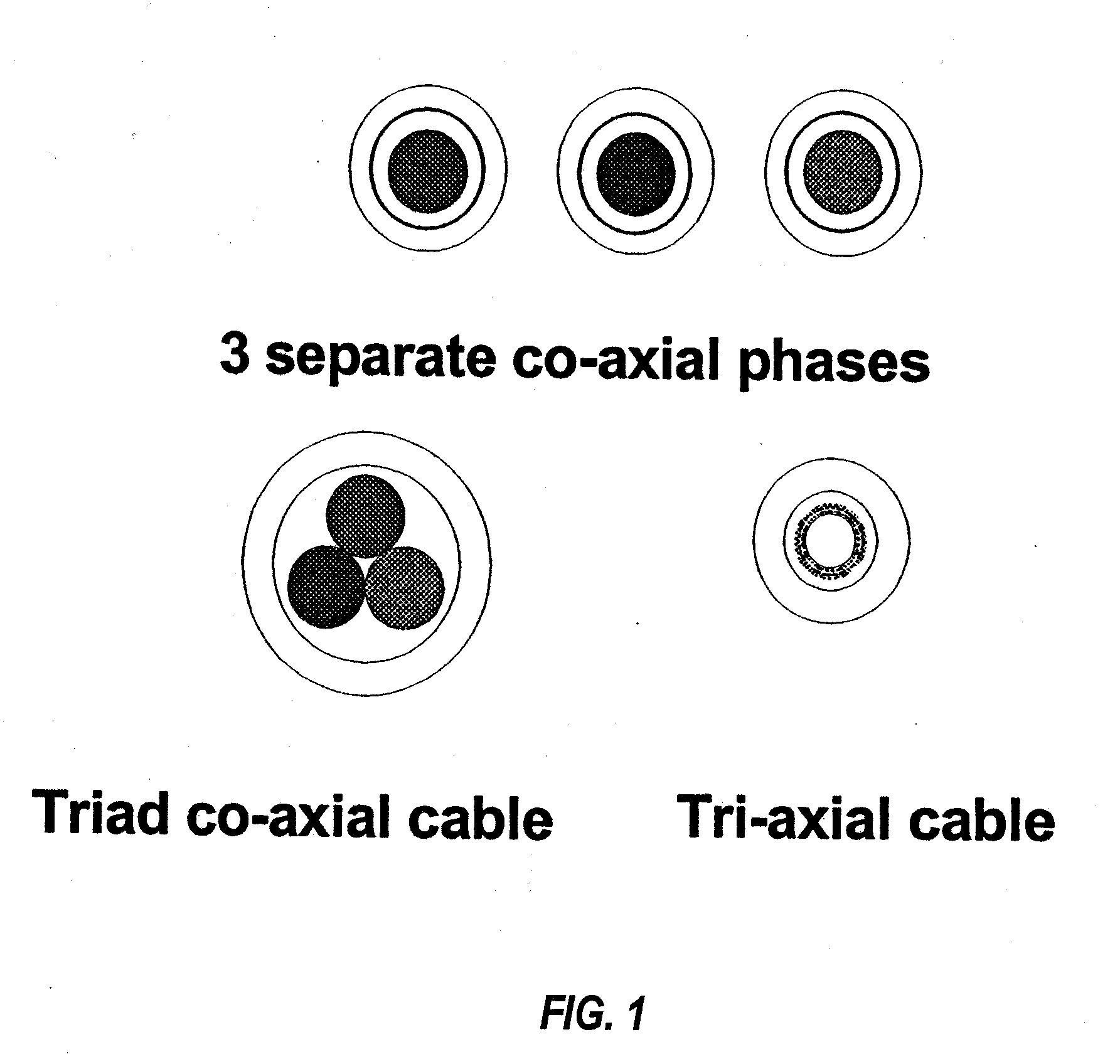

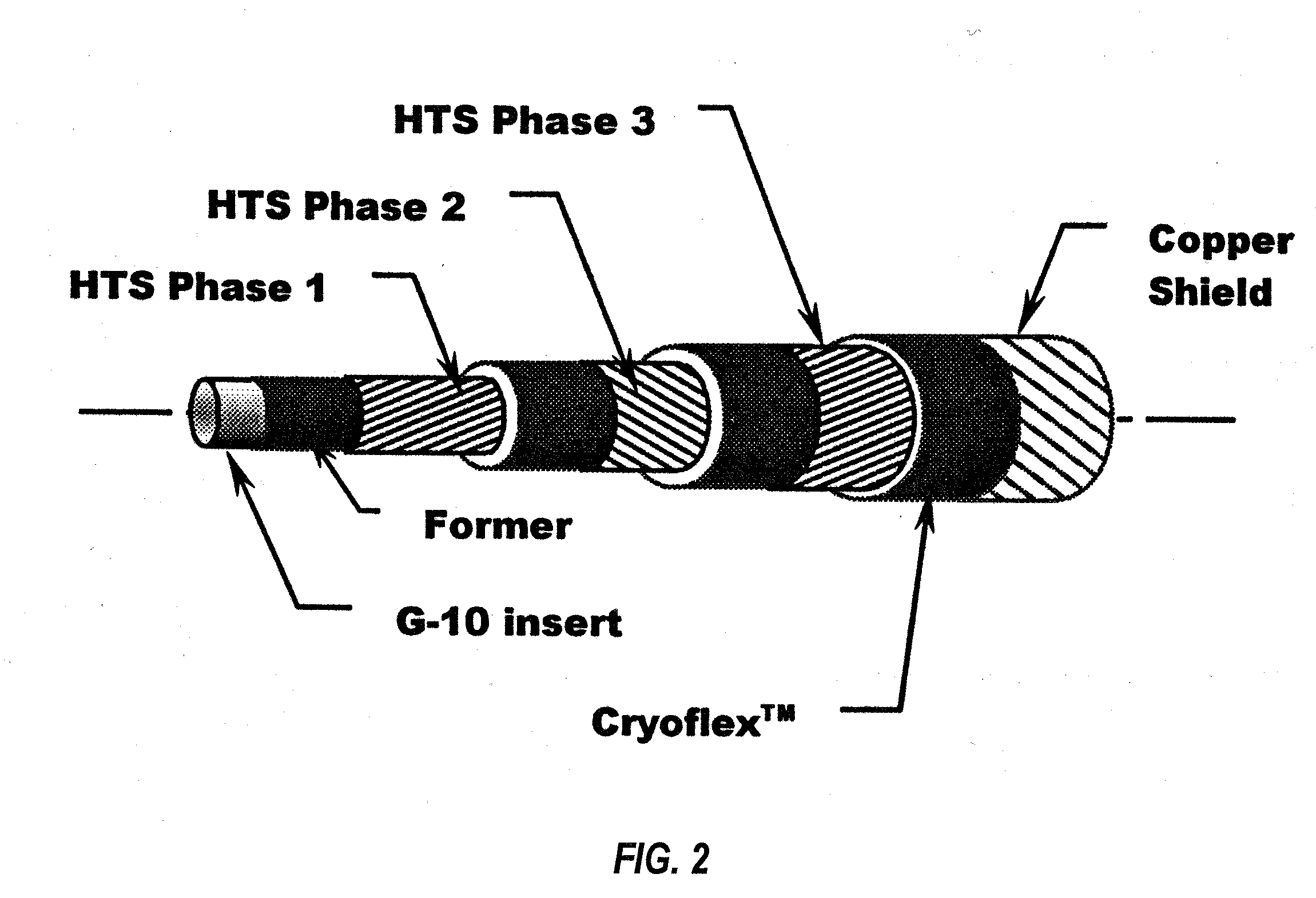

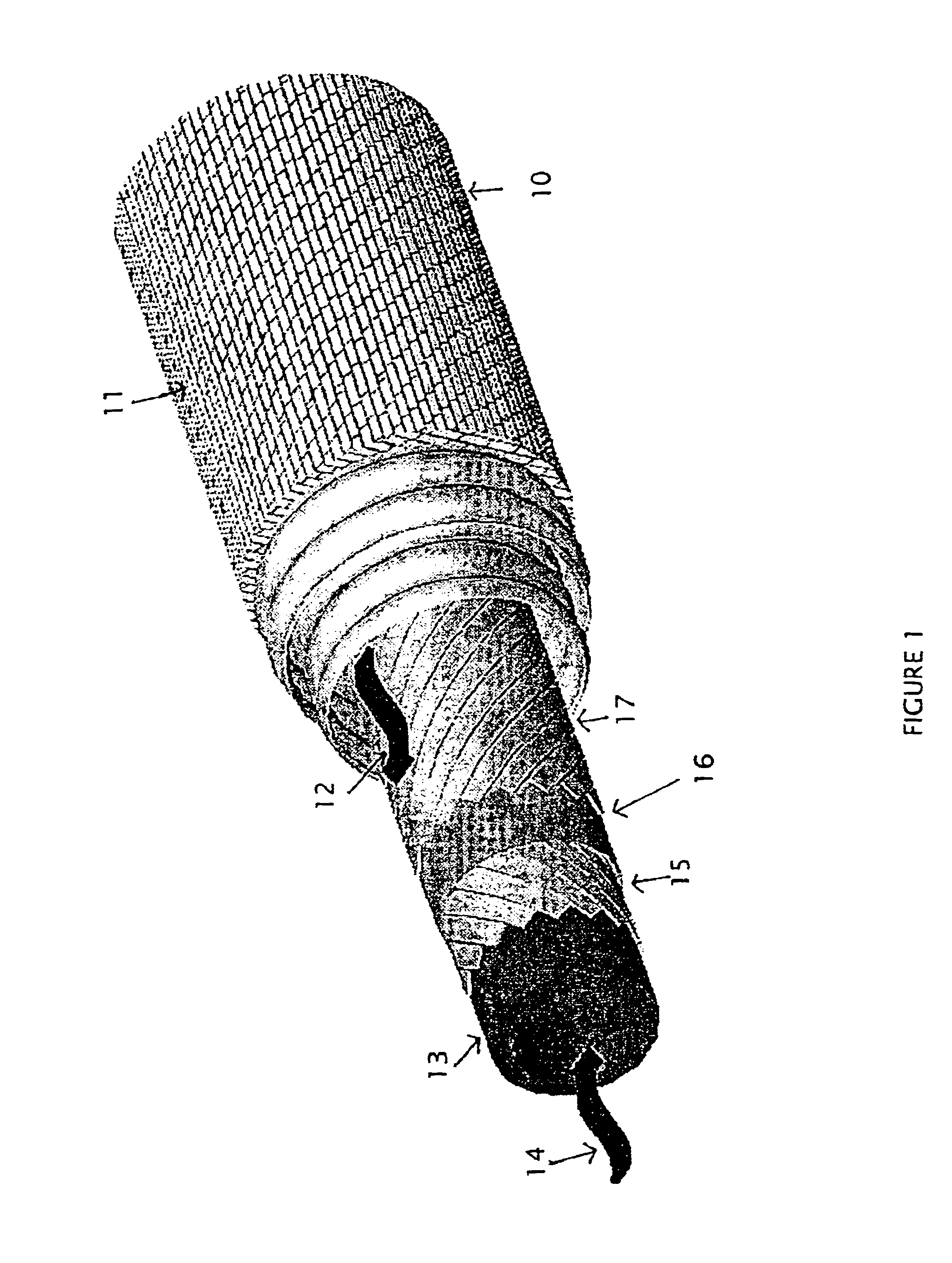

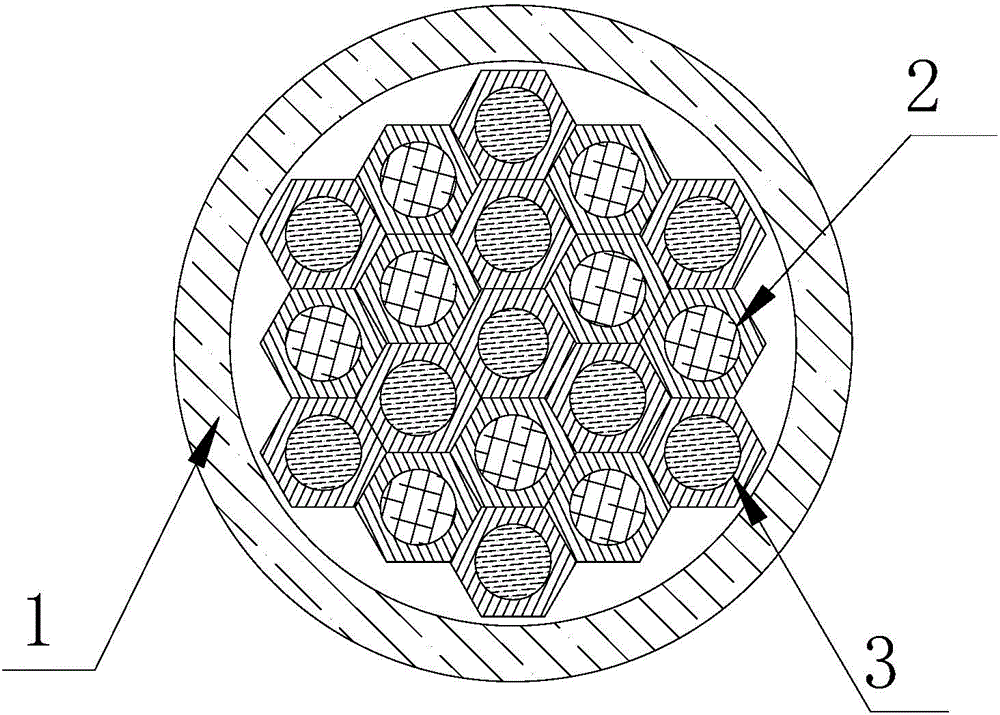

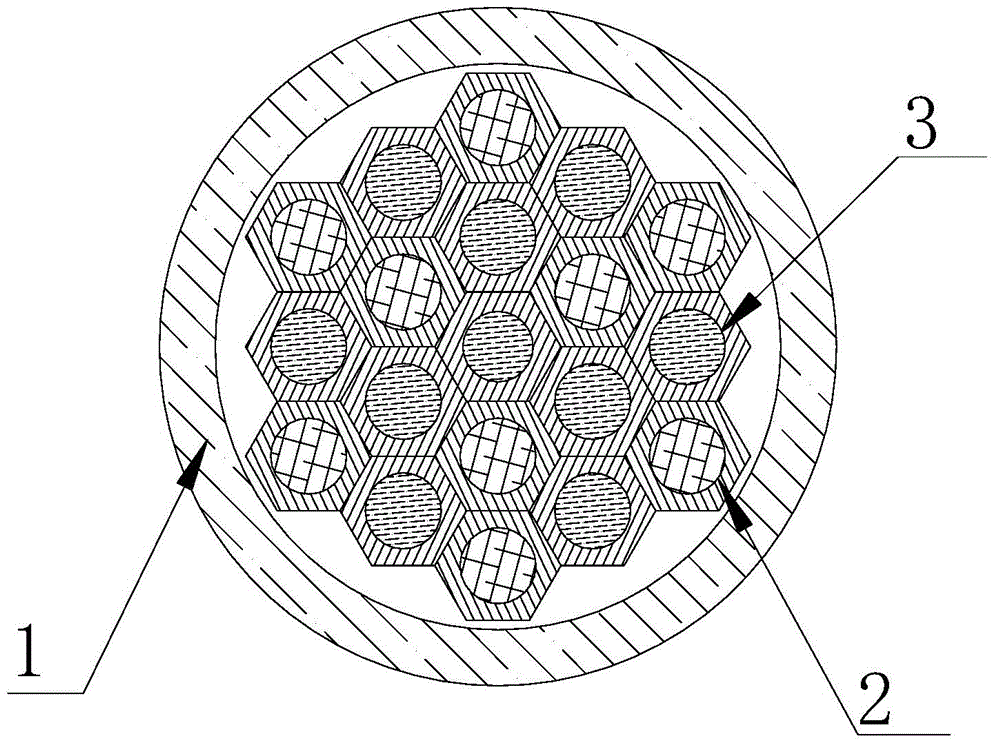

Triaxial Superconducting Cable and Termination Therefor

InactiveUS20080179070A1Improve superconductivityHigh currentSuperconductors/hyperconductorsCable fittings for cryogenic cablesSuperconducting magnetBand shape

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith. Methods of forming and terminating a triaxial superconductor are disclosed.

Owner:GOUGE MICHAEL J +4

Method for manufacturing composite Nb3Al/Nb multi-core superconducting wire

InactiveCN102543311AStable and excellent superconducting performanceHigh puritySuperconductors/hyperconductorsSuperconductor devicesThin lineSingle-core

The invention discloses a method for manufacturing a composite Nb3Al / Nb multi-core superconducting wire. The method comprises the following steps of: weighting Nb foil and Al foil based on a stoichiometric ratio of the Nb3Al; superposing the Nb foil and the Al foil and winding the Nb foil and the Al foil around a Nb rod, placing the Nb rod into a Nb tube, and drawing the Nb tube to a thin line of0.8-1mm to obtain a single-core wire; orderly placing the sections of the single-core wire into the Nb tube after cutting off the single-core wire to be multiple equal-length sections, and placing anequal-length Nb rod on the central axial line of the Nb tube; drawing and rolling the Nb tube to a circular or flat wire with the diameter of 1-2.5mm to obtain a multi-core wire; and cutting off the multi-core wire to short wires of 10cm, and carrying out a high-temperature treatment of 1900-2100 DEG C on the short wires for 0.05-0.2s by utilizing a pulse electric power under a vacuum condition to obtain the composite Nb3Al / Nb multi-core superconducting wires. The method disclosed by the invention has the advantages of short manufacturing period and high efficiency; in addition, the compositeNb3Al / Nb multi-core superconducting wire manufactured by the method has the advantages of compact connection, good uniformity, no separation situation, no impurity phase, and excellent superconducting performance.

Owner:SOUTHWEST JIAOTONG UNIV

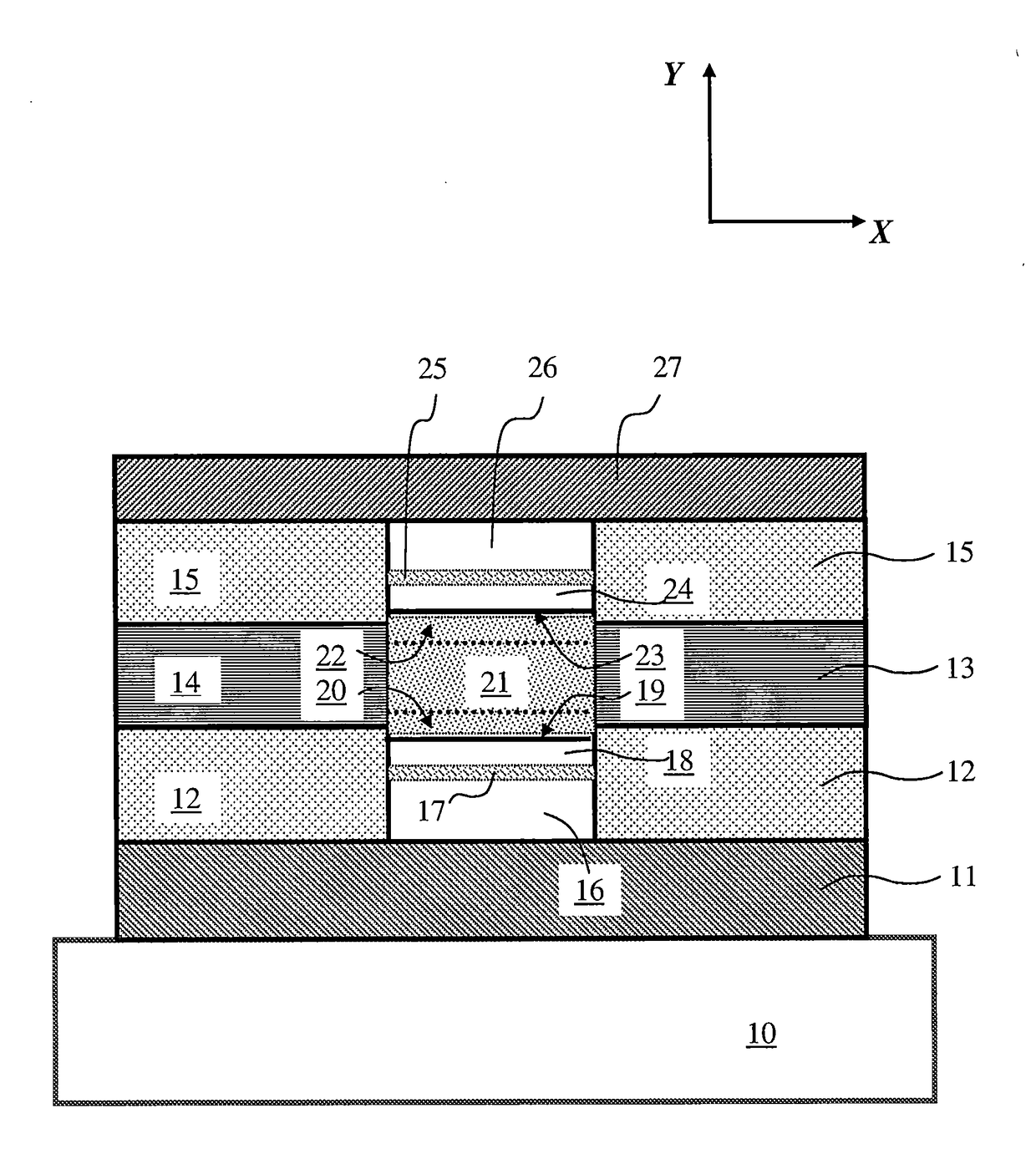

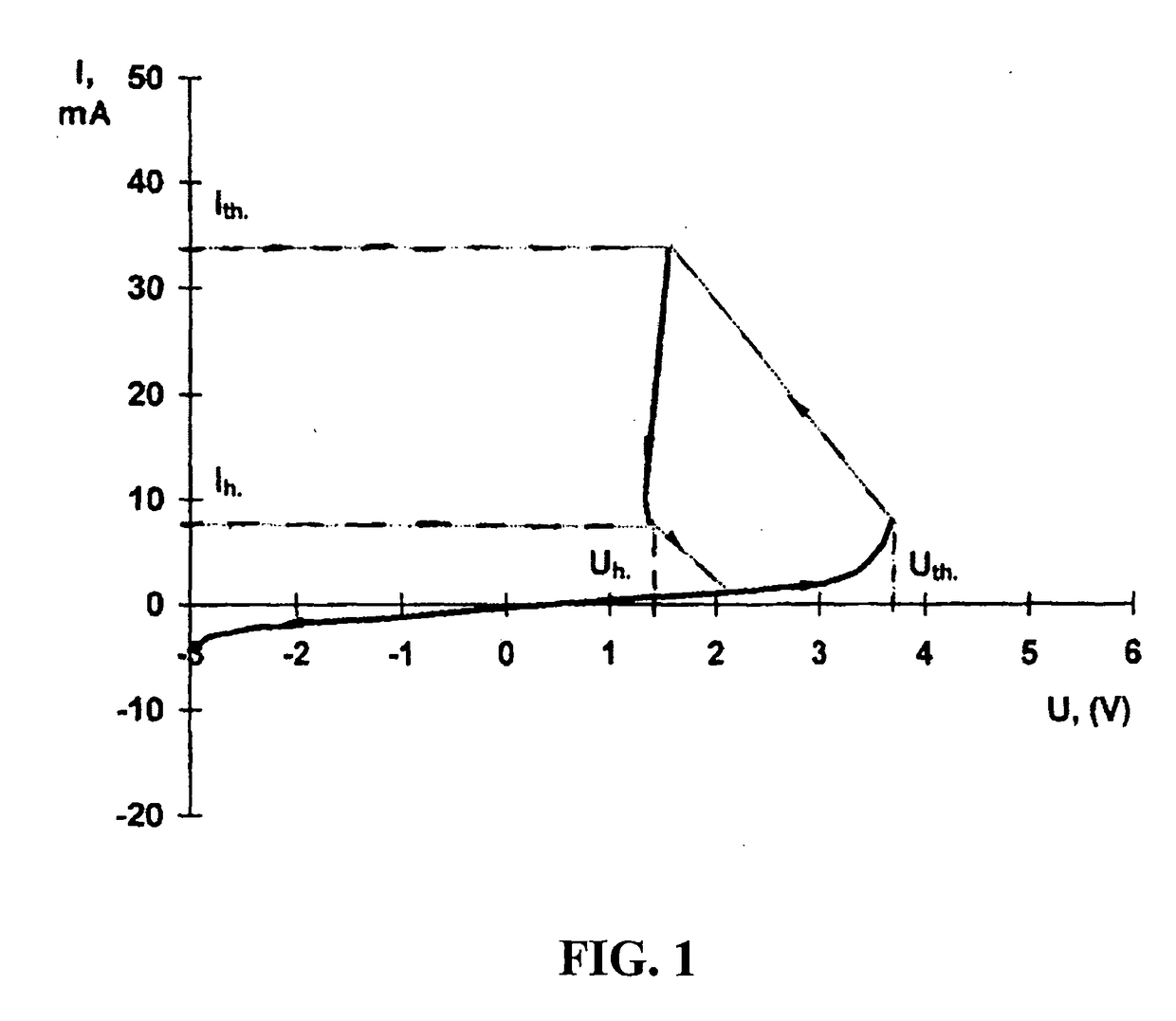

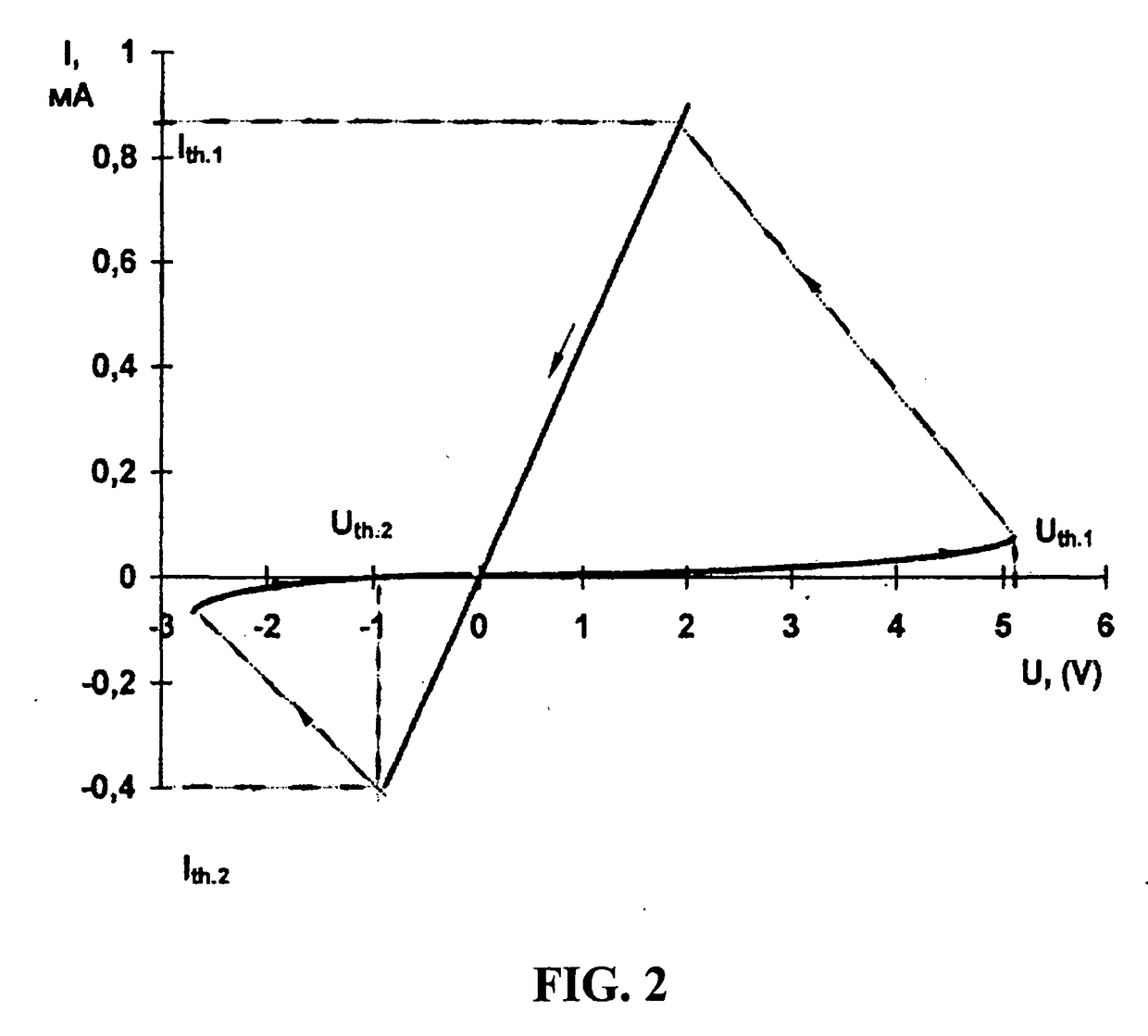

SEMICONDUCTOR MEMORY DEVICES FOR USE IN ELECTRICALLY ALTERABLE READ ONLY MEMORY (ROM) AND SEMICONDUCTOR THIN FILM DEVICES (SPINTRONS and SPIN-ORBITRONS)

ActiveUS20170069839A1Improve stabilityLow resistance stateElectrical apparatusLayered structurePhysics

An electrically alterable thin film memory device or non-volatile trigger which can be switched from a high resistance state to a low resistance state. The device increases the concentration of electrically active impurities at correspondent electrodes to which respect impurities would electro migrate during a large number of set-reset cycles. The device comprises a layered structure with memory layers formed on an interface of two regions as the result of the mutual mixing and migration of their constituents. One region contains an electrically active donor impurity. A thin layer of dielectric is placed in the other region. Each of the memory layers includes an interface of chalcogenide films.

Owner:TROYAN EUGENIY

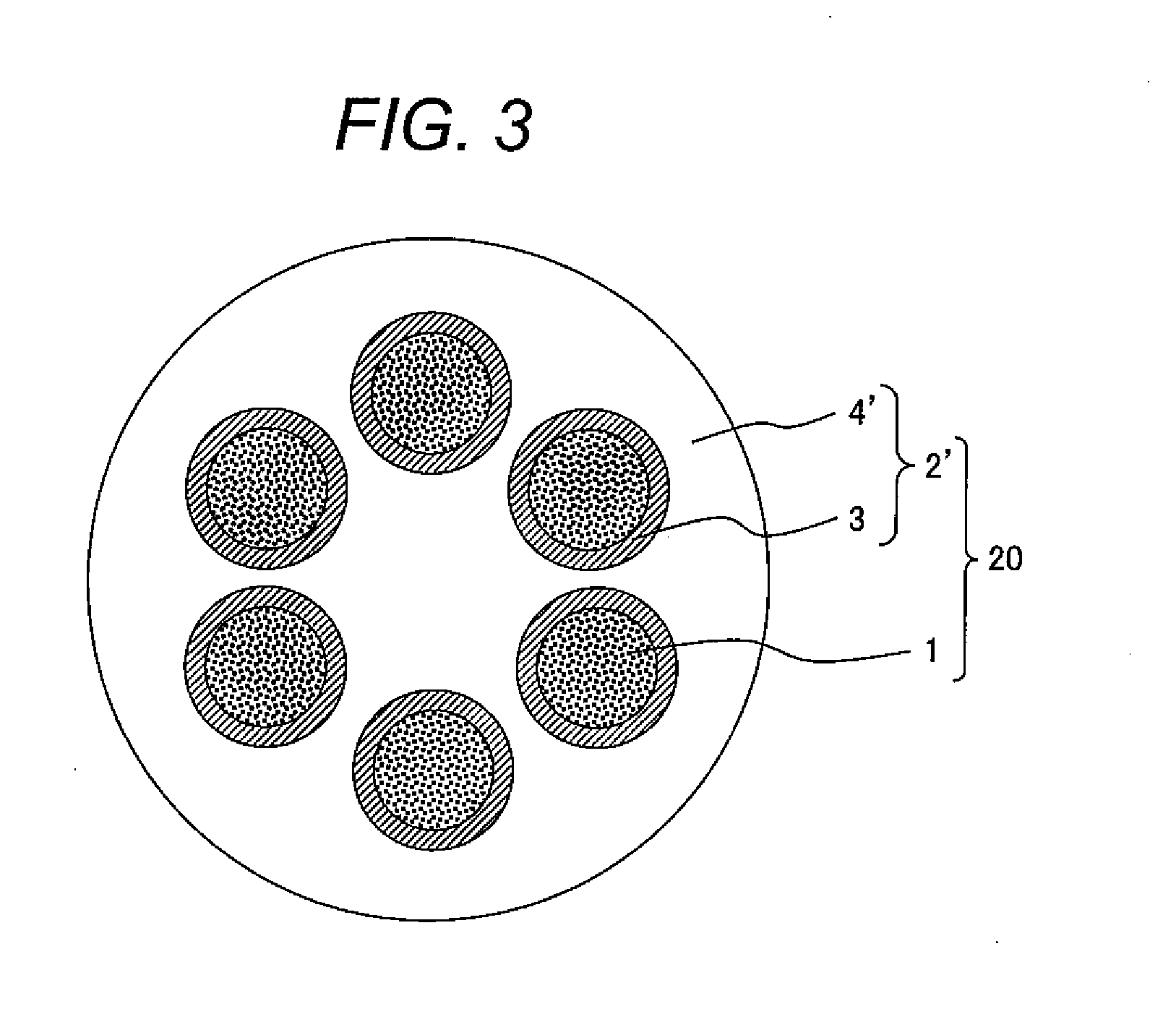

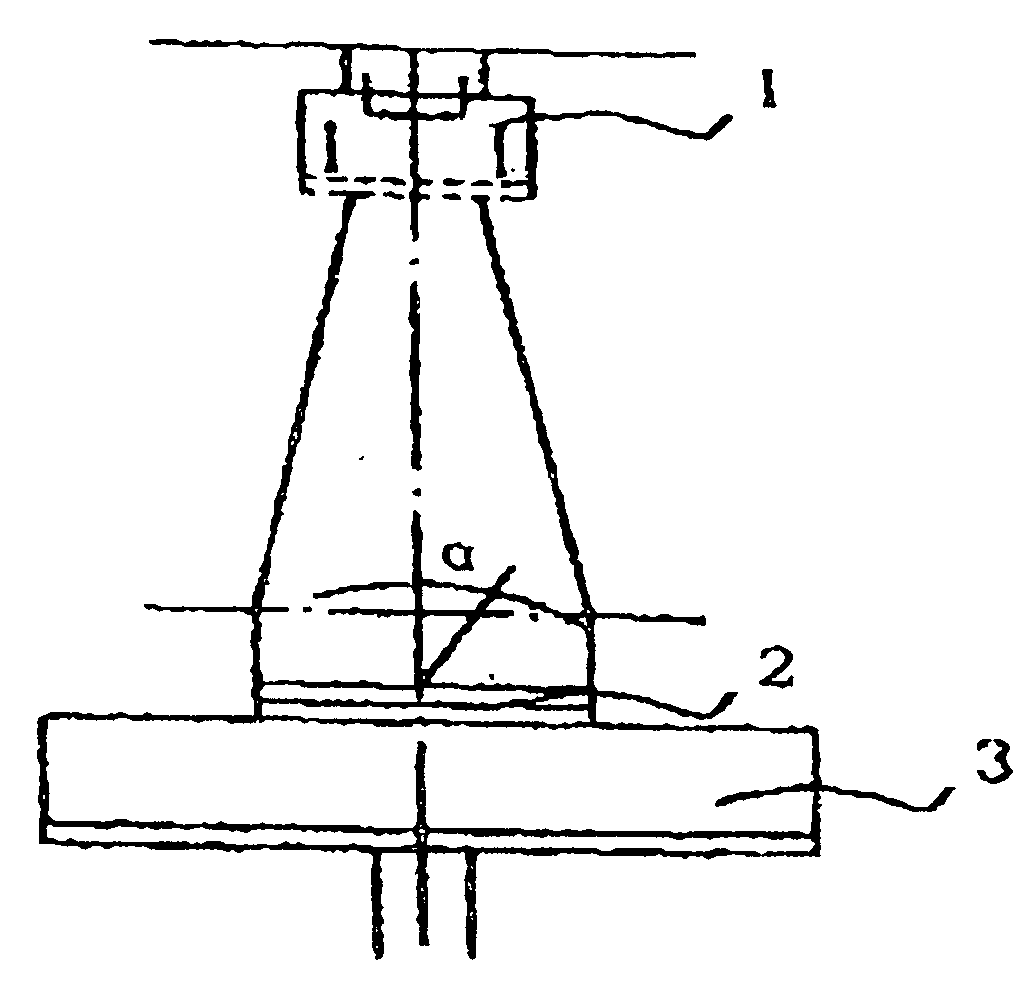

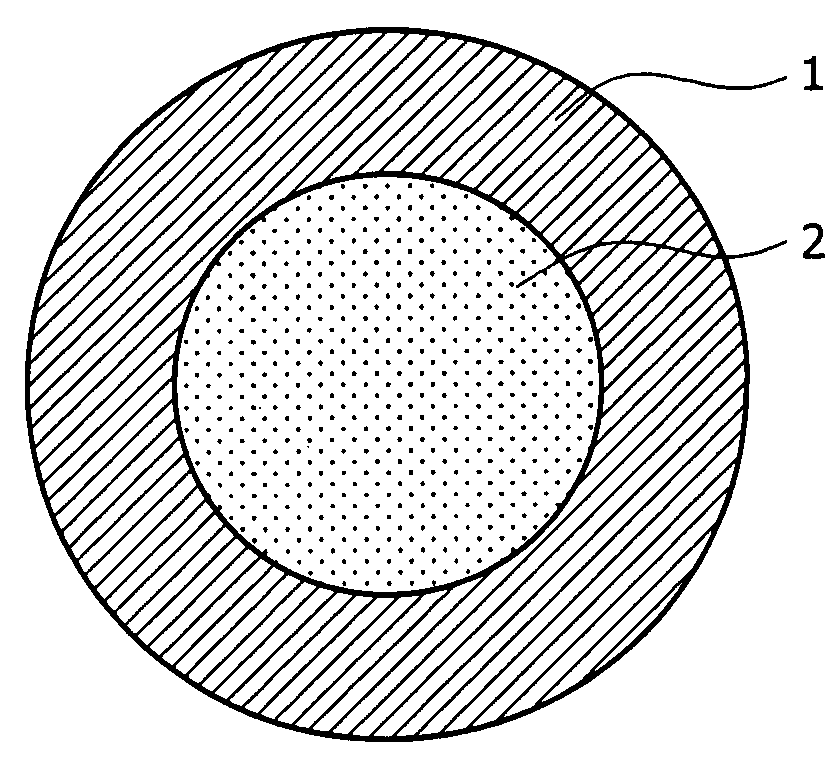

Magnesium diboride superconducting wire and method for manufacturing same

InactiveUS20120004110A1Improve superconductivitySuperconductors/hyperconductorsMagnetsMagnesium diborideFatty acid

It is an objective of the present invention to provide a method for manufacturing long lengths of MgB2 superconducting wire having excellent superconducting properties and an MgB2 superconducting wire manufactured thereby. There is provided a method for manufacturing a magnesium diboride superconducting wire, comprising the successive steps of: filling a metallic tube with a raw material powder; and subjecting the tube to wiredrawing processing, in which a fatty acid metal salt or a mixture of the fatty acid metal salt and a fatty acid is added to the raw material powder.

Owner:HITACHI LTD

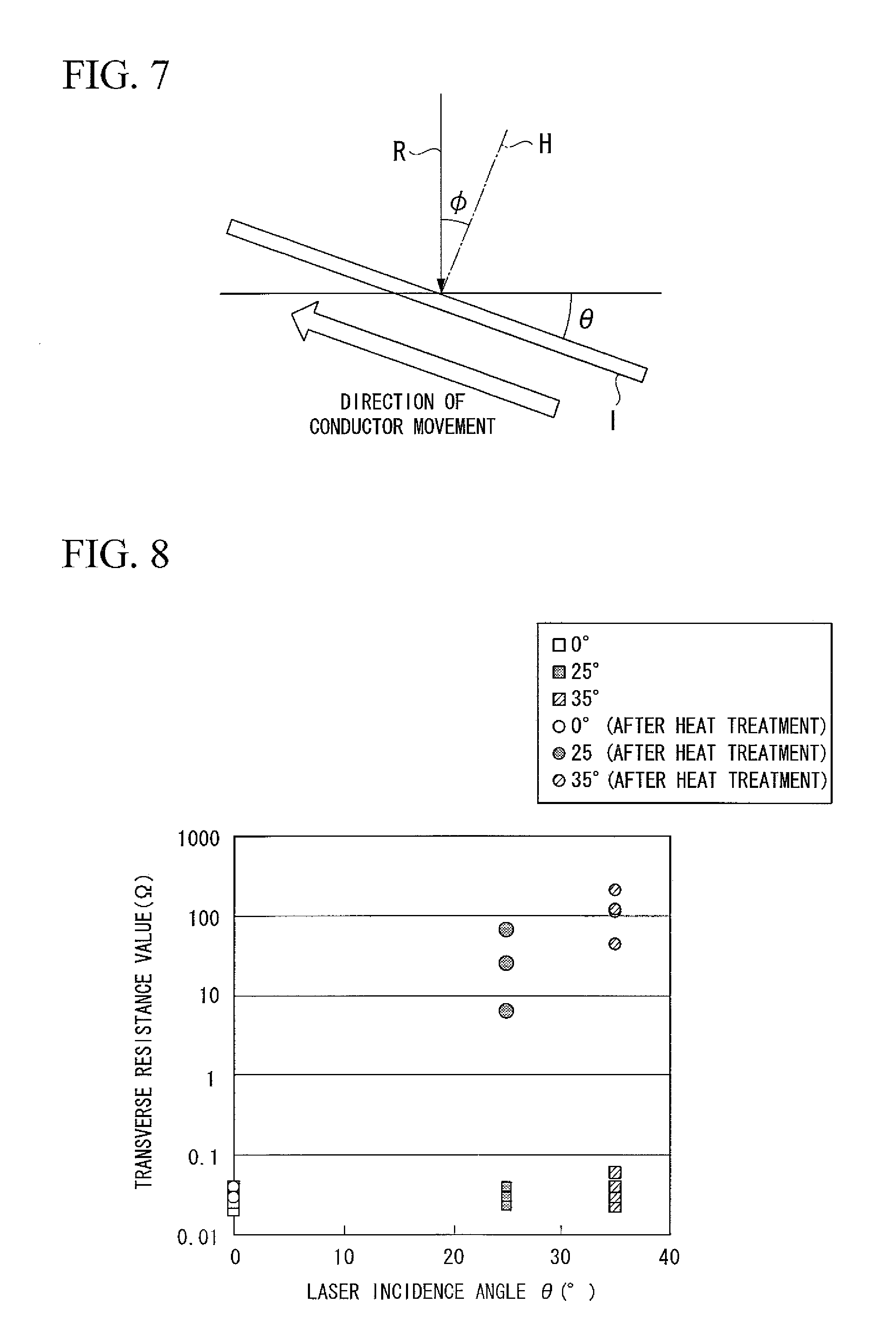

Surface improvement method in fabricating high temperature superconductor devices

InactiveUS20060172892A1Decrease eliminate stateDecrease eliminate and of surfaceSuperconductor device manufacture/treatmentSurface finishHigh-temperature superconductivity

A method of surface modification in fabricating High Temperature Superconducting devices, characterized in that bombarding the preformed material surface with a particle beam having energy, to improve the smoothness of the material surface and change the microstructure or internal defects of the processed material, wherein the energy of the particle beam is in the range of 5 ev to 50000 ev, and the incidence angle is in the range of 5 degree to 85 degree. In some cases, in order to achieve the desired superconductivity, the bombarded sample is annealed, and the annealing temperature is in the range of 100° C. to 1500° C. The present invention can improve the surface smoothness of the processed material, reduce the surface defect, change the microstructure of the material, and thereby improve the superconductivity of the whole device. The bombarded material comprises a substrate, a transition layer, superconducting layer or any combination of them during the process of the fabrication of the superconducting devices.

Owner:TSINGHUA UNIV

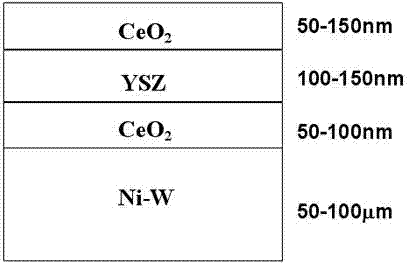

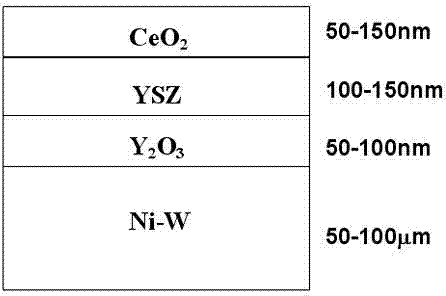

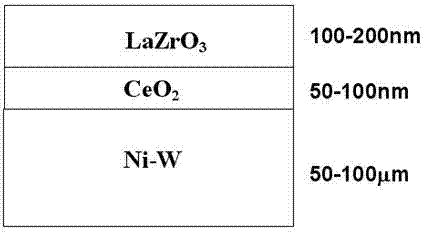

Simplified CeO2/LaZrO3 composite separating layer used for second generation high temperature superconductive tapes and its preparation method

ActiveCN102409297AImprove stabilityGood repeatabilityVacuum evaporation coatingSputtering coatingSurface finishHigh-temperature superconductivity

The invention provides a simplified CeO2 / LaZrO3 composite separating layer used for a second generation high temperature superconductive tapes and its preparation method. According to the invention, a simplified CeO2 / LaZrO3 double layers composite separating layer structure replaces a complex CeO2 / YSZ / CeO2 and CeO2 / YSZ / Y2O3 three layers composite separating layer, and a multichannel laser plated film technology replaces a traditional reacting direct current magnetron sputtering technology for preparing a composite separating layer structure on a Ni-W metal substrate. The invention has the advantages of stability, repeatability and reliability. The chemical property of the obtained CeO2 / LaZrO3 composite separating layer is stable, and has the characteristics of single(001) orientation, small thickness error and good surface fineness. A rare earth oxide superconducting layer (REBCO) prepared on the composite separating layer has superior superconductive performance, and is capable of satisfying the requirement for manufacturing a superconductive electric power device.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

Precursor for fabricating nb*sn superconducting wire, and nb*sn superconducting wire, and method for fabricating the same

InactiveCN1832058AImprove superconductivityUniform processingSuperconductors/hyperconductorsApparatus for heat treatmentNitrogenAlloy

A method for fabricating a Nb3Sn superconducting wire includes the steps of loading or inserting a core material containing at least Sn into a pipe member made of Nb or a Nb alloy, inserting the pipe member into a Cu billet to form a composite member, subjecting the composite member to diameter reduction, and then heat-treating the composite member to form a Nb3Sn superconducting layer from the inner surface of the pipe member, wherein, in the pipe member made of Nb or the Nb alloy after the diameter reduction, the average crystal grain size is 0.1 to 2 m, and preferably, the total concentration of oxygen, nitrogen, and carbon is 120 ppm or less.

Owner:KOBE STEEL LTD

Superconducting cable having a flexible former

InactiveUS6864430B2Improve superconductivityIncrease the critical currentSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentBand shapeBending strain

In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0.2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

Owner:SOUTHWIRE CO LLC

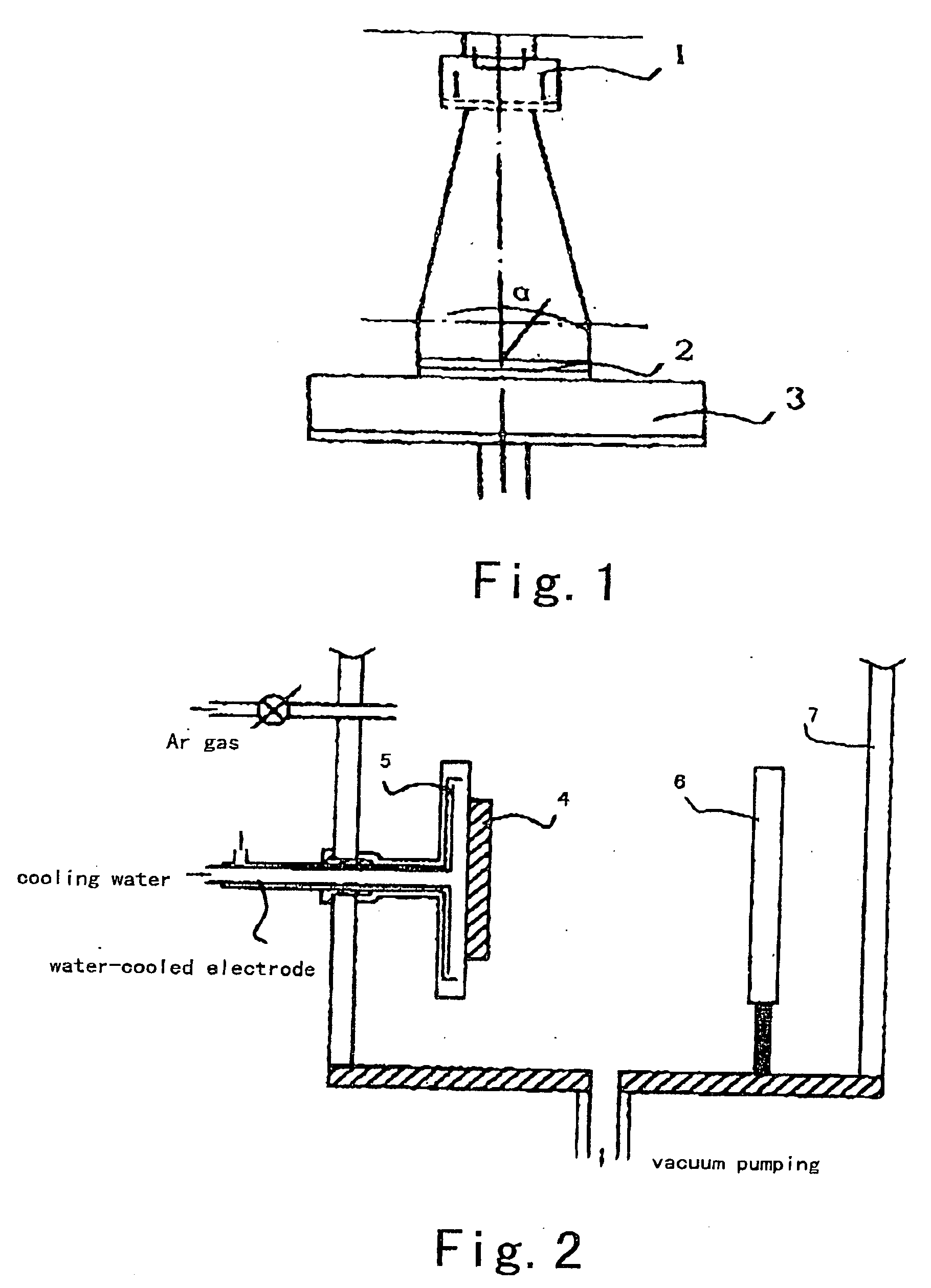

Explosive welding manufacturing method of high-purity niobium-oxygen-free copper composite plate

InactiveCN109604806AGuaranteed SuperconductivityReduce oxygen contentNon-electric welding apparatusNiobiumMechanical stability

The invention discloses an explosive welding manufacturing method of a high-purity niobium-oxygen-free copper composite plate. The method comprises the following steps that a high-purity niobium plateserves as a composite plate, an oxygen-free copper plate is used as a substrate, and high-purity niobium is manufactured in an explosive welding mode; and the quality purity of the high-purity niobium plate is not less than 99%, the thickness of the high-purity niobium plate is not larger than 2 mm, the oxygen content in the oxygen-free copper plate is less than 2 ppm, and the thickness of the oxygen-free copper plate is larger than 10 mm. According to the method, the composite surface of the high-purity niobium plate and the oxygen-free copper plate are subjected to high-speed collision through explosion welding to form a solid-phase metallurgical bonding to be combined, the defect that the oxidation of the high-purity niobium plate and oxygen absorption of the oxygen-free copper plate in the heating rolling process are avoided, the problem that the high-purity plates with relatively large elongation rates are difficult to cold rolling and rolling is solved, and the excellent superconducting performance of the high-purity niobium material is kept, and meanwhile, the thickness of a superconducting cavity is increased by the oxygen-free copper plate, and thus the mechanical stability of the superconducting cavity is enhanced.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

Manufacturing method of Nb3Sn superconductive wire using powder technique

InactiveUS7459030B2Uniform processingImprove superconductivitySuperconductors/hyperconductorsTransportation and packagingAlloy% diameter reduction

Disclosed is a manufacturing method of an Nb3Sn superconductive wire using a powder technique, the method including the steps of: filling, as a raw powder, an intermetallic compound powder obtained from a metallic powder containing at least one metallic powder selected from Ta powder and Nb powder, and Sn powder, or a mixture of the metallic powder and the Sn powder into a sheath made of Nb or an Nb based alloy; performing a diameter-reduction process on the sheath to form a wire; heat treating the wire; and, forming a superconductive layer on the interface between the sheath and the powder, wherein at least one of the metallic powders selected from the Ta powder and the Nb powder is obtained by aggregating fine particles (primary) in shape of coral to form secondary particles.

Owner:KOBE STEEL LTD

Method for manufacturing yttrium barium copper oxide target

InactiveCN102584205AAvoid introducingImprove compactnessYttrium barium copper oxidePhysical chemistry

The invention relates to a method for manufacturing a yttrium barium copper oxide target, which comprises the following steps of: (1) uniformly mixing Y2O3, BaO and CuO according to a certain ratio (the atomic ratio of Y:Ba:Cu=1:2:3) to obtain mixed powder, wherein the primary particle size of Y2O3, BaO and CuO is 100-300 nm, and the purity is greater than 99.9 wt%; (2) performing cold pressing on the mixed powder with a four-column hydraulic press, wherein the cold pressing pressure is 200-300 MPa; (3) placing the mixture in an oxygen normal-pressure sintering furnace, sintering the mixture at 800-950 DEG C, cooling the mixture after sintering is completed, taking out the mixture at normal pressure, and crushing the mixture into powder with 30-500 meshes; (4) performing cold pressing on the powder with the four-column hydraulic press to form a blank, wherein the cold pressing pressure is 30-50 MPa; (5) performing cold isostatic pressing on the blank, wherein the pressure is 200-300 MPa; and (6) sintering the blank in a furnace. The yttrium barium copper oxide target manufactured by the method has small grain size and high density.

Owner:苏州晶纯新材料有限公司

Preparation method of MgB2-NbTi composite superconducting wire

ActiveCN103606423AIncrease the critical current densityImprove current carrying capacitySuperconductors/hyperconductorsSuperconductor devicesSingle-coreSizing

The invention provides a preparation method of a MgB2-NbTi composite superconducting wire. The preparation method comprises the following steps: A, preparing a MgB2 single-core wire; B, sizing, cutting and acid pickling a NbTi single-core wire and the MgB2 single-core wire; C, assembling the NbTi single-core wire, the MgB2 single-core wire and a Cu pipe to obtain a MgB2-NbTi tube composite body; D, adopting a machining route combining drawing and hole-pattern rolling, and carrying out the appropriate annealing treatment, thereby obtaining the MgB2-NbTi composite wire; E, carrying out the phase treatment and time-efficiency treatment, thereby obtaining the MgB2-NbTi composite superconducting wire. The MgB2 single-core wire is assembled with the NbTi single-core wire, a machining technology combining the drawing and hole-pattern rolling and a heat treatment technology are adopted, the MgB2-NbTi superconducting wire with excellent superconducting performance is finally prepared, and the preparation method is promising in application prospect.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

Method for polymer-assistant depositing high temperature superconducting coating conductor superconducting layer

InactiveCN101271956AReduce formationImprove current carrying capacitySuperconductor device manufacture/treatmentFurnace temperatureElectrical conductor

A macromolecule-assisted method of deposition for a superconducting layer of a high-temperature superconductivity coating electrical conductor has the preparation method as follows: a. dissolving rare-earth acetate, barium acetate and cupric acetate in monoprop with a stoichiometric proportion that rare-earth: barium: cupric equals to 1:2:3 to acquire a precursor solution; b. adding PVB, PEG or PVP into the precursor solution with the weight ratio of 2-8:100 to acquire a coating colloid; c. coating the coating colloid on a substrate and heating for drying; d. placing the substrate in a tubular furnace to carry out decomposition heat treatment; e. rapidly heating up the furnace temperature to 800-900 DEG C under moist argon atmosphere for 5-15min, then lowering the temperature to 750-780 DEG C for 1-3 hours, and then lowering the temperature to 350-500 DEG C under the argon atmosphere for low temperature oxygen-permeation annealing treatment, and the superconducting layer is acquired by cooling. The method has the advantages of low cost and simple technique, which is applied to industrialized production; the superconducting layer prepared is characterized by high biaxial texture, flat and dense surface and good superconductivity.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com