Patents

Literature

103 results about "Spontaneous nucleation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

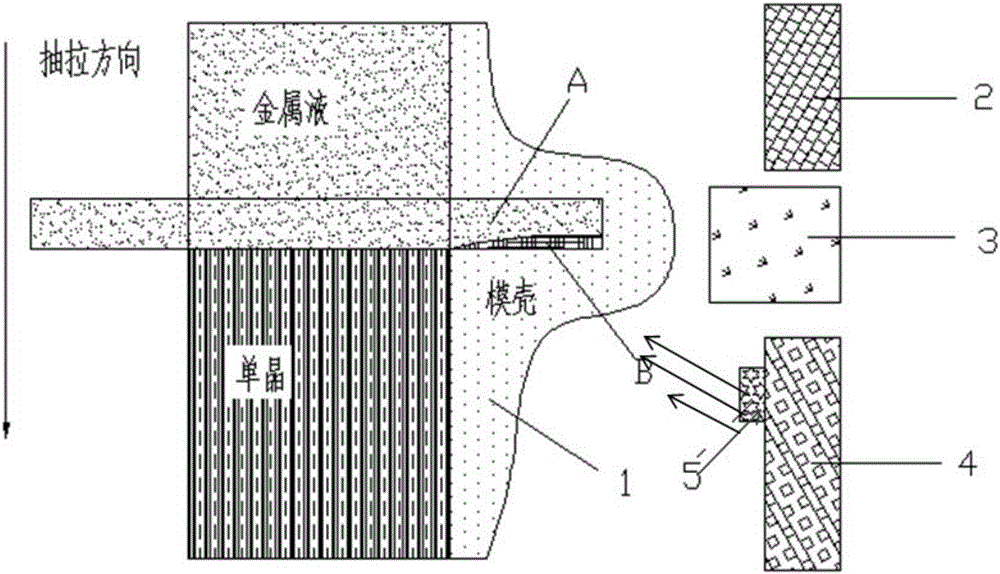

Method for preventing monocrystal blades from having mixed crystal defects

InactiveCN102166643APromote growthAvoid spontaneous nucleationPolycrystalline material growthFrom frozen solutionsFiberSpontaneous nucleation

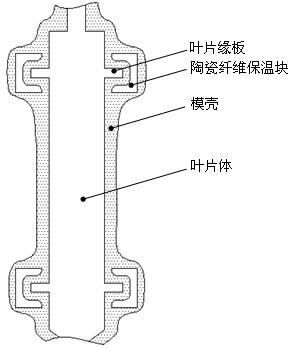

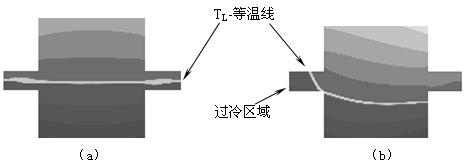

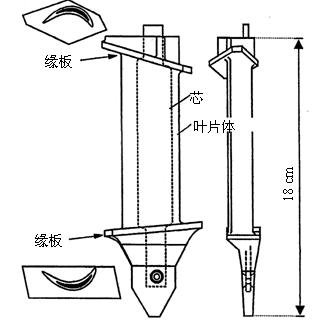

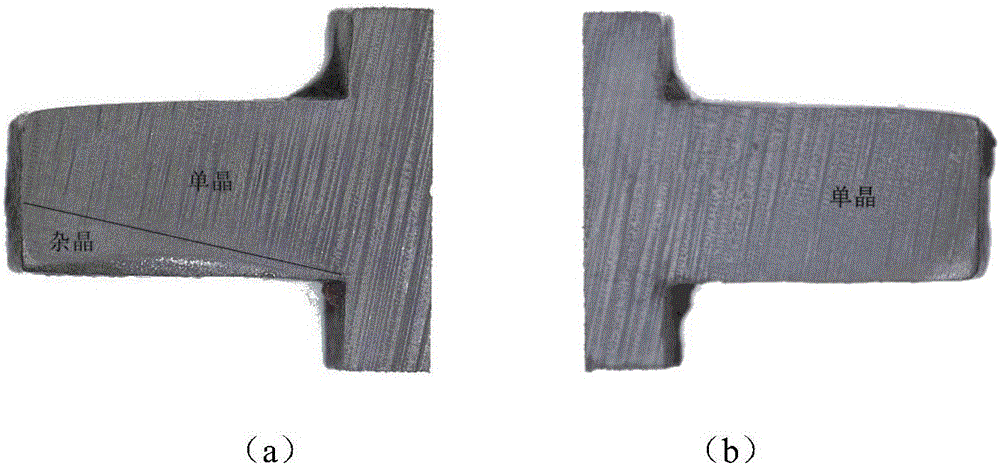

The invention relates to the field of directional solidification of alloys, particularly relates to a method for preventing monocrystal blades from having mixed crystal defects. The method is characterized in that in the process of preparing an investment casting mould case for monocrystal blade production, a ceramic fiber insulation block is implanted into the position on a mould case at a blademargin plate at which is easy to have mixed crystal defects, the ceramic fiber insulation block is prefabricated into a U-shaped block according to the shape of the mould case at the blade margin plate, and a U-shaped cavity of the ceramic fiber insulation block contains all mould cases at the blade margin plate. The method disclosed by the invention has the advantages that through using the characteristics that the thermal conductivity of the ceramic fiber insulation block is extremely low, the liquidus temperature TL-isotherm form (see Figure 2) generated when a solidification front reachesthe monocrystal blade margin plate in the process of alloy solidification at the monocrystal blade margin plate is controlled reasonably, so that when the margin plate is close to a directional solidification thermal baffle plate area, the heats are mainly outputted by a monocrystal blade body, and the spontaneous nucleation at the margin plate is avoided, thereby ensuring the smooth growth of monocrystals.

Owner:江苏中欧材料研究院有限公司 +1

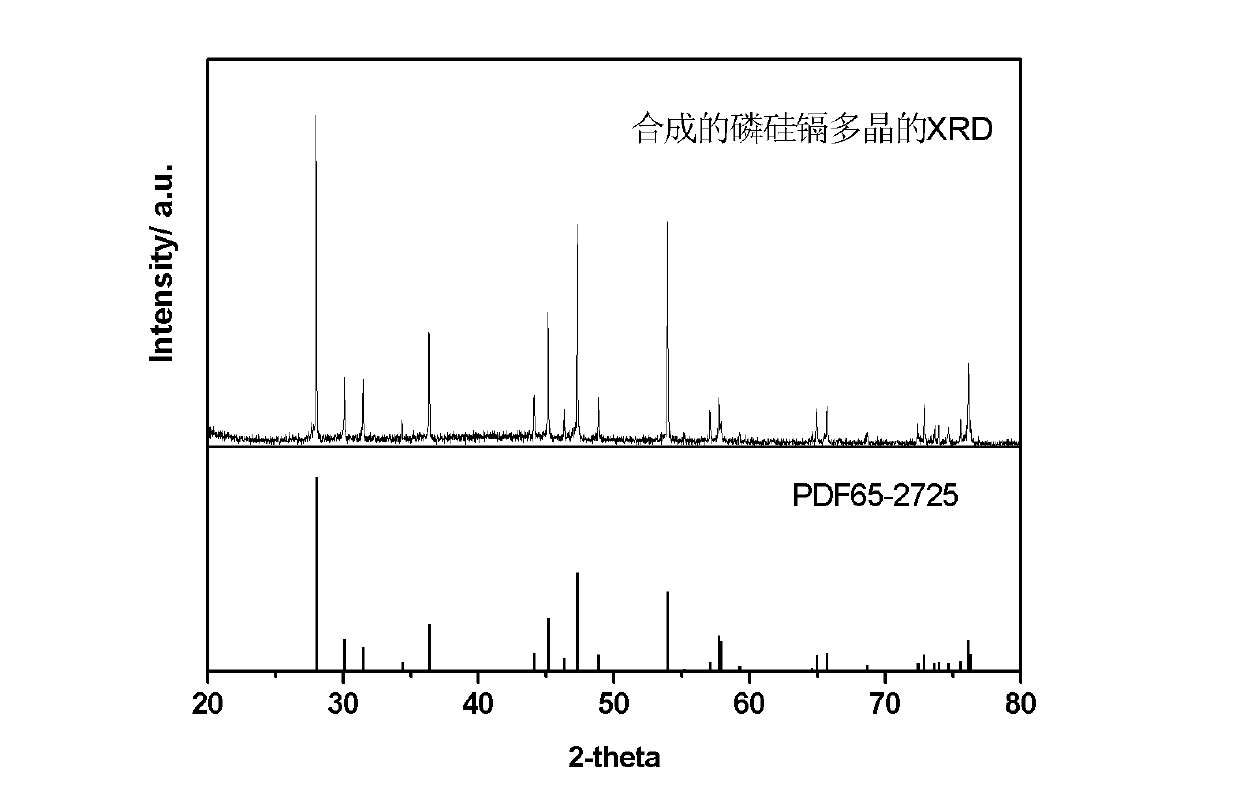

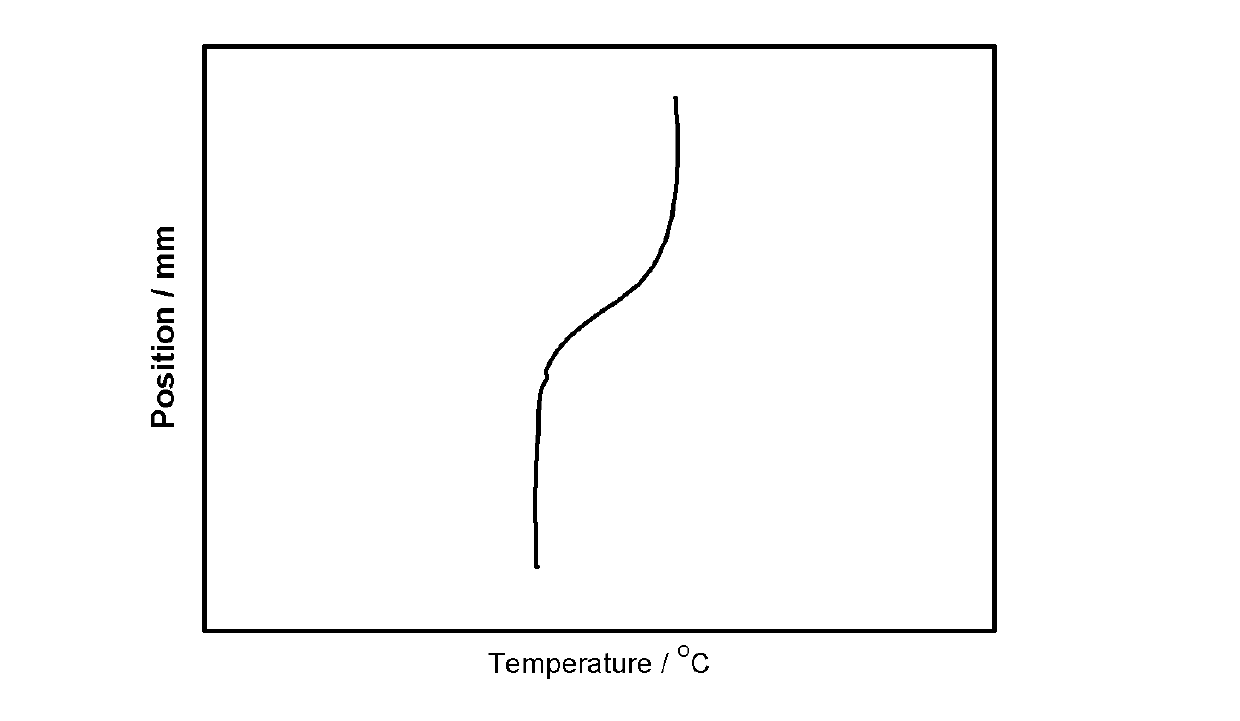

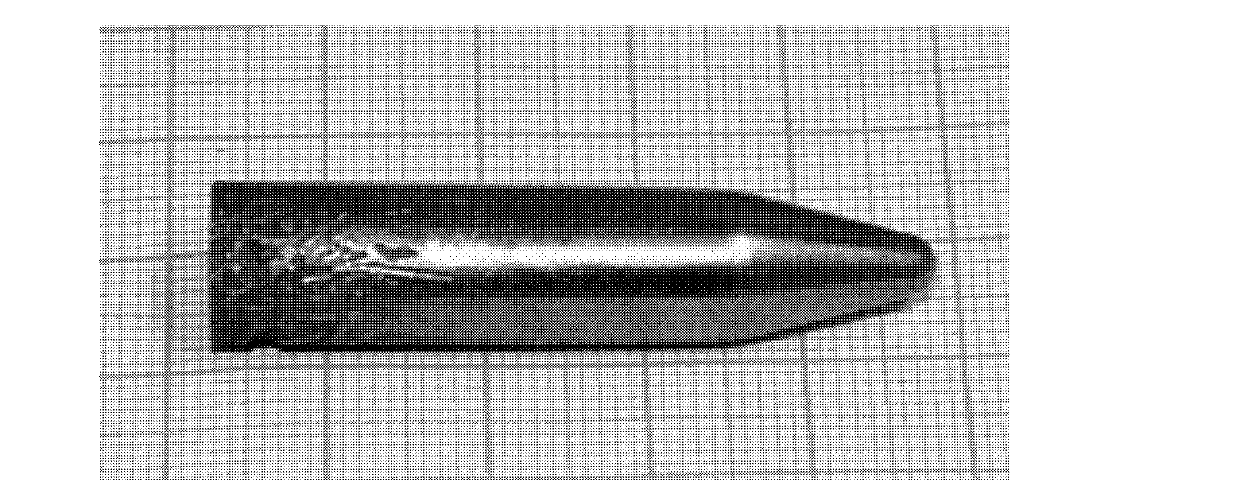

Horizontal growth device and growth method of phosphorus silicon cadmium mono-crystal

ActiveCN104047047AConducive to spontaneous nucleationLow costPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationCrystal orientation

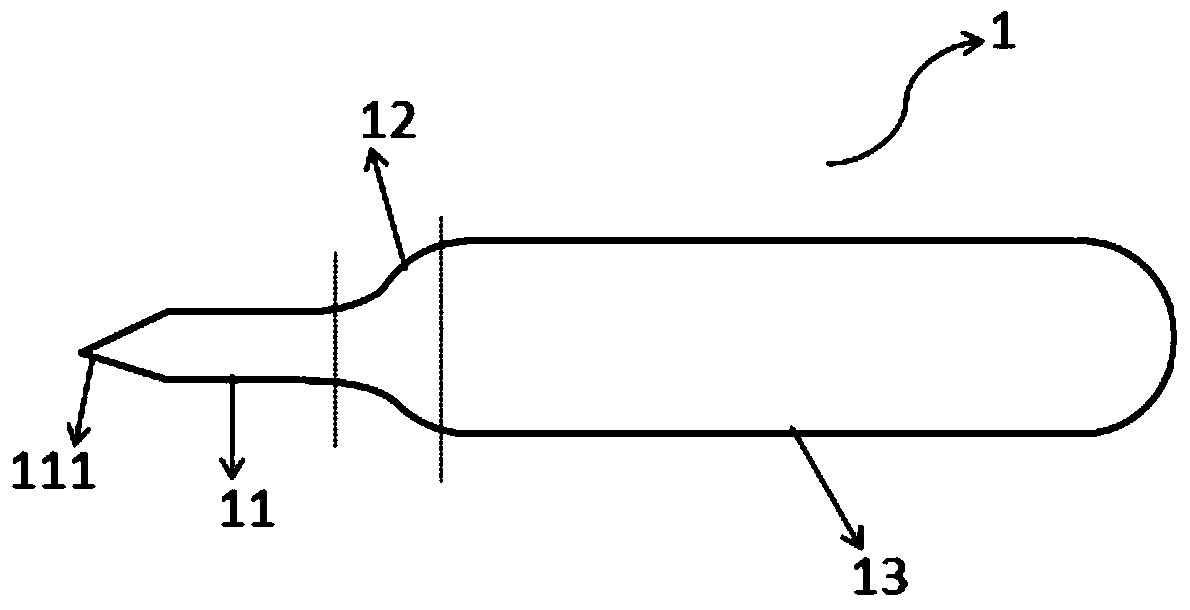

The invention discloses a horizontal growth device and growth method of a phosphorus silicon cadmium mono-crystal, belonging to the technical field of phosphorus silicon cadmium mono-crystal preparation. The device comprises an outer layer quartz tube, an inner layer quartz tube sleeved in the outer layer quartz tube, and a PBN boat-shaped crucible sleeved in the inner layer quartz tube, wherein the PBN boat-shaped crucible comprises a crystal nucleus growth section, a transition section and a mono-crystal growth section which are connected with one another in sequence; a first end part of the crystal nucleus growth section is set to be spire-shaped so as to improve the uniformity of crystal orientation in spontaneous nucleation. By virtue of the design of a double-layer quartz tube, inert gas is introduced between the quartz tubes, so that the problems of tube explosion extremely easily generated in the crystal growth process can be solved, and the stability of a thermal field and the durability of the growth device can be improved. The method is used for preparing the phosphorus silicon cadmium mono-crystal on a horizontal crystal growth furnace with the growth device by using a horizontal gradient freezing method so as to ensure a more stable crystallization process and reduce the defects of parasitic nucleation; the method is beneficial for obtaining a CSP mono-crystal with good mono-crystal performance and complete crystal lattice, and is simple in operation, easy in control and low in cost.

Owner:北京雷生强式科技有限责任公司 +1

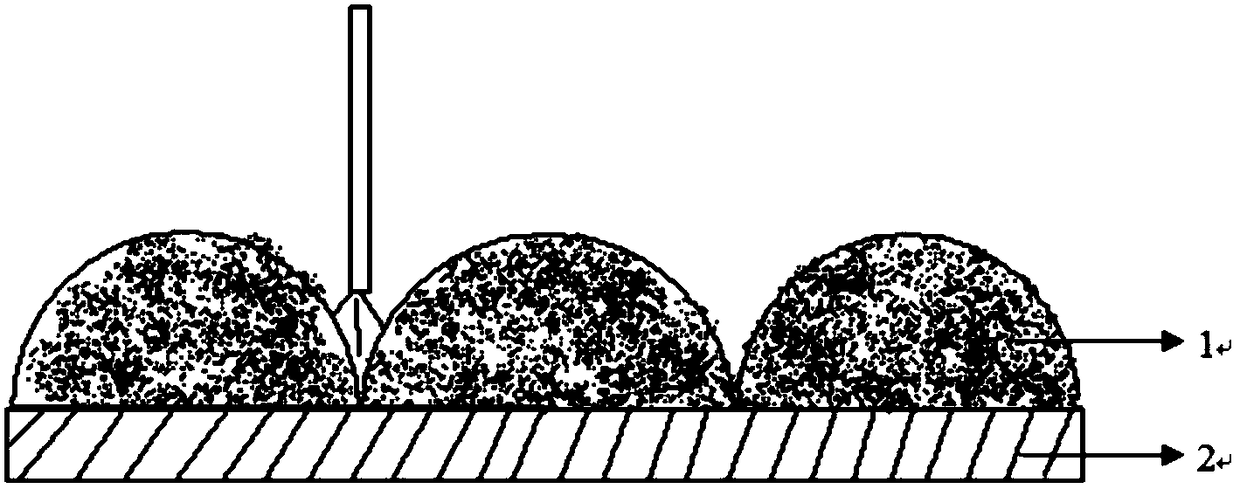

Metal-ceramic alloy powder block for build-up welding

ActiveCN109112381AImprove craftsmanshipEasy to use and flexibleTransportation and packagingMetal-working apparatusBorideCrack resistance

The invention provides a ternary boride metal-ceramic Mo2FeB2 alloy powder block for build-up welding. The ternary boride metal-ceramic Mo2FeB2 alloy powder block is prepared from the following raw materials in parts by weight: 20-38 parts of iron boron, 32-50 parts of molybdenum powder, 7-24 parts of iron powder, 2-4 parts of nano-titanium carbide powder and 2-4 parts of yttrium oxide powder. When the iron boron, the molybdenum powder and the iron powder are used as raw materials for carrying out a metallurgical reaction so as to synthesize Mo2FeB2, an appropriate amount of the nano-titaniumcarbide powder is added; in a process of welding metallurgy, since the melting point of the nano-titanium carbide powder is as high as 3140 DEG C, the nano-titanium carbide powder can be used as a dispersed Mo2FeB2 non-spontaneous nucleation core in liquid metal, and the formed ternary boride Mo2FeB2 is enabled to be distributed in a dispersed way; therefore, the build-up welding metal has excellent high temperature hardness, wear resistance as well as good toughness and crack resistance. The steps are simple, the operation is convenient, and the practicality is high.

Owner:SHANDONG UNIV

Polycrystalline synthesis method and single-crystal growth method of gallium selenide

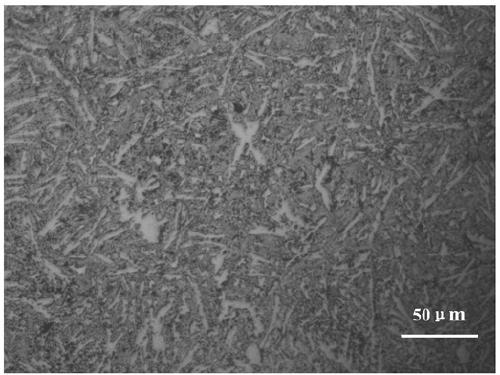

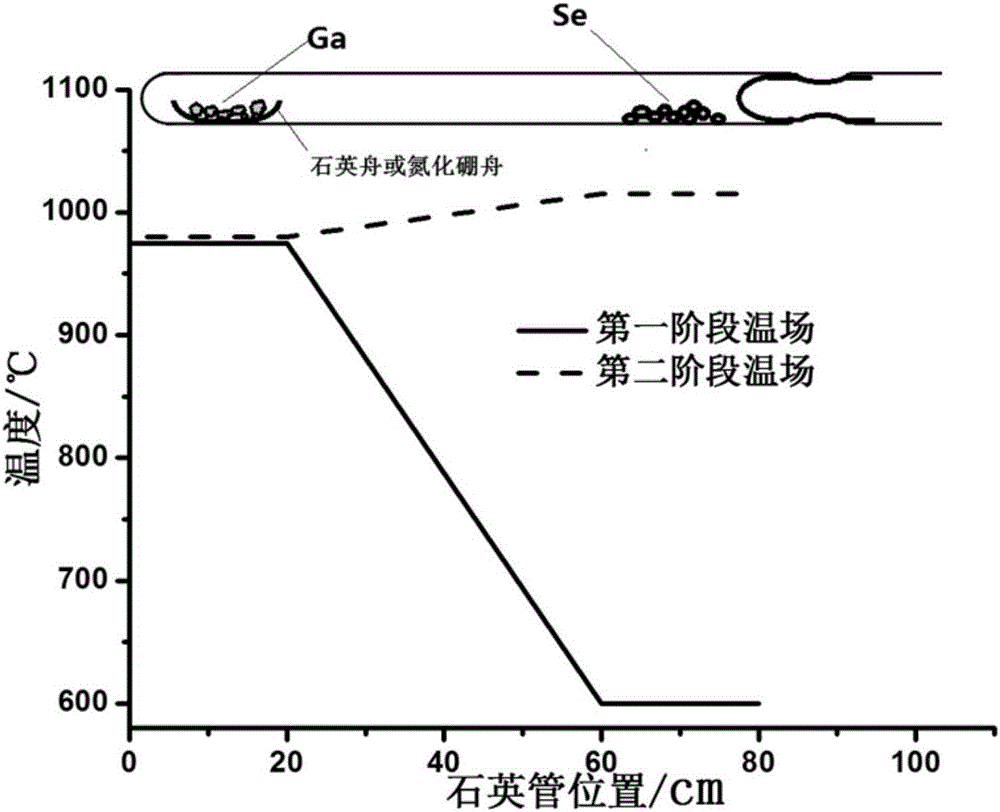

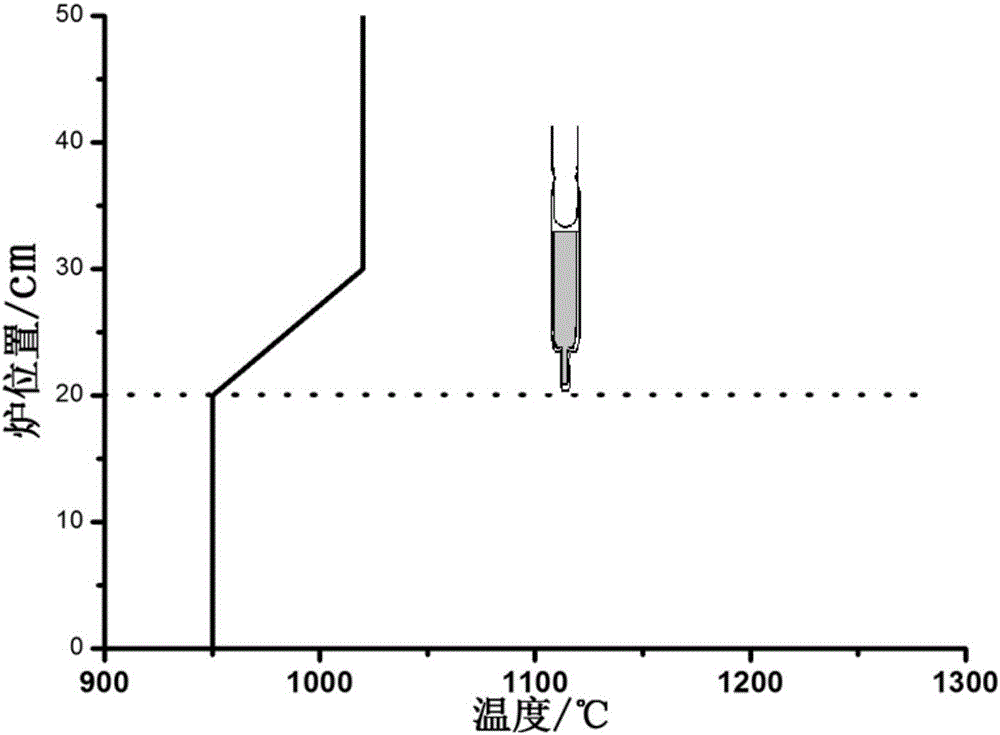

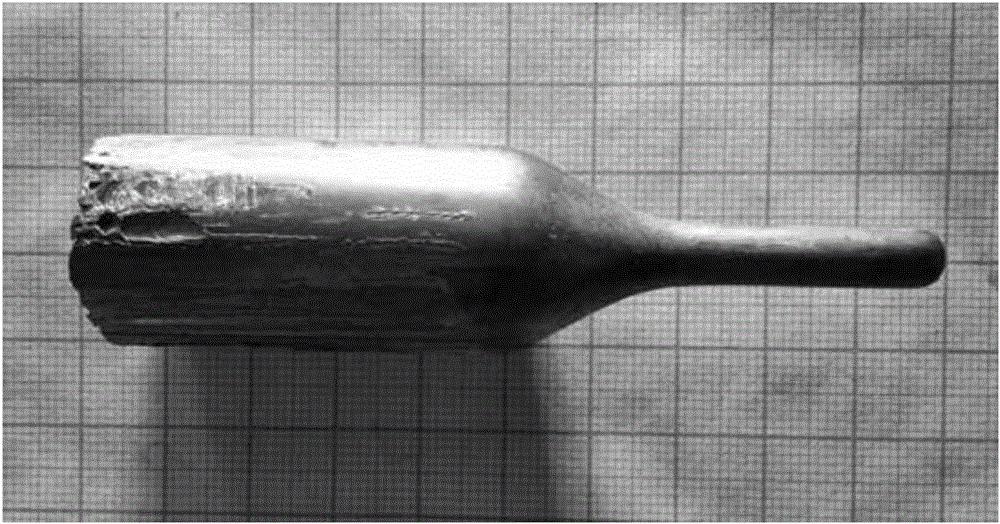

InactiveCN106149046ARaise the average scaleIncrease profitPolycrystalline material growthFrom frozen solutionsSynthesis methodsBoron nitride

The invention provides a polycrystalline synthesis method and a single-crystal growth method of gallium selenide and relates to polycrystalline synthesis and single-crystal growth methods of mid-infrared and far-infrared non-linear materials, aiming at solving the technical problems of existing GaSe polycrystalline synthesis that the stoichiometric deviation is great and the yield is low, an invalid crystal nucleus is prone to form in a spontaneous nucleation phase and a single-crystal growth direction is uncertain. Polycrystalline synthesis comprises the following steps: putting monomer Ga into a small boat and putting the small boat at one end of a quartz tube; putting Se at the other end of the quartz tube; after vacuumizing, carrying out heat sealing; putting the quartz tube into a horizontal double-temperature-region pipe type resistance furnace and synthesizing to obtain a GaSe poly-crystal, wherein the stoichiometric ratio is 1 to (1 to 1.05) and the yield is more than 97 percent. Single-crystal growth comprises the following steps: adding the GaSe poly-crystal into a PBN (Pyrolytic Boron Nitride) crucible; then vertically putting the PBN crucible into the quartz tube; after vacuumizing, carrying out heat sealing; putting the quartz tube into a vertical double-temperature-region pipe type resistance furnace; after the single-crystal growth is finished, obtaining a GaSe single-crystal. The gallium selenide can be used as the mid-infrared and far-infrared laser materials for realizing output of 8Mum to 10Mum laser.

Owner:HARBIN INST OF TECH

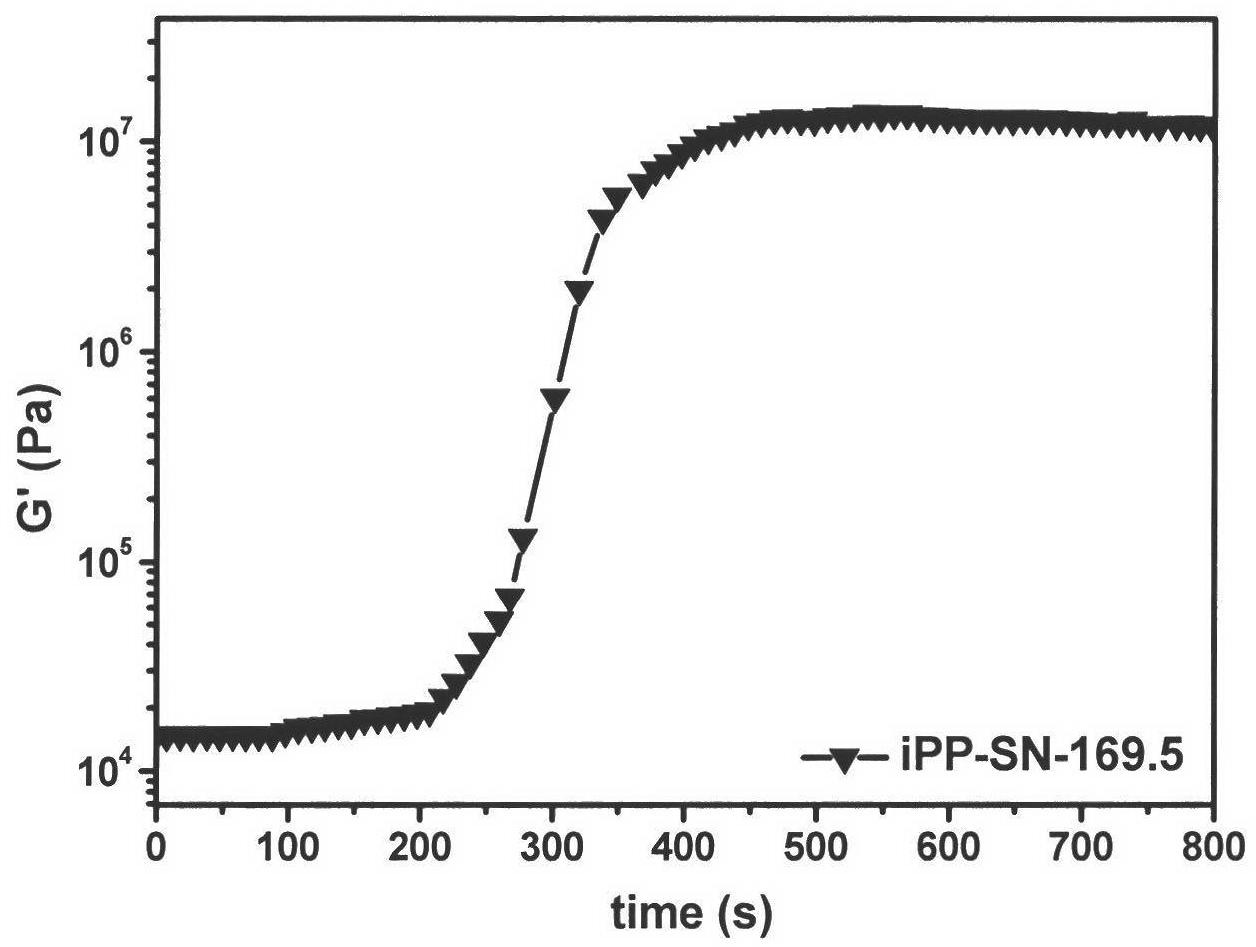

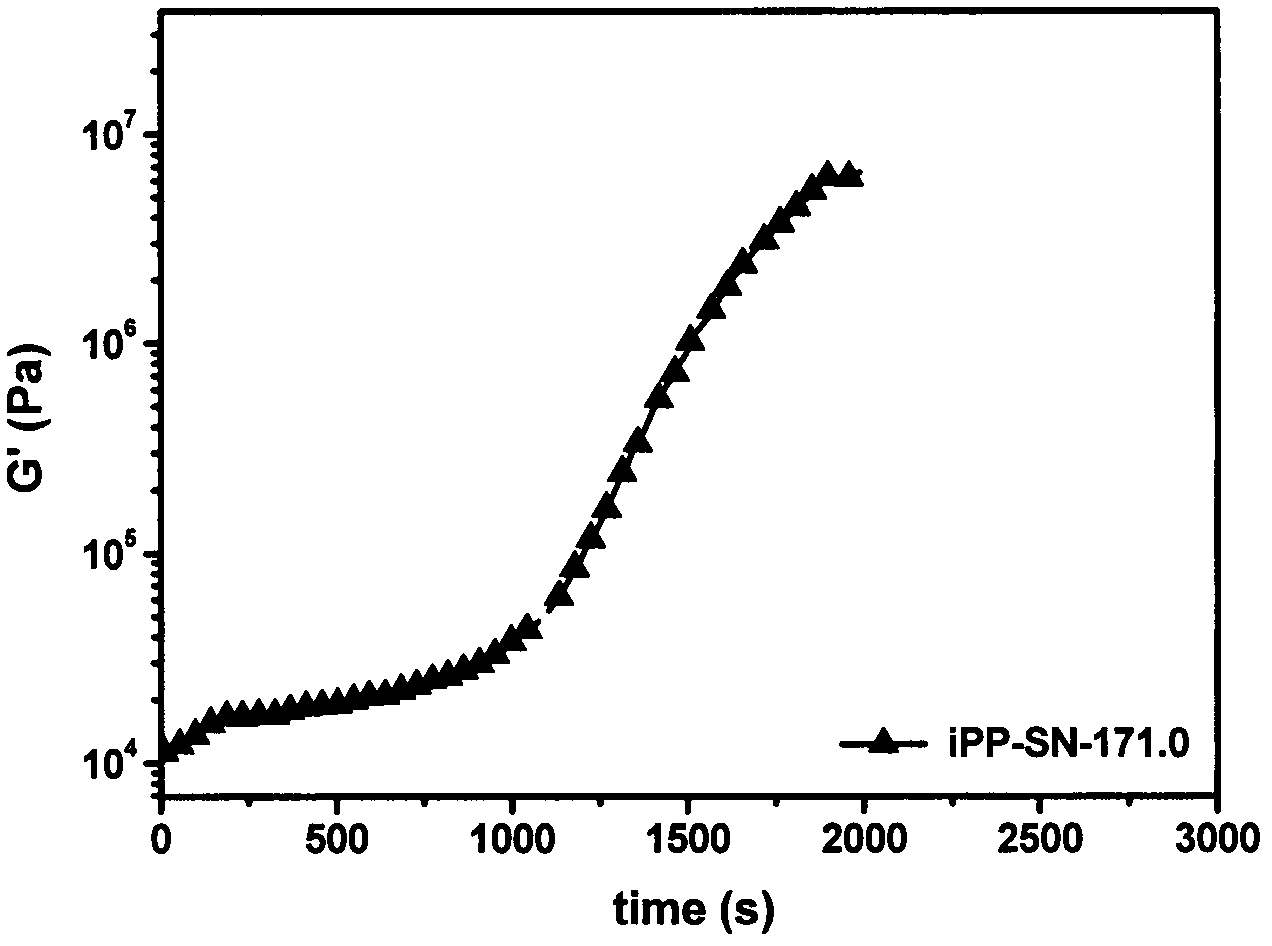

Method of regulating polypropylene crystallization behavior and crystal structure

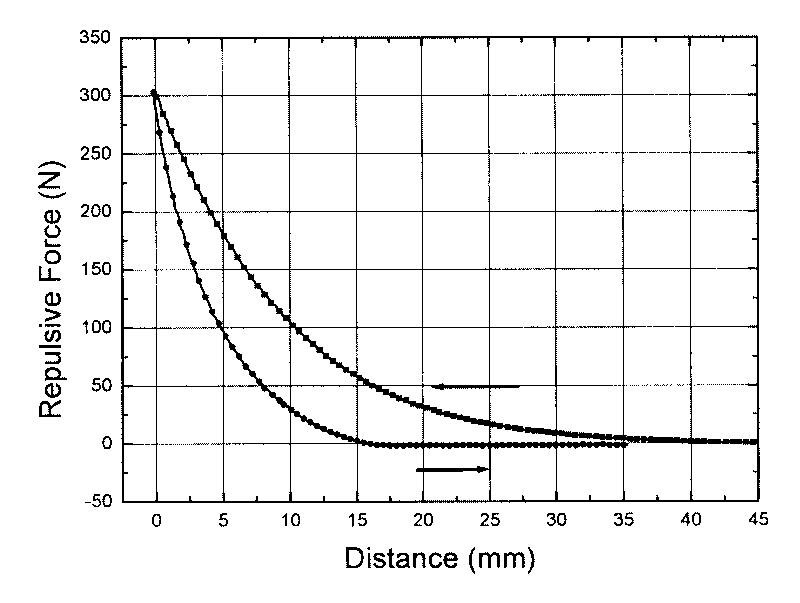

ActiveCN102408627ASimple and fast operationHigh control precisionFlow propertiesAuxillary controllers with auxillary heating devicesTemperature controlSpontaneous nucleation

The invention belongs to the technical field of chemical control and detection, and particularly relates to a method of regulating isotactic polypropylene (iPP) crystallization behavior and crystal structure. The invention is characterized in that a parallel-plate rheometer is used as a tool, and the crystal structure of polypropylene is regulated by the spontaneous nucleation characteristic of semi-crystalline polymer. The spontaneous nucleation temperature is regulated by precise temperature control of the rheometer so as to obtain isotactic polypropylene with various crystal structures. The method can not only prepare samples for performance tests, but also monitor the crystallization process of isotactic polypropylene, and realize on-line observation of the spontaneous nucleation effect. The method has the advantages of simple operations, precise regulation, and the like, and has wide application prospects in the fields of fine chemical industry and the like.

Owner:FUDAN UNIV

Method for preparing REBa2Cu3Ox (REBCO) high-temperature superconducting block material

InactiveCN102584250AControl supersaturationControl growth rateSpontaneous nucleationHigh temperature superconducting

The invention relates to a method for preparing a REBa2Cu3Ox (REBCO) high-temperature superconducting block material, in particular to a melt texture growth (MTG) method for the REBCO high-temperature superconducting block material. The MTG method for the REBCO high-temperature superconducting block material comprises the following steps of: a) mixing raw materials; b) grinding and calcining to obtain a superconducting material rough blank; c) tabletting; d) firing; and e) cooling to obtain the REBCO high-temperature superconducting block material, namely e1) cooling to buffer temperature, and preserving heat, e2) cooling to growth temperature, and preserving heat, and e3) quenching. By the method, the technical problem that the REBCO high-temperature superconducting block material fails to grow because spontaneous nucleation is generated when temperature is reduced from the maximum temperature to the growth temperature in the conventional MTG method is solved.

Owner:SHANGHAI JIAO TONG UNIV

Method for preventing mixed crystal defect of single crystal blade based on laser heating technology

ActiveCN106563773AAvoid miscellaneous crystalsPolycrystalline material growthFoundry mouldsHigh concentrationSpontaneous nucleation

The invention relates to the field of alloy directional solidification, in particular to a method for preventing a mixed crystal defect of a single crystal blade based on the laser heating technology. When a mold shell for single crystal blade production is prepared, on a back layer, slurry coating is independently carried out on a blade margin plate through slurry containing titanium diboride, and other mold shell preparation processes are not changed. In the directional solidification procedure of the single crystal blade, the position, where the mixed crystal defect is likely to occur and the margin plate is located, of the mold shell of the single crystal blade is subjected to laser heating, and by means of the effective absorption of the mold shell for laser energy, the margin plate of the single crystal blade is in a local heat preservation state. By means of the characteristics of high concentration and fast heating of the laser heating energy, the temperature of the margin plate is reasonably controlled when alloy of the margin plate of the single crystal blade is solidified, the situation that the margin plate is in a local supercooling state when close to a directional solidification thermal baffle region, then spontaneous nucleation occurs and the mixed crystal defect is caused is avoided, and thus smooth growth of single crystal is guaranteed.

Owner:JIANGSU UNIV

Spontaneous nucleation growth method for thallium bromide single-crystal

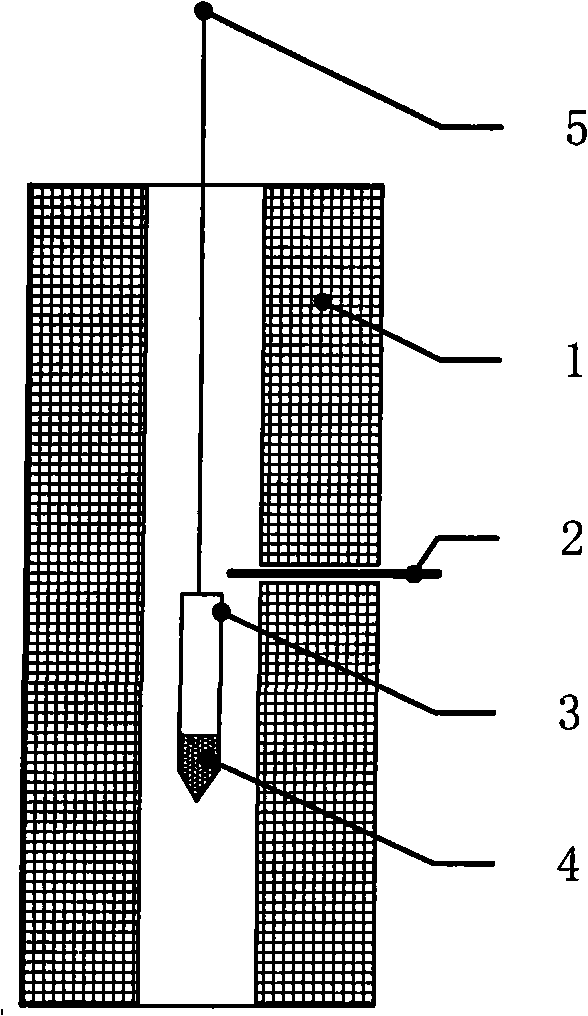

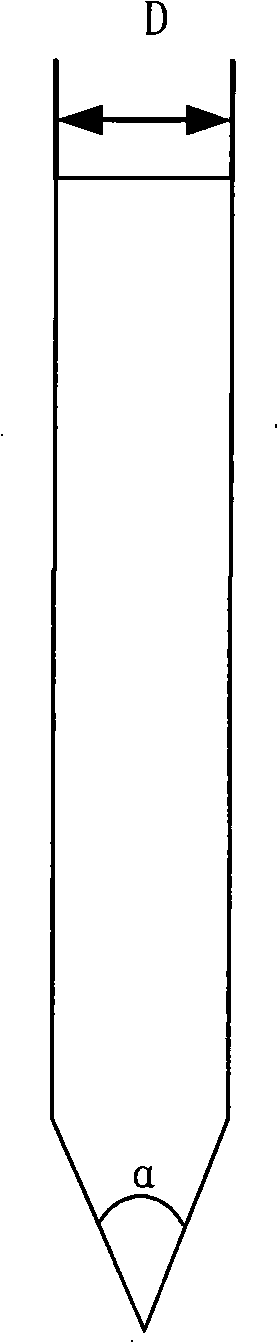

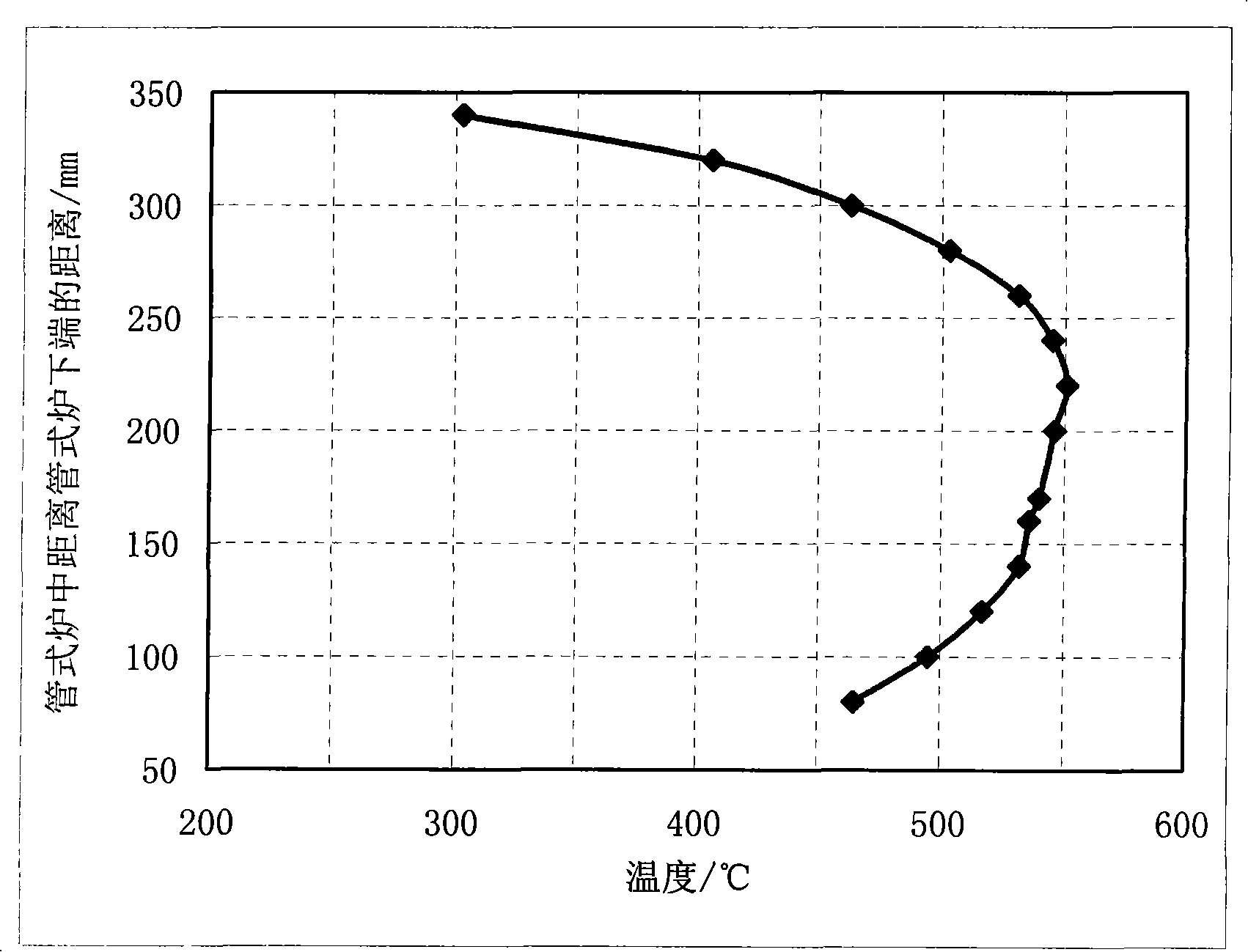

InactiveCN101260562ASimple processLow costPolycrystalline material growthFrom frozen solutionsVertical tubeSpontaneous nucleation

The invention provides a method for growing thallium bromide monocrystal by spontaneous nucleation, comprising the following steps of: 1) filling a thallium bromide material into a cylindrical ampoule with diameter of 8 to 15mm, vacuumizing, sealing, and processing one end of the ampoule into a cone with the cone angle between 15 and 45 degrees; 2) placing the ampoule into a vertical tube furnace with the conical end towards the bottom of the furnace, heating the vertical tube furnace to enable the temperature of the thallium bromide material in the conical tip not to be lower than the melting point of thallium bromide, raising the temperature from the conical tip upward to the inside of a top area of the thallium bromide material with the temperature gradient between 1.0 and 1.5 DEG C / mm, and then, insulating; 3) reducing the temperature of the tube furnace to between 450 and 460 DEG C at the speed between 1 and 5 DEG C / h; and 4) cooling the ampoule to room temperature along with the furnace. Because a heater and the ampoule are not required to be moved, the invention saves the complicated mechanical transmission device, simplifies the technology and reduces cost. The ampoule and the heater are both fixed, the temperature field is stable, heat inside the crystal and molten mass is uniformly distributed, a convex growth interface can be easily acquired, and the thallium bromide with good integrity and considerable size can be grown.

Owner:HUAZHONG UNIV OF SCI & TECH

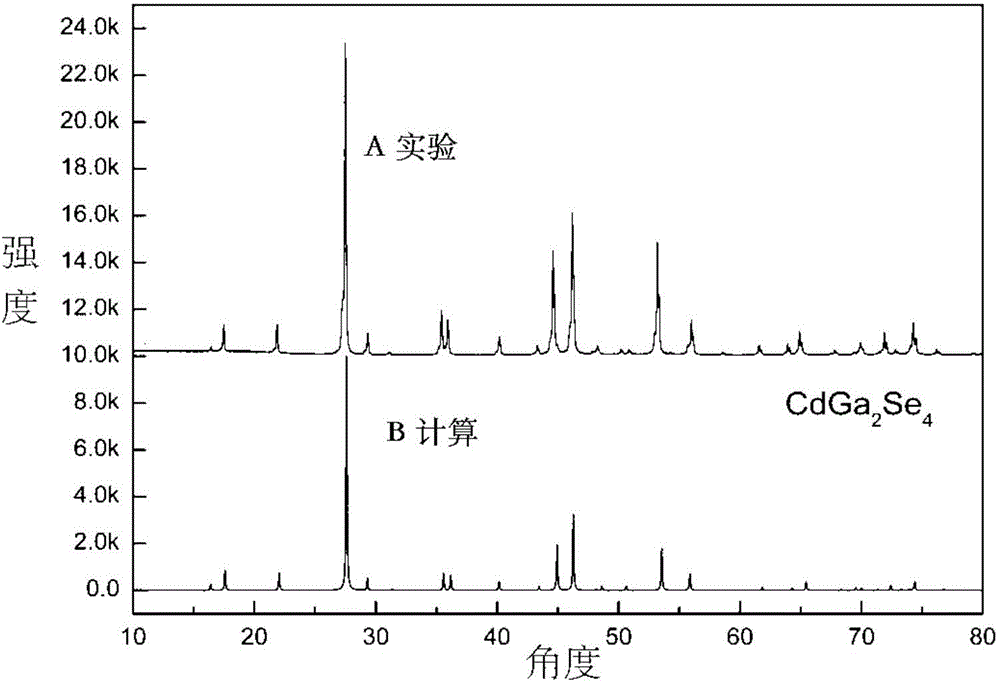

Long wave infrared nonlinear CdGa2Se4 crystal as well as growth method and use of crystal

ActiveCN104695022AImprove mechanical propertiesStable chemical propertiesPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationLong wave infrared

The invention relates to a long wave infrared nonlinear CdGa2Se4 crystal as well as a growth method and the use of the crystal. The CdGa2Se4 polycrystal material is synthesized by virtue of a high-temperature solid-phase reaction; the long wave infrared nonlinear CdGa2Se4 crystal is grown by use of a spontaneous nucleation Bridgman-Stockbarger method or an oriented seed crystal assisted Bridgman-Stockbarger method; the frequency doubling effect of the obtained nonlinear optical CdGa2Se4 crystal powder is about three times of that of AgGaS2, and the transparent waveband of the infrared region of the CdGa2Se4 crystal powder is capable of reaching long wave infrared 21 microns; besides, the CdGa2Se4 crystal powder is good in mechanical properties, stable in chemical properties, not prone to deliquescence, and suitable for orientation, cutting and polishing. The long wave infrared nonlinear CdGa2Se4 crystal is applicable to manufacturing infrared nonlinear optical devices.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

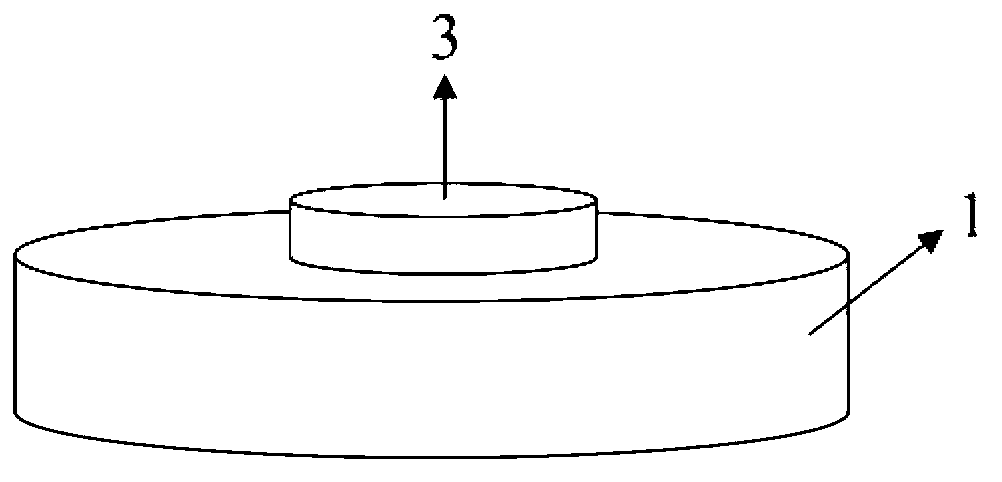

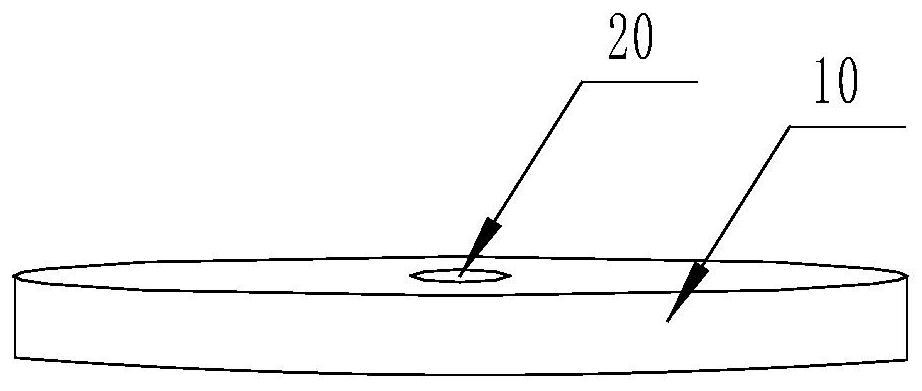

Seed crystal for aluminium nitride (ALN) crystal growth

ActiveCN102995124AAvoid crackingQuality assurancePolycrystalline material growthFrom condensed vaporsAfter treatmentSpontaneous nucleation

A seed crystal for aluminium nitride (ALN) crystal growth relates to a material for ALN crystal growth. A problem that spontaneous nucleation adopted at current is difficult to obtain a big-size ALN crystal and an impurity content of the ALN crystal grown by an alloplasm seed crystal method is high is solved. The seed crystal for ALN crystal growth is an ALN ceramic wafer after treatment of annealing process. The seed crystal for ALN crystal growth further can be an ALN ceramic wafer after treatment of annealing process and polishing in sequence, or an ALN thin film is pasted on the surface of a polished seed crystal to obtain the seed crystal for ALN crystal growth. The ALN crystal grown by using the seed crystal for ALN crystal growth is big in size and fewer in impurity content. The seed crystal is mainly applied to growth of the ALN crystal in a semiconductor device.

Owner:HARBIN INST OF TECH

Seeding mold for growing silicon crystals by using orientated solidification method and crystal growing method

InactiveCN102146580AFix placement issuesEliminate dislocationsPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationDislocation

Owner:GREENERGY CRYSTAL TECH

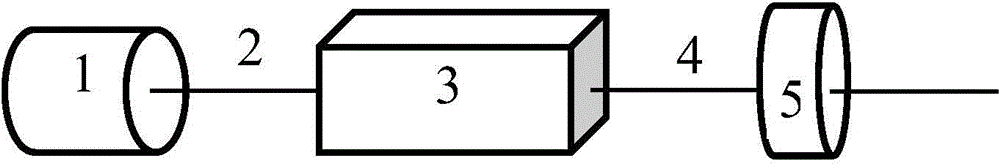

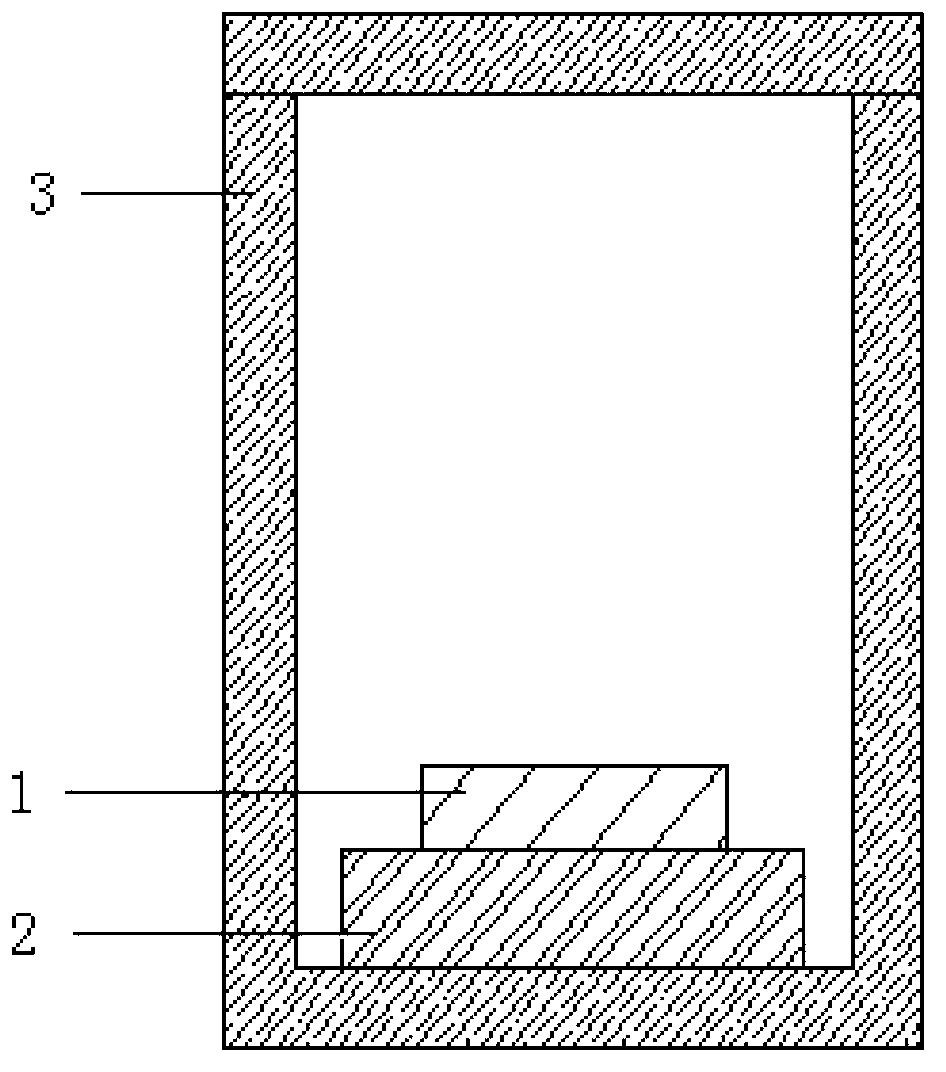

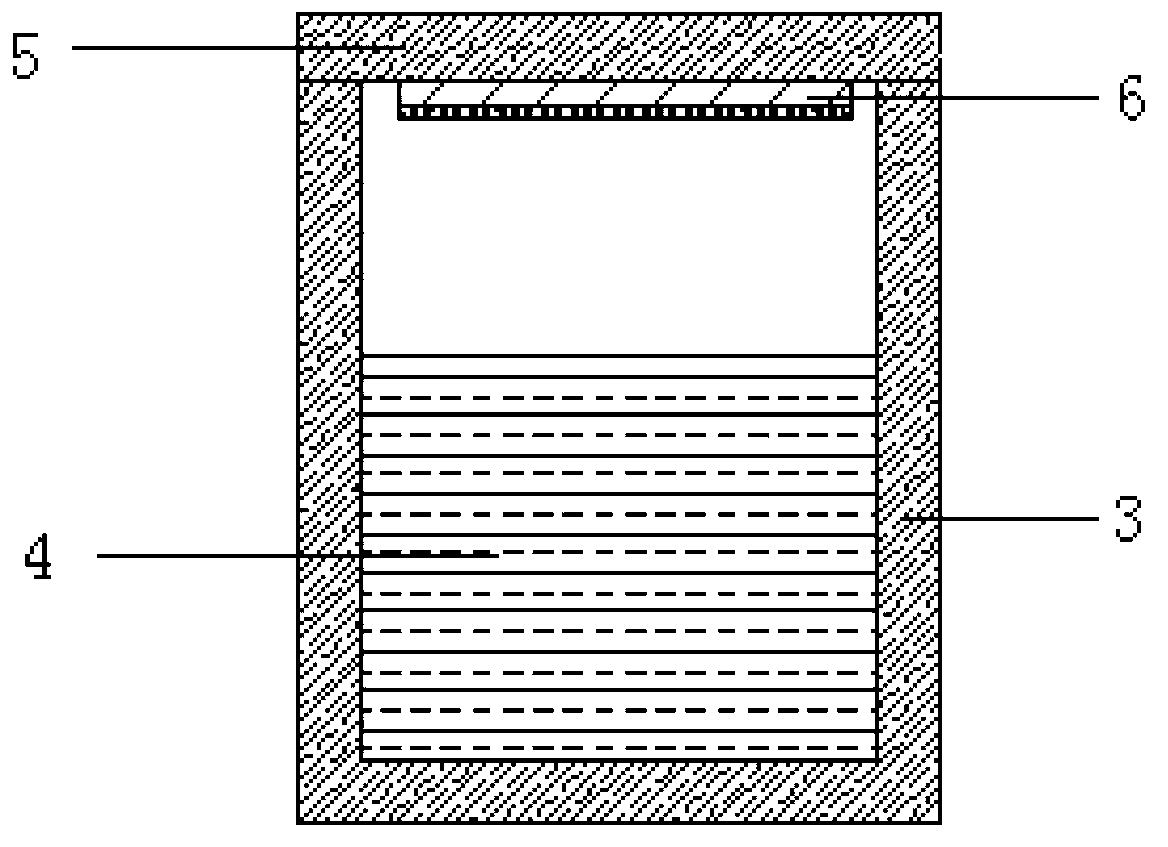

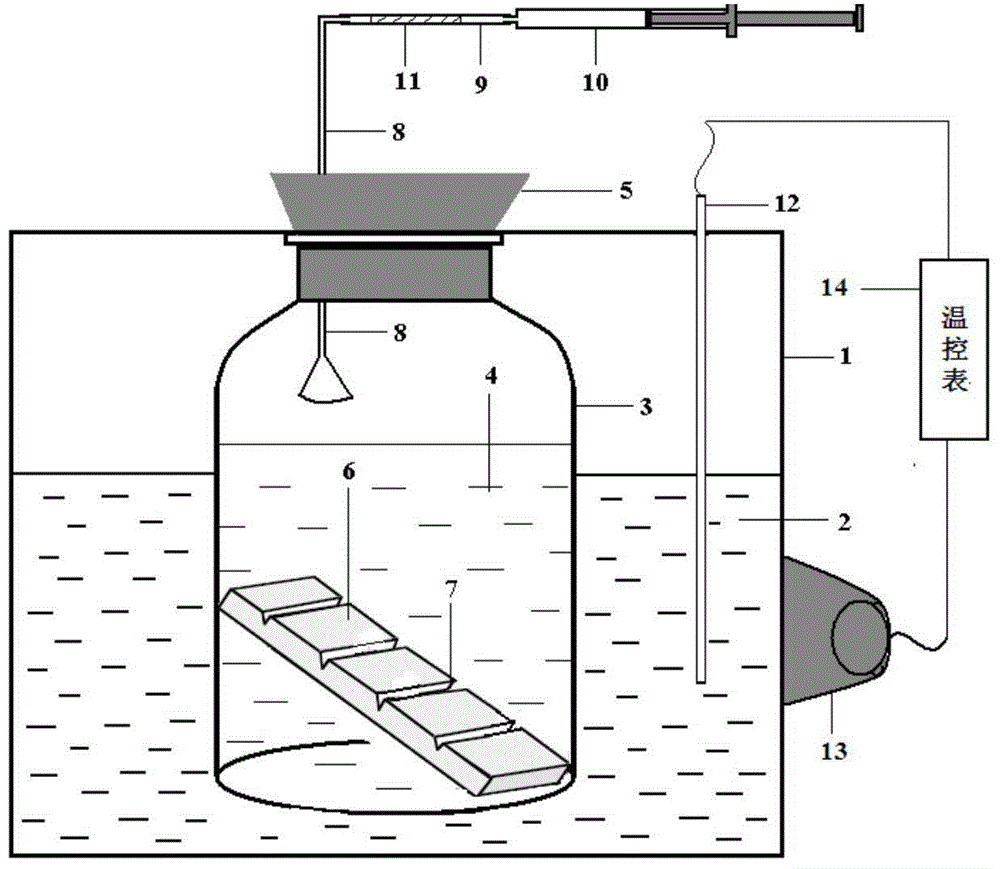

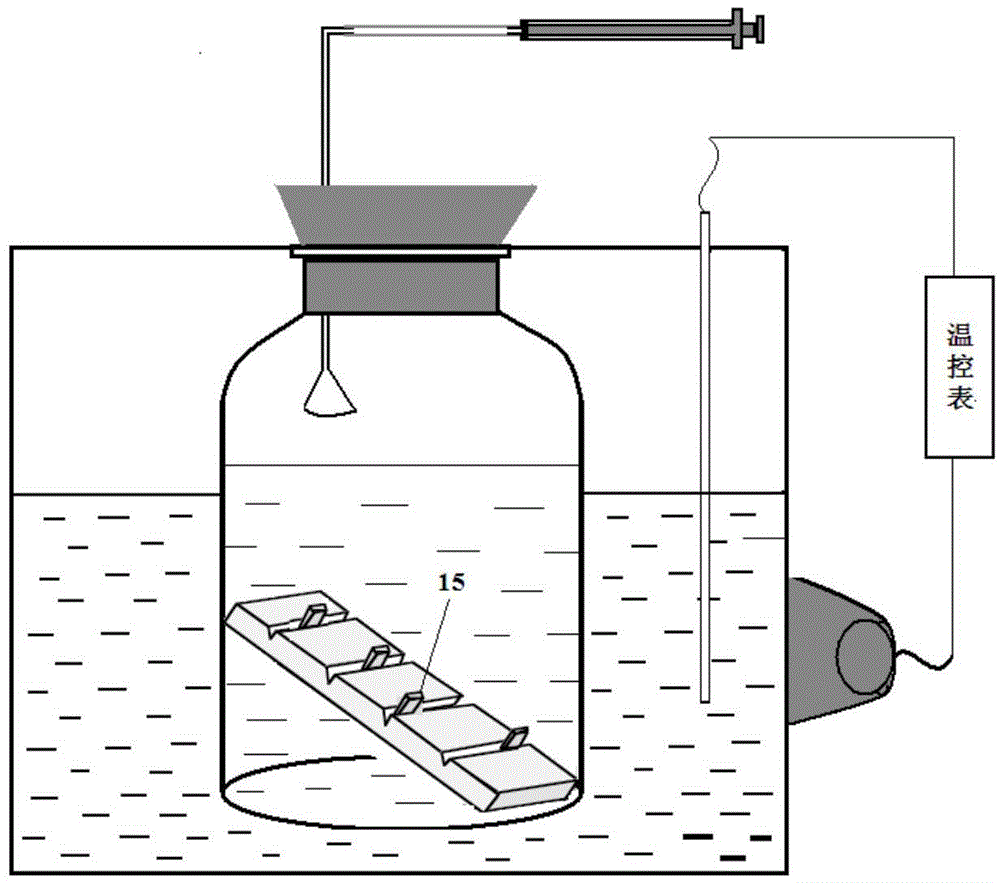

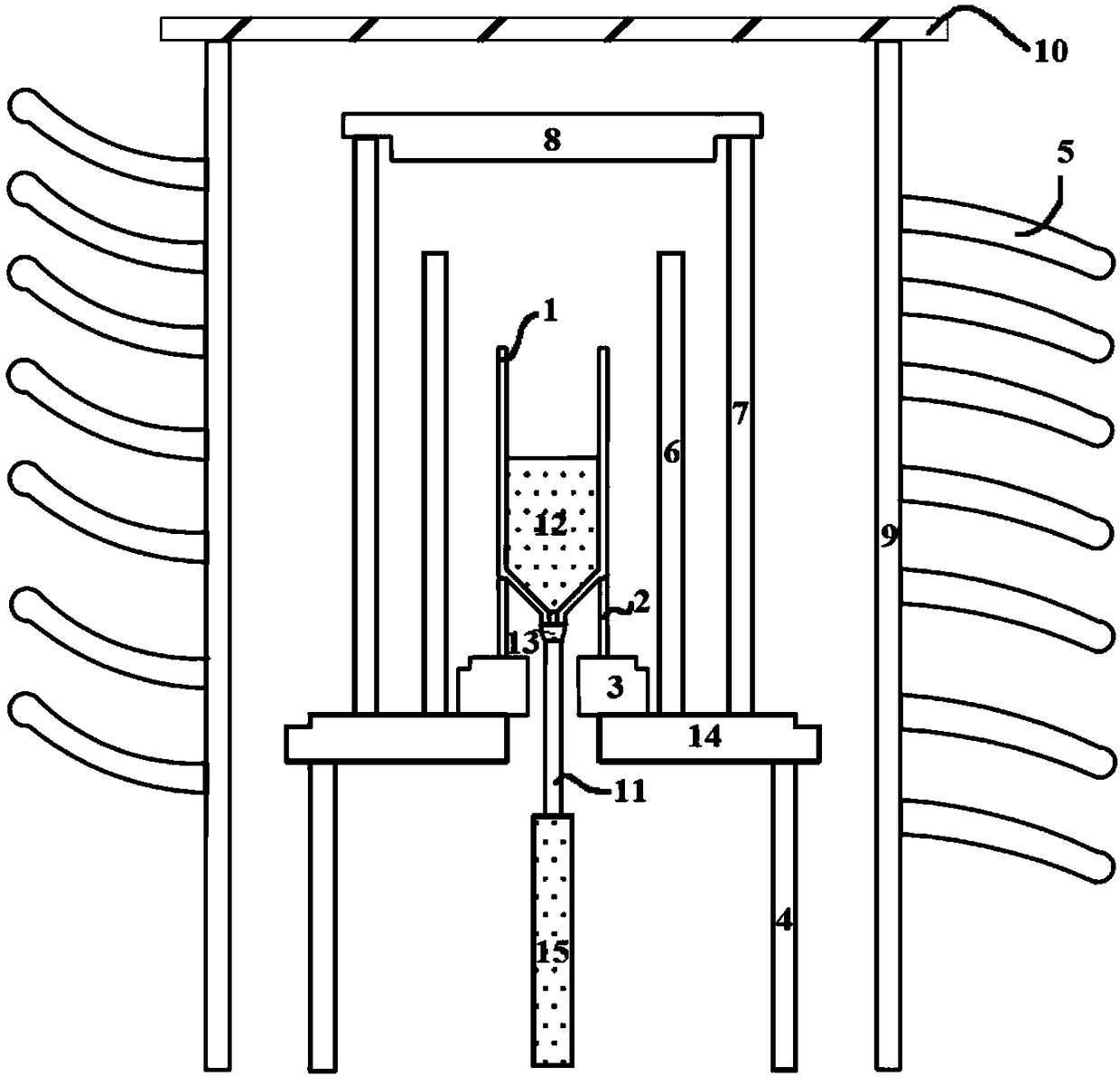

Controlled DAST crystal growing device for spontaneous nucleation process

InactiveCN104562174AIncrease success rateQuality improvementPolycrystalline material growthFrom normal temperature solutionsWater bathsElectricity

The invention belongs to the technical field of crystal growing equipment, and relates to a controlled DAST crystal growing device for a spontaneous nucleation process. A growing cylinder is fixedly placed in a water bath cylinder filled with water bath, a silica gel plug is mounted at the opening position of the upper part of the growing cylinder in a sealed manner, and the growing cylinder is filled with DAST crystal growing solutions; an inclined polytetrafluoroethylene plate is placed in the DAST crystal growing solutions; one end of a thin glass tube is formed into a tapered opening structure and vertically penetrates through the silica gel plug; an injector is placed outside the growing cylinder and is connected with the thin glass tube in a sealed manner through a flexible PVC pipe; a thermoelectric couple is mounted at one side of the top part of the water bath cylinder, and the thermoelectric couple is inserted into the water bath; an infrared heating lamp is placed on the outer side wall of the water bath cylinder; a temperature controlled meter is placed outside the water bath cylinder and is in electrical information communication with the thermoelectric couple and the infrared heating lamp; the structure of the device is simple, the usage and the operation are convenient, the effective control of the nucleation number and the position can be realized during the crystal growing, the success rate of the grown crystals is high, and the quality of the crystals is better.

Owner:QINGDAO UNIV

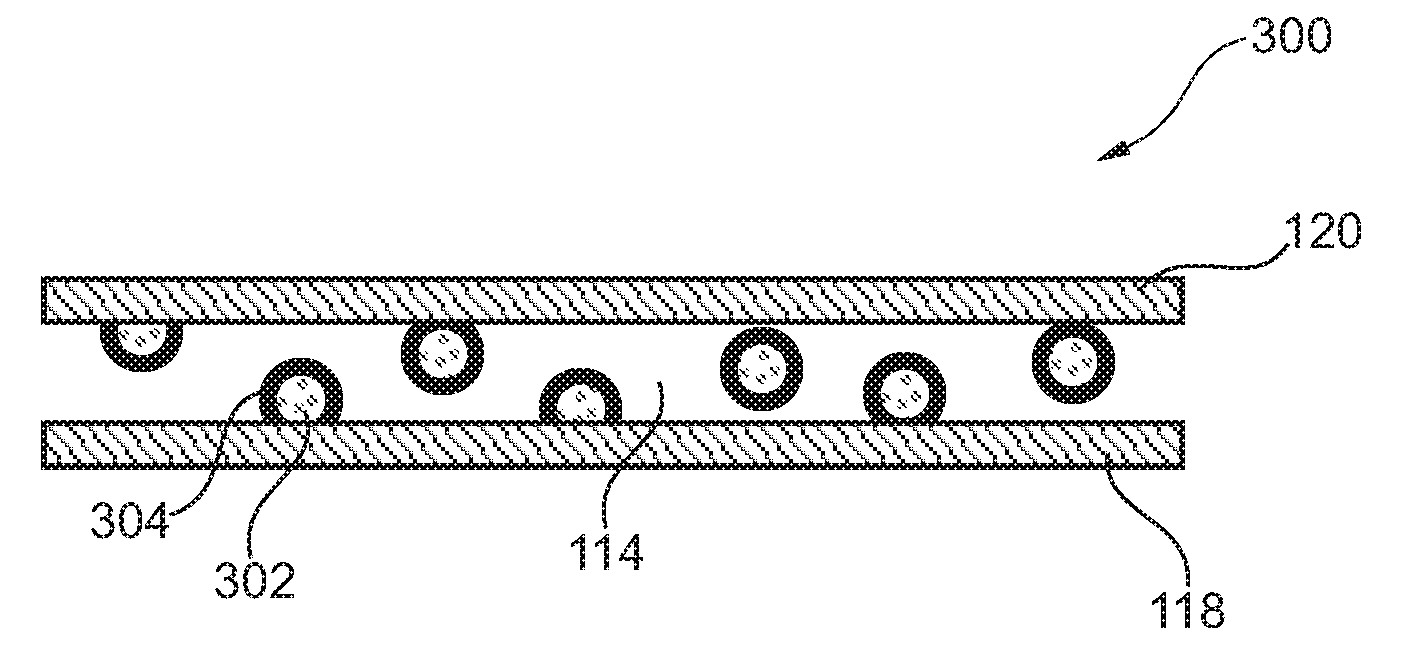

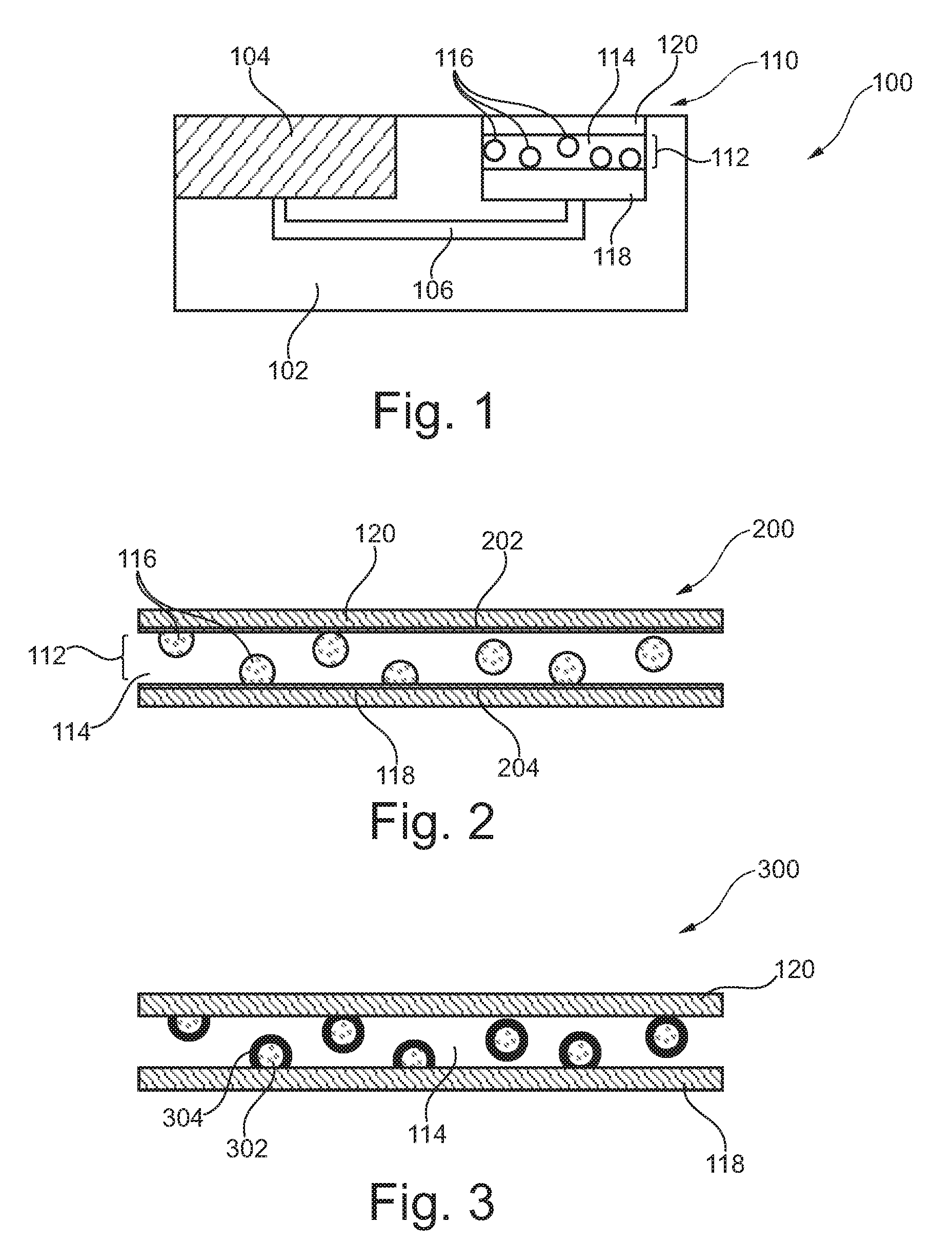

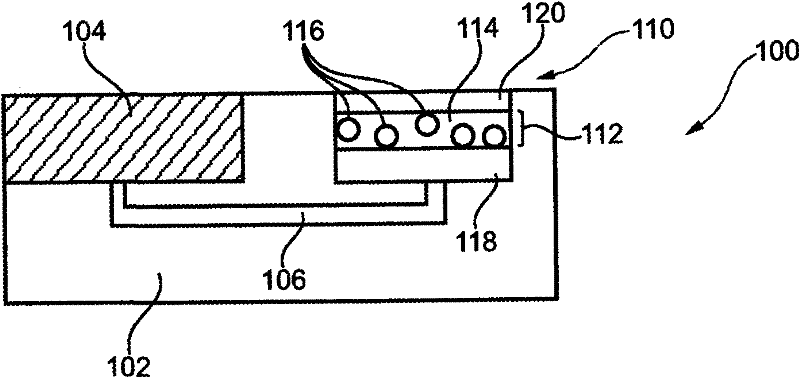

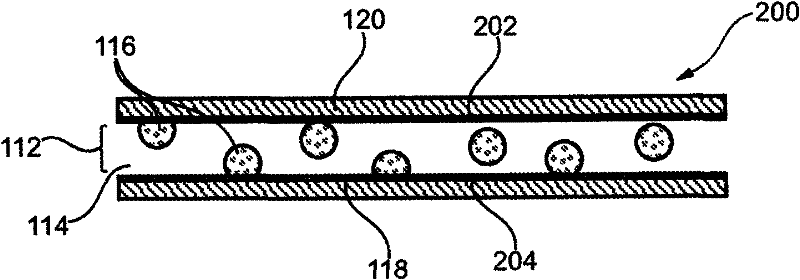

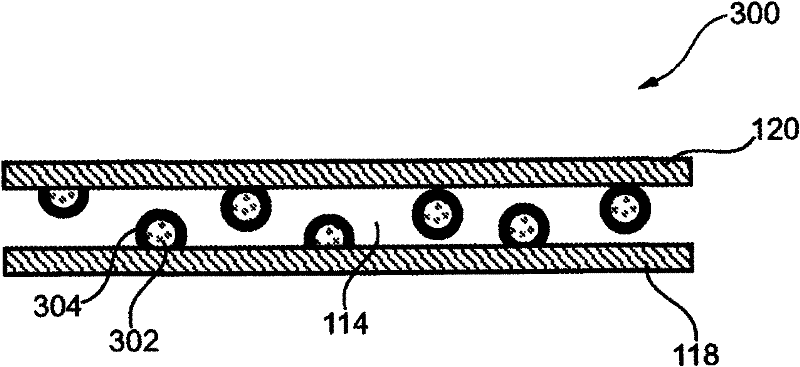

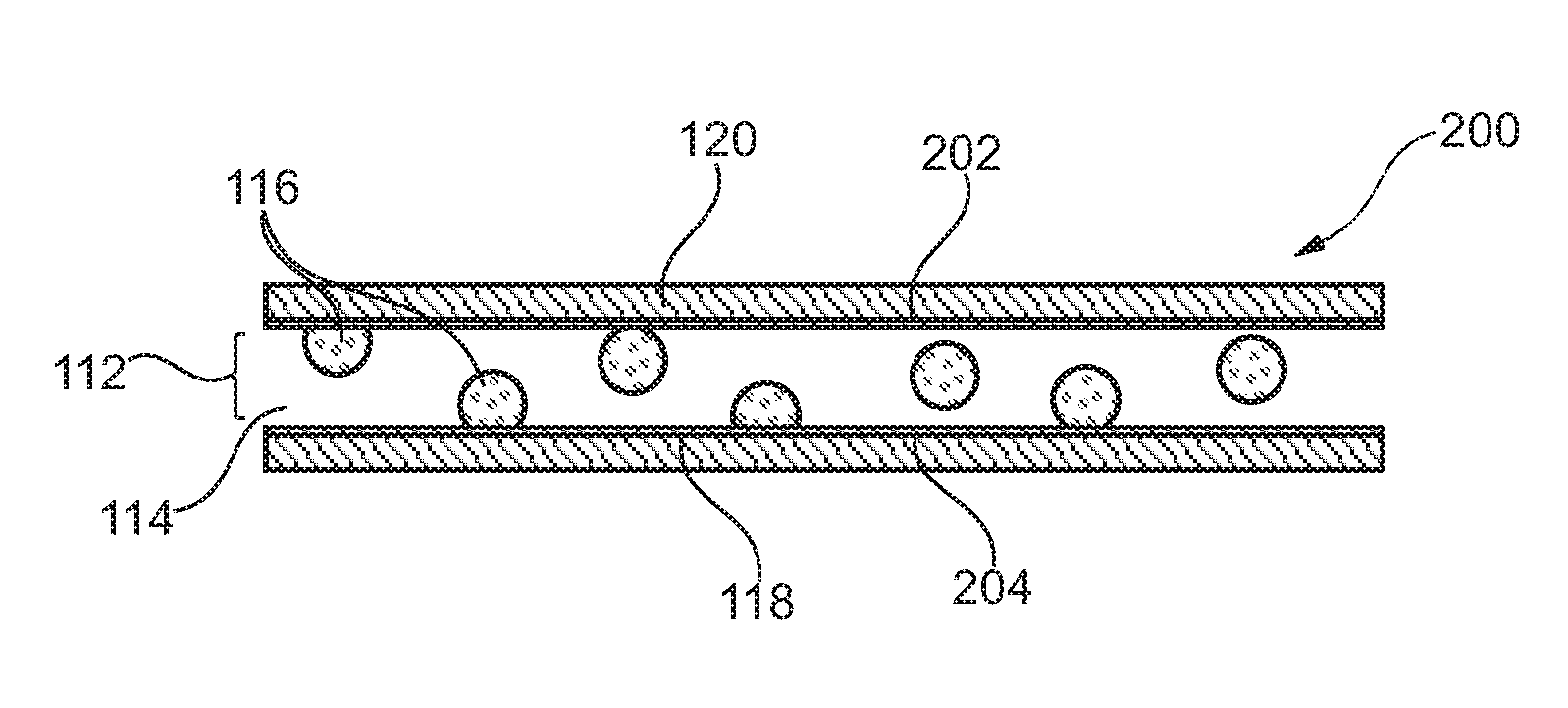

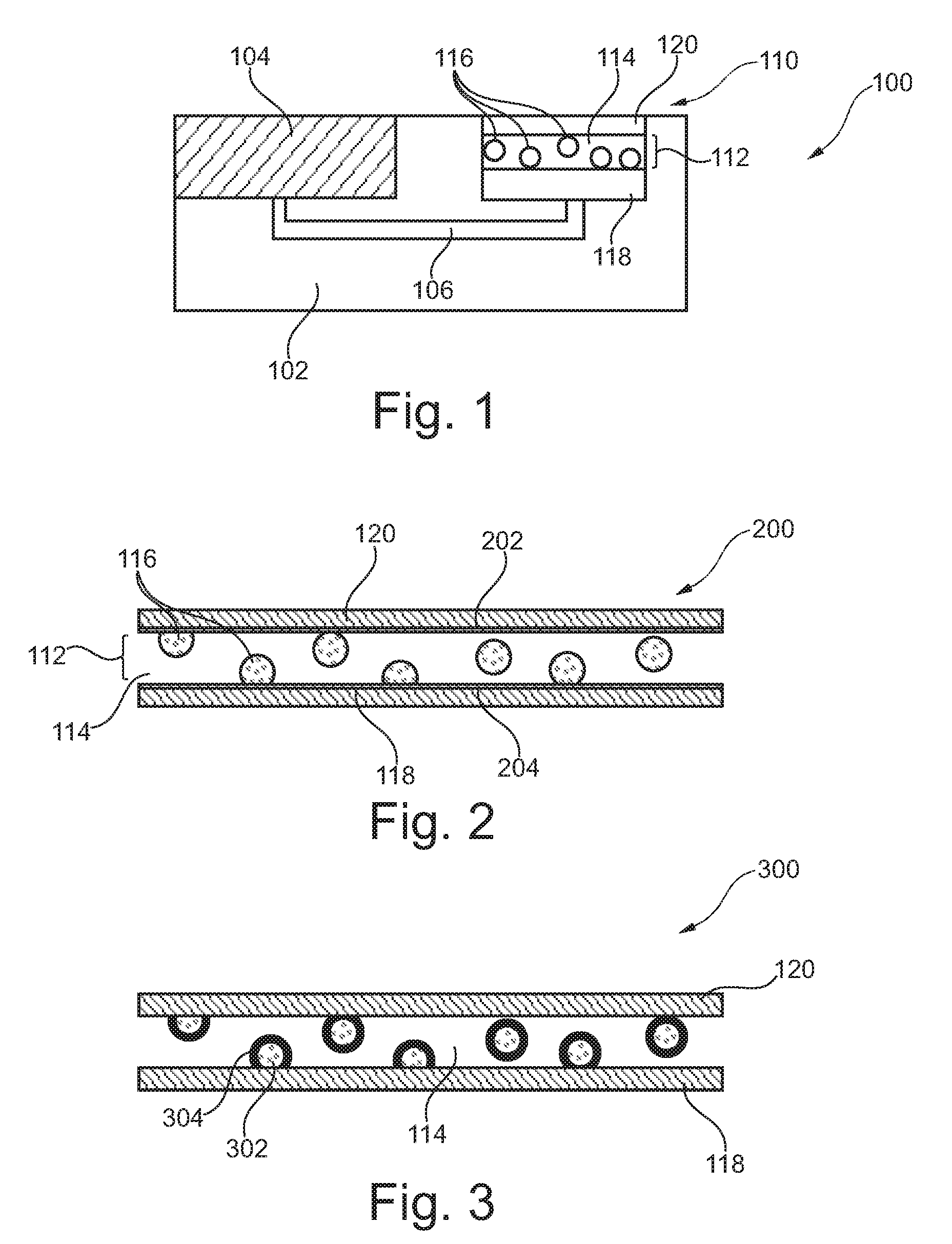

Capacitor and a method of manufacturing the same

ActiveUS20110147891A1Increase capacitanceFixed capacitor dielectricSemiconductor/solid-state device manufacturingDielectric matrixSpontaneous nucleation

A capacitor (110), wherein the capacitor (110) comprises a capacitor dielectric (112) comprising a dielectric matrix (114) of a first value of permittivity, and a plurality of nanoclusters (116) of a second value of permittivity which is larger than the first value of permittivity which are at least partially embedded in the dielectric matrix (114), wherein the plurality of nanoclusters (116) are formed in the dielectric matrix (114) by spontaneous nucleation.

Owner:NXP BV

Method for growing cerium-doped lanthanum bromide scintillation crystal by using out-of-phase seed crystal

ActiveCN102534775AControlled growthReduce usagePolycrystalline material growthFrom frozen solutionsChemical reactionScintillation crystals

The invention relates to a method for growing a cerium-doped lanthanum bromide scintillation crystal by using an out-of-phase seed crystal. The seed crystal made of a crystal material of which the structural parameters and symmetry are similar to those of a lanthanum bromide crystal is placed in a nucleation area at the bottom of a quartz crucible, the seed crystal material and lanthanum bromide are not subjected to chemical reaction, and the melting point of the seed crystal material is higher than that of the lanthanum bromide crystal. The crystal is grown by a crucible descending method, two-section temperature control is performed at the melting stage of a raw material to ensure that the upper part is cold and the lower part is hot, the convection effect of a melt is improved, the lanthanum bromide is nucleated on the surface of the seed crystal preferentially in the crucible descending process, the growth direction of the lanthanum bromide is consistent with the crystallographic direction of the seed crystal, and the lanthanum bromide crystal in the required direction is obtained by continuous growth. The method has the advantages that: a stable crystal material in air can be selected as the seed crystal, and the phenomenon that processing and anhydrous operation are difficult to perform when the lanthanum bromide crystal is taken as the seed crystal is avoided; and compared with a seed-crystal-free spontaneous nucleation growth method, the method has the advantage that: the success rate of oriented crystal growth is greatly improved.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

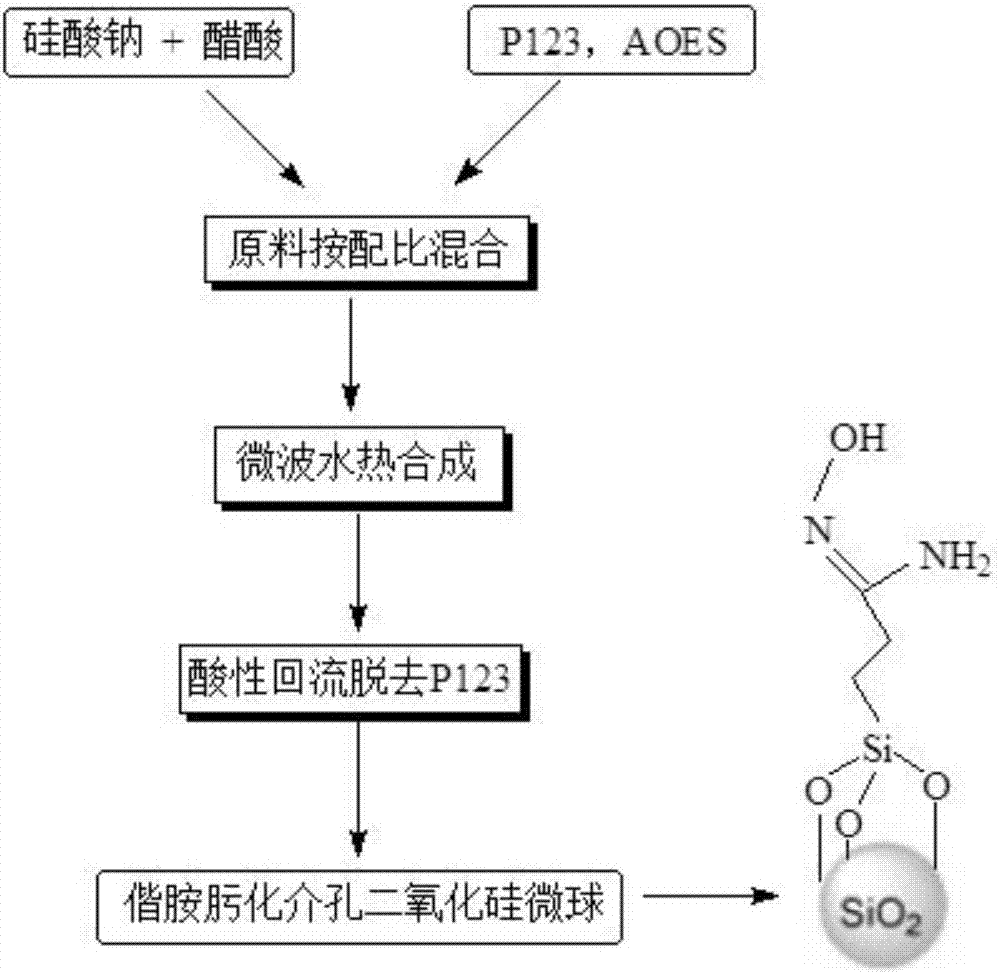

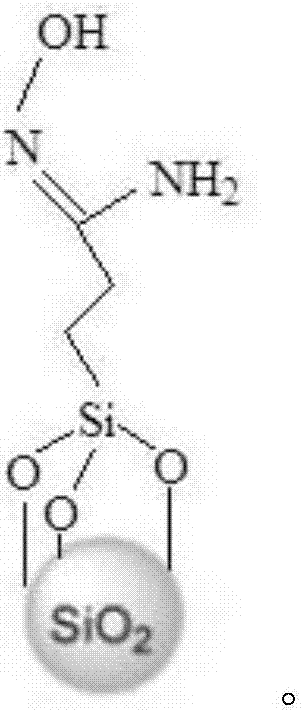

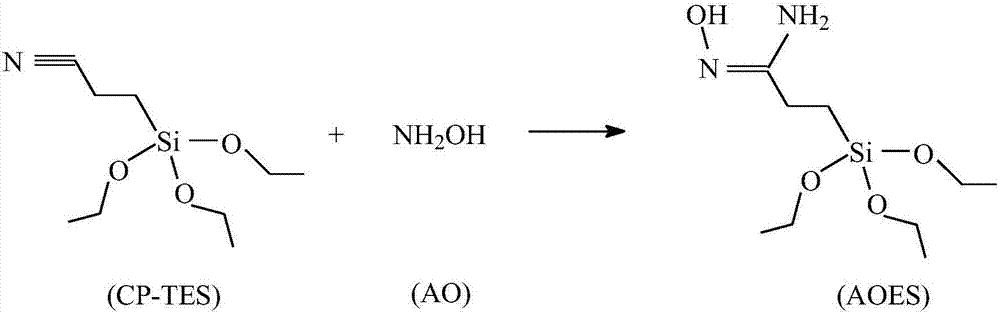

Amidoximated mesoporous silica microsphere adsorbent and preparation method thereof

InactiveCN106902747AUniform particle sizeReduce manufacturing costOther chemical processesAlkali metal oxides/hydroxidesSorbentMicrosphere

The invention provides an amidoximated mesoporous silica microsphere adsorbent. According to the invention, sodium silicate is used as a main raw material for synthesis of the adsorbent via a microwave hydrothermal method, and since sodium silicate is far cheaper than ethyl orthosilicate, production cost can be effectively reduced; reaction time can be substantially shortened to 12 to 18 h by using microwave hydrothermal synthesis, so production efficiency is enhanced; moreover, microwave hydrothermal synthesis can promote spontaneous nucleation and enables nucleation to be more uniform; furthermore, a functional group (an amidoxime group) is introduction via copolycondensation for modification of the adsorbent during microwave hydrothermal synthesis of the mesoporous silica microsphere adsorbent, so the prepared amidoximated mesoporous silica microsphere adsorbent has a well-developed ordered mesoporous structure and good mechanical strength and chemical stability, facilitates rapid entry of uranium into pore channels for adsorption and is applicable to separation and recovery of uranium in uranium-containing waste water.

Owner:EAST CHINA UNIV OF TECH

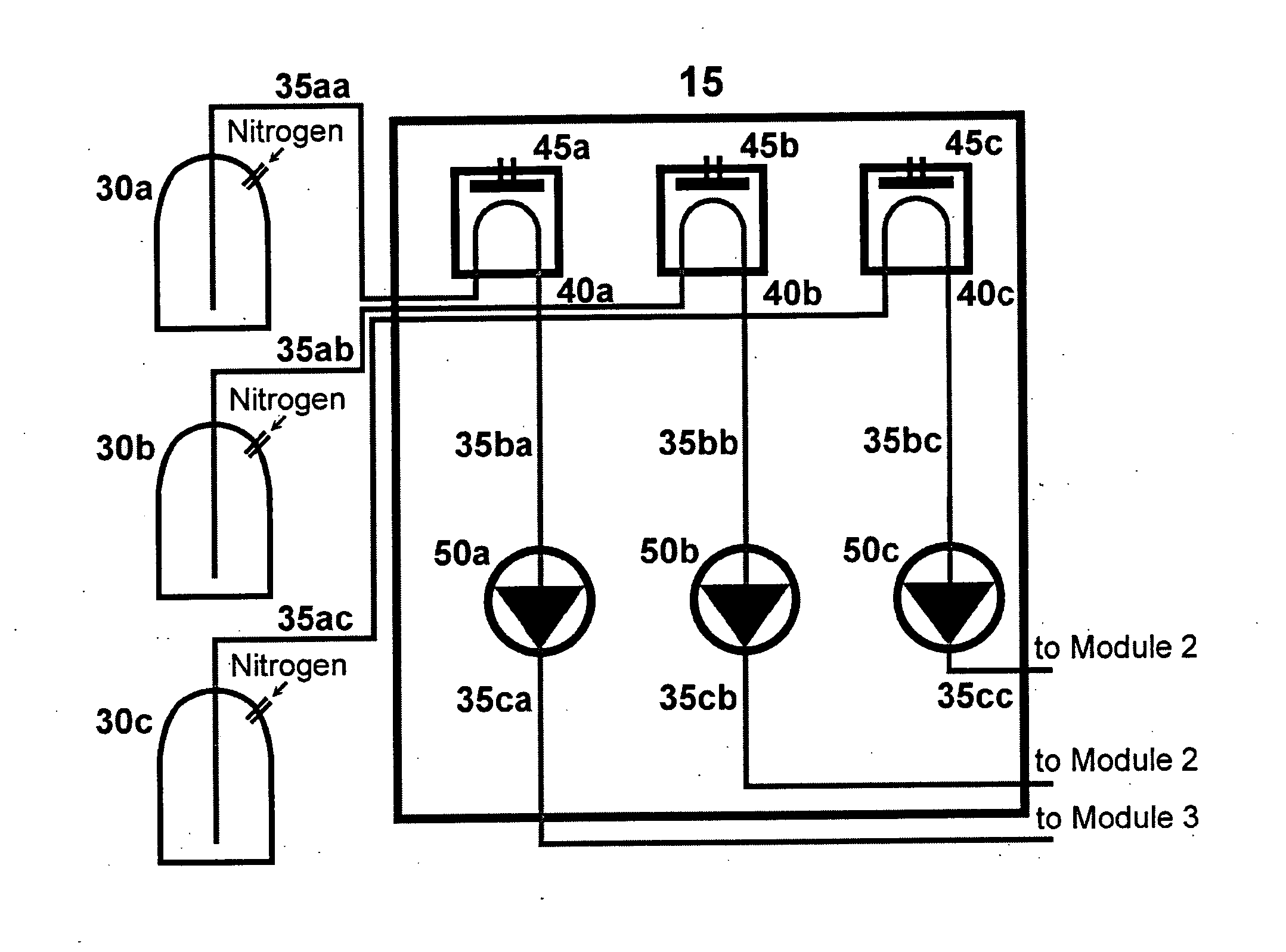

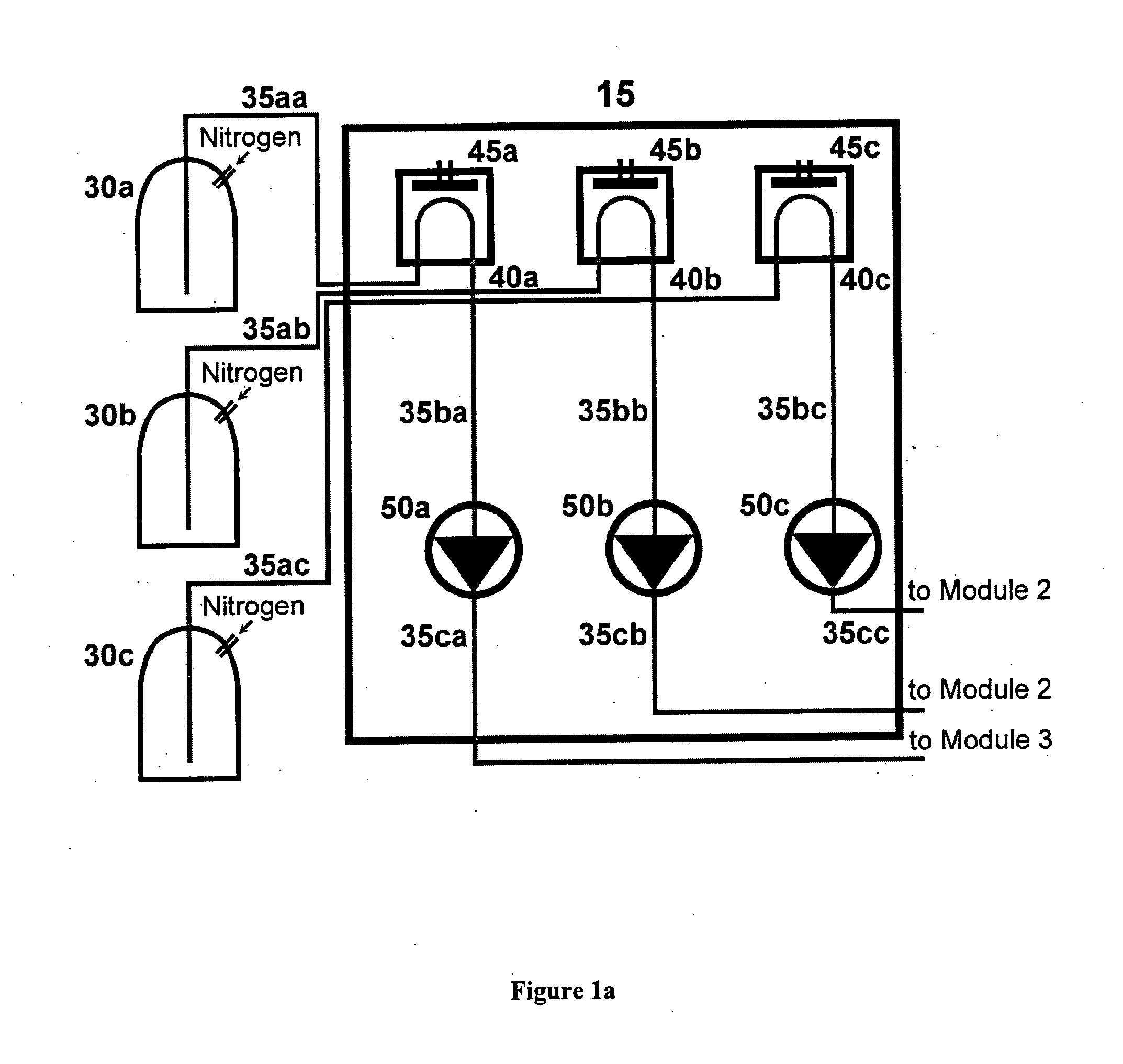

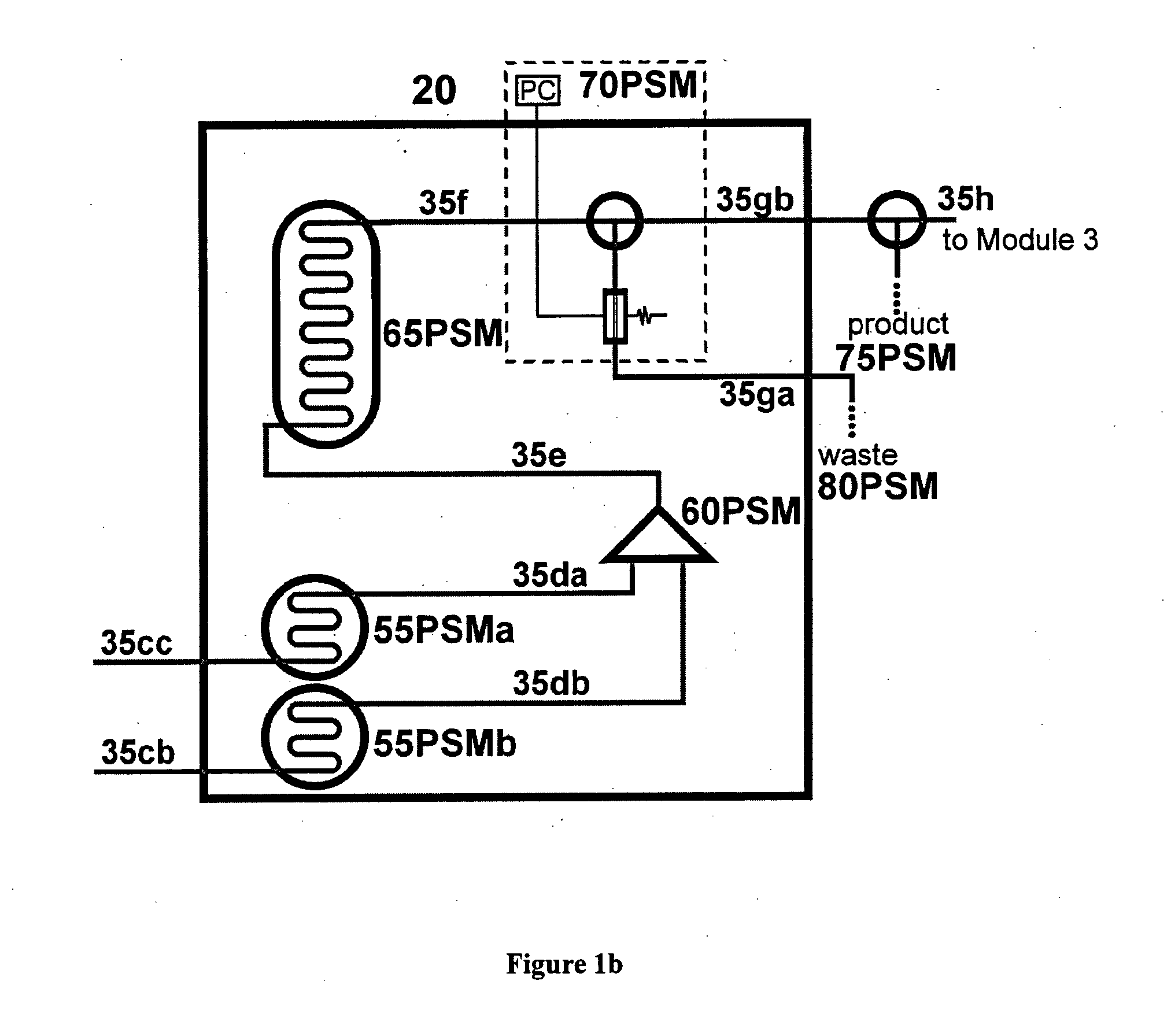

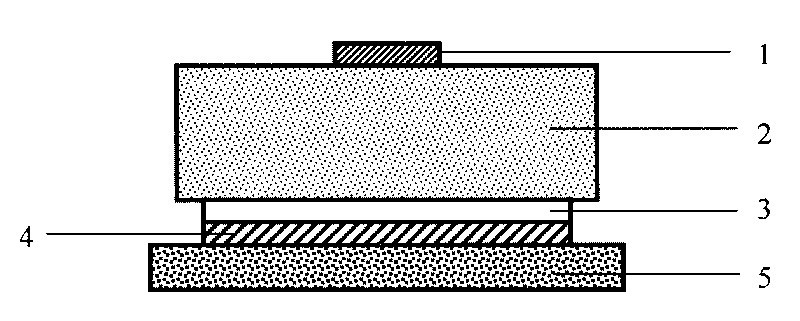

Reactor for the manufacture of nanoparticles

ActiveUS20110042611A1Small sizeUniform sizeMaterial nanotechnologyOther chemical processesSpontaneous nucleationCore shell nanoparticles

An apparatus (10) and a method (200) for the manufacture of nanoparticles. The apparatus and the method allows for the nucleation and growth of nanoparticles at independent temperatures. The independent temperatures allow for the growth of nanoparticles in a controlled environment avoiding spontaneous nucleation and allowing particle sizes to be controlled and facilitating the manufacture of particles of a substantially uniform size. Furthermore the apparatus (10) allows for the manufacture of core-shell nanoparticles and core-shell-shell nanoparticles.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

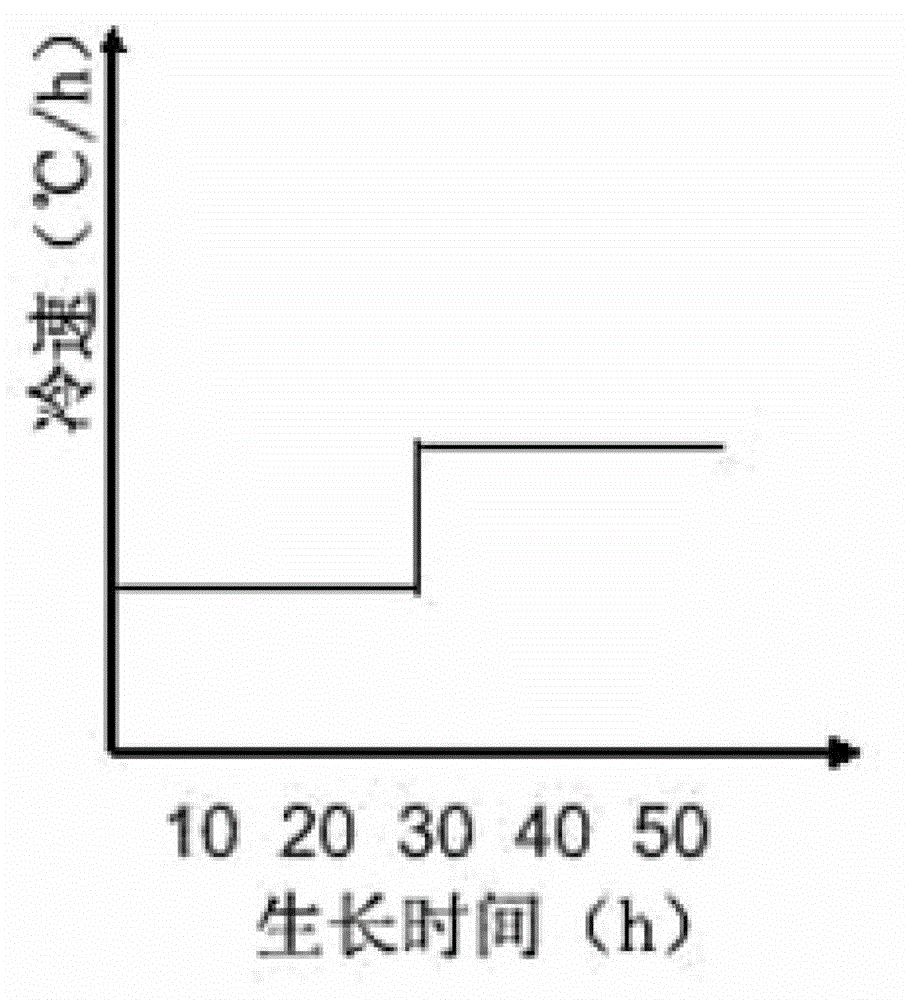

Method for quickly growing REBCO high-temperature superconducting block by stepped slow cooling acceleration

InactiveCN103060914APromote growthNo enrichmentPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationHigh temperature superconducting

The invention discloses a method for quickly growing an REBCO high-temperature superconducting block by stepped slow cooling acceleration, by using a c-axis-oriented NdBCO / YBCO / MgO film as a seed crystal, contacting the ab surface of the film seed crystal with the upper surface of a precursor block, putting the precursor block and the film seed crystal in a growth furnace, and carrying out melt structure growth. The temperature procedure of the growth furnace is as follows: heating from room temperature to 960 DEG C within 5 hours, and keeping the temperature for 3 hours; continuing heating to the maximum temperature Tmax, and keeping the temperature for 1-2 hours; cooling to the initial growth temperature Ts within 15 minutes; and growing the REBCO high-temperature superconducting block according to the stepped slow cooling acceleration growth procedure. The method disclosed by the invention can not generate spontaneous nucleation and second-phase enrichment on the premise of ensuring the induced growth of the seed crystal; and the gradually increasing cooling rate ensures the increasing driving force required by growth.

Owner:SHANGHAI JIAO TONG UNIV

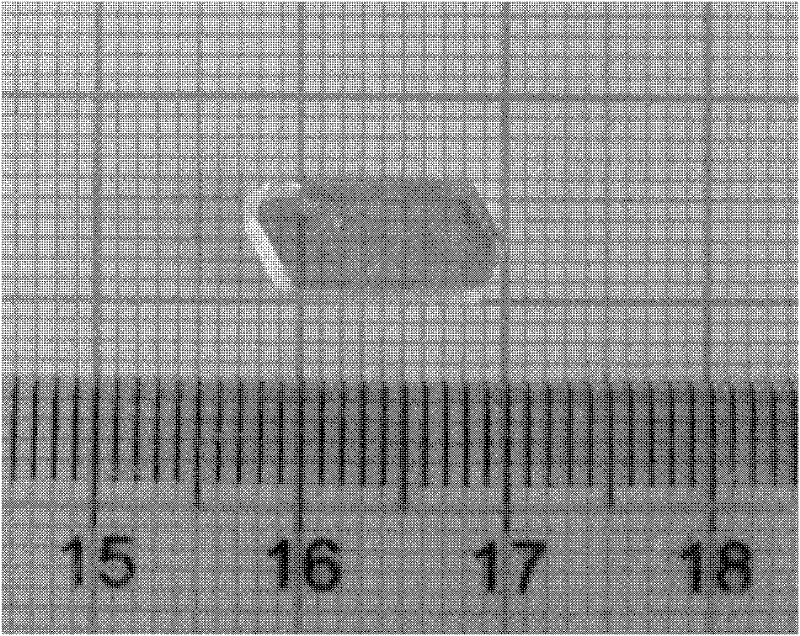

Method for growing phosphorus-silicon-cadmium single crystal

InactiveCN102168299AGood effectConvenient rotary controlPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationCrucible

The invention relates to a method for growing a phosphorus-silicon-cadmium single crystal. 1 part of silicon, 1 part of cadmium and 2-2.05 parts of phosphorus are synthesized into a phosphorus-silicon-cadmium polycrystal material, and the phosphorus-silicon-cadmium single crystal is grown by a crucible descending furnace by using a spontaneous nucleation growing method or oriented seed crystal growing method. The method comprises the following steps: directly filling the phosphorus-silicon-cadmium polycrystal material into a crucible, or filling the phosphorus-silicon-cadmium polycrystal material into the crucible after adding the seed crystal; putting the crucible into a silica tube, vacuumizing, and sealing the silica tube; putting the silica tube into a crucible descending furnace; and heating, descending the crucible, and finally cooling. The method provided by the invention can be used for preparing the high-purity high-quality phosphorus-silicon-cadmium single crystal.

Owner:SHANDONG UNIV

Method for growing large-size vanadium sodium iodate crystal by using hydrothermal method

ActiveCN102400222AQuality improvementSmall sizePolycrystalline material growthFrom normal temperature solutionsSpontaneous nucleationCrystal plane

The invention relates to a method for growing a large-size vanadium sodium iodate crystal by using a hydrothermal method. A Na-containing compound, a V-containing compound and an I-containing compound are used as raw materials in the method for growing the large-size vanadium sodium iodate crystal by using the hydrothermal method; and the crystal is grown in two manners, namely spontaneous nucleation and adoption of a seed crystal. According to the method, successful raw material proportion and growth processes are provided, growth of the massive crystal with a crystal plane is realized, and the maximum size of the crystal exceeds two centimeters.

Owner:徐翔

A capacitor and a method of manufacturing the same

InactiveCN102132367AIncrease capacitanceReduce leakage currentFixed capacitor dielectricDielectric matrixSpontaneous nucleation

A capacitor (110), wherein the capacitor (110) comprises a capacitor dielectric (112) comprising a dielectric matrix (114) of a first value of permittivity, and a plurality of nanoclusters (116) of a second value of permittivity which is larger than the first value of permittivity which are at least partially embedded in the dielectric matrix (114), wherein the plurality of nanoclusters (116) are formed in the dielectric matrix (114) by spontaneous nucleation.

Owner:NXP BV

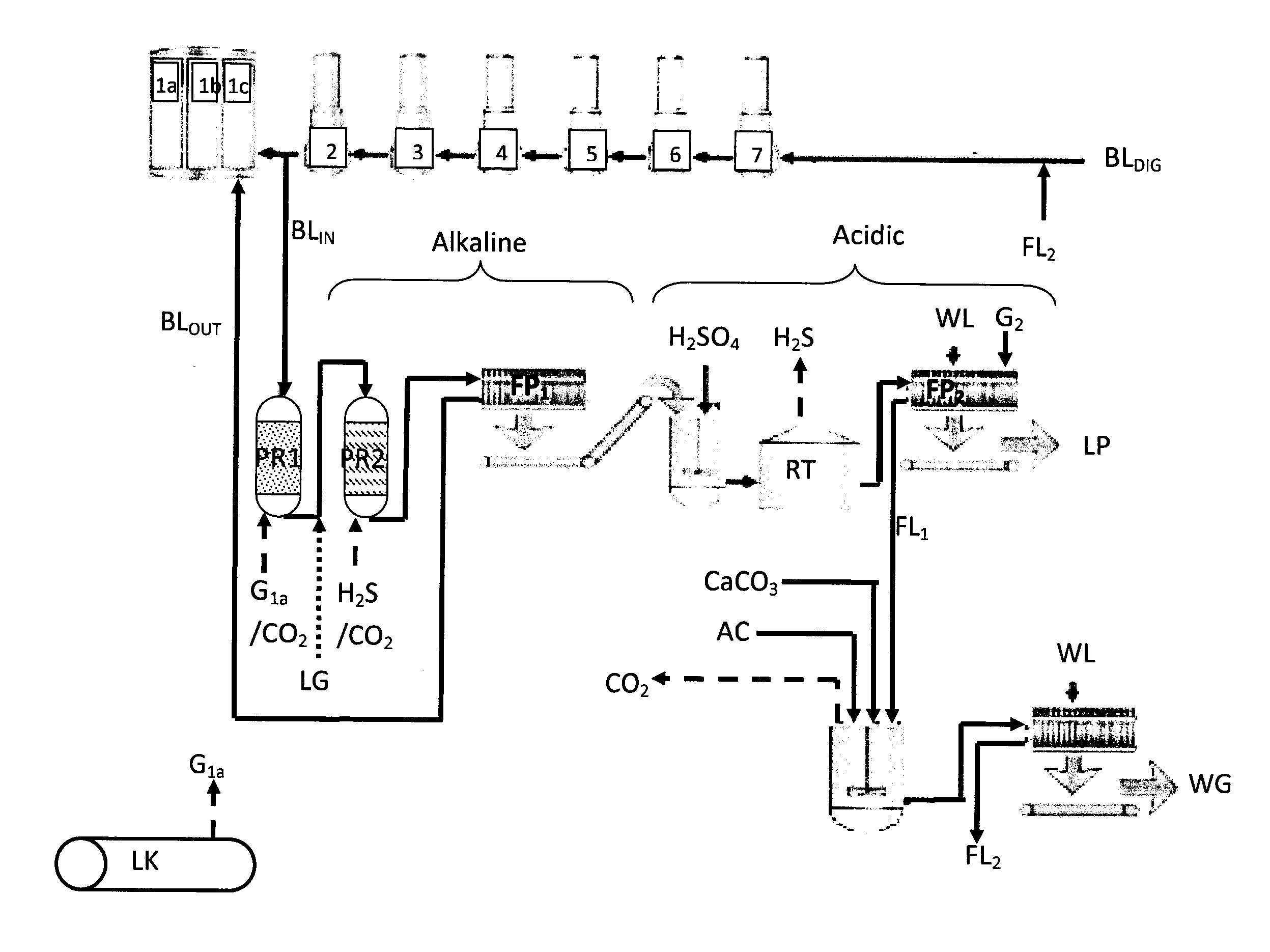

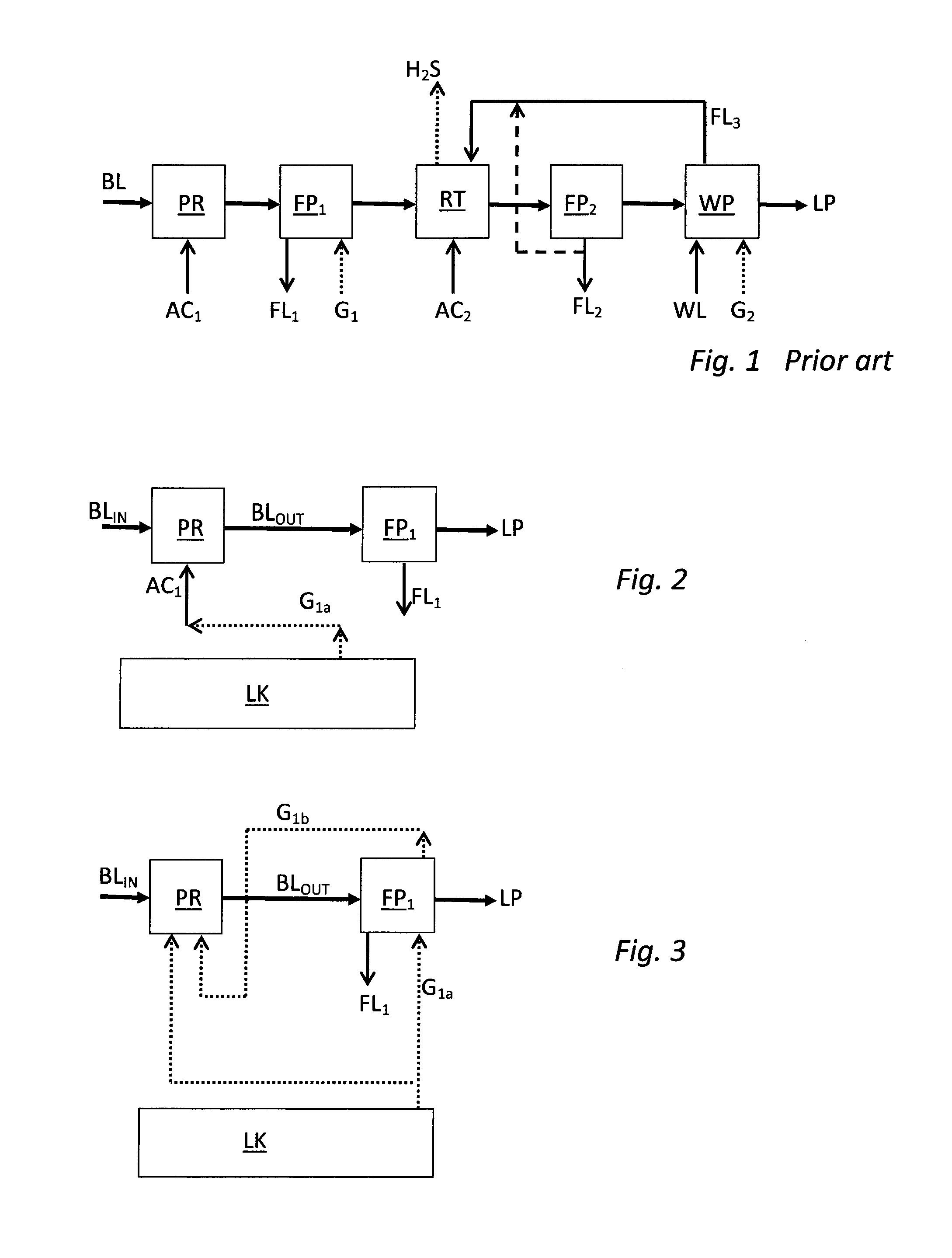

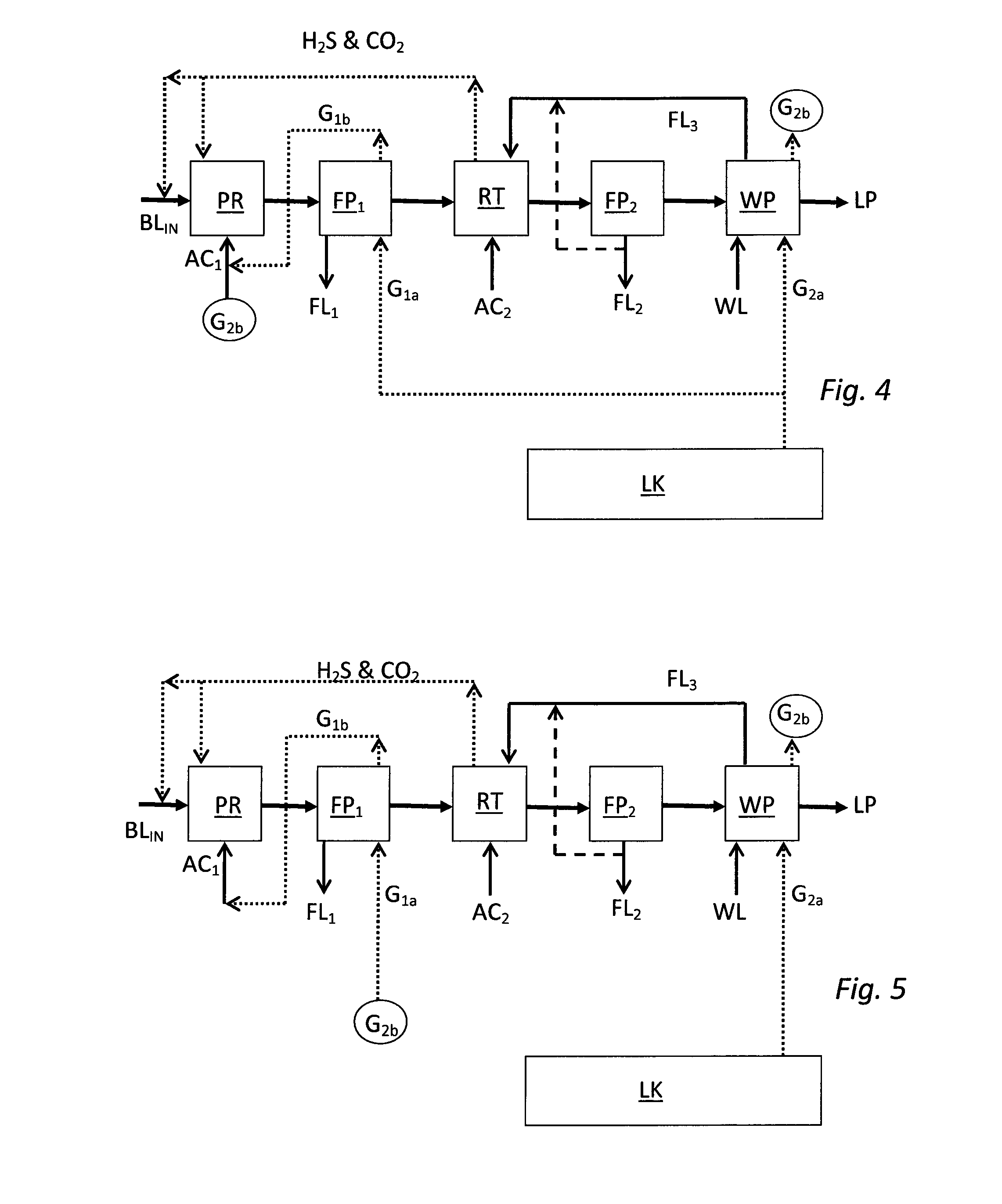

Method for lignin separation from black liquor

ActiveUS20150119559A1Improve filtering effectHigh yieldBiofuelsSolid fuelsBlack liquorSpontaneous nucleation

The method is for separation of lignin from original black liquor (BLIN) that has a first precipitation phase (PR1 / PR2) for precipitation of lignin by a first acidification using acidifier, CO2, at alkaline conditions, then separating a lignin cake with subsequent suspension of the lignin cake in a strong acid in order to leach out metals from the lignin followed by dewatering and obtaining a clean lignin product LP. Lignin germ particles (LG) are added to the original black liquor in the first precipitation stage, preferably between two phases in said precipitation stage, in order to increase lignin particle growth on such lignin germ particles instead of spontaneous nucleation of lignin particles in said original black liquor. This results in improved filterability in subsequent dewatering and lignin cake formation and hence an increased lignin yield.

Owner:VALMET AB

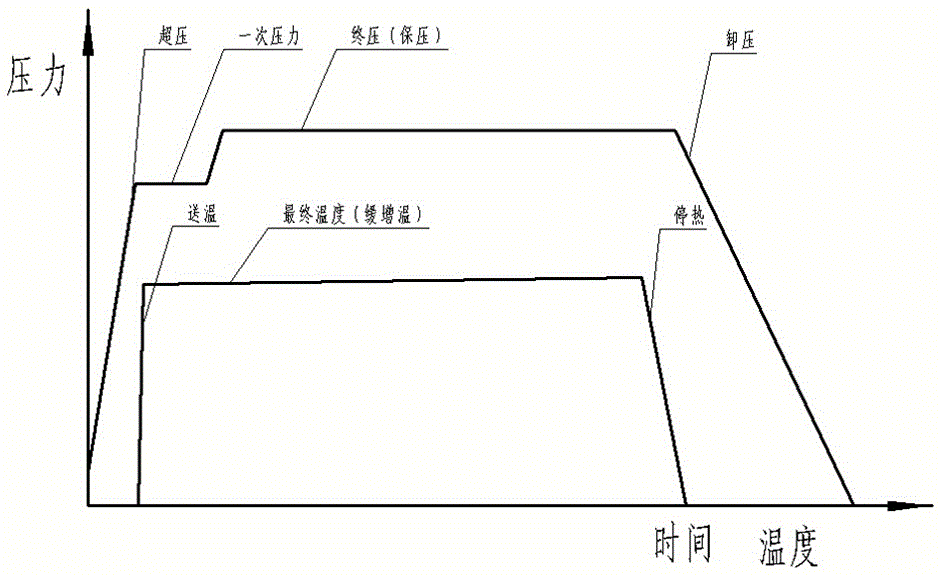

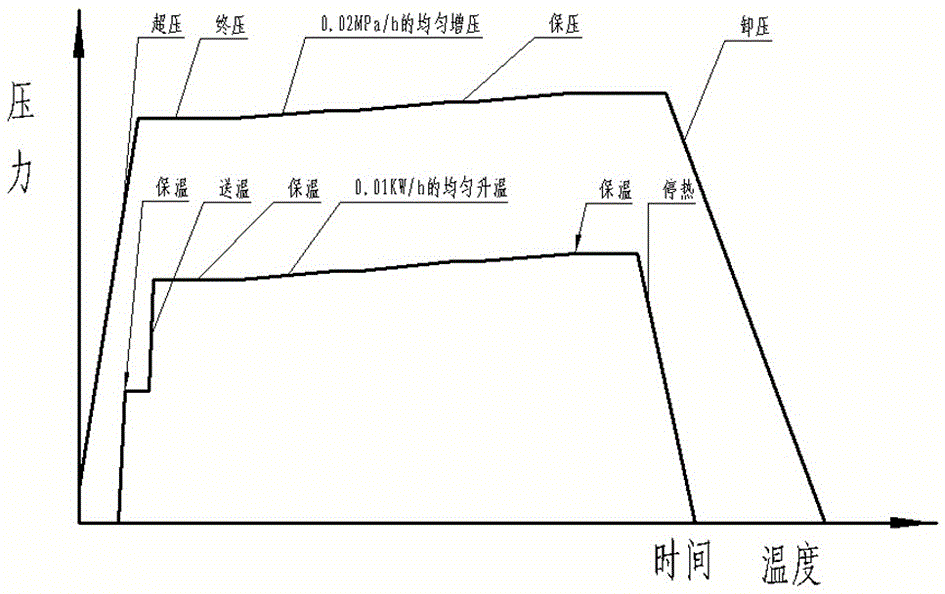

Synthetic process for gem grade diamond

ActiveCN106824002AImprove qualityStable growthUltra-high pressure processesPressure riseSpontaneous nucleation

A synthetic process for gem grade diamond comprises the following steps: (1) placing an assembled synthetic block in a high pressure chamber of a cubic press; after pressurizing the synthetic block to a final pressure of 90-95 MPa at one time, maintaining the pressure; when the pressure rises to 40-50% of the final pressure, starting heating and enabling the heating power to rise to 4-5 kw within 10-15 s; after preserving the heat of the synthetic block for 3-5 min, increasing the heating power to 9-10 kw for heat preservation; (2) after preserving the heat of the synthetic block for 5-10 h, entering a continuous heat preserving and pressure maintaining stage after continuous temperature increasing, heat preserving, pressure increasing and pressure maintaining; (3) after continuous heat preservation, stopping heating and cooling the synthetic block to room temperature; releasing the pressure when the temperature is halved; finishing the process till the pressure is released to normal pressure. The synthetic process for the gem grade diamond is especially suitable for multi-crystal-seed synthetic processes, can reasonably supply enough carbon source according to the growing speeds of crystal seeds in the control process and can enable the crystal seeds to stably grow for a long time without being affected by spontaneous nucleation to synthesize large particle size and inclusion-free high-quality diamond single crystal; the crystal is colorless and transparent and the quality of the crystal is good; the synthetic process for the gem grade diamond can realize mass production and low production cost.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

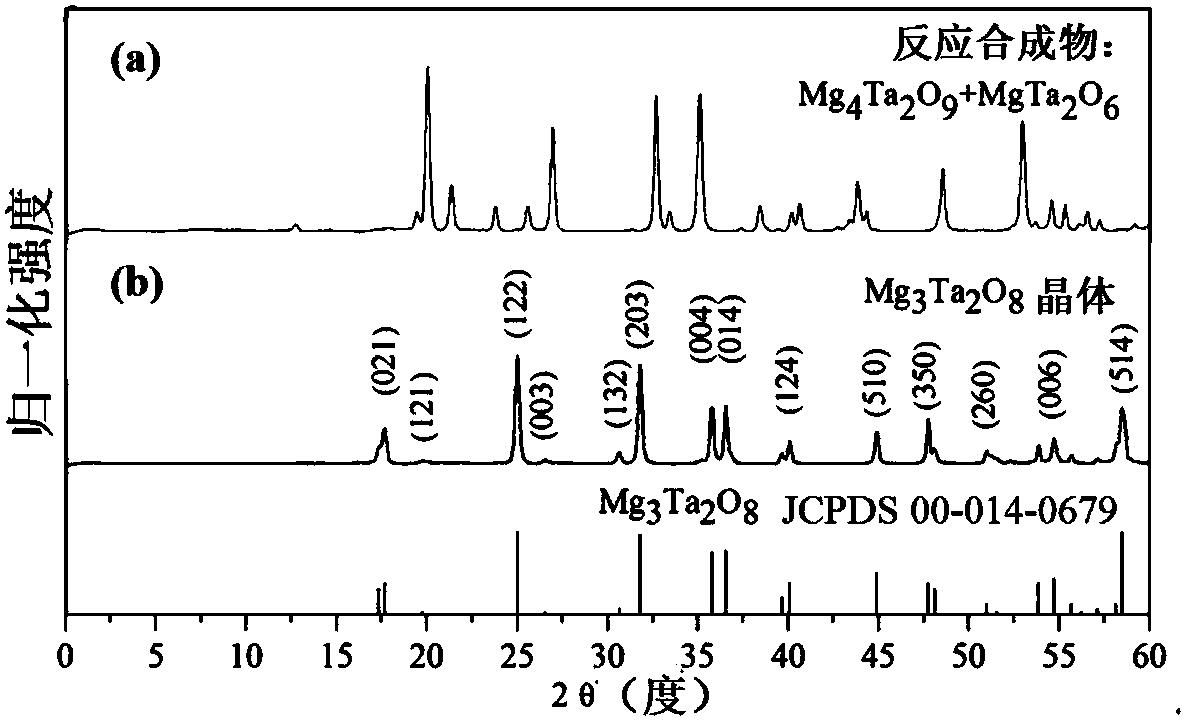

Magnesium niobate series crystals and preparation method thereof

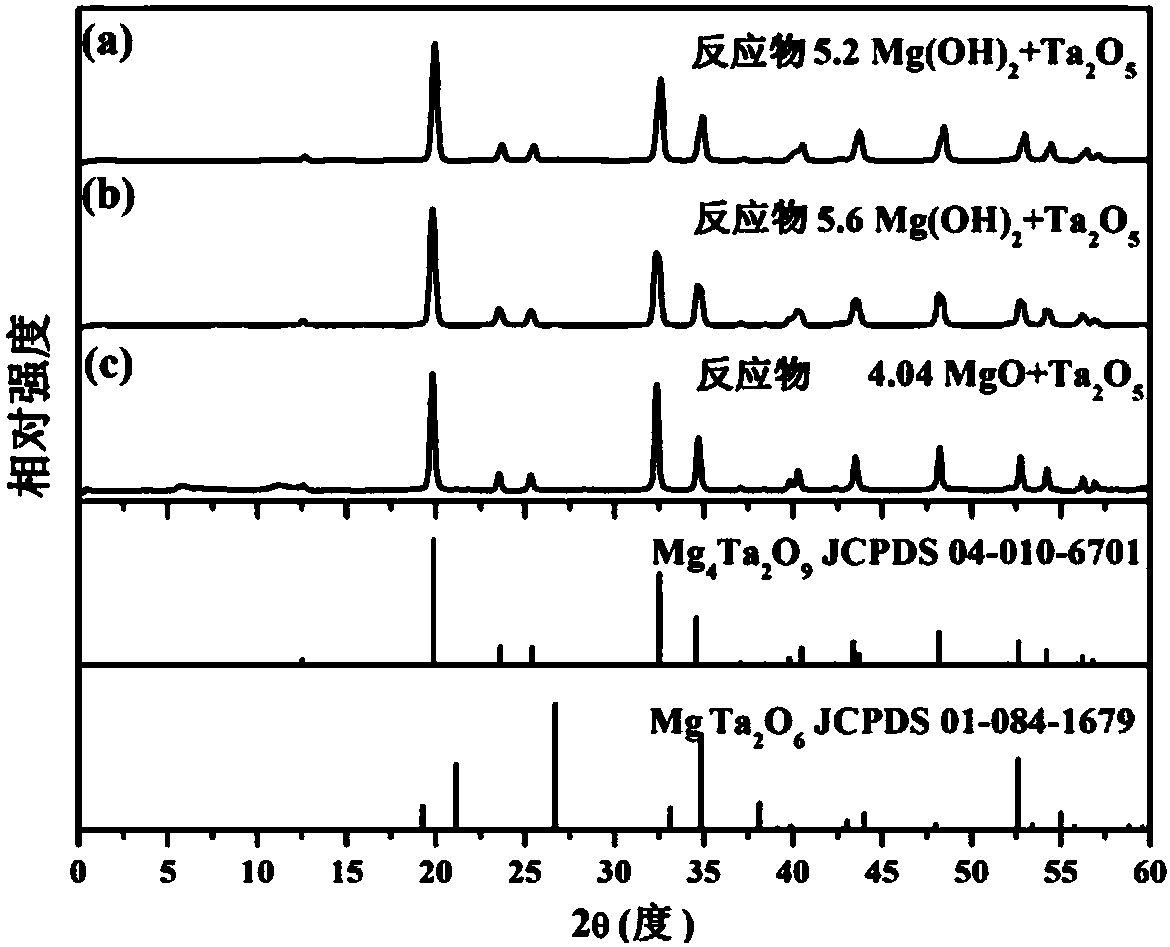

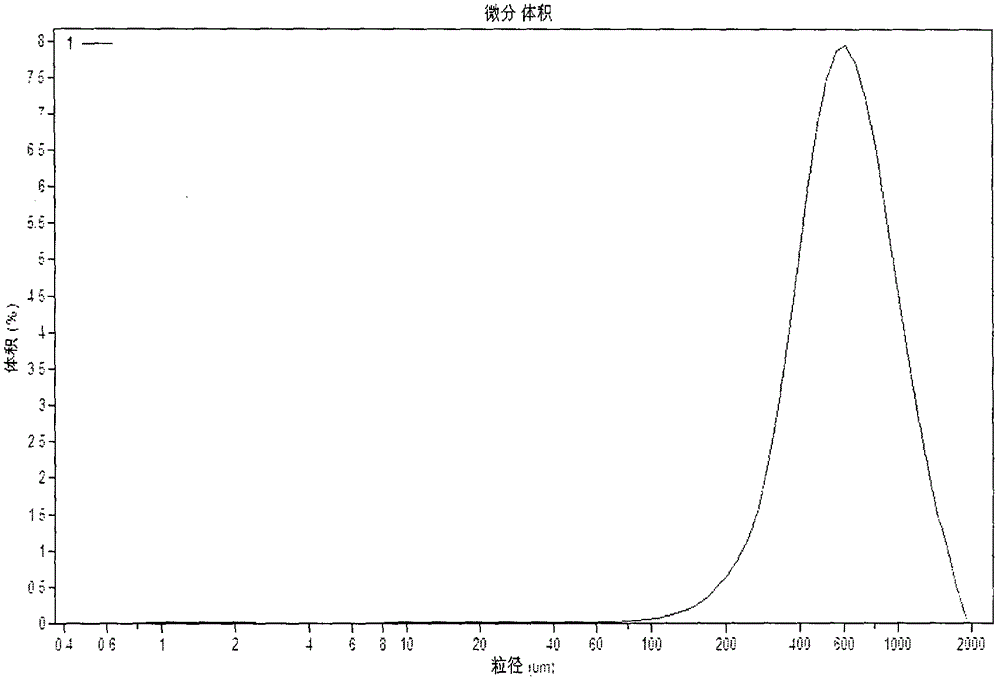

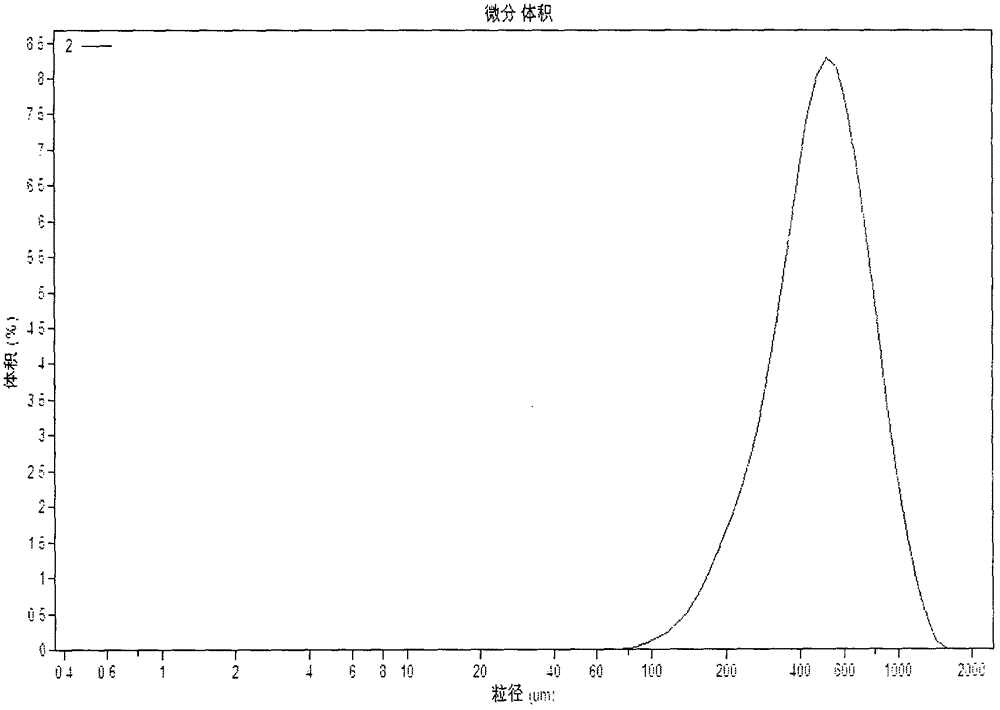

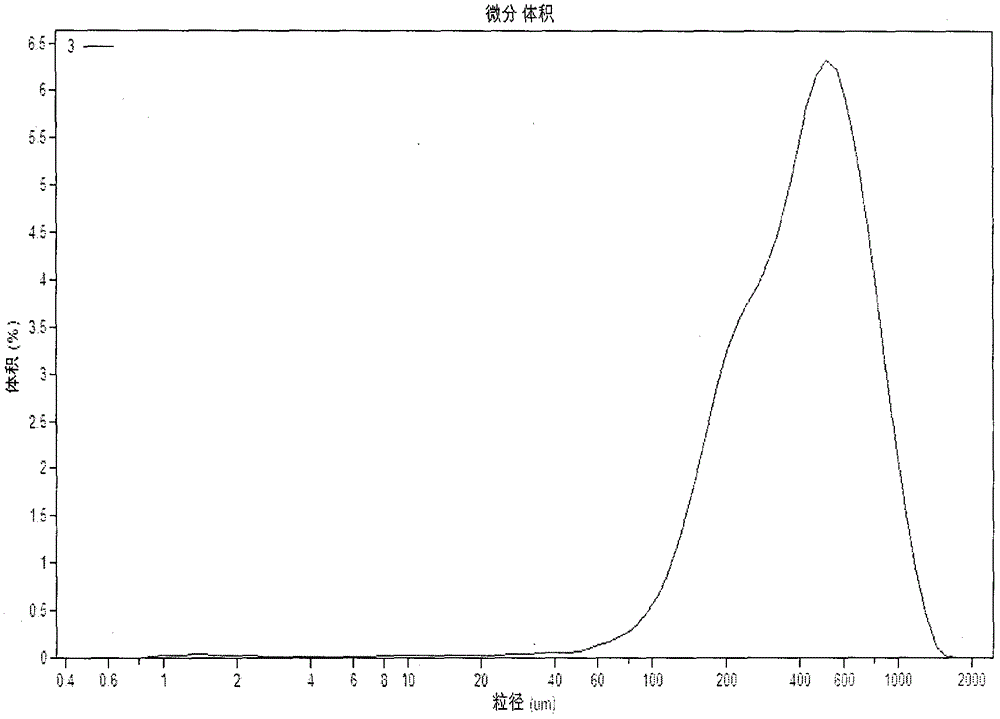

ActiveCN108203844AHigh crystalline integrityTransparent no macro defects noPolycrystalline material growthBy pulling from meltSpontaneous nucleationSingle crystal

The invention discloses magnesium niobate series crystals, namely a MgO-Ta2O5 pseudo binary system. The magnesium niobate series crystals are Mg4Ta2O9, Mg3Ta2O8 and MgTa2O6, respectively. A method forpreparing the magnesium niobate series crystals is also provided. High-purity MgTa2O6 and Mg4Ta2O9 powders are synthesized by solid phase reaction using excess MgO or Mg(OH)2 component compensation,and the centimeter-scale rod-shaped MgTa2O6 and Mg4Ta2O9 single crystal is grown by a micro-downdraw method. Using Mg4Ta2O9 and MgTa2O6 as melting starting materials, a centimeter-scale rod-shaped Mg3Ta2O8 single crystal is grown on a MgTa2O6 ceramic seed rod by a spontaneous nucleation technique. According to the magnesium niobate series crystals, the micro-downdraw method is adopted, and the high temperature gradient near a growth interface is effectively utilized, to achieve rapid and high uniform crystallization; and a post-heater is effectively utilized to solve the cracking problem caused by excessive thermal stress.

Owner:SHANGHAI INST OF TECH

Particle size regulation method of glycine periodic crystallization process

InactiveCN106748849ASimple processReduce operating costsOrganic compound preparationAmino-carboxyl compound preparationGlycineSpontaneous nucleation

The invention provides a method of regulating a particle size of a glycine crystal product by a manner of generating seed crystals via spontaneous nucleation. According to the method, a glycine saturated aqueous solution serves as a raw material; the quantity and the particle size of crystal nucleuses in a spontaneous nucleation process are controlled by regulating a nucleation supersaturation degree; and the glycine crystal product is obtained by cooling crystallization of the crystal nucleuses generated by the spontaneous nucleation as the seed crystals. The method particularly comprises the steps of cooling, nucleation induction at a constant temperature, grain growth at the constant temperature and the cooling crystallization. The glycine crystal product in different particle sizes can be prepared by using the method.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Capacitor and a method of manufacturing the same

ActiveUS8697516B2Increase capacitanceFixed capacitor dielectricSemiconductor/solid-state device manufacturingDielectric matrixSpontaneous nucleation

A capacitor (110), wherein the capacitor (110) comprises a capacitor dielectric (112) comprising a dielectric matrix (114) of a first value of permittivity, and a plurality of nanoclusters (116) of a second value of permittivity which is larger than the first value of permittivity which are at least partially embedded in the dielectric matrix (114), wherein the plurality of nanoclusters (116) are formed in the dielectric matrix (114) by spontaneous nucleation.

Owner:NXP BV

Preparing method of large diameter yttrium barium copper oxide superconducting single domain blocks

InactiveCN101723680AAvoid Orientation ProblemsSimple manufacturing processChemical mixturesYttrium barium copper oxide

The invention relates to a preparing method of large diameter yttrium barium copper oxide superconducting single domain blocks, which belongs to the preparing technical field of superconducting ceramic. The invention provides a method for growing large-size and high-temperature superconducting single domain blocks through improved top-seeded melt texture. The method adopts large-size samarium barium copper oxide (Sm-Ba-Cu-O) seed crystal and an yttrium barium copper oxide (Y-Ba-Cu-O) preforming green body which is prepared according to defined chemical mixtures, the former is laid on the top of the latter, and melt texture growth method is performed in a high-temperature condition. The method overcomes the problem that spontaneous nucleation is easy to occur during the process of melt texture growth of small-size seed crystal, and effectively realizes the growth of large-size high-temperature yttrium barium copper oxide superconducting single domain blocks through a top-seeded melt texture method.

Owner:SHANGHAI UNIV

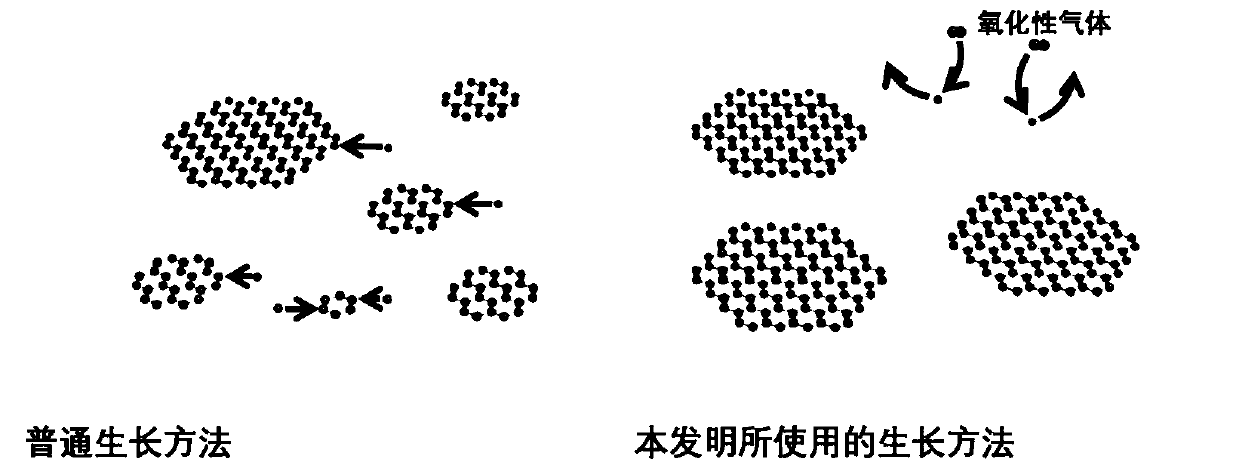

Graphene single crystal and growth method thereof

InactiveCN110904502AQuality is not affectedImprove conductivityPolycrystalline material growthFrom chemically reactive gasesChemical physicsSpontaneous nucleation

The invention provides a growth method of a graphene single crystal, and the method comprises the following steps: growing graphene on a substrate through chemical vapor deposition, and introducing anoxidizing gas in the growth process. The invention also provides the graphene single crystal formed by the method. According to the growth method, continuous spontaneous nucleation in the graphene growth process is inhibited as an entry point, and the formation of metastable nuclei in the graphene growth process is destroyed by continuously introducing a trace amount of the oxidizing gas for continuous passivation. According to the method, on the basis that the quality of the graphene is not influenced, the uniformity of the size of the domain region of the graphene is remarkably improved, and then the performance of the graphene in the aspects of electric conduction, heat conduction, mechanical strength and the like can be effectively improved.

Owner:BEIJING GRAPHENE INST +1

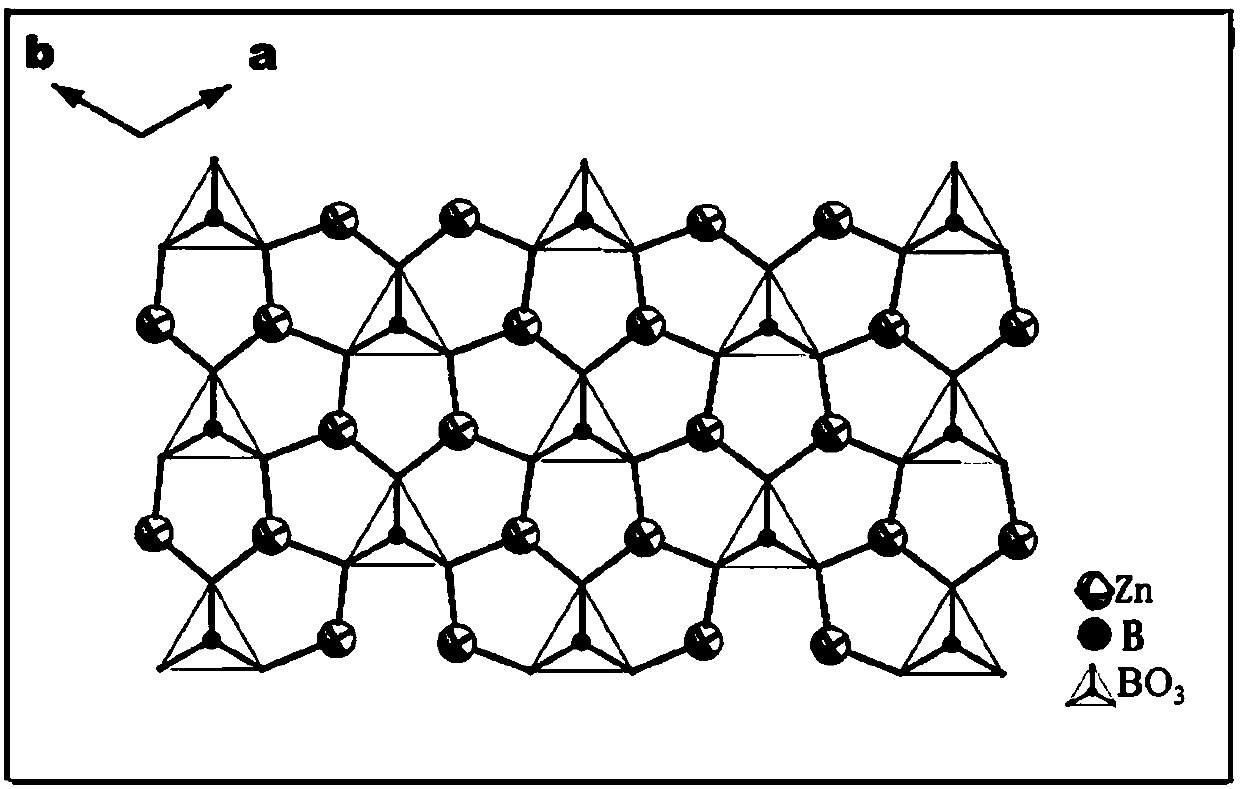

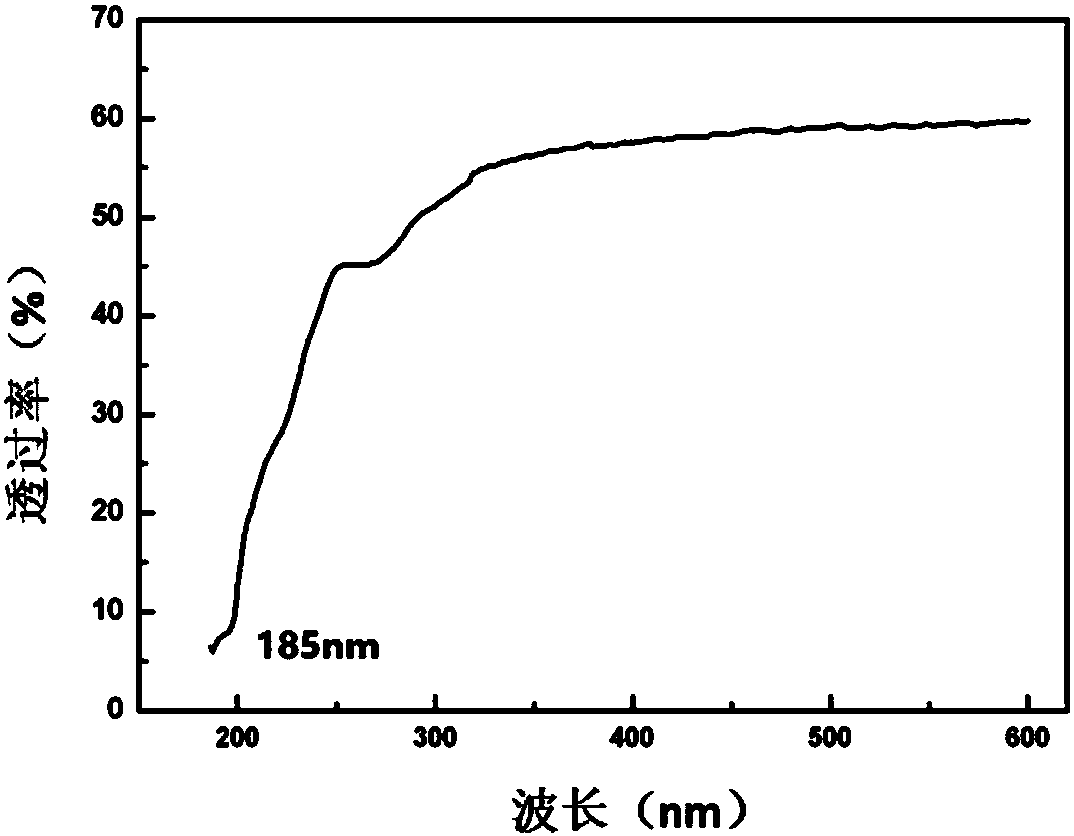

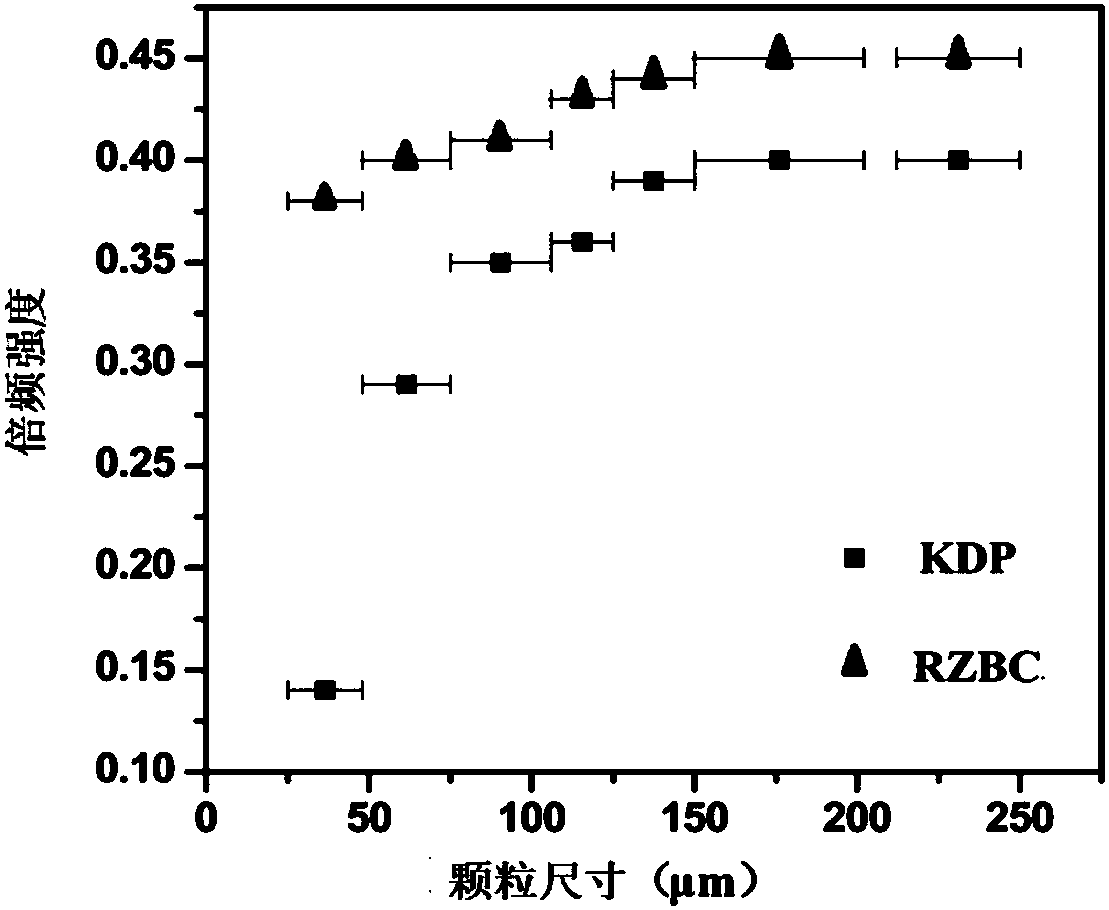

RbZn2BO3Cl2 nonlinear optical crystal, preparation method and application thereof

InactiveCN108018606AWide band of light transmissionImprove transmittancePolycrystalline material growthFrom solid stateNonlinear optical crystalSpace group

The invention relates to an RbZn2BO3Cl2 nonlinear optical crystal, preparation and application. The crystal does not have a symmetric center, belongs to a trigonal crystal system, has a space group ofR32, and has the cell parameters of: a=4.9698angstrom, b=4.9698angstrom, c= 27.178angstrom, alpha=beta=90degree, and gamma=120degree. A single crystal can be obtained in a self-flux system by a spontaneous nucleation method; a high temperature solid phase synthesis method is employed to obtain solid powder; high temperature melt spontaneous crystallization process growth is carried out to obtainlaminar and transparent single crystal without wrappage, the obtained crystal has wide light-transmitting wave band, and has high transmittance at 300-2000nm, and the ultraviolet cut-off edge is lessthan 200nm; powder frequency-doubling effect test shows that the crystal can achieve phase matching and the frequency-doubling effect is equivalent to that of KBe2BO3F2 crystal; the crystal has the advantages of high hardness, good mechanical properties, difficult fragmentation and deliquescence, easy processing and preservation, etc.; and the crystal can be used for preparation of nonlinear optical devices.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of pagoda-shaped large-size REBCO (RE-Ba-Cu-O) high-temperature superconductor block

InactiveCN103014861AThere is no problem of weak connection of grain boundariesNo effect on superconductivityPolycrystalline material growthFrom frozen solutionsYttrium barium copper oxideSpontaneous nucleation

The invention discloses a preparation method of a pagoda-shaped large-size REBCO (RE-Ba-Cu-O) high-temperature superconductor block. The preparation method comprises the following steps of: taking a c-axis oriented NdBCO / YBCO (Yttrium Barium Copper Oxide) / MgO film as a seed crystal, enabling an ab surface of the film seed crystal to be in contact with the upper surface of a precursor block, and putting the pagoda-shaped precursor block and the film seed crystal in a growth furnace to carry out fusion structure growth. The invention also discloses the pagoda-shaped large-size REBCO high-temperature superconductor block, which is a pagoda-shaped single-domain block and is free of weak connection of crystal boundaries. The preparation method of the pagoda-shaped large-size high-temperature superconductor block has the advantages that no spontaneous nucleation is generated due to application of an accelerated cooling method, the growth speed is high, and no seed crystal block needs to grow in advance, and can be used for growth of various REBCO high-temperature superconductor blocks and doping growth REBCO blocks. In addition, the preparation method is simple, easy to operate and is available in repeatability and controllability.

Owner:SHANGHAI JIAO TONG UNIV

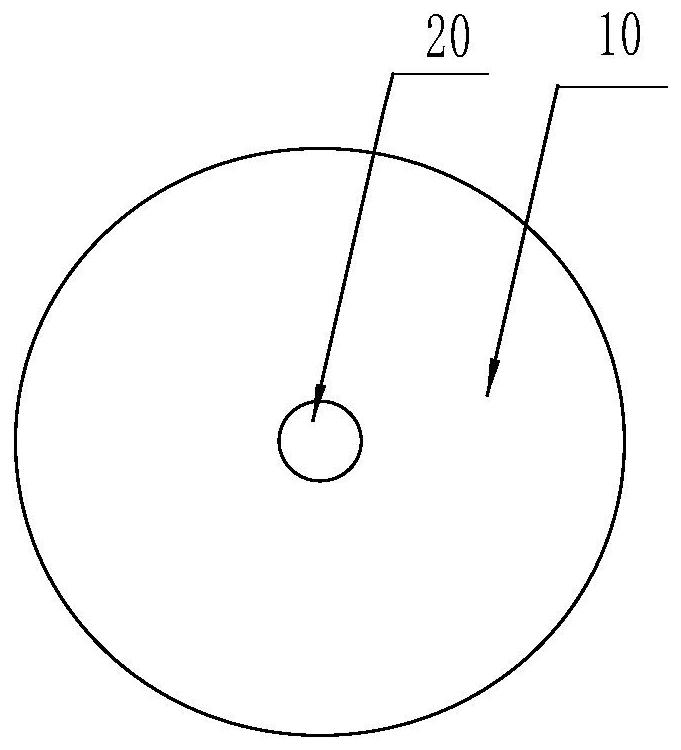

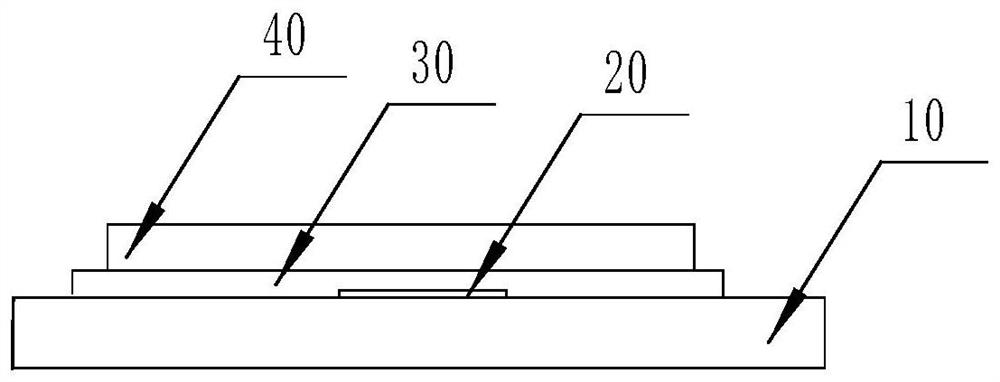

Seed crystal support and silicon carbide single crystal growth method

PendingCN111910246AQuality improvementReduce the number of nucleationPolycrystalline material growthFrom condensed vaporsSpontaneous nucleationPhysical chemistry

The invention provides a seed crystal support and a silicon carbide single crystal growth method. The method comprises the steps: arranging a heat conduction layer in the central area of a seed crystal support substrate, wherein the heat conductivity of the heat conduction layer is greater than that of the seed crystal support substrate. When SiC seed crystals are bonded on the seed crystal support for single crystal growth, the heat conductivity of the heat conduction layer in the central region of the seed crystal support is greater than that of the graphite seed crystal support substrate, so that the surface temperature of the seed crystals corresponding to the central region is lower than that of other regions of the seed crystals, the concentration of corresponding growth components is high, and the degree of supersaturation is high; when the supersaturation reaches the critical supersaturation degree, the nucleation begins; the temperature of other areas on the surface of the seed crystal is higher, so the critical supersaturation degree cannot be reached, and spontaneous nucleation cannot be realized. Therefore, the crystal nucleus formed in the central region can slowly grow by taking the crystal nucleus as the center, the advantages of the central crystal nucleus are established, and the silicon carbide single crystal is further obtained. The seed crystal surface temperature field is modulated through the heat conduction layer, the nucleation number is reduced, and the SiC crystal quality is improved.

Owner:广州南砂晶圆半导体技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com