Magnesium niobate series crystals and preparation method thereof

A technology of magnesium tantalate and crystals, which is applied in the field of microwave dielectric materials, magnesium tantalate series crystals and their preparation, can solve the problems of poor quality and performance of magnesium tantalate crystals, achieve transparent macroscopic defects, and solve the problems of easy cracking, Effects without macro defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

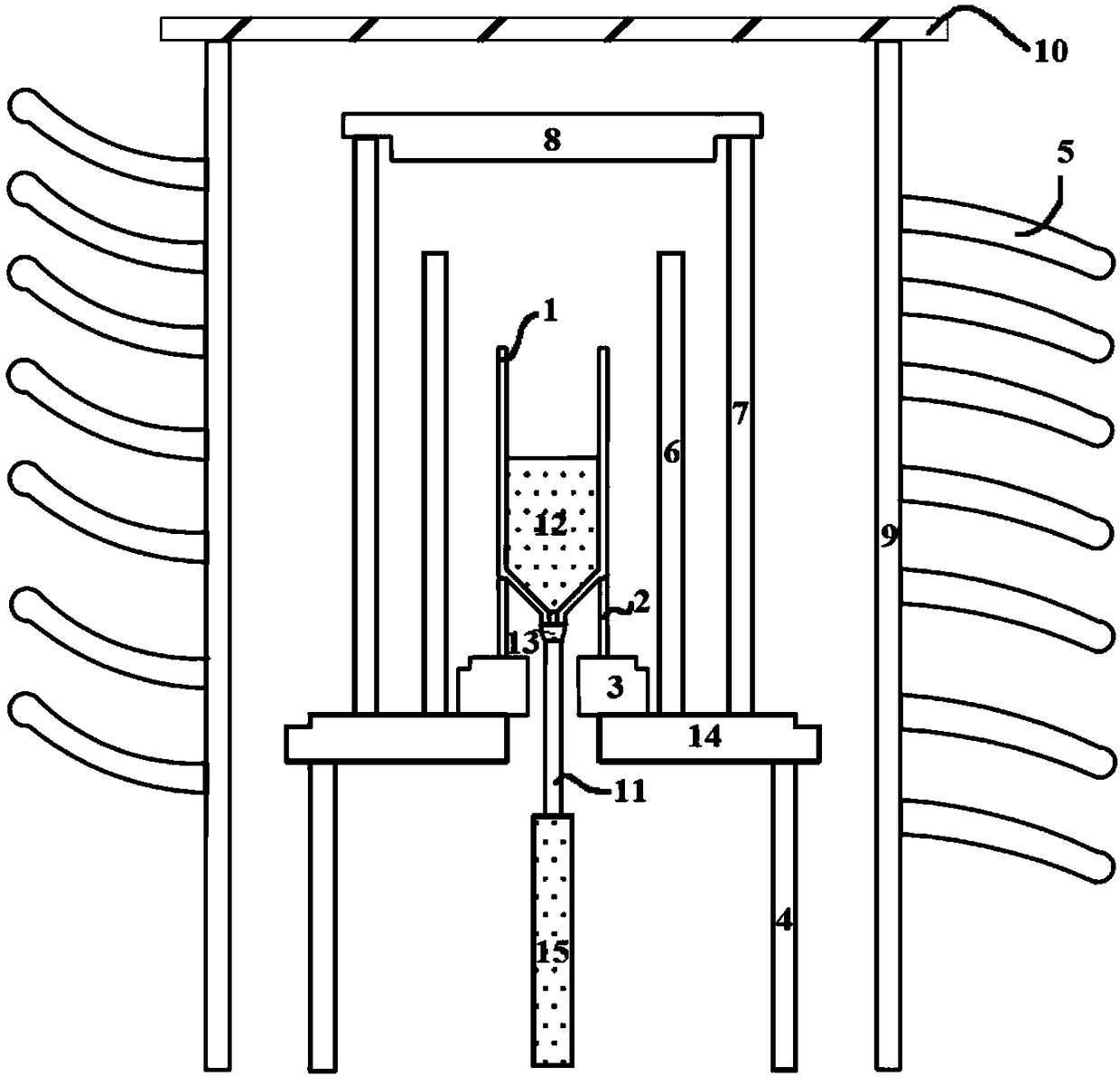

[0041] Embodiment 1 micro pull-down method grows Mg 4 Ta 2 o 9 the crystal

[0042] (1) Synthesis of high-purity Mg by solid phase reaction 4 Ta 2 o 9 Powder

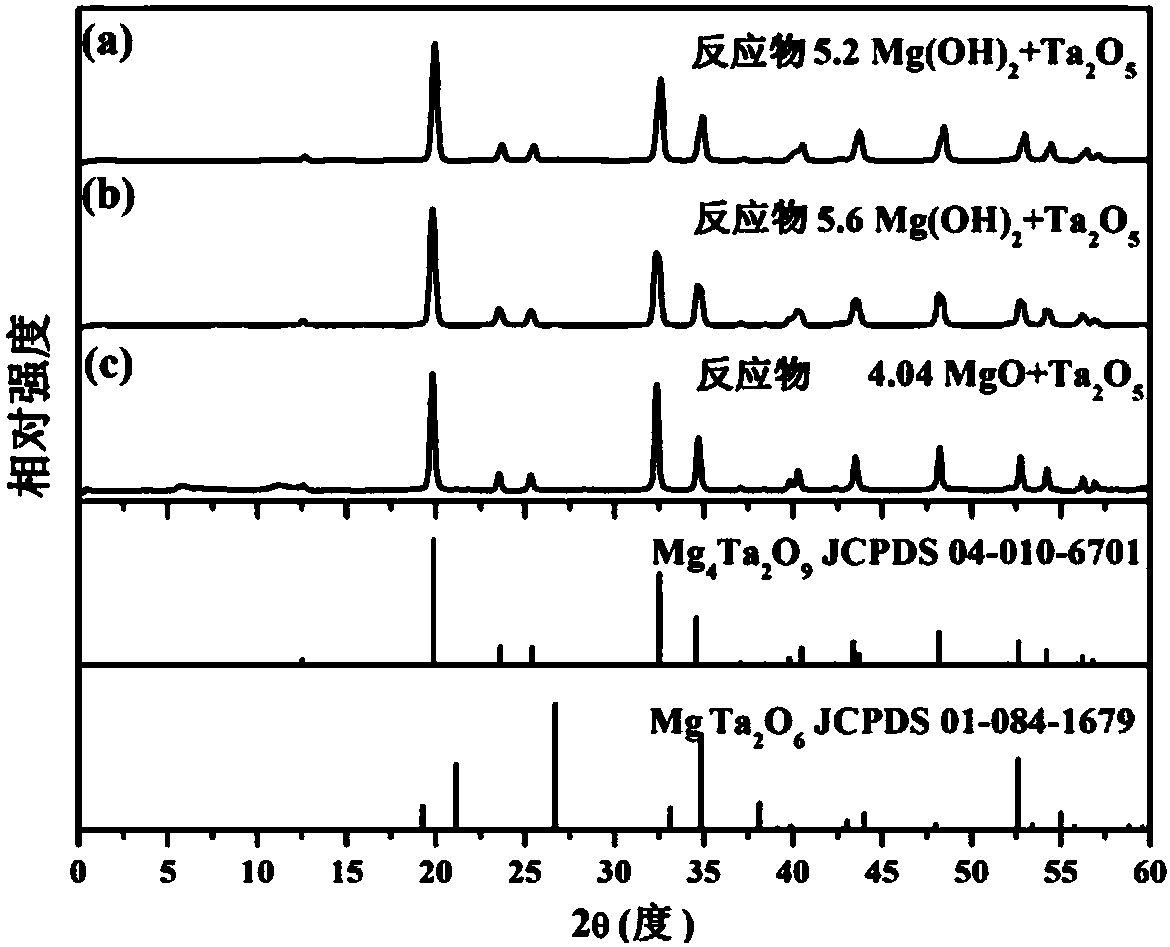

[0043] 1) 5.2Mg(OH) 2 :1Ta 2 o 5 Synthetic pure phase Mg 4 Ta 2 o 9 Powder

[0044] According to the molar ratio of 5.2:1, the Mg(OH) with a purity of 99.999% and 99.99% was weighed 2 and Ta 2 o 5 A total of 5g of raw materials were put into a mortar, ground and mixed, sieved with 220 mesh, and put into a ZrO 2 In the ball mill jar, mill on a ball mill for 1 hour. Under the action of 350MPa pressure, a cylindrical sheet with a size of Φ13mm×5mm was prepared, put into a muffle furnace for pre-firing at 1300°C for 16h, and the heating and cooling rate was 100°C / h. The phase-pure powder XRD ( figure 2 (a)) for characterization.

[0045] 2) 5.6Mg(OH) 2 :1Ta 2 o 5 Synthetic pure phase Mg 4 Ta 2 o 9 Powder

[0046] The ratio of raw materials was increased to 5.6:1, and the pre-fired temperature was ...

Embodiment 2

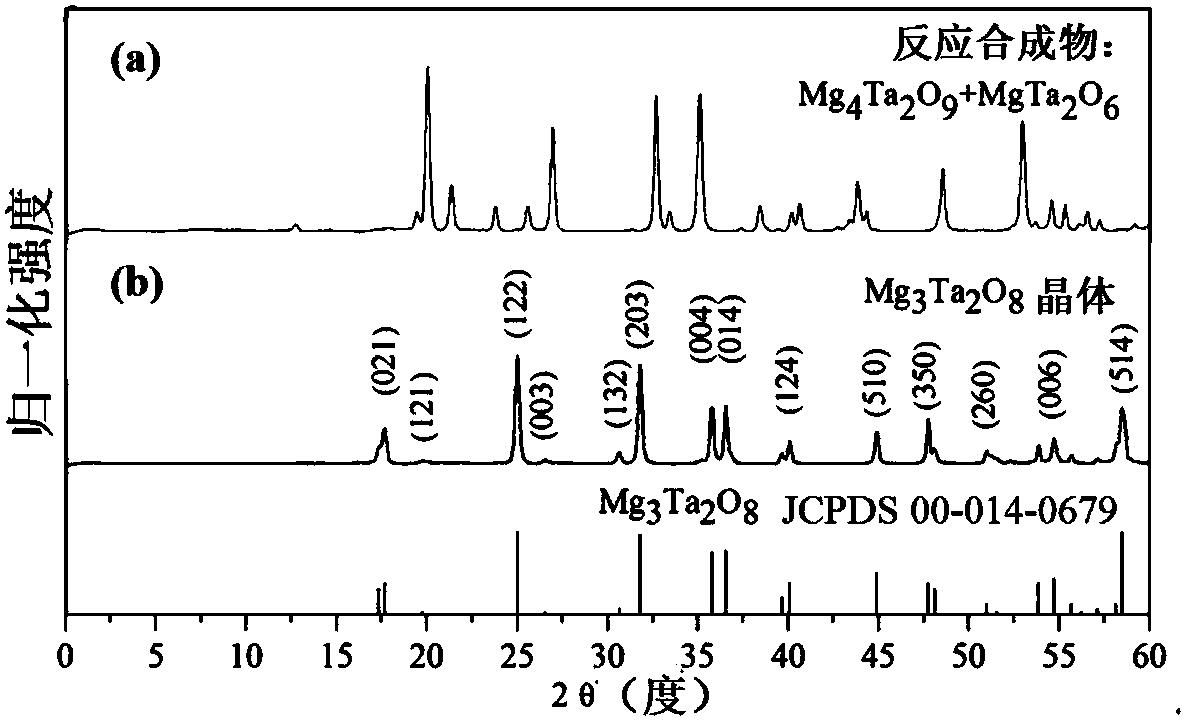

[0057] Embodiment 2 grows Mg by micro pull-down method 3 Ta 2 o 8 the crystal

[0058] The high-purity powder raw material Mg(OH) 2 (99.999%) and Ta 2 o 5 (99.99%) according to the molar ratio of 4:1 ingredients, a total of 5g into the mortar to grind and mix, 220 mesh sieve, put it into the ZrO 2 In the ball mill tank, mill on the ball mill for 1 hour, grind the milled material in the mortar again, sieve through 220 mesh, press 350MPa into a cylindrical piece with a size of Φ13mm×5mm, and put it into a high-temperature muffle furnace , set the pre-burning temperature to 1300°C, hold time to 16h, and heat up and down at a rate of 100°C / h. The phase purity of the obtained ceramic cylinder is characterized by powder XRD, and its spectrum features are as follows: Figure 7 (a). No Mg was found 3 Ta 2 o 8 Phase, is 0.62Mg 4 Ta 2 o 9 +0.38MgTa 2 o 6 Mixed phase, according to phase diagram analysis, its components are roughly in the Mg 3 Ta 2 o 8 near the componen...

Embodiment 3

[0062] Embodiment 3 grows MgTa by micro pull-down method 2 o 6 the crystal

[0063] The raw material Mg(OH) 2 (Noah chemical, 99.999%) and Ta 2 o 5 (Aldrich, 99.99%) weighed at a molar ratio of 1.15:1, mixed in a 5g mortar, sieved at 220 mesh, ball milled for 1h, and under 350MPa, a cylindrical piece of Φ13mm×5mm was prepared, and put into a muffle furnace for 1400 Pre-burn at ℃ for 8 hours, and heat up and down at 100℃ / h. Powder XRD, such as Figure 10 (a) shows that the obtained ceramic sheet is pure phase MgTa 2 o 6 . The synthesized pure phase MgTa 2 o 6 Powder and Mg(OH) 2 The powder is ball-milled and mixed at a molar ratio of 100:1, and a total of 5 g is dry-pressed into a column with a diameter of 13 mm. figure 1 shown in the Ir crucible, with Y 3 al 5 o 12 (referred to as YAG) single crystal rod as seed crystal, the upper end of the seed crystal is cut flat and polished, and kept clean and dry, fixed in the hollow Al 2 o 3 on the seed rod. Adjust var...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com