Fine pure plate-shaped grain cemented carbide and preparation method thereof

A hard alloy and pure plate technology, which is applied in the field of preparation of the fine and pure plate crystal hard alloy, can solve the problem of low fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

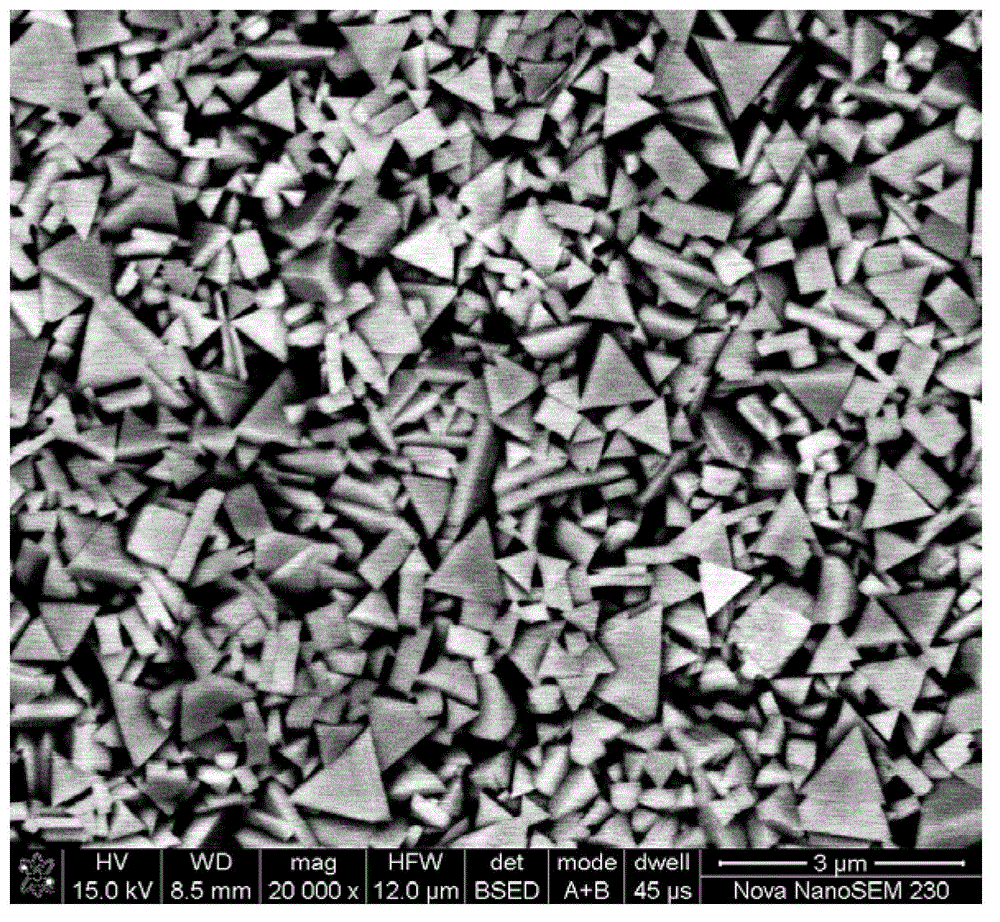

[0020] Using WC–12Co nanocomposite powder with a WC grain size of 90nm, Cr 3 C 2 , VC and anhydrous lanthanum nitrate as raw materials to prepare WC–12Co–0.96Cr 3 C2 –0.36VC–0.072La 2 o 3 Carbide. The alloy mixture was prepared by rolling wet grinding process, the wet grinding time was 40h, and the ball-to-material ratio was 5:1. During the wet grinding process, paraffin wax accounting for 1.5% of the total mass fraction of the alloy mixture and 1.5% of the total mass fraction of the alloy mixture were added. % PEG4000, using a mixed solution of alcohol and n-hexane with a volume ratio of 1:1 as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered in a 6MPa pressure sintering furnace. The sintering temperature was 1380°C, the holding time was 1h, and the pressure in the furnace during the holding stage was 5.6MPa. figure 1 It is a 3D high-resolution scanning electron microscope photo of the surface...

Embodiment 2

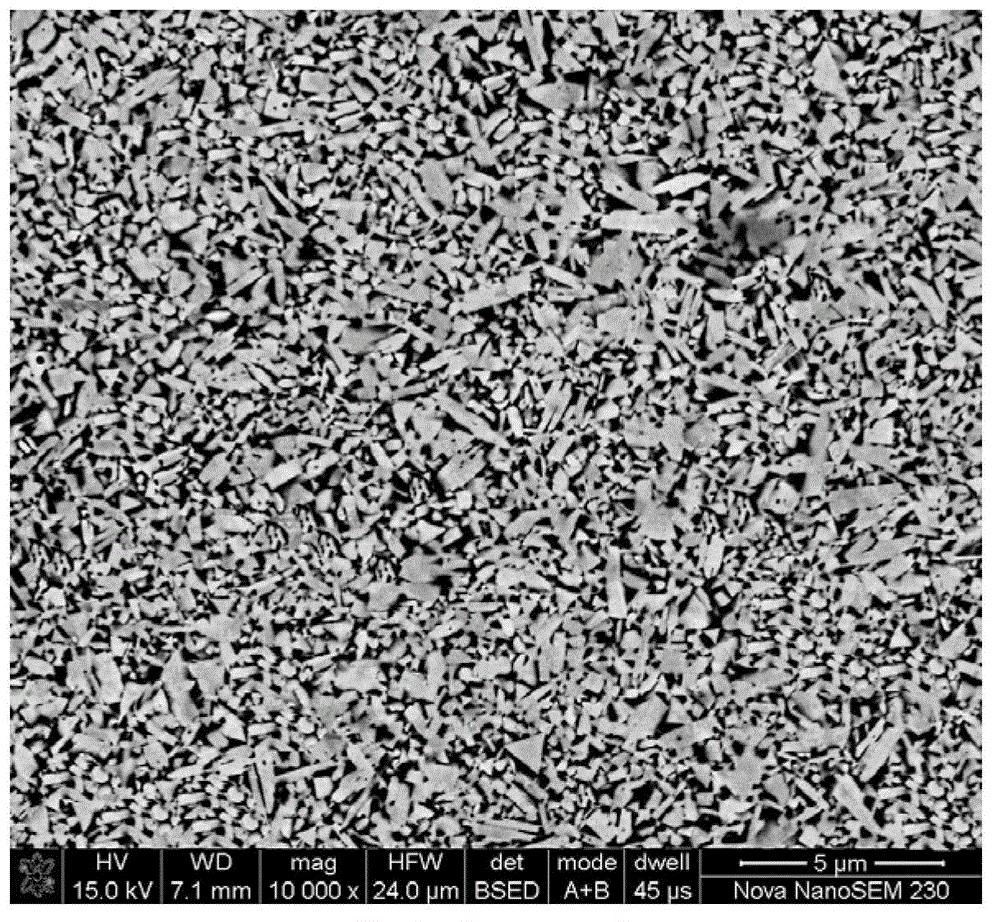

[0022] Using WC–12Co nanocomposite powder with a WC grain size of 90nm, Cr 3 C 2 , VC and anhydrous yttrium nitrate as raw materials to prepare WC–12Co–0.6Cr 3 C 2 –0.48VC–0.036Y 2 o 3 Carbide. The alloy mixture was prepared by rolling wet grinding process, the wet grinding time was 60h, and the ball-to-material ratio was 6:1. During the wet grinding process, paraffin wax accounting for 1.0% of the total mass fraction of the alloy mixture and 1.0% of the total mass fraction of the alloy mixture were added. % PEG4000, using a mixed solution of alcohol and n-hexane with a volume ratio of 1:1 as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered in a 10MPa pressure sintering furnace. The sintering temperature was 1360°C, the holding time was 1h, and the pressure in the furnace during the holding stage was 9.5MPa. The 3D microstructure measurement results on the surface of the alloy sintered body sh...

Embodiment 3

[0024] Using WC–12Co–0.72Cr with a WC grain size of 80nm 3 C 2 –0.36VC–0.054CeO 2 Nanocomposite powder as raw material to prepare WC–12Co–0.72Cr 3 C 2 –0.36VC–0.054CeO 2 Carbide. The alloy mixture was prepared by rolling wet grinding process, the wet grinding time was 50h, and the ball-to-material ratio was 4:1. During the wet grinding process, paraffin wax accounting for 1.2% of the total mass fraction of the alloy mixture and 1.2% of the total mass fraction of the alloy mixture were added. % PEG4000, using a mixed solution of alcohol and n-hexane with a volume ratio of 1:1 as the wet grinding medium. The alloy samples were pressed by the traditional molding process, and the alloy samples were sintered in a 6MPa pressure sintering furnace. The sintering temperature was 1400°C, the holding time was 1h, and the pressure in the furnace during the holding stage was 5.6MPa. The 3D microstructure measurement results on the surface of the alloy sintered body show that the aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com