Patents

Literature

2054 results about "Solid phase reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

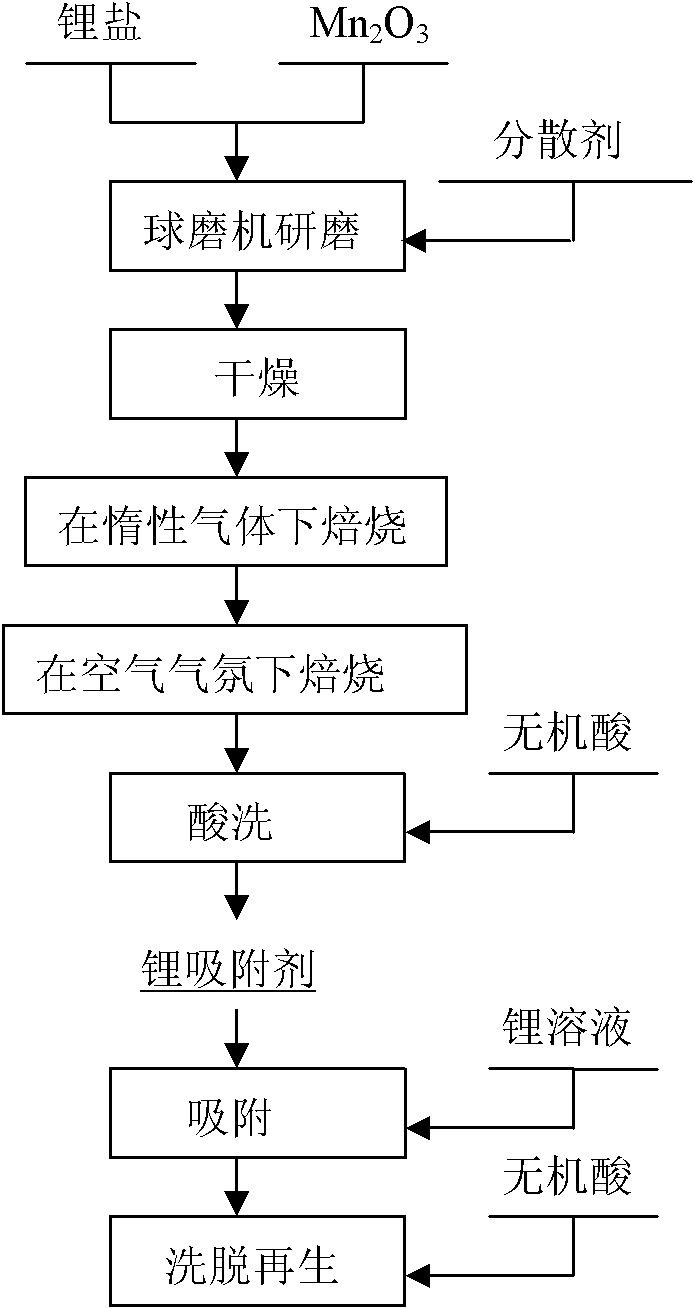

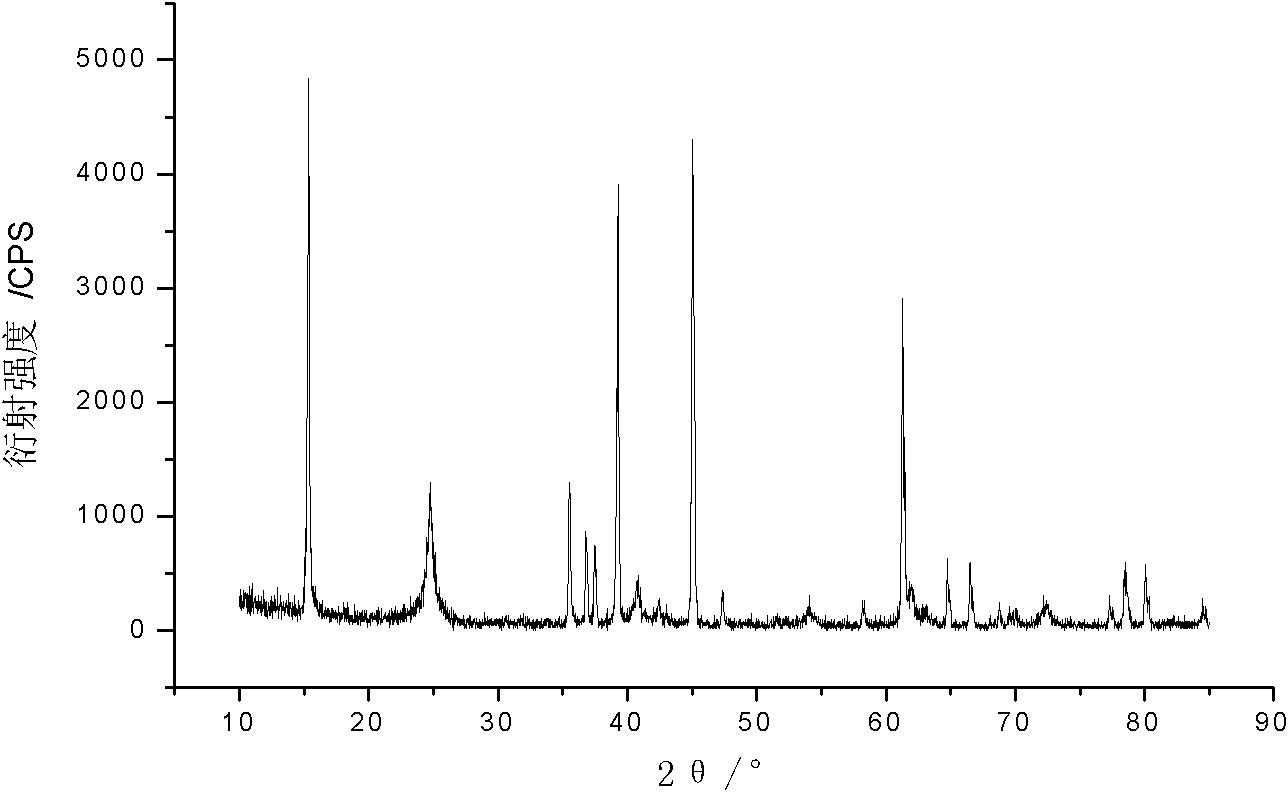

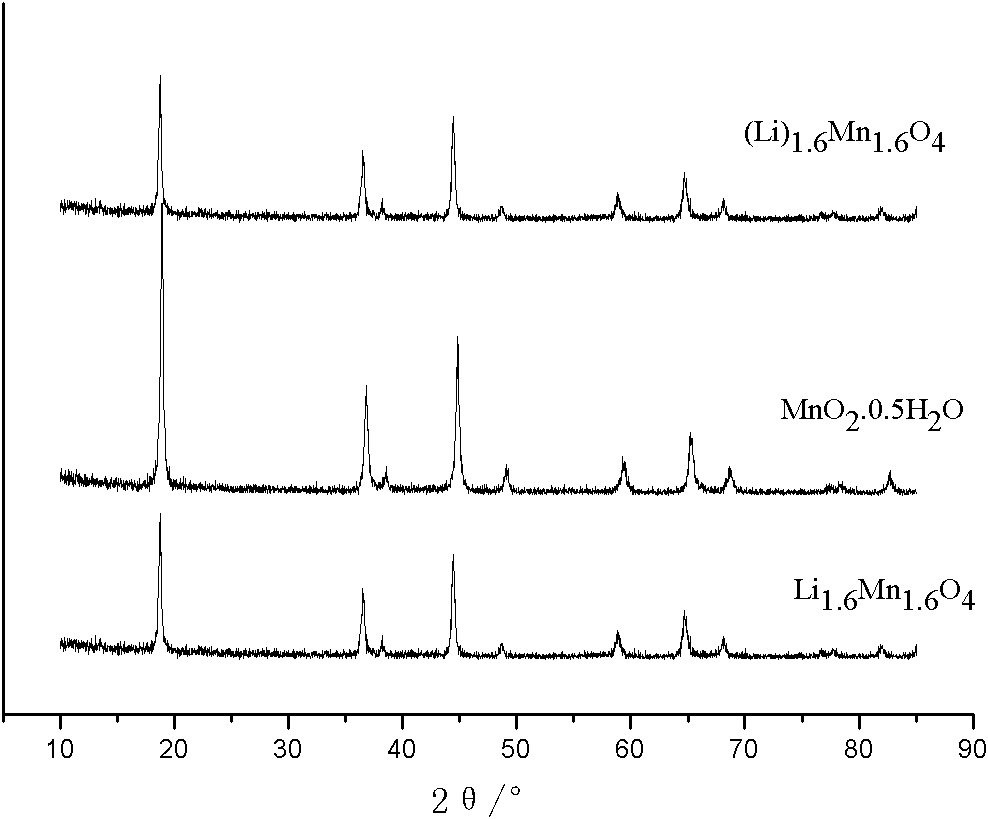

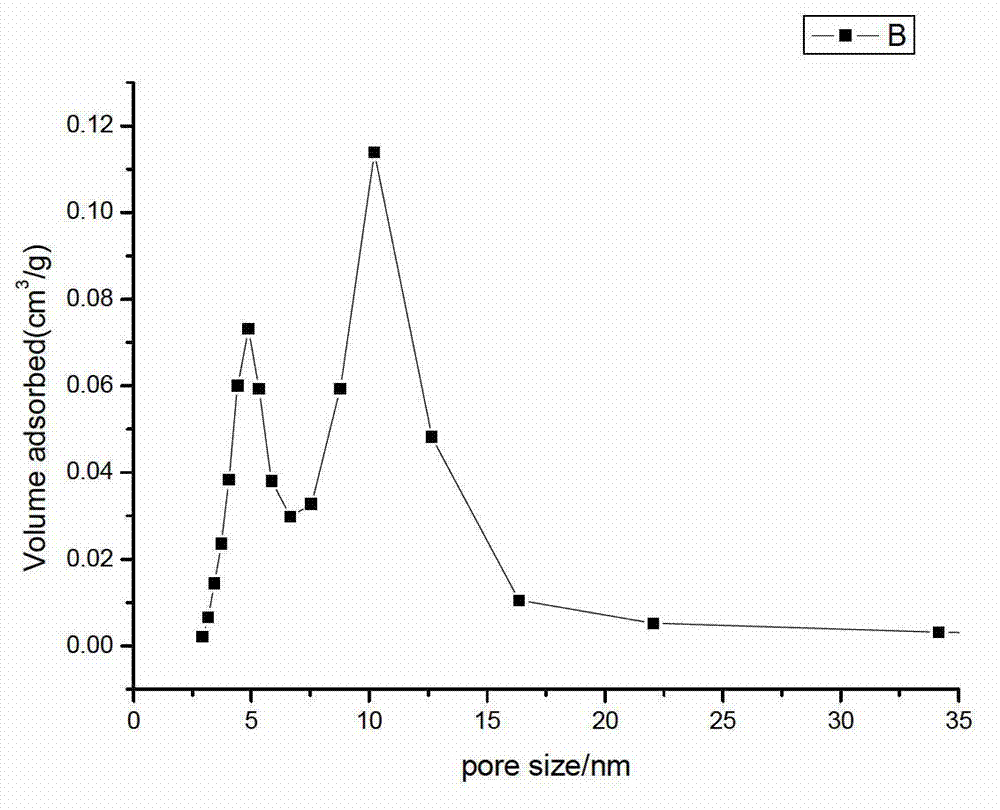

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

ActiveCN101961634ALow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

The invention discloses a method for preparing a manganese series lithium ion sieve adsorbent, and relates to a method for preparing an inorganic adsorbent for adsorbing lithium from liquid lithium resources such as brine of salt lake, seawater and the like. In the method, a cubic crystal ion sieve precursor Li1.6Mn1.6O4 is prepared from Mn2O3 and LiOH or Li2CO3 serving as raw materials by using two sections of solid-phase reactions, wherein the precursor also can be used as an anode material of a lithium ion battery. The precursor is acidized to obtain a lithium ion sieve adsorbent MnO2.0.5H2O (or expressed as H1.6Mn1.6O4), and the ion sieve is the lithium adsorbent which has high selectivity on lithium. The method has the advantages of simple and readily available raw materials, simple process, high adsorption capacity of the ion sieve, low cost, high purity of products and is easy to realize industrial production.

Owner:CENT SOUTH UNIV +1

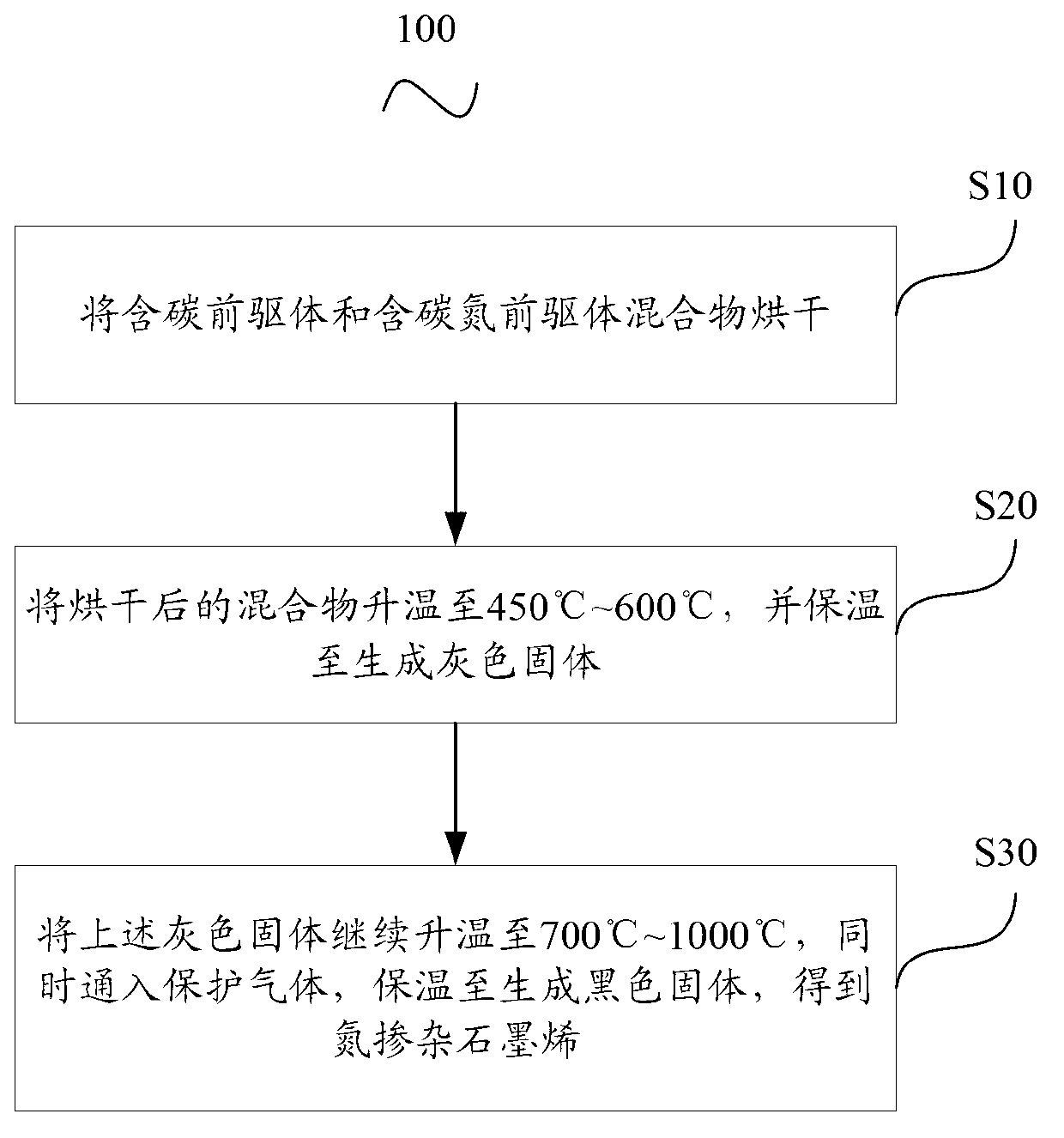

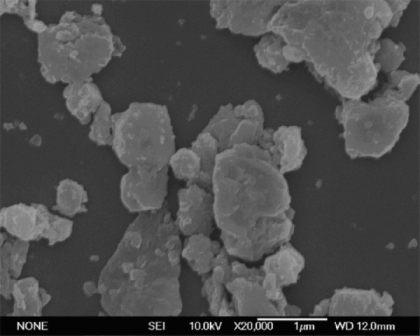

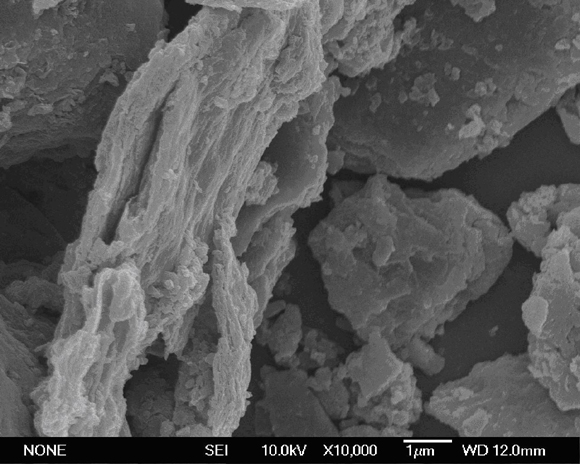

Method for preparing nitrogen-doped graphene and nitrogen-doped graphene

InactiveCN103274393ASimple processEase of industrial productionGrapheneSolid reactionCarbon Dioxide / Helium

The invention discloses a method for preparing nitrogen-doped graphene which comprises the following steps of: drying a mixture of a carbon-containing precursor and a carbon-nitrogen-containing precursor; raising the temperature of the dried mixture to be 450-600 DEG C, and keeping the temperature to generate gray solid; and continuously raising the temperature of the gray solid to be 700-1000 DEG C, introducing protective gas, keeping the temperature to generate black solid, and obtaining the nitrogen-doped graphene. According to the method for preparing nitrogen-doped graphene in the embodiment, the nitrogen-doped graphene is obtained under normal pressure and high temperature through a solid-phase reaction, the whole preparation method is simple in process, the nitrogen-doped graphene can be obtained without complex equipment, and industrial production is easily performed. In addition, the invention also provides nitrogen-doped graphene.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

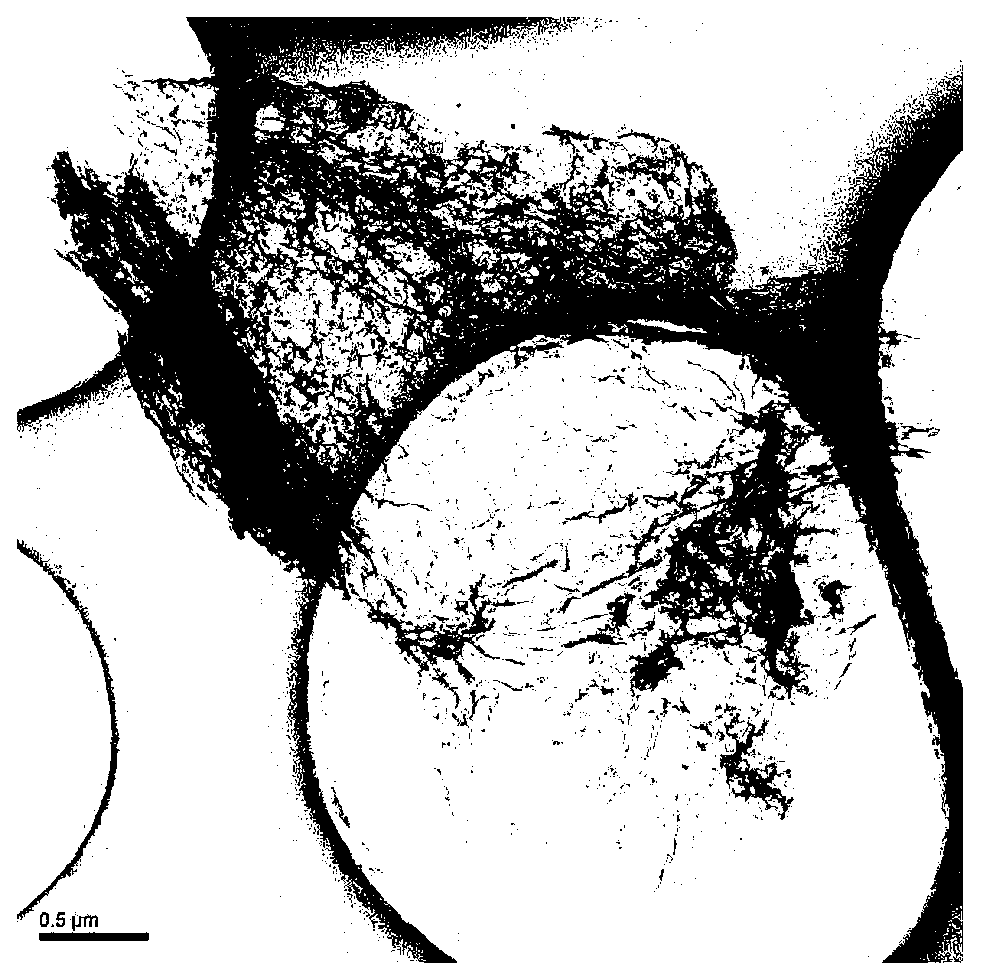

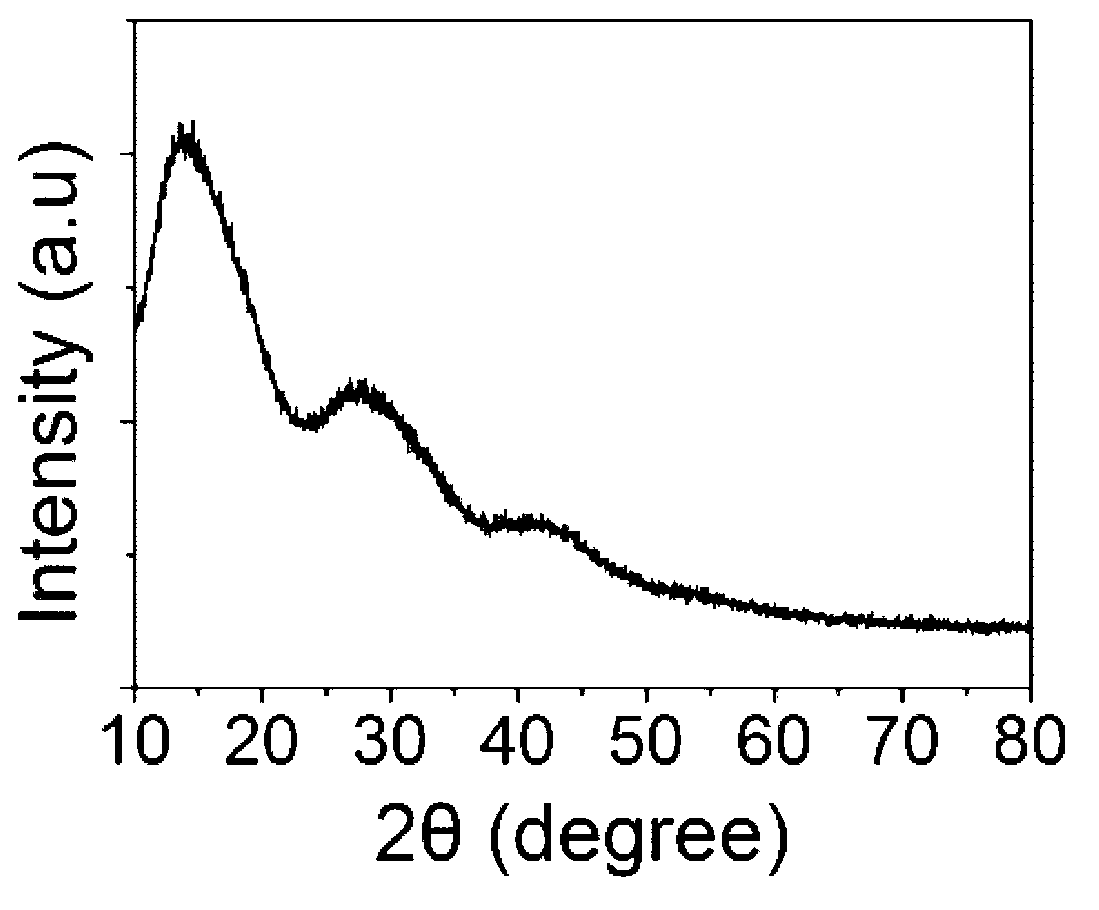

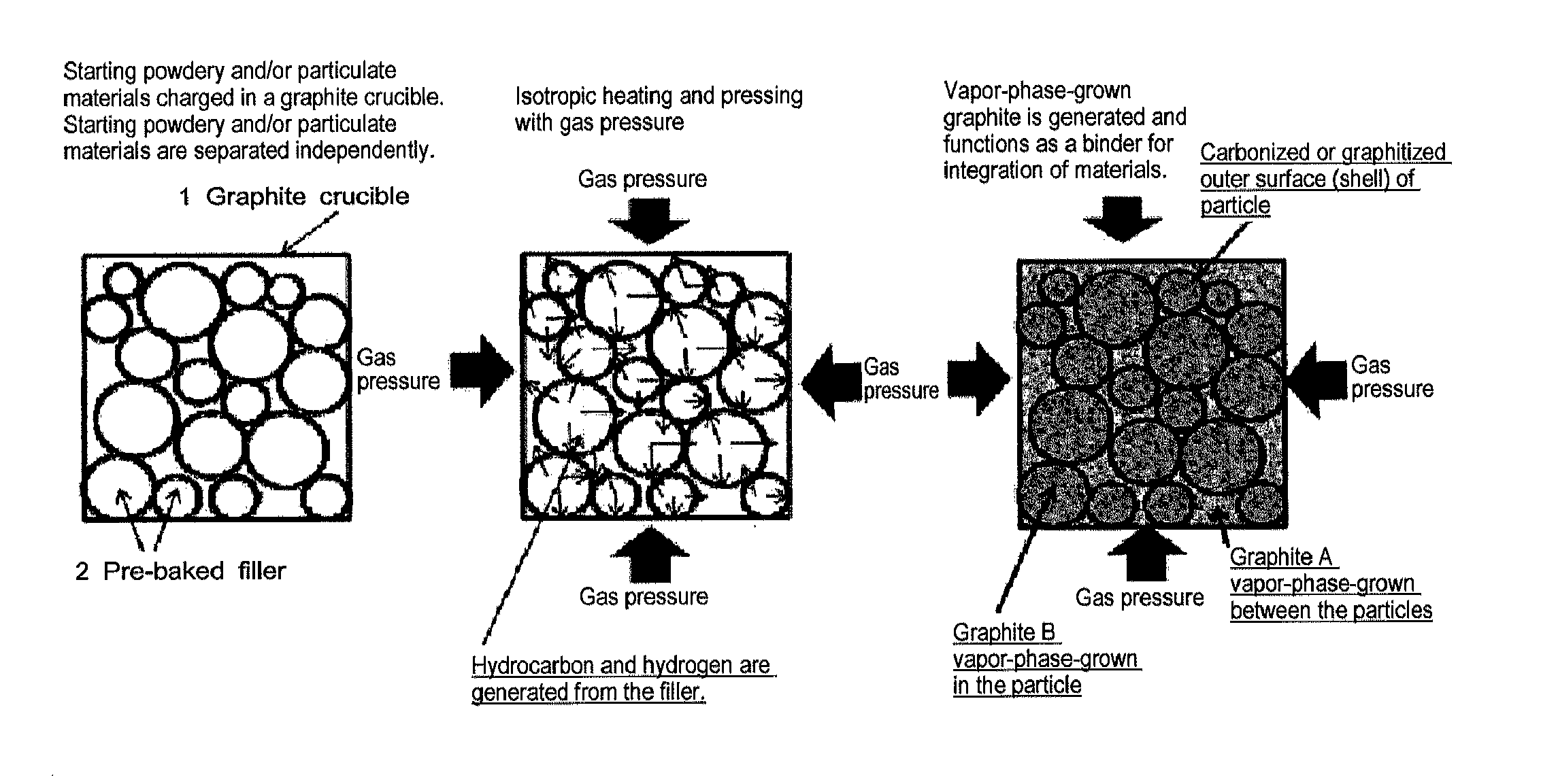

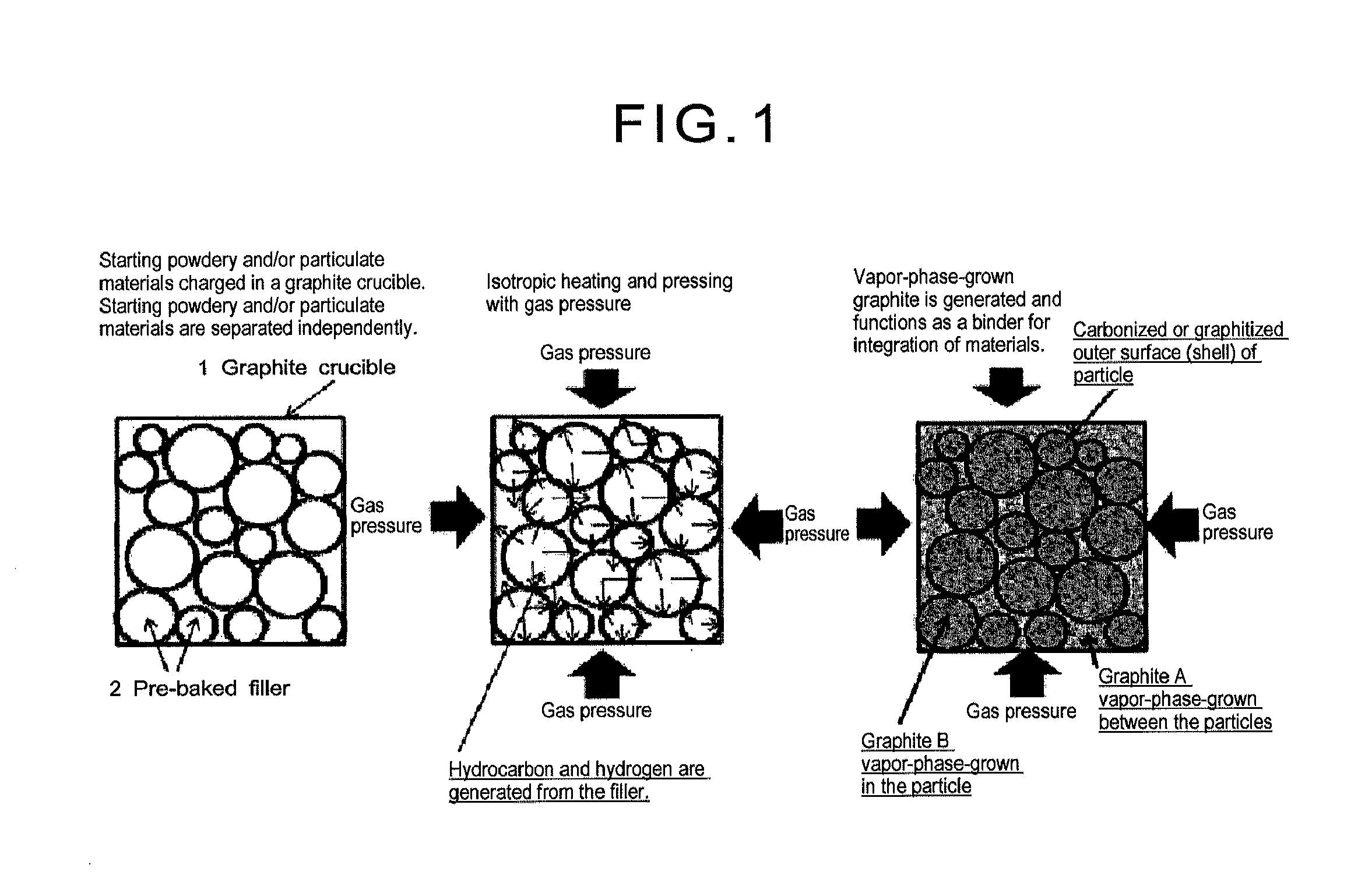

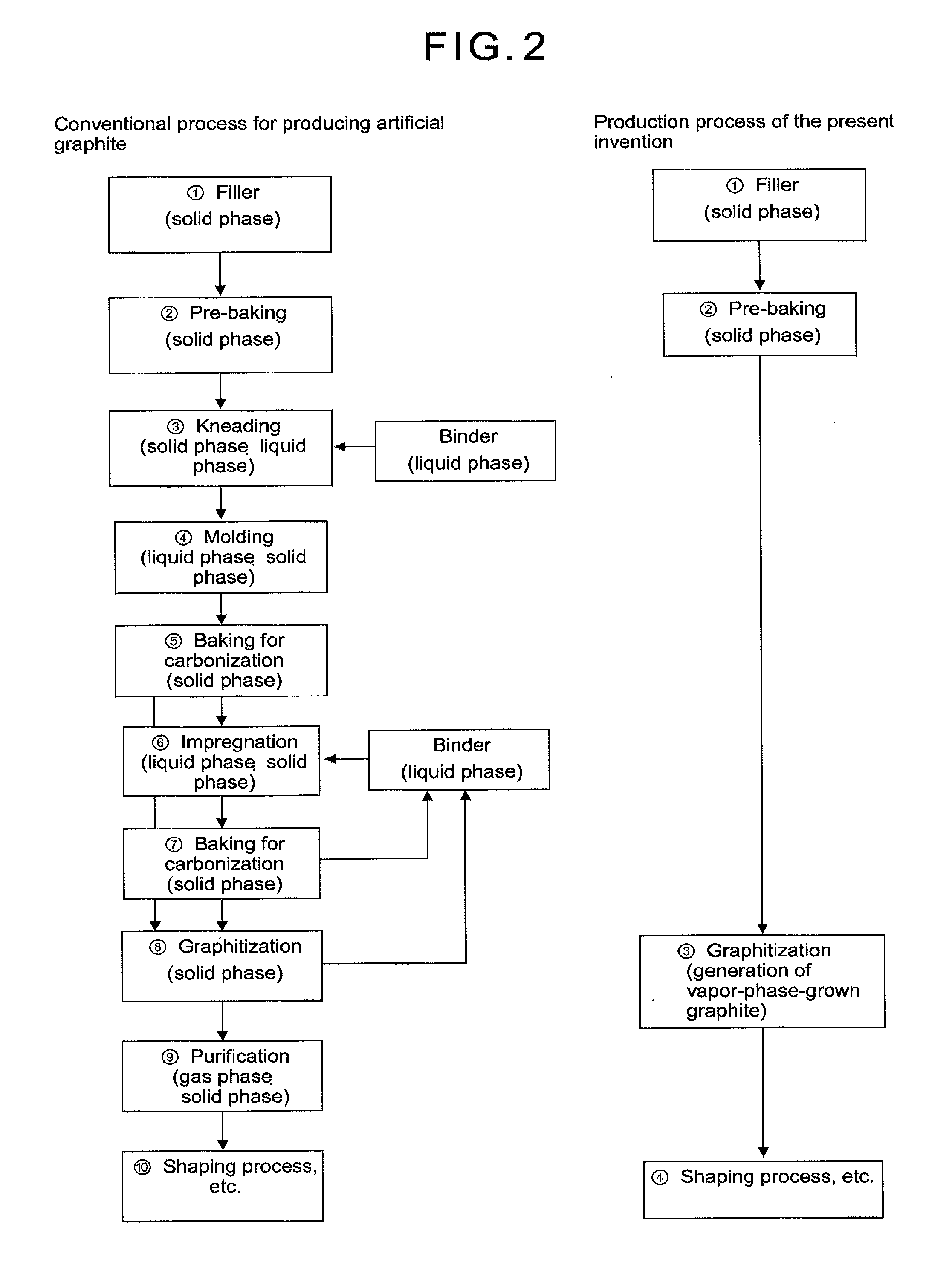

Carbon material and method for producing same

ActiveUS20120077020A1Simple processLow costMaterial nanotechnologyFullerenesGas phaseSource material

(Problem)In conventional method for producing artificial graphite, in order to obtain a product having excellent crystallinity, it was necessary to mold a filler and a binder and then repeat impregnation, carbonization and graphitization, and since carbonization and graphitization proceeded by a solid phase reaction, a period of time of as long as 2 to 3 months was required for the production and cost was high and further, a large size structure in the shape of column and cylinder could not be produced. In addition, nanocarbon materials such as carbon nanotube, carbon nanofiber and carbon nanohorn could not be produced.(Means to Solve)A properly pre-baked filler is sealed in a graphite vessel and is subsequently subjected to hot isostatic pressing (HIP) treatment, thereby allowing gases such as hydrocarbon and hydrogen to be generated from the filler and precipitating vapor-phase-grown graphite around and inside the filler using the generated gases as a source material, and thereby, an integrated structure of carbide of the filler and the vapor-phase-grown graphite is produced. In addition, nanocarbon materials are produced selectively and efficiently by adding a catalyst or adjusting the HIP treating temperature.

Owner:INCUBATION ALLIANCE

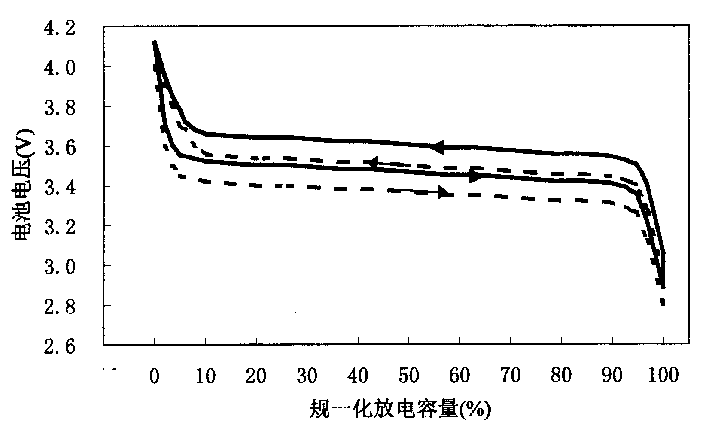

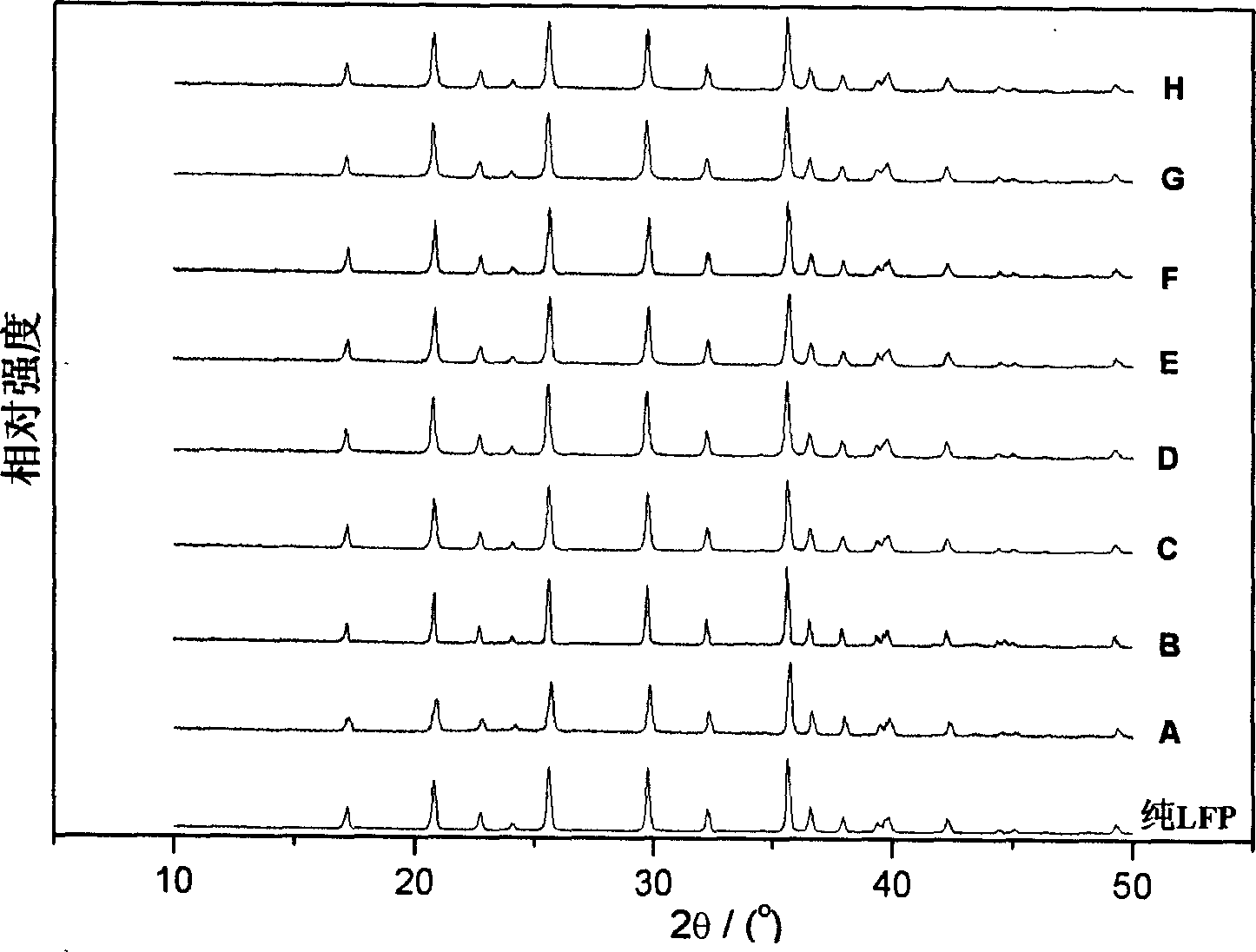

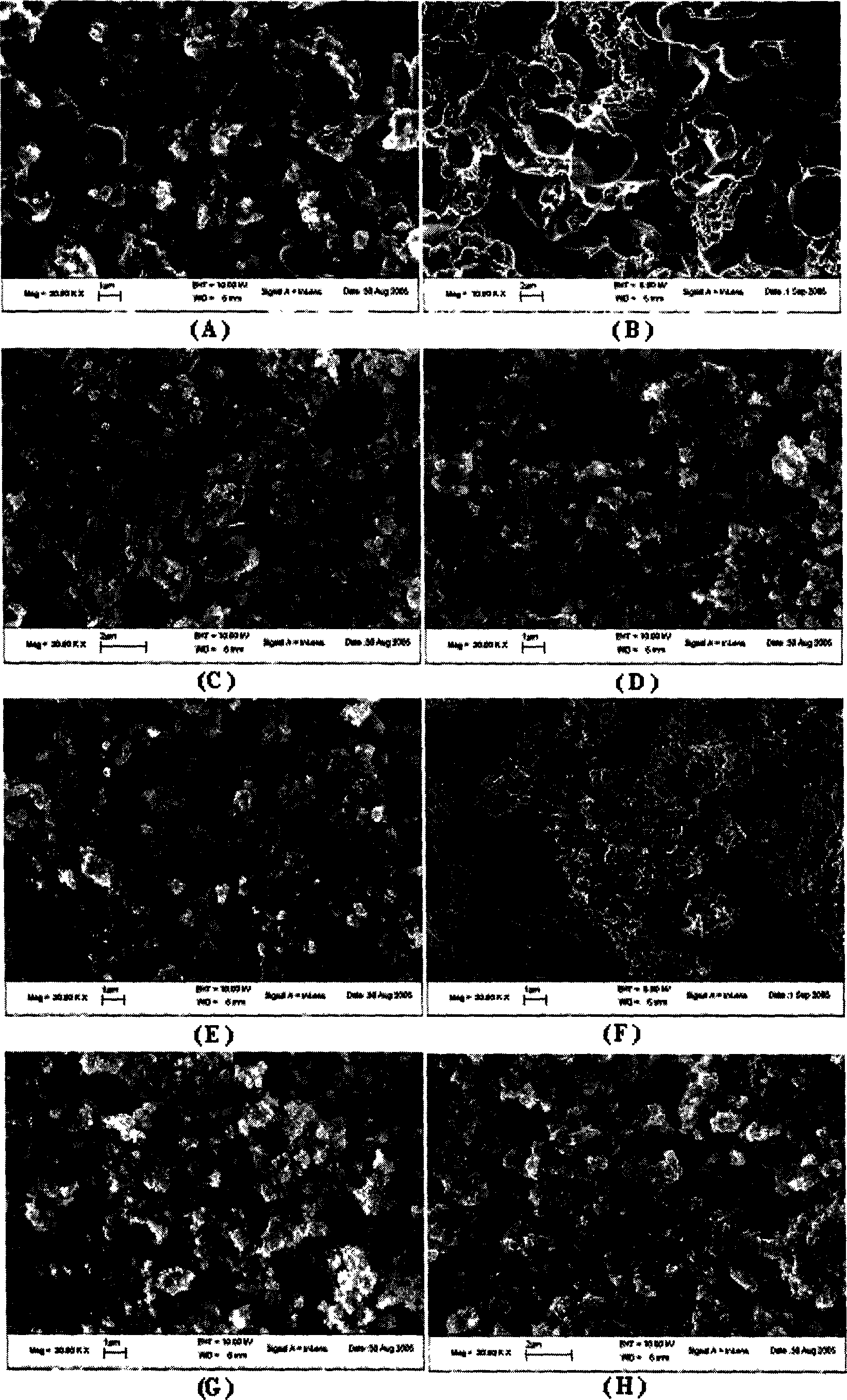

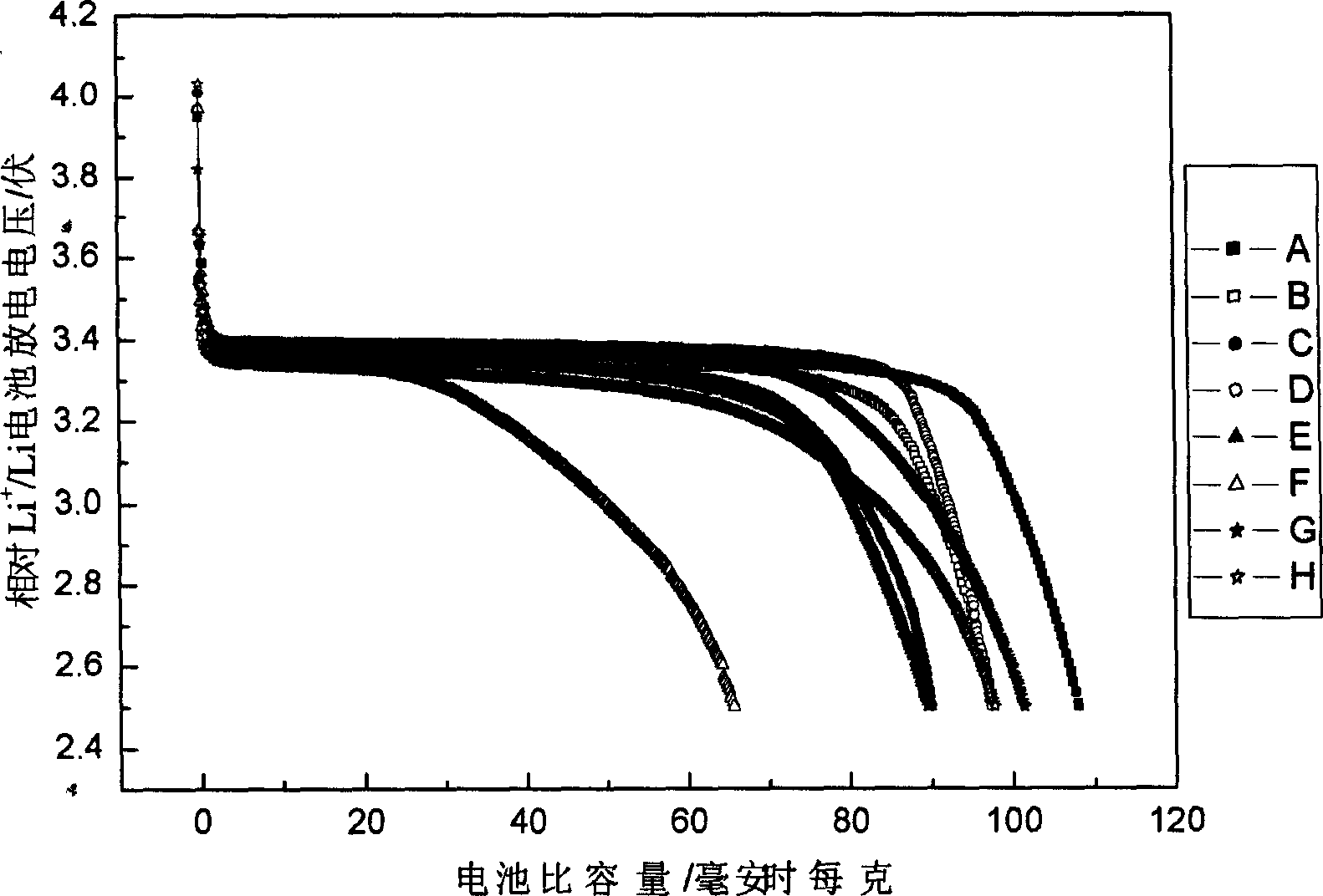

Lithium cell positive electrode materials and preparing method thereof

InactiveCN1457111AImprove conductivityHigh conductivity at room temperatureElectrode thermal treatmentPositive electrodesNano structuringElectrical battery

The chemical general formula of the material is expressed as follows: LixM1-xFePO4, where M is selected from Mg2+, Ca2+...P5+ etc. With conduction adulterant added, reaction at 500-900 deg.C for 10 hr. by using metal oxide, phoshpate, fluoride etc. and non saturated crystal of Li-Fe phoshpate through nonstoichiometric method obtains the crystal of Li-Fe phosphate with high conductivity, which can be expressed as LiFePO4-y. The formula of material prepared by using method of pressurized type substitution ion is LixM1-xFezM'1-z. The formula of material of solid power prepared by using method of solid phase reaction is as LixM1-xFezMn1-zPO4. The formula of anode material in nano structure prepared by using method of vacuum sputter deposition is LixFePO4-y, whose conductivity and discharge capacity can reach 10 to the power -2 S / cm and 240 Ah / g.

Owner:徐瑞松

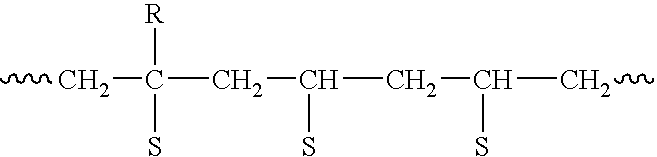

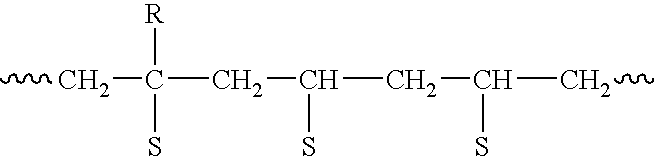

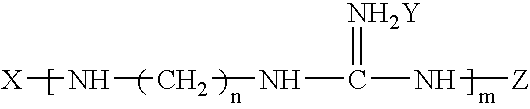

Preparation method of functional master batch of polyolefin and its application

ActiveUS7282538B2Maintain good propertiesReducing flowability and spinnabilityThin material handlingGraft polymer adhesivesFiberPolymer science

The present invention belongs to the field of polymerization and processing of polymer and relates to the preparation of a kind of functional polyolefin master batch. The functional master batch is produced by liquid phase, melt phase, or solid phase reaction after mixing the polyolefin resin, polyamine and guanidine salt oligomer, olefin monomer and initiator. The molecular structure of functional polyolefin master batch is shown below:wherein R is a polyamine and guanidine salt oligomer bonded onto polyolefin molecular chain by covalence bond, while S is one selected from hydrogen, chlorine, methyl, or phenyl group.Blending mentioned functional master batch with the corresponding polyolefin, the various antimicrobe products, such as fibers, film, pipe and other plastic articles can be obtained. Besides endowing products with excellent permanent antimicrobe property, it also provides fibers with good-dyeable and antistatic ability and bumpers with easy-paintable ability.

Owner:SHANGHAI SUJIE SCI TECH

Process for producing carbon coated iron lithium phosphate

InactiveCN101172599AElectrode manufacturing processesPhosphorus compoundsShortest distancePhosphate ion

The invention relates to a preparation method of lithium iron phosphate for the carbon cladding of a lithium ion battery. The prior lithium iron phosphate preparation technical art is complex, and has high cost. The invention has the synthetic process that: ferric oxide, phosphoric acid, simple organics and doped element compound are mixed and dried, the mol ratio of phosphate radical ion, ferric ion and doped element ion is 1:y:z, wherein, y is larger than or equal to 0.95 and smaller than or equal to 1, and y plus z is equal to 1; the mixture is added with lithium source compound, added with water to be mixed and dried, the mol ratio of lithium ion and phosphate radical ion is x:1, and x is larger than or equal to 0.95 and smaller than or equal to 1.05; the mixture which reacts for 2 to 20 hours under 500 to 800 DEG C is cooled in a furnace. The invention finally produces the precursor uniformly mixed with superfine crystal grain, and during the subsequent high temperature solid phase reaction, the end product lithium iron phosphate can be produced through shorter distance diffuseness of atoms. The end product has high purity, the crystallisation is good, the capacity is high, and the cycle stability is good.

Owner:HANGZHOU DIANZI UNIV

Prepn process of oxygen place doped lithium ferric phosphate powder

InactiveCN1772604AIncrease base capacityImprove cycle electrical performanceCell electrodesPhosphorus compoundsDopantLithium iron phosphate

The present invention belongs to the field of electrochemical power source material preparing technology, and is especially preparation process of oxygen place doped lithium ferric phosphate powder. The oxygen place doped lithium ferric phosphate as positive pole material in lithium ion cell has the molecular expression LiFeP(MxO4-x), and is prepared through mixing the dopant and the mother body material and sintering the mixture, or through solid phase reaction of the dopant and the mother body material. The preparation process has effective doping in the oxygen place of mother body material and the prepared material can raise the capacity and the circular discharge performance of the cell effectively and thus can find its wide application as positive pole material in secondary lithium ion cell and power cell.

Owner:TSINGHUA UNIV

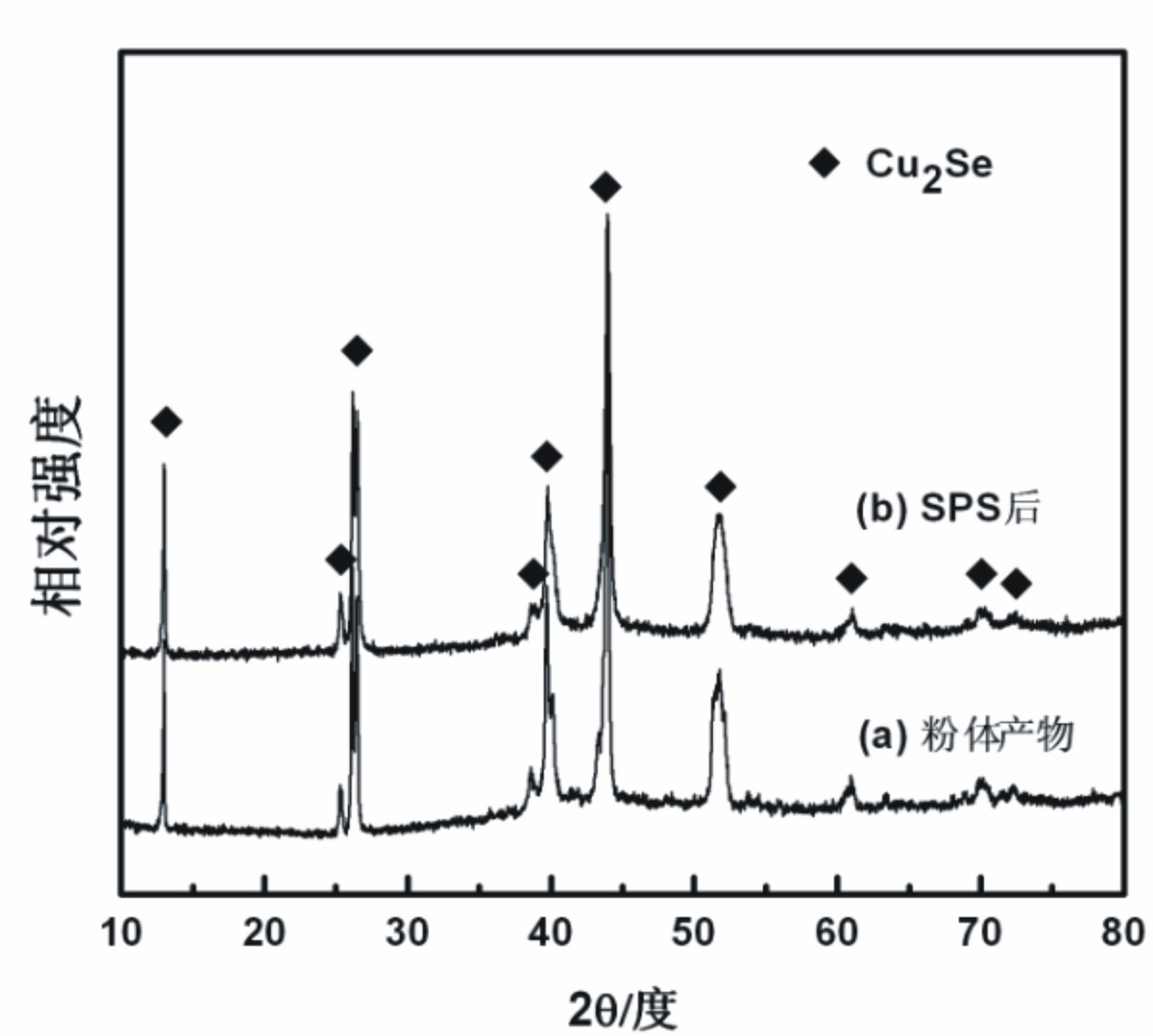

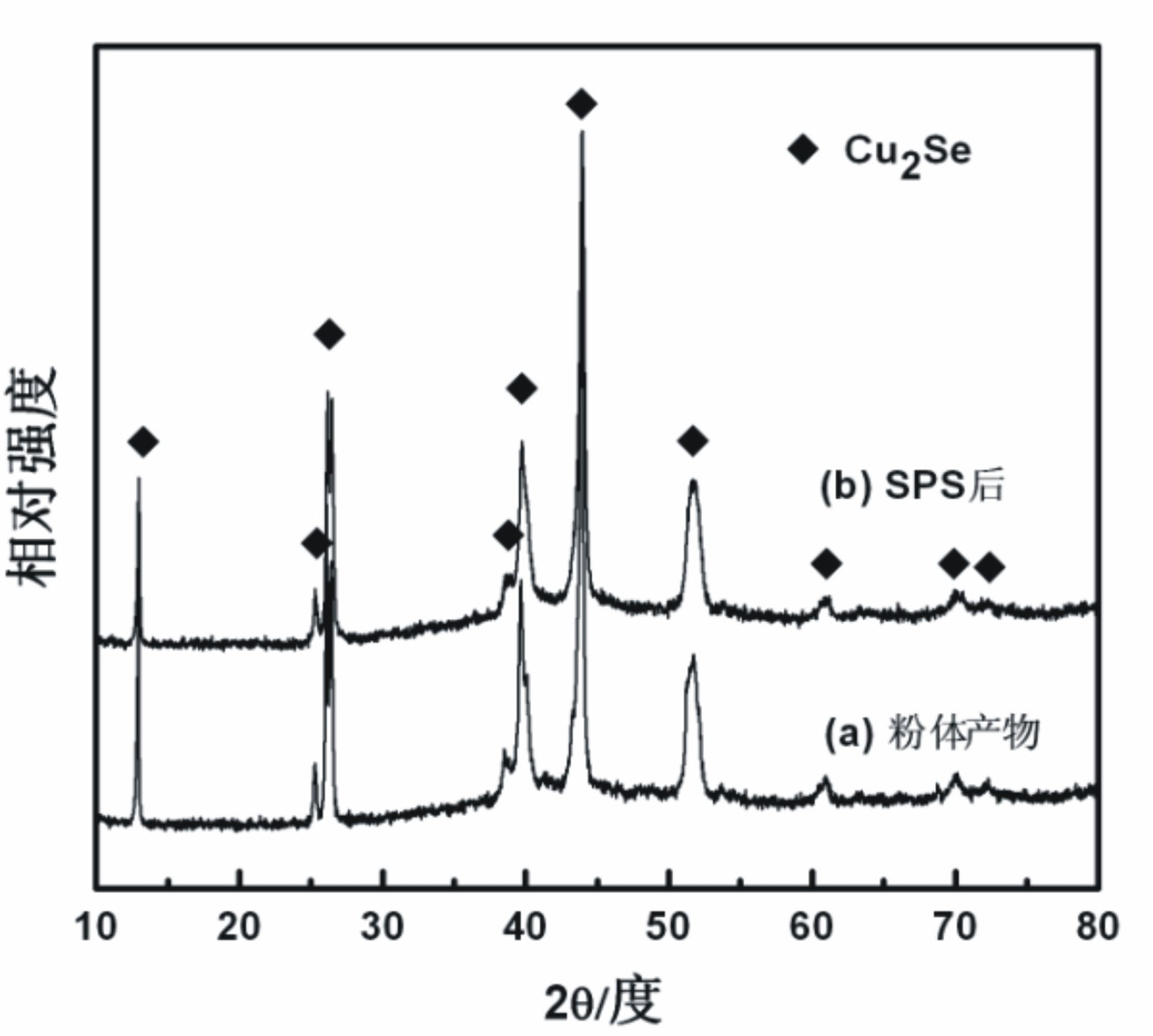

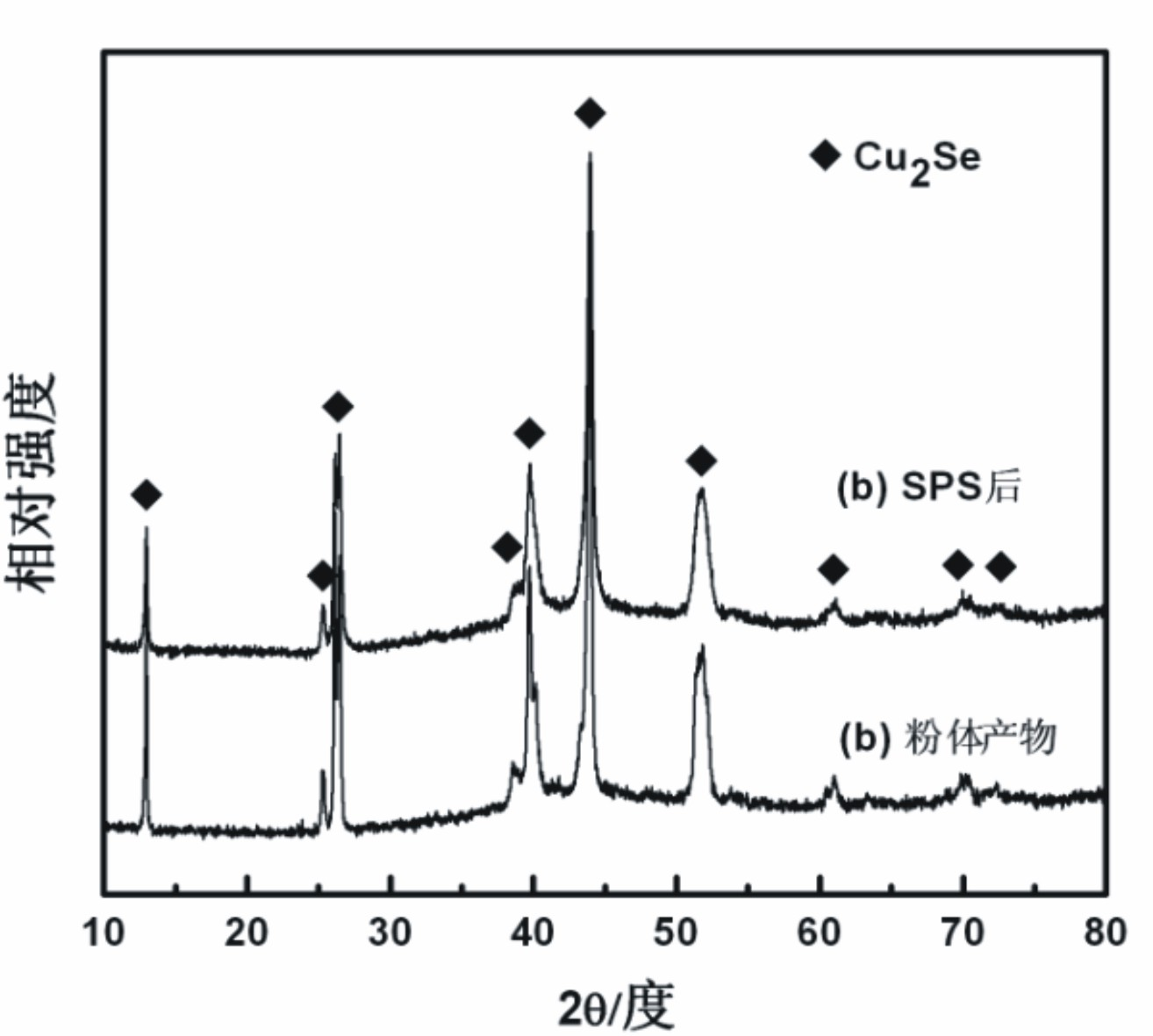

Method for preparing Cu2Se thermoelectric material by low-temperature solid-phase reaction

InactiveCN102674270ALow costControl compositionChemical industryBinary selenium/tellurium compoundsThermoelectric materialsMuffle furnace

The invention relates to a method for preparing a Cu2Se thermoelectric material. The method for preparing the Cu2Se thermoelectric material by the low-temperature solid-phase reaction is characterized by comprising the following step: 1) weighing Cu powder and Se powder according to the molar ratio of 2:1 and mixing the Cu powder and the Se powder uniformly to obtain mixed powder, wherein the Cu powder and the Se powder serve as raw materials; 2) pressing the mixed powder into a block body by using tablet press, placing the block body into a graphite crucible, vacuumizing, sealing into a quartz glass tube, placing into a muffle furnace, performing solid-phase reaction at the temperature of between 650 and 750 DEG C for 12 to 24 hours, and grinding the obtained product into powder; and 3) performing spark plasma sintering on the powder obtained in the step 2) to obtain a compact block body, namely the Cu2Se thermoelectric material. By the method, the raw materials have low cost; the reaction temperature is low; energy is saved; and the materials are fed according to the stoichiometric ratio of the Cu2Se, so the product composition can be controlled precisely; and the repeatability is high.

Owner:WUHAN UNIV OF TECH

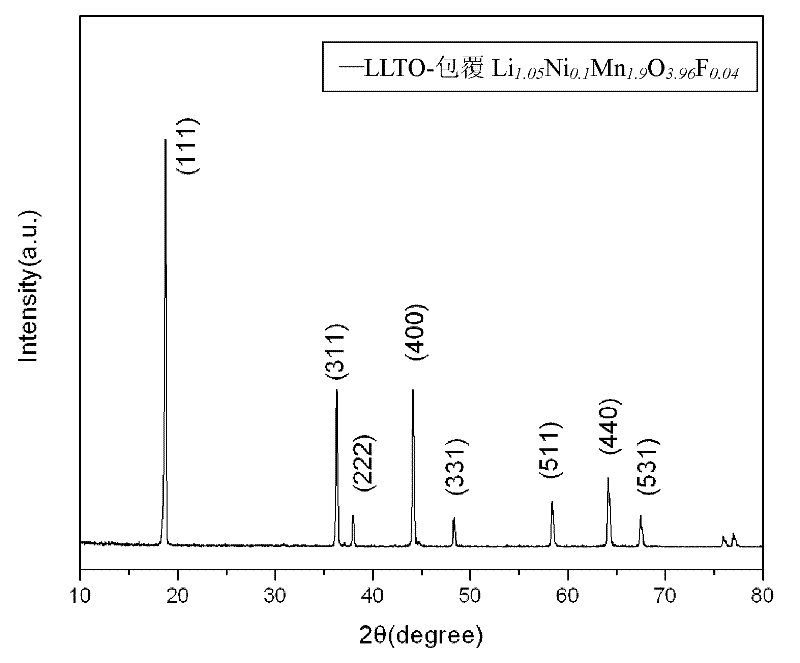

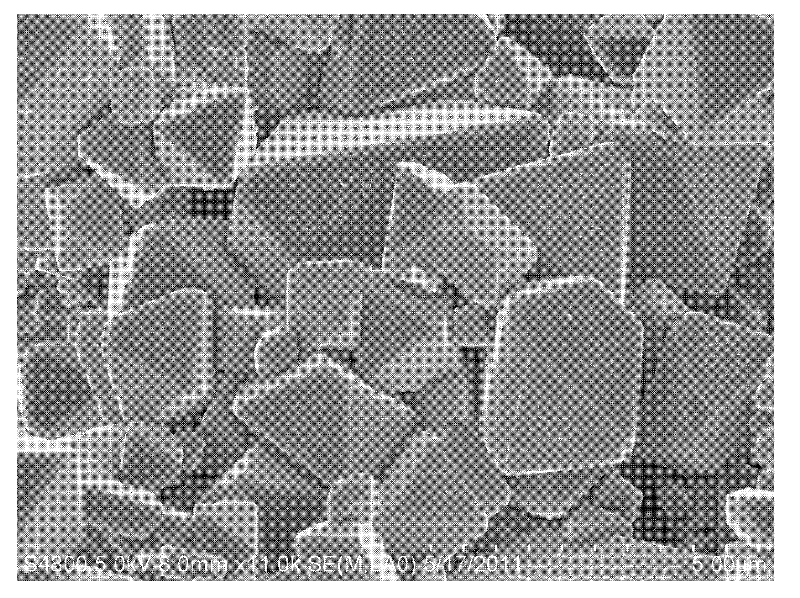

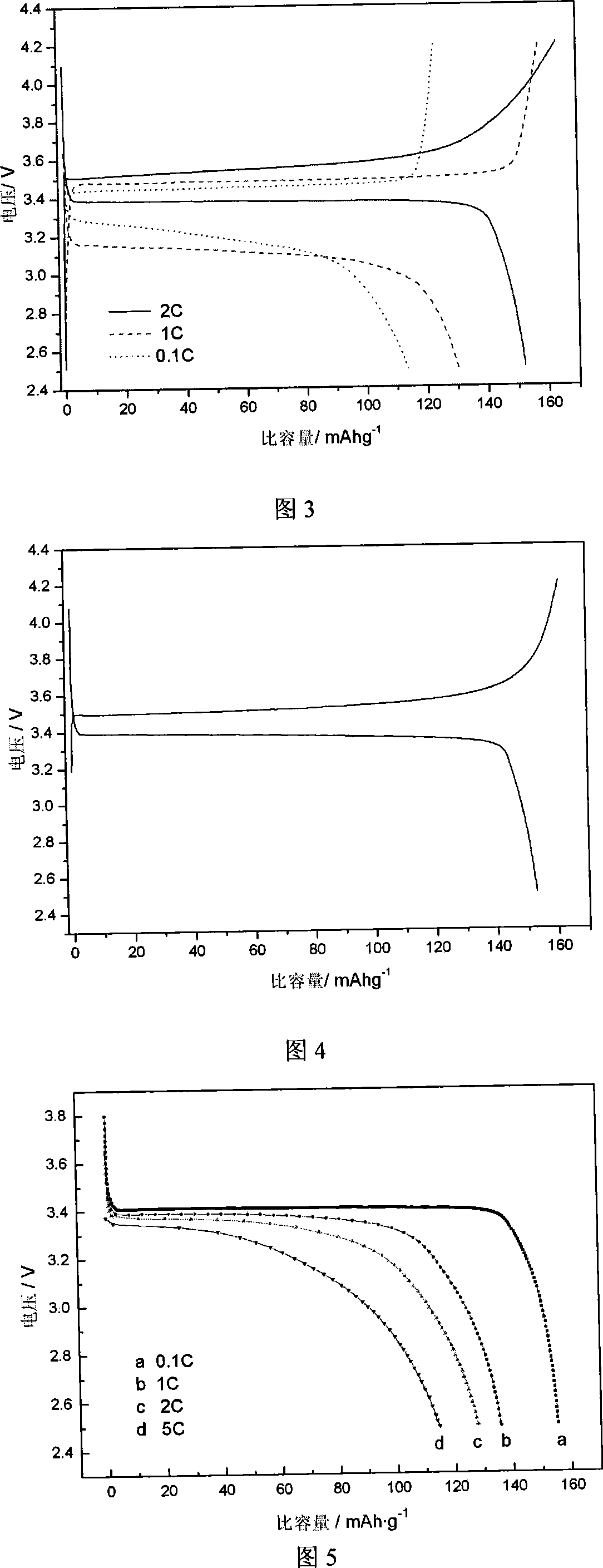

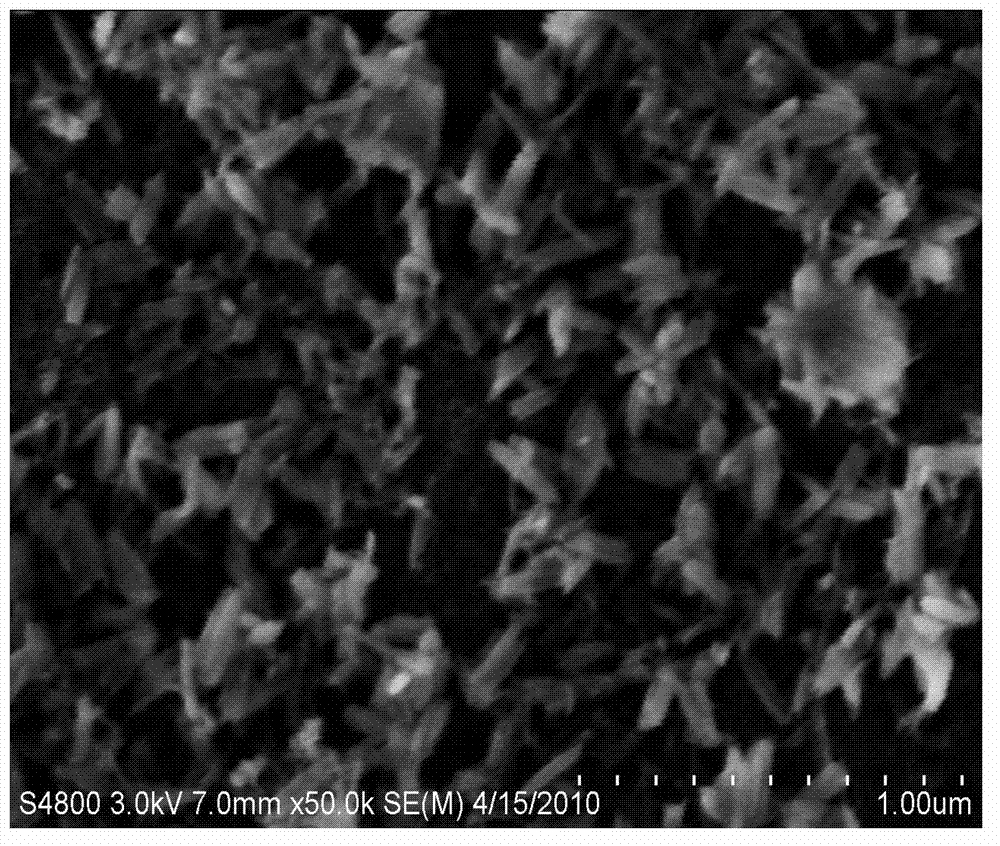

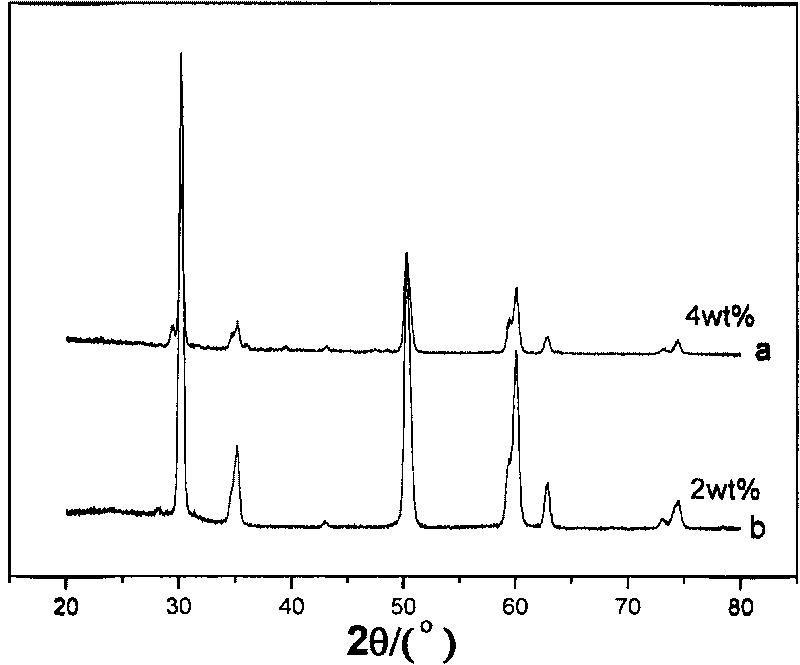

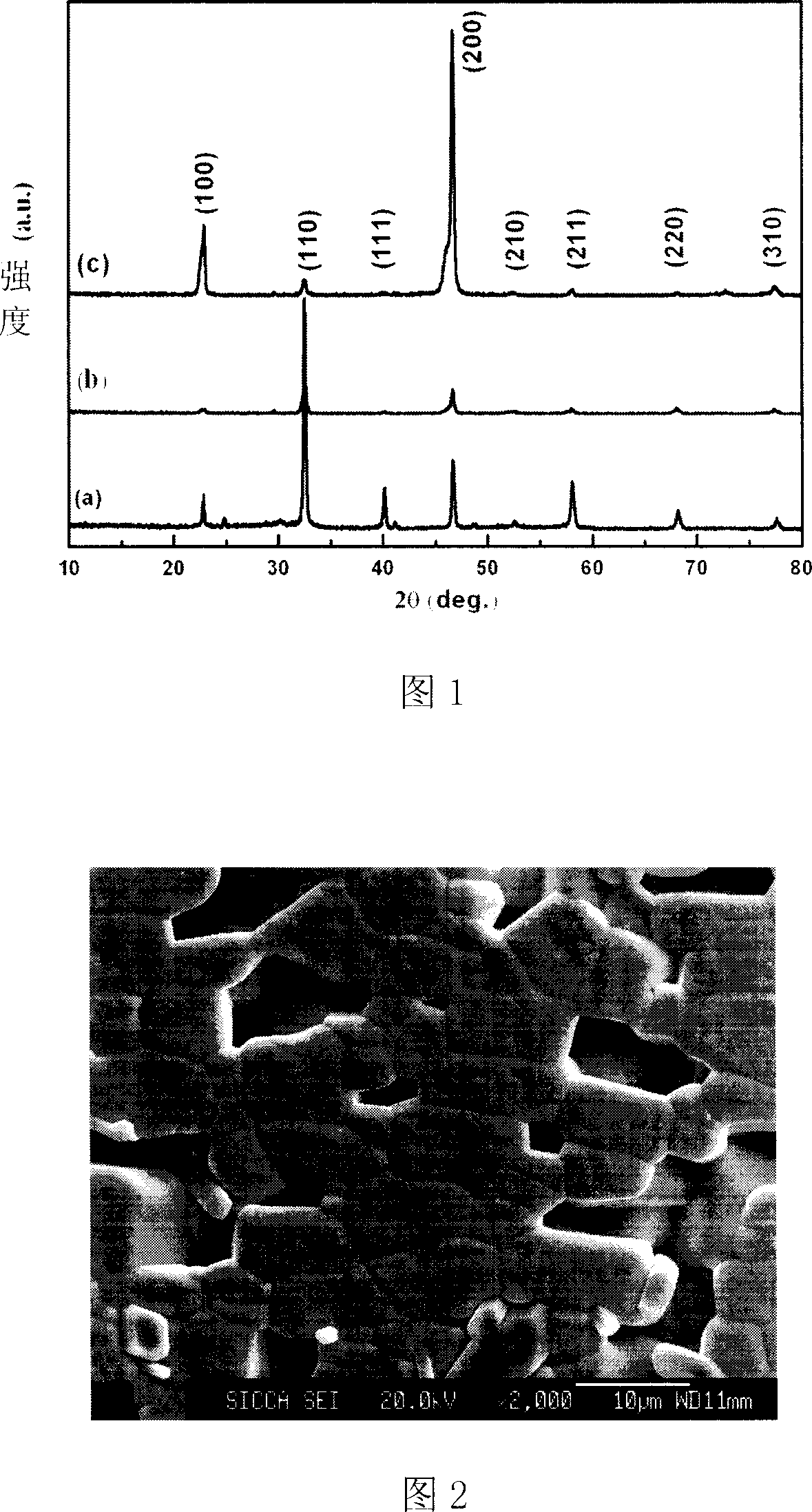

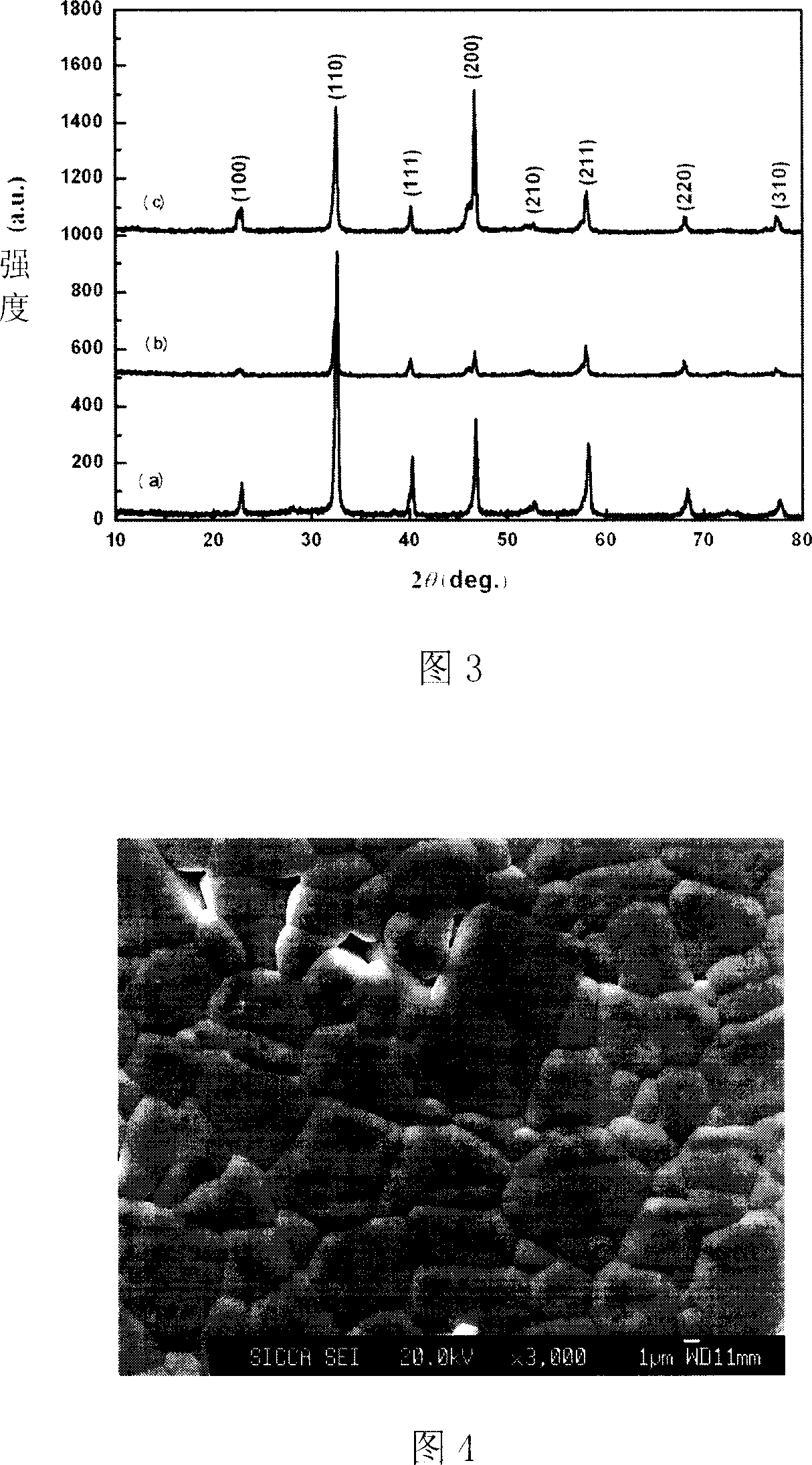

High-temperature manganic acid lithium cathode material and preparation method thereof

ActiveCN102244257AUniform and perfect spinel structureSimple processCell electrodesSolid state electrolytePower battery

The invention discloses a high-temperature manganic acid lithium cathode material and a preparation method thereof. Single crystal particles of the cathode material consists of a matrix and solid electrolyte which clads the surface of the matrix; the matrix is spinel manganic acid lithium which is doped with anions and cations; and the chemical formula of the material is Li1.05MxMn2-xO4-yQy, wherein M represents the doped cations; and Q represents the doped anions. The preparation method comprises the following steps of: firstly, preparing the spinel manganic acid lithium which is doped with the anions and the cations through solid phase reaction; secondly, synthesizing by using a molten-salt growth method to control a crystal form, and preparing the spinel manganic acid lithium having the particle size of 3 to 5 microns and the characteristic of an octahedron single crystal; and finally, cladding the spinel manganic acid lithium by using the solid electrolyte after the crystal form is controlled. The cathode material has high high-temperature performance and high rate cycle performance, and can be applied to electric automobiles or other kinds of lithium ion power batteries.

Owner:淮安新能源材料技术研究院

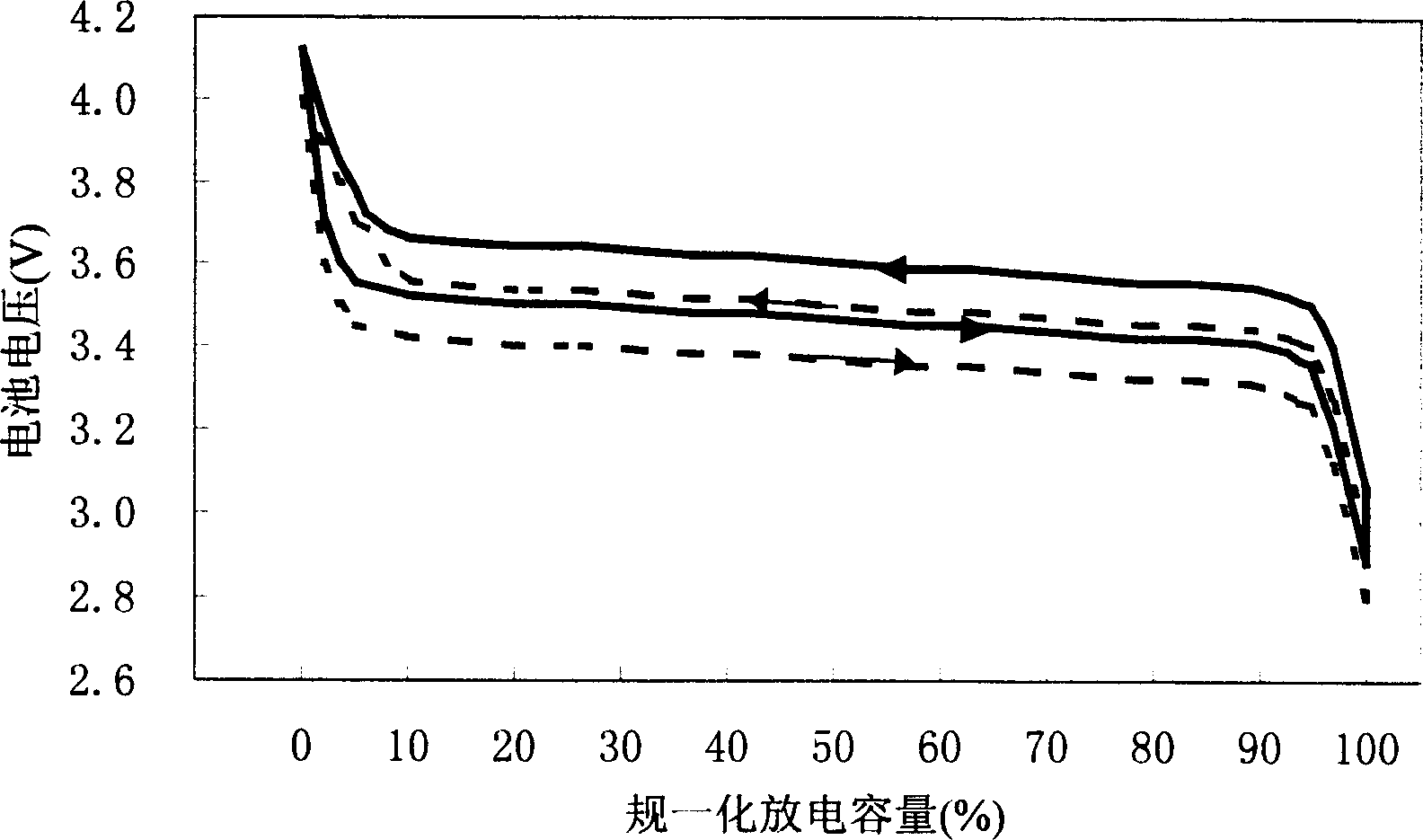

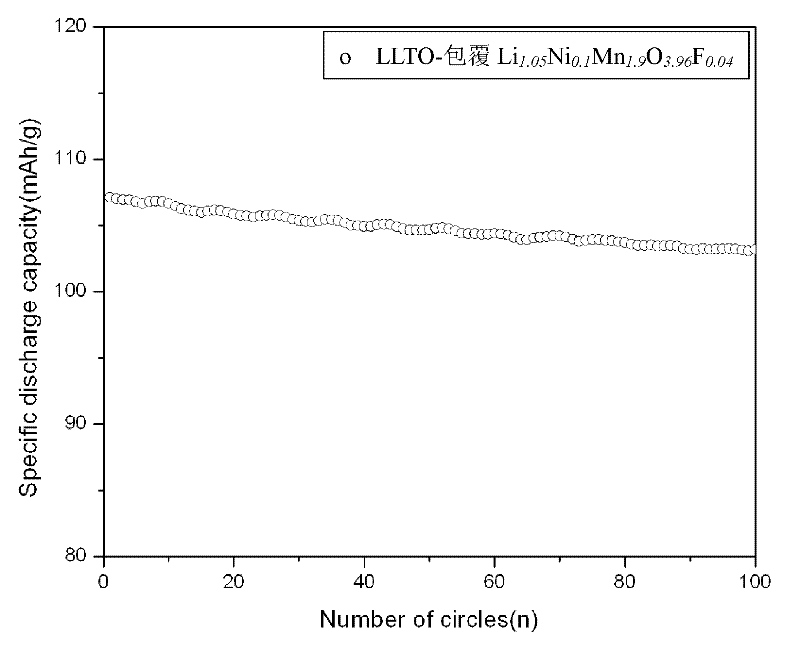

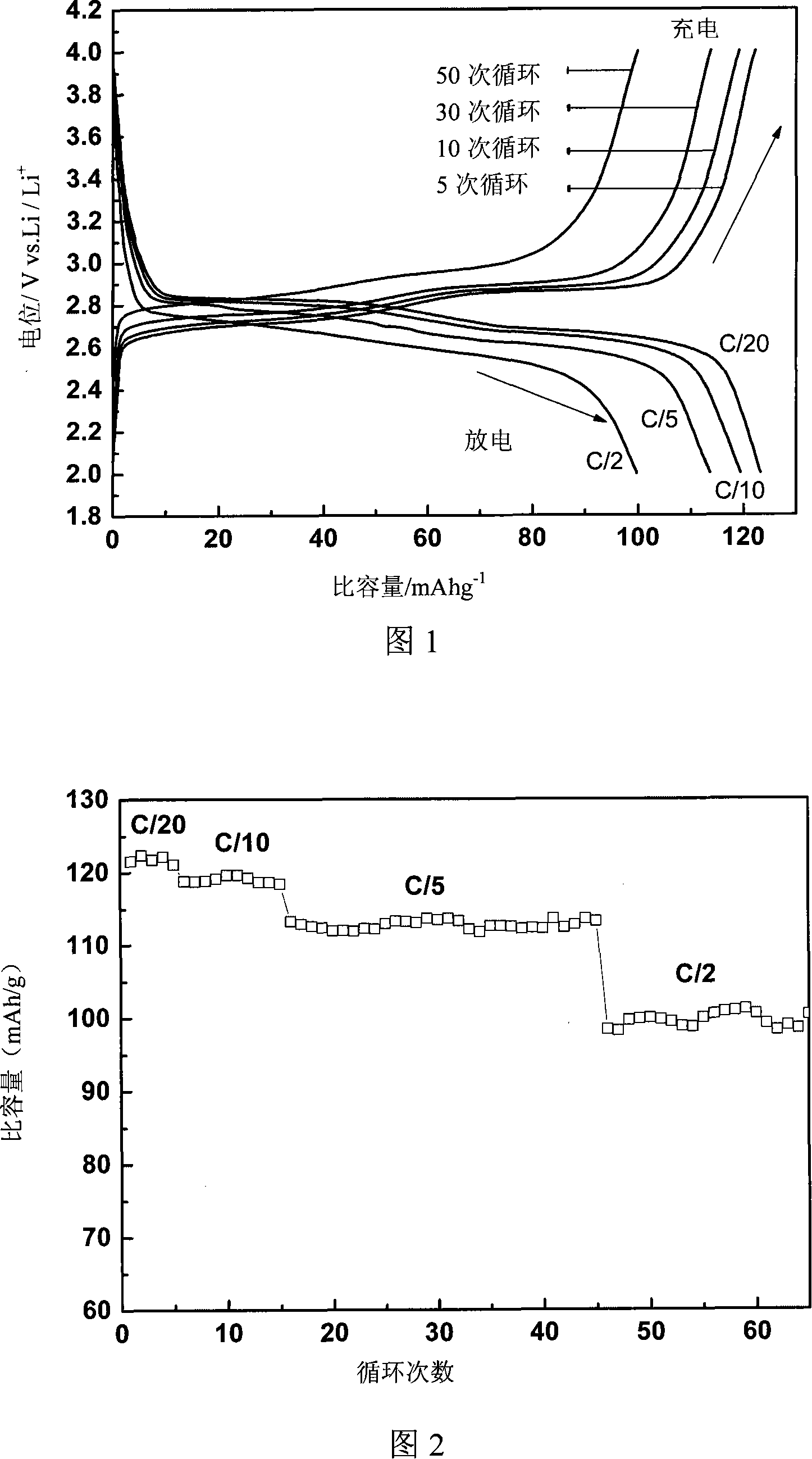

Anode material made of doped lithium-iron phosphate active material and carbon and method for producing the same

ActiveCN101212049ALow priceImprove securityElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateSolid reaction

The invention relates to an anode material composed by doping phosphate iron and lithium active substance and carbon and used for the secondary lithium battery and a manufacturing method thereof. The invention is characterized in that the general expression of the active substance is Li<3+Y>Fe<2-X>Mex(PO4)3(Me = Ti, Sc, Ge, Al, Zr, Mn, Hf, Nb, Ta, Mo, W, Ru, Ag, Sn, and Pb, etc.); the characteristic in preparation is that the raw material is synthesized into the crystal state of Li<3+Y>Fe<2-X>Mex(PO4)3 through a solid reaction, an hydrothermal method and a sol-gel method in a proper proportion. Then the prepared powder and the carbon is grinded and mixed through a planetary ball mill to obtain the anode material Li<3+Y>Fe<2-X>Mex(PO4)3 / C The specific capacity of the anode material can be up to 122mAhg<-1> (charging and discharging at the rate of C / 20) and 100mAhg<-1> (charging and discharging at the rate of C / 2); furthermore, the material has a good circulation performance and retentivity of specific capacity, thus providing a favorable anode material for the practicality of the secondary lithium ion battery.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

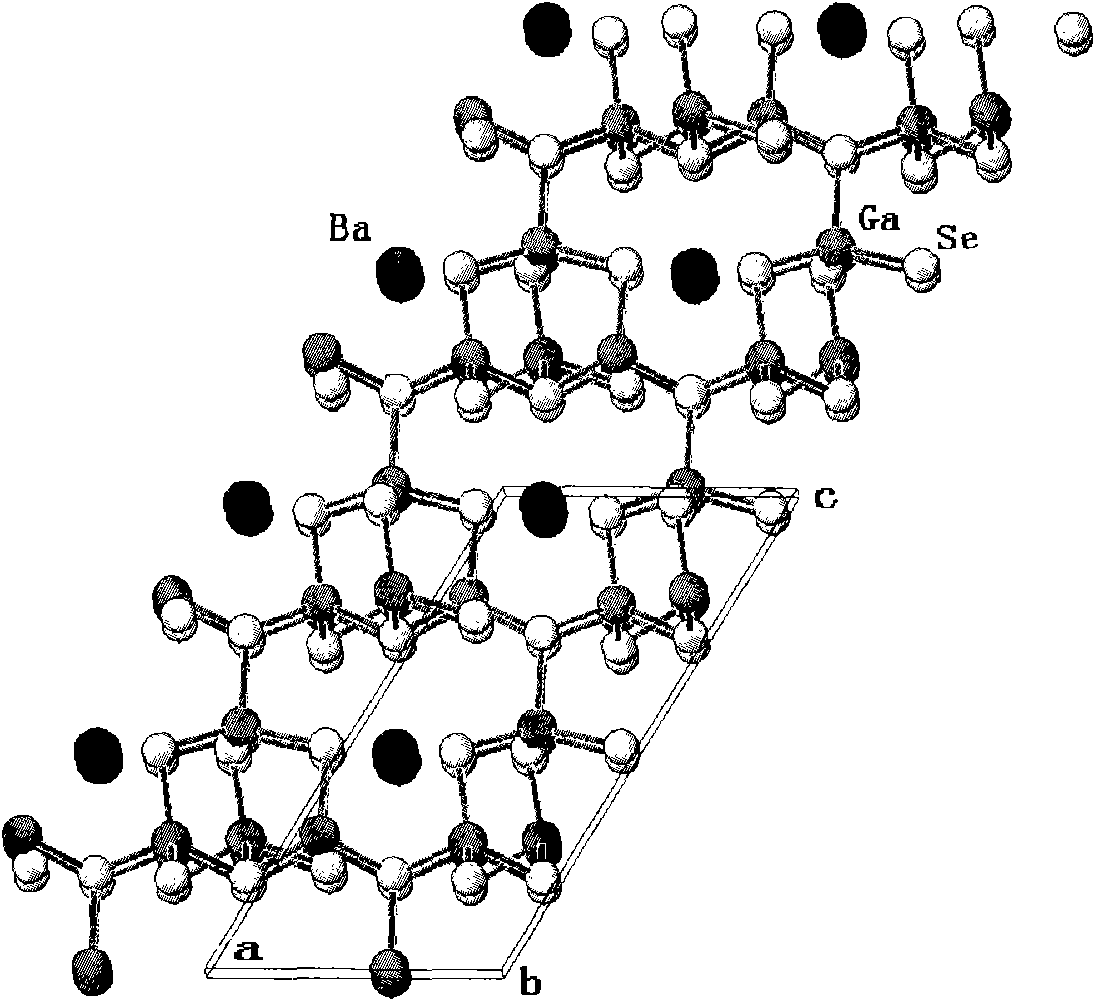

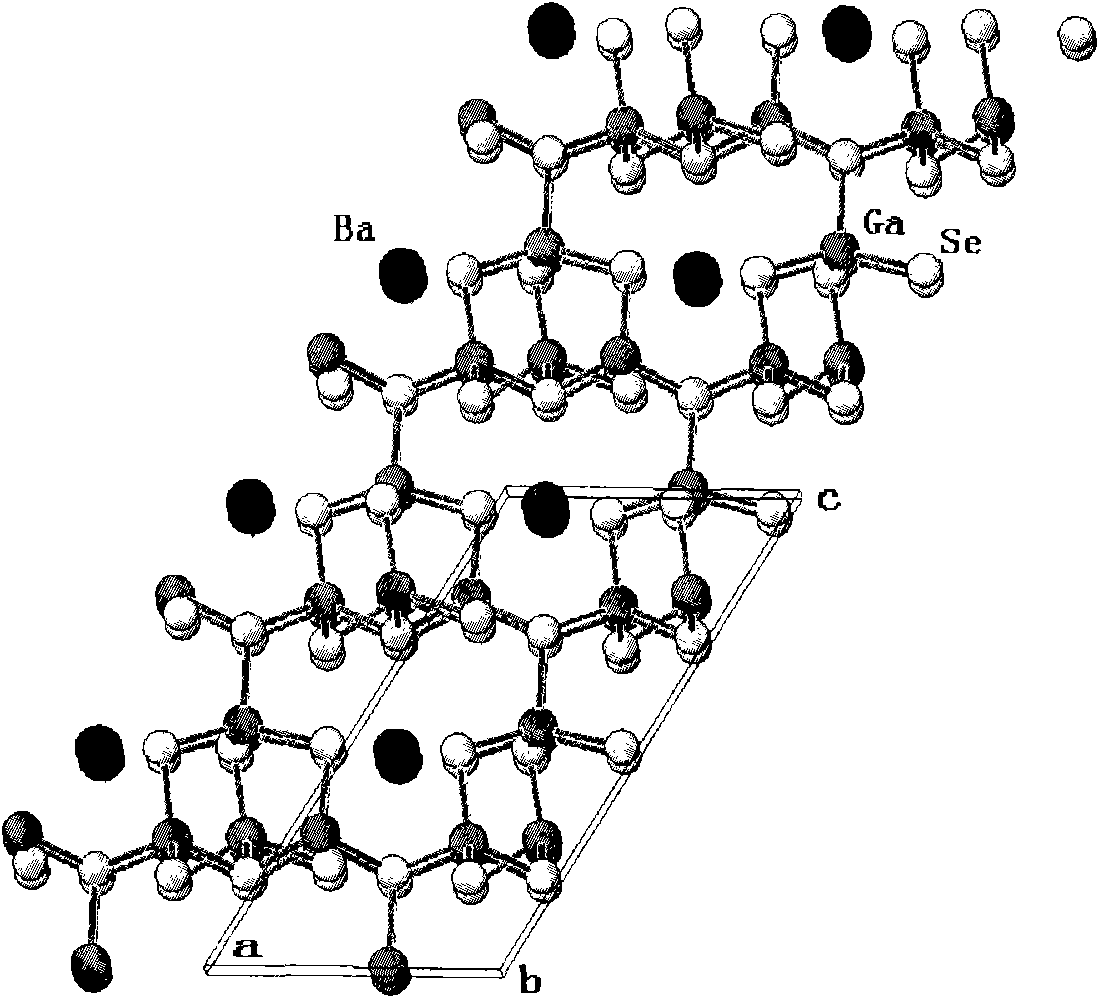

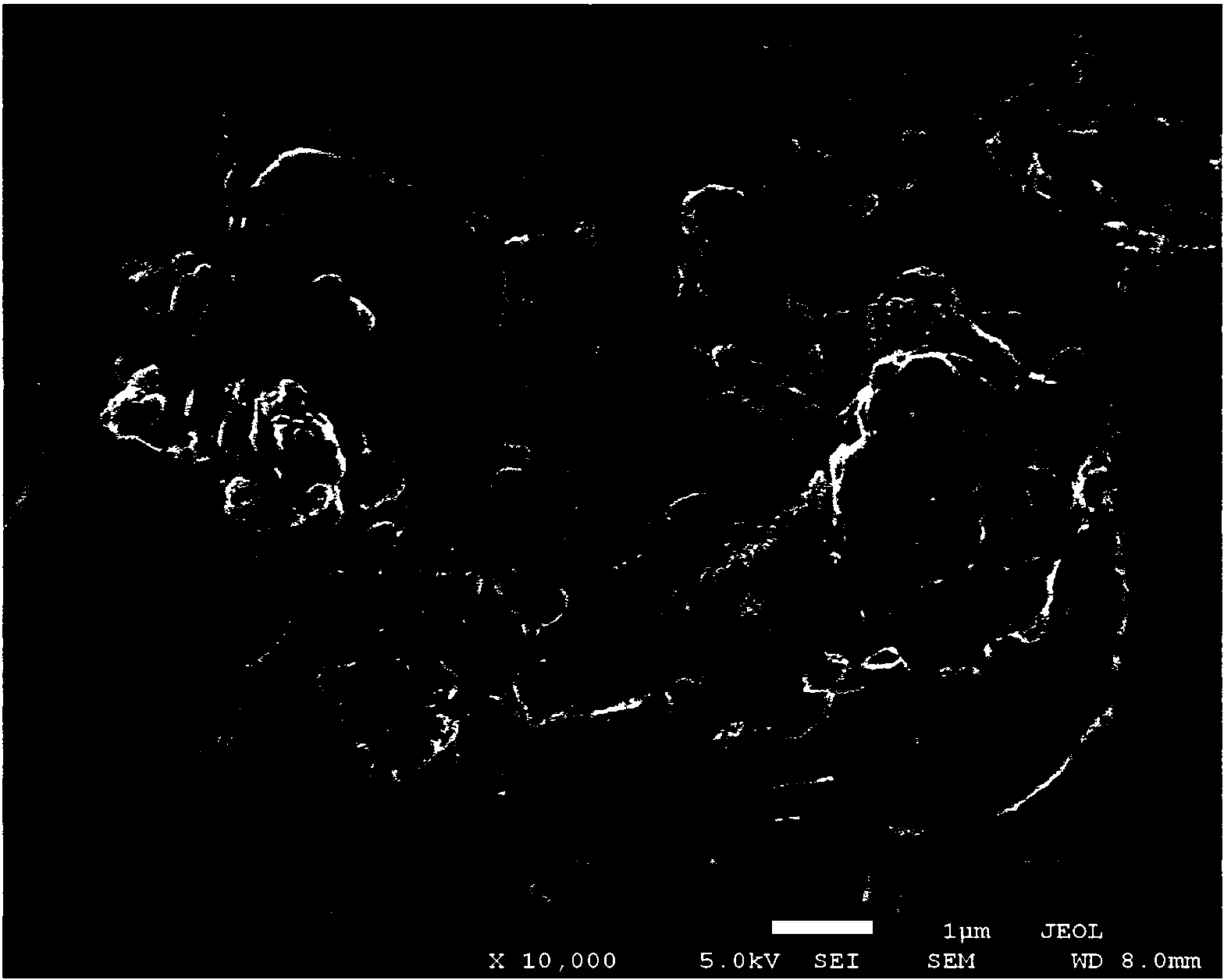

BaCa4Se7 compound, BaCa4Se7 nonlinear optical crystal, preparation method and application

ActiveCN101767778AWide band of light transmissionHigh hardnessPolycrystalline material growthAfter-treatment detailsNonlinear optical crystalOptical transparency

The invention relates to a BaCa4Se7 compound, a BaCa4Se7 nonlinear optical crystal, a preparation method and application. The BaCa4Se7 compound is prepared by adopting a solid-phase reaction, and the BaCa4Se7 nonlinear optical crystal is grown by adopting a high-temperature melt spontaneous crystallization method, a flux growth method or a Bridgman method. In the growth of the BaCa4Se7 nonlinear optical crystal, the crystal is easy to grow and transparent and has no package and the advantages of higher growing speed, low cost, easy obtaining of a crystal in a larger size, and the like. The obtained BaCa4Se7 nonlinear optical crystal has the advantages of wider optical transparency range, larger hardness, good mechanical property, difficult cracking and deliquescence, easy processing and storage, and the like. The BaCa4Se7 nonlinear optical crystal can be used for preparing a nonlinear optical device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

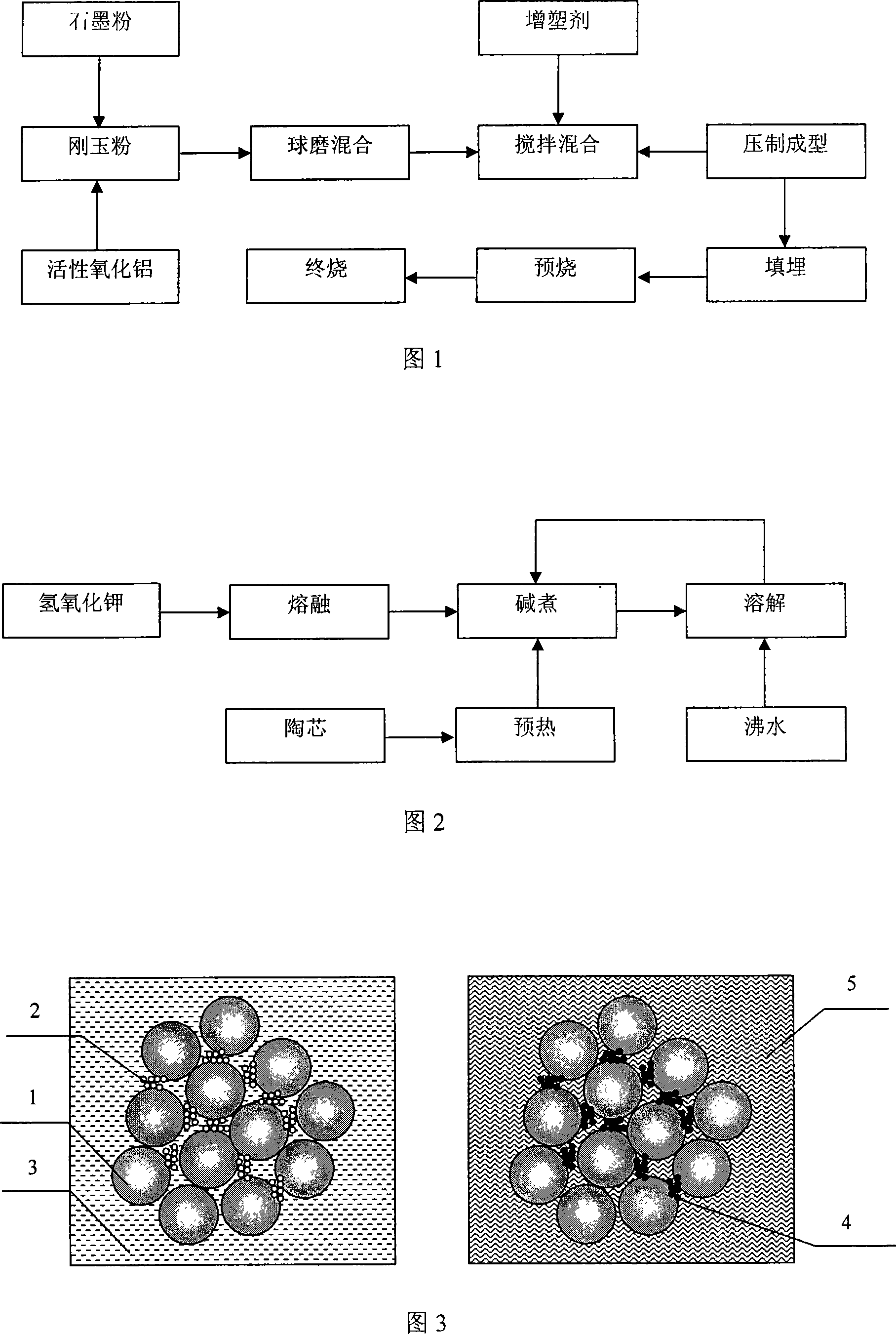

Method for making alumina ceramic core and core leach method

The invention discloses a method for manufacturing alumina ceramic cores, which adopts sintering of solid phase reaction, comprising two sintering methods of pre-sintering and final sintering; sintering temperature decreases to 1,350 to 1,500 DEG C from more than 1,500 DEG C in the prior art and creep resistance of high temperature is favorable. The invention also discloses a method for leaching the alumina ceramic cores. As in the process of the manufacture of the alumina ceramic cores, a volatile pore forming agent is adopted so that the forming alumina ceramic cores have relatively high porosity; in core leaching, melting alkali can reach the internal part of the alumina ceramic cores so as to integrally disperse the alumina ceramic cores. In the invention, a boiling water process and a repeated alkali cooking-dissolving- alkali cooking method are adopted, thus accelerating permeation, reaction and dissolving of the melting alkali to the internal part of the ceramic cores; the core leaching speed decreases to 10 to 16 hours from 25 to 30 hours in the prior art and the core leaching speed is accelerated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

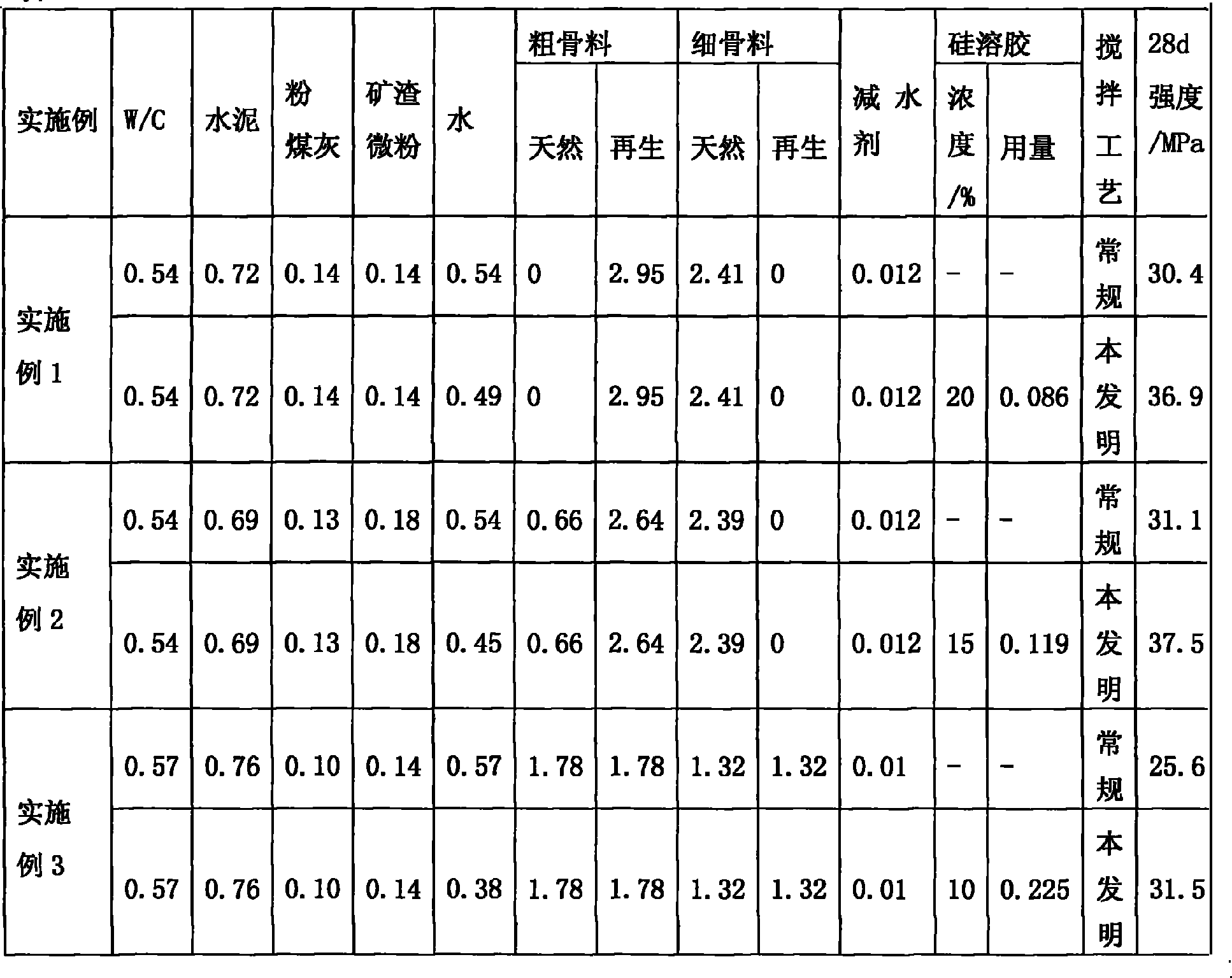

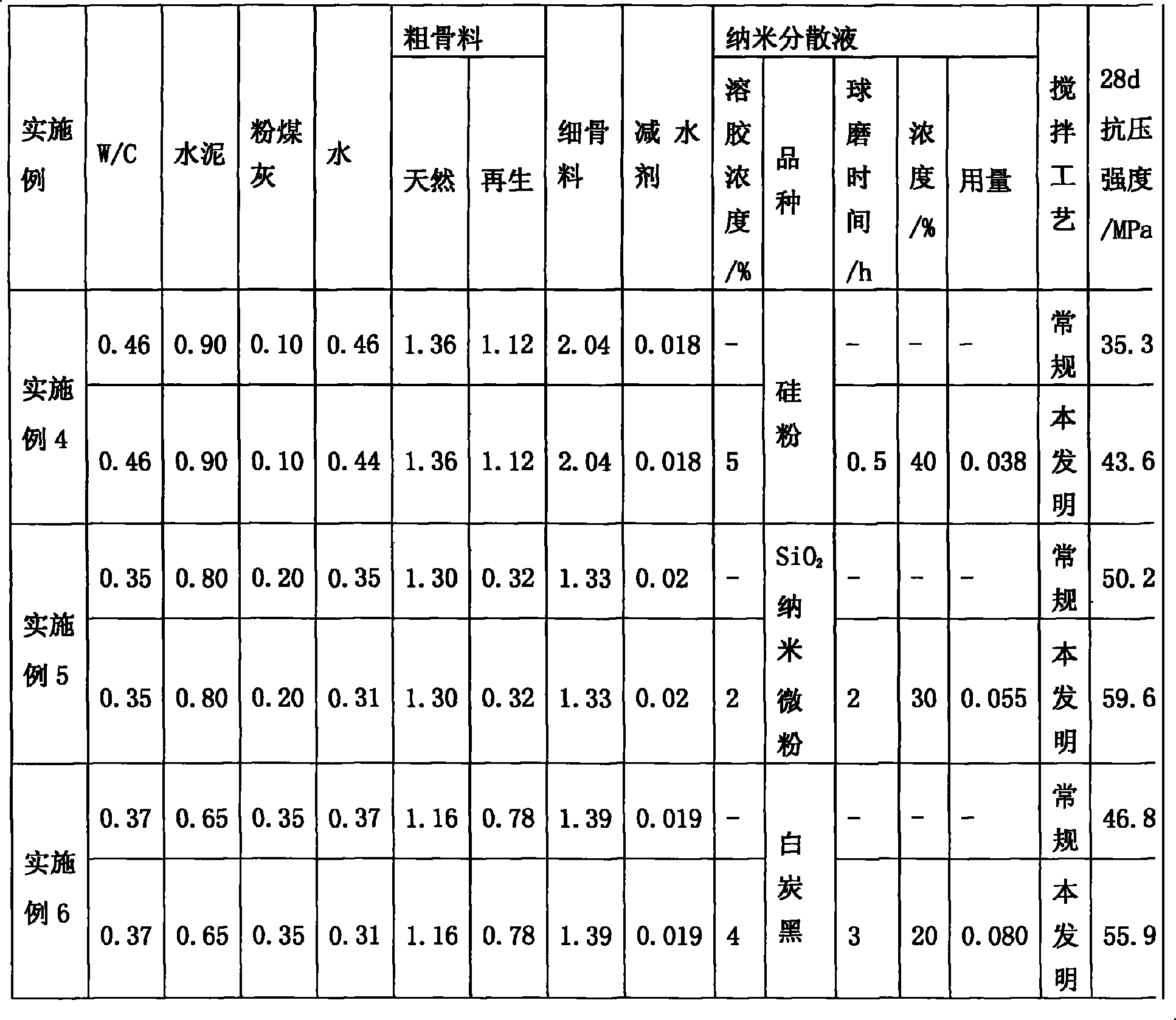

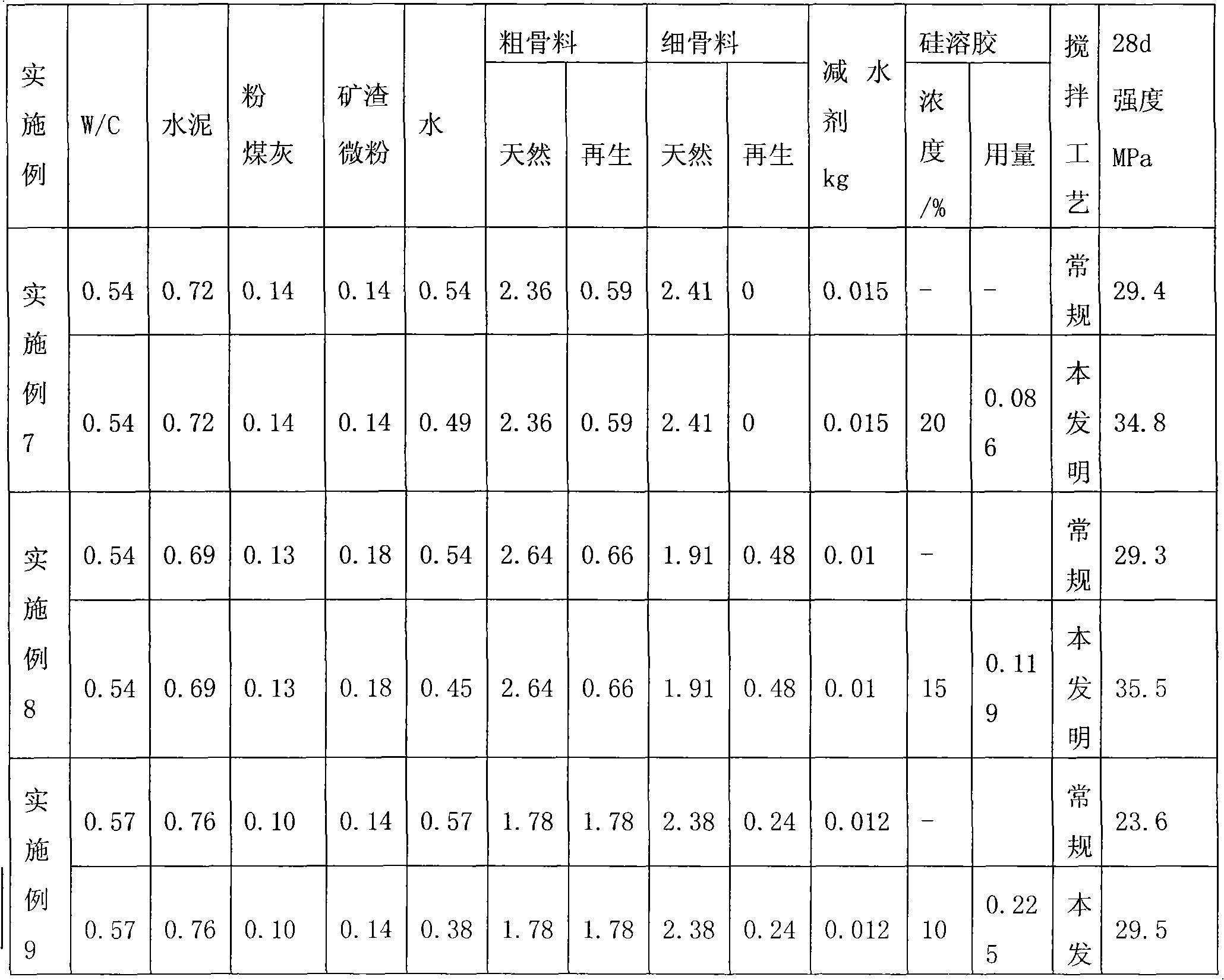

Nano reinforcing method for recycled aggregate concrete

InactiveCN102092993AHigh strengthImprove interfacial bond strengthSolid waste managementSuperplasticizerWater reducer

The invention discloses a nano reinforcing method for recycled aggregate concrete, which belongs to the technical fields of recycling comprehensive utilization of waste and production of building materials, and is mainly characterized by comprising the steps of: mixing and stirring a recycled aggregate and a nano particle dispersion for 5-10s; after the surface of the recycled aggregate is in a moist state, further mixing the recycled aggregate with all admixtures for 5-10s; and mixing and stirring with cement, water and a high-efficiency water reducing agent for 20-45s to obtain a nano-reinforced recycled aggregate concrete mixture. The nano reinforcing method has a principle that by changing a stirring process and introducing the nano dispersion, nano particles can be adsorbed into the opening pores and microcracks of the recycled aggregate, an admixture enriched layer is further formed on the surface of the recycled aggregate, the nano particles permeating into the interiors of the opening pores of the recycled aggregate and the admixture enriched layer formed on the surface of the recycled aggregate are used for jointly absorbing calcium hydroxide enriched on the surface and the pores of the recycled aggregate in the strength development process of the recycled aggregate concrete, a gelling material with higher strength is generated through hydration, liquid-phase or solid-phase reactions so as to reinforce the recycled aggregate per se and an interface between the recycled aggregate and set cement, and thus, the strength of the recycled aggregate concrete is enhanced. After the nano reinforcement, the recycled aggregate concrete has the 28-day compression strength improved by around 15-20%.

Owner:ZHEJIANG UNIV +1

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

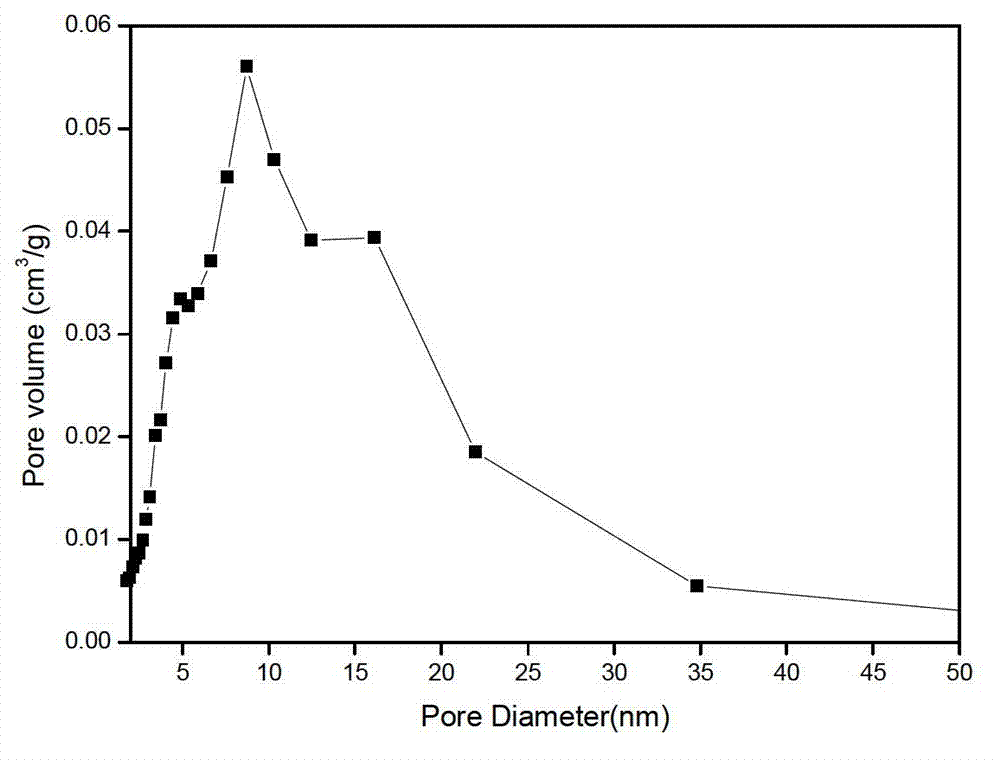

Solid phase preparation method for gamma-alumina with gradient distribution holes

InactiveCN102849763ALow costReduce manufacturing costCatalyst carriersAluminium oxide/hydroxide preparationAluminum CarbonateSolid reaction

The invention relates to a solid phase preparation method for gamma-alumina with gradient distribution holes. The method comprises: adopting a solid phase reaction to obtain a precursor ammonium aluminum carbonate hydroxide, and carrying out calcination to obtain gamma-alumina with a high specific surface area, gradient distribution holes and a large pore volume. The most prominent characteristic of the present invention comprises adopting a raw material solid phase reaction synthesis technology and controlling the property of the resulting gamma-alumina through synthesis conditions. In addition, the method of the present invention has characteristics of simpleness, easy operation, no requirement of addition of a pore-expanding agent, and cost saving, and is suitable for industrial mass production.

Owner:PETROCHINA CO LTD +1

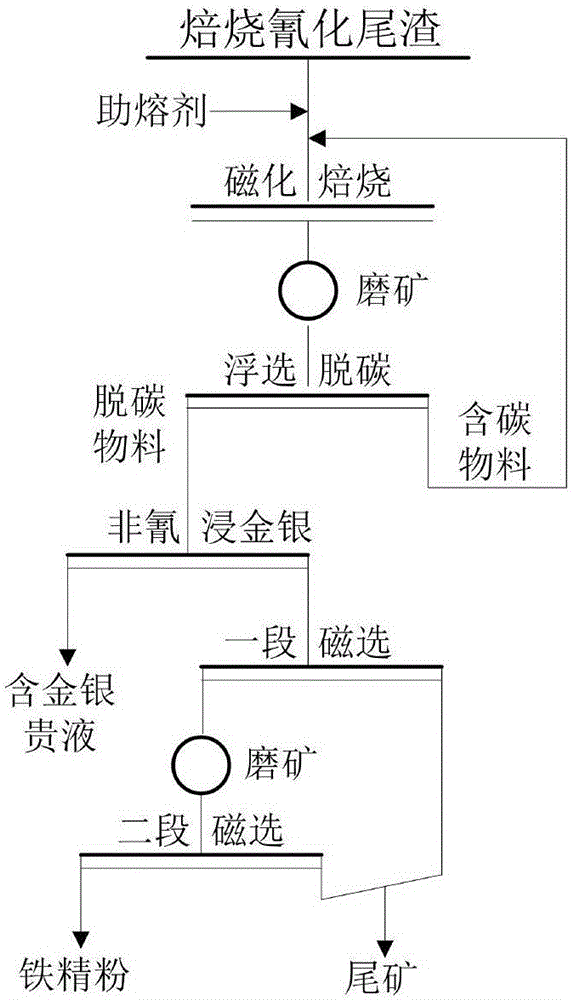

Method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings

ActiveCN106498177ARealize harmless treatmentLow toxicityProcess efficiency improvementSilicate mineralsGold leaching

The invention provides a method for recycling and synchronous harmless treatment of gold, silver and iron in roasting-cyanidation tailings, and belongs to the technical field of metallurgical waste residue utilization. The method comprises the following steps: mixing dried roasting-cyanidation tailings with a fluxing agent and a reducing agent; carrying out roasting at 750 to 900 DEG C for 3 to 5 hours; conducting water quenching on hot roasted sand for cooling; carrying out ore grinding and flotation to remove residual carbon; leaching gold and silver with an environment-friendly gold leaching agent; and conducting magnetic separation on the leaching residue to obtain fine iron powder. Containing no highly toxic cyanide, the rejects belong to general industry solid waste. As the fluxing agent is added for magnetic roasting, not only can gold and silver coated with an iron mineral be exposed, but also the fluxing agent can perform a solid-phase reaction with a silicate mineral to generate a dissoluble silicate, and gold and silver coated with the dissoluble silicate can also be exposed after ore grinding. According to the method, gold, silver and iron in the roasting-cyanidation tailings are recycled, harmless treatment is realized synchronously, and the purpose of clean production is realized.

Owner:UNIV OF SCI & TECH BEIJING

Graphene/phosphoric acid iron-lithium composite material with sandwich structure and preparation method thereof

InactiveCN102148371ASimple preparation processShort preparation cycleNon-aqueous electrolyte accumulator electrodesO-Phosphoric AcidLithium-ion battery

The invention relates to a graphene / phosphoric acid iron-lithium composite material with a 'sandwich' structure and a preparation method thereof. The structure characteristics of the graphene / phosphoric acid iron-lithium composite material are that: blocky particles are formed by a grapheme laminated sheet which is completely coated by a phosphoric acid iron-lithium shell; and the insides of the particles present a similar 'sandwich' structure overlapped by a plurality of layers of phosphoric acid iron-lithium and graphene one by one. The preparation method thereof adopts a 'two-step' method. The characteristic steps are as follows: a graphene / phosphoric acid iron precursor with a 'sandwich' structure is compounded by a liquid phase method during the first step; then lithium is embedded in the second step; lithium iodide liquid phase low temperature reaction is adopted for embedding the lithium; then the graphene / phosphoric acid iron-lithium composite material is obtained through high temperature calcination under reducing (inertia) atmospheres; moreover, the graphene / phosphoric acid iron-lithium composite material can also be formed by the embedding of the lithium through high temperature solid phase reaction. The graphene / phosphoric acid iron-lithium composite material prepared by the method has high capacity and good charging-discharging circulating performances, and is suitable to be used as an anode material of a lithium ion battery.

Owner:SHANGHAI UNIV

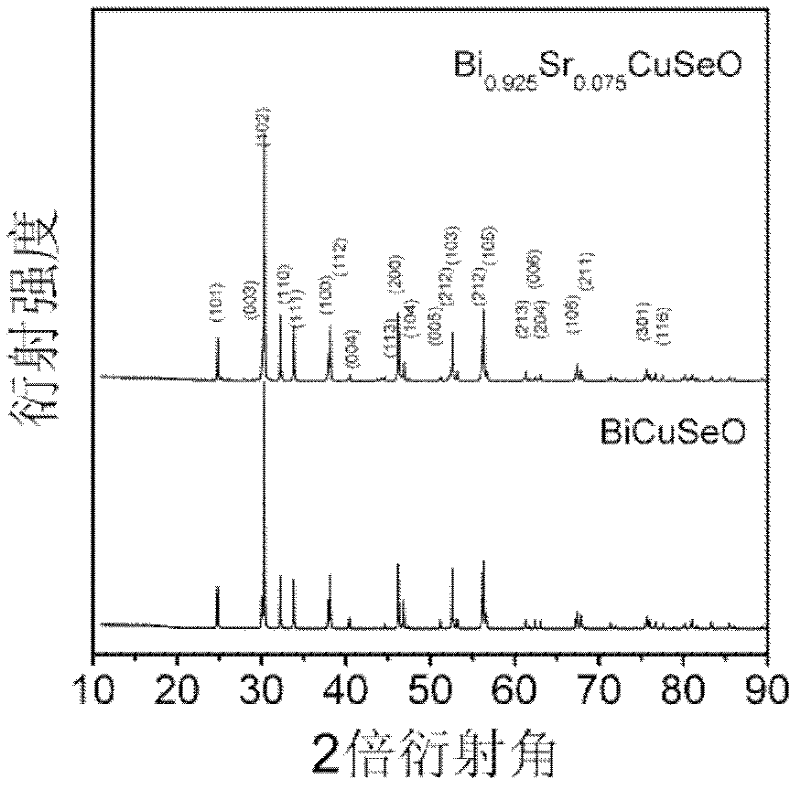

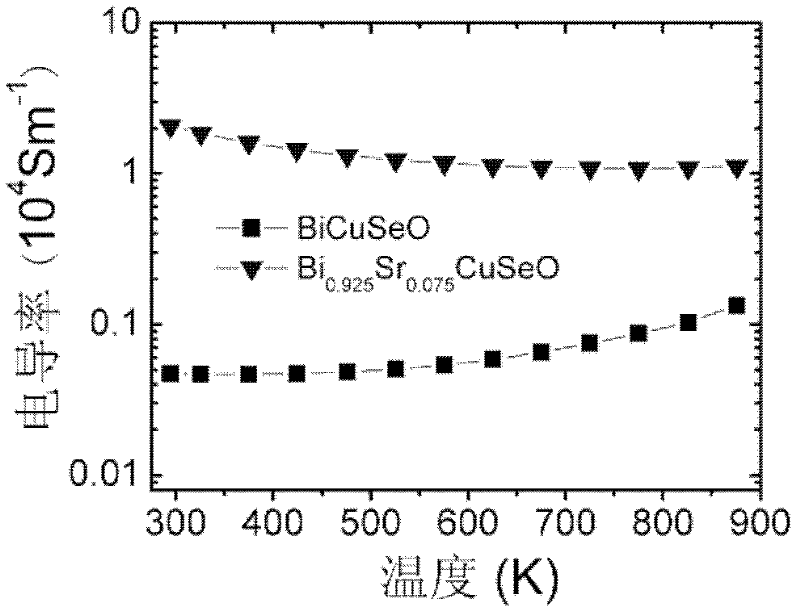

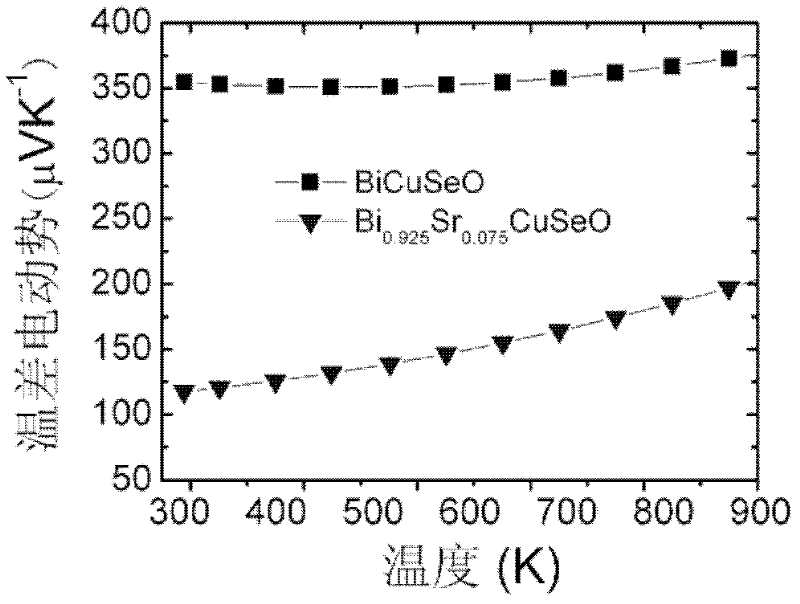

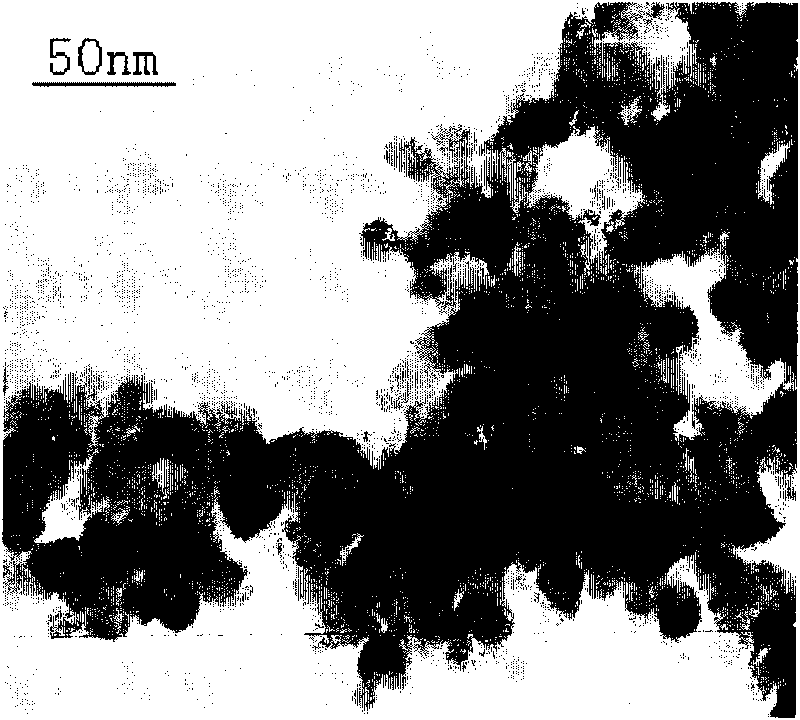

Sr-doping oxide BiCuSeO thermoelectric material and preparation method thereof

ActiveCN102655204AImprove conductivityReduce conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsNew energy

The invention discloses a Sr-doping oxide BiCuSeO thermoelectric material and a preparation method of the Sr-doping oxide BiCuSeO thermoelectric material, belonging to the technical field of new energy source materials. The preparation method comprises the following steps of ball-milling material mixing, solid-phase sintering, ball-milling refining, and discharging plasma sintering, and specifically comprises the following steps of: mixing Bi2O3 with the purity of 99.99%, SrO with the purity of 99.99%, Cu with the purity of 99.99%, Se with the purity of 99.99% and Bi with the purity of 99.99% according to a stoichiometric ratio, uniformly mixing in a ball milling manner, carrying out cold-pressing, carrying out a solid-phase reaction, pulverizing in the ball milling manner, and then carrying out the discharging plasma sintering to prepare Bi1-xSrxCuSeOoxide block bodies (x=0-0.125). Compared with other oxide thermoelectric materials, the Sr-doping oxide BiCuSeO thermoelectric material disclosed by the invention has the advantages of high conductivity, high temperature-difference electrodynamic potential, low thermal conductivity and the like; and the preparation method has the advantages of simple and convenient process, short synthesis and formation times and the like.

Owner:BEIHANG UNIV

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

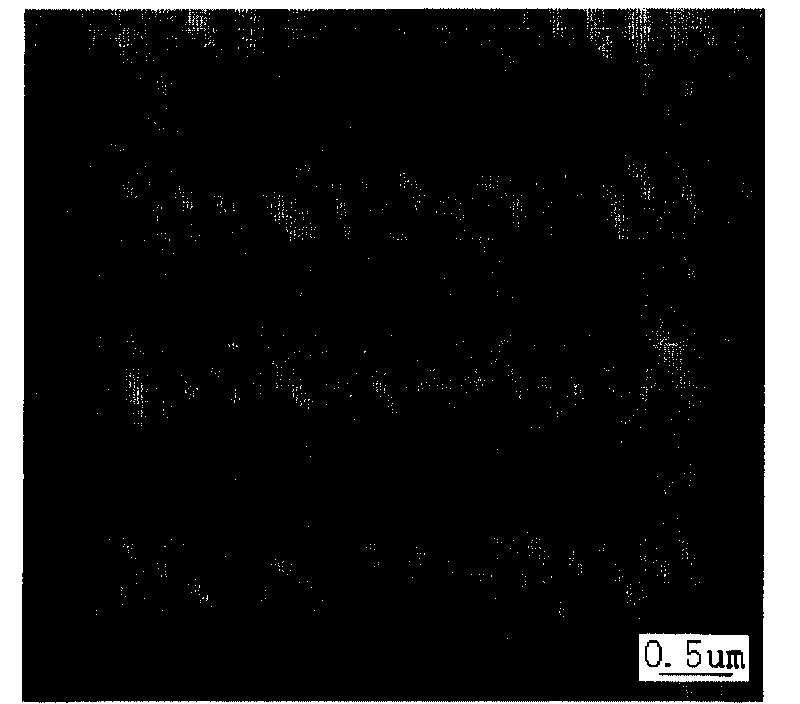

Lithium nickel cobalt manganese oxygen/stannic oxide composite anode material doped with metal elements and method for preparing lithium nickel cobalt manganese oxygen/stannic oxide composite anode material

InactiveCN102332585AImproved magnification performanceImprove cycle performanceCell electrodesManganeseOxide composite

The invention relates to the technical field of electrode materials of lithium ion batteries and preparation of the electrode materials, in particular to a lithium nickel cobalt manganese oxygen / stannic oxide composite anode material doped with metal elements and a method for preparing the lithium nickel cobalt manganese oxygen / stannic oxide composite anode material. The lithium nickel cobalt manganese oxygen / stannic oxide composite anode material doped with the metal elements is expressed by LiNixCoyMnzRzO2 / SnO2 and obtained by performing high-temperature solid-phase reaction on nickel, cobalt and manganese compounds, lithium salt, doped metal compounds and stannic compounds. By doping the metal elements and coating the stannic oxide, the initial discharge capacity, multiplying power performance and cycle stability of the material can be effectively improved. The material is prepared by using all-solid-phase reaction, and the process is simple in flow and convenient to operate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

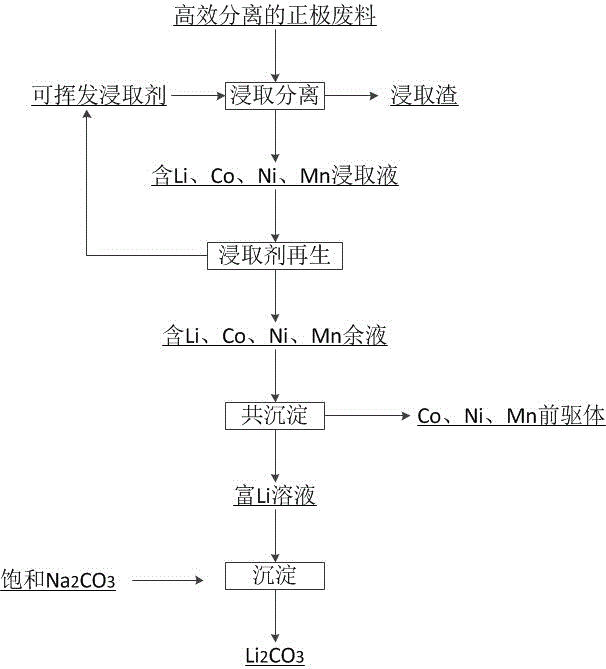

Method for recovering positive electrode material precursor and lithium carbonate from positive electrode waste material of lithium ion battery

ActiveCN106848474AWide range of sourcesLow priceWaste accumulators reclaimingProcess efficiency improvementAdditive ingredientMixed materials

The invention provides a method for recovering a positive electrode material precursor and lithium carbonate from a positive electrode waste material of a lithium ion battery. The method comprises carrying out mechanical crushing on the waste produced by battery production or waste or old batteries, carrying out sorting to obtain impurity-containing positive electrode powder, carrying out immersion through a reducing agent-containing volatile leaching agent to obtain extract, carrying out concentration rectification, regenerating the volatile leaching agent, adjusting ingredients of the raffinate containing Co, Ni, Mn and Li, carrying out coprecipitation on Co, Ni and Mn, carrying out solid-liquid separation, further treating the Li-rich solution to obtain high-purity lithium carbonate, and carrying out a high temperature solid-phase reaction process on the mixed materials of Co, Ni and Mn precursors to obtain a positive electrode active material. The method is simple and is free of a complicated impurity removal process and an extraction enrichment technology. The extraction agent has a wide source, high extraction selectivity and high extraction efficiency. After the extraction reaction, the extraction agent can be recovered and recycled through concentration rectification. The method reduces a cost, can produce high-quality Co, Ni and Mn precursors and high-quality lithium carbonate and has a good application prospect.

Owner:BOTREE CYCLING SCI &TECH CO LTD

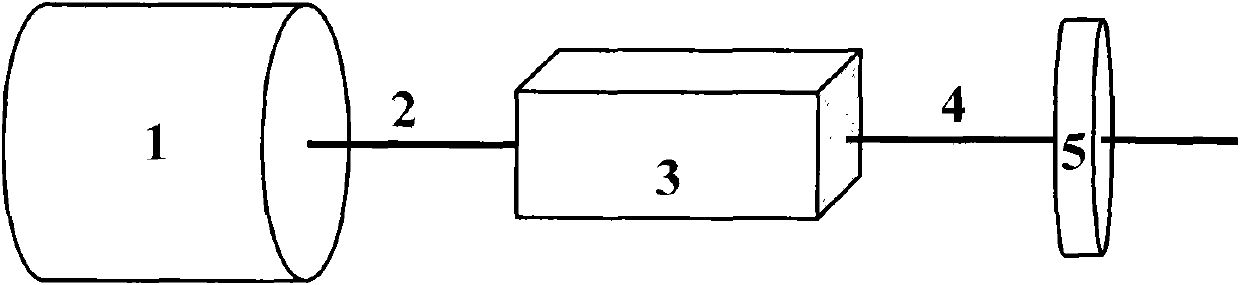

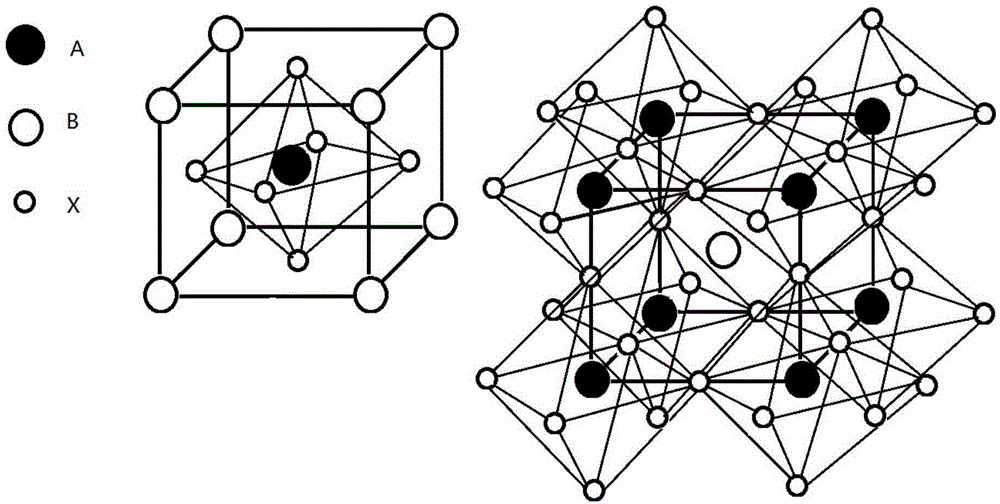

Perovskite type material preparation method and equipment and machining method of photovoltaic device made from perovskite type material

InactiveCN104485425AImprove performanceLow costFinal product manufactureSolid-state devicesMaterials preparationGas phase

The invention relates to a perovskite type material preparation method and equipment, and a machining method of a photovoltaic device made from a perovskite type material. The invention provides the method for preparing the perovskite type material by a gaseous phase-solid phase reaction and a method for preparing a matrix deposited with a precursor BX2 film by adopting a vapor deposition method, and provides special equipment for the methods. The perovskite type material preparation method can be used for machining a photovoltaic element, and the obtained photovoltaic element has excellent photoelectric property.

Owner:TSINGHUA UNIV

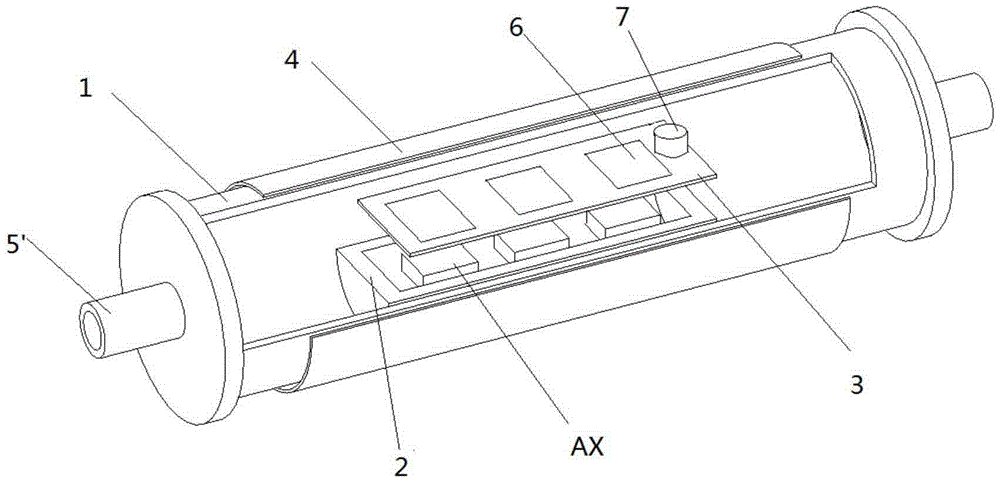

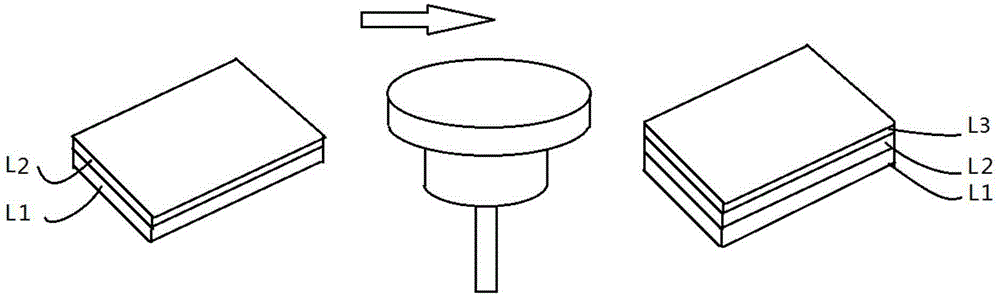

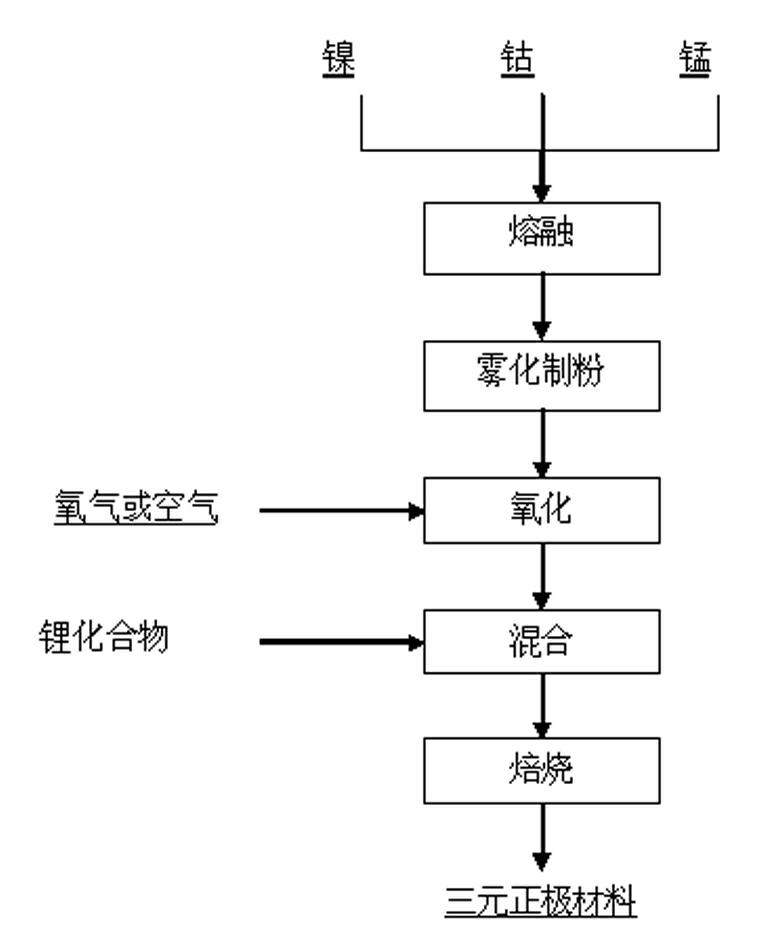

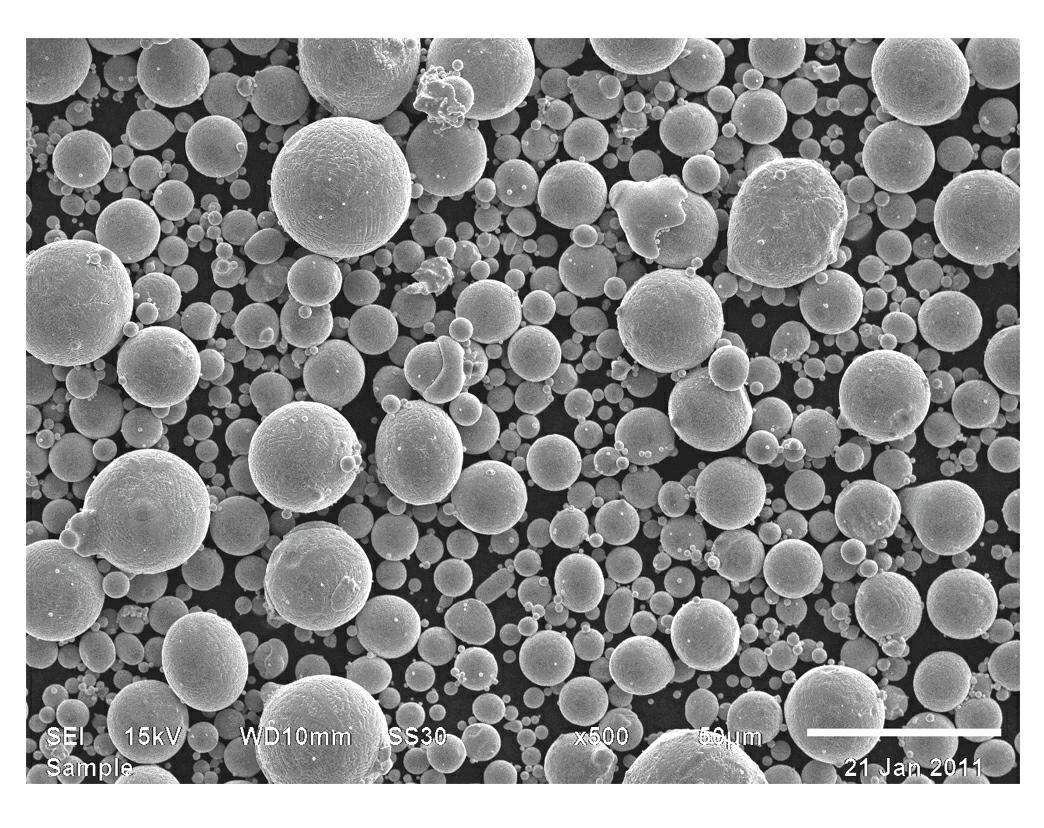

Ternary cathode material and production method thereof

The invention discloses a ternary cathode material and a production method thereof. The production method comprises the following steps of melting mixing materials of metallic nickel, cobalt and manganese at high temperature under the protection of inert gas or nitrogen; executing spray granulation after melting, and then oxidizing to obtain nickel, cobalt and manganese alloy oxide; and roasting the nickel, cobalt and manganese alloy oxide and a lithium compound at a temperature of 600-1050 DEG C after mixing according to the metallic element content mole ratio of (Ni+Co+Mn): Li=1:(1-1):1.15 to obtain the ternary cathode material, wherein the ternary cathode material is epigranular, regular spherical or similar to sphere, has large tap density, higher charge-discharge capacity and better electrochemical cycle performance. The ternary cathode material is prepared by adopting nickel, cobalt and manganese as raw materials and adopting full solid-phase reaction so as to completely avoid the environment pollution caused in the process of preparing a precursor by adopting a wet process. The invention has the advantages of simple process flow, convenience for operation and high production efficiency.

Owner:先进储能材料国家工程研究中心有限责任公司

Preparation method and application of graded porous carbon material

The invention discloses a preparation method of a graded porous carbon material. The preparation method comprises the following steps: sufficiently grinding a reaction raw material, obtaining a carbon precursor material having a core-shell structure by virtue of solid-phase reaction, carbonizing the carbon precursor material in one step at high temperature in an inert atmosphere, and removing a template to obtain the graded porous carbon material. The prepared graded porous carbon material is large in specific surface area and has an adjustable micropore-mesoporous graded porous structure; when being applied to the fields such as super-capacitors and lithium-sulfur batteries, the graded porous carbon material is excellent in electrochemical properties. The method is simple in process, environment-friendly and capable of realizing low-cost large-scale preparation of the graded porous carbon material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

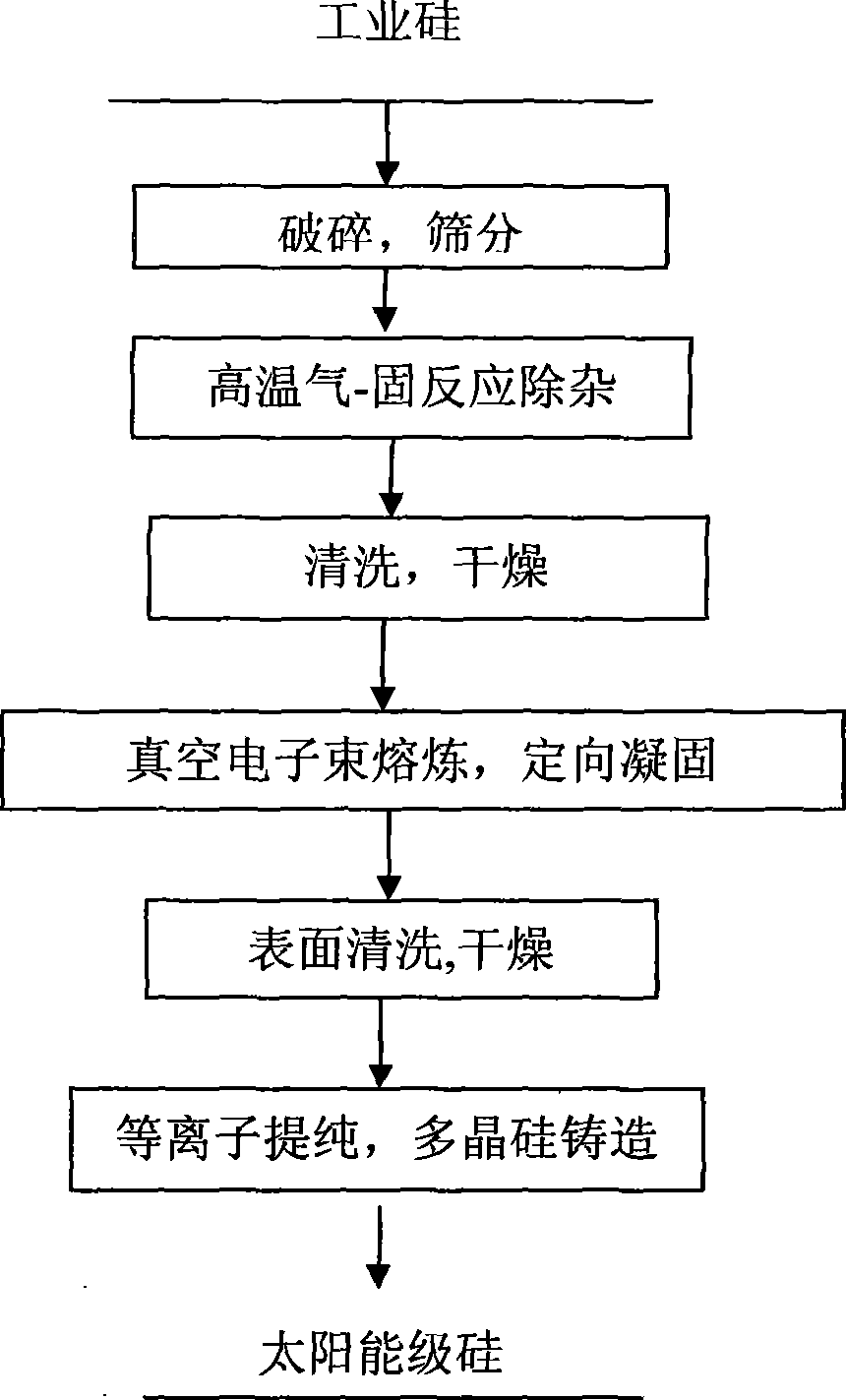

Method for purifying industrial silicon for preparing solar grade silicon

ActiveCN101475174ADirect preparationRemove difficult problemSilicon compoundsPre treatmentHigh activity

The invention discloses a method for preparing solar-grade silicon through purification of industrial silicon (2N). The method comprises that: the industrial silicon is subjected to primary pulverization pretreatment and is put into a high-temperature solid-phase reaction furnace; the industrial silicon and active gas are subjected to gas-solid reaction at high temperature to achieve the aim of removing metal impurities; then crystalline silicon is cleaned; the purity of the crystalline silicon reaches as high as 99.999 percent (5N), and is further subjected to vacuum melting of electron beams and oriented condensation treatment; finally, active atmosphere plasma is adopted to further purify the crystalline silicon, and volatile elements which have high activity and are easily oxidized to generate high saturated vapor pressure are removed; and polysilicon is cast in an integrated furnace for casting plasma polysilicon and is directly used for manufacturing a cell chip. The method combines high-temperature gas-solid reaction to remove the metal impurities, the electron beams to remove the volatile elements and a plasma purification and casting integrated furnace technology, improves the purity of the polysilicon to 99.99999 percent (7N) and, fully meets requirement of a solar cell industry on the solar-grade silicon.

Owner:晶海洋半导体材料(东海)有限公司 +1

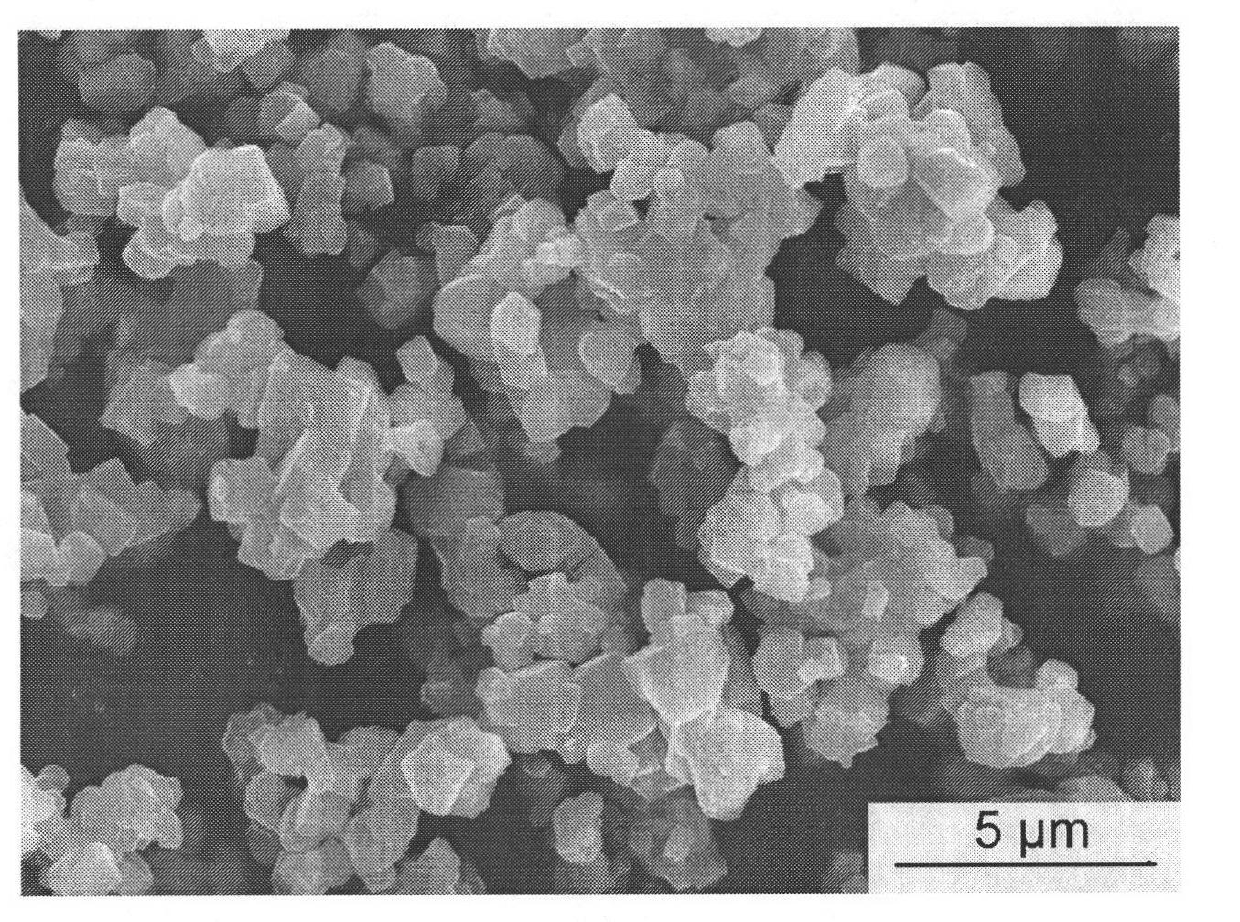

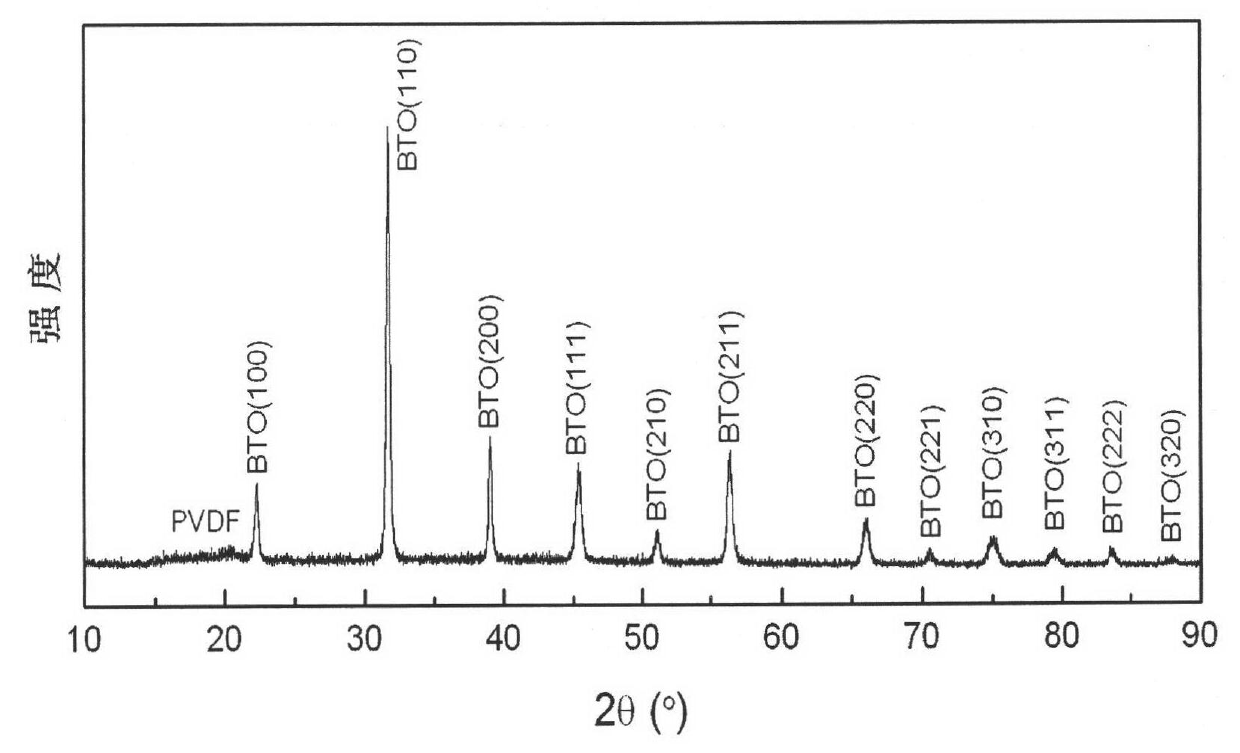

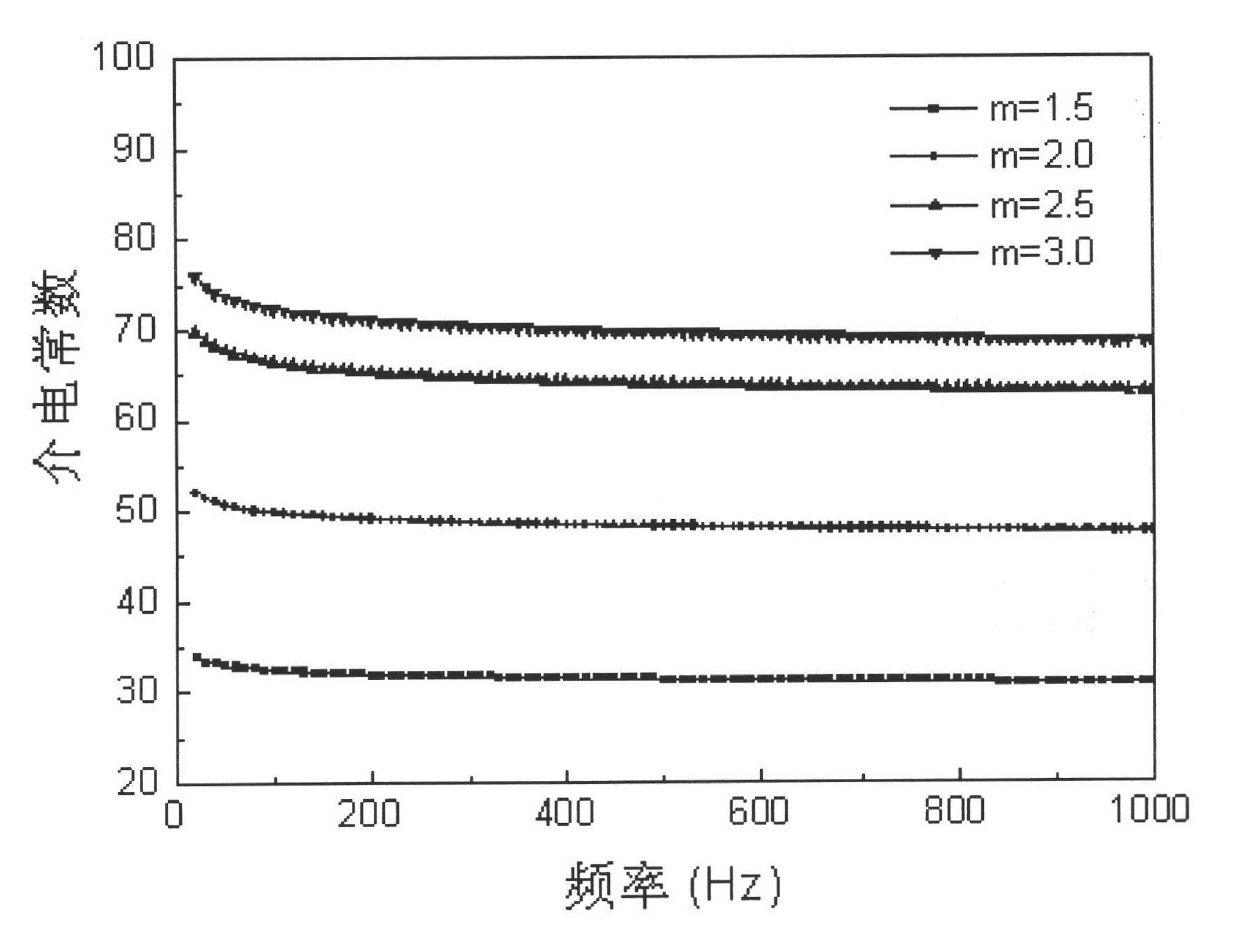

Barium titanate/polyvinylidene fluoride composite dielectric film and preparation method thereof

ActiveCN102558718AImproved rheological propertiesIncrease BTO contentBarium titanateSolid state reaction method

The invention provides a barium titanate / polyvinylidene fluoride composite dielectric film and a preparation method thereof. The film comprises barium titanate and polyvinylidene fluoride with the weight ratio of 1.5-5.0:1, and the thickness of the film is less than 50 mu m. In the frequency range of 100 Hz-1 MHz, the relative dielectric constant of the film can reach more than 70, and the dielectric loss is lower than 5*10<-2>. By compounding BaTiO3 ceramic and PVDF polymer, the dielectric film material with high dielectric constant and low dielectric loss is prepared. According to the invention, the barium titanate / polyvinylidene fluoride composite dielectric film with uniform distribution of ceramic particles, controllable thickness, high dielectric constant and low dielectric loss is prepared by preparing barium titanate ceramic powder through solid phase reaction or chemical coprecipitation and then using high temperature drying gel method or solvent induced phase separation gel method. The dielectric film is especially suitable for capacitor, ferroelectric memory, and other electronic devices.

Owner:GRIMAT ENG INST CO LTD

Lead-less piezoelectric sodium bismuth titanate-bariumtitanate ceramic and its prepn process

InactiveCN101020608AEasy to prepareEasy to printPiezoelectric/electrostrictive/magnetostrictive devicesScreen printingBarium titanate

The present invention is one kind of lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic, and belongs to the field of lead-less piezoelectric ceramic. The lead-less piezoelectric sodium bismuth titanate-barium titanate ceramic has the chemical formula of (Na1 / 2Bi1 / 2)1-xBaxTiO3, where, x is 0.05-0.1, and has ceramic crystal grains parallel to the grain boundary. Its preparation process includes the following steps: molten salt procedure to synthesize Bi4Ti3O12 template or solid phase reaction procedure to synthesize Na0.5Bi4.5Ti4O15 precursor material powder; preparing slurring with Na2CO3, BaCO3, Bi2O3 and nanometer TiO2; silk screen printing to obtain thick ceramic film; cutting, superposing and sintering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

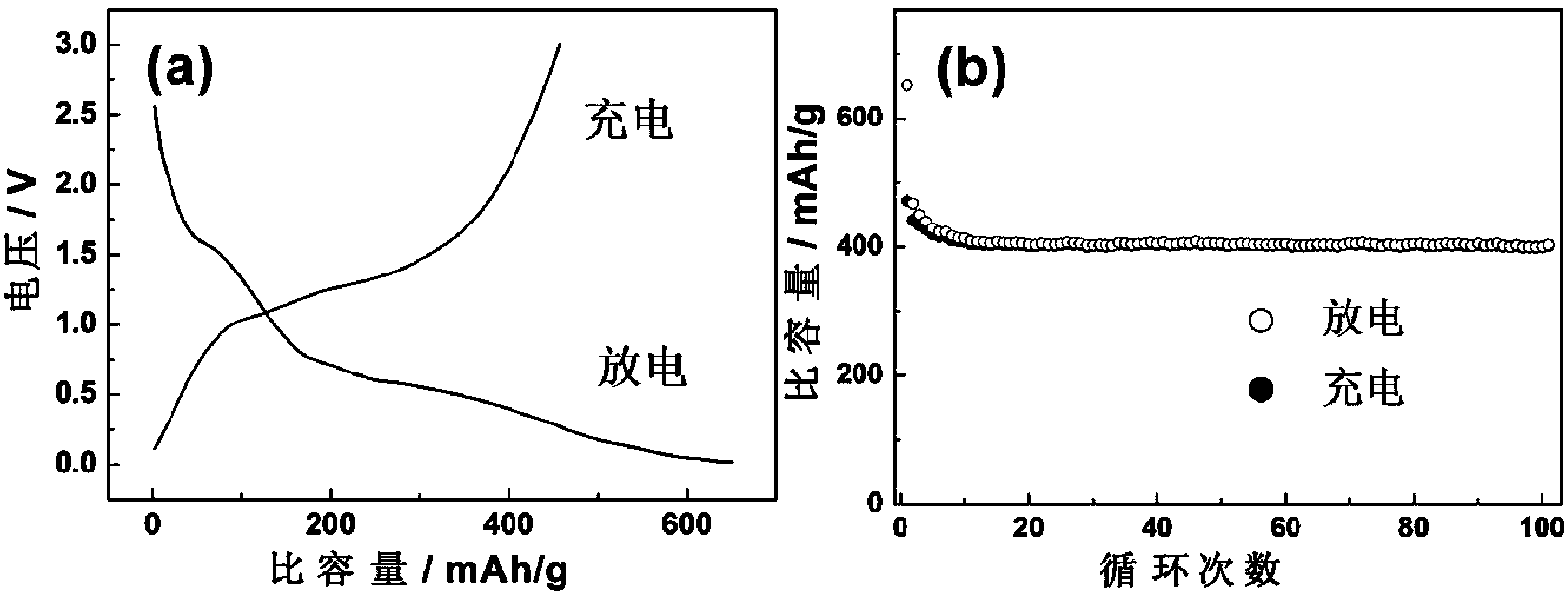

Lithium ion battery anode material Li3VO4 and preparation method thereof

The invention provides a Li3VO4 cathode anode material and a preparation method thereof, particularly a novel lithium ion battery anode material Li3VO4 prapared by carrying out hydrothermal reaction on vanadium pentoxide, lithium carbonate and hexamethylenetetramine used as precursors. The hydrothermal reaction is utilized to prepare an intermediate phase product, and the intermediate phase product is gradually subjected to solid-phase reaction while reaction energy is supplied by high temperature heating, thereby finally obtaining the Li3VO4 with favorable crystallinity. The first charge and discharge capacities of the Li3VO4 are respectively 523 and 423 mAh / g, and the charge and discharge capacities after 100 loops are still 398 mAh / g; and the grain size is uniform, and is less than 200nm.

Owner:CHINA THREE GORGES UNIV

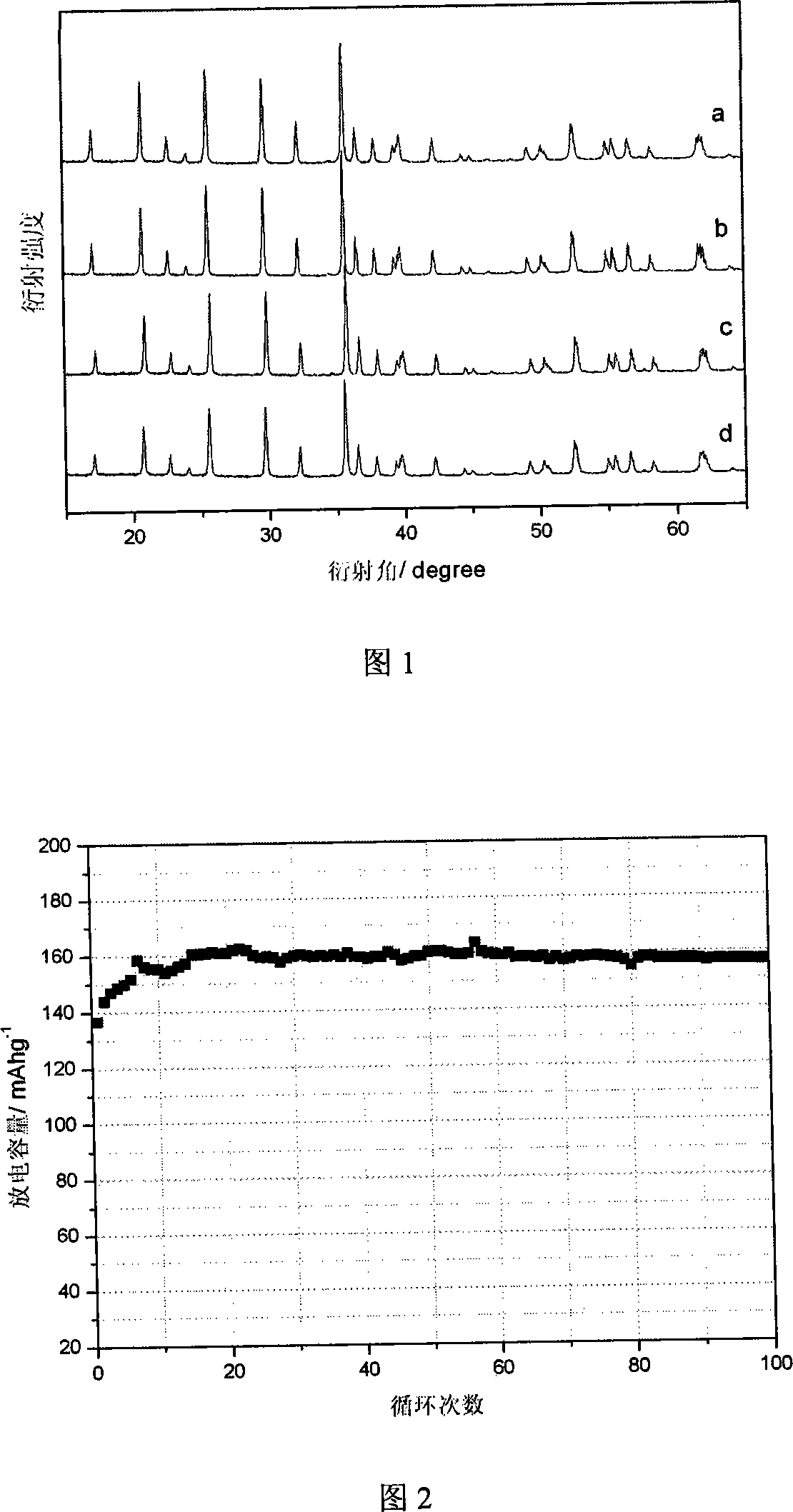

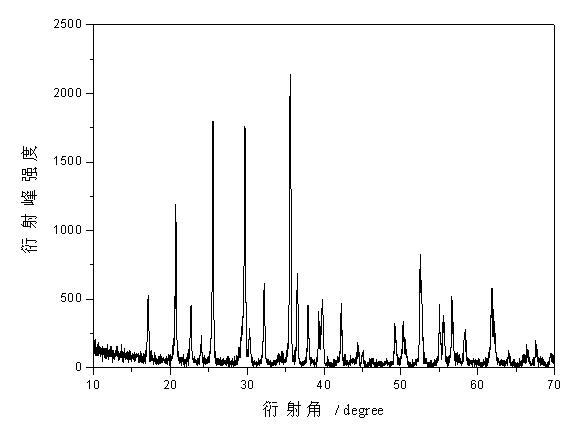

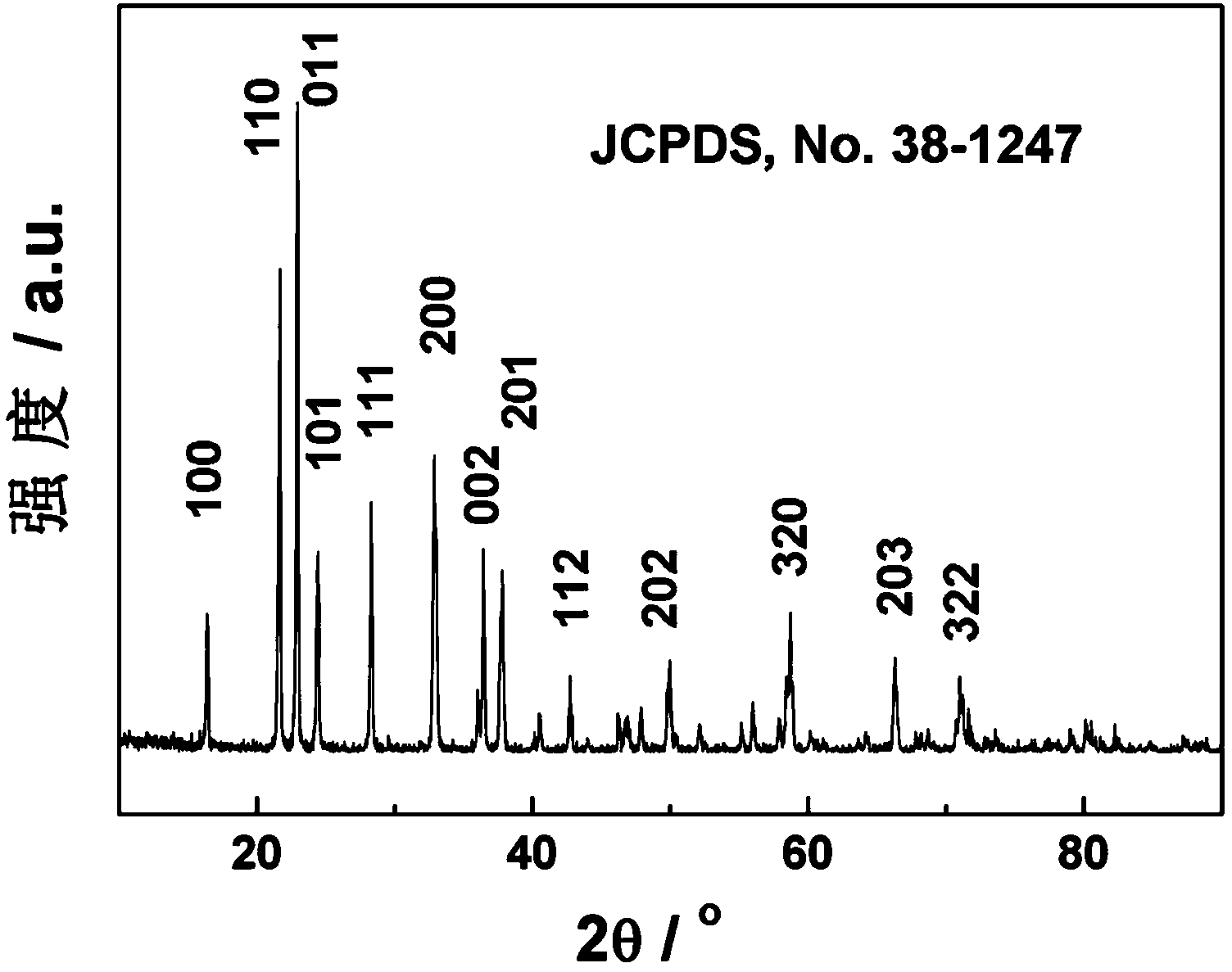

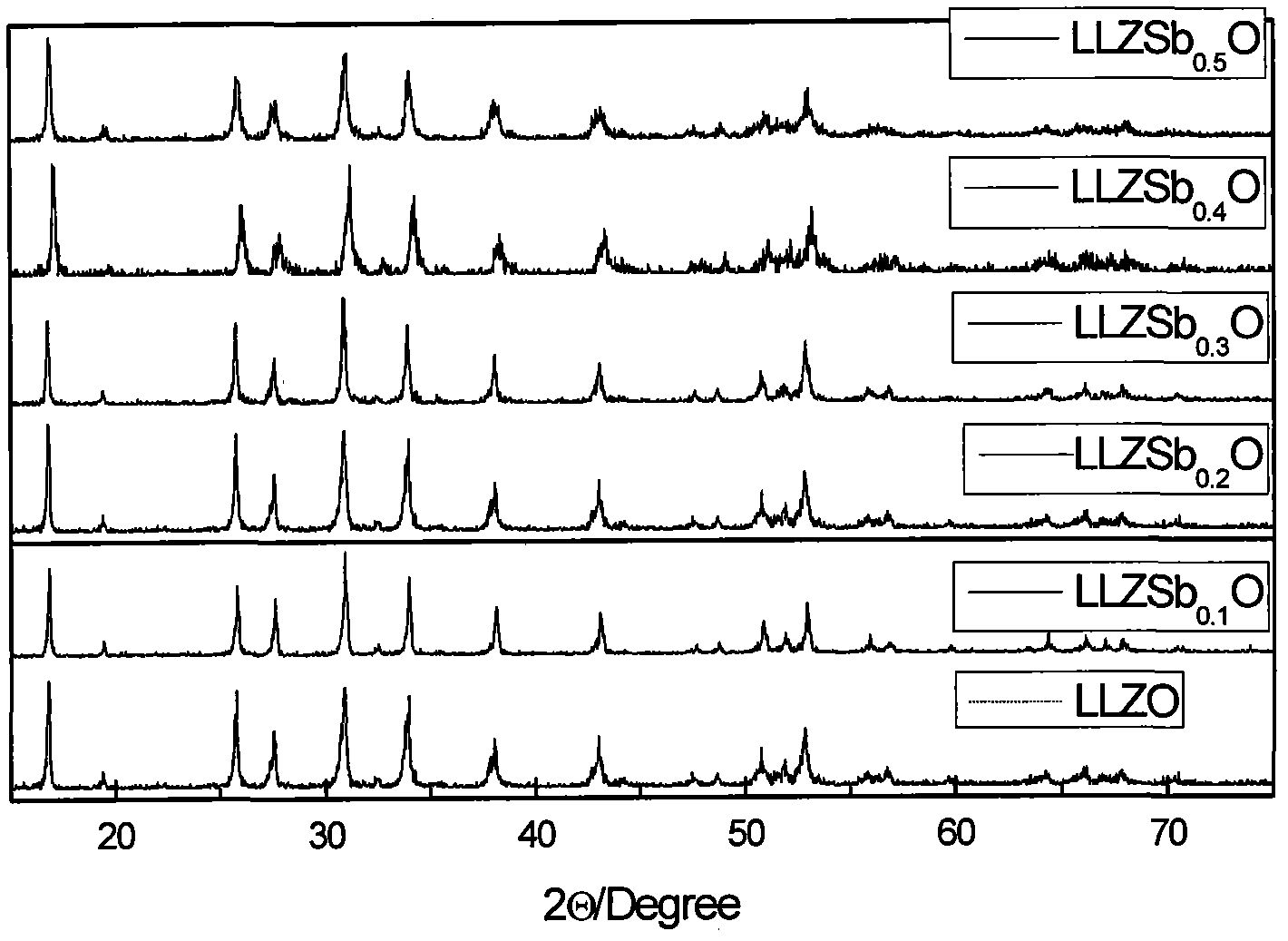

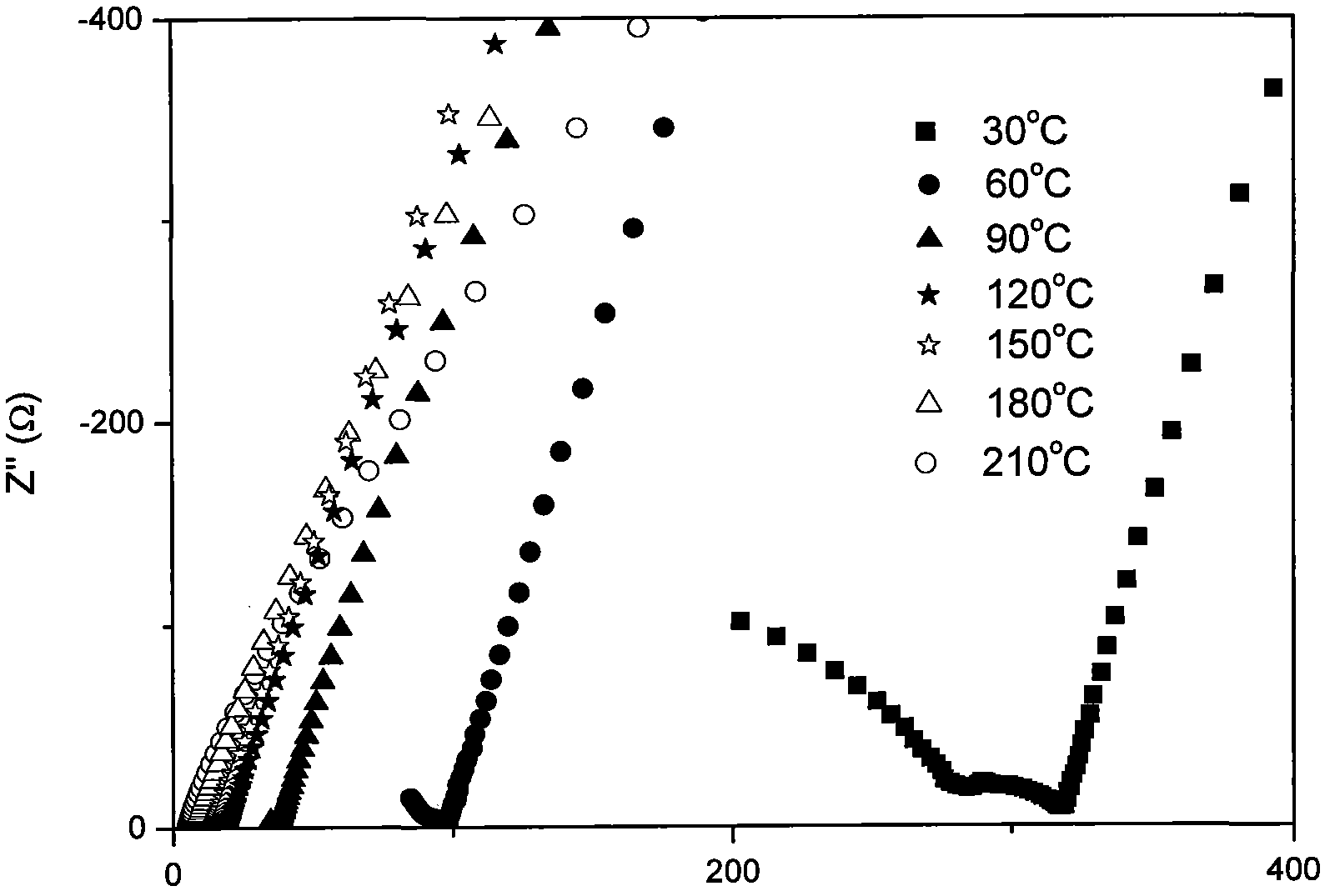

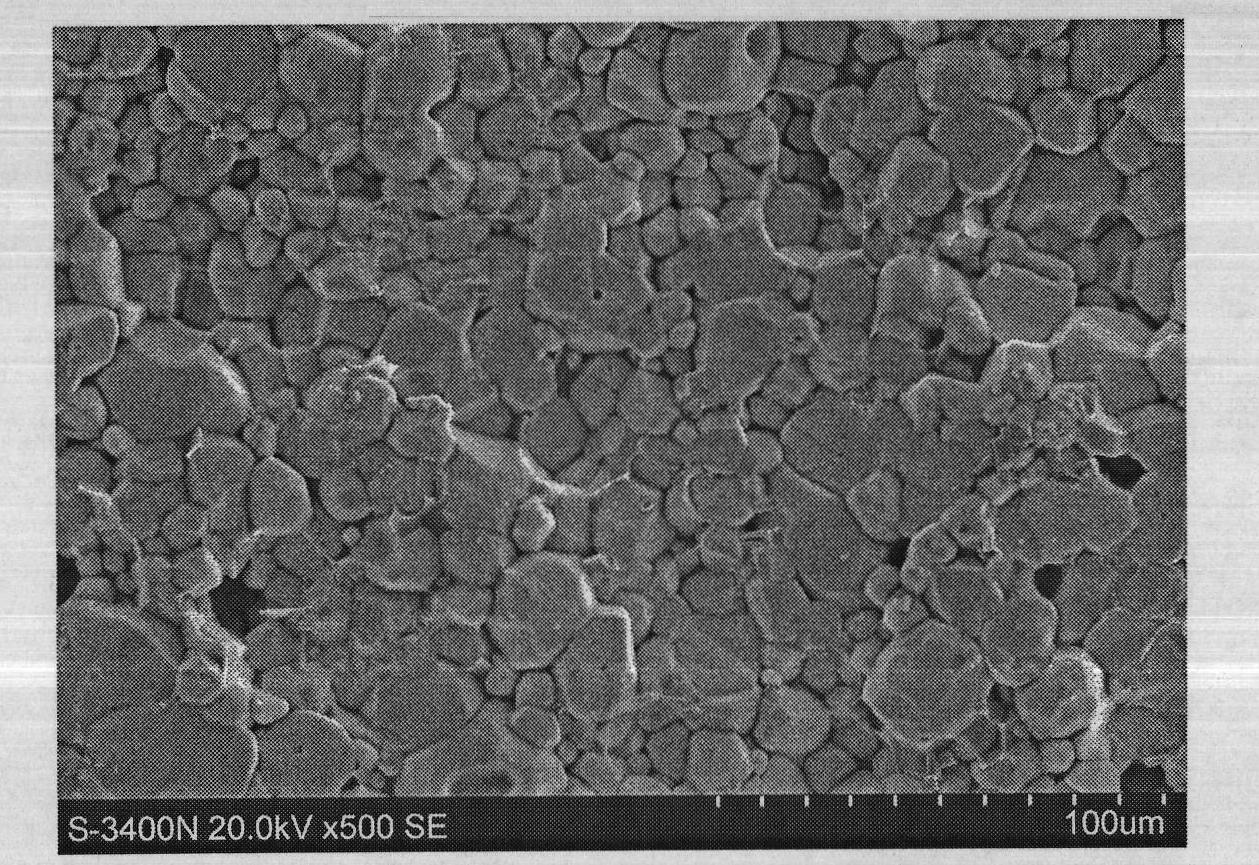

Stibonium-doped quasi garnet-structured lithium ion crystalline-state solid electrolyte material and synthesis method thereof

The invention provides a novel quasi garnet-structured lithium ion conductor (Li7-xLa3Zr2-xSbxO12, wherein x is more than 0 and less than or equal to 0.5) crystalline-state ceramic solid electrolyte material and a synthesis method thereof, and belongs to the field of lithium ion batteries. A novel quasi garnet-structured lithium ion conductor is synthesized by conventional solid-phase reaction. X-ray diffraction (XRD) diffraction peaks of Sb-doped samples show that the Sb-doped samples all have crystalline -state cubic phase quasi garnet-structures in the Sb doped range. The maximum lithium ion conductivity can reach 3.42*10<-4>S / cm at room temperature (30 DEG C). The sample is synthesized by the conventional solid phase method, a preparation process is simple, and sintering time is short. Zr is partially replaced by high-valence Sb, so the lithium ion vacancy is increased, the ionic conductivity is improved obviously, and antimonous oxide is low in price compared with zirconia, so manufacturing cost is reduced. Therefore, the synthesized compact ceramic solid electrolyte material can be probably applied to a lithium ion battery.

Owner:INNER MONGOLIA UNIV OF TECH

Molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and preparation method thereof

The invention discloses molybdenum-based ultralow-temperature sintering microwave medium ceramic materials and a preparation method thereof. Based on a general structural formula of A4B3O12, a series of ceramic materials, which can be sintered at a temperature lower than 7,000 DEG C and have excellent microwave dielectrical properties ( a dielectric constant of 8.5 to 11.1 and a quality factor Qfof between 36,000 and 108,000GHz), can be obtained by using low-valence cation (such as Li<+>, Zn<2+>, Ca<2+>, Cu<2+>, Mg<2+>, Al<3+>, In<3+>, Cr<3+> and Ga<3+>) composite at a position A and a high-valence cation Mo<6+> at a position B and by using the conventional solid-phase reaction sintering method. The concrete structural expression of the ceramic material comprises Li2M<2+>2(MoO4)3(M<2+> may be Zn<2+>, Ca<2+>, Cu<2+> and Mg<2+>) and Li3M<3+>(MoO4)3(M<3+> may be Al<3+>, In<3+>, Cr<3+> and Ga<3+>).

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com