Nano reinforcing method for recycled aggregate concrete

A technology for recycling aggregate and concrete, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of increased equipment investment and production costs, increased vacuum equipment, difficult to regenerate aggregate reinforcement, etc. problems, to achieve the effect of increasing compressive strength, increasing strength, and improving interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

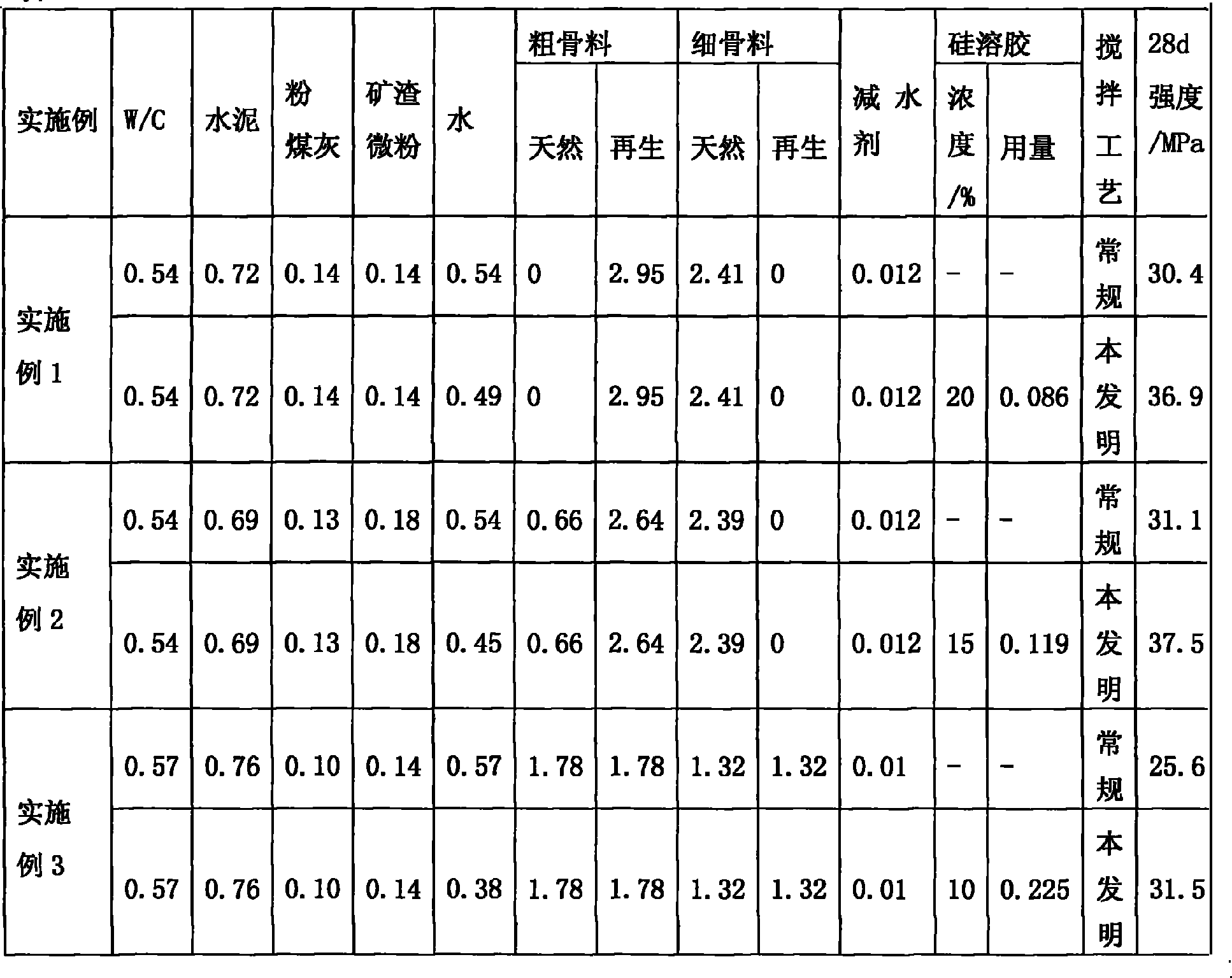

Embodiment 1~3

[0016] Natural coarse aggregate is natural coarse aggregate with continuous particle size between 4.75mm and 19mm in particle size. The natural fine aggregate is a mixed sand made by mixing artificial sand and ultra-fine sand in a ratio of 80:20. The cement uses PO42.5 ordinary Portland cement from Qianchao Cement Plant. Regenerated aggregate is to roughly crush the discarded concrete with an original strength grade of about C30-C50 in the laboratory, then crush it with a jaw crusher, and sieve it into continuous-grained recycled coarse bone with a particle size between 4.75mm and 19mm. material and recycled fine aggregate <4.75mm, the superplasticizer used is SP404 superplasticizer. The silica sol used is NS-30 silica sol produced by Zhejiang Shangyu Yuda Chemical Co., Ltd. When using it, the silica sol is directly added to water in a certain proportion to prepare silica sol with a mass concentration of 10-20%; the admixture used is slag powder It is Shagang S95 grade blast...

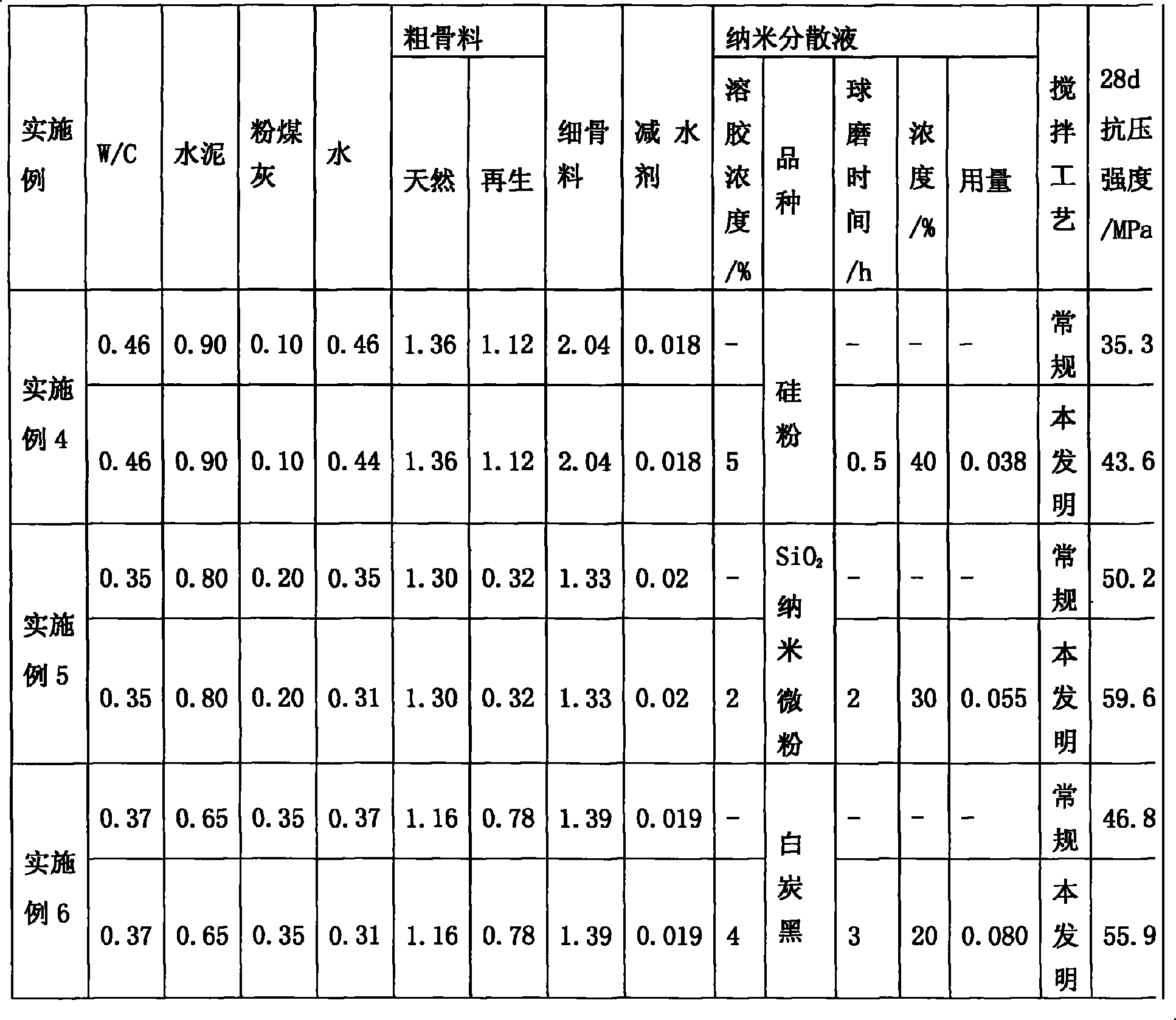

Embodiment 4~6

[0020] Natural coarse aggregate is natural coarse aggregate with continuous particle size between 4.75mm and 19mm in particle size. The natural fine aggregate is medium sand with a fineness modulus of 2.53, and the grading is qualified. The cement uses PO42.5 ordinary Portland cement from Qianchao Cement Plant. Regenerated aggregate is to roughly crush the discarded concrete with an original strength grade of about C30-C50 in the laboratory, then crush it with a jaw crusher, and sieve it into continuous-grained recycled coarse bone with a particle size between 4.75mm and 19mm. The high-efficiency water reducer used is SP404 type high-efficiency water reducer, and the silica sol used is NS-30 type silica sol produced by Zhejiang Shangyu Yuda Chemical Co., Ltd.; the silica powder used was purchased from Elkem (International) Shanghai Co., Ltd. The white carbon black was purchased from Zhejiang Genglou Chemical Co., Ltd. The nano-SiO2 powder used was produced by Zhejiang Shangyu...

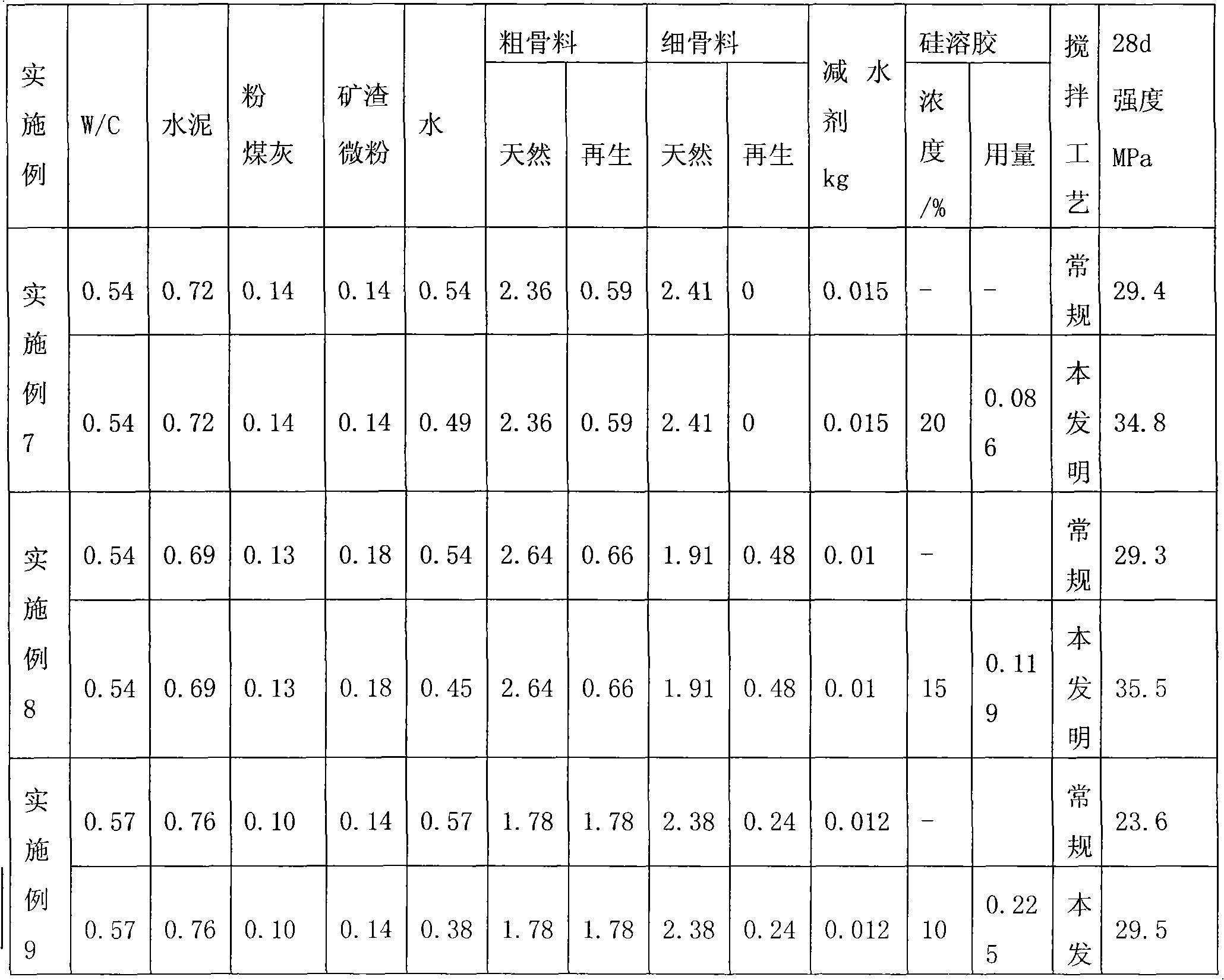

Embodiment 7~9

[0025] Natural coarse aggregate is natural coarse aggregate with continuous particle size between 4.75mm and 19mm in particle size. The natural fine aggregate is a mixture of artificial sand and ultra-fine sand in a ratio of 80:20. The cement uses PO42.5 ordinary Portland cement from Qianchao Cement Plant. Regenerated aggregate is coarsely crushed waste sintered ordinary bricks with a strength grade of MU10-MU20, then crushed by a jaw crusher, and sieved into continuous-grained recycled coarse aggregate with a particle size of 4.75mm-19mm and < 4.75mm recycled fine aggregate. Superplasticizer SP404 superplasticizer. The silica sol used is NS-30 type silica sol produced by Zhejiang Shangyu Yuda Chemical Co., Ltd.; the admixture slag powder used is Shagang S95 grade blast furnace slag powder, and the fly ash used is Grade II from Hangzhou Boneng Thermal Power Co., Ltd. fly ash.

[0026]The concrete mix ratio of each embodiment is shown in Table 3. When mixing concrete, firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com