Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

A technology of chemical vapor deposition and solid phase method, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of uneven particle size distribution, low electronic conductivity, high synthesis temperature, etc., and achieve improved magnification Charge-discharge and cycle performance, improved uniformity and conductivity, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Will Li 2 CO 3 , FeC 2 o 4 2H 2 O and NH 4 h 2 PO 4 Weigh 25g according to the stoichiometric ratio of Li:Fe:P=1:1:1, mix evenly, and ball mill for 6h on a planetary ball mill; 2 Pre-fired at 300°C for 5 hours in the atmosphere, ball milled for 2 hours after natural cooling to obtain powder materials; transferred to a tube furnace to heat at a heating rate of 30°C / min, and used benzene as an organic precursor, and carbonized on the surface of the material by chemical vapor deposition. Coating, gas flow rate 50mL / min, calcination at constant temperature of 600°C for 8h. Lithium-ion battery lithium iron phosphate (LiFePO 4 ) positive electrode material. The average particle size of the material is measured to be 2~10μm, and the tap density is 1.65g / cm 3 .

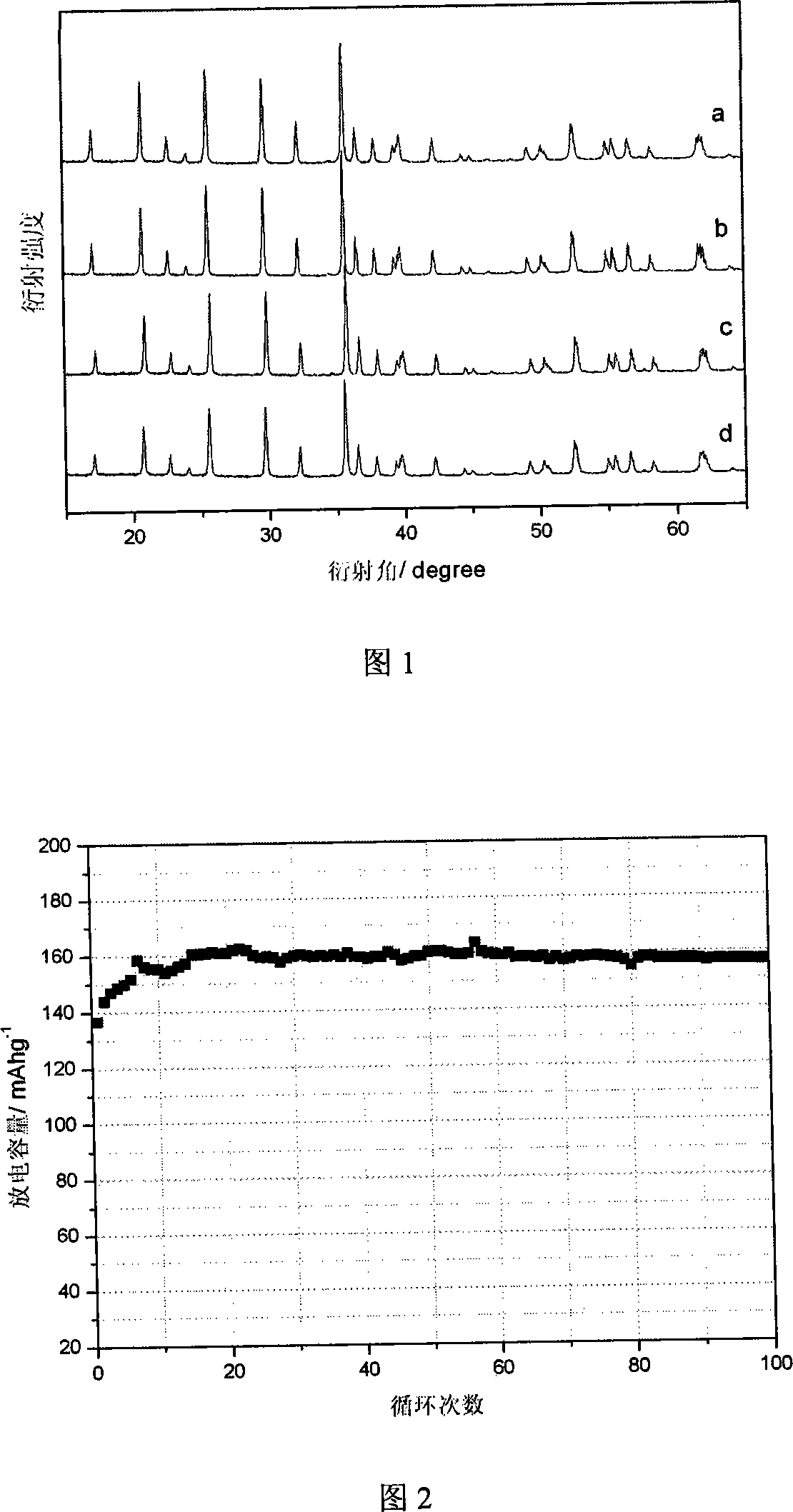

[0031]The XRD of the product is shown in the curve a in Figure 1. It can be seen from the figure that a pure-phase orthorhombic olivine-type lithium iron phosphate cathode material was prepared by using a so...

Embodiment 2

[0033] LiCH 3 COO, FeC 2 o 4 2H 2 O and (NH 4 ) 2 HPO 4 Weigh 20g according to the stoichiometric ratio of Li:Fe:P=1:1:1, mix with 3.5g polyvinyl alcohol (PVA) evenly, and ball mill on planetary ball mill for 8h; in Ar atmosphere, the precursor Pre-fired at 400°C for 6 hours, and ball milled for 5 hours after natural cooling to obtain powder materials; transfer to a tube furnace to heat at a heating rate of 10°C / min, and use toluene as an organic precursor to coat carbon on the surface of the material by chemical vapor deposition , the gas flow rate is 100mL / min, and it is calcined at a constant temperature of 700°C for 24h. Lithium-ion battery lithium iron phosphate (LiFePO 4 ) positive electrode material. The average particle size of the material is measured to be 1~10μm, and the tap density is 1.58g / cm 3 .

[0034] The XRD pattern of the product is shown in the curve b in Figure 1. It can be seen from the figure that the product has no impurities and is a single o...

Embodiment 3

[0036] LiOH·H 2 O, FePO 4 4H 2 Weigh 30g of O according to the stoichiometric ratio of Li:Fe(P)=1:1, mix it with 6g of sucrose evenly, and mill it on a planetary ball mill for 8 hours; 2 In the atmosphere, the precursor was pre-fired at 300 °C for 10 h, and after natural cooling, ball milled for 6 h to obtain the powder material; it was transferred to a tube furnace and heated at a heating rate of 15 °C / min, and biphenyl was used as an organic precursor. Chemical vapor deposition method Carbon coating is carried out on the surface of the material, the gas flow rate is 200mL / min, and it is calcined at a constant temperature of 750°C for 48h. Lithium-ion battery lithium iron phosphate (LiFePO 4 ) positive electrode material. The average particle size of the material is measured to be 3~8μm, and the tap density is 1.42g / cm 3 .

[0037] The XRD pattern of the product is shown in the curve c in Fig. 1. It can be seen from the figure that the product has no impurities and is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com