Method and device for manufacturing glass and products obtained with the aid of said method

A manufacturing method and equipment technology, applied in refining and homogenizing molten glass, rotary refining under low pressure, flat glass field, can solve problems such as not helping the uniformity of glass, and achieve the goal of improving refining quality, increasing output, and increasing output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

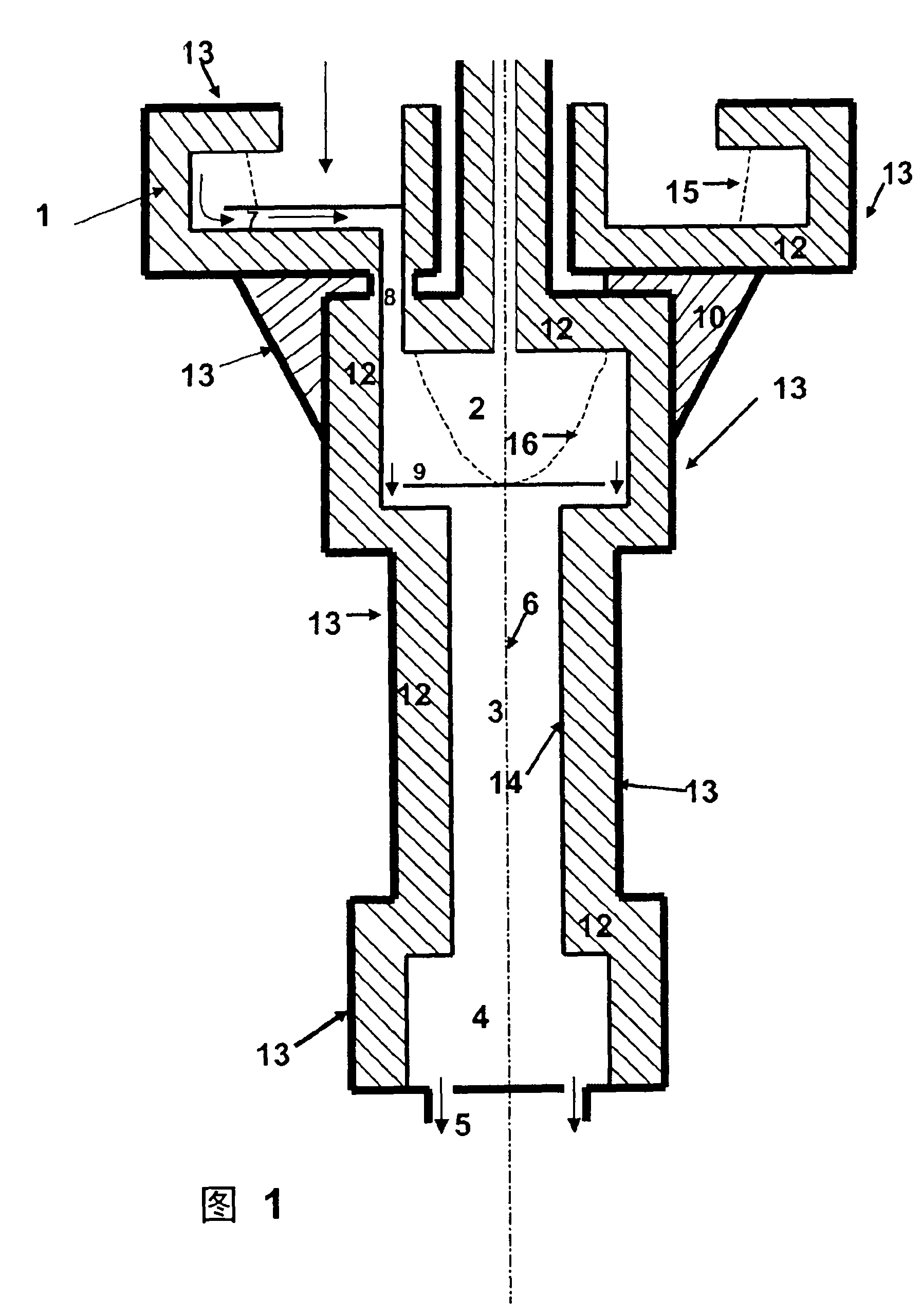

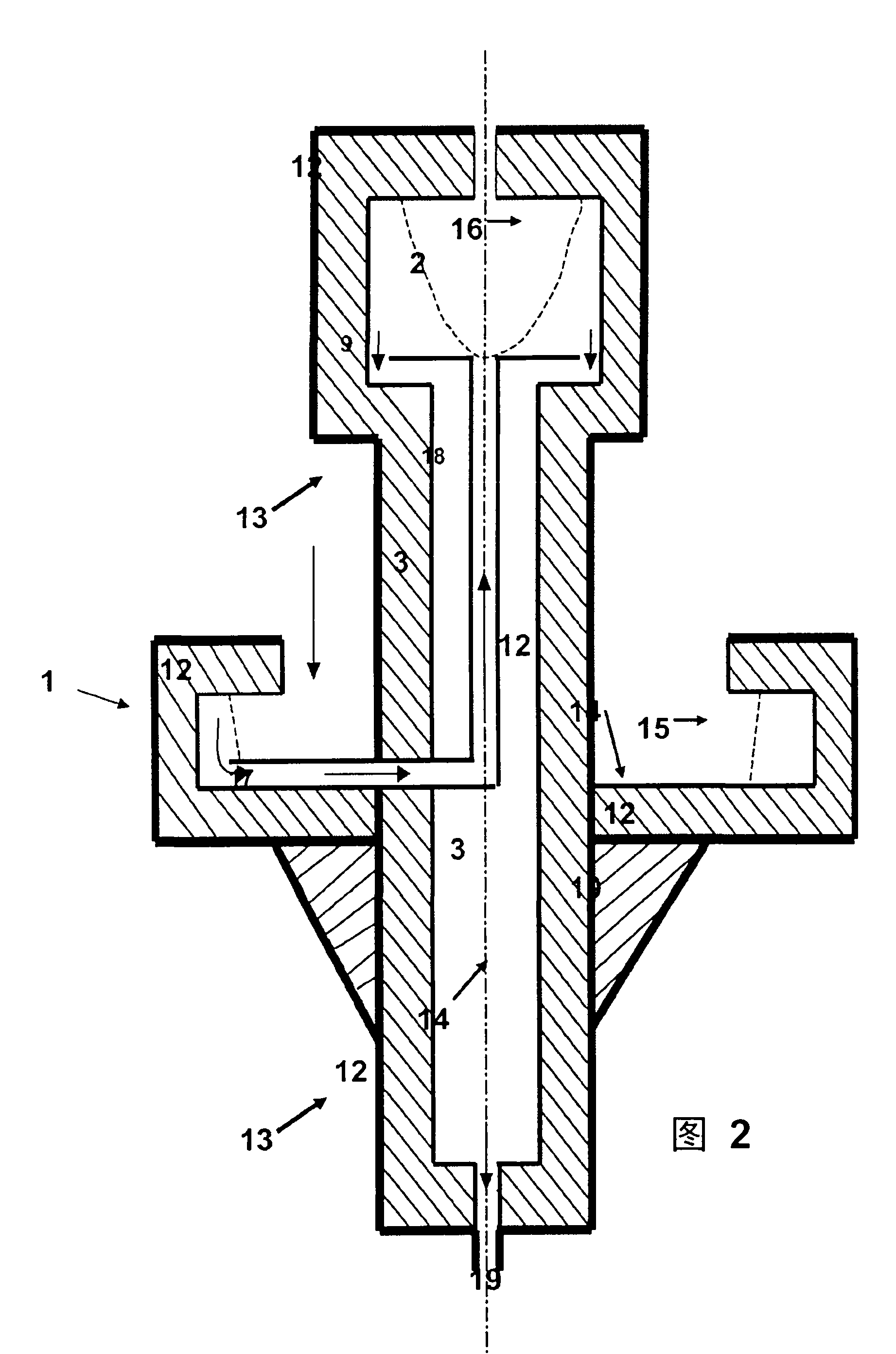

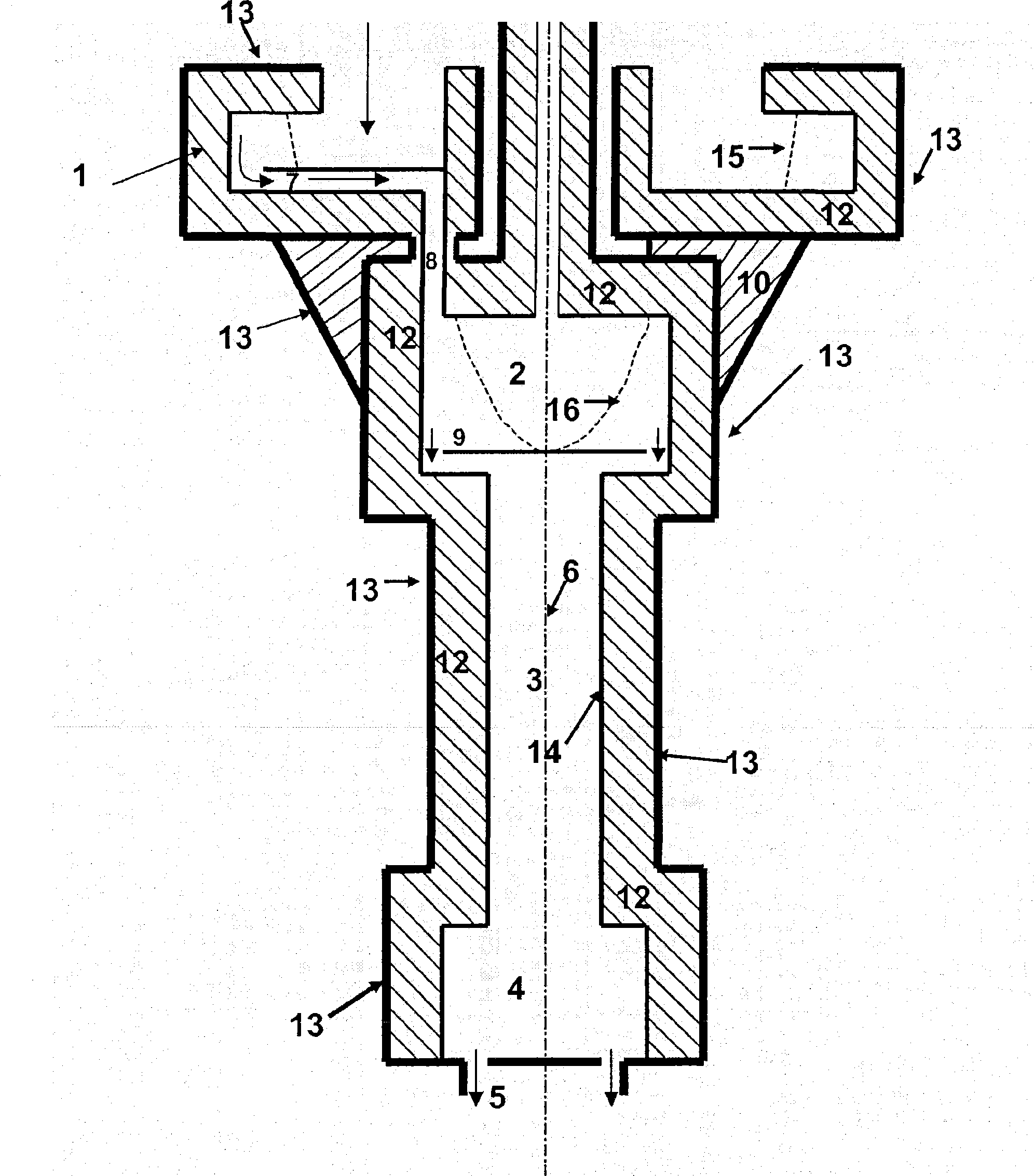

[0147] Figure 1 shows a vertical section through an apparatus according to the invention in an embodiment in which the feed container is located above the vacuum chamber.

[0148] The entire device, which has a height of approximately 2.50 m, can rotate about a vertical axis of rotation 6 indicated by dotted lines, the axis of rotation of which has a substantially cylindrical geometry. The device consists of an outer shell 13 of heat-resistant steel and a platinum lining 14 of platinum with an inner diameter of 150 mm (diameters in the range of 50 to 300 mm are particularly suitable for the device of the invention). The application of the device and the constituent features of the device can thus be described.

[0149] Unrefined molten glass of the soda-lime-silica type was obtained in a furnace comprising two submerged burners, a feeder at substantially atmospheric pressure and a temperature of 1,400°C and at Melting takes place at a position remote from the axis of rotation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com