Patents

Literature

61 results about "Cylindrical geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cylindrical coordinate geometry, also known as cyclic coordinate geometry, is a scheme for guiding a robot arm in three dimensions. A cylindrical coordinate system is a polar system with an extra coordinate added for elevation.

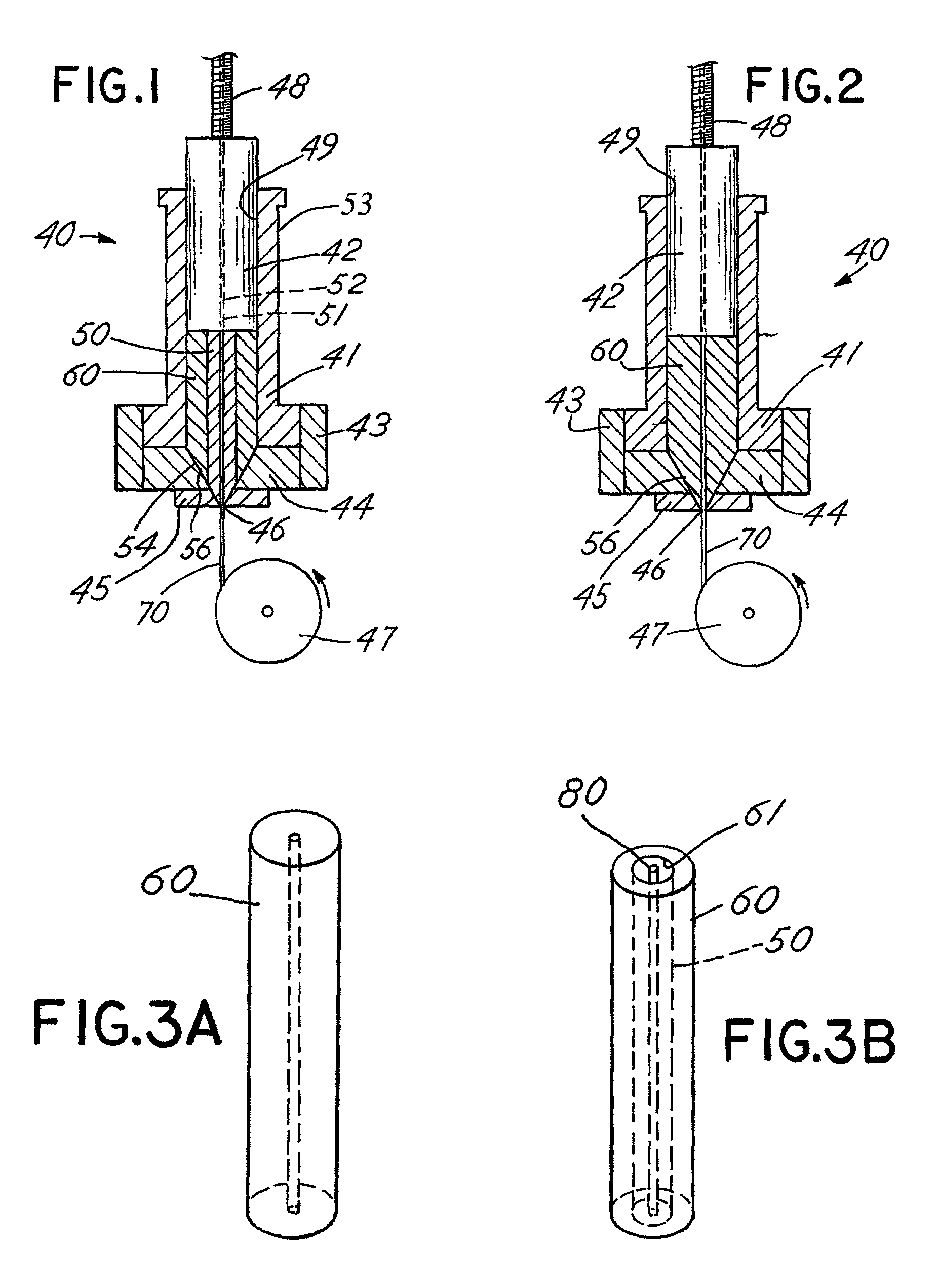

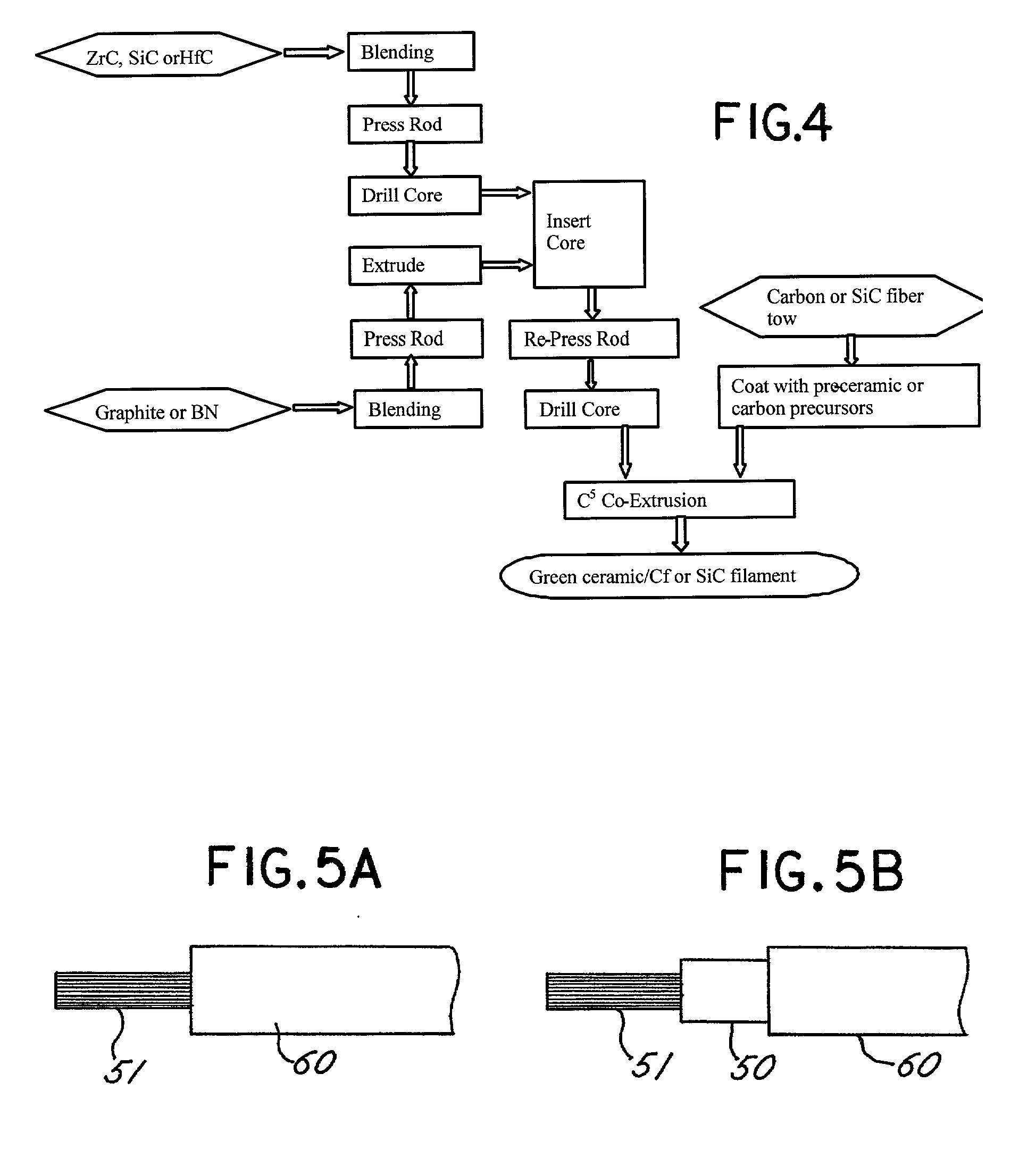

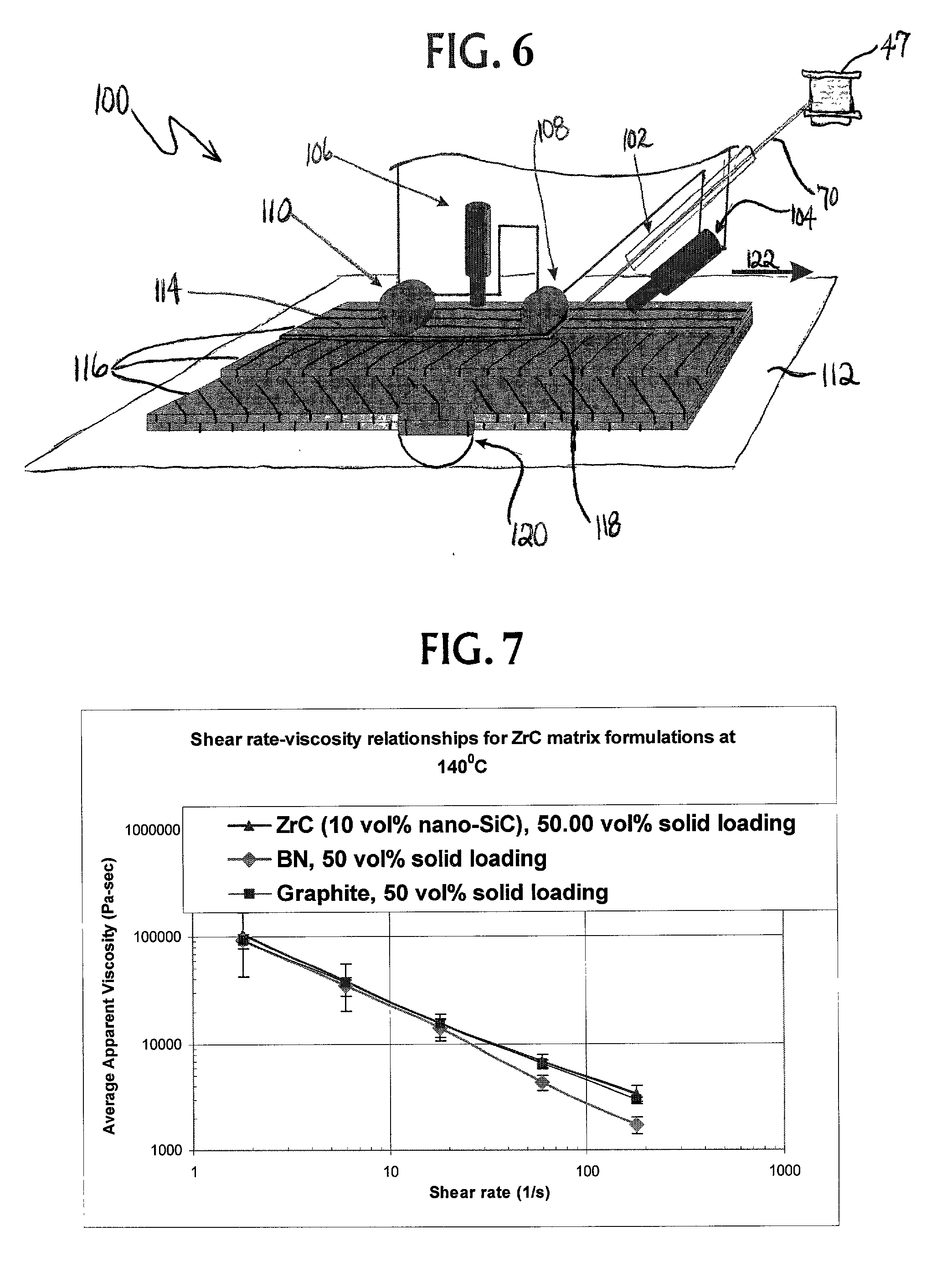

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

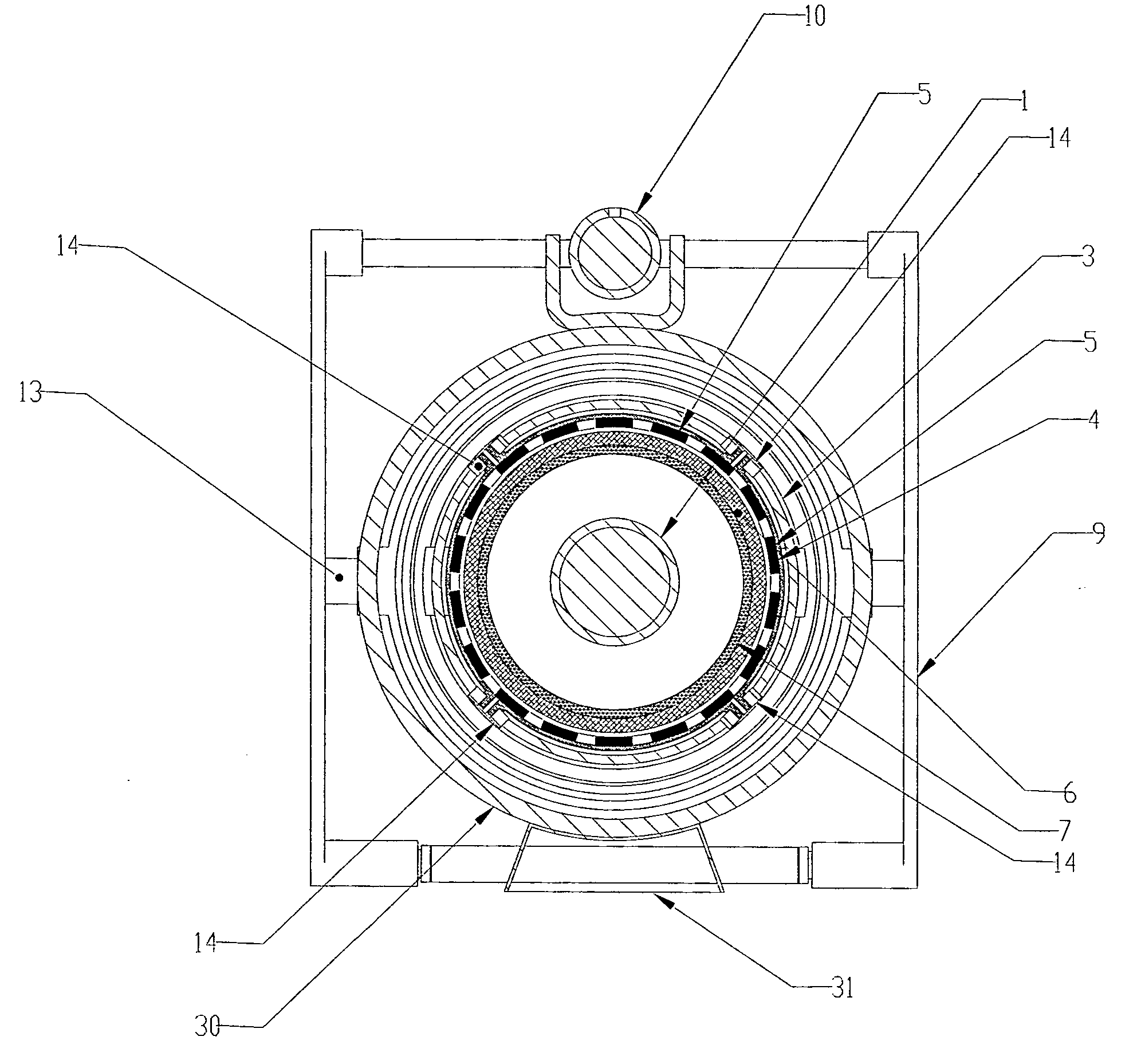

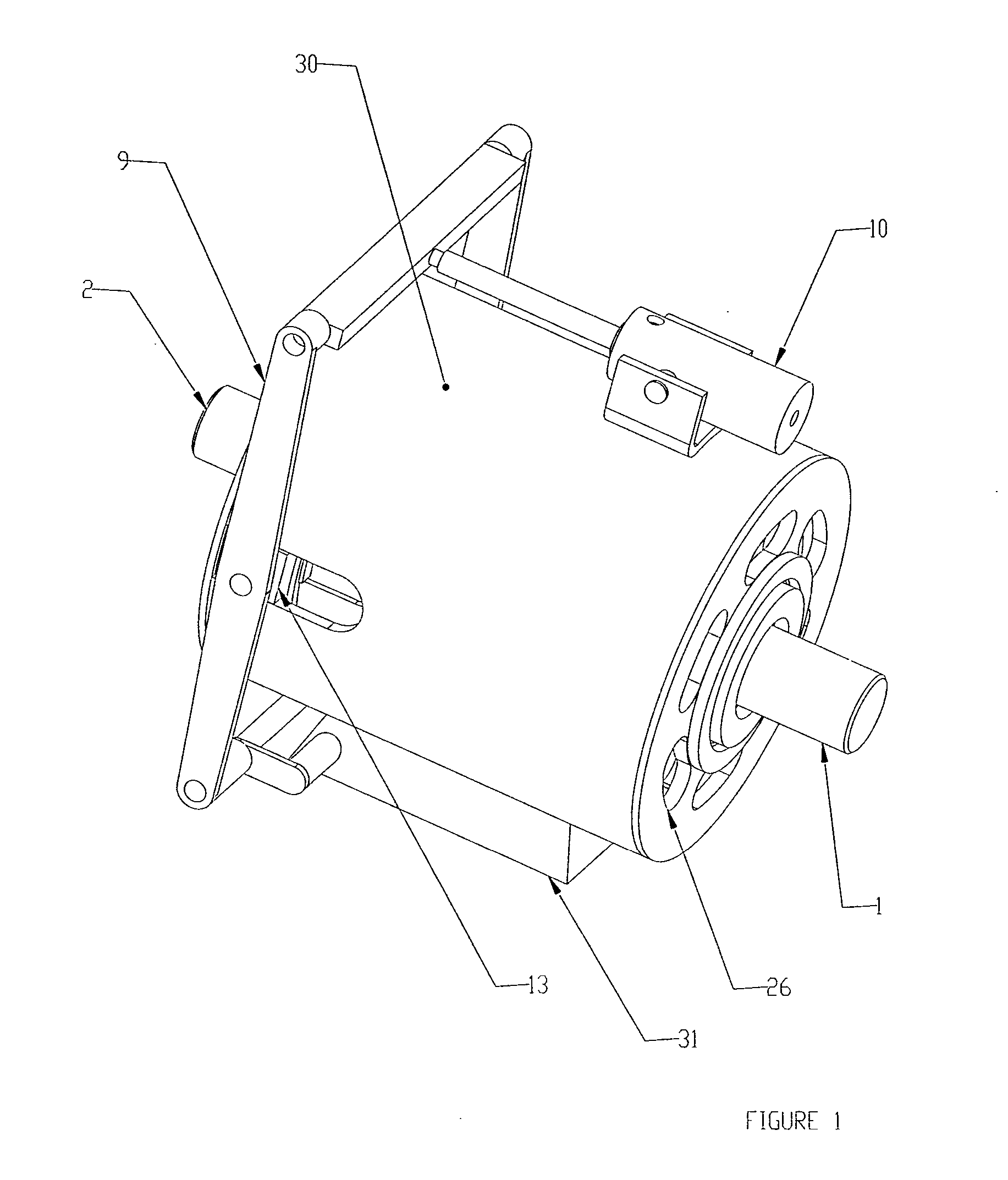

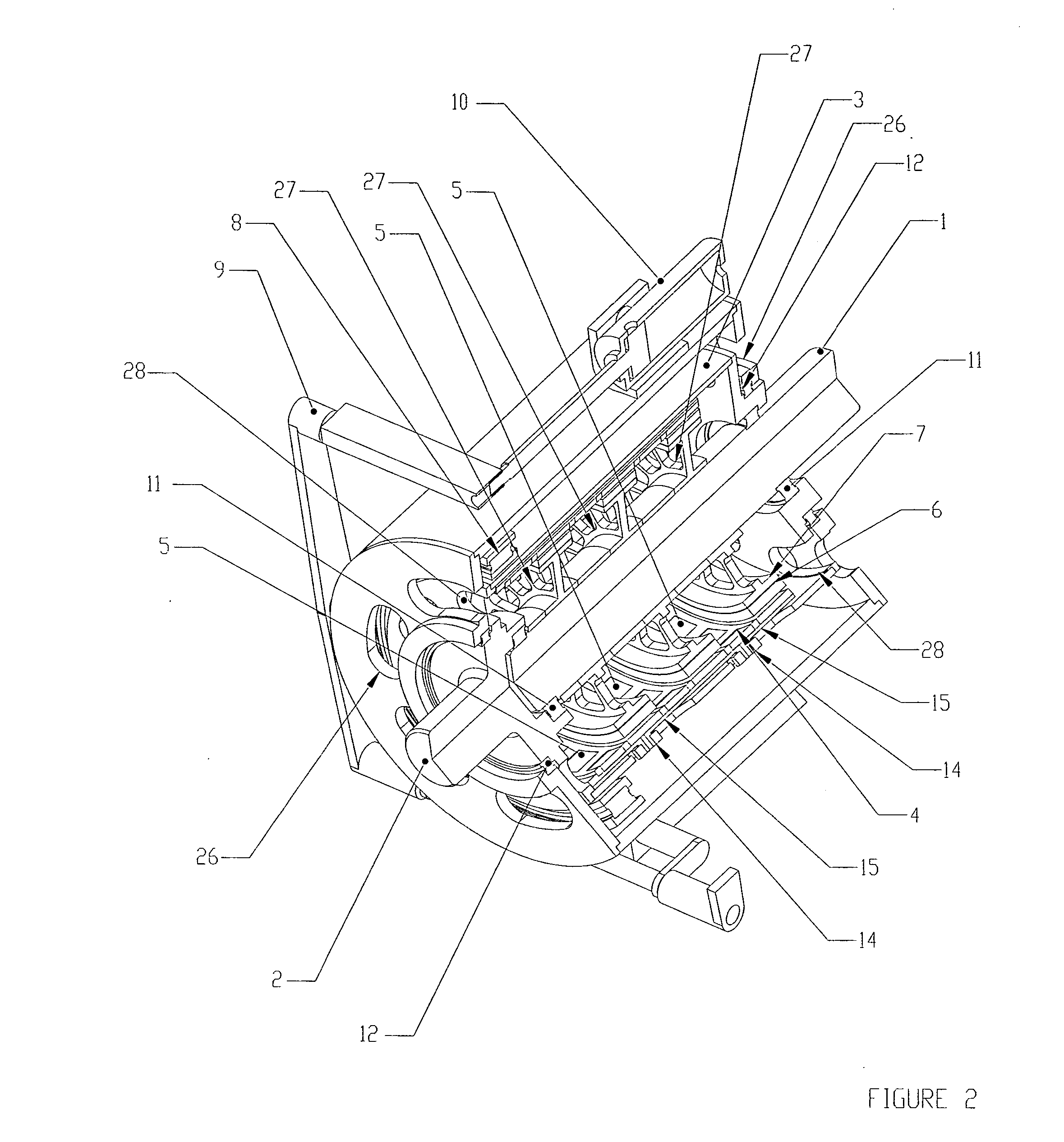

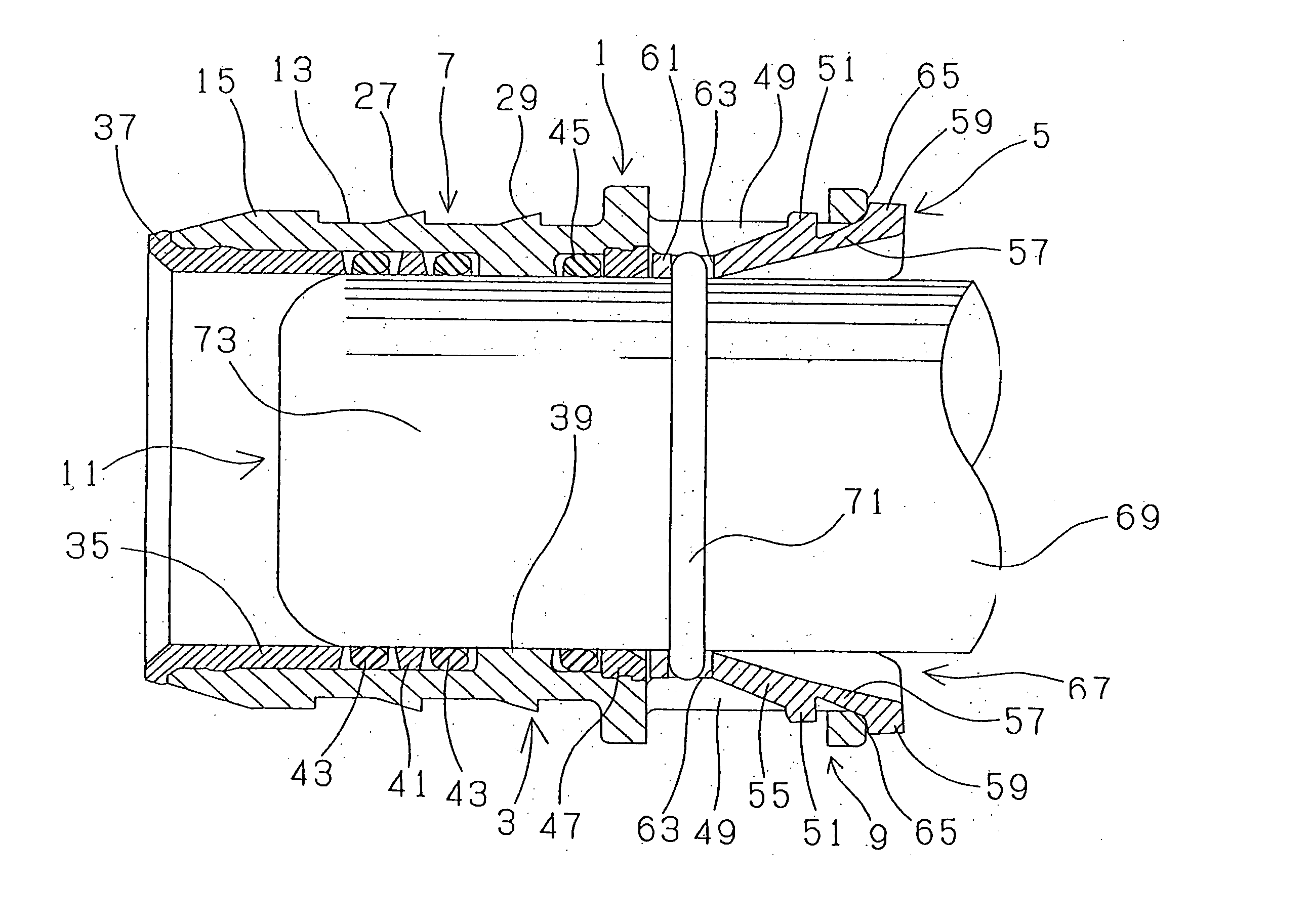

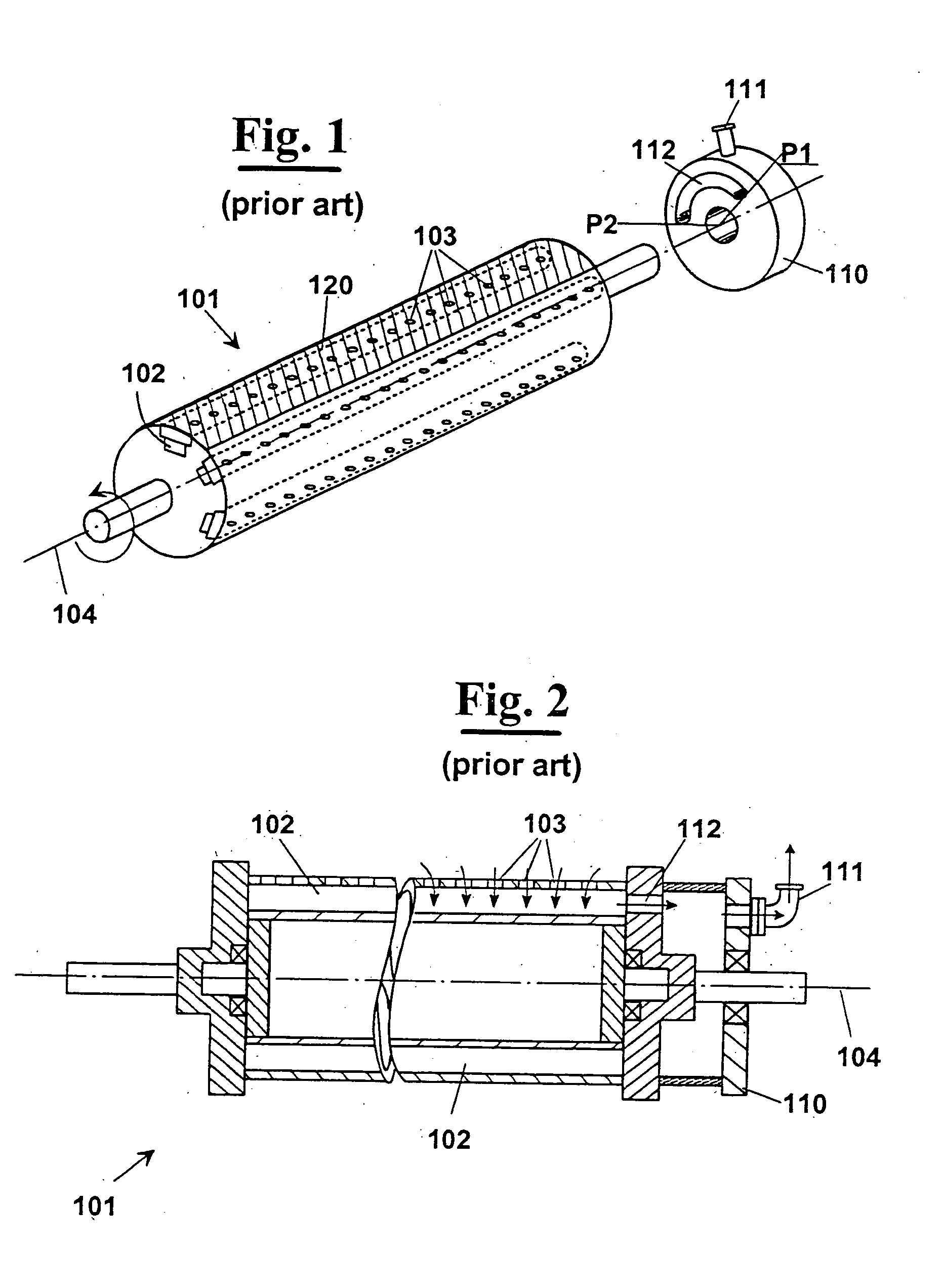

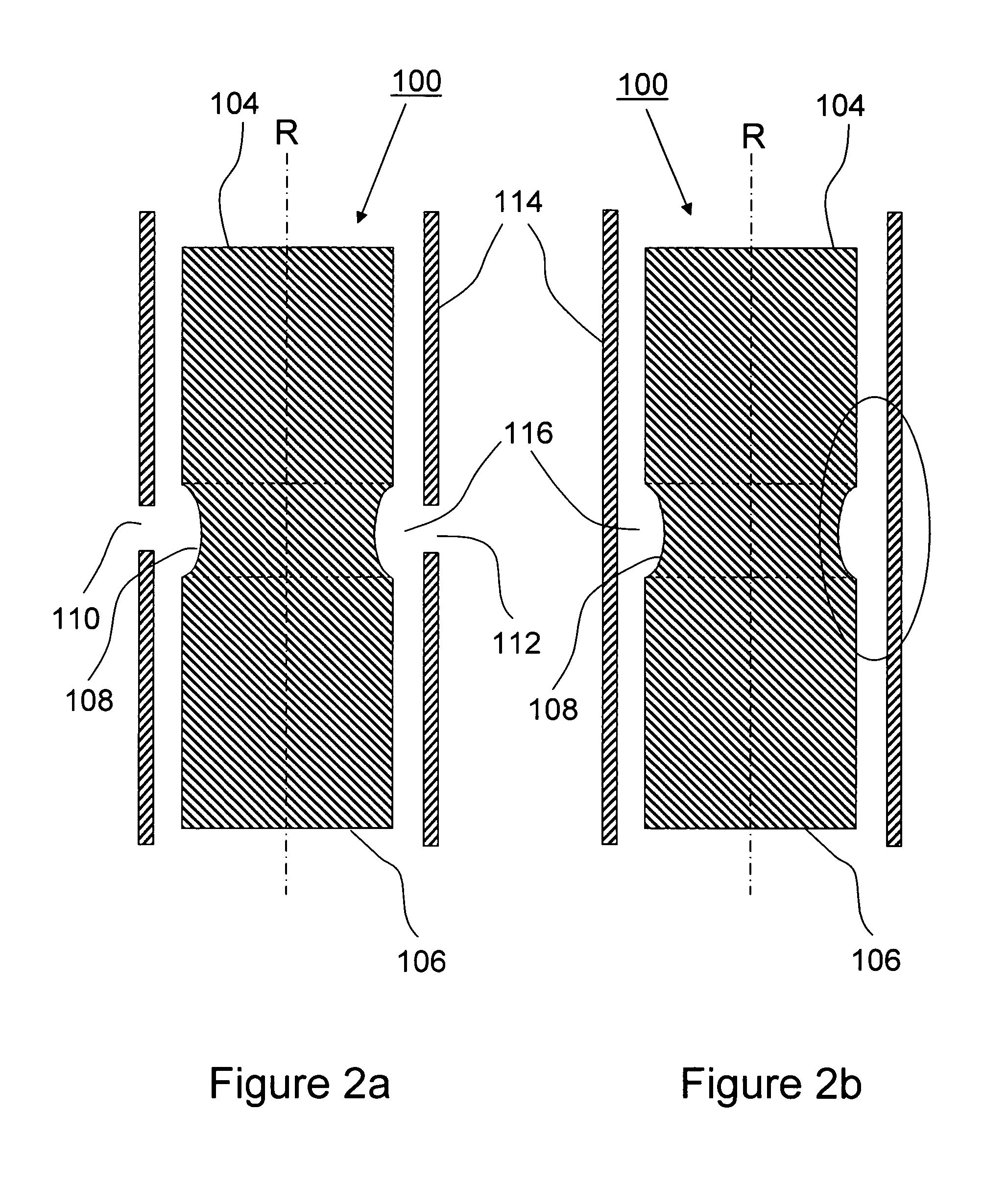

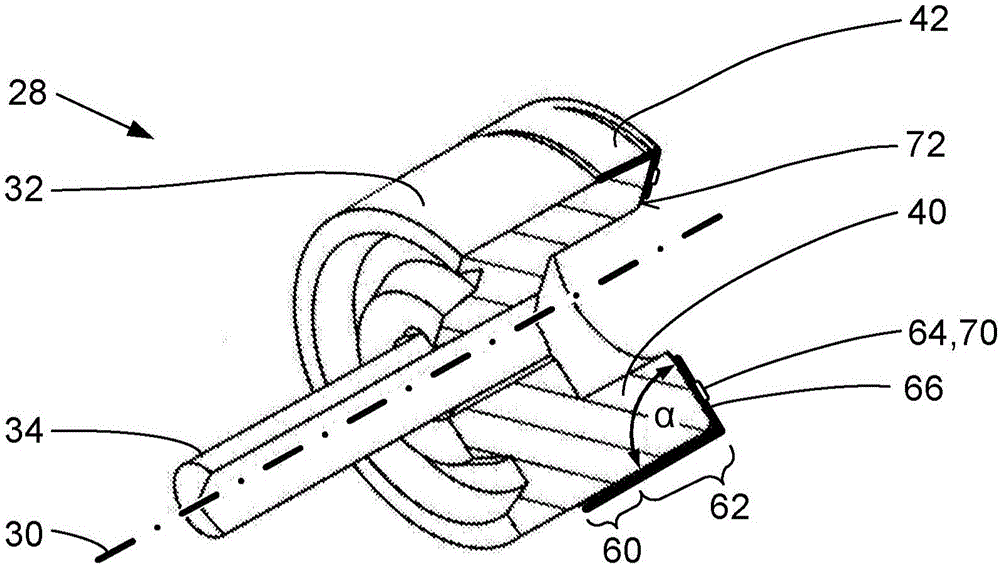

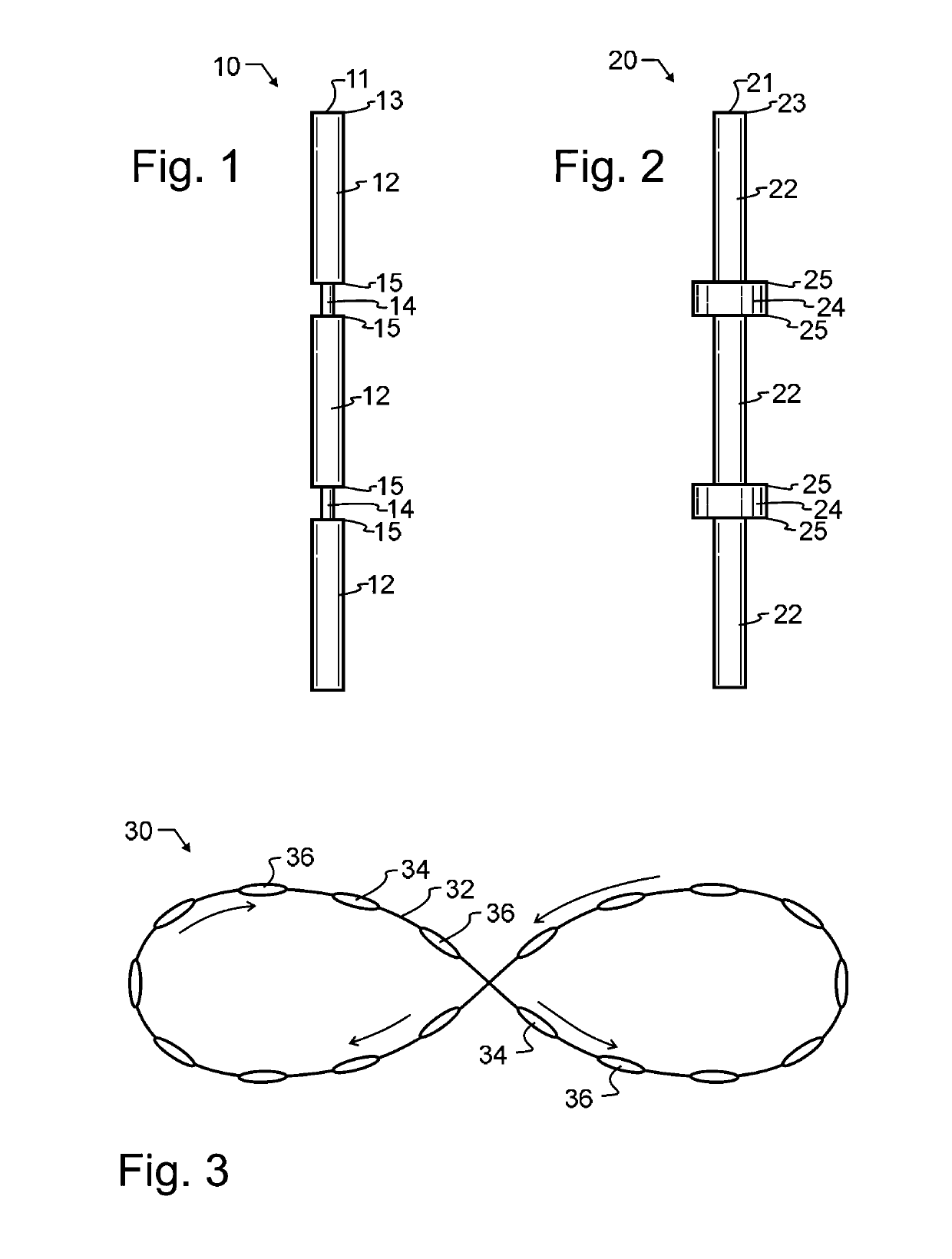

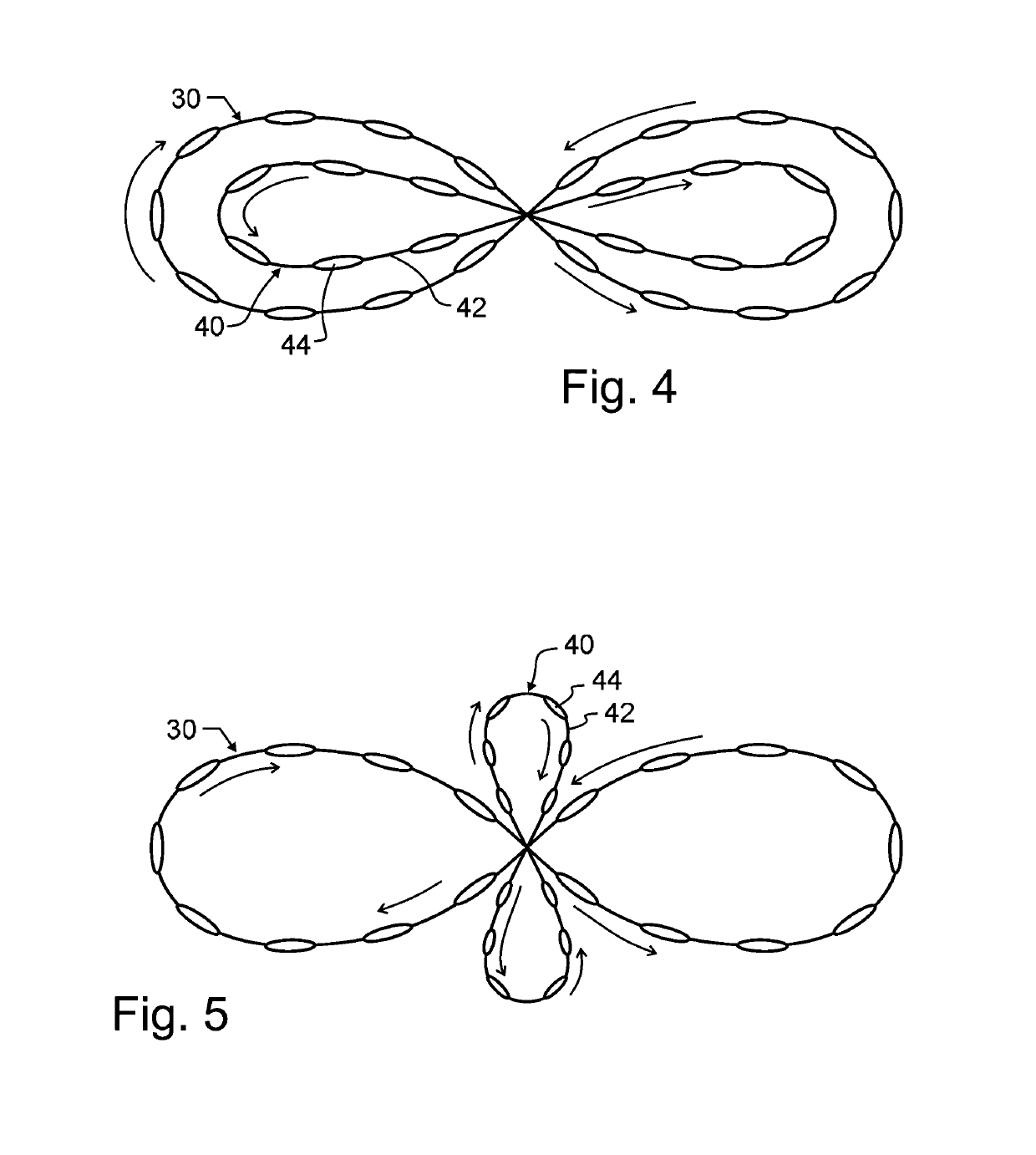

Apparatus for transferring torque magnetically

ActiveUS20050189830A1Overcome limitationsMagnetically actuated clutchesDynamo-electric gearsEngineeringCylindrical geometry

An apparatus for transferring torque magnetically with a primary rotary member and a secondary rotary member. The primary rotary member has permanent magnets mounted circumferentially on a cylinder, the secondary rotary member having a cylindrical geometry with electroconductive material arranged on its outer periphery and parallel to the axes of the rotary members. The secondary rotary member also having magnetically permeable material. The secondary rotary member is placed partially or totally inside the primary rotating member. The secondary rotary member's axial position relative to the primary rotating member can be varied by a suitable mechanical structure. This causes the two rotary members to axially overlap one another more or less as desired. Rotation of the primary rotary member causes rotation of the secondary rotary member, since magnetic flux lines emanating from the permanent magnets mounted on the primary rotating member, cut through all, or part of, the electroconductive material placed on the periphery of the secondary rotary member. This can vary the torque transmitted between the two rotary members, thereby enabling the varying of the rotational speed of the secondary rotary member relative to the primary rotary member.

Owner:OSERAN WILLIAM A +1

Molded micro-needles

Owner:BONSENS

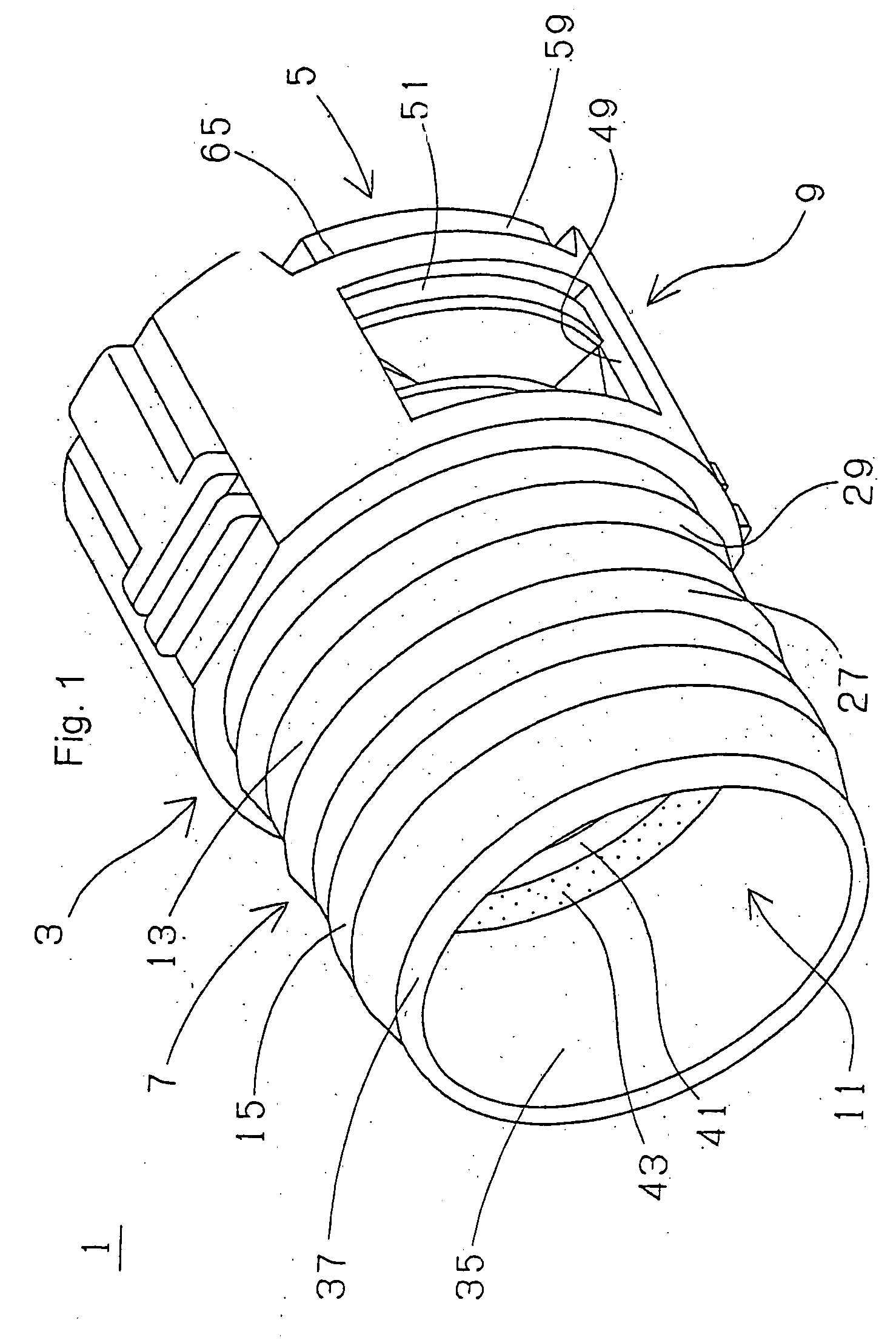

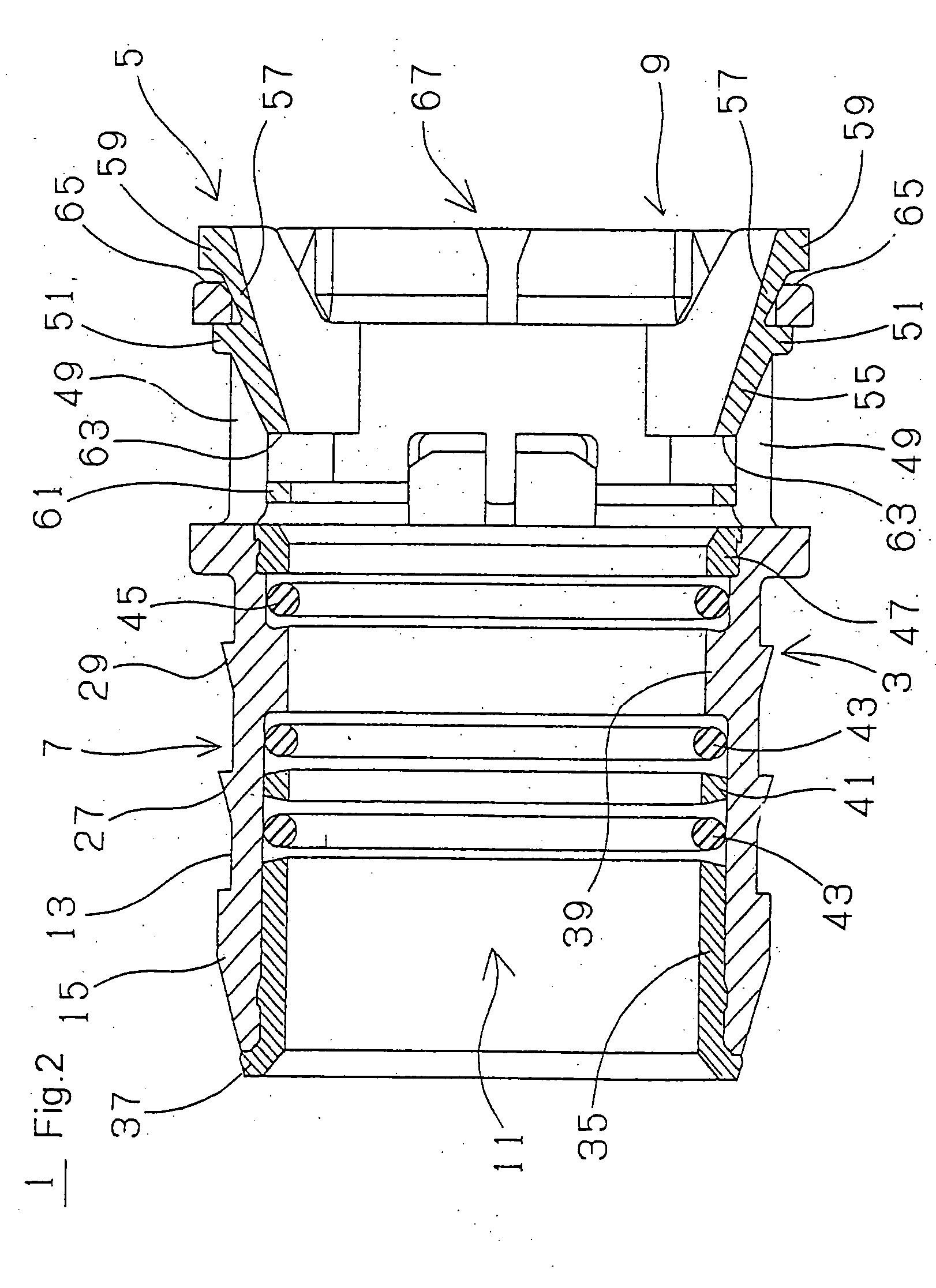

Connecting structure for a thermoplastic tube, integrated assembly and method

InactiveUS20050040649A1Prevent disengagementImprove heat resistancePipe elementsCouplingsCylindrical geometryMechanical engineering

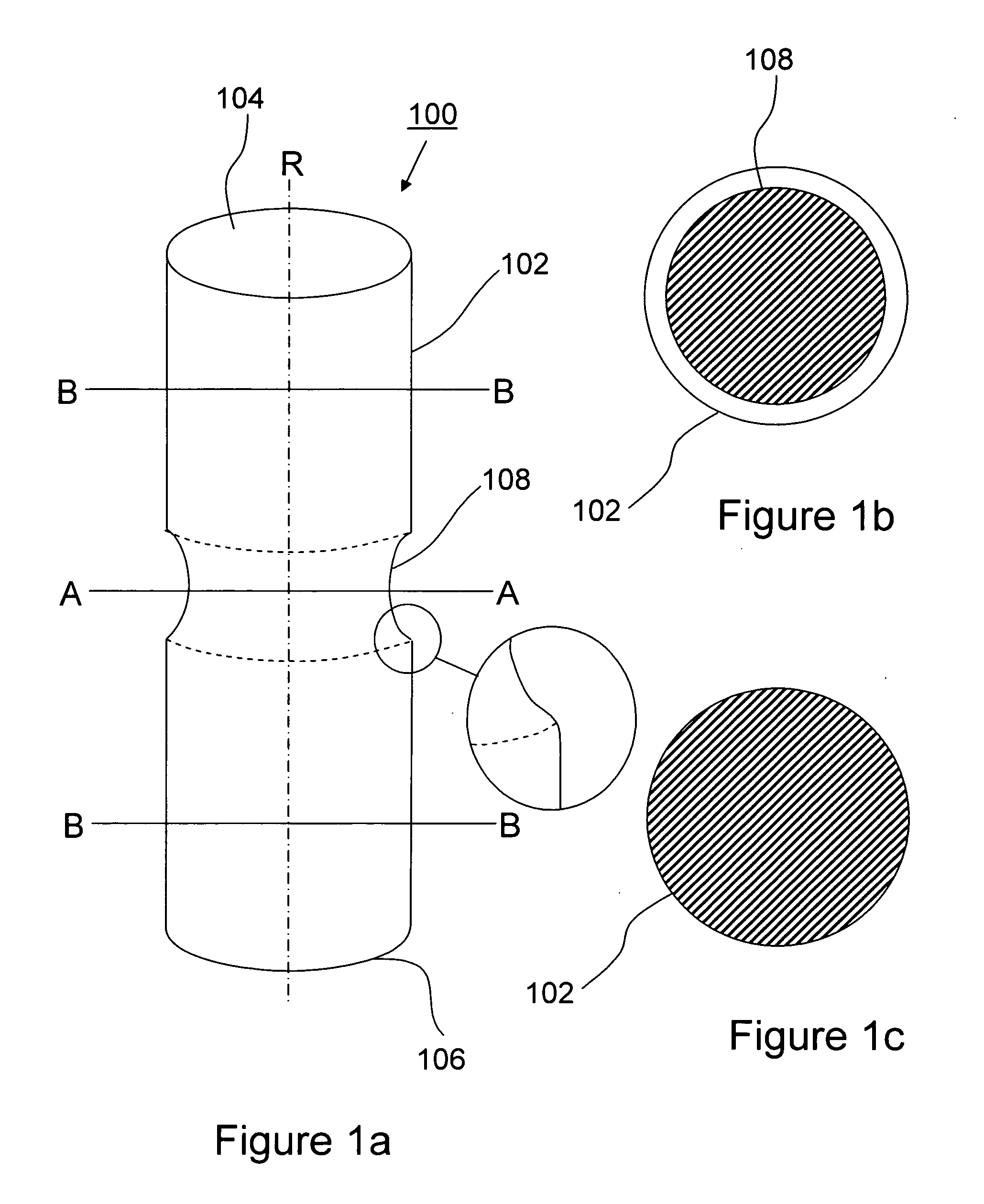

A connecting structure and method for affixing an open end of a tube composed from thermoplastic resin material(s) to a tube connecting portion of a quick connector having a cylindrical geometry and at least one annular stopper on the cylindrical outer circumference thereof with said tube connecting portion being adapted to be press fitted into said open end of said resin tube. The connecting structure comprises; an annular band composed of elastomeric rubber which surrounds the open end of said resin tube adjacent the location of attachment to said quick connector having a length at least equal to the diameter of the cylindrical outer circumference of the quick connector and a diameter such that a tightening force is applied to the resin tube upon press fitting said tube connecting portion into the open end of said resin tube to prevent disengagement therefrom. The connecting structure forms an integrated assembly with the tube connecting portion of the quick connector.

Owner:SUMITOMO RIKO CO LTD

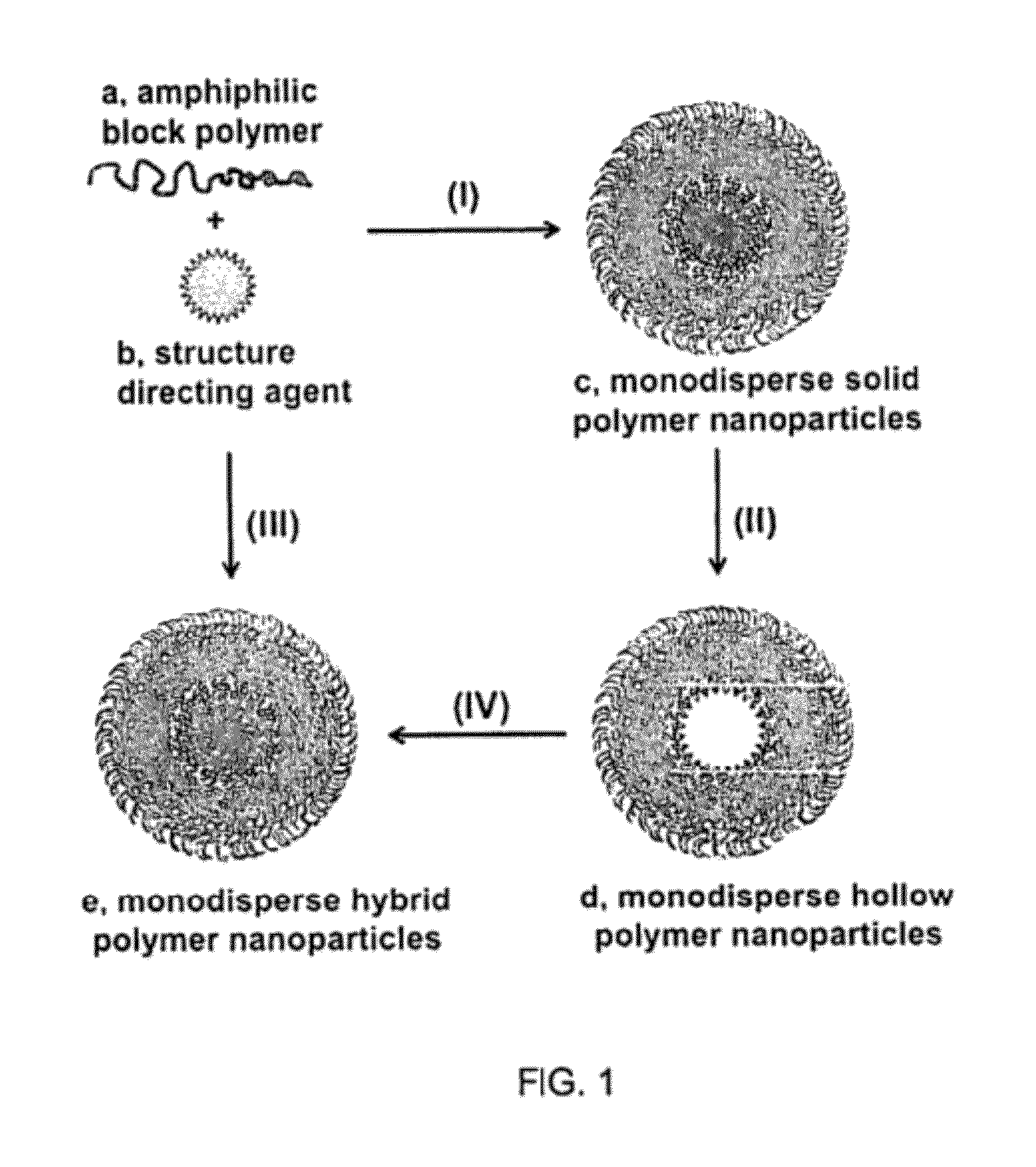

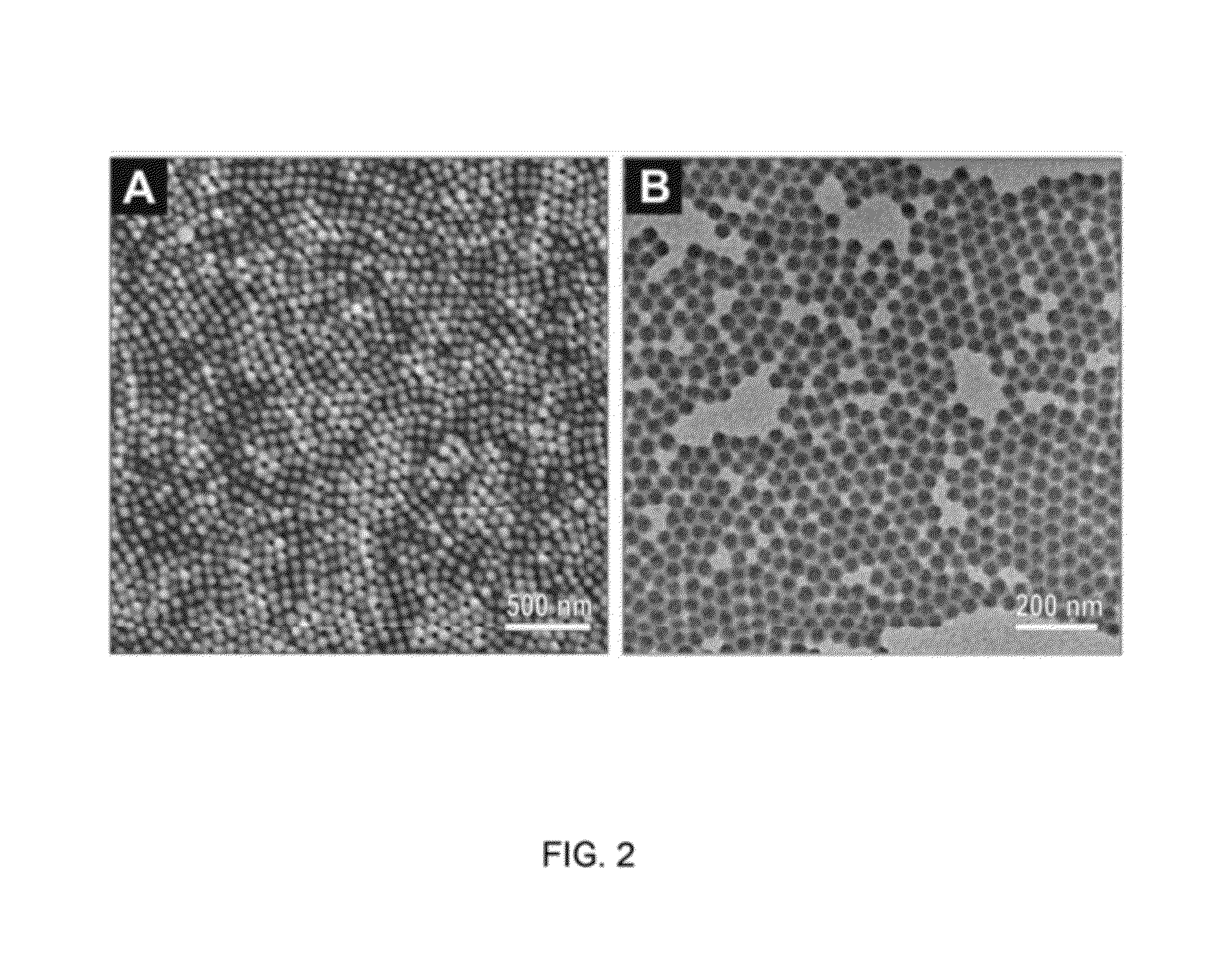

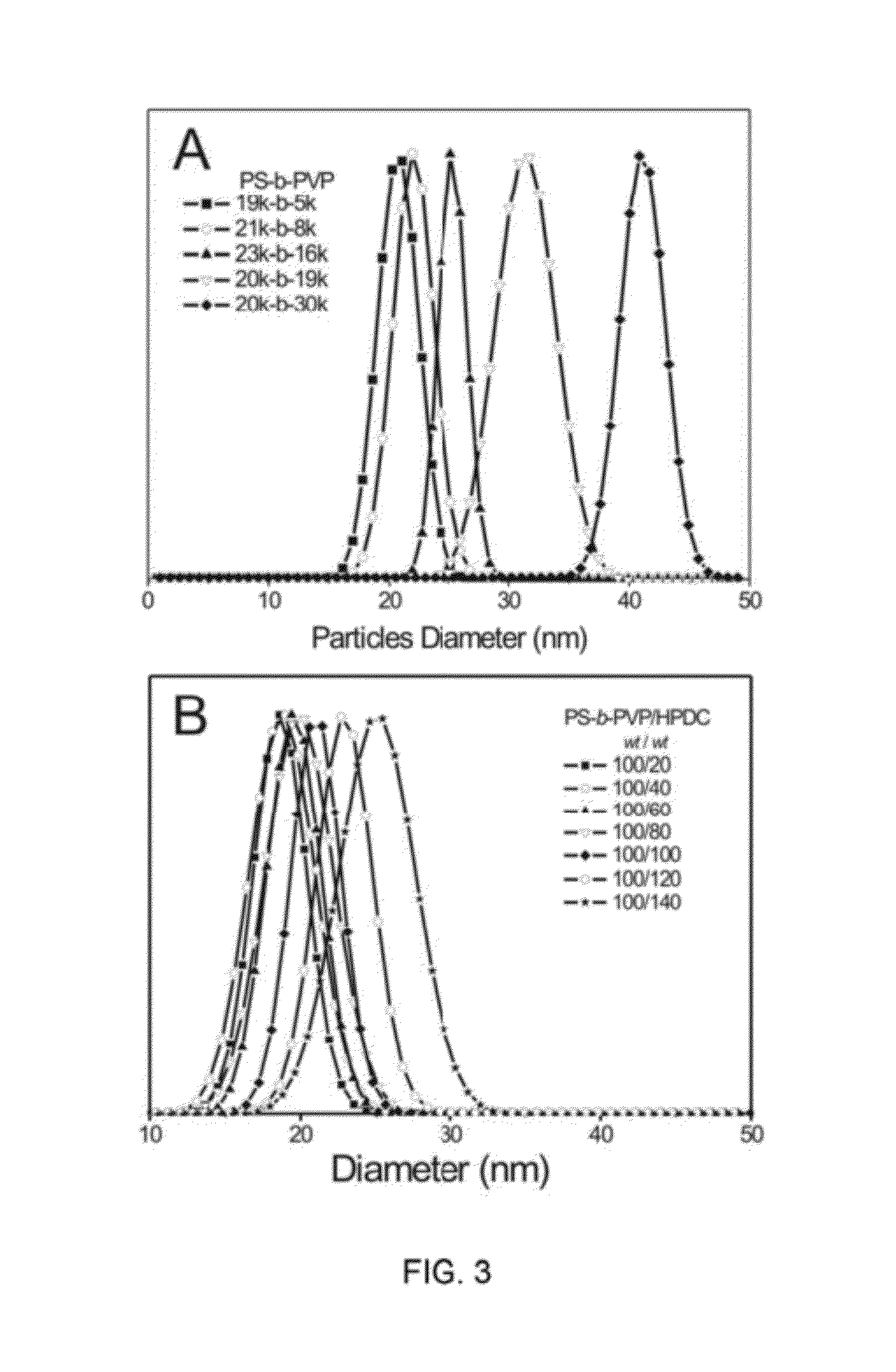

Method of making monodisperse nanoparticles

ActiveUS8288001B1Liquid surface applicatorsSynthetic resin layered productsCrystallographyNanoparticle

A method of making particles of either spherical or cylindrical geometry with a characteristic diameter less than 50 nanometers by mixing at least one structure directing agent dissolved in a solvent with at least one amphiphilic block copolymer dissolved in a solvent to make a solution containing particles, where the particles can be subsequently separated and dispersed in a solvent of choice.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC +1

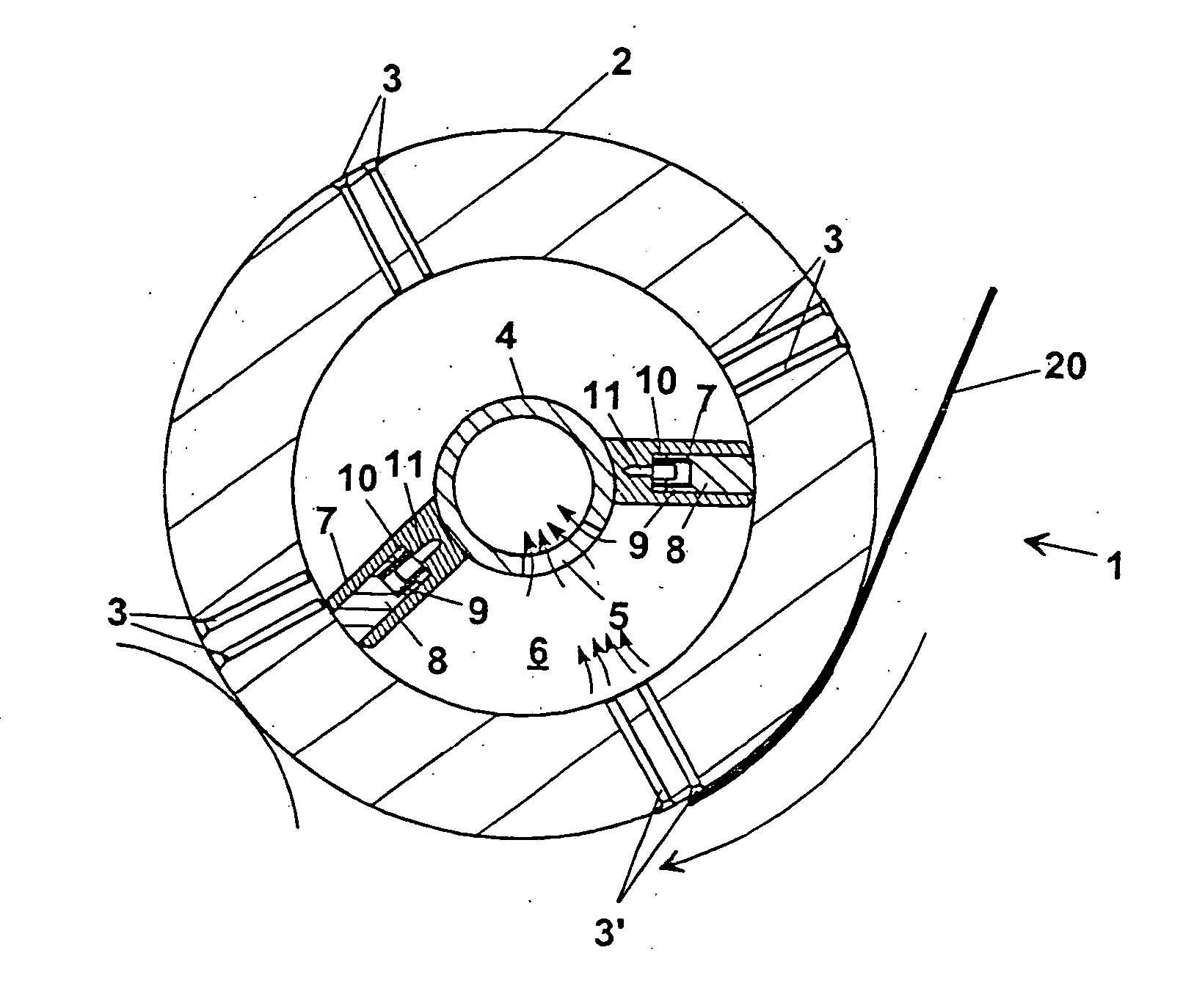

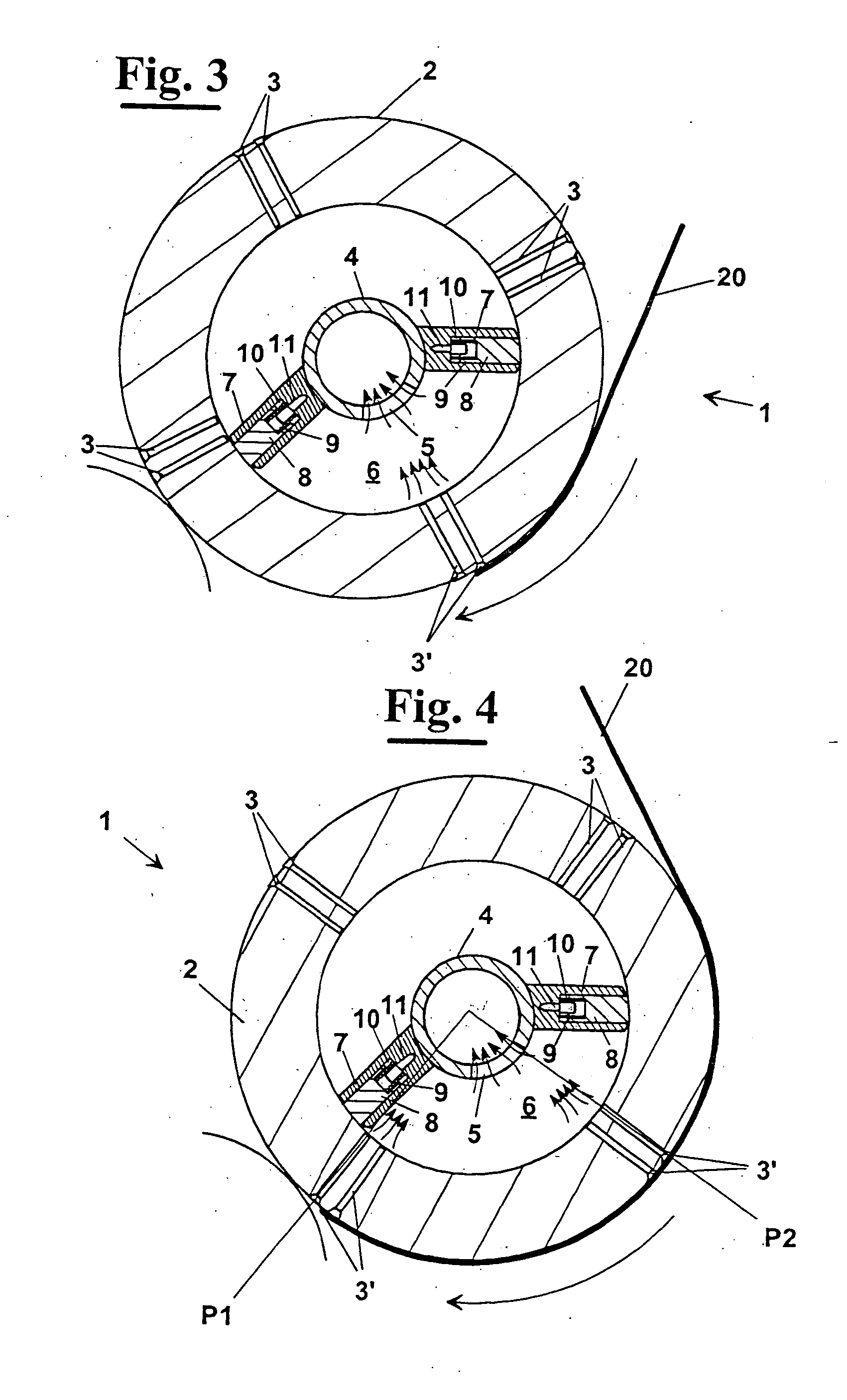

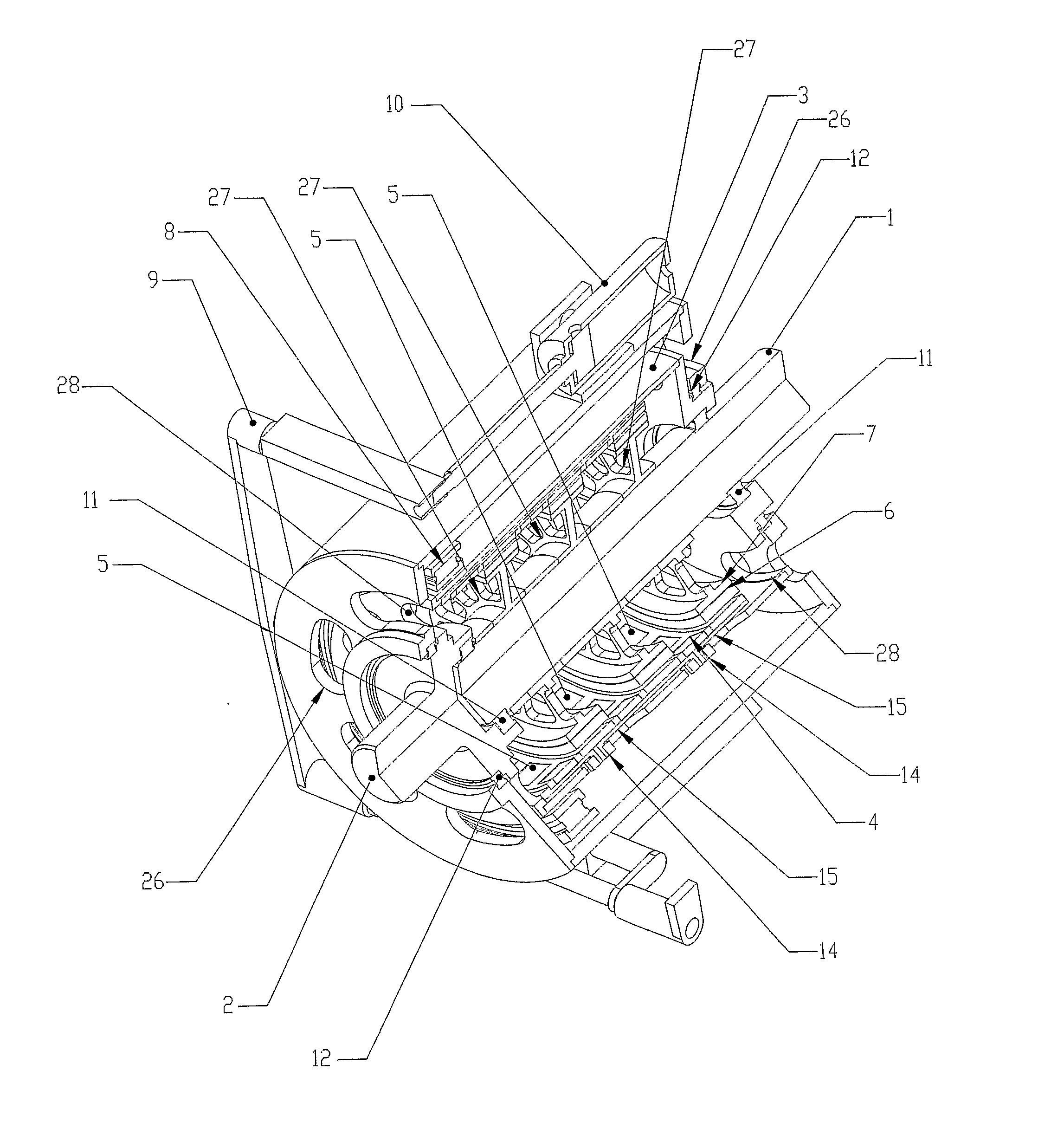

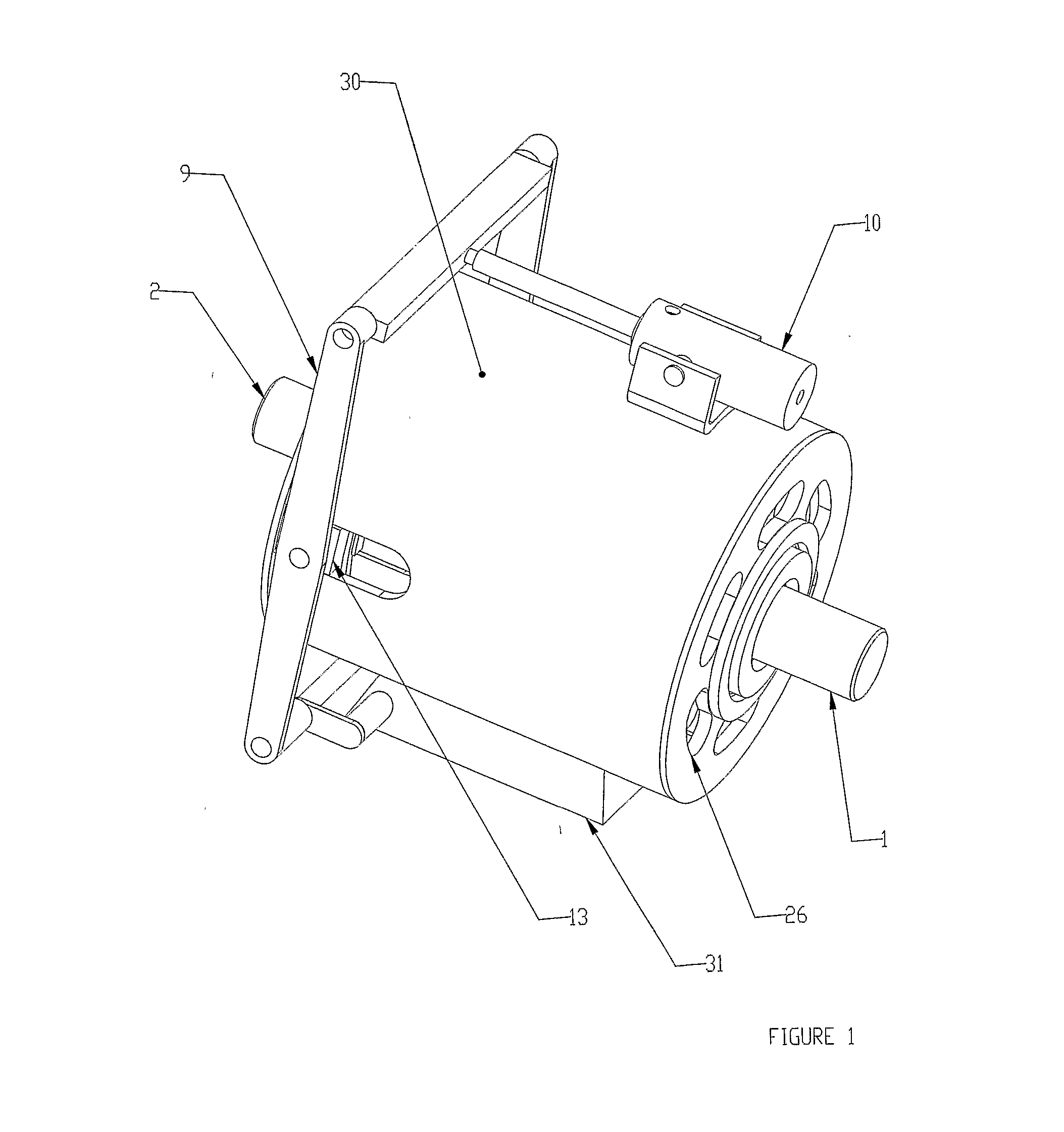

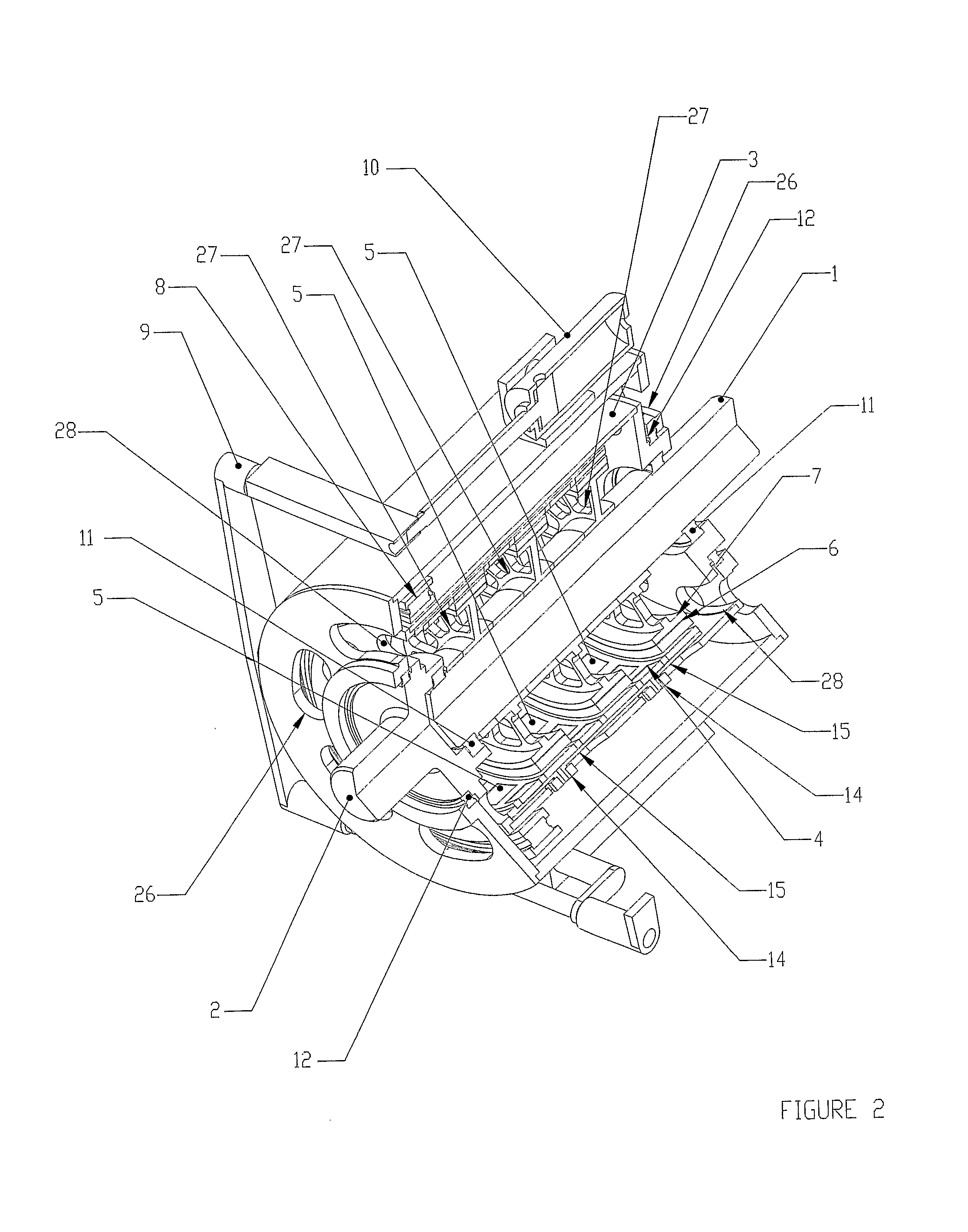

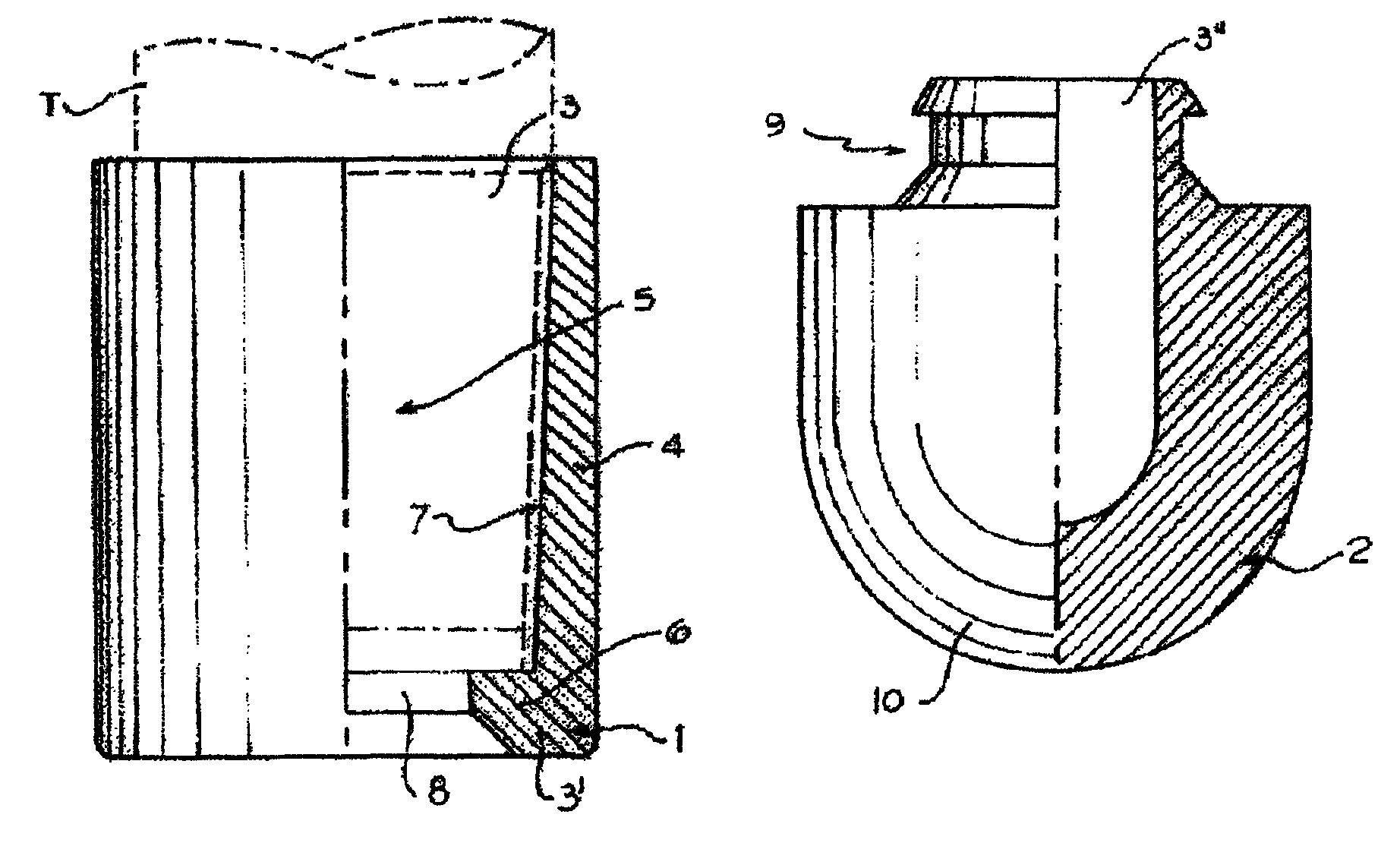

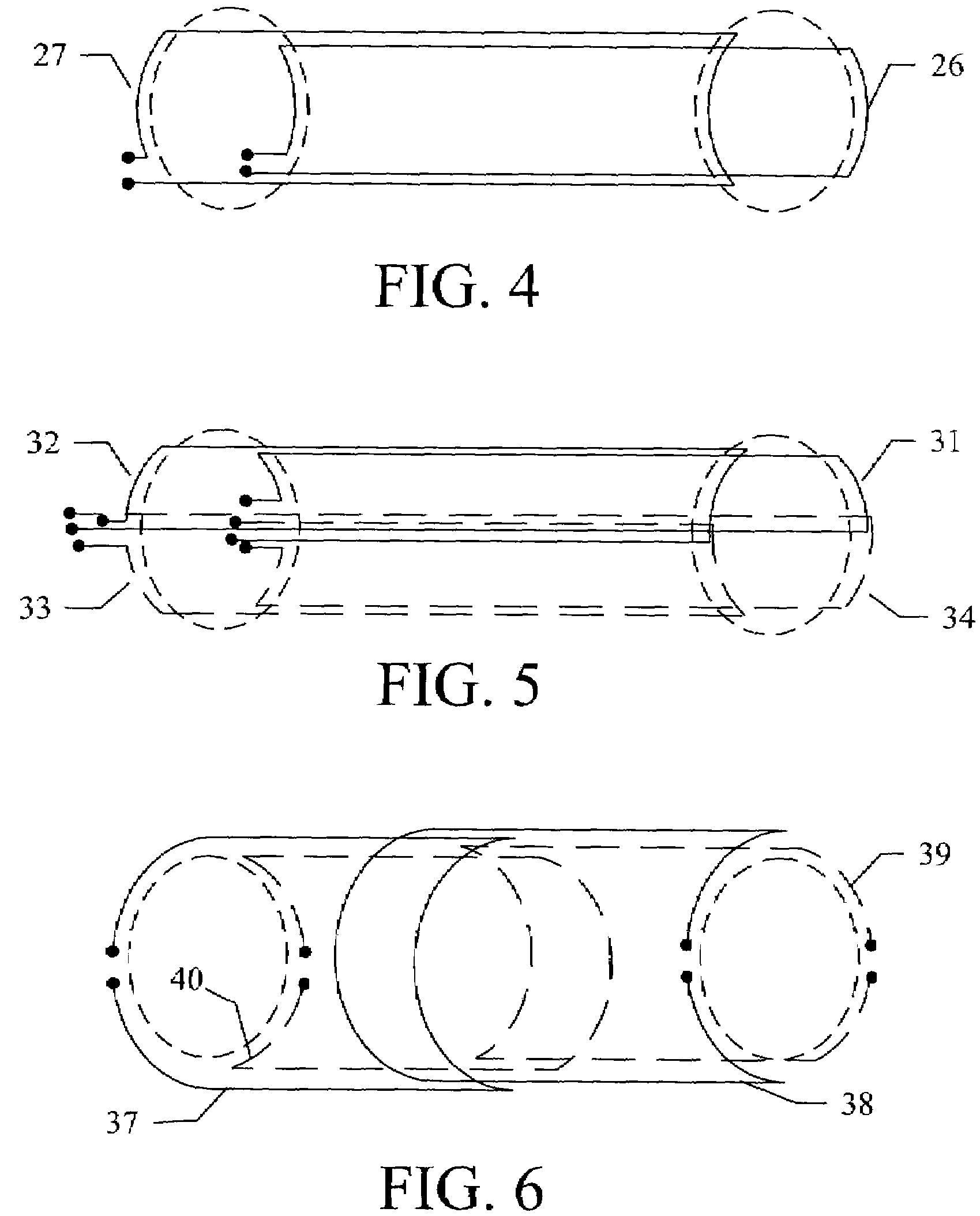

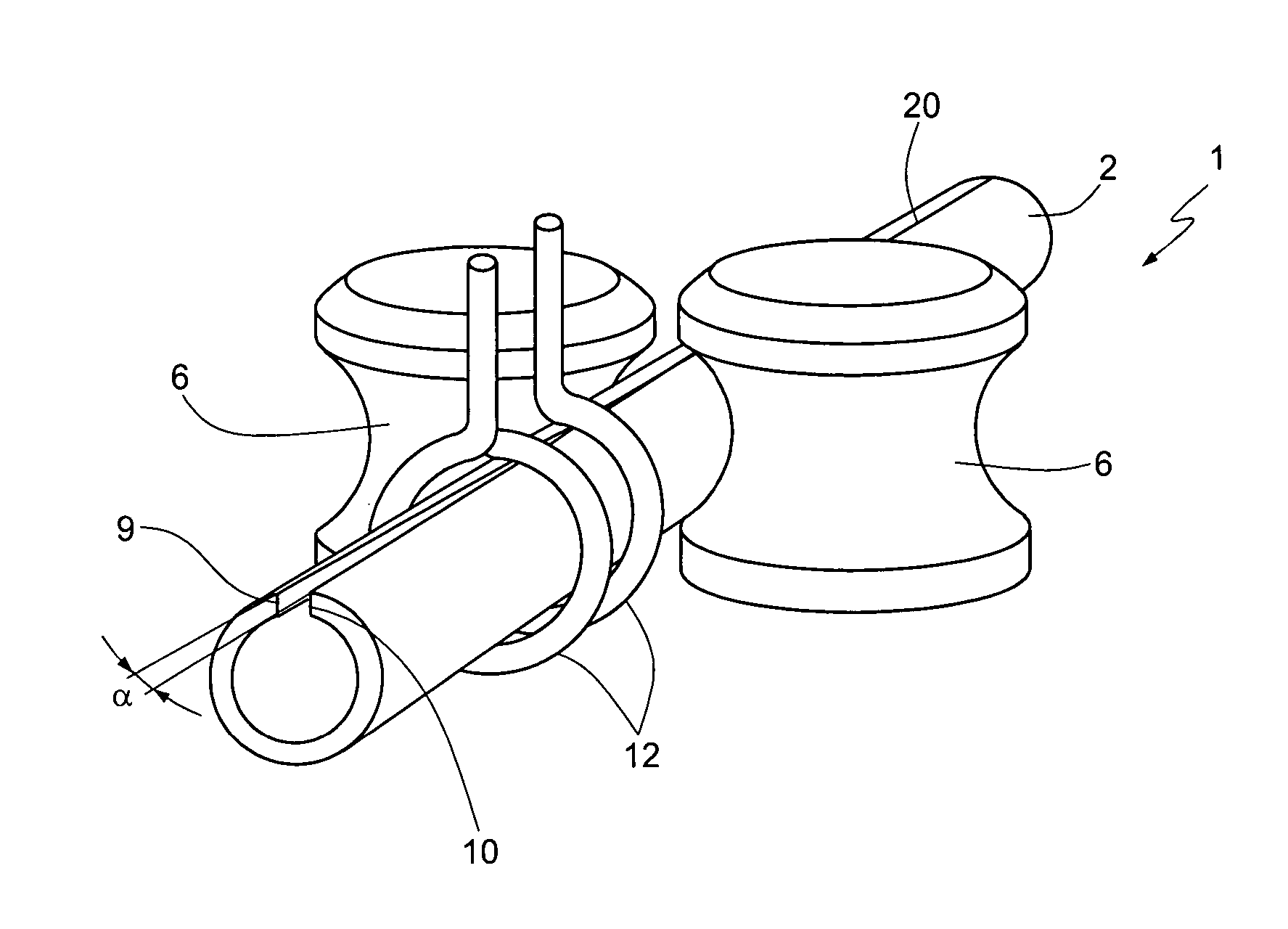

Conveying roller for a paper web, machines equipped therewith and methods of use

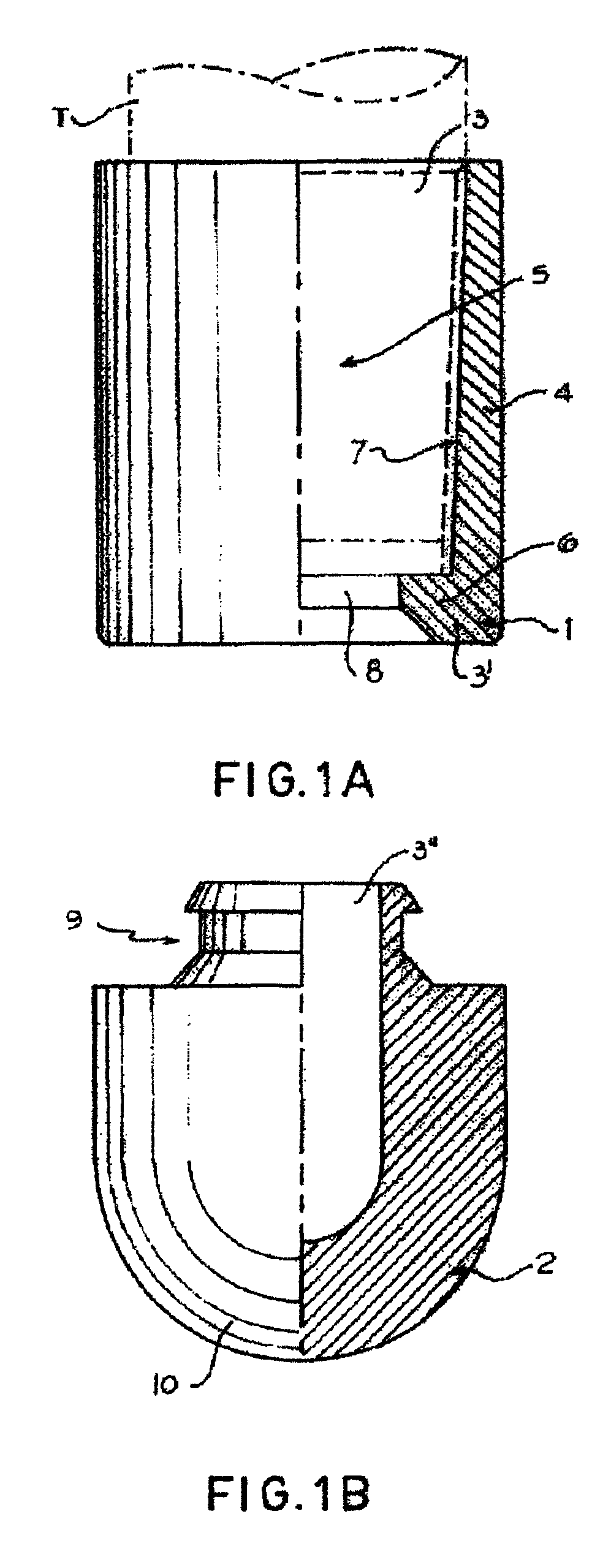

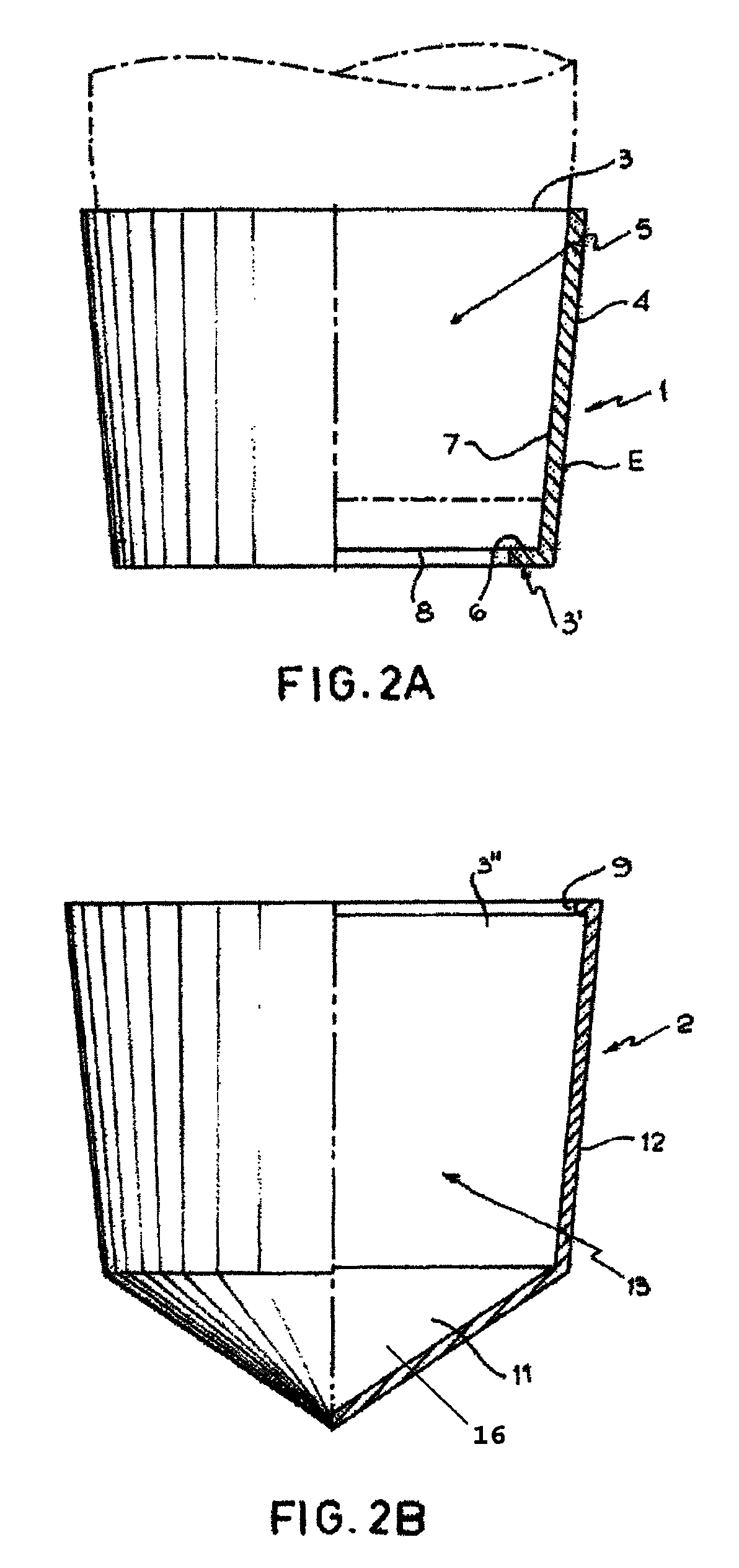

The roller (1) is used for conveying a web or sheet of paper (20) in paper converting machines, for example, a rewinding, a winding, an interfolding machine. It comprises a first outer cylindrical tubular body (2) equipped with a plurality of radial holes (3), arranged according to substantially longitudinal rows, capable of rotating with respect to a second inner fixed body (4) co-axial to it and connected to a suction system. The second body (4) has tubular cylindrical geometry like the first body (2) and has a plurality of apertures (5) and two radial boards (7) arranged at opposite sides with respect to the apertures (5). The inner surface of the first cylindrical tubular body (2), together with the radial boards (7) and to the external surface of the second tubular body (4), define a suction chamber (6) that brings selectively in communication selected rows of holes (3) of the first cylindrical tubular body (2) with the apertures (5) of the second tubular body (4) and then with the suction system of the machine during the relative rotation of the two bodies. Therefore, a web or sheet of paper (20) adheres to the external surface of the first body (2) only in the portion P1P2 of surface set between the rows of holes (3') that communicates with the suction chamber (FIG. 4).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

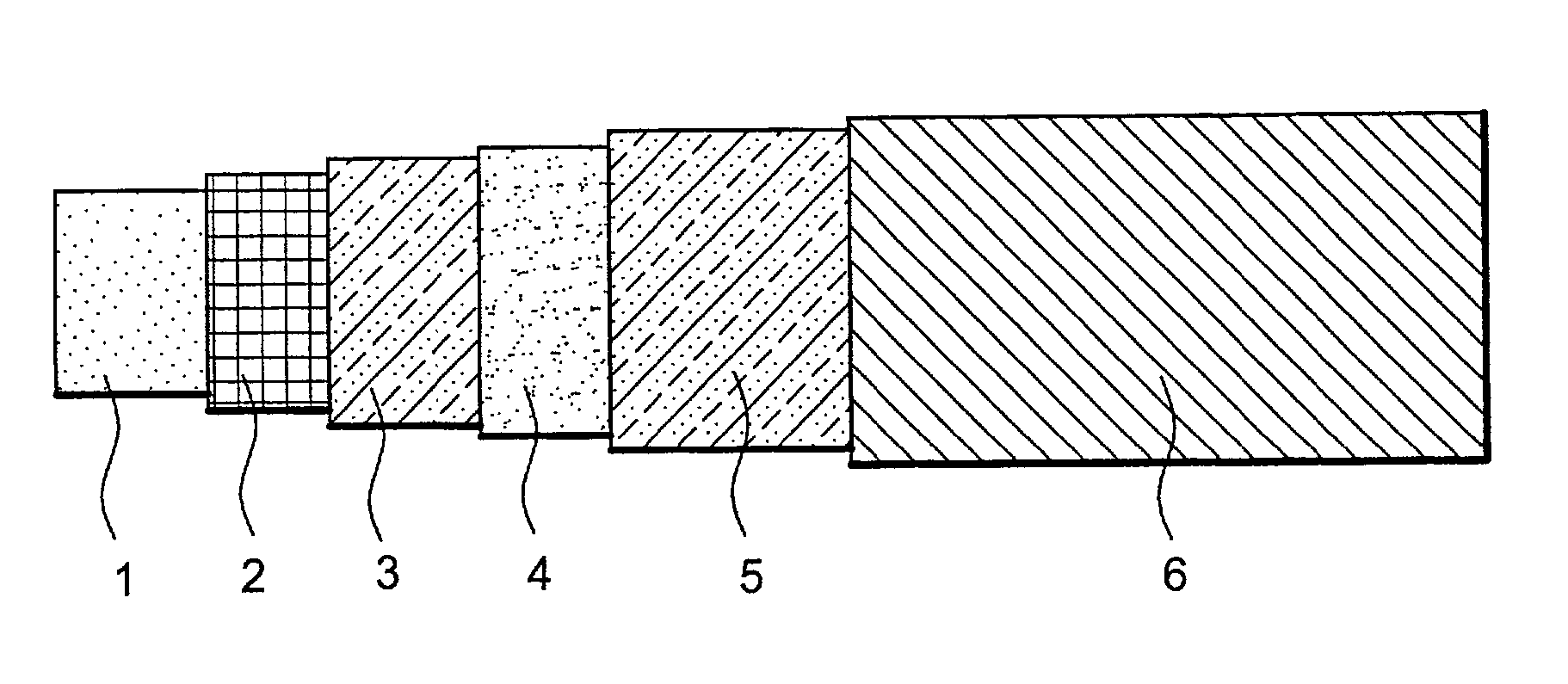

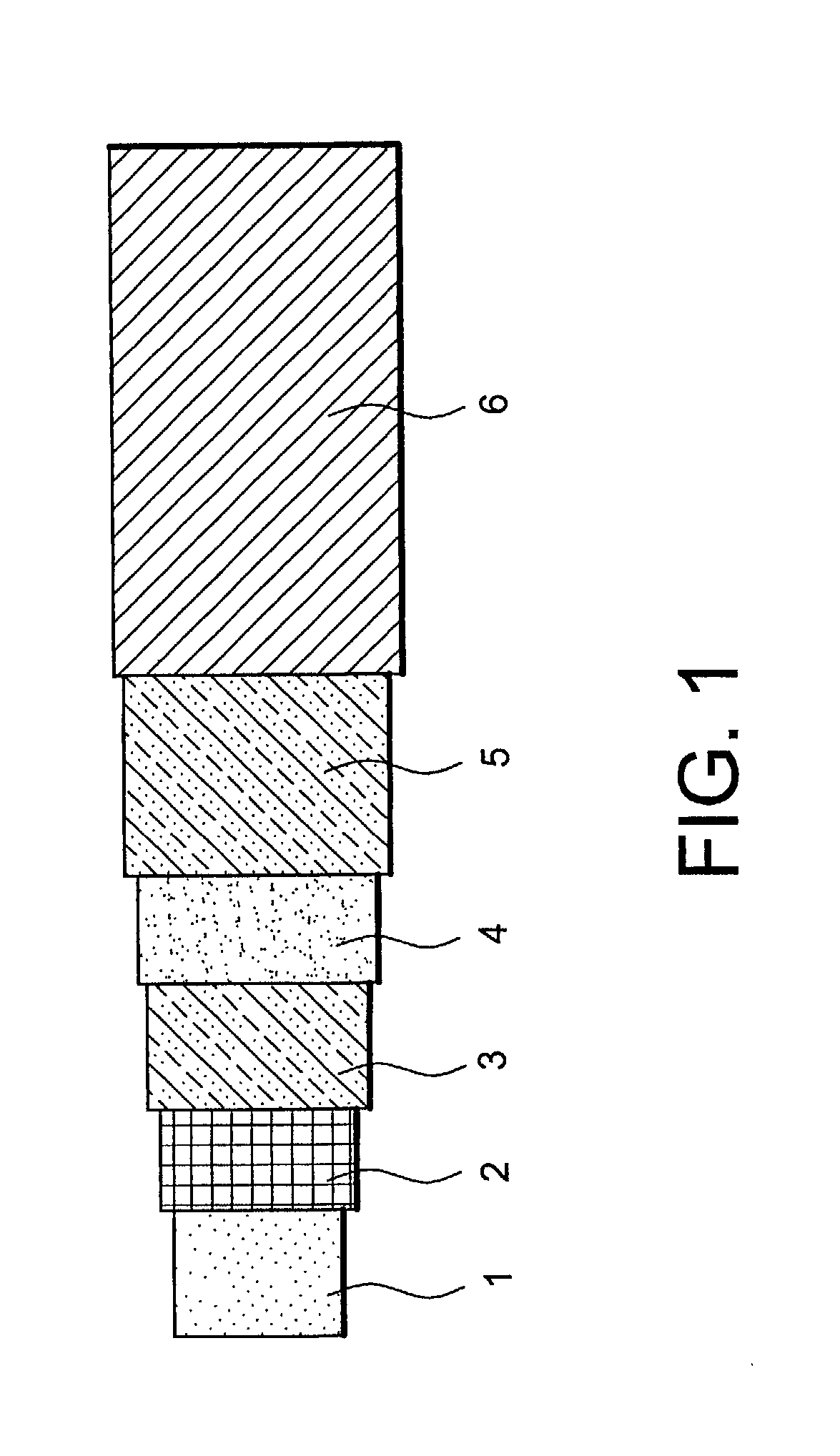

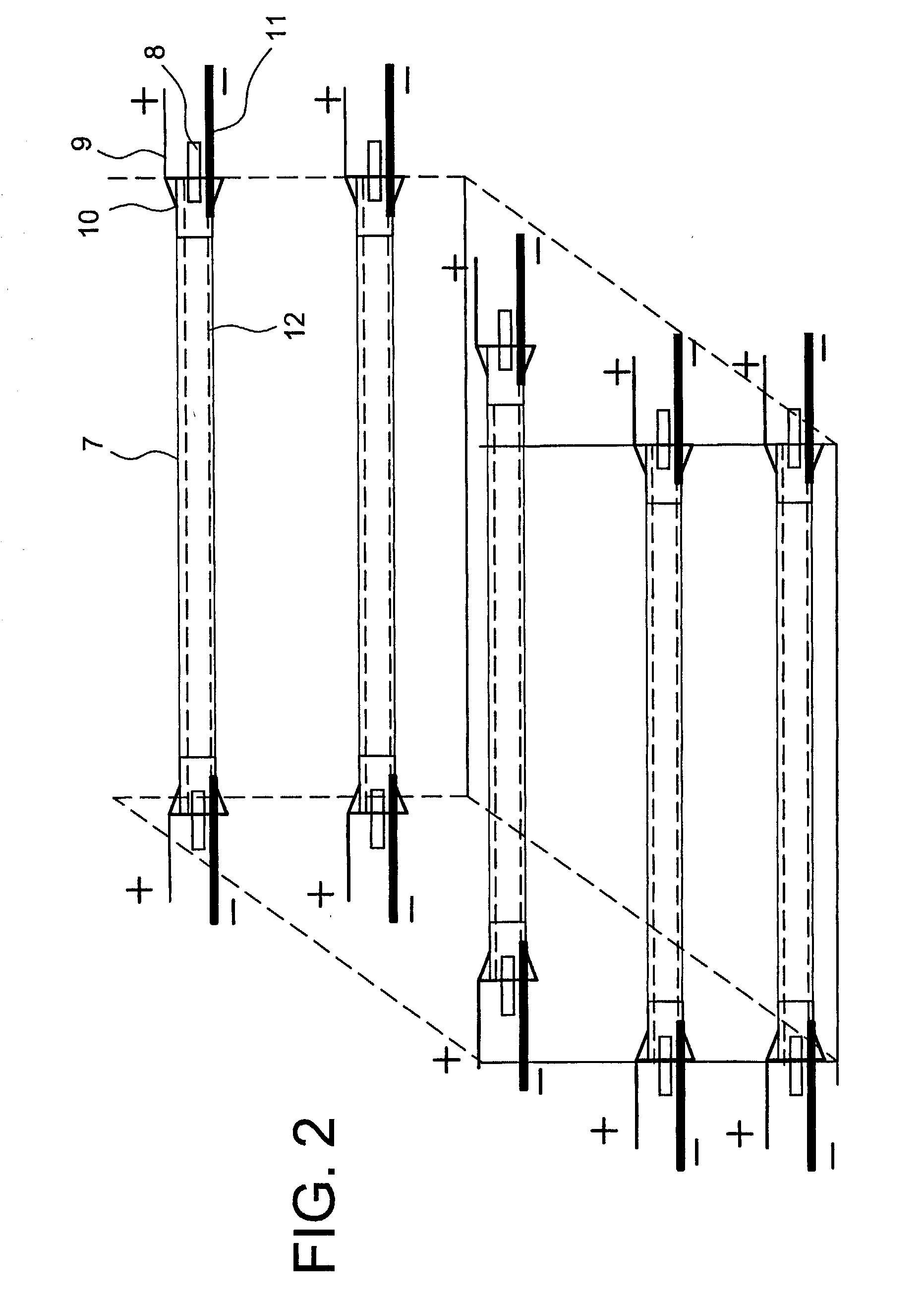

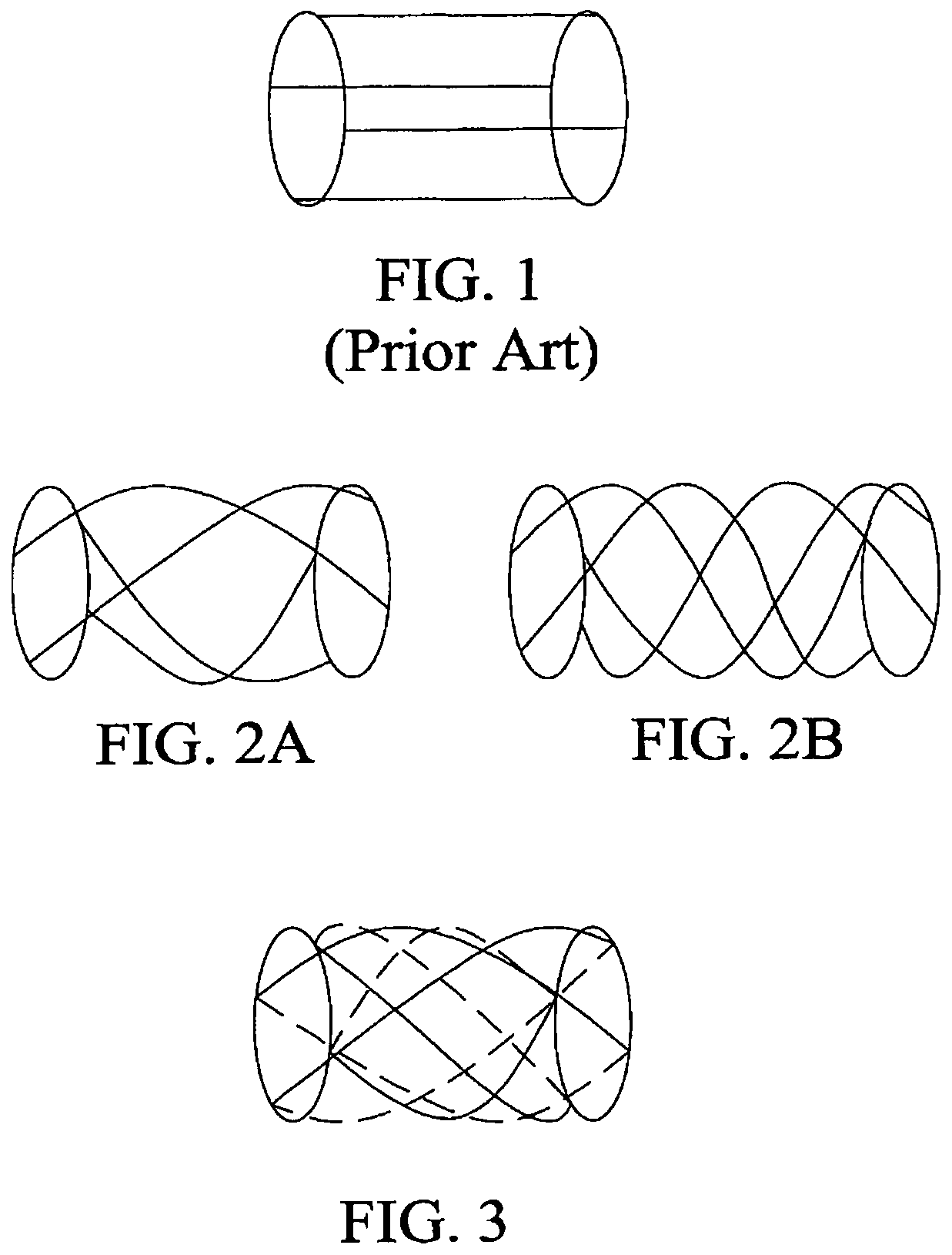

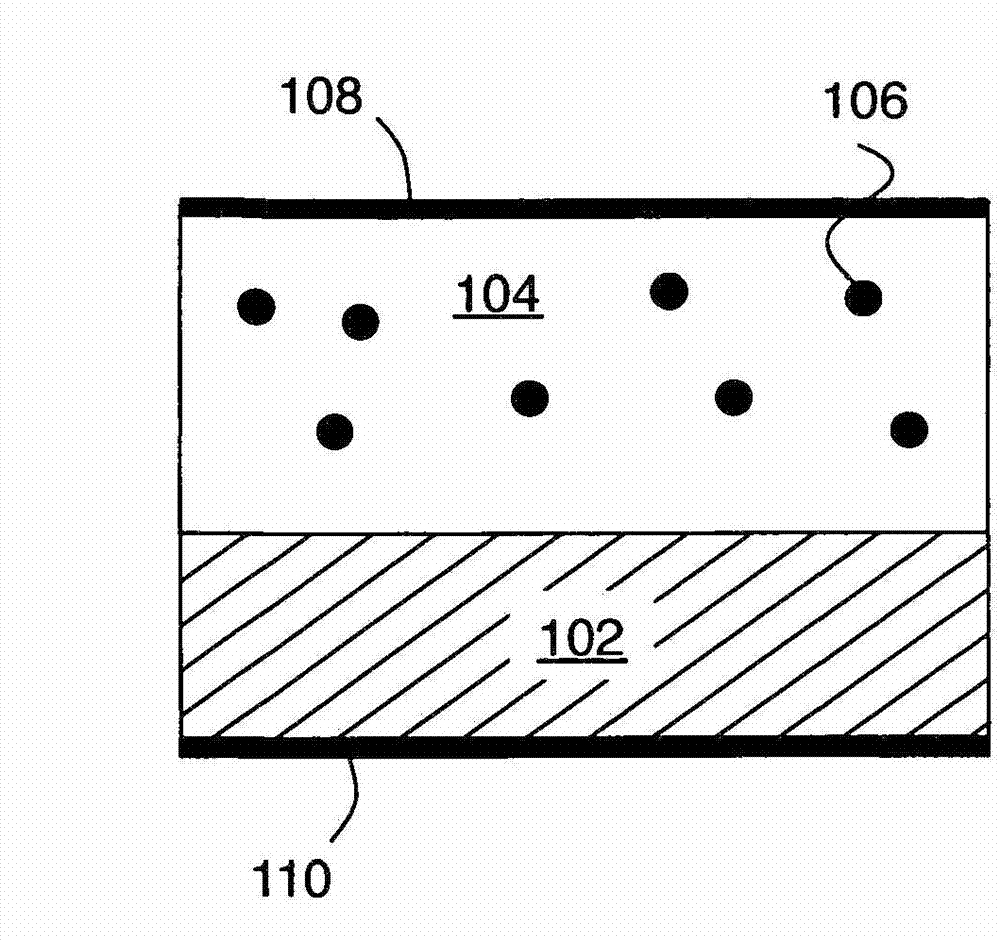

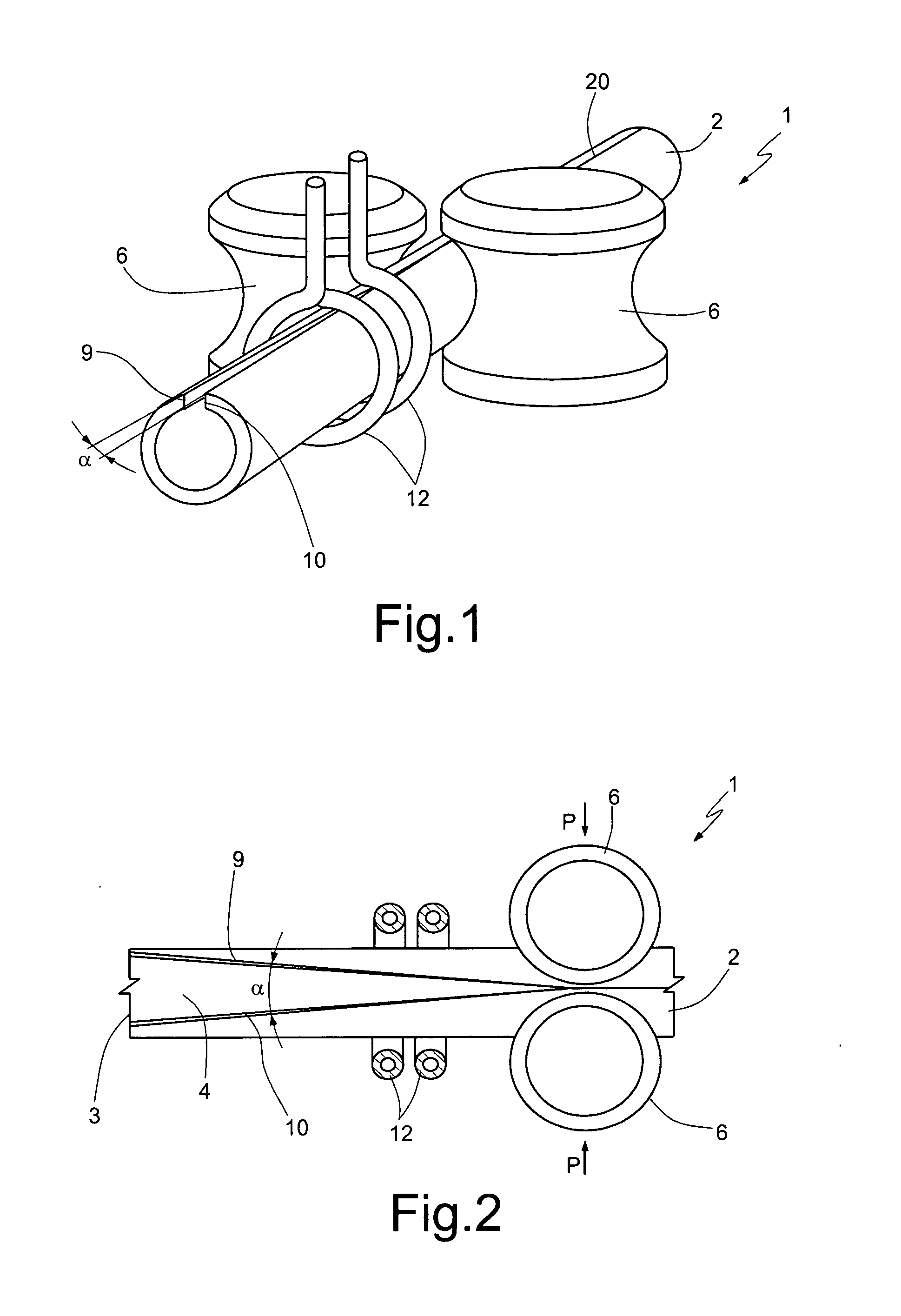

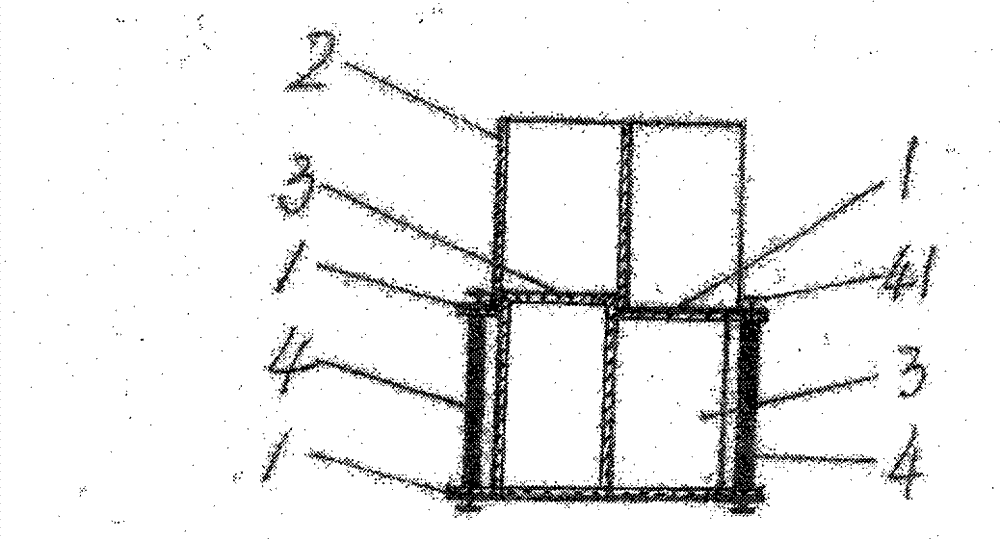

Process for making a fuel cell with cylindrical geometry

The invention relates to a process for production of an electrode-membrane-electrode assembly on a cylindrical substrate (1), characterized in that the electrode-membrane-electrode assembly is made by successively depositing an electrode layer (2, 3), a membrane layer (4) and an electrode layer (5, 6) around the said cylindrical substrate, the said substrate being composed of a material that can be totally or partially eliminated during an elimination step at the end of the said process. The invention also relates to an electrode-membrane-electrode assembly obtained by the said process and a fuel cell comprising at least one such electrode-membrane-electrode assembly.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

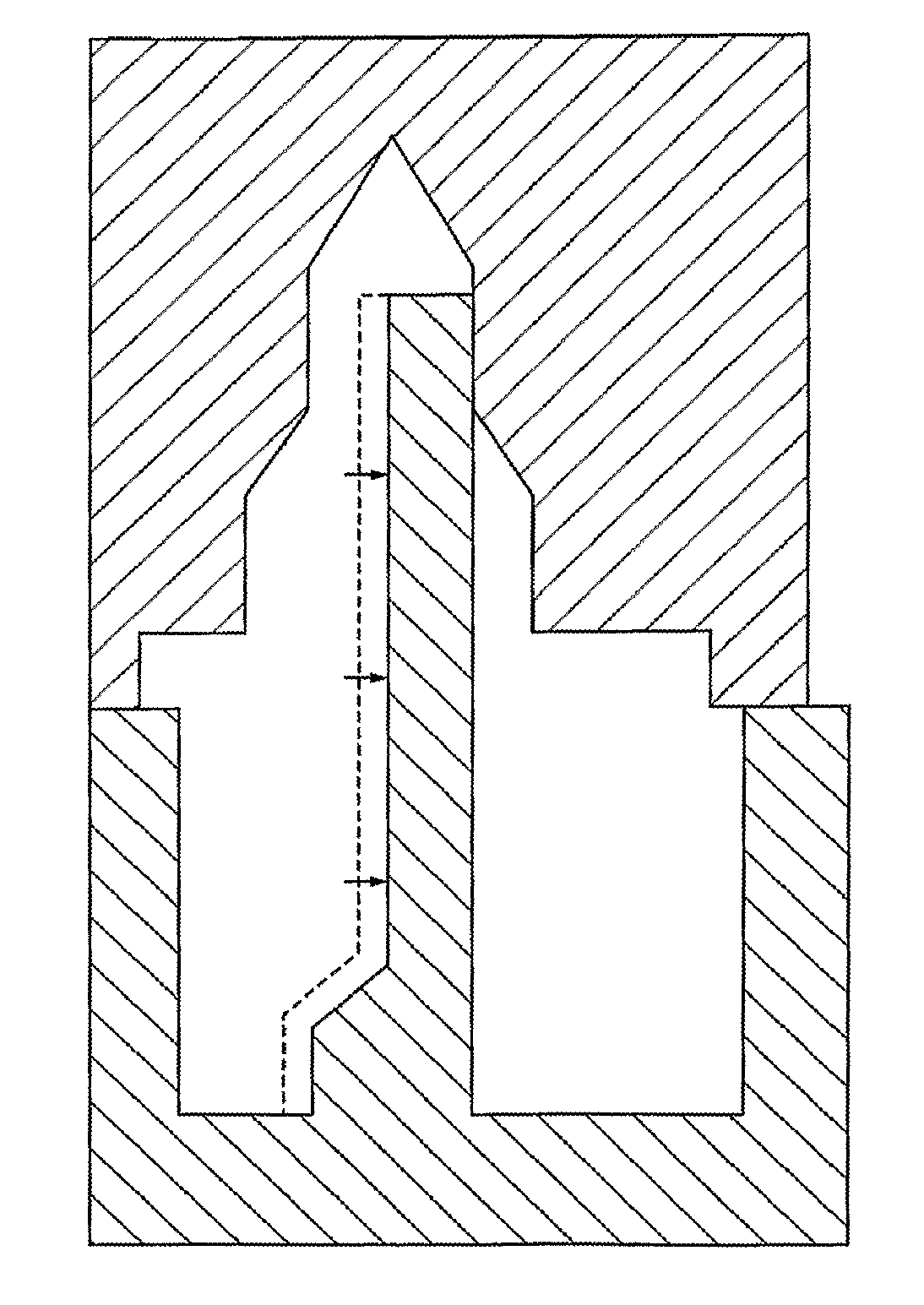

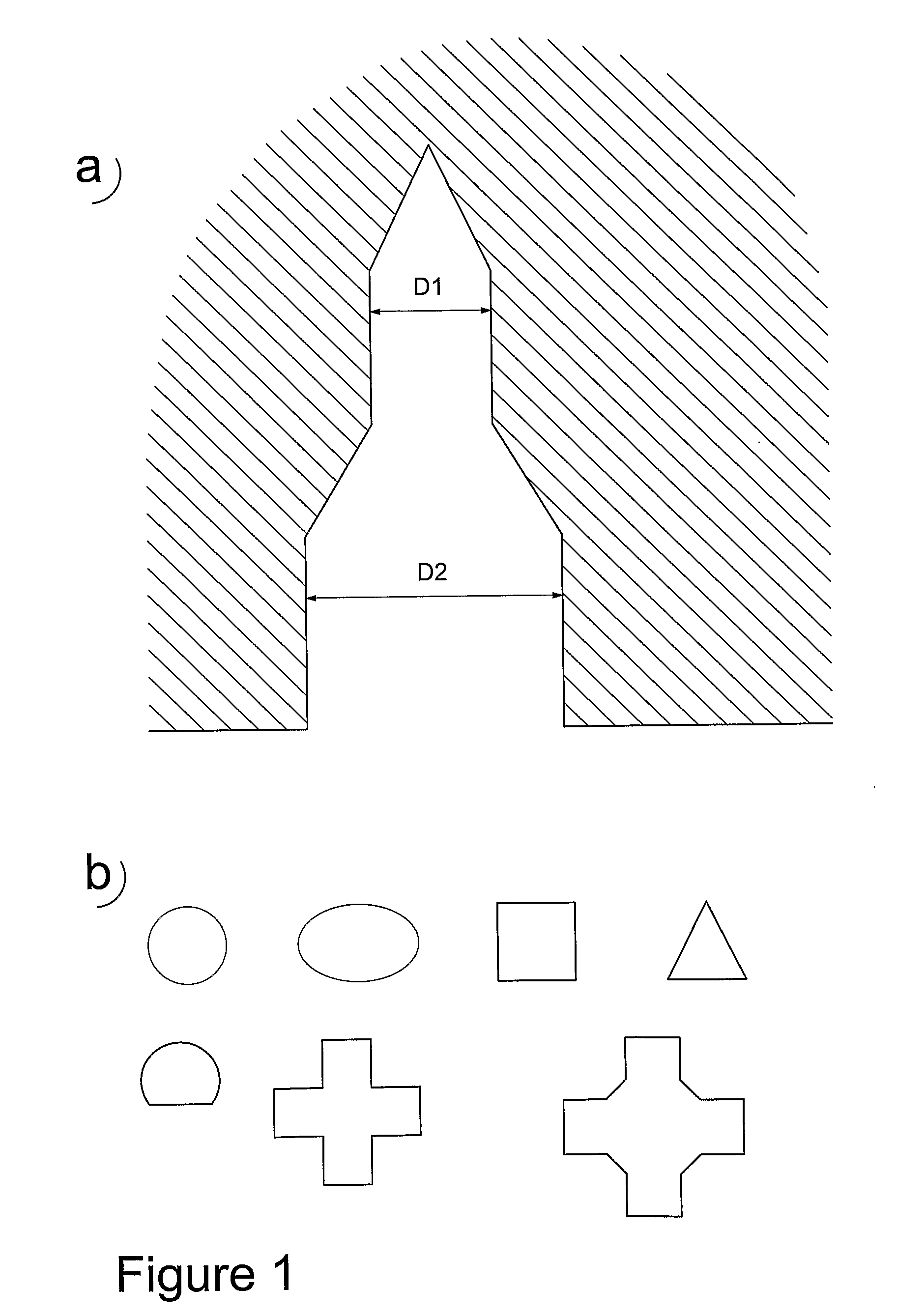

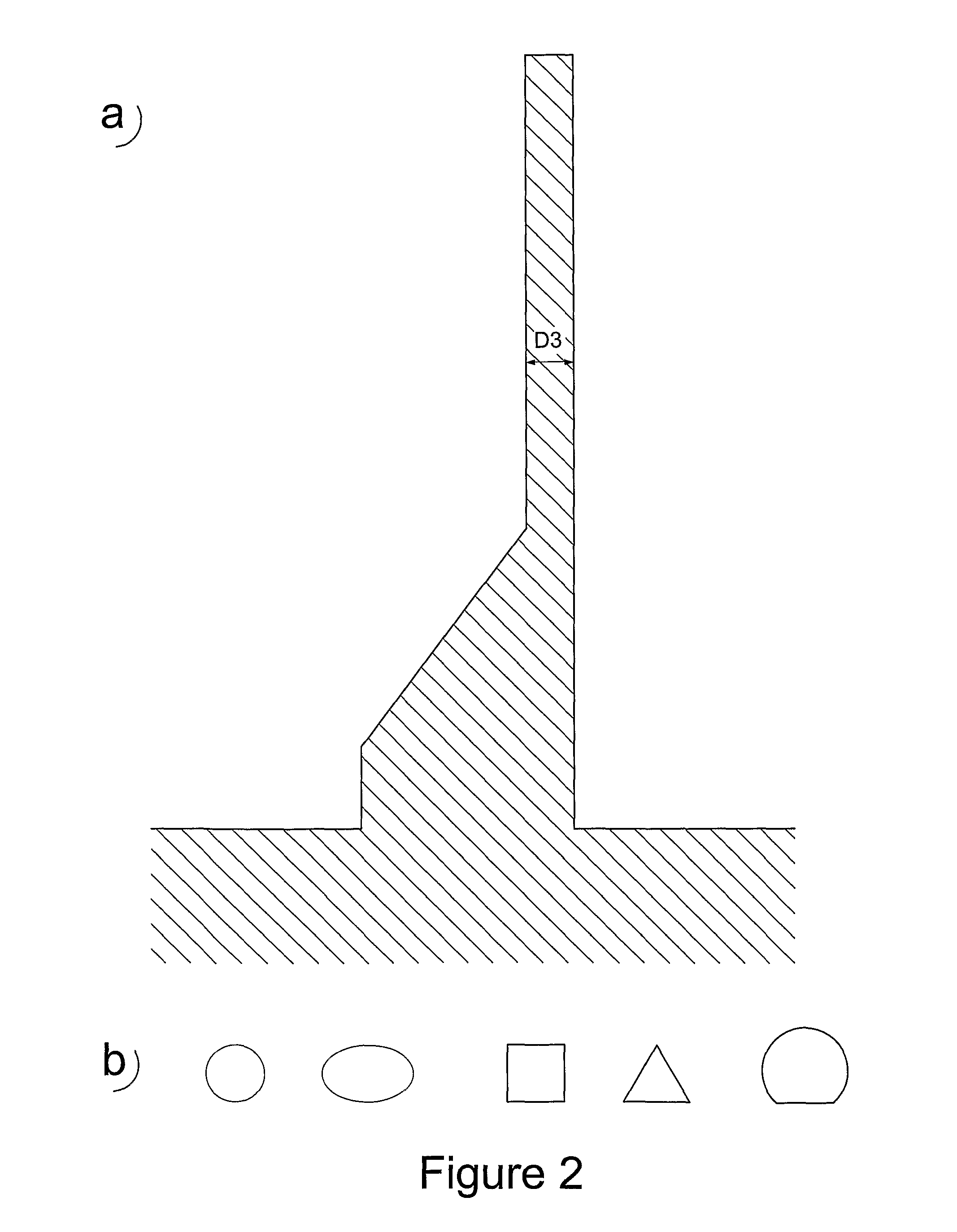

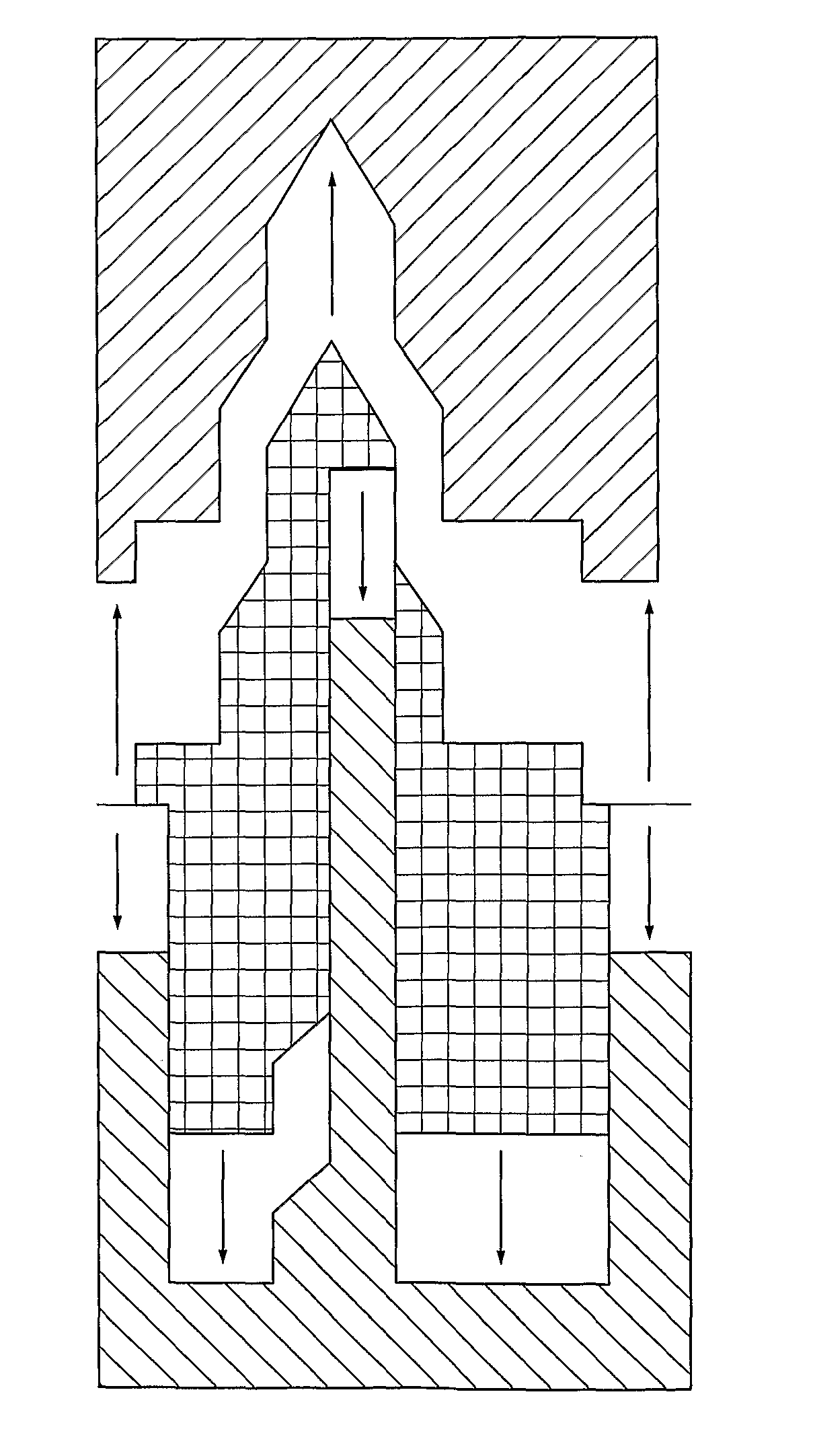

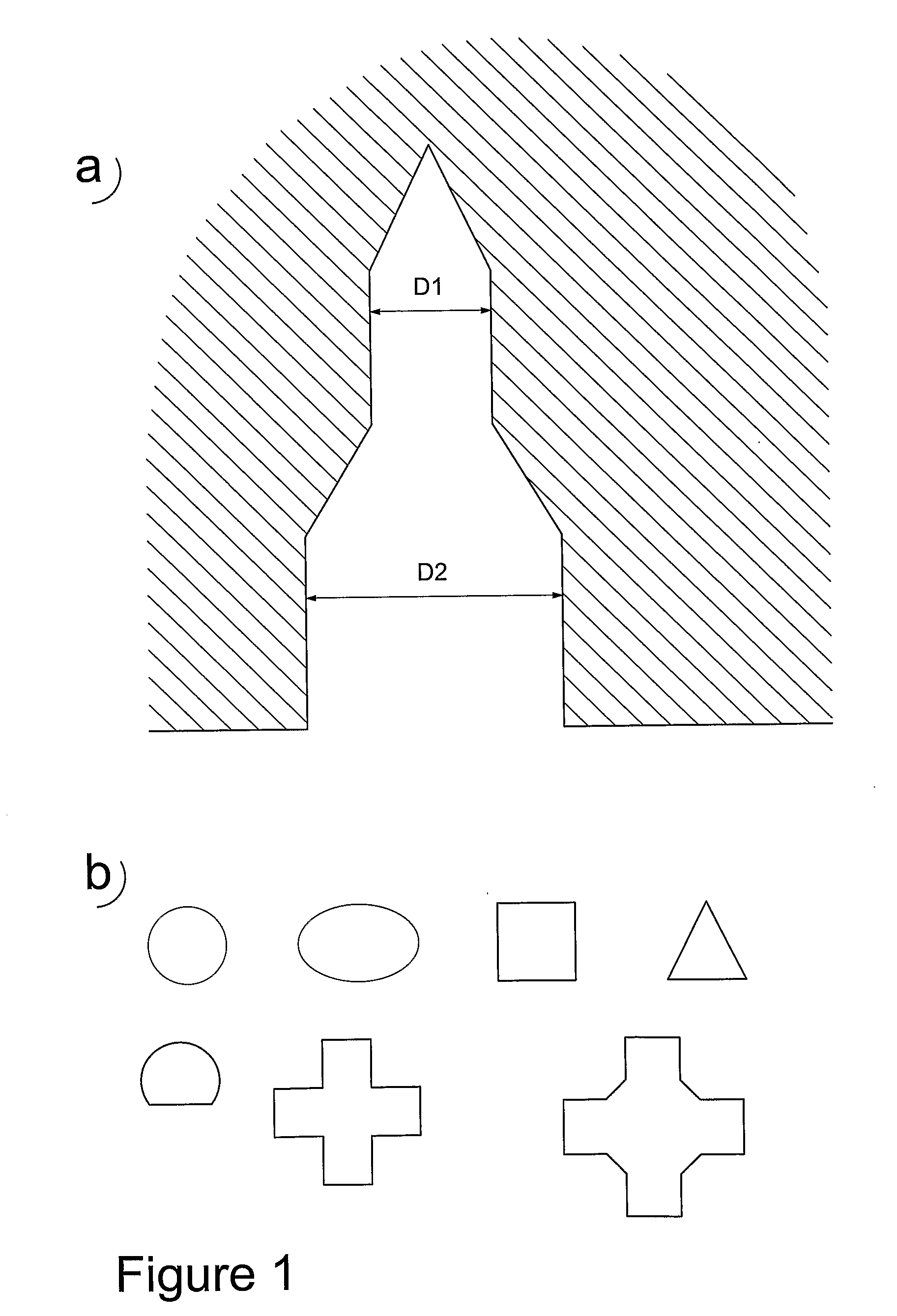

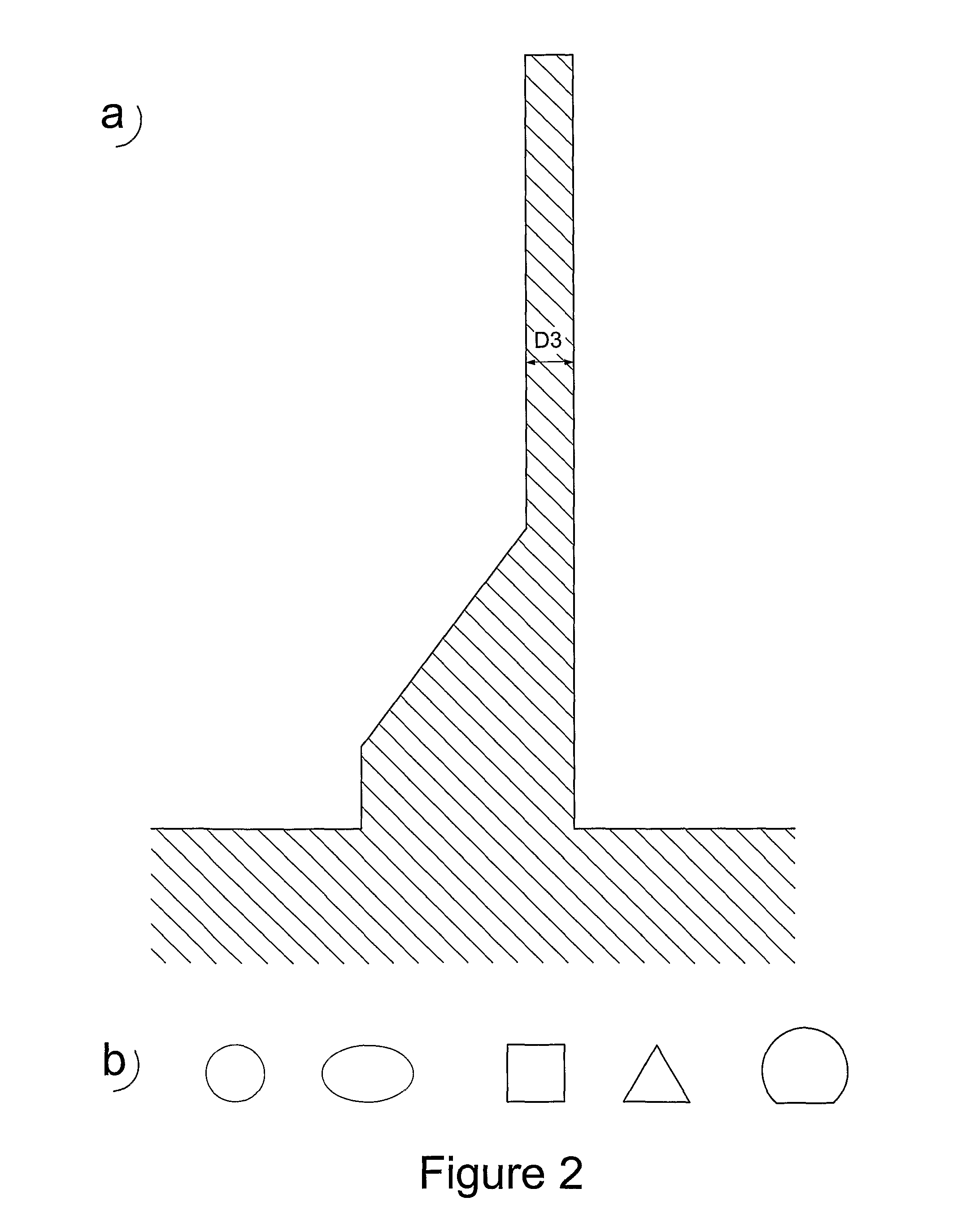

Molded Micro-Needles

Method of hollow micro-projections having side walls and at least one opening in a side wall, by a molding technique. The hollow micro-projections are defined by a first, negative mold defining the exterior shape of the micro-projections and a second, positive mold defining the hollow interior shape of the micro-projections. The method includes injecting a moldable material into the space between the two molds, in a state where they have been brought together. The positive and negative molds each have an essentially cylindrical geometry. In the process of bringing the molds together, the mold halves are laterally off-set with respect to each other, such that the distance between an inner wall of the negative mold and the positive mold in the area, ranges from zero to a finite distance. Micro-projections and arrays of micro-projections are also disclosed.

Owner:BONSENS

Apparatus for transferring torque magnetically

InactiveUS20070205681A1Magnetically actuated clutchesDynamo-electric gearsConductive materialsEngineering

An apparatus for transferring torque magnetically with a primary rotary member and a secondary rotary member. The primary rotary member has permanent magnets mounted circumferentially on a cylinder, the secondary rotary member having a cylindrical geometry with electroconductive material arranged on its outer periphery and parallel to the axes of the rotary members. The secondary rotary member also having magnetically permeable material. The secondary rotary member is placed partially or totally inside the primary rotating member. The secondary rotary member's axial position relative to the primary rotating member can be varied by a suitable mechanical structure. This causes the two rotary members to axially overlap one another more or less as desired. Rotation of the primary rotary member causes rotation of the secondary rotary member, since magnetic flux lines emanating from the permanent magnets mounted on the primary rotating member, cut through all, or part of, the electroconductive material placed on the periphery of the secondary rotary member. This can vary the torque transmitted between the two rotary members, thereby enabling the varying of the rotational speed of the secondary rotary member relative to the primary rotary member.

Owner:OSERAN WILLIAM A +1

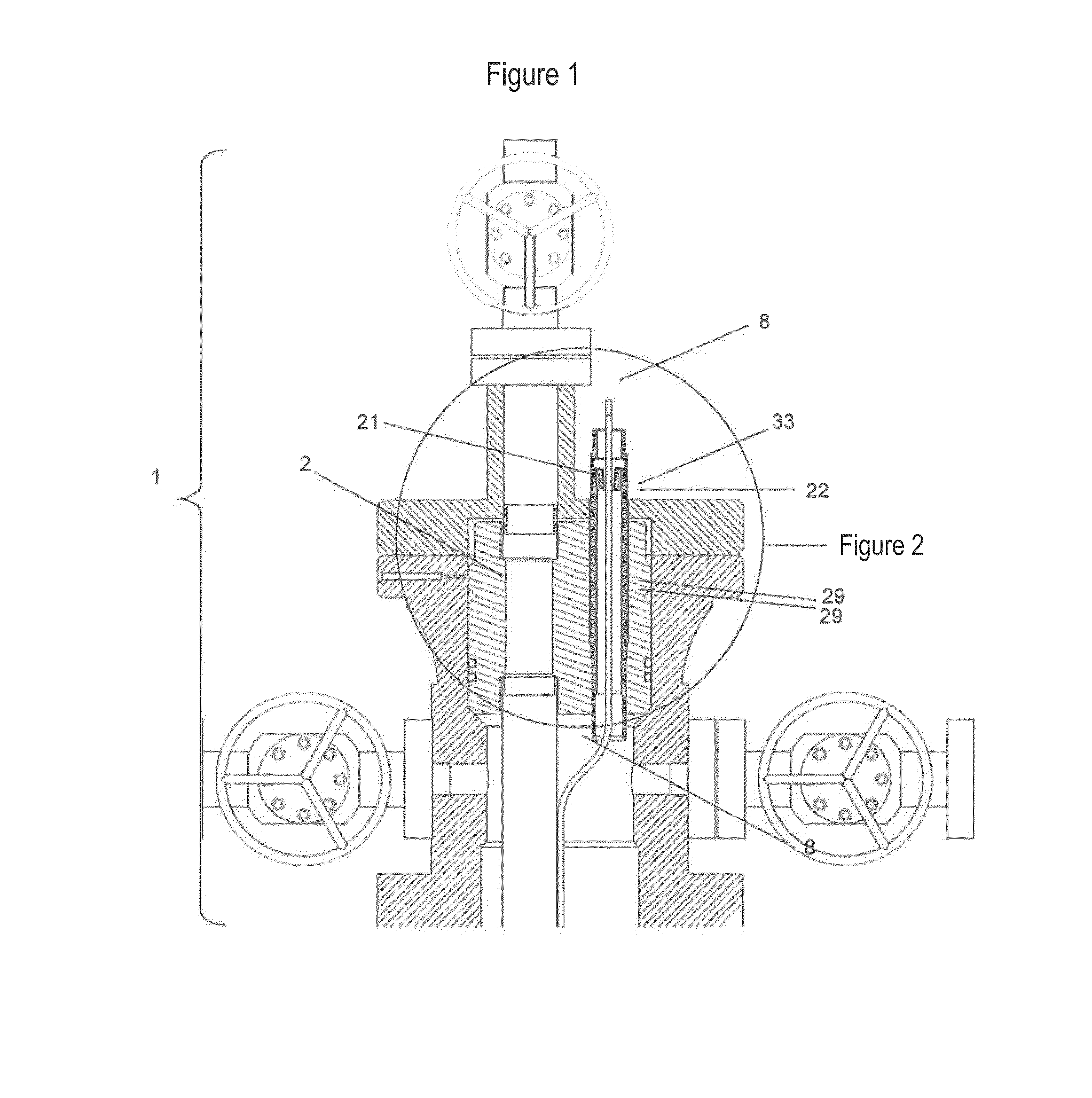

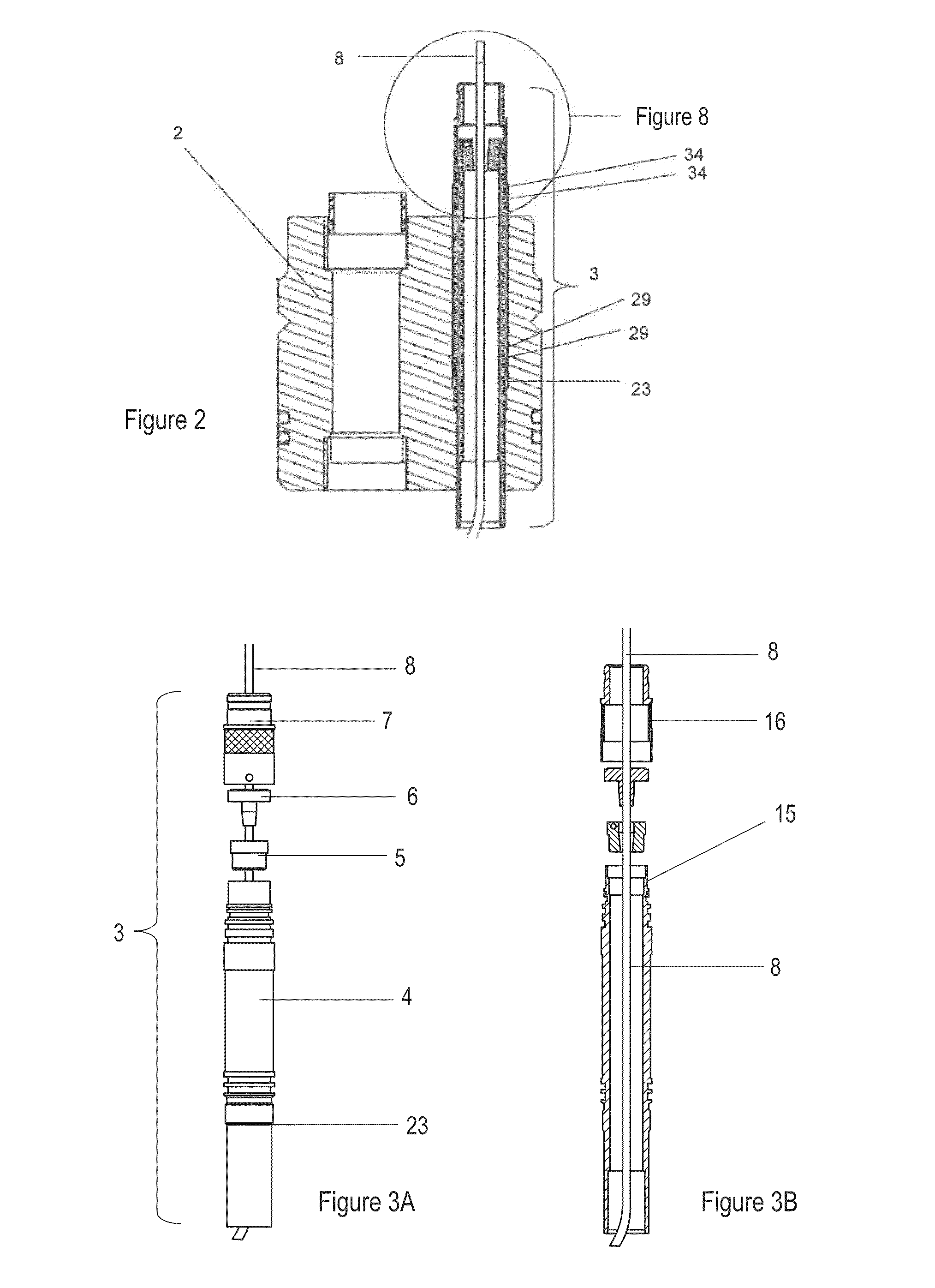

High pressure mechanical seal for cables and power lines in oil wells

The present high pressure mechanical seal features a novel configuration capable of sealing from one up to simultaneously five power conduction lines, flow injection lines or control lines, in the same device. Adaptable to different configurations, types and size of conduction lines existing in the industry. The power conduction lines can be a cable of an electro-submersible pump or the cable in a down hole heater; the flow and control lines can be diluents injector capillaries or data and instrumentation cables or any other type of conduction line which can enter the inner atmosphere of the wellbore. Conduction lines are generally shaped as uniform cylindrical elements, which vary in diameter and material due to the cylindrical geometry, are adaptable to the sealing system of the present invention, such that the equipment can seal from only one line up to five lines depending on the requirement of the user.

Owner:SOLPETROCOL

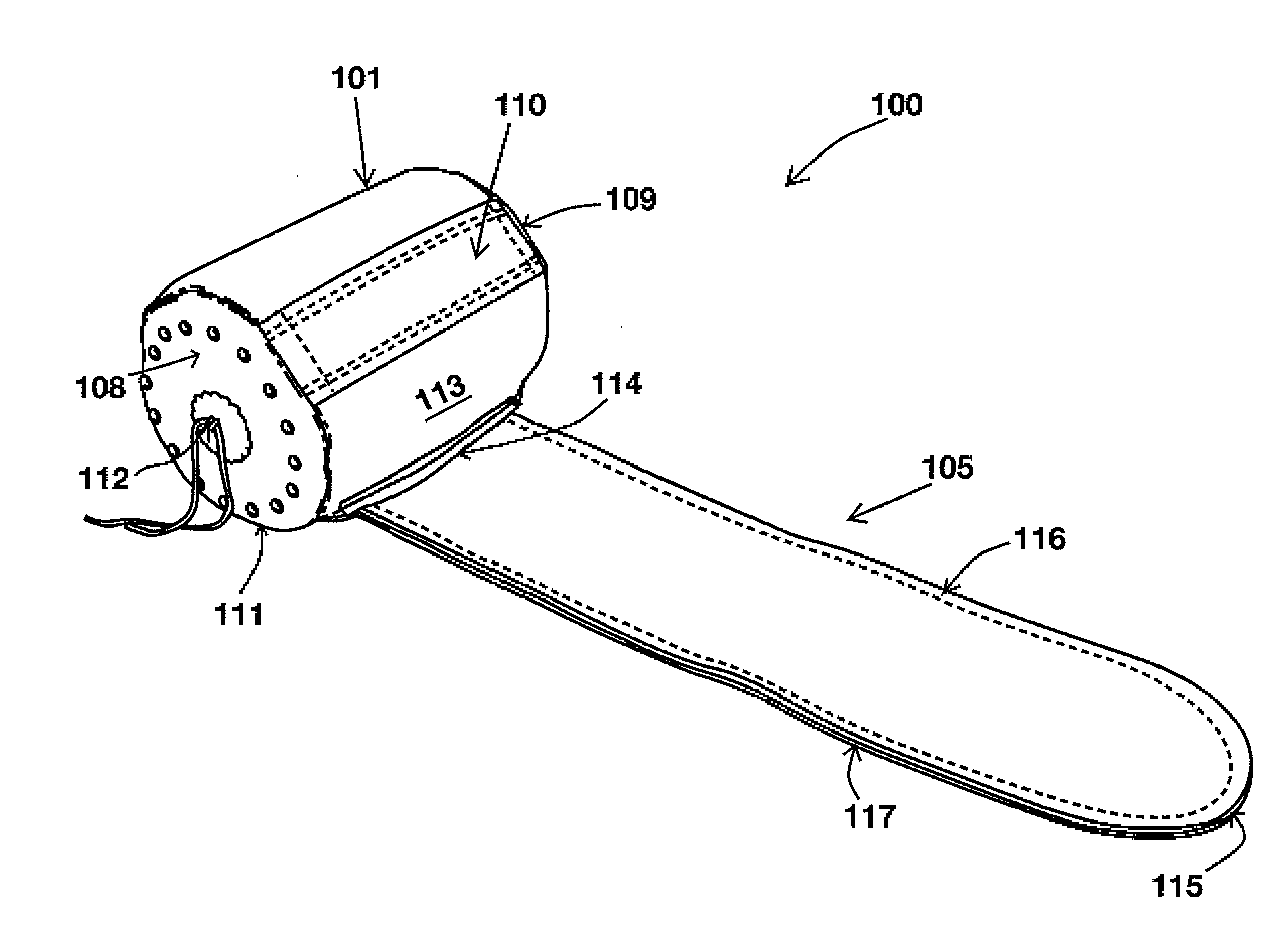

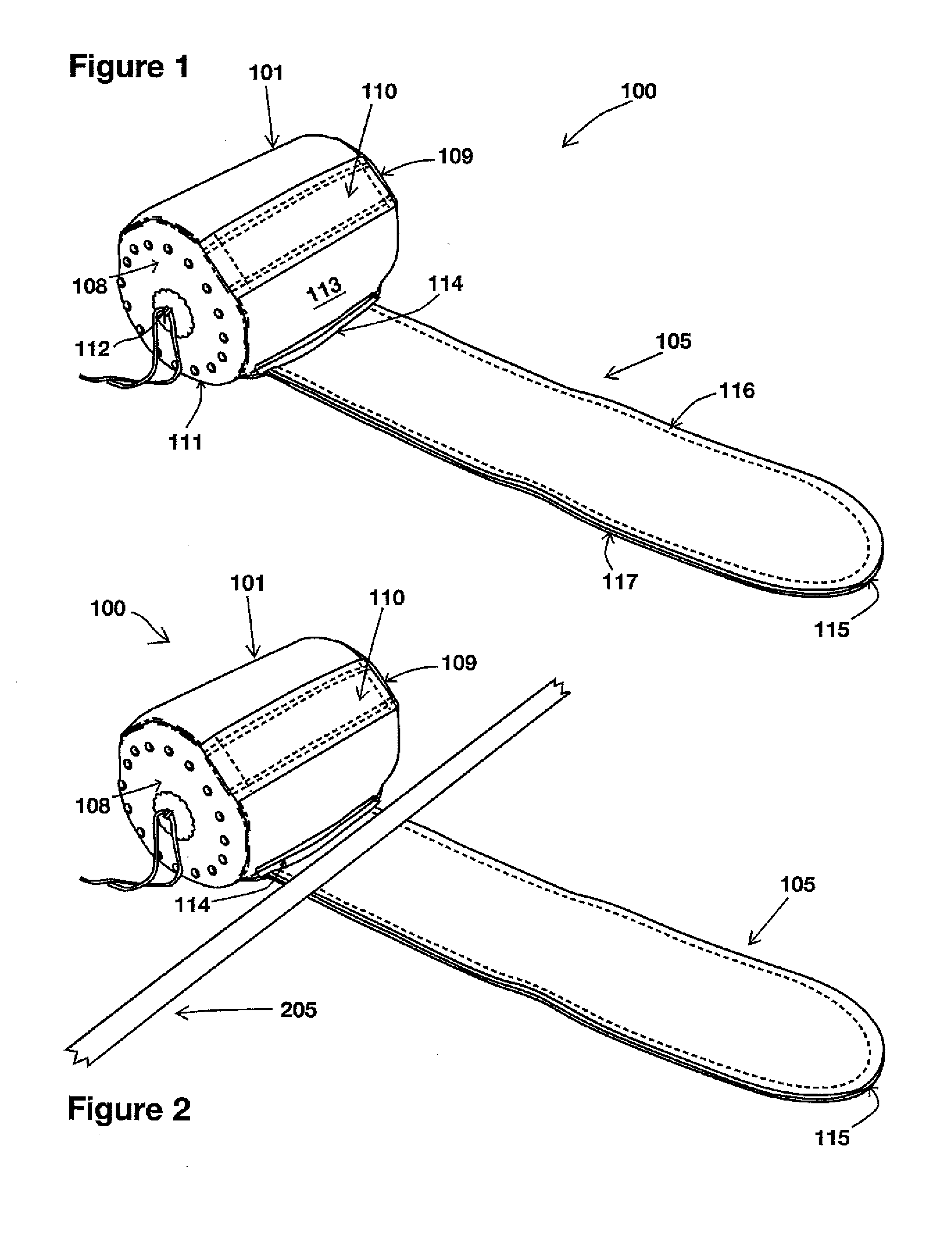

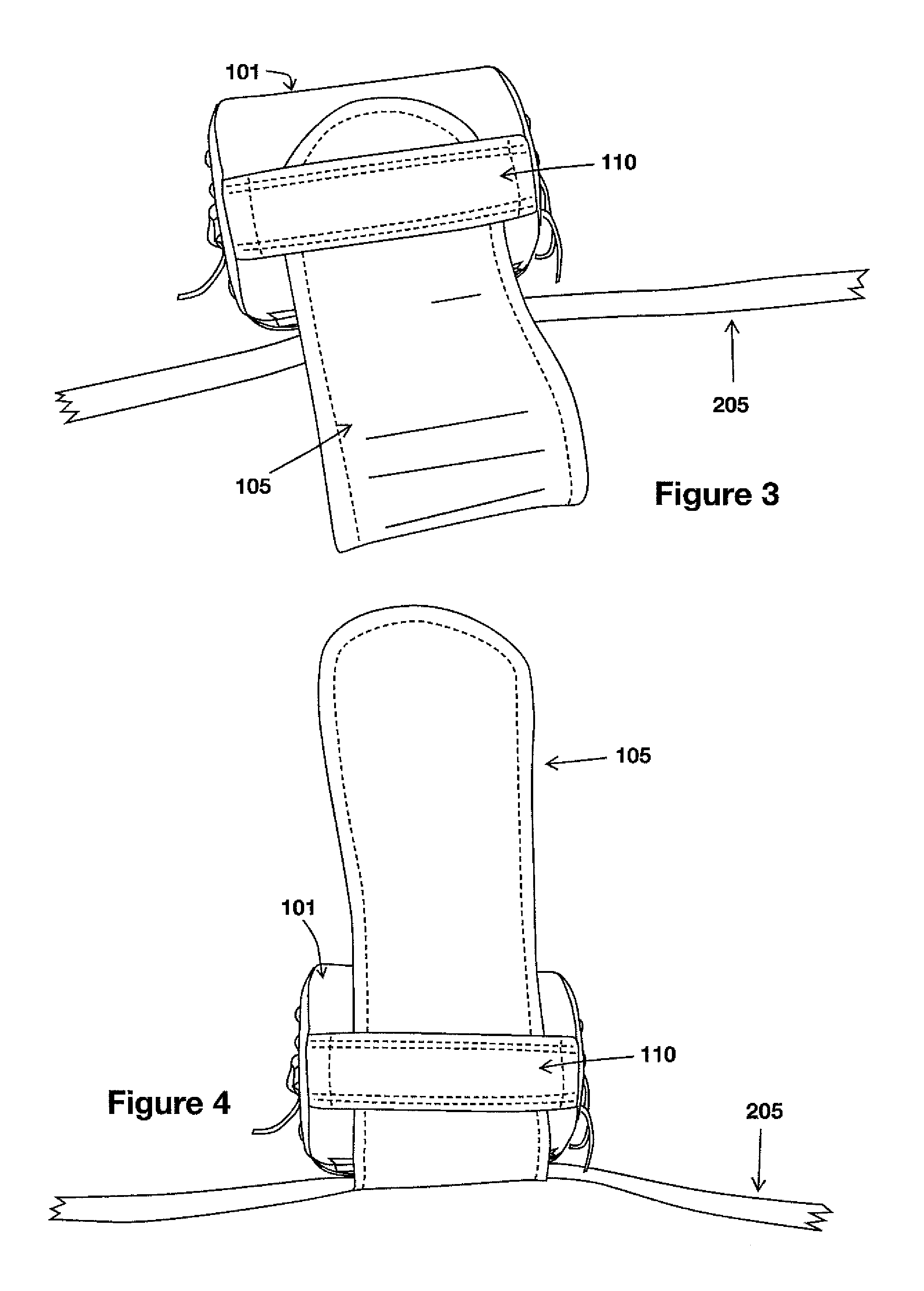

Motorcycle Backrest

A motorcycle backrest is claimed. The motorcycle backrest a closed-end, substantially cylindrical geometry filled with a resilient stuffing, having an elongated tongue tangentially extended therefrom, and at least one strap connected on either end of the cylinder running substantially parallel thereto. The motorcycle backrest is maintained in position on the motorcycle by threading the elongated tongue through an existing motorcycle seat strap, or through a retro-fit belt or strap secured around the motorcycle seat between the driver and passenger portion of the motorcycle seat. Next, the tongue is threaded through the strap of the motorcycle backrest. The elongated tongue is of sufficient length so that, when installed, the driver sits on the tongue thereby ensuring the backrest stays in place during the operation of the motorcycle.

Owner:MILLS CLARENCE H

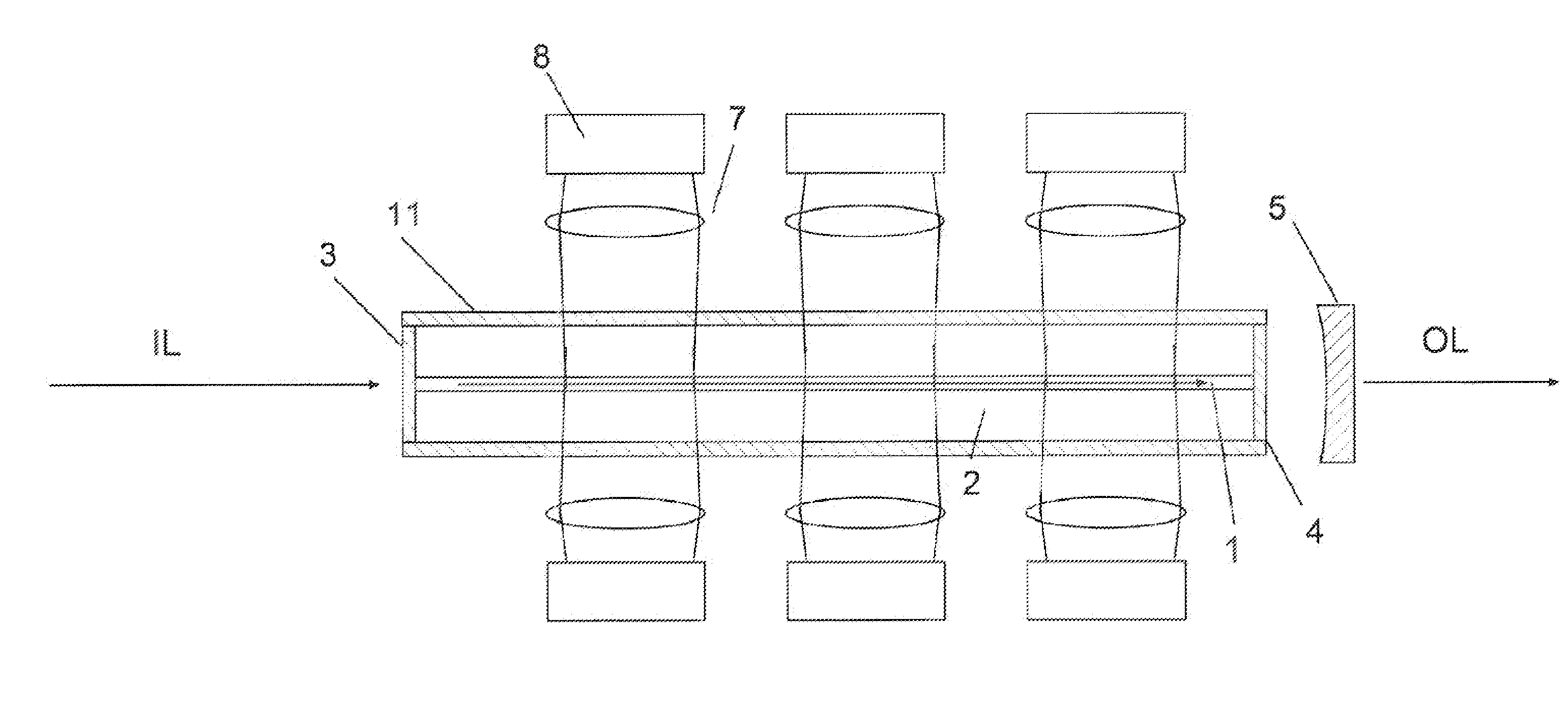

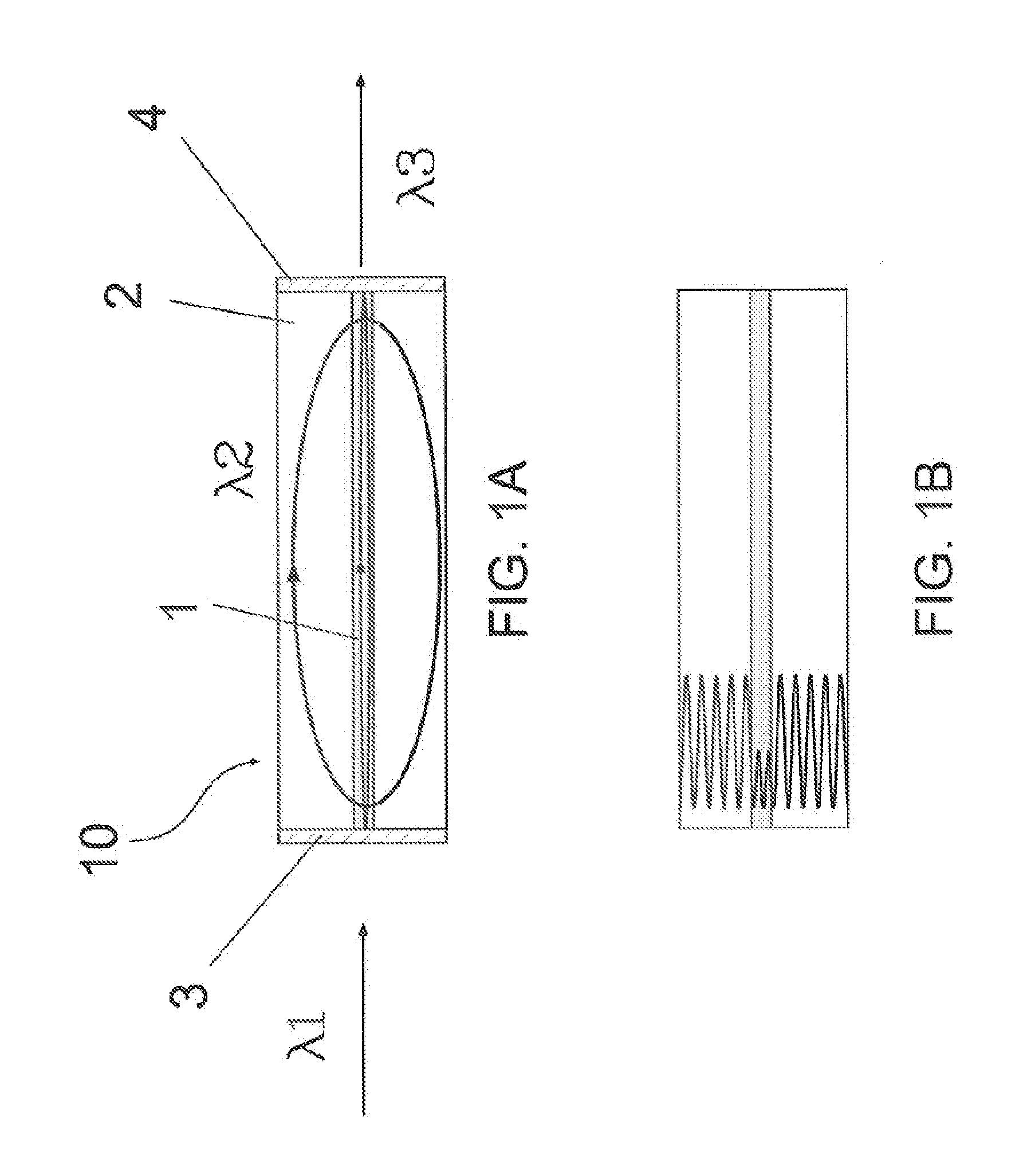

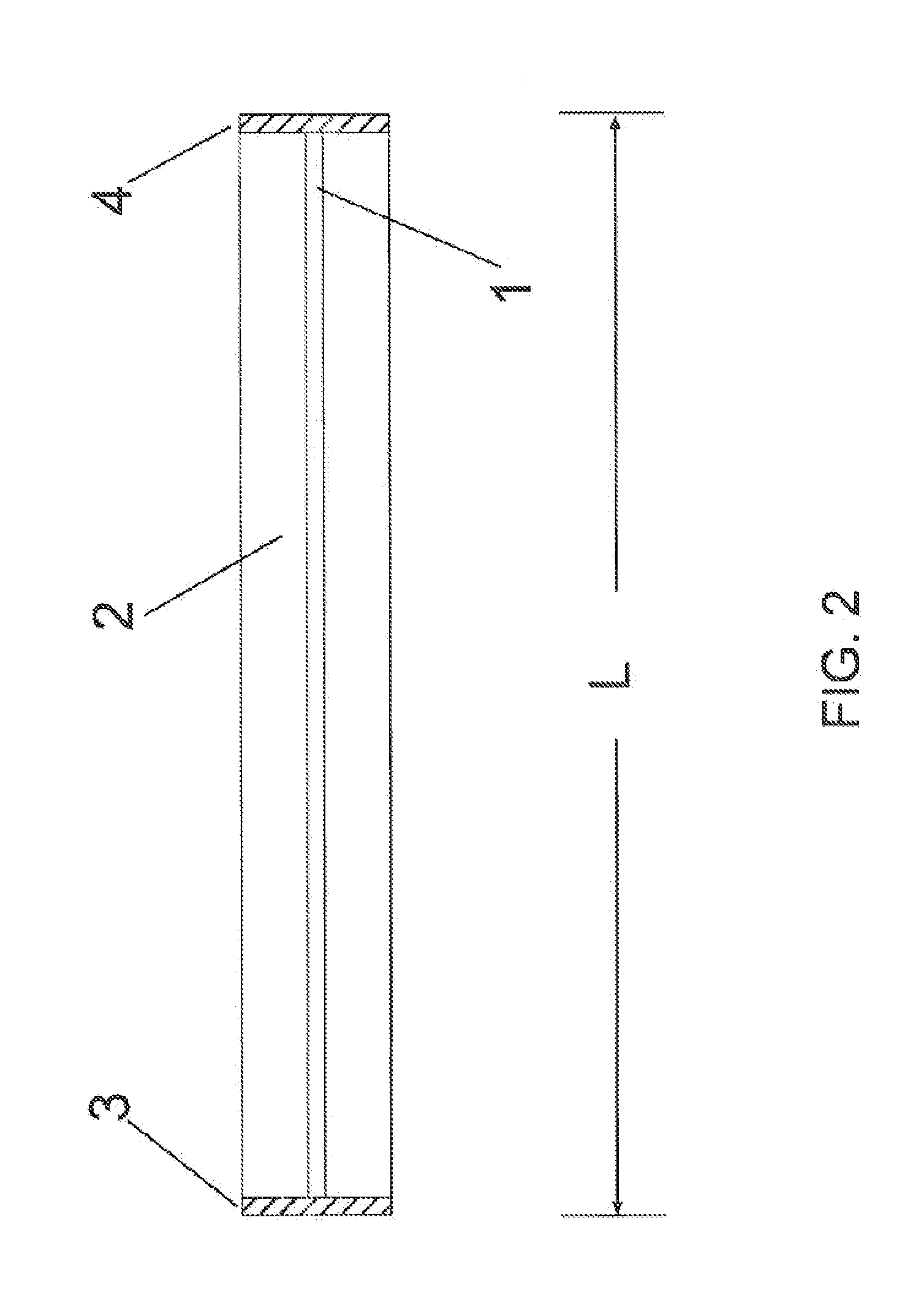

Composite laser gain medium

ActiveUS20150236470A1Small refractive indexLaser using scattering effectsActive medium materialDopantRare-earth element

A composite laser gain medium is comprised of a first rare-earth element doped core; and a second rare-earth element doped cladding, at least partially, adjacent to the core. A portion of the lasing by the cladding at one wavelength within the composite laser gain medium is absorbed by the core so as to cause lasing of the core at a different wavelength. At least two distinct rare earth element pairs may be used in embodiments: (1) thulium (Tm) as a cladding rare-earth dopant and holmium (Ho) as the core rare-earth dopant; and (2) ytterbium (Yb) as a cladding rare-earth dopant and erbium (Er) as the core rare-earth dopant. Other rare earth element pairs are also believed possible. The laser composite gain medium may be configured to have a slab, or a cylindrical geometry.

Owner:US SEC THE ARMY THE

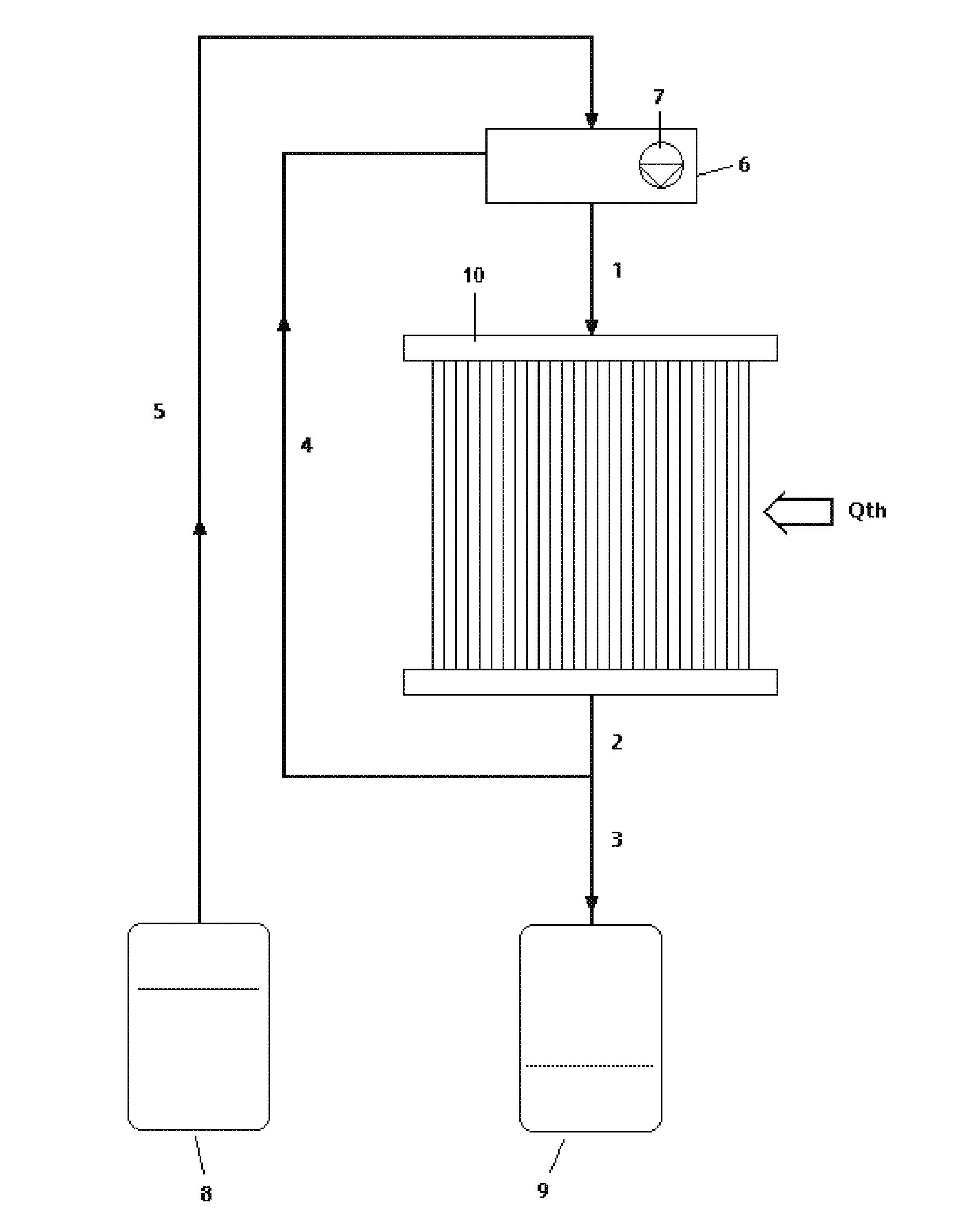

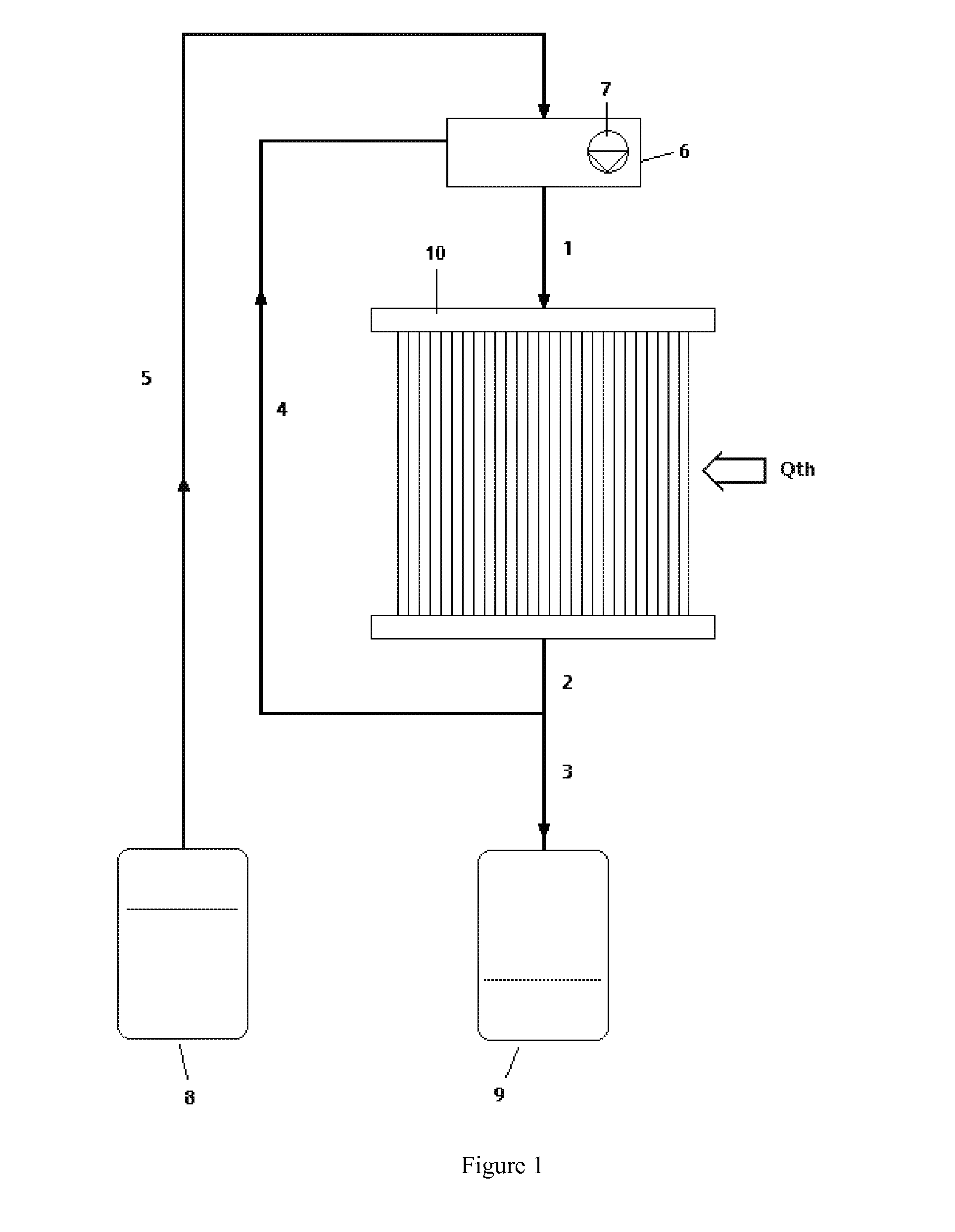

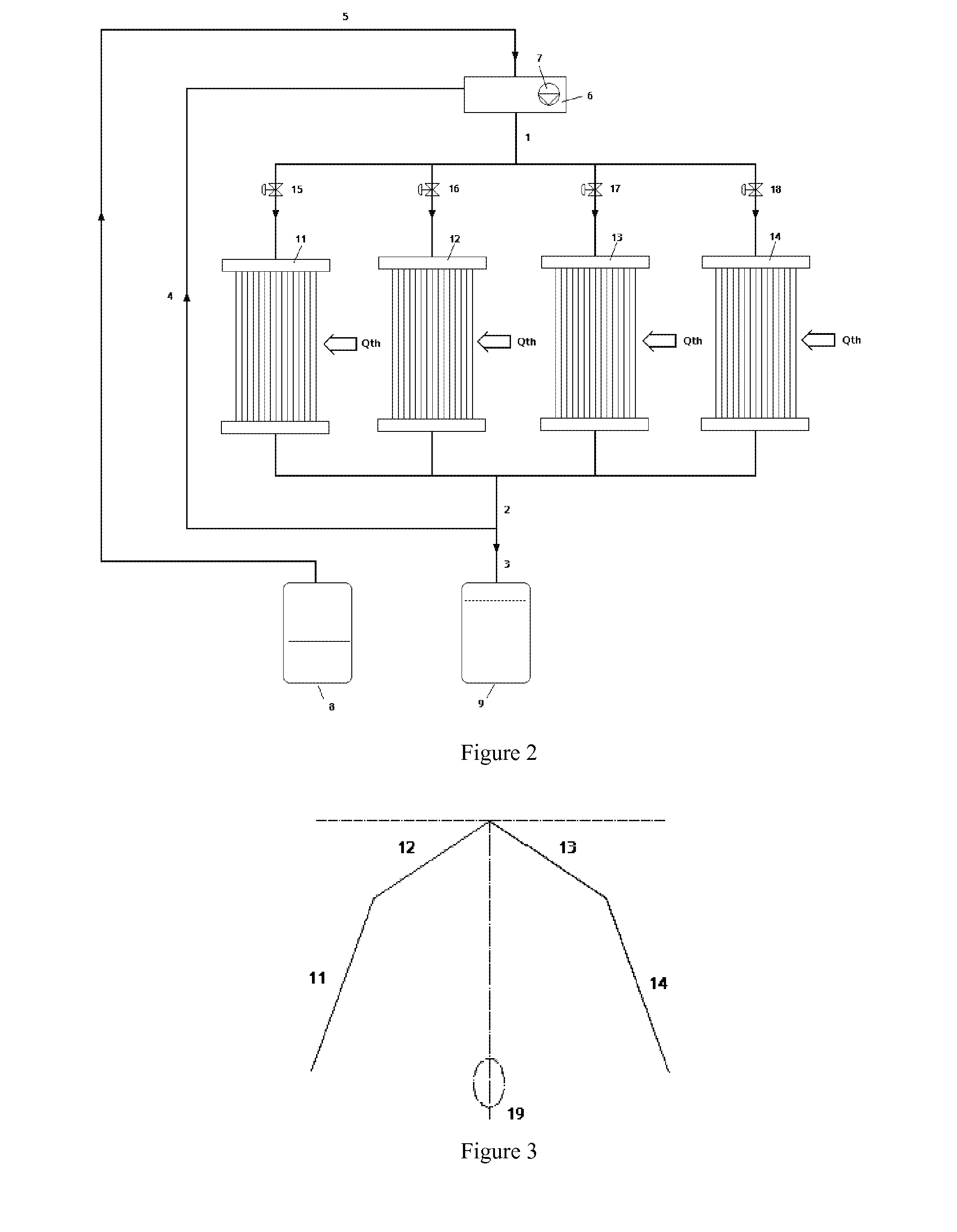

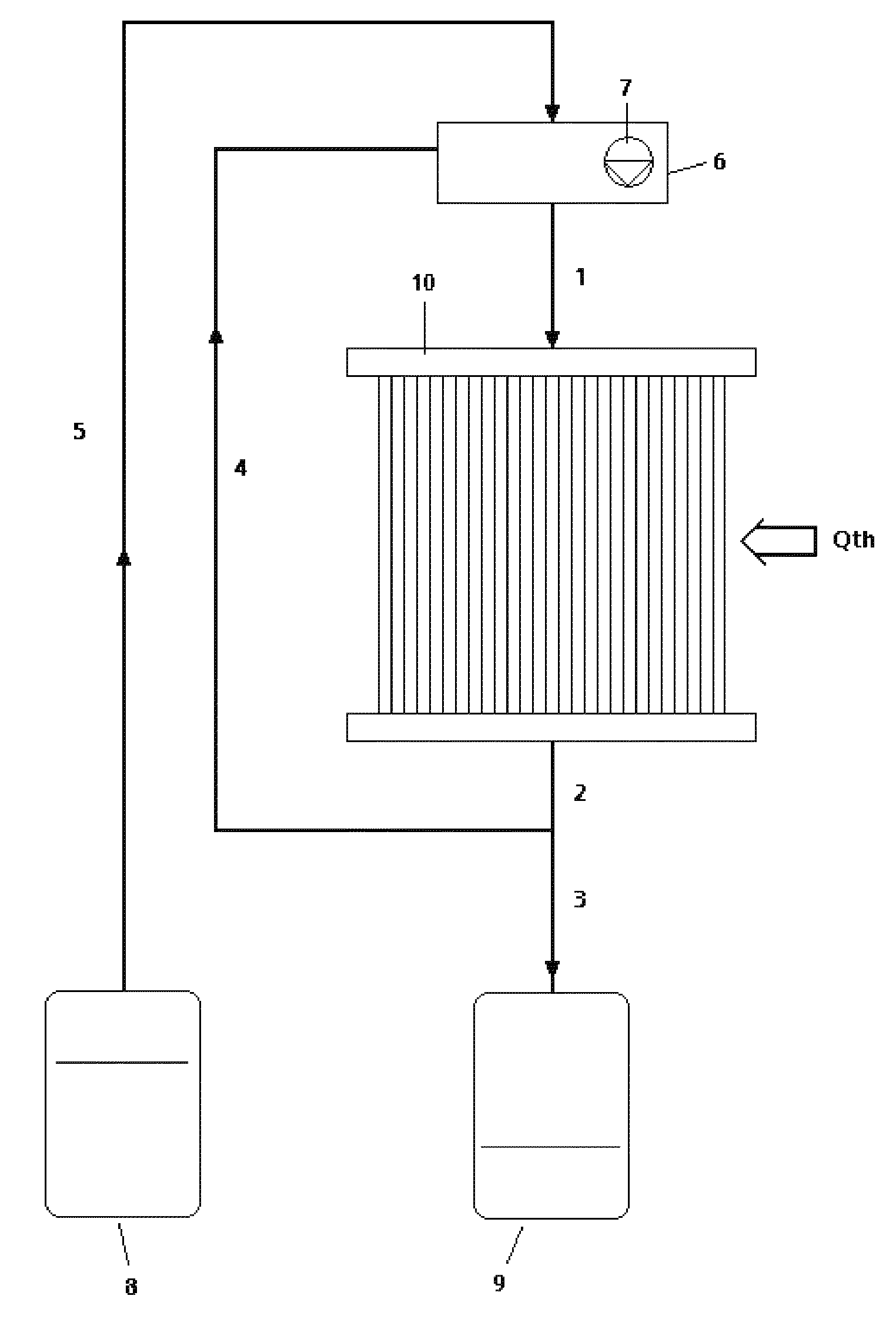

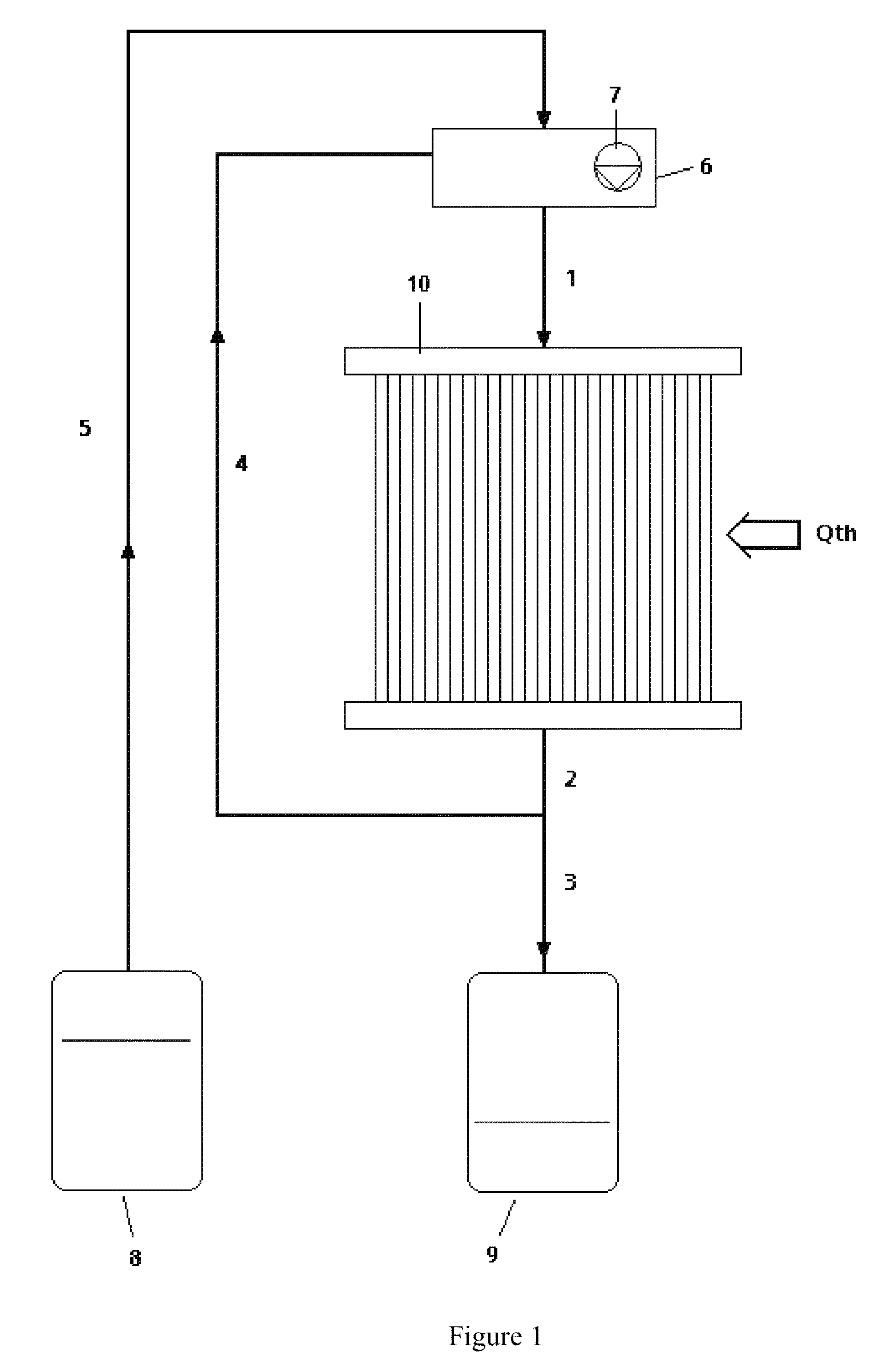

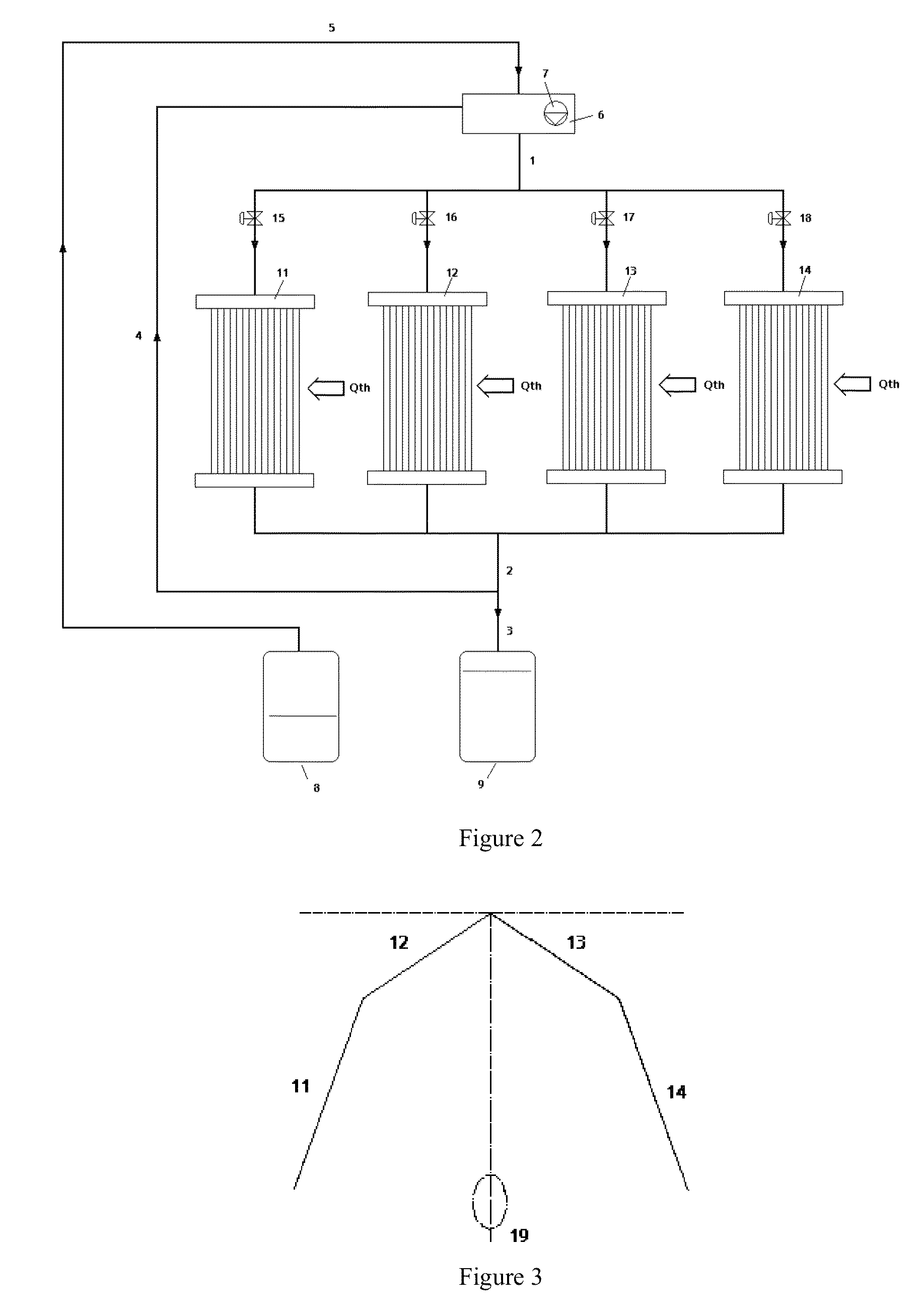

Molten salt solar receiver and procedure to reduce the temperature gradient in said receiver

ActiveUS20130199517A1Easy to controlReduce the differenceSolar heating energyFrom solar energyMolten saltEngineering

Molten salt solar receiver and procedure to reduce the temperature gradient in said receiver. The receiver consists of at least one panel of semi cylindrical geometry, formed by a combination of vertical pipes. The receiver (10) is supplied with a heat transfer fluid made up of molten salts which originate from a recirculation system which is composed of a mixture deposit (6), a hot salt storage tank (9) and a cold salt storage tank (8); the mixture tank (6) which is supplied by a part of the hot heat transfer fluid (4) which exits the receiver (10) and the cold heat transfer fluid (5) which exits the cold salt storage tank (8); the hot salt storage tank is connected to the exit of the receiver (10) so that a part of the heat transfer fluid which does not recirculate is stored (3).

Owner:ABENGOA SOLAR NEW TECH SA

End protector device for tubular structures

InactiveUS8011391B2Improve the immunityProtect the endDrilling rodsClosure using stoppersEngineeringCylindrical geometry

A protector device for the ends of the tubular goods, such as tubes for the oil industry, OCTG, line pipes and the like is provided. The protector device may include two pieces, a generally elongate protector body and a bumper reinforcement that may be reversibly connected to the protector body. The protector body may be configured in a cylindrical geometry having a first end and a second end interconnected by lateral walls and defining a socket. The second end of the body further comprises a shoulder and an opening defining a socket in which a tubular good may be inserted. The bumper reinforcement includes an external curved or conical surface, capable of deforming in reaction to an external force in order to protect an enclosed tubular good.

Owner:SIDERCA I C

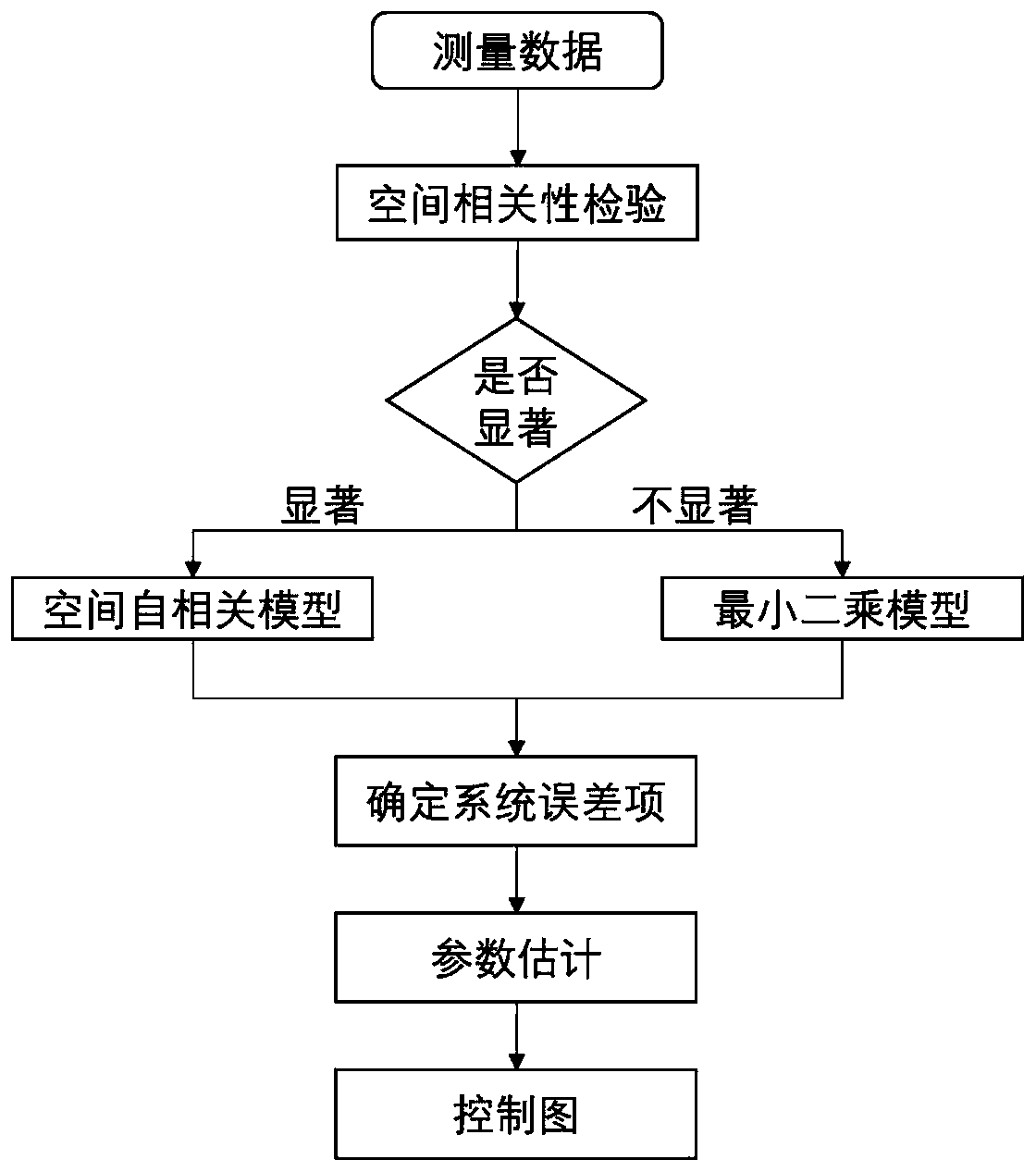

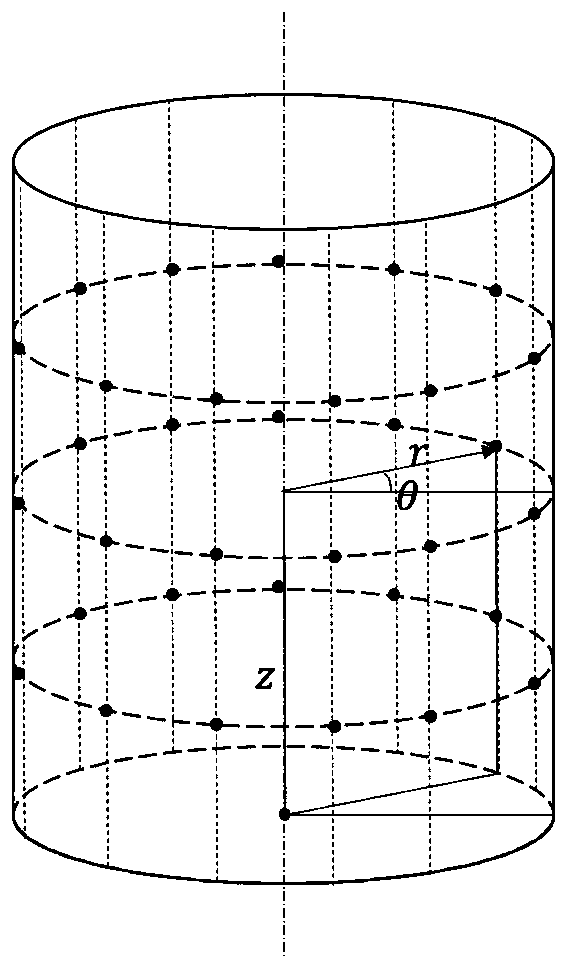

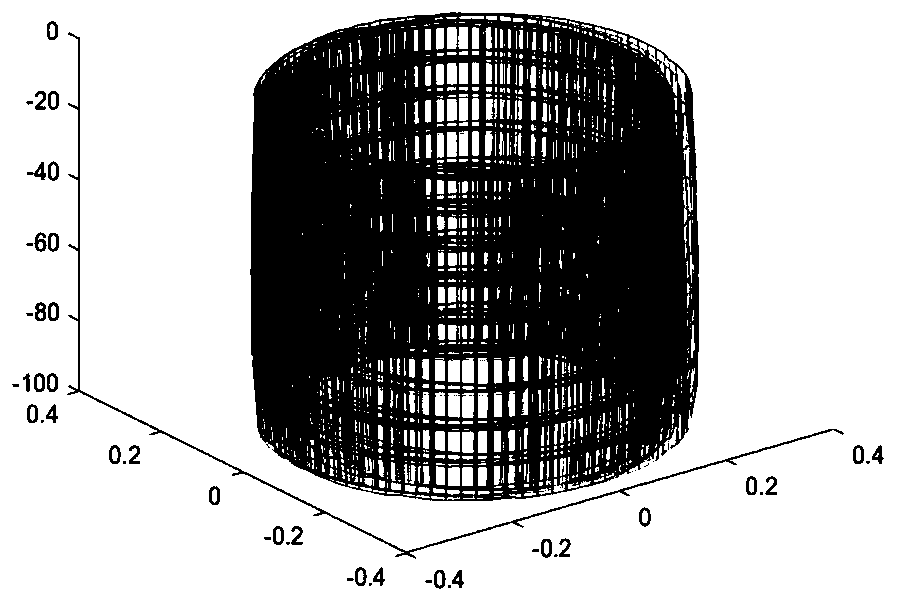

Method and system for monitoring spatially correlated cylindrical shape error and medium

ActiveCN110245395ATrue and detailed descriptionImprove detection accuracyMeasurement devicesDesign optimisation/simulationSpatial correlationGeometric error

The invention provides a spatially correlated cylindrical shape error monitoring method and system and a medium, and the method comprises a surface measurement step of measuring the surface of a cylinder, and obtaining the three-dimensional coordinate data of a measurement point; a data processing step of obtaining an error value of the measurement point according to the obtained three-dimensional coordinate data of the measurement point; and a spatial correlation judgment step of judging whether the error value of the measurement point has the spatial correlation or not according to the obtained error value of the measurement point, and obtaining a spatial correlation judgment result. The monitoring method and system of the cylindrical geometric error with spatial correlation provided by the invention can reflect the form of the processing error more accurately, remove the influence of the spatial correlation on the measurement result and effectively improve the recognition rate of unqualified products, and improves the defect that the traditional cylinder quality monitoring cannot reflect the geometric shape of the cylinder and the defect of the spatial correlation caused by a large number of measuring points.

Owner:SHANGHAI JIAO TONG UNIV

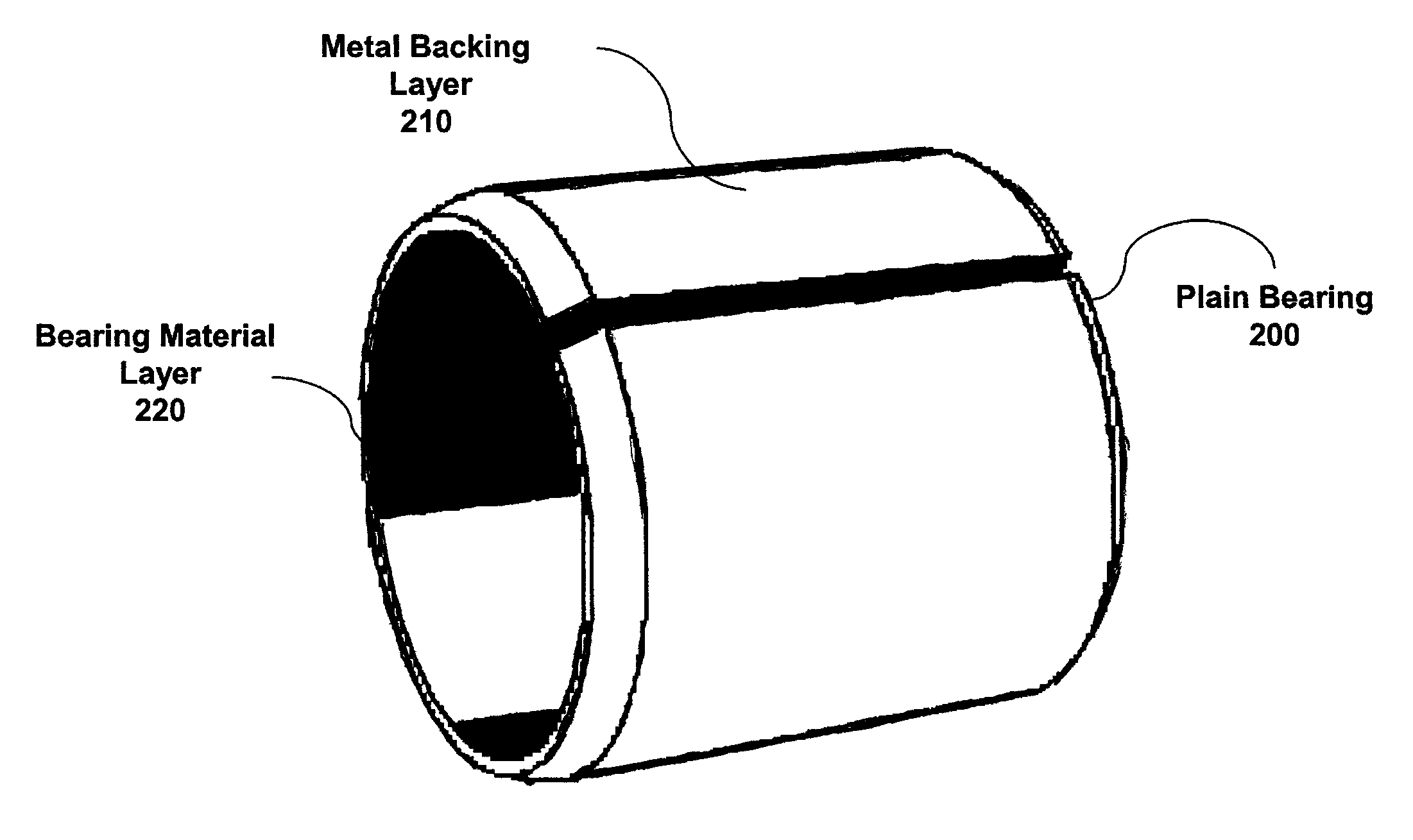

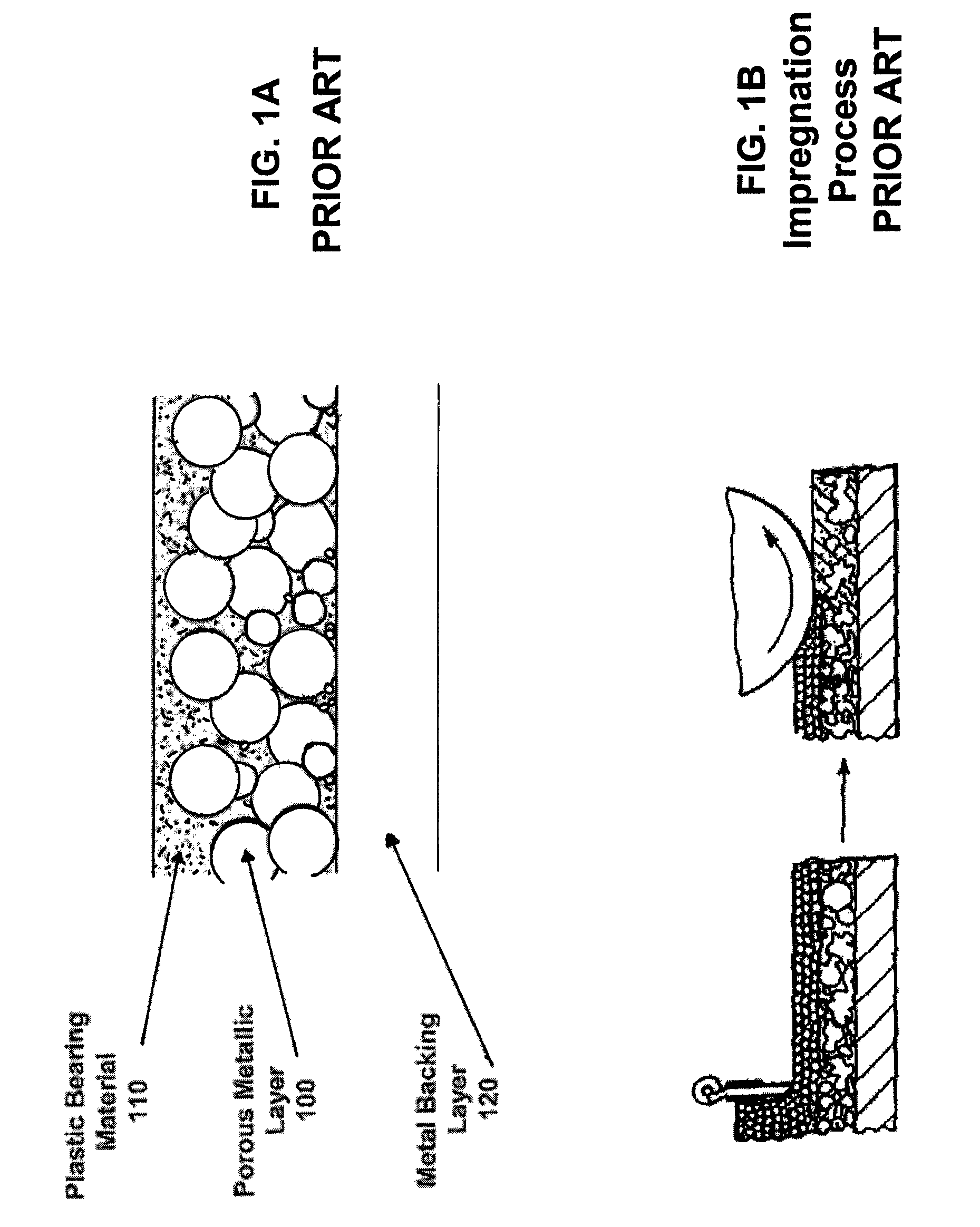

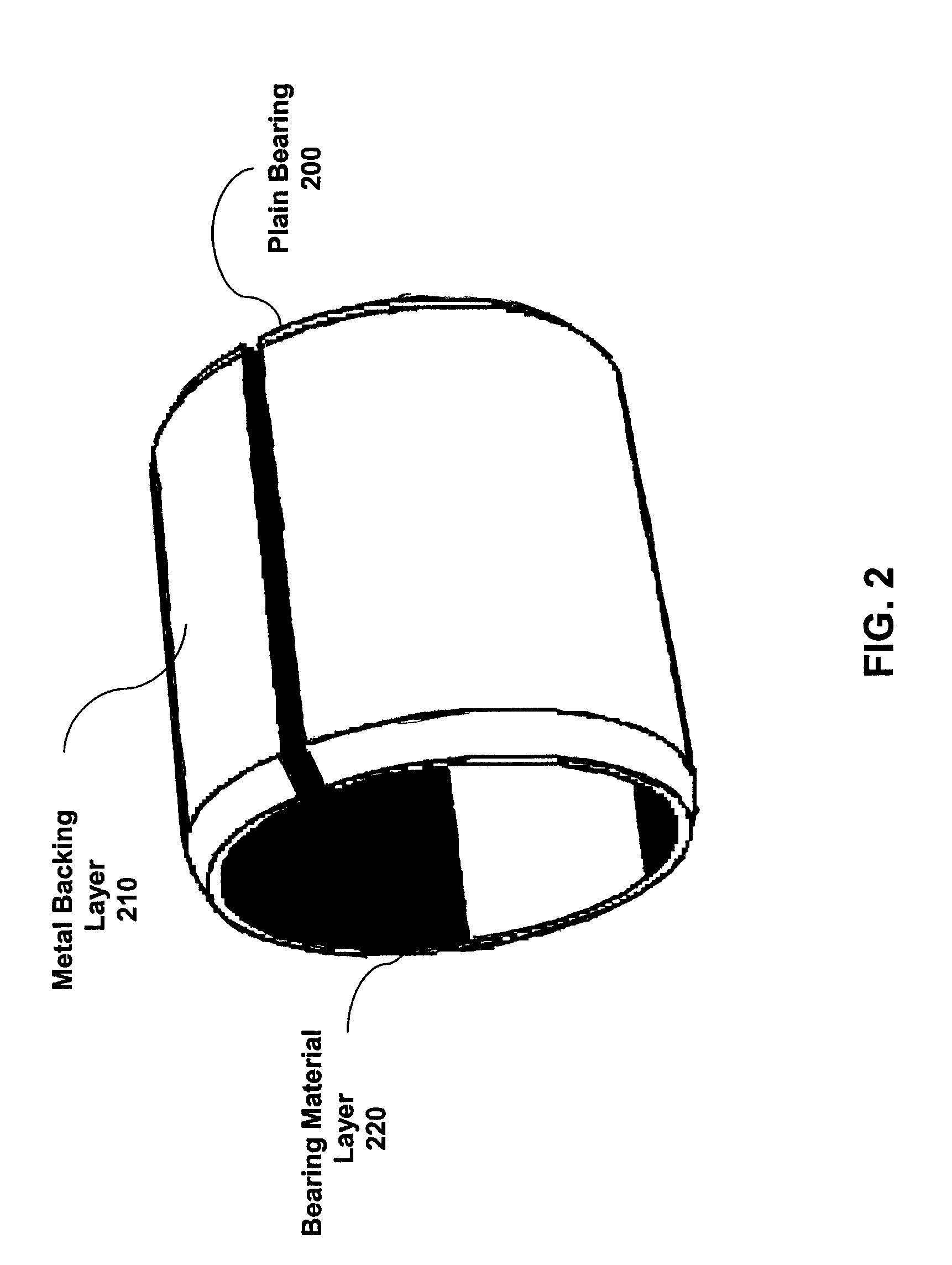

Metal-backed plain bearing

ActiveUS8931957B2Easy to operateSimilar of adhesionLiquid surface applicatorsBearing bushesResin matrixPliability

A bearing comprises a resin matrix filled with fluoropolymer, graphite, and other discrete particles of an additive material that is attached to a backing material. The specific selection and mix of fillers with the resin matrix provides the desired blend of bearing properties such as wear resistance, fatigue and erosion resistance and low friction whilst maintaining sufficient flexibility for being formed into flanged cylindrical geometries without detriment to the adherence of the lining to the backing. A method for manufacturing a bearing comprises depositing to a backing material a fluid polymer bearing material comprised of a resin matrix filled with fluoropolymer, various fillers, and discrete particles of an additive to form a continuous consolidated bearing material, and curing the lining material to bond the lining material onto the backing material.

Owner:GGB U S HOLDCO LLC

FAIMS electrodes with lateral ion focusing

InactiveUS7468511B2Stability-of-path spectrometersTime-of-flight spectrometersDiffusionMedial surface

A FAIMS cell including one of side-to-side cylindrical geometry electrodes and stacked-plate electrodes is adapted with a medial surface feature for focusing ions along a lateral direction within an ion separation region of the FAIMS cell. The medial surface feature is provided as one of a recessed channel within an electrode surface and a protruding ridge extending from an electrode surface. The medial surface feature is aligned with a defined aggregate direction of ion travel within the ion separation region for focusing ions along the lateral direction in opposition to the tendency of ions to spread out as a result of space charge repulsion, ion-ion repulsive forces, diffusion and gas flows. The electrical field and fluid dynamic effects produced by the medial surface feature beneficially affect ion transmission efficiency through the FAIMS cell.

Owner:THERMO FINNIGAN

FAIMS electrodes with lateral ion focusing

InactiveUS20080067366A1Stability-of-path spectrometersIsotope separationMedial surfaceCylindrical geometry

A FAIMS cell including one of side-to-side cylindrical geometry electrodes and stacked-plate electrodes is adapted with a medial surface feature for focusing ions along a lateral direction within an ion separation region of the FAIMS cell. The medial surface feature is provided as one of a recessed channel within an electrode surface and a protruding ridge extending from an electrode surface. The medial surface feature is aligned with a defined aggregate direction of ion travel within the ion separation region for focusing ions along the lateral direction in opposition to the tendency of ions to spread out as a result of space charge repulsion, ion-ion repulsive forces, diffusion and gas flows. The electrical field and fluid dynamic effects produced by the medial surface feature beneficially affect ion transmission efficiency through the FAIMS cell.

Owner:THERMO FINNIGAN

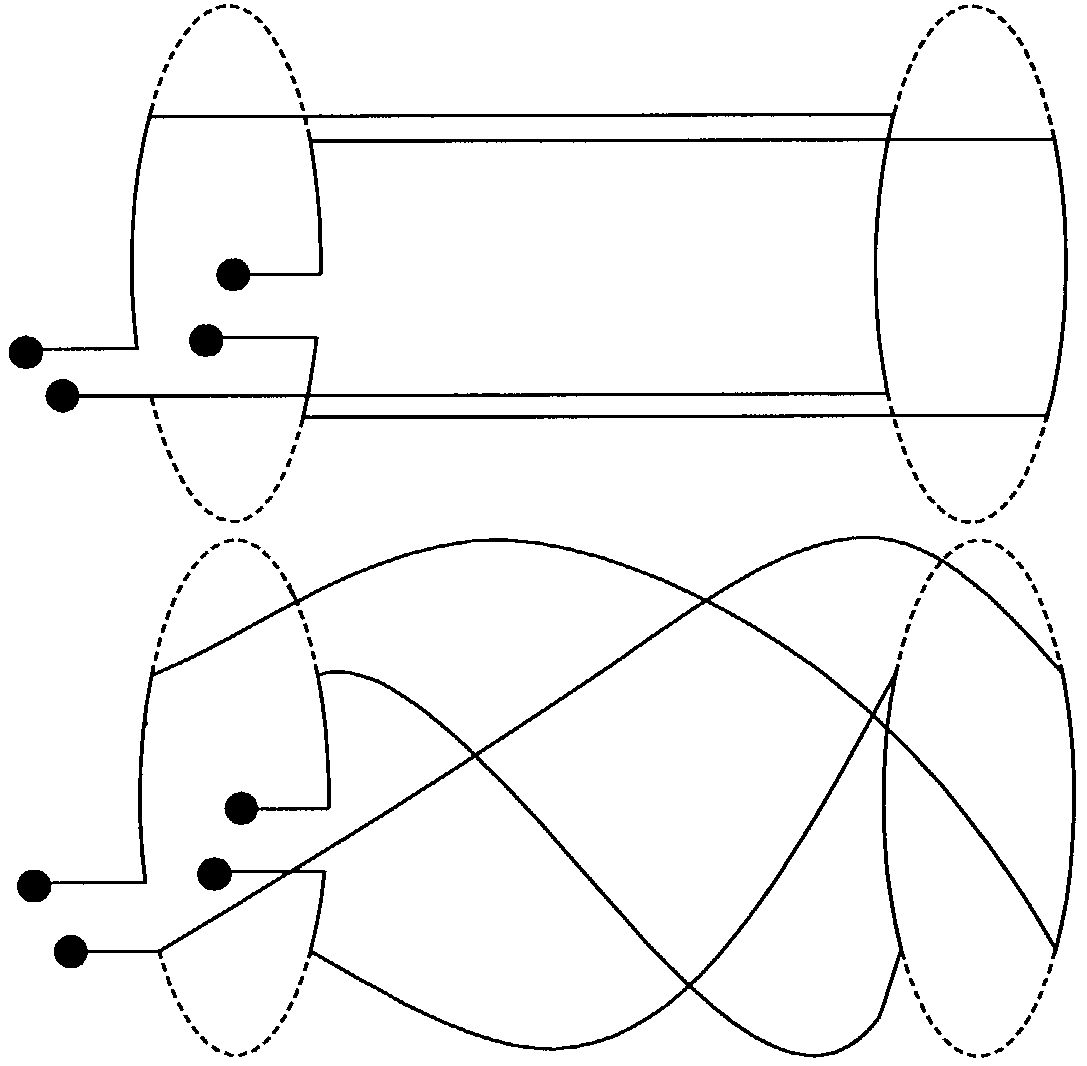

Method and apparatus for magnetic resonance imaging incorporating a spiral coil

InactiveUS7233147B2Improve signal-to-noise ratioHighly desirable resultElectric/magnetic detectionMeasurements using magnetic resonanceSaddle coilHelmholtz coil

The subject invention pertains to a method and apparatus utilizing one or more spiral coils, such as spiral birdcage coils, spiral saddle coils, Helmholtz coil pairs, and other spiral volume and spiral surface coils. The spiral coils of the subject array can be substantially isolated from each other while covering nearly the same volume or surface. For cylindrical geometrics, isolation can be enhanced by having the rotation, or change in direction from one end of the coil to the other, be 2nπ, where n is an integer.

Owner:INVIVO CORP

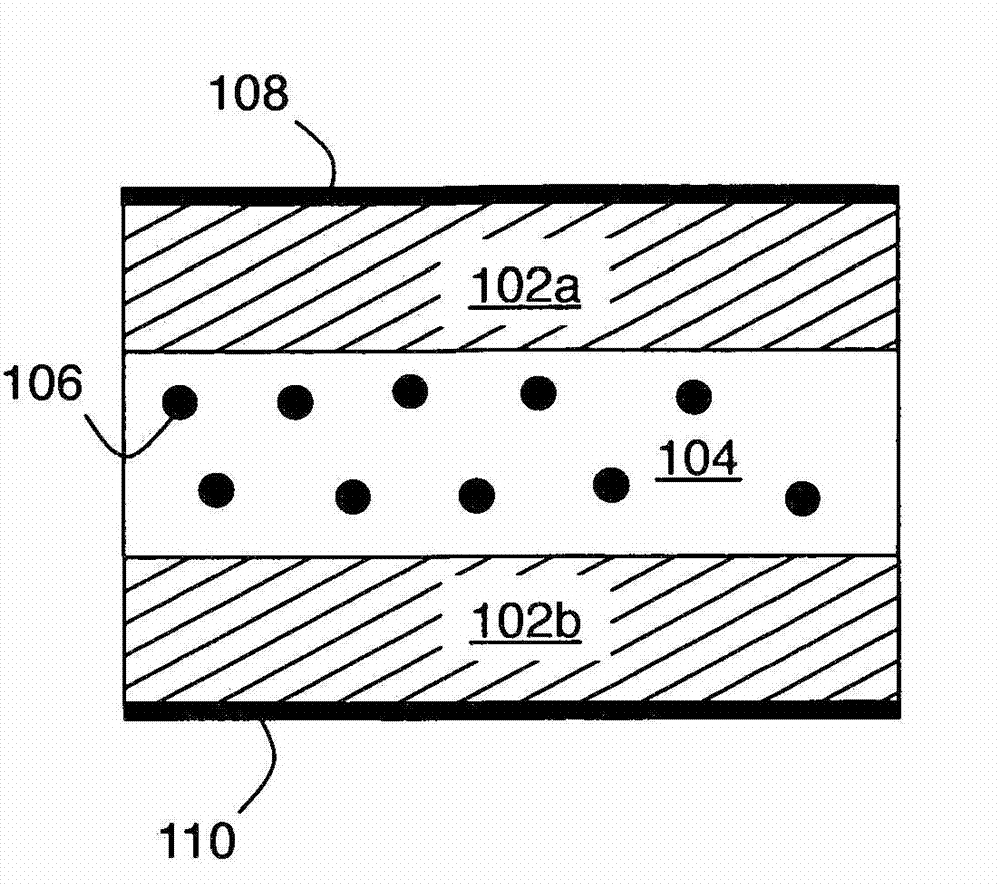

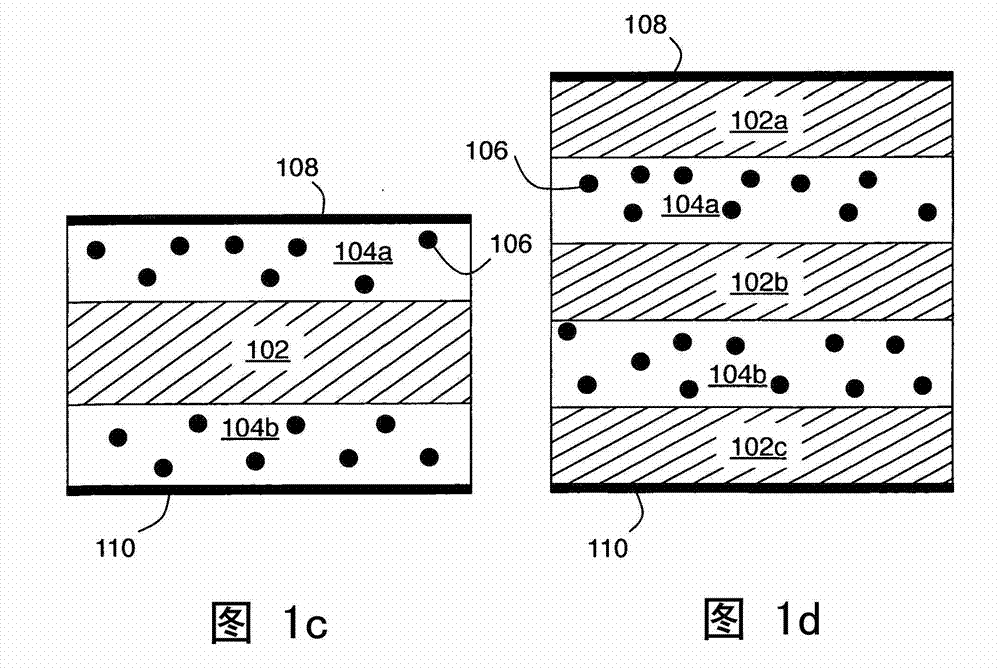

High energy storage capacitor by embedding tunneling nano-structures

InactiveCN102959658AHigh energy density storageHigh Power Density StorageHybrid capacitor separatorsThin/thick film capacitorNano structuringHigh energy

In an All-Electron Battery (AEB), inclusions embedded in an active region between two electrodes of a capacitor provide enhanced energy storage. Electrons can tunnel to / from and / or between the inclusions, thereby increasing the charge storage density relative to. a conventional capacitor. One or more barrier layers is present in an AEB to block DC current flow through the device. The AEB effect can be enhanced by using multi-layer active regions having inclusion layers with the inclusions separated by spacer layers that don't have the inclusions. The use of cylindrical geometry or wrap around electrodes and / or barrier layers in a planar geometry can enhance the basic AEB effect. Other physical effects that can be employed in connection with the AEB effect are excited state energy storage, and formation of a Bose-Einstein condensate (BEC).

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

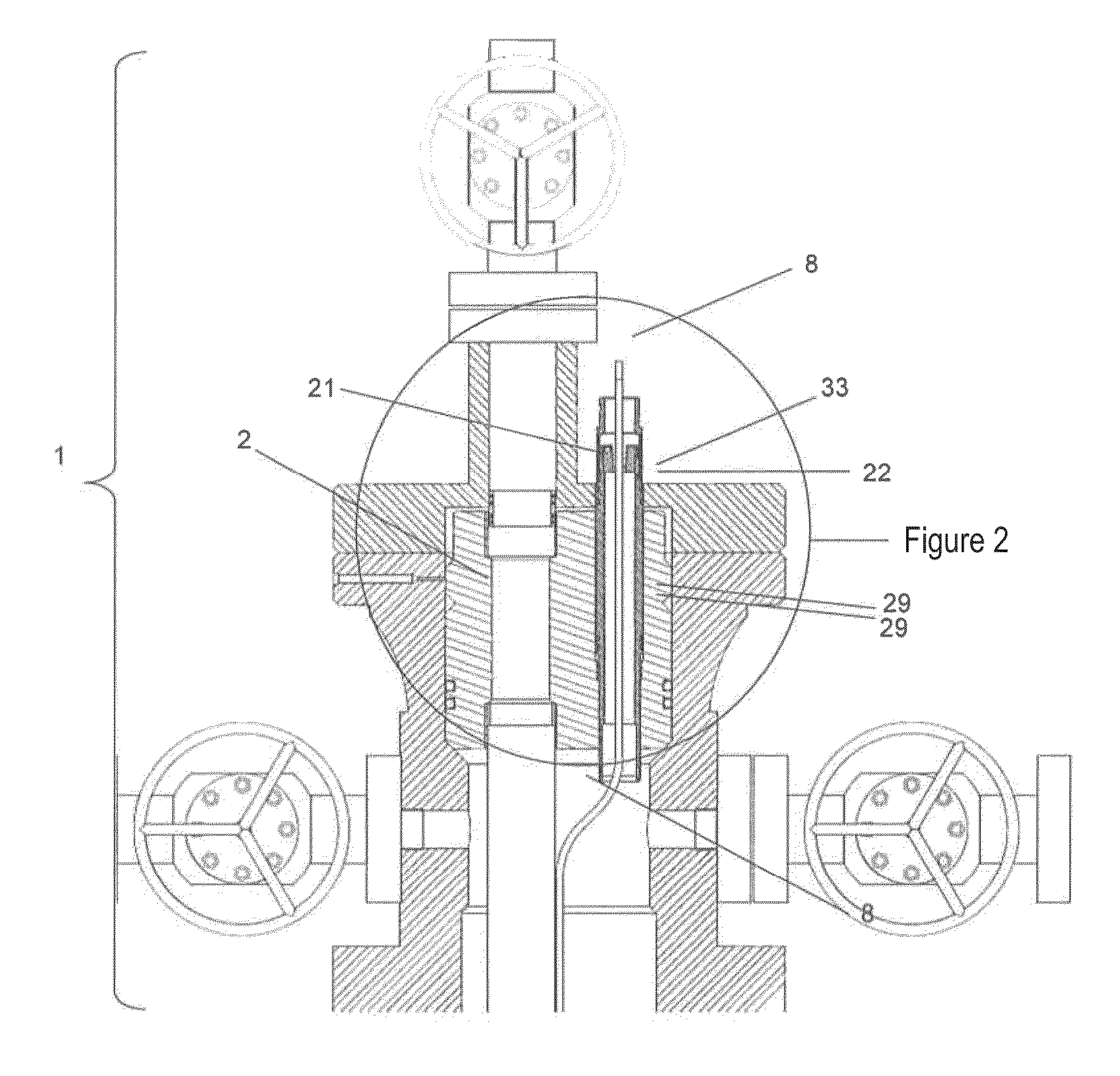

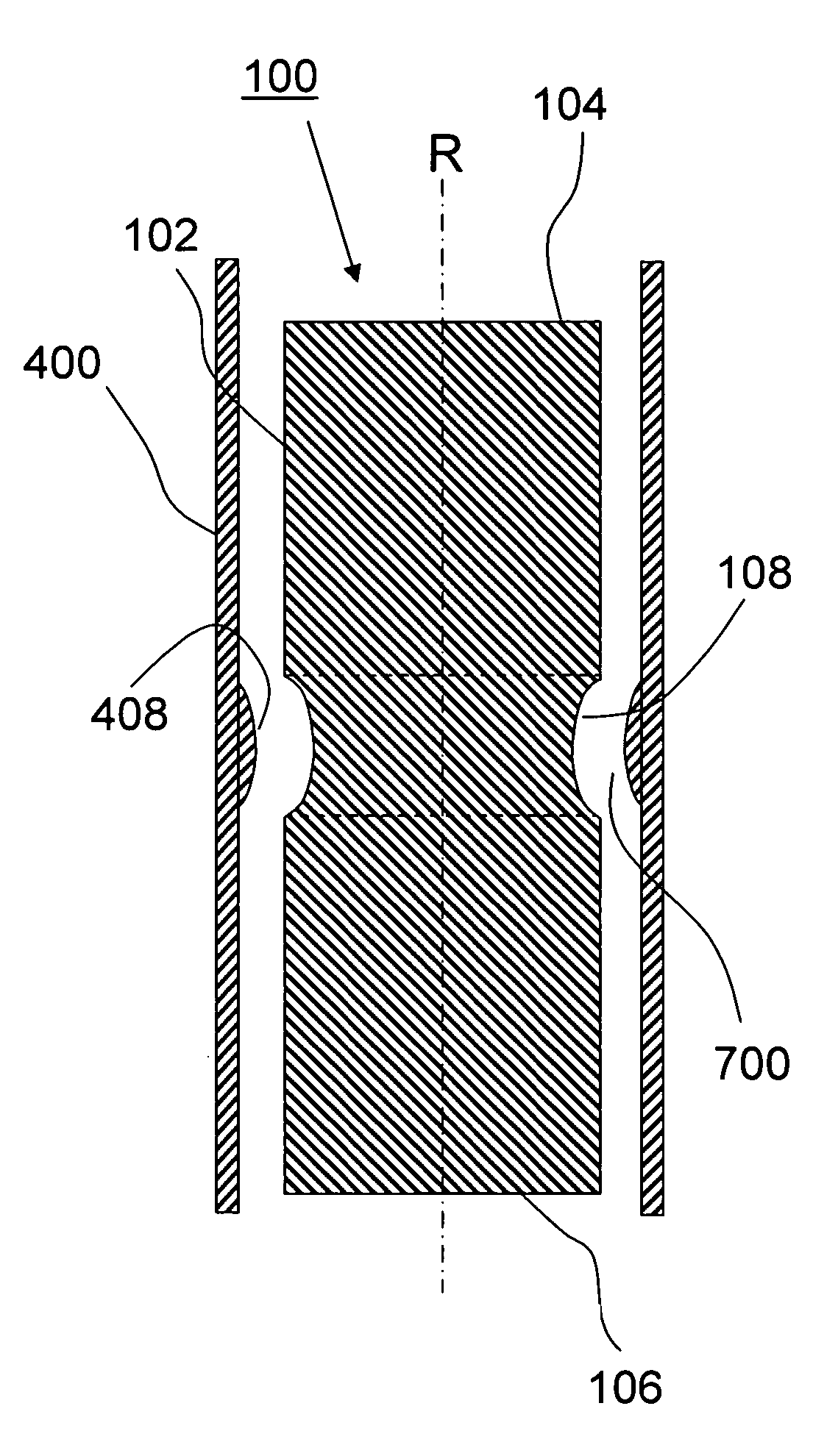

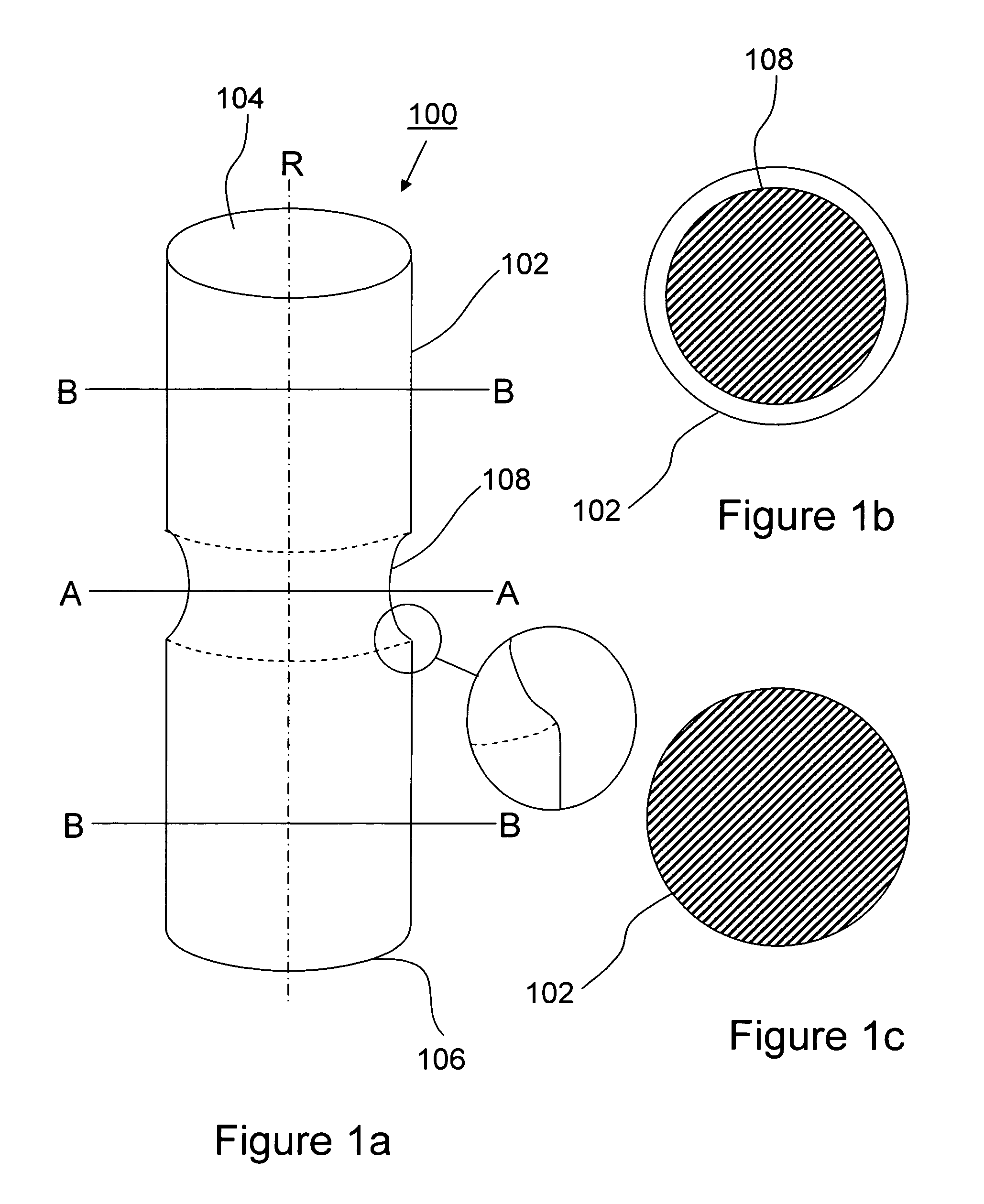

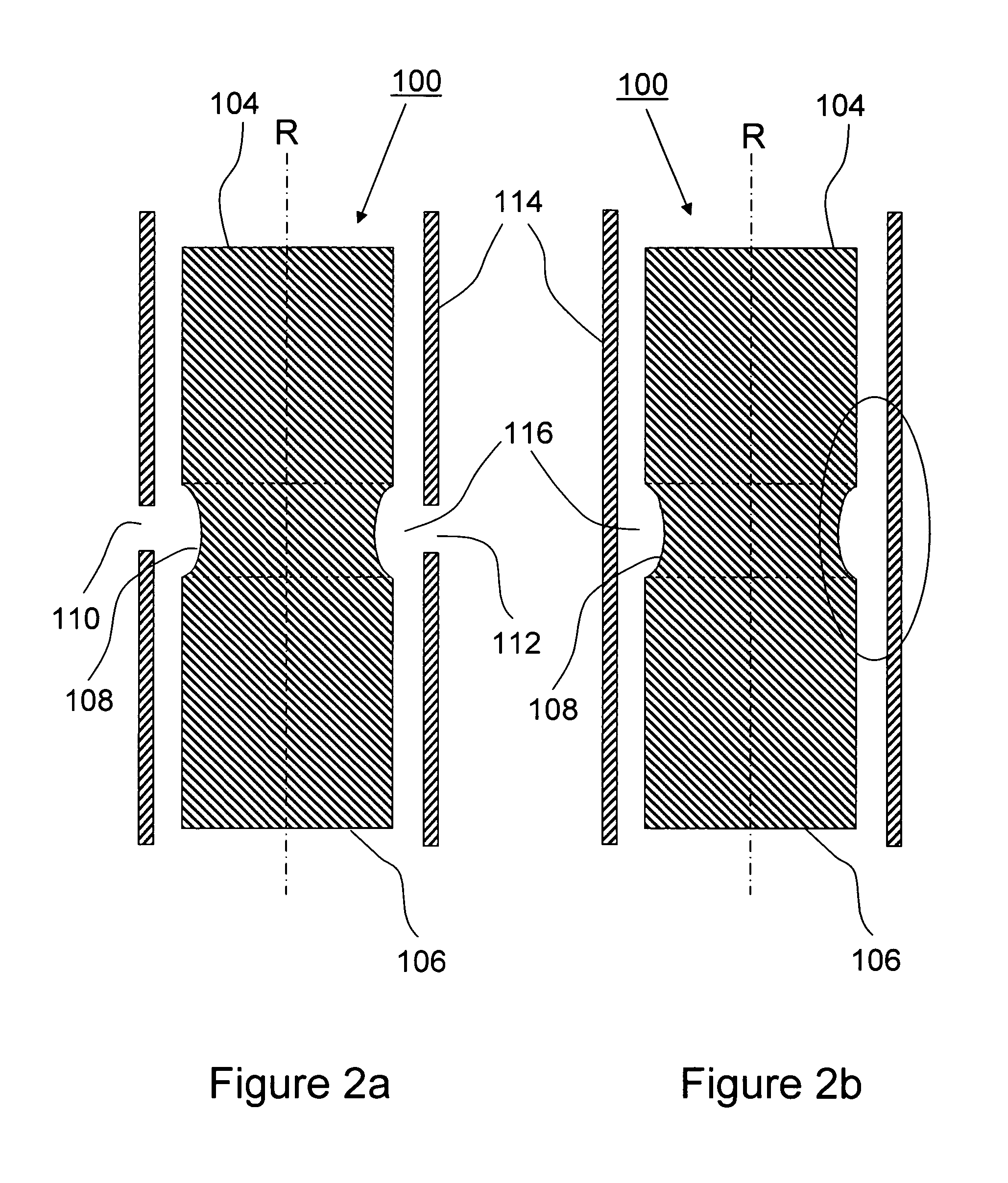

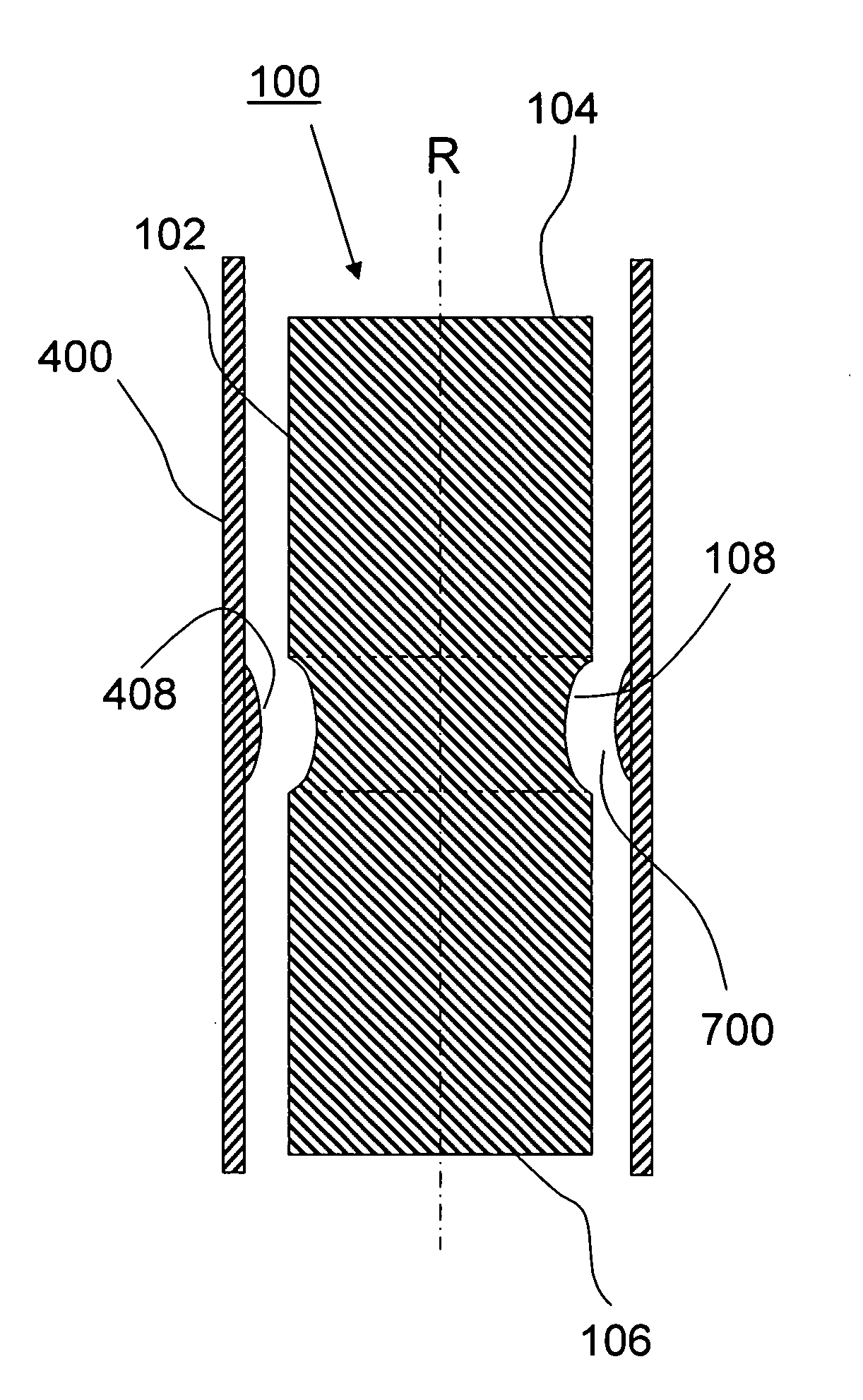

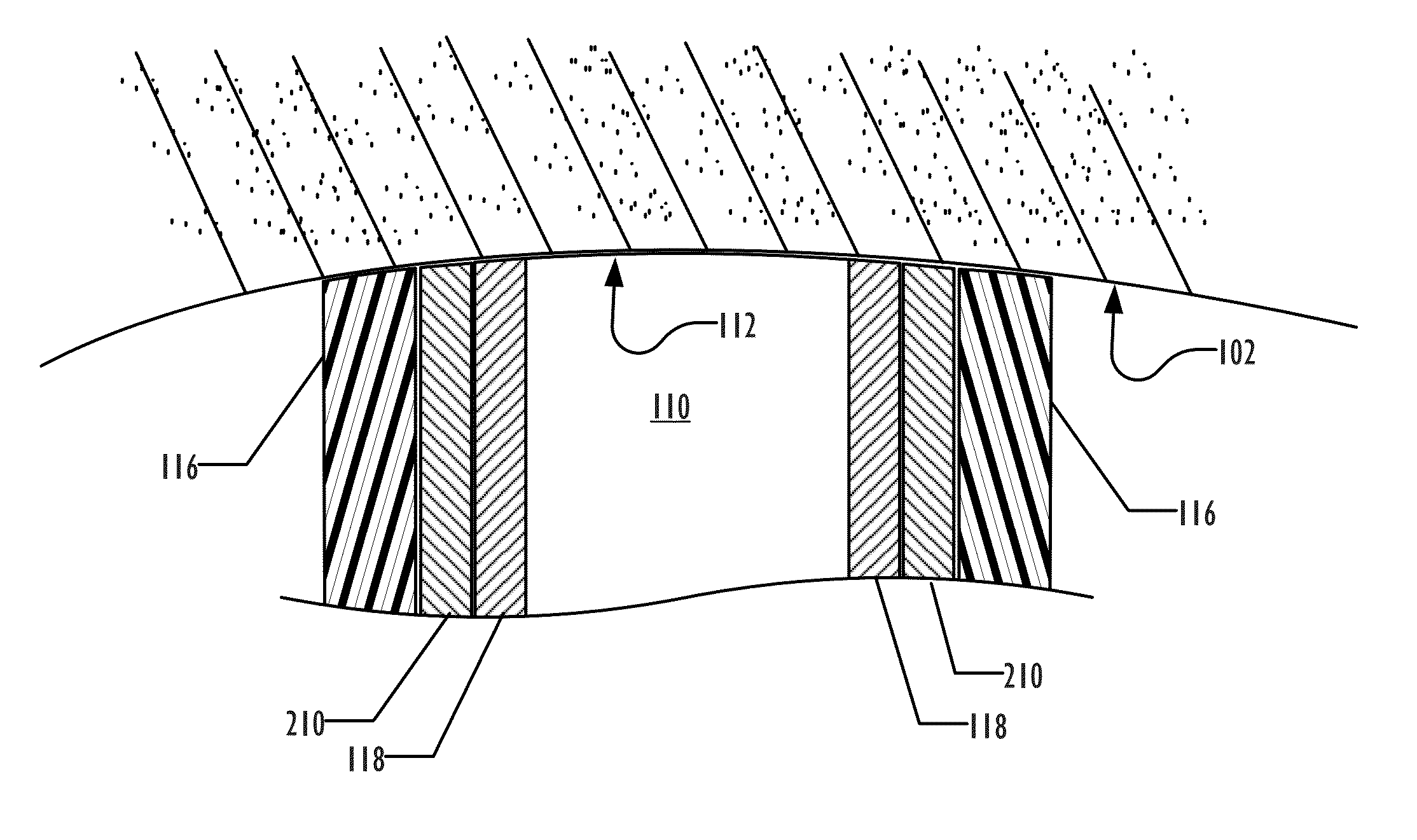

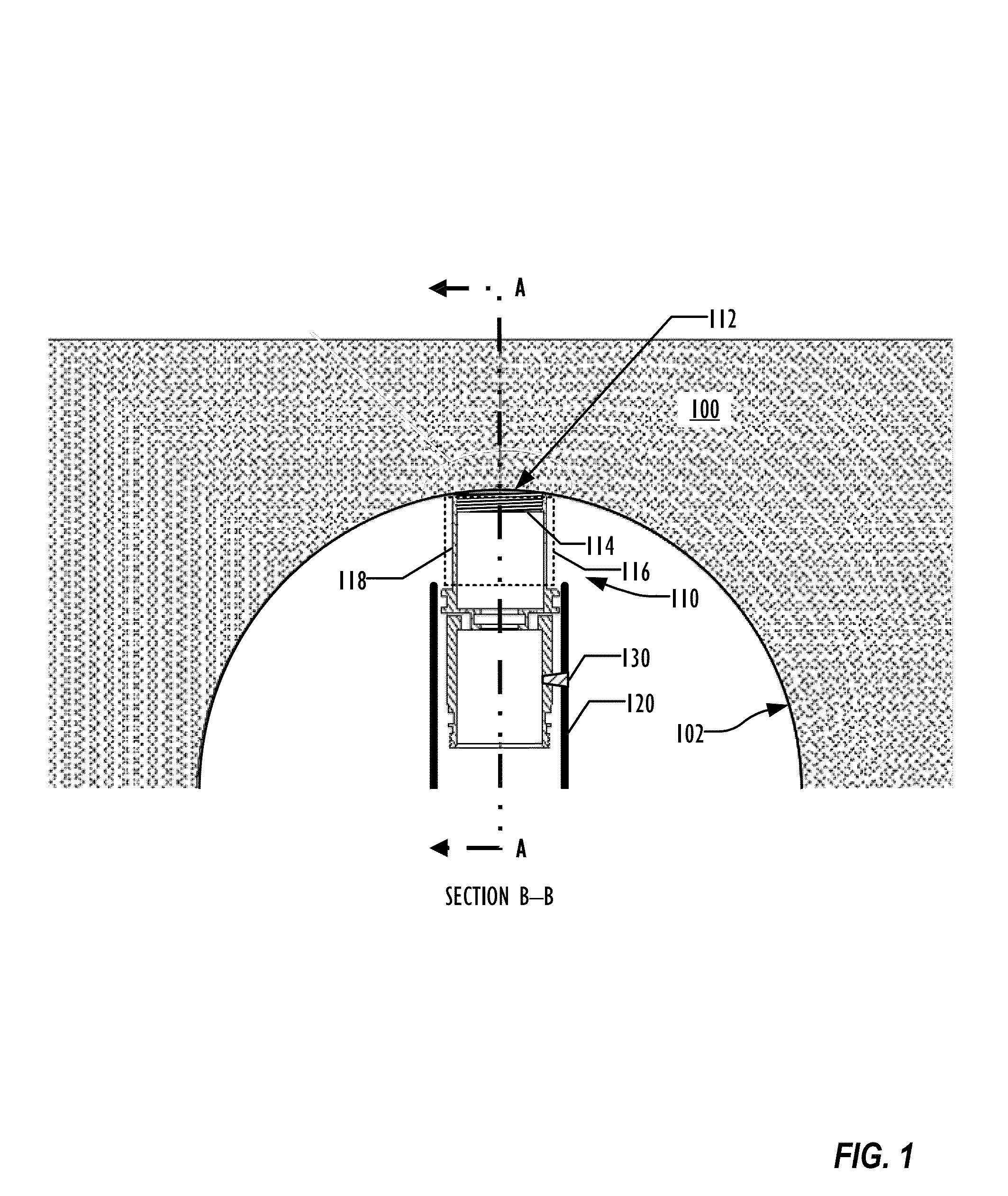

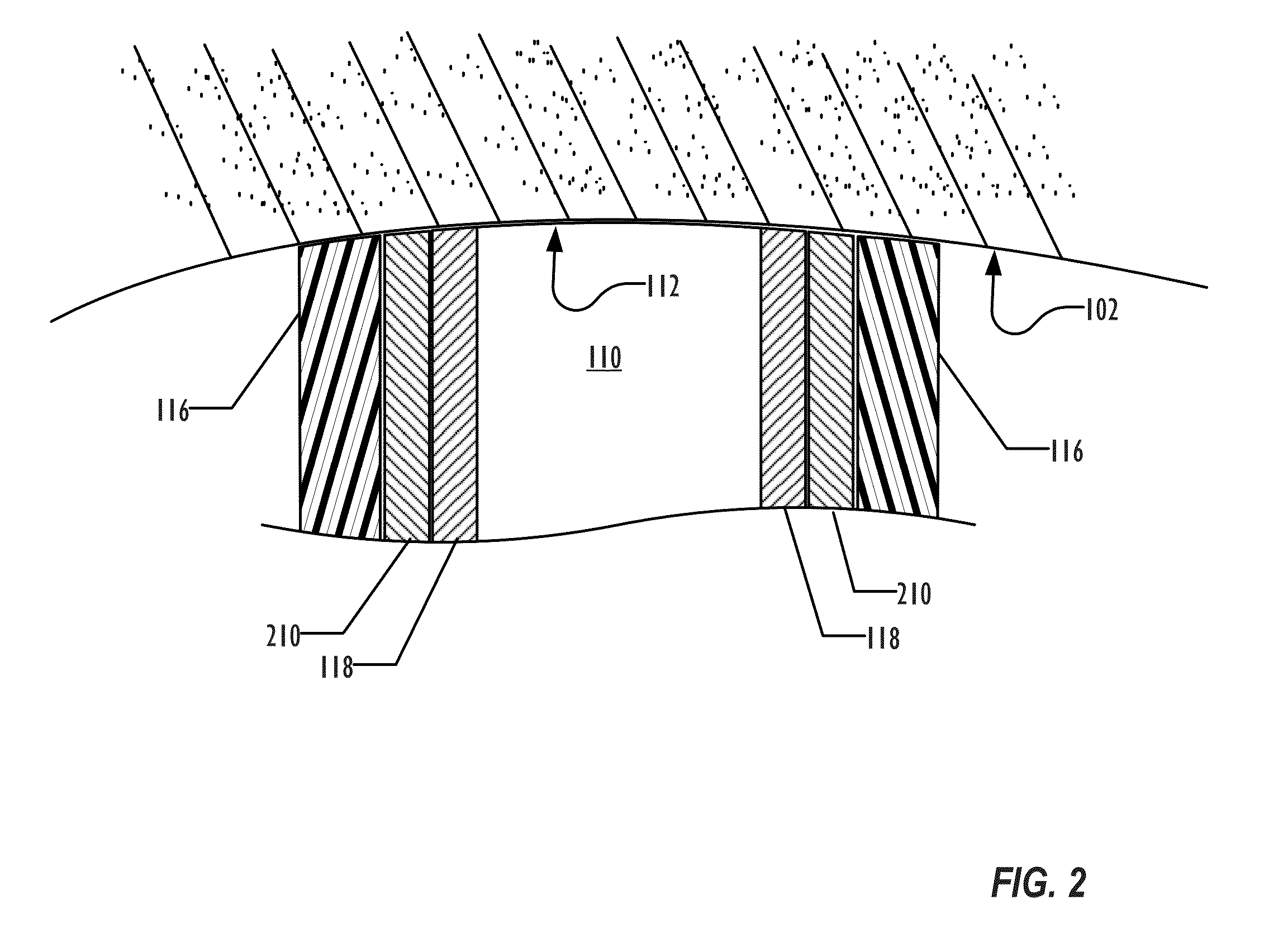

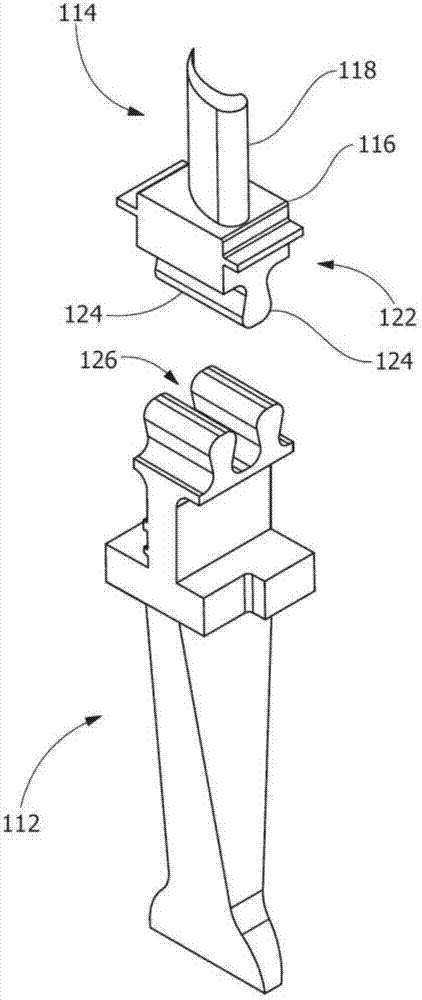

Cylindrical shaped snorkel interface on evaluation probe

A snorkel and pad for use with a formation testing tool is formed with a cylindrical geometry at the interface where the snorkel and pad contacts the inner surface of a borehole. The cylindrical geometry reduces or eliminates gaps that a flat interface surface would leave between the snorkel and the inner surface of the borehole, reducing the possibility that a surrounding pad could extrude through the gap. The snorkel is prevented from rotating during operation, ensuring the correct orientation of the cylindrical geometry interface surface relative to the inner surface of the borehole. The snorkel may be used as part of a formation testing system.

Owner:WEATHERFORD TECH HLDG LLC

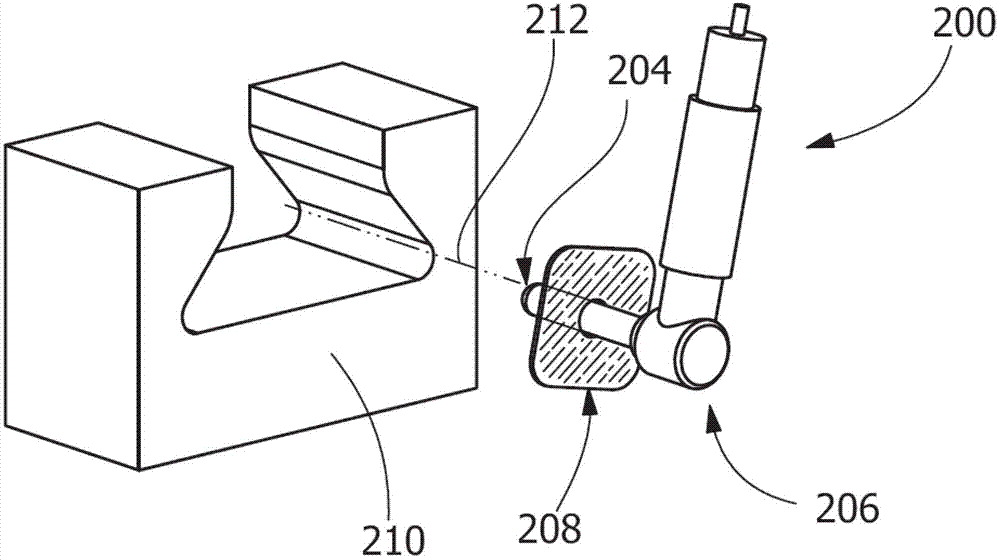

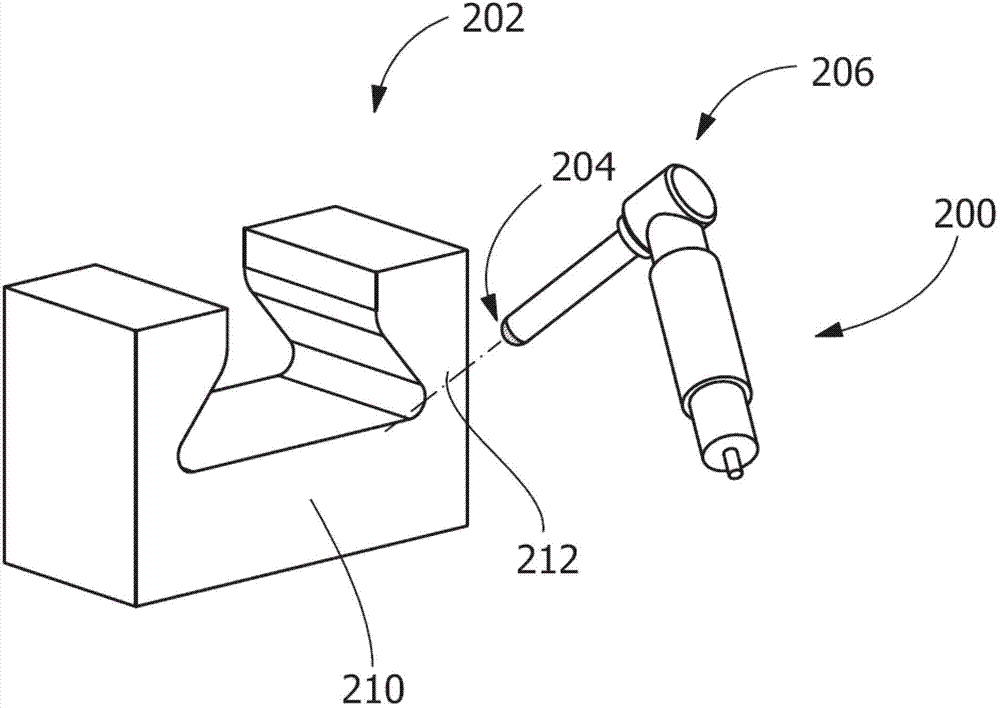

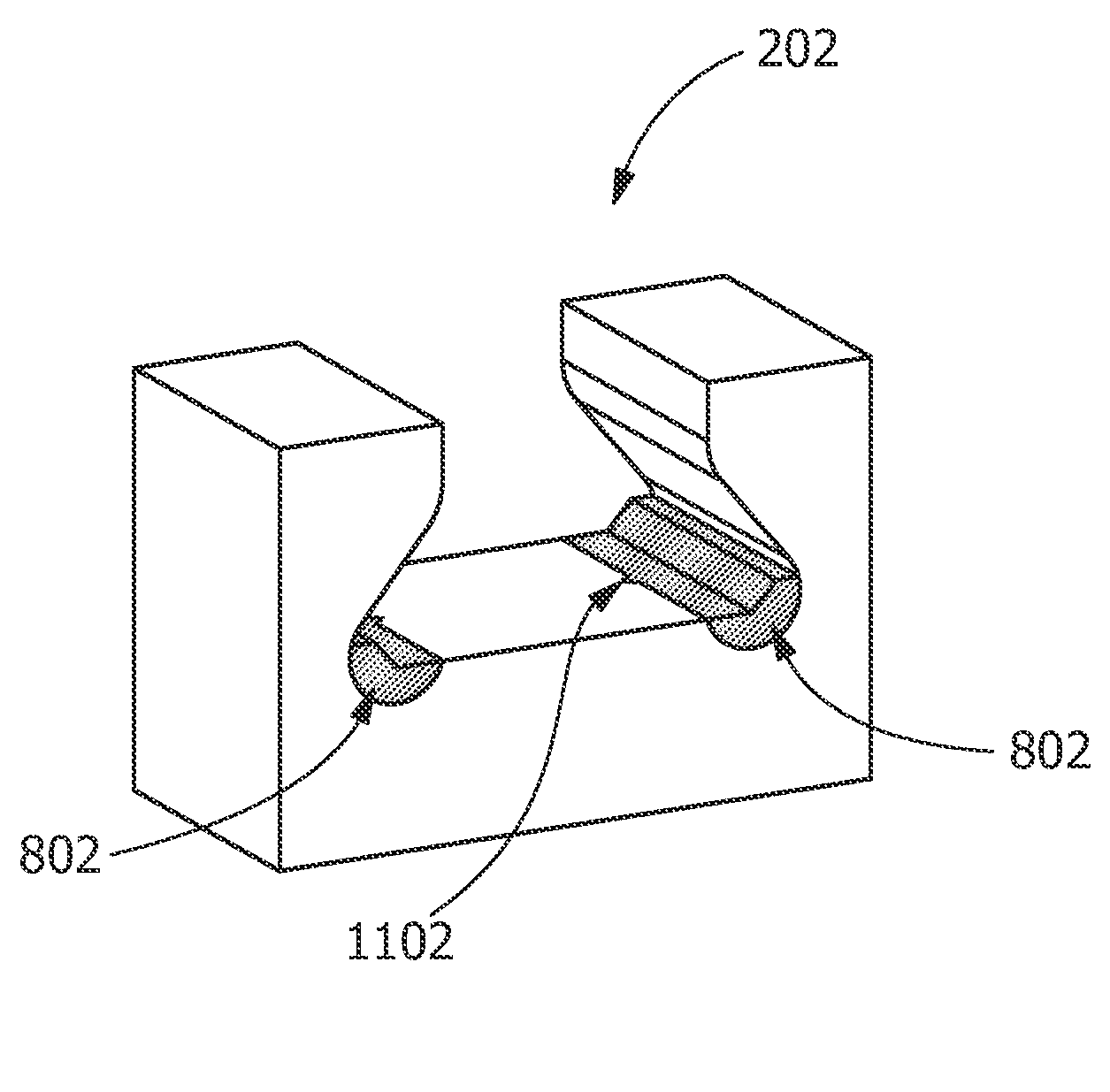

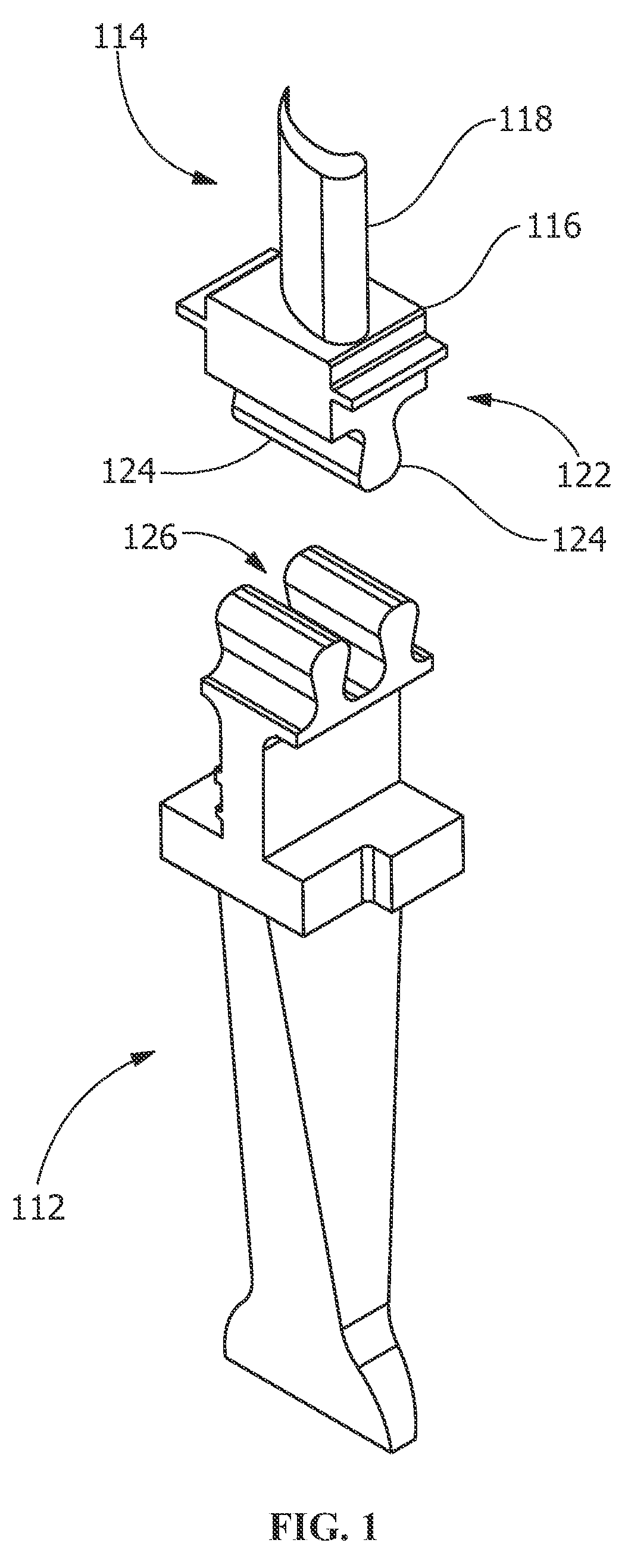

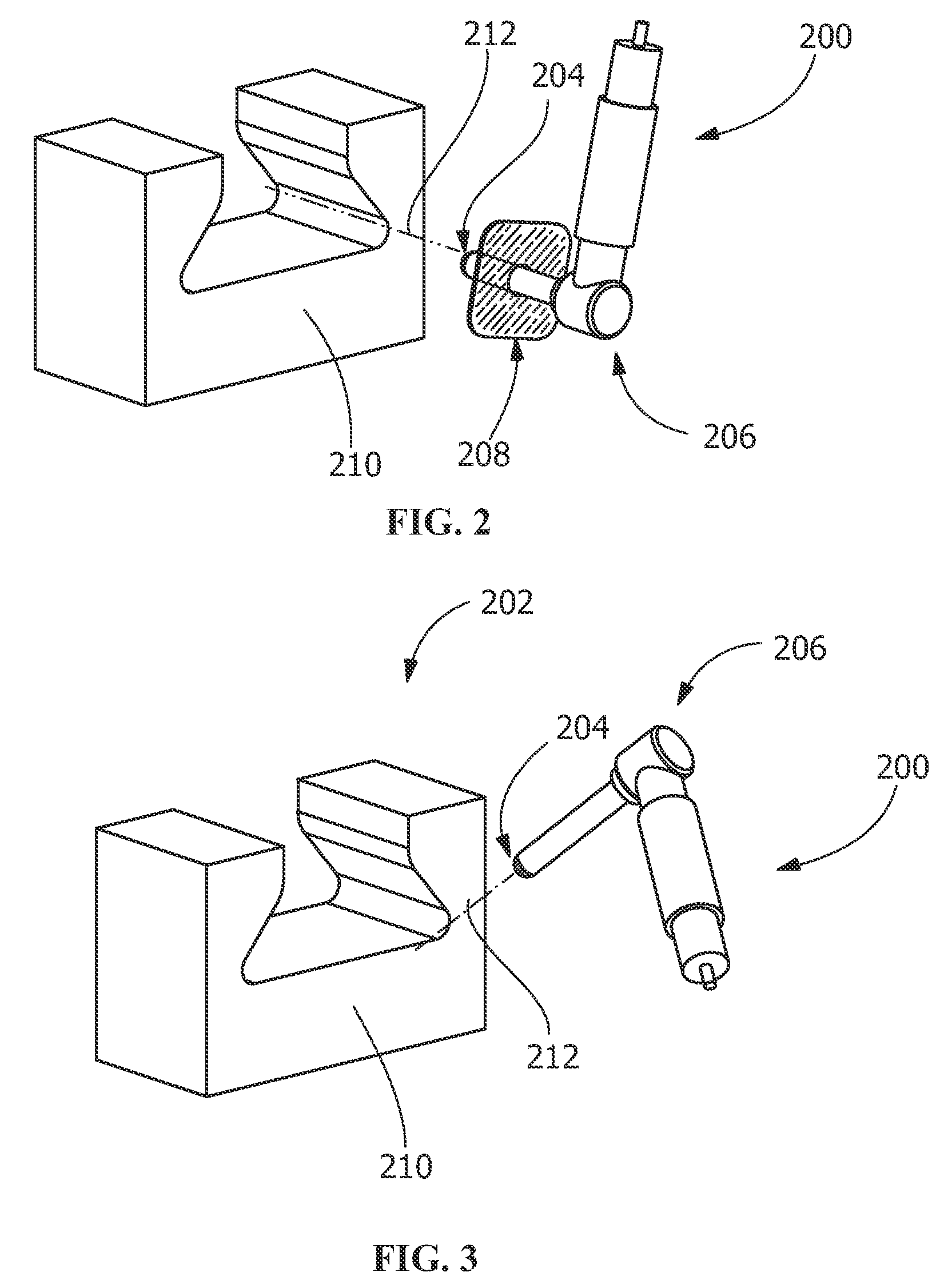

Process of repairing a component, a repair tool for a component, and a component

A process of repairing a component, a repair tool for a component, and a component are disclosed. The process includes removing material from a region of the component. The removing forms a through-cut in the component, forms a substantially partial-frustoconical geometry in the component, forms a substantially partial-spherical geometry in the component, forms a substantially partial-elliptical geometry in the component, forms a substantially partial-cylindrical geometry in the component, is in a direction substantially perpendicular to a surface of the component, is in a direction substantially inclined with respect to the surface of the component, or a combination thereof. The repair tool includes a securing mechanism and a cutting portion for removing a region. The component includes a region formed by removing material.

Owner:GENERAL ELECTRIC TECH GMBH

Process of repairing a component, a repair tool for a component, and a component

A process of repairing a component, a repair tool for a component, and a component are disclosed. The process includes removing material from a region of the component. The removing forms a through-cut in the component, forms a partial-frustoconical geometry in the component, forms a substantially partial-frustoconical geometry in the component, forms a partial-spherical geometry in the component, forms a substantially partial-spherical geometry in the component, forms a partial-elliptical geometry in the component, forms a substantially partial-elliptical geometry in the component, forms a partial-cylindrical geometry in the component, forms a substantially partial-cylindrical geometry in the component, is in a direction substantially perpendicular to a surface of the component, is in a direction substantially inclined with respect to the surface of the component, or a combination thereof. The repair tool includes a securing mechanism and a cutting portion for removing a region. The component includes a region formed by removing material.

Owner:GENERAL ELECTRIC CO

Method for the production of tubes for heat exchangers from precipitation-hardened alloys by high-frequency induction welding

InactiveUS20080060722A1Simple and inexpensive to implementExcellent mechanical propertiesFurnace typesHigh frequency current welding apparatusIngotCylindrical geometry

Described herein is an embodiment of a method for the production of tubes for heat exchangers, including the steps of: a) producing an ingot with rectangular cross section (plate) b) hot-rolling said plate so as to form a blank c) rapidly cooling said blank by spraying water inside a purposely designed cooling tunnel d) cold-rolling said blank until a strip or skelp is obtained e) forming the tube starting from the skelp to pass from the plane geometry of the skelp to the cylindrical geometry of the tube and welding the tube; in which the ingot is formed starting from an alloy that can undergo precipitation hardening, and the tube is welded by high-frequency induction welding.

Owner:KME ITAL

Molten salt solar receiver and procedure to reduce the temperature gradient in said receiver

ActiveUS9182149B2Easy to controlReduce the differenceSolar heating energySolar heat devicesMolten saltEngineering

Owner:ABENGOA SOLAR NEW TECH SA

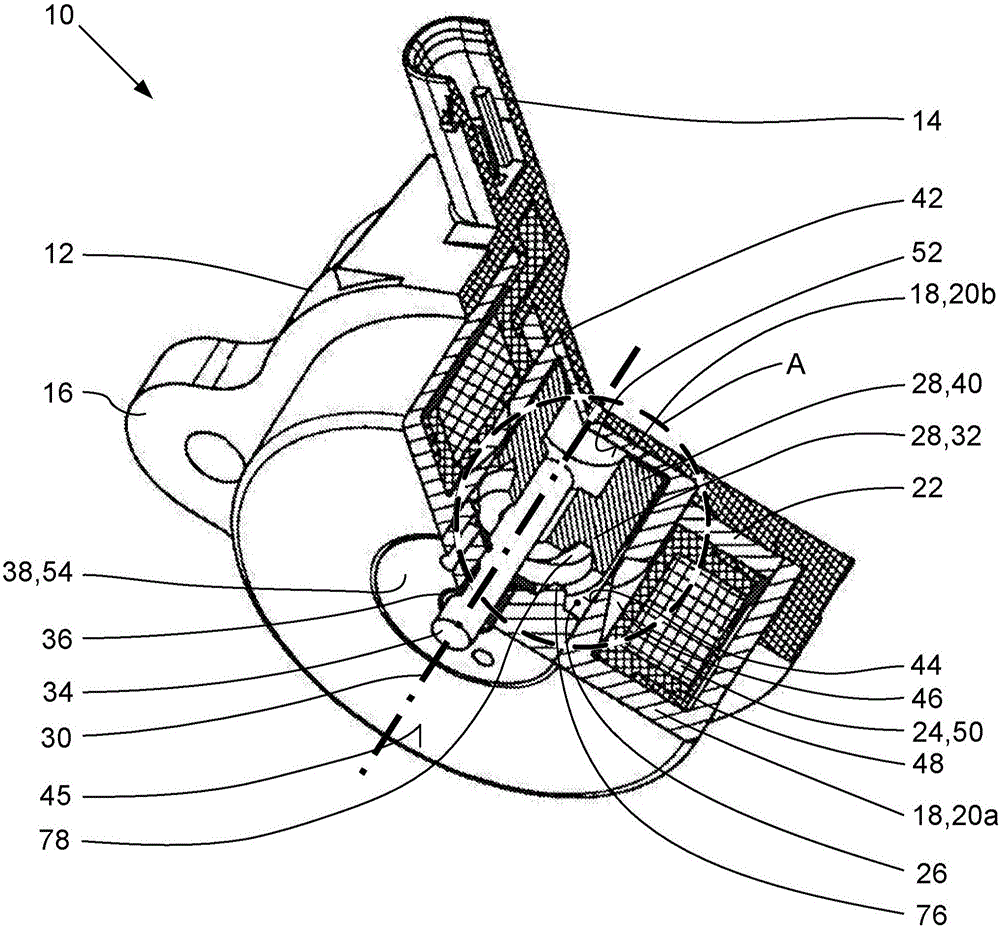

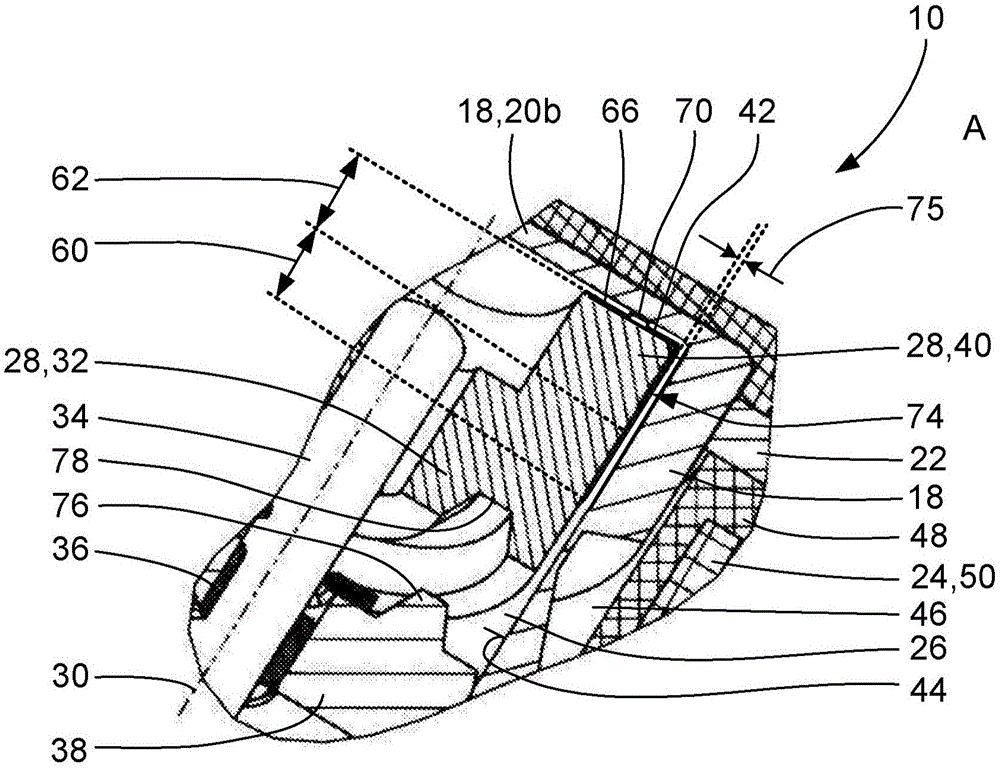

Electromagnetic actuating device

ActiveCN106461110APrevent adhesionSimple structureOperating means/releasing devices for valvesCores/yokesElectricityManufacturing technology

The invention relates to an electromagnetic actuating device (10) for a valve, having an armature (28) which is arranged in a hollow cylindrical armature chamber (28) so as to be axially displaceable between two axial stops (52, 54), wherein the armature chamber (26) is delimited by a magnet yoke (18; 22), wherein an electrical coil (24) extends coaxially around the armature (28), and wherein the magnet yoke (18, 22) is at least partially arranged in a housing (12). According to the invention, the actuating device (10) is characterized in that the armature (28) has a cylindrical geometry with a base (32) remote from the housing and with a hollow cylindrical end section (40) situated axially opposite, in that the base (32), which is remote from the housing, of the armature (28) is connected to an actuating plunger (34), in that a guide sleeve (42) is mounted axially onto the hollow cylindrical end section (40) of the armature (23), and in that, on that end of the guide sleeve (42) which is remote from the actuating plunger, there is arranged or formed an adhesion prevention device (84) which prevents or at least greatly impedes axial adhesion of the armature (28) to the magnet yoke (18, 22). The guide sleeve (42), which can be produced with very high accuracy in terms of manufacturing, with integrated adhesion prevention device (84) makes it possible to realize a reduction in width of the parasitic air gap between the armature (28) and the magnet yoke in order to increase the actuation forces of the actuating device (10) with a simultaneously reduced number of components.

Owner:SCHAEFFLER TECH AG & CO KG

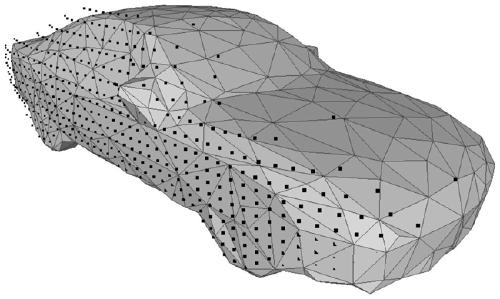

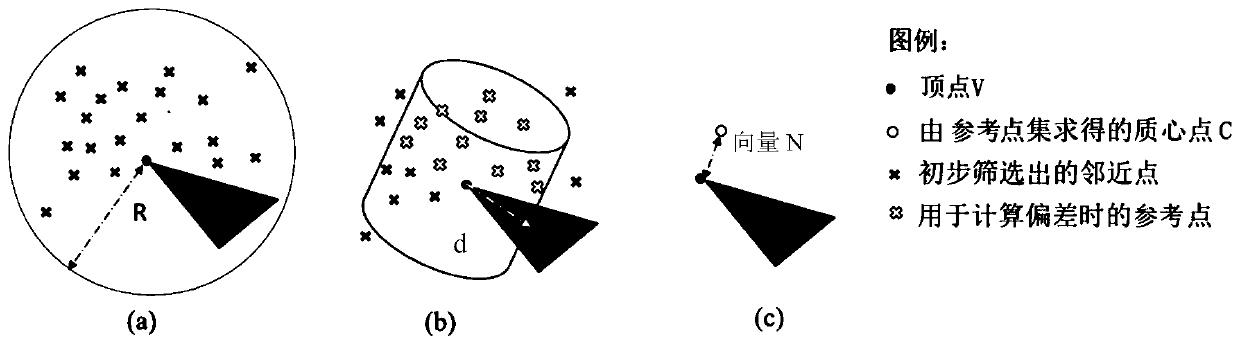

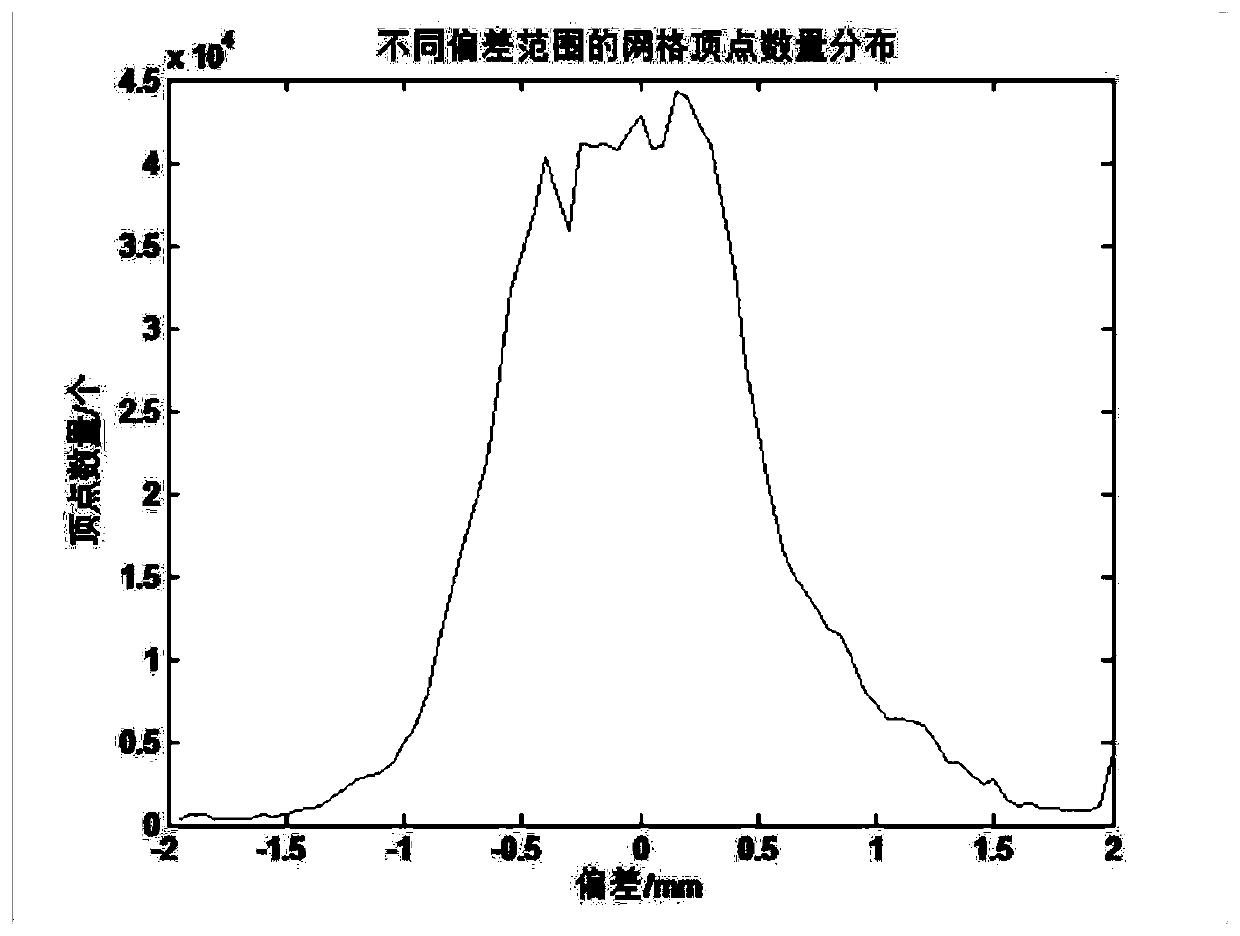

Point cloud error calculation method

The invention discloses a point cloud error calculation method, which processes an actually tested point cloud and a theoretical grid curved surface, comprising the following steps: searching an adjacent point set of a vertex V through employing a nearest neighbor search method; calculating the Euclidean distance between the vertex V and the centroid of the first graphic patch; constructing a cylindrical search space by taking the vertex V as a cylindrical geometric center; traversing each point in the adjacent point set, screening out each reference point from the adjacent point set, and storing the reference points as a reference point set; solving a centroid C of the reference point set, and recording a directed distance L between the centroid C and the vertex V as a point cloud error;and traversing each vertex V in the theoretical grid curved surface to obtain a point cloud error between a reference point set corresponding to each vertex V and the theoretical grid curved surface.The point cloud error calculation method can quantify the error between the actually tested point cloud and the theoretical grid curved surface of the object to be measured, and can be used for evaluating the quality of actually tested point cloud data.

Owner:易思维(杭州)科技有限公司

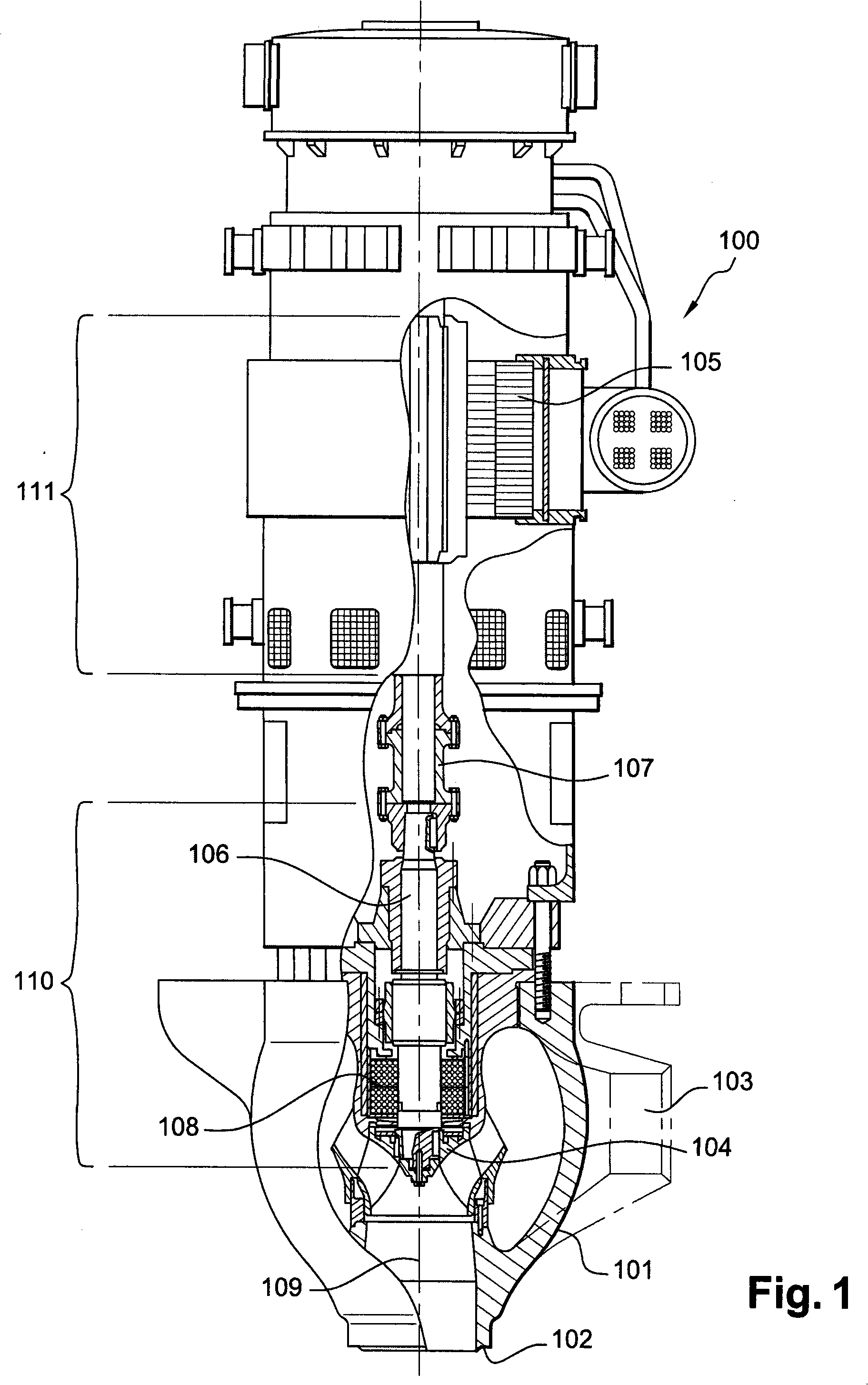

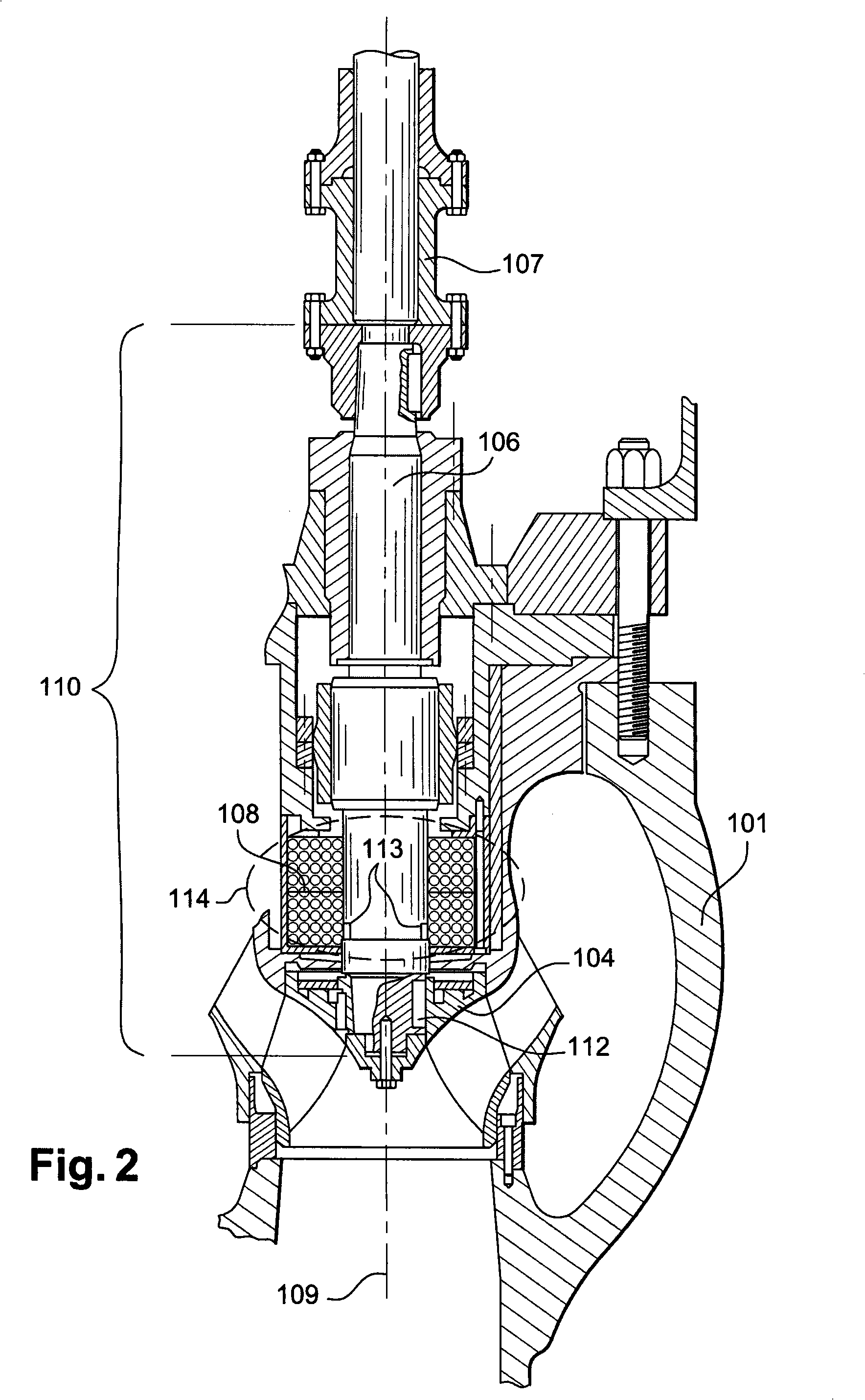

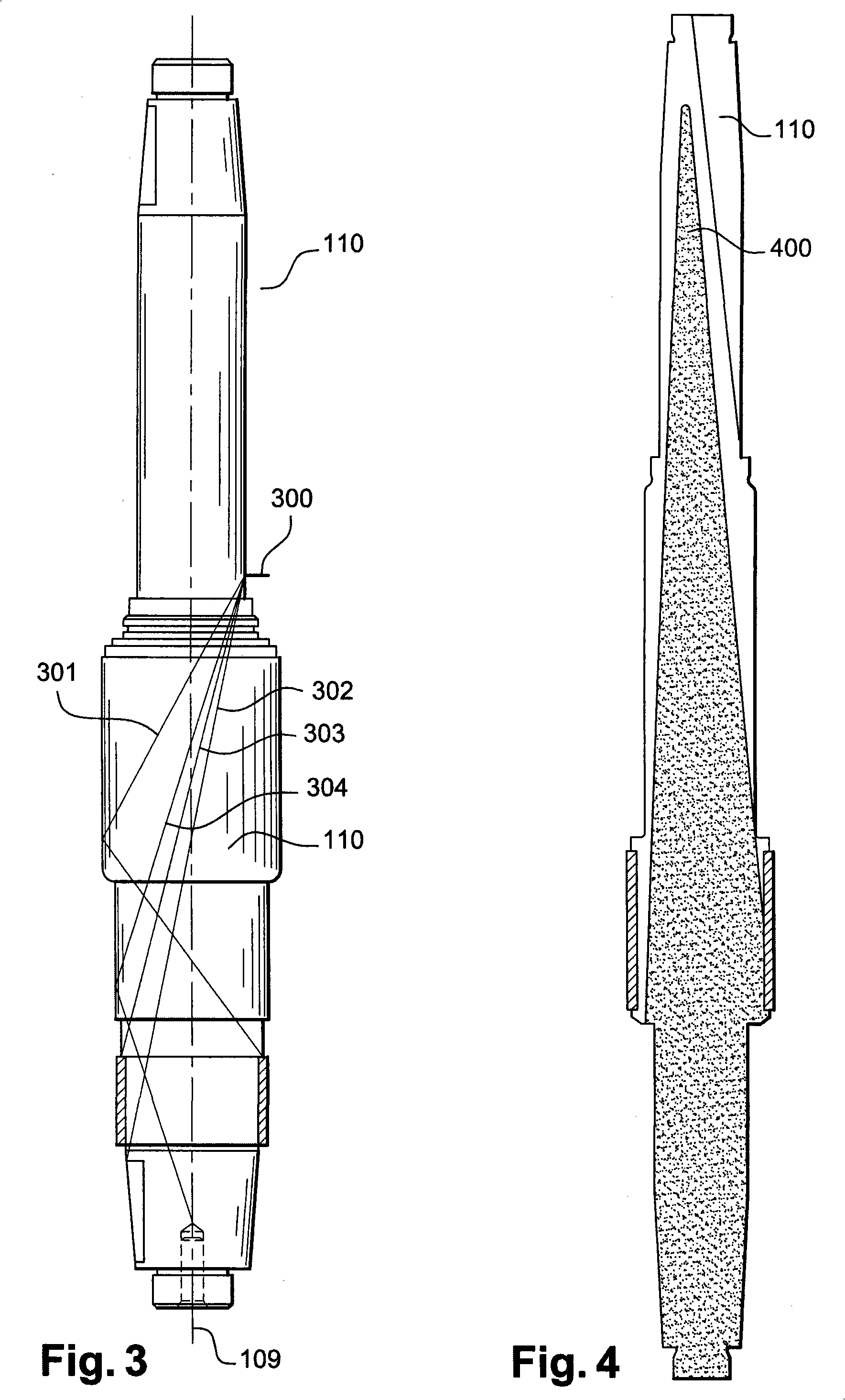

Method for inspecting the state of a rotating machine drive shaft

InactiveCN101322028AAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationIndependent elementDrive shaft

The invention relates to a method for non-distructive testing of a drive shaft (110), which is accessible from one end thereof, by means of an annular ultrasonic multi- element longitudinal wave transducer (900;1000) comprising independent elements excitable by equifrequent electric pulses for which the inventive method consists in applying different electronic phase shiftings to the pulses transmitted thereto. Said electronic phase shifting makes it possible to focus or deviate a final beam which is synthesised by the totality of elements forming the transducer and to concentrate said final beam in such a way that a generally cylindrical cross-section thereof substantially smaller than the testable shaft cross-section is adopted and is highly energetic at a long distance by a wave guide action produced by the cylindrical shape of the shaft.

Owner:FRAMATOME ANP

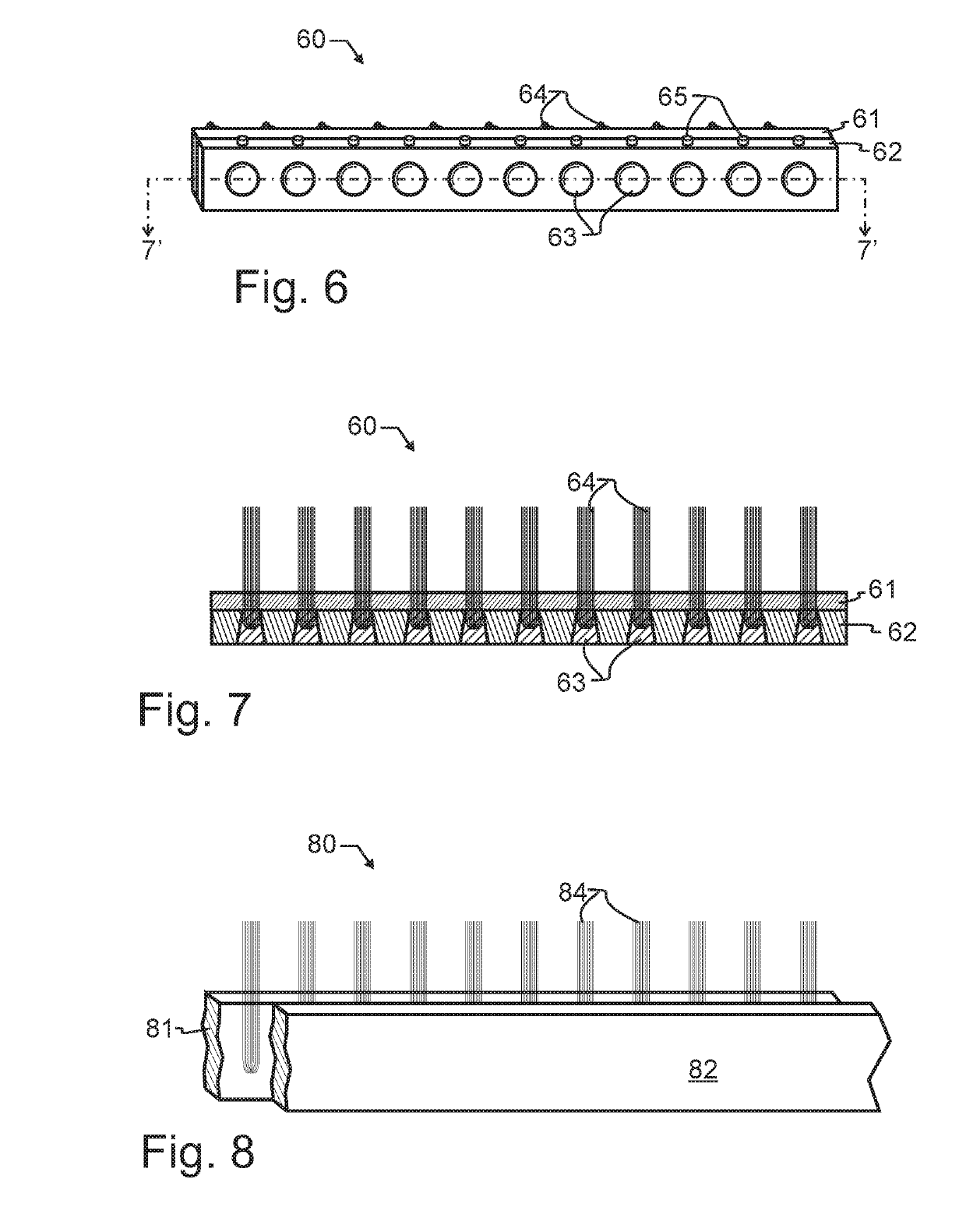

Infinity brush

ActiveUS10251472B1Enhance brushingImprove cleaning experienceGum massageCarpet cleanersBristleEngineering

An infinity brush has a flaccid belt configured to define a lemniscate. A plurality of work-contacting segments protrude from and are carried by the flaccid belt. A mechanical drive rotates the flaccid belt. Various embodiments of the flaccid belt include a single lemniscate, a plurality of lemniscates, and various simulated lemniscates. In one embodiment, the infinity brush bristle includes non-cylindrical brush bristles with a longitudinal shaft having at least one diameter transition, while other bristles comprise beads of various oval, circular, and cylindrical geometries.

Owner:HERVIG DANA P

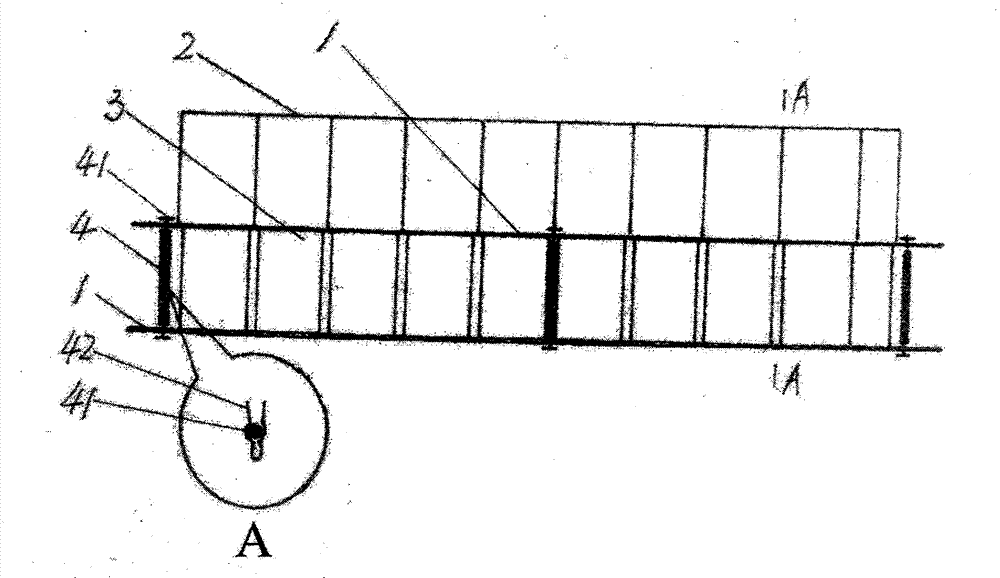

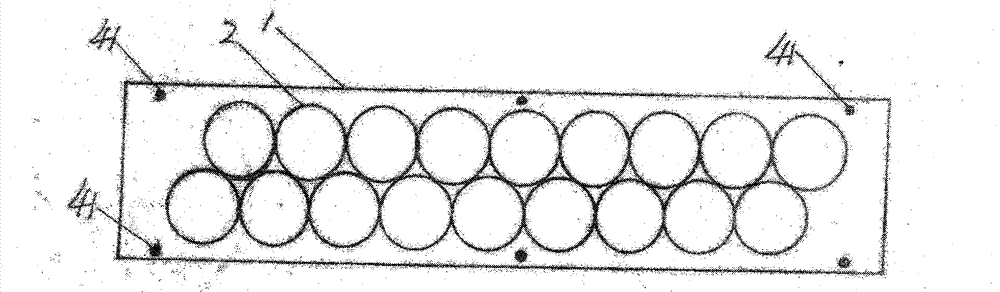

Fast royal jelly extracting equipment consisting of parallel battens and cylindrical geometry bodies

The invention relates to fast royal jelly extracting equipment consisting of parallel battens and cylindrical geometry bodies. The fast royal jelly extracting equipment consists of the battens, a cylindrical royal jelly bowl, a cylindrical royal jelly bowl plug and support screw bolts, wherein the cylindrical royal jelly bowl is connected with one batten, the cylindrical royal jelly bowl plug is connected with the other batten, the cylindrical royal jelly bowl is in bearing insertion connection with the cylindrical royal jelly bowl, and the two battens are parallel and are connected through the support screw bolts. The fast royal jelly extracting equipment has the advantages that the structure is simple, the operation is convenient, the investment is little, the royal jelly taking speed is high, safety and reliability are realized, the cost is low, and the practicability is high.

Owner:曹玉升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com