Patents

Literature

91 results about "Skelp" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Skelp (sometimes spelled scelp) is wrought iron or steel that is rolled or forged into narrow strips and ready to be made into pipe or tubing by being bent (into a cylindrical shape) and welded. The word is most commonly used in the traditional terminology of smithing and in the iron and steel industries. Before the 20th century, the welding was likely to be forge welding. In the 20th and 21st centuries, it has been likelier to be arc welding or gas welding.

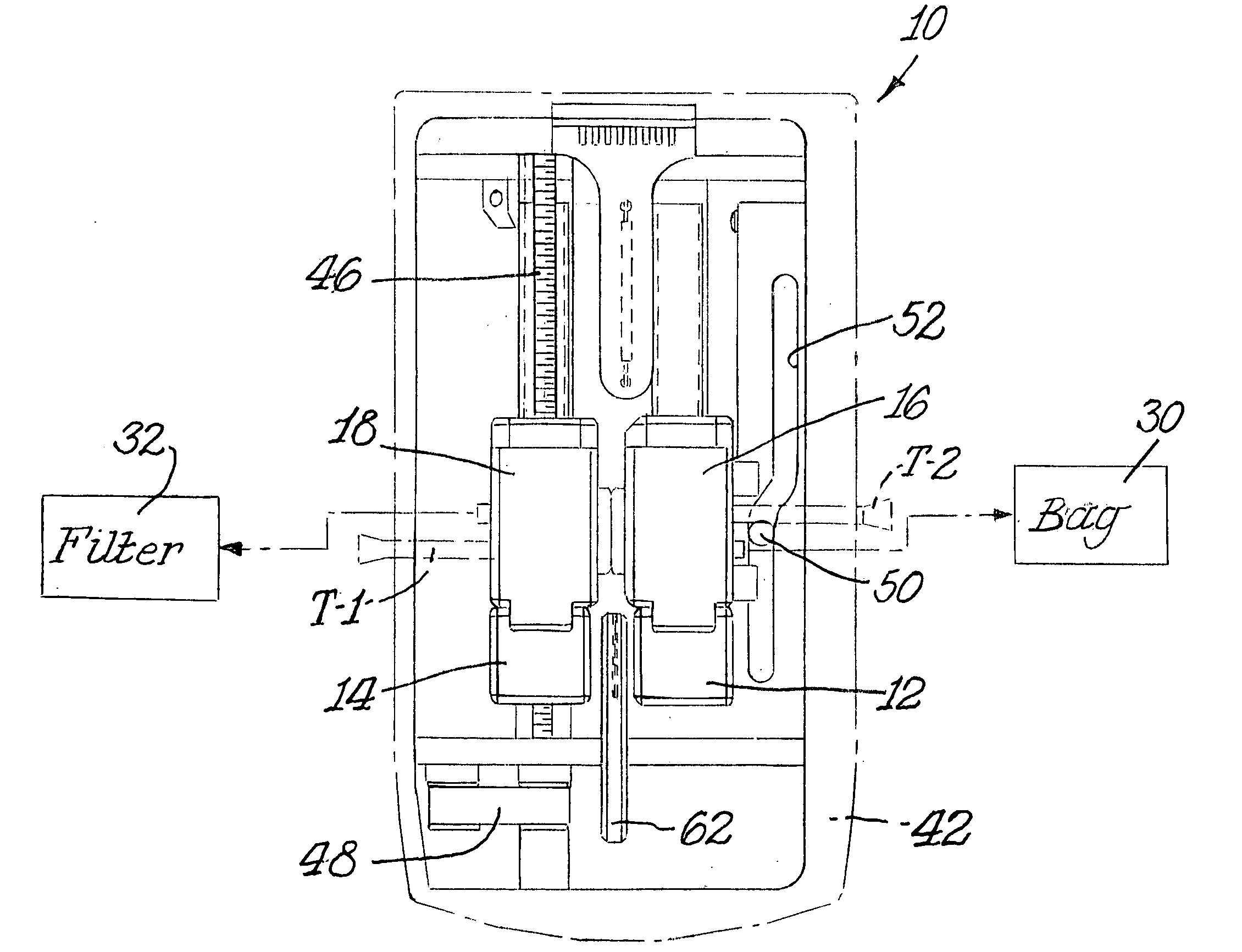

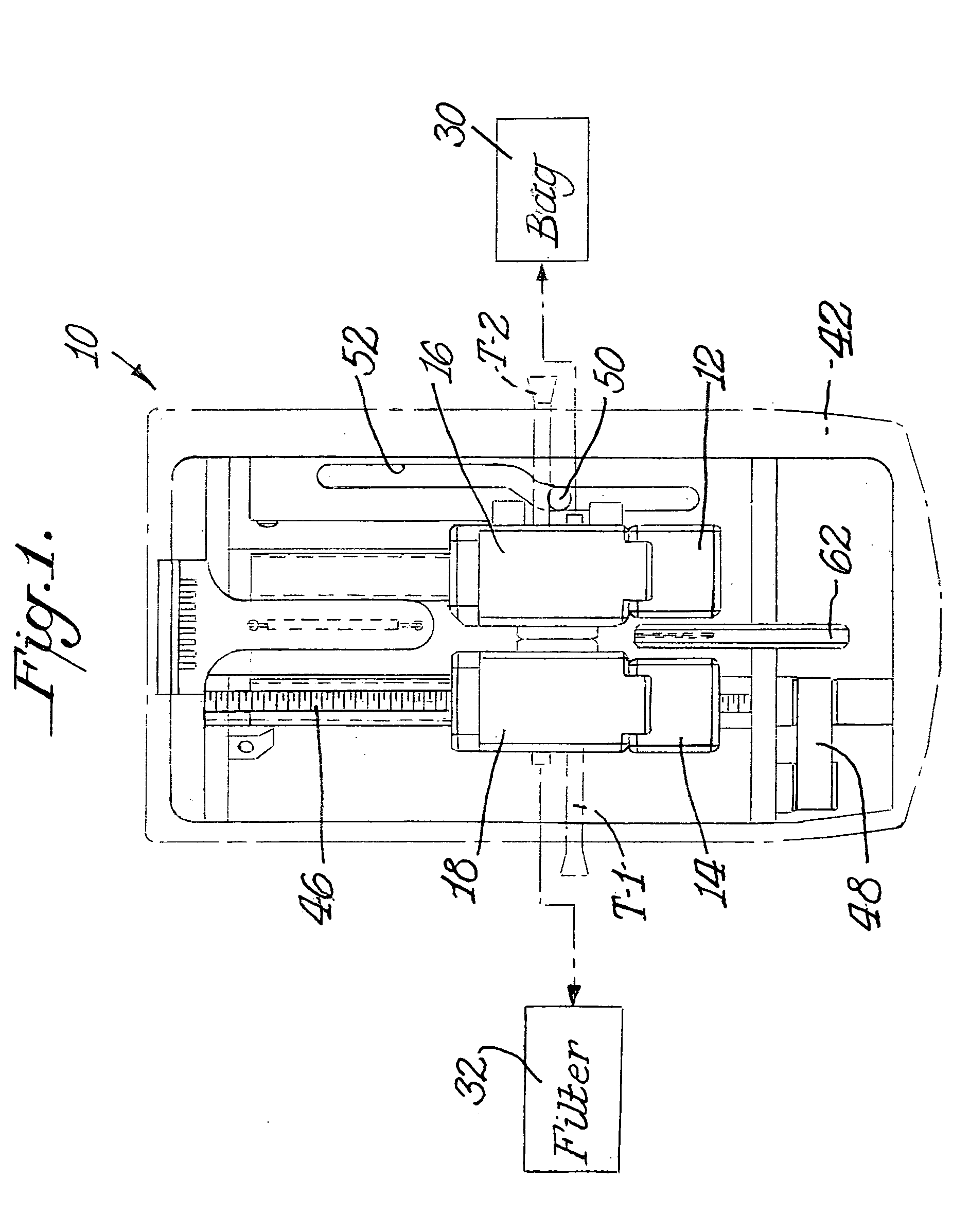

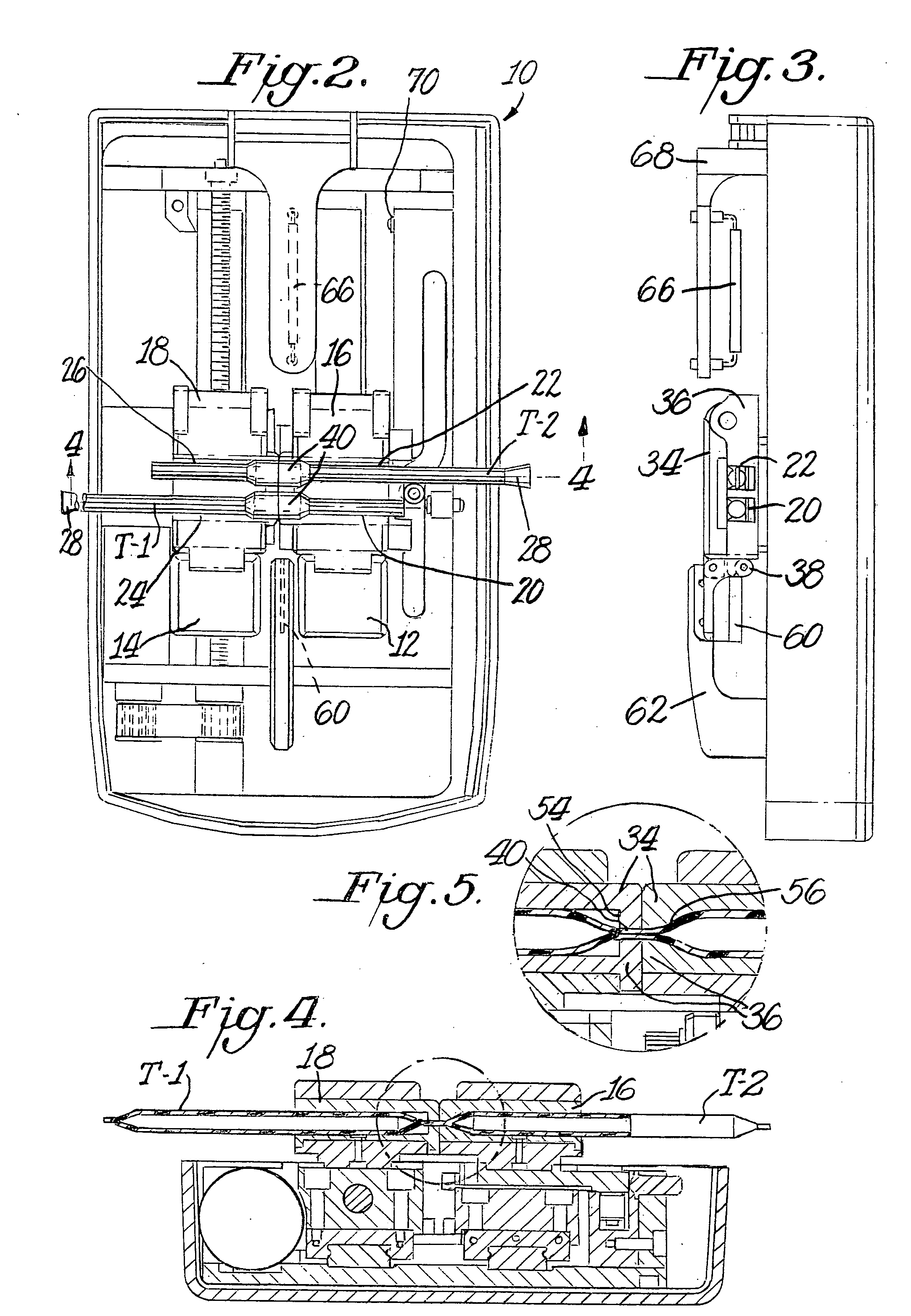

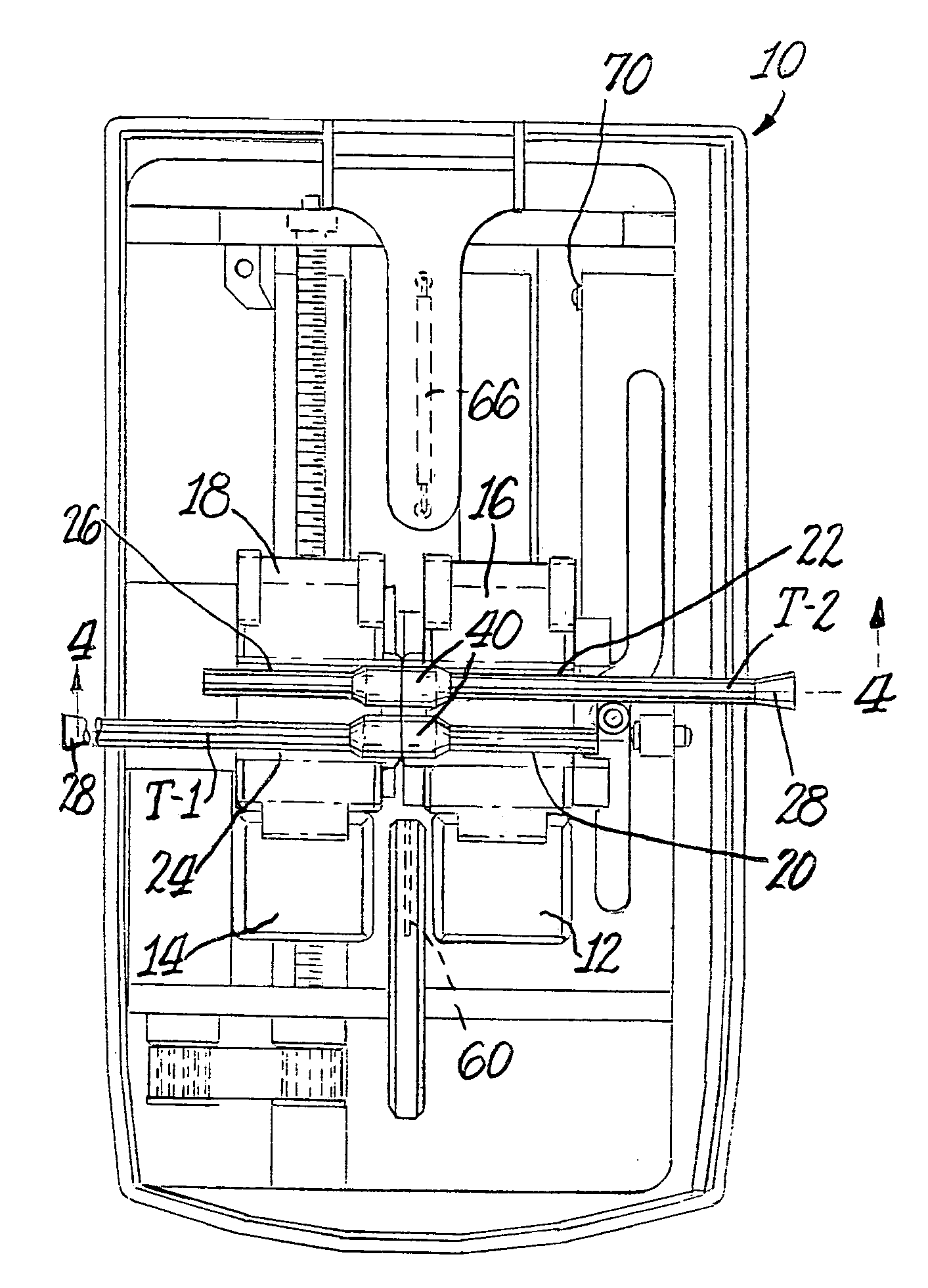

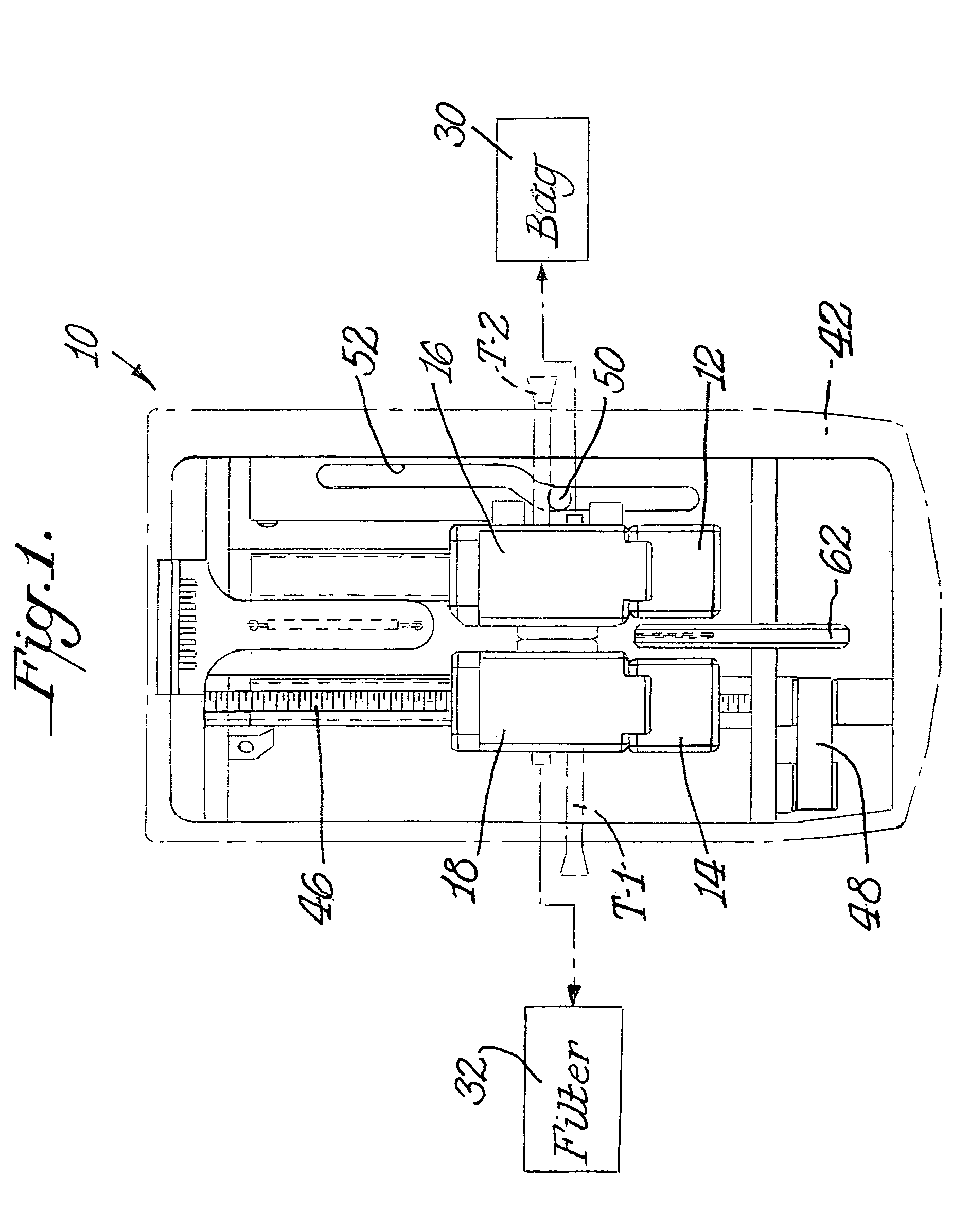

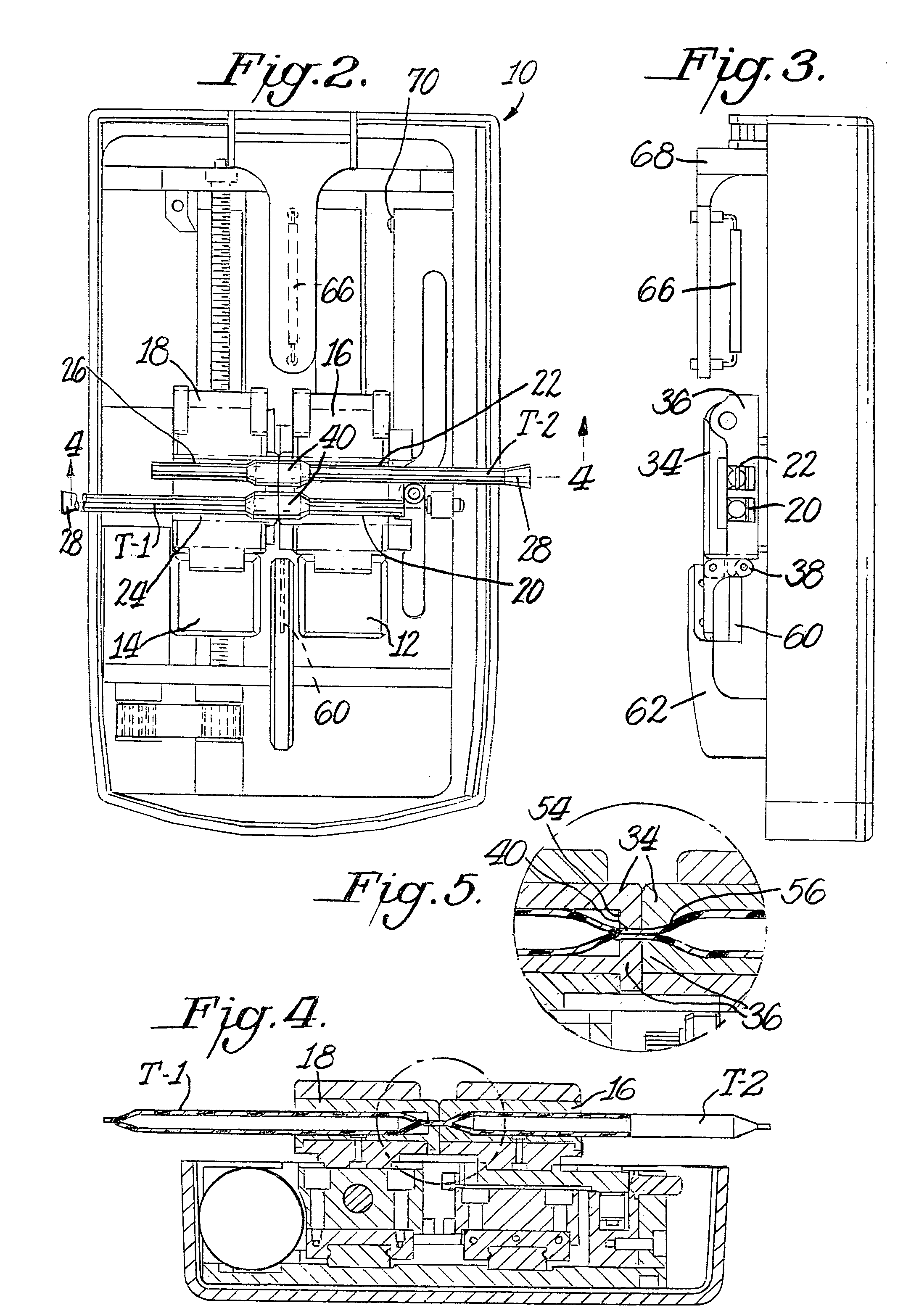

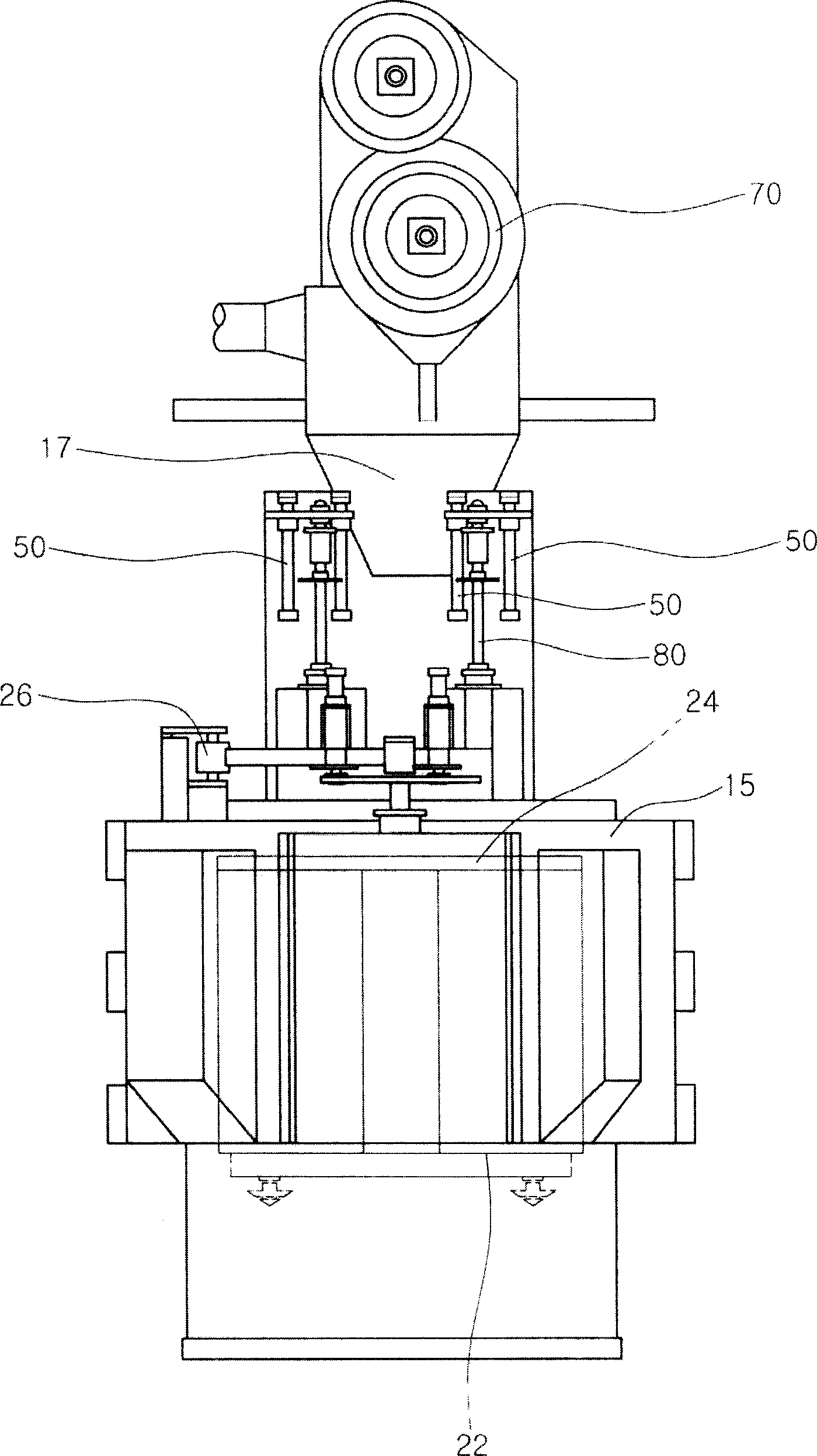

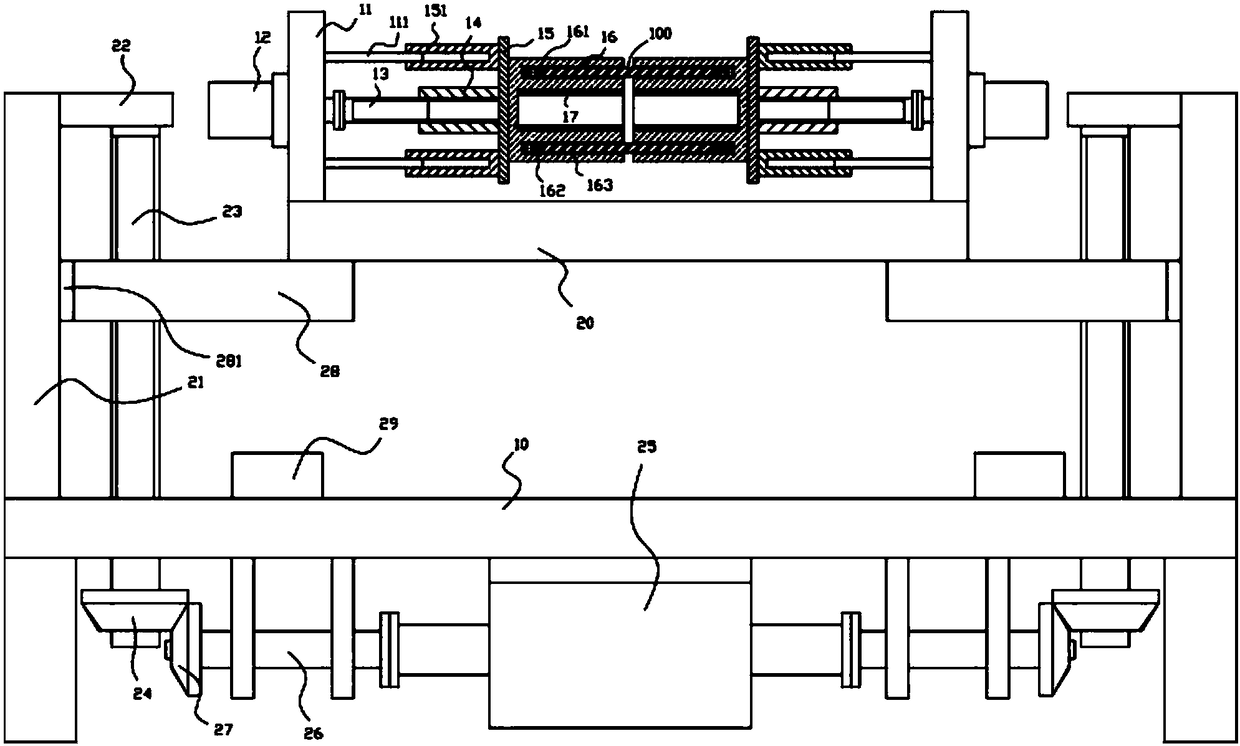

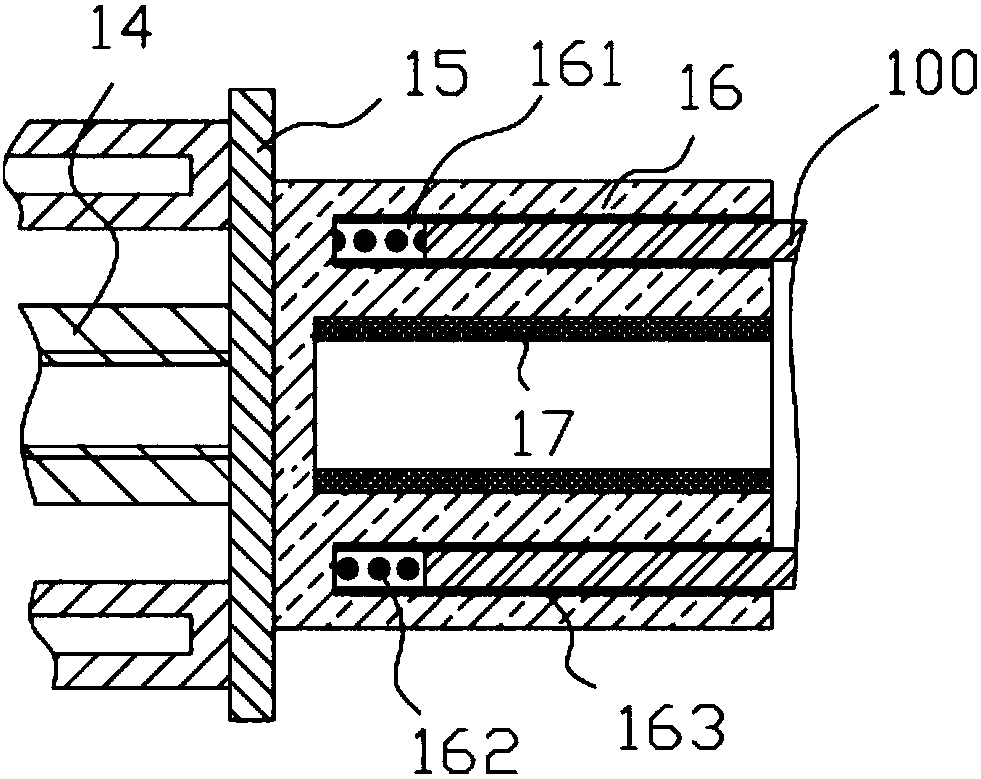

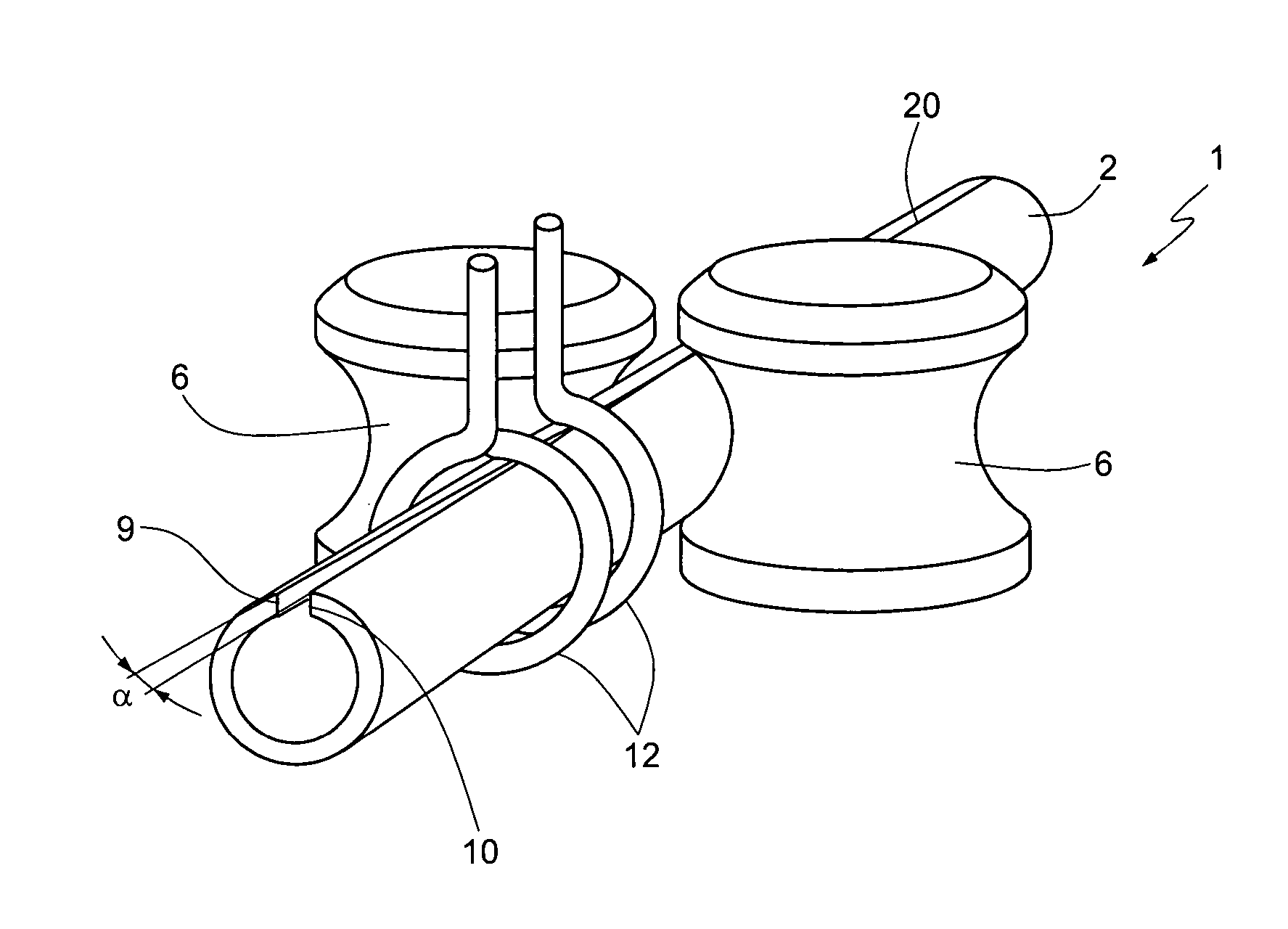

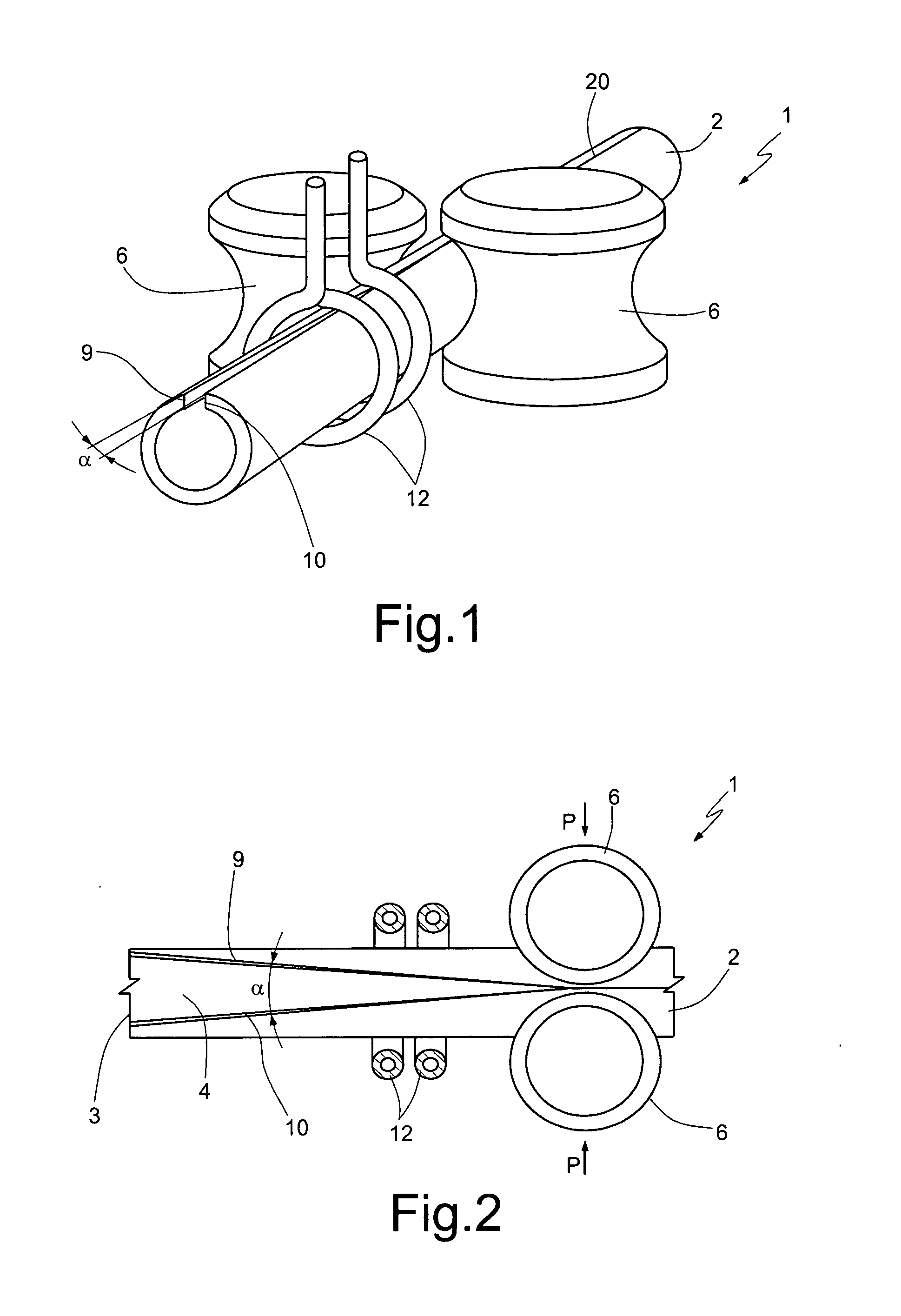

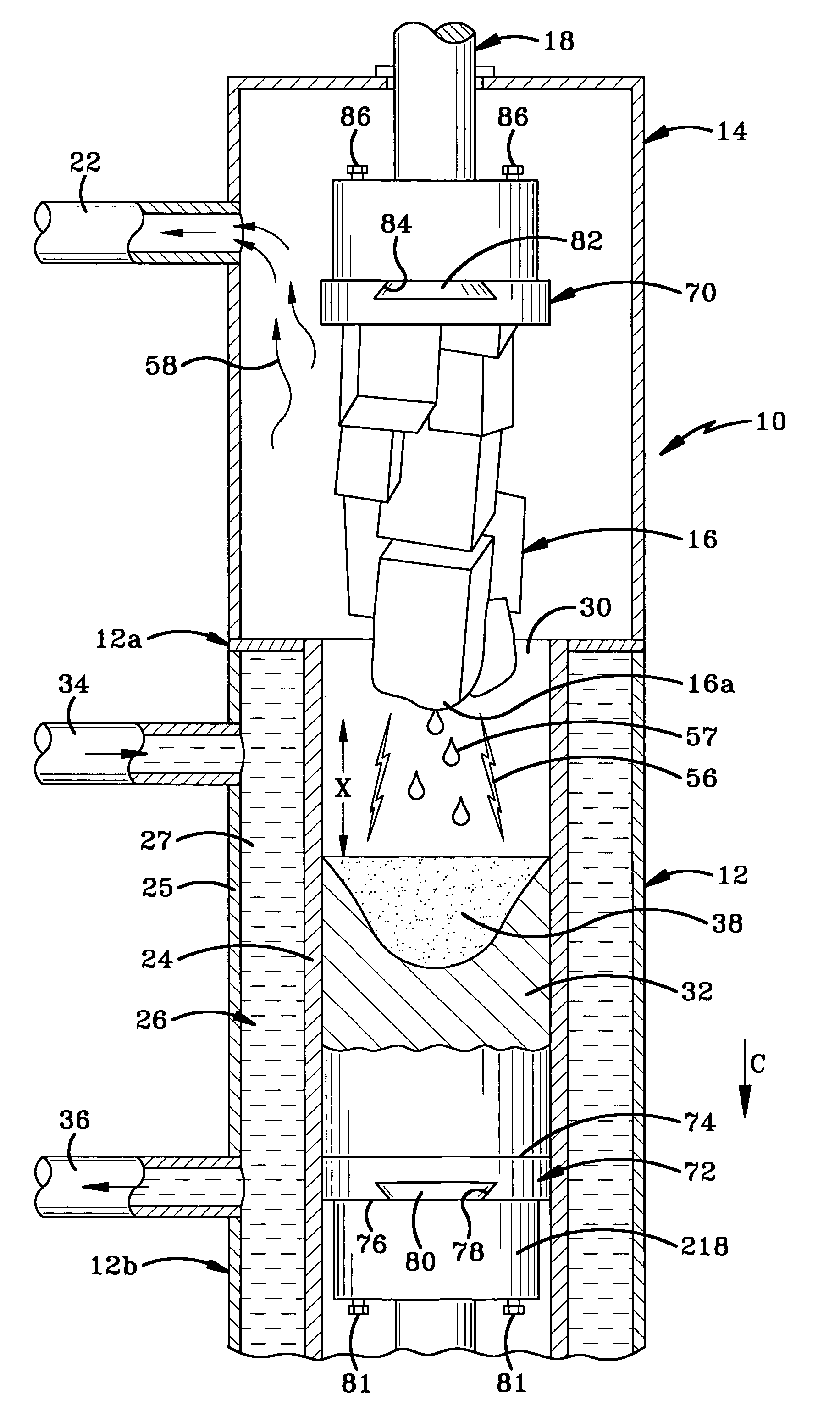

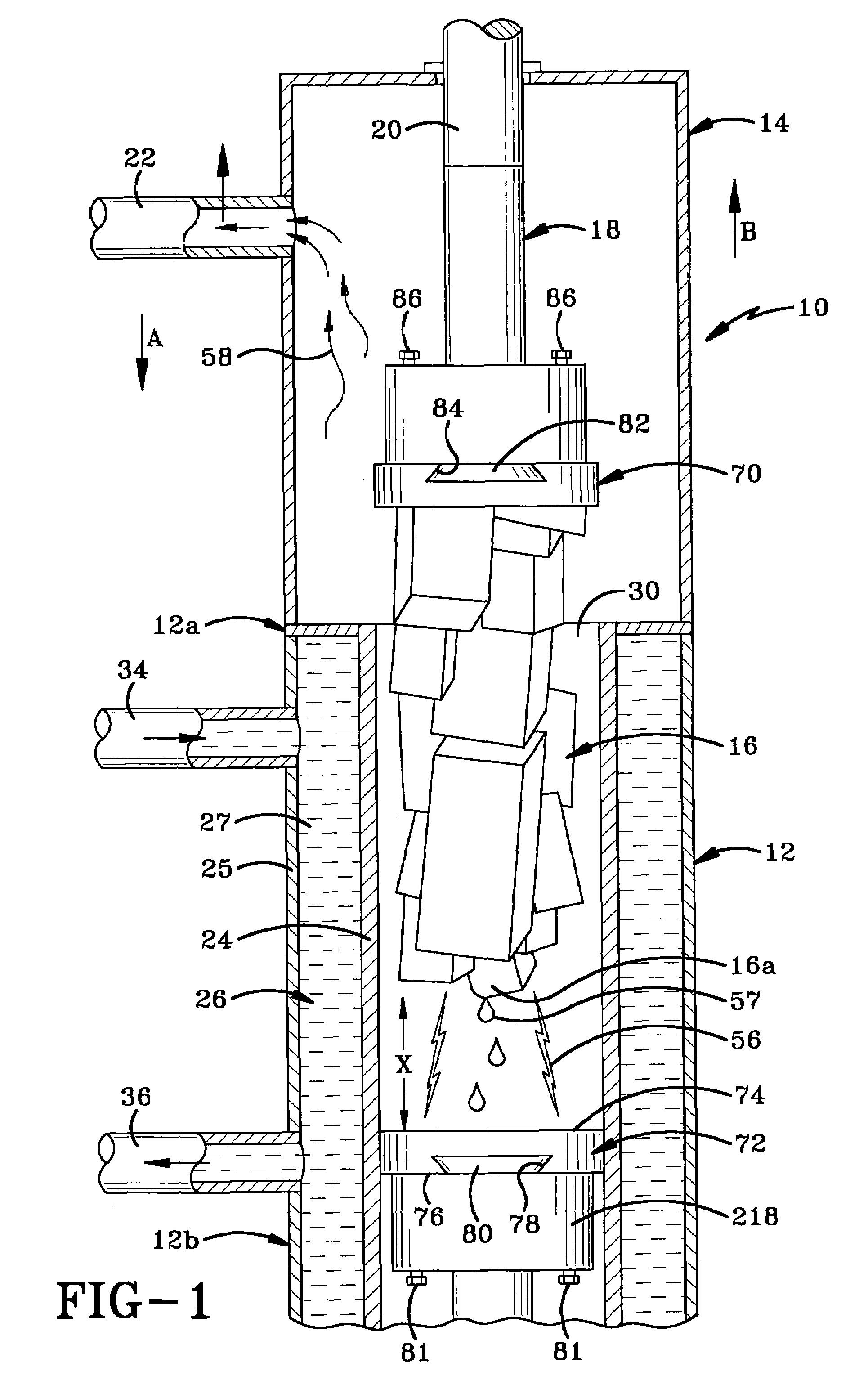

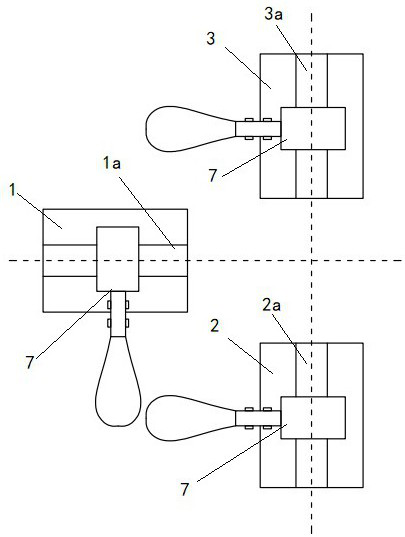

Device for welding plastic tubes

Plastic tubes are welded by first placing the plastic tubes across aligned tube slots in a pair of side by side tube holders. The tubes are clamped to create a fluid free area. The clamps in one of the tube holders are shifted laterally away from the other tube holders to increase the fluid free area of each tube. A cold cutting device cuts through the clamped tubes to create four stub ends. The four stub ends are heated / melted. The stub ends are realigned so that the one stub end in one holder is aligned with the other stub end of the other tube holder and the realigned stub ends are pressed into contact with each other to create a weld seam.

Owner:GENESIS BPS

Device for welding plastic tubes

Plastic tubes are welded by first placing the plastic tubes across aligned tube slots in a pair of side by side tube holders. The tubes are clamped to create a fluid free area. The clamps in one of the tube holders are shifted laterally away from the other tube holders to increase the fluid free area of each tube. A cold cutting device cuts through the clamped tubes to create four stub ends. The four stub ends are heated / melted. The stub ends are realigned so that the one stub end in one holder is aligned with the other stub end of the other tube holder and the realigned stub ends are pressed into contact with each other to create a weld seam.

Owner:GENESIS BPS

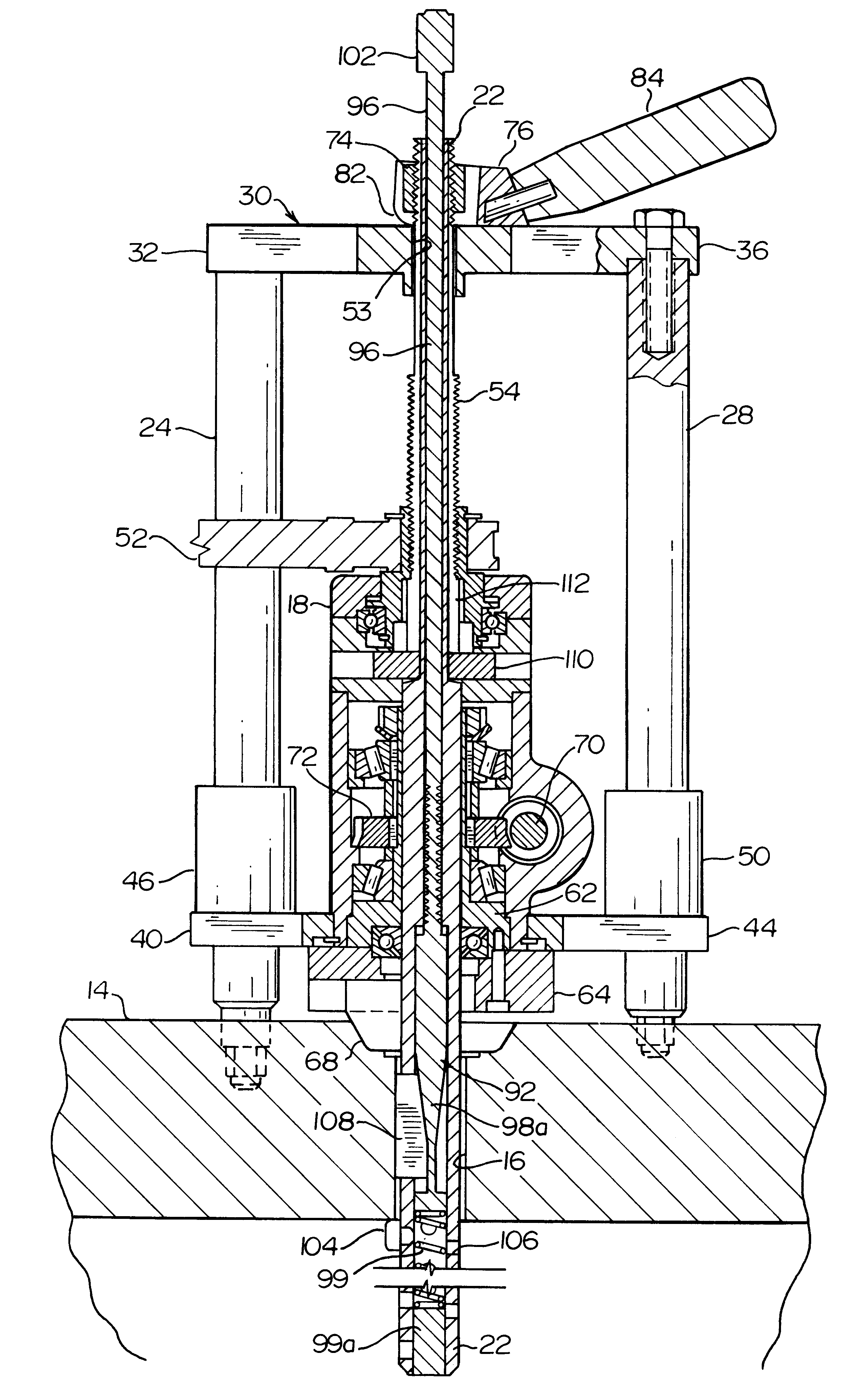

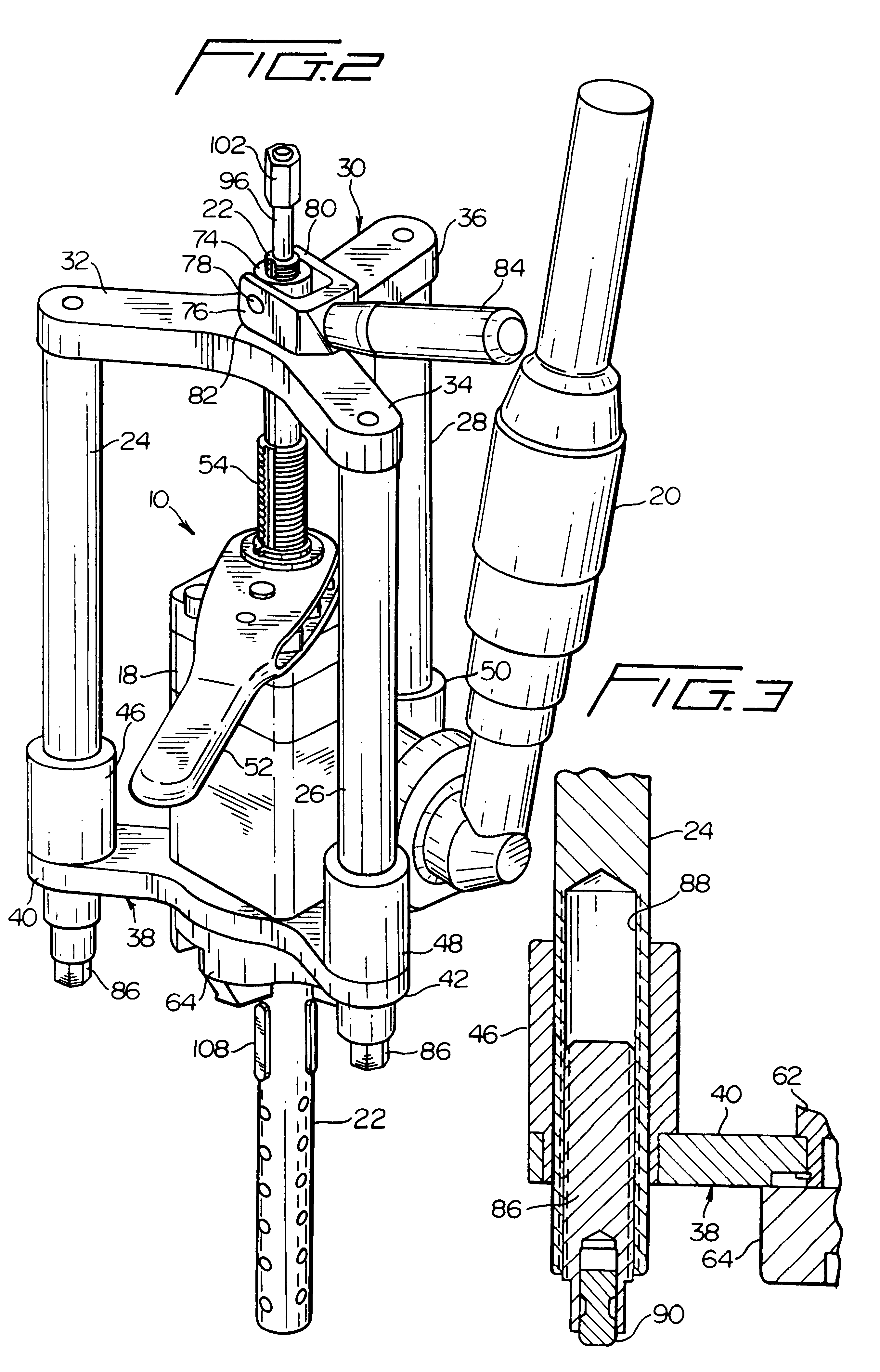

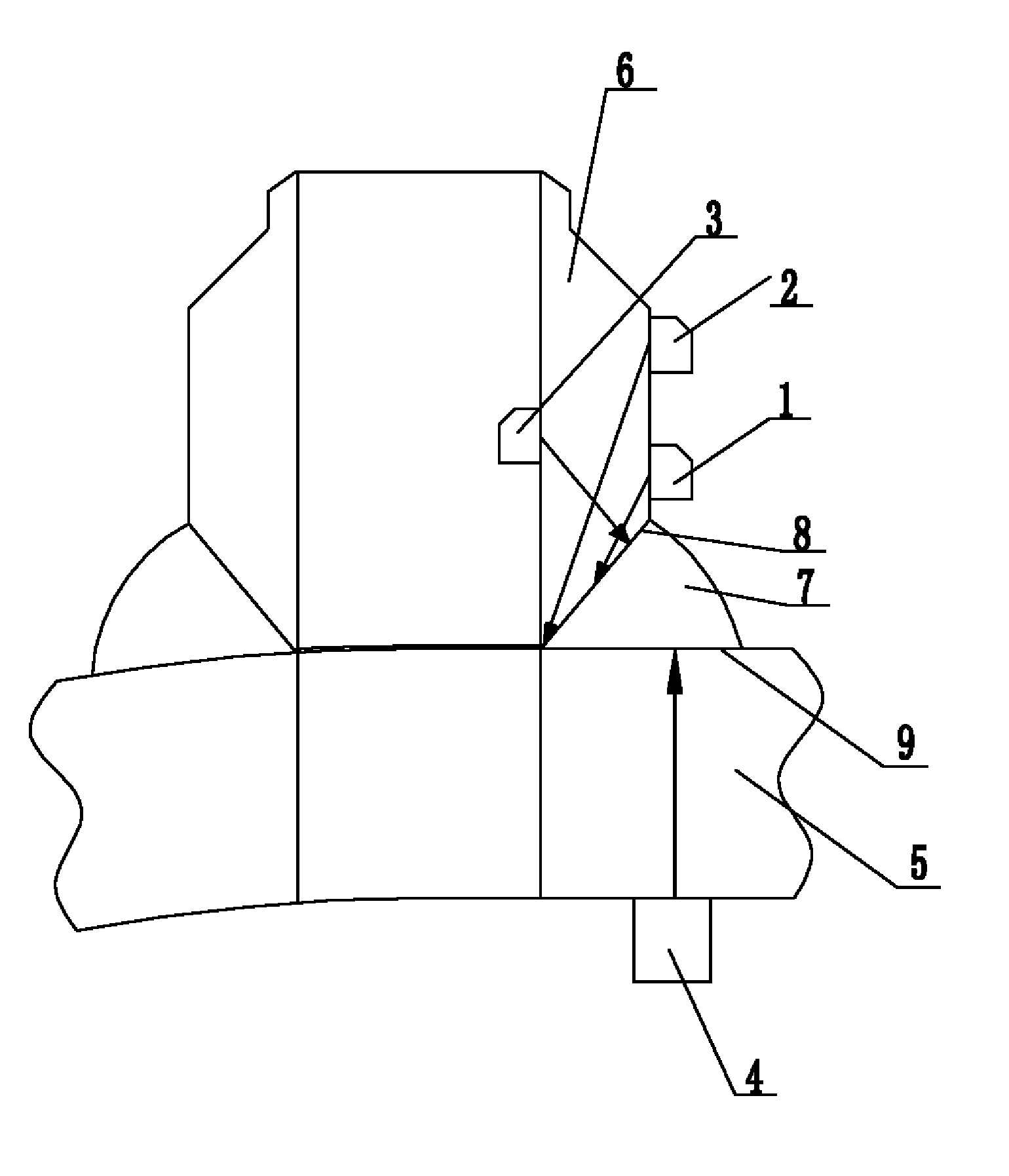

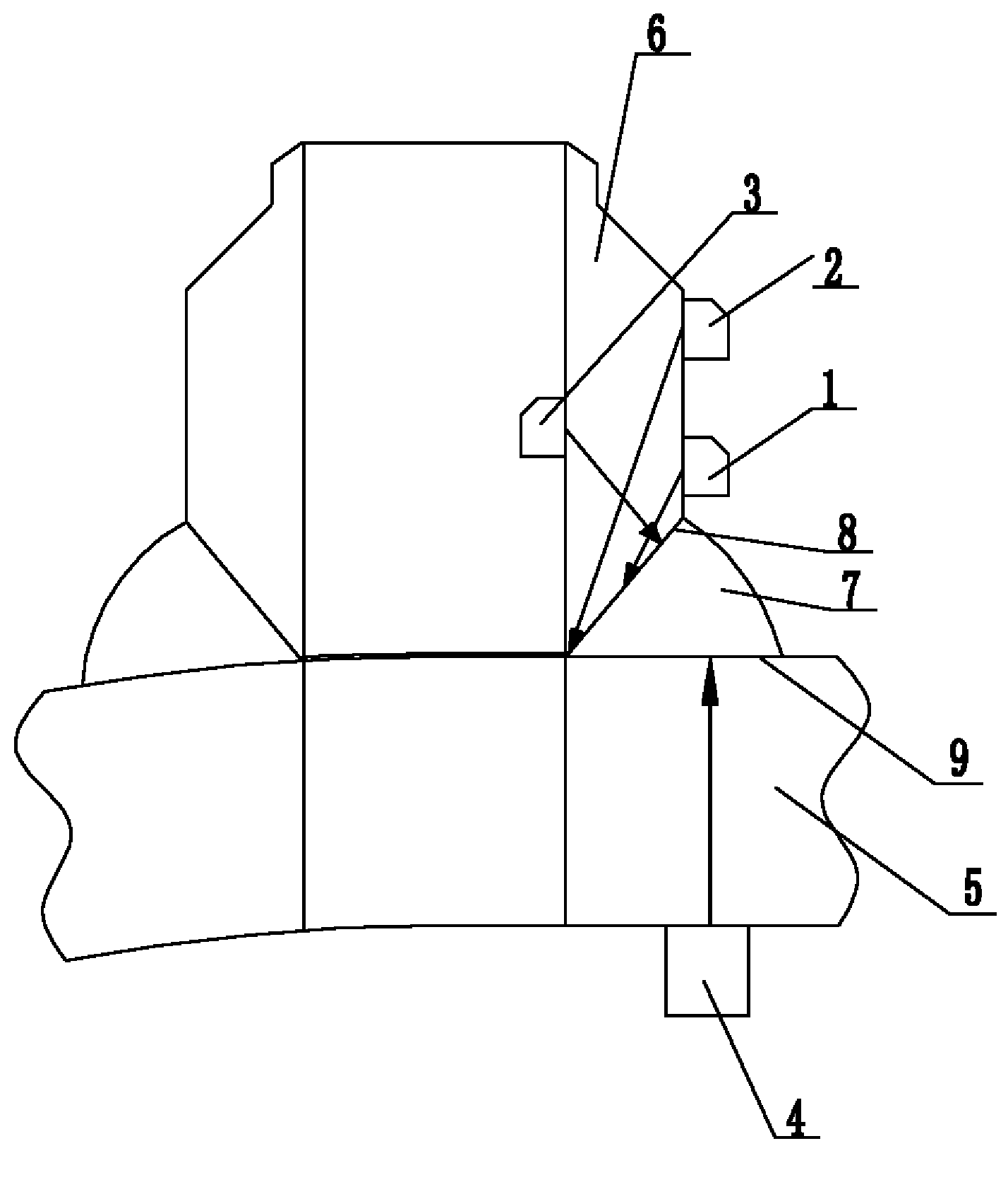

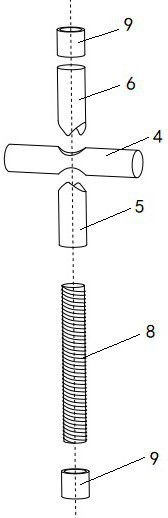

Portable machine tool for conditioning header tube openings for butt-welding tubes

A portable machine tool for removing stub ends of heat exchange tubes from a heat exchanger header or other plate structure and preparing the tube opening in the header for butt-welding a new tube at the opening. The tool includes a mandrel that may be locked within the tube opening and a plurality of stabilizing legs extending between the mandrel and the header for stabilizing the mandrel during machine tool operation. A cutting head is mounted concentrically on the mandrel and is advanced into engagement with the stub end of a heat exchange tube and it's respective opening to remove the stub end and prepare the opening for welding the new tube thereon.

Owner:TRI TOOL INC

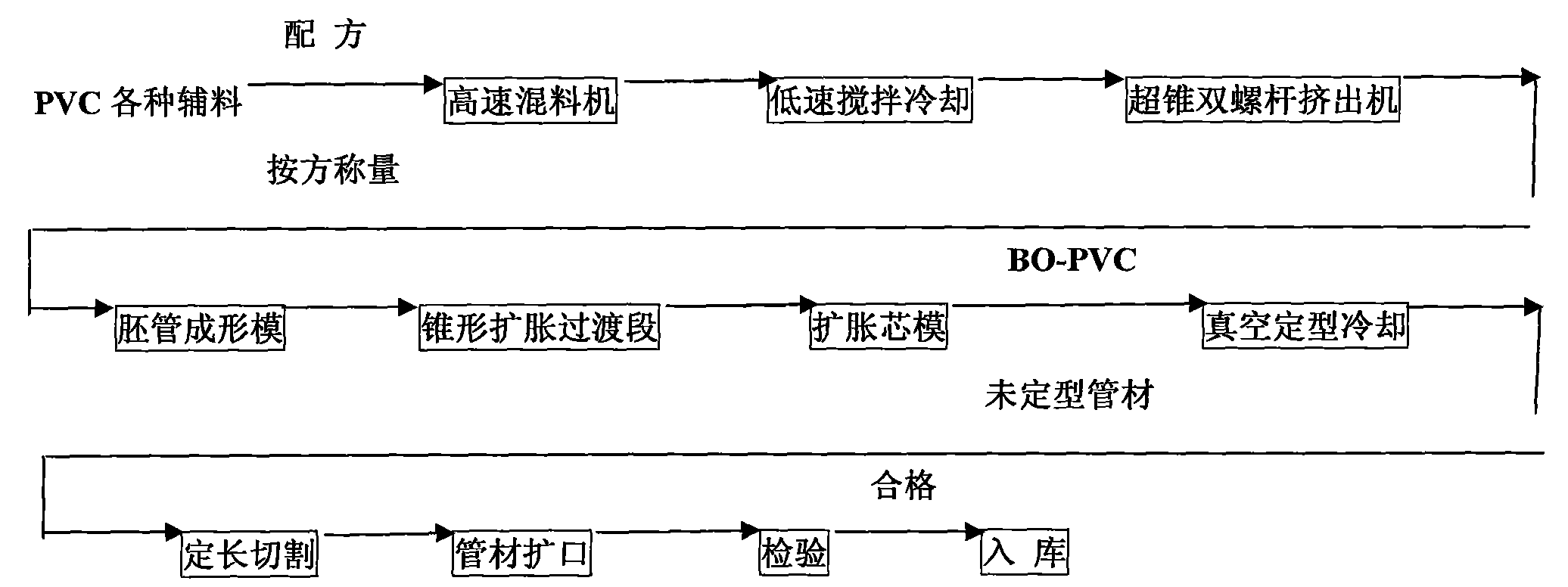

Production process for biaxially orienting polyvinyl chloride pressure-bearing pipe material on line

The invention relates to a production process for biaxially orienting polyvinyl chloride pressure-bearing pipe material on line. The production process comprises the following steps of: (1) taking polyvinyl chloride resin, stabilizer, processing aid, lubricant, impact modifier, composite filler and anatase titanium dioxide for stock preparation; (2) placing the stock into a high-speed kneader forhigh-speed kneading and discharging; (3) placing the stock into a low-speed cooling mixer for stirring and cooling for later use; (4) adding the stock into a hypercone double-screw extruder, and conveying molten material to a skelp molding mould; (5) expanding and extending a skelp in the skelp molding mould, and then sending the skelp into a sizing sleeve, and obtaining the polyvinyl chloride pressure-bearing pipe material after cooling; (6) cutting the molded pipe material according to a fixed length; (7) flaring the pipe material; and (8) detecting. The invention has the advantages that theinvention initiates the technological production process for biaxially orienting BO-PVC pressure-bearing pipe material on line; the selected materials and the molded pipe material do not pollute theenvironment; and the continuous and stable molding and processing are guaranteed.

Owner:杭州波达塑料科技股份有限公司

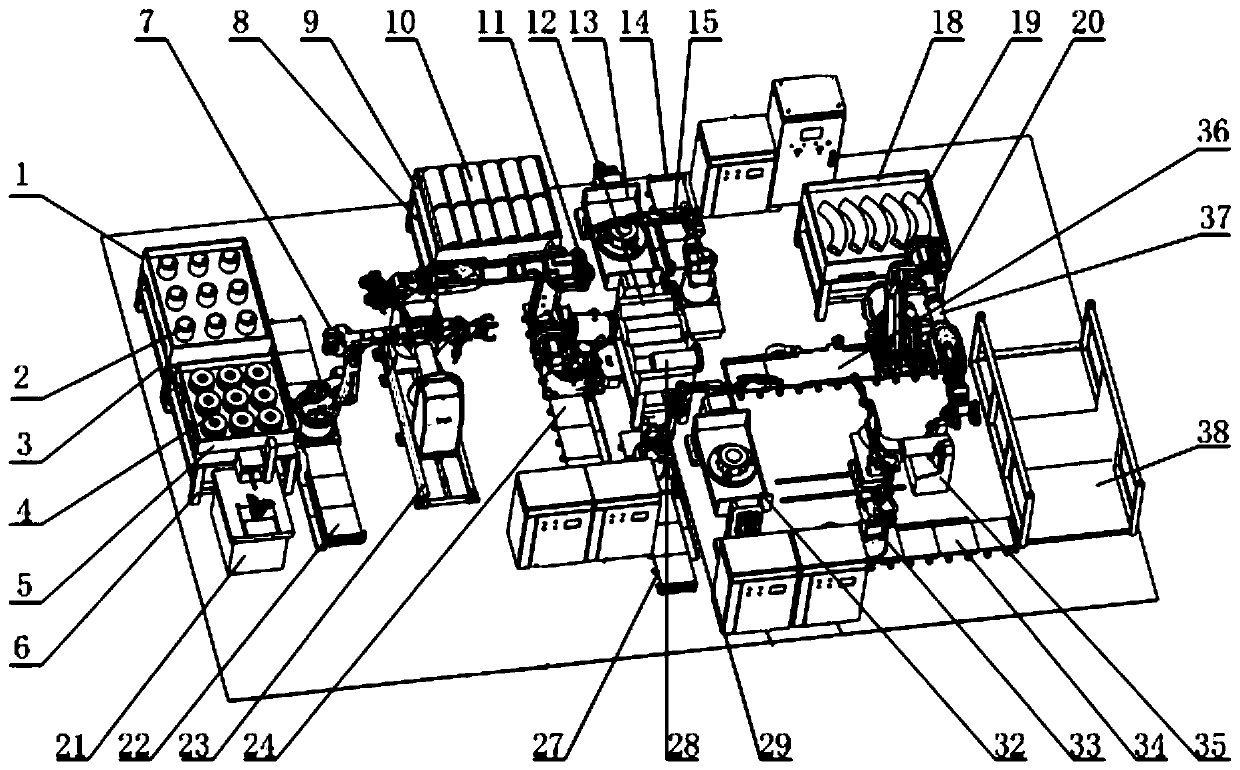

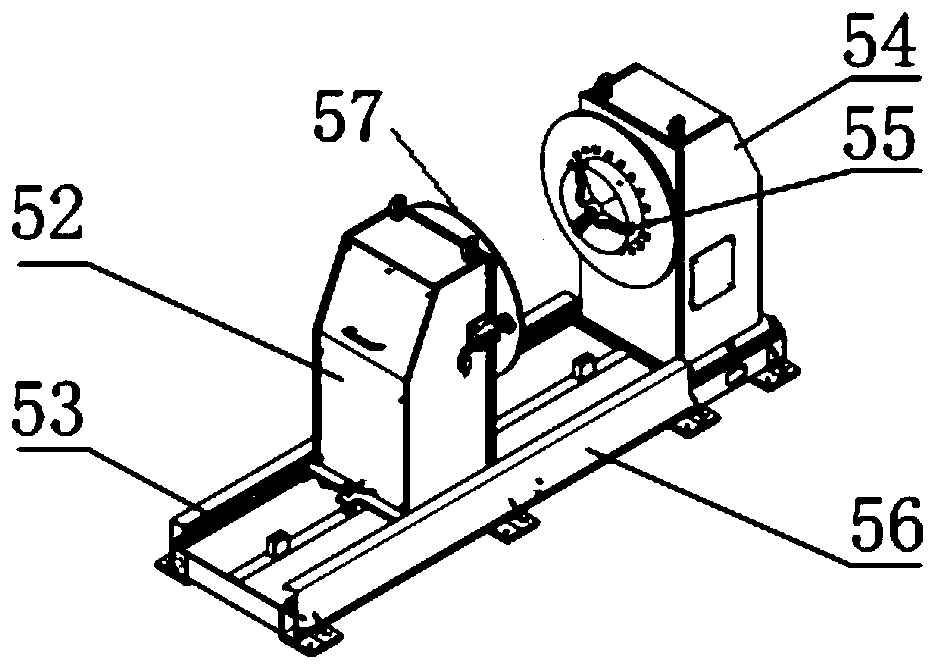

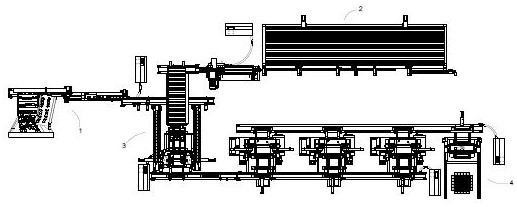

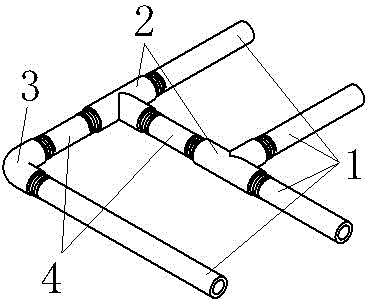

Short pipe-flange/sleeve/elbow full-automatic coupling and welding workstation

InactiveCN110757033ARealize fully automatic logisticsEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesPipe wrenchPipe fitting

The invention discloses a short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation. The short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation comprises ashort pipe-flange / sleeve coupling station, a short pipe-flange / sleeve welding station and a short pipe-elbow coupling and welding station. The short pipe-flange / sleeve coupling station comprises a grabbing / welding robot, a head and tail type automatic coupling machine, carrying robots, an automatic marking machine, a flange material platform, a sleeve material platform and a short pipe material platform. The feeding operation of short pipes, flanges and sleeves, the marking operation of the flanges and the assembly and spot welding operation of the short pipes and the flanges / sleeves are achieved. The short pipe-flange / sleeve welding station comprises welding robots, rotary type position changing machines and a transfer locating platform. The feeding, welding and discharging operation ofthe short pipes to be welded is achieved. The short pipe-elbow coupling and welding station comprises a carrying robot, a pipe wrench type position changing machine, a welding robot, an elbow materialplatform and a finished product material frame. The feeding, coupling and welding operation of the short pipes and elbows and the discharging operation of welded finished products are achieved. The short pipe-flange / sleeve / elbow full-automatic coupling and welding workstation can improve the automation level of short pipe and pipe fitting coupling and welding operation.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

Efficient precise blanking method for pipe thermal stress prefabrication microcracks

InactiveCN103317320AIncreased stress concentration effectGerminate fastStress concentrationHeater Rod

An efficient precise blanking method for pipe thermal stress prefabrication microcracks comprises the steps of taking a long pipe, opening V-shaped grooves on every small section along the blanking length, dividing the long pipe into short pipes, then placing a ceramic heating rod in inner holes of the short pipes to heat the short pipes, removing a heating device after heating is finished rapidly, starting a rapid cooling device to rapidly cool parts between the V-shaped grooves of the short pipes to enable the microcracks to be generated at the positions of sharp ends of the V-shaped grooves of the short pipes, and feeding the short pipes with the microcracks into a blanking machine fixing clamp after cooling is finished so as to perform blanking. Blanking is performed after material thermal stress effect and stress concentration effect and the like are utilized to urge the pipes to generate the microcracks. The efficient precise blanking method has the advantages of being high in efficiency, saving materials and good in blanking quality and the like.

Owner:XI AN JIAOTONG UNIV

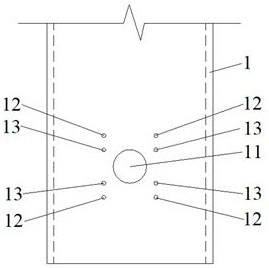

Short-pipe radial fillet weld ultrasonic flaw detection method

InactiveCN101943679AShorten the production cycleNo need to increase process marginAnalysing solids using sonic/ultrasonic/infrasonic wavesFillet weldEngineering

The invention provides a short-pipe radial fillet weld ultrasonic flaw detection method, which does not waste forge pieces, does not generate the secondary process cost, and has high whole efficiency, short production period and low cost. The invention comprises a boiler barrel and a short pipe, wherein, the short pipe is connected with the boiler barrel through welding the fillet weld. The invention is characterized in that oblique probes with different refraction angles are arranged on the excircle surface of the short pipe; ultrasonic wave ejected by the oblique probe is aligned with the fillet weld and the weld cross section of the short pipe; after moving to a certain distance, each probe of the oblique probe ensures that the ultrasonic wave thereof covers the whole fillet weld and the weld cross section of the short pipe; the movable range of each probe of the oblique probe is within the excircle surface of a radial straight pipe of the short pipe; the inner surface of the boiler barrel is provided with a straight probe; the ultrasonic wave ejected by the straight probe is aligned with the fillet weld and the weld cross section of the boiler barrel; and after moving to a certain distance, each probe of the straight probe ensures that the ultrasonic wave of the probe covers the whole fillet weld and the weld cross section of the boiler barrel.

Owner:WUXI HUAGUANG BOILER

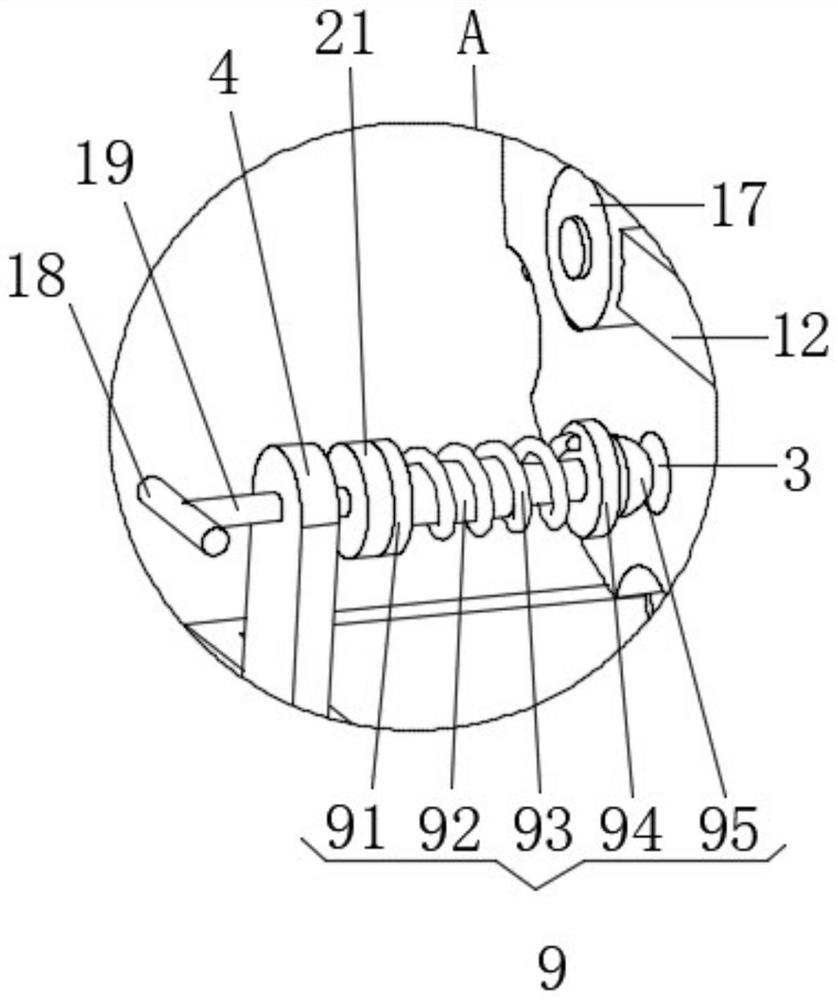

Wedge top type ultralow-temperature ball valve

ActiveCN105619027AReduce frictionReduce the impactPlug valvesOther manufacturing equipments/toolsBall valveImpact test

The invention discloses a wedge top type ultralow-temperature ball valve and a preparation method. Chemical element components of stainless steel are determined in percentage by weight as follows: 0.02-0.5% of carbon, 0.10-0.15% of silicon, 0.7-1.1% of manganese, 0.5% of nickel, 15-19% of chromium, 4% of molybdenum, 0.5% of copper, 0.05% of boron, 0.05% of phosphorus, 0.3% of nitrogen, and the balance of Fe. The wedge top type ultralow-temperature ball valve has unexpected ultralow-temperature performance. A welding line between a butt-welded end of a valve body and a short pipe has an impact value of below -285 DEG C. A welding process qualification report can refer to the ASMEB31.3 standard requirements; the V-shaped impact test below -285 DEG C is performed; and the transverse expansion value of standard sample test is lower than 0.25 mm.

Owner:JIANG SU YAN DIAN FA MEN CO LTD

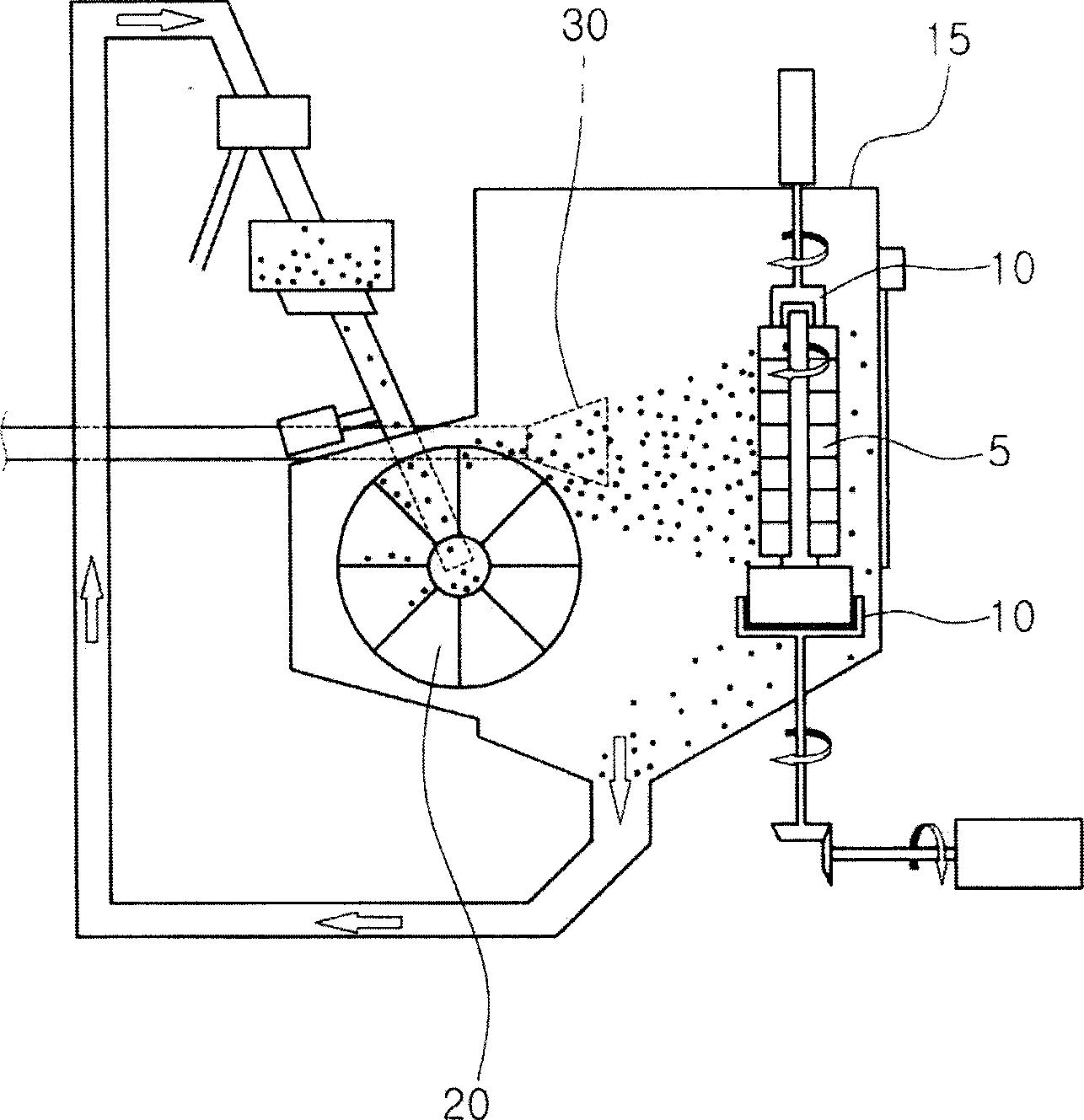

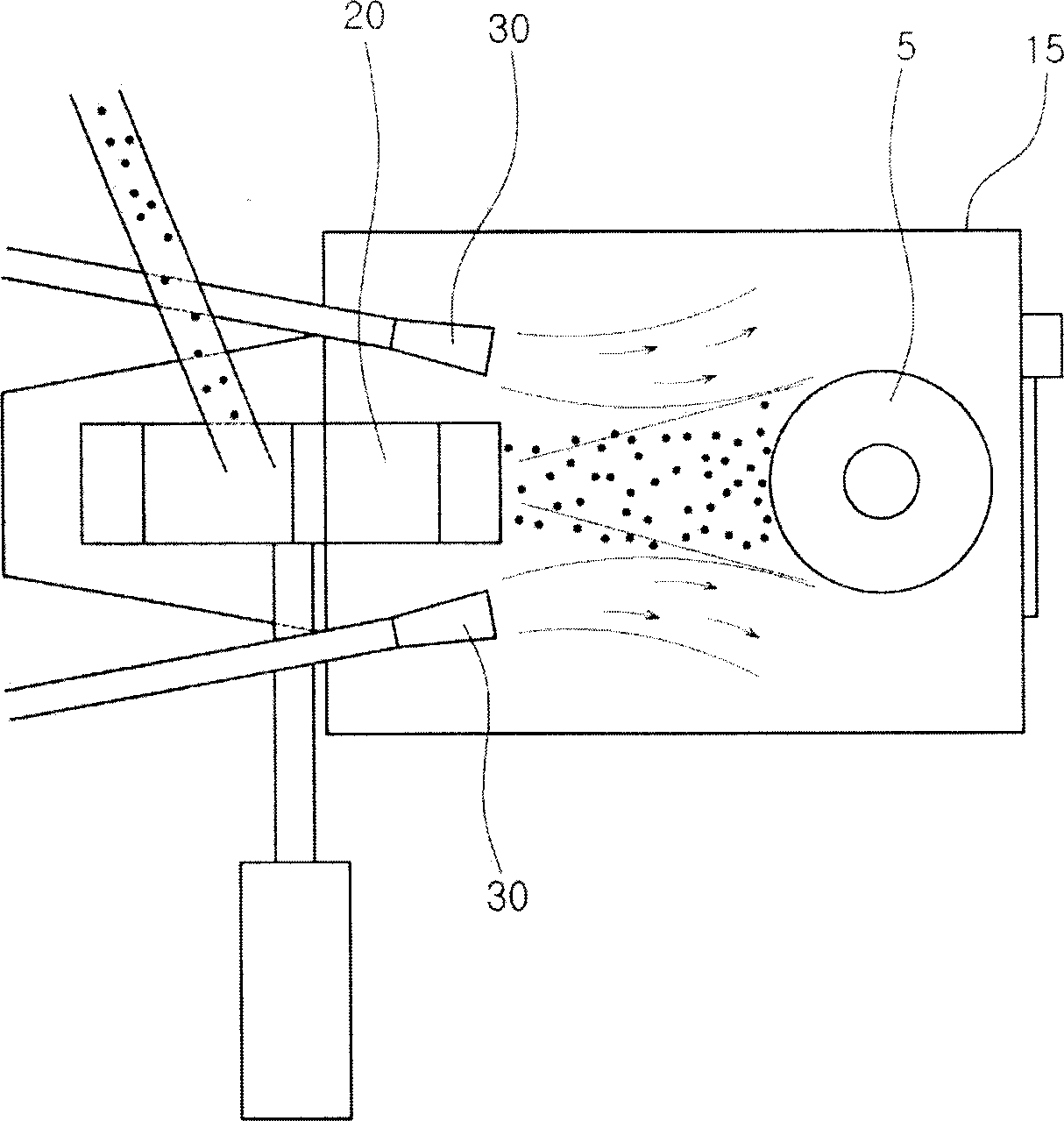

Grit blasting appts.

InactiveCN1660544AImprove surface cooling efficiencyQuality improvementImpeller wheelsBlast gunsSurface coolingRotational axis

The present invention involving a cloudbursttreatment equipment,specifically a equipment which can improve the work piece superficial cooling efficiency.According to one aspect of the invention,providing a kind of cloudbursttreatment equipment which includes body(15),a couple of clamping articles(12,14) which is installed on the body rotatablely and can close each other along the rotational axis,pump wheel(20) which situates at one side of the clamping articles(12,14),ball lump feed send exchanger(17) which connects to the pump wheel(20),the first skelp blower(45) which situates inner the body(15) and can jet cooling air parallelly to the rotating axis of the work piece(5),reflector(55) which situates at the lateral of the pump wheel(20),the second skelp blower(60) which situates at the reflector(55) and can jet cooling air to the face of the work piece(5),air coolant feed send heat exchanger(50) which connects to the first and second skelp exchanger(45,60).

Owner:兴亚产机株式会社

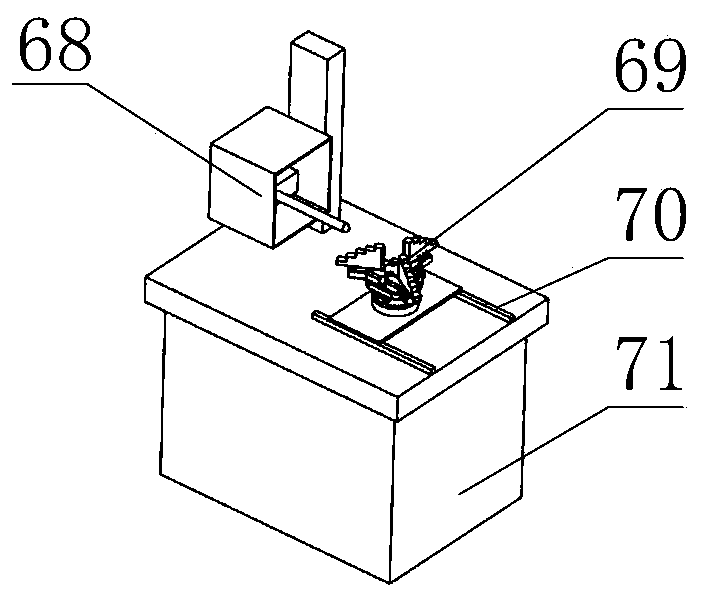

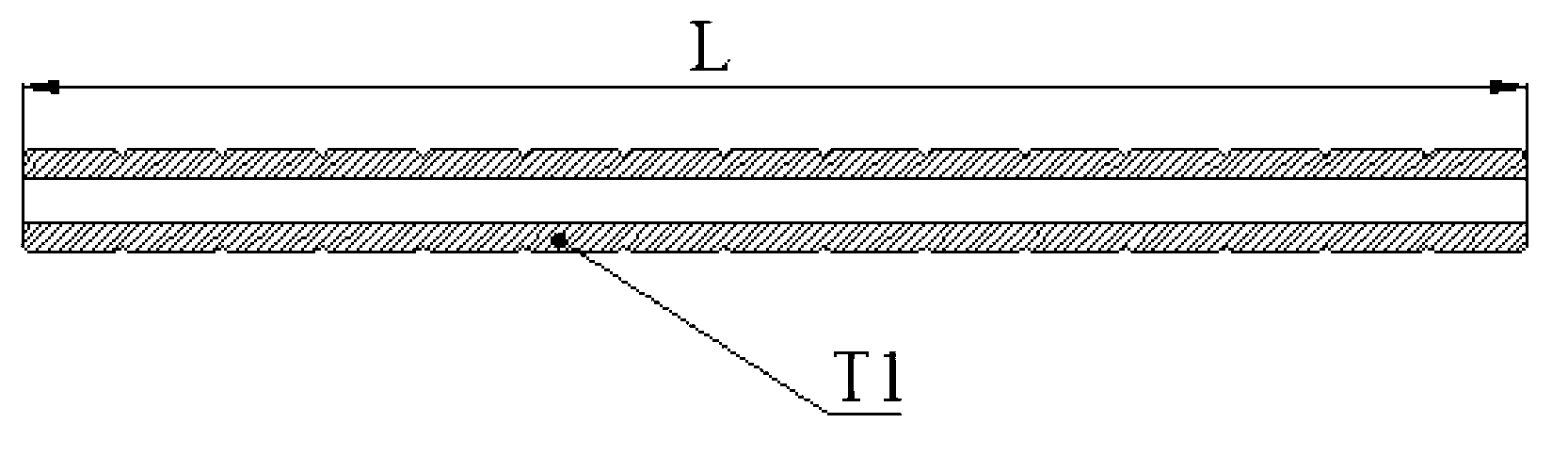

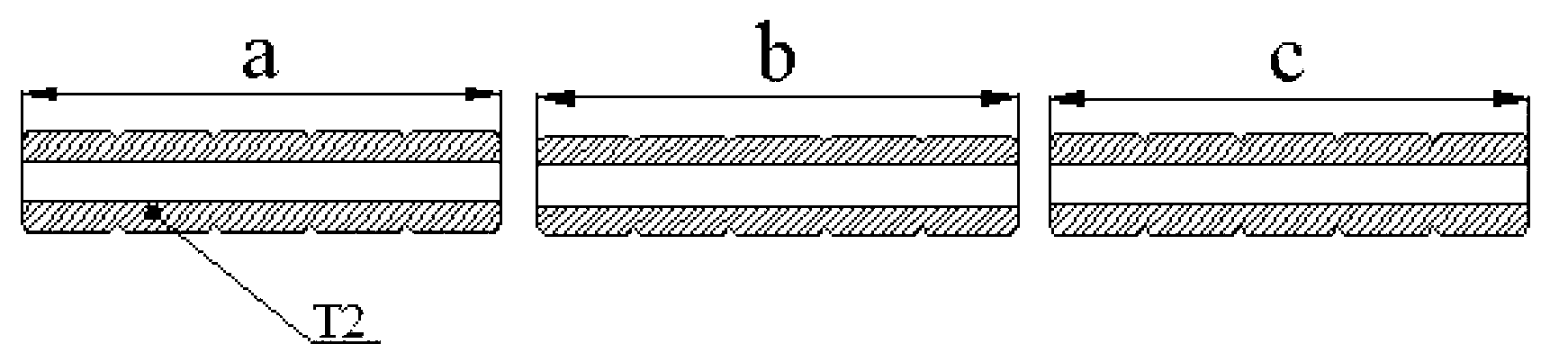

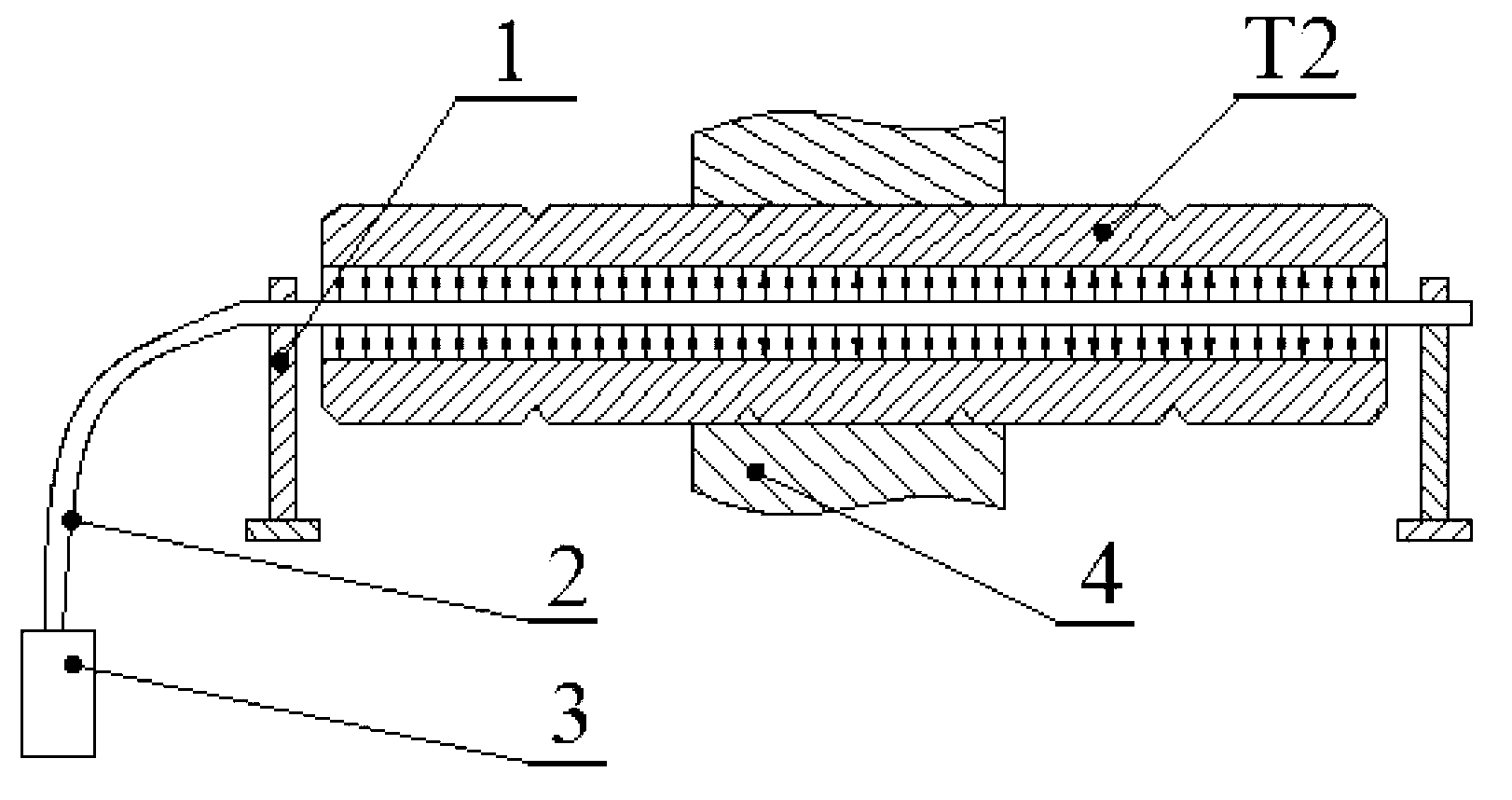

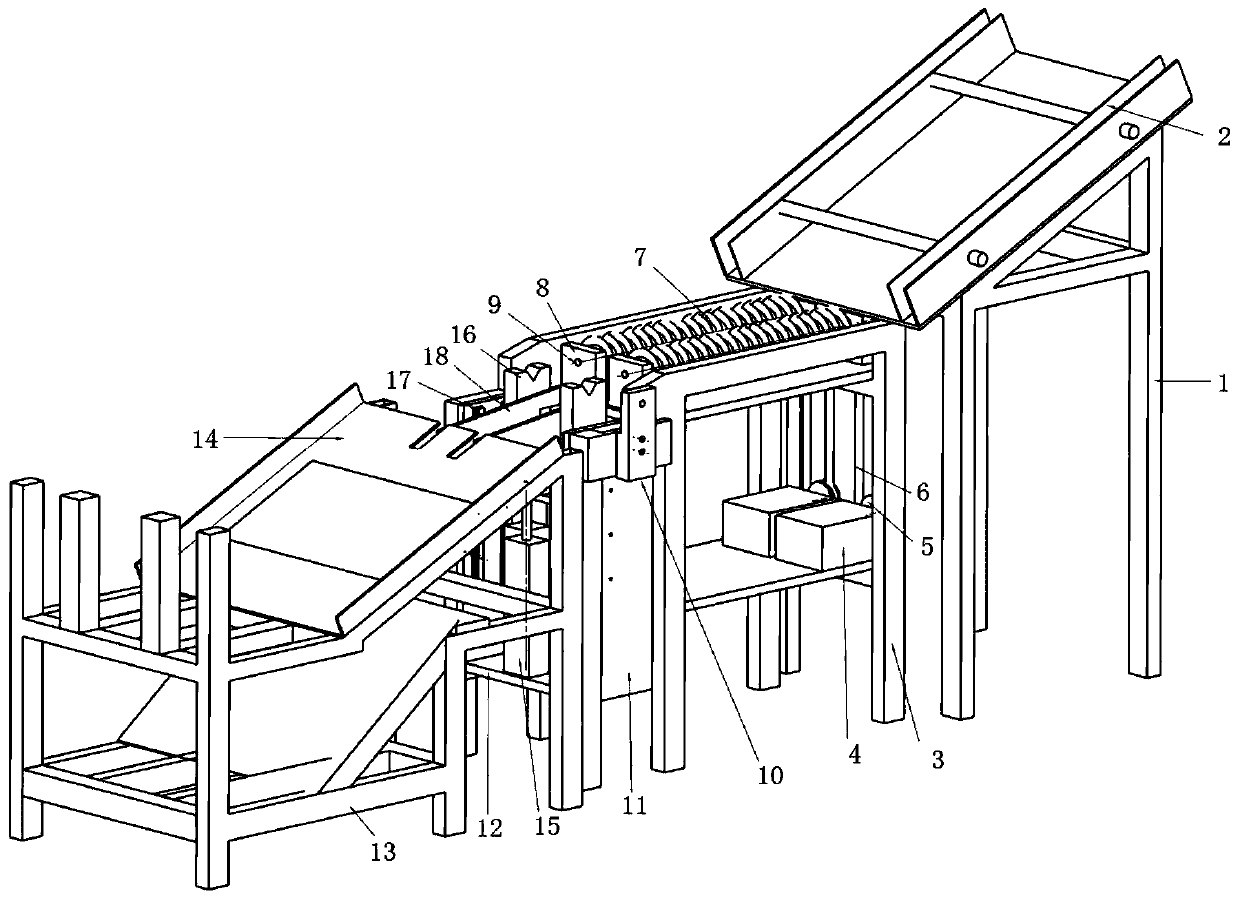

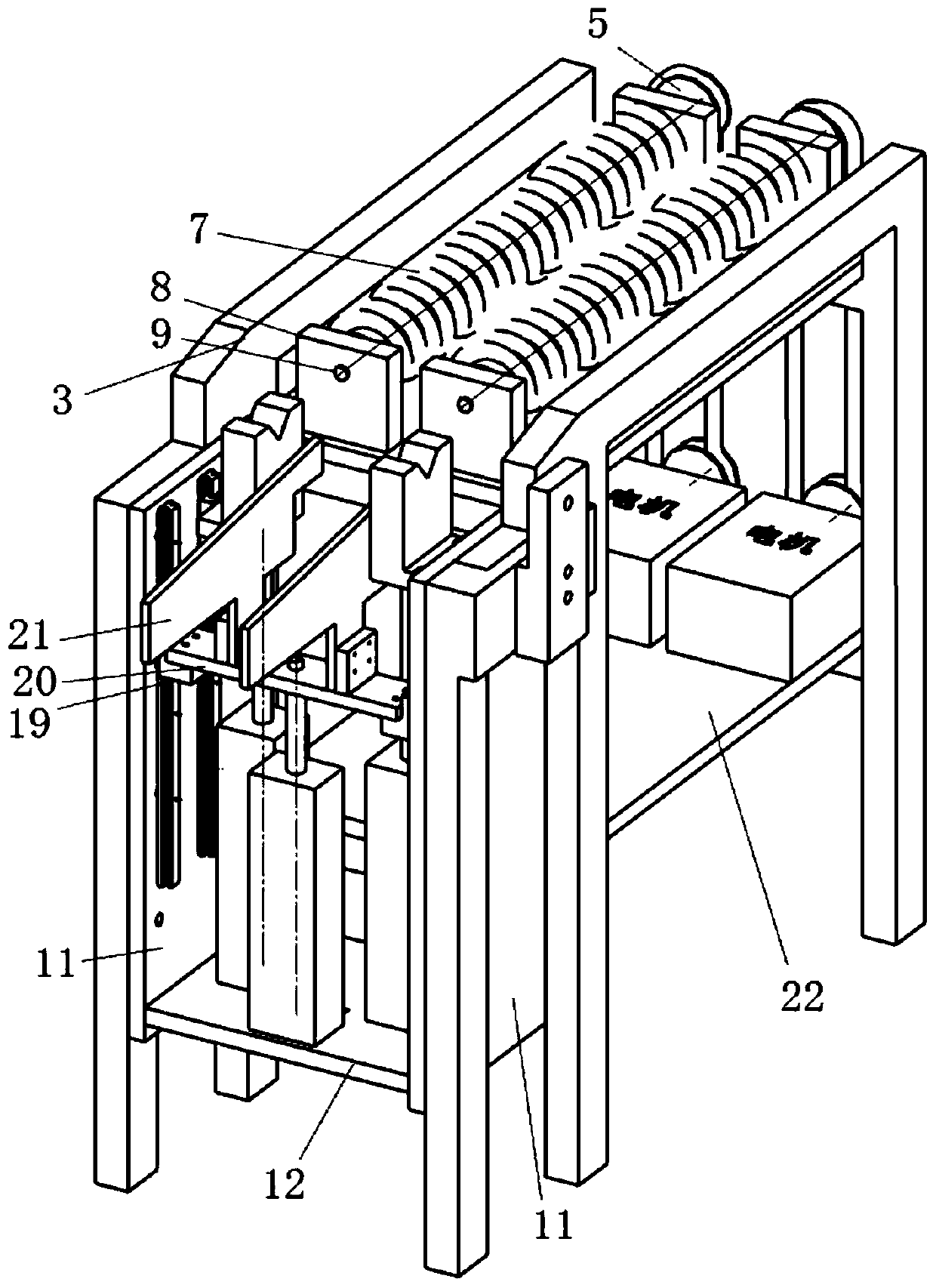

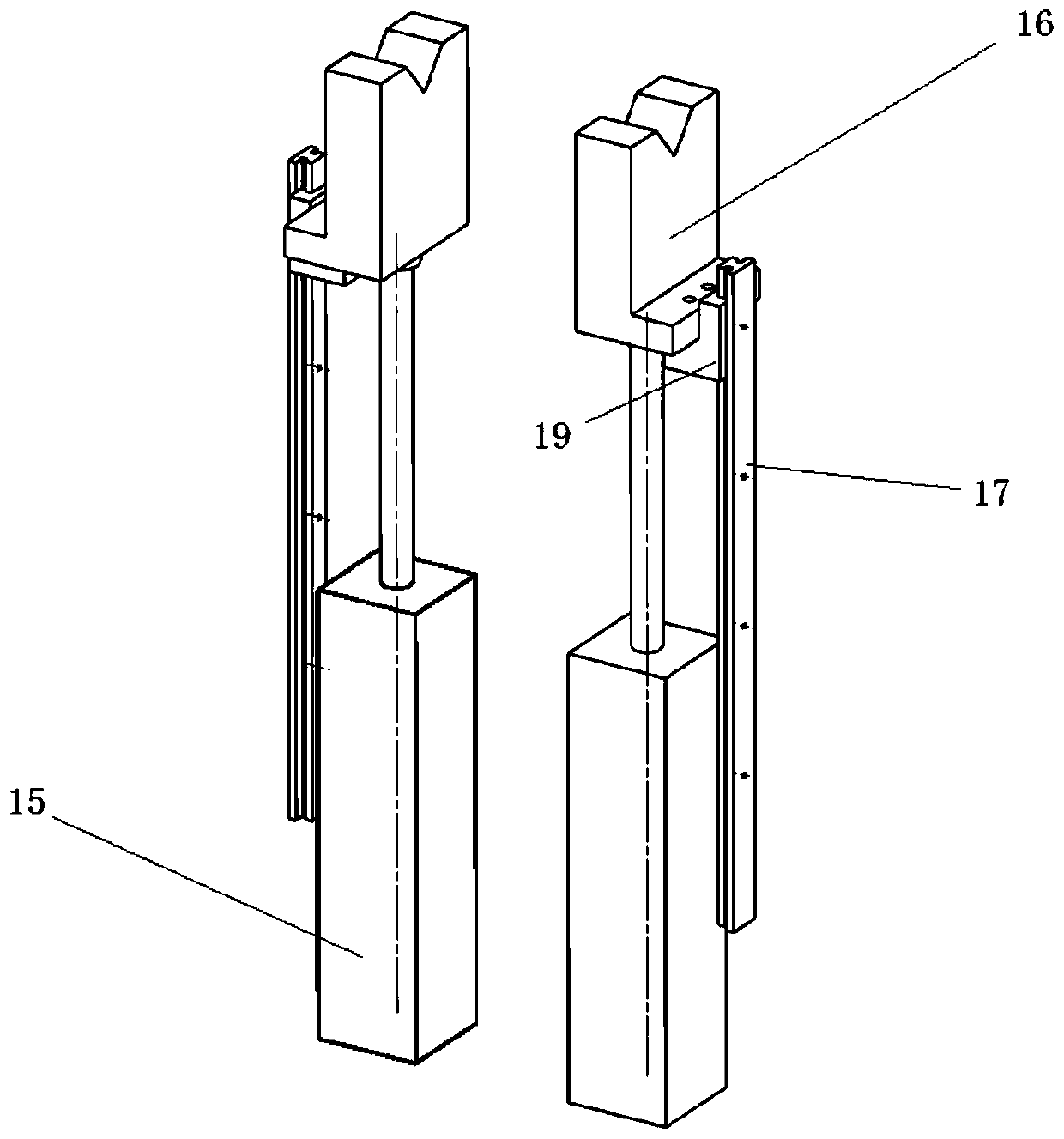

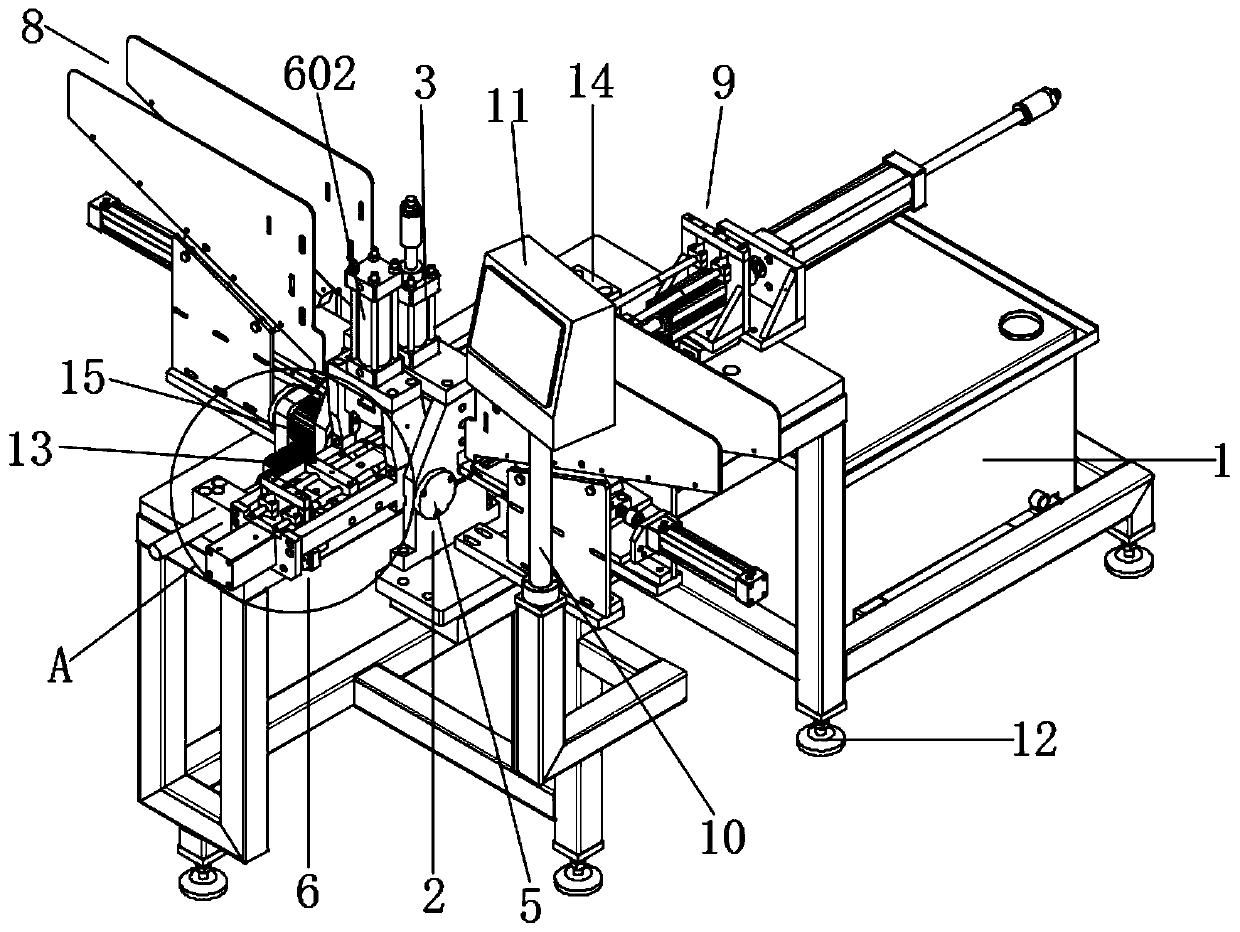

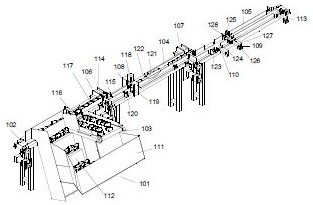

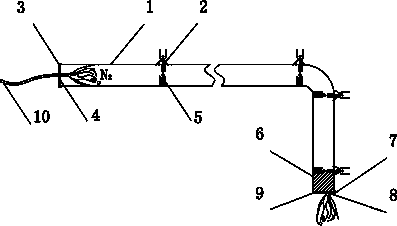

Feeding and discharging device for simultaneous eddy current flaw detection applied to inner and outer walls of stainless steel short pipe

InactiveCN110803499ARealize sequential feedingAdjustable feeding intervalConveyor partsSS - Stainless steelSkelp

The invention relates to a feeding and discharging device for simultaneous eddy current flaw detection applied to inner and outer walls of a stainless steel short pipe. The feeding and discharging device comprises a feeding assembly, a conveying assembly, a detection matching assembly and a discharging assembly which are sequentially arranged in the advancing direction of the stainless steel shortpipe, wherein the detection matching assembly comprises two V-groove supports and a moving platform, wherein the two V-groove supports can vertically lift up and down, and the moving platform is arranged between the two V-groove supports and is capable of lifting up and down; and the tops of the V-groove supports are machined with a V-shaped groove capable of stably placing a stainless steel short pipe, and the top of the moving platform is machined with a guide inclined plane for receiving the conveying assembly and the discharging assembly. Compared with the prior art, the method can ensurethe matching consistency with the eddy current detection process, the unstable influence during detection is avoided, and finally the reliability of the detection result is ensured; and in the wholedetection process, successive feeding of the steel pipes can be achieved, the feeding interval time of the steel pipes can be regulated, time and labor are saved, and flexible and reliable effects areachieved.

Owner:SHANGHAI INST OF TECH

Deburring welded pipe

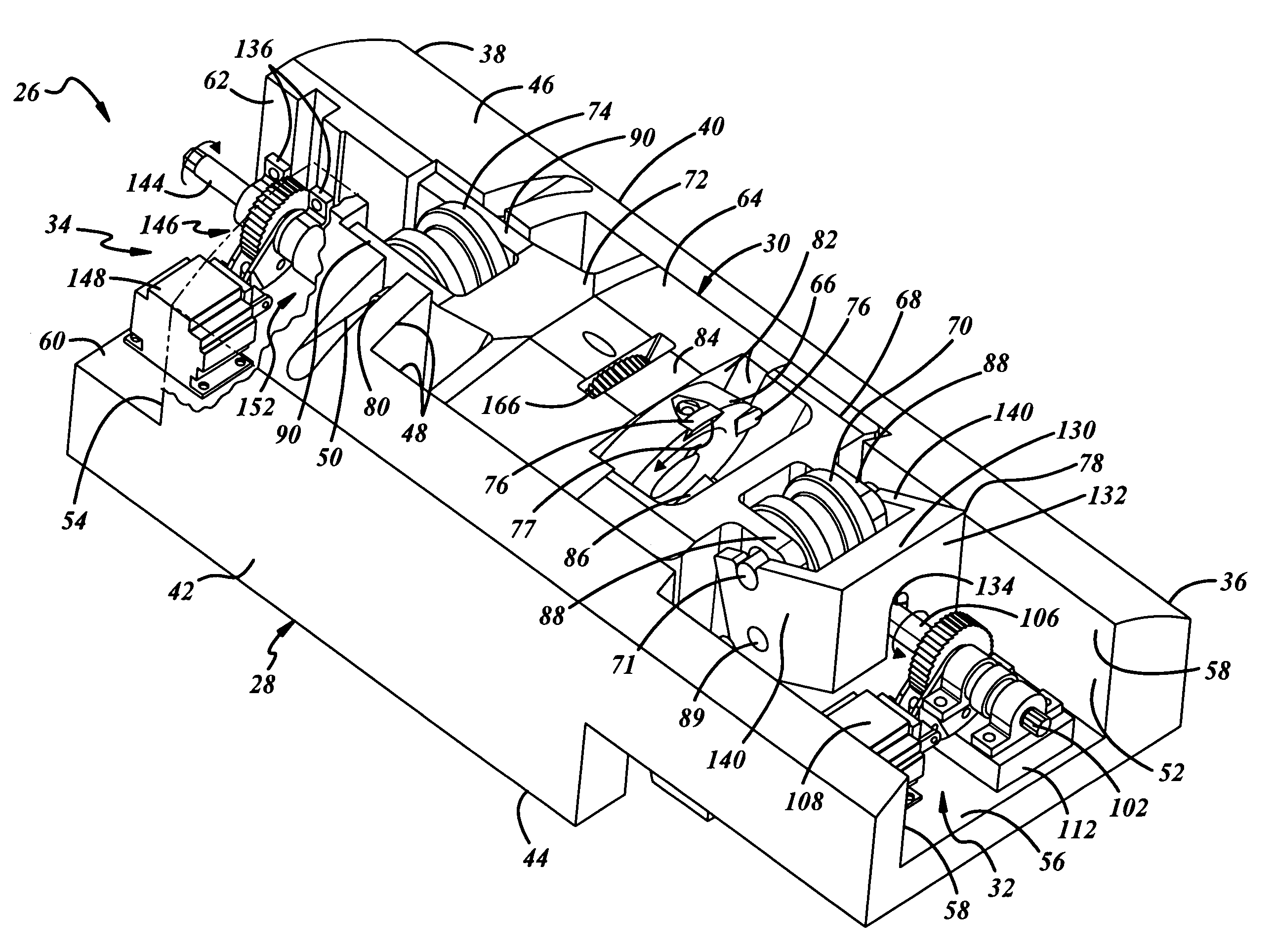

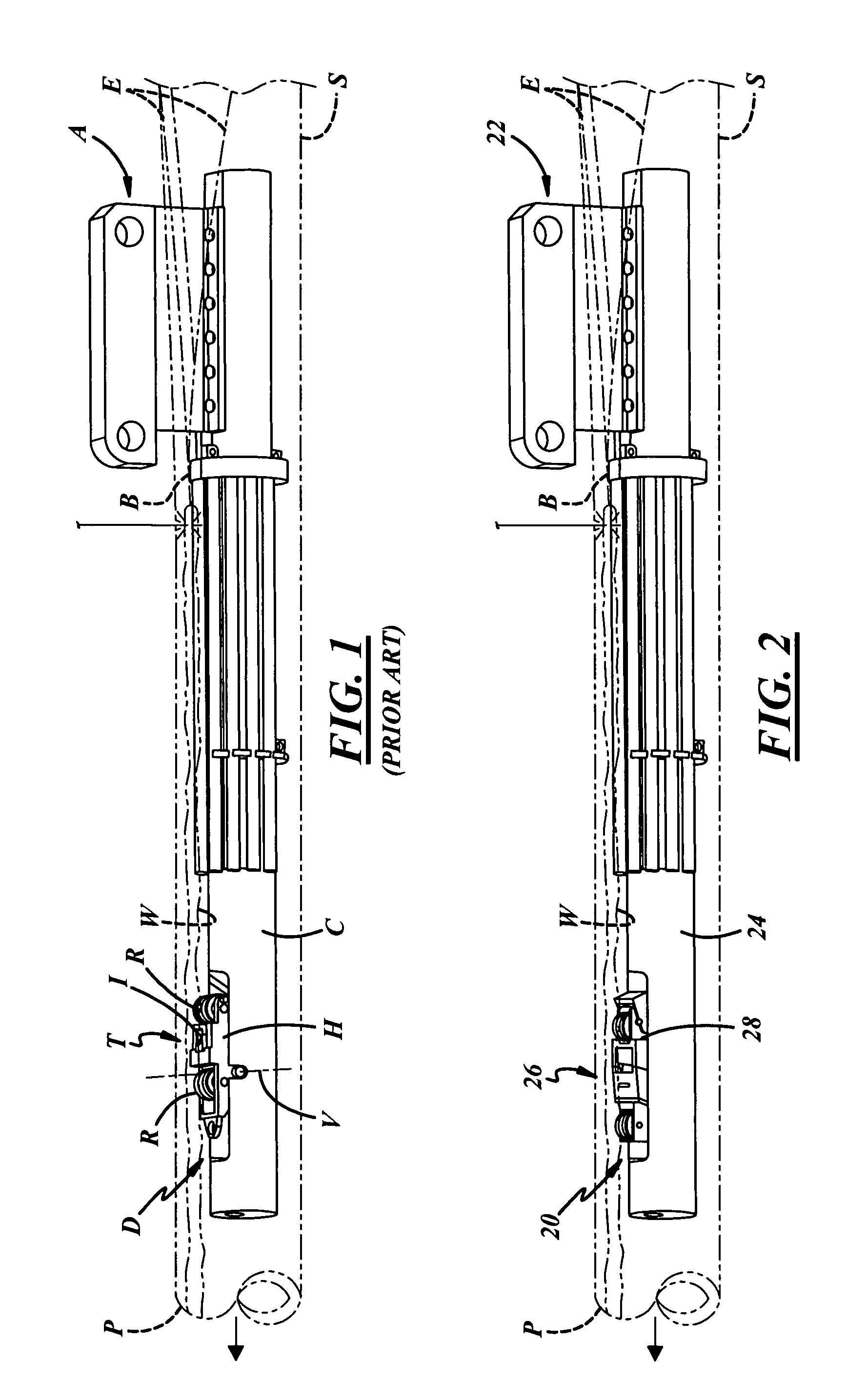

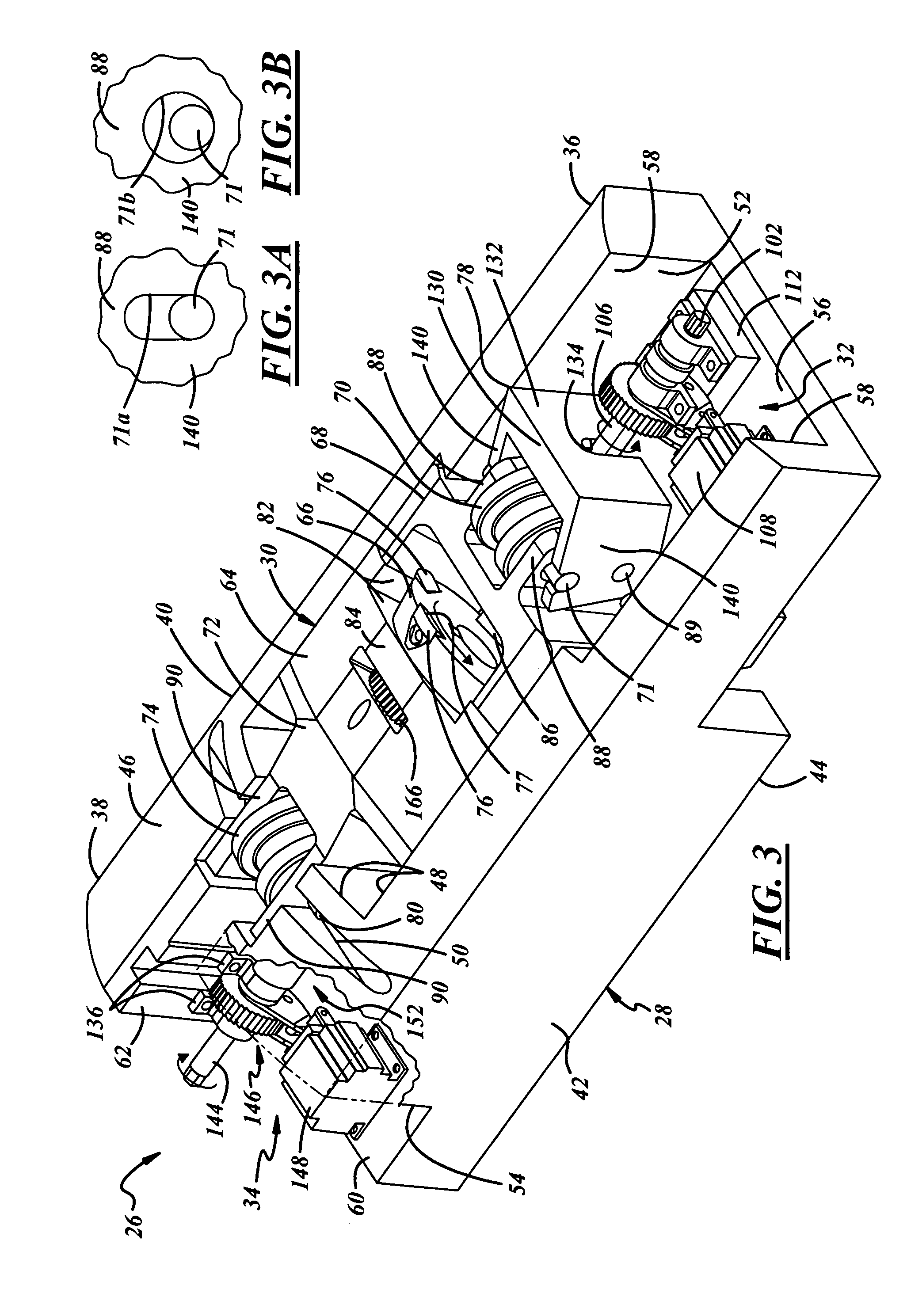

InactiveUS7695224B2Simple designEconomical manufacture and assemblyWelding/cutting auxillary devicesPlaning/slotting machinesButt weldingFurring

Owner:LUMCO MFG

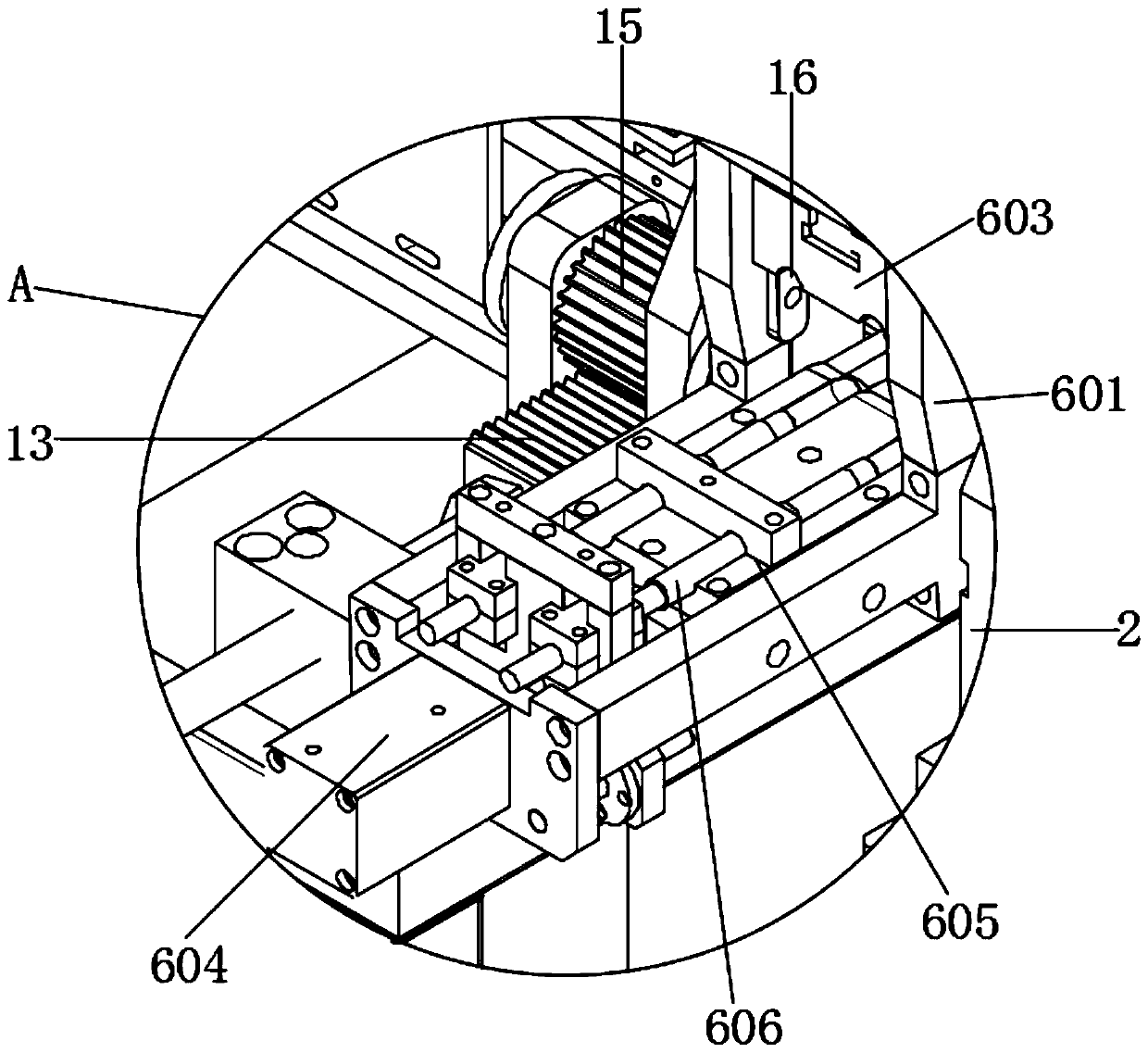

Height-adjustable clamping mechanism for aluminum alloy short pipe cutting

InactiveCN108393532AStable clampingGuaranteed subsequent cutting effectShearing machine accessoriesArchitectural engineeringSkelp

The invention discloses a height-adjustable clamping mechanism for aluminum alloy short pipe cutting. The height-adjustable clamping mechanism comprises a rack and a lifting bottom plate; vertical lifting supporting plates are fixed to the left side and the right side of the top face of a top plate of the rack; upper horizontal supporting plates are fixed to the inner side walls of the top faces of the vertical lifting supporting plates; two vertical adjusting screw rods are located on the two sides of the top plate of the rack; the top ends of the vertical adjusting screw rods are hinged to the corresponding upper horizontal supporting plates, the lower portions of the vertical adjusting screw rods are hinged to the corresponding top plate of the rack, the bottom ends of the vertical adjusting screw rods extend out of the bottom face of the top plate of the rack, and lifting bevel gears are fixed to the bottom ends of the vertical adjusting screw rods; and a double-output-shaft adjusting motor is fixed to the middle of the bottom face of the top plate of the rack. According to the height-adjustable clamping mechanism, a to-be-machined short pipe can be firmly clamped, and the outer side wall and the inner side wall of the to-be-machined short pipe are both supported, so that the subsequent cutting effect is guaranteed, deformation is avoided, the high and low positions of theto-be-machined short pipe can be adjusted through the height-adjustable clamping mechanism, and the cutting effect is improved.

Owner:FOSHAN BENJIEPU ELECTROMECHANICAL TECH CO LTD

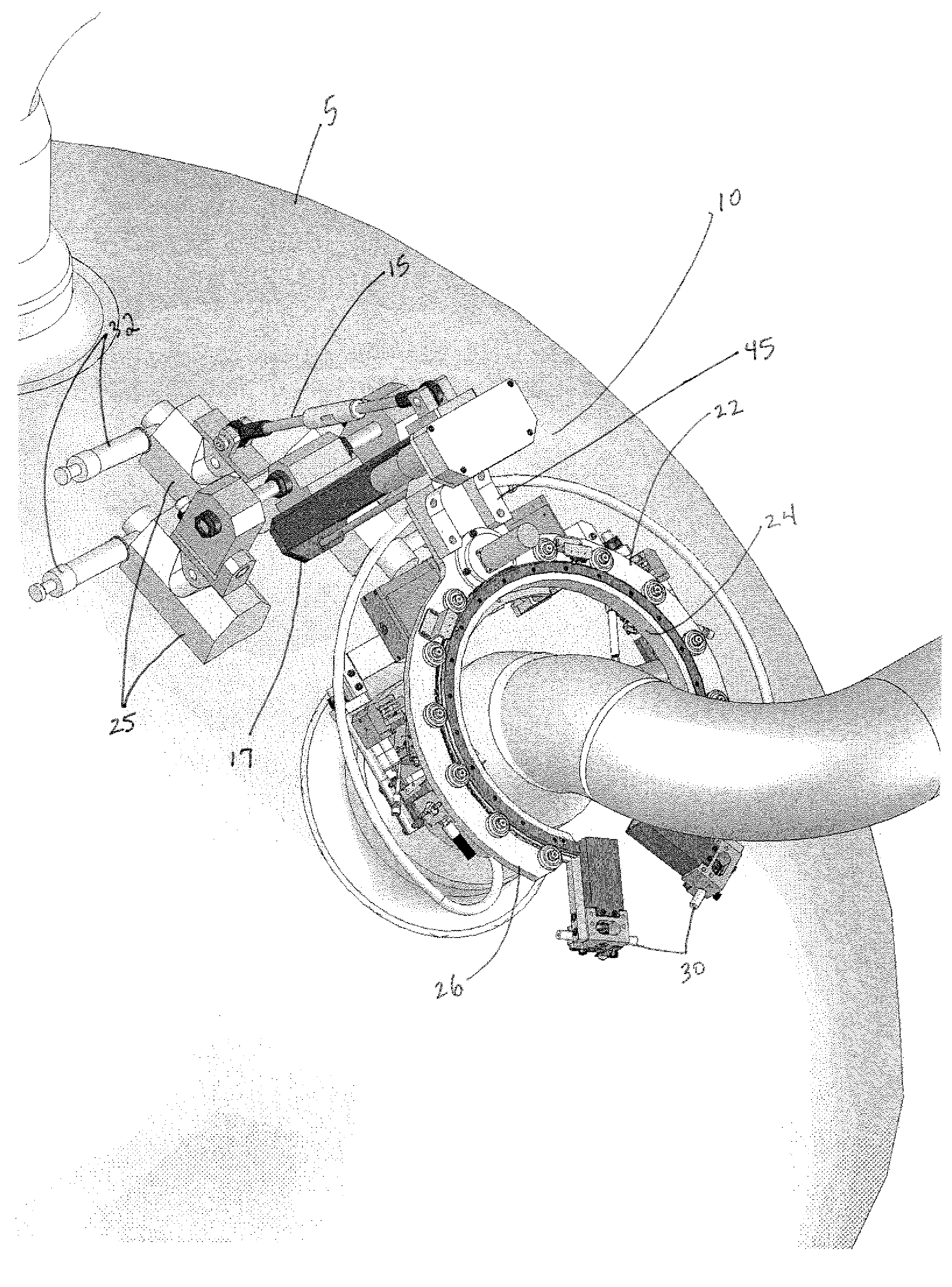

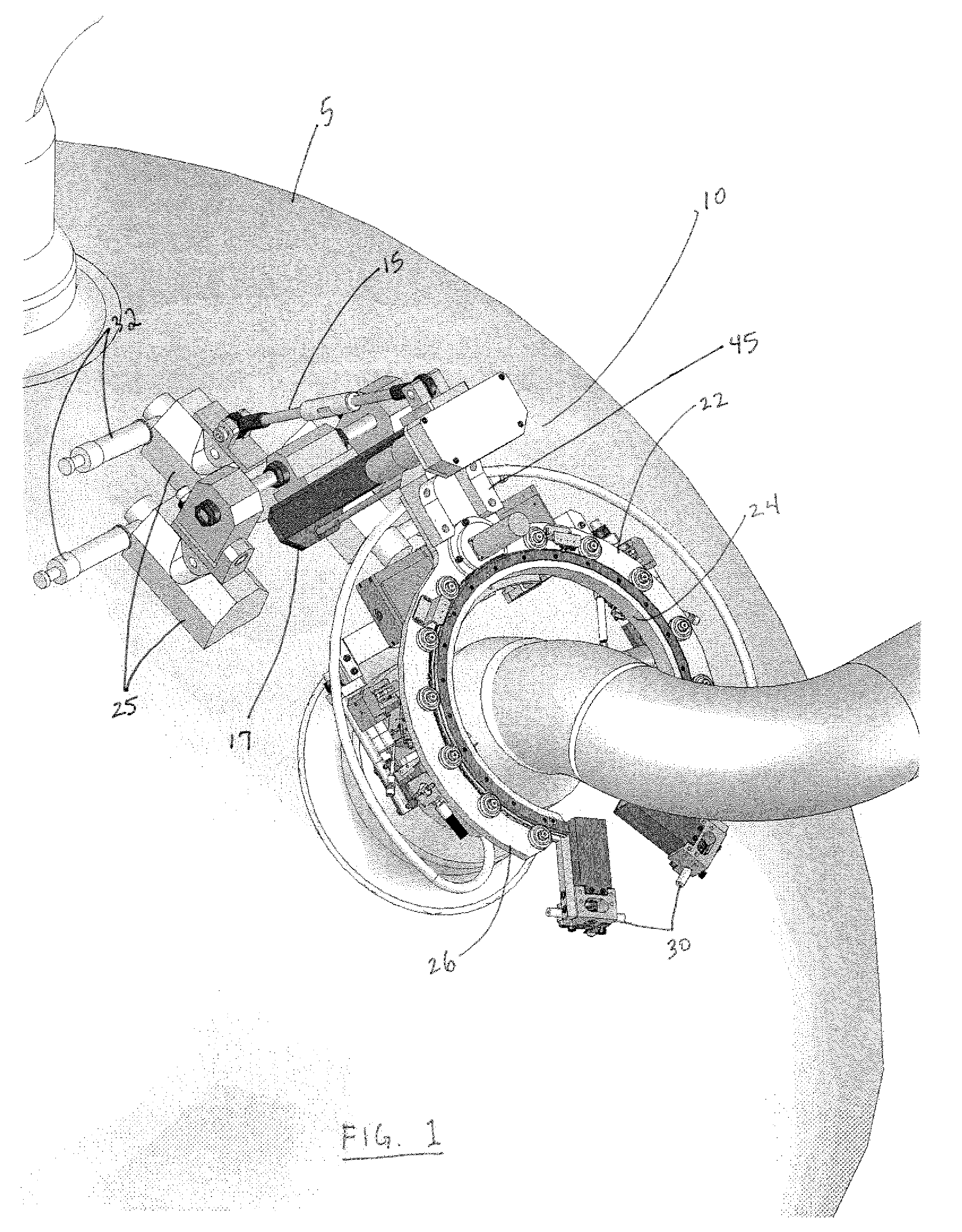

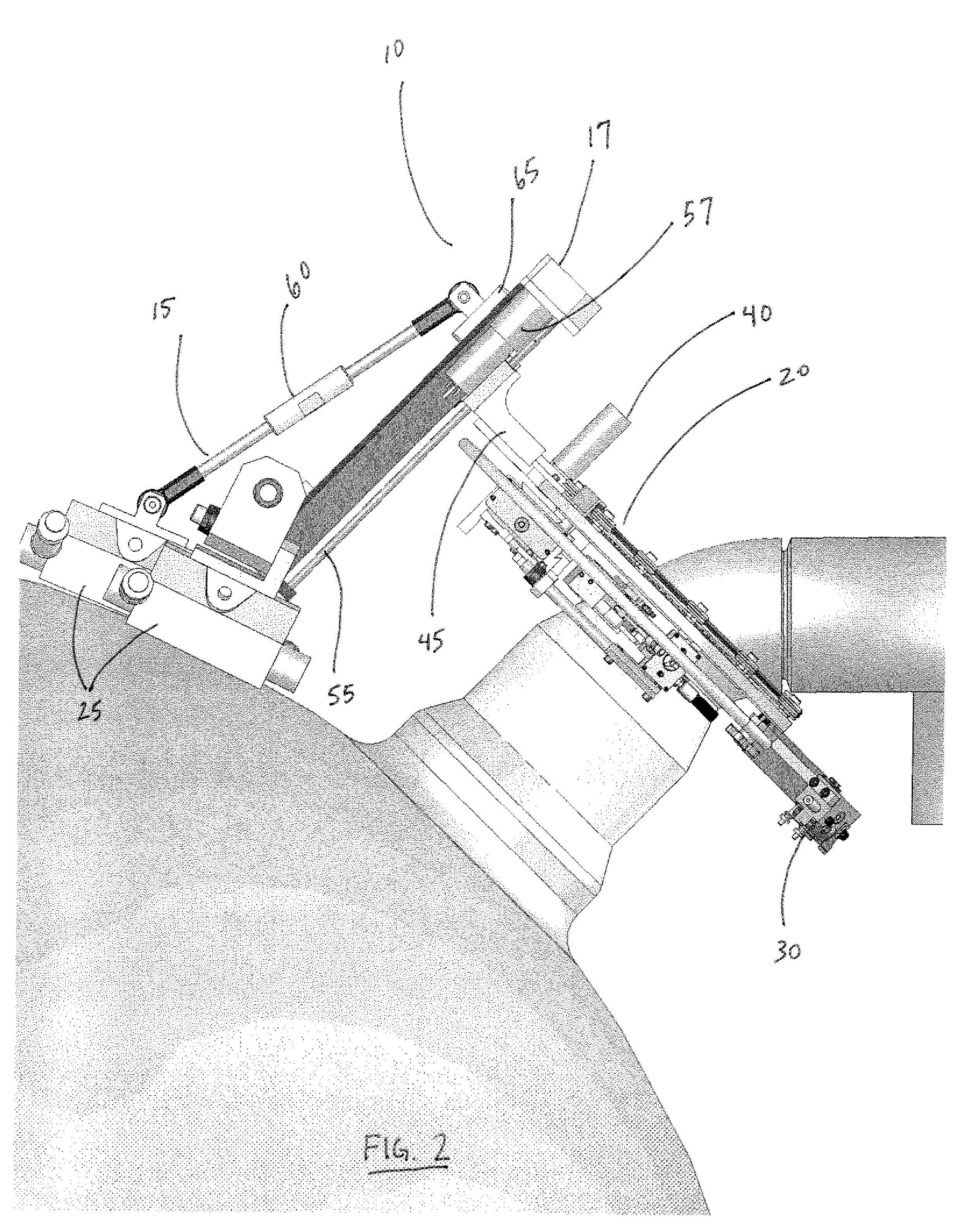

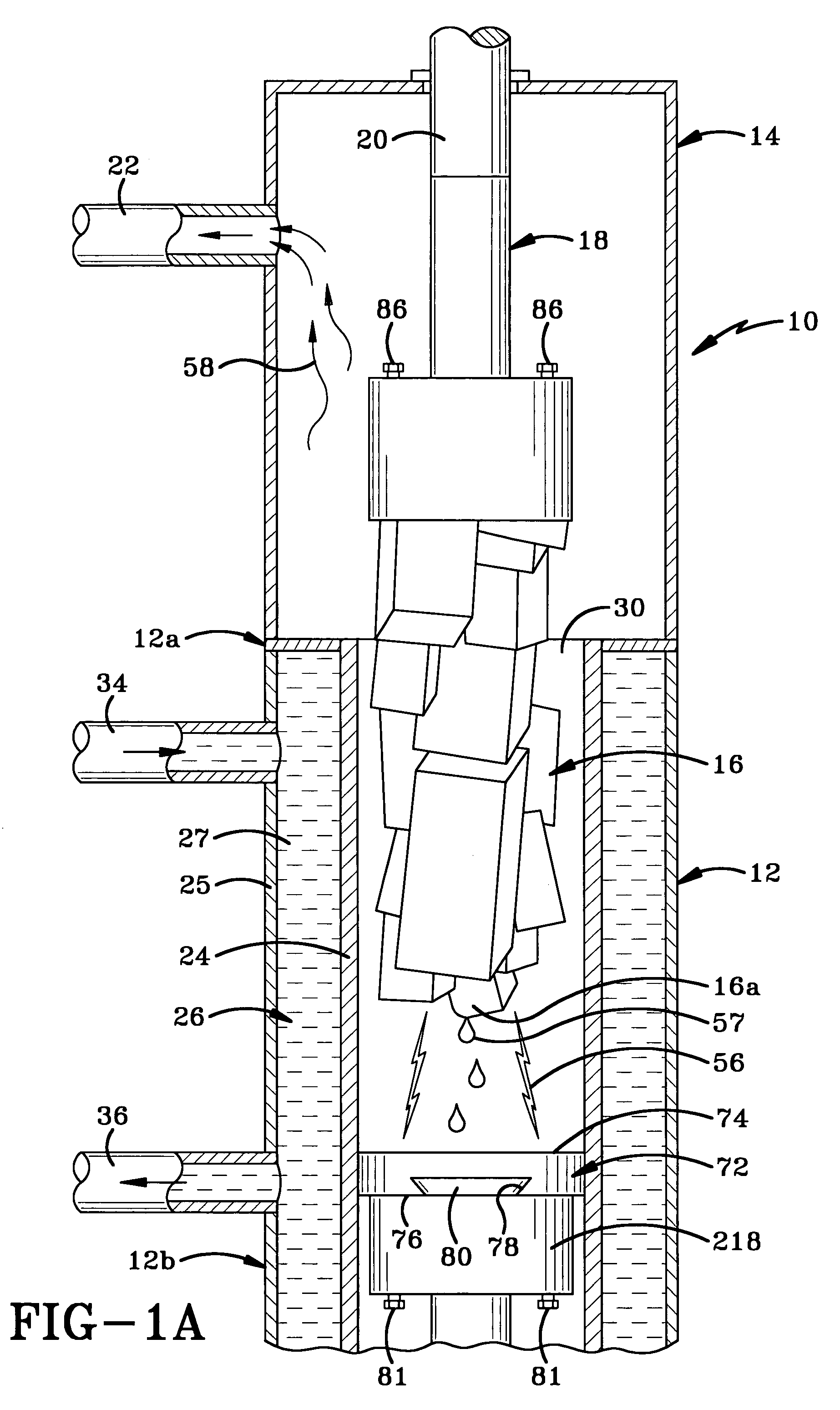

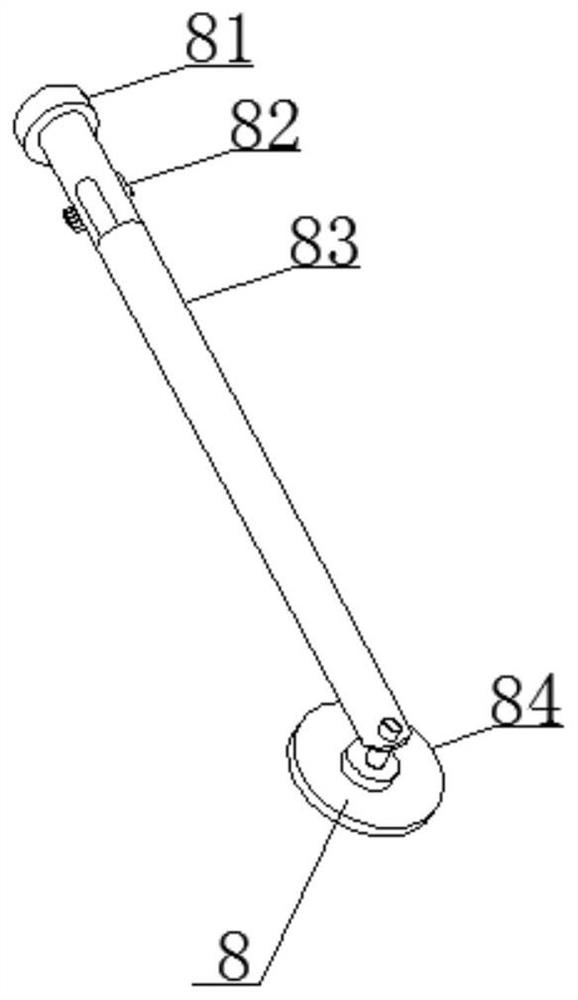

Equipment and process for applying an external structural weld to piping and similarly shaped pressure boundary components

An apparatus and / or process for applying a weld overlay to a nozzle or piping spool of complex configuration is disclosed. In an exemplary embodiment, the welding apparatus comprises a mounting assembly having a plurality of magnetic foot pads, a tension support rod attached at one end to one of the magnetic foot pads, an upper attachment pad at the opposite end of the rod, and a bottom attachment pad attached to at least one other magnetic foot pad; a travel guide, the travel guide attached to the upper attachment pad at one end and the bottom attachment pad at the other end; and a head assembly attached to the travel guide, the head assembly having: i) a track ring assembly having an inner ring and an outer ring, ii.) at least two opposed weld heads attached to the inner track ring, iii.) at least one movable wire feed drive mechanism on the track ring, and iv.) a drive mechanism located on the outer ring of the track ring, the drive mechanism adapted to permit rotation of the inner ring and the weld heads around the component to be welded.

Owner:AZZ WSI

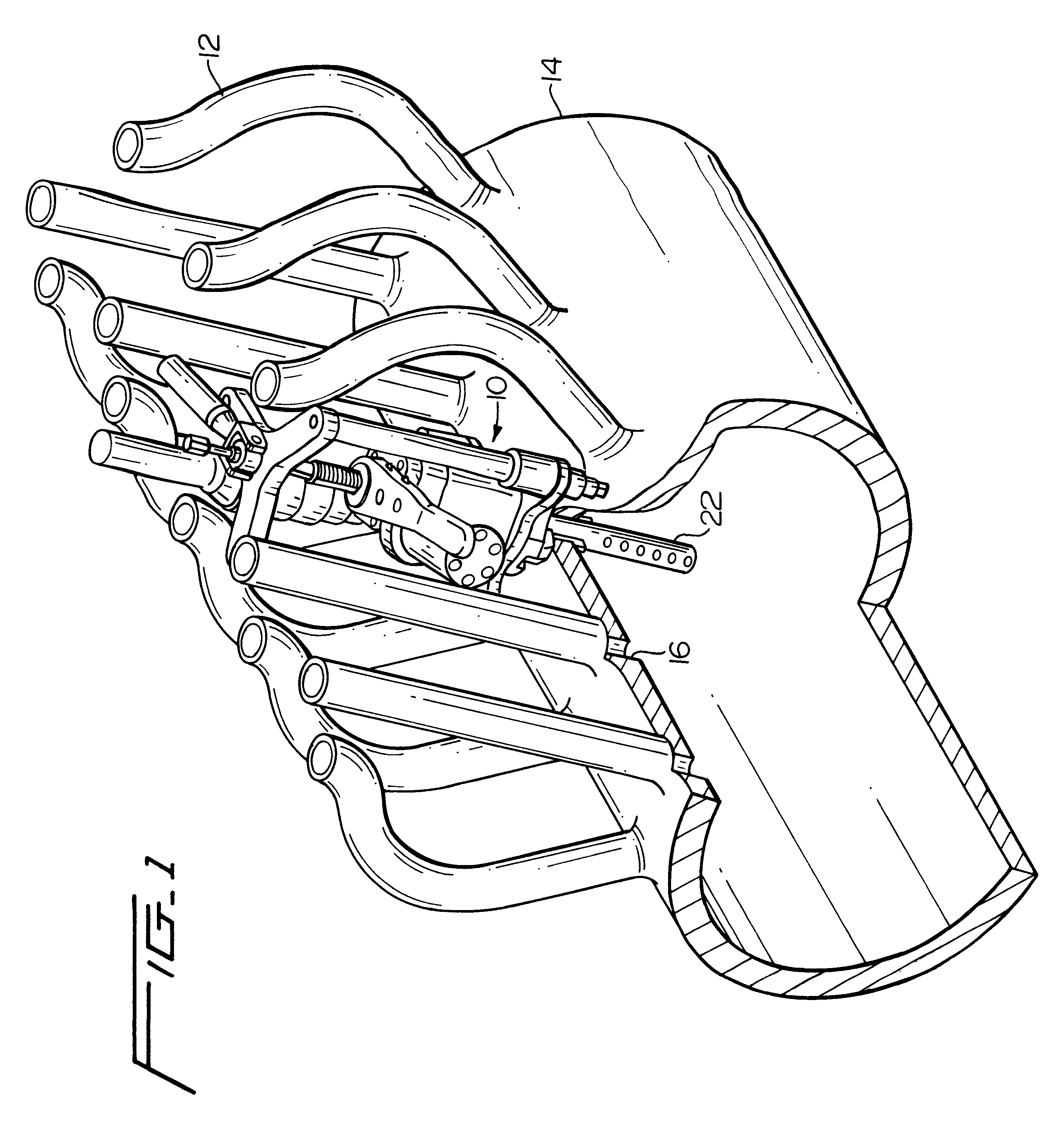

Manufacturing process of stainless steel bent tube type exhaust manifold

The invention discloses a manufacturing process of a stainless steel bent tube type exhaust manifold. The manufacturing process comprises the following steps: cutting a stainless steel coiled sheet to steel belts with the corresponding width according to the diameter of the exhaust manifold to be manufactured; performing cold roll forming on the steel belts on a pipe welding machine to obtain pipe billets; using a solid-state high frequency welder to weld the seams of the pipe billets and obtain a straight seam raw material long pipe, wherein the welding frequency of the solid-state high frequency welder is 150-300KHz and the walking linear velocity of the pipe billets is 60-80m / min; cutting the raw material long pipe to raw material short pipes with the corresponding length according to the length of the exhaust manifold to be manufactured; processing the raw material short pipes on a machine tool to form plug-in installation sections and sealing slope sections and obtain exhaust manifold billets; and bending the exhaust manifold billets on a bending machine to obtain bent tube type exhaust manifolds with the required shape. The consumable material of the manufacturing process is less; and the manufactured bent tube type exhaust manifold has the advantages of high heat-conducting efficiency, oxidation resistance, high temperature strength, low thermal fatigue and the like.

Owner:无锡鼎丰不锈钢管有限公司

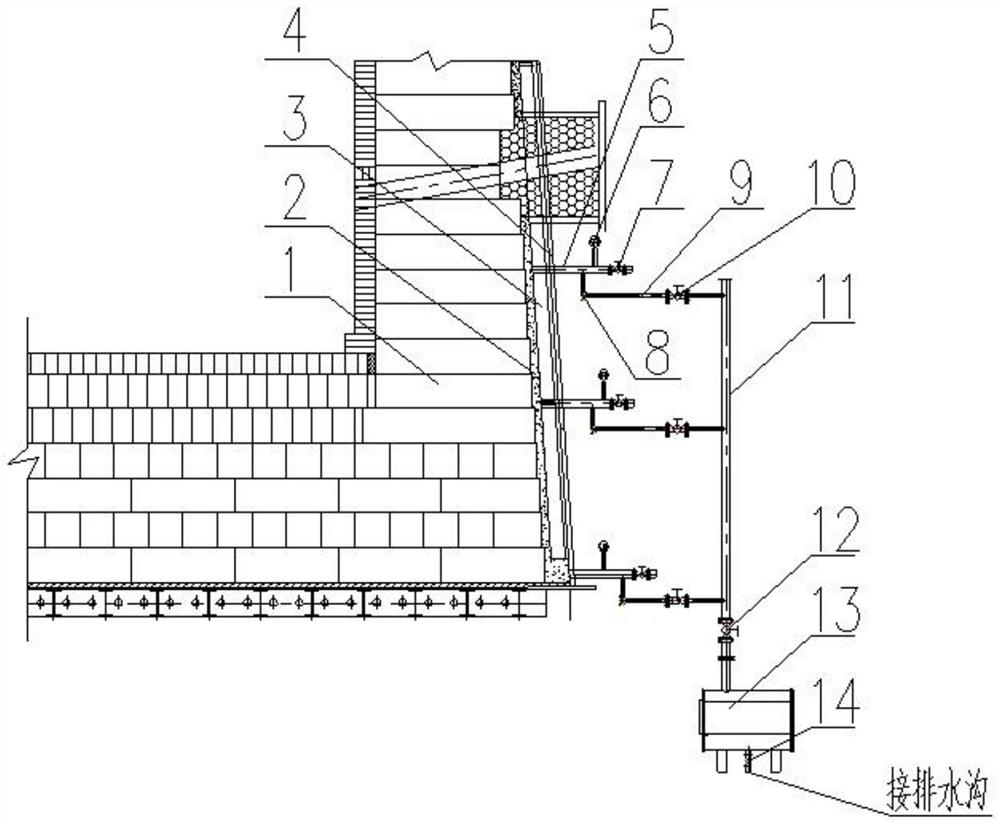

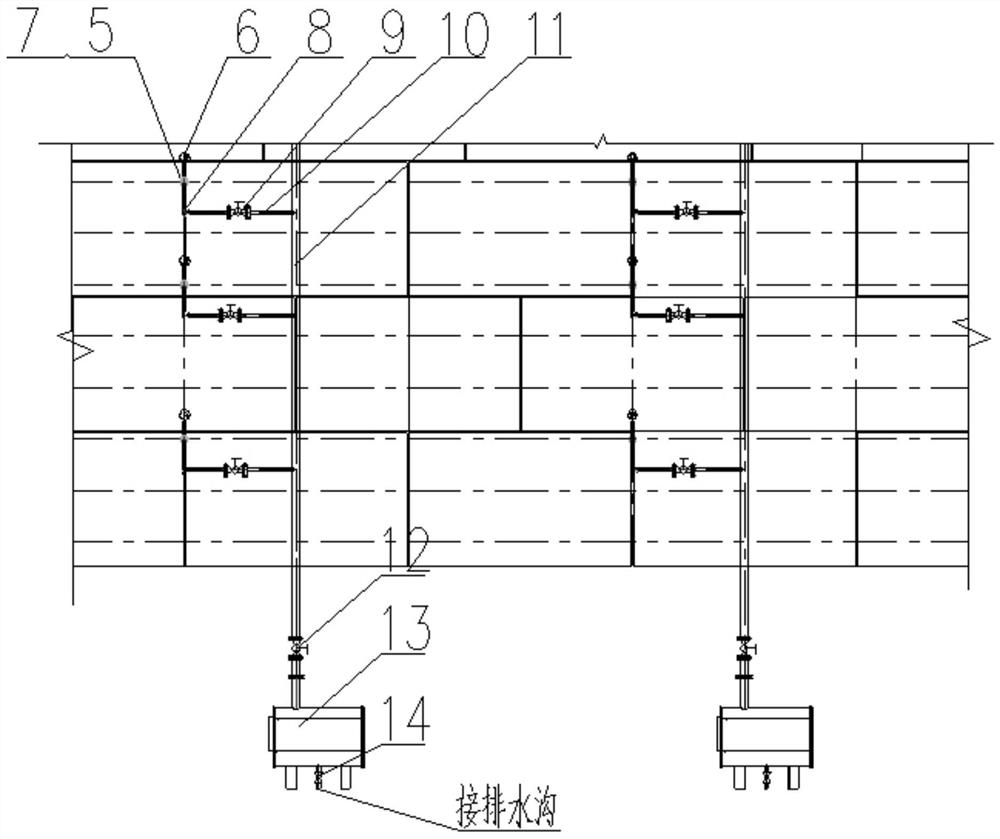

Drain system for blast furnace hearth standing water

PendingCN111850204AGuarantee unimpededClear the blockage in timeDischarge devicesChecking devicesStraight tubeEngineering

The invention relates to a drain system for blast furnace hearth standing water, and belongs to the field of blast furnaces. The drain system comprises short drain pipes, branch drain pipes and a maindrain pipe. The tail end of the main drain pipe is connected with an automatic drain device. Pressure detection devices and overhaul valves are arranged on the short drain pipes. The overhaul valvesare arranged at the positions, behind the pressure detection devices, of the tail ends of the short drain pipes. The branch drain pipes comprise straight pipe sections I and straight pipe sections II.One ends of the straight pipe sections I are connected with one ends of the straight pipe sections II through overhaul three-way valves to form L-shaped pipe body structures, the other ends of the straight pipe sections are connected to the short drain pipes, and the other ends of the straight pipe sections II are connected to the main drain pipe. The whole drain pipeline composition is simple, the standing water gathered in furnace hearths in the production process of the blast furnaces can be drained in time, online unblocking can be achieved, maintenance is convenient, the service life ofthe blast furnace hearths is prolonged, and economic benefits are increased.

Owner:CISDI ENG CO LTD +2

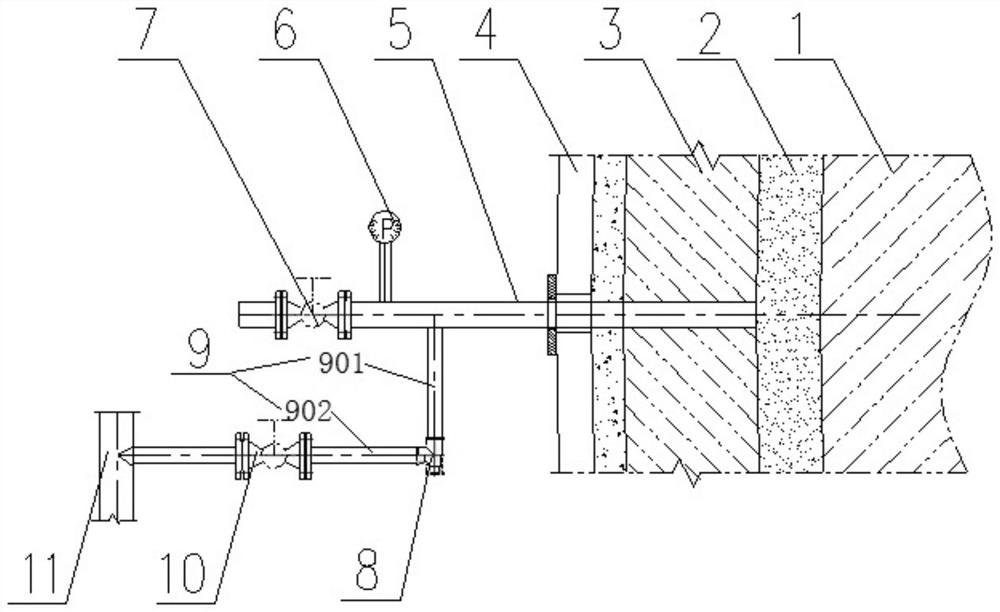

Blast furnace hearth and blast furnace hearth pouring long life prolonging method

InactiveCN111893231AImprove heat transfer performanceImprove pouring effectBlast furnace detailsCooling devicesBrickEngineering

The invention relates to a blast furnace hearth and a blast furnace hearth pouring long life prolonging method. The blast furnace hearth comprises a furnace shell, a pouring layer, a cooling wall, a ramming layer, carbon bricks and a furnace hearth pouring layer. The side walls of the furnace shell, the pouring layer, the cooling wall, the ramming layer, the carbon bricks and the furnace hearth pouring layer are arranged in sequence from outside to inside, and the furnace bottoms of the furnace hearth pouring layer and the carbon bricks are arranged from top to bottom. The method comprises thesteps that after the charge level is lowered, the water fetching amount for cooling furnace hearth scrap iron in slag is controlled through intermittent water fetching operation and evaporation cooling operation; a first drill hole and a second drill hole are formed in the furnace hearth region according to the thickness calculation of the furnace shell, the pouring layer and the cooling wall, and the first drill hole and the second drill hole communicate with each other; a press-in short pipe is arranged in the first drill hole, a valve is installed on the short pipe to be used for follow-upair exhaust, drainage and press-in operation, and the valve is closed after the operation is accomplished; baking operation is conducted after furnace hearth pouring operation is accomplished, and drain valves are sequentially opened to conduct air exhaust and drainage; and the baking operation of the furnace hearth is accomplished, and carbon quality materials are pressed into the cooling wall and the ramming layer by the press-in short pipe in the blowing-in material charging process after the drain valves are opened to drain water.

Owner:SGIS SONGSHAN CO LTD

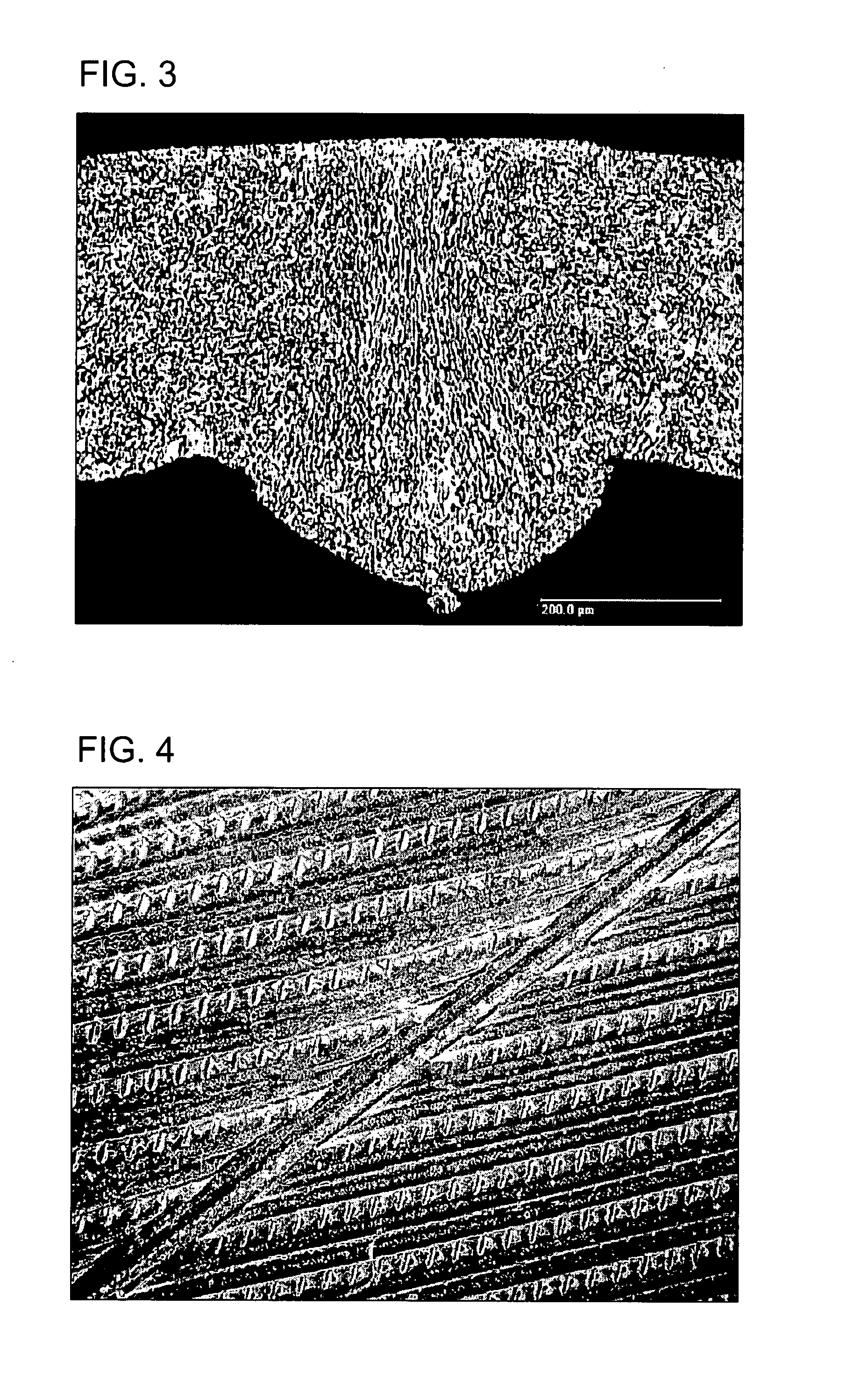

Method for the production of tubes for heat exchangers from precipitation-hardened alloys by high-frequency induction welding

InactiveUS20080060722A1Simple and inexpensive to implementExcellent mechanical propertiesFurnace typesHigh frequency current welding apparatusIngotCylindrical geometry

Described herein is an embodiment of a method for the production of tubes for heat exchangers, including the steps of: a) producing an ingot with rectangular cross section (plate) b) hot-rolling said plate so as to form a blank c) rapidly cooling said blank by spraying water inside a purposely designed cooling tunnel d) cold-rolling said blank until a strip or skelp is obtained e) forming the tube starting from the skelp to pass from the plane geometry of the skelp to the cylindrical geometry of the tube and welding the tube; in which the ingot is formed starting from an alloy that can undergo precipitation hardening, and the tube is welded by high-frequency induction welding.

Owner:KME ITAL

Method of manufacturing electrodes and a reusable header for use therewith

ActiveUS6983007B2Good adhesionEasy detachmentElectric discharge heatingTitanium electrodePolymer science

A method of manufacturing titanium electrodes in a vacuum arc remelting furnace as well as a reusable header for use in the remelting process is disclosed. An electrode may be attached to the reusable header and remelted in the furnace a number of times until a final ingot of the desired metallurgical quality is produced. The header and electrode are provided with a complimentarily shaped interlocking recess and projection to secure them together. The electrode may alternatively be integrally formed with a starter stub that includes a recess or projection that interlocks with a complimentarily shaped projection or recess on the header. At least a section of the header is made of the same metal as the electrode to be melted to reduce contamination of the ingot being formed in the furnace. Alternatively the starter stub is made from the same metal as the electrode.

Owner:HOWMET AEROSPACE INC

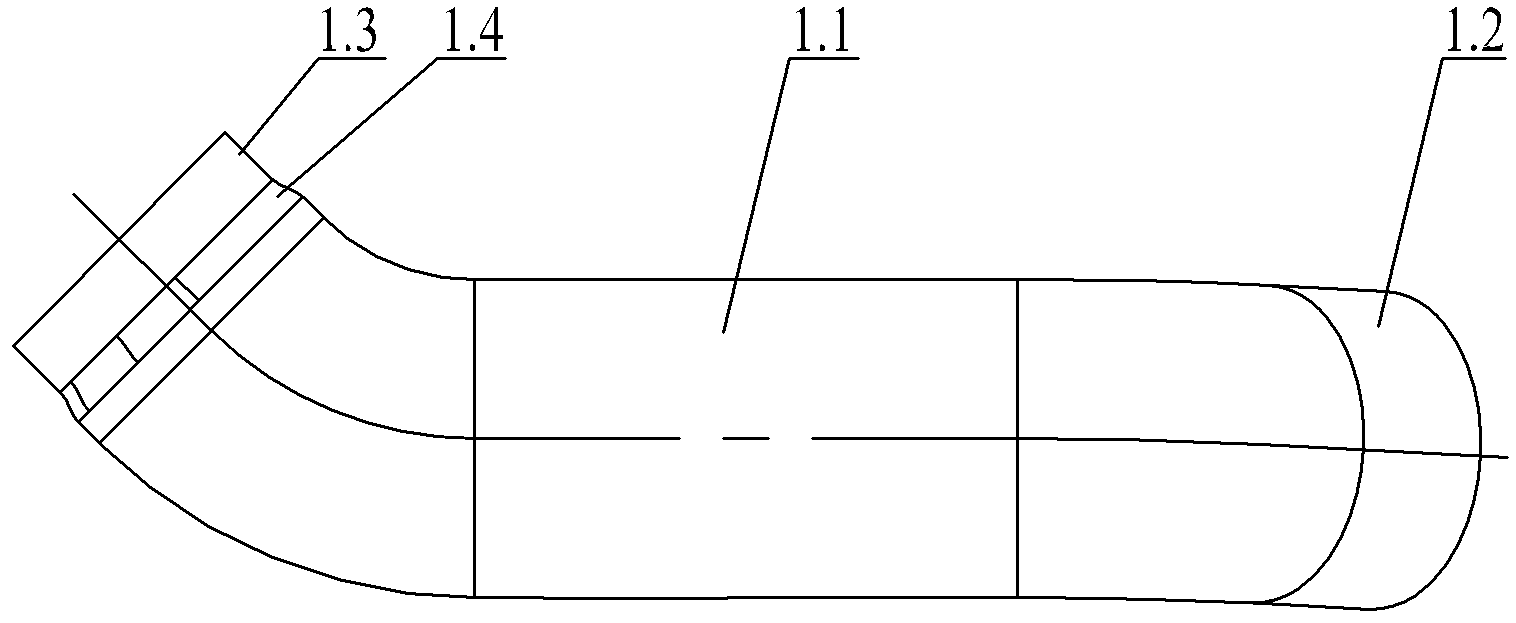

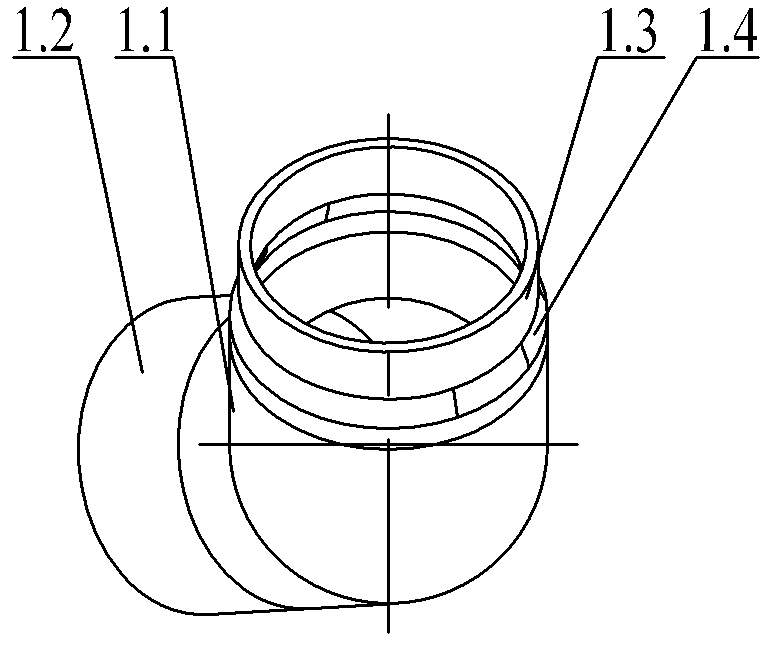

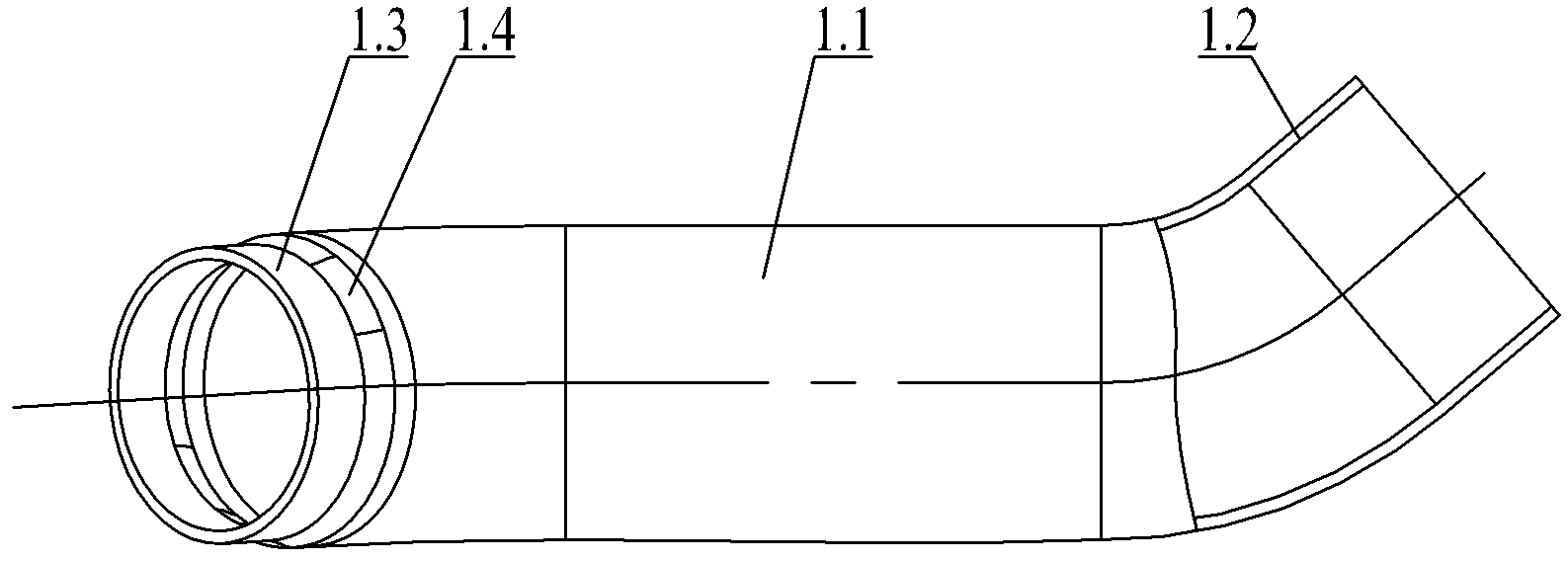

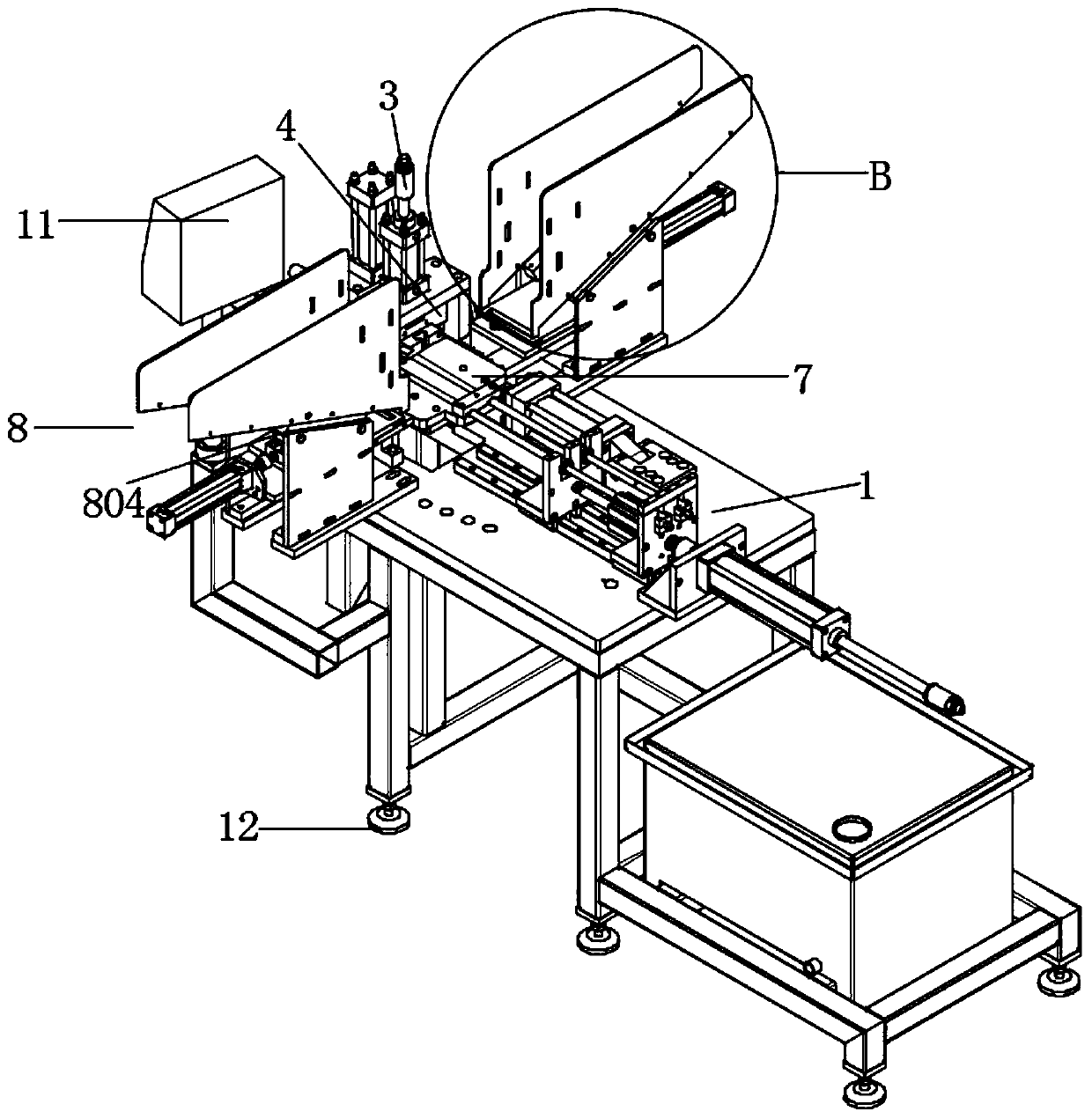

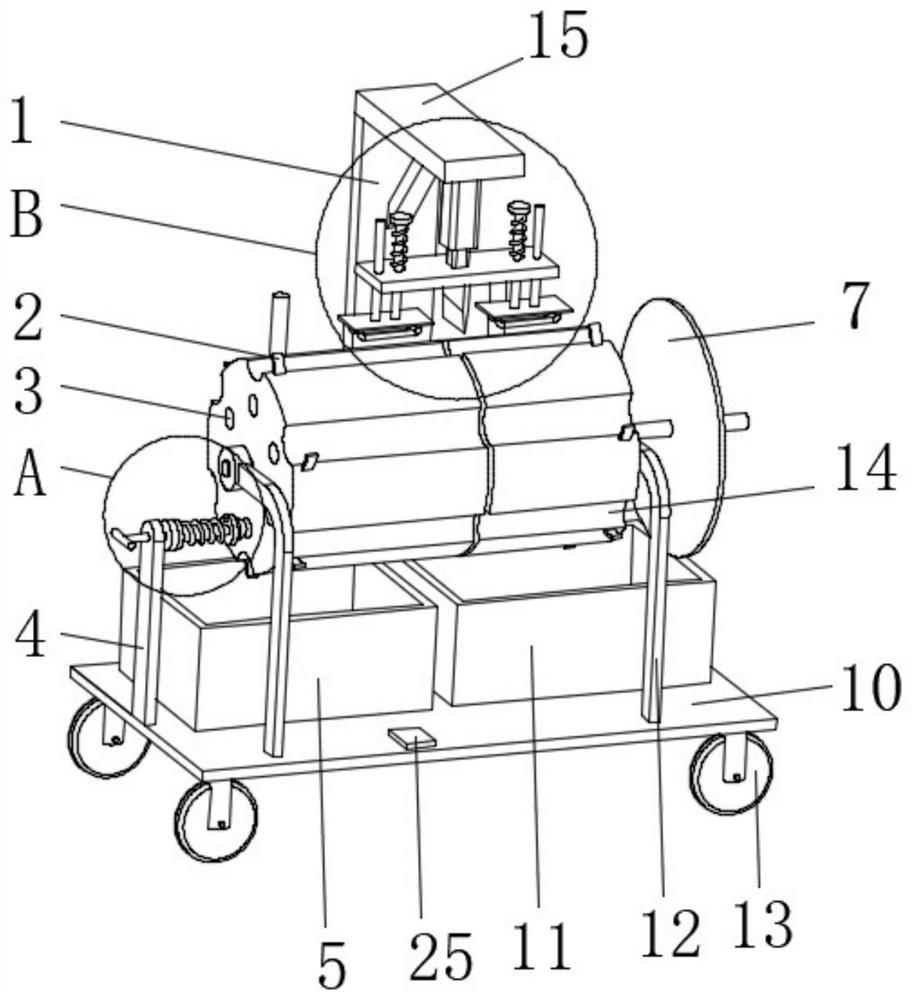

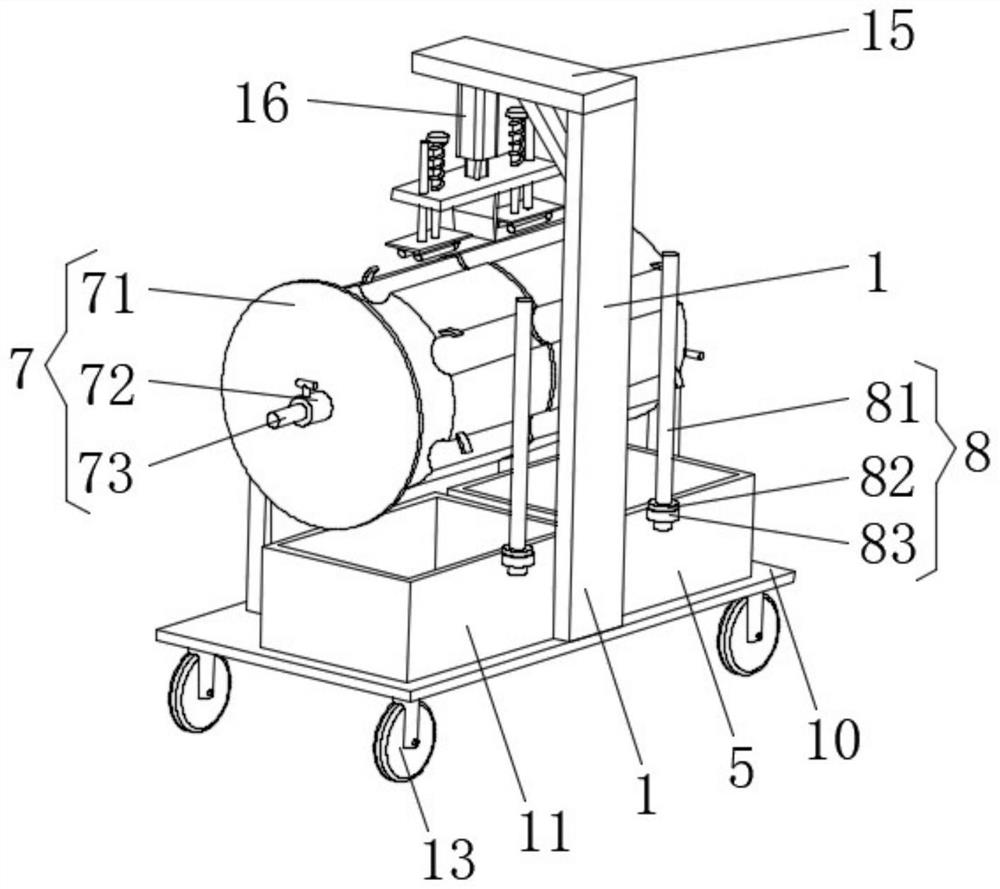

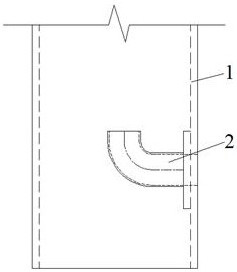

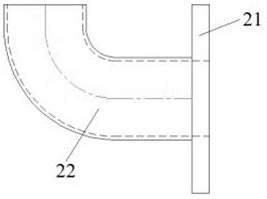

Copper pipe bending machine

ActiveCN110666012ACurvature is accurateFully automatedMetal-working feeding devicesPositioning devicesEngineeringSkelp

The invention discloses a copper pipe bending machine in the technical field of pipe bending machines. The copper pipe bending machine comprises a rack. The upper end of the rack is fixedly connectedwith a mold processing piece. The upper end of the mold processing piece is fixedly connected with an adjustable air cylinder. The power end of the adjustable air cylinder penetrates through the upperend of a mold processing piece and is fixedly connected to a follow-up mold. One side of the mold processing piece is rotatably connected with a pipe bending mechanism through a rotating shaft. The upper end of the rack is fixedly connected with a placing plate on the other side of the mold processing piece. Feeding mechanisms are arranged at the front end and the rear end of the placing plate. Apositioning mechanism is arranged on the other side of the placing plate and at the upper end of the rack, so that a pipe needing to be bent can be firmly fixed in the placing plate and does not movein the bending process. Therefore, it is ensured that the pipe bending degree is accurate, and accidents caused after the pipe flies out are further avoided. The bending position of a short pipe canbe adjusted according to the positions of two sets of positioning plates. Pipe bending automation of the liquid storage device type short pipes is achieved. The working efficiency is greatly improved.The labor intensity of workers is reduced.

Owner:安徽省荣源智能科技有限公司

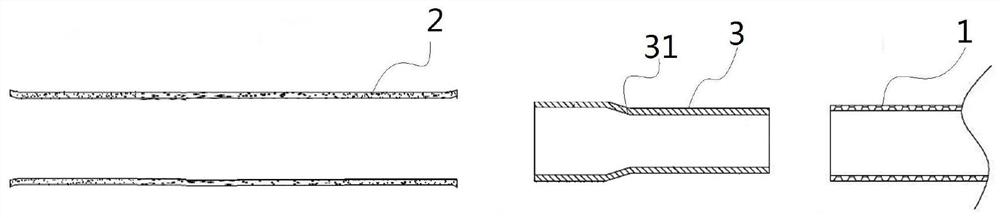

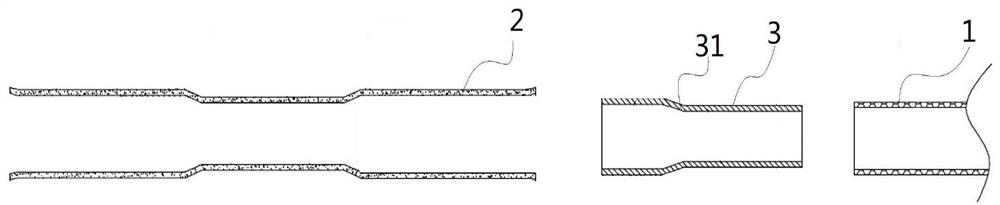

A tensile-strengthened connection method for metal pipe fittings

ActiveCN112628488BEasy to processImprove connection construction efficiencyNon-disconnectible pipe-jointsPipe fittingStructural engineering

Owner:深圳市喜德丽实业有限公司

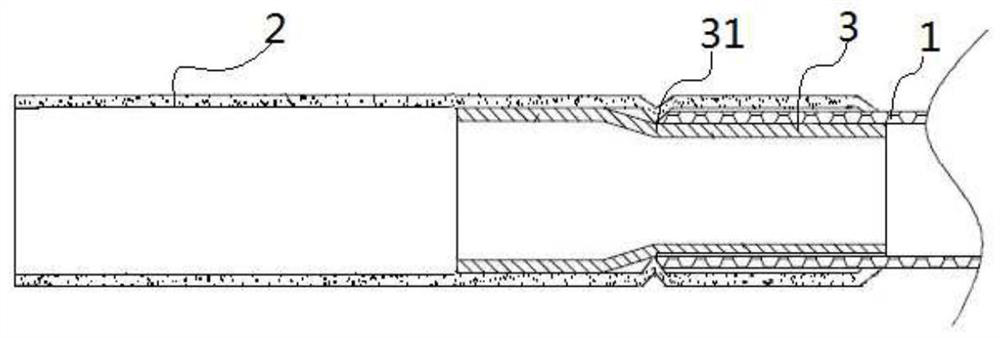

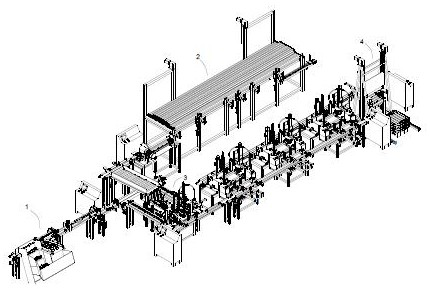

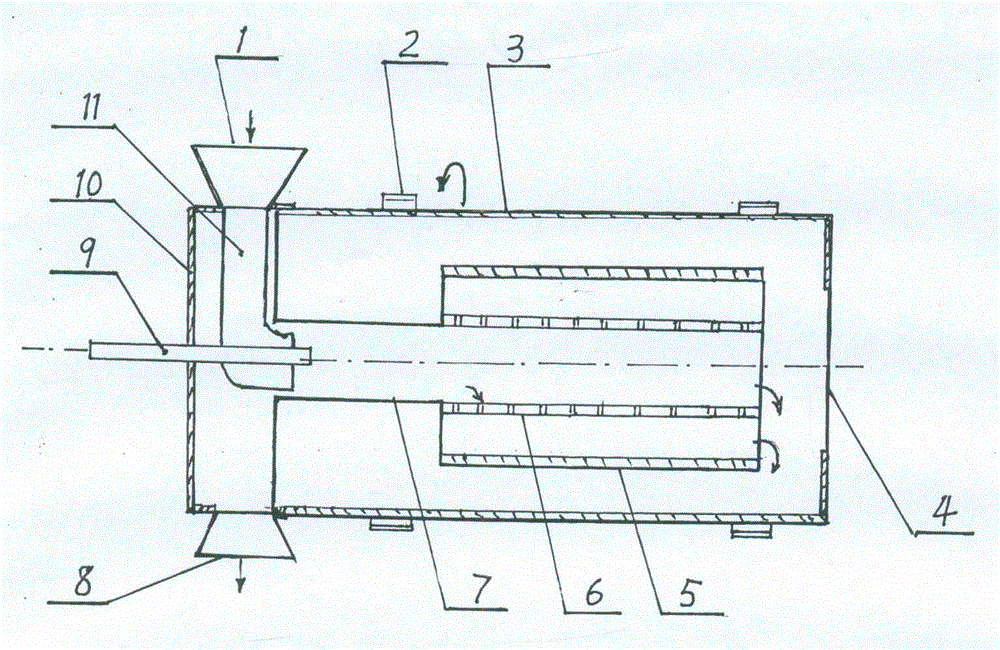

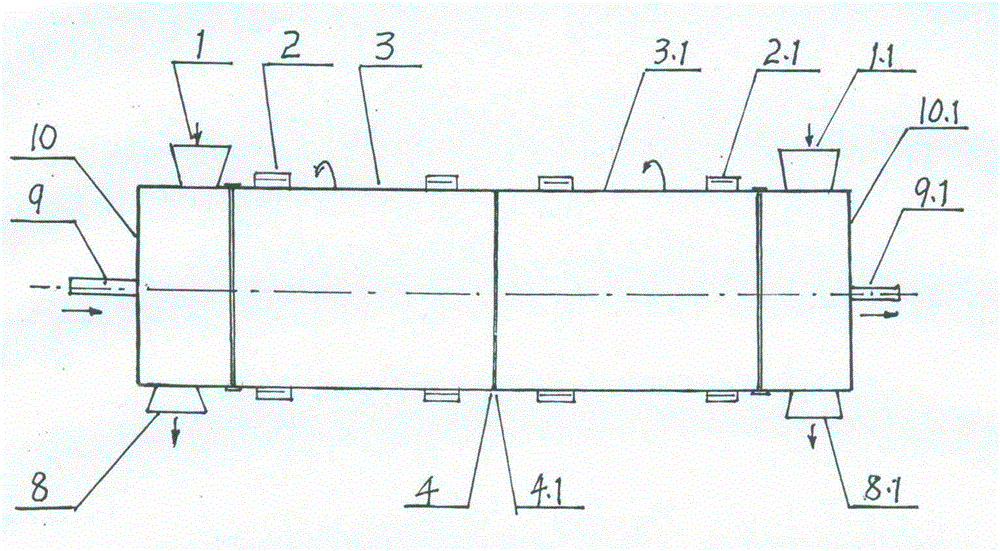

Full-automatic production line for heating radiators

PendingCN113103017AReasonable structureStrong consistencyOther manufacturing equipments/toolsProcess engineeringSkelp

The invention discloses an automatic production line for heating radiators. The automatic production line comprises an automatic radiator head sorting and directional discharging device, an automatic pipe distributing device, an automatic welding device and a finished product stacking device, and the automatic radiator head sorting and directional discharging device and the automatic pipe distributing device convey radiator heads into the automatic welding device and cut the radiator heads into short pipes with the same length. The radiator heads and the short pipes are welded and fixed into a finished product after being combined by the automatic welding device. The finished product is sent into the finished product stacking device and is sent out for stacking. The production line is reasonable in structure, full-process automation of heating radiator production is achieved through cooperation of all the devices and mechanisms, the product consistency is high, meanwhile, the efficiency is high, the production cost can be effectively reduced, and the market competitiveness of enterprises is improved.

Owner:河北中迅通自动化设备有限公司

Automatic pipe fitting cutting equipment with double stations and for screening materials

InactiveCN111804976AEnsure personal safetyImprove work efficiencyTube shearing machinesSortingPipe fittingMaterial distribution

The invention discloses automatic pipe fitting cutting equipment with double stations and for screening materials. The automatic pipe fitting cutting equipment comprises a bottom plate, wherein, fouruniversal wheels with brake pads are uniformly installed on the lower surface of the bottom plate, a circular column is arranged on the upper part of the bottom plate, supporting rods at the left andright ends of the circular column are correspondingly and fixedly connected with inner rings of two first bearings, outer rings of the two first bearings are correspondingly and fixedly connected to upper ends of two bending rods, the lower ends of the two bending rods are correspondingly and fixedly connected with the front side of the lower surface of the bottom plate, six cutting pipe placing grooves are formed in the side surface of the circular column around the axis of the circular column, an annular groove is formed in the middle of the side surface of the circular column, a cutting pipe positioning device is installed on the supporting rod at the right end of the circular column, the left end of the upper surface of the bottom plate is fixedly connected with the lower ends of the supporting rods, and screw holes and screw rods on the supporting rods are connected in a threaded mode. After processing, a long pipe and a short pipe automatically receive the materials separately, manual material distribution by the staff is not needed, the working efficiency is greatly improved, and the personal safety of workers is ensured.

Owner:东阳市俊华电器销售有限公司

Overall welding method of stainless steel pipeline

ActiveCN104028907APrevent oxidationAvoid pollutionWelding/cutting auxillary devicesPipeline systemsSS - Stainless steelSpot welding

The invention relates to the technical field of stainless steel welding, and disclosed an overall welding method of a stainless steel pipeline. The overall welding method includes the steps that firstly, pollution layers on welding openings of the stainless steel pipeline are removed, and the start end of the stainless pipeline is closed through a sealing cover; secondly, spot welding is conducted on the whole stainless steel pipeline, and the welding openings are sealed through masking paper; thirdly, a stainless steel test weld short pipe is arranged at the tail end of the stainless steel pipeline in a spot welding mode, the spot welding portion is sealed through masking paper, the other end of the stainless steel test weld short pipe is sealed through transparent adhesive tape, and a small hole is formed in the sealing portion; fourthly, a nitrogen pipeline penetrates through a sealing ring at the start end of the stainless steel pipeline and is inflated with nitrogen for 30 minutes, and test weld is conducted in the joint of the stainless steel test weld short pipe and the stainless steel pipeline; fifthly, the color of a weld joint is observed through the sealing portion of the stainless steel test weld short pipe until the weld joint turns from black to blue; sixthly, the inflation amount of nitrogen is maintained, and welding points of the whole stainless steel pipeline are welded. By the application of the overall welding method, welding work quality and efficiency are improved.

Owner:柏诚系统科技股份有限公司

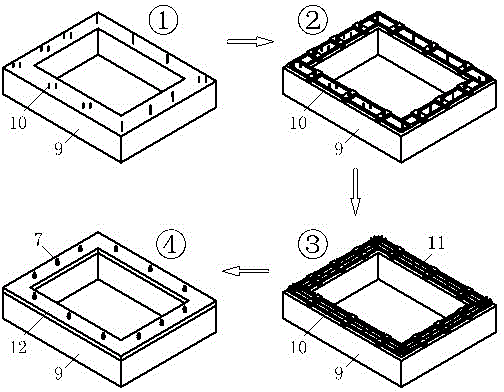

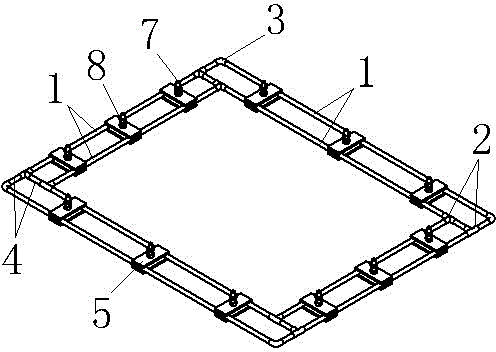

Embedded bolt positioning method and positioning frame applied to same

InactiveCN104675126AFixed flexible and accurateFlexible and precise positioningFoundation engineeringBuilding material handlingPipe fittingSkelp

The invention discloses an embedded bolt positioning method and a positioning frame applied to same. The embedded bolt positioning method comprises connecting steel tubes, elbows and tee joints into a hollow-square-shaped frame; fixing a group of embedded bolt modules into parallel steel tubes on four edges of the hollow-square-shaped frame according to design requirements; then placing the hollow-square-shaped frame onto the top surface of a foundation in a mode that the head portions of embedded bolts are placed upwards; pouring the hollow-square-shaped frame with the embedded bolts onto the foundation. According to the embedded bolt positioning method, the pipes are connected into the hollow-square-shaped frame; by selecting long pipes of different lengths, the dimensions of the inner frame and the outer frame of the hollow-square-shaped frame can be adjusted freely, and by selecting short pipes of different lengths, the spacing between the inner frame and the outer frame of the hollow-square-shaped frame can be adjusted to adapt to embedded bolts with different foundations, different diameters and different positioning requirements; during site construction, the embedded bolts can be positioned and fixed flexibly and accurately, use flexibility and convenience can be obtained, and construction welding workload can be reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

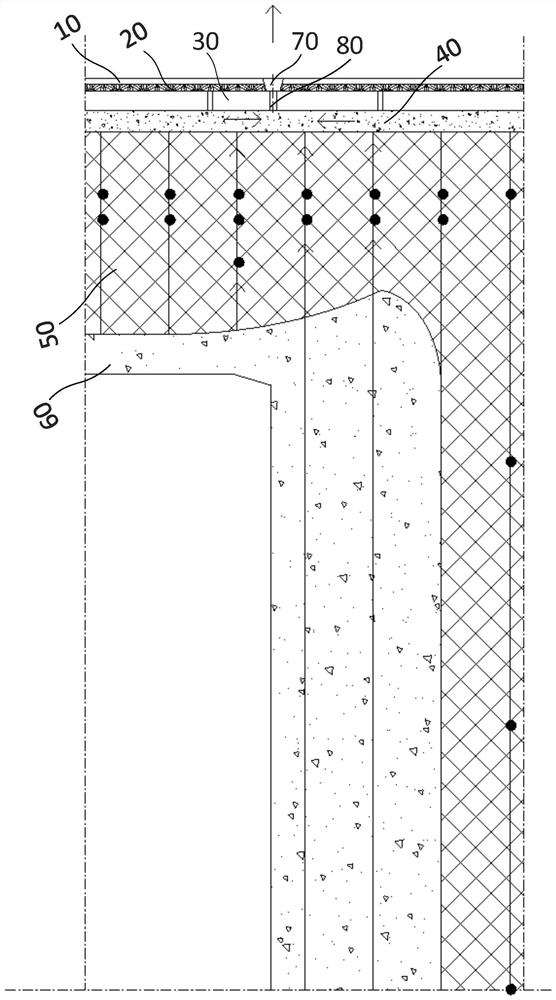

Check valve for jacking construction of concrete-filled steel tubular column and using method of check valve

InactiveCN114109042AEnsure construction efficiencyReduce requirements for on-site construction conditionsStrutsCheck valvesArchitectural engineeringCheck valve

Owner:SHANDONG SANJIAN CONSTR ENG +2

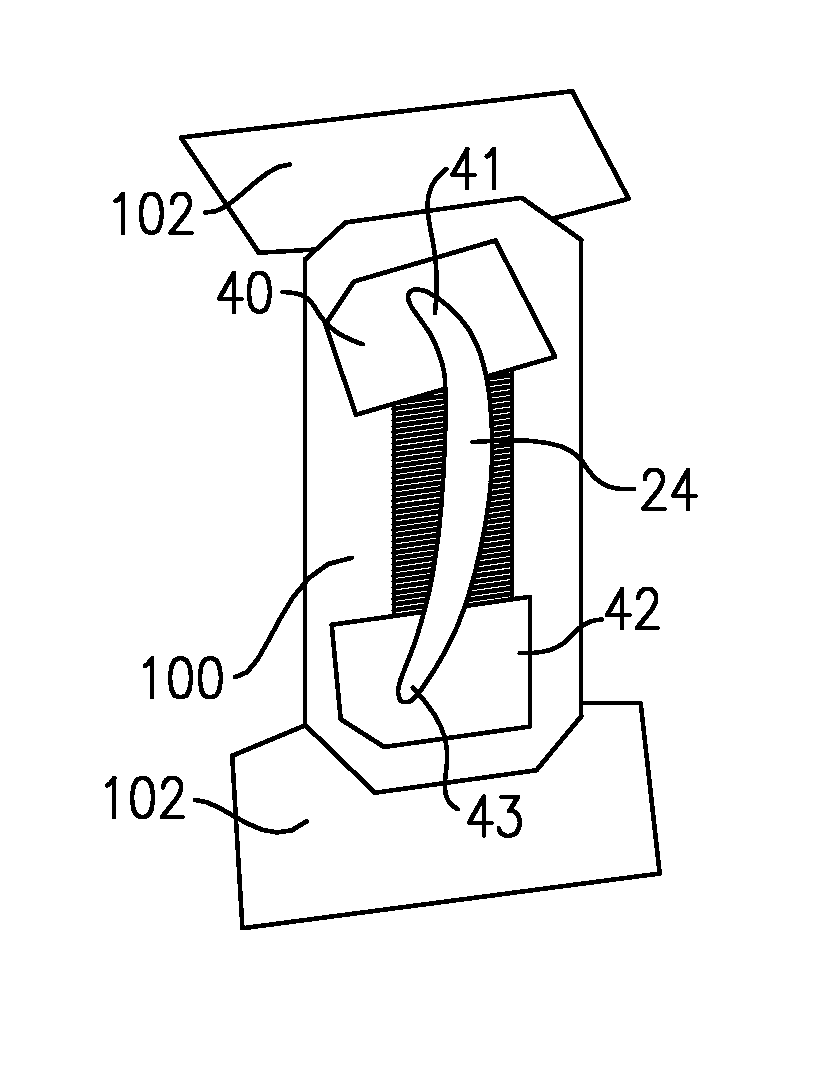

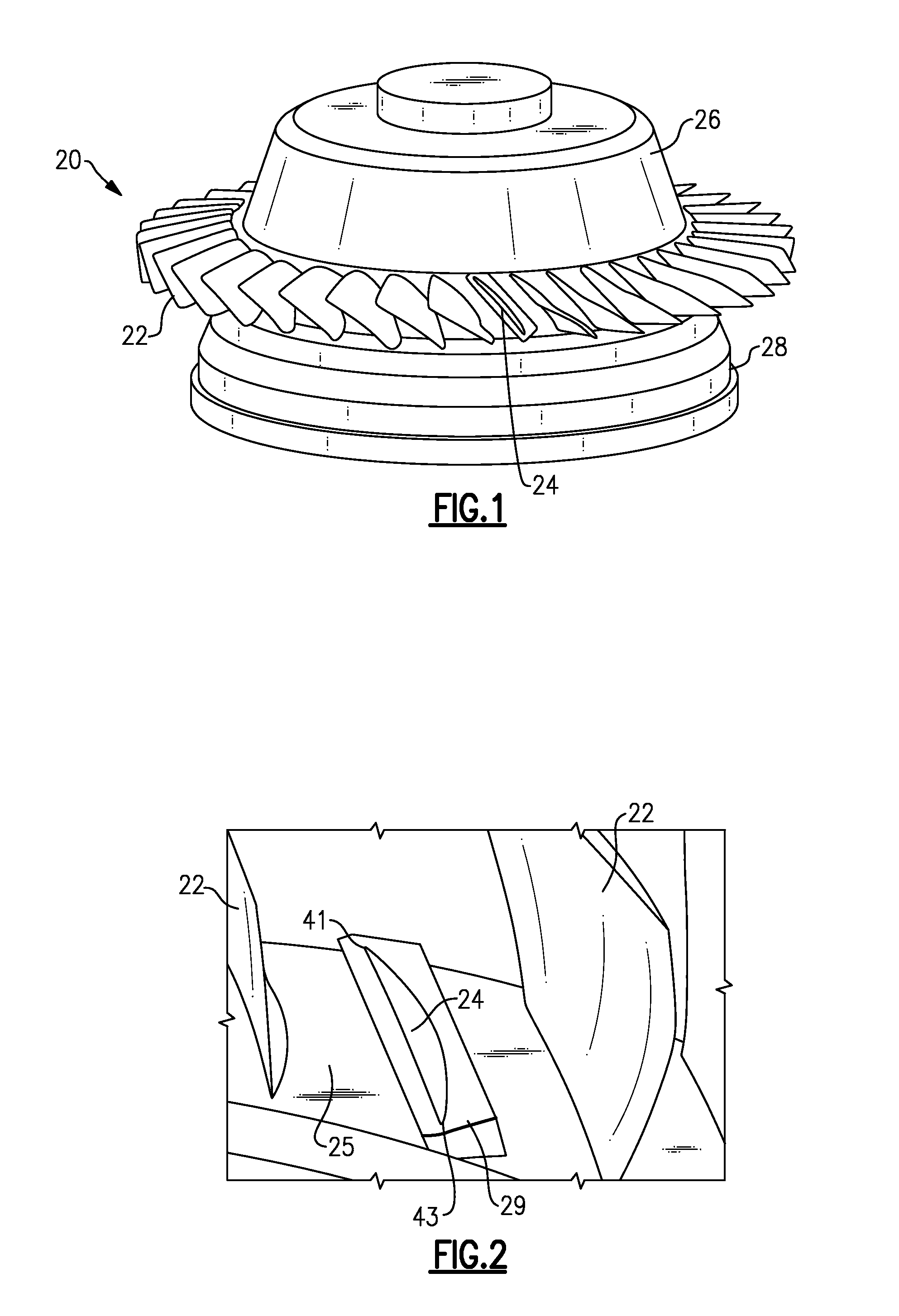

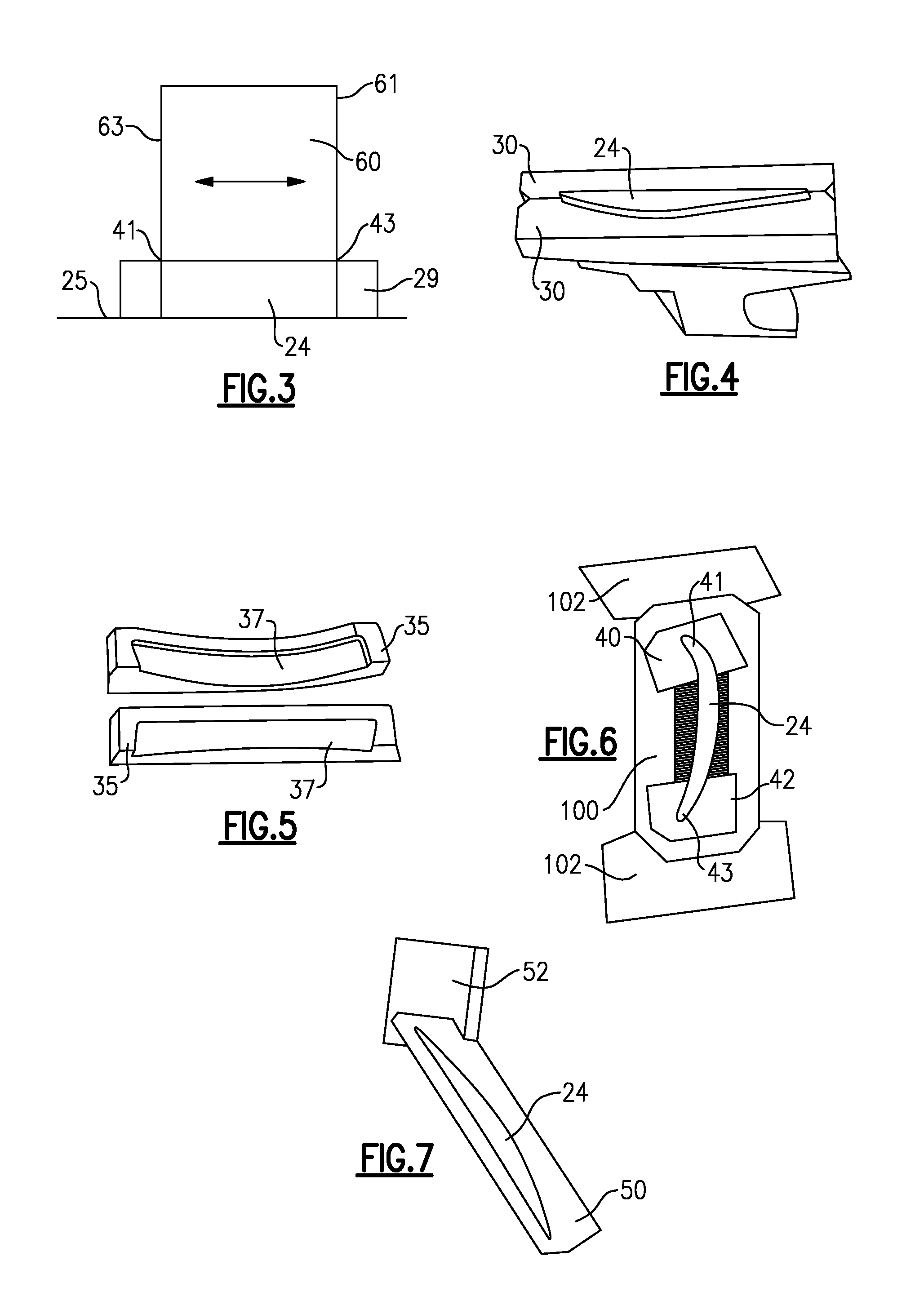

Consumable collar for linear friction welding of blade replacement for damaged integrally bladed rotors

A method of repairing an integrally bladed rotor includes the steps of placing a support collar around at least a leading and trailing edge portions of the blade stub, and performing linear friction welding to add a replacement airfoil to the blade stub. The linear friction welding is generally along a direction between the leading and trailing edges. In addition, the support collar leading and trailing edge portions are connected together.

Owner:RTX CORP

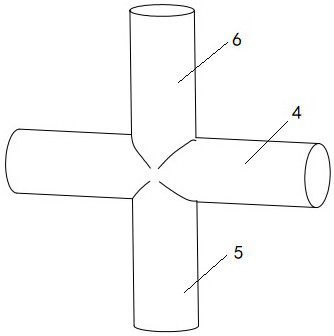

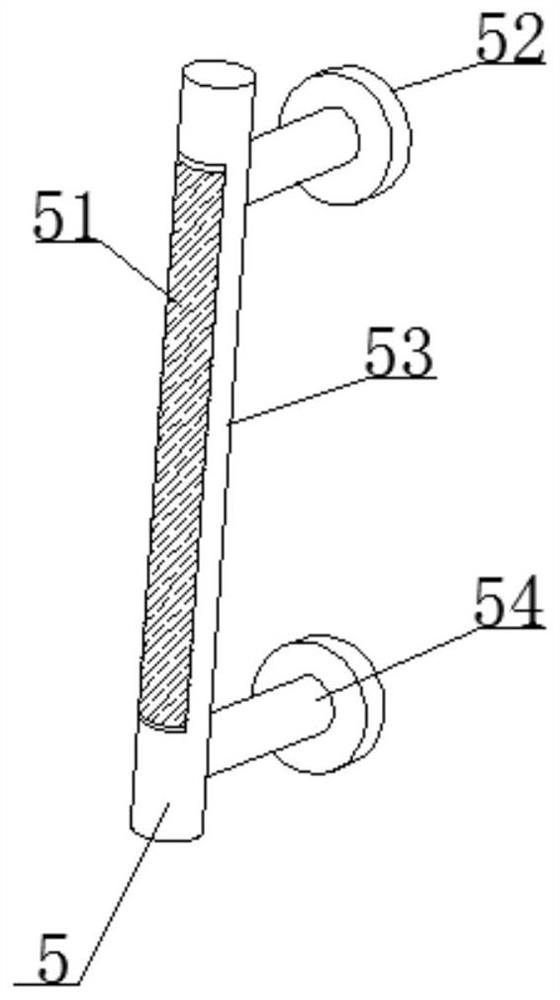

Circular tube cross-shaped welding auxiliary clamping method

InactiveCN111644746AReduce energy consumptionEasy Axial AlignmentMetal working apparatusLaser beam welding apparatusStructural engineeringSkelp

The invention discloses a circular tube cross-shaped welding auxiliary clamping method. The circular tube cross-shaped welding auxiliary clamping method includes the steps that a guide rod is axiallysleeved with a first short tube in a penetrating manner, transversely penetrates through a long tube from a welding position and is axially sleeved with a second short tube in a penetrating manner insequence, so that the first short tube, the long tube and the second short tube form a cross-shaped structure; cap pillars are arranged at the two ends of the guide rod, and the relative positions ofthe cap pillars and the guide rod are fixed so that the first short tube and the second short tube are stressed axially; and the cross-shaped structure is clamped by a clamping device and then welded.According to the circular tube cross-shaped welding auxiliary clamping method, the deformation of the short tube welding position is avoided on the premise that the clamping efficiency is not affected, and the welding qualification rate of a product is greatly improved.

Owner:江苏统联科技股份有限公司

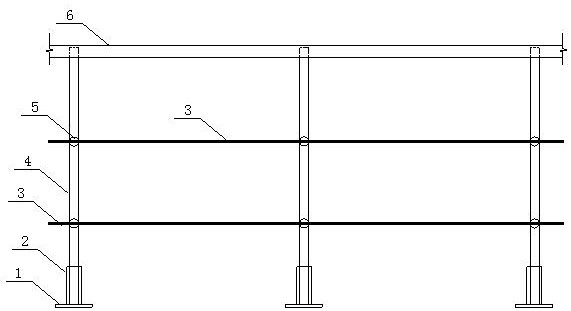

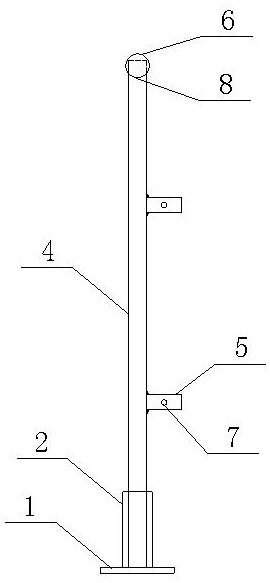

Methods for manufacturing and installing steel stair temporary safety guardrail

InactiveCN111851882ASimple structureEasy to manufactureBalustersBuilding material handlingSkelpMechanical engineering

The invention discloses methods for manufacturing and installing a steel stair temporary safety guardrail. The methods for manufacturing and installing the steel stair temporary safety guardrail are characterized by comprising a, the method for manufacturing the steel stair temporary safety guardrail, wherein the guardrail comprises a plurality of bases, vertical rods, a main cross rod and an auxiliary cross rod, the bases are provided with a steel plate bottom plate, and b, the method for installing the steel stair temporary safety guardrail, wherein the method comprises the following steps of (1) fixedly welding the multiple bases and steel beams around a stairway at multiple points, (2) directly inserting the vertical rods into steel sleeve pipes of the bases with the same number and intervals as the bases; (3) aligning single-side opening positions of the main cross rod with the vertical rod positions; and (4) penetrating from central holes (16 mm in diameter) of short pipes weldedon the vertical rods by using on-site 14-thread steel bars or 12-thread steel bars. The methods for manufacturing and installing the steel stair temporary safety guardrail have the advantages that the guardrail is simple in structure and convenient to manufacture, the engineering quality is safe and reliable, the overall stability is high, the guardrail can be circularly used and the engineeringcost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

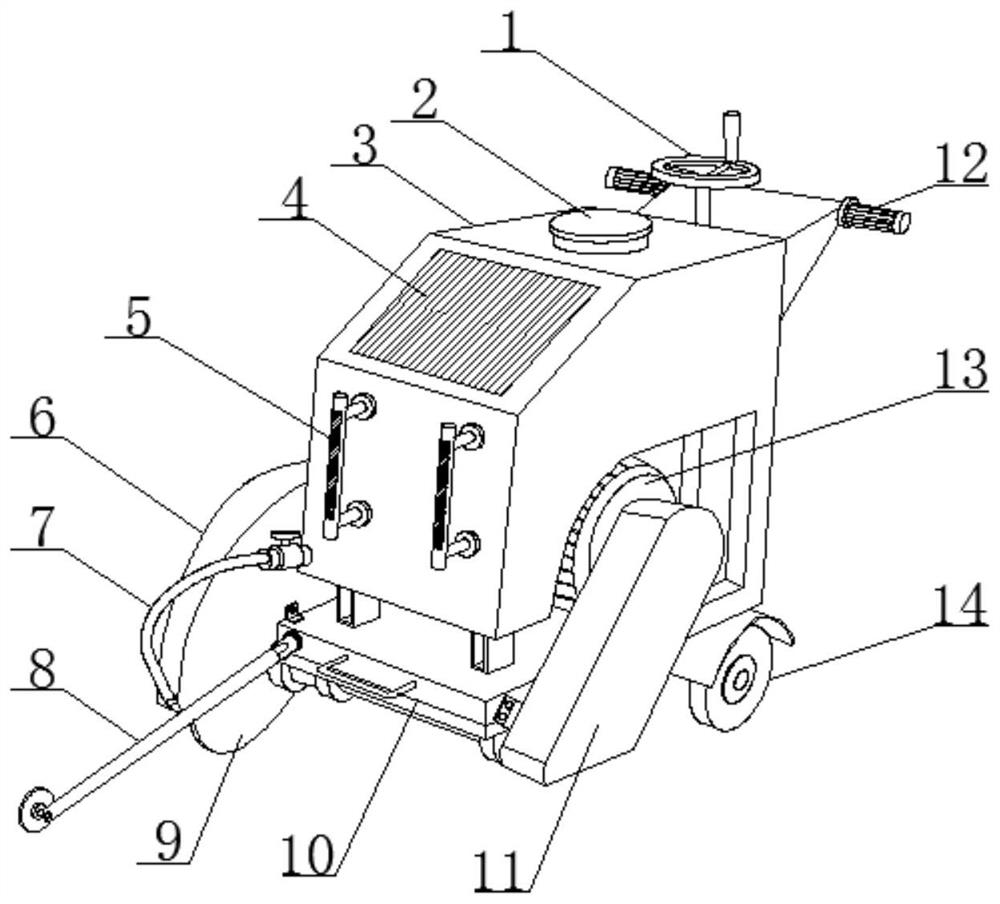

Pavement cutting equipment for building construction

InactiveCN112080998AEasy to viewEasy to moveRoads maintainenceArchitectural engineeringElectric machinery

The invention discloses pavement cutting equipment for building construction. The pavement cutting equipment comprises a bottom machine body and a driving motor; the driving motor is fixedly installedin the middle of the upper end of the bottom machine body; auxiliary roller rods are arranged at the front end of the bottom machine body; rear side rotating wheels are arranged on the two sides of the rear end of the bottom machine body; an outer side rotating mechanism is arranged at the position, located on the bottom machine body, of the outer end of the driving motor; the water liquid position of a water tank shell can be conveniently checked through a liquid level sight gauge composed of observation glass, a fixed outer ring, a hollow pipeline and a fixed short pipe, and the fixed outerring of the liquid level sight gauge is connected to the water tank shell in a welded mode, so that falling is not likely to happen in the using process. In addition, the inside of the water tank shell is through, so that a water source can flow conveniently, when the pavement cutting equipment is used, a U-shaped pipe is composed of the hollow pipe and the fixed short pipe, the observation glasson the outer side of the hollow pipe can be used for well checking, people can be reminded conveniently during the using process, and therefore cutting is more convenient during the using process.

Owner:江苏科建建筑加固有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com