Drain system for blast furnace hearth standing water

A drainage system and blast furnace technology, applied in the blast furnace field, can solve the problems of not considering the pipeline cleaning measures, affecting the drainage effect of the blast furnace hearth, and complicated drainage pipeline layout, etc., and achieve the effect of simple composition, reduced impact, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

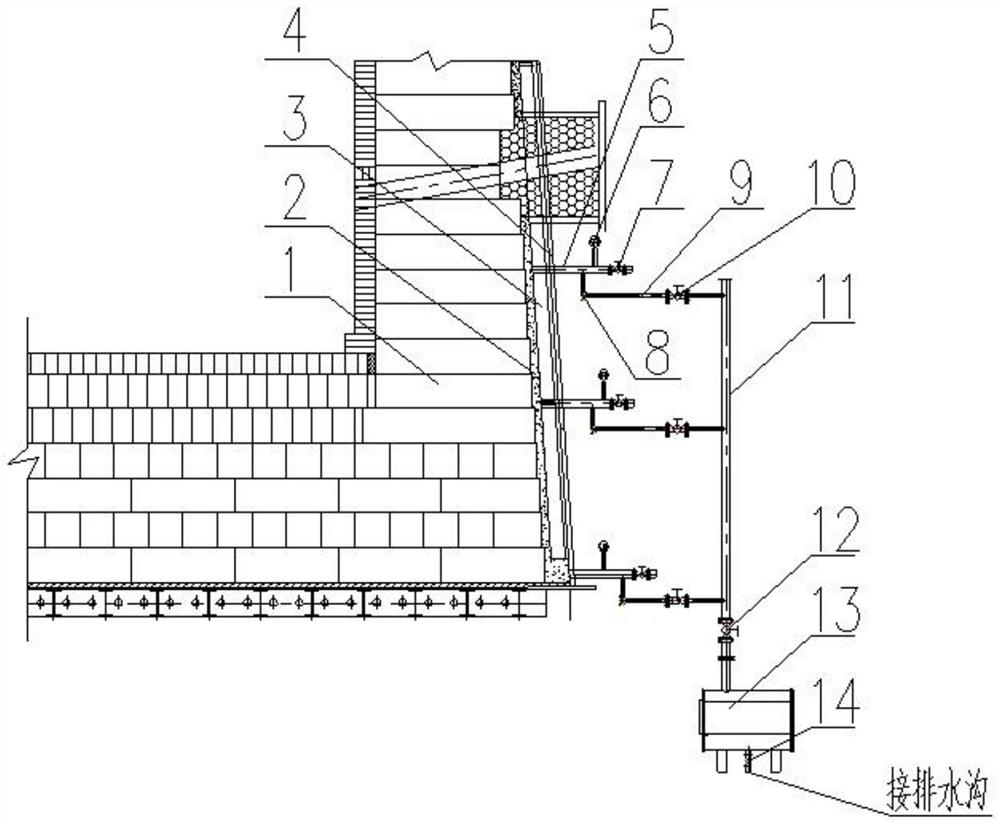

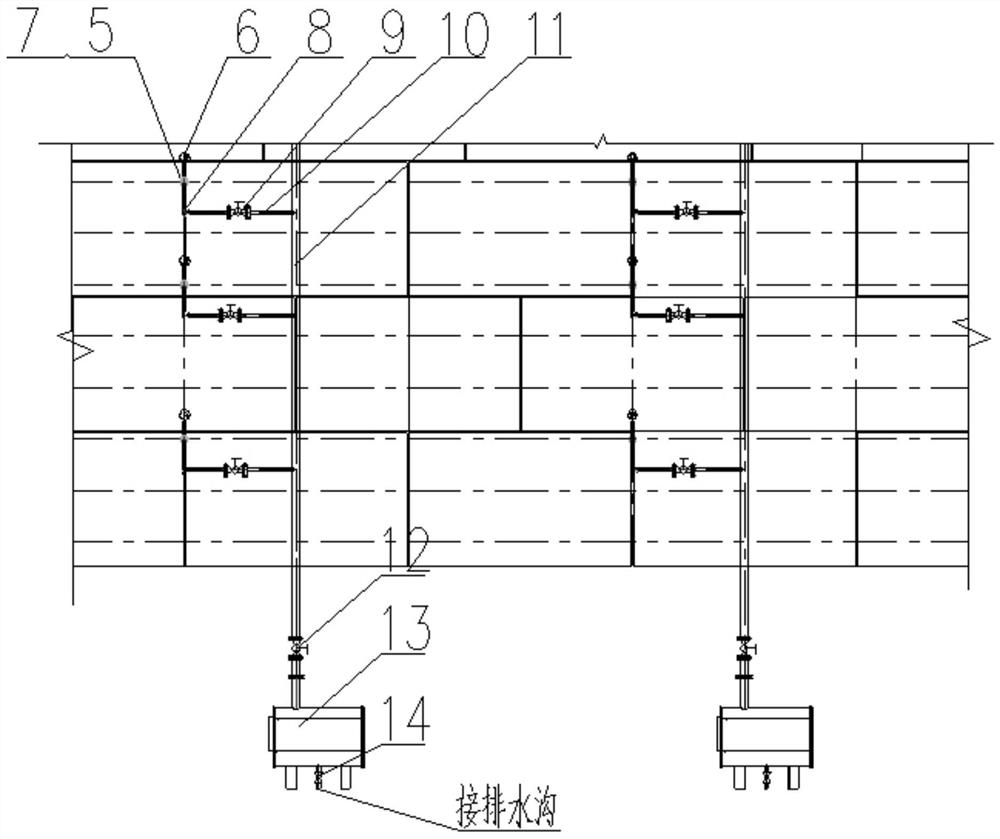

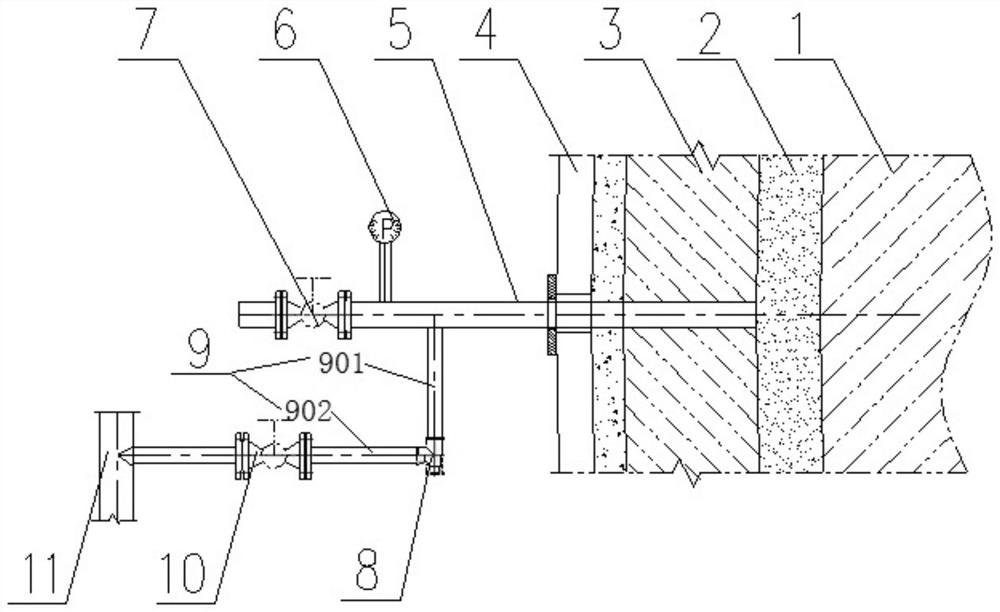

[0048] Such as Figure 1 to Figure 3 , Figure 5 as well as Figure 8 As shown, the water inlet end of the short drainage pipe 5 is shared with other orifices, and extends into the hearth of the blast furnace to collect accumulated water in the blast furnace furnace. Other orifices can be thermocouple holes, or grouting holes or reserved holes, etc., if When there is no available hole on the wall of the blast furnace, the short drain pipe 5 is directly drilled into the wall of the blast furnace. When the short drainage pipe 5 shares the orifice with the grouting hole or the reserved hole, the cooling equipment 3 provided on the cold surface of the joint filler 2 is a cooling wall, and the outer side of the cooling wall is a furnace shell 4 made of steel plate, and the short drainage pipe 5 is sequentially Pass through the furnace shell 4, the cooling equipment 3, and the joint filler 2 to extend into the refractory brick 1, and the outer end of the short drainage pipe 5 is f...

Embodiment 2

[0050] Such as figure 1 , figure 2 , Figure 4 , Figure 6 to Figure 8 As shown, the water inlet end of the short drainage pipe 5 passes through the furnace wall of the blast furnace to collect accumulated water in the blast furnace. During installation, it is also possible to use the fixing bolt holes of the cooling device 3 to set a drainage pipeline to discharge the accumulated water in the furnace hearth. . Generally, the cooling equipment 3 is fixed to the furnace shell 4 with 4 solid bolts 19, and 1 to 2 of the solid bolts 19 can be replaced with hollow bolts 18 under the premise of ensuring safety, and the short drain pipe 5 and the fixing bolts of the cooling equipment 3 The holes are shared. After the cooling equipment 3 is installed, holes are drilled on the bolt hole sealing cover 17. The short drain pipe 5 passes through the bolt hole sealing cover 17 and is connected with the hollow bolt 18, so that the accumulated water in the furnace hearth can be directly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com