Driving motor stator water-cooling method and device

A technology for driving motors and water-cooling devices, applied in electromechanical devices, electrical components, electric components, etc., can solve problems such as increasing the maintenance workload and cost of cooling equipment, insufficient cooling of rotors and bearings, and reducing the effective diameter of stators, etc. , to achieve good cooling effect, large water capacity, and ensure the smooth flow of the waterway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

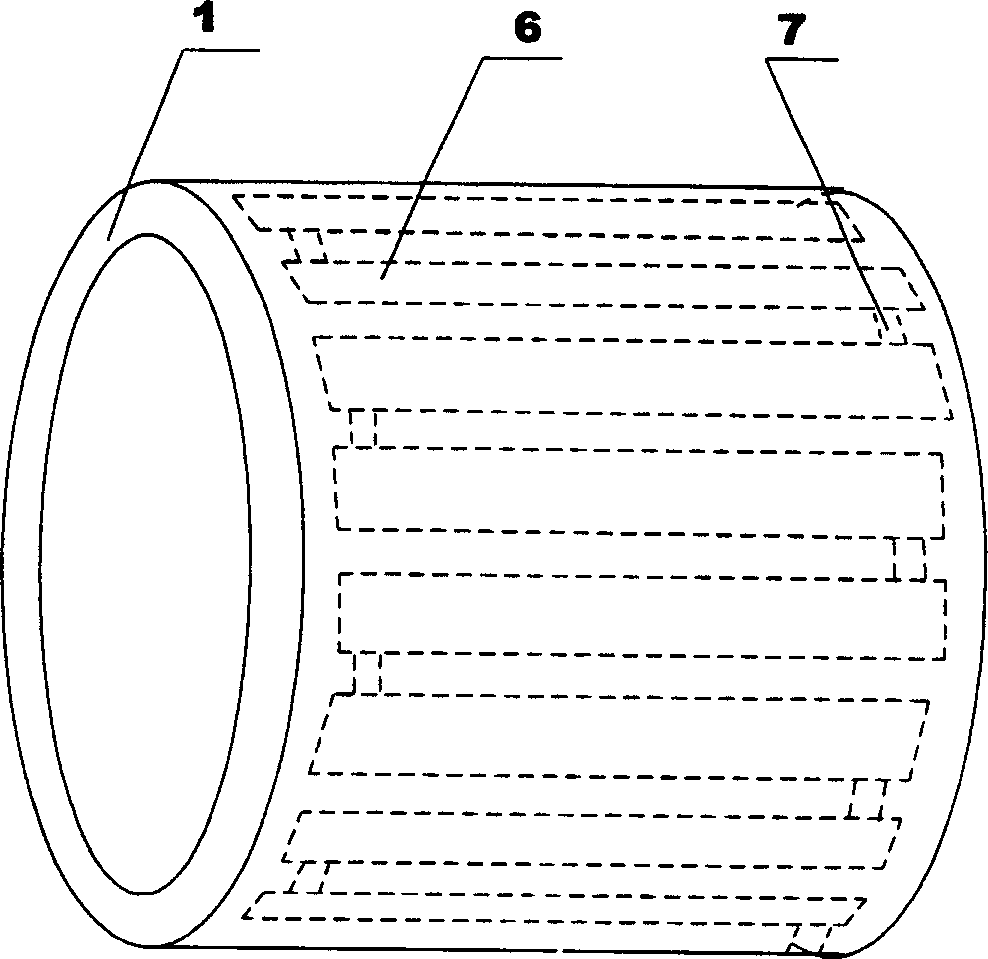

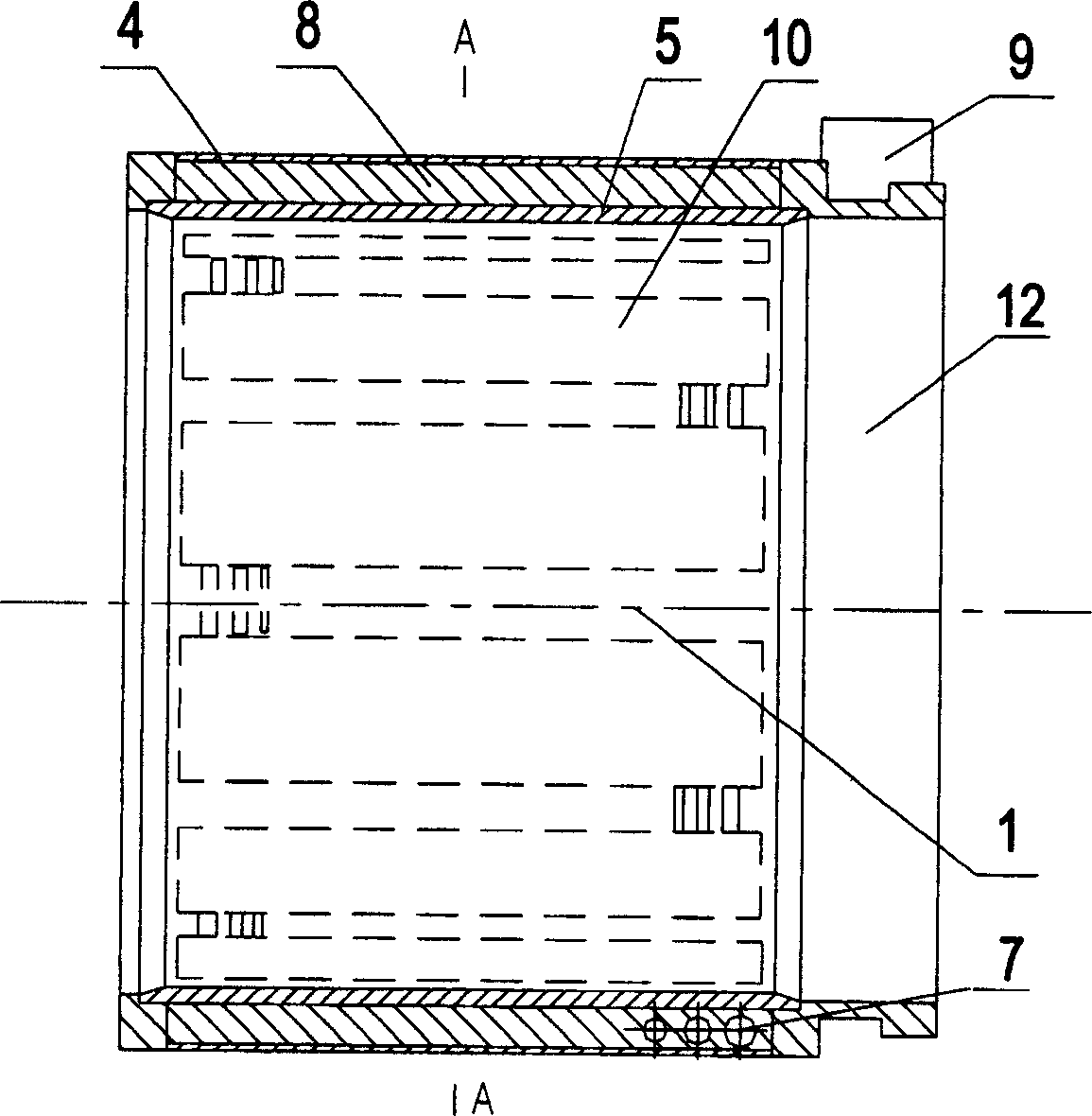

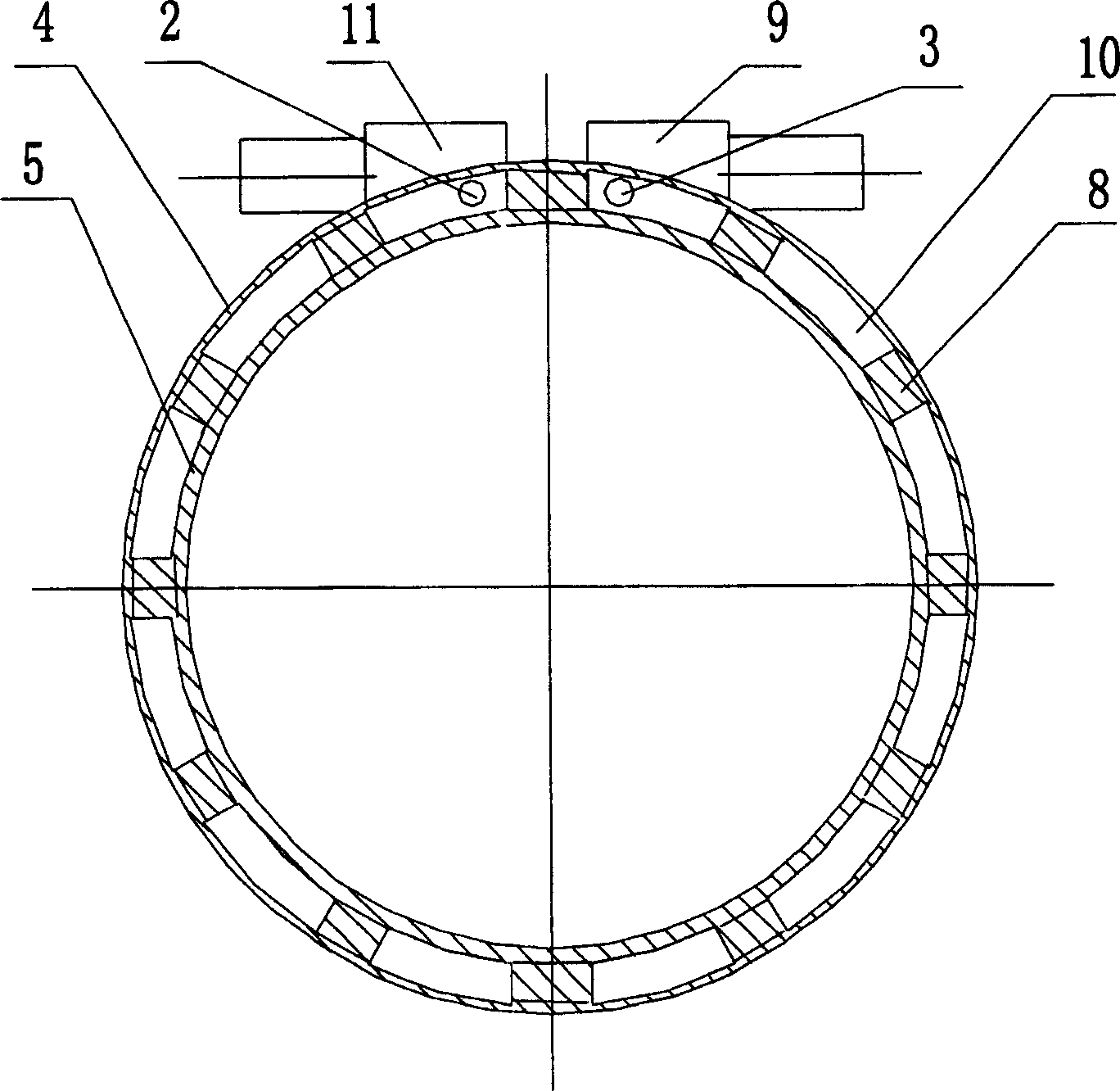

[0041] A squirrel-cage motor (such as figure 2 , 3 shown), including the stator frame 1 and the cooling channel 6, the stator frame 1 is cooled by the cooling channel 6 arranged in the stator frame 1 along the axial direction of the stator frame ring, and the heat dissipation of the stator is through the stator The cooling water circulates and dissipates heat in the non-spiral circuitous cooling channel in the base 1. The cooling water channel 6 in the stator frame is arranged in an "S" shape along the axial direction of the stator frame ring. The structure of the circuitous cooling water channel 6 is that inside and outside the inner and outer closed long strip cooling water tanks 10 are arranged in the stator frame 1 ring along the axial direction of the ring surface, and squirrel cage ribs 8 are arranged between every two water tanks, and the long strip cooling water tanks 10 are formed by The inner wall 4 and the outer wall 5 of the thin-walled cylindrical structure are...

Embodiment 2

[0043] A squirrel-cage motor, including a stator frame 1 and a cooling water channel 6, the stator frame 1 is cooled by the cooling water channel 6 arranged in the stator frame 1 along the axial direction of the stator frame ring, and the heat dissipation of the stator The heat is dissipated through the cooling water circulation in the non-spiral detour cooling water channel in the stator base 1 . The cooling water channel 6 in the stator frame is arranged in a labyrinth way along the axial direction of the stator frame ring. The structure of the circuitous cooling water channel 6 is that inside and outside the inner and outer closed long strip cooling water tanks 10 are arranged in the stator frame 1 ring along the axial direction of the ring surface, and squirrel cage ribs 8 are arranged between every two water tanks, and the long strip cooling water tanks 10 are formed by The inner wall 4 and the outer wall 5 of the thin-walled cylindrical structure are closed into elongate...

Embodiment 3

[0045] A squirrel-cage motor, including a stator frame 1 and a cooling water channel 6, the stator frame 1 is cooled by the cooling water channel 6 arranged in the stator frame 1 along the axial direction of the stator frame ring, and the heat dissipation of the stator The heat is dissipated through the cooling water circulation in the non-spiral detour cooling water channel in the stator base 1 . The cooling water channel 6 in the stator frame is arranged in a labyrinth way along the axial direction of the stator frame ring. The structure of the circuitous cooling water channel 6 is that inside and outside the inner and outer closed long strip cooling water tanks 10 are arranged in the stator frame 1 ring along the axial direction of the ring surface, and squirrel cage ribs 8 are arranged between every two water tanks, and the long strip cooling water tanks 10 are formed by The inner wall 4 and the outer wall 5 of the thin-walled cylindrical structure are closed into elongate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com