Water cooling method and structure for traction electric machine

A traction motor and water cooling technology, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of adding cooling equipment, tight space, high thermal overload of motors, etc., and achieve the effect of small flow requirements and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

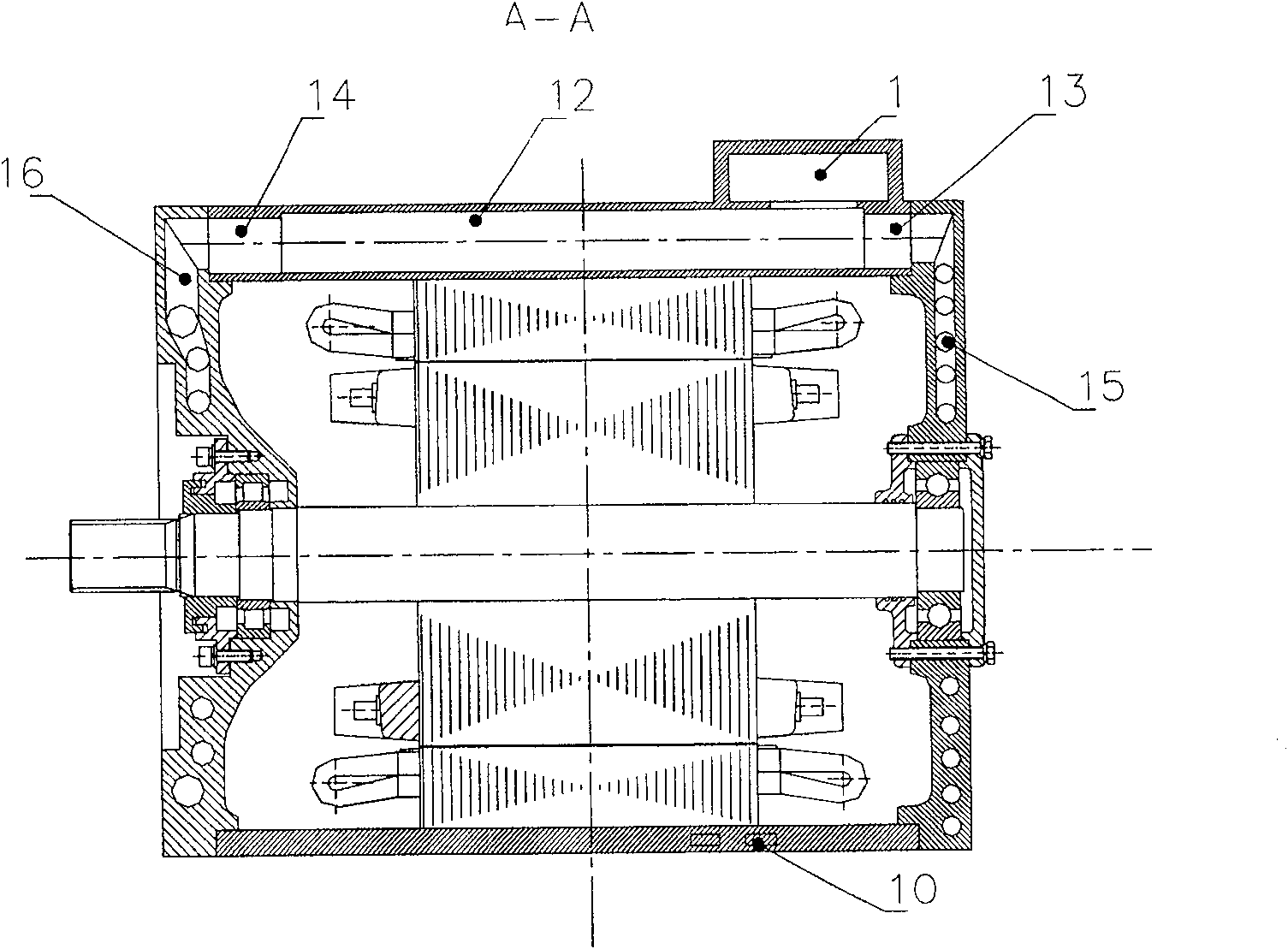

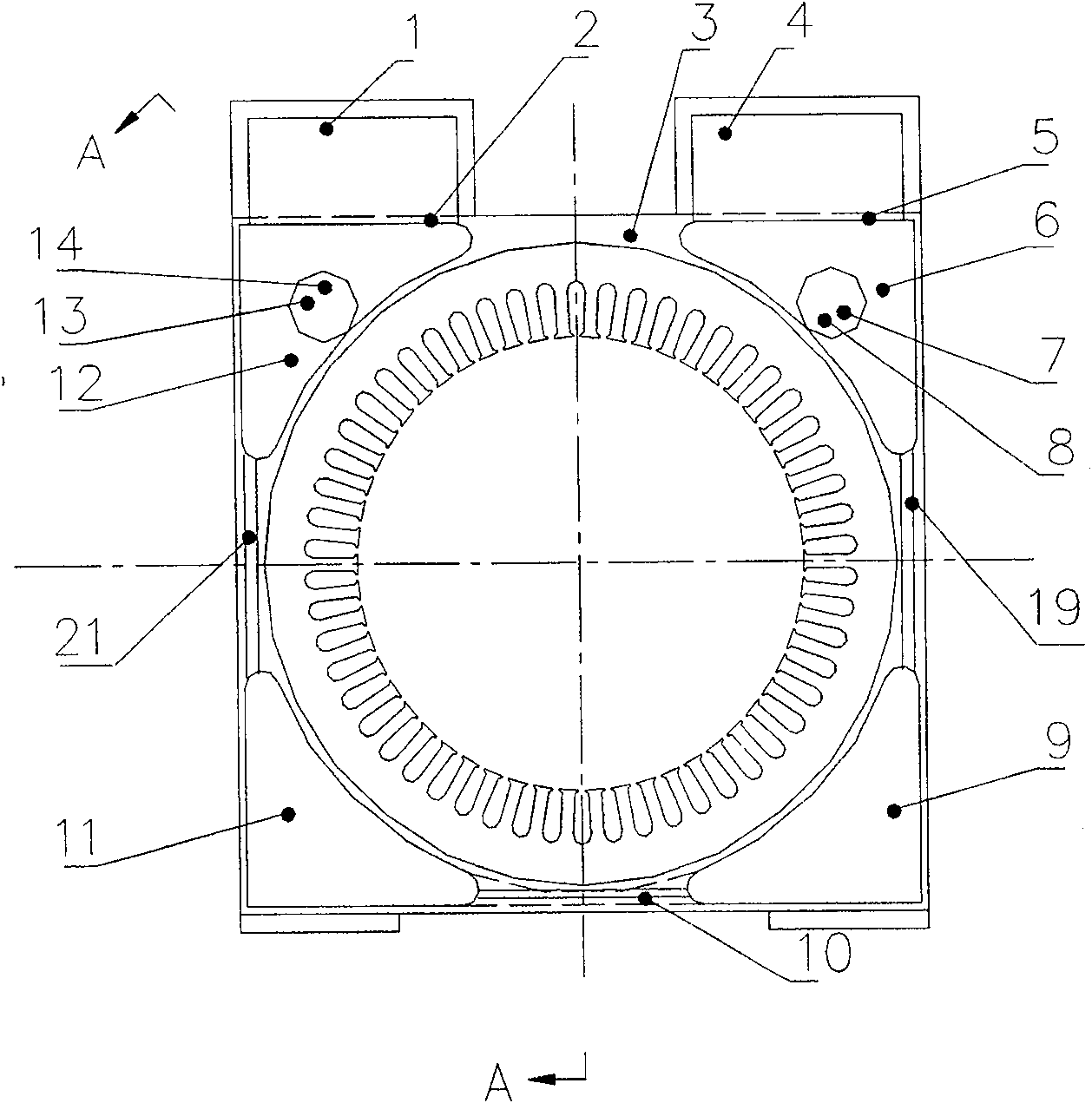

[0051] A water-cooled structure for a traction motor. The heat dissipation of the traction motor is carried out through a four-channel cooling stator heat dissipation structure with an outer side and an inner circle. The four corners formed by the outer square outer wall form four cooling water channels arranged in a straight line in the axial direction, and are separated from each other by the ribs formed at the thinnest part of the inner ring of the machine base and the outer square outer shell, and then connected into one through the connecting hole. The cooling circuit arranged in a roundabout way, the cooling of the traction motor is dissipated through the circulation of cooling water in the square roundabout water channel. The motor water-cooling structure includes a motor casing 3, a front end cover 18, and a rear end cover 20. The radial section of the motor base 2 is square on the outside and circular on the inside. And it matches the outer circle of the conventional ...

Embodiment 2

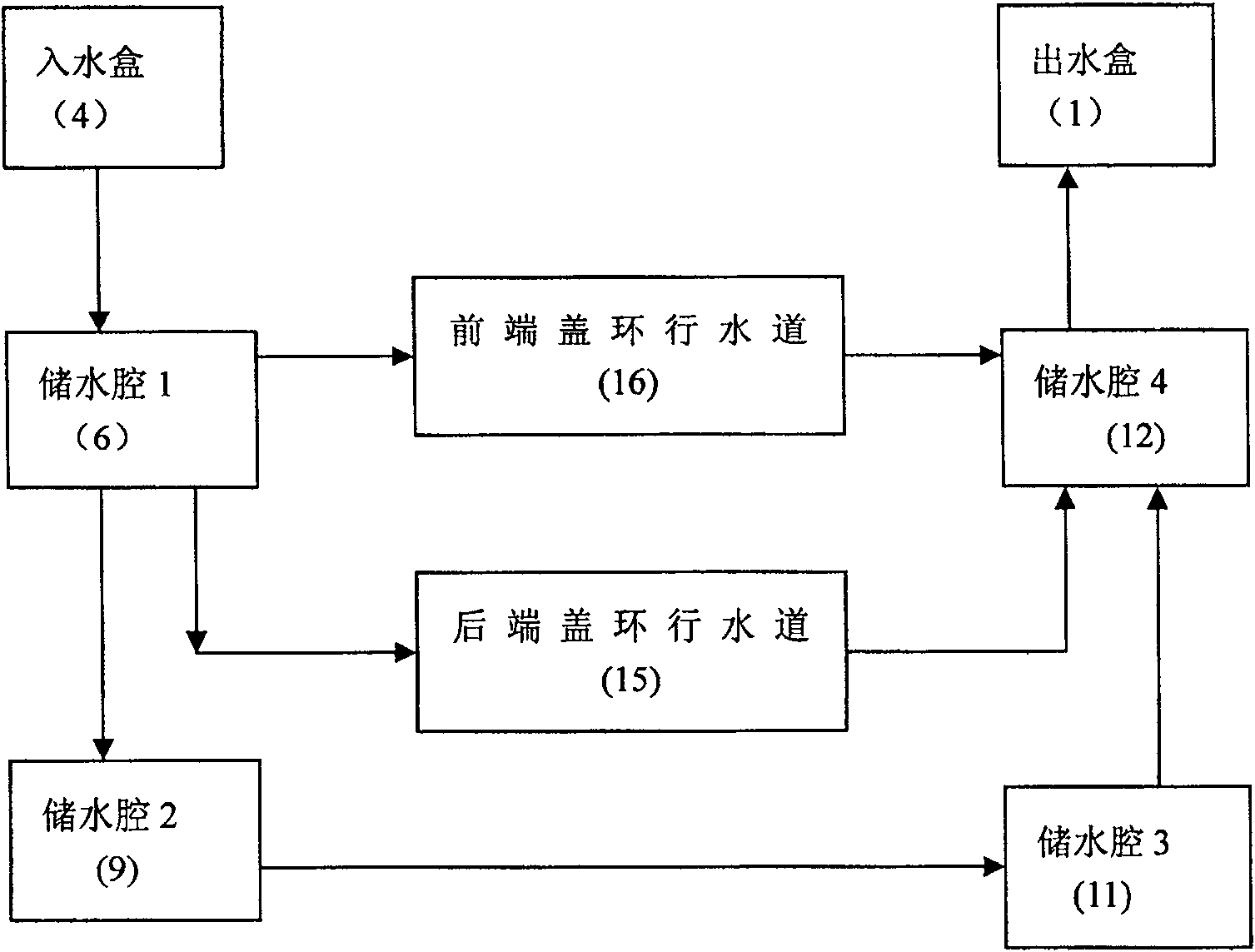

[0054] A traction motor water-cooled structure. The heat dissipation of the traction motor is carried out through a stator heat dissipation structure composed of a four-channel cooling stator cooling structure with an outer side and an inner circle, and an annular cooling water channel on the end cover to form a cooling circuit arranged in a circuitous manner. cooling. The motor case 3, the front end cover 18, the rear end cover 20, and the radial section of the motor base 2 are square outside and circular inside. In this way, the space can be fully utilized, and the installation size of the motor is small. And it matches the outer circle of the conventional iron core punching sheet, and the motor base uses the gap between the outer square and inner circle geometric figures to form four cavities as water storage chambers 6, 9, 11, 12, forming a motor casing 3 with cooling; Holes are directly opened on the motor casing 3 to communicate with the water storage cavity, that is, t...

Embodiment 3

[0057] The cooling method of the third embodiment is the same as that of the second embodiment, but in order to increase the contact surface between the water and the casing, which is conducive to heat conduction, the water storage chambers 6, 9, 11 formed by the four corners of the motor casing 3 , 12, each water storage cavity can be decomposed into more than one smaller water storage cavity, and each sub-storage cavity is connected directly or in a roundabout way through the connecting hole to form a direct or roundabout cooling water channel .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com