Patents

Literature

1237results about How to "Reduce temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

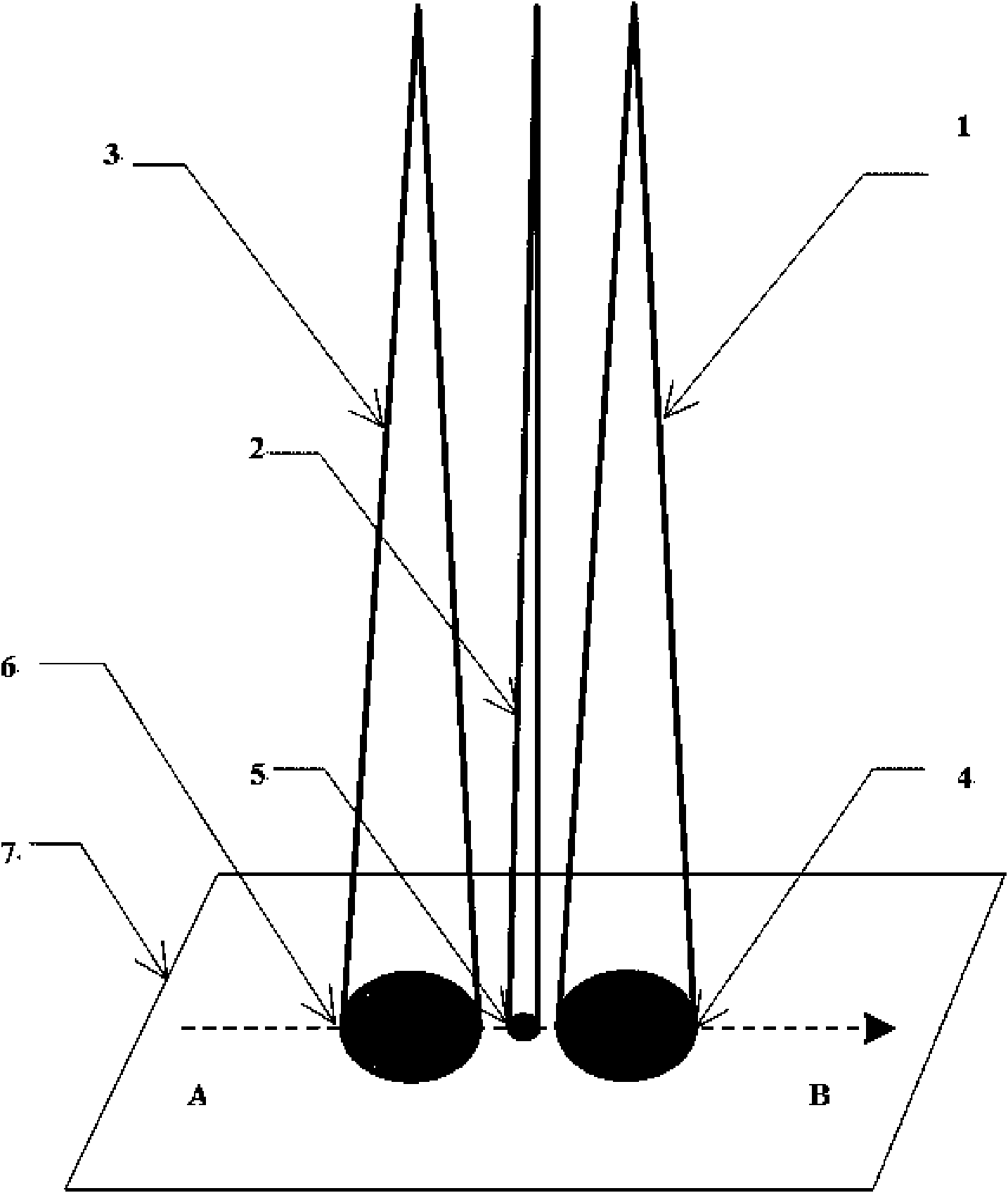

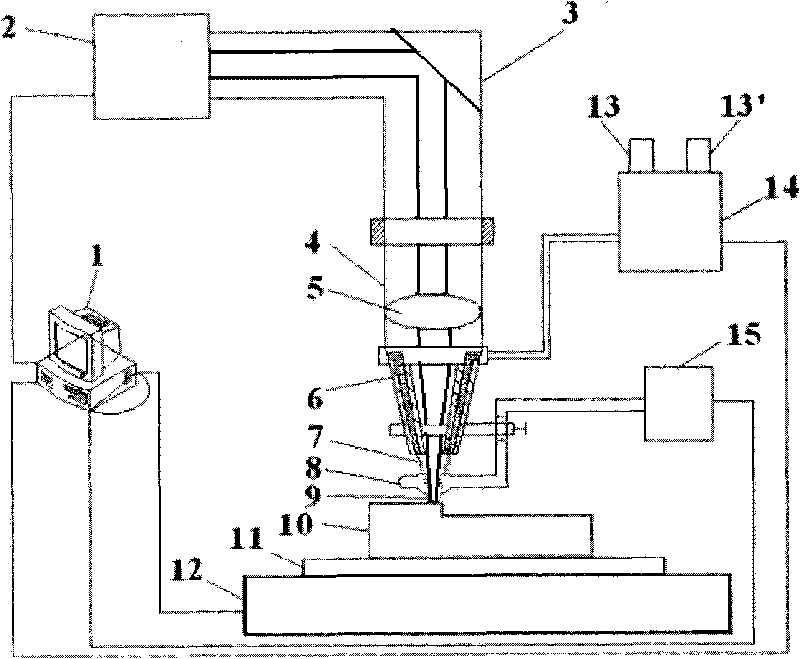

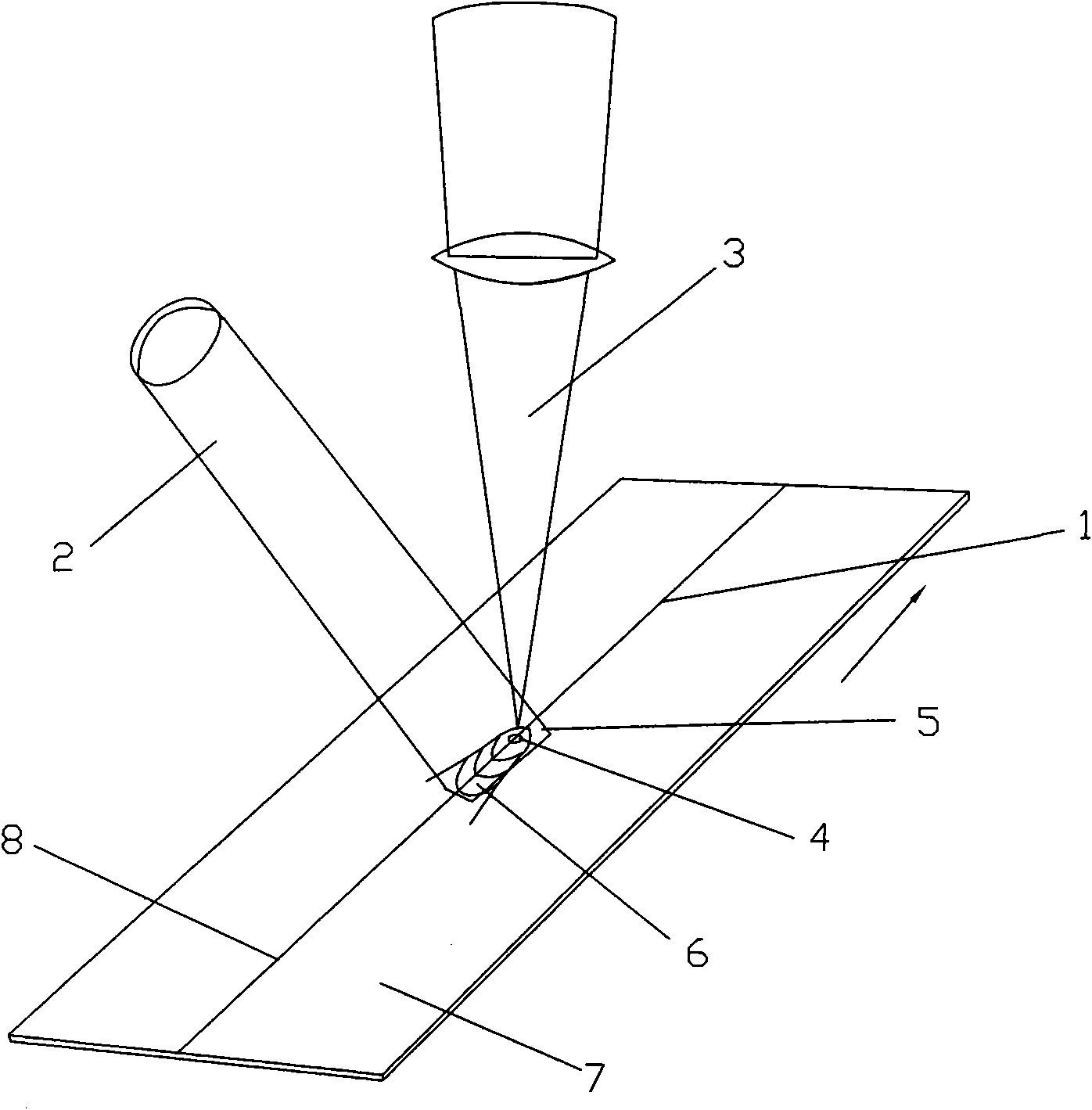

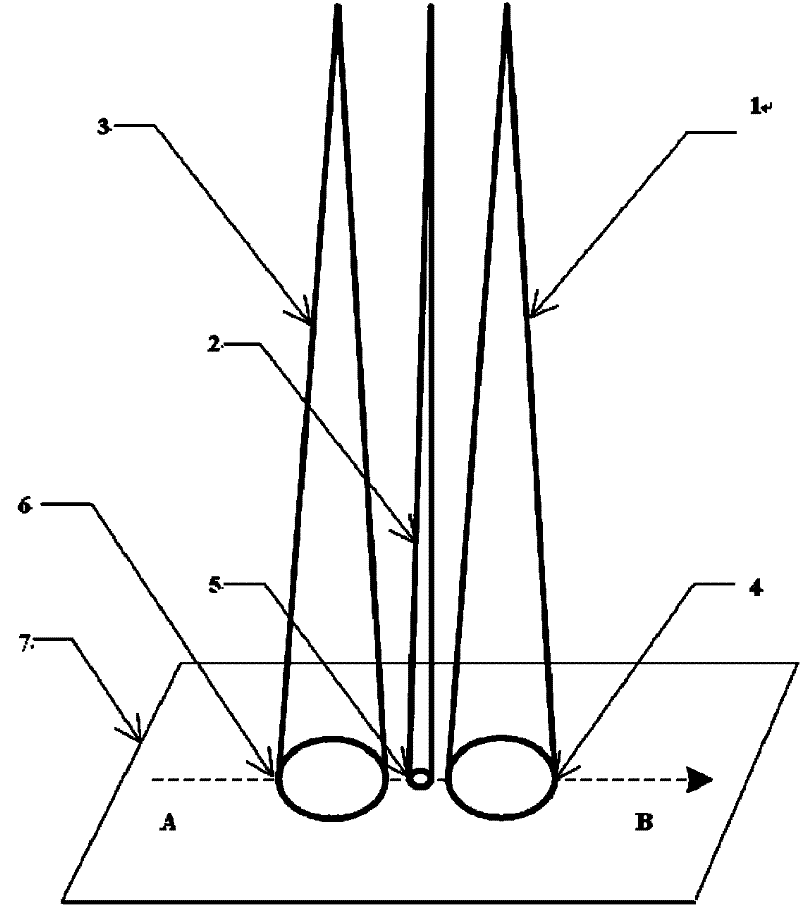

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

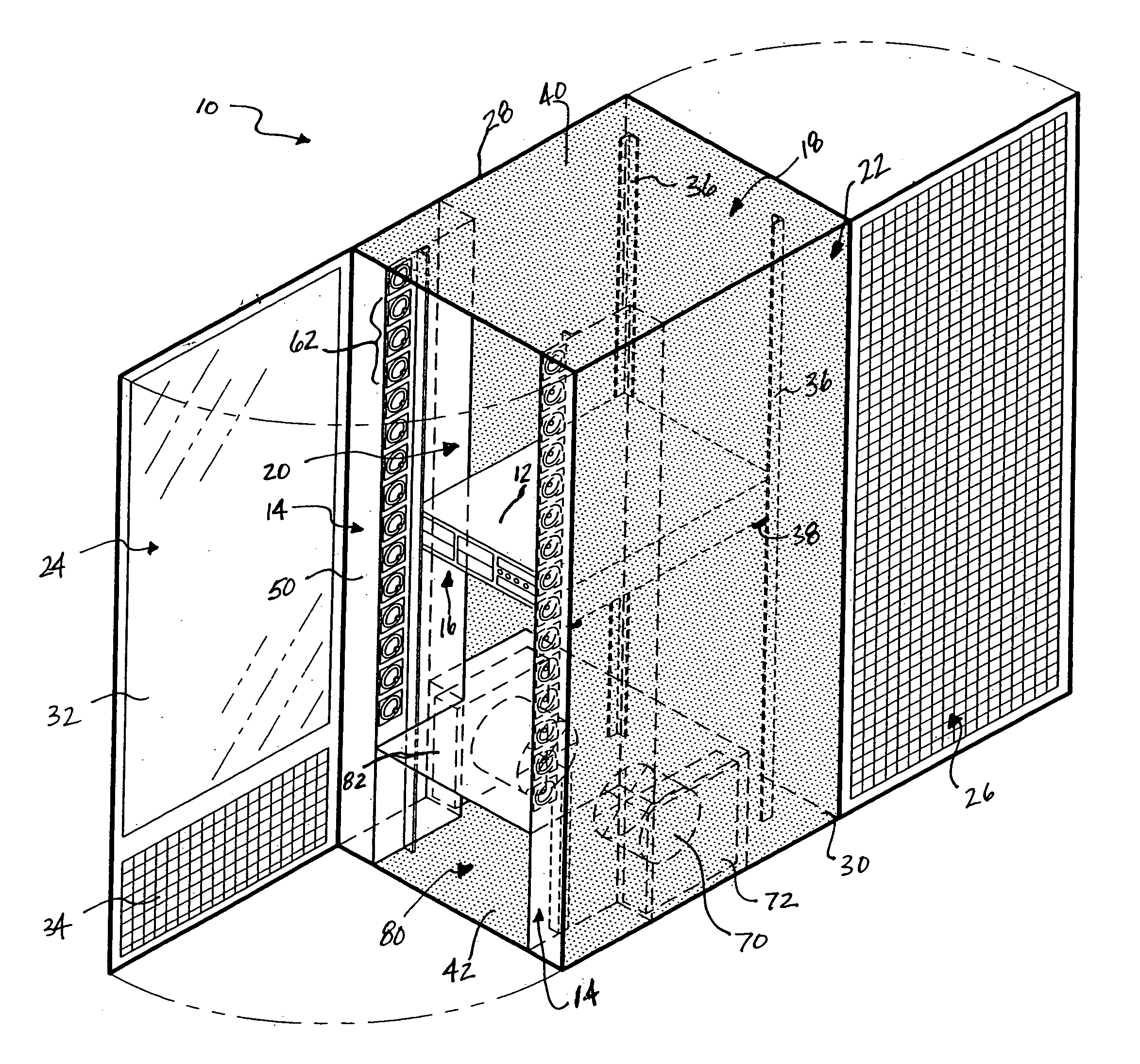

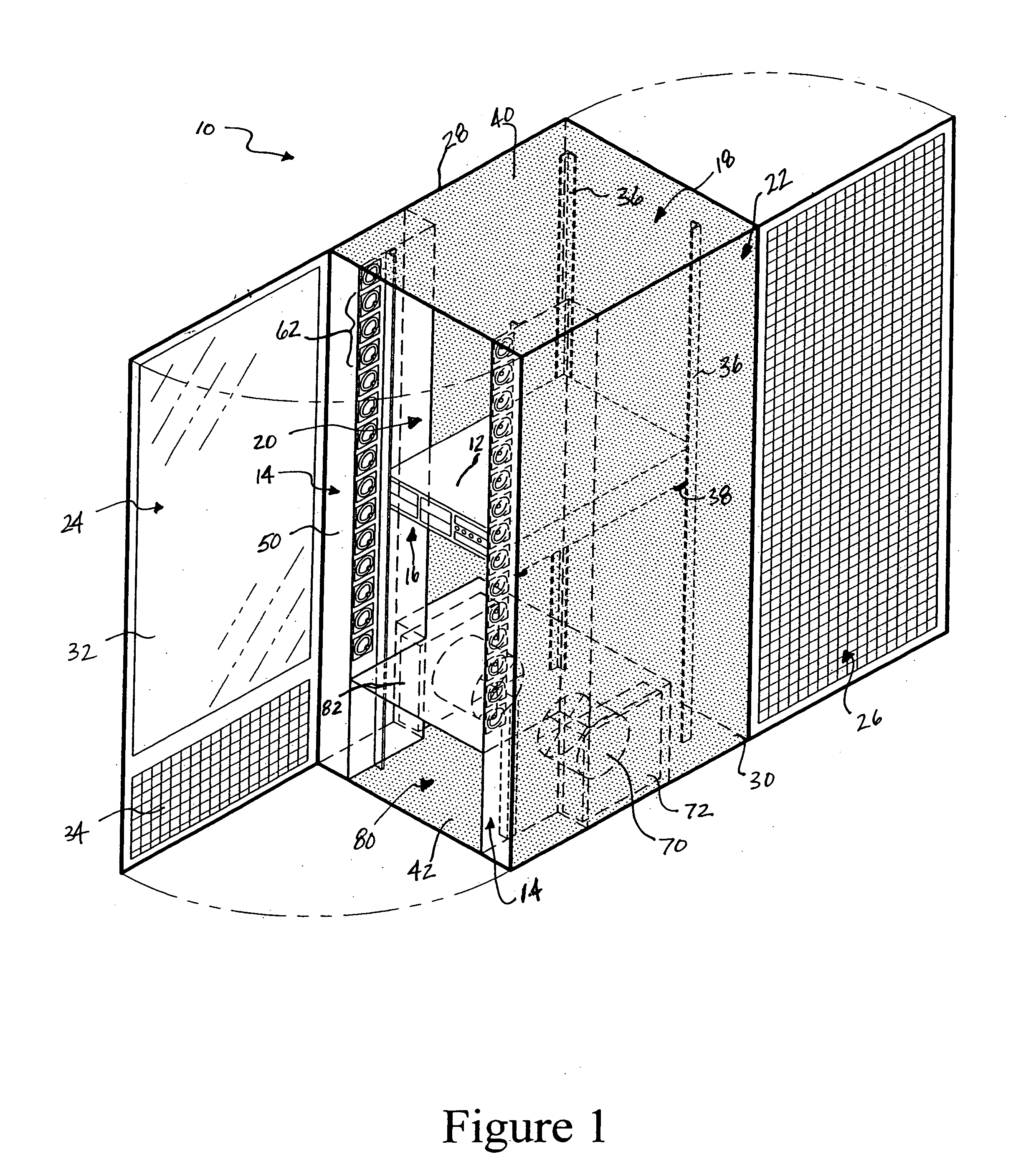

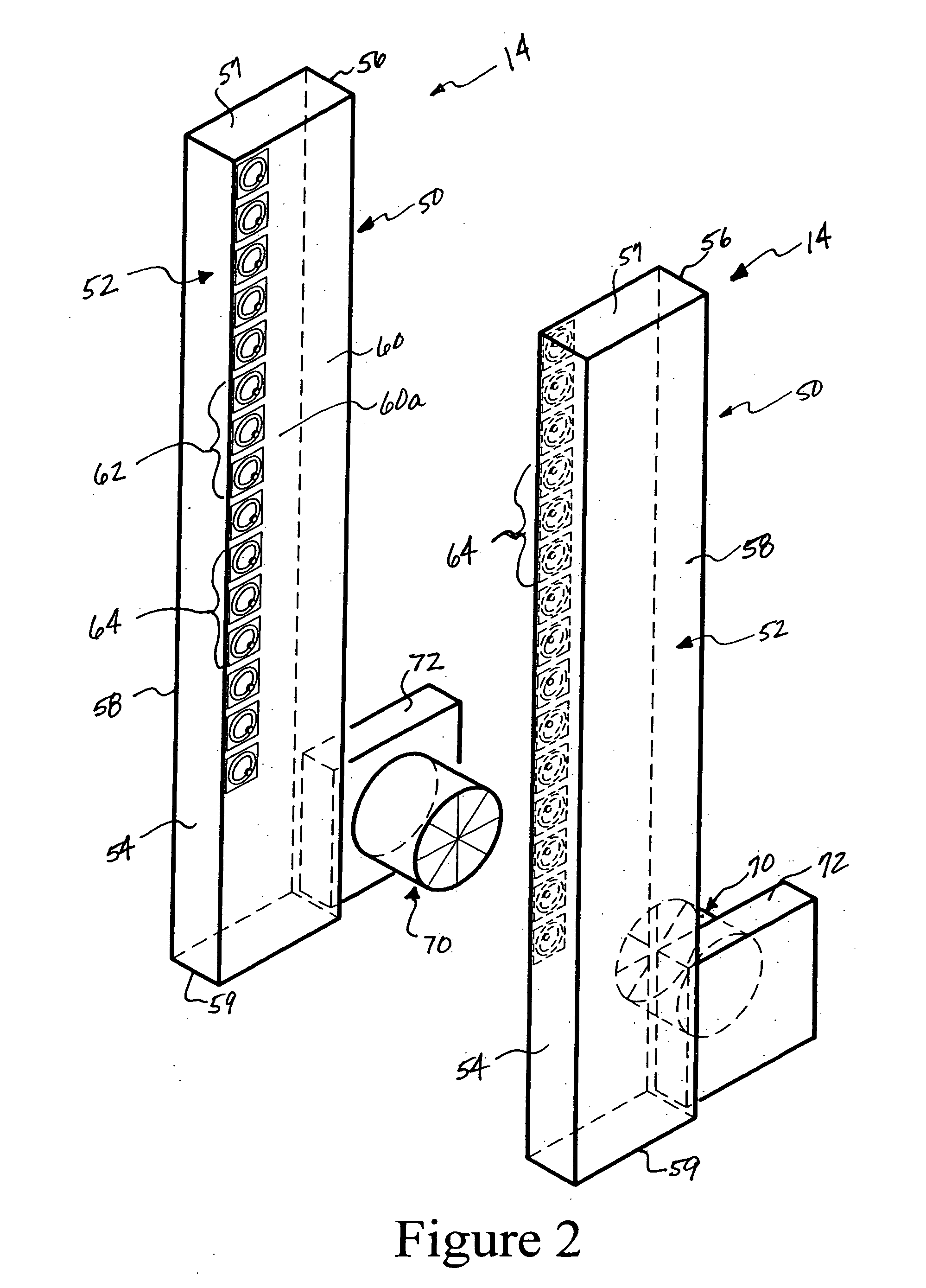

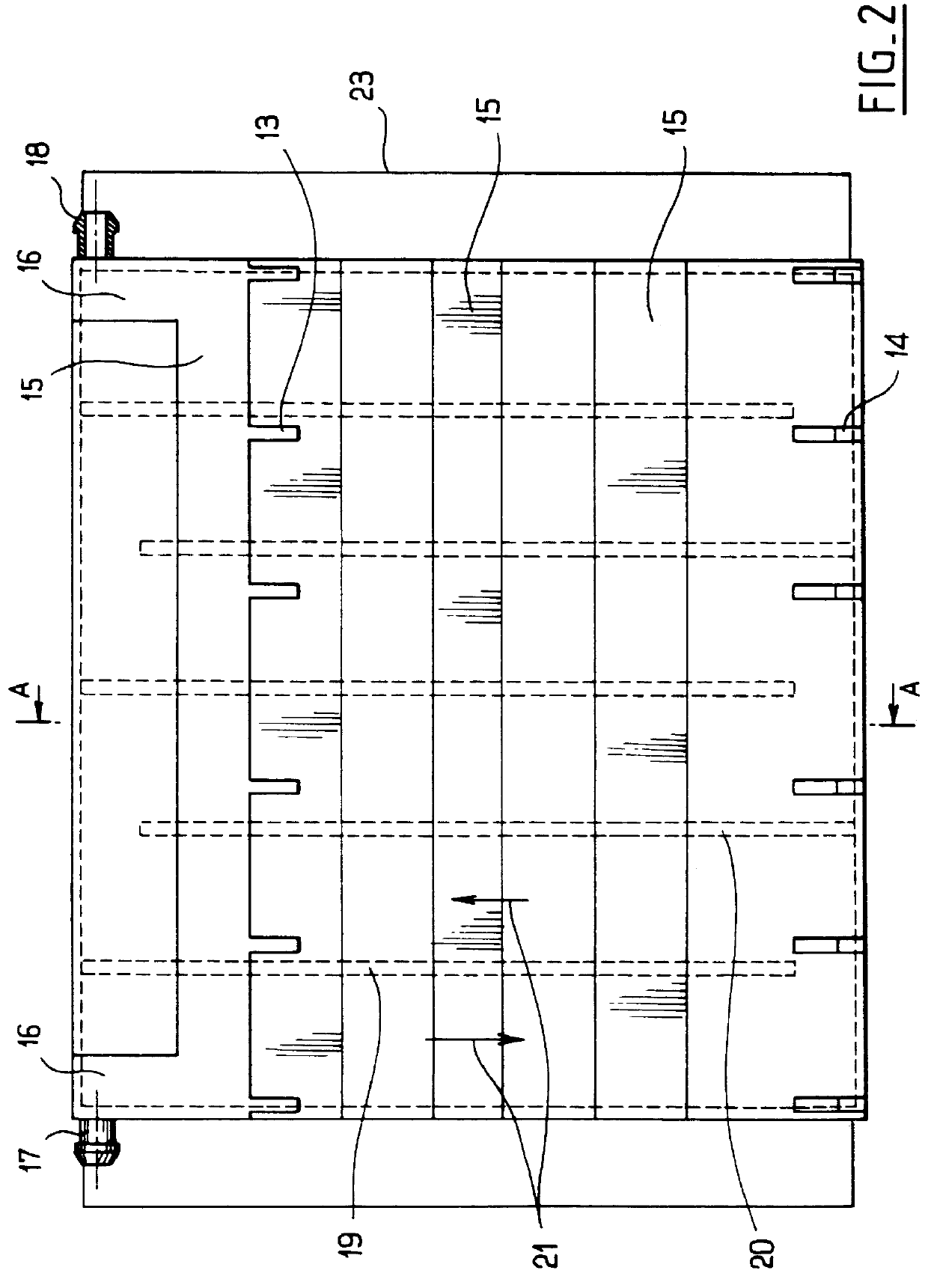

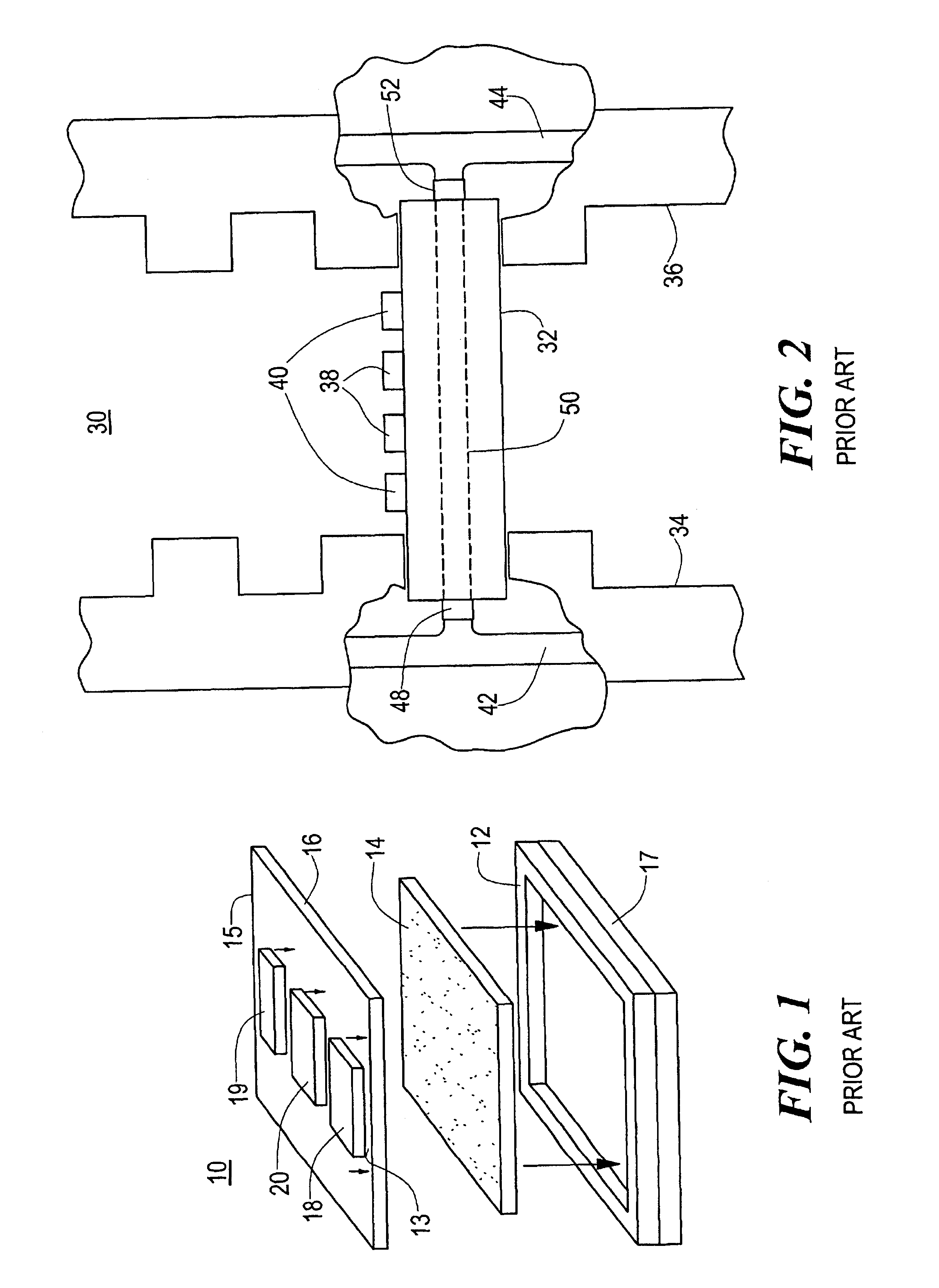

Cabinet for computer devices with air distribution device

InactiveUS20050153649A1Reduce temperature gradientReduce gradientShow cabinetsLighting and heating apparatusDistribution systemComputer device

A cabinet for housing computer devices with an internal air distribution system is disclosed. The cabinet includes an internal chamber defined by a side wall arrangement having at least a front wall. The cabinet includes a support structure for computer devices, wherein the support structure is positioned within the internal chamber of the cabinet. The air distribution device comprises an elongated duct defining a passageway for air distribution. The duct is positioned within the internal chamber and has a plurality of adjustable air discharge ports that are in fluid communication with the passageway. The air distribution device further includes an inlet fan in fluid communication with the passageway. By precisely directing cool air to a frontal portion of the computer devices, the air distribution device reduces the temperature gradients within the cabinet and the quantity of heat that accumulates in the cabinet during operation of the computer devices.

Owner:POWER OF 4 LLC

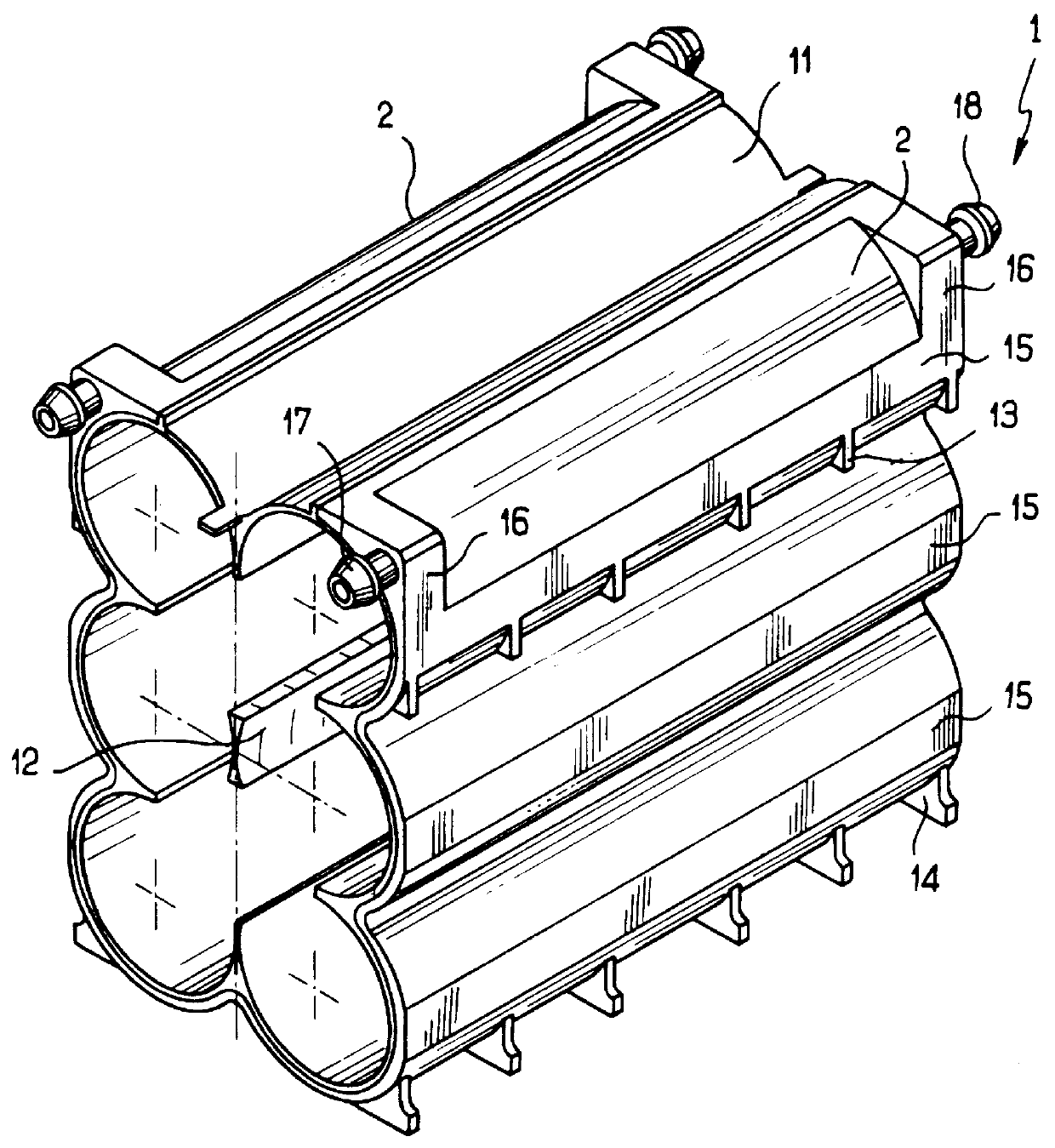

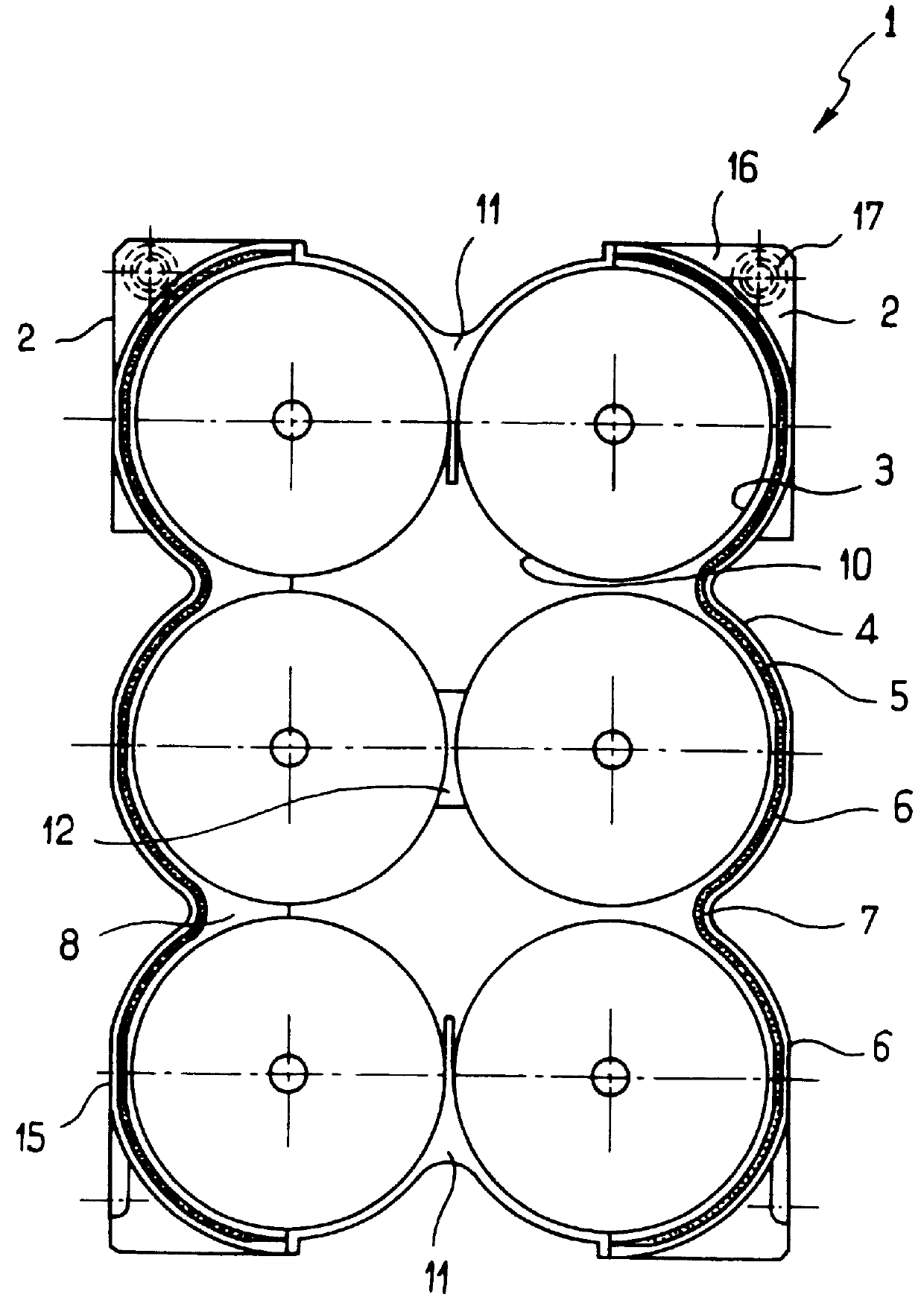

Device for controlling the temperature of a battery of electrochemical cells

InactiveUS6087038AImprove temperature uniformityReduce temperature gradientNon-aqueous electrolyte accumulatorsCell temperature controlDouble wallJunction point

In this device for controlling the temperature of a battery of cylindrically-shaped electrochemical cells placed side by side, heat is conveyed by the flow of a heat-conveying fluid, which flow takes place inside a double wall whose section is in the form of circular arcs interconnected at their ends so that the junction points between the arcs are substantially in alignment. Relief is disposed in a baffle configuration inside the double wall to constrain the fluid to flow parallel to said section, alternately in one direction and then in the opposite direction. The wall is disposed against the battery in such a manner that each of the circular arcs is disposed coaxially against one of the cells.

Owner:SAFT FINANCE S AR L

Synchronous sintering process for electronic beam selection zone and three dimension layered producing device

ActiveCN1648802AHigh speedHigh precisionComputer controlElectron beam welding apparatusRapid scanHeat stress

The present invention relates to technology and apparatus with high energy beam to sinter or melt and deposit material successively to realize laminated solid manufacture. The present invention features that the electronic beam scan controller controls the electronic beam to scan fast in pattern projection mode for heating powder homogeneously. Each scanning of the electronic beam has short time in the selected area, so that the scan initiating point has no great temperature change generated during the whole scanning course. Through one or several frames of scanning, the material in the forming area has temperature synchronously raised to reach the sintering or re-melting temperature for deposition onto the forming area before synchronous cooling. The present invention has greatly reduced heat stress and raised forming precision and quality.

Owner:TSINGHUA UNIV

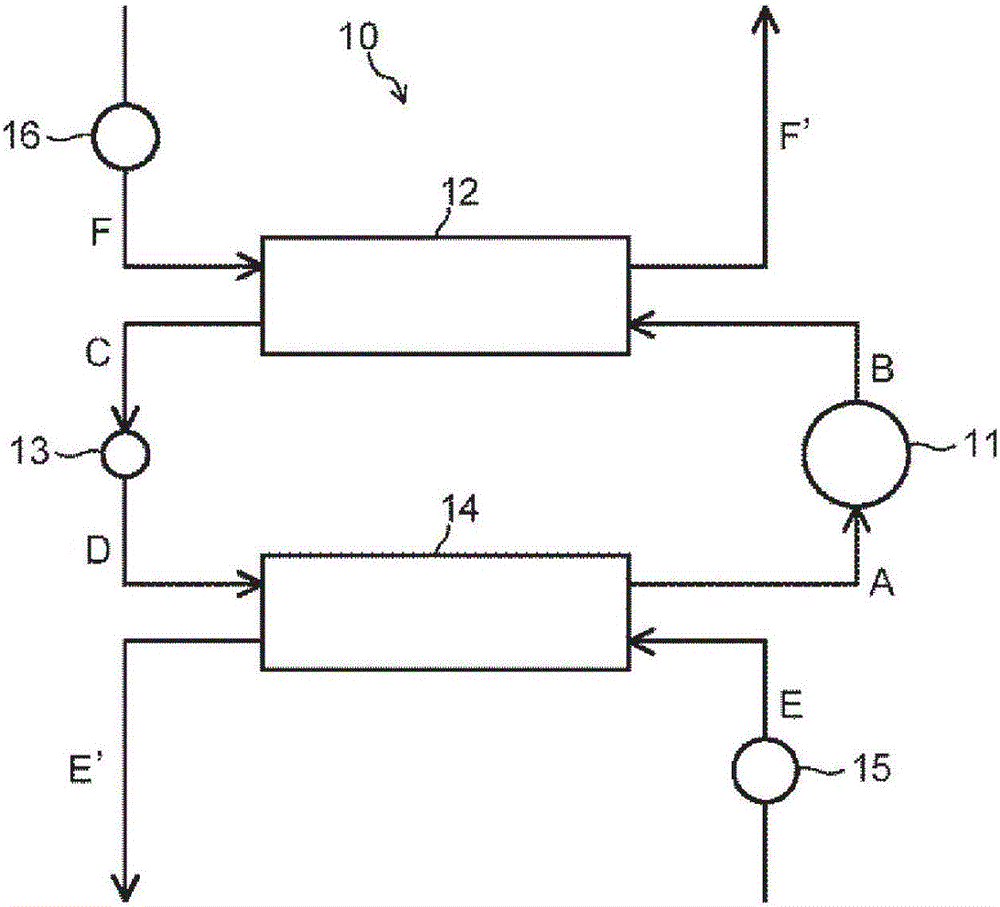

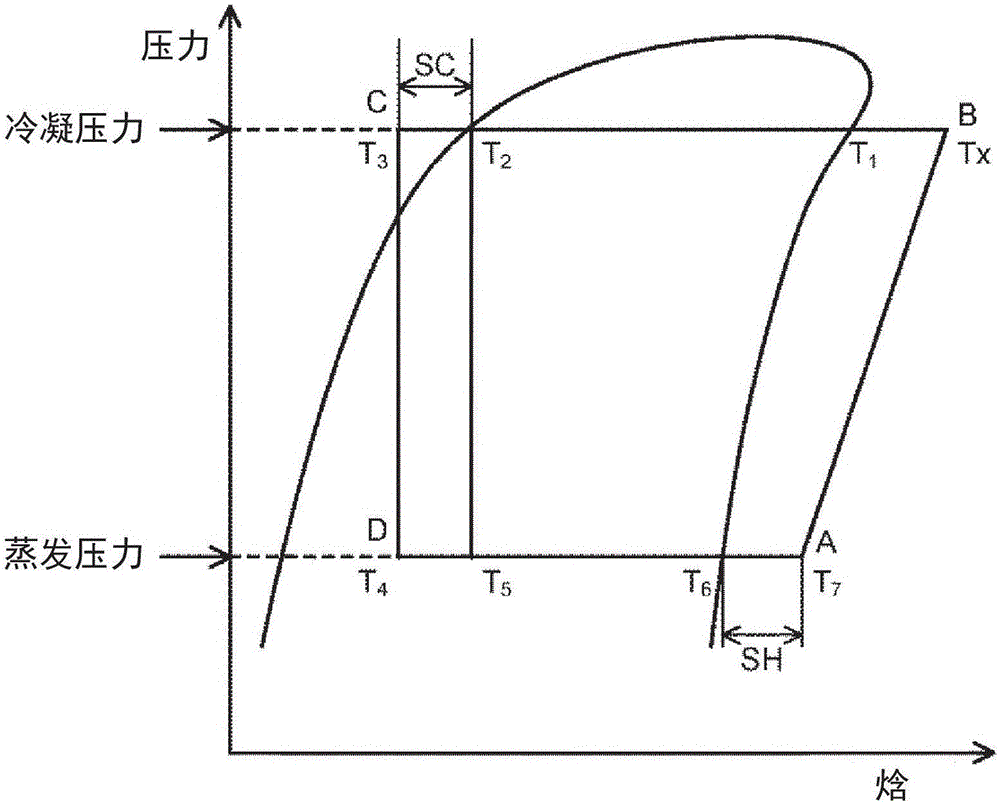

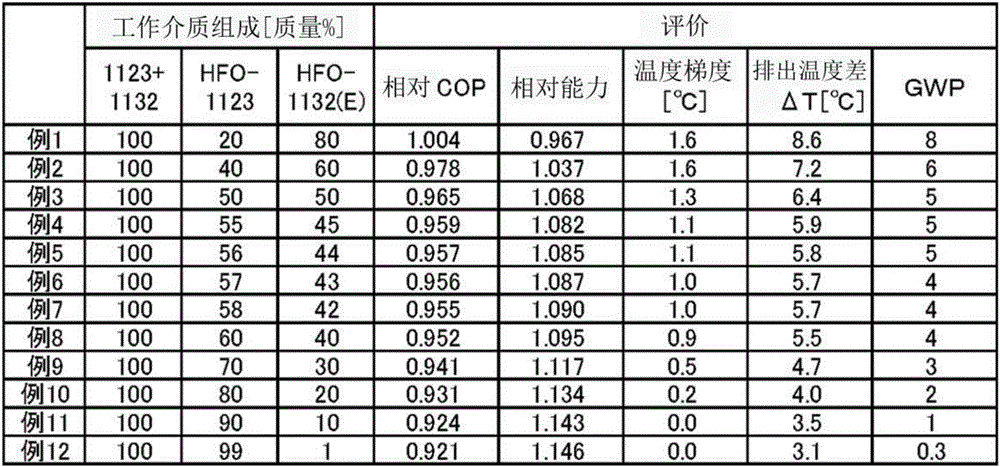

Working medium for heat cycles, composition for heat-cycle systems, and heat-cycle system

ActiveCN106133110AReduce temperature gradientLower discharge temperatureCompressorCompression machines with non-reversible cycleEngineeringRefrigeration

Provided are: a working medium for heat cycles which has a low impact on global warming, a low temperature gradient, and a sufficiently low discharge temperature, and which exhibits excellent cycle performance (i.e. refrigeration capacity and coefficient of performance); a composition for heat-cycle systems; and a heat-cycle system. The working medium for heat cycles includes trifluoroethylene and 1, 2-difluoroethylene. Also provided are: a composition for heat-cycle systems; and a heat-cycle system which uses the working medium and the composition. It is prefereable that, in the working medium for heat cycles, the ratio of the total amount of trifluoroethylene and 1, 2-difluoroethylene be at least 20 mass%, and equal to or less than 100 mass%.

Owner:AGC INC

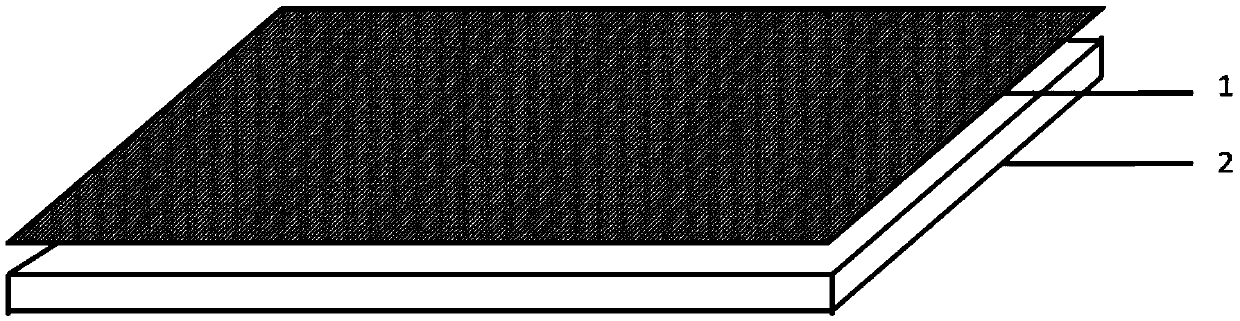

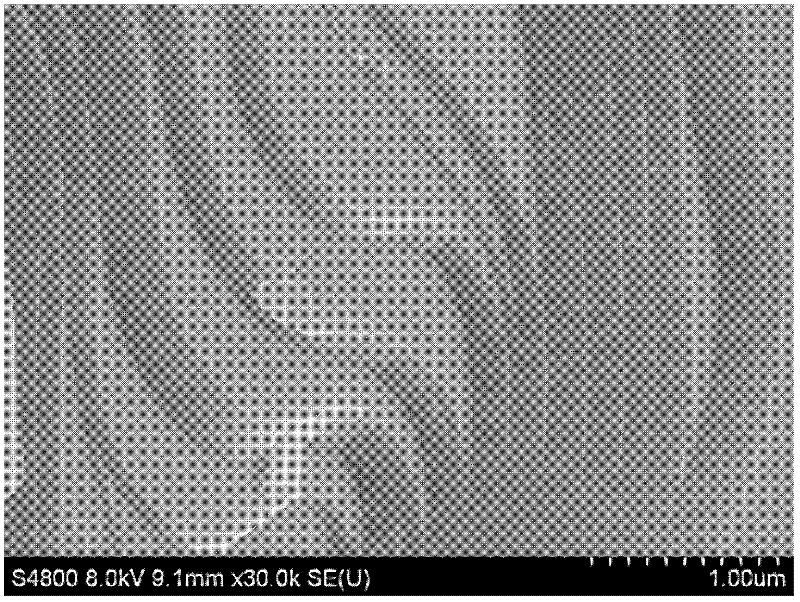

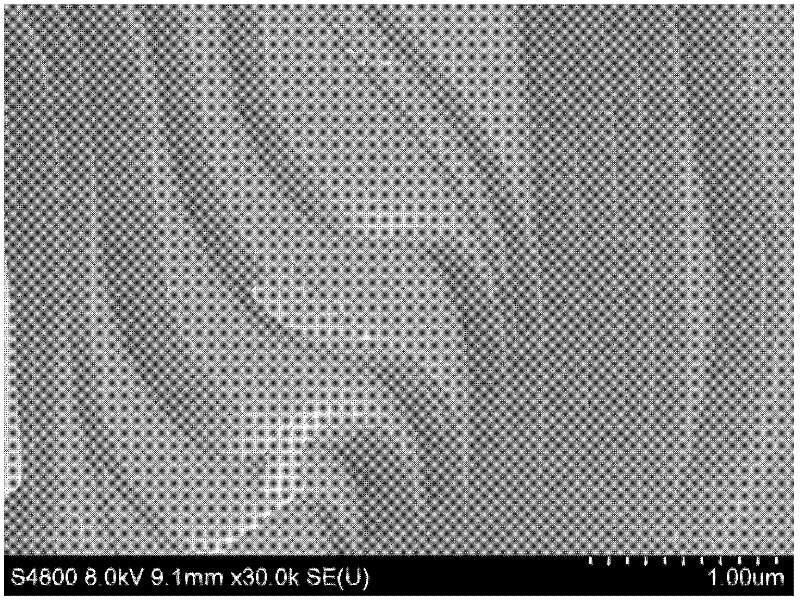

Composite graphene infrared radiation and heat conduction film and manufacturing method thereof

ActiveCN105514066AImprove infrared radiation performanceFast heat conductionSemiconductor/solid-state device detailsConjugated diene hydrocarbon coatingsOptoelectronicsHeat sink

The invention discloses a composite graphene infrared radiation and heat conduction film and a manufacturing method of the composite graphene infrared radiation and heat conduction film, and is characterized in that a substrate is provided with a composite graphene infrared radiation coating layer. According to the manufacturing method of the composite graphene infrared radiation and heat conduction film disclosed by the invention, a thin film manufactured by utilizing good infrared radiation capacity and good heat conduction capacity of a composite graphene infrared radiation material has the good heat conduction capacity in both directions which are parallel to and vertical to the substrate, so that heat can be rapidly transferred from a heating part to a heat sink device or an environment, the heat conduction efficiency is increased, local hot points in a device are removed, and temperature gradient in a heat conduction path is reduced; the composite graphene infrared radiation and heat conduction film disclosed by the invention has the advantages that the manufacturing is simple and convenient, and a powerful support is provided for high integration of electronic devices and rapid heat conduction of heating devices.

Owner:宿州晶禾科技有限公司

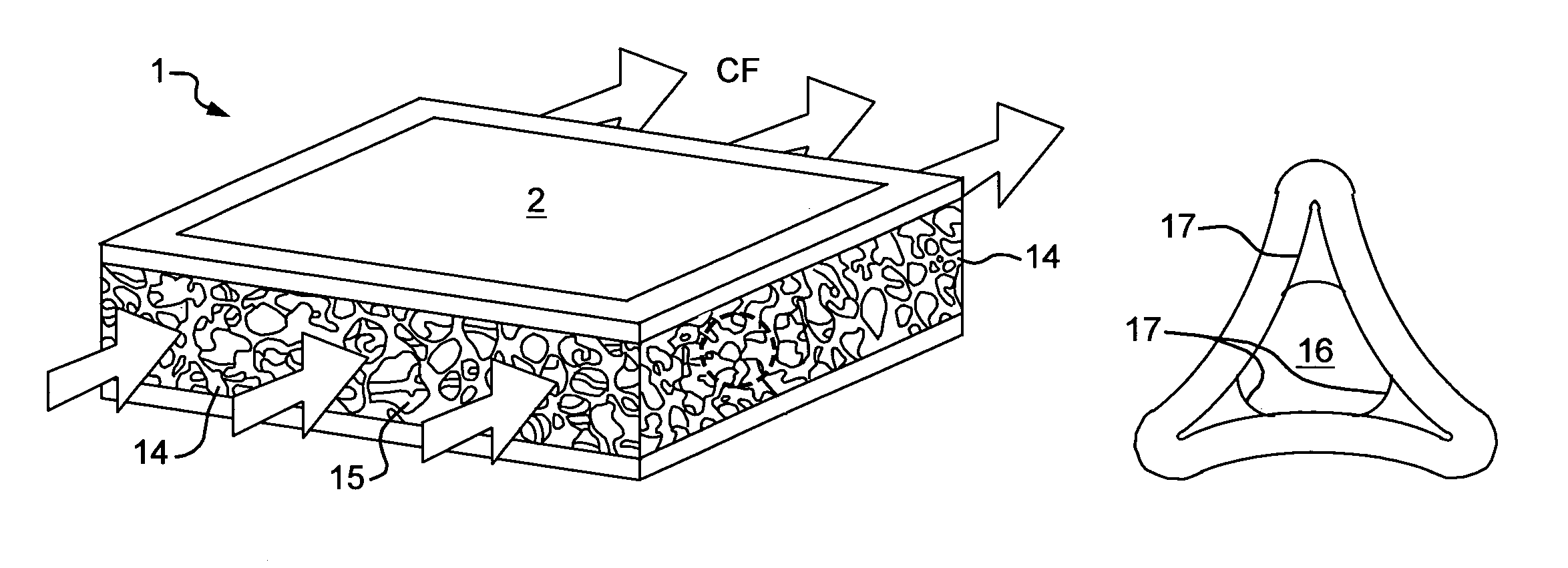

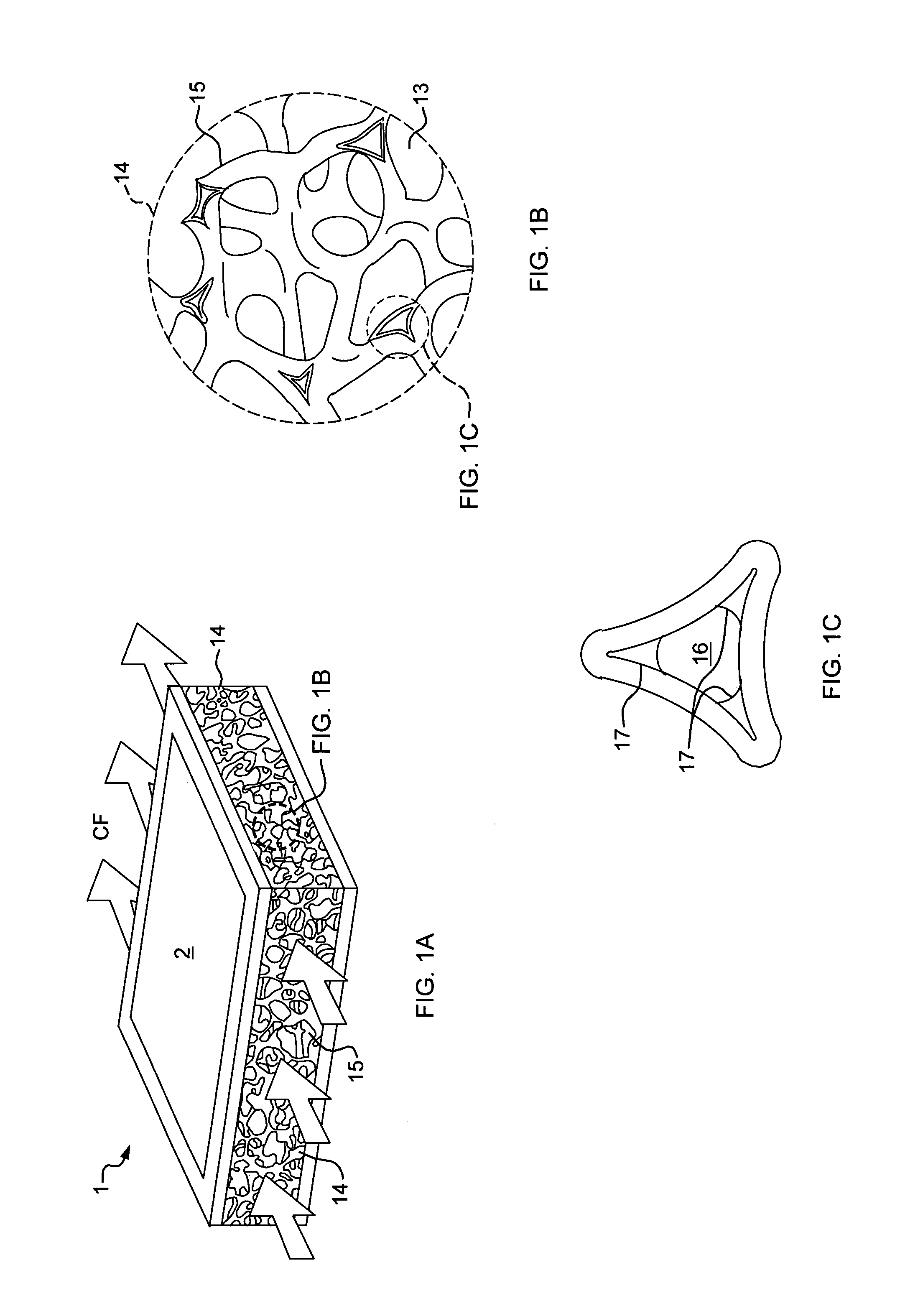

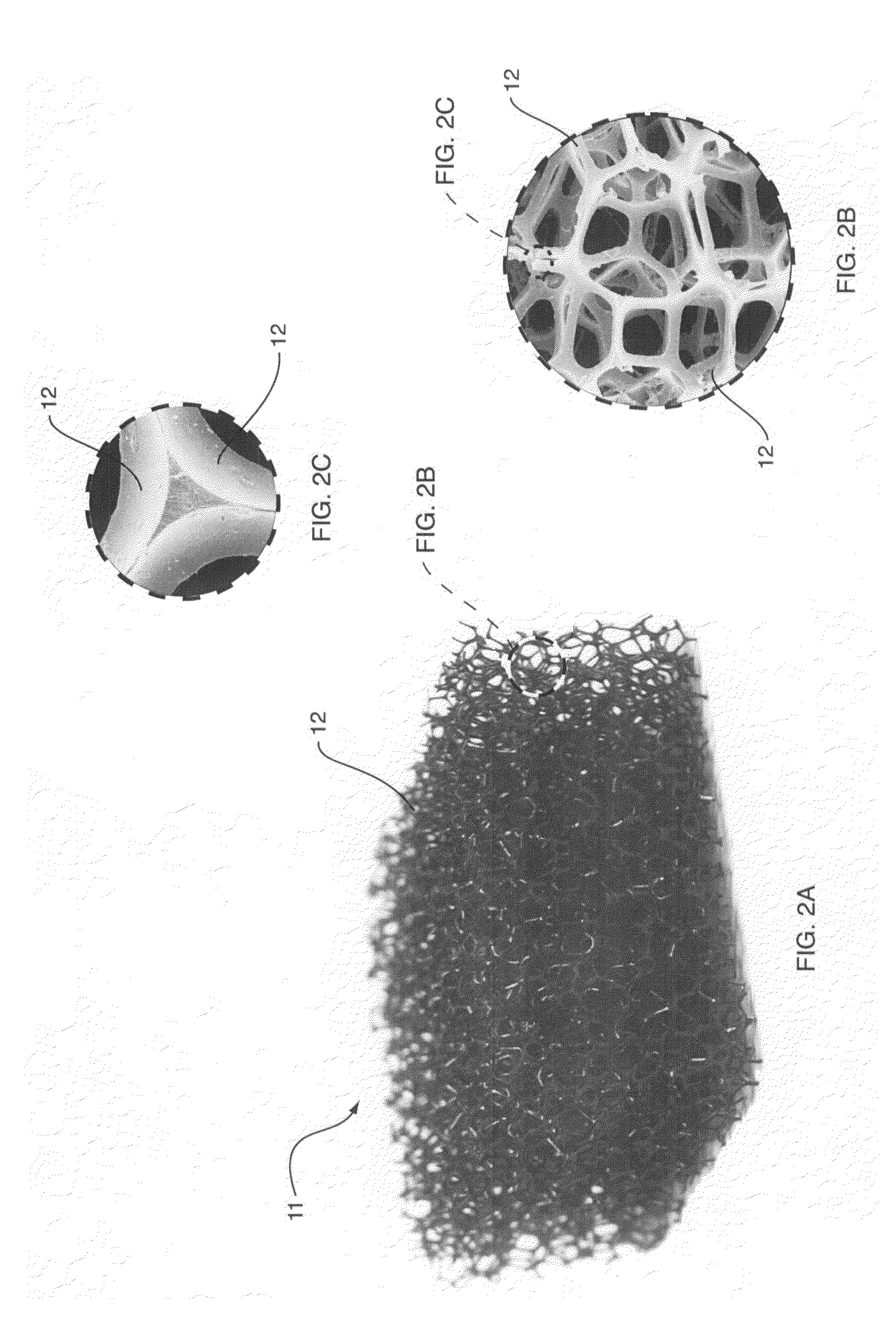

Heat exchange foam

InactiveUS7401643B2Improve efficiencyReduce temperature gradientVacuum evaporation coatingSputtering coatingWorking fluidVaporization

A method and an apparatus for the efficient transfer of heat utilizing micro heat pipes that include a cellular foam or interconnected cellular / truss network having hollow ligaments. A predetermined fraction of the internal volume of the hollow ligaments is filled with a carefully chosen working fluid, and the ends of the hollow ligaments are sealed. In operation, the working fluid evaporates in the region of high heat flux and condenses in regions of lower temperature, resulting in the transfer or redistribution of the fluid's latent heat of vaporization. For open cell foams and interconnected networks, a second fluid flowing through the open cells, separate from the working fluid but also in thermal contact with the hollow ligaments, assists in the transfer of heat from the foam and networks.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

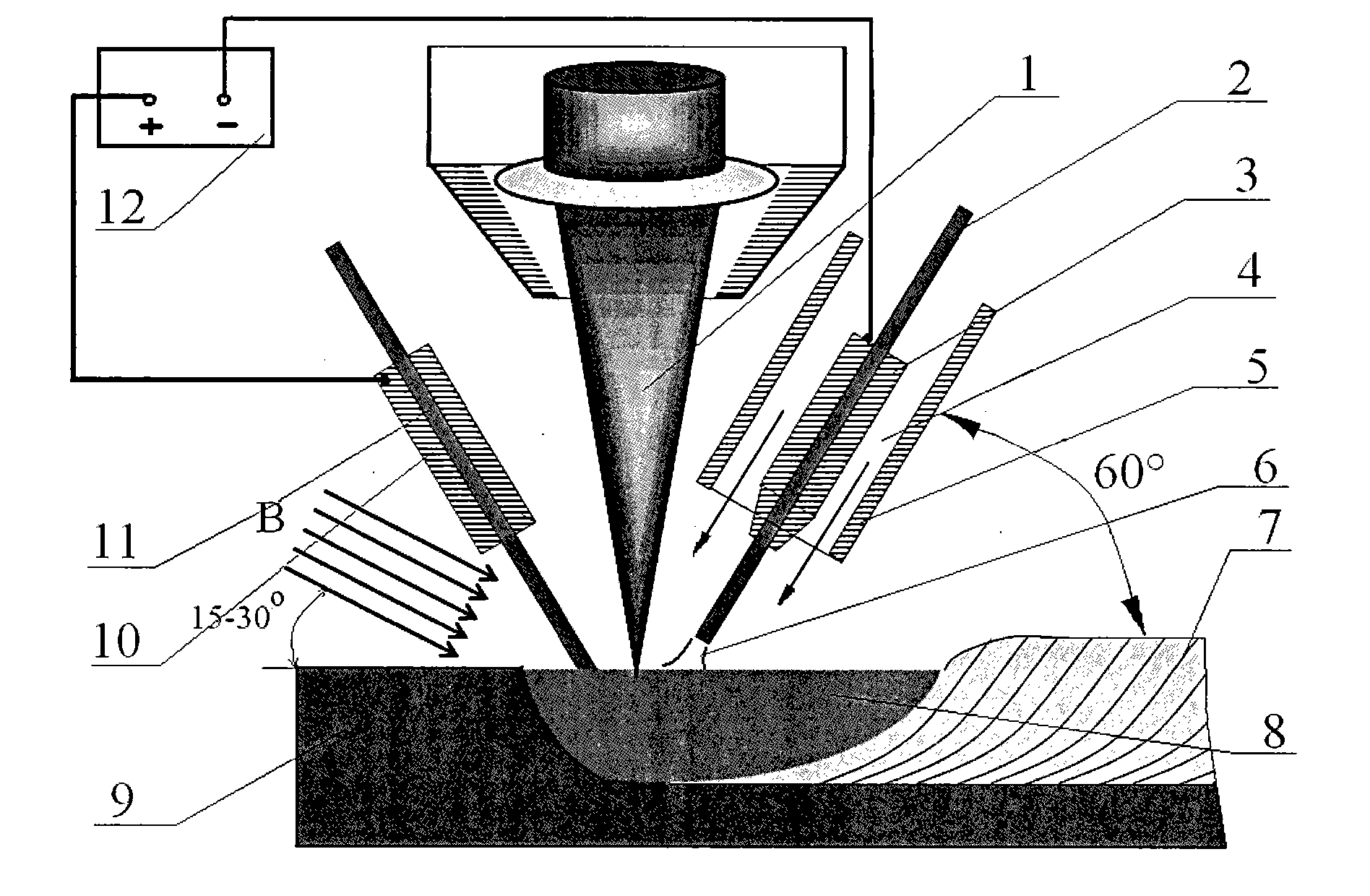

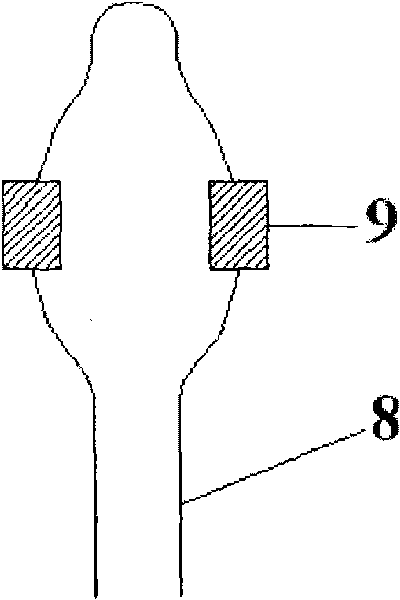

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

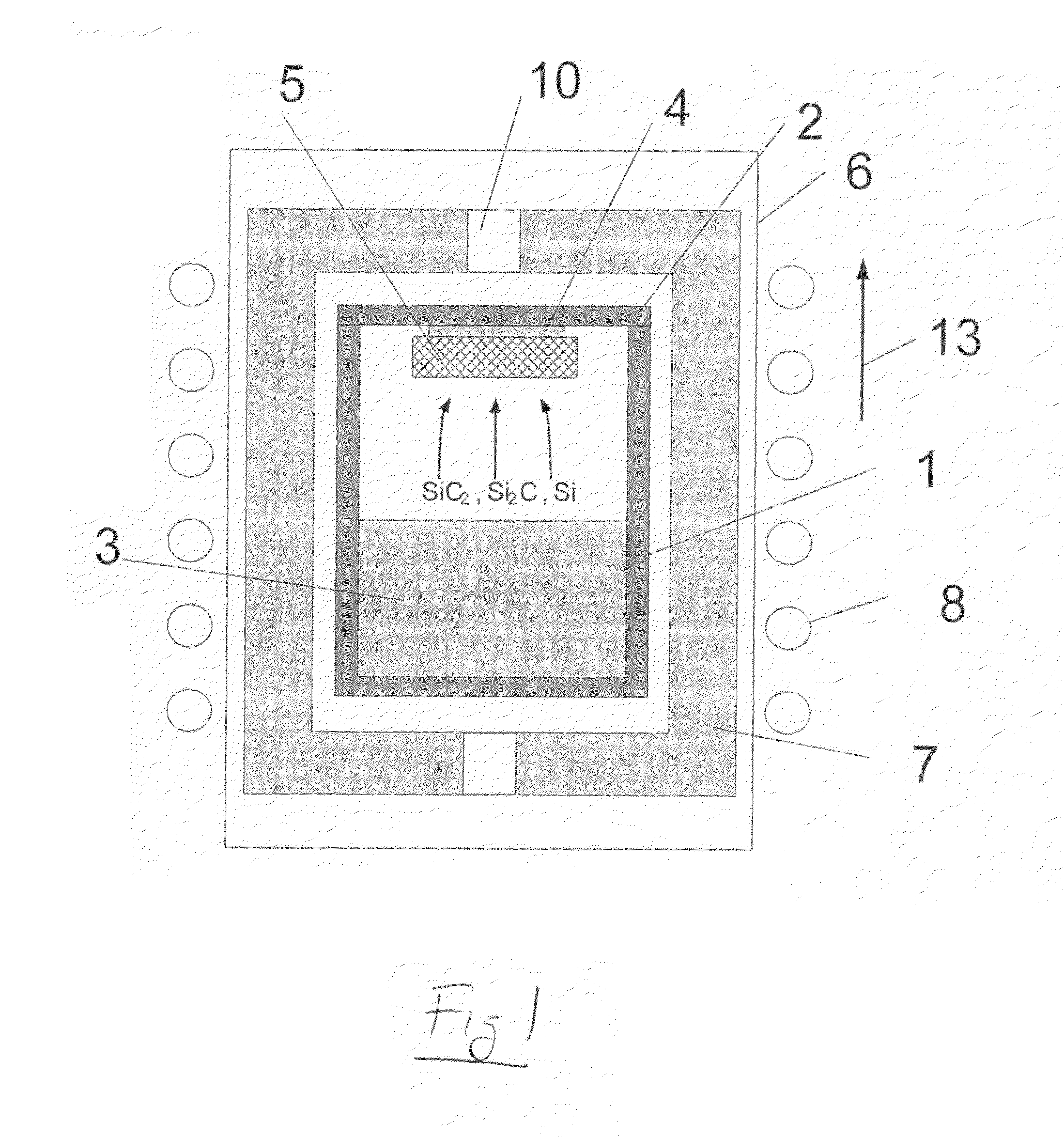

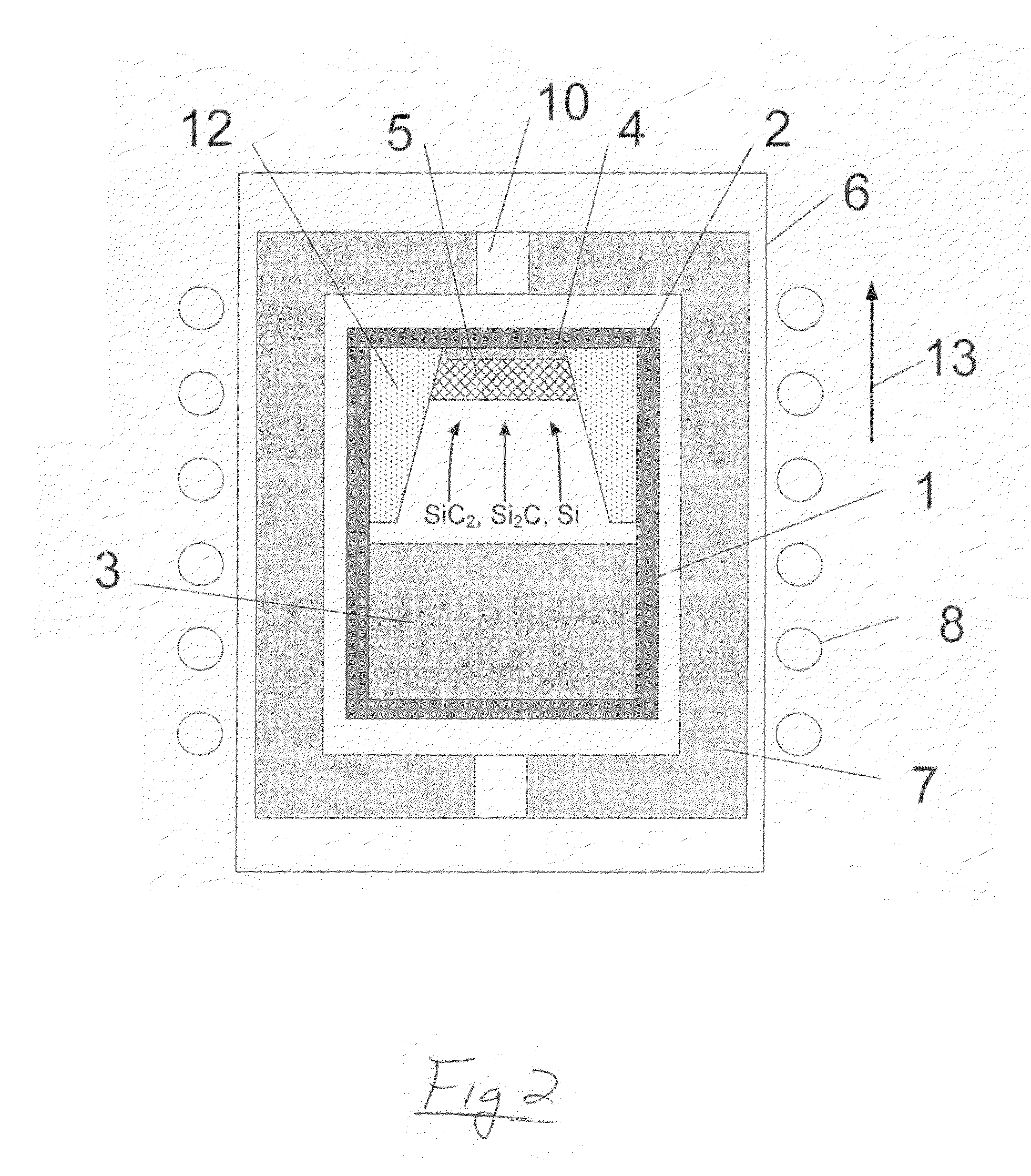

Method of annealing a sublimation grown crystal

InactiveUS7767022B1Minimize temperature gradientReduce temperature gradientPolycrystalline material growthAfter-treatment detailsCrucibleSource material

A crystal is sublimation grown in a crucible by way of a temperature gradient in the presence of between 1 and 200 Torr of inert gas. The pressure of the inert gas is then increased to between 300 and 600 Torr, while the temperature gradient is maintained substantially constant. The temperature gradient is then reduced and the temperature in the crucible is increased sufficiently to anneal the crystal. Following cooling and removal from the crucible, the crystal is heated in the presence of oxygen in an enclosure to a temperature sufficient to remove unwanted material from the crystal. Following cooling and removal from the enclosure, the crystal surrounded by another instance of the source material is heated in a crucible in the presence 200 and 600 Torr of inert gas to a temperature sufficient to anneal the crystal.

Owner:II VI

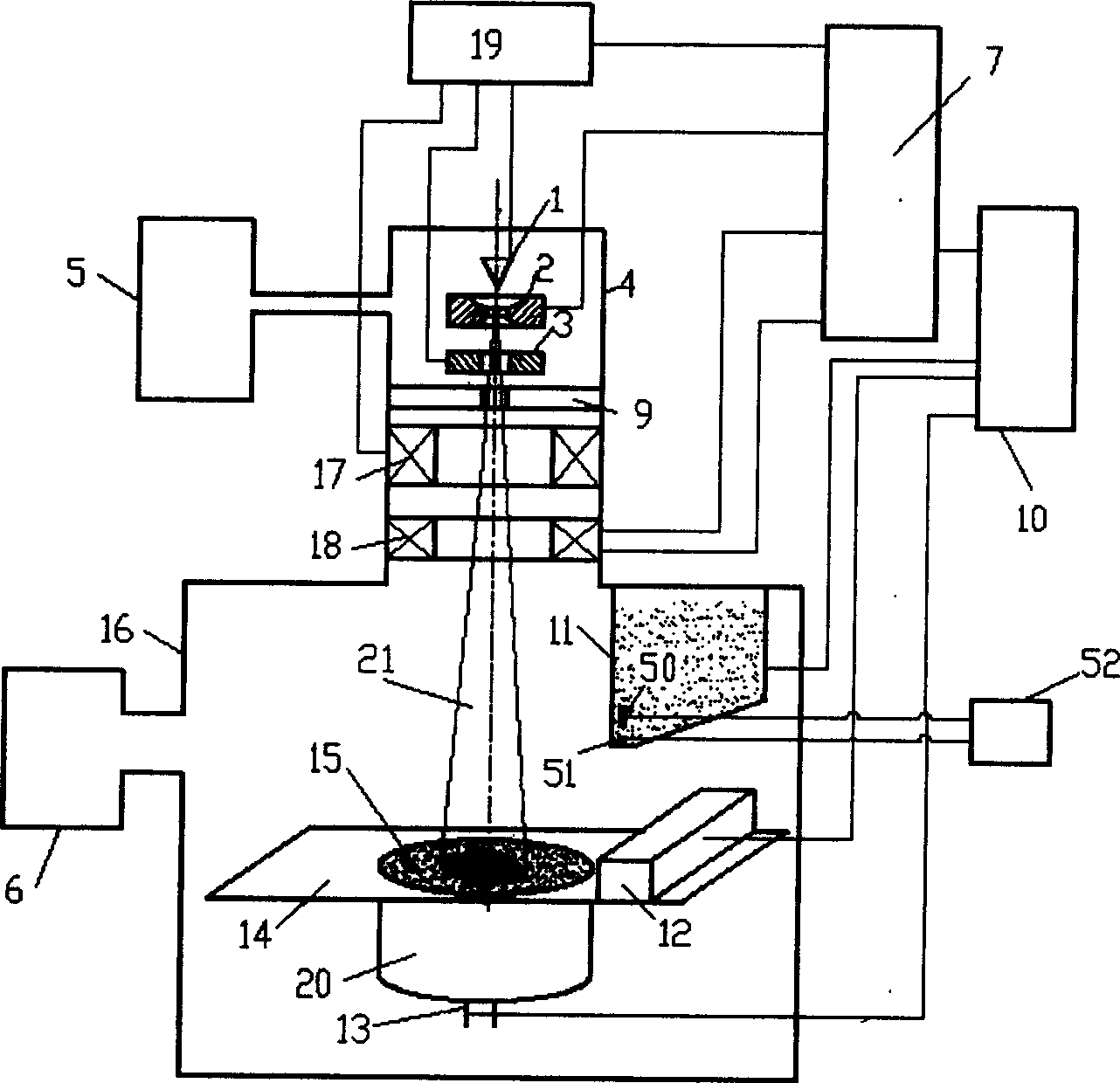

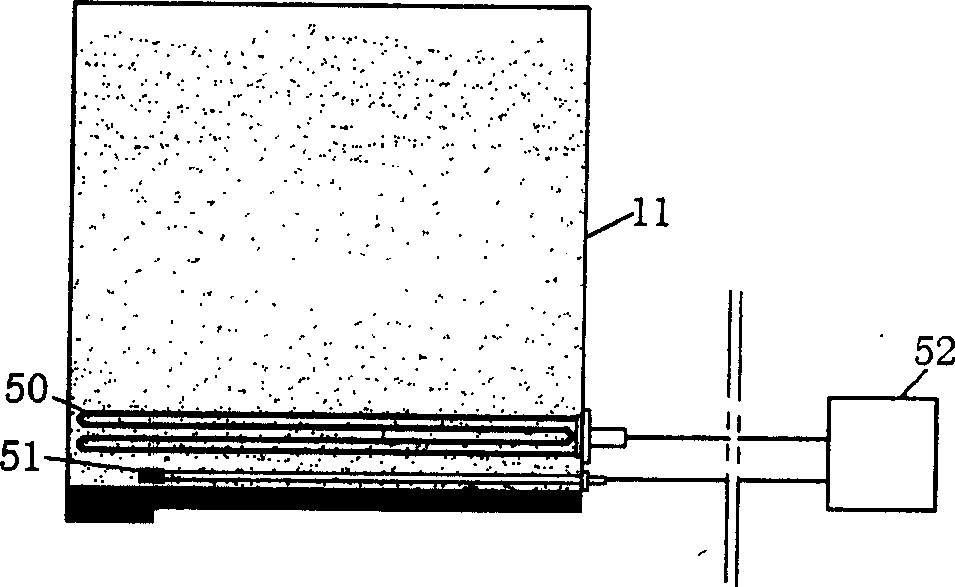

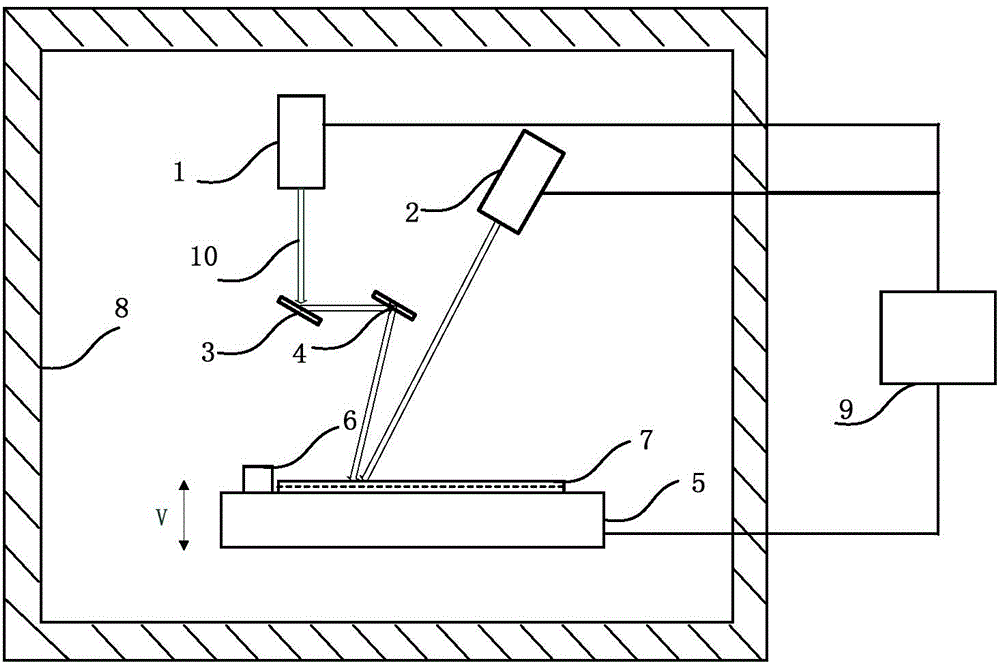

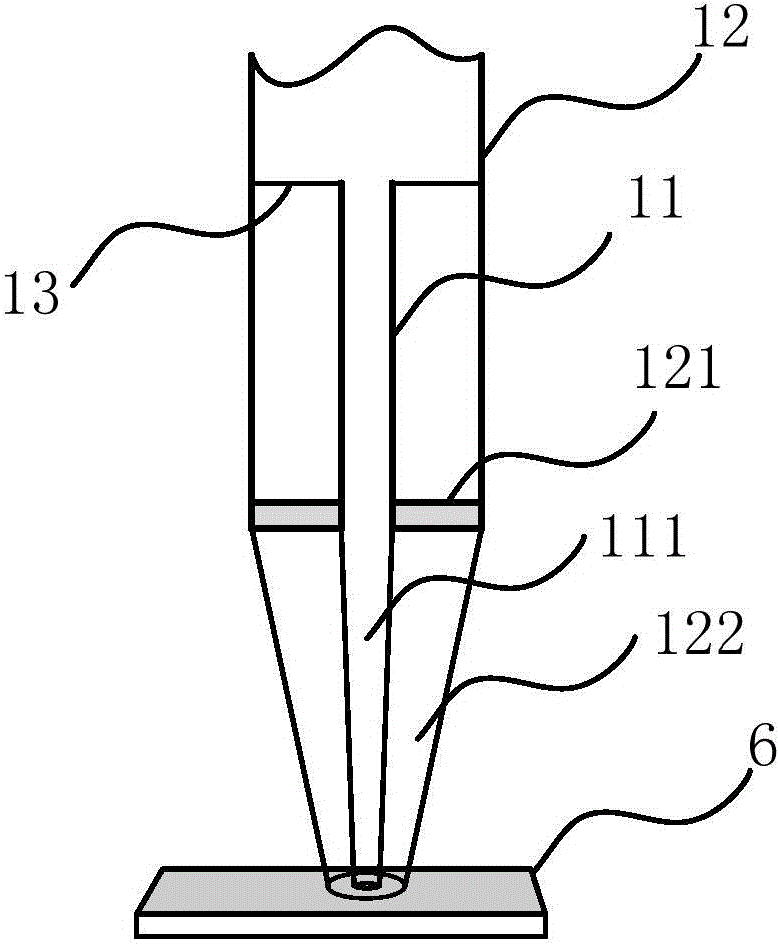

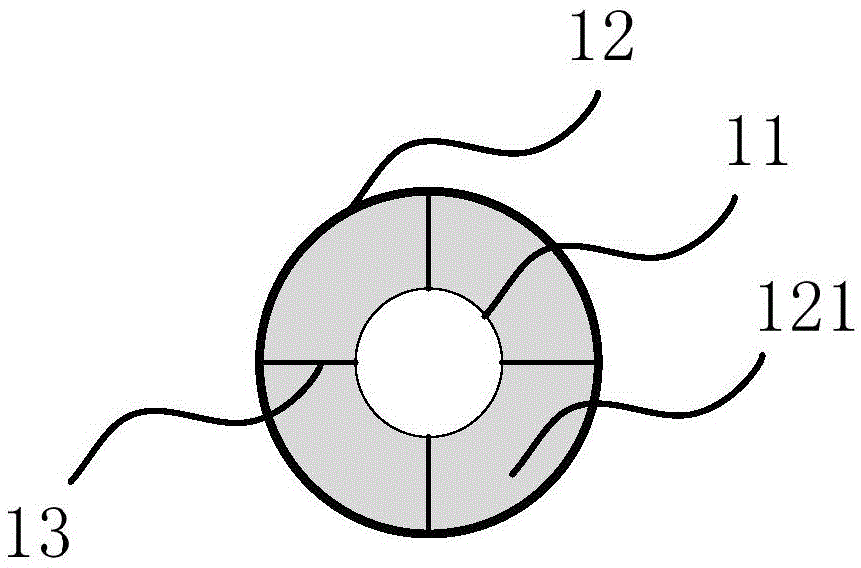

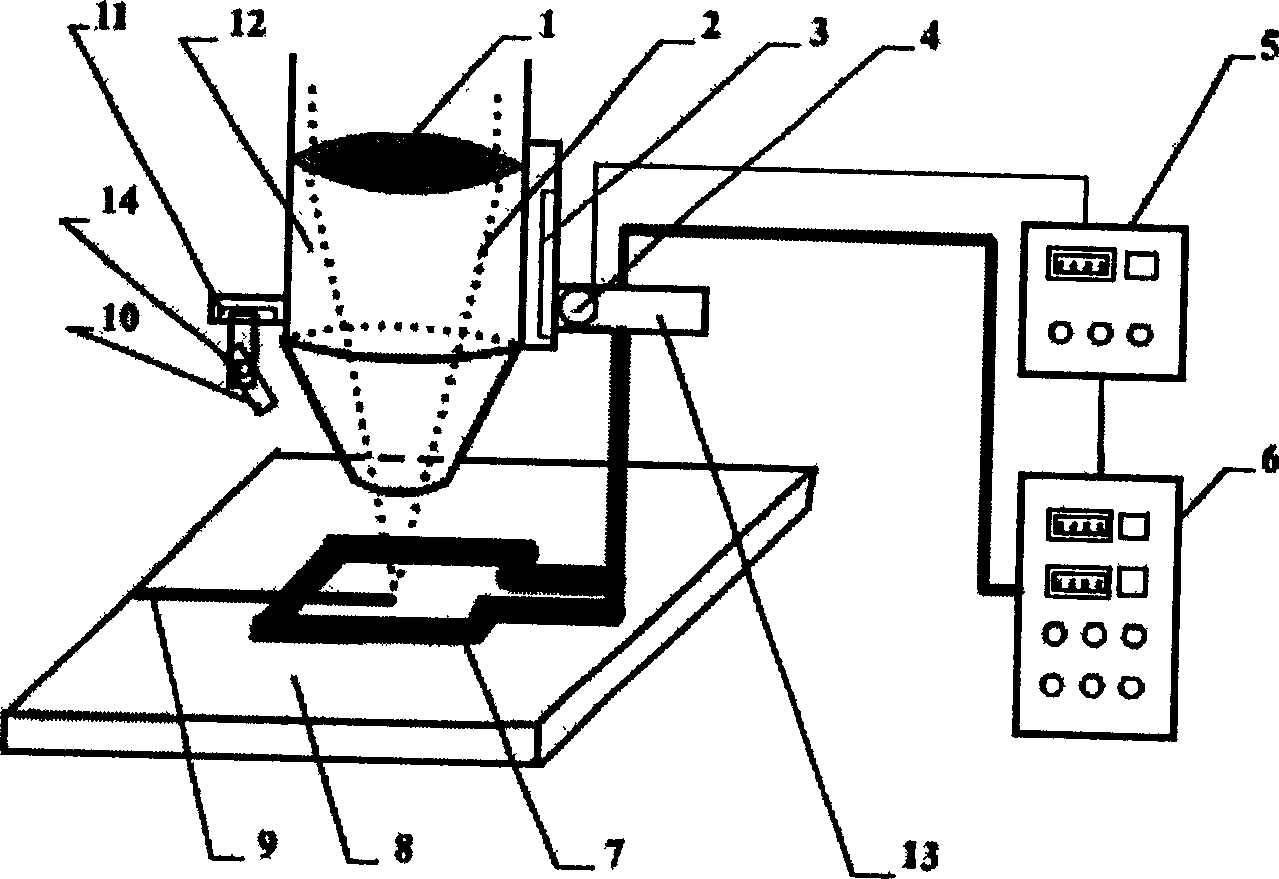

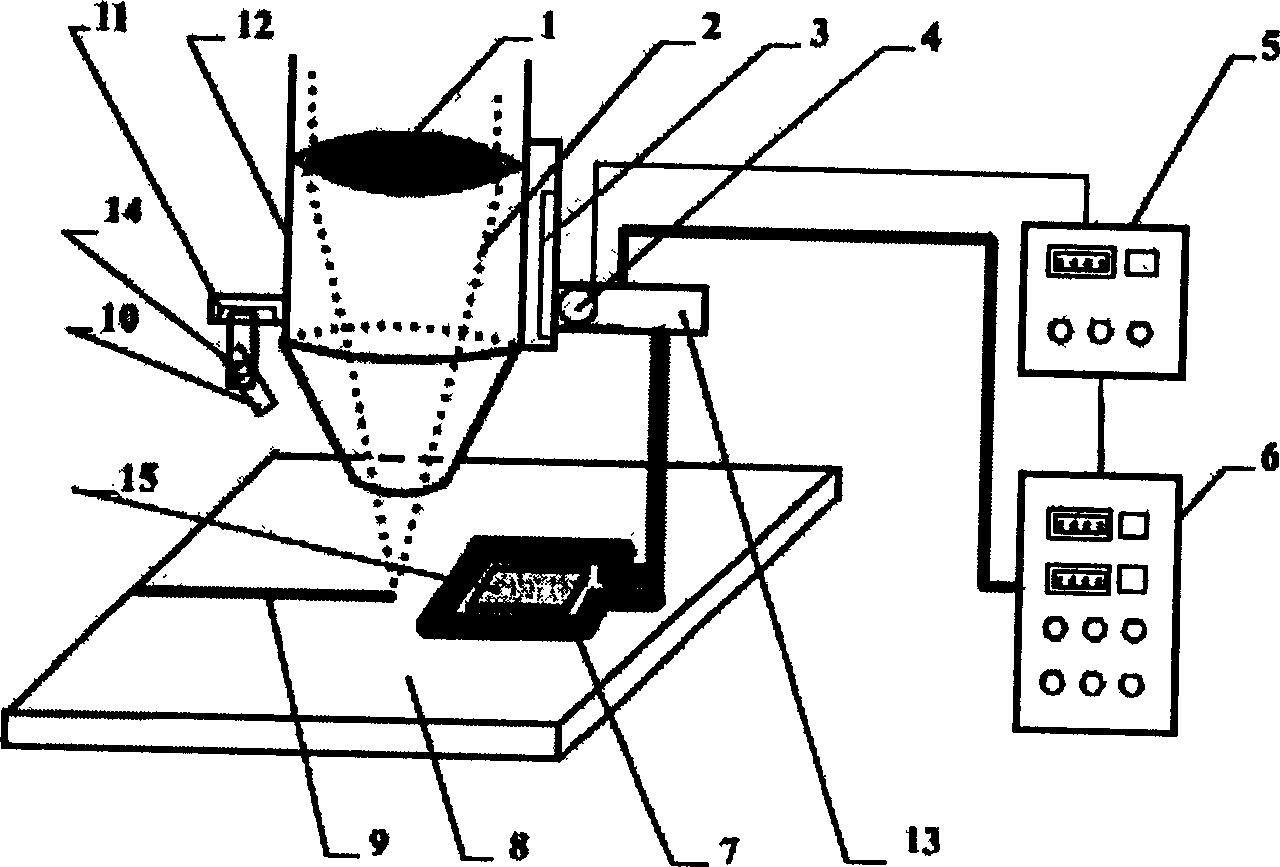

High polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control

ActiveCN103978307ALess frizzReduce temperature gradientAdditive manufacturing apparatus3D object support structuresUltravioletThermostat

The invention discloses a high polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control. The device comprises a thermostat, a laser head, a non-contact type temperature monitoring device, a scanning galvanometer, a machining platform, a powder paving device, a machining material and a computer control system. The laser head adopts a dual-tube core structure, an inner tube and an outer tube are coaxially fixed, one or more than one gradual-change neutral filter piece is arranged between the two tubes, and the laser transmittance of the filter piece(s) is radially reduced from the inner tube to the outer tube. The method comprises the following steps: presetting the machining temperature by the control system, in the process of machining, monitoring the temperature rise condition of an object to be machined in real time under the irradiation of laser by the non-contact type temperature monitoring device, feeding back to the control system, recording the increased value of the temperature within a certain time, and obtaining the absorption capability of the material to be machined to the laser and the temperature rise degree by the system, so that according to the preset machining temperature value, the laser output power can be calculated, the laser power can be timely adjusted, and the machining temperature can be precisely controlled.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for rapidly preparing gradient metal ceramic composite material by laser induction hybrid cladding

InactiveCN101709468AIncrease profitImprove efficiencyMetallic material coating processesStrength of materialsMechanical property

The invention relates to a method for rapidly preparing a gradient metal ceramic composite material by laser induction hybrid cladding, which is characterized by comprising the following steps of: (1) generating a 3-D CAD solid model of a gradient metal ceramic composite material component by utilizing special CAD software or a reverse technology in a computer; (2) generating a processing program; (3) controlling the distance between the surface of a base material surface and an induction coil within the range of 2-10 mm; (4) locating a focused CO2 laser beam in an induction heating area; and (5) lifting a laser induction hybrid cladding processing head to the distance equal to the thickness of a CAD 2-D sheet. The invention has the advantages that: (1) a bulk metal ceramic composite material part the ceramic phase of which is continuously tunable along the material thickness direction within 0-100percent by weight is obtained; (2) the use ratio of laser energy and laser cladding efficiency are greatly improved; (3) the metal ceramic composite material with compact tissue but without cracks is obtained; (4) special tools and fixtures are not needed in the manufacturing process, and the flexibility is high; and (5) the mechanical property, the abrasive resistance and the corrosion resistance of the gradient metal ceramic composite material are greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

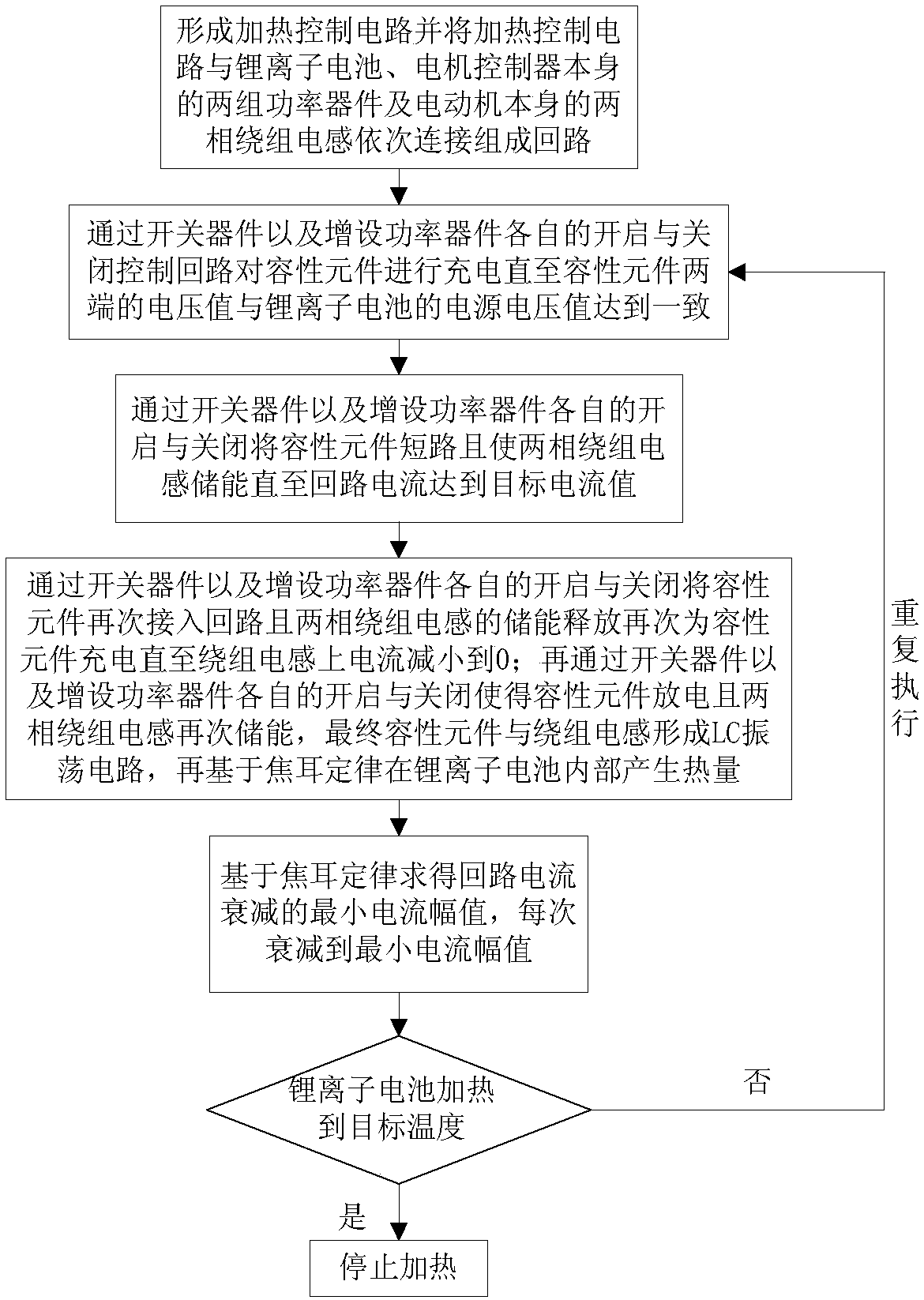

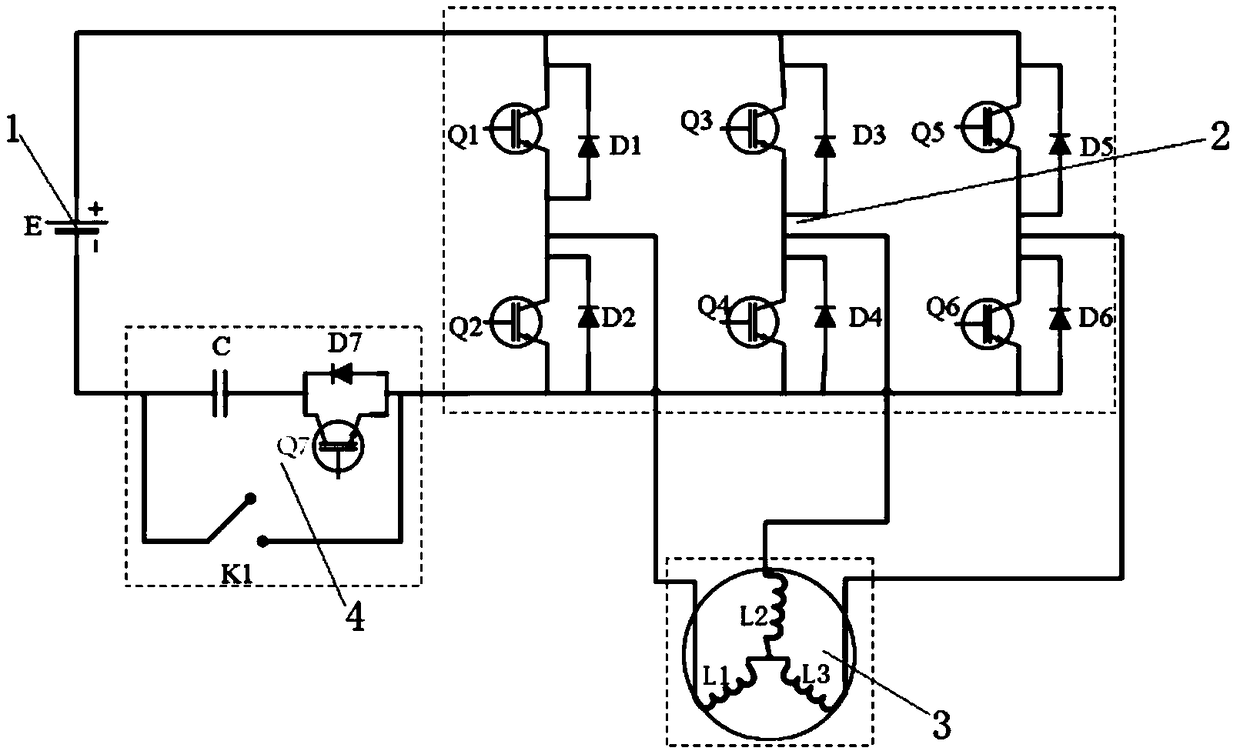

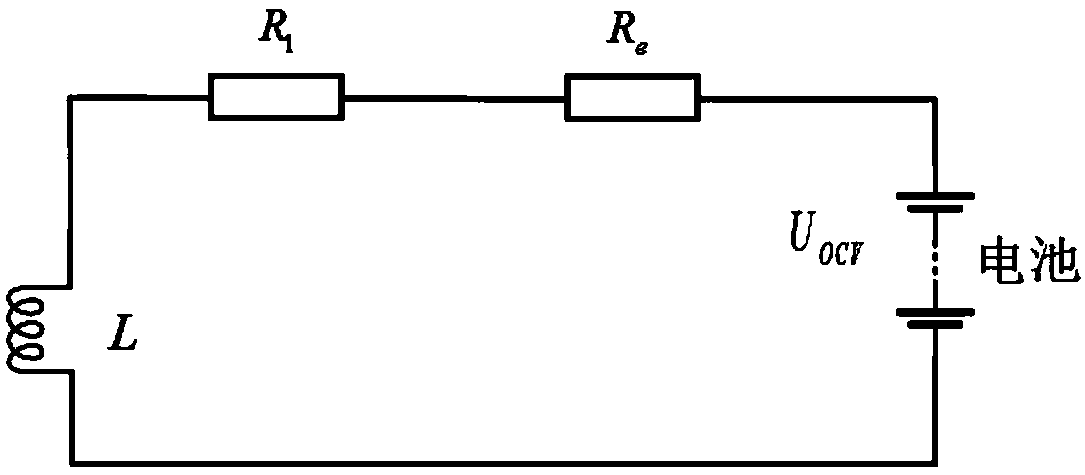

Low-temperature heating control method for lithium ion battery

ActiveCN108847513ASolve the problem of poor charge and discharge performanceExtended service lifeSecondary cellsVehicular energy storageElectrical batterySimple component

A low-temperature heating control method for a lithium ion battery includes the following steps: first selecting a capacitive component; connecting the capacitive component and an additional power device in series, and then connecting a switch device in parallel to form a heating control circuit; then sequentially connecting the heating control circuit with the lithium ion battery, two sets of power devices of a motor controller body, and two-phase winding inductance of a electromotor to form a loop; and controlling charge and discharge of the capacitive component and magnetic energy storage and release of the two-phase winding inductance by opening and closing of the switch device and the additional power device to enable an LC oscillating circuit to be formed between the capacitive element and the winding inductance, generating a high-frequency alternating current, generating heat inside the lithium ion battery based on a joule law, and allowing to repeatedly operating the heating process to achieve continuous oscillation and continuous heat production until heating the lithium ion battery to a target temperature. The low-temperature heating control method for the lithium ion battery can be achieved by only adding a simple component to an inherent structure of an electric vehicle, and has the characteristics of good heating effect, high thermal efficiency and low usage cost.

Owner:BEIHANG UNIV

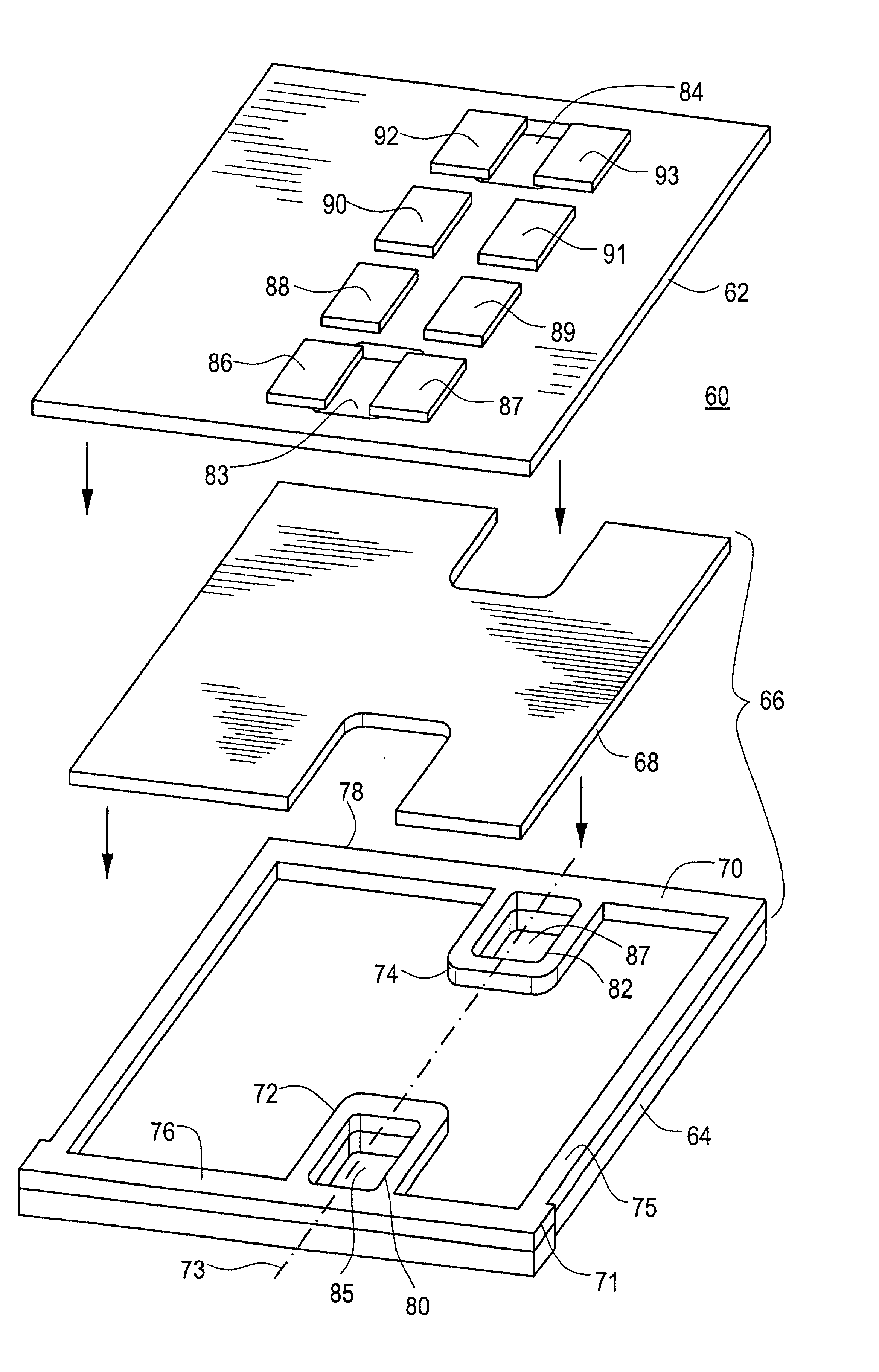

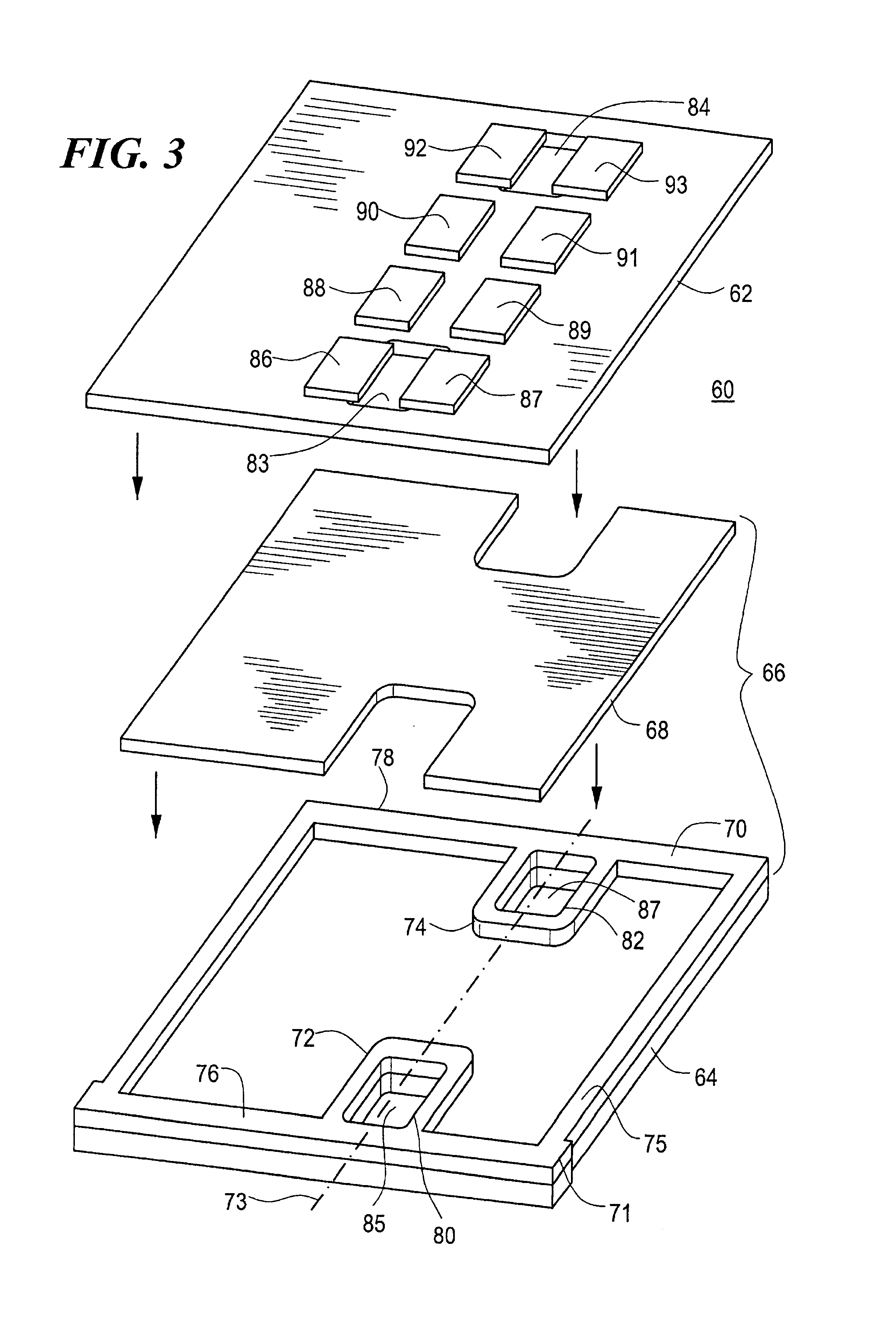

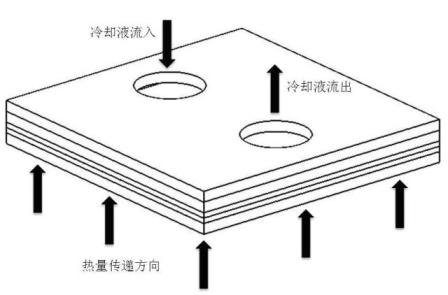

Cold plate assembly

ActiveUS6903931B2Eliminate needReduce temperature gradientParticular array feeding systemsSemiconductor/solid-state device detailsAluminiumRadar systems

An edge cooled graphite core aluminum cold plate for use in phased array radar systems, the cold plate including opposing aluminum skins, and a core layer sandwiched between the opposing aluminum skins. The core layer includes graphite surrounded by an aluminum body. The aluminum body includes inwardly directed tabs extending from opposing cooled edges of the cold plate, the inwardly directed aluminum tabs having orifices therethrough. The opposing aluminum skins also includes orifices therethrough aligned with the orifices in the tabs of the aluminum body to reduce the conductivity of the cooled edges of the cold plate thus reducing the temperature gradient between edge mounted heat sources and inwardly mounted heat sources without adversely affecting the structural integrity of the graphite core layer.

Owner:RAYTHEON CO

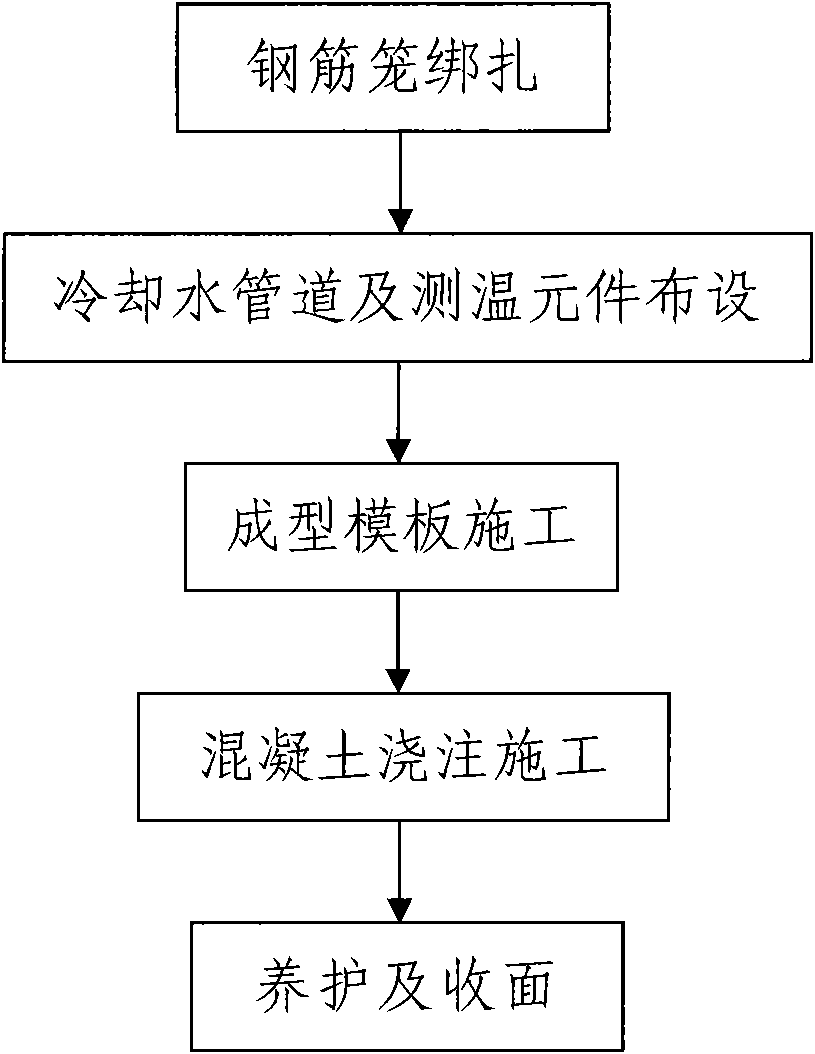

Construction method of large-volume concrete bearing platform with one-time pouring in winter

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

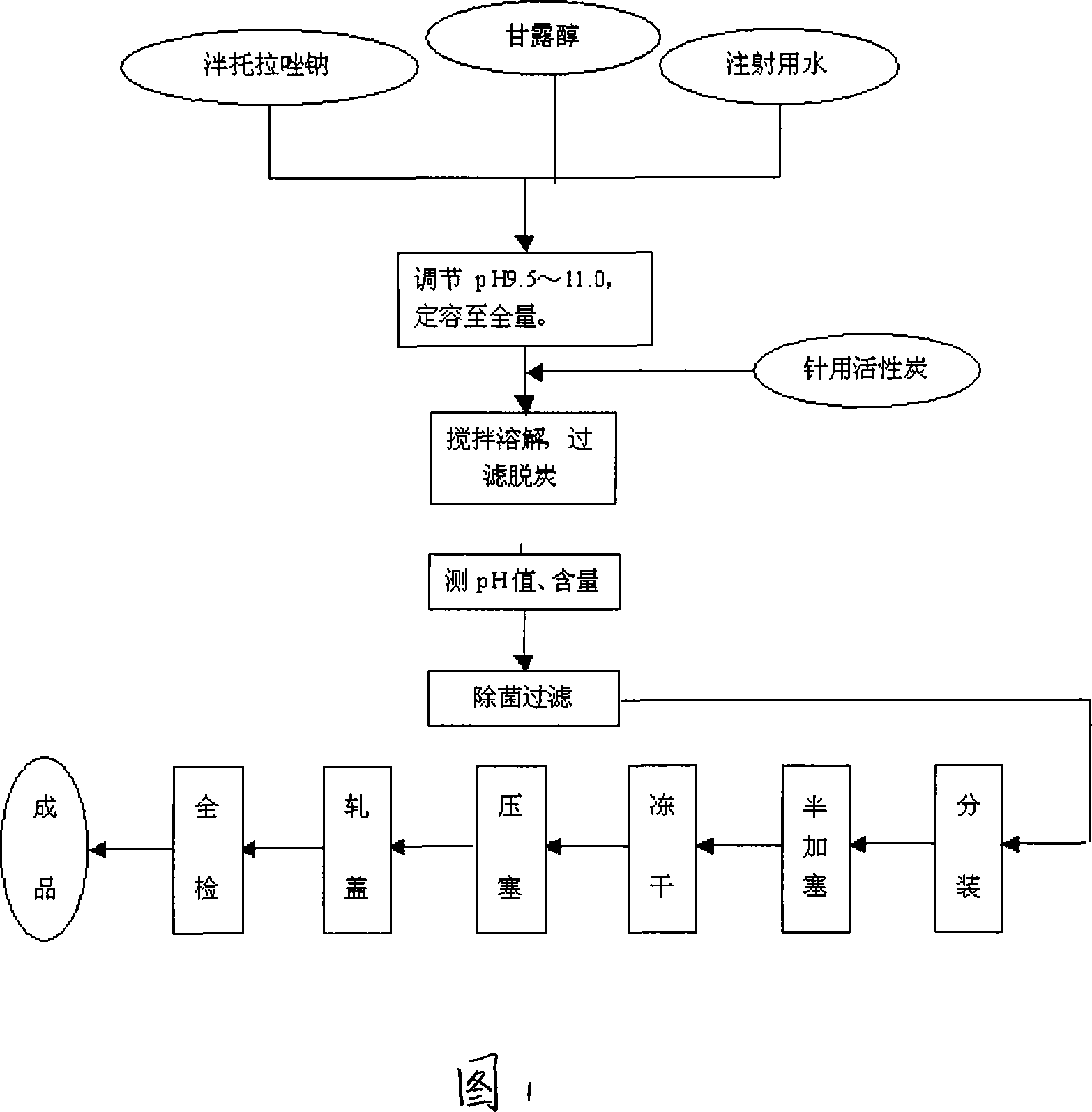

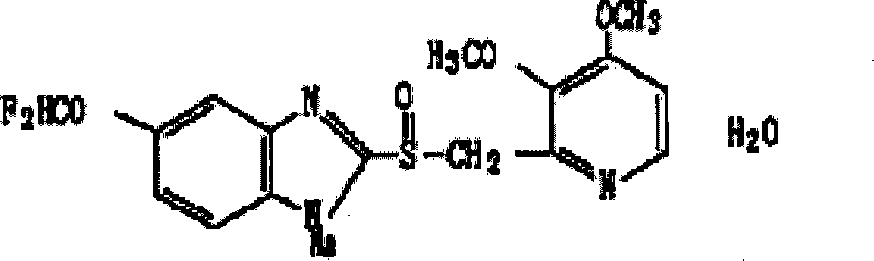

Pantoprazole sodium freeze-dried powder injection and preparing method thereof

ActiveCN101229138ASimple recipeLittle side effectsPowder deliveryOrganic active ingredientsSolubilityMANNITOL/SORBITOL

The invention aims at providing a pantoprazole sodium freeze-dried powder injection and comprises pantoprazole sodium and mannitol with the weight ratio of 1: 2 to 5. The invention is simple in formula and little in side effect; products prepared by the method are plump in appearance, good in complex solubility and excellent in quality with the adoption of an advanced freezing and drying process.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

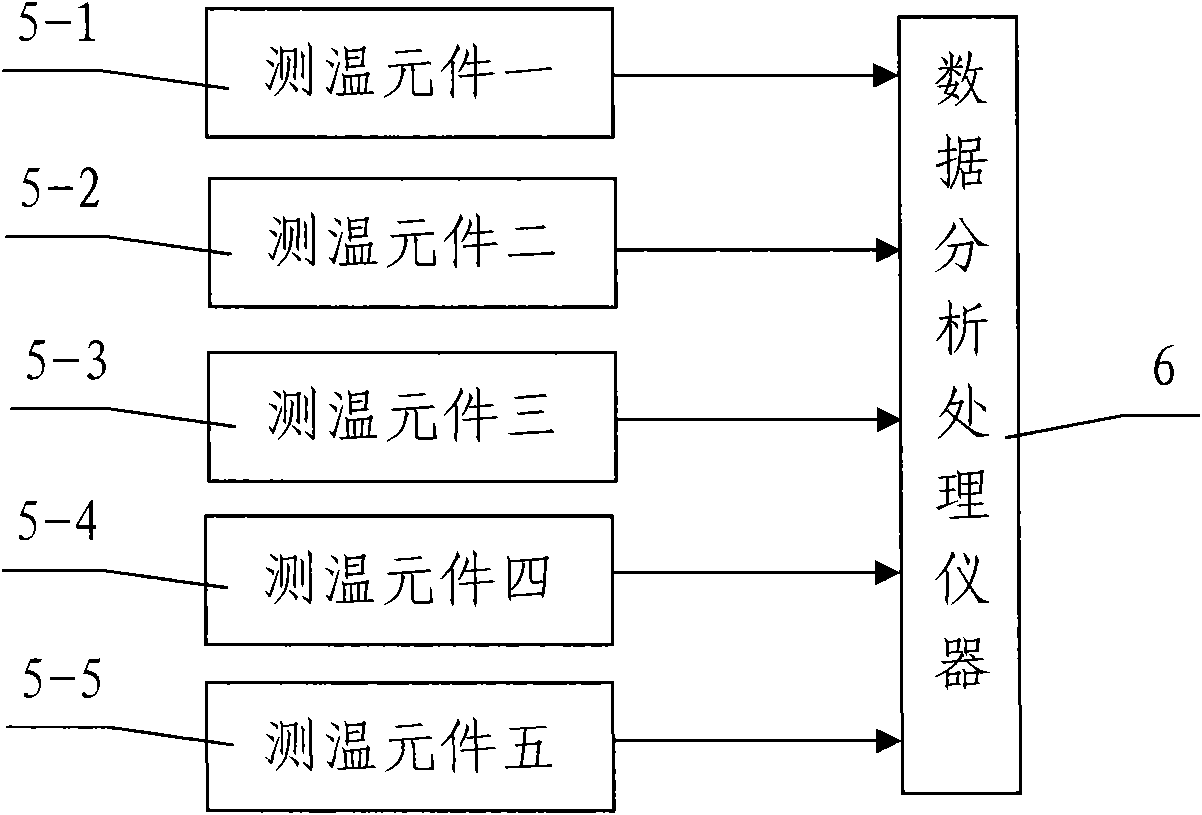

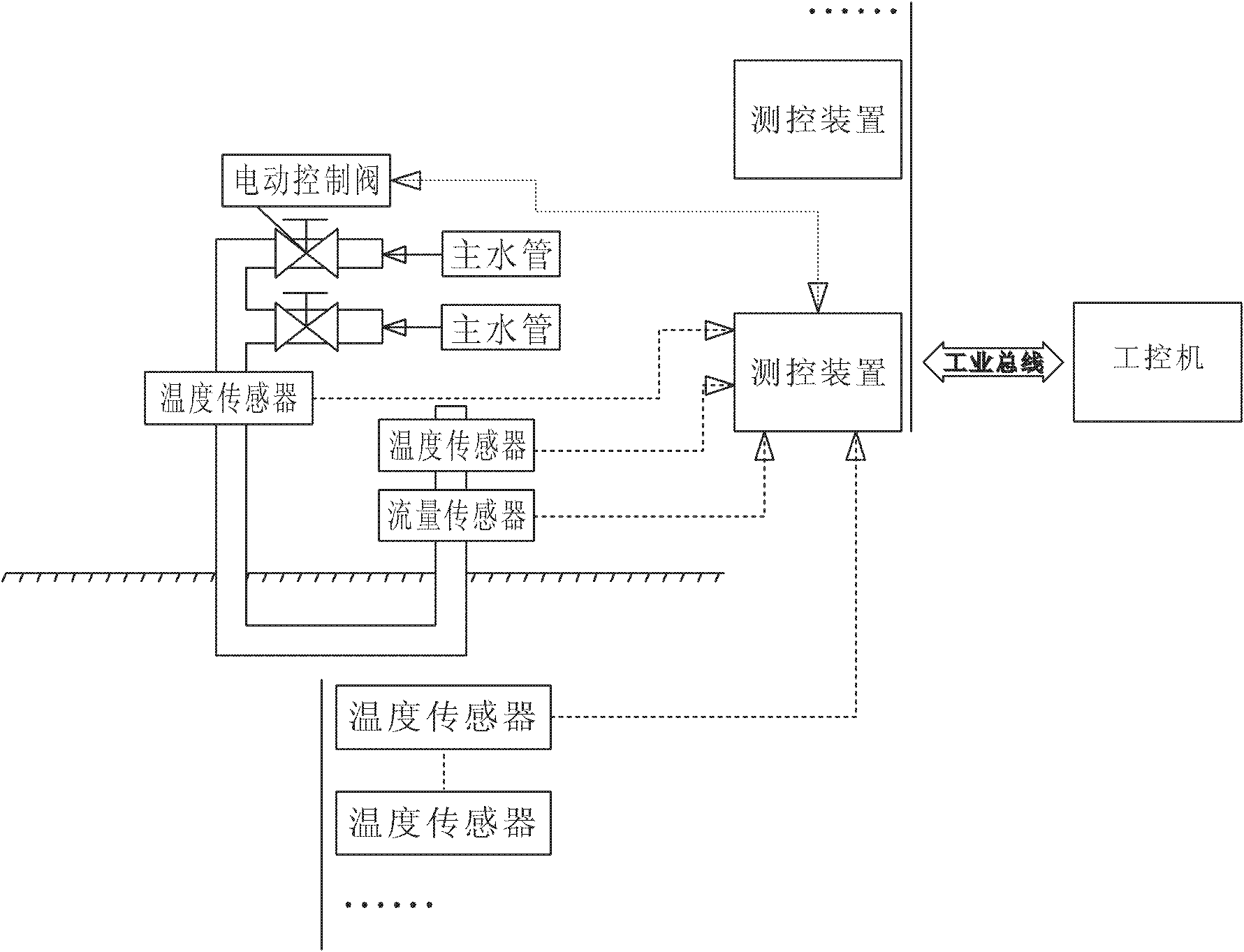

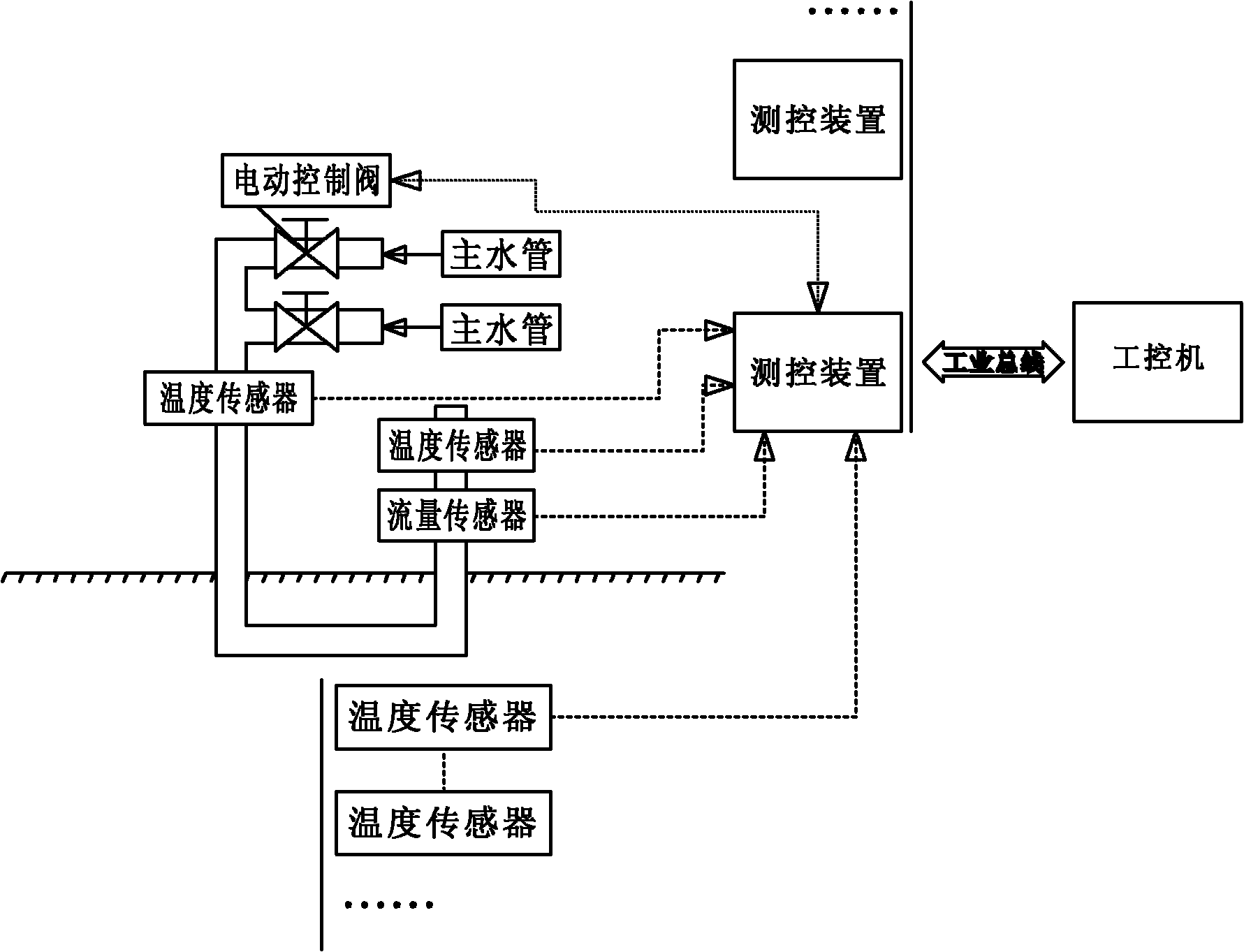

Intelligent cooling water passage system for concrete

The invention relates to an intelligent cooling water passage system for concrete, which is characterized in that (1) a temperature sensor is installed in the concrete and is used for measuring the temperature of the concrete; (2) a flow sensor, a temperature sensor and an electric control valve are installed on a cooling water pipe; (3) measurement and control devices are installed near the electric control valve and are connected with the sensors and the electric control valve through cables; (4) a plurality of the measurement and control devices are connected with an industrial control computer through an industrial bus; and (5) according to temperature, flow signals and opening information acquired by the measurement and control devices, a program in the industrial control computer sends control signals for controlling the electric control valve, and the measurement and control devices control the opening of the electric control valve and regulate the water passage flow and the water passage temperature, thereby realizing the purpose of reducing the temperature gradient to the maximum, reducing the tension stress of the temperature of the concrete, and achieving the effect on preventing cracks from occurring on the concrete.

Owner:HUBEI GEZHOUBA TESTING

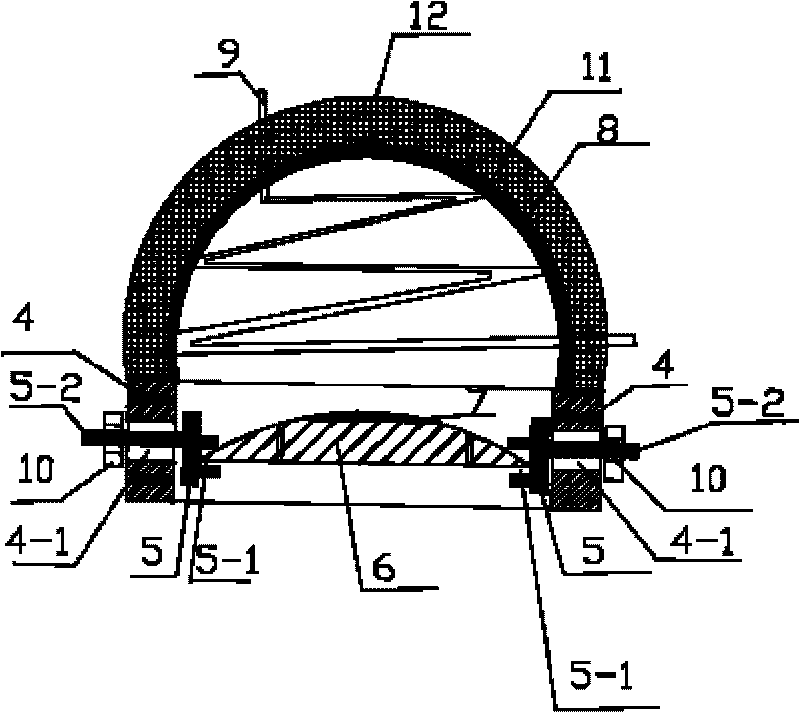

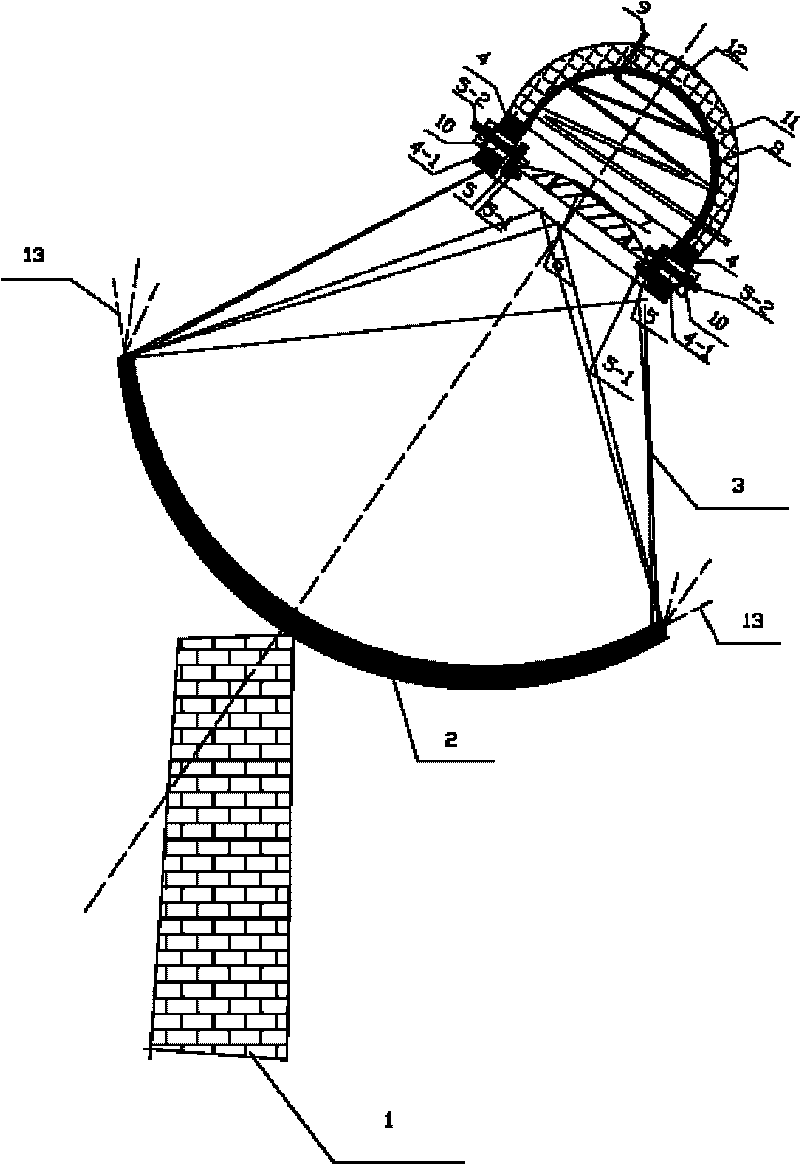

Cavity type solar heat absorber provided with optical window

InactiveCN101706161ANo burn-through phenomenonEvenly distributedSolar heating energySolar heat devicesStress concentrationHeat flow

The invention relates to a cavity type solar heat absorber provided with an optical window, which relates to the technical field of solar energy and aims to solve the problems that the solar energy radiant heat flows absorbed by the conventional solar heat absorber are not distributed evenly so that the heat absorber has an over-high local temperature and is easy to be burnt through. The cavity type solar heat absorber comprises the heat absorber and heat absorbing tubes; the heat absorbing tubes are coiled up on the internal wall of the heat absorber according to the shape of the inner cavity of the heat absorber; and the shape of the inner cavity of the heat absorber is semi-spherical. The cavity type solar heat absorber also comprises an upward convex optical glass body and a protecting sheet; the heat absorber is a hollow cavity body; the protecting sheet is annular and is fixed on an inlet of the heat absorber; the upward convex optical glass body is arranged on the protecting sheet; and an inlet surface of the upward convex optical glass body facing the heat absorber is a convex surface, while an inlet surface backing on to the heat absorber is a flat surface. The cavity type solar heat absorber can efficiently receive radiant heat and transfer heat to working fluids so as to reduce local high temperatures and thermal stress concentrations on the wall surfaces of the heat absorbing tubes. The cavity type solar heat absorber can be widely used in the field of solar heat absorbers.

Owner:HARBIN INST OF TECH

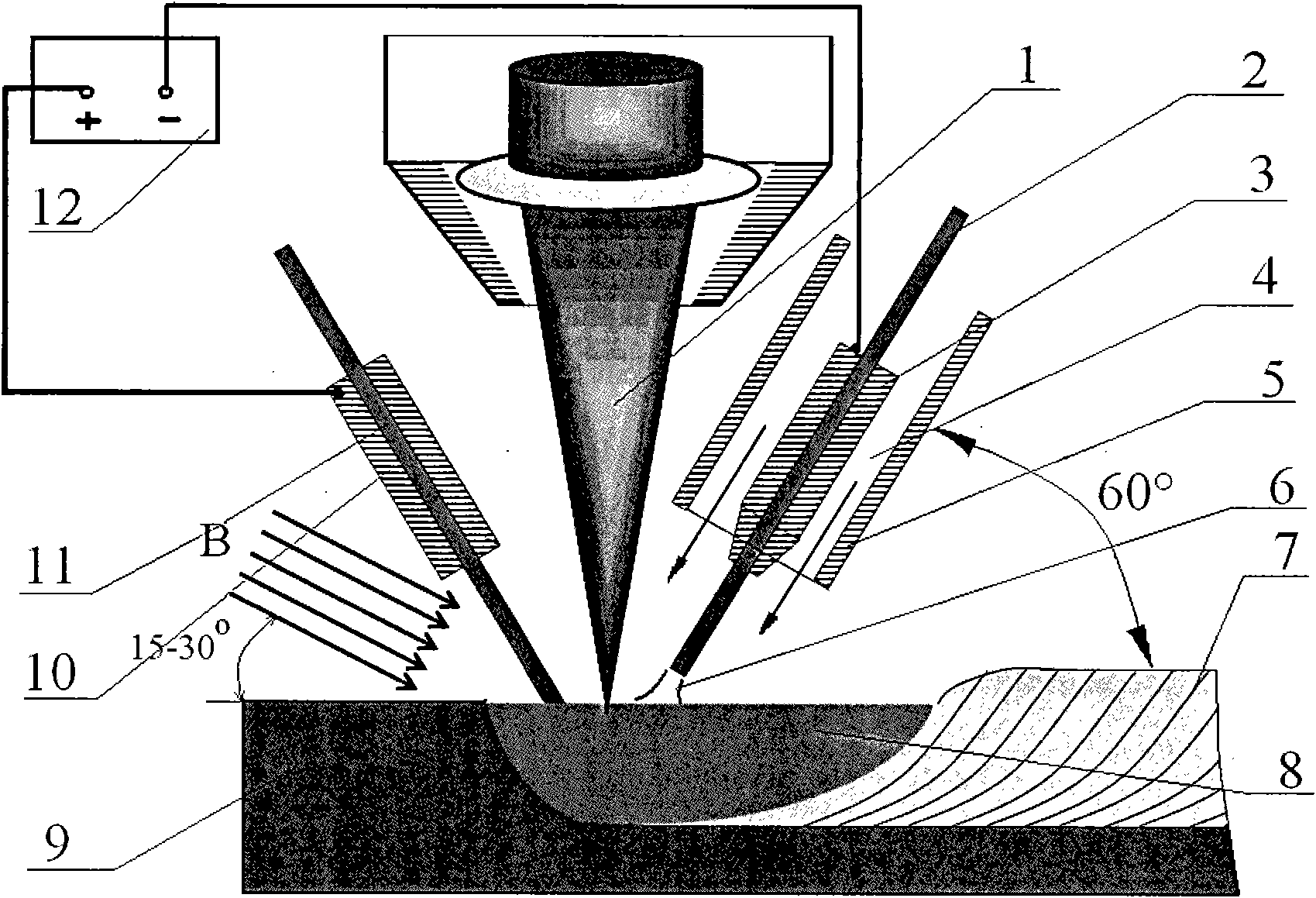

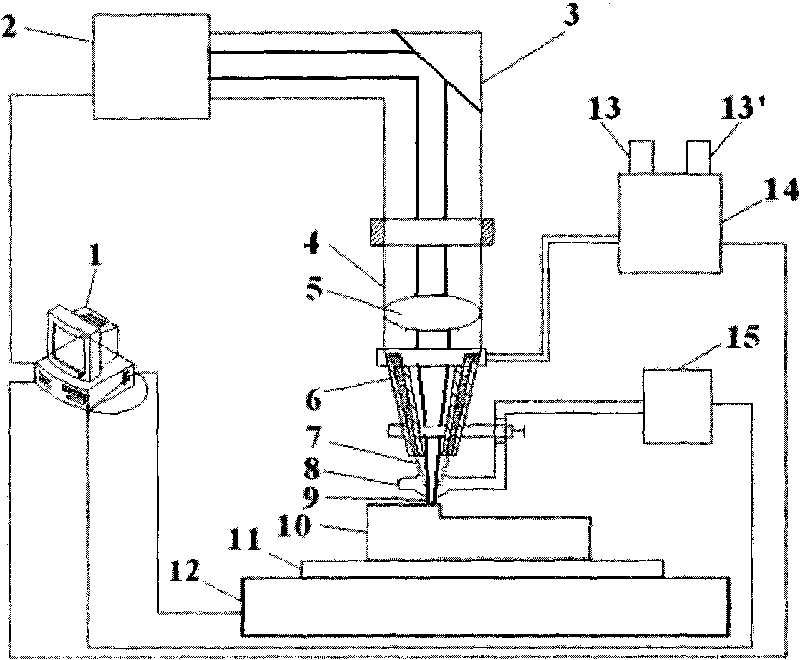

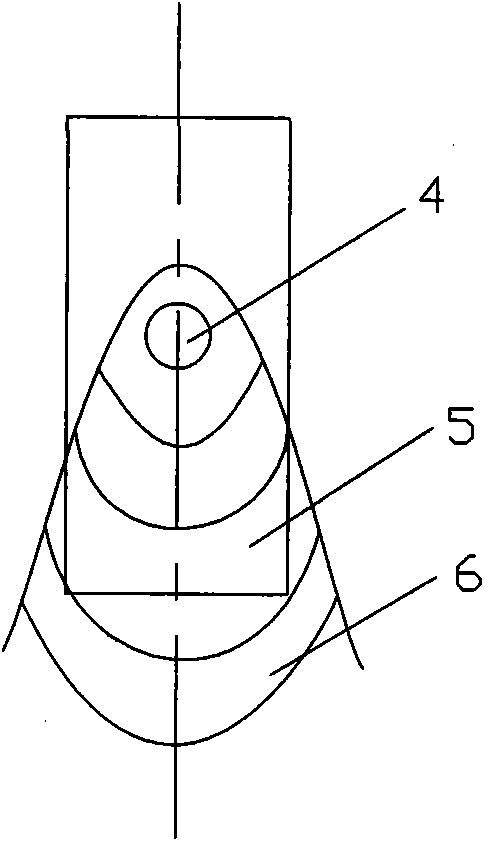

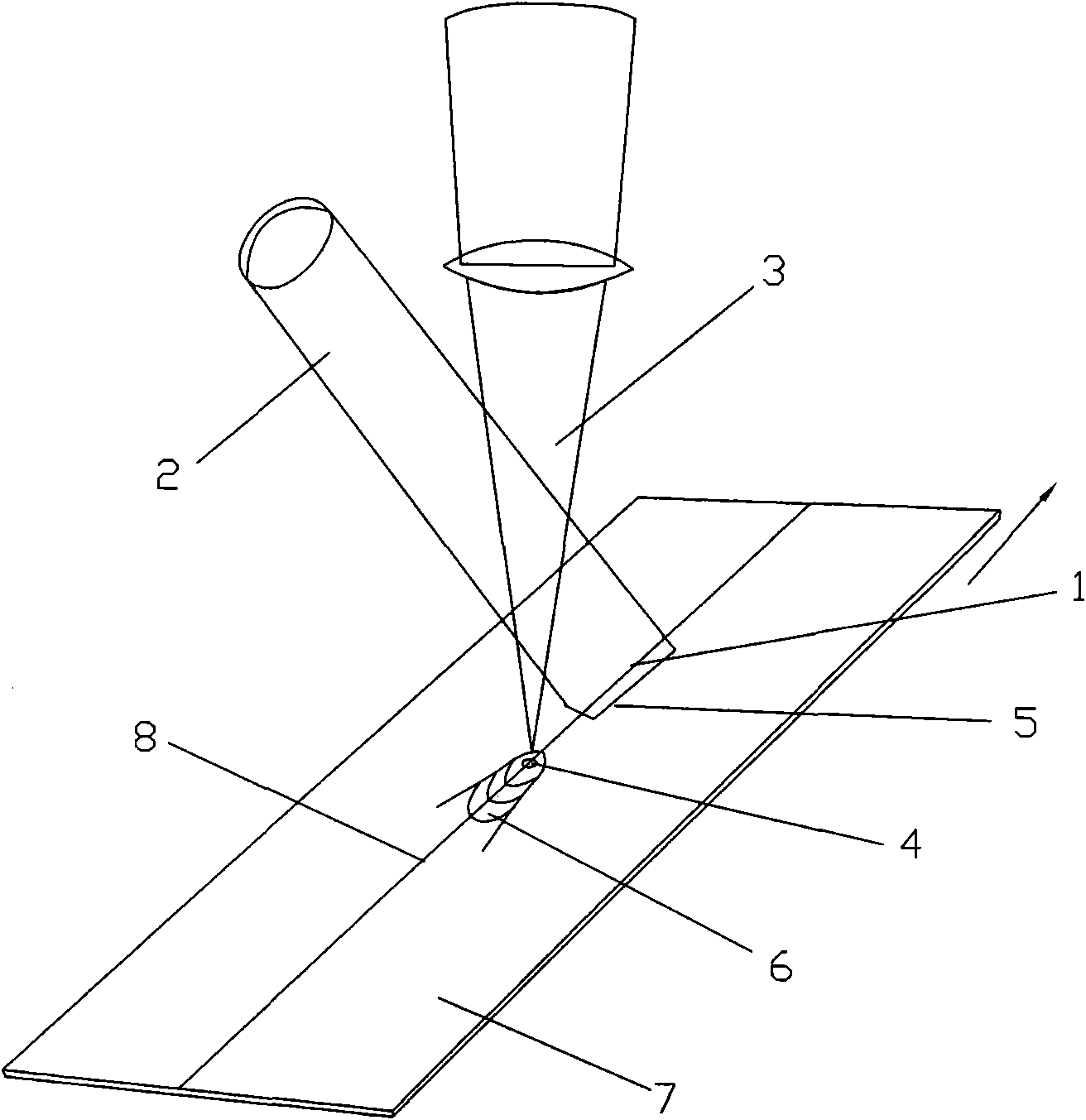

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

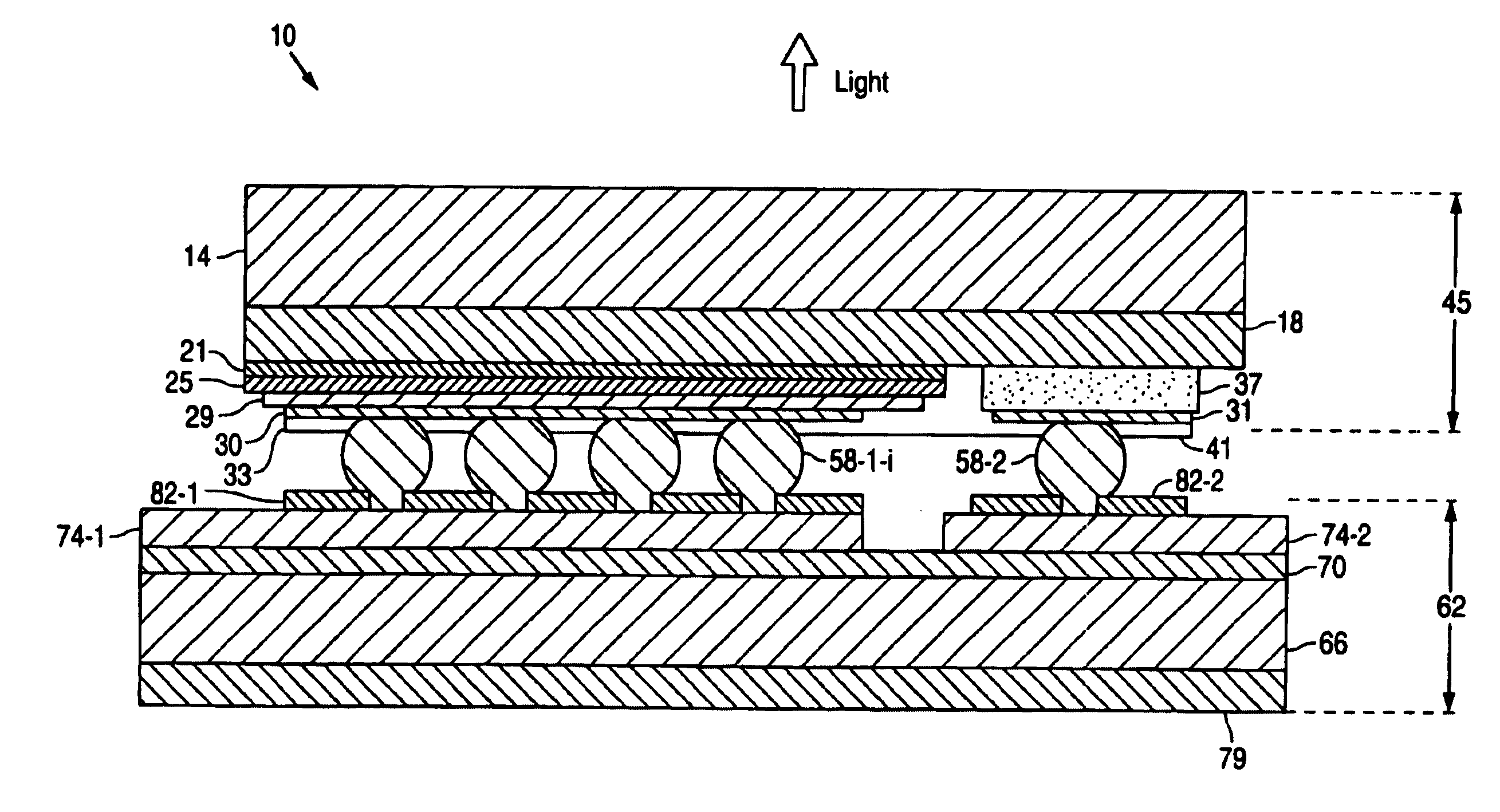

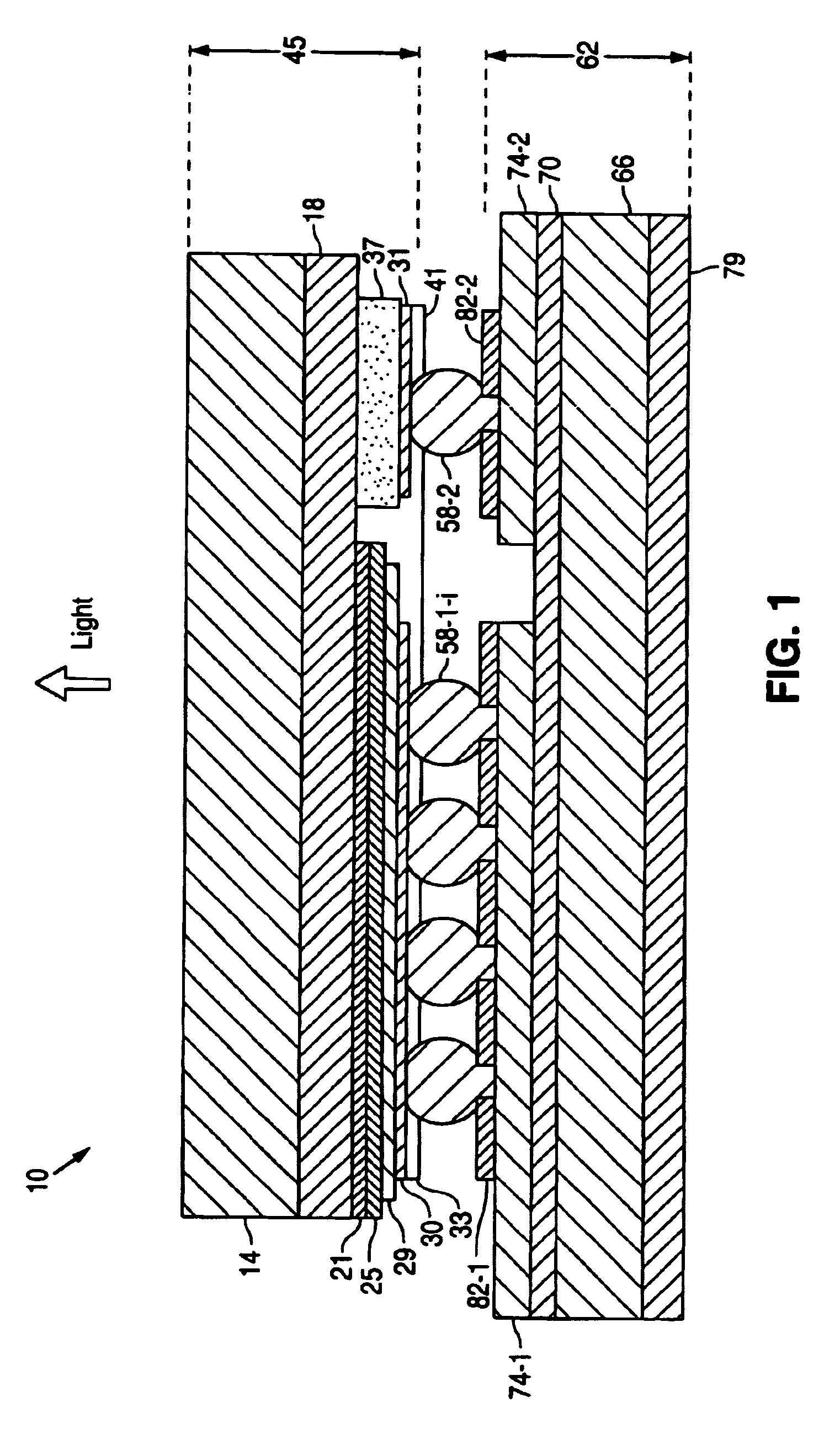

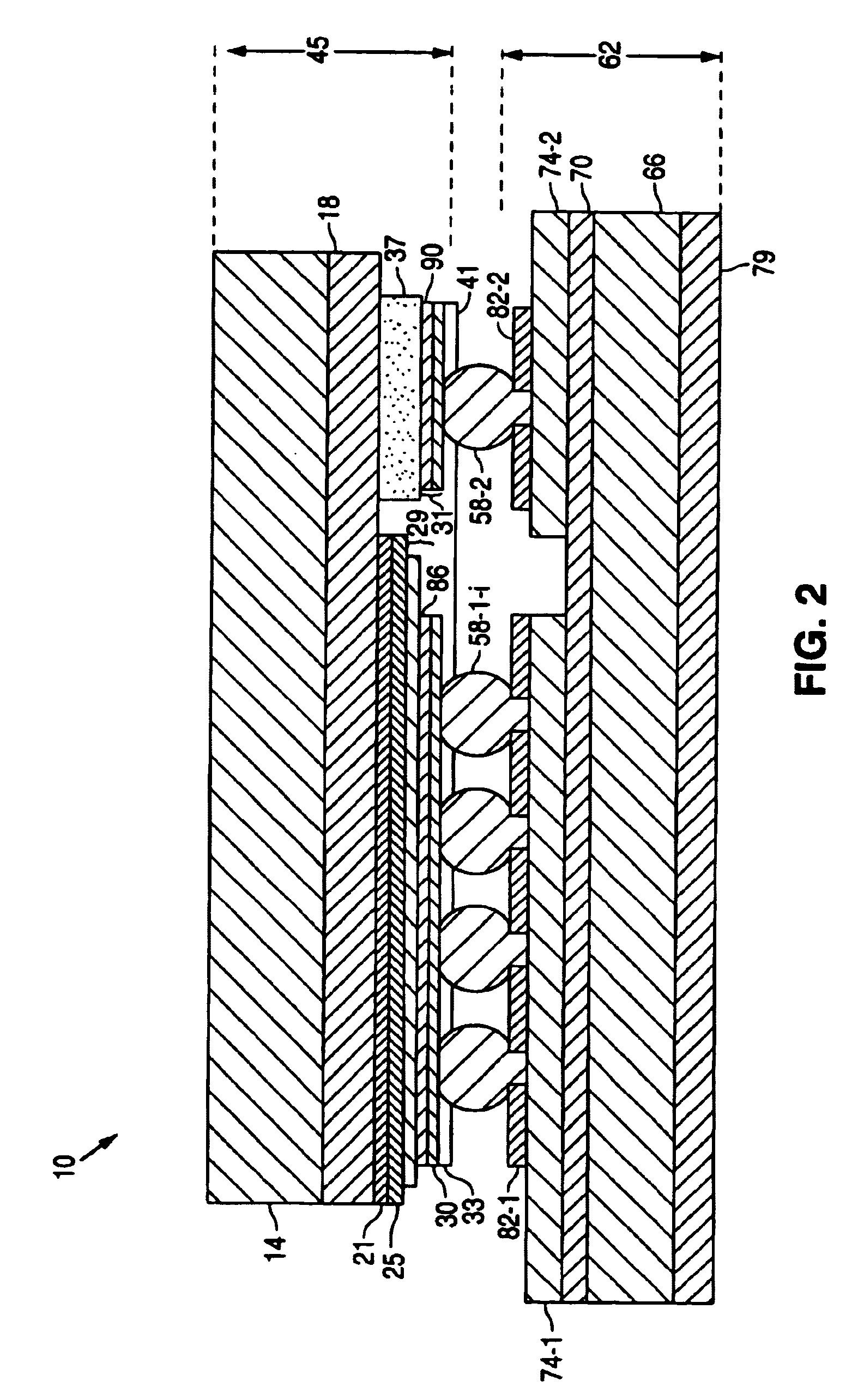

High-powered light emitting device with improved thermal properties

InactiveUS6977396B2Reduce temperature gradientDischarge tube luminescnet screensLamp detailsPhysicsSolder interconnect

A light emitting device includes a first semiconductor layer of a first conductivity type, an active region, and a second semiconductor layer of a second conductivity type. First and second contacts are connected to the first and second semiconductor layers. In some embodiments at least one of the first and second contacts has a thickness greater than 3.5 microns. In some embodiments, a first heat extraction layer is connected to one of the first and second contacts. In some embodiments, one of the first and second contacts is connected to a submount by a solder interconnect having a length greater than a width. In some embodiments, an underfill is disposed between a submount and one of the first and second interconnects.

Owner:LUMILEDS

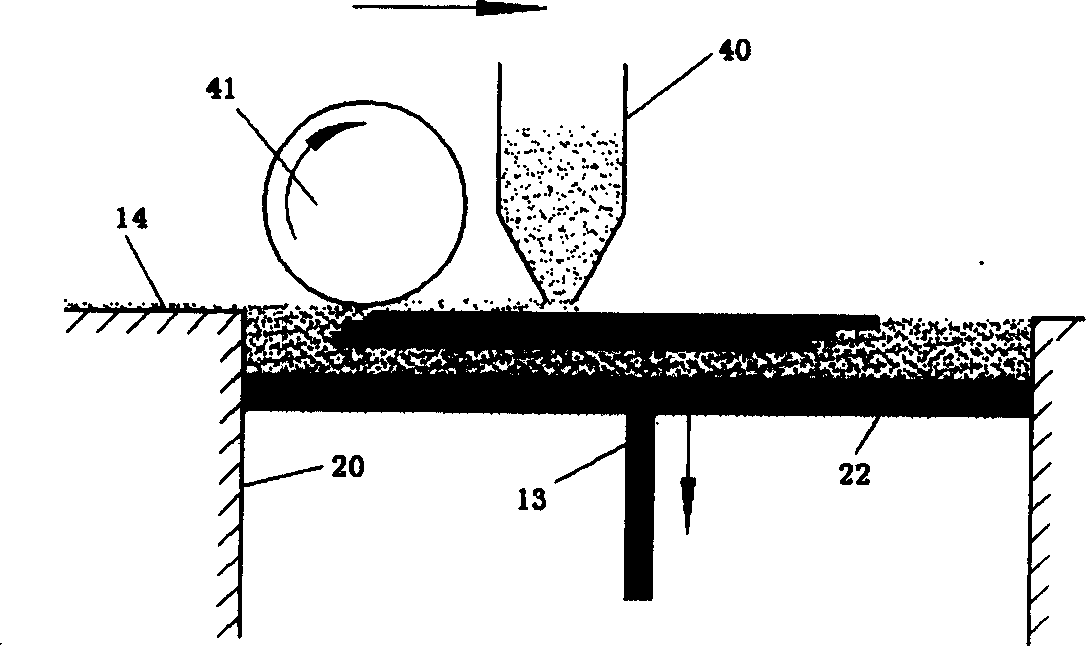

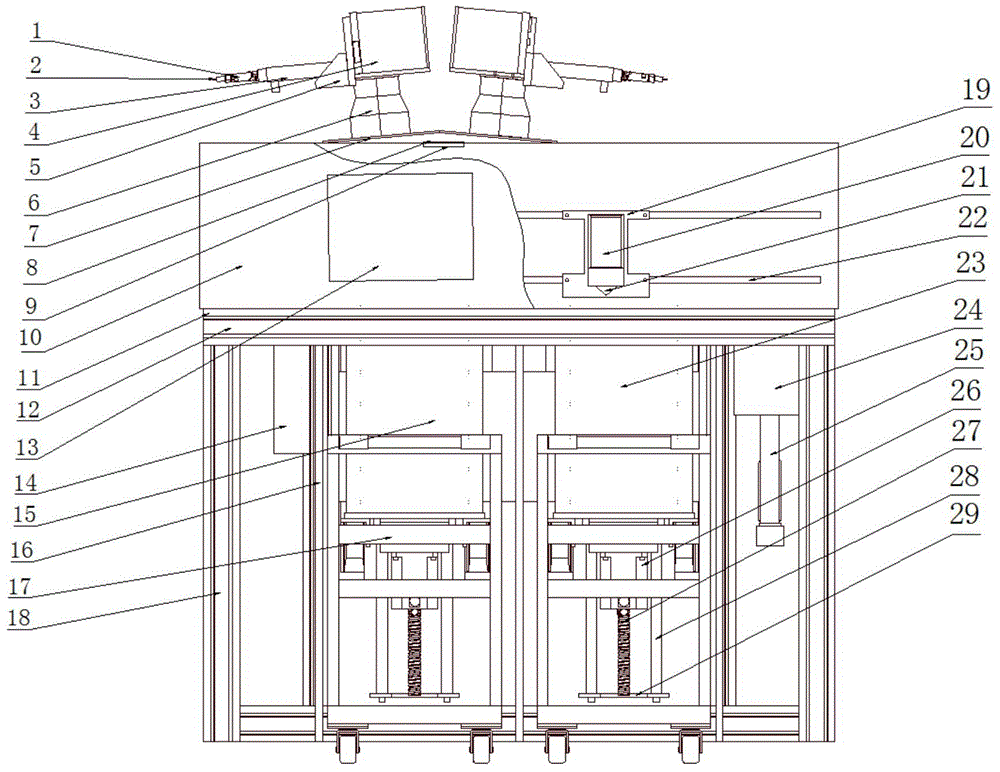

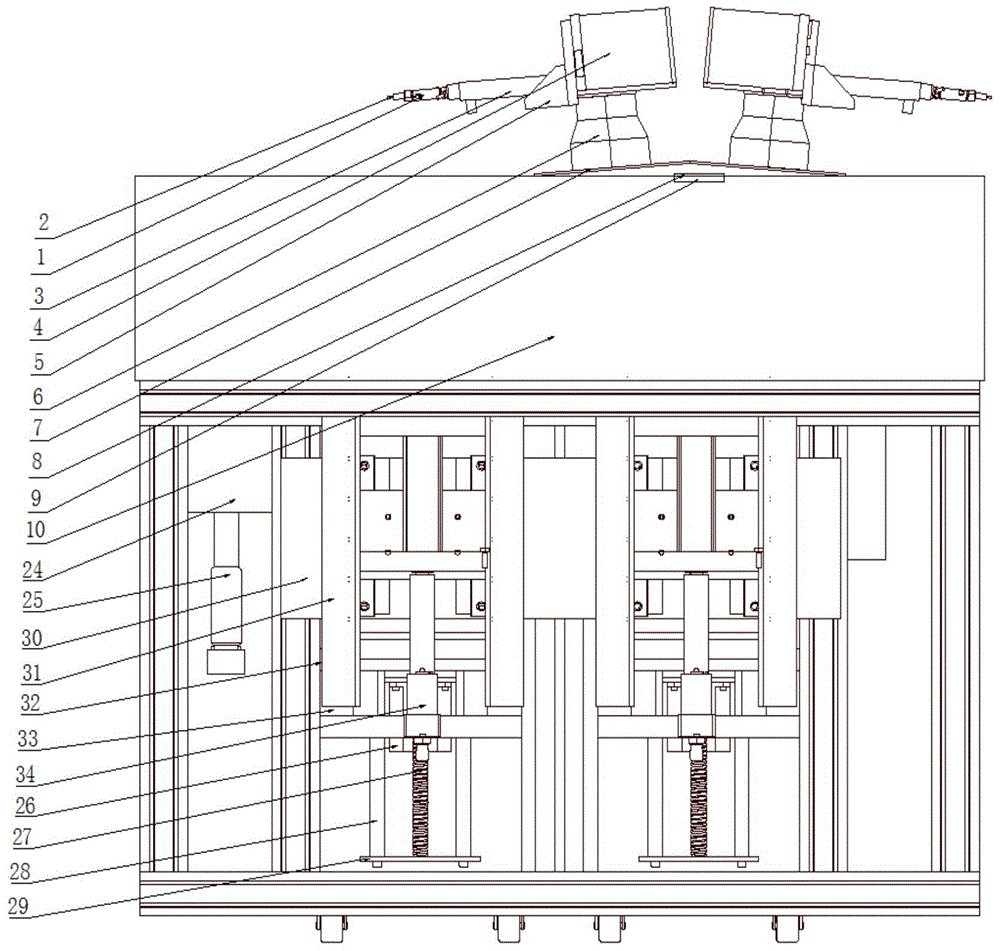

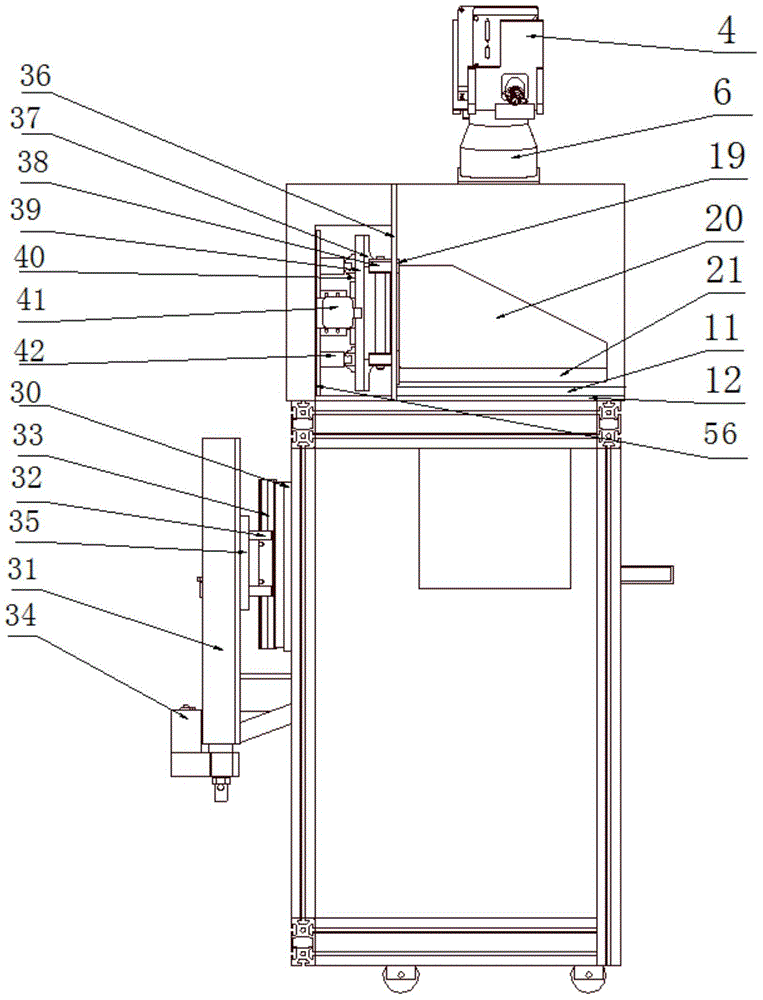

Dual-beam laser selective melting and moulding equipment with exchangeable powder cylinder

ActiveCN105039970AEasy to replaceImprove absorption rateMetallic material coating processesDual beamLight beam

The invention discloses dual-beam laser selective melting and moulding equipment with an exchangeable powder cylinder. The equipment comprises two optical systems, a frame, a workbench plate, a powder feeding cylinder, a powder storage cylinder, a moulding cylinder, a powder returning cylinder, a moulding cavity, and two first driving mechanisms, which are used to respectively drive the moulding cylinder and powder feeding cylinder to move up and down. The workbench plate is fixed on the frame, the moulding cavity is fixed on the upper surface of the workbench plate, and the powder returning cylinder, the moulding cylinder, the powder feeding cylinder, and powder storage cylinder are fixed on the lower surface of the workbench plate from left to right in sequence. A scraper is arranged in the moulding cavity, and a second driving mechanism is arranged on the frame. A substrate is arranged in the powder feeding cylinder, a substrate is arranged in the moulding cylinder, the lower ends of the powder feeding cylinder and the moulding cylinder are both provided with a cylinder end cover, and the substrates are connected to a first piston system. A second piston system is arranged in the powder storage cylinder. The provided equipment has a high moulding efficiency and is capable of effectively reducing the deformation and cracking of members.

Owner:XI AN JIAOTONG UNIV

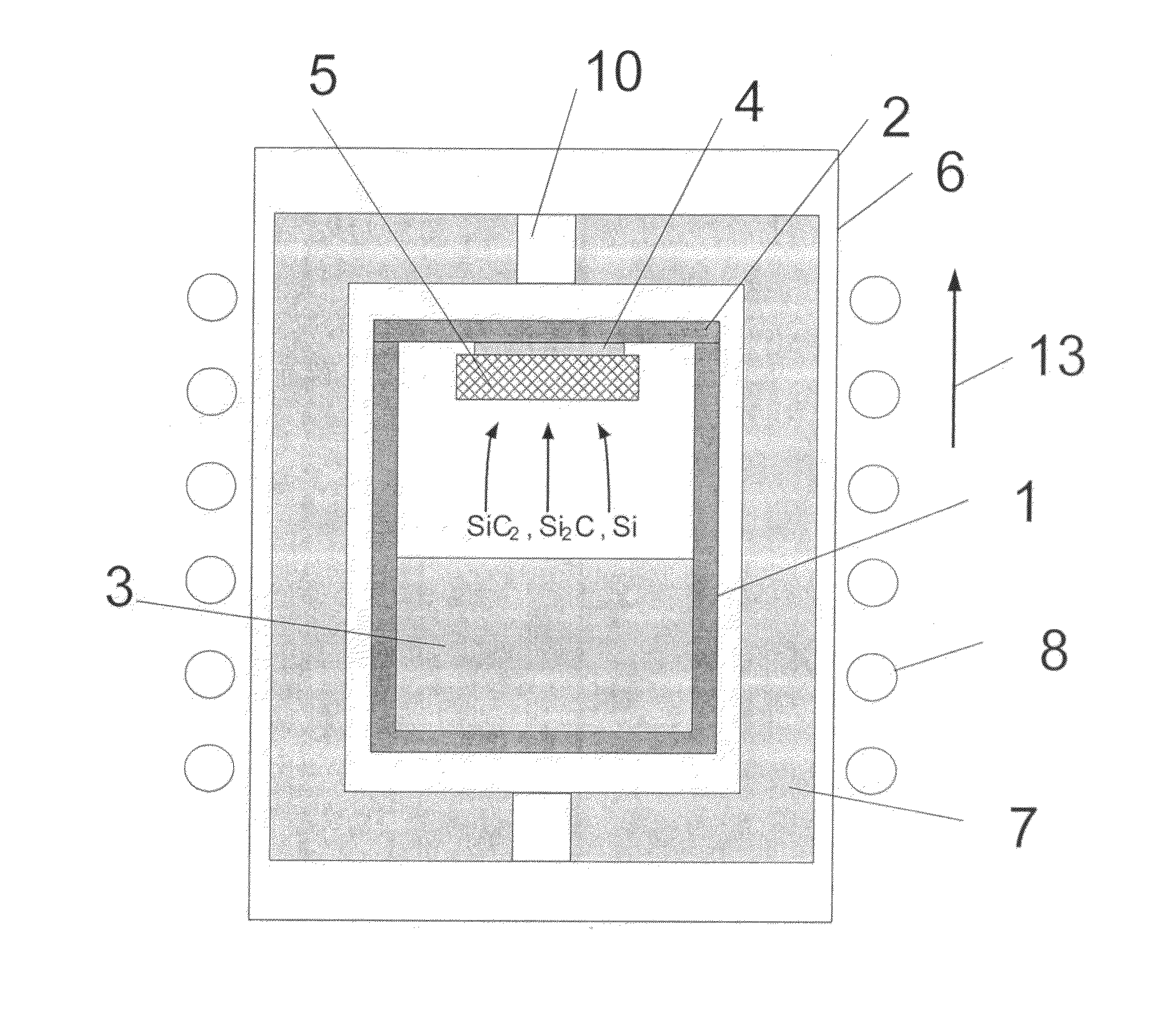

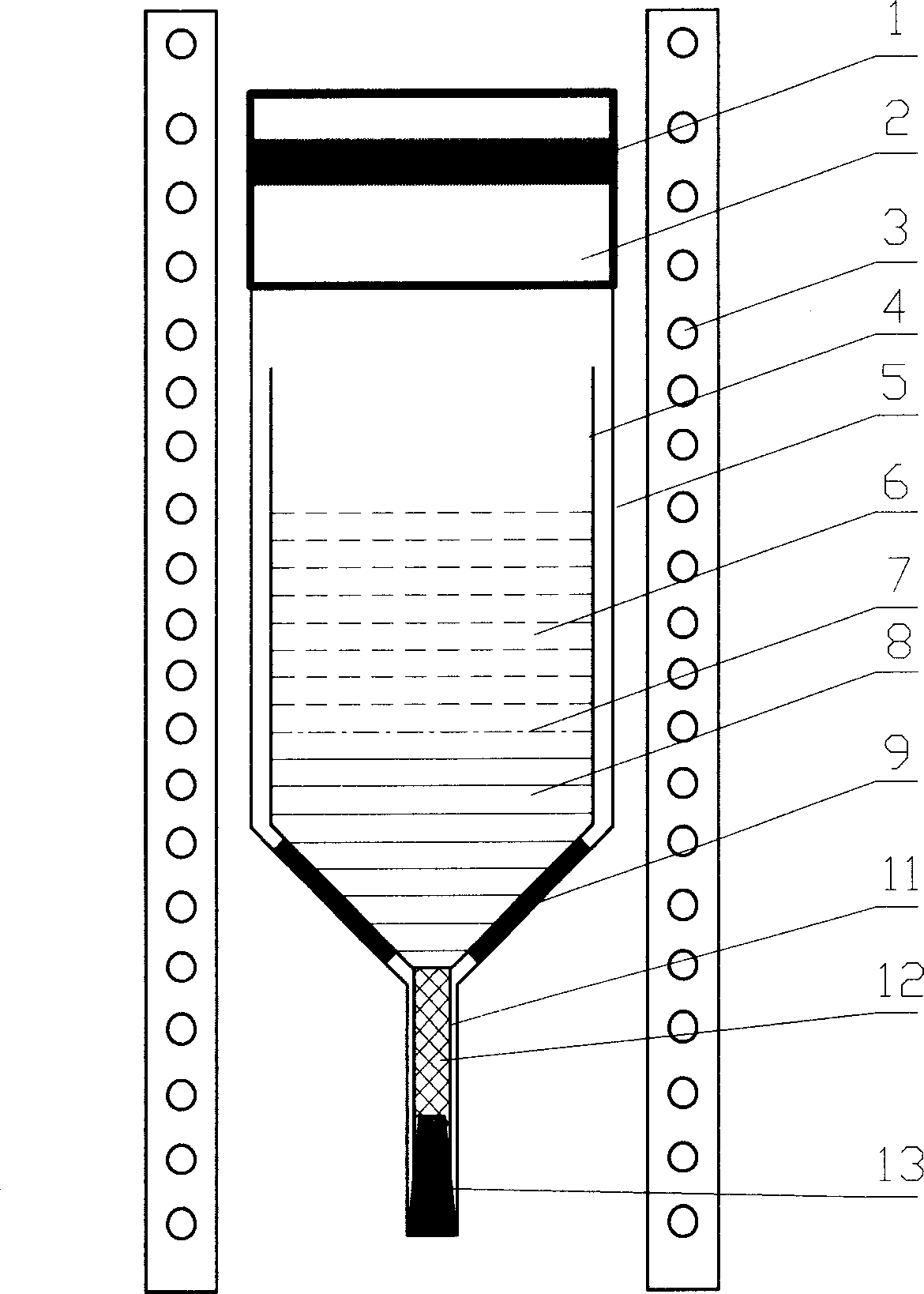

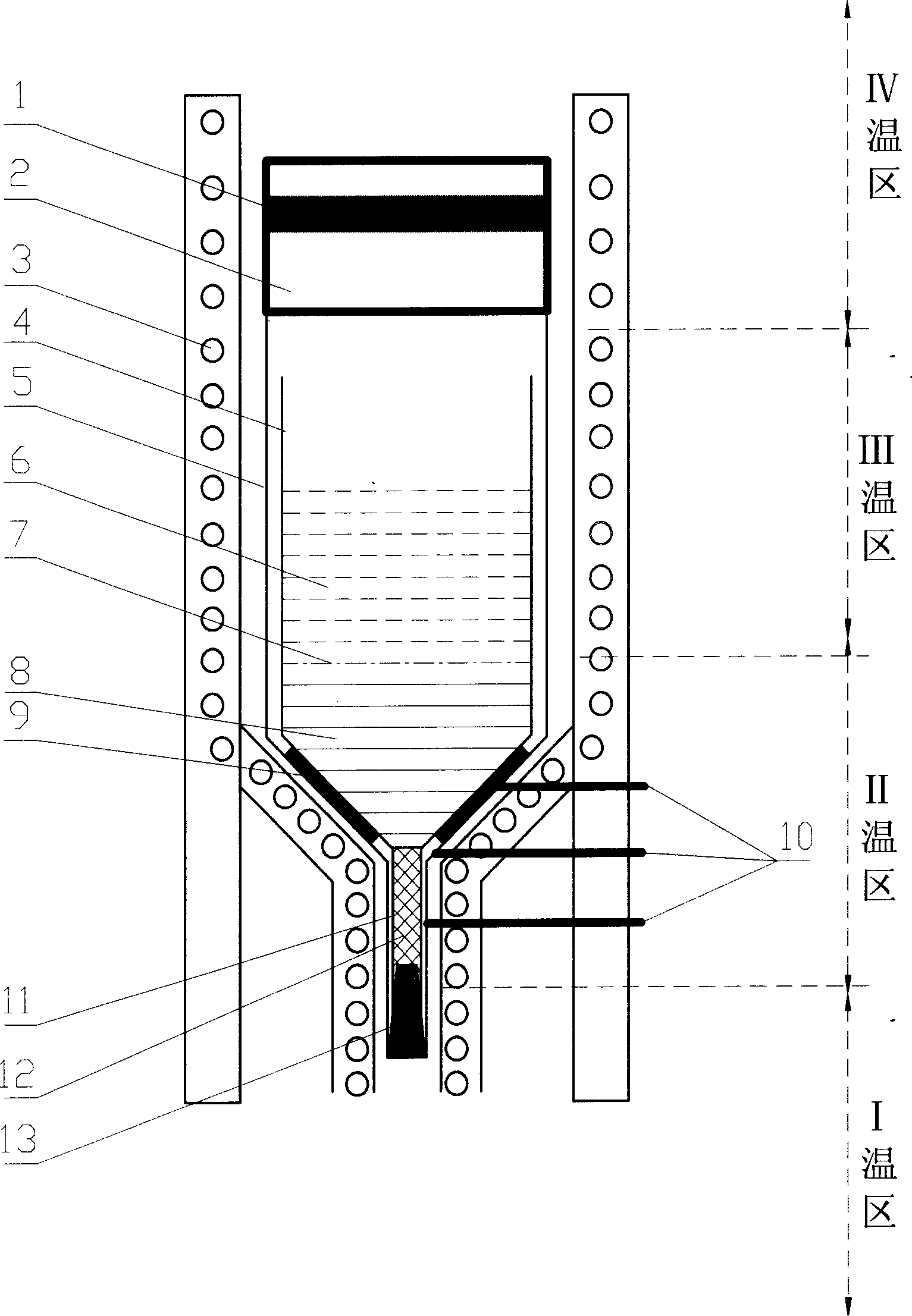

Precise vertical temperature-difference gradient condensation single crystal growth device and method thereof

InactiveCN1865527ALow temperature gradientReduce defect densityPolycrystalline material growthFrom frozen solutionsSemiconductor materialsEngineering

The invention discloses a growing device and method of precise vertical differential temperature gradient condensate monocrystal, which is characterized by the following: the heating element of heating device distributes evenly around the peripheral of copple, which is started from copple conversing point; the heating element attaches and distributes evenly along copple cone until covering the mouth position of copple, which makes temperature detecting couple touches quartz container wall through heating element. The invention improves eh quality and production rate of crystal, which is fit for III-V or II-IV composition semiconductor material.

Owner:长治虹源科技晶片技术有限公司

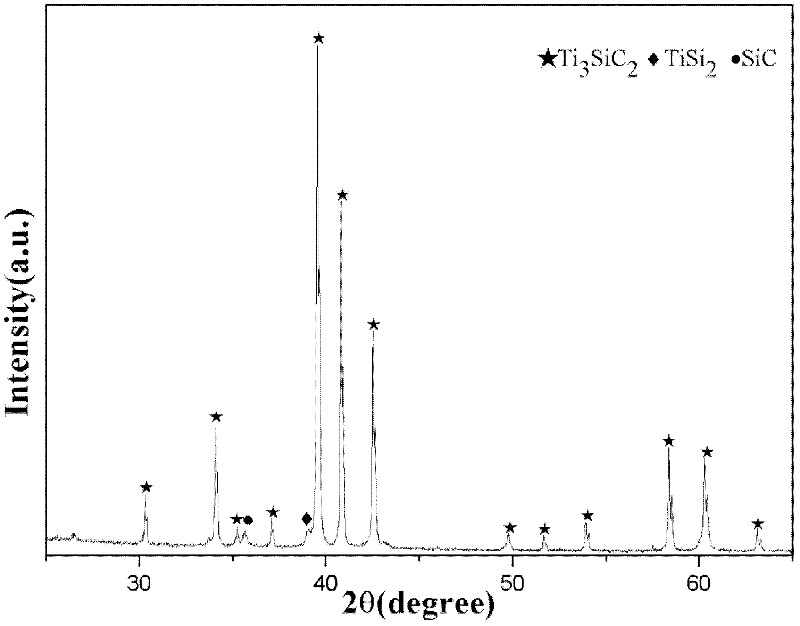

Method for preparing high-purity MAX-phase ceramic powder

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

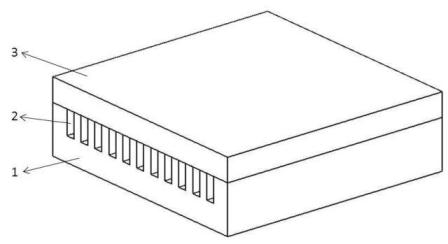

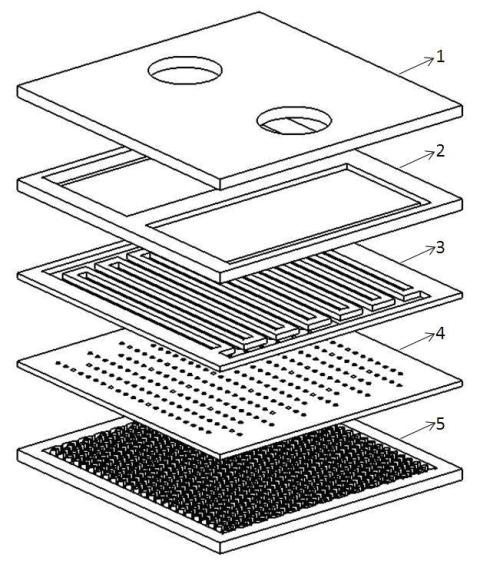

Prism-array jet micro-channel radiator

InactiveCN102014598AReduce temperature gradientFull heat exchangeCooling/ventilation/heating modificationsJet flowPrism

The invention relates to a prism-array jet micro-channel radiator. The radiator comprises a prism-array structure, a jet structure, an outlet-inlet cross structure, a liquid separating structure and an outlet-inlet arrangement structure. In the invention, cooling liquid enters the radiator via an inlet and then is led to side clearance through the liquid separating structure so as not to be mixedwith cooling liquid at an outlet; the distance between the outlet and the inlet is shortened by means of the comb-shaped outlet-inlet cross structure so as to reduce pressure drop; after reaching themultihole jet flow structure, the cooling liquid can be uniformly introduced onto a heated silicon substrate so that the temperature of the substrate is more uniform, heat is more easily taken away by the generated turbulent flow and meanwhile the pressure drop is also reduced by the jet structure; and finally the cooling liquid easily forms turbulent flow by means of the prism-array structure sothat the heat transferred to the prism structure from the substrate is more easily taken away, thus increasing the heat exchange efficiency. The prism-array radiator can be used in a cooler for microstructures such as an electronic chip, an LED and the like.

Owner:SHANGHAI UNIV

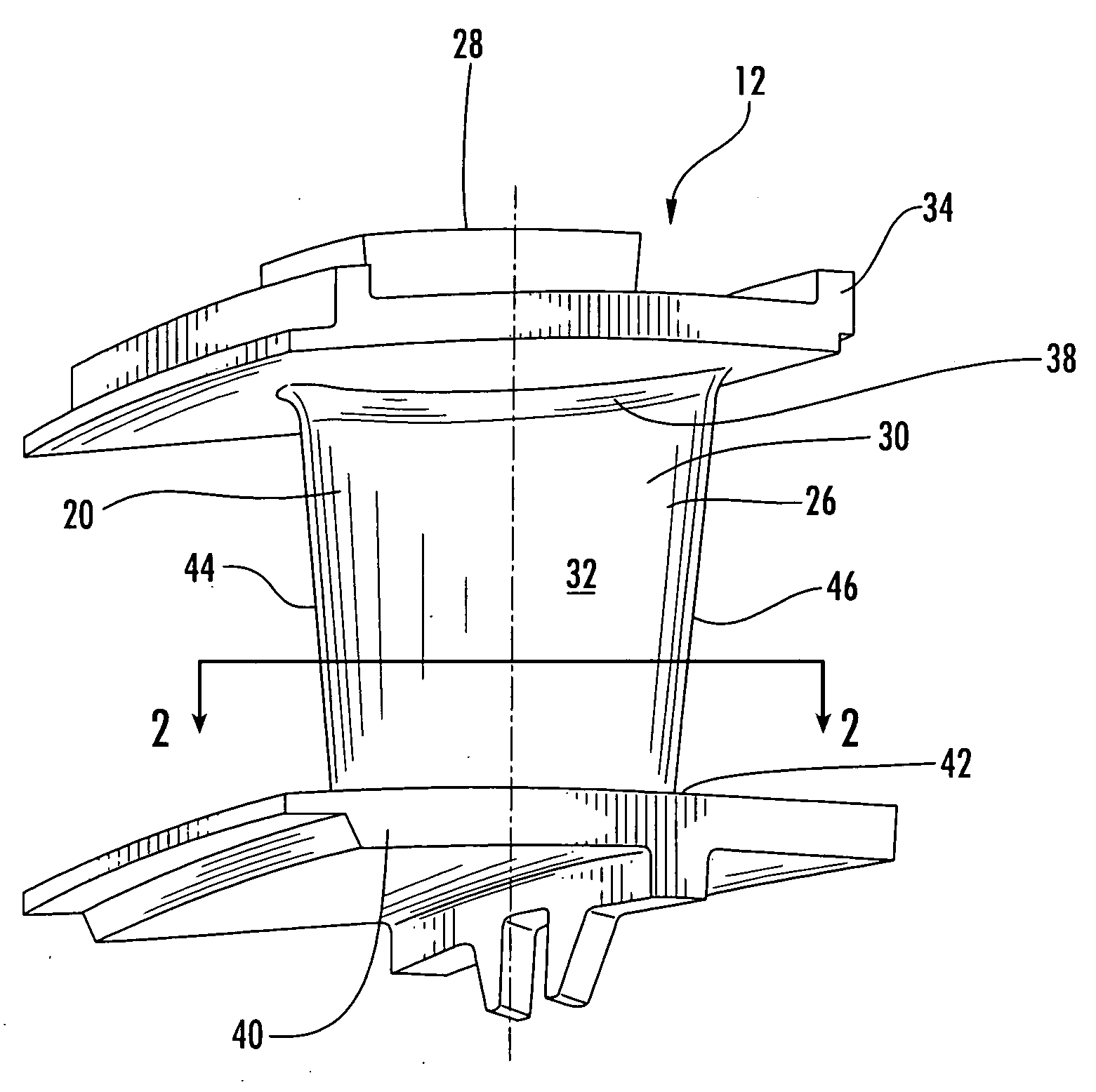

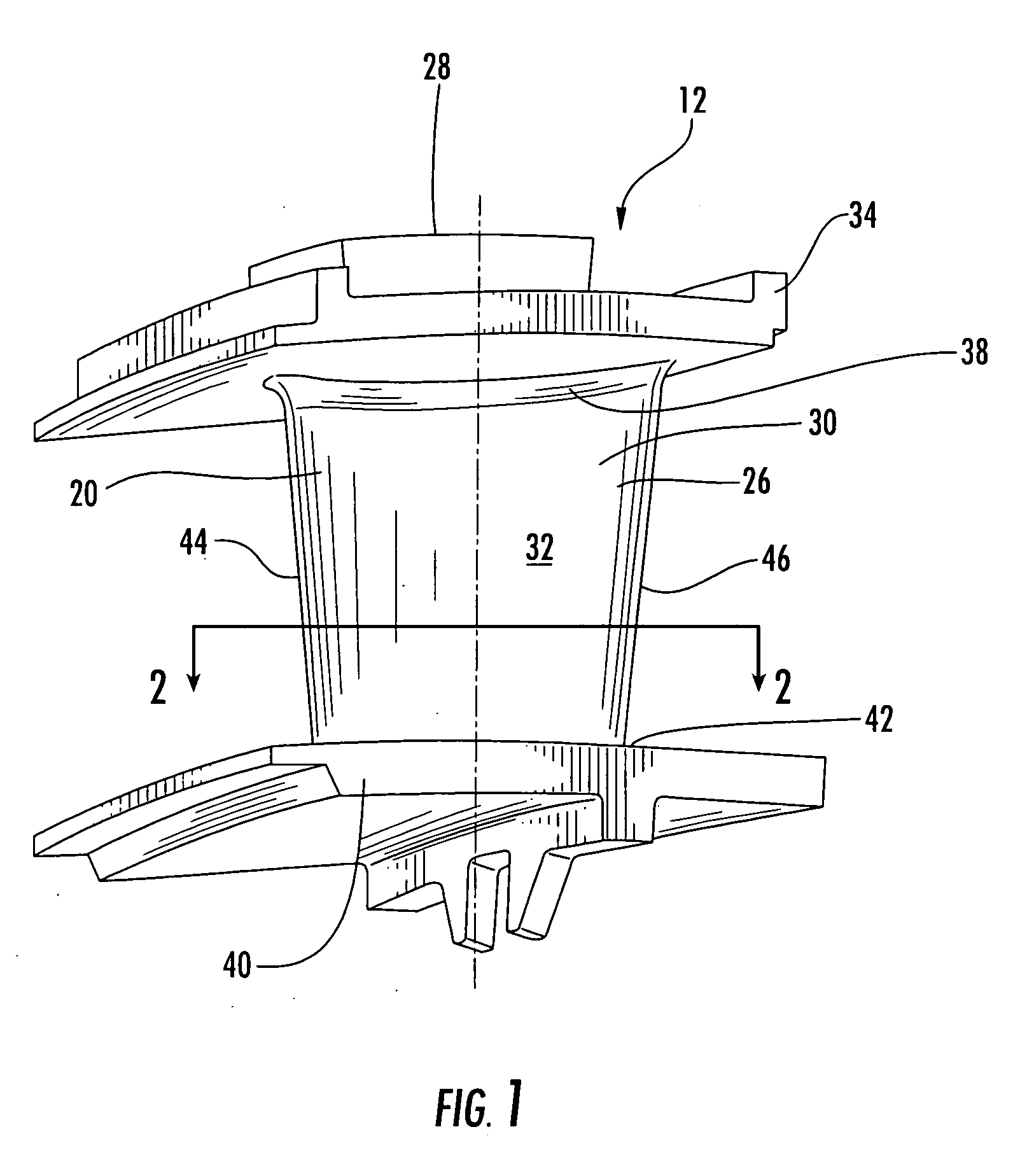

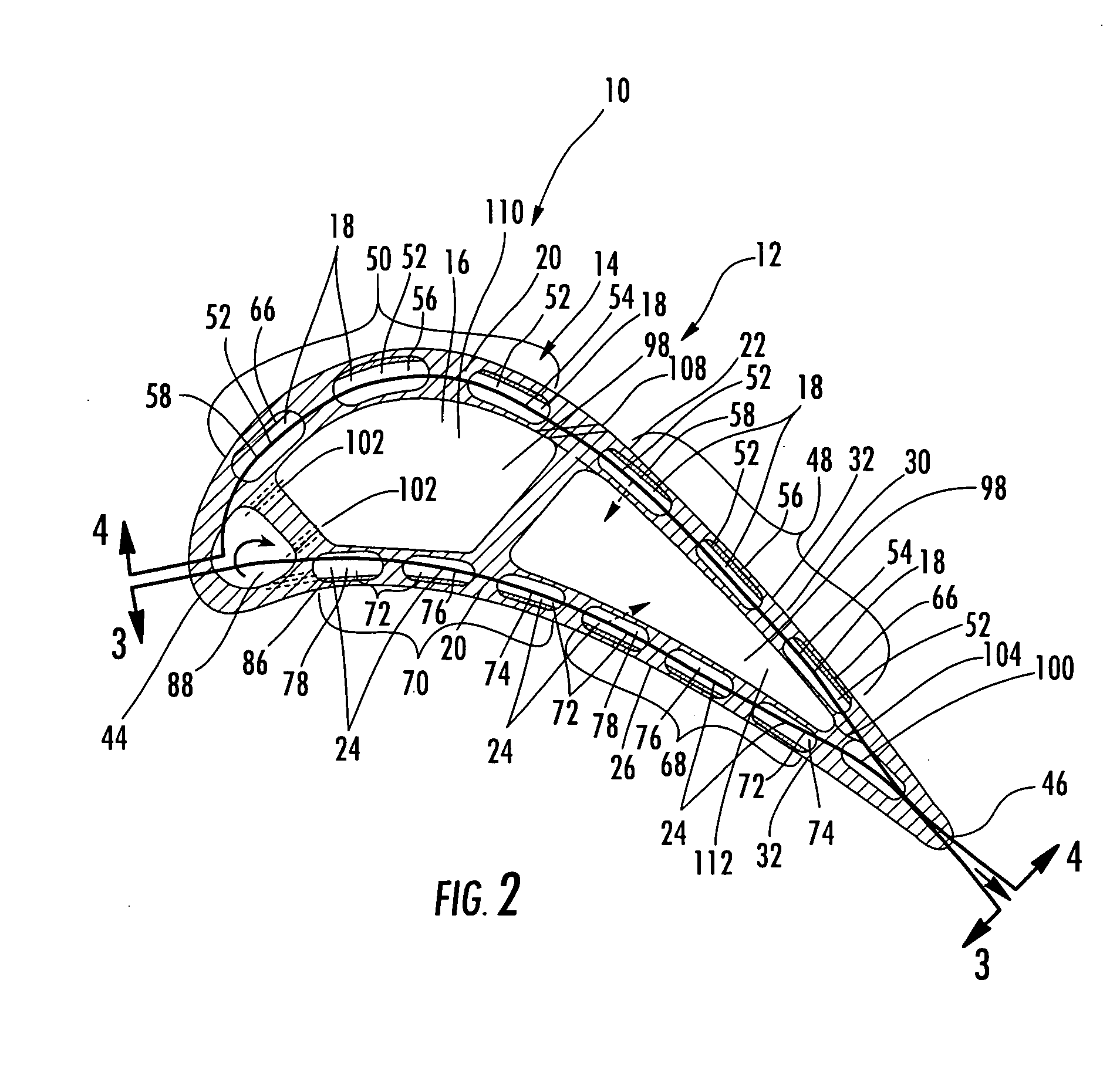

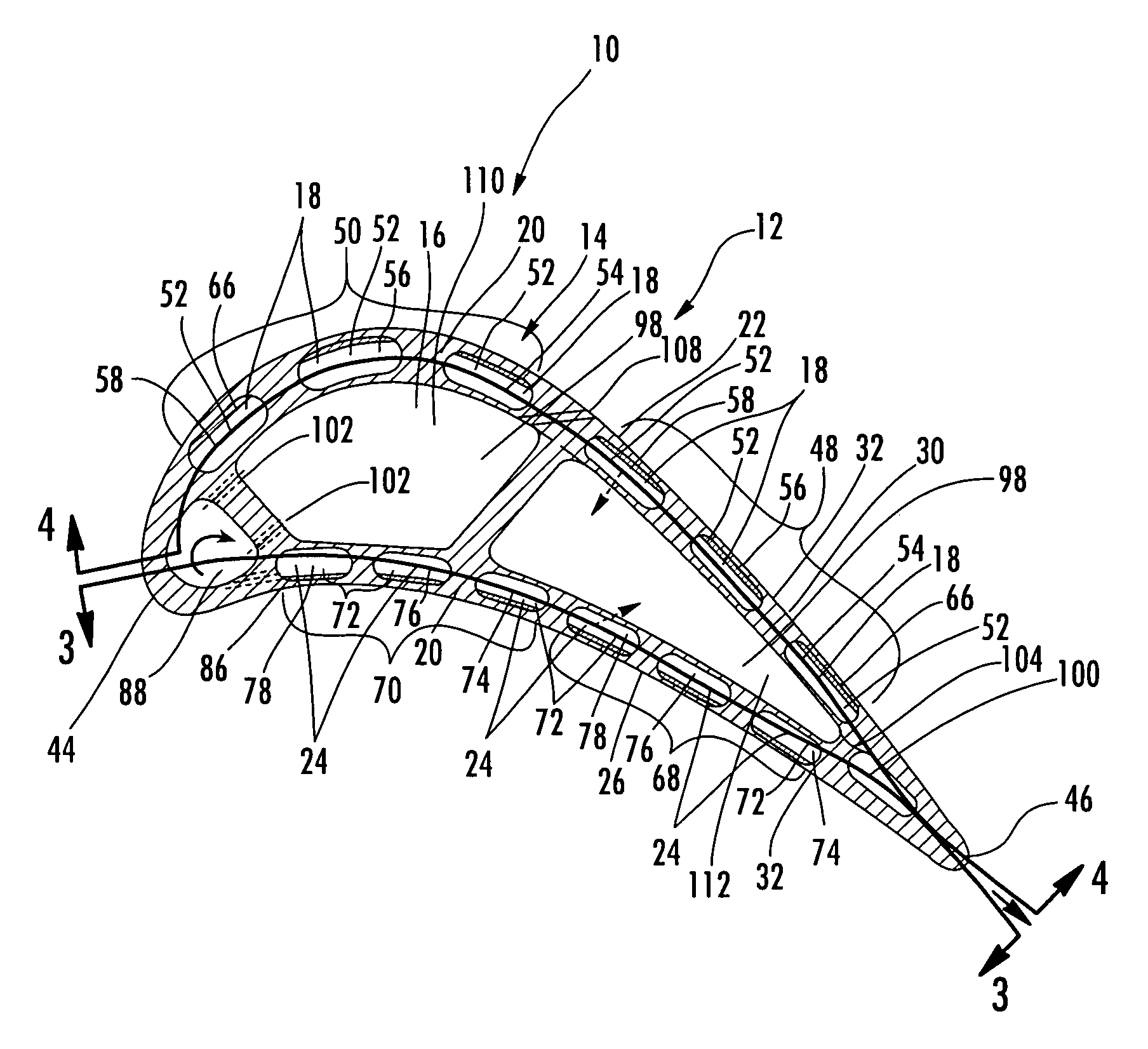

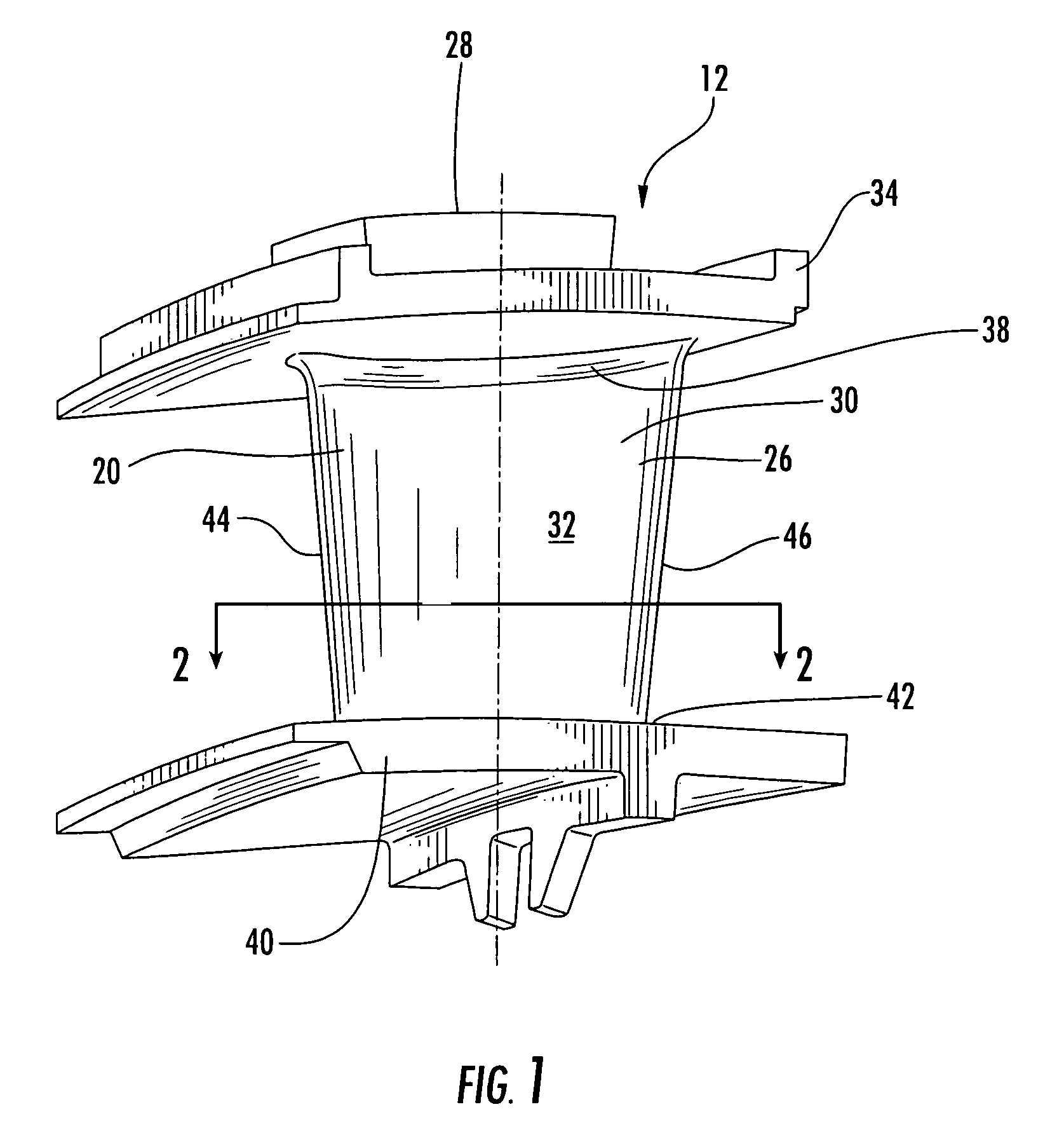

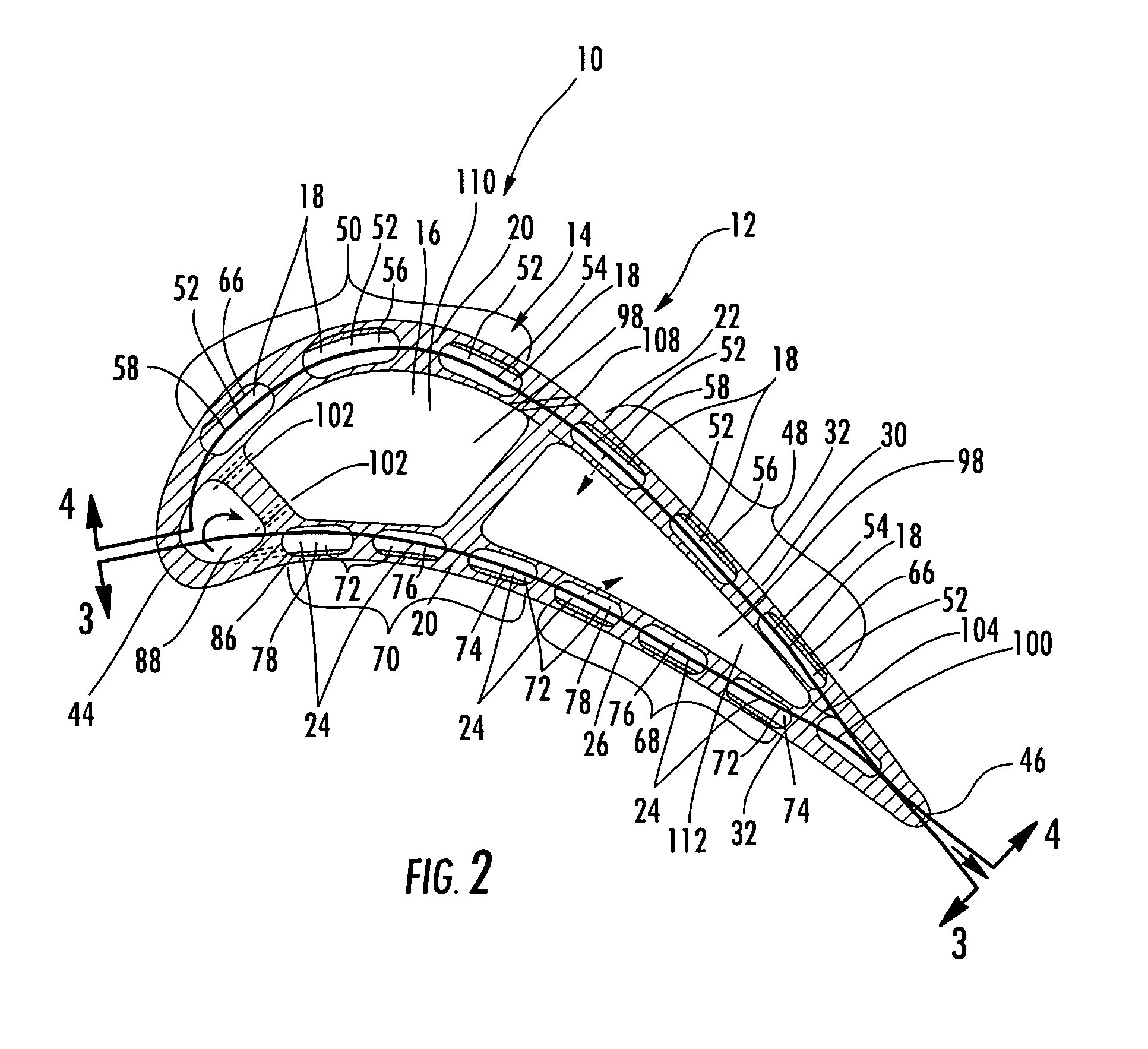

Turbine airfoil with near wall multi-serpentine cooling channels

InactiveUS20090104042A1Improve design flexibilityRaise the potentialPropellersEngine manufactureCooling chamberTurbine

A turbine airfoil usable in a turbine engine and having at least one cooling system. At least a portion of the cooling system may be positioned in an outer wall of the turbine airfoil and be formed from at least one suction side serpentine cooling chamber and at least one pressure side serpentine cooling chamber. Each of the suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source first before being passed through other components of the cooling system. The cooling fluids may then be passed into a mid-chord cooling chamber to cool internal aspects of the turbine airfoil, yet prevent creation of a large temperature gradient between outer surfaces of the turbine airfoil and inner aspects.

Owner:SIEMENS ENERGY INC

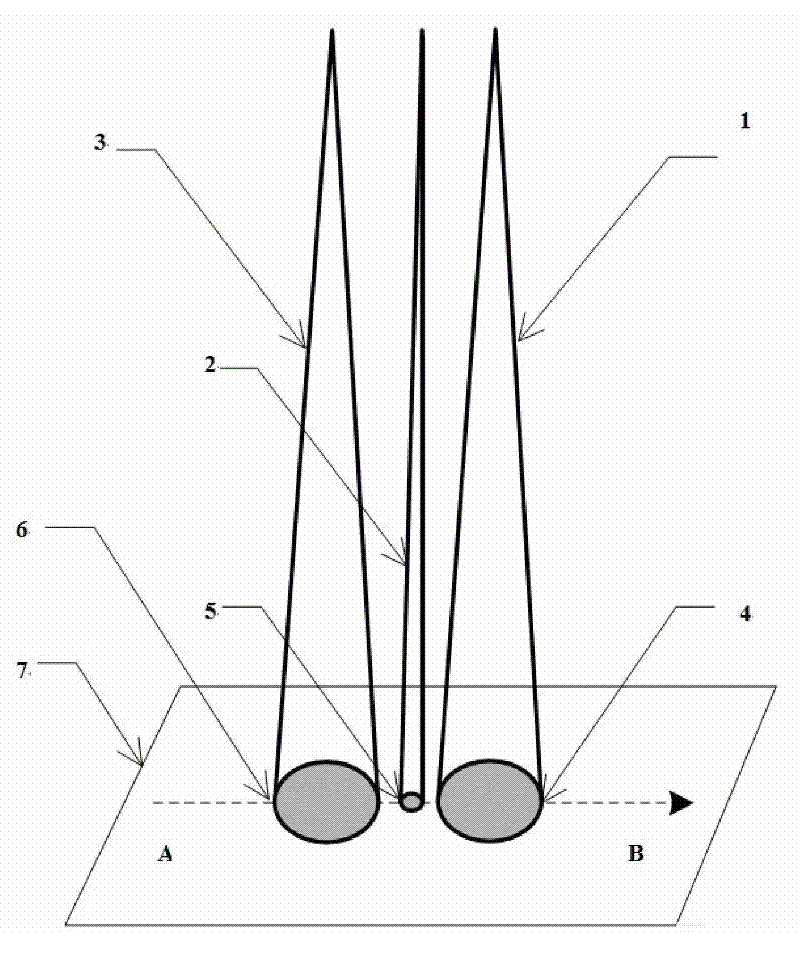

Method and system for transporting flows of fluid hydrocarbons containing wax, asphaltenes, and/or other precipitating solids

ActiveUS7261810B2Costly removalSimpler and steady operationRefining by heating/coolingWorking-up pitch/asphalt/bitumenWaxCrystallization temperature

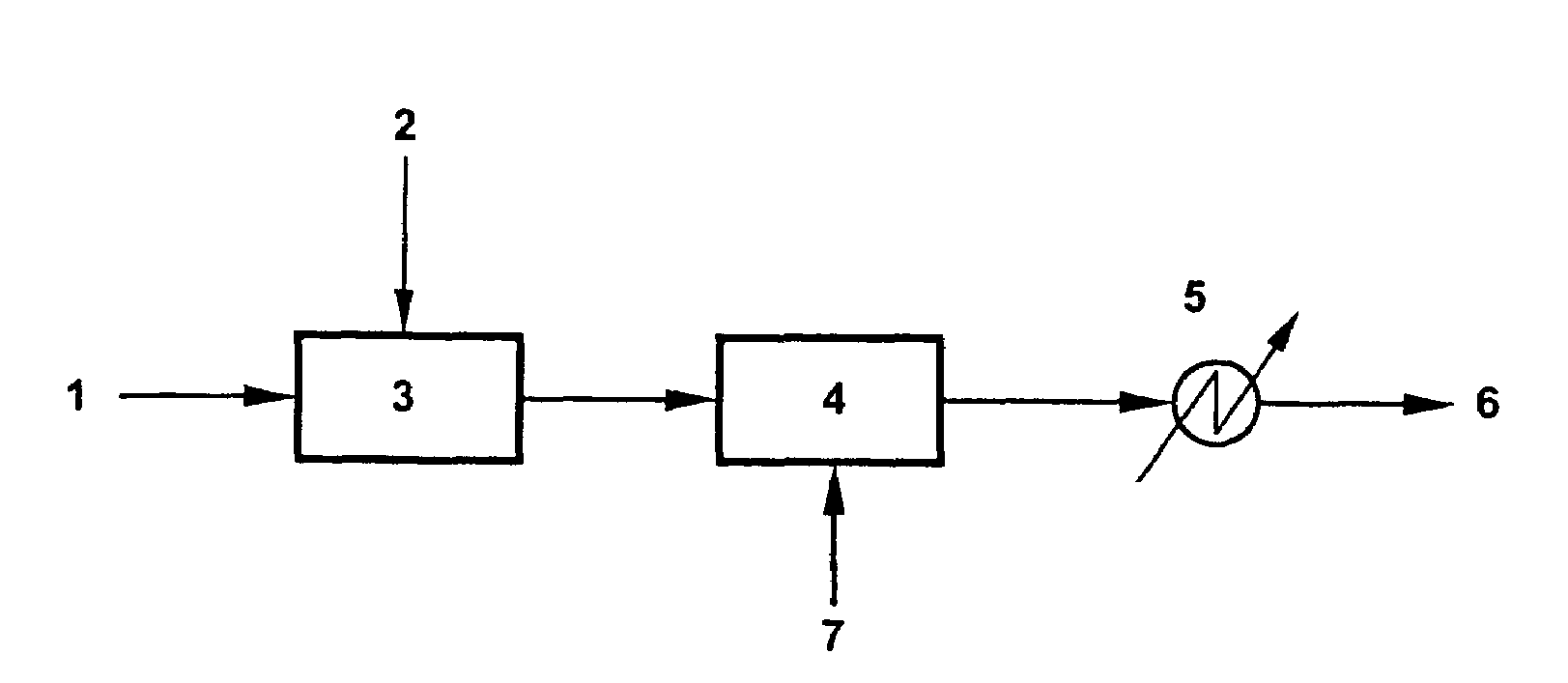

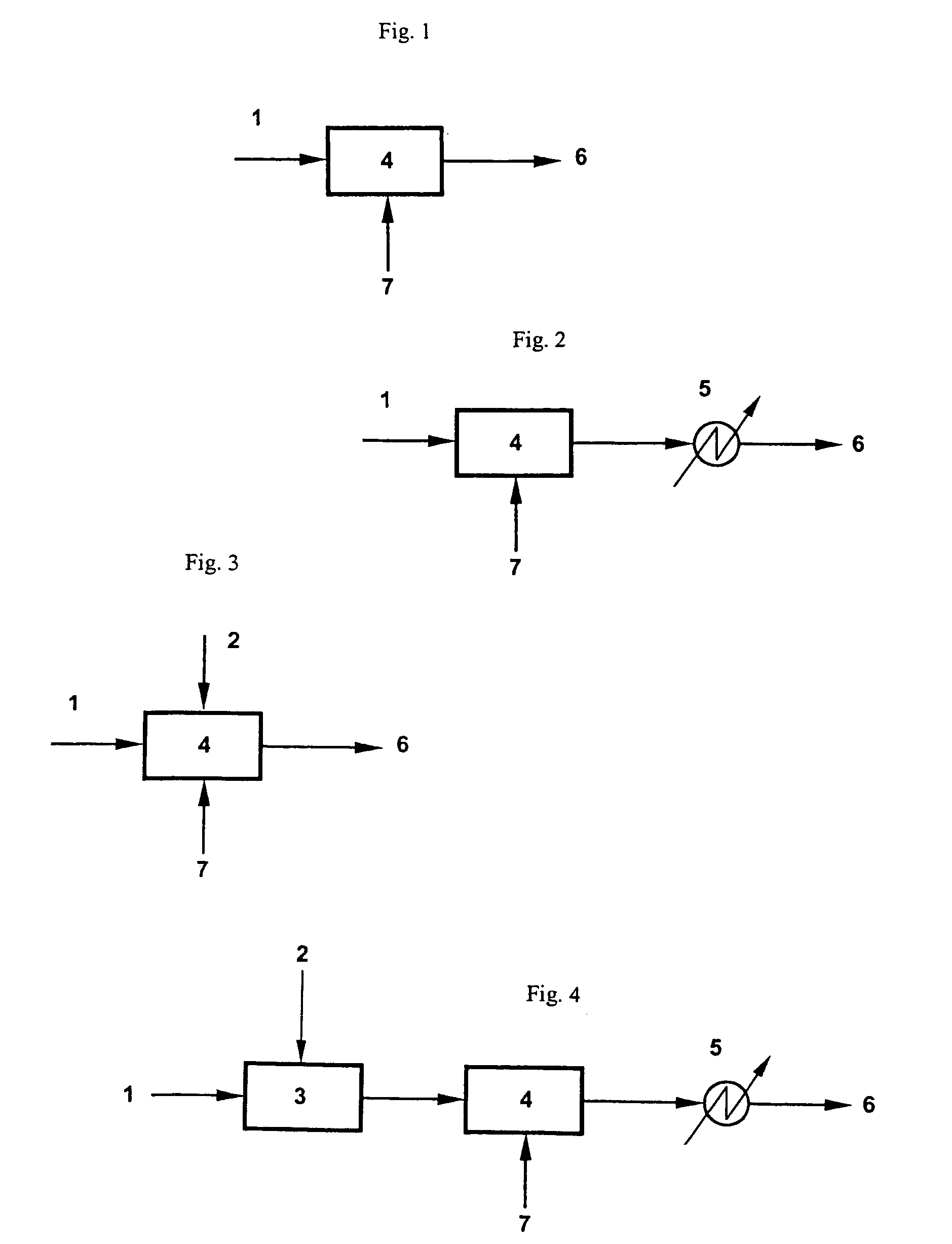

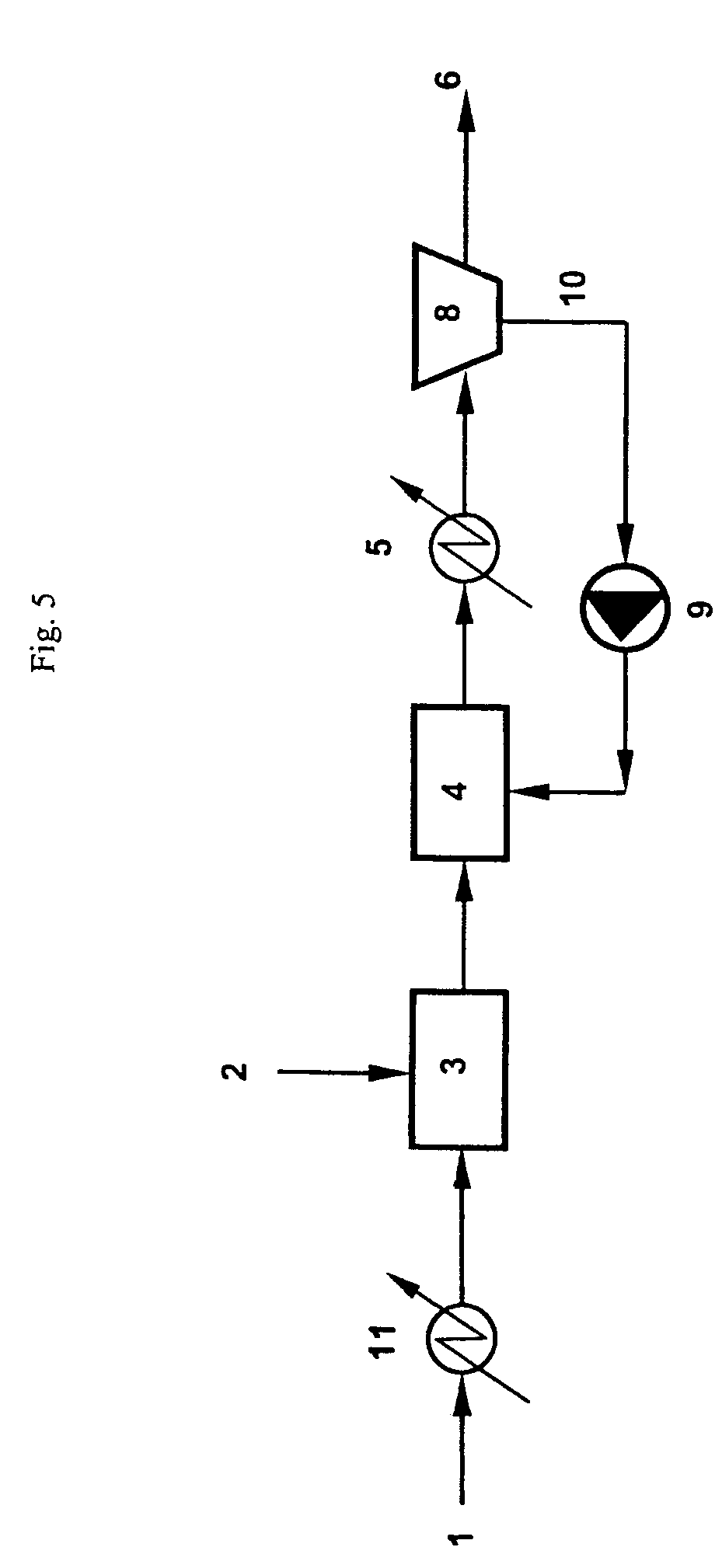

A method and a system for transporting a flow of fluid hydrocarbons containing wax and / or asphaltenes or any other precipitating solids through a treatment and transportation system including a pipeline are disclosed. The flow of fluid hydrocarbons is introduced into a reactor (4), where it is mixed with another fluid flow having a temperature below a crystallization temperature for the wax and / or asphaltenes or other solids and containing particles or crystals acting as nucleating and / or growth cores for the wax and / or asphaltenes or other solids, the mixing temperature providing precipitation of the wax and / or asphaltenes or other solids from the flow of fluid hydrocarbons, and the effluent flow of hydrocarbons and particles is conveyed from the reactor (4) to a pipeline (6) for transportation.

Owner:SINVENT AS +2

Laser-high frequency induction composite welder and its method

InactiveCN1554510ARealize simultaneous mobile heatingImprove absorption rateHigh frequency current welding apparatusLaser beam welding apparatusMetallic materialsInductor

The present invention provides welder and welding method combining two different kinds of heat source, laser and HF inductor, and adopts real-time temperature monitor and control to overcome the demerits of common laser welding of metal material, which has low energy utilization and is likely to produce air hole. During welding, two kinds of heat source are used to heat the welded part and near part simultaneously. The welder of the present invention has laser welding head as the main body comprising integrated induction heating winding and infrared sensor. Compared with common laser welding, the present invention has greatly raised production efficiency and welding quality and can realize 2D and 3D welding.

Owner:HUAZHONG UNIV OF SCI & TECH

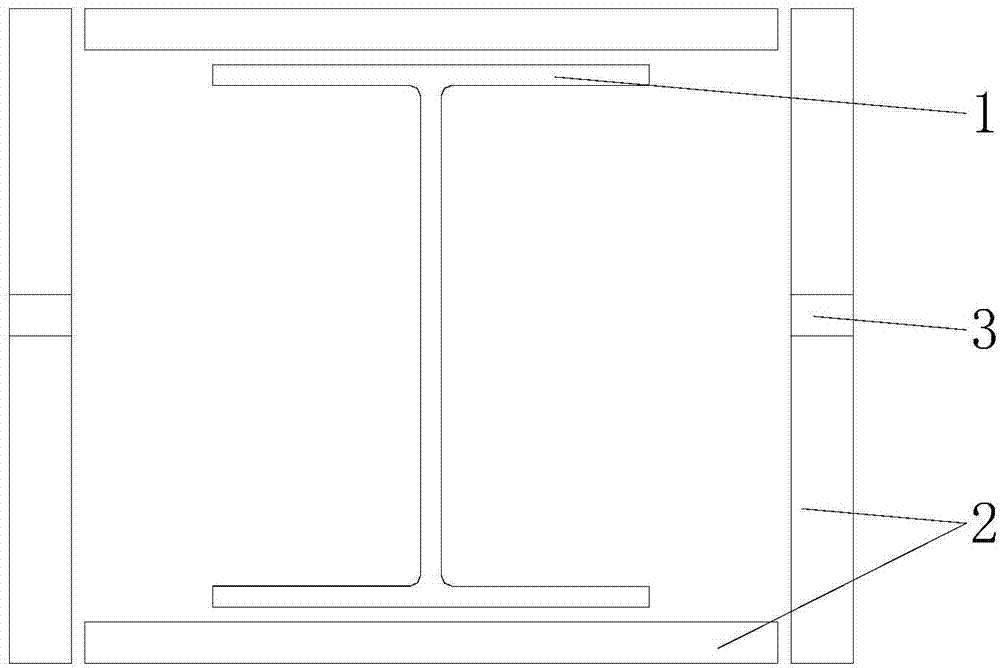

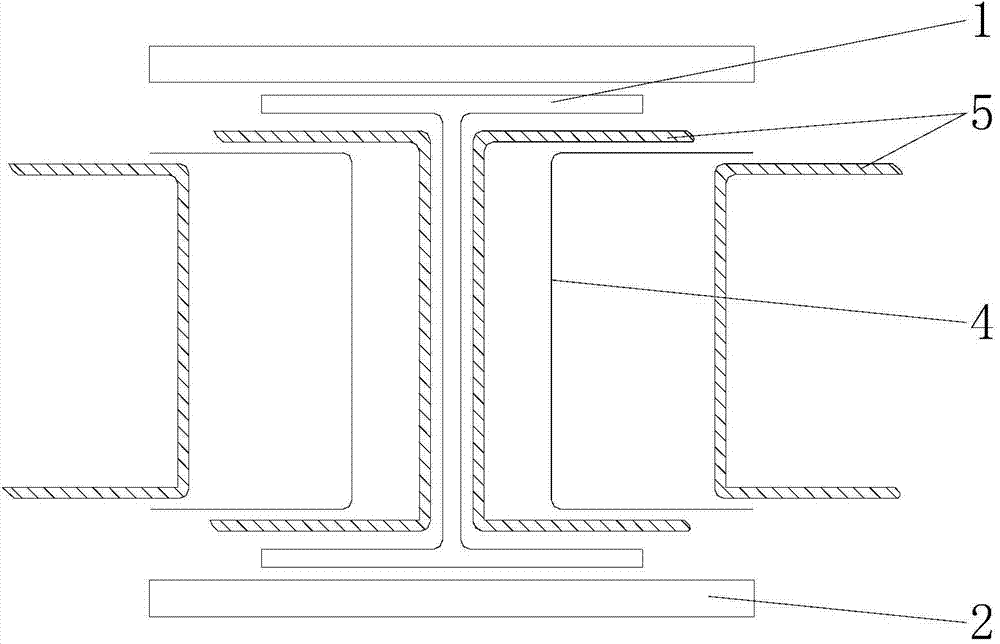

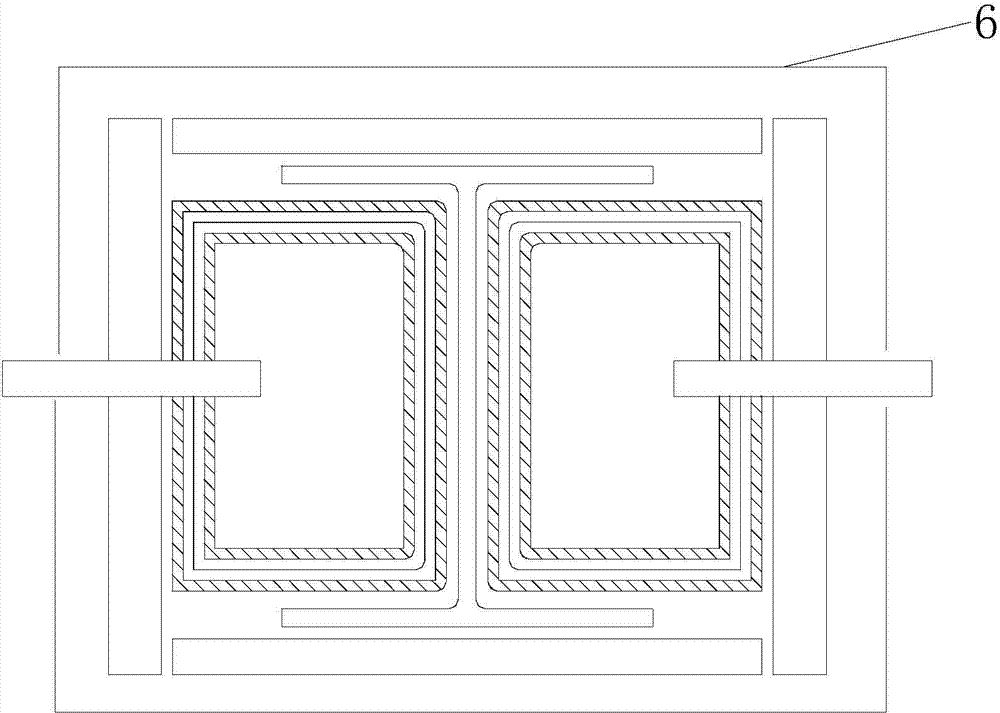

Molding method for composite material structural member with I-shaped section

The invention discloses a molding method for a composite material structural member with an I-shaped section. The composite material structural member is molded by taking a metal fake member and a molding mould to mould a glass fiber enhanced silicone rubber airbag and taking the airbag as a core mould to be combined with the molding mould. The molding method has the advantages that with the adoption of a silicone rubber airbag molded structural member, firstly, the wall of the airbag is thin, the heat transferring performance is good, the temperature gradient of the structural member and the edge is small, and the inner quality of the molded structural member is guaranteed; secondly, silicone rubber on the surface of the airbag is elastic so as to have the effect of a pressure equalizing cushion; the surface quality of a molded part is good; thirdly, the silicone rubber airbag is combined with a box-shaped structure of the airbag; meanwhile, the two ends of the I-shaped structural member are connected by the silicone rubber, the structural rigidity of the airbag is great and the molding position and the size precision of a web are guaranteed; fourthly, the airbag can be used repeatedly and can be manufactured conveniently again so that the production cost is reduced effectively; the whole molding method can uniformly apply a pressure to the web and an edge strip of the structural member and the pressure is equal to a tank pressure.

Owner:航天海鹰(镇江)特种材料有限公司

Turbine airfoil with near wall multi-serpentine cooling channels

A turbine airfoil usable in a turbine engine and having at least one cooling system. At least a portion of the cooling system may be positioned in an outer wall of the turbine airfoil and be formed from at least one suction side serpentine cooling chamber and at least one pressure side serpentine cooling chamber. Each of the suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source first before being passed through other components of the cooling system. The cooling fluids may then be passed into a mid-chord cooling chamber to cool internal aspects of the turbine airfoil, yet prevent creation of a large temperature gradient between outer surfaces of the turbine airfoil and inner aspects.

Owner:SIEMENS ENERGY INC

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

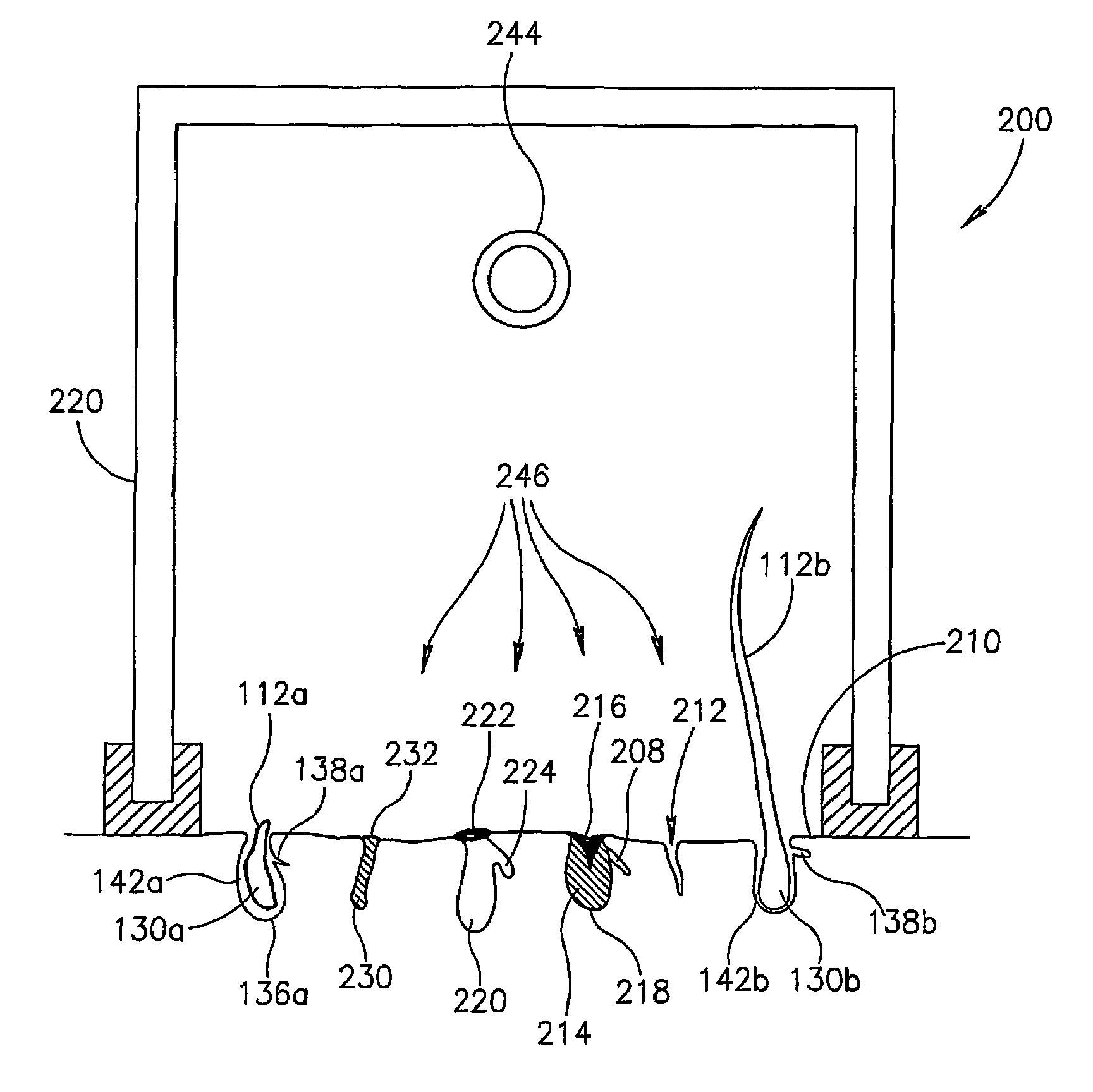

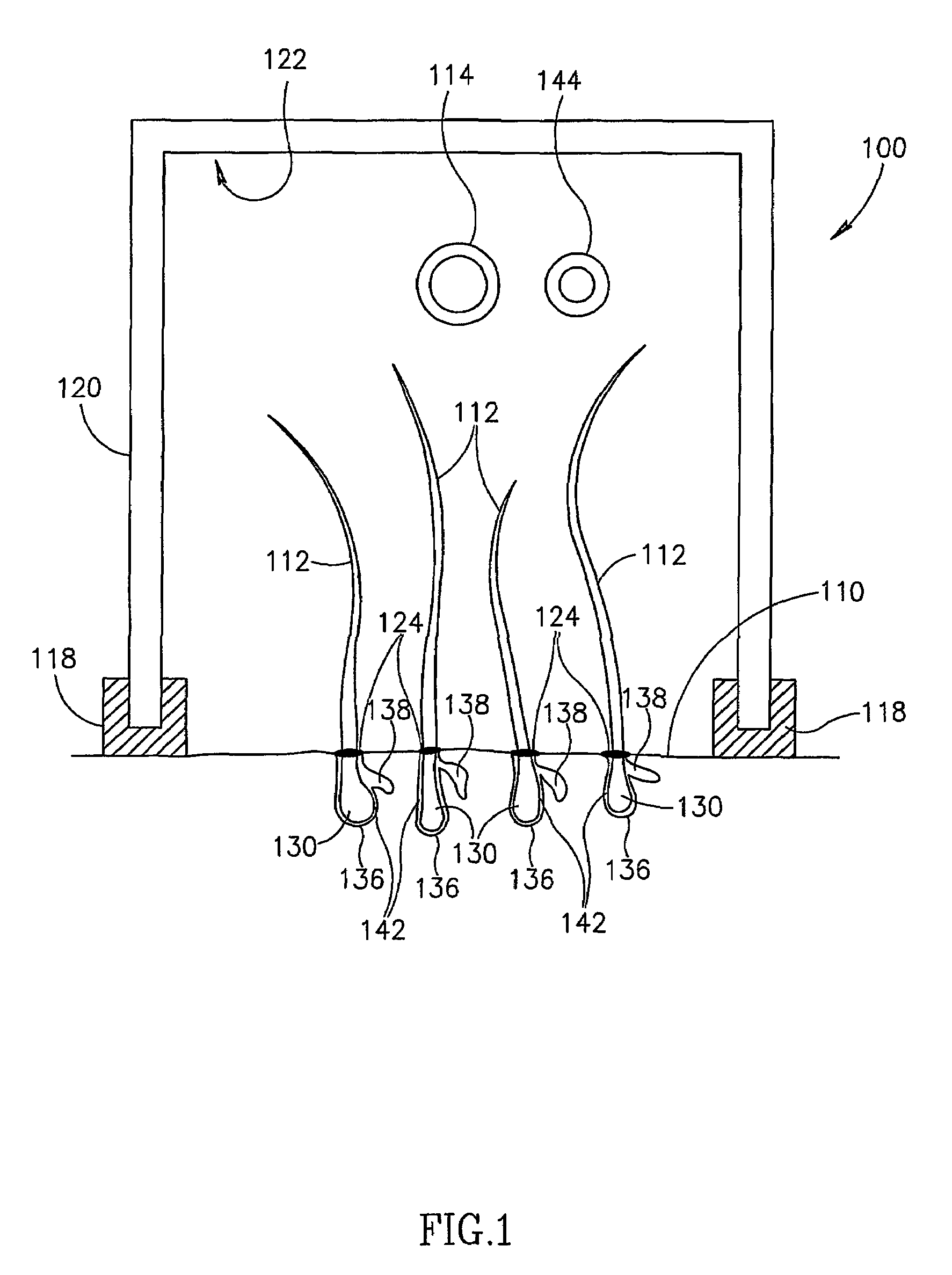

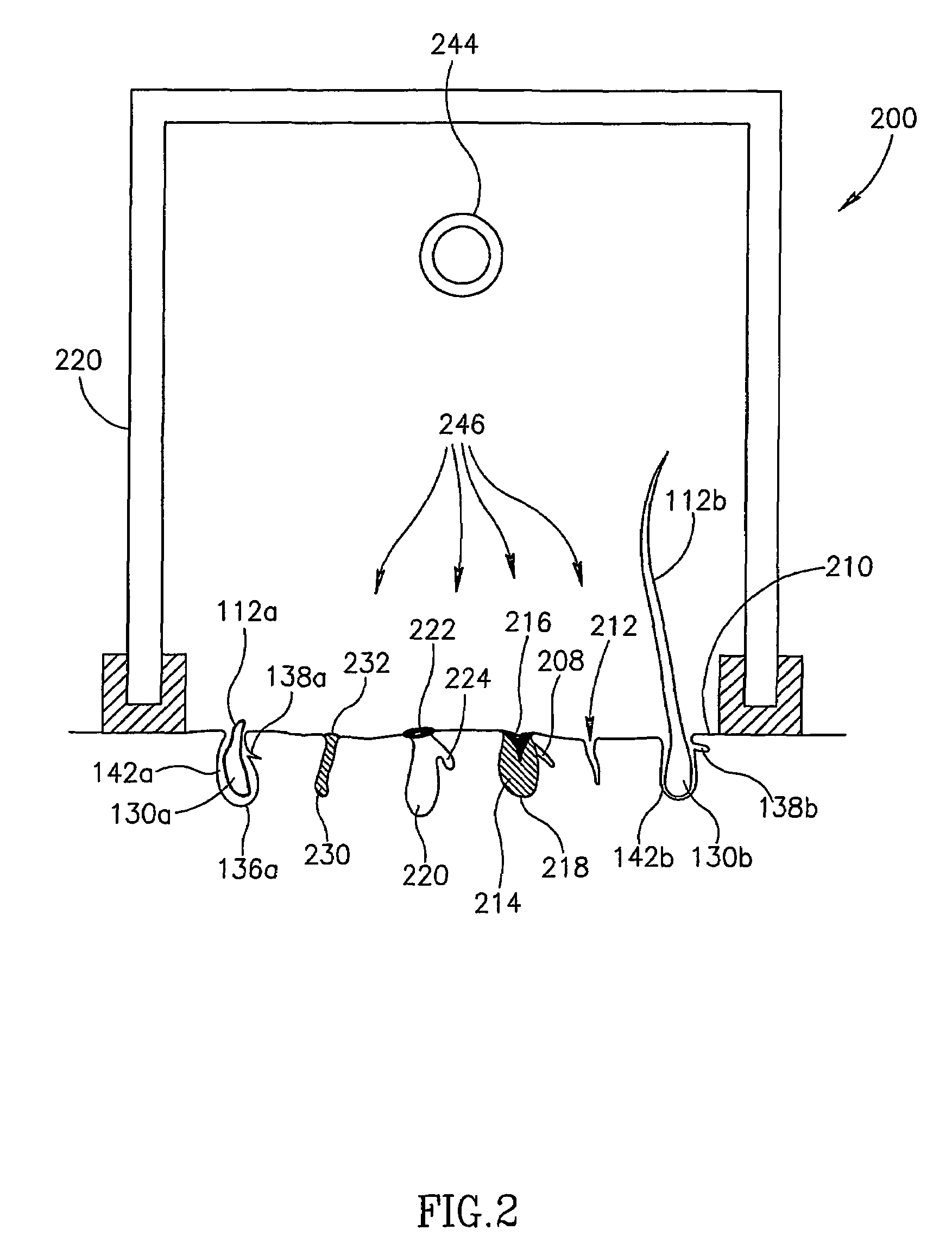

Acne treatment

InactiveUS7470270B2Reduce intensityShorten the durationDiagnosticsSurgical instruments for heatingTreatment acneAcne treatment

A method and apparatus (100) are provided for treating acne using pulsed radiant energy (246) to destroy or partially destroy one or more hairs (112), without damaging the skin, or, alternatively, to destroy or partially destroy one or more acne-related structures without damaging either skin or hair.

Owner:RADIANCY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com