Cavity type solar heat absorber provided with optical window

A solar heat absorber and optical window technology, applied in the field of solar energy, can solve the problems of high local temperature of the heat absorber, prone to burn-through, uneven distribution of solar radiation heat flow, etc., to reduce temperature gradient and reduce overheating The probability of spotting and thermal stress concentration, the effect of increasing the internal absorption area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

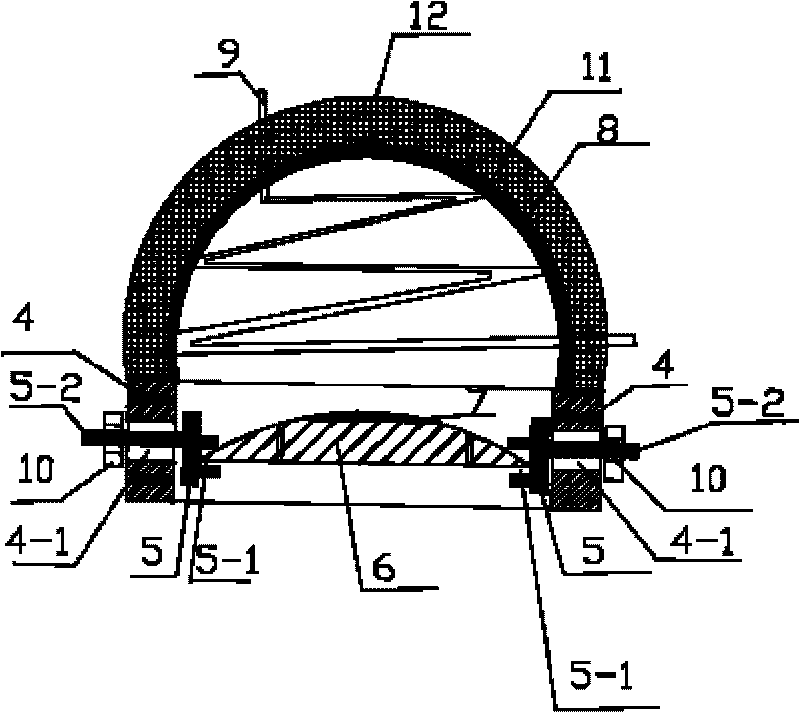

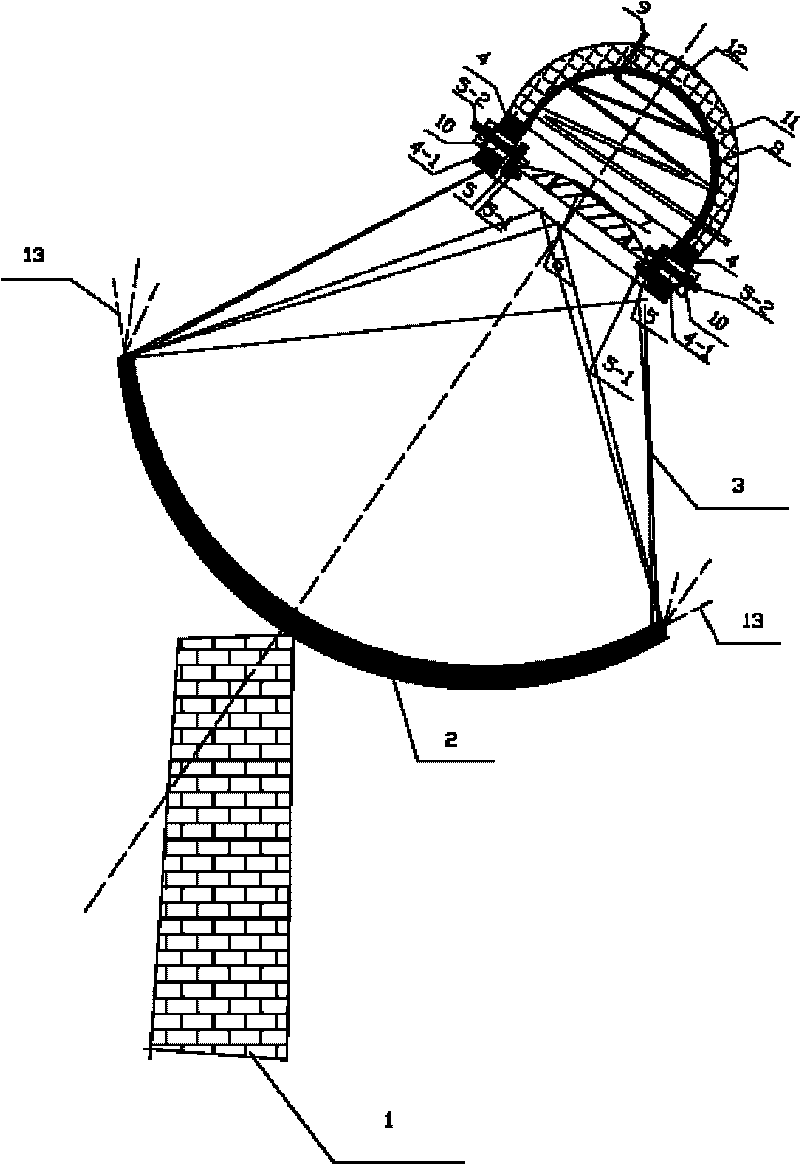

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises heat absorber 8 and heat absorption pipe 9, and described heat absorption pipe 9 is inserted into the cavity of heat absorber 8, and heat absorption pipe 9 follows the inner cavity shape of heat absorber 8 The disk is placed on the inner wall of the heat absorber 8, the shape of the inner cavity of the heat absorber 8 is hemispherical, and it also includes an upwardly convex optical glass body 6 and a guard plate 4, the heat absorber 8 is a hollow body, and the guard plate 4 The protective plate 4 is fixed on the inlet of the heat absorber 8, and the convex optical glass body 6 is arranged on the protective plate 4. The surface of the upward convex optical glass body 6 facing the entrance of the heat absorber 8 is a convex surface, facing away from the absorber. The inlet surface of the heater 8 is a plane.

[0008] The protective plate 4 in this embodiment is a part ...

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that it also includes an adjustable movable bolt 5 and a nut 10, and the adjustable movable bolt 5 includes a U-shaped notch 5-1 and a screw rod 5-2 , two grooves 4-1 are arranged on the circumferential wall of the guard plate 4, the grooves 4-1 are distributed along the axial direction of the guard plate 4, and the two grooves 4-1 are respectively arranged in the diameter direction of the guard plate 4 The two ends of the two ends, the screw 5-2 of the adjustable movable bolt 5 is inserted into the groove 4-1 of the guard plate 4, the U-shaped notch 5-1 of the adjustable movable bolt 5 contains the edge of the convex optical glass body 6, and the screw The cap 10 is screwed on the outer end of the screw 5-2.

[0010] The working principle of the adjustable movable bolt 5 described in this embodiment is: when adjusting the position of the convex optical glass body 6, first unscrew the nut 10, and t...

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the convex surface of the convex optical glass body 6 is covered with a heat-resistant anti-reflection film 7 .

[0012] In this embodiment, the convex surface of the convex optical glass body 6 may be covered with a heat-resistant anti-reflection film 7 as required. When the solar radiation heat flow 13 passes through the convex optical glass body 6 above the heat absorber 8, the The heat-resistant anti-reflection film 7 can enhance the absorbed solar radiation heat flow 13 and prevent the loss of heat flow of the heat absorber 8 body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com