Patents

Literature

174results about How to "Uniform distribution of temperature field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

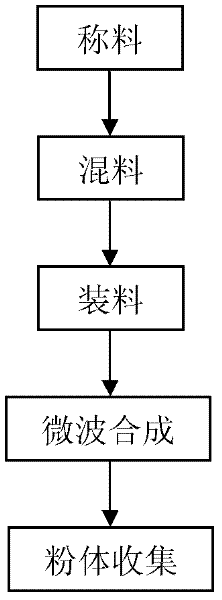

Method for preparing high-purity MAX-phase ceramic powder

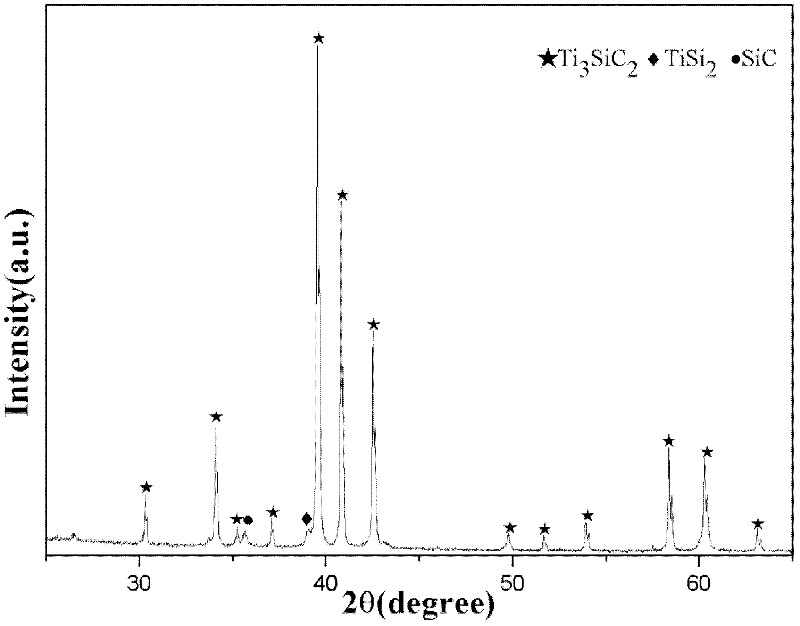

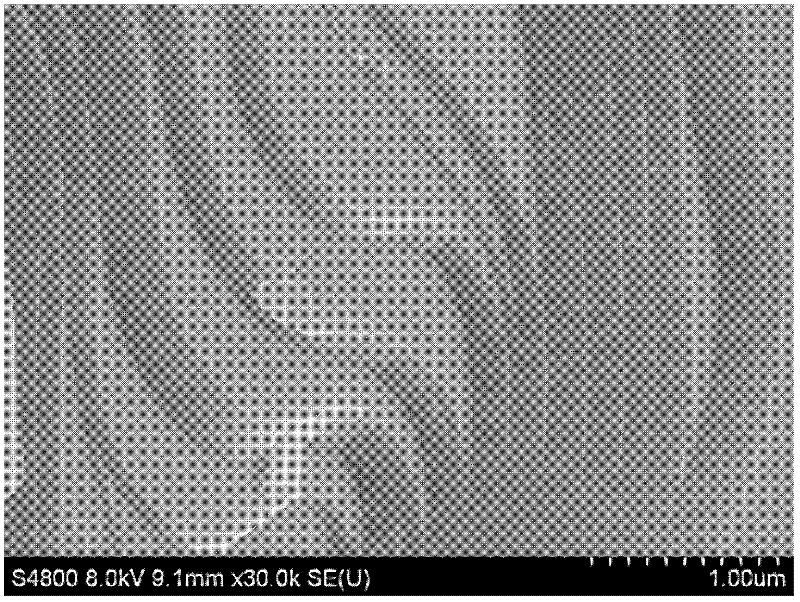

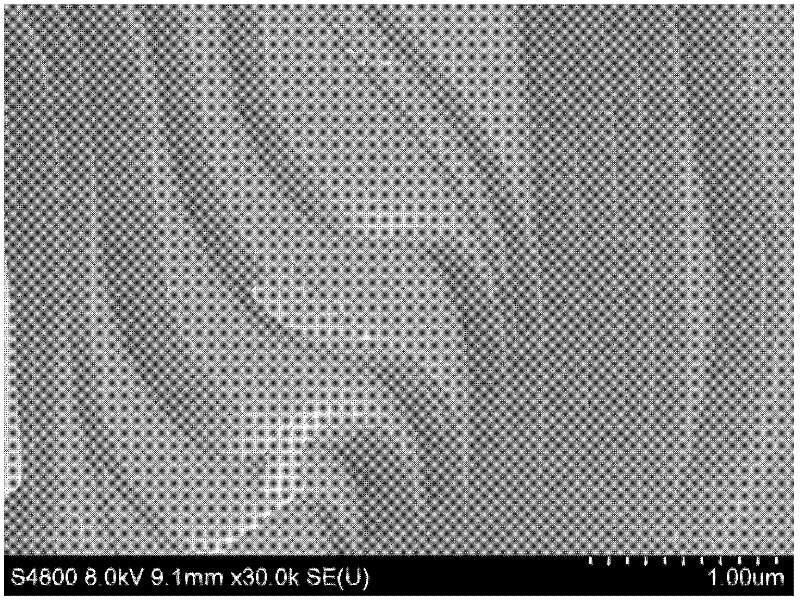

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

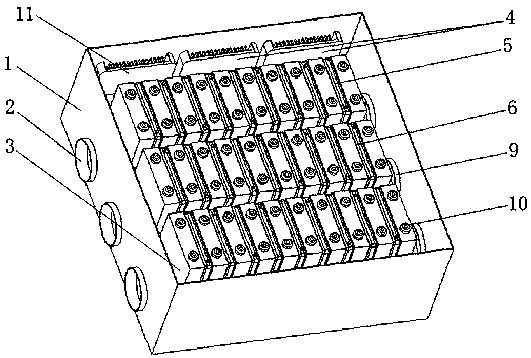

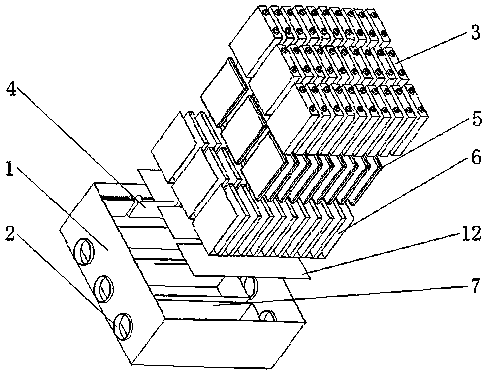

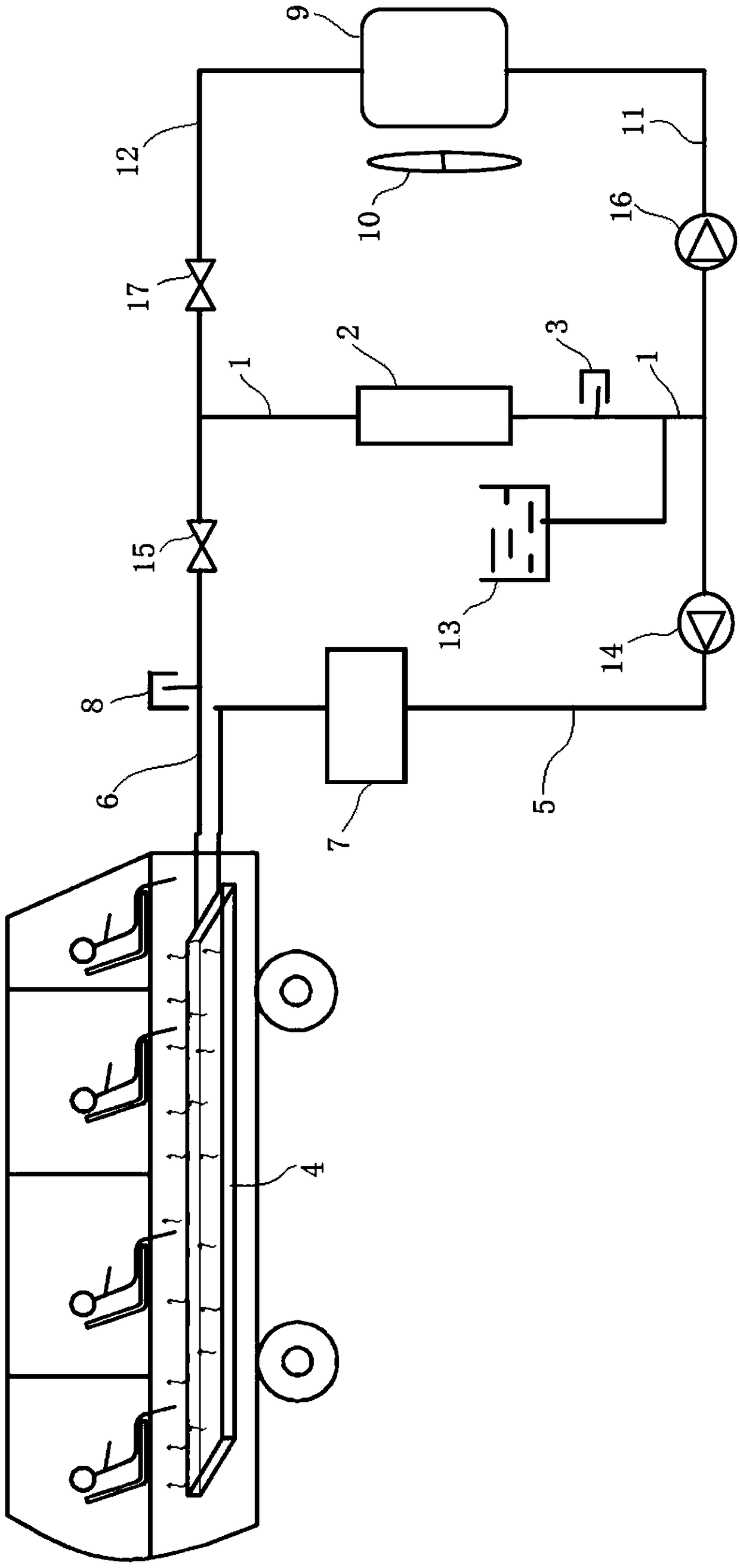

Heat management coupling system of power lithium battery pack

PendingCN107863588AConvenient temperature field distributionFew influencing factorsSecondary cellsCoupling systemPhase change temperature

The invention discloses a heat management coupling system of a power lithium battery. An air blowing fan and an air sucking fan are respectively installed on the front side and the rear side of a boxbody; a BMS battery management system and a heat management controller are fixedly installed on one side in the box body; one end of a temperature sensor is connected at the positive electrode end ofa battery module group, and the other end of a temperature sensor is connected with the BMS battery management system; the heat management controller is signally connected with an electrical heating film, the air blowing fan and the air sucking fan; through real-time collection, analysis and processing of a temperature signal, the BMS battery management system makes the heat management controlleradopt measurements of heating, cooling or heat preservation to control the temperature of the lithium battery. The heat management coupling system ensures that the influence factor of environmental temperature on the battery pack is minimized, and therefore achieves the purposes of heat dissipation during high-temperature, heating during low-temperature and phase-change temperature control, wherein the maintenance and replace methods of the phase-change material pack are more concise and convenient, and the device makes the temperature field distribution of the battery module group more even and accordant.

Owner:NANCHANG HANGKONG UNIVERSITY

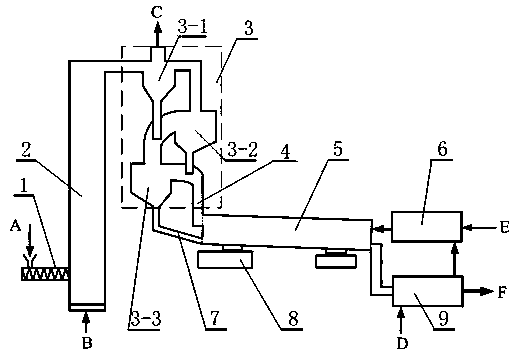

Method for producing grain sizes even distributed antimony trioxide in single crystal type, and equipment

ActiveCN1873061ASolution to short lifeUniform particle size distributionPolycrystalline material growthAntimony compoundsSingle crystalAntimony trioxide

This invention discloses method and equipment for producing Sb203 single crystal with evenly-distributed particle sizes. The method comprises: (1) melting Sb metal in a reverberatory antimony trioxide furnace, and introducing air to the Sb melt surface in the furnace to oxidize Sb into Sb203 vapor; (2) introducing to a wind-blowing reactor and a crystallizer in sequence for three-step cooling and crystallization; (3) discharging through the output pipe of the furnace, and collecting with a dust-collecting system to obtain Sb203 single crystal powder with an average particle size of 0.2-3.5 mum, Sb203 content of 99.6% and whiteness higher than 98.5%. The method has such advantages as high yield, low energy consumption, long furnace service life, high automation degree, stable operation and wide raw material resources.

Owner:广西华锑科技有限公司

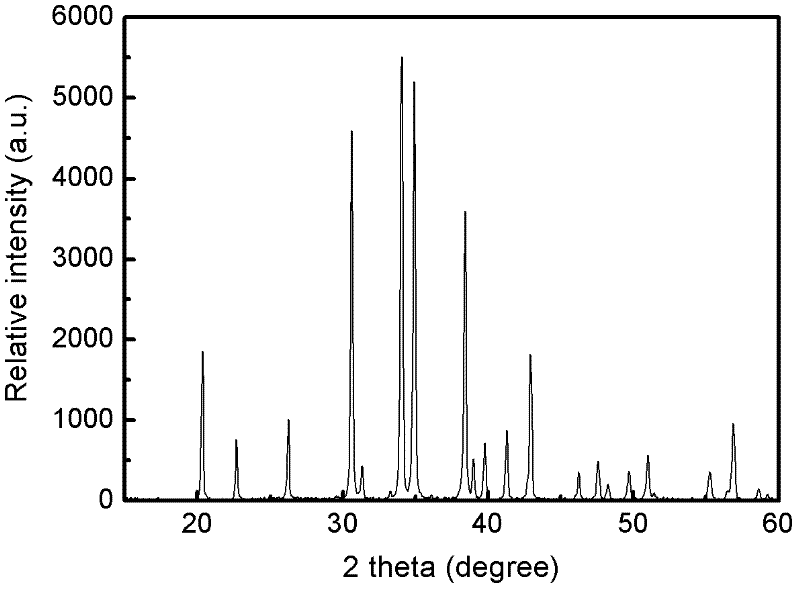

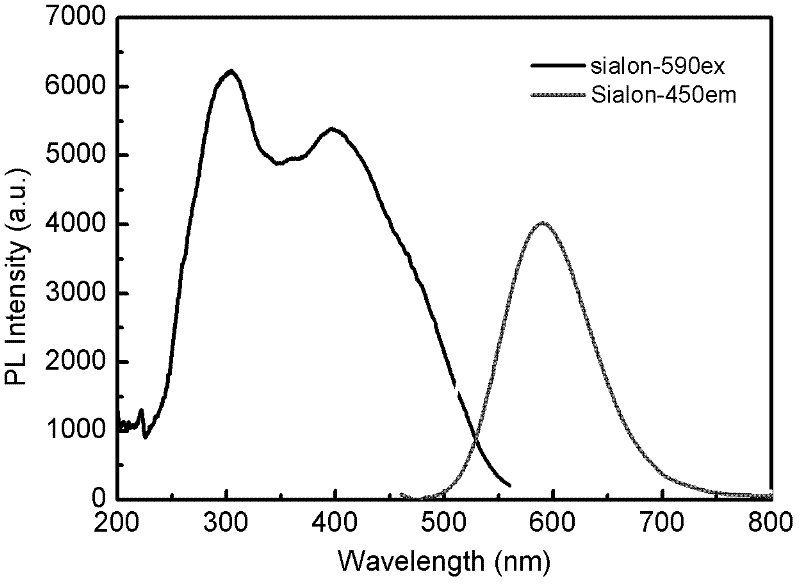

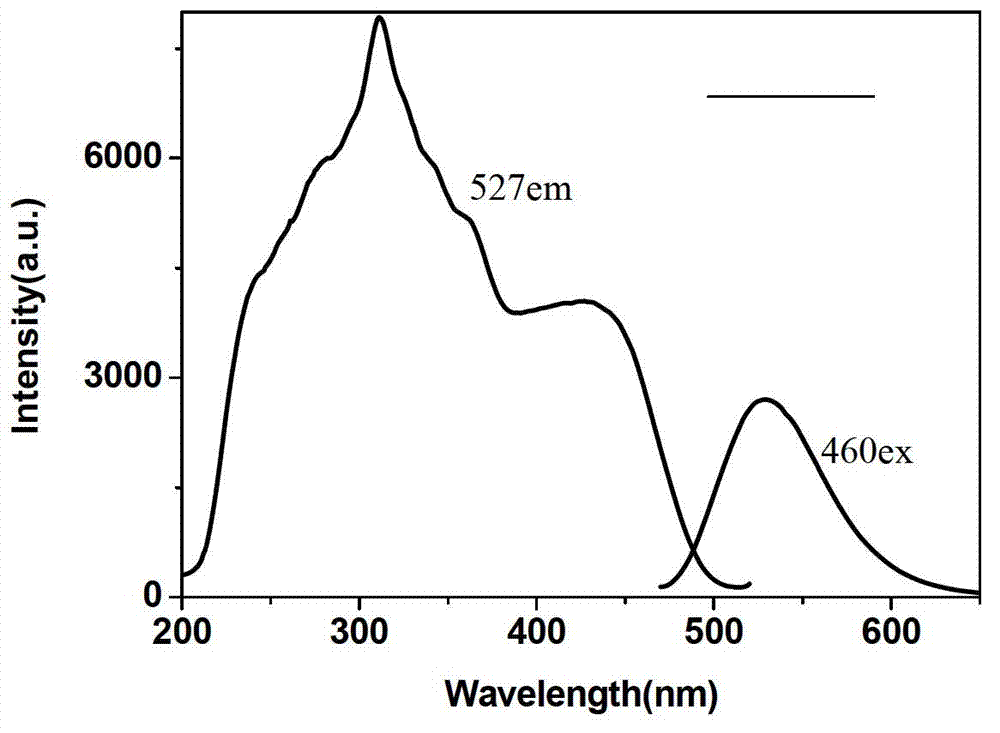

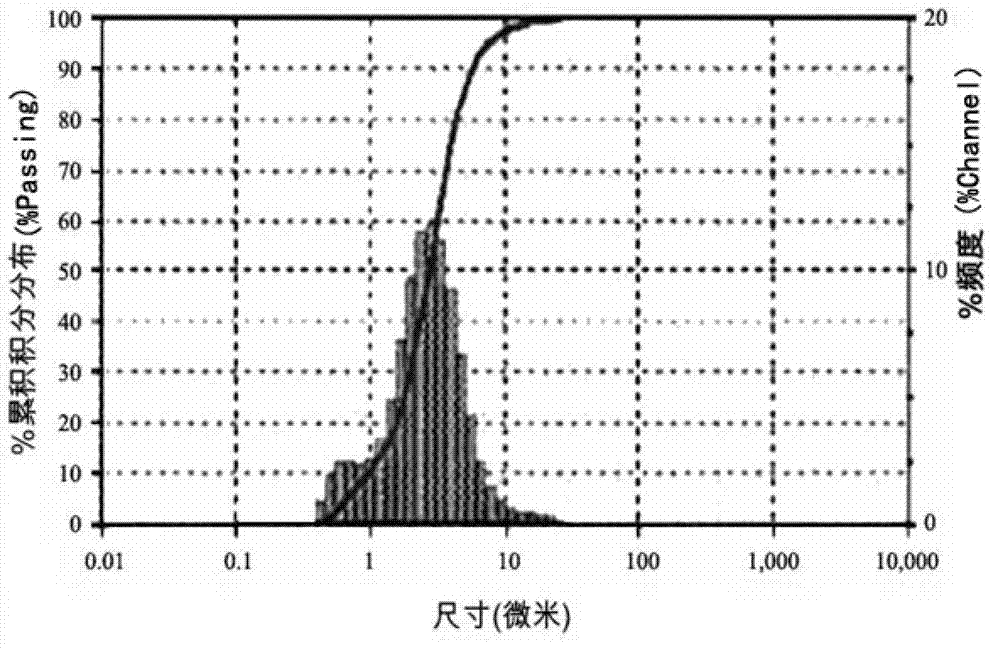

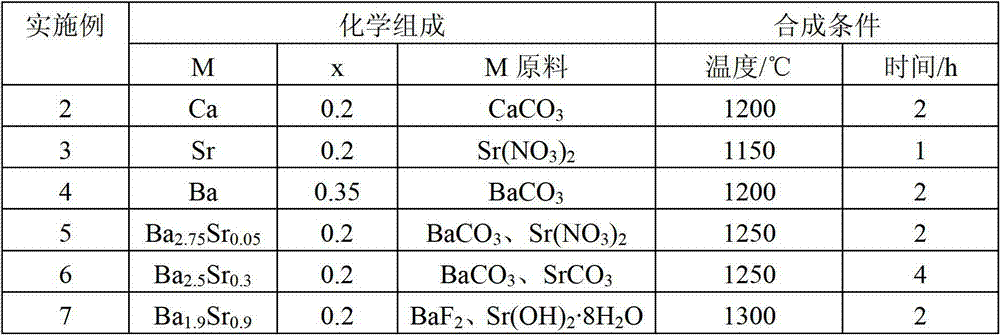

A kind of preparation method of nitride/oxynitride fluorescent powder for white light LED

InactiveCN102260500AUniform distribution of temperature fieldReduce temperature gradientElectroluminescent light sourcesGas discharge lamp usagePolymer scienceHigh pressure

Provided is a method for preparing a nitride / oxynitride fluorescent powder used by a white LED. The raw material is weighted according to the chemometry of each element in the chemical formula of a nitride / oxynitride fluorescent powder and loaded into a sagger made of a wave-transparent material after being mixed uniformly, then the sagger is placed into a professional microwave oven, in a fixed gas atmosphere, and the fluorescent powder is obtained by adjusting the microwave power to control the warming rate, heating to the resultant temperature, and finally cooling and grinding. As compared to methods in the prior art, the method is performed under normal pressure, reducing the resultant temperature, shortening the production period, and greatly reducing the production costs; and the fluorescent powder obtained has good crystallinity, fine grain size, a narrow granularity distribution range, good grain dispersibility, and a regular shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

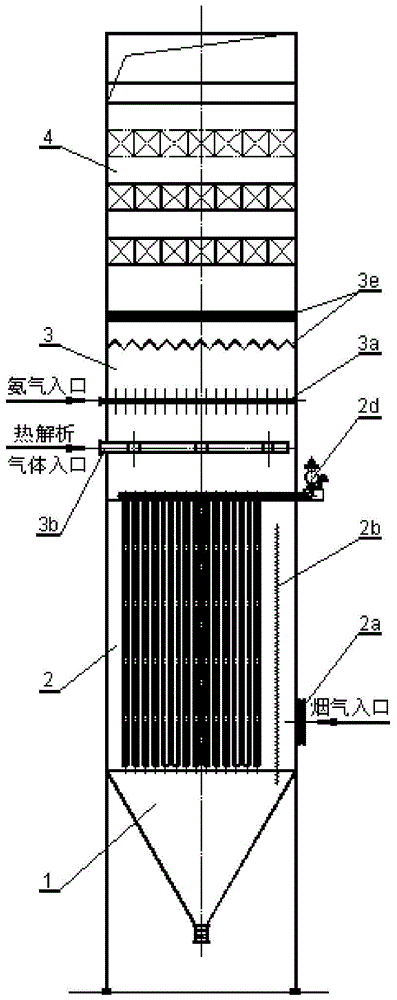

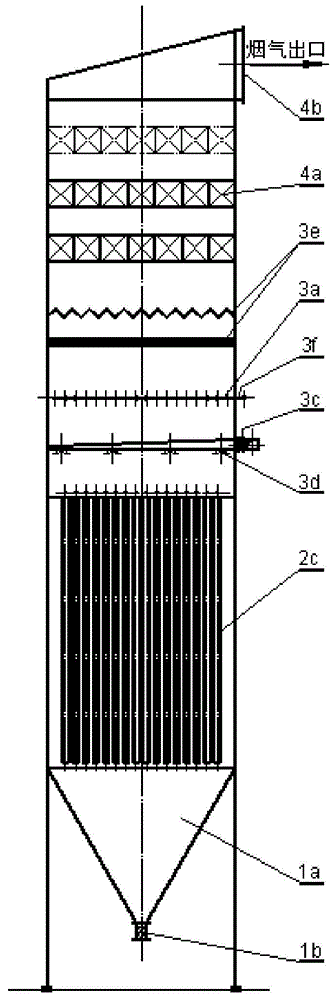

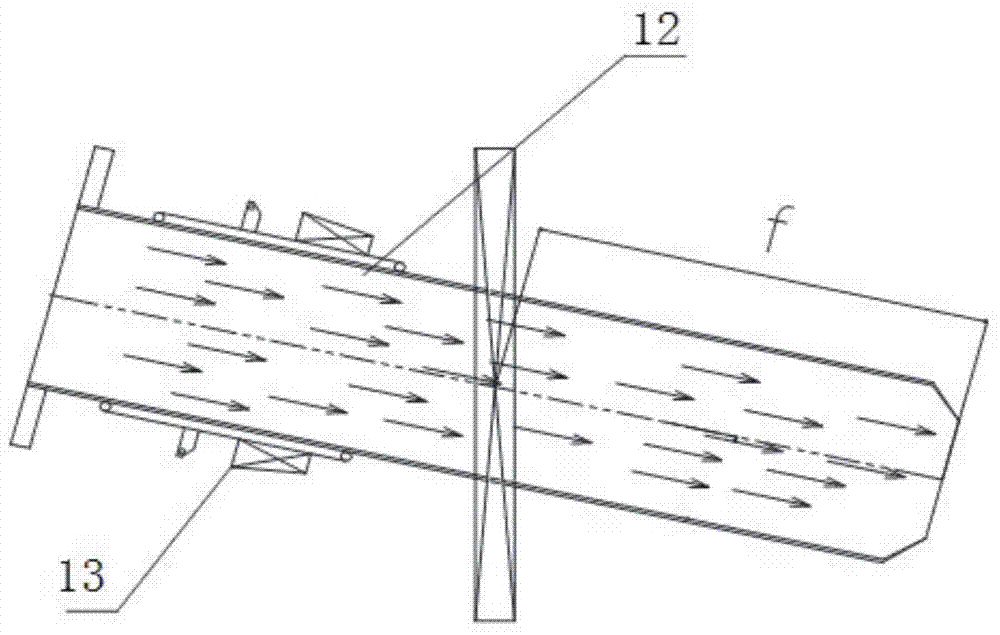

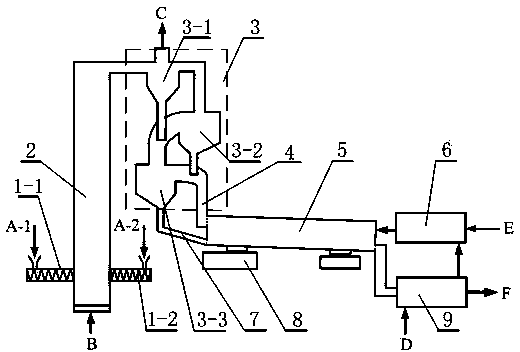

Medium and low temperature denitration, dedusting and thermo-analysis integrated method and device

InactiveCN104399371AReduce investmentLow running costCombination devicesDispersed particle filtrationParticulatesFlue gas

The invention relates to a medium and low temperature denitration, dedusting and thermo-analysis integrated method and a device. The device is formed by combining a dedusting filter bag layer, a denitration catalyst layer and a field thermo-analysis regeneration structure layer and comprises a particulate collection and discharge section, a flue gas purification and filtration section, a mixed analysis regeneration section and a denitration reaction section. The denitration catalyst structure layer is arranged on the top of the bag purification layer, and the dedusting is carried out before denitration, so that abrasion of dust to a denitration catalyst can be reduced. The thermo-analysis regeneration structure layer is arranged between the denitration catalyst structure layer and the bag purification layer; analysis and regeneration of the denitration catalyst are achieved by supplying high-temperature analysis gas on line regularly; continuous efficient use of the medium and low temperature catalyst is kept; and normal operation of a flue gas denitration technology is unaffected. Static pressure mixing devices are arranged in the mixed analysis regeneration section, and uniform distribution of a velocity field and a temperature field of flue gas on a cross section of the device is achieved by a pressure equalization effect of the static pressure mixing devices and the filter bag resistance layer.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

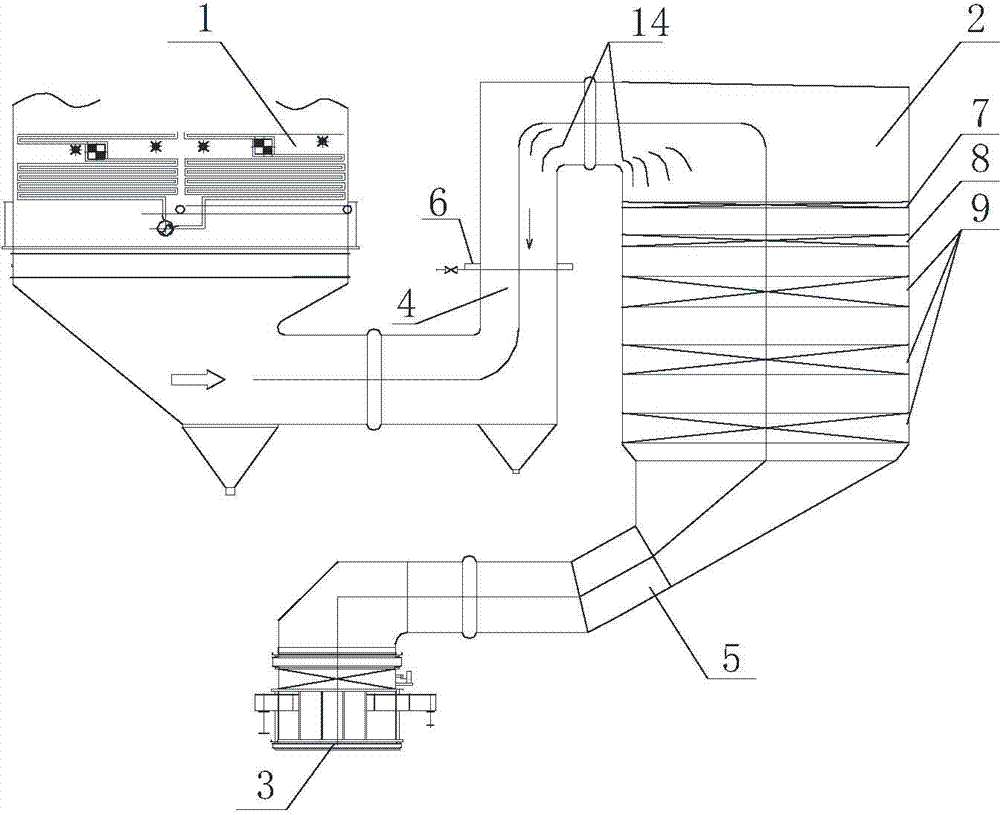

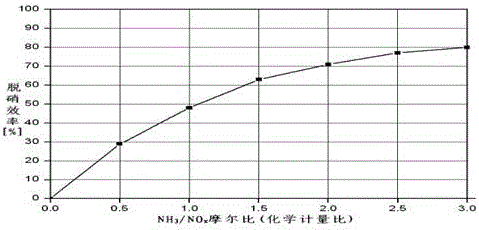

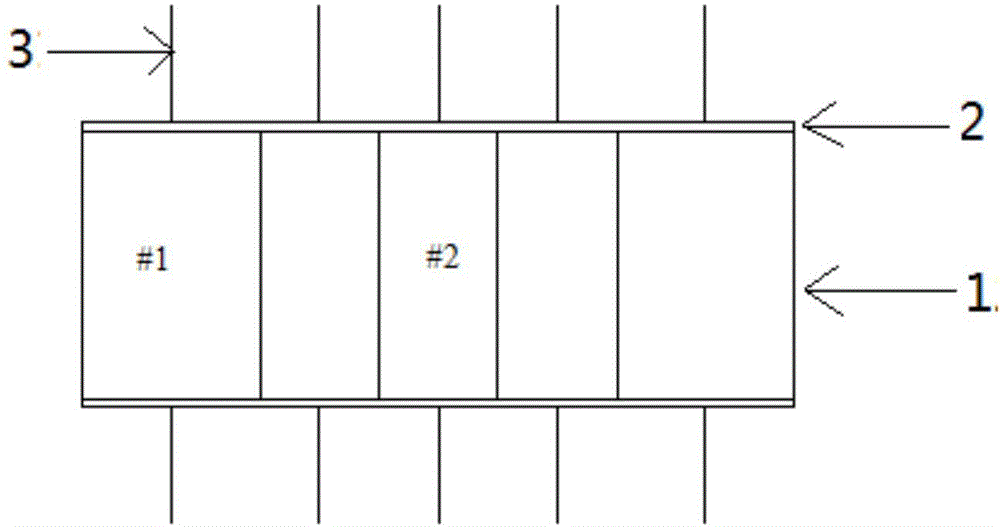

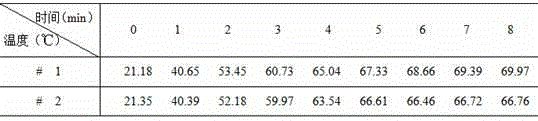

SCR (Selective Catalytic Reduction) flue gas denitration device and flue gas denitration method

InactiveCN104741001ASolve the resistanceReduce resistanceLighting and heating apparatusDispersed particle separationAir preheaterFlue gas

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration device and a flue gas denitration method. The SCR flue gas denitration device comprises a coal economizer (1), a denitration reactor (2) and an air preheater (3), wherein the bottom of the coal economizer (1) is connected with the top of the denitration reactor (2) by an inlet flue (4), the bottom of the denitration reactor (2) is connected with the air preheater (3) by an outlet flue (5), an ammonia spraying device (6) is arranged in the inlet flue (4), and an ash crushing device (7), a rectifying layer (8) and a catalyst layer (9) are sequentially arranged in the denitration reactor (2) from top to bottom. The denitration method comprises the steps of ammonia gas mixture preparation, ammonia spraying, denitration and exhausting. According to the invention, through the reasonable setting of a nozzle, an effect of mixing sprayed ammonia with flue gas is better, and the uniformity of a temperature field in a flue can be effectively guaranteed, thereby improving the denitration efficiency.

Owner:CHINA HUADIAN ENG +1

Continuous graphitizing ultra-high temperature tube furnace

ActiveCN102797075ASmall sizeMeet the production process requirementsFibre chemical featuresFurnace temperatureCarbon composites

The invention discloses a continuous graphitizing ultra-high temperature tube furnace, whose heating working temperature falls within a range of 2200-2800 DEG C. A structure of the continuous graphitizing ultra-high temperature tube furnace comprises a muffle furnace hearth, a protective tube, a heat insulation refractory layer and a furnace shell. A graphite muffle furnace hearth is tubular, is divided into three temperature areas and is an unique heating body. Water cooling copper electrodes are mounted at two ends of the muffle furnace hearth; the protective tube with an adjusting device is arranged outside the muffle furnace hearth; the protective tube is positioned between the muffle furnace hearth and the heat insulation refractory material; and the axis of the protective tube can be adjusted by the adjusting device. A heat insulation system, which is formed by a soft graphite felt, a soft felt, a carbon / carbon composite material and other materials, is arranged in a furnace body; the airtight furnace shell with a water cooling steel structure is arranged outside the heat insulation system; the water cooling furnace shell comprises a plurality of independent water cooling chambers; and the chambers are respectively used for cooling different areas of the furnace body. The continuous graphitizing ultra-high temperature tube furnace disclosed by the invention has the advantages of high working furnace temperature, uniform and stable temperature field, less muffle furnace hearth surface heat accumulation phenomenon, long muffle furnace hearth service life, simple structure, easiness for machining and so on.

Owner:ATA CARBON FIBER TECH GUANGZHOU

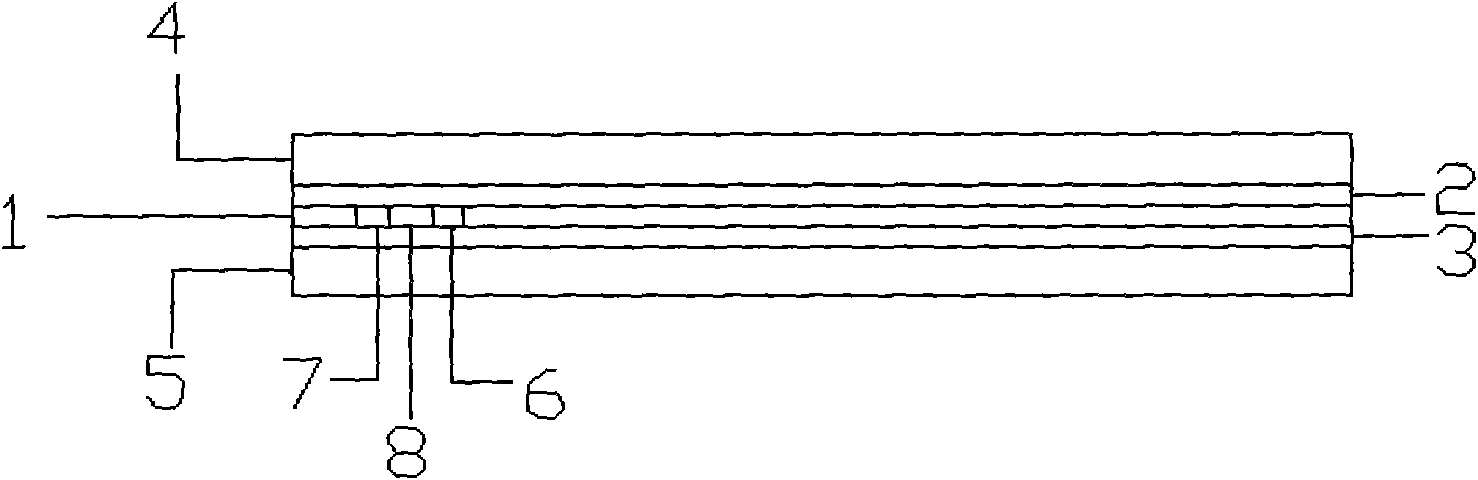

Preparation method for large-area lead iodide thick film and implementation equipment thereof

InactiveCN104164649AImprove crystallization uniformityUniform distribution of temperature fieldVacuum evaporation coatingSputtering coatingGraphiteQuartz

The invention discloses a preparation method for a large-area lead iodide thick film and implementation equipment thereof. According to the invention, in a vacuum cavity of the equipment, the raw material high purity lead iodide powder is spread on a raw material carrier graphite sheet, which is placed on a flat heater, a directional heat dissipation plate equipped with a substrate at the bottom is supported by a quartz block over the raw material, in an environment with a vacuum degree of 10<-1>Pa-10<-5>Pa, starting the flat heater to heat the raw material to gasify it, and the raw material gas condenses and deposits at the low temperature substrate, thus forming the dense lead iodide polycrystal film. With the method and equipment provided by the invention, the lead iodide polycrystal thick film with a thickness of 50-1000 micrometers, an area of 5*5cm<2>-50*50cm<2>, uniform thickness and excellent properties can be prepared on the substrate. Also, the preparation process is simple and low in cost, thus being suitable for industrial mass production.

Owner:朱 兴华 +1

Vacuum sublimation purifying method for high-purity arsenic and vacuum sublimation furnace thereof

InactiveCN101225479AGood separation and condensation effectAvoid dischargeTemperature controlPurification methods

The invention relates to a vacuum sublimation purification method of high-purity arsenic, sublimating in vacuum sublimation sealed furnace, which comprises a heating furnace, a vacuum tank and a sublimation inner sleeve; wherein, a circular water jacket is arranged on the top of the vacuum tank; the vacuum tank under the circular water jacket is arranged in the heating furnace; the sublimation inner sleeve is arranged in the vacuum tank and comprises a bottom charging crucible, a middle high-purity arsenic implantation condenser and a top gas impurity condensing collector. A high boiling point high melting point element condensing ring is arranged between the charging crucible and the high-purity arsenic implantation condenser. A baffle is arranged between the high-purity arsenic implantation condenser and the gas impurity condensing collector. The gas impurity condensing collector is arranged in the circular water jacket on the top of the vacuum tank. The vacuum sublimation purification method of high-purity arsenic, sublimating in vacuum sublimation sealed furnace has the advantages of having rational structure, three segments of balance furnace temperatures, certain vacuum degree, precise temperature control, finished warming curve, uniform temperature field distribution, good repeatability, high product quality of the same arsenic after sublimating one time, good impurity separating condensing results, and low purification cost.

Owner:郑桂昌

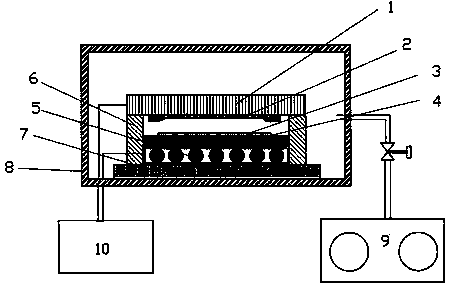

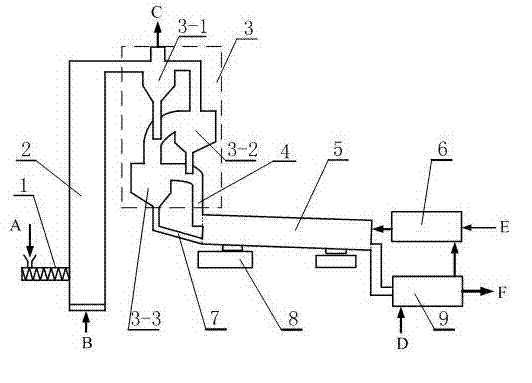

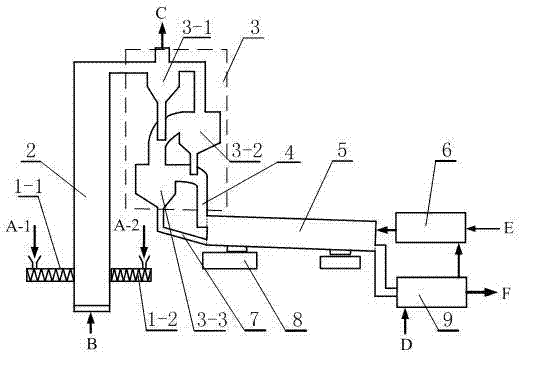

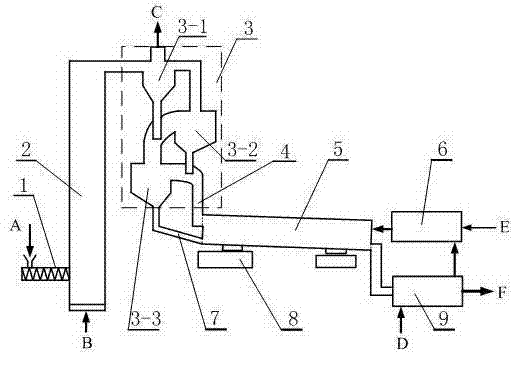

Mini combustion-type semiconductor thermo-electric generator

InactiveCN101860280ASafe and stable jobUniform distribution of temperature fieldGenerators/motorsAviationCombustor

The invention relates to a mini combustion-type semiconductor thermo-electric generator, which belongs to the field of electronic devices. The thermo-electric generator orderly comprises an upper thermo-electric generating sheet (4), an upper thermal-isolating baffle (2), a combustor (1), a lower thermal-isolating baffle (3) and a lower thermo-electric generating sheet (5) from top to bottom, wherein the combustor (1) comprises a substrate (9), the substrate (9) is orderly provided with a gas inlet channel (7), a combustion chamber (10) and a gas outlet channel (6), and the gas inlet channel (7) and the gas outlet channel (6) are in a parallel structure; and the diameters of the gas inlet channel (7) and the gas outlet channel (6) vary. The invention aims at the field of personal combat cells, has the advantages of small size, light weight and high continuous operation performance, and is especially suitable to provide power for mini devices in the aspects of field, military affairs and aviation with no common power sources in the field of high technology.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

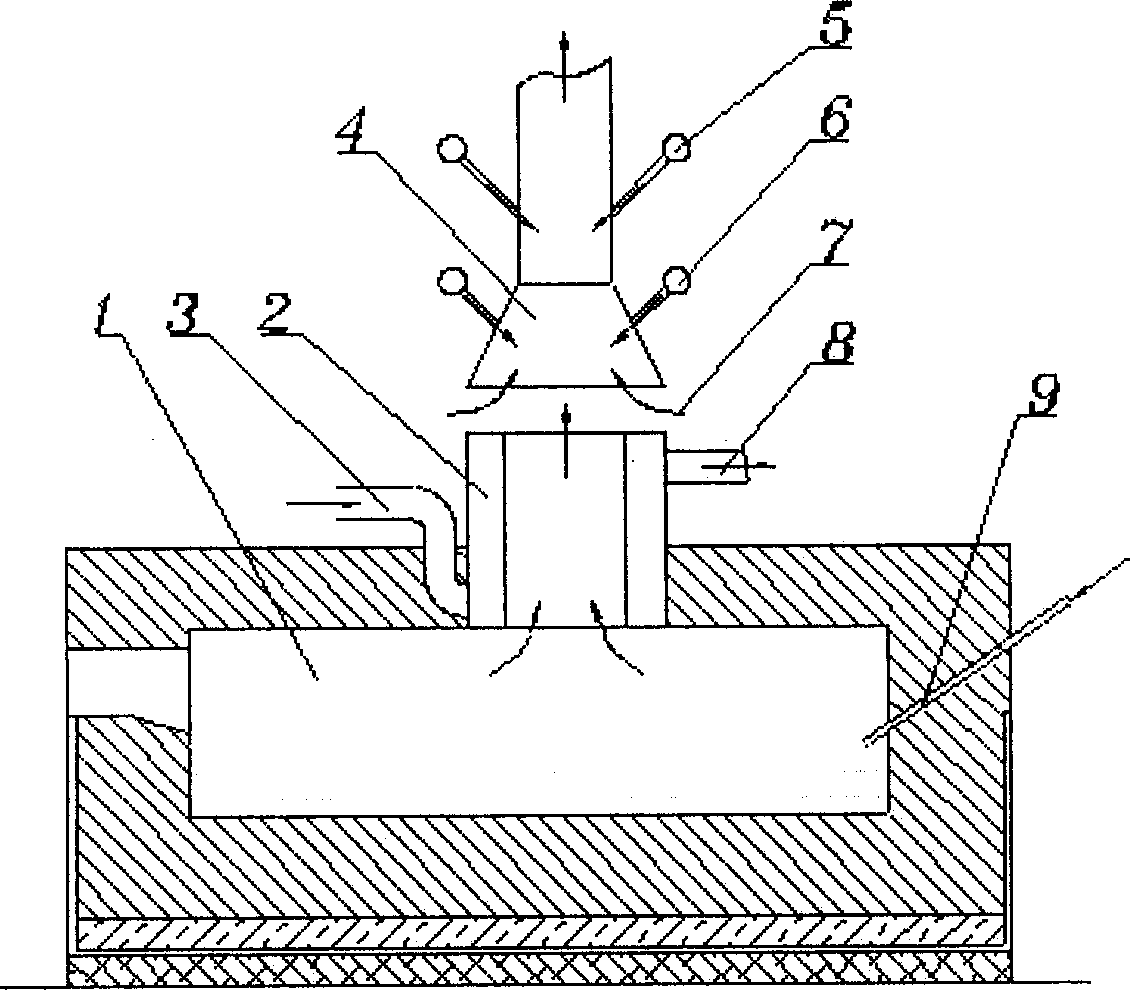

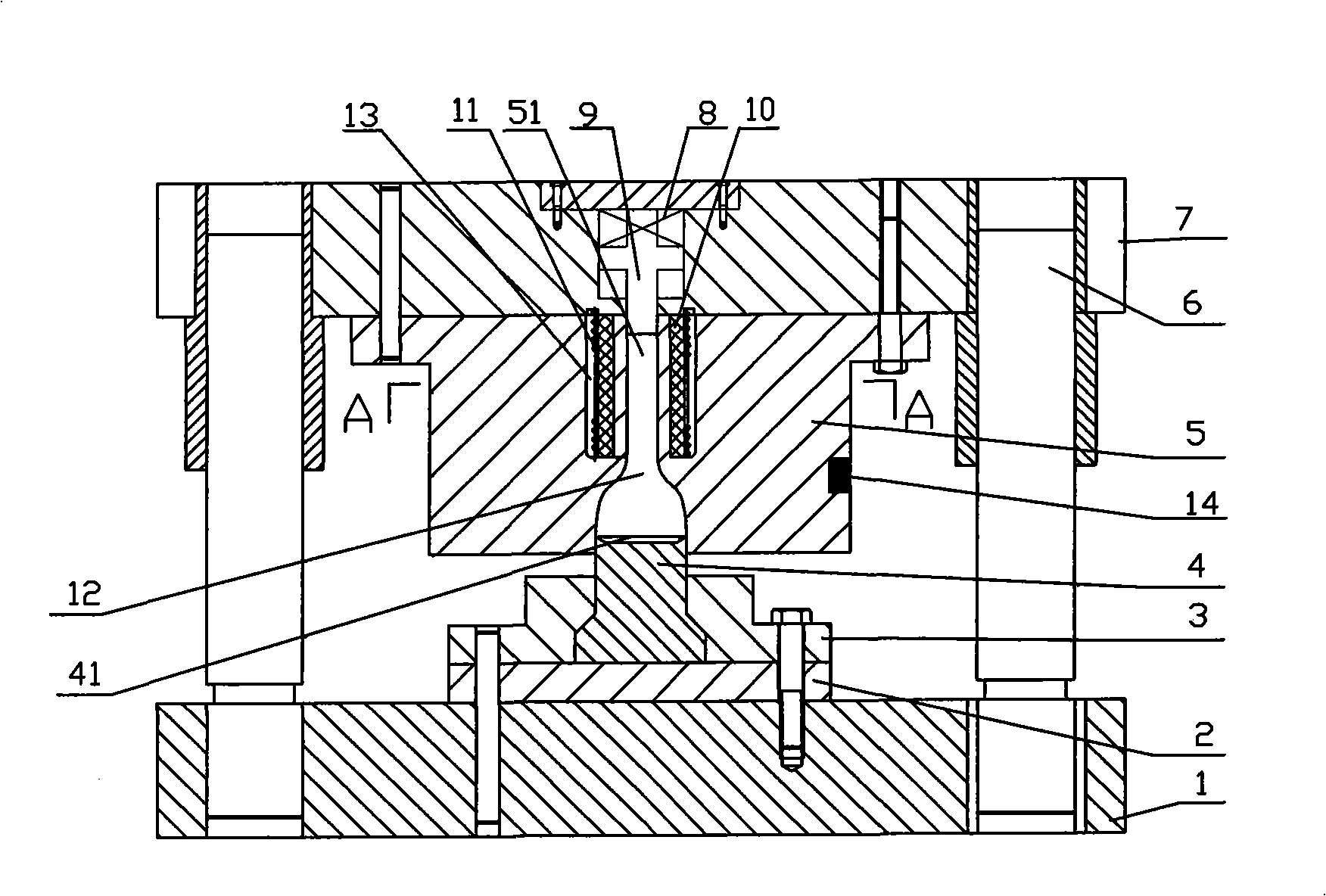

Automobile out star wheel isothermal extrusion preliminary shaping device

InactiveCN101264489AReduce temperature gradientReduce lossExtrusion diesPass rateMechanical engineering

The invention discloses a pre-forming device of automobile external star wheel by isothermal extrusion, which comprises a punch and a female die, the punch and the female die are laterally fixed and vertically movably matched by means of a guide pillar. The female die is provided with a die cavity, and a heating device is arranged at the periphery of the die cavity. The heating unit is arranged at the die cavity of the invention to maintain the outer layer temperature of the mold. The pre-forming device has the advantages of greatly reducing the geothermal gradient of blank and mold, effectively lessening the thermal dispersion of blank in the forming process, achieving the extrusion pre-forming under the isothermal condition, avoiding the situation that the die cavity can not be filled due to excessively fast temperature drop, material deformation and resistance increase, thus improving the pass rate of finished products, and reducing waste.

Owner:CHONGQING UNIV

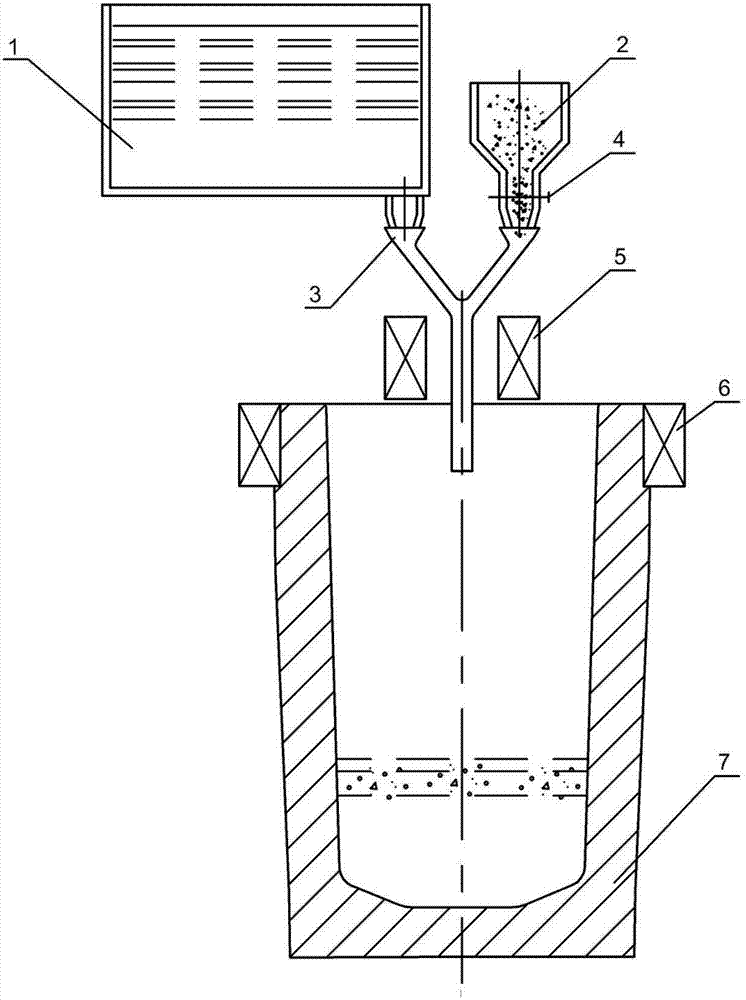

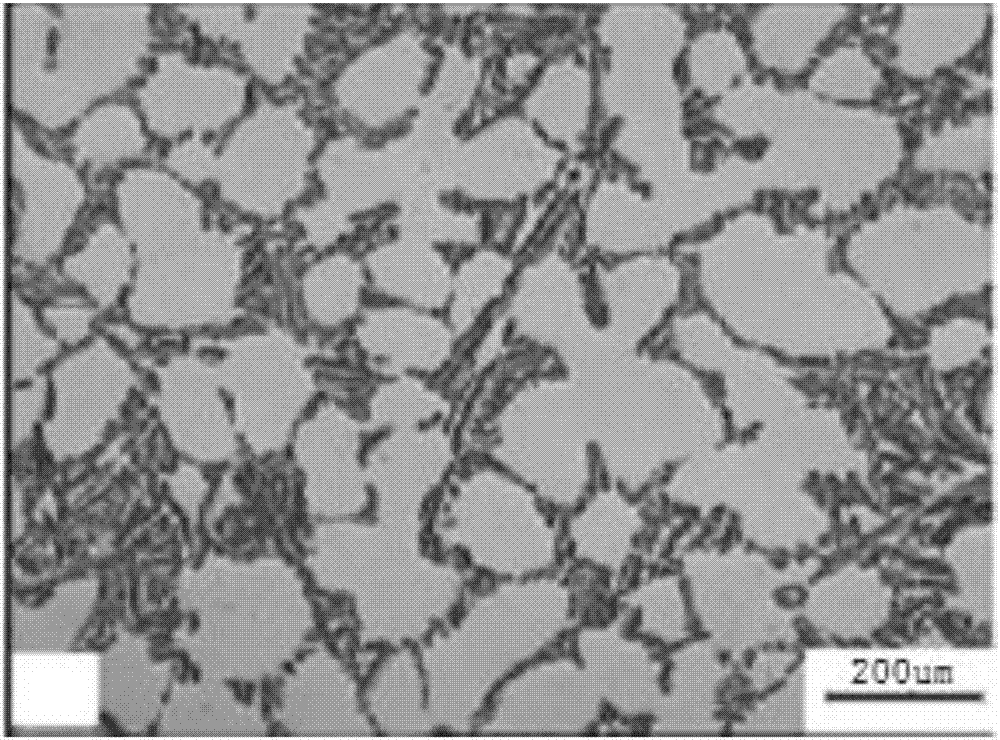

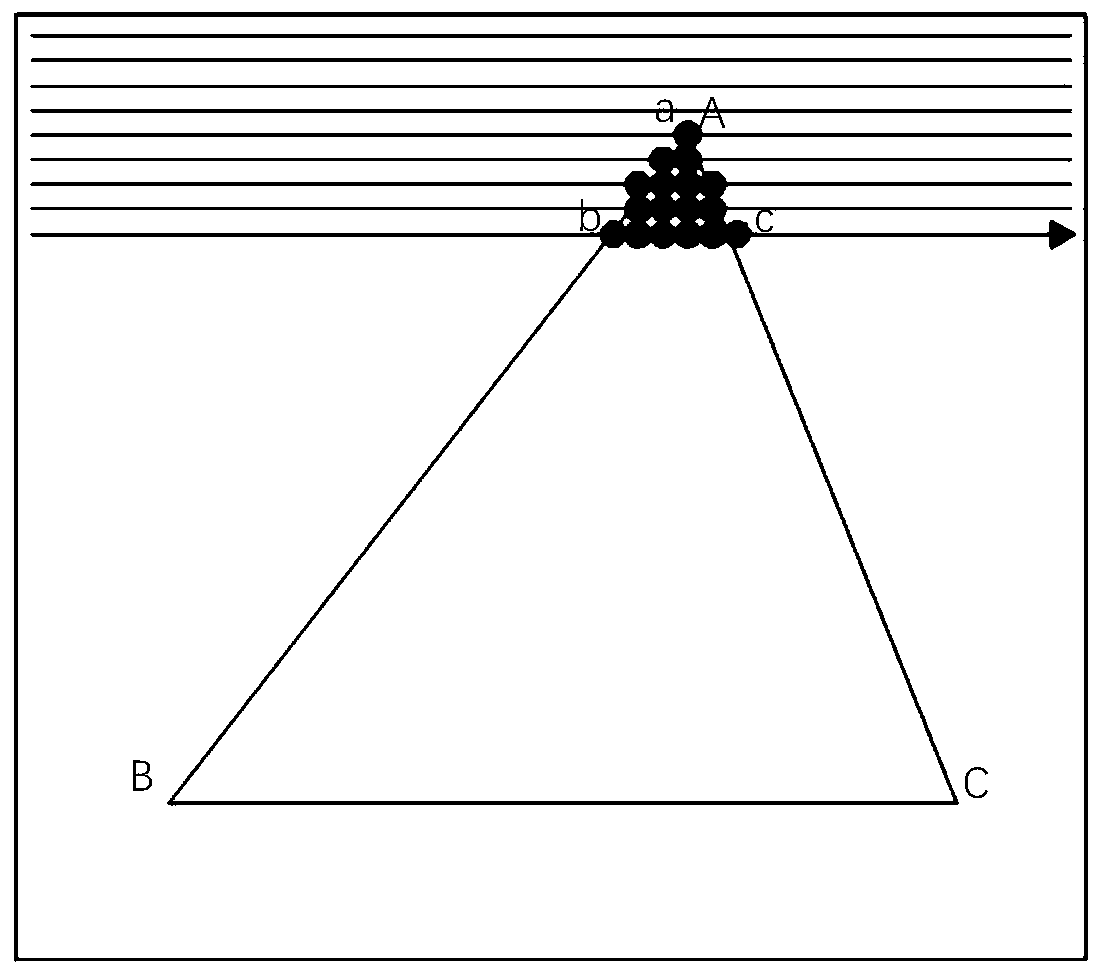

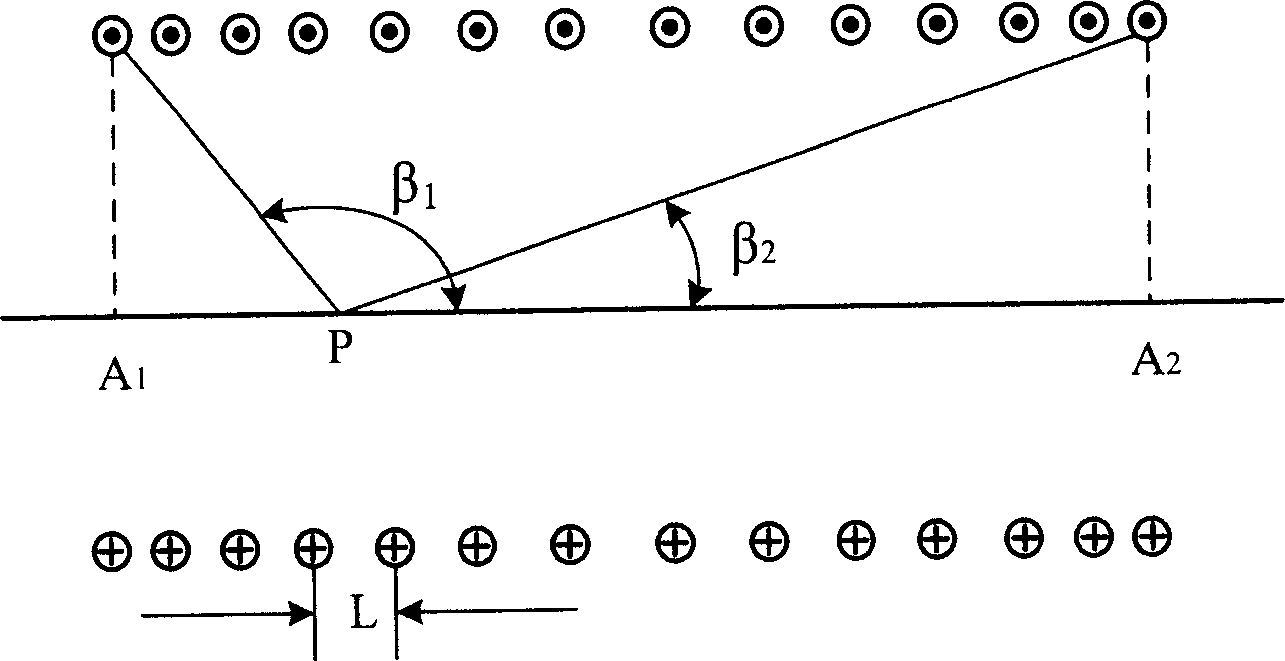

Method for manufacturing large ingot through electromagnetically-controlled self-inoculation treatment

The invention relates to a method for manufacturing a large ingot through electromagnetically-controlled self-inoculation treatment. The method comprises the steps as follows: (1) a Y-shaped double-phase conveying nozzle is adopted for molten metal casting, and an electromagnetic device I is arranged on the outer side of the straight section of the double-phase conveying nozzle; an electromagnetic device II is arranged on the outer side of an ingot mold riser; (2) an ingot mold and the double-phase conveying nozzle are preheated before casting; (3) argon shielding is performed during casting, an inoculant is added when the liquid level of molten metal rises to 1 / 2-2 / 3 of the height of an inner cavity of the ingot mold, meanwhile, the electromagnetic device I is started, and the electromagnetic device II is started when the liquid level of molten metal rises to the height of the ingot mold riser line; and both the electromagnetic device I and the electromagnetic device II run at the low frequency; (4) after casting is completed, the electromagnetic device I is shut down, the electromagnetic device II s adjusted to run at the intermediate frequency from the low frequency, and heat insulation is performed on the ingot mold riser part by the aid of the Joule heating effect of the intermediate-frequency magnetic field until the ingot is solidified. With the method, the solidification structure of the steel ingot can be refined, the center segregation can be reduced, the center porosity can be reduced, and thus the inner and outer quality of the ingot can be improved.

Owner:UNIV OF SCI & TECH LIAONING

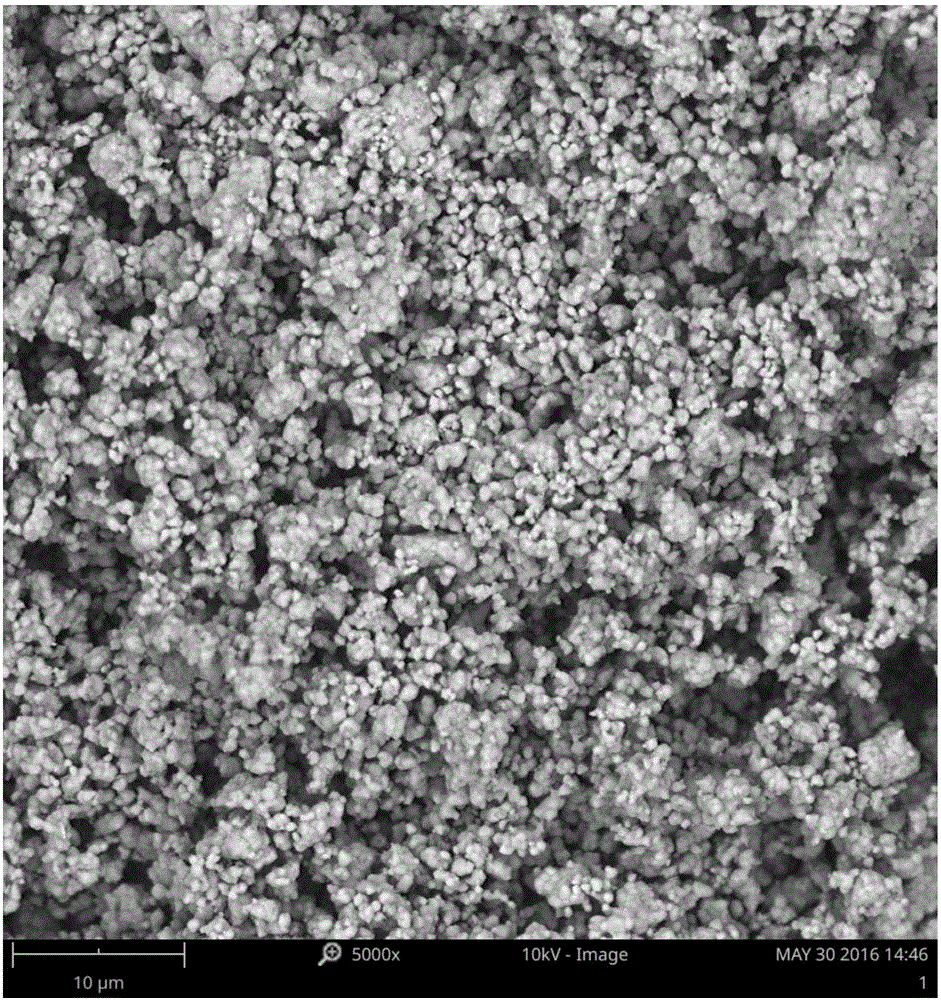

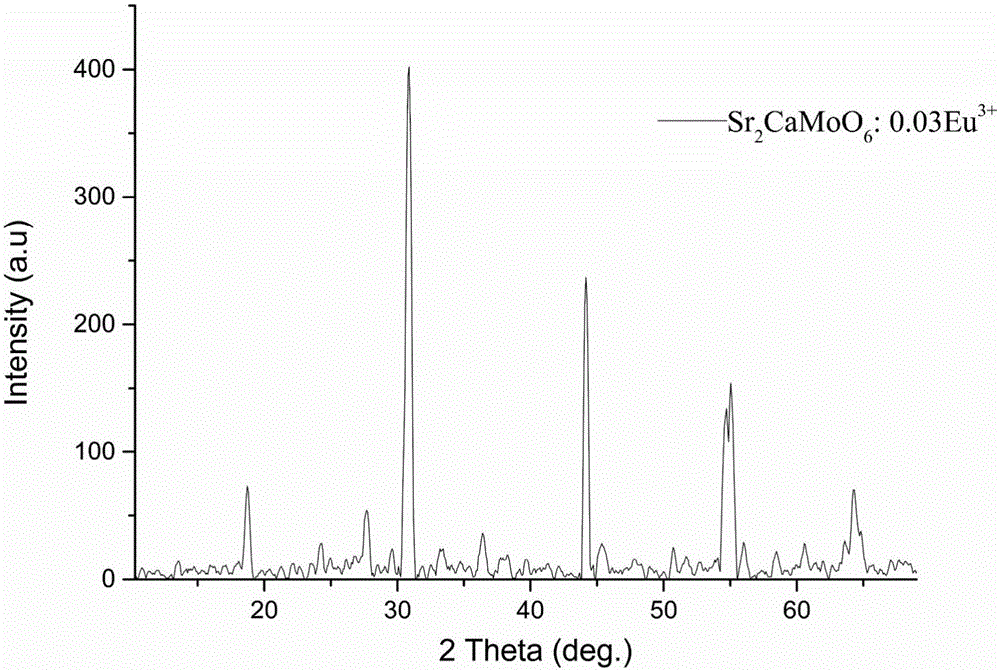

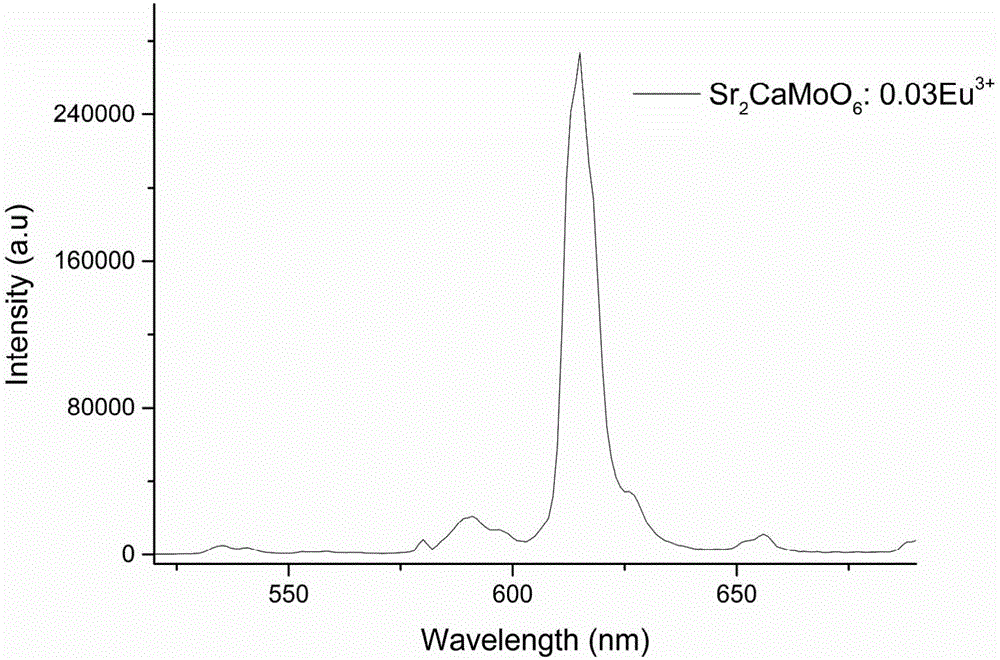

Preparation method of Eu<3+> doped molybdate red fluorescent powder used for white light LED (Light Emitting Diode)

InactiveCN106190119AReduced sinteringShort sintering timeEnergy efficient lightingLuminescent compositionsMolybdateMicrowave

The invention discloses a preparation method of Eu<3+> doped molybdate red fluorescent powder used for a white light LED (Light Emitting Diode). A chemical formula of the red fluorescent powder is Sr2CaMoO6:xEu<3+>, wherein x is greater than or equal to 0.01 and less than or equal to 0.15. Raw materials are weighed according to a stoichiometric ratio, the raw materials and a fluxing agent are fully and evenly mixed, and a mixture is added into double crucibles made of corundum, wave absorbent is arranged between the double crucibles, the double crucibles are loaded into a microvan, temperature is quickly raised to 750 to 950DEG C, the mixture is sintered in an oxidation environment, and heat preservation time is 0.5 to 4h; finally, cooling, grinding, washing and drying are carried out to obtain the red fluorescent powder used for the white light LED. During microvan sintering, the fluxing agent is added to accelerate the formation and growth of molybdate polycrystal, the sintering degree of the fluorescent powder is obviously lowered, sintering time is obviously shortened, a powder body is loose and does not need to be mechanically smashed, in addition, the shapes of aluminate fluorescent powder particles are effectively controlled, and the particles with a small particle diameter and even distribution are obtained, wherein the appearance of the particles is similar to a sphere.

Owner:SHANGHAI INST OF TECH

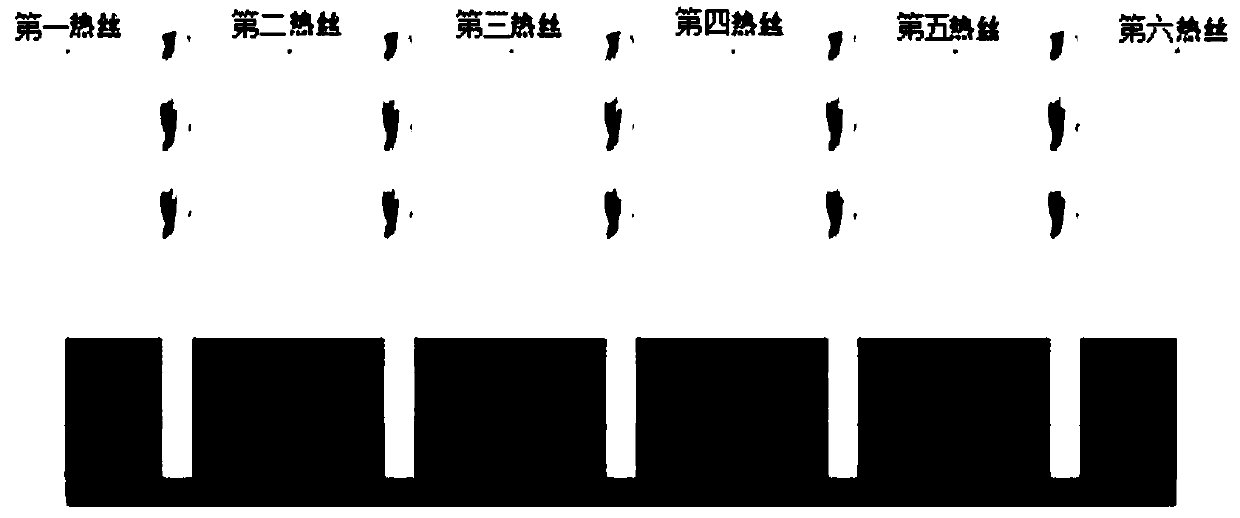

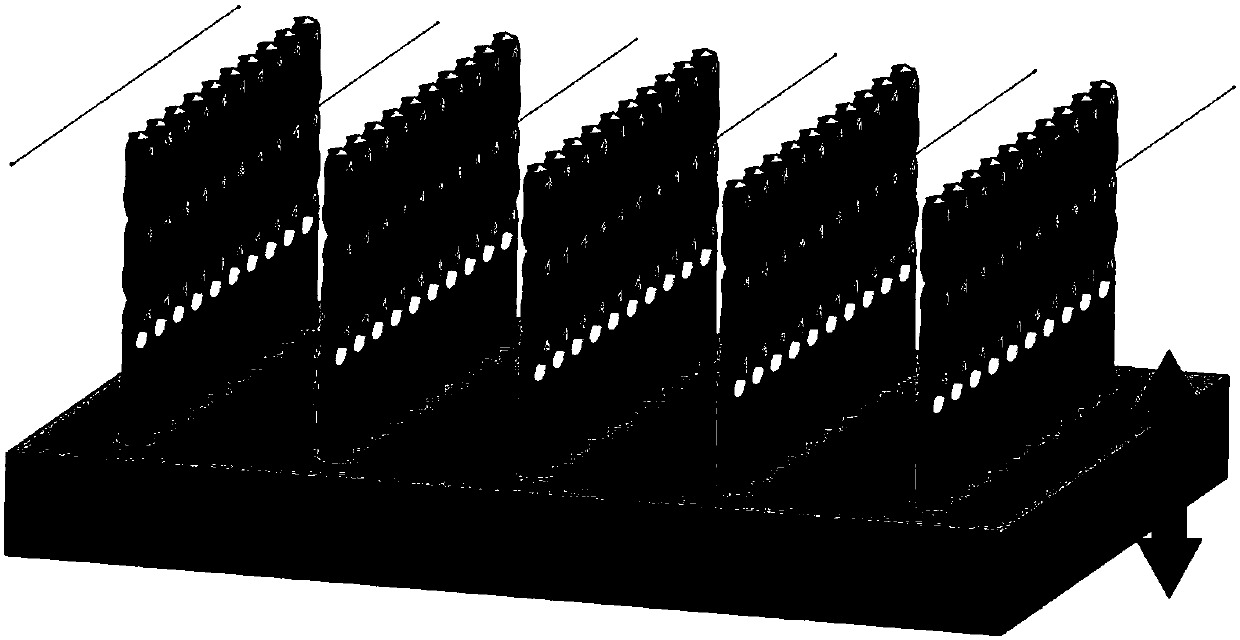

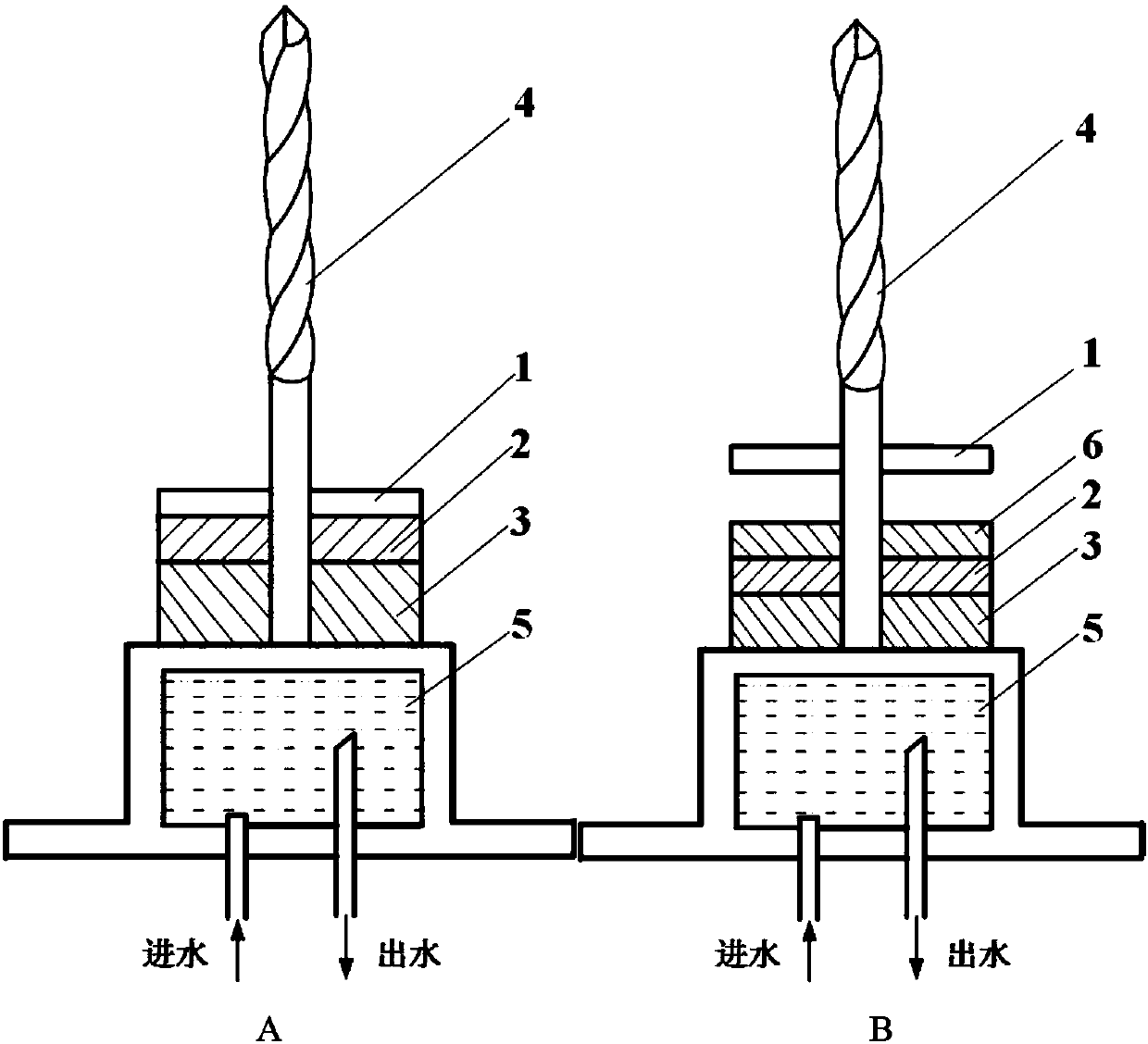

HFCVD batch preparation method of complex-shaped diamond-coated cutter

ActiveCN108559970AEvenly distributedQuality improvementChemical vapor deposition coatingHydrogenCarbon impurities

The invention discloses an HFCVD batch preparation method of a complex-shaped diamond film coated cutter. A handle of the complex-shaped cutter after being pretreated is inserted into a cutter coolingbase to be placed on the water-cooled workbench of HFCVD equipment. The cutter cooling base is formed by optimally matching a molybdenum sheet layer, a graphitic layer, a red copper layer or a stainless steel layer, and a drill hole matched with the handle in diameter and length is formed in the cutter cooling base. The HFCVD equipment adopts a single-layer hot filament. In the cutter mounting and film growing processes, the HFCVD equipment can realize free lifting of the cutter cooling base by controlling the lifting of the water-cooled workbench. Hydrogen, a carbon source and a doped sourceenter into the surface of the complex-shaped cutter to deposit a single-layer or composite diamond film. The HFCVD batch preparation method can conveniently and effectively control the temperature value of the blade area of the cutter, ensures the uniform distribution of a temperature field and a density field of a reactive group, ensures the uniform deposition of the diamond film, and avoids ofdepositing carbon impurities on the handle position to cause the phenomenon of a black bar.

Owner:SHANGHAI JIAO TONG UNIV

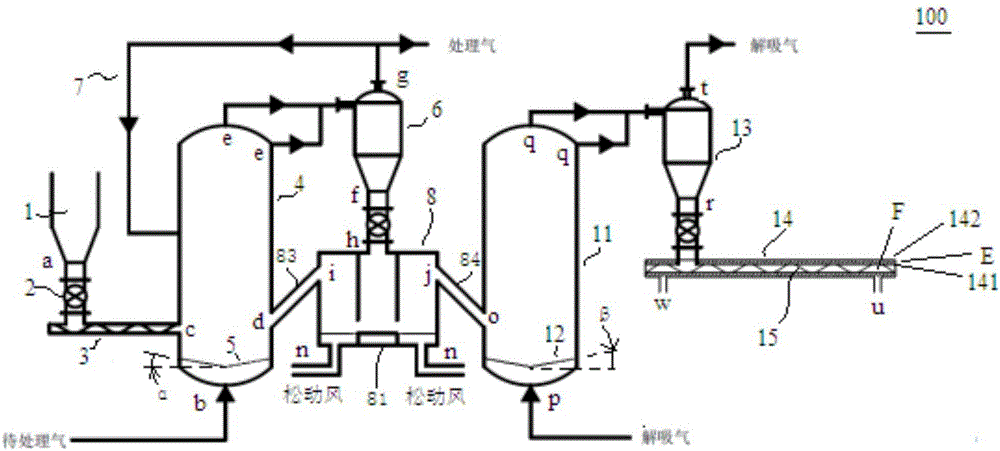

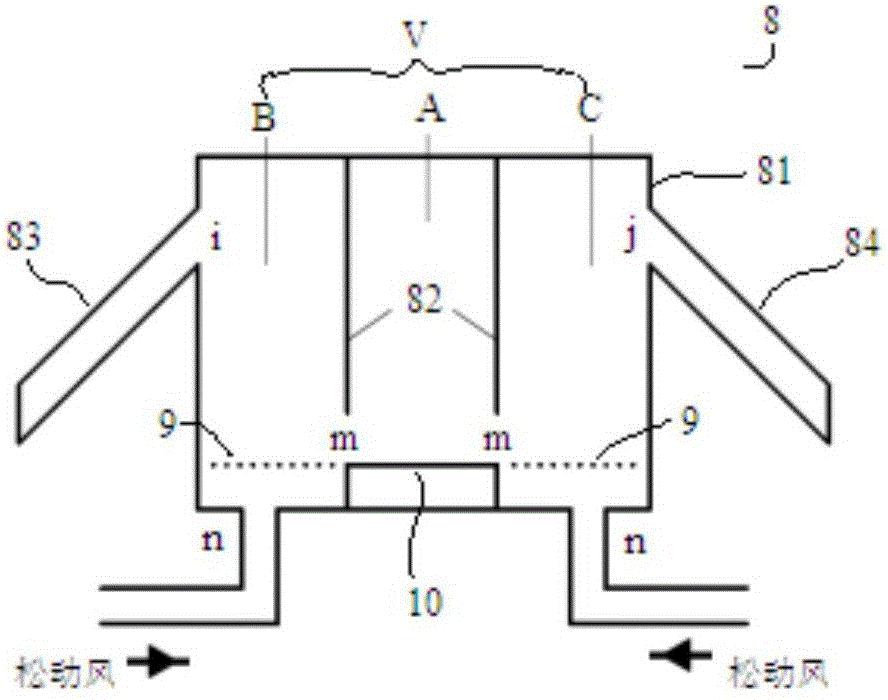

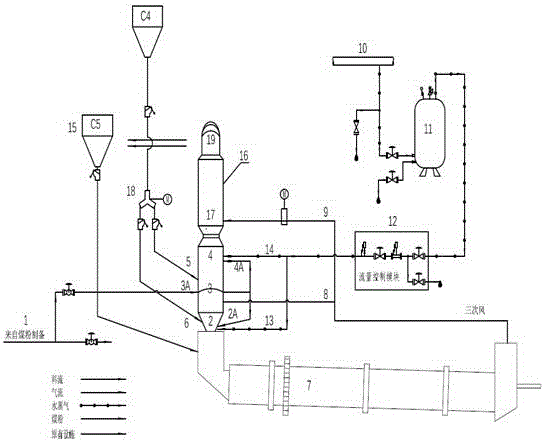

Fluidized bed gas adsorption-desorption system and treatment method thereof

ActiveCN105903314AHigh gas velocityReduce labor intensityDispersed particle separationGas solidFluidized bed

The invention discloses a fluidized bed gas adsorption-desorption system and a treatment method thereof. The system includes an adsorption fluidized bed, a regeneration fluidized bed, an adsorption side gas-solid separator, a desorption side gas-solid separator and a feed divider. The adsorption fluidized bed has an adsorbent inlet, a to-be-treated gas inlet, a first returned material inlet and a first mixture outlet. The adsorption side gas-solid separator is connected to the first mixture outlet. The regeneration fluidized bed has a second returned material inlet, a desorption gas inlet, and a second mixture outlet. The desorption side gas-solid separator is connected to the second mixture outlet. The feed divider has a feed inlet, an adsorption side divided material outlet and a desorption side divided material outlet, the feed inlet is connected to an adsorption side solid-discharge port of the adsorption side gas-solid separator, the adsorption side divided material outlet is connected to the first returned material inlet, and the desorption side divided material outlet is connected to the second returned material inlet. The system provided by the invention is easy to operate, the system treatment ability is enhanced, and the adsorption efficiency, adsorption economical efficiency and operation continuity are improved.

Owner:SHENWU TECH GRP CO LTD

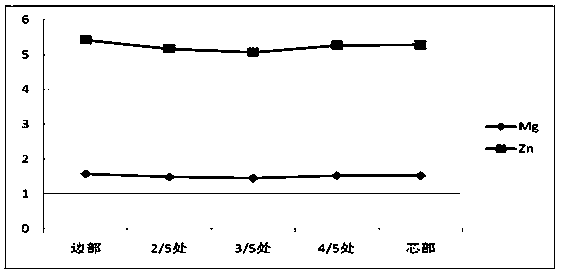

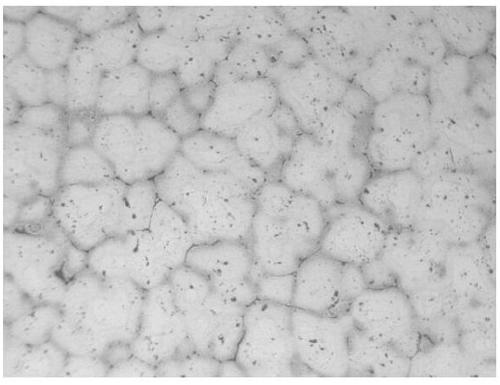

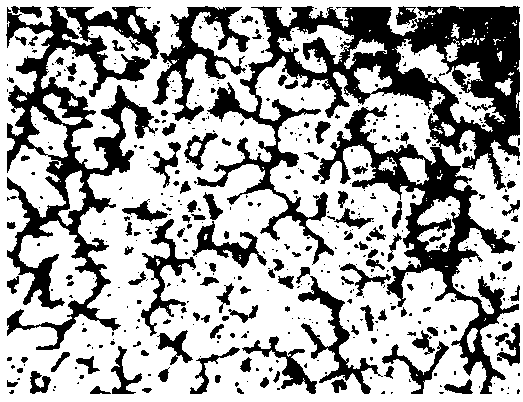

Preparation method of Al-Zn-Mg large-sized flat cast ingot

The invention relates to a preparation method of an Al-Zn-Mg large-sized flat cast ingot. The preparation method includes the following steps that preparing is conducted; smelting is conducted; heat preservation is conducted; degassing and filtering are conducted; on-line grain refinement is conducted; casting is conducted, specifically, a lower casting pipe is used for casting, a distribution bagis installed at the bottom of the lower casting pipe, and an aluminum melt can flow in a semi-closed cavity formed by a crystallizer and a dummy bar head in the crystallizer; and homogenization treatment is conducted. The preparation method of the Al-Zn-Mg large-sized flat cast ingot can effectively solve the problems of uneven composition and prone cracking of the large-sized flat cast ingot.

Owner:广西南南铝加工有限公司

Preparation method of M3Si6O12N2: xRe system green fluorescent powder

InactiveCN102888218AHigh activityFacilitated DiffusionGas discharge lamp usageLuminescent compositionsRare-earth elementLight-emitting diode

The invention discloses a preparation method of M3Si6O12N2: xRe system green fluorescent powder. According to the preparation method, M is one or the mixture of more than two of Ca, Sr and Ba; Re means a rare-earth element; and x is more than or equal to 0.2 mol% and less than or equal to 20mol%. The method comprises the steps as follows: weighing raw materials based on the stoichiometric ratio of various elements in the chemical formula of fluorescent powder; fully and uniformly mixing the raw materials; then placing the mixture into a sagger manufactured by a wave-transmitting material; positioning the sagger into a special microwave oven; adjusting the microwave power to control the temperature raise rate under a certain gas atmosphere; heating to reach the synthesizing temperature; and finally, cooling and simply grinding to obtain the system green fluorescent powder. Compared with traditional high-temperature solid phase method, the preparation method disclosed by the invention adopts microwave heating, therefore, the synthesizing temperature is reduced to 1000 to 1500 DEG C, moreover, the reaction time is reduced, and the production efficiency is improved; and the prepared green fluorescent powder has the advantages of fine grain size, high crystallizing performance, narrow range of size distribution, regular appearance and shape, high particle dispersing performance, and the like, and is specifically applied to white light and backlight LEDs (Light Emitting Diodes).

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Energy-saving heating system for new energy electric vehicle and working method thereof

PendingCN108382163ASave electricityReduced Power RequirementsAir-treating devicesVehicle heating/cooling devicesElectricityNew energy

The invention discloses an energy-saving heating system for a new energy electric vehicle and a working method thereof. The heating system comprises a heat dissipation device for a motor and an electronic control device, a floor heating heat supply device and a low-temperature cooling device; the heat dissipation device for the motor and the electronic control device comprises a heat dissipation circulating water pipe used for absorbing heat dissipated from the motor and the electronic control device, the floor heating heat supply device comprises a floor heating radiator arranged under the feet of a driver and passengers, the low-temperature cooling device comprises a low-temperature cooler and an electronic fan, a water inlet pipe of the floor heating radiator and a water inlet pipe of the low-temperature cooler are connected with a water outlet of the heat dissipation circulating water pipe separately, a water outlet pipe of the floor heating radiator and a water outlet pipe of thelow-temperature cooler are connected with a water inlet of the heat dissipation circulating water pipe separately, and the electronic fan is used for blowing air outside the vehicle to the surface ofthe low-temperature cooler; the heating system can utilize the heat generated by the motor and the electric control device to supply heat to the whole vehicle, the electricity consumption for heatingis reduced accordingly, and meanwhile the problems can also be solved that the distribution uniformity of the temperature in the vehicle is poor and the noise is increased.

Owner:NANJING XIEZHONG AUTO AIRCONDITIONER CO CO LTD

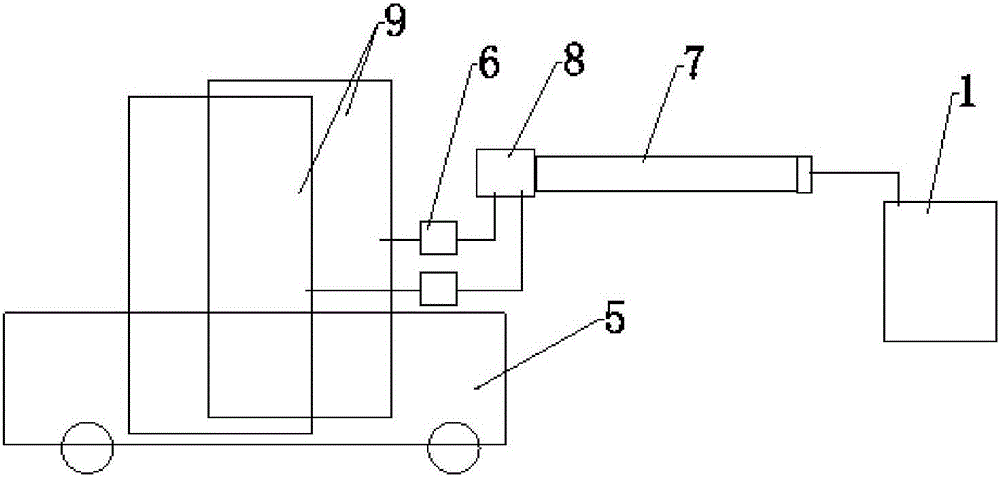

Production equipment and technology for cathode or anode material of converter-type lithium battery

Owner:济宁市无界科技有限公司

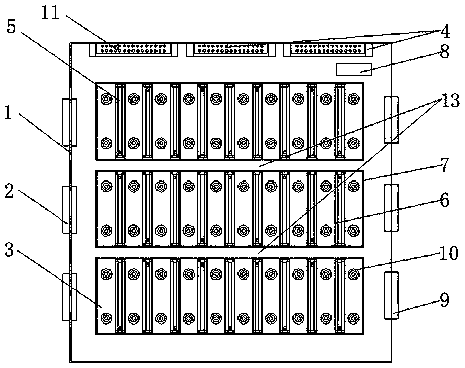

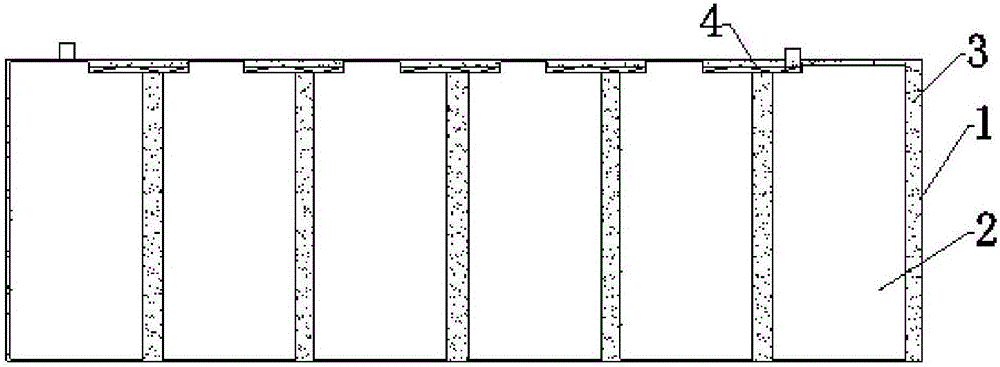

Safety power lithium battery module

InactiveCN106207076APerformance is not affectedUniform distribution of temperature fieldFinal product manufactureCell component detailsEngineeringLithium battery

The invention discloses a safety power lithium battery module. The safety power lithium battery module comprises a plurality of battery cores, corresponding compound current cut-off sheets and glue, wherein the plurality of battery cores are arranged in a lithium battery module shell; the glue is placed in the lithium battery module shell; and the glue is filled among the battery cores in the lithium battery module shell, or among the battery cores and into the corresponding compound current cut-off sheets in a pouring way. The lithium battery module is safe and reliable to use, and has stable performance and uniform heat dissipation.

Owner:FIRST NEW ENERGY GRP CO LTD

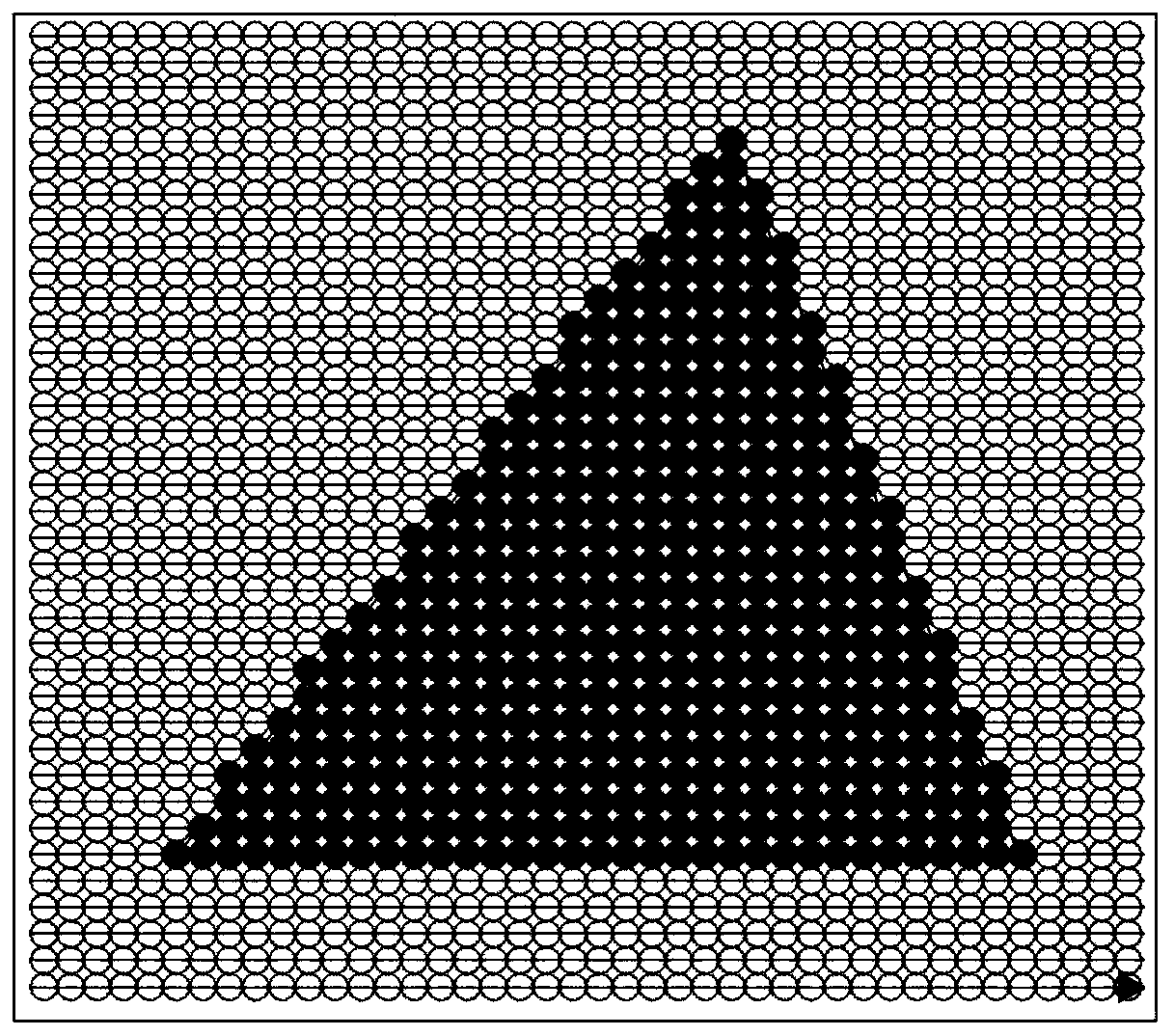

Surface molding metal material additive manufacturing method

ActiveCN110434333AImprove production efficiencyArea array forming process is simpleAdditive manufacturing apparatusIncreasing energy efficiencyDot matrixHeat stress

The invention provides a surface molding metal material additive manufacturing method. The surface molding metal material additive manufacturing method comprises the following steps of (1) parameter setting; (2) slicing treatment; (3) laser beam splitting in the x-direction; (4) laser beam splitting in the Y-direction; (5) shading; and (6) part molding. Through the surface molding metal material additive manufacturing method, the heating mechanism of parts in the molding process is improved, the temperature field of the parts is distributed more evenly, the temperature gradient is reduced, andgeneration of warping and fracture defects of the molded parts due to heat stress and heat deformation is reduced. Compared with a traditional laser dot matrix scanning from-point-to-plane and layer-by-layer stacking molding method, a layer of the cross section of each part can be directly molded through area array molding, and then the part is subjected to stacking molding layer by layer. Thus,the area array molding process is simpler, and the metal material additive manufacturing efficiency can be improved.

Owner:ZHEJIANG UNIV OF TECH

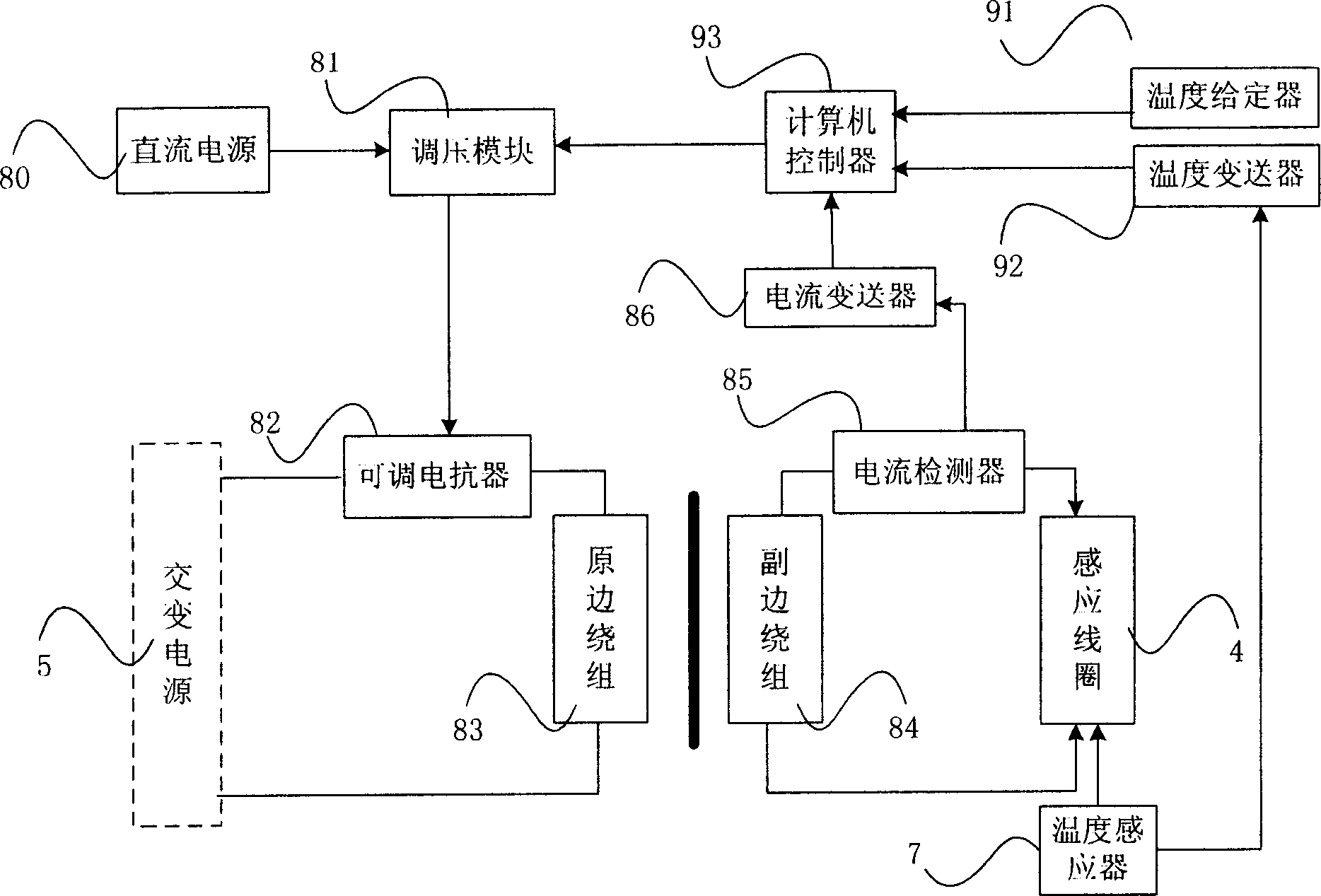

Petroleum heating device

InactiveCN1807964AUniform distribution of temperature fieldHigh electrothermal efficiencyPipeline systemsTemperature controlMetallic materials

The invention relates to an oil heating device, which comprises a heating tube made form non-metallic material. Wherein, the heating tube via the support elements comprises the heating elements made form metals to heat the oil; the outer surface of said heating tube is coiled with the sensing coil connecting the alternating current power. The invention uses the electromagnetic sensing theory to heat transmitted oil inside the oil tube, with high electric heating efficiency and reduce the heat loss, without using thermal-insulating material to avoid the heat loss between the heated oil and the heat source. It has less maintenance and lower cost. The oil in the heating tube can be heated when flowing along the inner and outer surfaces of heating elements, while the temperature field inside the oil is uniform distributed to make the temperature control easily. The invention makes the heating elements emit heat according to the electromagnetic sensing theory and uses the heating elements to heat oil without environment pollution.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

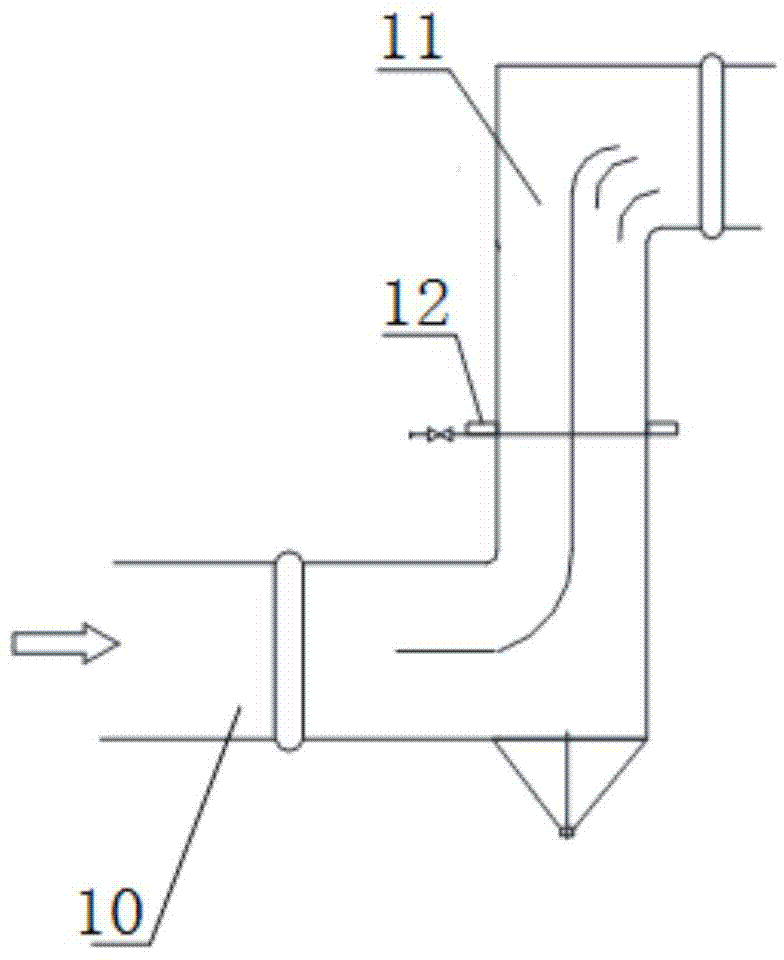

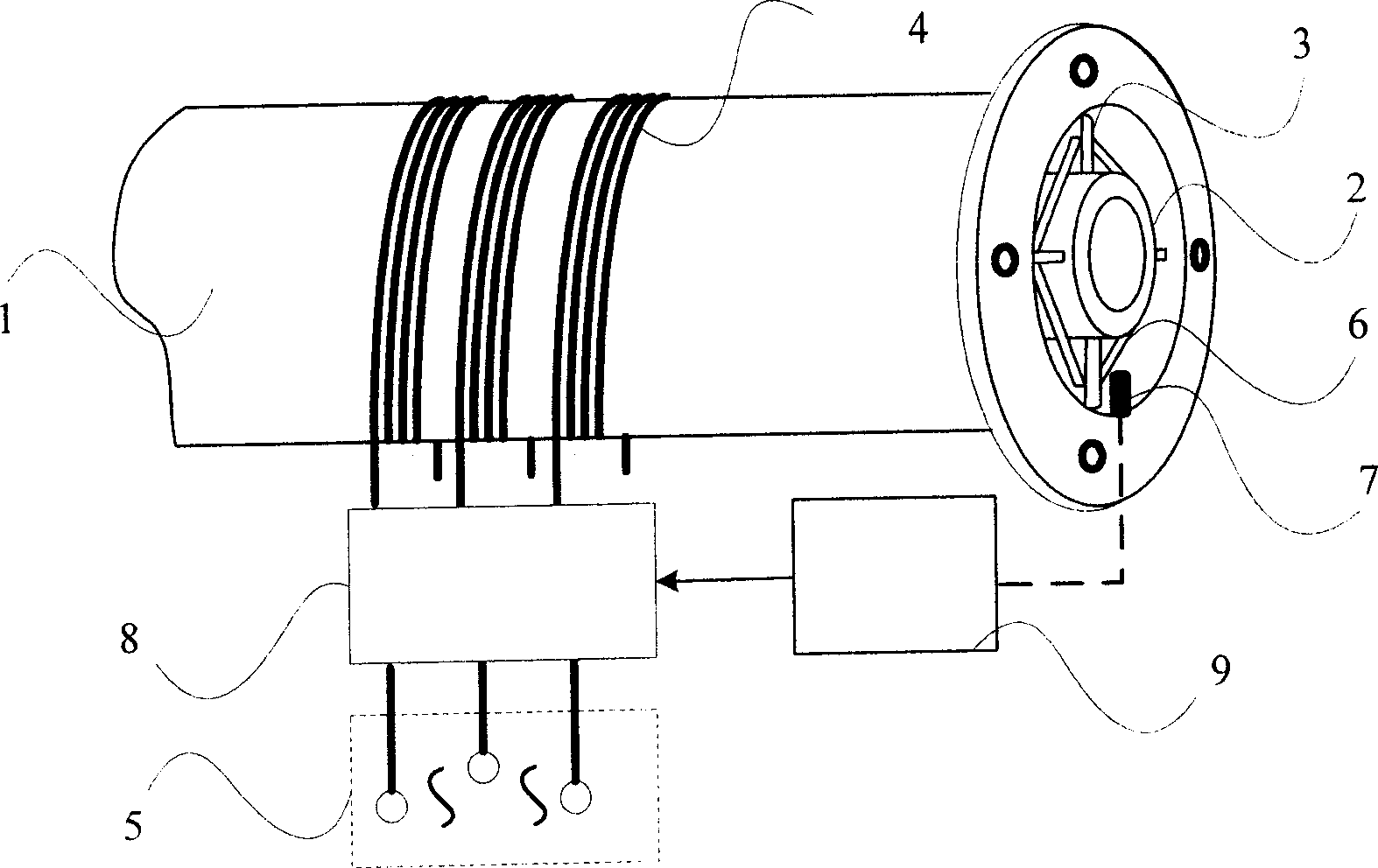

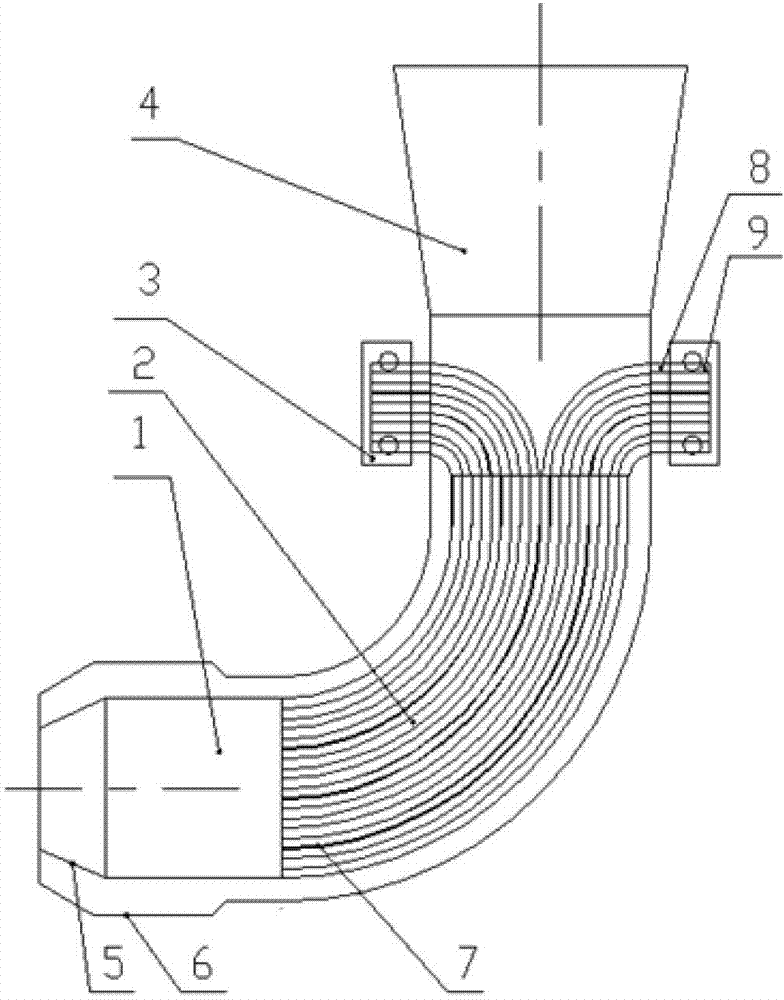

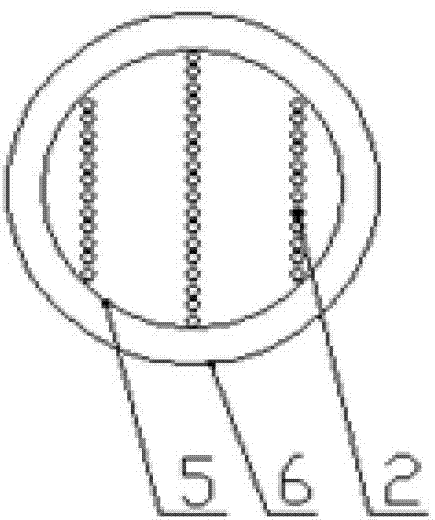

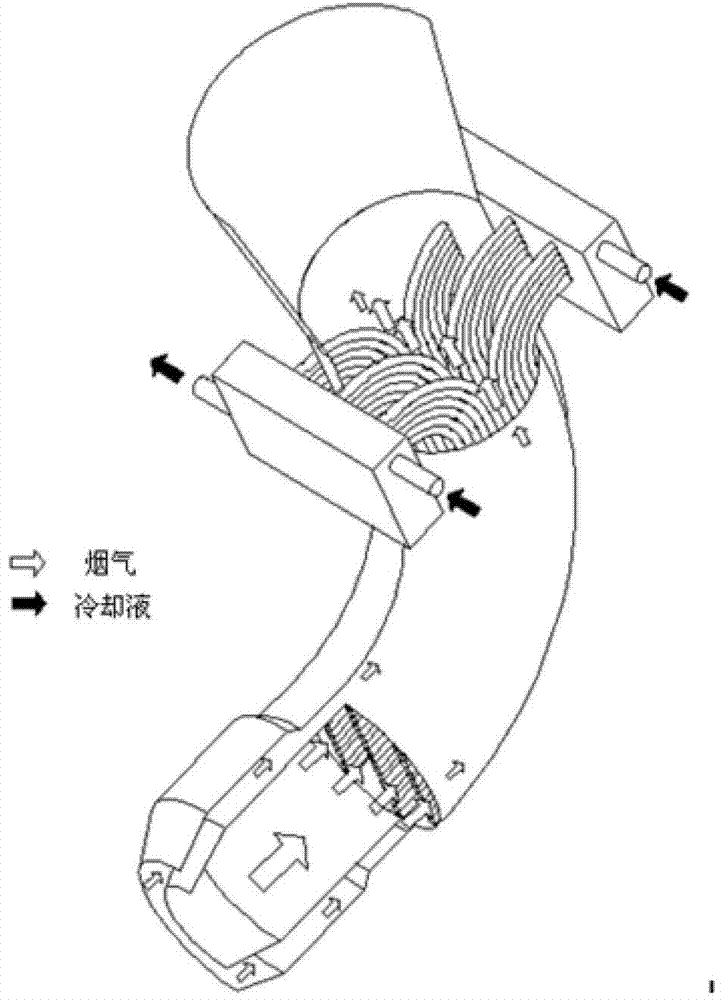

Infrared inhibiting device for smoke extraction of gas turbines of ships

InactiveCN103195576AUniform distribution of temperature fieldSimple structureExhaust apparatusTurbine/propulsion engine coolingCooling effectEvaporation

The invention aims at providing an infrared inhibiting device for the smoke extraction of gas turbines of ships. The infrared inhibiting device comprises a heat pipe row, as well as an exhausting straight and bent pipe and an exhausting diffuser pipe which are connected mutually. The exhausting straight and bent pipe comprises a double-layered cylinder wall structure which comprises an inner wall and an external wall. A main flow area is formed in the inner wall and an injection area is formed between the inner wall and the external wall. The heat pipe row comprises heat pipes which are distributed in parallel mutually. The heat pipes comprise evaporation sections, conveying sections and condensation sections. The evaporation sections are arranged in the inner wall of the exhausting straight and bent pipe, the condensation sections is arranged in a cooling device and the conveying sections are connected with the evaporation sections and the condensation sections. The device has the advantages of simplicity in structure, convenience in use, good exhausting and cooling effects, uniformity in distribution of temperature fields of an exhaust outlet, few effects on incoming flow and obvious infrared inhibiting effects.

Owner:三亚哈尔滨工程大学南海创新发展基地

Electromagnetic stirring generating device, method and application of composite time-varying magnetic field

ActiveCN110252975AImprove fatigue performanceSmall mechanical propertiesPhysicsElectromagnetic stirring

The invention relates to an electromagnetic stirring generating device, method and application of a composite time-varying magnetic field. The device is a composite rotating magnetic field electromagnetic stirring generating device or a time-varying magnetic field generating device, or a traveling wave magnetic field electromagnetic stirring generating device. According to the method and the application, in the continuous casting, semi-continuous casting or die casting process, the electromagnetic stirring generating device of the composite time-varying magnetic field acts on a crystallizer for continuous casting or semi-continuous casting, a secondary cooling zone and any one position or multiple positions of the tail end or a riser in the mold casting production, liquid level and the like, so that the mechanical property of a casting blank is improved by improving the component segregation and the shrinkage porosity of the casting blank. Compared with the continuous casting or semi-continuous casting or die-casting production process, electromagnetic stirring or time-varying magnetic fields are independently applied, so that the shrinkage porosity and component segregation of the core of the casting blank are remarkably improved.

Owner:SHANGHAI UNIV

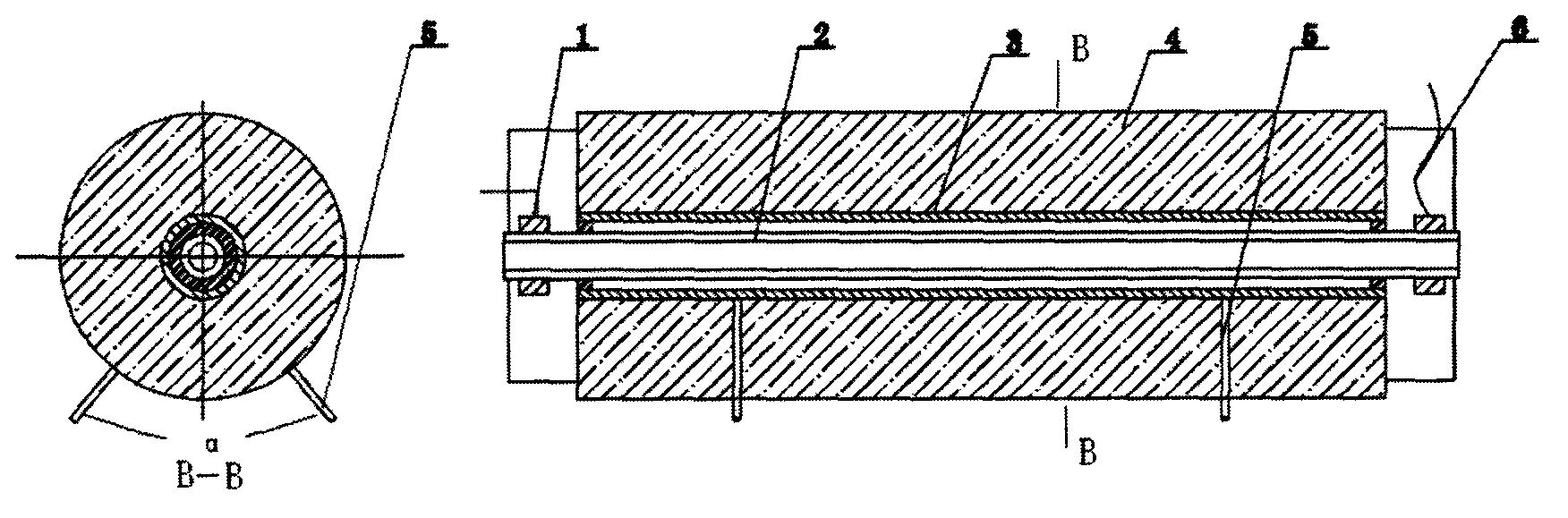

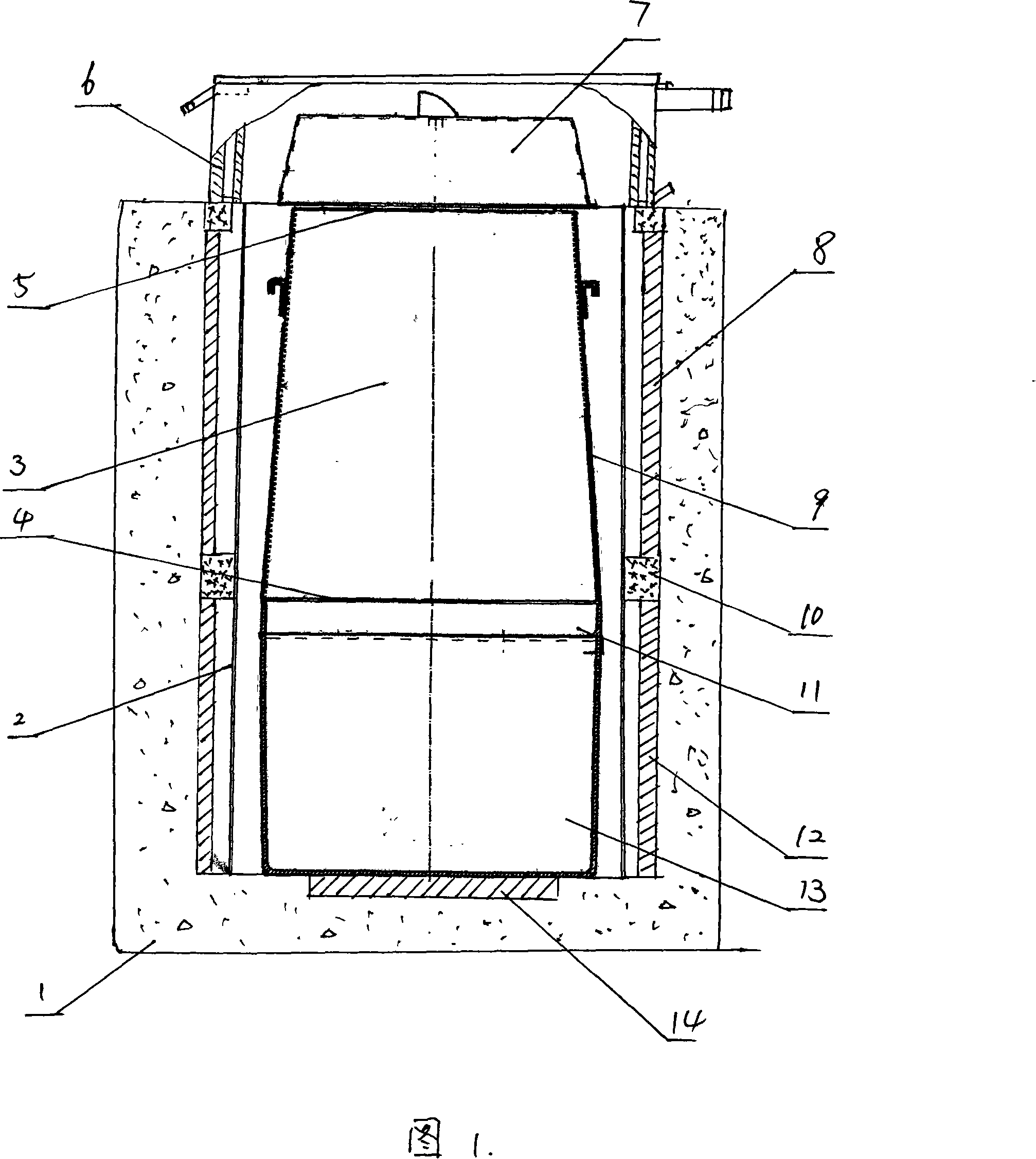

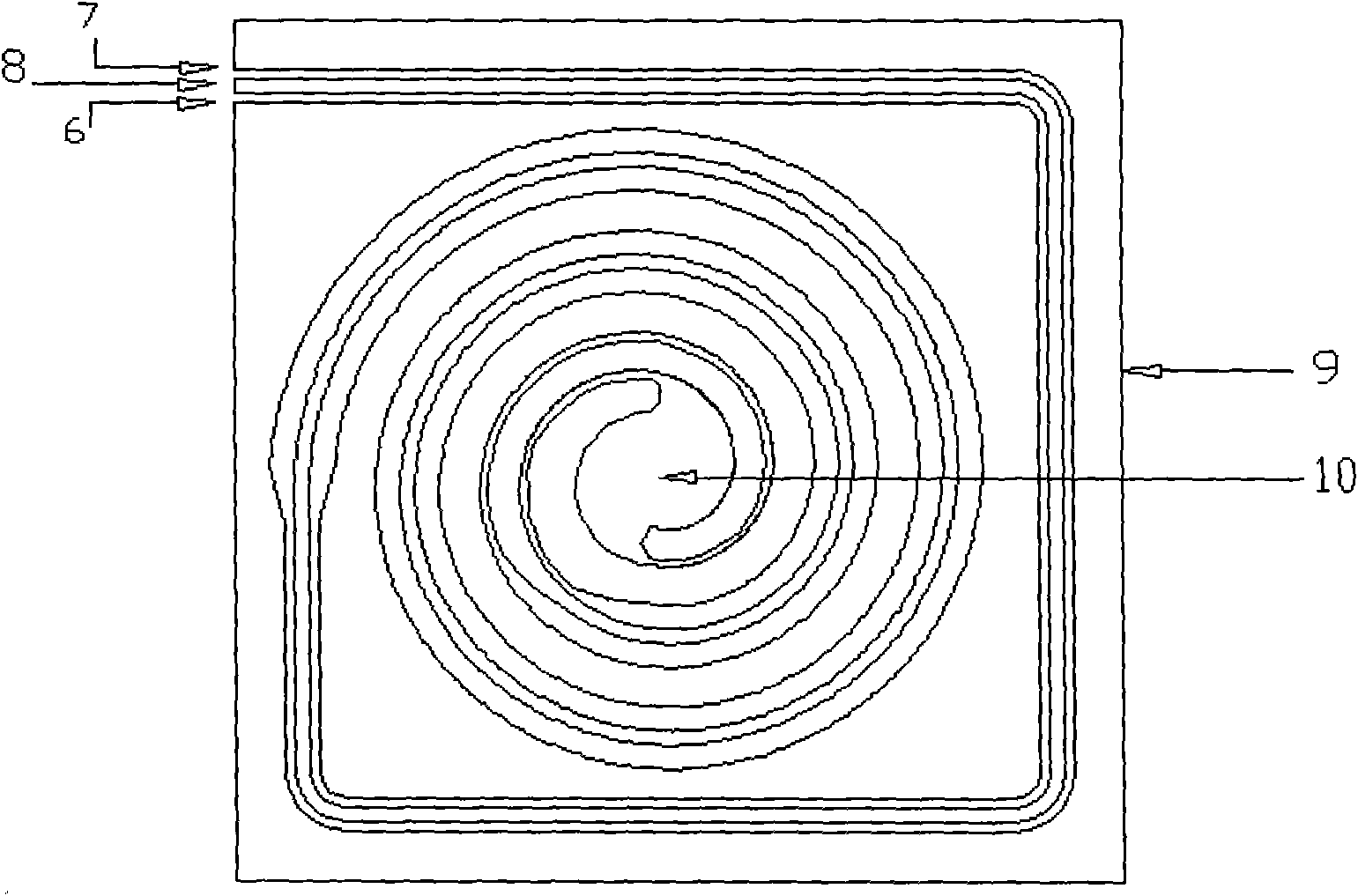

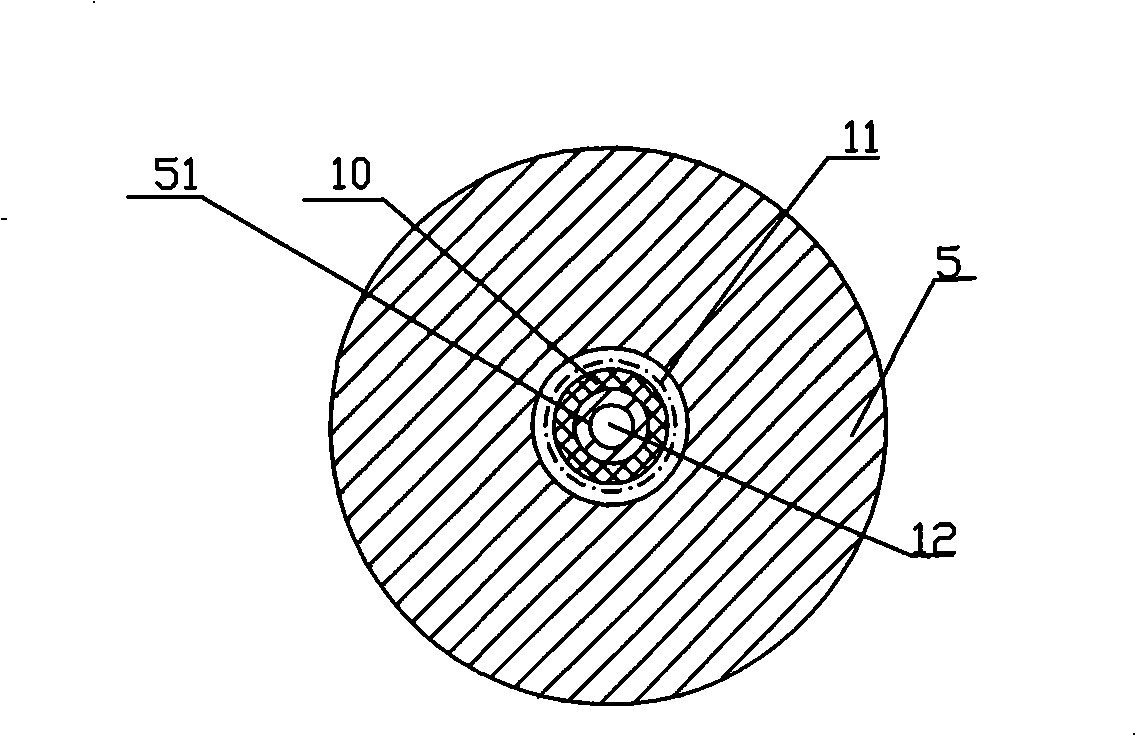

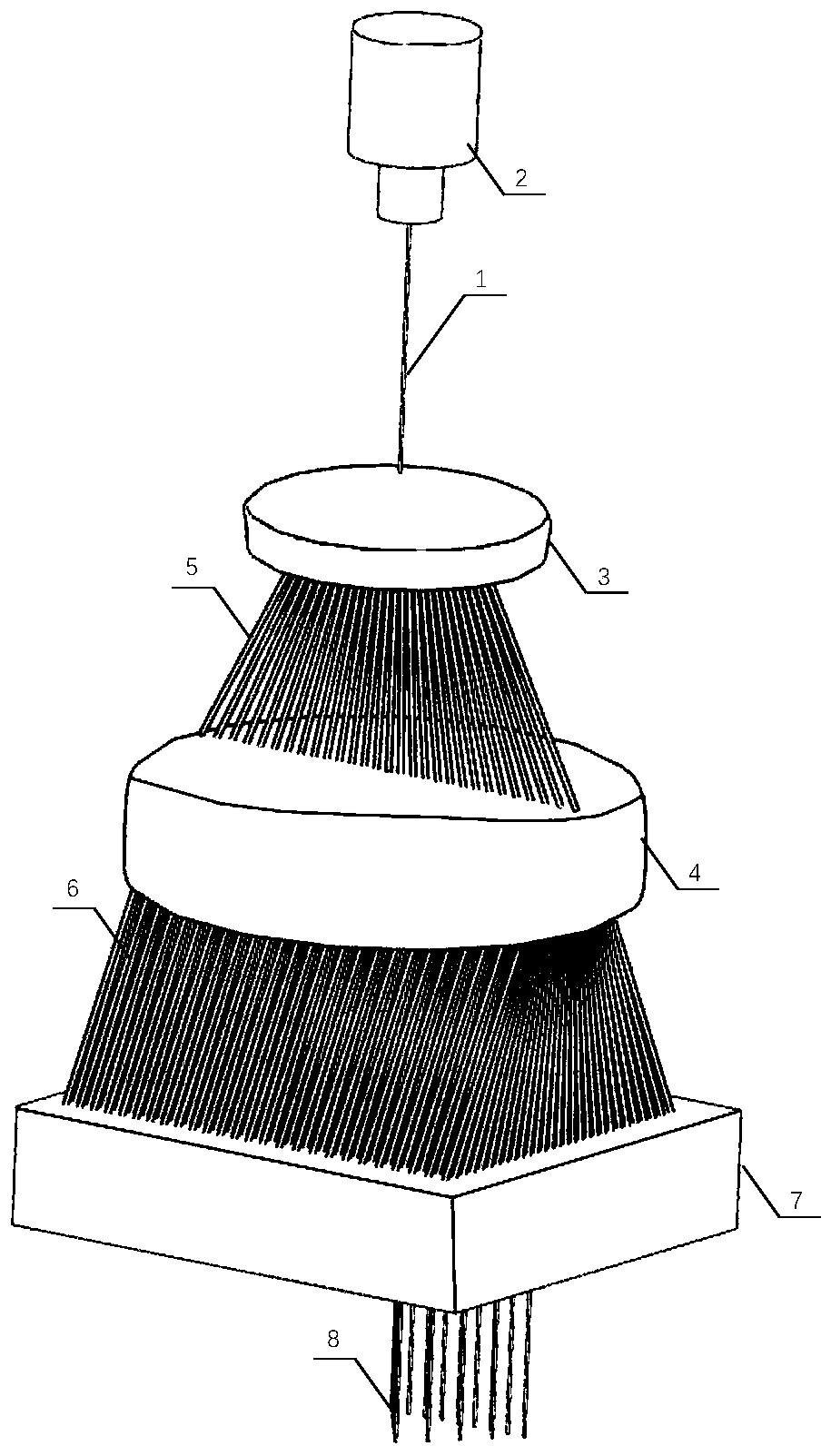

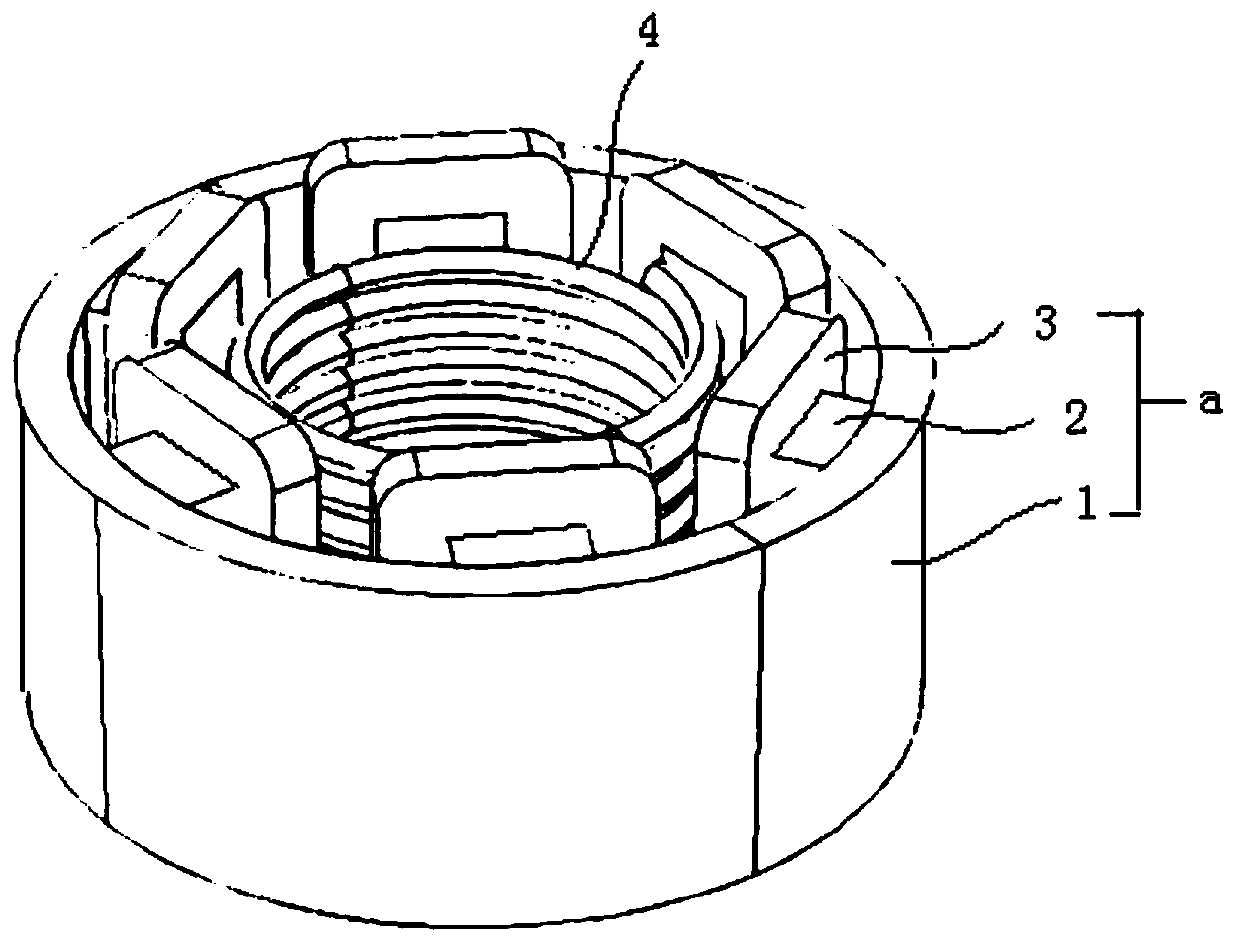

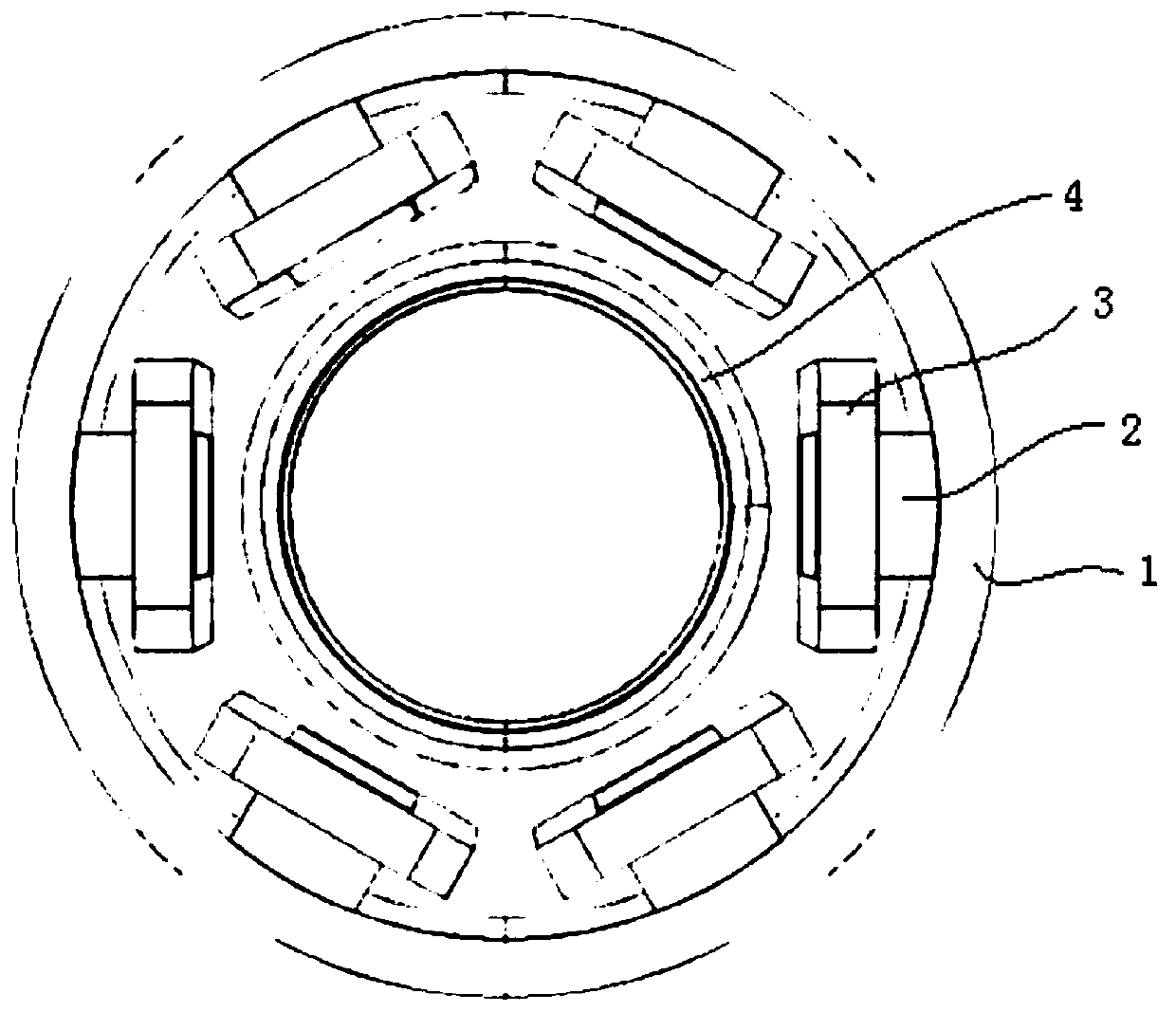

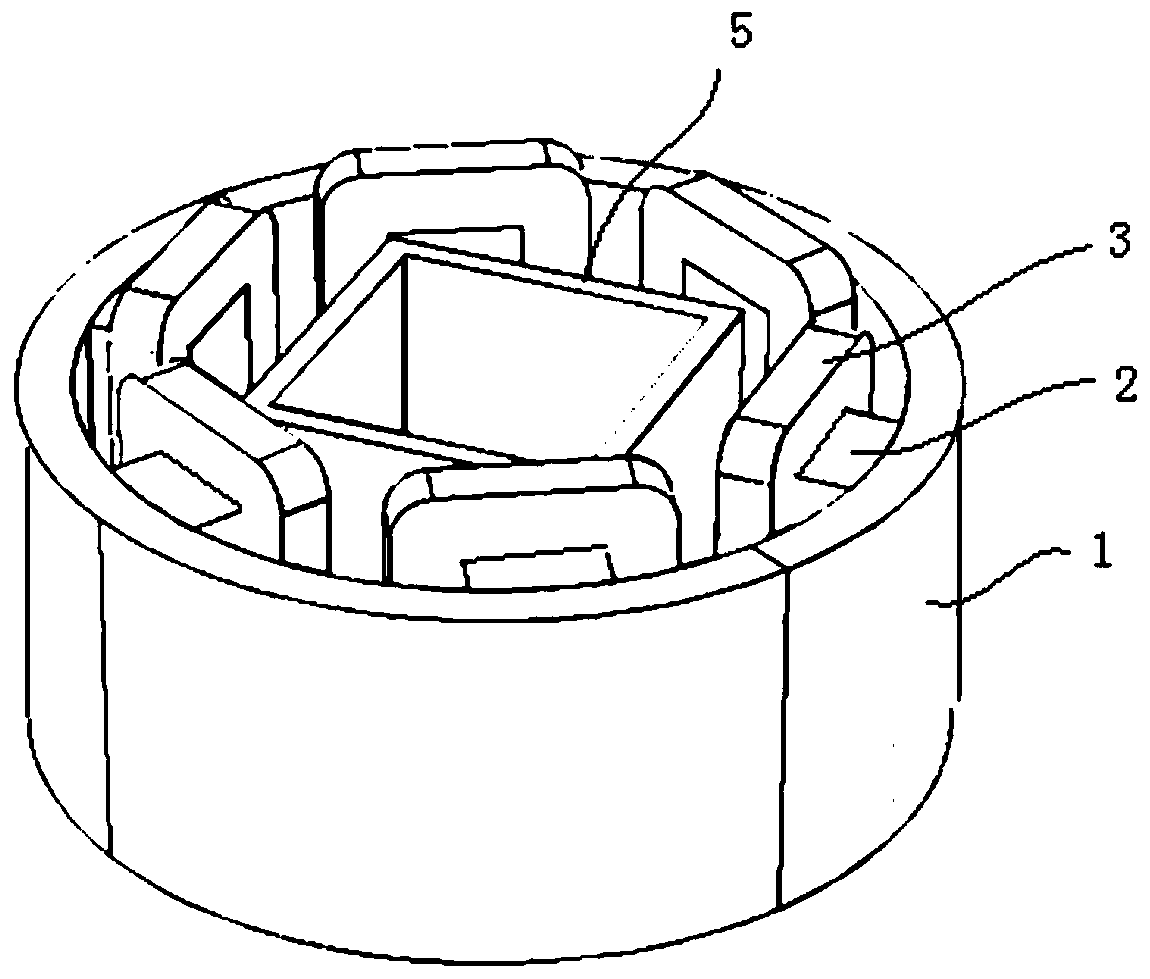

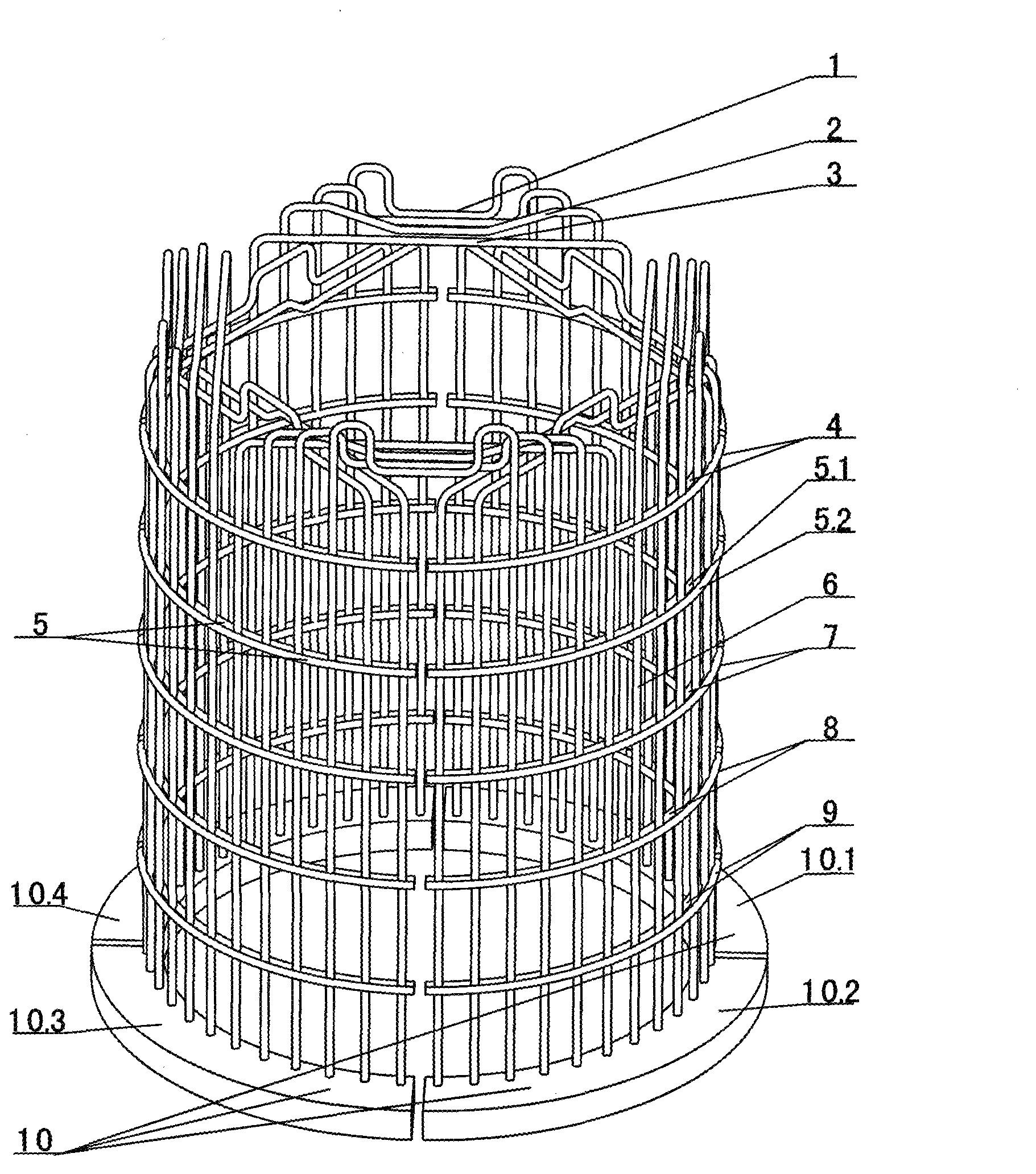

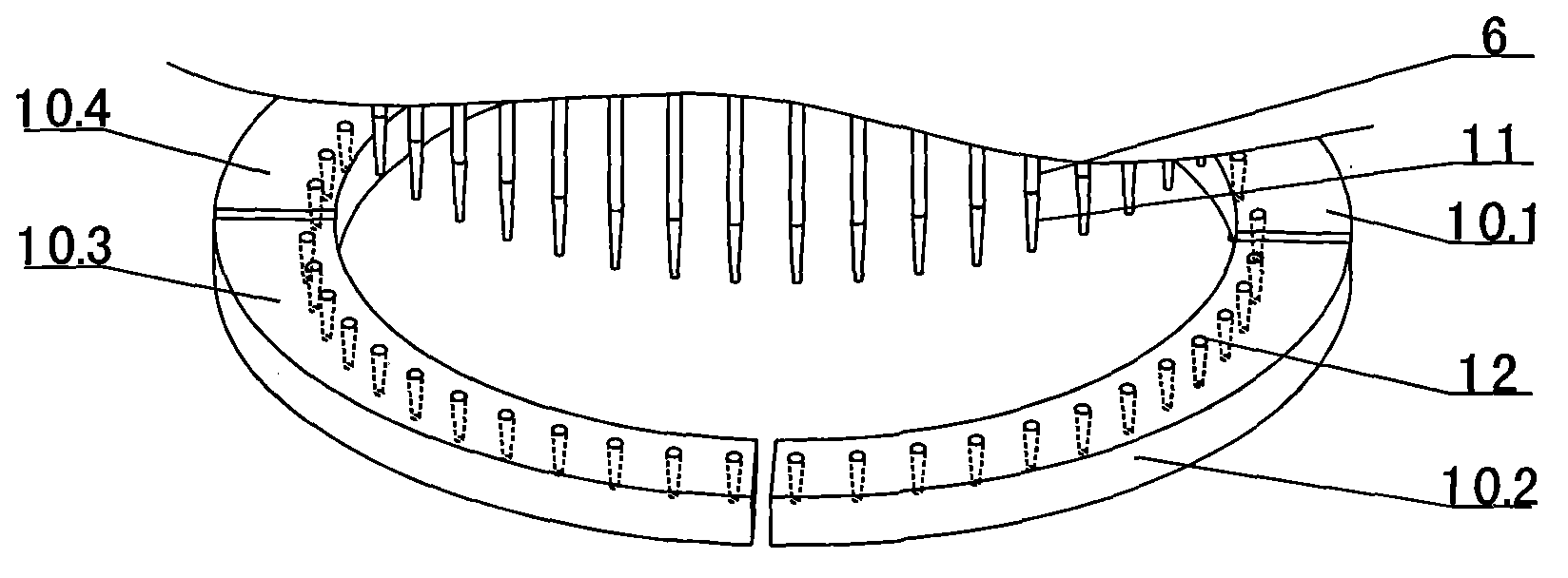

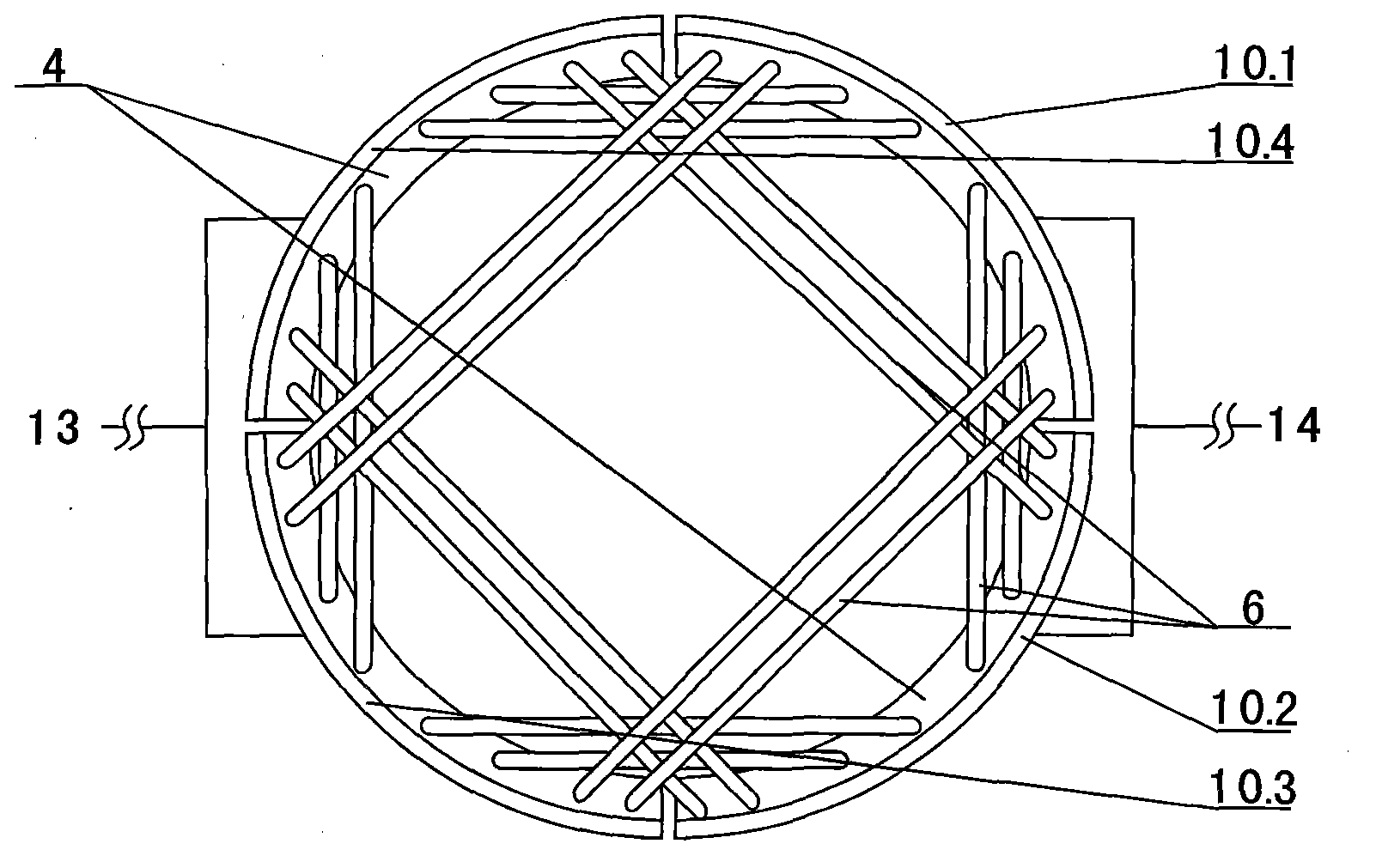

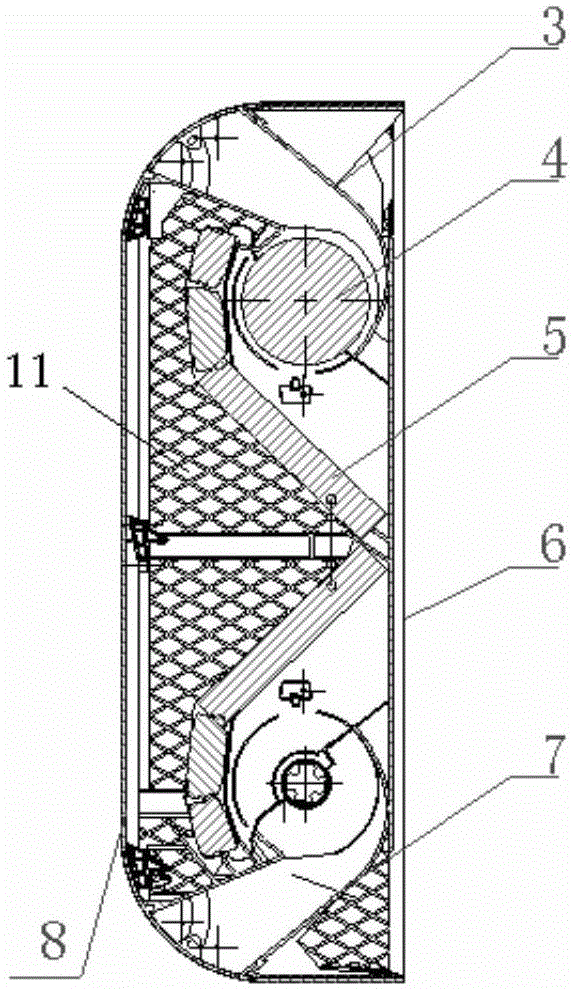

Cage-type heating unit for crystal growth

InactiveCN102936753AObtain small temperature gradient requirementsUniform distribution of temperature fieldAfter-treatment apparatusBy pulling from meltLarge sizeCrystal growth

The invention relates to a cage-type heating unit for crystal growth, belonging to the field of artificial crystals. A plurality of heating rods (6) are annularly arranged in a staggered mode; the lower part of the annularly arranged heating rods (6) is connected with at least two bases (10); a complete circle is uniformly divided into the at least two bases (10); an interval is arranged between the butt surfaces of every two adjacent bases (10); the middle part of the annularly arranged heating rods (6) is provided with series connection mechanisms which have the same quantity and same structure as the bases (10) and are connected with the same heating rods (6) in series, so that the heating rods (6) form a cage-type structure heating unit; and the bases (10) are connected with a negative electrode (14) and a positive electrode (13), so that the cage-type heating unit forms an heating electrode layout of which the electrodes converge via the upper part. The invention adopts the multivalve cage-type heating form, and acquires balanced temperature field distribution of the heating unit; and the invention is especially suitable for multi-temperature area requirements for large-size high-melting-point crystal growth.

Owner:LUOYANG JINNUO MECHANICAL ENG

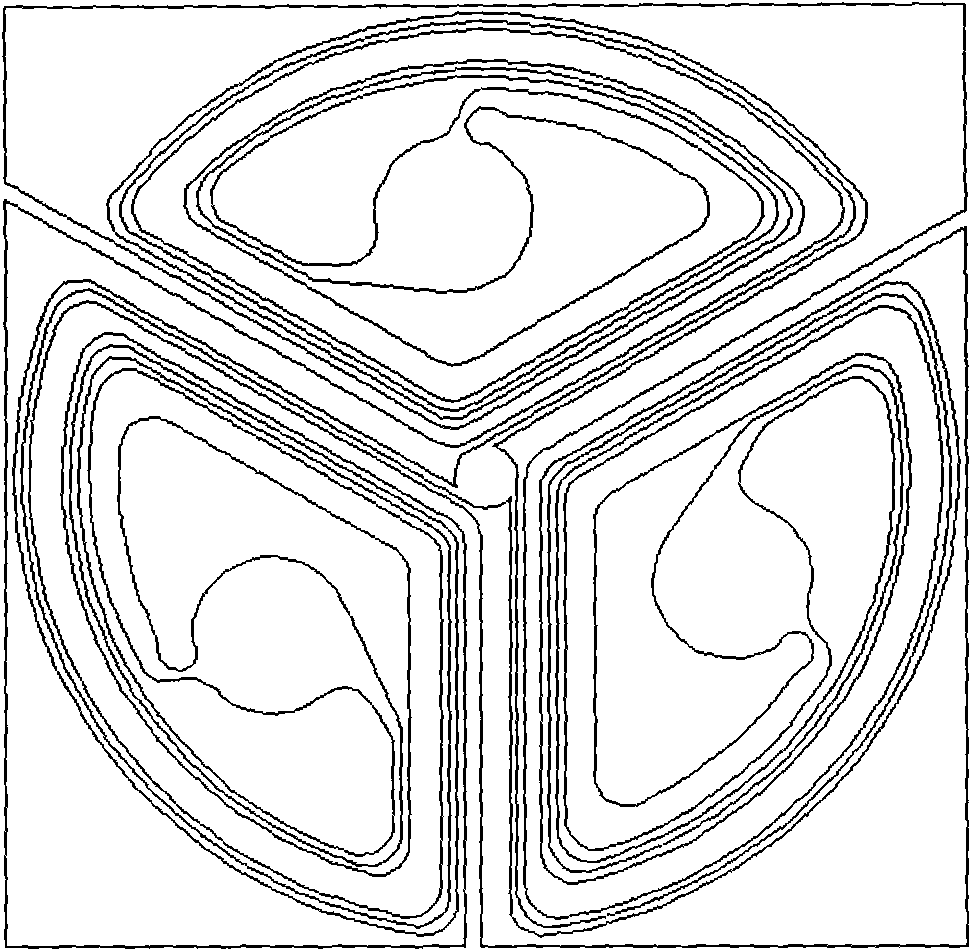

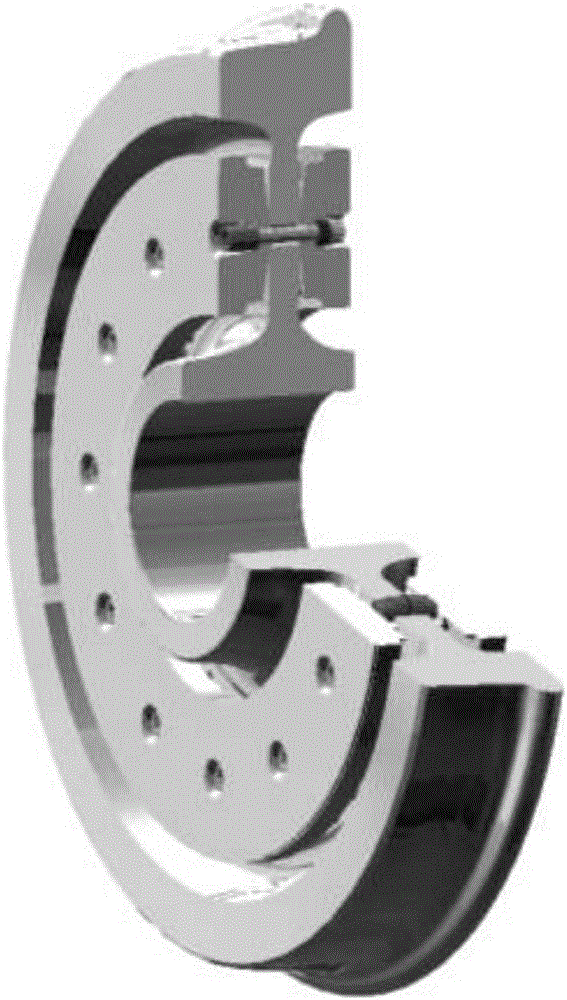

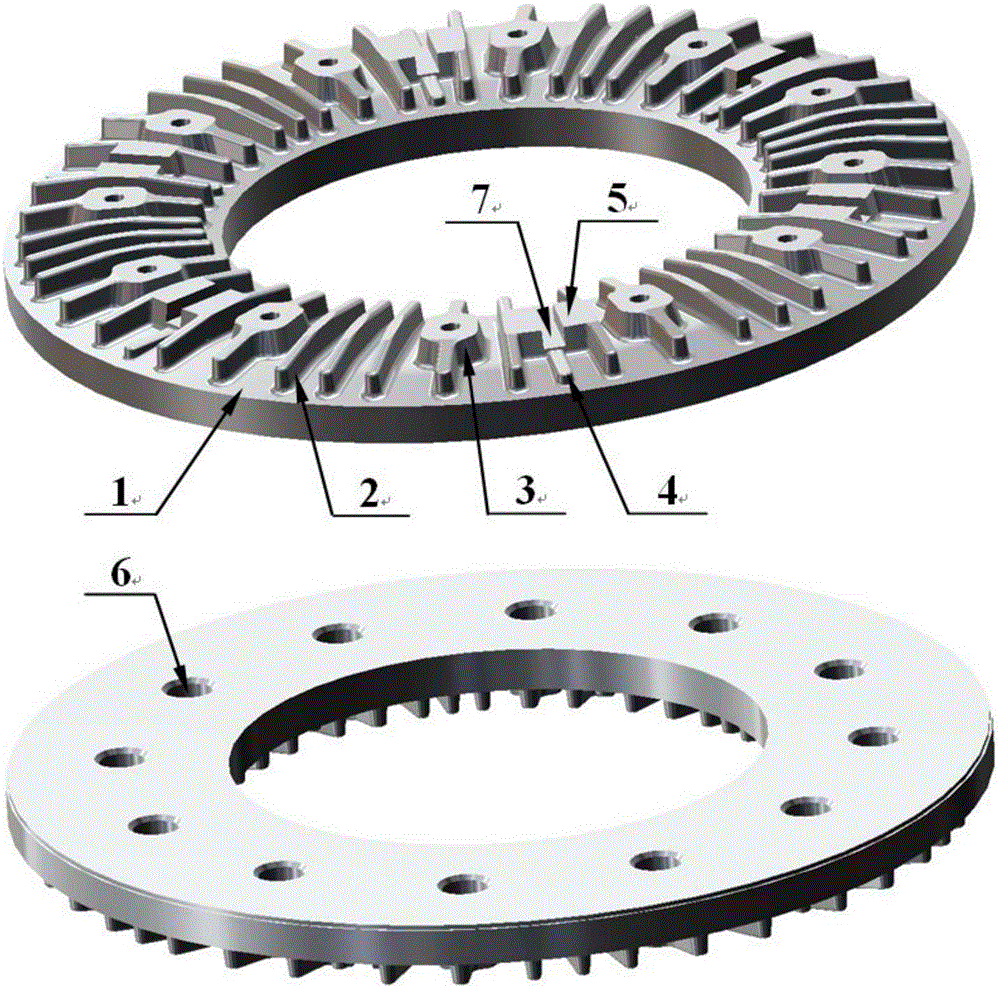

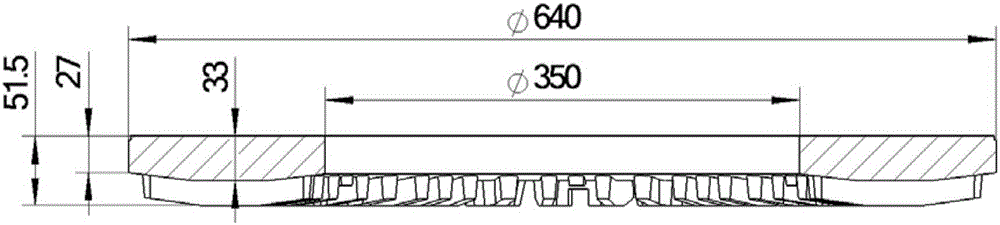

High-heat-capacity SiCp/Al composite material wheel-mounted brake disc bodies

The invention relates to high-heat-capacity SiCp / Al composite material wheel-mounted brake disc bodies. The high-heat-capacity SiCp / Al composite material wheel-mounted brake disc bodies are made of SiCp / Al composite materials. Each high-heat-capacity SiCp / Al composite material wheel-mounted brake disc body comprises a friction ring (1), high plate bars (2), connection columns (3), short plate bars (4), positioning columns (5), bolt holes (6) and positioning grooves (7), wherein the section of the friction ring (1) is trapezoid; every three high plate bars (2) fall into one set, and totally six sets of high plate bars (2) are evenly distributed in the circumferential direction; each combined bar A is composed of one high plate bar (2) and one connection column (3), and twelve combined bars A are evenly distributed in the circumferential direction; each combined bar B is composed of two high plate bars (2), one short plate bar (4) and one positioning column (5), and six combined bars B are evenly distributed in the circumferential direction; the bolt holes (6) are formed in the connection columns (3); and the positioning grooves (7) are formed in the positioning columns (5). The two disc bodies are located on the two sides of a wheel, axial positioning between the disc bodies and the wheel is achieved through bolts, and circumferential positioning between the disc bodies and the wheel is achieved through positioning pins. The disc bodies deform concertedly, the internal temperature is even, and stress is small.

Owner:NANJING CRRC PUZHEN HAITAI BRAKE EQUIP CO LTD

Upper and lower exhaust wall-mounted air conditioning indoor unit

InactiveCN105135521AImprove heat transfer effectSolve the discomfortDucting arrangementsLighting and heating apparatusEngineeringAir conditioning

The invention relates to the technical field of air conditioners, in particular to an upper and lower exhaust wall-mounted air conditioning indoor unit. The upper and lower exhaust wall-mounted air conditioning indoor unit comprises a shell, an upper crossflow wind wheel, a lower crossflow wind wheel, an upper evaporator, a lower evaporator, a first wind way and a second wind way, wherein a wind inlet is formed on a side surface end plate of the shell; indoor return wind enters two side cavities from side surface end plates at two sides, and enters a wind inlet cavity formed among the upper evaporator, the lower evaporator and a front panel of the shell; then, an air current is divided into two ways for heat exchange by the upper evaporator and the lower evaporator, and is blown out from the first wind way and the second wind way after being guided by the upper crossflow wind wheel and the lower crossflow wind wheel; the wind blown out from the first wind way reaches an indoor ceiling to form an absorption effect, and sinks after being blown for a longer distance; and as the wind inlet is arranged on the side surface end plate, the indoor air current structure is formed to surrounding wind to intensify the indoor air disturbance, the indoor temperature field distribution is more uniform, and the temperature is more comfortable.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

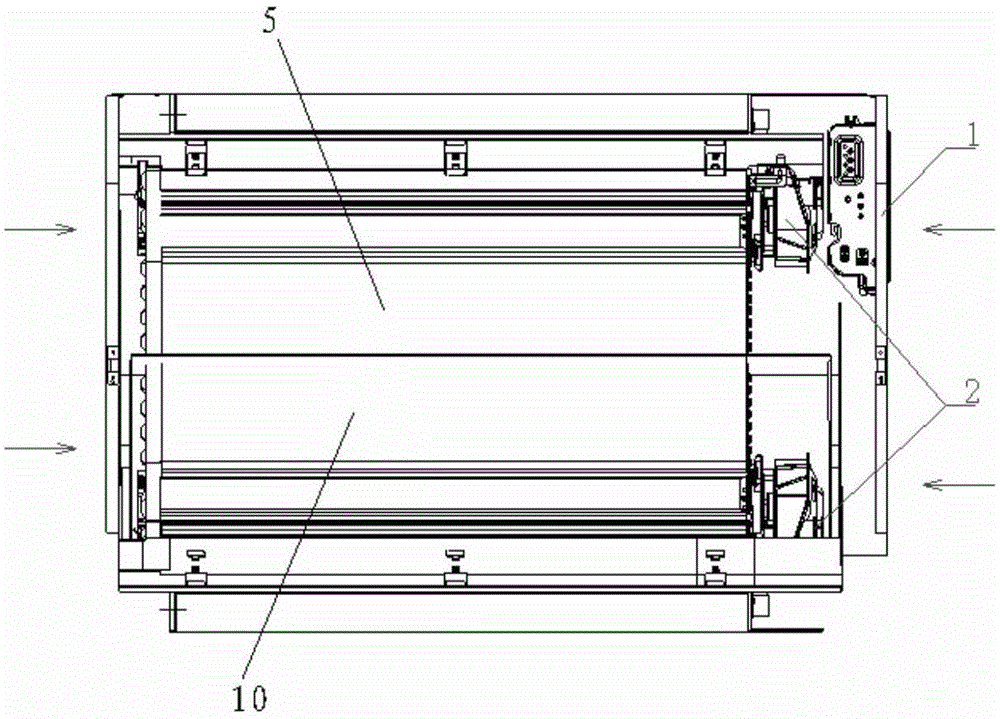

Production equipment and technology for cathode or anode material of converter-type lithium battery

InactiveCN102522526AAddress the degree of automationSolve productivityCell electrodesCombustorFluidized bed

The present invention discloses production equipment and a technology for a cathode material or an anode material of a converter-type lithium battery, the production equipment comprises a feeder, a fluidized bed mixing device, a gas-solid settlement separation component, a flue pipe, a converter, a combustor, a discharge duct, a motor and a particle cooler; the technical process comprises the following steps the prepared raw materials enter into the fluidized bed mixing device through the feeder, air is introduced and mixed with the prepared raw materials, then is carried with air to the gas-solid settlement separation component, the raw materials are separated with air and enters into the converter, then reacted at 500-900 DEG C to generate the lithium battery cathode or anode material, the produced lithium battery cathode or anode materials are delivered into the particle cooler and then discharged. The production equipment solves the defects of low automation degree, discontinuous production in original equipments, and the lithium battery cathode or anode materials can be produced with high efficiency, low energy consumption and continuous production.

Owner:济宁市无界科技有限公司

ERD (Efficient Reburning Denitration)+coal saturated steam catalytic combustion denitration device and technique

ActiveCN106675650AReduce the burden onImprove efficiencyGasification processes detailsBulk chemical productionSurge tankSystem stability

The invention discloses an ERD + coal saturated steam catalytic combustion denitration device. The ERD + coal saturated steam catalytic combustion denitration device comprises a decomposing furnace, wherein a secondary air inlet is formed in the bottom of the decomposing furnace, and connected with a cement rotary kiln; the decomposing furnace comprises a reduction zone, a main burning zone, a reburning zone and a burning-out zone from the bottom up, a reduction zone saturated steam catalytic combustor and a reburning zone saturated steam catalytic combustor are respectively mounted in the reduction zone and the reburning zone; the reduction zone saturated steam catalytic combustor and the reburning zone saturated steam catalytic combustor are connected with a steam flow metering device, the steam flow metering device is connected with a steam surge tank, the steam surge tank is connected with a steam main pipe, the main burning zone and the burning-out zone are respectively connected with tertiary air and over-fire air, and are oxygen enriched combustion zones, to ensure that pulverized coal of the system is burnt out. The invention further discloses an ERD + coal saturated steam catalytic combustion denitration technique, and has the advantages of high denitration efficiency, simple and easily operated technological process, low operation cost, high system stability, optimized clinker production technology, energy-saving and consumption-reducing effects and the like.

Owner:上海三融环保工程有限公司 +1

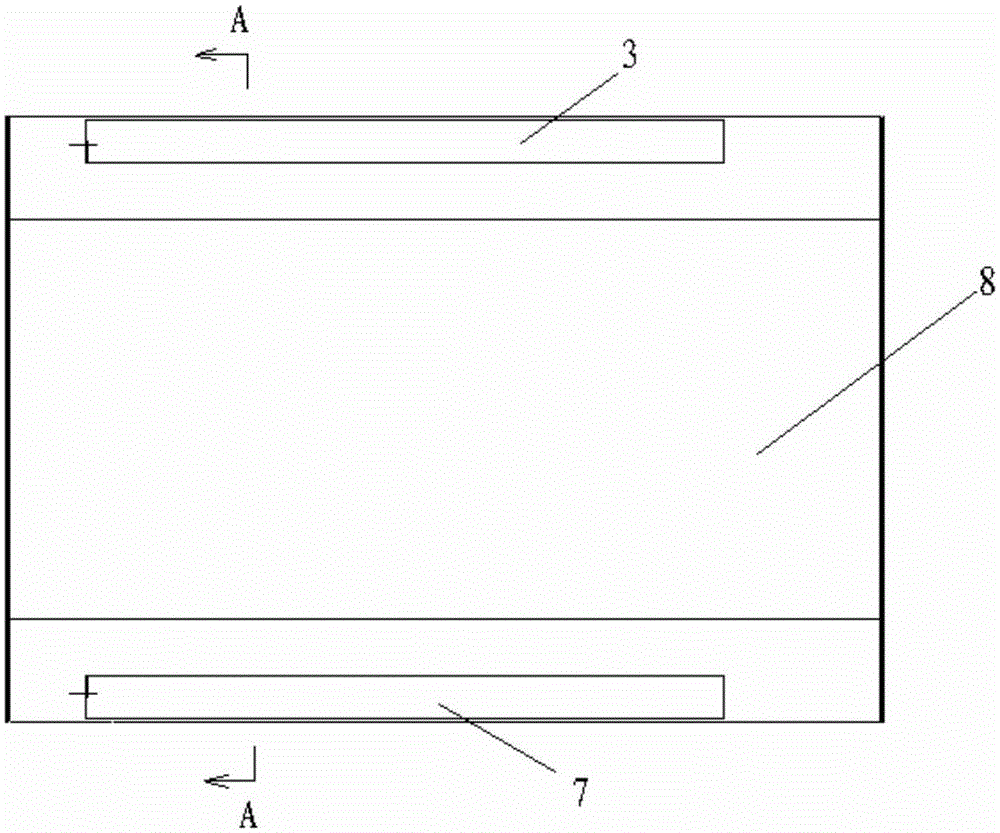

Method used for manufacturing ITO heating plate for large-area LCD screen

InactiveCN104090392AUniform distribution of temperature fieldWork wellNon-linear opticsResistWorking life

The invention discloses a method for manufacturing an ITO heating plate for a large-area LCD screen. An area division heating mode is adopted for design, and an etching method is adopted for dividing a whole ITO substrate into areas according to a certain area proportion. Specifically, the method comprises the following steps of cleaning, resist coating, exposing, developing, ITO etching, electrode preparing and glue enveloping. The method has the advantages that the temperature field distribution of an ITO glass panel is uniform, the work effect of the LCD panel is good, and the working life of the LCD screen is prolonged.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com