Medium and low temperature denitration, dedusting and thermo-analysis integrated method and device

A low-temperature denitration and thermal desorption technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of affecting the low-temperature denitration efficiency, unable to set up a bag filter and a denitration reactor at the same time, etc., so as to omit the ash cleaning system. , the effect of reducing operating costs and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

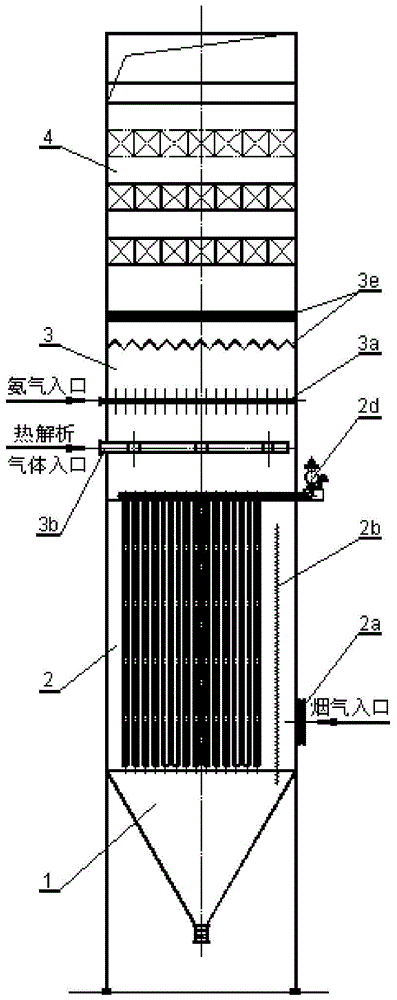

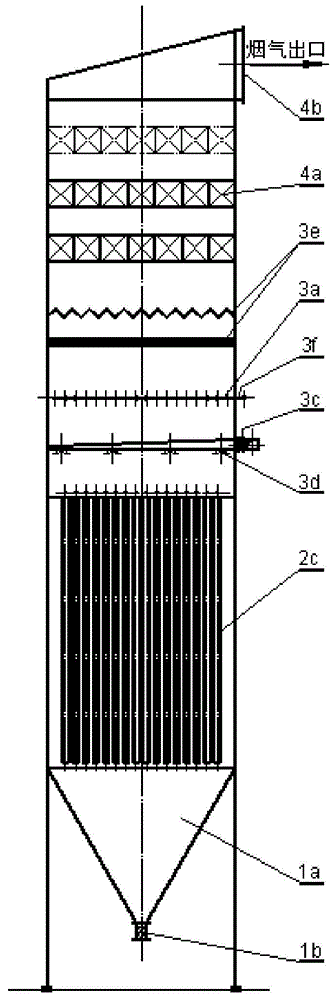

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

[0038] The invention is an integrated equipment for dust removal, denitrification and on-site thermal analysis of medium and low temperature flue gas. Mix well, and discharge into the atmosphere after being denitrated by the denitrification catalyst. In order to prevent the ammonium bisulfate and other substances generated when the flue gas passes through the catalyst from condensing at low temperature and sticking to the surface of the denitrification catalyst, a high-temperature thermal analysis device is installed, and the hot flue gas at 380-400 °C is used for online thermal analysis regeneration of the catalyst, and the medium temperature is maintained. The low-temperature denitrification catalyst has a continuous and efficient service life. At the same time, through the filter bag and the equipment structure layer, the uniform distribution of the flue gas velocity f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com