Patents

Literature

41results about How to "Achieve uniform distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

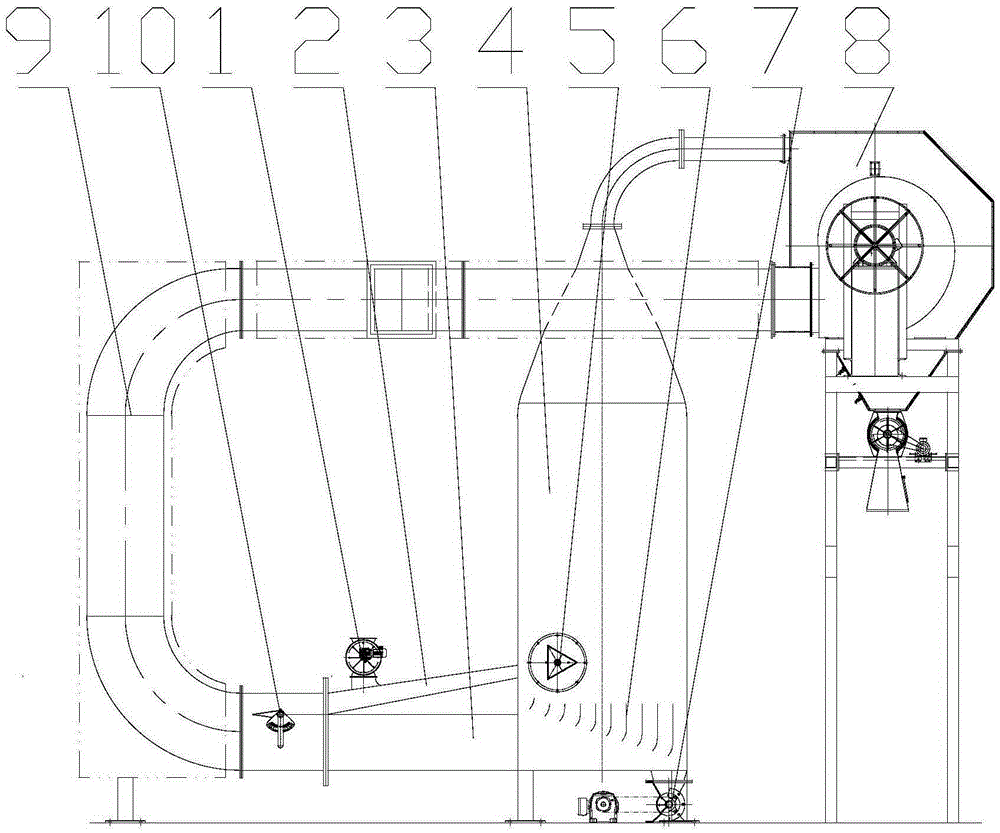

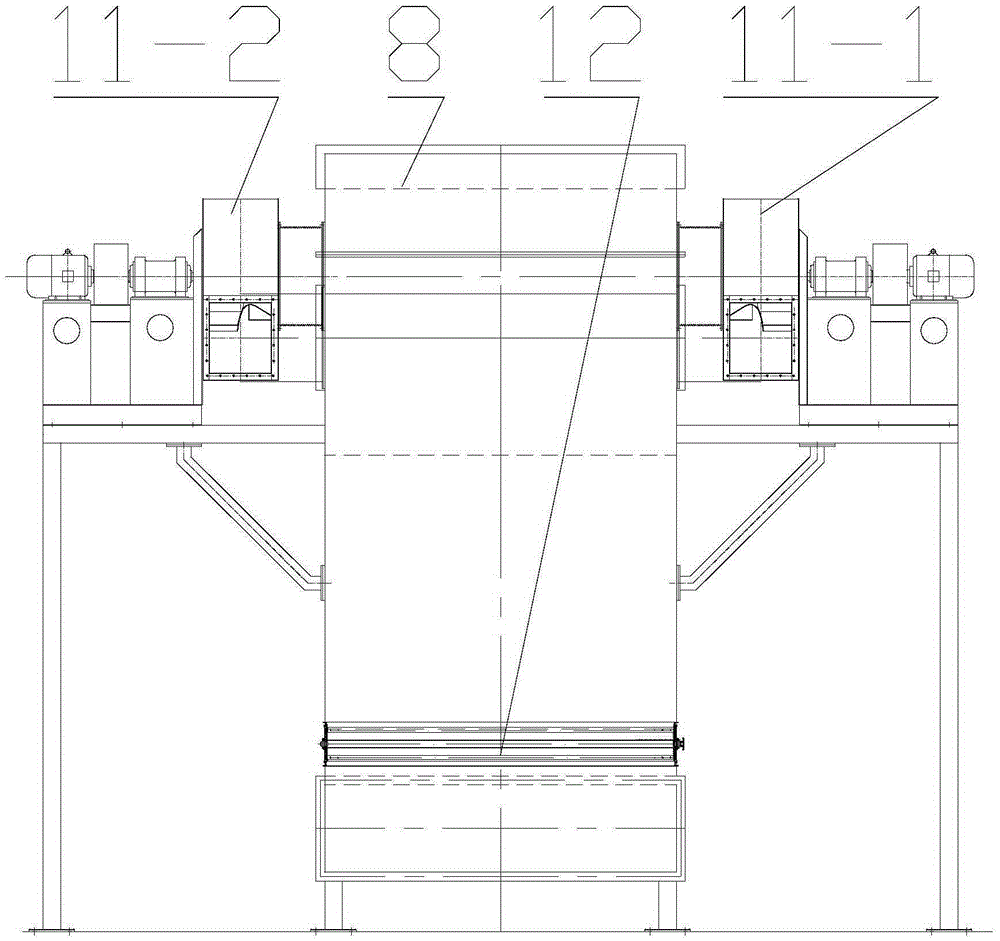

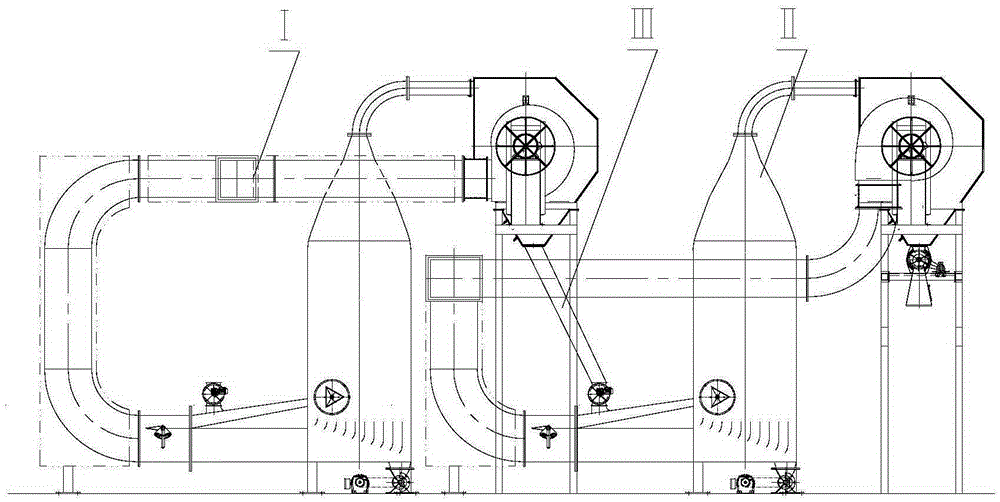

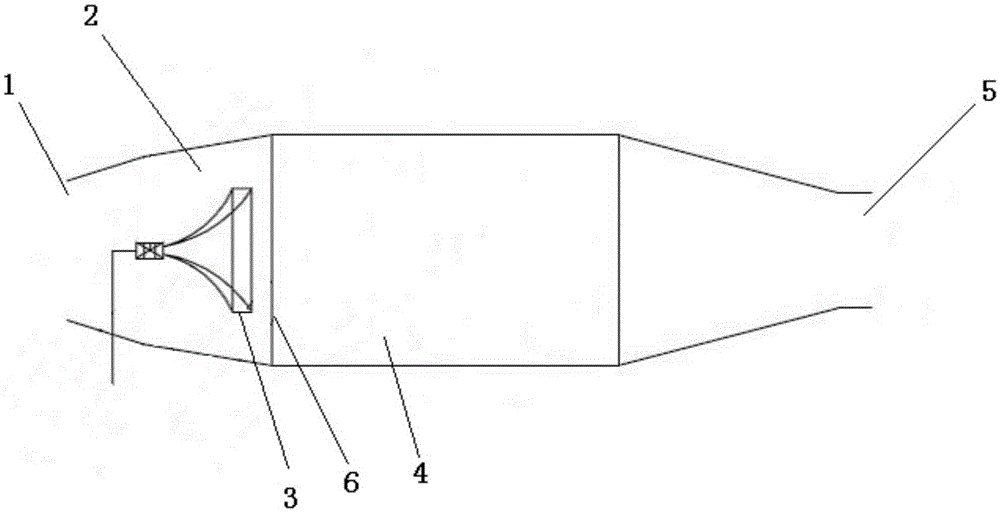

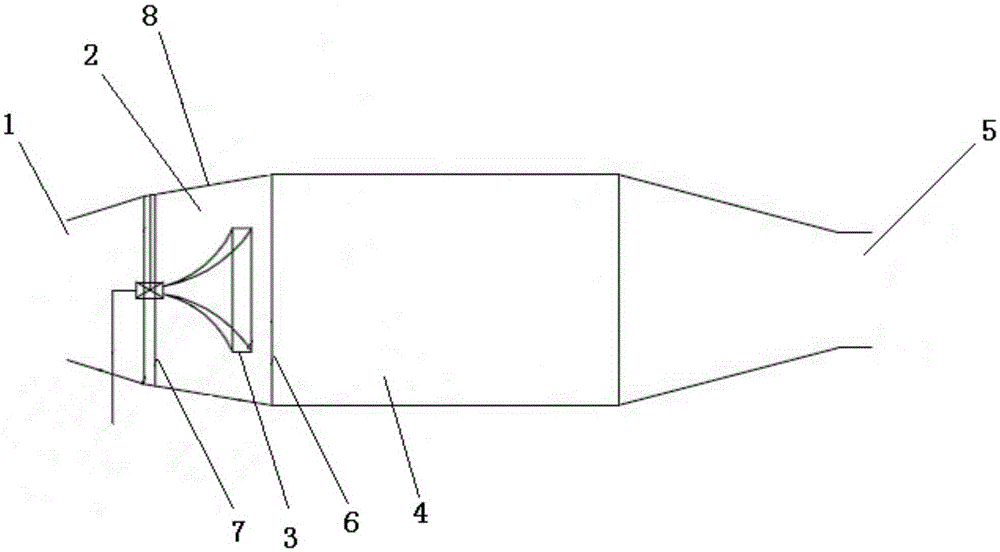

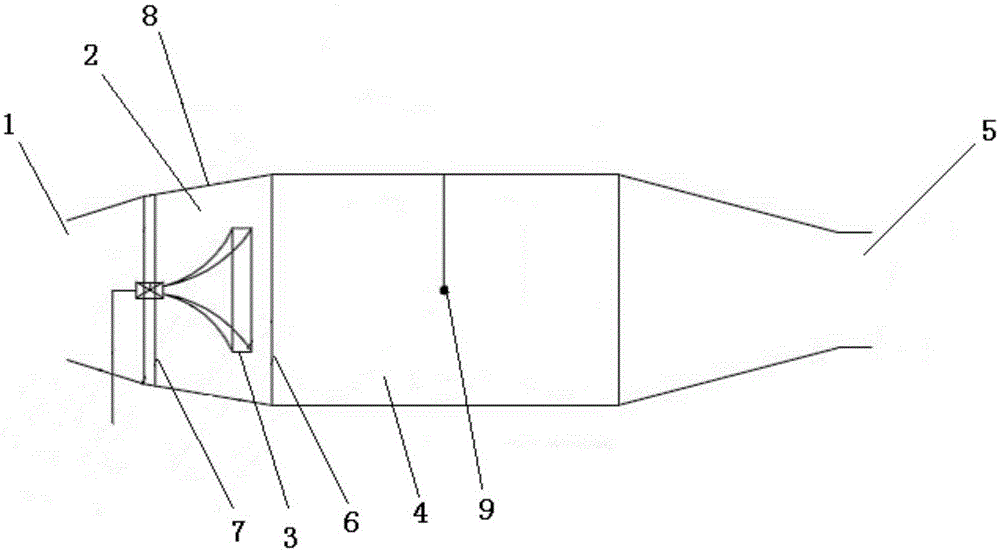

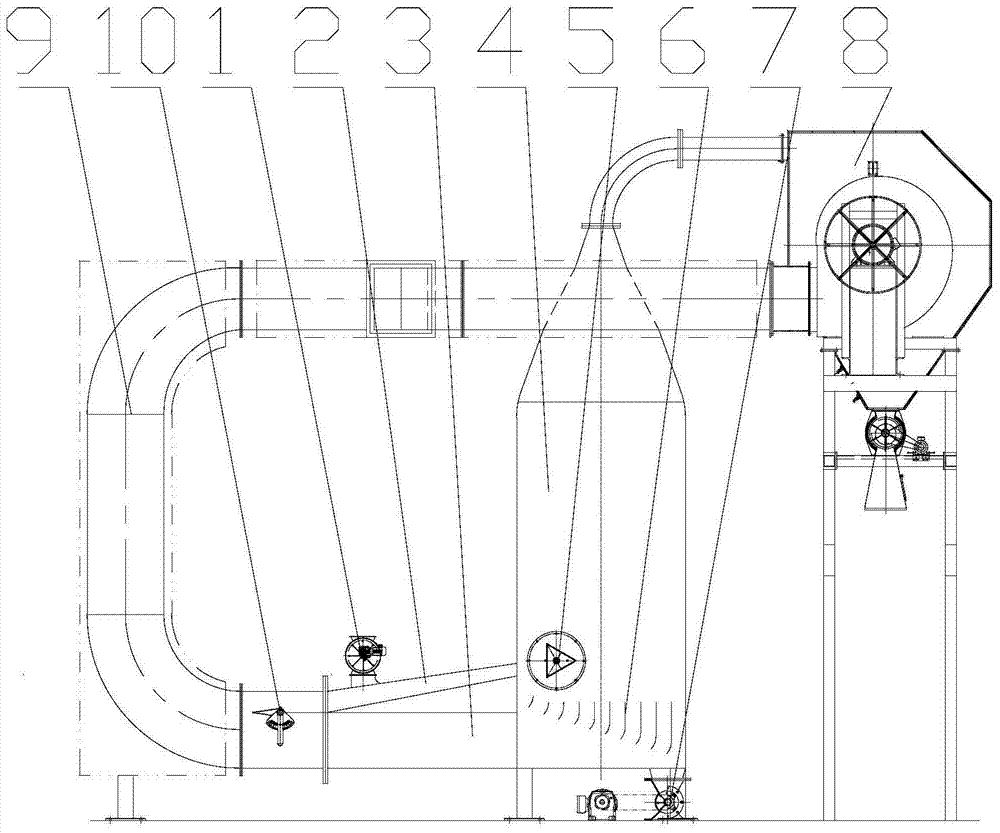

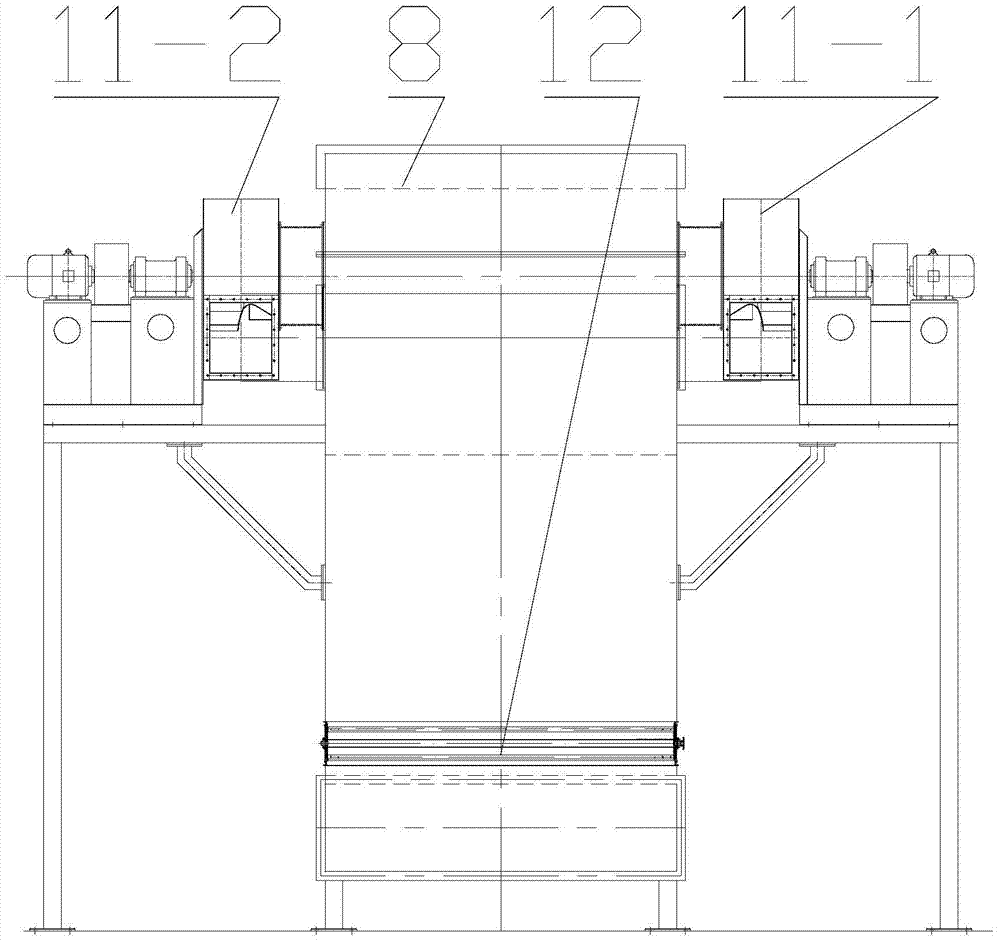

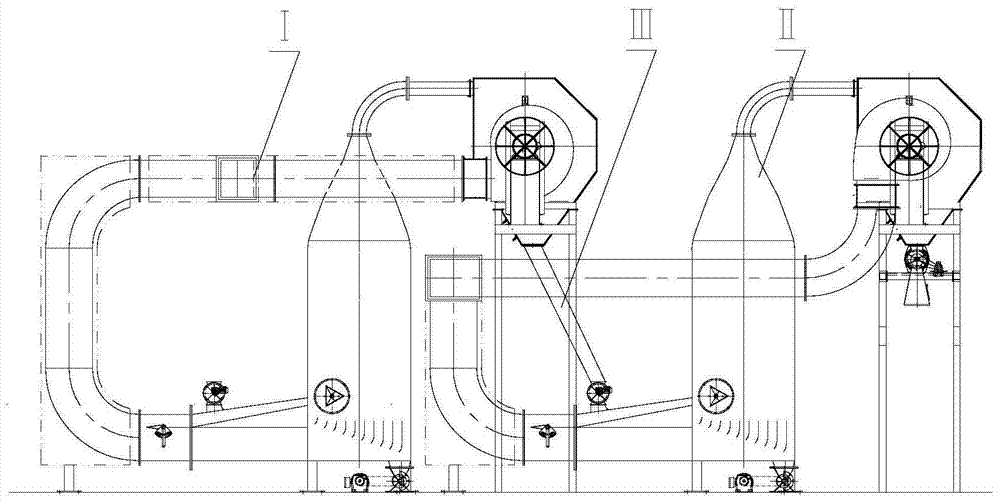

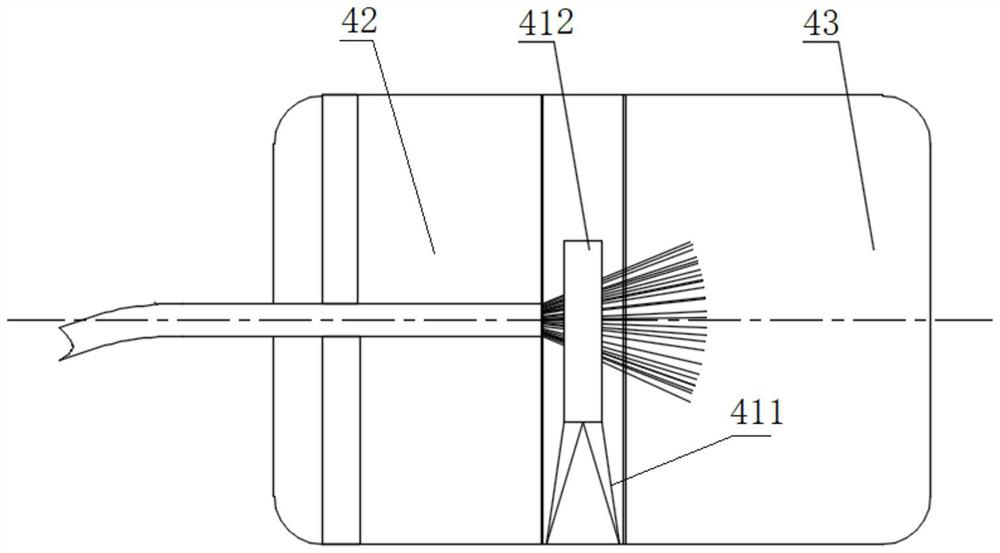

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

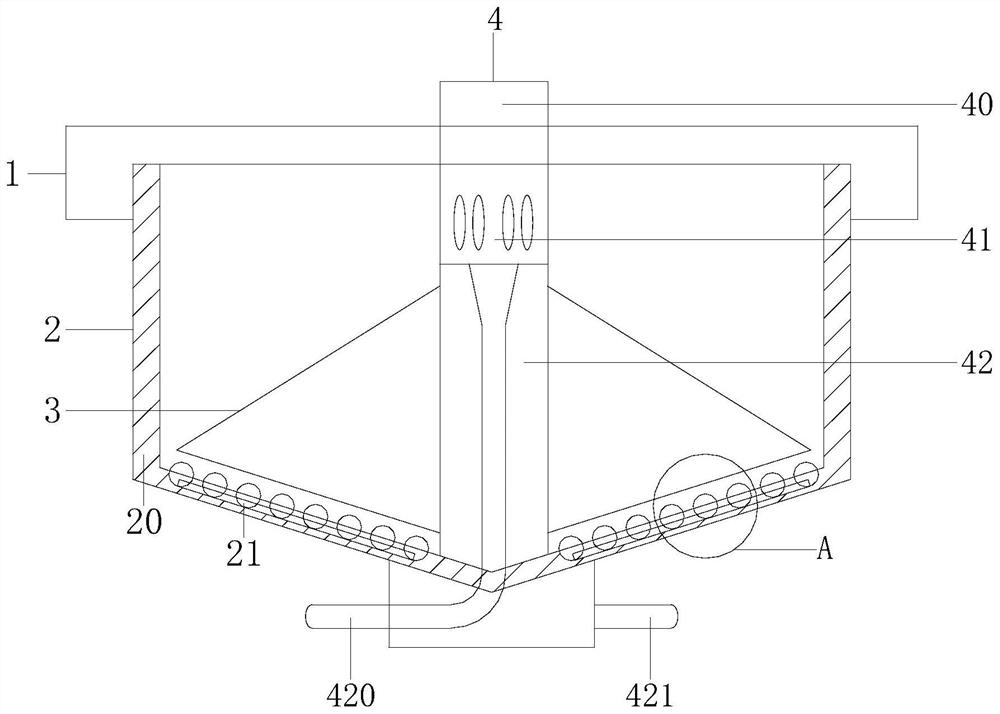

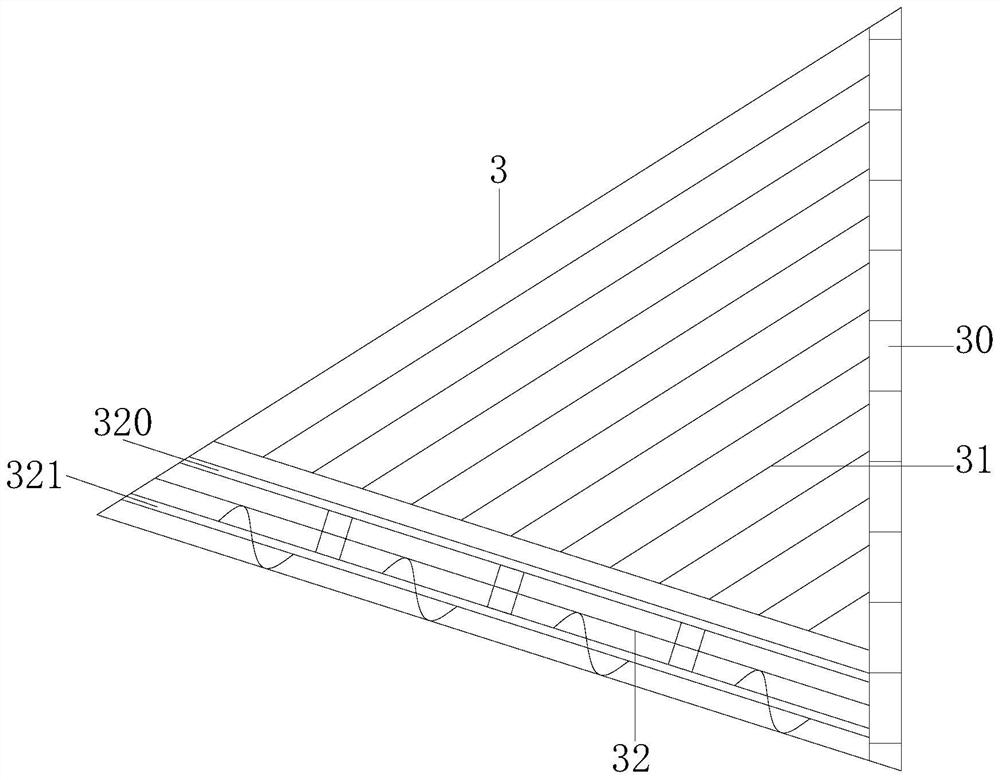

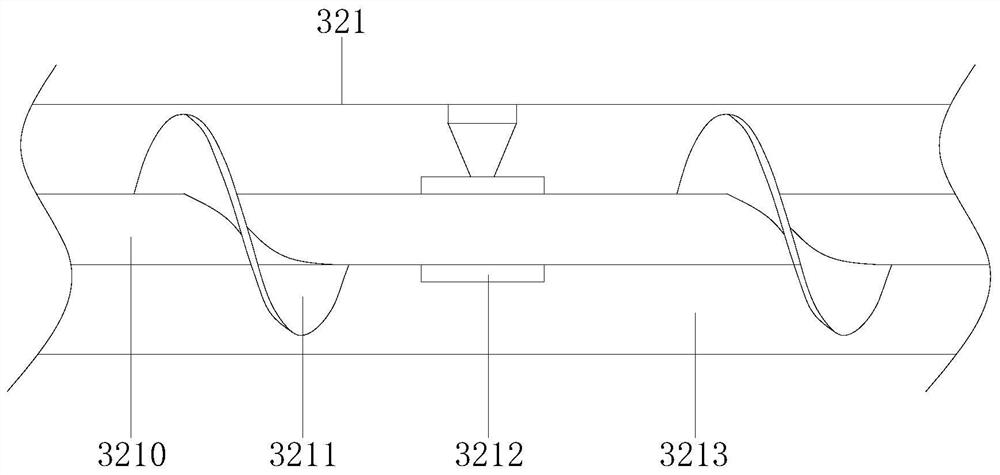

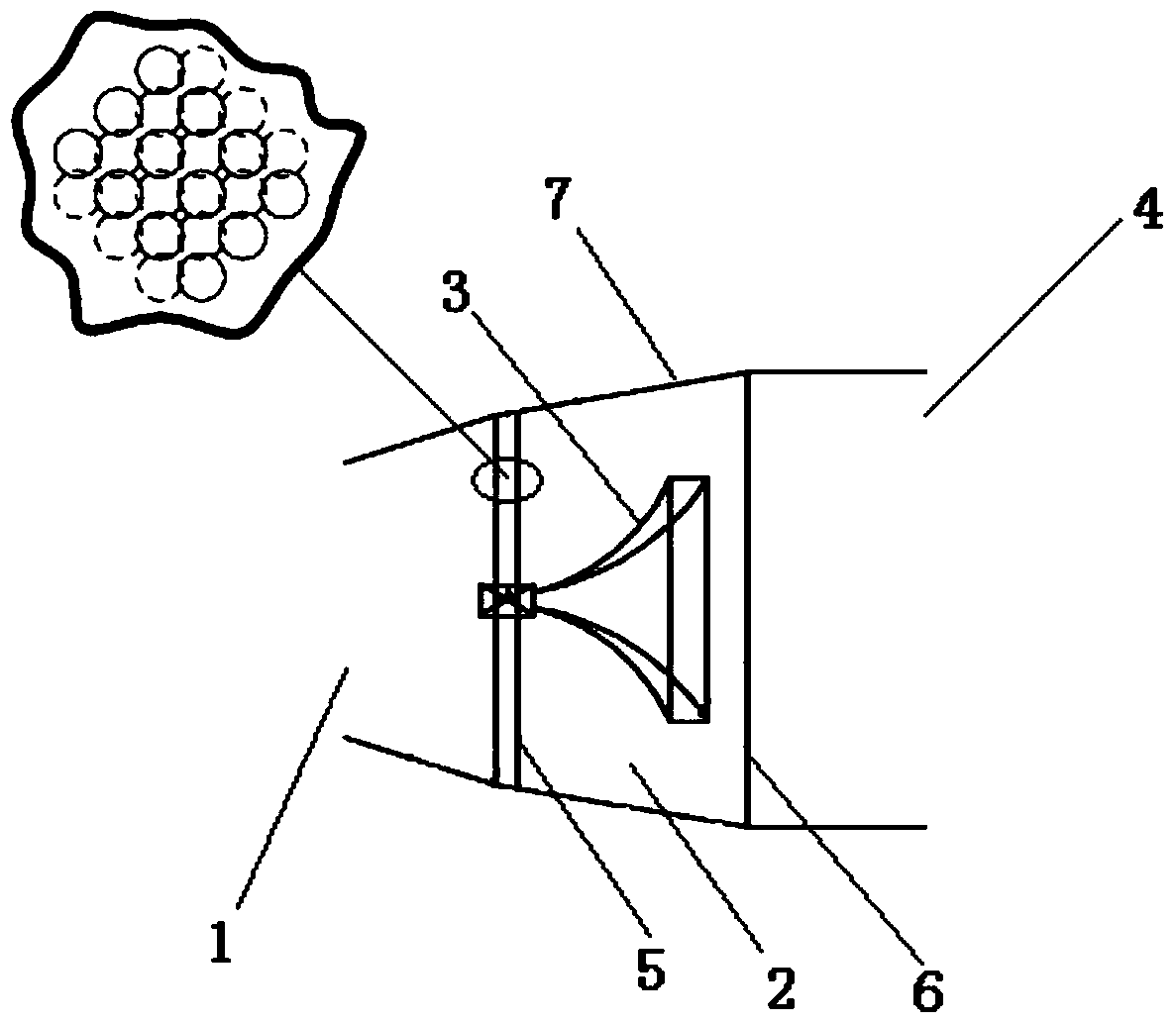

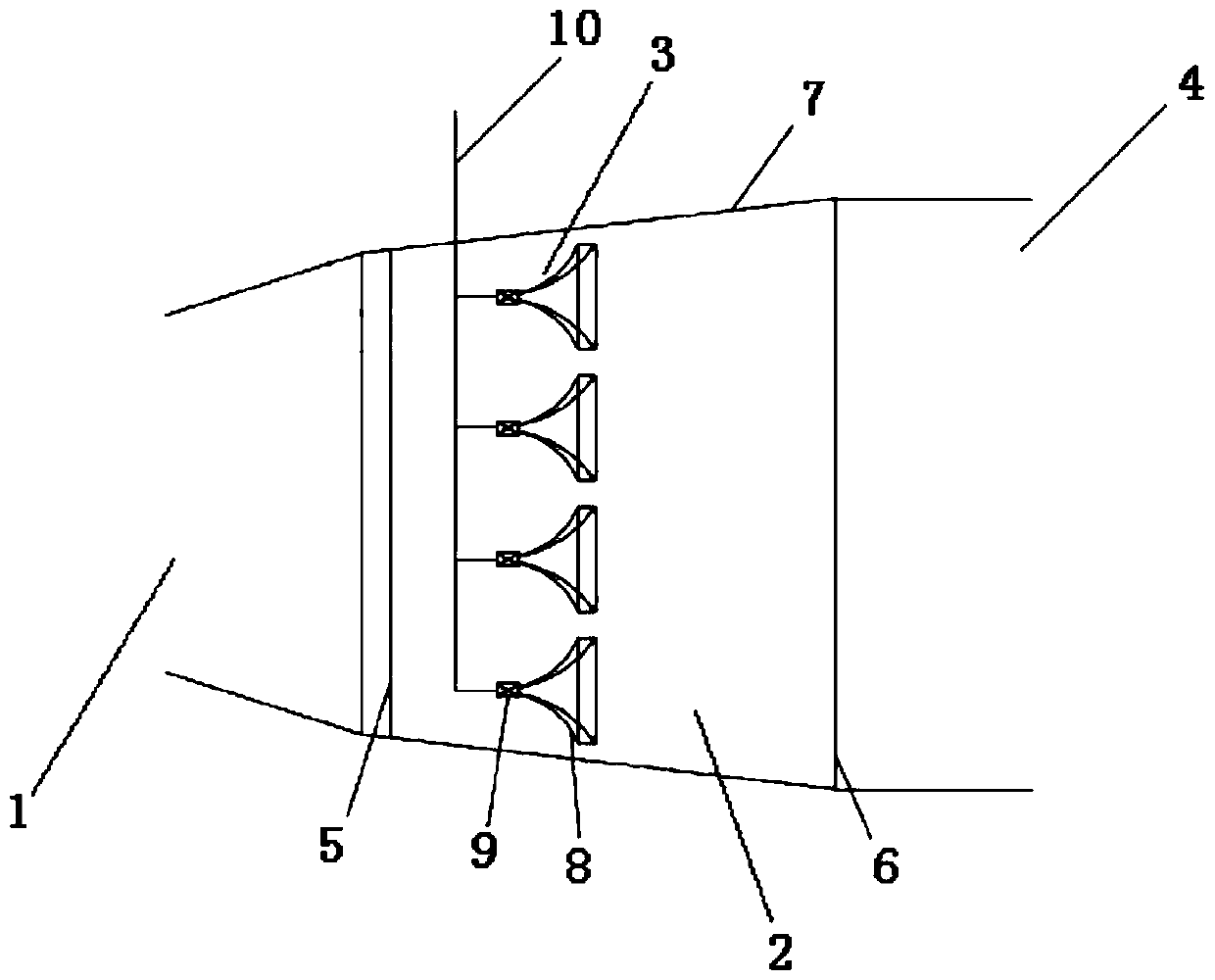

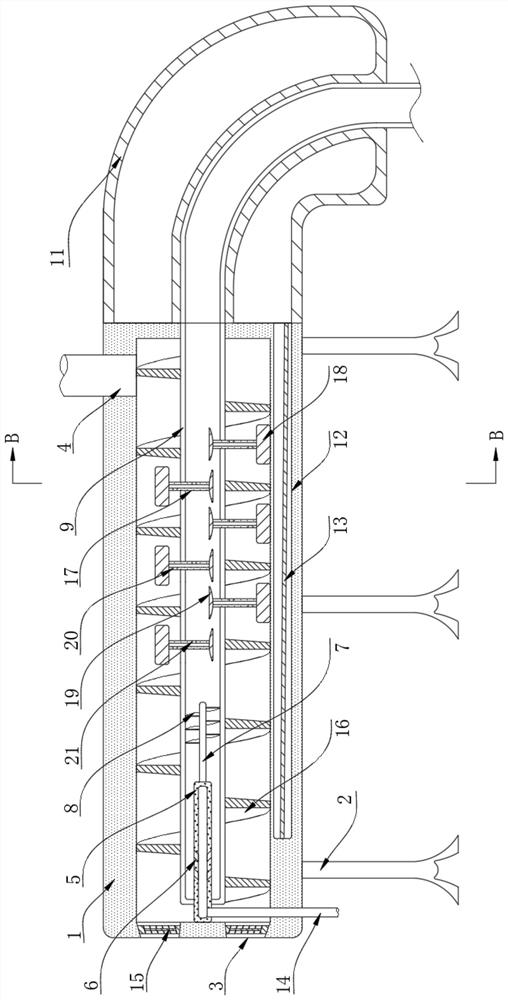

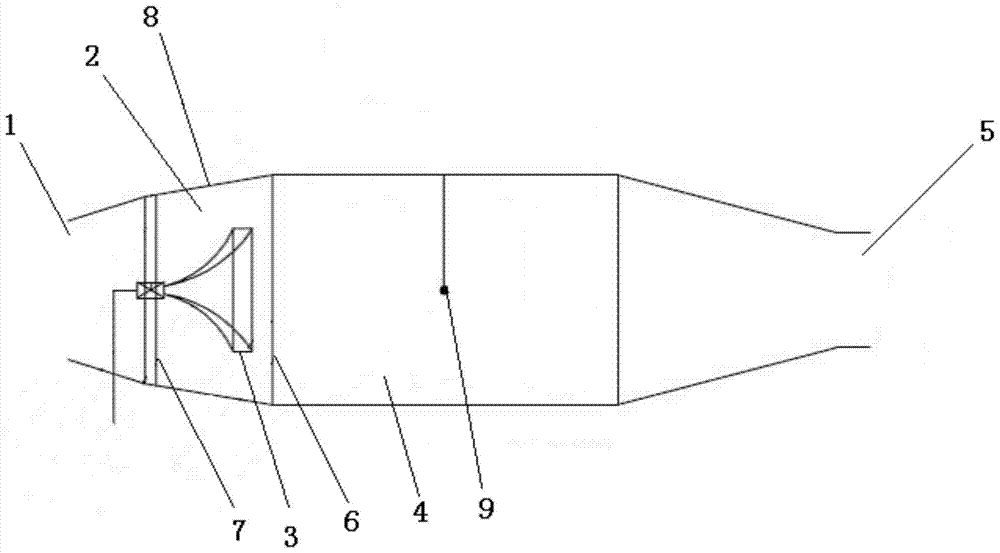

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

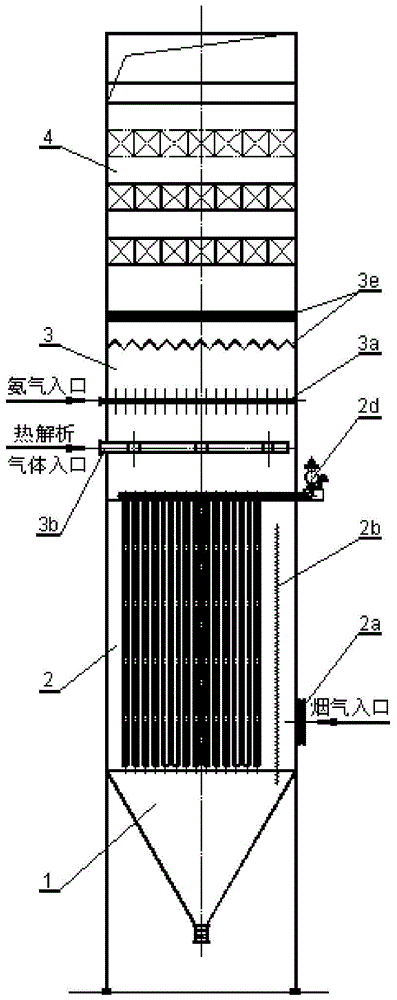

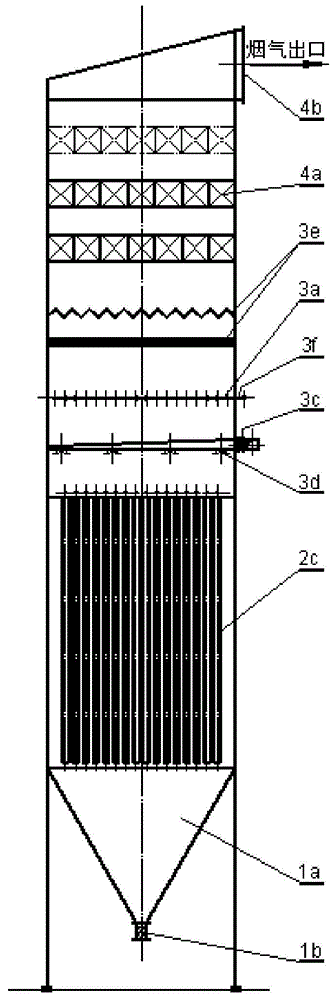

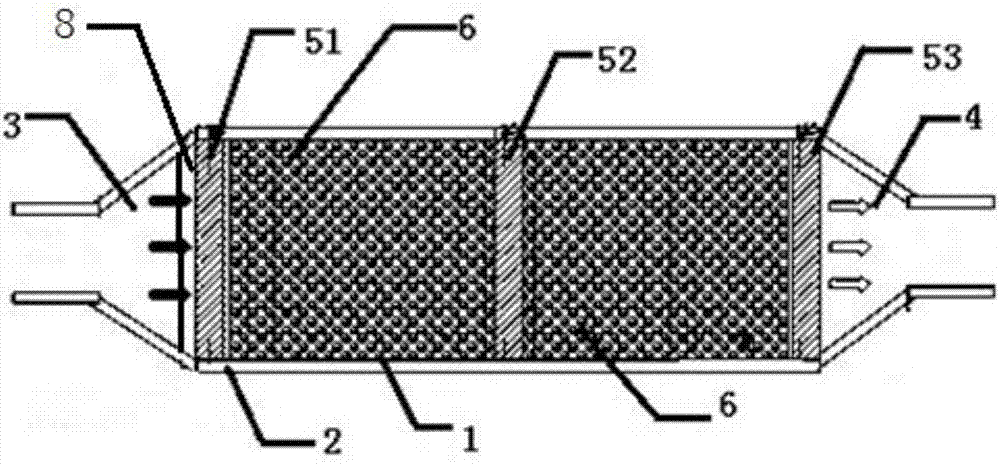

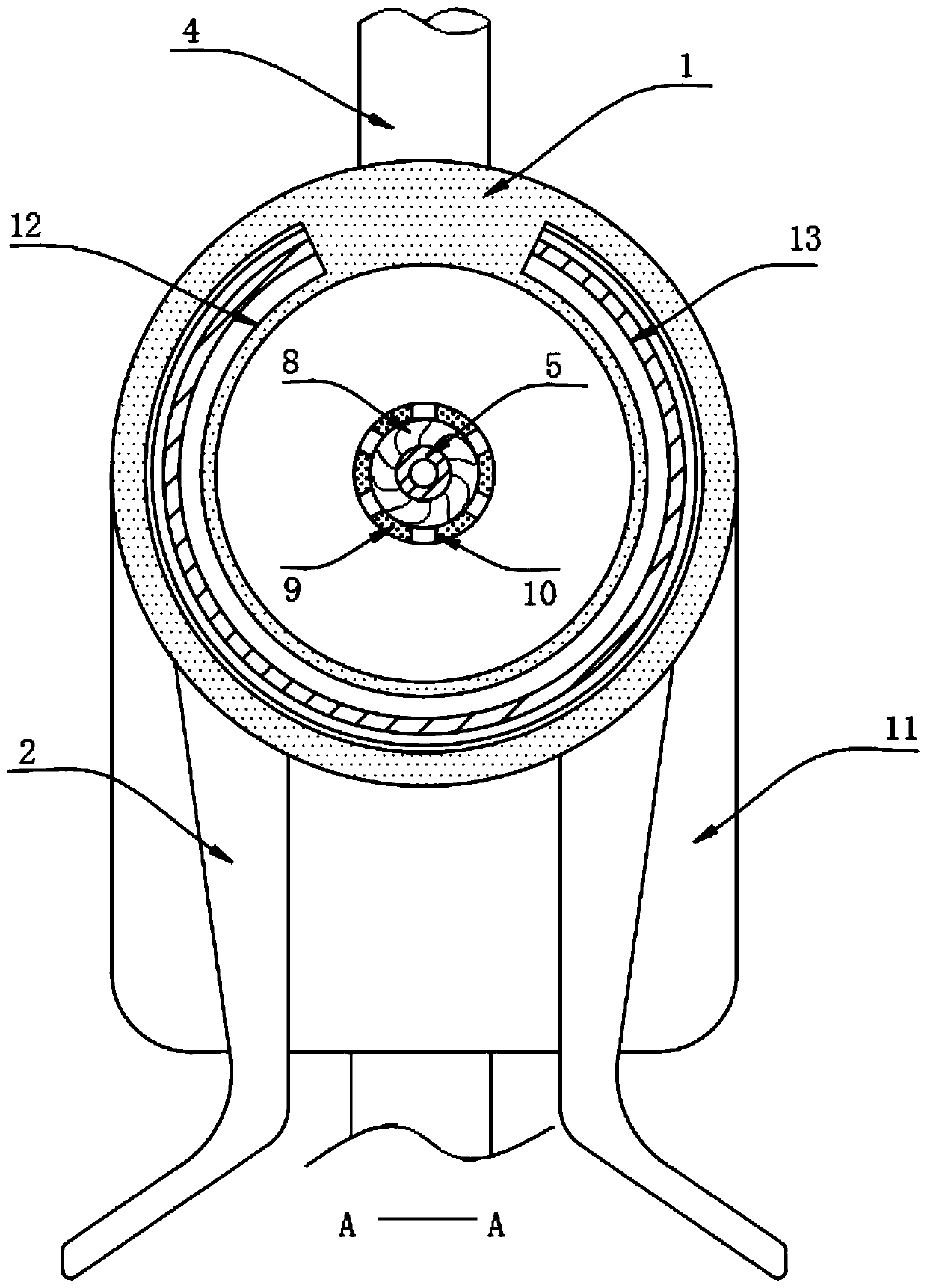

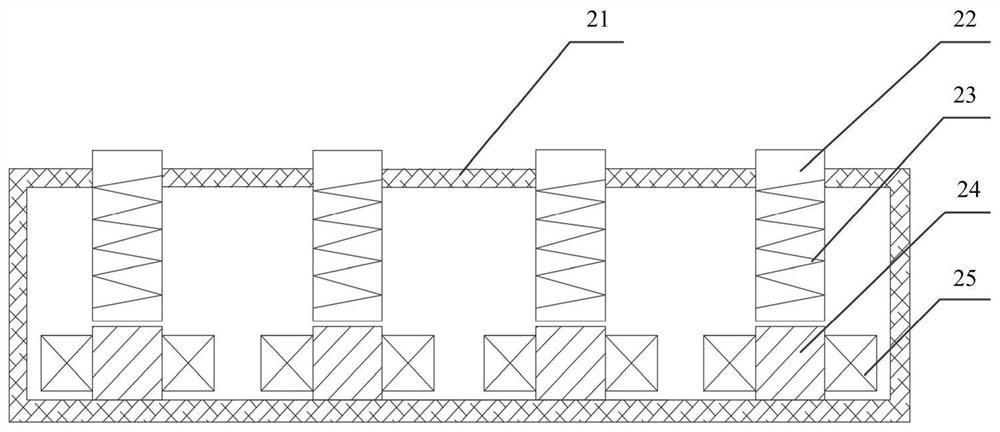

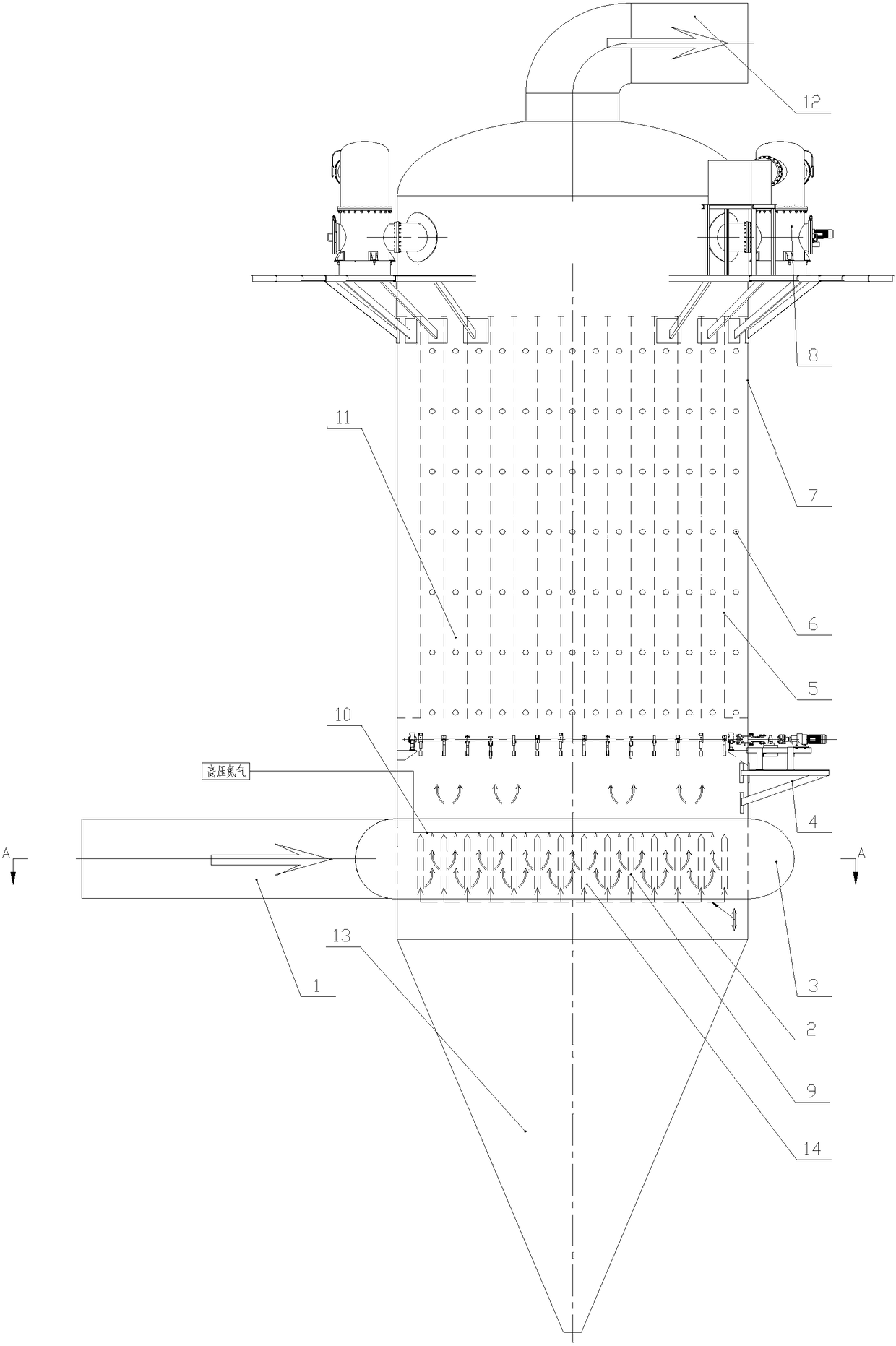

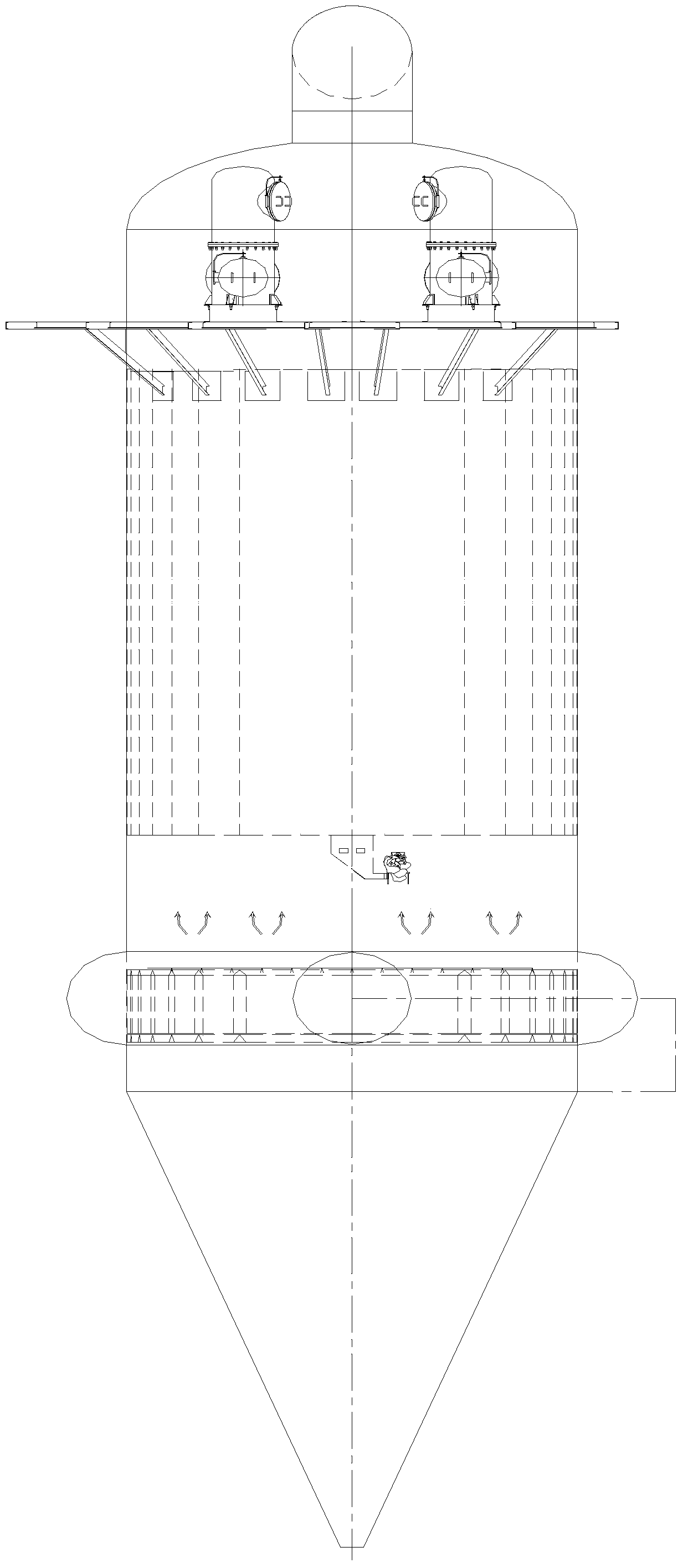

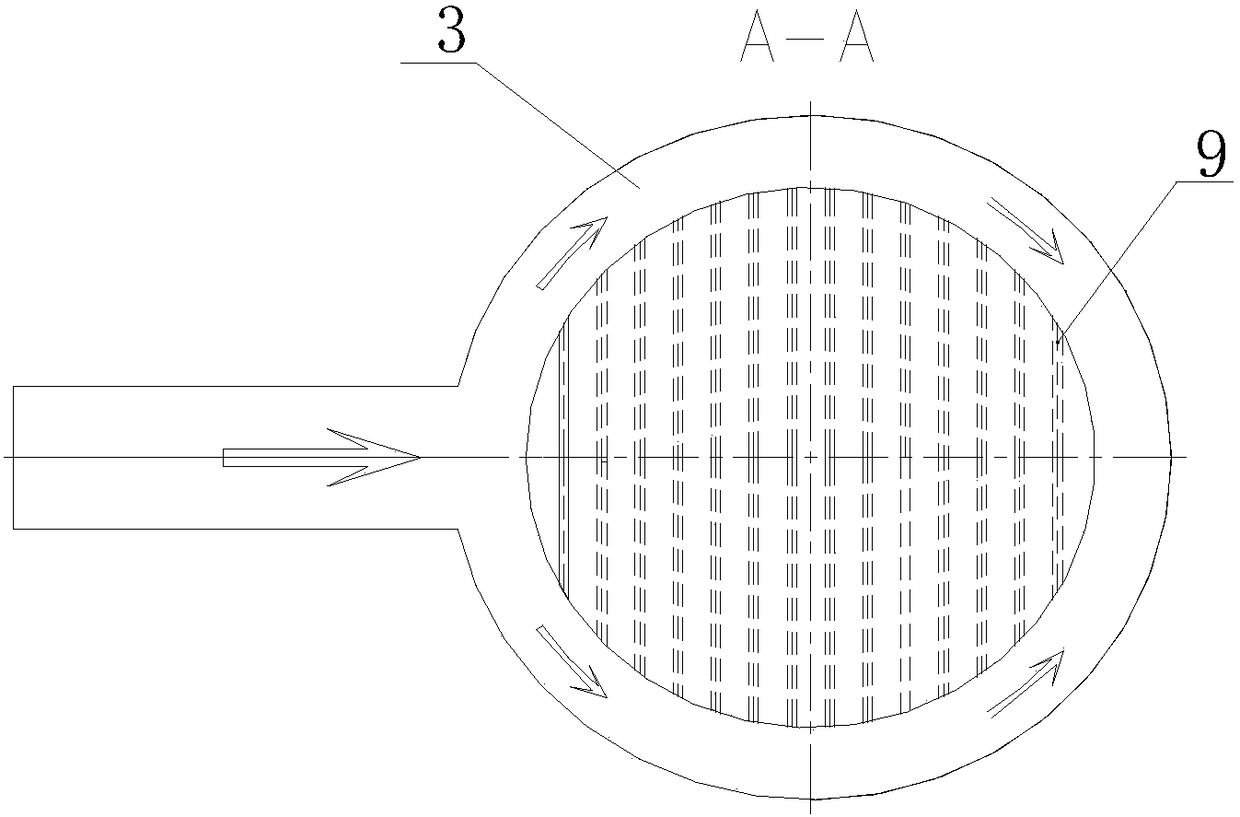

Medium and low temperature denitration, dedusting and thermo-analysis integrated method and device

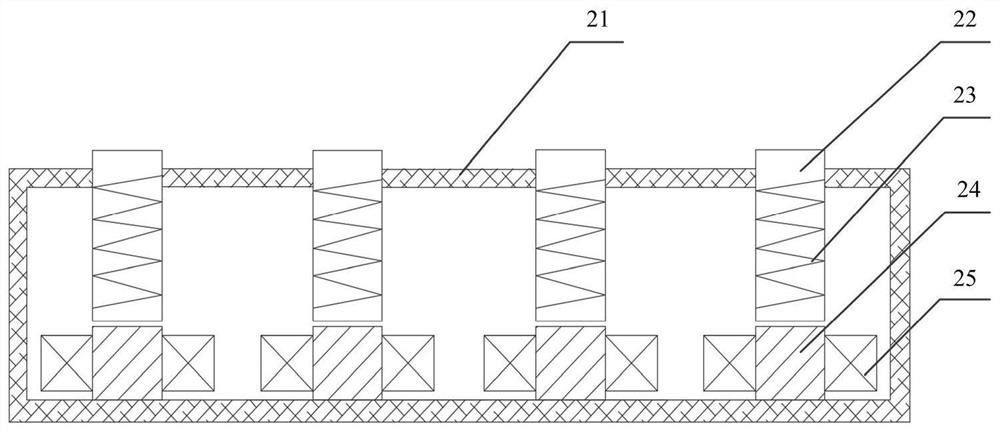

InactiveCN104399371AReduce investmentLow running costCombination devicesDispersed particle filtrationParticulatesFlue gas

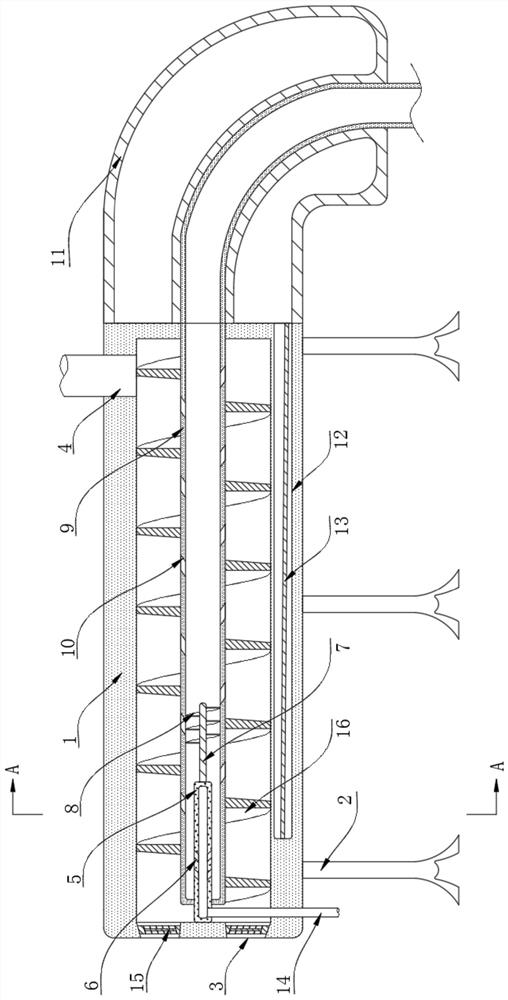

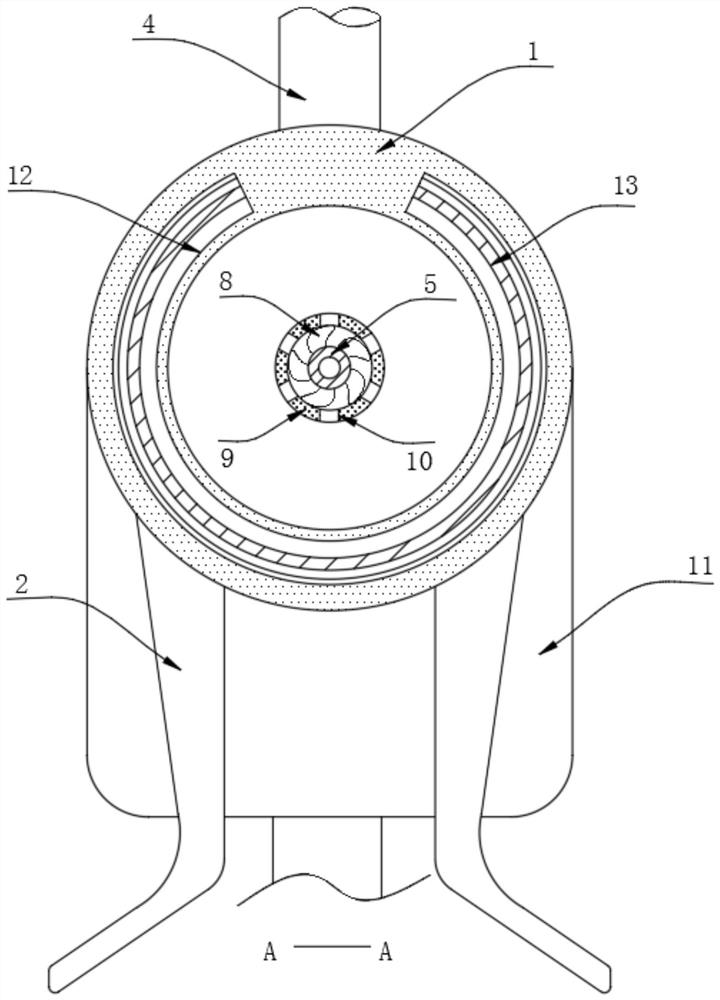

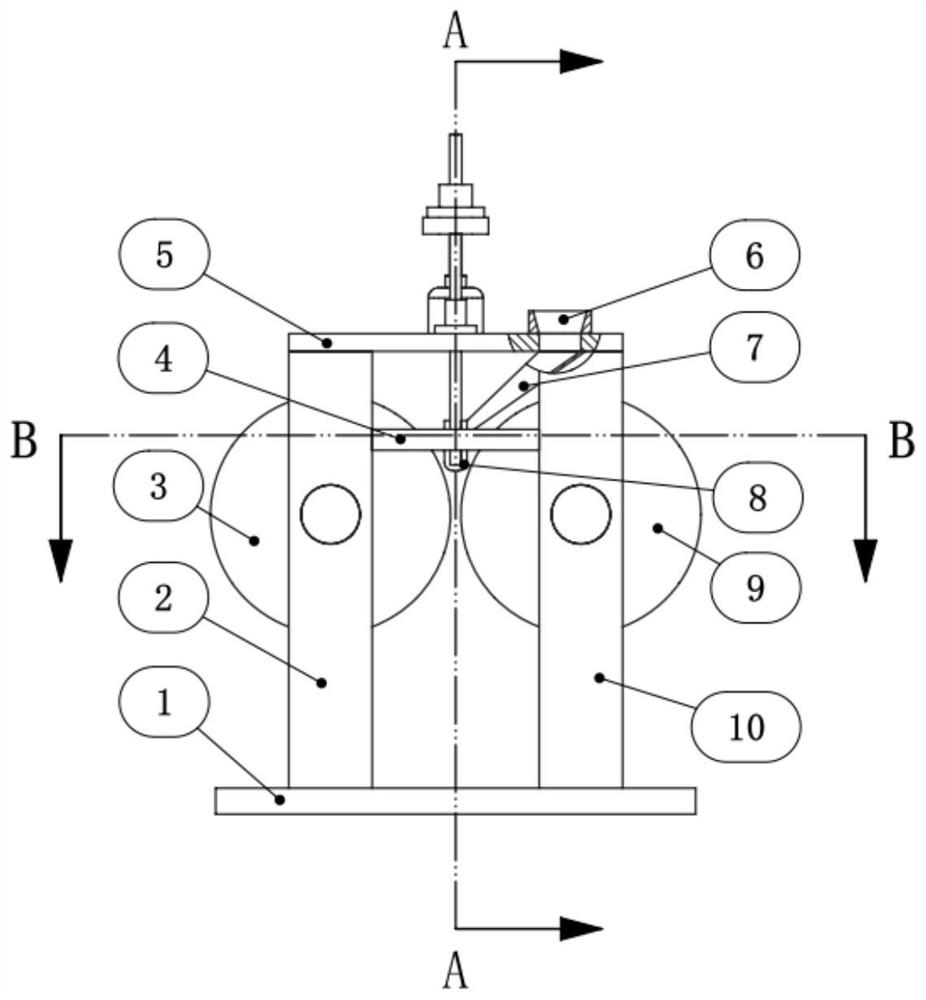

The invention relates to a medium and low temperature denitration, dedusting and thermo-analysis integrated method and a device. The device is formed by combining a dedusting filter bag layer, a denitration catalyst layer and a field thermo-analysis regeneration structure layer and comprises a particulate collection and discharge section, a flue gas purification and filtration section, a mixed analysis regeneration section and a denitration reaction section. The denitration catalyst structure layer is arranged on the top of the bag purification layer, and the dedusting is carried out before denitration, so that abrasion of dust to a denitration catalyst can be reduced. The thermo-analysis regeneration structure layer is arranged between the denitration catalyst structure layer and the bag purification layer; analysis and regeneration of the denitration catalyst are achieved by supplying high-temperature analysis gas on line regularly; continuous efficient use of the medium and low temperature catalyst is kept; and normal operation of a flue gas denitration technology is unaffected. Static pressure mixing devices are arranged in the mixed analysis regeneration section, and uniform distribution of a velocity field and a temperature field of flue gas on a cross section of the device is achieved by a pressure equalization effect of the static pressure mixing devices and the filter bag resistance layer.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

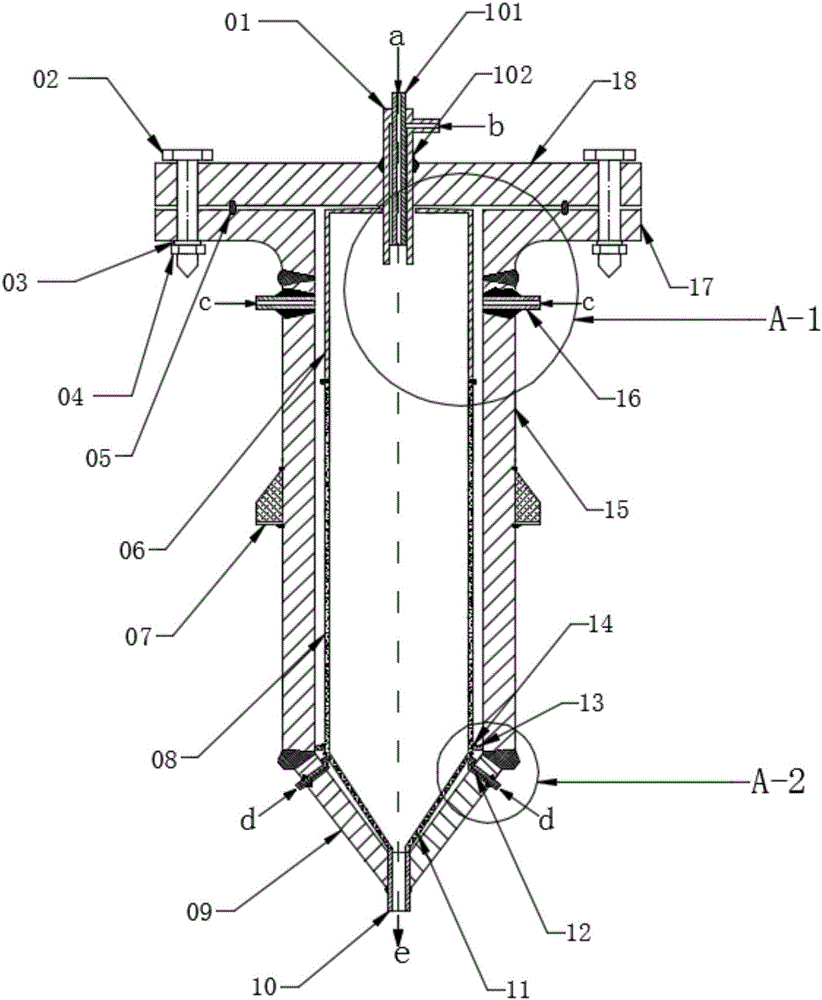

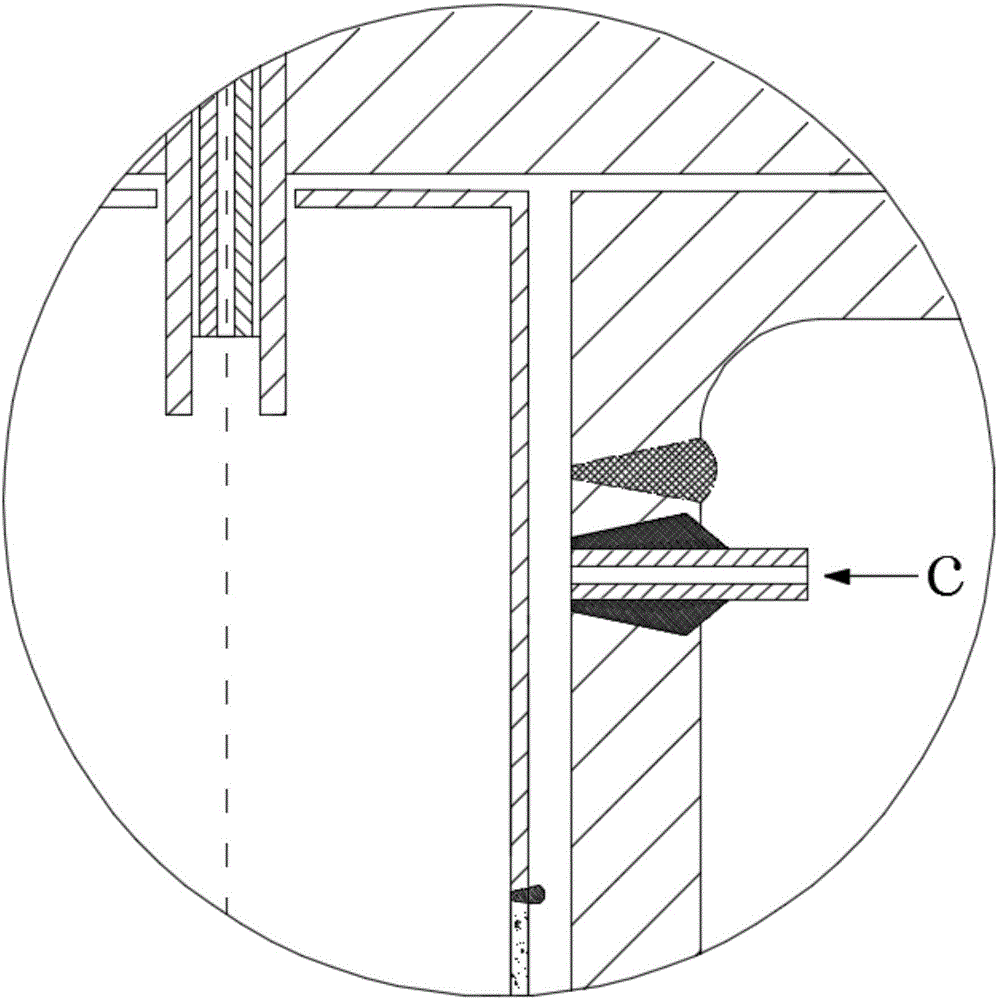

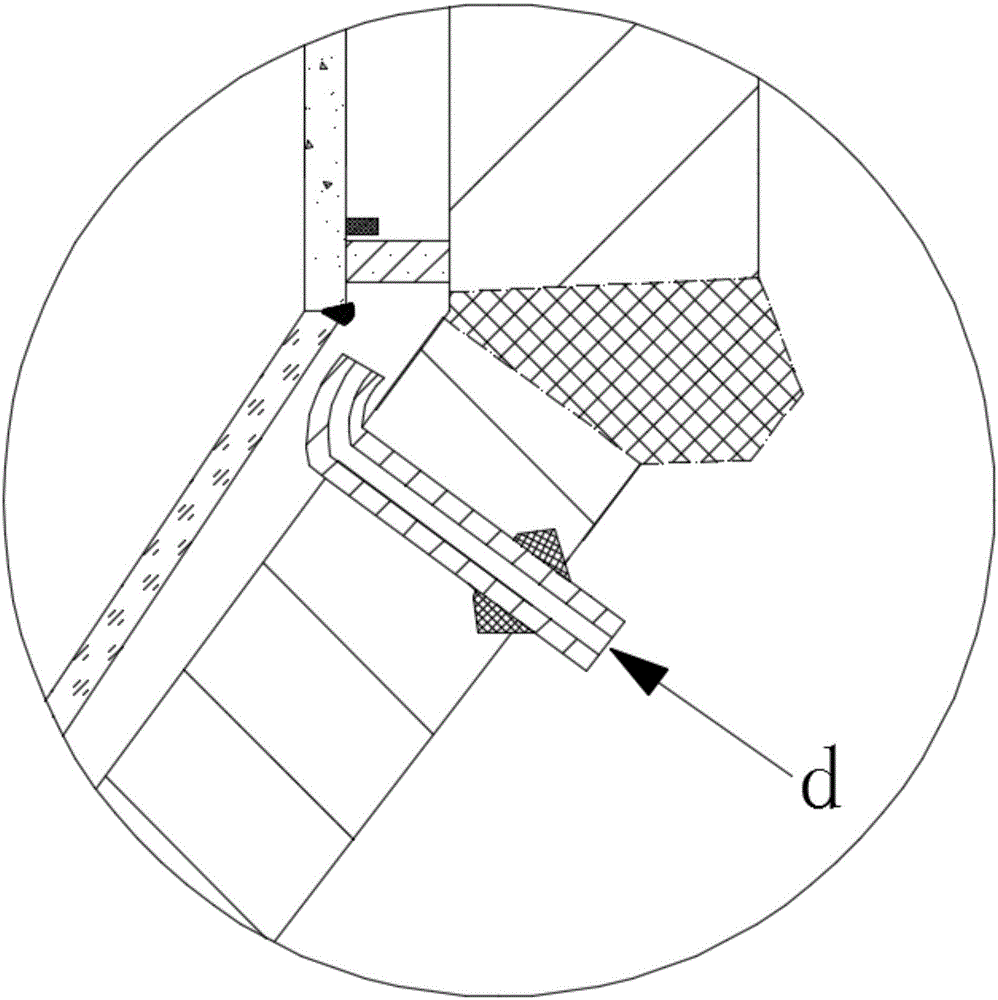

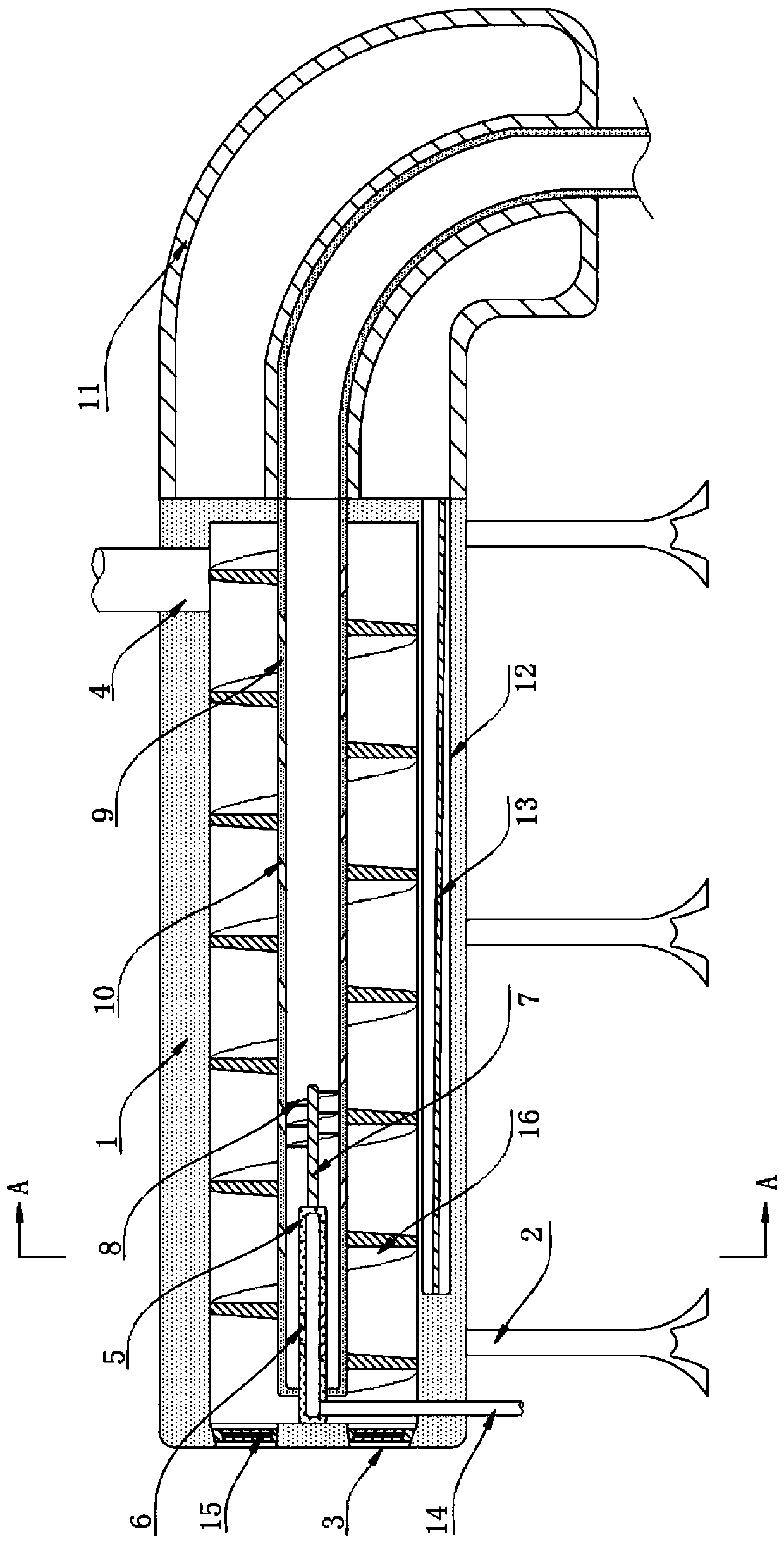

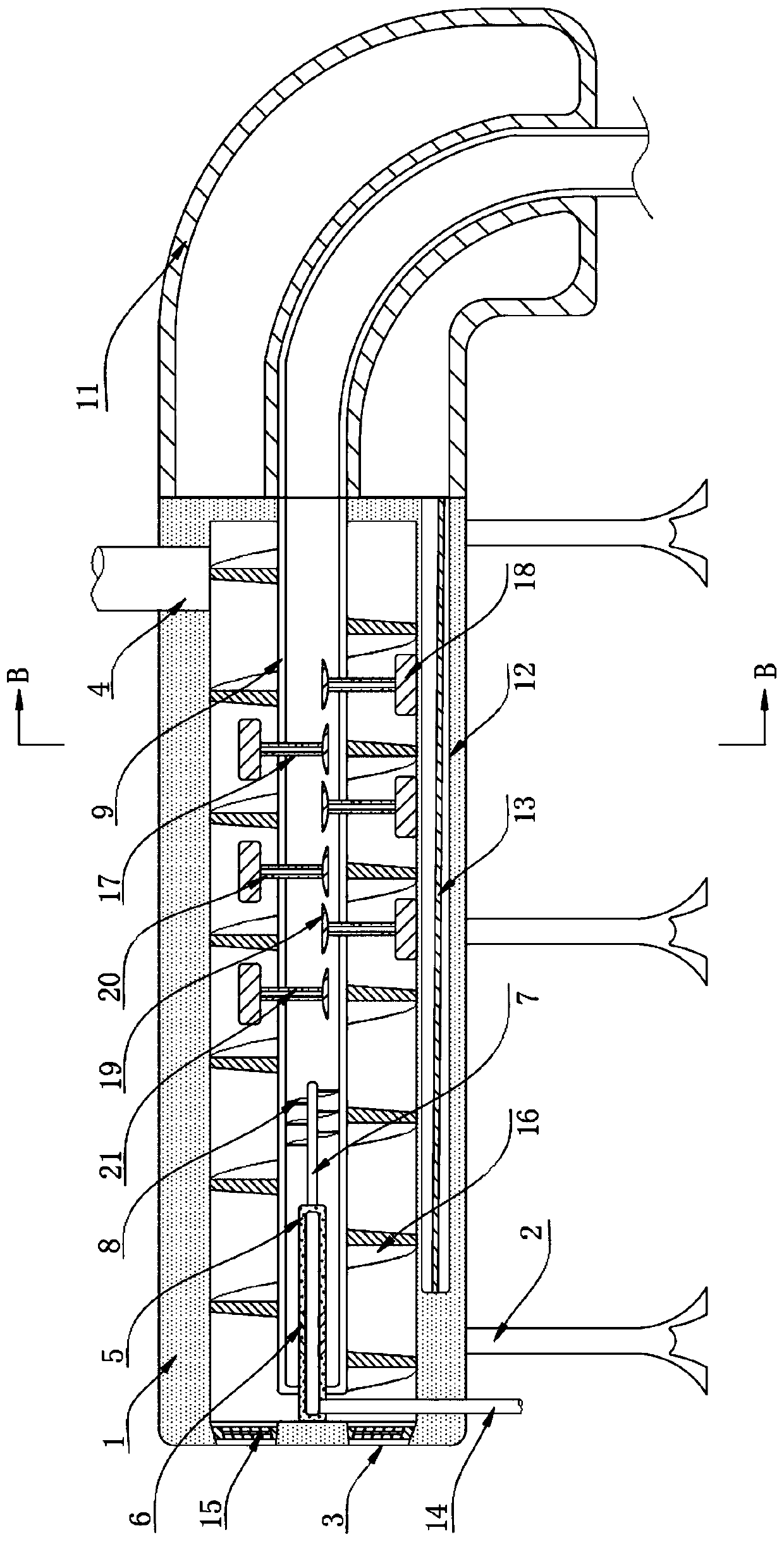

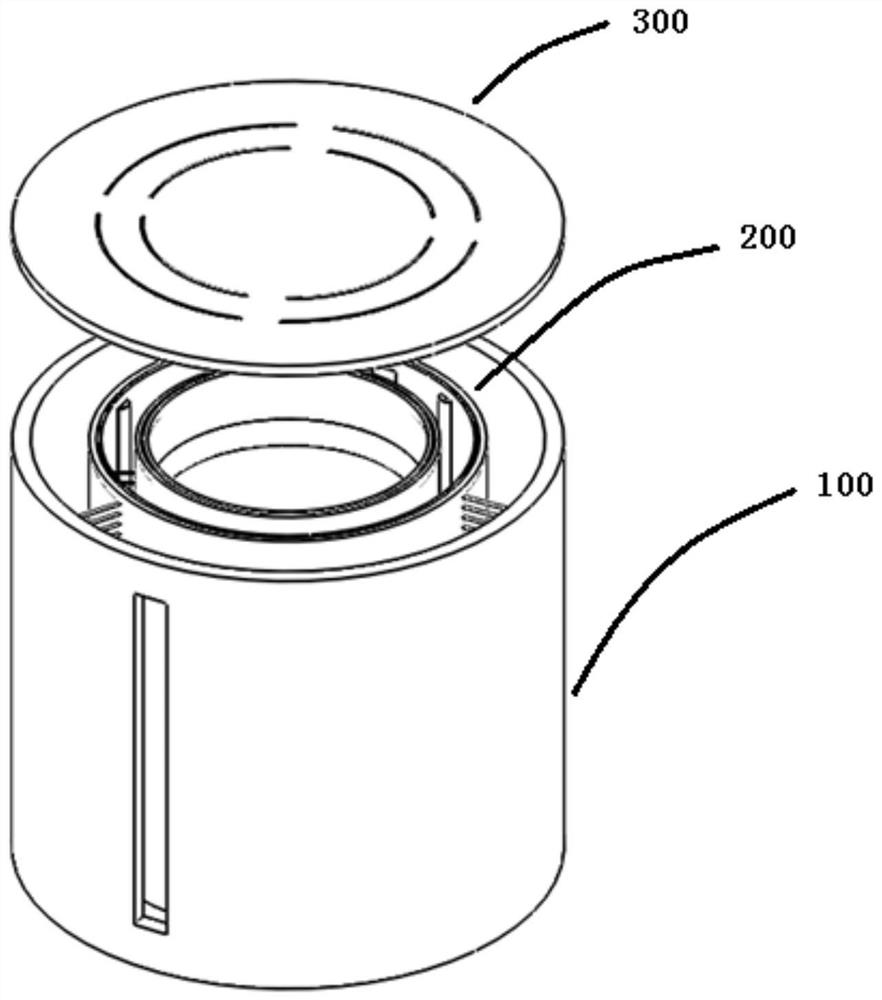

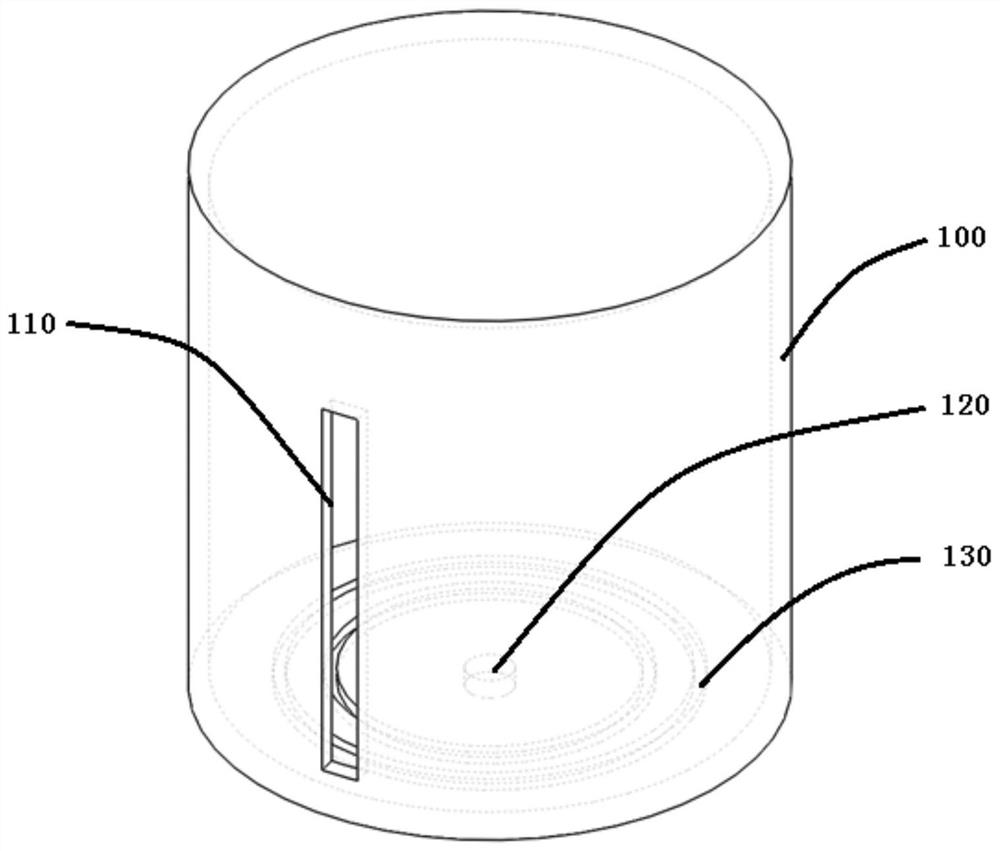

Supercritical water oxidation reactor

ActiveCN106219725AEvenly distributedImprove protectionWater treatment parameter controlSludge treatmentEngineeringSupercritical water oxidation

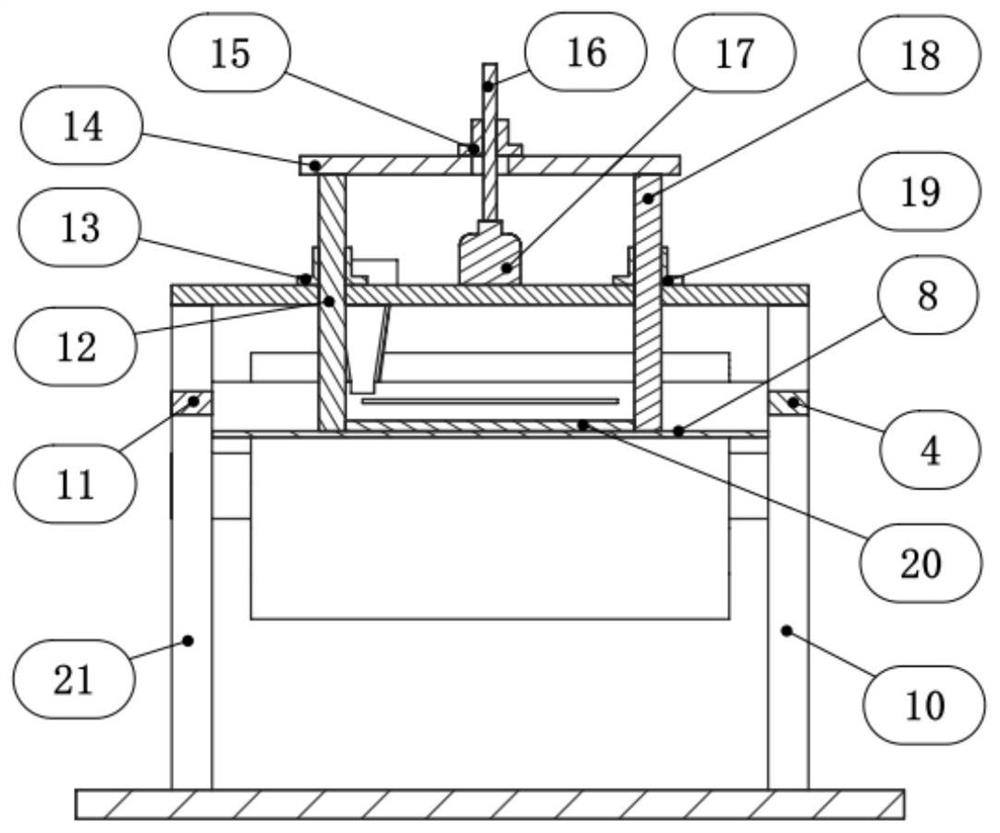

The invention relates to technical fields of environment protection and chemical engineering, in particular to a supercritical water oxidation reactor. The supercritical water oxidation reactor comprises an inner shell and an outer shell which are coaxially arranged; the inner shell is divided into an upper cylinder and a lower cone; the cylinder comprises an upper-section hole-free pipe and a lower-section straight porous pipe; the cone is of a tapered porous wall; the outer shell comprises an upper connection flange, a middle straight pressure bearing wall and a lower tapered bearing wall; a first ring gap is formed between the cylinder portion and the straight pressure bearing wall as well as the connection flange; a second ring gap is formed between the tapered porous wall and the tapered pressure bearing wall; an isolation ring is arranged between the first ring gap and the second ring gap; a high-temperature evaporated-water injection pipe is arranged on the upper portion of the straight pressure bearing wall; a low-temperature evaporated-water injection pipe is arranged on the upper portion of the tapered pressure bearing wall, and an outlet pipe is arranged at the bottom of the tapered pressure bearing wall; a nozzle pipe penetrating the top center of the inner shell is coaxially arranged on the connection flange. By the arrangement, evaporated water can be distributed evenly, and inhibition to center reaction during operation is avoided.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

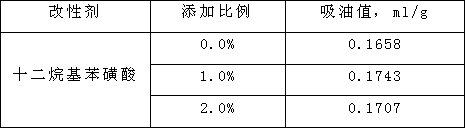

Negative electrode paste performance improvement method

PendingCN108281615AGood dispersionAchieve uniform distributionCell electrodesIonPerformance improvement

The invention discloses a negative electrode paste performance improvement method. The method comprises the following steps of A, paste preparation: a, adding deionized water and CMC to a stirring bucket; b, adding conductive carbon black to the paste after the paste is stirred in the step a; c, adding negative electrode graphite, DBSA and the residual solvent; d, adding weighed SBR; e, performingscreening on the stirred paste; B, coating: a, setting stationary knife table parameters, and starting a heating switch to set a warm area temperature; b, putting negative electrode paste into a material groove; c, starting a coater and performing debugging; and d, after debugging is qualified, starting a host to perform coating as normal. By adoption of the method, a modifying agent dodecylbenzene sulfonic acid is skillfully added in the paste preparation process; and on the basis, the adding working procedures of each added component are controlled reasonably in the preparation process, andstirring parameters are limited reasonably after each component is added so as to improve negative electrode particle dispersity, thereby realizing graphite powder particle uniform distribution and improving the paste performance.

Owner:宁夏科捷锂电池股份有限公司

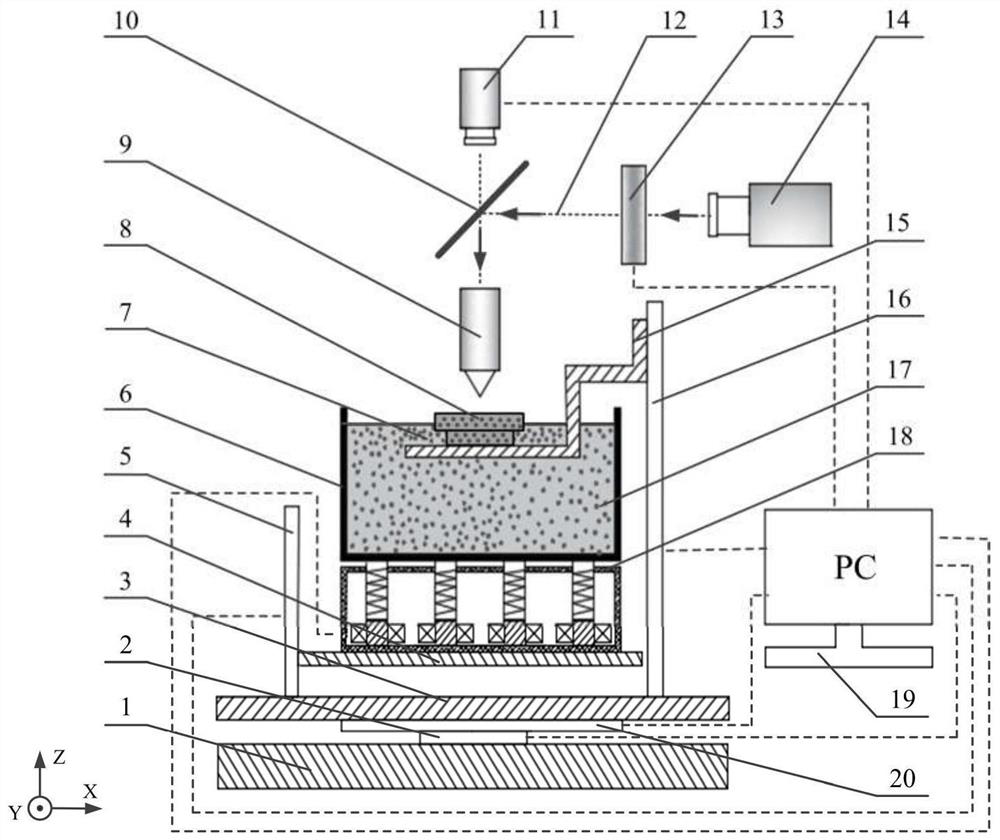

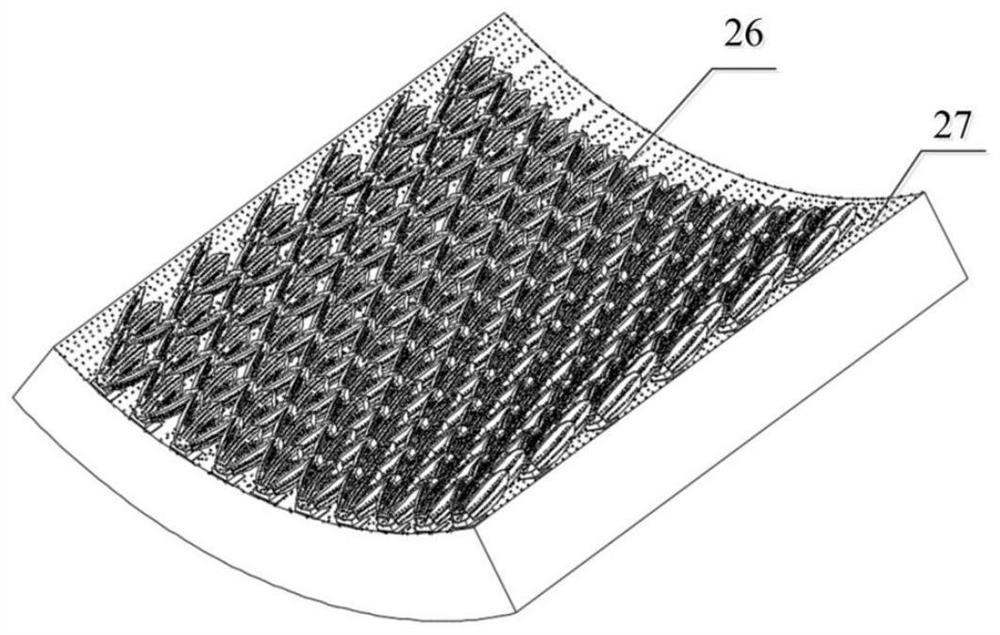

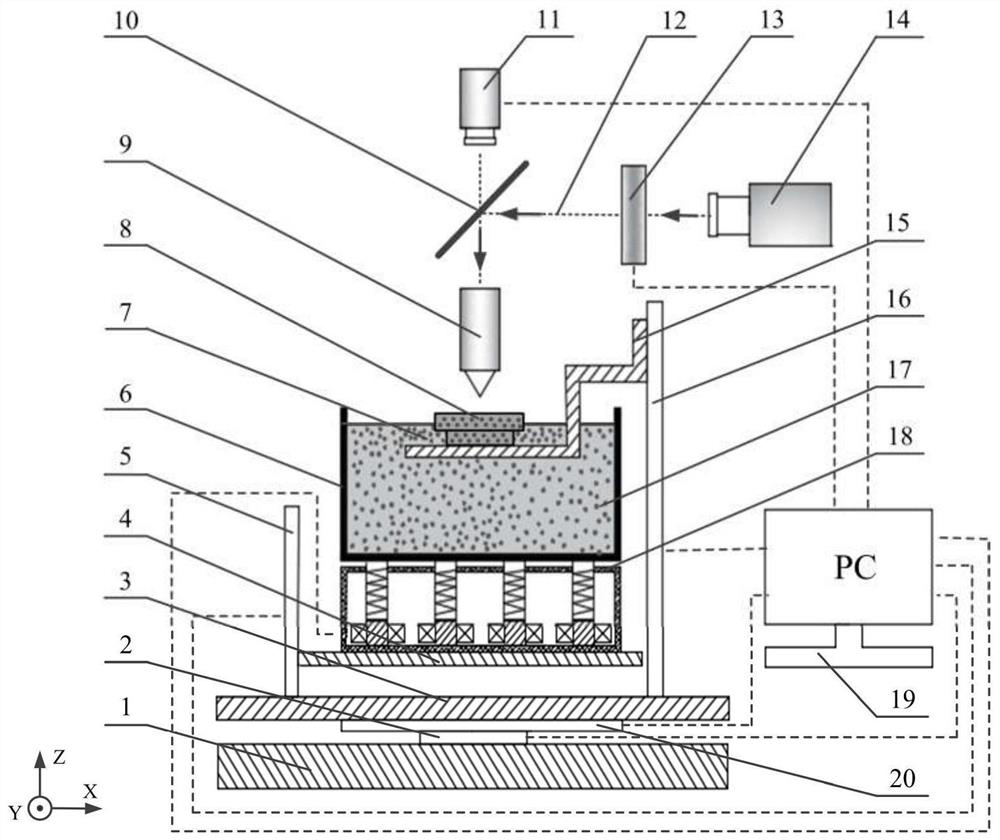

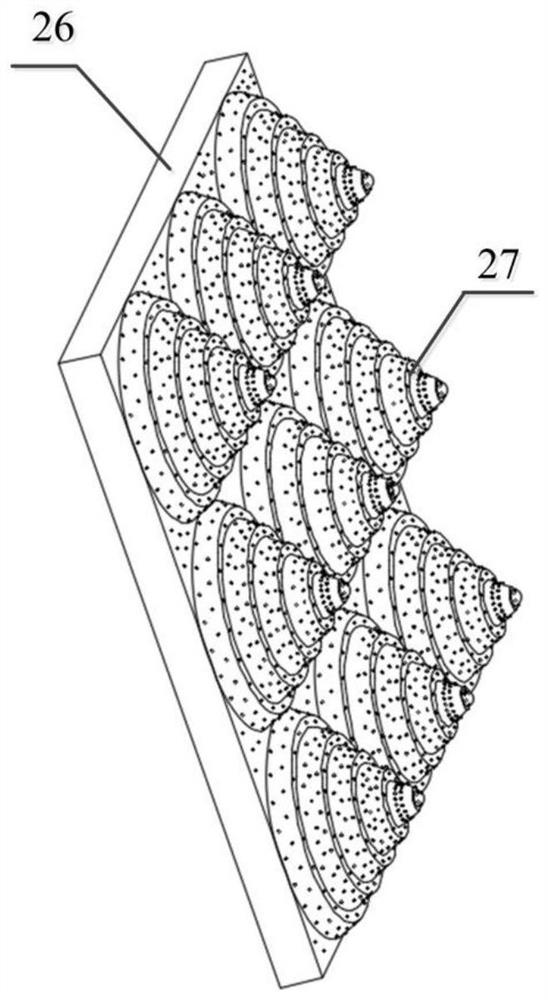

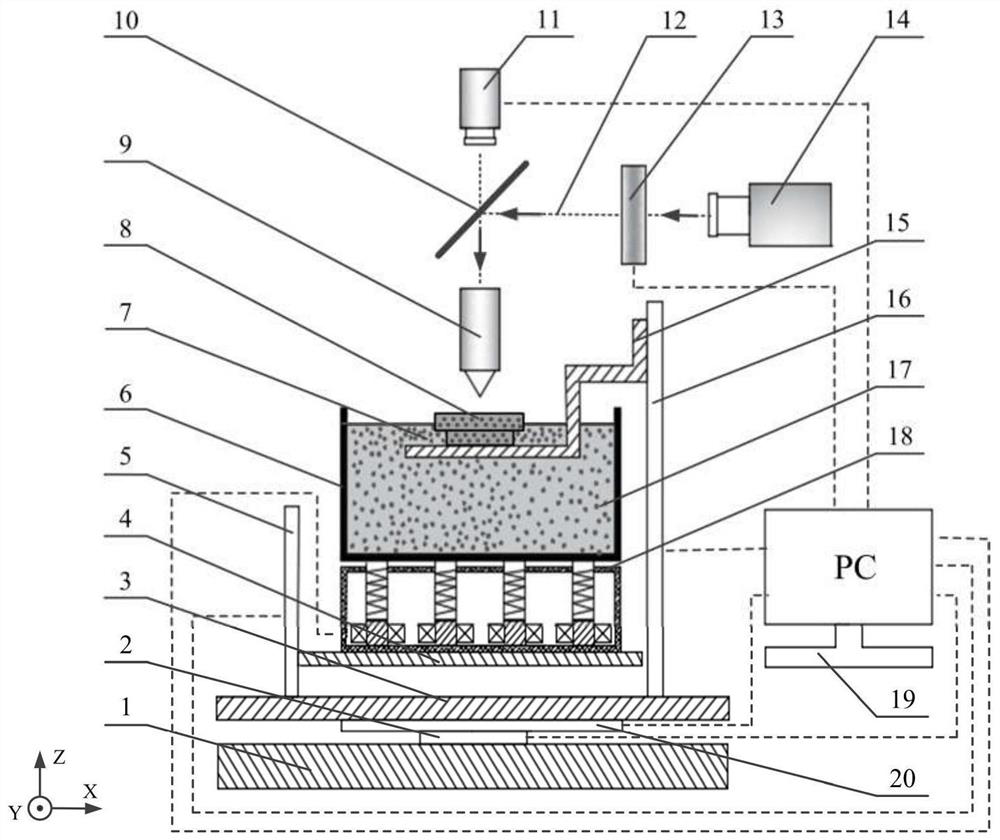

Surface microstructural array with self-transportation performance and forming method thereof

InactiveCN111688184AImprove condensation efficiencyDispersed nanoparticlesManufacturing platforms/substrates3D object support structuresParticle aggregationComposite structure

The invention discloses a surface microstructural array with self-transportation performance and a forming method thereof. A single microstructure of the surface microstructural array is a shark scaleimitating structure, the shark scale imitating structures are triangular protrusions and are made from photosensitive resin, and the size is in micron order. Nano particles are distributed on the surfaces of the microstructures, and micro / nano composite structures are formed by the nano particles and the shark scale imitating structures. Multiple composite structures are evenly distributed on thetarget face of a formed part, and the surface microstructural array is formed. According to the forming method of the microstructural array, the surface microstructural array is prepared through an electromagnetically assisted vibrating face projection micro-stereoscopic photoetching system according to certain steps. According to the surface microstructural array, automatic transportation of condensate liquid drops can be achieved, and the condensation efficiency is improved. According to the forming method, by means of high-frequency vibration of an electromagnetic assisted vibration device, nano particle aggregations can be reduced, even distribution of the nano particles is achieved, and the forming precision and the forming quality are improved. A forming system moving platform can do horizontal rectilinear motion in the Y-axis direction and the X-axis direction, the area of a forming layer face and the size of the formed part are expanded, the forming time is shortened, and theforming efficiency is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reactor for purifying organic waste gas under cooperation of plasmas and ultraviolet ray catalysis

PendingCN106890566AAchieve decompositionGood effectGas treatmentDispersed particle filtrationInsulation layerDecomposition

The invention discloses a reactor for purifying organic waste gas under cooperation of plasmas and ultraviolet ray catalysis. The reactor comprises a shell and an insulation layer, wherein the insulation layer is fixed outside the shell; a plurality of plasma discharge units, a gas inlet, a gas outlet and a filter dust removal unit are arranged in the shell; each plasma discharge unit comprises two stainless steel plates which are located at two ends of the plasma discharge unit; each filter dust removal unit is located between each gas inlet and the corresponding plasma discharge unit; each gas inlet is connected with one end of each filter dust removal unit; and the other end of each filter dust removal unit is connected with the gas outlet through the multiple plasma discharge units. According to the reactor for catalytically purifying the organic waste gas under cooperation of the plasmas and the ultraviolet ray catalysis, the plasmas, photocatalysis and adsorption action are organically combined, so that thorough decomposition and harmlessness of the organic waste gas are realized; the plasmas and the photocatalysis promote each other and work synergistically, so that the effect is outstanding.

Owner:浙江旭达环保技术有限公司

Energy-saving and high-efficiency thermal desorption system for soil remediation

ActiveCN110586635AAchieve separationReduce manual laborContaminated soil reclamationSoil remediationEngineering

The invention discloses an energy-saving and high-efficiency thermal desorption system for soil remediation. The thermal desorption system comprises a cylindrical thermal desorption box, a plurality of groups of brackets for supporting the thermal desorption box which are symmetrically fixed on the lower side of the circumferential outer wall of the thermal desorption box, a set of discharge holeswhich are arranged through the side wall of the thermal desorption box, a feed pipe which is inserted through the circumferential side wall of the thermal desorption box far away from one end of thedischarge hole, a fixing cylinder which is welded on the inner wall of the thermal desorption box near one end of the discharge hole, and an air inlet pipe communicated with the inside of the fixing cylinder and inserted through the circumferential side wall of the thermal desorption box. The advantages are: the introduced high-speed and high-temperature airflow will drive the rotating blades to rotate, furthermore, the driving rotating blade drives an auger rotating rod to rotate, and the soil can be pushed through the pushing effect of the auger blade on the surface of the auger rotating rod, thus forming a continuous thermal desorption process, requiring no artificial soil replacement and no additional driving force, so that the whole process is more convenient, efficient and energy-saving.

Owner:MINGDA MARINE ENG CO LTD

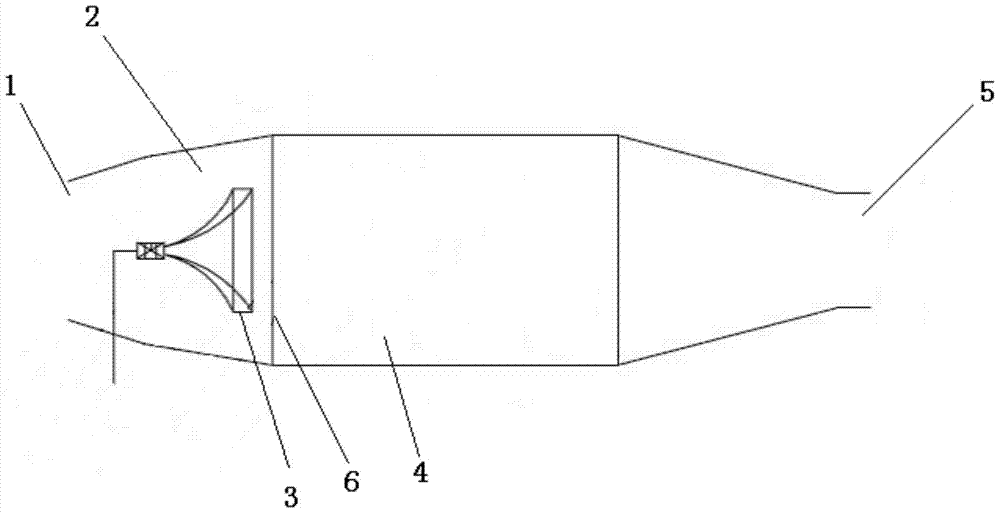

Large-space dirt removal device with gas-sound complex fields uniformly distributed and dirt removal method of large-space dirt removal device

ActiveCN105276593AReduce lossConducive to uniform distributionSolid removalEngineeringSound production

The invention discloses a large-space dirt removal device with gas-sound complex fields uniformly distributed and a dirt removal method of the large-space dirt removal device. The dirt removal device comprises a device inlet, a gas-sound field uniform-distribution space, sound wave dust blowing devices, a dirt removal space and a device outlet. The gas-sound field uniform-distribution space is arranged behind the device inlet and internally provided with the sound wave dust blowing devices. The dirt removal space is arranged behind the gas-sound field uniform-distribution space. The device outlet is formed behind the dirt removal space. A gas-sound flow guide plate is arranged behind the sound wave dust blowing devices in the gas-sound field uniform-distribution space. The sound production directions of the sound wave dust blowing devices face the gas-sound flow guide plate. The dirt removal method includes the steps that after air flow is introduced into the device, the air flow is uniformly guided to form uniform air flow, then the uniform air flow and sound waves produced by the sound wave dust blowing devices are uniformized in the gas-sound field uniform-distribution space, then are uniformized and rectified through the gas-sound flow guide plate and then enter the dirt removal space, dirt removal is conducted on the device in the dirt removal space, and meanwhile local serious dirt accumulation can be prevented effectively.

Owner:NANJING CHANGRONG ACOUSTIC INC

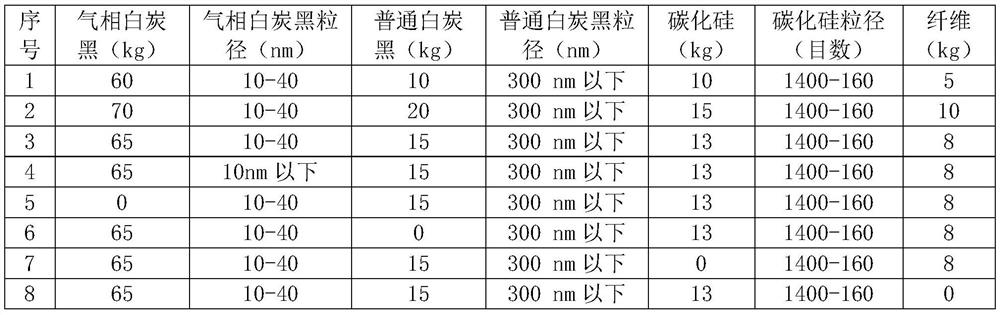

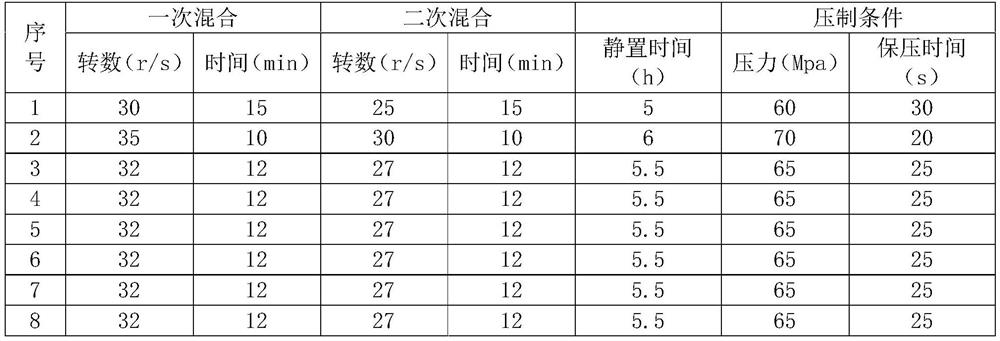

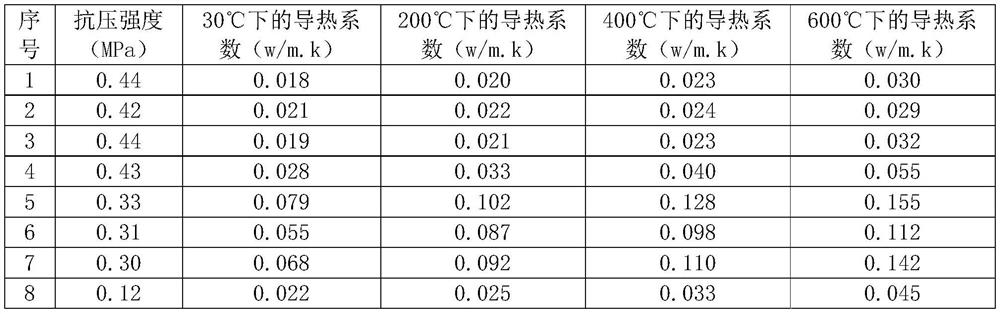

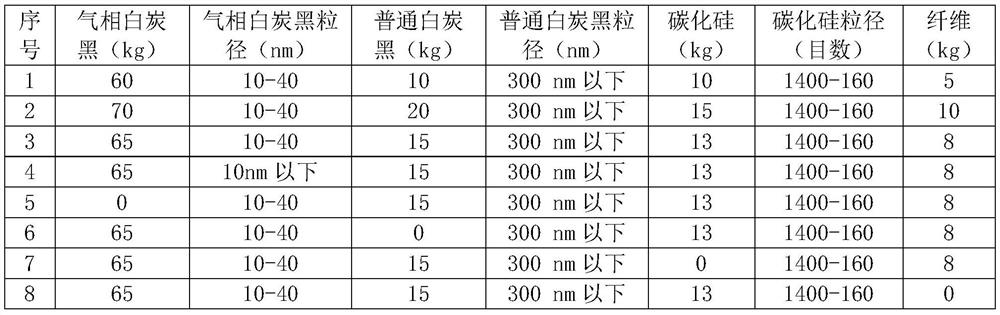

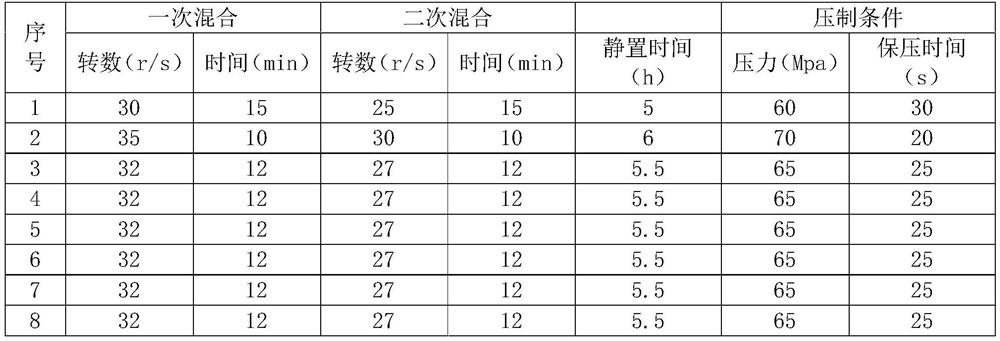

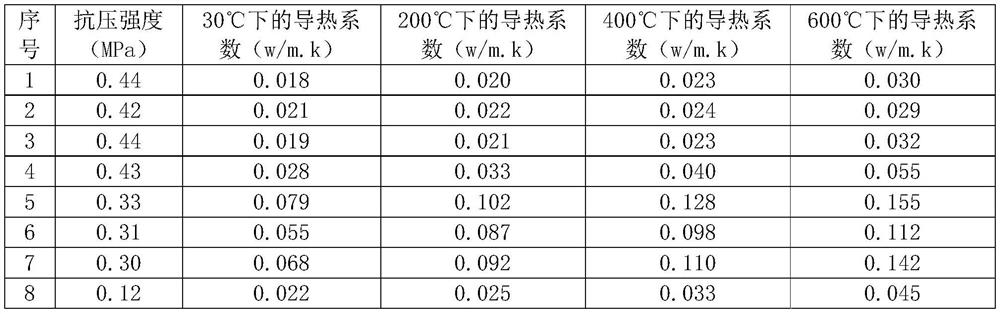

Low-thermal-conductivity thermal insulation material and preparation method thereof

ActiveCN111609252AGood thickening effectNot easy to absorb moistureThermal insulationPipe protection by thermal insulationCarbide siliconFiber

The invention discloses a low-thermal-conductivity thermal insulation material and a preparation method thereof. The low-thermal-conductivity thermal insulation material is prepared from the followingraw materials of, in parts by mass, 60 parts-70 parts of fumed silica; 10 parts-20 parts of common silica; 10 parts-15 parts of silicon carbide, and 5 parts-10 parts of fibers. The fumed silica and the common silica are combined for use, so that the characteristics of good thickening property and difficulty in moisture absorption of the fumed silica can be exerted, meanwhile, the characteristic of polyhydroxyl of the common silica can be exerted, the fumed silica can be better compounded with the fibers, and the moisture absorption characteristic can be inhibited due to the low content of thefumed silica; and the silicon carbide has radiation resistance and wear resistance, the silicon carbide is used as an intermediate substance in the thermal insulation material, and the fumed silica,the common silica and the fibers are filled in the silicon carbide, so that the silicon carbide has relatively high strength on the premise of ensuring a low heat conductivity coefficient.

Owner:山东金石节能材料有限公司

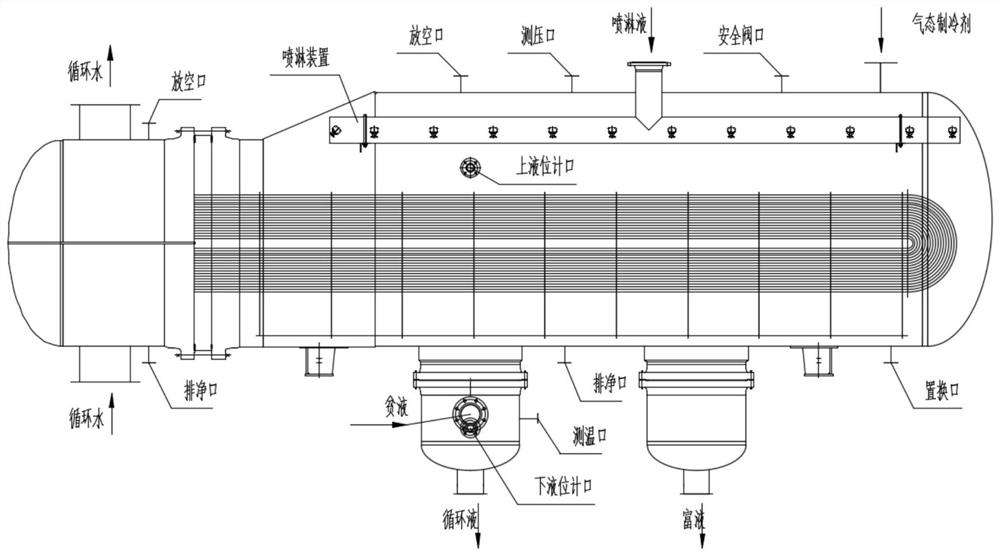

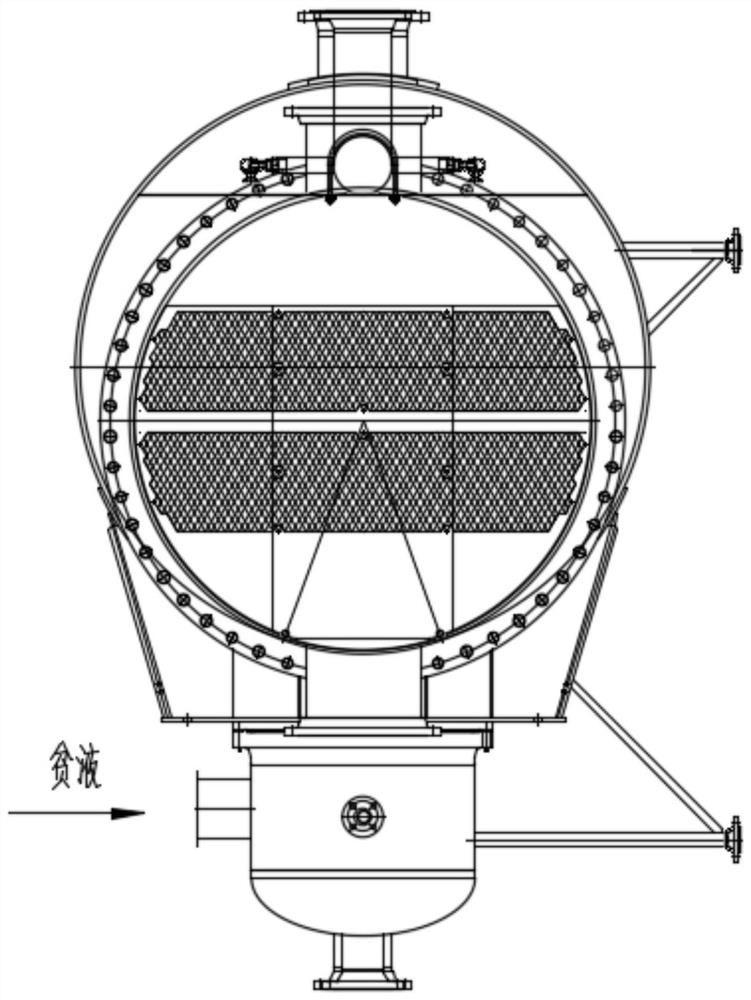

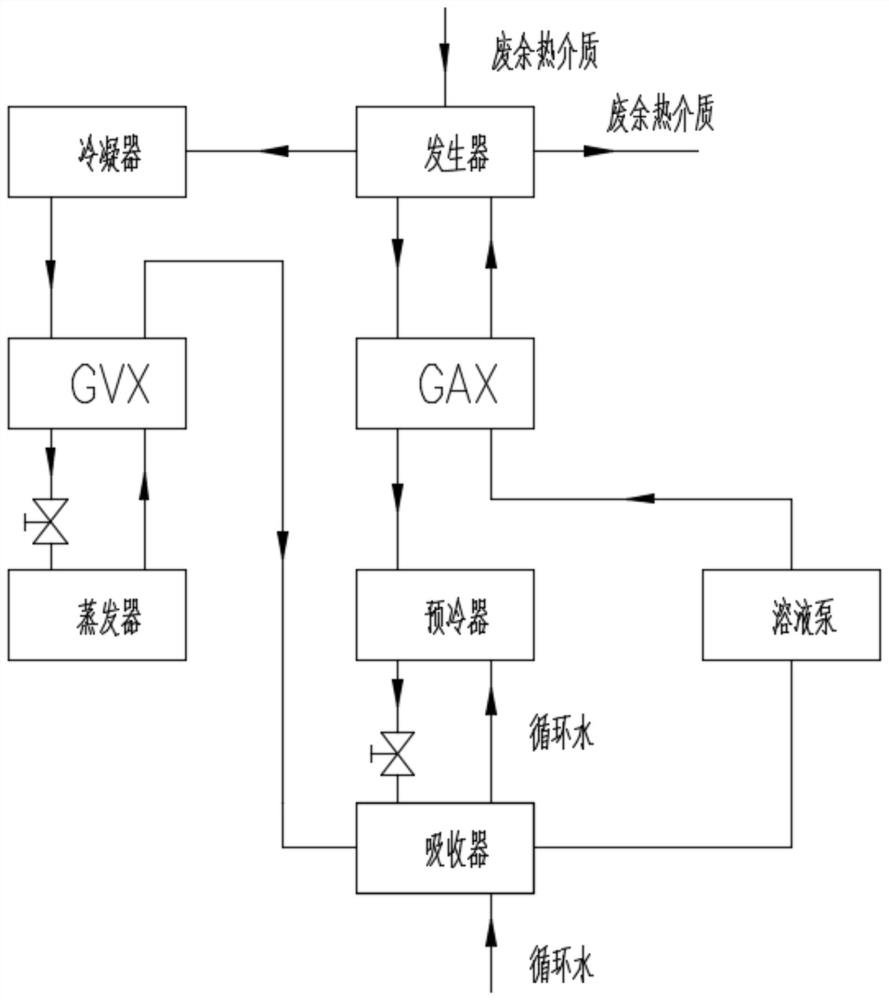

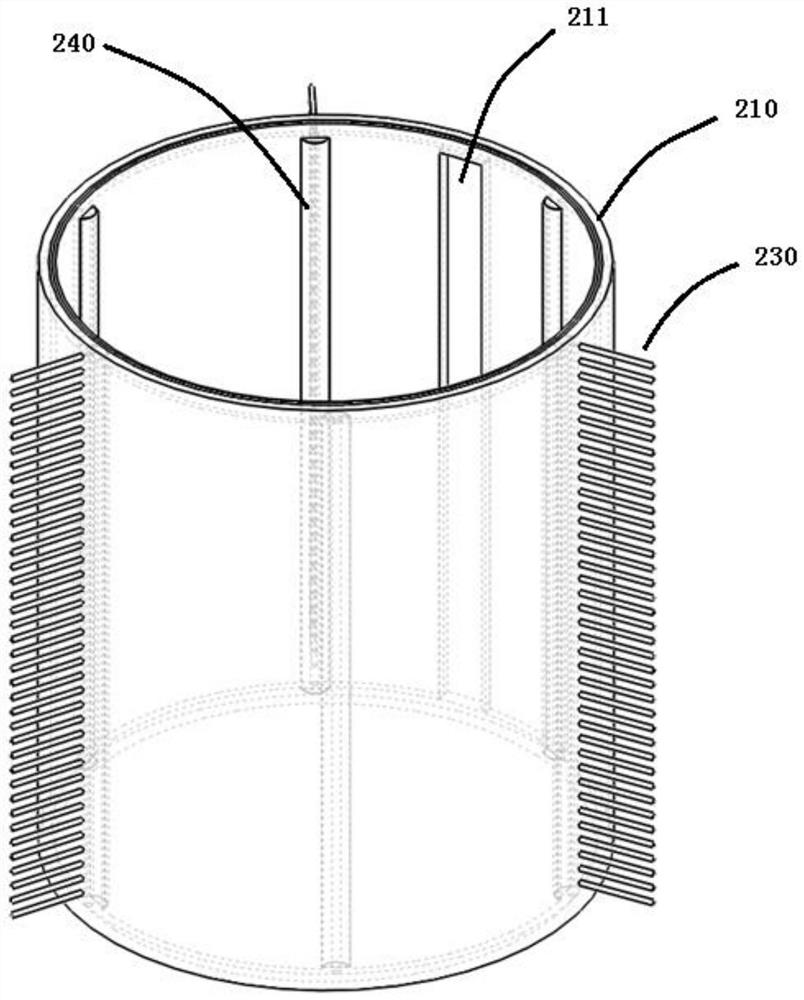

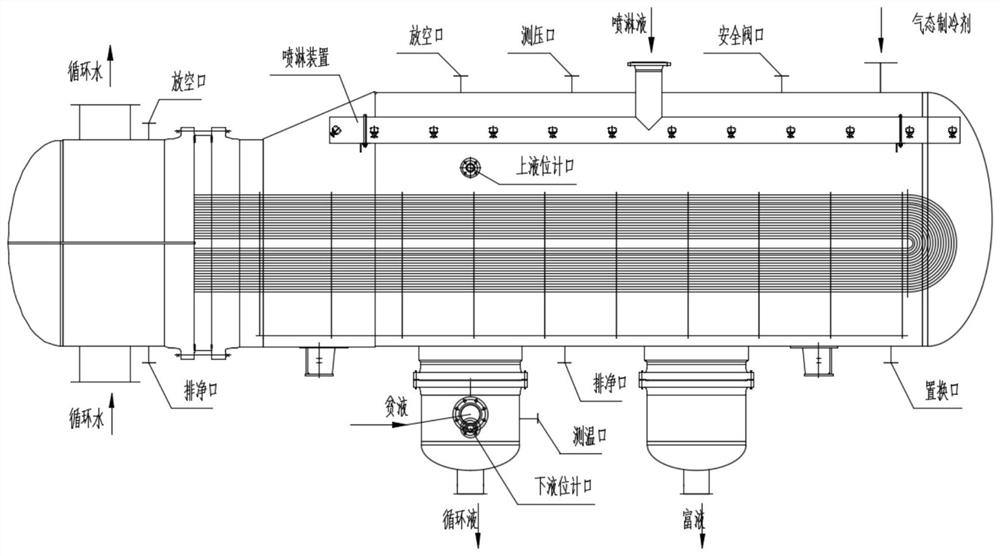

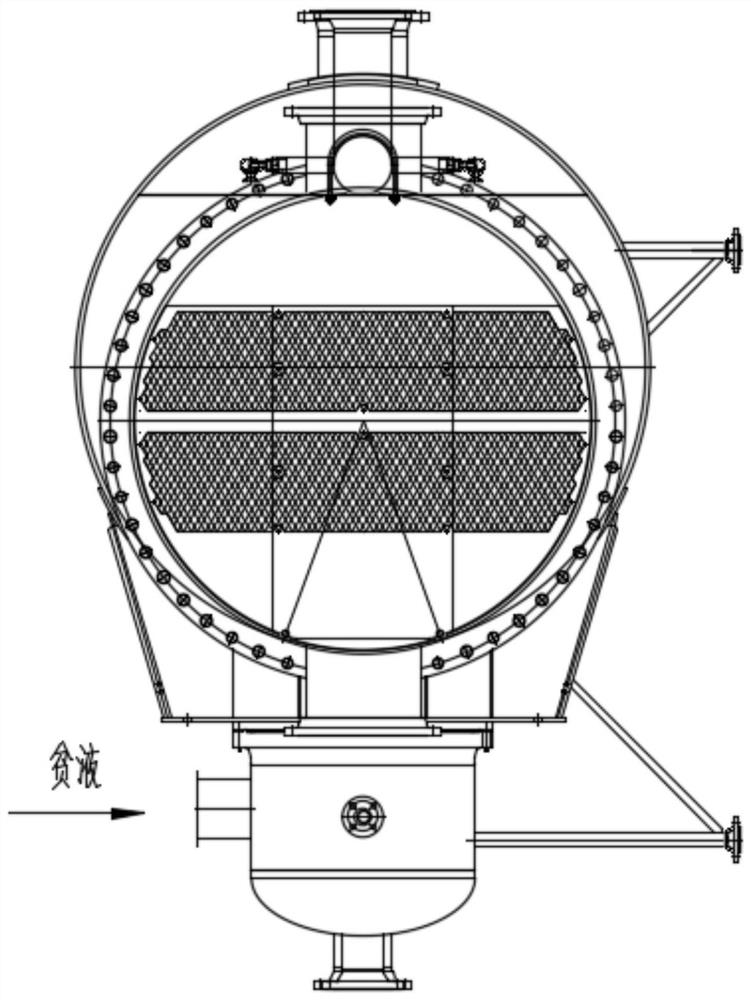

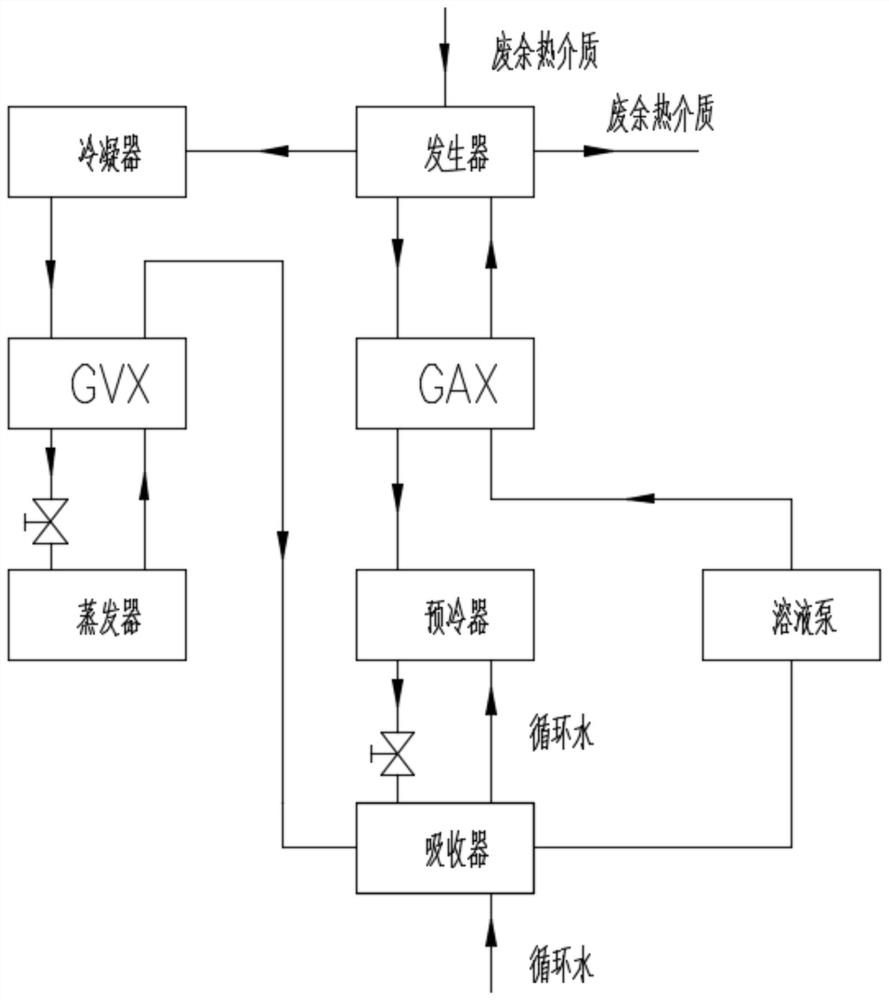

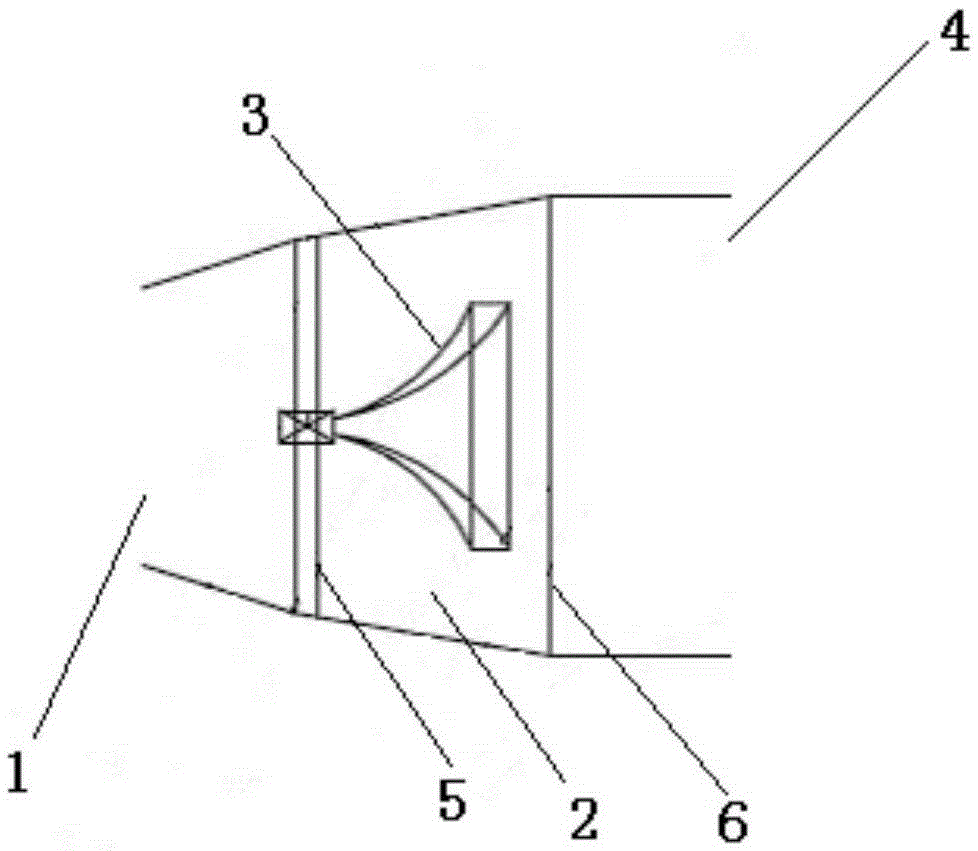

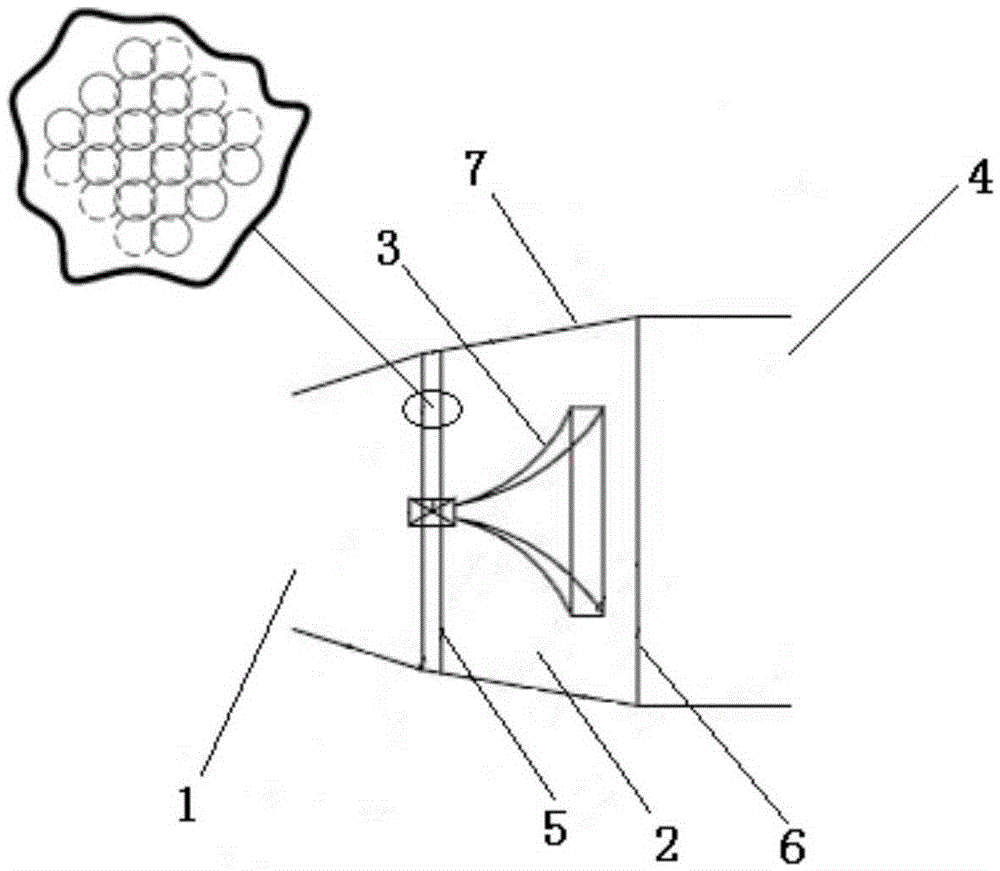

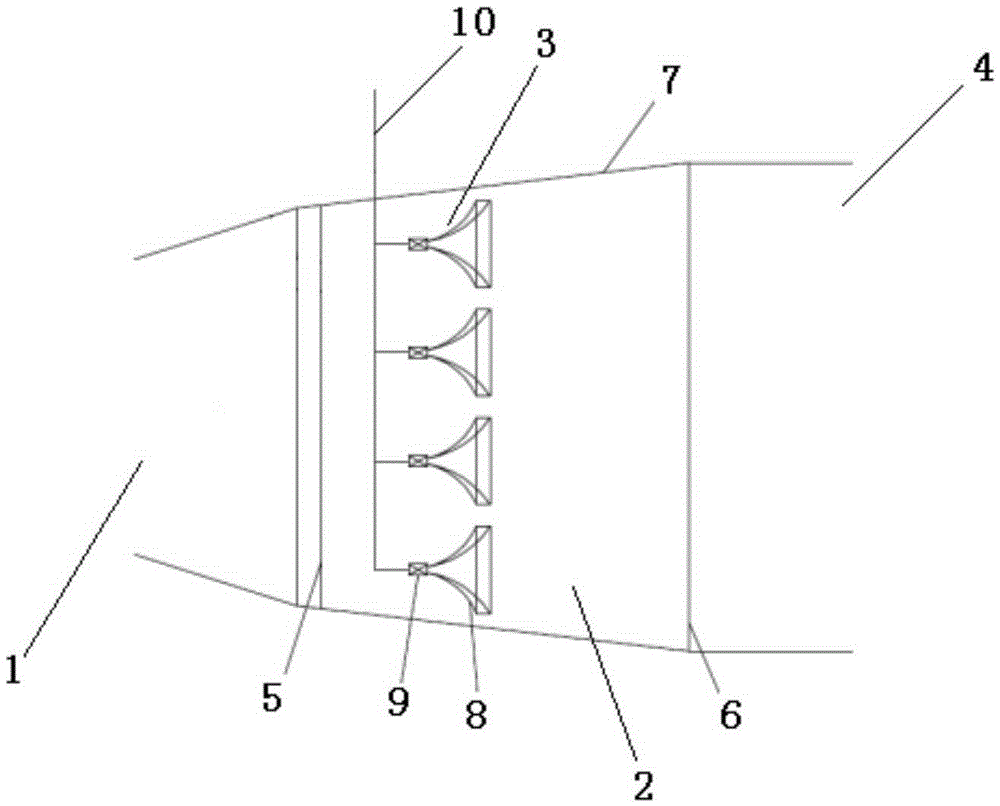

Novel absorber and absorption type refrigeration system thereof

ActiveCN113758053AAchieve uniform distributionIncrease the areaClimate change adaptationAbsorbers/adsorbersEngineeringRefrigeration

The invention relates to a novel absorber and an absorption type refrigeration system thereof, and belongs to the technical field of absorption type refrigeration. The novel absorber comprises a pipe box and a shell, a U-shaped pipe bundle is arranged in the shell, an upper layer spraying device and a lower layer spraying device are arranged in the shell, and the first layer spraying device is fixed to the top end of the shell and is arranged above an upper layer pipe bundle. The second spraying device is arranged in a U-shaped groove of a side U-shaped pipe bundle, two main air inlet pipes are arranged on the two sides of the shell, linearly-arranged branch air pipes are arranged between each main air inlet pipe and the shell, and the pipe box is provided with a circulating water inlet and a circulating water outlet which are connected with the pipe bundle. Circulating water of the circulating water outlet in the pipe box is utilized to exchange heat with barren liquor entering the shell so as to precool the barren liquor. Compared with an absorber structure in the prior art, the double-layer spraying and multi-position air inlet mode is adopted, so that the absorption efficiency of the absorber is improved to be about 95%.

Owner:ANHUI WATERPOWER ENERGY SAVING TECH

Surface microstructure array with water mist collecting function and molding method thereof

InactiveCN111688186AAchieve uniform distributionIncrease contact areaManufacturing platforms/substrates3D object support structuresMicron scaleTarget surface

The invention discloses a surface microstructure array with a water mist collecting function and a molding method thereof. A single microstructure of the surface microstructure array is a circular truncated cone pyramid structure, the structure is formed by overlaying multiple layers of circular truncated cones, the material is photosensitive resin, and the bottom radius of each layer of circulartruncated cone is reduced layer by layer and forms a micron structure; nano particles are distributed on the surface of the microstructure to form a micron / nano composite structure with the circular truncated cone pyramid structure; and a plurality of composite structures are uniformly distributed on the target surface of a molded part, namely, the surface microstructure array is formed. The molding method for the surface microstructure array utilizes a set of electromagnetic assisted vibration surface to project a micro-stereolithography system and follows certain steps to complete the preparation. The surface microstructure array provided by the invention can increase the contact area between the microstructure and the water mist, and improve the recovery efficiency of the water mist; the molding method provided by the invention reduces the agglomeration of nanoparticles, realizes uniform distribution and improves the forming accuracy and quality through the high-frequency vibrationof an electromagnetic auxiliary vibration device; and a mobile platform of a forming system can move horizontally and linearly in the Y-axis and X-axis directions, the area of a molding layer and thesize of the molded part are expanded, the molding time is reduced, and the molding efficiency is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

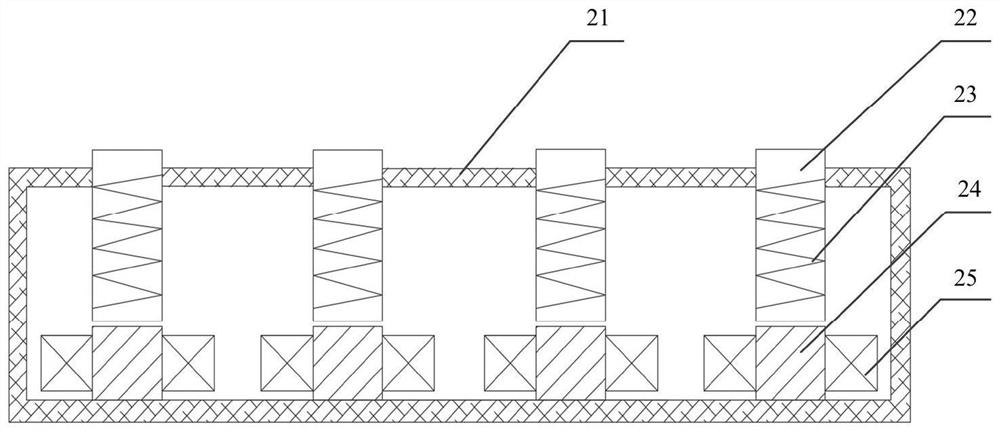

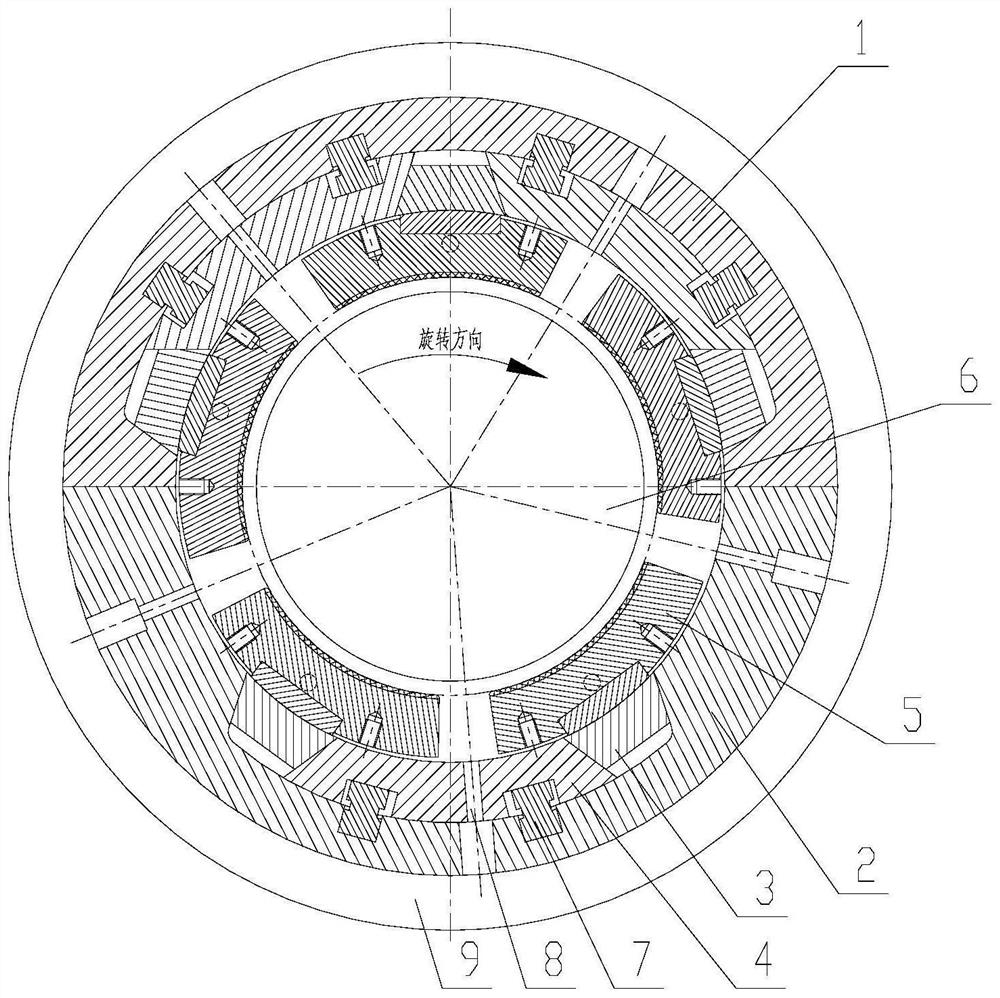

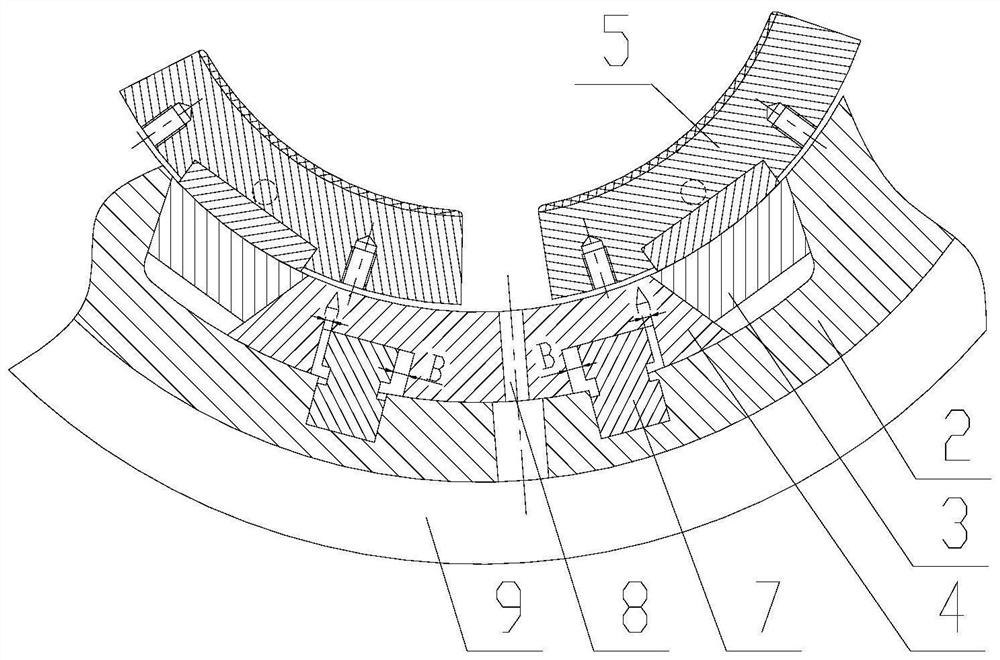

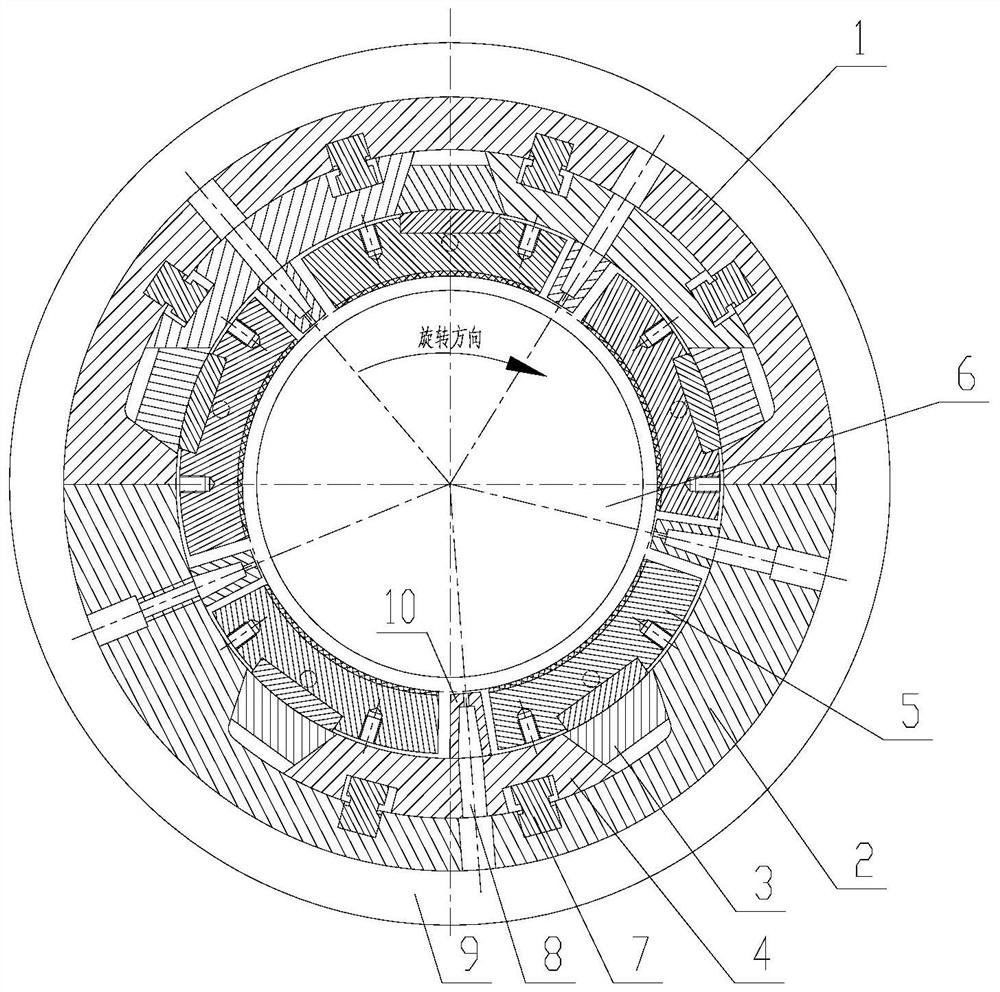

A load balancing sliding bearing

ActiveCN112211903BEven by forceTo achieve even load distributionBearing componentsSliding contact bearingsClassical mechanicsControl theory

The invention discloses a load balancing sliding bearing, which relates to the technical field of sliding bearings; it comprises a bearing body, a supporting pad block and a load balancing adjustment mechanism. The blocks are arranged corresponding to the supporting pads and are in contact with the supporting pads. The moving load equalizing block is connected with the bearing body and the rotating load equalizing block, so that the sliding of the moving load equalizing block along the radial direction of the bearing can be transformed into the sliding of the rotating load equalizing block along the Circumferential rotation, and then during the operation of supporting the sliding bearing, the supporting pads are linked together through the load-sharing adjustment mechanism, and the gap between each supporting pad and the journal is adaptively adjusted; through the implementation of this technical solution, the current situation is effectively solved. There is a technical problem of unbalanced force between the supporting pads of the sliding bearing. The uniform clearance and uniform force of the pads are respectively for the upper half tile and the lower half tile. The load is evenly distributed to achieve the characteristics of force balance among the supporting tiles.

Owner:DONGFANG TURBINE CO LTD

A microbial continuous fermentation system and connected fermentation method

ActiveCN111394225BReduce agglomeration and precipitationClean thoroughlyBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

Owner:上海天智绿色食品有限公司 +1

Sewage treatment precipitation device

InactiveCN112121477ARealize reasonable controlEasy to detectSedimentation settling tanksWater flowSewage treatment

The invention discloses a sewage treatment precipitation device, which structurally comprises a box cover, a box body, a rotating body and a drainage structure, wherein the box cover is arranged on the box body, the box body is connected with the drainage structure, the rotating body is arranged on the drainage structure, the box body is composed of a U-shaped box and a material moving structure,the U-shaped box is provided with the material moving structure, and the drainage structure comprises an upper column, a hole column and a pipe supporting column, the hole column is connected with theupper column and the pipe supporting column in a mounting mode, the pipe supporting column is provided with an outlet pipe and an inlet pipe, the rotating body comprises a rotating body mounting shaft, an inclined flow plate and a flow detection structure, and the rotating body mounting shaft is connected with the inclined flow plate in a mounting mode. The rotating body mounting shaft rotates onthe pipe supporting column, detection is conducted through a bottom detector and an upper detector when the rotating body mounting shaft passes through the flow detection structure, water flow sampling and detection are conducted, and the detection is convenient and rapid, the distance between the rotating balls changes when the rotating balls move, reasonable control over the precipitation areaand the water flow state is achieved, and the precipitation effect and the separation efficiency are improved.

Owner:邱晨霞

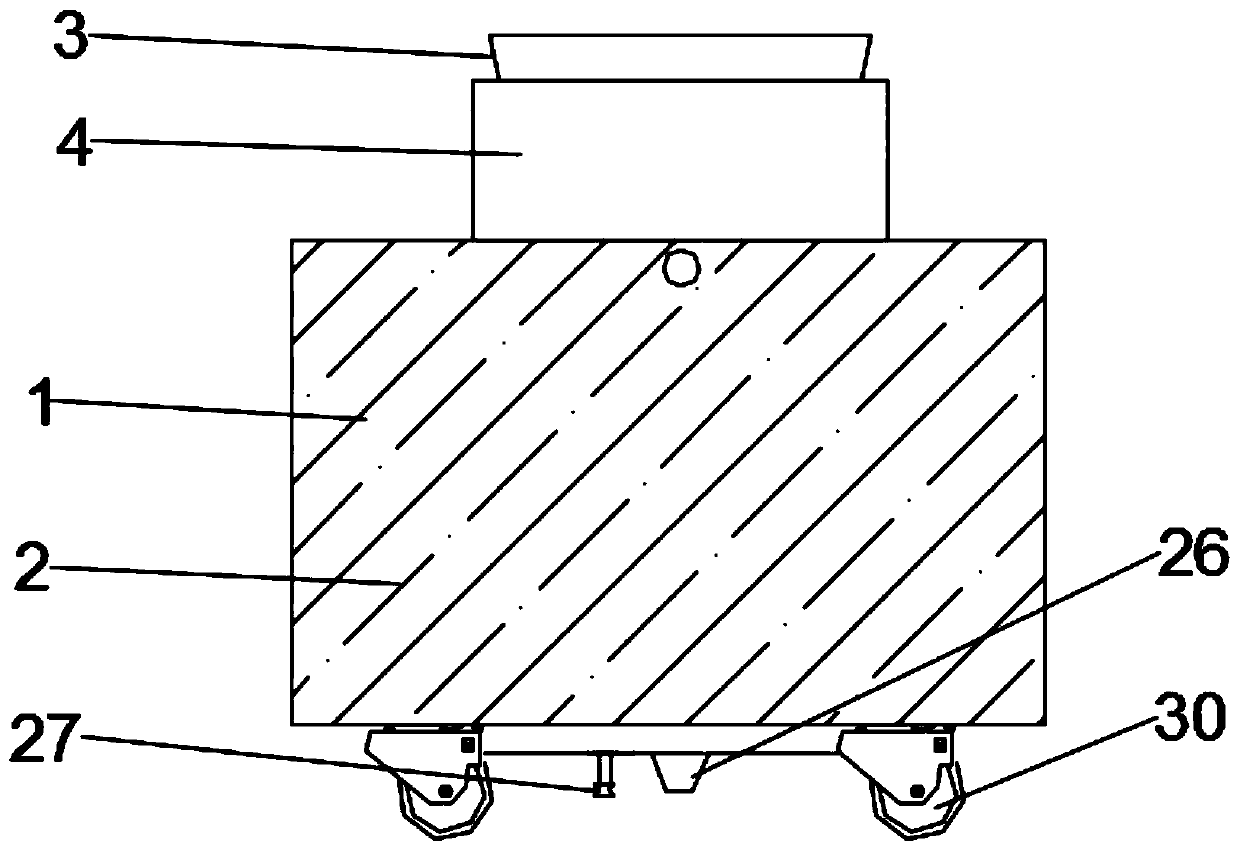

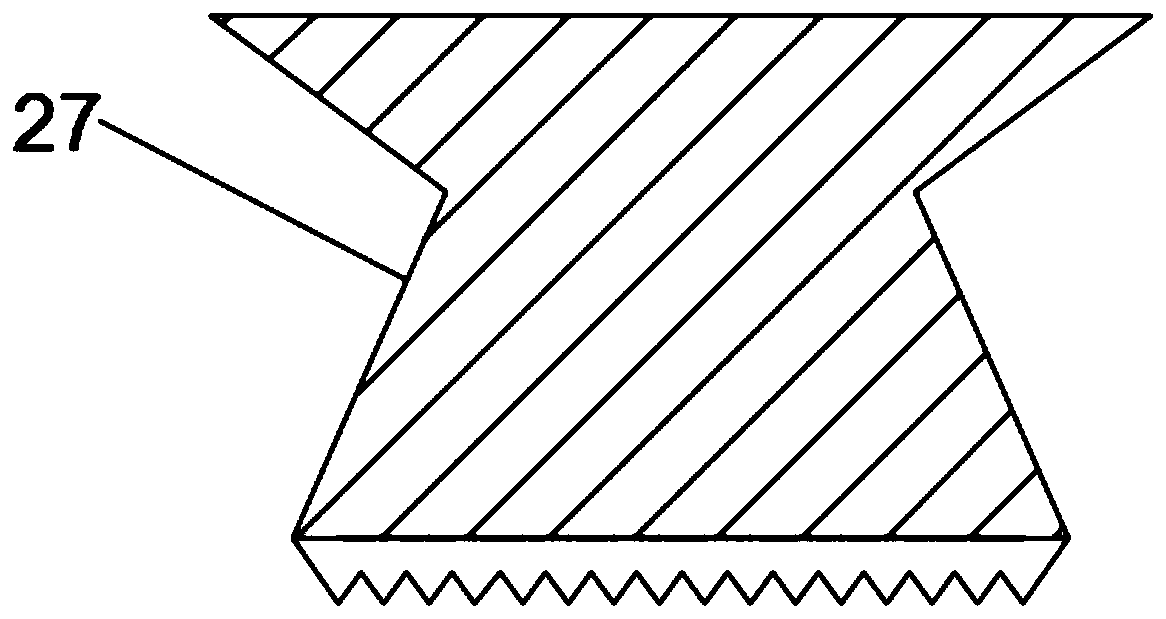

A planter capable of effectively increasing the germination rate of seeds

ActiveCN108575209BContribute to uniform distributionHelp managementSievingSeed and root treatmentSeederAgricultural engineering

The invention discloses a seeder capable of effectively improving the germination rate of seeds. The seeder comprises a device body, support plates, a seed flow sharing box and a seeding chamber, wherein the support plates are symmetrically disposed on both sides of the device body, rollers are welded to bottoms of the support plates, the seed flow sharing box is installed above a position betweenthe support plates, and a material inlet is formed in the top of the seed flow sharing box; a turntable is arranged in the middle of the interior of the seed flow sharing box, a sieve is arranged atthe bottom of the seed flow sharing box, a chemical spraying chamber is formed in the lower part of the seed flow sharing box, and the seed flow sharing box communicates with the chemical spraying chamber; the lower part of the chemical spraying chamber is connected with the seeding chamber, an inner cavity is formed in the seeding chamber, a third limiting guide rail is installed at the bottom ofthe inner cavity in the seeding chamber, and a slide plate is slidably installed in the third limiting guide rail. Through the seeder, the burden of a worker can be reduced, the germination rate of the seeds can be improved significantly, the problem of slow seed growth caused by excessively large seeding density of the seeds can be solved, and the seeding speed can also be accelerated.

Owner:济南新绿洲农业发展有限公司

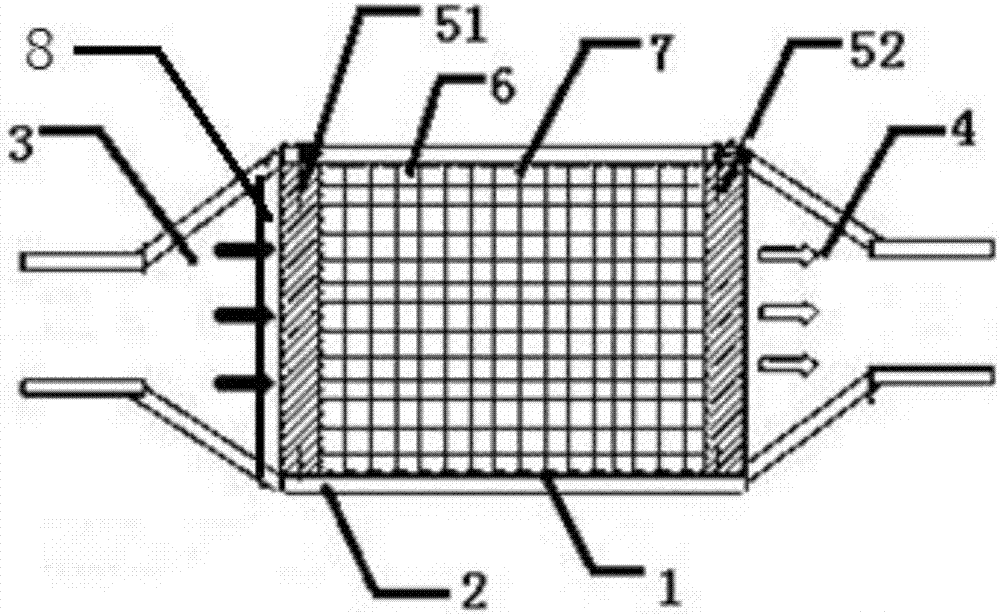

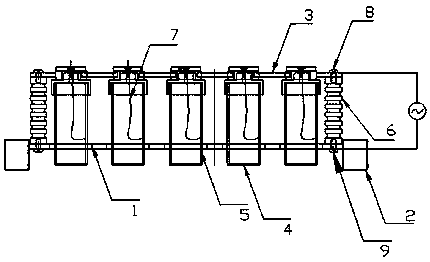

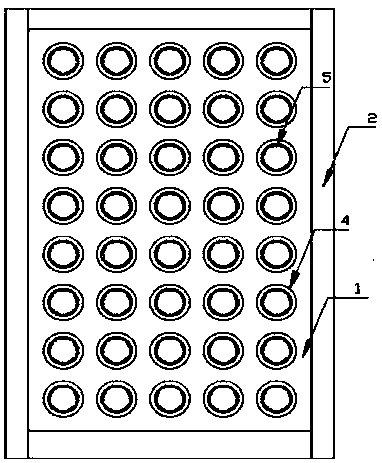

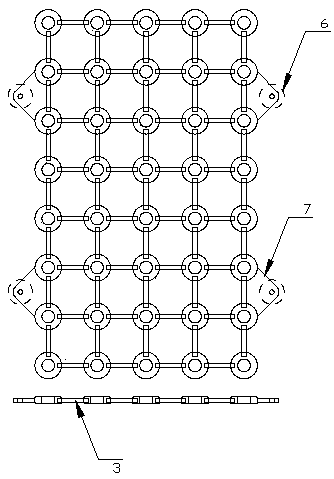

Device and method for generating dielectric barrier discharge plasma

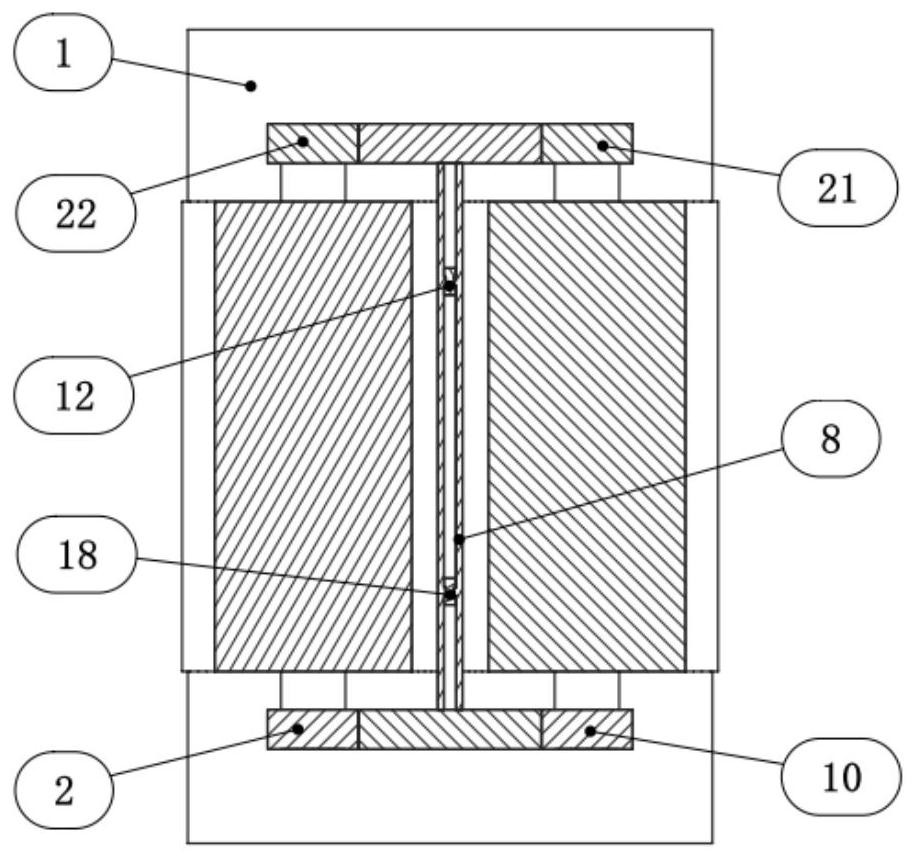

ActiveCN105517311BCompact structureImprove uniform distributionPlasma techniqueSmall footprintInorganic materials

The invention relates to a dielectric barrier discharge plasma generation device and a dielectric barrier discharge plasma generation method. The dielectric barrier discharge plasma generation device comprises porous conductive metal plates, a fixing disk frame and an electrode conductive fixing frame, wherein the fixing disk frame and the electrode conductive fixing frame are connected with the porous conductive metal plates. A plurality of round inorganic material pipes are arranged inside the porous conductive metal plates in a sleeved manner, a conductive film is arranged on the inner wall of each round inorganic material pipe, the electrode conductive fixing frame is arranged at the tops of the round inorganic material pipes, an electrical lead is connected outside each round inorganic material pipe, and insulation columns are arranged at two ends of the round inorganic material pipes symmetrically and are connected with the round inorganic material pipes through the electrical leads. The dielectric barrier discharge plasma generation device and the dielectric barrier discharge plasma generation method have the advantages that multiple groups of coaxial cylindrical type discharge tubes are combined together in a rectangular manner to form an integrated discharge reaction device compact in structure; the device is convenient to mount, small in occupied space and convenient for uniform air flow distribution; multi-layer porous conductive metal plates can be arranged vertically to achieve multi-stage degradation reaction, so that pollutant purifying efficiency is improved.

Owner:赛瑞意(江苏)生物设备有限公司

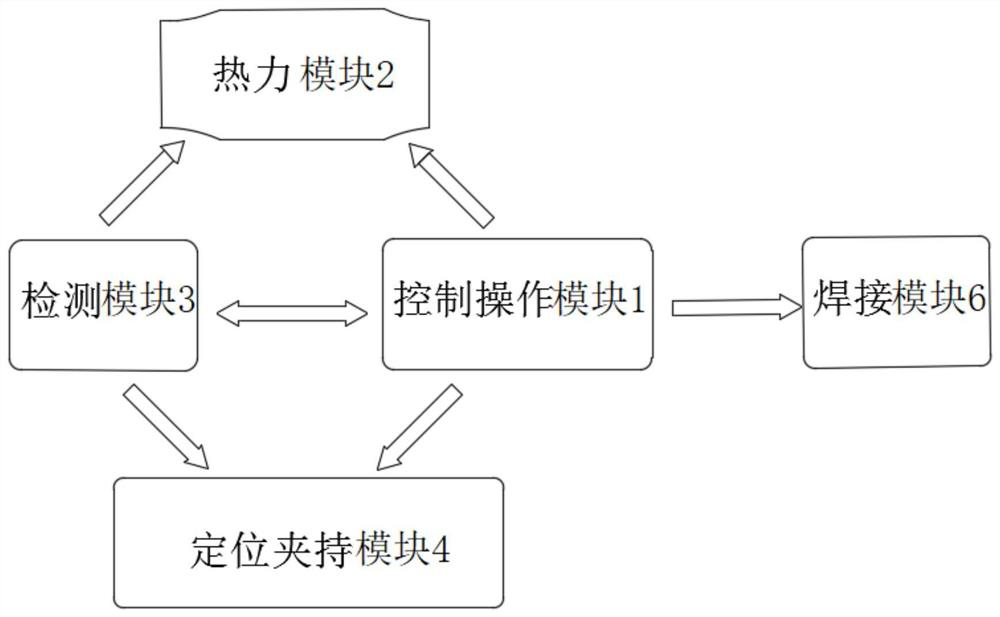

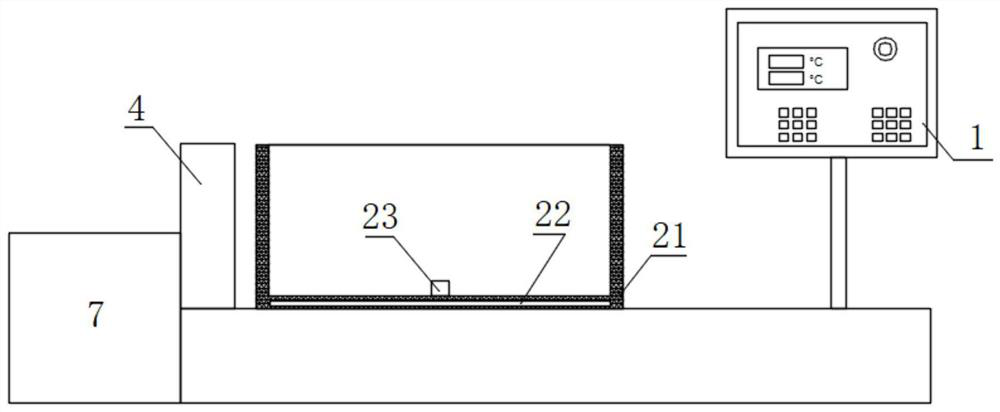

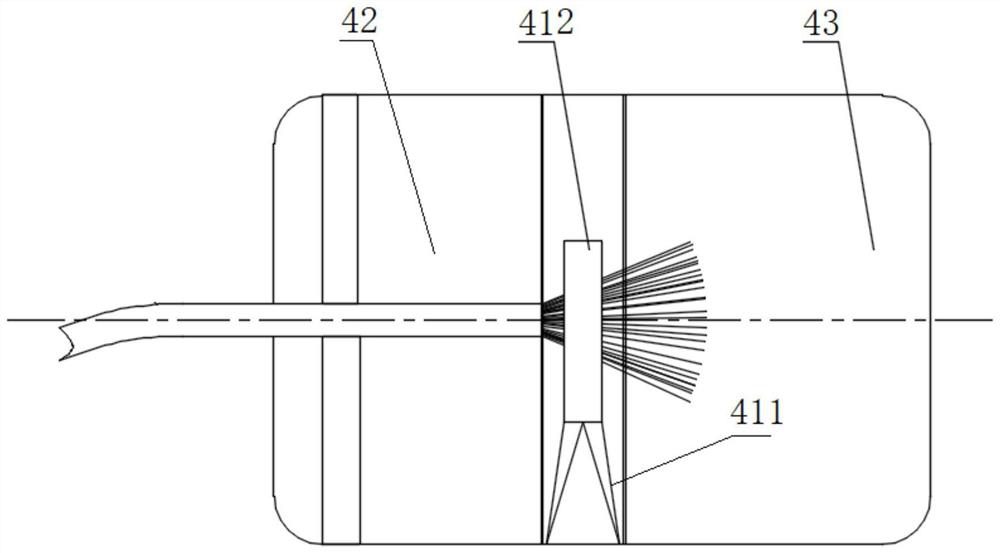

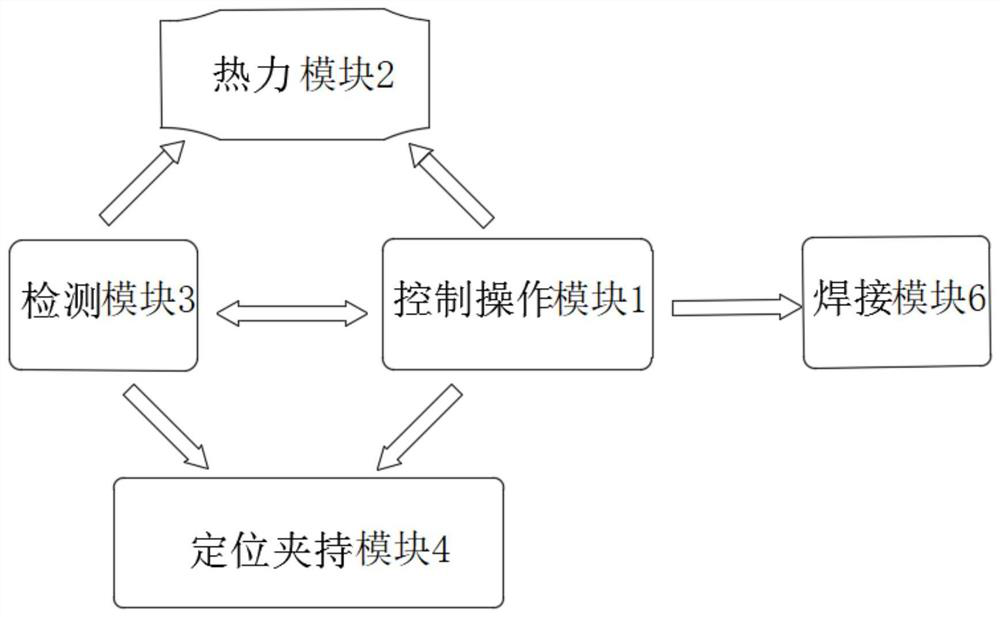

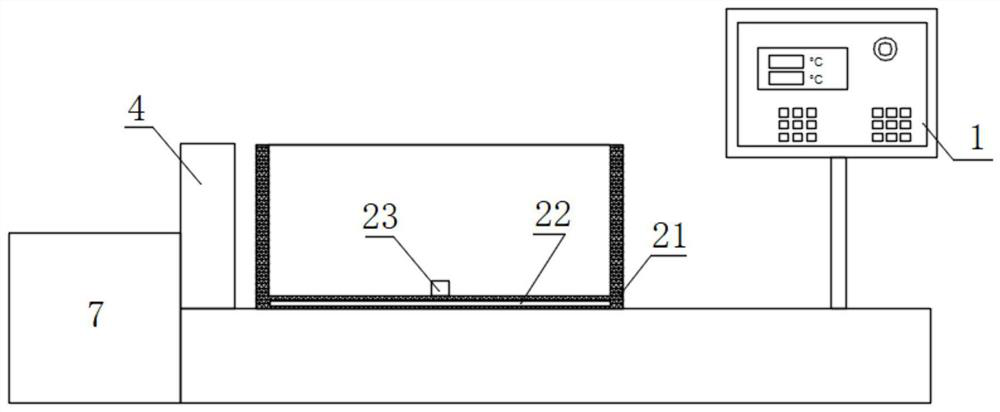

Litz wire welding device

ActiveCN112404626AReduce handlingRealize automatic wire bondingHeating appliancesSoldering auxillary devicesThermodynamicsLitz wire

The invention discloses a litz wire welding device. The device comprises a control operation module, a thermal module, a detection module and a positioning and clamping module; the thermal module provides heat required by welding; the detection module detects temperature data of the thermal module and displacement data of the positioning and clamping module and sends the temperature data and the displacement data to the control operation module; the positioning and clamping module is used for positioning and clamping a litz wire to be welded; and the control operation module receives the detection data transmitted by the detection module and controls the temperature of the thermal module and the displacement of the positioning and clamping module. The litz wire welding device can achieve reliable welding of the large-section litz wires, automatic welding of the litz wires is achieved, and welding is more attractive and reliable while the production efficiency is improved.

Owner:XJ TRANSFORMER +2

A kind of low thermal conductivity thermal insulation material and preparation method thereof

ActiveCN111609252BGood thickening effectNot easy to absorb moistureThermal insulationPipe protection by thermal insulationCarbide siliconFiber

A heat insulating material with low thermal conductivity and a preparation method thereof, comprising the following raw materials in parts by mass: fumed white carbon black: 60-70 parts; ordinary white carbon black: 10-20 parts; silicon carbide: 10-15 parts; fiber : 5‑10 servings. This application uses fumed white carbon black and ordinary white carbon black for combined use, so that the characteristics of good thickening and difficult moisture absorption of fumed white carbon black can be brought into play, and at the same time, the characteristics of ordinary white carbon black with multiple hydroxyl groups can be played Composite better with fibers, but its low content can suppress the hygroscopic characteristics; while silicon carbide has radiation resistance and wear resistance, silicon carbide itself is used as an intermediate substance in heat insulation materials, and gas phase white carbon Black and ordinary silica and fiber are filled in it, so that it can have relatively high strength under the premise of ensuring low thermal conductivity.

Owner:山东金石节能材料有限公司

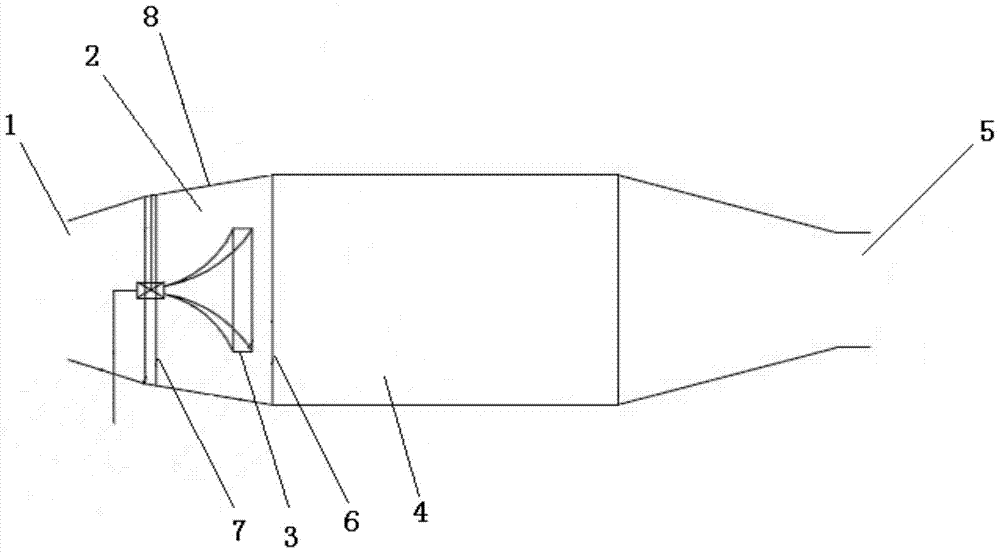

An aeroacoustic composite field uniform distribution device and uniform distribution method thereof

ActiveCN105276594BAchieve uniform distributionImprove the degree of uniformitySolid removalSound energyEngineering

The invention discloses an aeroacoustic composite field uniform distribution device and a uniform distribution method thereof. The uniform distribution device includes a device inlet, an aeroacoustic field distribution space, a sounding device, and a device outlet, wherein an air intake plate is arranged at the device inlet, and the device There is an aeroacoustic deflector at the exit; the aeroacoustic average layout space is the space enclosed by the air intake plate, the aeroacoustic deflector and the space wall between them; the sounding device is set in the aeroacoustic average layout space . The invention realizes the uniform distribution of an aeroacoustic composite material energy flow field, and can promote the improvement of the uniform distribution degree of the composite flow field through the interaction between different material energy fields. The device of the invention has a compact structure, and the method is simple to implement, and can realize the uniform arrangement of the aeroacoustic composite field in the true sense, which is of great significance for energy saving and environmental protection, and has popularization value.

Owner:NANJING CHANGRONG ACOUSTIC INC

An energy-saving and efficient thermal desorption system for soil remediation

ActiveCN110586635BAchieve separationReduce manual laborContaminated soil reclamationSoil remediationEngineering

The invention discloses an energy-saving and high-efficiency thermal desorption system for soil remediation, which comprises a cylindrical thermal desorption box. The lower side of the peripheral outer wall of the thermal desorption box is symmetrically fixed with multiple groups of brackets for supporting the thermal desorption box. A group of discharge holes are provided through the side wall of the thermal stripping box, a feed pipe is inserted through the circumferential side wall of the end of the thermal stripping box away from the discharge hole, and a feed pipe is inserted at the end of the thermal stripping box near the discharge hole. A fixed cylinder is welded on the inner wall of the heat removal box, and an air inlet pipe communicating with the interior of the fixed cylinder is inserted through the circumferential side wall of the heat removal box. The advantage is that the high-speed and high-temperature airflow will drive the driving blades to rotate, and then the driving blades will drive the auger shaft to rotate, and the soil will be pushed forward by the propulsion of the auger blades on the surface of the auger shaft, forming a continuous heat flow. The desorption process does not need to replace the soil artificially, and does not need to provide additional driving force, making the whole process more convenient, efficient and energy-saving.

Owner:MINGDA MARINE ENG CO LTD

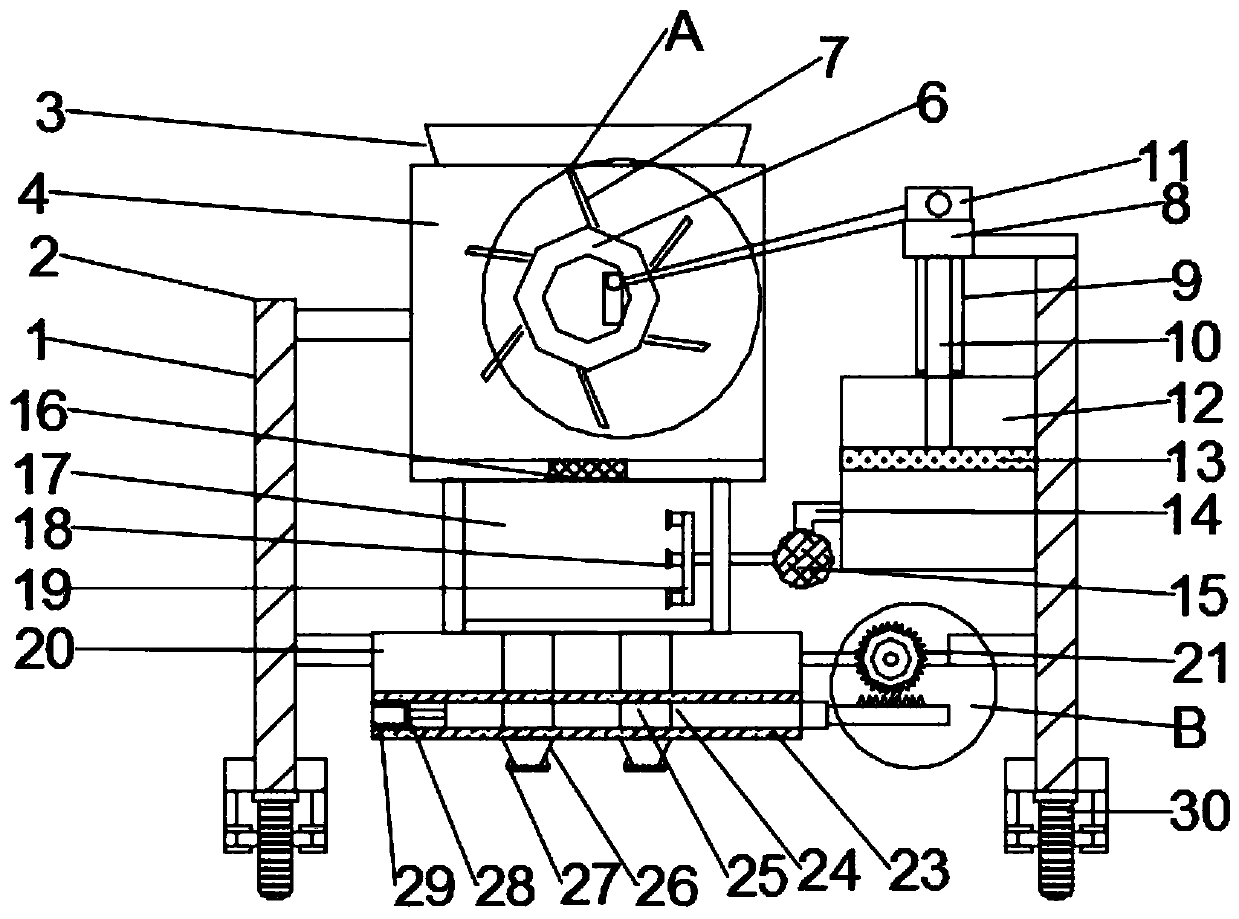

Flow distribution device for light alloy casting and rolling

The invention discloses a flow distribution device for light alloy casting and rolling, which belongs to the field of light alloy casting. Aiming at the shunt block widely used in the current distribution system of metal melt in the existing casting and rolling process, its shape has a great influence on the flow of the melt. As a result, the melt distribution in the cavity is uneven, and the melt is mostly in a turbulent state. Defects such as pores are prone to occur during the casting and rolling process, which seriously affects the performance of the casting. Both sides of the molten metal tank in the present invention are provided with symmetrical slot holes, and when the melt liquid level reaches the positions of the slot holes on both sides of the molten metal tank, the molten metal will be inclined from both sides of the molten metal tank. The holes flow out at the same time and are evenly distributed on the surfaces of the left roll and the right roll respectively to realize symmetrical casting and rolling. In addition, the rising speed of the metal melt supporting plate guide column fixed connecting plate is precisely controlled by the motor, which can effectively prevent the influence of speed fluctuation on the quality of cast and rolled parts. The device has a simple structure, can effectively realize uniform distribution of liquid flow, and can reduce turbulent flow as much as possible.

Owner:JILIN UNIV

Efficient shredded tobacco winnowing method and equipment

ActiveCN105396782BAchieve uniform distributionGood dispersionGas current separationEngineeringEnergy consumption

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

A litz wire welding device

ActiveCN112404626BReduce handlingRealize automatic wire bondingHeating appliancesSoldering auxillary devicesLitz wireControl engineering

Owner:XJ TRANSFORMER +2

A new type of absorber and its absorption refrigeration system

ActiveCN113758053BAchieve uniform distributionIncrease the areaClimate change adaptationAbsorbers/adsorbersEngineeringRefrigeration

The invention relates to a novel absorber and an absorption refrigeration system thereof, belonging to the technical field of absorption refrigeration. The first-layer spraying device is fixed on the top of the shell, and the first-layer spraying device is arranged above the upper-layer tube bundle, and the second spraying device is arranged in the U-shaped groove of the side U-shaped tube bundle. There are two groups of main air intake pipes on the side, and each group of main air intake pipes is provided with linearly arranged air distribution pipes between the casing and the pipe box. The circulating water at the circulating water outlet on the tank exchanges heat with the lean liquid entering the shell to pre-cool the lean liquid. Compared with the absorber structure of the prior art, the present invention adopts the double-layer spraying + multiple air intake methods, so that the absorption efficiency of the absorber is increased by about 95%.

Owner:ANHUI WATERPOWER ENERGY SAVING TECH

Gas-sound complex field uniform-distribution device and uniform-distribution method thereof

ActiveCN105276594AAchieve uniform distributionImprove the degree of uniformitySolid removalEngineeringSound production

The invention discloses a gas-sound complex field uniform-distribution device and a uniform-distribution method thereof. The uniform-distribution device comprises a device inlet, a gas-sound field uniform-distribution space, sound production devices and a device outlet. A gas inlet plate is arranged on the device inlet. A gas-sound flow guide plate is arranged on the device outlet. The gas-sound field uniform-distribution space is a space defined by the air inlet plate, the gas-sound flow guide plate and a space wall between the air inlet plate and the gas-sound flow guide plate. The sound production devices are arranged in the gas-sound field uniform-distribution space. By means of the gas-sound complex field uniform-distribution device and the uniform-distribution method, uniform distribution of gas-sound complex matter energy flow fields is achieved, and the complex flow field uniform-distribution degree is promoted to be increased through the interaction effect among different matter energy fields; the device is compact in structure, the method is easy to implement, gas-sound complex field uniform-distribution can be achieved in real sense, and the device and the method have an important significance in energy saving and environment protection and has the popularization value.

Owner:NANJING CHANGRONG ACOUSTIC INC

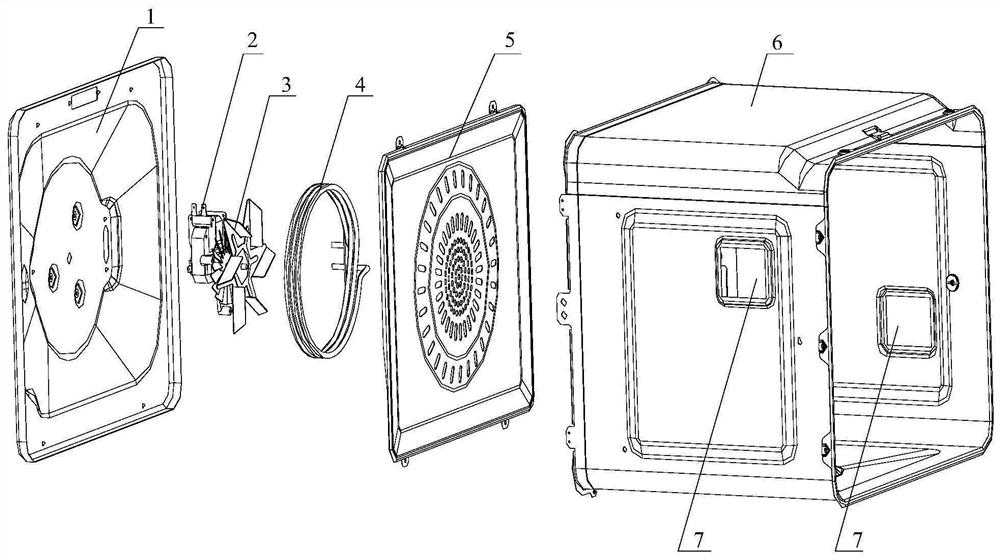

Oven and hot air control device thereof

PendingCN113647843AAchieve uniform distributionTemperature increases on the leftRoasters/grillsAir volumeHot blast

The invention discloses an oven and a hot air control device thereof; the hot air control device comprises a fan capable of rotating forwards and backwards, heating pipes, temperature sensors, and a controller; and when the fan rotates forwards, the air outlet amount of the right half part of the fan is larger than that of the left half part of the fan; the heating pipes are uniformly arranged in the circumferential direction of the fan; the temperature sensors are arranged in the oven and comprise a left side temperature sensor located on the left side of the fan and a right side temperature sensor located on the right side of the fan; a controller is used for obtaining the temperatures measured by the left side temperature sensor and the rear side temperature sensor and controlling the working state of the fan to change, and when the temperature value detected by the left side temperature sensor is larger than the temperature value detected by the right side temperature sensor, the controller controls the fan to rotate forwards; when the temperature value detected by the left side temperature sensor is smaller than the temperature value detected by the right side temperature sensor, the controller controls the fan to rotate reversely. The purpose of controlling the temperature is achieved through the control process, and uniform distribution of heat is achieved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

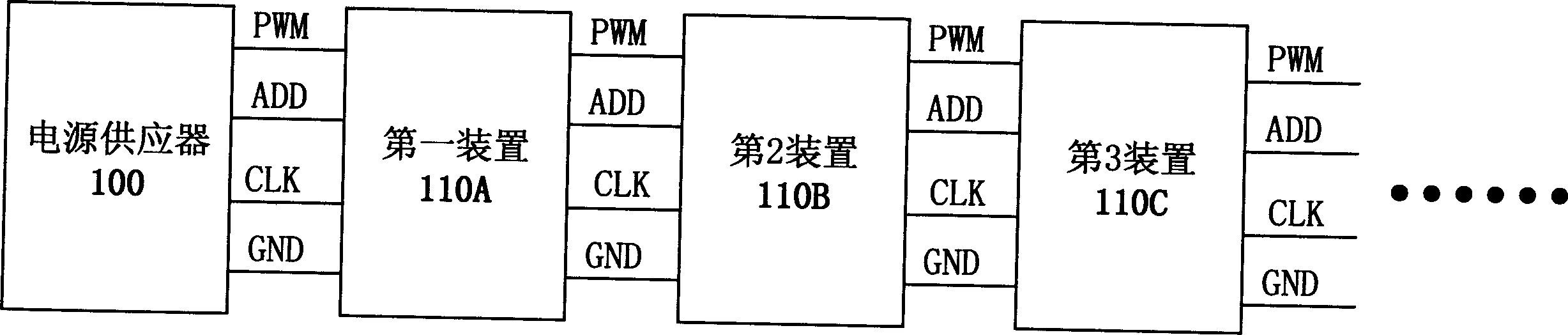

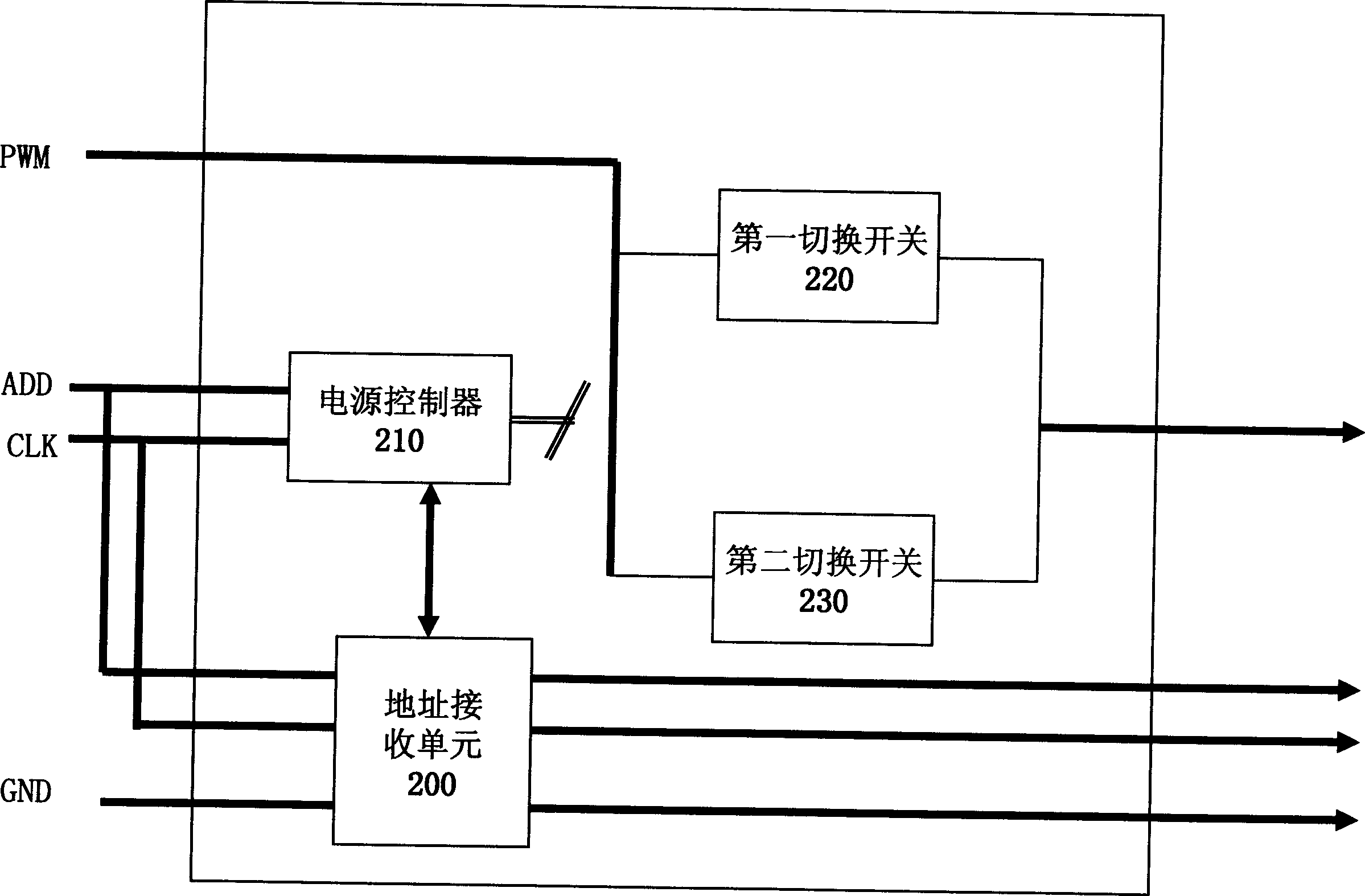

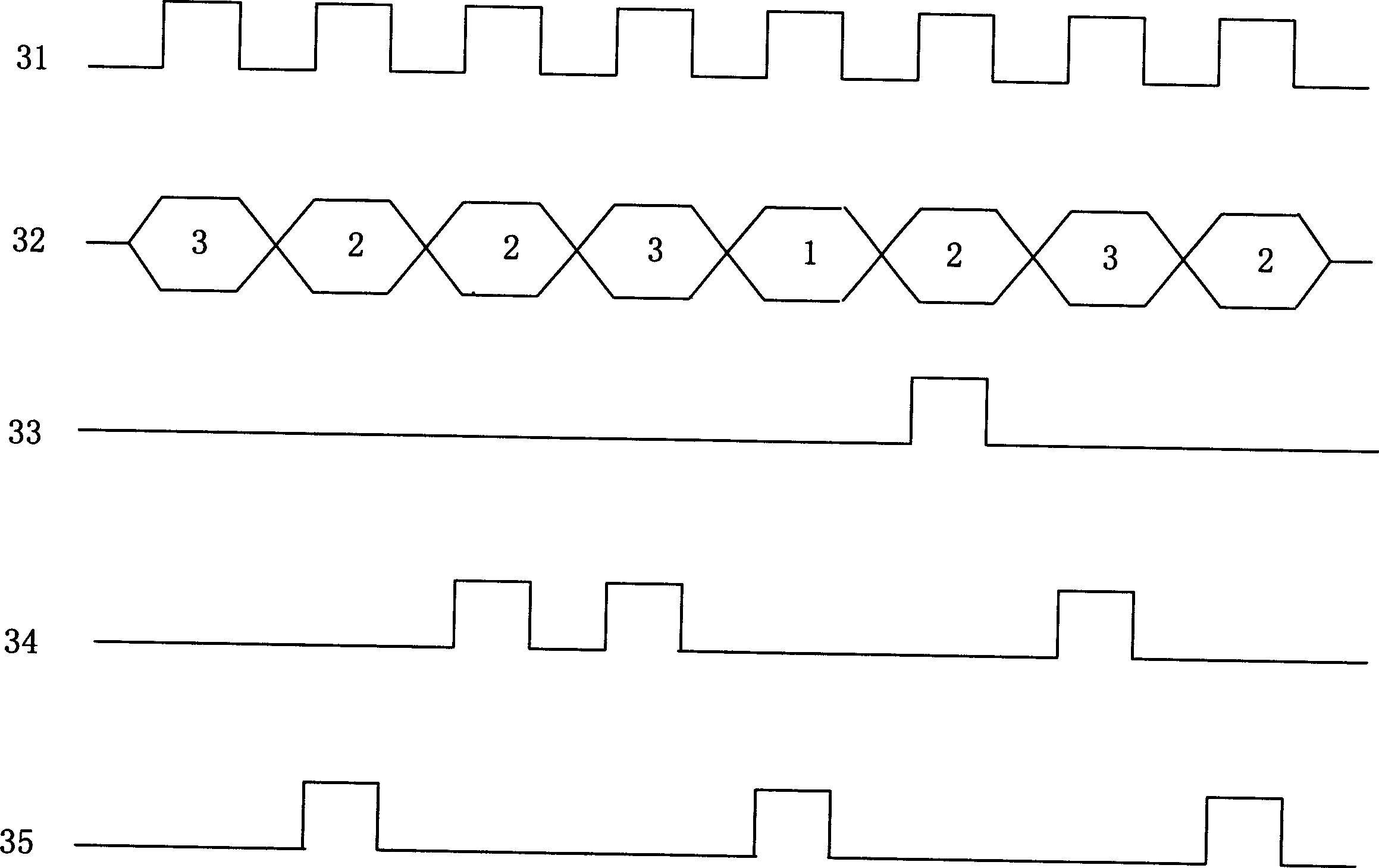

Line concentration system for uniform power supply

InactiveCN1571239AAchieve uniform distributionDc network circuit arrangementsAc-dc network circuit arrangementsControl signalTransfer switch

The invention is an power supply distribution uniting hub system, prearranging a device priority table to determine a power supply waveform of each device to provide power supply for many devices, containing: a power supplier and many devices; each device at least contains: an address receiving unit, outputting an address control signal; a power supply controller, outputting a pulse width modulation (PWM) control signal; a first transfer switch coupled with the PWM port and the power supply controller to output the power supply waveform according to the PWM control signal; and a second transfer switch coupled with the PWM port and the power supply controller to selectively switching on or off the next PWM port according to the PWM control signal.

Owner:INVENTEC CORP

A dry-process vertical electrostatic precipitator for gas

ActiveCN105062572BRealize current sharingAchieve dust removal effectCombination devicesElectrostatic separationDust controlEnvironmental engineering

Owner:CISDI ENG CO LTD +1

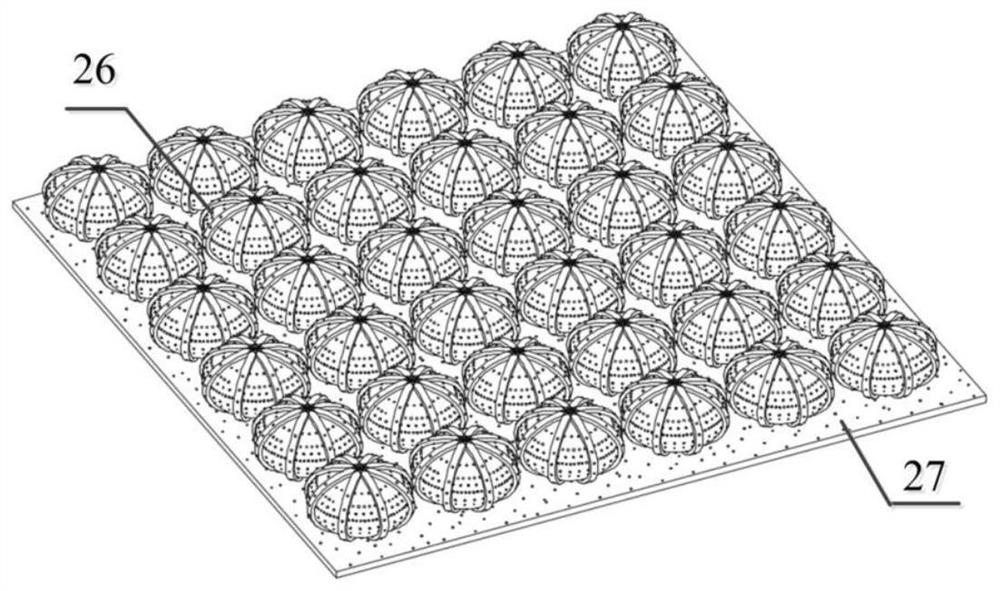

Surface microstructure array with bacterial adhesion resistance and forming method of surface microstructure array

InactiveCN111688183AGood self-cleaning performanceMicrostructure shape and size controllableManufacturing platforms/substrates3D object support structuresPhysicsChemistry

The invention discloses a surface microstructure array with bacterial adhesion resistance and a forming method of the surface microstructure array. A single microstructure of the surface microstructure array is of a sea urchin pavilion structure, the material is photosensitive resin, and the size is micron; nano particles are distributed on the surface of the single microstructure and form a micron / nano composite structure with the sea urchin pavilion structure; and the plurality of composite structures are uniformly distributed on the target surface of a formed part to form the surface microstructure array. According to the forming method of the surface microstructure array, the preparation of the surface microstructure array is completed by using a set of electromagnetic assisted vibration surface projection micro-stereo photoetching system according to certain steps. According to the surface microstructure array, the bacterial adhesion resistance, the adsorption resistance and the self-cleaning performance are good, and the morphology and size of the microstructures are controllable. According to the forming method, through the high-frequency vibration of the electromagnetic assisted vibration device, the agglomeration of the nano particles is reduced, the uniform distribution of the nano particles is realized, and the forming precision and the forming quality are improved;and a movable platform of a forming system can horizontally and linearly move along the Y-axis direction and the X-axis direction, so that the area of a forming layer is enlarged, the size of the formed part is increased, the forming time is reduced, and the forming efficiency is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A large-space descaling device with aeroacoustic composite field uniform distribution and its descaling method

ActiveCN105276593BAchieve uniform distributionImprove the degree of uniformitySolid removalEngineeringAcoustic space

The invention discloses a large-space descaling device and a descaling method with an evenly distributed aeroacoustic composite field. The descaling device includes a device inlet, an aeroacoustic field-distributed space, an acoustic soot blowing device, a descaling space, and a device outlet. Among them, there is an aero-acoustic field arrangement space behind the device entrance, a sonic soot blowing device is installed in the aero-acoustic field arrangement space, a descaling space is set after the aero-acoustic field arrangement space, and a device outlet is set after the aero-acoustic field arrangement space; An aeroacoustic deflector is arranged behind the sonic soot blowing device in the space, and the sounding direction of the sonic soot blowing device faces the aeroacoustic deflector. The descaling method is that after the airflow enters the device, the airflow is firstly averaged to form the airflow after the average flow, and then it is fluidized together with the sound waves emitted by the sonic soot blowing device in the aeroacoustic average field layout space, and then the airflow is averaged by the aeroacoustic deflector. After flow and rectification, it enters the descaling space to descale the equipment set in the descaling space, and at the same time, it can effectively prevent local serious scaling.

Owner:NANJING CHANGRONG ACOUSTIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com