Patents

Literature

44results about How to "Improve winnowing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

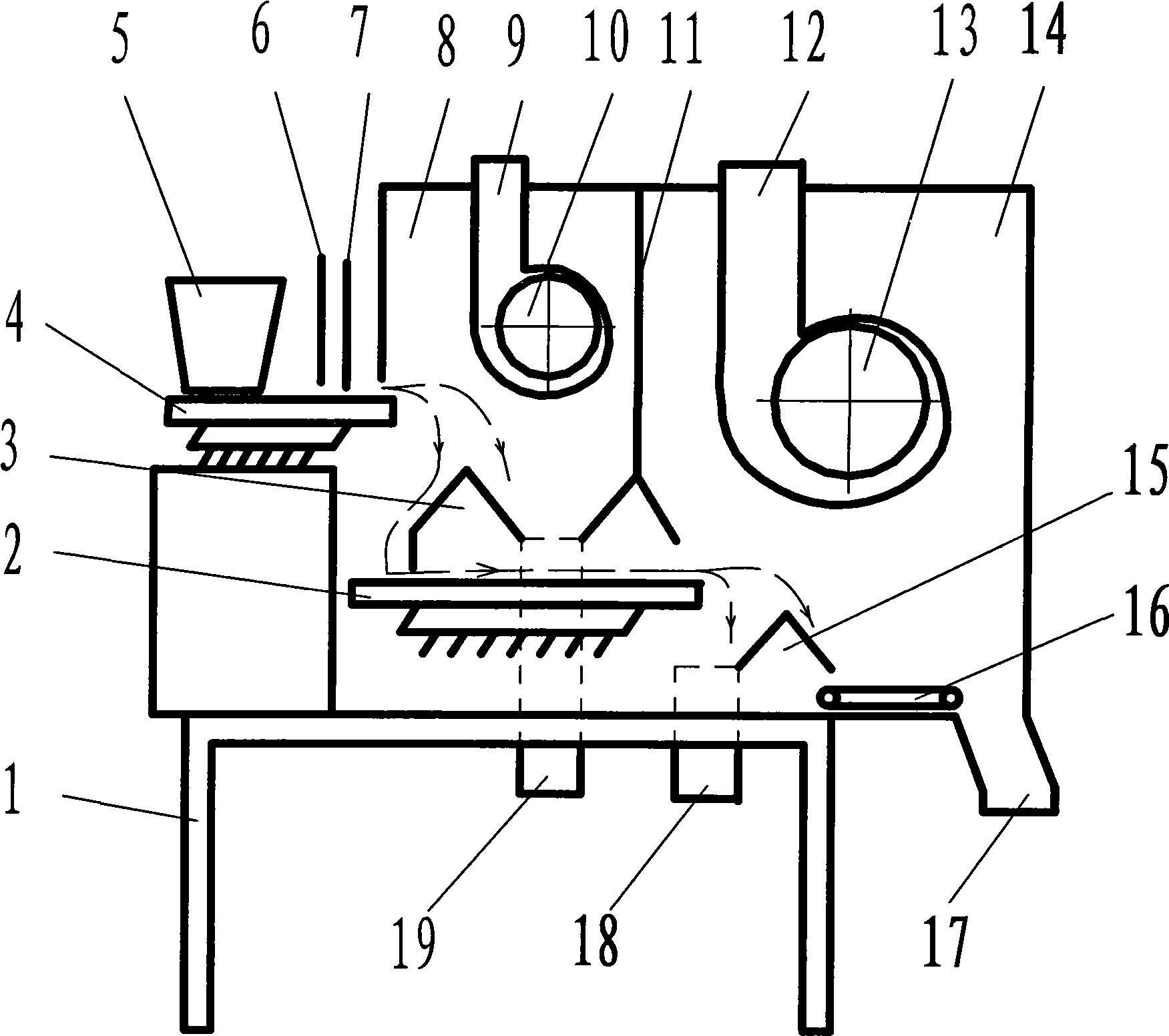

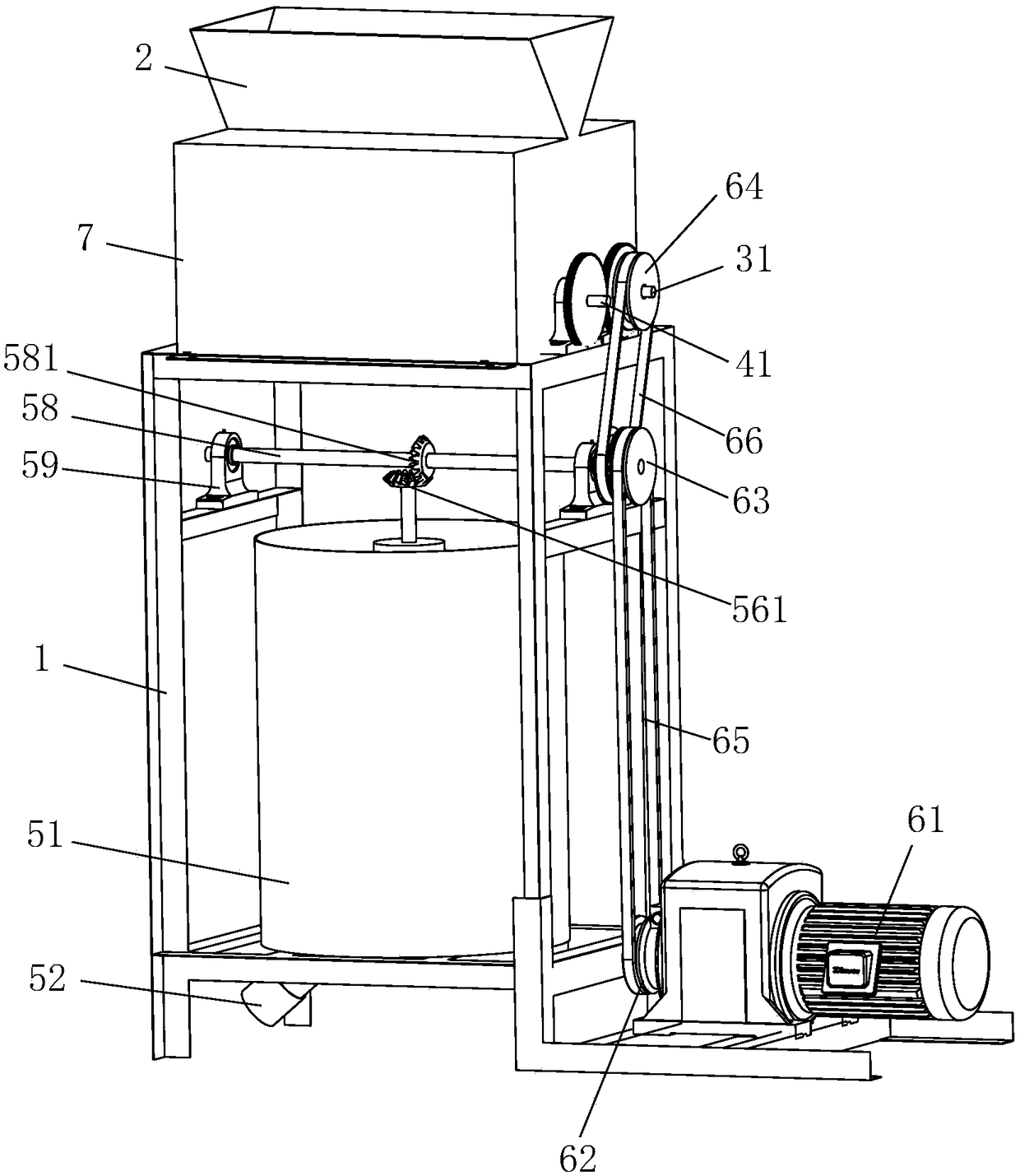

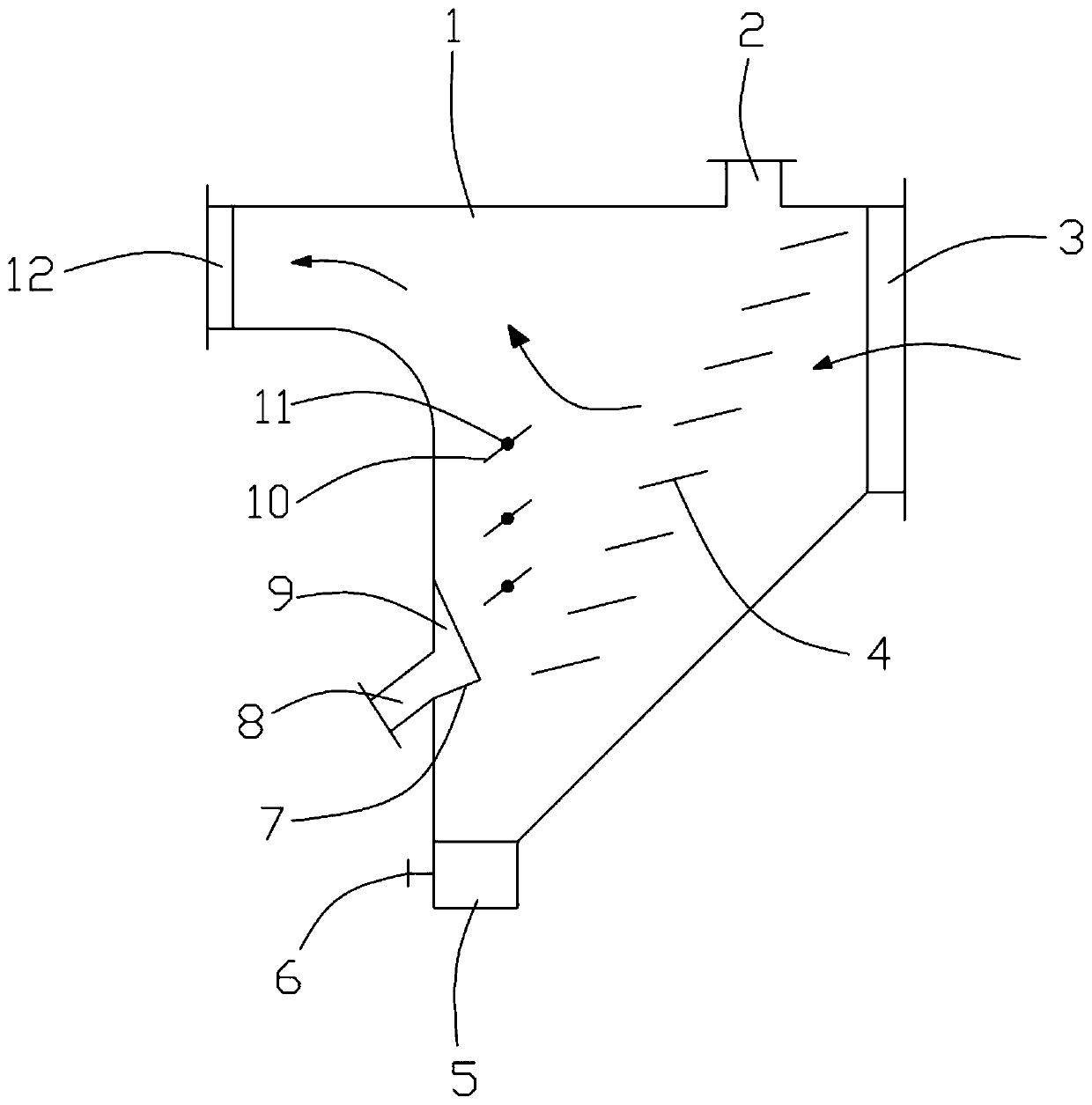

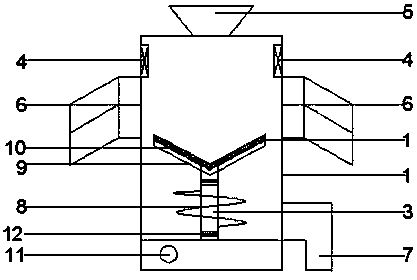

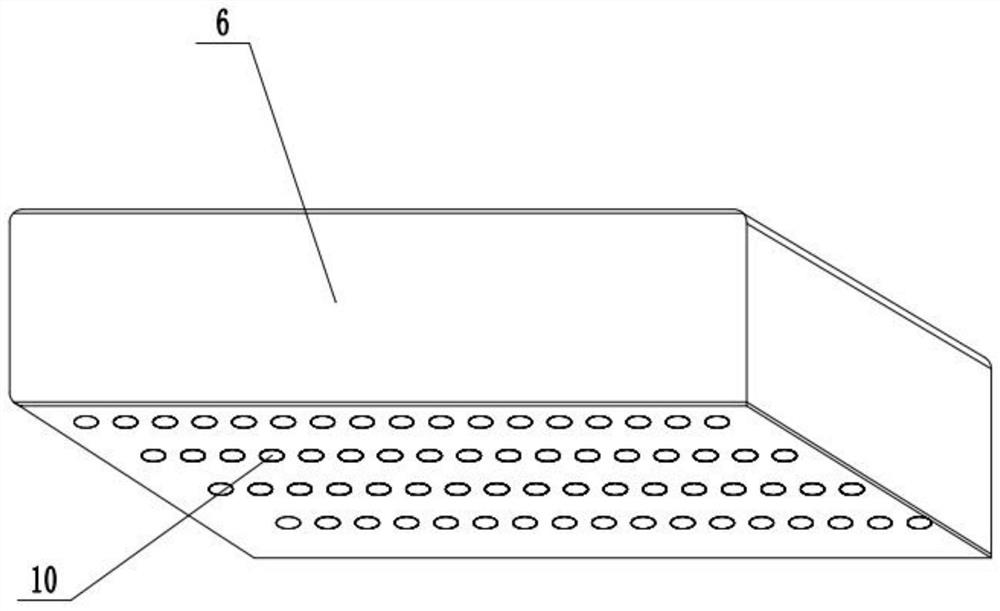

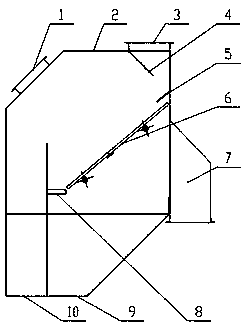

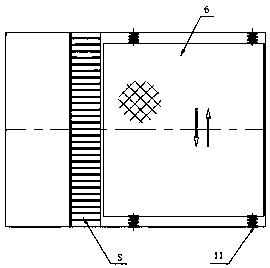

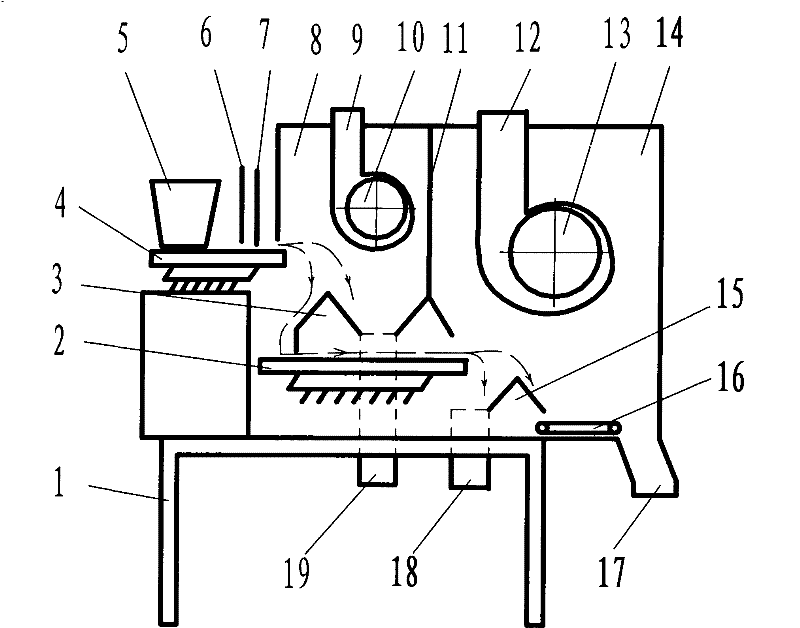

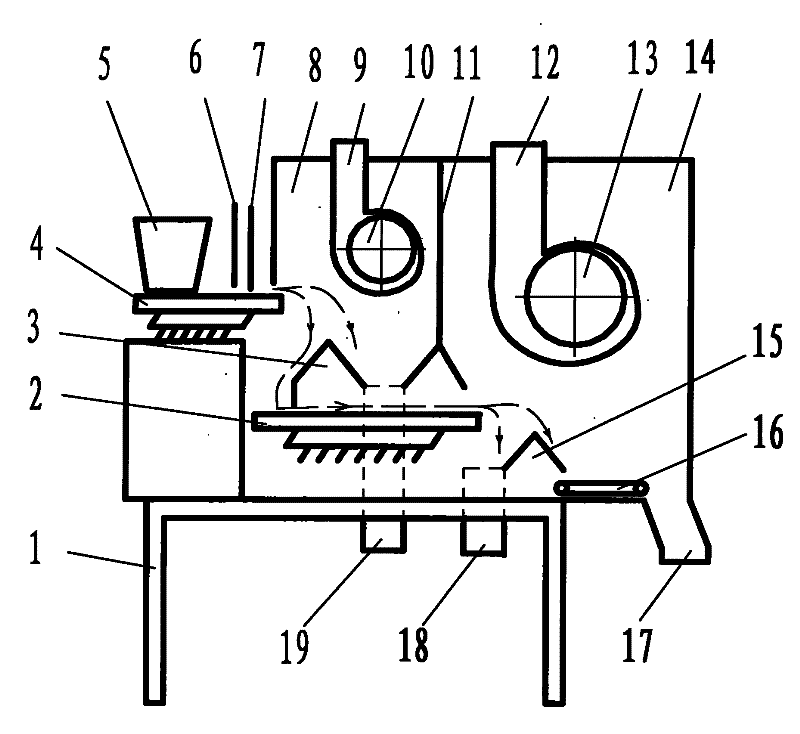

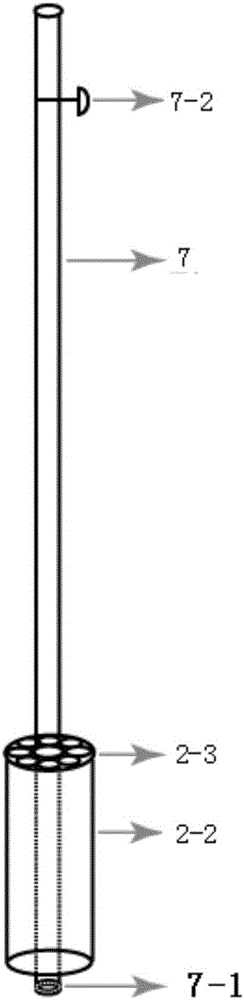

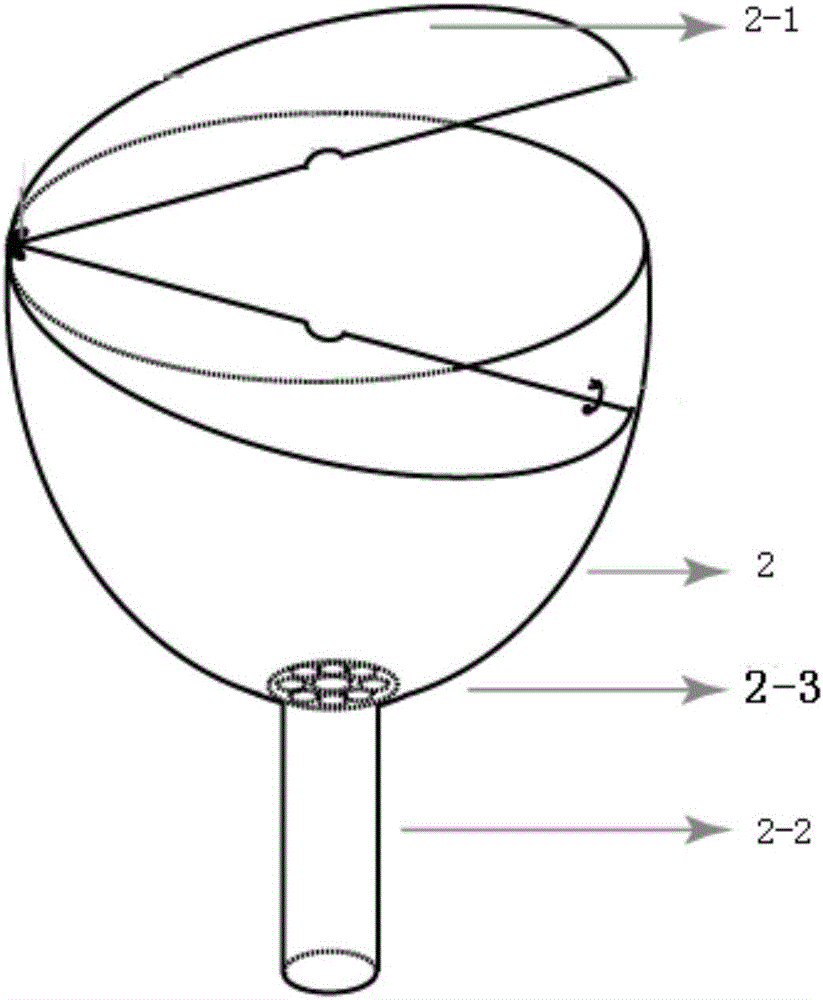

Tea-leaf wind selection device

InactiveCN101507458AGuaranteed qualityReasonable designPre-extraction tea treatmentEngineeringConveyor belt

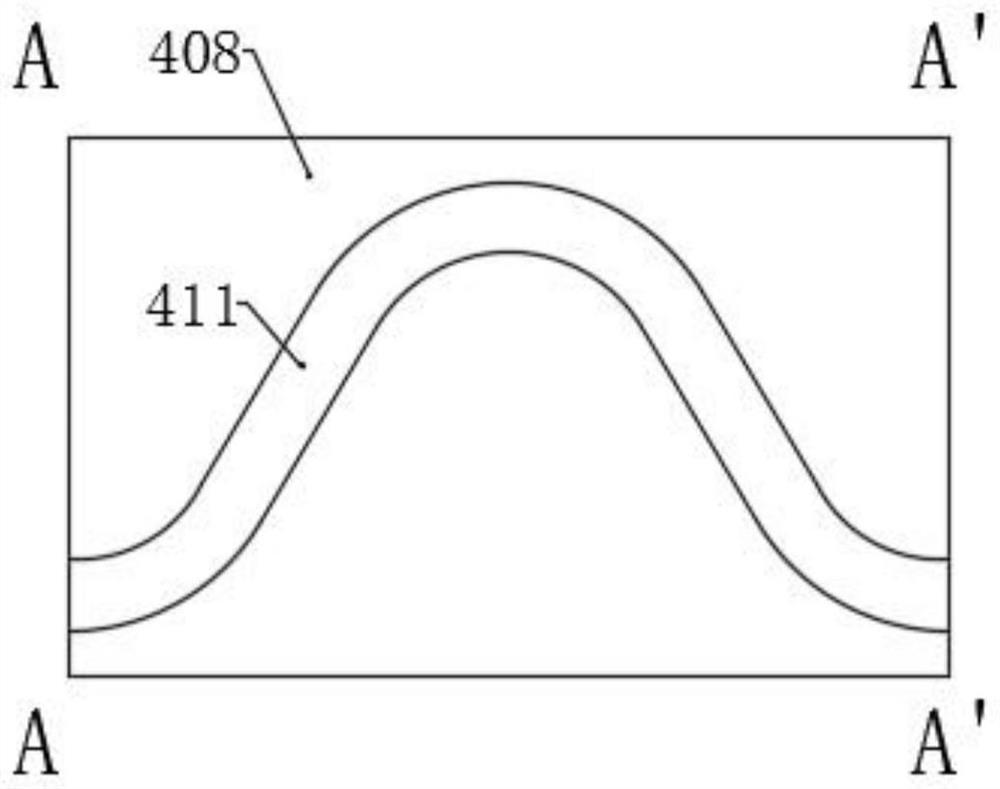

The invention relates to a wind separator for tea, which comprises a feeding hopper and a primary feeding vibrating groove which is positioned under the feeding hopper. The wind separator for the tea is characterized in that the upper side of a discharging end of the primary feeding vibrating groove is provided with a small negative-pressure gas channel, and the lower side of the discharging end of the primary feeding vibrating groove is provided with a secondary vibrating groove; the middle part of the secondary vibrating groove is provided with a funnel-shaped light yellow leaf collecting opening which can be lead to the bottom of the secondary vibrating groove; a triangular guide bevel is arranged between the funnel-shaped light yellow leaf collecting opening and the primary feeding vibrating groove; and the upper side of the discharging end of the secondary vibrating groove is provided with a large negative-pressure gas channel, and the lower side of the discharging end of the secondary vibrating groove is provided with an inclusion discharge opening which is close to the discharging end of the secondary vibrating groove and a discharge conveyor belt which is positioned on the outside of the inclusion discharge opening in turn. The device not only has the function of simultaneously removing light yellow leaves and sandstone inclusion in the tea, but also greatly improves the wind separation efficiency and effectively reduces the error pick-up rate so as to guarantee the quality of the tea subjected to wind separation.

Owner:FUJIAN AGRI & FORESTRY UNIV +1

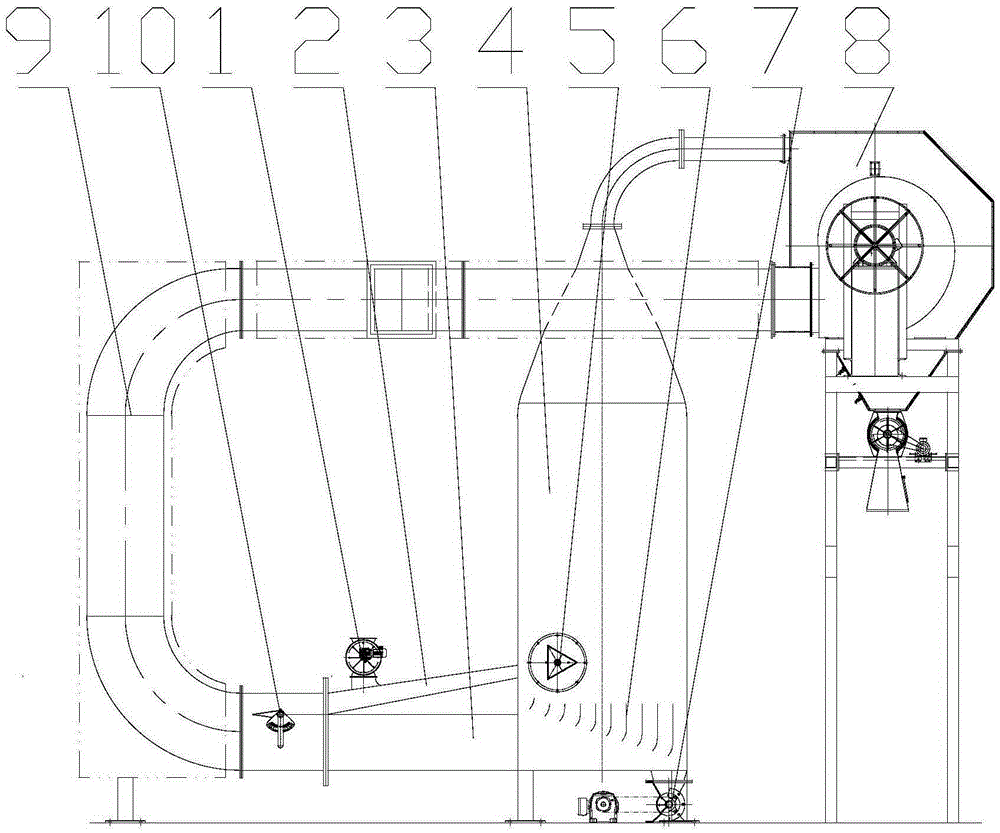

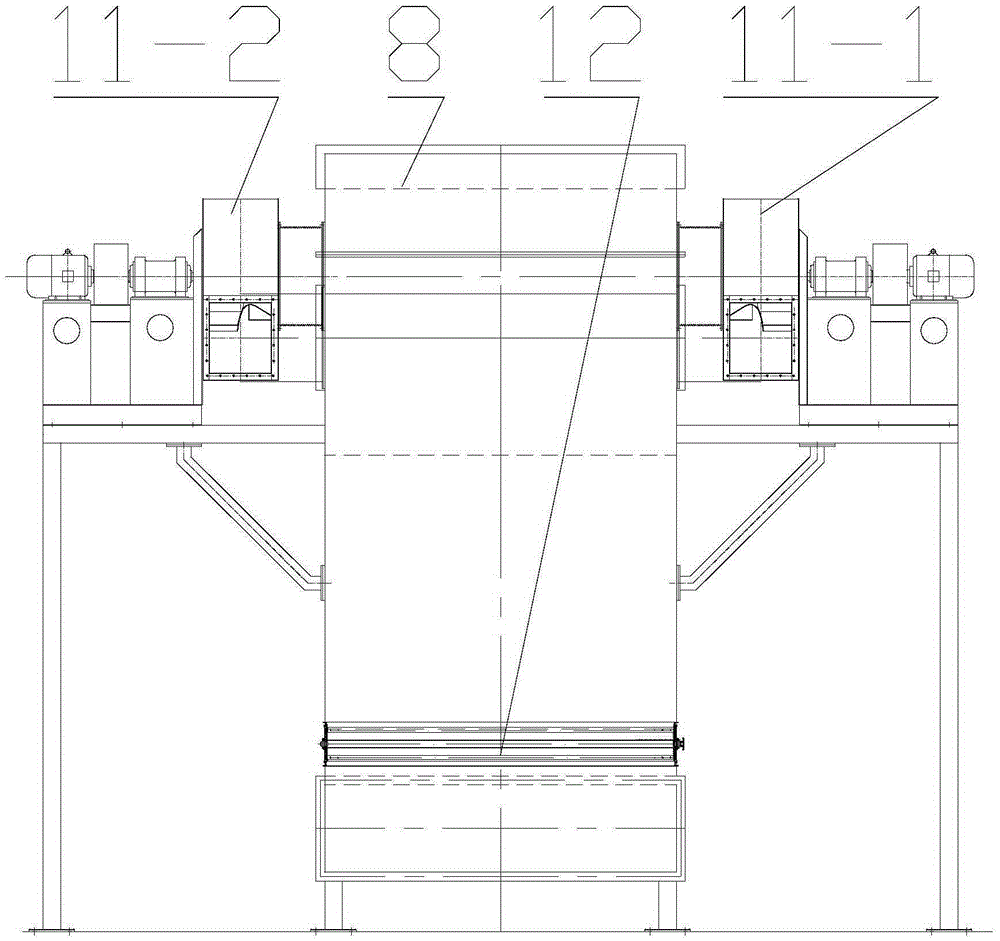

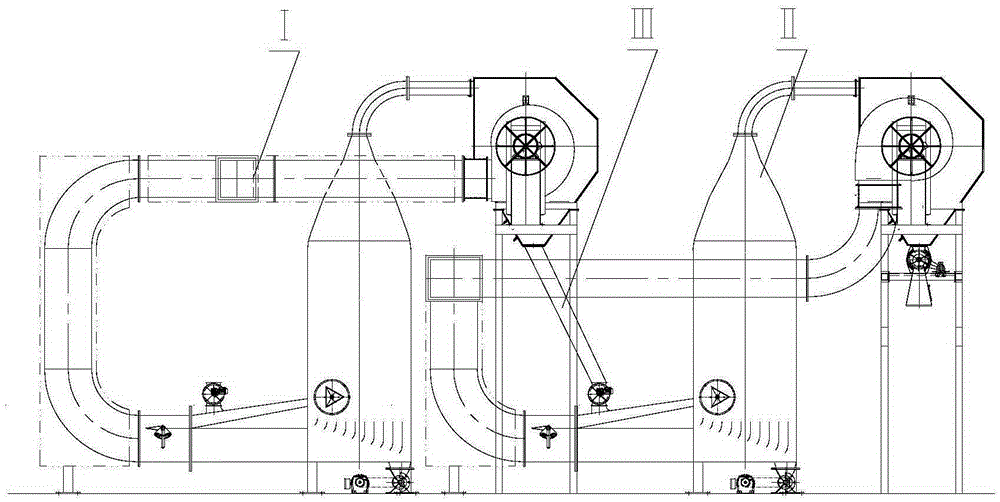

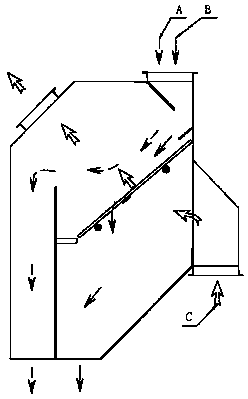

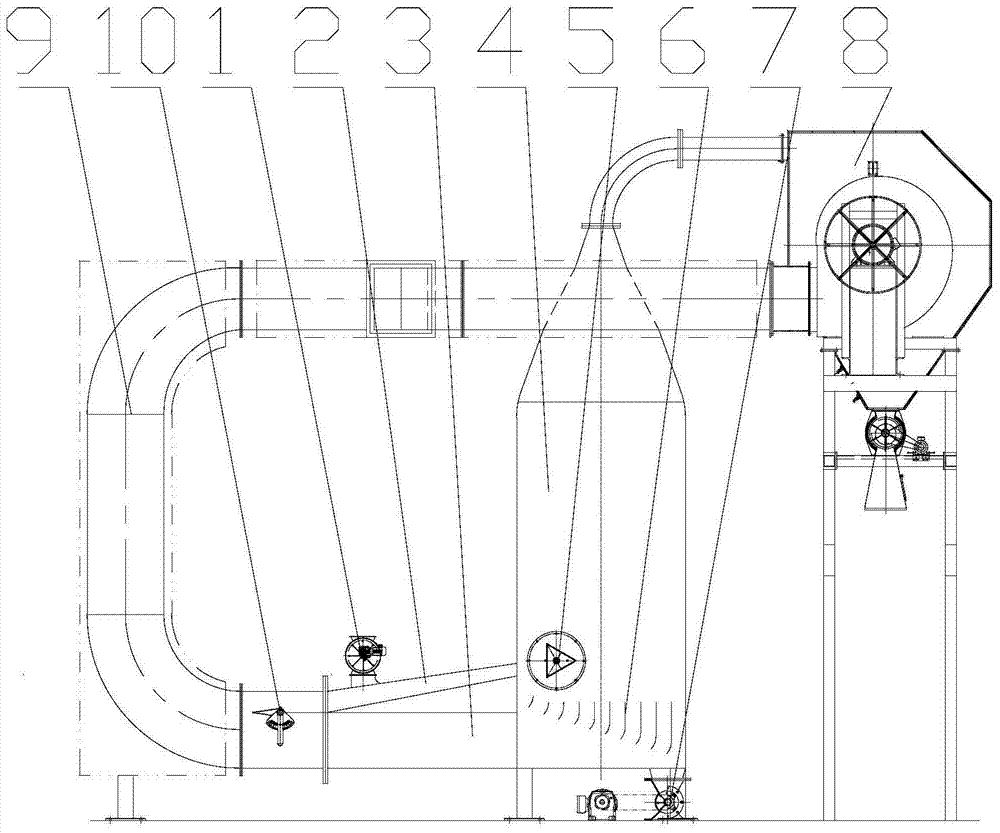

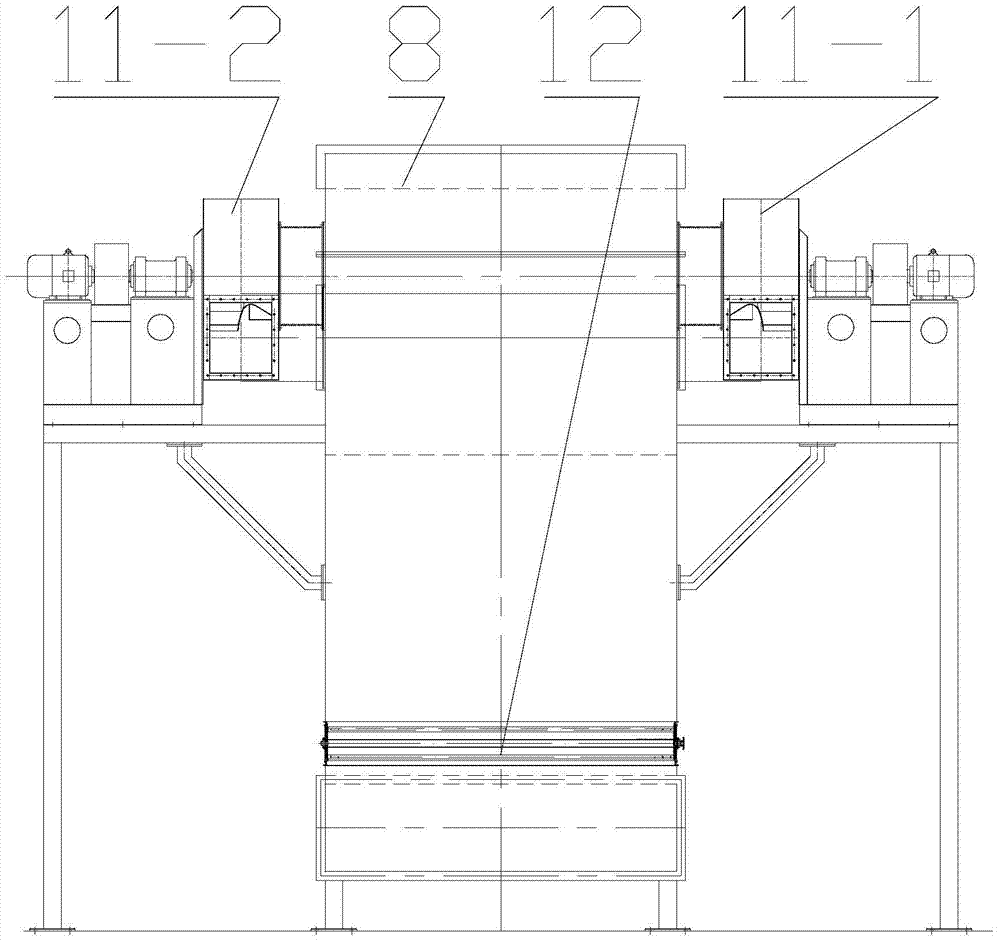

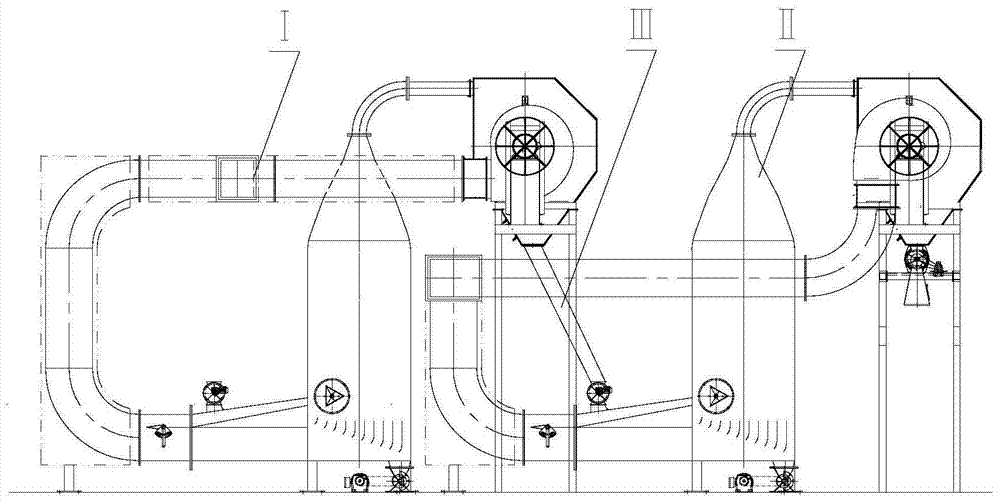

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

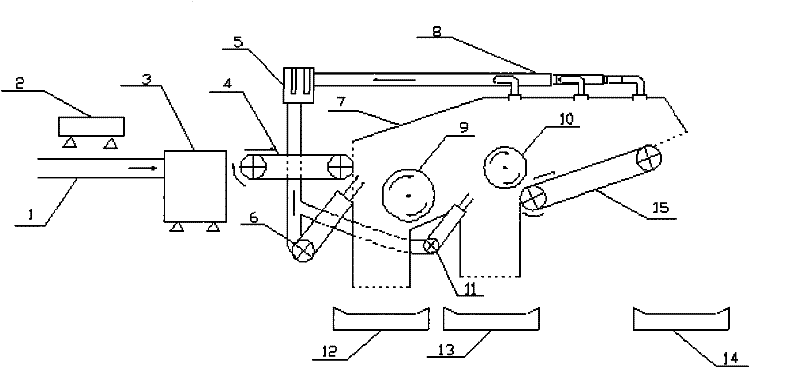

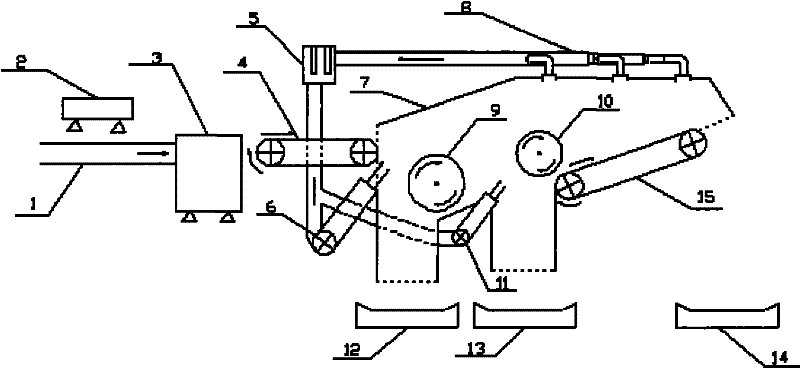

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

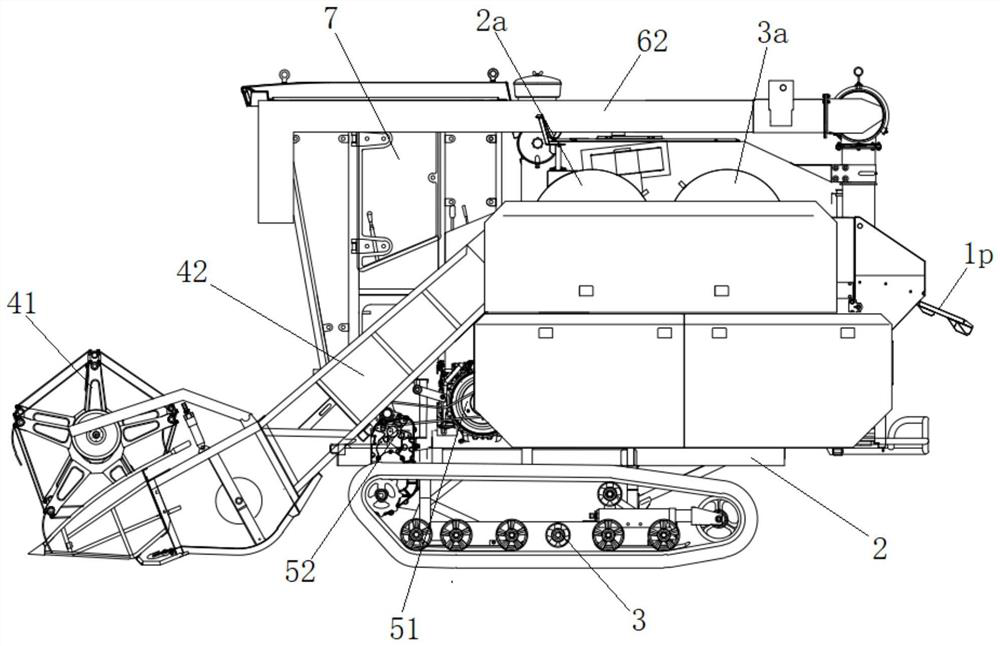

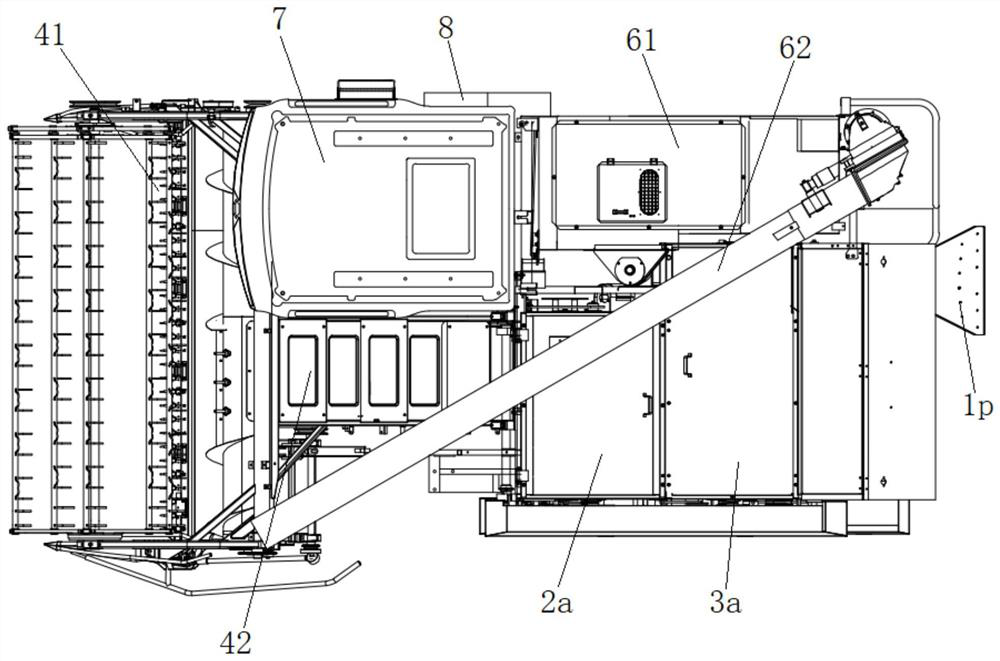

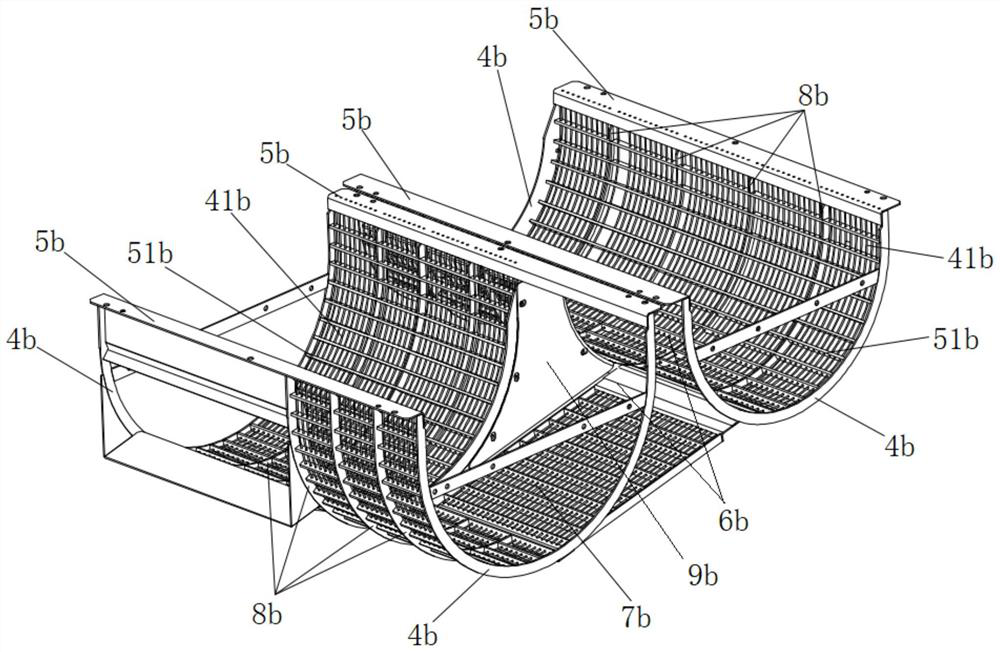

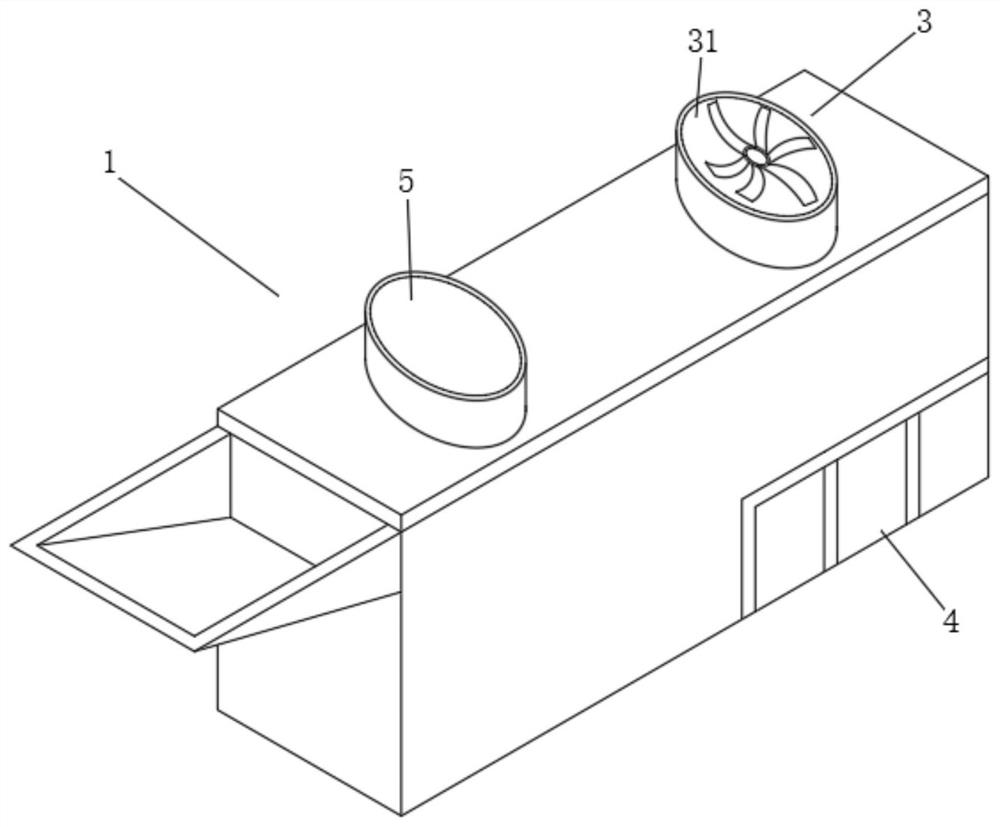

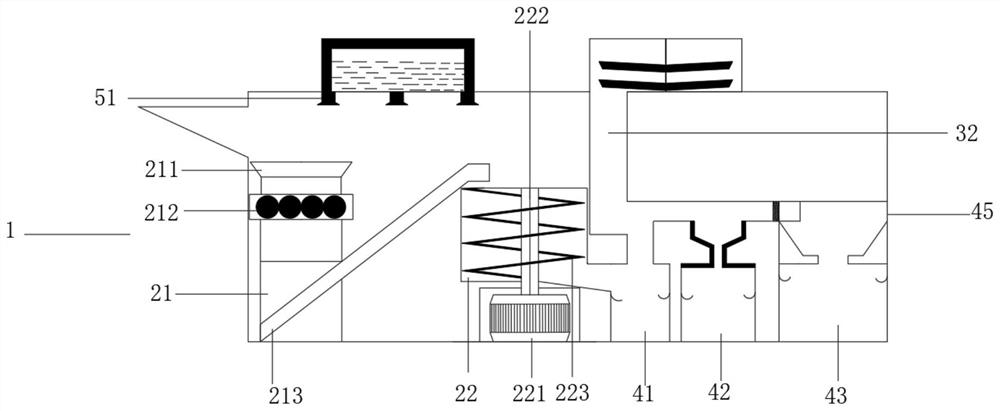

Combine harvester

PendingCN112690086ASmooth feedingGuaranteed stabilityMowersThreshersAgricultural engineeringGrain storage

The invention provides a combine harvester. A feeding port is formed in the middle of a frame, so that a connecting port between a crop conveying structure communicated with the feeding port and a header is located at the position, close to the middle, of the header, and crops are fed into the connecting port from the two sides of the header more evenly; and meanwhile, a scattering structure is arranged close to a grain storage assembly, the crops enter from the middle of the front end of the harvester and are partially scattered out from the middle of the tail end of the harvester through the n-shaped threshing direction of a double-helix threshing conveying system, and the stability of the gravity center of the combine harvester is guaranteed. A cleaning transmission system is arranged at the outer side of a threshing system, centralized transmission is achieved, and installation and debug are convenient. The whole harvester is compact in structure, small in occupied space, high in maneuverability and remarkable in operation efficiency, and the gravity center is always kept stable in the empty operation and harvesting operation process.

Owner:JIANGSU WORLD AGRI MACHINERY

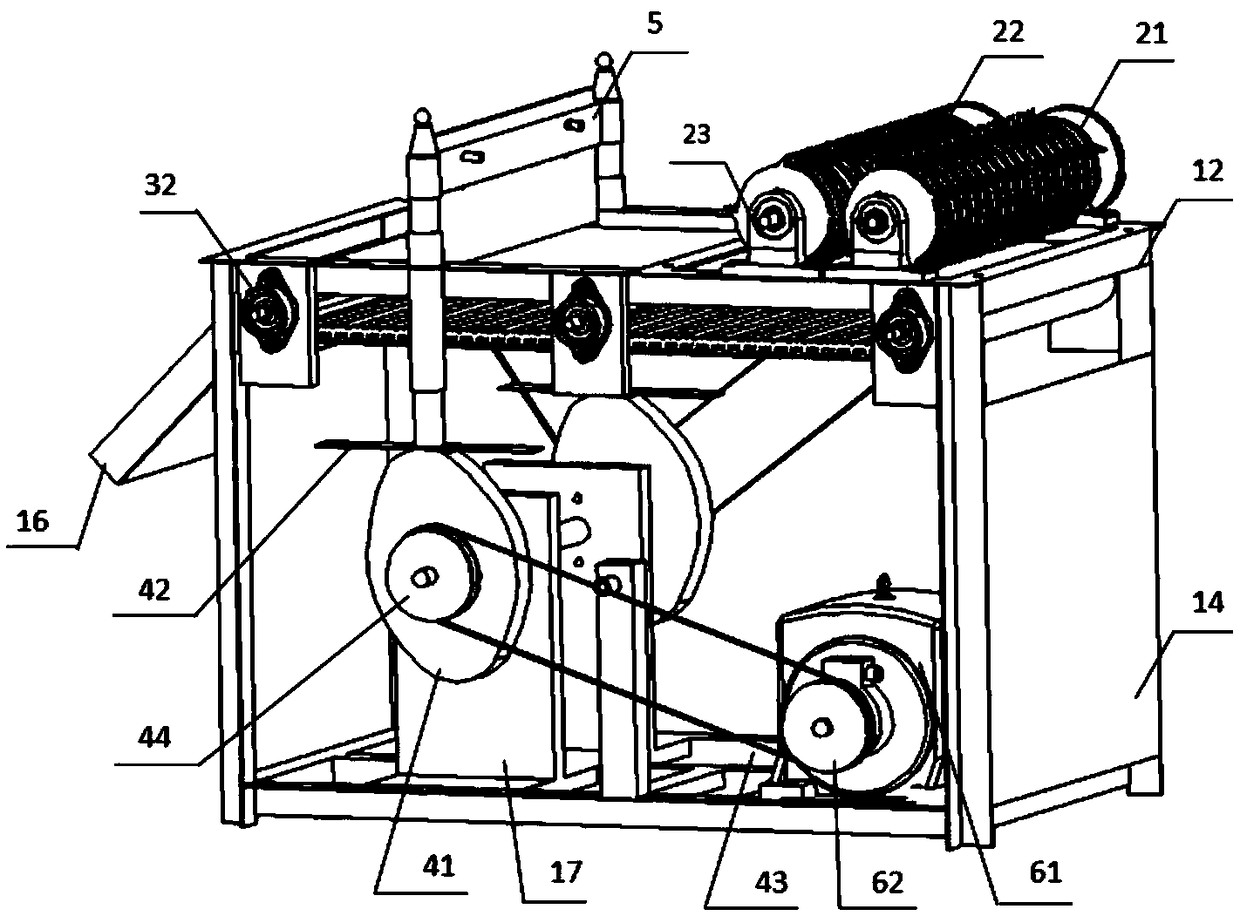

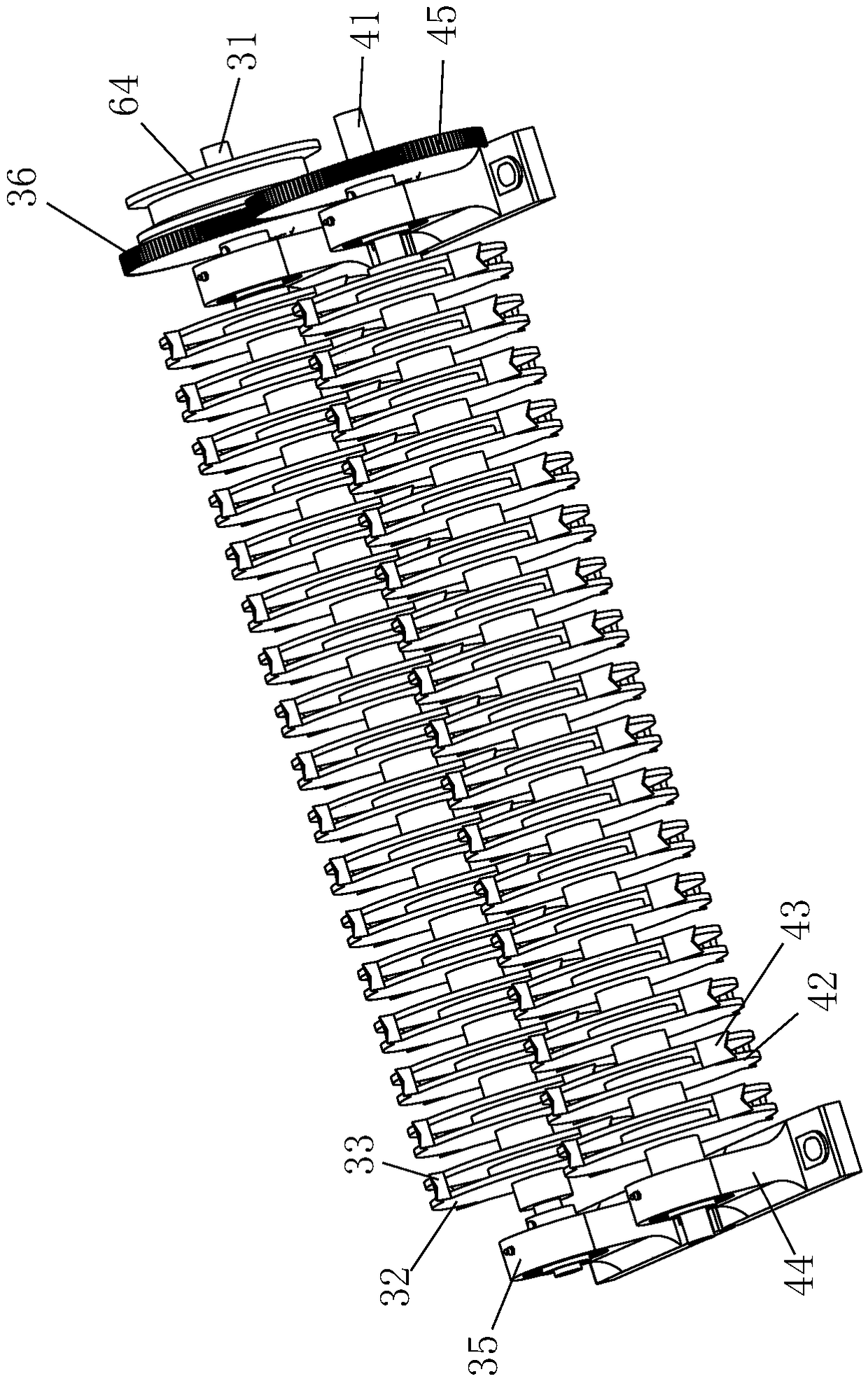

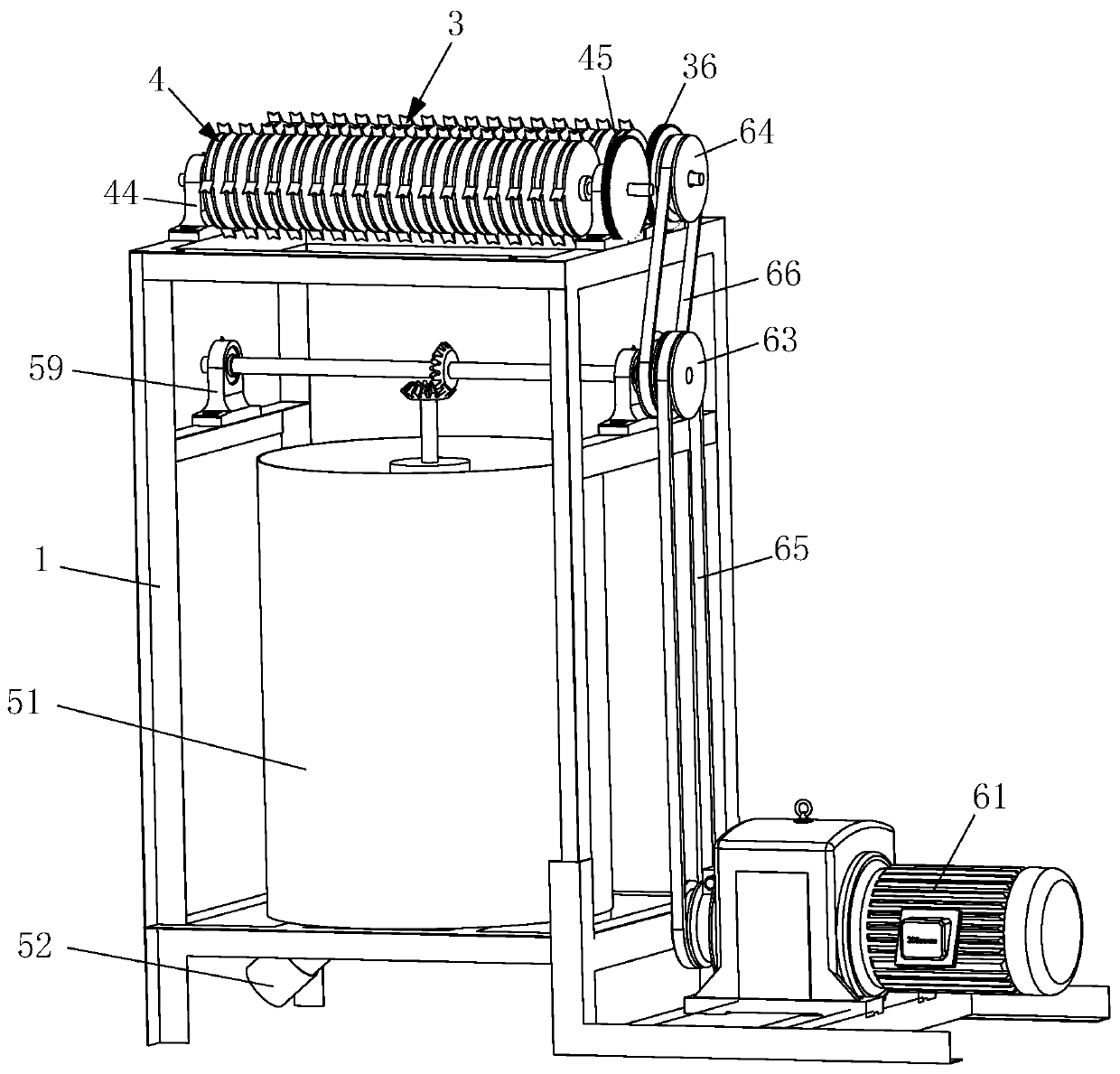

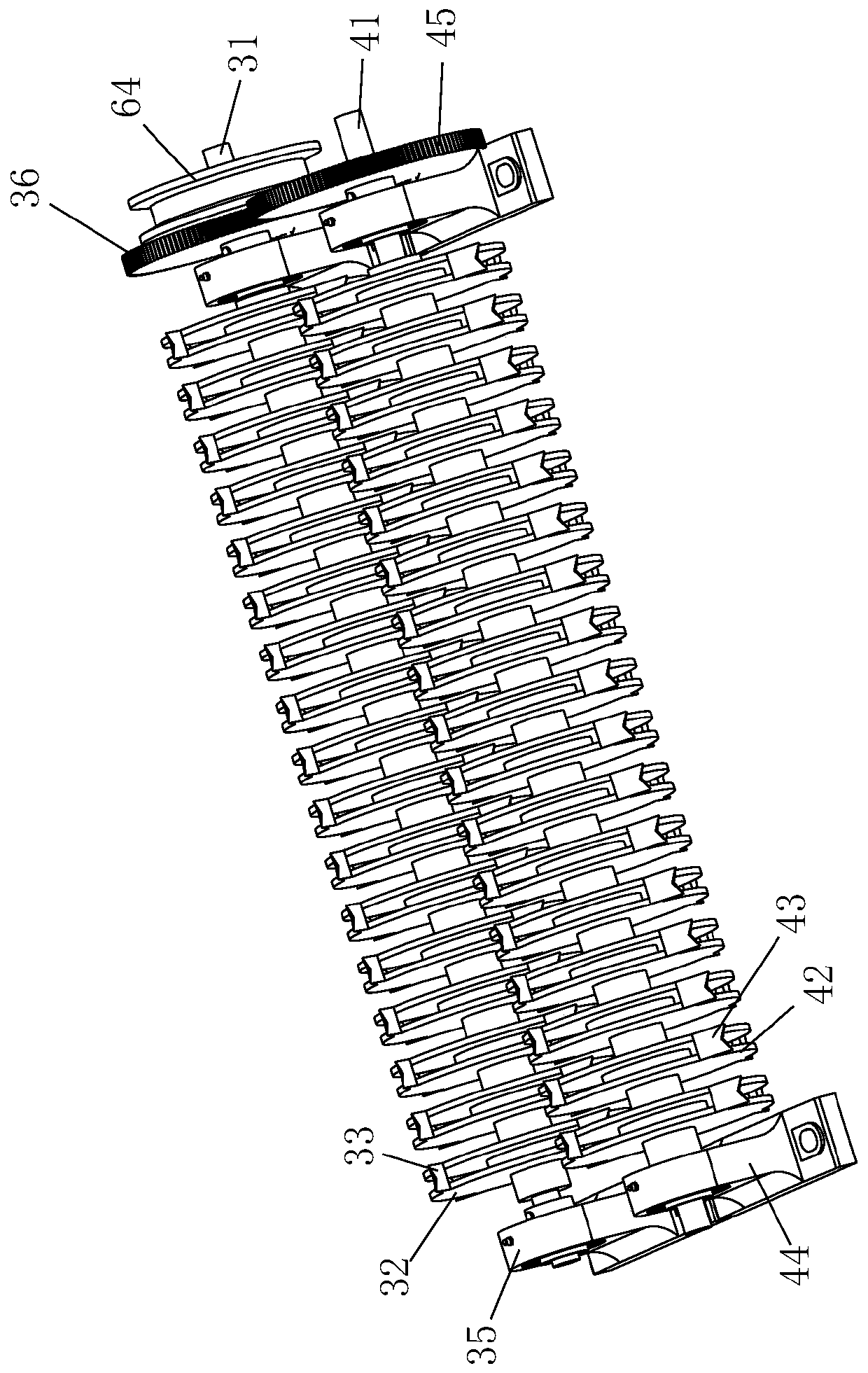

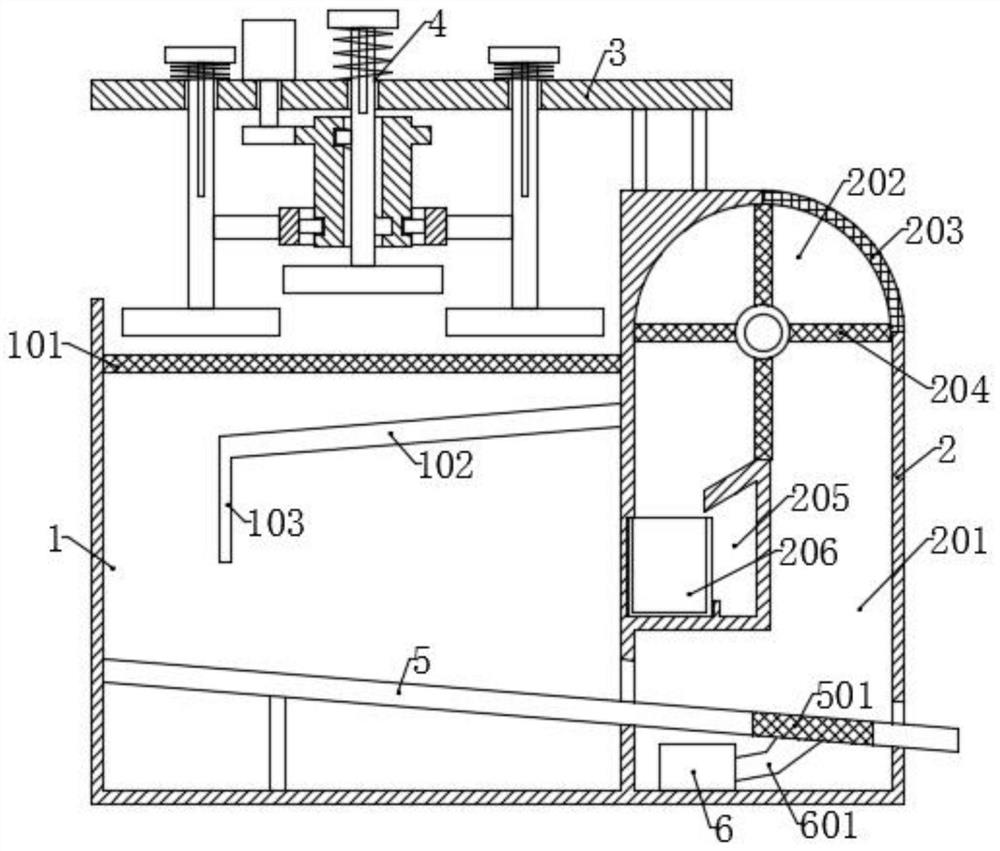

Regular shape crushing and cutting device for waste power battery inner core

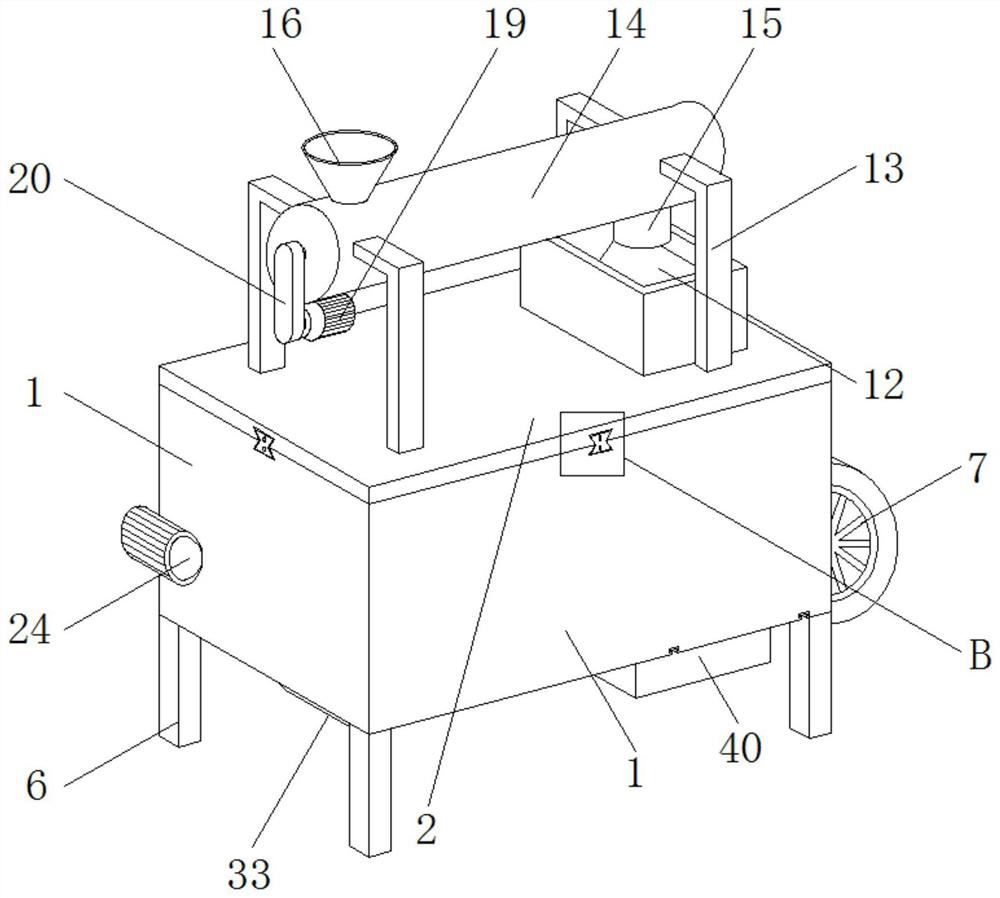

ActiveCN108722596ARealize grading winnowingImprove winnowing efficiencyGrain treatmentsPower batteryEngineering

The invention discloses a regular shape crushing and cutting device for a waste power battery inner core. The regular shape crushing and cutting device comprises a rack, a crushing device body, a conveyer belt device, a push rod mechanism, a cutter device and a drive device. The rack comprises a feeding hopper and a rack body, the rack body is provided with the crushing device body and the cutterdevice, and the rack body is internally provided with the push rod mechanism. The upper portion of the crushing device is connected with the feeding hopper, and the lower portion of the crushing device is connected with the conveyer belt device. The drive device is installed on a lower side cross beam of the rack body, and the drive device comprises a motor 61. When the regular shape crushing andcutting device works, the motor is started, waste power batteries enter the feeding hopper, long-stripe-shaped flakes are formed after the batteries are crushed by the crushing device, the flakes fallinto a lower conveyer belt, the conveyer belt conveys the flakes below the cutter device at a uniform speed, the cutter device uniformly cuts the flakes into blocks under the push of the push rod mechanism, and the blocks are sent into a storage container through a discharging hopper.

Owner:HEFEI UNIV OF TECH

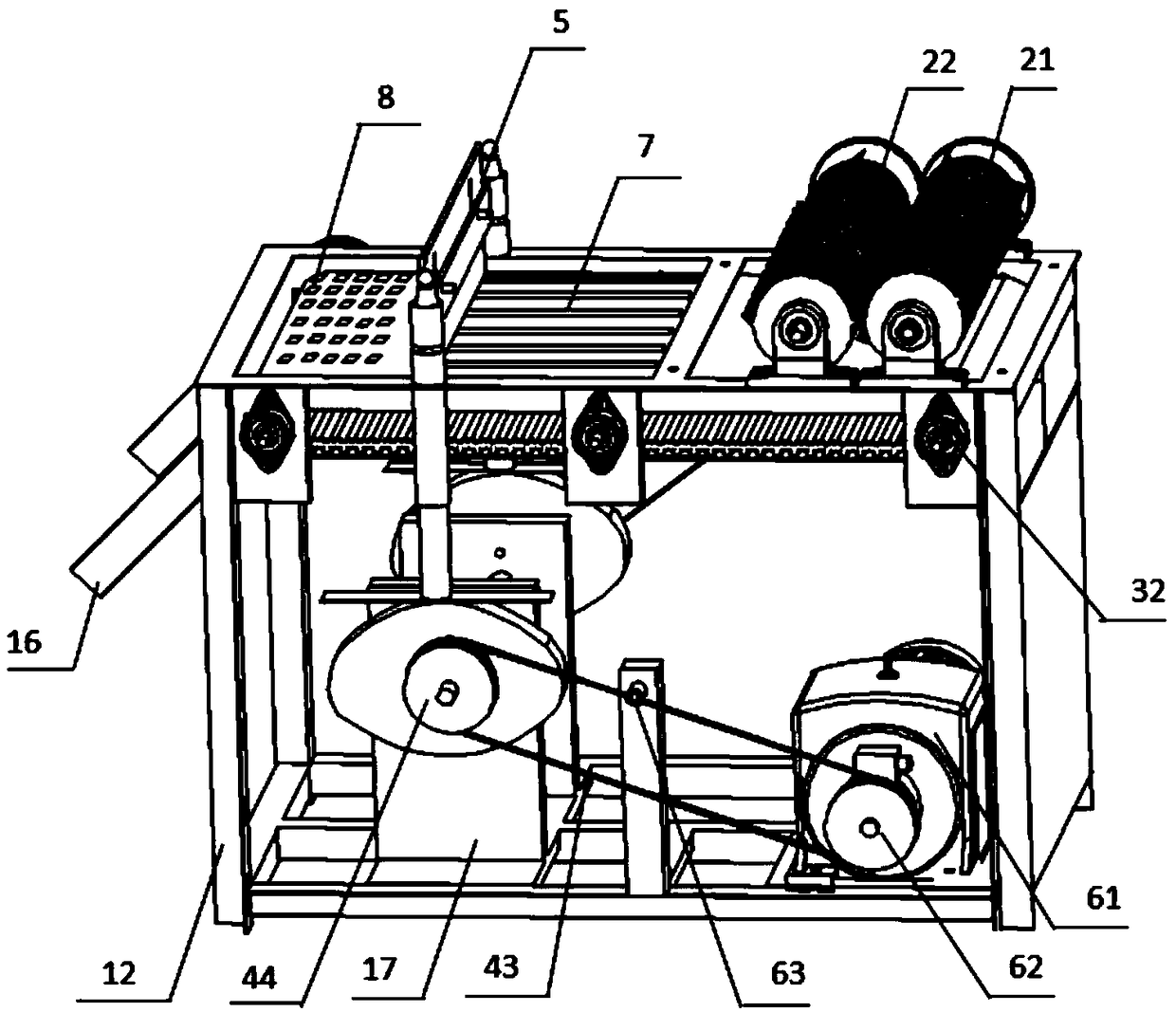

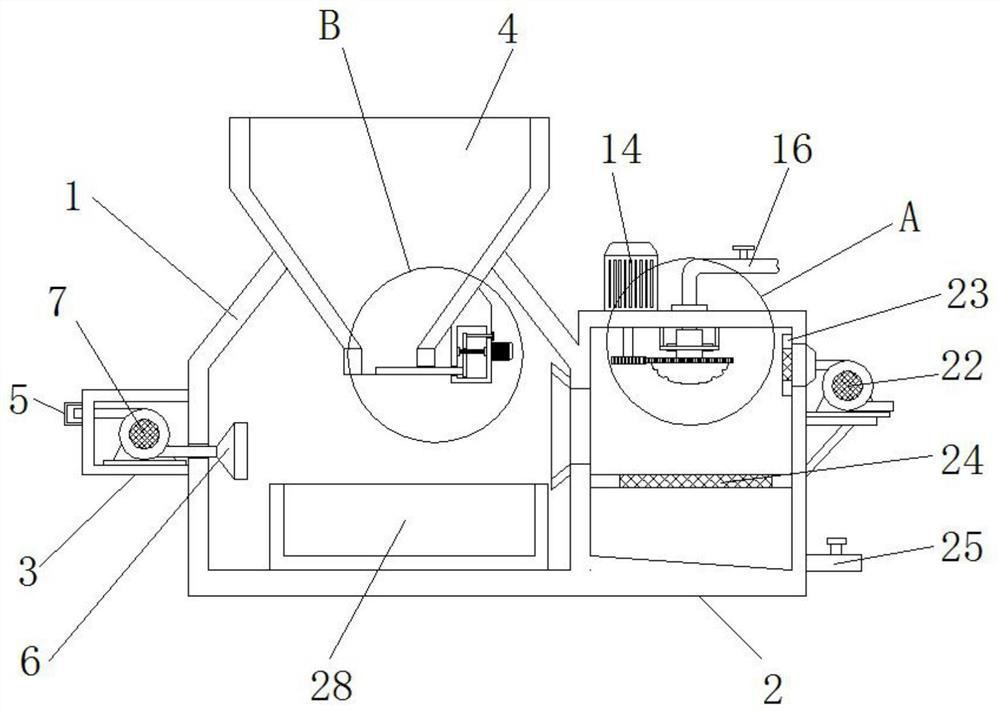

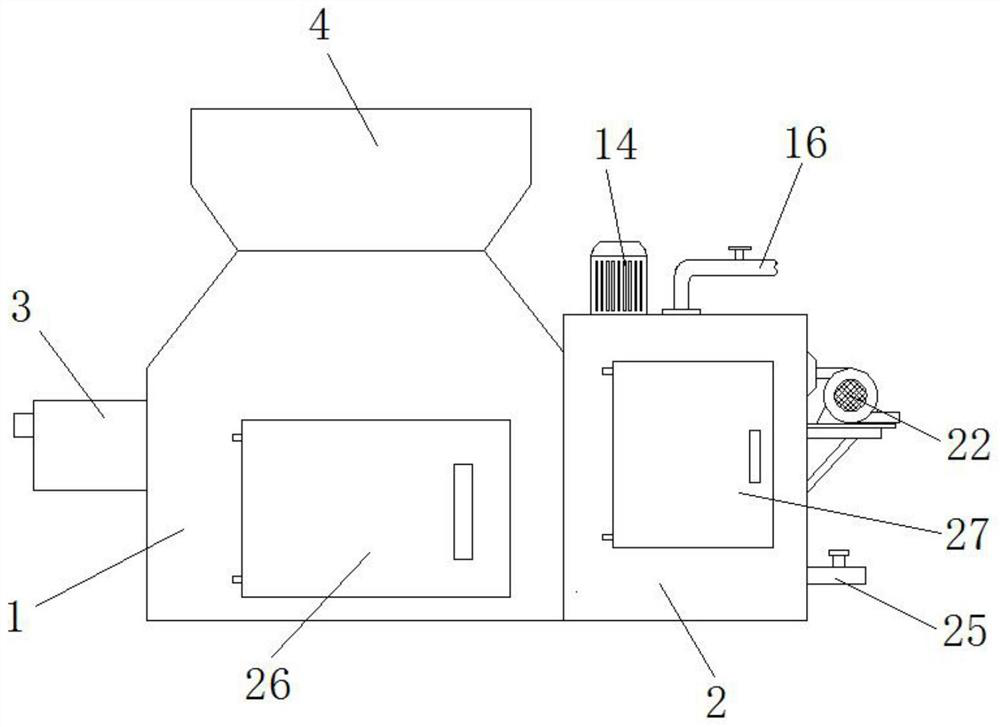

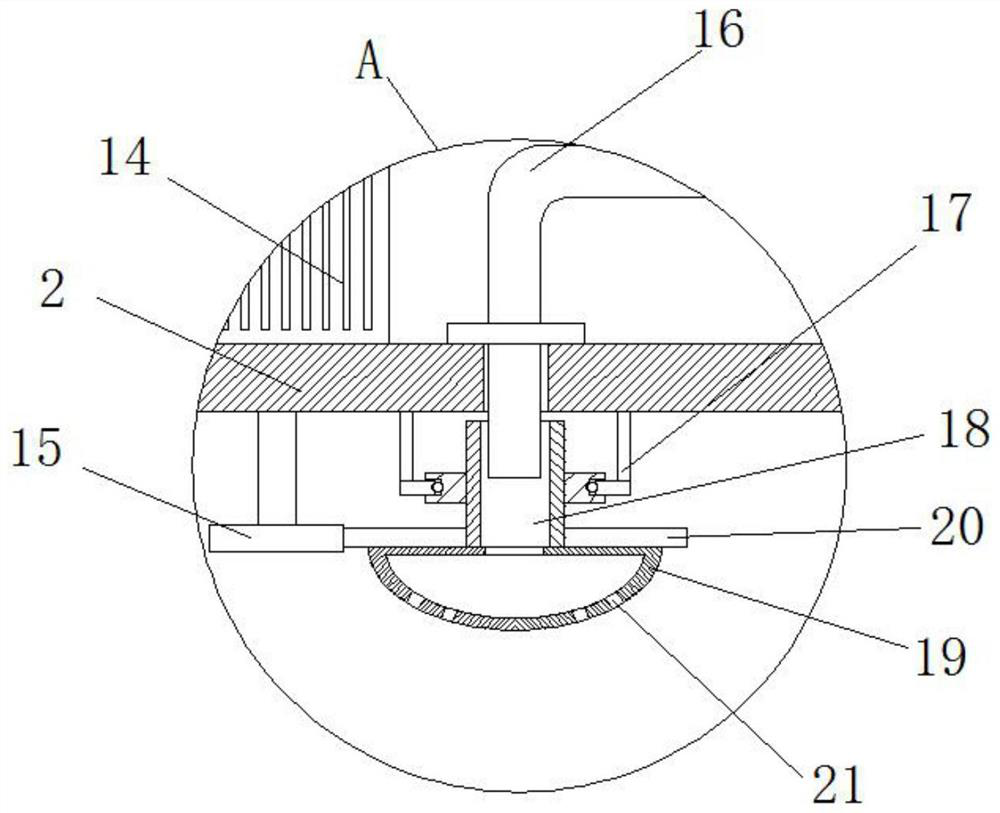

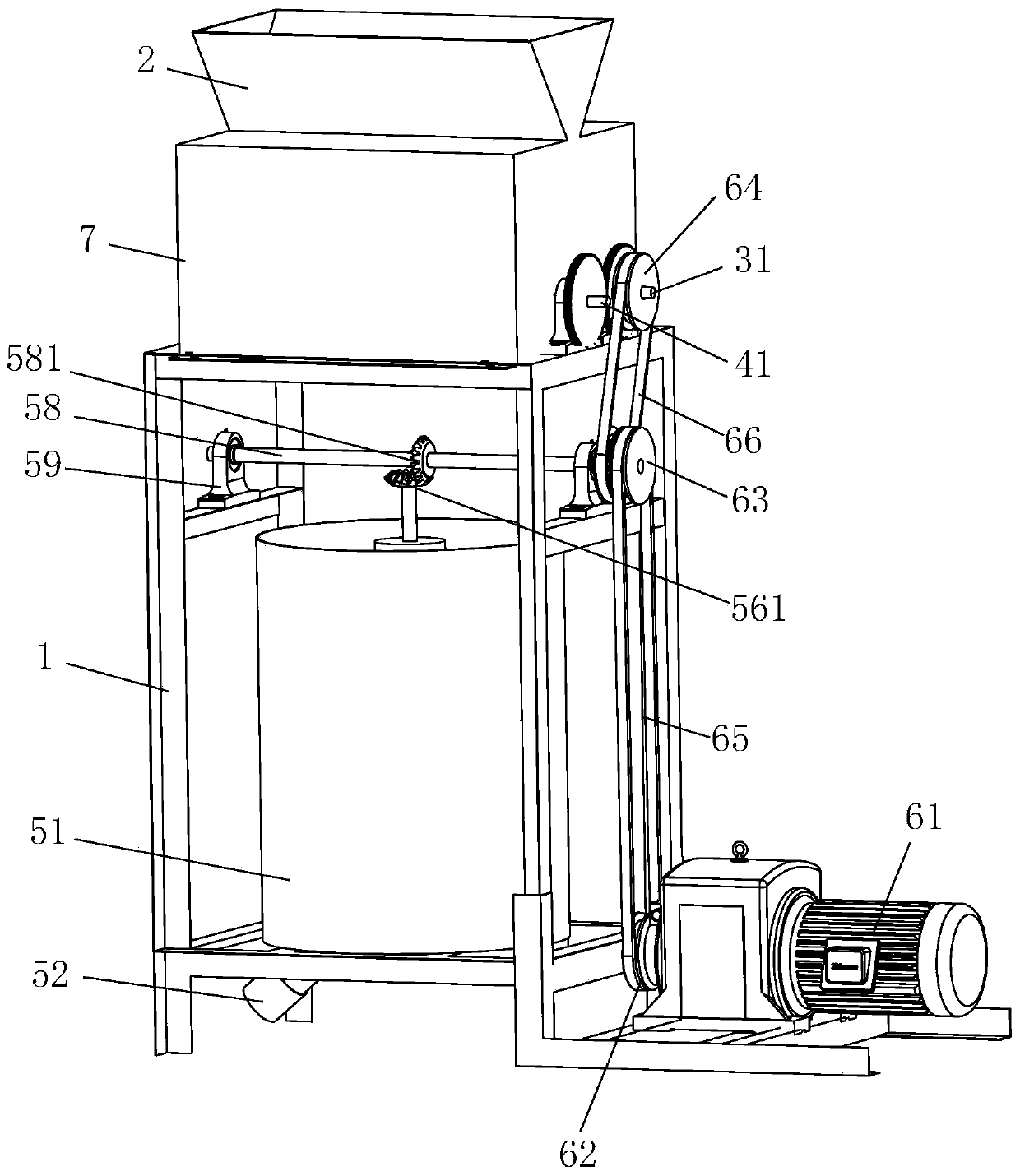

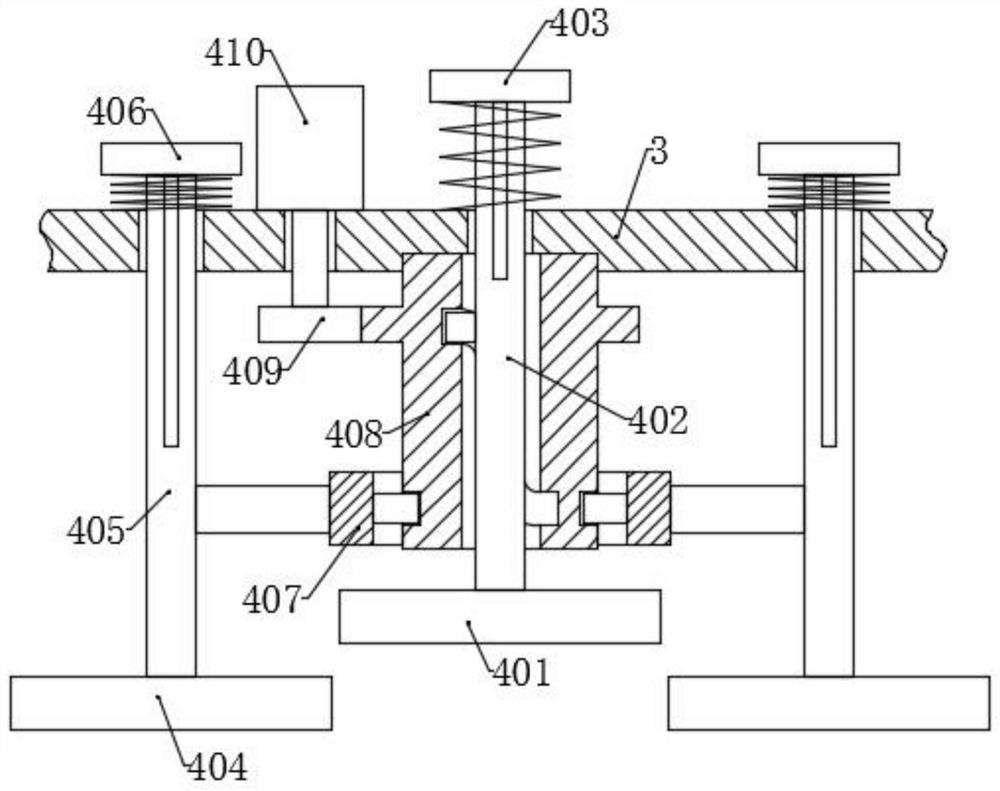

Crushing stirring device for waste LiFePO4 power battery

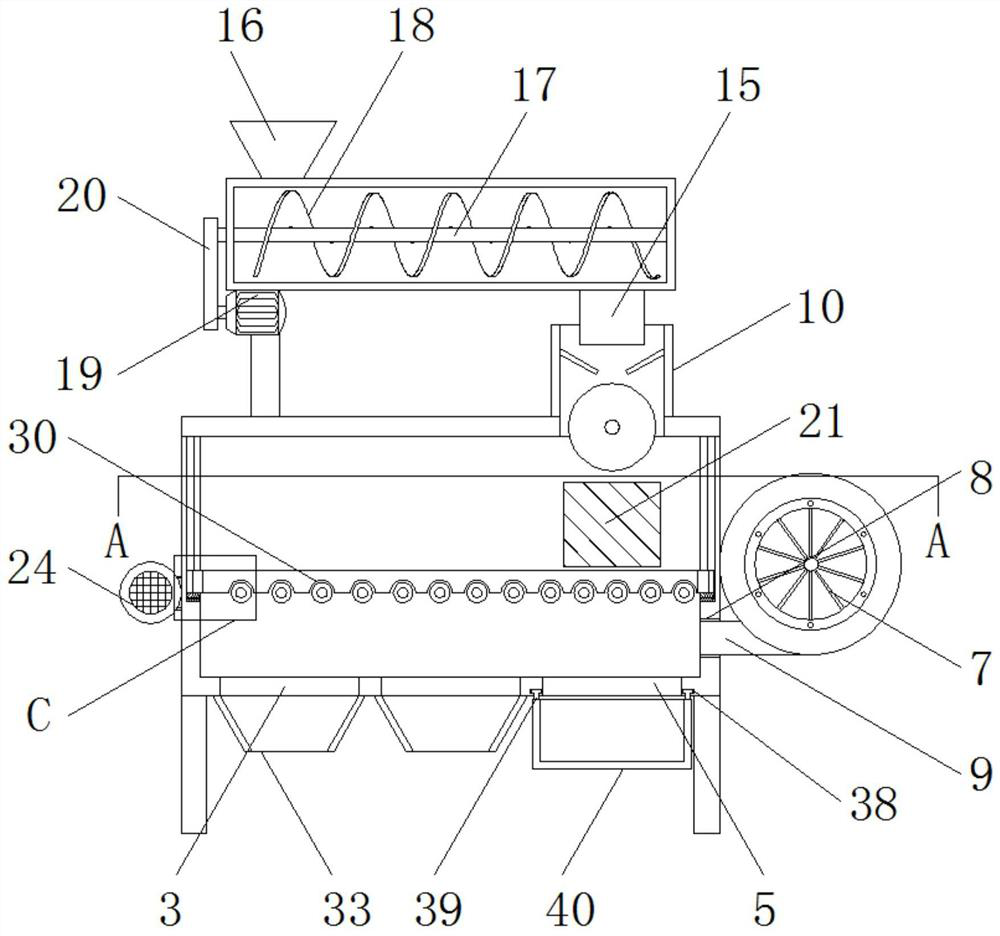

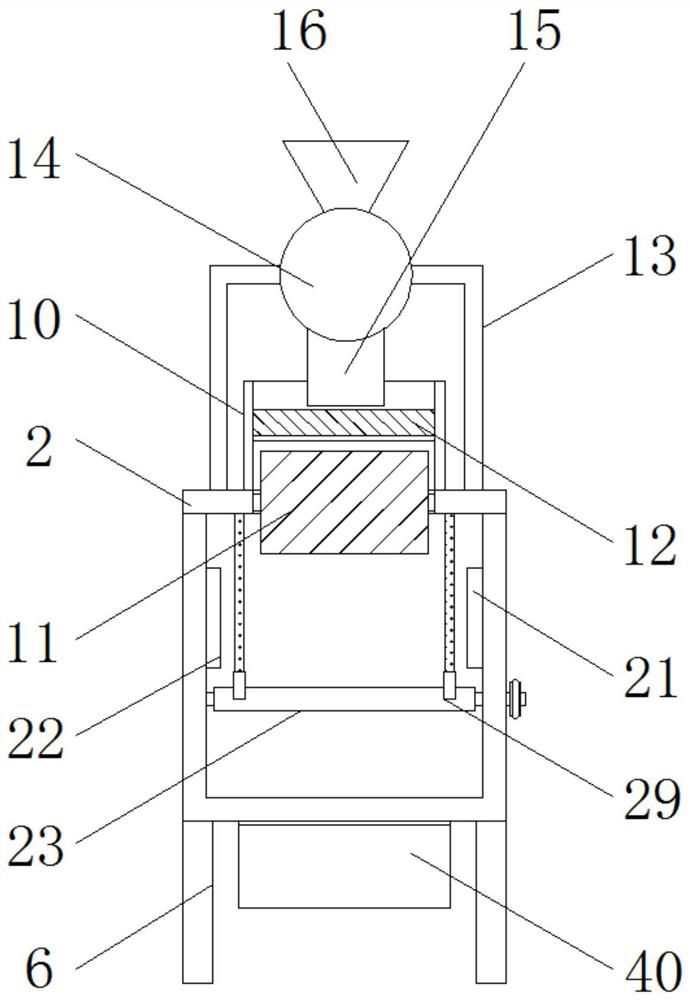

ActiveCN109395852AEfficient separationImprove winnowing efficiencyRotary stirring mixersTransportation and packagingCopper foilCurrent collector

The invention relates to a crushing stirring device for a waste LiFePO4 power battery. The crushing stirring device comprises a frame and a crushing device fixed on the frame; a feeding hopper is arranged above the crushing device; a stirring device is arranged under the crushing device; the crushing device and the stirring device are both connected with a power device; the crushing device comprises a driving hob set and a driven hob set which are oppositely arranged; the stirring device comprises a stirring barrel, a stirrer arranged in the stirring barrel and a discharging pipe arranged on the bottom of the stirring barrel; dilute alkali liquor is filled in the stirring barrel. According to the technical scheme of the invention, the crushing device is used for grinding and cutting the waste LiFePO4 power battery so as to form regularly shaped sheet crushed aggregates, and then the stirring device is used for effectively separating powder on anode aluminum foil current collector and cathode copper foil current collector so as to supply a reliable guarantee for the subsequent winnowing process and increase the winnowing efficiency.

Owner:HEFEI UNIV OF TECH

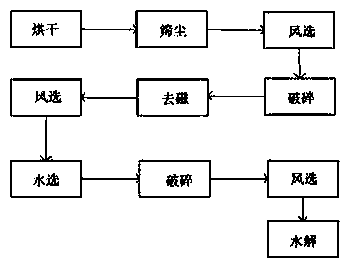

Garbage sorting treatment method

The invention provides a garbage sorting treatment method which occupies small area, can avoid pollution and effectively treat toxic gas, has no residue and is short in treatment time, low in operation cost, high in product quality and free of secondary pollution. According to the technical scheme, the garbage sorting treatment method is characterized by comprising the following steps: drying, performing dust screening, winnowing, crushing, de-magnetizing, winnowing, performing water separating, crushing, winnowing, hydrolyzing and discharging hydrolyzed garbage from a hydrolysis tank.

Owner:河南省洁苑环保科技有限公司

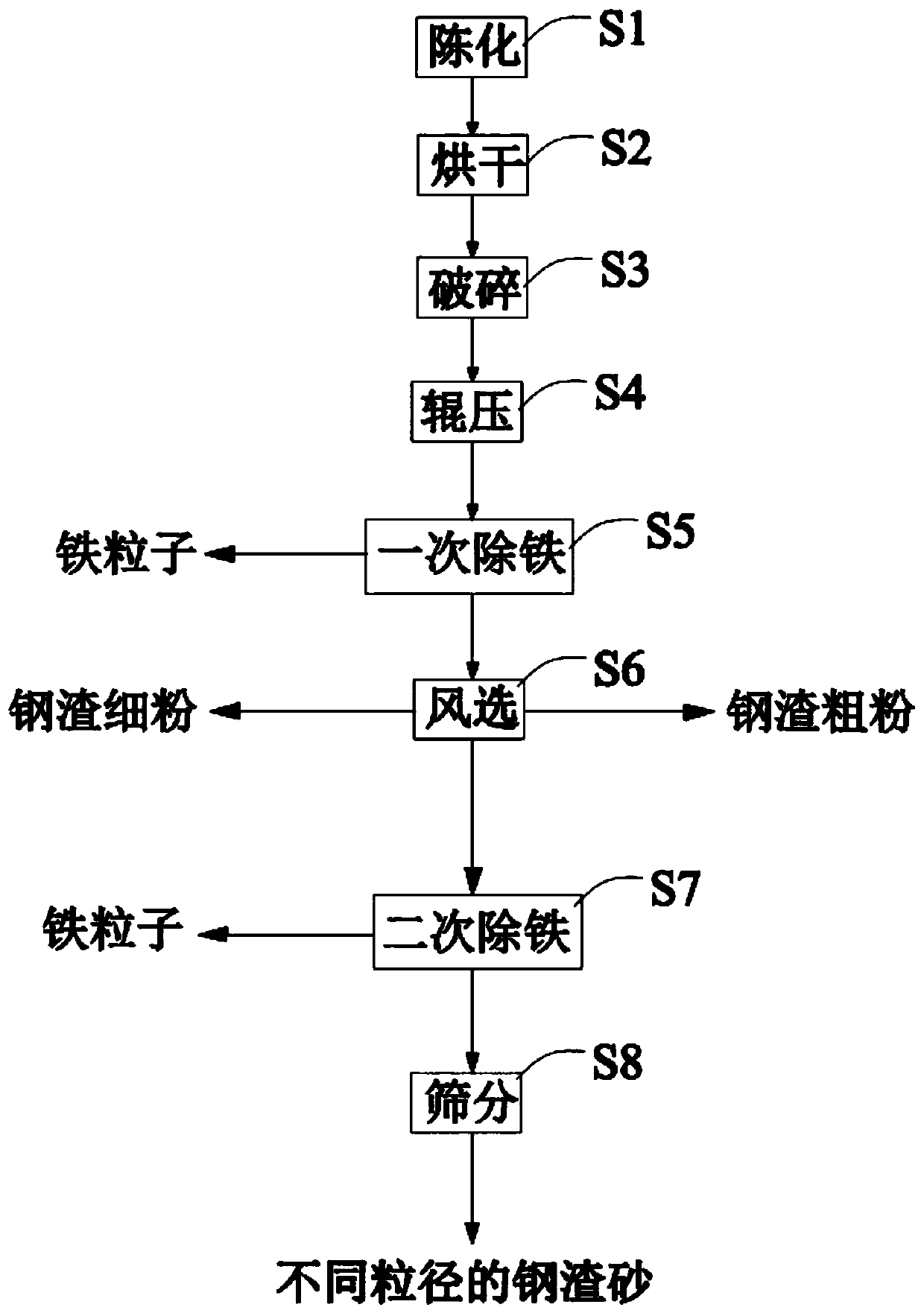

Comprehensive steel slag utilization method

PendingCN109734336AIncreased efficiency of subsequent rollingReduce the burden onSolid waste disposalProcess efficiency improvementSlagMagnetic separator

The invention discloses a comprehensive steel slag utilization method which includes the steps: S1 ageing: stacking steel slag for 3 months or more to obtain aged steel slag; S2 drying the aged steelslag to obtain dried steel slag; S3 crushing the dried steel slag to obtain crushed steel slag; S4 rolling the crushed steel slag to obtain rolled steel slag; S5 primary iron removal: feeding the rolled steel slag into a magnetic separator to perform first iron removal to obtain iron particles I and steel slag after primary iron removal; S6 air separation: feeding the steel slag after primary ironremoval into an air separation device, and performing air separation to obtain fine steel slag powder, steel slag and sand mixture and steel slag coarse materials; S7 secondary iron removal: performing secondary iron removal on the steel slag and sand mixture to obtain iron particles II and steel slag and sand mixture after secondary iron removal; S8 screening the steel slag and sand mixture to obtain steel slag sand with different particle diameters. According to the method, waste steel slag generated in the steel making process serves as a raw material, so that the iron particles, the finesteel slag powder and the steel slag sand with the different particle diameters are prepared in a united manner, and the steel slag is comprehensively utilized.

Owner:湘潭玉峰新材料科技有限公司

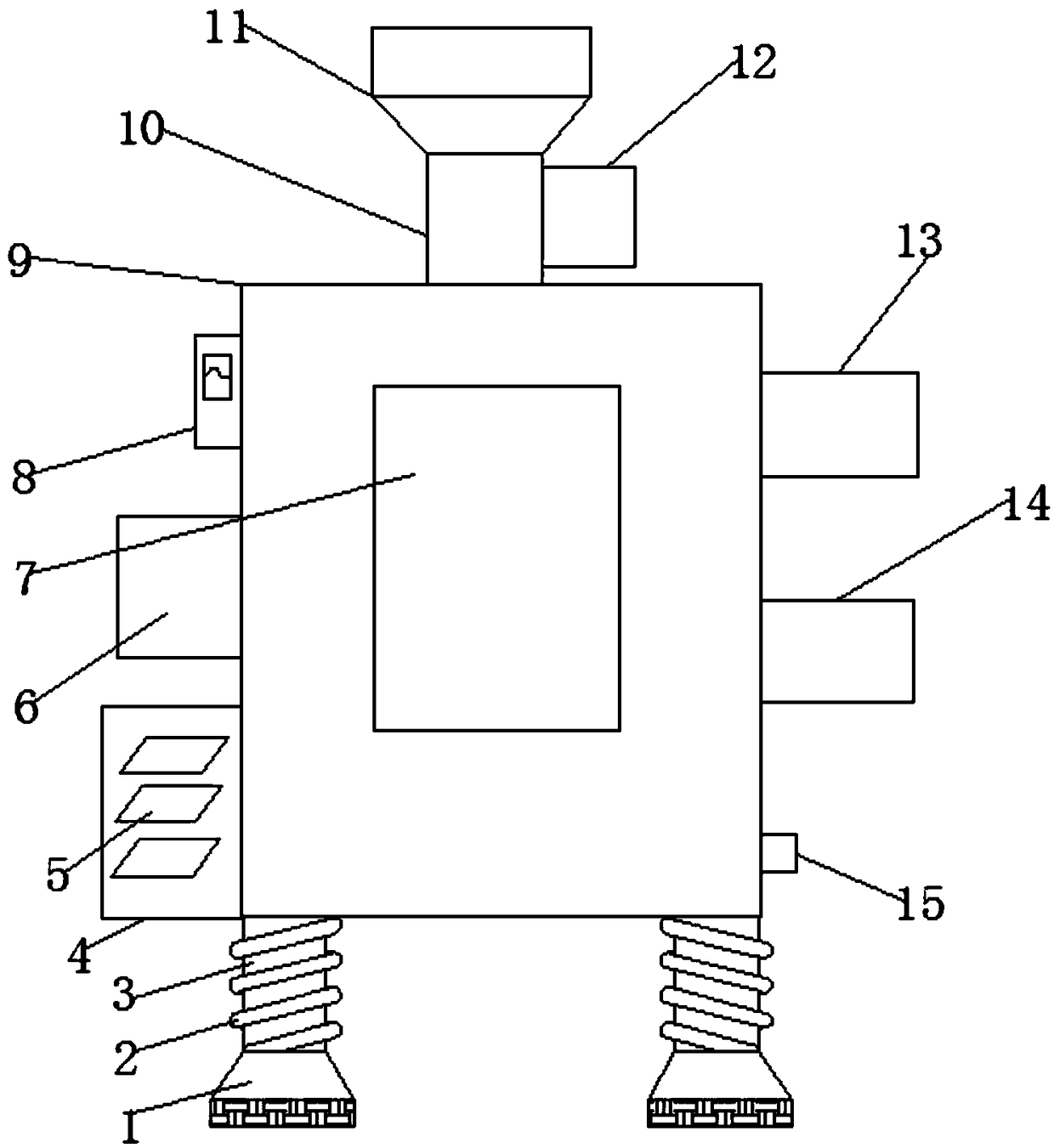

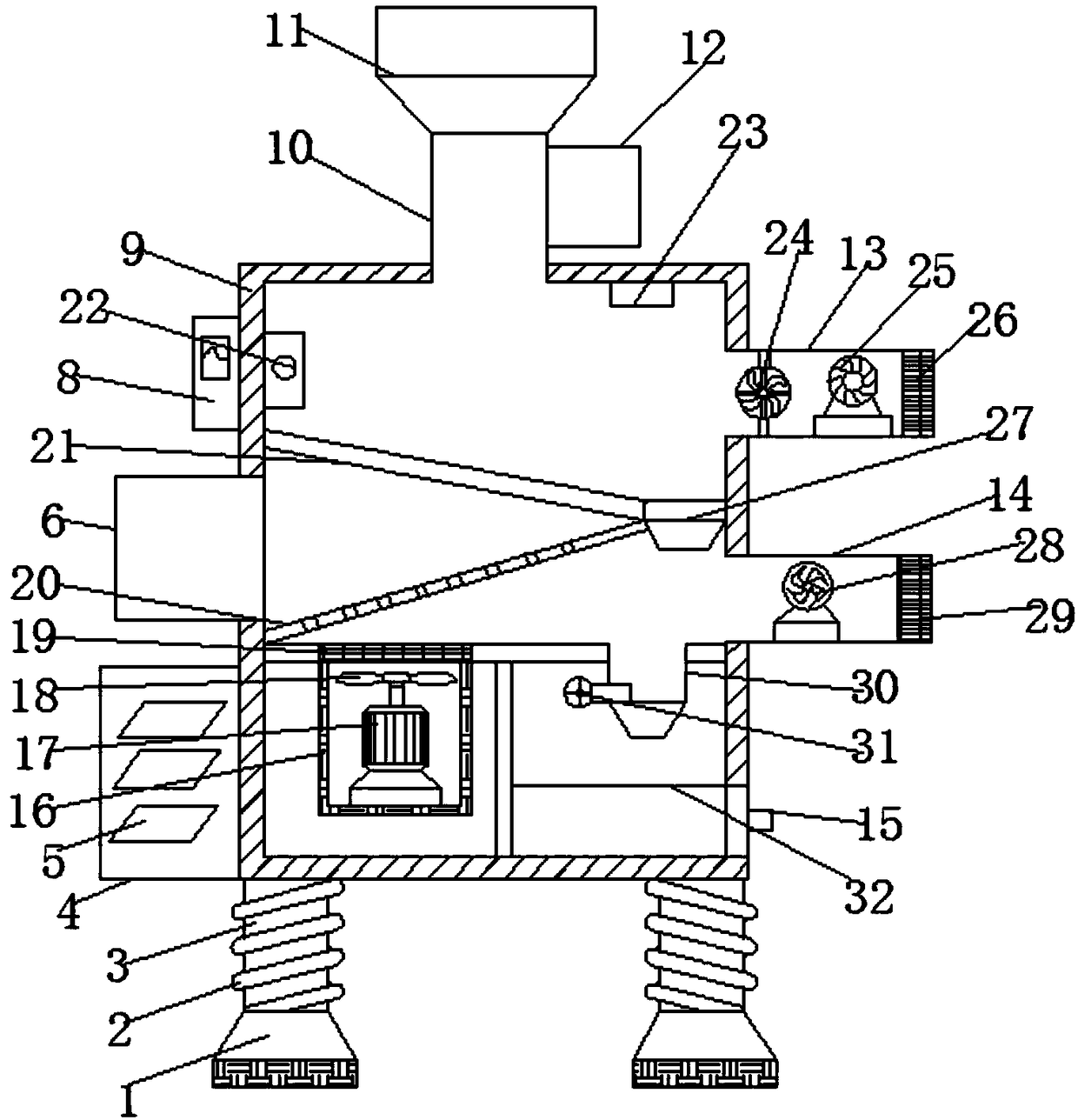

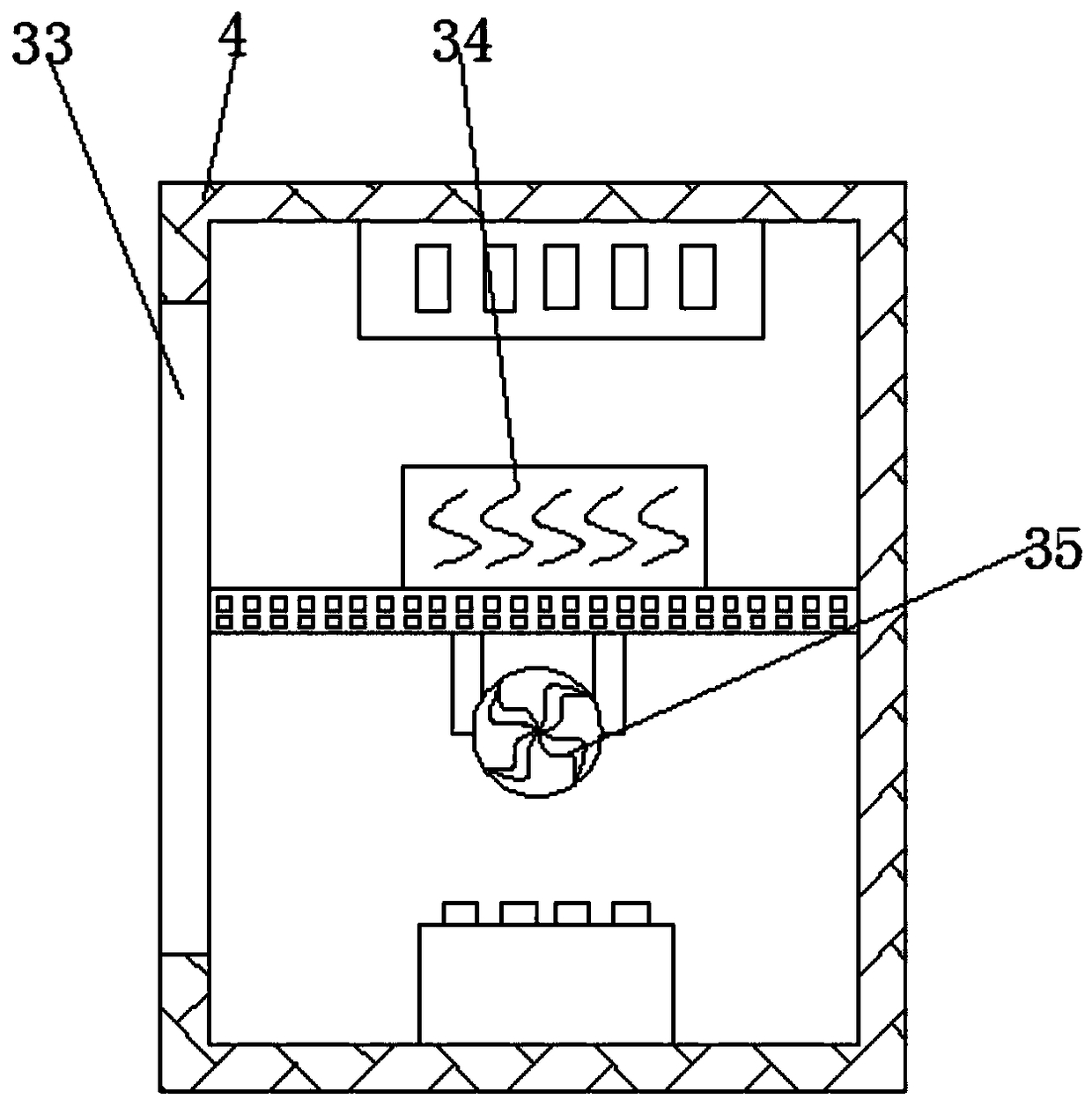

Multi-purpose winnowing device for drug producing machining

ActiveCN108855476AEasy to crushEasy to sortGas current separationNon-rotating vibration suppressionEngineeringMachining

The invention belongs to the technical field of winnowing devices, and particularly relates to a multi-purpose winnowing device for drug producing machining. The multi-purpose winnowing device for drug producing machining solves the technical problems that drug particles are too large, and cannot be subject to winnowing, and dust generated by winnowing cannot be treated. According to the technicalscheme, the device comprises a shell, a heater is fixed to the inner wall of one side of the shell through a screw, a material guide plate is fixed to the lower portion of the heater through a screw,a discharging hopper is welded between the end, away from the heater, of the material guide plate and the shell, the outer wall of the side, close to the material guide plate, of the discharging hopper is fixedly provided with a baffle through a screw, through holes distributed at equal distances are formed in the outer wall of the baffle, and the inner walls of the two sides of the shell are fixedly provided with the same transverse partition board through screws. The device is exquisite in structure, diverse in function and capable of smashing fed drugs, the subsequent drug sorting is facilitated, the winnowing efficiency is improved, and dust generated by winnowing can be conveniently removed.

Owner:安徽华善堂中药饮片有限公司

Husked rice separating and screening device for rice processing

InactiveCN111804588AControl flow rateAdjustable sizeGas current separationDispersed particle filtrationAgricultural scienceAgricultural engineering

The invention discloses a husked rice separating and screening device for rice processing. The husked rice separating and screening device comprises a winnowing box, wherein a discharging hopper is fixedly arranged at the top end of the winnowing box; a dust removal box is fixedly connected to one side of the winnowing box; a mounting box is fixedly connected to one side, far away from the dust removal box, of the winnowing box; a first air blower is fixedly arranged in the mounting box; a speed adjusting box is fixedly connected to one side of an opening in the bottom end of the discharging hopper; a first rotating motor is fixedly arranged on the speed adjusting box; and a threaded rod which is horizontally arranged is rotationally arranged in the speed adjusting box. The husked rice separating and screening device is ingenious in structure and convenient to use, the effect of rapidly winnowing the rice can be achieved, the winnowing efficiency is high, the effect is good, rice husksand dust are sucked into the dust removal box, dust removal is carried out through water mist sprayed out by rotating a container, a large amount of dust cannot be generated in the whole winnowing process, the situation that workers inhale dust is effectively prevented, and the health of the workers can be effectively protected.

Owner:ANHUI FUNING RICE IND CO LTD

Rice winnowing machine

InactiveCN107855275AEasy to dryImprove winnowing effectGas current separationDrying gas arrangementsAir velocityHusk

The invention discloses a rice winnowing machine which comprises a case, an exhausting blade, a rotary shaft and drying machines, wherein a feeding hole is formed in the top of the case; husk outletsare formed in the upper side of the case, are V-shaped and are mounted at the top of the rotary shaft; a rice outlet is formed in the lower side of the case; the rotary shaft is hollow and communicates with the exhausting blade; the drying machines are arranged on two sides of the interior of the case; a spiral rotating vane is mounted on the rotary shaft; and turntables are arranged at two ends of the spiral rotating vane on the rotary shaft. According to the rice winnowing machine, the drying machines are arranged in the case to rapidly dry damp unhusked rice for winnowing; and a V-shaped rack is designed to have high air velocity , so that rice husks can be blown into the husk outlets in two sides of the case, and the winnowing efficiency is improved.

Owner:天长市天鑫粮油贸易有限责任公司

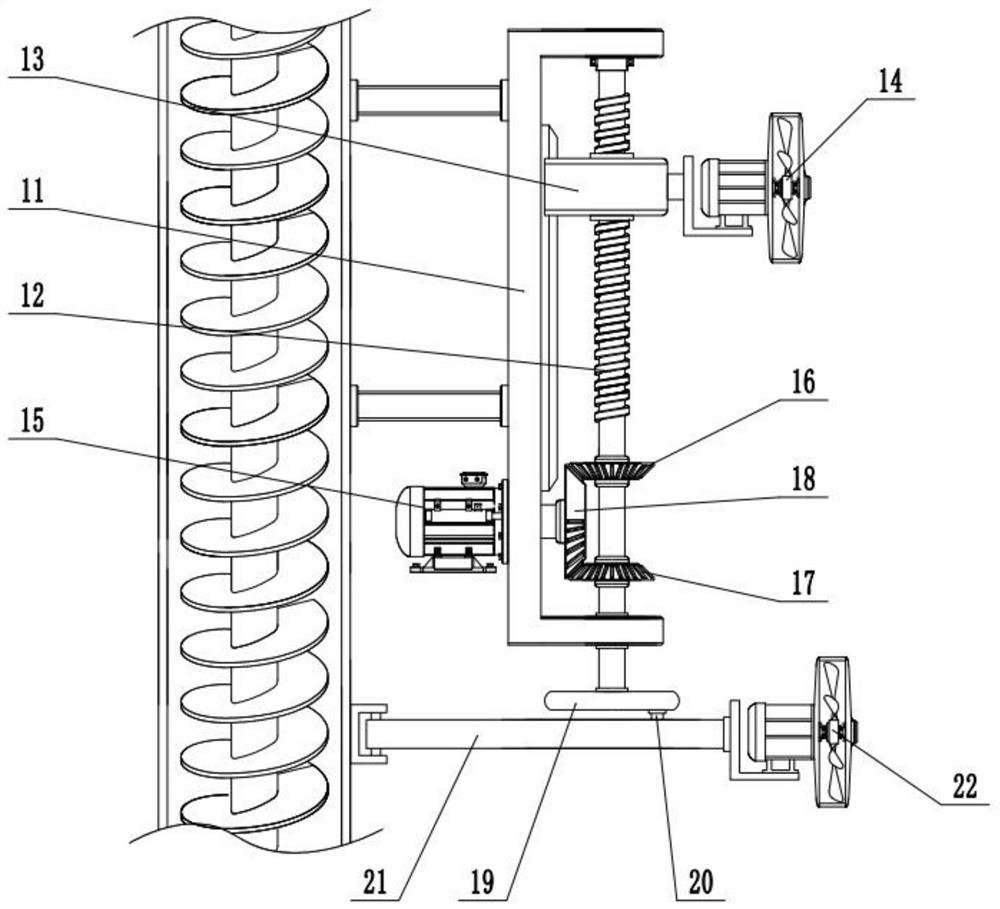

Tea grading winnowing device with good impurity removal effect

InactiveCN112474049AGood effect of removing impuritiesEasy to assemble and disassemblePre-extraction tea treatmentGas current separationAgricultural engineeringTea leaf

The present invention discloses a tea grading winnowing device with good impurity removal effect. The tea grading winnowing device with the good impurity removal effect comprises a winnowing box, an upper cover is movably connected to the upper end of the winnowing box, a first discharging port, a second discharging port and an impurity removal port are sequentially formed in the lower end of thewinnowing box from left to right, and symmetrically-arranged supporting legs are fixedly connected to the lower end of the winnowing box; a centrifugal fan is fixedly connected to the right end of thewinnowing box, an air inlet is formed in the right end of the winnowing box, an air pipe is arranged between the air inlet and the centrifugal fan, a feeding port is fixedly connected to the right side of the upper end of the upper cover, a permanent magnet roller is rotatably connected into the feeding port, and guide plates which are arranged in a bilateral symmetry mode are fixedly connected into the feeding port. A spiral blade is fixedly connected to the outer side of the rotating shaft. According to the tea grading winnowing device with the good impurity removal effect, tea leaves are graded, classified storage of the tea leaves is facilitated, the winnowing efficiency is improved, the normal effect of the conveying rollers on the tea leaves is guaranteed, magnetic impurities in thetea leaves are adsorbed, and an upper cover is convenient to disassemble and assemble.

Owner:杨玲

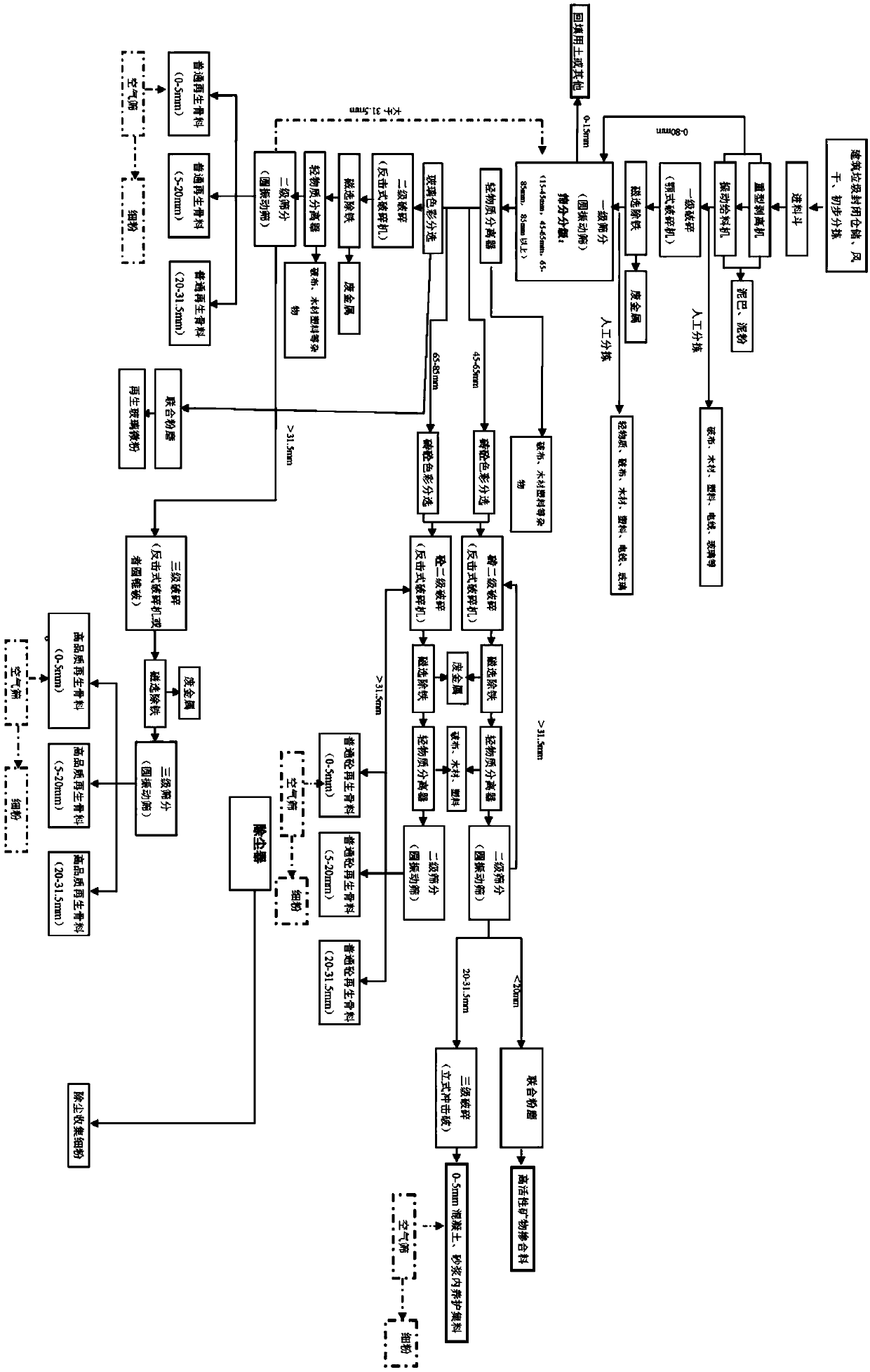

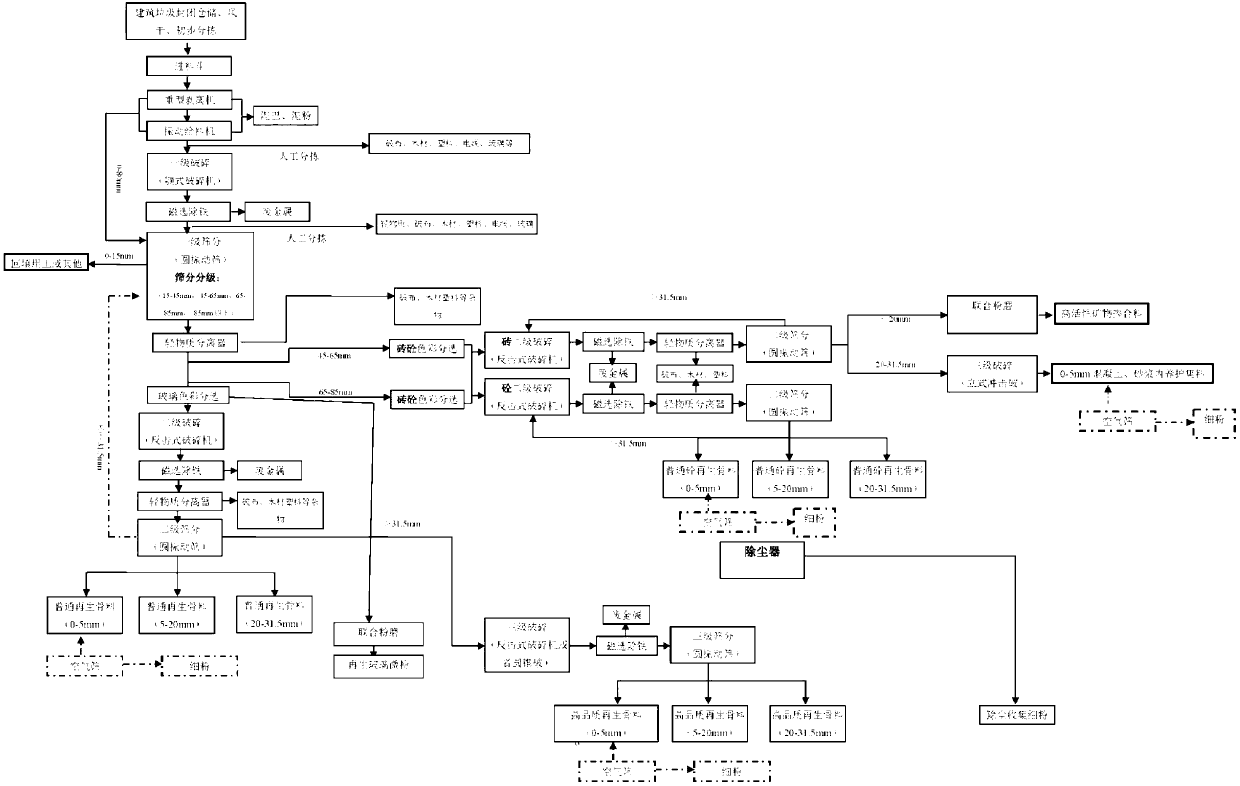

A high-quality construction solid waste treatment process

ActiveCN106830728BRealize refined classificationRealize resource utilizationConstruction waste recoverySolid waste disposalThree stageResource utilization

The invention discloses a fine treatment process for building solid waste, mainly comprising the following steps: pretreatment in a storage yard of building solid waste, including airing and manual sorting; stripping of mud powder and mud blocks, three-stage crushing, three-stage screening, manual sorting, air separation, magnetic separation, color separation, screening of different-hardness solid waste by different sorting techniques and combined grinding and dry type sand washing techniques, thereby preparing 2 kinds of novel green mineral aggregate, namely common recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, and high-strength high-quality recycled aggregate with particle sizes of 0-5mm, 5-20mm and 20-31.5mm, 5 types of high-quality, high-added value recycled products such as mortar and concrete curing aggregate, inertia micropowder and other sorted products. The fine treatment process for building solid waste realizes fine, high-added value treatment of building solid waste, achieves 100% resource utilization, and makes a great breakthrough in fine treatment in the resource utilization industry of building solid waste.

Owner:中建西部建设西南有限公司 +1

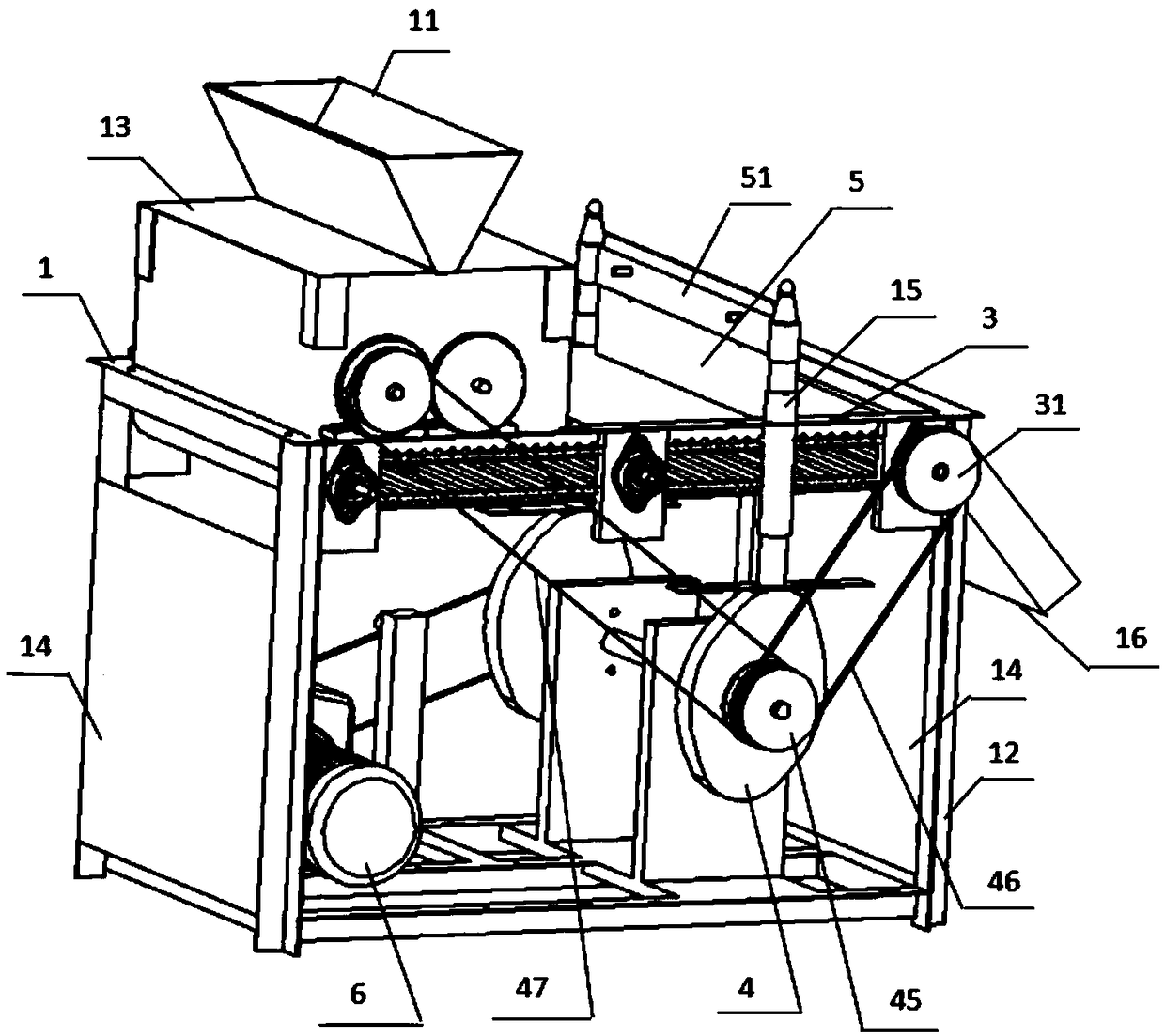

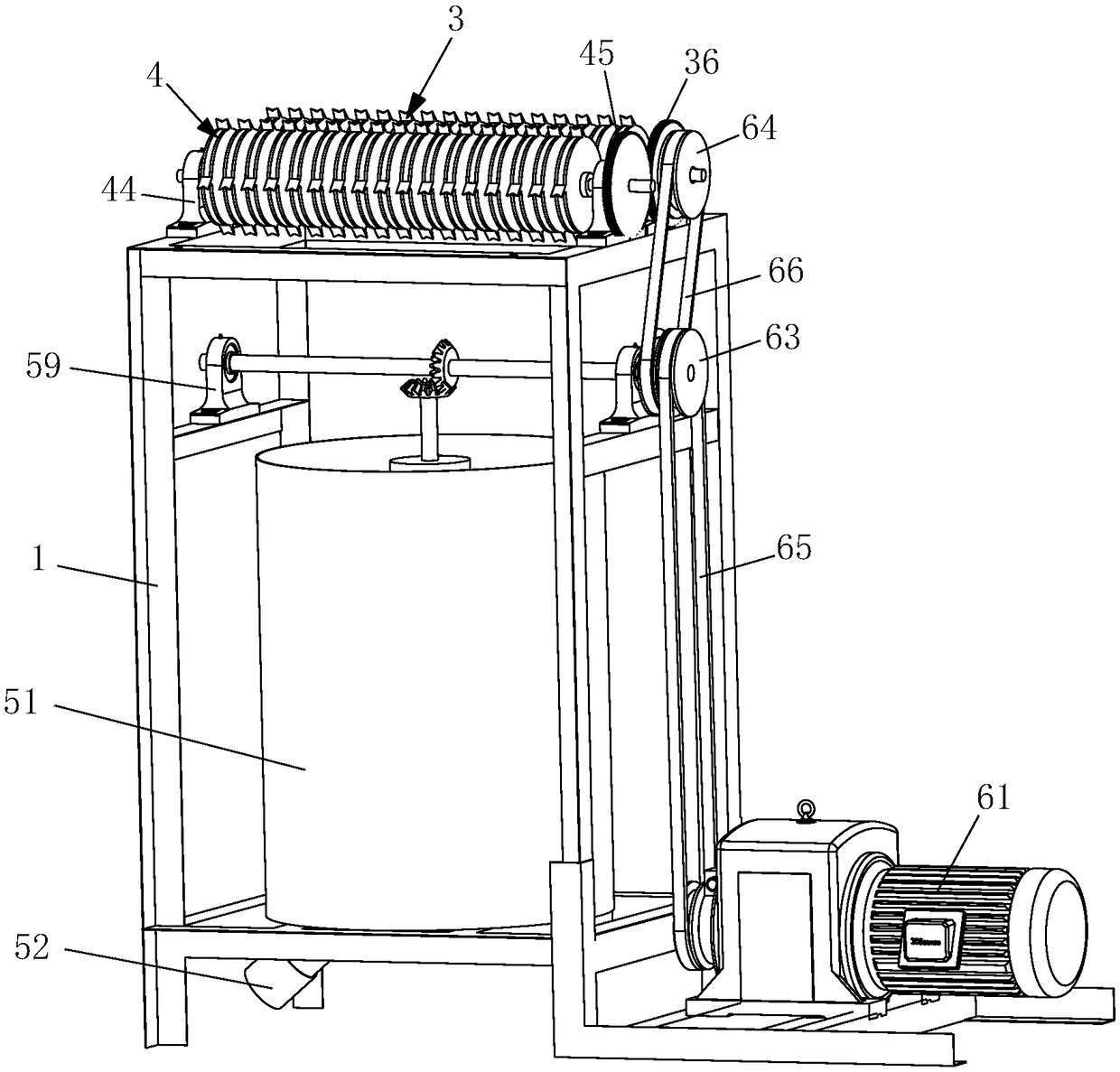

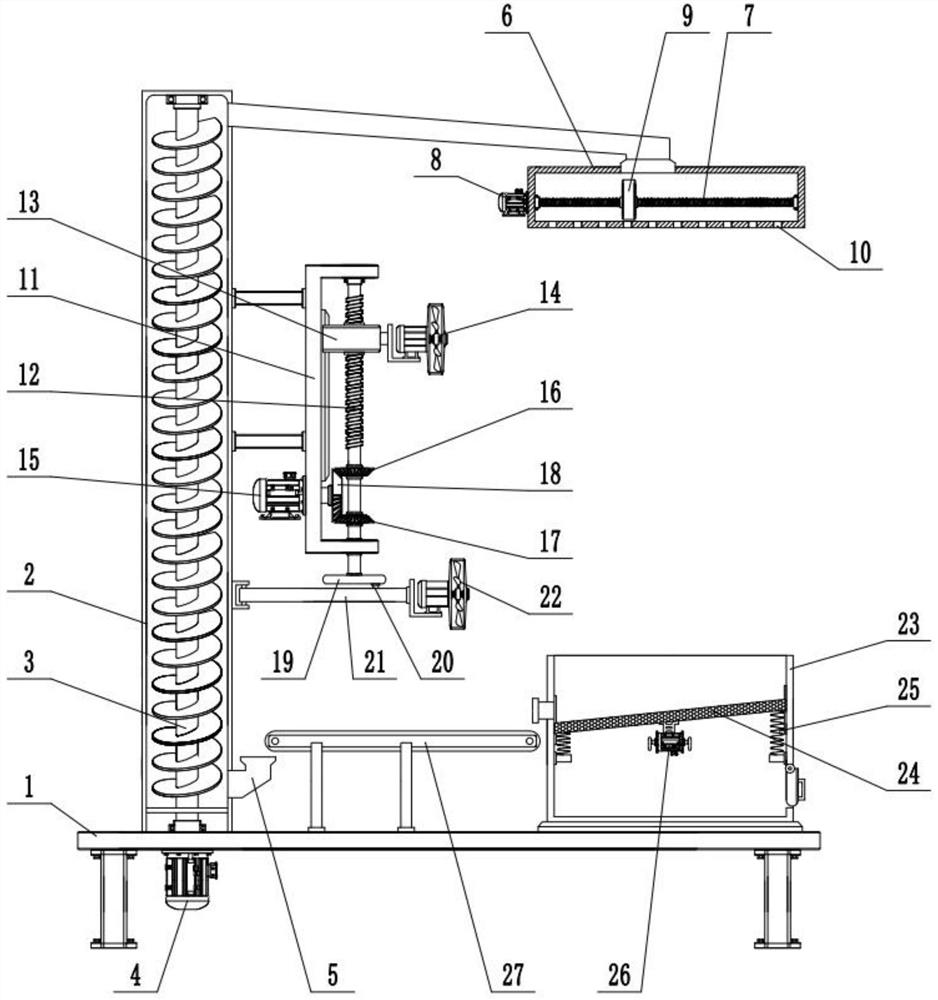

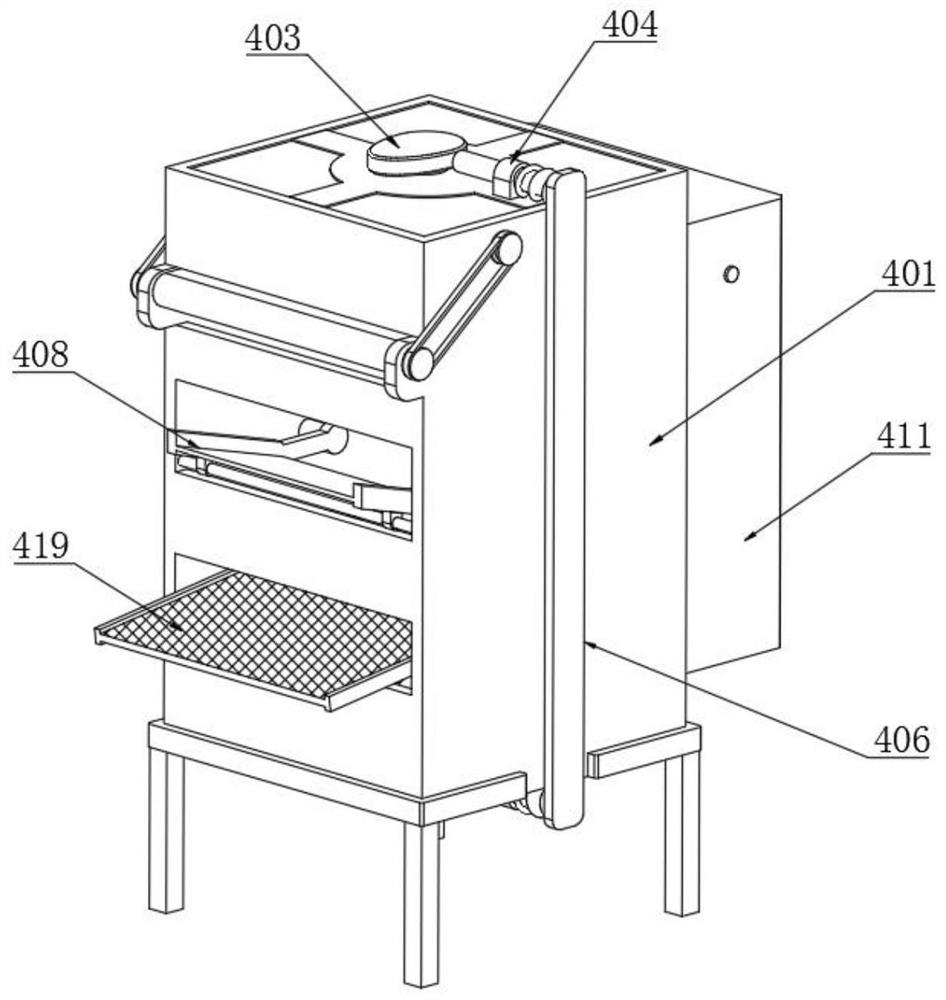

Grinding and polishing machine for medicine capsule

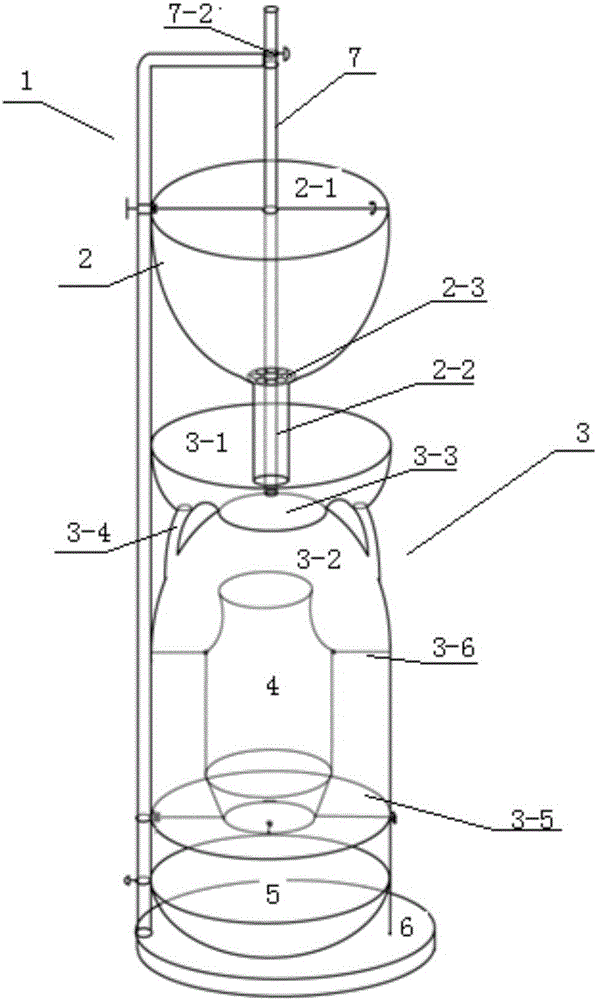

ActiveCN108145581AExtend polishing timeImprove polishing effectPolishing machinesGrinding work supportsEngineeringMechanical engineering

The invention relates to the technical field of pharmaceutical production equipment, in particular to a grinding and polishing machine for a medicine capsule. The grinding and polishing machine for the medicine capsule comprises a machine body, a feeding mechanism and a waste collecting mechanism, wherein the feeding mechanism is under the machine body, and the waste collecting mechanism is underthe machine body. A grinding and polishing device is arranged in the machine body. The grinding and polishing device comprises a rotating shaft, a coarse throwing bucket and a fine throwing bucket, wherein the coarse throwing bucket is fixedly connected with the rotating shaft, and the fine throwing bucket is arranged on the lower portion of the coarse throwing bucket. A spiral material returningblade is arranged in the coarse throwing bucket. A first bushing is arranged in the outer surface of the fine throwing bucket, and the first bushing is a spiral shape. The inner surface of the fine throwing bucket is provided with a second bushing, and the second bushing and the first bushing are in an opposite spiral shape. The upper portion of the machine body is provided with a first driving motor which is used to drive the rotating shaft to rotate. According to the graded polishing toward the capsule, the polishing effect of the capsule is improved. The rotating shaft is arranged into a hollow structure, the air flow inside the rotating shaft improves the air selection of the capsule only with a shell, and the effect of air selection and polishing is good.

Owner:秦皇岛大恩药业有限公司

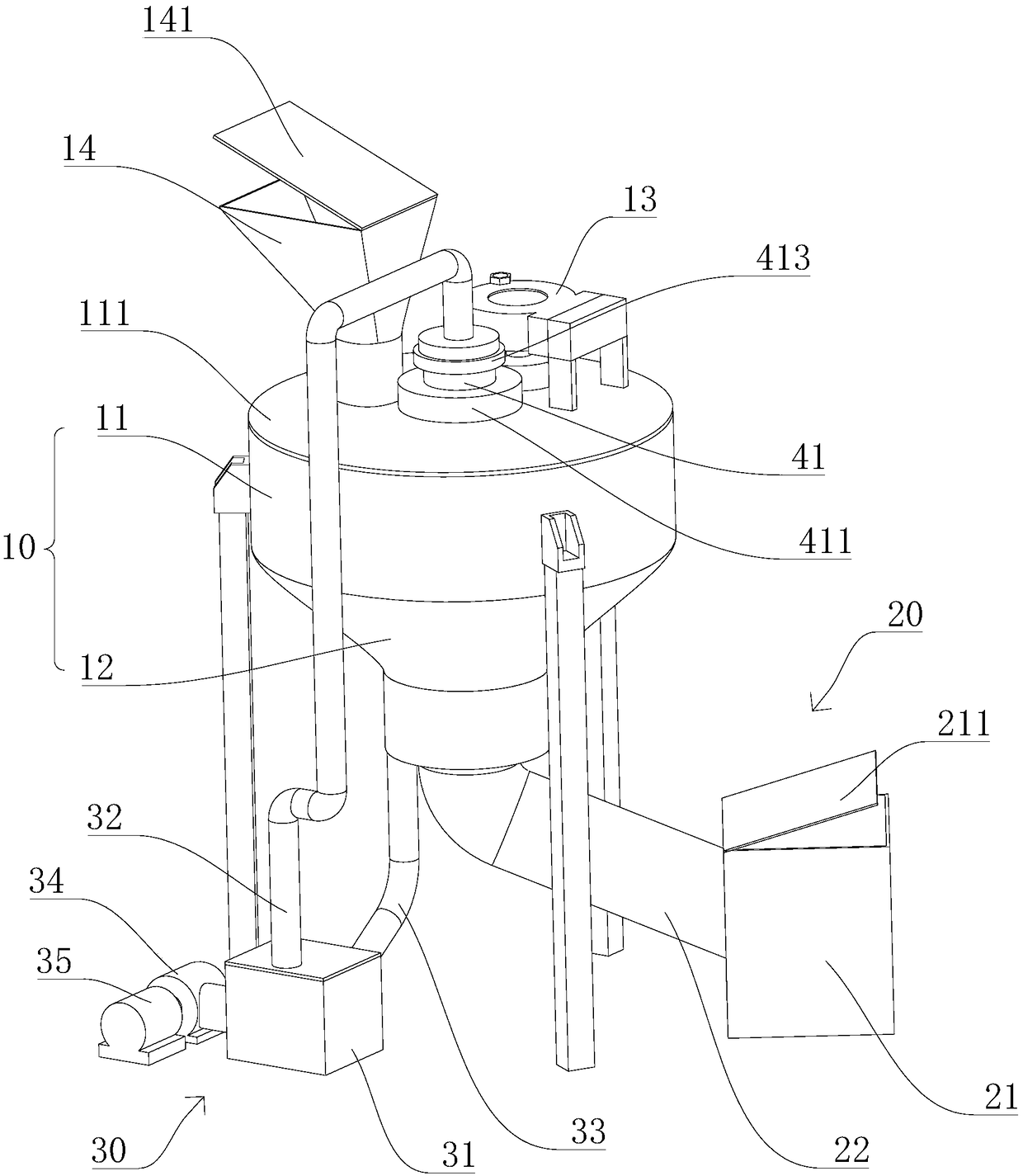

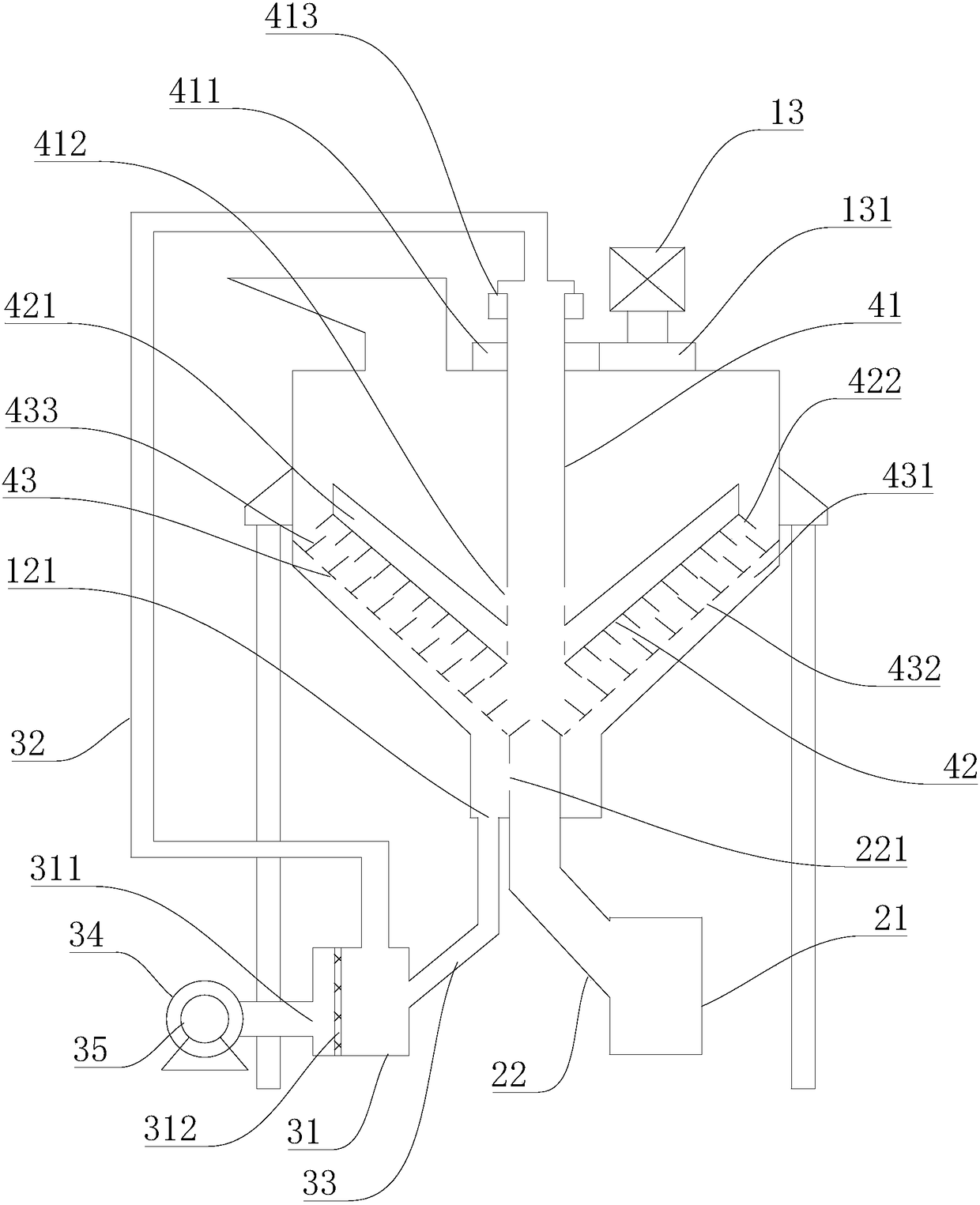

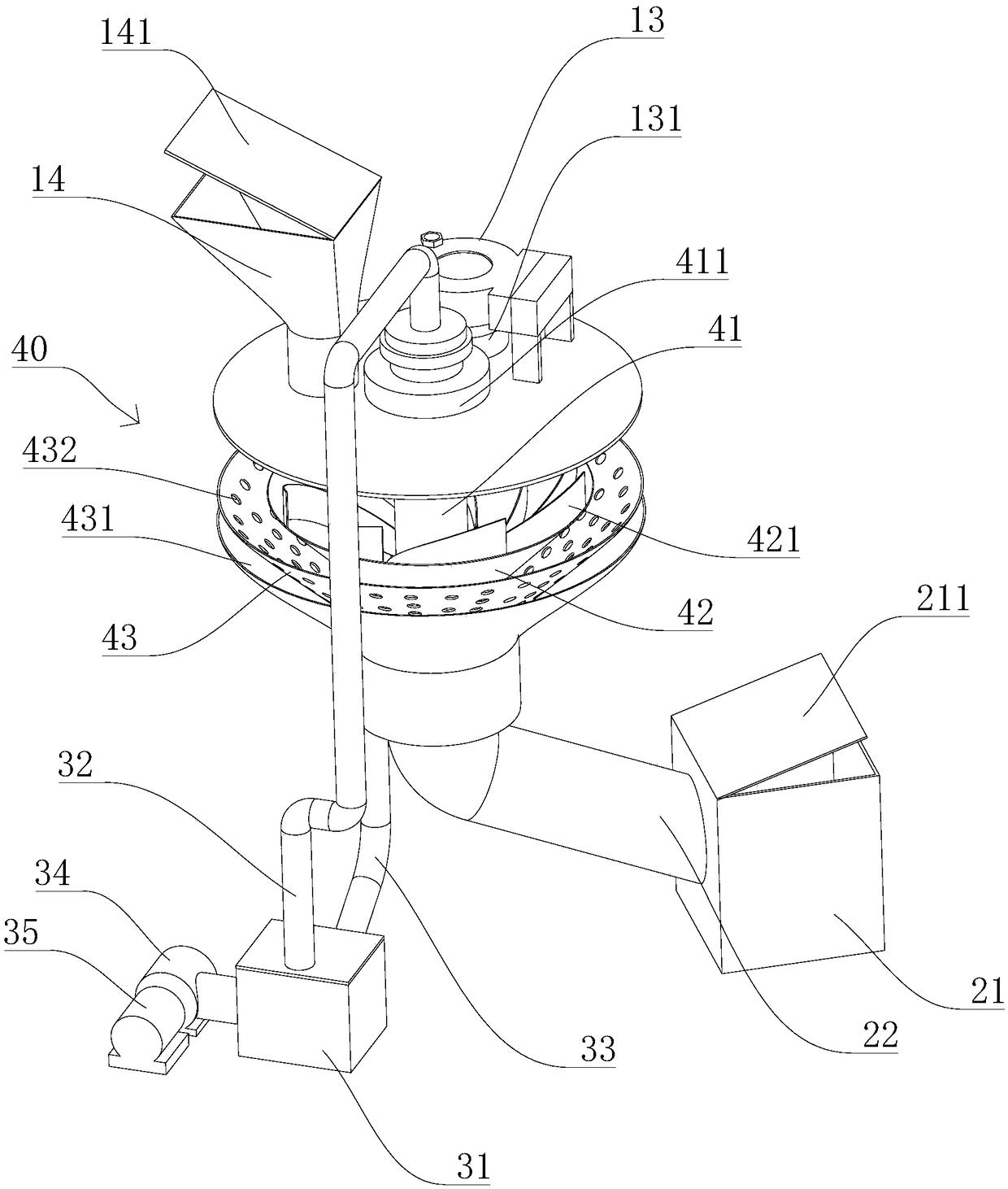

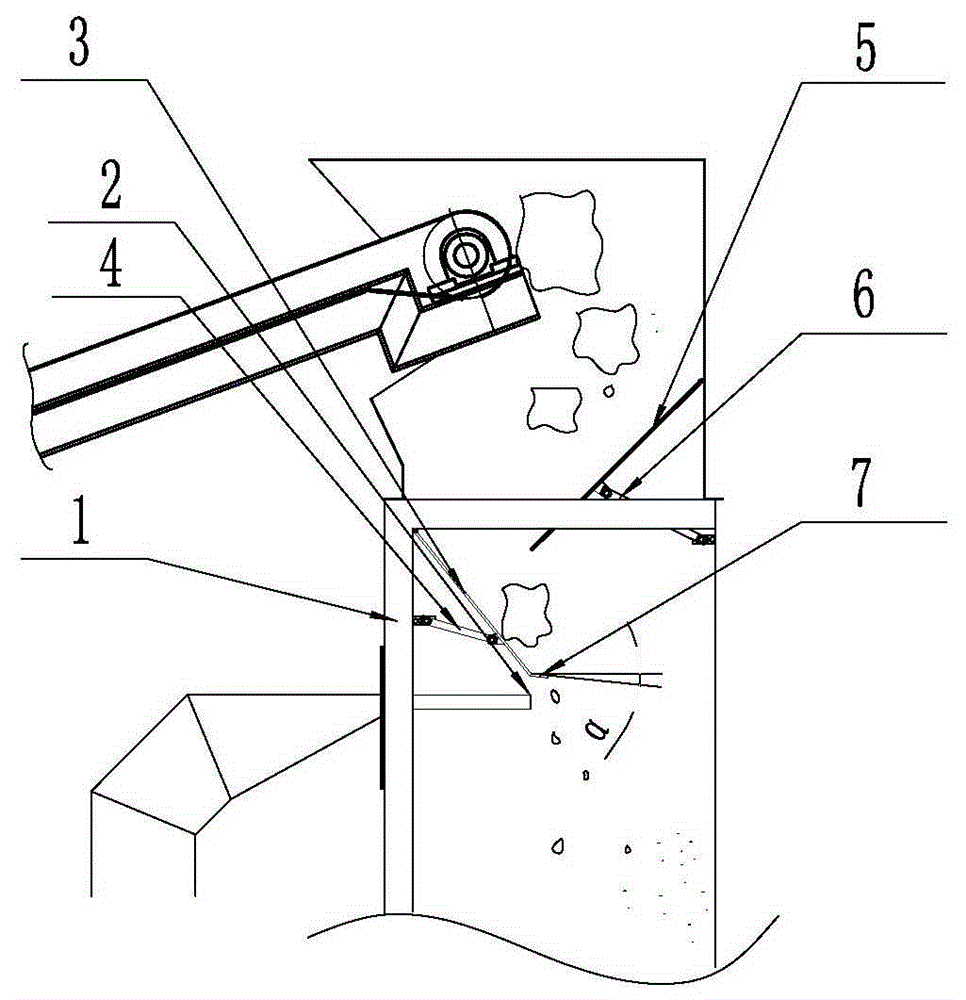

Construction waste screening equipment and screening method

ActiveCN104759413BExtended service lifeImprove screening effectGas current separationScreening effectScreening method

The invention relates to the field of building rubbish recycling, in particular to building rubbish screening equipment and screening method. The building rubbish screening equipment comprises a sorting chamber, a throwing device, a wind power device and a medium-heavy object sorting device, and a first separation region and a second separation region are arranged in the sorting chamber; the throwing device conveys material to the first separation region; the wind power device uses the wind power to lift the material thrown from the first separation region; the medium-heavy object sorting device comprises a double-layer sorting barrel, a negative pressure mechanism, a fan and a barrel body drive mechanism. The building rubbish screening equipment can separate the building rubbish into heavy substance, medium-heavy substance and light substance according to the need, and the screening effect is good; the heavy material does not collide with the double-layer sorting barrel in the screening process, and the service life of the double-layer sorting barrel is prolonged; the material throwing angle and power of the throwing device can be regulated according to the need in the screening process, and the adaptive capacity of the equipment is greatly improved; the building rubbish screening equipment is capable of effectively lowering the equipment load and improving the winnowing efficiency.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

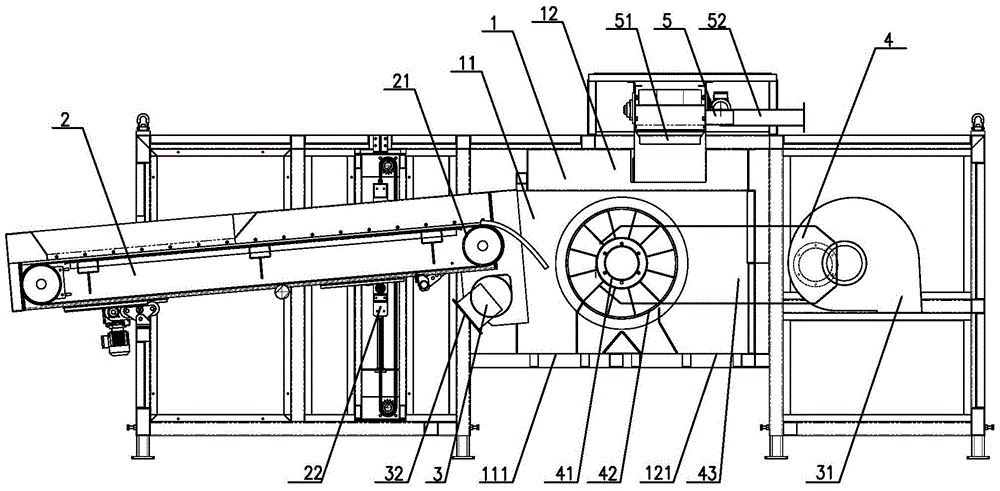

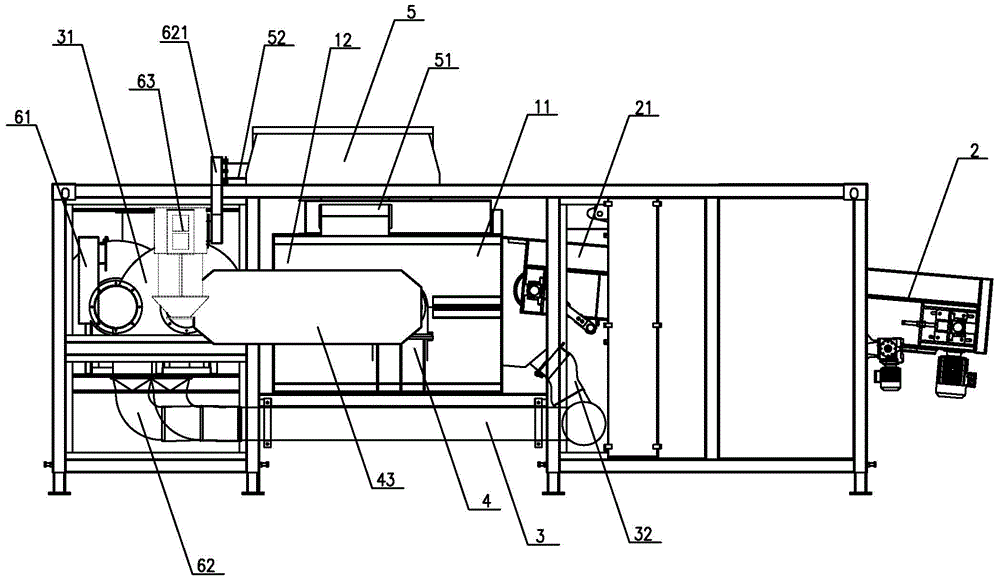

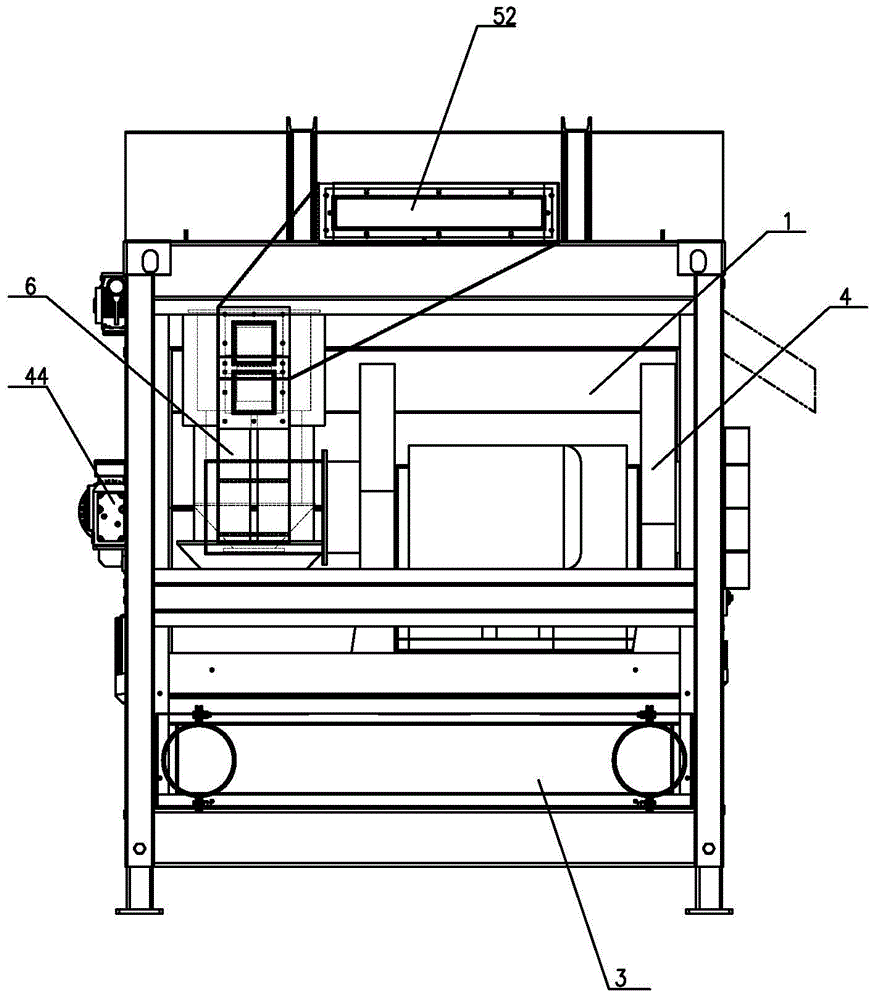

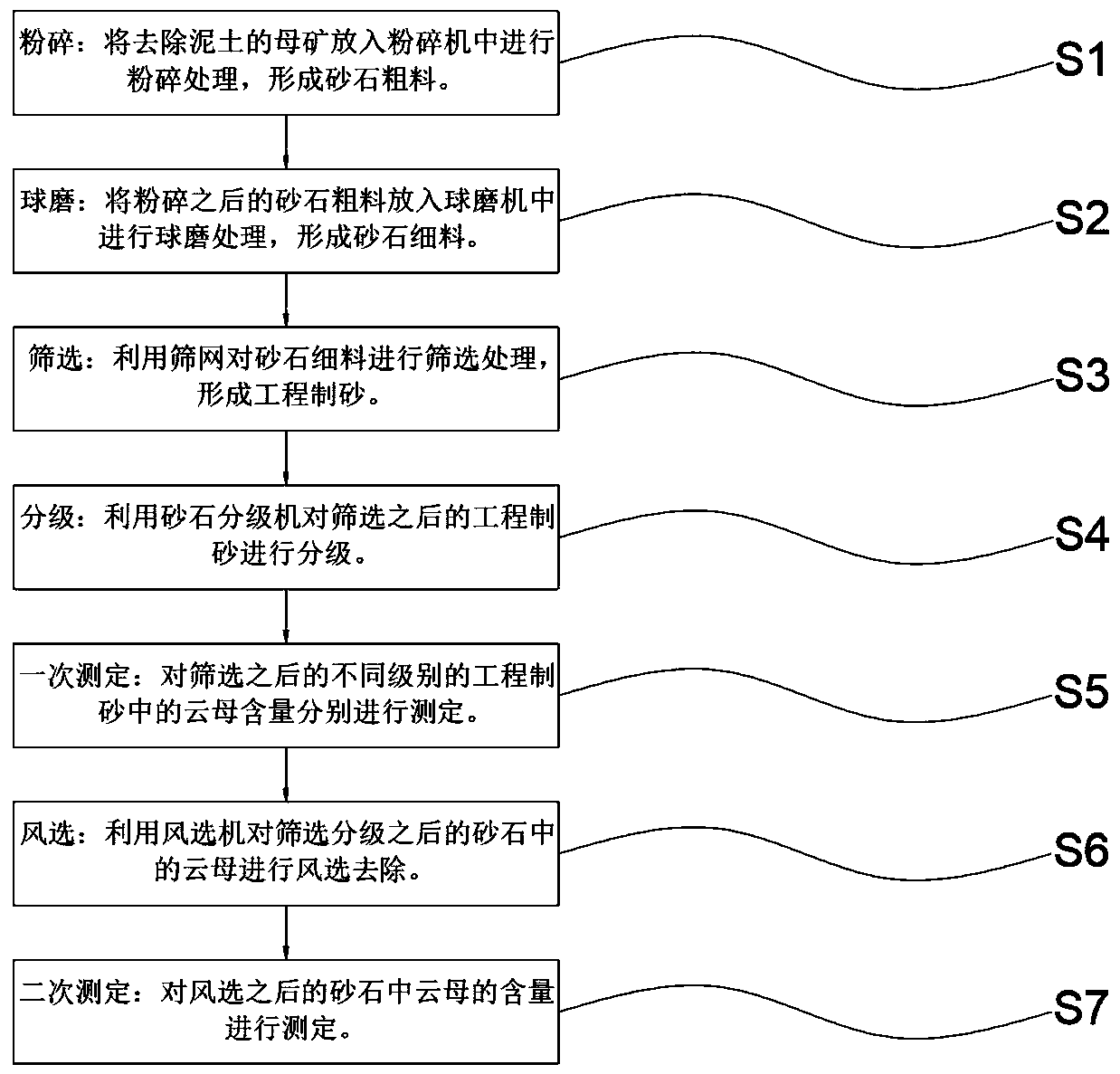

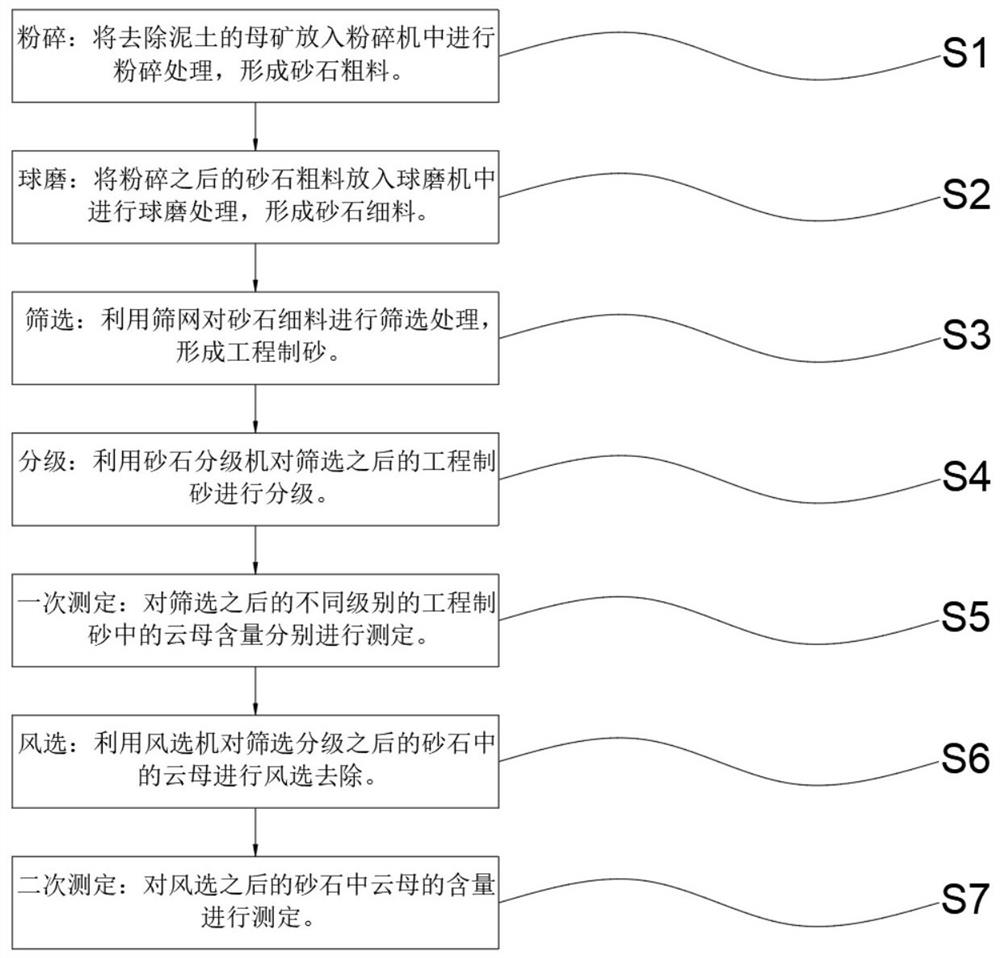

Engineering sand making method

The invention discloses an engineering sand making method. The method comprises the following steps: S1, crushing: crushing mother ores to obtain coarse sandstones; S2, ball-milling: ball-milling thecoarse sandstones to obtain fine sandstones; S3, screening: screening the fine sandstones to obtain sandstones with needed specifications; S4, grading: grading the sandstones to obtain sands with different grades; S5, detecting the mica content: detecting the mica content of the sands with each grade; S6, performing air separation: removing mica from the sands with different grades by air separation, wherein the frequency of air separation is determined according to the measured mica content in the sand sample with each grade; and S7, secondarily detecting the mica content: detecting the micacontent of the sands obtained by the air separation again. The method has the advantages of low cost, easiness in operation, high efficiency, good reliability, and realization of accurate control of the mica content and effective improvement of the sand quality.

Owner:STATE GRID CORP OF CHINA +2

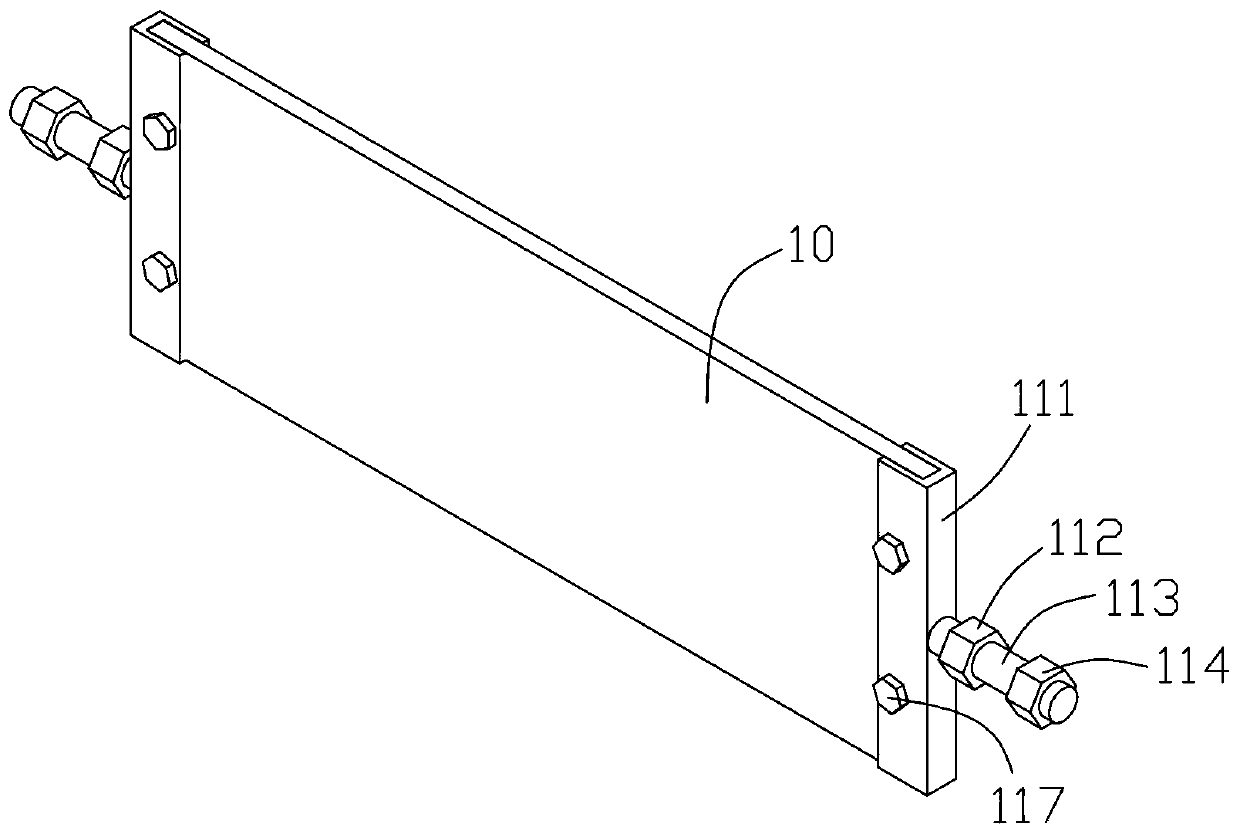

Seed winnowing assembly and pasture variety screening device

InactiveCN112756257AEasy to dropExpand the blowing rangeSievingGas current separationAgricultural scienceAgricultural engineering

The invention relates to the technical field of animal husbandry, in particular to a seed winnowing assembly and pasture variety screening device. The seed winnowing assembly comprises a rack, wherein a circulating barrel is fixedly installed on the rack, a discharging opening is formed in the top of the circulating barrel, a material distributing hopper is installed at the discharging opening, a fixing frame is fixedly installed on the side wall of the circulating barrel, a second lead screw is rotatably mounted in the fixing frame, a lifting block is in threaded connection with the second lead screw, an upper air blower is fixedly mounted on the side wall of the lifting block, pasture seeds to be treated are put into a screening box, the pasture seeds are conveyed to a circulating feeding port through a conveying belt and enter a circulating cylinder, the pasture seeds are conveyed to the screening box through a conveying belt, the pasture seeds are flatly laid in the material distributing hopper through a slicking assembly, the pasture seeds can conveniently fall down through dispersing holes, impurities with small density mixed in the pasture seeds are separated out through the upper air blower and a lower air blower, the upper air blower is driven by a third motor to move up and down, the lower air blower is driven to swing in a reciprocating mode, and the air blowing range is expanded.

Owner:湖南德人牧业科技有限公司

A light-weight debris separation system for construction waste recycling

ActiveCN105013706BSimple structureSmall footprintSievingGas current separationSystems designSmall footprint

The invention relates to a light foreign material separation system used for regeneration treatment of construction waste. It includes a casing with a feed inlet on the top of the casing, a feed baffle, a bulk material plate and a vibrating screen in sequence below the feeding inlet in the casing, and a grate bar is provided on the bottom side of the vibrating screen. Partitions, vibrating screens and grate partitions are the material outlets set on the casing; the casing is provided with air inlets and outlets, and the air inlets and outlets are respectively located on the two sides of the casing separated by the vibrating screen. side, wherein: the air inlet is located below the side of the vibrating screen, and the air outlet is located above the side of the vibrating screen; the bottom of the air outlet is the impurity outlet arranged on the casing. The invention aims at the disadvantages of low efficiency and lack of pertinence of the existing equipment, and the system has simple and reasonable structural design, low cost, small occupied area, high impurity removal efficiency and no dust pollution.

Owner:上海建冶路桥机器设备有限公司

Tea-leaf wind selection device

The invention relates to a wind separator for tea, which comprises a feeding hopper and a primary feeding vibrating groove which is positioned under the feeding hopper. The wind separator for the tea is characterized in that the upper side of a discharging end of the primary feeding vibrating groove is provided with a small negative-pressure gas channel, and the lower side of the discharging end of the primary feeding vibrating groove is provided with a secondary vibrating groove; the middle part of the secondary vibrating groove is provided with a funnel-shaped light yellow leaf collecting opening which can be lead to the bottom of the secondary vibrating groove; a triangular guide bevel is arranged between the funnel-shaped light yellow leaf collecting opening and the primary feeding vibrating groove; and the upper side of the discharging end of the secondary vibrating groove is provided with a large negative-pressure gas channel, and the lower side of the discharging end of the secondary vibrating groove is provided with an inclusion discharge opening which is close to the discharging end of the secondary vibrating groove and a discharge conveyor belt which is positioned on theoutside of the inclusion discharge opening in turn. The device not only has the function of simultaneously removing light yellow leaves and sandstone inclusion in the tea, but also greatly improves the wind separation efficiency and effectively reduces the error pick-up rate so as to guarantee the quality of the tea subjected to wind separation.

Owner:FUJIAN AGRI & FORESTRY UNIV +1

A pharmaceutical capsule grinding and polishing machine

ActiveCN108145581BExtend polishing timeImprove polishing effectPolishing machinesGrinding work supportsBiochemical engineeringAirflow

The invention relates to the technical field of pharmaceutical production equipment, in particular to a grinding and polishing machine for a medicine capsule. The grinding and polishing machine for the medicine capsule comprises a machine body, a feeding mechanism and a waste collecting mechanism, wherein the feeding mechanism is under the machine body, and the waste collecting mechanism is underthe machine body. A grinding and polishing device is arranged in the machine body. The grinding and polishing device comprises a rotating shaft, a coarse throwing bucket and a fine throwing bucket, wherein the coarse throwing bucket is fixedly connected with the rotating shaft, and the fine throwing bucket is arranged on the lower portion of the coarse throwing bucket. A spiral material returningblade is arranged in the coarse throwing bucket. A first bushing is arranged in the outer surface of the fine throwing bucket, and the first bushing is a spiral shape. The inner surface of the fine throwing bucket is provided with a second bushing, and the second bushing and the first bushing are in an opposite spiral shape. The upper portion of the machine body is provided with a first driving motor which is used to drive the rotating shaft to rotate. According to the graded polishing toward the capsule, the polishing effect of the capsule is improved. The rotating shaft is arranged into a hollow structure, the air flow inside the rotating shaft improves the air selection of the capsule only with a shell, and the effect of air selection and polishing is good.

Owner:秦皇岛大恩药业有限公司

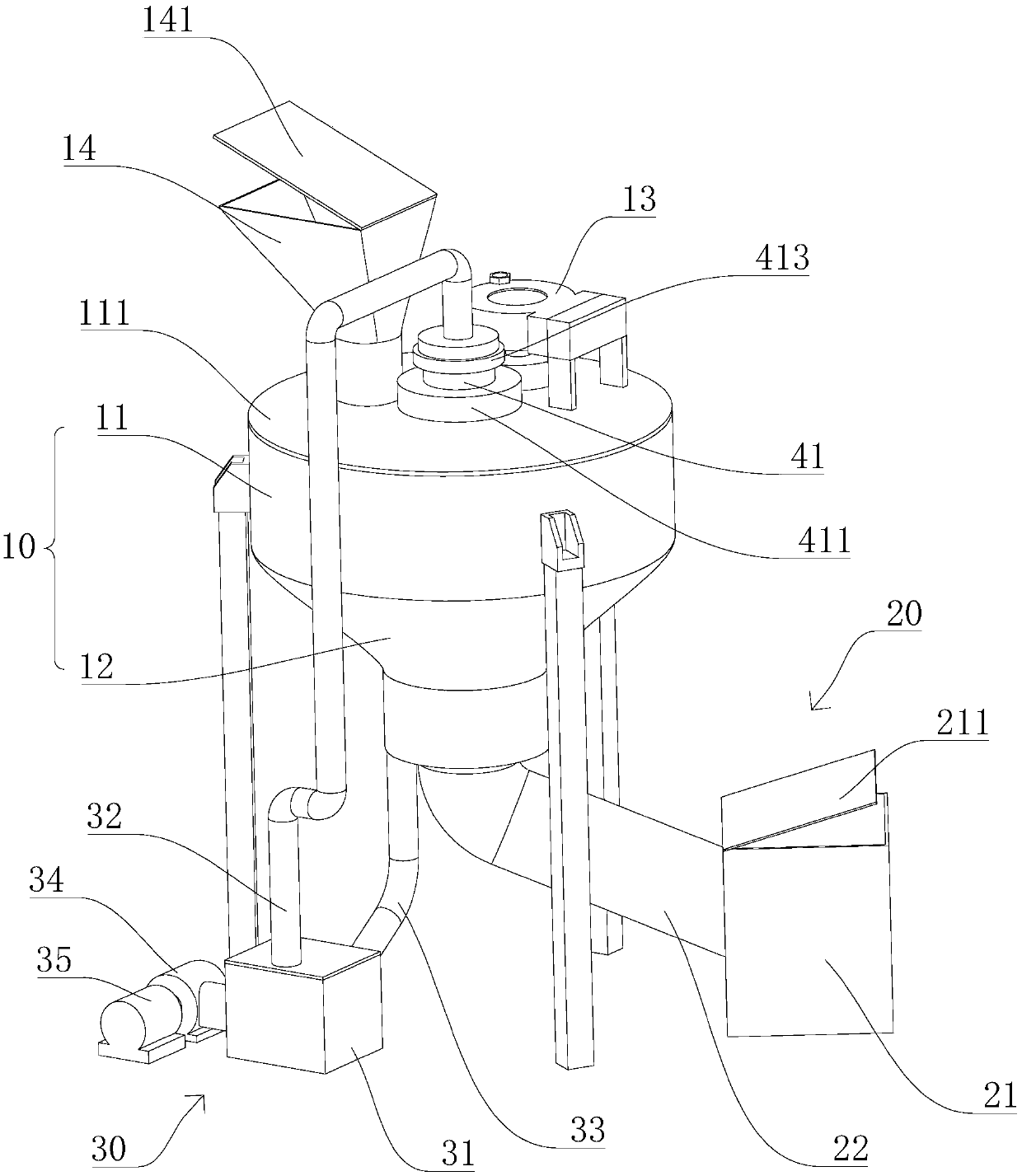

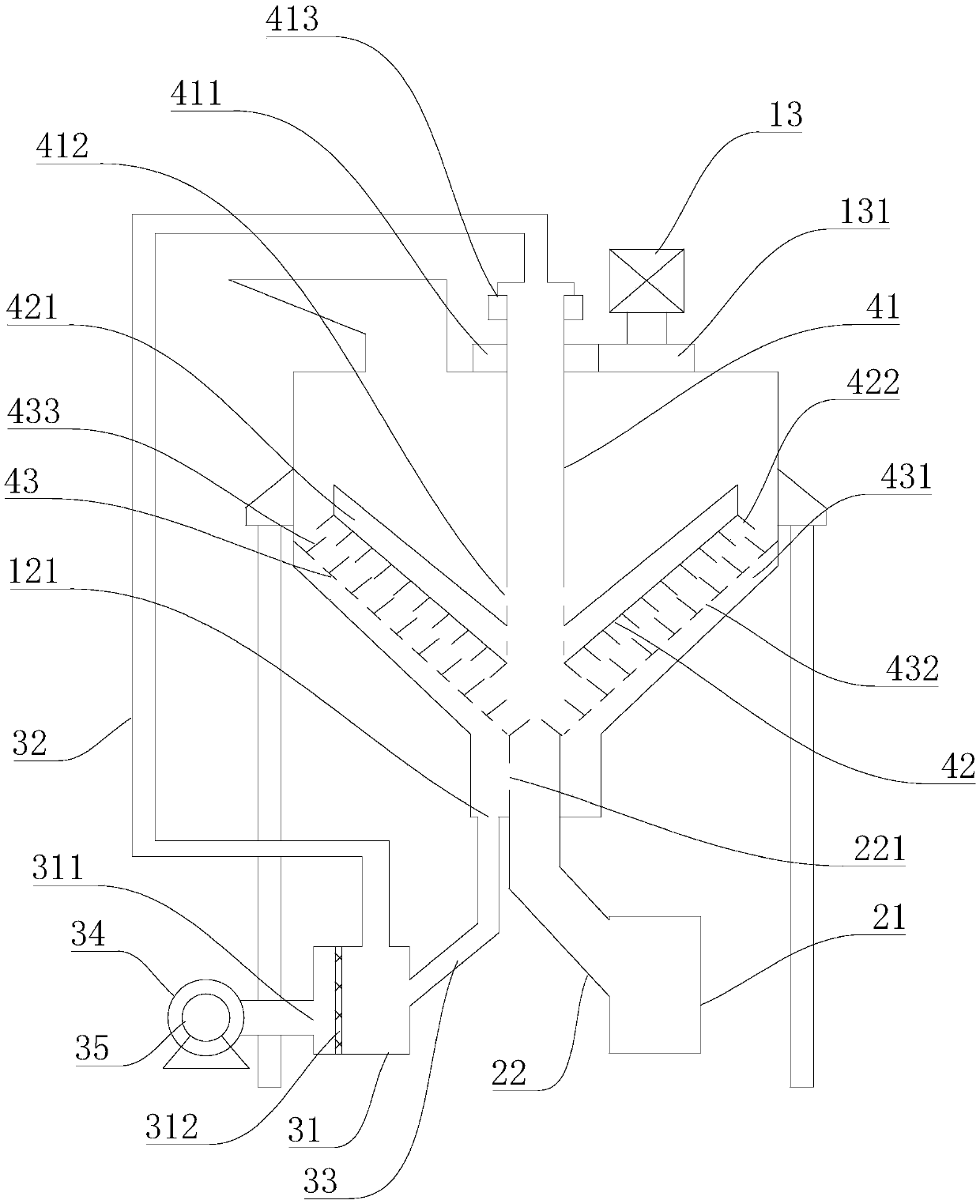

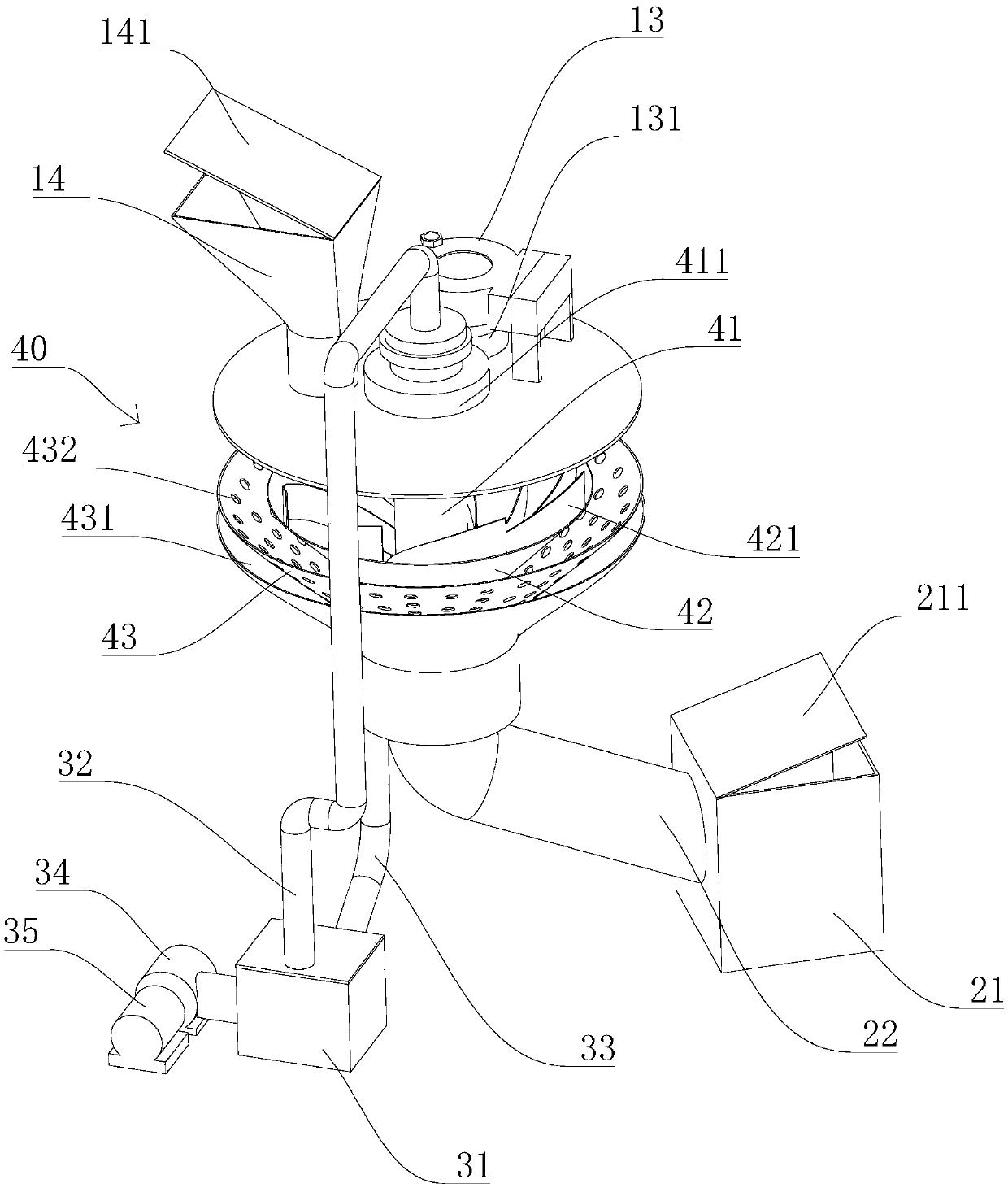

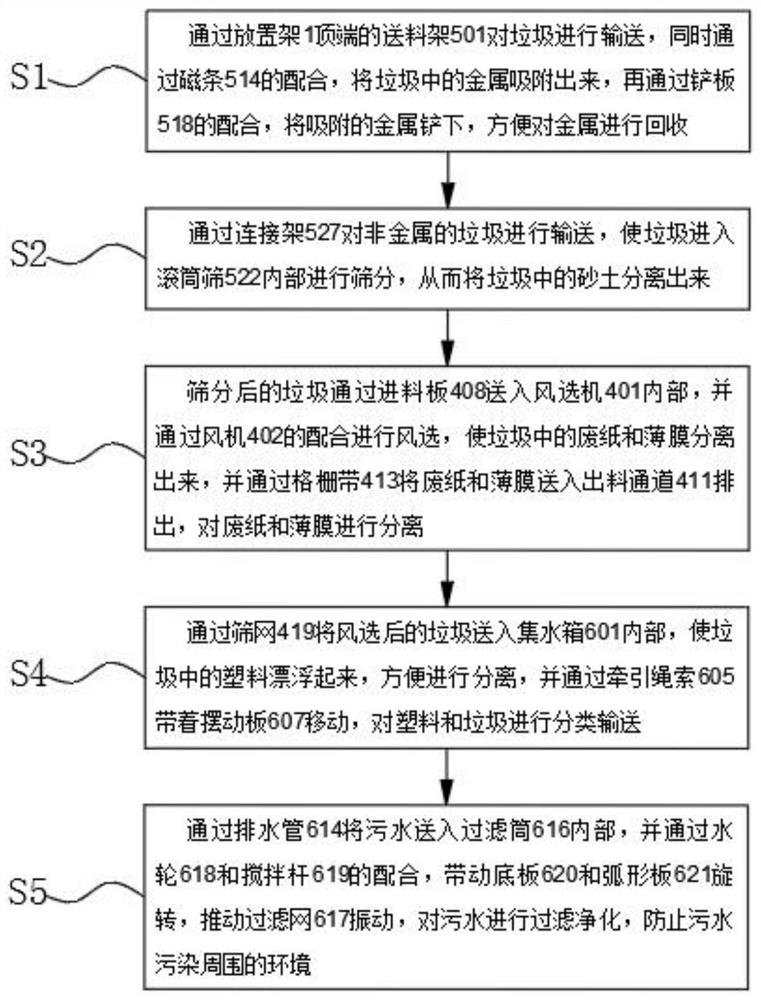

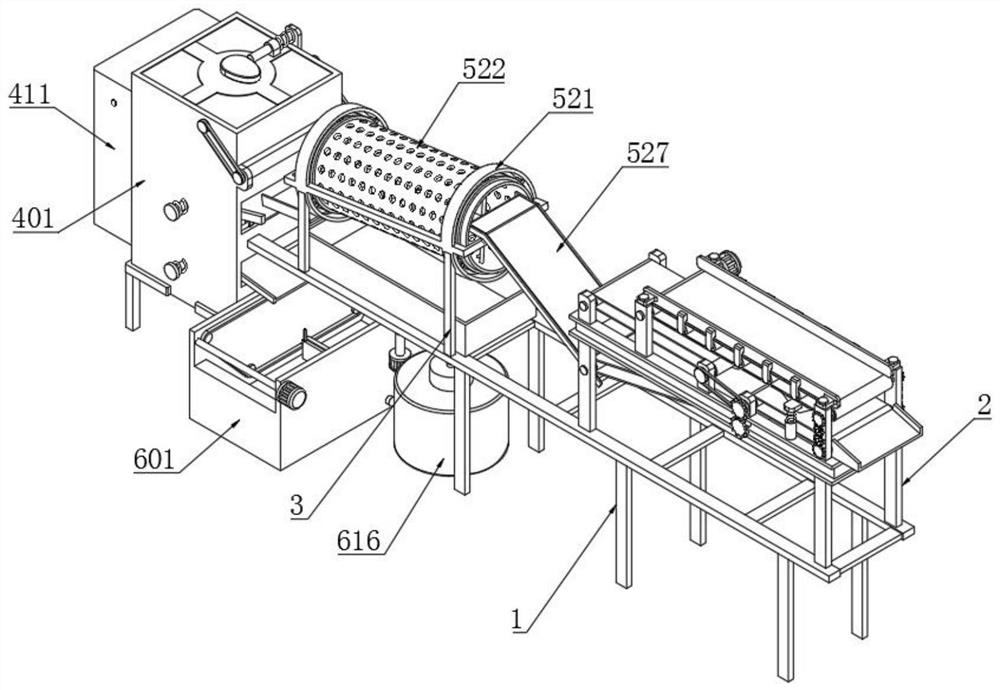

An efficient garbage classification method

ActiveCN113578732BEasy to feedEasy to recycleSievingGas current separationElectric machineTransmission belt

The invention discloses a high-efficiency garbage sorting method, comprising the following steps: S1. The garbage is transported through a feeding rack at the top of the placing rack, and at the same time, the metal in the garbage is adsorbed by the cooperation of the magnetic strip, and then the cooperation of the shovel plate is carried out. , the adsorbed metal is shoveled down to facilitate the recovery of the metal. S2, the non-metallic garbage is transported through the connecting frame, so that the garbage enters the drum screen for screening, so as to separate the sand in the garbage. The structure of the present invention It is scientific and reasonable, safe and convenient to use. It is equipped with a wind screening and screening mechanism, and the waste is conveniently fed into the wind separator through the feeding plate. Blow up with the film to make the waste paper and film fit with the grid belt, and then drive the worm to rotate through the turbine, and make the transmission wheel and the transmission belt cooperate to drive the cross bar and the grid belt to move, and the waste paper and film are discharged.

Owner:雅生活明日环境发展有限公司

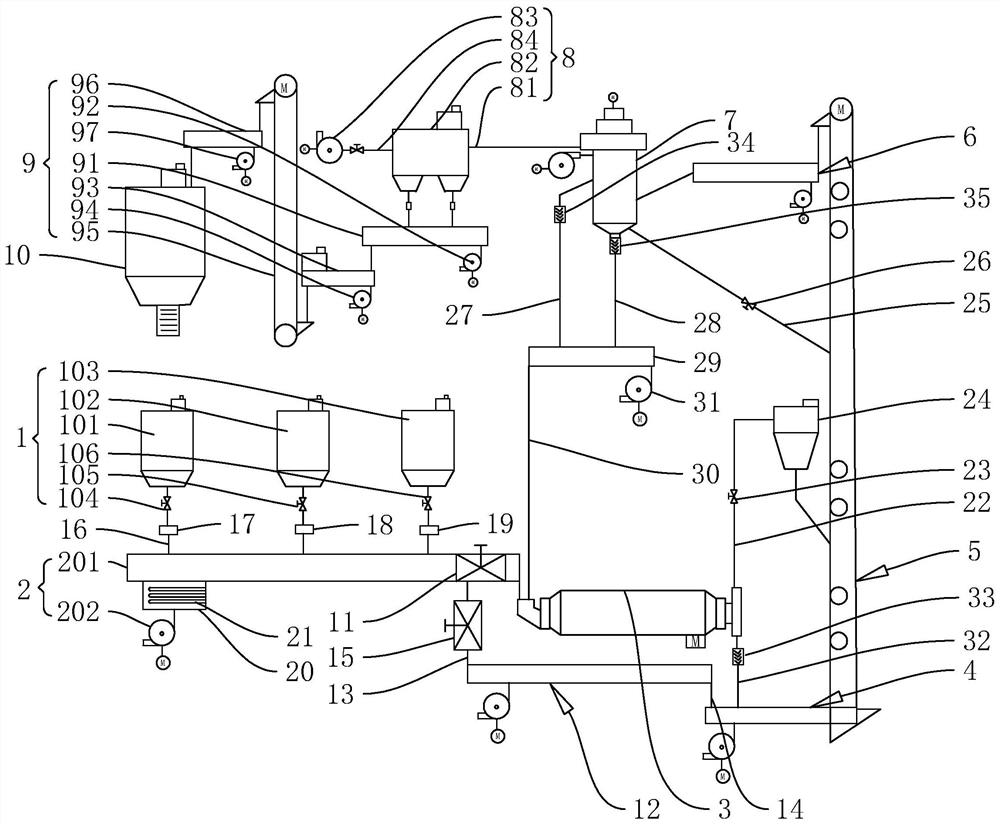

A kind of superfine fly ash production system and production process

ActiveCN112024094BQuality improvementFully milledGas current separationGrain treatmentsThermodynamicsEngineering

Owner:陕西正元麟电环保产业有限公司

One for waste lifepo 4 Crushing and stirring device for power battery

ActiveCN109395852BEfficient separationImprove winnowing efficiencyRotary stirring mixersTransportation and packagingPower batteryCopper foil

The invention relates to a method for waste LiFePO 4 The crushing and stirring device of the power battery includes a frame and a crushing device fixed on the frame. A feeding hopper is provided above the crushing device, and a stirring device is provided below the crushing device. The crushing device and the stirring device The devices are all connected to the power unit. The crushing device includes a driving hob set and a driven hob set opposite to each other. The mixing device includes a mixing bucket, a stirring body placed in the mixing bucket, and a mixing body arranged at the bottom of the mixing bucket. The discharge pipe, filled with dilute lye in the mixing barrel. As can be seen from the foregoing technical scheme, the present invention disposes of waste LiFePO by means of a crushing device. 4 The power battery is rolled and cut to form regular-shaped flakes, and then the powder on the positive aluminum foil current collector and the negative electrode copper foil current collector are effectively separated by the stirring device, which provides reliable air for the subsequent winnowing process. Guarantee, improve the efficiency of winnowing.

Owner:HEFEI UNIV OF TECH

Blanking device for garbage winnowing equipment

InactiveCN103286071BEasy to clogWinnowing effect is reducedGas current separationEngineeringAir separation

The invention provides a material falling device of garbage air classification equipment, the material falling device of the garbage air classification equipment is used for controlling garbage falling in the equipment which utilizes wind power to separate the garbage, the garbage is separated by enlarging the falling distance of the garbage to be separated through wind power and controlling the falling speed of the garbage to separate the garbage, and air classification efficiency is improved. Due to the adoption of the technology, an upper material baffle is located under a garbage inlet position, the back end of the upper material baffle is hinged to a garbage air classification equipment shell body, the front end of the upper material baffle inclines downwards, the upper material baffle and a lower material baffle are arranged in a staggered mode on a longitudinal section of the upper material baffle and a longitudinal section of the lower material baffle respectively, the longitudinal section of the upper material baffle is perpendicular to the longitudinal section of the lower material baffle, and the front end of the lower material baffle is arranged above a draught fan opening. Through the technical scheme, the technical problems that the dispersion degree of the garbage is low and the air classification effect is influenced due to the fact that no garbage falling device is arranged between the draught fan opening of existing garbage air classification equipment and a garbage inlet are solved.

Owner:QINGDAO UNIV OF SCI & TECH

A kind of engineering sand making method

The invention discloses a method for engineering sand production, which comprises the following steps: S1, crushing: crushing parent ore to obtain coarse sand and gravel; S2, ball milling: performing ball milling on the obtained coarse sand and gravel to obtain sand and gravel Fine material; S3, screening: screening the obtained sand and gravel fine material to obtain sand and gravel of required specifications; S4, grading: classifying the obtained sand and gravel to obtain sand of different grades; S5, determination of mica content: for each The sand of grade carries out the mensuration of mica content respectively; S6, winnowing: adopt winnowing to remove the mica in the sand of each different grade, the number of times of described winnowing is determined according to the mica content in the sand sample of each grade measured; S7. Secondary determination of mica content: measure again the content of mica in the sand obtained by winnowing. The method of the invention has the advantages of low cost, simple operation, high efficiency and good reliability, can realize precise control of mica content and effectively improve sand quality.

Owner:STATE GRID CORP OF CHINA +2

Solid waste sorting equipment and treatment system

InactiveCN112808390AImprove winnowing efficiencyImprove separation efficiencyGas current separationMedical waste disposalTool bitElectric machinery

The invention relates to the technical field of solid waste sorting, in particular to solid waste sorting equipment and a treatment system. The solid waste sorting equipment comprises a sorting equipment body, the sorting equipment body comprises a solid waste smashing mechanism, a winnowing mechanism and sorting boxes, the solid waste smashing mechanism comprises a first smashing mechanism and a second smashing mechanism, and the first smashing mechanism comprises a feeding port, a winding drum and a conveying belt; and the bottom of the first smashing mechanism is provided with one side of the conveying belt, the conveying belt is obliquely arranged, the bottom of the other side of the conveying belt is provided with the second smashing mechanism, the second smashing mechanism is provided with a motor, a connecting shaft and a rotary tool bit, the rotary tool bit is welded and fixed to the other side, and the four sorting boxes are arranged at one side of the second smashing mechanism. According to the solid waste sorting equipment, a multi-stage smashing and multi-stage recycling system is adopted, solid waste can be changed into particulate matters through the two stages of smashing mechanisms, then different solid particles are winnowed through a winnowing machine, the winnowing and separating efficiency is improved, and the practicability of solid waste separation is improved.

Owner:新沂市新南环保产业技术研究院有限公司

Rapeseed screening equipment for agricultural production and processing

ActiveCN111014036BEasy to disengageAvoid contactSievingGas current separationAgricultural engineeringAgricultural science

The invention discloses a kind of rapeseed screening equipment for agricultural production and processing in the technical field of agricultural production and processing, which includes a separation box, a screening box fixed on the right side of the separation box and a separation mechanism. plate and a blanking plate, the screening box is provided with a first fan, an air inlet channel, a collection chamber and a rotating chamber, and a rotating assembly is provided in the rotating chamber. Beat the straw through the detachment mechanism to detach the rapeseed, and fall to the material guide plate after the first screening of the detachment filter, and then move along the feeder plate for winnowing, so that the lighter slag, etc., enters The air inlet channel is thickly collected. After the rapeseed moves obliquely upwards, it falls to the lower right on the cutting board. The detachment, detachment screen screening and winnowing are completed continuously. The detachment is convenient and can prevent the rapeseed from contacting the bottom surface and contaminating more Dust is screened twice, with good screening effect and high work efficiency.

Owner:湖南湘山生物科技有限公司

Air separation device and method of garbage

InactiveCN101823019BImprove sorting efficiencyAchieve separationGas current separationWet separationMagnetic separatorAir separation

The invention relates to an air separation device for domestic garbage. The whole device comprises a preprocessing unit and an air separation unit, wherein the preprocessing unit contains a feed belt, a magnetic separator and a crusher, and the air separation unit comprises a charging belt, a dedusting filter cartridge, a first circulating fan, an air separation chamber, an air return pipeline, a first roller, a second roller, a second circulating fan, a heavy substance storage bin, an intermediate-weight substance storage bin, and a light substance storage bin. In the invention, the separation of the domestic garbage is realized by the following steps: the domestic garbage entering the magnetic separator for the magnetic separation through the feed belt, removing metal, after crushing the garbage entering the air separation chamber through the charging belt, the circulating fan controlling the an average section air speed in the air separation chamber of 8m / s, the air amount of 3400m<3> / h, separating the domestic garbage in the air separation chamber because of density variation; the heavy substance in the domestic garbage directly falling to the heavy substance storage bin because of large density; the heavy substance in the domestic garbage falling into the heavy substance storage bin after diversion under the joint action of the air force and the first roller, controlling the rotation speed of the first roller as 19rpm; while the light substance in the domestic garbage keeping on moving under the drive of the air force, and entering the light substance storage bin through a belt pulley under the drive of the second roller, controlling the rotation speed of the second roller as 38rpm, the returning air connecting the dedusting filter cartridge through the pipes for dust separation, then returning to the circulating fan.

Owner:BEIJING HAOHAI TIANJI TECH +1

A melon seed sorting device and its application method

ActiveCN104492707BEfficient winnowingSimple structureGas current separationEngineeringAir separation

Owner:SHANDONG CROP GERMPLASM CENT

Efficient shredded tobacco winnowing method and equipment

ActiveCN105396782BAchieve uniform distributionGood dispersionGas current separationEngineeringEnergy consumption

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

Air separation device applied to impurities of silicon powder

InactiveCN109351630AImprove separation efficiencyImprove winnowing efficiencyGas current separationAir separationEngineering

The invention relates to an air separation device applied to impurities of silicon powder, belongs to the field of the photovoltaic technology and aims to solve the problem of inconvenient removal ofimpurities in silicon powder in the prior art. The air separation device comprises a box body, wherein an air blower is arranged on the side of the box body; a feeding opening is formed in the top ofthe box body; a first sieving net, a second sieving net and a third sieving net are respectively arranged in the box body; a discharging opening is formed in one side away from the air blower in the box body; mesh numbers of the first sieving net, the second sieving net and the third sieving net are gradually increased; a powder collection box is arranged under each of the first sieving net, the second sieving net and the third sieving net. Through the air separation device applied to the impurities of silicon powder, the powder is filtered by the sieve nets with different pore sizes, so thatthe powder falls into different powder collection boxes according to different pore sizes; then the powder is artificially sorted; the sorting efficiency can be improved.

Owner:ZHEJIANG YIYANG SOLAR TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com