Efficient shredded tobacco winnowing method and equipment

An air separation equipment and air separation technology are applied in chemical instruments and methods, solid separation, separation of solids from solids by air flow, etc. Separation, difficult to achieve separation of cut tobacco stems and other problems, to improve the efficiency of air separation, improve the purification rate and yield, and reduce the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

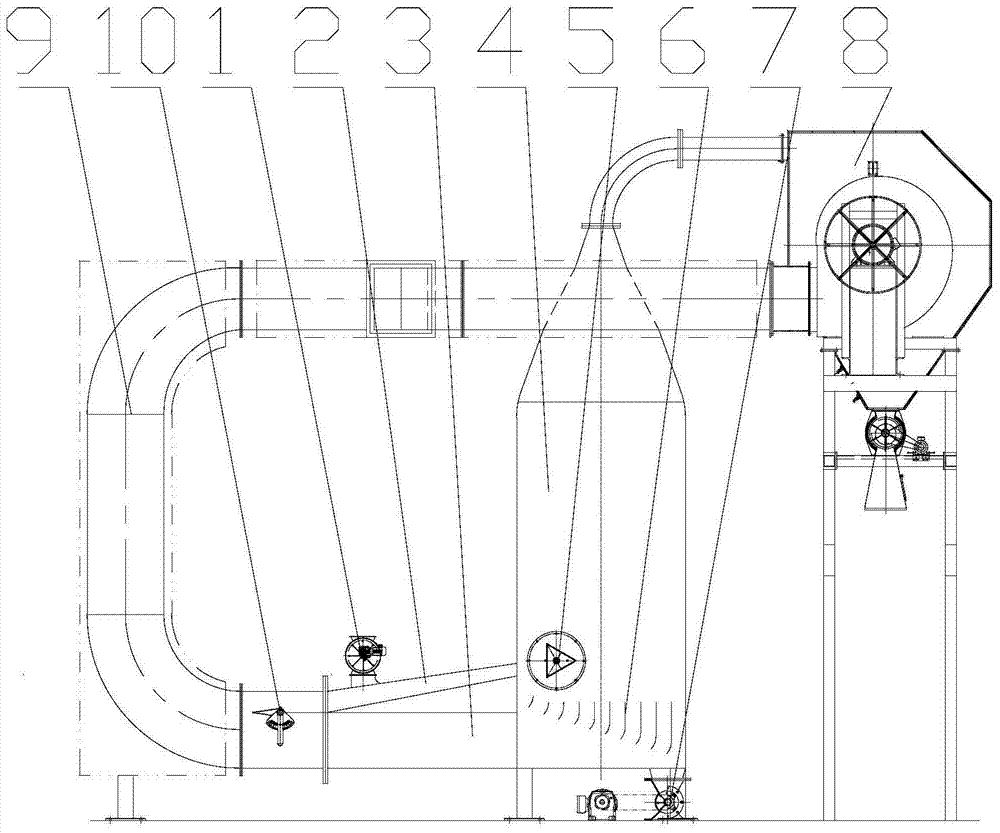

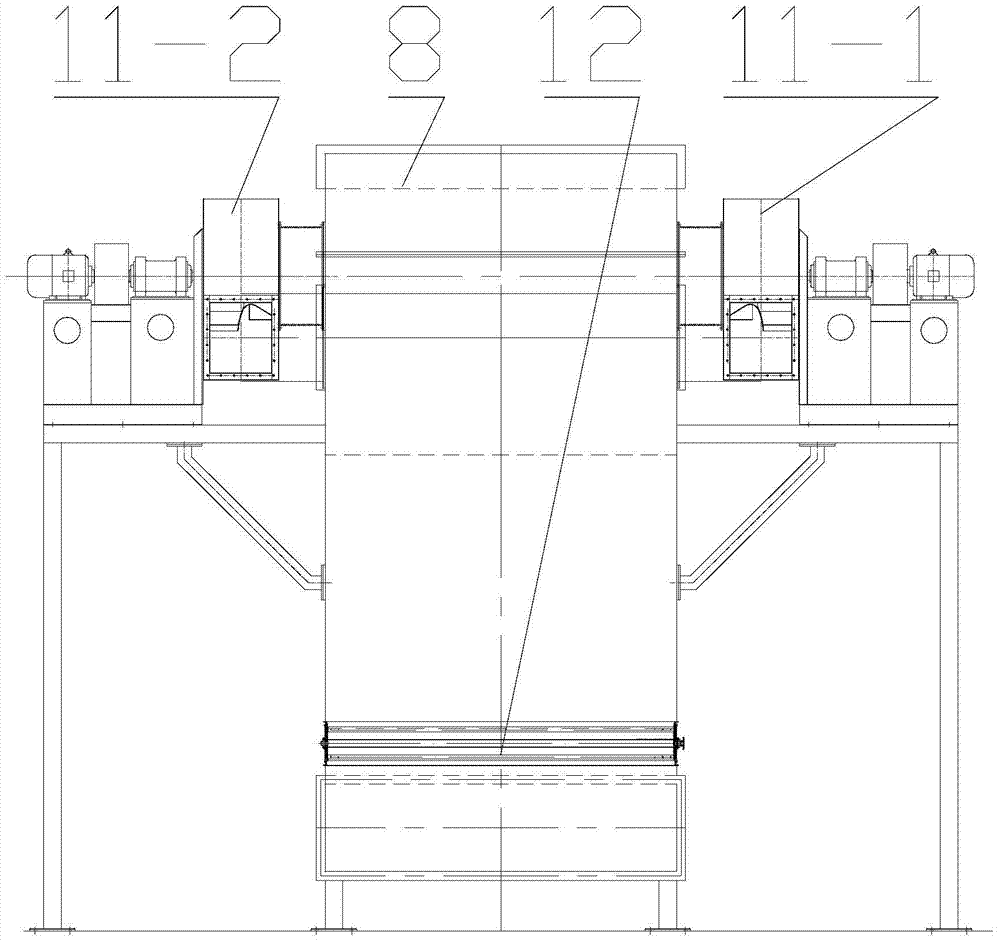

[0034] Such as figure 1 , 2 As shown, the shredded tobacco winnowing equipment provided by the present invention comprises a feed air lock 1, a feed pipe 2, an air inlet pipe 3, a winnowing chamber 4, and a tangential feeder 8; the feed pipe 2 and the feed air lock 1 connection; the air selection chamber is connected with the feed pipe 2 and the air inlet pipe 3 respectively; the bottom end of the air selection chamber 4 is connected with the stem-out air lock 7, and the top of the air selection chamber is connected with the tangential feeder 8; The chamber 4 is provided with material equalizing rollers 5 and air equalizing plates 6. The air equalizing plates are vertically arranged and evenly distributed in the winnowing room. The general distance is about 50-100 mm. The lower end of the air equalizing plates faces the air outlet of the air inlet pipe. Tilting, facing the direction of the wind, the mouth of the air equalizing plate is vertically upward, the main function of ...

Embodiment 2

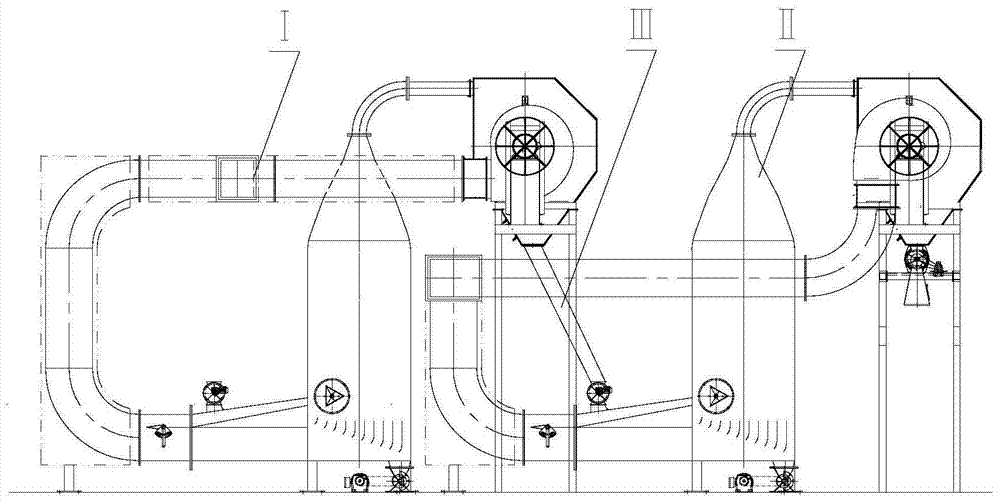

[0041] The structure of this embodiment is arranged as image 3 As shown, the first-level winnowing equipment I and the second-level winnowing equipment II all adopt the shredded tobacco winnowing equipment in Embodiment 1, and the first-level winnowing equipment I and the second-level winnowing equipment II are connected by connecting pipe III, that is , the discharge port of the tangential feeder of the primary wind separation equipment I is connected to the feed air lock of the secondary wind separation equipment II through the connecting pipe III. In this scheme, the wind speed selected for the winnowing wind in the winnowing room of the first-level winnowing equipment I is higher than the average level, about 3-4.5m / s, so as to ensure the removal of stems in the process of winnowing. The silk content is small, and the purity of cut tobacco after the first winnowing is about 60-80%. After the second winnowing equipment II winnows again, the object of the second winnowing i...

Embodiment 3

[0043] The structure of this embodiment is arranged as Figure 4 As shown, the primary winnowing equipment I adopts the shredded tobacco winnowing equipment in Embodiment 1, IV is an improved secondary winnowing machine, and the connecting pipe V is used to connect between I and IV, that is, the primary winnowing equipment I The stem-out air lock is connected to the feed port of the secondary winnowing machine IV through the connecting pipe V. The outlet of the secondary winnowing machine sends the shredded tobacco to the belt conveyor Ⅵ through the tangential feeder, and merges with the shredded tobacco picked out by the first winnowing equipment Ⅰ. In this scheme, the wind speed selected for the air selection in the air selection room of the first-level air selection equipment I is lower than the average level, about 2-3.5m / s, so that the shredded tobacco selected by air can be guaranteed in the process of air selection. The purity rate is greater than 90%, and the shredded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com