Patents

Literature

1120results about How to "Uniform feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

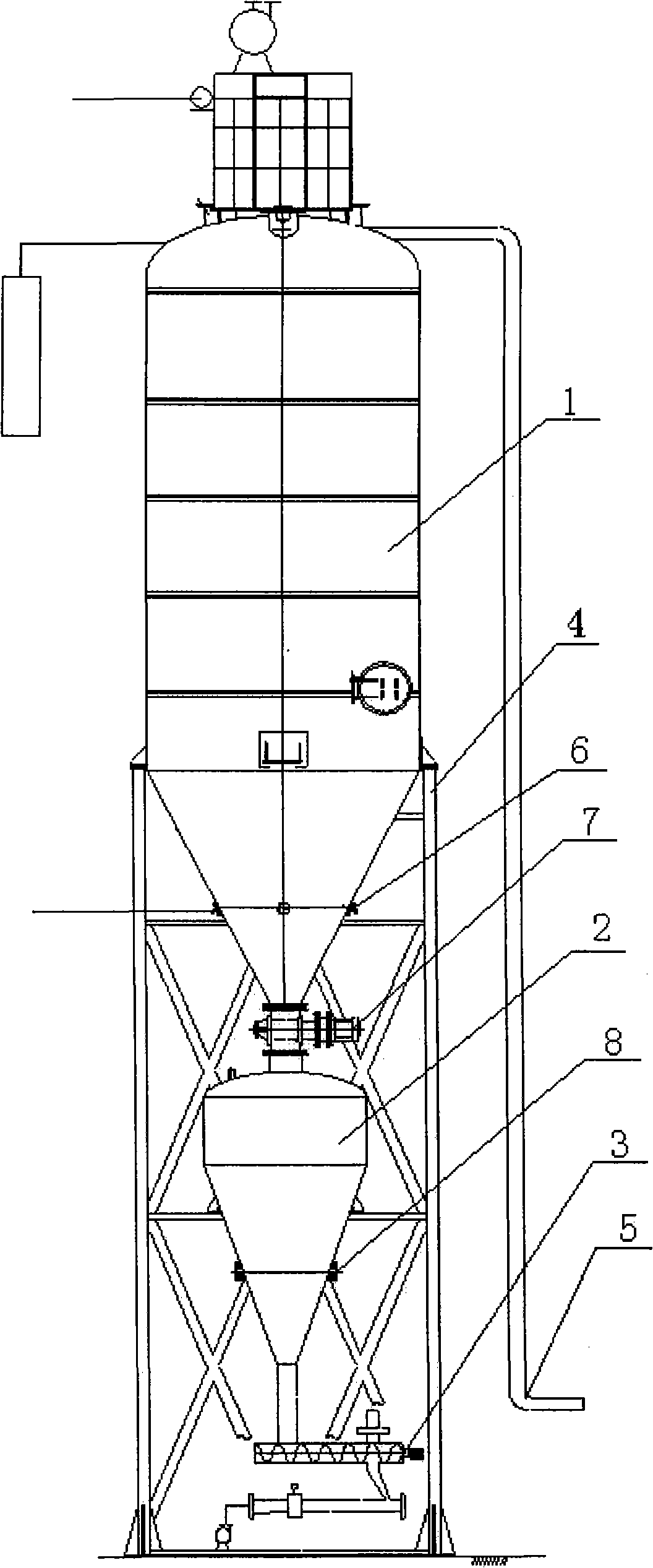

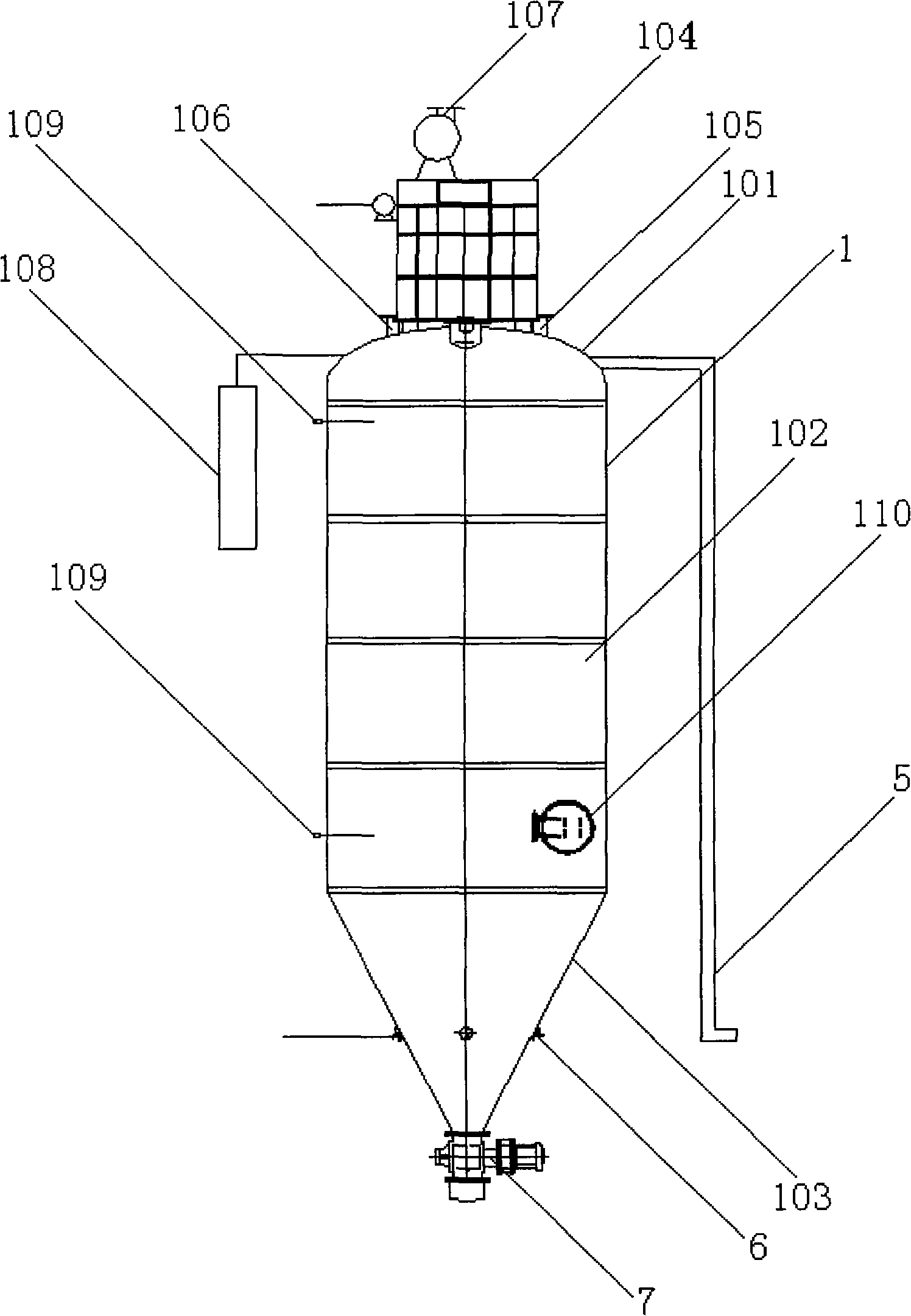

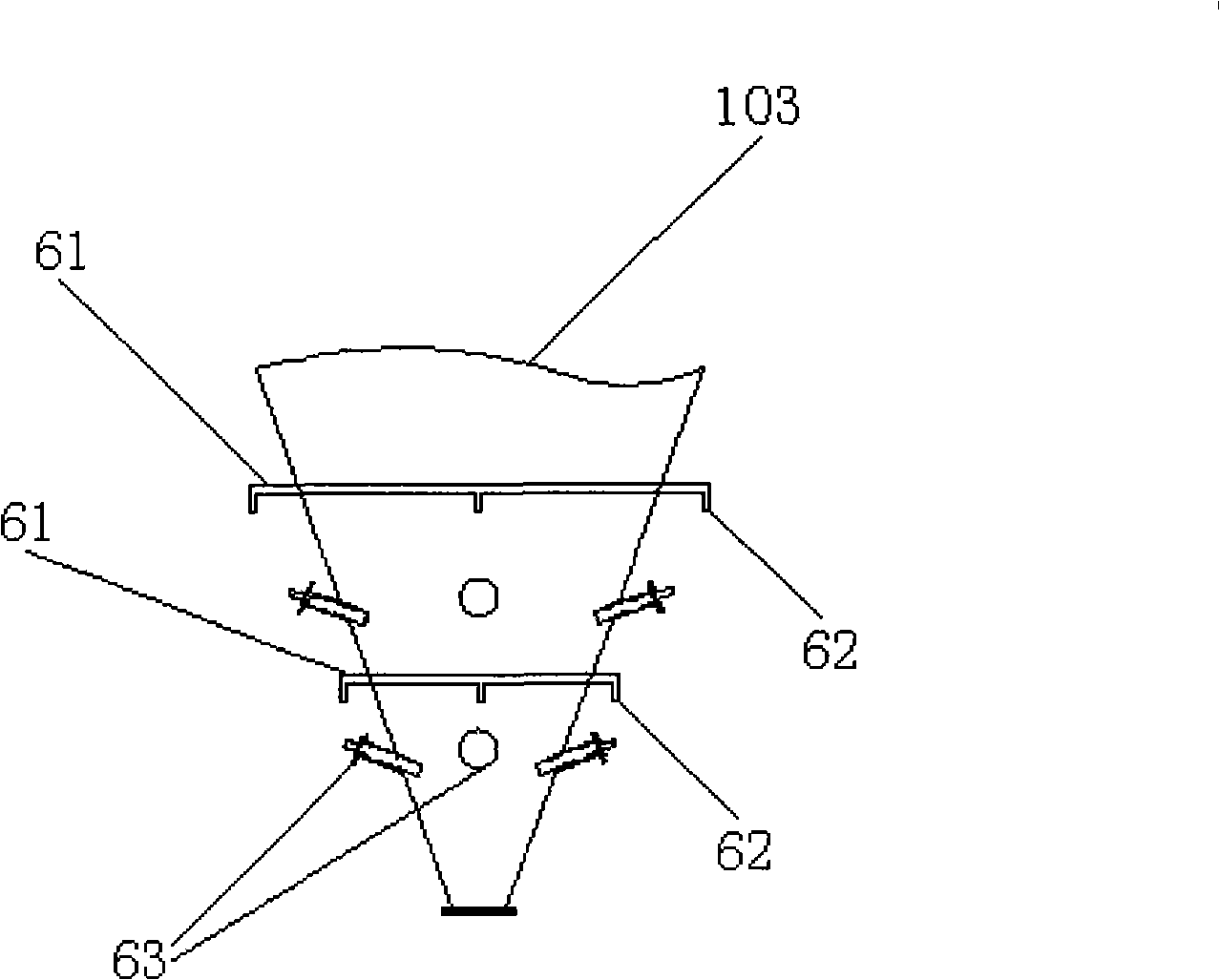

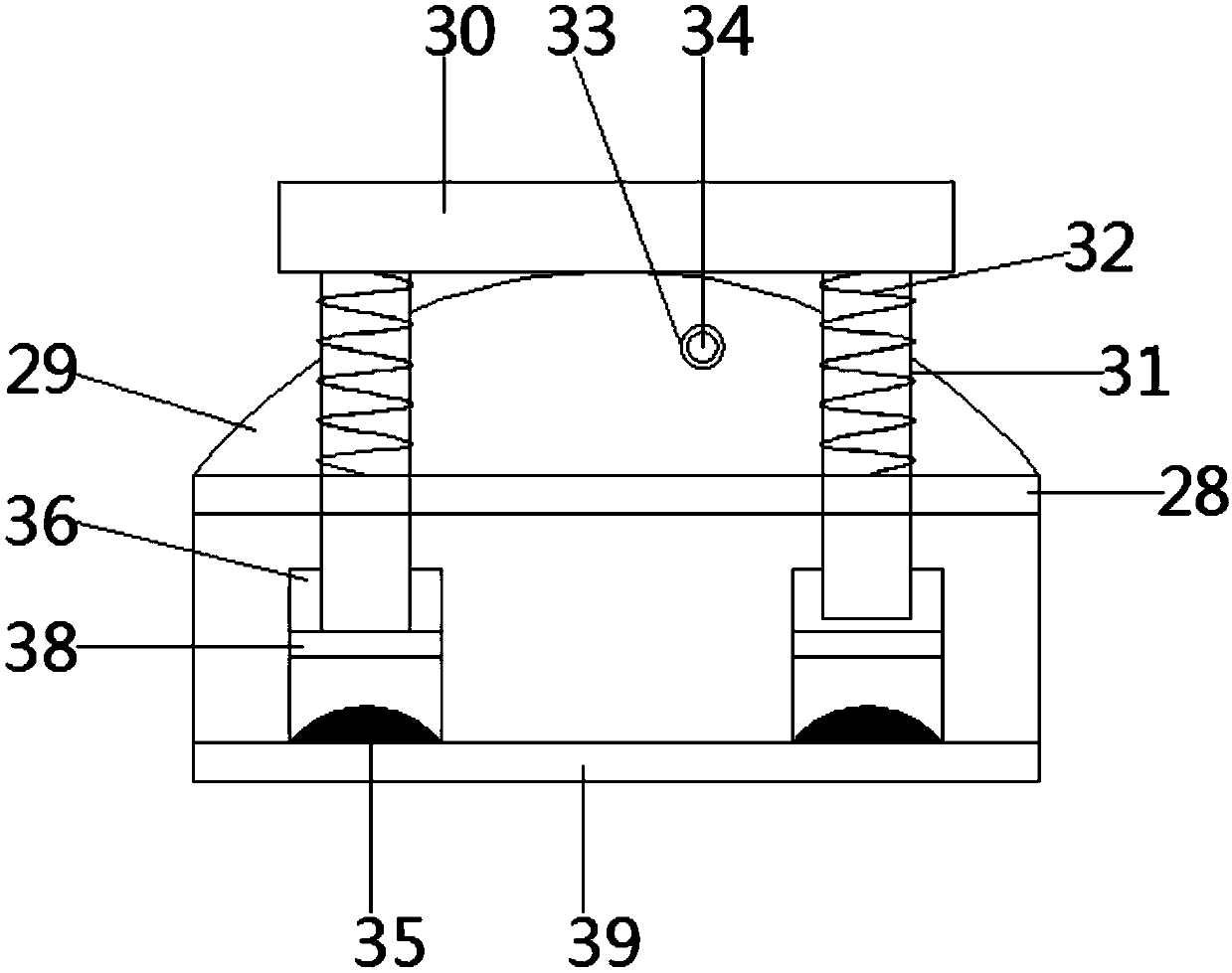

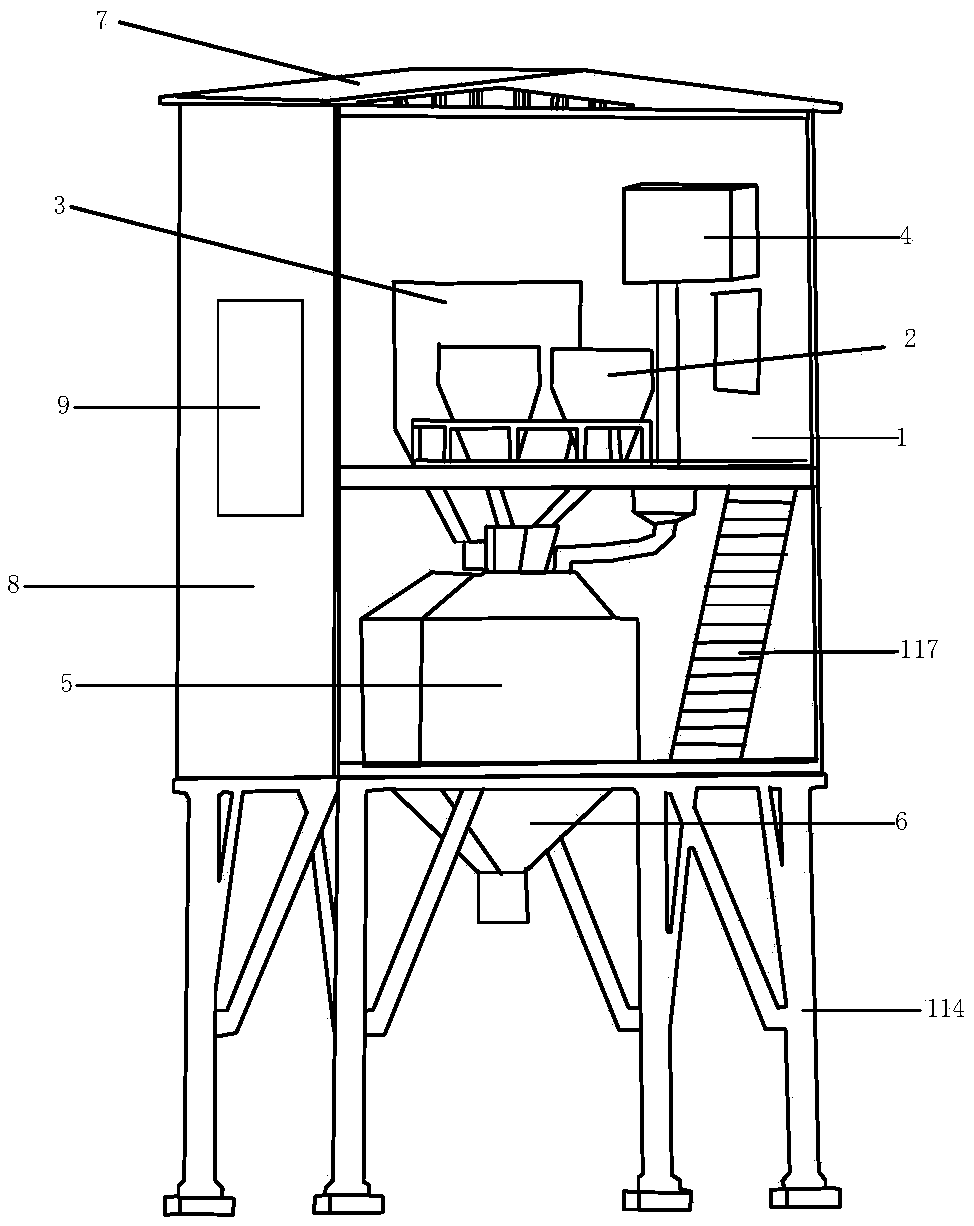

Combined coal powder storage and supply system

The invention relates to a combined coal powder storage and supply system which comprises a coal powder storage tank, a weighing coal powder supply silo, a pulse-free coal powder supply device and a support; the coal powder storage tank is vertically arranged at the top of the support, the weighing coal powder supply silo is vertically arranged on the support below the coal powder storage tank, the pulse-free coal powder supply device is arranged below a discharging opening of the weighing coal powder supply silo, and a flexible connector in the center at the top of a sealing head of the weighing coal powder supply silo is connected with a discharging opening of the coal powder storage tank through a rotary valve; and a fluidization component is arranged on the outer wall of a conical hopper of the coal powder storage tank, and a coal powder anti-arching stirring device is arranged on a hopper of the weighing coal powder supply silo. The invention has compact structure, reasonable layout, automatic feeding and stable supply and can solve the problems frequently existing in the ordinary coal storage silo and the supply silo of birdnesting, bridging, rat hole, channeling, wall build-up, breakage, self combustion, and the like; and the invention can be widely used in any situation where the small and medium-sized industrial coal powder boilers are required.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

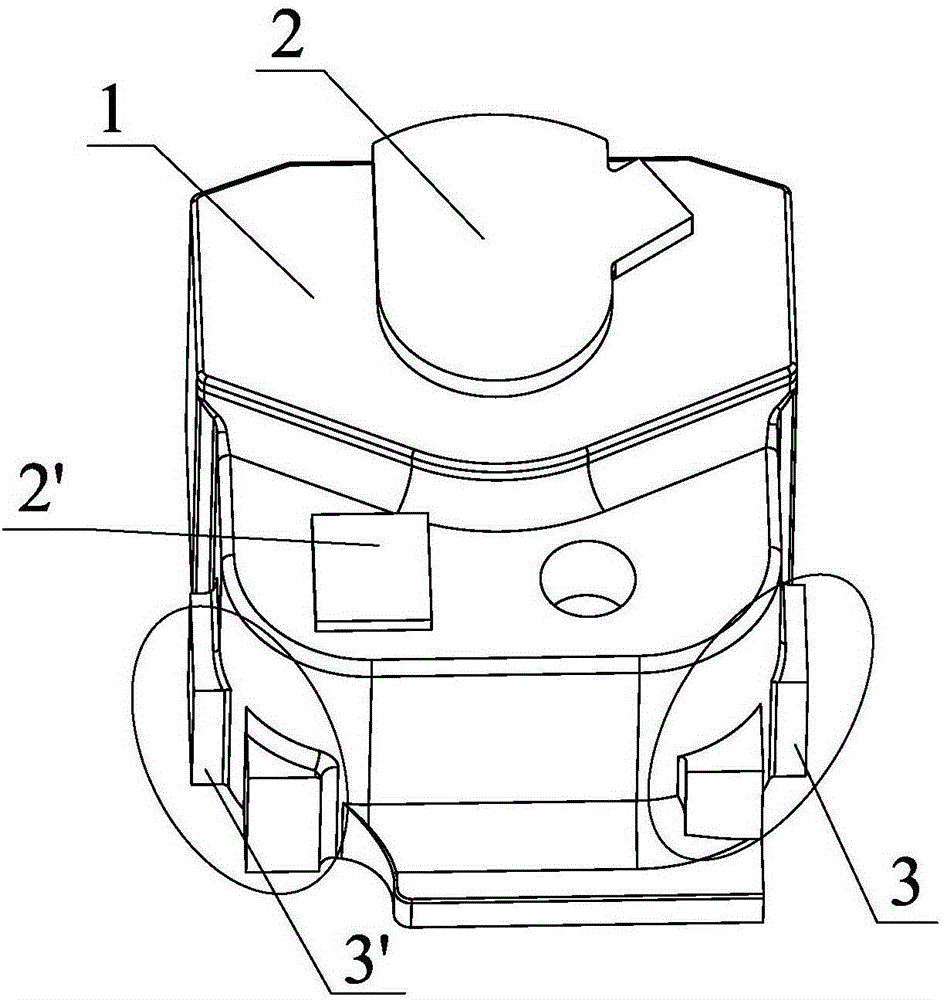

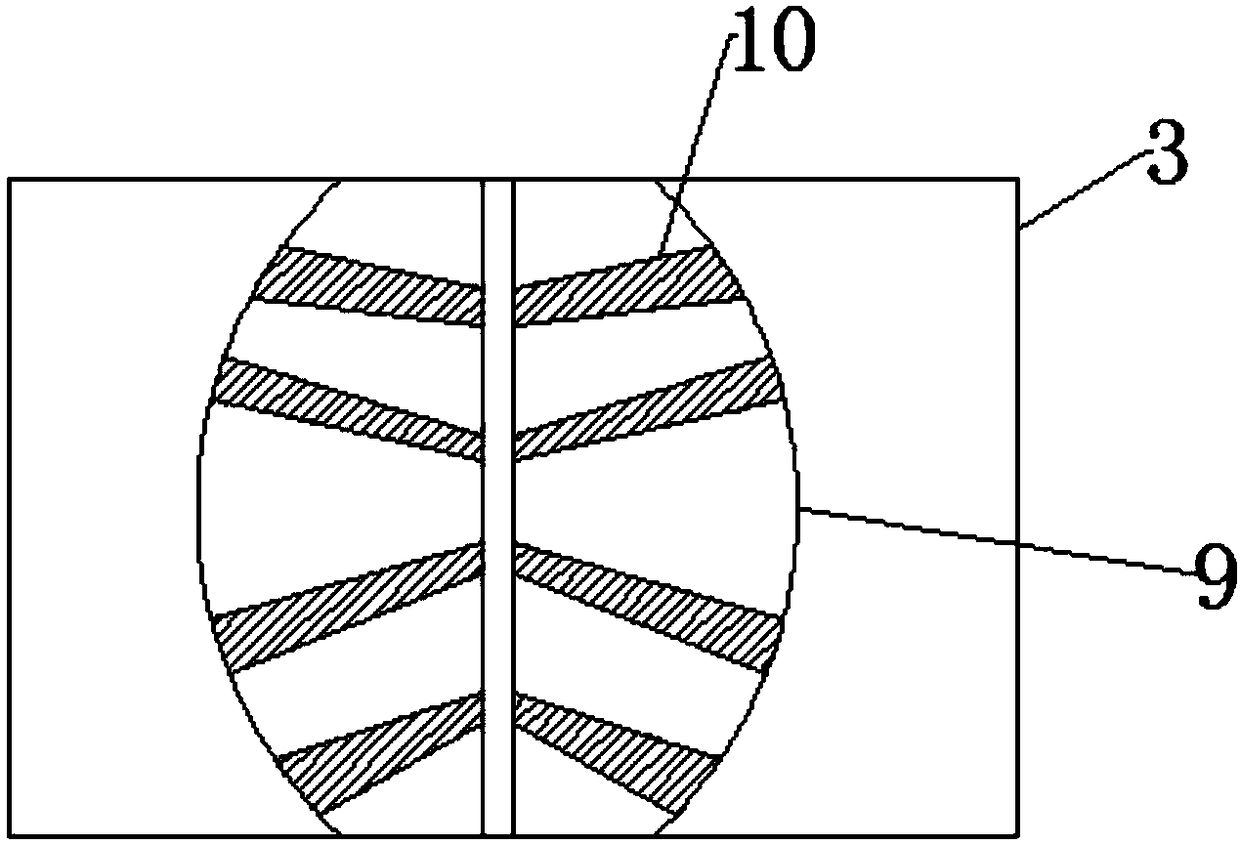

Core assembly moulding sand mould structure for gearbox shell castings and core assembly moulding method

The invention relates to a core assembly moulding sand mould structure for gearbox shell castings and a core assembly moulding method. The core assembly moulding sand mould structure for the gearbox shell castings comprises inner cavity sand cores, outer contour sand cores and a pouring system sand mould for core assembly moulding; The inner cavity sand cores and the outer contour sand cores are assembled to form mould cavities for the shell castings; the upper side of the upper end face of each shell casting is provided with multiple round feeders, and a plurality of chilling blocks are arranged in each outer contour sand core among the corresponding round feeders; supplement structures are arranged in each outer contour sand core corresponding to the sides of side bosses on the lower parts of the side walls of the corresponding shell casting, and an insulating layer is arranged on the outer side of each supplement structure; and ingates communicated with the mould cavities of the corresponding castings are arranged in the pouring system sand mould. According to the core assembly moulding sand mould structure disclosed by the invention, moulding and casting cost of the castings is reduced; the work load of subsequent machining of the castings is reduced; and the production efficiency is improved.

Owner:KOCEL STEEL

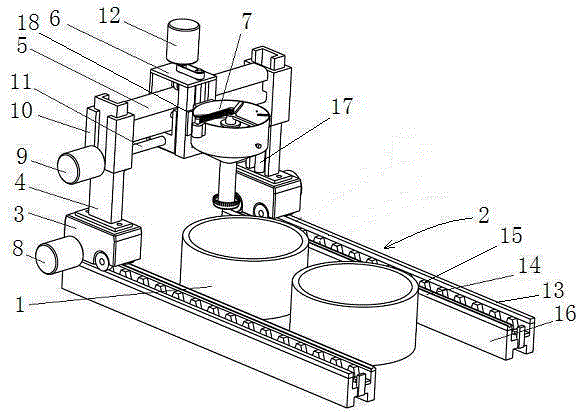

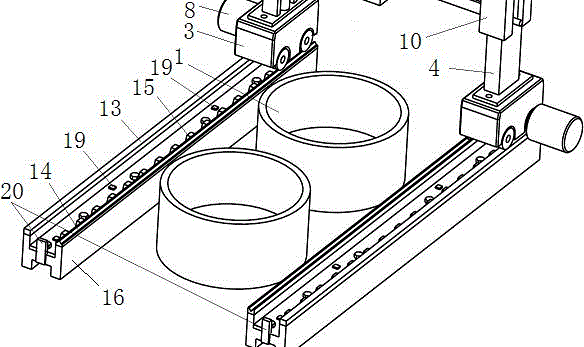

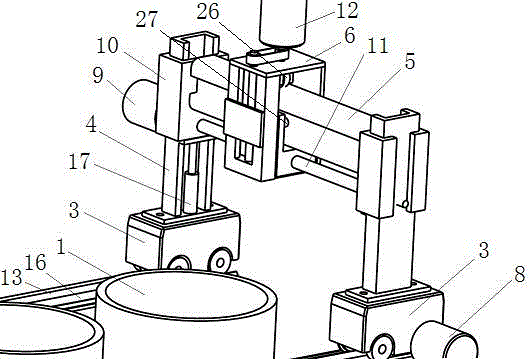

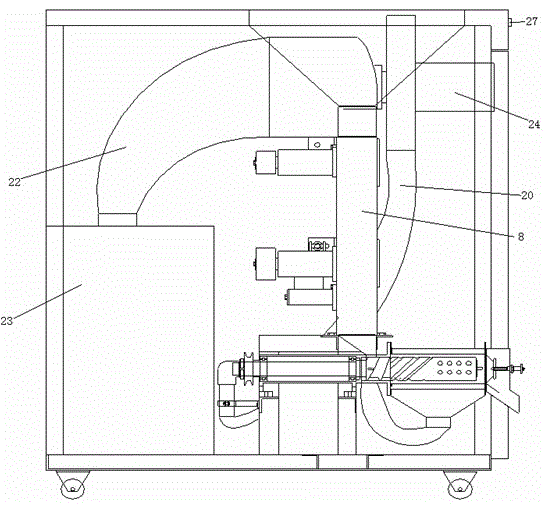

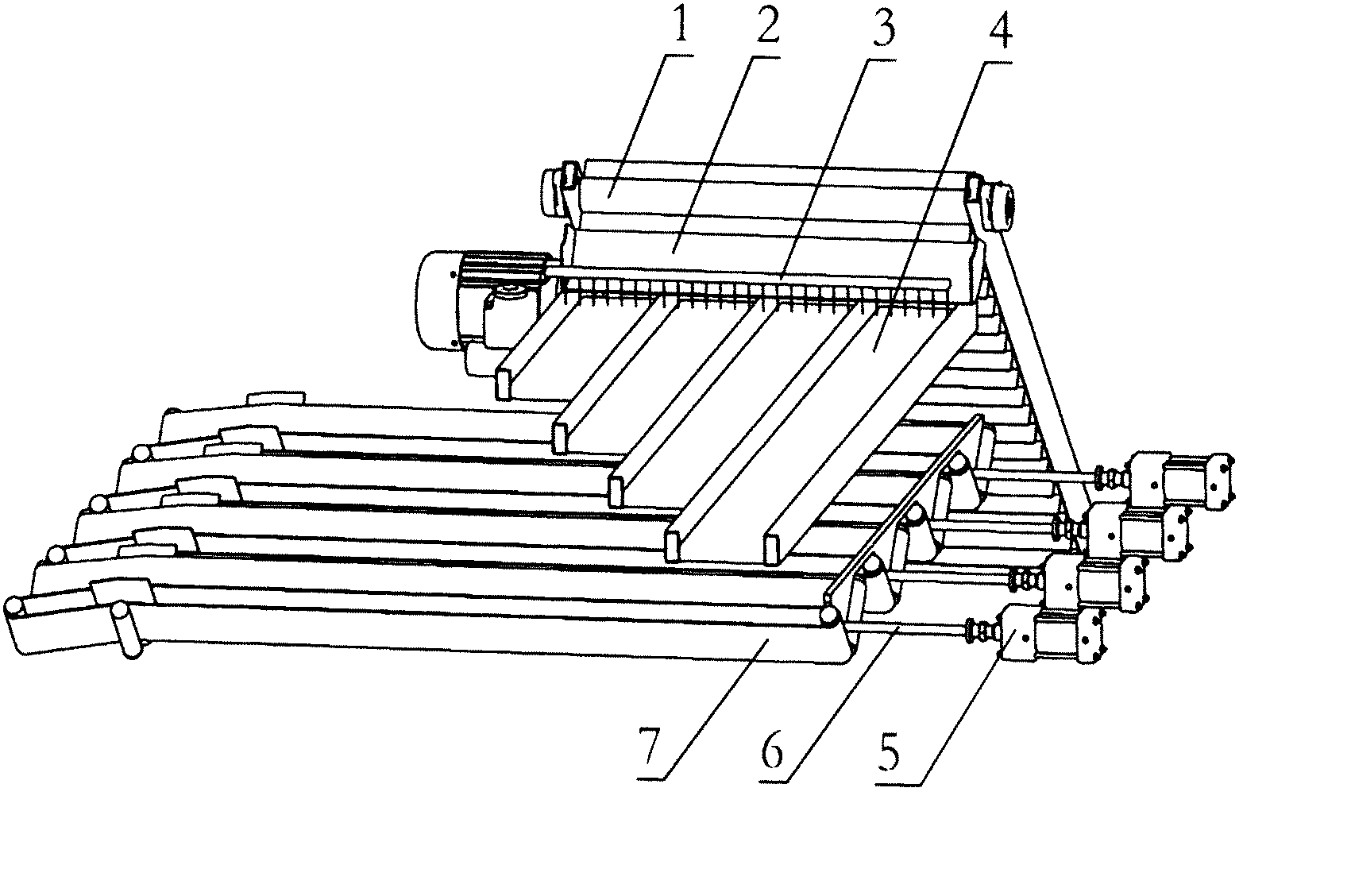

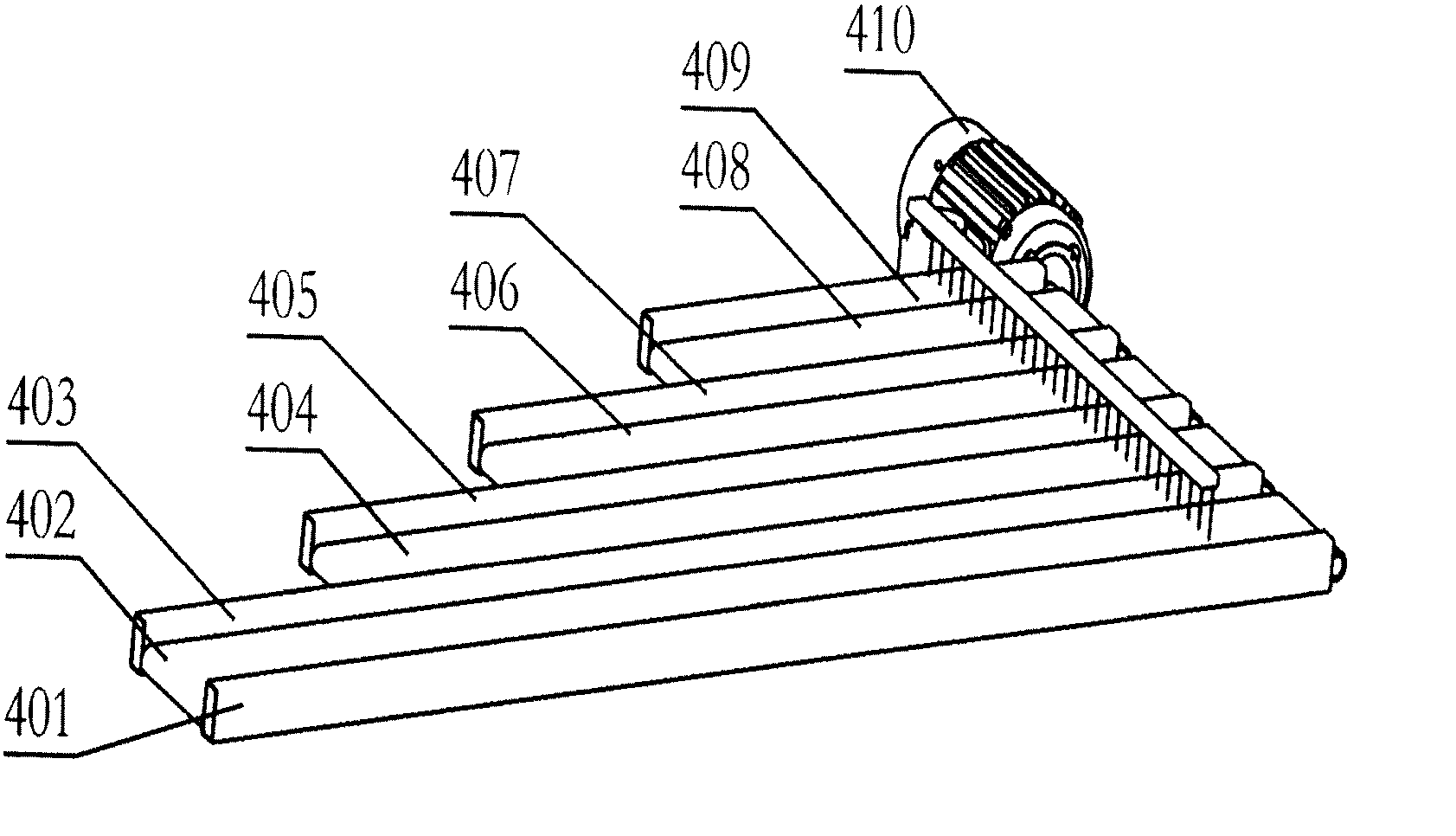

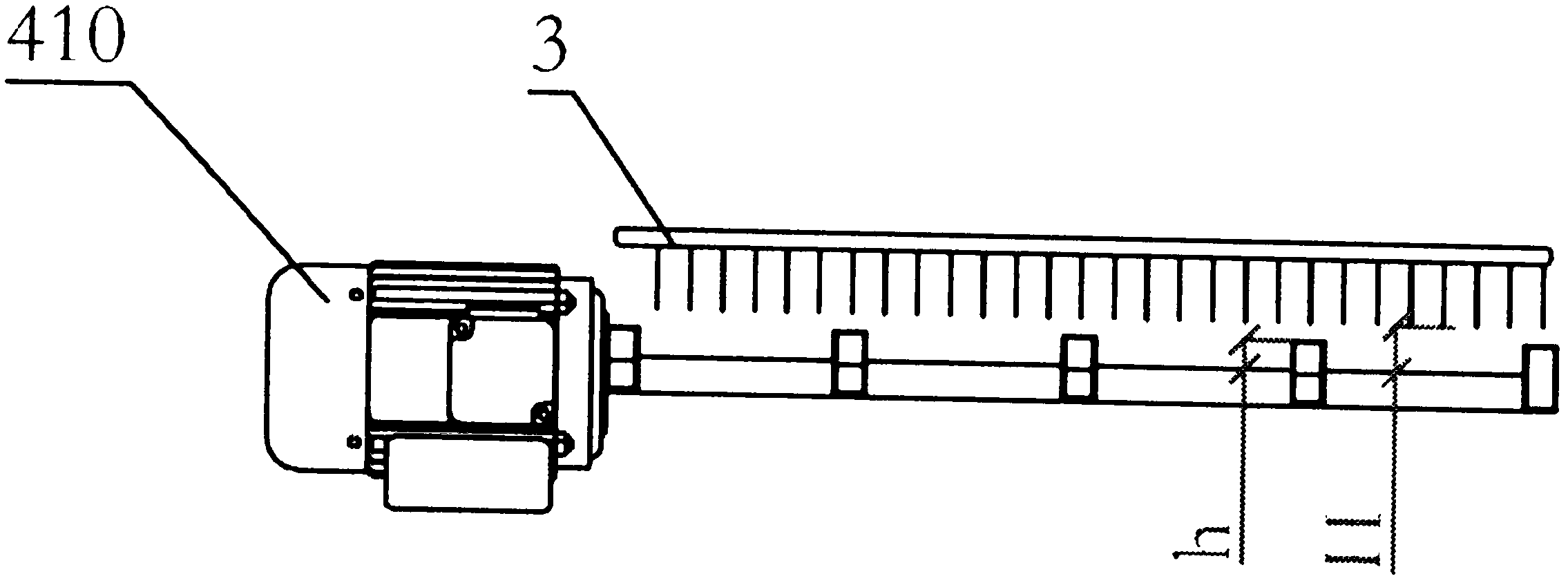

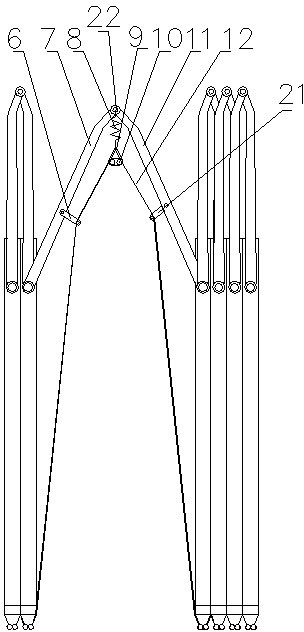

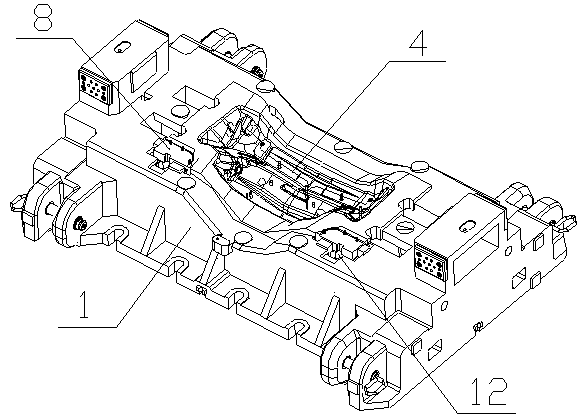

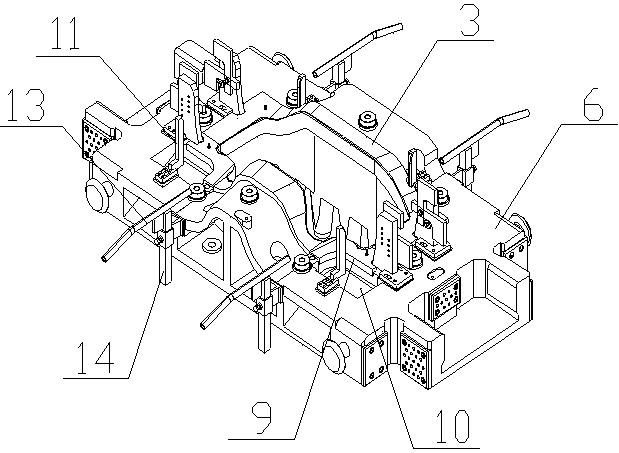

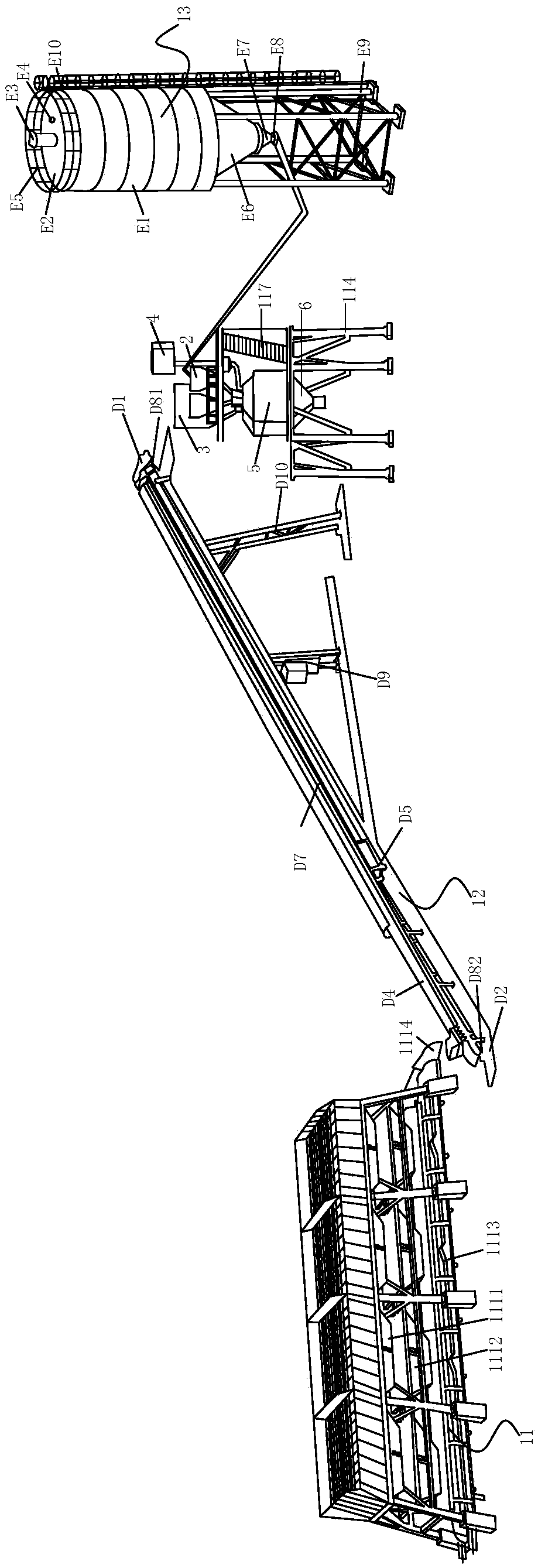

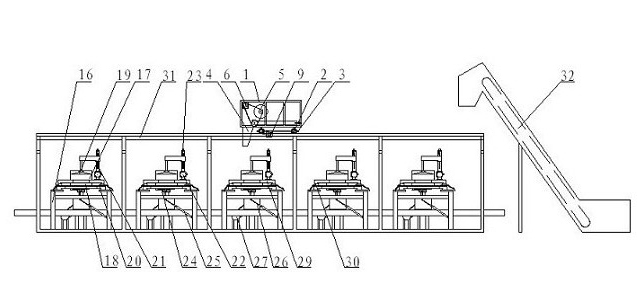

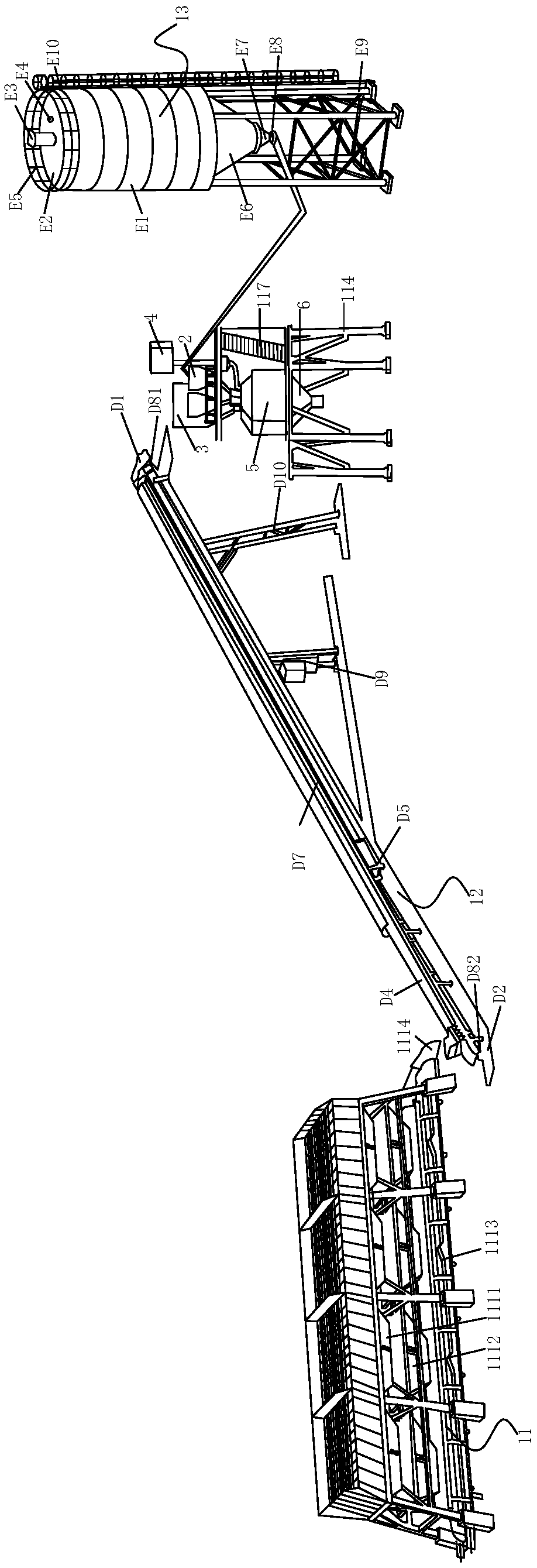

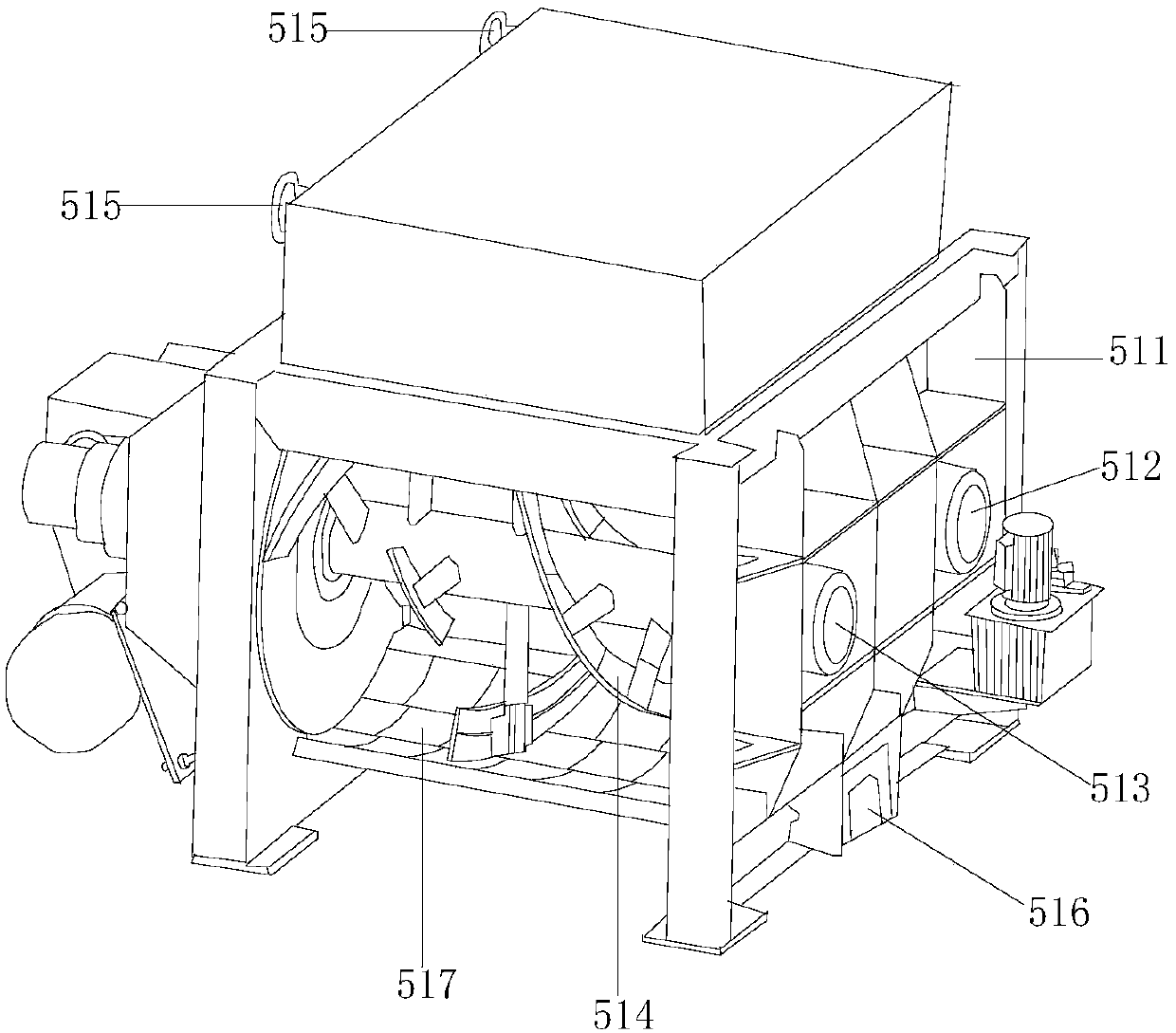

Gantry fermented grain automatic loading machine and loading method

InactiveCN104816954AIncrease loading capacityLower performance requirementsConveyorsAlcoholic beverage preparationSteam pressureControl system

The invention discloses a gantry fermented grain automatic loading machine. The gantry fermented grain automatic loading machine comprises a gantry fermented grain loading robot, a fermented grain loading execution mechanism, a binocular vision identifying system and a control system, wherein the gantry fermented grain loading robot consists of two horizontal guide rails, two stand columns, a cross beam and a ram; the fermented grain loading execution mechanism is mounted on the ram; and the binocular vision identifying system comprises a steam running identification thermal infrared imager and a height identification thermal infrared imager, whose output ends are connected to an input end of the control system. The gantry fermented grain loading robot is excellent in loading capacity, and the performance requirement of the robot can be reduced, so that the equipment cost investment is reduced; the guide rails consisting of a flat guide rail, a V-shaped guide rail and a rack composition are adopted to bear the position deviation caused by slight displacement generated in the fermented grain loading motion process, so that the material distributing and feeding accuracy is guaranteed, and the distilling effect is improved; and the binocular vision identifying system is adopted to obtain the material surface temperature distribution and height, so that fermented grains are uniform to prevent the air way blockage and the steam pressure, and the distillation effect is guaranteed.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

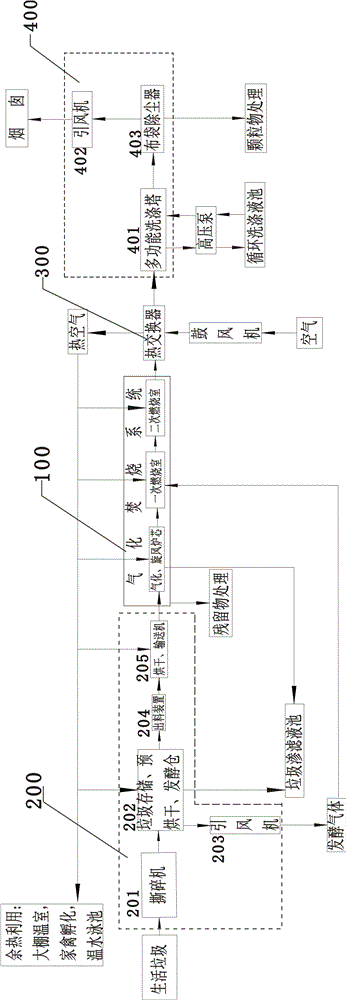

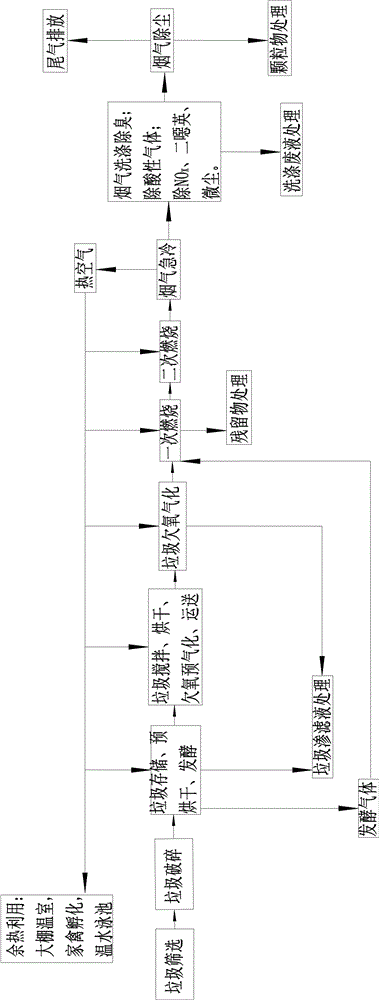

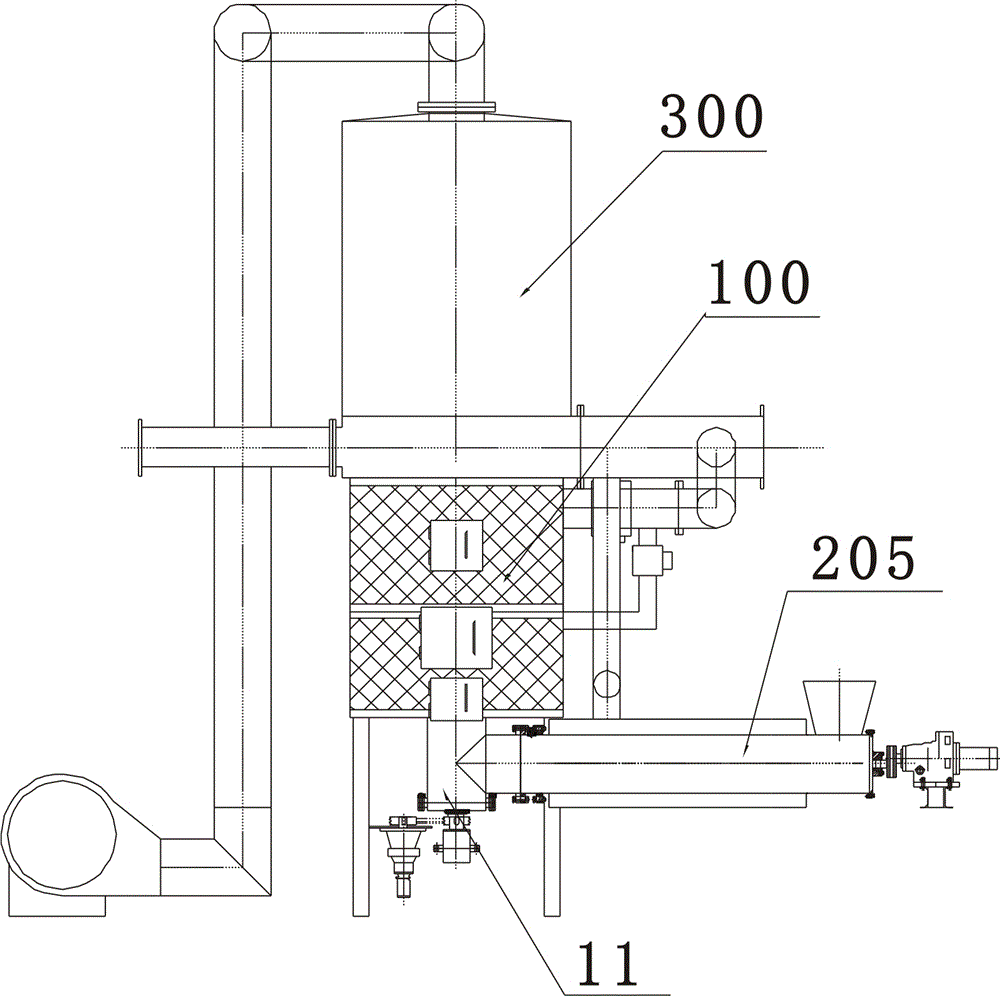

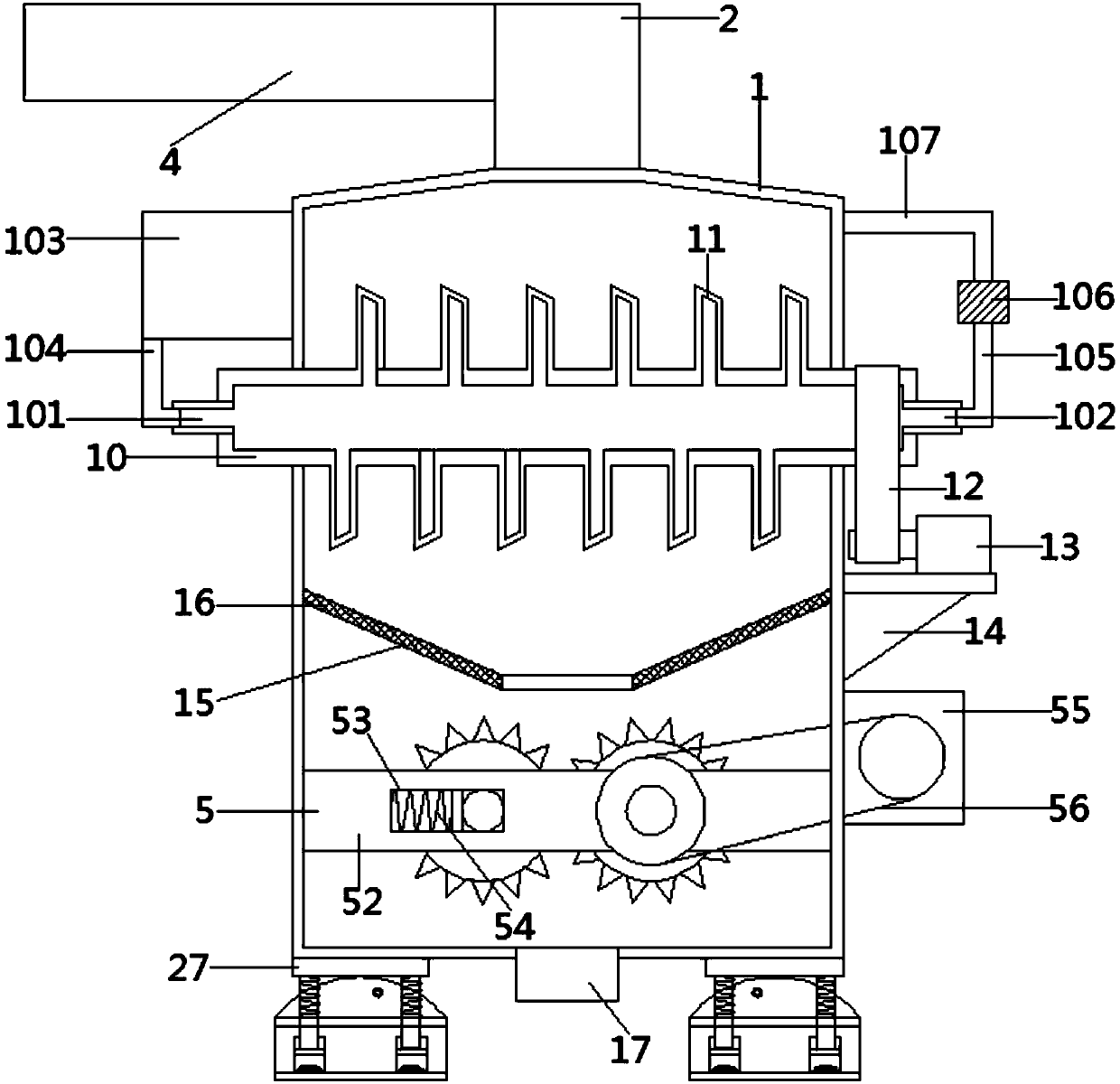

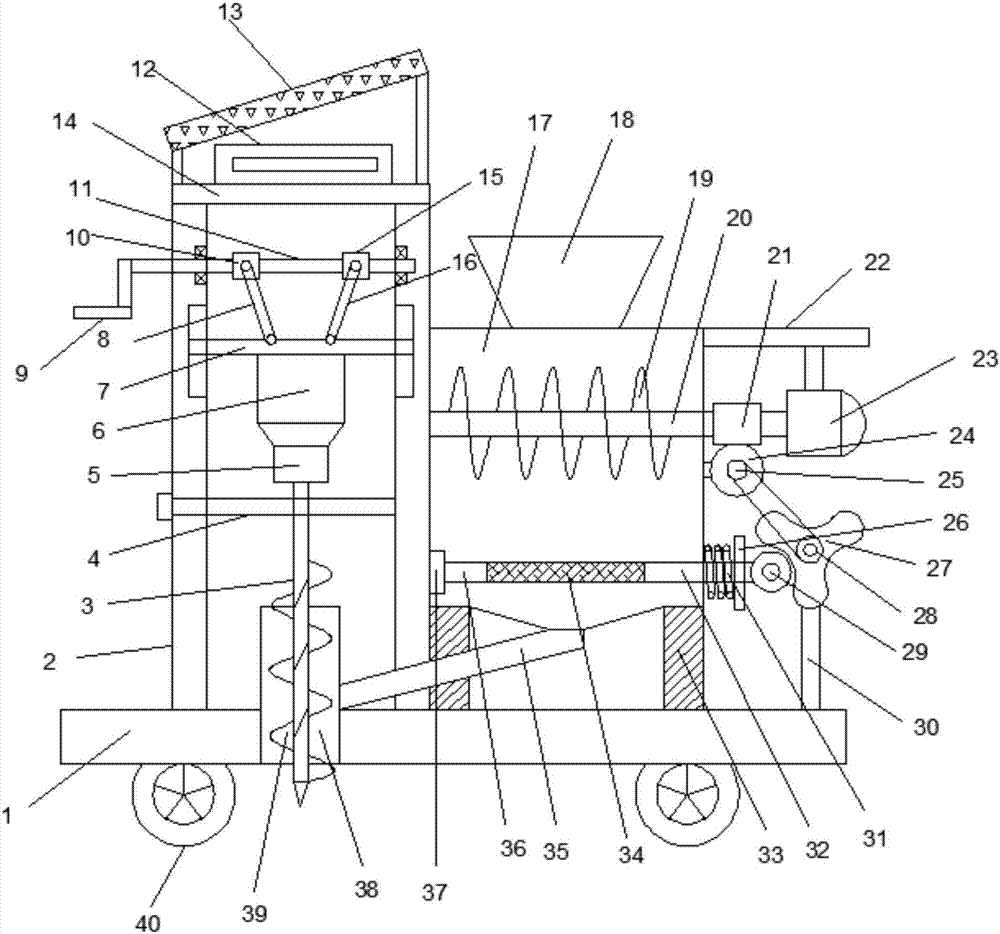

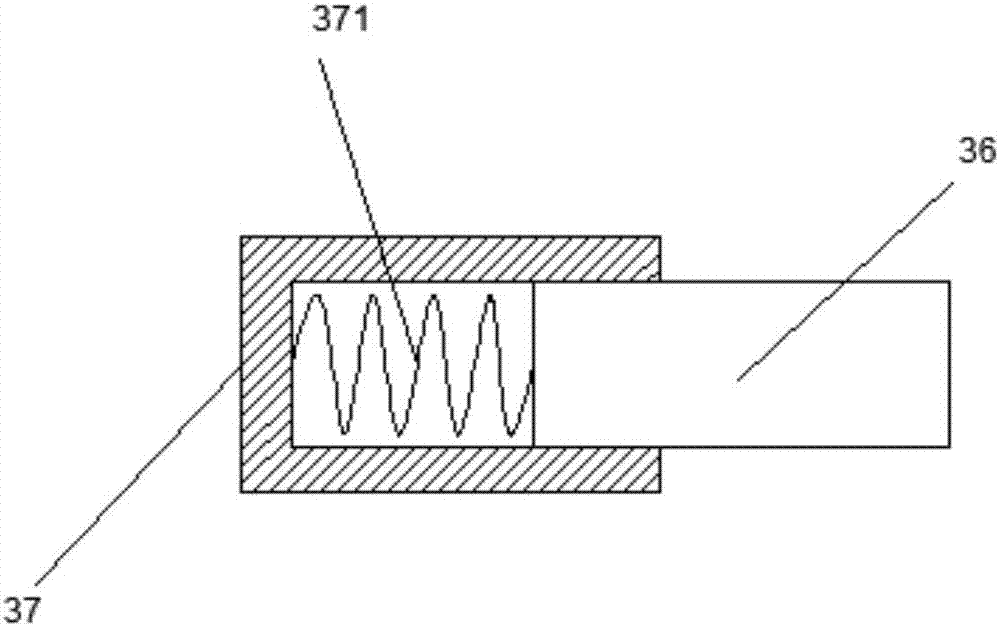

Small-scale efficient domestic garbage gasification incineration system and incineration method

InactiveCN105757673AImplement deep preprocessingAchieve clearingIncinerator apparatusCombustionFlue gas

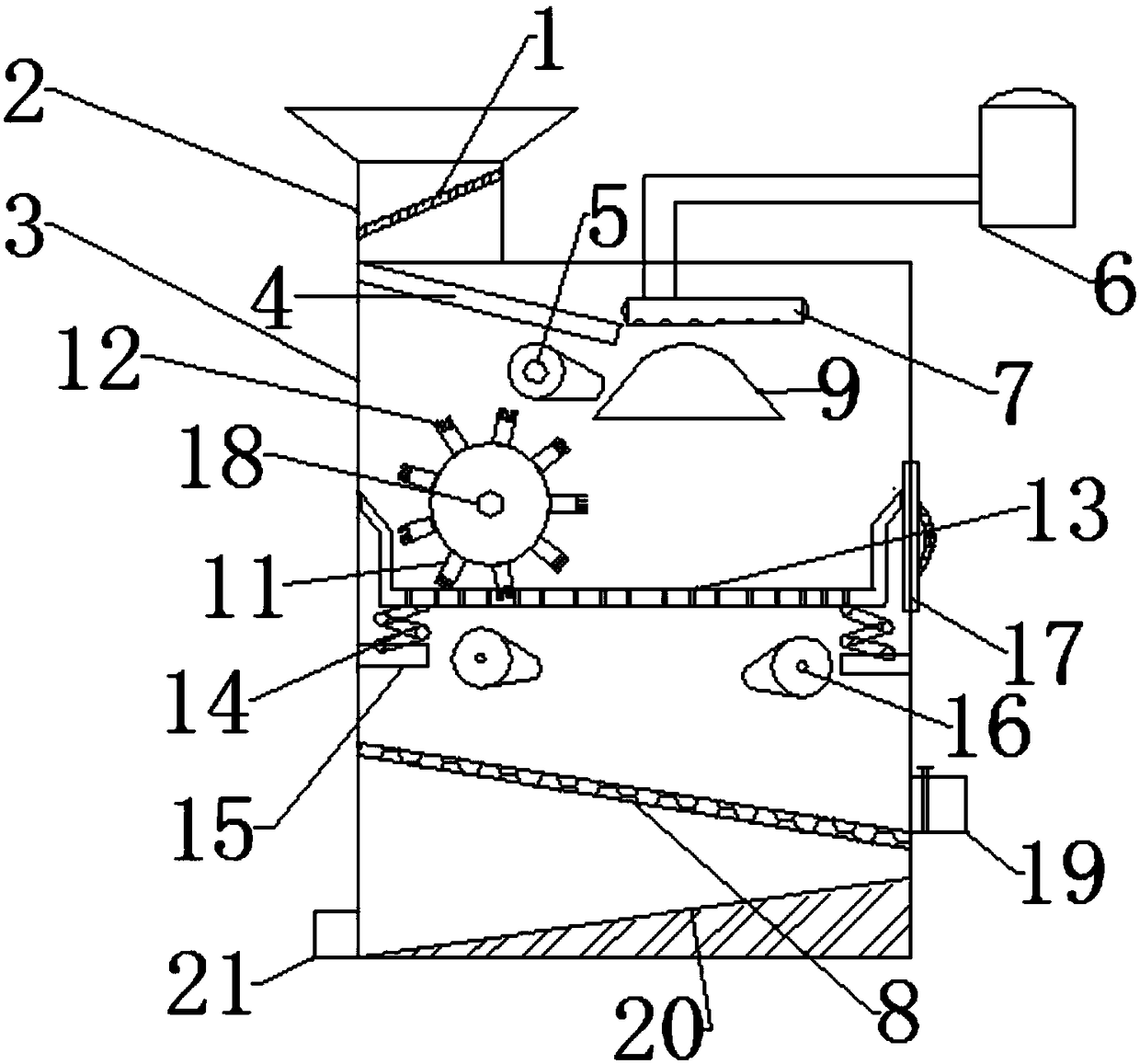

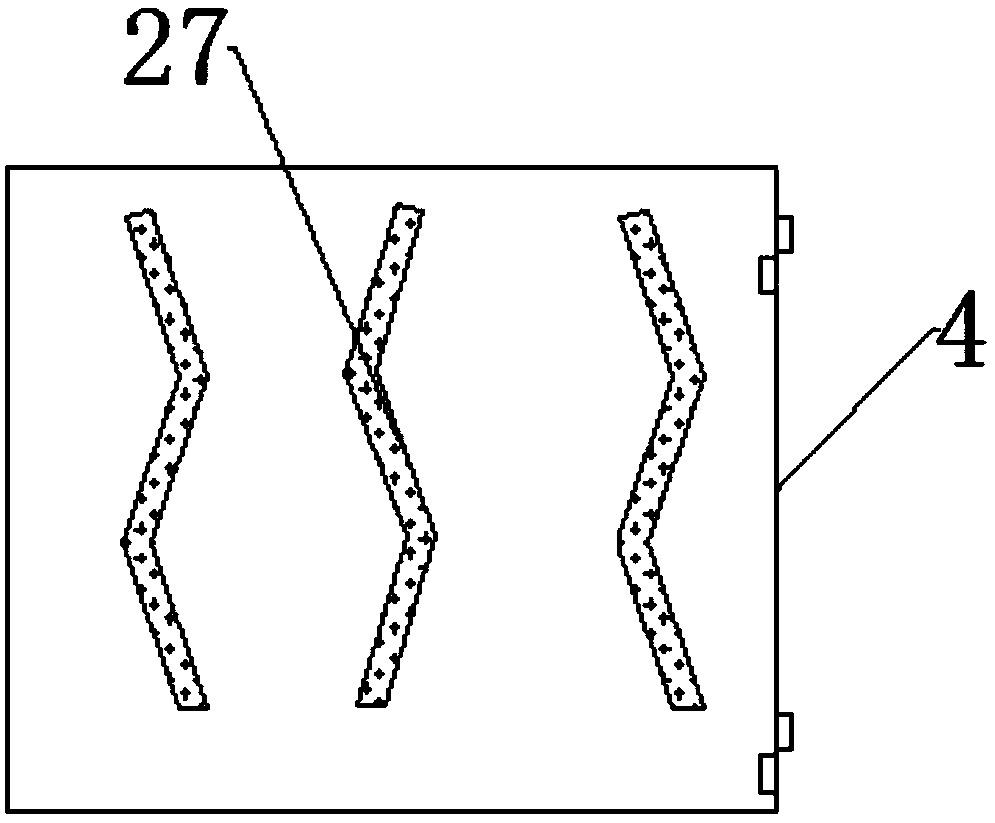

The invention discloses a small-scale efficient domestic garbage gasification incineration system and an incineration method. The small-scale efficient domestic garbage gasification incineration system comprises a domestic garbage gasification incinerator, a domestic garbage pretreatment system, a heat exchanger and a flue gas treatment system. The small-scale efficient domestic garbage gasification incineration system and the incineration method have the advantages that the defects of high pollutant content of flue gas and incineration incompleteness, unthoroughness and nonuniformity caused by irrationality and nonuniformity of feeding in incineration and lack of pretreatment of the domestic garbage in use of existing small-scale domestic garbage incineration systems can be overcome, and the domestic garbage gasification incineration system is innovatively designed on the basis of an original biofuel gasifier; a storage bin for pretreatment of original domestic garbage, a discharging machine and garbage drying and conveying devices are designed, and a gasification furnace core which realizes uniform and quantitative feeding and provides strong turbulence air to enable continuous turnover and quick combustion of domestic garbage is designed.

Owner:SICHUAN TIANYI ENVIRONMENTAL PROTECTION CO LTD

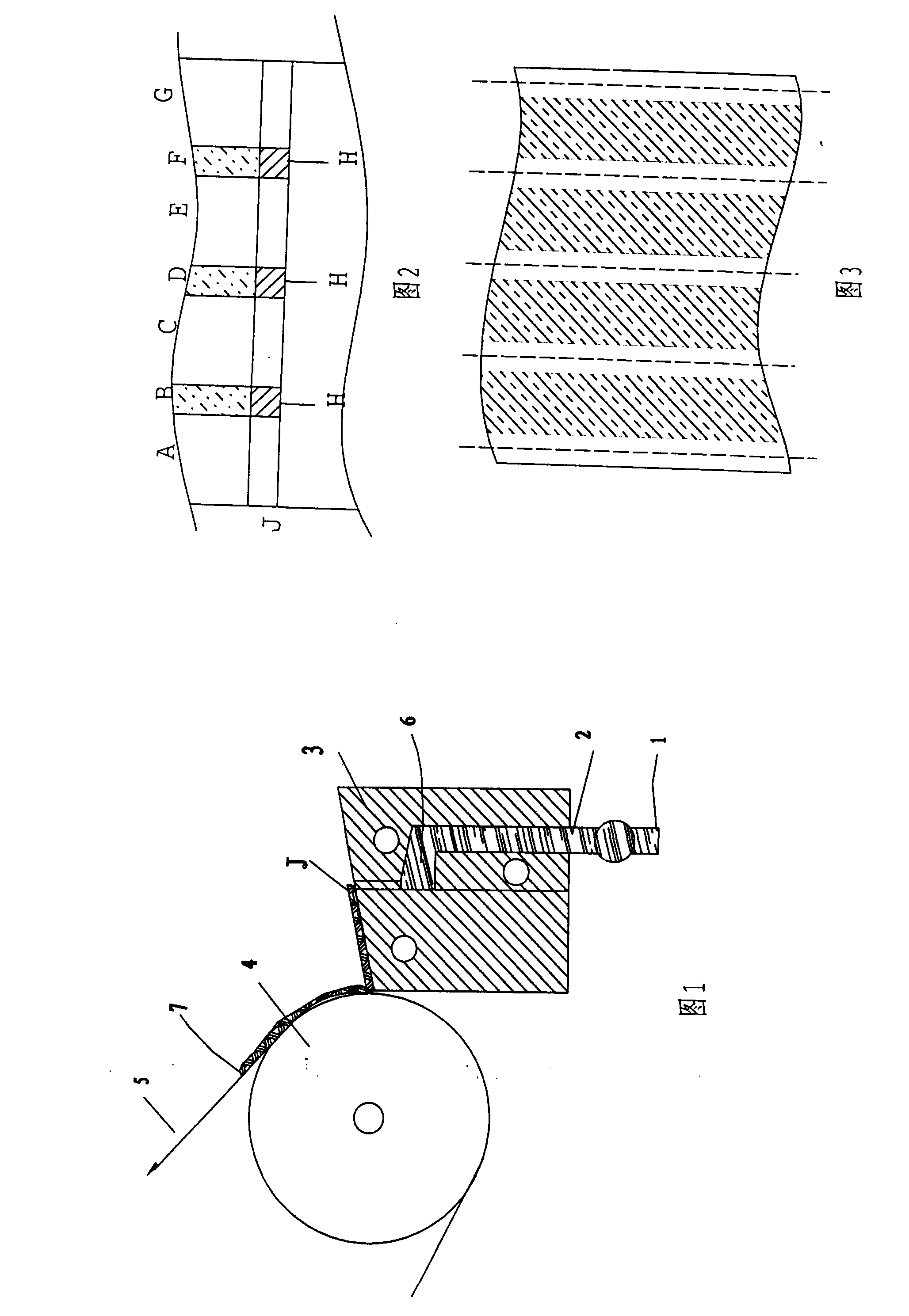

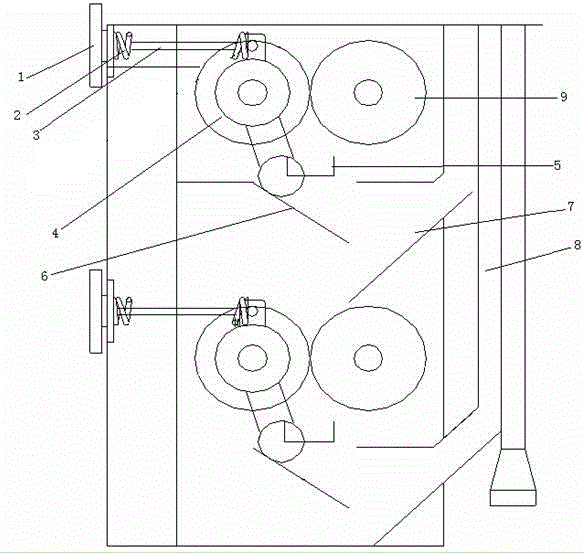

A pole piece coating method and coating nozzle

InactiveCN101157076AUniform thicknessImprove efficiencyLiquid surface applicatorsElectrode manufacturing processesPole pieceEngineering

The invention relates to a pole piece coating method and a coating nozzle. The invention has the method that in the width direction of a coating head of an incline extrusion coating machine a coating material section and a sealing section are arranged at intervals according to the design parameters of a pole piece, and laid into a foil tape to be continuously coated when the machine is started, thereby obtaining the pole piece extending along the direction of a transporting tape in the blank area of the sealing section. The invention fully combines the advantages of a prior incline extrusion coating method and a discontinuous coating method, the coating can be continuous, the efficiency is high, and the thickness of the pole piece is uniform and consistent. The invention also provides the coating nozzle used for the implementation of the coating, the material feeding of the coating nozzle is uniform, the processing is simple, and the adjustment is flexible and accurate.

Owner:CHINA LUCKY FILM CORP

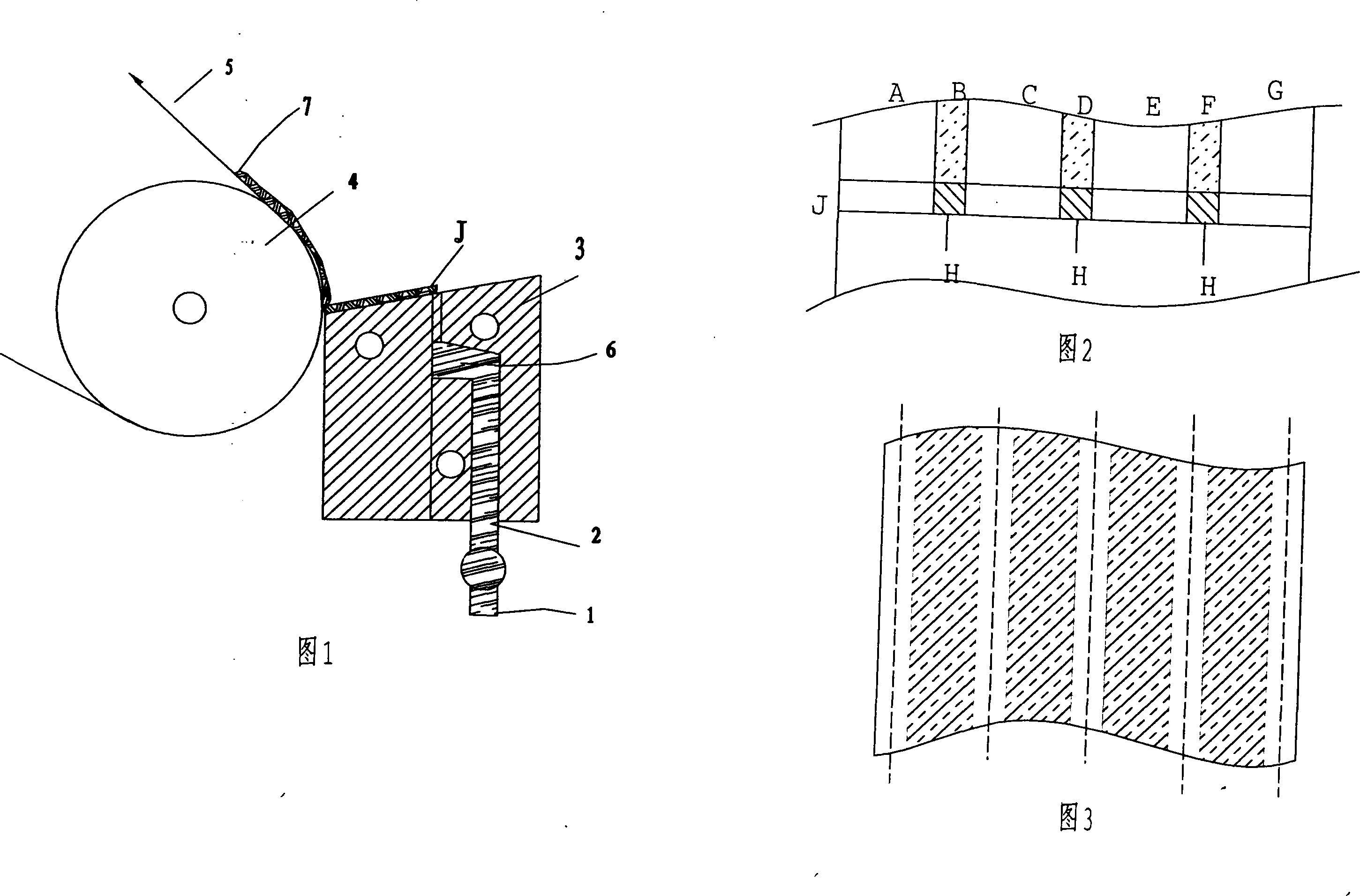

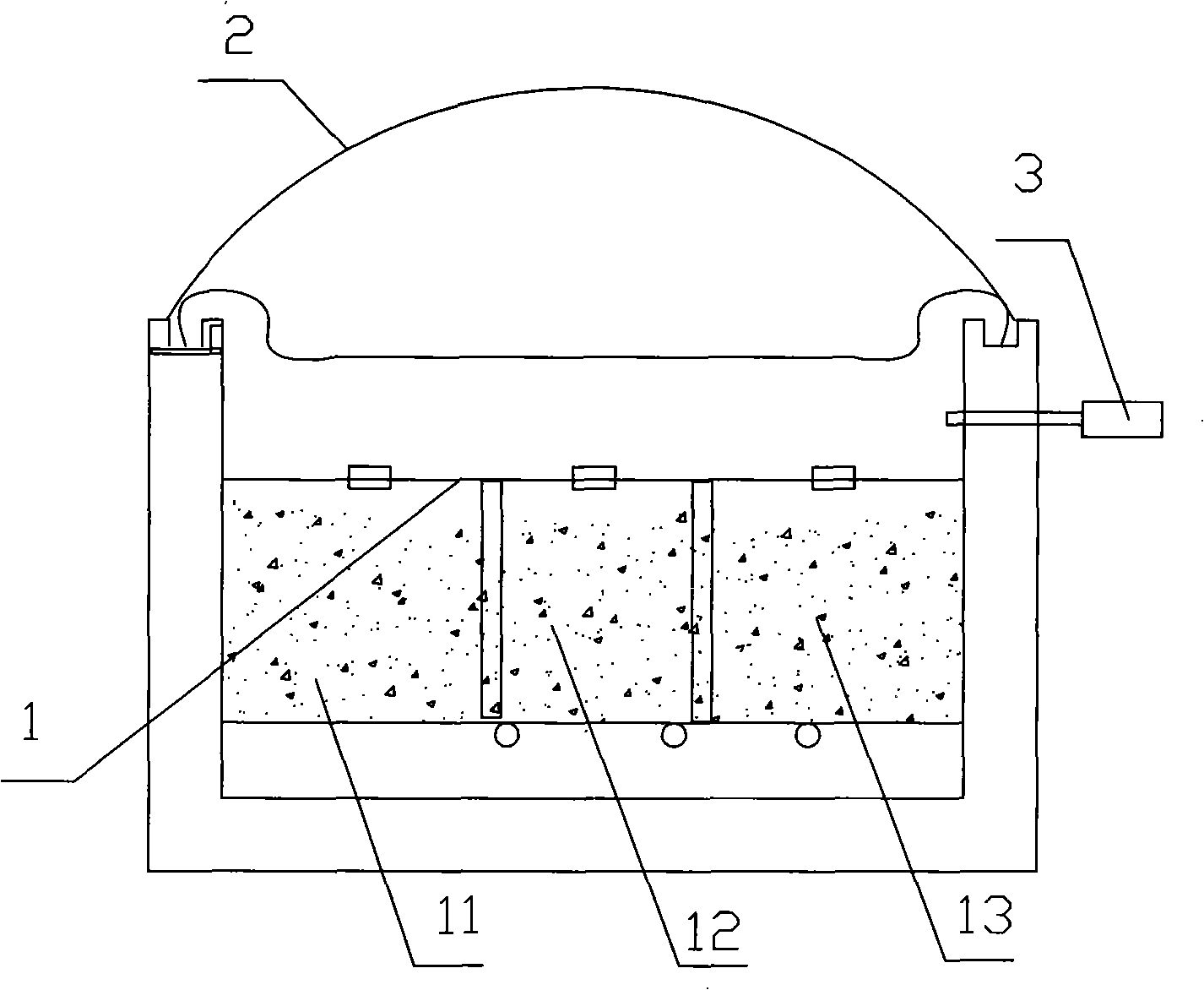

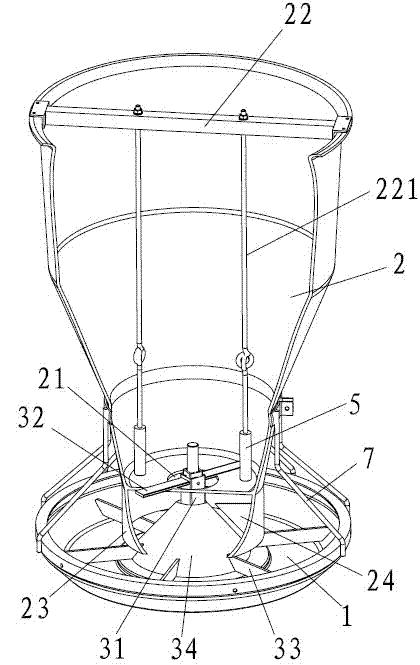

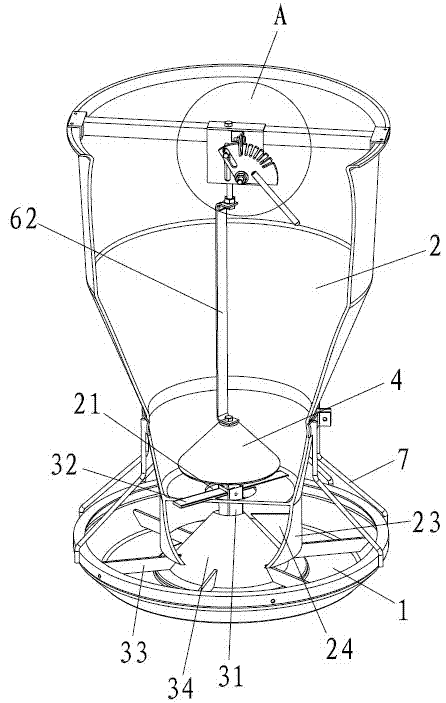

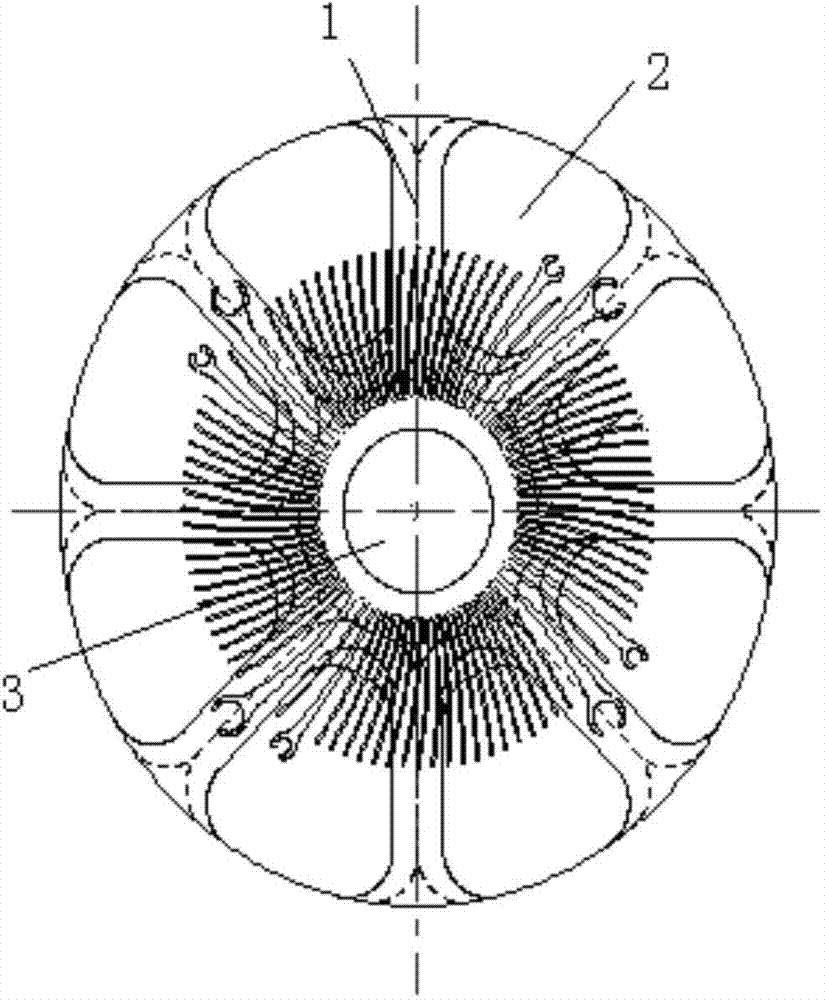

Large-sized open mouthed combined methane tank

InactiveCN101353623ALimited activity spaceFree from wear and tearBioreactor/fermenter combinationsBiological substance pretreatmentsCirculating pumpCharge and discharge

The invention discloses a large-scale open compound methane tank, including a fermenting tank (1), a gas collection and storage device (2), and an air feeder (3) connected with the fermenting tank, wherein, the fermenting tank includes a plurality of independent fermenting tanks which can be communicated or disconnected mutually. The methane tank also includes the gas collection and storage device, the air feeder, a solar warming device, a charging / discharging device and an anti-encrustation device of the methane tank. When in use, as the structure of the invention is provided with a plurality of independent fermenting tanks, the air can be fed continuously in the raw material renewal process; the charging / discharging device accelerates the material charging and discharging; the gas collection and storage device of the methane tank has low construction cost, a software cover can be opened or retracted according to gas production, a gas collection and storage chamber can be changed according to the methane quantity, the pressure in the gas collection and storage chamber can not be too high, and the solar warming device increases the temperature in the methane tank so as to lead the straw material to produce the methane under the suitable temperature in winter; and a circulating pump is used for spraying the methane fluid onto the straw material through a nozzle so as to avoid encrustation.

Owner:南阳市绿野循环农业研究所 +1

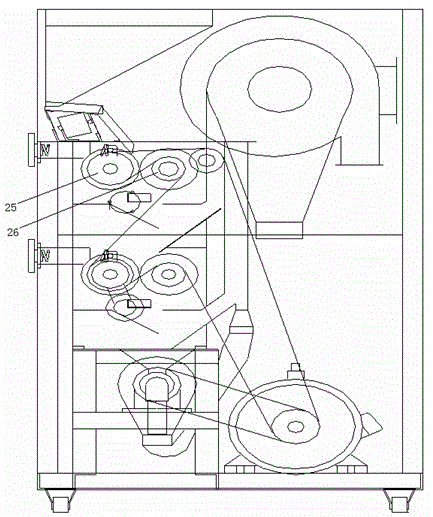

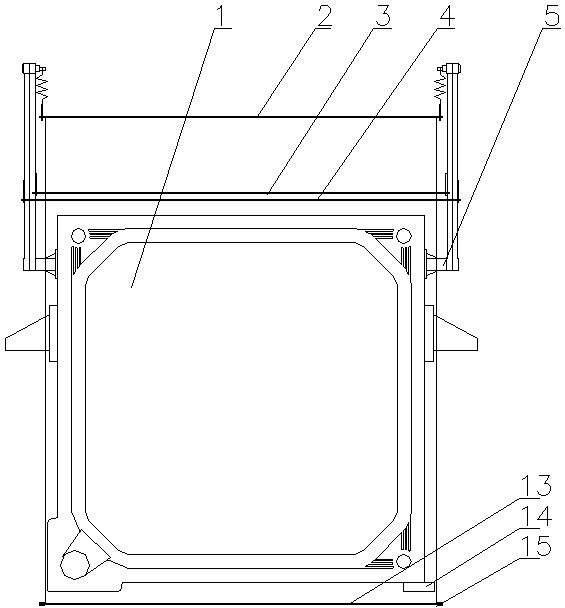

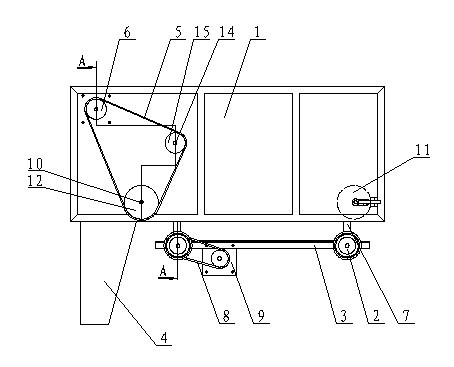

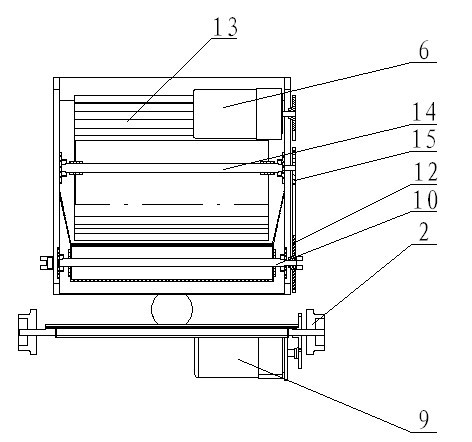

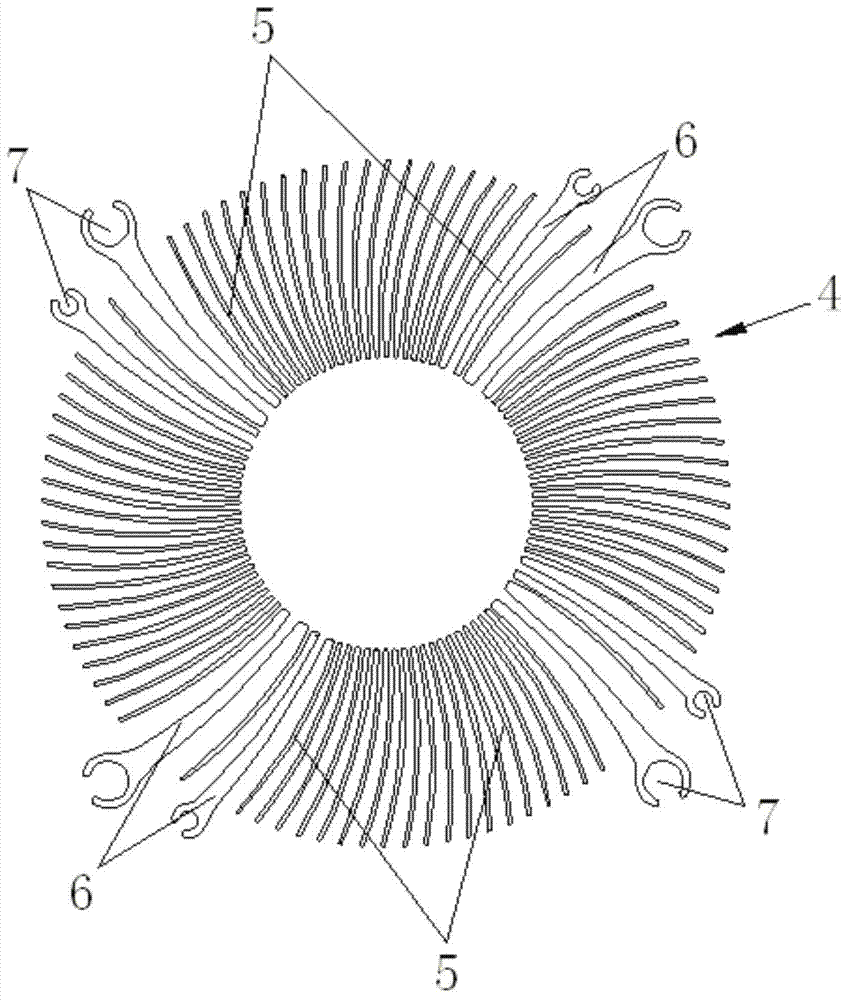

Processing technique and device of milled rice with embryo

ActiveCN102909110ASimple structureUniform feedingGrain huskingGrain polishingBranBiomedical engineering

Provided are a processing technique and device of milled rice with embryo. The processing device of milled rice with embryo comprises a feeding device, a rice hulling system, a rice milling device, a discharging device, a bran discharging device, a power device, a transmission device and an electric control device. The feeding device, the rice hulling system, the rice milling device and the discharging device are sequentially connected. The rice milling device is further connected with the bran discharging device. The power device is connected with the feeding device, the rice hulling system and the rice milling device through the transmission device. The rice hulling system comprises a first rice hulling device and a second rice hulling device. The processing device is simple in structure, the processing technique is high in germ-remaining rate, environment is protected, and energy consumption is low.

Owner:长沙锐思粮食机械有限公司

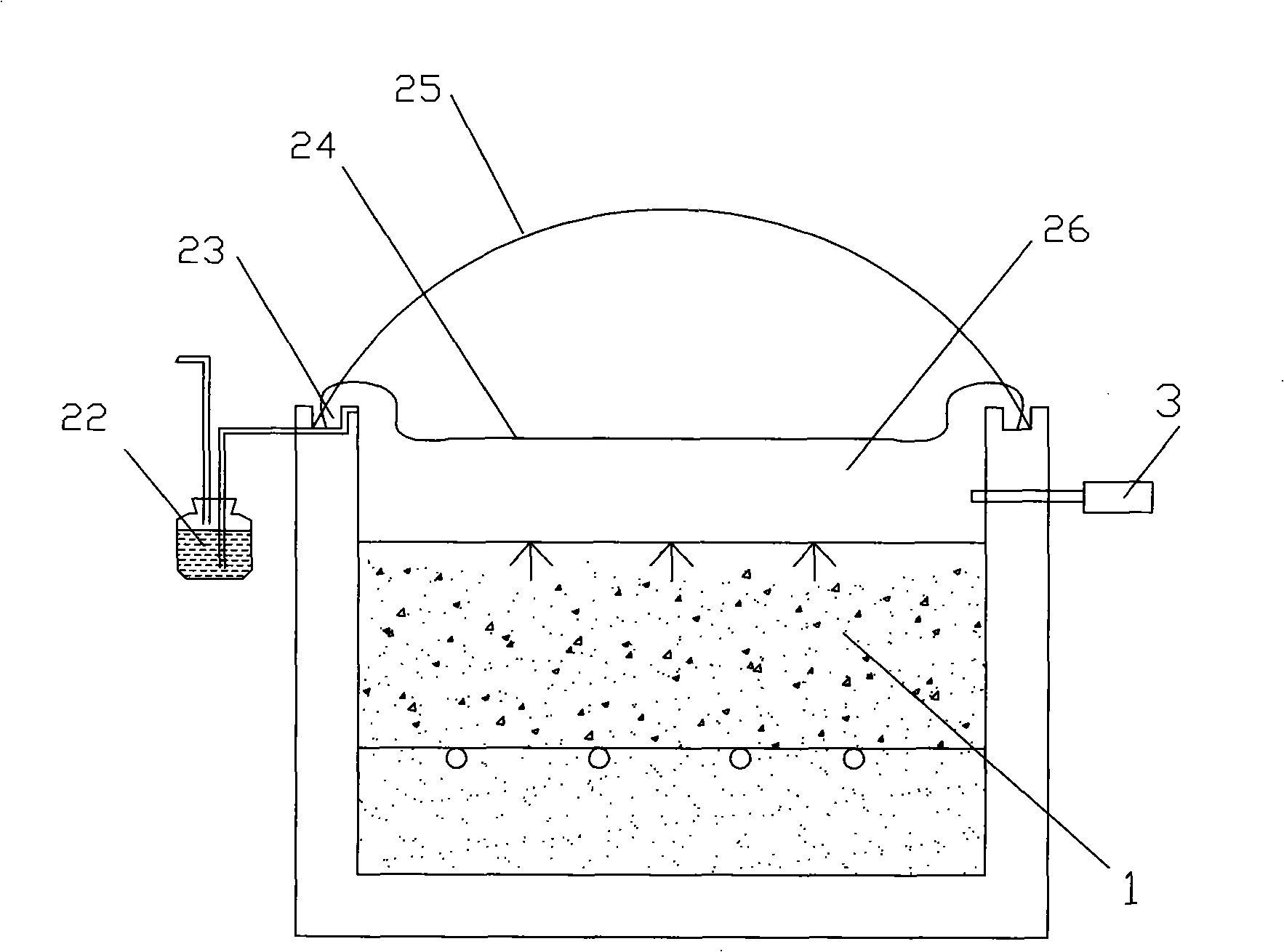

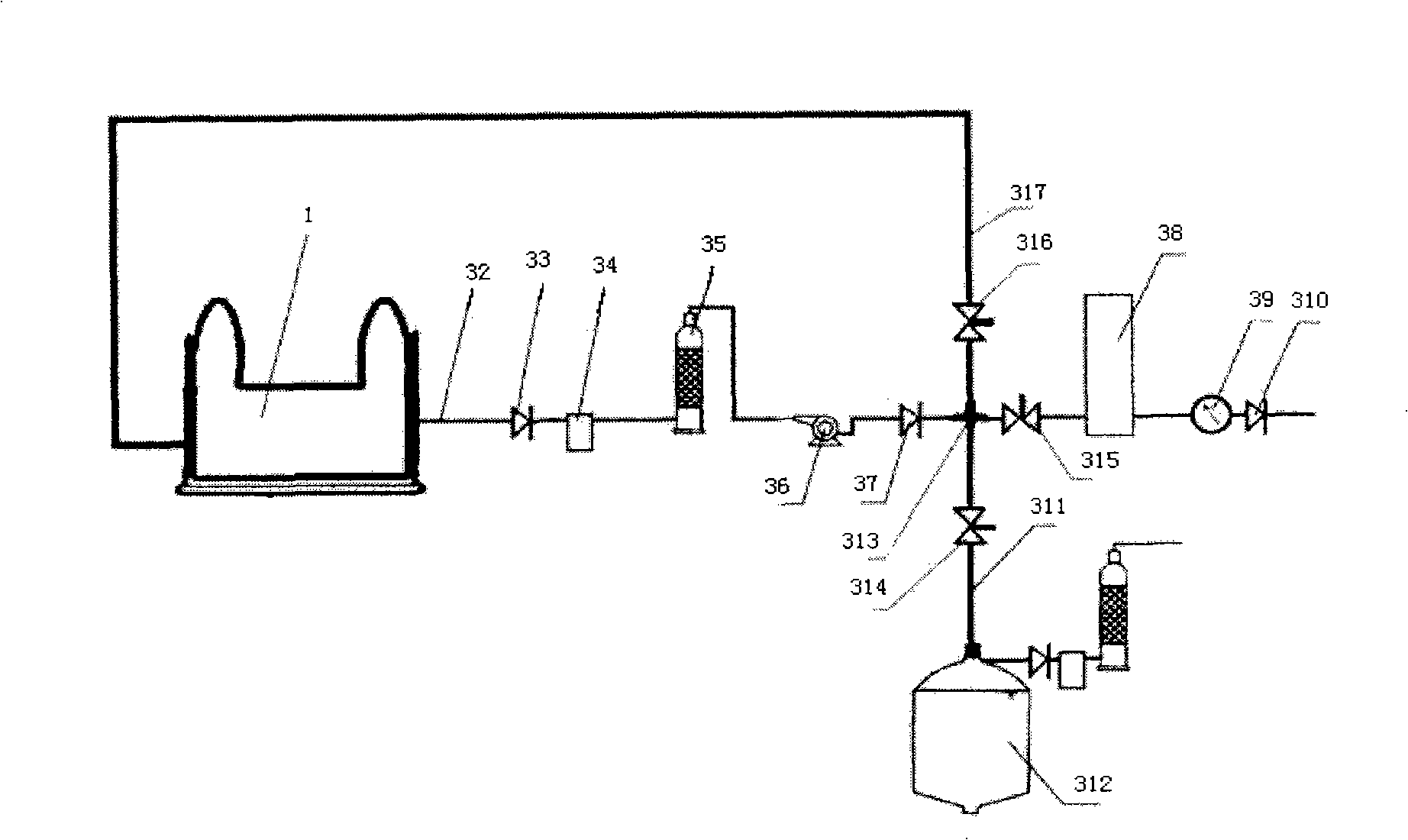

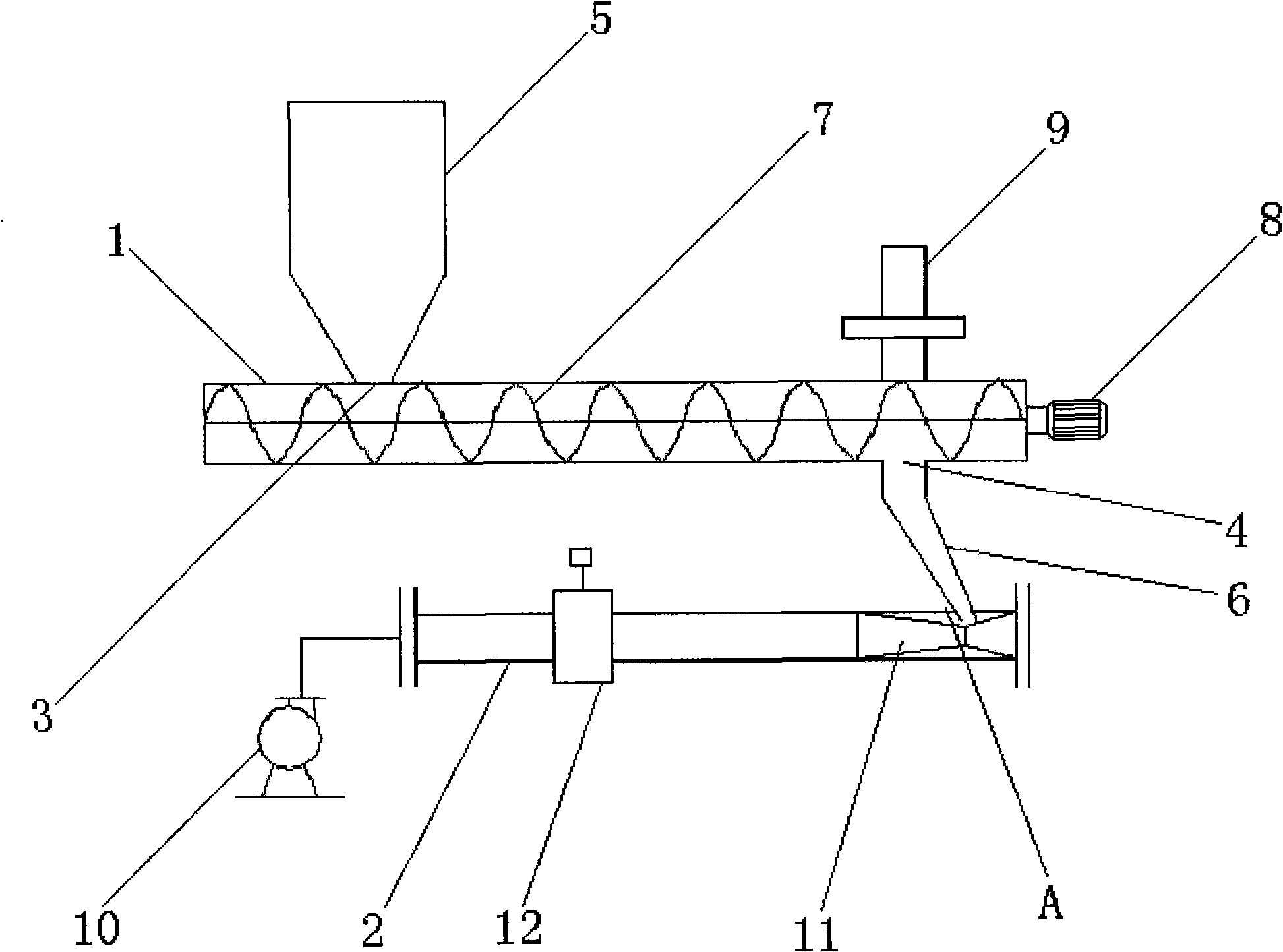

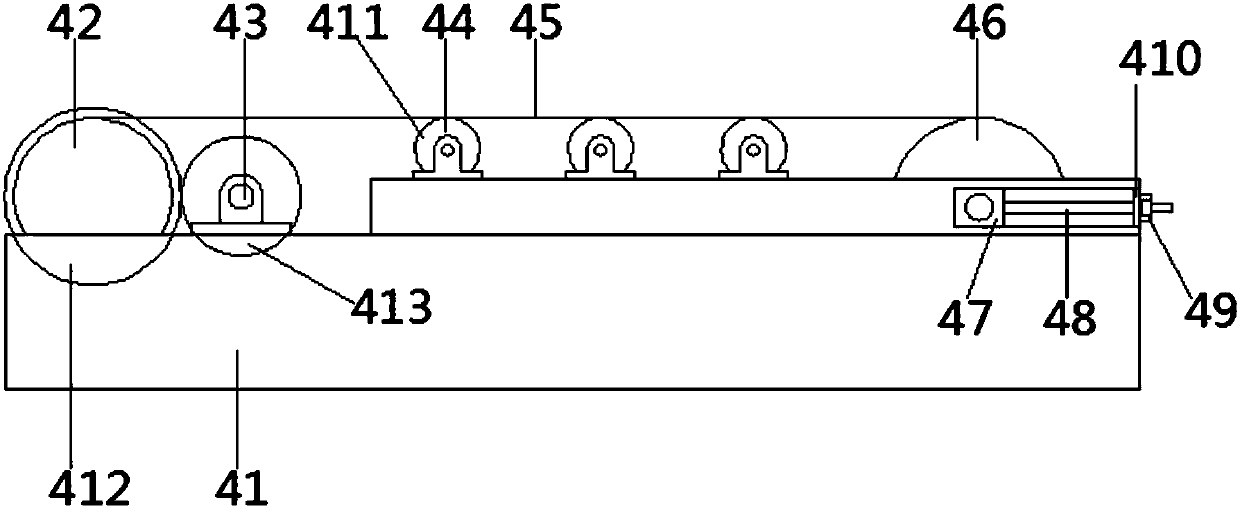

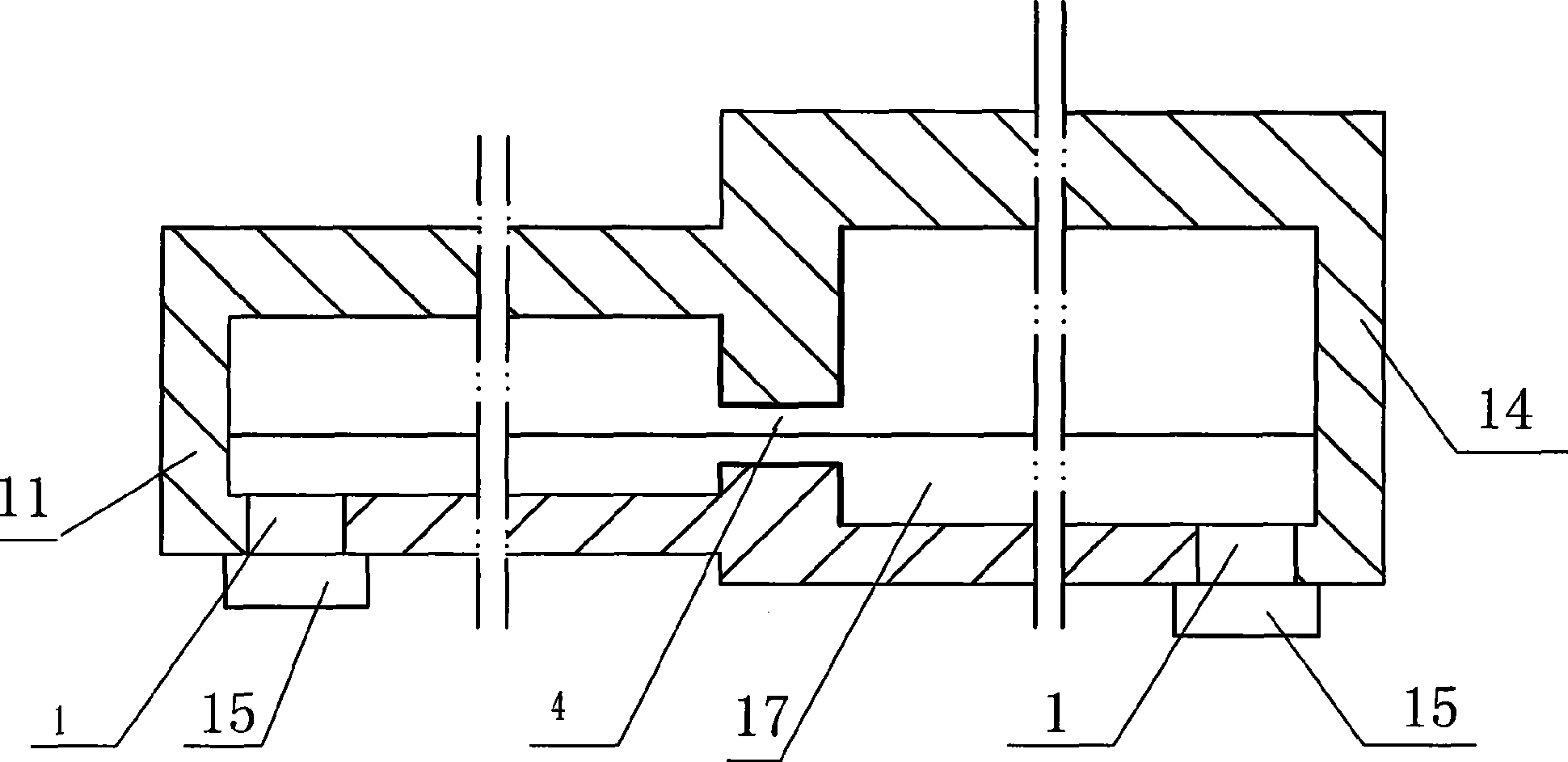

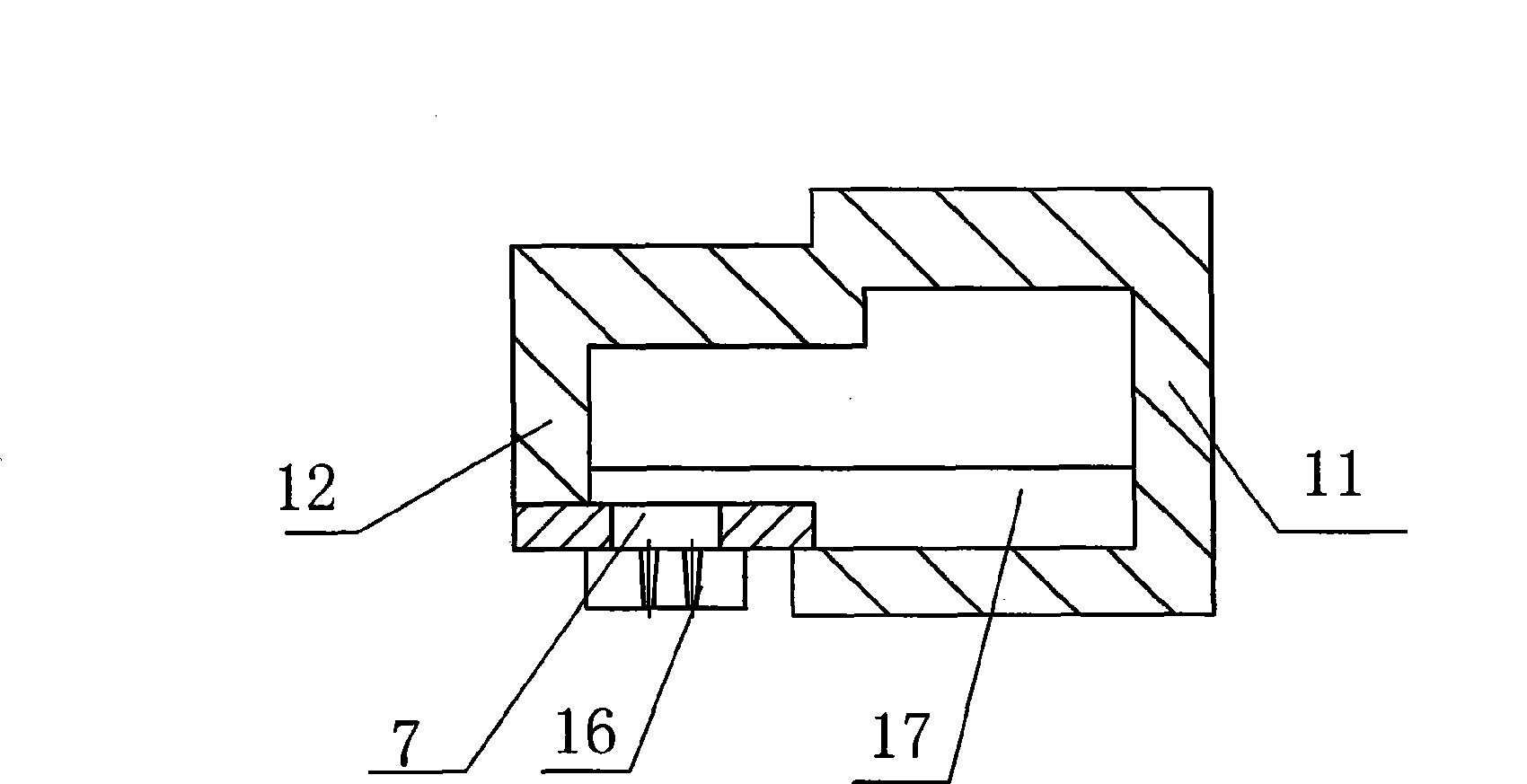

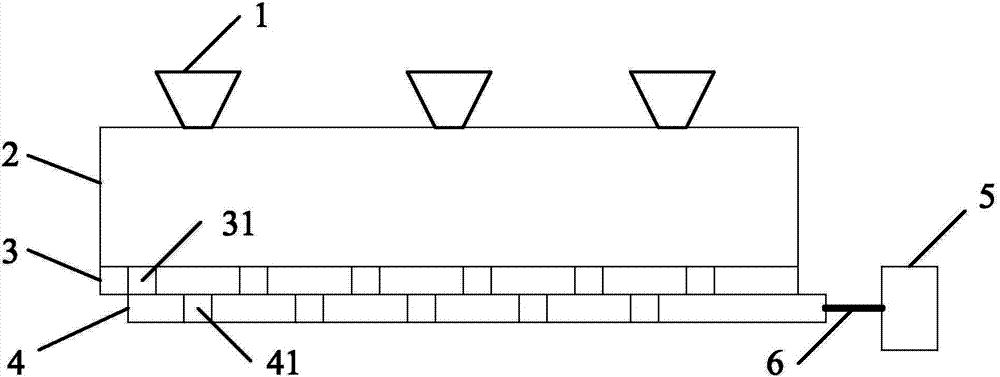

Pulse-free coal powder supply device

The invention relates to a pulse-free coal powder supply device which is characterized by comprising a delivery pipe and an air pipe arranged below the delivery pipe; the two ends of the delivery pipe are sealed, a feeding opening is arranged at the upper side adjacent to one end of the delivery pipe, and a discharging opening is arranged at the lower side adjacent to the other end of the delivery pipe; the feeding opening is radially connected with a storage silo and the discharging opening is radially connected with a blanking pipe; the upper half part of the blanking pipe is vertical and the lower half part of the blanking pipe is inclined towards the outer side of the delivery pipe; a feed screw is arranged in the delivery pipe, and one end of the feed screw, adjacent to the discharging opening, is connected with the output end of a motor; a voltage stabilizer is radially connected on the delivery pipe and adjacent to one end of the motor; the blanking pipe is radially connected at one end of the air pipe and an air blower is connected at the other port of the air pipe; the lower half part of the blanking pipe is obliquely connected in the air pipe and an included angle is formed between the lower half part of the blanking pipe and the air pipe; a Venturi structure is arranged at the joint between the air pipe and the blanking pipe; and a regulating valve is also arranged on the air pipe. The invention can effectively avoid the phenomenon that the coal powder is accumulated and blocked and is not delivered smoothly in the coal delivery pipeline, has the advantages of rapid, uniform and pulse-free continuous coal powder feeding and is suitable for the small and medium-sized industrial coal powder boiler systems.

Owner:CHINA COAL RES INST

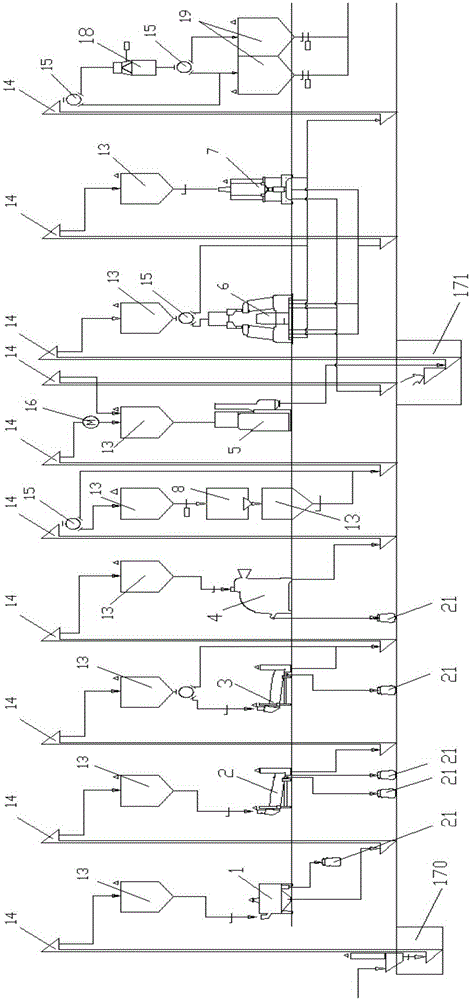

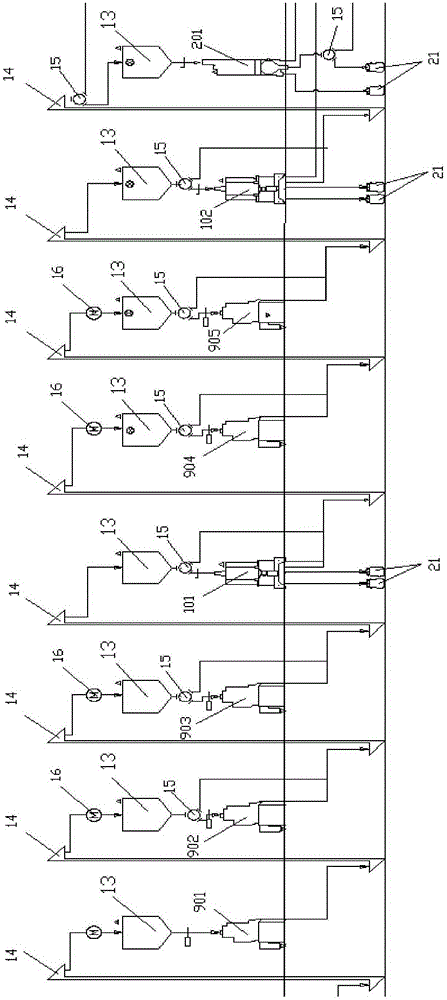

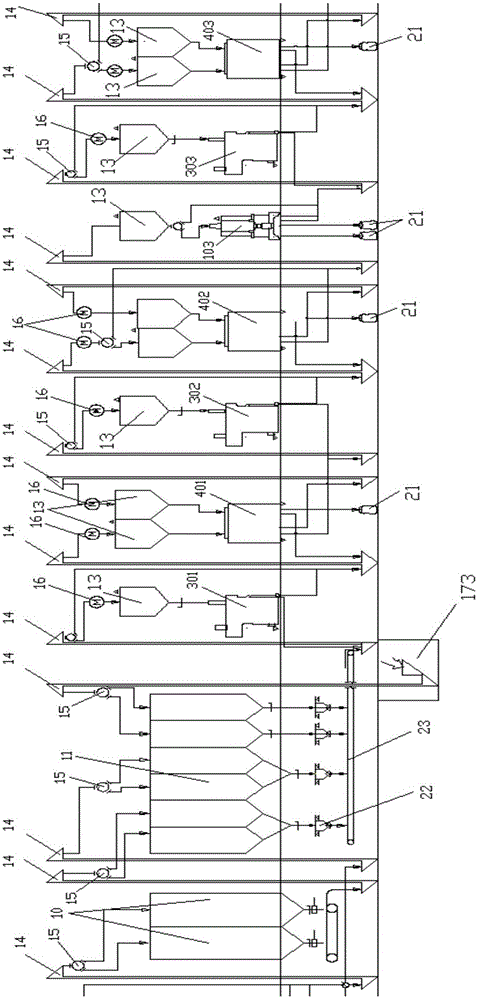

Long-shaped rice processing method and system

The invention discloses a long-shaped rice processing method and system. The processing method comprises the steps of cleaning, stone removal, husking and rice husk separation, roughness improvement, multistage rice milling, multistage polishing, multistage color sorting and the like; in addition, the steps including buffering through a buffering bin and magnetic separation are conducted before the main steps. By means of the long-shaped rice processing method and system, the appearance, color and taste of rice obtained through processing are all improved greatly, the product quality is improved, the broken rice rate is reduced, and the milled rice rate is increased.

Owner:湖北天斌机械有限公司

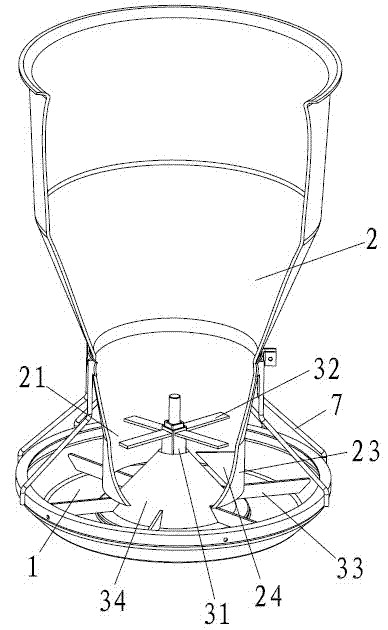

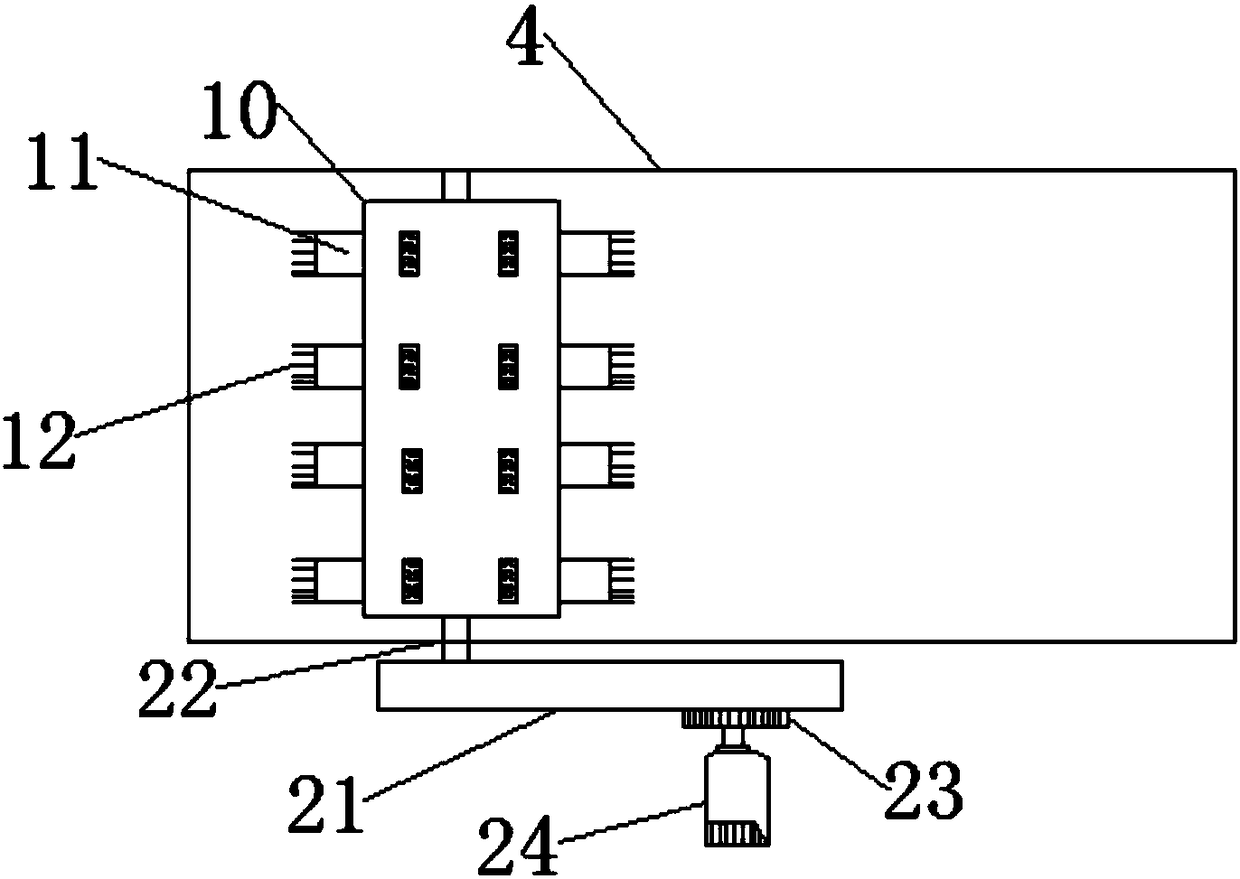

A multi-channel fruit and vegetable sorting machine with uniform feeding and single row sorting device

A uniform feeding and single row sorting device for a multi-channel fruit and vegetable sorting machine, at least including a brush, a feeding conveying device, an anti-clogging push rod and a fruit and vegetable single row sorting device; the brush is installed above the feeding conveying device; the feeding conveying device It includes at least a speed-regulating motor and two or more feeding conveyor belts; the fruit and vegetable single-row sorting device is installed horizontally below the feeding conveyor device and is vertical to it, and each fruit and vegetable single-row sorting device is installed at the same height and equidistance, and its number is the same as The feeding conveyor belts are the same, and the fruit and vegetable single row sorting device at least includes a left conveyor belt and a right conveyor belt arranged in a V shape with different speeds; feed end. The invention has a compact structure, realizes uniform feeding of fruits and vegetables in the multi-channel sorting machine and rapid single-row sorting, can effectively prevent fruits and vegetables from being blocked at the feeding end of the single-row sorting device, and improves the efficiency of fruit and vegetable sorting.

Owner:NORTHWEST A & F UNIV

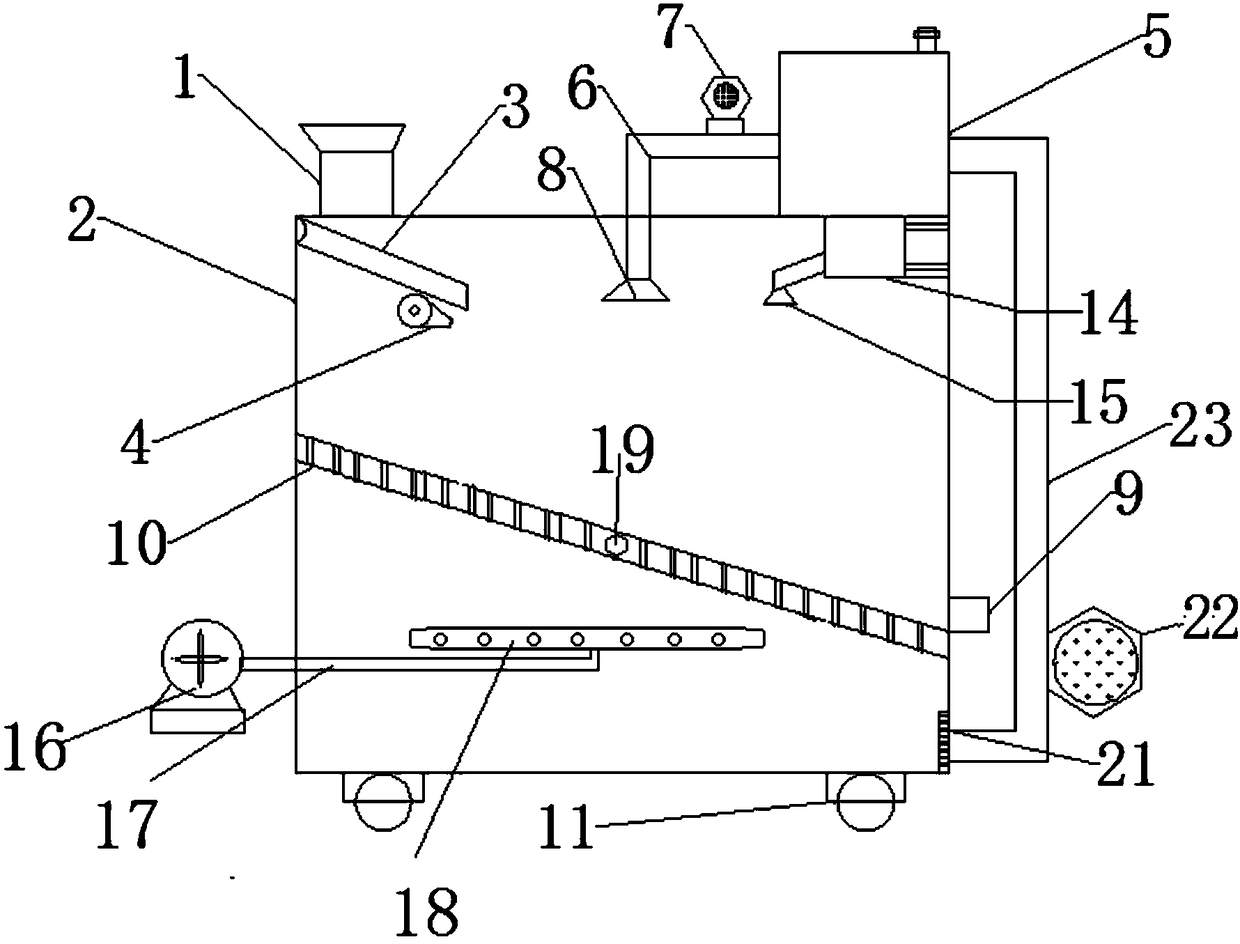

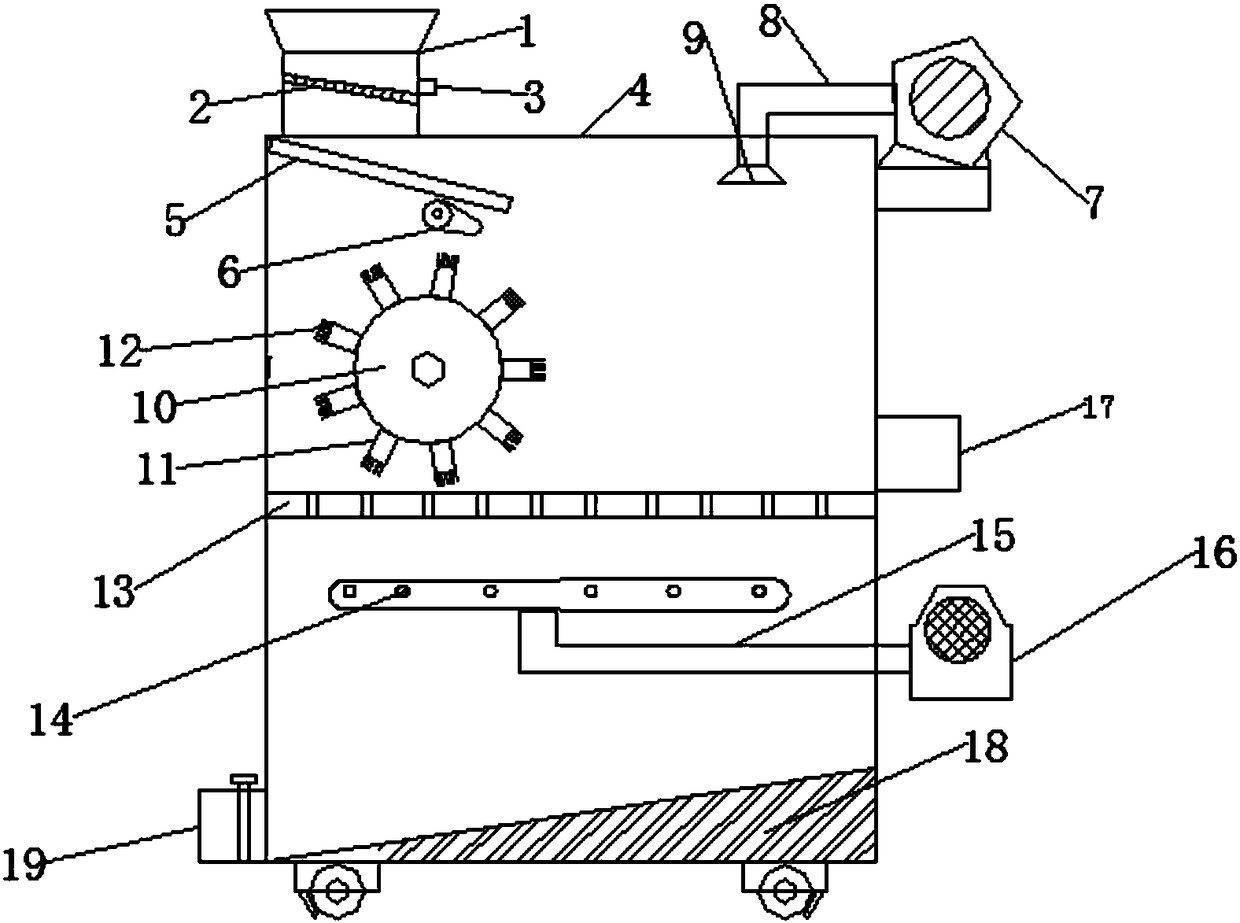

Garbage treatment apparatus for environmental protection engineering

InactiveCN107755038AIncrease workloadIncrease the feeding speedNon-rotating vibration suppressionGrain treatmentsEnvironmental resistanceDrive shaft

The invention discloses a garbage treatment apparatus for environmental protection engineering. The garbage treatment apparatus comprises a machine body, wherein the upper side of the machine body isprovided with a material inlet, the water inlet is connected with a material inlet pipe, the left side of the material inlet pipe is connected with a belt loading apparatus, and the belt loading apparatus comprises frame bodies as well as a driving roller, a driving shaft, three supporting rollers and a tension roller which are arranged between the frame bodies by virtue of a bearing seat frame from left to right. By adopting the belt loading apparatus to automatically load materials, the working efficiency is increased; moreover, the automatic discharging can be realized; by arranging an upper crushing mechanism and a lower crushing mechanism, and the crushing effect is ensured, the crushing efficiency is increased; water circularly flowing inside a rotating shaft can bring away the heatgenerated by the friction, the cooling can be performed without stopping, the crushing machine can work continuously, the excessive feeding can be prevented from damaging the rolling rollers, and theservice life is prolonged; the vibration of the machine body can be greatly reduced, and the stability is improved.

Owner:邓雨佳

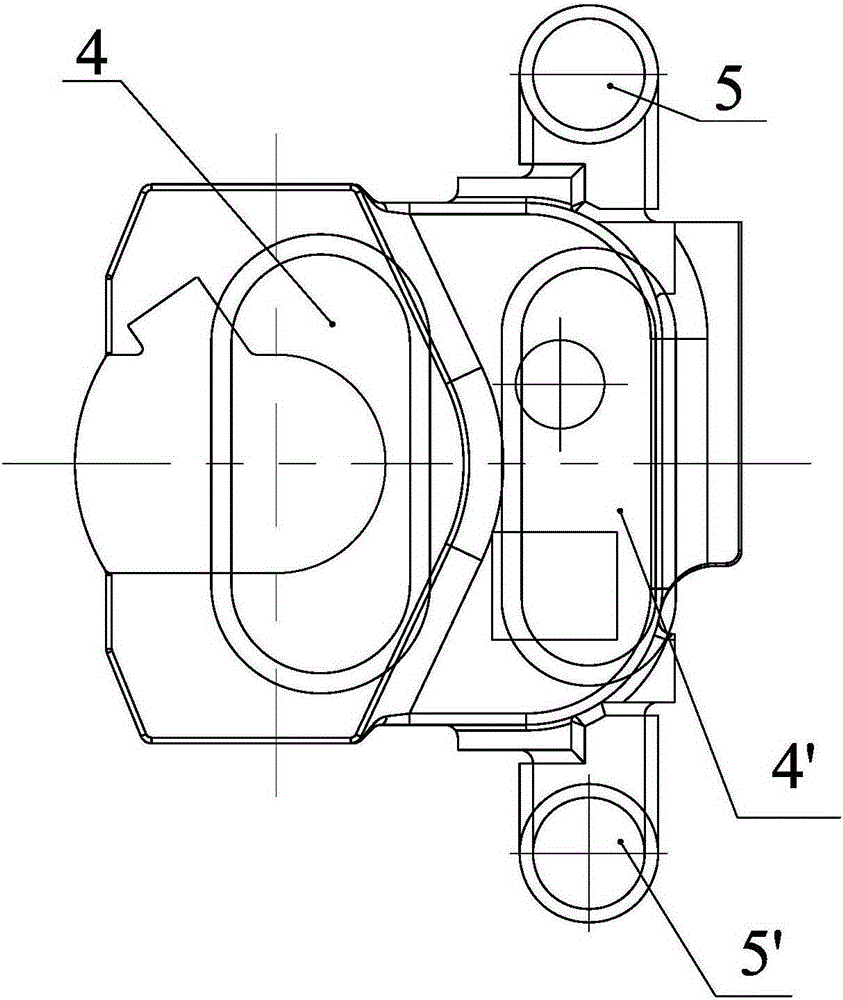

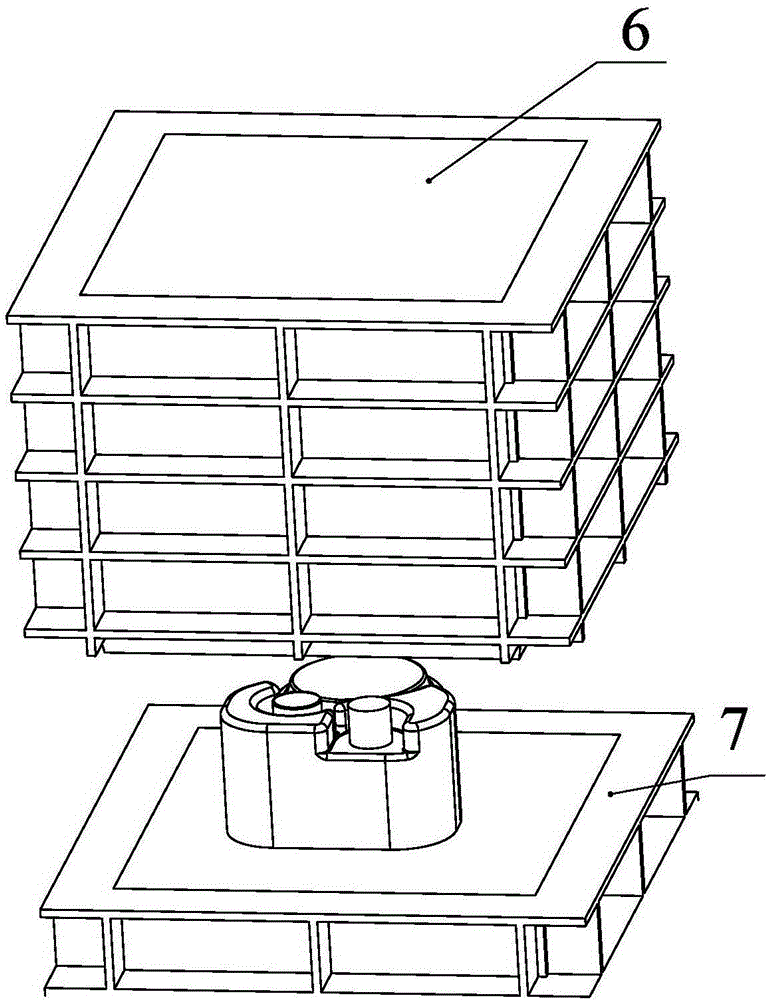

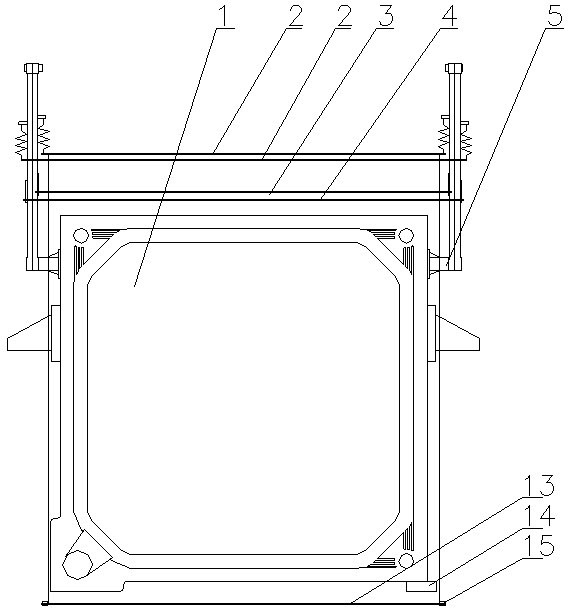

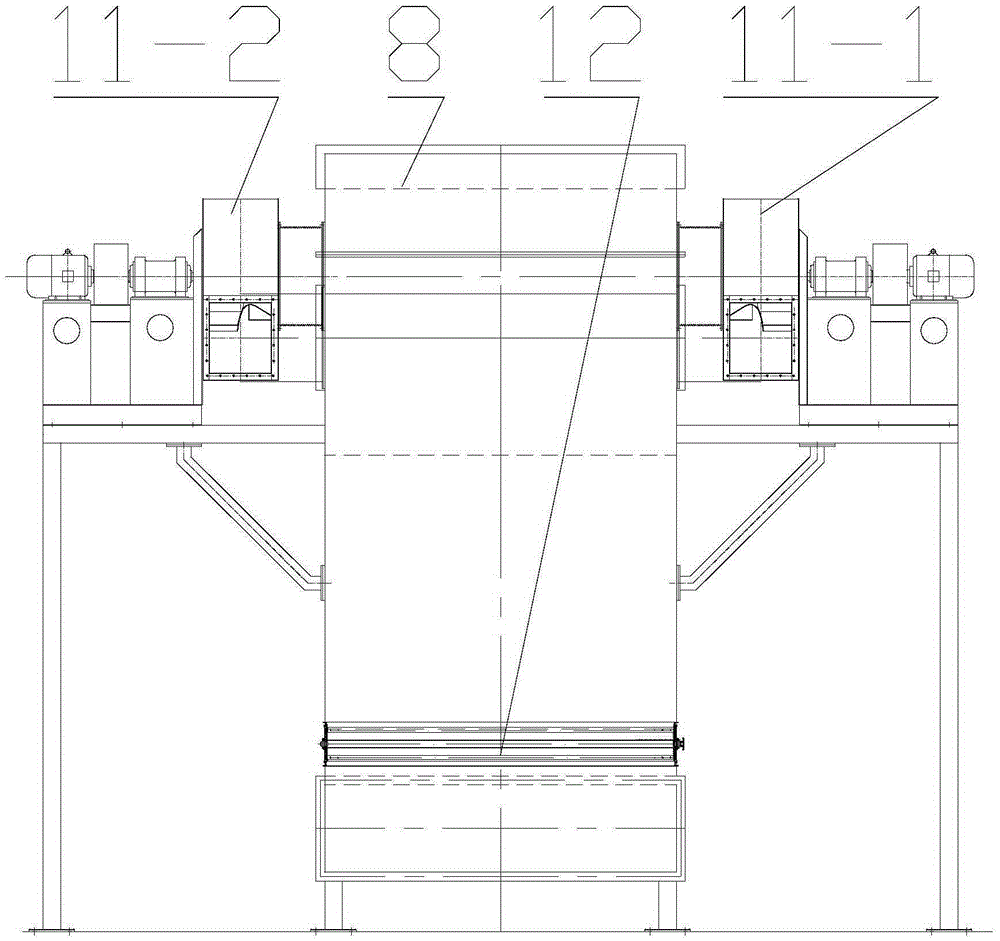

All crank unloading device for press filter

The invention relates to an all crank unloading device for press filter. At present, there is no all crank unloading device for press filter with reasonable structural design and reliable performance. The device comprises plural all crank unloading mechanisms. The all crank unloading mechanism includes two lower-corner feeding filter plates, two outer crank arms, two inner crank arms, two long cloth supporting swing plates, two short cloth supporting swing plates, a long cloth supporting roll, a short cloth supporting roll, two crank arm connection shafts, two pieces of lower-corner feeding filter cloth, two filter cloth sinker rods, two balance blocks, a sinker rod locking unit, and a suspension vibrating mechanism. One outer crank arm and one inner crank arm on the same side of the lower-corner feeding filter plate are connected via one crank arm connection shaft, the two filter cloth sinker rods are connected at the lower parts of the two pieces of lower-corner feeding filter cloth in a penetrating manner, and adjacent two filter cloth sinker rods in adjacent two all crank unloading mechanisms are fixed through the sinker rod locking unit. The device provided by the invention has unloading assisting effects on both upper and lower half parts of a filter cake during crank unloading.

Owner:ZHEJIANG HUAZHANG TECH

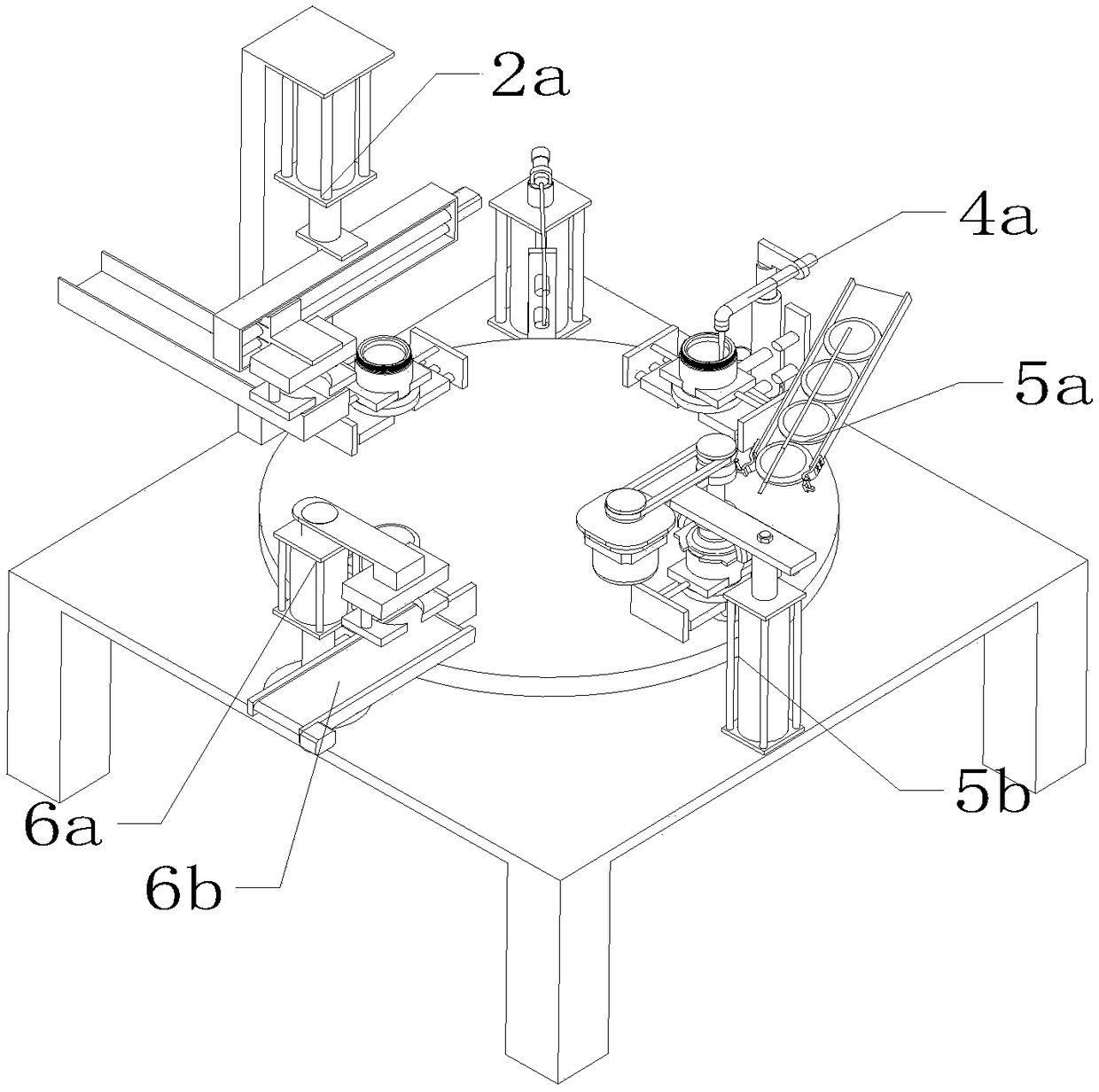

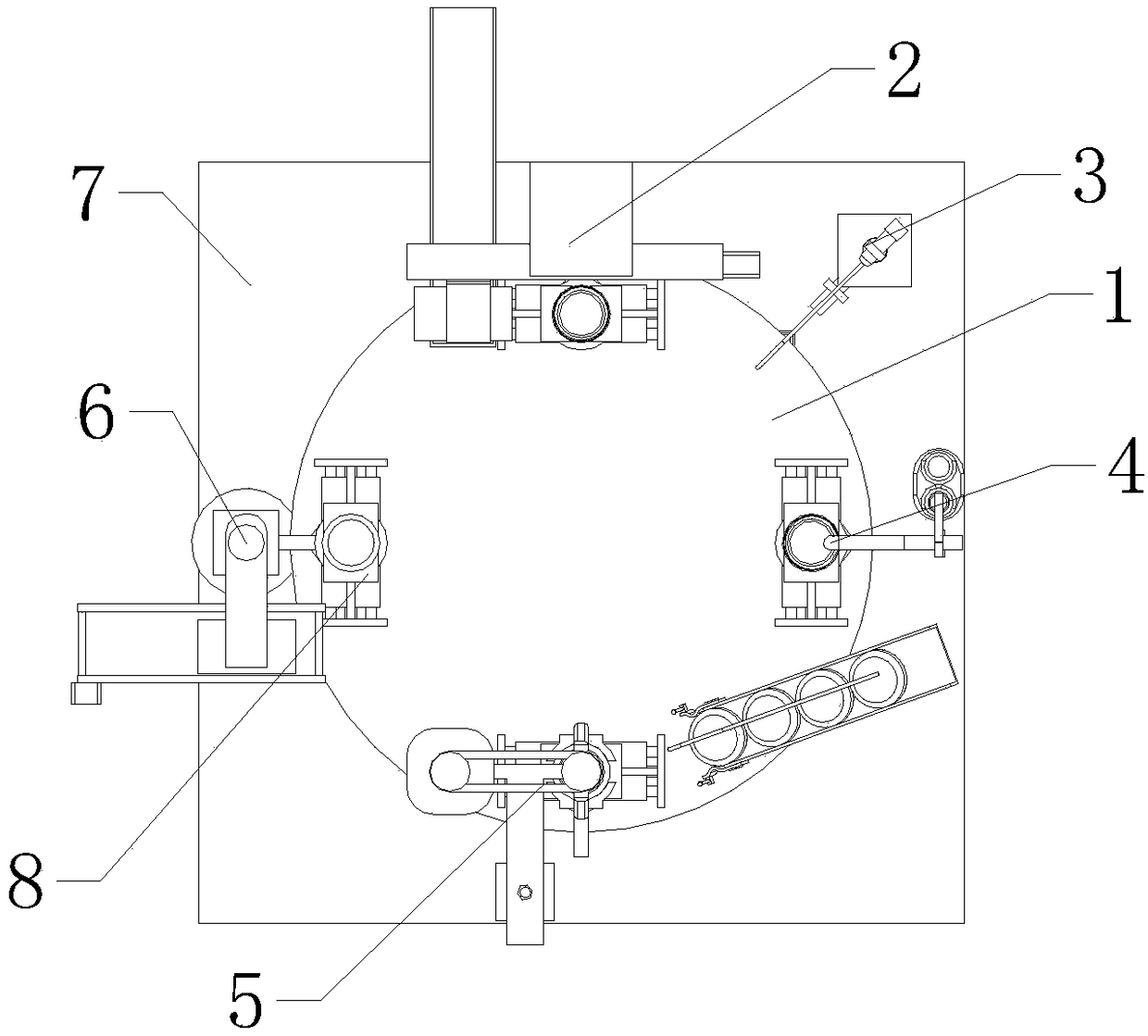

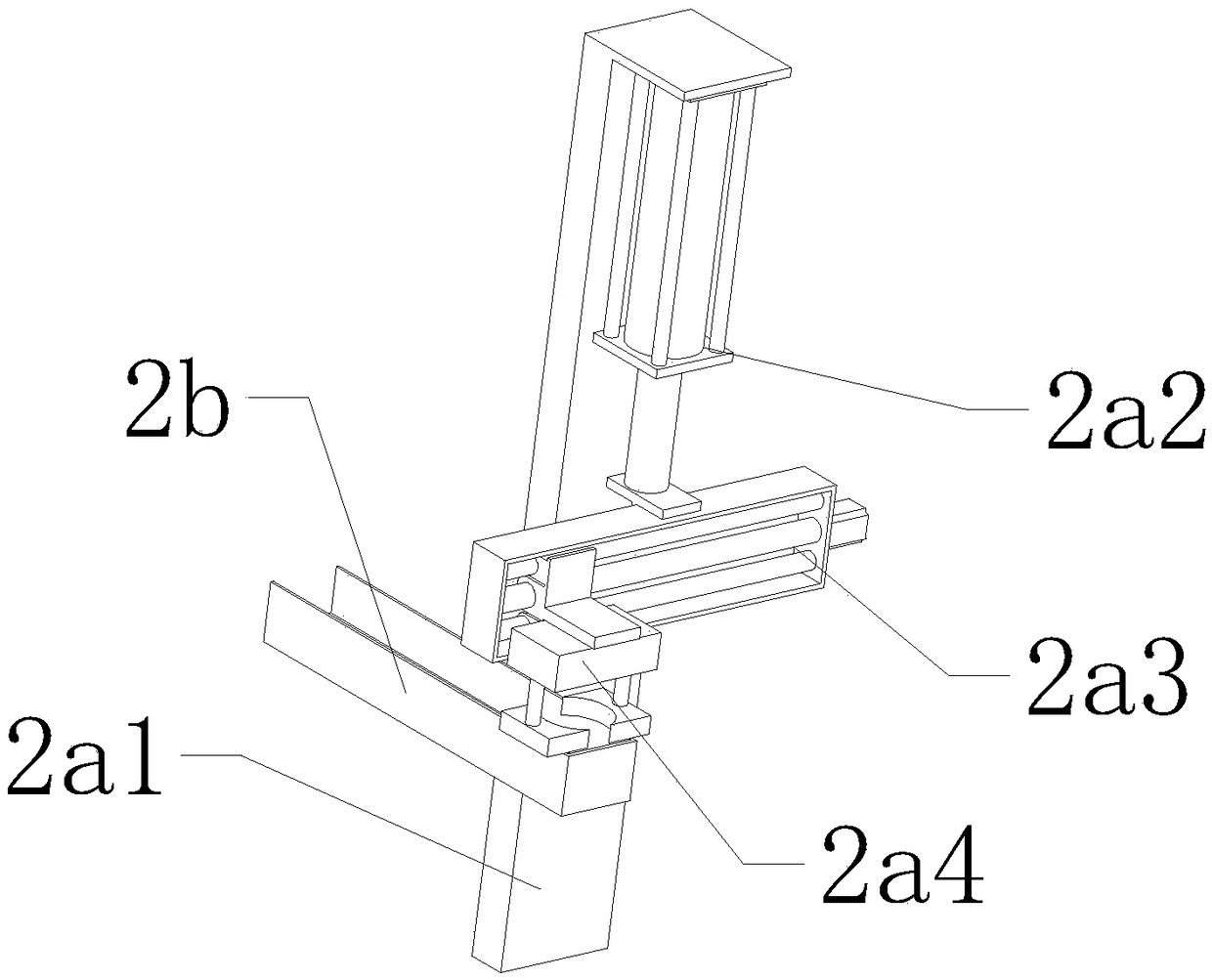

Honey filling device

InactiveCN108862169AEnsure hygieneThorough internal cleaningBottle-handling machinesLiquid bottlingEngineeringBottle cap

The invention relates to the field of honey filling, in particular to a honey filling device. The honey filling device comprises a base, a rotating workbench, a bottle body feeding station, a dust removal station, a honey filling station, a bottle cap feeding station and a discharging station, the rotating workbench comprises a workbench rotating motor, a dividing plate and a rotating disc, the dividing plate is fixedly arranged on the base, the dividing plate is connected with the output end of the workbench rotating motor, the rotating disc is horizontally arranged at the output end of the dividing plate, the rotating disc is further provided with four workpiece clamps which are used for filling, the bottle body feeding station, the dust removal station, the honey filling station, the bottle cap feeding station and the discharging station are sequentially arranged in the clockwise direction of the periphery of the rotating disc, the bottle body feeding station comprises a feeding mechanical arm, the honey filling station comprises a feeding assembly, the bottle cap feeding station comprises a cap screwing assembly used for screwing a bottle cap and a bottle body, and the discharging station comprises a discharging mechanical arm. And therefore, automatic filling is achieved.

Owner:郴州市蜂尚蜂业有限公司

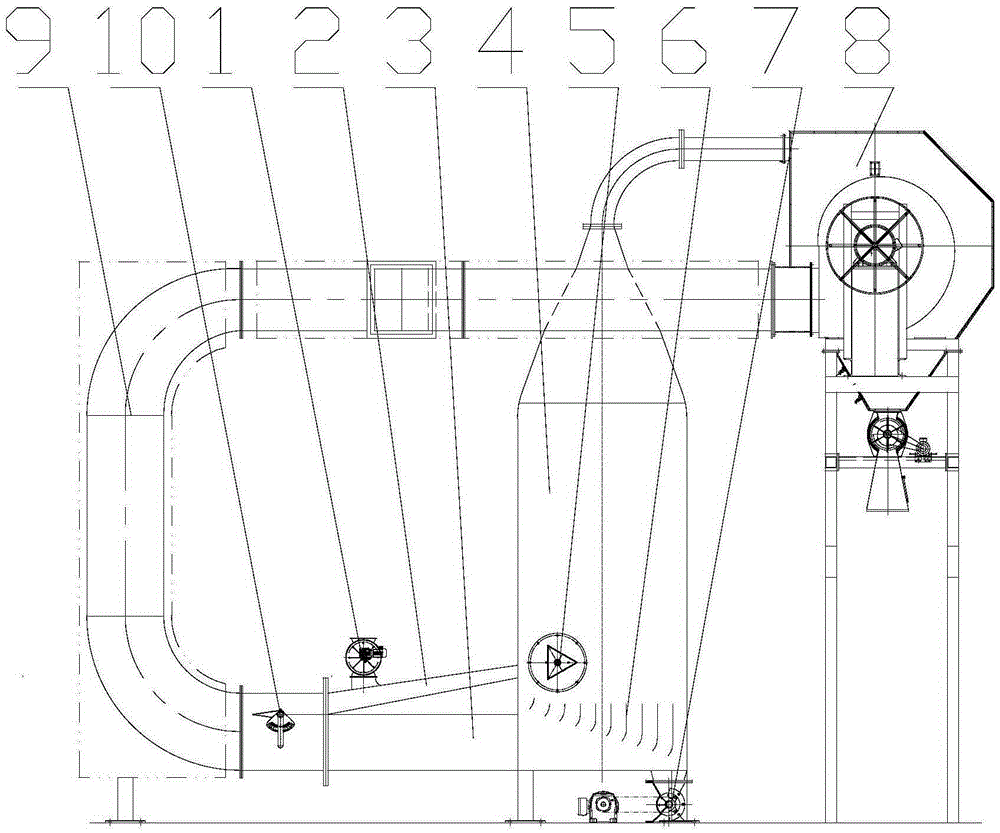

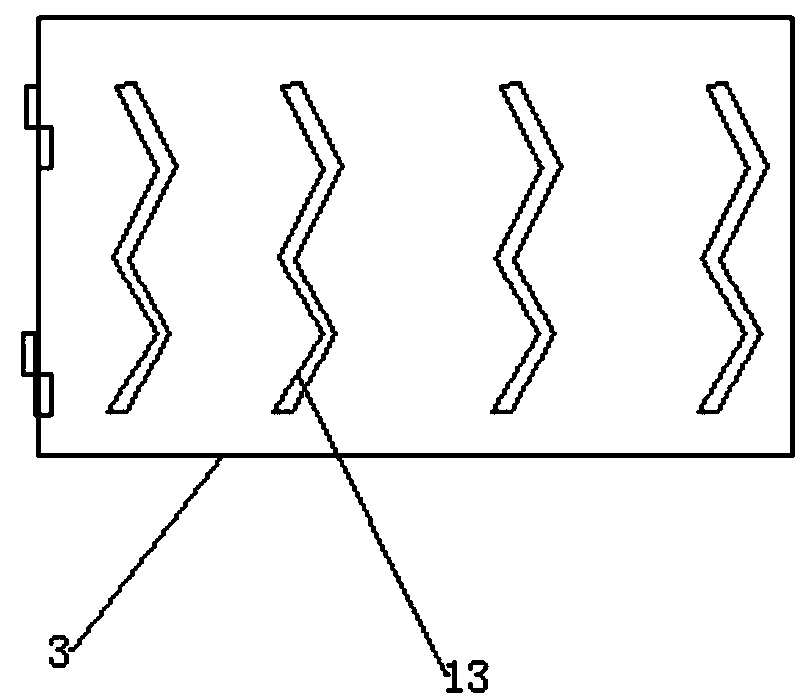

Method and device for efficiently winnowing tobacco shreds

ActiveCN105396782AAchieve uniform distributionGood dispersionGas current separationEngineeringEqualization

The invention provides a method and device for efficiently winnowing tobacco shreds. Tobacco materials are fed into a winnowing chamber through conveying air, and the tobacco materials are loosened by a material equalization roll in the winnowing chamber and evenly distributed in the winnowing chamber; winnowing air is fed into the winnowing chamber, suspension winnowing is carried out on the tobacco materials in the winnowing chamber, and sundries are separated out; and meanwhile, the caked tobacco materials are suspended on air equalization plates in the winnowing chamber and are repeatedly jolted to be loosened under the action of upward blown winnowing air and gravity. A multilevel winnowing scheme is further designed, the amount of the materials subjected to secondary winnowing is greatly reduced, and therefore the purity of the tobacco shreds is improved, and energy consumption for winnowing is effectively reduced. According to the method and device, the winnowing efficiency is high, the purity of the tobacco shreds is high, and crushing is greatly reduced.

Owner:ZHISI HLDG GRP

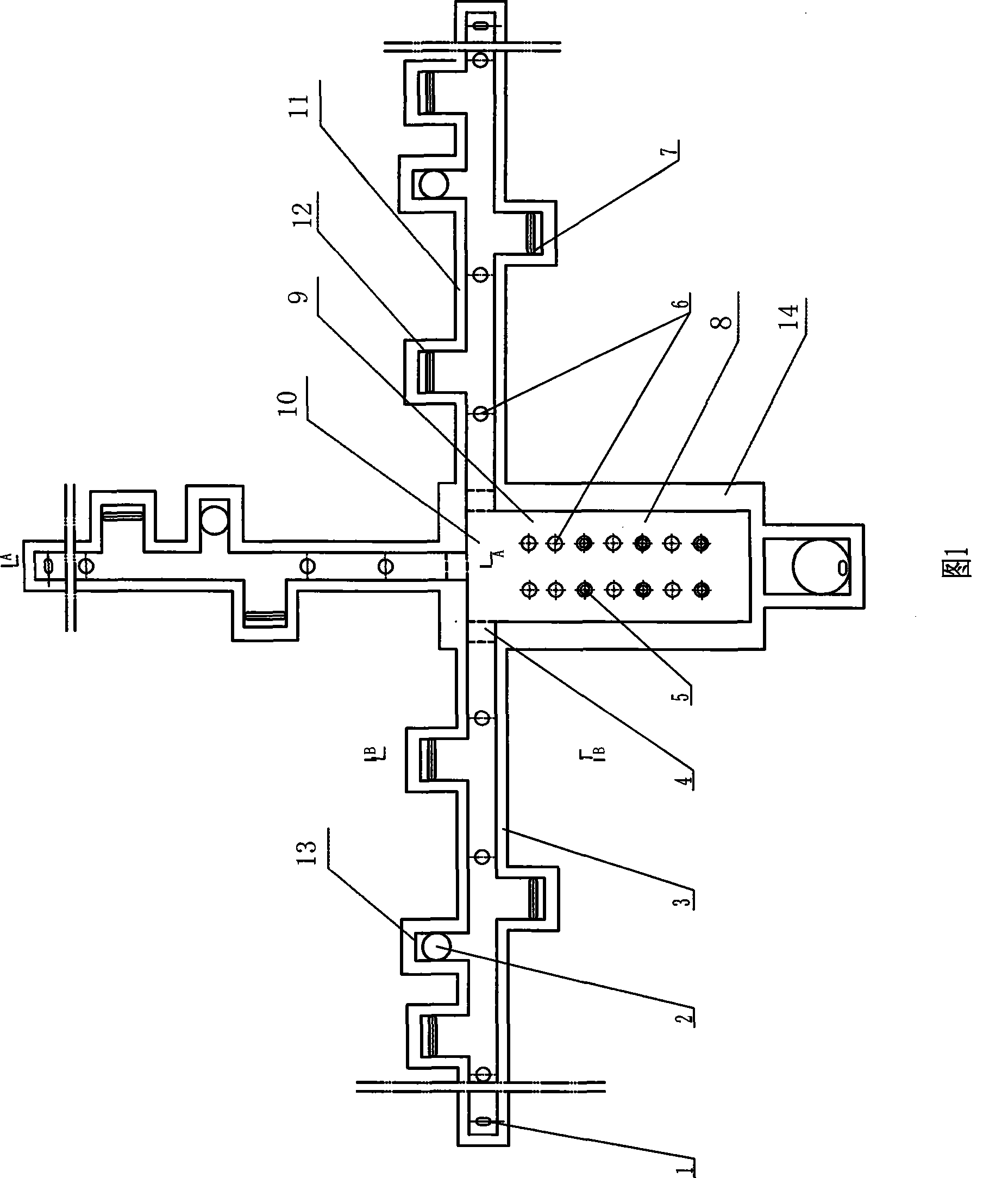

Tank furnace for producing basalt continuous fiber

ActiveCN101397182AHigh melting temperatureGuaranteed temperatureForehearthsTank furnacesMelting tankFiber

The invention relates to a tank furnace for producing basalt continuous filament and pertains to the technical field of novel inorganic non-metallic material processing equipment, the main characteristics are that the furnace body consists of a melting tank and material channels, the melting tank and the material channels are connected by non-submerged dog-holes, the melting tank is divided into a melting area and a homogenization area, a burner is arranged at the top of the furnace vertically, the burner guns of melting area and the feeding pipes are arranged in intervals, and the strong melting area of even feeding and even heating is formed. The material channels are arranged in three directions in the homogenization area of the melting tank, burner guns are arranged in the material channel in sections, the temperature of the fused mass in the material channels is guaranteed, more than 12 wiredrawing shaping areas are evenly arranged in each material channel so as to supply basalt melt mass for the wiredrawing bushing well, emptying devices are arranged at the tail part of the melting tank and the tail parts of all material channels, during the operation, the operation of discharging the meltwater can be carried out when impurities are stored in the meltwater for a long time or the varieties of raw materials are changed. The invention is in favor of improving the quality and industrialized production of the basalt continuous filament.

Owner:江苏天龙玄武岩连续纤维股份有限公司

Preparation method of anesthesia stem and plastic composite material

ActiveCN101081934AReduce extrusion resistanceImprove mobilityPlastic compoundingWood-plastic composite

The present invention discloses preparation process of composite material of hemp stalk and plastic. The composite material is prepared through mixing hemp stalk powder and mineral powder to obtain composite hemp stalk powder, extruding and pelletizing to obtain composite hemp stalk pellet, mixing with plastic, and pelletizing or extruding into product. The composite material is environment friendly, reusable and low in cost.

Owner:凌彩百川(新兴)科技有限公司

Gravel flushing device for constructional engineering

InactiveCN108687020AImprove cleanlinessUniform feedingSievingScreeningWater filterArchitectural engineering

The invention discloses a gravel flushing device for constructional engineering. The gravel flushing device comprises a sand inlet pipe, a screening box, a water spray tank, a water filter film plate,a table plate, a vibration screening basket, a rotating barrel and a water outlet pipe. The sand inlet pipe is arranged at the top end of the screening box. A grid is obliquely arranged in the sand inlet pipe. One side of a feeding plate is hinged to the inner wall of the top end of the screening box. The table plate is arranged in the screening box. Sand sliding grooves are formed in the side wall of the table plate. The water spray tank is mounted at the top end of the screening box. The bottom end of the water spray tank is connected with a spray head through a water passing pipe. The spray head is arranged in the top end of the screening box. Fixed blocks are arranged on the inner wall of the screening box. The upper surface of each fixed block is fixedly connected with one end of a spring, and the other ends of the springs are in contact connection with the bottom face of the vibration screening basket. The rotating barrel is arranged above the vibration screening basket. A semicircular gear is connected with an output shaft of a rotary motor. The water filter film plate is obliquely arranged in the screening box. According to the gravel flushing device, gravel flushing is facilitated, resources are saved, waste is avoided, the structure is simple, use is convenient, and popularization is facilitated.

Owner:北京艺轩吉装饰工程有限公司

Catalyst component for ethylene polymerization and catalyst thereof

The invention provides a solid catalyst component for ethylene polymerization or copolymerization, which does not adopt silica gel and the like as carriers, but uses a solid containing magnesium and titanium as the carrier component and loads a certain quantity of a titanium compound, an electron donor and an activator, and the catalyst component has the advantages of relatively narrow particle size distribution, high activity of the catalyst and obtainment of a polymer with low content of fine powder, thereby being applicable to slurry polymerization or vapor phase polymerization of ethylene, in particular to the polymerization process of a vapor phase fluidized bed of the ethylene which feeds the catalyst in the slurry form.

Owner:CHINA PETROLEUM & CHEM CORP +1

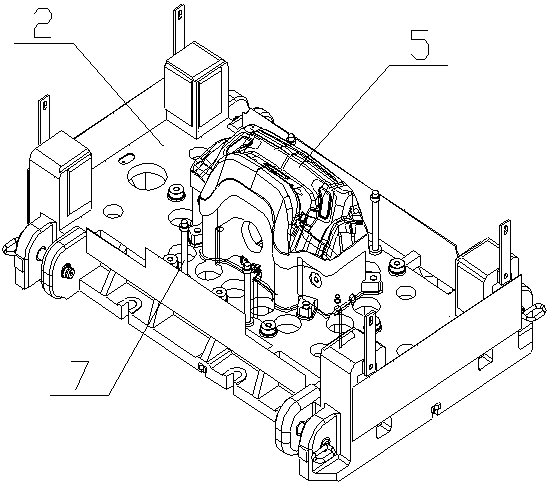

Drawing forming die for rear section of lateral tail board of rear end of sports utility vehicle (SUV)

ActiveCN103406455AImprove ductilityAvoid crackingShaping toolsMetal-working feeding devicesEngineeringSport utility vehicle

The invention discloses a drawing forming die for the rear section of a lateral tail board of the rear end of a SUV. The drawing forming die comprises an upper die base, a lower die base, an upper die, a lower die and a blank holder and further comprises two upper blades and two lower blades. Cutting edge sides of the lower blades are in horizontal L shapes, and cutting edge sides of the upper blades are in shapes matched with the cutting edge sides of the lower blades. A blade groove matched with the lower blades is arranged at the positions close to two ends on the feeding side of the blank holder respectively, the ends of the blade grooves penetrate the ends of the blank holder, the two lower blades are mounted in the two blade grooves correspondingly, and cutting edges of the lower blades are disposed on the outside of the blank holder. The upper blades are mounted on the upper die, and positions of the upper blades are corresponding to the positions of the lower blades. Two material board support frames are further arranged on the feeding side of the blank holder and comprise support rods arranged horizontally, and the support rods are connected with one side of a blank holder frame, which is close to the feeding side of the blank holder, through vertical rods and connectors. By means of the drawing forming die, the drawing forming quality can be guaranteed, and the machining efficiency can be improved.

Owner:贵州至信实业有限公司

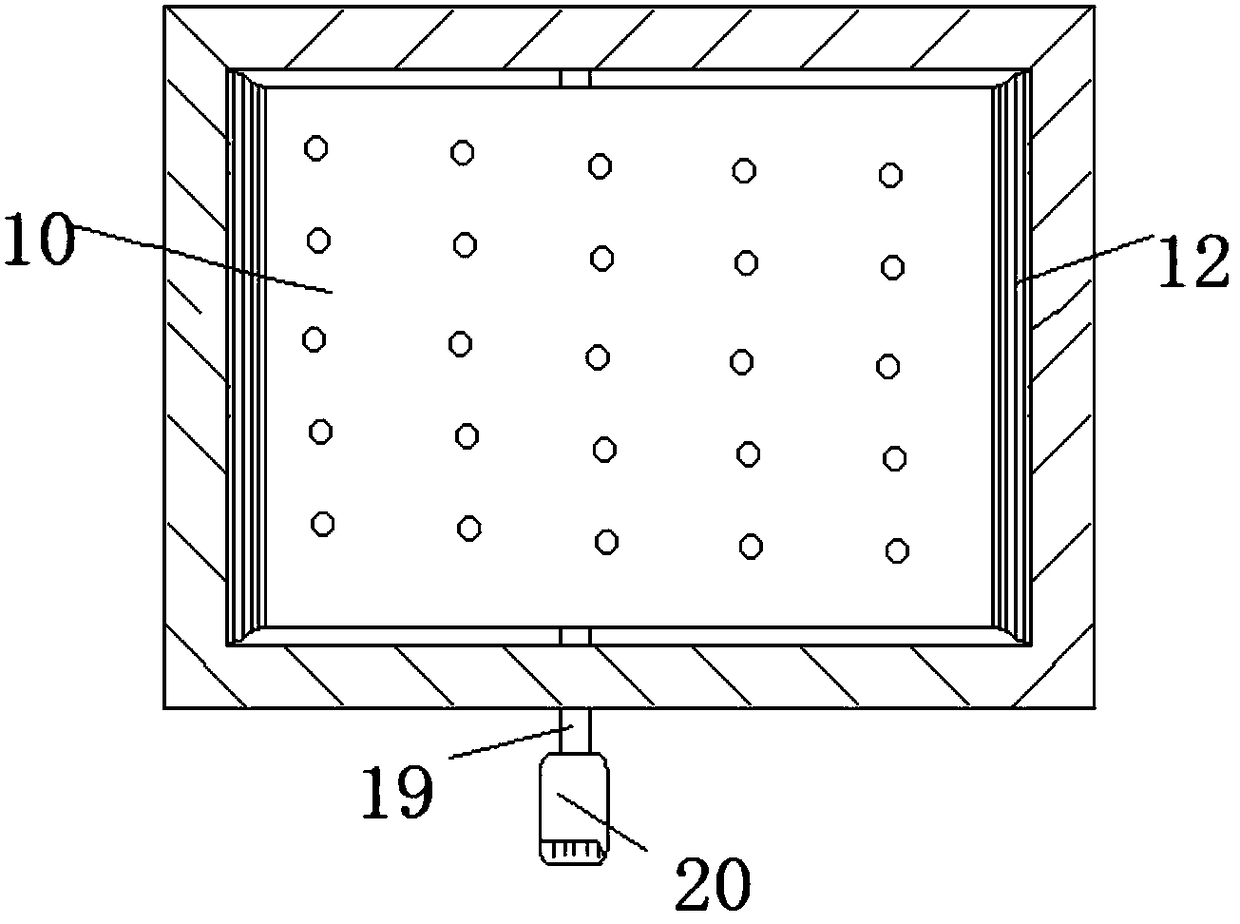

Blending device

InactiveCN103587854AImprove work efficiencyReduce labor intensityLarge containersLivestock breedingEngineering

The invention discloses a blending device. The blending device comprises a feeding opening, a material storing cavity wall, an upper-layer bottom plate and a lower-layer bottom plate, wherein a plurality of discharging holes are uniformly formed in the upper-layer bottom plate and the lower-layer bottom plate in a correspondence manner; material storing space is formed by the upper-layer bottom plate and the material storing cavity wall; the lower-layer bottom plate clings to the upper-layer bottom plate; and a driving mechanism is connected with the lower-layer bottom plate through a driving rod. By the blending device, mechanical and automatic blending is realized; and the work efficiency is high, the labor intensity of workers is low, materials are fed uniformly, and the blending device is suitable for large-scale, medium-scale and small-scale livestock breeding.

Owner:ANHUI CHANGQING ELECTRONICS MACHINERY GRP

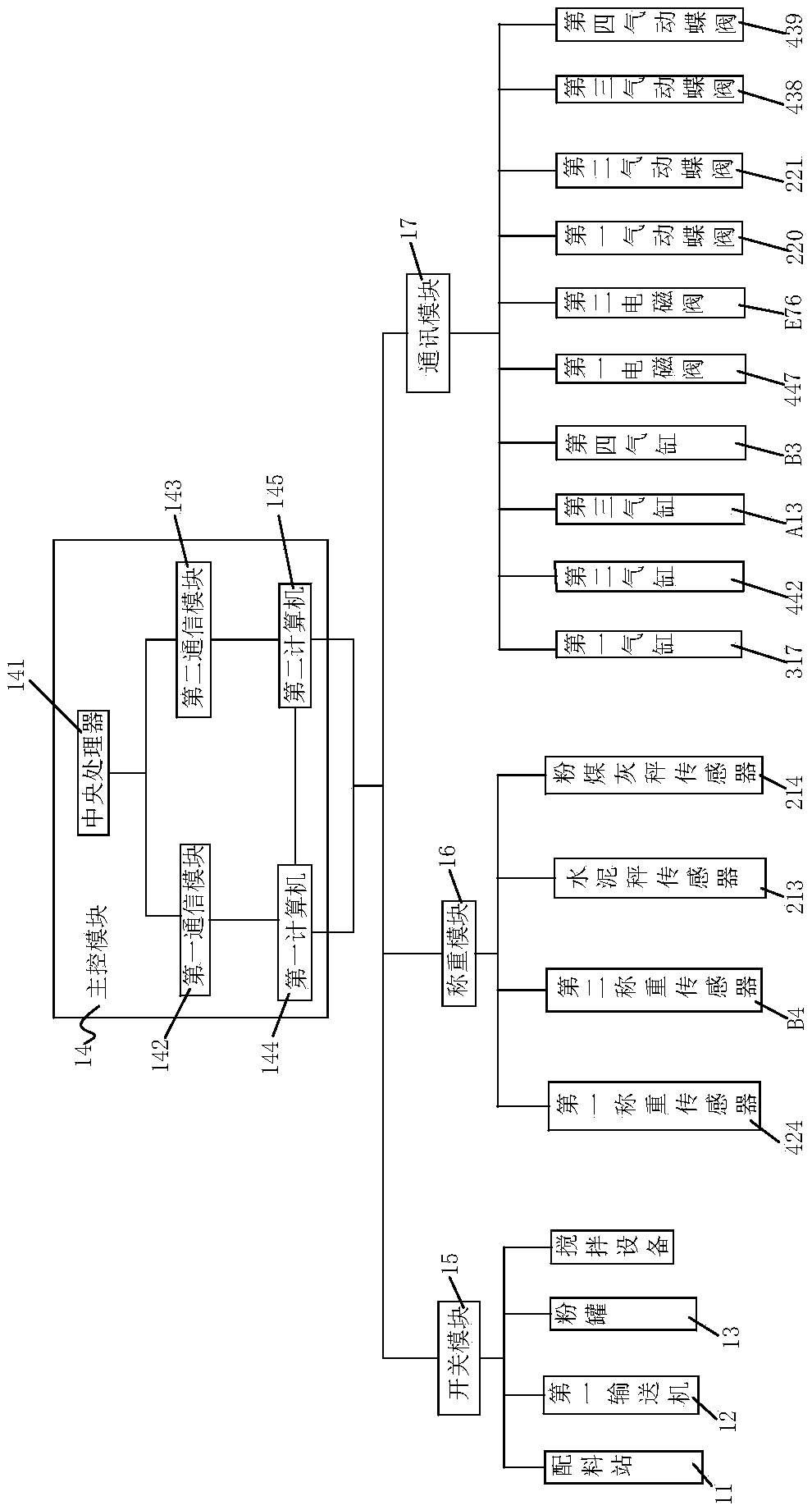

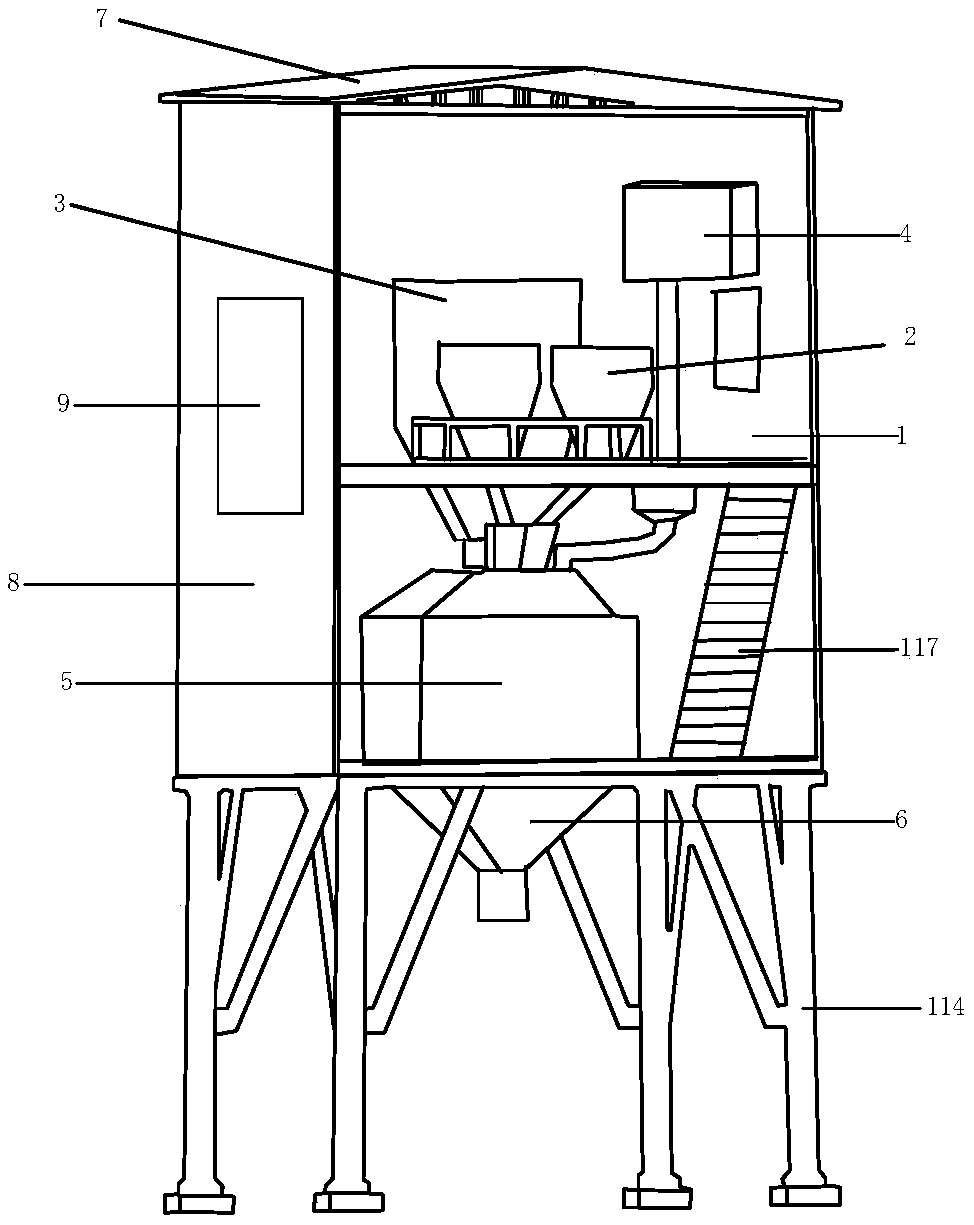

Concrete production equipment

PendingCN109352830APrevent deviationIncrease productivityMixing operation control apparatusIngredients weighing apparatusEquipment useEnergy consumption

The invention discloses concrete production equipment which comprises a concrete mixing station and a control system used for controlling the concrete mixing station. The concrete mixing station comprises a material preparation station used for supplying aggregate, a first conveyor used for transmitting aggregate, a powder tank used for storing powder and mixing equipment used for mixing, one endof the first conveyor is arranged below the material preparation station, the other end of the first conveyor is arranged on the mixing equipment, and the powder tank is connected with the mixing equipment. The control system comprises a master control module and a switch module connected with the master control module and used for controlling the concrete mixing station to be opened or closed, and the switch module is connected with the material preparation station, the first conveyor, the powder tank and the mixing equipment. The concrete production equipment has the advantages of being lowin energy consumption, high in yield, accurate in matching and convenient to control.

Owner:杭州德全建材有限公司

Automatic feeding device and kneading device for tea leaves

InactiveCN101884355ASave operating procedures and timeExact pressurePre-extraction tea treatmentTurning framesElectric machinery

The invention discloses an automatic feeding device and a kneading device for tea leaves, wherein the automatic feeding device for the tea leaves comprises a charging box for accommodating the tea leaves; a lower end face of the charging box is provided with a frame with a wheel for walking on a rail and a discharge outlet for discharging; the discharge outlet is provided with a discharge hopper;a tea leaf transportation mechanism is arranged at the bottom of the charging box, and a leaf distributing machine is arranged above the tea leaf transportation mechanism; and both the tea leaf transportation mechanism and the leaf distributing machine are connected with a motor, which is arranged on the charging box, through a chain. The kneading device for the tea leaves comprises a stander, a power transmission mechanism for controlling the rotation of a kneading barrel, a kneading disc which is arranged below the kneading barrel, a pressure mechanism for controlling the pressure of a gland, and a material unloading device; and an edge of the kneading disc is provided with a blowing device for cleaning remainders in the kneading disc. The automatic feeding device and the kneading device for the tea leaves have the advantages of ingenious conception, simple structure and high degree of automation; and by using the two devices, the tea leaves can be weighed, fed, discharged automatically, unloaded and kneaded uniformly, so that the work efficiency is improved greatly.

Owner:CHONGQING ACAD OF AGRI SCI

Wet-and-dry automatic feeding trough

ActiveCN102763603AImprove toggle effectAvoid cakingAnimal feeding devicesEngineeringAnimal husbandry

The invention relates to the technical field of animal husbandry equipment, and particularly relates to a wet-and-dry automatic feeding trough which is especially suitable for being applied to the feeding of live pigs. According to the technical scheme, the wet-and-dry automatic feeding trough comprises a feed trough, a feed basket and a driving lever structure, wherein the feed basket is arranged above the feed trough and provided with a discharge hole, and the driving lever structure is used for achieving an effect of automatic feeding; and the automatic feeding trough is characterized in that the driving lever structure comprises a rotating shaft, a rotating arm, a driving lever and a material dispersing platform, wherein the rotating arm is arranged on the rotating shaft and close to the discharge hole and extends outwards along the middle part of the discharge hole, the driving lever is arranged on the rotating shaft and used for driving the rotating arm to rotate through the rotating shaft, and the material dispersing platform is arranged below the discharge hole, sleeved on the exterior of the rotating shaft, linked with the driving lever, and used for enabling feeds to slide towards the periphery of the feed trough along the rotating shaft in the horizontal direction. The automatic feeding trough disclosed by the invention has the advantages of uniformity in feeding, smoothness in feeding and blocking avoidance, and is suitable for not only dry feeds, but also wet feeds.

Owner:COMAX LIVESTOCK TECH JIANGSU CO LTD

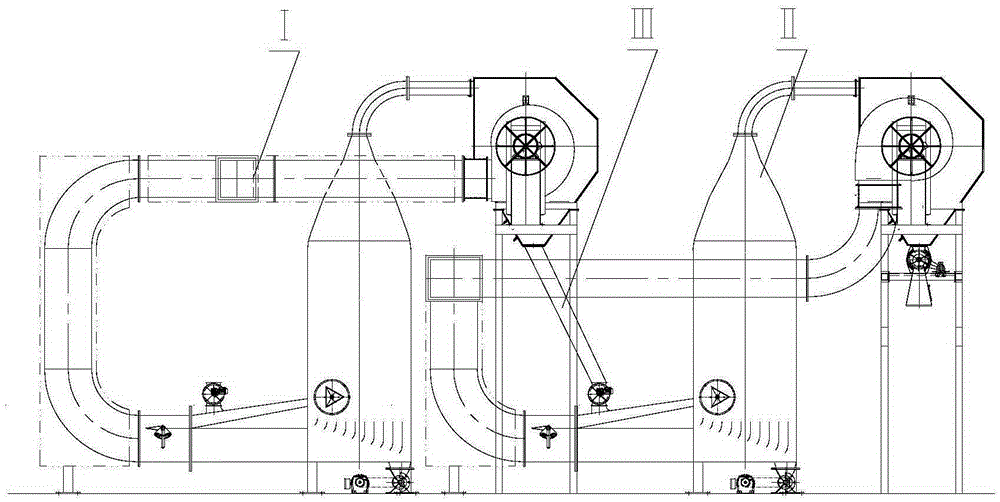

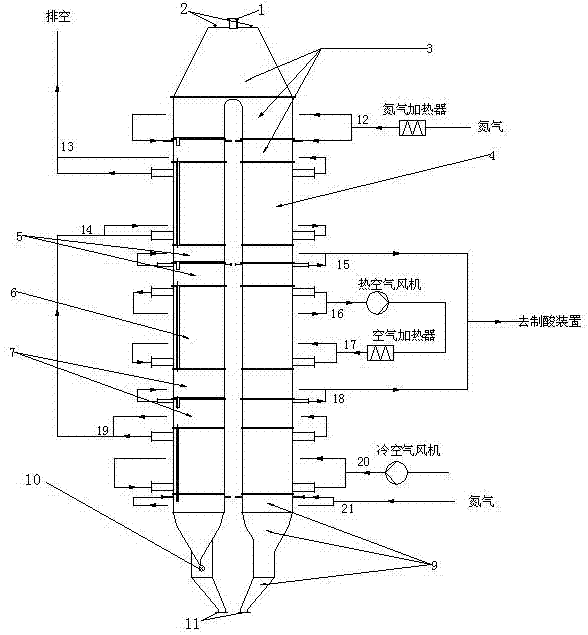

Three-section type carbon-based catalyst regeneration tower system

PendingCN107537591ARealize comprehensive utilizationAvoid corrosionCatalyst regeneration/reactivationThermodynamicsPtru catalyst

The invention provides a three-section type carbon-based catalyst regeneration tower system which can improve an energy utilization rate in a carbon-based catalyst regeneration process and enhance matching and flexibility between a carbon-base catalyst regeneration tower and a desulfurization and denitrification adsorption tower. A tower body of the three-section type carbon-based catalyst regeneration tower system disclosed by the invention is sequentially divided into a preparing section, a preheating section, a first transition section, a heating section, a second transition section, a cooling section and an outlet section from top to bottom; the three sections of the preheating section, the heating section and the cooling section are all of tube-shell type heat exchange structures; thetower body of the regeneration tower serves as a tube pass, a carbon-based catalyst passes through the tube pass, and a heat exchange medium passes through a shell pass; the carbon-based catalyst enters to the tower top and reaches the bottom of the regeneration tower through the tube pass; the first transition section is arranged between the preheating section and the heating section, the secondtransition section is arranged between the heating section and the cooling section, the two transition sections are used for exhausting enrichment SO2 gas in the tower, and the exhausted SO2 gas is introduced into an acid making device.

Owner:GUODIAN SCI & TECH RES INST

Ore efficient aeration vibration cleaning device

The invention discloses an ore efficient aeration vibration cleaning device which comprises a feeding pipe, a treatment box, a material shake plate, a water storage box, a water spray pipe, a screen plate, a dust collector, an aeration machine, a center rotating shaft and a backflow pipe. The feeding pipe is arranged at the top end of the treatment box. The material shake plate is further arrangedin the treatment box. The water storage box is mounted at the top end of the treatment box. The water spray pipe is arranged on the water storage box. A spray head is arranged at the outlet end of the water spray pipe. The dust collector is mounted on the inner wall of the top end of the treatment box. The screen plate is obliquely arranged in the treatment box. An ore discharging pipe is arranged on the side wall of the treatment box. The center rotating shaft is fixedly arranged at the center position of the screen plate. One end of the center rotating shaft penetrates the side wall of thetreatment box to be connected with an output shaft of a forward and reverse rotation motor. The treatment box communicates with the aeration machine. According to the ore efficient aeration vibrationcleaning device, safety is improved; the ore surfaces can be cleaned conveniently; the work efficiency and effect are improved; water is cyclically used; energy is saved; the use cost is reduced; thestructure is simple; use is convenient; and popularization is facilitated.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

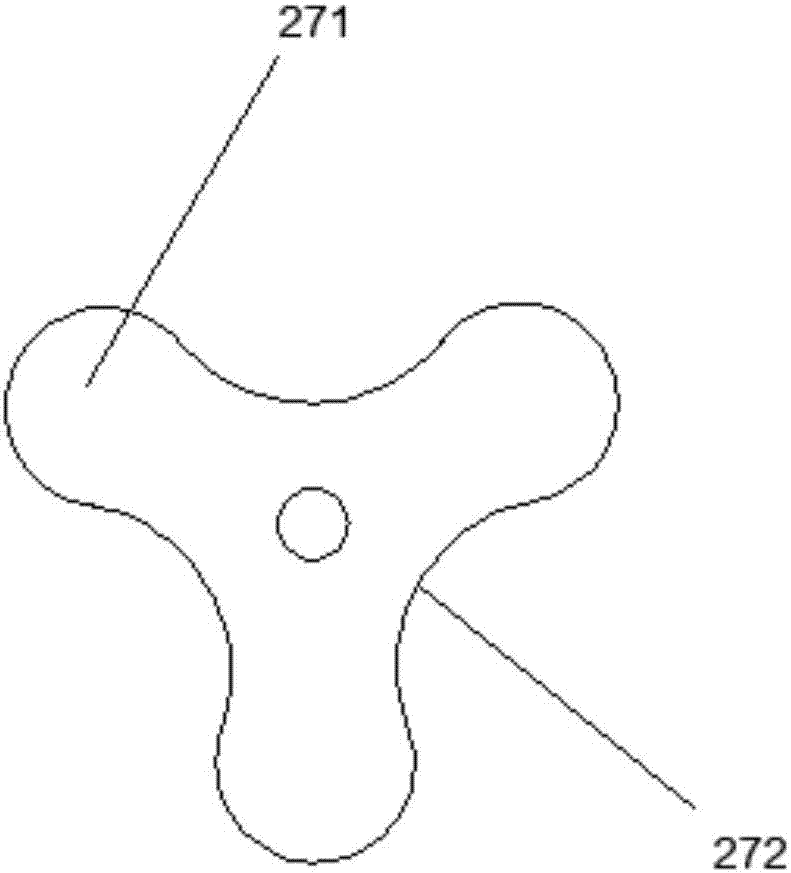

Concrete mixing station

PendingCN109571766APrevent deviationIncrease productivityDischarging apparatusMixing operation control apparatusMechanical engineeringConstruction aggregate

The invention discloses a concrete mixing station, comprising a batching station for supplying aggregate, a first conveyor for conveying the aggregate, a powder tank for storing powder and stirring equipment for stirring, wherein the batching station comprises a storage bin for storing the aggregate, a second conveyor for conveying the aggregate to the first conveyor and a material guiding devicefor pouring the aggregate onto the first conveyor; one end of the first conveyor is arrange under the material guiding device; the other end of the first conveyor is arrange on the stirring equipment;the powder tank is connected with the stirring equipment; the aggregate enters the stirring equipment from the batching station through the first conveyor; the powder enters the stirring equipment from the powder tank; and the stirring equipment mixes and stirs the aggregate and powder. The concrete mixing station provided by the invention has the advantages of low energy consumption, high yield,accurate proportioning, compact and reasonable design and quick installation.

Owner:郑涛涛

Road surface casting machine of concrete for municipal engineering construction

InactiveCN107299584AReasonable structureInnovative designRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a concrete pavement pouring machine for municipal engineering construction, which comprises a support seat, a support frame is fixedly connected to the left side of the upper end of the support seat, a screw rod is connected to the middle part of the upper end of the support frame, and a lifting plate is connected to the lower ends of the left tie rod and the right tie rod. The middle part of the lower end of the lifting plate is connected with a drive motor, the lower end of the drive motor is connected with a reducer, the reducer is connected with a pouring shaft, the upper end of the support seat is connected with a support leg, the upper end of the support leg is connected with a concrete box, and the upper end of the concrete box is connected with a stirring shaft , the right end of the stirring shaft is connected with a worm, the lower end of the worm is meshed with a worm wheel, the middle part of the worm wheel is connected with a driving pulley coaxially, the driving pulley is connected with a driven pulley through a belt, and the middle part of the driven pulley is connected with a Y-shaped cam at a coaxial position . The invention realizes the uniform feeding of the concrete in the concrete box, and also realizes the lifting type mixing of the concrete during the pouring process, and avoids the upper and lower stratification of the concrete.

Owner:丁家琪

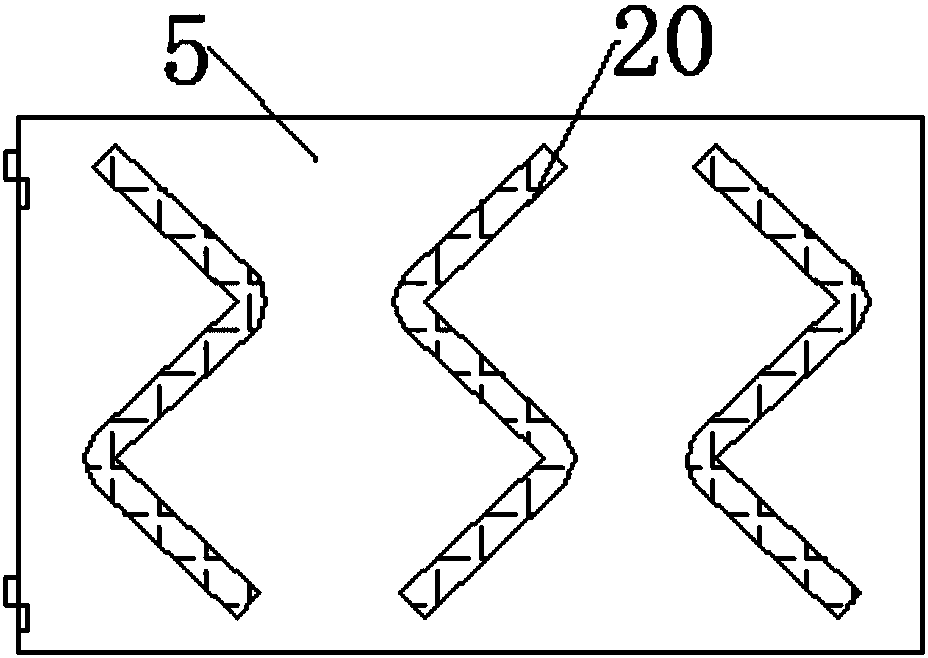

High-multiple aluminum profile extrusion die and extrusion technology

ActiveCN103586303AImprove cooling effectIngenious designExtrusion diesSurface roughnessTooth position

The invention discloses a high-multiple aluminum profile extrusion die which comprises an upper die and a lower die and is characterized in that a plurality of shunting bridges are uniformly distributed on the material feeding surface of the upper die along the circumference; a plurality of shunting holes are formed among the shunting bridges; a false shunt is arranged at the center of the material feeding surface of the upper die; a welding chamber is formed in the upper die; the material feeding end of the lower die is designed into a plane; the lower die is provided with a working tape communicated with a material guide opening; a plurality of tooth position die holes and a plurality of assembling position die holes are formed in the working tape. The invention also discloses an extrusion technology for producing an aluminum profile through the die. The high-multiple aluminum profile extrusion die disclosed by the invention guarantees the consistency of flowing speeds and flow rates of metals under a design form that the flow rates are uniformly distributed to all the shunting hole structures, so that stress on the die is alleviated. The working tape of the extrusion die is ingenious and compact in design and can achieve flatness, perpendicularity and low surface roughness after being treated, so that the yield of products is improved, and the profile extruded through the working tape has a good heat dissipation effect.

Owner:东莞市东联铝业有限公司

Safe and high-efficiency grain air injection screening device

InactiveCN108097591AImprove efficiencyGood effectSievingGas current separationBristleWorking environment

The invention discloses a safe and high-efficiency grain air injection screening device. The safe and high-efficiency grain air injection screening device comprises a feeding pipe, a screening box, amaterial shaking plate, a dust collector, a rotary drum, scraper plates, bristle brushes, a filter plate, an aerating device, an inclined guide plate and a rotary motor. The feeding pipe is arranged at the top end of the screening box. The material shaking plate is arranged in the screening box. The top end of the screening box communicates with the dust collector. A dust collection pipe is arranged on the dust collector. A dust collection port is formed in the outlet end of the dust collection pipe. The inner walls of the screening box are movably connected with the two ends of the filter plate. A discharging pipe is arranged on one side of the screening box. The screening box communicates with the aerating device. The rotary drum is arranged above the filter plate. The scraper plates arearranged on the outer edge wall of the rotary drum. The bristle brushes are arranged at the ends of the scraper plates. Full grain is screened out, meanwhile, the situation that dust and other thingsfly to the air and affect the air quality is avoided, the health safety of the working environment is improved, the safety and health of respiratory tracts are ensured, the working efficiency and effect are improved, and the safe and high-efficiency grain air injection screening device is simple in structure, convenient to use and beneficial for popularization.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

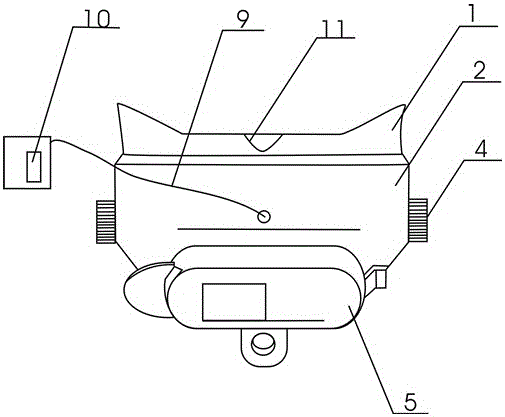

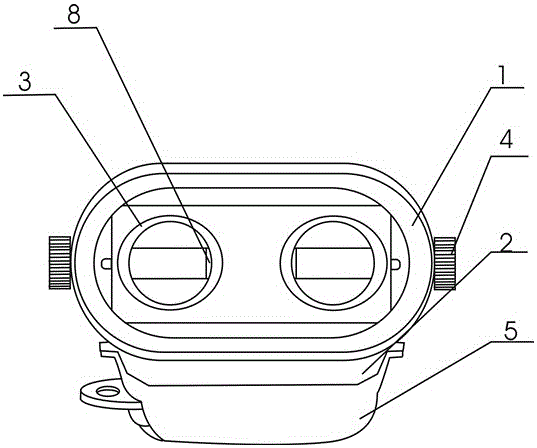

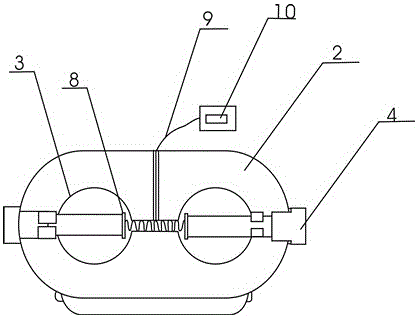

Novel intelligent moxibustion physiotherapy eye care instrument

ActiveCN104997626AGood curative effectEvenly distributedDevices for heating/cooling reflex pointsPhysical medicine and rehabilitationPhysical therapy

The invention provides a novel intelligent moxibustion physiotherapy eye care instrument. The novel intelligent moxibustion physiotherapy eye care instrument comprises an eye patch and a main body, the lower side of the eye patch is connected with the main body through a clip; walnut shell brackets for placing walnut shells, moxa stick knobs for fixing moxa sticks, and a moxibustion soot accommodating groove are arranged in the main body; the novel intelligent moxibustion physiotherapy eye care instrument further comprises adjustable ventilation openings, fixed ventilation holes, automatic ignition devices, an ignition device conducting wire and an ignition device switch; the eye patch, the walnut shell brackets and the soot accommodating groove are connected sequentially; the radian curve of the eye patch is well-designed in accordance with the contour of a human craniofacial bone and by taking into account meridians and acupuncture points around eyes, a relatively closed space can be formed between the eye patch and the eye area during moxibustion, heat energy generated during moxibustion can act on the walnut shells soaked with a medical liquid, and generated superheated steam can be uniformly distributed to the eyes and the meridians and the acupuncture points around the eyes, so that the unique effects of moxibustion and fumigation of the instrument are fully realized; not only is energy saved, but also the curative effects of moxibustion and fumigation are improved.

Owner:TIANJIN XIANGJIUTANG MOXIBUSTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com