Drawing forming die for rear section of lateral tail board of rear end of sports utility vehicle (SUV)

A molding die and rear-end side technology, which is applied in the field of drawing forming dies for the rear section of the rear tailgate of SUV cars, can solve the problems of affecting the drawing forming quality, poor drawing forming quality, and low processing efficiency, and achieve guaranteed The effect of drawing forming quality, ensuring smooth progress, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

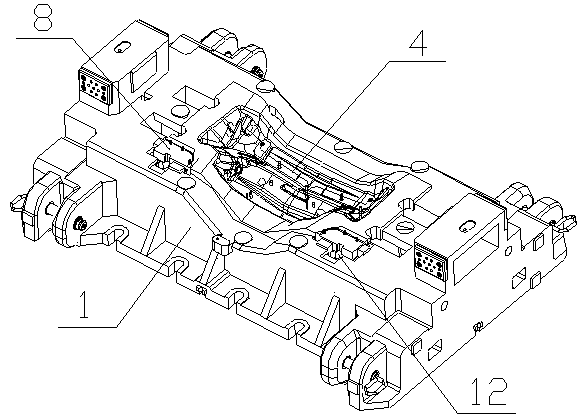

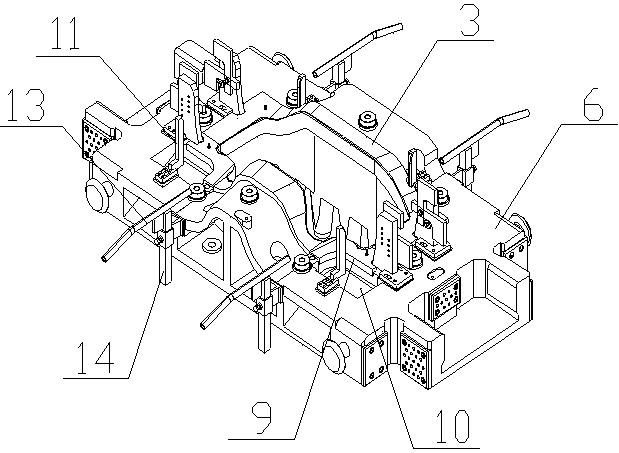

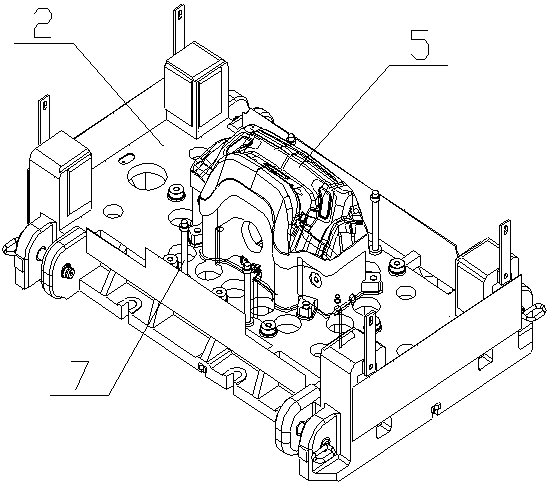

[0020] Example: see figure 1 , figure 2 and image 3 , a kind of SUV rear-end side tailgate rear segment drawing forming die, comprises upper mold base, lower mold base, upper mold 1, lower mold 2 and blank holder 3, and described upper mold 1 and lower mold 2 are respectively fixed Installed on the upper die base and the lower die base, the upper die 1 has a die 4, and the lower die 2 has a punch 5. The blank holder 3 is installed on the blank holder frame 6, and the blank holder frame 6 is installed on the lower mold base through the ejector mechanism 7 and is positioned above the lower mold 2. One end of the ejector mechanism 7 It is connected with the lower die base, and the other end passes through the lower die 2 and is connected with the blank holder frame 6, and the blank holder frame 6 is lifted up by the ejector rod mechanism 7. And this blank holder frame 6 can move up and down, when the blank holder frame 6 moves downwards, the punch 5 on the lower die 2 can pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com