Core assembly moulding sand mould structure for gearbox shell castings and core assembly moulding method

A core forming and gearbox technology, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of increasing the feeding pressure of the open riser, reducing the yield, and increasing the size of the open riser. The effect of increasing subsidized thermal insulation performance, shortening processing costs, and improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

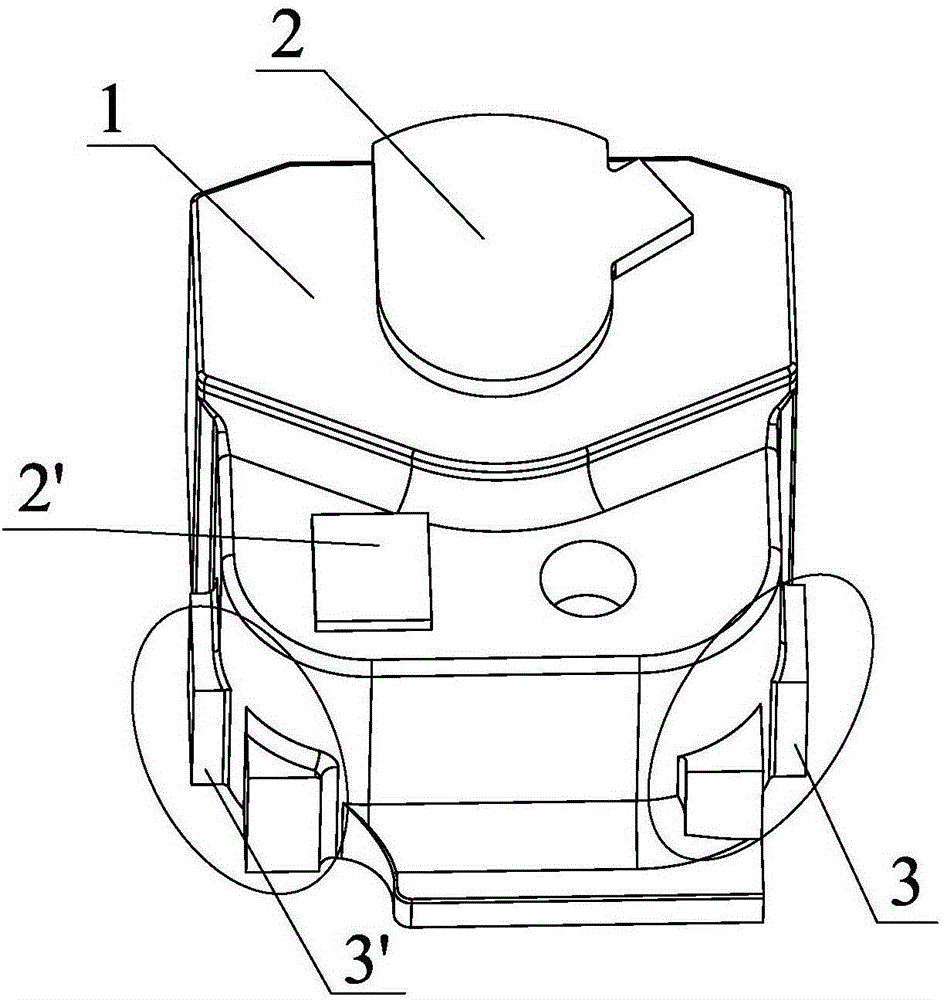

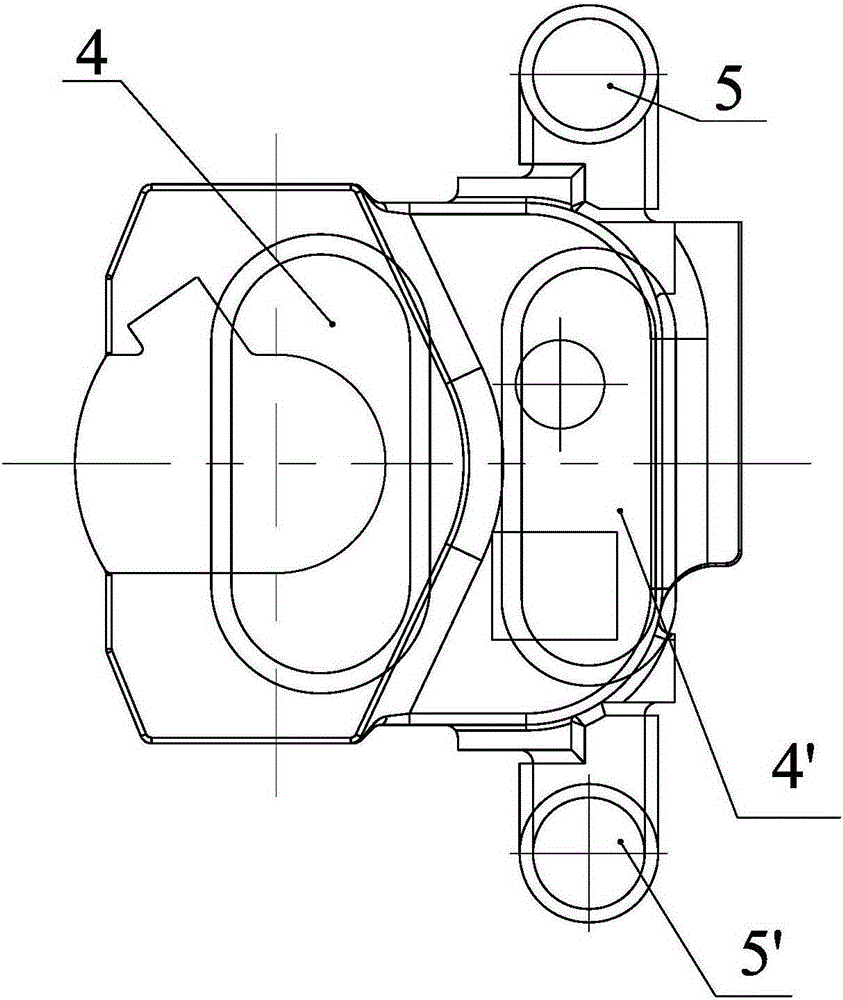

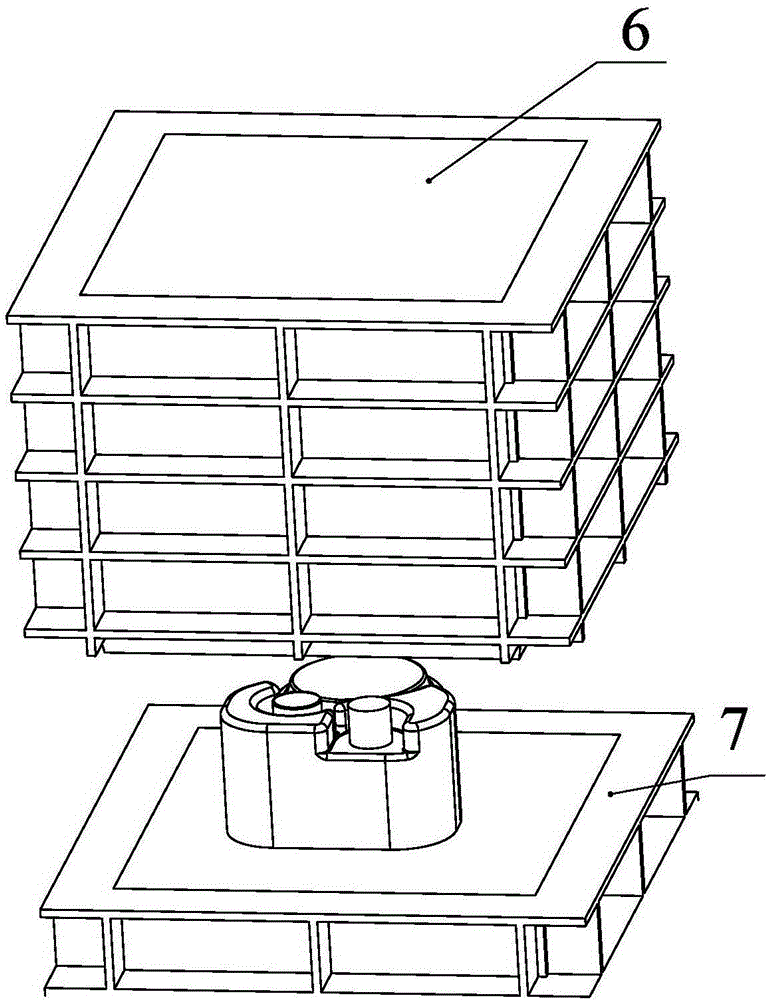

[0032] like Figure 4 — Figure 8 As shown, the core molding sand mold structure of the gearbox housing casting includes the inner cavity sand core 11, the outer contour sand core 12 and the pouring system sand mold 13, and the inner cavity sand core 11 and the outer contour sand core 12 are molded together. Finally, the cavity of the shell casting is formed. Several circular risers are arranged on the upper surface of the shell casting, and a number of cold irons 903 are set in the outer contour sand core between the circular risers. The side convex under the side wall of the casting A subsidy 905 is provided in the sand core corresponding to the outer contour of the table side, and an insulation layer is provided outside the subsidy 905; an inner sprue connected with the cavity of the casting is provided in the sand mold 13 of the gating system.

[0033] To facilitate precise packing, such as Image 6 and Figure 7 , in the outer contour sand core, the circular riser incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com