Patents

Literature

998results about How to "Improve packaging quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

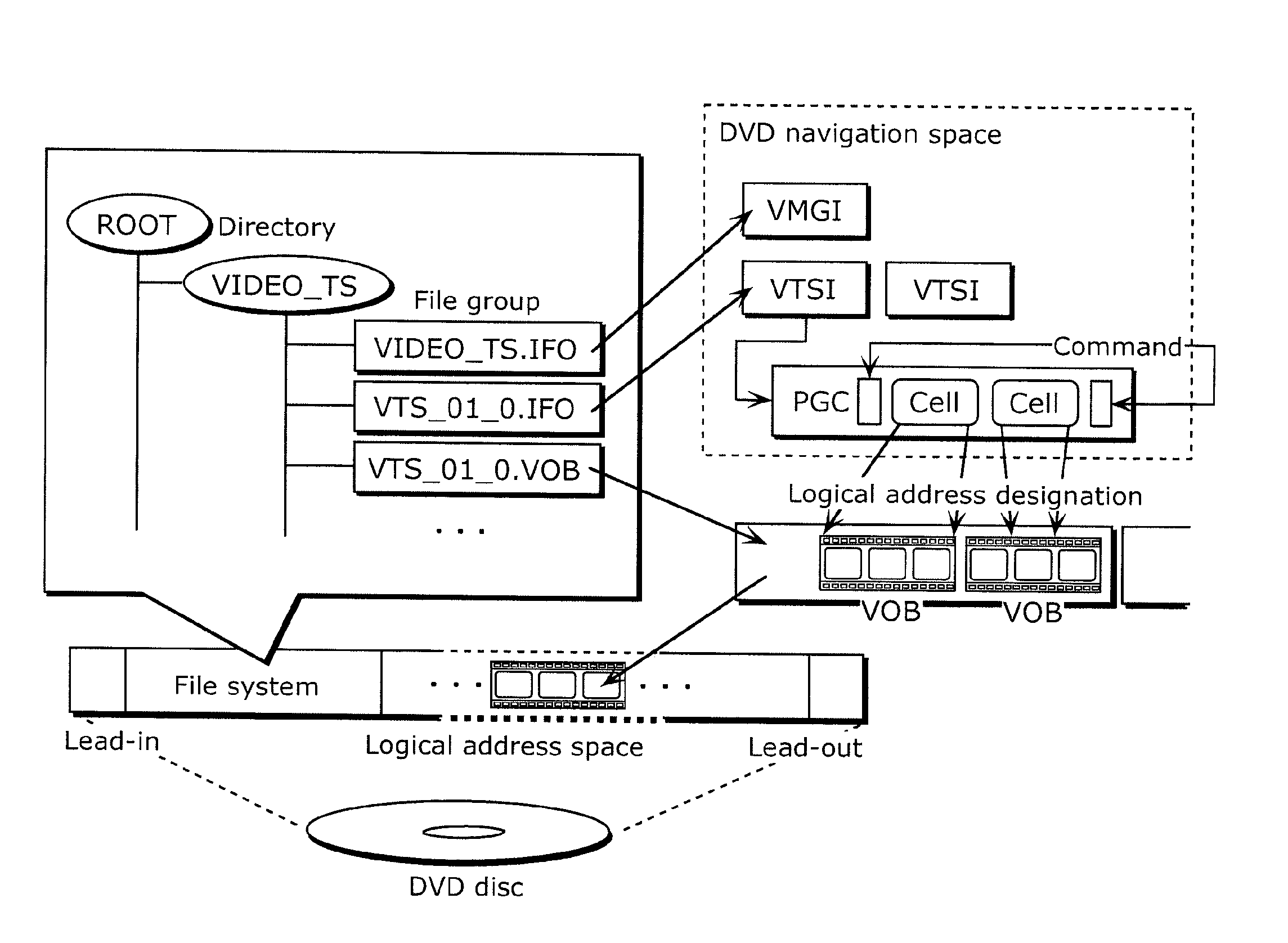

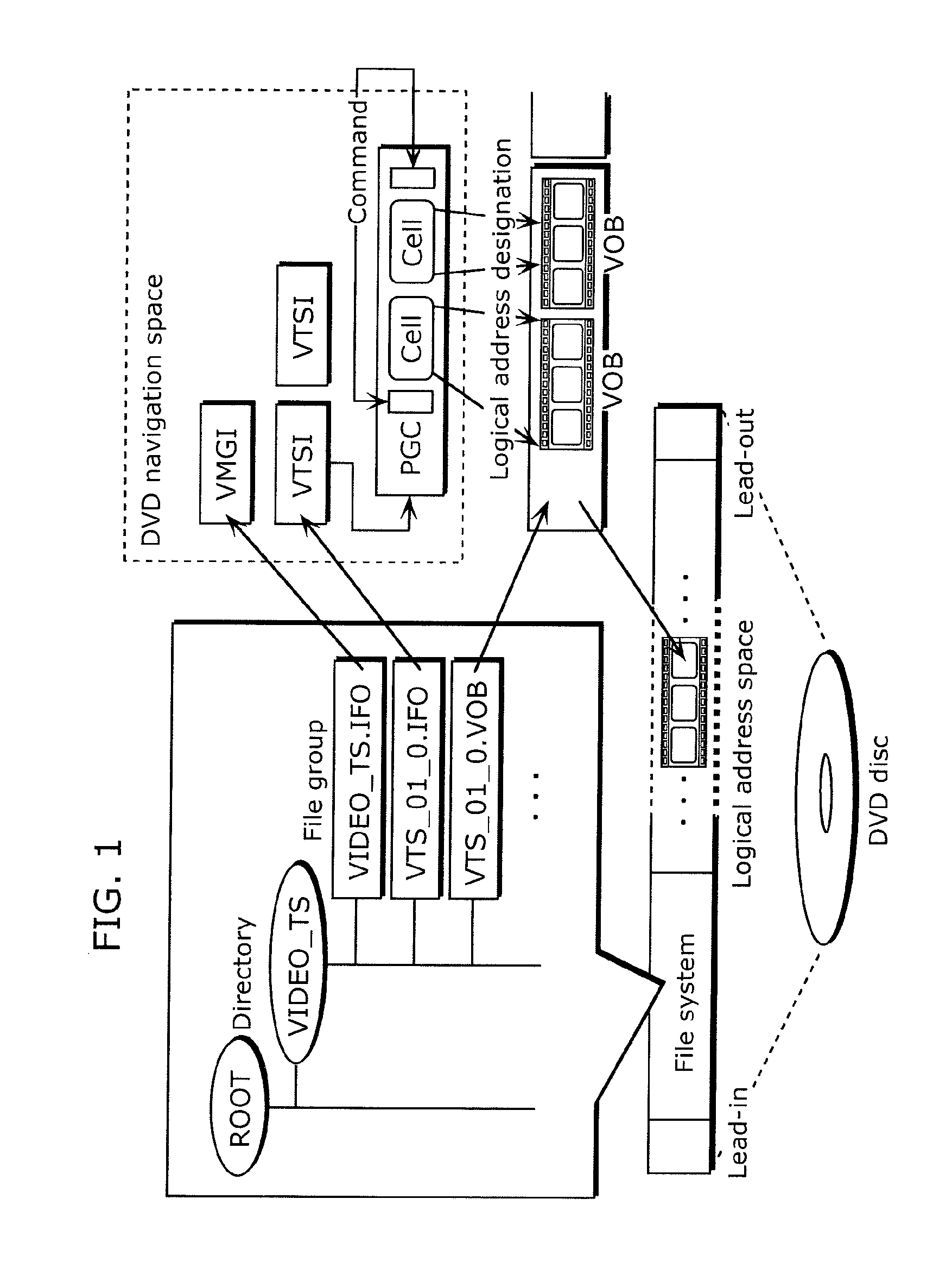

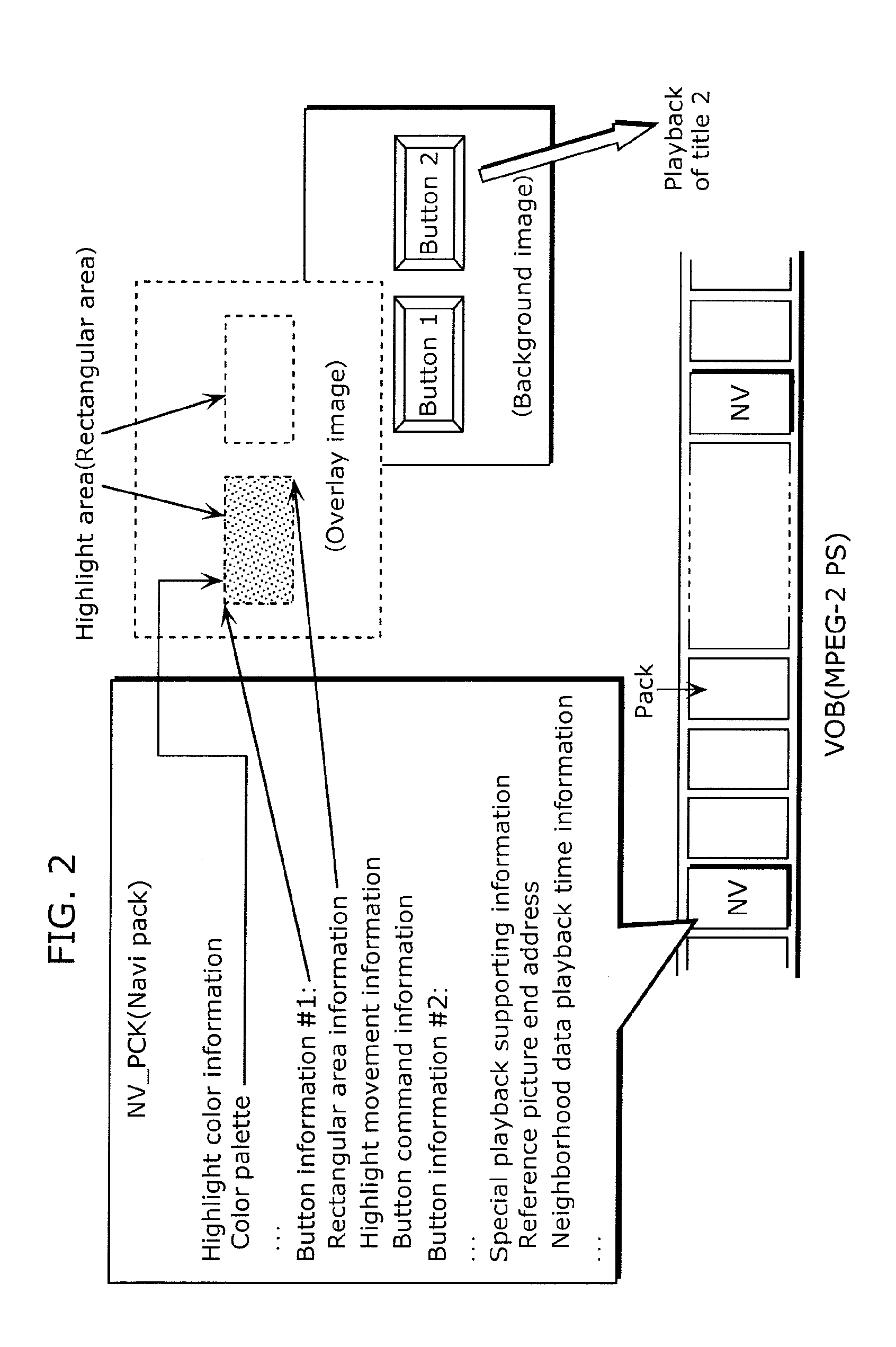

Moving image coding method, moving image coding device, moving image recording method, recording medium, moving image playback method, moving image playback device, and moving image playback system

ActiveUS20100040351A1Reduce processing loadImprove packaging qualityTelevision system detailsRecording carrier detailsComputer hardwareImage recording

A moving image coding method that can prevent playback discontinuity without an increase in processing load during playback is provided.The moving image coding method codes a video stream that includes a first moving image and a second moving image to be overlaid on the first moving image. The moving image coding method includes: a step of determining a continuous playback section that is a group of partial sections and is subject to continuous playback, in the video stream (S5301 to S5303); a step of coding the first and second moving images in the partial sections constituting the continuous playback section, under a constraint that prevents a threshold from being changed in the continuous playback section, the threshold being used for a transparency process by a luminance key in the overlaying (S5304); and a step of generating management information including flag information which indicates that the threshold is fixed in the continuous playback section (S5305).

Owner:PANASONIC CORP

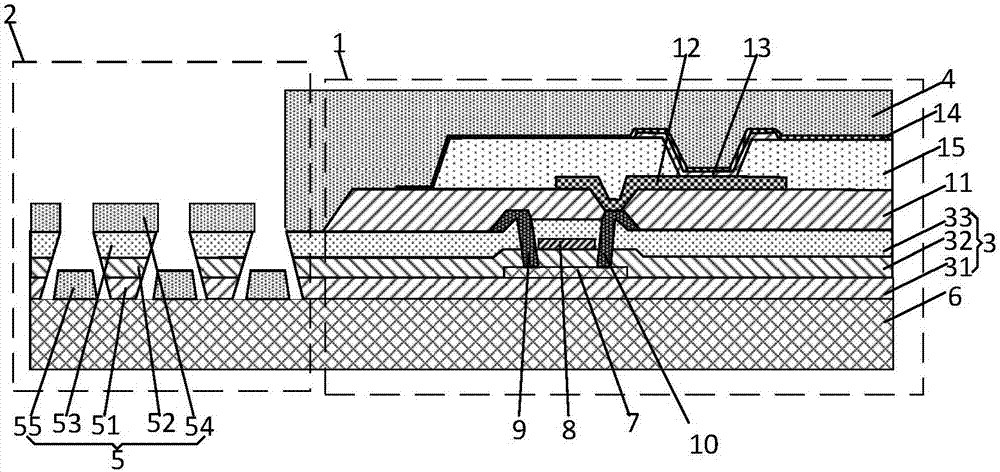

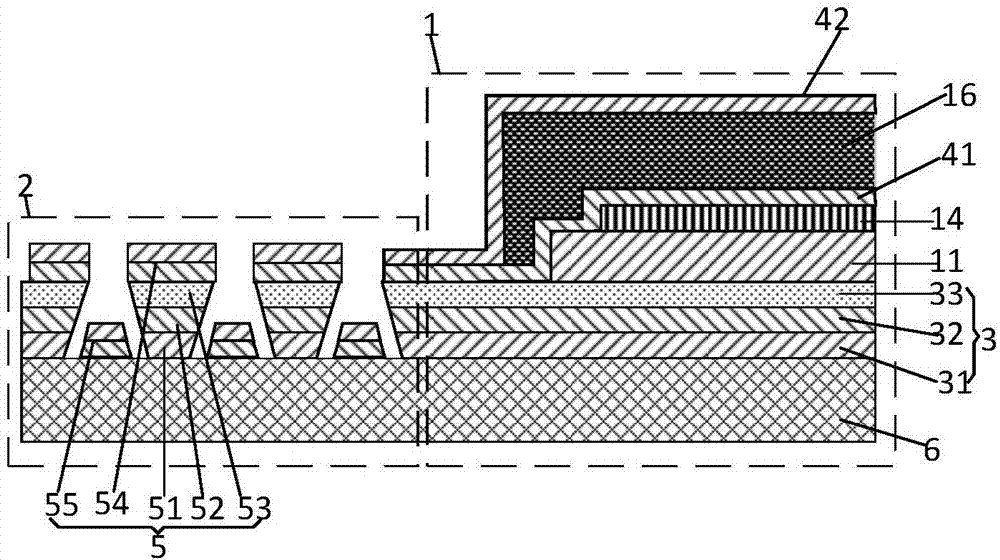

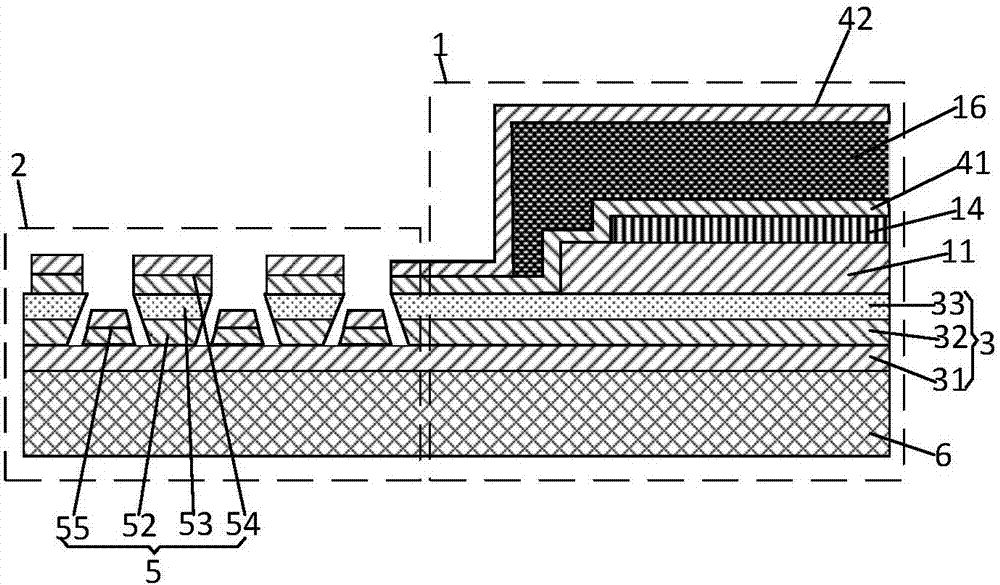

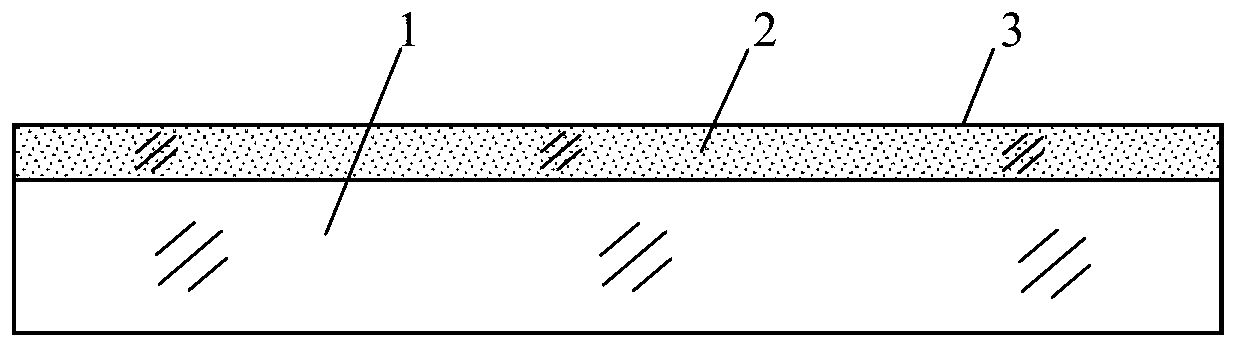

Display panel, preparation method thereof and display device

ActiveCN107180923AVisibility is not destroyedAchieving Narrow BezelsSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The present invention provides a display panel, a preparation method thereof and a display device. The display panel comprises a display area and a frame area. The display area and the frame area are respectively provided with an inorganic insulating layer and an inorganic encapsulating layer. A discontinuity structure is arranged inside each of the inorganic insulating layer and the inorganic encapsulating layer of the frame area, and the discontinuity structure can block the crack propagation in the inorganic insulating layer and the inorganic encapsulating layer. The discontinuity structure of the display panel is capable of blocking the propagation path of cracks in the inorganic insulating layer and the inorganic encapsulating layer and generated near a cutting line. Therefore, cracks in the inorganic insulating layer and the inorganic encapsulating layer and generated near the cutting line cannot be extended to the display area of the display panel. As a result, the display performance of the display panel is not damaged. Meanwhile, the narrow frame of the display panel can be realized.

Owner:BOE TECH GRP CO LTD

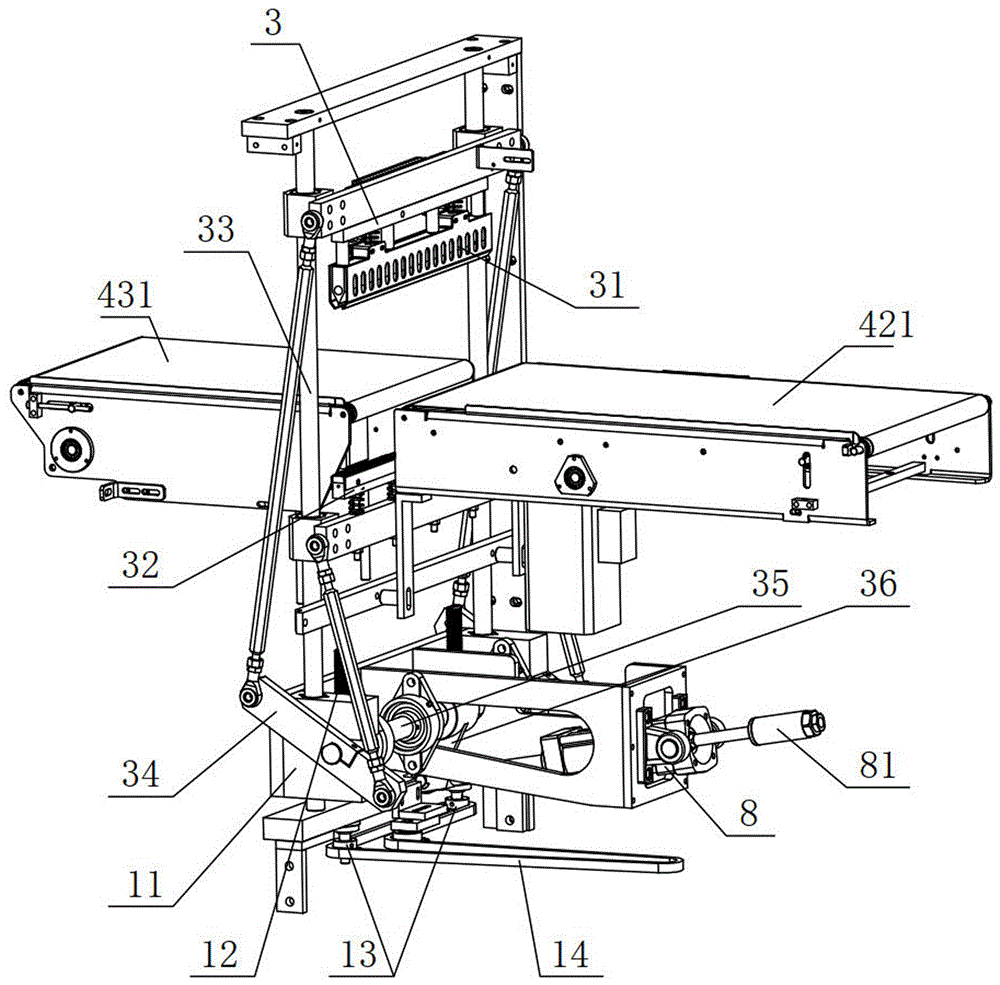

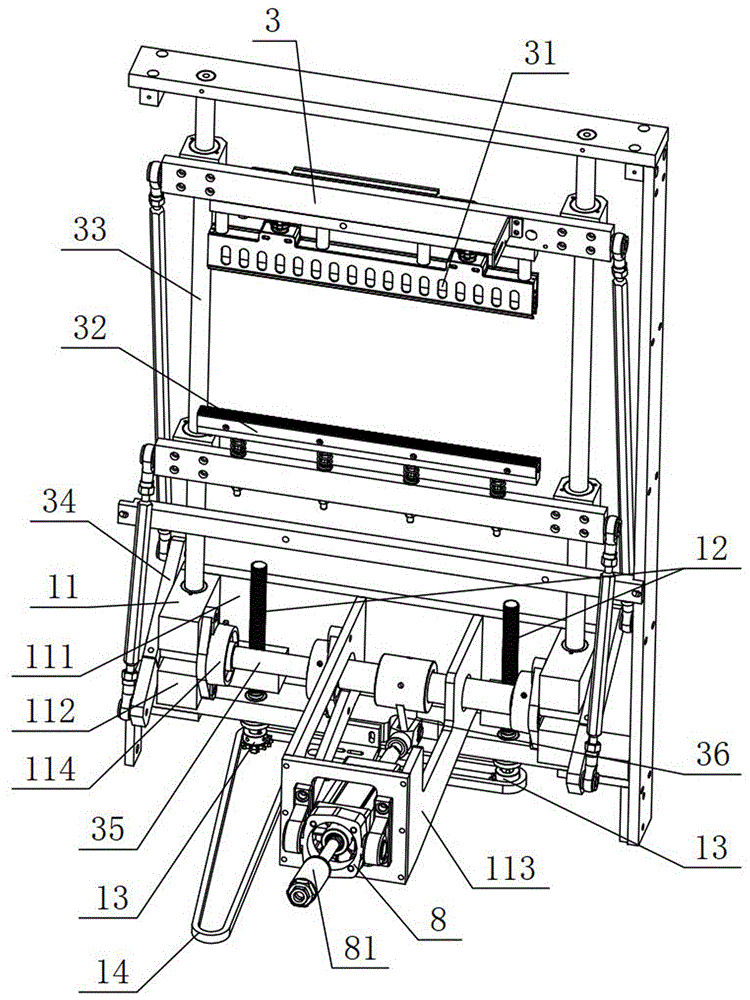

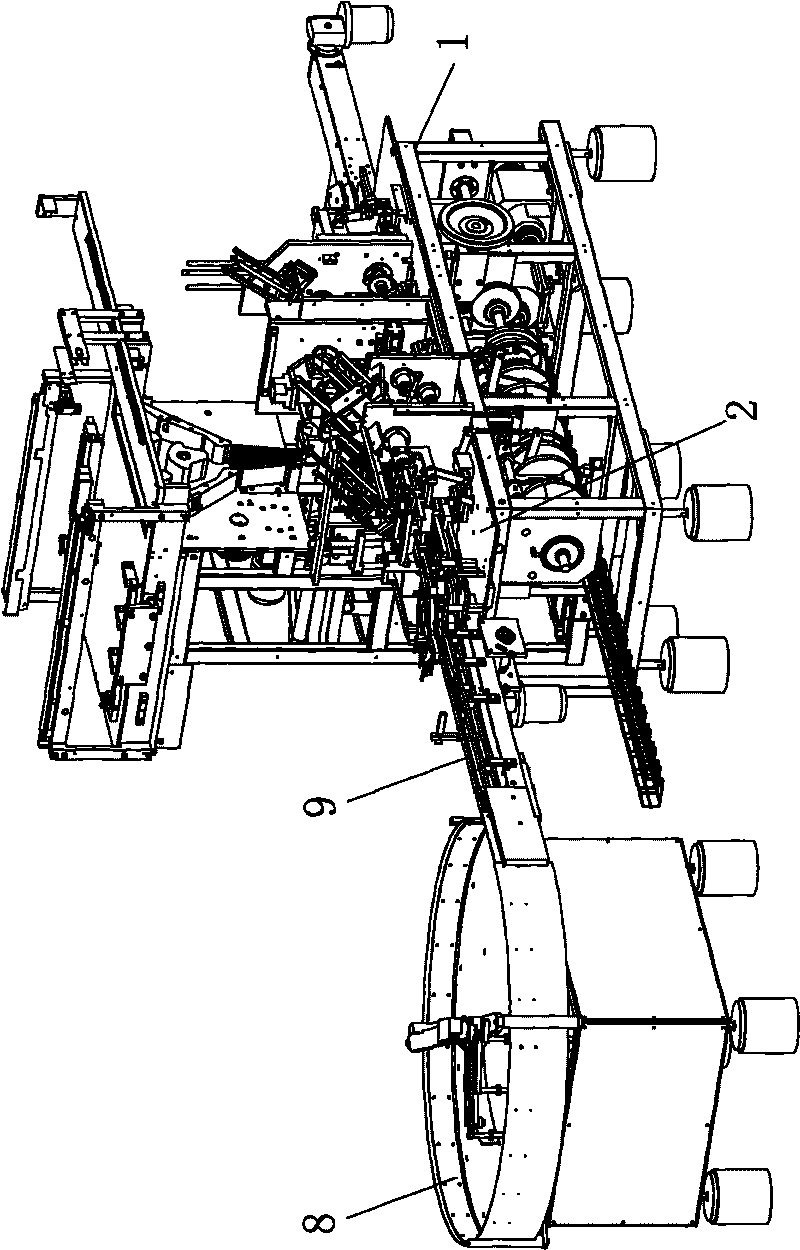

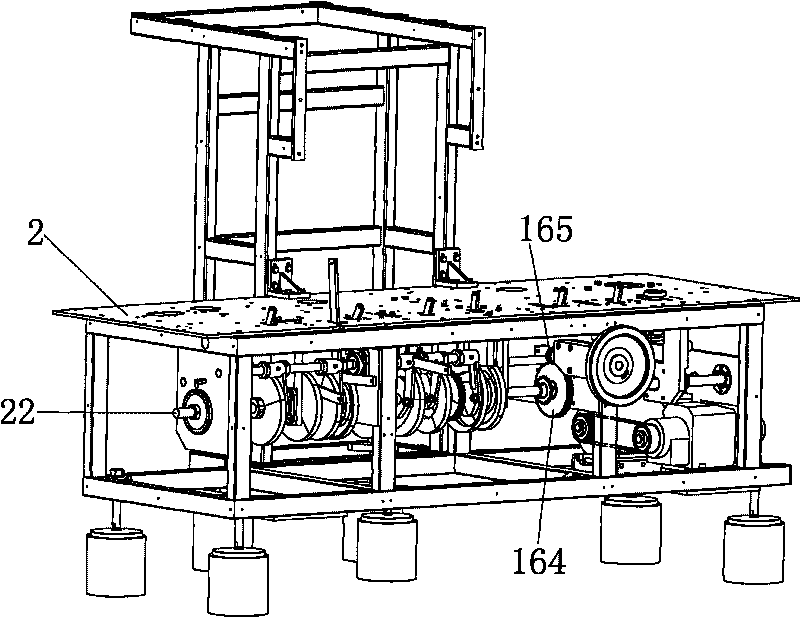

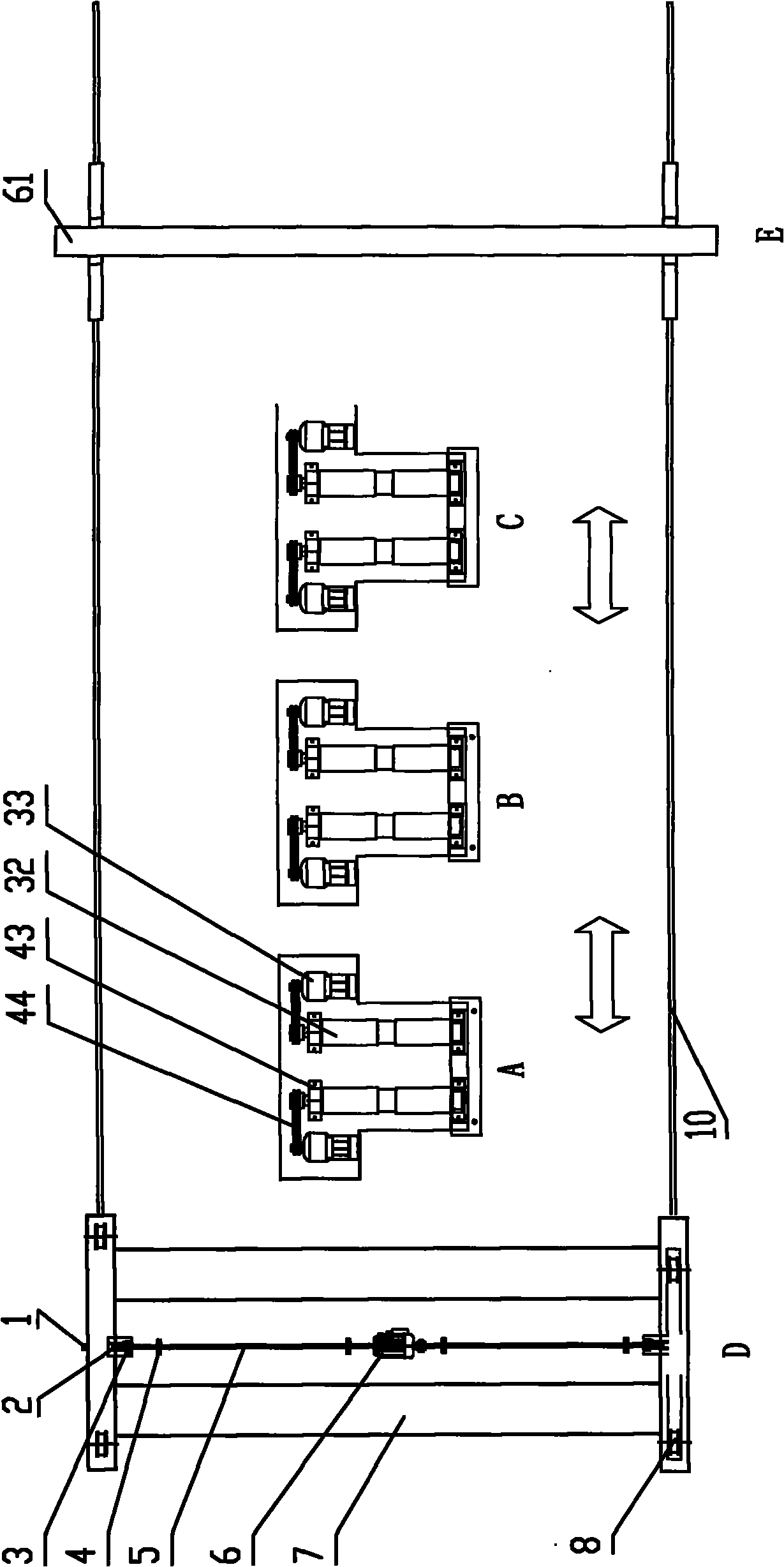

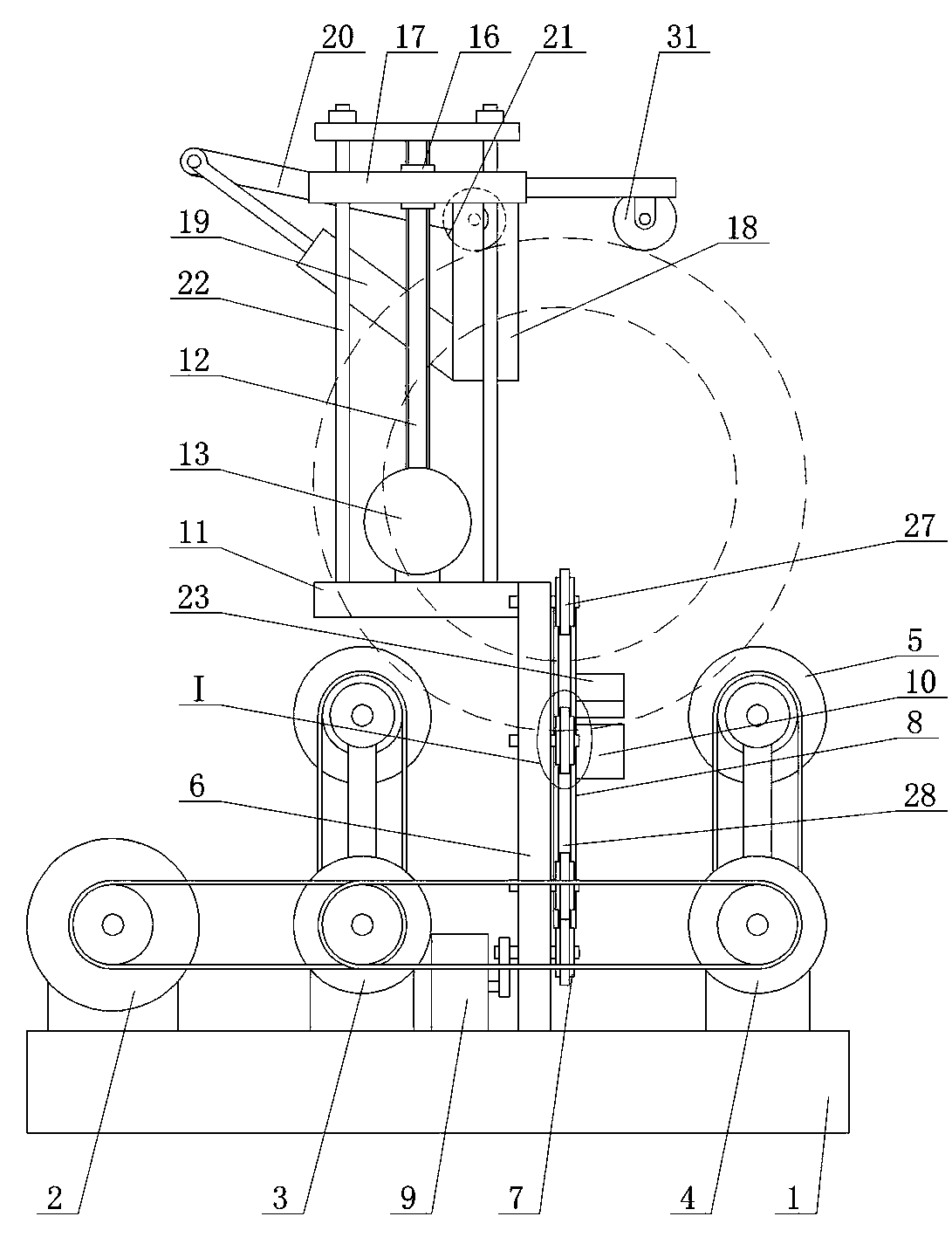

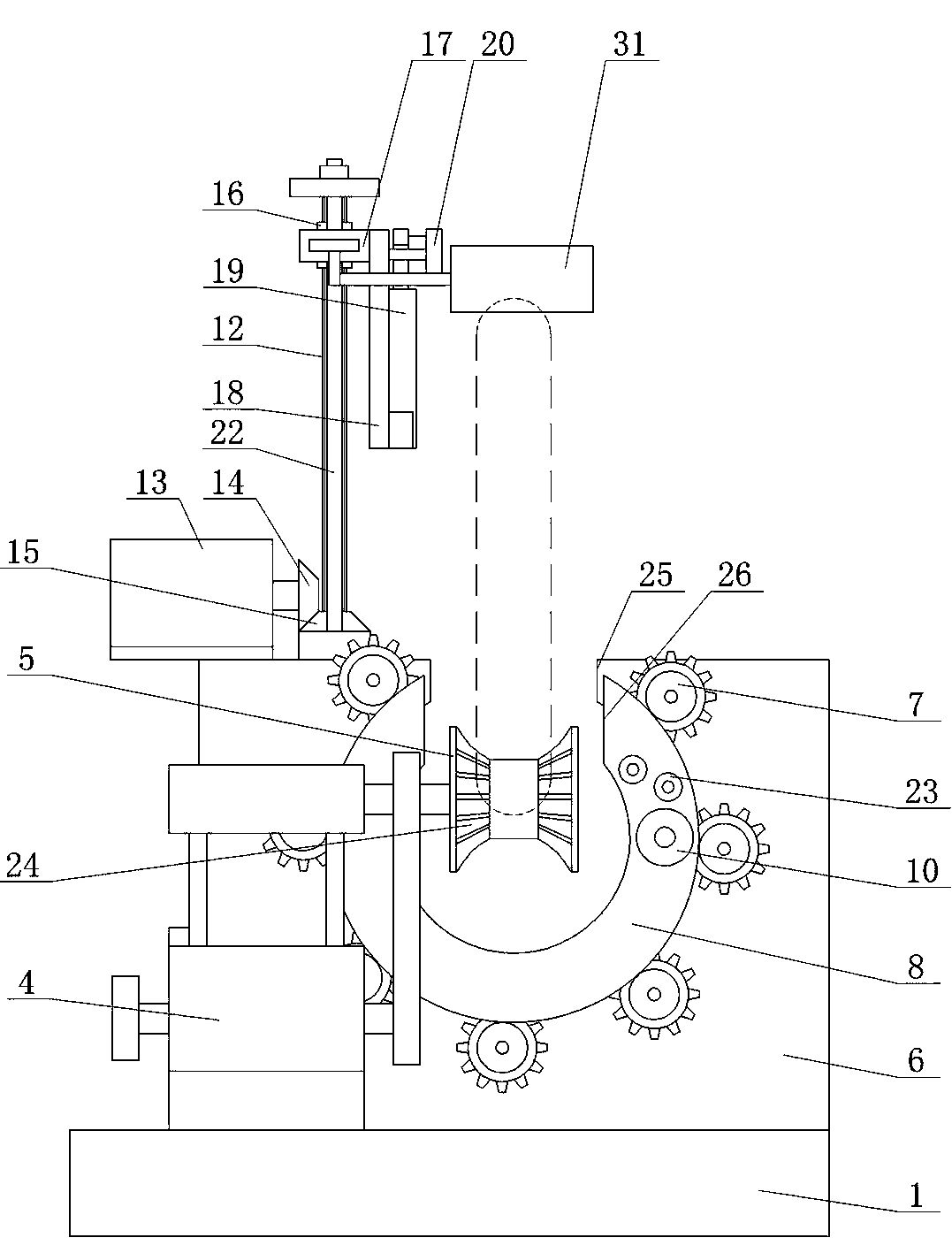

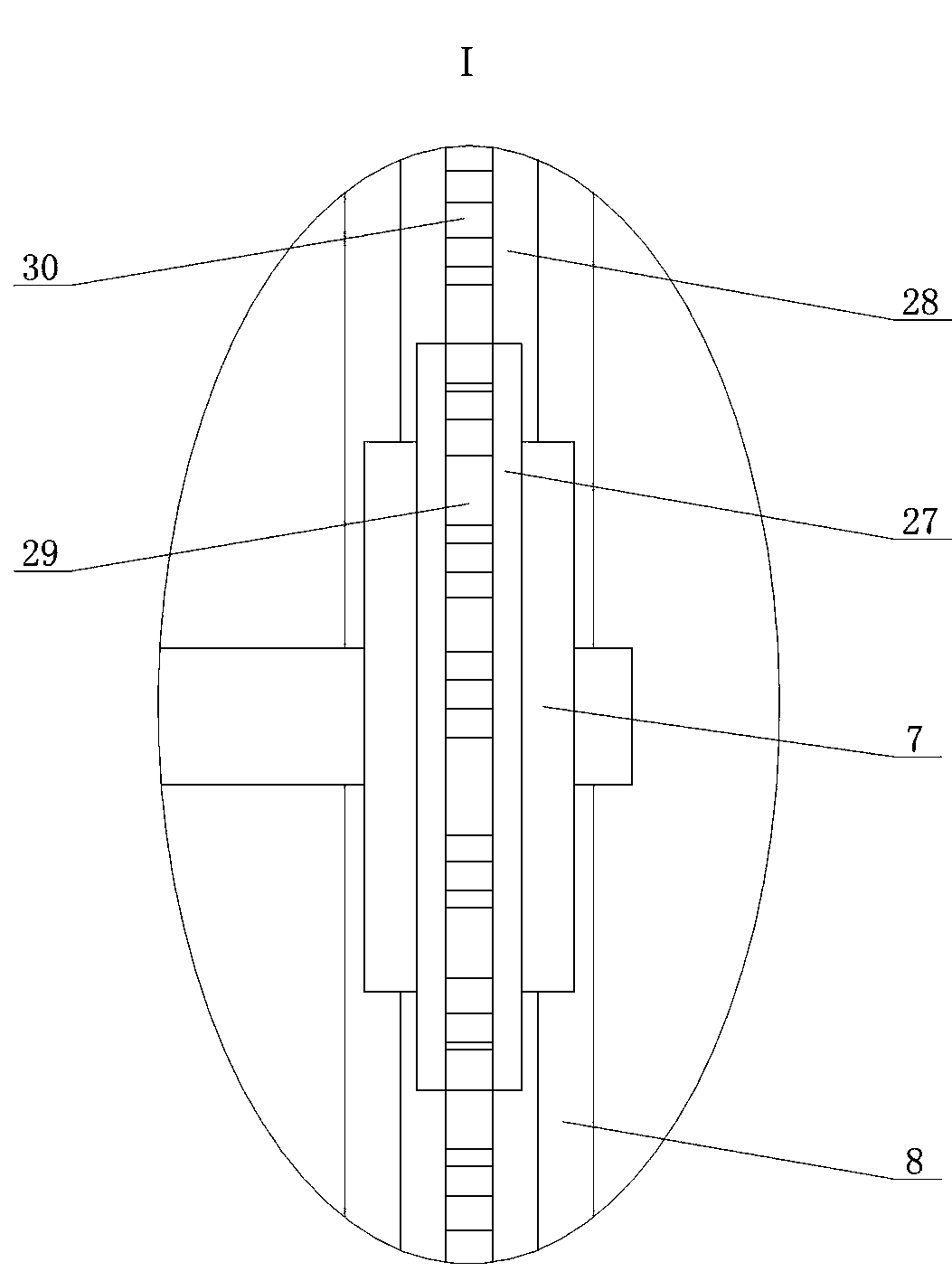

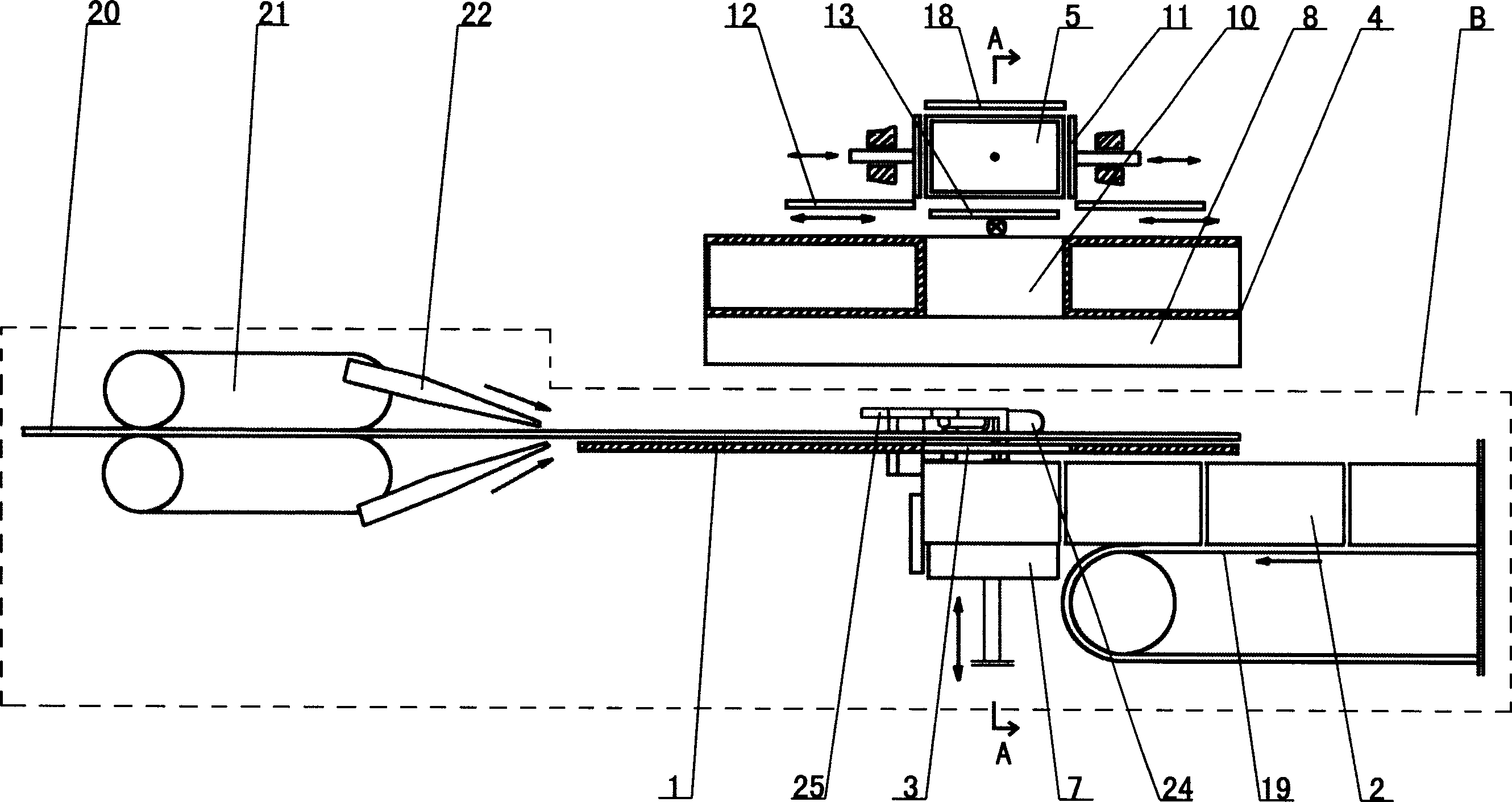

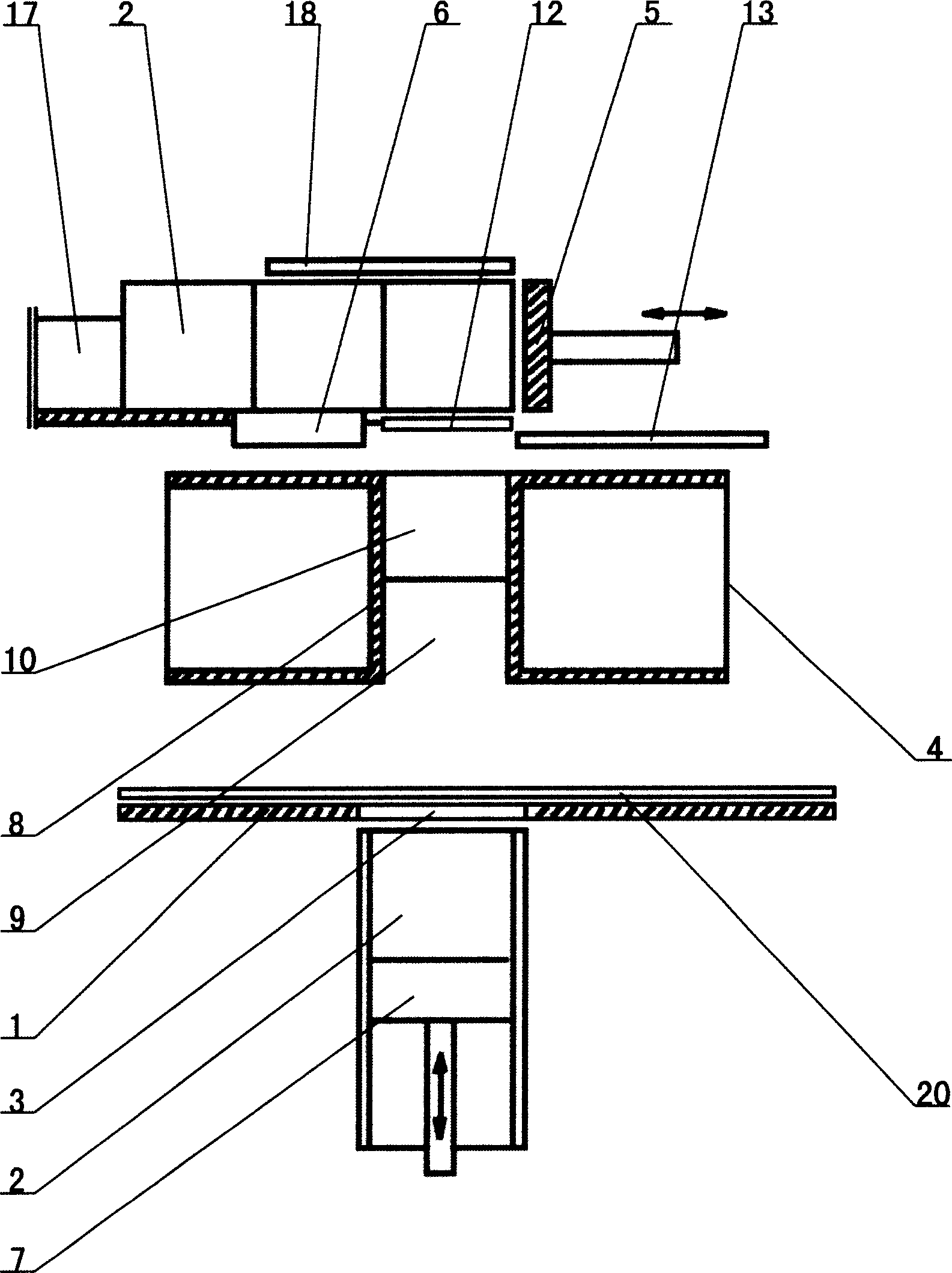

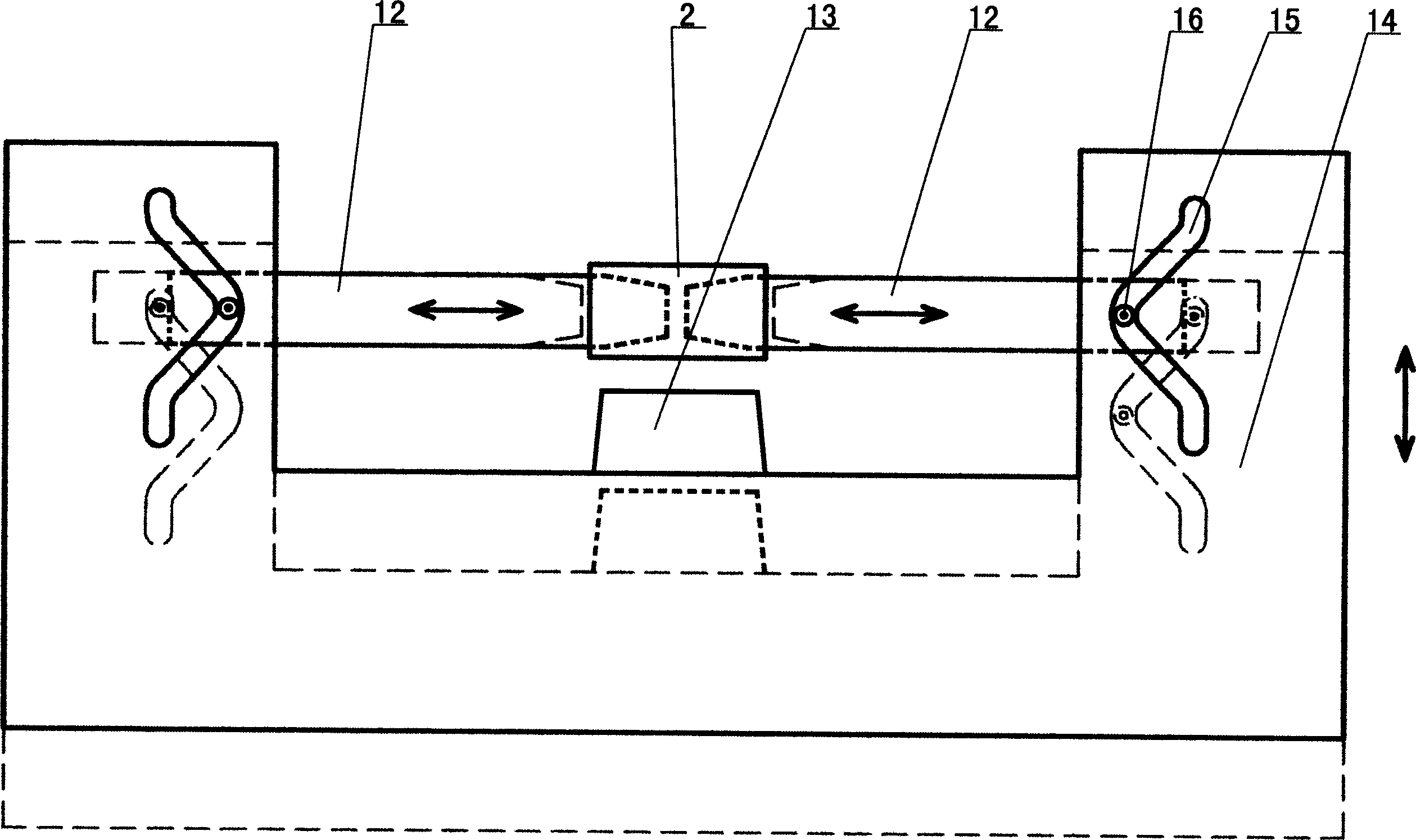

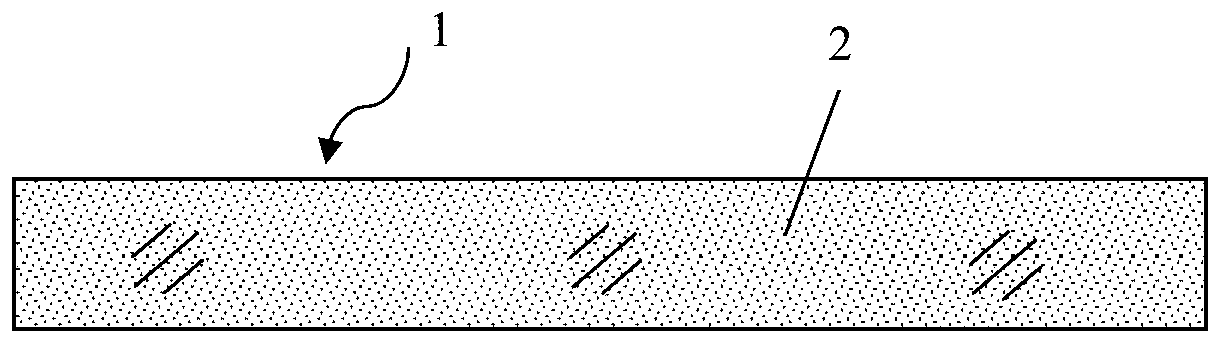

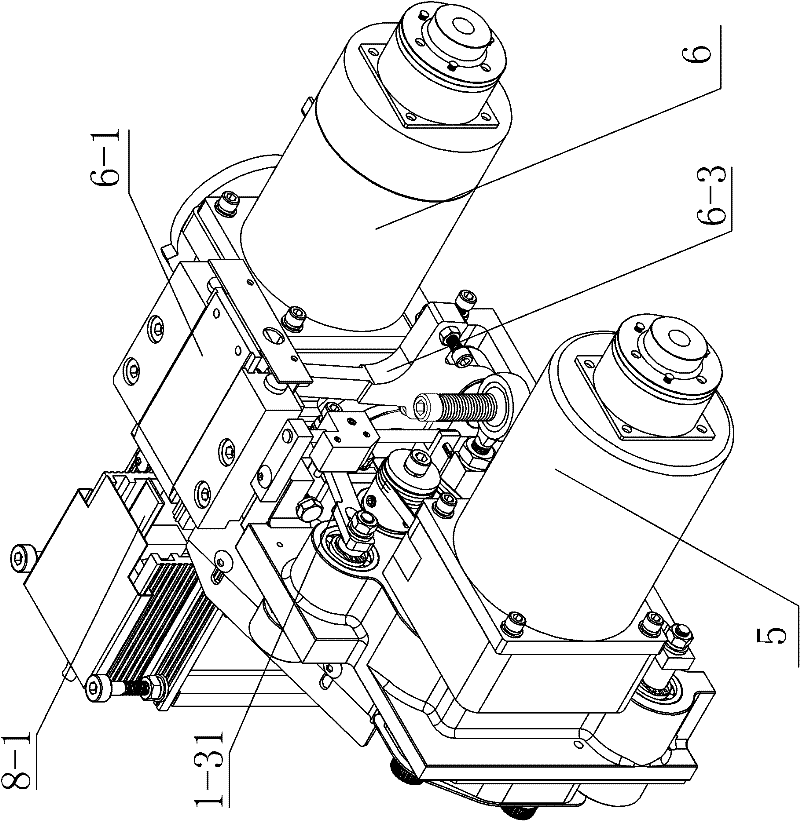

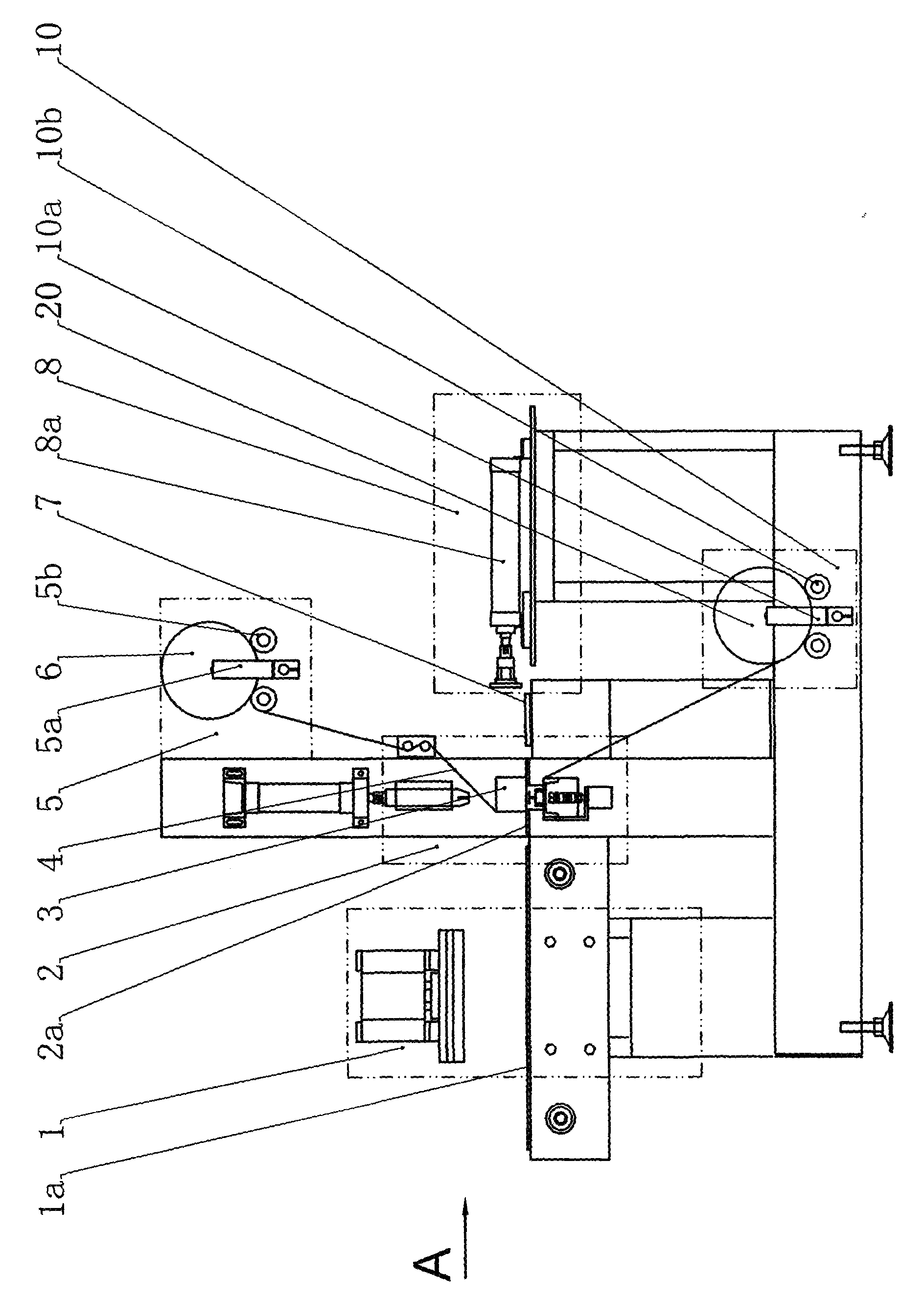

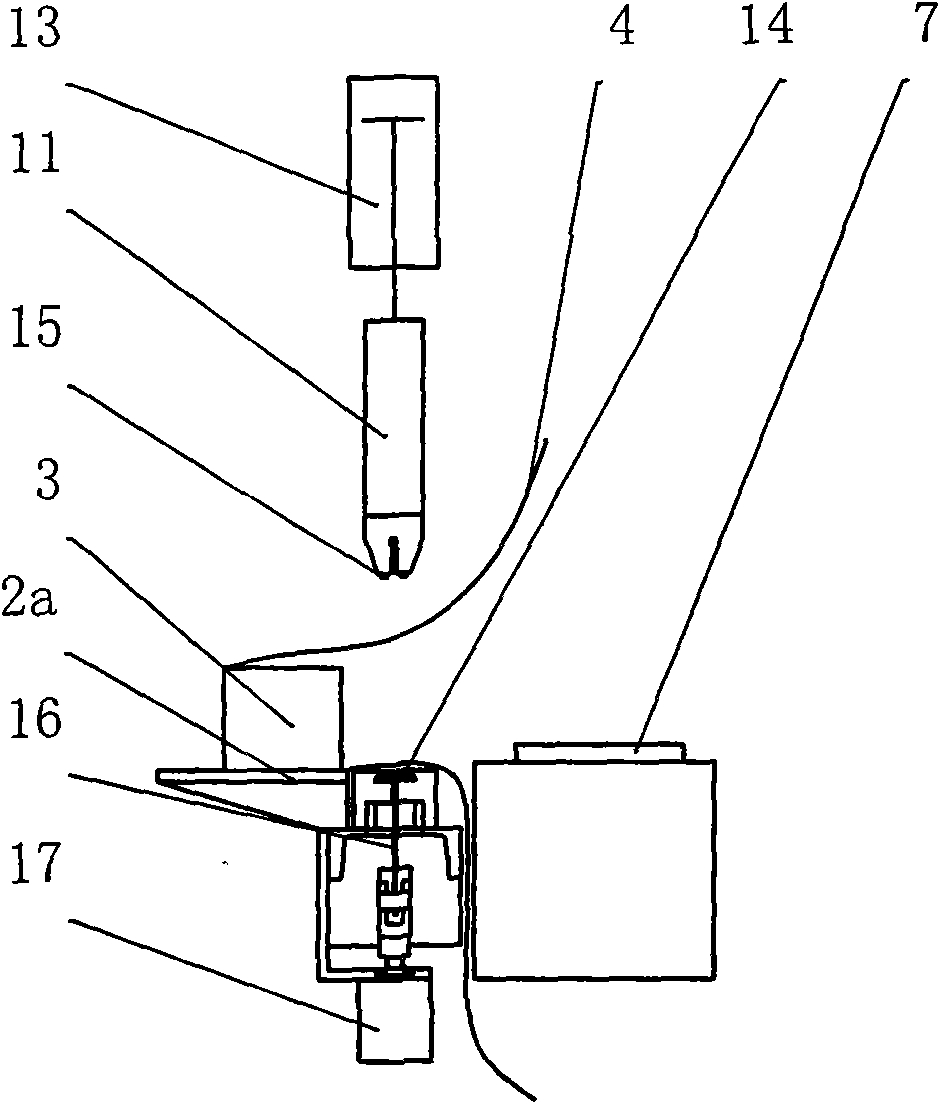

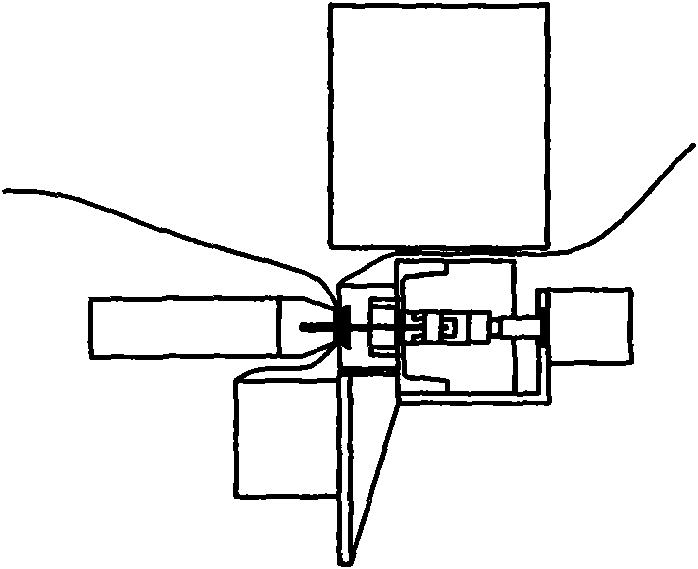

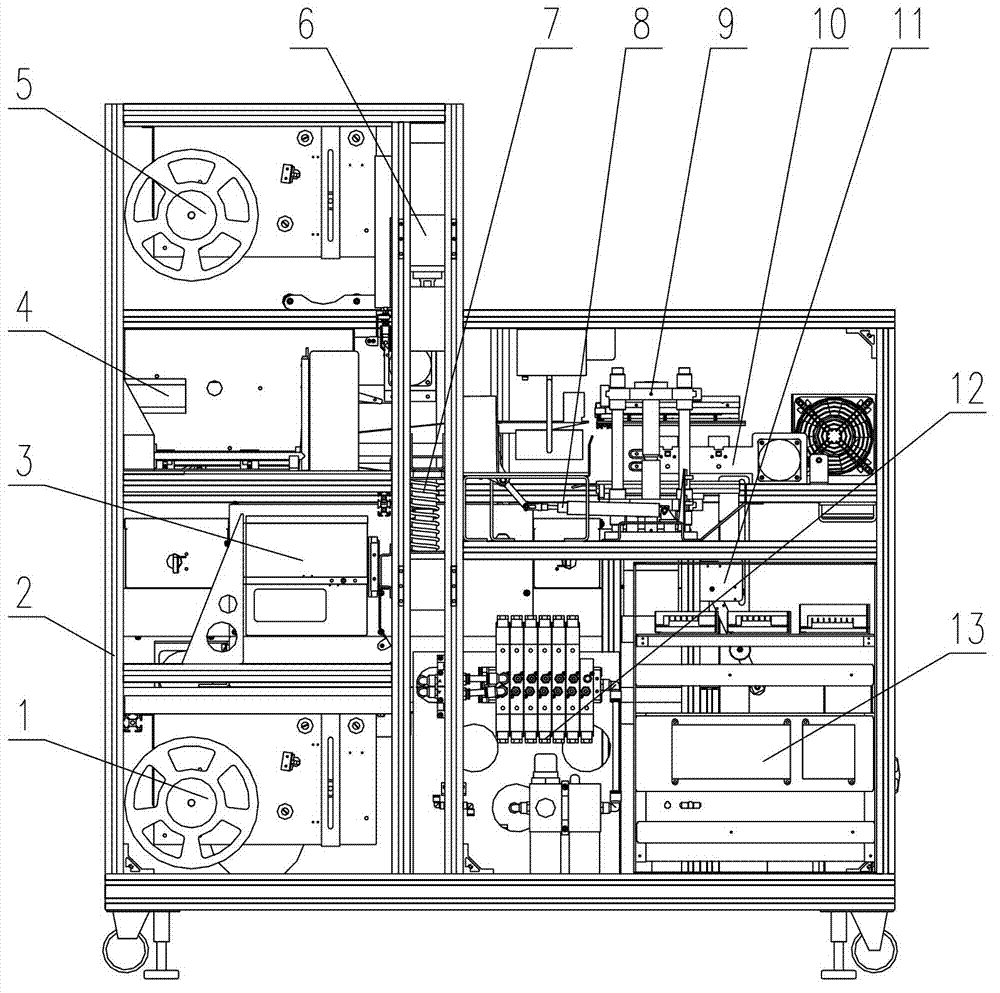

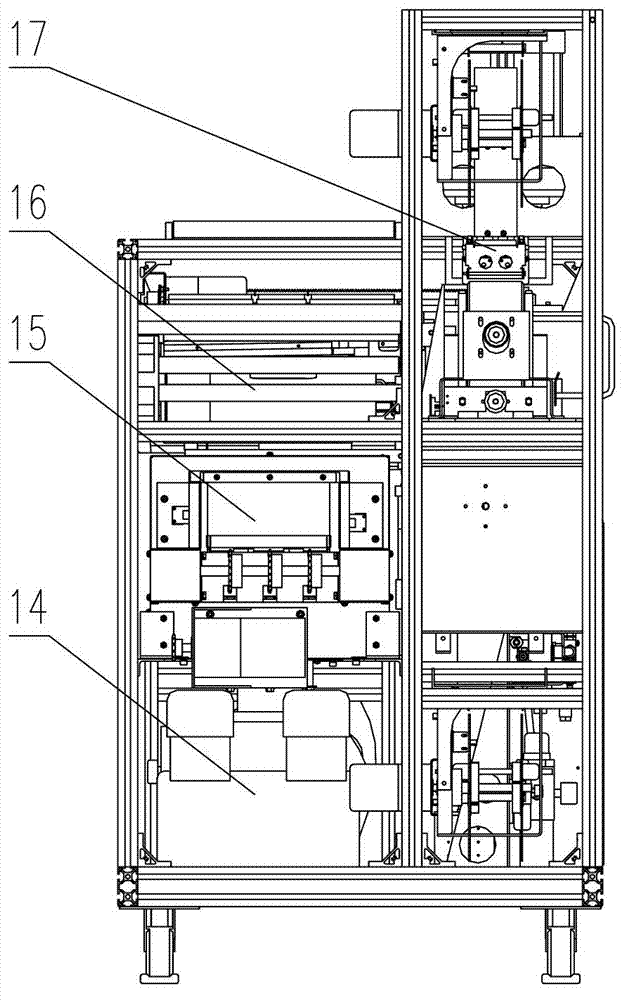

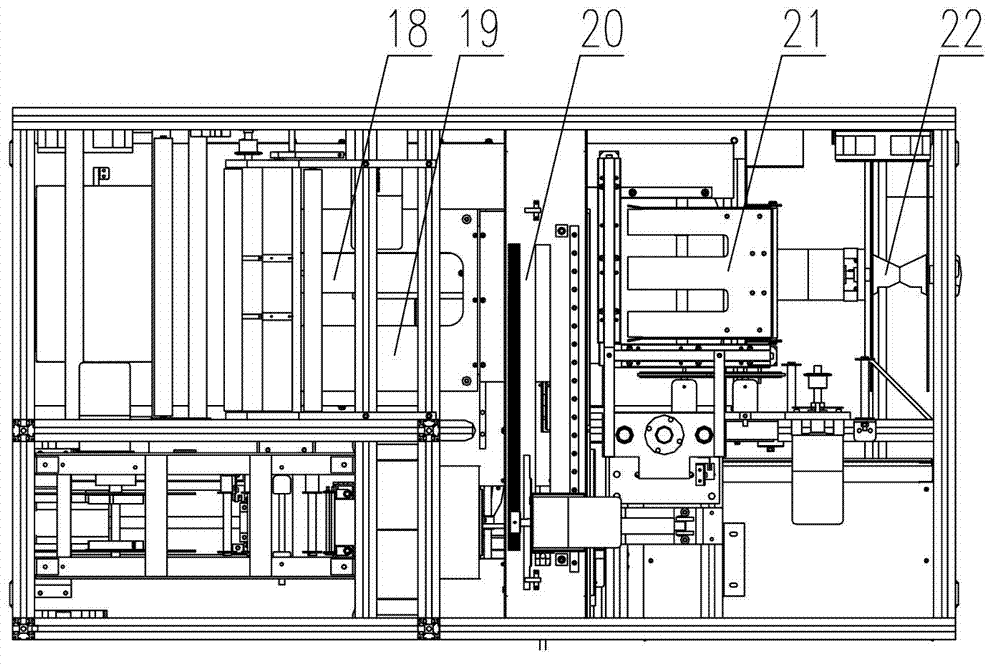

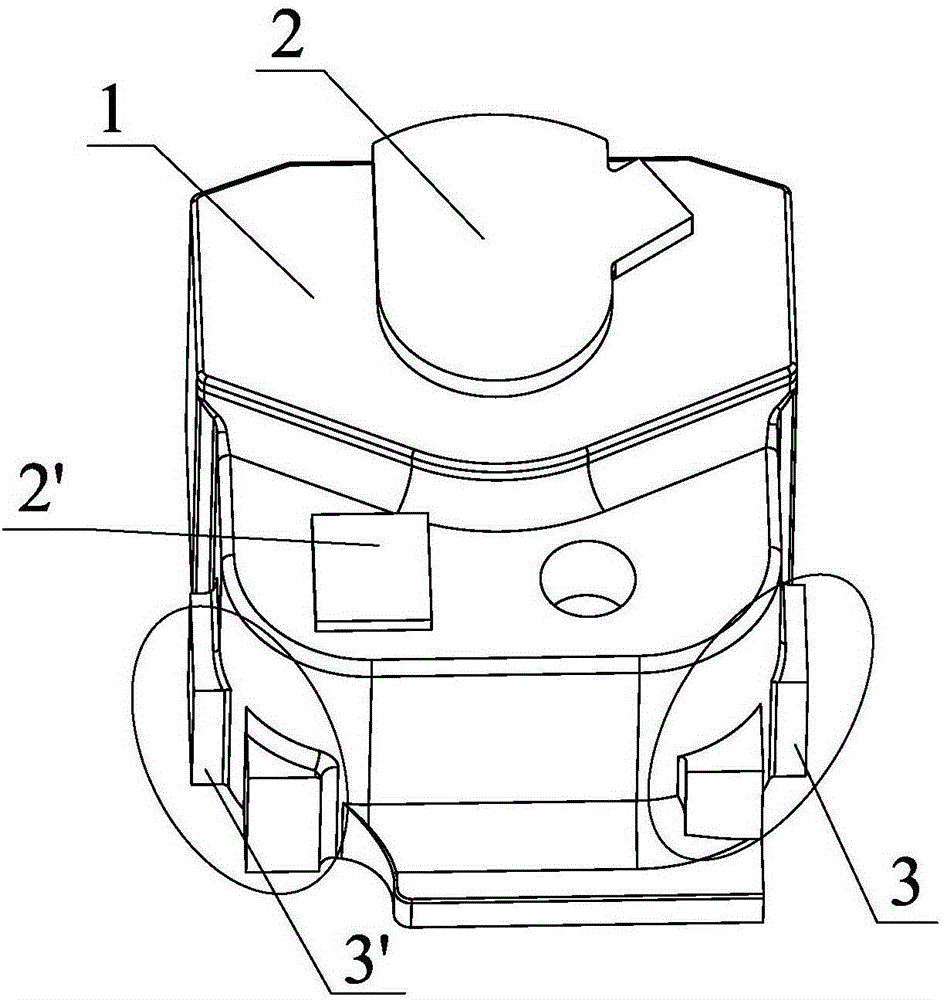

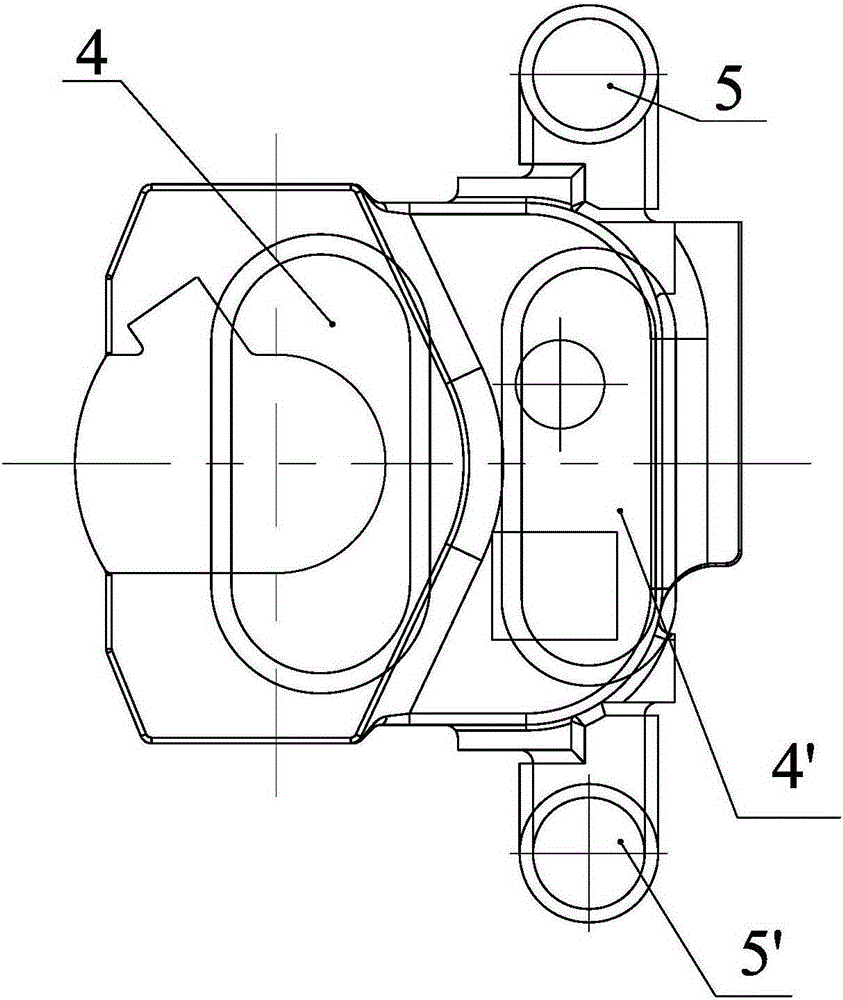

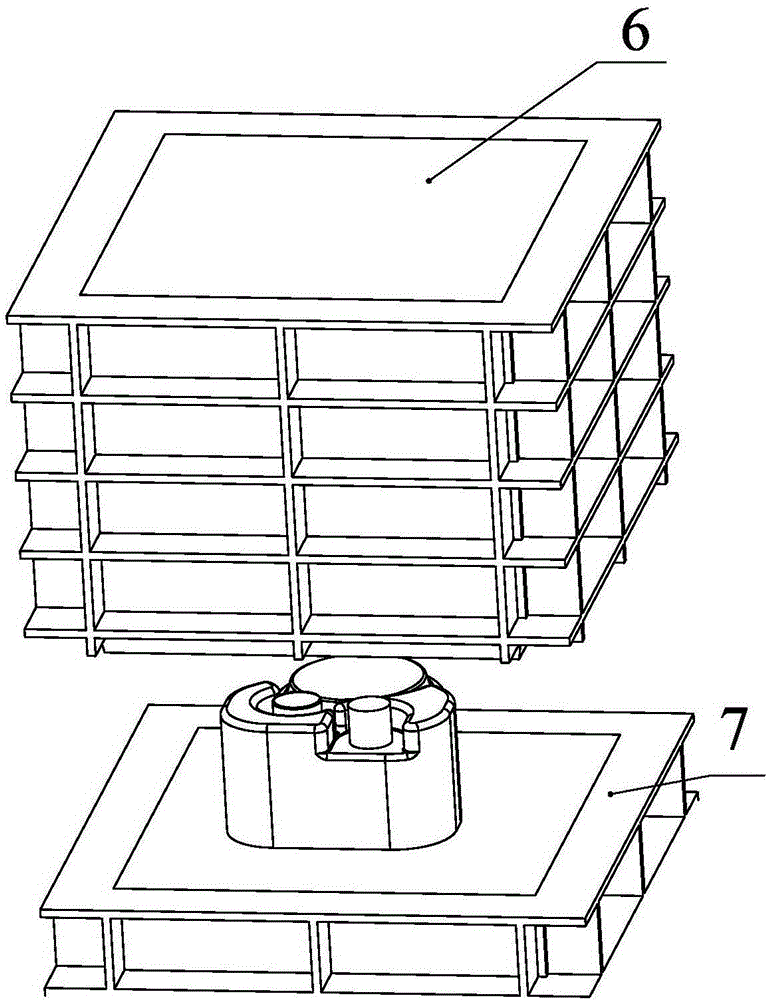

Materials packing machine

InactiveCN1736801AImprove packaging qualityImprove work efficiencyWrapping material feeding apparatusWrappingMaterials sciencePackaging machine

Disclosed is a material packing device, which contains a film feed device, a charging device and a packaging film forming enveloping device, and is characterized in that: said film feed device contains a film cutting mechanism; said packaging film forming enveloping device contains a packaging film supporting board fixed on the stand, the supporting board being equipped with material through-holes, all shapes and dimensions of which match with pre-packaging material; and the packaging film forming enveloping device contains a packaging film former above the material through-hole, a material fixing clamping part and material pushing part above the packaging film former, a group of material floor packaging hands and a scalding enveloping plate for enveloping packaging film of material floor between the packaging film former and the material clamping part, and a material lifting part which can send the material to material fixing clamping part from below the packaging film supporting board; the material fixing clamping part and material pushing part which moves vertically. The device can complete automatically the packaging of material, especially the rectangle material, the packaging quality perfect and stable, and the work efficiency high.

Owner:汕头市金海湾包装机械有限公司

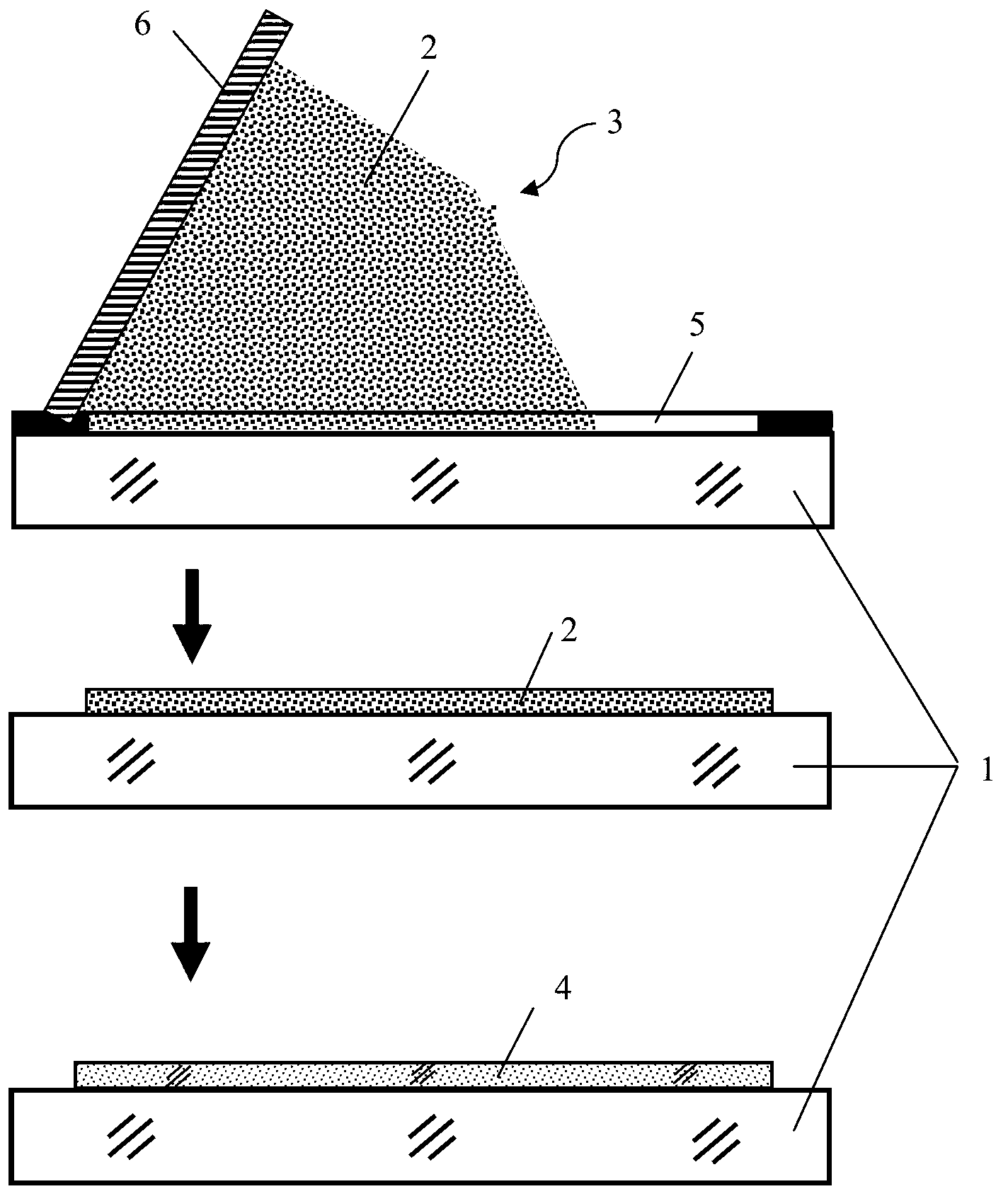

Fluorescent glass sheet and preparation method thereof

ActiveCN103011614AImprove the quality of LED packagingAchieve color temperatureFluorescenceLed packaging

The invention discloses a fluorescent glass sheet and a preparation method thereof. A pulp layer with fluorescent powder is coated on the surface of a glass substrate sheet, wherein the main ingredients of the pulp consist of low-temperature glass powder, fluorescent powder, an intensifier, an adhesive, a dispersing agent and the like; the glass substrate sheet coated with the pulp layer is sintered; and the glass sheet with the fluorescent powder is obtained by controlling the sintering process. The fluorescent glass sheet is mainly applied to LED (Light Emitting Diode) packaging, the fluorescent powder preparation process can be reduced, and the packaging material and process cost are reduced; due to the high heat conductivity and the heat stability of the fluorescent glass sheet, the performance and the reliability of an LED module and a lamp can be remarkably improved; and at the same time, as the surface fluorescent powder layer is uniform in thickness and is far away from an LED chip, the LED packaging quality can be improved, and the effective control on color temperatures, chromaticity coordinates and color rendering indexes is realized. The fluorescent glass sheet can be used for packaging LED chips of various colors, can realize the single LED chip packaging and can also be used for multi-chip array LED module and LED lamp packaging, so that the method is simple and easy to carry out, and the fluorescent glass sheet is suitable for production in scale.

Owner:武汉利之达科技股份有限公司

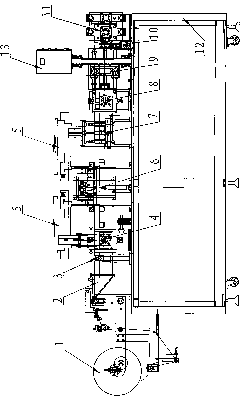

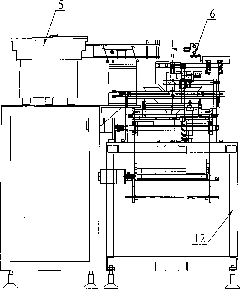

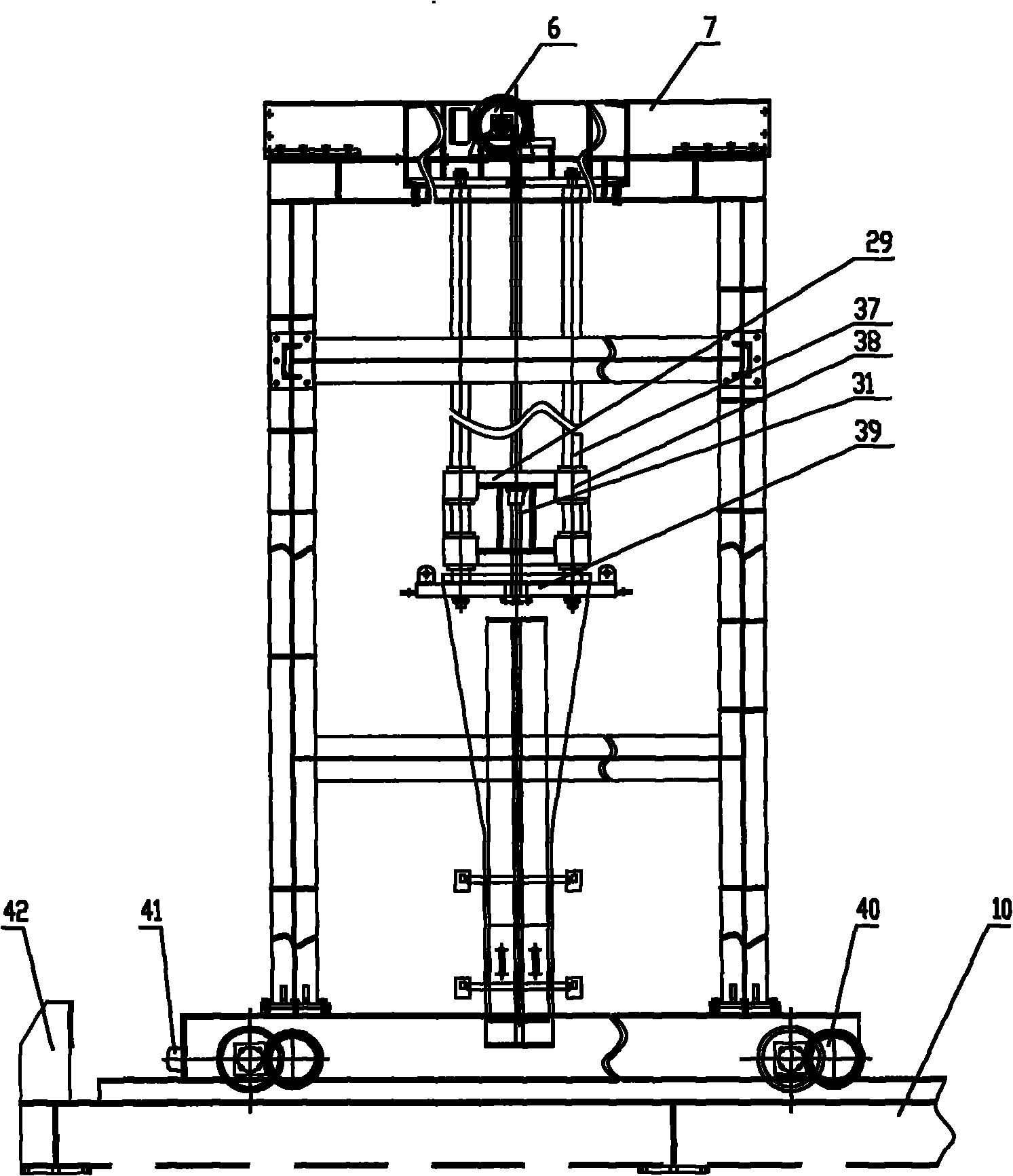

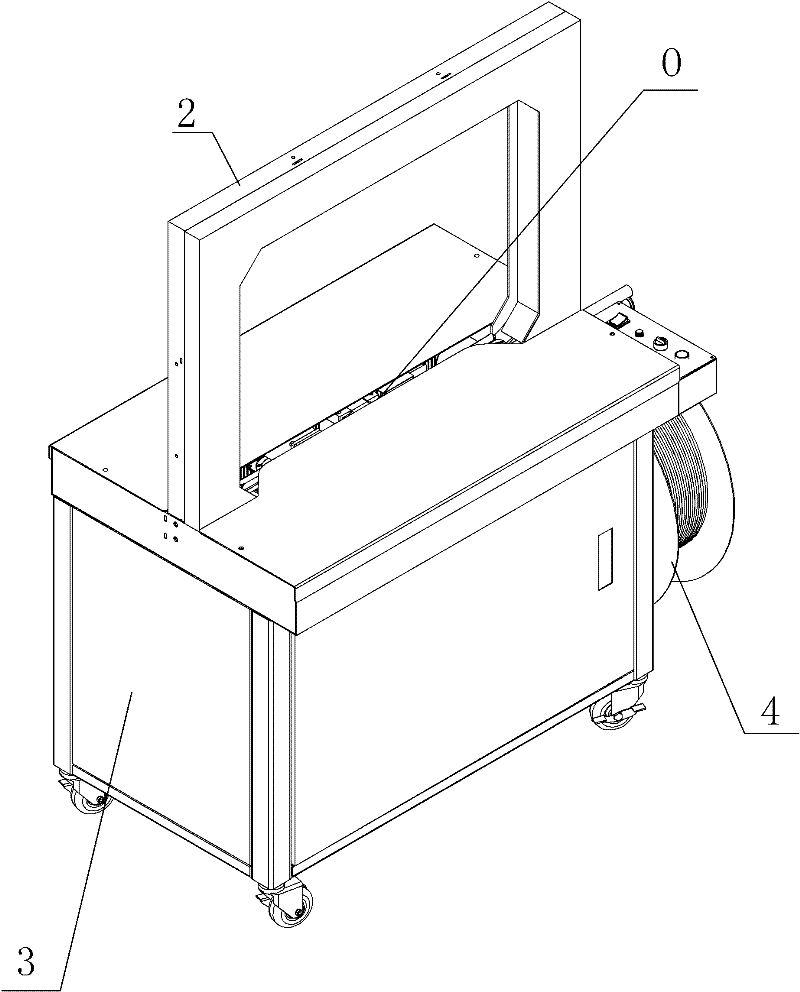

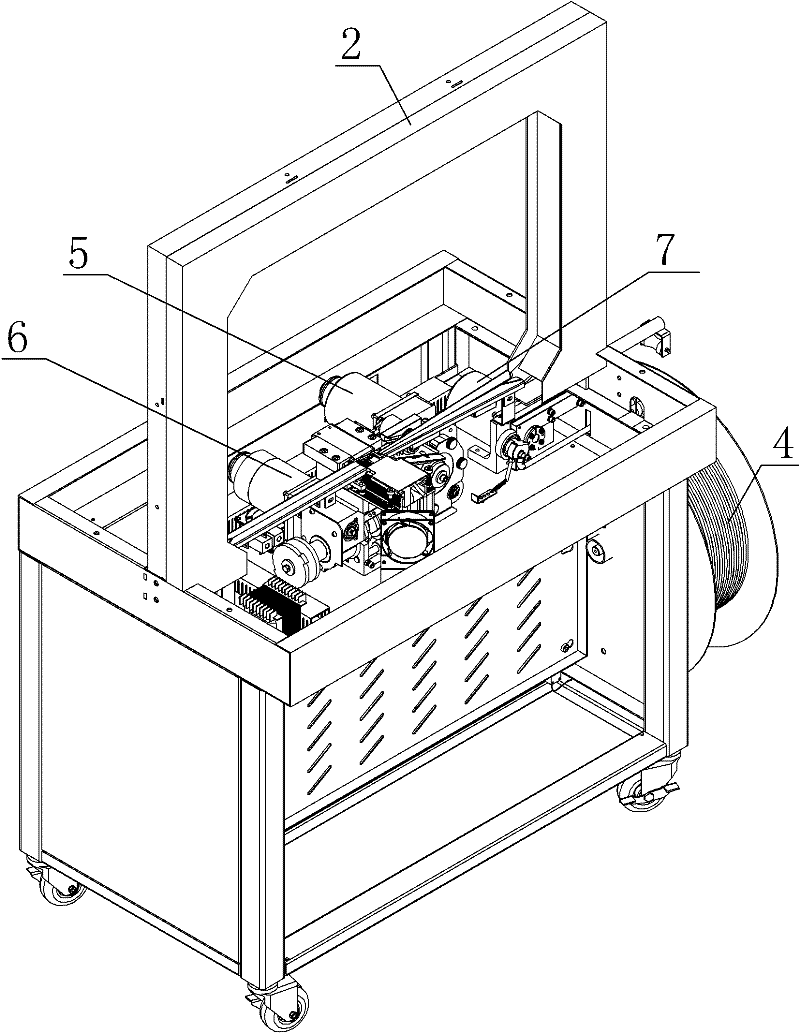

Novel packing machine

ActiveCN102530291AReasonable configurationEasy to controlBinding material applicationBundling machine detailsFixed frameEngineering

The invention provides a novel packing machine. A vertical mounting plate is arranged at the lower half part of the packing machine, a horizontal mounting plate is fixed at the upper part of the vertical mounting plate, a fixing frame is arranged at the upper half part of the vertical mounting plate and wraps the left part, right part and upper part of an article banding station, the mounting plates and the fixing frame are arranged on a rack of the packing machine, and a tape spool is arranged at the lower part of the packing machine; and a movement of the packing machine and a pre-sending belt device are arranged on the horizontal mounting plate, a retreating belt and tensioning belt device is arranged in the movement of the packing machine and comprises a retreating belt mechanism and a tensioning belt mechanism. According to the novel packing machine, all the functional devices are reasonable in configuration and convenient and simple in control, the packing quality can be improved, and the comprehensive improvement of the packing efficiency and the reliable work can be facilitated.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

Self-Locking Fastener

InactiveUS20130031756A1Easy and convenient to useEasy and convenient to and operateSnap fastenersFlexible elementsEngineeringSelf locking

Owner:DONGGUAN MASTER INK CO LTD

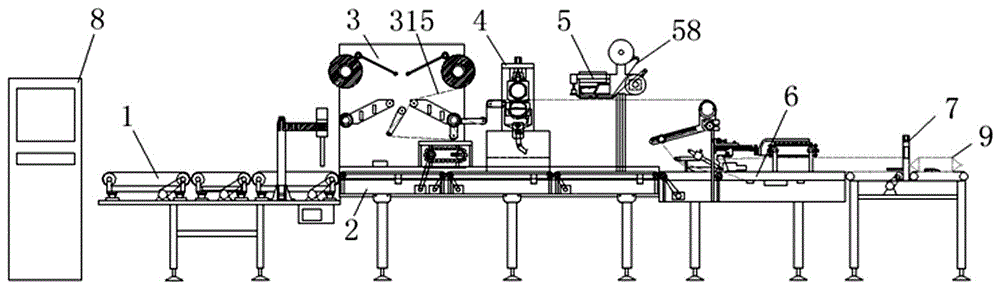

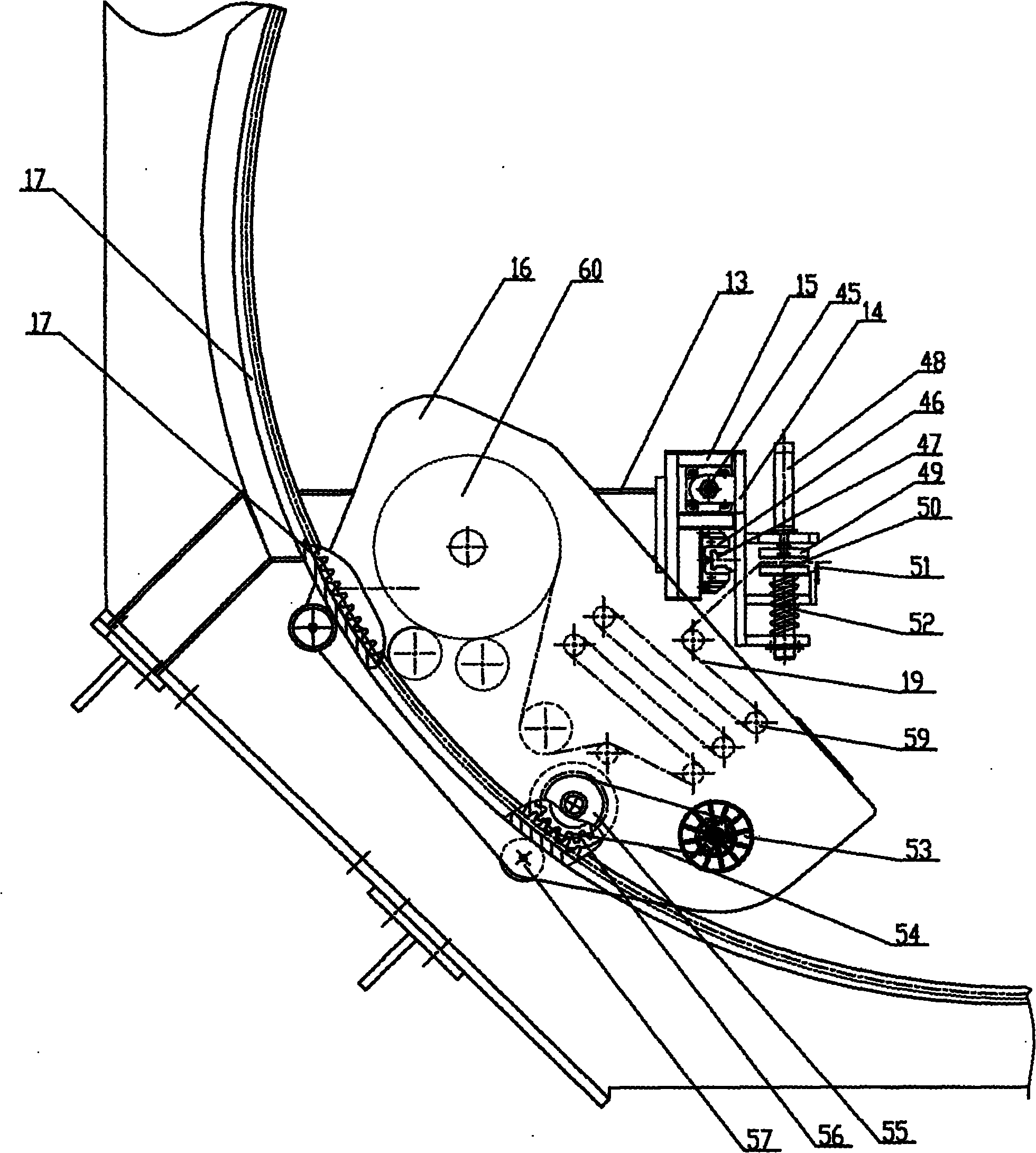

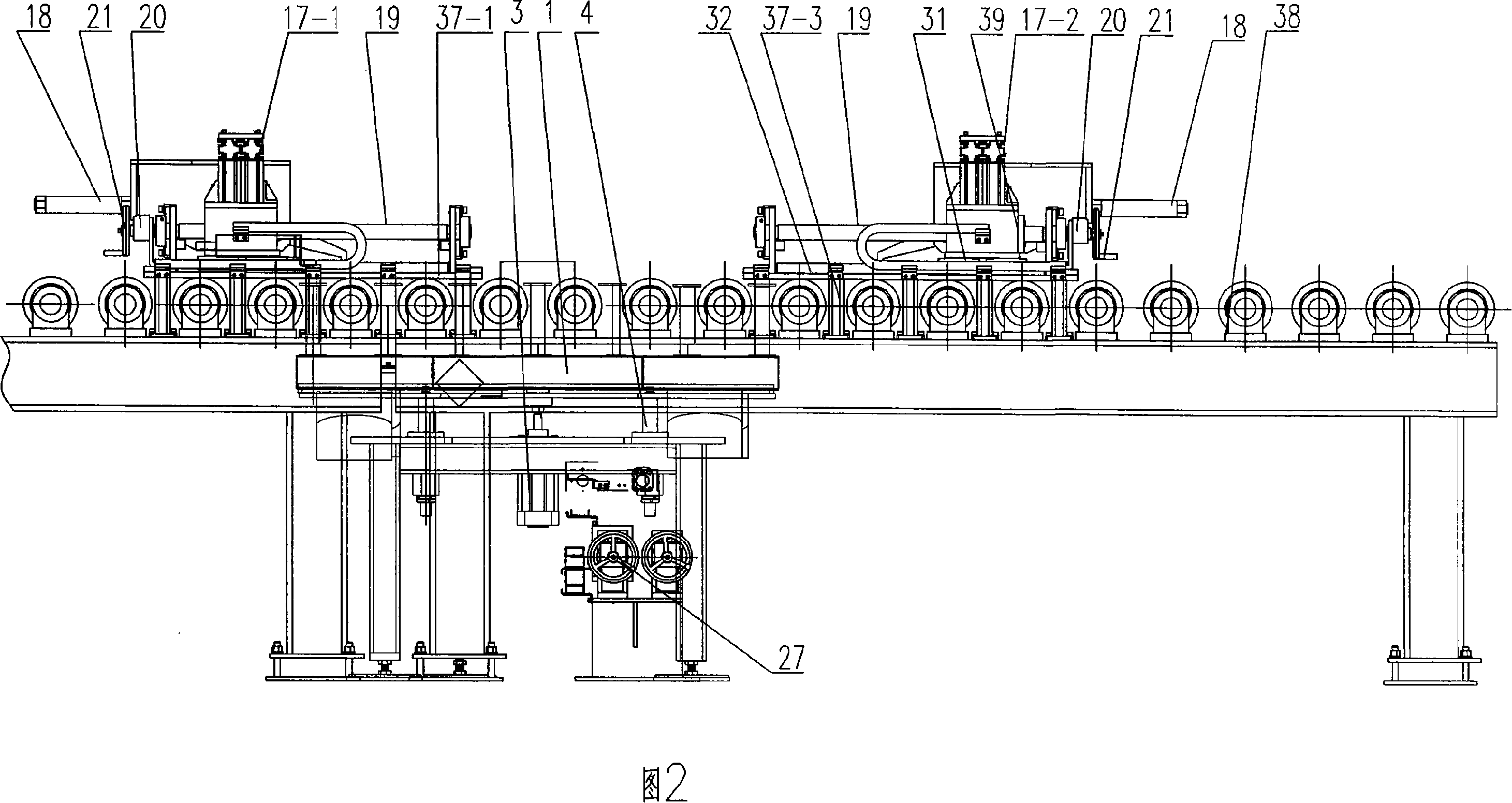

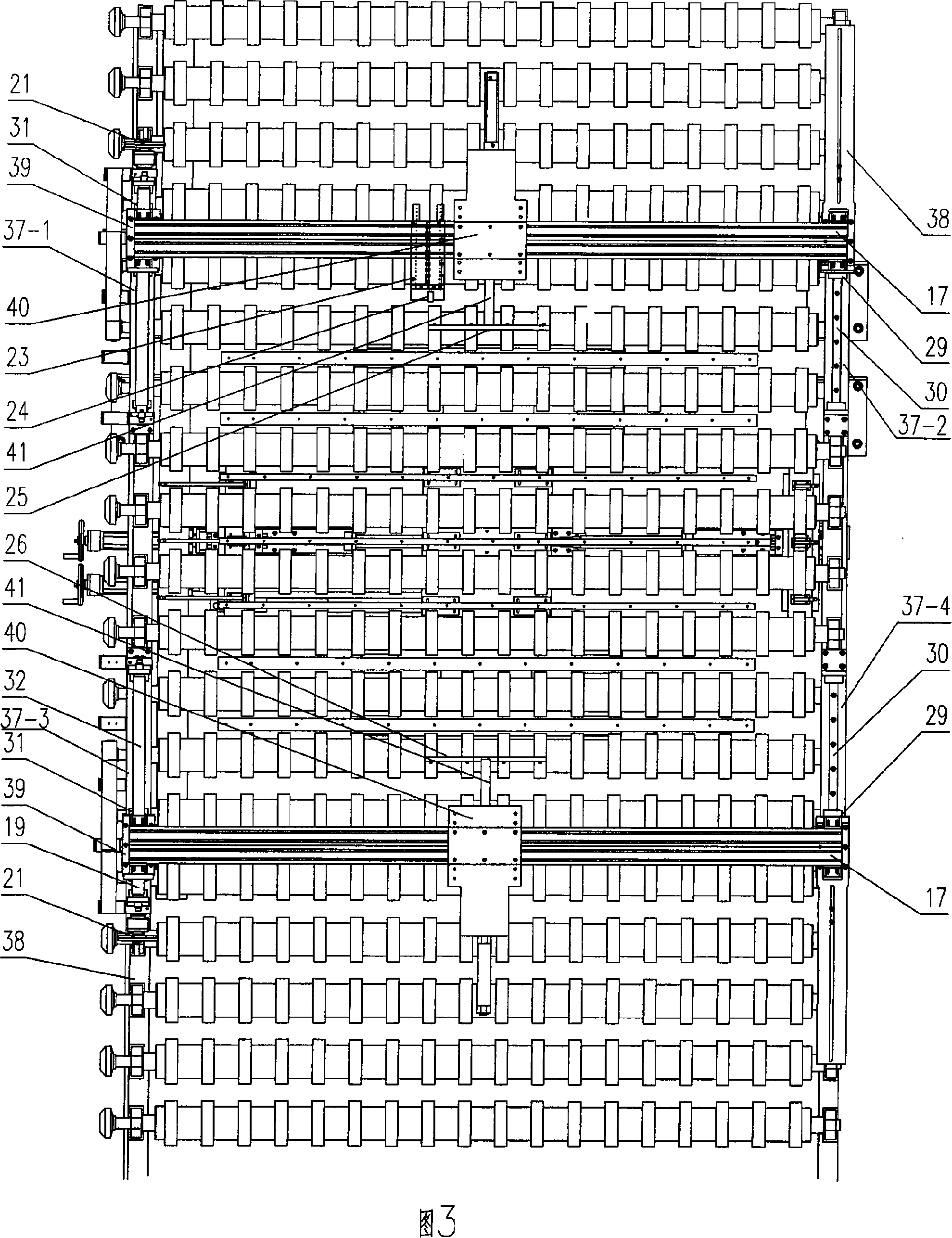

Automatic film sealing machine for welding rods

ActiveCN101767660AReduce labor intensityImprove packaging qualityWrapping material feeding apparatusWrappingEngineeringPlastic film

The invention discloses an automatic film sealing machine for welding rods, comprising a conveyor belt, an upper film feeding mechanism, a lower film feeding mechanism, a side film sealing mechanism, two end sealing mechanisms and a pushing mechanism, wherein the pushing mechanism is arranged at the right side of the conveyor belt and is vertical to the direction of the conveyor belt, and a pushing reciprocating unit is arranged on the pushing mechanism; the side film sealing mechanism and the end sealing mechanisms are sequentially arranged at the extending parts of the pushing mechanism at the left side of the conveyor belt, and the height of a side film sealing worktable and an end sealing conveyor belt are equal to the height of the conveyor belt; a plastic film which connected with an upper rolling film and a lower rolling film into a whole is arranged between the side film sealing mechanism and the conveyor belt, and the upper and the lower film feeding mechanisms are respectively arranged at the upper and the lower parts of the side film sealing worktable; and the two end seal mechanisms have the same structure and are symmetrically arranged at the front and the rear sides of a welding rod packing box moving forward. The invention has the beneficial effects that: two operations of bagging and sealing are reduced, and the labor intensity is decreased; and the outer packing quality of the product and the humidity resistance are improved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

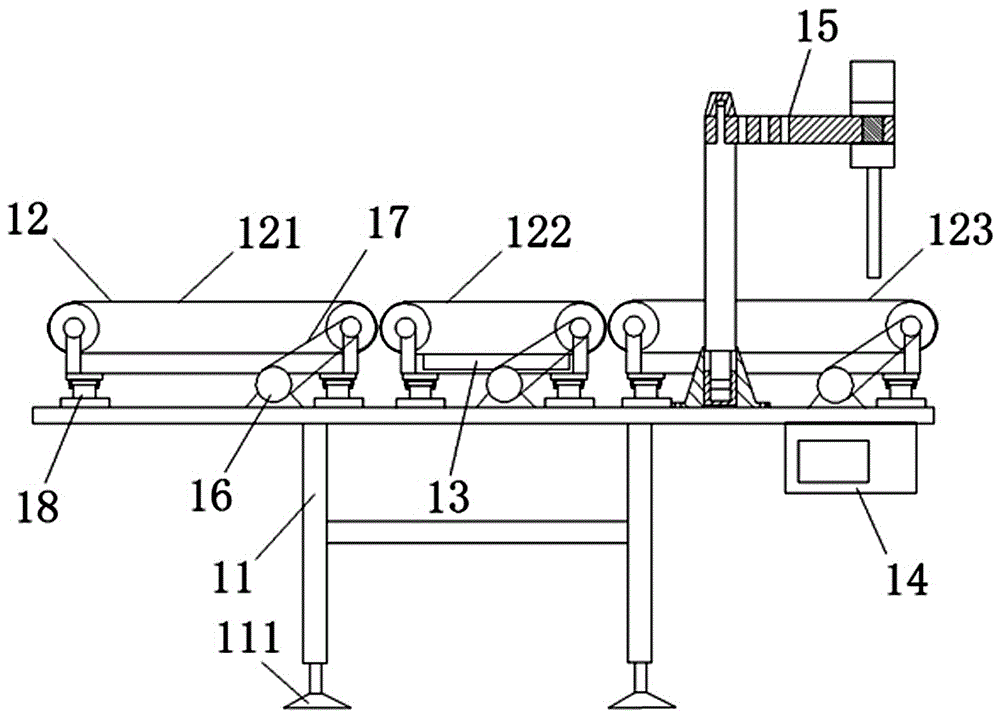

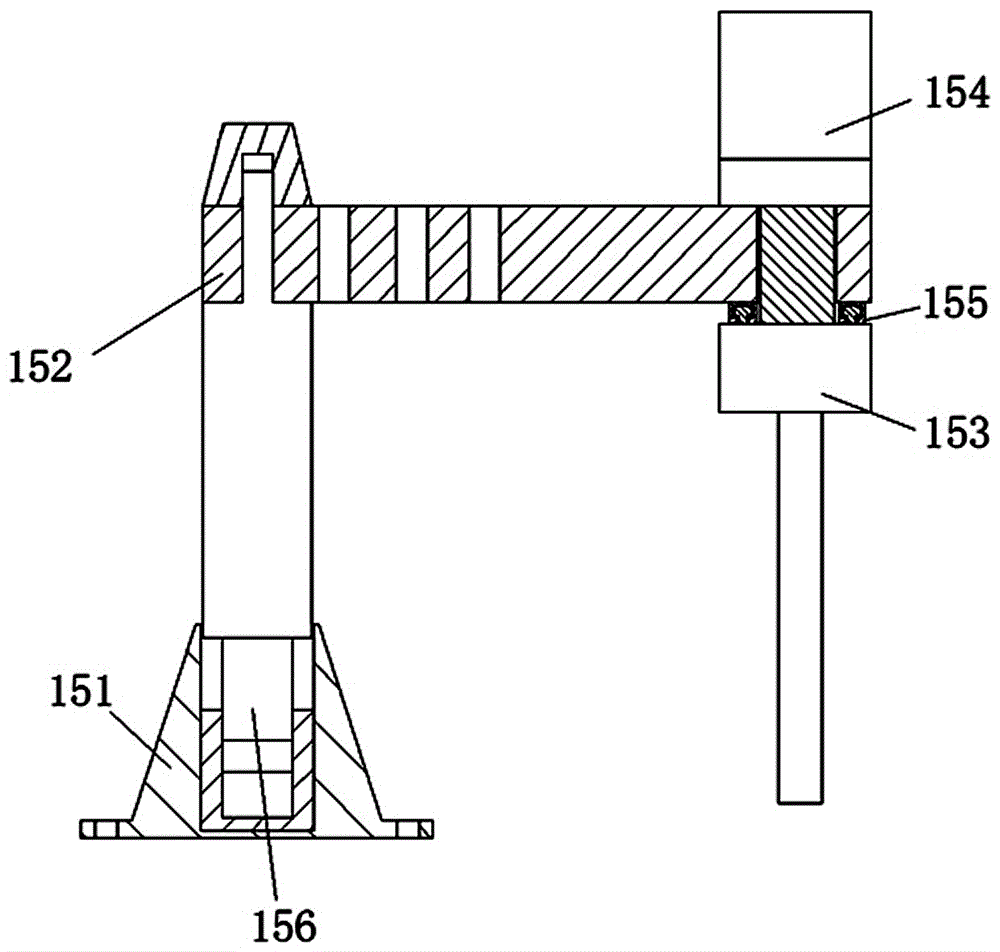

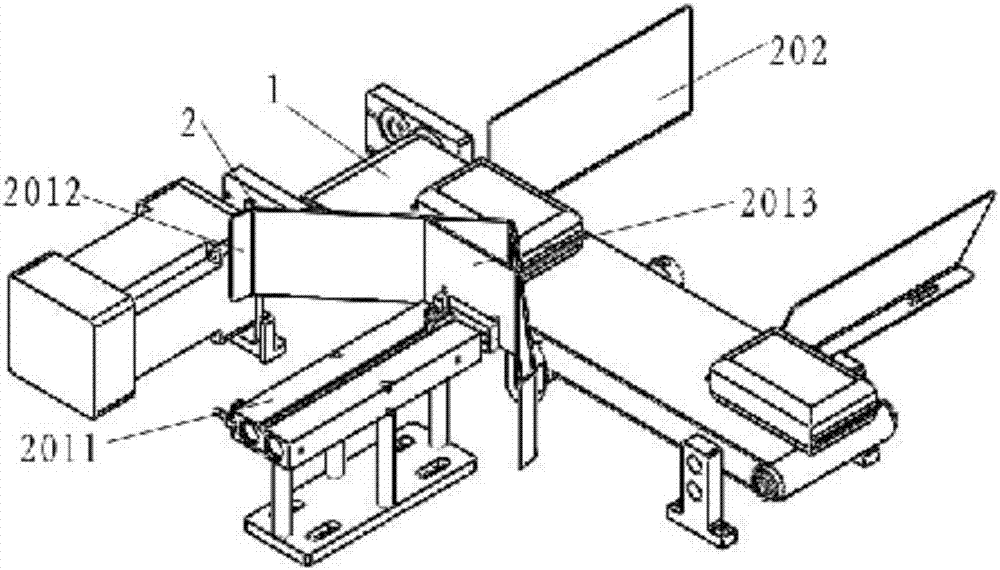

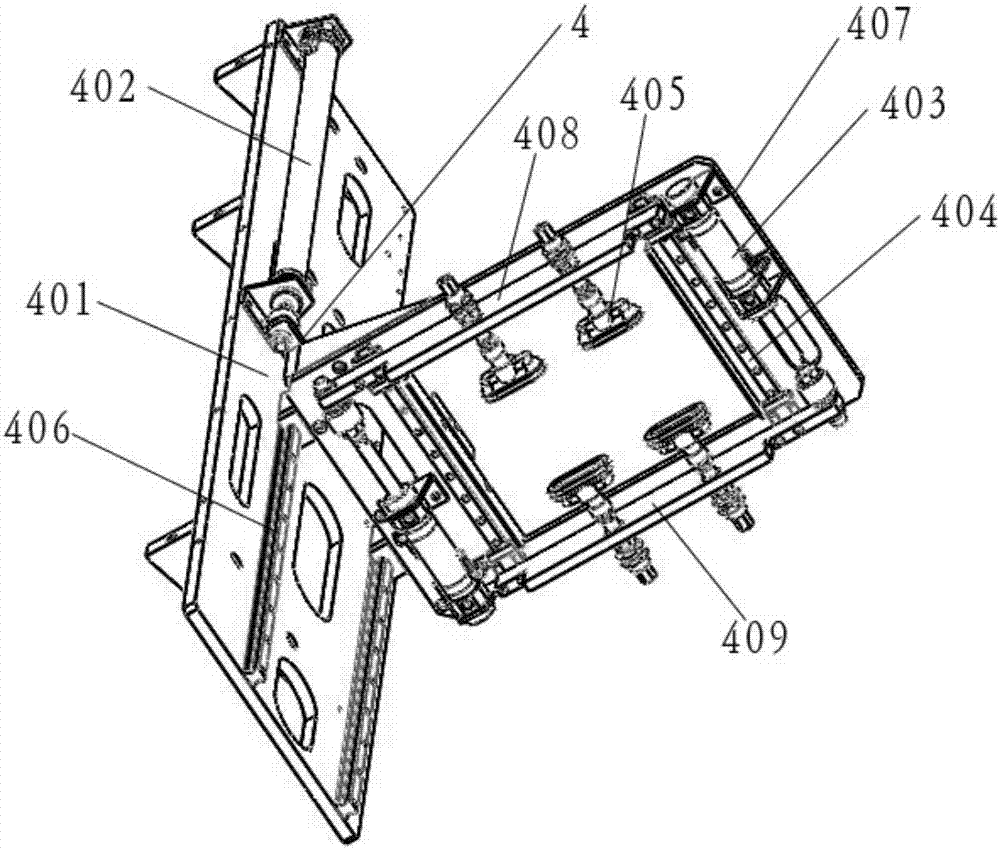

Glass alignment positioning system for the ultra-thin glass on-line automatic sheet-fetching

ActiveCN101139049ASolve the key technical problems of offlineImprove yieldRegistering devicesCharge manipulationEngineeringThin glass

The present invention discloses a glass centroid positioning system for ultra-thin glass online automatic film-taking, comprising a front and back centroid device for front and back positioning of the glass, a left and right centroid device for left and right postioning of the glass as well as an air flotation device of wind collection box, the front and back centroid device is arranged on the upper part of a glass transportation line, the air floatation device of wind collection box is arranged between the front and back centroid device and below a glass transportation branch line, and the left and right centroid device is arranged on the two sides of the air floating device of wind collection box; when the glass is transported to the right position, a blower blows to the wind box, meanwhile, the wind box moves upward, the glass is blew upward, the front and back centroid device clamps the front and back of the glass, the left and right centroid device moves upward to clamp the glass, and the glass waits for grasping of a handling robot after centroid and positioning. The present invention can position accurately in the whole process of production and solves key technical problem of ultra-thin glass offline while also avoiding the problem of surface scratching, pollution and damage of manual offline and package.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Banknote plastic packaging machine and banknote packaging method

ActiveCN102897340AImprove packaging qualityImprove preservation qualityPaper article packagingWrappers shrinkagePlastic packagingControl system

The invention provides a banknote plastic packaging machine and a banknote packaging method. The banknote plastic packaging machine comprises a frame, an upper plastic film frame, a lower plastic film frame, a lifting mechanism, a driving system and a control system, wherein the frame is divided into a plurality of layers of mounting areas from top to bottom by a plurality of baffle plates; a primary plastic package unit is arranged in the mounting area between the upper plastic film frame and the lower plastic film frame and used for conducting primary plastic package on plastic packaged banknotes by a plastic film, and the secondary plastic package unit is parallel to the primary plastic package unit and is used for conducting the secondary plastic package on the plastic packaged banknotes by heat shrinkage films; the lifting mechanism is arranged in front of an L-shaped banknote pushing mechanism and used for conveying the plastic packaged banknotes subjected to secondary plastic package to a heat shrinkage furnace, and the heat shrinkage furnace is arranged below the lifting mechanism and used for conducting heat shrinkage treatment on the plastic packaged banknotes subjected to secondary sealing and cutting. According to the banknote plastic packaging machine, the banknote damaging rate is reduced, the banknote drawing can be avoided, the banknote storage quality is improved, the environment of the banknote storage warehouse is improved, the logistics management of the banknotes is facilitated, the volume of the machine is small, and the degree of automation is high.

Owner:ZHEJIANG ZHONGDA PACKAGING EQUIP +1

Core assembly moulding sand mould structure for gearbox shell castings and core assembly moulding method

The invention relates to a core assembly moulding sand mould structure for gearbox shell castings and a core assembly moulding method. The core assembly moulding sand mould structure for the gearbox shell castings comprises inner cavity sand cores, outer contour sand cores and a pouring system sand mould for core assembly moulding; The inner cavity sand cores and the outer contour sand cores are assembled to form mould cavities for the shell castings; the upper side of the upper end face of each shell casting is provided with multiple round feeders, and a plurality of chilling blocks are arranged in each outer contour sand core among the corresponding round feeders; supplement structures are arranged in each outer contour sand core corresponding to the sides of side bosses on the lower parts of the side walls of the corresponding shell casting, and an insulating layer is arranged on the outer side of each supplement structure; and ingates communicated with the mould cavities of the corresponding castings are arranged in the pouring system sand mould. According to the core assembly moulding sand mould structure disclosed by the invention, moulding and casting cost of the castings is reduced; the work load of subsequent machining of the castings is reduced; and the production efficiency is improved.

Owner:KOCEL STEEL

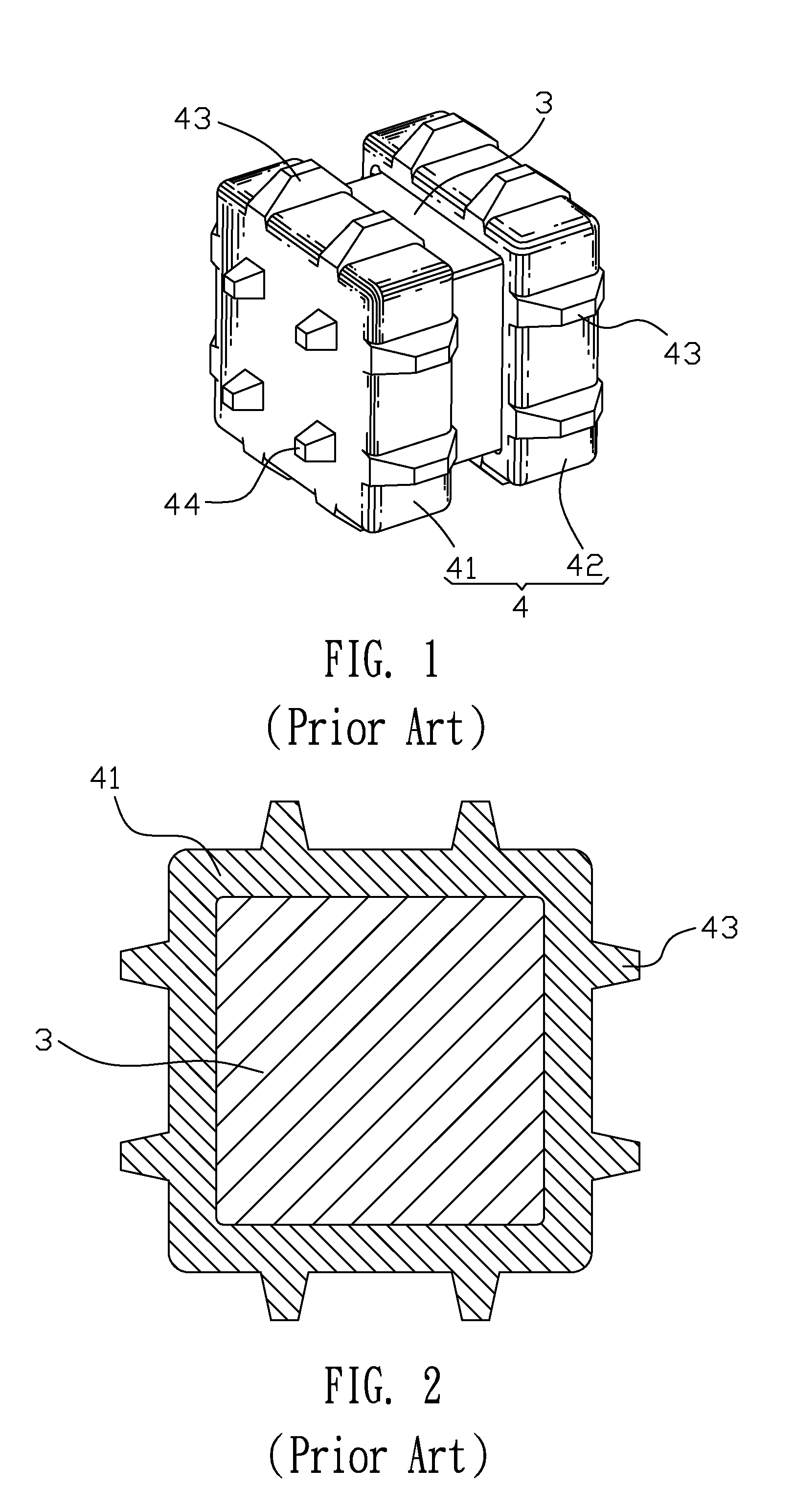

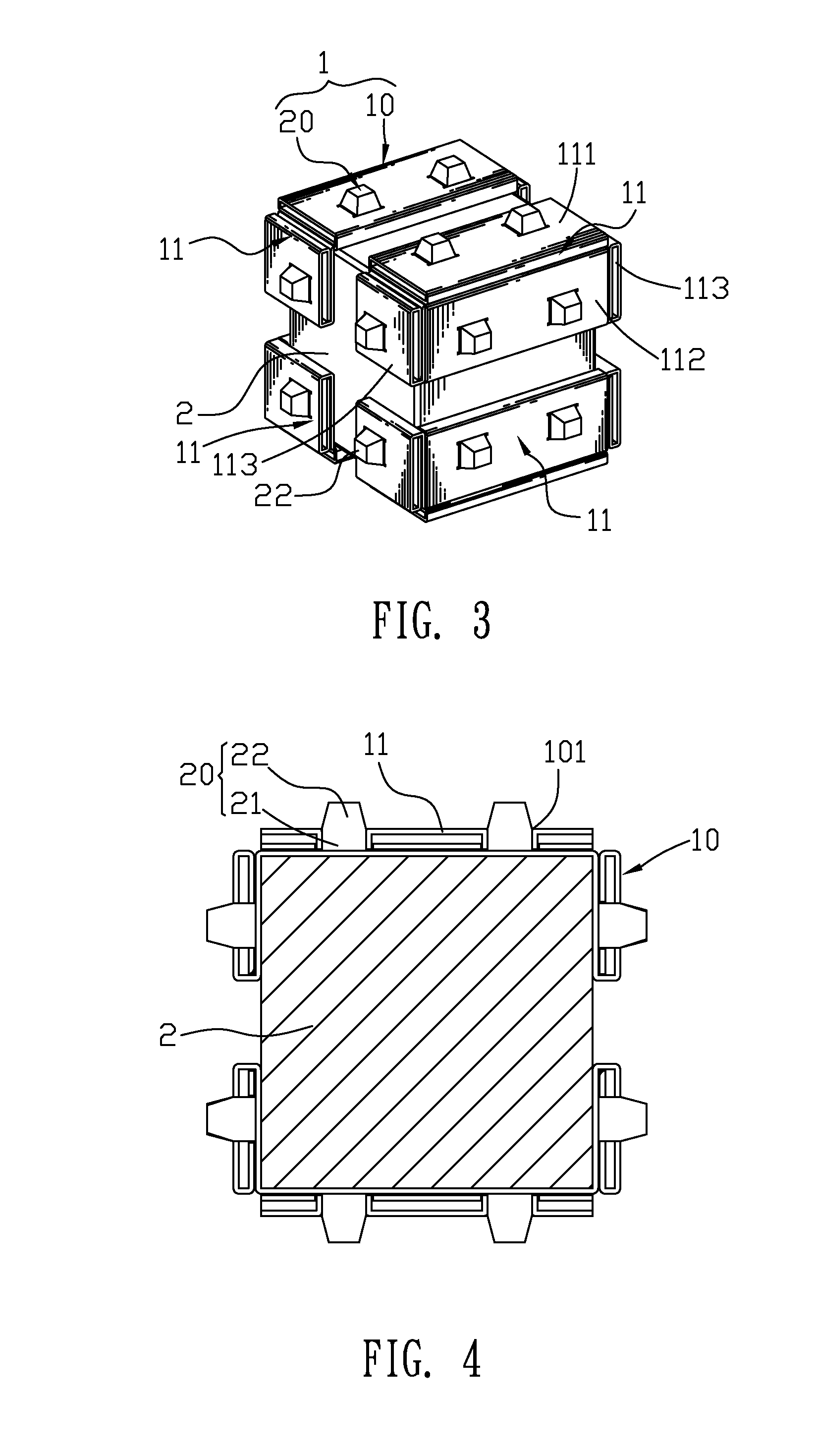

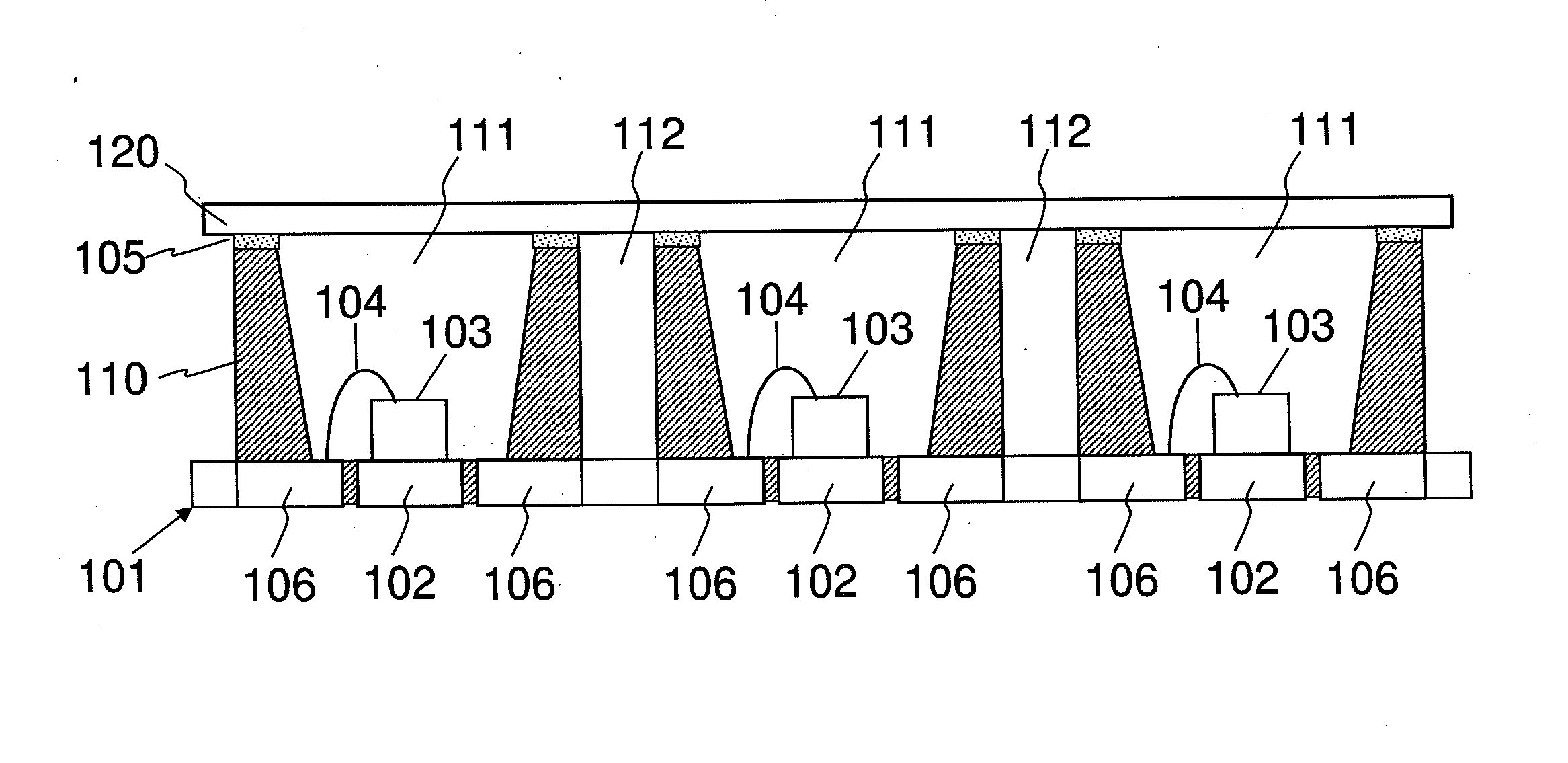

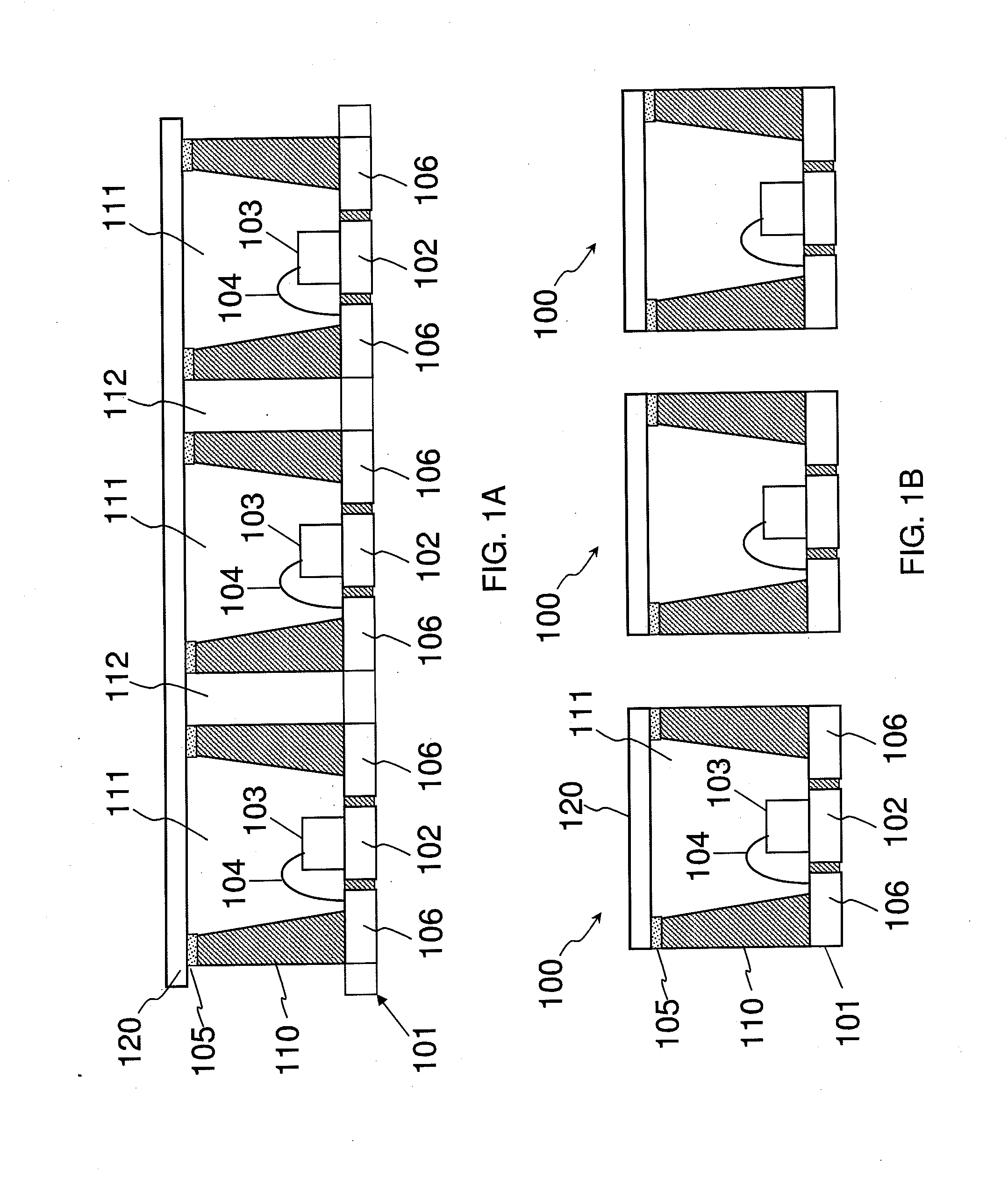

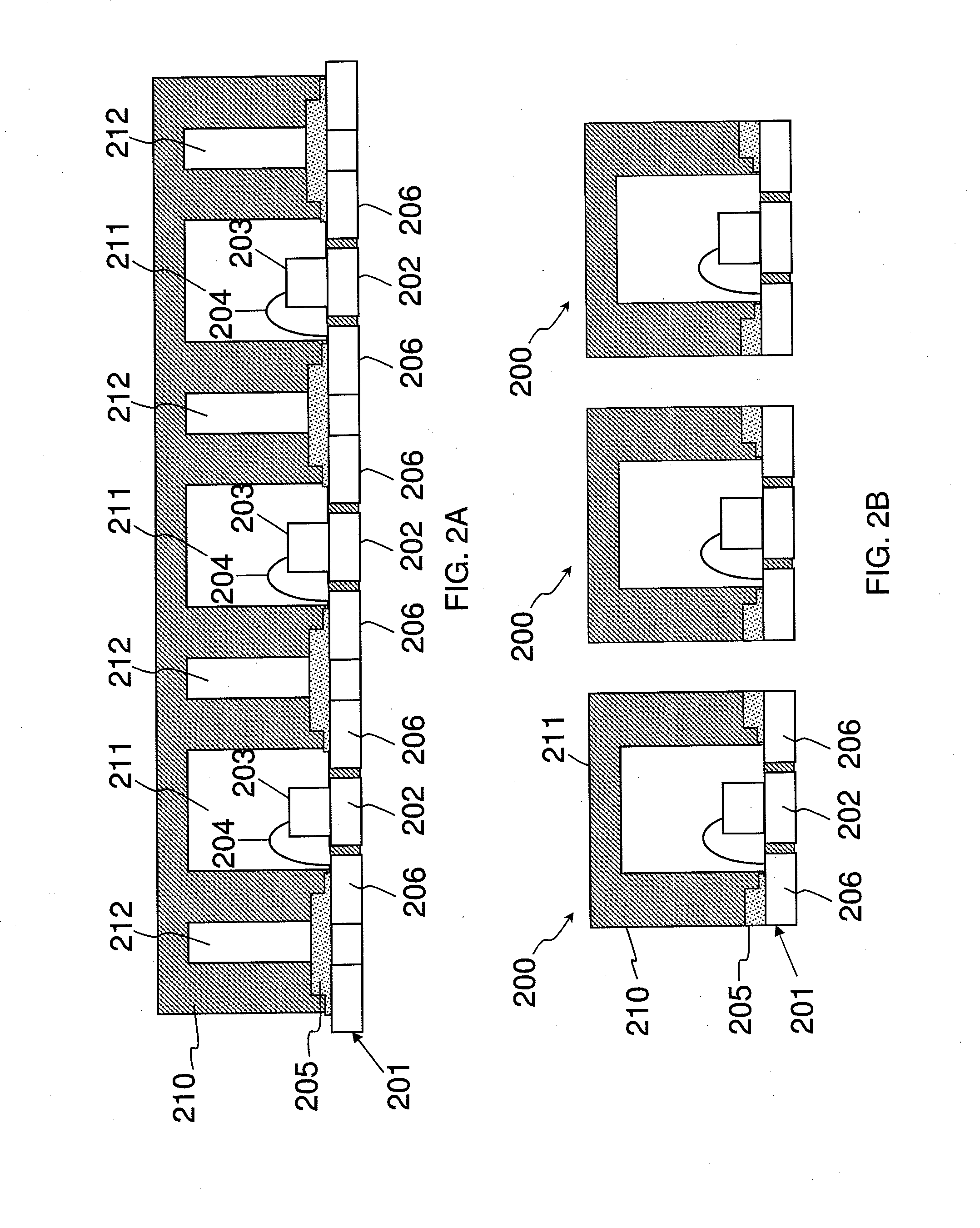

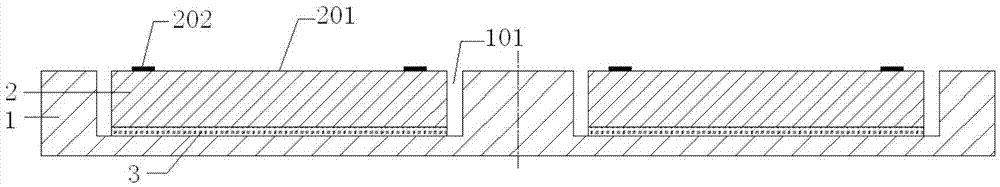

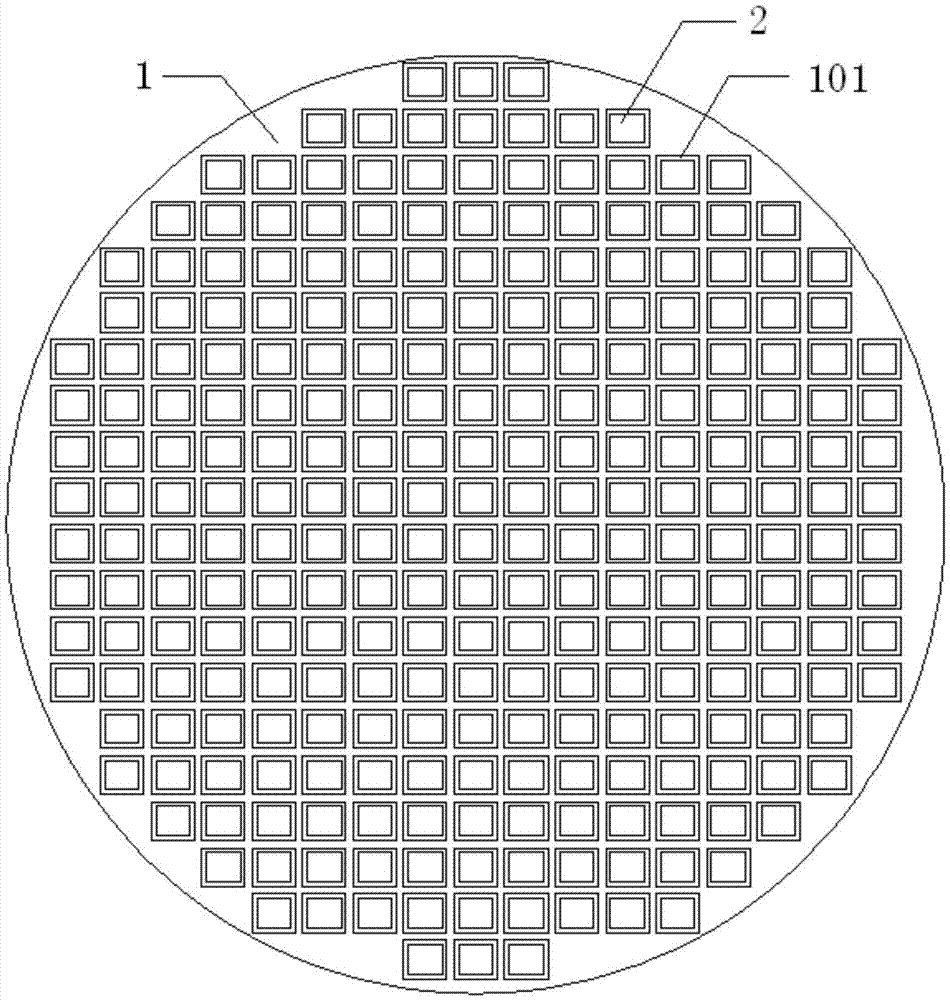

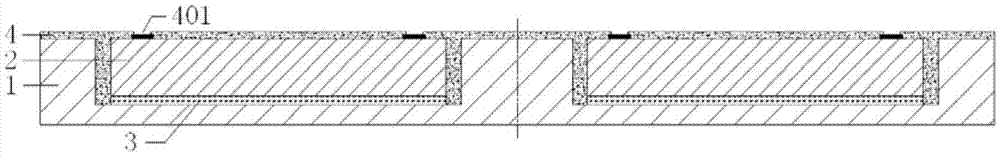

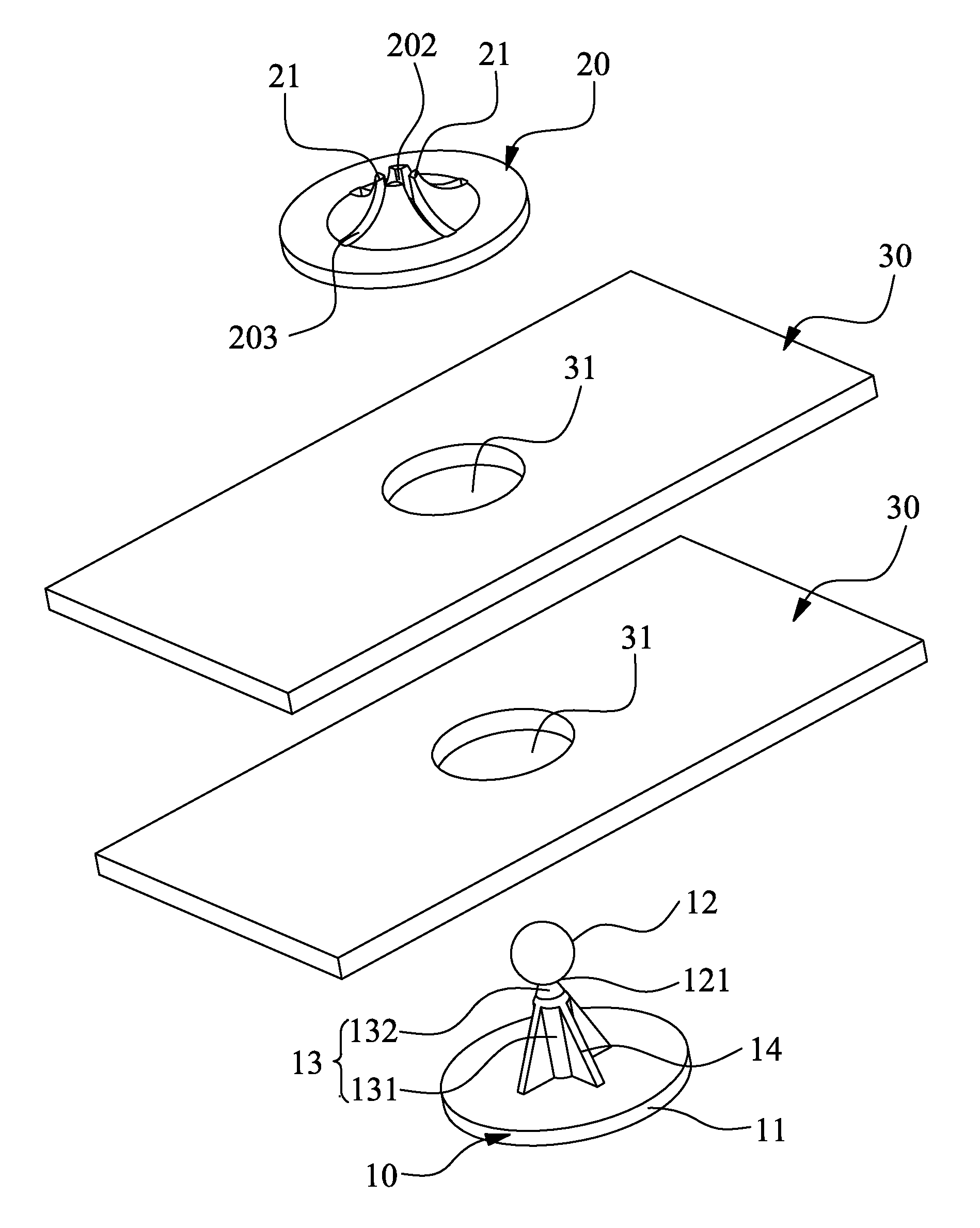

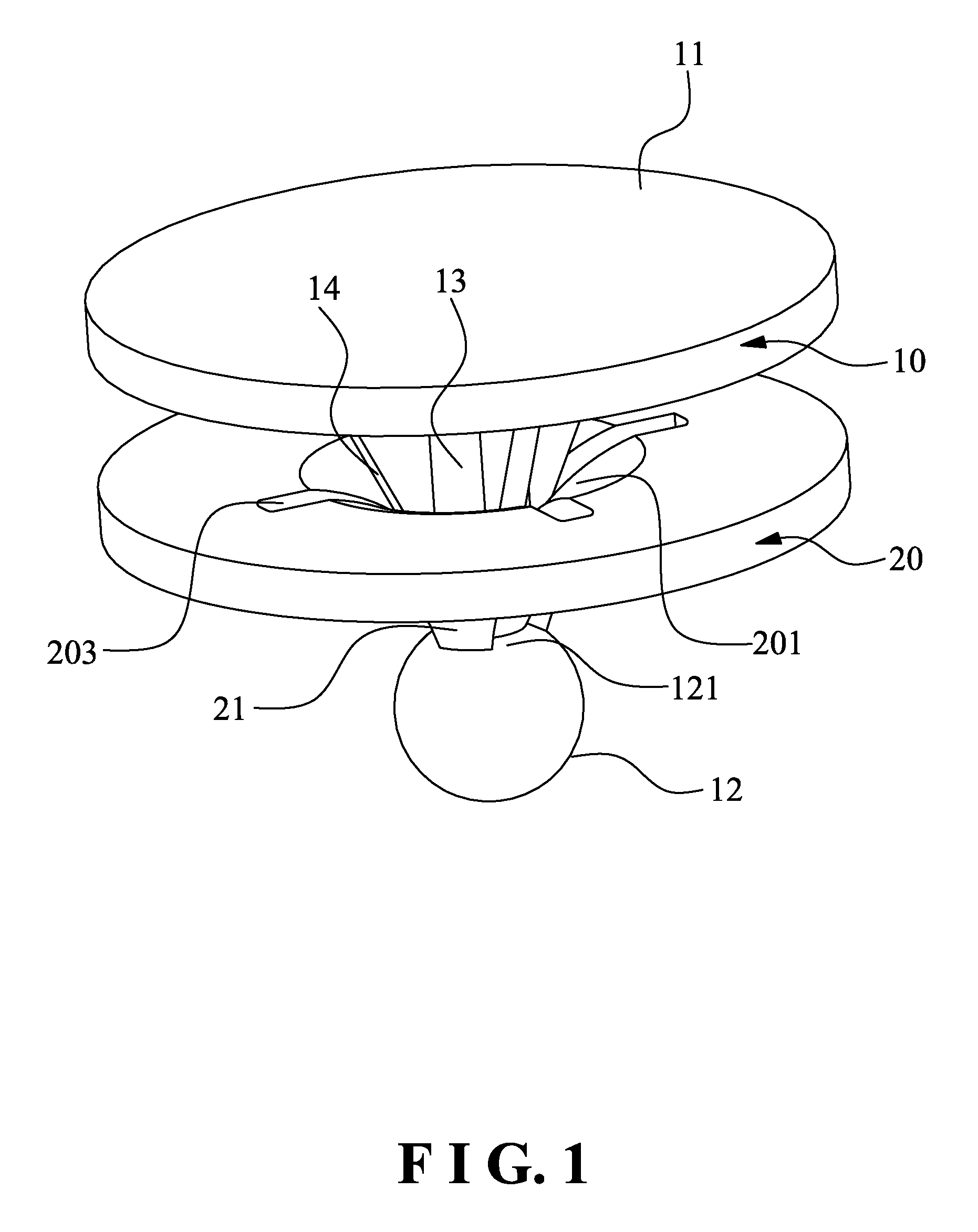

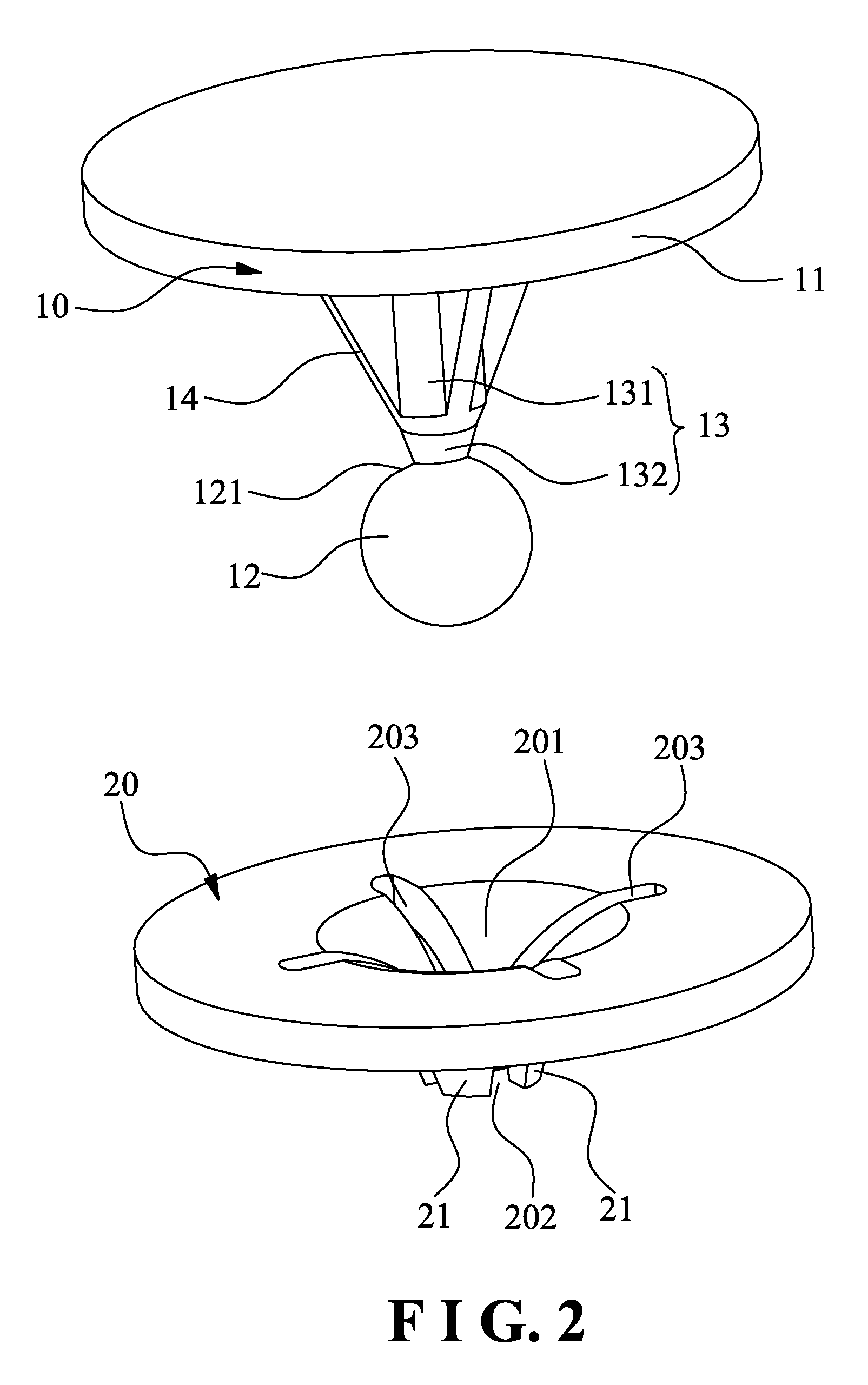

[quad flat no-lead package structure and manufacturing method thereof]

ActiveUS20050073055A1High I/O pad densityImprove packaging qualitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

The present invention provides a QFN package structure, comprising a chip carrier and at least a chip. The chip is disposed on the top surface of the chip carrier, while the back surface of the chip carrier includes a plurality of flat no-lead conductive leads as I / O pads of the chip carrier for the external circuitry. A plurality of pads, corresponding to bonding pads of the chip, is disposed on the top surface of the chip carrier. The aforementioned package structure can employ wiring bonding technology, flip chip technology or surface mount technology to attach the chip to the chip carrier.

Owner:UNITED MICROELECTRONICS CORP

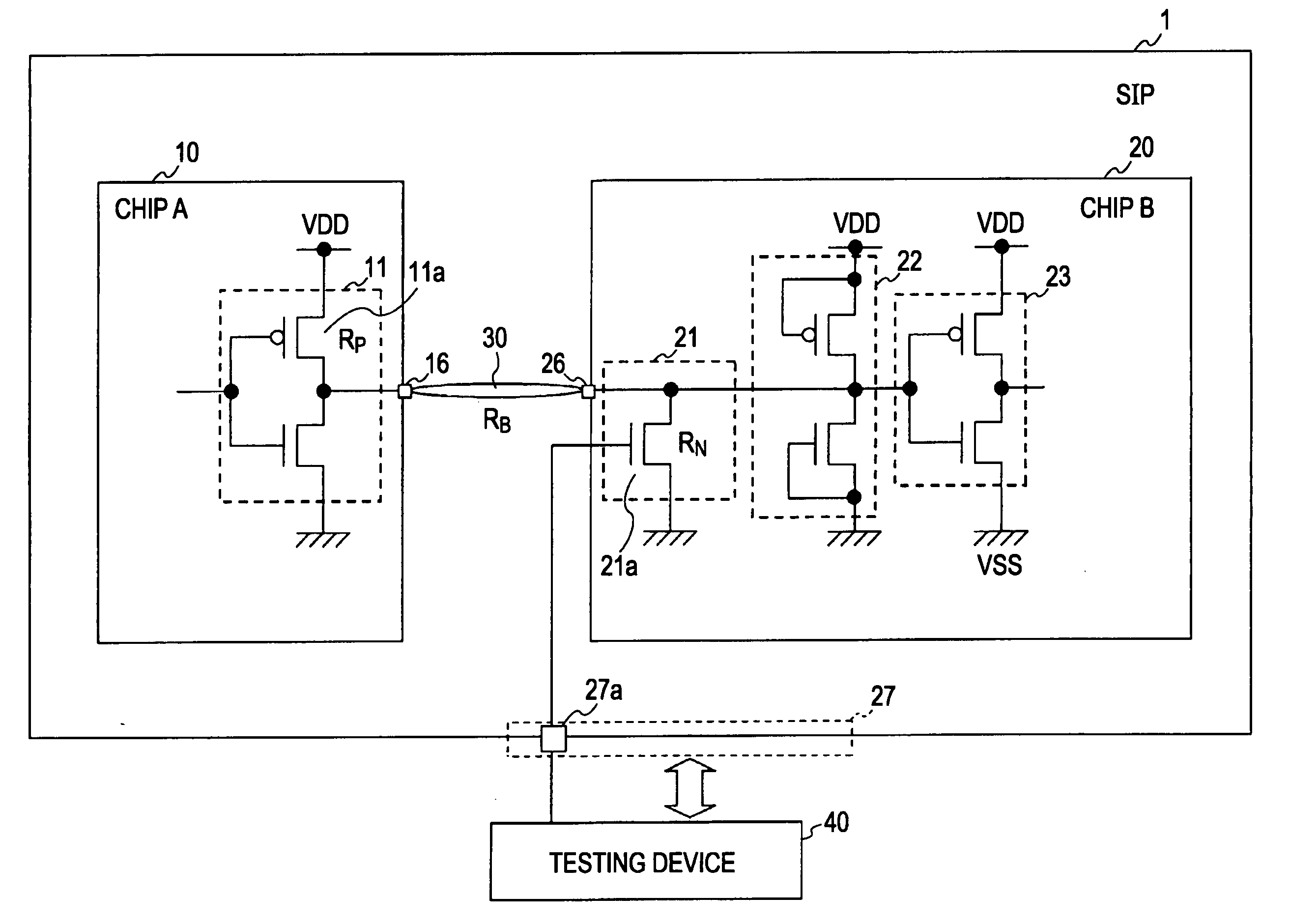

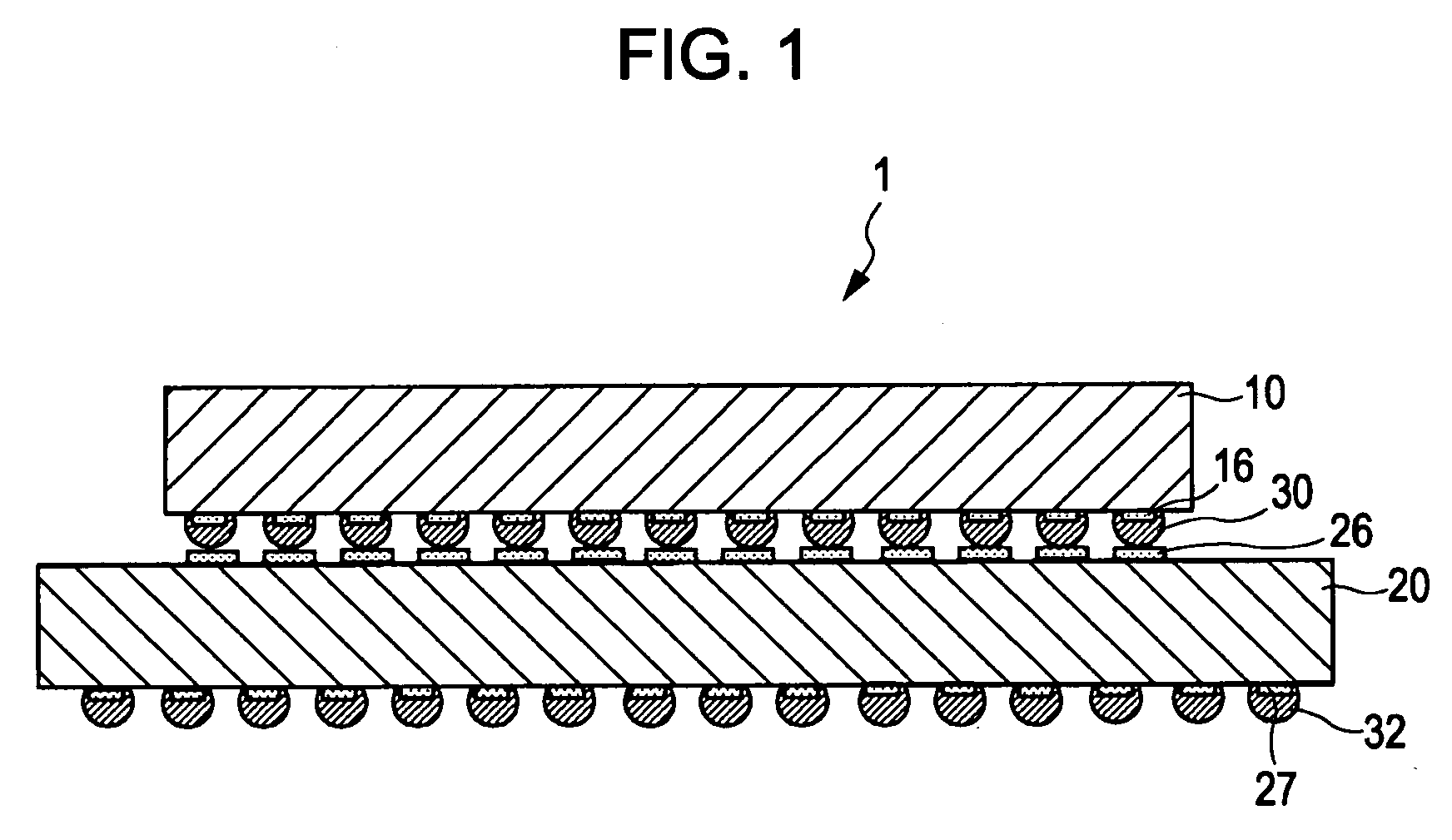

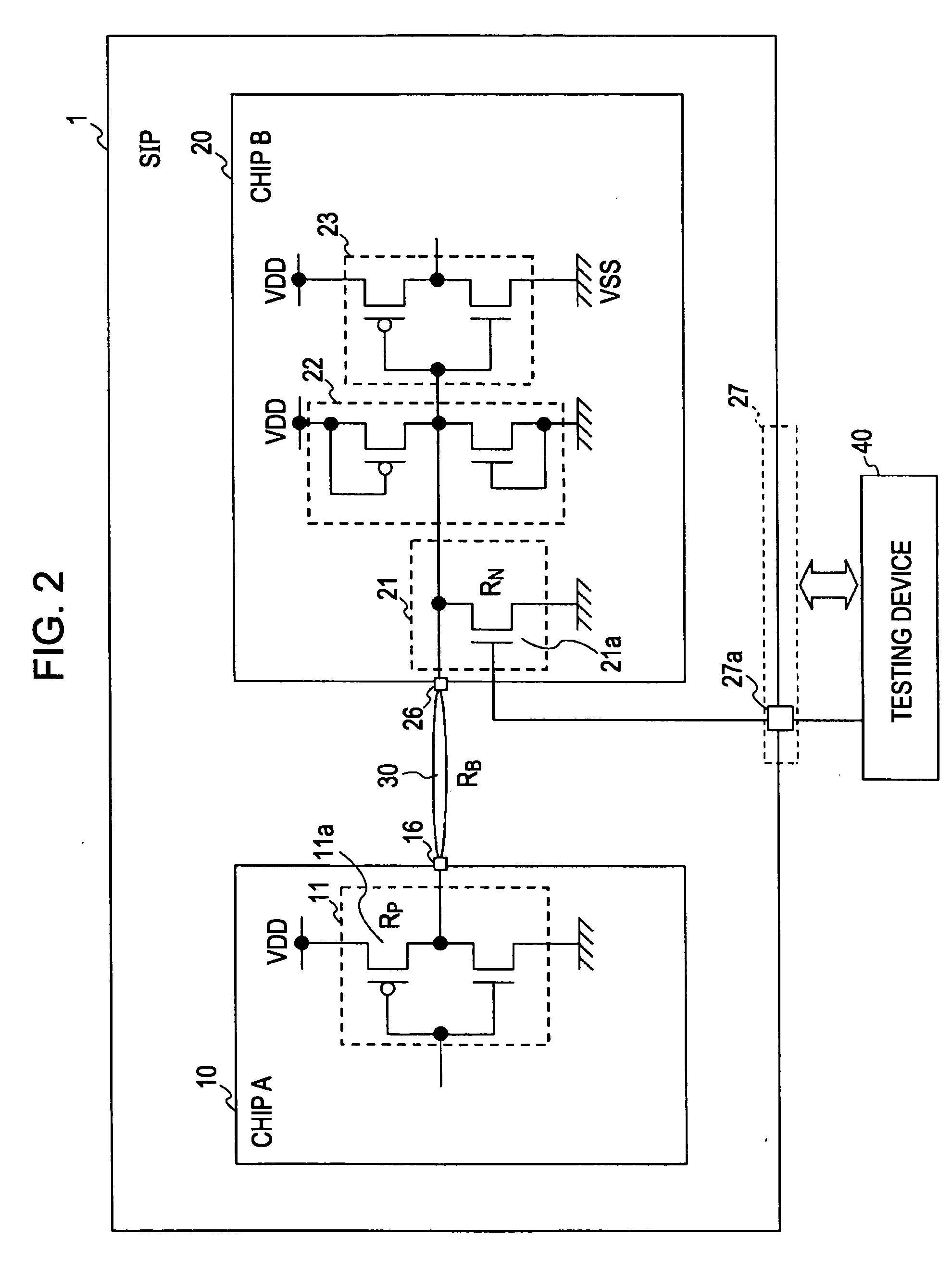

Semiconductor integrated circuit and method for testing connection state between semiconductor integrated circuits

InactiveUS20060232292A1Eliminate the problemImprove packaging qualitySemiconductor/solid-state device testing/measurementElectric connection testingEngineeringSemiconductor

A semiconductor integrated circuit including an input terminal and an input circuit connected to the input terminal includes the following elements. A testing circuit is provided between the input terminal and the input circuit, and changes a resistance value between the input terminal and a predetermined potential. A test terminal is adapted to operate the testing circuit.

Owner:SONY CORP

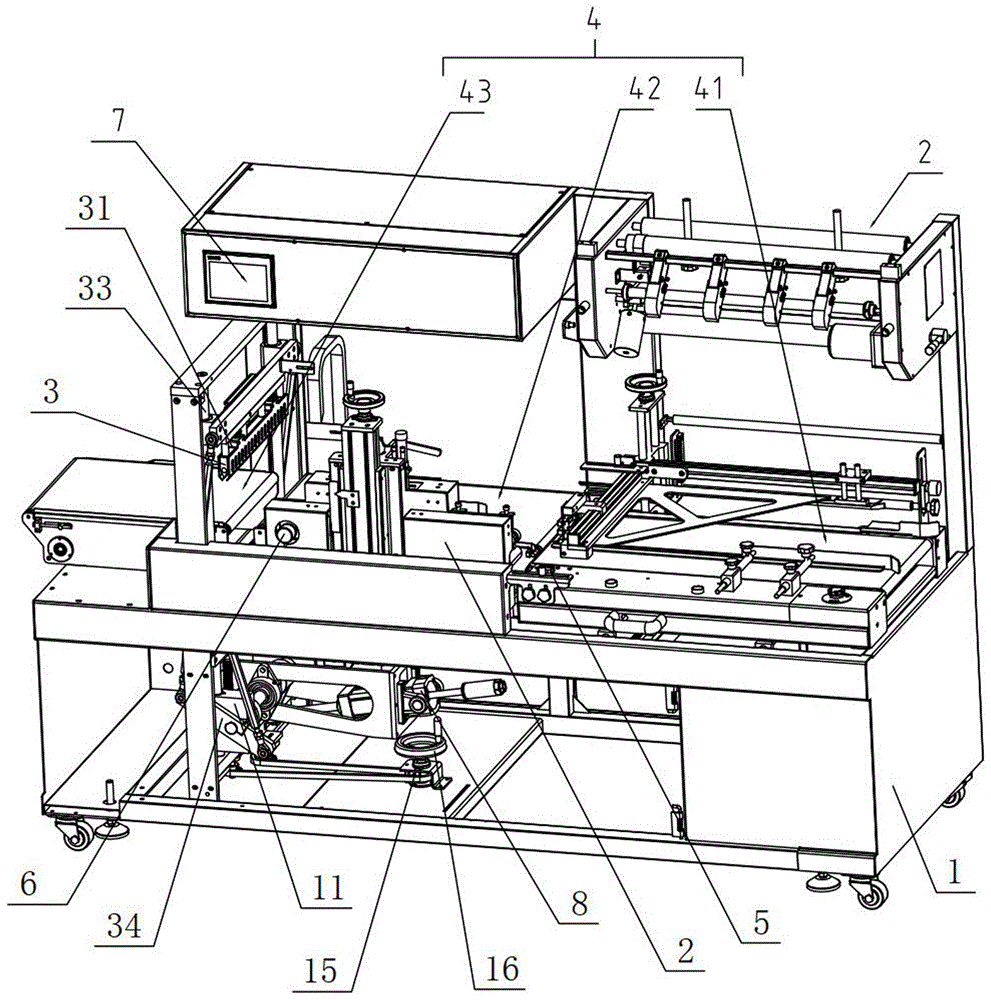

Full-automatic film seal-cutting packaging machine

ActiveCN106586137AShrink evenlyImprove packaging qualityPackaging automatic controlElectric machineryThin membrane

The invention discloses a full-automatic film seal-cutting packaging machine. The full-automatic film seal-cutting packaging machine is characterized by comprising a machine frame, a film conveying and sleeving device, a seal-cutting device and a conveying device; the conveying device comprises a first conveying mechanism, a second conveying mechanism and a third conveying mechanism; the seal-cutting device comprises an upper seal-cutting piece, a lower seal-cutting piece, a vertical rod and a swing piece; when the swing piece is driven to rotate in the forward direction or in the backward direction, the upper seal-cutting piece and the lower seal-cutting piece are driven to get close to or get away from each other; the swing piece is arranged movably in the vertical direction, so that the seal-cutting position when the upper seal-cutting piece and the lower seal-cutting piece are folded and the relative height of the working plane of the conveying device are adjusted; the machine frame is provided with an encoder and a programmable controller; the encoder is used for monitoring the stir quantity in real time and feeding the stir quantity back to the programmable controller; and the driving distance of a second motor is the new film packaging length of a packaged product. By the adoption of the full-automatic film seal-cutting packaging machine, the front film allowance length and the rear film allowance length of the product can be kept consistent, the height of a longitudinal seal-cutting mechanism can be easily adjusted according to to-be-packaged objects of different specifications, and the packaging quality is improved.

Owner:ZHEJIANG DINGYE MACHINERY

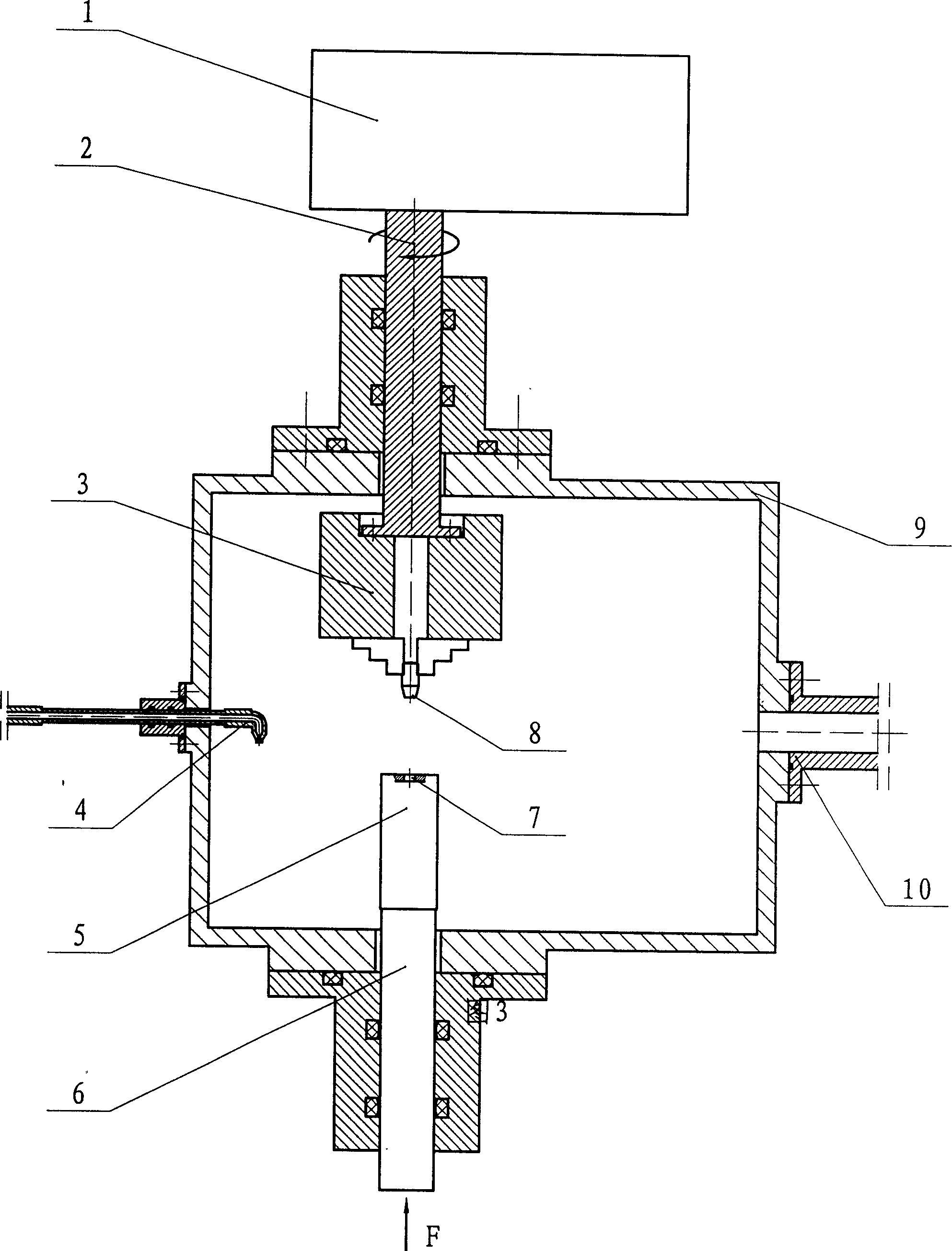

Heat pipe vacuum sealing method and apparatus thereof

InactiveCN1737484AImprove packaging qualityHigh degree of automationIndirect heat exchangersHeat exchange apparatusFriction weldingProduction rate

This invention relates to a heat pipe vacuum sealing method and device, characterized in that it uses heat transfer agent heat exchanging equipment to seal. The sealing method comprises the following steps: a) preparing the sealing hole in the heat pipe to be sealed; b) evacuating and charging pump in vacuum chamber; c) welding the sealing to the prepared sealing hole by the friction welding or ultrasonic welding, forming sealing welding. The sealing device comprises vacuum generating system, a heat pipe to be sealed, an orientation fasten system and a prefilling system, wherein the heat pipe and the orientation fasten system are set in the vacuum chamber, after evacuating and prefilling, the fasten system will grasp the sealing block to the sealing hole to weld.

Owner:林项武

Fruit packaging system

ActiveCN106395032AReduce consumptionReduce labor costsWrapping material feeding apparatusWrapper twisting/gatheringAgricultural engineeringOperating cost

The invention discloses a fruit packaging system. The fruit packaging system comprises a weighing and screening device, a fruit conveying device, a film conveying device, a film perforating device, a labeling device, a bag making device, a bag closing device and a control device, wherein the weighing and screening device, the fruit conveying device, the bag making device and the bag closing device are sequentially connected in an end-to-end mode, the film conveying device, the film perforating device and the labeling device are sequentially installed on the fruit conveying device in the length direction of the fruit conveying device, and the control device is connected to the weighing and screening device, the fruit conveying device, the film perforating device, the labeling device and cutting equipment. According to the fruit packaging system, the labor cost is reduced, the production efficiency and the packaging quality are improved, consumption of fruits is reduced, the operating cost is lowered, safety production is guaranteed, equipment maintenance is simple and convenient, and equipment can be adjusted and arranged according to different kinds of fruits so that the operating requirements of different kinds can be met.

Owner:深圳百果园实业(集团)股份有限公司

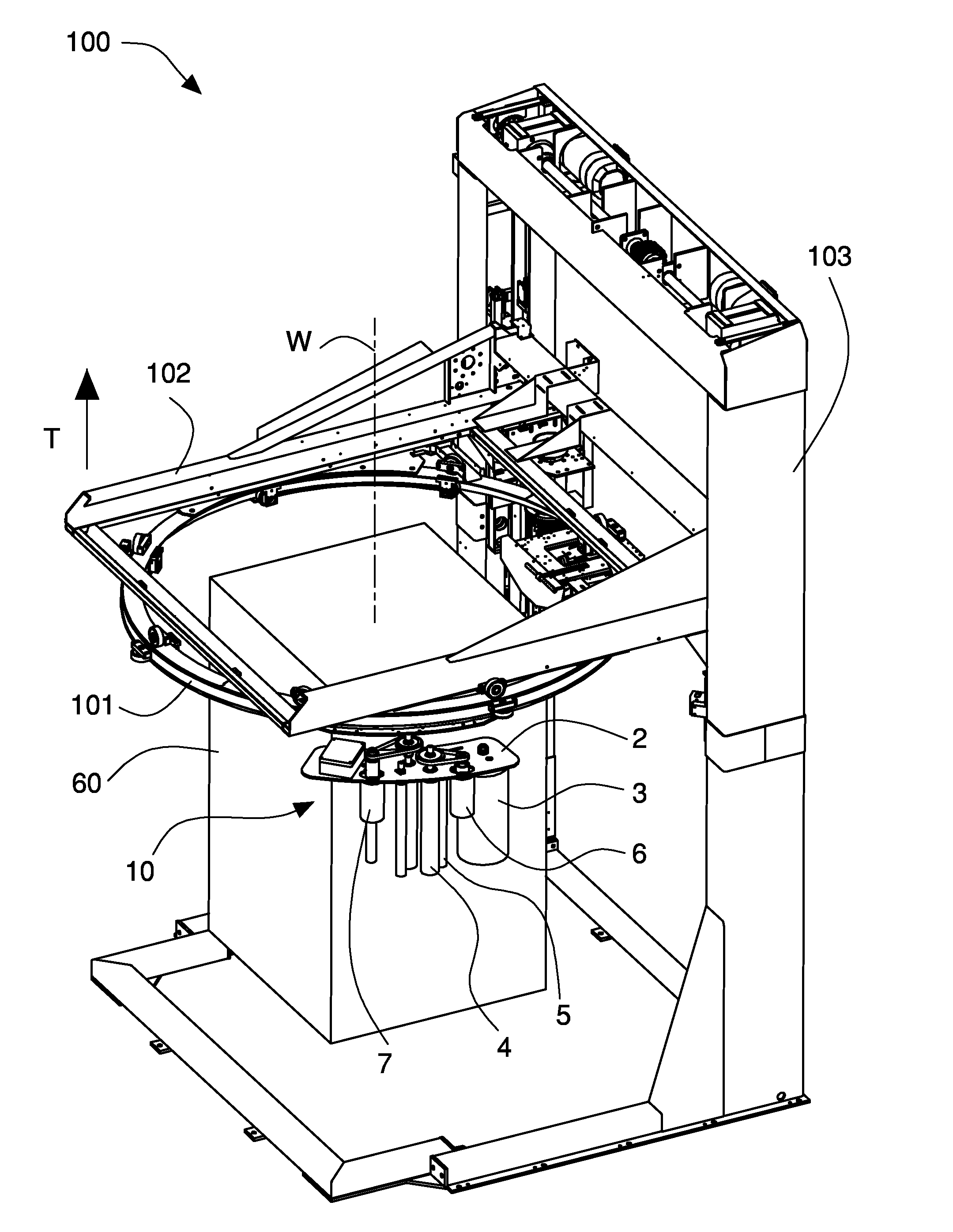

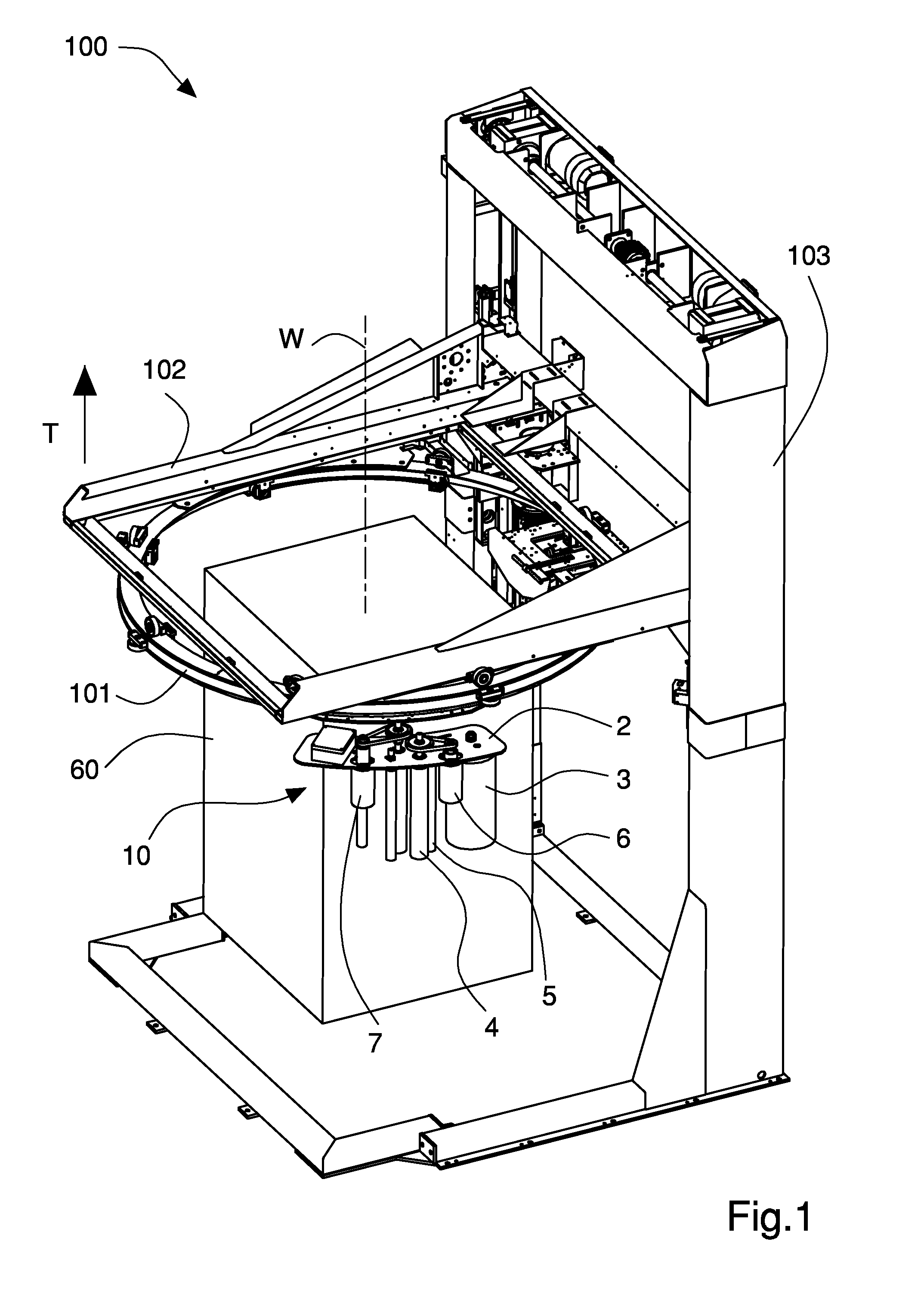

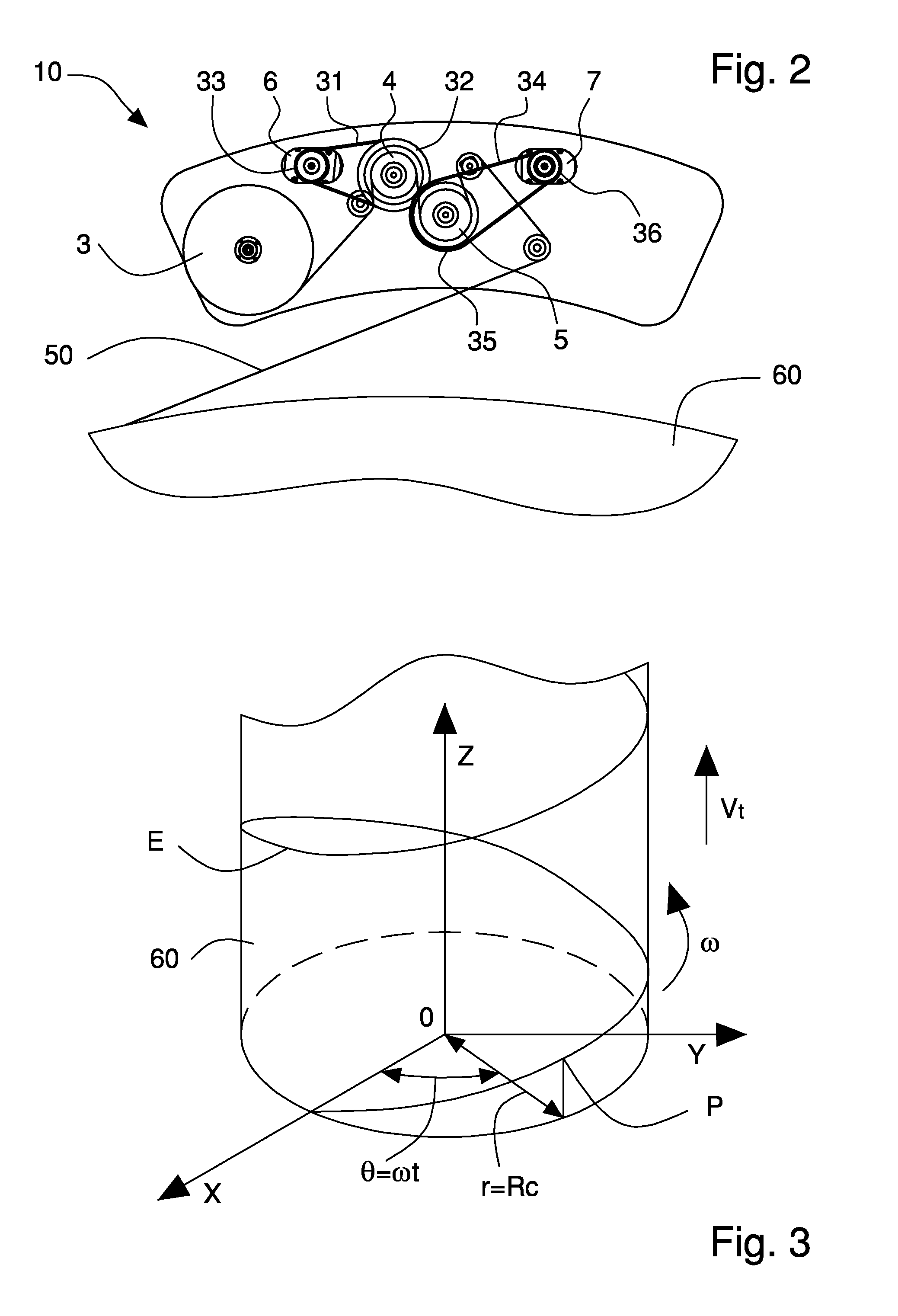

Wrapping method

ActiveUS20140123605A1Improve packaging qualityPrestretching mechanismWrapper folding/bending apparatusEffective lengthEngineering

A method for wrapping a load with a film by a wrapping machine including an unwinding apparatus provided with a reel of the film includes moving the wrapping apparatus and the load in relation to one another and unwinding from the reel an established effective length of film per revolution of the wrapping apparatus or of the load. The established effective length of film is calculated with the formula: where: Sf. initial length of film is determined on the basis of dimension and / or shape of the load; w: rotation speed around a wrapping axis of the unwinding apparatus or of the load; Vt: movement speed of the unwinding apparatus parallel to the rotation axis; ωmax: maximum rotation speed around the wrapping axis of the unwinding apparatus or of the load; Δcorr: corrective parameter.

Owner:AETNA GROUP

Disposable plastic needle cylinder transferring device

InactiveCN101508354ASave spaceReduce labor intensityToothed gearingsPackaging automatic controlEngineeringMechanical engineering

The invention relates to a one-off plastic syringe conveying device, which belongs to the technical field of packing machinery. The conveying device comprises a stander, a turntable base, a turntable, a first guide rail, a pressing plate, a pair of first lead-out guide rails, and a first guiding groove between the pair of the first lead-out guide rails. The conveying device is characterized by further comprising a pair of second lead-out guide rails, at least one second guide rail and a sorting block, wherein the pair of the second lead-out guide rails corresponds to the lower parts of the pair of the first lead-out guide rails and corresponds to a gap path; a second guiding groove is formed between the pair of the second lead-out guide rails; the second guiding groove corresponds to the first guiding groove; the second guide rail corresponds to the lower part of the first guide rail, and a first passage is formed between the second guide rail and the first guide rail; the sorting block is fixed with the turntable base at the part corresponding to the gap path; and a needle-drawing groove is formed in the length direction of the sorting block. The one-off plastic syringe conveying device has the advantages of not only lightening the labor intensity for workers and improving the packaging efficiency and the packaging quality of a rear path, but also thoroughly putting an end to disqualified syringes to flow into the packaging processes.

Owner:常熟乙星包装机械有限公司

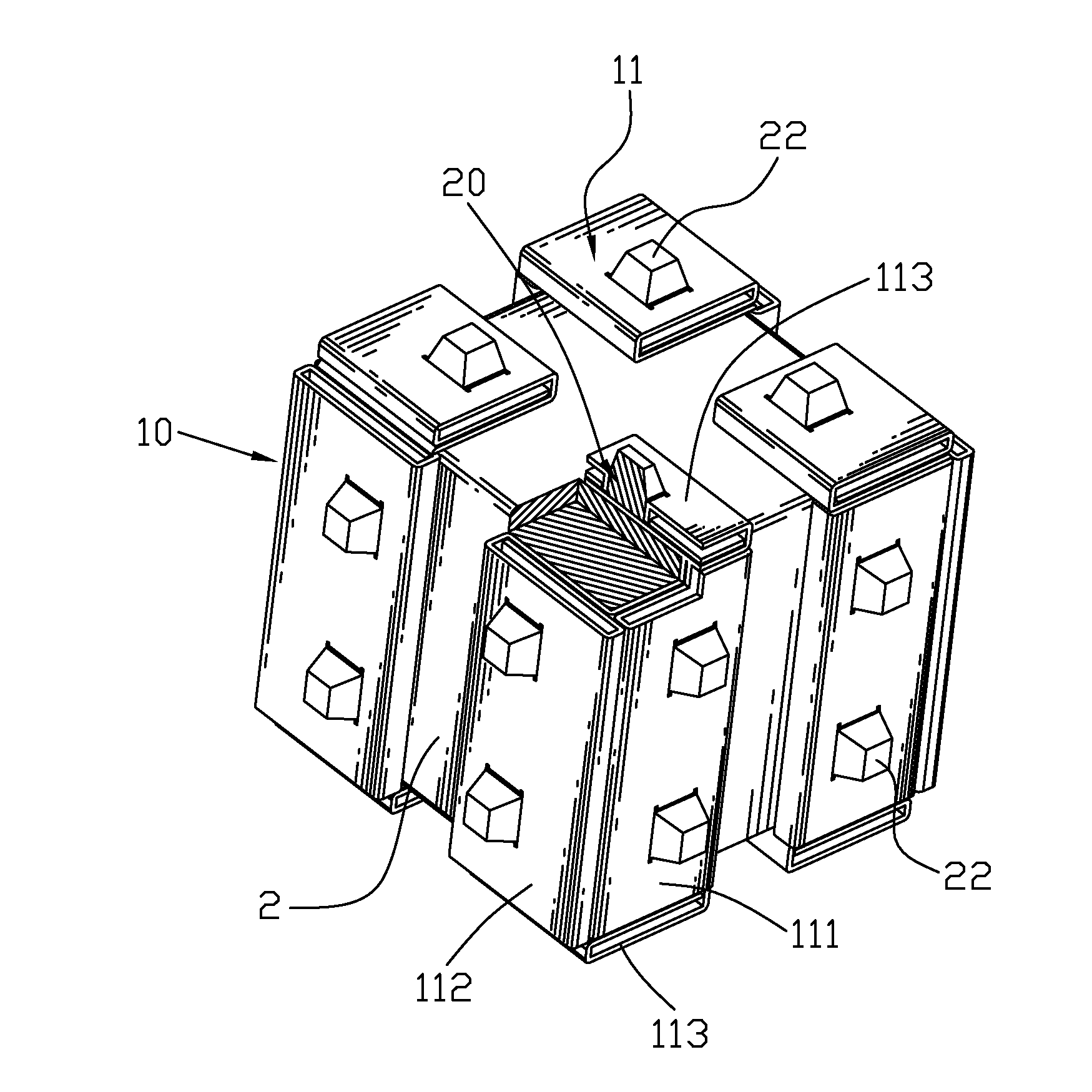

Packaging case

InactiveUS20130233754A1Avoid crackingReduce material costsContainers to prevent mechanical damageEngineeringTransportation cost

A packaging case adapted for packing an article therein includes a fastening shell and a plurality of buffering elements. Each wall of the fastening shell defines at least one insertion hole. The buffering elements are dismountably inserted into the insertion holes of the fastening shell with tops thereof projecting out of the insertion holes. The fastening shell and the buffering elements are designed separately, so the buffering elements fully afford an external force struck on the buffering elements for effectively preventing cracks being caused between each buffering element and the fastening shell. Accordingly, the fastening shell is designed with a thinner thickness to lower a material cost and a transportation cost. Furthermore, the buffering elements assembled to the fastening shell are changeable to make the buffering elements dismountably inserted into the insertion holes properly and simply. So a better buffering function of the packaging case is realized.

Owner:FOXLINK IMAGE TECH

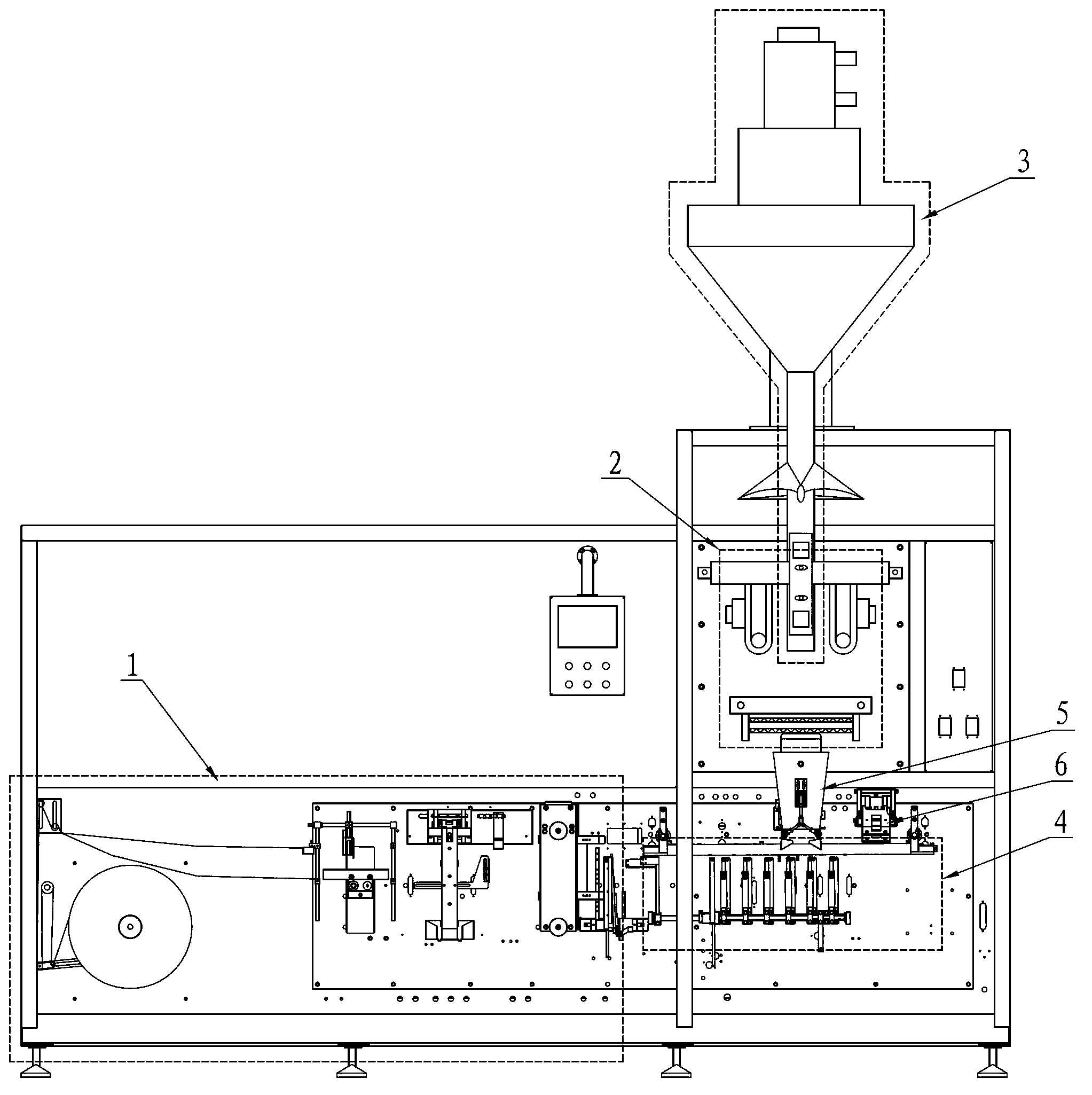

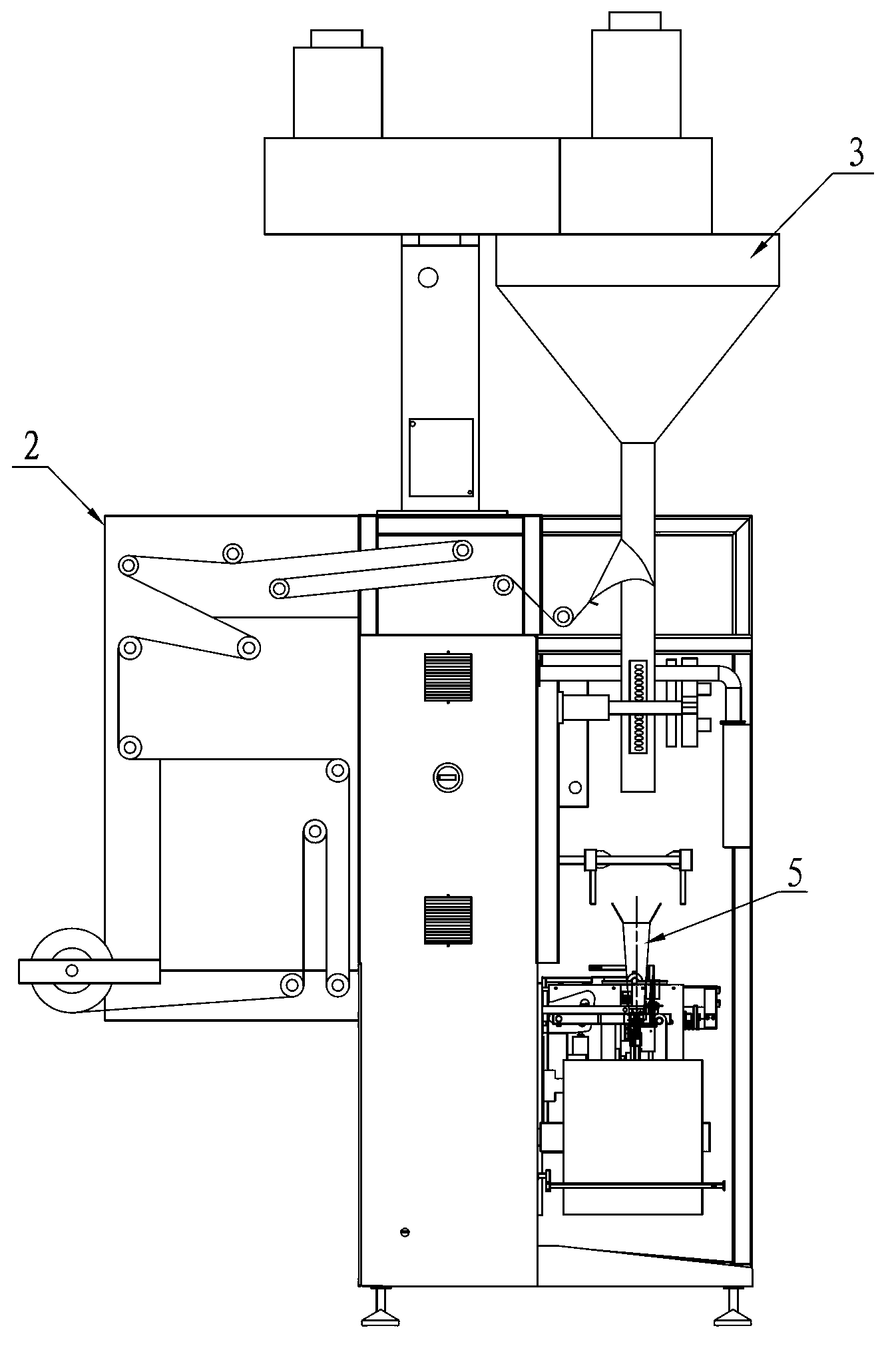

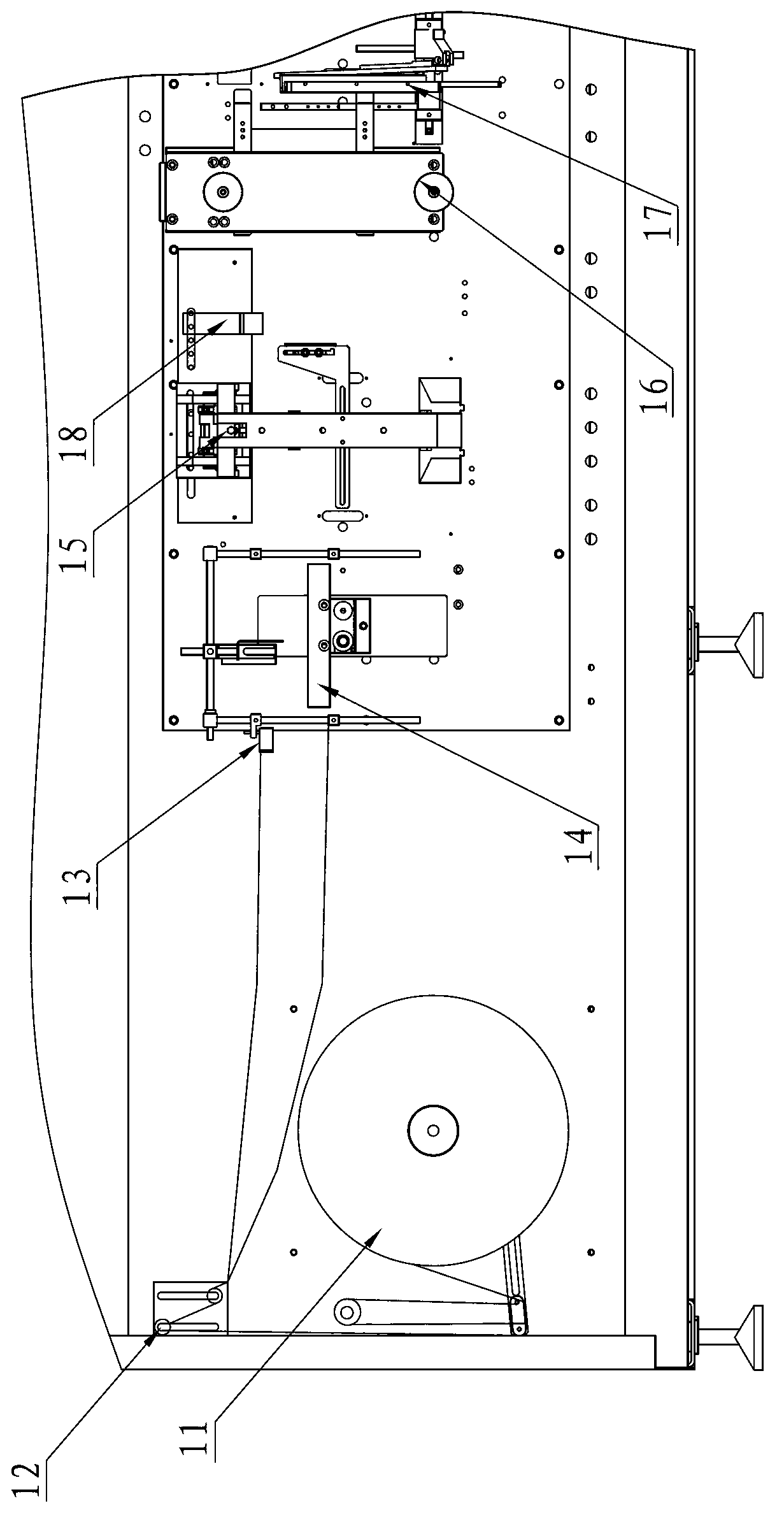

Full-automatic inner and outer bag packing machine capable of making outer bags for pesticides

InactiveCN103287591AImprove ergonomicsImprove packaging qualitySolid materialControl systemMechanical engineering

A full-automatic inner and outer bag packing machine capable of making outer bags for pesticides comprises a horizontal outer bag making device, an upright inner bag making device, an inner bag material metering and filling device, a reciprocating outer bag drawing and clamping device, a device for accurately feeding inner bags into the outer bags and a top sealing device for upper openings of the outer bags. The outer packing bags are made by the horizontal outer bag making device, the inner bags are made, vertically sealed, horizontally sealed and shorn by the upright inner bag making device, pesticide materials are metered and filled into the inner bags by the inner bag material metering and filling device, the outer bags are clamped, conveyed, opened and wiped in a linear reciprocating manner by the reciprocating outer bag drawing and clamping device, each conveyed outer bag is required to be accurately positioned under the device for accurately feeding the inner bags into the outer bags in a corresponding conveying procedure, the device for accurately feeding the inner bags into the outer bags completes secondarily poking edges of the upper openings of the outer bags and accurately feeding the inner bags into the outer bags, and top seals on the outer bags fed with the inner bags are sealed at a high temperature by the top sealing device for the upper openings of the outer bags. The full-automatic inner and outer bag packing machine has the advantages that various components act under a coordination effect of a control system, and accordingly mechanical bag-in-bag packing can be performed on the pesticide materials.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

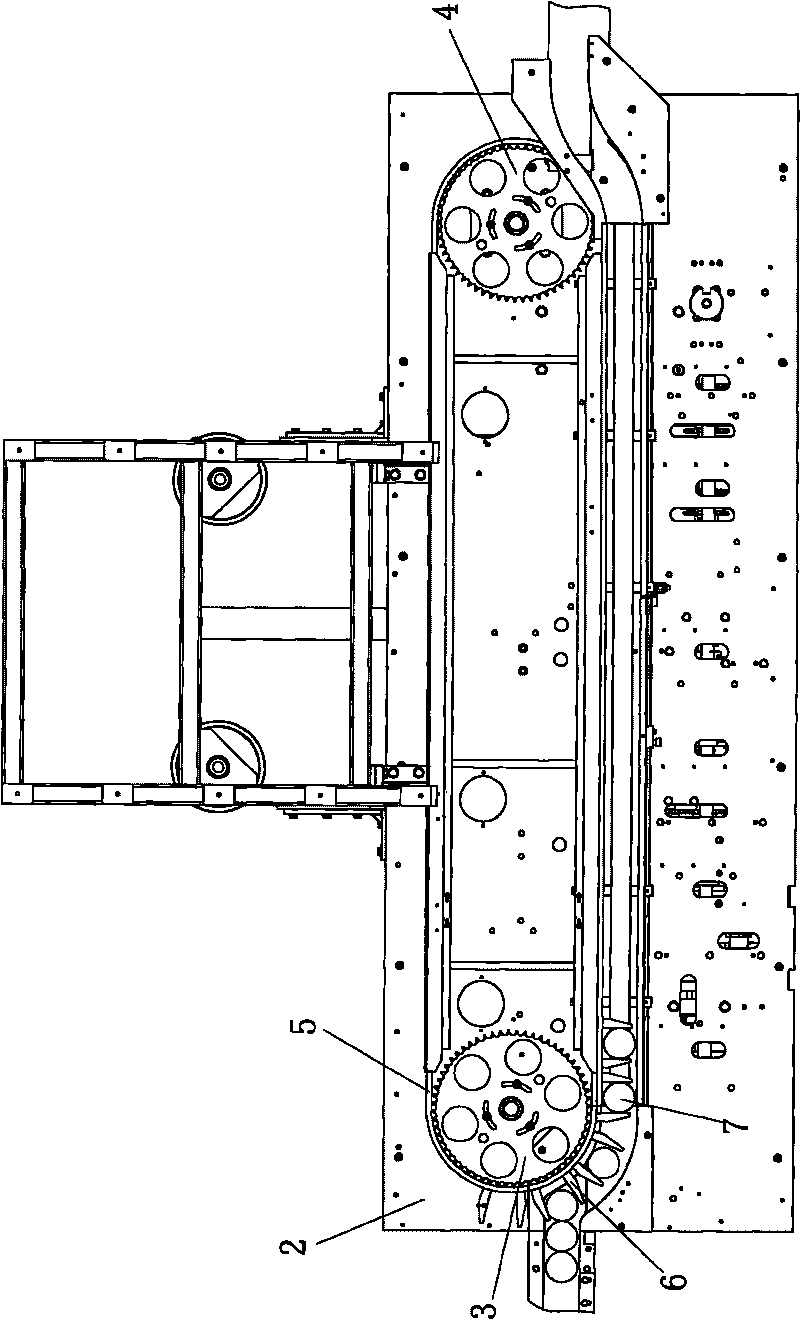

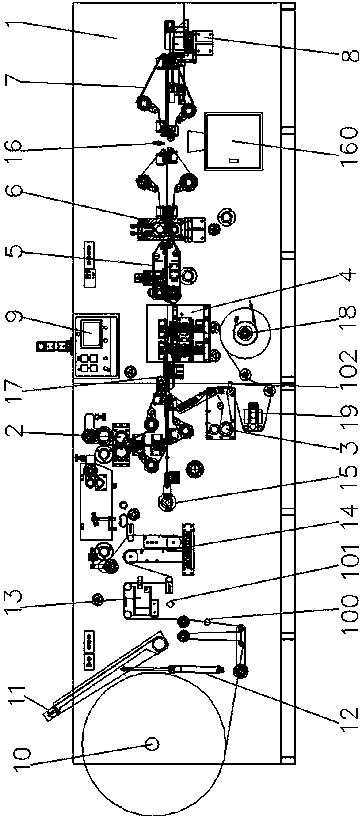

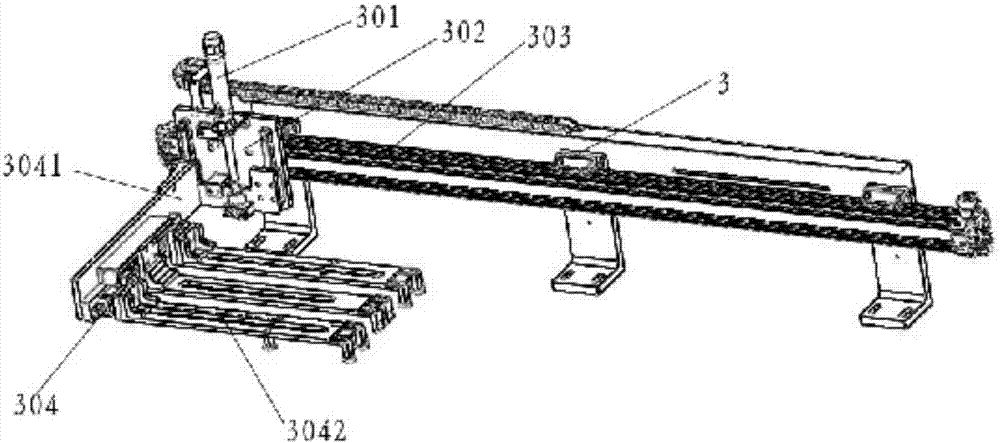

Tinned cigarette packing machine

ActiveCN101691142AAutomate the packaging processNot easy to polluteWrapping material feeding apparatusPackaging cigaretteDrive motorSprocket

The invention discloses a tinned cigarette packing machine comprising a rack which is provided with a working platform. The working platform is provided with a front driven sprocket and a rear driving sprocket, wherein the driving sprocket is connected with a stepping main driving mechanism which drives the rear driving sprocket to rotate; the front driven sprocket and the rear driving sprocket are respectively tensioned with a chain, the chain is provided with a can clamp, and the chain and the clamp form a conveying chain; a turntable is arranged in front of the working platform, the center of the turntable is provided with a turntable spindle which is connected with the output shaft used for rotating a driving motor; the turntable is provided with an outlet, the back of the outlet of the turntable is communicated with a conveying rail used for conveying the cigarette tin, and the rear end of the conveying rail is connected with the conveying chain; the upper part of the conveying chain sequentially comprises a lining paper supplying and canning station, a drawing paper supplying and canning station, a cigarette supplying and canning station, a bottom cover paper supplying and canning station and the bottom cover supplying and canning station from front to back in conveying direction. The invention realizes automatic packing of tinned cigarettes.

Owner:宁波升瀚烟草机械有限公司

Full-automatic single wet tissue packaging machine

InactiveCN104058139ASolve the problem of incorrect folding widthSolve the problem that manual inspection is not in placeWrapping material feeding apparatusWrapper twisting/gatheringElectrical controlWet wipe

The invention discloses a full-automatic single wet tissue packaging machine, which comprises a rack and optical fiber probes mounted on the rack, wherein a rotary shaft for fixing a raw material, a feeder for feeding the row material, a lifting air cylinder for controlling the feeder to move up and down, a correcting mechanism for correcting the row material, a longitudinal folding mechanism, a horizontal folding mechanism, a cutting mechanism, a wrapping mechanism, a rotary shaft for fixing a packaging film, a coding machine for printing the packaging film, a packaging film pulling mechanism for conveying the packaging film, a longitudinal packaging film sealing mechanism, a packaging film pulling exhaust mechanism, a horizontal packaging film sealing mechanism, a blowing removing nozzle, a finished product conveyer belt, a counting and stacking mechanism and an electric control box for controlling the operation of each mechanism are arranged on the rack. The full-automatic single wet tissue packaging machine solves the problem of raw material waste caused by the incorrect folding width of the material, can automatically inspect products, increases the packaging quality of the products, has an automatic counting and stacking function, and solves the problem that manual counting is difficult.

Owner:QUANZHOU CHUANGDA MACHINERY MFG

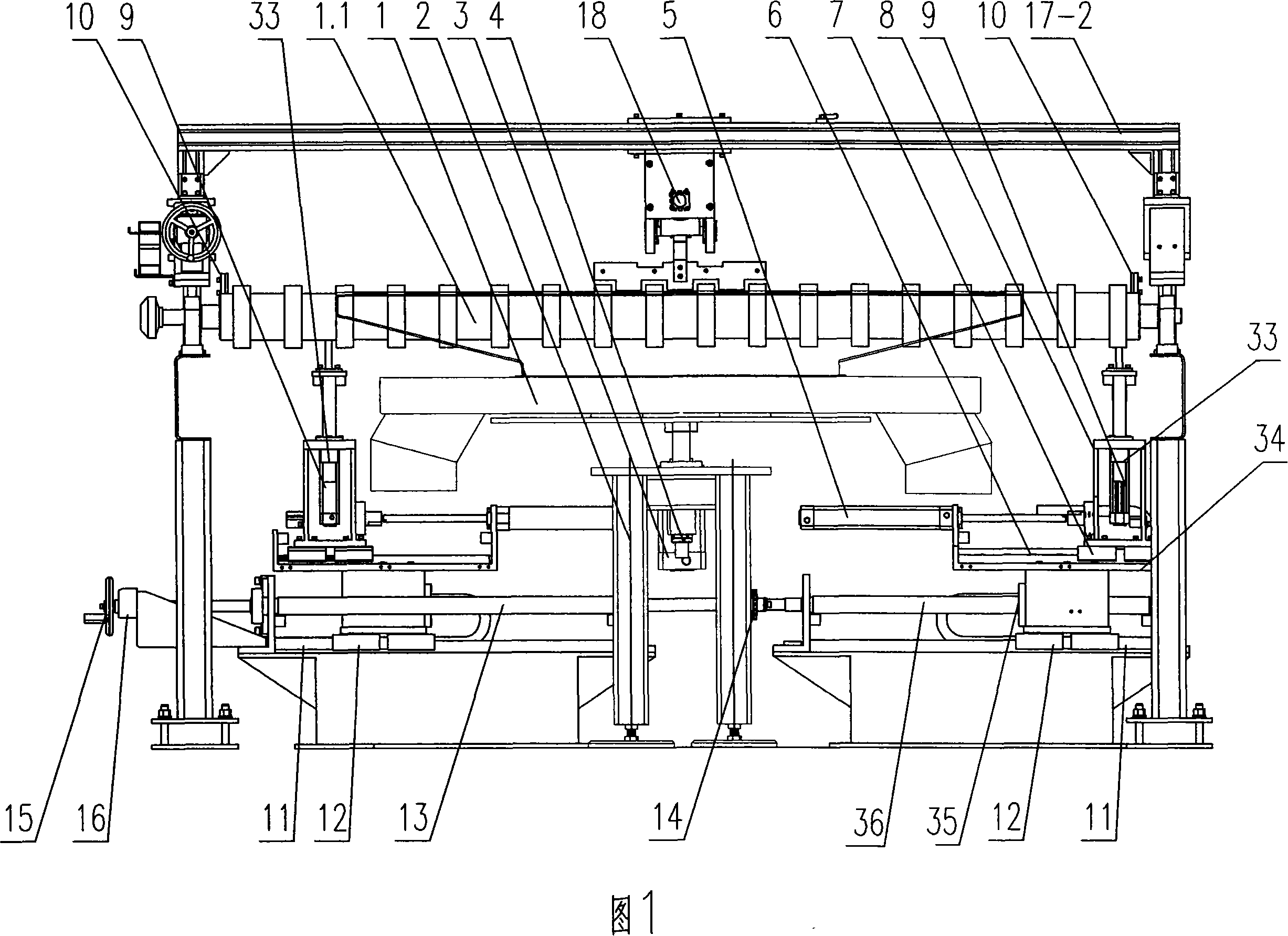

Automatic packaging process for winding thin film on steel coil

InactiveCN101804873AReduce labor intensityEasy to operateWrapping material feeding apparatusWrapping with article rotationWinding machineThin membrane

The invention relates to an automatic packaging process for winding a thin film on a steel coil. A device for the process comprises a hoist, an automatic thin film winding machine for packaging the steel coil, a rolling machine and an electrical control device. The process adopts the technical key points that the steel coil is put on carrier rollers of the rolling machine by using the hoist; the automatic thin film winding machine is started to move on a track, and a lifting beam is moved when the automatic thin film winding machine moves to the upper side the rolling machine; a left C-shaped frame and a right C-shaped frame relatively move to close; a thin film carriage circularly moves along the closed guide rail and passes through the center of an inner hole of the steel coil which is supported on the rolling machine and rotates; the thin film is wound on the steel coil until the winding work ends; the steel coil packaged with the thin film is hoisted by the hoist; and then an outer protection plate and a side protection plate which are made of steel are put in and bundled by using band steel to finish the thin film winding and packaging works of the steel coil. The process has reasonable arrangement of packaging steps, and the used winding machine has simple structure, easy operation and labor and material saving, obviously lightens the labor intensity of operators, improves the operation efficiency and the packaging quality, reduces the packaging cost and completely meets the requirements on the production speed and the packaging quality of the steel coil.

Owner:鞍山市弘鑫包装材料有限公司

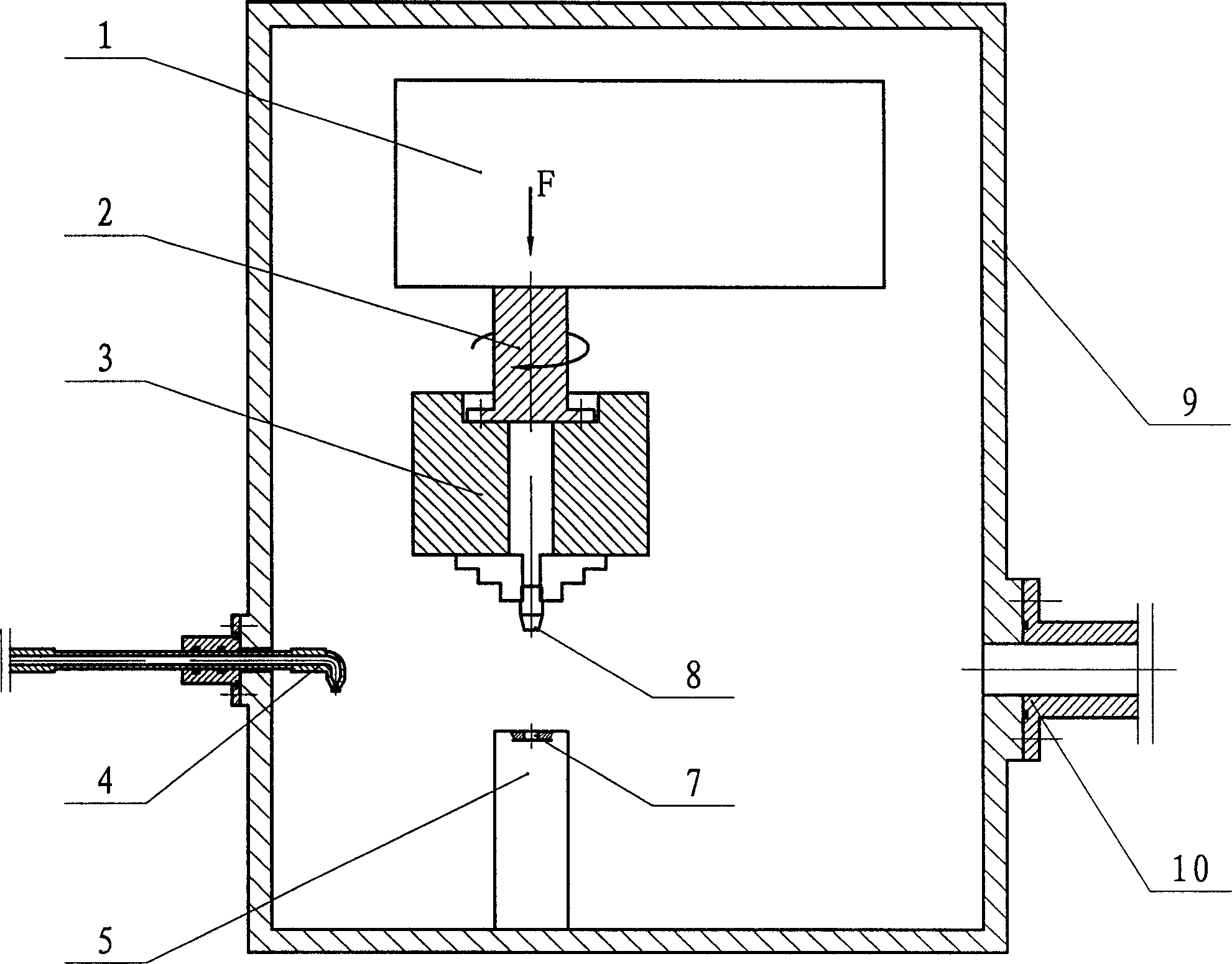

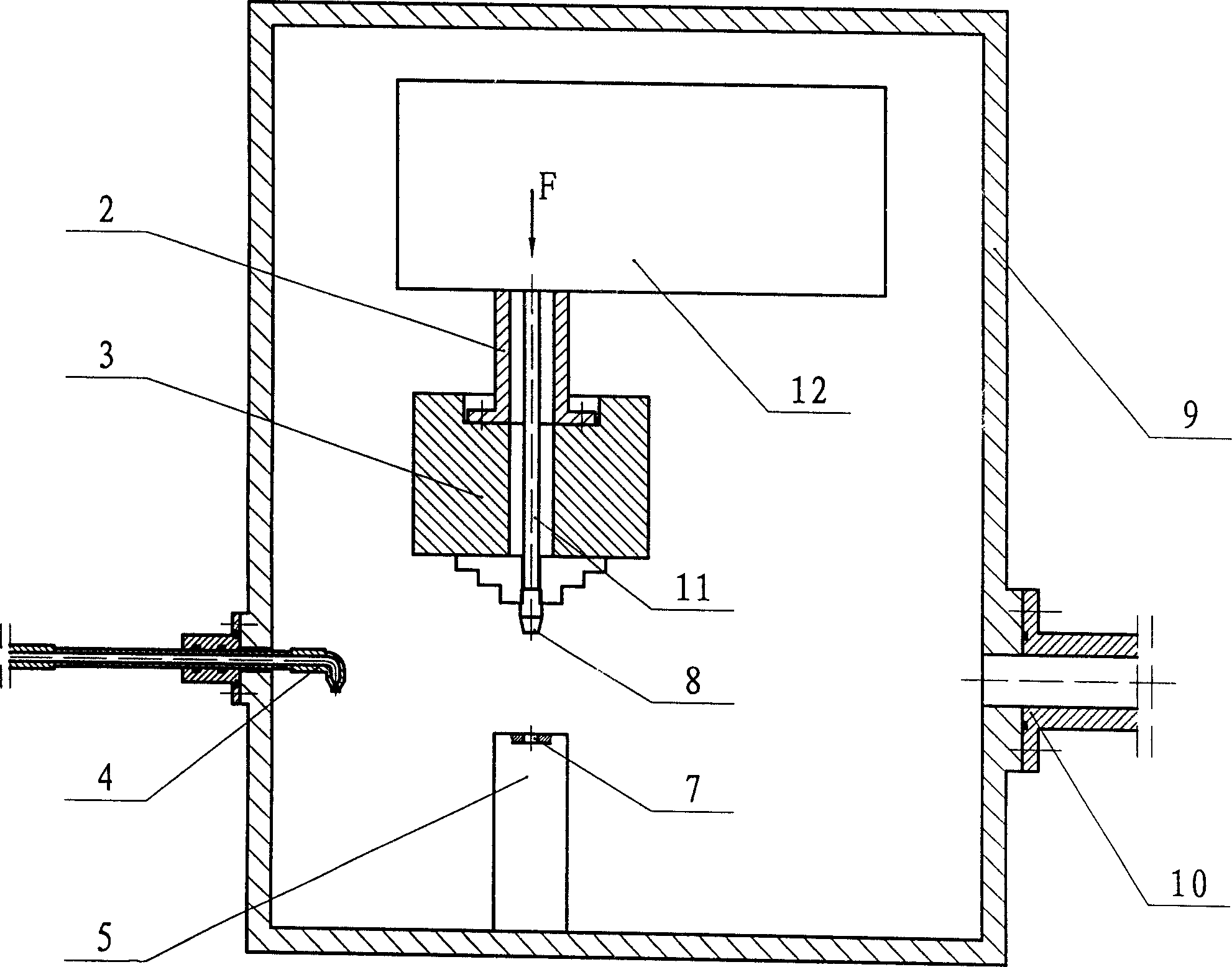

Structure and method for air cavity packaging

InactiveUS20140103518A1Reduce generationImprove packaging qualitySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A structure and method for air cavity packaging, the structure comprises a carrier having plural die pads and leads, plural dies, plural wires, plural walls, and a lid. The dies are mounted on the die pads. The wires electrically connect the dies to the leads. The plural walls are disposed on the carrier and form plural cavities in a way that each cavity contains at least one die pad and plural leads, and each wall is provided with at least one air vent for exhausting air to the outside. The lid is attached on the plural walls via an adhesive agent to seal the plural air cavities, so that the plural connected air cavity packages are formed.

Owner:WIN SEMICON

Fan-out package method of embedded silicon substrate

ActiveCN105448752AEasy to operateHigh precisionSolid-state devicesSemiconductor/solid-state device manufacturingLine widthLaser exposure

The invention discloses a fan-out package method of an embedded silicon substrate. The fan-out package method comprises the following steps of firstly, embedding a chip onto a silicon substrate wafer in a wafer level; secondly, laminating a plurality of silicon substrate wafers on a panel for panel level package during a fan out process; and finally, fabricating salient points or planting welding balls in the wafer level. According to the fan-out package method, the chip is embedded onto the silicon substrate wafer and then panel level package is carried out, the maneuverability and the accuracy of package are improved, and the warpage of a panel is reduced; the comprehensive alignment accuracy is improved by respective alignment adjustment on each wafer during direct laser exposure in the panel level process, so that fan-out package processing of a fine-pitch bonding pad chip is facilitated; and during the process from wafer level package to panel level package, the advantages of wide metal wiring line width, small line distance and high accuracy of wafer level package and the multiplied package quantity of the panel level package are combined, the package quality and efficiency are obviously improved, and the package cost is greatly reduced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

Low-temperature heat-seal shrinking packaging film used for cigarettes and manufacturing method thereof

InactiveCN105619990AReduce heat sealing temperatureReduce energy consumptionSynthetic resin layered productsLaminationElastomerMasterbatch

The invention relates to a low-temperature heat-seal shrinking packaging film used for cigarettes. The packaging film comprises a surface layer A, a core layer B and a surface layer C; the surface layer A is prepared from, by mass, 70-80 parts of an ethylene-butene-propylene terpolymer, 2-10 parts of an ethylene-butene copolymer, 12-22 parts of a slipping agent, 3-13 parts of an antisticking agent and 0.5-1.5 parts of a wear-resisting agent, wherein the slipping agent is composed of erucyl amide and dimethicone, and the antisticking agent is composed of PMMA and silicon dioxide powder; the core layer B is prepared from 65-80 parts of homo-polypropylene, 24-32 parts of stiffness improving master batch and 2-6 parts of anti-static master batch; the surface layer C is prepared from 80-90 parts of an ethylene-butene-propylene terpolymer, 5-15 parts of ethylene-butene copolymerized elastomer, 2-5 parts of a slipping agent and 3-10 parts of an antisticking agent, the slipping agent is dimethicone and the antisticking agent is PMMA. The three-layer coextruded packaging film is lower in heat-seal temperature, energy consumption is reduced, and the cigarette case packaging quality is improved.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

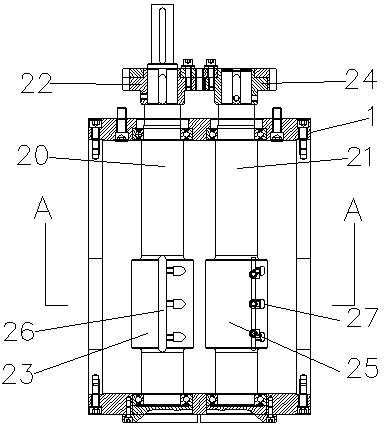

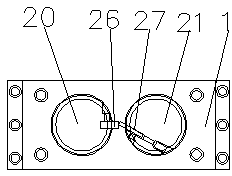

Three-roller tire packaging machine

ActiveCN104003009AImprove packaging qualityCompact structureWrapping with article rotationEngineeringPackaging machine

A three-roller tire packaging machine comprises a base, wherein a vertical plate is installed on the base, a first rotating wheel and a second rotating wheel are respectively arranged on two sides of the vertical plate and connected with corresponding riding wheels driving belts. A plurality of connecting wheels are installed on the side wall of one side of the vertical plate, at least one connecting wheel is connected with a second motor, annular rotating rings are installed among the connecting wheels in a matched mode, winding drums are installed on the rotating rings and wrapped by packaging belts, a first opening is formed in the vertical plate, and second openings are formed in the rotating rings. A pressing device is arranged at the top end of the vertical plate. The three-roller tire packaging machine has the advantages that the machine supports a tire through two riding wheels, the pressing device is in contact with the upper end of the tire, the tire is in contact with the winding drums on the rotating rings and evenly wrapped by winding the packaging belts so that the tire is kept stable and does not deform in the rotating process, and the tire packaging quality is improved.

Owner:山东大宏智能设备股份有限公司

Intelligent adjustable bread packaging equipment

ActiveCN107244446ARealize intelligenceRealize regulationPackaging machinesPackaging bakeryOutput deviceEngineering

The invention discloses intelligent adjustable bread packaging equipment which comprises a conveying device used for conveying bread to be packaged. The conveying device is provided with a horizontally-arranged chain plate conveying belt. The feeding end of the chain plate conveying belt is provided with a fault recycling device. The discharging end of the chain plate conveying belt is provided with a separation groove. One side of the separation groove is provided with a pushing device which pushes bread in the separation groove to a packaging device opened by a bagging device. A packaging bag used for the bagging device is output by an adjustable packaging bag output device and transferred by a taking device. The fault conditions can be intelligently avoided, intelligent seamless connection of the packaging process is achieved, labor is reduced, the production efficiency is greatly improved, the cost is saved, adjustment can be achieved according to different sizes of packaging bags, accordingly, different specifications of products can be packaged, the applicability is high, the structure is simple, and adjustment is convenient.

Owner:福建达峰智能科技股份有限公司

Intelligent packer with manipulator for receiving and sending swabs and quantificationally dosing and use method thereof

InactiveCN101823569AImprove packaging qualityImprove packaging efficiencyWrapping material feeding apparatusPackage sterilisationDisinfectantProgrammable logic controller

The invention relates to an intelligent packer with a manipulator for receiving and sending swabs and quantificationally dosing, comprising an uncoiling film sending device, a centering folding mechanism, an optoelectronic switch, a trilateral heat-sealing device, swab sorting devices, a swab receiving and sending manipulator, a quantificationally priming device, an upside heat-sealing device, a traction device, a roller brush output device, a shearing mechanism, a stand and an electrical equipment control device, wherein the uncoiling film sending device, the centering folding mechanism, the optoelectronic switch, the trilateral heat-sealing device, the swab receiving and sending manipulator, the quantificationally priming device, the upside heat-sealing device, the traction device, the roller brush output device, the shearing mechanism and the electrical equipment control device are in sequence arranged on the stand, the two groups of swab sorting devices are arranged at the same side of the swab receiving and sending manipulator, and the electrical equipment control device comprises a PLC (Programmable Logic Controller). The manipulator can continuously receive swabs and directly put the swab in a packaging bag after turning for 180 degrees, quantificational bacteriacide is injected in the bag to be packaged so as to be right absorbed by the swabs and the action among each process step can be coordinated and controlled by the PLC, therefore, the packer can count the swabs with handles and carry out quantificational injection of disinfectant and sealing.

Owner:JIANGSU PROVINCE JIANERKANG MEDICAL DRESSING CO LTD

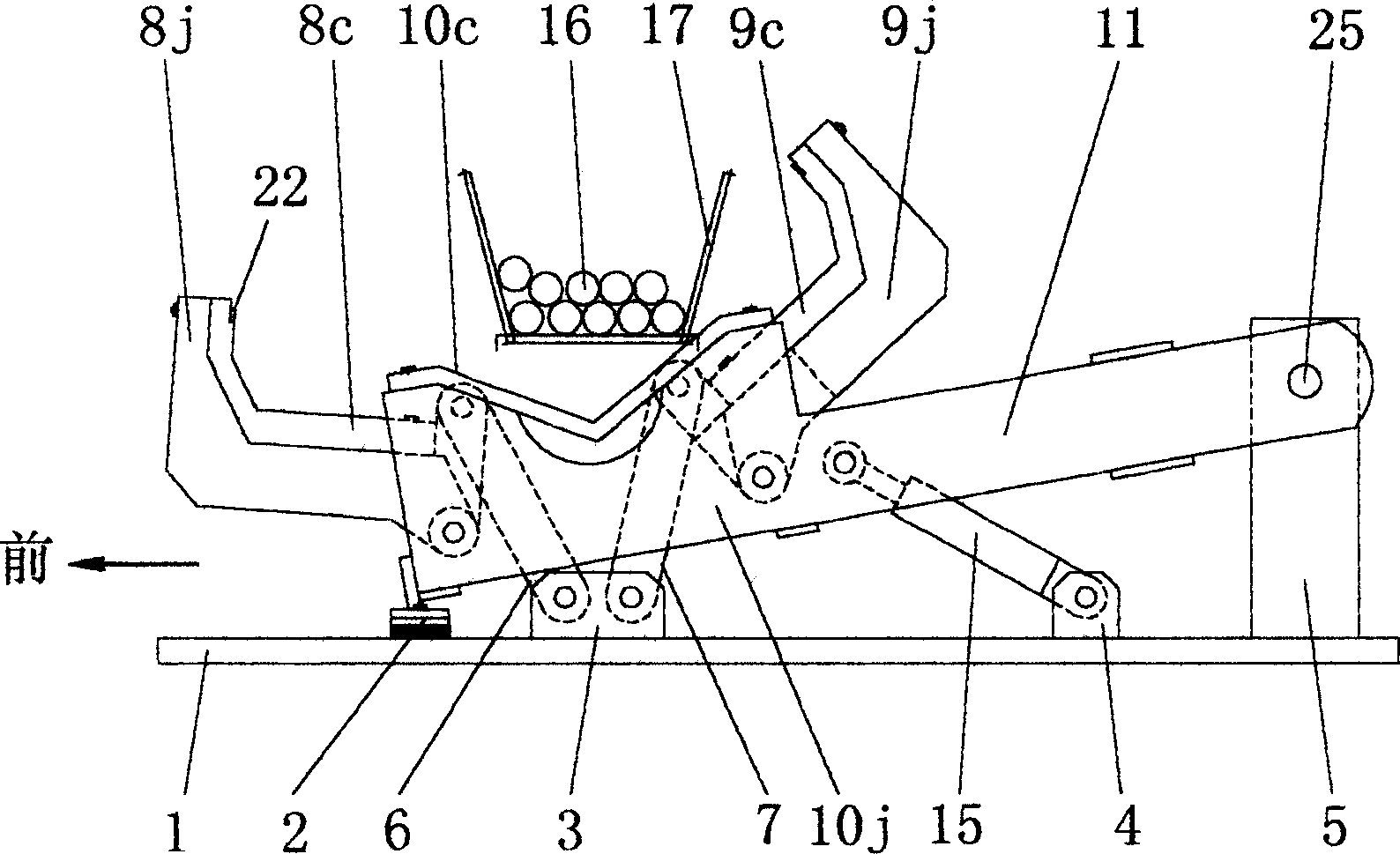

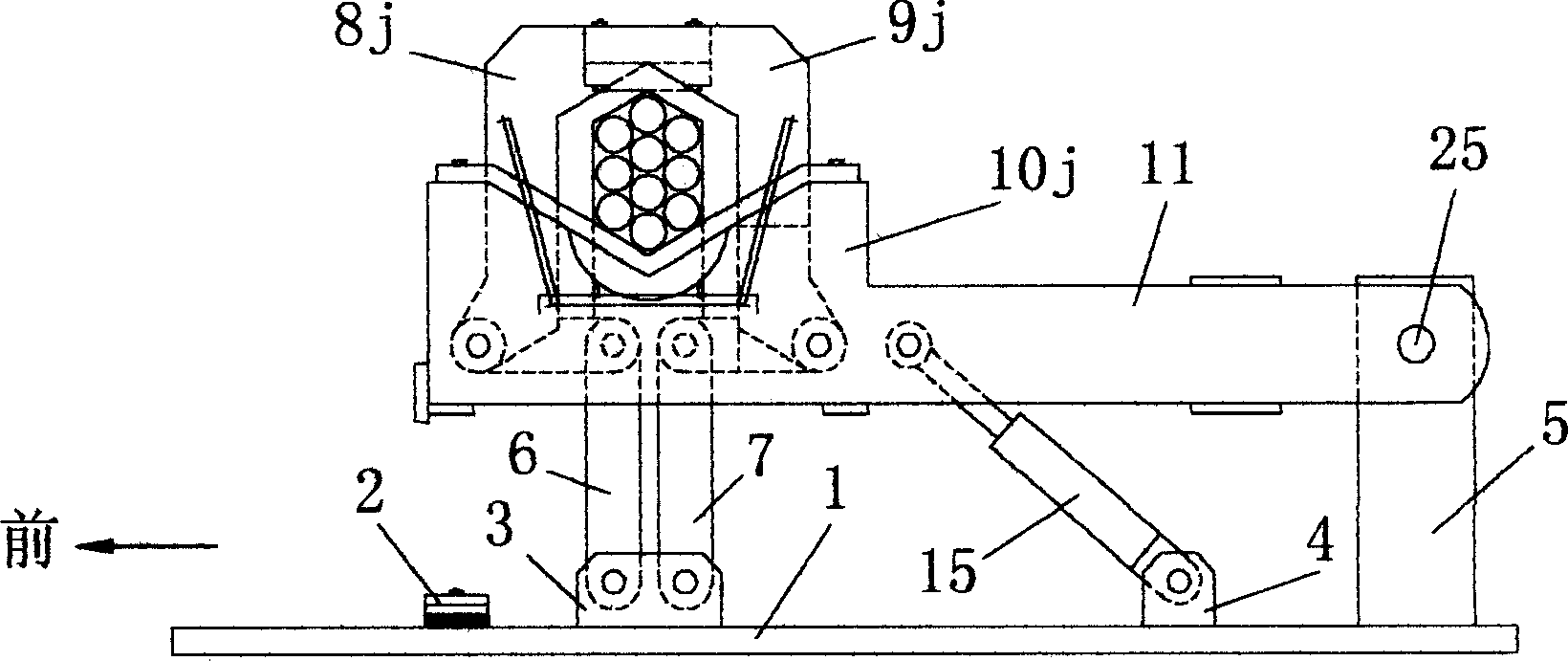

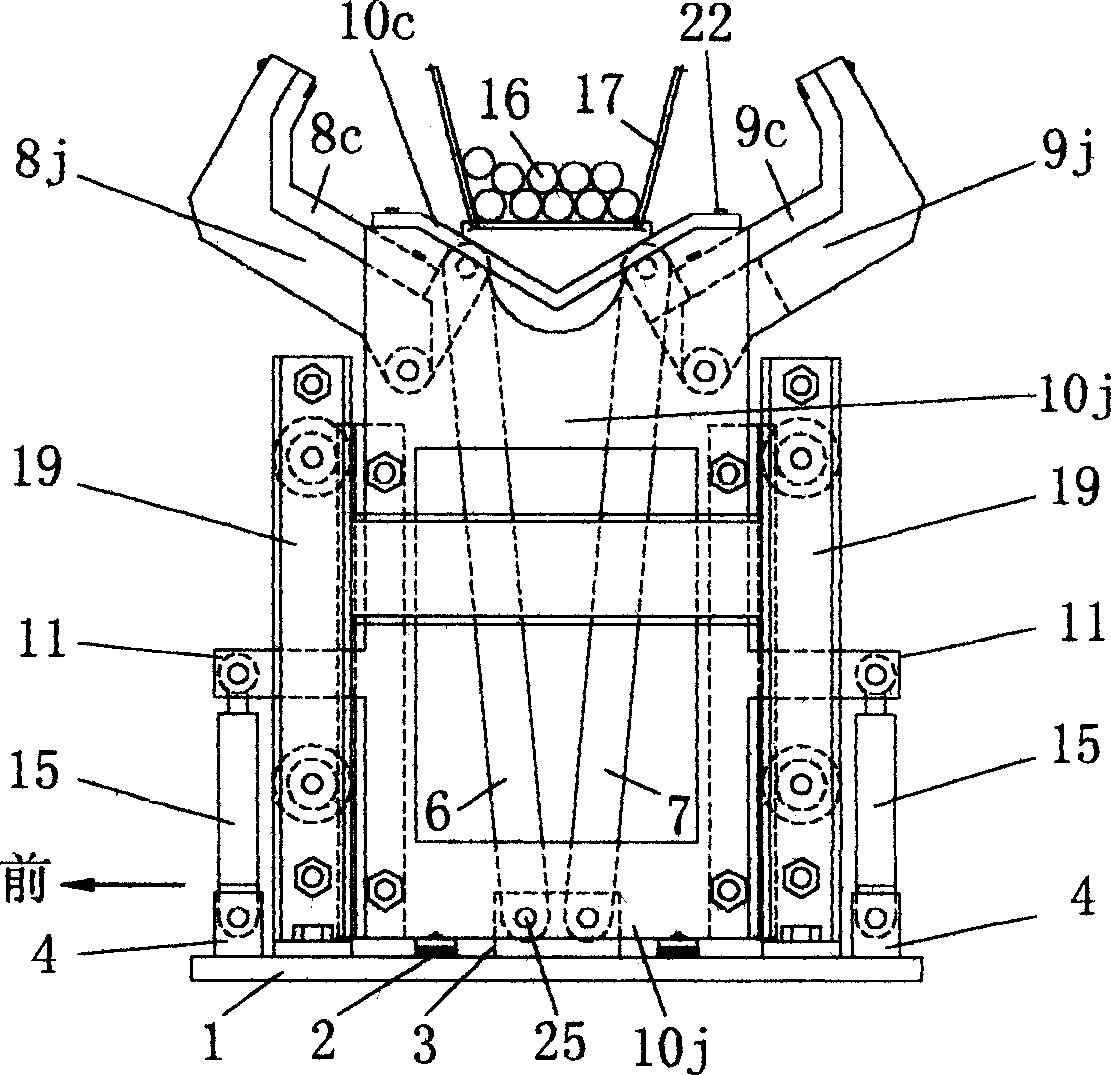

Steel bar bounding, clamping and forming method and device thereof

InactiveCN1733552AImprove packaging qualityLow production costBundling machine detailsSteel barEngineering

This invention provides a method and device to clamp and shape the metallurgical bar material before baling; wherein, the method comprises two steps: first, holding up the material on conveying trough bottom to make material on sides of baling form place lay on guide slope, arranging the near material on interlaced place along the opposite movement direction of front and back jaws; second, the front and back jaws extrude the bar material toward upper space till clamp and shape. The jaw of this device can be integrated or combined type, wherein the latter can clamp small and large size bar materials into circular and hexagon separately. The invention has special form process with wide size and long service life.

Owner:耿宝峰

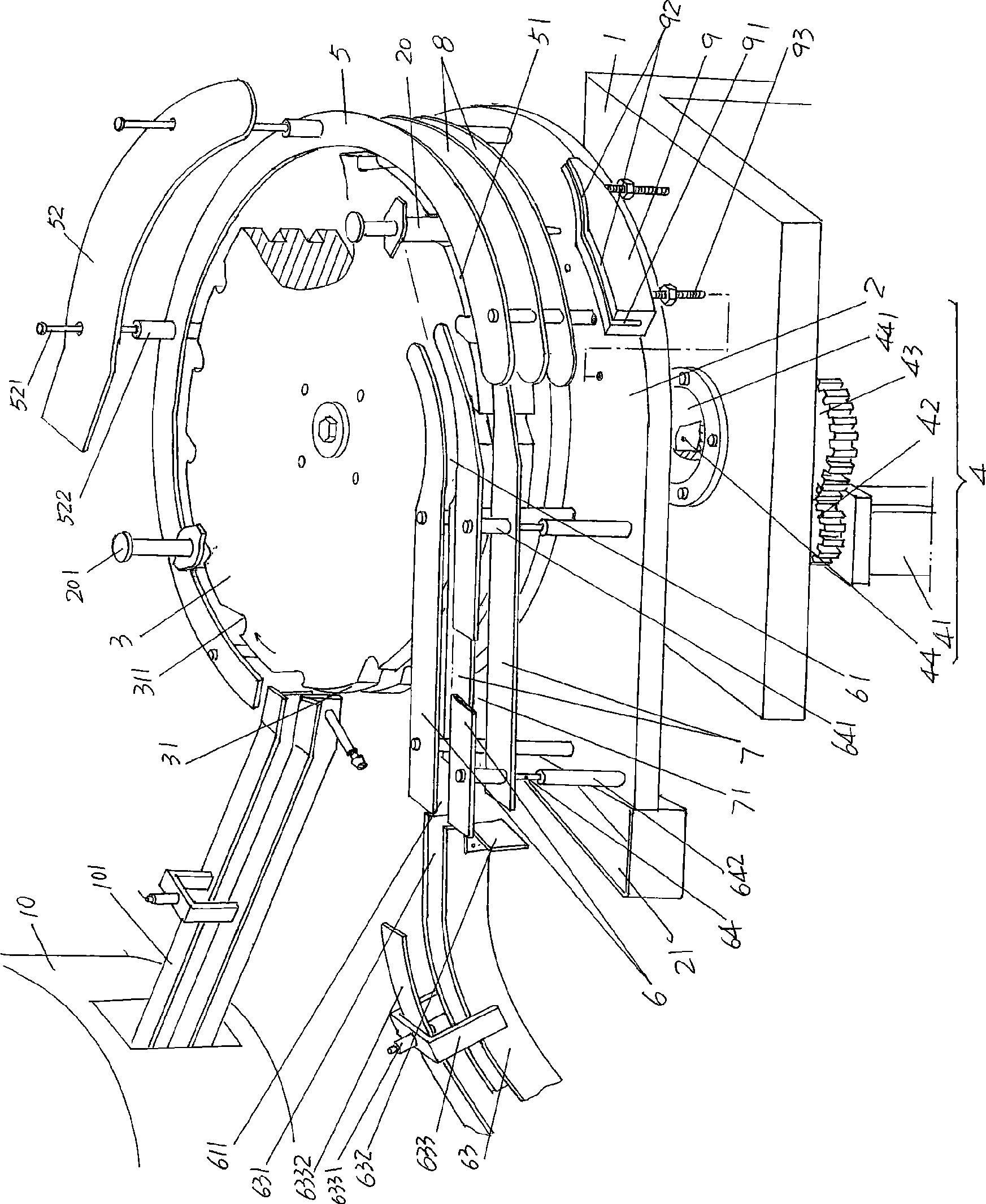

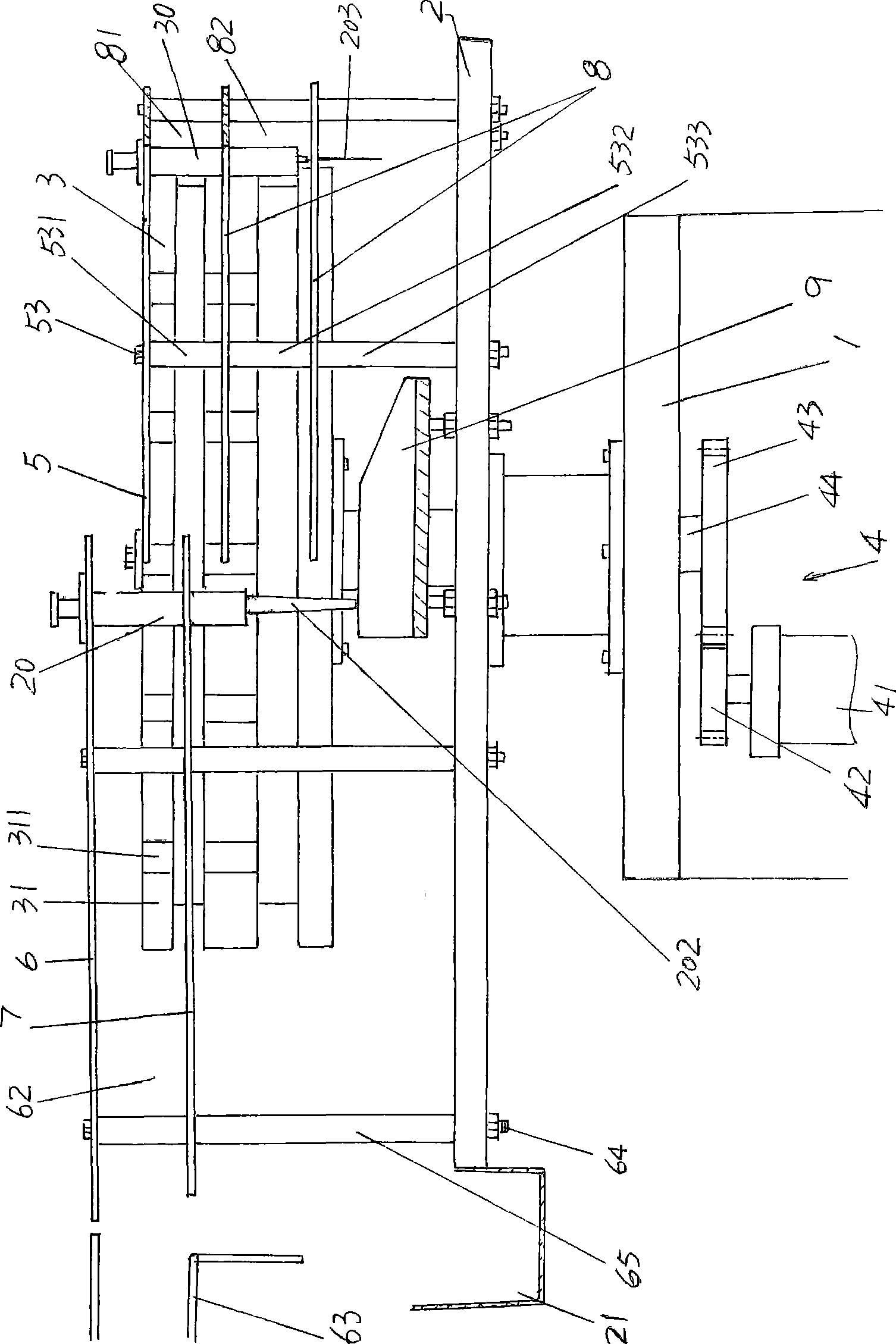

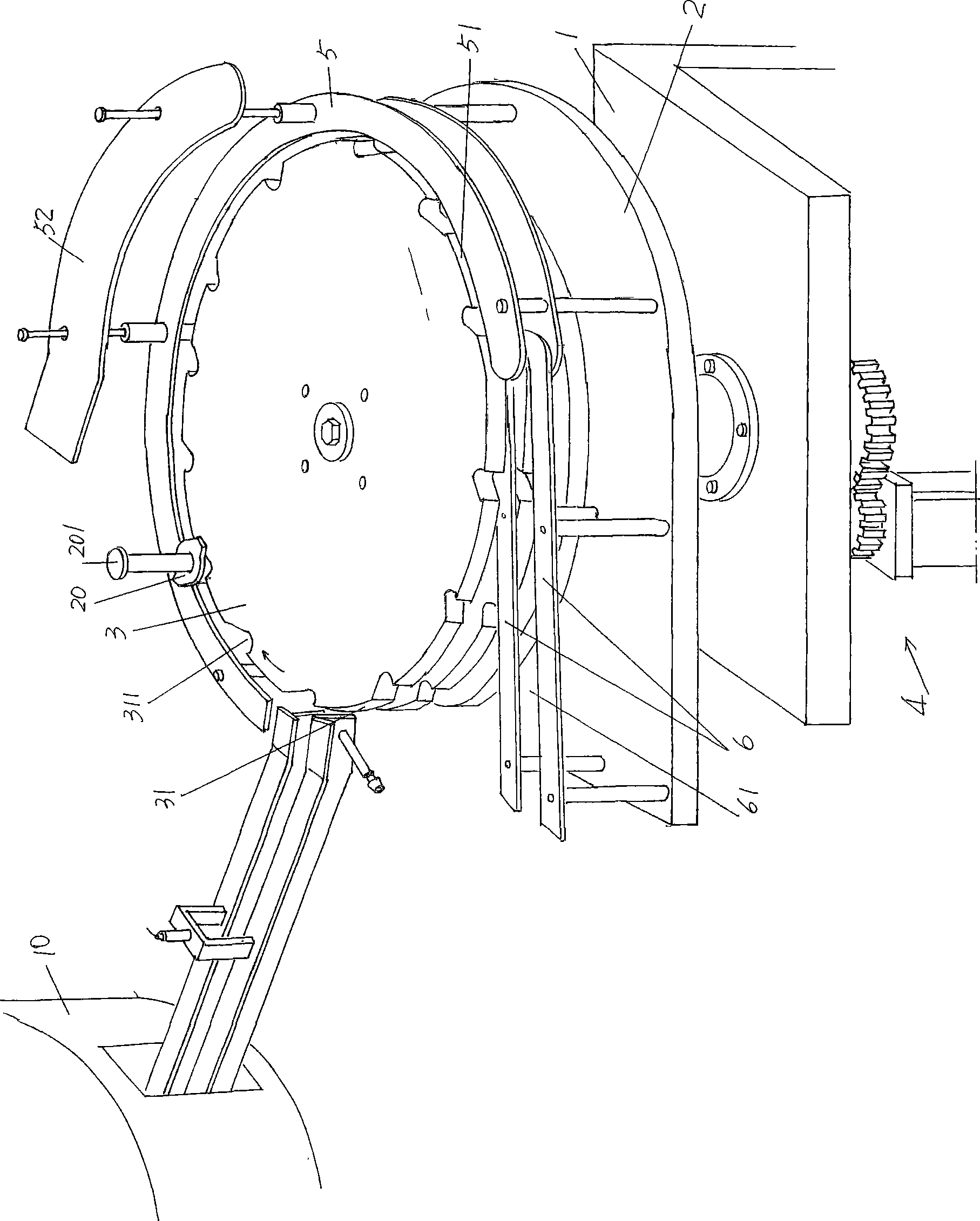

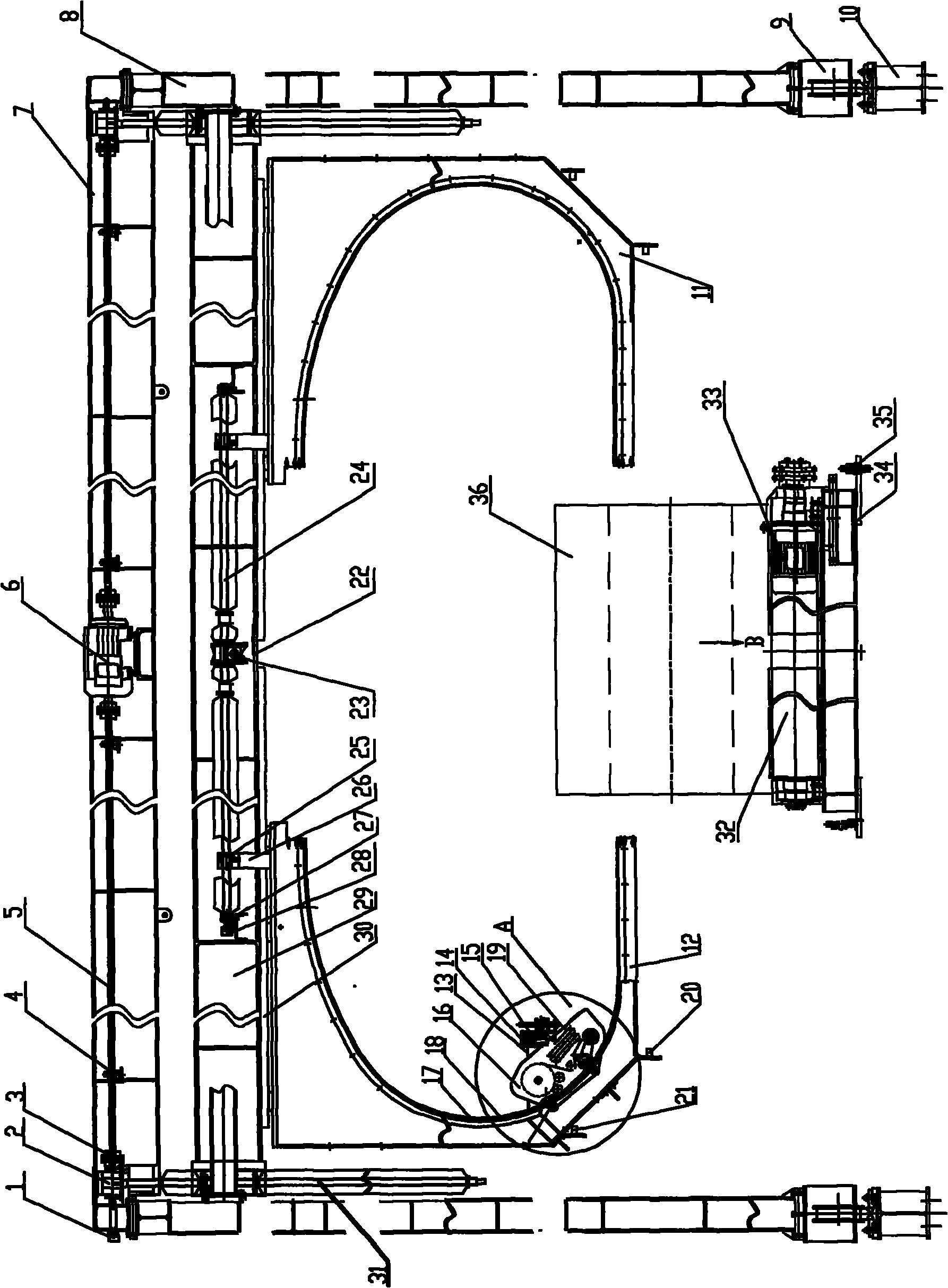

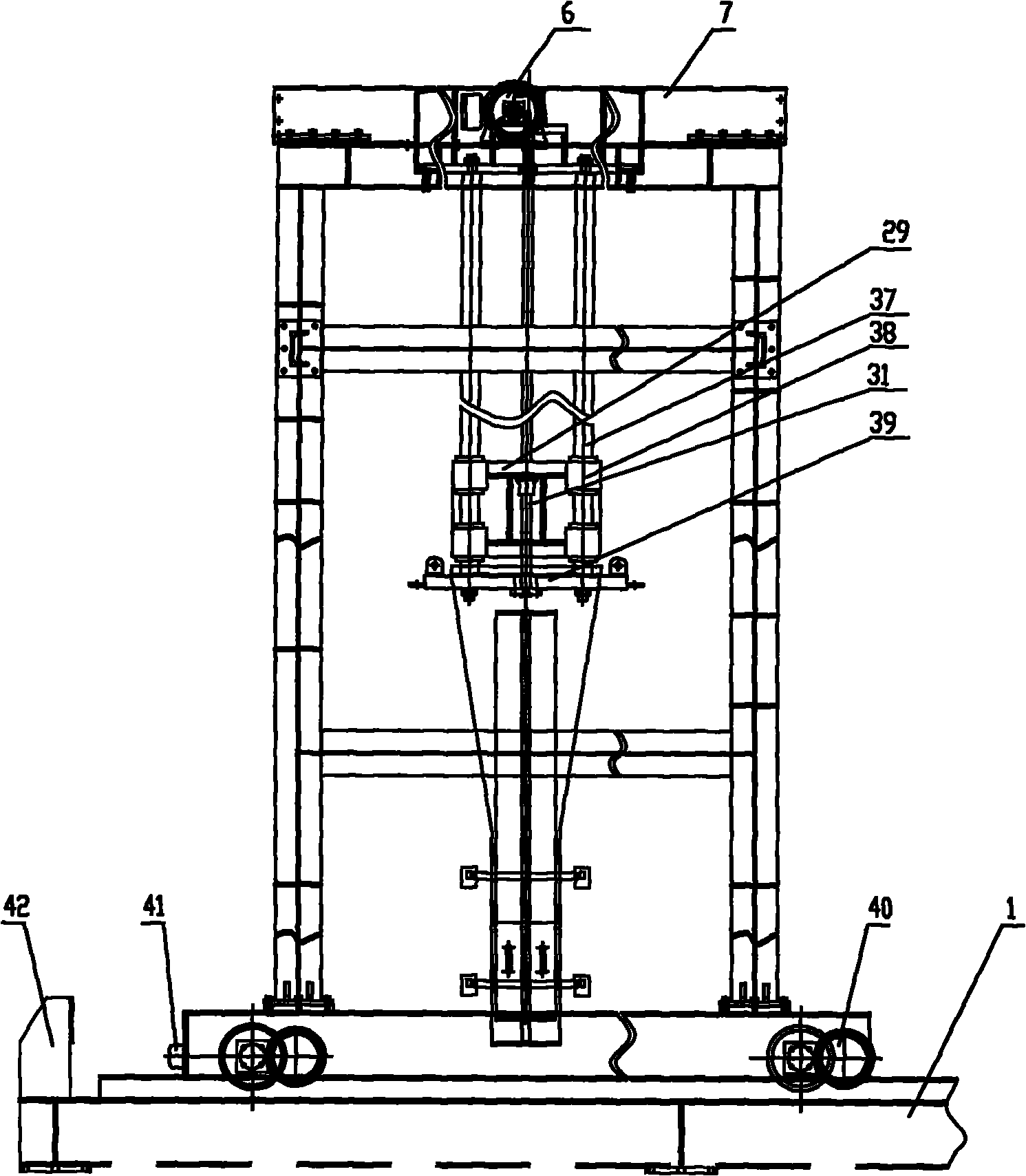

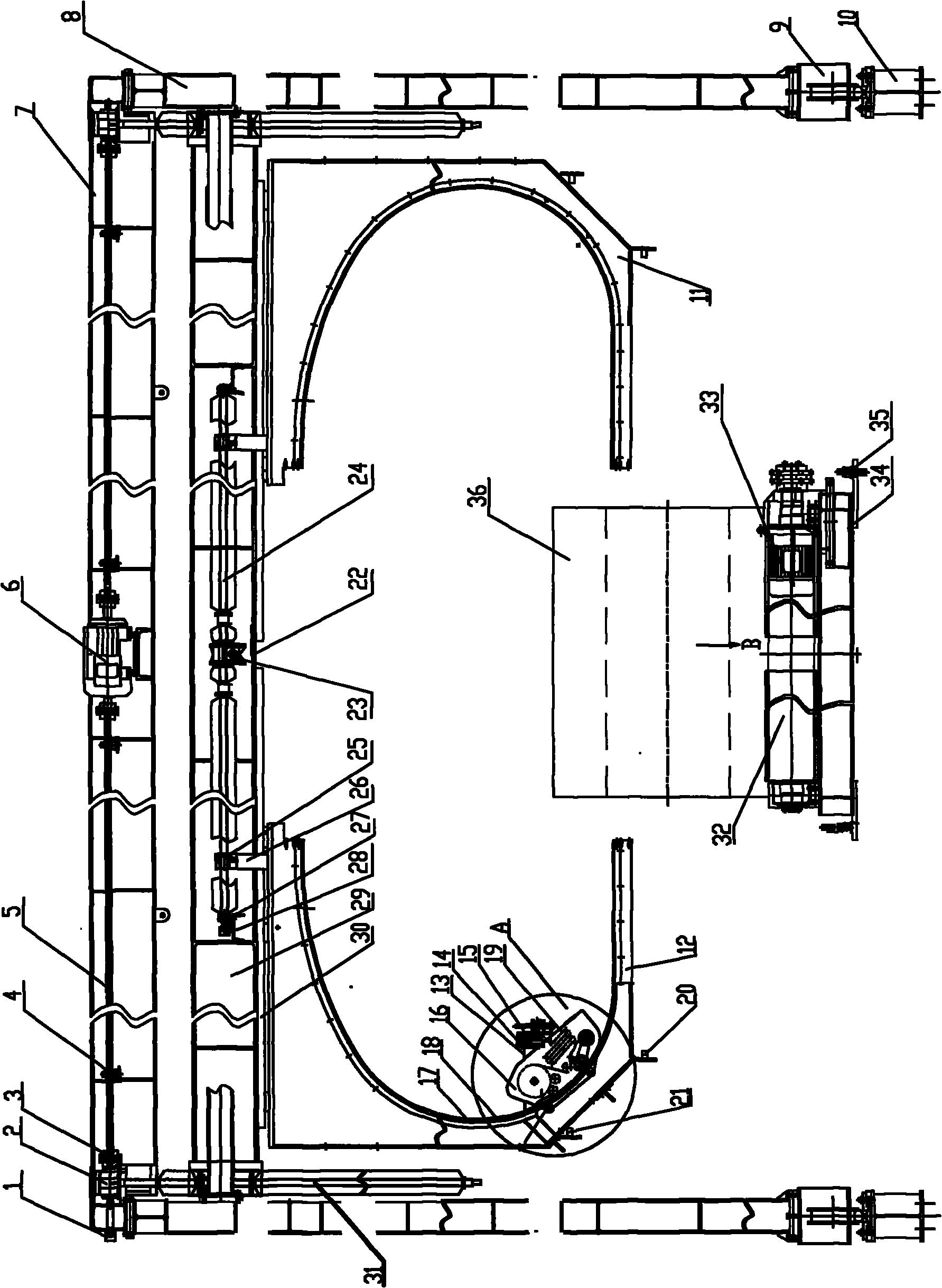

Automatic thin film winding machine for packaging steel coils

InactiveCN101804872AReduce labor intensityEasy to operateWrapping material feeding apparatusWrapping with article rotationWinding machineElectrical control

The invention relates to an automatic thin film winding machine for packaging steel coils, solving the problems of low production efficiency, and the like of the traditional manual packaging. The winding machine comprises a main framework, a main framework connecting beam, a thin film carriage and an electrical control device. The invention adopts the technical key points that a packaging and rolling mechanism comprising a lifting beam, a left C-shaped frame, a right C-shaped frame, the thin film carriage, a thin film drawing and cutting device and a rolling machine is arranged on the main framework connecting beam; the lifting beam is driven to move up and down by utilizing a lifting transmission device; the left C-shaped frame and the right C-shaped frame which are symmetrically arranged carry out left and right relative movements through the drive of a translation and transmission device; the thin film carriage for releasing a packaging thin film moves around a closed circular track formed by the left C-shaped frame and the right C-shaped frame; and carrier rollers of the rolling machine support a packaged steel coil to continuously rotate so as to realize automatic packaging. The winding machine has reasonable structural design, simplified and fluent working procedures, easy control, wide application, reliable property and labor and material saving, obviously lightens the labor intensity of operators and improves the production efficiency and the packaging quality, and meanwhile, the appearance aesthetics are increased.

Owner:鞍山市弘鑫包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[quad flat no-lead package structure and manufacturing method thereof] [quad flat no-lead package structure and manufacturing method thereof]](https://images-eureka.patsnap.com/patent_img/9b07bc5c-5b04-45bc-8282-35c9e2e1004d/US20050073055A1-20050407-D00000.png)

![[quad flat no-lead package structure and manufacturing method thereof] [quad flat no-lead package structure and manufacturing method thereof]](https://images-eureka.patsnap.com/patent_img/9b07bc5c-5b04-45bc-8282-35c9e2e1004d/US20050073055A1-20050407-D00001.png)

![[quad flat no-lead package structure and manufacturing method thereof] [quad flat no-lead package structure and manufacturing method thereof]](https://images-eureka.patsnap.com/patent_img/9b07bc5c-5b04-45bc-8282-35c9e2e1004d/US20050073055A1-20050407-D00002.png)