Display panel, preparation method thereof and display device

A display panel and display area technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of OLED display device packaging and display performance damage, complex structure, poor packaging coverage, etc., to improve packaging. Quality and display performance, the effect of reducing bezels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

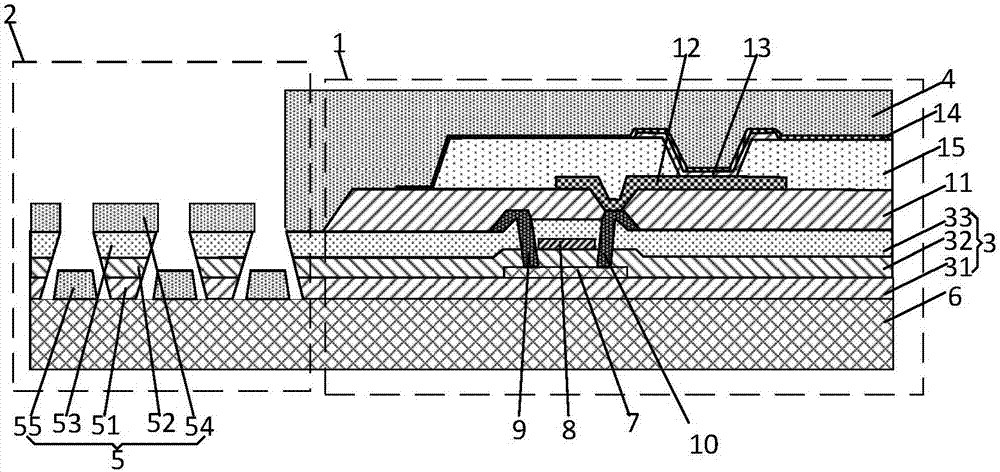

[0060] This embodiment provides a display panel, such as figure 1 and figure 2 As shown, including the display area 1 and the frame area 2, the display area 1 and the frame area 2 are both provided with an inorganic insulating layer 3 and an inorganic encapsulation layer 4, and both the inorganic insulating layer 3 and the inorganic encapsulation layer 4 of the frame area 2 are formed with discontinuities The structure 5, the discontinuous structure 5 can block the crack propagation in the inorganic insulating layer 3 and the inorganic encapsulation layer 4 .

[0061] By forming the discontinuous structure 5 in the inorganic insulating layer 3 and the inorganic encapsulation layer 4 of the frame area 2, when the display panel is cut from the motherboard, the discontinuous structure 5 can block the inorganic insulating layer 3 and the inorganic encapsulation layer near the cutting line. The propagation path of the cracks generated in the layer 4, so that the cracks generated ...

Embodiment 2

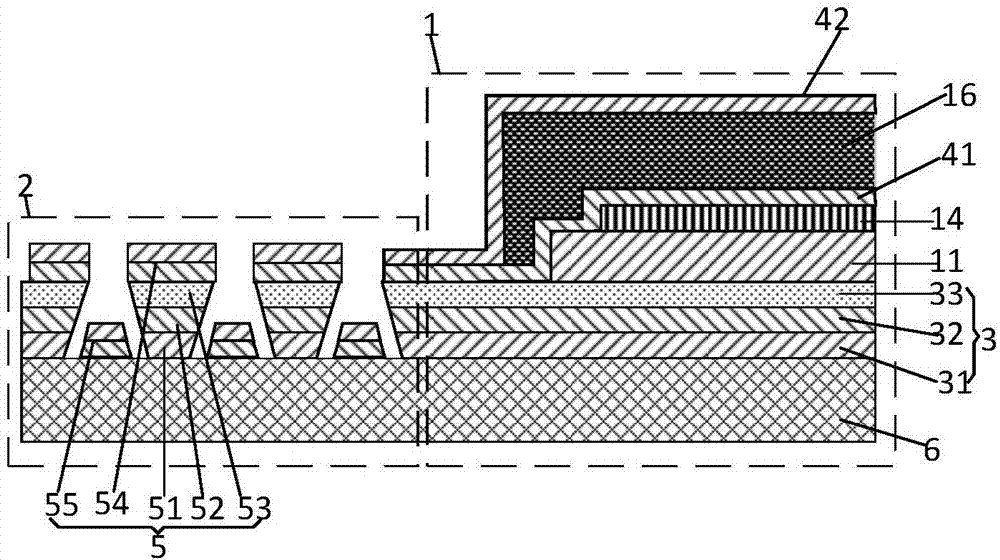

[0081] This embodiment provides a display panel, which is different from that in Embodiment 1, such as image 3 As shown, the discontinuous structure 5 includes a second inverted truncated cone structure 52 and a third inverted truncated cone structure 53 respectively formed in the gate insulating layer 32 and the passivation layer 33, the second inverted truncated cone structure 52 and the gate insulating layer 32 The other parts are spaced apart from each other; the third inverted truncated cone structure 53 is spaced apart from other parts of the passivation layer 33; the second inverted truncated cone structure 52 and the third inverted truncated cone structure 53 correspond to each other and overlap each other to form an inverted truncated cone shape the whole frame. The discontinuous structure 5 also includes a first structure 54 and a second structure 55 formed in the inorganic encapsulation layer 4, the first structure 54 is correspondingly arranged above the third inv...

Embodiment 3

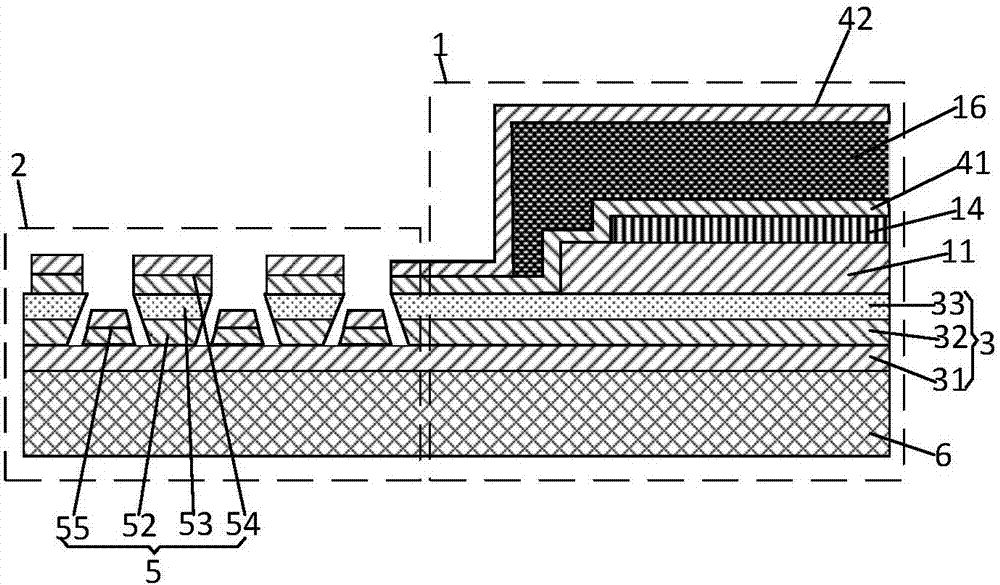

[0091] This embodiment provides a display panel, which is different from Embodiment 1-2, such as Figure 4 As shown, the inorganic insulating layer 3 also includes a pixel definition layer 15, a part of the pixel definition layer 15 is arranged in the display area 1, and the other part is arranged in the frame area 2; in the frame area 2, the pixel definition layer 15 is overlaid on the passivation layer 33 .

[0092] In this embodiment, the discontinuous structure 5 further includes a fourth inverted frustum structure 56 formed in the pixel defining layer 15 , and the fourth inverted frustum structure 56 is spaced apart from other parts of the pixel defining layer 15 . The fourth inverted frustum structure 56 corresponds to the first inverted frustum structure 51 , the second inverted frustum structure 52 and the third inverted frustum structure 53 and overlaps each other to form an inverted frustum-like integral structure. The first structure 54 is correspondingly located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com