Three-roller tire packaging machine

A technology for packaging machines and tires, which is applied in the direction of packaging and item rotation wrapping, etc. It can solve the problems of low tire packaging quality and achieve the effects of improving tire packaging quality, simple and compact structure, and easy use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

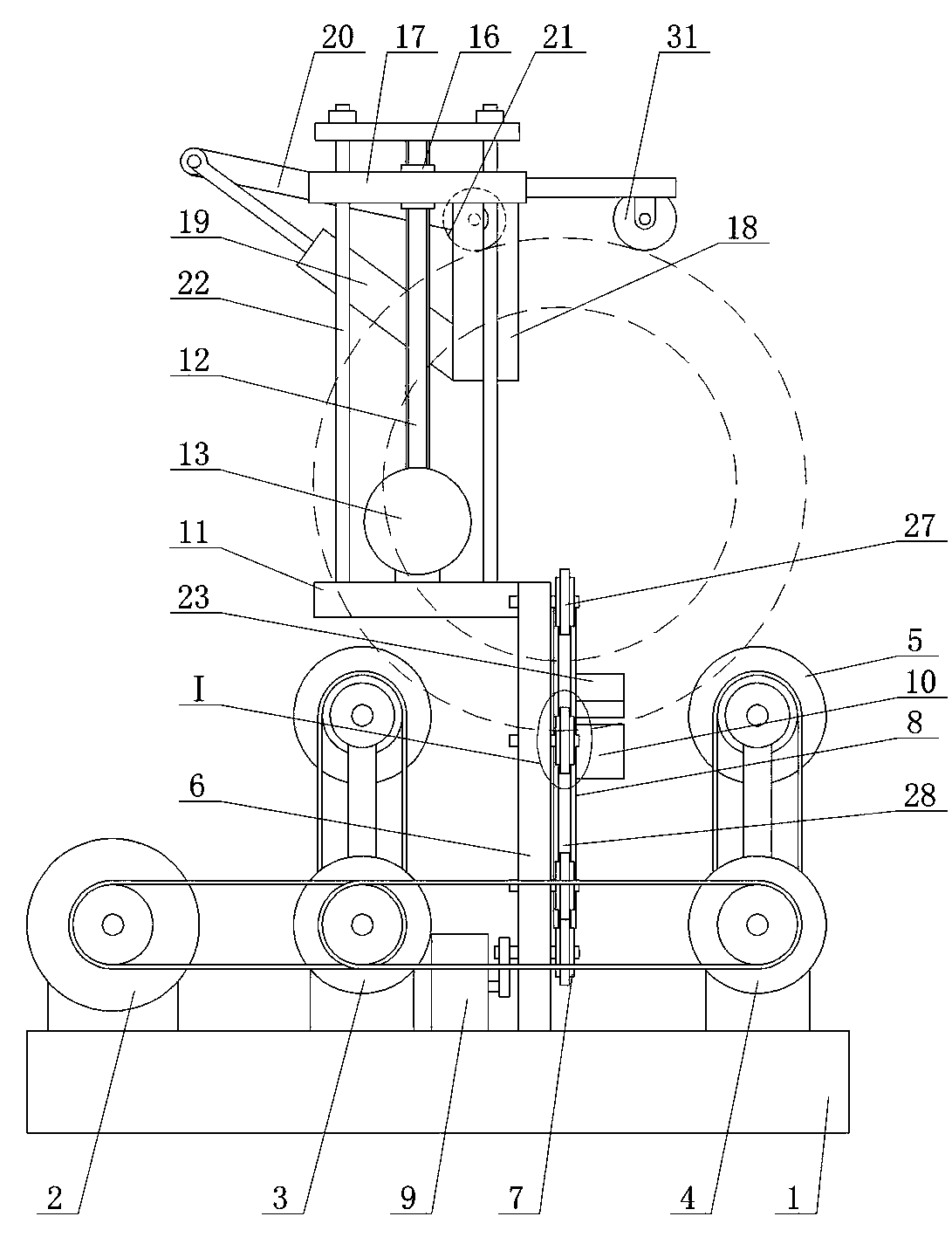

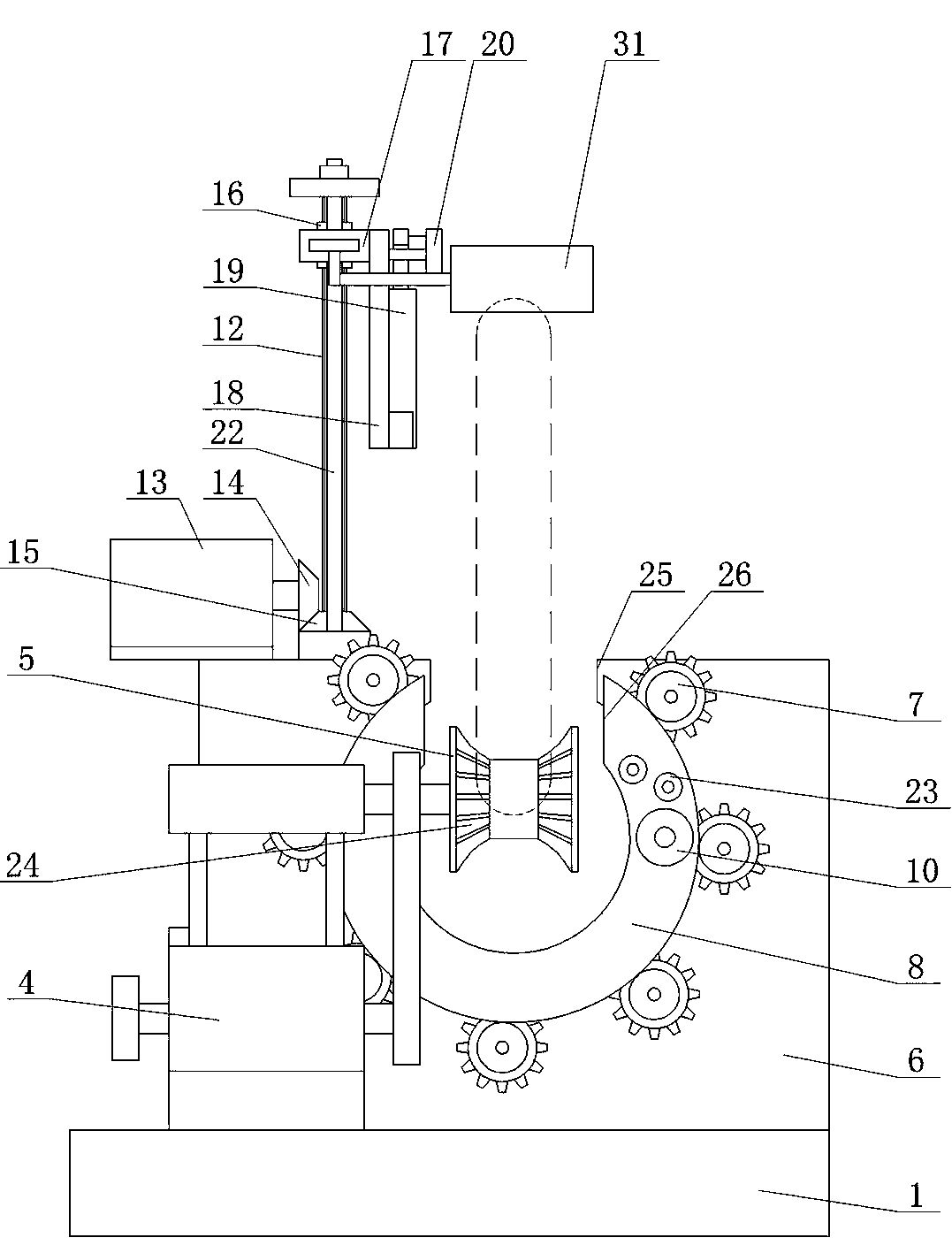

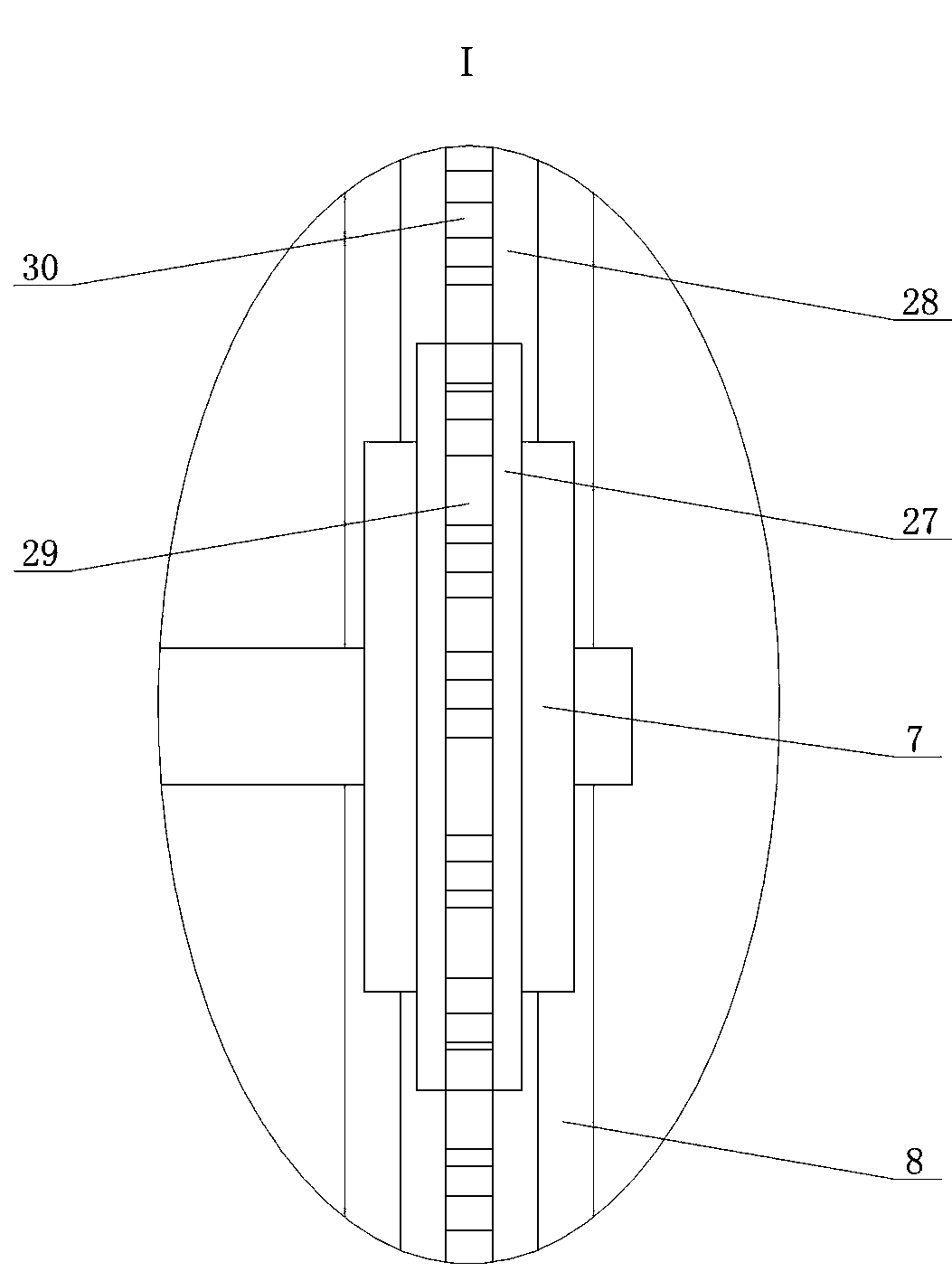

[0009] The three-roller tire packaging machine includes a base 1, a riser 6 is installed on the base 1, a first runner 3 and a second runner 4 are respectively arranged on both sides of the riser 6, and the first runner 3 and the second runner 4 are connected The first motor 2, the first motor 2, the first runner 3 and the second runner 4 are all installed on the base 1, and a supporting roller 5 is respectively installed on the first runner 3 and the second runner 4, and the first runner Both the wheel 3 and the second running wheel 4 are connected with the corresponding support wheel 5 through a transmission belt. Several connecting wheels 7 are installed on one side wall of the riser 6, at least two connecting wheels 7 are connected to the second motor 9, the second motor 9 is fixed on the base 1, and several connecting wheels 7 are connected around the two supporting wheels 5 The midpoint is circular and evenly distributed, and the ring-shaped swivel 8 is installed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com