Intelligent packer with manipulator for receiving and sending swabs and quantificationally dosing and use method thereof

A technology of manipulator and packaging machine, applied in packaging machine, packaging, transportation packaging and other directions, can solve the problem of no automatic packaging machine, etc., and achieve the effect of high packaging efficiency and high packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

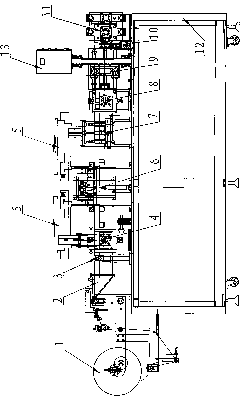

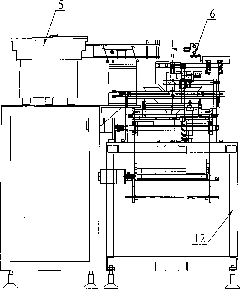

[0015] The manipulator of the present invention picks up and sends cotton swabs, and the quantitative dosing intelligent packaging machine, as attached Figure 1-3 As shown, it includes an unwinding film feeding device 1, a centering folding device 2, a photoelectric switch for controlling bag width 3, a three-side heat sealing device 4, a cotton swab sorting device 5, a cotton swab receiving and unloading robot 6, and a quantitative liquid injection device 7 , top heat sealing device 8, traction device 9, rolling brush output device 10, shearing device 11, frame 12 and electrical control device 13, wherein, unwinding film feeding device 1, centering folding device 2, control bag width Photoelectric switch 3, three-side heat-sealing device 4, cotton swab receiving and releasing manipulator 6, quantitative liquid injection device 7, upper heat-sealing device 8, traction device 9, roller brush output device 10, and shearing device 11 are installed on the frame 12 in sequence , f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com