Patents

Literature

102results about How to "Reduce heat sealing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toughening type three-layer coextru-laminated film and preparation method thereof

ActiveCN101913279AImproves toughness and impact strengthReduce heat sealing temperatureSynthetic resin layered productsPolypropyleneNitrogen gas

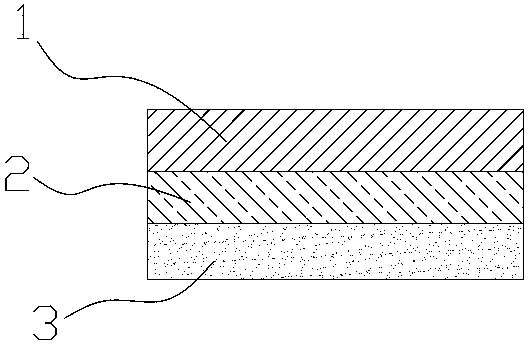

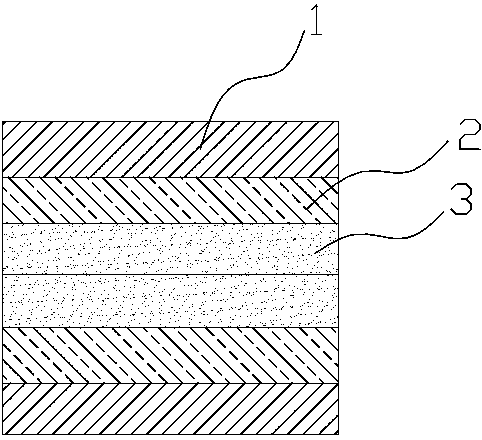

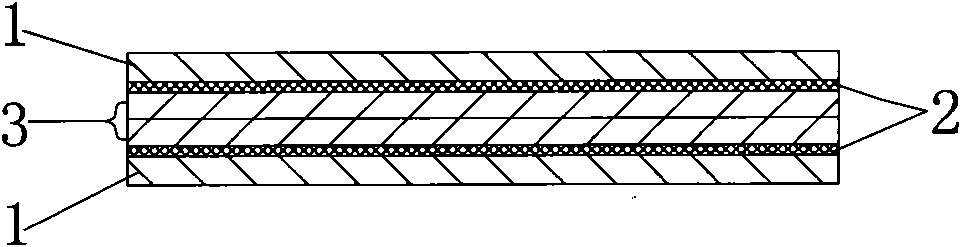

The invention discloses a toughening type three-layer coextru-laminated film and a preparation method thereof. The film is co-extruded by three layers through a casting machine and is provided with an outer layer, a middle layer and an inner layer which are laminated together, wherein the middle layer is made of polypropylene hydrocarbon elastomer and polypropylene in a weight ratio of 1:10 to 1:3; and the melt index of the polypropylene hydrocarbon elastomer is between 6 and 12. In the toughening type three-layer coextru-laminated film, the middle layer is prepared by blending or co-extruding the polypropylene hydrocarbon elastomer and the polypropylene after the scheme is adopted. Compared with the conventional CPP film, the toughening type three-layer coextru-laminated film improves impact resistance strength and toughness of the laminated film, does not influence the barrier property of the laminated film, and is particularly suitable for packing oily nitrogen charging products such as eggs, bread and the like.

Owner:KAIDA GRP CO LTD FJ

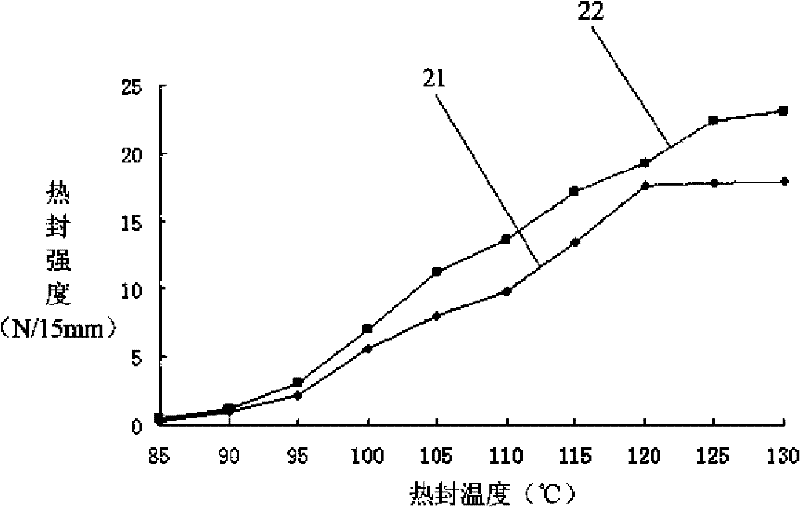

Hot-seal functional stretch film

InactiveCN102190824ANo heat sealabilityAvoid warpingFlexible coversWrappersBlow moldingOptical property

The invention provides a functional stretch film with hot seal property, and in particular relates to a hot-seal unidirectional or bidirectional stretch film, which has the hot seal strength of more than or equal to 3N / 15mm and the thickness of more than or equal to 0.010mm and less than or equal to 0.150mm and which is formed by a single layer, two layers or more than two layers of polyolefine resin by an auxiliary co-mixing process and a blow molding, flow casting extrusion stretching or co-extrusion stretching process. The functional stretch film solves the technical problem that the effective hot seal cannot be achieved on an occasion with higher hot-seal requirements due to difficult obtaining of hot seal or serious hot-seal performance reduction when the polyolefin film is stretched. The product has the advantages of high mechanical strength, excellent optical property, obviously high water vapor resistance, anti-puncturing property and extremely good seal grease resistance and anti-pollution hot seal property, and can be widely applied to bags and automatic filling type sealed packages of foods, articles of daily use, cosmetics, chemicals, pesticides, military products and medical products as well as intaglio printing films and flexographic printing films, particularly various hot-seal materials under the dry-type lamination, wet-type lamination and extrusion lamination processing conditions.

Owner:江苏彩华包装集团公司 +1

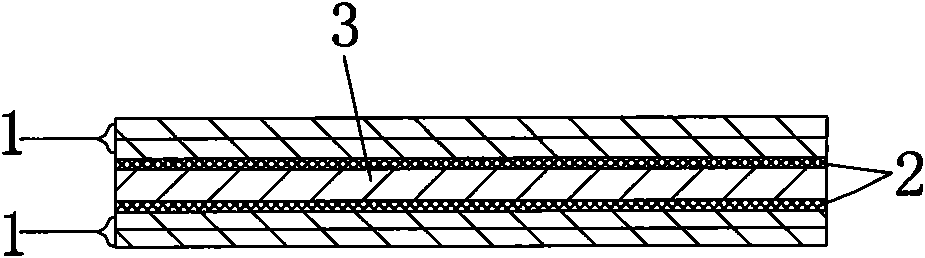

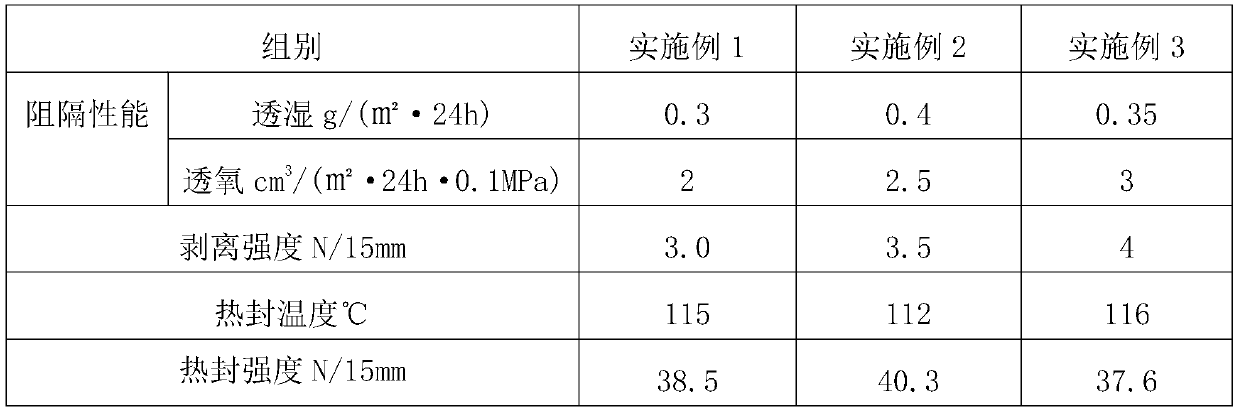

Low-temperature heat-seal shrinking packaging film used for cigarettes and manufacturing method thereof

InactiveCN105619990AReduce heat sealing temperatureReduce energy consumptionSynthetic resin layered productsLaminationElastomerMasterbatch

The invention relates to a low-temperature heat-seal shrinking packaging film used for cigarettes. The packaging film comprises a surface layer A, a core layer B and a surface layer C; the surface layer A is prepared from, by mass, 70-80 parts of an ethylene-butene-propylene terpolymer, 2-10 parts of an ethylene-butene copolymer, 12-22 parts of a slipping agent, 3-13 parts of an antisticking agent and 0.5-1.5 parts of a wear-resisting agent, wherein the slipping agent is composed of erucyl amide and dimethicone, and the antisticking agent is composed of PMMA and silicon dioxide powder; the core layer B is prepared from 65-80 parts of homo-polypropylene, 24-32 parts of stiffness improving master batch and 2-6 parts of anti-static master batch; the surface layer C is prepared from 80-90 parts of an ethylene-butene-propylene terpolymer, 5-15 parts of ethylene-butene copolymerized elastomer, 2-5 parts of a slipping agent and 3-10 parts of an antisticking agent, the slipping agent is dimethicone and the antisticking agent is PMMA. The three-layer coextruded packaging film is lower in heat-seal temperature, energy consumption is reduced, and the cigarette case packaging quality is improved.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

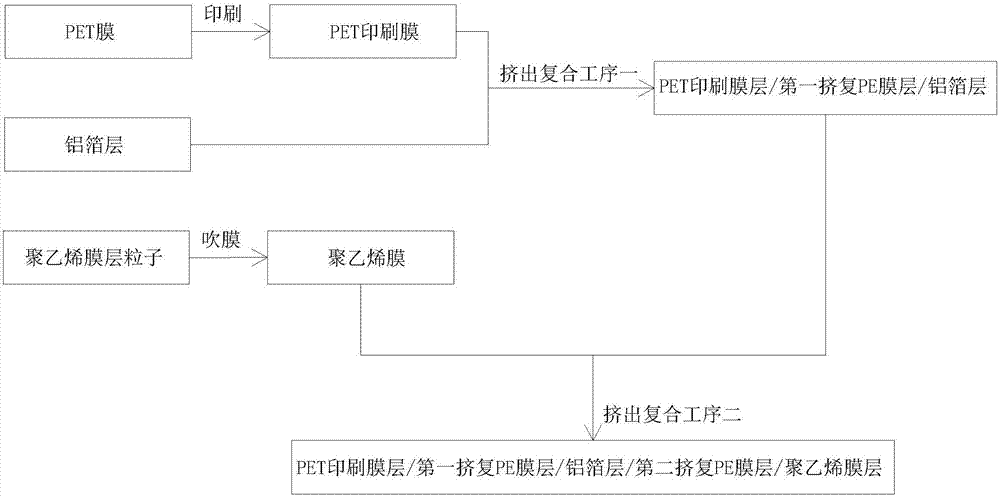

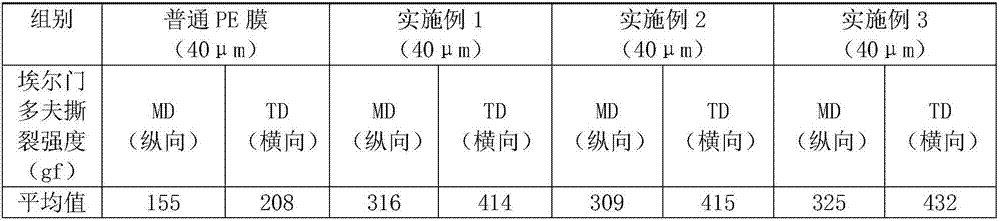

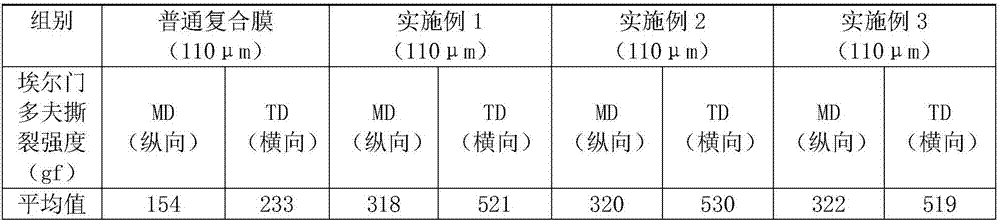

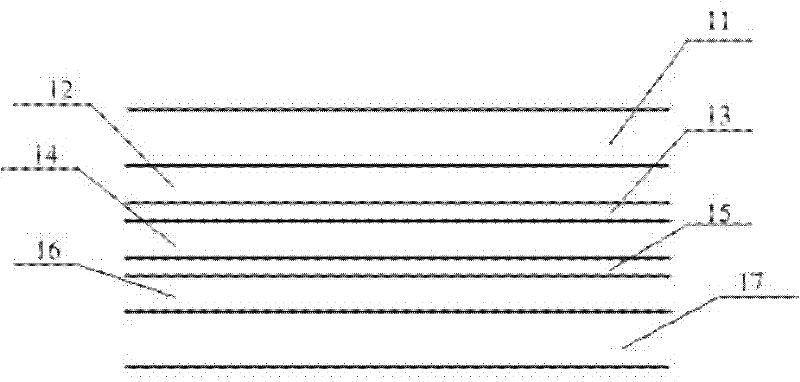

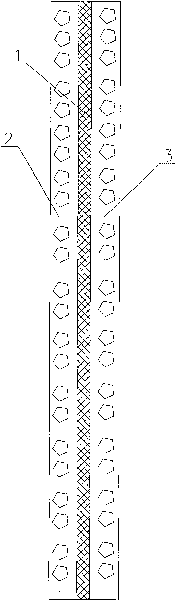

Tear-resistant polyethylene film, composite membrane and preparation method thereof

ActiveCN107323053AHigh peel strengthHigh heat sealing strengthFlexible coversWrappersTear resistanceAluminum foil

The invention relates to a tear-resistant polyethylene film, a composite membrane and a preparation method thereof. The polyethylene film comprises a corona layer, a middle layer and a heat sealing layer, wherein the corona layer and the middle layer are each composed of first metallocene PE, octa-carbon LLDPE and processing aids, and the heat sealing layer is composed of the first metallocene PE, second metallocene PE, silicone, a slipping agent and an opening agent. The composite membrane is formed by a PET printing membrane layer, a first extruded PE membrane layer, an aluminum foil layer, a second extruded PE membrane layer and a polyethylene membrane layer which are sequentially fitted in the membrane layer thickness direction; the extruded PE membrane layer comprises a first adhesive layer in fit with the aluminum foil layer and a second adhesive layer in fit with the PET printing membrane layer or the polyethylene membrane layer, wherein the first adhesive layer is composed of third metallocene PE and adhesive resin, and the second adhesive layer is composed of the third metallocene PE and color master batch. The polyethylene film and the composite membrane disclosed by the invention have higher tear resistance strength. In addition, the composite membrane has excellent humidity resistance property.

Owner:HUANGSHAN NOVEL

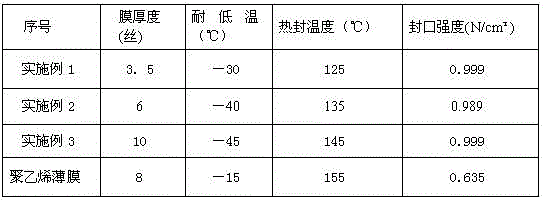

Low temperature resistant triple coextrusion composite film and preparation method thereof

ActiveCN101927591AImprove low temperature resistance and freeze resistanceLow temperature flexibilitySynthetic resin layered productsComposite filmMass ratio

The invention discloses a low temperature resistant triple coextrusion composite film and a preparation method thereof. The composite film in the invention is formed through carrying out triple coextrusion by a casting machine, and comprises an outer layer, a middle layer and an inner layer which are composited together; the materials of the middle layer adopt metallocene low-density linear polyethylene and polypropylene at the mass ratio of 1:10-1:1; and the melt index of the metallocene low-density linear polyethylene is 1-3.5. After the scheme is adopted, compared with the traditional CPP film, the low temperature resistant triple coextrusion composite film of the invention has the advantages of greatly improving the low temperature resistant and freezing resistance performance, being capable of being normally used under the environment of minus 30 DEG C, having no influence on the barrier property and strength thereof and being particularly suitable for packaging of quick frozen products such as boiled dumplings, sweet soup balls and the like.

Owner:KAIDA GRP CO LTD FJ

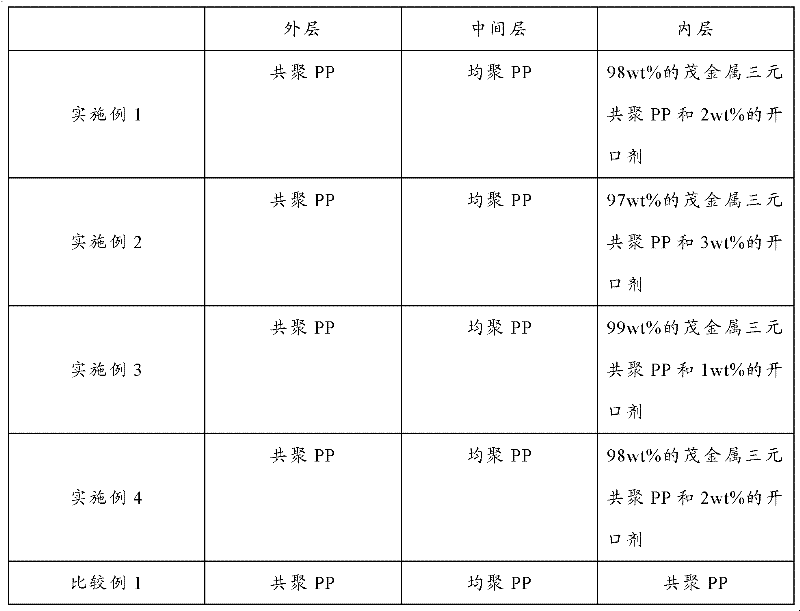

Composite film for candy packaging and preparation method thereof

InactiveCN102350829ALow melting pointHigh instant bond strengthFlexible coversWrappersComposite filmPolyethylene terephthalate

The invention provides a composite film for candy packaging and a preparation method thereof. The composite film for candy packaging successively comprises a polyethylene glycol terephthalate layer and an aluminizing casting polypropylene layer, wherein, the aluminizing casting polypropylene layer successively comprises an aluminized layer and a casting polypropylene (CPP) layer, the CPP layer successively comprises a corona layer, a core layer and an internal layer, and the internal layer comprises 97-99 wt% of metallocene polypropylene terpolymer and 1-3 wt% of opening agent. The composite film for candy packaging provided herein can lower heat-sealing temperature of the packaging film and simultaneously guarantee heat-sealing intensity, so as to satisfy the requirements of a high speed packaging machine for heat-sealing, and improves the packaging efficiency.

Owner:HUANGSHAN NOVEL

Heat sealing film and preparation method thereof

ActiveCN102225644AReduce heat sealing temperatureLow tensile strengthFlexible coversWrappersBlow moldingPolymer science

The invention provides a heat sealing film. The film comprises a first polyethylene layer, a first metallocene polypropylene layer and a polypropylene layer which contact in sequence, wherein the first metallocene polypropylene layer comprises not less than 25% by mass of a metallocene ethylene-propylene copolymer. The invention also provides a preparation method of the heat sealing film. The preparation method comprises the following steps: carrying out extrusion molding on polyethylene, the metallocene ethylene-propylene copolymer and polypropylene to obtain a hot melt tube containing the first polyethylene layer, the metallocene polypropylene layer and the polypropylene layer which contact in sequence; blow molding the hot melt tube into the film, and cooling and shaping; and carrying out corona processing on an outer surface of the cooled and shaped film to obtain the heat sealing film. The heat sealing film with good performances can be obtained through controlling the thickness of the heat sealing film provided by the present invention in a thin scope, so the packing difficulty is reduced and the packing speed is improved.

Owner:HUANGSHAN NOVEL

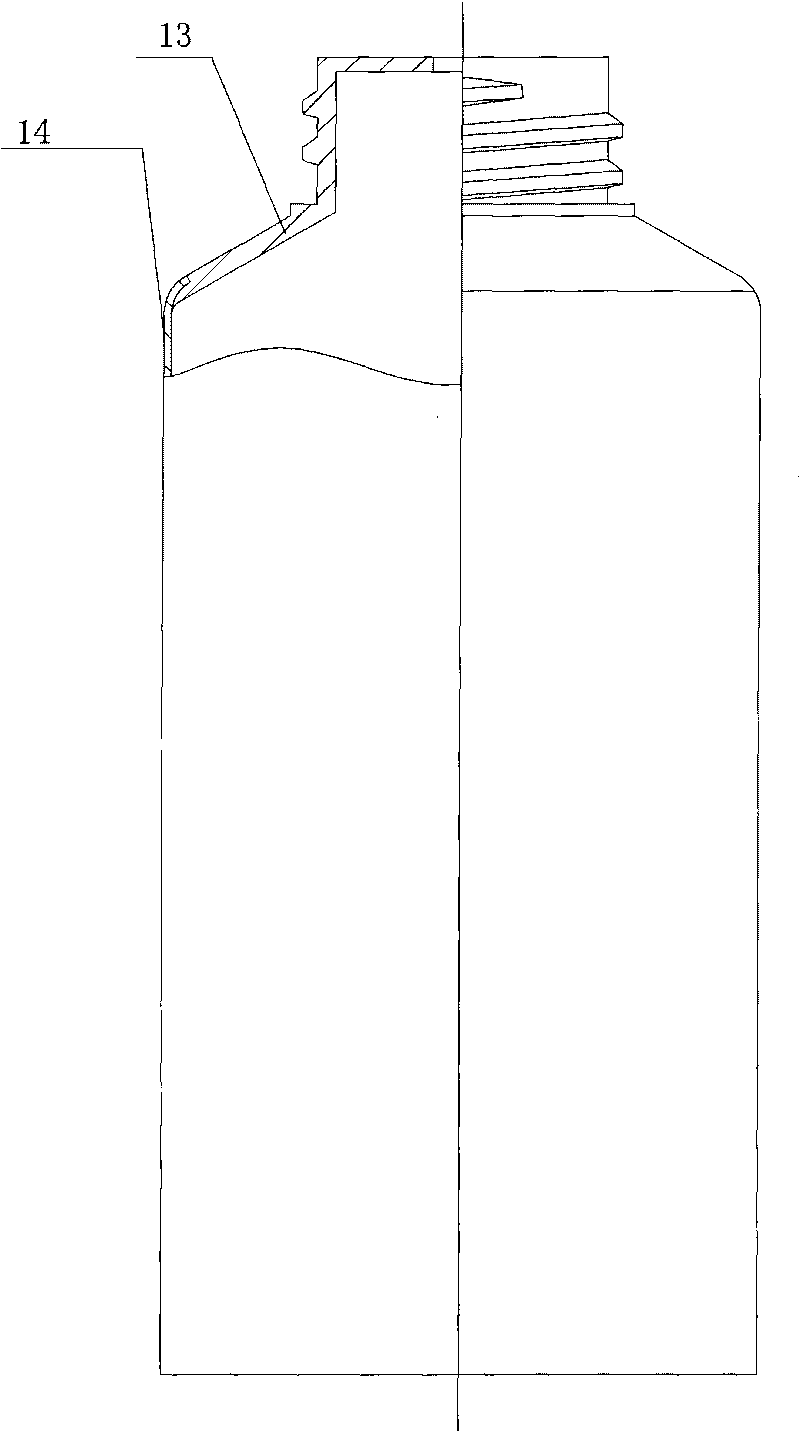

Coextrusion composite polypropylene soft pipe and production method

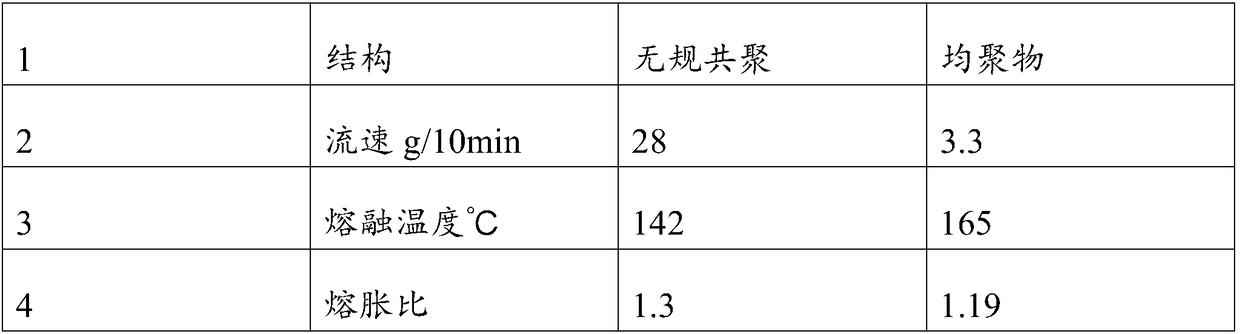

InactiveCN101761707AReduce crystallinityHigh crystallinityFlexible pipesTubular articlesMelt flow indexPolypropylene

The invention relates to a coextrusion composite polypropylene soft pipe and a production method; the coextrusion composite polypropylene soft pipe comprises a pipe head and a pipe body, the pipe body is a composite structure with 2-5 layers, wherein at least one layer material is the polypropylene or the mixture of the polypropylene and polyethylene, the raw material of the polypropylene adopts 0.5-2.0g / 10min of melt index and is random copolymerization polypropylene catalyzed by metallocene catalyst; the pipe body of the soft pipe is produced by adopting coextrusion process, especially, raw materials of all layers of the pipe body of the soft pipe are added in respective single screw extrusion machine from each hopper, and the materials are melted and are coextruded out from the same molding mixing machine, and then drawing, cooling, vacuum formation, heat treatment, traction, and fixed length cutting are carried out, so as to obtain the pipe body, and mature head injection, printing, post processing, packaging and other procedures are carried out to the pipe body, so as to obtain the composite polypropylene soft pipe finished product. The composite polypropylene soft pipe has high transparency and is harder than the existing product, and the whole weight of the soft pipe is reduced.

Owner:SHANGHAI MEIYING PLASTICS

Low-temperature heat-sealing non-paper packaging film for cigarettes in carton and manufacturing method thereof

InactiveCN105644092AReduce heat sealing temperatureImprove qualityFlexible coversWrappersPolypropyleneEngineering

The invention relates to a low-temperature heat-sealing shrinkable packaging film for cigarettes. The packaging film comprises a surface layer A, a core layer B and a surface layer C. The surface layer A comprises, by weight, 70-80 parts of an ethene-butylene-propylene terpolymer, 2-10 parts of an ethene-butylene copolymer elastomer, 12-22 parts of a slipping agent, 3-13 parts of an antisticking agent and 0.5-1.5 parts of a wear-resisting agent, wherein the slipping agent is composed of Erucylamide and dimethicone; and the antisticking agent is composed of PMMA and silicon dioxide powder. The core layer B comprises, by weight, 65-80 parts of homo-polypropylene, 24-32 parts of stiffening master batch and 2-6 parts of antistatic master batch. The surface layer C comprises, by weight, 45-60 parts of an ethene-butylene-propylene terpolymer, 30-50 parts of an ethene-butylene copolymer elastomer, 2-5 parts of slipping agent and 3-10 parts of an antisticking agent, wherein the slipping agent is dimethicone; and the antisticking agent is PMMA. The three-layer co-extrusion packaging film has lower heat-sealing temperature, energy consumption is saved, and external packing quality of cigarettes in carton is raised.

Owner:JIANGYIN ZHONGDA FLEXIBLE PLASTIC NEW MATERIALS CO LTD

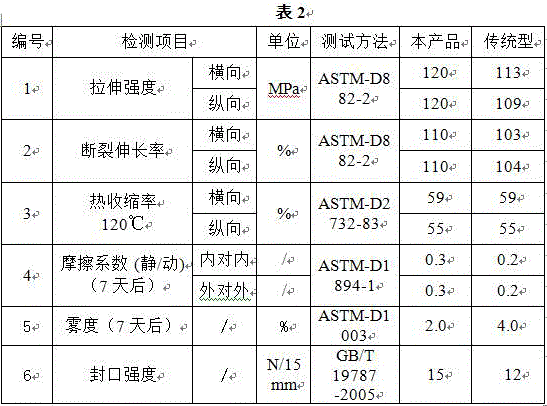

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

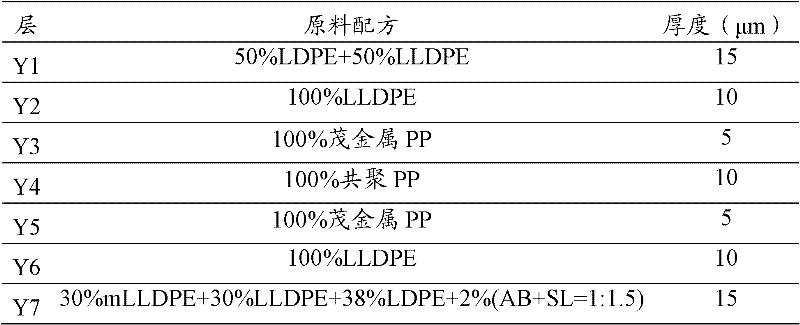

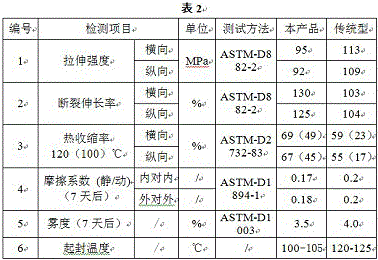

Three-layer co-extrusion ultra-low temperature heat-sealing package thin film

ActiveCN109605890AGood light transmissionReduce heat sealing temperatureFlexible coversWrappersEngineeringCo extrusion

The invention discloses a three-layer co-extrusion ultra-low temperature heat-sealing package thin film, and belongs to the field of package films. America imported metallocene is added into an outerlayer, Japanese imported metallocene is added into a middle layer and an inner layer, the outer layer, the middle layer and the inner layer are different in formula and uniformly mixed according to formulas, three-layer thin film extrusion is formed through a co-extrusion die head, and finally the three-layer co-extrusion ultra-low temperature heat-sealing package thin film is prepared. Compared with a common package thin film, the three-layer co-extrusion ultra-low temperature heat-sealing package thin film has improved transparency and strength, and is quite low in heat sealing temperature and quite suitable for high-speed low-temperature package, wherein the heat sealing temperature can reach 80 DEG C or below to the minimum degree.

Owner:HENAN YINFENG PLASTIC

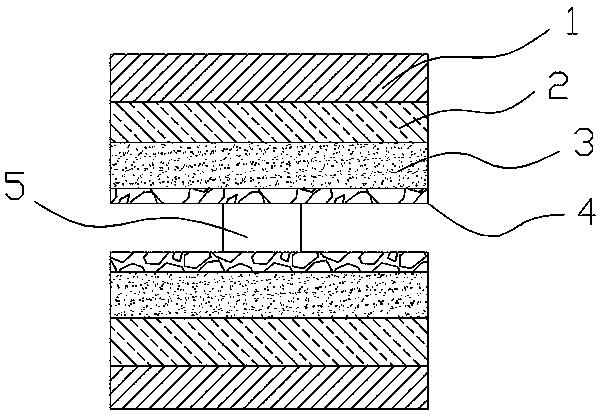

Lithium ion battery plastic-aluminum membrane heat-sealing technology

ActiveCN104282945AIncreased sealing pressureExtend heat sealing timeFinal product manufactureCell component detailsEngineeringUltimate tensile strength

The invention discloses a lithium ion battery plastic-aluminum membrane heat-sealing technology, and solves the problems that sealing edges of a plastic-aluminum membrane heat-sealed by a lithium ion battery plastic-aluminum membrane heat-sealing technology in the prior art are easy to wrinkle, poor in smoothness, and inconsistent in heat sealing strength. The lithium ion battery plastic-aluminum membrane heat-sealing technology comprises of top sealing and side sealing of the plastic-aluminum membrane, the top sealing and side sealing of the plastic-aluminum membrane comprises of primary top sealing and secondary top sealing, and the side sealing of the plastic-aluminum membrane comprises of primary side sealing and secondary side sealing. According to the lithium ion battery plastic-aluminum membrane heat-sealing technology, on the basis of determined optimal top sealing process parameters and optimal side sealing process parameters, step-by-step top sealing and side sealing are used, top sealing process parameters and side sealing process of parameters each step are adjusted and optimized, the problems that the sealing edges of the plastic-aluminum membrane sealed by primary top sealing and side sealing in the prior art are easy to wrinkle, poor in smoothness, and inconsistent in heat sealing strength for the reason that a completely melted CPP layer material is extruded out from the plastic-aluminum membrane are effectively resolved, and the plastic-aluminum membrane prepared by the lithium ion battery plastic-aluminum membrane heat-sealing technology is smooth in surface, uniform in thickness, and good in heat sealing strength.

Owner:WANXIANG 123 CO LTD

Coated paper and production method thereof

InactiveCN108914686AHigh transparencySmall shrinkageSynthetic resin layered productsPaper coatingUltimate tensile strengthPolypropylene

The invention provides a coated paper and a production method thereof and relates to the technical field of packaging materials. The coated paper comprises a base paper and a coating film layer. The coating film layer coats the surface of the base paper. The coating film layer is prepared from a polypropylene material through coating and thus the coated paper has the advantages of good transparency, small shrinkage, low heat sealing temperature, high bonding strength, beautiful appearance, good waterproof performances, high strength, microwave heating and low cost.

Owner:福建益百利包装材料有限公司

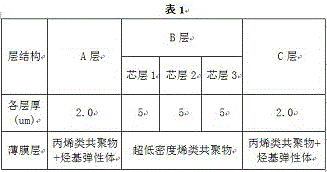

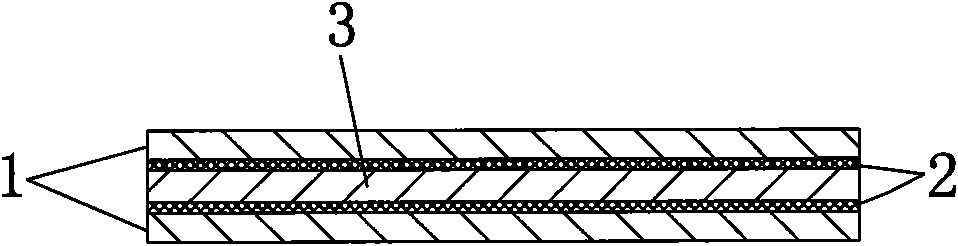

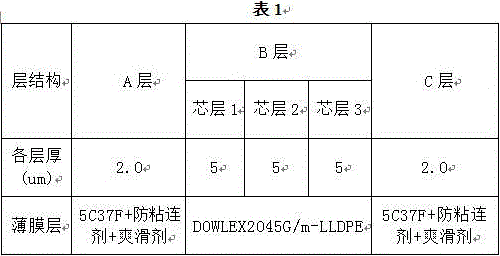

Polyolefin bidirectional stretching film and preparation method thereof

ActiveCN106626654AWide sealing temperature rangeMeeting Packaging NeedsFlexible coversWrappersLow-density polyethyleneElastomer

The invention discloses a polyolefin bidirectional stretching film and a preparation method thereof, wherein the polyolefin bidirectional stretching film comprises five layers of layered structures including an upper surface layer, three core layers and a lower surface layer in sequential distribution, wherein the upper surface layer and the lower surface layer are prepared from the following ingredients including 50 to 80 parts of propylene copolymers, 20 to 40 parts of alkylene elastomers, 1 to 6 parts of anti-adhesion agents and 1 to 4 parts of slipping agents; each of the three core layers is prepared from the following ingredients including 69 to 100 parts of ultra-low density polyethylene, 0.1 to 30 parts of vinyl copolymers and 0.01 to 1 part of slipping agents. The technical scheme provided by the invention has the advantages of low hot sealing temperature, wide hot sealing temperature range, soft product hand feeling and high flexibility; the shrinkage effect and the hot sealing performance of the film can be obviously improved; the product performance is improved.

Owner:聚银塑料包装制品(深圳)有限公司

New composite film

InactiveCN101830086ASmall water absorptionGuaranteed softnessFlexible coversWrappersComposite filmPolyurethane adhesive

The invention discloses a novel composite film. The composite film consists of an upper outer layer, a lower outer layer and a middle core layer, wherein the core layer and the outer layers are compounded into a whole by adhesive. The outer layer can be in a single layer structure, a double-layer structure or a multi-layer structure which consists of more than two layers of single film. The core layer can be in a single layer structure, a double-layer structure or a multi-layer structure which consists of more than two layers of single film. The core layer is made of polyethylene glycol terephthalate PET has the density of 1.395g / cm<3>-1.405g / cm<3> and the thickness of 10 micrometers to 50 micrometers. The outer layer is made of one of low-density polythene (LDPE), high-density polythene (HDPE) and casting polypropylene (CPP), and also can be made by mixing two or more than two of low-density polythene (LDPE), high-density polythene (HDPE), casting polypropylene (CPP) and metallocene polythene (mPE). The adhesive is one of single-component polyurethane adhesive, bicomponent polyurethane adhesive, alcohol-soluble polyurethane adhesive and water-soluble polyurethane adhesive. The overall thickness of the composite film is 25 micrometers to 150 micrometers.

Owner:徐建学

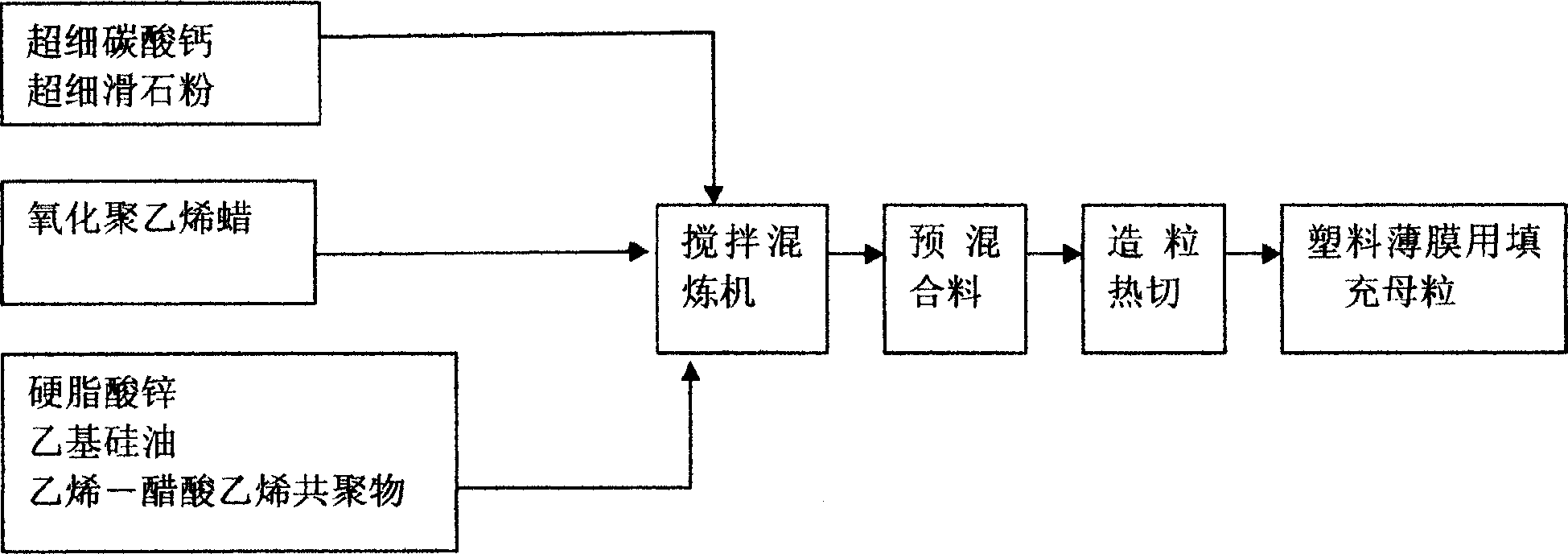

Filling agglomerate for plastic film and its preparation method

The invention involves a preparation method for masterbatch used in plastic film. The referred masterbatch includes: superfine CaCO3 25~70, superfine talc (SFT) powders 5~40, ethylene-vinyl acetate copolymer 17.5~25, oxidized polyethylene wax 1.5~6, ethyl silicone oil 4, and zinc stearate 1~5, wherein the average particle size of the superfine calcium carbonate is 5-10 micron, and the average size of SFT is 6-10 micron. The method comprises: adding CaCO3 and SFT into a stirring mixer, stirring till the temperature of the mixture at 100-130degreeC, adding oxidized polyethylene wax and stirring for 3~5 minutes, adding zinc stearate, ethyl silicone oil, ethylene-vinyl acetate copolymer respectively and stirring for 3 minutes to obtain a pre-mixture, placing the pre-mixture in a cocurrent twin-screw machine, granulating, cutting, cooling, and packaging to obtain the final product. The prepared masterbatch has good mechanical properties, dispersibility, and high economic nature.

Owner:SHANGHAI LINDA PLASTIC CHEM CO LTD

Biaxially-oriented polypropylene (BOPP) coated heat sealable film

ActiveCN102555381AGood printabilityGood wipe resistanceSynthetic resin layered productsAntioxidantMetallurgy

The invention belongs to the technical field of packaging materials and relates to a biaxially-oriented polypropylene (BOPP) coated heat sealable film, which is characterized by comprising a function layer, a core layer and a sub function layer, wherein the core layer is positioned between the function layer and the sub function layer, and the function layer, the core layer and the sub function layer are subjected to co-extrusion and biaxial tension to form a whole; the BOPP coated heat sealable film comprises 1 to 8 mass percent of function layer, 91 to 98 mass percent of core layer and 1 to 5 mass percent of sub function layer; the function layer is prepared from the following raw materials in percentage by mass: 55 percent of acetic ether, 10 percent of C9 hydrogenated petroleum resin, 18 percent of polypropylene, 13 percent of polyvinyl alcohol, 2 percent of sodium hydroxide, 1 percent of antioxidant and 1 percent of dispersing agent; the core layer is prepared from the following raw materials in percentage by mass: 73 to 82 percent of polypropylene, 10 to 15 percent of stiffening agent and 8 to 12 percent of anti-static slipping agent; and the sub function layer is prepared from the following raw materials in percentage by mass: 1 percent of SiO2 and 99 percent of propylene copolymer. The BOPP coated heat sealable film has the characteristics of good printing performance and low heat sealing temperature.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Easy-to-uncover aluminum-plastic cover film for cosmetic cover ring as well as production technology and application

PendingCN110328933AUniform bondingHigh bonding strengthFlexible coversWrappersEthylene propylene copolymerPolypropylene

The invention relates to an easy-to-uncover aluminum-plastic cover film for a cosmetic cover ring. The aluminum-plastic cover film comprises an outer layer, an aluminum foil layer and a heat sealing layer, wherein the outer layer and the heat sealing layer are arranged on the upper side surface and the lower side surface of the aluminum foil layer respectively, the outer layer and the aluminum foil layer are connected through an adhesive, the aluminum foil layer and the heat sealing layer are connected through the adhesive, the outer layer is a PET (polyethylene terephthalate) thin film layerof 6-30 mu m, the aluminum foil layer is O-state aluminum foil of 6-50 mu m, the heat sealing layer is a PE (polyethylene) thin film layer of 30-50 mu m, and the PE thin film layer is prepared from 50wt%-90wt% of ethylene-propylene copolymer elastomers and 10wt%-50wt% of PE. The invention further relates to a production technology and an application of the easy-to-uncover aluminum-plastic cover film for the cosmetic cover ring. The easy-to-uncover aluminum-plastic cover film for the cosmetic cover ring is lower in heat sealing temperature, high in heat sealing strength and good in heat sealinguniformity when subjected to heat sealing with the PP (polypropylene) or PE cover ring, and the cosmetic cover ring is not easily opened under certain air pressure impact when the cosmetic cover ringand the easy-to-uncover aluminum-plastic cover film are composited and then sealed with other packaging bodies.

Owner:江阴苏达汇诚复合材料有限公司

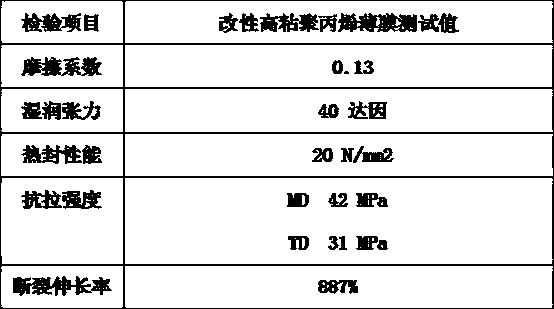

Flexible packaging modified CPP (Chlorinated Polypropylene) thin film and production method thereof

InactiveCN103522695AHeat sealing temperature reachesEasy to processFlexible coversWrappersEngineeringPolypropylene

The invention discloses a flexible packaging modified CPP (Chlorinated Polypropylene) thin film, and relates to a food thin film. The flexible packaging modified CPP thin film comprises a corona outer layer, a middle bonding layer and a hot-sealing inner layer, wherein the corona outer layer comprises 20-40 percentage by weight of homopolymerization PP (Polypropylene) and 60-80% percentage by weight of copolymerization PP, the middle bonding layer comprises 70 percentage by weight of copolymerization PP and 30 percentage by weight of metallocene; and the hot-sealing inner layer comprises 25 percentage by weight of doublet PE (Poly Ethylene) and 75 percentage by weight of copolymerization PP. Compared with the prior art, the flexible packaging modified CPP thin film disclosed by the invention has the advantages that contents can be set in a packaging stage, the bad phenomena such as skewing or fragmentation does not occur, and after packaging, the overall appearance of products such as the flatness and the stiffness is improved.

Owner:CHENGDU ZHONGBAO ZHUANGDA MEMBRANE

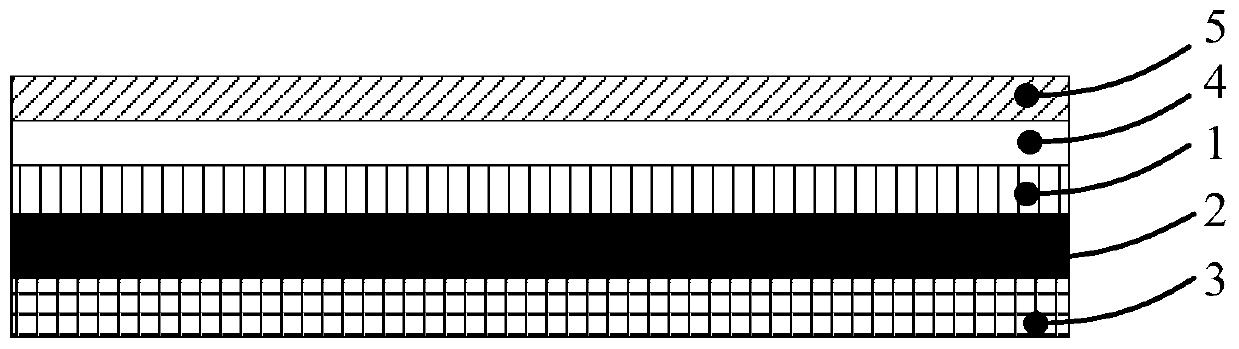

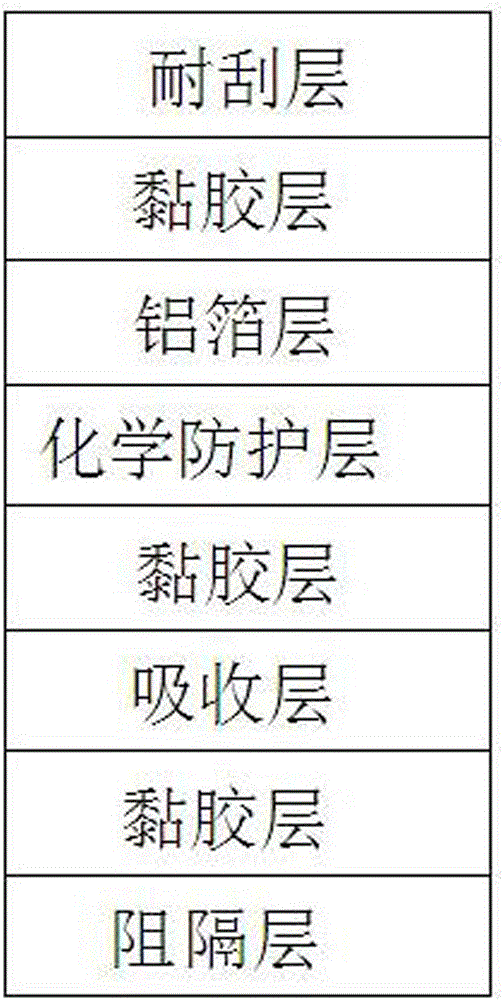

Water-resistant and anti-flatulence aluminum-plastic film for packaging lithium battery and preparation method of water-resistant and anti-flatulence aluminum-plastic film

ActiveCN106450046AImprove oxygen and water resistance performanceAvoid erosionSynthetic resin layered productsElectrical equipmentWater resistantPlastic film

The invention discloses a water-resistant and anti-flatulence aluminum-plastic film for packaging a lithium battery and a preparation method of the water-resistant and anti-flatulence aluminum-plastic film. The water-resistant and anti-flatulence aluminum-plastic film is characterized by sequentially comprising a scratch-resistant layer, an aluminum foil layer, a chemical protection layer, an absorption layer and a barrier layer from outside to inside, wherein adhesive layers are arranged between the scratch-resistant layer and the aluminum foil layer, between the chemical protection layer and the absorption layer and between the absorption layer and the barrier layer; and the aluminum foil layer and the chemical protection layer are formed together. The water-resistant and anti-flatulence aluminum-plastic film is formed by the steps of firstly preparing the scratch-resistant layer and forming the chemical protection layer, the absorption layer formed by a gas absorption layer and a water absorption layer, a mechanical support layer, a low-temperature heat seal layer and the barrier layer on the surface of aluminum foil; and then coating the adjacent surfaces of the scratch-resistant layer and the aluminum foil layer, the adjacent surfaces of the chemical protection layer and the absorption layer and the adjacent surfaces of the absorption layer and the barrier layer with the adhesive layers, and simultaneously compounding the scratch-resistant layer, the aluminum foil layer, the chemical protection layer, the absorption layer and the barrier layer through a roller press. The water-resistant and anti-flatulence aluminum-plastic film has water-resistant and anti-flatulence functions. By adopting the water-resistant and anti-flatulence aluminum-plastic film, the security of the lithium battery can be improved and the service life of the lithium battery can be prolonged.

Owner:江苏华谷新材料有限公司

Multilayer frozen polyethylene film

InactiveCN102909925AReduce heat sealing temperatureImprove piercing performanceSynthetic resin layered productsThin membranePolymer chemistry

The invention provides a multilayer frozen polyethylene film which comprises three layers of polyethylene film, including a protective layer, a heat-resistant layer and a hot seal layer from top to bottom. The multilayer frozen polyethylene film is 3-10dmm in thickness. The multilayer frozen polyethylene film is high in low temperature resistance, higher in hot sealing speed, higher in firmness, and more reliable and safer to storage, quality guarantee, transport and the like of packaged goods.

Owner:ANHUI KOYO HENGDA PACKING MATERIAL SCI & TECH

Preparation method of modified casting polypropylene film and easy-to-tear PET-AL-CPP medicine-packaging composite film

InactiveCN111716858AFast deliveryReduce adverse effectsSynthetic resin layered productsPharmaceutical containersPolymer scienceComposite film

The invention discloses a preparation method of a modified casting polypropylene film and an easy-to-tear PET-AL-CPP composite film. The invention aims to solve the problems that CPP in an existing PET-AL-CPP composite film is good in toughness and a flexible packaging bag prepared from the existing PET-AL-CPP composite film and used for packaging a liquid medicine is not easy to tear, poor in linear tearing performance and prone to causing splashing or side leakage of the liquid medicine. The preparation method of the invention comprises the following steps: adding 1-5 parts of a silicon dioxide coated aluminum oxide nanomaterial into 95-97 parts of polypropylene resin, and carrying out blending, melting and granulating to obtain a polypropylene inner-layer mixture; and 2, extruding polypropylene outer-layer resin and the polypropylene inner-layer mixture of obtained in the step 1 to obtain the polypropylene film. The film prepared in the invention has the advantages of good comprehensive performance, easiness in tearing, good linear tearing performance and the like.

Owner:SICHUAN HUILI IND

Ultralow temperature heat-sealing tape-casting polypropylene aluminum plating film

InactiveCN103802389AReduce heat sealing temperatureGood adaptability to aluminum platingFlexible coversWrappersInter layerCo extrusion

The invention discloses an ultralow temperature heat-sealing tape-casting polypropylene aluminum plating film, wherein a base film of the aluminum plating film is produced by adopting a three-layer co-extrusion tape-casting method, the three layers are a corona layer, an intermediate layer and a heat-sealing layer respectively; through performing vacuum aluminum plating on the surface of the corona layer of the base film, the ultralow temperature heat-sealing tape-casting polypropylene aluminum plating film is obtained; due to the adoption of the ultralow temperature heat-sealing tape-casting polypropylene aluminum plating film, the heat-sealing temperature can be effectively reduced, the aluminum plating adaptability is preferable, the crystal point and the stratification are avoided, the production efficiency is improved, and the production cost is reduced.

Owner:安徽双津实业有限公司

Preparation method of low-temperature-resisting three-layer co-extruded composite thin film

ActiveCN103252955AImprove low temperature resistance and freeze resistanceLow temperature flexibilityFlexible coversWrappersLinear low-density polyethyleneAnti freezing

The invention discloses a preparation method of a low-temperature-resisting three-layer co-extruded composite thin film. The composite thin film is formed by co-extruding three layers through a casting machine and is provided with an outer layer, a middle layer and an inner layer, which are compounded together, wherein raw materials of the middle layer comprise metallocene linear low density polyethylene and polypropylene in a weight ratio of 1:10 to 1:1, and the fusion index of the metallocene linear low density polyethylene is 1-3.5. With the adoption of the scheme, when a conventional CPP (Chlorinated Polypropylene) thin film is compared with the low-temperature-resisting three-layer co-extruded composite thin film, the low-temperature-resisting and anti-freezing performance of the co-extruded three-layered composite thin film is greatly improved, the low-temperature-resisting three-layer co-extruded composite thin film can be normally used in an environment of -30 DEG C and the barrier property and the strength of the composite thin film are not influenced, and thus the low-temperature-resisting three-layer co-extruded composite thin film is particularly suitable for packaging of quick frozen products including dumplings, rice dumplings and the like.

Owner:KAIDA GRP CO LTD FJ

High-resistance high-speed auto-inflation food packaging film and production process thereof

PendingCN110065269AHigh barrierHigh peel strengthFlexible coversWrappersHigh resistanceLow-density polyethylene

The invention relates to a high-resistance high-speed auto-inflation food packaging film and a production process thereof. The packaging film is formed by compounding an aluminum-plated PE film and aPET printing film in a dry mode. The aluminum-plated PE film comprises a corona layer, a middle layer and a heat seal layer. The corona layer comprises linear low density polyethylene and polycycloolefin according to the mass ratio of (83-87):(13-17). The middle layer comprises linear low density polyethylene, low density polyethylene and high density polyethylene according to the mass ratio of (48-52):(23-27):(23-27). The heat seal layer comprises low density polyethylene, an olefin plastic body, linear low density polyethylene, silicone and a processing agent according to the mass ratio of (48-52):(23-27):(23-27):(1.3-1.7):(0.1-0.3). The packaging film is suitable for meeting the requirements of a high-speed packaging device and has high resistance, low heat seal temperature, high heat seal strength, high in pressure resistance and low in broken package air leakage rate.

Owner:HUANGSHAN NOVEL

Polyolefin bidirectional stretching surface hanging film and preparation method thereof

ActiveCN106626655ASolve the problem of friction and easy wearMeet the needs of high-speed packaging packagingFlexible coversWrappersSurface layerPolyolefin

The invention discloses a polyolefin bidirectional stretching surface hanging film and a preparation method thereof, wherein the polyolefin bidirectional stretching surface hanging film comprises five layers of layered structures including an upper surface layer, three core layers and a lower surface layer in sequential distribution; each of the upper surface layer and the lower surface layer is prepared from the following ingredients including 88 to 97 parts of propylene copolymers, 3 to 8 parts of anti-adhesion agents and 0.1 to 1 part of slipping agents; each of the three core layers is prepared from the following ingredients including 99 to 100 parts of linear low-density vinyl copolymers and 0.1 to 1 part of slipping agents. The technical scheme provided by the invention has the characteristics of high thermal sealing intensity, wide hot sealing temperature range and hot smoothness; the problem of easy abrasion due to friction between the film and a packaging box is solved; the product transparency and the hot sealing performance of the product can be obviously improved.

Owner:聚银塑料包装制品(深圳)有限公司

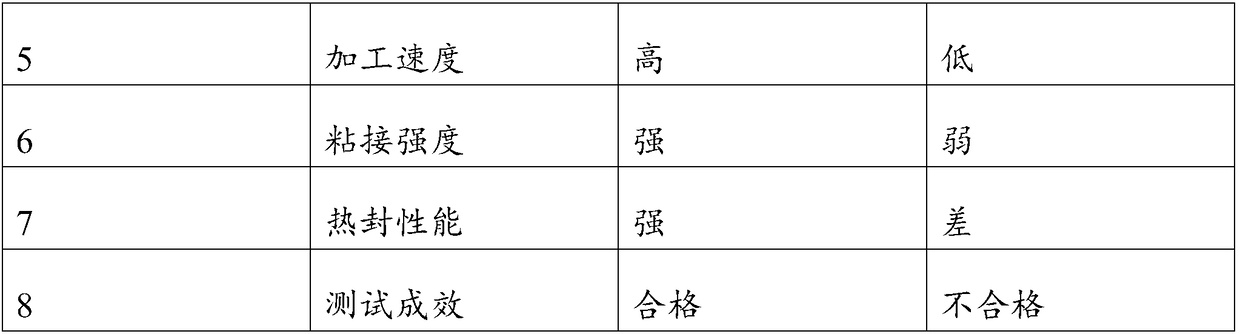

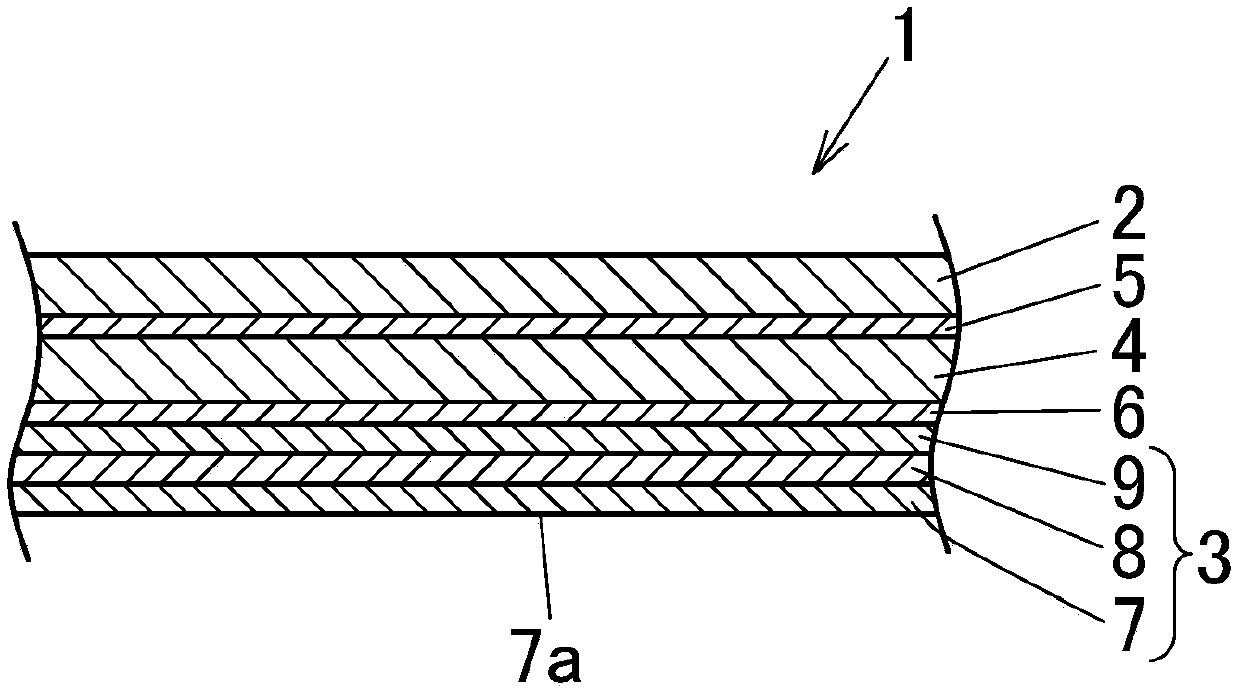

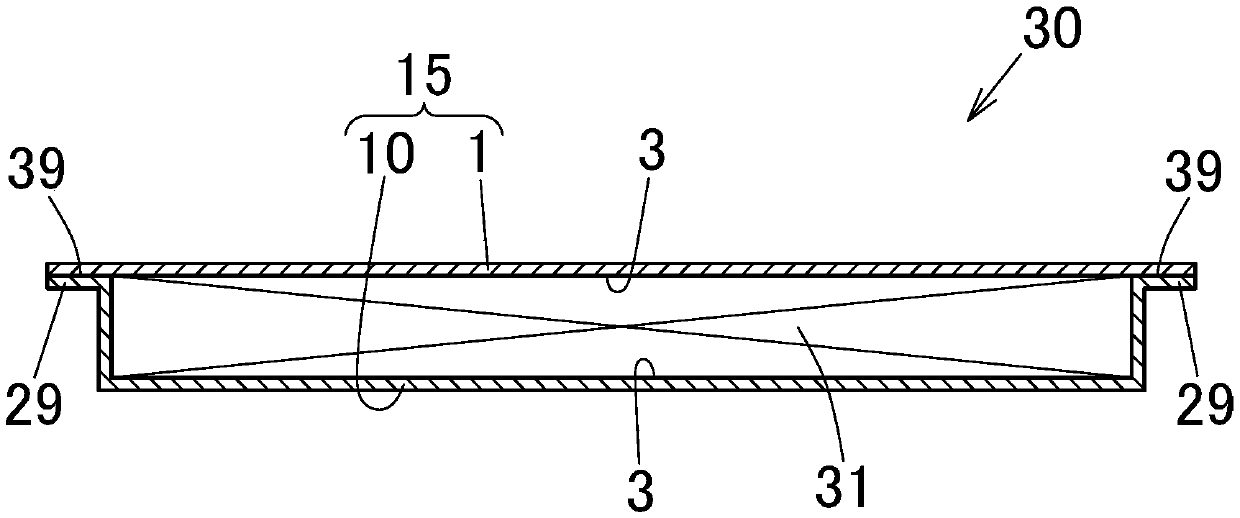

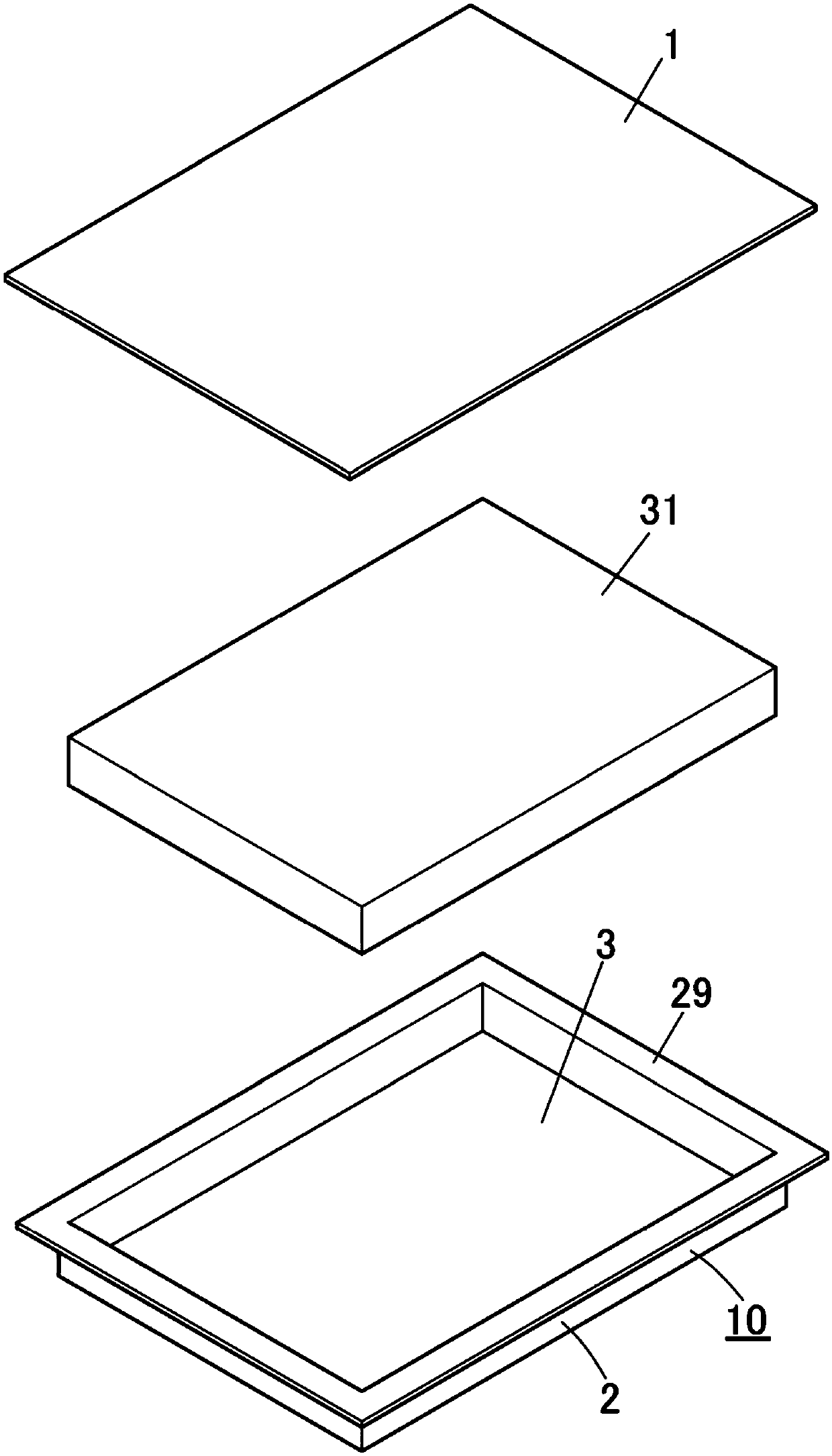

Outer material for power storage device, external case for power storage device and power storage device

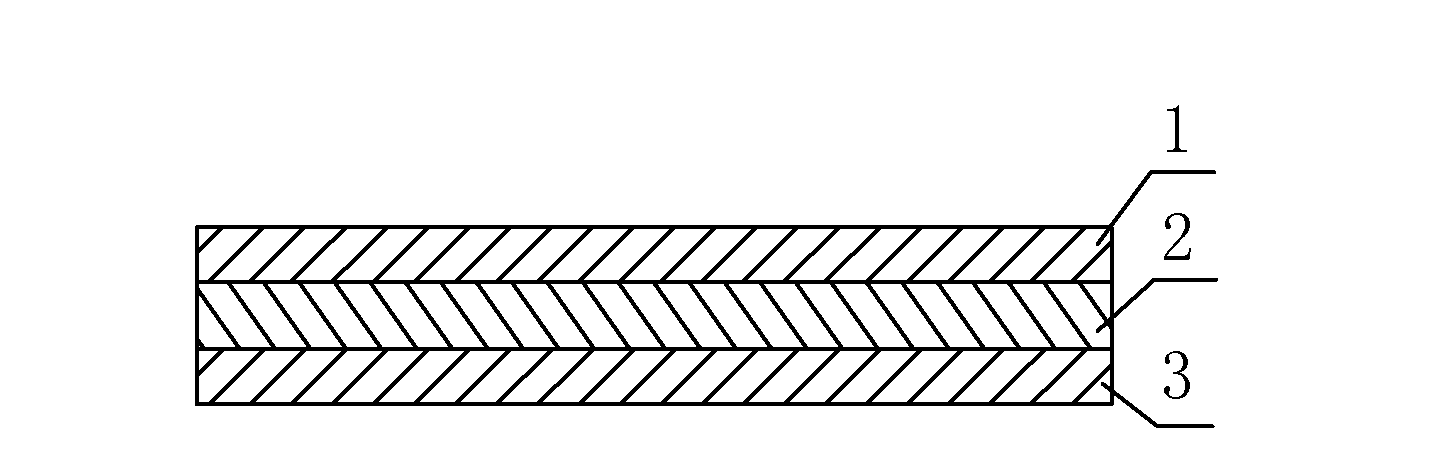

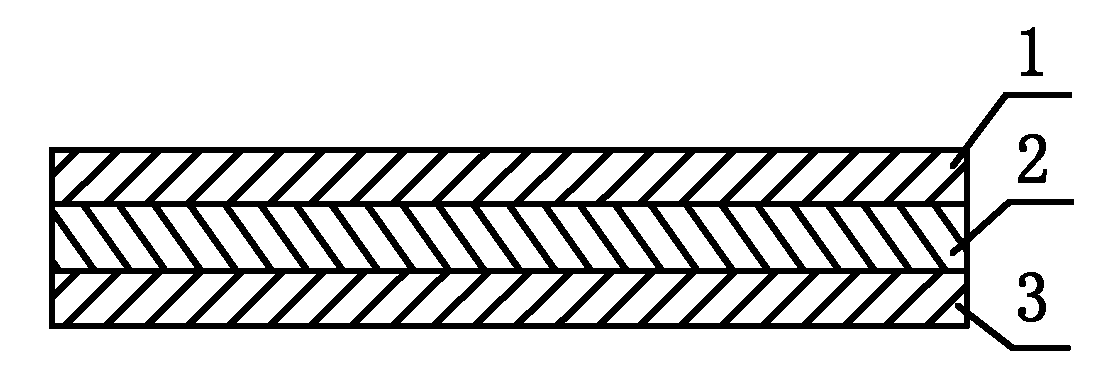

ActiveCN109585706AReduce exudationInhibition of attached pollutionSynthetic resin layered productsJackets/cases materialsMetal foilTurbidity

The invention relates to an outer material for a power storage device, an external case for the power storage device and the power storage device. the outer material includes a substrate layer (2) asan outer layer, a hot melt resin layer (3) as an inner layer, and a metal foil layer (4) between the substrate layer and the hot melt resin layer. The hot melt resin layer is formed by three or more layers of laminates of a first hot melt resin layer (7) / second hot melt resin layer (8) / third hot melt resin layer (9). Through the structure, the outer material which can ensure good shaping performance and which can inhibit white turbidity can be provided.

Owner:乐索纳克包装股份有限公司

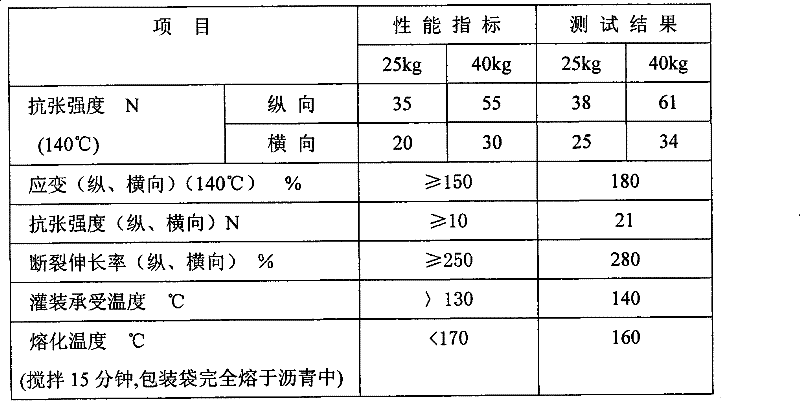

Polyolefin / polycarbonate alloy film for meltable asphalt packing bag and production method thereof

The invention discloses a polyolefin / polycarbonate alloy film for fusible asphalt packaging bags, and a production method thereof. The polyolefin / polycarbonate alloy film mainly comprises the following raw material components: polypropylene, polyethylene, polycarbonate, acrylate polymer, dicumyl peroxide, polyethylene wax and antioxidant. A production process of the polyolefin / polycarbonate alloyfilm mainly comprises the following steps of melting, mixing, extruding film blank, blowing and molding film, cooling and setting. The polyolefin / polycarbonate alloy film for the fusible asphalt packaging bags provided by the invention can bear a temperature up to 140 DEG C when the packaging bags are filled with asphalt; when the asphalt is used in construction, the asphalt together with the packaging bags is put into a heating container and stirred for about 15 minutes at a temperature between 160 and 165 DEG C, and then the packaging bags can completely melt in the asphalt without residue;and the own production and processing temperature of the film is only between 170 and 185 DEG C which is far lower than the processing temperature (210 to 250 DEG C in general) of polypropylene, polycarbonate, polyethylene and other base materials.

Owner:SICHUAN JIANYANG HUASEN FILM IND

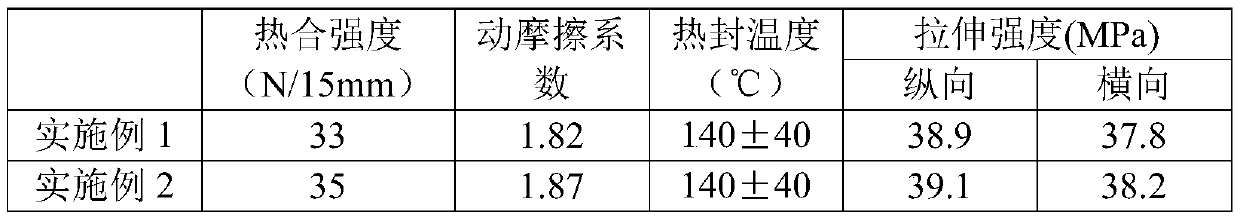

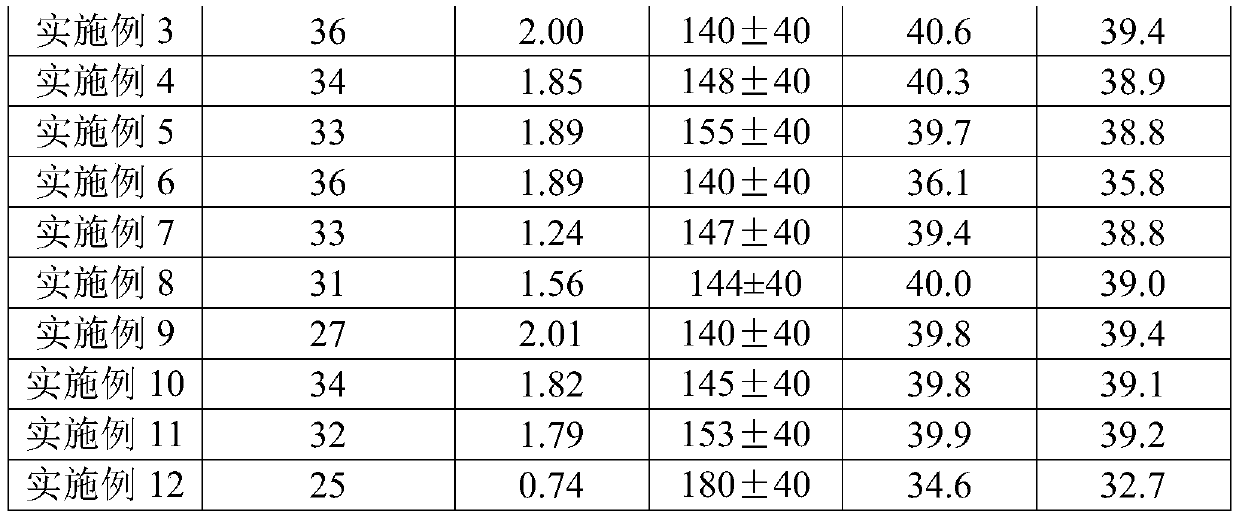

Three-layer co-extrusion heavy packaging film and preparation method thereof

ActiveCN111483196AImprove stiffnessIncrease the surface friction coefficientPackage recyclingFlexible coversHigh surfaceMechanical engineering

The invention relates to the field of packaging films, in particular to a three-layer co-extrusion heavy packaging film and a preparation method thereof. The three-layer co-extrusion heavy packaging film comprises an inner layer, a middle layer and an outer layer which are sequentially arranged from inside to outside. The three-layer co-extrusion heavy packaging film provided by the invention hasthe advantages of good stiffness, high surface friction coefficient of the heavy packaging film, no stack slipping, low heat-sealing temperature, wide heat-sealing window, heat-sealing temperature aslow as 100 DEG C and heat-sealing window of 140 parts + / -40 DEG C, can meet the requirements of enterprises with special downstream packaging requirements, and realizes on-line continuous rapid packaging. Compared with a traditional heavy packaging bag, the packaging bag can be used in areas requiring low temperature and large heat sealing environment change difference.

Owner:GUANGZHOU XINWEN PLASTIC

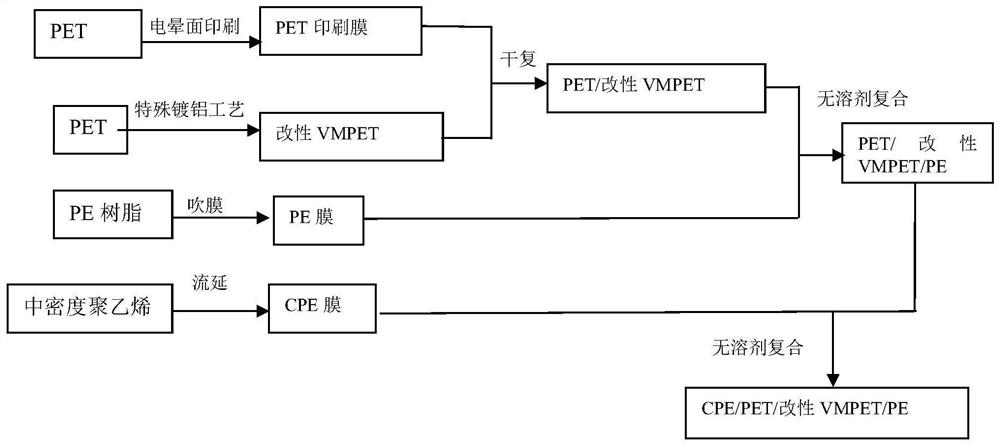

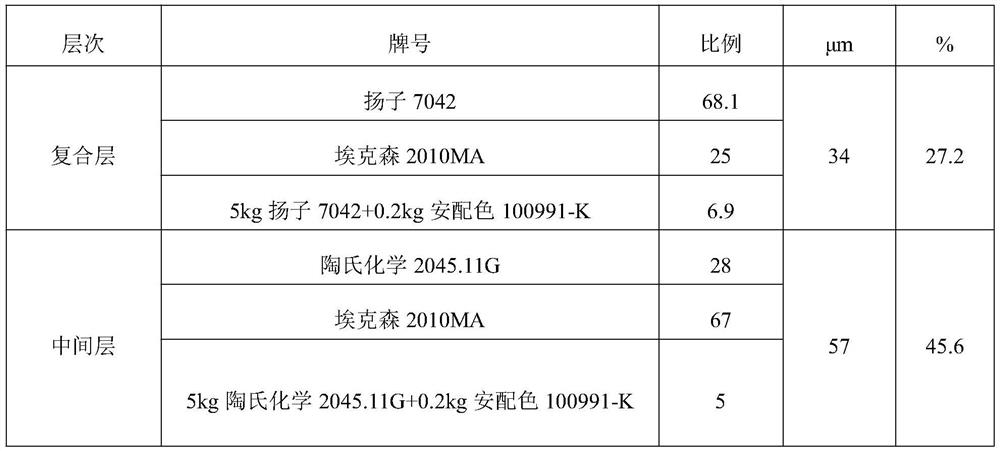

High-barrier antiskid packaging film and preparation method thereof

PendingCN113829707AGood lookingImprove stiffnessFlexible coversWrappersPolymer sciencePolyethylene terephthalate

The invention relates to the technical field of packaging materials, in particular to a high-barrier antiskid packaging film and a preparation method thereof. The packaging film is composed of a CPE film, a PET film, a modified VMPET film and a PE film which are sequentially layered, the CPE film and the PE film are prepared in a three-layer co-extrusion forming mode, and one face of the VMPET film is reversely plated with an aluminum-plated layer formed by metal aluminum, so that the barrier property, the aluminum layer adhesive force and the corona value attenuation period are all obviously improved, and under the severe high-humidity and high-temperature conditions, the interface of the packaged PET / VMPET aluminum plating layer is not layered, so that the integrity of the package is ensured, and the contents are not deteriorated; the packaging material with the CPE (heat-resistant) / PET (polyethylene terephthalate) / modified VMPET / PE (low-temperature) composite structure has the characteristics of balanced internal and external structures, flat bag shape, soft buffering of the outer-layer CPE, puncture and falling resistance, high static friction and good stacking and transporting effect, the problems of stacking slipping and unsmooth transportation are solved, and the whole large package is high in tearing strength and puncture resistance, and can resist falling and impact bag breaking.

Owner:HUANGSHAN NOVEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com