Preparation method of modified casting polypropylene film and easy-to-tear PET-AL-CPP medicine-packaging composite film

A technology of casting polypropylene and polypropylene, applied in the directions of pharmaceutical packaging, packaging, household packaging, etc., can solve the problems of poor tear straightness, liquid medicine splashing, difficult to tear, etc., so as to reduce the heat sealing temperature and alleviate the bad Influence and improve the effect of heating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

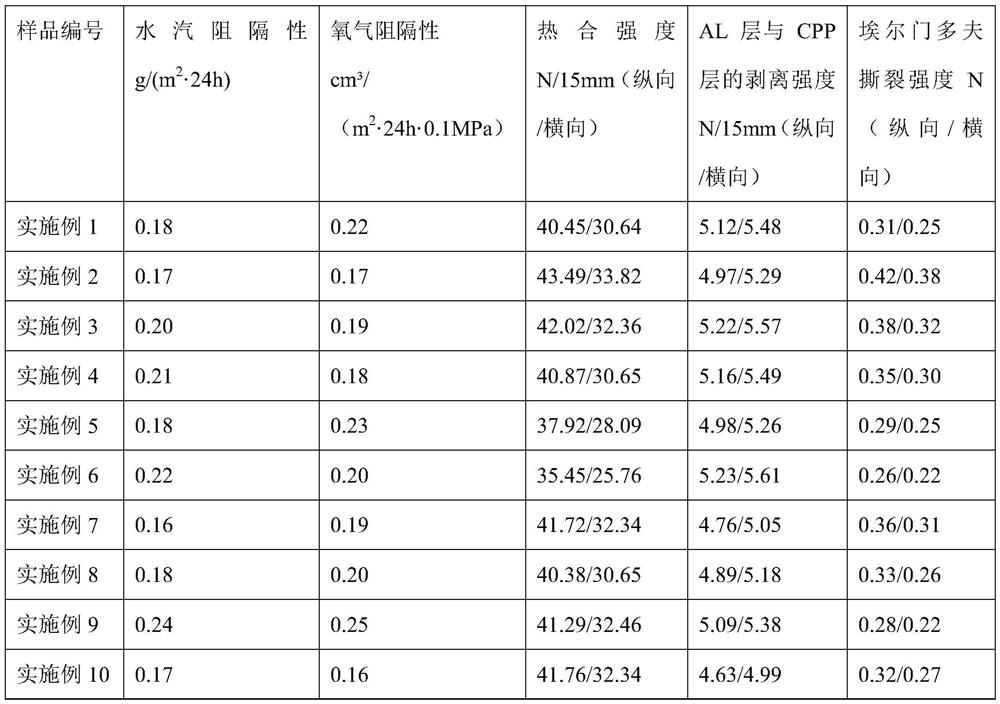

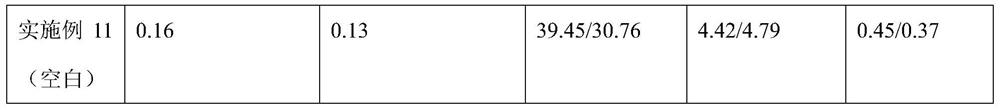

Examples

Embodiment 1

[0045]Preparation of modified cast polypropylene:

[0046] 8 parts of phenolic resin and 90 parts of polypropylene are stirred and mixed and banburyed to obtain a mixture of polypropylene outer layers, and 3 parts of silica-coated alumina nanomaterials are added to 97 parts of polypropylene resin to blend, melt and then make The mixture of the polypropylene inner layer is obtained from the particles, and the particle diameter of the silica-coated alumina nanometer material is 50-150nm.

[0047] The polypropylene outer layer compound and the polypropylene inner layer compound are respectively added to the extruder, melted at 220°C, cast through a T-shaped die, and finally quenched by a cooling roll to form a film. The temperature of the T-die was 210°C.

[0048] The preparation method of the silica-coated alumina nanometer material adopts the chemical vapor deposition technology of the prior art.

[0049] Preparation of PET-AL-CPP Composite Film for Pharmaceutical Packaging ...

Embodiment 2-5

[0057] In order to verify the impact of silica-coated alumina nanomaterials on the performance of CPP, under the same conditions as in Example 1, Examples 2-5 set different mass ratios of the inorganic phase to the amount of polypropylene in the inner layer of polypropylene

Embodiment 2

[0059] No silica-coated alumina nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com