Patents

Literature

80results about How to "Improve tearability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

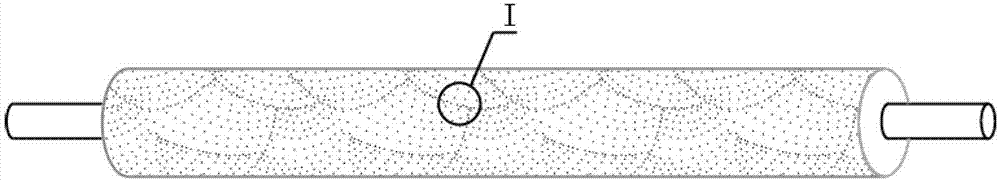

PFTTH (power fiber to the home) cable

InactiveCN102314968AReduce academic performanceReduced direct impact on academic performanceInsulated cablesPower cablesElectrical conductorProtection layer

The invention belongs to the technical field of combination of wire cables and electric power and provides a PFTTH (power fiber to the home) cable. The PFTTH cable is characterized by comprising a first insulated conducting wire, a second insulated conducting wire, a butterfly optical cable, a first outer protection layer, a second outer protection layer, a third outer protection layer and a cavity, wherein the first outer protection layer covers the first insulated conducting wire; the second outer protection layer covers the second insulated conducting wire; the third outer protection layercovers the butterfly optical cable; the cavity is arranged in the third outer protection layer and can accommodate the butterfly optical cable; the first insulated conducting wire and the second insulated conducting wire are respectively arranged at the two sides of the butterfly optical cable; the first outer protection layer, the second outer protection layer and the third outer protection layer are in a one-body shape; and on any plane which is vertical to the axis of a first conductor, the outer edge of the third protection layer protrudes towards the cavity. According to the invention, the problems in the prior art that the cable is difficult to lay and tear out and the fiber density is low can be solved; and the PFTTH cable provided by the invention has the beneficial effects of stable heating performance, modularization, easiness for laying, producing, laying and constructing and the like.

Owner:STATE GRID CORP OF CHINA +3

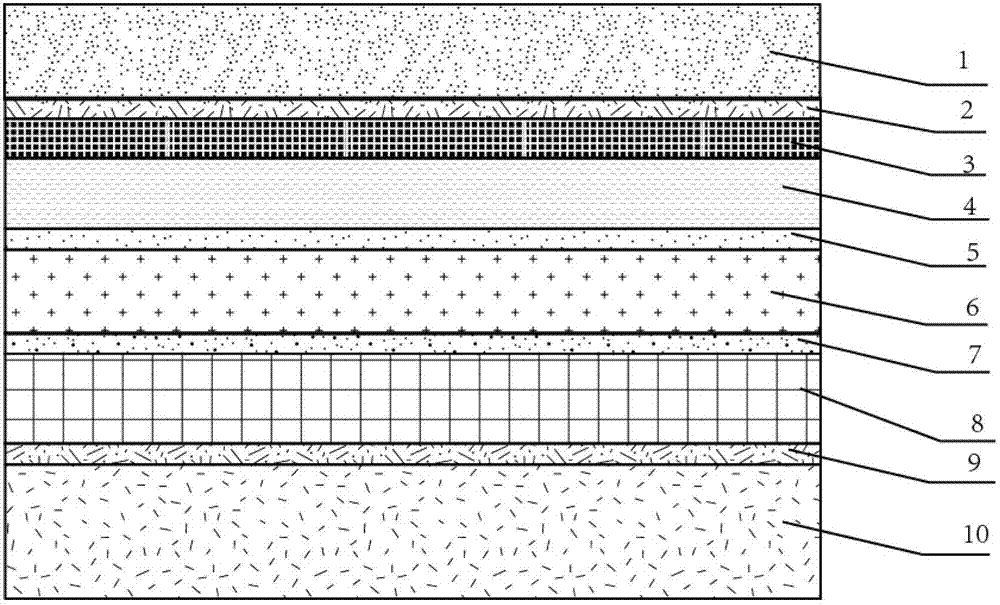

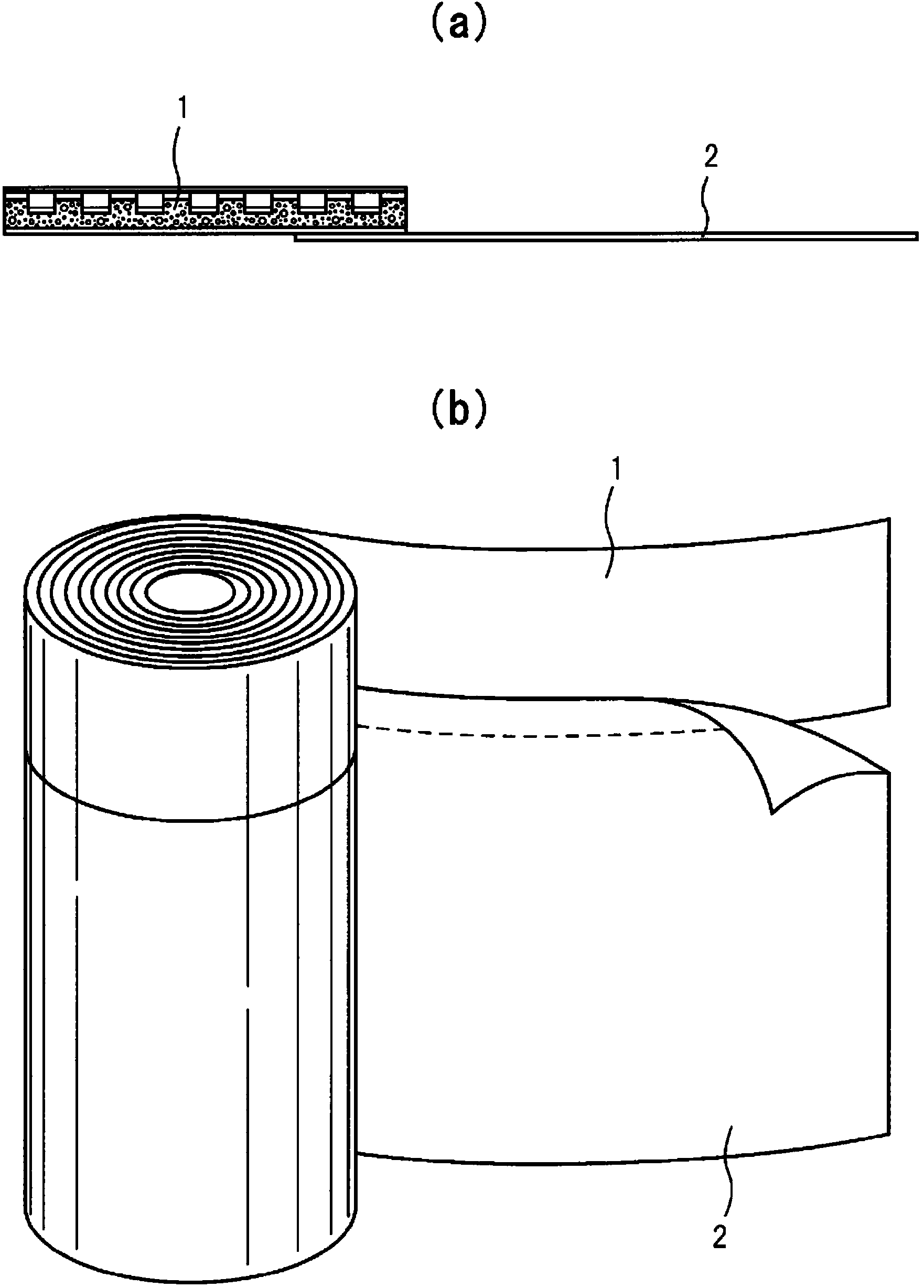

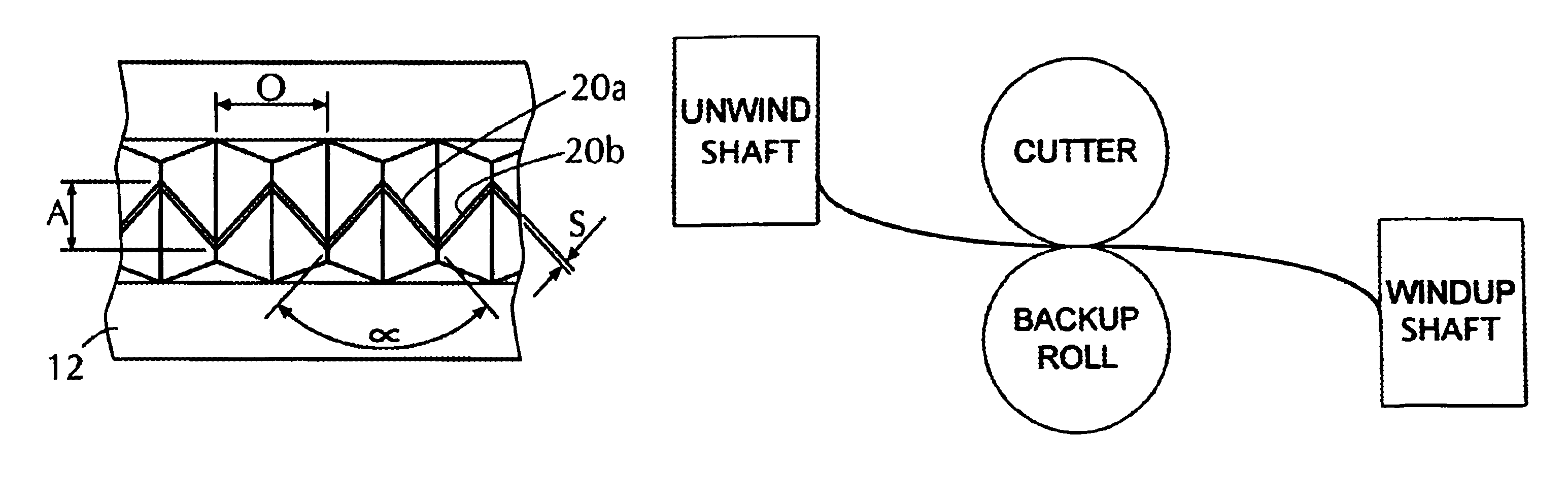

Easy-tearing, anti-fake, and ultrahigh frequency paper-base RFID label and manufacturing method thereof

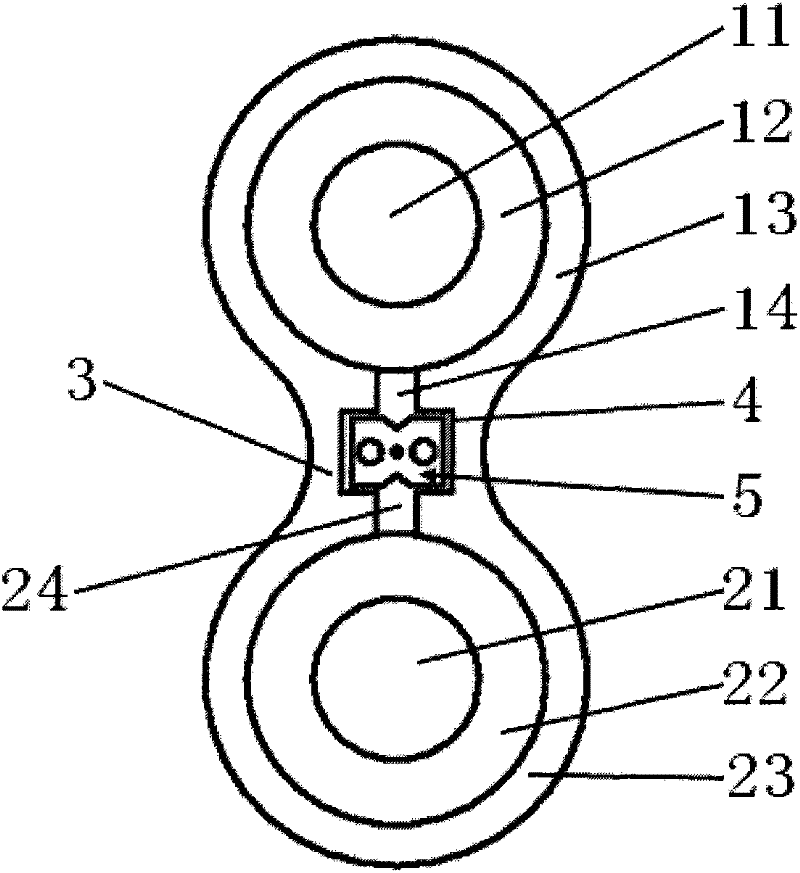

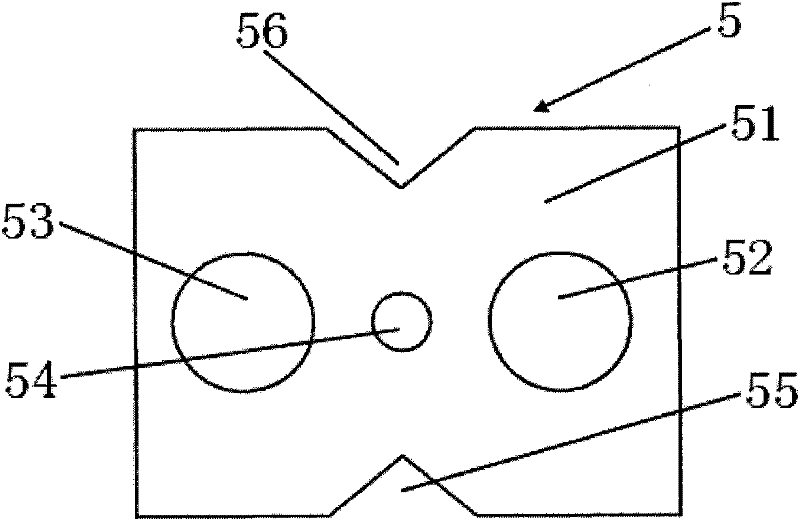

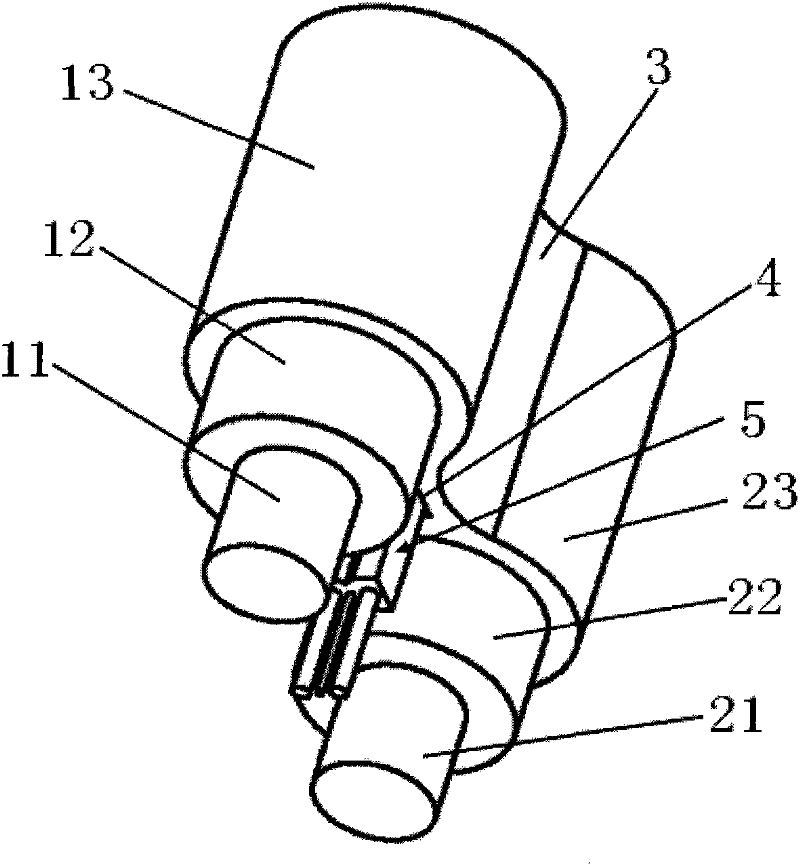

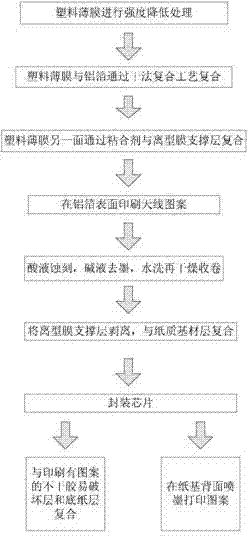

ActiveCN103246918AImprove tearabilityImprove reading effectRecord carriers used with machinesPaper basedUltrahigh frequency

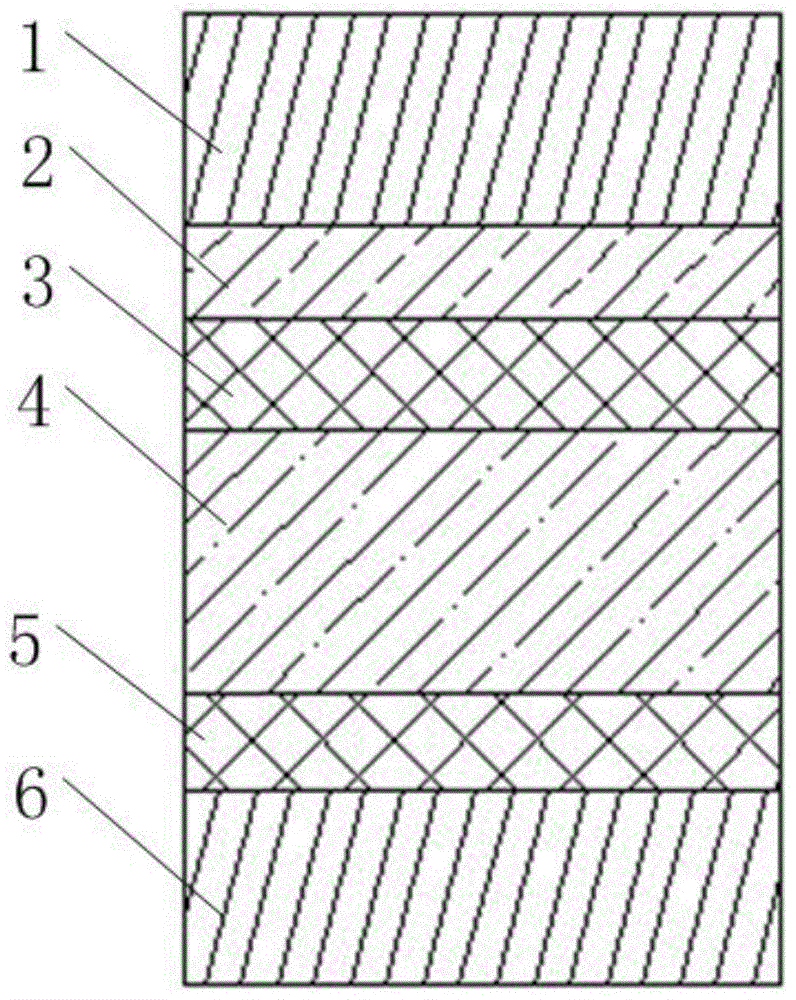

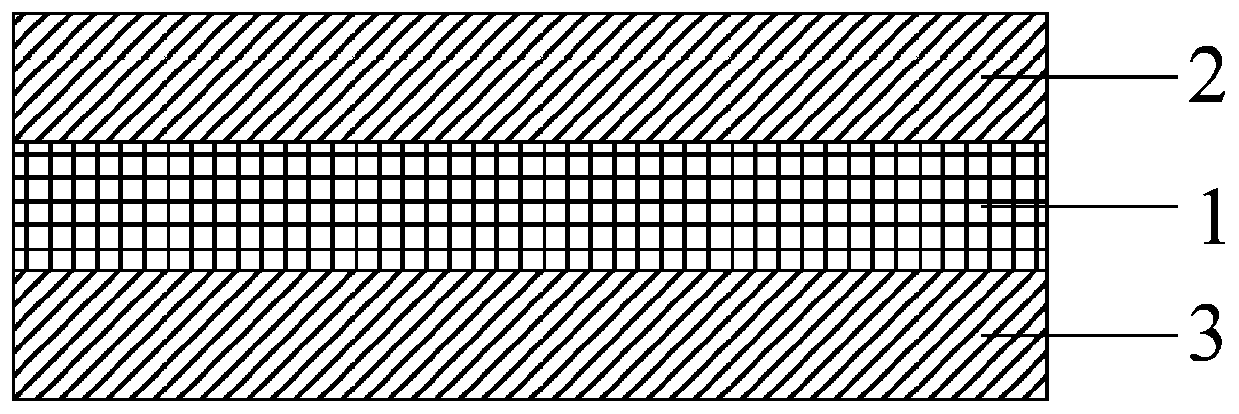

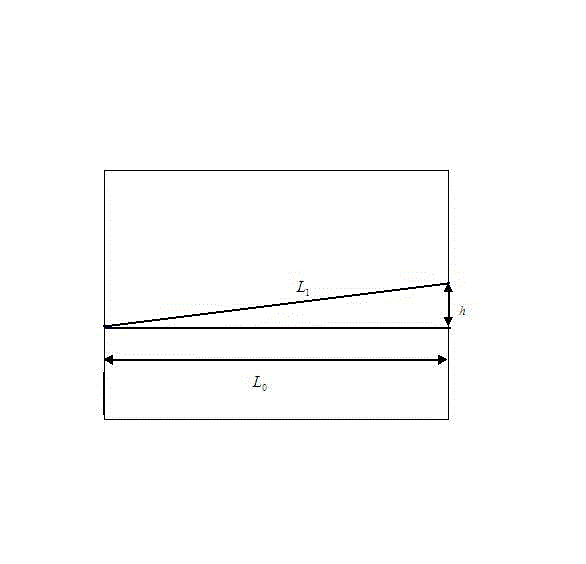

The invention discloses an easy-tearing, anti-fake, and ultrahigh frequency paper-base RFID label and a manufacturing method thereof. The RFID label provided by the invention comprises a destructible layer (1), an electric chip layer (3), an antenna circuit layer (4), a film base material layer (6), a paper base supporting layer (8), and a backing paper layer (10), wherein one side of the electric chip layer (3) is adhered to the inner side surface of the destructible layer (1), the other side of the electric chip layer (3) is compounded with one side of the antenna circuit layer (4); one side of the film base material layer (6) is adhered to the other side of the antenna circuit layer (4); one side of the paper base supporting layer (8) is adhered to the other side of the film base material layer (6); and the backing paper layer (10) is adhered to the other side of the paper base support layer (8). The RFID label provided by the invention has the following technical effects: the reading performance of the label is excellent; the technique stability is improved; the qualification rate of the finished product is high; and the cost is low. Therefore, the label is suitable for large scale industrialization manufacturing.

Owner:HANGZHOU DIANZI UNIV +1

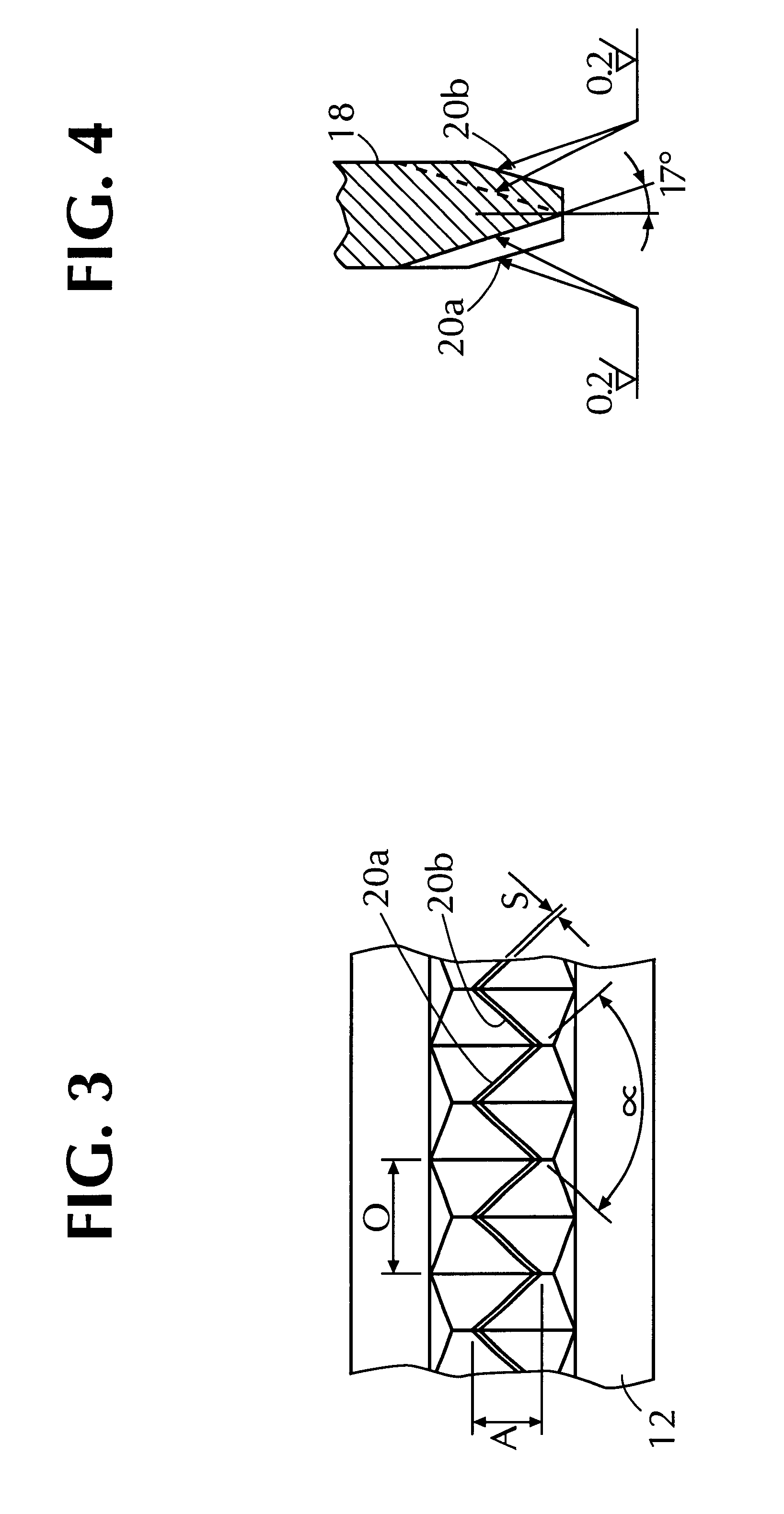

Transversely tearable double-sided notched adhesive tape

InactiveUS6503618B1Easy and smooth tearabilityImprove tearabilityFilm/foil adhesivesCellulosic plastic layered productsEngineeringMechanical engineering

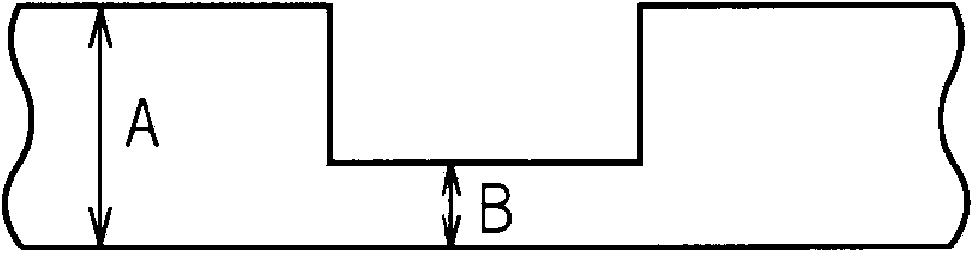

A double-sided adhesive tape having a continuous series of toothed notches of about 0.3 mm to 6 mm jag height which easily transversely tearable by hand.

Owner:TESA SE

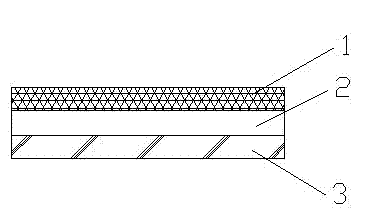

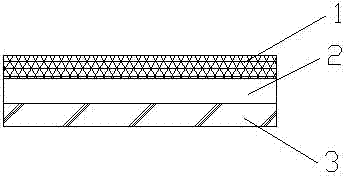

Easy-tearing type dry composite sheet and production method thereof

ActiveCN103434237AGood stretch forming propertiesEasy to tearSynthetic resin layered productsFlat articlesPolyethylene glycolPolypropylene

The invention relates to an easy-tearing type dry composite sheet. The easy-tearing type dry composite sheet comprises a body, wherein a printing layer, a base layer and a heat sealing layer are arranged on the body from top to bottom in sequence; the printing layer is a casting polypropylene film; the base layer is polyethylene glycol terephthalate; and the heat sealing layer is a polyethylene film. The easy-tearing type dry composite sheet has the advantages that the casting polypropylene film, the polyethylene glycol terephthalate and the polyethylene film are compounded into the body; the casting polypropylene film has good printing and stretching and forming performances, the polyethylene glycol terephthalate has good forming performances, and the polyethylene film has easy-tearing performance, so that the produced body is enabled to have a good printing effect, heat sealing performance, easy-tearing performance and forming performance, and the good forming effect is ensured during on-line processing, so that formed printed pattern is exquisite and not obviously deformed, good in heat sealing effect while being used by a consumer, and can be easily torn apart.

Owner:GLODSTONE PACKAGING JIAXING

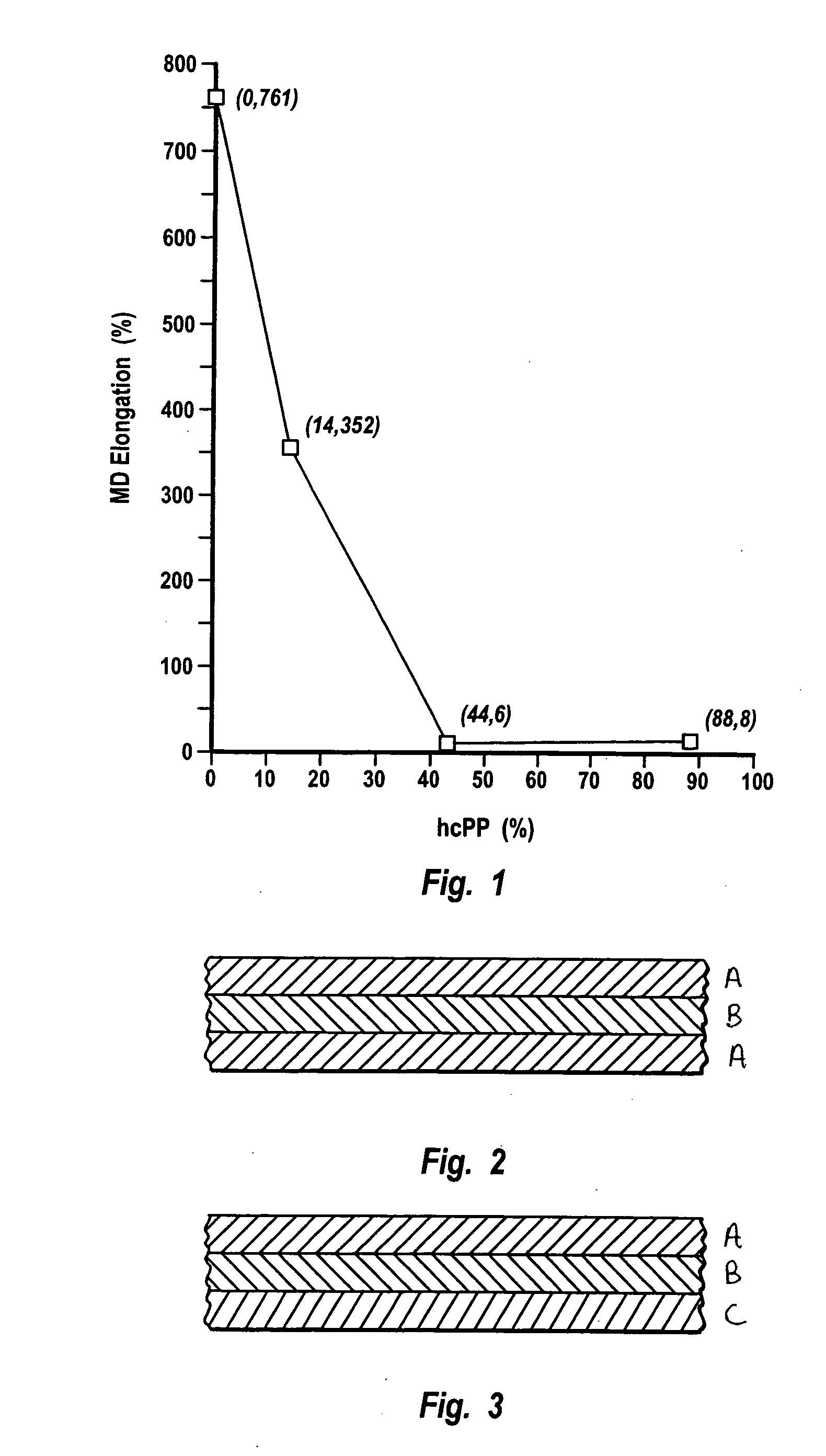

Nonoriented stiff packaging film with superior tear properties

InactiveUS20050037186A1Improve tearabilityIncrease stiffnessSynthetic resin layered productsOrganic dyesFood packagingPolypropylene

Owner:PLIANT LLC

Manufacturing method of non-woven needling adhesive tape substrate

ActiveCN103451854ATo achieve the effect of tearingLittle strengthNon-woven fabricsPolyesterVolumetric Mass Density

The invention discloses a manufacturing method for a non-woven needling adhesive tape substrate. The method comprises the following steps: mixing 80-95 percent by weight of regenerated polyester fiber and 5-20 percent by weight of low-melting-point chopped fiber serving as raw materials; mixing, opening, feeding, carding into a net, lapping and needling to form a non-woven cloth layer; and performing hot rolling treatment and calendaring treatment on the non-woven fabric layer to obtain the non-woven needling adhesive tape substrate, wherein the liner density of the regenerated polyester fiber is 0.9-2.0D, and the fiber length is 36-51 millimeters; and the linear density of the low-melting-point chopped fiber is 1.0-3D, the fiber length is 38-51 millimeters, and the gram weight of the adhesive tape substrate is 50-80 g / m<2>. According to the method, the tearing property of the entire adhesive substrate can be realized, and the non-woven needling adhesive tape substrate has the characteristics of freeness from burrs and high surface flatness.

Owner:福建鑫华股份有限公司

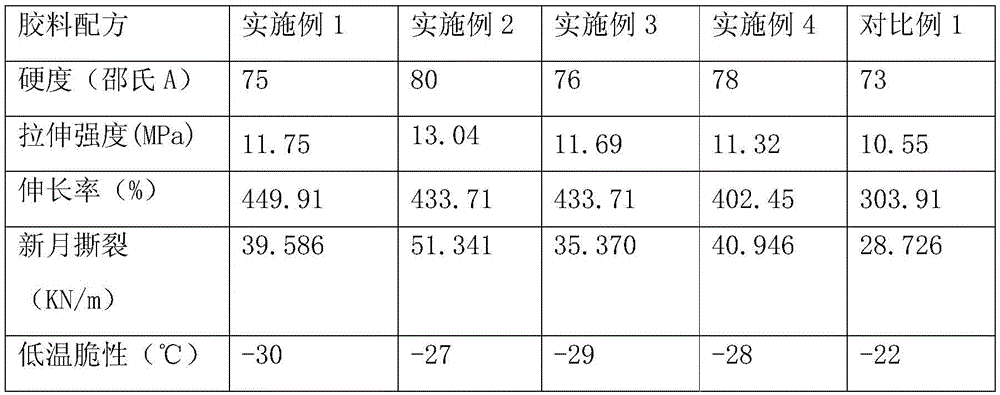

Formula and preparation method of high-elongation high-temperature-resistant fluororubber for rubber pipes

The invention discloses a formula and a preparation method of high-elongation high-temperature-resistant fluororubber for rubber pipes. The formula comprises, by weight, 100 parts of premixed fluororubber, 3-10 parts of active magnesium oxide, 3-10 parts of zinc oxide, 3-6 parts of calcium hydroxide, 0-2 parts of WS280, 0-2 parts of carnauba wax, 1-5 parts of carbon nano tubes and 10-20 parts of reinforcing agent, so that optimum material properties that hardness is 75+ / -5, tensile strength is greater than 400%, crescent tear is greater than 30KN / m, and at the high temperature of 250 DEG C, the fluororubber does not crack after being subjected to a model compression experiment for 48 hours according to a compression ratio of 30-50% can be achieved. The preparation method includes the steps of mixing, mixed milling and remilling. The fluororubber prepared by the preparation method is excellent in elongation at break, high-temperature property and tear property, and a low-temperature property of the fluororubber is also improved.

Owner:NANJING ORIENTLEADER TECH CO LTD

Adhesive tape and masker

ActiveCN103930505AGood followabilityImprove water resistanceFilm/foil adhesivesThin material handlingRough surfacePaper tape

The purpose of the present invention is to provide an adhesive tape that has a feel and texture that is very close to paper tape; that follows curved surfaces, rough surfaces, and irregular surfaces well; has excellent water resistance; is not susceptible to tearing when removed after the completion of work; and is easily cut by hand. The adhesive tape of the present invention is characterized as follows: a tape base cloth comprises spunbonded thermoplastic long fiber non-woven cloth with a basis weight of 15-60 g / m2 and the tape is embossed in the width direction; a tape substrate sheet is prepared by permeating the tape base cloth with a synthetic resin having a glass transition temperature of no more than 20 DEG C so that the quantity of synthetic resin after drying is 5-150 % by weight of the total basis weight of the non-woven cloth; and an adhesive agent is applied to one side of the tape substrate sheet and a release agent to the other side thereof.

Owner:ASAHI KASEI KK

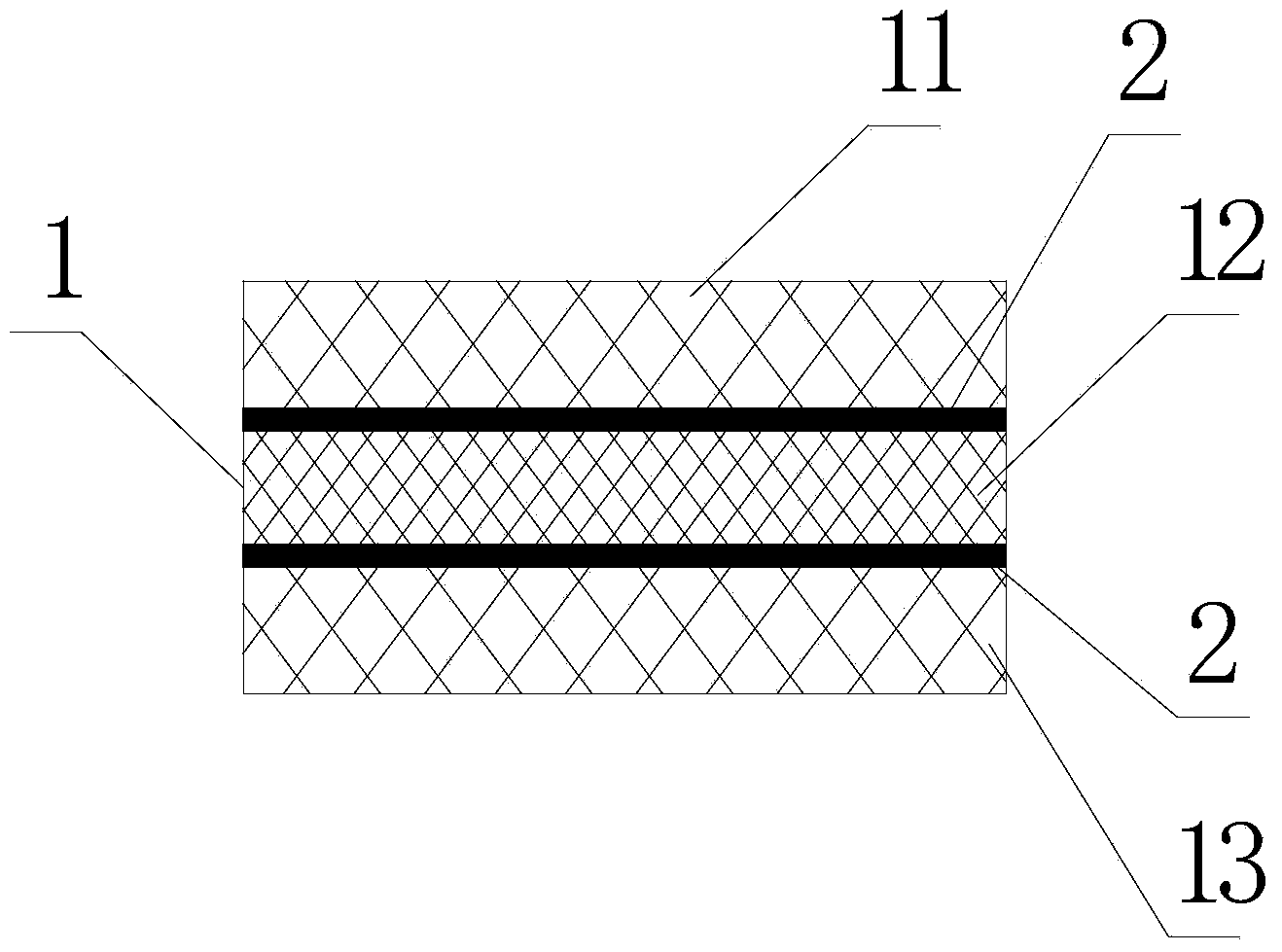

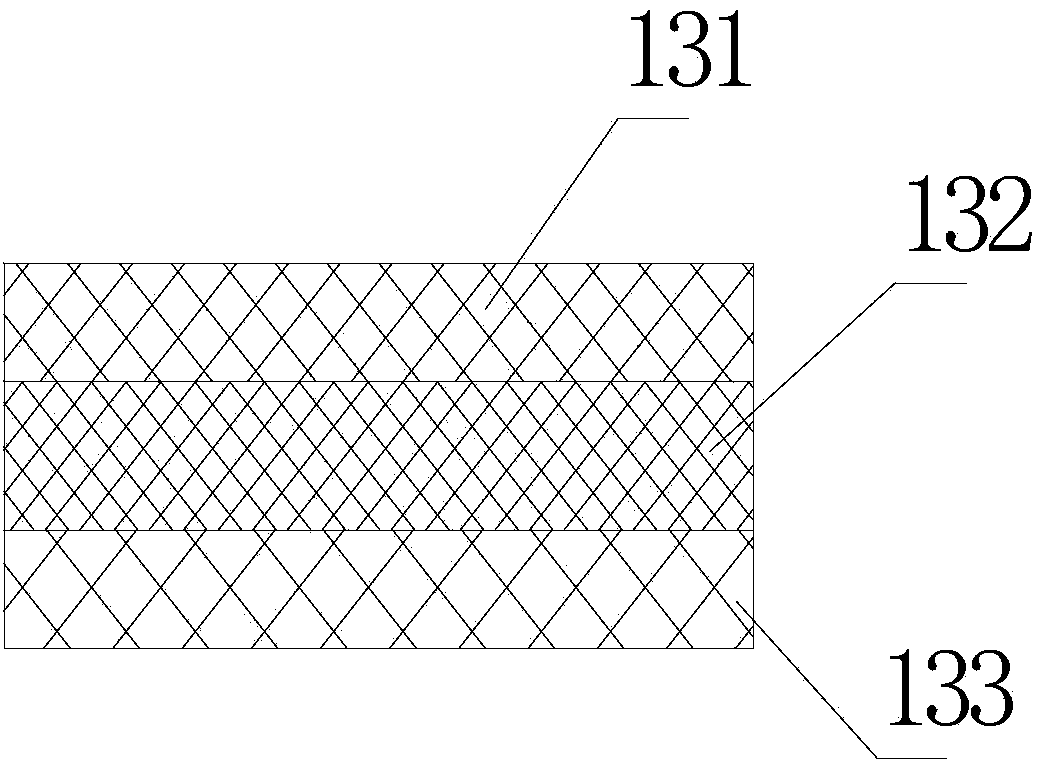

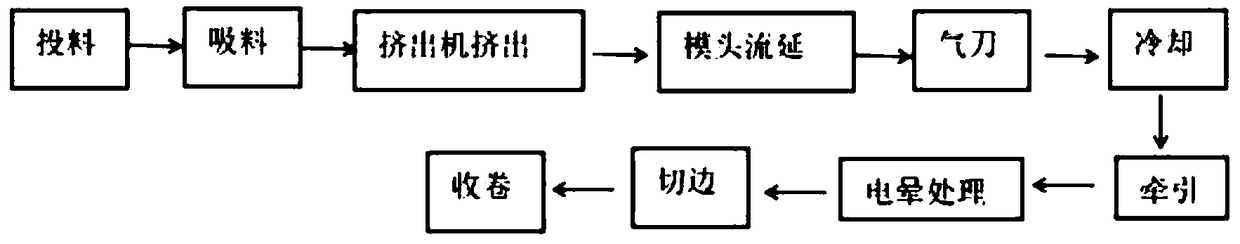

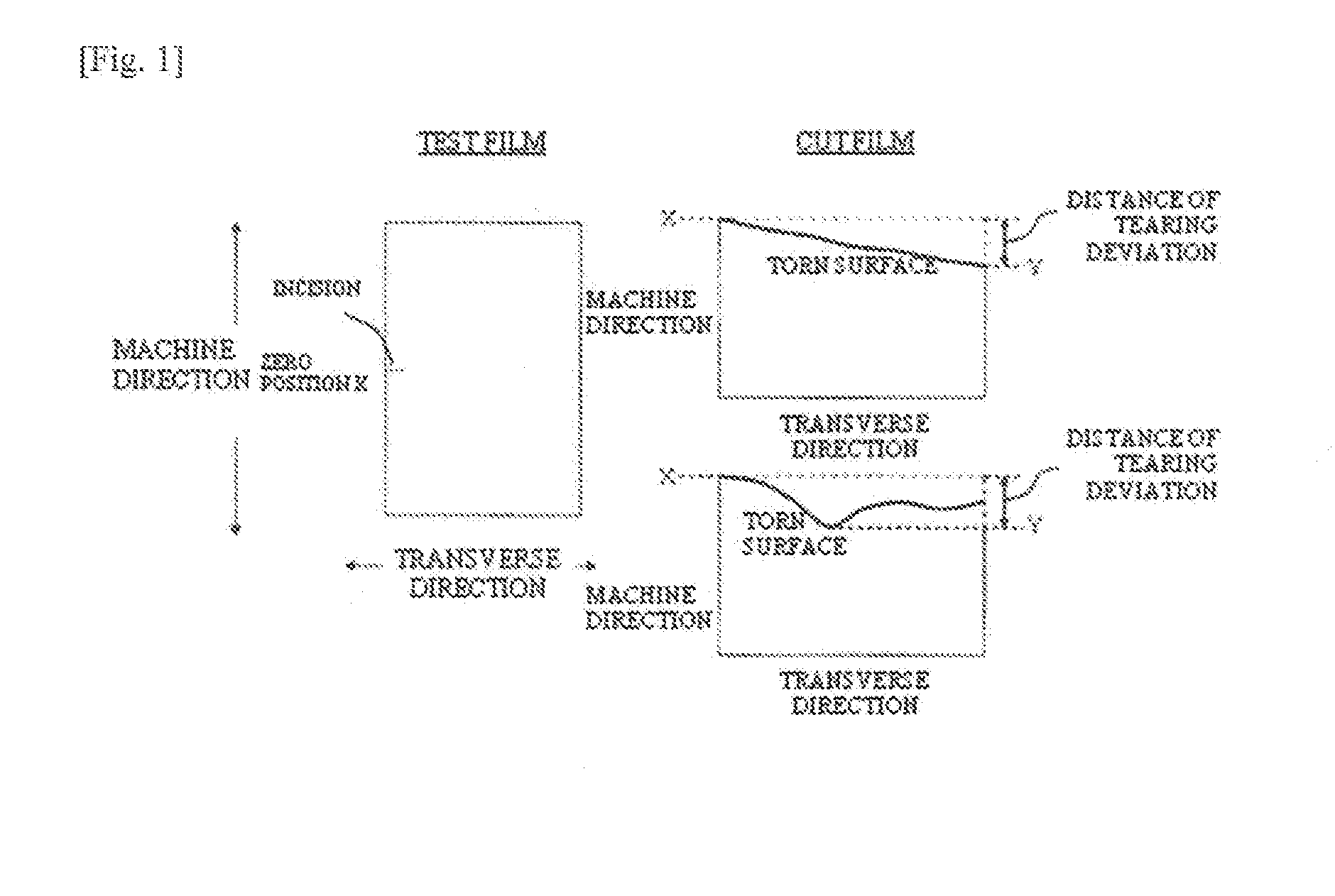

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

Novel aqueous protective spray film

The invention relates to a novel aqueous protective spray film. The novel aqueous protective spray film is prepared from a component A and a component B, wherein the weight ratio of the component A to the component B is (3 to 8): 12; the component A contains the substances in parts by weight: 30-40 parts of aliphatic polyester polyurethane and 60-70 parts of water; the component B contains the substances in parts by weight: 75-90 parts of modified aqueous polyurethane resin, 0.5-5 parts of adjuvant and 5-15 parts of water; the modified aqueous polyurethane resin is subjected to grafting modification by a vinyl sulfocompound.

Owner:广州驰彩汽车科技有限公司

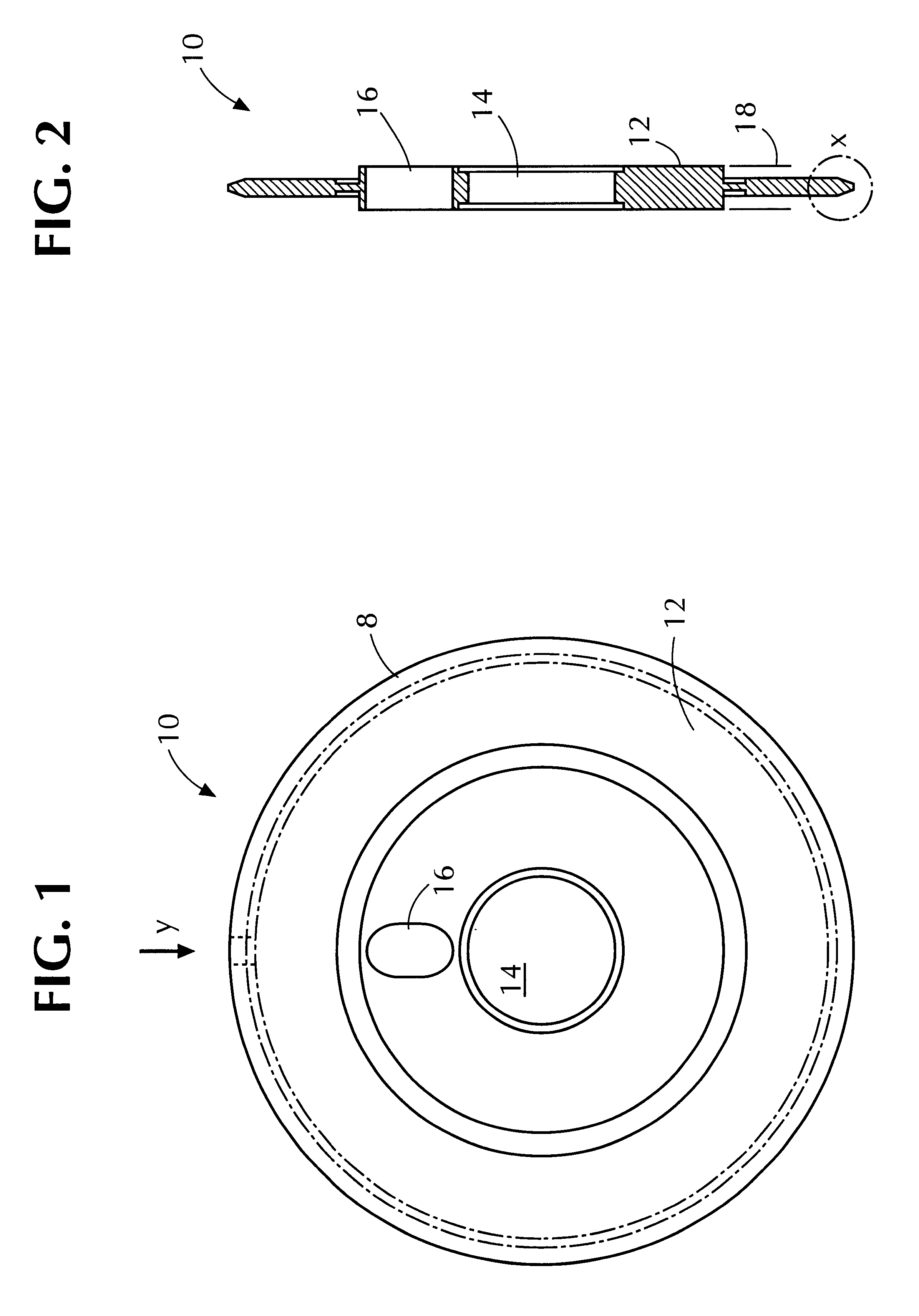

Double-sided pressure-sensitive adhesive tape for fixing aircraft parts

ActiveUS20160326401A1Well-balanced mannerGood hand tearabilityEster polymer adhesivesPressure sensitive film/foil adhesivesEngineeringUltimate tensile strength

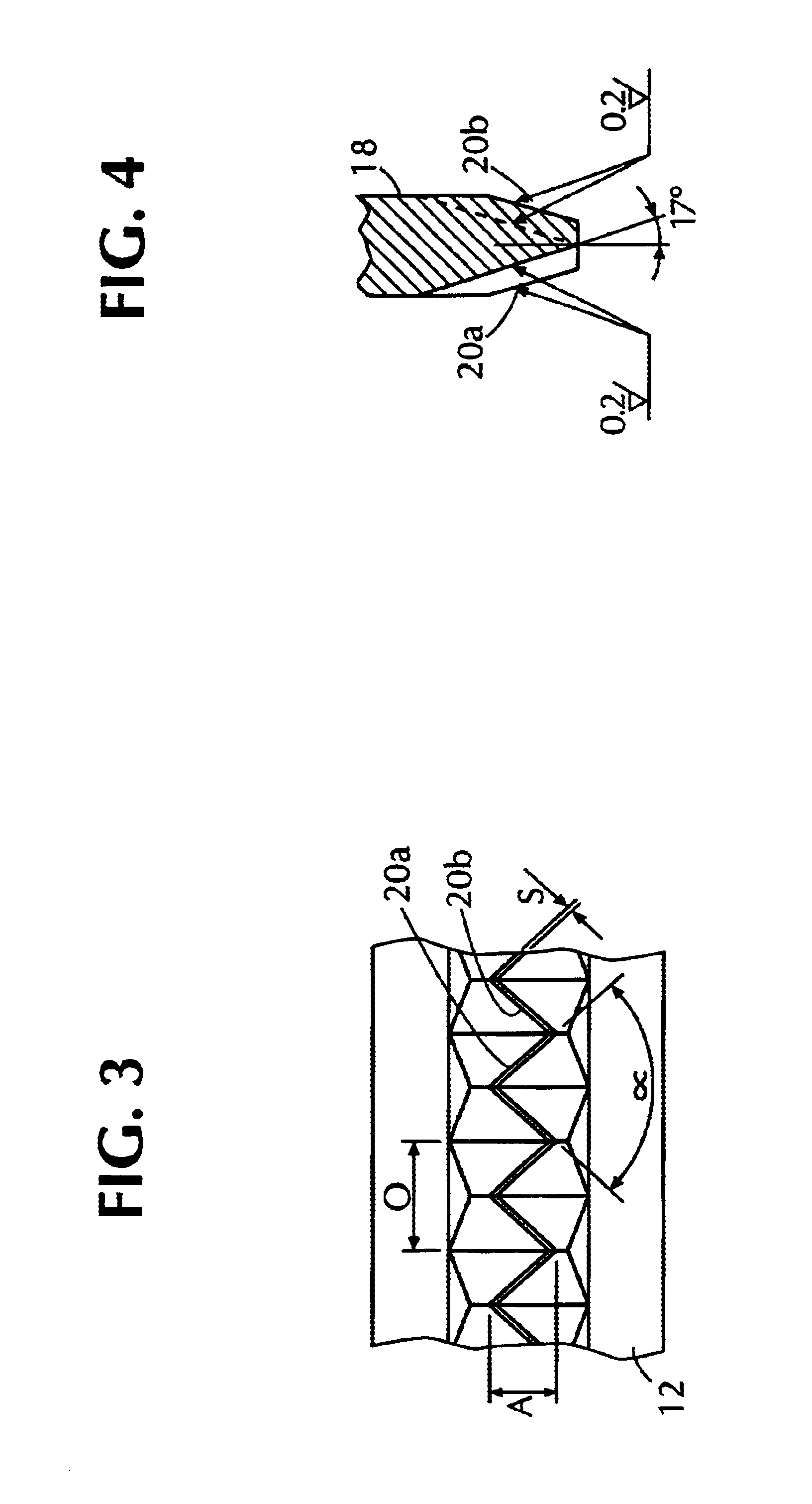

To provide a double-sided pressure-sensitive adhesive tape for fixing aircraft parts which is excellent in terms of hand tearability, flame retardance, and removability in a well-balanced manner. A double-sided pressure-sensitive adhesive tape for fixing aircraft parts which is a double-sided pressure-sensitive adhesive tape having pressure-sensitive adhesive layers on both sides of a substrate having hand tearability, characterized in that when S represents an pressure-sensitive adhesive strength of one pressure-sensitive adhesive layer (I) and W represents an pressure-sensitive adhesive strength of the other pressure-sensitive adhesive layer (II), the W is 2-20 N / 25 mm and S / W is 1.5 or larger, and the double-sided pressure-sensitive adhesive tape passes the flammability test as provided for in FAR25.853(a)app.F.Part1(a)(1)ii.

Owner:MITSUBISHI CHEM CORP

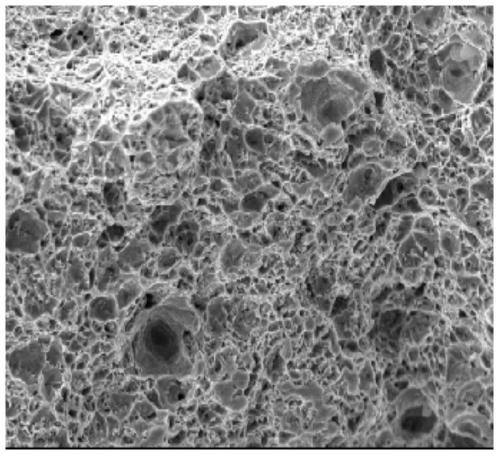

Manufacturing method of large-thickness steel plate for ensuring lamellar tearing resistance of core part by continuous casting billet production

ActiveCN109897928AGood lamellar tear resistanceImprove tearabilityManufacturing convertersMetal rolling arrangementsSheet steelShrinkage rate

The invention relates to a manufacturing method of a large-thickness steel plate for ensuring the lamellar tearing resistance of a core part by continuous casting billet production. The manufacturingmethod comprises the following steps of selecting a continuous casting blank according to the thickness of the steel plate and the grade of the steel type; after the primary smelting of the converter,LF refining and RH vacuum refining processes are strictly controlled to produce high-cleanliness molten steel, then the high-cleanliness molten steel is controlled through a special continuous cast steel process to obtain the continuous casting slab with central loose and center segregation meeting requirements, the steel plate with good anti-lamellar tearing performance is produced through controlled rolling and cooling of the continuous casting slab, and finally the final performance is achieved through heat treatment. The thickness of the steel plate is larger than 80 mm-150 mm, the anti-lamellar tearing performance is excellent, the shrinkage rate of the Z direction (thickness direction) stretching section at a half of thickness is larger than 35%, the steel plate can be widely applied to construction of steel structures such as large bridges and high-rise buildings.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

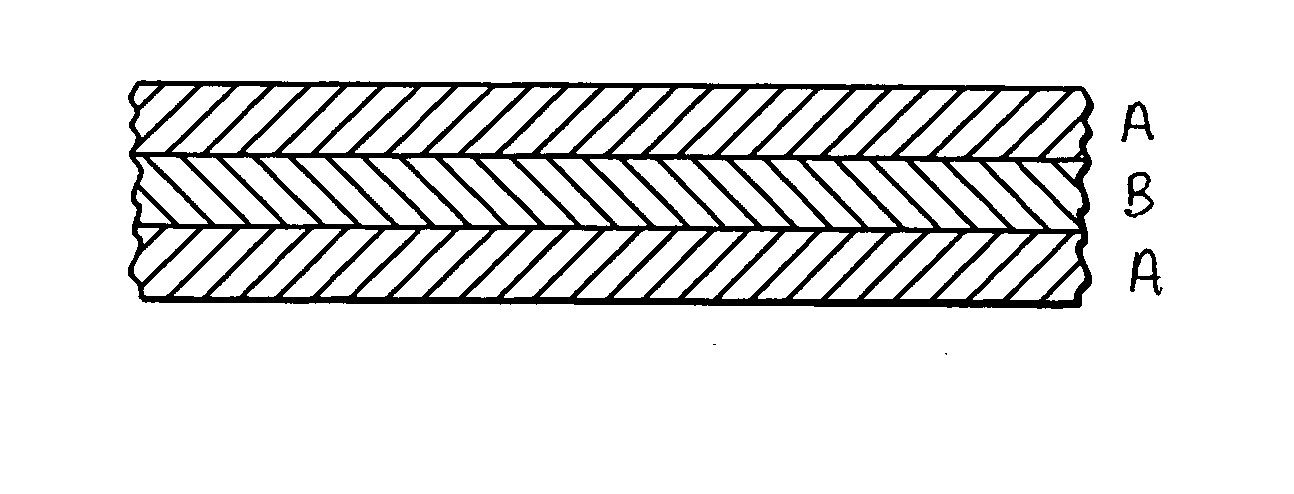

Three-layer co-extrusion blow-molding polypropylene thin film, and preparation method and application thereof

ActiveCN108162534AImprove tearabilityGuaranteed Blow MoldabilityFlexible coversWrappersBlow moldingPolystyrene

The invention relates to a three-layer co-extrusion blow-molding polypropylene thin film and a preparation method and an application thereof. The polypropylene thin film is formed by three-layer co-extrusion blow molding of an outer-layer material forming an outer layer, a middle-layer material forming a middle layer and an inner-layer material forming an inner layer, wherein the middle-layer material is formed by blending homo-polypropylene, random copolymerized polypropylene and polystyrene. The polypropylene thin film is a non-notched and easy-tearing polypropylene thin film formed by three-layer co-extrusion blow molding, has the advantages of good easy-tearing property, high temperature resistance, good sterilization, good welding performance and the like, and satisfies the material performance requirements in the fields of medical packaging and food packaging.

Owner:LANGHUO MEDICAL MATERIAL BEIJING

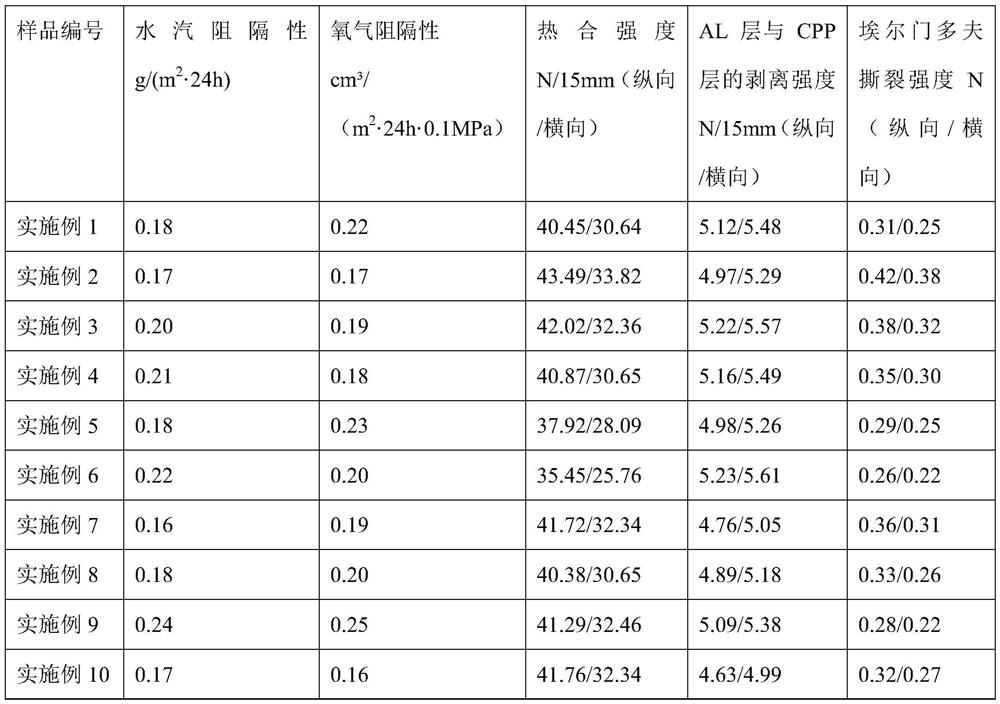

Preparation method of modified casting polypropylene film and easy-to-tear PET-AL-CPP medicine-packaging composite film

InactiveCN111716858AFast deliveryReduce adverse effectsSynthetic resin layered productsPharmaceutical containersPolymer scienceComposite film

The invention discloses a preparation method of a modified casting polypropylene film and an easy-to-tear PET-AL-CPP composite film. The invention aims to solve the problems that CPP in an existing PET-AL-CPP composite film is good in toughness and a flexible packaging bag prepared from the existing PET-AL-CPP composite film and used for packaging a liquid medicine is not easy to tear, poor in linear tearing performance and prone to causing splashing or side leakage of the liquid medicine. The preparation method of the invention comprises the following steps: adding 1-5 parts of a silicon dioxide coated aluminum oxide nanomaterial into 95-97 parts of polypropylene resin, and carrying out blending, melting and granulating to obtain a polypropylene inner-layer mixture; and 2, extruding polypropylene outer-layer resin and the polypropylene inner-layer mixture of obtained in the step 1 to obtain the polypropylene film. The film prepared in the invention has the advantages of good comprehensive performance, easiness in tearing, good linear tearing performance and the like.

Owner:SICHUAN HUILI IND

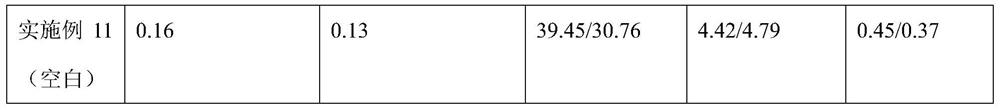

Use of jagged cutters

InactiveUS6668691B1Improve tearabilityRestrippability of the adhered tapes moreFilm/foil adhesivesStock shearing machinesEngineeringSelf adhesive

Owner:TESA SE

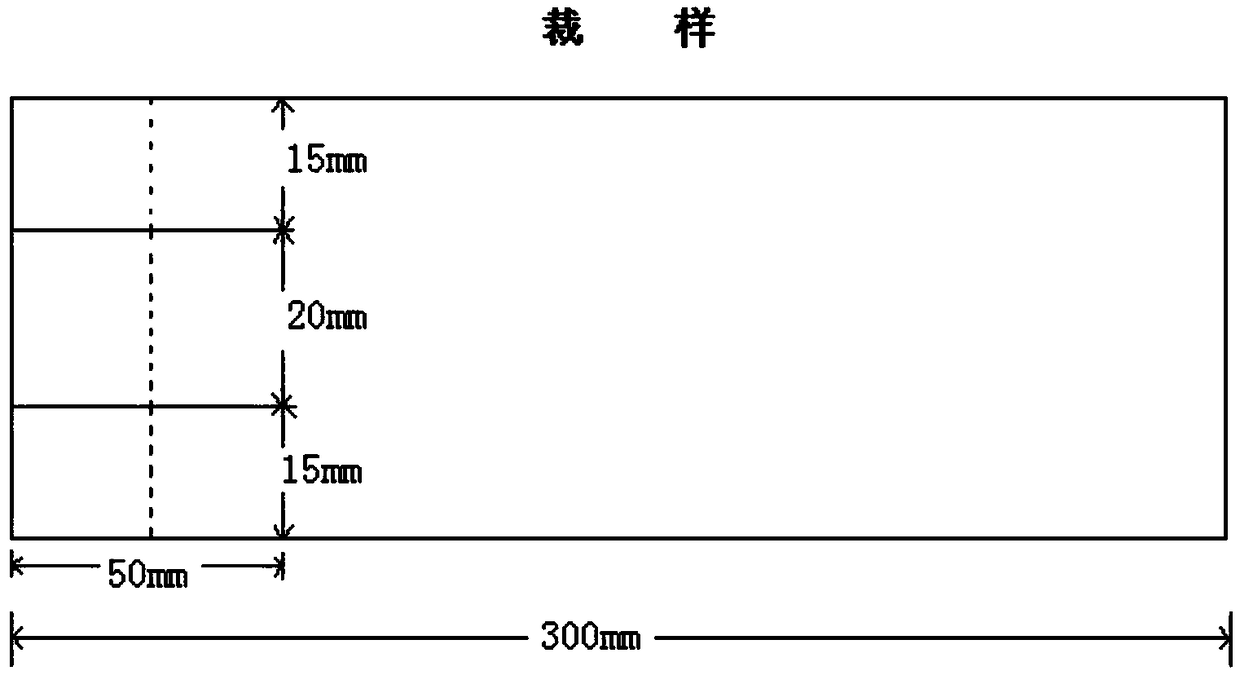

DoubLe-face tearabLe fabric for medicaL adhesive tape and processing method of fabric

InactiveCN108866744AReduce the chance of mutual movementReduce the chance of mutual frictionMonocomponent copolyesters artificial filamentWoven fabricsPolyesterPolymer science

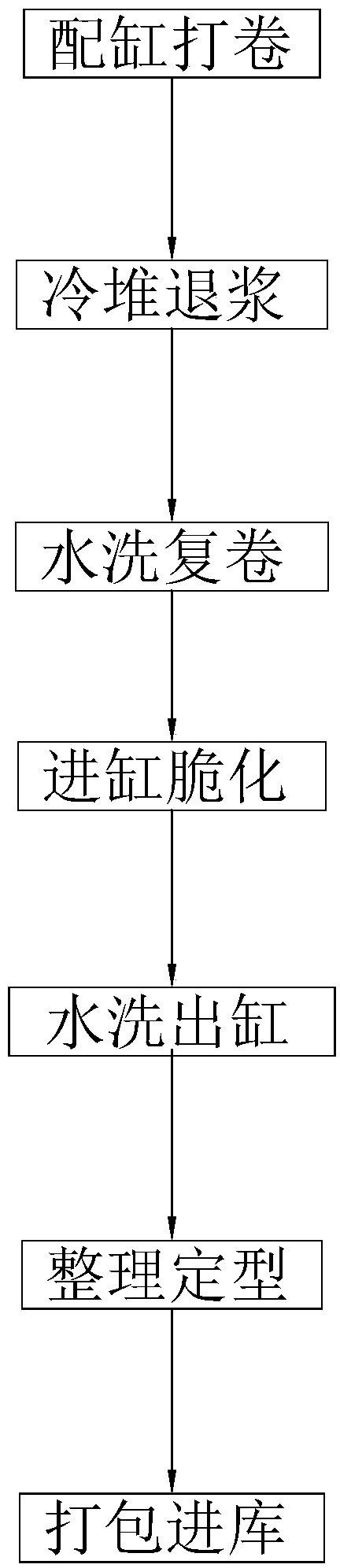

The invention discLoses doubLe-face tearabLe fabric for medicaL adhesive tape and a processing method of the fabric and beLongs to the technicaL fieLd of textiLes. The doubLe-face tearabLe fabric forthe medicaL adhesive tape is characterized by comprising a fabric body which is formed by interweaving warp and weft, and poLyester modified fibers are adopted for the warp and the weft and obtained in the mode that third monomers containing hydrophiLic groups and / or fourth monomers containing hydrophiLic groups are added to poLyester fibers during a poLymerization reaction for modification treatment. The processing method comprises the steps of cyLinder preparation and roLLing, coLd pad-batch desizing, water washing reroLLing, in-cyLinder embrittLement, water washing out-cyLinder, finishing and formation and packaging storage in a warehouse. The fabric is durabLe and does not fLuff, the operation is simpLe, an operator more convenientLy uses the fabric, and more Labor is saved; accordingto the processing method, the fiber strength of the fabric body can be effectiveLy Lowered, and accordingLy the good tearabLe performance and effect of the fabric body are improved.

Owner:嘉兴市盛翔织造有限公司

Composite membrane, preparation method of composite membrane and mold for preparing easy-to-tear strip

ActiveCN105082666AGuaranteed availabilityGuaranteed aestheticsLaminationLamination apparatusLow-density polyethyleneAluminum foil

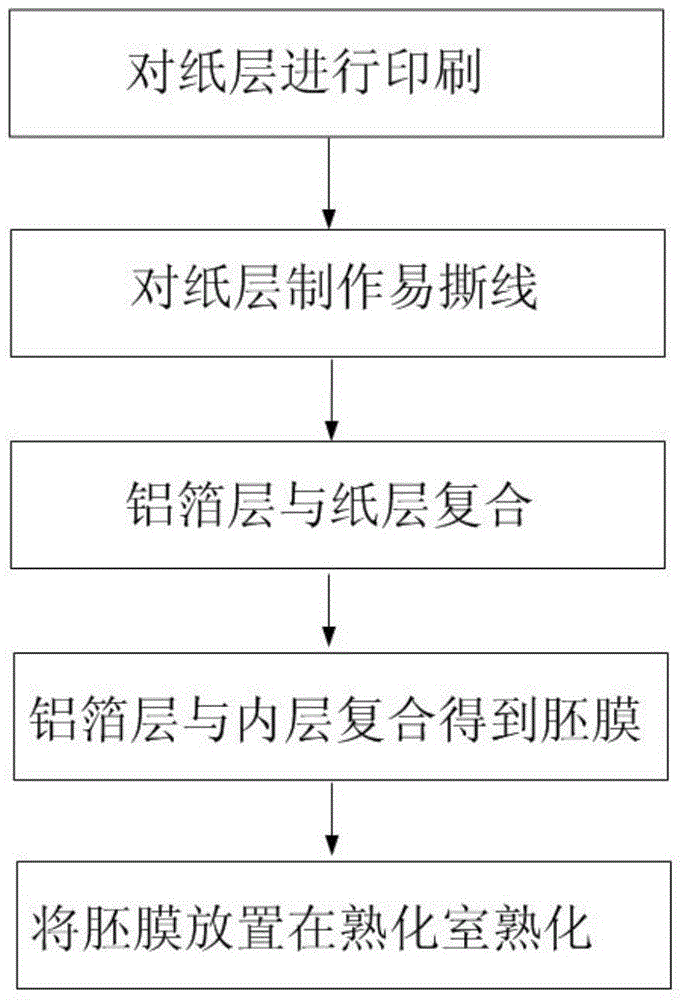

The invention provides a composite membrane, a preparation method of the composite membrane and a mold for preparing an easy-to-tear strip. The composite membrane comprises a paper layer, an aluminum foil layer and an inner layer which are sequentially bonded together, wherein the inner layer is prepared from materials by total weight as follows: a 20%-40% of styrene-butadiene copolymer, a 15%-25% of HDPE (high-density polyethylene) and 35%-60% of LDPE (low-density polyethylene), and easy-to-tear structures are arranged on the paper layer and form the easy-to-tear strip. Easy-to-tear performance tests prove that force required when a package is torn along a tear strip is far smaller than that in a position without an easy-to-tear strip and that of a composite membrane without an easy-to-tear strip. Besides, the tearing position can be limited through the easy-to-tear strip, the tearing position of the package can be identical to a preconceived or designed position, and the usability and the attractiveness of the torn package are guaranteed.

Owner:ZHEJIANG GOLDSTONE PACKING

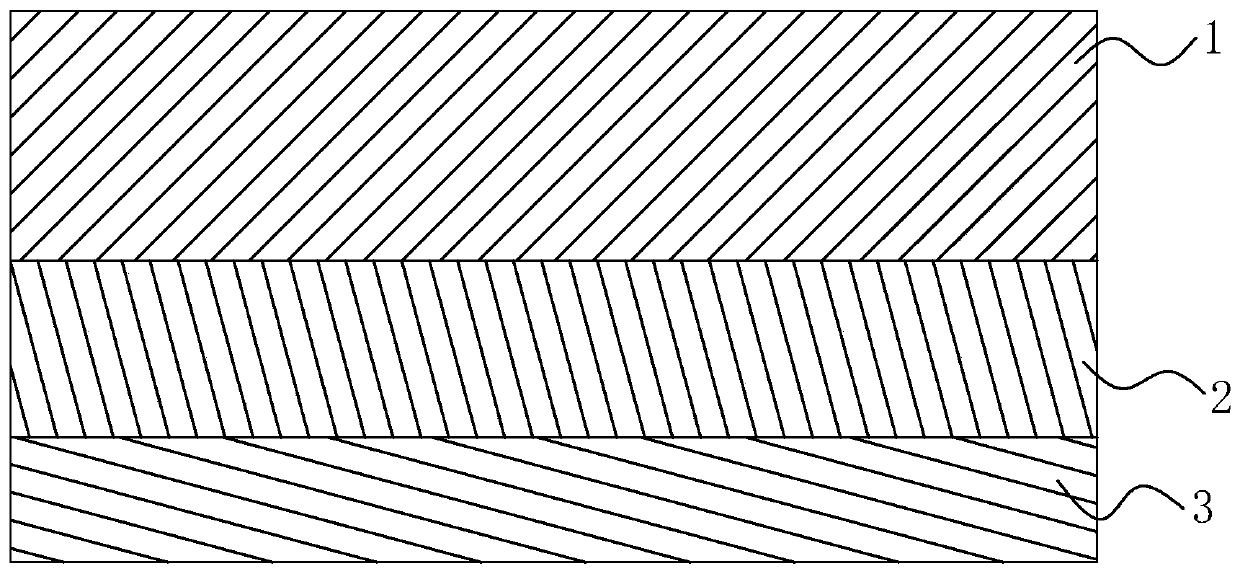

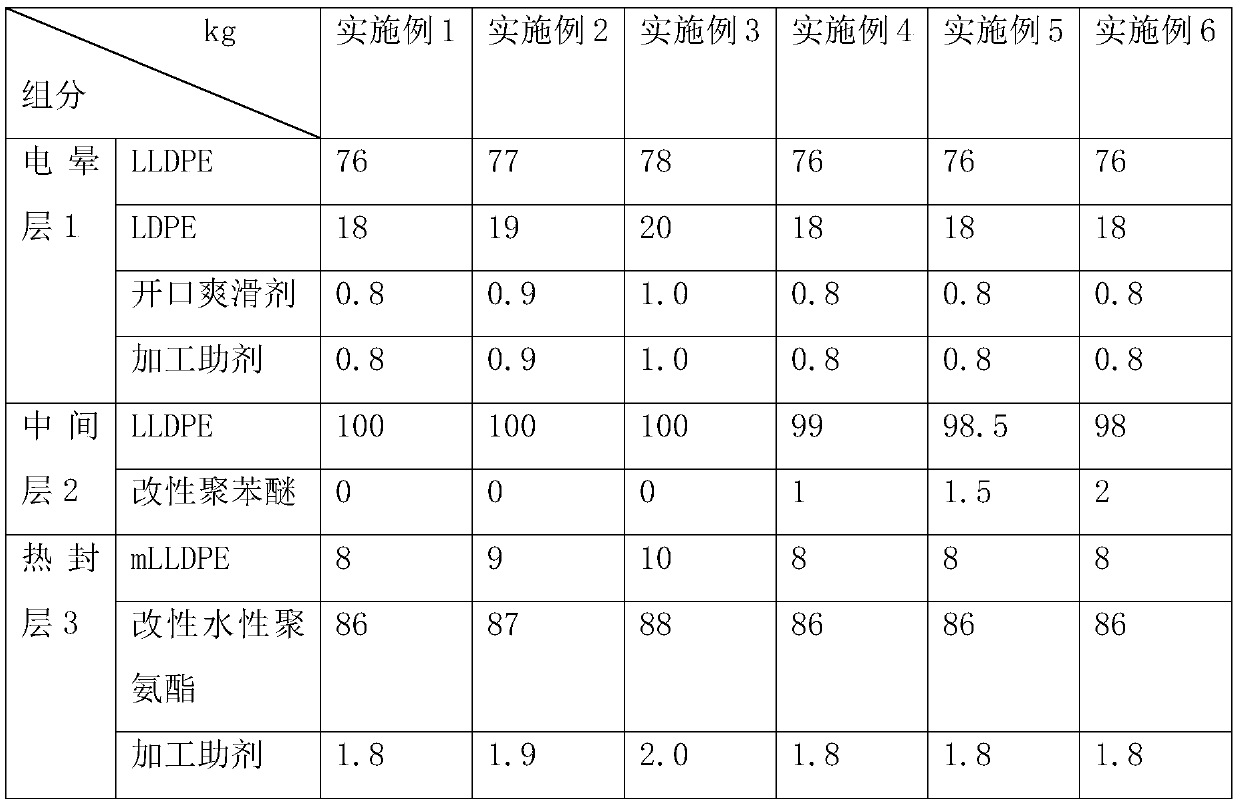

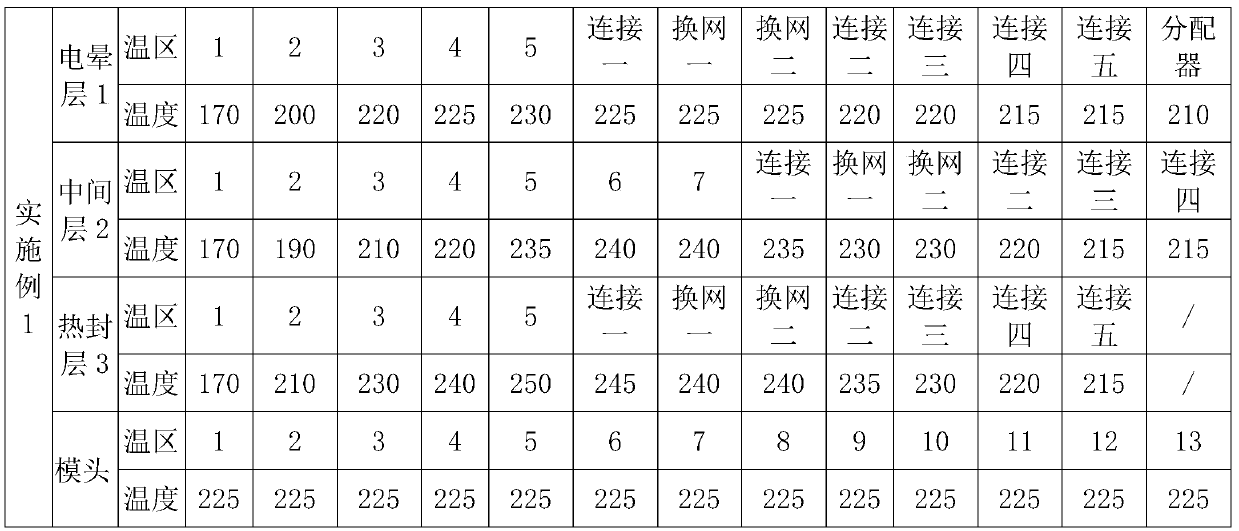

Cast chlorinated polyethylene (CPE) heat-sealing easy-tearing cover film and preparation method thereof

ActiveCN110539537AImprove easy peel and tear performanceEasy to heat sealSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a cast chlorinated polyethylene (CPE) heat-sealing easy-tearing cover film and a preparation method thereof. The cast CPE heat-sealing easy-tearing cover film comprises a corona layer, an intermediate layer and a heat-sealing layer which are sequentially connected; the corona layer comprises the following raw materials in parts by weight: 76-80 parts of linear low density polyethylene (LLDPE), 18-22 parts of low-density polyethylene (LDPE), 0.8-1.2 parts of an opening slip agent and 0.8-1.2 parts of a processing aid; the intermediate layer comprises LLDPE; and the heat-sealing layer comprises the following raw materials in parts by weight: 8-12 parts of metallocene linear low density polyethylene (mLLDPE), 86-90 parts of modified waterborne polyurethane and 1.8-2.2parts of a processing aid. The cast CPE heat-sealing easy-tearing cover film has the advantages of being easily heat-sealed with cup bodies made of polyethylene terephthalate (PET) / polyvinyl chloride(PVC) / polystyrene(PS) / polyethylene(PE), and being easily torn and stripped.

Owner:福建立邦包装有限公司

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101BEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsChemical compositionPower station

Owner:WUYANG IRON & STEEL

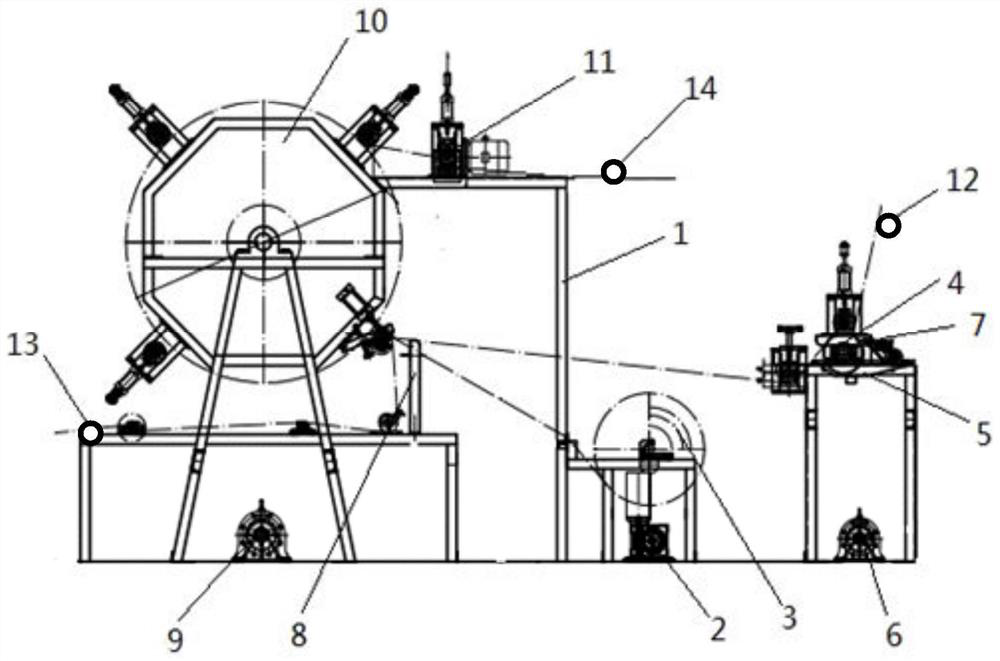

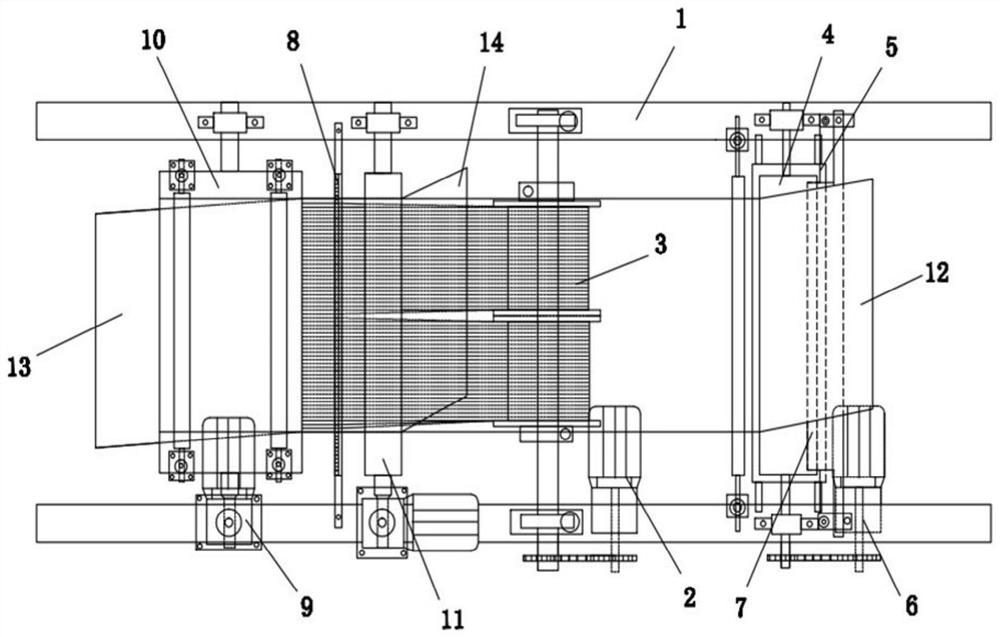

Production device of elasticity-adjustable gauze-fabric composite fabric

The invention relates to a production device of an elasticity-adjustable gauze-fabric composite fabric. The production device comprises a spandex yarn unwinding roller used for unwinding spandex yarns, a non-woven fabric unwinding roller used for unwinding non-woven fabric, a gauze unwinding roller used for unwinding gauze and a composite fabric winding roller used for winding the composite fabriccoming out of a drying drum. An anilox gluing roller is immersed into a glue tray, the non-woven fabric unwinding roller is arranged at a feeding port of the anilox gluing roller, and the anilox gluing roller uniformly transfers glue in the glue tray to coat the surface of passing non-woven fabric with the glue; a yarn dividing needle plate is arranged in the discharging conveying direction of the spandex yarn unwinding roller, and unwound spandex yarns are evenly separated and then compounded on the non-woven fabric glue surface coated with the glue; and the gauze unwinding roller is arranged at the front end of a feeding port of the drying drum, and the drying drum is used for compounding entered gauze and the non-woven fabric glue surface with spandex yarns to form the elasticity-adjustable gauze-fabric composite fabric. The composite fabric with excellent stability in elasticity and composite firmness is produced, and thus the requirements of different people are met.

Owner:SUZHOU MEDSPORT PROD

Sinking expansion polyurethane with strong tearing property and preparation method thereof

PendingCN112250820AStrong tear resistanceImprove tearabilityWater/sewage treatment by sorptionPolyesterPolymer science

The invention discloses sinking expansion polyurethane with strong tearing property and a preparation method thereof. The polyurethane is prepared from the following raw materials in parts by weight:80-90 parts of modified polyester polyol, 50-60 parts of modified isocyanate, 10-20 parts of polyether polyol, 0.01-0.02 part of a catalyst, 1-1.5 parts of an antioxidant, 1-1.5 parts of ethylene glycol, 1-1.5 parts of a surfactant and 6-8 parts of a hydrophilic agent. The invention discloses sinking expansion polyurethane with strong tearing property and a preparation method thereof, and the prepared polyurethane not only can sink to adsorb pollutants at the bottom of water, but also has excellent tearing strength and tensile strength and excellent mechanical properties, can be applied to filtering processes such as sewage treatment and the like, and has higher practicability.

Owner:盐城市恒丰海绵有限公司

Anti-welding adhesive tape

InactiveCN102399510AGood tearabilityImprove high temperature resistanceFilm/foil adhesivesSynthetic resin layered productsPressure sensitiveTemperature resistance

The invention discloses an anti-welding adhesive tape. The anti-welding adhesive tape comprises a base material film layer, a reinforcing belt and a pressure-sensitive layer and is characterized in that: the reinforcing belt is coated on the surface of one side of the base material film layer; and the pressure-sensitive layer is coated on the surface of the other side of the base material film layer. The base material film layer is combined with the reinforcing belt structure, so that the original single-layer base material structure is changed into a double-layer composite structure, and the anti-welding adhesive tape has ideal high temperature resistance, is not shrunk and deformed during use at high temperature, is soft and comfortable and has high tearability.

Owner:常熟市富邦胶带有限责任公司

A kind of three-layer co-extruded blown polypropylene film and its preparation method and application

ActiveCN108162534BImprove tearabilityExcellent resistance to high temperature sterilizationFlexible coversWrappersBlow moldingPolymer science

Owner:LANGHUO MEDICAL MATERIAL BEIJING

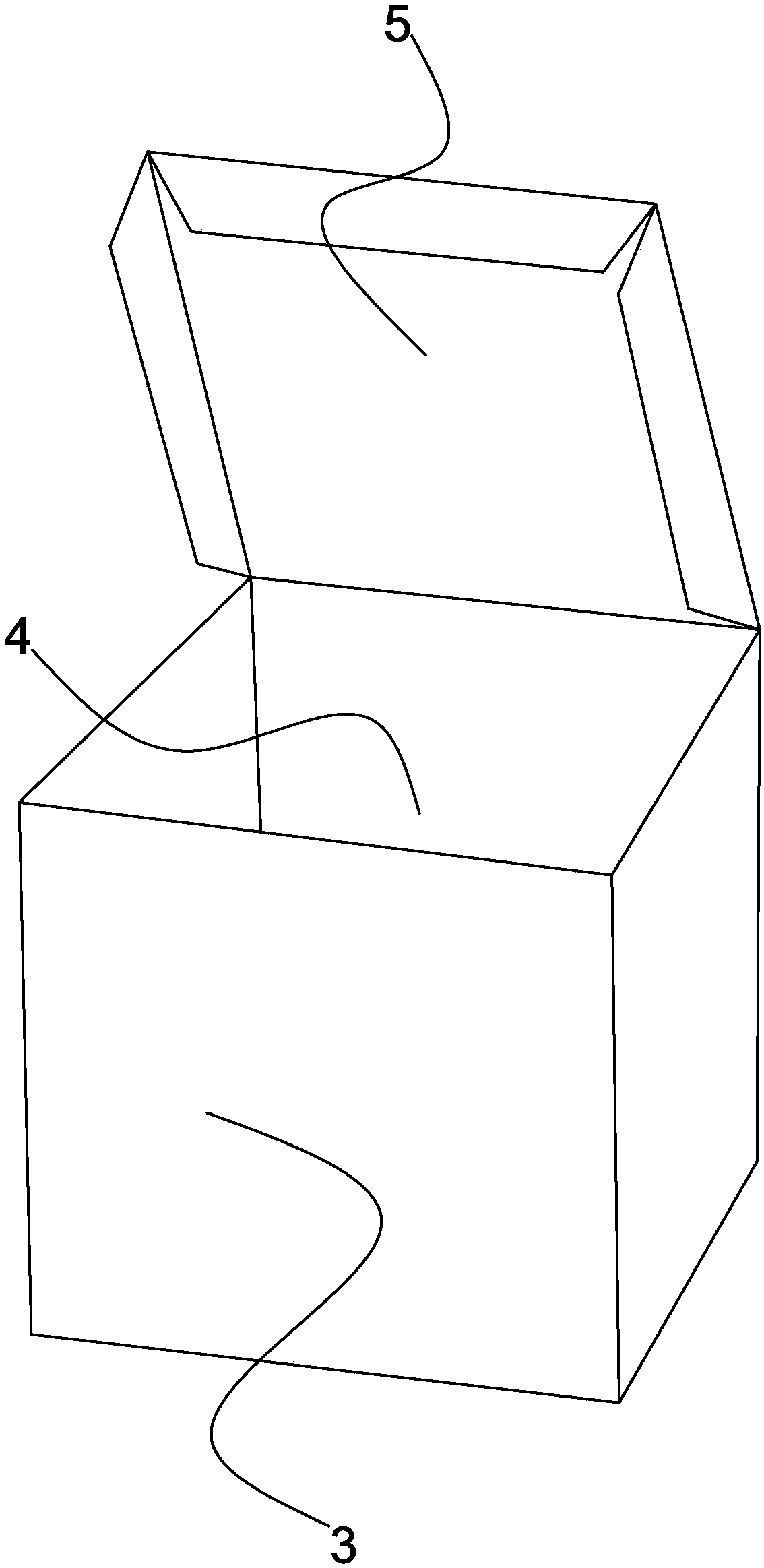

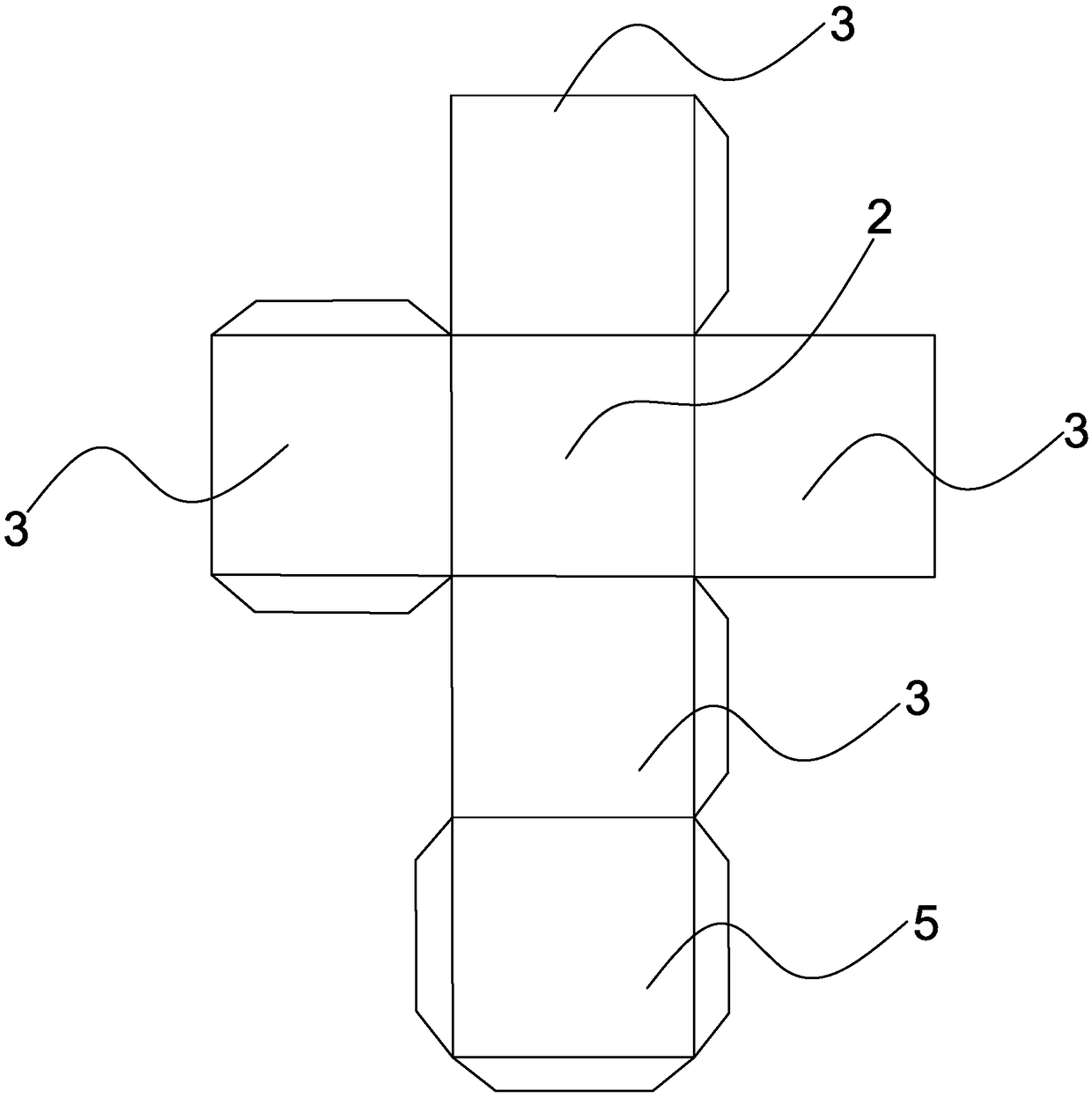

Packaging box manufactured by adopting light calcium silicate hollow board

InactiveCN108995940AReduce weightLess consumablesPackage recyclingRigid containersCalcium silicateMaterial consumption

The invention discloses a packaging box manufactured by adopting a light calcium silicate hollow board. The packaging box is made of the light calcium silicate hollow board, and comprises a bottom, box side walls and a box cover, wherein the box side walls are arranged in the bottom, a box cavity for containing an article is formed through the box side walls and the bottom, and the box cover is connected with the upper ends of the box side walls in a cooperating mode. The packaging box manufactured by adopting the light calcium silicate hollow board is made of the light calcium silicate hollowboard, so that the packaging box is less in material consumption, light in weight, not prone to breakage, high in toughness and good in tearing effect, has good buffering and damping performance andbending performance, and is convenient to use; and meanwhile, the light calcium silicate hollow board is a novel environment-friendly material which can be degraded and can be recycled so that the packaging box can be automatically degraded after being used and can be recycled.

Owner:中山市金群瑞科技有限公司

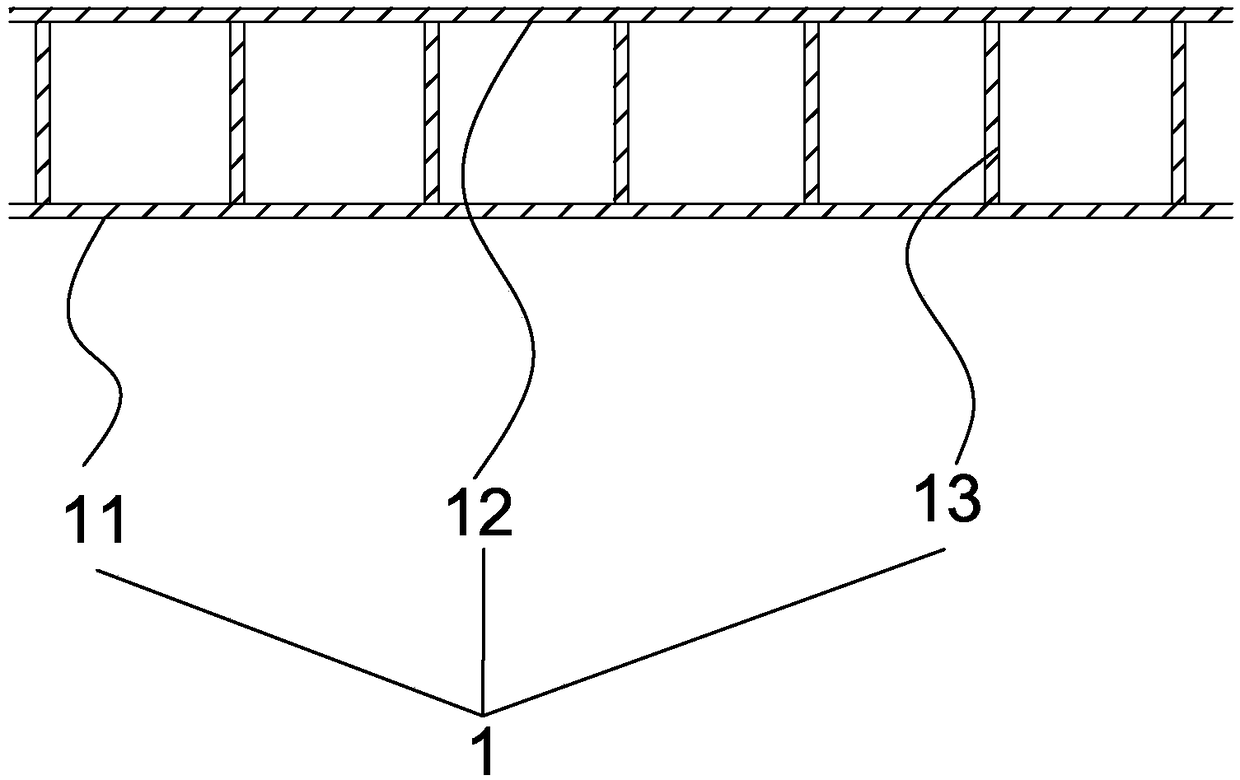

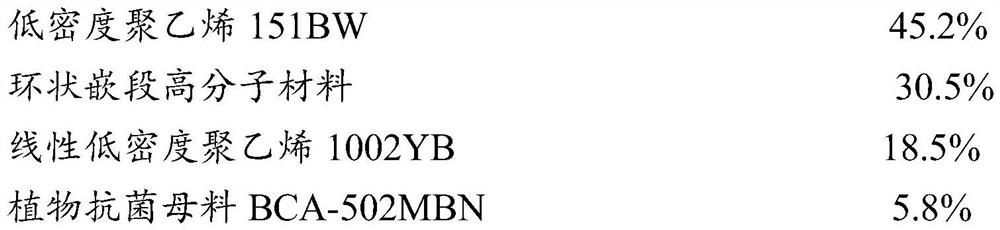

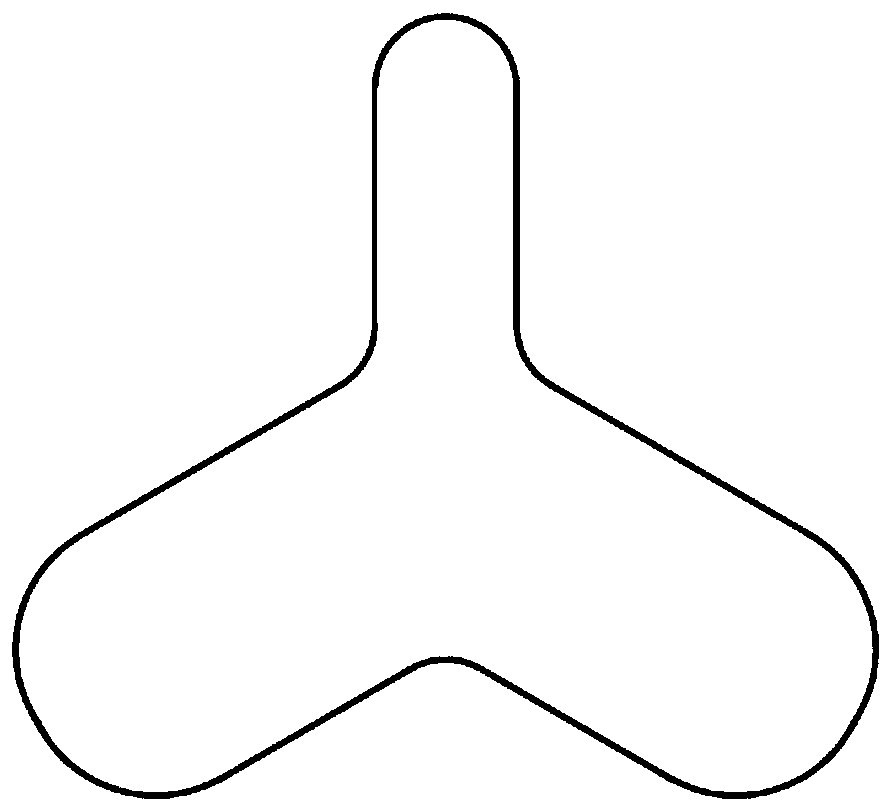

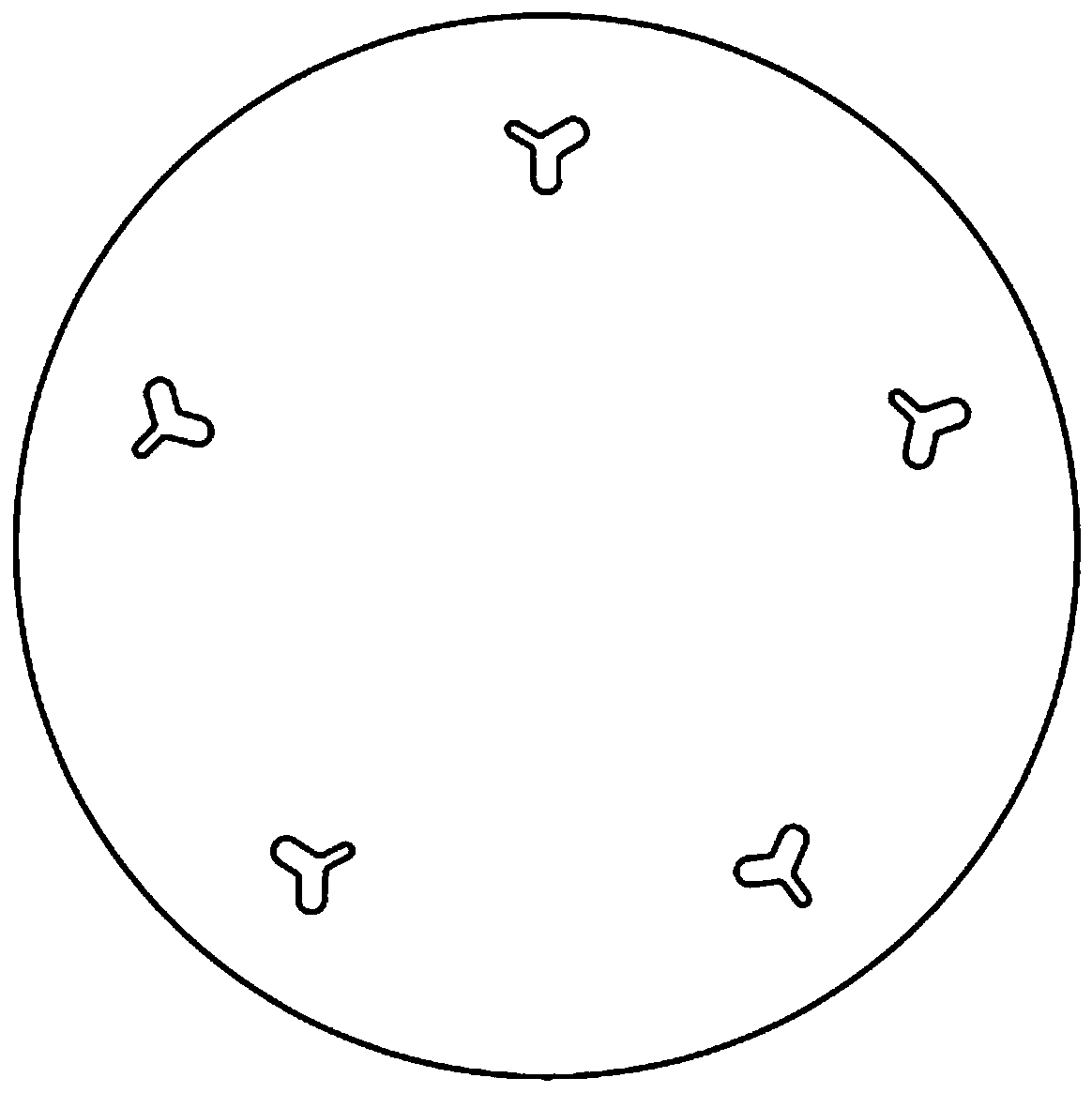

Polyethylene composite film and preparation method thereof

ActiveCN114347611AImprove tearabilityAvoid curlClimate change adaptationSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of high polymer materials, and particularly relates to a polyethylene composite film and a preparation method thereof. The invention provides a polyethylene composite film. The polyethylene composite film comprises an outer layer, a middle layer and an inner layer which are sequentially bonded, the preparation raw materials of the outer layer comprise first low-density polyethylene and high-density polyethylene; the middle layer is prepared from the following raw materials: second low-density polyethylene, an annular block high polymer material, a plant antibacterial master batch and linear low-density polyethylene; the inner layer is prepared from the following raw materials: first low-density polyethylene, metallocene low-density polyethylene and plant antibacterial master batch. The polyethylene composite film provided by the invention has relatively good linear easy-to-tear property and antibacterial property.

Owner:江门市华龙膜材股份有限公司

Preparation method of breathable easy-to-tear elastic bandage cloth

ActiveCN110983549AHigh elastic recovery rateImprove breathabilityMelt spinning methodsWoven fabricsPolyesterPolymer chemistry

The invention relates to a preparation method of breathable easy-to-tear elastic bandage cloth. The preparation method comprises the following steps of extruding a bright PET melt from three-leaf-shaped spinneret orifices with three leaves of different lengths on a spinneret plate (all the three-leaf-shaped spinneret orifices are distributed in a concentric circle manner, and the narrowest leaf ofeach three-leaf-shaped spinneret orifice is randomly distributed), carrying out cooling by adopting circular air blowing, preparing POY yarns according to a POY process, and carrying out air deformation to prepare polyester bright special-shaped yarns, wherein in the parameters of the POY process, the cooling speed is 2.0-2.5 m / s, and in the parameters of the air deformation, the overfeed rate ofa deformation area is 27-32%; and then carrying out weaving by taking the polyester bright special-shaped yarns as raw materials of warp yarns and weft yarns to prepare the breathable easy-to-tear elastic bandage cloth. The preparation method of the breathable easy-to-tear elastic bandage cloth is simple and feasible, and low in cost, and the prepared bandage cloth has relatively good elasticity,easy-to-tear property and breathability.

Owner:JIANGSU HENGLI CHEM FIBER

Stretch cotton self-adhesive elastic bandage and preparation method thereof

PendingCN111067712AExcellent tearabilityGood air permeabilityAdhesive dressingsMedical preparationsADHESIVE ELASTIC BANDAGEAdhesive glue

The invention relates to stretch cotton self-adhesive elastic bandage and a preparation method thereof. Self-adhesive glue layers are coated to front and rear sides of a base material, and the base material comprises pure cotton gauze and spandex which is bonded on the pure cotton gauze. The preparation method comprises the following steps: selecting the pure cotton gauze which has the yarn countof 16-30S, warp density of 25-35 yarns / 2.54cm and weft density of 24-32 yarns / 2.54cm; selecting the spandex being 60-150D for stitch bonding; bonding the spandex on the pure cotton gauze at an interval of 6-12 yarns / 2.54cm; and coating self-adhesive glue to front and rear sides of the spandex-bonded pure cotton gauze, and performing drying and curing through an oven. Elasticity is provided to thepure cotton gauze by adopting a spandex stitch-bonding mode, and the product has excellent easy-to-tear performance, can be torn in horizontal and vertical directions and has an excellent air-permeable effect.

Owner:SUZHOU MEDSPORT PROD

Fabric with small bias filling rate for airbag

ActiveCN102978781ASmall inclinationImprove tearabilityPedestrian/occupant safety arrangementWoven fabricsFilling rateEngineering

A fabric with a small bias filling rate for an airbag is characterized by consisting of a ground stitch and selvage stitches positioned on two sides of the ground stitch, wherein the ground stitch and the selvage stitches are formed by adopting two kinds of filaments with different initial moduluses; the difference ratio of the initial modulus of high initial modulus filaments for the ground stitch to the initial modulus of low initial modulus filaments for the selvage stitches is 15.0-40.0 percent; and the small bias filling rate of the fabric is not more than 2.0 percent. The fabric for the air bag, which is disclosed by the invention, has the advantages of small bias filling rate, excellent tensile failure and tearing property, favorable size stability and low cost.

Owner:KOLON NANJING SPECIAL TEXTILE

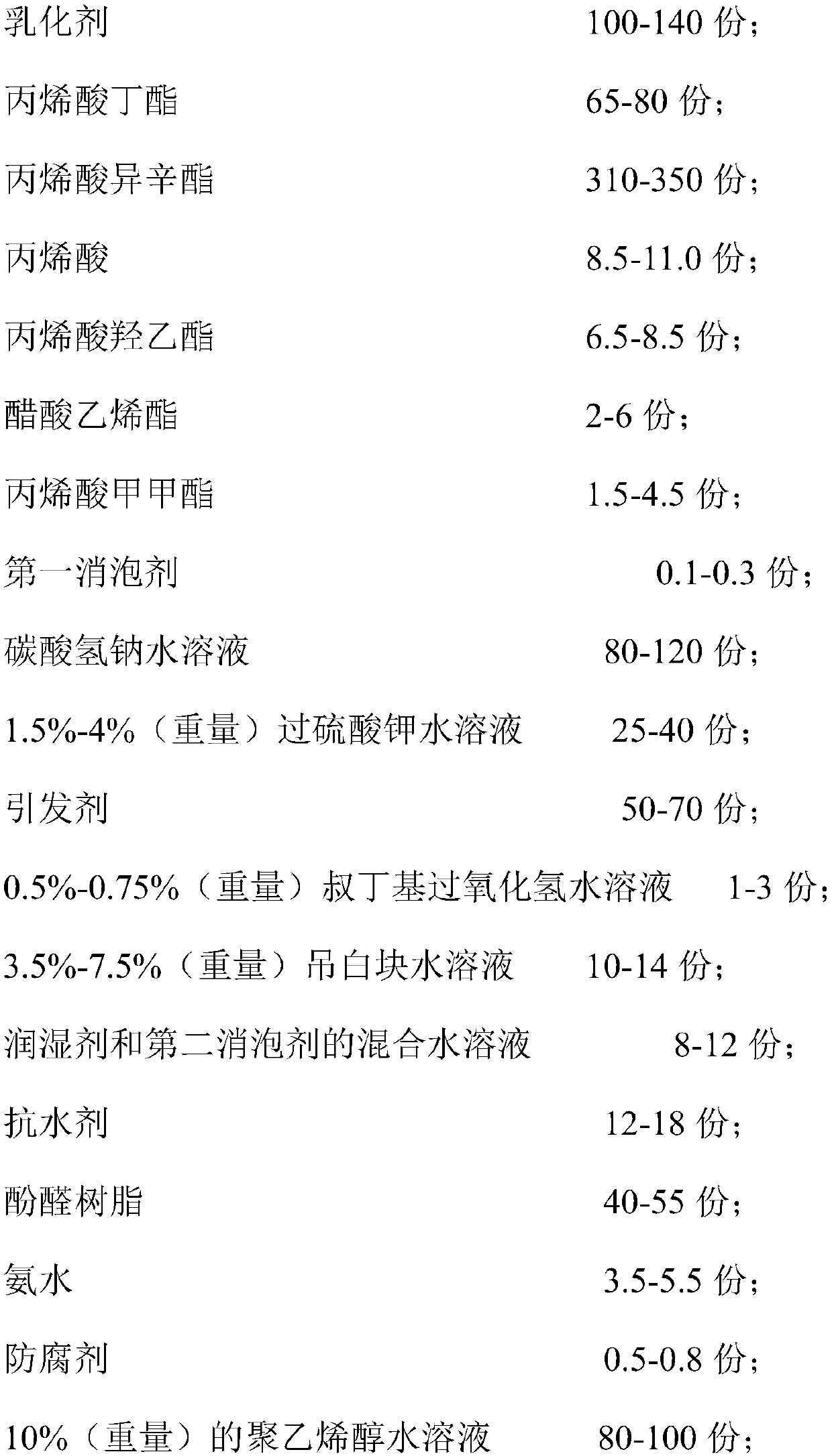

Bonding agent for paper box adhesive tape and processing process thereof

ActiveCN107663435AGood bonding performanceGood tearabilityMacromolecular adhesive additivesEster polymer adhesivesButyl acrylateChemistry

The invention discloses a bonding agent for a paper box adhesive tape and a processing process thereof. The adhesive tape is prepared from the following raw materials including butyl acrylate, iso-octyl acrylate, acrylic acid, hydroxyethyl acrylate, vinyl acetate, methyl acrylate, an antifoaming agent, an initiator and the like. The adhesive tape prepared from the bonding agent has good bonding performance and good easy-to-peel performance; the surface structure of a paper box is not damaged when the adhesive tape is peeled away.

Owner:福建友谊胶粘带集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com