Bonding agent for paper box adhesive tape and processing process thereof

An adhesive and tape technology, applied in the directions of polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of destroying the surface structure of the carton, and achieve the effect of good bonding performance and good tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

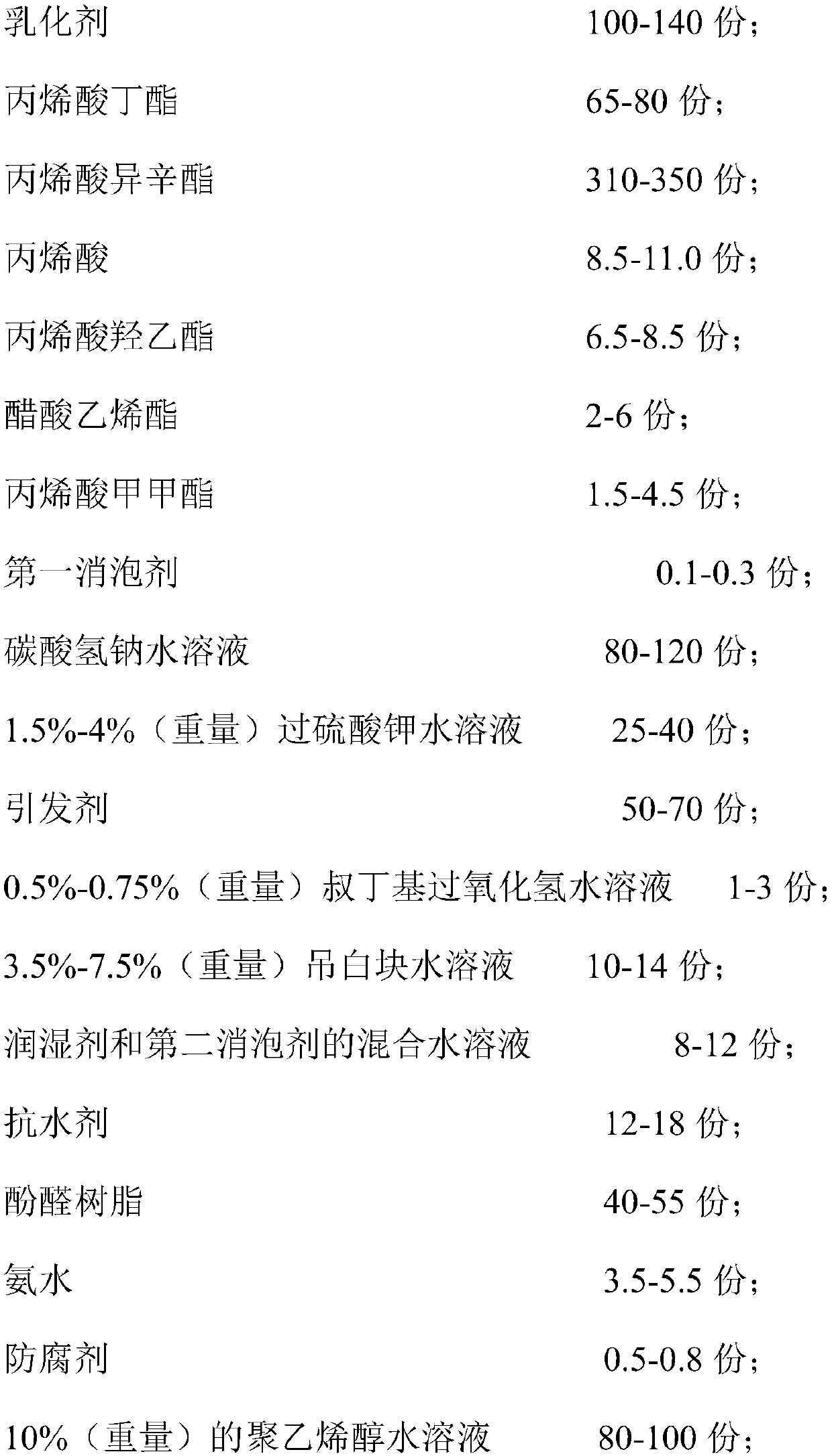

Method used

Image

Examples

Embodiment 1

[0034] A kind of processing technology for the adhesive of carton tape, comprises the steps:

[0035] (1) Add 1.5 parts by weight of ethoxyethanol sulfosuccinate disodium salt, 0.7 parts by weight of polyethoxylated fatty alcohol and 100 parts by weight of deionized water into the emulsification tank and stir for 20 minute;

[0036] (2) 65 parts by weight of butyl acrylate, 310 parts by weight of isooctyl acrylate, 8.5 parts by weight of acrylic acid, 6.5 parts by weight of hydroxyethyl acrylate, 2 parts by weight of vinyl acetate, 1.5 parts by weight of methyl acrylate Add ester and 0.1 parts by weight of polydimethylsiloxane into the container and mix thoroughly, then add into the emulsification tank containing the solution of step (1), and stir evenly to form a pre-emulsion;

[0037] (3) when the temperature is 62 DEG C, adding the concentration of 80 parts by weight to the reactor is an aqueous sodium bicarbonate solution of 0.4% (weight);

[0038] (4) Reactor continues ...

Embodiment 2

[0049] A kind of processing technology for the adhesive of carton tape, comprises the steps:

[0050](1) Add 1.7 parts by weight of ethoxyethanol sulfosuccinate disodium salt, 0.9 parts by weight of polyethoxylated fatty alcohol and 110 parts by weight of deionized water into the emulsification tank and stir for 20 minute;

[0051] (2) 70 parts by weight of butyl acrylate, 320 parts by weight of isooctyl acrylate, 9 parts by weight of acrylic acid, 7 parts by weight of hydroxyethyl acrylate, 3 parts by weight of vinyl acetate, 2 parts by weight of methyl acrylate After the ester and 0.15 parts by weight of polydimethylsiloxane are added to the container and fully mixed, they are added to the emulsification tank equipped with the solution of step (1), and stirred evenly to form a pre-emulsion;

[0052] (3) when the temperature is 58 DEG C, adding the concentration of 90 parts by weight to the reactor is an aqueous sodium bicarbonate solution of 0.6% (weight);

[0053] (4) Rea...

Embodiment 3

[0064] A kind of processing technology for the adhesive of carton tape, comprises the steps:

[0065] (1) Add 1.8 parts by weight of ethoxyethanol sulfosuccinate disodium salt, 0.9 parts by weight of polyethoxylated fatty alcohol and 120 parts by weight of deionized water into the emulsification tank and stir for 25 minute;

[0066] (2) 75 parts by weight of butyl acrylate, 330 parts by weight of isooctyl acrylate, 10 parts by weight of acrylic acid, 8 parts by weight of hydroxyethyl acrylate, 4 parts by weight of vinyl acetate, 2.5 parts by weight of methyl acrylate After the ester and 0.2 parts by weight of polydimethylsiloxane are added to the container and fully mixed, they are added to the emulsification tank equipped with the solution of step (1), and stirred evenly to form a pre-emulsion;

[0067] (3) When the temperature is 65° C., adding 100 parts by weight of an aqueous sodium bicarbonate solution to the reaction kettle is 0.6% (weight);

[0068] (4) Reactor contin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Holding power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com