Electrochromatic epoxy resin polymer and preparation method thereof

An epoxy resin and electrochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of easy peeling off of the film and difficulty in measuring the electrochromic performance, and achieve good bonding performance, good mechanical properties, Good effect of acid and alkali resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

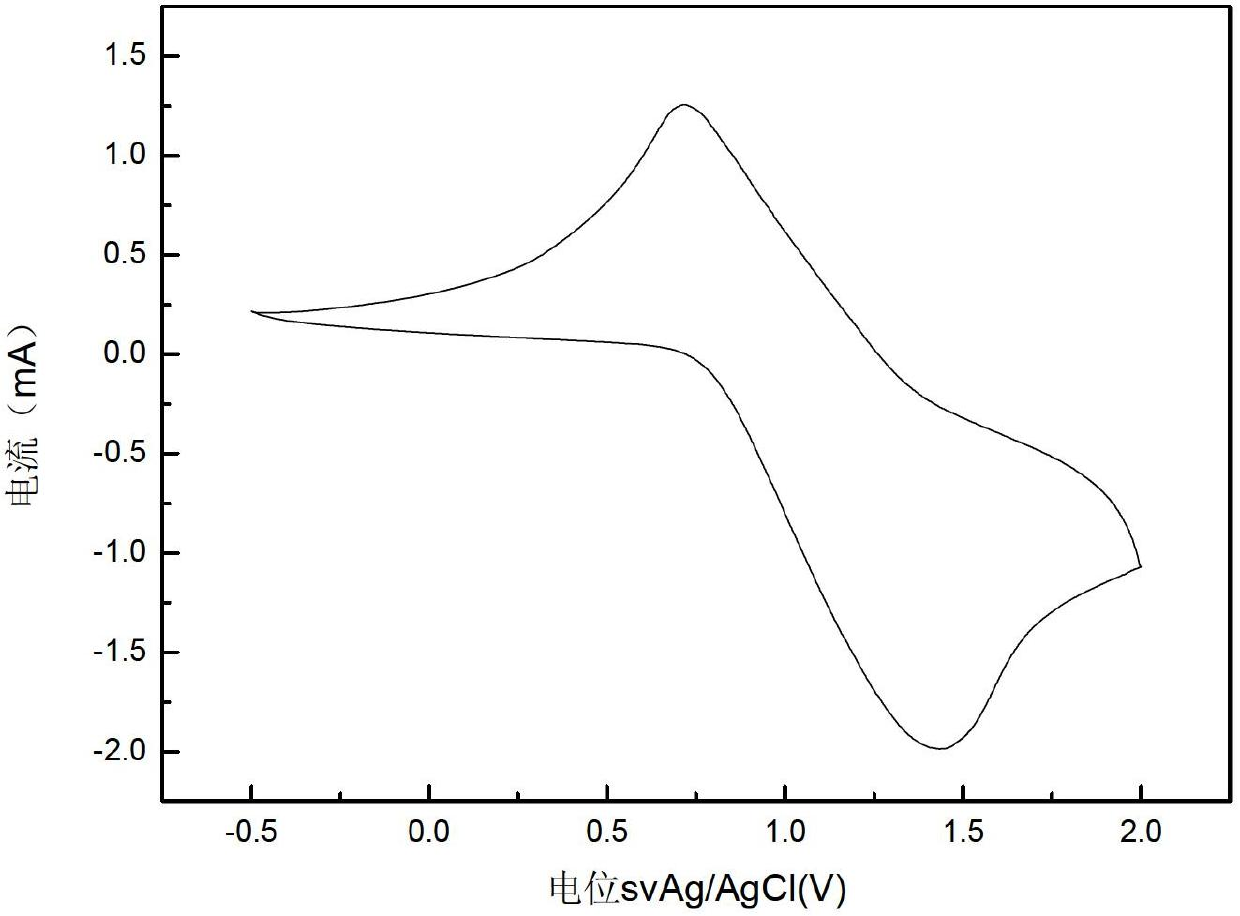

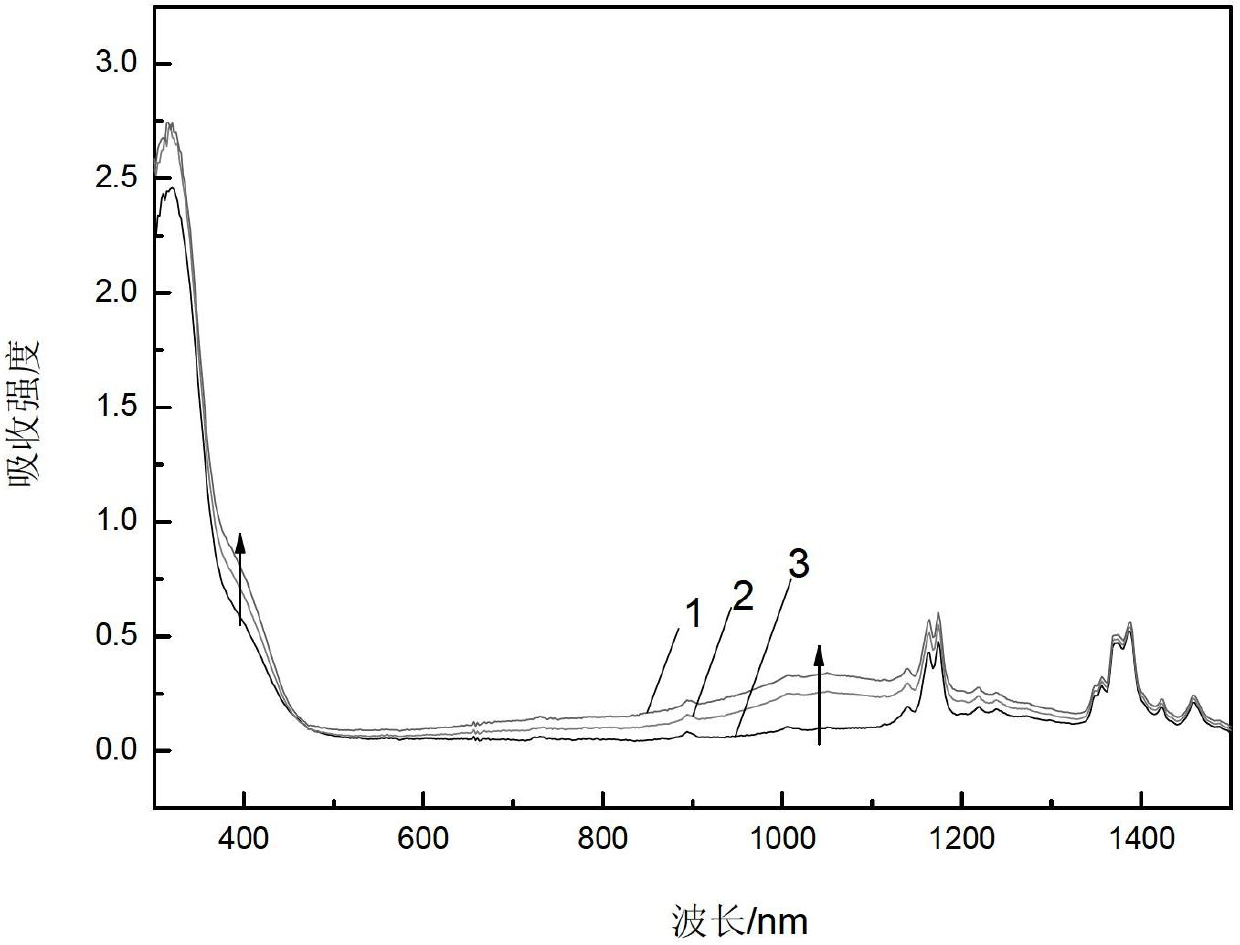

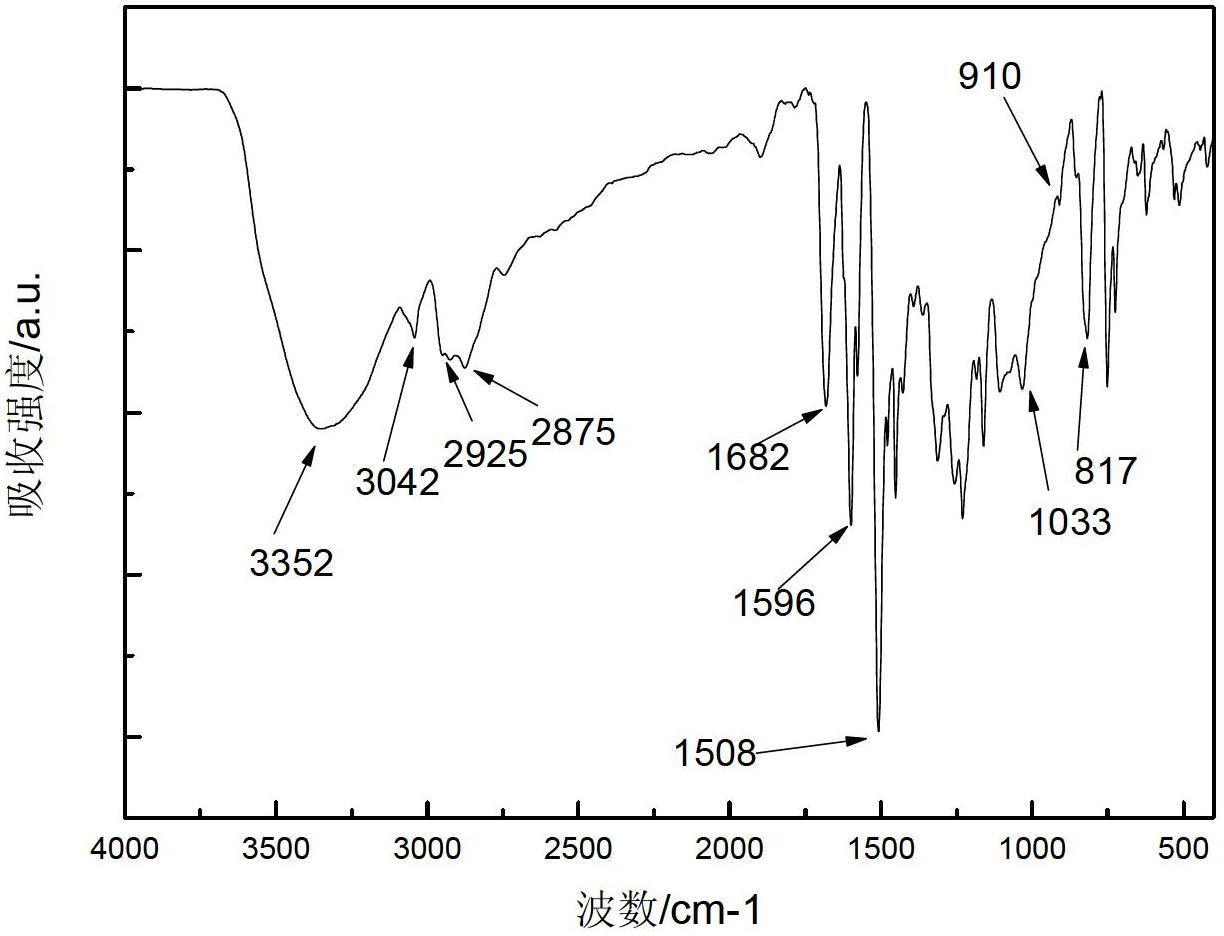

[0036] Embodiment 1: The chemical structural formula of a kind of epoxy resin polymer with electrochromic performance in this embodiment is as follows:

[0037]

[0038] Among them, n is 10~20, R is

[0039]

[0040]

[0041] The epoxy resin polymer of this embodiment has good bonding performance, a shear strength of about 30MPa, good acid and alkali resistance and heat resistance, and the highest service temperature can reach 120°C. It has good mechanical properties, and at the same time has aniline Electrochromic properties. The self-luminous response speed of the epoxy resin polymer in this embodiment is 1000 times that of liquid crystals, and has potential value in the development of molecular designers. The epoxy resin polymer synthesized in this embodiment has an epoxy value of 0.12-0.30 equivalent / 100g, and has adhesive and coating properties.

specific Embodiment approach 2

[0042] Specific embodiment two: a kind of preparation method of epoxy resin polymer with electrochromic performance of the present embodiment is carried out according to the following steps:

[0043] 1. Synthesis of monomers

[0044] a. Mix diaminotriphenylamine derivatives and p-hydroxybenzaldehyde in a molar ratio of 1:2~3 to obtain a mixture; b. Mix the mixture obtained in step a and the solvent in a mass-volume ratio of 0.8-2.1g : Mix 100mL evenly to obtain a mixture, then raise the temperature to 120°C~140°C under nitrogen protection, stir at a speed of 20~50rpm for 12h, when the solvent in the mixture evaporates until the volume of the mixture is the original volume At 1 / 4, stop stirring and collect the remaining 1 / 4 volume of liquid; c. Put the remaining 1 / 4 volume of liquid collected in step b into distilled water, let it stand for 6~12h, and then put it under the condition of vacuum degree of 0.09MPa Suction filtration under low temperature to collect the solid phase...

specific Embodiment approach 3

[0048] Specific embodiment 3: The difference between this embodiment and specific embodiment 2 is that the diaminotriphenylamine derivative described in step 1 is 4,4′-diamino-4″-N-carbazolyltriphenylamine, N, N-bis(4-aminophenyl)-N′,N′-diphenyl-1,4-phenylenediamine, N′-(4-aminophenyl)-N′-(4-ethoxy) Phenyl-1,4-phenylenediamine, N,N′-bis(β-naphthyl)-N,N′-bis(4-aniline)-p-phenylenediamine or N′-(4-aminophenyl) -N'-phenyl-1,4-phenylenediamine, N',N'-diphenyl-N,N'-bis(4-aniline)-p-phenylenediamine, N',N'-diphenyl -N,N'-bis(4-phenylamine)biphenylenediamine or N,N'-bis(α-naphthyl)-N,N'-bis(4-phenylamine)biphenylenediamine.Others are the same as step 2 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com