High-cohesiveness back film of solar cell and processing technology thereof

A solar cell and high-adhesive technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced adhesive performance between the backsheet and EVA, complicated adhesive processing technology, poor adhesive performance, etc., to achieve good Good barrier and bonding performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

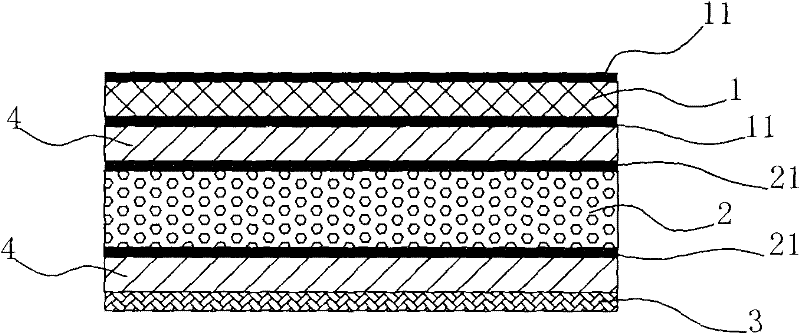

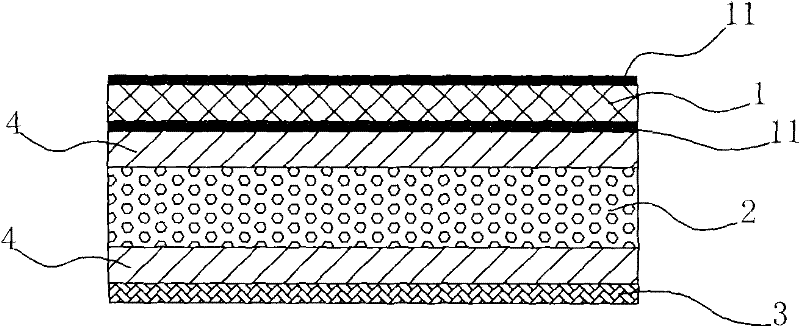

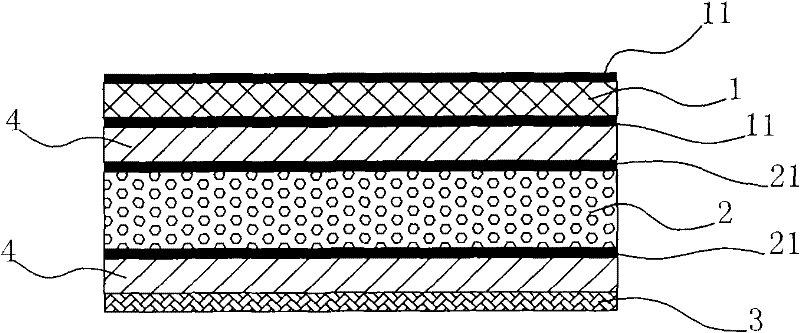

[0040] For embodiment 1, a kind of processing technology of the back film of solar cell with high adhesiveness provided by the present invention mainly comprises the following steps:

[0041] (1) Perform plasma fluorosiliconization treatment on the surface 1 of the fluororesin polymer layer to activate the surface of the substrate, where the substrate refers to the fluororesin polymer layer. Plasma nitrogen silicon oxyalkylation treatment is performed on the surface of the base layer 2 to activate the surface of the base layer 2. The plasma treatment process adopted may be a relatively mature plasma treatment process in the prior art. Here, the fluorosiloxane compound is coated on the surface of the fluororesin polymer layer by spraying, rolling or dipping, so that the surface of the fluororesin polymer layer forms a fluorosiloxane film layer. Coating the nitrogen-siloxane compound on the surface of the base layer 2 by spraying, rolling or dipping, so that the surface of the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com