Patents

Literature

152results about How to "Dense film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

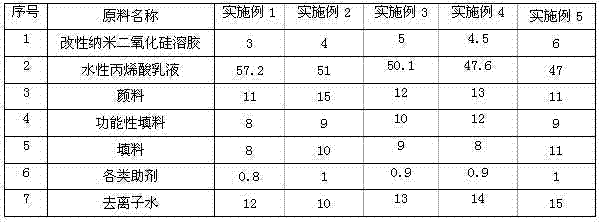

Application of nano silicon dioxide sol in water-based steel structure anticorrosive paint and protective paint

The invention provides application of a nano silicon dioxide sol in a water-based steel structure anticorrosive paint, which comprises the following steps: adding a KH560 silane coupling agent, which accounts for 2-5% of acidic silica sol, into the silica sol, and coupling at 55+ / -5 DEG C to form a modified nano silicon dioxide sol; and adding into a water-based acrylic acid emulsion so as to be applied to the water-based industrial paint for steel structure corrosion resistance. The invention also provides a water-based steel structure anticorrosive paint comprises 3-6% of modified nano silicon dioxide sol, 40-60% of water-based acrylic acid emulsion, 11-16% of pigment, 16-21% of filler, 0.8-1.0% of various assistants and 10-15% of deionized water. The nano silicon dioxide sol is treated by the special technique, and reasonably matched with the emulsion to prepare the nano silicon dioxide sol modified acrylic acid water-based paint, so that the film-forming density and water resistance of the product are greatly enhanced, thereby obviously improving the protective property of the product.

Owner:CHONGQING HAILIAN WATERBORNE COATING

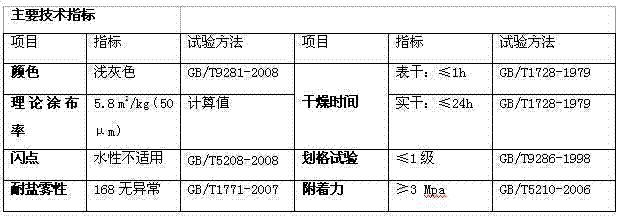

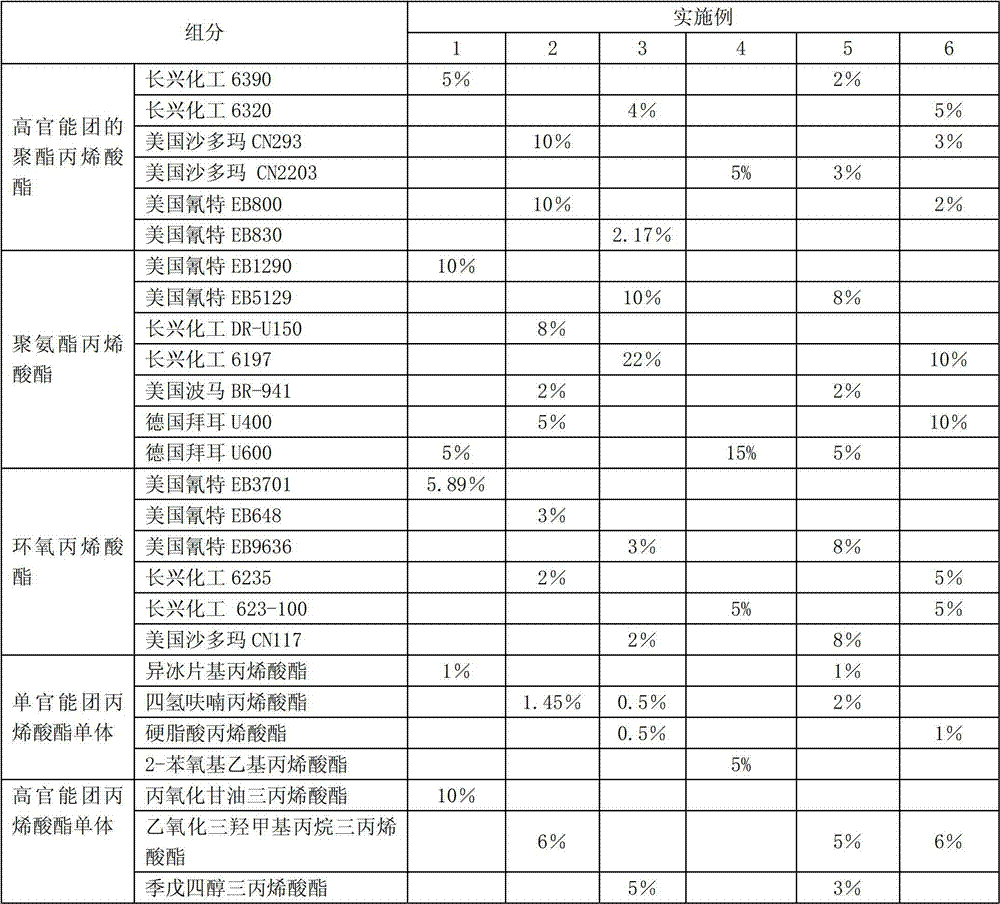

Ultraviolet curing coating composition for tectorial color steel plate

InactiveCN103073990AGood adhesionGood flexibilityPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterWater vapor

The invention discloses an ultraviolet curing coating composition for a tectorial color steel plate. The ultraviolet curing coating composition for the tectorial color steel plate comprises the following components in percentage by weight: 5 to 20 percent of high-functional-group polyester acrylate, 15 to 32 percent of urethane acrylate, 5 to 16 percent of epoxy acrylate, 1 to 5 percent of single-functional-group acrylate monomer, 10 to 25 percent of high-functional-group acrylate monomer, 2 to 5 percent of acrylic acid esterified acrylate, 2 to 6 percent of photoinitiator, 0.1 to 1.5 percent of flatting agent, 0.01 to 0.05 percent of polymerization inhibitor, and 40 to 58 percent of solvent. Compared with the prior art, the product provided by the invention has prominent adhesion fastness with a polyester film, is quick in coating curing and compact in film formation, and has flexibility and high surface hardness; after the coating film is adhered to the steel plate and subjected to cold and hot impact, crack is avoided; and after the film coated steel plate is steamed by high-temperature water vapor, color change and dim of the surface are avoided.

Owner:SHANGHAI WEIKAI CHEM

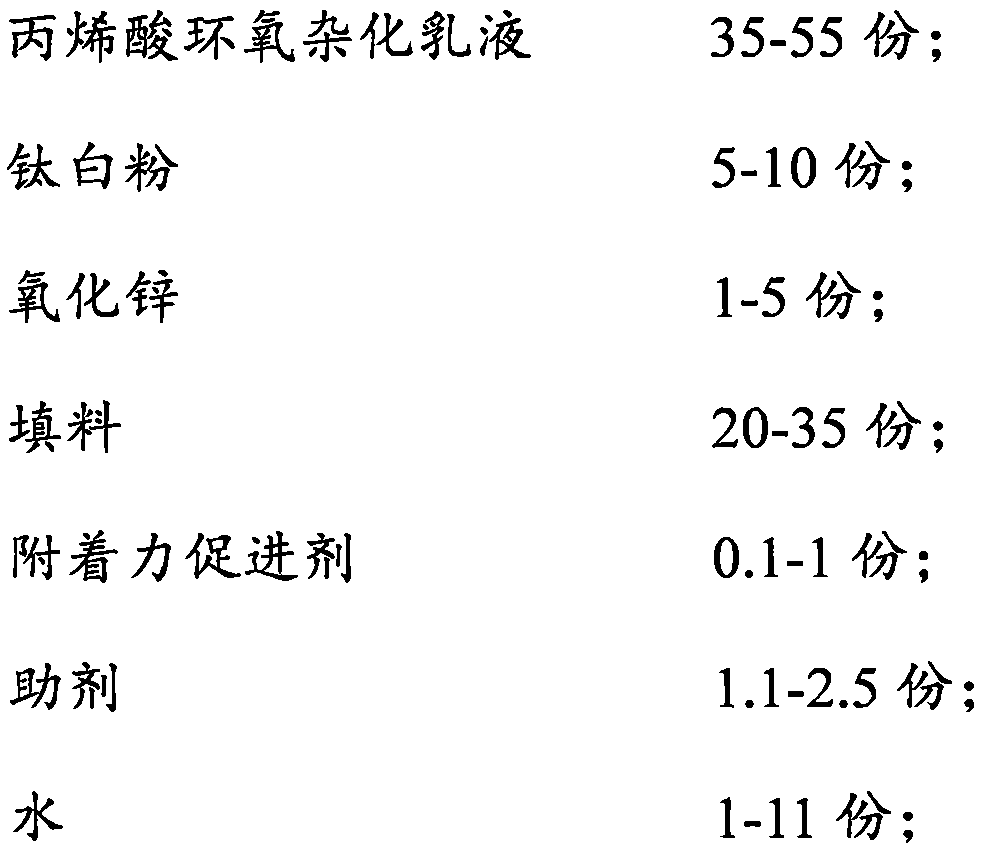

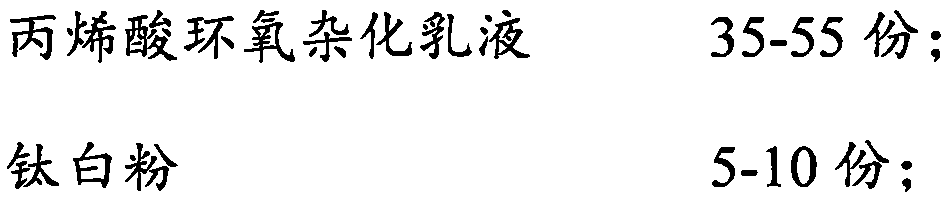

Two-component aqueous acrylate-epoxy resin hybrid coating

The invention discloses a two-component aqueous acrylate-epoxy resin hybrid coating. The epoxy resin part comprises 35-55 parts of an acrylate-epoxy resin hybrid emulsion, 5-10 parts of titanium dioxide, 1-5 parts of zinc oxide, 20-35 parts of a filler, 0.1-1 part of an adhesion promoter, 1.1-2.5 parts of an auxiliary agent and 1-11 parts of water. The curing agent part comprises 1-3 parts of aqueous organic amine. Through use of the hybrid system of an acrylate emulsion and epoxy resin, the anticorrosion coating with a fast drying rate, high film formation density, high weatherability and excellent salt mist resistance is prepared. Through formula optimization and curing agent mixing, the coating is a metal anticorrosion waterproof coating with a long service life, good application properties, good low temperature flexibility, good corrosion resistance, high hardness and good contamination resistance. The two-component aqueous acrylate-epoxy resin hybrid coating effectively prolongs a metal device usage time limit, can be used in terrace paint, saves a cost and provides a value for the society.

Owner:苏州匠品材料科技有限公司

Method for Producing Aqueous Enteric Coating Liquid, Solid Preparation, and Method for Producing Same

InactiveUS20140370091A1High viscosityReduce production efficiencyBiocideOrganic active ingredientsCellulosePlasticizer

An enteric preparation having a film-forming property and acid resistance is provided by using a simple and efficient method without using a special cooling apparatus. More specifically, provided is a method for producing an aqueous enteric coating liquid including the steps of: partially neutralizing an aqueous suspension including a cellulosic enteric material with an aqueous alkali solution, and mixing the partially-neutralized aqueous suspension with a plasticizer. Also provided is a solid preparation including a core including a drug and a coating portion obtained by coating the core with the produced aqueous enteric coating liquid. Further, provided is a method for producing a solid preparation, including respective steps in the method for producing an aqueous enteric coating liquid and a step of coating a core including a drug with the produced aqueous enteric coating liquid.

Owner:SHIN ETSU CHEM IND CO LTD

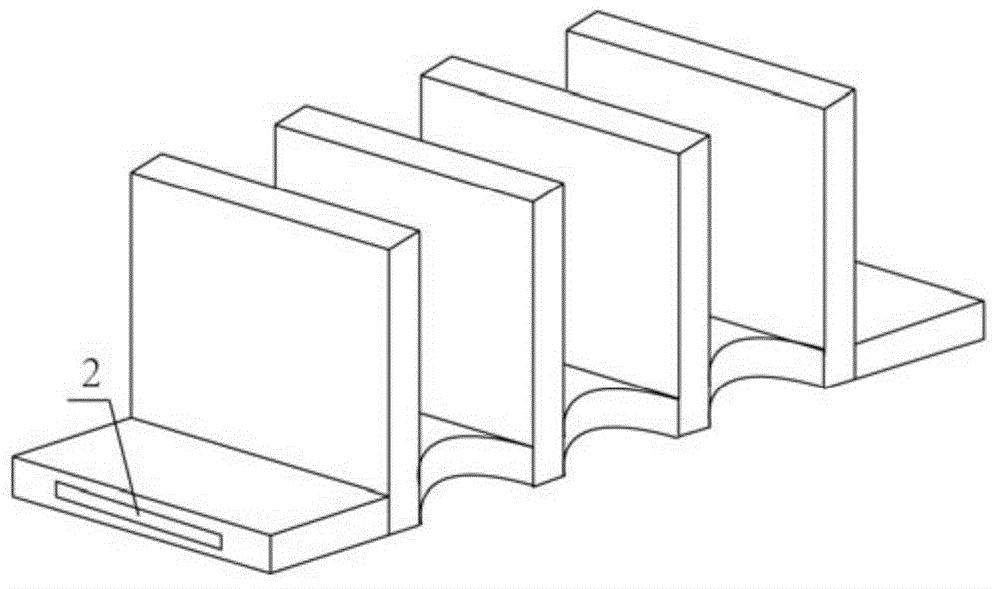

Preparation of flexible high-resistance multi-layer transparent conductive film

InactiveCN101476109AExtended service lifeDense filmConductive layers on insulating-supportsLayered productsHigh energy particleOxide

The invention provides a method for preparing a flexible high resistance multi-layer transparent conductive film which includes steps as follows: forming a titanium dioxide layer, a silicon dioxide layer, an indium tin oxide layer, a zinc-aluminium oxide layer or zinc-gallium oxide layer continuously and orderly on one surface of a flexible base material PET polyester film by using a mid-frequency magnetron sputtering technique; temperature reaching to 120 DEG C or more by using heat energy generated by bombardment continuously and deposition of the high-energy particle on the PET polyester film, and controlling oxide-indium atom ratio between 1.26-1.29 for obtaining the indium tin oxide layer with crystal structure; adhibiting another side of the PET polyester with one side of the second layer PET polyester, setting a hard coating on another side of the second layer PET polyester; forming the titanium dioxide layer and the silicon dioxide layer continuously and orderly on the hard coating by using mid-frequency magnetron sputtering technique. The product has better resistance stability and durability, has advantages of short production flow, high efficiency and low cost. The product is not easy to warp in follow processing flow.

Owner:甘国工

Preparation method of vinyl acetate-acrylate copolymerization emulsion

The invention discloses a preparation method of vinyl acetate-acrylate copolymerization emulsion, comprising the steps of adding 55-65 parts of water by weight, 0.01-4 parts of surfactant by weight, 0.5-2 parts of pH stabilizer by weight and 0.1-1 part of alkyl alcohol by weight into a reaction kettle with an agitator, a thermometer, a nitrogen tube and a reflux condenser, adding part of mixed monomers of mixed chain transfer agents, adequately emulsifying, raising temperature to a reaction temperature, adding part of initiators, reacting for 0.5 hour, and obtaining the seed emulsion when the emulsion has blue lights; dripping the rest mixed monomers into the reaction kettle with the seed emulsion, finishing dripping within 3 hours, synchronously supplementing the rest initiators, after finishing feeding, keeping the reaction temperature, reacting for 3 hours, raising temperature to 85 DEG C, continuously reacting for 0.5 hour so as to reduce the content of residual monomers, and then adding a neutralizing agent, adjusting the pH value of the emulsion to be neutral, cooling down and discharging material, and filtering to obtain the nanometer-sized emulsion. The obtained emulsion has a particle diameter smaller than 100nm and has excellent storage stability and other comprehensive performances.

Owner:SICHUAN UNIV

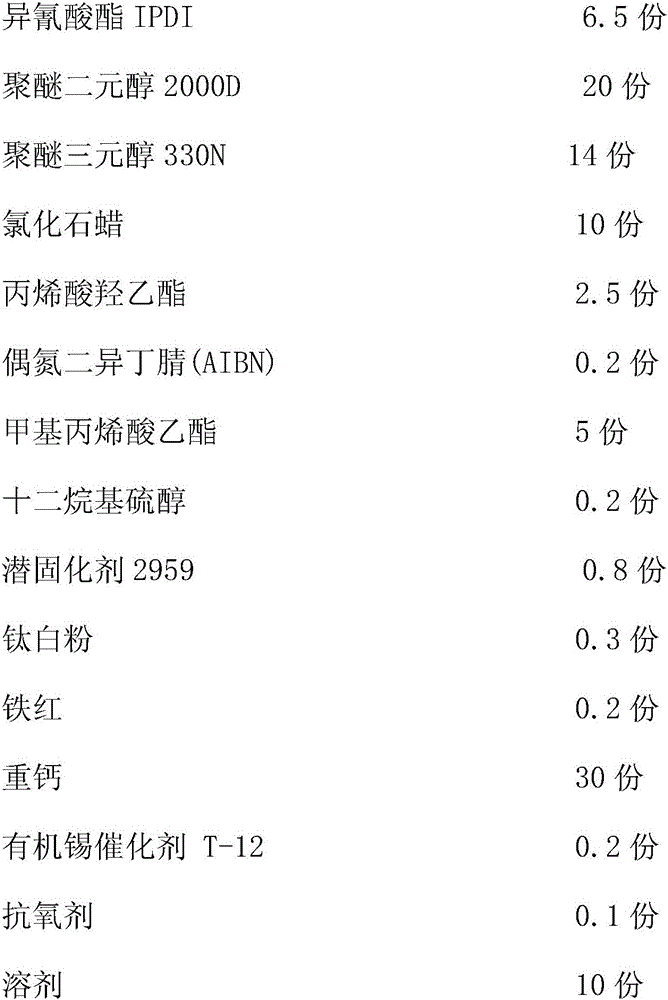

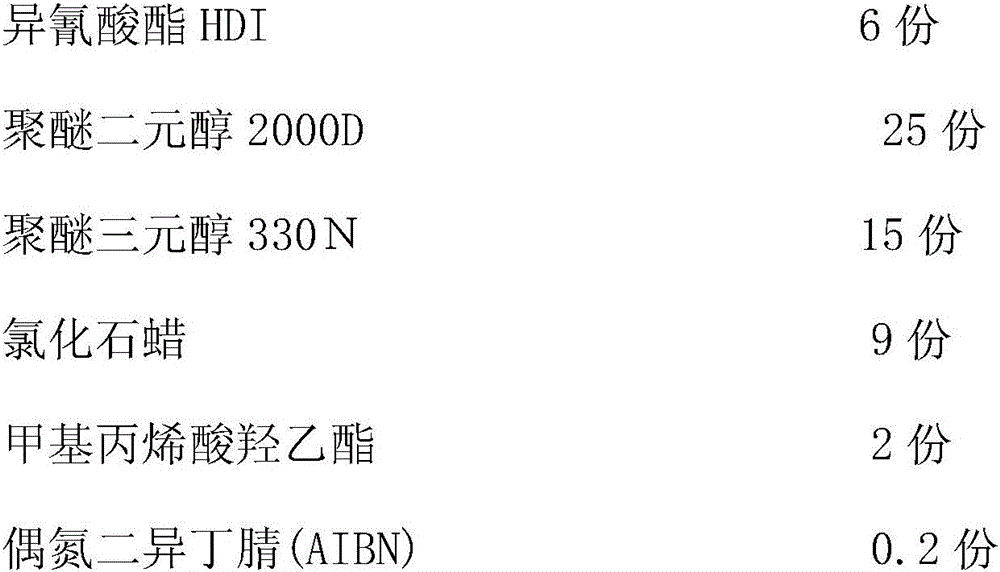

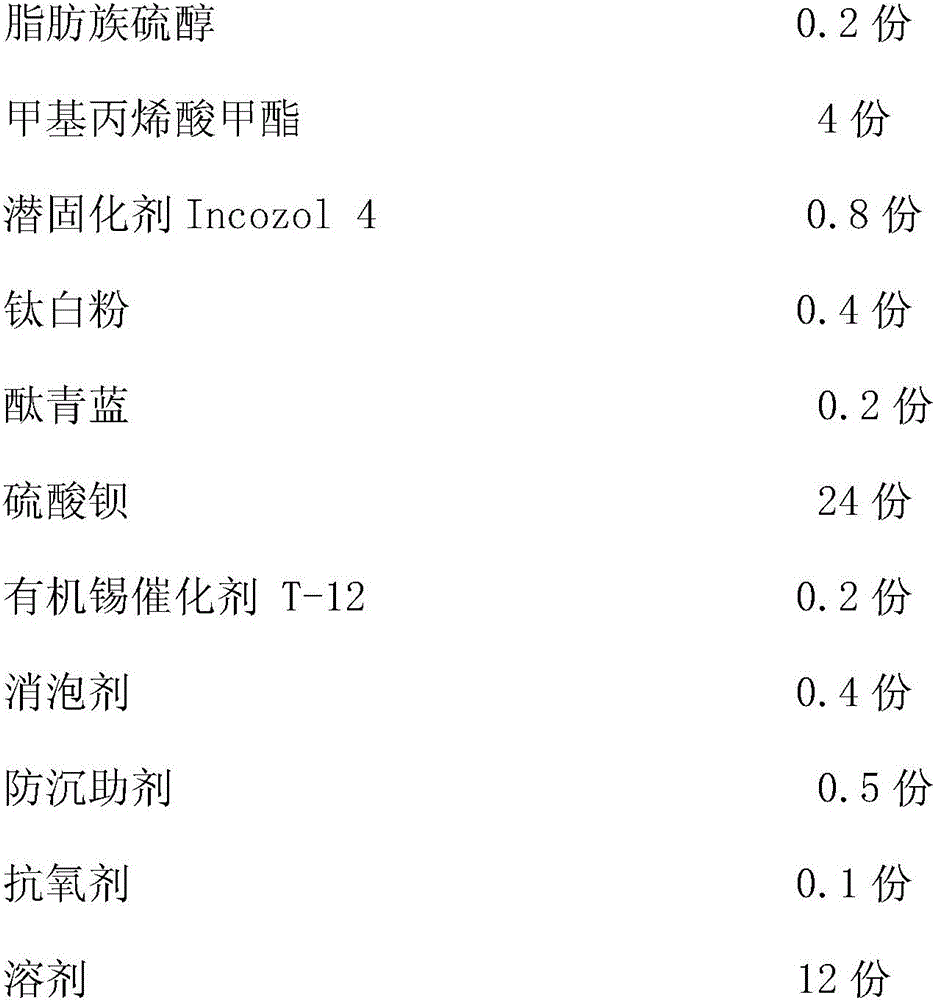

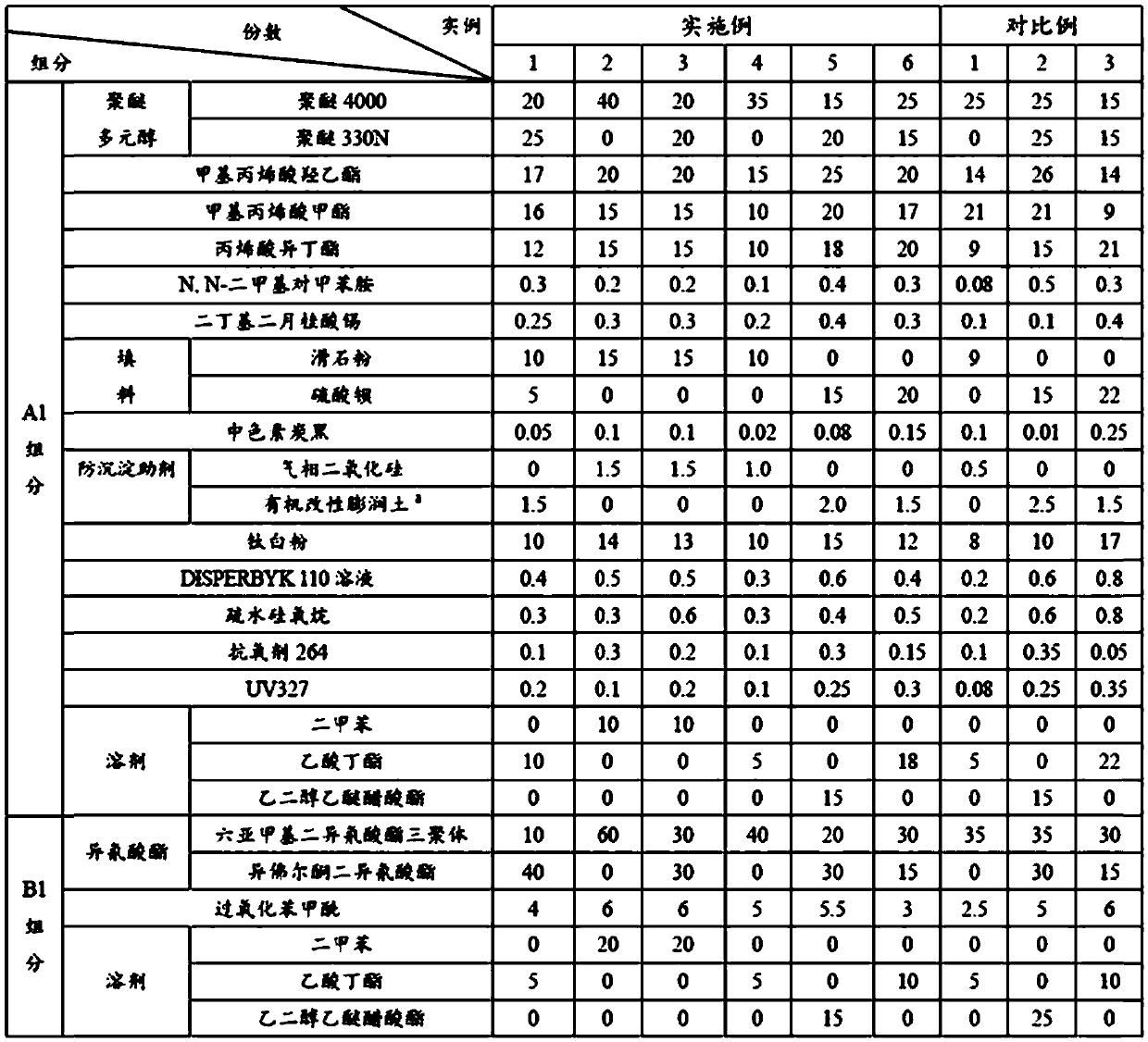

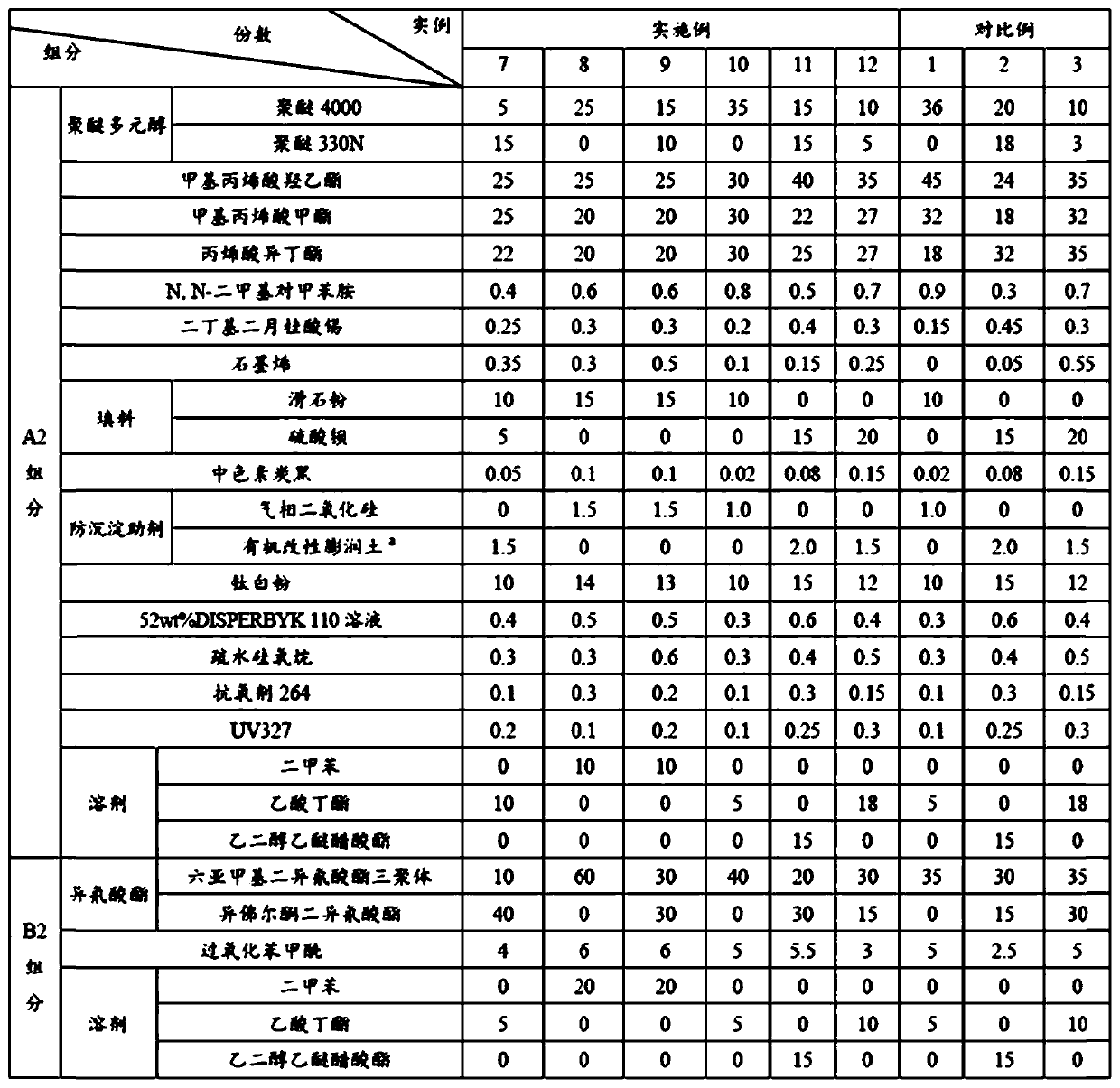

Single-component exposed acrylic acid modified polyurethane waterproof paint and preparation method

ActiveCN106634547AThe molecular weight of the reaction is largeReduce viscosityPolyurea/polyurethane coatingsSolventHydroxy compound

The invention provides single-component exposed acrylic acid modified polyurethane waterproof paint and a preparation method. The modified polyurethane waterproof paint is prepared from the following raw materials in parts by weight: 5 to 20 parts of isocyanate, 20 to 40 parts of hydroxyl terminated polyether, 2 to 10 parts of acrylate, 0.2 to 5 parts of a latent curing agent, 5 to 15 parts of a plasticizer, 5 to 20 parts of a solvent, 10 to 40 parts of pigment filling, 0.2 to 1 part of a catalyst, 0.1 to 1 part of a chain transferring agent, 0.2 to 1 part of an initiator and 0.1 to 1 part of a high-temperature auxiliary agent. The invention further provides the preparation method of the single-component exposed acrylic acid modified polyurethane waterproof paint. The single-component exposed acrylic acid modified polyurethane waterproof paint provided by the invention has the advantages of high strength, dense thin film and reliability of construction; the polyurethane waterproof paint has good weather resistance; the single-component polyurethane waterproof paint has a good waterproof performance, also has excellent weather resistance and high brightness and is suitable for construction of exposed base planes.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Water-soluble environment-friendly anti-rusting agent, and preparation method and application thereof

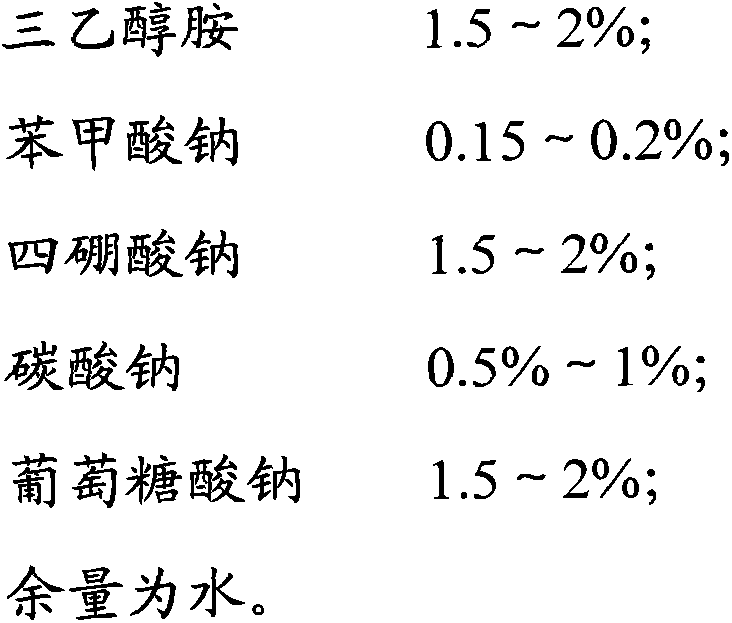

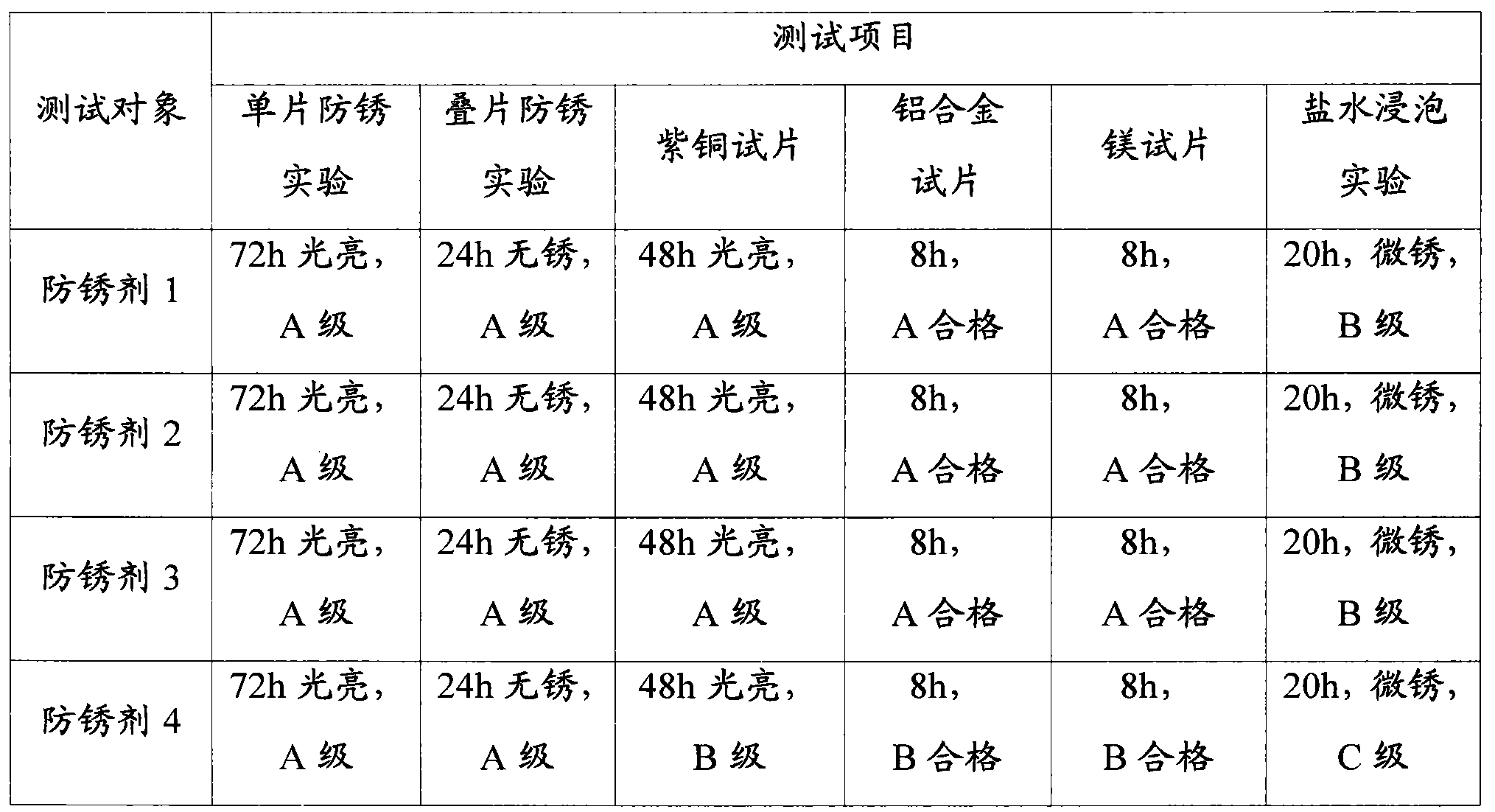

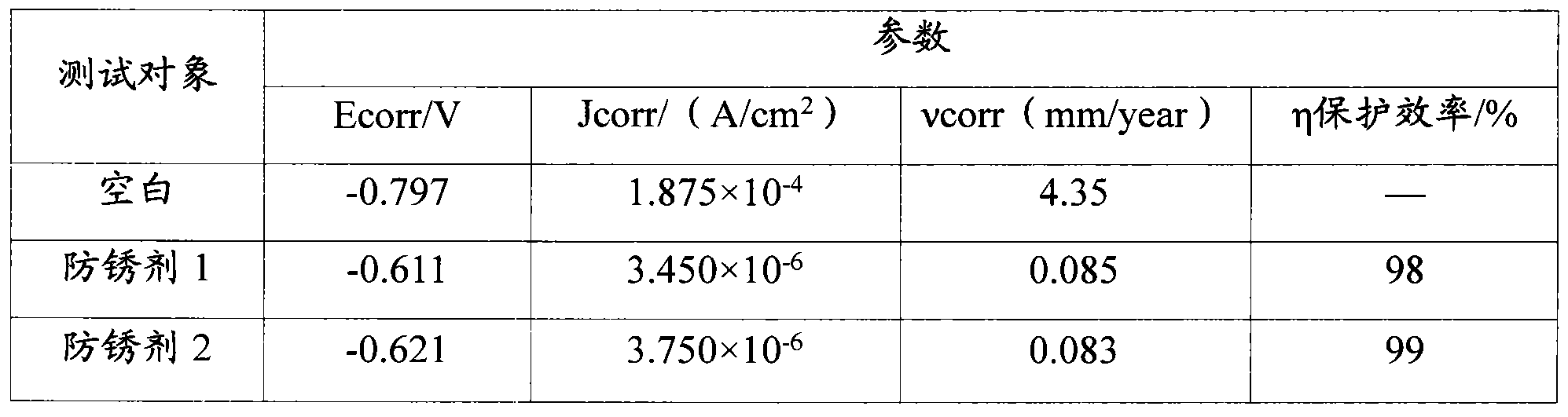

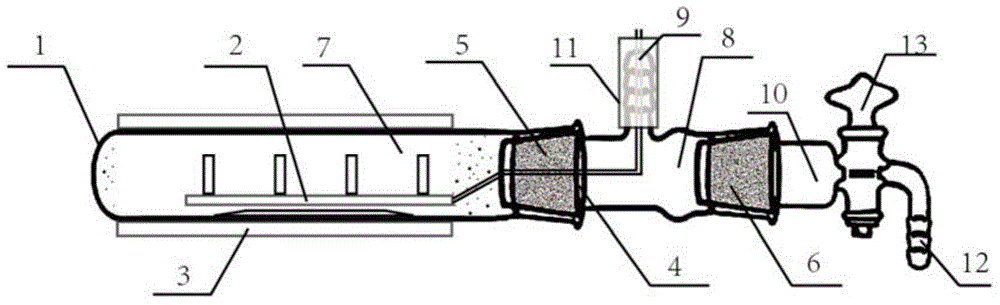

The invention provides a water-soluble environment-friendly anti-rusting agent, and a preparation method and application thereof. The water-soluble environment-friendly anti-rusting agent comprises the following components in percentage by mass: 1.5 to 2 percent triethanolamine, 0.15 to 0.2 percent of sodium benzoate, 1.5 to 2 percent of sodium tetraborate, 0.5 to 1 percent of sodium carbonate, 1.5 to 2 percent of sodium gluconate and the balance of water. The anti-rusting agent is prepared by mixing and uniformly stirring the components, and the pH value of the anti-rusting agent is adjusted to be 8 to 10 by adjusting the amount of each component in a mixing and stirring process. The water-soluble environment-friendly anti-rusting agent can be used for the anti-rusting protection of ferrous metal such as cast iron and steel and nonferrous metal such as copper, aluminum and magnesium, is free of environmental pollution, harmless to a human body, low in cost and easy to prepare, has superior anti-rusting effects, and is applied to the anti-rusting of various kinds of metal, and the required components are simple and easily available.

Owner:SOUTHWEST UNIVERSITY

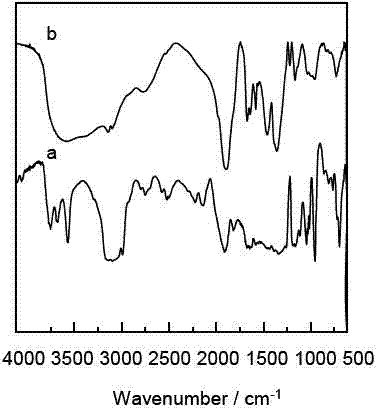

Method for preparing organic ammonium metal halide film

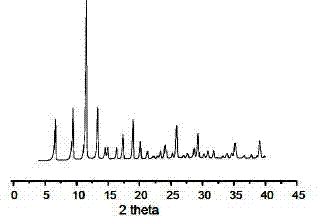

InactiveCN104404478AImprove diffractionStrenuous exerciseChemical vapor deposition coatingChemical reactionCharge carrier mobility

The invention discloses a method for preparing an organic ammonium metal halide film. A half-closed type carrier gas free hot wall type low-pressure chemical vapor deposition method process is adopted to prepare the organic ammonium metal halide film. The method comprises the following steps: firstly, preparing a metal halide (MX2) film on a quartz substrate by using a dry method or a wet method, and transferring the metal halide (MX2) film into a glass tube for annealing, wherein one end of the glass tube is sealed and the other end is grounded; secondly, transferring the energy to organic ammonium (AX) powder inside the glass tube through a hot wall, forming steam blocks through self-diffusion of AX steam in low vacuum, performing chemical reaction on MX2 with a hot substrate to generate the film which is uniform in thickness, good in appearance, high in light absorption rate and smooth in surface, and performing in-situ annealing so as to generate the AMX3 film which is dense in structure and high in crystallinity degree. The method has the advantages that in-situ annealing can be performed in the film formation process, continuous vacuuming is not needed, the preparation time is shortened, the energy consumption is reduced, the filming efficiency is high, the charge capture trap in the film is reduced, and the carrier mobility is increased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for preparing nigrescent phosphatizing solution

InactiveCN101130863ADense filmEasy to prepareMetallic material coating processesPhosphoric acidNickel

The present invention relates to a blackening phosphating solution for phosphating metal surface. Its raw material composition contains (by wt%) 30%-35% of phosphoric acid, 6%-8% of zinc oxide, 12%-20% of zinc nitrate, 0.9%-1.8% of citric acid, 0.2%-0.5% of nickel nitrate, 0.7%-1.1% of sodium fluoroborate, 1.2%-1.9% of sodium m-nitrobenzenesulfonate, 3%-5% of sodium tungstate and the rest is water. Besides, said invention also provides its preparation method and concrete operation steps.

Owner:冯为民

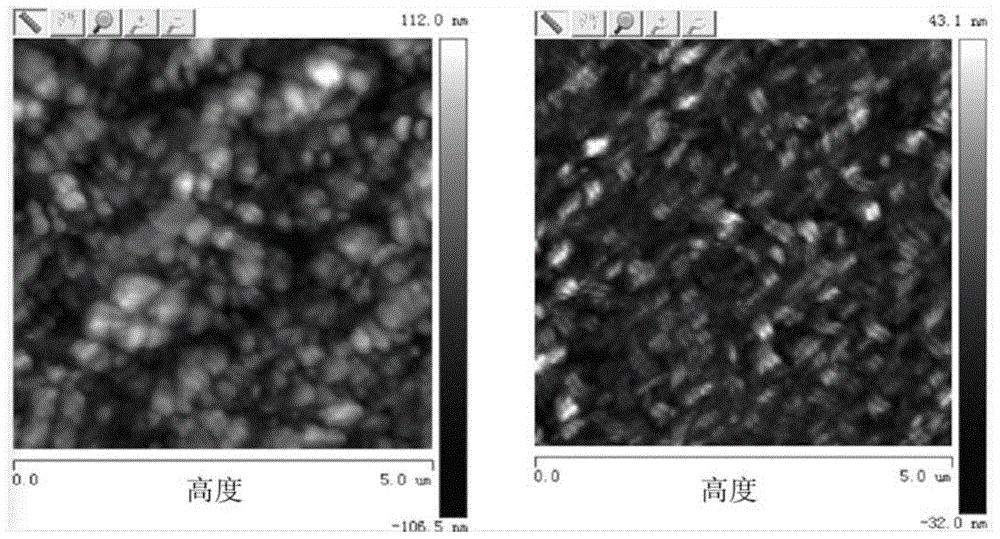

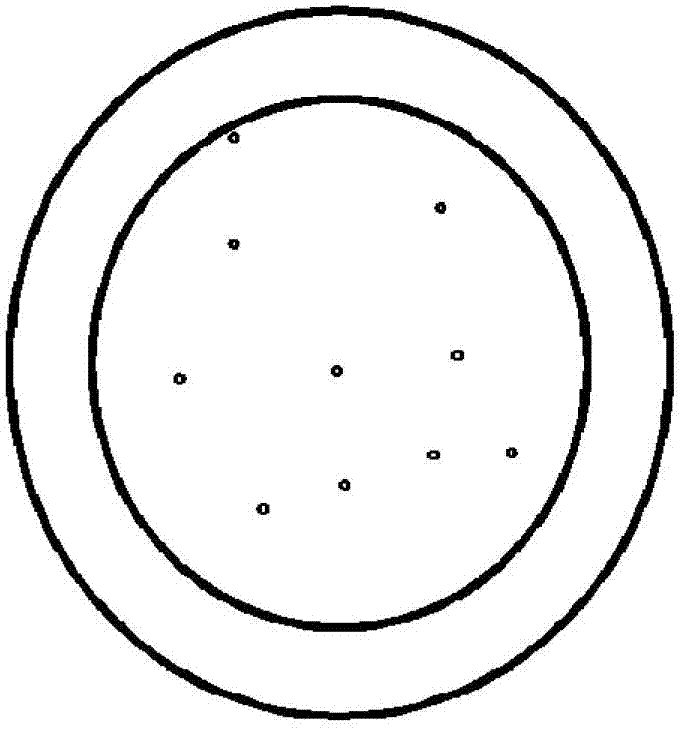

Method for preparing metal organic framework (MOF) membrane

ActiveCN102773025AEasy to manufactureLow costSemi-permeable membranesPolymethyl methacrylateMetal-organic framework

The invention belongs to the field of the preparation of an MOF membrane on a novel membrane growth substrate, and concretely relates to a method for preparing the MOF membrane on an acidified polymethyl methacrylate membrane substrate. The method has the advantages of membrane formation on surfaces of various carriers, expandable application range of the MOF material and the like.

Owner:KEY LAB OF INORGANIC SYNTHESIS & PEPARATIVE CHEM AT JILIN UNIV IN ZHUHAI

Waterproof high-adhesive-force corrosion-resistant coating for ships

InactiveCN104927515AStrong adhesionImprove waterproof performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesiveDefoaming Agents

The invention discloses a waterproof high-adhesive-force corrosion-resistant coating for ships. The waterproof high-adhesive-force corrosion-resistant coating comprises the following materials in parts by weight: 20-50 parts of acrylic emulsion, 5-10 parts of alcohol ester 12, 5-10 parts of alga mud mineral, 1-3 parts of nano titanium dioxide, 10-15 parts of modified kaolinite, 15-20 parts of polyurethane, 3-5 parts of rosin modified phenolic resin, 1-3 parts of polyisocyanate, 1-2 parts of film-forming additive, 15-20 parts of propylene glycol monomethyl ether, 10-15 parts of acetic ether, 2-8 parts of dilauryl thiodipropionate, 1-1.3 parts of leveling agent, 1-2 parts of defoaming agent, 2-4 parts of anti-precipitation agent, 0.5-1.2 parts of silane coupling agent, 1-2 parts of barium sulfate, 1-4 parts of anti-rusting powder, 2-5 parts of talcum powder, 1-3 parts of zinc chrome, 1-3 parts of alkaline type zinc chrome and 1-4 parts of organic azo red. The waterproof high-adhesive-force corrosion-resistant coating disclosed by the invention is excellent in waterproof property, strong in adhesive force, excellent in corrosion resistance and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

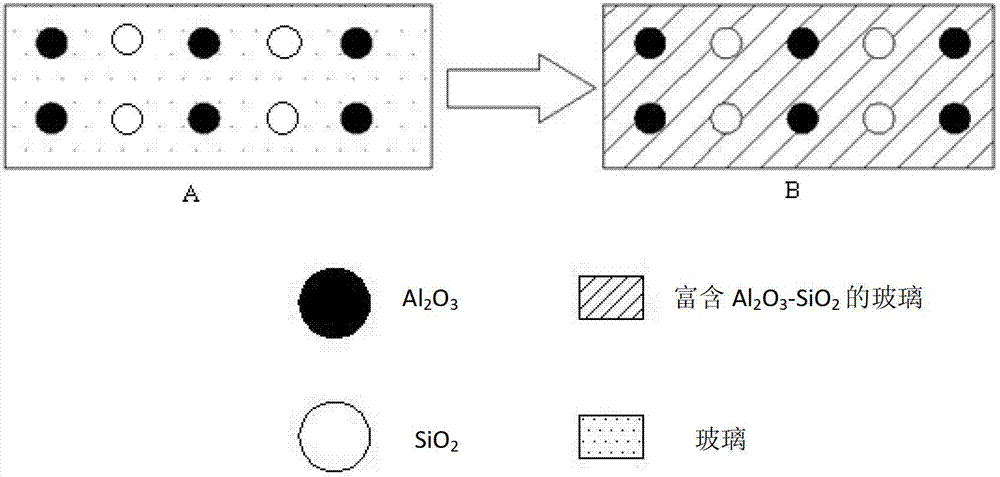

Coating material for platinum material in high-temperature environment and preparation method thereof

The invention provides a coating material for a platinum material in a high-temperature environment and a preparation method thereof. The coating material comprises the following components in percentage by mass: 50-80% of glass powder, 10-30% of aluminum oxide, 5-20% of silicon dioxide and 0-5% of water glass, wherein the silicon dioxide is introduced by means of silica sol or silicon dioxide granules and silica sol. The preparation method of the coating material comprises a sintering method and a water dispersion method. According to the invention, the generation of bubbles in glass caused by hydrogen penetration and the volatilization loss of the platinum material subjected to oxidation corrosion can be prevented, thereby achieving certain practical meanings for improving the yield of a production line and prolonging the life of a glass manufacturing device.

Owner:IRICO DISPLAY DEVICES

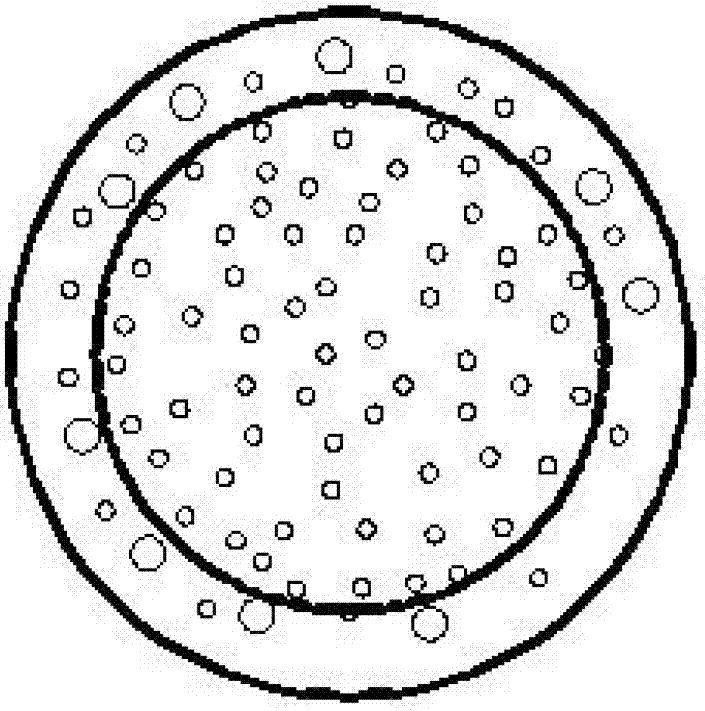

Transforming anti-corrosion enhanced coating for absorbing environmental corrosive substances

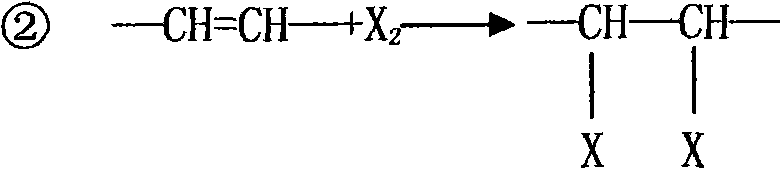

InactiveCN101709168AIncreased chlorine contentDense filmRubber derivative coatingsAnti-corrosive paintsHydrogen halideVoid ratio

The invention relates to an enhanced novel anti-corrosion coating, which contains a certain amount of non-aromatic pi-bonding substances in addition to a film-forming resin, wherein the non-aromatic pi-bonding substances can absorb corrosive substances (hydrogen halide, halogen gas and the like) in the environment and react with the corrosive substances to transform into a part of a film-forming substance, so the halogen content in a lacquer film is higher, empty spaces in the film are filled, and the void ratio, the water absorption and the penetrability of the film are greatly reduced to improve the corrosion resistance of the coating.

Owner:贵阳神迪科技有限公司

Surface-modified coating and preparation method and application thereof

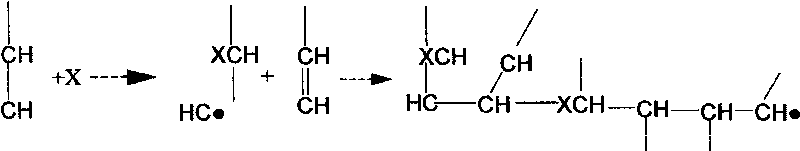

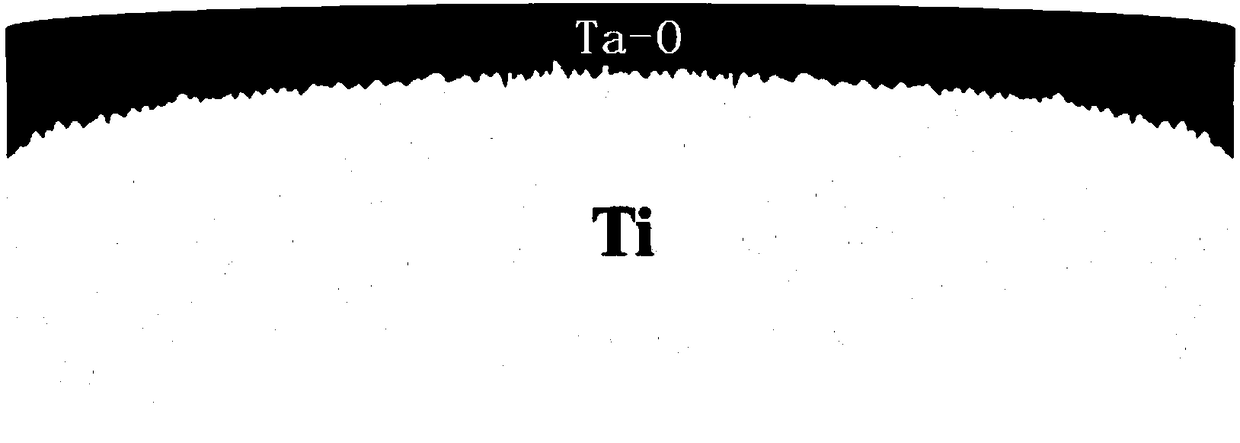

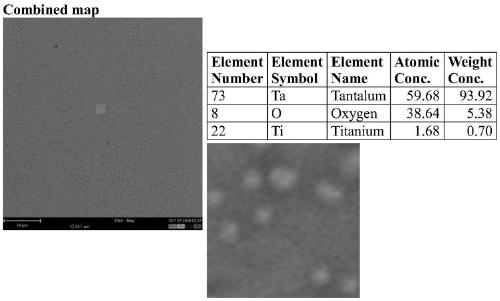

ActiveCN109487199AGood chemical stabilityIon dissolution is smallMolten spray coatingVacuum evaporation coatingIon beam sputteringWear resistance

The invention discloses a surface-modified coating and a preparation method and application thereof. The surface-modified coating comprises from inside to outside an inner-layer porous titanium coating and an outer-layer Ta-O layer. The preparation method for the surface-modified coating comprises the steps that titanium powder is adopted as a raw material, and plasma spraying is adopted so that aporous-structured titanium coating is prepared on the surface of a base material; and tantalum is adopted as a target material, through oxygen, an ion beam sputtering coating method is adopted, and aTa-O coating is prepared on the surface of the porous titanium coating. The surface-modified coating can be used for preparing a repair and substituent material of hard tissues. The surface-modifiedcoating has both good wear resistance and anti-corrosion property and low elastic modulus; and in addition, the surface-modified coating is bonded closely with the base material and small in stress.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

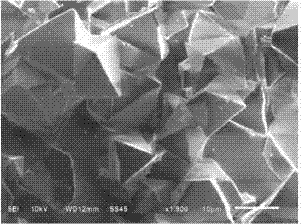

Process for preparing rare earth nano-films by sol-gal method

InactiveCN1544697AEvenly distributedDense filmPretreated surfacesSolid/suspension decomposition chemical coatingRare earthRoom temperature

The invention is a preparing method of rare-earth nano film by sol-gel method. It preprocesses a monocrystalline silicon slice, soak the silicon slice in the royal water, heats the royal water by electric cooker, naturally cools at room temperature, takes out the silicon slice, repeatedly washes by deionized water, then places in dry vessel for drying; or preprocess the glass substrate slice by hydroxylation, processes by Priahan solution at room temperature, drip-washes by a large amount of deionized water and dries; dips the processed substrate slice in the prepared sol solution, placing still and then pulls, then places the substrate slice in the drier, puts in the oven for drying or repeats the above mentioned operations to prepare multilayer films; places the monocrystalline silicon slice or glass substrate slice covered with films into muffle for preserving heat, slowly raises the temperature to 500 deg.C, preserves heat and naturally cools to room temperature, and obtains the rare-earth nano film at once. It can reduce the friction coefficient from 0.5 without any film to 0.2, and has completely friction reducing action.

Owner:SHANGHAI JIAO TONG UNIV

Coating and partial freezing preservation method for hairtail

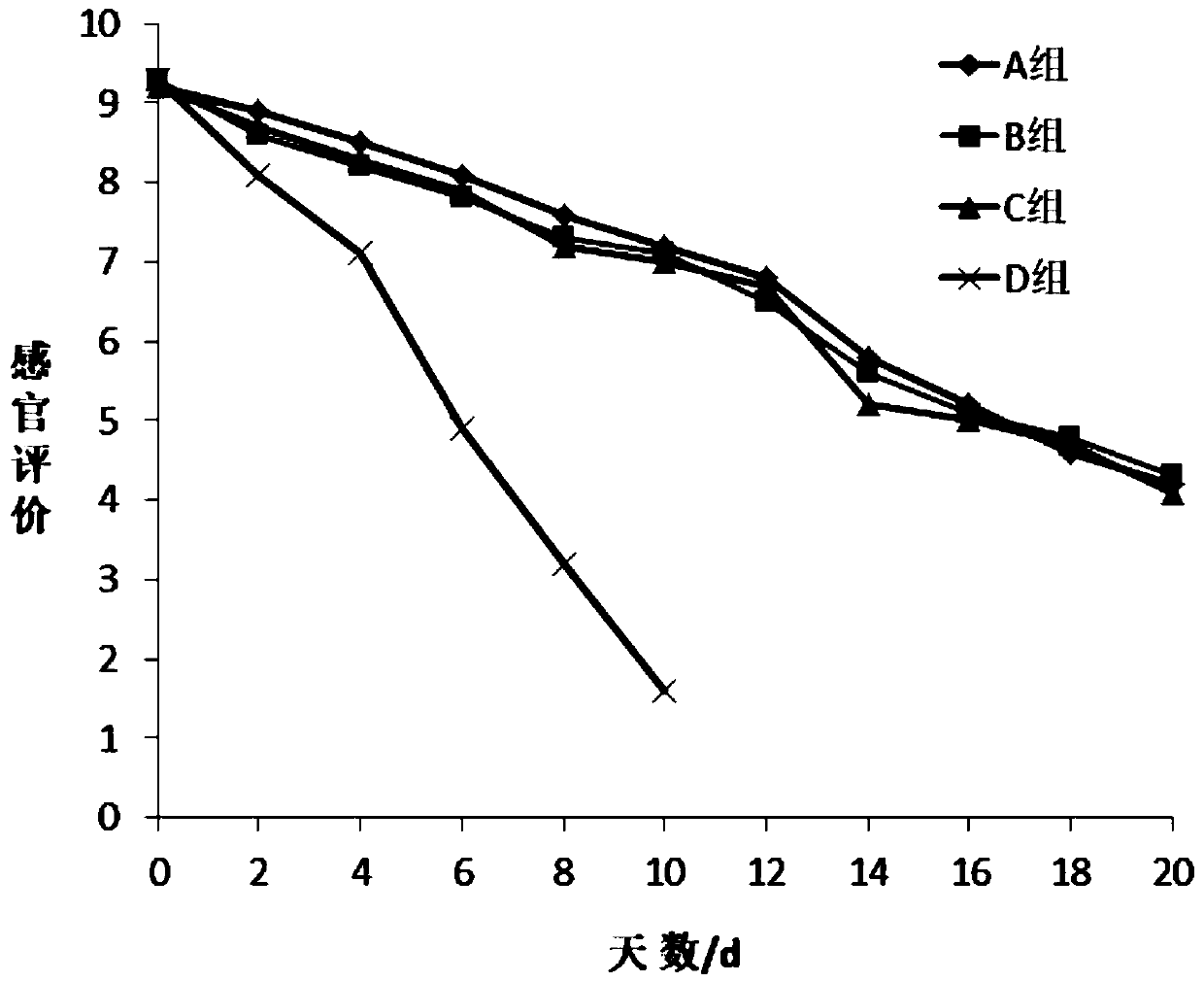

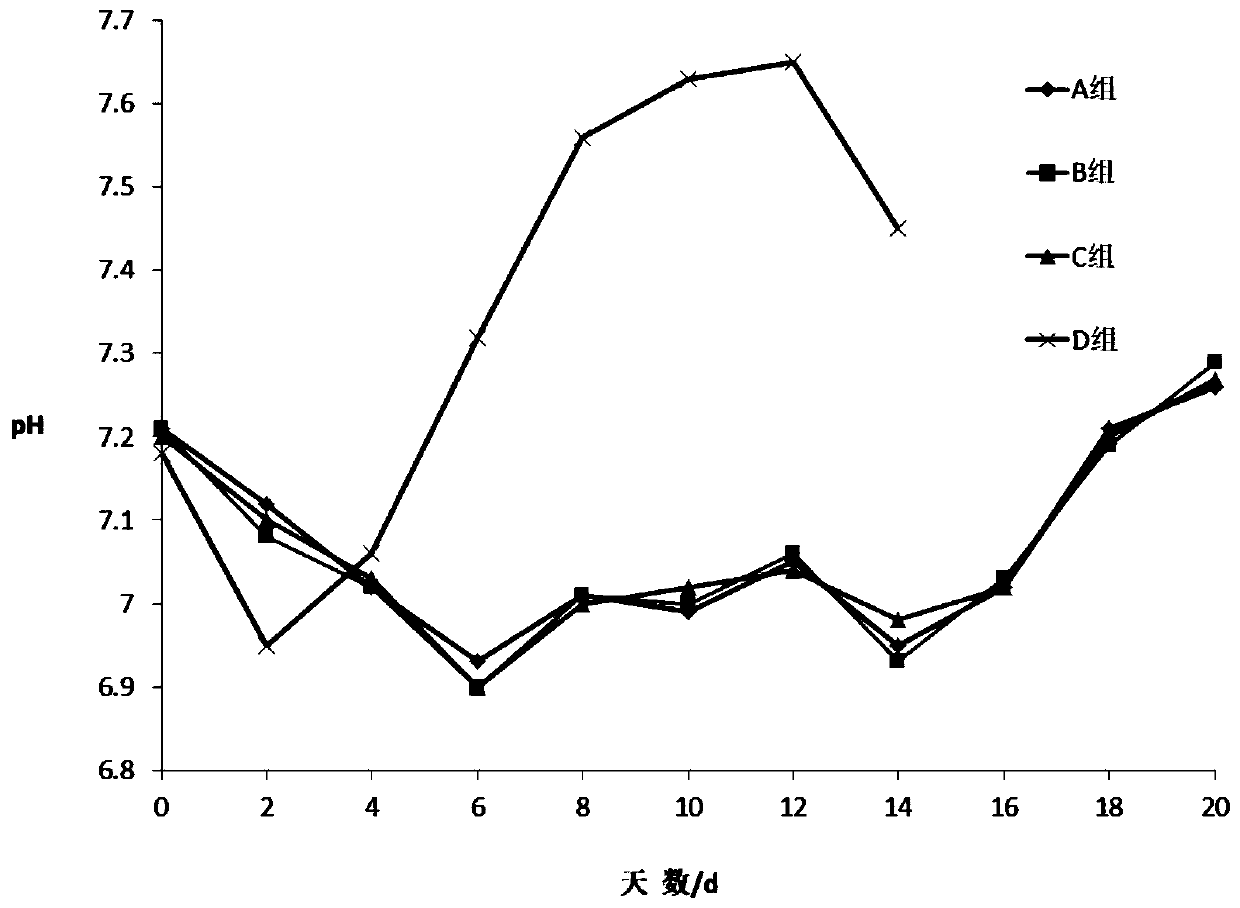

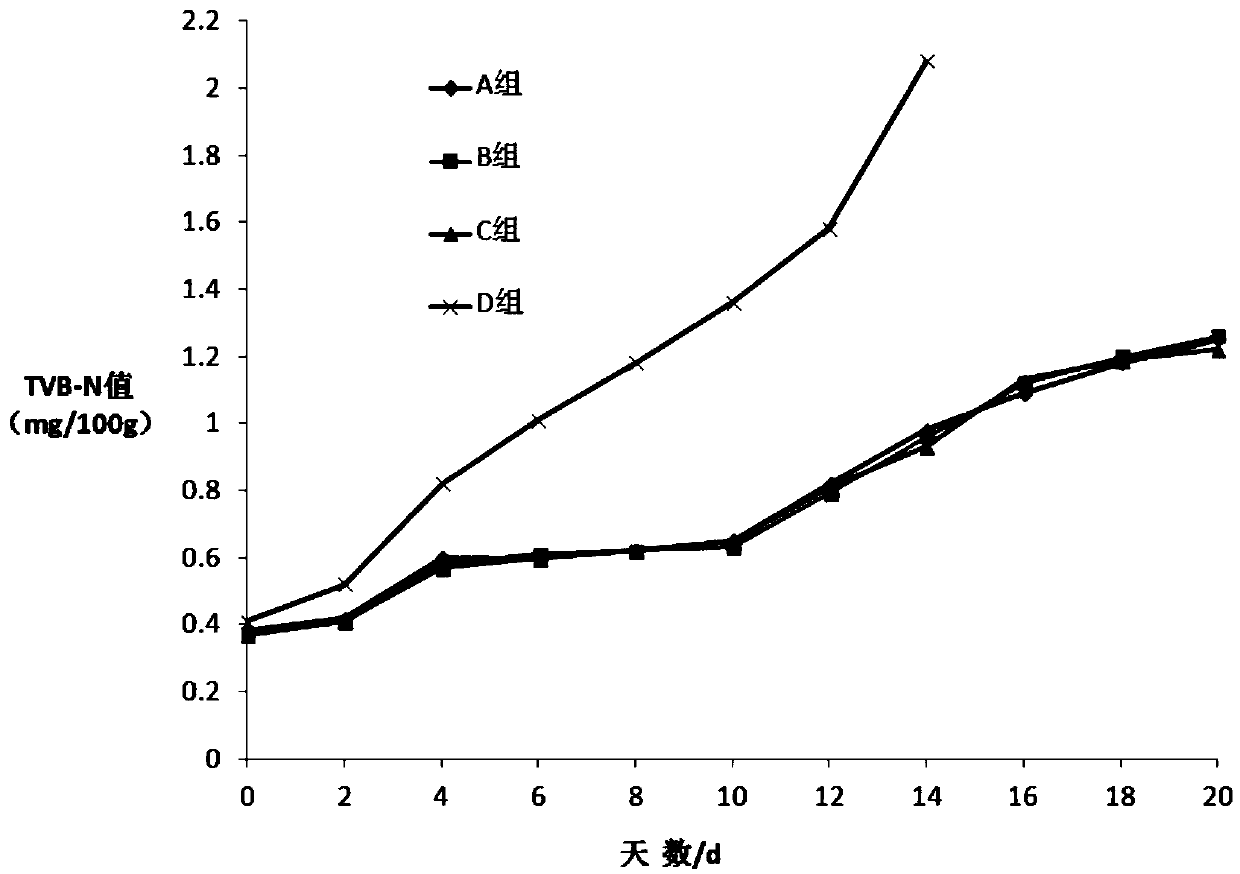

ActiveCN109566718AAvoid crackingInhibition of reproductionFood freezingMeat/fish preservation by freezing/coolingOperabilityPreservation methods

The invention discloses a coating and partial freezing preservation method for hairtail. The method comprises the following steps of (1) carrying out pretreatment; (2) carrying out sterilization; (3)carrying out surface dewatering; (4) carrying out dipping and coating; (5) carrying out vacuum cooling and drying; (6) carrying out low-temperature quick-freezing; and (7) carrying out partial freezing cold storage. The coating and partial freezing preservation method for the hairtail has the advantages that the hairtail is preserved through a combined coating and partial freezing preservation technology, the steps are simple, the operability is high, the juice loss rate in the unfreezing process of the hairtail can be decreased, the physicochemical properties and the sensory quality of the hairtail can be well maintained, and the shelf life of storage and sale of the hairtail in the partial freezing state can be obviously prolonged.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

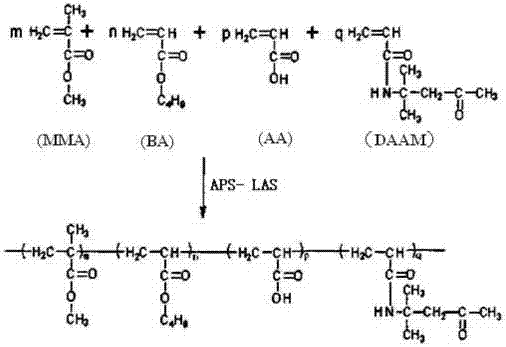

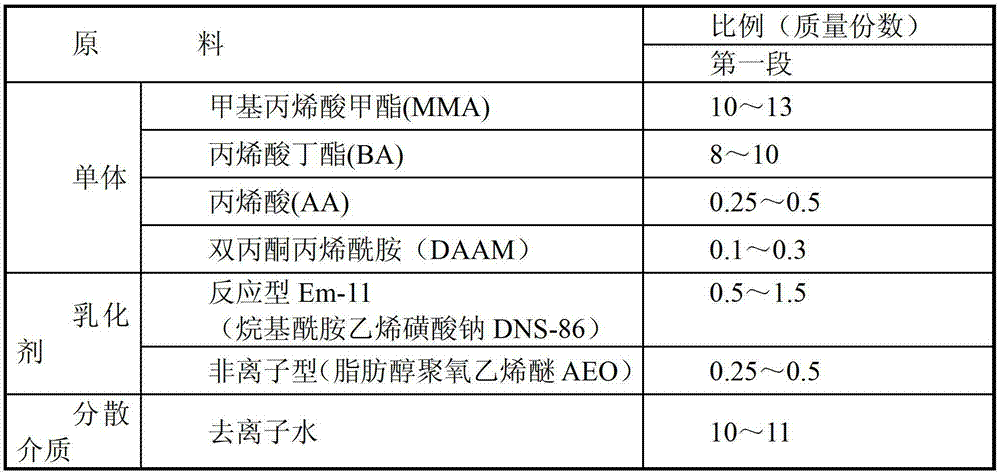

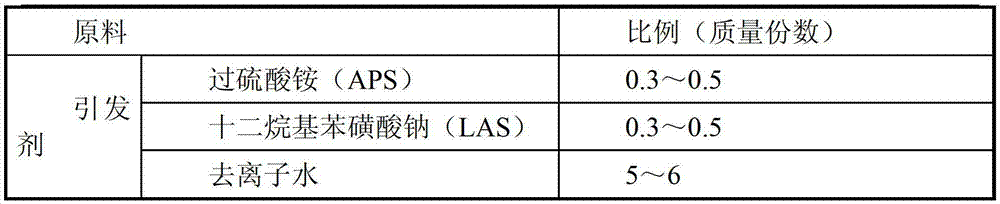

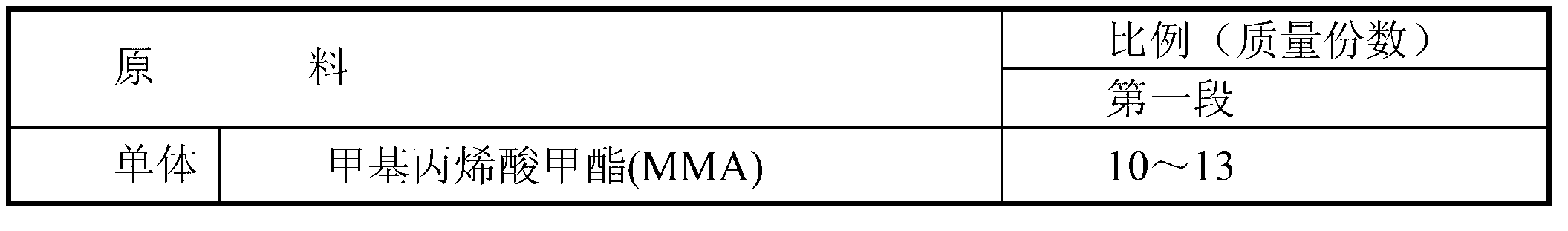

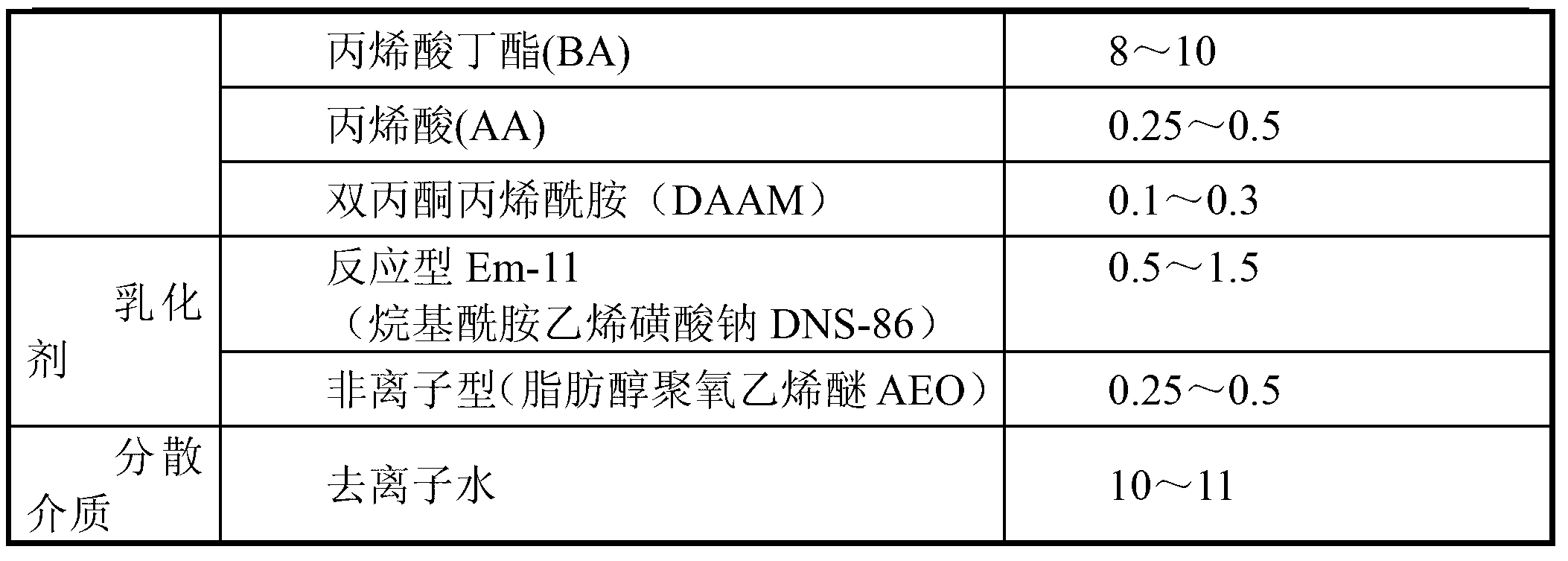

Water-based polyacrylate emulsion

The invention discloses a water-based polyacrylate emulsion, which is prepared from a preliminary emulsion, a seed emulsion, a secondary emulsion, 10% adipic dihydrazide aqueous solution and ammonia water, wherein the preliminary emulsion is prepared from methyl methacrylate, butyl acrylate, acrylic acid, diacetone-acryloamide, sodium alkyl amide vinyl sulfonate, fatty alcohol-polyoxyethylene ether and de-ionized water; the secondary emulsion is composed of monomers and an emulsifier, and the monomers include methyl methacrylate, butyl acrylate, acrylic acid and diacetone-acryloamide; and the emulsifier is prepared from fatty alcohol-polyoxyethylene ether and de-ionized water. The water-based polyacrylate emulsion is characterized in that diacetone-acryloamide (DAAM) is introduced into the system and simultaneously, adipic dihydrazide (ADH) is introduced to modify the branch chain so that the cross-linking sites in a system can be increased through introduction of diacetone-acryloamide (DAAM) and adipic dihydrazide (ADH) to modify a branch chain, so that the self-cross-linking performance of water-based PA can be improved and medium-temperature self-cross-linked base slurry is formed; and the roasting temperature can be appropriately reduced by 10-30 DEG C so that energy source can be saved.

Owner:长兴三伟热熔胶有限公司

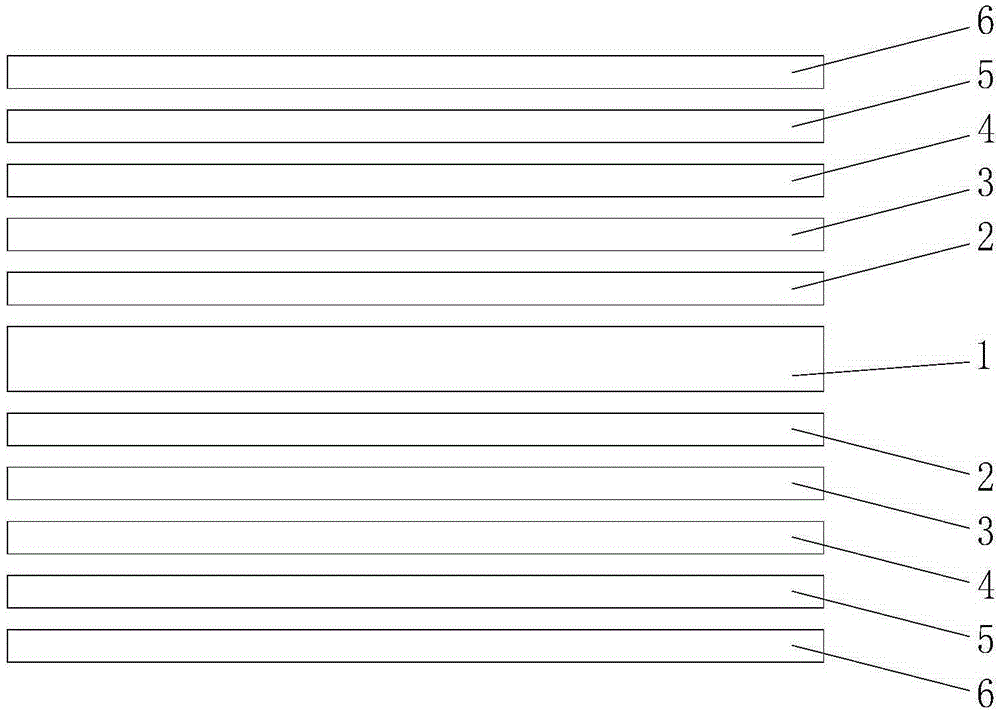

Blue light filtering, water and oil dirt preventing and wear resisting lens and preparation method thereof

The invention relates to a blue light filtering, water and oil dirt preventing and wear resisting lens and a preparation method thereof. The lens comprises a substrate, and the inner surface and the outer surface of the substrate are provided with first films, second films, third films, fourth films and fifth films sequentially and symmetrically from inside to outside. The first films are titanium oxide layers, and the thickness ranges from 10 nm to 100 nm. The second films are silicon dioxide layers, and the thickness ranges from 50 nm to 100 nm. The third films are metal layers, and the thickness ranges from 5 nm to 20 nm. The fourth films are high-hardness layers, and the thickness ranges from 10 nm to 50 nm. The fifth films are fluoride layers, and the thickness ranges from 3 nm to 10 nm. The preparation method comprises the following steps that 1, the substrate is washed; 2, the inner surface and the outer surface of the substrate are coated with the films respectively. The lens can effectively filter out 33% of harmful blue light and dazzling light or above, visual fatigue can be effectively relieved, the wear resistance of the lens can be remarkably improved through the high-hardness layers, and the fluoride layers have the good hydrophobicity and oil dirt preventing function.

Owner:OURLOOK ZHANGZHOU OPTICAL TECH

Treatment method for waterproof bamboo product

InactiveCN108466349AHigh hardnessImprove toughnessAntifouling/underwater paintsWood treatment detailsEmulsionIodine

The invention discloses a treatment method for waterproof bamboo products. The method comprises the following steps: hacking bamboo, removing bamboo green, removing tabaxir, drying in the sun to obtain bamboo chips; uniformly mixing ammoniacal copper quaternary and water, adding the bamboo chips, standing in high temperature, performing solid-liquid separation to obtain pre-treated bamboo wood; drying the pre-treated bamboo wood, putting the bamboo wood in a carbide furnace to perform carbonization treatment, filtering, immersing in oil mixture, taking the bamboo wood out, drying, then, coating a pre-treatment varnish on the surface, solidifying, and drying, weaving to obtain a waterproof bamboo product. The pre-treatment varnish is prepared by the following process: adding a cluister beamcompound, lignum cinnamomi camphorae powders, a dispersing agent, and a thickener into a styrene-acrylic emulsion, stirring, reducing stirring speed, adding water, a coalescing agent, acetyl tributylcitrate, 3-iodine-2-propinyl butyl carbamic acid ester, a wetting agent, and an antifoaming agent, stirring uniformly, filtering, to obtain the pre-treatment varnish.

Owner:安徽泓浩竹科技股份有限公司

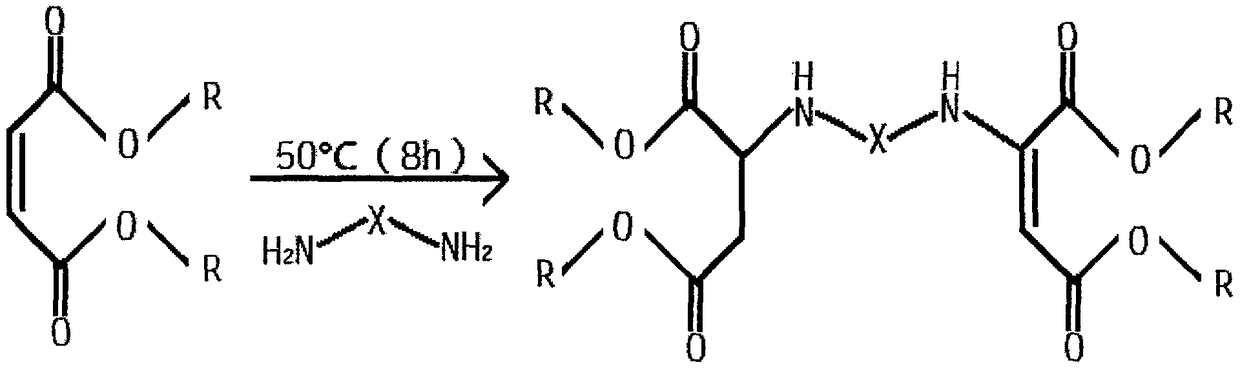

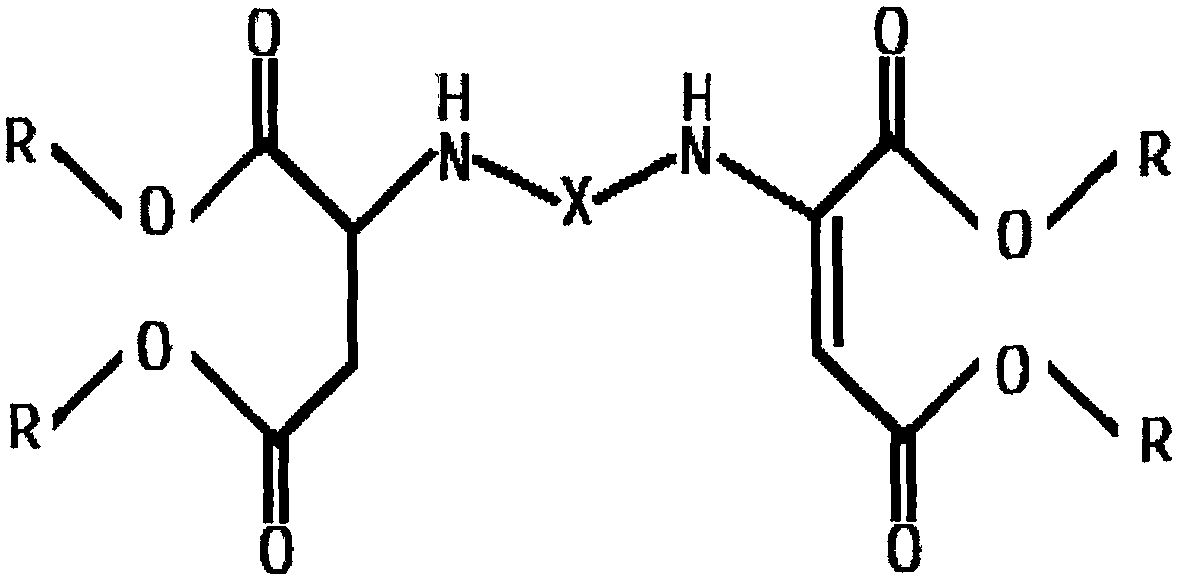

A novel synthetic method of polyaspartic polyurea resin

The invention discloses a novel synthetic method of polyaspartic polyurea resin, and relates to the technical field of chemical engineering. The method includes two stages, namely a first stage in which a raw material formula and a process are strictly controlled to promote a reaction between an organic primary amine having multiple functional groups and dialkyl maleate, and a second stage in which a target product that is the polyaspartic polyurea resin is obtained with a high convention ratio by subjecting the material synthesized in the first stage to special-process retreatment. The methodwhen used for resin synthesis has advantages of 1) short synthesis time, an increased production efficiency and reduced energy consumption; and 2) a high product conversion ratio, no organic primaryamine or dialkyl maleate monomer in the product, and capability of being more environmentally friendly. After the polyaspartic polyurea resin forms film, the film is dense and protective performance is greatly improved. The polyaspartic polyurea resin is mainly applied in outdoor coatings having stringent requirements on waterproofness, corrosion resistance and weather fastness.

Owner:郭文祥

Method for preparing sulfonic silane-rare earth nanometer compound membrane on single crystal silicon sheet surface

InactiveCN1670248ANo pollution in the processSimple processing methodMetallic material coating processesSilanesRare earth

A method is for making sulfonic acid radical silicane-tombarthitenanometer coextruded film on the surface of a monocryst a self-assemblage process on the surface to make said film, which comprises the following steps: putting the monocrystalline silicon chip into aqua regia to heating it for 5-6 hours, cooling it at the room temperature, washing and drying it, and immersing it into the mercaptosilicane solution for 6-8 hours, after the flush process, weathering it with nitrogen, then putting it into the aquacare to reacting, for oxygenating the end mercapto group to sulfonic group, and adding the chip into the tombarthite self-assemblage solution with tombarthite compound, ethanol, ethylene diamine tetraacetic acid, chlor ammonia, aquacare and aquacare to assemble, and then getting the sulfonic acid radical silicane-tombarthite self-assemblage nanometer coextruded film. The invention provides an easy technique, and the tombarthite self-assemblage film made on the surface of the monocrystalline silicon chip can lower friction and improve wear-resistance dramatically.

Owner:SHANGHAI JIAO TONG UNIV

Production method of self-assemble rare earth nanometer membrane on glass substrate surface

A process for preparing self-assembling rare earth nano films on the surface of glass substrate surface comprising, pre-processing the glass substrate through hydroxylating, disposing by Pirahan solution wherein the volumetric ratio of H2SO4 : H2O2 = 70 : 30 at room temperature for 30 min, eluting with deionized water, drying in baking oven, immersing the processed glass substrate into prepared rare earth modifier, stewing for 8 hrs, taking out for deionized water flushing, placing into baking oven after being dried at ambient temperature, maintaining 120 deg. C for 1 hour, the weight percentage of the rare earth modifier constituent being, alcohol 60-80%, rare earth compound 4.5-7%, ethylenediamine tetra-acetic acid 1-4%, ammonium chloride 2-5%, carbonyldiamide 15-25%, nitric acid 0.5-1.5%.

Owner:SHANGHAI JIAO TONG UNIV

Polymer cement waterproof slurry prepared from superfine cement

The invention provides polymer cement waterproof slurry prepared from superfine cement, belonging to the field of building materials. The polymer cement waterproof slurry comprises powder and liquid, wherein the liquid contains 80-100 parts of styrene-acrylic emulsion, 1-3 parts of defoaming agent, 1-3 parts of preservative and 50-150 parts of water by weight; the powder contains 300-350 parts of superfine cement, 150-200 parts of calcium carbonate, 100-150 parts of quartz sand and 0.1-5 parts of aid by weight. The polymer cement waterproof slurry has the effects of avoiding the phenomenon of sand sedimentation and further densifying skeleton structures.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Novel antirust agent for marine machinery and method for preparing same

The invention discloses a novel antirust agent for marine machinery, which is prepared from raw material which comprises the following components in parts by weight: 200-400 parts by weight of sodium metasilicate, 8-14 of polymeric alkylol amine, 4-6 of sodium borate, 6-10 of disodium ethylenediamine tetraacetate, 2-6 of sodium citrate. The novel antirust agent for marine machinery provided by the invention, which contains sodium metasilicate as the main ingredient and is cheap and environmental friendly, can form a dense film on the surface of marine machinery and has notable antirust effect, especially under serious marine conditions.

Owner:山东龙港硅业科技有限公司

Cleaning and prefilming agent and preparation method and application thereof

The invention discloses a cleaning and prefilming agent which is used for dissolving dirt on metal surfaces and forming inorganic films and organic films on the metal surfaces, and the inorganic filmsand the organic films intersect each other on the metal surfaces to form compact inorganic organic composite films. The ingredients of the cleaning and prefilming agent comprise organic carboxylic acid and salts thereof, sodium gluconate, inorganic zinc salt, organic acid polymers, a chelating agent, inorganic base and deionized water, and the weight percentage of all the ingredients in the cleaning and prefilming agent is 5-30% of organic carboxylic acid and salts thereof, 10-20% of sodium gluconate, 3-10% of inorganic zinc salt, 5-20% of organic acid polymers, 1-5% of the chelating agent, 10-30% of inorganic base and the balance deionized water. By means of the cleaning and prefilming agent, the purposes of protecting equipment and prolonging the equipment life are achieved, when the cleaning and prefilming agent is used for circulating cold water treatment, cleaning and prefilming can be finished at one time, adjustment of the system pH is not needed, and the cleaning and prefilming procedure is simplified.

Owner:XIAN JINGDA CHEM

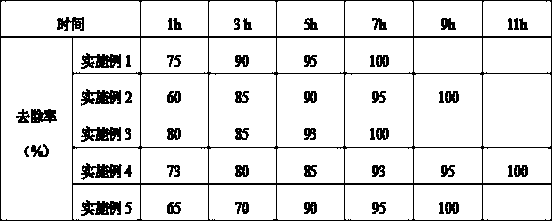

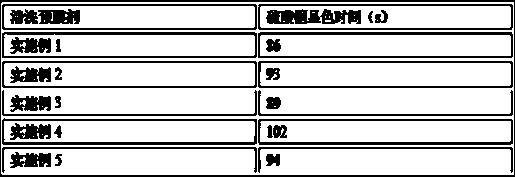

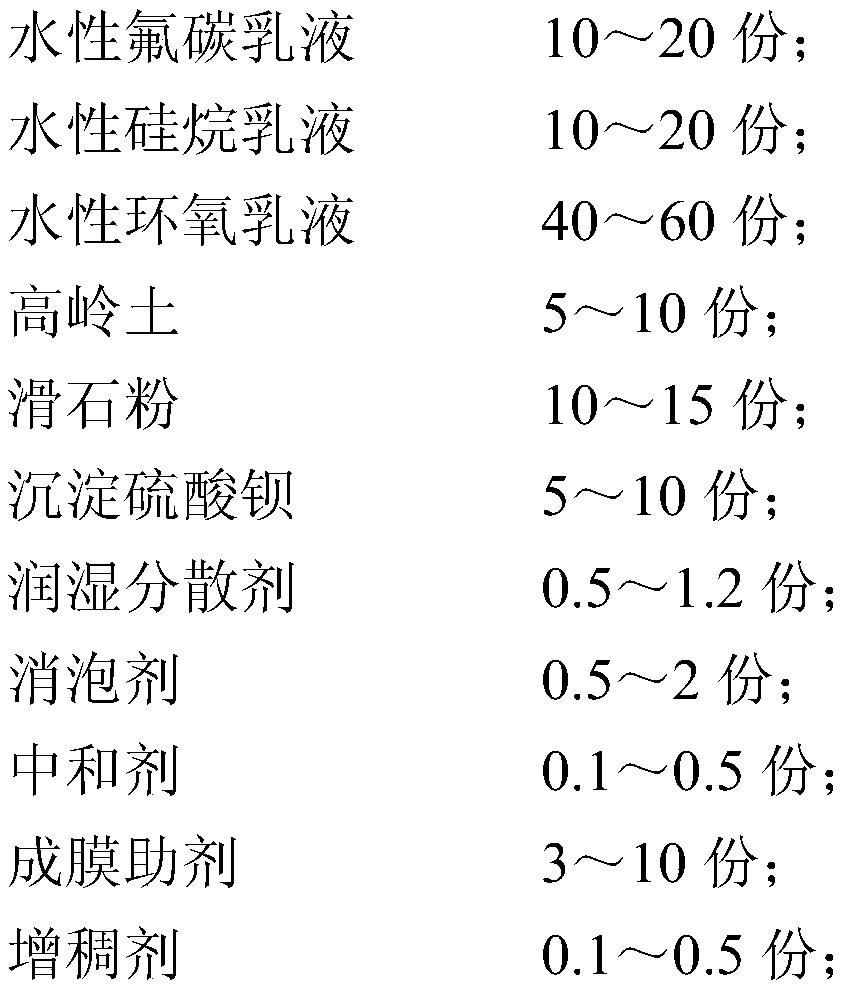

Water-based anticorrosive paint, preparation and application in field of concrete structure protection

InactiveCN109135502AImprove mechanical propertiesImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

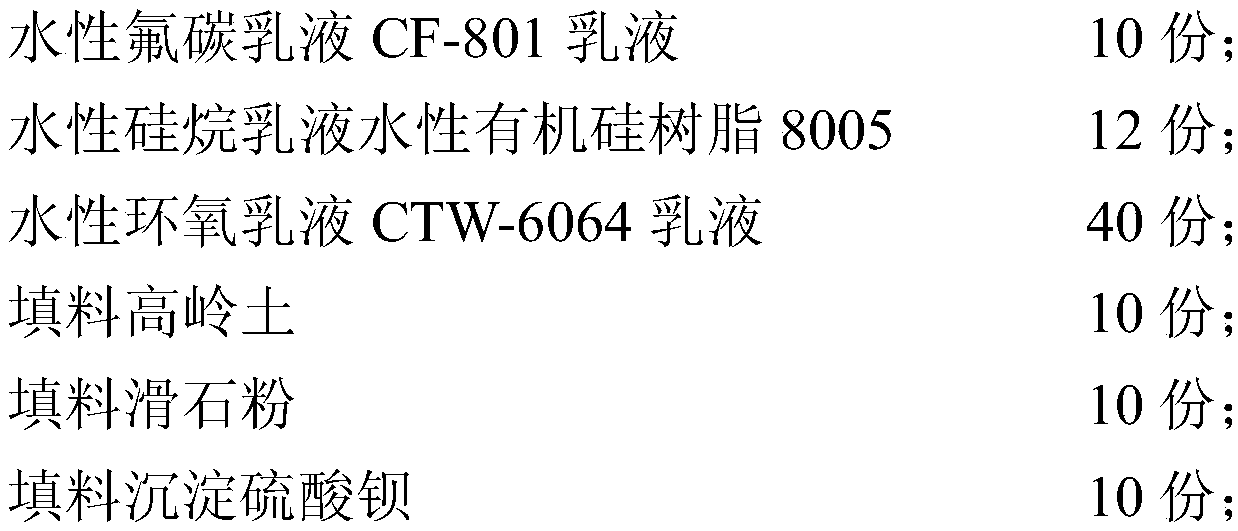

The invention relates to the technical field of anticorrosive paint, in particular to water-based anticorrosive paint, preparation and application in the field of concrete structure protection. The water-based anticorrosive paint comprises a component jia and a component yi, the component jia is prepared from, by weight, 10-20 parts of water-based fluorocarbon emulsion, 10-20 parts of water-basedsilane emulsion, 40-60 parts of water-based epoxy emulsion, 5-10 parts of kaolin, 10-15 parts of talcum powder, 5-10 parts of precipitated barium sulphate, 0.5-1.2 parts of wetting dispersant, 0.5-2parts of defoaming agent, 0.1-0.5 part of neutralizer, 3-10 parts of film forming auxiliary agent, 0.1-0.5 part of thickening agent and 7-15 parts of water, and the component yi is water-based alicyclic amine curing agent. The paint has two functions of sealing primer and finishing paint, has excellent weather resistance performance, adhesive force, alkali resistance performance and concrete permeability, is small in environmental pollution, and can be widely applied to concrete structures of urban viaducts.

Owner:洛阳双瑞防腐工程技术有限公司

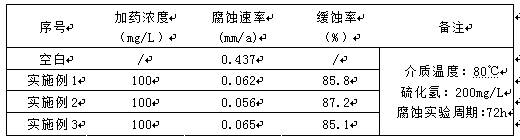

Oil-soluble hydrogen sulfide-proof corrosion inhibitor

ActiveCN103450865ADense filmImprove adsorption capacityBorehole/well accessoriesAcetic acidPhosphate

The invention discloses an oil-soluble hydrogen sulfide-proof corrosion inhibitor and relates to the technical field of chemical reagent formulas for the oil fields. The oil-soluble hydrogen sulfide-proof corrosion inhibitor comprises the following components by weight percent: 20-30% of sorbitan monooleate, 10%-20% of nonylphenoxy-acetic acid, 5%-10% of octyl phosphate and 40%-65% of solvent. The oil-soluble hydrogen sulfide-proof corrosion inhibitor is capable of effectively preventing the corrosion of a shaft and a gathering pipeline caused by H2S and sulfides, and has the characteristics of low dosage, low cost, no pollution on the environment and the like, and also has excellent protection effect in the produced liquid; simultaneously, the oil-soluble hydrogen sulfide-proof corrosion inhibitor has good capacity of inhibiting hydrogen embrittlement caused by H2S, and has good compatibility with the conventional chemical reagents used in the oil fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

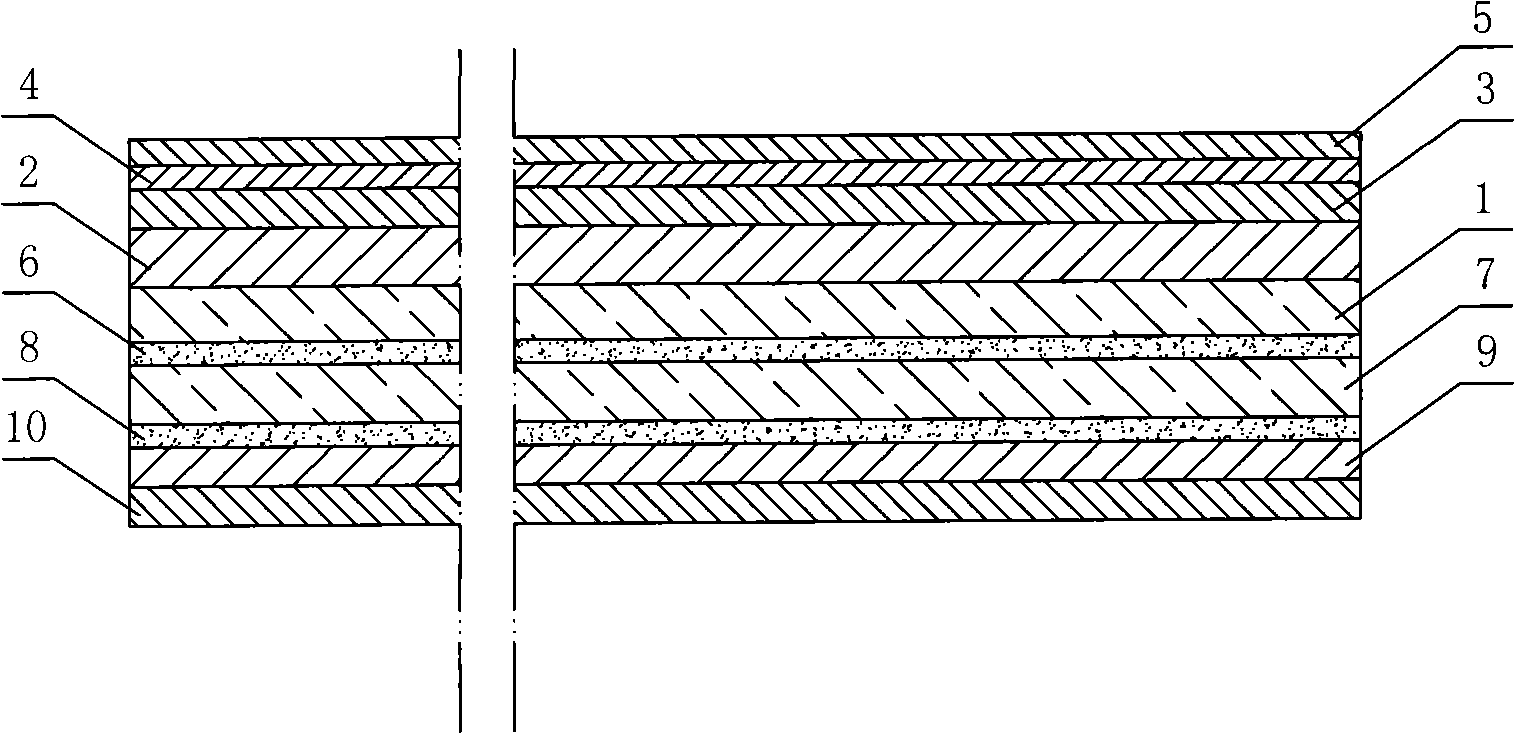

Composite water-proof layer for ballast track concrete bridge deck and construction method of composite water-proof layer

ActiveCN109826094AReduce engineering costsIncreased durabilityBridge structural detailsCoatingsMolecular materialsBridge deck

The invention provides a composite water-proof layer for a railway ballast track concrete bridge deck and a construction method of the composite water-proof layer. The composite water-proof layer comprises a modified polyurethane compound finish paint layer, a modified polyurethane compound primer layer and a closed primer layer from top to bottom. The invention further provides raw material compositions of the modified polyurethane compound finish paint layer and the modified polyurethane compound primer layer and a preparation method of the modified polyurethane compound finish paint layer and the modified polyurethane compound primer layer. The composite water-proof layer is directly formed between the concrete bridge deck and a railway ballast by using a high-molecular material, a concrete protection layer does not need to be laid, the project cost of the concrete protection layer can be saved, the structure dead load can be reduced, and it is of an important significance in improving the durability of the railway concrete bridge. Moreover, the adhesive strength between the novel water-proof layer and the concrete bridge deck is high, and water breakthrough can be effectively reduced.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +3

Self-cross-linking type waterborne polyacrylate powder-free base slurry for clothing fusible interlining

The present invention discloses a self-cross-linking type waterborne polyacrylate powder-free base slurry for a clothing fusible interlining. The self-cross-linking type waterborne polyacrylate powder-free base slurry is prepared from a waterborne polyacrylate emulsion, a waterborne acrylic acid thickener, an additive, deionized water and ammonia water, wherein the waterborne polyacrylate emulsion is prepared from a pre-emulsion, a seed emulsion, a secondary emulsion, a 10% adipic dihydrazide aqueous solution and ammonia water. According to the present invention, diacetone acrylamide (DAAM) is introduced into the system, and the adipic dihydrazide (ADH) modified branch chain is introduced, such that the cross-linking sites in the system can be increased so as to improve a self-cross-linking performance of the aqueous PA and form the medium temperature self-cross-linking type base slurry; and the baking temperature can be appropriately reduced by 10-30 DEG C so as to save energy sources.

Owner:长兴三伟热熔胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com