Application of nano silicon dioxide sol in water-based steel structure anticorrosive paint and protective paint

A technology of nano-silica and steel structure, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor water resistance of anti-corrosion paint, achieve good water resistance, prevent penetration, and improve anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific embodiments.

[0019] 1. The nano-silica sol of the present invention is applied in the water-based steel structure anticorrosion paint, and the acidic silica sol (a colloidal solution of nano-scale polymer inorganic metasilicate with a solid content of 25%) is added to 2-5% of the silica sol KH560 silane coupling agent (glycidyl ether oxypropyl trimethoxysilane), coupled at 55±5°C to form a modified nano-silica sol; then added to water-based acrylic emulsion for steel structure Corrosive water-based industrial coatings.

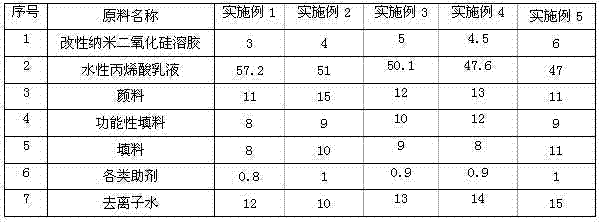

[0020] Two, the embodiment of water-based steel structure anticorrosion paint, formula composition comprises the raw material of following weight percentage:

[0021]

[0022] 3. Preparation method of water-based steel structure anticorrosion paint:

[0023] (1) First put the acidic silica sol collagen solution into the reactor, heat it to 55°C with a wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com